Patents

Literature

42results about How to "Art appreciation value is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of imitation hollowed-out artwork

InactiveCN1476992AMeet homeMeet the needs of the industrialization of the decoration industryOrnamental structuresGlass fiberSilica gel

The present invention relates to a method for making imitation hollowed-out ornamental work by utilizing chemical material. The method includes the following steps: using unsaturated polyester resin in which the solidifying agent, accelerator and filler are added as raw material, pouring it into silicon gel mould duplicated by using hollowed-out ornamental work, then demoulding so as to obtain the invented product. It also includes pour-forming method at twice by adding glass fibre as reinforcing material.

Owner:刘宏

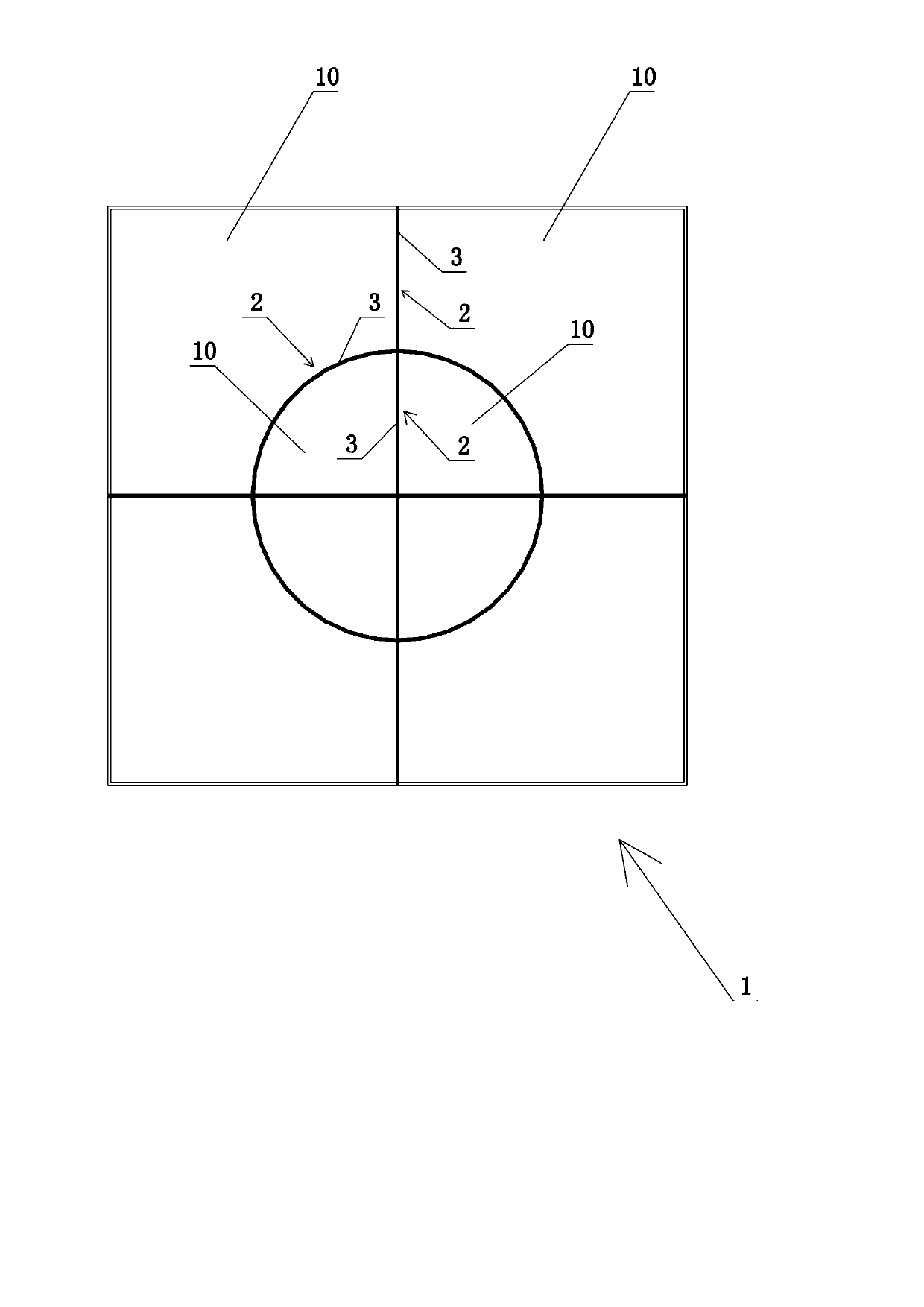

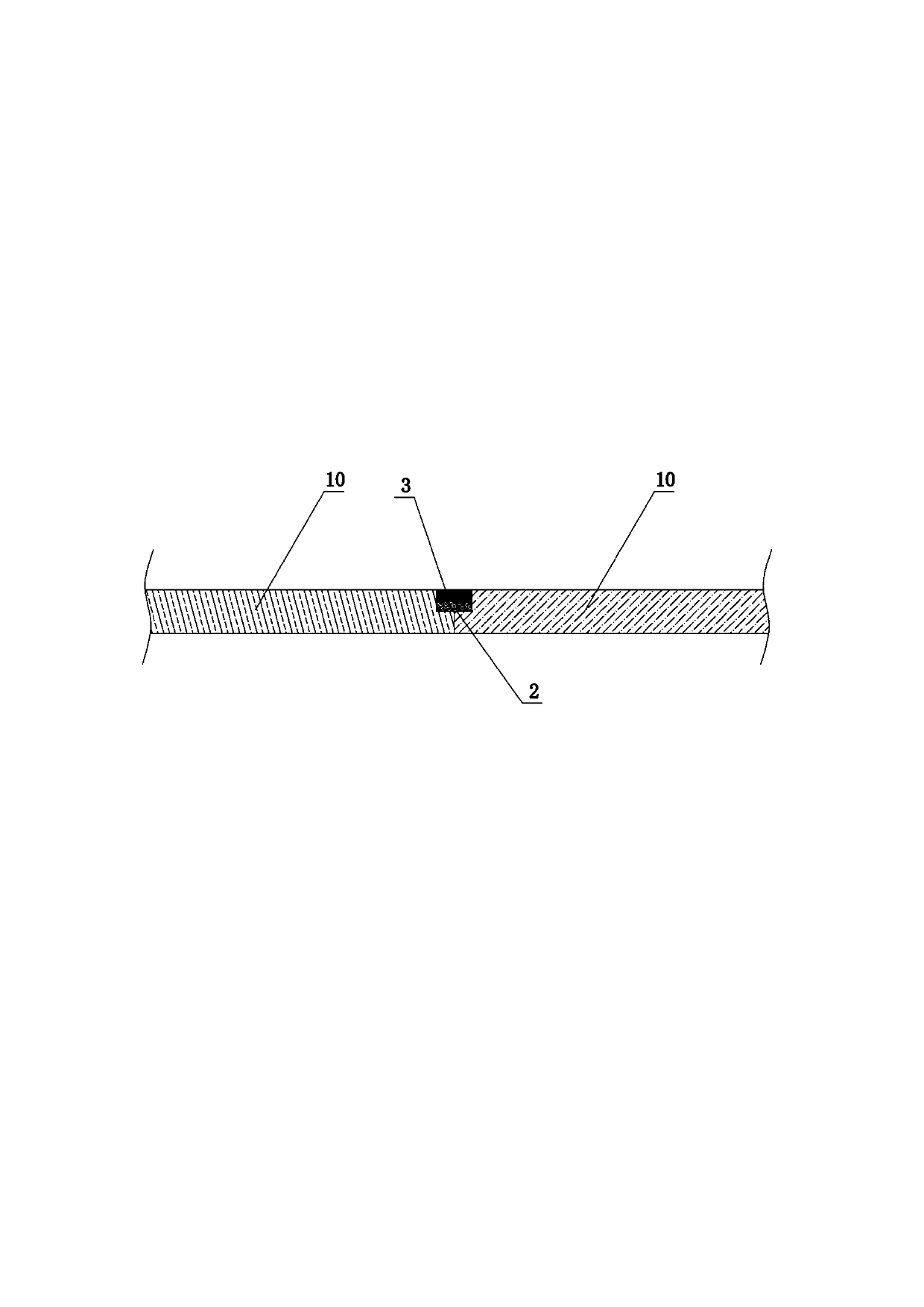

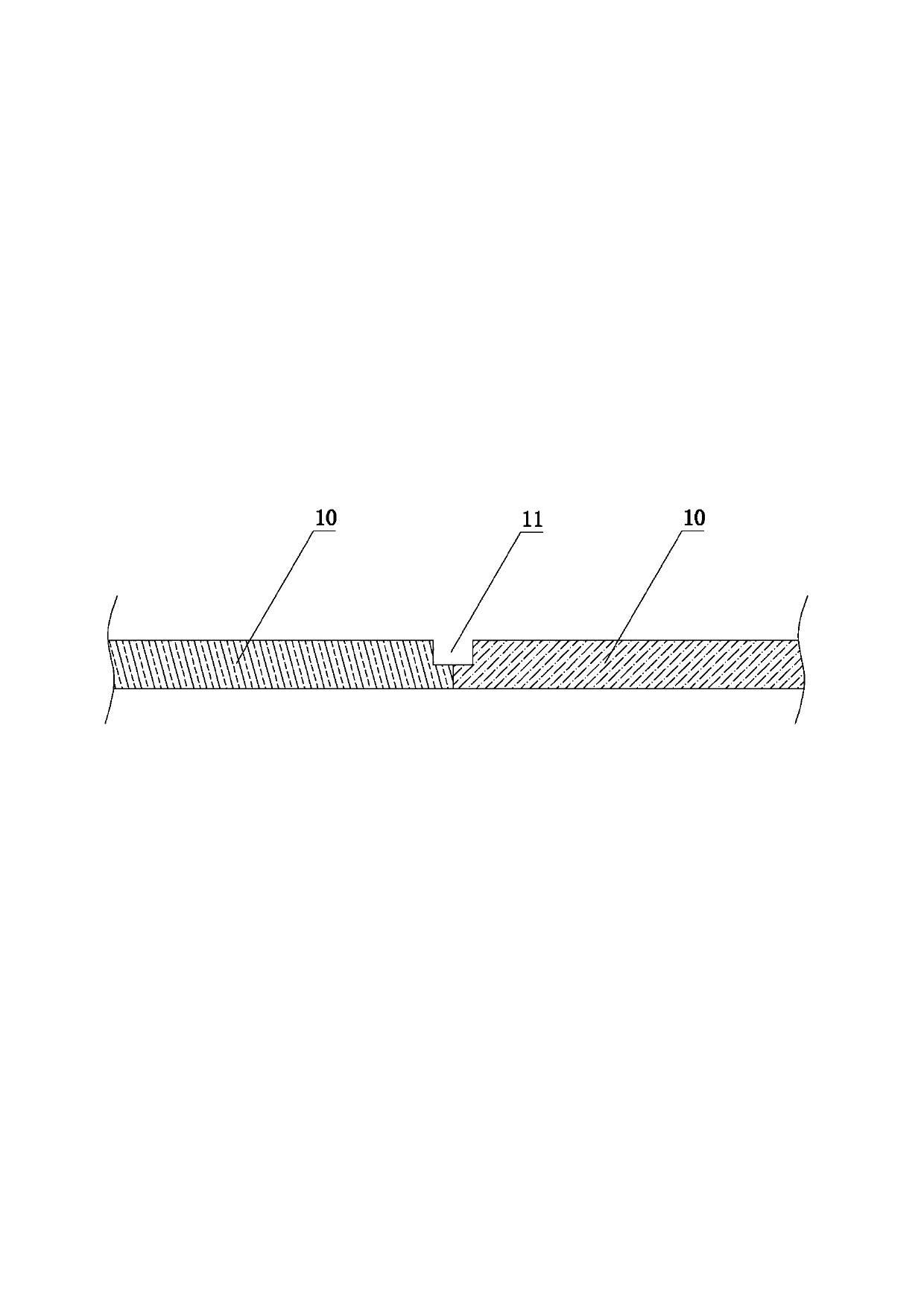

Splicing stone and splicing process

InactiveCN102717648AArt appreciation value is highTo beautifyCovering/liningsOrnamental structuresWhole bodyAdditional values

