Splicing stone and splicing process

A stone and craftsmanship technology, applied in the field of mosaic stone and splicing technology, can solve the problems that affect the overall aesthetics of the product and unsatisfactory splicing technology, so as to achieve the effect of increasing added value, improving artistic appreciation value, and improving the quality of perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

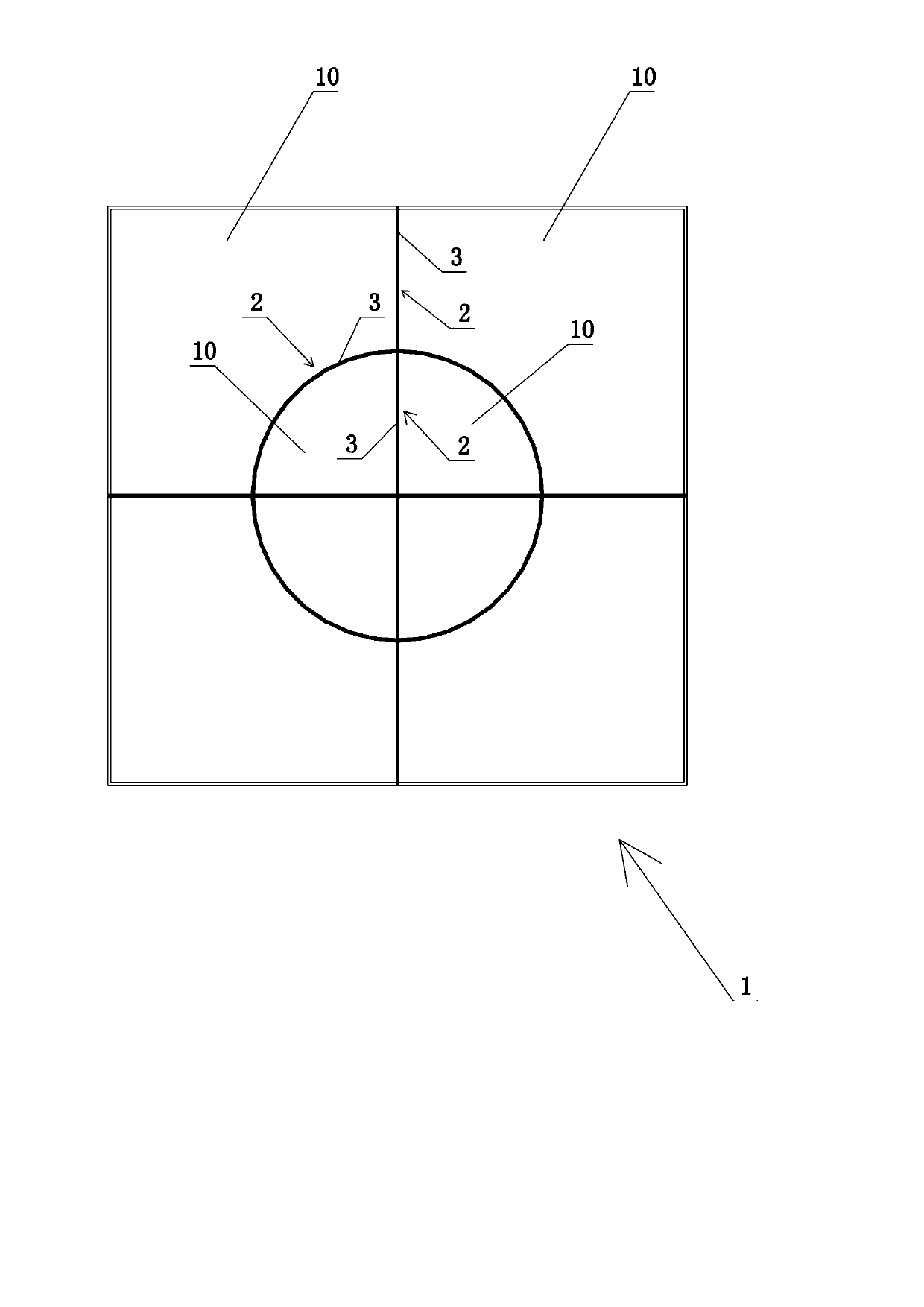

