Patents

Literature

143results about How to "Improve the quality of look and feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

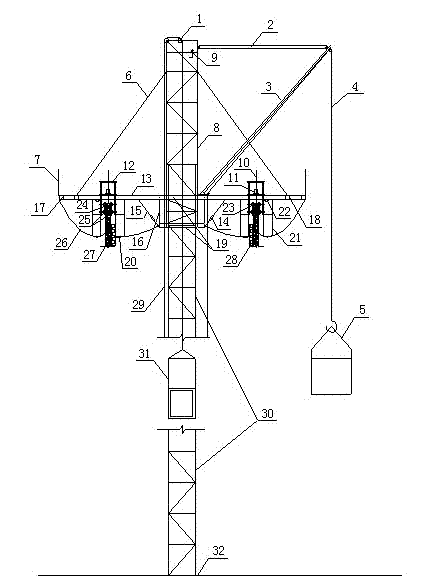

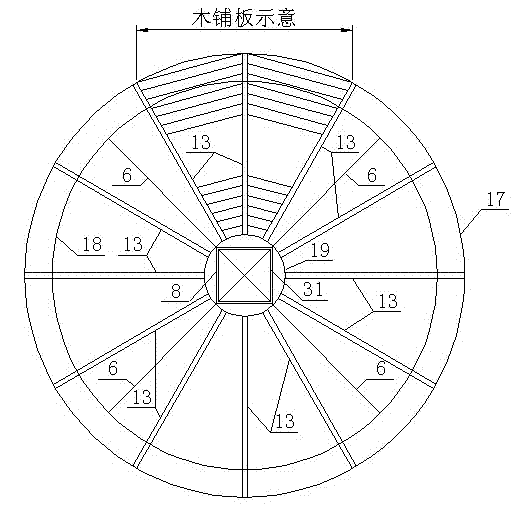

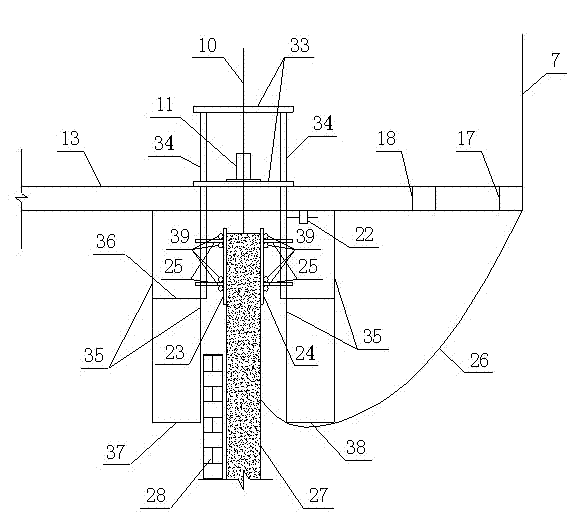

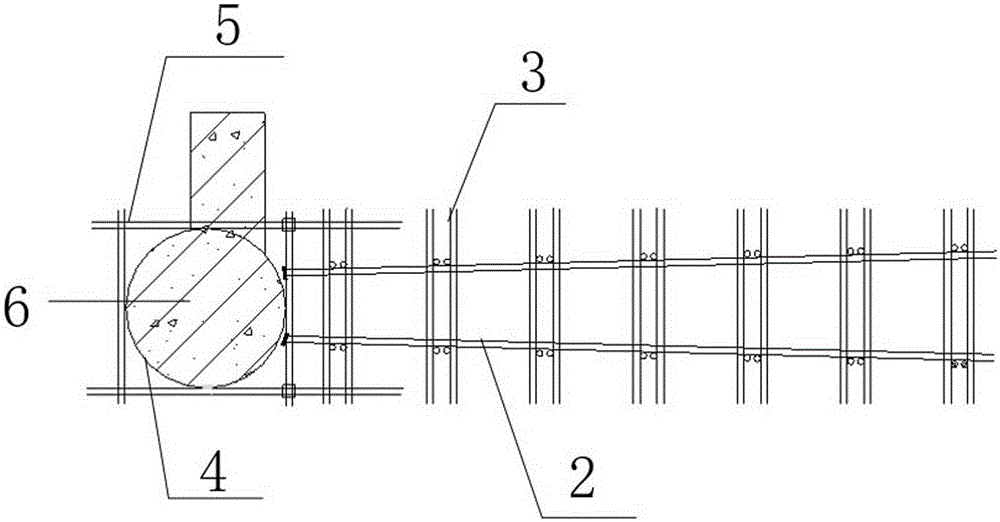

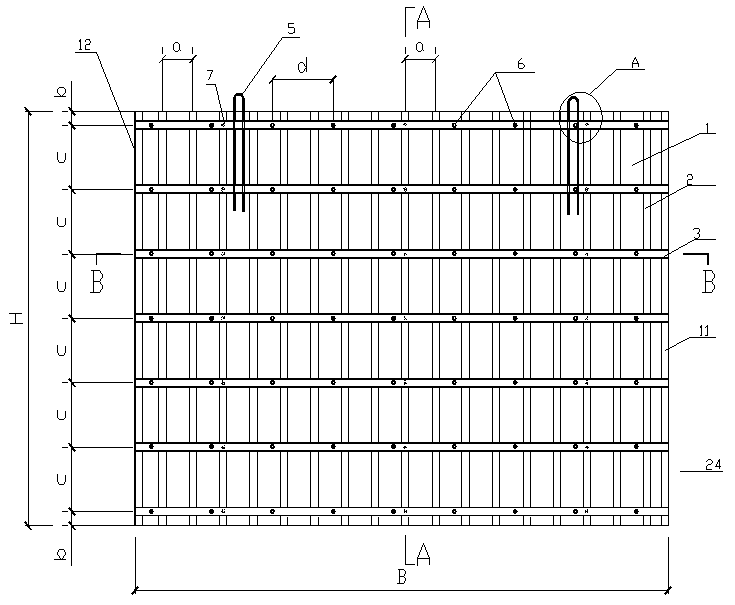

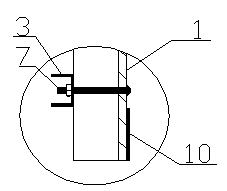

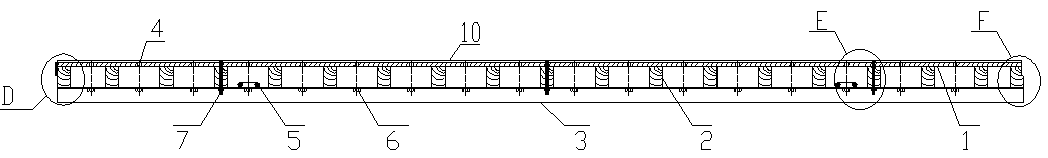

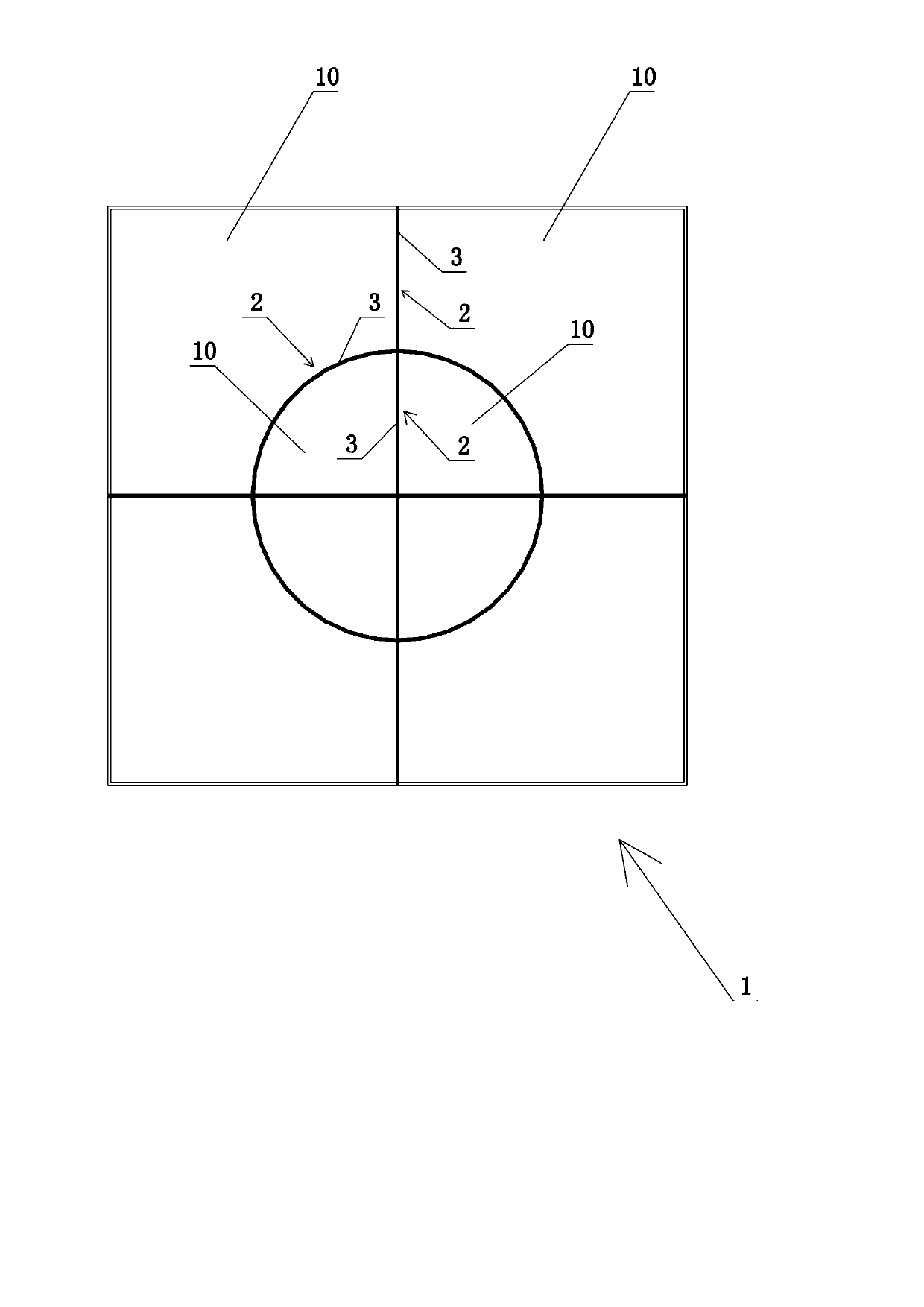

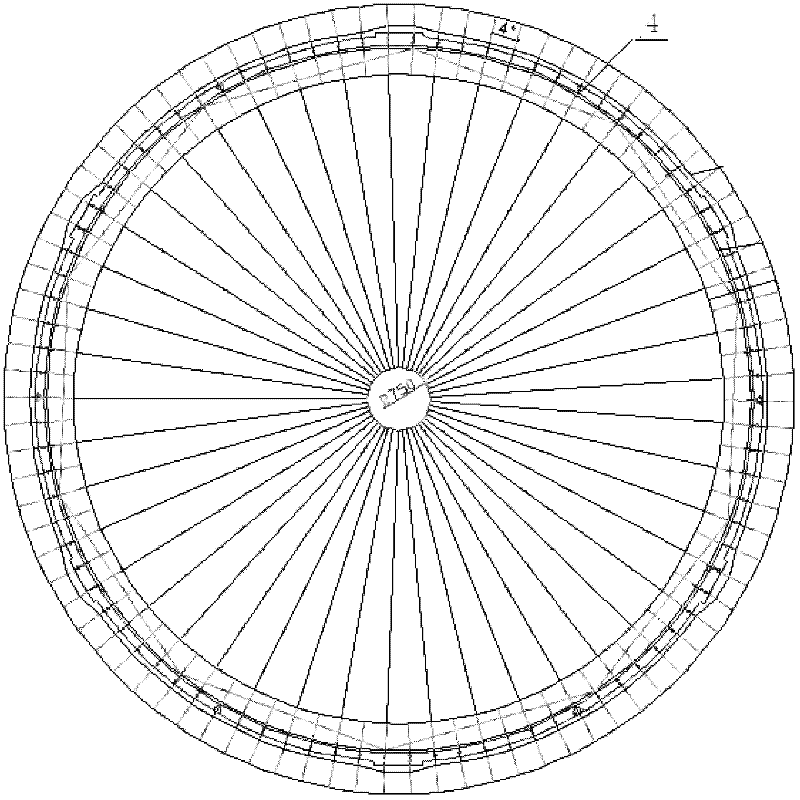

Construction method of circular reinforced concrete chimney cylinder wall and hydraulic sliding mould device

ActiveCN102535843ALess one-time investmentReduce construction costsForms/shuttering/falseworksBuilding material handlingReinforced concreteAssembly disassembly

The invention discloses a construction method of a circular reinforced concrete chimney cylinder wall, and a hydraulic sliding mould device, wherein a hydraulic sliding mould construction method is a rapid construction method of dynamically and continuously molding concrete; loads such as an operation platform and a template are completely supported on a support rod which is stabilized by low-age concrete and has small rigidity; the operation platform and the template are driven to climb along the cylinder wall by a hydraulic jack; and the hydraulic jack climbs on the support rod by an oil path system. The hydraulic sliding mould construction employing the sliding mould as an external cylinder wall and building a lining adopts an ''outside sliding and inside building'' construction process featured by synchronously constructing the external cylinder wall and the lining. The hydraulic sliding mould construction is featured by dynamic continuous construction, having fast construction speed in comparison with mould reverse, symmetrically distributing the hydraulic jack on the circumference of the chimney cylinder wall, forming the template by combining a fixed template with a moveable plate and a contracting and separating template, convenient to assemble and dismount as well as regulate the diameter and the circumference of the combined template structure, capable of gradually decreasing the diameter and the circumference of the combined template structure along with the diameter change of the chimney diameter. The hydraulic sliding mould construction is advantaged in few invested construction operators and convenient management.

Owner:马鞍山钢铁建设集团有限公司

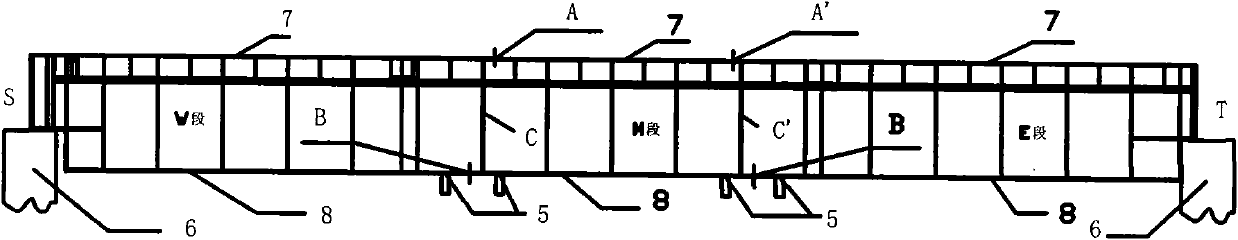

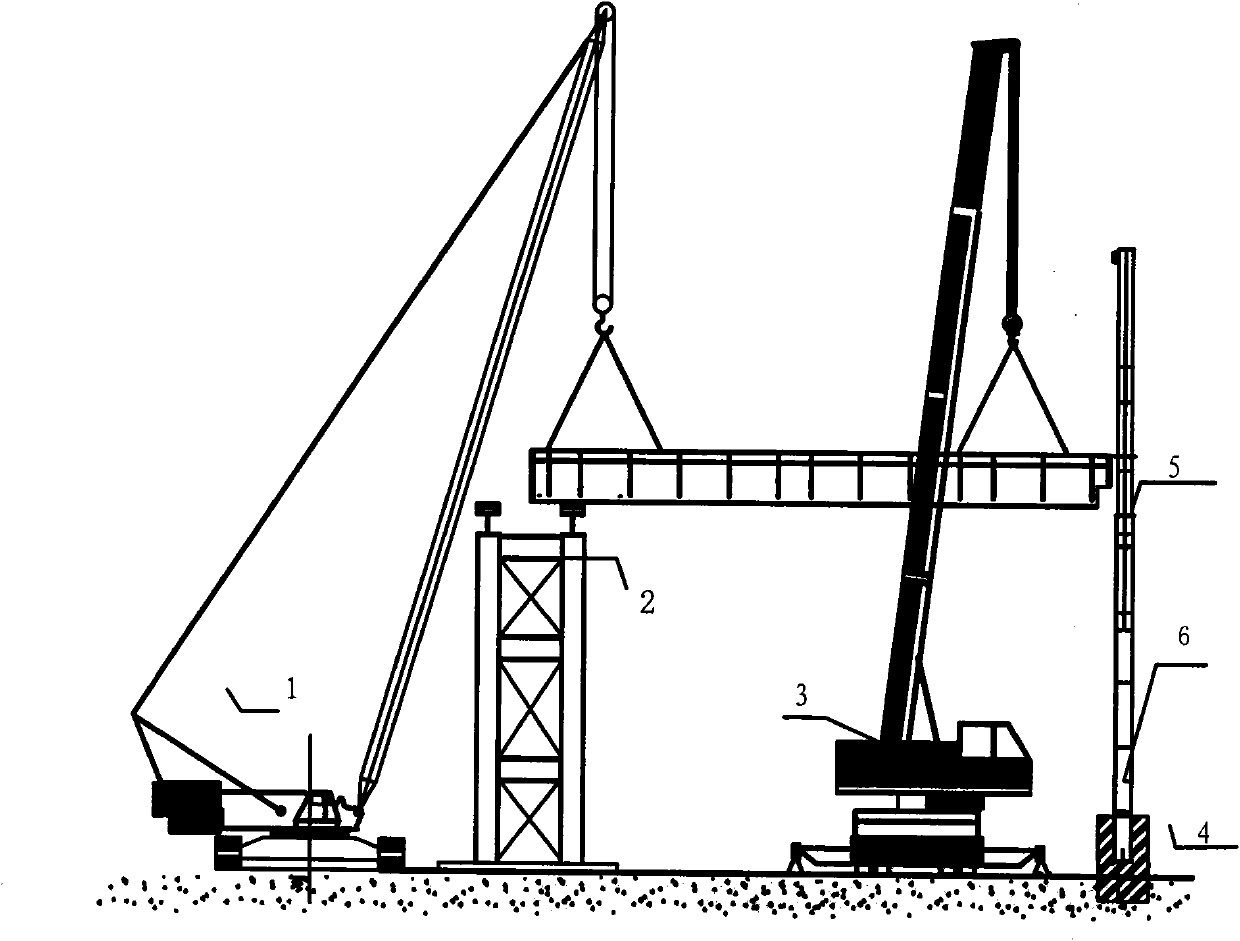

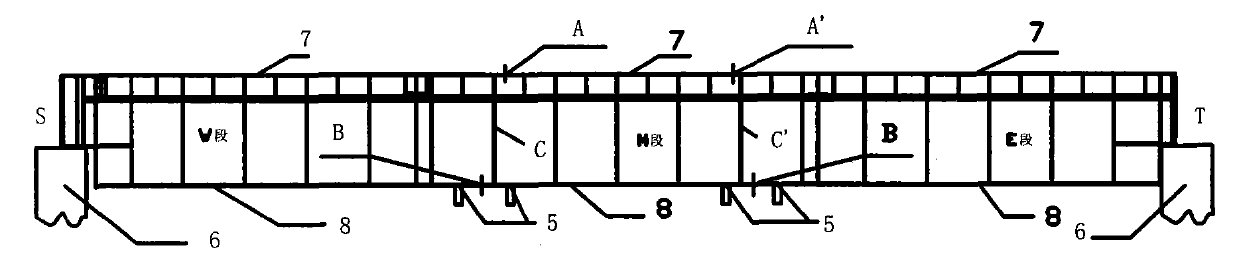

Onsite splicing and mounting method for extra-large and overweight box crane girders

ActiveCN102086000AImprove the quality of look and feelGood lookingLoad-engaging elementsSteel columnsTruck

The invention discloses an onsite splicing and mounting method for an extra-large and overweight box crane girder. The box crane girder consists of three sections, namely a W section, an M section and an E section, wherein the three sections of girders are connected on two steel columns; and the onsite splicing and mounting method for the crane girder is characterized by comprising the following steps of: 1, respectively assembling the three sections of the girders in a factory before the box crane girder enters the site, arranging two brackets at positions of splicing interfaces of the three sections on the box crane girder according to the lengths of the three sections between the two steel columns, arranging a lifting jack on a platform of the brackets, and measuring positioning lines on crossbeams of the brackets; and 2, splicing and mounting the box crane girder on site and at high altitude, namely manufacturing the extra-large and overweight box girder into the three sections of the girders in the factory, introducing the sections into the site according to a lifting sequence of the W section, the M section and the E section, directly lifting the sections by employing a 120t crawler crane and a 260t truck crane, lifting to right places by sections, splicing and welding, and unloading and detaching the brackets after the box crane girder passes the welding construction defect detection.

