Luminescent cement-based grindstone terrace system and construction process thereof

A cement-based, luminous technology, applied in buildings, building structures, floors, etc., can solve the problems of limiting the wide-scale application of epoxy grindstone floors and high cost, achieving the effect of low cost and avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

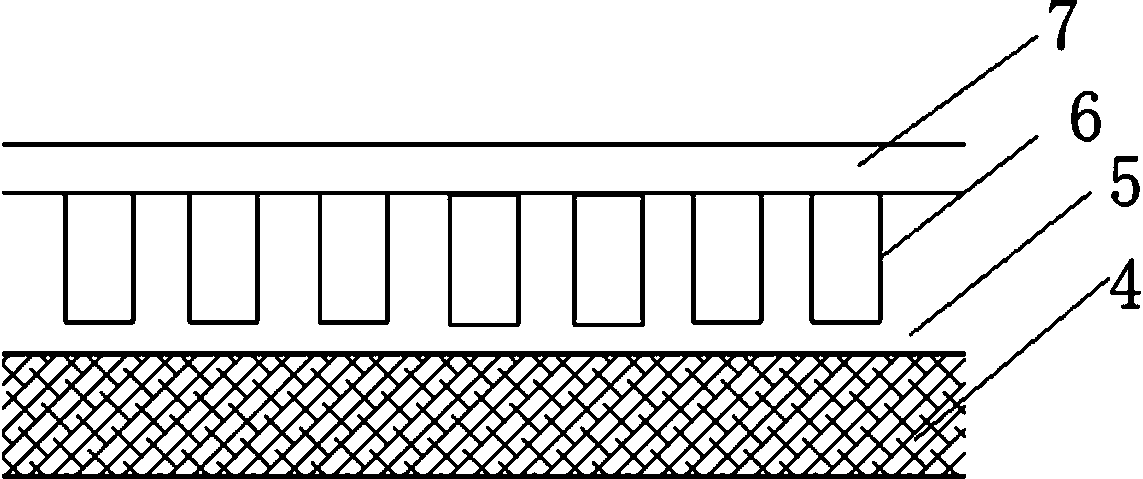

[0037] The luminescent cement-based terrazzo floor system of the present invention mainly needs two kinds of raw materials: prefabricated luminous glass aggregate and premixed concrete binder. This embodiment will provide the structure and manufacturing process of the prefabricated luminescent glass aggregate.