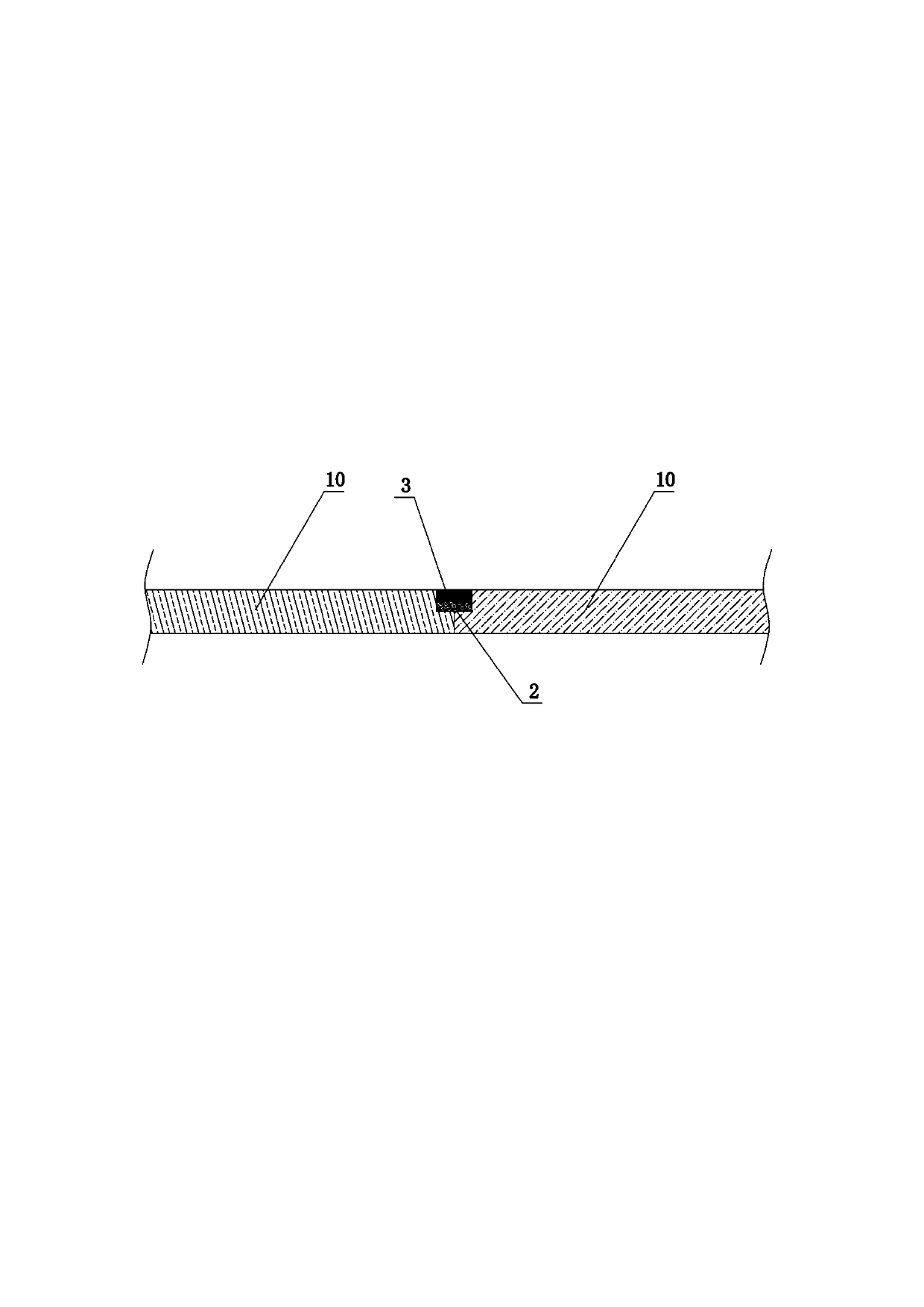

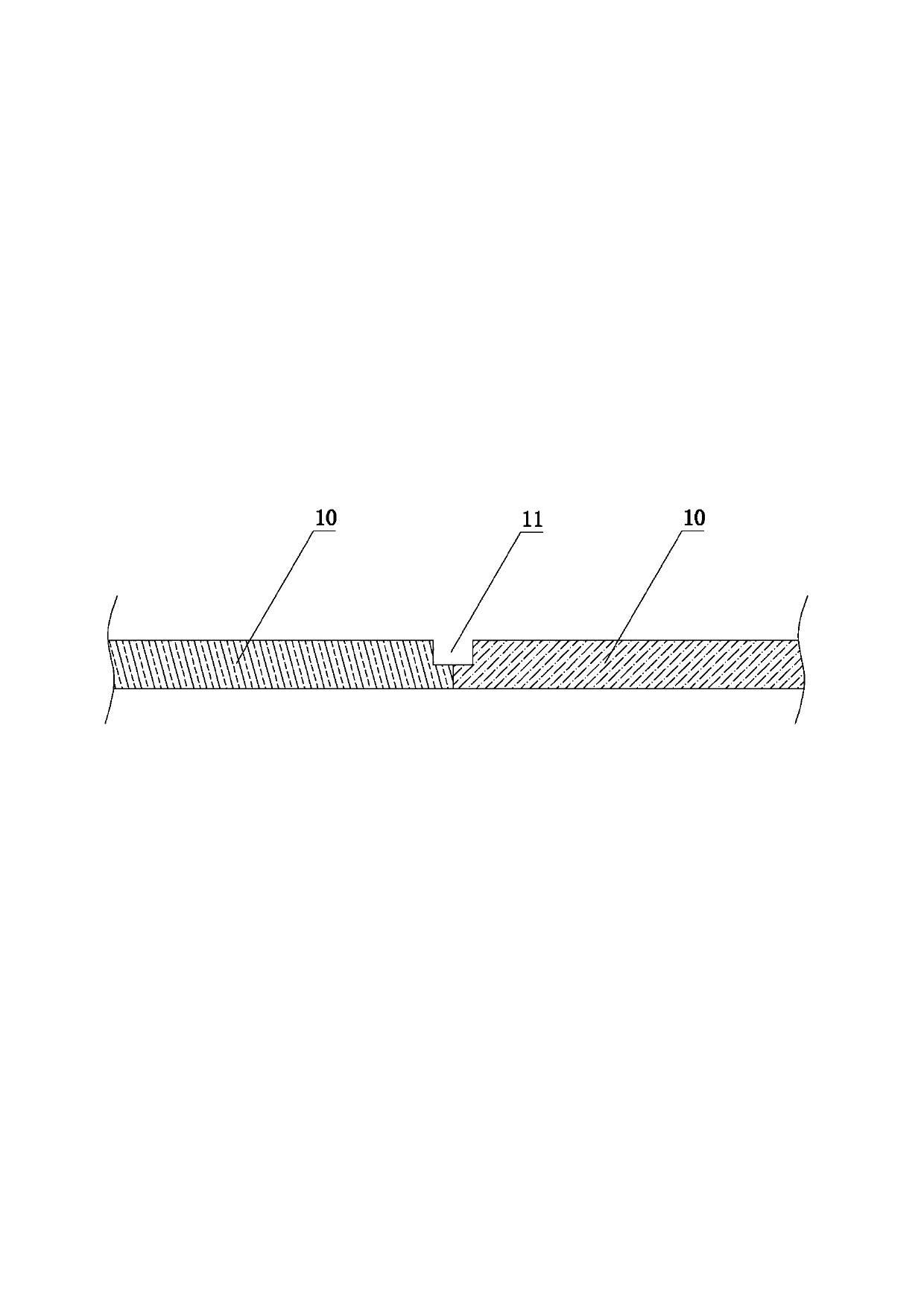

[0023] Refer to attached figure 1 , figure 2 and image 3 . A mosaic stone, including a stone body 1 spliced by block sheets 10 of different patterns, and also includes a decorative line 2, each seam on the upper surface of the stone body 1 is provided with a pattern that matches the decorative line 2 The groove 11, the decorative line 2 is located in the groove 11. The decorative line 2 is a metal decorative line formed in the groove 11 by brush plating, and the upper surface of the metal decorative line is coated with a transparent protective layer 3 .

[0024] A mosaic stone splicing process, comprising the following steps:

[0025] 1) Mosaic: the stone body 1 is formed by splicing block sheets 10 of different patterns;

[0026] 2) Washing tank: a groove 11 is washed out at each seam on the upper surface of the stone body 1 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com