Owner:MCC5 GROUP CORP SHANGHAI

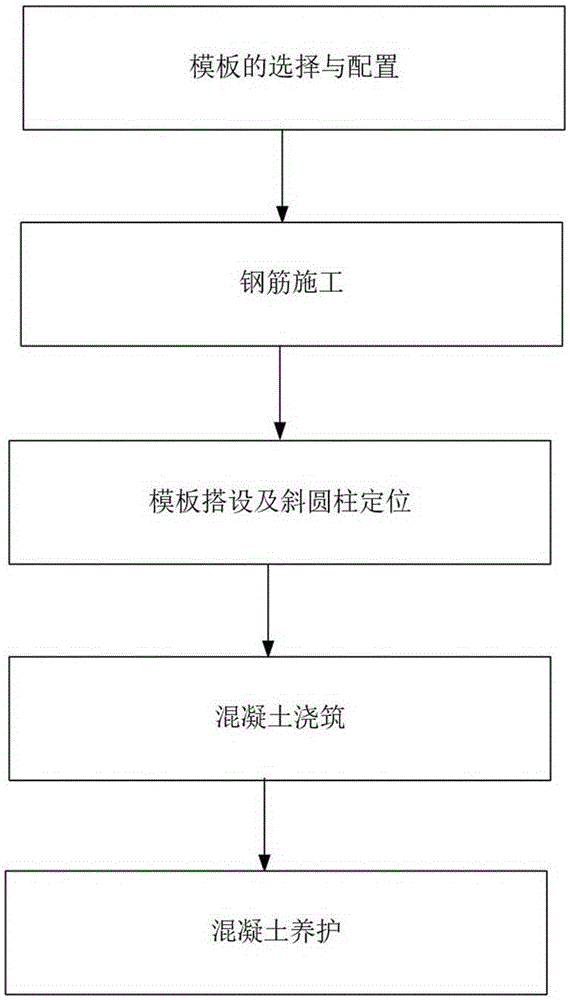

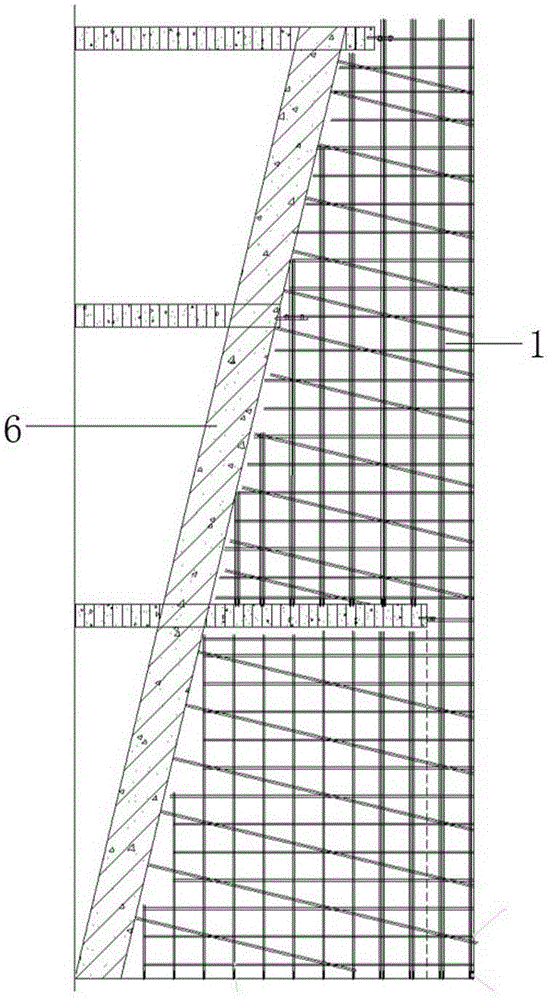

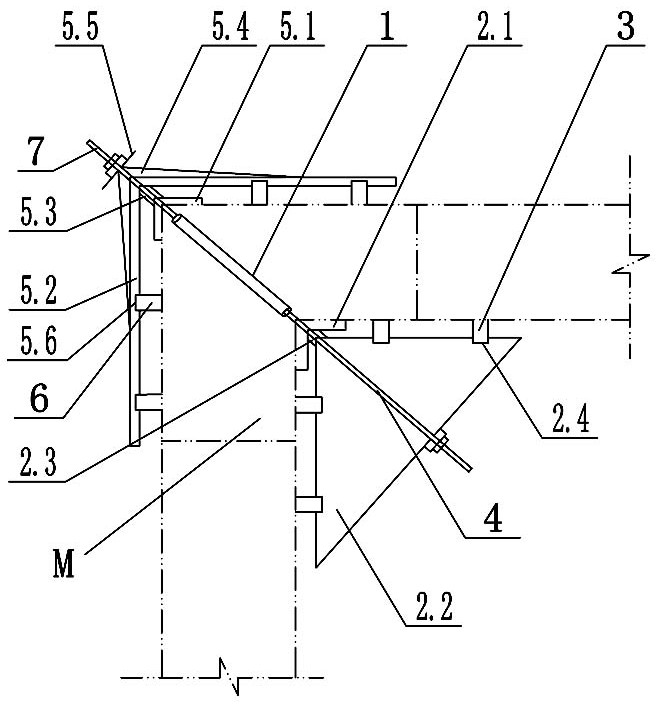

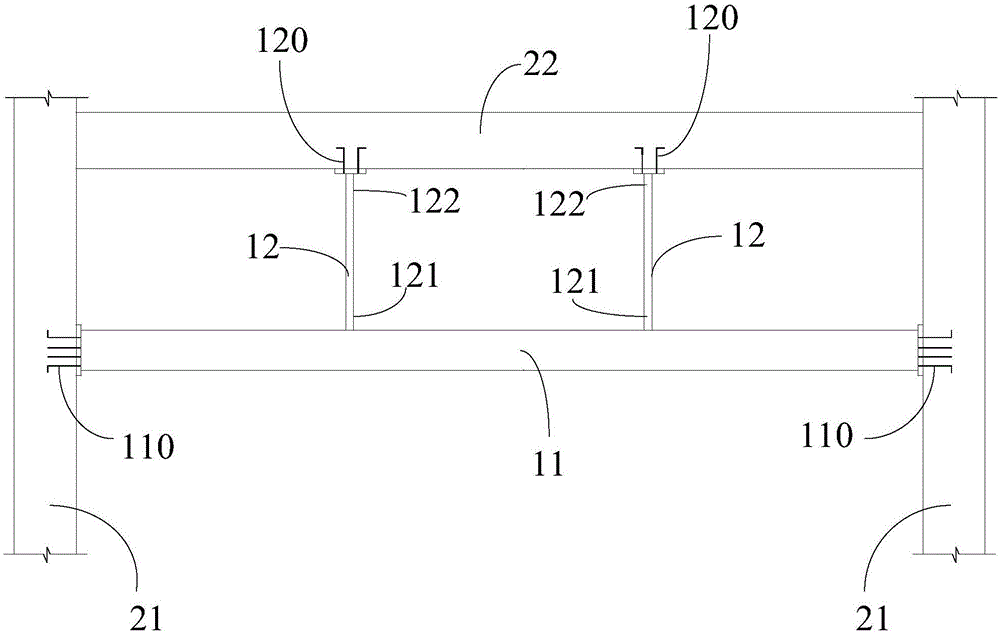

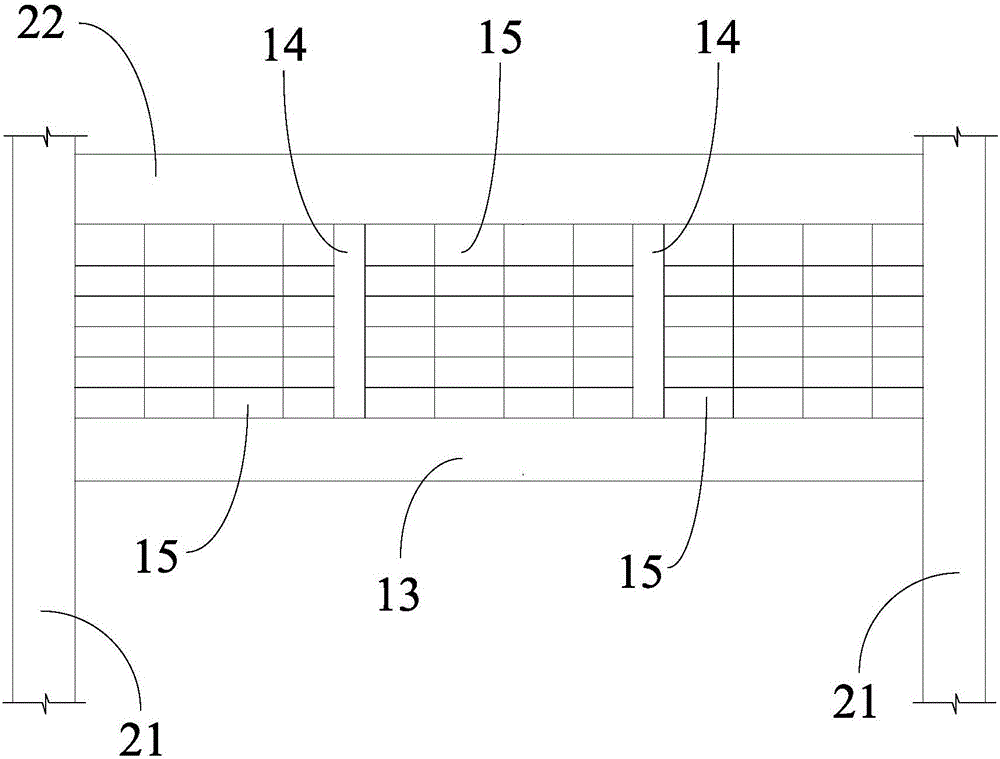

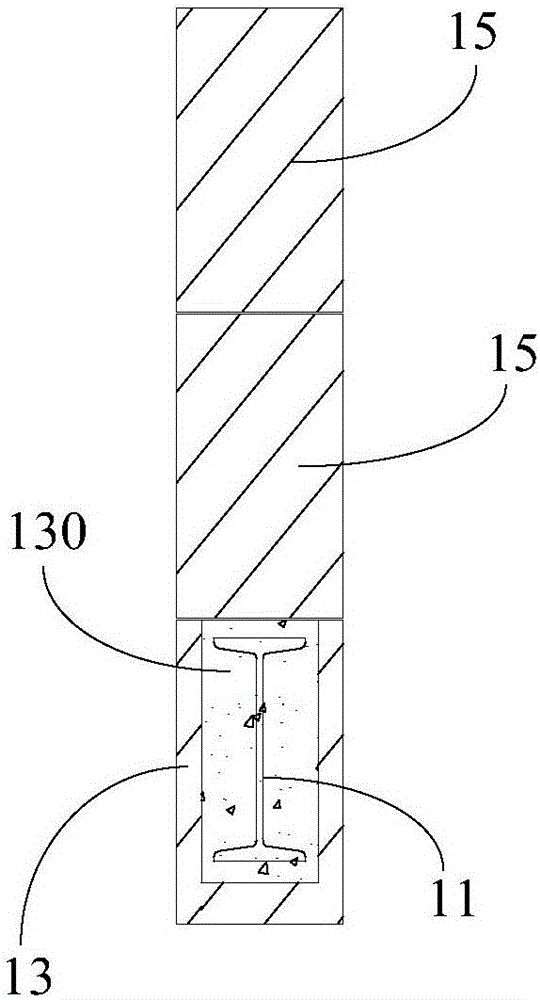

Construction method and construction template for ultrahigh oblique concrete column

InactiveCN105239725AImprove the quality of look and feelStrutsForms/shuttering/falseworksRebarTower crane

The invention discloses a construction method and a construction template for an ultrahigh oblique concrete column. The construction method comprises the following steps: step 1, template selecting and configuring; step 2, rebar construction; step 3, template erecting and oblique column positioning; step 4, concrete pouring, wherein the oblique column concrete is poured by preferentially adopting a concrete auto pump, and tower crane transporting pouring is adopted for a place which cannot be poured by the auto pump; step 5, maintenance for the poured concrete. The construction template comprises a column template, an octothorpe hoop, an all-around scaffold and an independent support frame, wherein the column template comprises multiple template pieces with cambered structure; the octothorpe hoop is fixed at the periphery of the column template; and the all-around scaffold is supported on the bottom surface of a building, and the independent support frame is supported on the side face of the column template. The construction method and the construction template have the beneficial effects that through optimized selection of the template, a creative positioning method and a strictly-controlled pouring and vibrating operation process, the formed oblique column has a smooth surface, and the appearance quality is greatly improved.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

