Patents

Literature

47 results about "Glass aggregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

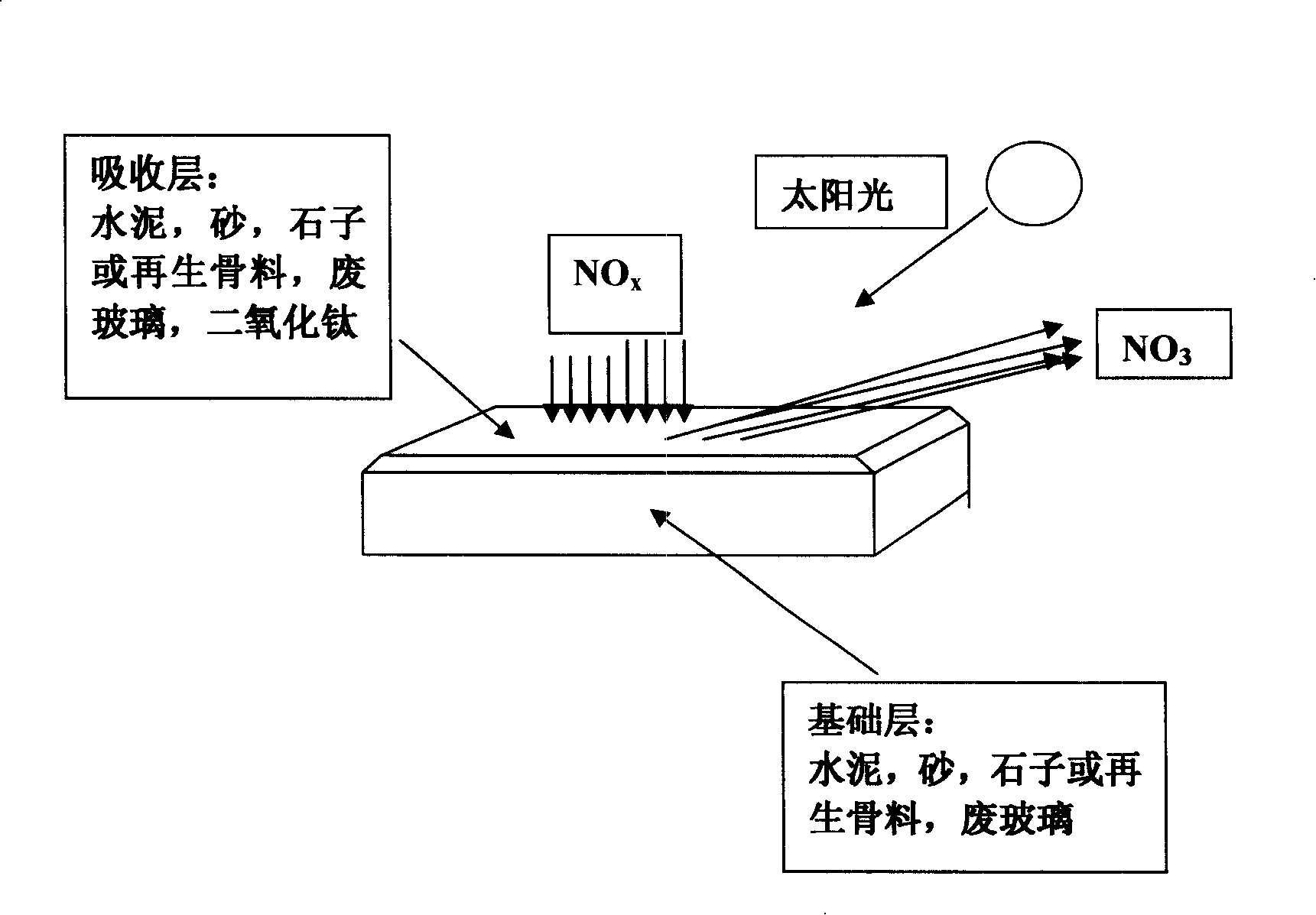

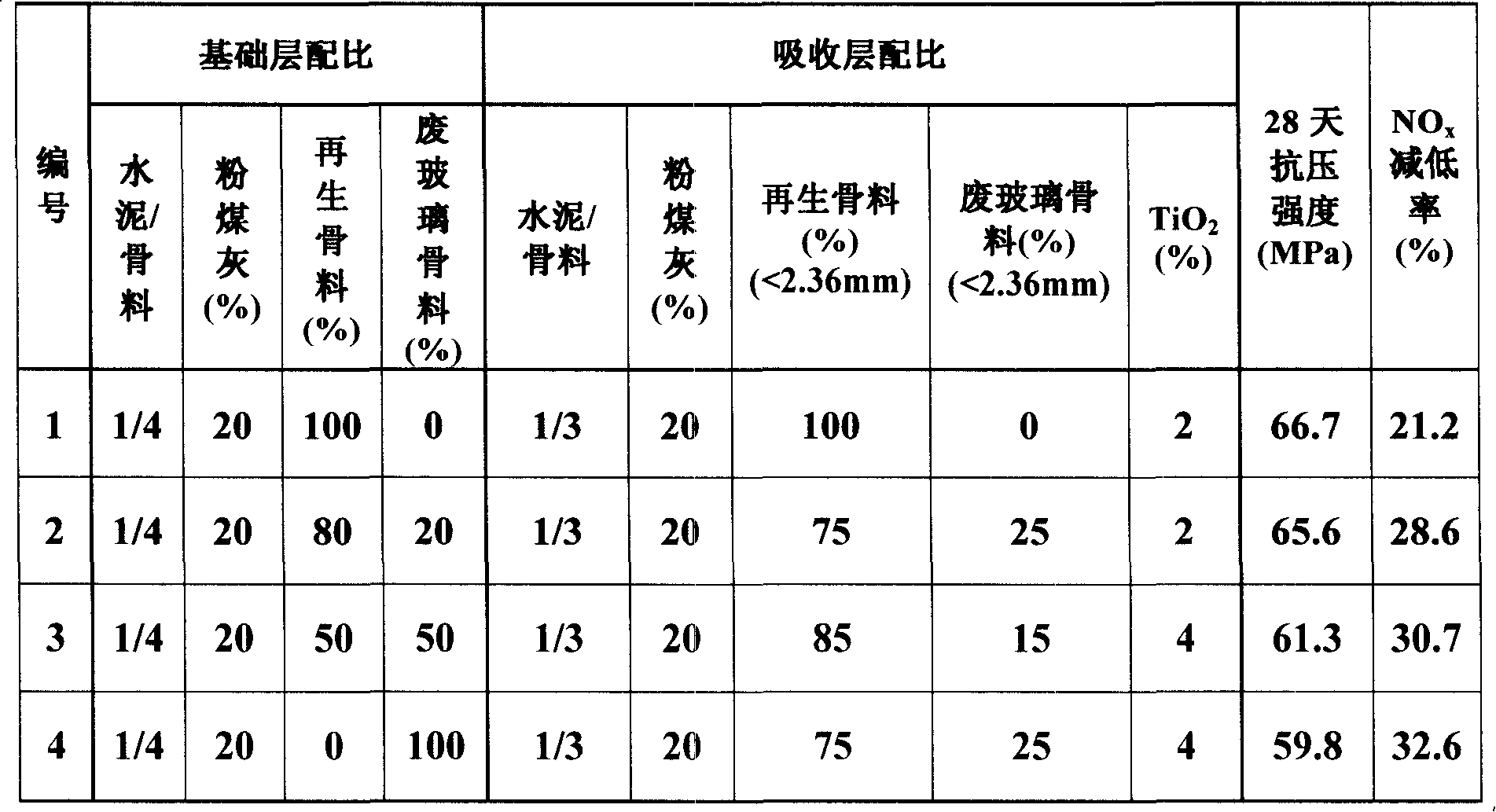

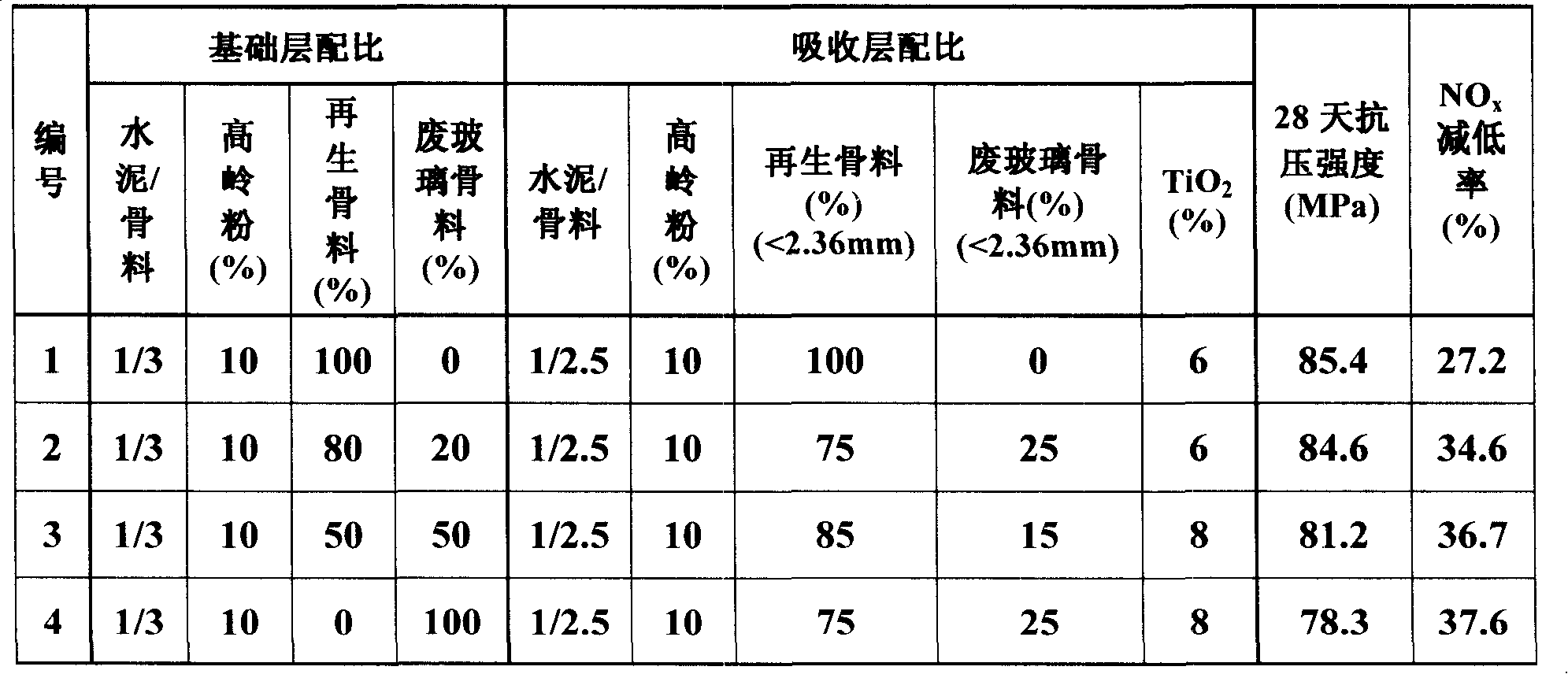

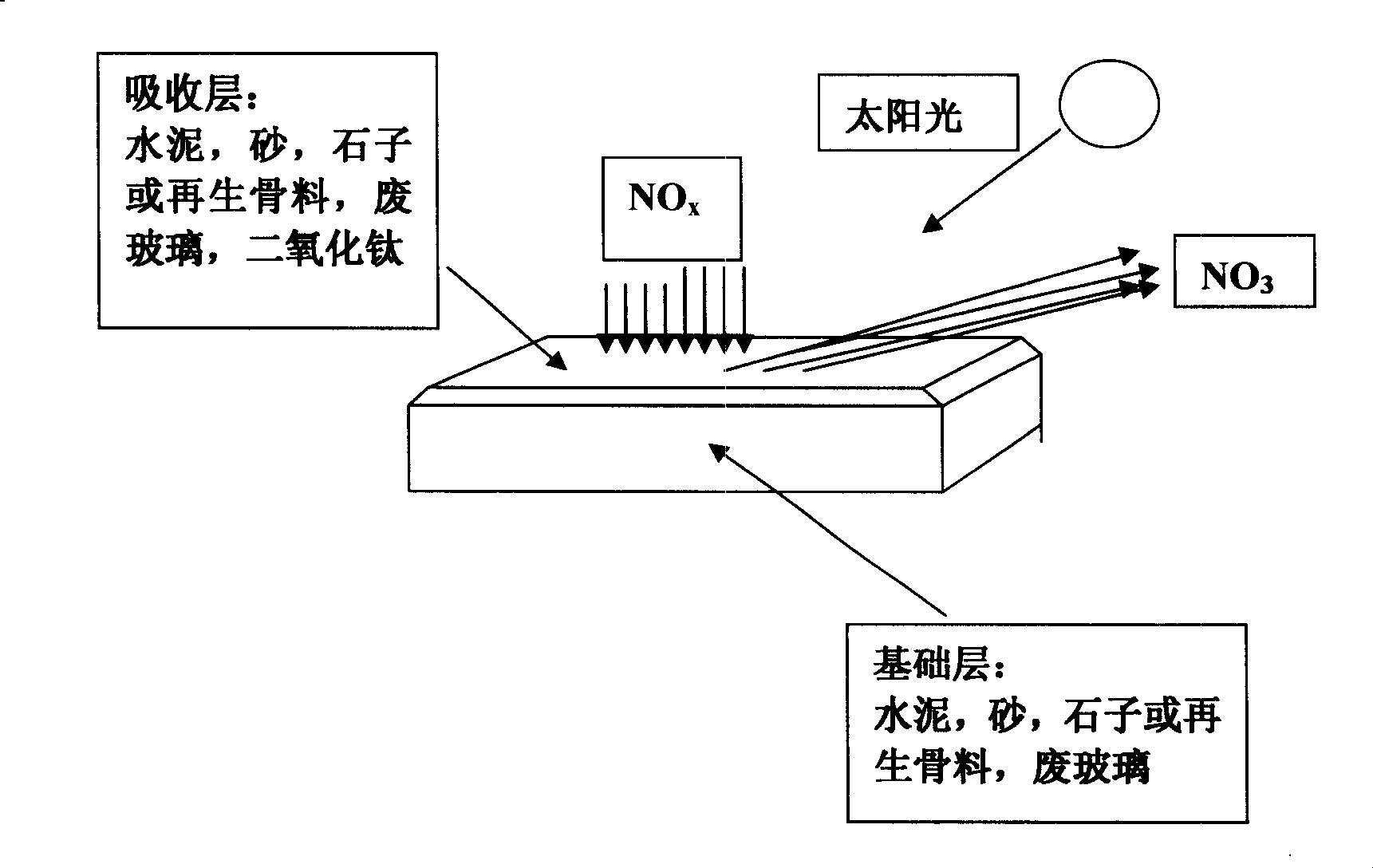

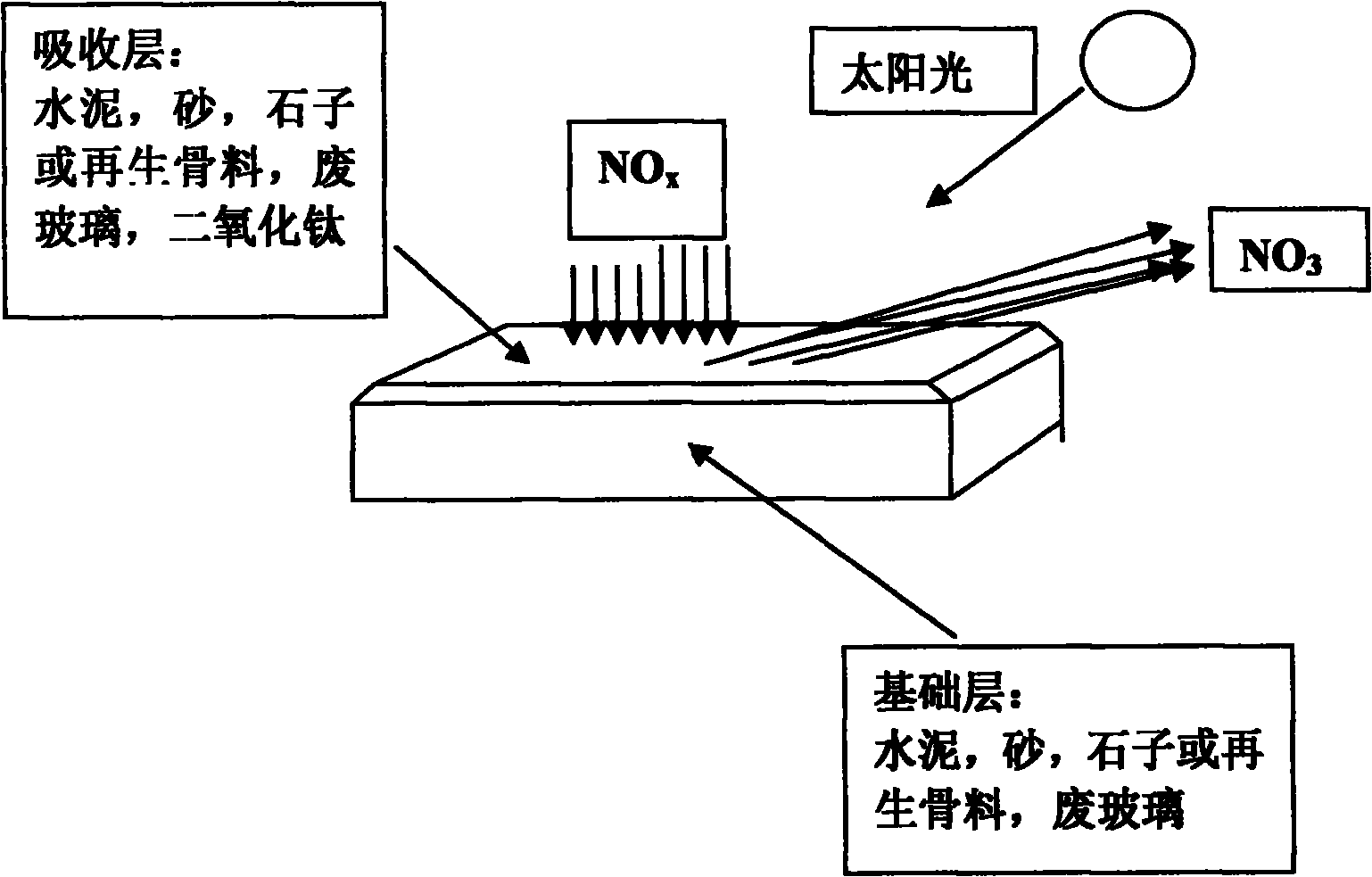

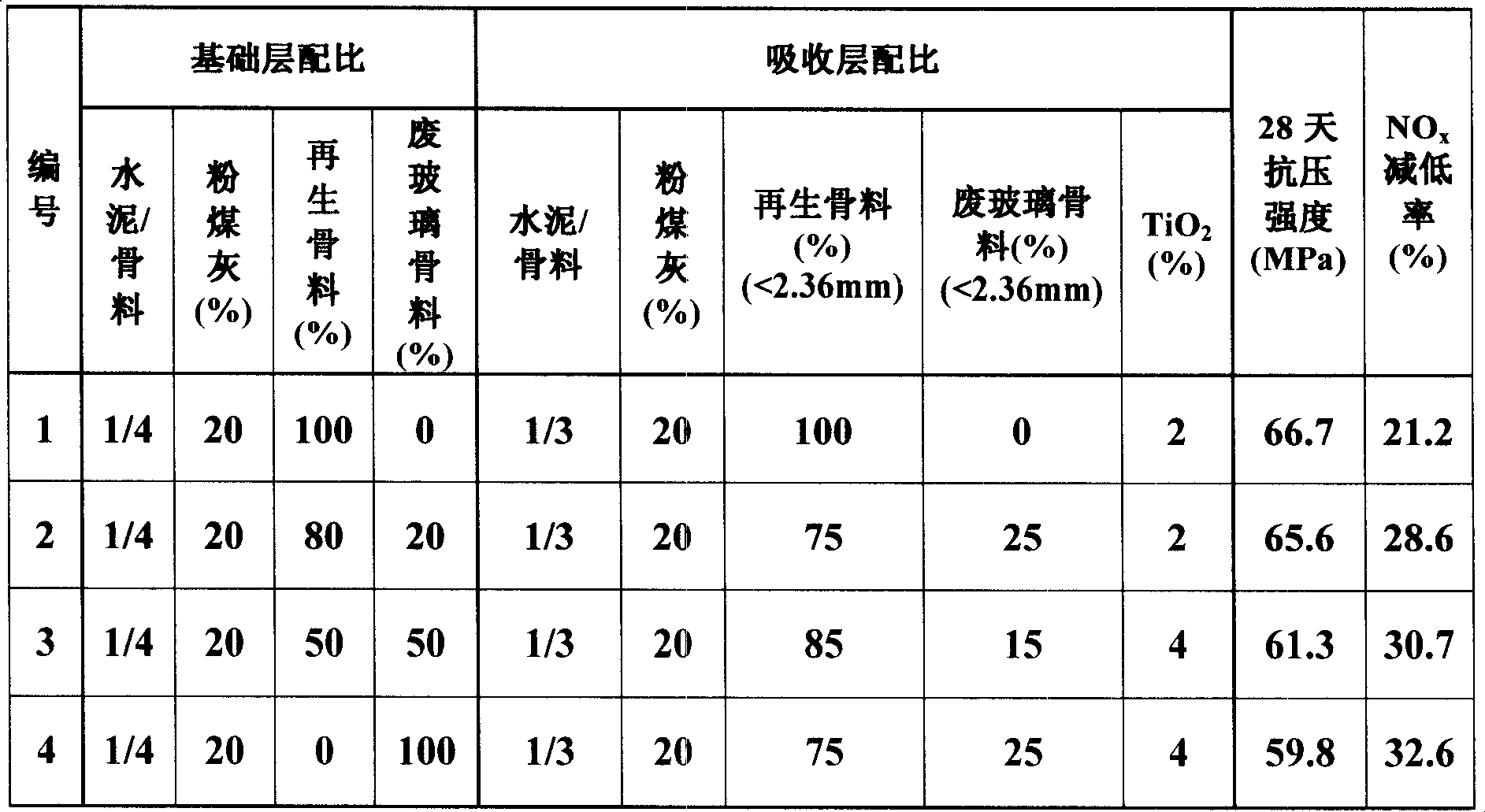

Concrete paving brick capable of purifying air and method for manufacturing the same

The invention provides a concrete paving brick capable of clarifying air produced by using building waste and recycled glass and the manufacturing method thereof. The paving brick comprises an absorption layer and a foundation layer, the absorption layer