Patents

Literature

237 results about "Terrazzo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terrazzo is a composite material, poured in place or precast, which is used for floor and wall treatments. It consists of chips of marble, quartz, granite, glass, or other suitable material, poured with a cementitious binder (for chemical binding), polymeric (for physical binding), or a combination of both. Metal strips often divide sections, or changes in color or material in a pattern. Additional chips may be sprinkled atop the mix before it sets. After it is cured it is ground and polished smooth or otherwise finished to produce a uniformly textured surface. "Terrazzo" is also often to used to describe any pattern similar to the original terrazzo floors.

Method of making monolithic terrazzo floors having seamlessly integrated inlays

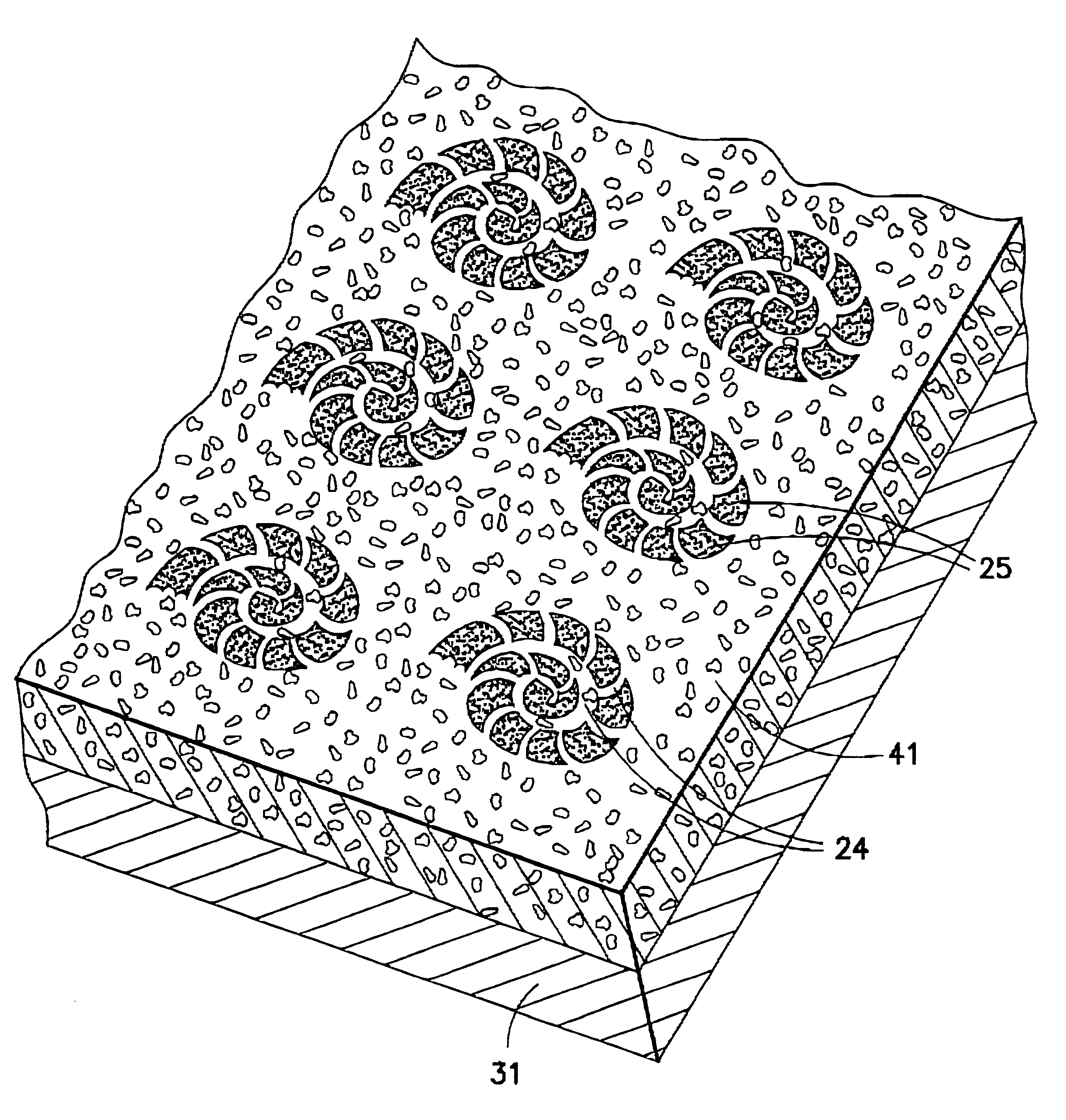

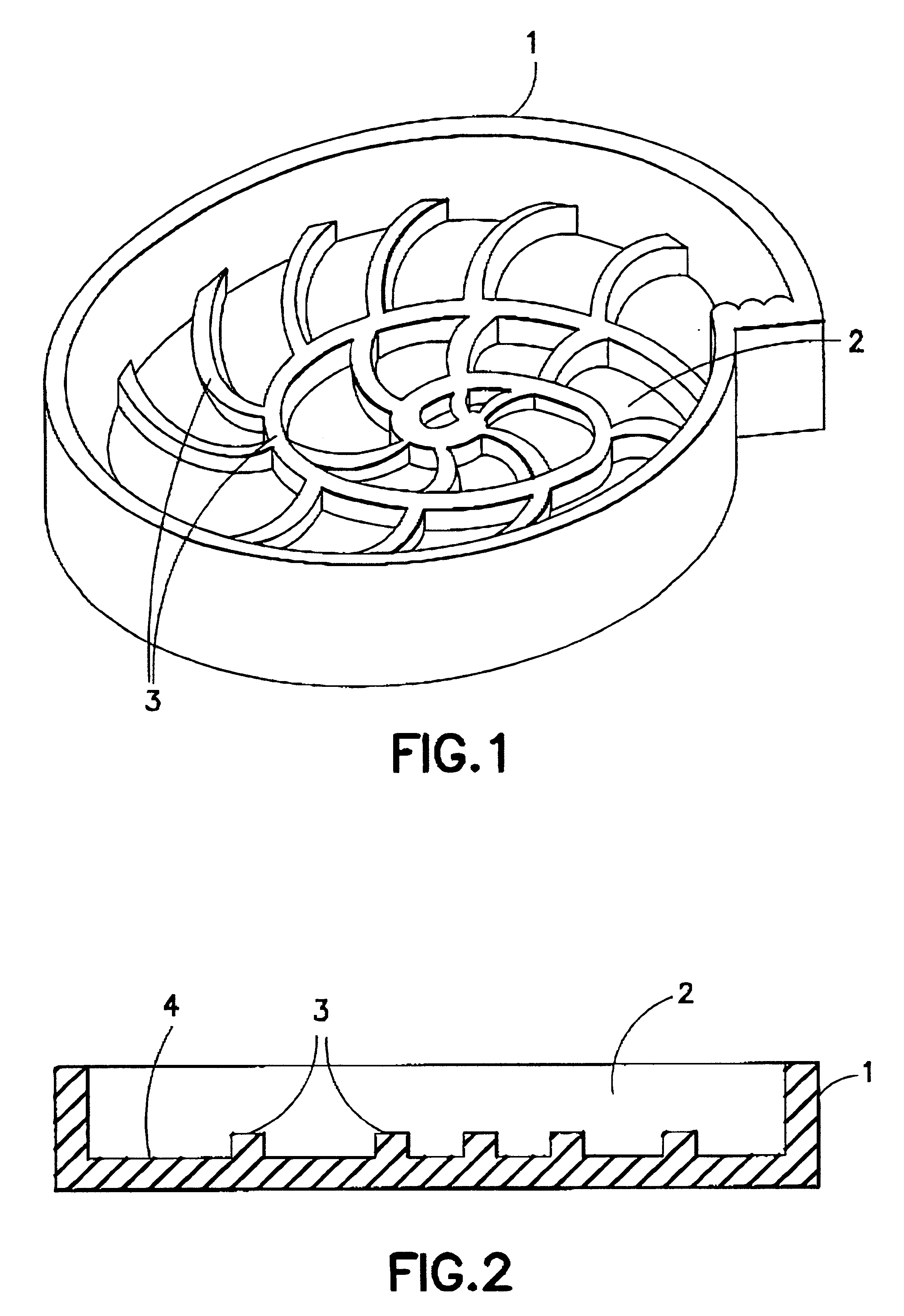

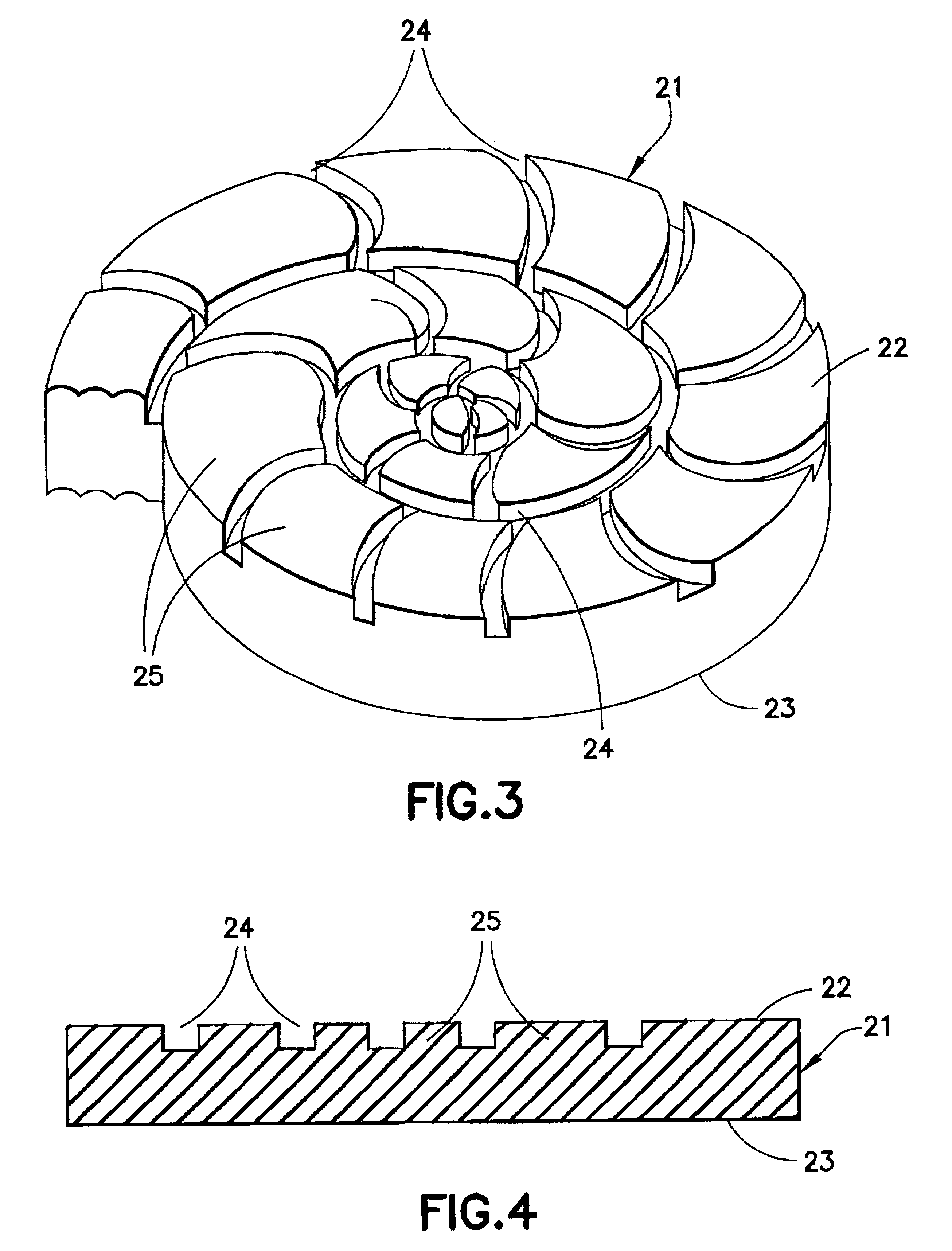

A method of making terrazzo floors with design inlays. The method utilizes pre-molded inserts as inlays in the finished floor, and generally includes four steps. First, inserts are pre-molded, which has design elements in terms of their color, nature of inclusions (chips, glass fragments, etc. and their colors), shape and / or a pattern of grooves in their upper surfaces. Second, the pre-molded inserts are placed on and affixed to the sub-flooring in a predetermined arrangement. Third, epoxy flooring mixture is poured to a height that fills the grooves in the inserts' upper surfaces and preferably cover the inserts. Fourth, the floor, after cured and hardened, is ground and polished to expose the upper surfaces of the inserts, which now become seamlessly integrated inlays within the overall finished floor. The designs in the inlays are viewable because the inserts contain different visual ingredients (pigments, colored plastic or glass chips, etc) in contrast with the overall floor and they are outlined by the filled grooves.

Owner:SEDAKA ALEN

Top coating for indoor and outdoor temporary removable graphics and system and method for making, applying and removing such graphics

InactiveUS20080264559A1Lamination ancillary operationsChemical paints/ink removersGraphicsEngineering

A composition for a removable top coating for protecting the exposed face of a temporary removable graphic is provided. A remover for the transferred graphic image is provided that completely dissolves the temporary removable graphic, but does not affect the commonly encountered substrates such as concrete, brick, wooden floors, asphalt surfaces, terrazzo and motor vehicle body surfaces, marine and aeronautical craft surfaces. A method for making, applying and removing the temporary removable graphic is provided.