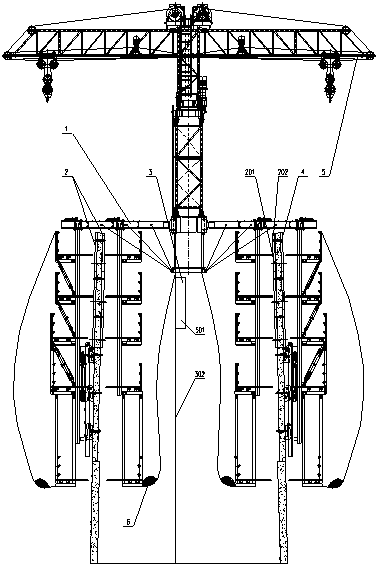

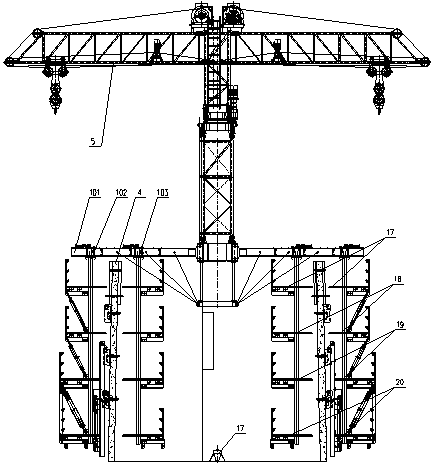

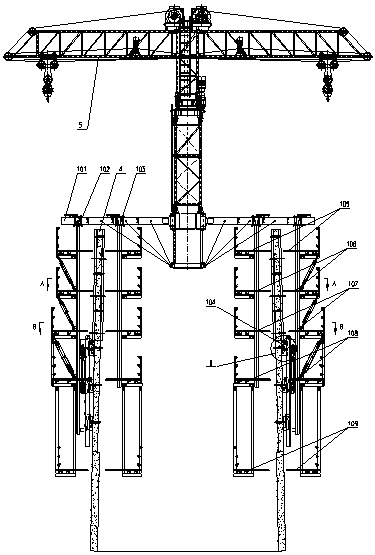

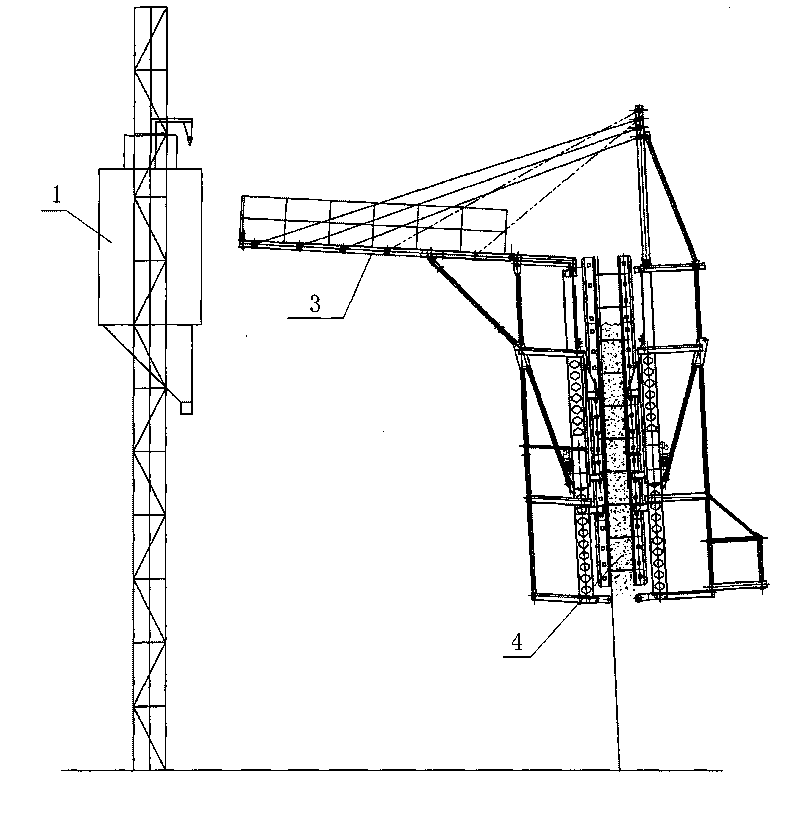

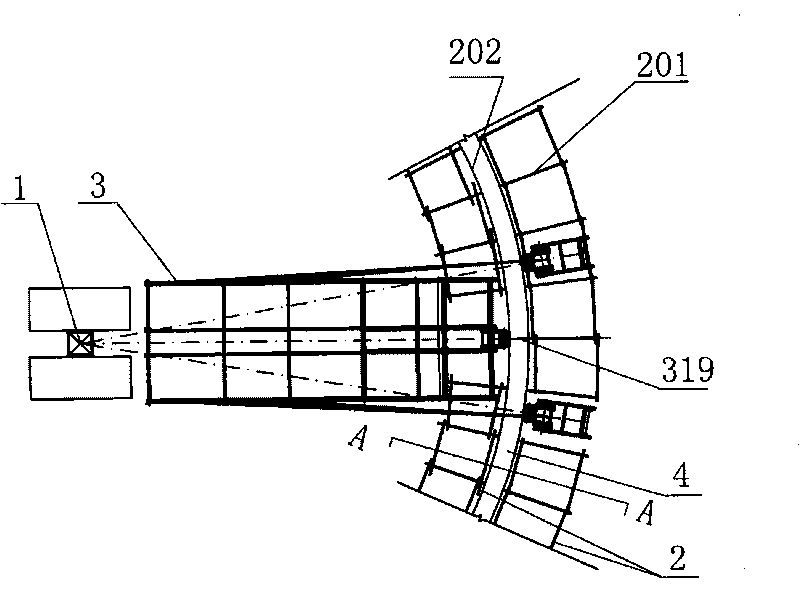

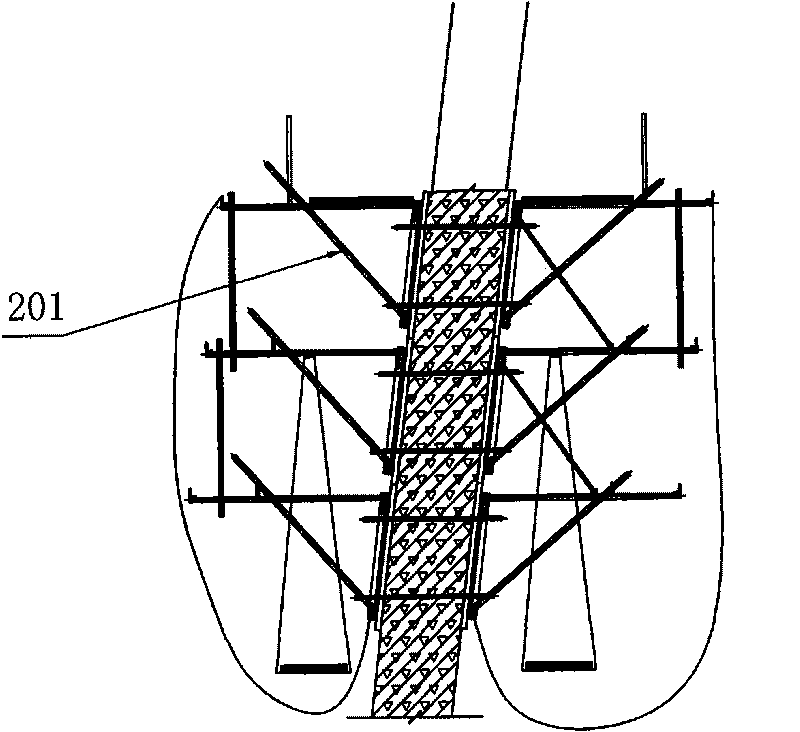

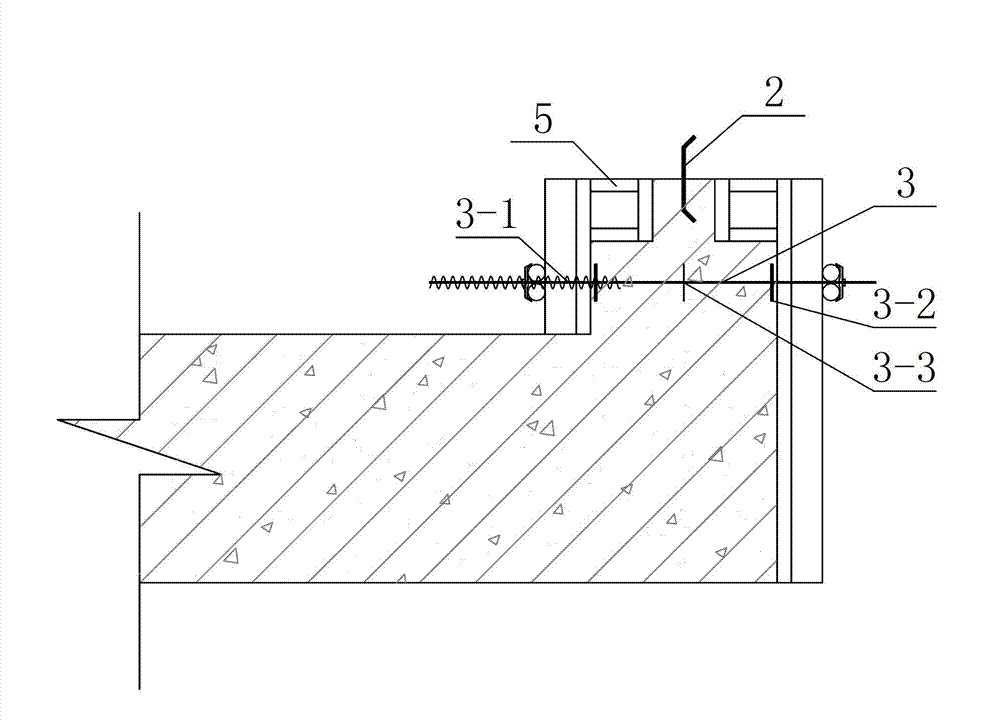

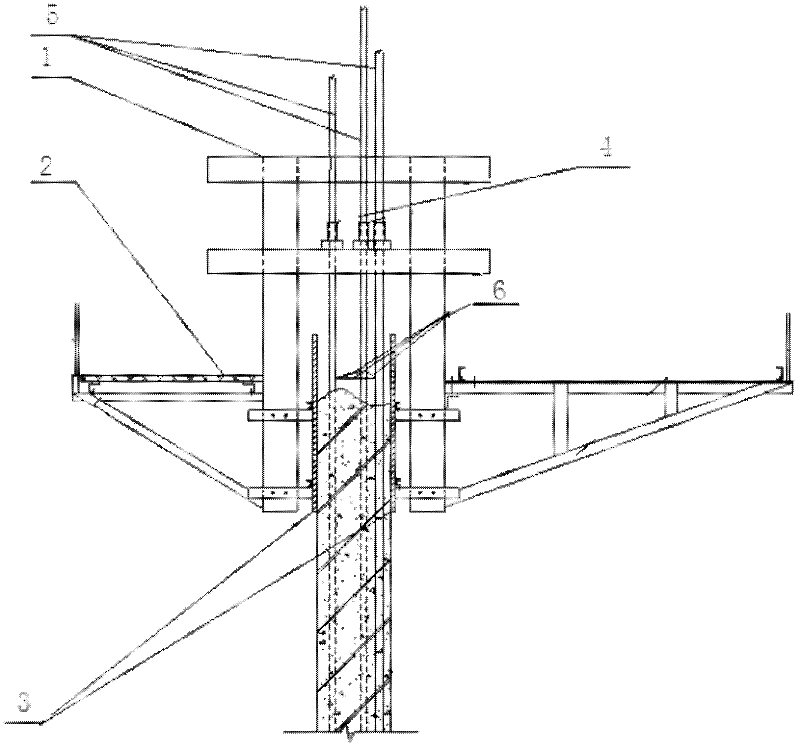

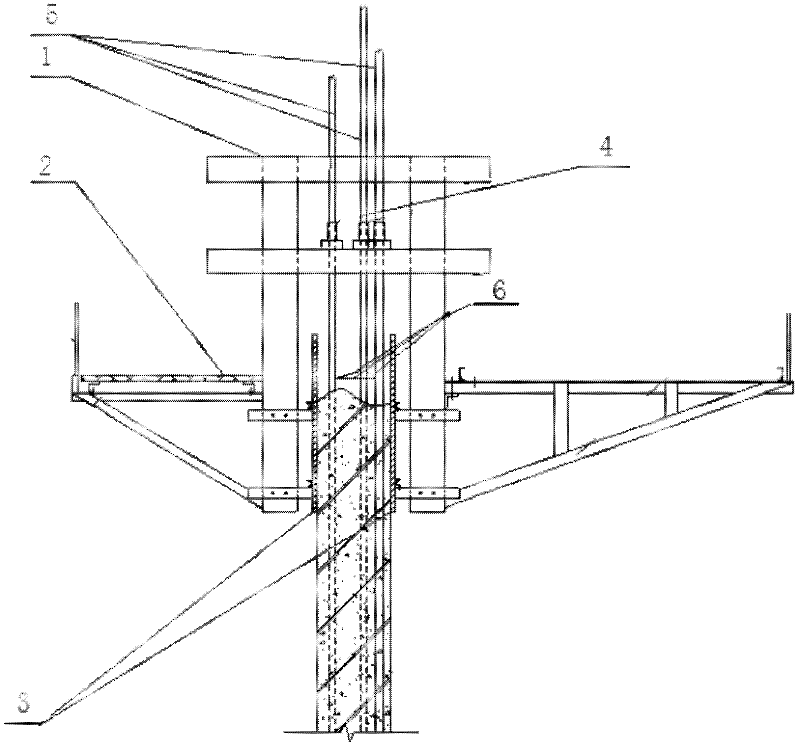

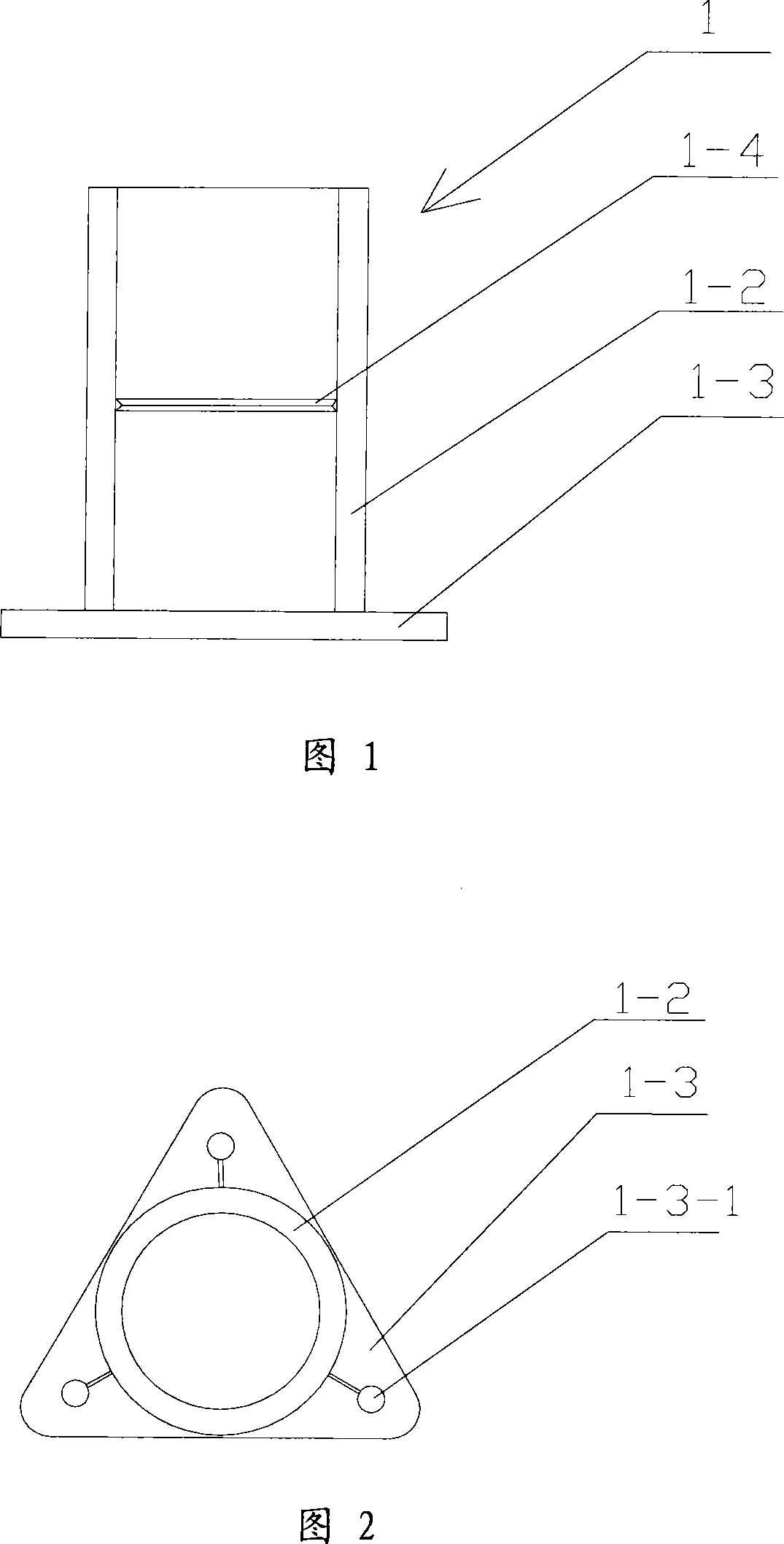

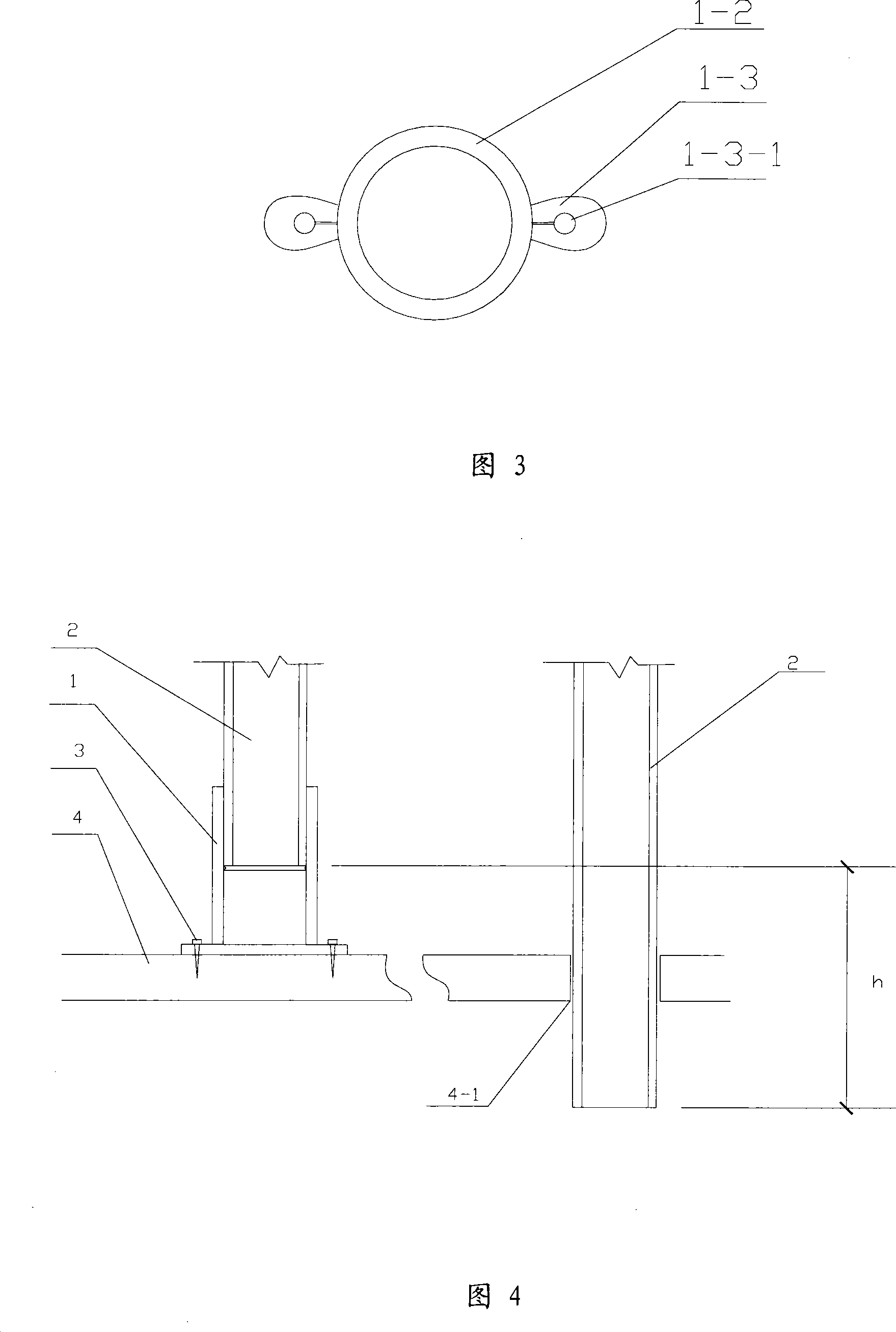

Construction method for barrel wall of prestressed concrete wind power tower and special construction equipment

PendingCN107697818ANo strength, no special requirementsImprove the quality of look and feelWind motor supports/mountsWind energy generationElectricityFalsework

The invention relates to a construction method for the barrel wall of a prestressed concrete wind power tower and special construction equipment. The construction method comprises the following steps:mounting a wall-attaching device, the special construction equipment and a 2t double cantilever flat-top crane on the basis that the barrel wall of the wind power tower is poured previously; conveying operating personnel to an annular telescopic construction platform through a manned lifting machine; enabling the annular telescopic construction platform, a turnover lifting platform and an inner suspension platform of the special construction equipment to form a multi-layer annular horizontal conveying platform to carry out constructions such as steel bar binding, concrete pouring and inner and outer adjustable arc template assembling and disassembling; using by turning around the inner and outer adjustable arc templates layer by layer, and lifting the special construction equipment and aclimbing guide rail alternatively until the concrete construction of the barrel wall of the wind power tower frame is completed; and adjusting the pushing device of the annular telescopic constructionplatform in time along with the radius reduction of the wind power tower during the lifting process of the special construction equipment, and contracting the turnover lifting platform; dismantling the inner suspension platform when the construction near the top of the wind power tower is to be carried out, connecting the drum ring of the annular telescopic construction platform with a bracket seat pre-buried when the construction of the top of the wind power tower is carried out, and erecting a temporary scaffolding platform to complete the construction of the barrel wall at the top of the wind power tower.

Owner:KERUN ELECTRO MECHANICAL ENG

Construction method for chimney wall and special electric jacking flat bridge

InactiveCN101696604APatchwork is regularFlat seam is smooth and smoothForms/shuttering/falseworksTowersRolloverEngineering

The invention discloses a construction method for a chimney wall and a special electric jacking flat bridge. The construction method comprises the following steps of: building a bottom tube body on a basis of chimney by using a tripod rollover system; mounting a construction lifter in the center of the chimney to serve as vertical transportation equipment; erecting the electric jacking flat bridge, and supporting a large center platform of the electric jacking flat bridge through an elastic brace rod; vertically conveying the large center platform through the vertical transportation equipment, and annularly and horizontally conveying the large center platform through an annular horizontal transportation passage consisting of internal and external hoisting frames and hoisting platforms of the electric jacking flat bridge and tripods; binding steel bars, dismounting the tripods and templates, hoisting the internal and external hoisting frames, and performing concrete pouring construction; recycling the tripods layer by layer till the construction is finished; timely cutting off redundant parts of the large center platform along with the reduction of the radius of the chimney, and detaching the external hoisting frame at the outer end of the elastic brace rod; and detaching the internal hoisting frame after the construction reaches the top. The construction method has the advantages that the problem of high-altitude horizontal transportation can be solved, the abutted seams of the templates are regular, the quality is easy to control, the impression is good, the construction is safe, the construction speed is high, and the one-time investment is less.