The invention provides a splicing stone, comprising a stone main body formed by splicing different block-shaped sheet materials with different patterns and further comprising decorative moldings, wherein grooves adapted to the decorative moldings are arranged on all splicing seams on the upper surface of the stone main body; the decorative moldings are formed in the grooves through utilizing a manner of electroplating or spraying paint or chemically plating or embedding gold; and transparent protection layers can be coated on the upper surfaces of the decorative moldings. After the block-shaped sheet materials with the different patterns are spliced to form the stone main body, all the splicing seams on the upper surface of the stone main body are further subjected to beautifying treatment; glue in the splicing seams on the upper surface of the stone main body can be better covered up and a certain separation effect on a color difference of the stone main body exists; and a range of selecting materials is improved and the decorative moldings have beautifying and decoration effects on the splicing stone, so that the total body of the splicing stone can be more beautiful and the additional value of a product is further improved.

Owner:FUJIAN XISHI

Simulative electric fireplace

ActiveCN104697026AColorfulStrong visual impactDomestic stoves or rangesElectrical heating fuelElectricityEngineering

The invention provides a simulative electric fireplace. The simulative electric fireplace comprises a fireplace bin, the back of the fireplace bin is provided with a stereoscopic flame screen, a dynamic flame generator is arranged behind the stereoscopic flame screen, and a light emitter is arranged at the bottom of the dynamic flame generator; a simulative carbon bed is arranged at the bottom of the fireplace bin and coupled to the stereoscopic flame screen. In the fireplace bin, people can see the completely stereoscopic carbon bed protruding in front of the stereoscopic flame curtain and stereoscopic and multilayer flame, smoke and sparks spurious and elegant behind and above the simulative carbon bed. Images on the stereoscopic flame screen are distinct and bright in color visually and have high vision impact force and looks real, vivid and obvious and quite high artistic appreciation value.