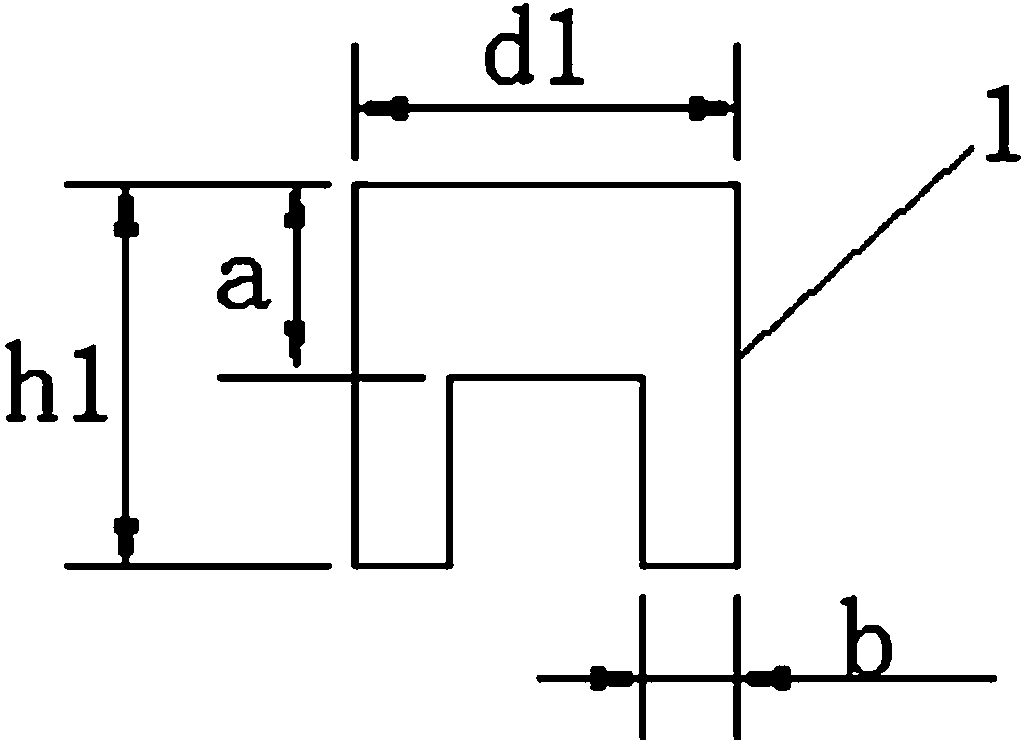

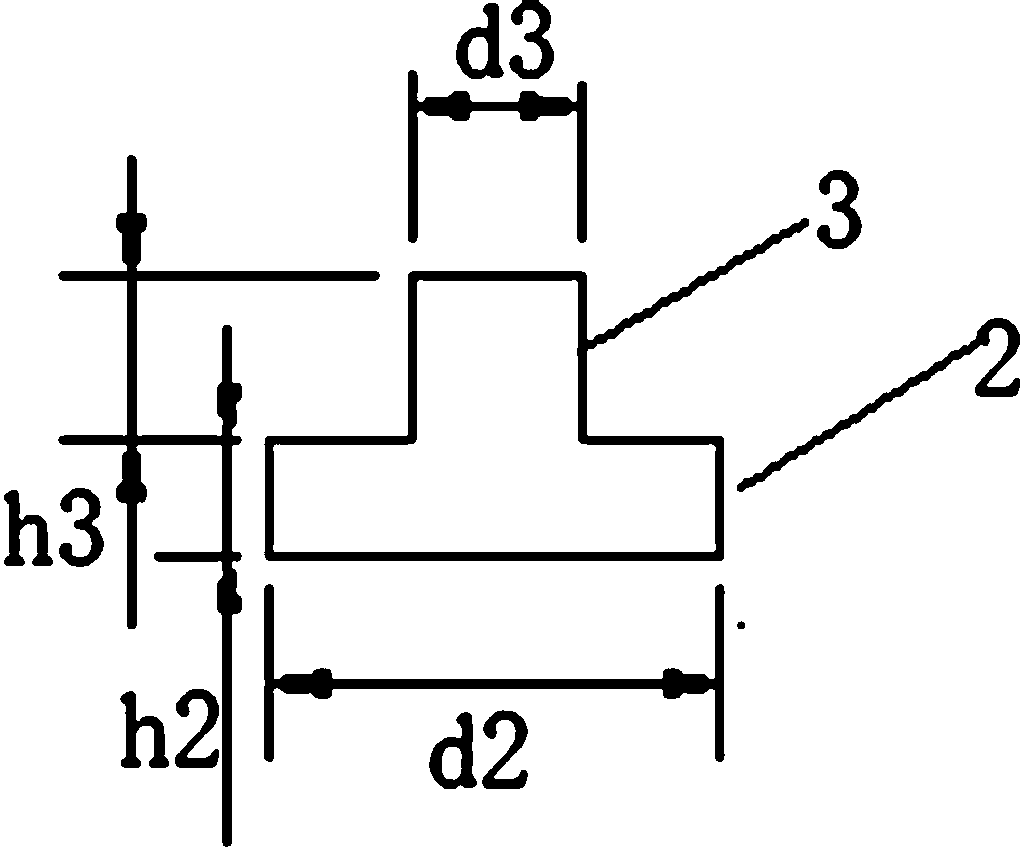

[0038] The prefabricated luminescent glass aggregate is composed of a bottomless hollow glass column 1 and a glass bottom cover 2 with a cylindrical protrusion 3 in the middle. For the structures of the bottomless hollow glass column 1 and the glass bottom cover 2, see figure 1 with figure 2 . The top surfaces of the protrusions 3 are brush-coated with a long-lasting phosphor layer. Long afterglow phosphor is a luminescent material based on alkaline earth strontium aluminate and doped with dysprosium, europium and other rare earth elements as activators. It has no radioactive pollution and can achieve the effect of excitation for ten minutes and continuous luminesce...

Embodiment 2

[0046] This embodiment is an embodiment of a premixed concrete binder, and the premixed concrete binder is a non-shrinking concrete binder.

[0047] In this embodiment, the premixed concrete binder includes components in the following weight ratio: high belite quick-setting quick-hardening cement: finely ground quartz sand: titanium dioxide: rubber powder: tartaric acid: powder water reducer: defoamer :thickener=1:1.1944:0.0556:0.0139:(0~0.0056):0.0042:0.0027:0.0014.

[0048] In this embodiment, the high belite fast-setting rapid-hardening cement is 42.5 low-alkali sulphoaluminate cement. The finely ground quartz sand is continuously graded white quartz sand of 20 mesh to 150 mesh. The fineness of titanium dioxide is 350 mesh. The rubber powder is a redispersible vinyl acetate / ethylene copolymer, its solid content is >98%, the minimum film forming temperature is 4°C, the particle size (400μm) sieve does not exceed 4%, and the main particle size is 0.5~8μm. The fineness of t...

Embodiment 3

[0052] This example will provide the construction process of the luminescent cement-based terrazzo floor system.

[0053] This construction project mainly includes three major steps: (1) base-level pretreatment; (2) slurry spreading and fixing prefabricated luminescent glass aggregate; (3) floor grinding and polishing.

[0054] The three steps will be described in detail below.

[0055] The first step is grass-roots preprocessing.

[0056] The purpose of pretreatment on the base is to obtain a flat base, so that the flatness of the base meets the requirements. First, the surface of the concrete base is milled, shot blasted and / or ground; then, the cracks and holes on the surface of the concrete base are repaired with premixed concrete binder to obtain a hard and flat concrete base. In this embodiment, the flatness of the pretreated concrete base is required to be 3mm / 2m.

[0057] After the base pretreatment is completed, fully wet the treated concrete base with tap water, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com