Owner:DONGDIAN YANTA ENG +1

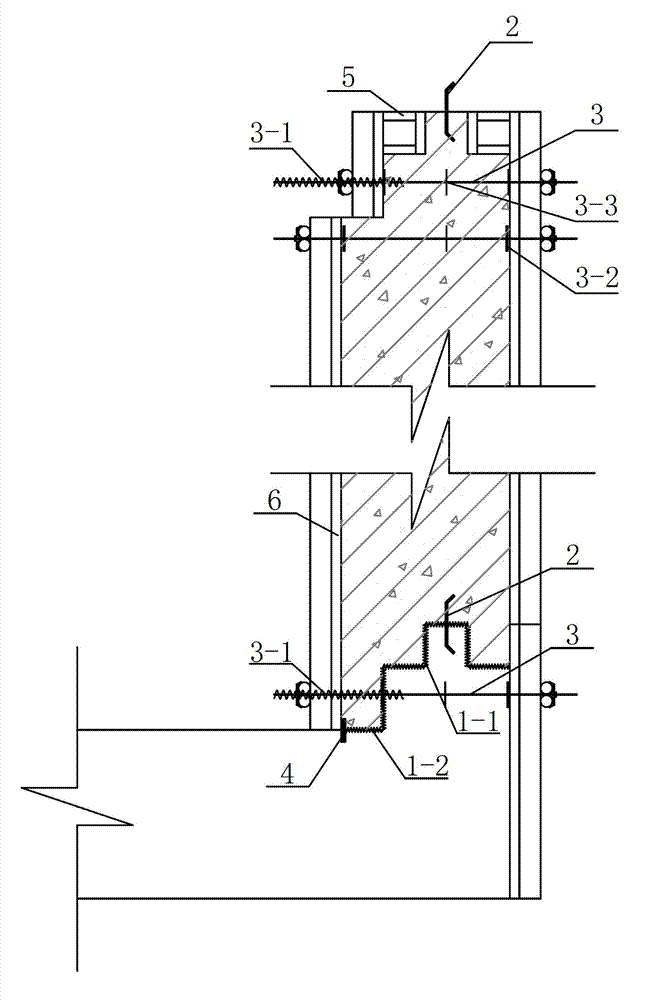

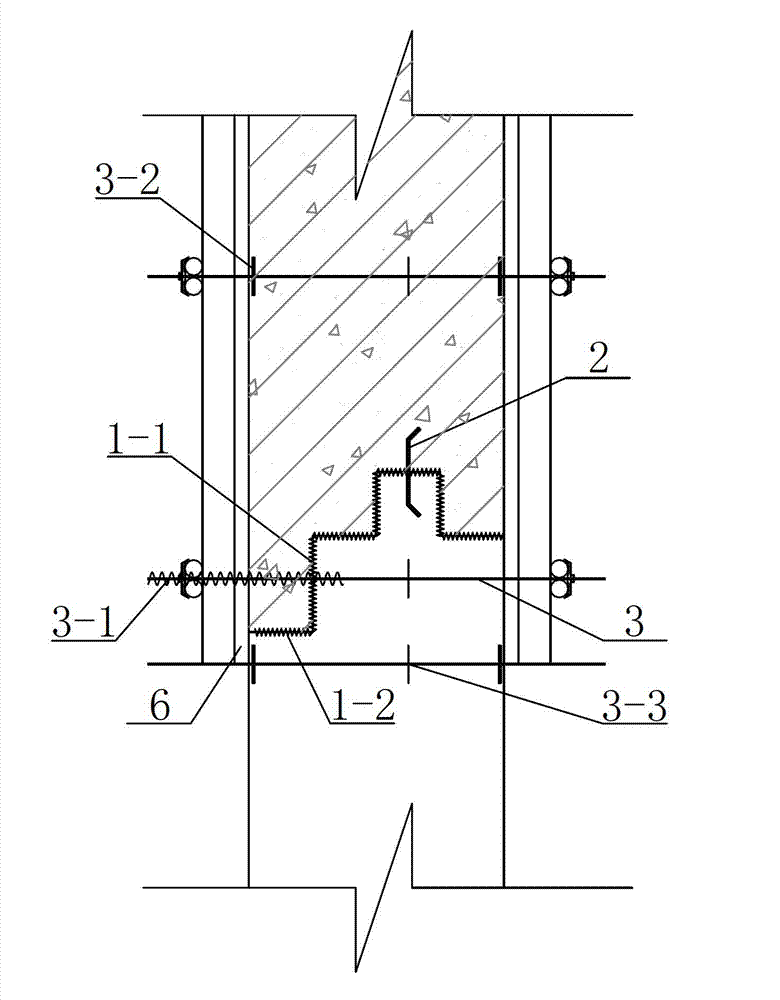

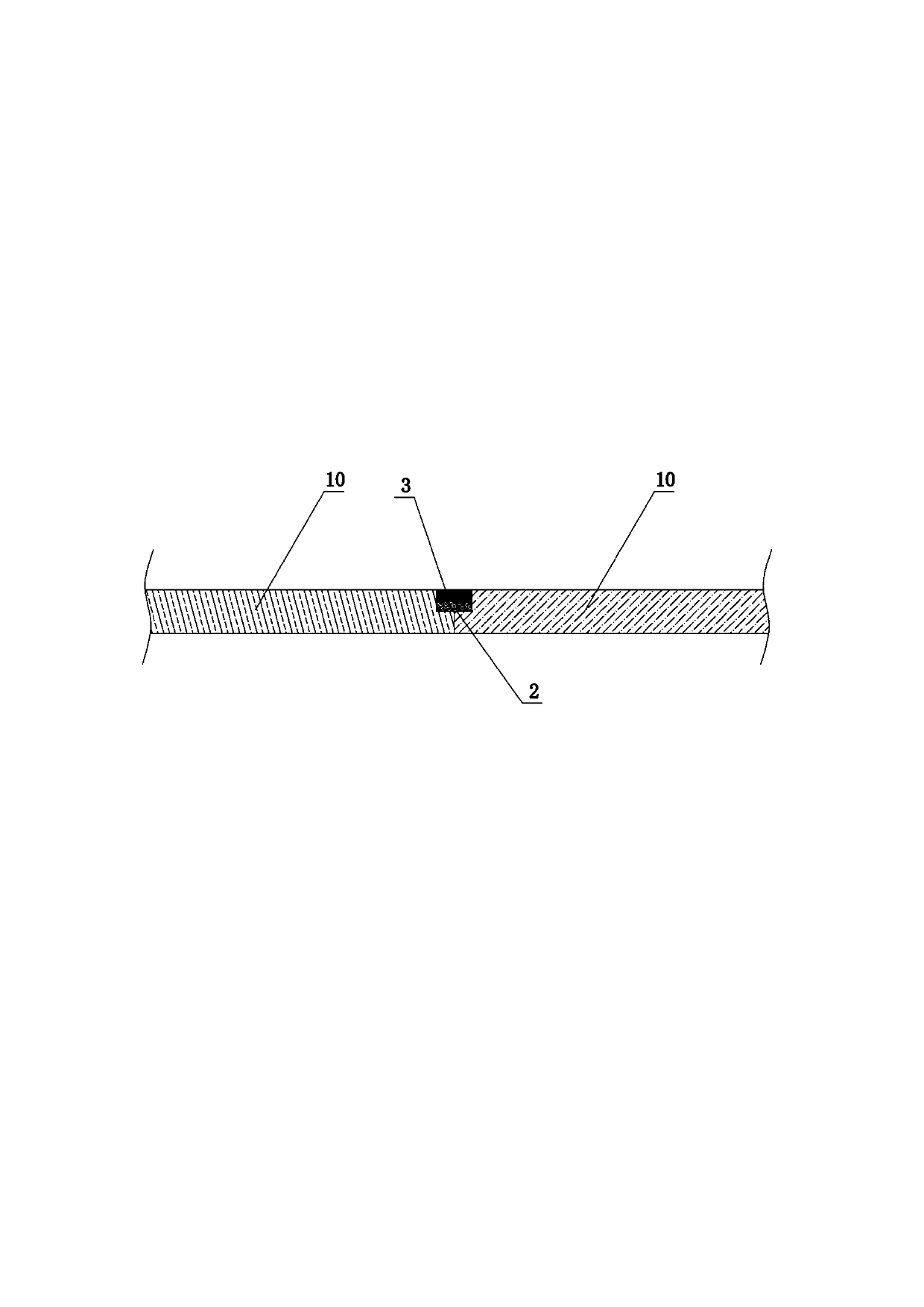

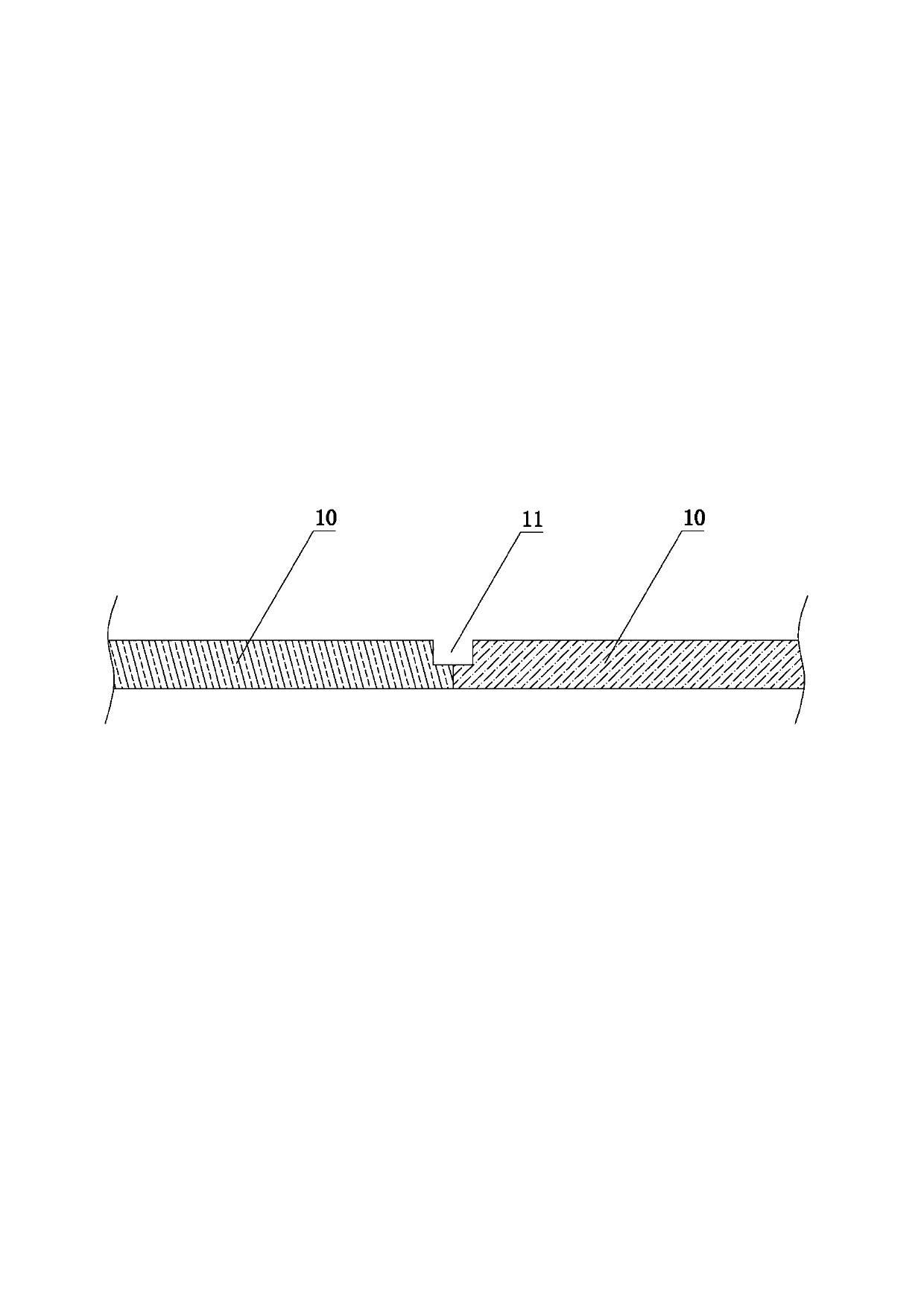

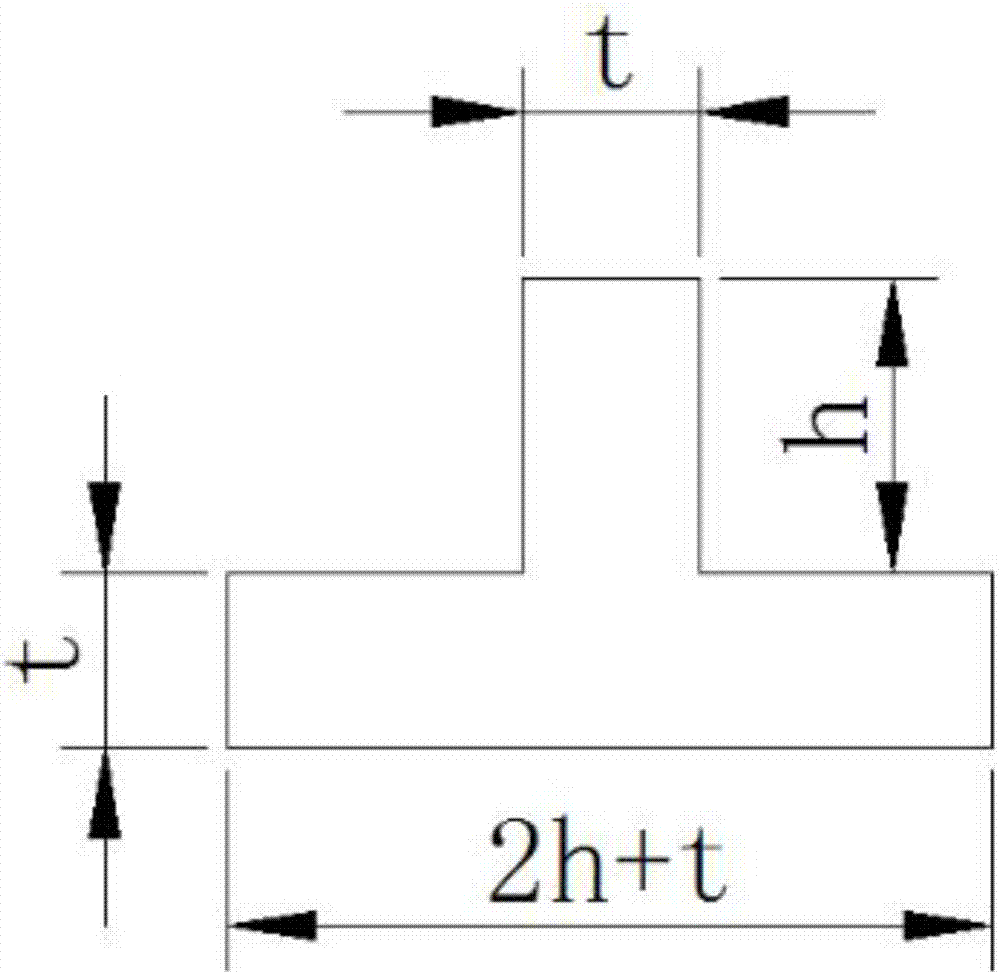

Construction gap of underground waterproof concrete structure and wall template installation method thereof

ActiveCN102900103AExtended permeation pathImprove impermeabilityArtificial islandsUnderwater structuresArchitectural engineeringSurface construction

The invention discloses a construction gap of an underground waterproof concrete structure and a wall template installation method thereof. Aiming at the technical problem that a wall template of a ladder-shaped construction gap is difficult to install and easy to deform, on the basis of a novel ladder-shaped construction gap, short wood beams are used for controlling forming of the construction gap, the template is fixed by a split boltwith reserved threads secondarily, numerous specific construction measures of a reinforced steel bar blocking foot fixed on a base plate, a transom arranged on the split bolt and the like reduce wall surface construction gaps, improve impression quality of concrete surface, improve anti-permeability capacity of the waterproof concrete structure, reduce leakage of buildings, guarantee that the structure is more stable, controlsectional dimension of a wall body, prevent the wall body from deforming, guarantee construction quality, is simple and easy inconstruction operation, improve working efficiency, and reduce construction cost.

Owner:TIANJIN 20 CONSTR

Novel cast-in-place waterstone ground surface layer construction method

ActiveCN104563507AImprove the quality of look and feelImprove the finishBuilding material handlingTerrazzoWetting

The invention discloses a novel cast-in-place waterstone ground surface layer construction method. The novel cast-in-place waterstone ground surface layer construction method comprises the following steps: (1) treating a base layer; (2) pouring water and wetting; (3) carrying out ground bottom ash screeding; 4) paving bottom ash; (5) carrying out mesh division by elastic lines; (6) embedding dividing strips; (7) brushing a bonding layer; (8) paving stone particle slurry; (9) rolling compactly, and paving and flattening; (10) carrying out trial grinding; (12) finely grinding; (13) feeding a concrete curing agent; (14) precisely grinding; (15) carrying out crystal face treatment on the surface of a waterstone. The novel cast-in-place waterstone ground surface layer construction method has the advantages that the surface smoothness of the waterstone is high; the surface hardness reaches Grade5-7; the waterstone has permeation resistance and is waterproof and dirt-proof, has the water permeation rate of being less than 0.8, and is oil-proof, weak-acid-proof, weak-alkali-proof and salt-fog-proof; the comprehensive performance of natural protection exceeds that of any existing stone product; a cast-in-place waterstone ground has zero dead angle when being ground and polished, and the ground appearance quality is greatly improved when being compared with that of a traditional method.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method

InactiveCN107060171ALow costSolve common quality problemsFloorsFlooringSurface layerReinforced concrete

The invention relates to a large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method. The one-step forming method comprises the steps of template erection, steel bar binding, expansion reinforcing band arrangement, elevation measurement, steel bar elevation check, laser leveler adjustment, concrete pouring, laser leveler leveling, professional leveling, diamond sand spreading, grinding and flexible compacting, polishing, construction seam cutting, curing, finished product curing and upper structure construction. According to the one-step forming method, a structural floor is used as a base layer, a diamond sand floor surface layer and a structure are subjected to one-step pouring forming, the common quality problem that the floor surface layer is prone to forming hollow protrusions due to secondary pouring is avoided, meanwhile, one concrete base layer is reduced, and cost is greatly reduced. The floor is fully covered with recyclable materials such as plastic films and templates so that an upper main structure can continue to be conveniently constructed.