Owner:东莞市智桥电器制造有限公司

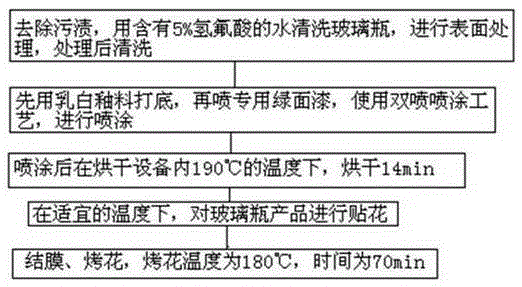

Novel spraying manufacturing process of glass bottles

InactiveCN105252946AHigh degree of simulationSensory grade improvementDecorative surface effectsIron contentMaterials science

A novel spraying manufacturing process of glass bottles comprises the steps of (1), carrying out preparation before spraying, wherein the transparent semi-finished glass bottles with the iron content smaller than or equal to 0.055% are selected, dirt on the glass bottles are removed, water containing 5% of hydrofluoric acid is used for cleaning the glass bottles and the glass bottles continue being cleaned after the treatment; (2), spraying semi-finished products, wherein milky-white glazes and green glazes are selected, the milky-white glazes are used for priming, the green glazes are sprayed as finish paint, and the double-spraying process is adopted in spraying; (3), drying the glass bottles, wherein the glass bottles are dried in drying equipment; (4), sticking decorations to the glass bottles, wherein the decorations are stuck to the glass bottles at appropriate temperature; (5), firing the decorations, after the decorations are stuck, film combining and decoration firing are carried out on the products. By applying the novel spraying manufacturing process to white spirit bottle production, the produced products are high in simulation degree and can simulate jade, stone, wood, copper and the like, and the appearance grade of the products is obviously improved compared with existing common products. In addition, the produced glass bottles are high-value-added products, and the economic benefit of each bottle can be increased by 0.5-1.5 yuan.

Owner:SHANDONG JINGFENG GLASS TECH CO LTD

Production method of sculpture art work embossed painting ceramic railing product

The invention relates to a production method of a sculpture art work embossed painting ceramic railing product. The production method comprises the following steps: mixing ceramic gypsum powder with water to solidify and form cement-like material, then using the material to prepare the two tetrahedronal ends of a railing, separately installing one or a plurality of circular arc, flat circular arc or square arc bosses on the connection part of each circular arc, flat circular arc or square arc transitional surface and each tetrahedron, wherein the medium-end of the ceramic railing is a cylinder with unequal diameters or a rectangular brick shaped cylinder or a flat cylinder; after preparing a railing model, using sodium silicate to taste carved oil soil on the railing model, sculpturing or curving embossments; or designing a 'Riverside Scene at Qingming Festival' picture according to a drawing, using ceramic carved oil soil to carefully sculpturing characters, animals, birds and flowers, landscapes and other clay shapes, after sculpturing, and using sodium silicate for ceramic or other glues to taste the sculptures on the ceramic railing gypsum model according to the patterns on the drawing and the pattern sequence to prepare the embossed railing model with an embossed painting.

Owner:谢礼荣

Third-dimensional ecologic wallpaper and exterior wall tile

The invention relates to a third-dimensional ecologic wallpaper and an exterior wall tile. The formula of the third-dimensional ecologic wallpaper and the exterior wall tile comprises, by mass, 20-99% of rubber, 1-50% of a flame retardation material, 1-75% of stone sand or powder, 1-10% of a pigment, 0.5-30% of a curing agent, 1-50% of an assistant, and 1-75% of fiber or rice straw analog filler; or comprises, by mass, 1-99% of flexible resin, 1-99% of rigid resin, 1-50% of the flame retardation material, 0.5-60% of the curing agent, 1-50% of the assistant, 1-10% of the pigment, 1-75% of stone sand or powder analog, and 1-75% of the fiber or rice straw analog filler. The wallpaper and the exterior wall tile have the advantages of temperature toleration, good flame retardation performance, certain artistic appreciating values, extremely less pollution discharge and electricity consumption due to no traditional printing or gas combustion technologies in the production process, recycling, safety, low carbon and environmental protection.

Owner:惠州市创鑫隆实业有限公司

Potted landscape apple word sticking technology

InactiveCN1830240AMany patternsGood effectDecorative surface effectsCultivating equipmentsBonsaiFruit tree

A technique for sticking the word or character on the surface of apple fruit growing in pottery pot includes such steps as choosing the high-quality apple fruit borne on the branches facing south or southwest, carving words or characters or pattern on color paper, sticking the carved paper on the surface of chosen apple fruits, applying organic fertilizer, and spreading optically reflecting film around the apple tree.