comprises cement, aggregate, titanium oxide and coal ash or kaolinite powder, the aggregate of the absorption layer comprises recycled aggregate, waste glass aggregate and sand or stones; the foundation layer comprises cement, aggregate and coal ash or kaolinite powder, the aggregate of the foundation layer comprises recycled aggregate, waste glass aggregate and sand or stones. The paving brick of the invention has good function of absorbing exhaust gas and good strength.

Owner:THE HONG KONG POLYTECHNIC UNIV

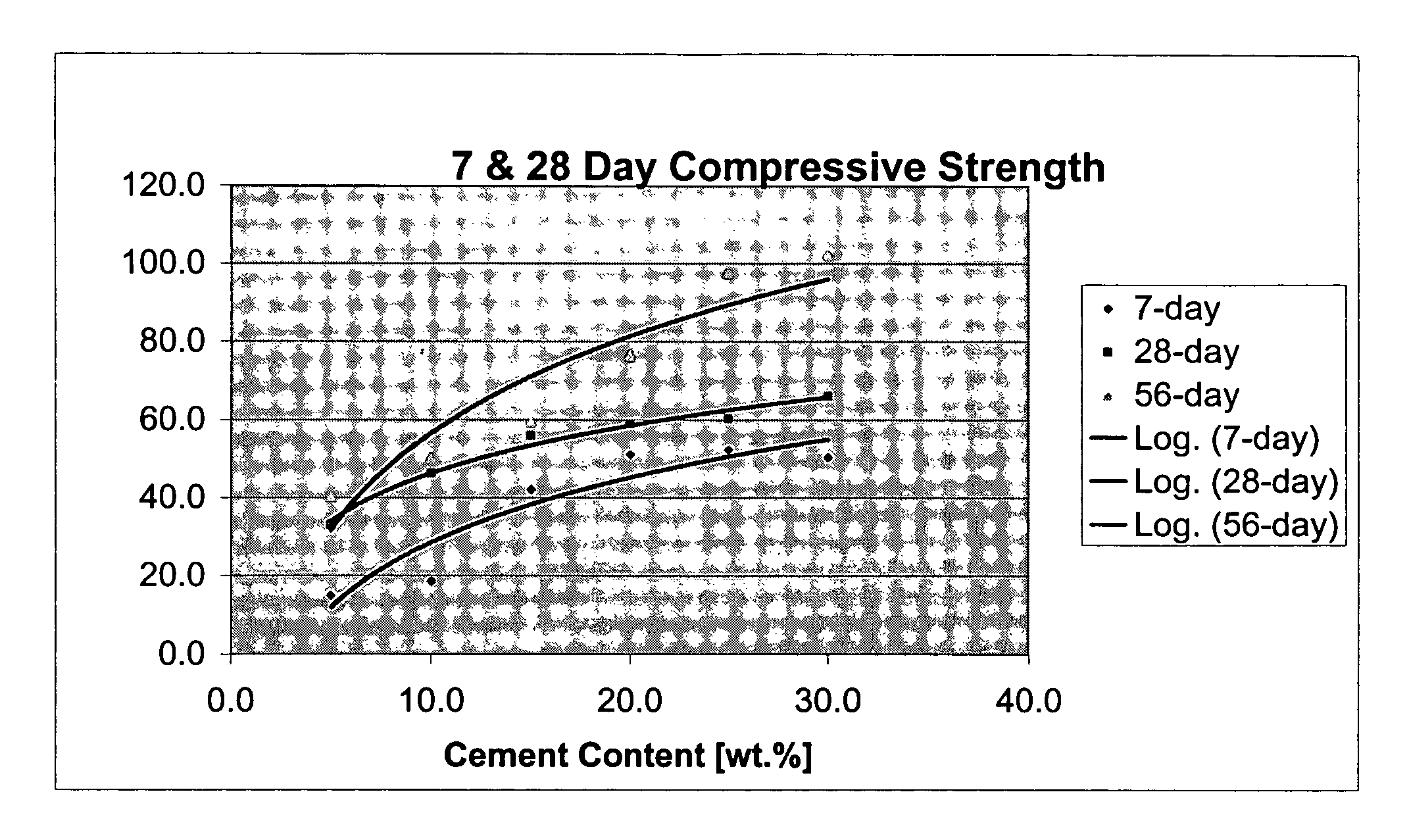

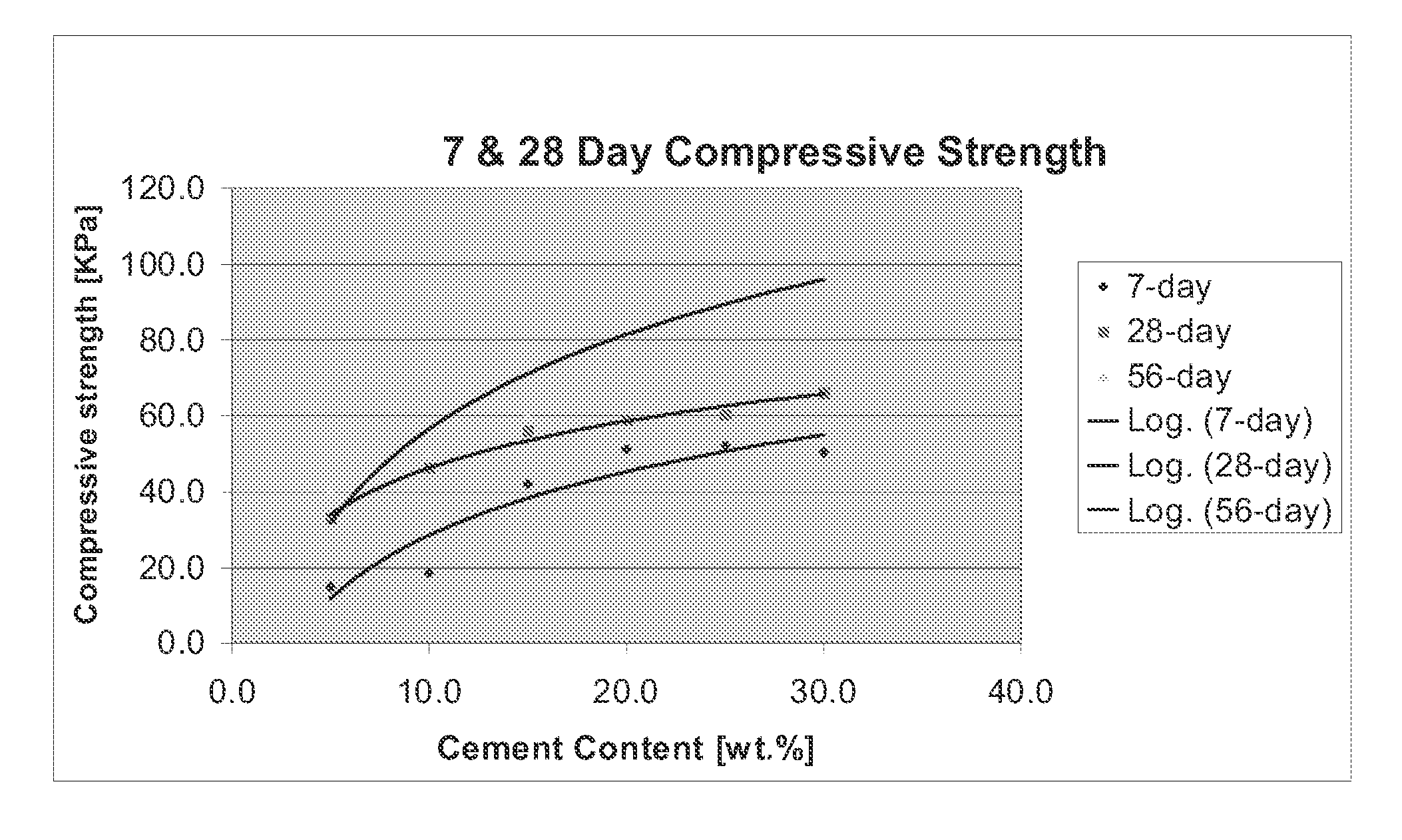

Cementitious composition incorporating high levels of glass aggregate for producing solid surfaces