Owner:SHANGHAI SENXIN CONSTR ENG

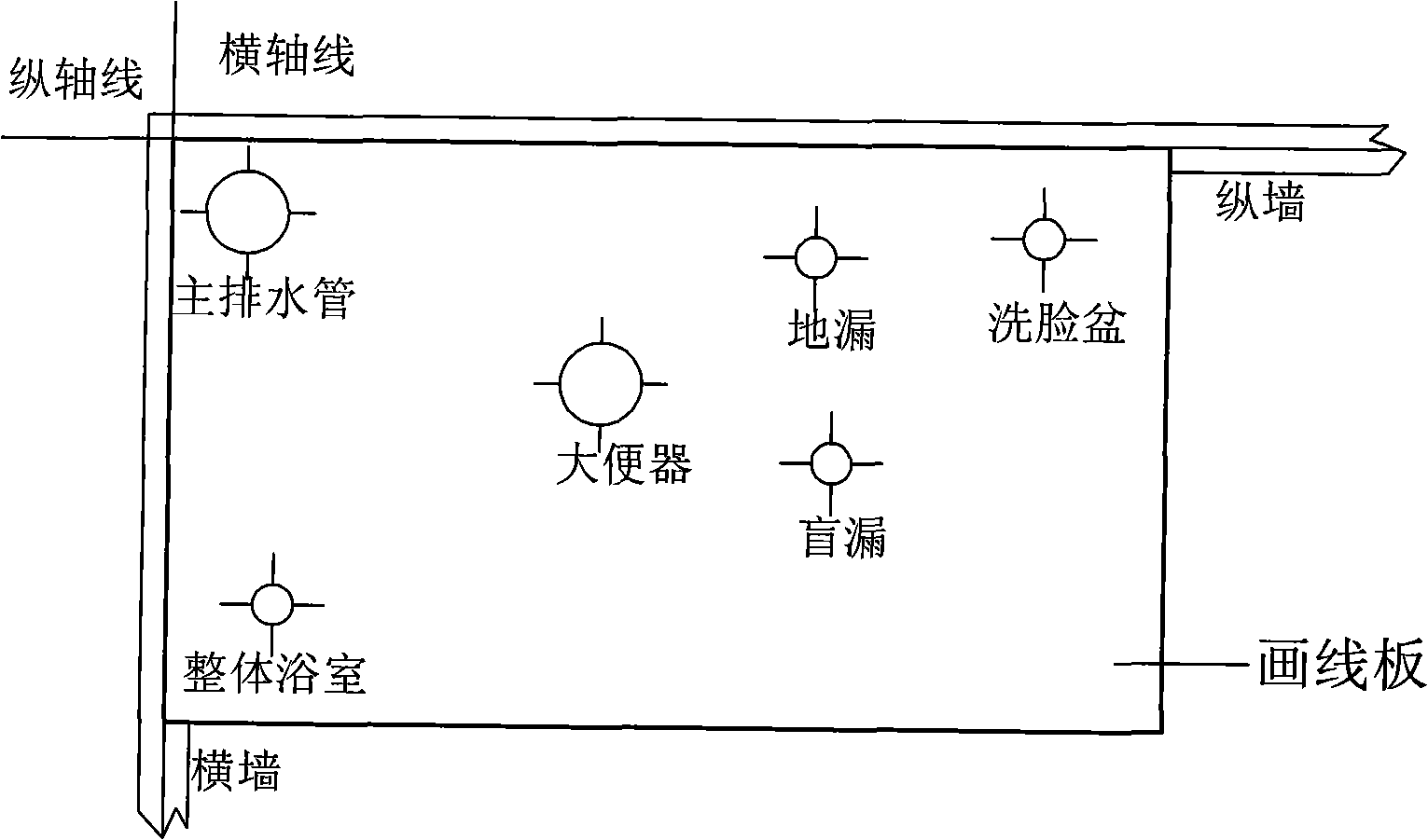

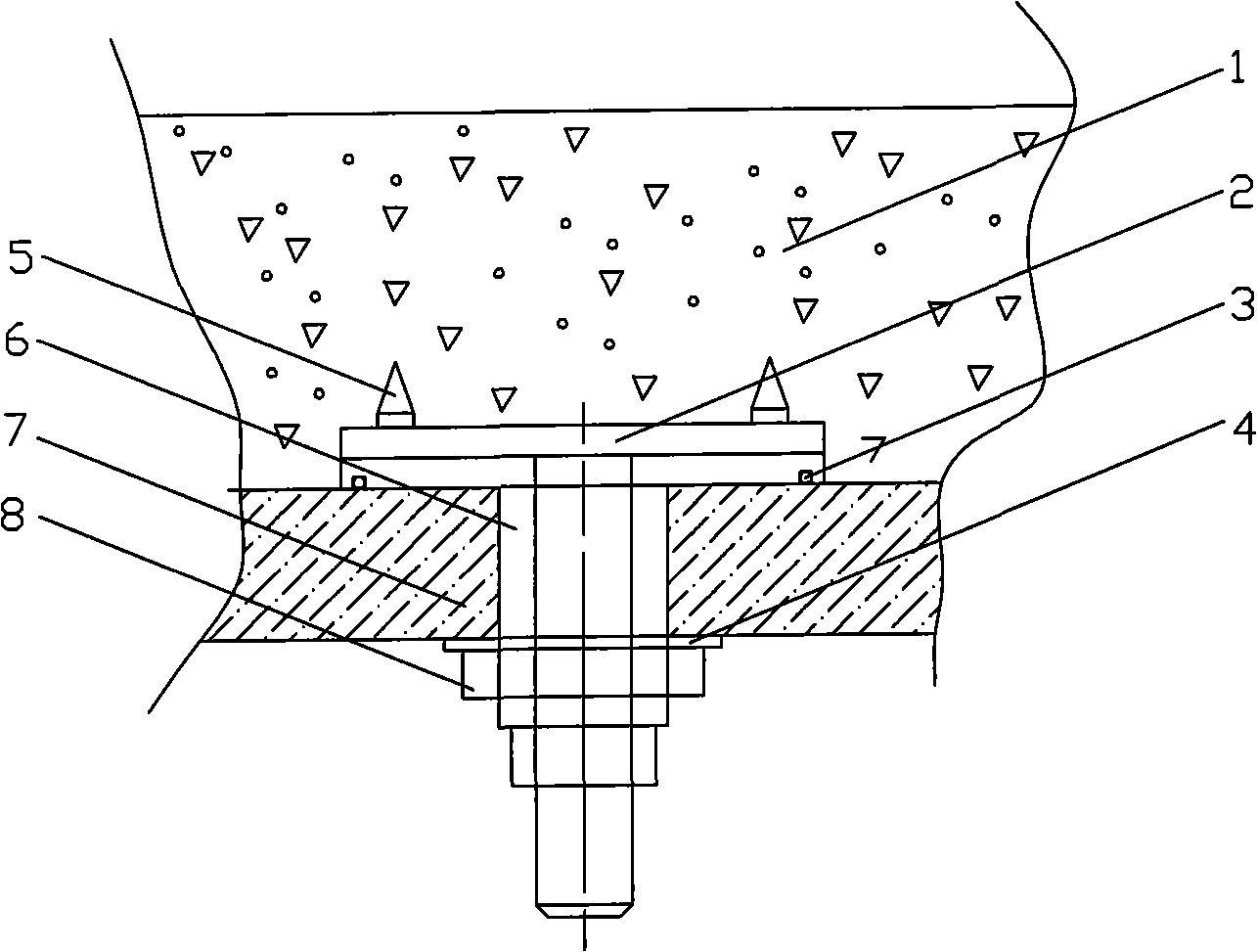

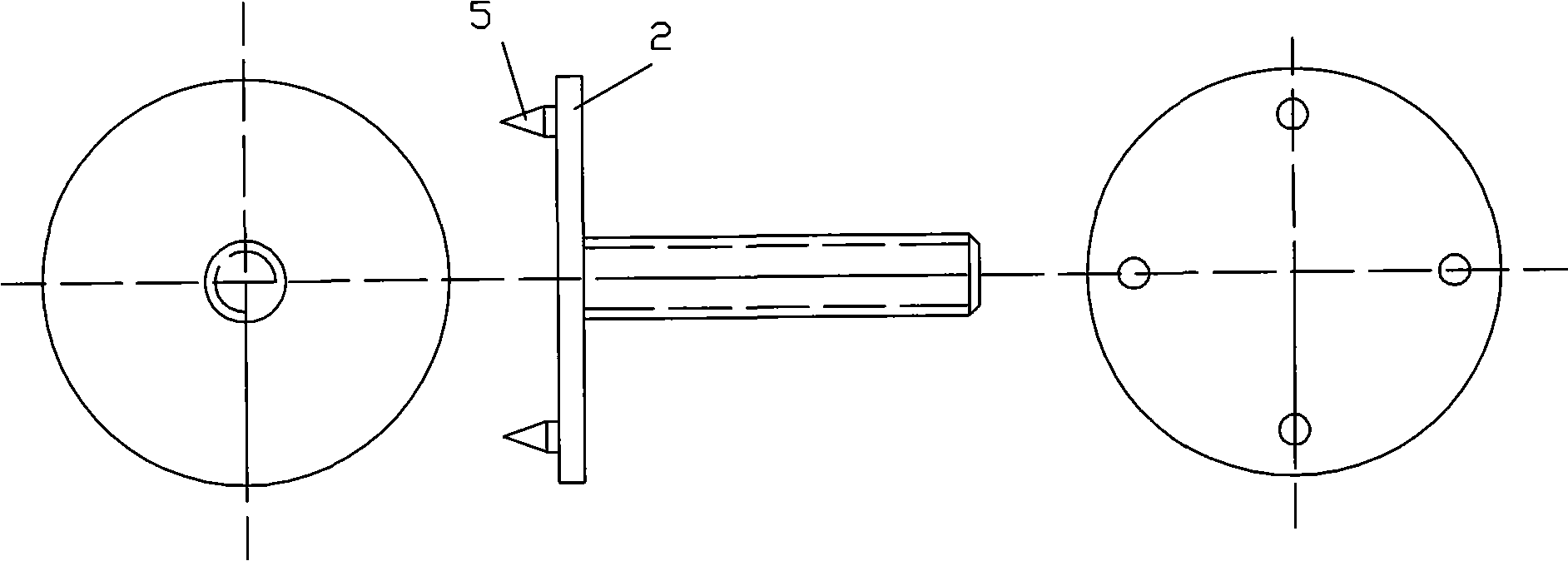

Novel device for installing discharge ducts of kitchens and toilets and method therefor

InactiveCN101525899AAccurate and fast positioningAvoid damageDomestic plumbingForms/shuttering/falseworksPre embeddingToilet

The invention provides a novel device for installing discharge ducts of kitchens and toilets and a method therefor, which is suitable for the installation engineering of the discharge ducts adopting PVC plastics pipes in kitchens, toilets, lavatories, and the like, of domestic blocks and public buildings. The device comprises three parts: pre-embedded pipe joints, fixed anchor pegs and templates. Before casting cast-in-place concrete floors, the position of each duct of a drainage system that perforates through the floors is carved on the templates, the pre-embedded pipe joints with all kinds of apertures are fixed on the templates by the fixed anchor pegs according to the carved positions, after the fixed anchor pegs and the bottom templates of the cast-in-place floors are removed, a drainage system can be installed on the pre-embedded pipe joints via the way of upper socket jointing and lower socket jointing with special glue. The invention changes the traditional installing method of the preset holes of the ducts of the kitchens and the toilets into a pre-embedded construction method, wherein, the pre-embedded holes perforate through the floors, avoids various quality defects of the pre-embedded holes caused by the traditional installing construction, and removes the common faults of leakage of the ducts of the kitchens and the toilets. The device has low cost, simple pre-embedded installing operating technology, convenient and fast construction, as well as good work-saving and materials-saving quality; in addition the method is the best construction method for solving the quality problem of the leakage of the floors in the kitchens and the toilets.

Owner:湖北全洲扬子江建设工程有限公司 +3

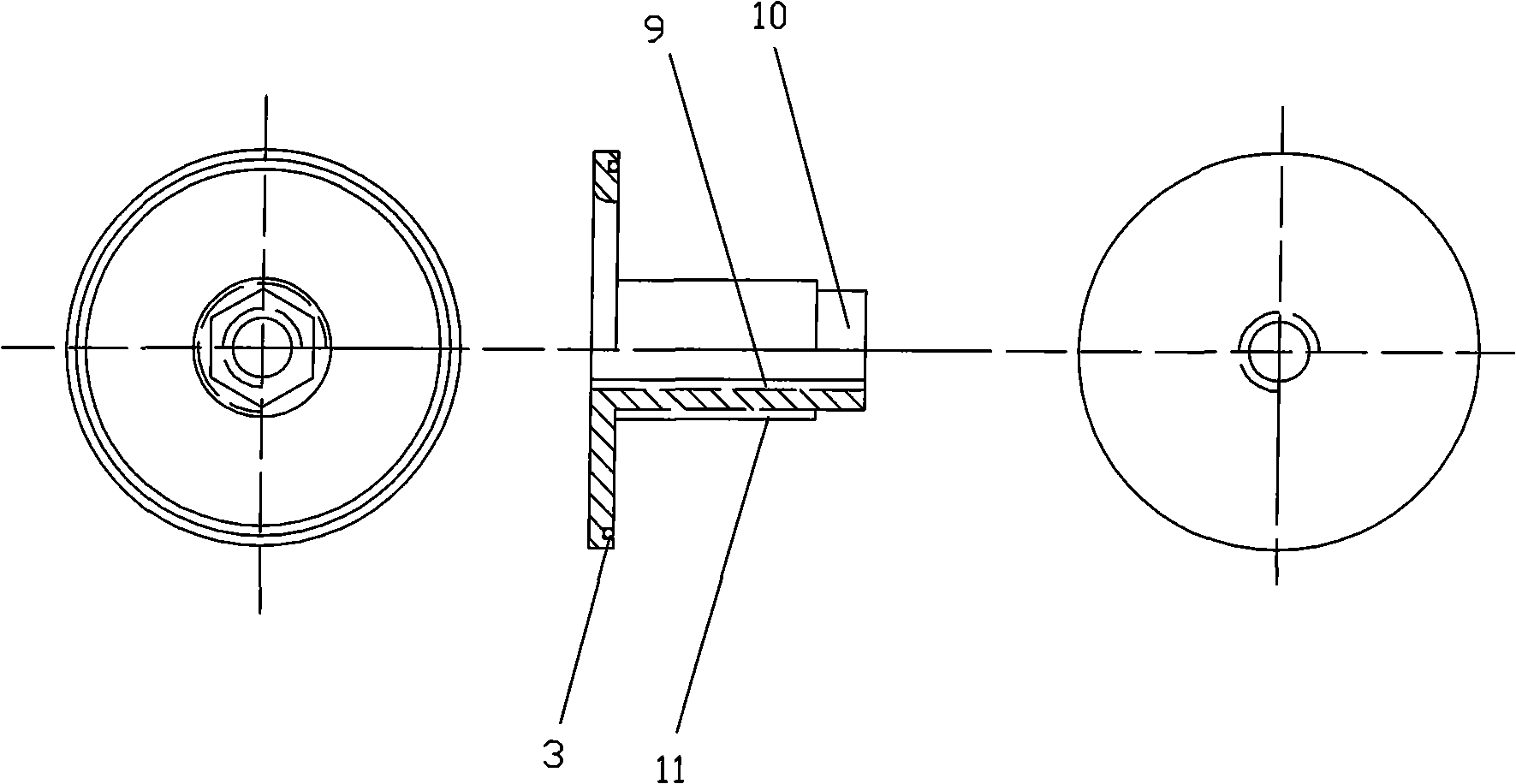

Device for easily demoulding concrete form and a demoulding method

ActiveCN101525940AAvoid pollutionImprove general performanceForming/stuttering elementsSocial benefitsEconomic benefits

The invention provides a device for easily demoulding concrete form and a demoulding method, belonging to the field of architectural construction. The device comprising a form board, a fixed plate with a threaded rod and a six point sleeve with internal and external threads; wherein, the internal surface of the end part of the sleeve is sealed with the surface of the form board by an alkali-resisting O-shaped seal ring; the sleeve penetrates through the hole of the form board, is fixed by a nut out of the form board in a way that passing through a carrier ring, and forms a hexagonal structure on the end part; and the fixed plate with the threaded rod and the sleeve with the internal and external threads are connected in a sealing way by screw thread thereof. After the concrete reaches to demoulding intensity, twisting the sleeve, the form board relatively moves to the concrete so as to be separated, and the bolt connection set is dissembled from the form board so as to be used at the next time. The form board does not need to be coated with separant, therefore, the invention is free of noise and dust pollution, has simple structure, strong popularity and convenient operation, is safe and reliable, has fast demoulding speed, improves demoulding work efficiency, reduces labor intensity of workers, prolongs the service life of form board and heightens the appearance quality of the concrete. The device can achieve good social benefit, economic benefit and environmental benefit.

Owner:湖北中浩建筑有限责任公司

Shaping template for shear wall in deformation joint position of high-rise building

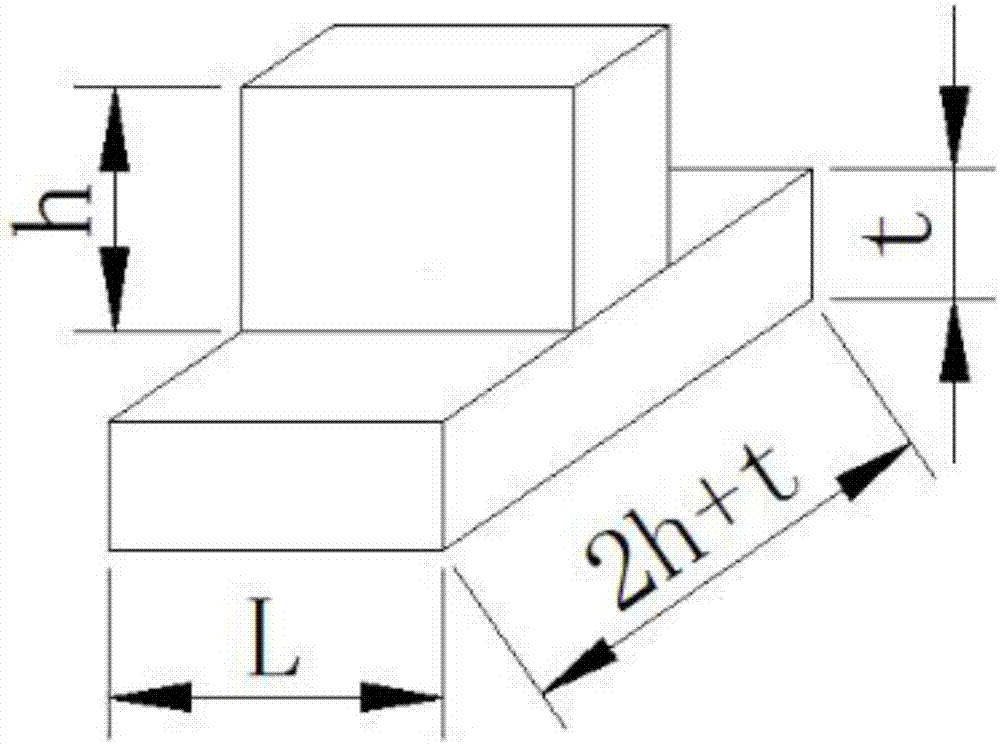

InactiveCN102704678AImprove molding qualityImprove the quality of look and feelForms/shuttering/falseworksHigh riseShear wall

The invention relates to a shaping template for a shear wall in a deformation joint position of a high-rise building. The shaping template comprises a rectangular bamboo plywood, wherein square wood sticks are respectively arranged on the periphery of one side surface of the bamboo plywood, so as to form a square frame; erect square timber secondary ribs are uniformly distributed on the side surface of the bamboo plywood in the square frame; channel steel main ribs are uniformly formed on the outer sides of the square timber secondary ribs; the channel steel main ribs are perpendicular to the square timber secondary ribs; more than two short bolts connected with the bamboo plywood are arranged on the channel steel main ribs; through holes are uniformly formed in web plates in groove mouths of the channel steel main ribs; a screw cap is arranged at each through hole; two inverted U-shaped hoisting rings are uniformly arranged on a long edge on one side of the bamboo plywood, a steel plate strip is arranged on the long edge of one side of the other side surface of the bamboo plywood in a parallel manner, and a horizontal rubber seal strip is arranged on the long edge of the other side of the other side surface of the bamboo plywood in a parallel manner; in addition, a vertical rubber seal strip is arranged on a short edge of one side of the bamboo plywood in a parallel manner, and an inner concave groove-shaped groove is formed on the short edge of the other side of the bamboo plywood in a parallel manner. The shaping template is simple to process, can achieve integral lifting, improves the working efficiency, has high construction speed, and shortens the construction period.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

Splicing stone and splicing process

InactiveCN102717648AArt appreciation value is highTo beautifyCovering/liningsOrnamental structuresWhole bodyAdditional values

The invention provides a splicing stone, comprising a stone main body formed by splicing different block-shaped sheet materials with different patterns and further comprising decorative moldings, wherein grooves adapted to the decorative moldings are arranged on all splicing seams on the upper surface of the stone main body; the decorative moldings are formed in the grooves through utilizing a manner of electroplating or spraying paint or chemically plating or embedding gold; and transparent protection layers can be coated on the upper surfaces of the decorative moldings. After the block-shaped sheet materials with the different patterns are spliced to form the stone main body, all the splicing seams on the upper surface of the stone main body are further subjected to beautifying treatment; glue in the splicing seams on the upper surface of the stone main body can be better covered up and a certain separation effect on a color difference of the stone main body exists; and a range of selecting materials is improved and the decorative moldings have beautifying and decoration effects on the splicing stone, so that the total body of the splicing stone can be more beautiful and the additional value of a product is further improved.

Owner:FUJIAN XISHI

Construction technology of interchange type bare concrete anti-collision guardrails

ActiveCN105755954AIncrease stirringQuality improvementBridge structural detailsSocial benefitsEconomic benefits

The invention relates to the technical field of building construction, in particular to a construction technology of interchange type bare concrete anti-collision guardrails.According to the construction technology of the interchange type bare concrete anti-collision guardrails, concrete template planning is reasonably performed, the template manufacturing and installation technology is improved, the release agent and concrete composition is selected, the concrete mixing and vibrating quality is improved, concrete demolding post-maintenance and protection are enhanced, and other means are adopted, so that the common quality problem of common concrete is eliminated, the overall appearance quality of bridge pier stud concrete is improved, the city appearance and city environment are beautified, and social benefits are improved.According to the construction technology, all construction procedures are improved, the construction scheme is optimized, concrete defects are reduced, the construction period is shortened, resources are saved, economic benefits are improved, and the popularization and application prospects are achieved.The interchange type bare concrete anti-collision guardrails are manufactured and installed, the formed anti-collision guardrails are consistent in color, and no obvious color aberration exists.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