Owner:OCONEE COATING TECH LLC

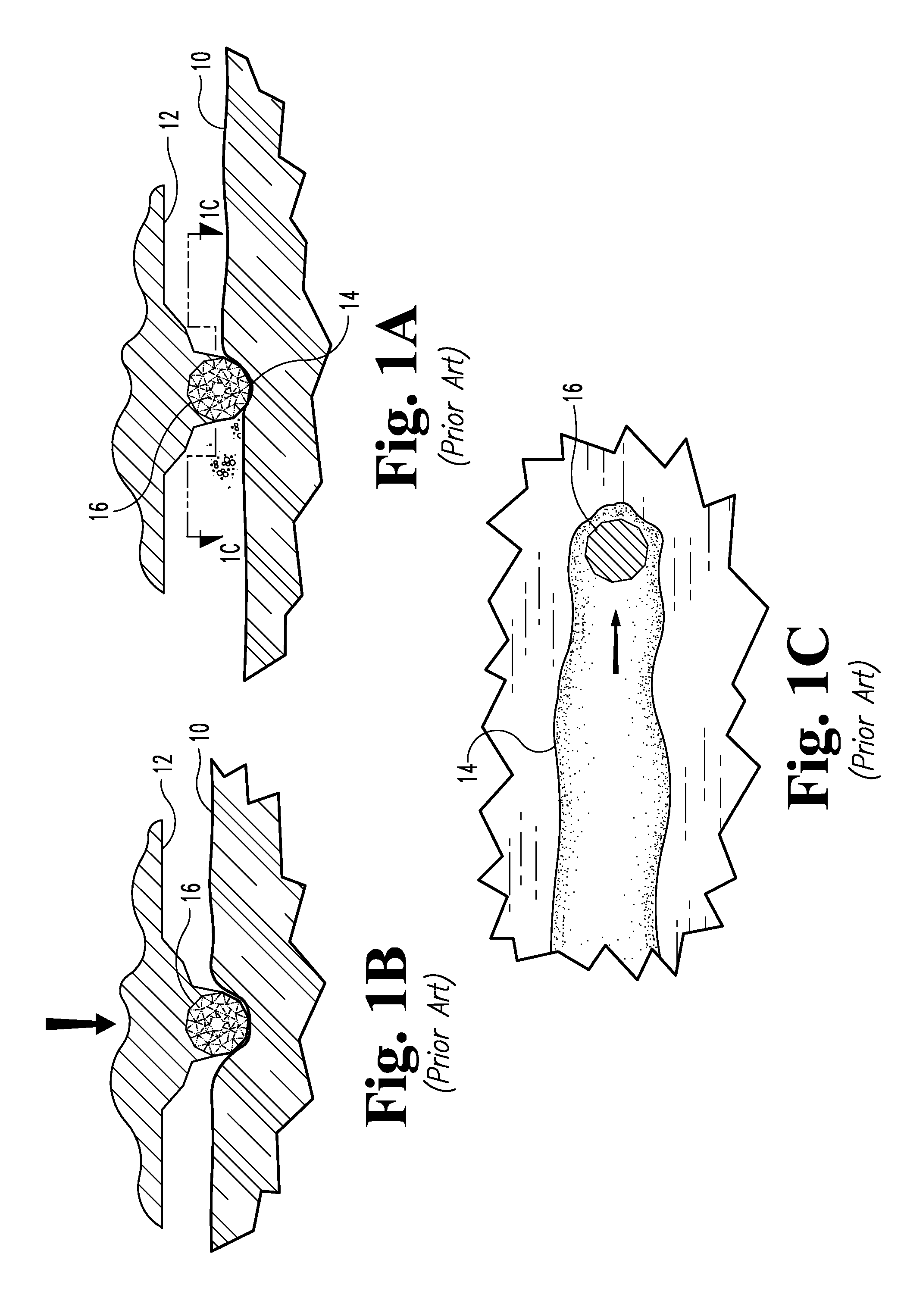

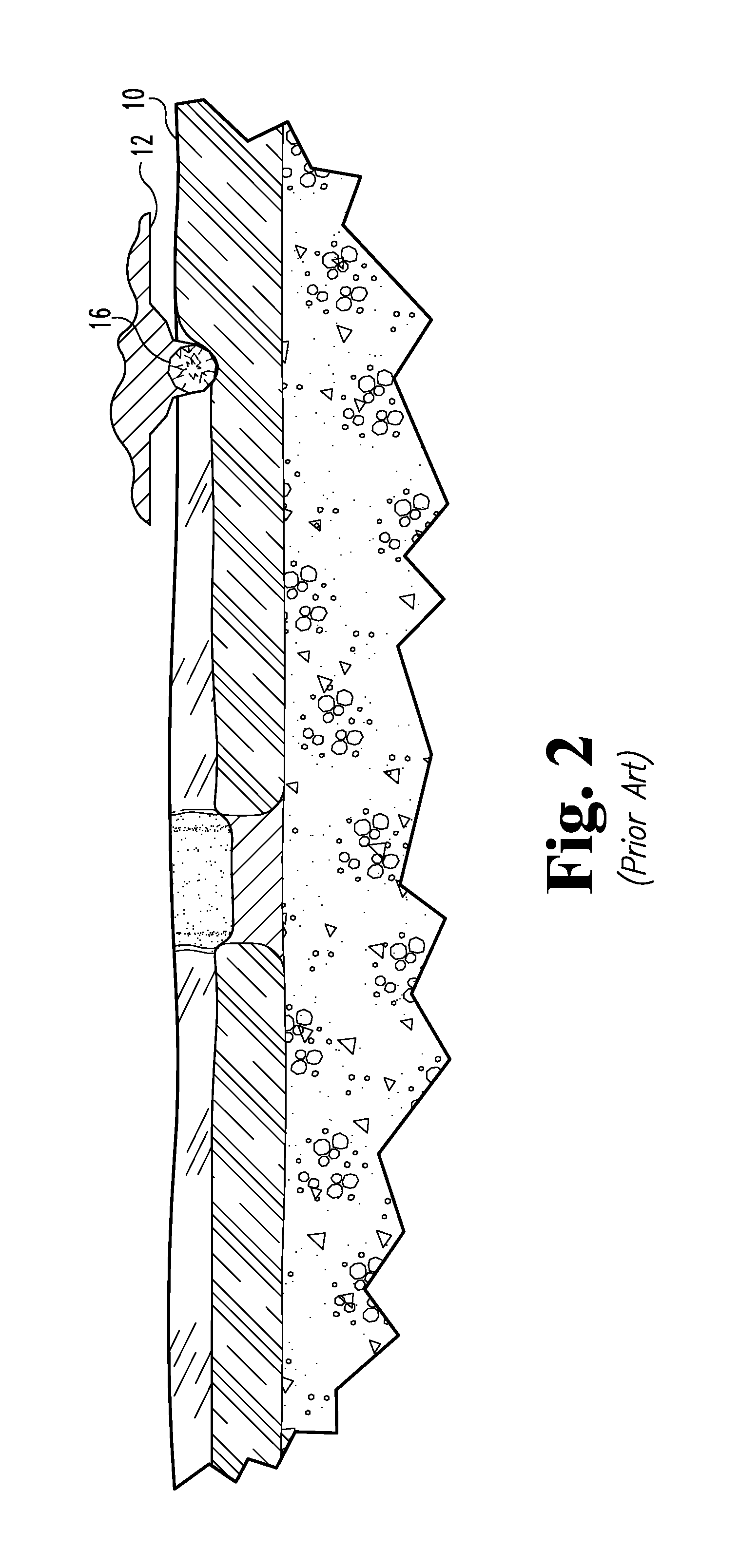

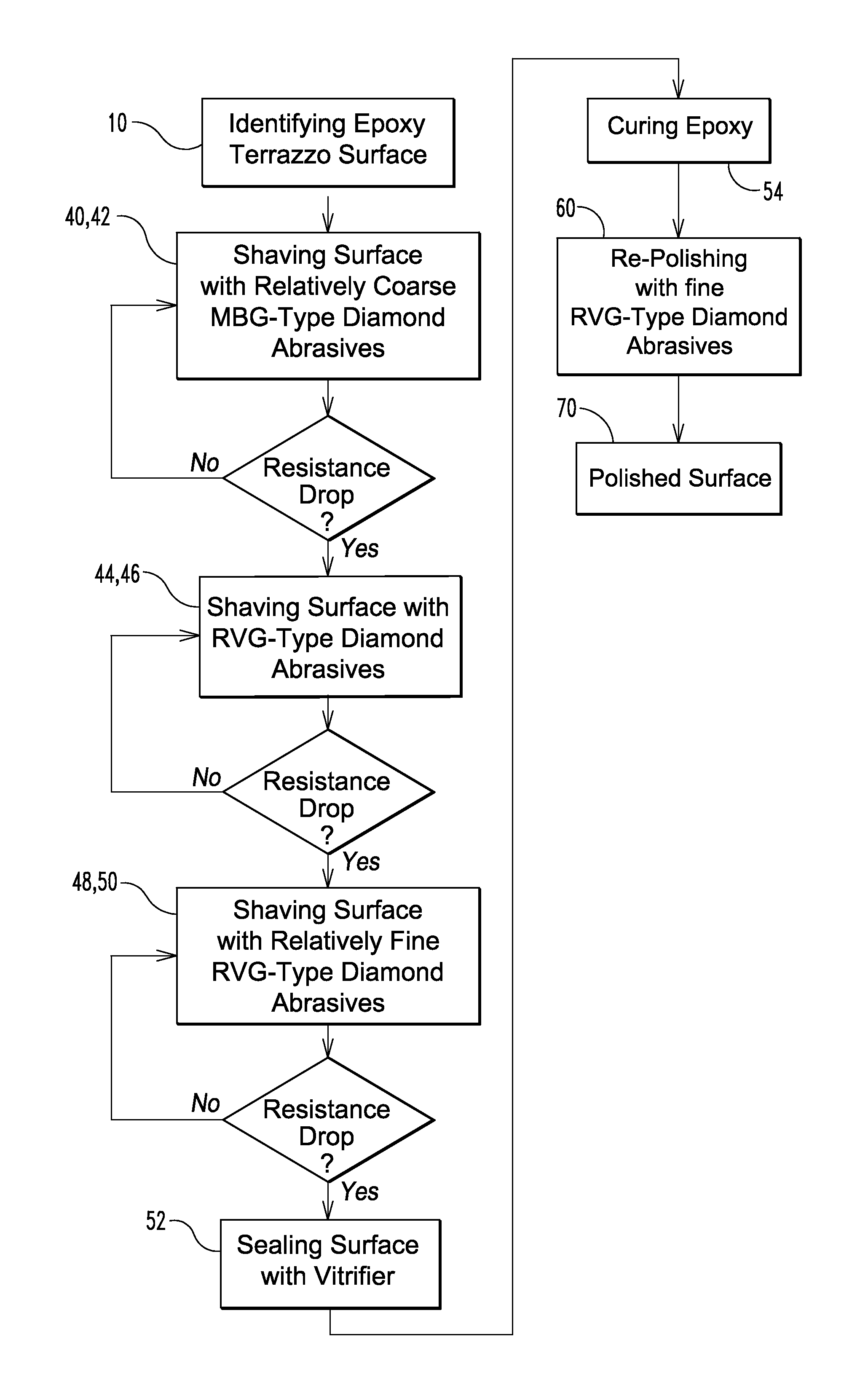

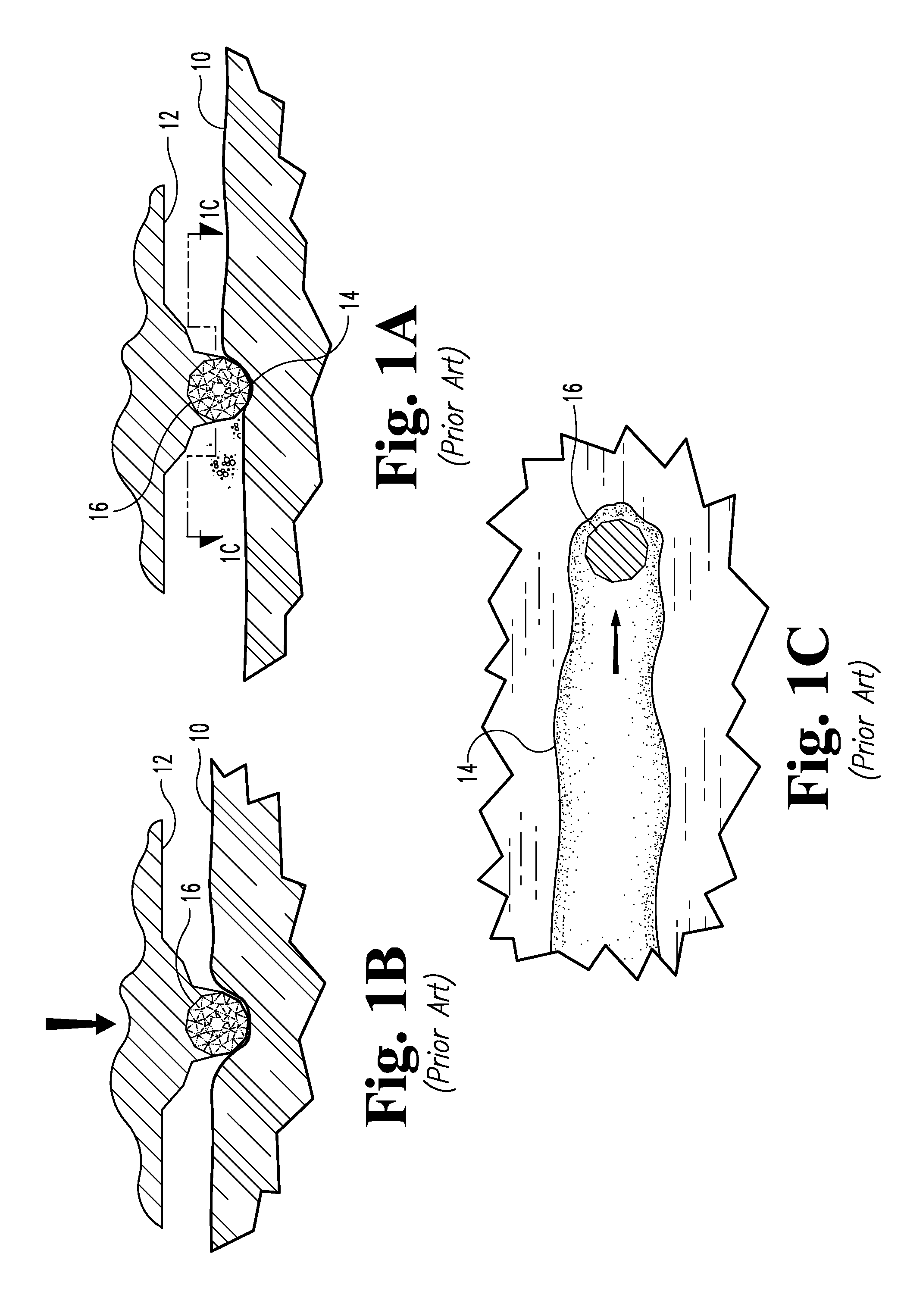

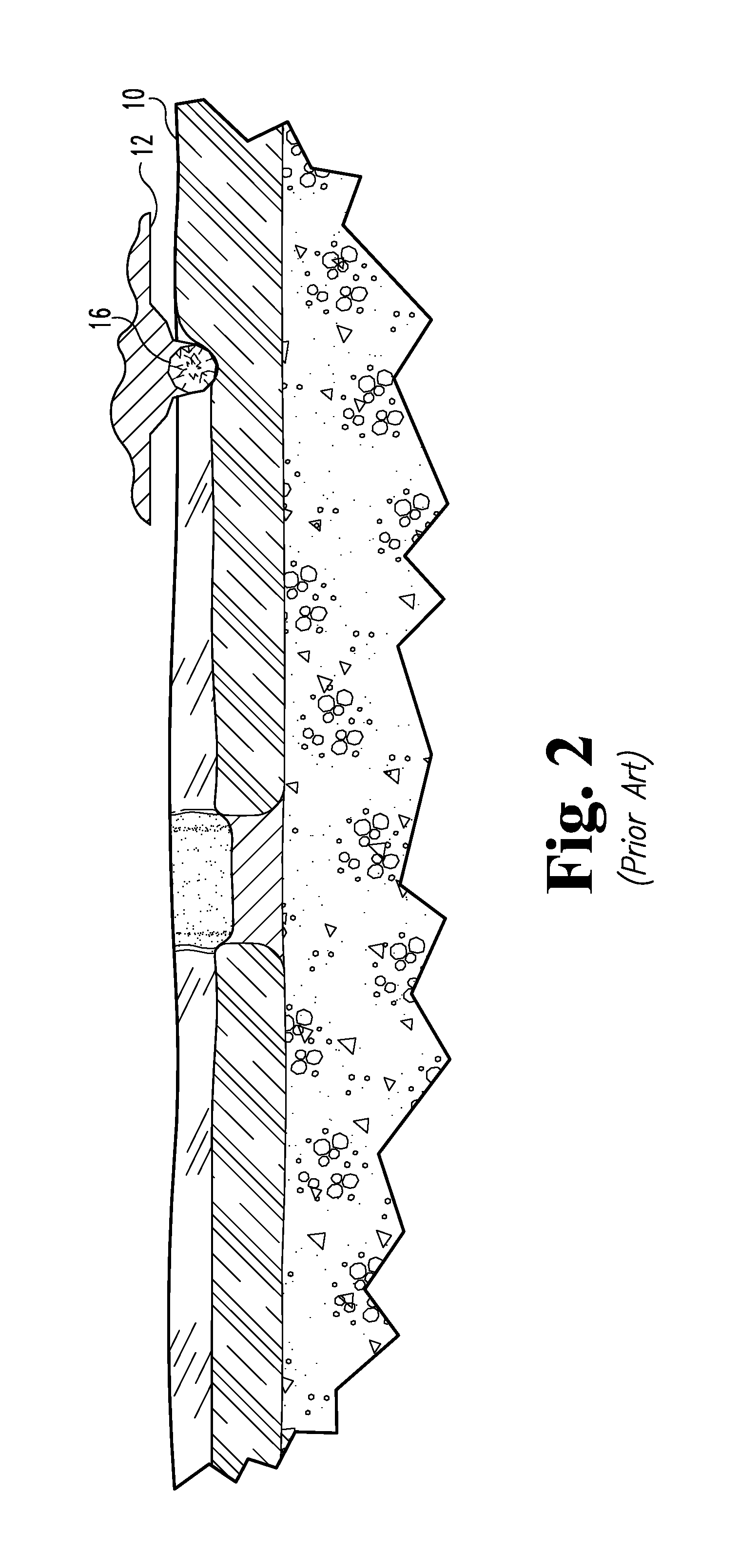

Epoxy terrazzo flooring and method for polishing the same

ActiveUS20100240282A1Simple methodPortable grinding machinesStone-like material working toolsEpoxyTerrazzo

A method of polishing a marble terrazzo floor, including shaving the surface with a first plurality of first diamond abrasive particles, and shaving the surface with a second plurality of second diamond abrasive particles. The first diamond abrasive particles are MBG-type mesh crystals characterized by a first average size, wherein the second diamond abrasive particles MBG-type mesh crystals characterized by a second, smaller average size, and wherein the diamond abrasive particles substantially laterally impact surface protrusions.