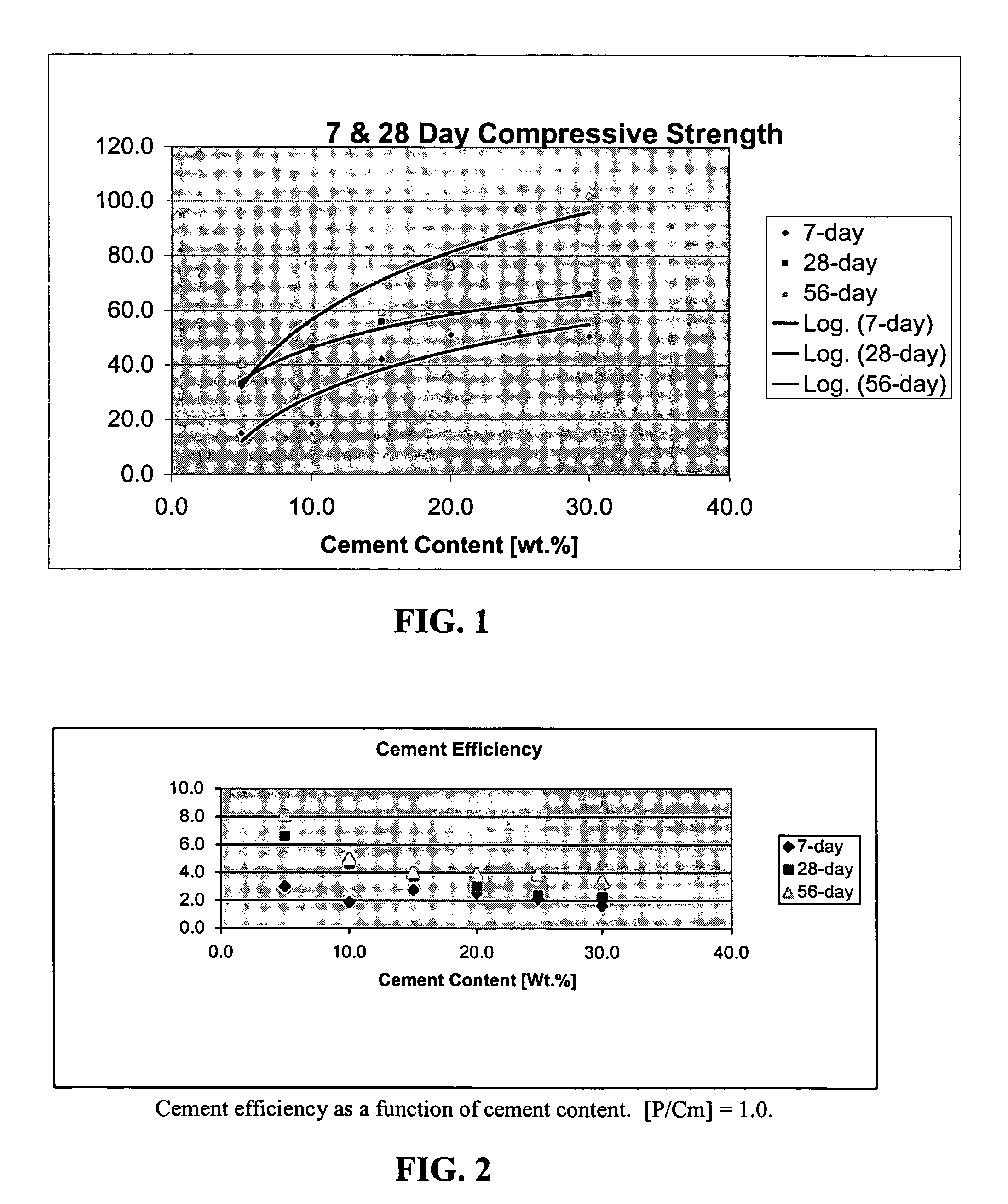

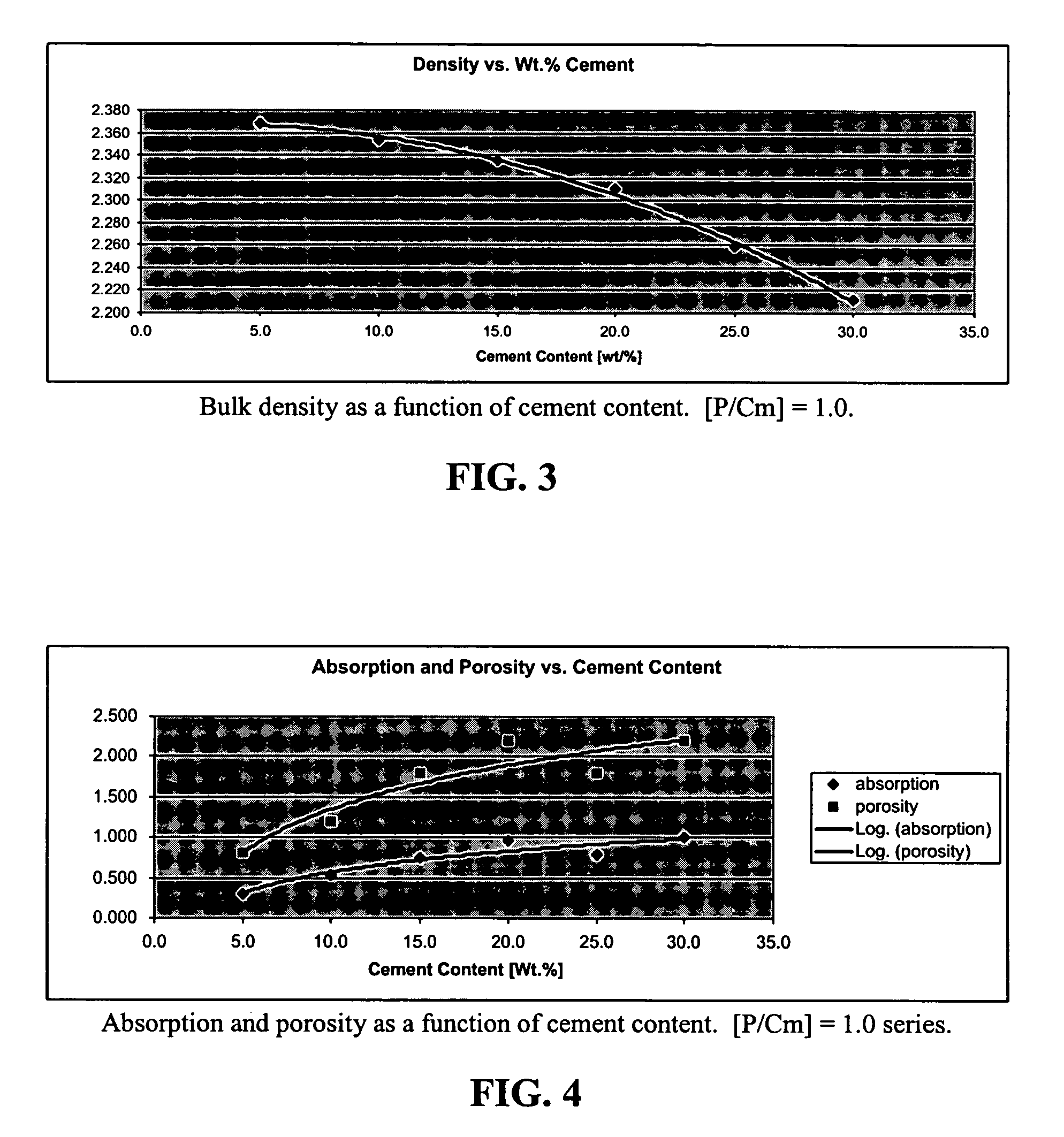

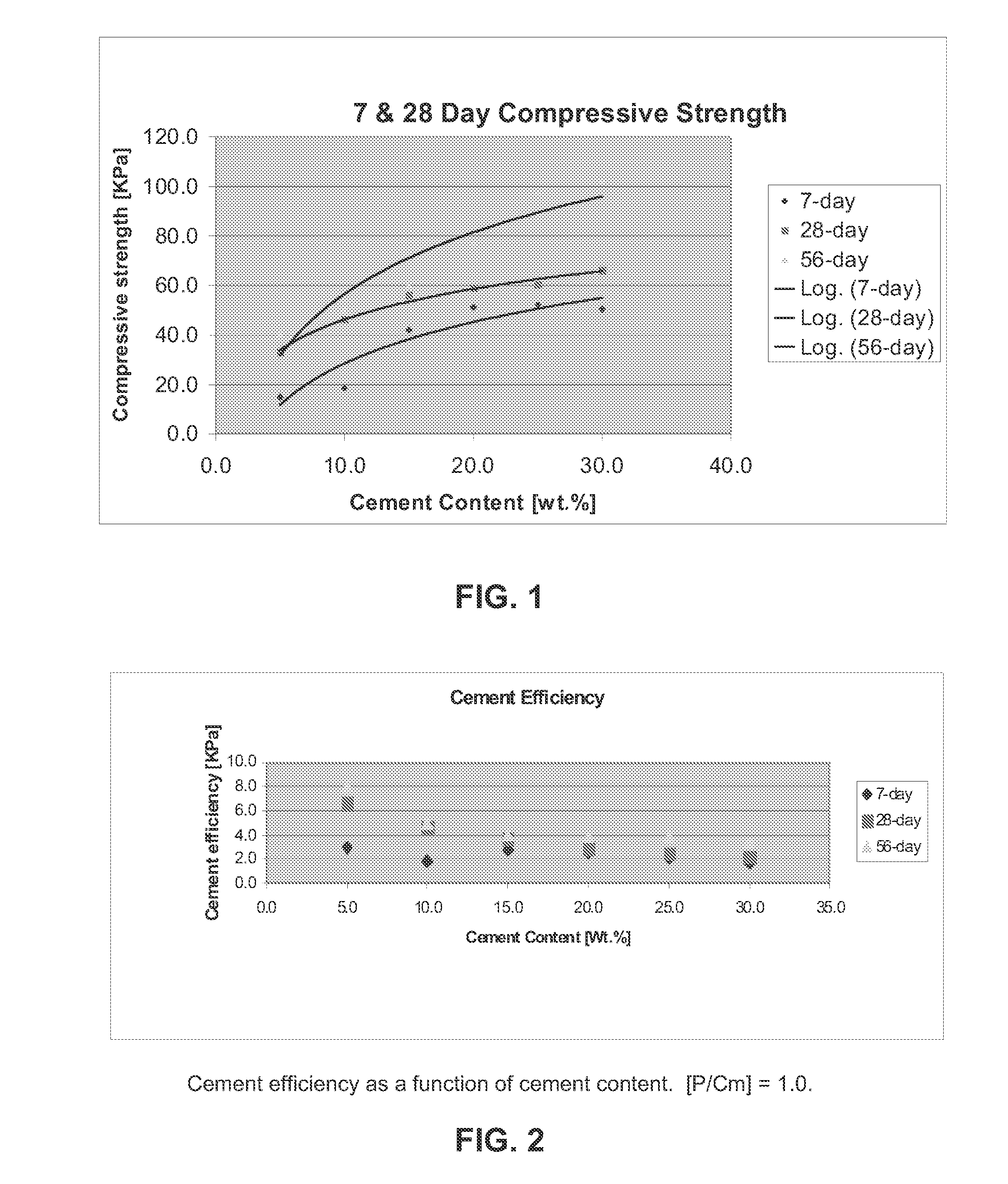

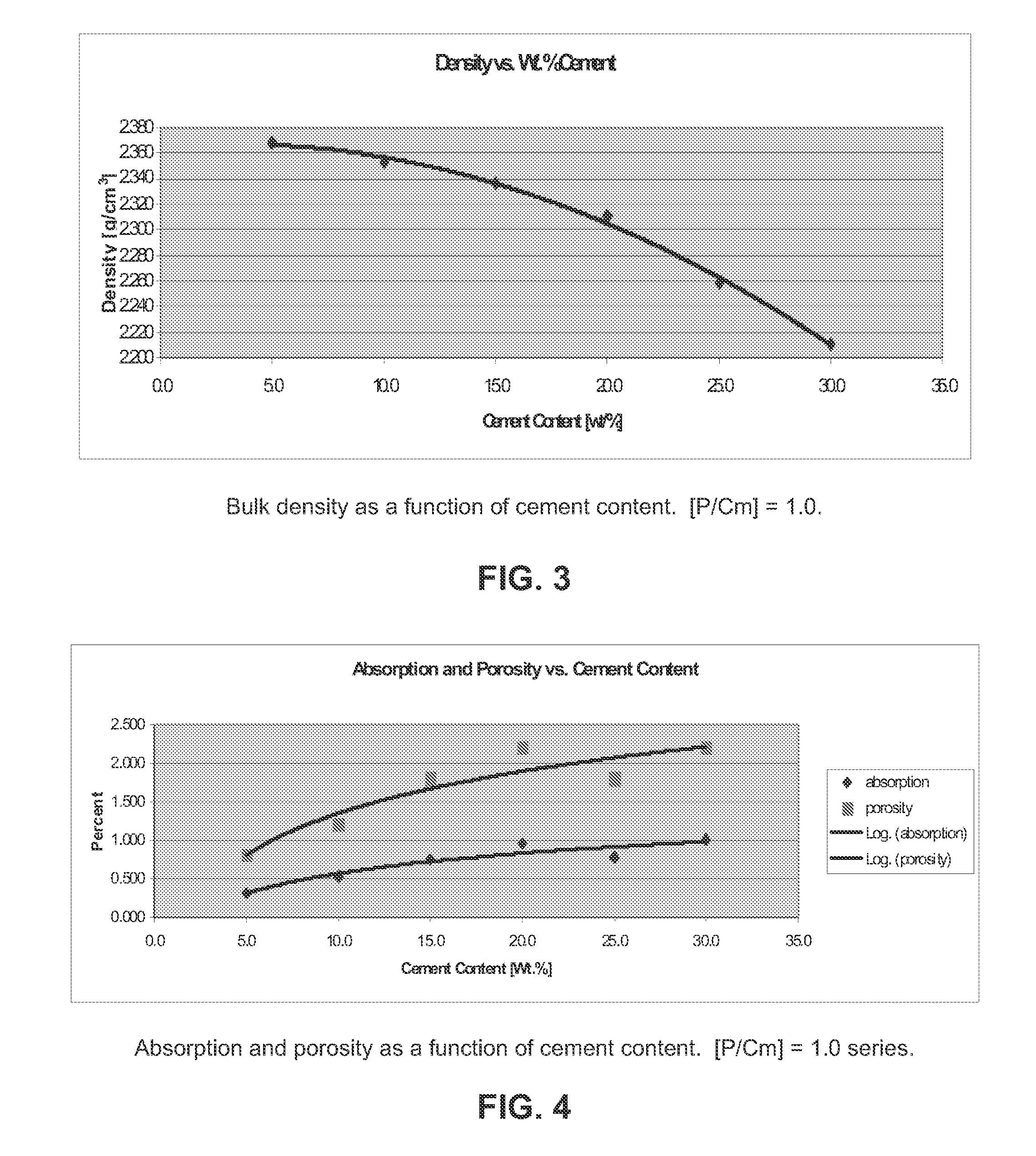

ActiveUS7771529B1Moderate pHControllable brightness coefficientSolid waste managementPorosityHigh density

A cementitious composition for high density, low porosity sheet-form building materials having solid surfaces is comprised of cement, pozzolans, and a high percentage of fine and / or coarse glass aggregate, preferably present in an amount which by weight is at least 60% of the composition. The cement content is relatively low, preferably in the range of about 3% to 20% by weight, and the pozzolan to cement ratio is relatively high, preferably equal to or greater than unity, but which can suitably be in the range from 0.25 to 4. The composition preferably uses recycled glass and preferably has a high recycle content. The sheet-form material made in accordance with the invention can be used to provide exposed solid surfaces, for example, surfaces for shower walls and floors, counter-tops, table-tops, and the like, where low hydraulic permeability and high compressive and tensile strength are desired.