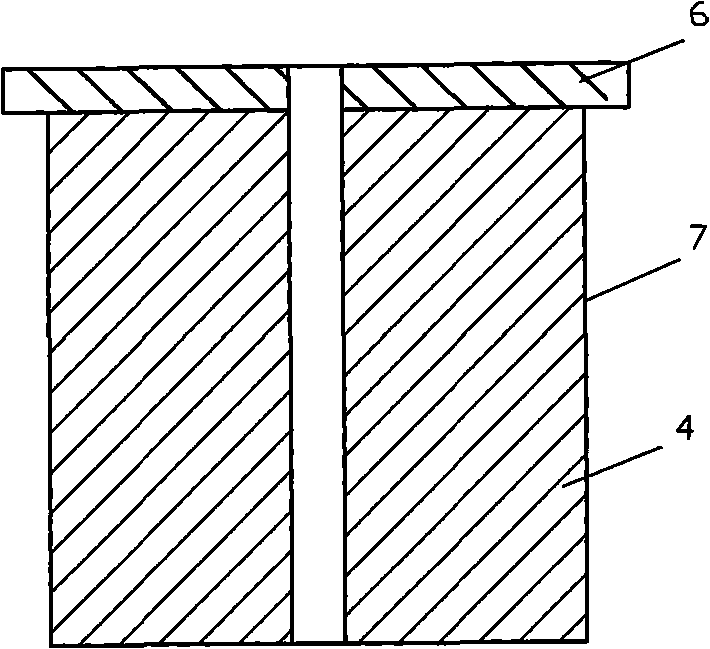

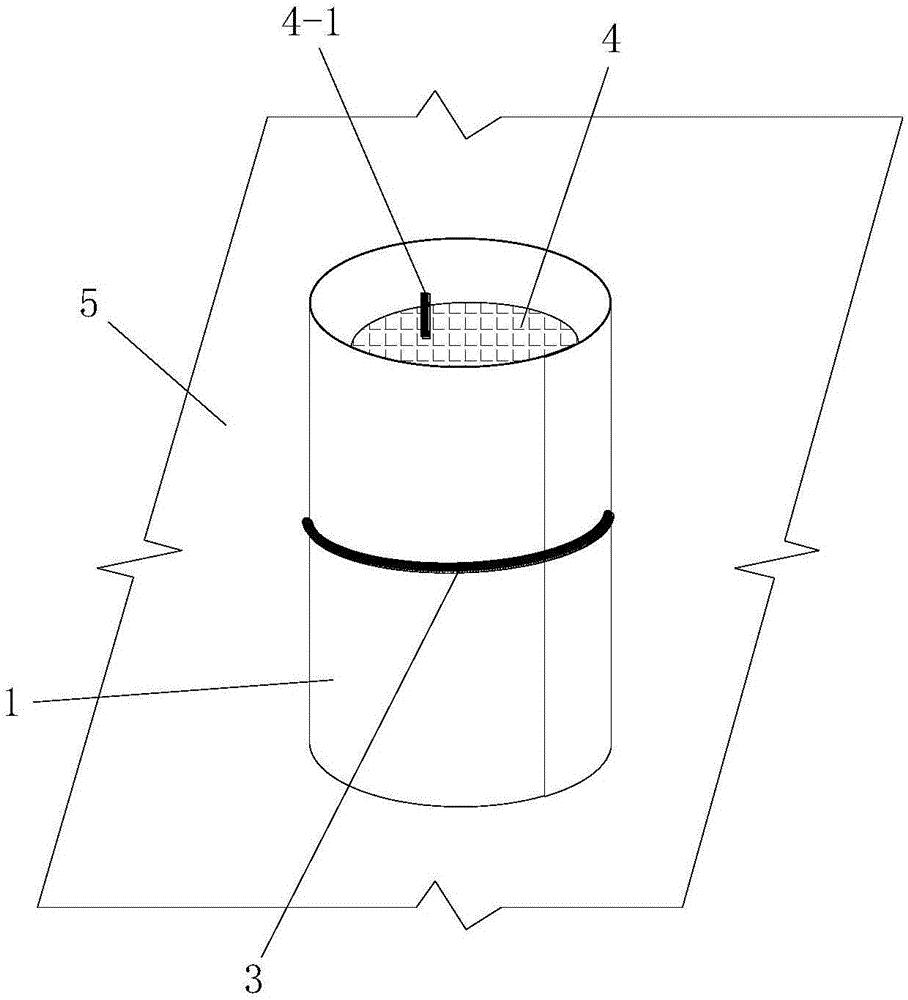

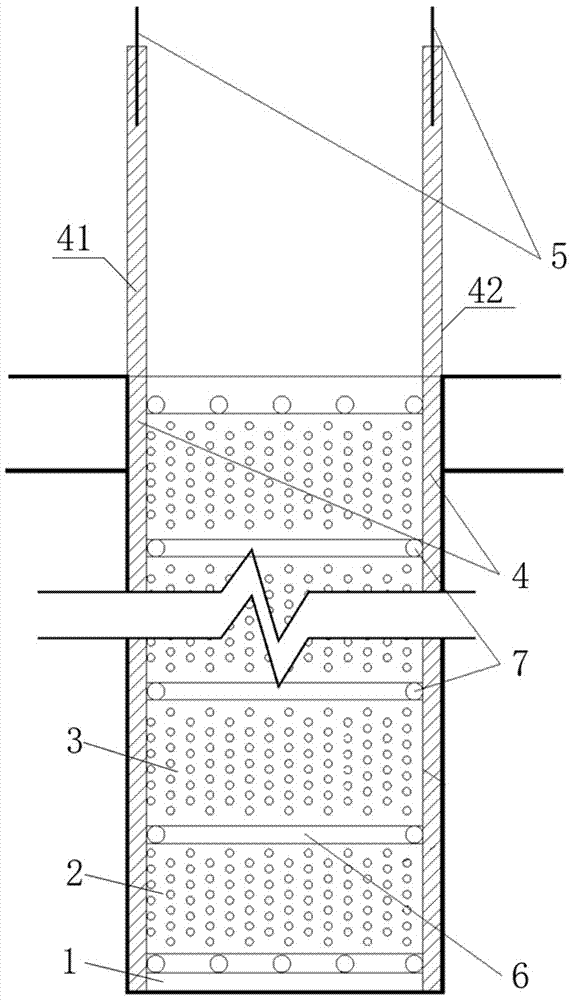

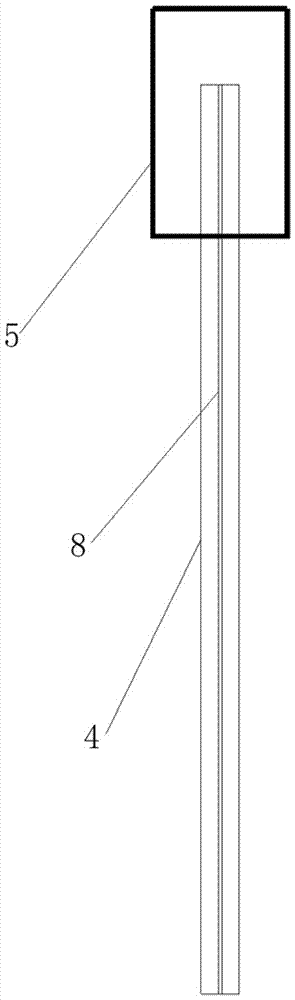

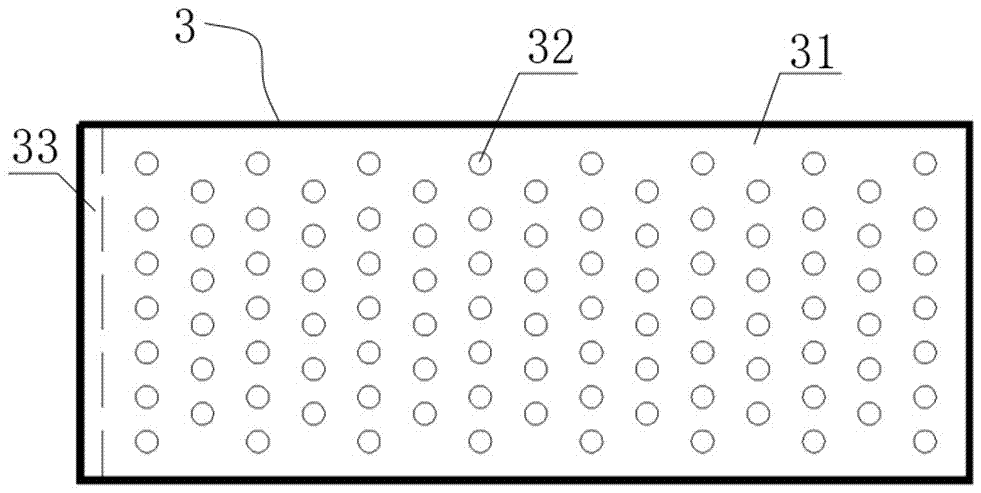

Silo flexible slip form torsion resistance construction device

InactiveCN102444275AEasy to reverseSolve difficult technical problemsForms/shuttering/falseworksSteel barEngineering

The invention discloses a silo flexible slip form torsion resistance construction device, which comprises a hoisting frame, an operation platform, a template and a combined torsion resistant column, and is characterized in that the combined torsion resistant column uniformly distributed around the silo wall includes supporting rods and connecting rods; the three supporting rod are arranged to form a regular triangle; and a regular triangle lattice column is formed by welding the three connecting rods between the three supporting rods. The connecting rods have a clearance of 350 to 400 mm, and are made of steel bars with 20mm as the minimum diameter. In the invention, the combined torsion resistant column is uniformly distributed around the silo wall, so as to solve the technical problems that large-diameter silo flexible slip form is easy to twist and difficult to correct in construction; appearance quality of the external silo wall is improved, and structural safety of buildings is enhanced; further the silo flexible slip form torsion resistance construction device is reasonably designed, has a simple structure, is convenient to operate, and has the low cost.

Owner:CHINA COAL BUILDING & INSTALLATION ENG GRP +1

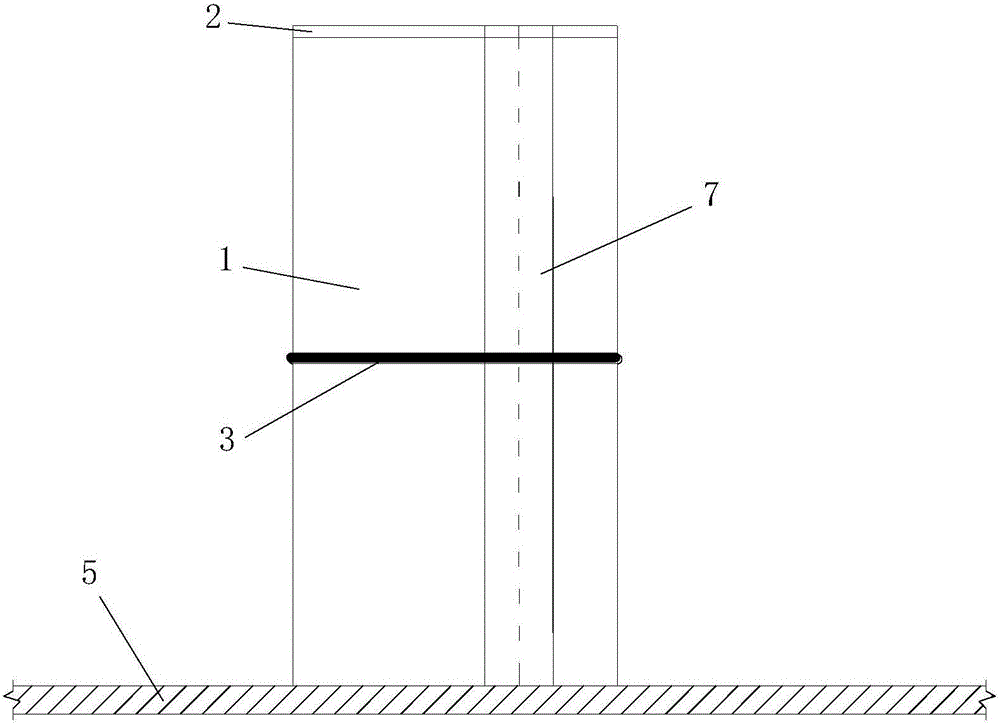

Locating sleeve buried beforehand for electrical installation project

The invention discloses a pre-embedded locating conduit for electrical installation engineering, comprising a base and a conduit body on the base. An inner cavity matched with the sleeved pre-embedded conduit is arranged in the conduit body. Screw holes are arranged on the base. The prior art has the problems that electrical installation pre-embedding procedure damages the formwork, the verticality of the pre-embedded conduit can not be controlled, and the casting quality of concrete surrounding the pre-embedded conduit is bad. However, the pre-embedded locating conduit for electrical installation engineering has the advantages of solving the problems of the prior art, no damaging the template, effectively controlling the position and the verticality of the pre-embedded conduit, improving the concrete quality. The pre-embedded locating conduit for electrical installation engineering has also the advantages of low cost, and convenient manufacture.

Owner:RONGHUA CONSTR GRP CO LTD

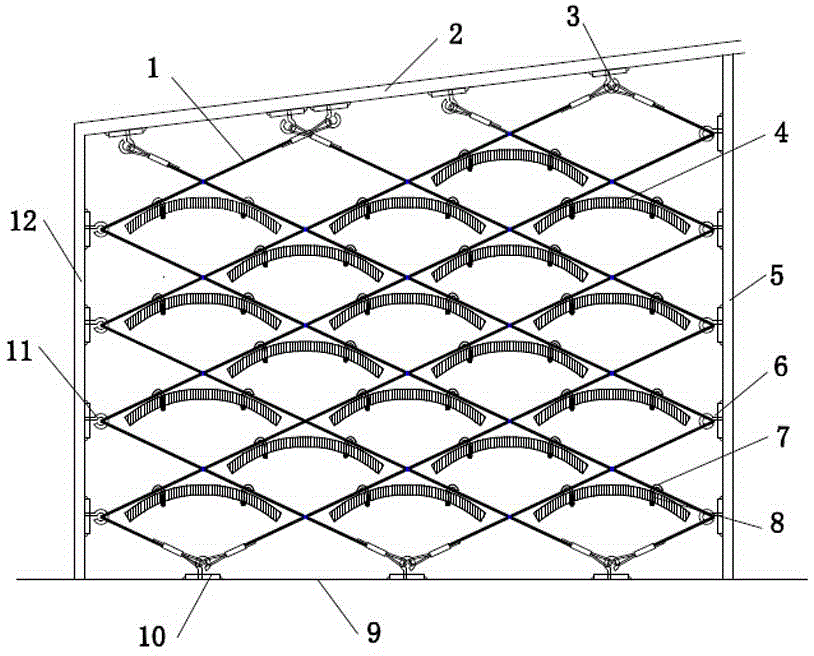

Tile hanging type exterior facade decoration curtain wall in pseudo-classic architecture and construction technology thereof

ActiveCN104818790AGood outdoor adaptabilityHarmonious and unified environmentWallsSteel columnsBuilding construction

The invention relates to a tile hanging type exterior facade decoration curtain wall in pseudo-classic architecture and a construction technology thereof. The tile hanging type exterior facade decoration curtain wall comprises a square steel structure and tiles. The square steel structure is connected with the tiles through rope bodies. The square steel structure comprises a first steel column, a steel beam and a second steel column, wherein the first steel column, the steel beam and the second steel column are connected sequentially. The first steel column and the second steel column are vertically arranged on the ground. The lower surface of the steel beam is provided with two rows of parallel steel beam hand rings. The inner side face of the first steel column is provided with two rows of parallel first hand rings. The inner side face of the second steel column is provided with two rows of parallel second hand rings. The ground is provided with two rows of third hand rings. One end of each rope body is fixed on one steel beam hand ring, and the other end of each rope body sequentially passes through one second hand ring and one first hand ring and is fixed on one third hand ring to form two rows of parallel rope net structures. The tiles are hung on the two rows of the rope nets respectively through lifting hooks. The tile hanging type exterior facade decoration curtain wall is simple in structure and convenient to operate and can embody Chinese ancient cultural lasting appeal.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

Rotten root prevention construction method for shear walls, columns and other concrete vertical structures

InactiveCN106639319AEliminate root rotImprove the quality of look and feelStrutsWallsEngineeringRebar

The invention discloses a rotten root prevention construction method for shear walls, columns and other concrete vertical structures. The method comprises the steps of 1 formulating a formwork project construction scheme, 2 fitting a die, 3 determining shear wall and column side boundaries, and performing paying-off along the shear wall and column side boundaries, 4 performing cutting along the shear wall and column side boundaries and chiseling a groove, 5 installing shear wall and column root backform reinforcing steel bars, 6 inspecting and finishing a formwork, and uniformly coating an oil releasing agent, 7 installing the formwork, 8 inspecting the perpendicularity and flatness of the formwork and accepting the formwork, 9 straightening an outer wall external formwork, staircases, elevator shaft formworks and lower wall suspension wires, 10 plastering the formwork root with cement mortar and pouring concrete, and 11 removing the formwork. According to the rotten root prevention construction method for shear walls, columns and other concrete vertical structures, the rotten root phenomenon of the shear walls, columns and other concrete vertical structures is eliminated, the appearance quality of a finished product is improved, the durability is good, following repairing procedures are avoided, and the time limit for a project is shortened.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Faced concrete outer wall template construction method

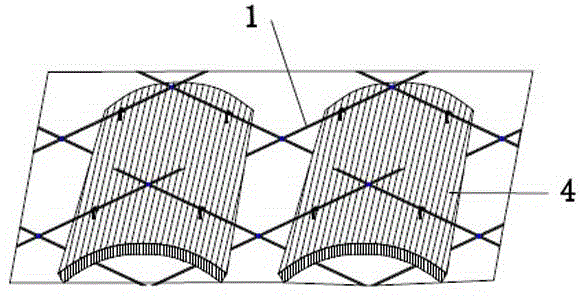

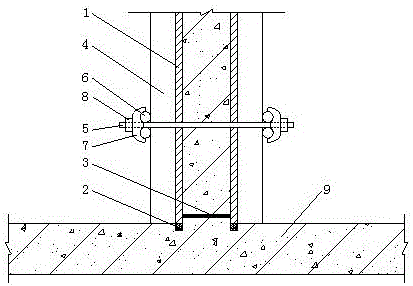

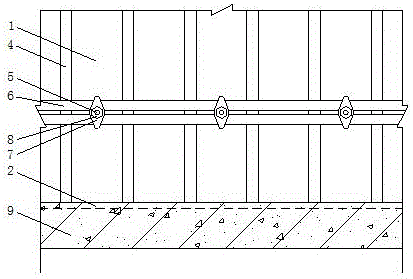

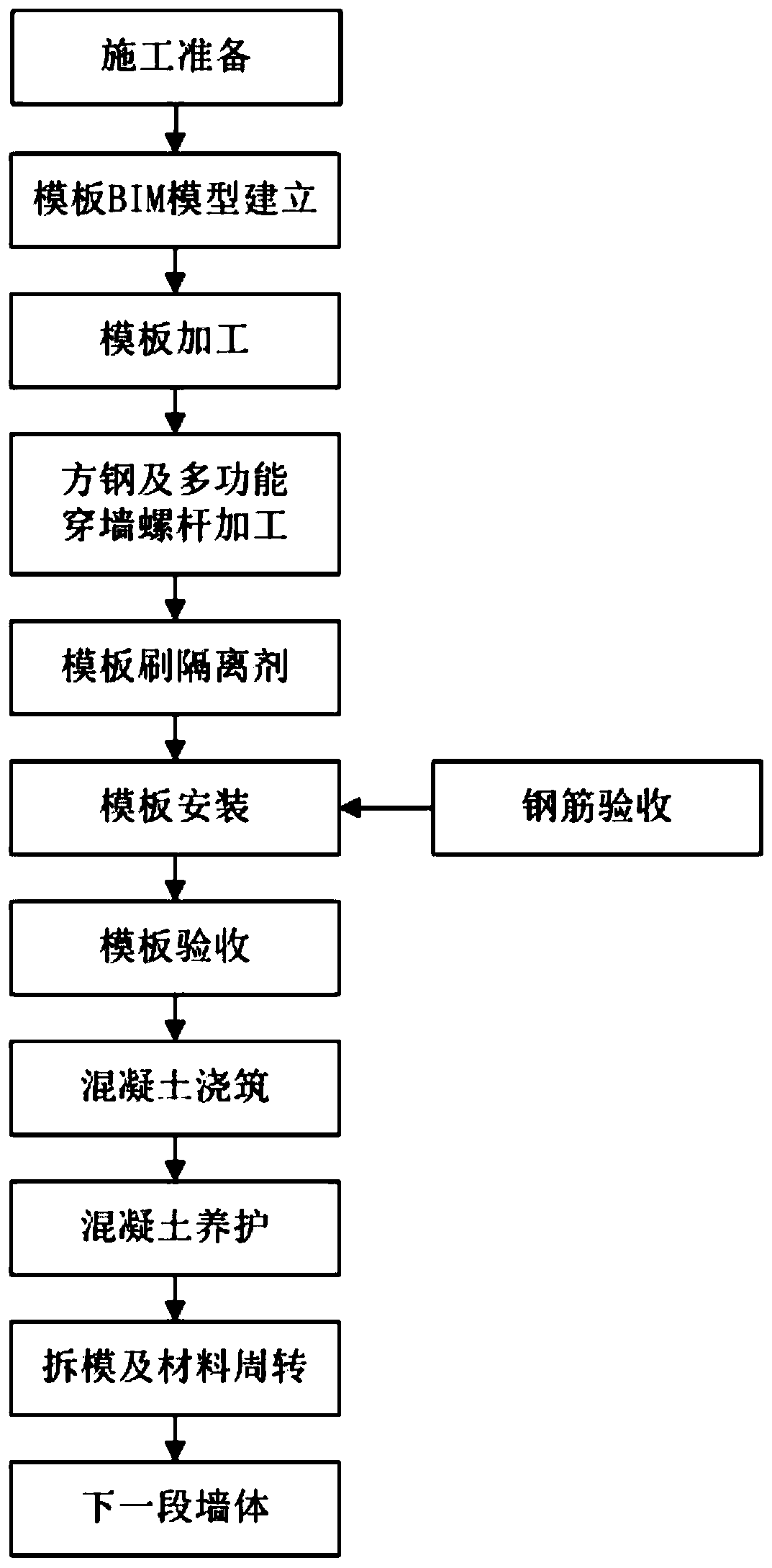

InactiveCN111005557AEvenly distributedFacilitate customization in advanceGeometric CADForms/shuttering/falseworksSteel tubeScrew system