Owner:YOUNG IDEAS LIMITED LIABILITY

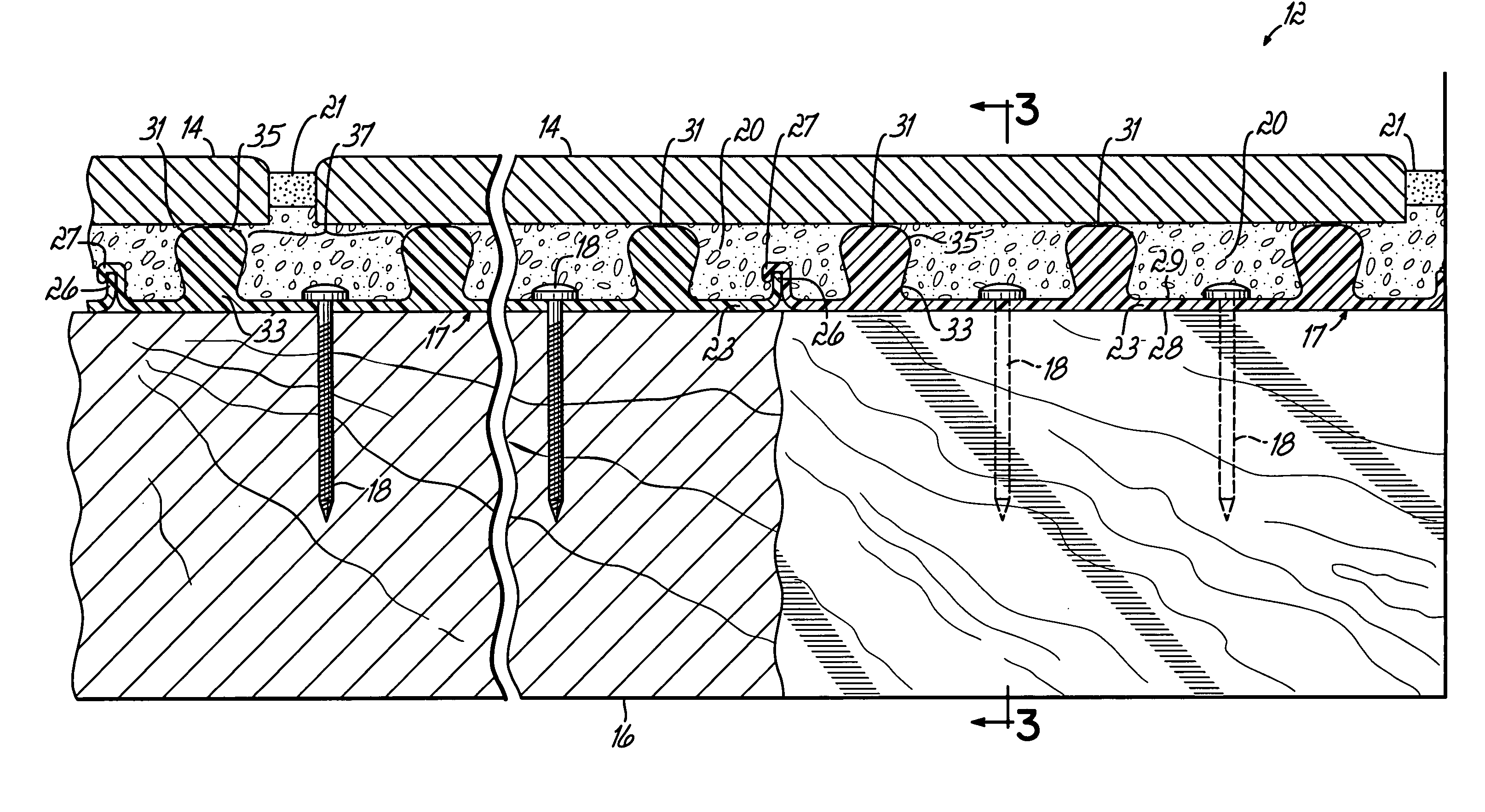

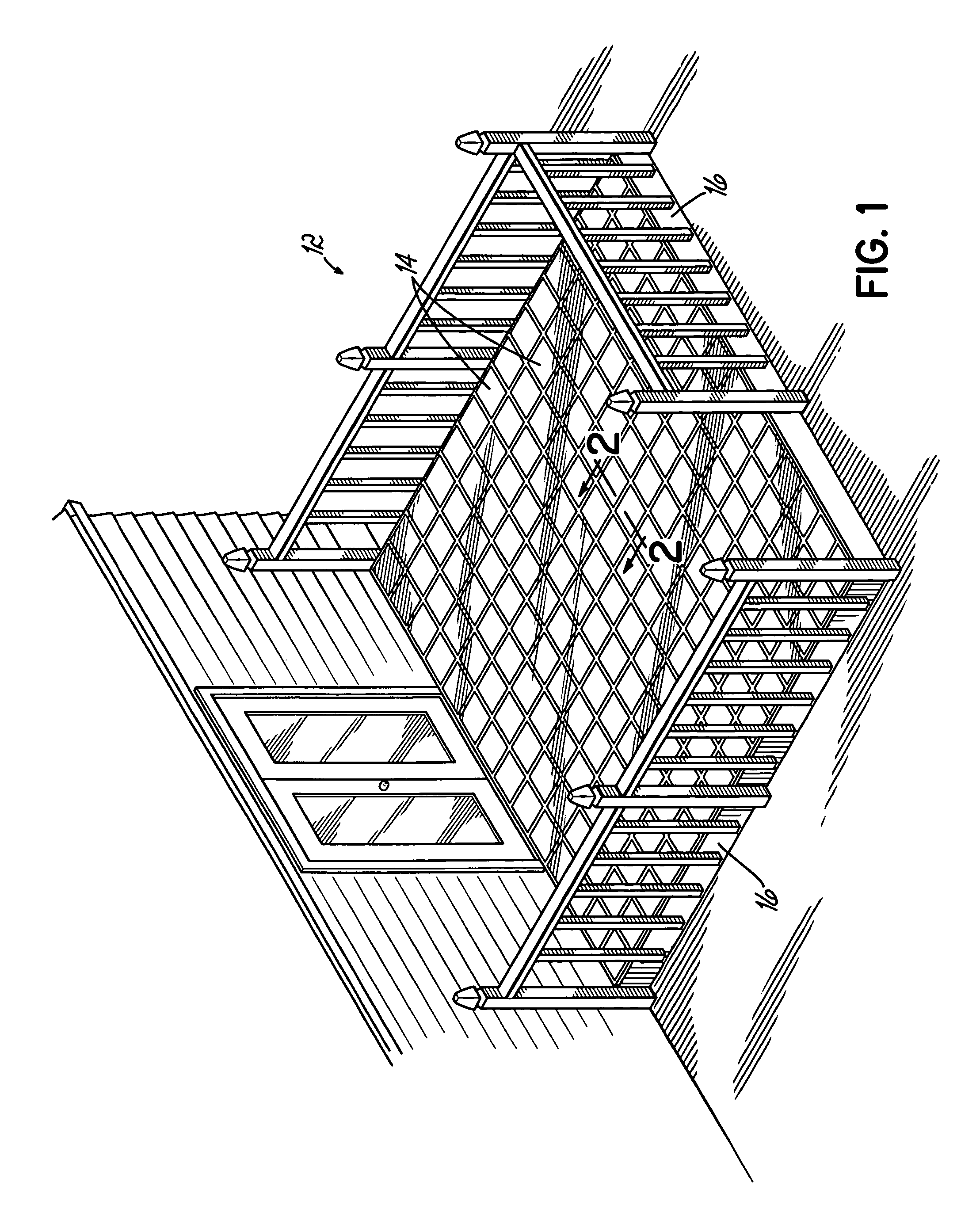

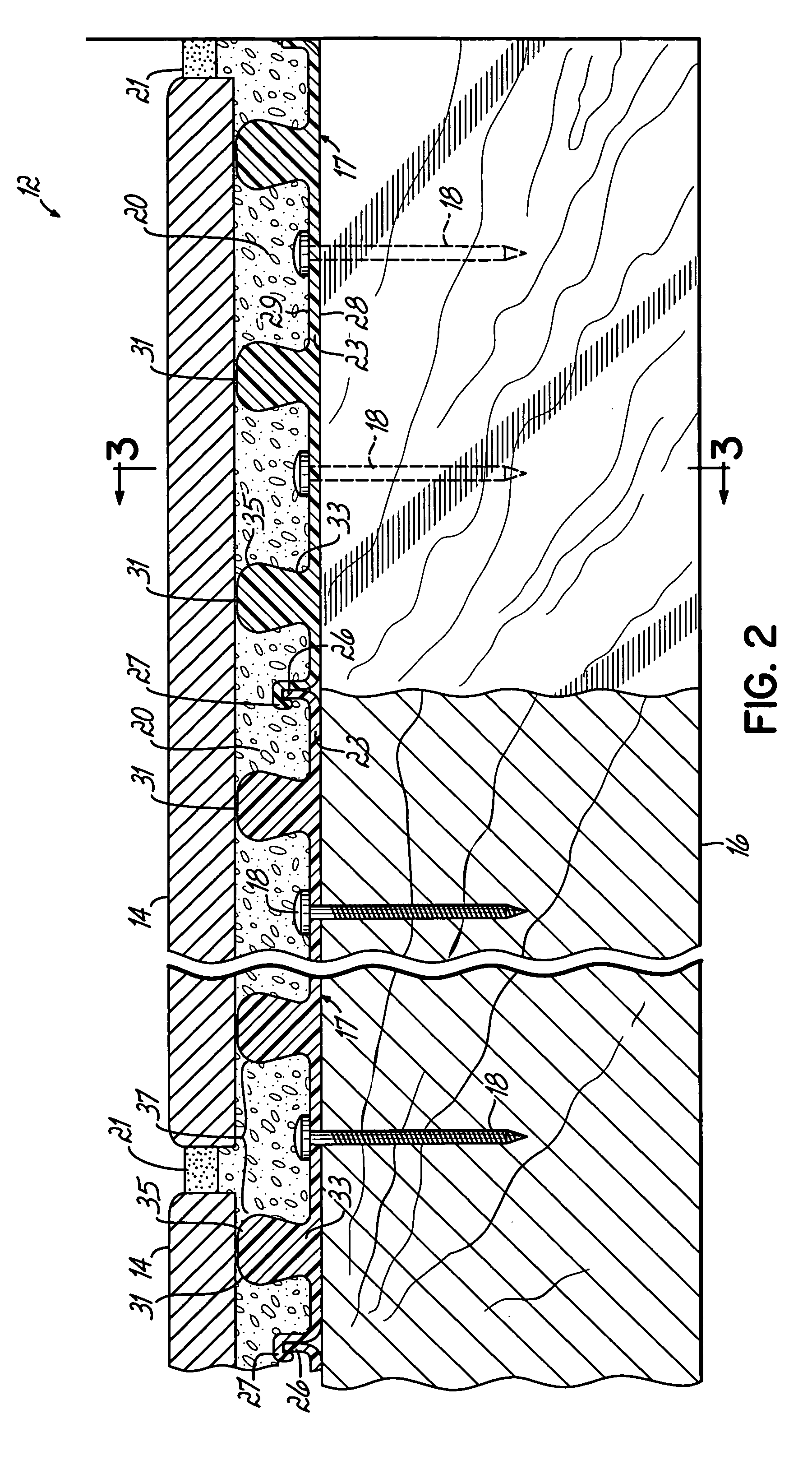

Underlayment for tile surface

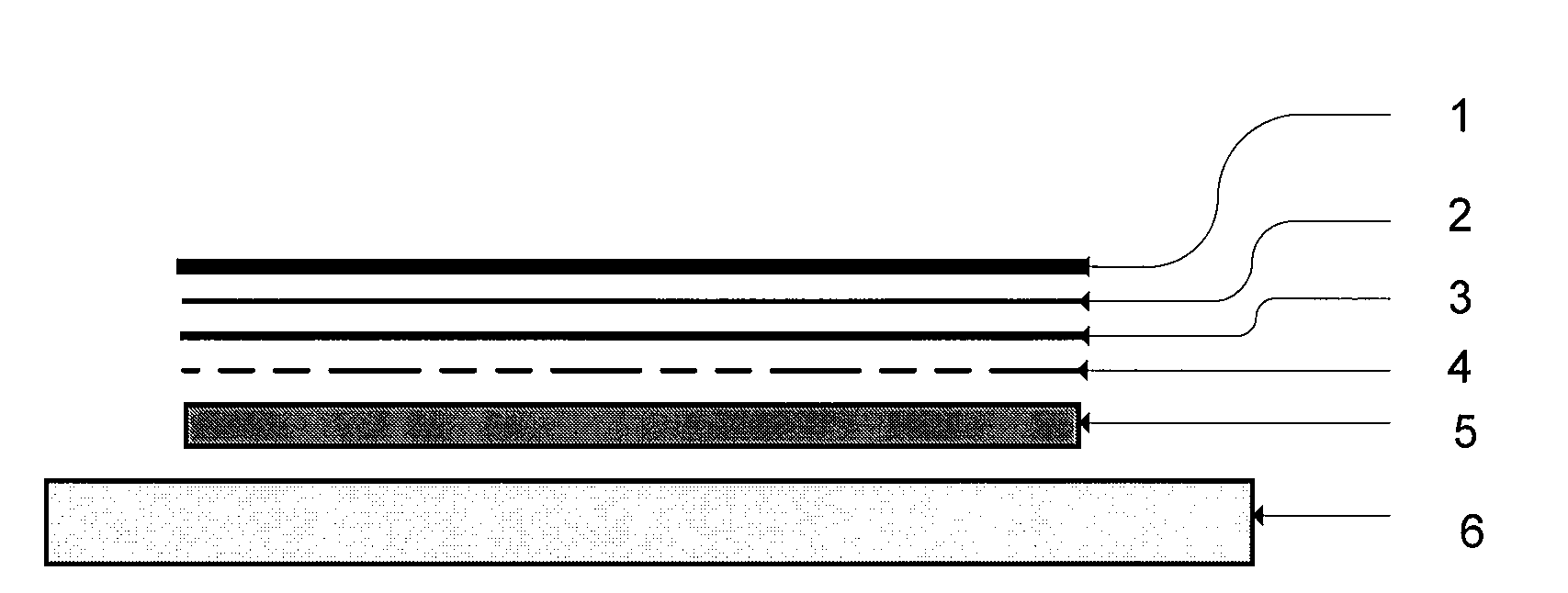

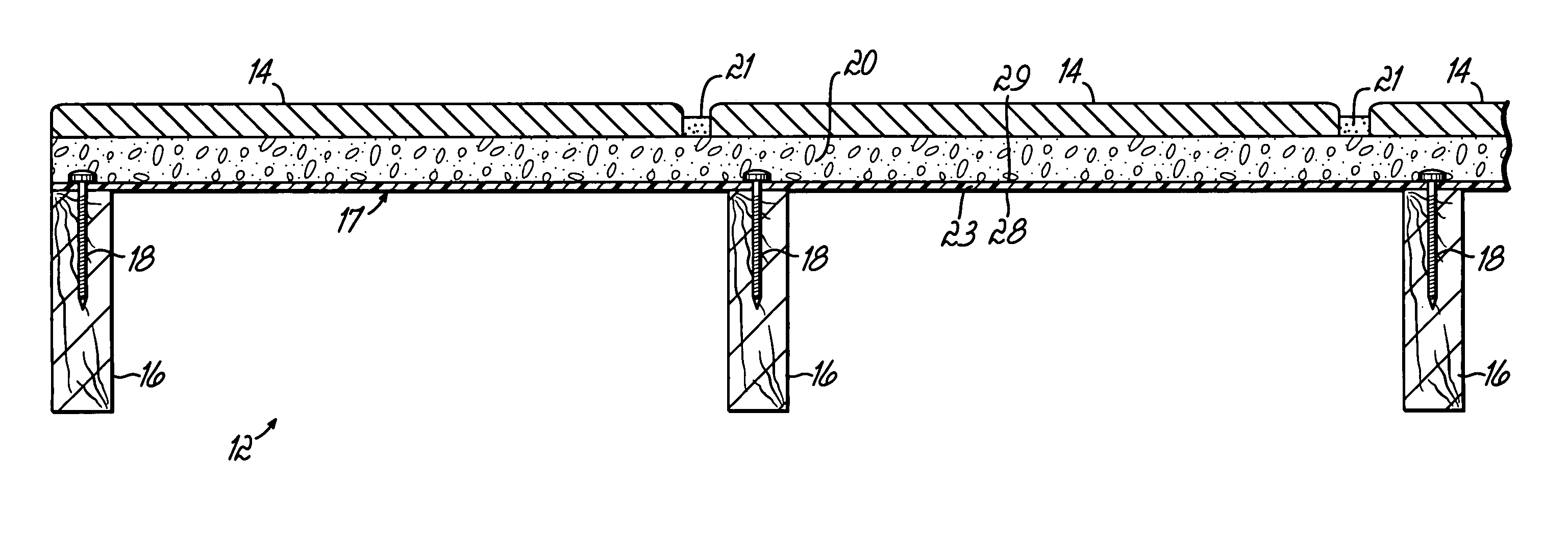

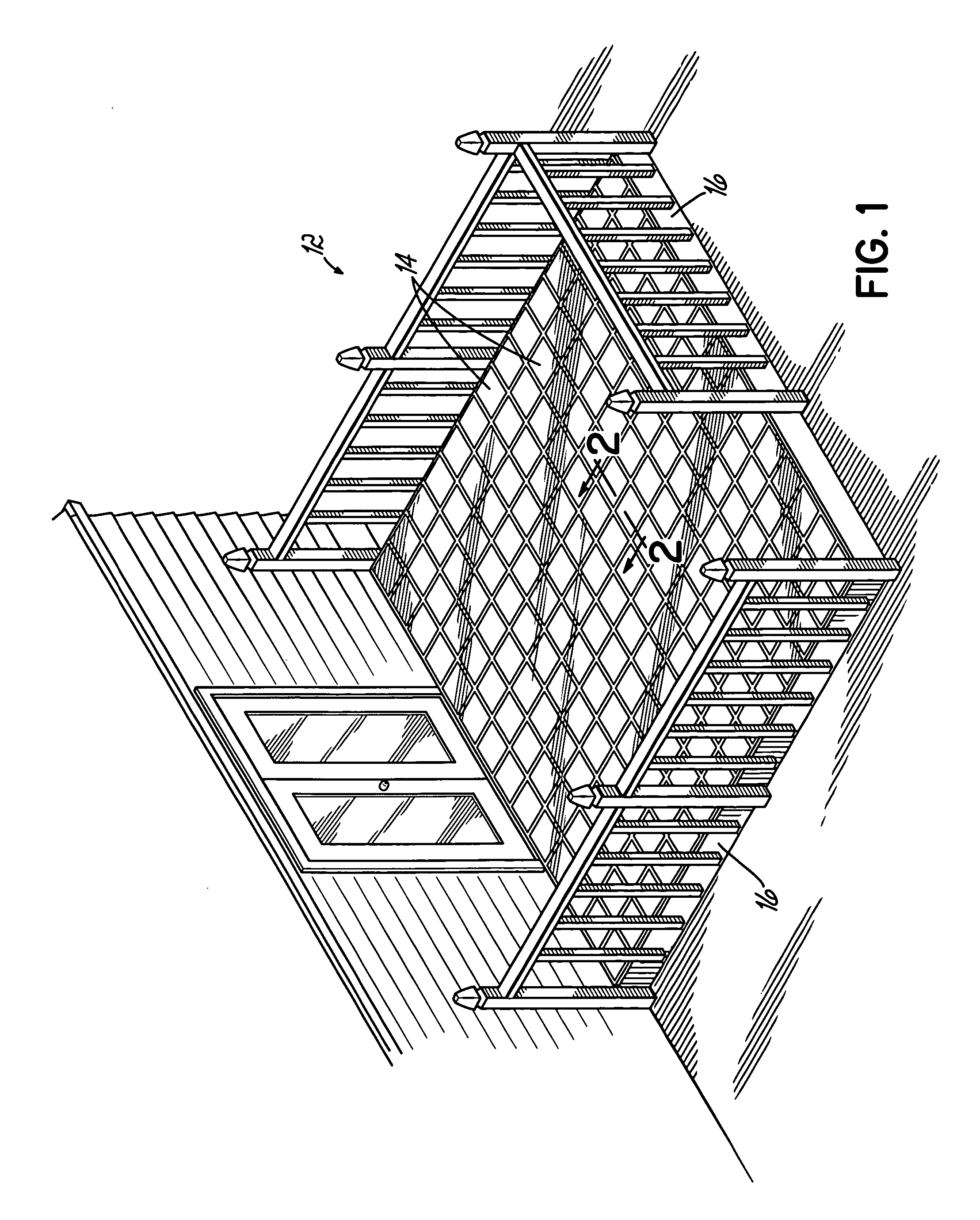

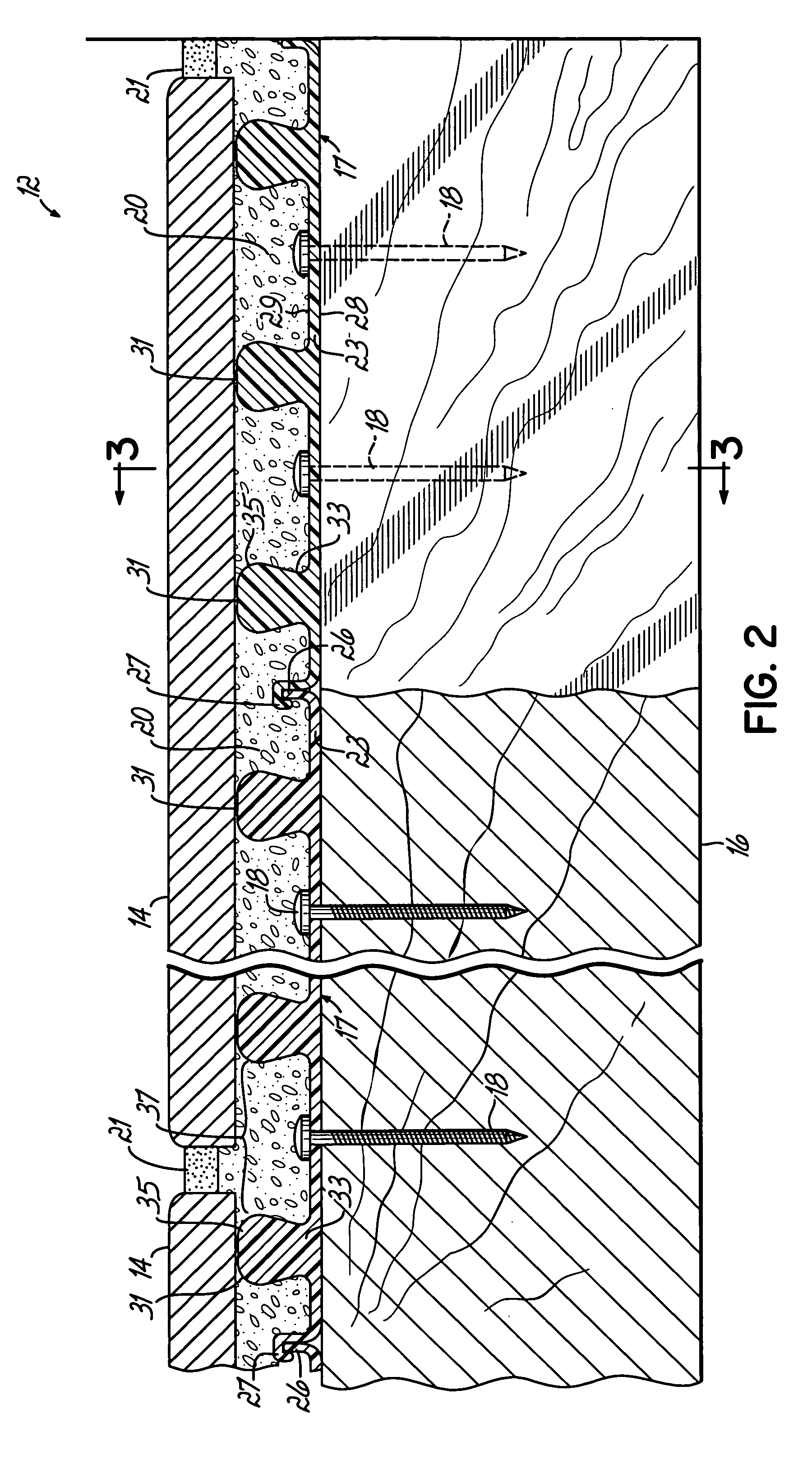

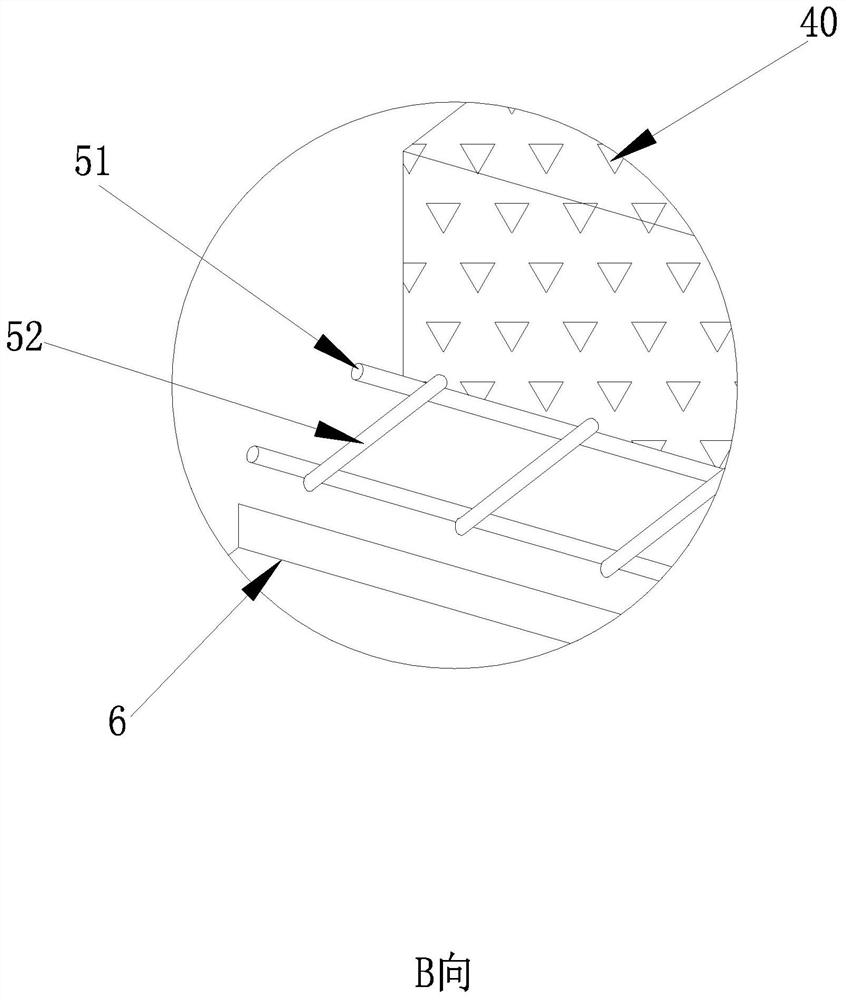

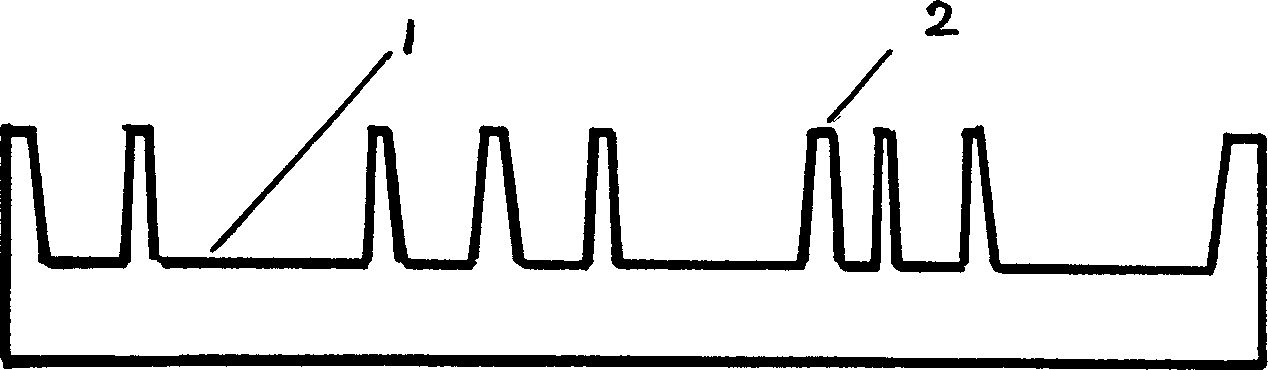

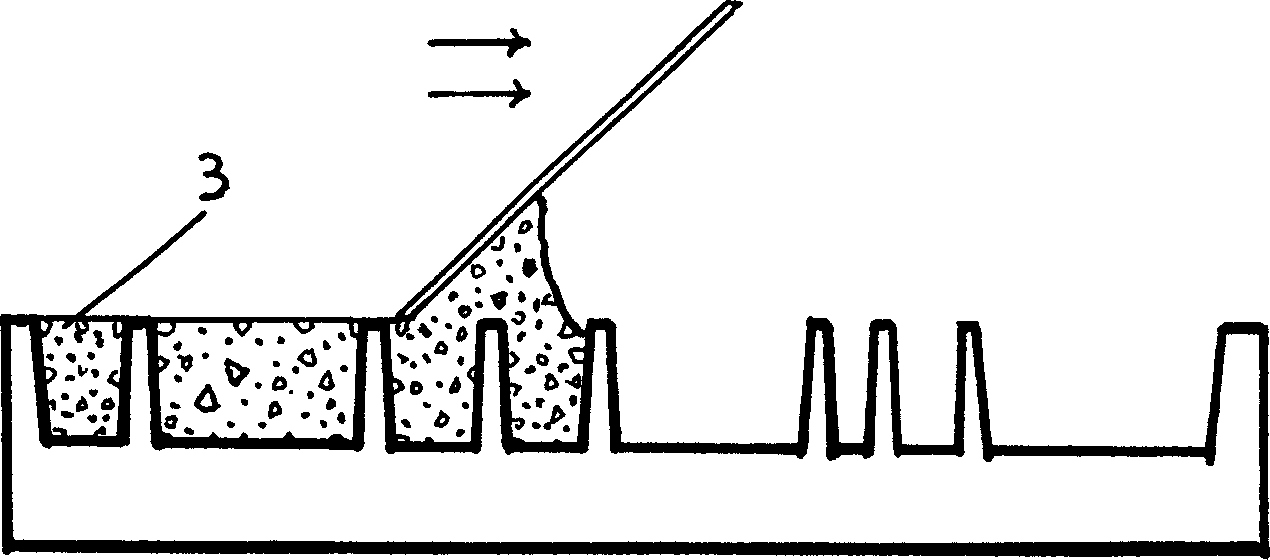

Fiber-reinforced pultruded planks serve as underlayment for tile, stone or terrazzo. In one embodiment, the planks have a thin base surface with a plurality of elongated ridges. The planks have interlocking tongue and groove edges. The elongated ridges have a narrow base and a wider distal portion wherein the areas between adjacent ridges have a trapezoidal cross sectional configuration with the thin base resting on the support. Tile can be adhered to the surface using a rigid cementitious adhesive which fills in the trapezoidal area, creating a very rigid support structure. If the planks are reversed with the ridges resting on the support, tile or stone can be adhered to the relatively smooth thin base with an epoxy adhesive.

Owner:TILEDIY

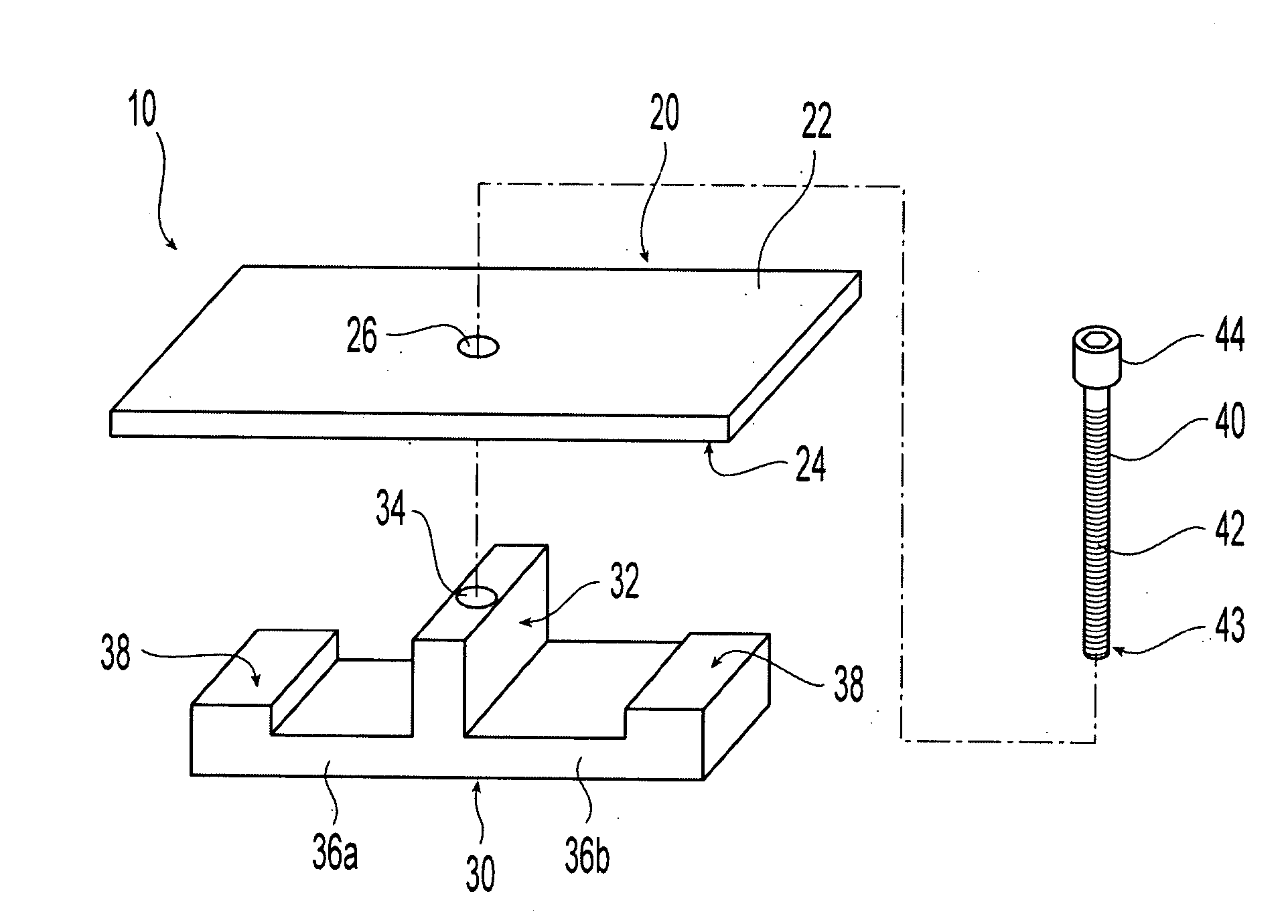

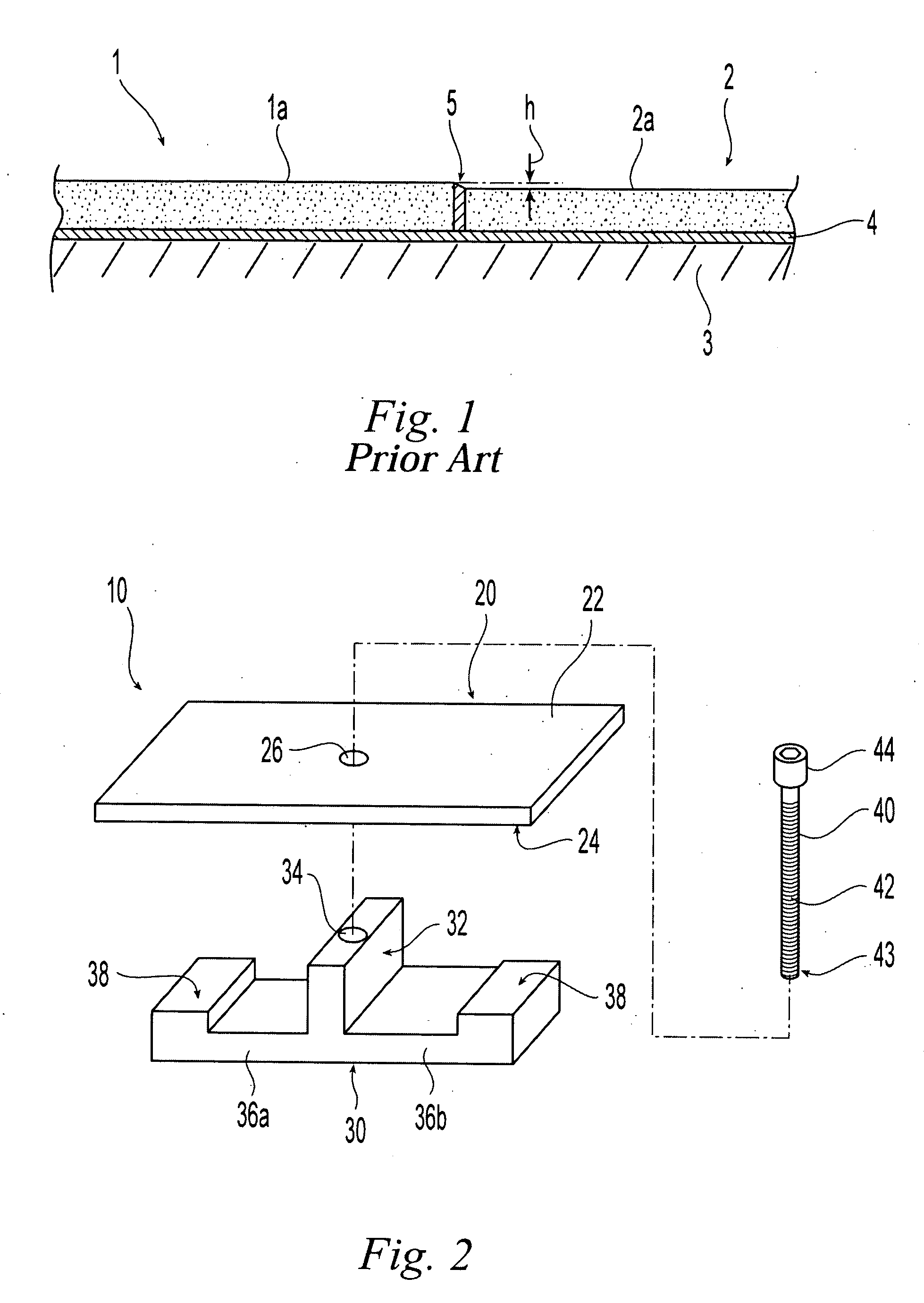

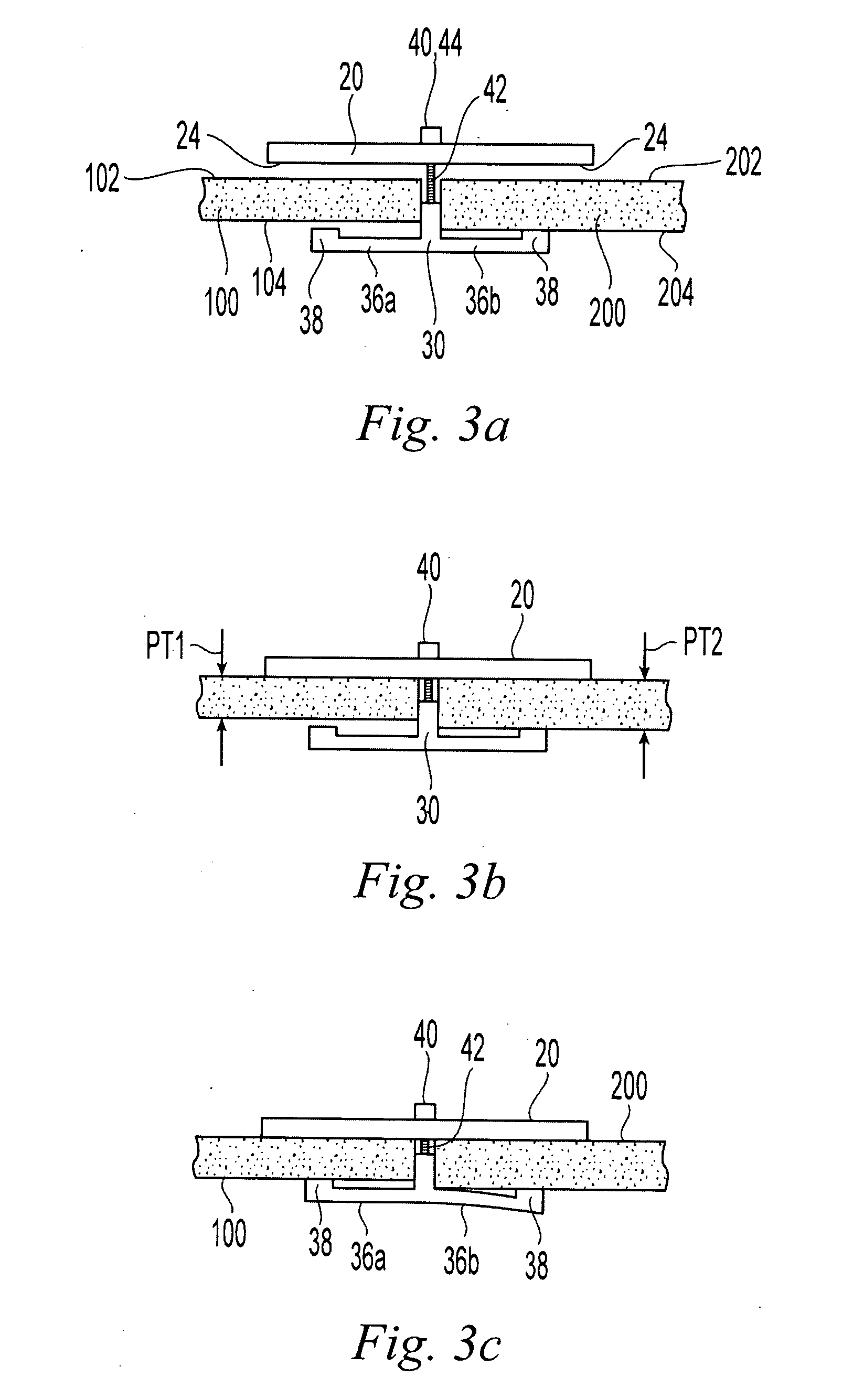

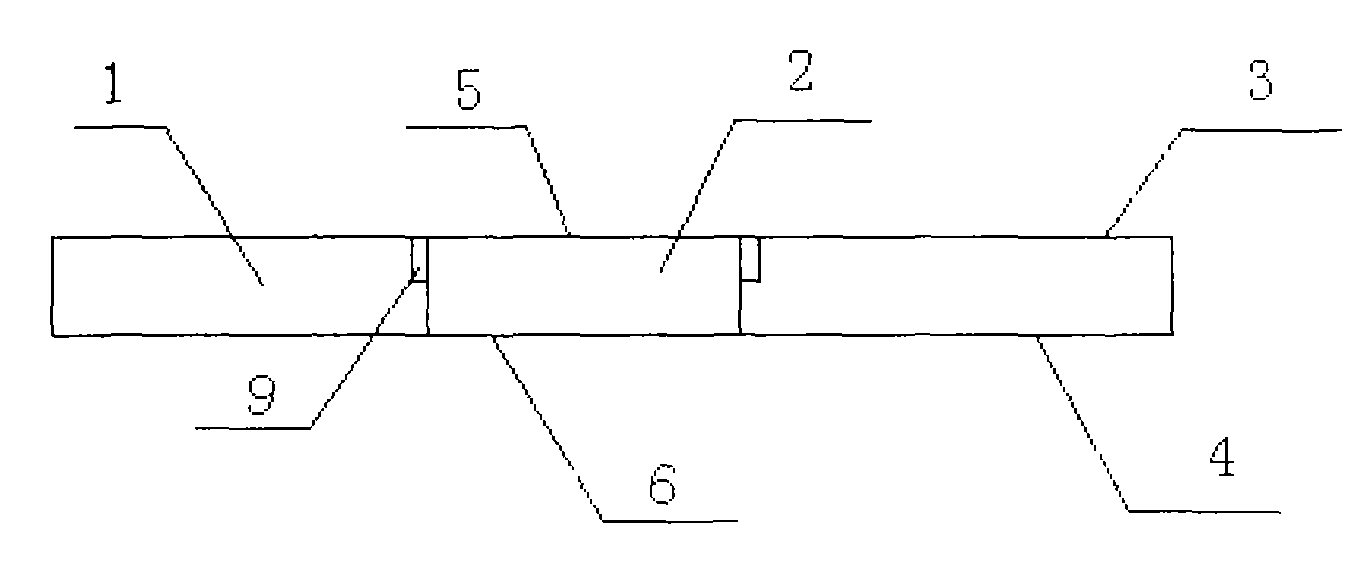

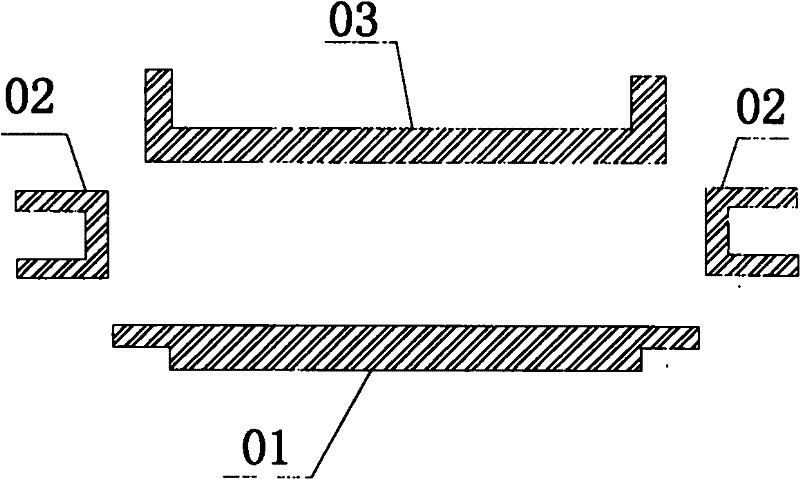

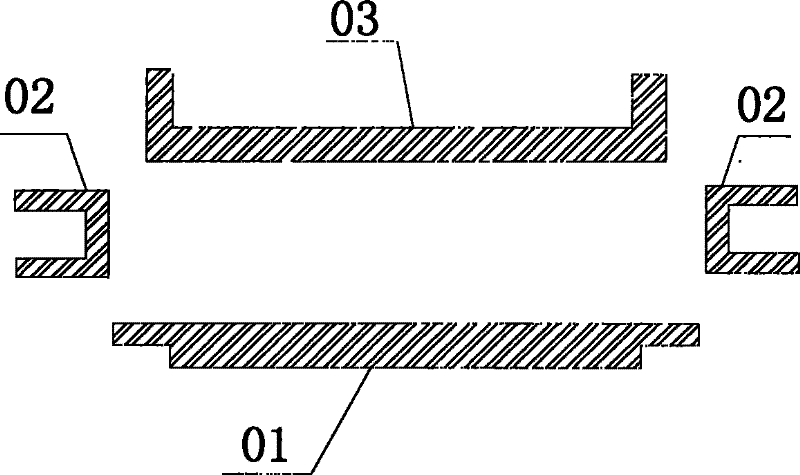

Planarizing panel clip and method of use

A panel clip is disclosed for aligning precast Terrazzo panels to eliminate “lippage.” The clip comprises a rigid top portion screwed to an adjustable bottom portion, and adjacent panels are fixed therebetween. The rigid top portion fixes the top surfaces of the panels in the same plane, while the adjustable bottom portion automatically conforms to the bottom surfaces of the panels, even where the panels are of differing thicknesses. The bottom portion can be of a unitary flexible plastic design, of a pivoting multi-piece design, or of a thin deformable metal design. One or both of the portions can have a neck region for providing a desired offset between adjacent panels. Once an underlying setting compound has cured, the top portion can be removed, leaving the bottom portion in place to be grouted over. A method of use is also disclosed, as is a kit.