Owner:POLYCOR STONE CORP +5

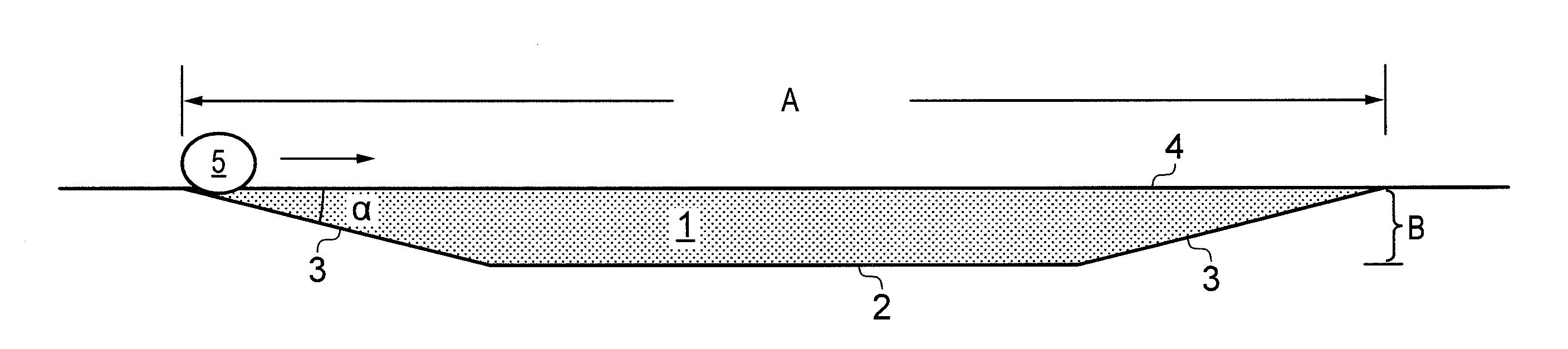

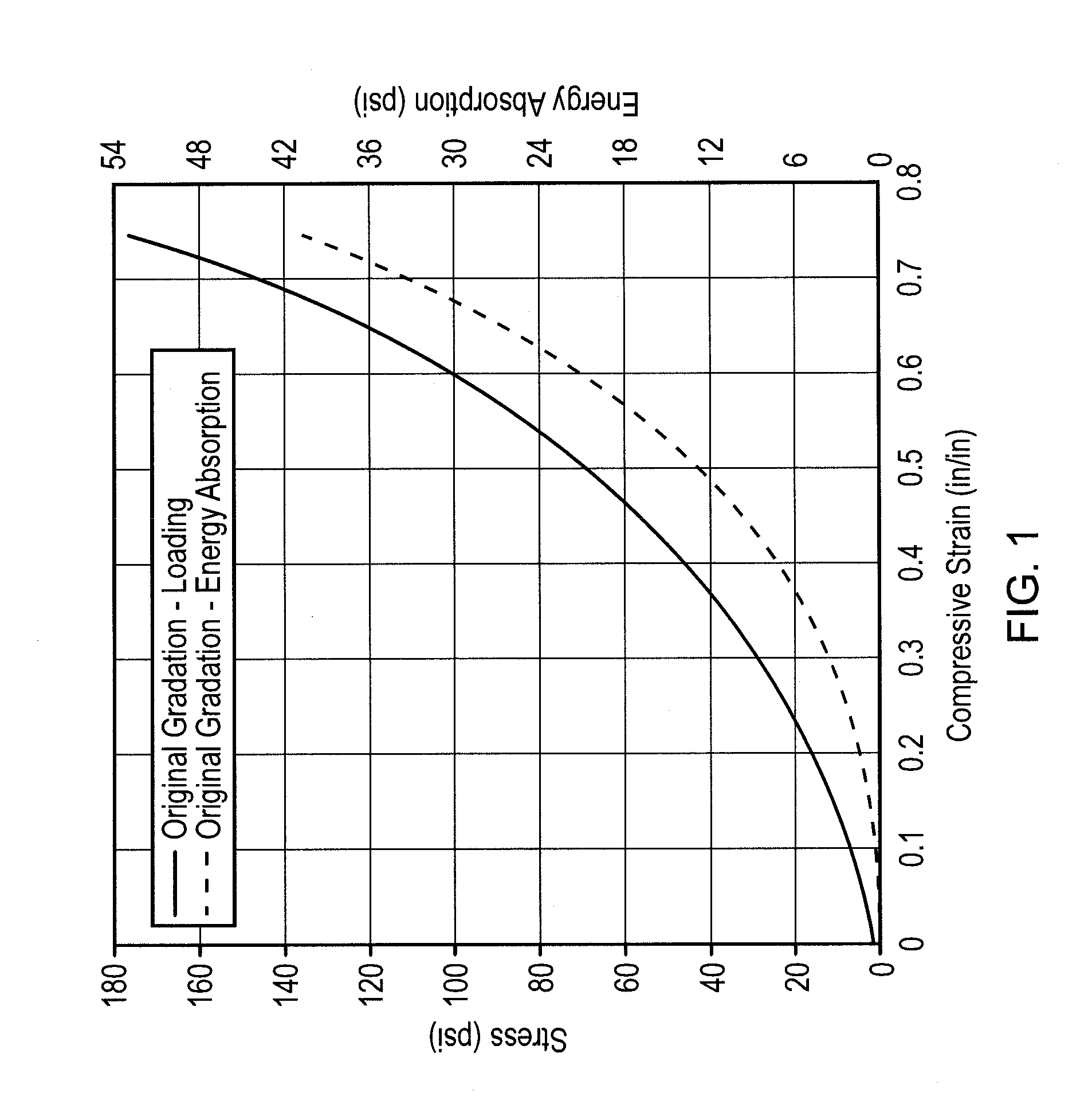

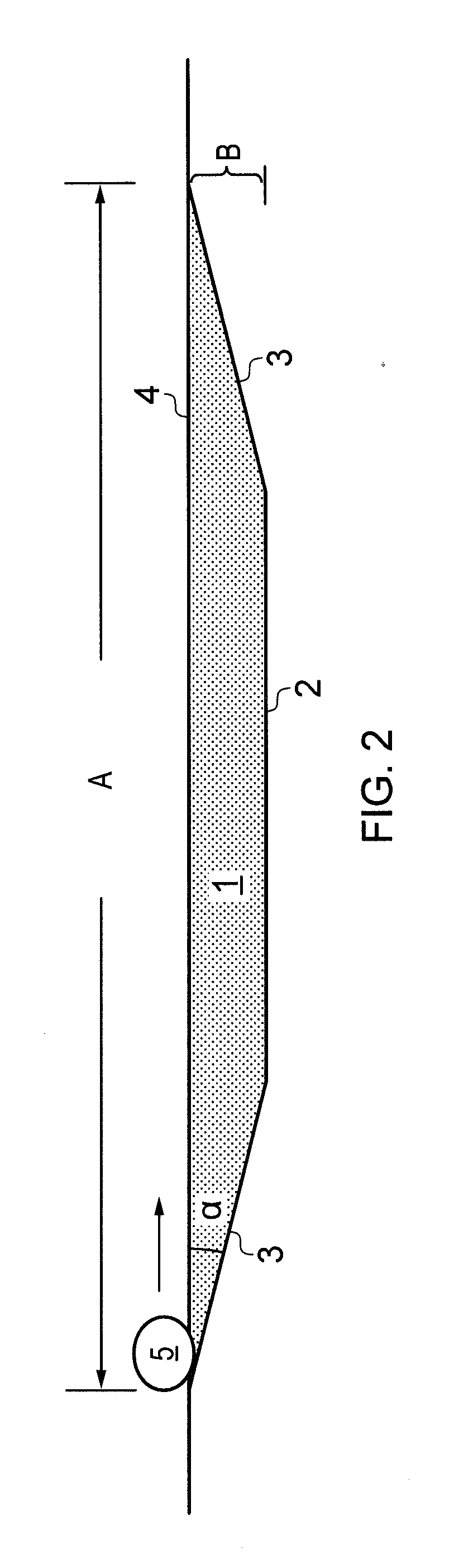

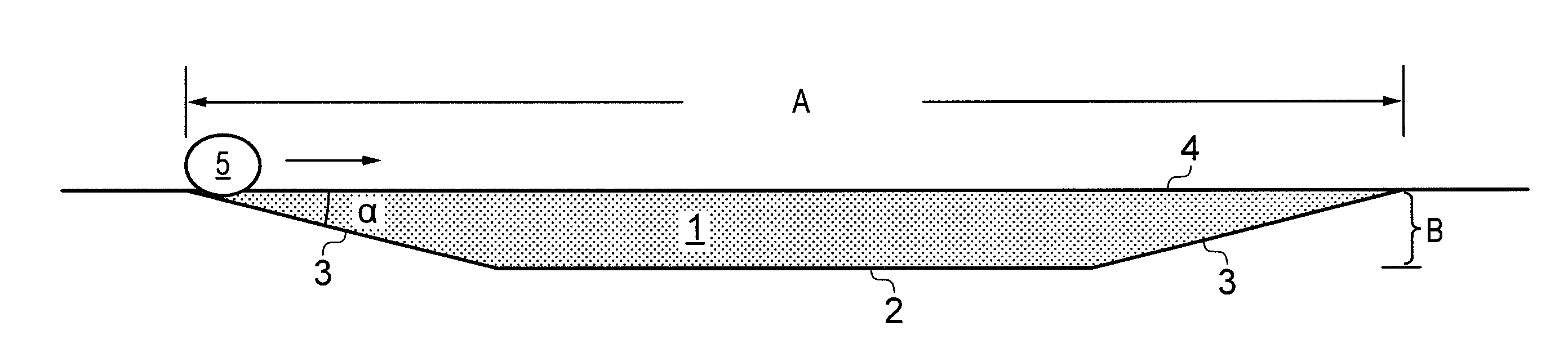

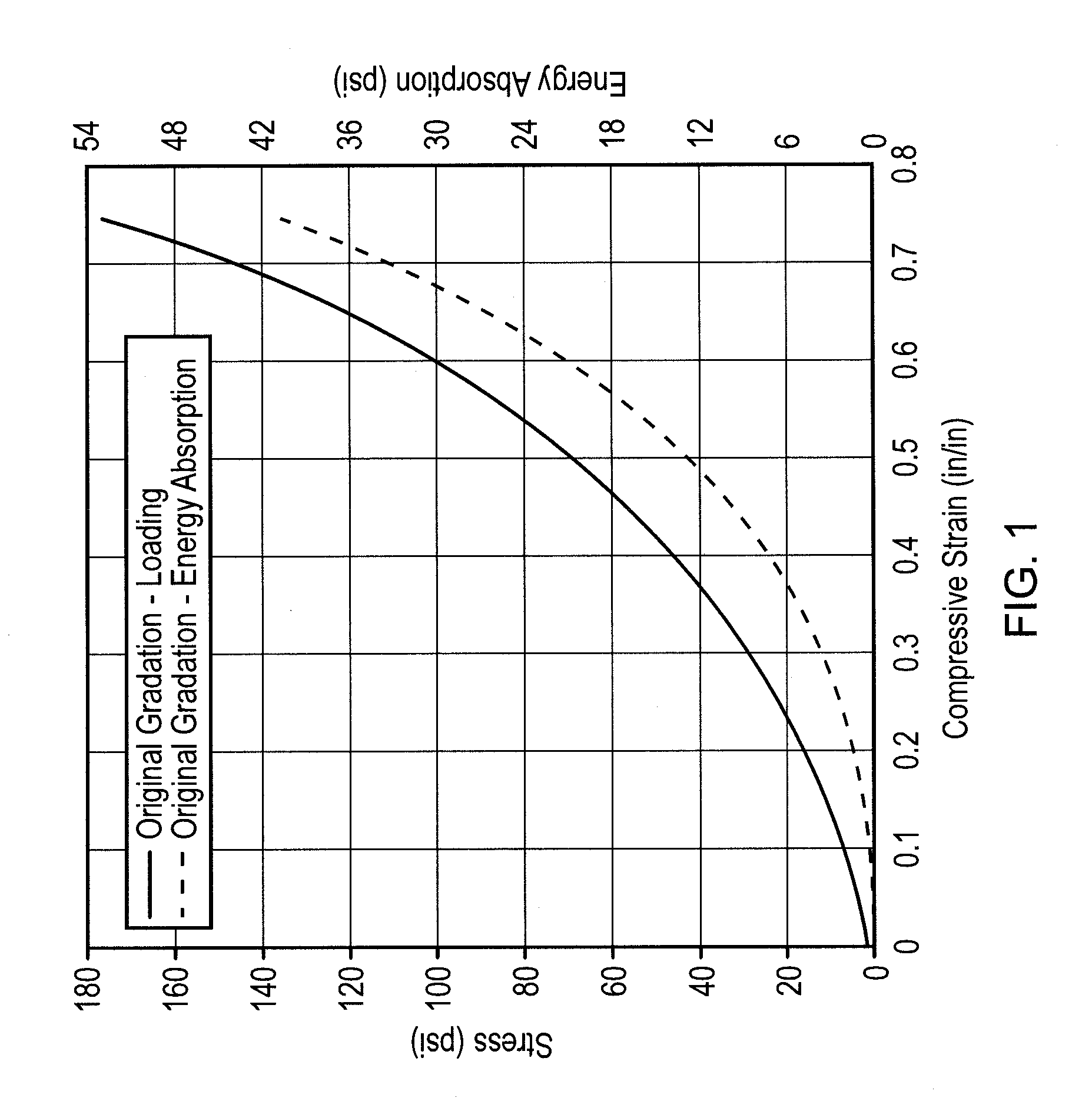

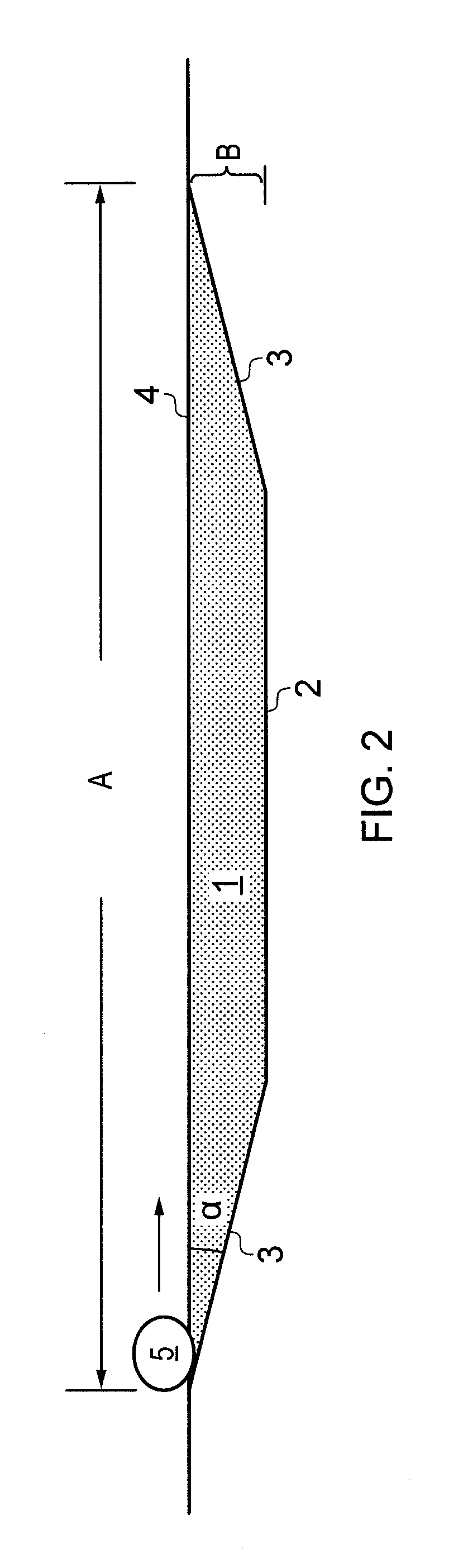

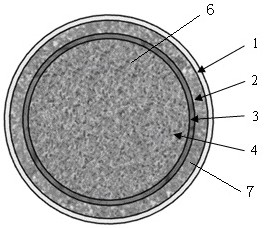

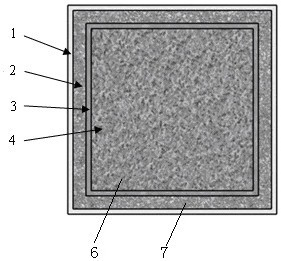

Vehicle arresting bed

ActiveUS20120057931A1Suitable for useReduce environmental impactHelicopter landing platformIn situ pavingsGlass aggregateAirplane

Arresting beds for decelerating vehicles, especially passenger air-crafts unable to stop on available run-way, including a vehicle arresting system. The vehicle arresting system also includes a bed filled with foamed glass aggregate with particle sizes ranging from 0.25 cm to 15 cm and nominal void fractions from about 70 to 98%, and a top cover covering the upper surface of the bed of foamed glass aggregate.

Owner:RUNWAYSAFE EURO AB

Vehicle arresting bed

ActiveUS8579542B2Suitable for useReduce environmental impactArrester hooksIn situ pavingsGlass aggregateAirplane

Arresting beds for decelerating vehicles, especially passenger air-crafts unable to stop on available run-way, including a vehicle arresting system. The vehicle arresting system also includes a bed filled with foamed glass aggregate with particle sizes ranging from 0.25 cm to 15 cm and nominal void fractions from about 70 to 98%, and a top cover covering the upper surface of the bed of foamed glass aggregate.

Owner:RUNWAYSAFE EURO AB

CaO-MgO-Al2O3-SiO2 microcrystalline glass and preparation method thereof

InactiveCN102173592ALower crystallization activation energyImprove growth indexDevitrificationActivation energy

The invention discloses a CaO-MgO-Al2O3-SiO2 microcrystalline glass which is composed of glass aggregate and oxide nucleating agent accounting for 3wt% of glass aggregate, wherein the glass aggregate is composed of the following components in percentage by weight: 50-55wt% of SiO2, 6-10wt% of MgO, 15-18wt% of CaO, 10-12wt% of Al2O3, 3-6wt% of Na2O and / or K2O, 8wt% of CaF2 and 1wt% of Sb2O3. The invention simultaneously provides a preparation method of the CaO-MgO-Al2O3-SiO2 microcrystalline glass. In the CaO-MgO-Al2O3-SiO2 microcrystalline glass, nucleating agent of oxide and fluoride is adopted, so that the devitrification activation energy of a system is lowered, a crystal growth index is improved, and the devitrification capability of the microcrystalline glass is greatly enhanced, thereby bringing convenience for preparing the microcrystalline glass with a whole method.

Owner:ZHEJIANG UNIV

Artificial quartz stone slabs and preparation method thereof

The invention relates to artificial quartz stone slabs. The artificial quartz stone slabs comprise quartz sands, glass aggregates, quartz powder, unsaturated polyester resin, a color paste, a curing agent and a coupling agent, granularity of quartz sands and glass aggregates is greater than or equal to 4 meshes and less than or equal to 20 meshes, the components in proportion are 35-50% of quartz sands, 15-30% of glass aggregates, 20-35% of quartz powder, 8-12% of unsaturated polyester resin, 0.3-0.7% of color paste, weight of the curing agent accounts for 0.8-2.0% of weight of unsaturated polyester resin, the weight of the coupling agent accounts for 0.5-1.5% of that of the unsaturated polyester resin, and the weight of graphene accounts for 0.5-3% of that of the unsaturated polyester resin. Through mesh requirement of quartz sand, the artificial quartz stone slabs have the advantages of high impact resistance, good intensity, no deformation and difficult fracture; and the product has excellent comprehensive performance, and prolongs the usage life of the artificial quartz stone.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Method for preparing compound microcrystalline glass based on raw material of iron tailings

The invention relates to a method for preparing compound microcrystalline glass based on a raw material of iron tailings. The method comprises the following steps of: paving and sprinkling the raw material for preparing the microcrystalline glass on a refractory slab according to a microcrystalline glass aggregate of a certain thickness, wherein the nucleation temperature is 880-890 DEG C, the holding time is 50-60 minutes, the crystallization temperature is 1130-1140 DEG C, and the holding time is 85-95 minutes; then gradually cooling down until the temperature is less than or equal to 100 DEG C; drawing; and shaping. According to the method, the microcrystalline glass aggregate prepared from the iron tailings is used as a filler, the prepared compound microcrystalline glass is not taupe anymore, and silicon, aluminum, zinc, calcium and magnesium of different colors can be added as main components to form the microcrystalline glass aggregate of a wollastonite crystallization system, so that the color of the compound microcrystalline glass based on the raw material of the iron tailings is enriched, and decorative needs are met.

Owner:DONGPING QINGYANG TECH

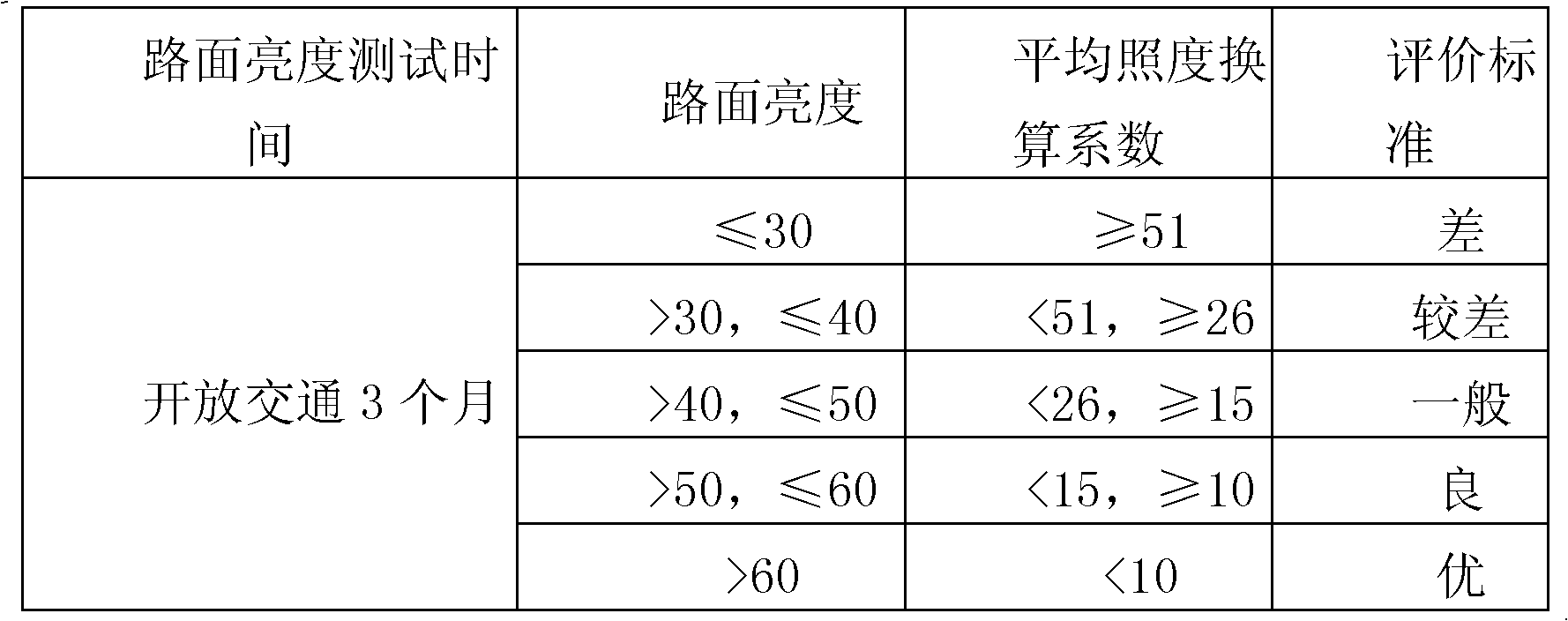

High-identification-property bituminous pavement material and method for paving same

The invention belongs to the field of road engineering and relates to a high-identification-property bituminous pavement material and a method for paving the materia, which are suitable for highways of a second grade and below, rural roads, urban secondary roads and urban roads below the urban secondary roads, block roads, community roads, roads of tunnels, overpasses and the like, as well as road sections in which illumination is not available or illumination brightness is insufficient and a certain potential safety hazards of traffic exist. The high-identification-property bituminous pavement material is mainly characterized in that glass aggregates are doped in a bituminous mixture, the brightness of pavement can be increased by utilizing the reflecting performance of the glass aggregates, and thus, the identification property of the pavement at night can be enhanced to a certain extent. The technological method provided by the invention is simple in process and free of additional equipment requirements, waste glass raw materials can be fully utilized, the identification property of the pavement at night is greatly enhanced under the condition of not obviously increasing the construction cost, and thus, the traffic safety of the road is guaranteed in a better way.