Owner:燕兴华

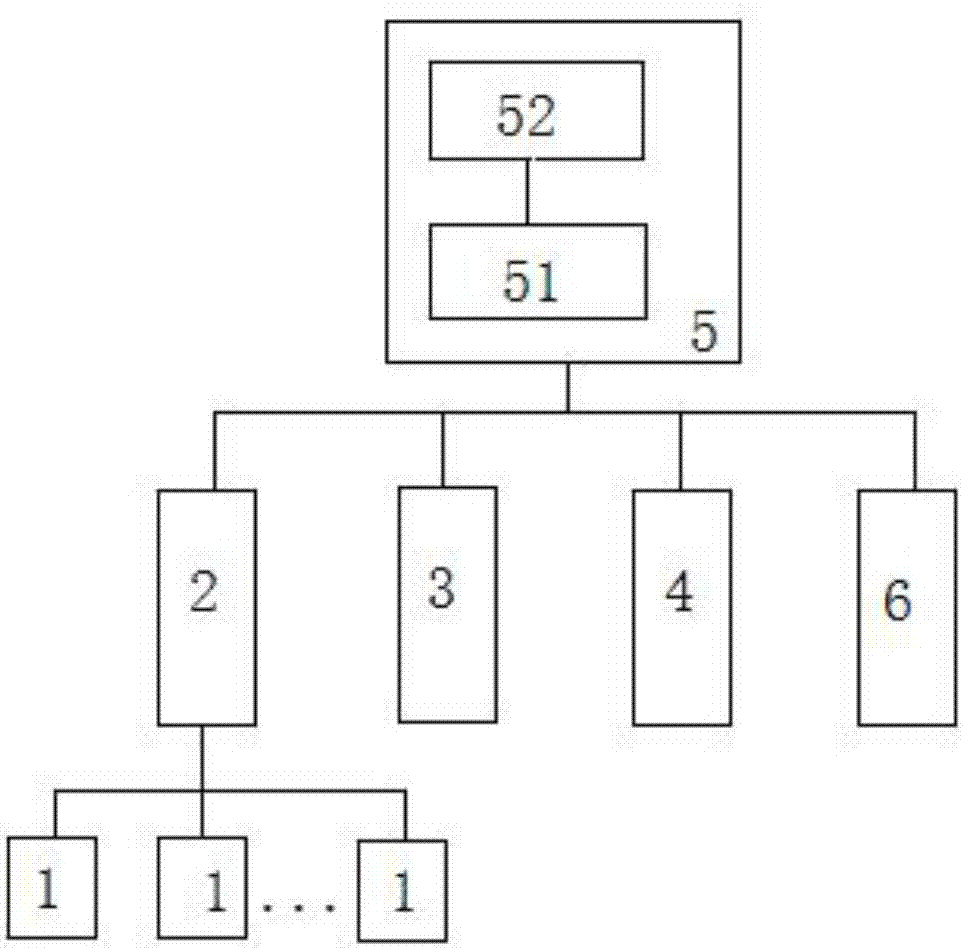

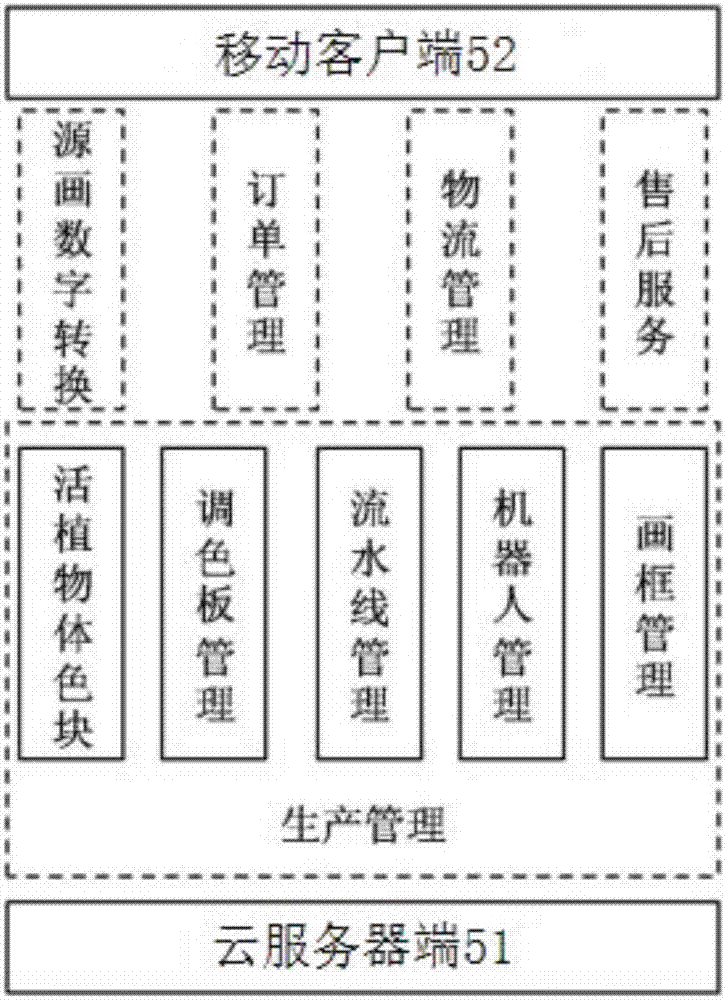

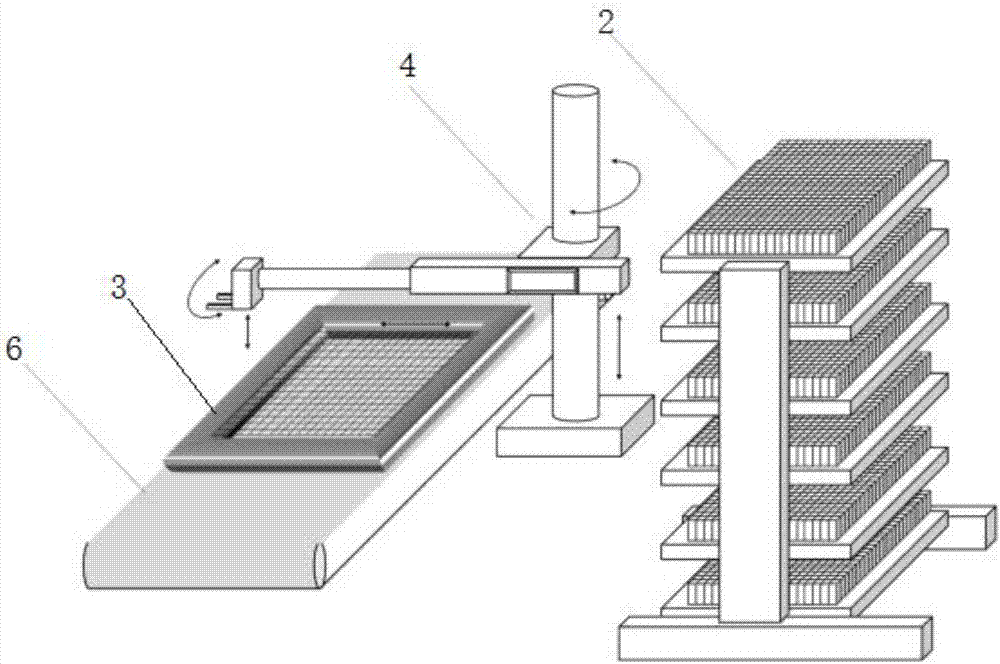

Live plant body coding artistic picture production system and method

PendingCN107221003AIncrease productivityFunction increaseProgramme-controlled manipulatorImage analysisComputer graphics (images)Vision sensor

The present invention discloses a live plant body coding artistic picture production system and method. The system comprises unit live plant body color lumps, a live plant body color palette module, a frame module, a drawing robot and a management system. The unit live plant body color lumps are standard-size single-color plants arranged in the live plant body color palette module; A plurality of spaces with standard sizes capable of holding unit live plant body color lumps are arranged at the live plant body color palette module and the frame module in the uniform array arrangement mode; and the drawing robot has a vision sensor which is in communication connection with the management system and is configured to receive an instruction of the management system select the unit live plant body color lumps with colors according with the requirements from the live plant body color palette module and take out and accurately put the unit live plant body color lumps to an assigned position in the frame module. The single-color plants are subjected to standardization and are taken as the minimum unit pixels of the artistic picture to drive the drawing robot to employ the color palette module to complete the live plant body copy of the artistic picture so as to realize combination of the painting art and industrialization greening product production technology.

Owner:太微恒道新科技(深圳)有限公司

Application of pearl glaze or flash glaze or pearl essence in preparing ceramic handrail

The invention relates to application of pearl glaze, glisten glaze or pearl powder during the production of ceramic railing and pertains to the technical field of building material. Pearl glaze and turpentine are mixed according to the ratio of 1:2, glisten glaze and turpentine are mixed according to the ratio of 1:0.5 and pearl powder and hand drawing oil are mixed according to the ratio of 1:1, all applied to the treatment raw materials of the surface of the ceramic railing. Then the raw materials are respectively coated on the ceramic railing on normal way, the ceramic railing coated with the raw materials is put in a normal curing device, cured for 3-4h under the temperature of 700-800 DEG C and cooled, then ceramic railing with pearl glaze, glisten glaze or pearl powder is obtained. The method has the advantages of simple preparation, broadening the application of pearl glaze, glisten glaze or pearl powder and endowing the product with novel appearance, various colors and more artistic appreciation value. The invention can be widely applied to ceramic railing of various structures.