Owner:ANGELOZZI ROCCO P JR

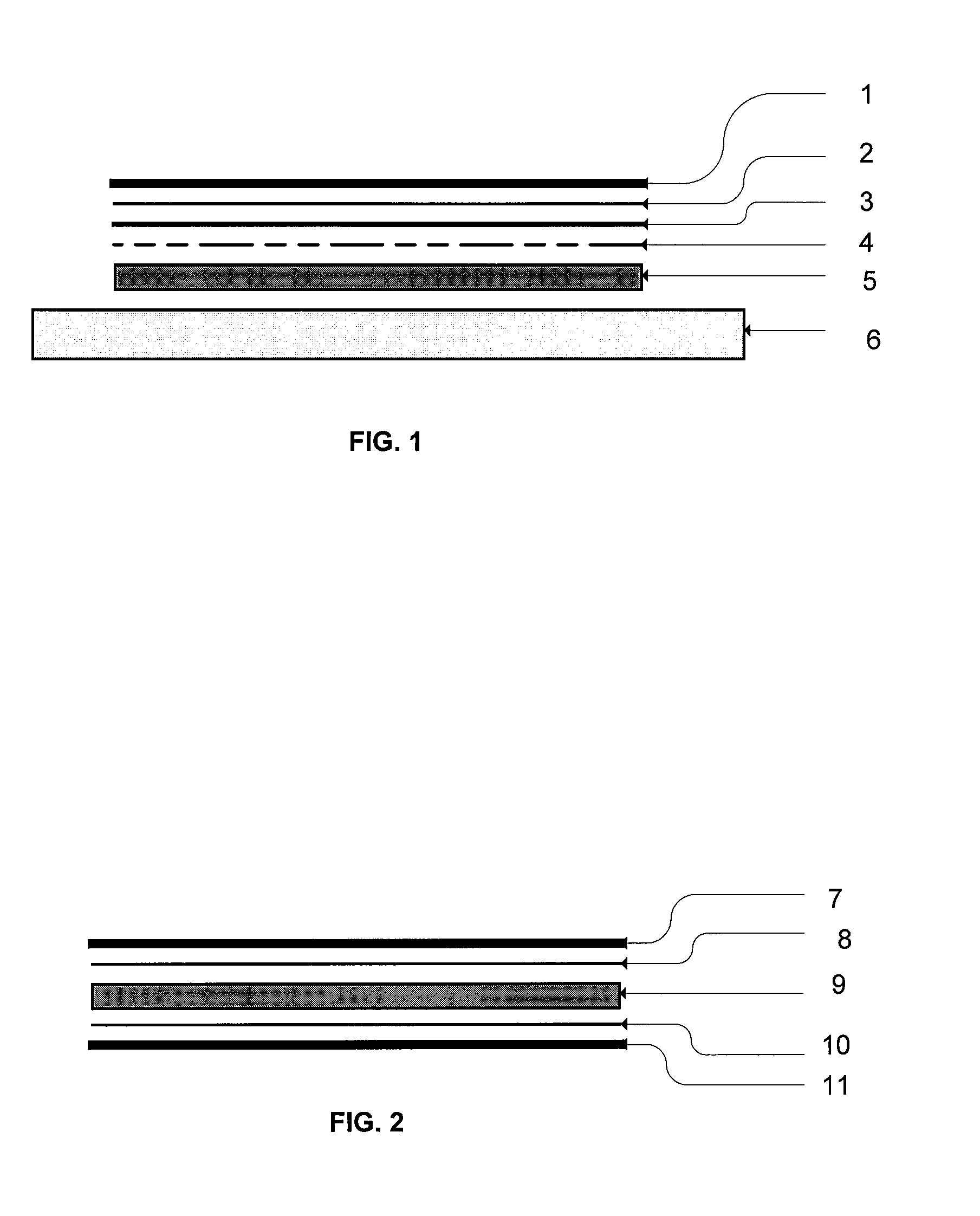

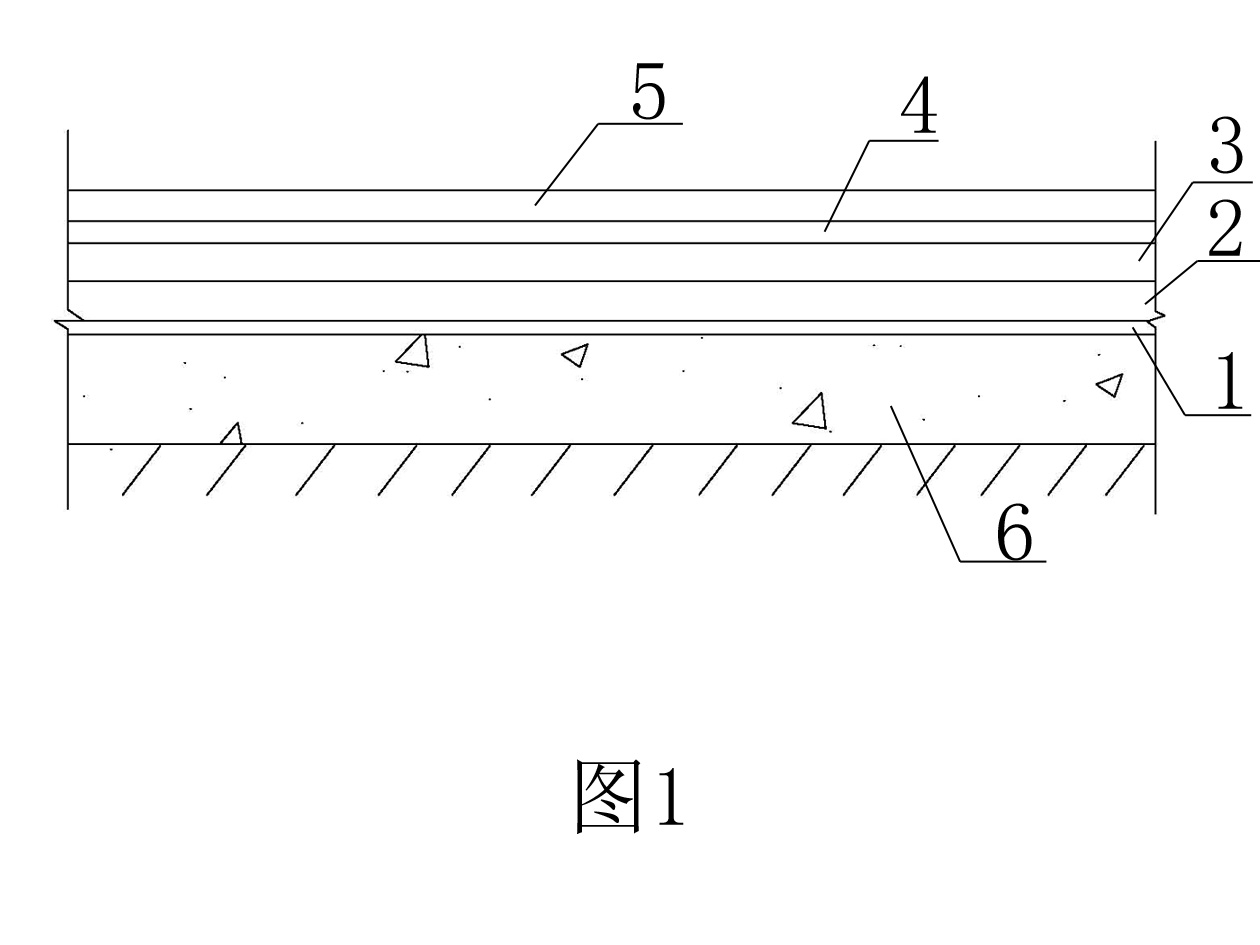

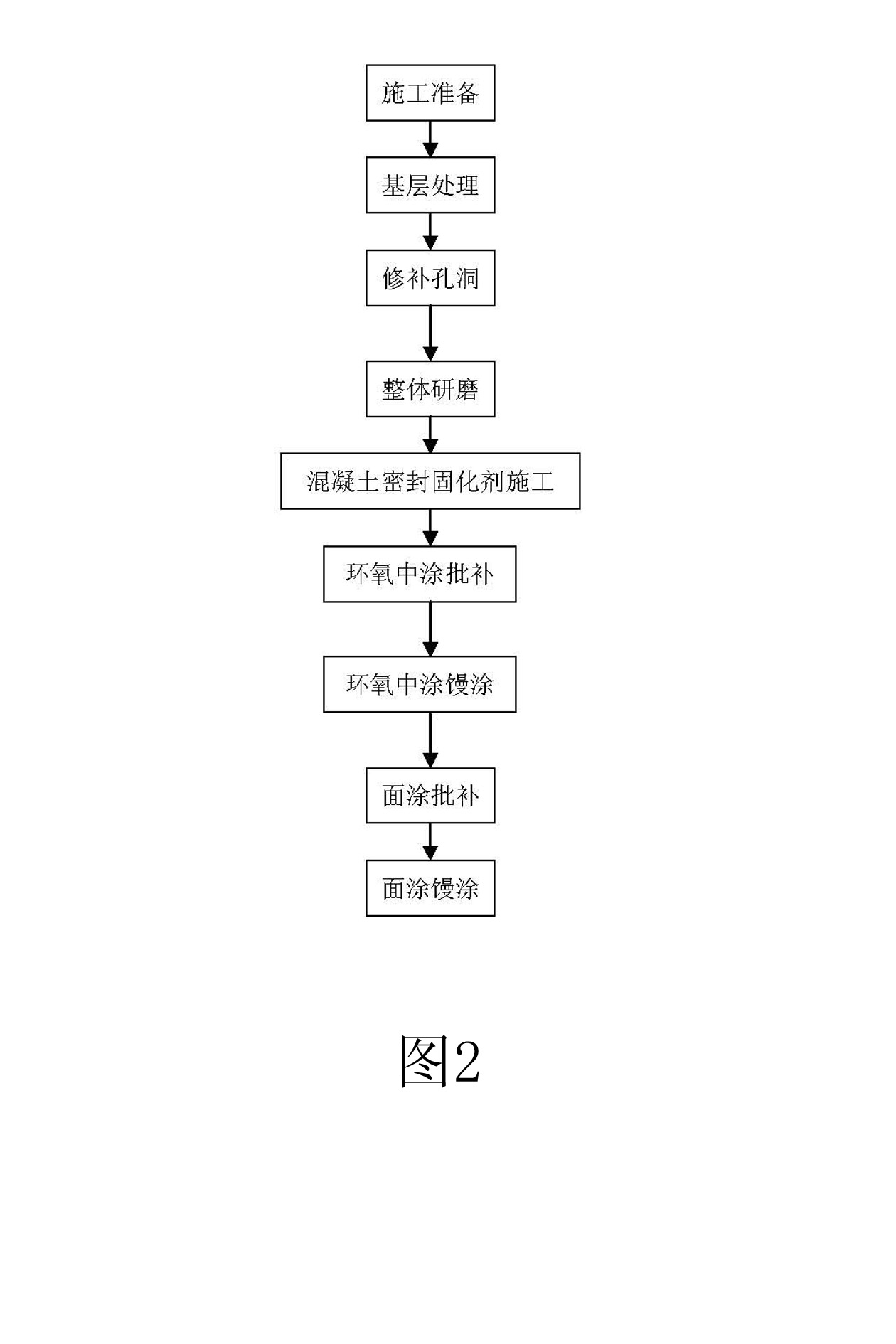

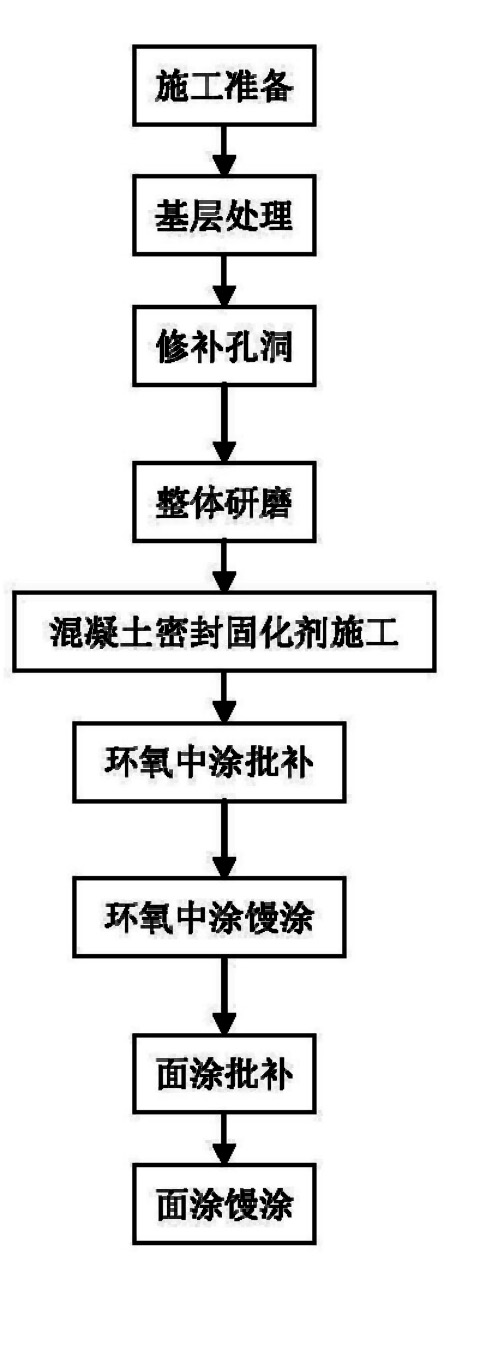

Epoxy self-leveling floor with concrete sealing curing agent and construction method thereof

ActiveCN102061798AHigh strengthExtend your lifeBuilding material handlingFlooringEpoxyMechanical equipment

The invention relates to an epoxy self-leveling floor with a concrete sealing curing agent and a construction method thereof. An epoxy surface coating batch filling layer with quartz powder is additionally provided on the basis of the traditional self-leveling floor; the sealing treatment of a base layer is modified from the traditional sealing bottom coated on the surface of the concrete base layer to a concrete sealing curing agent base layer doped into the concrete base layer so as to overcome the defects that the traditional method has higher requirements on the construction condition and the construction can be carried out in layers to reduce construction intervals. The invention can be widely applied to surface treatment of new and old concrete, waterstone, mortar, gypsum and all exposed concrete and construction materials, in particular to ground treatment of moisture-proof basements, refrigeration houses, workshops where mechanical equipment works and the like.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG

Underlayment for tile surface

Owner:TILEDIY

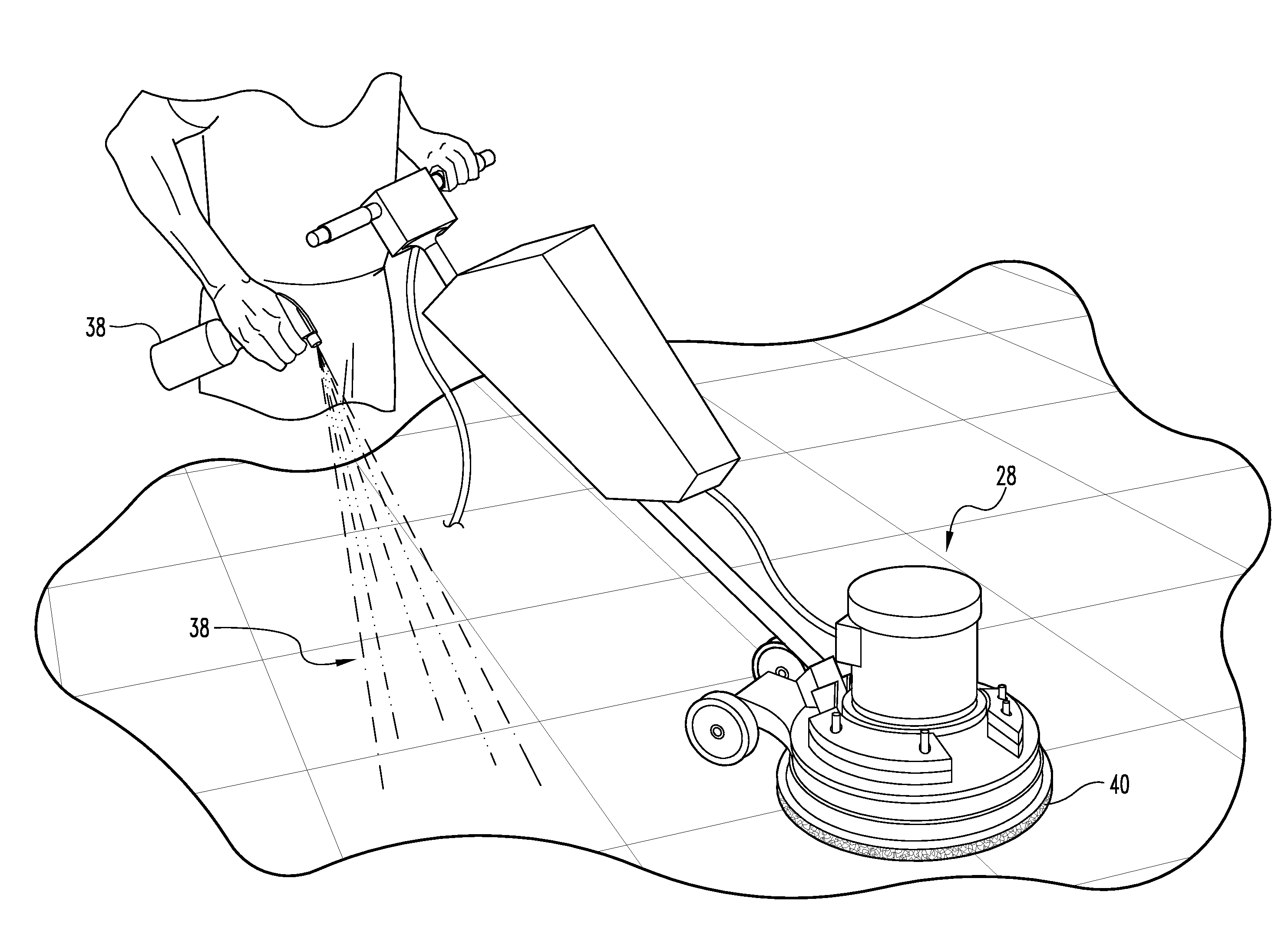

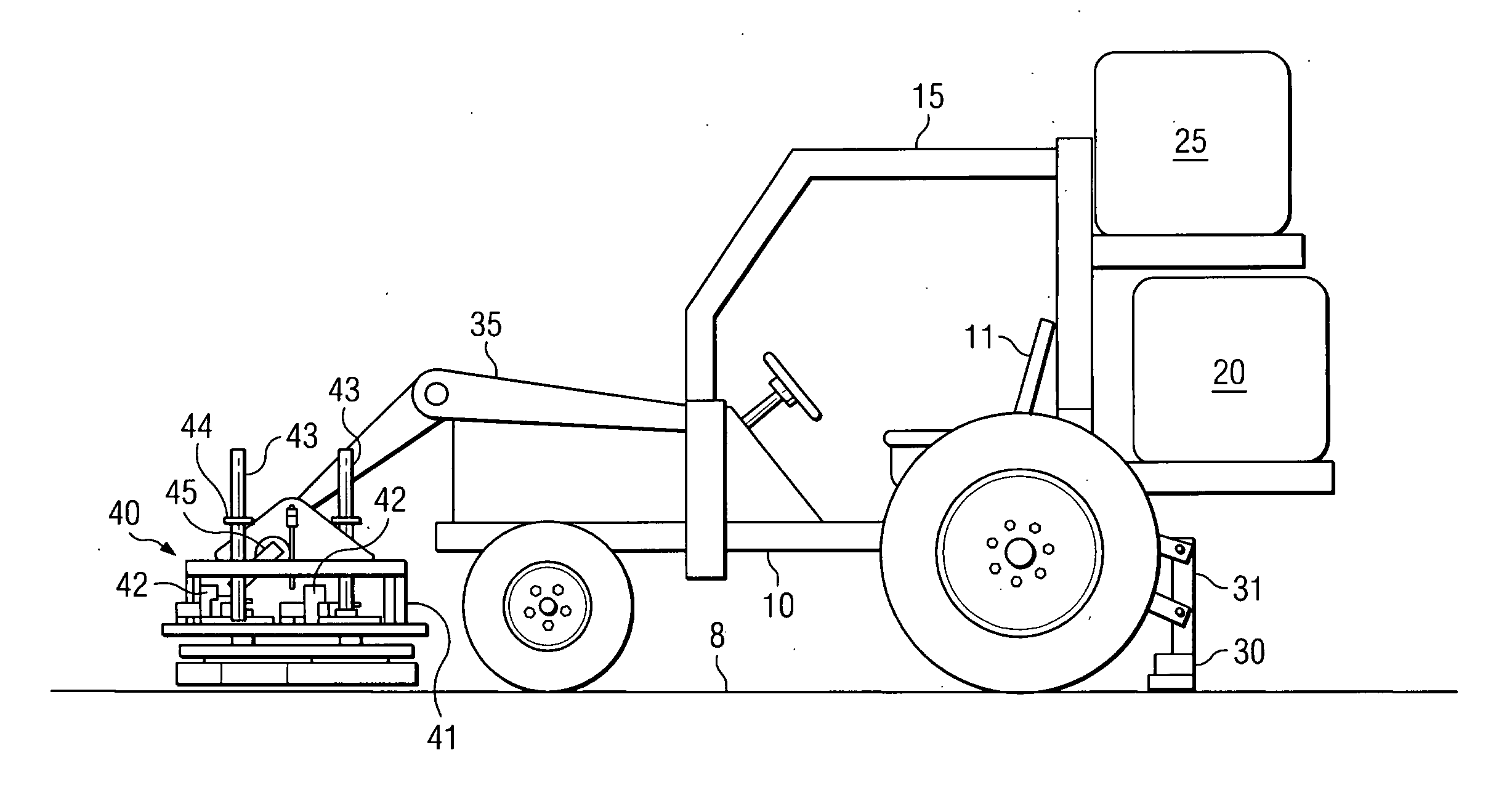

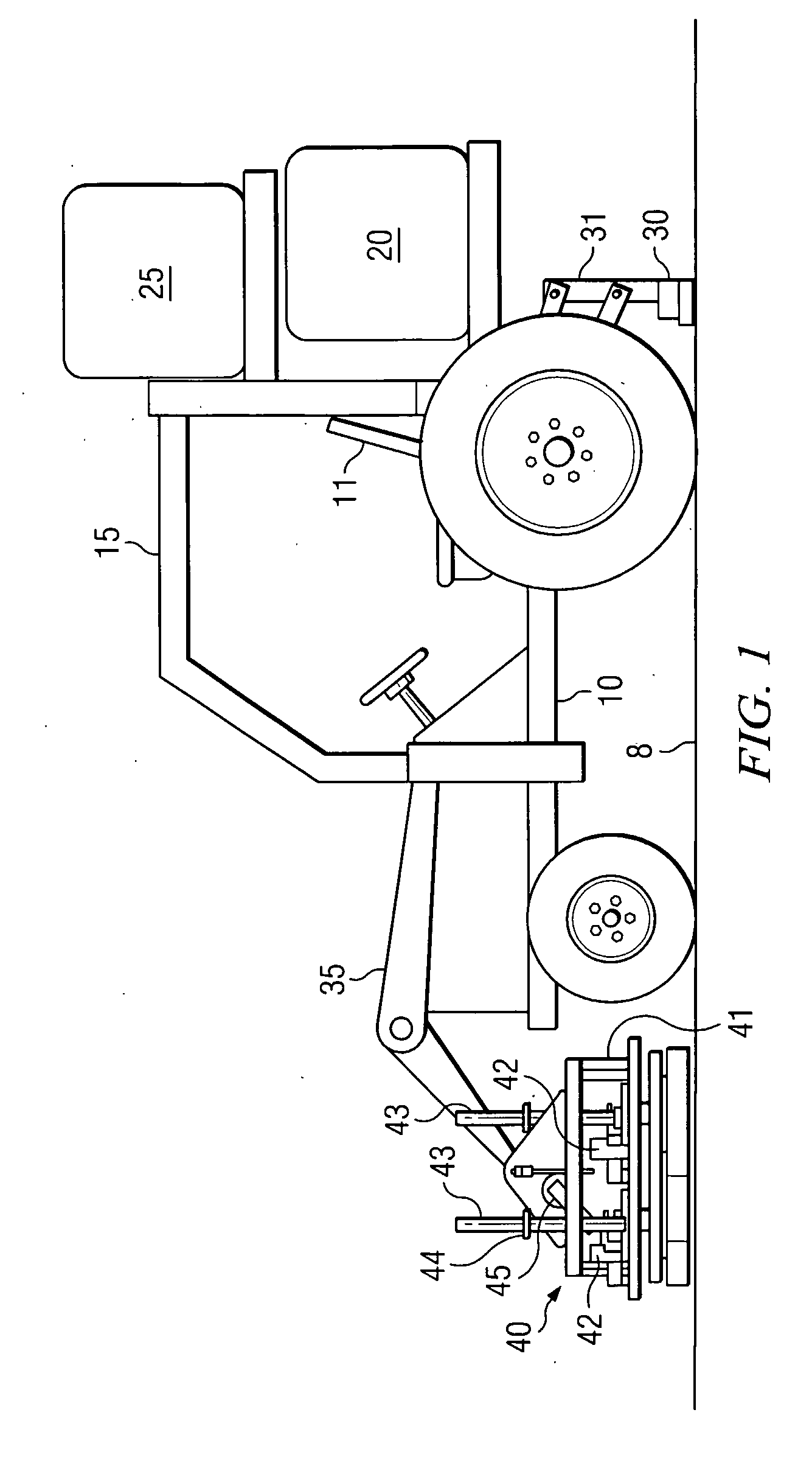

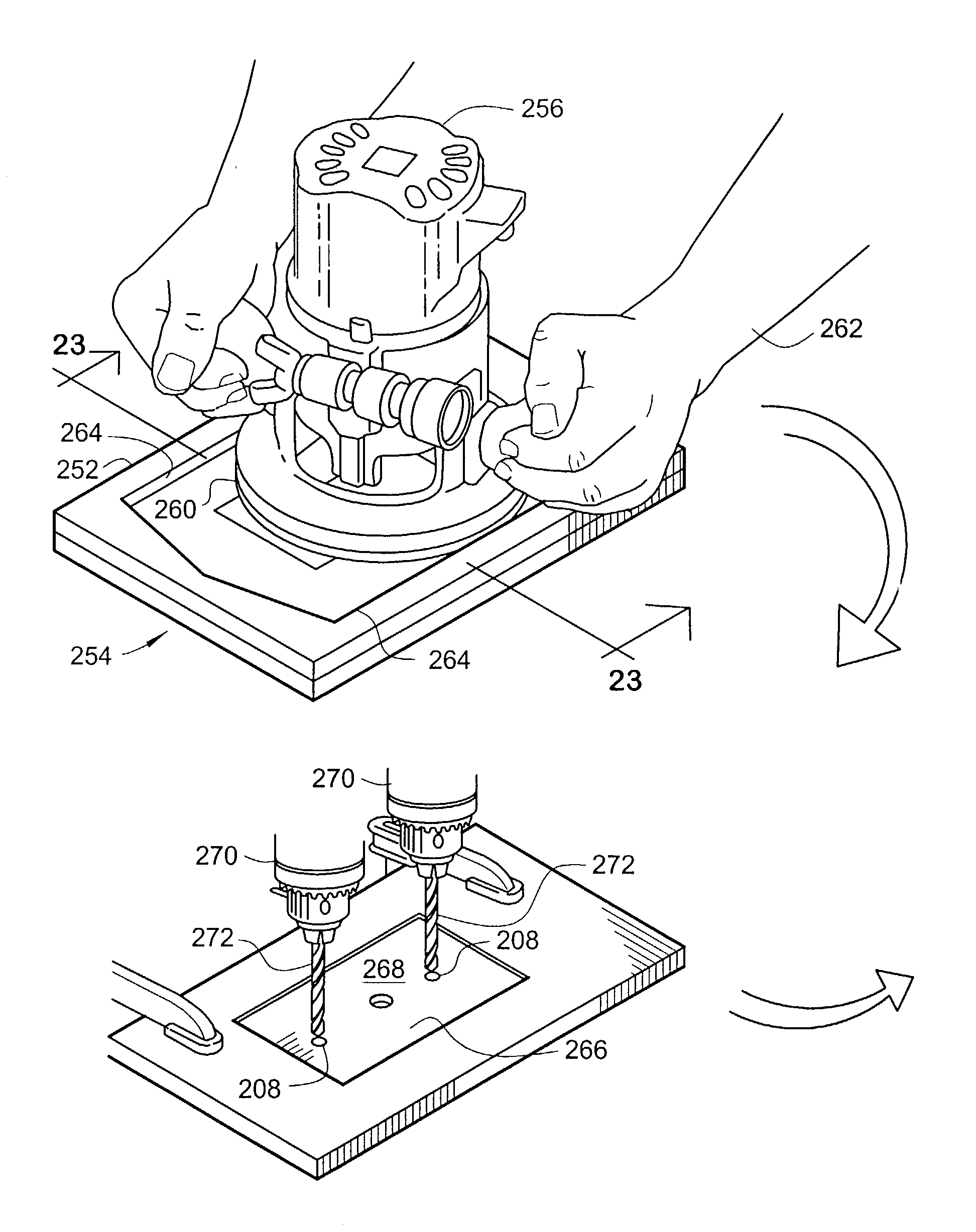

Riding Floor Polishing and Grinding Machine for Treating Concrete, Terrazzo, Stone and Similar Surfaces

InactiveUS20070264917A1Sufficient vertical forceMore vertical forcePortable grinding machinesPlane surface grinding machinesTerrazzoSingle pass

The invention is a riding floor polishing and grinding machine that uses one or more gangs of polishing heads (242) to treat concrete and similar surface flooring (208). A compact vehicle (210) equipped with a front loader arm (235) is fitted with a module (240) containing the gang(s) of polishing head. The vehicle (210) is capable of raising and rotating the module to easily change the pads attached to the polishing heads. Each polishing head is individually powered by a motor and floats over the floor surface. The pads attached to the polishing heads can be of many different types, preferably diamond-impregnated polishing pads. The invention enables operator to more quickly and efficiently remove material from a floor surface. The design also enables gangs of pads to be mounted with different grit ratings to perform different treatment operations using a single machine in a single pass over a floor surface.