Owner:BEIJING UNIV OF TECH

Production method of freehand microcrystalline glass board

The invention relates to a production method of a freehand microcrystalline glass board. The production method comprises the following steps of respectively preparing seven microcrystalline glass aggregates with different colors, getting the microcrystalline glass aggregates with any two or more colors and uniformly scattering the microcrystalline glass aggregates with different colors in a stainless steel mould frame with a textured grating in sequence; moving a glass gate board at the bottom of the stainless steel mould frame for dropping the microcrystalline glass aggregates into a fireproof mould sprayed with an aluminum oxide sizing agent which is 1mm thick, and the fireproof mould carrying the microcrystalline glass aggregates enters a roller kiln; preheating, fusing the aggregates, crystallizing and preserving the heat at 1100 DEG C-1150 DEG C, cooling and discharging out of the kiln for firing a freehand microcrystalline glass board crude product with whole-body textures; and carrying out surface coarse-grinding, fine-grinding and polishing to obtain a freehand microcrystalline glass board finished product with clear texture patterns and board glossiness of over 90 degrees. The freehand microcrystalline glass board prepared by the production method disclosed by the invention has abundant colors, line textures from the inside to the outside, and physical and chemical performances better than those of a stone.

Owner:王顺军

Microcrystalline glass aggregate raw material, method and raw material and method for preparing low-fluorine high-strength microcrystalline glass plate

The invention discloses a microcrystalline glass aggregate raw material, a method and a raw material and method for preparing a low-fluorine high-strength microcrystalline glass plate. The microcrystalline glass aggregate raw material comprises 2-mesh glass ceramic granules, 8-mesh glass ceramic granules, 10-mesh glass ceramic granules and 20-mesh glass ceramic granules. Granules are used as raw materials, nucleation treatment, crystallization treatment and sintering treatment are carried out on the granules, and melting treatment for forming is not needed any more, so that the process of preparing the low-fluorine high-strength microcrystalline glass plate is optimized.

Owner:内蒙古建亨能源科技有限公司

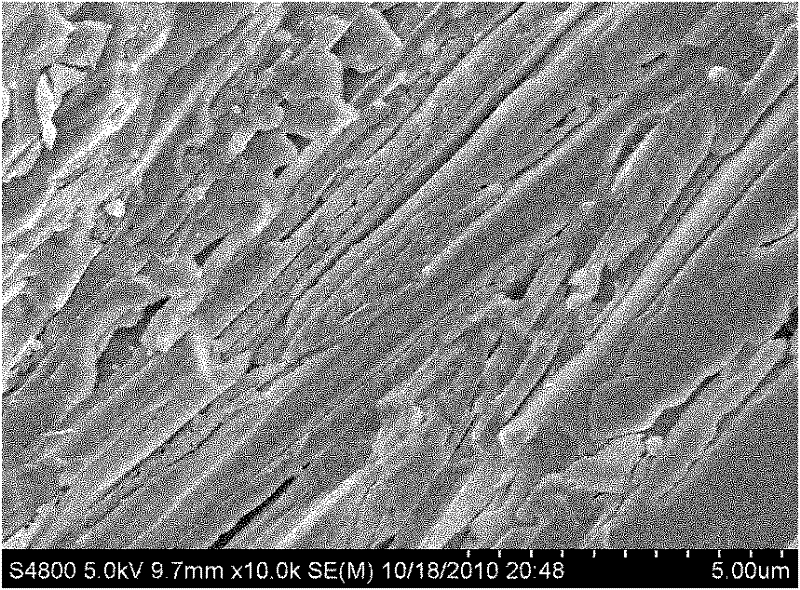

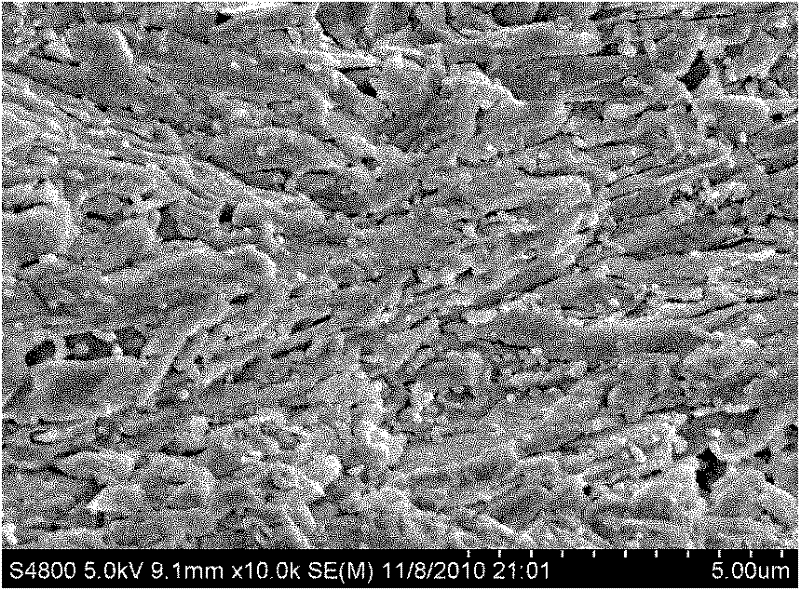

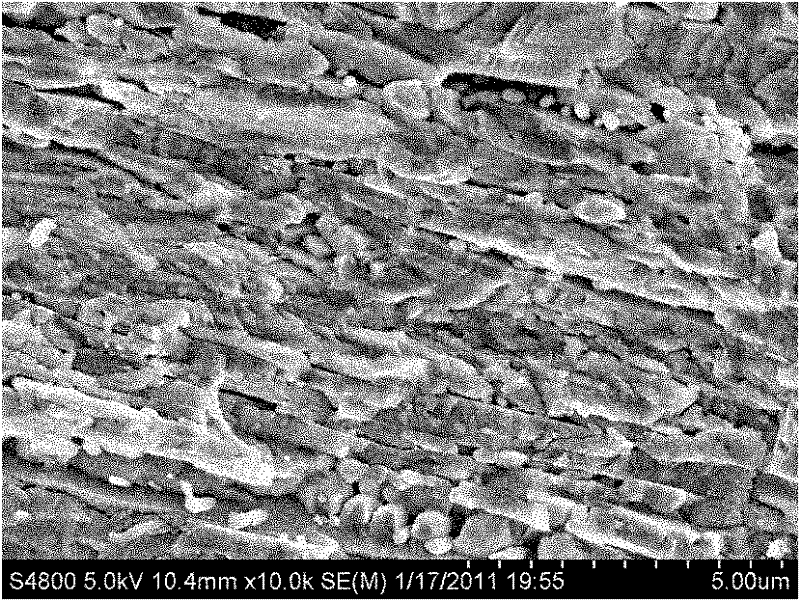

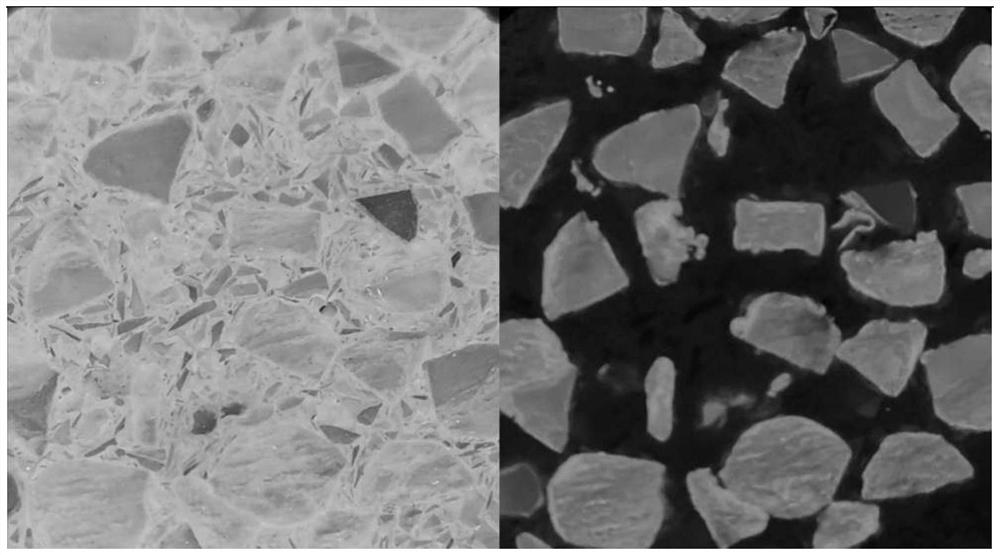

Method for improving interface adhesion between glass aggregate and asphalt by using nanometer iron oxide

The invention discloses a method for improving the interface adhesion between glass aggregate and asphalt by using nanometer iron oxide. The nanometer iron oxide is used to improve the interface adhesion between glass aggregate and asphalt in order to improve the glass aggregate utilization rate and realize good adhesion, good durability, small energy consumption and no pollution to environment. The method comprises the following steps: 1, cleaning and drying the glass aggregate for later use; 2, preparing a nanometer iron oxide solution, immersing the glass aggregate in step 1 in the nanometer iron oxide solution, and taking out and drying the glass aggregate after the surface of the glass aggregate is completed infiltrated with the nanometer iron oxide solution; and 3, immersing the glass aggregate obtained in step 2 in hot matrix asphalt to make the surface of the glass aggregate completely wrapped with the matrix asphalt.

Owner:CHANGAN UNIV

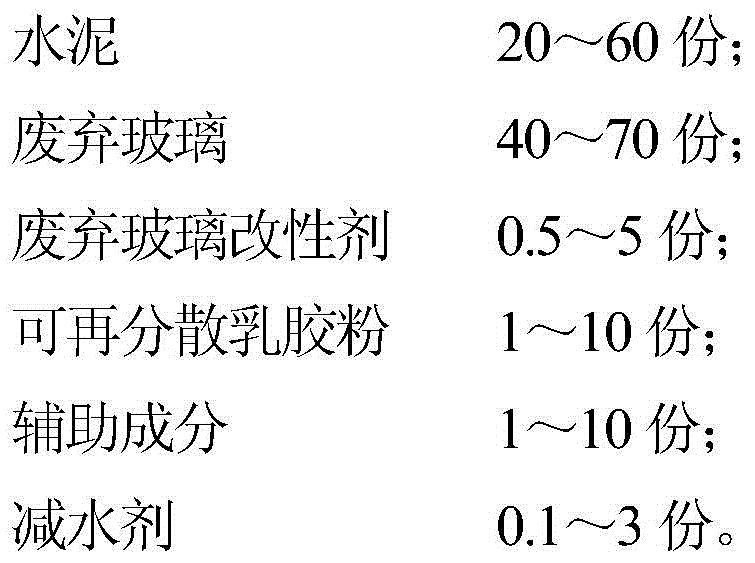

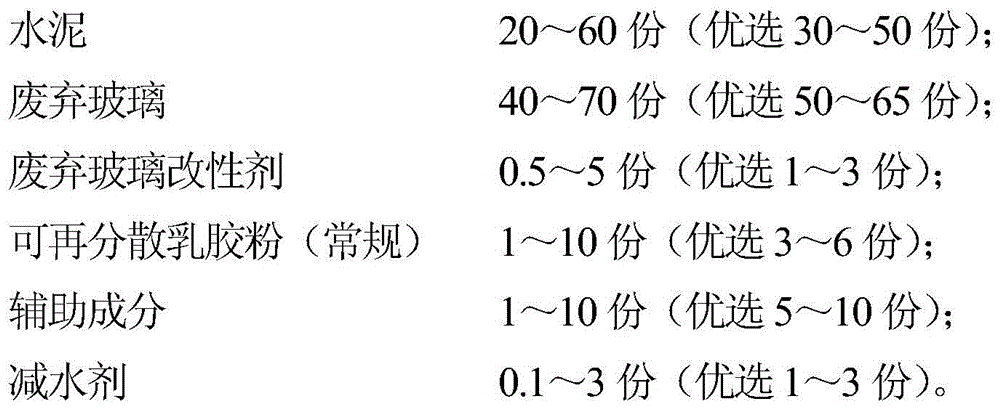

Wear-resistant ground material using waste glass and preparation method thereof

The invention relates to the field of wear-resistant ground material, and in particular, relates to a wear-resistant ground material using waste glass and a preparation method thereof. The wear-resistant ground material comprises the components in parts by mass: 20-60 parts of cement; 40-70 parts of the waste glass; 0.5-5 parts of a waste glass modification agent; 1-10 parts of a redispersible latex powder; and 1-10 parts of auxiliary components. The preparation method comprises the steps: firstly, washing the waste glass cleanly, and processing the waste glass into particles; fully mixing the waste glass modification agent with the cement; then fully mixing the cement fully mixed with the modification agent with the redispersible latex powder and the auxiliary components; and then adding the waste glass aggregate, mixing until the color and the interface are mixed uniformly, weighing, and packing. The wear-resistant ground material has the advantages of high strength, high wear resistance, good gloss, anti-pollution function, beautiful appearance and low cost, can achieve waste utilization and environmental protection, and is suitable for road surfaces, factory floors and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Luminescent cement-based grindstone terrace system and construction process thereof

The invention discloses a luminescent cement-based grindstone terrace system and a construction process thereof. A grindstone terrace comprises a concrete base layer and a concrete cemented layer which is poured on the concrete base layer; prefabricated luminescent glass aggregate located at the same height is vertically distributed in the concrete cemented layer, and the top face of the prefabricated luminescent glass aggregate is exactly exposed; the prefabricated luminescent glass aggregate is composed of a bottomless vacuum glass column and a glass bottom cover, wherein the middle of the glass bottom cover is provided with a cylindrical protrusion; the top face of the protrusion is brushed with a long-afterglow fluorescent powder layer; and the glass bottom cover is bonded to an opening in the bottom end of the bottomless vacuum glass column, and the protrusion arranged on the glass bottom cover is located in the bottomless vacuum glass column. Basic materials of the grindstone terrace are all inorganic materials, thus the construction cost is low, and the potential safety hazard existing in an epoxy grindstone terrace is avoided; and the process is convenient and rapid, and the luminescent grindstone terrace with the better artistic aesthetic feeling can be obtained.