Owner:谢礼荣

Novel silk floss stereograph making method

ActiveCN104401173AWide variety of sourcesSimple processSpecial ornamental structuresFiberEngineering

The invention discloses a novel silk floss stereograph making method. Secondary innovation is carried out on the basis of an original fiber stereograph provided by the inventor, the defect that certain detail parts, such as water waves and hair can only be presented by a plain line technology in the traditional technology is overcome, plain lines are changed into a wavy form through carrying out technology processing improvement by an innovation technique, and the artistic presentation form is more natural, vivid and stereoscopic. The original slightly stiff artistic creation technique is replaced, the detail presenting style of the fiber stereograph is more perfect and layered, and the figure of the whole picture looks more natural and soft. The technology is low in cost and simple in stereograph making, but the practicability is strong, and the artistic appreciation value of the silk floss stereograph is greatly improved. The novel silk floss stereograph making method can also be used for making various landscape paintings, figure paintings, animal paintings, artistic paintings and the like.

Owner:威海海依达斯文化产业发展有限公司

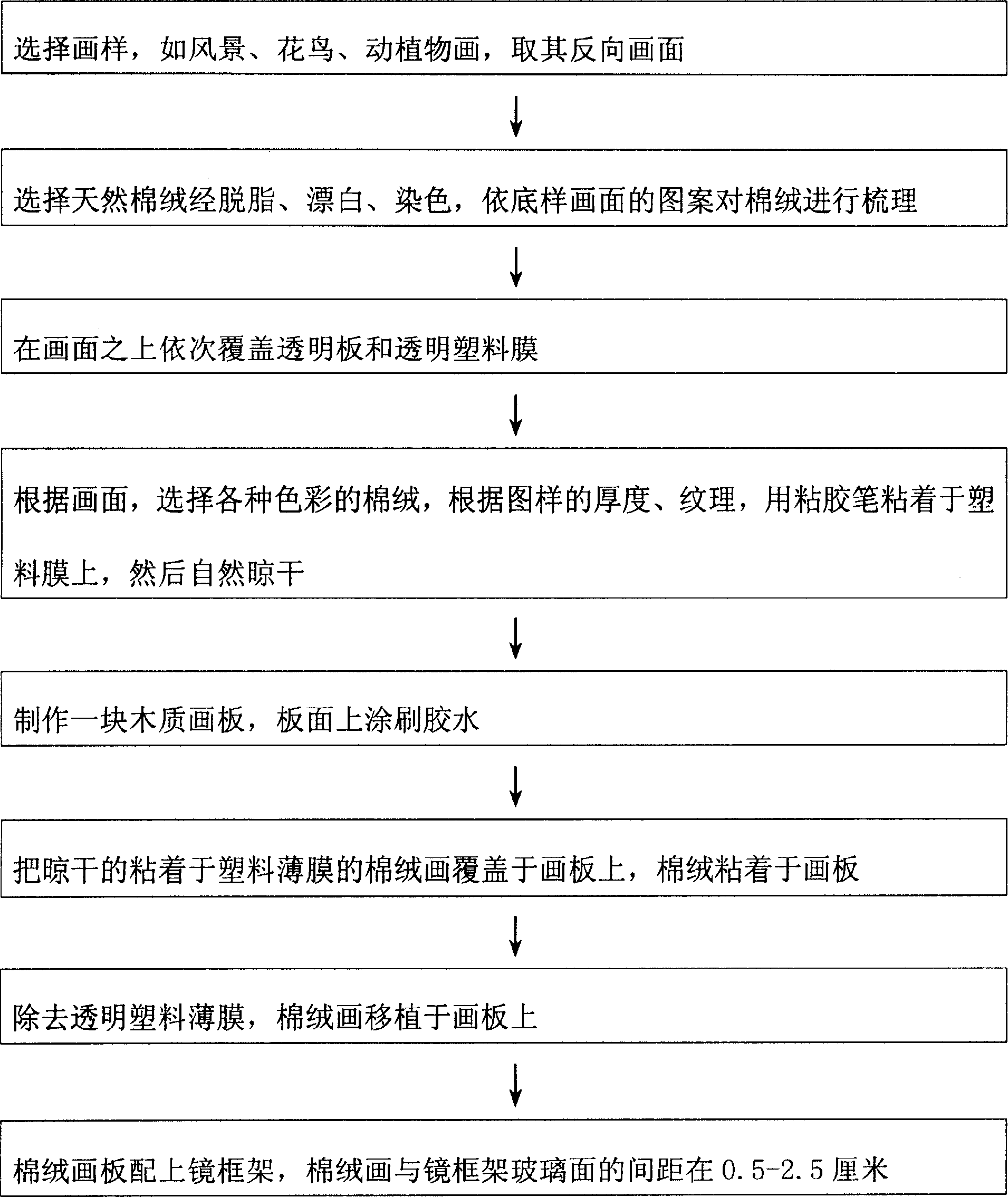

Manufacturing method of cotton flock picture

InactiveCN1785694ASimple and fast operationImprove ergonomicsSpecial ornamental structuresSpecial artistic techniquesManufacturing technologyEngineering