Owner:BADGER MACHINE

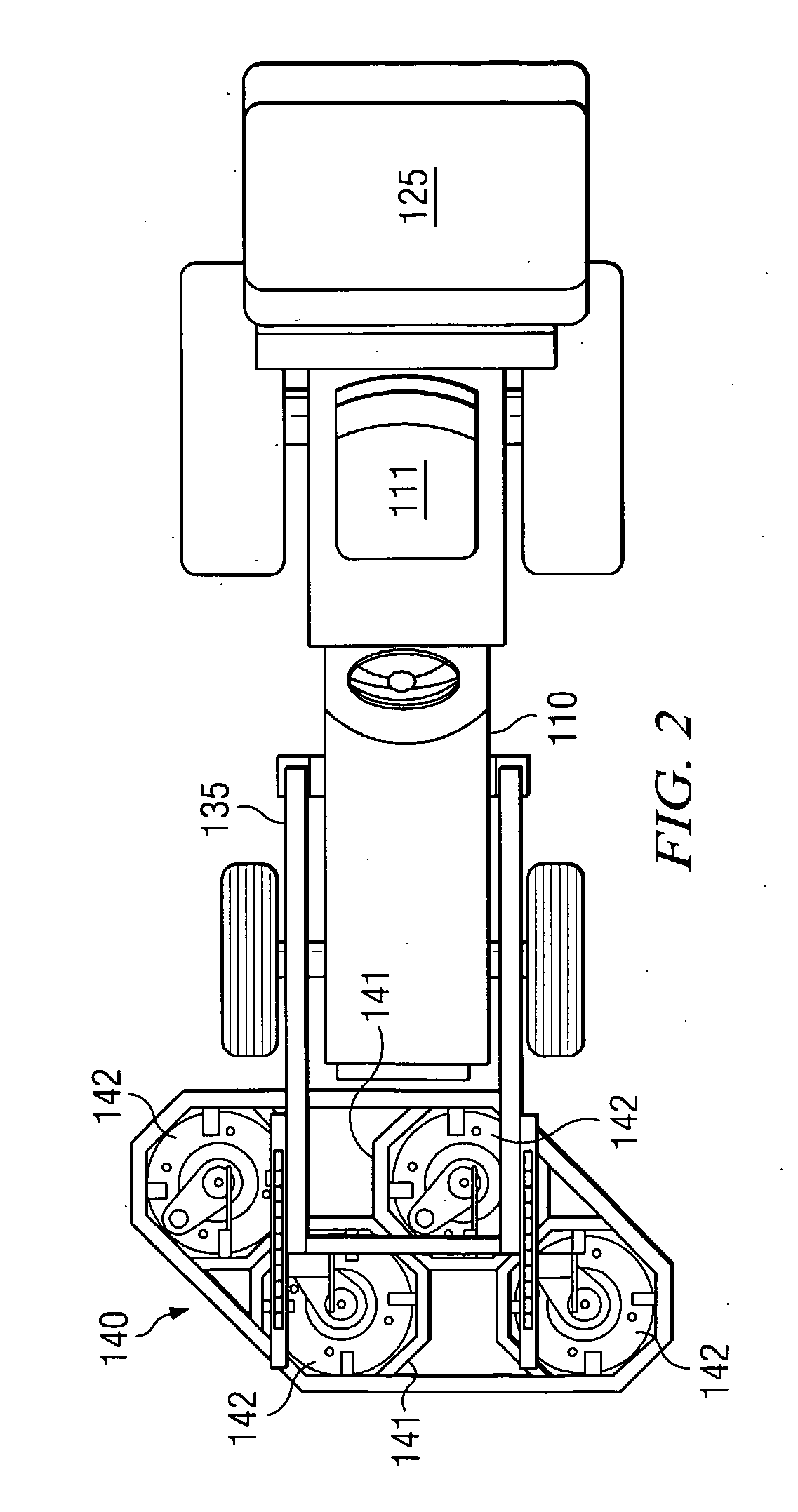

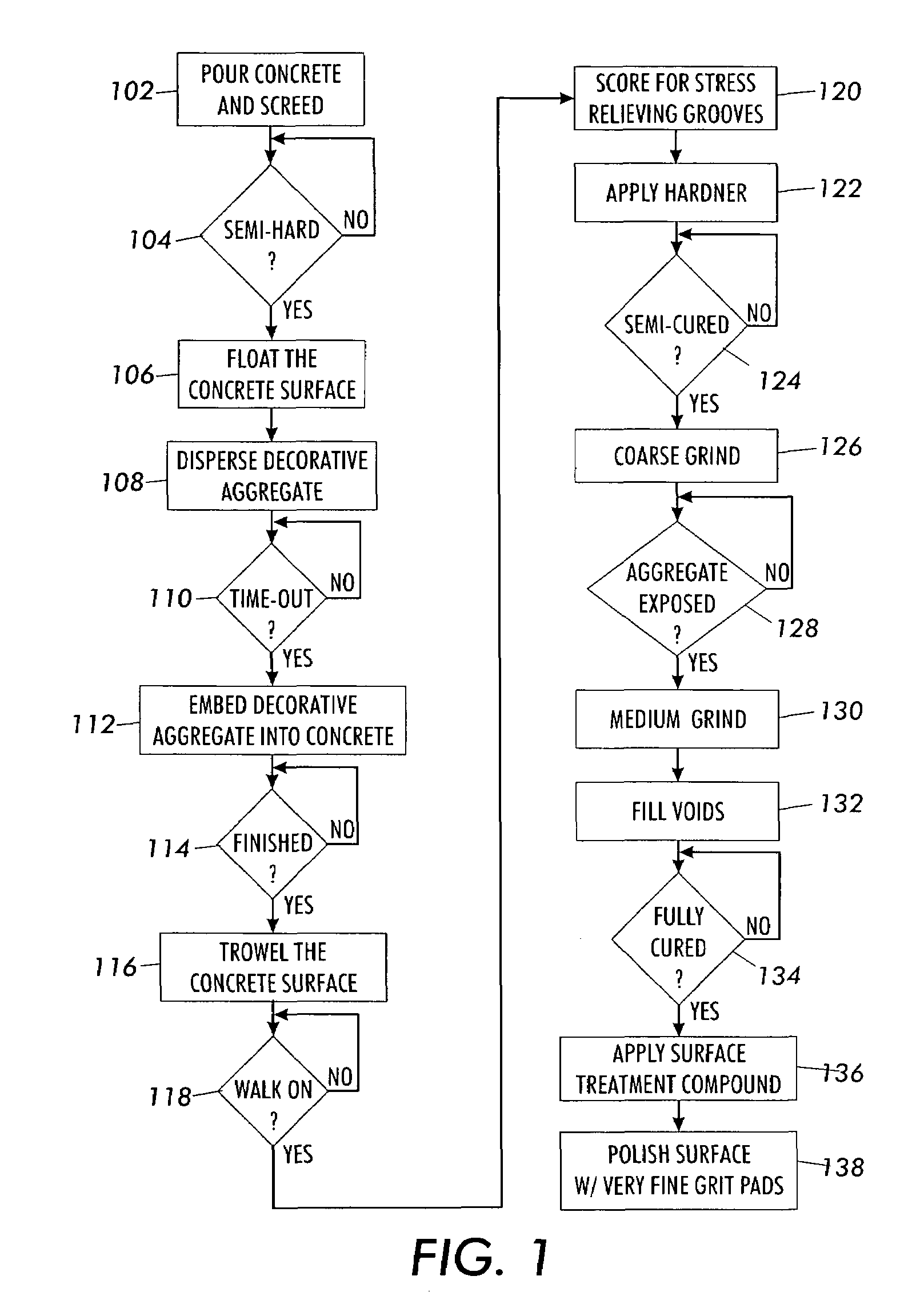

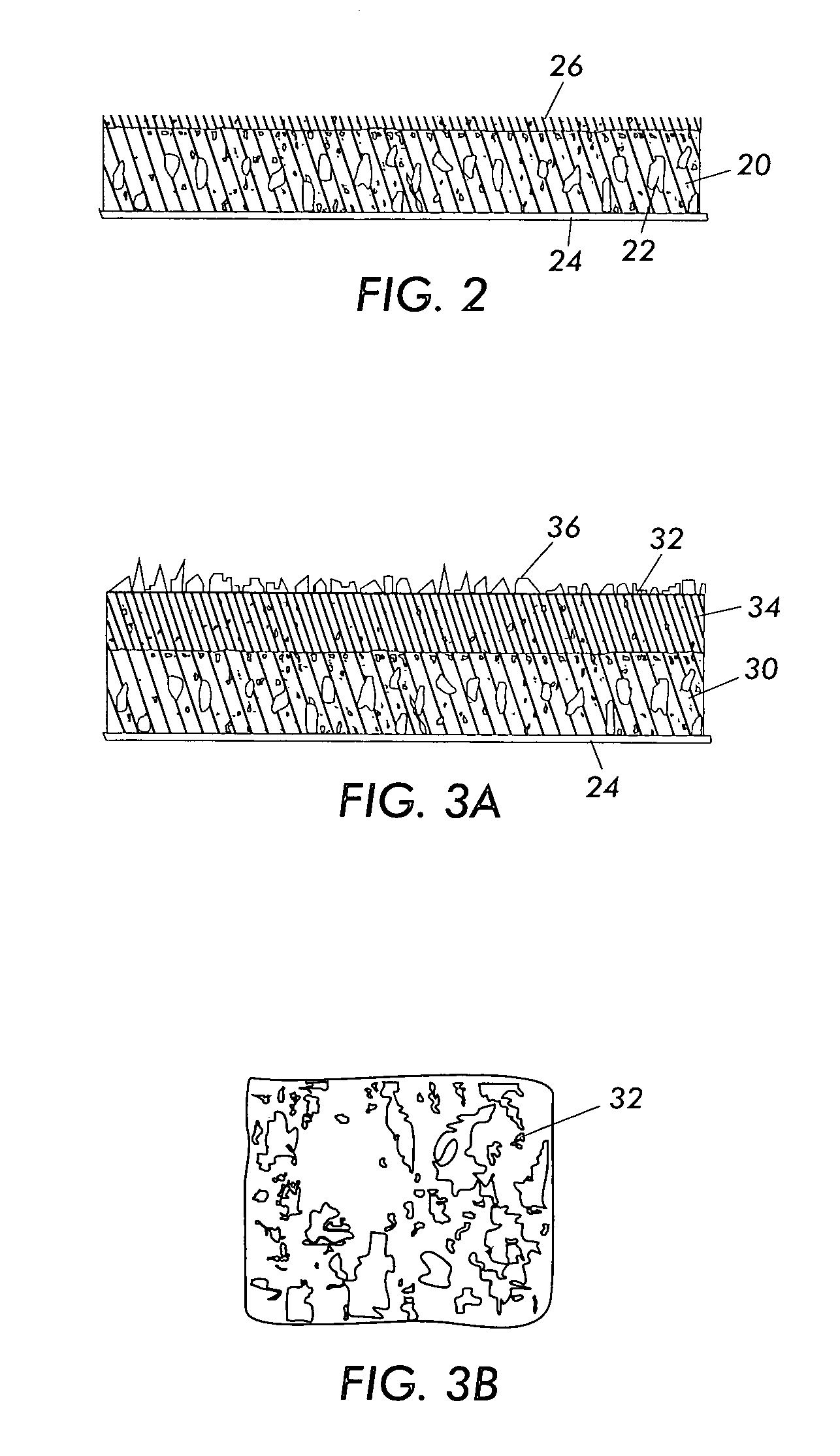

Method for the aesthetic surface treatment of a monolithic concrete floor and product of the method

This invention relates generally to a method for forming a concrete floor as a monolithic unit, wherein a wet concrete mix is deposited and worked to achieve a generally uniform flatness of concrete and adding to the top layer thereof a decorative aggregate material. Subsequently, the surface of the concrete is worked, allowed to partially cure and then ground and polished to substantially remove surface irregularities and reveal the decorative aggregate. The floor surface may then be coated with a sealant to achieve a terrazzo-like appearance.

Owner:TERR CON DECORATIVE CONCRETE FLOORS

Paving method of epoxy terrazzo floor

The invention discloses a paving method of an epoxy terrazzo floor, and belongs to the field of epoxy floors. The hardness, the abrasive resistance, the impact resistance, or the like, of the epoxy floor paved by the disclosed method can hardly meet the application needs synchronously. The paving method of the epoxy terrazzo floor comprises the following steps: firstly, polishing the ground, removing the dust, and coating a priming paint; secondly, ultrasonically stirring epoxy resin, vinyl acetate, phospholipid, aggregate, and nanometer zinc oxide for 10-30 minutes, then adding sodium silicate, epoxy curing agent DMP-30, and defoaming agent therein for being uniformly stirred, and then applying the mixture onto the ground, thereby finishing paving the epoxy terrazzo floor after coarse polishing and fine polishing. The paving method of the epoxy terrazzo floor can be widely applied to the decoration construction of the floor of large-scale public buildings such as airports, hotels, conference centers, and exhibition halls.

Owner:哈尔滨中建璟园科技开发有限公司

Novel cast-in-place waterstone ground surface layer construction method

ActiveCN104563507AImprove the quality of look and feelImprove the finishBuilding material handlingTerrazzoWetting

The invention discloses a novel cast-in-place waterstone ground surface layer construction method. The novel cast-in-place waterstone ground surface layer construction method comprises the following steps: (1) treating a base layer; (2) pouring water and wetting; (3) carrying out ground bottom ash screeding; 4) paving bottom ash; (5) carrying out mesh division by elastic lines; (6) embedding dividing strips; (7) brushing a bonding layer; (8) paving stone particle slurry; (9) rolling compactly, and paving and flattening; (10) carrying out trial grinding; (12) finely grinding; (13) feeding a concrete curing agent; (14) precisely grinding; (15) carrying out crystal face treatment on the surface of a waterstone. The novel cast-in-place waterstone ground surface layer construction method has the advantages that the surface smoothness of the waterstone is high; the surface hardness reaches Grade5-7; the waterstone has permeation resistance and is waterproof and dirt-proof, has the water permeation rate of being less than 0.8, and is oil-proof, weak-acid-proof, weak-alkali-proof and salt-fog-proof; the comprehensive performance of natural protection exceeds that of any existing stone product; a cast-in-place waterstone ground has zero dead angle when being ground and polished, and the ground appearance quality is greatly improved when being compared with that of a traditional method.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

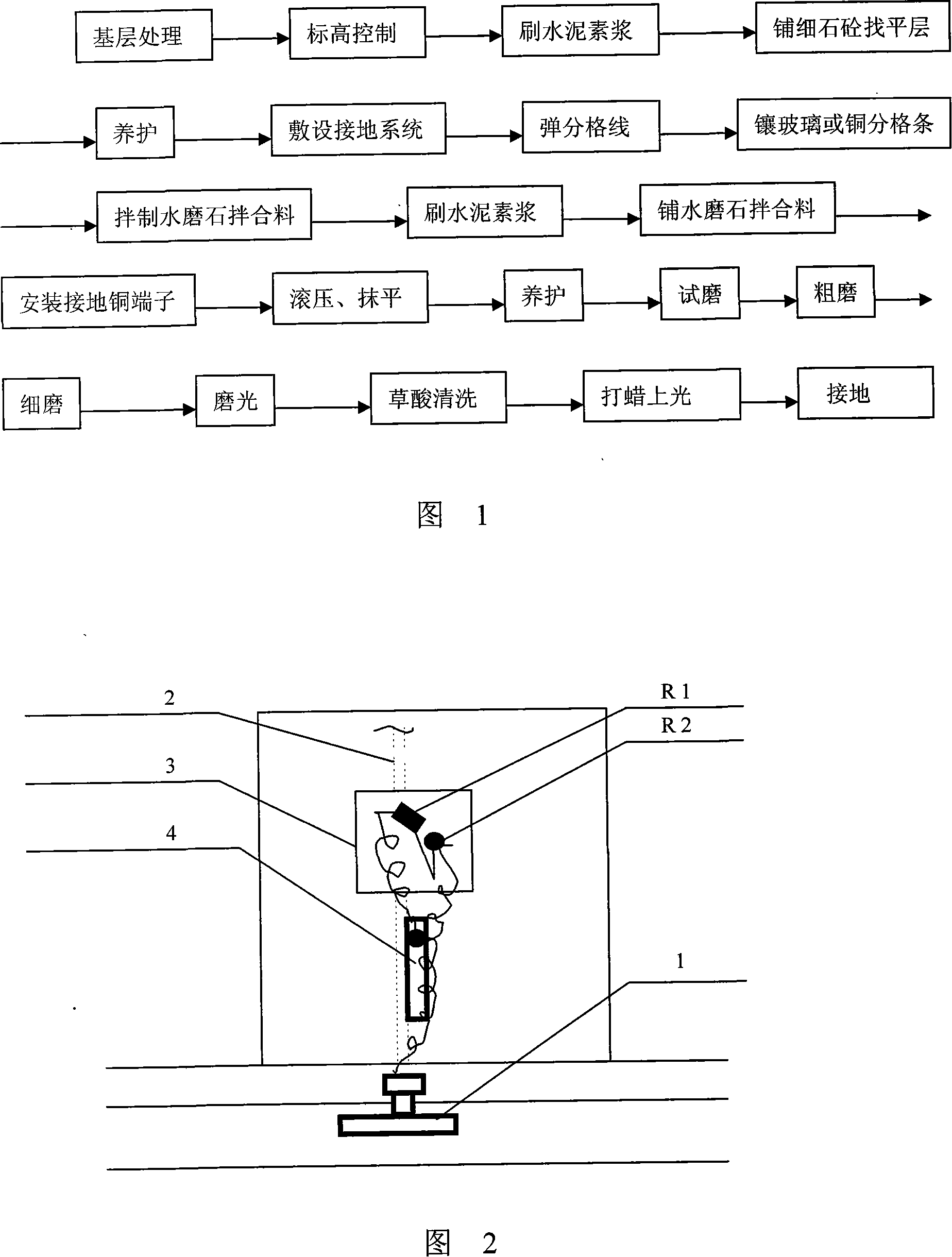

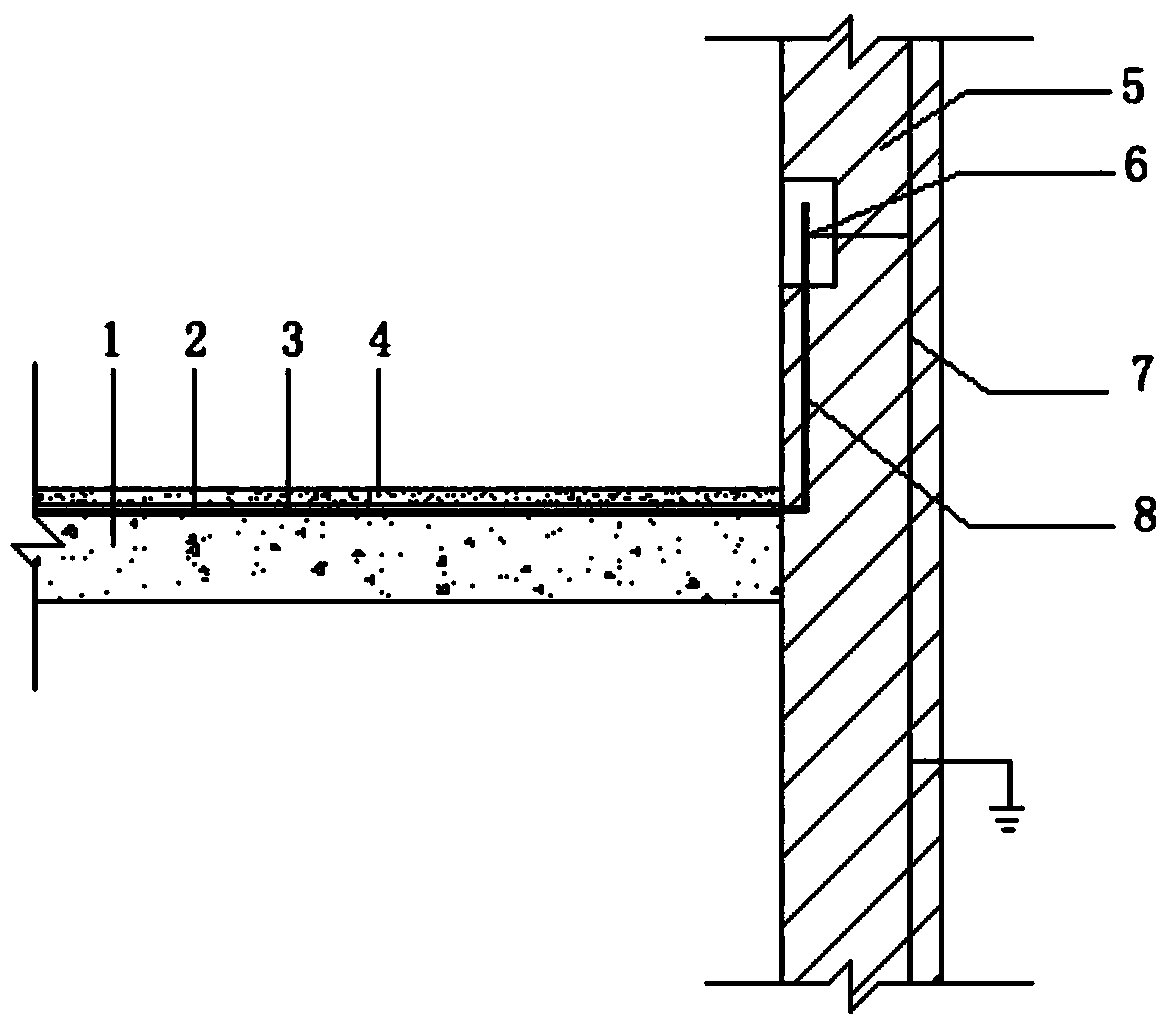

On site antistatic terrazzo ground construction method

The invention discloses an on-site construction method of anti-static terrazzo floors, which comprises the steps of leveling blanket construction, partitioning strip embedment, terrazzo mixture layout, maintenance, terrazzo surface polishing, and terrazzo surface finishing. The method further comprises the steps of grounding system layout, ground terminal layout and ground wire connection. The volume ratio of concrete and rock ballast in the terrazzo mixture is 1:1.5-1:2.5 and the volume ratio of common terrazzo ballast and ballast subjected to anti-static treatment is 1:2. With the technical proposal, the cost price of the inventive anti-static terrazzo floor is reduced to 1 / 3-1 / 4 of that of anti-static raised floor and the construction cost is greatly reduced. Additionally, compared with the anti-static raised floor, the inventive anti-static terrazzo floor doesn't reduce the net storey height of the building and increase the available height space of equipment room; and the floor has the advantages of long service life, no risk of damage, and reduced maintenance cost.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Wet lay-up process for epoxy terrazzo floor

The invention relates to the technical field of epoxy terrazzo construction and discloses a wet lay-up process for an epoxy terrazzo floor. The wet lay-up process comprises the steps of (a) grading sand and stone to obtain graded sand; (2) uniformly mixing the epoxy resin material and a curing agent to obtain an epoxy resin mixture; (3) adding the graded sand to a stirring device in which epoxy terrazzo is filled and stirring, then adding the epoxy resin mixture and uniformly stirring; (4) spreading the mixture on a road bed to be constructed, then leveling the floor, finishing and compacting the sand material; (5) after the mixture is completely hardened, grouting with the epoxy resin mixture so that the voids in the floor is completely filled; and (6) after the epoxy resin mixture is completely hardened, polishing the floor. The wet lay-up process disclosed by the invention is simple, the effective conservation of materials is achieved, and the fabricated epoxy terrazzo floor has the characteristics of smooth structure, dust-proof and moisture-proof properties and wear resistance.