Owner:武汉富洛泰克材料科技有限公司

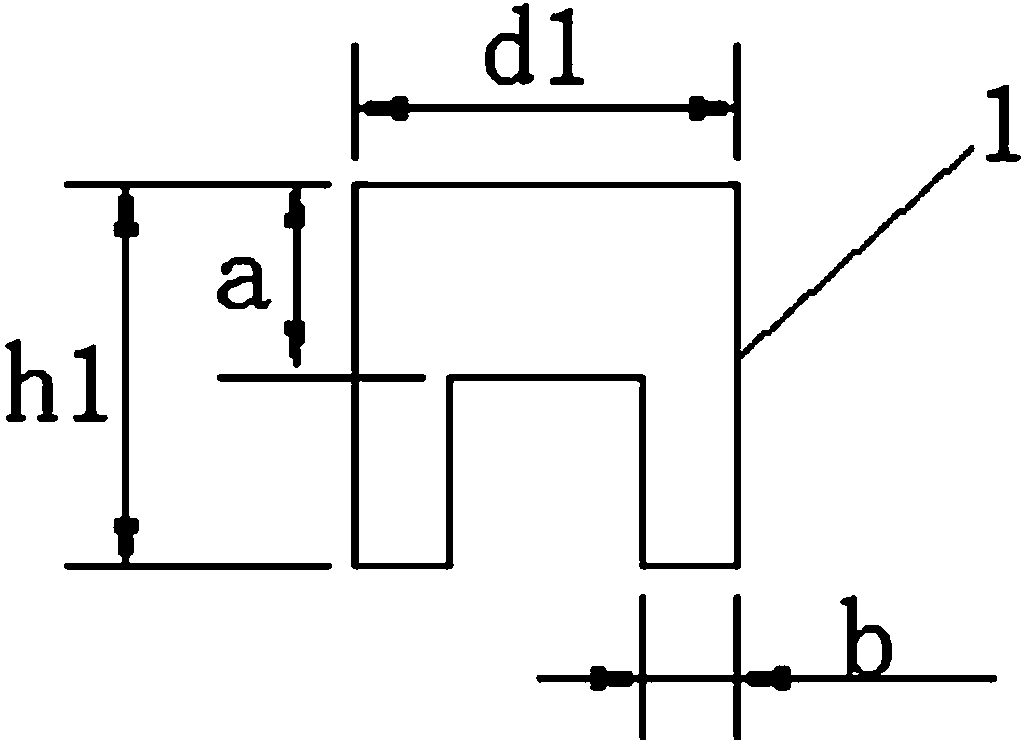

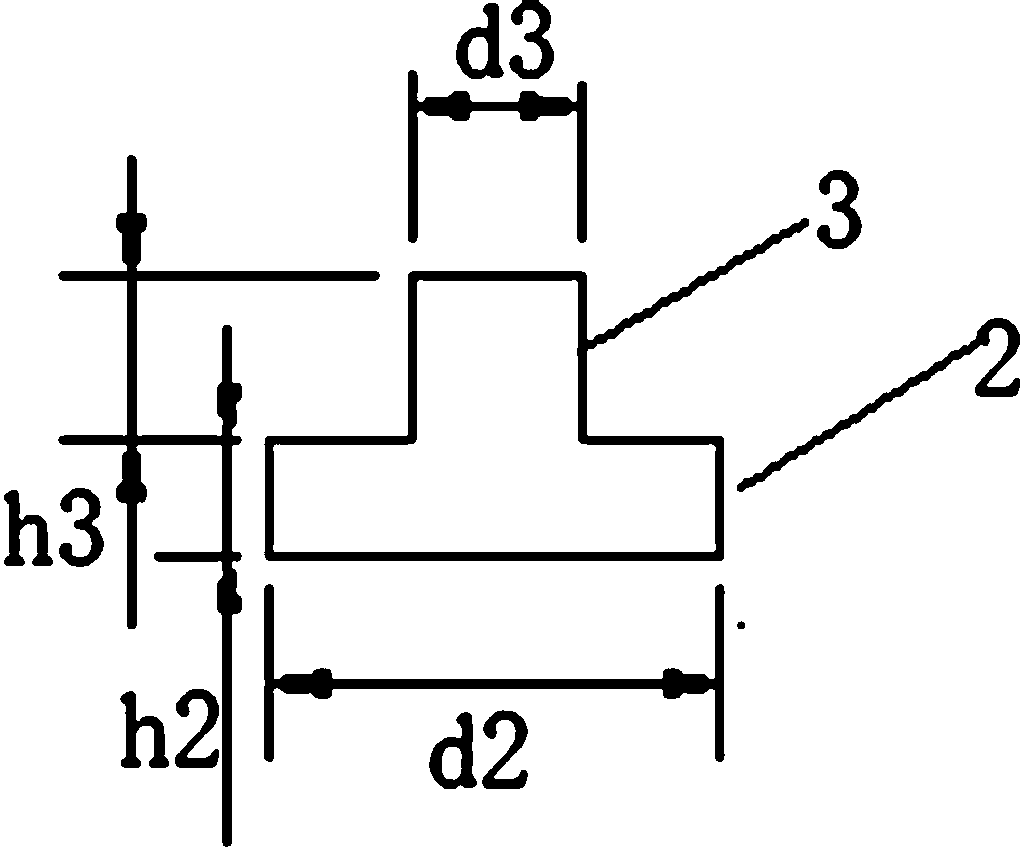

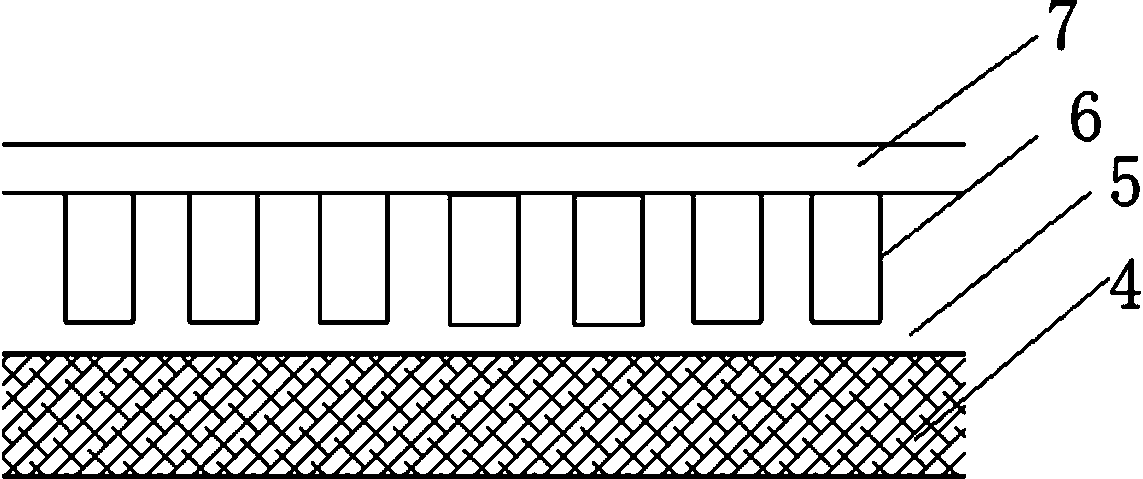

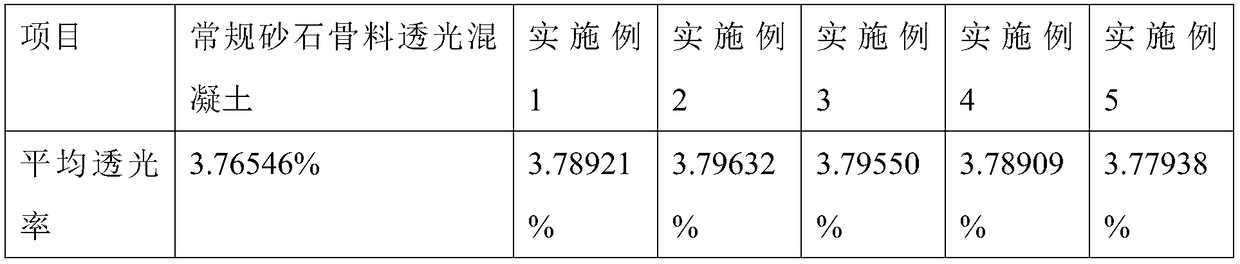

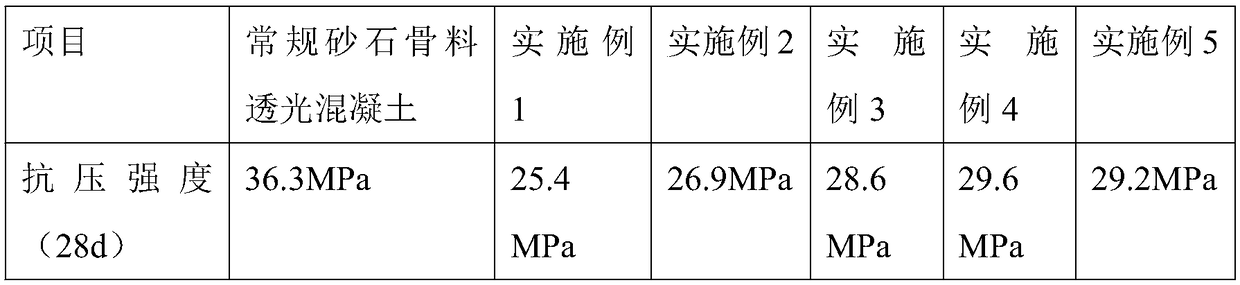

Fine glass aggregate light permeable concrete and preparation method thereof

The invention belongs to the field of building materials and in particular provides fine glass aggregate light permeable concrete and a preparation method thereof. The fine glass aggregate light permeable concrete is prepared from the following raw materials in parts by weight: 125-135 parts of water, 245-270 parts of cement, 100-120 parts of coal ash, 30-35 parts of silicon ash, 550-600 parts offine glass aggregate, 4-5 parts of a water reduction agent, 0.15-0.20 part of a thickening agent, 1.5-2.0 parts of a defoaming agent and 0.8-1.1 parts of an anti-cracking fiber, wherein the raw materials are uniformly mixed and cast into a mold full of a plastic optical fiber. As waste glass is adopted as the fine aggregate for completely replacing natural sand / machine-made sand in light permeableconcrete, property requirements of the light permeable concrete can be met, and a novel way is provided for resource utilization of the waste glass and natural sand resource conservation.

Owner:成都宏基建材股份有限公司

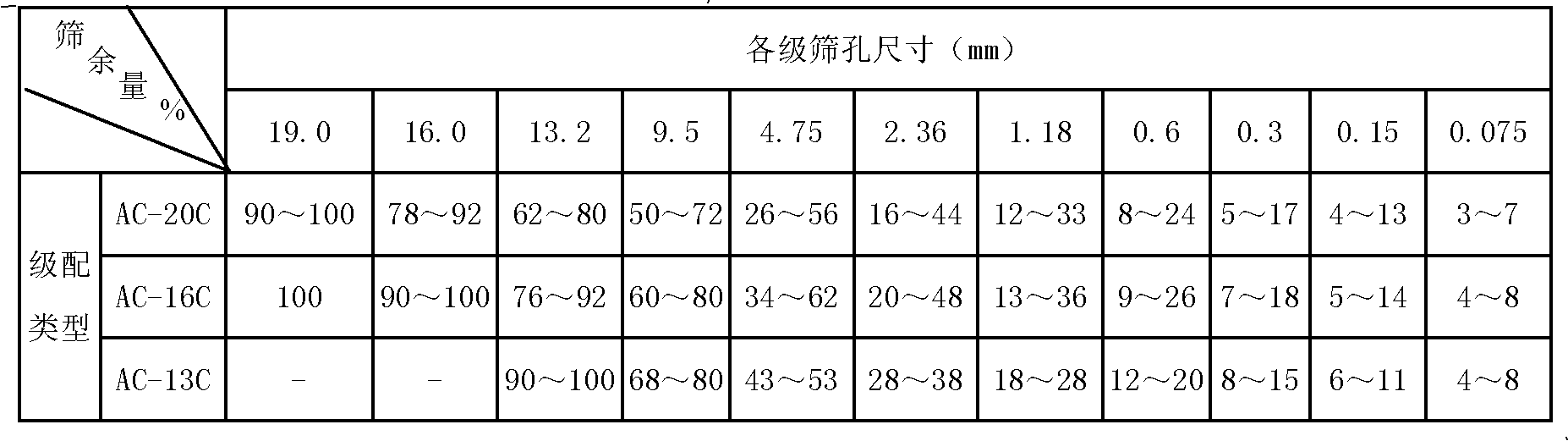

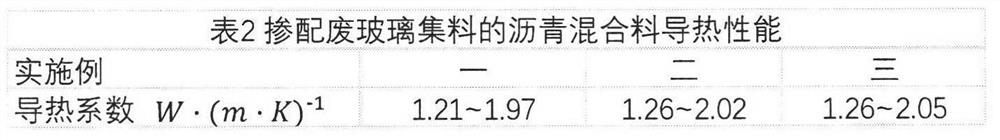

Bituminous mixture doped with glass aggregates and preparation method thereof

The invention discloses a bituminous mixture doped with glass aggregates and a preparation method thereof. The invention aims to prepare a mixture having the advantages of excellent deformation performance and thermodynamic performance and high water stability and high-temperature stability, so as to increase the use ratio of the waste glass and protect the environment. The bituminous mixture comprises the following materials in parts by weight: 6.0-10.0 parts of matrix asphalt, 12.0-20.0 parts of coarse glass aggregates, 6.0-18.0 parts of fine glass aggregates, 8.0-16.0 parts of mineral powder and 1.0-1.5 parts of a TPS modifier, wherein the grain sizes of the coarse glass aggregates are more than 4.75mm but less than or equal to 16mm; the grain sizes of the fine glass aggregates are more than 0.6mm but less than or equal to 4.75mm; and limestone mineral powder is used as the mineral powder.

Owner:CHANGAN UNIV

Manufacturing method of green, environment-friendly and multifunctional concrete building blocks

The invention aims to provide a manufacturing method of multifunctional concrete building blocks through effectively pressing building wastes, recycled lead-containing waste cathode ray tube cone glass (TFG) and Nano-TiO2 through a pressing machine. The method comprises the following steps: uniformly dry-stirring cement, fly ash, recycled fine aggregates, recycled coarse aggregates, the Nano-TiO2and lead-containing waste glass aggregates subjected to acid washing to obtain a mixture; then adding water into the mixture; finally putting the obtained mixture into a steel mould; firstly performing pressing and compaction at a first time by using the pressing machine; leveling the mixture on the surface of a test piece and then performing pressing and molding by using the pressing machine to obtain the green, environment-friendly and multifunctional concrete building blocks. According to the concrete building blocks manufactured by using the method disclosed by the invention, the requirements on mechanical performance and durability performance can be met; moreover, the concrete building blocks also have a plurality of practical functions, such as sealing and safekeeping of lead oxide,radiation prevention and air purification, and can be applied to places, such as roads, hospitals, factories and nuclear industry, which require air purification or X-ray protection.

Owner:HUNAN UNIV

Concrete paving brick capable of purifying air and method for manufacturing the same

Owner:THE HONG KONG POLYTECHNIC UNIV

Application of waste glass and preparation method of colorful tempered-glass aggregate for slippery road surface

InactiveCN106145623AEasy to form porcelainSave energyGlass shaping apparatusMetallurgyExpanded clay aggregate

The invention discloses an application of waste glass and a preparation method of colorful tempered-glass aggregate for a slippery road surface. The preparation method includes: using the waste glass as the colorful tempered-glass aggregate for the slippery road surface; grinding the waste glass into powder, adding high-temperature pigment, and pelleting through high-strength rolling to form irregular particles; quickly calcining the irregular particulars at low temperature to have the same sintered into high-strength anti-sliding color particles. The colorful tempered-glass aggregate is made by recycling the waste glass, waste materials are utilized, and environmental protection is achieved; dry powder is used for pelleting during the entire course, drying is not needed, and energy is saved; low-temperature quick calcining is adopted, calcination can be performed at the temperature ranging from 650 degrees to 700 degrees, and the calcination temperature of the ceramic particles of an ordinary road surface ranges from 1000 degrees to 1100 degrees; as it measured, one-ton of fire coal can be saved for each production of one-ton of the aggregate; granulation calcination of the glass powder is adopted, so that melting point is low, porcelain is easily formed on the surface of the aggregate which is more colorful than common ceramic particles and free from fast color.

Owner:广东邦宁新材料科技有限公司

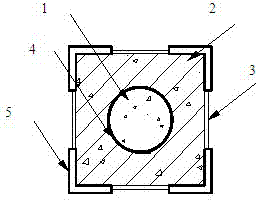

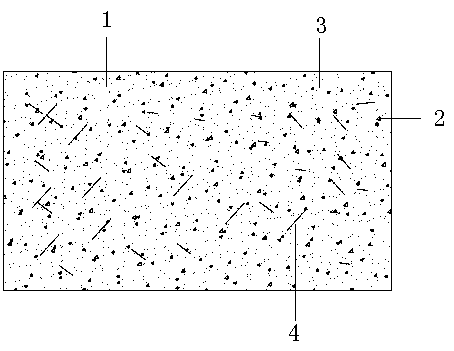

Steel rib-steel tube glass concrete combined column

The invention relates to a concrete component, and in particular relates to a steel rib-steel tube glass concrete combined column in civil engineering. The steel rib-steel tube glass concrete combined column consists of steel tubes, steel ribs and glass concrete, and concrete comprises glass fragments serving as aggregates; the glass concrete comprises coarse glass aggregates with grain diameter of 5-30mm, and fine glass aggregates with grain diameter of 0.1-3mm; according to the volume of each cubic meter of the glass concrete, 300-1,500kg of the coarse aggregate glass, 300-1,500kg of the fine aggregate glass, 400-600kg of the cement and 150-300kg of water are mixed sufficiently; the glass concrete comprises elementary glass, organic glass and inorganic glass. The steel rib-steel tube glass concrete combined column is a main component of a building frame structure in high-rise buildings, and has the characteristics of high bearing capacity, high rigidity, light weight, good plasticity and toughness, good impact and fatigue resistance, excellent earthquake resistance and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