Owner:广东恒辉建设集团股份有限公司

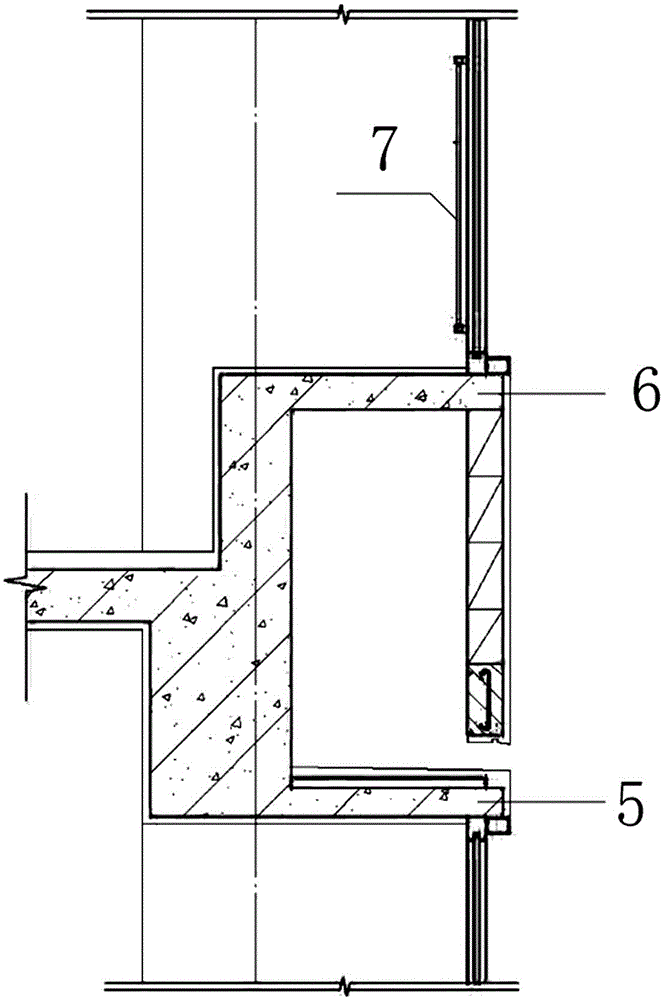

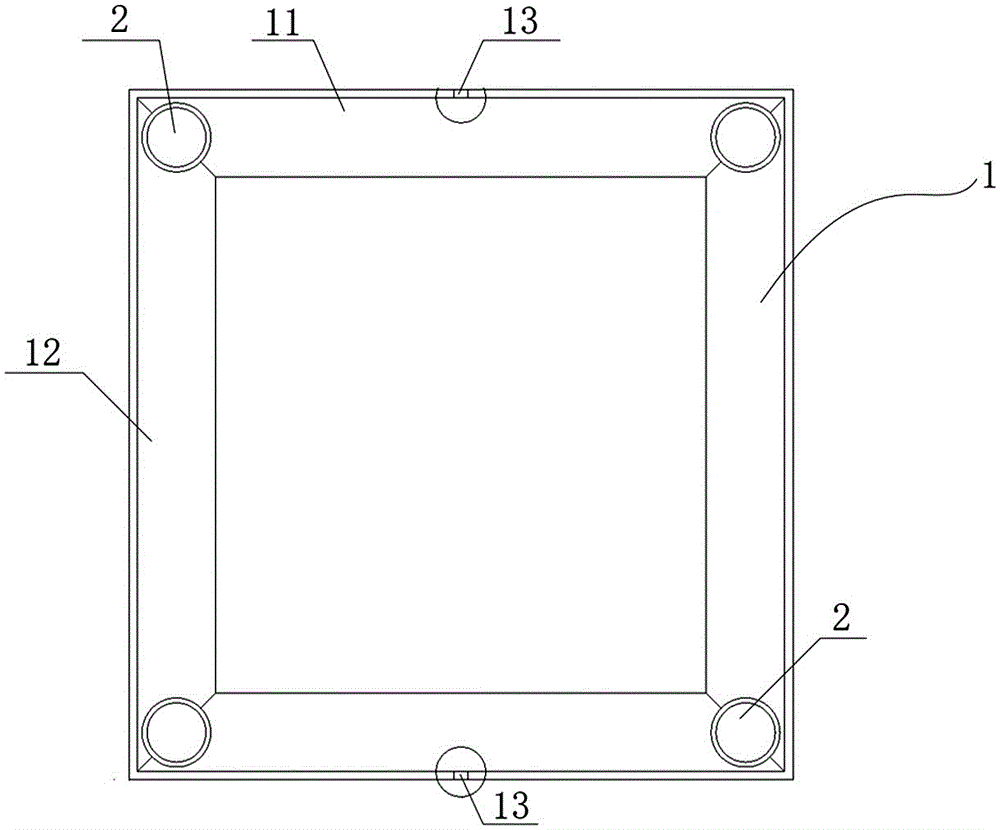

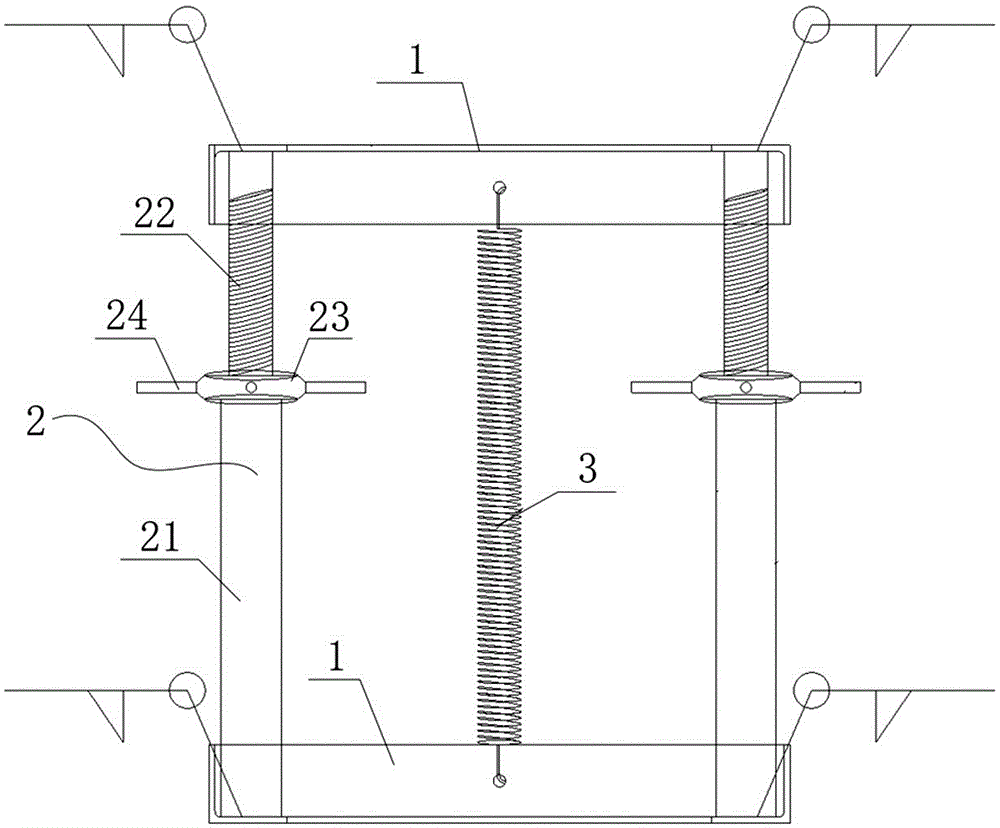

Elastic support platform for construction of bay window and bay window construction method

InactiveCN105040974AReduce in quantitySimplify construction stepsForms/shuttering/falseworksBuilding material handlingMarine engineeringBay window

The invention discloses an elastic support platform for construction of a bay window and a bay window construction method, wherein the elastic support platform comprises a first support frame, lead screws, a second support frame, sleeves, adjusting locks and elastic pulling parts, the first support frame is provided with mounting holes, one end of the lead screws are fixed on four side corners of the first support frame, the second support frame is provided with mounting holes, one end of the sleeves are fixed on four side corners of the second support frame, the adjusting locks are arranged on the end heads of the sleeves, the lead screws pass through the sleeves, the depths of the lead screws going into the sleeves are adjusted through the adjusting locks, one end of the elastic pulling parts are connected into the mounting holes of the first support frame, and the other ends of the elastic pulling parts are connected into the mounting holes of the second support frame. The elastic support platform for construction of the bay window and the bay window construction method achieve to cast an upper and a lower bay plates of a bay window, are simple in construction step, reduce construction cost input, and prevent leakage hidden danger of outer walls. The elastic support platform for construction of the bay window and the bay window construction method enable first support parts to fall off under the action of elastic force when dismounting a template, and reduce difficulty and labor strength of artificial dismounting.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A construction method of cast-in-place terrazzo ground surface

The invention discloses a novel cast-in-place waterstone ground surface layer construction method. The novel cast-in-place waterstone ground surface layer construction method comprises the following steps: (1) treating a base layer; (2) pouring water and wetting; (3) carrying out ground bottom ash screeding; 4) paving bottom ash; (5) carrying out mesh division by elastic lines; (6) embedding dividing strips; (7) brushing a bonding layer; (8) paving stone particle slurry; (9) rolling compactly, and paving and flattening; (10) carrying out trial grinding; (12) finely grinding; (13) feeding a concrete curing agent; (14) precisely grinding; (15) carrying out crystal face treatment on the surface of a waterstone. The novel cast-in-place waterstone ground surface layer construction method has the advantages that the surface smoothness of the waterstone is high; the surface hardness reaches Grade5-7; the waterstone has permeation resistance and is waterproof and dirt-proof, has the water permeation rate of being less than 0.8, and is oil-proof, weak-acid-proof, weak-alkali-proof and salt-fog-proof; the comprehensive performance of natural protection exceeds that of any existing stone product; a cast-in-place waterstone ground has zero dead angle when being ground and polished, and the ground appearance quality is greatly improved when being compared with that of a traditional method.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Construction method for controlling masonry horizontal mortar joint thickness and vertical masonry mortar joint width

InactiveCN107246149ANo need for limited construction techniquesNo need for restricted visionBuilding material handlingMortar jointBuilding construction

The invention discloses a construction method for controlling the masonry horizontal mortar joint thickness and the vertical masonry mortar joint width. The method comprises the steps of manufacturing a mortar joint control member, ejecting a masonry axial line and edge line, cleaning a base and marshaling a bottom layer masonry unit, arranging a mortar joint control member and completing masonry marshaling. The construction method for controlling the masonry horizontal mortar joint thickness and the vertical masonry mortar joint width has the advantages of being easy to operate, being not limited by construction technologies and visual deviation of marshaling personnel, being convenient to construct, being capable of controlling the thickness of a horizontal mortar joint and the width of a vertical mortar joint at any time in the marshaling process, and therefore providing powerful guarantee for improving the construction efficiency; the adopted mortar joint control member is prefabricated by adopting concrete remained in casting in a united way, waste can be turned into wealth, material waste is avoided, the uniformity of the thickness of the mortar joints is guaranteed at the same time, therefore the marshaling quality is reliably guaranteed, and the quality of appearance is also drastically improved.

Owner:TIANJIN 20 CONSTR

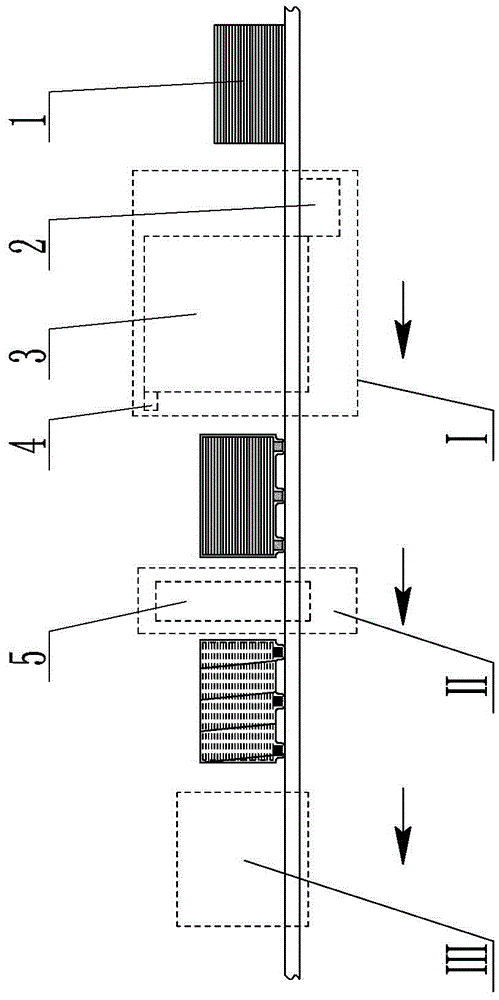

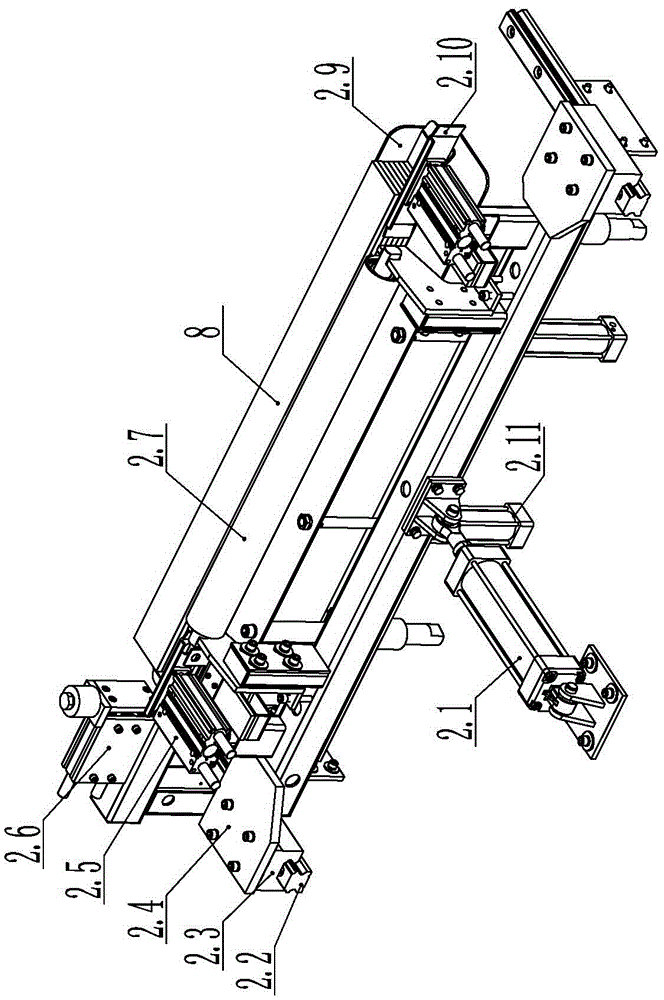

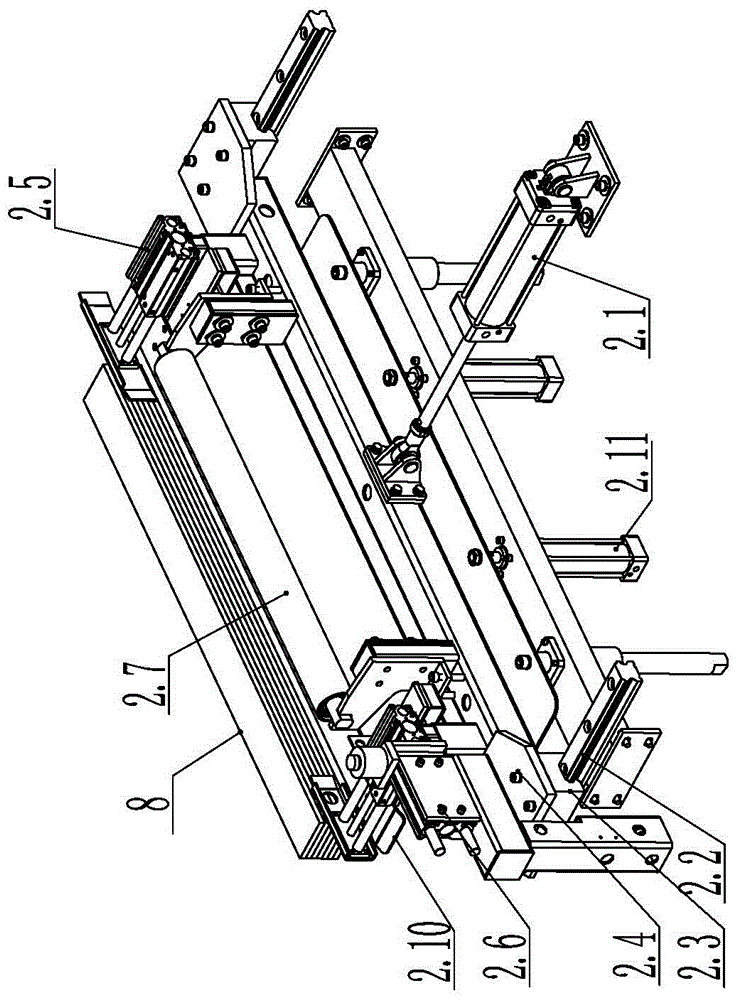

Inflatable adjustable type construction mold for reserved hole in concrete structure plate, and construction method

InactiveCN106049862ASimple structureEasy to processForms/shuttering/falseworksStructural engineeringBuilding construction

The invention discloses an inflatable adjustable type construction mold for a reserved hole in a concrete structure plate, and a construction method. The mold comprises a cylinder formed by rolling of a rectangular iron sheet, a circular cover plate for plugging an upper end opening of the cylinder, and an inflatable air bag placed in the cylinder, wherein the cylinder is vertically arranged, and the outer diameter of the cylinder is the same as the hole diameter of the reserved hole needing to be constructed in the concrete structure plate; the inflatable air bag is a cylindrical air bag, and the inflatable air bag and the cylinder are coaxially arranged; and the bottom of the cylinder is supported on a shaping template of the concrete structure plate, the cylinder and the circular cover plate form an outer sleeve, and an outer sleeve fixing piece for fixing the outer sleeve is arranged on the shaping template. The construction method comprises the following steps of I, erecting the shaping template; II, performing measurement and paying-off; III, mounting the mold; IV, casting concrete; and V, dismantling the mold. The inflatable adjustable type construction mold disclosed by the invention is reasonable in design, simple and convenient to mount and dismantle, and good in use effects; after concrete is finally coagulated, the mold is dismantled, so that the quality of the constructed and shaped reserved hole can be effectively guaranteed, and the accuracy of the position of the reserved hole can be guaranteed.

Owner:THE TENTH CONSTR OF SHANXI CONSTR ENG GROUP OPERATE FUNCTION

Automatic packaging method and equipment for gypsum board

ActiveCN106394961AReduce usageSave packaging resourcesWrappers shrinkageWrapping material feeding apparatusCushioningEngineering

The invention relates to an automatic packaging method and equipment for a gypsum board and belongs to the field of automatic packaging process and equipment for gypsum boards. The method is characterized by comprising the steps of: performing laminating packaging on a stack body of the gypsum board twice, wherein laminating packaging at the two times comprises annular monolayer longitudinal laminating and packaging on the top, bottom, front and back sides and spiral winding laminating at least on the top, bottom, left and right sides; and putting a cushioning leg in two laminating packaging layers. According to the method provided by the invention, by means of large-area longitudinal laminating, use of longitudinal spiral winding overlapped films can be reduced, so that the packaging resources are saved and the production cost is lowered; as the upper film of the gypsum board stack body is an entire film body due to longitudinal laminating without water seepage cracks, the appearance quality of external package is enhanced while the gypsum board can be effectively protected. According to the method provided by the invention, the cushioning leg is put in a double-layered film, so that the cushioning leg is more firmly fixed and is unlikely to fall off, and therefore, follow-up gypsum stack body stacking and transferring work is favorably performed.