Owner:宿州典跃新型建筑材料有限公司

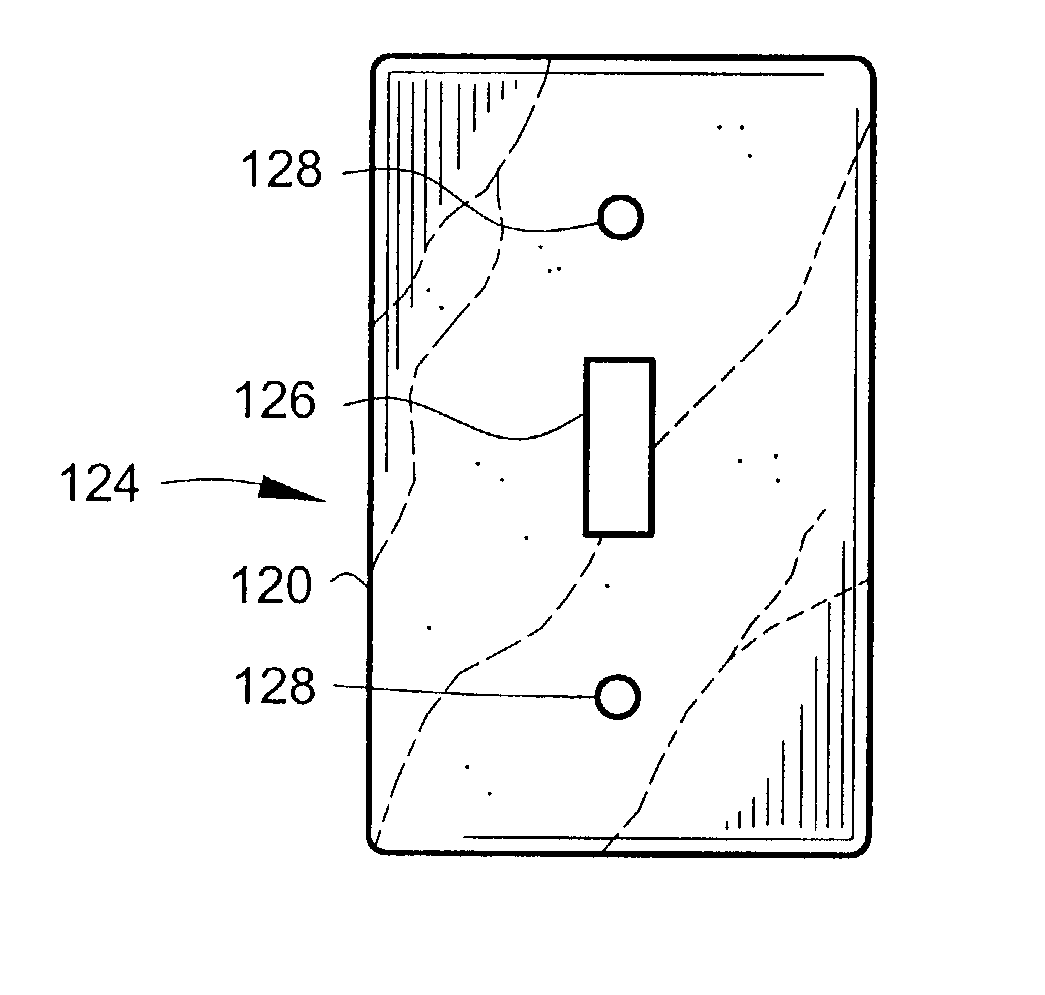

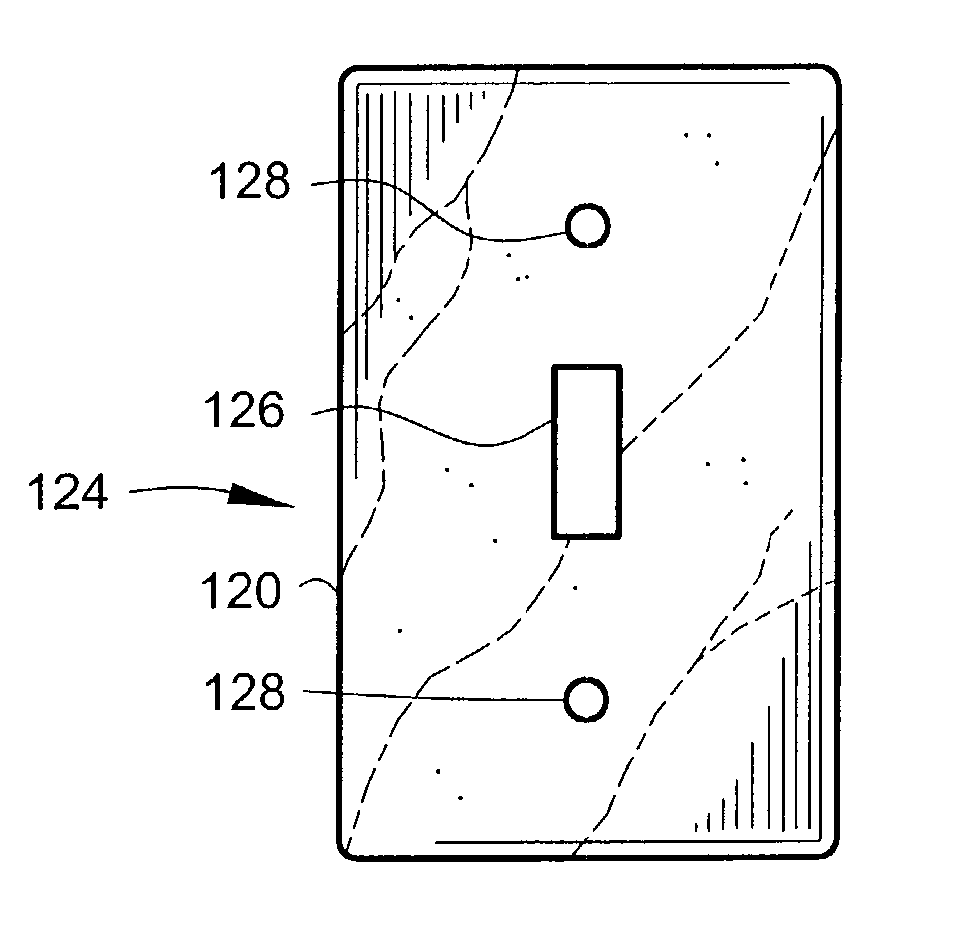

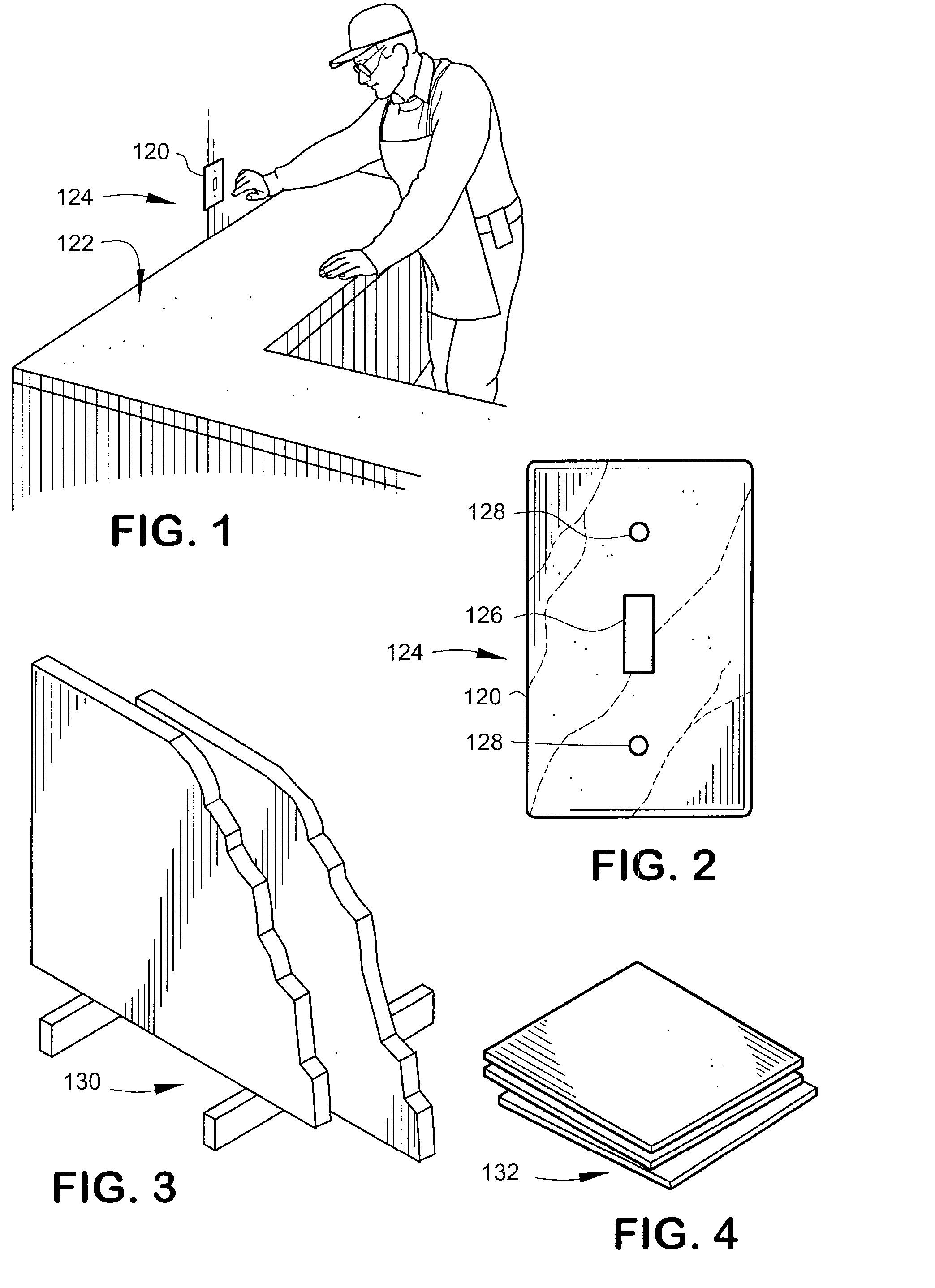

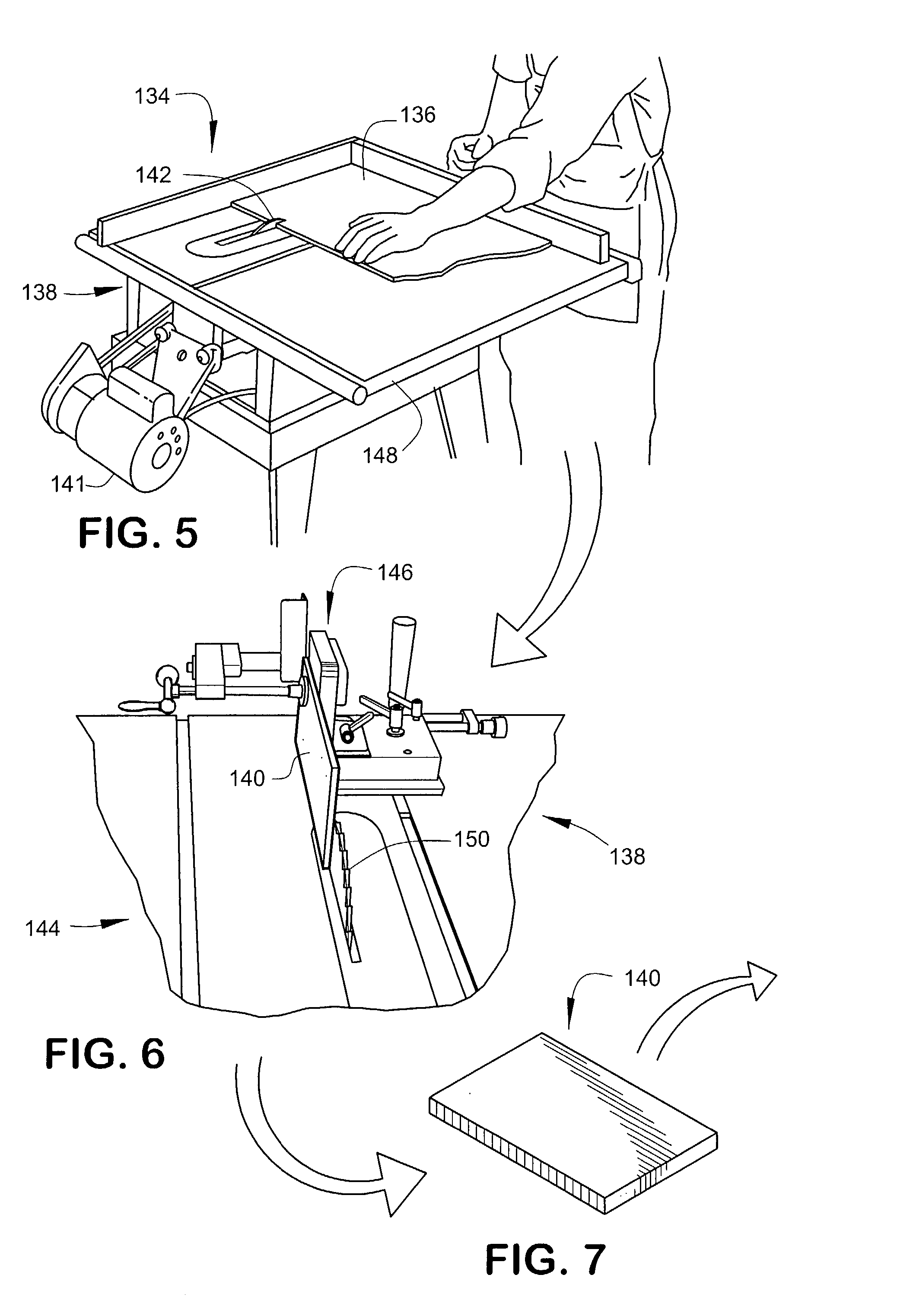

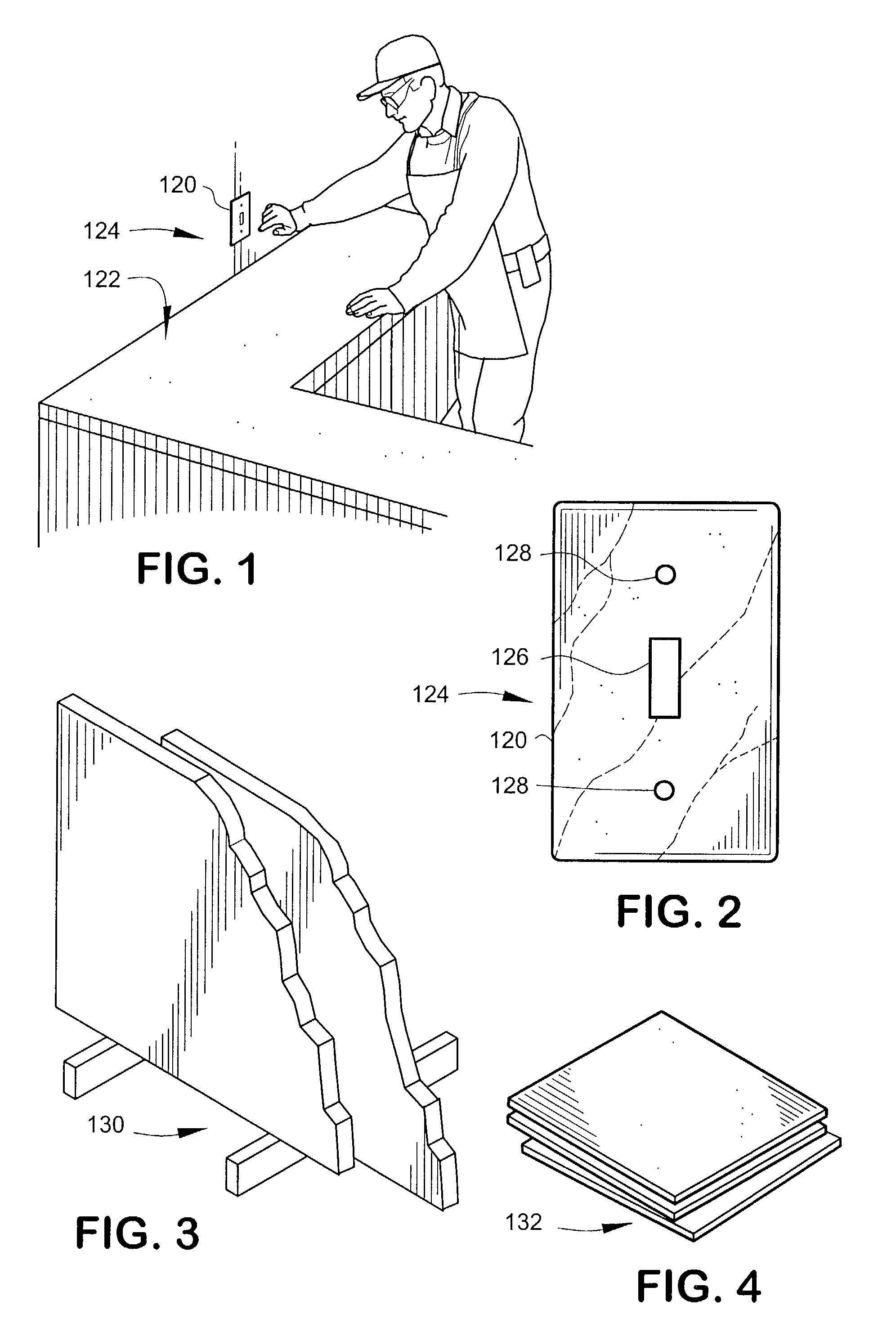

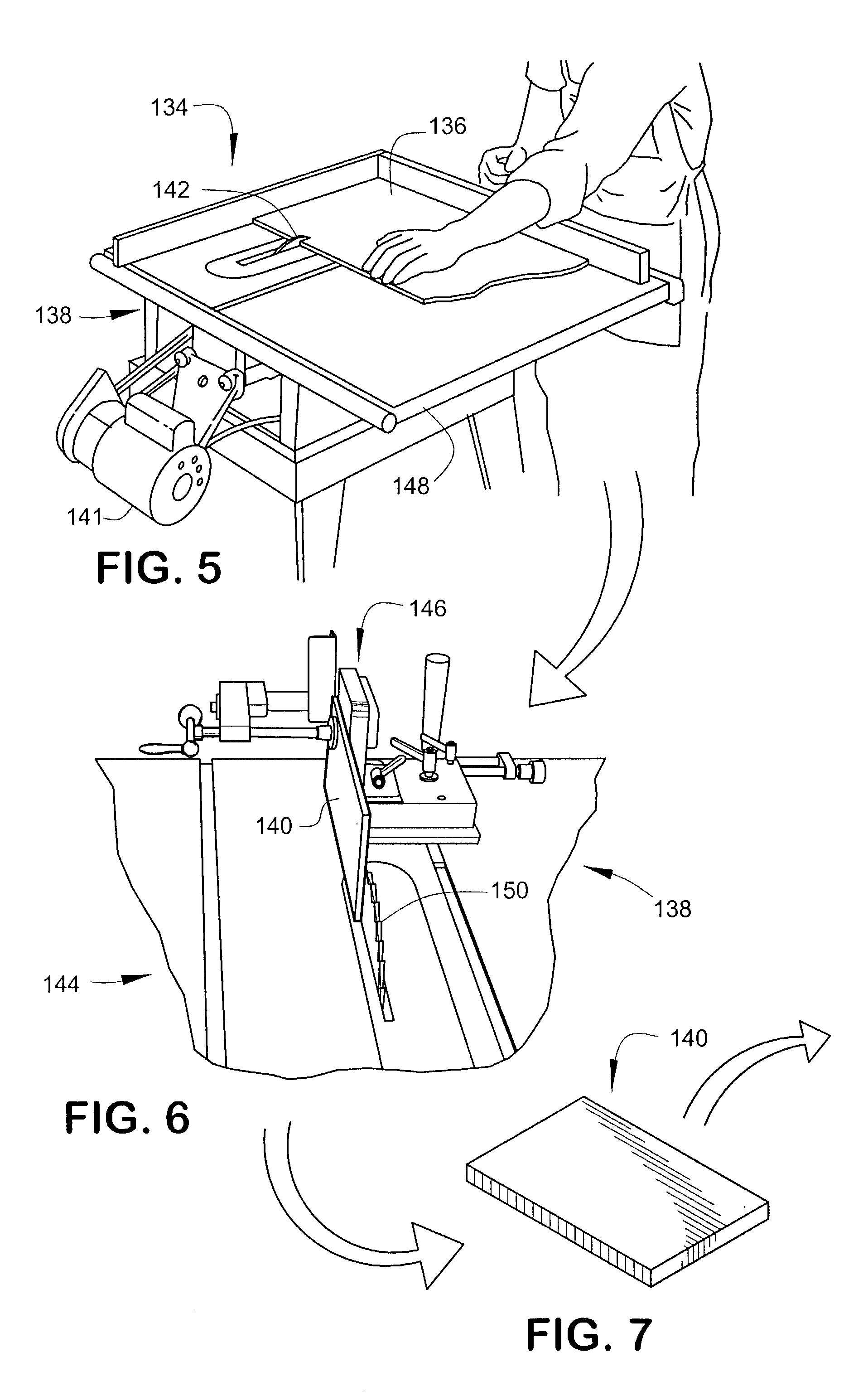

System for matched-stone cover plates

InactiveUS20030106703A1Easy to handleReduce thicknessCasings/cabinets/drawers detailsGrinding work supportsGranolithicEngineering

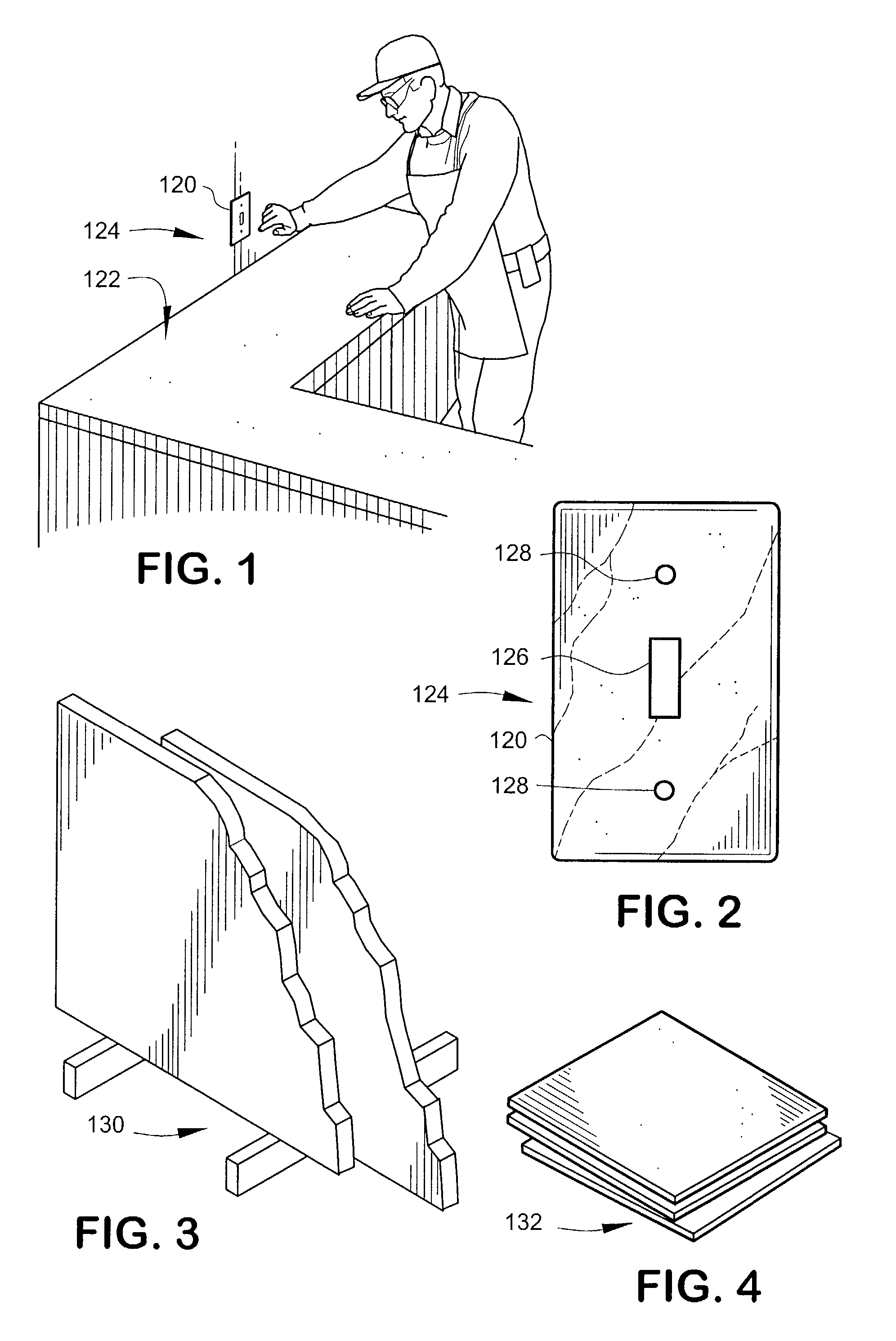

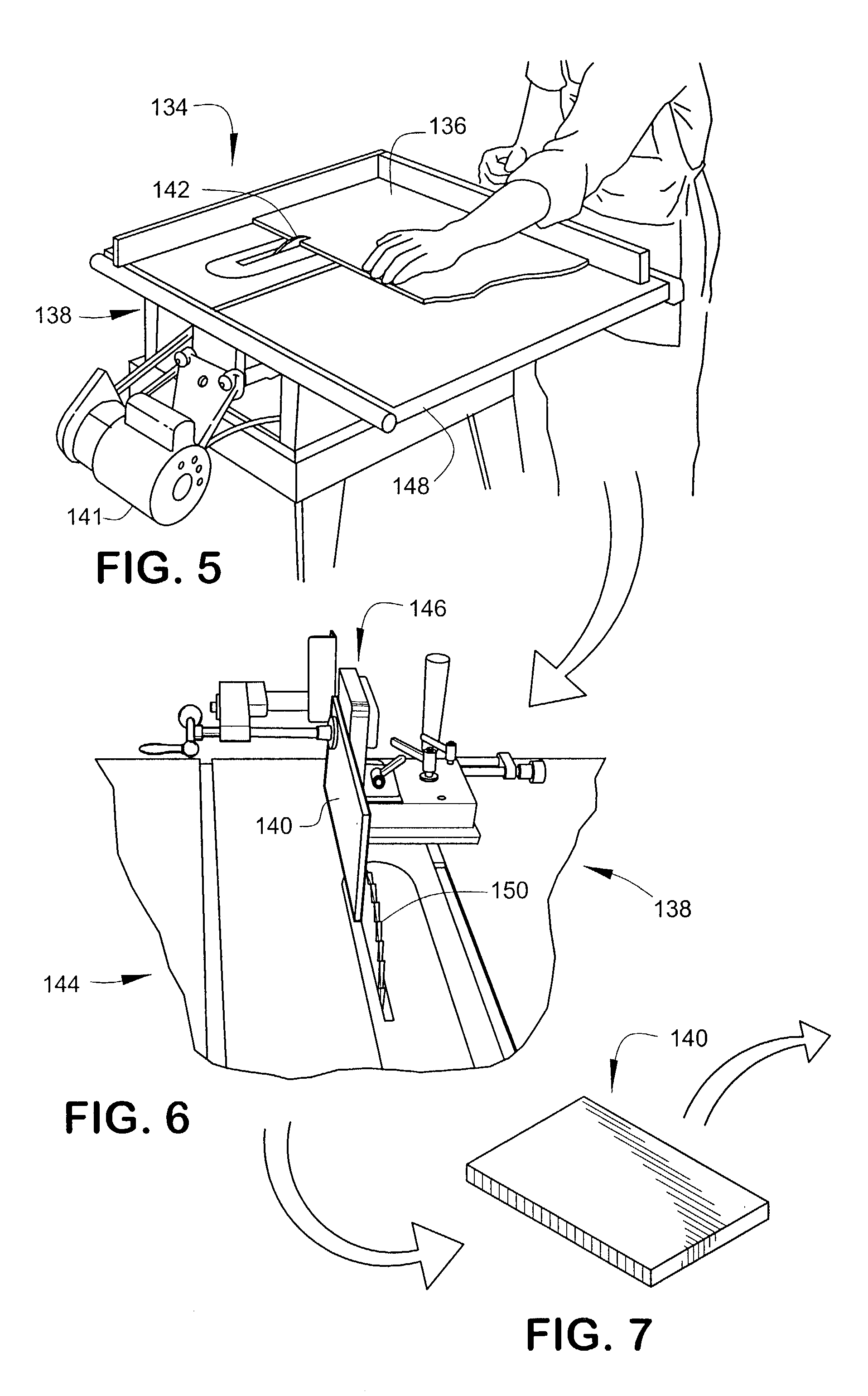

A cover plate system for making custom natural stone cover plates for electrical outlets, wall switches and other outlets and openings over which it is desired to place a natural stone cover plate. The natural stone cover plates are made from quarried stone, cultured stone, and natural rock materials such as terrazzo, marble, and granite preferably supplied by the homeowner, or end user, to a central factory, then manufactured, then shipped back to the end user to match other such material being used in the end user's building.

Owner:WILSON RONALD J

Recycling method for cast-in-situ terrazzo floor polishing waste slurry

ActiveCN102837261BNo pollutionLow costFiltration circuitsGrinding/polishing safety devicesWater resourcesCofferdam

Owner:JIANGSU JIAYANGHUALIAN BUILDING & DECORATION CO LTD

Integrated terrazzo floor and production method thereof

The invention belongs to the field of building construction, and particularly relates to an integrated terrazzo floor and a production method thereof. The production method comprises the steps of uniformly scattering a Yuhua stone aggregate on a primarily solidified concrete base 3-5 h after concrete pouring; and then, carrying out sleeking and levelling. The concrete comprises the following raw materials: cement, waste residues of glass, emery, marble powder, epoxy resin and water, wherein the weight ratio of cement to waste residues of glass to emery to marble powder to epoxy resin to water is 35 to 80 to 75 to 50 to 10 to 17. Construction of the floor is simple, the cost is low, and the obtained floor is abrasion-resistant and environment-friendly, and is long in service life.