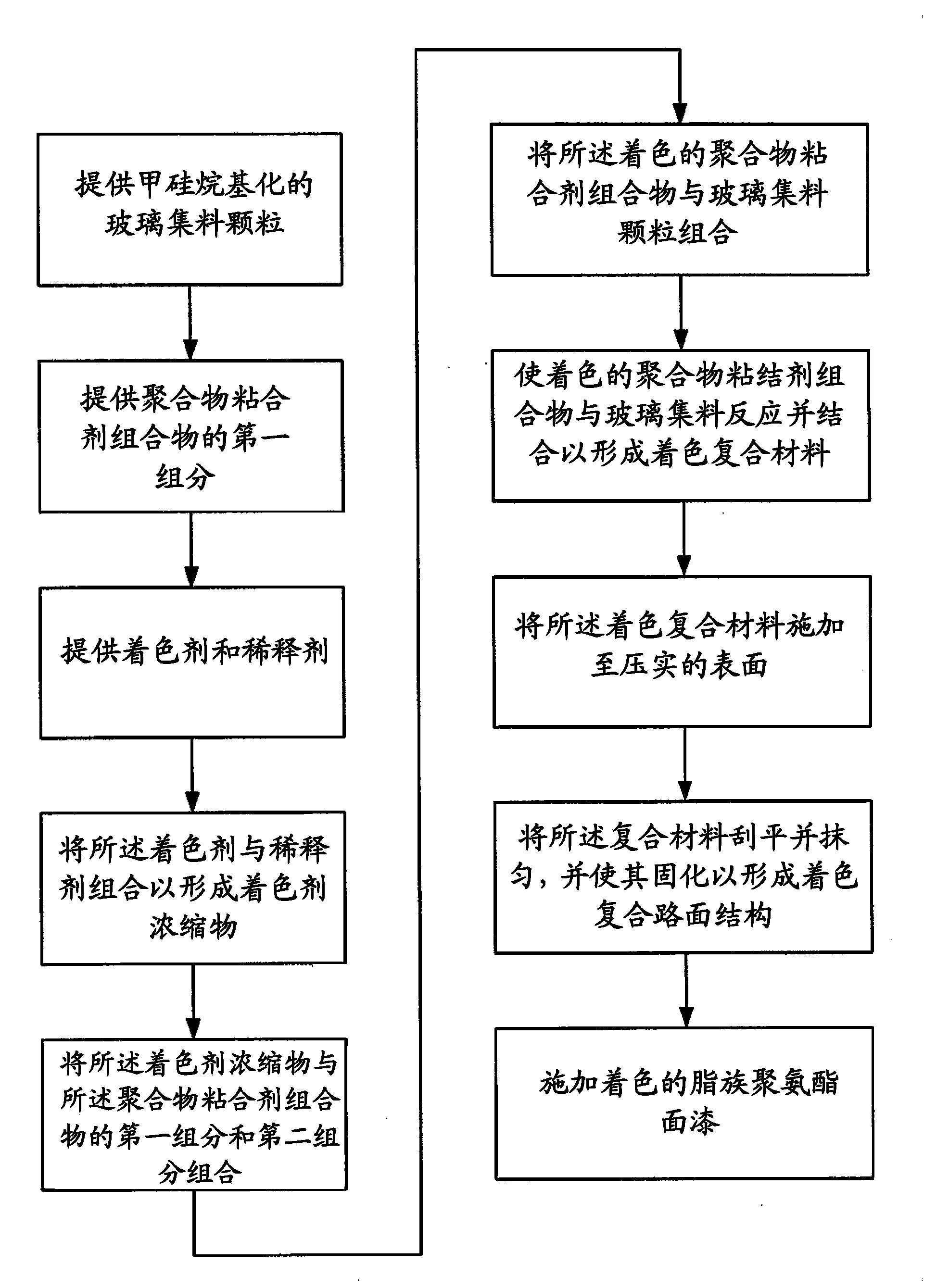

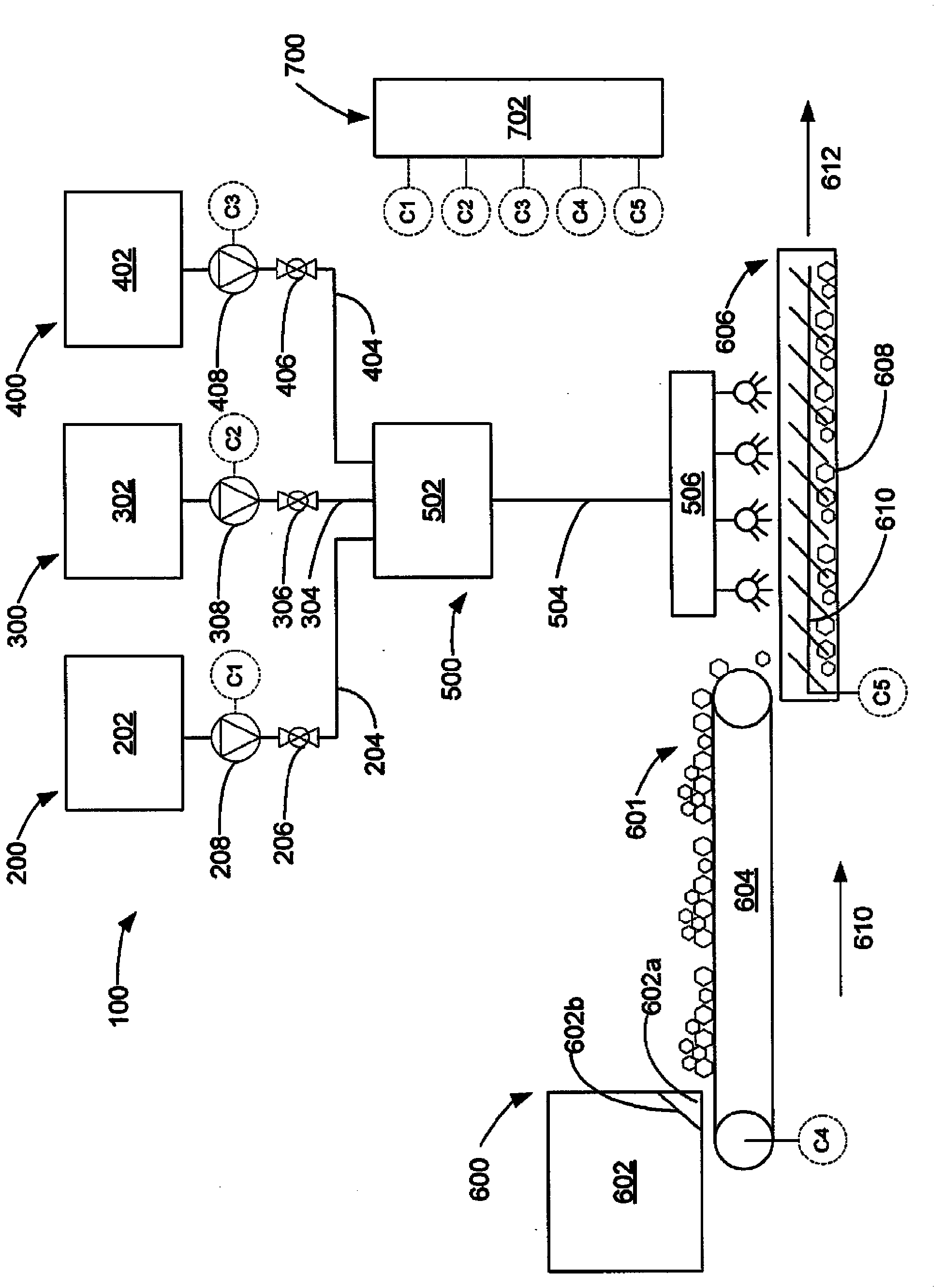

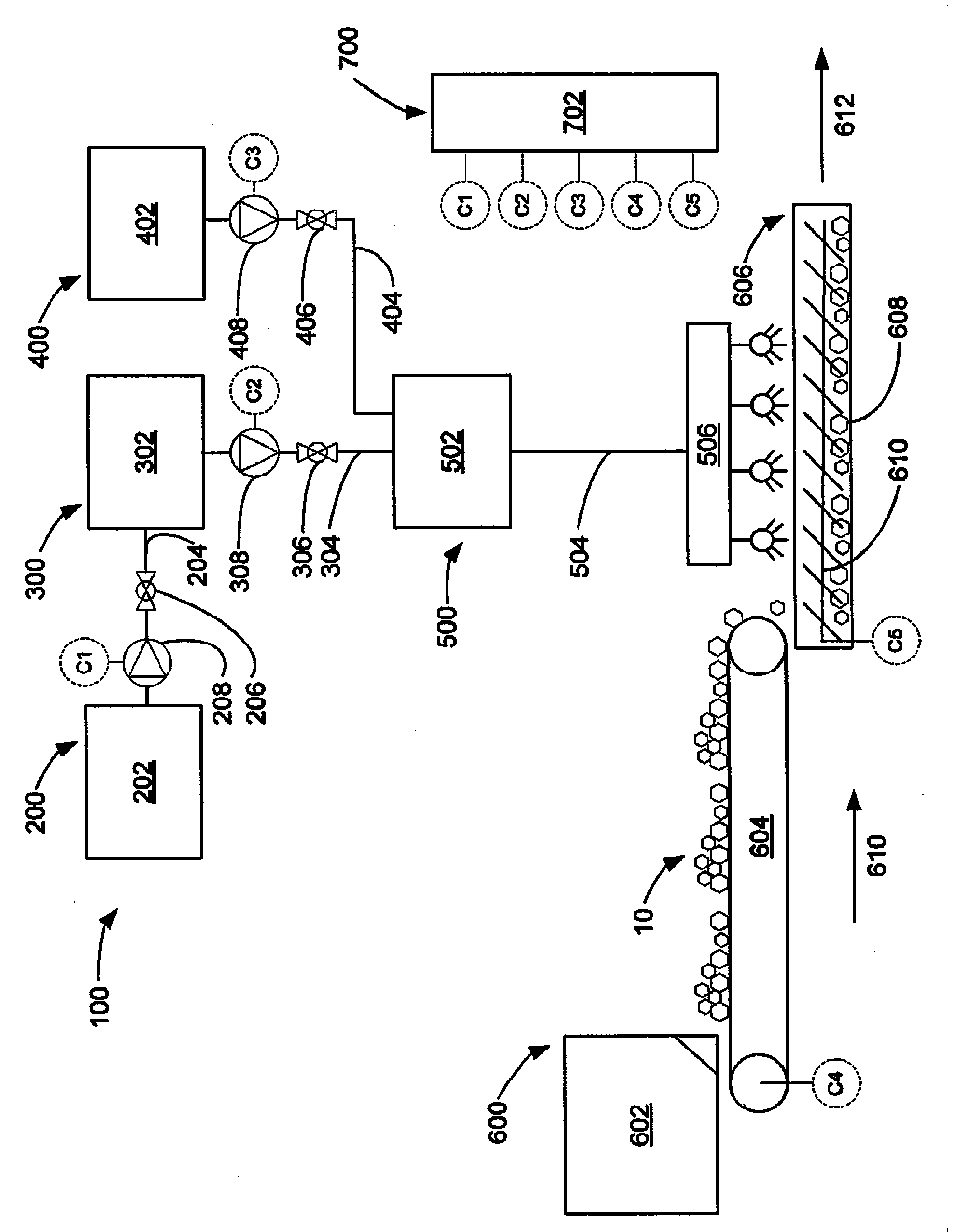

Colored composite pavement structure

A process for making a colored composite pavement structure comprising silylated glass aggregate particles and a polymeric binder composition is disclosed. Systems and methods are also disclosed for providing a colored composite material that cures into a pavement structure. In one embodiment, a colorant concentrate is provided by combining an inorganic colorant with a portion of a first component of a polymeric binder composition. The colorant concentrate can then be combined with the first and second components of the polymeric binder composition to provide a colored polymeric binder composition. The colored polymeric binder composition may then be applied to silylated glass aggregate particles to provide a colored composite material that cures into a pavement structure.

Owner:BASF AG

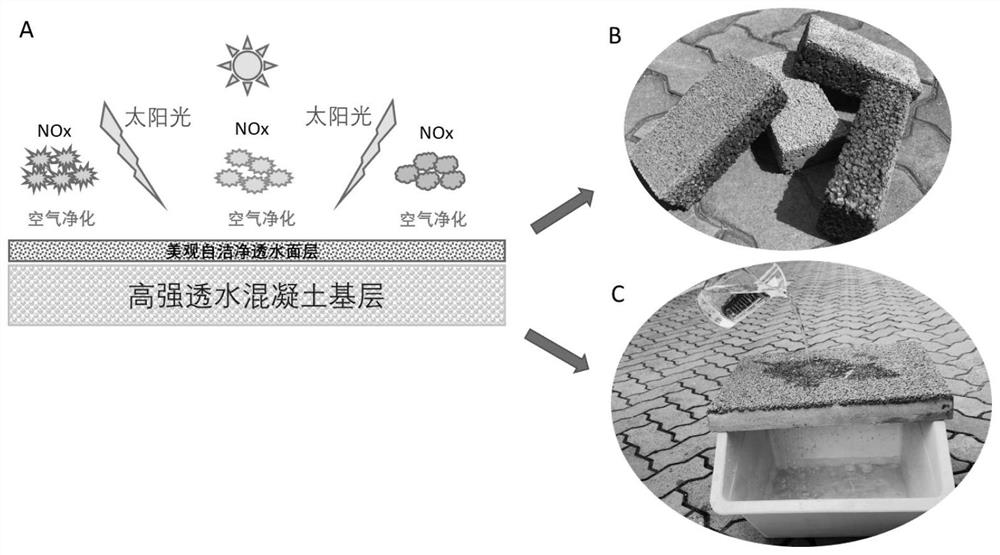

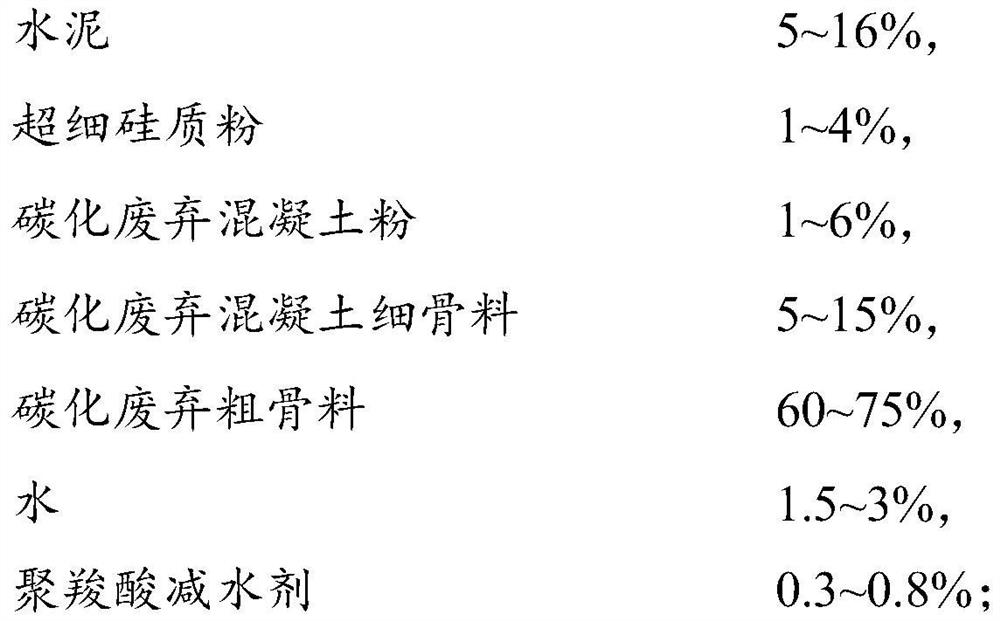

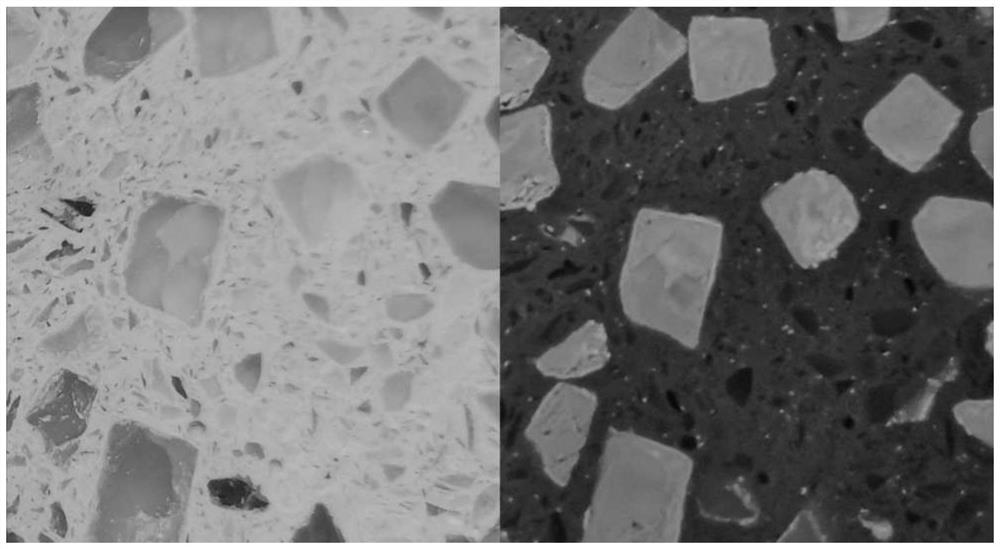

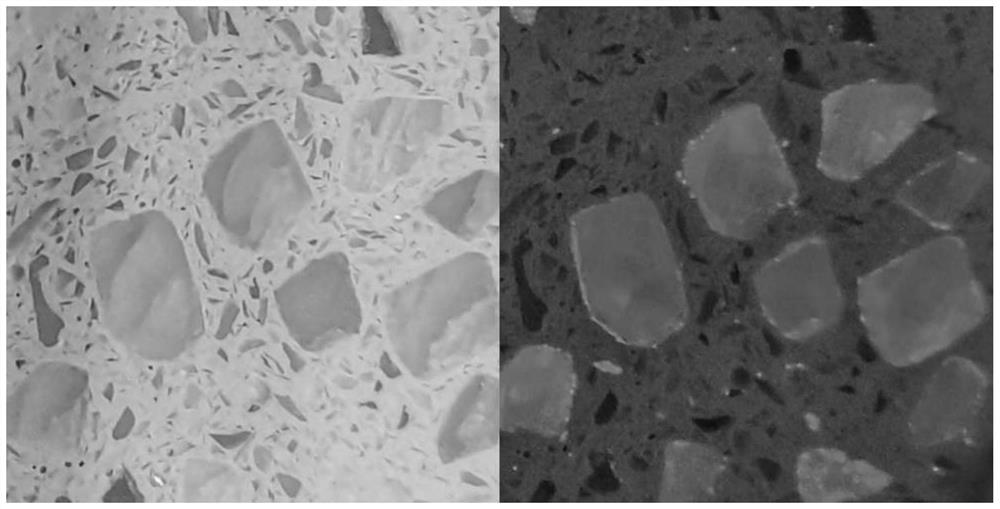

Carbon sequestration type multifunctional high-strength pervious concrete and preparation method thereof, and pavement

PendingCN113387650AImprove skid resistanceReduce manufacturing costIn situ pavingsCeramicwareSuperplasticizerCarboxylic acid

The invention belongs to the technical field of building materials, and particularly relates to carbon sequestration type multifunctional high-strength pervious concrete and a preparation method thereof, and a pavement. The carbon sequestration type multifunctional high-strength pervious concrete provided by the invention comprises a base layer composition and a surface layer composition. The base layer composition is prepared from the following components in percentage by mass: 5 to 16% of cement, 1 to 4% of superfine siliceous powder, 1 to 6% of carbonized waste concrete powder, 5 to 15% of carbonized waste concrete fine aggregate, 60 to 75% of carbonized waste coarse aggregate, 1.5 to 3% of water and 0.3 to 0.8% of a polycarboxylate superplasticizer. The surface layer composition comprises the following components in percentage by mass: 5-16% of cement, 1-4% of superfine siliceous powder, 1-6% of carbonized waste concrete powder, 65-80% of glass aggregate, 1.5-3% of water, 0.3-0.8% of a polycarboxylate superplasticizer, 0.1-3% of a photocatalyst and 0.2-3% of pigment. The invention provides the concrete with high strength and high water permeability.