Owner:ZIBO REEBOW AUTOMATION EQUIP CO LTD

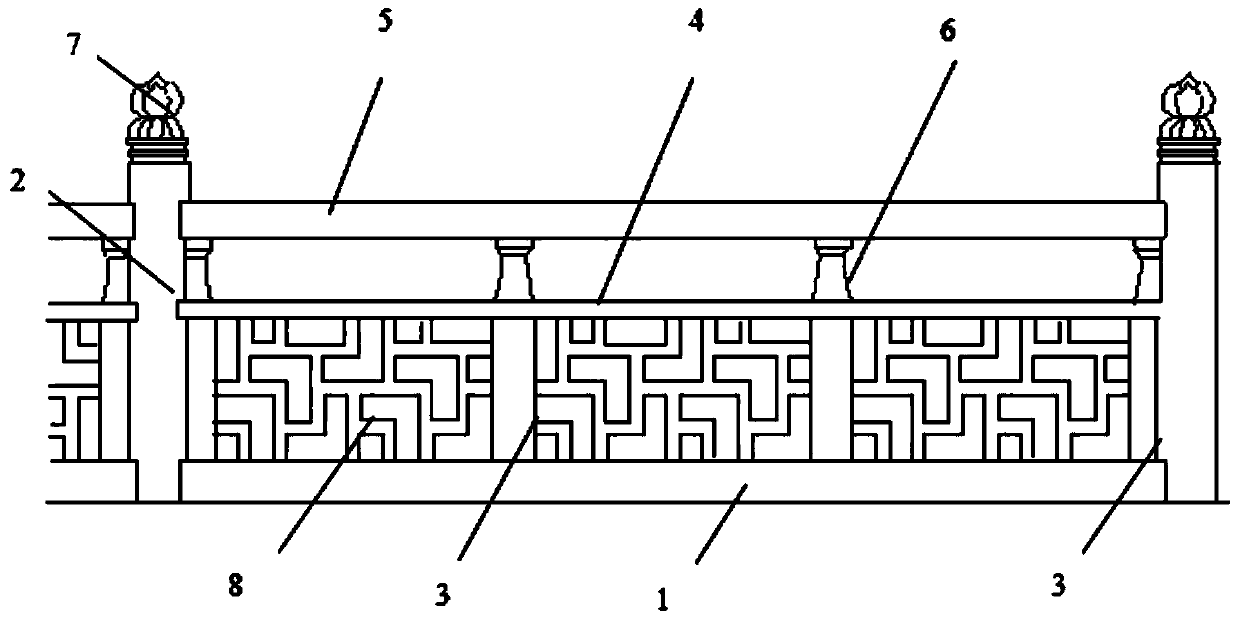

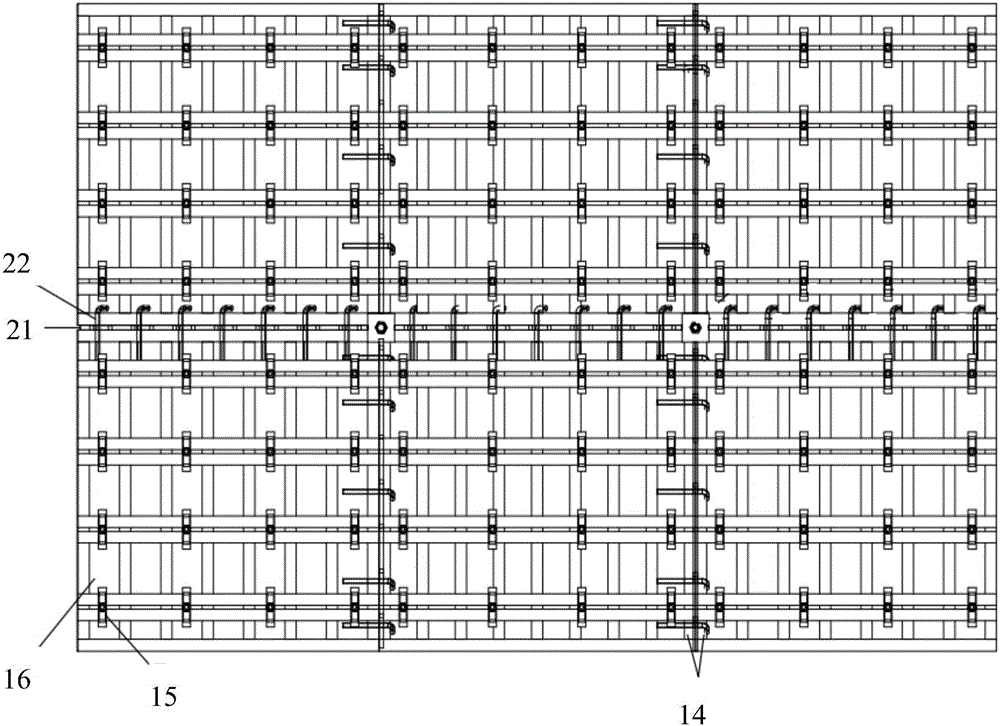

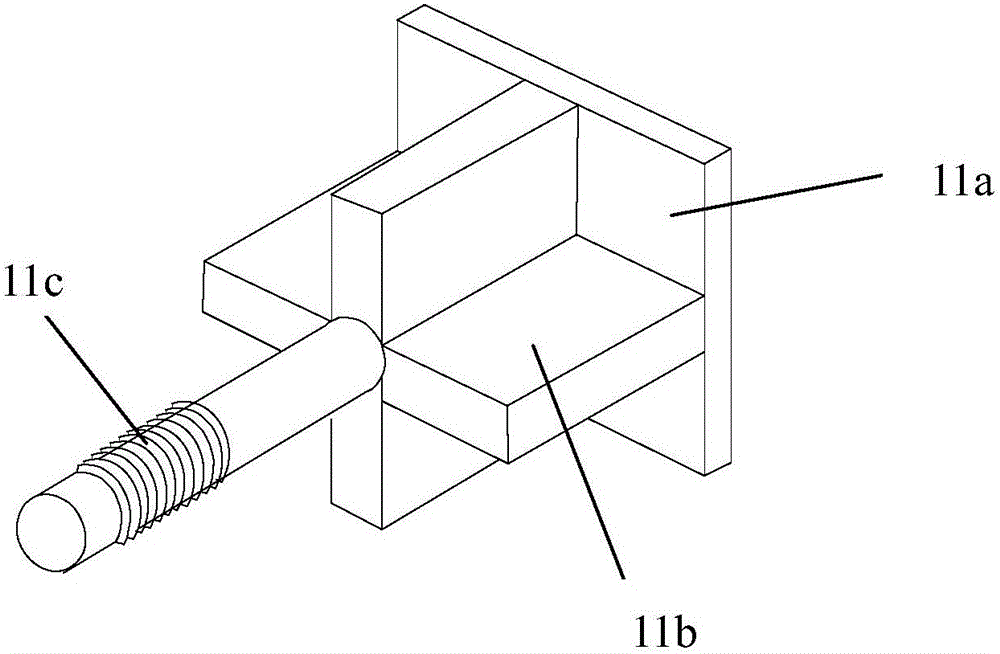

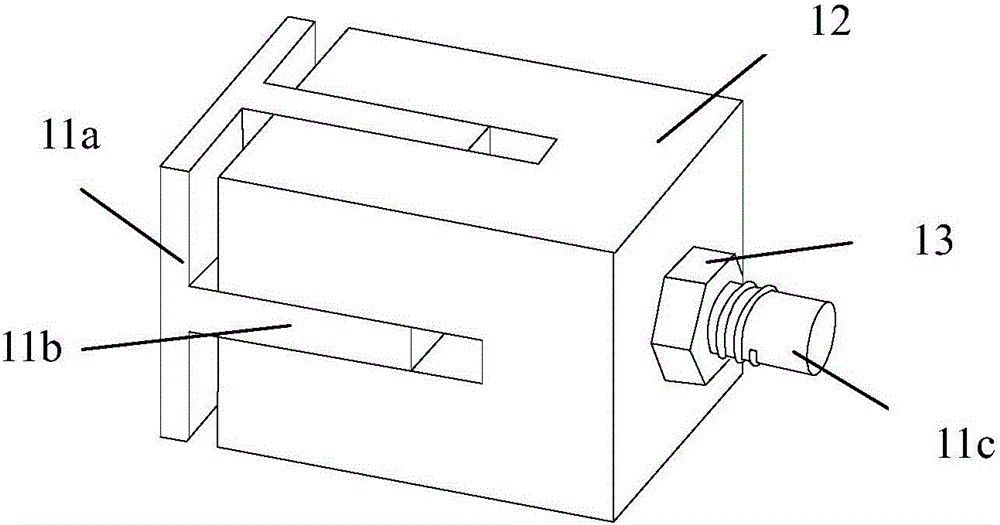

Bare concrete handrail combination overall-pouring one-step forming construction technology of pseudo-classic architecture

InactiveCN103993778AImprove integrityIncreased durabilityFencingStairway-like structuresHandrailBuilding construction

The invention discloses a bare concrete handrail combination overall-pouring one-step forming construction technology of a pseudo-classic architecture. Small prefabs are manufactured firstly, then component templates of handrails and the small prefabs are combined and connected, so that necessary gaps are formed in concrete of the components from bottom to top, construction joint pouring is not needed, and the effect of bare concrete is achieved finally. According to the technology, overall combination pouring in place of the handrail of the pseudo-classic architecture and the effect of the bare concrete can be achieved, concrete cracks of the handrails are completely prevented, multiple technological innovations are achieved, and the bare concrete handrail combination overall-pouring one-step forming construction technology of the pseudo-classic architecture is formed in a summarized mode. Work efficiency is improved, appearance quality of the surface of the handrails is improved, so that integrality and durability of the handrails are improved, repairing and maintaining cost is greatly reduced, and the technology is a new practical technique which is economical, applicable and capable of being popularized.

Owner:SHAANXI CONSTR ENG GRP NO 7 BUILDING ENG

Erecting method for reinforced concrete wall formworks

ActiveCN106088579AEasy to operateEasy constructionForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksRebarReinforced concrete

The invention discloses an erecting method for reinforced concrete wall formworks. A line-shaped splicing joint between every two adjacent formworks is reinforced through a line-shaped splicing joint anti-explosion mold assembly and square timber, and a cross-shaped splicing joint formed among every four adjacent formworks is reinforced through a cross-shaped splicing joint anti-explosion mold assembly; after mounting of each layer of formworks is completed, secondary back edges and main back edges are mounted outside the formworks, and the spliced formworks are primarily fixed through split bolts; and then the positions of the formworks are corrected, the split bolts are fastened, the cross-shaped splicing joint anti-explosion mold assemblies are fastened, the line-shaped splicing joint anti-explosion mold assemblies are fastened, and erecting of the formworks is completed. The method improves the safety of the formworks and the working efficiency, and is easy to implement, convenient to construct and capable of relieving the work intensity and reducing labor cost by 30% or more.

Owner:MCC TIANGONG GROUP

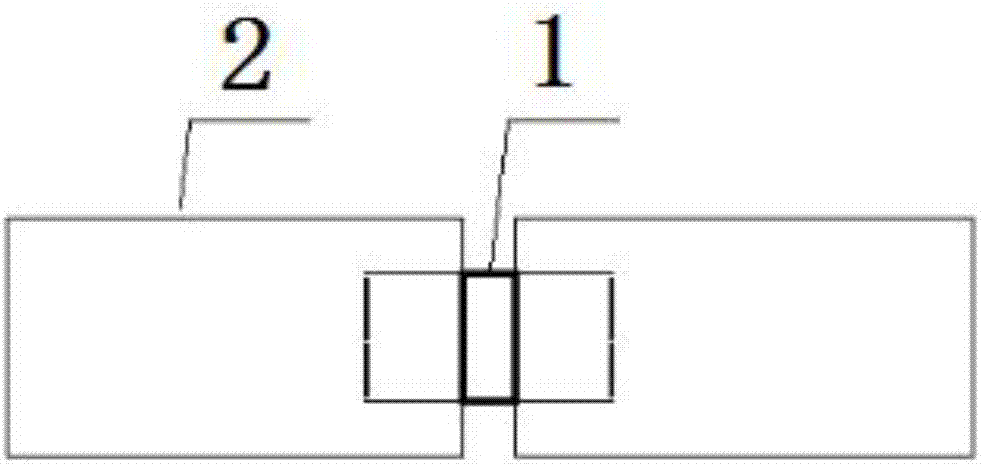

Intercepting device and construction method for different grades of concrete

PendingCN107013035AAvoid pollutionImprove structural safety and concrete visual qualityForms/shuttering/falseworksSteel platesLow graded

The invention discloses an intercepting device and a construction method for different grades of concrete. The intercepting device comprises a first support rod, a second support rod, an un-punched cutting steel plate and a punched cutting steel plate, wherein the first support rod is provided with a steel plate mounting groove with the length direction consistent with that of the first support rod and is fixedly connected with the inner side of a first side mold, and the steel plate mounting groove of the first support rod faces towards a second side mold; the second support rod is provided with a steel plate mounting groove with the length direction consistent with that of the second support rod and is fixedly connected with the inner side of the second side mold, and the steel plate mounting groove of the second support rod faces towards the first side mold; the un-punched cutting steel plate is mounted between the first support rod and the second support rod; and the punched cutting steel plate is mounted between the first support rod and the second support rod. By utilizing the intercepting device and the construction method for different grades of concrete, the problems that a low-grade concrete region is polluted by high-grade concrete and cold joints are formed in the root of a beam in a low-grade concrete region can be completely avoided.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

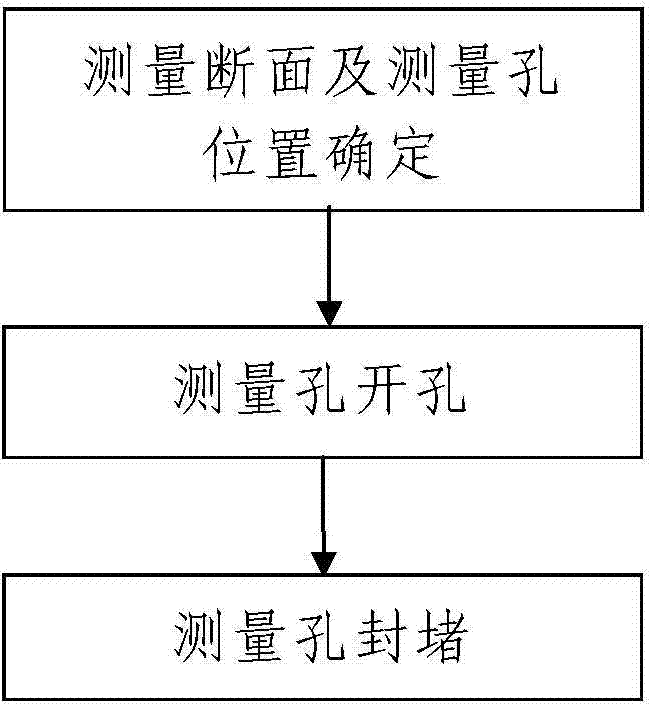

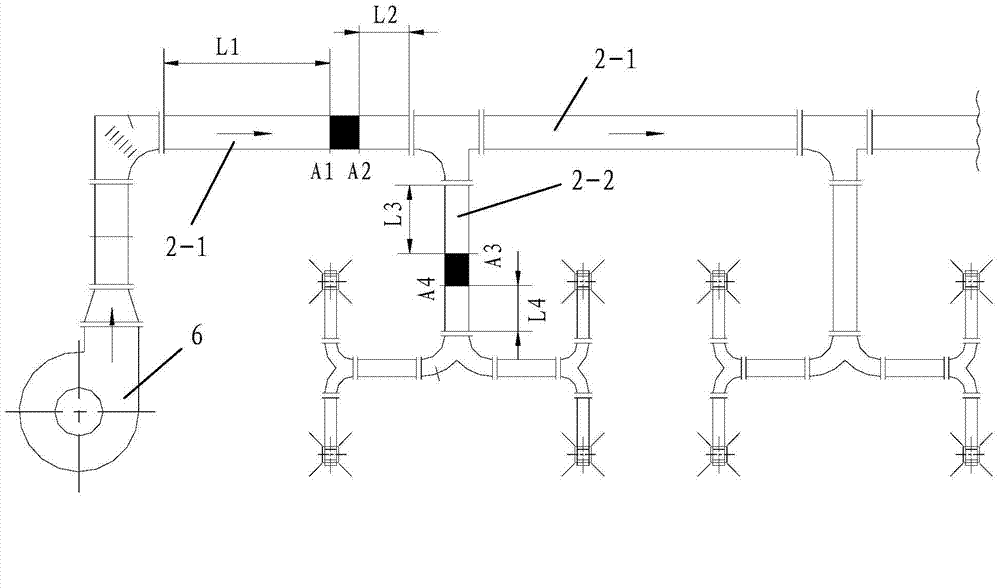

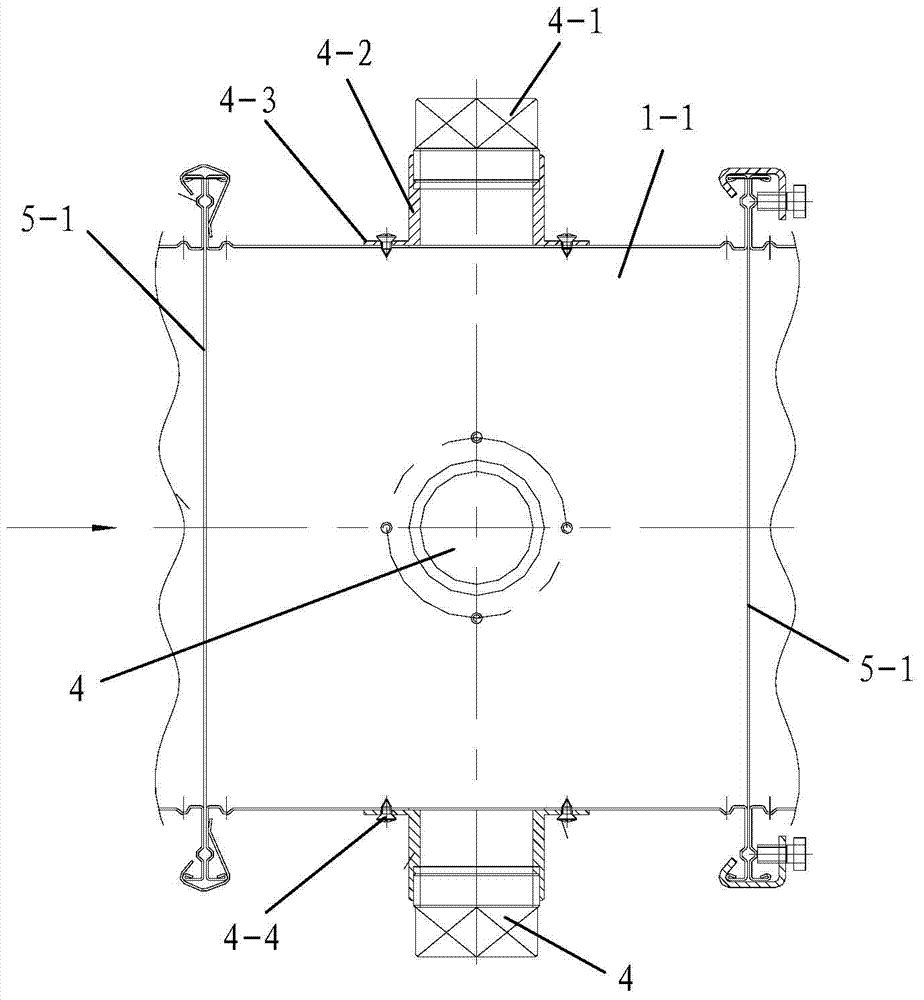

Hole-opening method for measuring holes for testing performances of ventilation and air conditioning system

ActiveCN104772497ASimple stepsReasonable designMetal working apparatusTest performanceTest requirements

The invention discloses a hole-opening method for measuring holes for testing performances of a ventilation and air conditioning system. The hole-opening method comprises the following steps: I, determining positions of measuring sections and the measuring holes: according to pre-designed test requirements of the ventilation and air conditioning system, determining quantity of to-be-tested test sections on a to-be-tested flue, the position of each test section as well as quantity of to-be-opened measuring holes in each test section and hole position of each measuring hole; II, opening and sealing measuring holes: respectively opening all measuring holes in the to-be-tested flue, and sealing each measuring hole as follows: 201, opening holes: drilling by adopting drilling equipment; 202, sealing the measuring holes: sealing processed and formed measuring holes by adopting a sealing part. The hole-opening method disclosed by the invention is simple in step, reasonable in design, convenient to realize, high in working efficiency, good in using effect and capable of simply, conveniently and quickly completing a hole-opening process of measuring holes of an air hose, and guaranteeing the performance test effects of the ventilation and air conditioning system.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

Reinforced concrete chimney big steel mould integral lifting construction method

ActiveCN106284997ASimplified lifting systemWeld firmlyForms/shuttering/falseworksBuilding material handlingFalseworkReinforced concrete

The invention relates to a chimney construction method, and specially relates to a reinforced concrete chimney big steel mould integral lifting construction method comprising the following steps: 1, aligning and locating according to a cylindrical structure, erecting an all-round scaffold on a chimney base plate, and reserving a square hole in middle of an operation platform to serve as a basket or bucket up-down channel; 2, installing a vertical transport facility; 3, installing a cold rolling big steel template; 4, installing a wire rope fastener at the end of a wire rope after the cold rolling big steel template is installed, wherein one end of the wire rope on the fastener is a fixed end, and the other end is a movable end; 5, integrally dismounting and lifting the cold rolling big steel template; 6, binding cylinder wall steel bars and embedded parts according to a conventional construction process, laying firebricks, mounting a thermal insulation layer, and pouring concrete layer by layer until the construction is finished. The reinforced concrete chimney big steel mould integral lifting construction method simplifies lifting equipment, reduces high altitude constructions, and can improve construction efficiency.

Owner:CHINA MCC20 GRP CORP

Corner reinforcing part for constructional column formwork and formwork reinforcing method

PendingCN111809868AImprove work efficiencyHigh material turnover rateForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention discloses a corner reinforcing part for a constructional column formwork. The corner reinforcing part comprises an embedded part, an internal corner reinforcing part, first formwork reinforcing parts and an internal connecting assembly. The embedded part is arranged in a constructional column, the central axis of an insertion cavity at the end part of the embedded part corresponds tothe angle vertex of the constructional column, the internal corner reinforcing part is arranged on the inner side of a constructional column internal formwork, the head part of the internal corner reinforcing part is positioned at the corner of the internal formwork, two side edges of the internal corner reinforcing part and the internal template are arranged in a spaced mode, a first through hole is formed in the internal corner reinforcing part in a front-back penetrating mode, the first formwork reinforcing parts are arranged between the two side edges of the internal corner reinforcing part and the internal formwork at intervals, the internal connecting assembly comprises a first double-thread screw and a first nut matched with the first double-thread screw, one end of the first double-thread screw is arranged in the insertion cavity, the other end of the first double-thread screw is fixedly connected with the internal corner reinforcing part through the first nut, the head part of the internal corner reinforcing part presses the corner of the internal formwork, and meanwhile the first formwork reinforcing parts press the internal formwork. The invention further discloses a formwork reinforcing method using the corner reinforcing part. The work efficiency of constructional column formwork reinforcing is greatly improved.

Owner:河南五建第二建筑安装有限公司

Autoclaved aerated block lintel and construction method thereof

The invention discloses an autoclaved aerated block lintel and a construction method thereof. The construction method comprises the steps that first pre-buried components are arranged on vertical main structures on the two sides of a lintel; second pre-buried components are arranged at the bottom of a horizontal main structure on the top of the lintel; a lintel bottom bracing is fixedly mounted between the first pre-buried components arranged on the vertical main structures on the two sides of the lintel; lintel vertical bracings are fixedly mounted between the second pre-buried components and the lintel bottom bracing; the outer side of the lintel bottom bracing and the outer sides of the lintel vertical bracings are cladded by an autoclaved aerated masonry shell to form lintel bottom bracing casting space and lintel vertical bracing casting space which internally communicate with each other; concrete casting is conducted in the lintel bottom bracing casting space and the lintel vertical bracing casting space to form a lintel combination bracing; and autoclaved aerated blocks are constructed on the lintel combination bracing, and lintel construction is completed. The autoclaved aerated block lintel and the construction method thereof are applied to the construction method of an autoclaved aerated block large-span hole lintel, and have the characteristics of convenient construction and little size deviation compared with a traditional cast-in-place concrete lintel, formwork erection is omitted, and the appearance quality is improved.

Owner:DALIAN BRANCH OF CHINA CONSTR EIGHTH ENG DIV CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com