Owner:FUZHOU ROYAL FLOOR

System for matched-stone cover plates

InactiveUS20030037952A1Easy to handleReduce thicknessCasings/cabinets/drawers detailsGrinding work supportsGranolithicEngineering

A cover plate system for making custom natural stone cover plates for electrical outlets, wall switches and other outlets and openings over which it is desired to place a natural stone cover plate. The natural stone cover plates are made from quarried stone, cultured stone, and natural rock materials such as terrazzo, marble, and granite preferably supplied by the homeowner, or end user, to a central factory, then manufactured, then shipped back to the end user to match other such material being used in the end user's building.

Owner:WILSON RONALD J

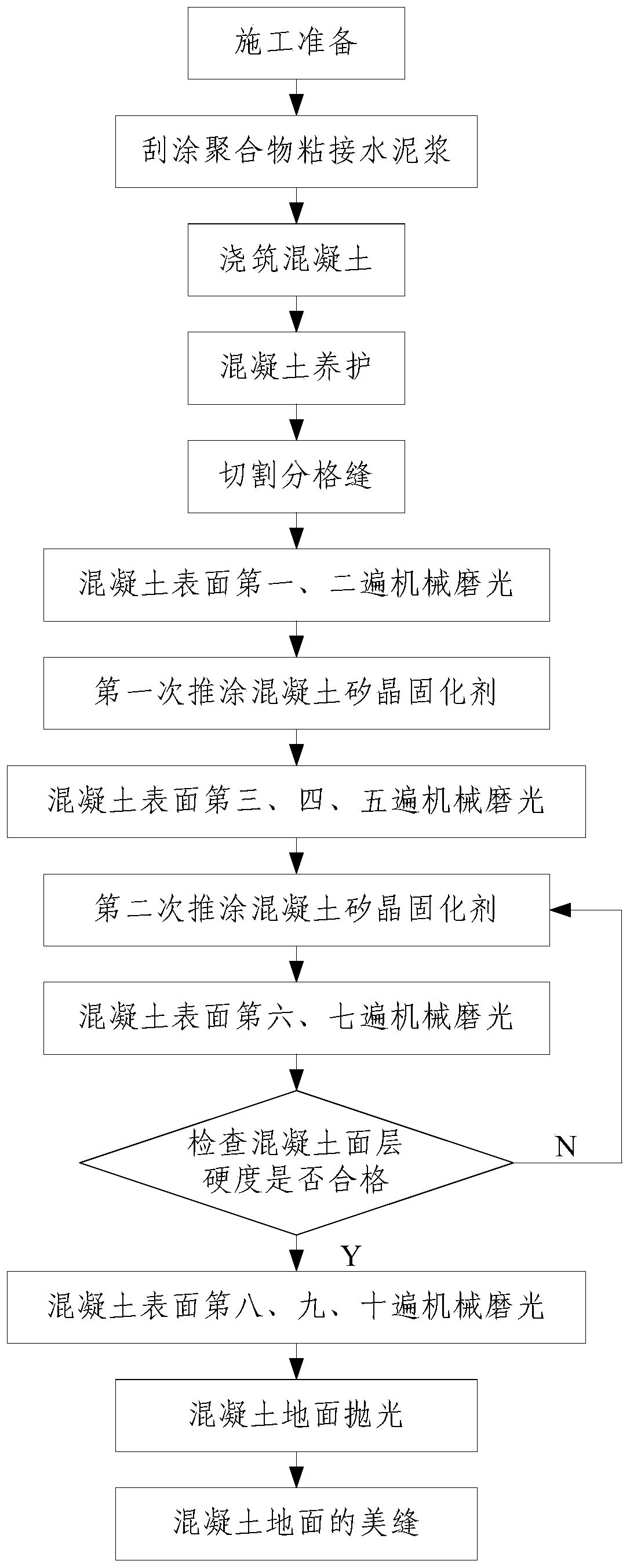

Abrasion-resistant concrete terrazzo floor construction method

InactiveCN109797945AImprove performanceVariety of colorsFlooringPlane surface grinding machinesCement pasteTerrazzo

The invention discloses an abrasion-resistant concrete terrazzo floor construction method. The abrasion-resistant concrete terrazzo floor construction method includes the steps of 1, construction preparation, 2, scrape coating of polymer binding cement paste, 3, concreting, 4, concrete curing, 5, dividing joint cutting, 6, first and second mechanical lapping of concrete surfaces, 7, first push coating of silicon-on-insulator curing agents, 8, third, fourth and fifth mechanical lapping of concrete surfaces, 9, second push coating of silicon-on-insulator curing agents, 10, sixth and seventh mechanical lapping of concrete surfaces, 11, concrete surface check, 12, eighth, ninth and tenth mechanical lapping of concrete surfaces, 13, concrete floor polishing, and 14, caulk sealing of concrete surfaces. The abrasion-resistant concrete terrazzo floor construction method has the advantages that the silicon-on-insulator curing agents permeate into the concrete surfaces by conducting push coatingtwice during multi-time concrete surface lapping, and therefore the concrete floor surfaces are reinforced, cured and hardened to form non-expansion shrinkproof high-strength compounds of smooth andabrasion-resistant structures.

Owner:陕西建工集团股份有限公司

A construction method of cast-in-place terrazzo ground surface

The invention discloses a novel cast-in-place waterstone ground surface layer construction method. The novel cast-in-place waterstone ground surface layer construction method comprises the following steps: (1) treating a base layer; (2) pouring water and wetting; (3) carrying out ground bottom ash screeding; 4) paving bottom ash; (5) carrying out mesh division by elastic lines; (6) embedding dividing strips; (7) brushing a bonding layer; (8) paving stone particle slurry; (9) rolling compactly, and paving and flattening; (10) carrying out trial grinding; (12) finely grinding; (13) feeding a concrete curing agent; (14) precisely grinding; (15) carrying out crystal face treatment on the surface of a waterstone. The novel cast-in-place waterstone ground surface layer construction method has the advantages that the surface smoothness of the waterstone is high; the surface hardness reaches Grade5-7; the waterstone has permeation resistance and is waterproof and dirt-proof, has the water permeation rate of being less than 0.8, and is oil-proof, weak-acid-proof, weak-alkali-proof and salt-fog-proof; the comprehensive performance of natural protection exceeds that of any existing stone product; a cast-in-place waterstone ground has zero dead angle when being ground and polished, and the ground appearance quality is greatly improved when being compared with that of a traditional method.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Epoxy terrazzo flooring and method for polishing the same

A method of polishing a marble terrazzo floor, including shaving the surface with a first plurality of first diamond abrasive particles, and shaving the surface with a second plurality of second diamond abrasive particles. The first diamond abrasive particles are MBG-type mesh crystals characterized by a first average size, wherein the second diamond abrasive particles MBG-type mesh crystals characterized by a second, smaller average size, and wherein the diamond abrasive particles substantially laterally impact surface protrusions.

Owner:YOUNG IDEAS LIMITED LIABILITY

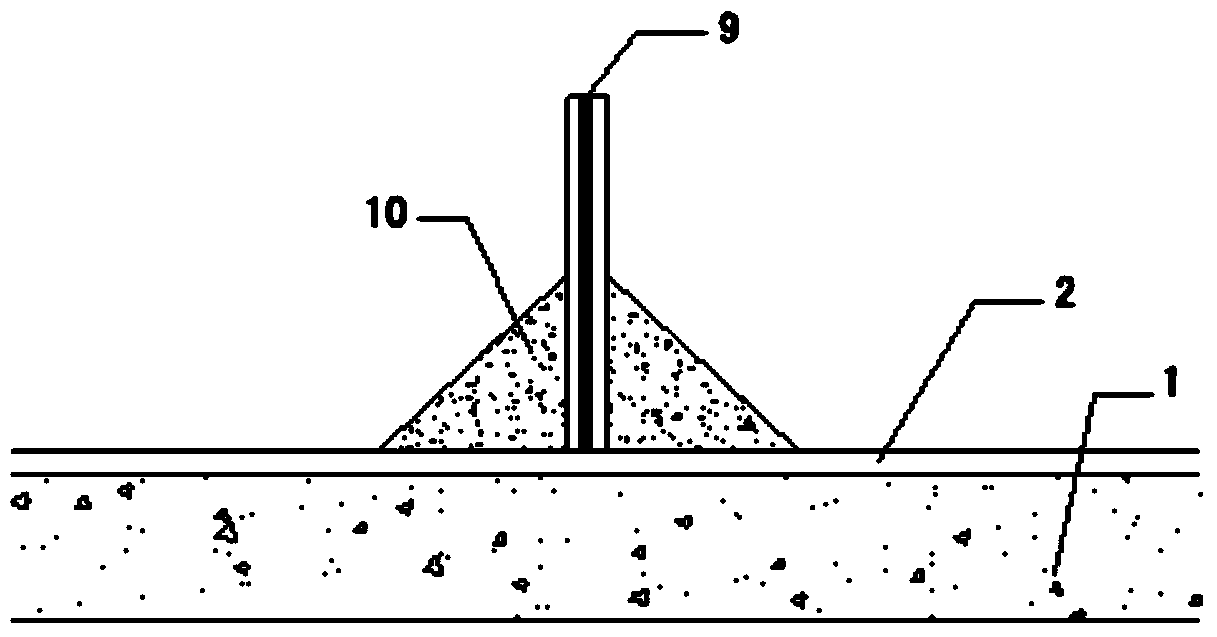

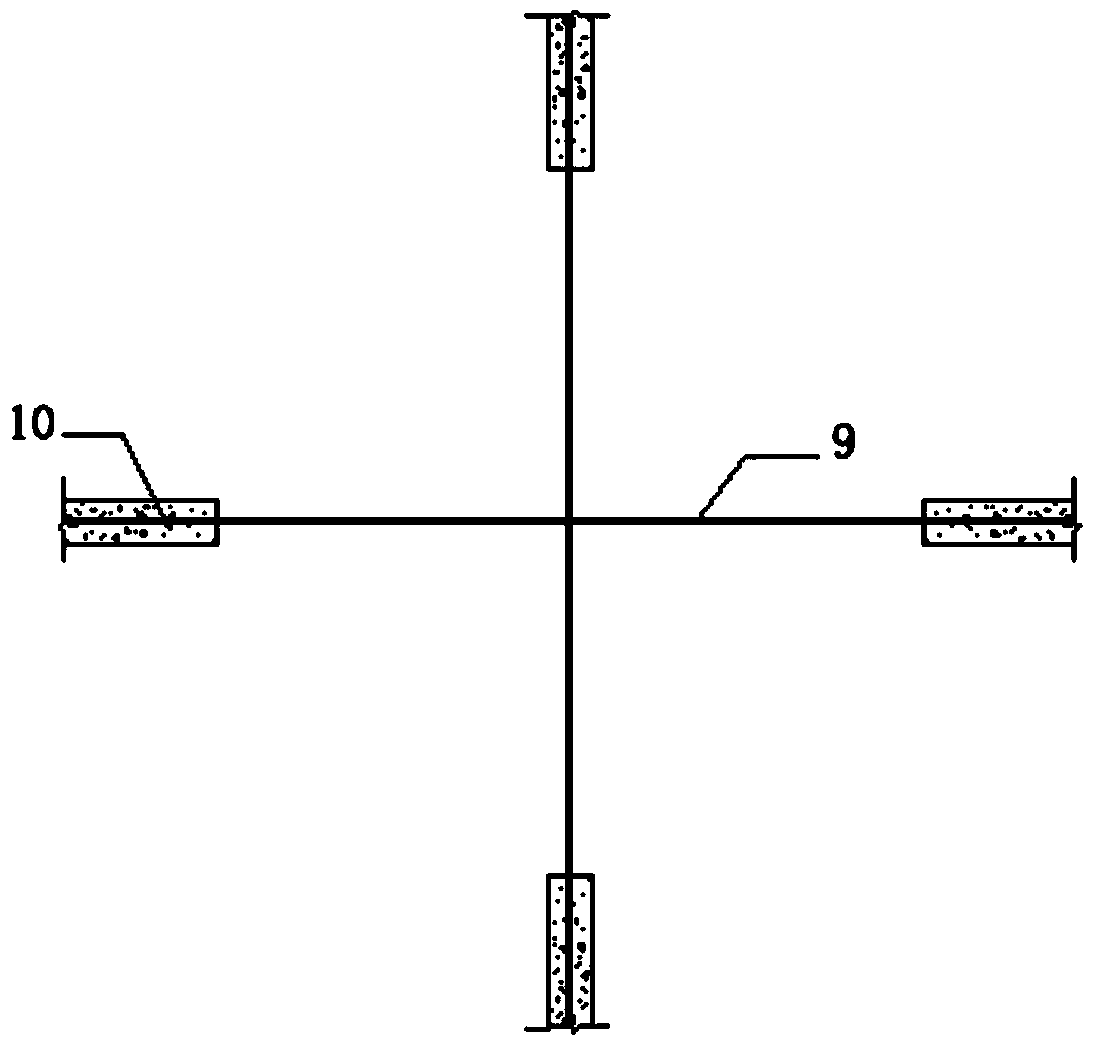

Copper plate grounding grid antistatic terrazzo floor construction process

The invention discloses a copper plate grounding grid antistatic terrazzo floor construction process which includes the steps of firstly, constructing a cement ground base layer; secondly, painting an insulating isolation layer; thirdly, laying ESD copper plate grounding grids; fourthly, retaining an ESD grounding connecting box; fifthly, embedding glass grid separating strips; sixthly, laying an antistatic terrazzo surface layer. By the method, construction cost is lowered without affecting the load-bearing performance and pressure resistance of the ground, the constructed copper plate grounding grid antistatic terrazzo floor is fast, stable and reliable in static discharge grounding performance and long in service life.

Owner:ZHEJIANG HAITIAN CONSTR GROUP

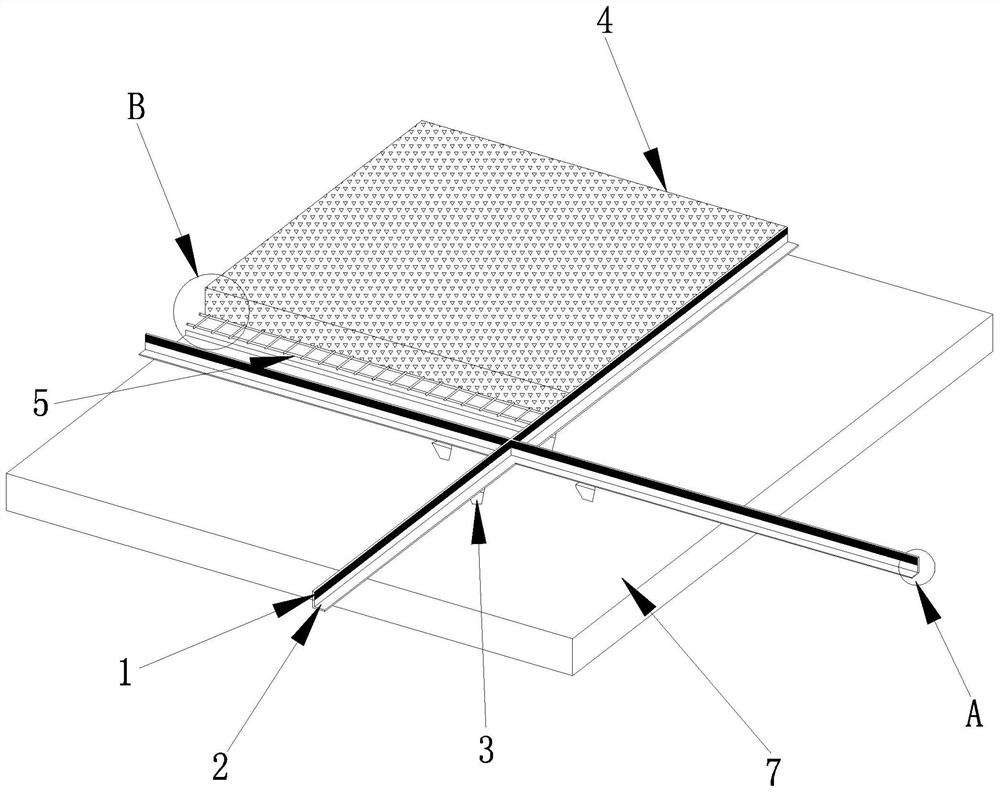

Cast-in-place inorganic artificial terrazzo floor-on-grade and construction method thereof

ActiveCN111997303AUniform textureSimple structureFlooringArchitectural engineeringMesh reinforcement

The invention relates to a cast-in-place inorganic artificial terrazzo floor-on-grade and a construction method thereof. The cast-in-place inorganic artificial terrazzo floor-on-grade comprises a plurality of concrete base layers assembled on the ground of a building, wherein a separating mechanism for separating the plurality of concrete base layers is further arranged on the ground of the building in a distributed mode, and latticed steel bar mesh sheets are arranged in the plurality of concrete base layers in a laid mode; and the separating mechanism comprises a plurality of wooden wedges,positioning clamping strips are assembled on the wooden wedges, and copper strips are arranged on the positioning clamping strips in a distributed mode. The cast-in-place inorganic artificial terrazzofloor-on-grade is simple in structure and convenient to use, and after the concrete base layers are cast in place on the terrazzo floor-on-grade, a floor-on-grade face layer which is uniform in texture, bright, delicate and durable can be obtained through special mechanical grinding; and the functionality, attractiveness and environmental protection property of the inorganic artificial terrazzo floor-on-grade can meet the requirements of different use units for different functions and purposes.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

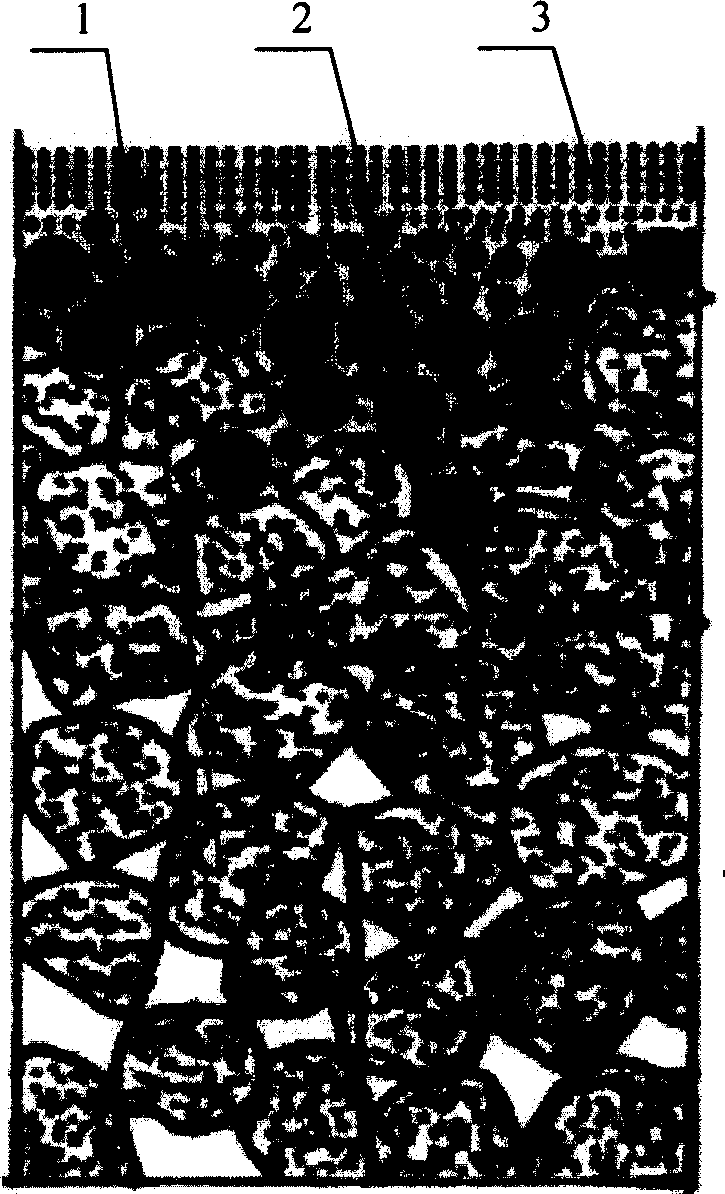

Terrazzo made from siliconized crystal and fabricating technique thereof

The present invention discloses a crystal silicon-infiltrated terrazzo and its production process. It has terrazo base layer, crystal silicon-infiltrated layer and silicon dioxide crystal surface layer, its surface hardness can reach Rockwell's 6-7 level, and its smooth finish can be up to 90-100 deg. and its water absorption is less than or equal to 0.8%, and the depth of its crystal silicon-infiltrated layer cna raech 1-10 mm, and its structure density is greater than or equal to 2.5 g / cu.m, and is above 1.5 times that of traditional terrazzo.

Owner:邓玉明

Biological enzyme finishing process for jean

InactiveCN103526555AFlat surfaceClear textureBiochemical fibre treatmentDry-cleaning apparatus for textilesCelluloseThree stage

The invention relates to a biological enzyme finishing process for jean. The finishing process is mainly divided into three stages: the first stage is pre-washing and amylase desizing, the second stage is cellulose enzyme washing, and the third stage is detergent washing, clean water washing and drying. The technological processes are as follows: enzyme desizing, water washing, enzyme washing, enzyme inactivation, water washing, soft finish and drying. The biological enzyme finishing process for the jean has the benefits as follows: the jean finished with the process is bright and clean in surface, smooth and clear in line and has permanent fuzzing resistance and pilling resistance. Compared with a previous terrazzo washing process, the technological process is shortened, the production cost is reduced, and damage to a fabric, equipment and a human body is avoided.