Owner:THE HONG KONG POLYTECHNIC UNIV

Waste glass self-luminous aggregate concrete decorative material and preparation method thereof

The invention discloses a waste glass self-luminous aggregate concrete decorative material and a preparation method thereof, and belongs to the field of solid waste recycling and building materials. According to the invention, the waste glass is recycled, the application range of the concrete material is expanded, and the problems of high sintering temperature, easy introduction of impurities andthe like in the preparation process of the luminescent glass are solved. The method specifically comprises the following steps: 1, cleaning, crushing and sieving waste glass to form glass aggregate; 2, stirring an adhesive and the glass aggregate to uniformly mix the adhesive and the glass aggregate; 3, mixing and stirring a long-afterglow luminescent material to enable the long-afterglow luminescent material to coat the surface of the glass-adhesive mixture, and curing to form self-luminescent glass aggregate; 4, uniformly stirring a cementing material, the glass aggregate, the luminescent glass aggregate, an additive, water and the like, and carrying out die-filling molding; and 5, after hardening, demoulding and curing to obtain the waste glass luminescent aggregate concrete decorativematerial. The decorative material disclosed by the invention can be applied to various decorative concrete products, can greatly save the power consumption cost under the condition of meeting the decorative aesthetic property, and is environment-friendly.

Owner:HUNAN UNIV

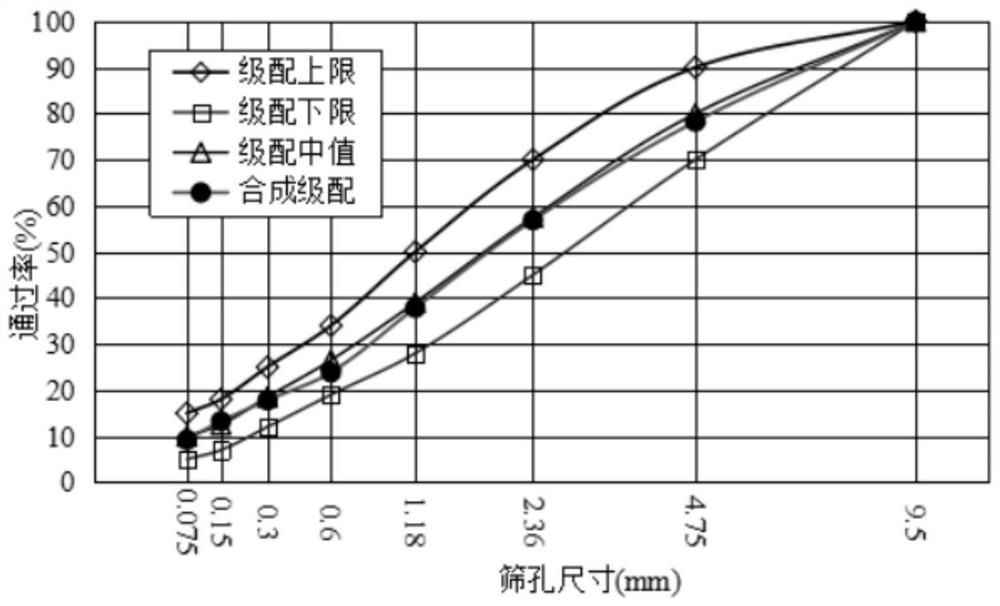

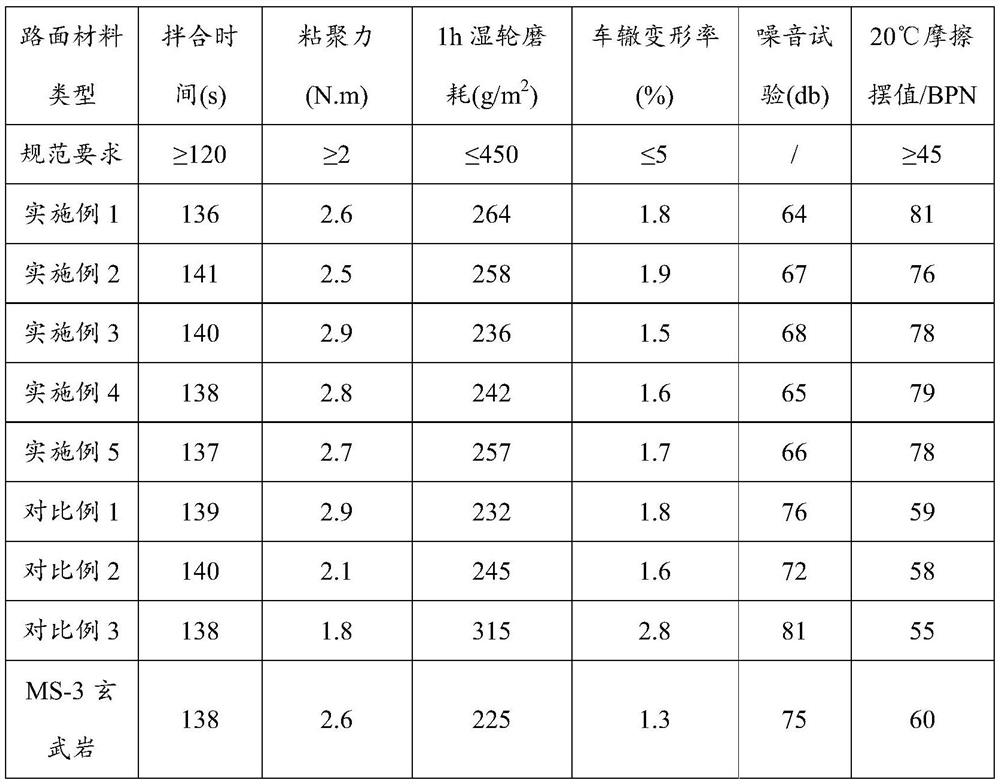

Micro-surfacing pavement material and preparation method thereof

The invention relates to a micro-surfacing pavement material and a preparation method thereof. The micro-surfacing pavement material is prepared from aggregate, emulsified asphalt and water, and the mass ratio of the aggregate to the emulsified asphalt to the water is 1:(0.06-0.08):(0.05-0.06); the aggregate is prepared from the following components in percentage by mass: 30-42 percent of steel slag coarse aggregate, 42-46 percent of steel slag fine aggregate, 5-12 percent of glass aggregate, 1-3 percent of rubber particle aggregate and 5-7 percent of filler. The invention also comprises a preparation method of the micro-surfacing pavement material, and the preparation method comprises the following steps: mixing the steel slag coarse aggregate, the steel slag fine aggregate, the glass aggregate, the rubber particle aggregate and the filler according to the proportion of each component, adding water for wetting, adding the emulsified asphalt, and mixing to obtain the micro-surfacing pavement material. The micro-surfacing pavement material has excellent and stable skid resistance and wear resistance, and the BPN value is as high as 81.

Owner:WUHAN UNIV OF TECH

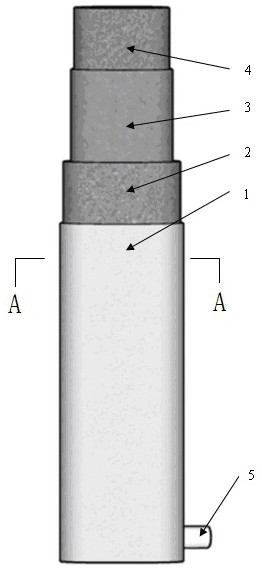

Novel concrete-filled steel tube composite column filled with steel slag and waste glass concrete and preparation method thereof

PendingCN112227603AImprove restraintImprove corrosion resistanceStrutsFeeding arrangmentsSlagGlass aggregate

The invention relates to a novel concrete-filled steel tube composite column filled with steel slag and waste glass concrete and a preparation method thereof. The novel concrete-filled steel tube composite column filled with the steel slag and waste glass concrete is characterized in that the novel concrete-filled steel tube composite column filled with steel slag and waste glass concrete comprises a stainless steel outer steel tube and a carbon steel inner steel tube concentrically arranged in the stainless steel outer steel tube; the tube diameter of the carbon steel inner steel pipe is smaller than that of the stainless steel outer steel tube; steel slag and waste glass aggregate concrete is poured into an inner cavity formed in the carbon steel inner steel tube; steel slag lightweightaggregate concrete is poured into an annular partition cavity formed between the carbon steel inner steel tube and the stainless steel outer steel tube; the lower part of the stainless steel outer steel tube and the lower part of the carbon steel inner steel tube extend into an inner cavity from the outside of the stainless steel outer steel tube to form a concrete pouring tube; and at least one discharging port is formed in the concrete pouring tube. The novel concrete-filled steel tube composite column filled with the steel slag and waste glass concrete stainless steel pipe concrete composite column has the advantages that the ductility is good, the energy dissipation capacity is high and the novel concrete-filled steel tube composite column is suitable for being used in areas with highearthquake fortification requirements.

Owner:FUZHOU UNIV

Asphalt mixture doped with waste glass aggregate and preparation method of asphalt mixture

The invention discloses an asphalt mixture doped with waste glass aggregate and a preparation method of the asphalt mixture, and aims to improve the doping amount of the waste glass aggregate to about30% to the maximum extent by taking fixed mineral aggregate gradation and replacing mineral aggregates with corresponding particle sizes with the same mass of the waste glass aggregate. Meanwhile, the problem that the adhesiveness of common asphalt and glass aggregate is insufficient is solved. The obtained mixture not only can keep good pavement performance, but also can reduce the pavement surface temperature in summer. In addition, the use of the mixture can greatly promote the recycling of the waste glass, and accords with the ideas of green energy conservation, environmental protection and sustainable development. The asphalt mixture is prepared from the following components in parts by mass: 4.3 to 5.3 parts of matrix asphalt, 2.5 to 7.5 parts of waste glass aggregate, 60.1 to 63.0parts of coarse aggregate, 22.9 to 25.2 parts of fine aggregate and 4.7 to 4.8 parts of mineral powder.

Owner:NANJING FORESTRY UNIV

Method of producing a cementitious sheet-form material having a high level of glass aggregate and a solid surface

ActiveUS20110037200A1High densityReduce porositySolid waste managementCeramic shaping apparatusGlass aggregateAqueous solution

Owner:POLYCOR VETRAZZO +5

A method of improving interfacial adhesion between glass aggregate and asphalt by using nano-iron oxide

The invention discloses a method for improving the interface adhesion between glass aggregate and asphalt by using nanometer iron oxide. The nanometer iron oxide is used to improve the interface adhesion between glass aggregate and asphalt in order to improve the glass aggregate utilization rate and realize good adhesion, good durability, small energy consumption and no pollution to environment. The method comprises the following steps: 1, cleaning and drying the glass aggregate for later use; 2, preparing a nanometer iron oxide solution, immersing the glass aggregate in step 1 in the nanometer iron oxide solution, and taking out and drying the glass aggregate after the surface of the glass aggregate is completed infiltrated with the nanometer iron oxide solution; and 3, immersing the glass aggregate obtained in step 2 in hot matrix asphalt to make the surface of the glass aggregate completely wrapped with the matrix asphalt.

Owner:CHANGAN UNIV

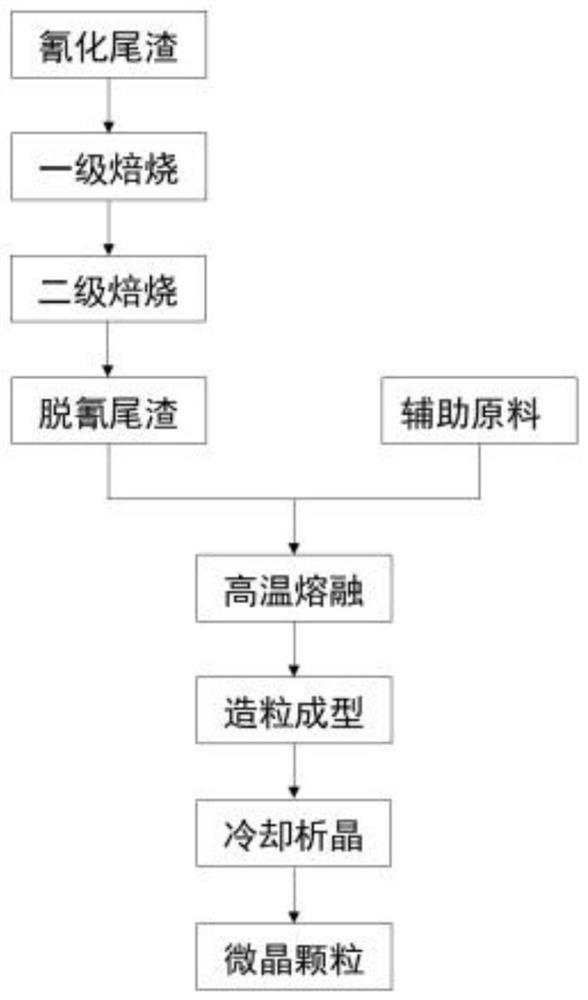

Method for harmlessly treating cyaniding tailings by utilizing microcrystalline glass granule surface crystallization process

ActiveCN112390526AAchieve solidificationImprove stabilityGlass shaping apparatusProcess efficiency improvementPhysical chemistryEngineering

The invention provides a method for harmlessly treating cyaniding tailings by using a microcrystalline glass aggregate surface crystallization process, which comprises the following steps: carrying out two-stage roasting decyanation on the cyaniding tailings subjected to filter pressing, proportioning the decyanated cyaniding tailings and auxiliary components according to a certain ratio, meltingthe batch at high temperature to obtain a glass liquid, after high-temperature molten glass is uniformly clarified, by a granulator, carrying out granulation, autonomously carrying out surface crystallization on the prepared glass particles in air to form microcrystalline glass particles of a 'ground curtain ' structure with crystal shells on the surfaces and amorphous cores inside, wherein heavymetal elements in the cyaniding tailings can serve as phase forming components in the crystal shells to form a new crystal phase, and solidifying the heavy metal elements in the amorphous core in a glass grid of the amorphous core. The microcrystalline glass particles can be used for preparing novel cementing materials for mine cemented filling and filling body aggregates. The method provided by the invention can realize heavy metal solidification of the cyaniding tailings and comprehensive utilization of the microcrystalline glass solidified body.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Photosensitive controllable rapid-hardening concrete pouring material and construction method thereof

InactiveCN111499258AHigh strengthControlled hardeningBridge erection/assemblyBridge strengtheningGlass fiberArchitectural engineering

The invention discloses a photosensitive controllable rapid hardening concrete pouring material and a construction method. The pouring material comprises shadowless glue, transparent stone or broken glass aggregate, sand and glass fibers, wherein the transparent stone or broken glass aggregate, the sand and the glass fibers are uniformly stirred and then mixed with the shadowless glue, and full stirring is conducted to obtain the pouring material. According to the method, sunlight irradiation is avoided in the stirring process, and an LED lamp is adopted for illumination; then the pouring material is injected into a mold for molding treatment, a gravity self-leveling mode is adopted for horizontal pouring, and a transparent organic glass mold without an ultraviolet filtering effect is adopted for side pouring; an ultraviolet lamp is adopted for irradiation, ultraviolet rays penetrate into the pouring material through the transparent aggregate and the glass fibers, and the shadowless glue is cured and formed under irradiation of the ultraviolet rays; and the mold is dismounted and directly irradiated by sunlight, so the strength of the pouring material after curing is improved. Thepouring material and the construction method can be used for rapid construction and emergency repair of a concrete structure, and have the characteristics of short curing time, high strength after curing, good durability and the like.

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

Hybrid nanoparticle reinforced ecological pervious concrete and preparation method thereof

The invention discloses hybrid nanoparticle reinforced ecological pervious concrete and a preparation method thereof, wherein the ecological pervious concrete comprises 200 to 350 parts of cement, 15to 60 parts of fly ash, 200 to 900 parts of broken stone, 200 to 800 parts of waste glass aggregate, 0.02 to 0.06 part of cellulose ether, 0.05 to 0.3 part of fatty alcohol emulsion, 3 to 15 parts ofnano titanium dioxide, 12 to 25 parts of a hybrid nanoparticle solution and 60 to 120 parts of water. The preparation method of the concrete comprises the following steps: (1) uniformly mixing water,nano titanium dioxide and waste glass aggregate to obtain a mixture; (2) preparing a hybrid nanoparticle solution; (3) adding cement, fly ash, broken stone, cellulose ether, fatty alcohol emulsion andthe hybrid nanoparticle solution into the mixture obtained in the step (1), and stirring; and (4) pouring the product obtained in the step (2) into a mold, maintaining for 7-28 days, and demolding toobtain the hybrid nanoparticle reinforced ecological pervious concrete. According to the concrete, the degradation effect of pervious concrete on pollutants can be improved, the corrosion resistancecoefficient of the concrete reaches 96%, the pervious coefficient reaches 5.1 mm / s, and the 28d compressive strength reaches 35.5 Mpa.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com