Owner:KUNSHAN P&X GARMENTS

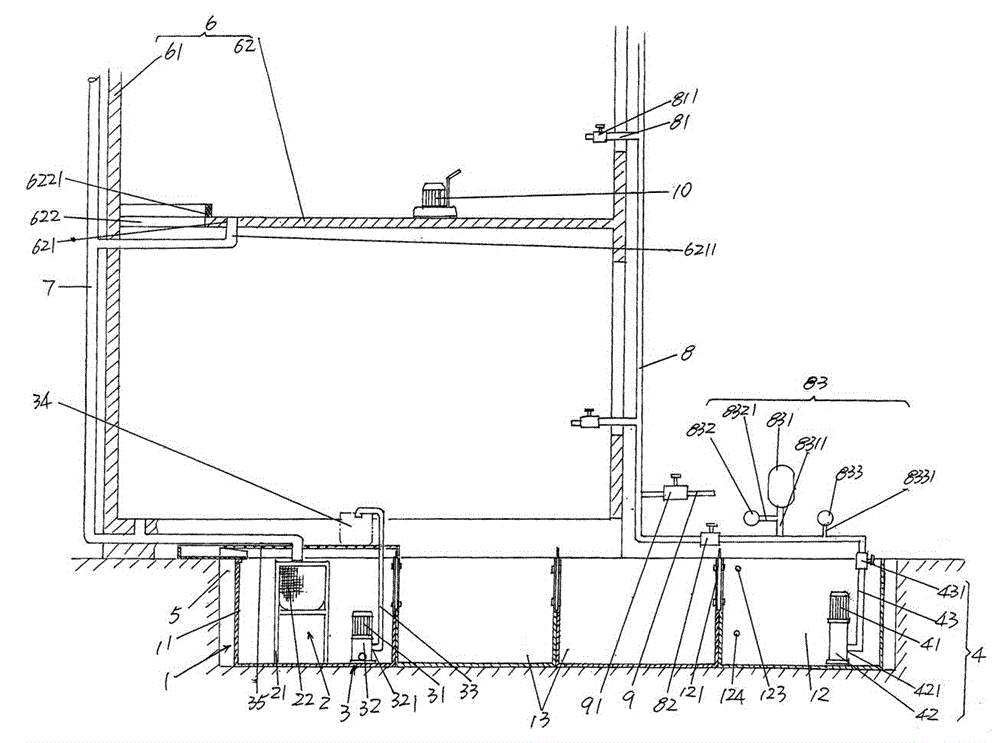

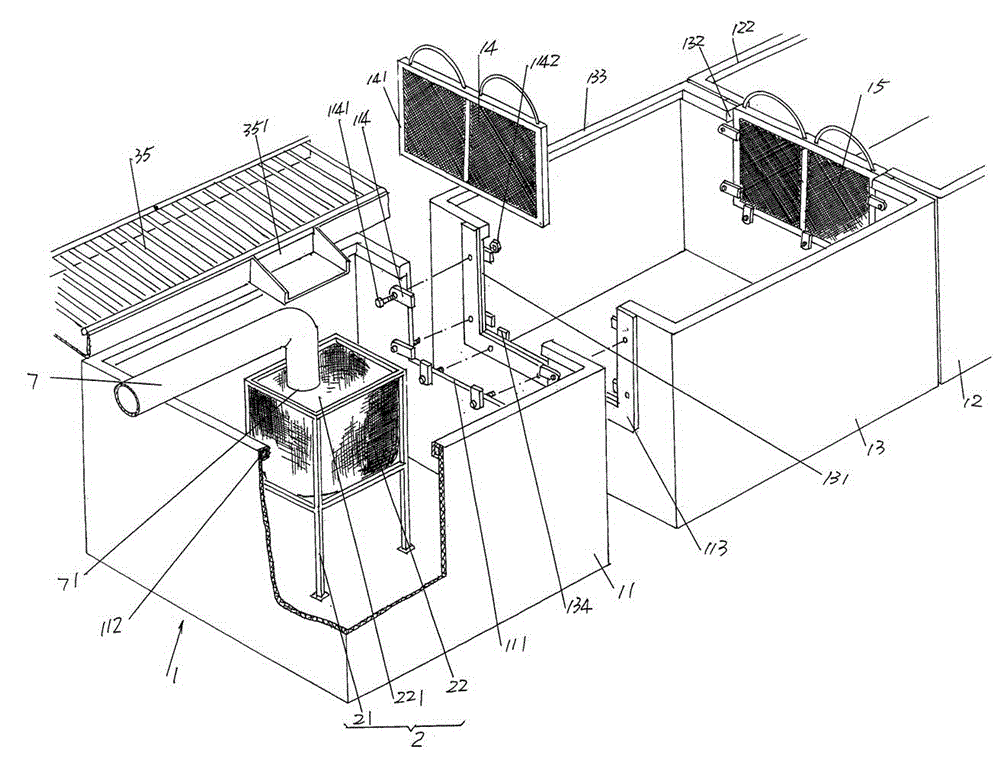

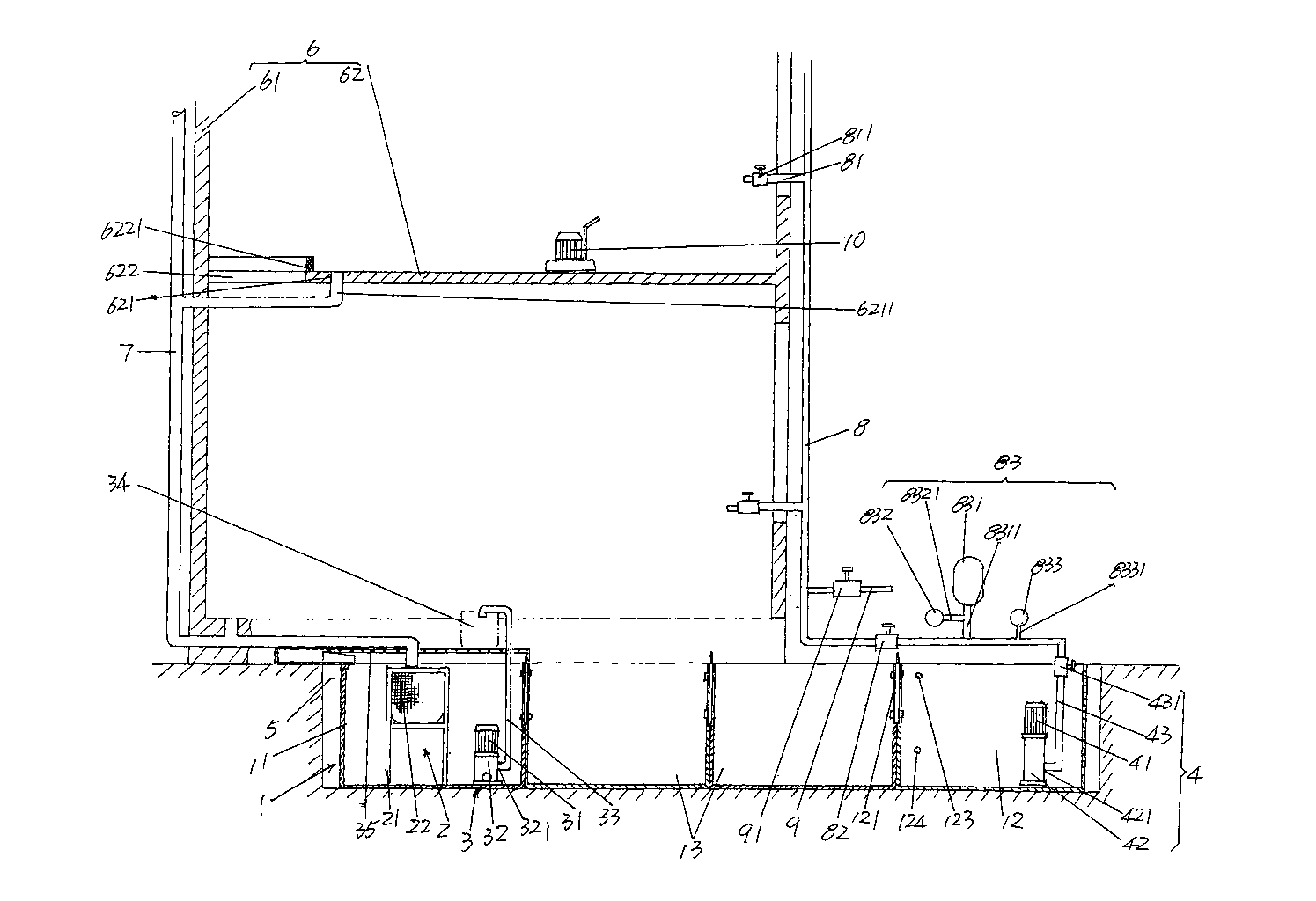

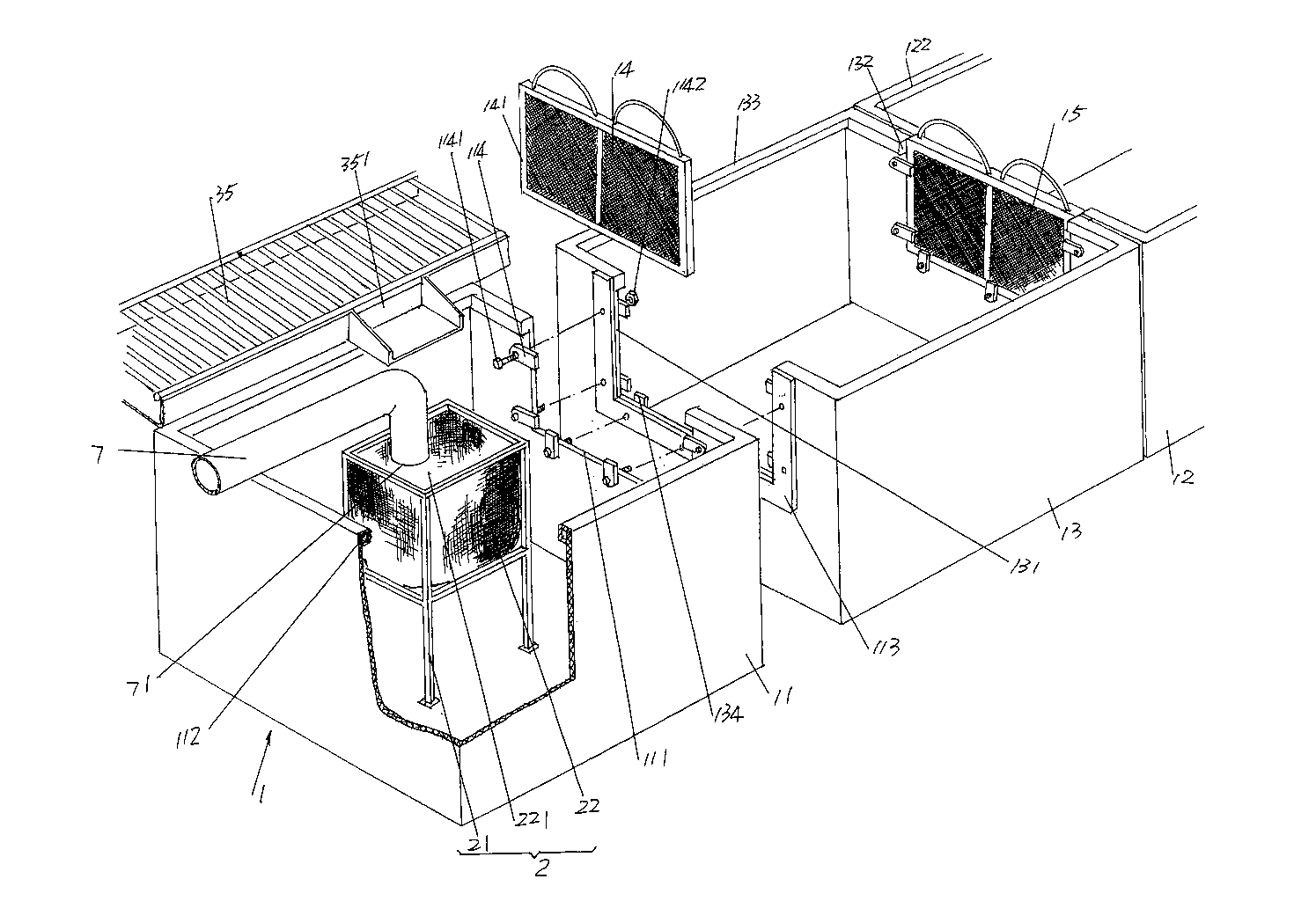

Recycling method for cast-in-situ terrazzo floor polishing waste slurry

ActiveCN102837261ANo pollutionLow costFiltration circuitsGrinding/polishing safety devicesWater resourcesCofferdam

The invention relates to a recycling method for cast-in-situ terrazzo floor polishing waste slurry and belongs to the technical field of building terrace green environment-friendly construction. The recycling method comprises the following steps: preparing a waste slurry collecting filtering precipitation separation mechanism; digging a box pit for placing the waste slurry collecting filtering precipitation separation mechanism; paving a waste slurry discharging pipe and a clean water recycling guiding pipe along an outer wall of a wall of a building; arranging a coffer for stopping slurry escaping at a ladder port and a door opening of the floor terrace of the building in which the polishing construction operation is performed; and recycling and reusing the waste slurry. The recycling method has the advantages that: the cost is saved and the manpower investment for digging and / or building on the terrace is reduced; the original address is free from any pollution, thereby achieving environmental protection; water in a clean water reusing tank can be used for polishing, so that the valuable water resource is saved; and the filtered slag and precipitates can be used for constructing a decorative wall of the building, so that the best use of the slurry is achieved and the secondary pollution is eliminated.

Owner:JIANGSU JIAYANGHUALIAN BUILDING & DECORATION CO LTD

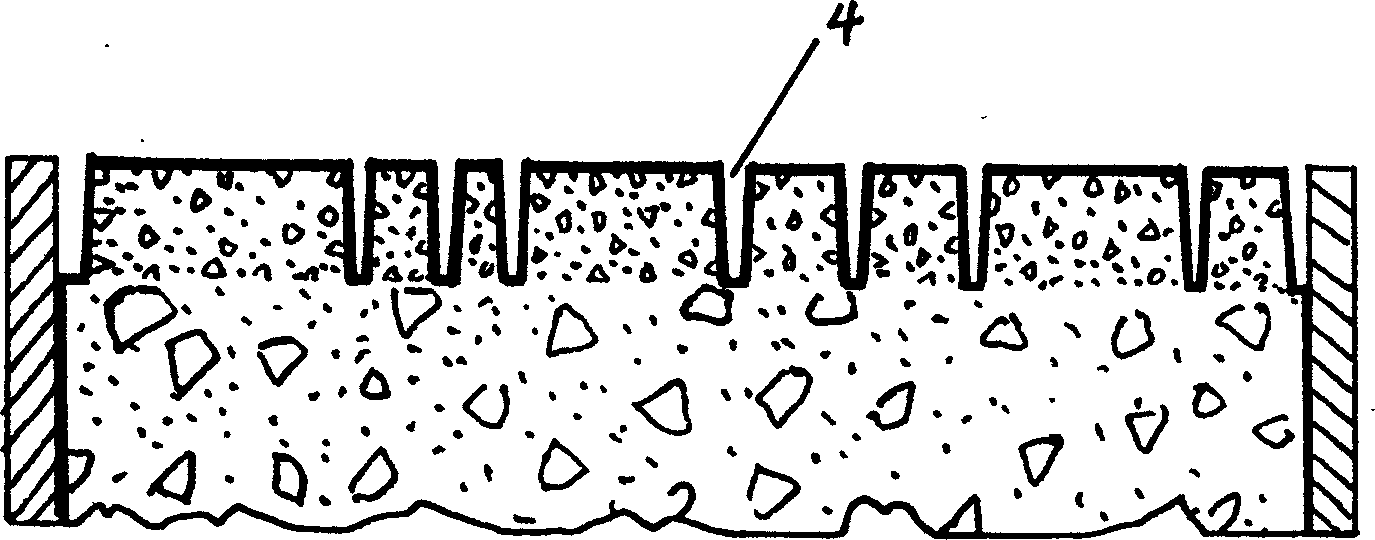

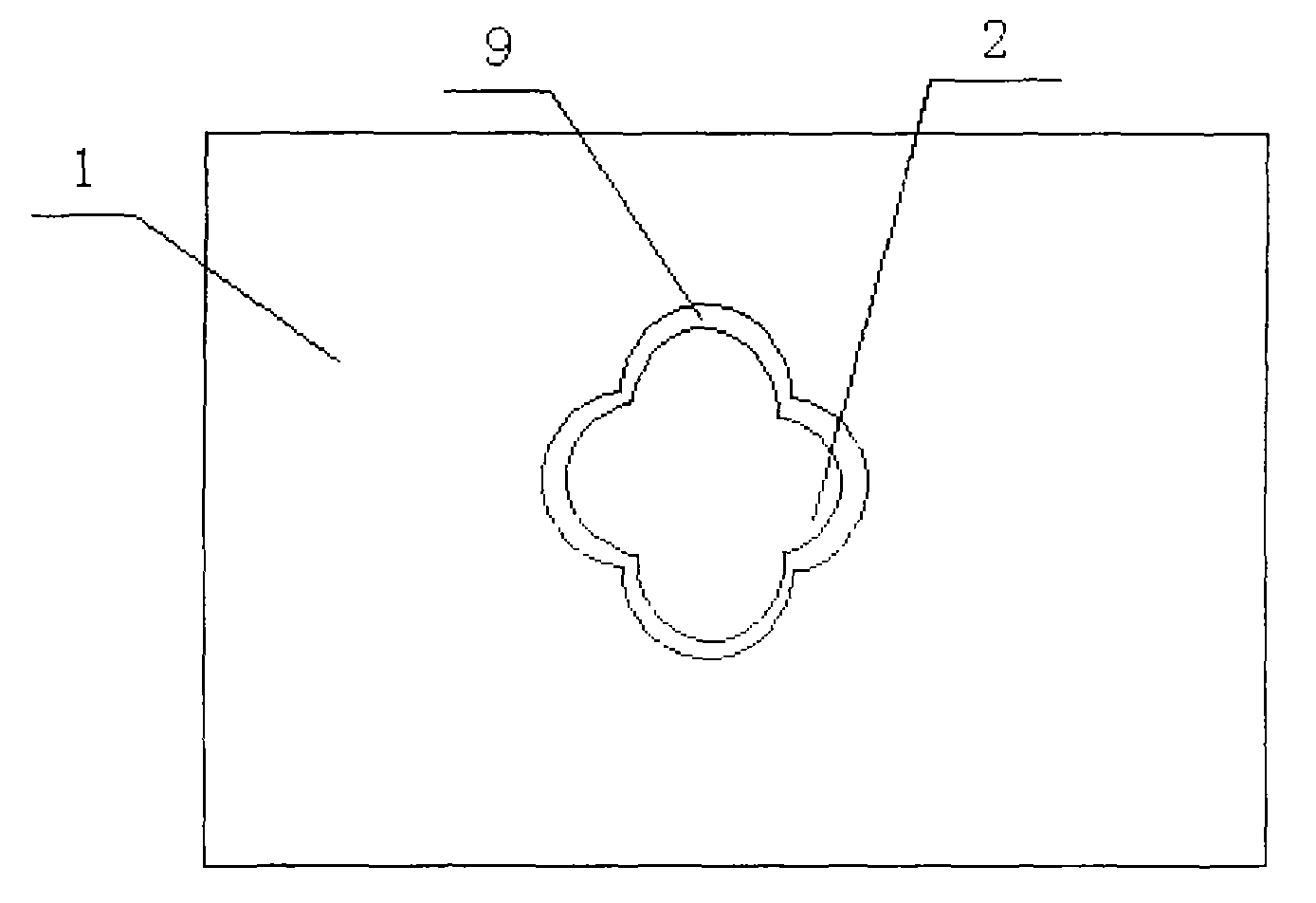

Machining method for artificial waterstone slabstone

InactiveCN1472051AResolve source issuesSolve problems such as falling offCeramic shaping apparatusArtificial stoneTerrazzo

A process for preparing artificial terrazo tile includes such steps as putting the lining mould with slot pattern in frame mould, filling color cement mortar in the slot, pouring concrete, solidifying, demoulding, filling one or more kinds of color cement mortar in the slot, solidifying and grinding. Its advantages are simple process, and low cost.

Owner:王鸿庆

System for matched-stone cover plates

InactiveUS7344433B2Easy to handleReduce thicknessCasings/cabinets/drawers detailsGrinding work supportsGranolithicEngineering

A cover plate system for making custom natural stone cover plates for electrical outlets, wall switches and other outlets and openings over which it is desired to place a natural stone cover plate. The natural stone cover plates are made from quarried stone, cultured stone, and natural rock materials such as terrazzo, marble, and granite preferably supplied by the homeowner, or end user, to a central factory, then manufactured, then shipped back to the end user to match other such material being used in the end user's building.

Owner:WILSON RONALD J

Colorful terrazzo floor brick and production method thereof

InactiveCN101555726AShort processing timeLow costMould separation apparatusMixing operation control apparatusBrickTerrazzo

The invention discloses a colorful terrazzo floor brick and a production method thereof; the floor brick consists of a substrate with certain thickness and a colorful pattern plate; a colorful pattern die with the thickness less than that of the substrate is fixedly bonded between the substrate and the colorful pattern plate; the invention also discloses a method for processing the colorful terrazzo floor brick; the method adopts a one-step molding method; the produced colorful terrazzo floor brick has small thickness, low cost and strong market competitiveness; furthermore, the method for producing the colorful pattern terrazzo floor brick is simple and feasible, can realize pattern diversity and type diversity and can meet the requirement of the market excellently.

Owner:李万成

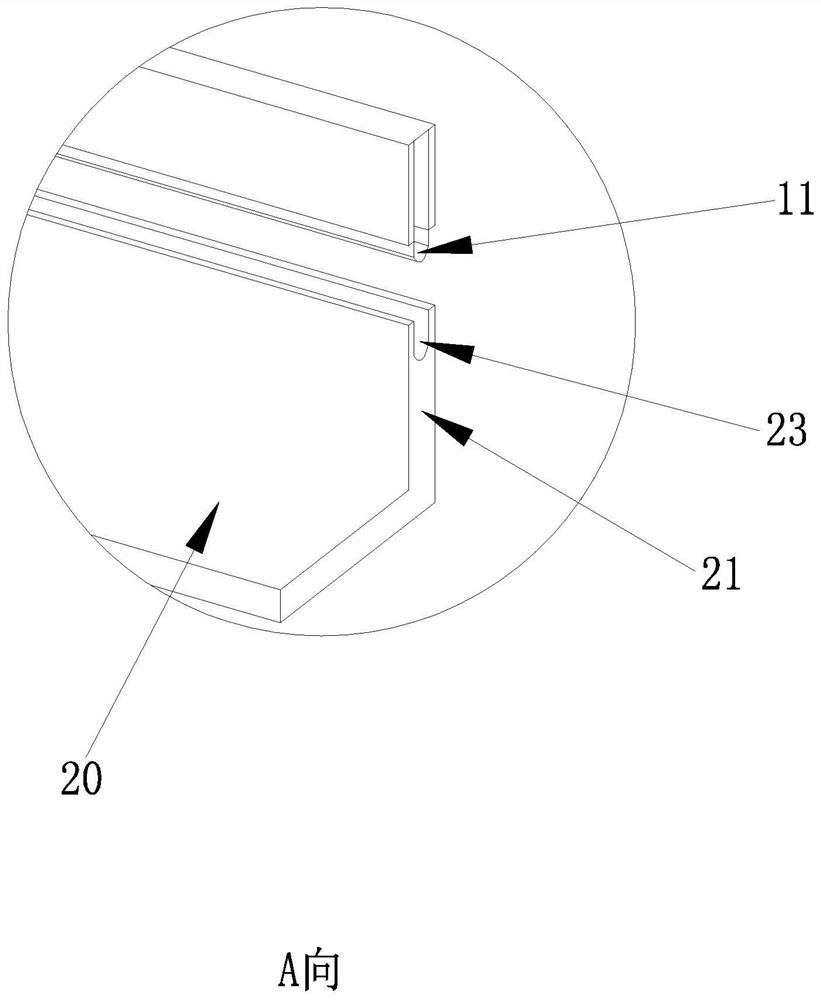

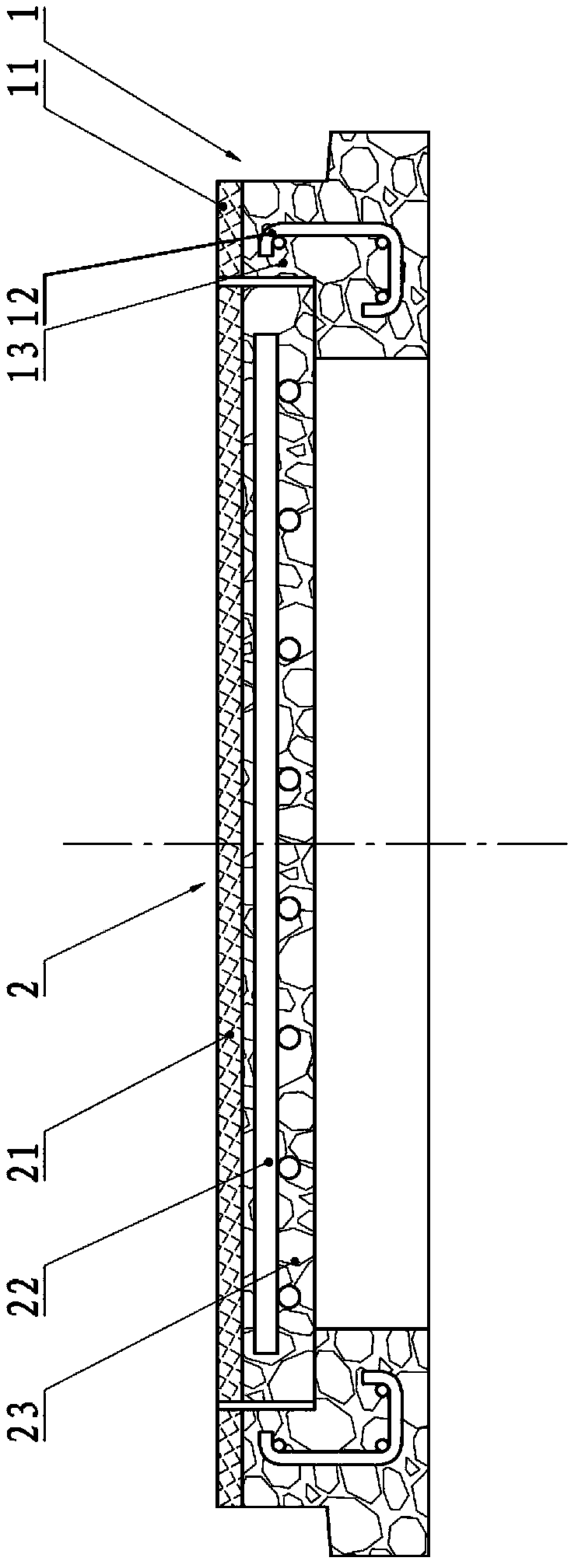

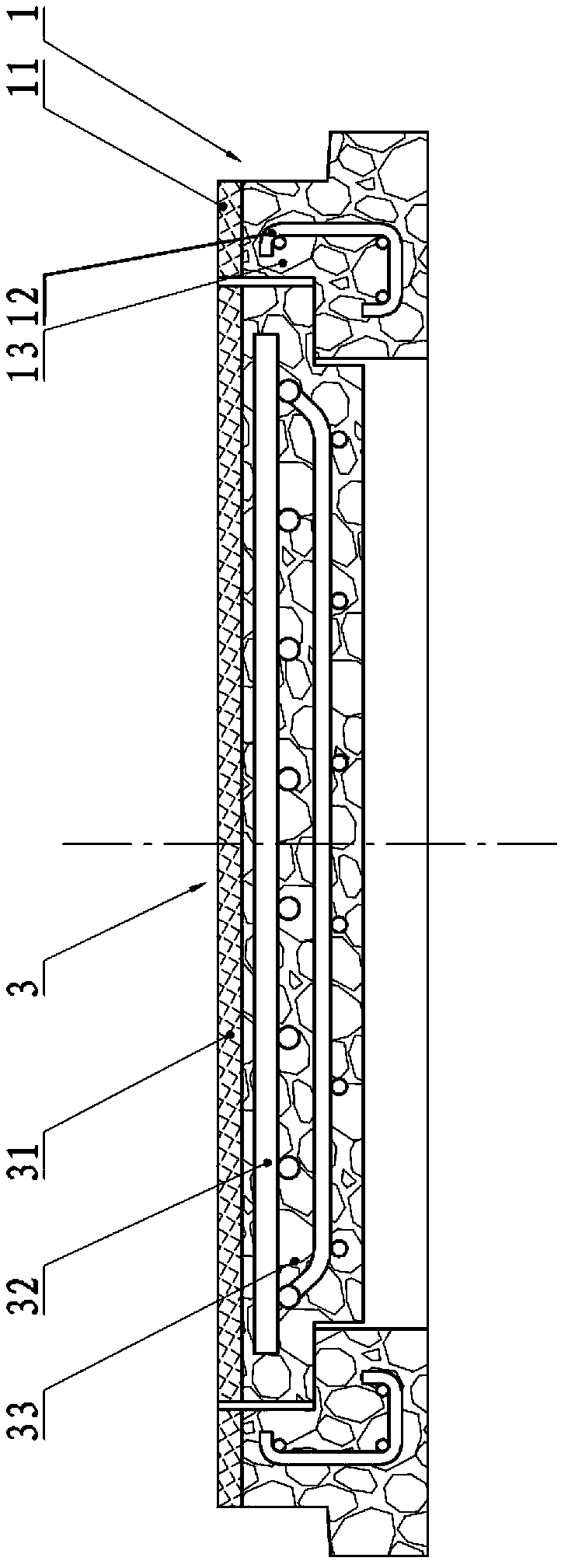

Steel fiber reinforced concrete manhole cover and producing method thereof

InactiveCN103452139ALow recycling valueImprove adhesionArtificial islandsCeramic shaping apparatusCelluloseAdhesive

The invention provides a steel fiber reinforced concrete manhole cover which is poured and formed by steel fiber reinforced concrete with a steel skeleton (22). The concrete comprises a terrazzo surface layer (21) and a steel fiber reinforced concrete base layer (23). The terrazzo surface layer (21) is made of 0.05-0.06 part of cellulose ether by mass and 0.10-0.12 part of building powder adhesive by mass, and the steel fiber reinforced concrete base layer (23) is made of 0.10-0.12 part of cellulose ether by mass and 0.20-0.24 part of building powder adhesive by weight. The invention further provides a producing method of the steel fiber reinforced concrete manhole cover; the terrazzo surface layer is separated out on the upper surface, and the cellulose ether and the building powder adhesive are added in the terrazzo and the concrete. Compared with the prior art, the steel fiber reinforced concrete manhole cover has the advantages that the surface of the steel fiber reinforced concrete manhole cover can be obtained by grinding or other post-processing, and the adhesion is improved to a certain extent. The manhole cover in the level of E600 is tested according to GB26537-2011, and the cracking load is 380N and is increased by 27%.

Owner:ZHOUSHAN PUTUO HENGBAO NEW BUILDING MATERIALS CO LTD

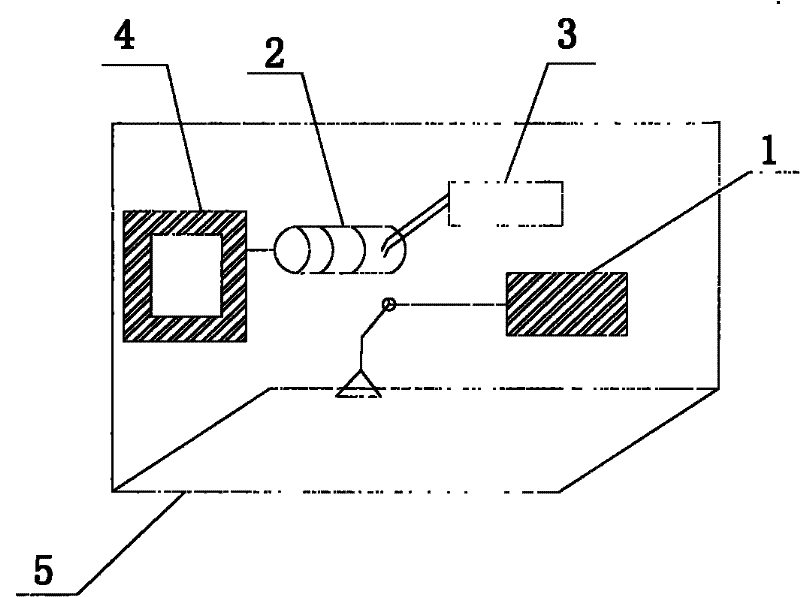

A terrazzo brick forming machine

The present invention disclosed a water milling stone brick formation machine, including raw materials, forced mixers, quantitative feeders, and molding hosts. It is characterized by the stone brick molding mold of the forming host.The molding mold is composed of two sidelines with a length of 600mm, an upper cover and bottom mold with a length greater than 600mm. By adjusting the position of the mold position, the mold size reaches 600*600mm;Make the pressure of 600 meals, so that the produced water millstone bricks are strong, density, and not easy to break.The design of the invention is cleverly designed to prepare a new type of water milling stone brick, and the pressure is good, and it is not easy to break.

Owner:常熟通江机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com