The present invention relates to a method for making cotton wool picture. Said method includes the following steps: selecting picture sample, using its reverse side surface; dyeing cotton wool and carding; on the picture surface successively laying a transparent plate and a layer of transparent plastic film; according to the pattern and colour of picture selecting cotton wool and making said cotton wool be adhered on the plastic film, and drying by airing; selecting a picture board and brushing viscose on the picture board; laying dried cotton wool picture on the picture board; removing plastic film and transplanting the cotton wool picture on the picture board.

Owner:陈方星

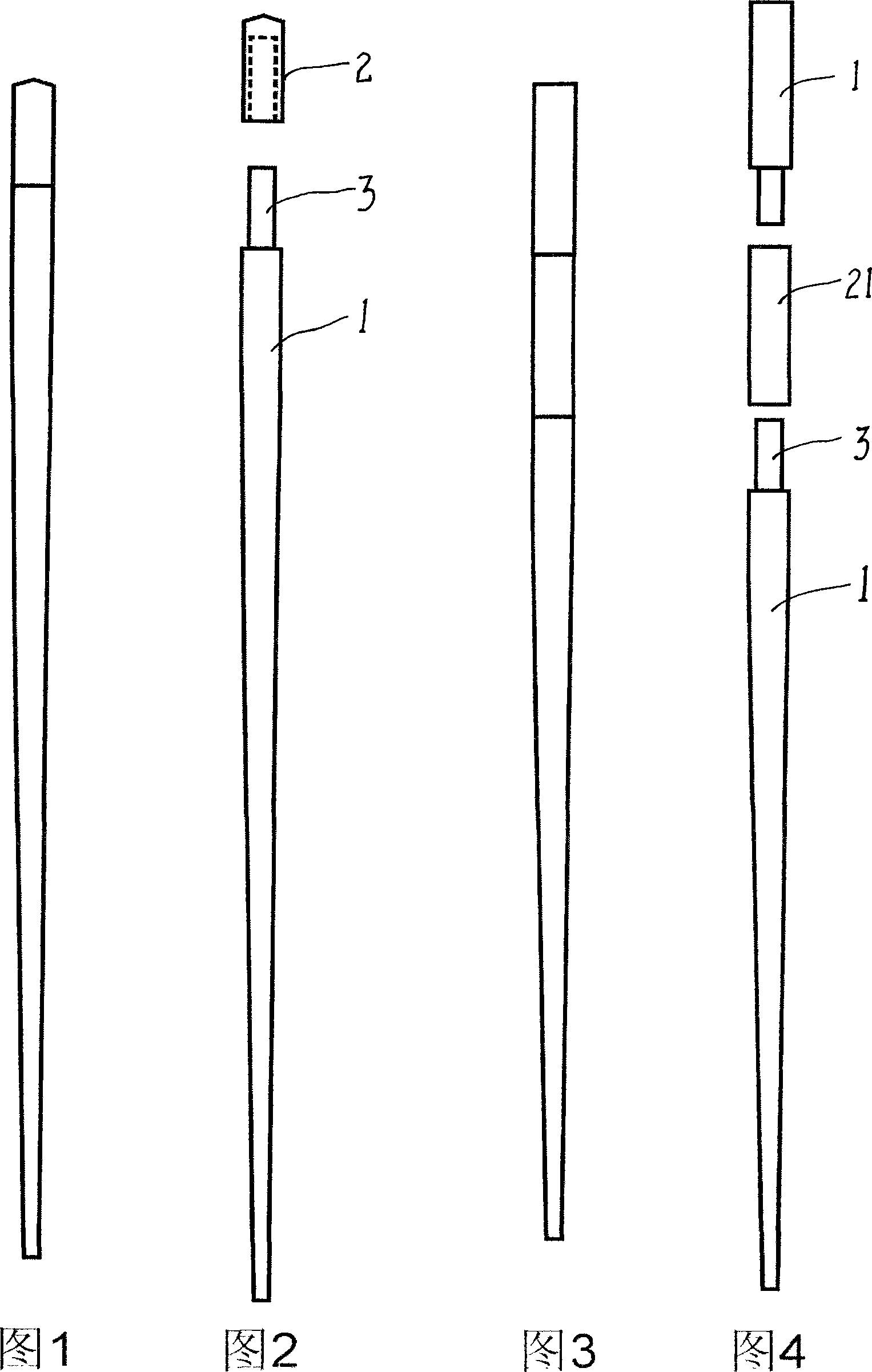

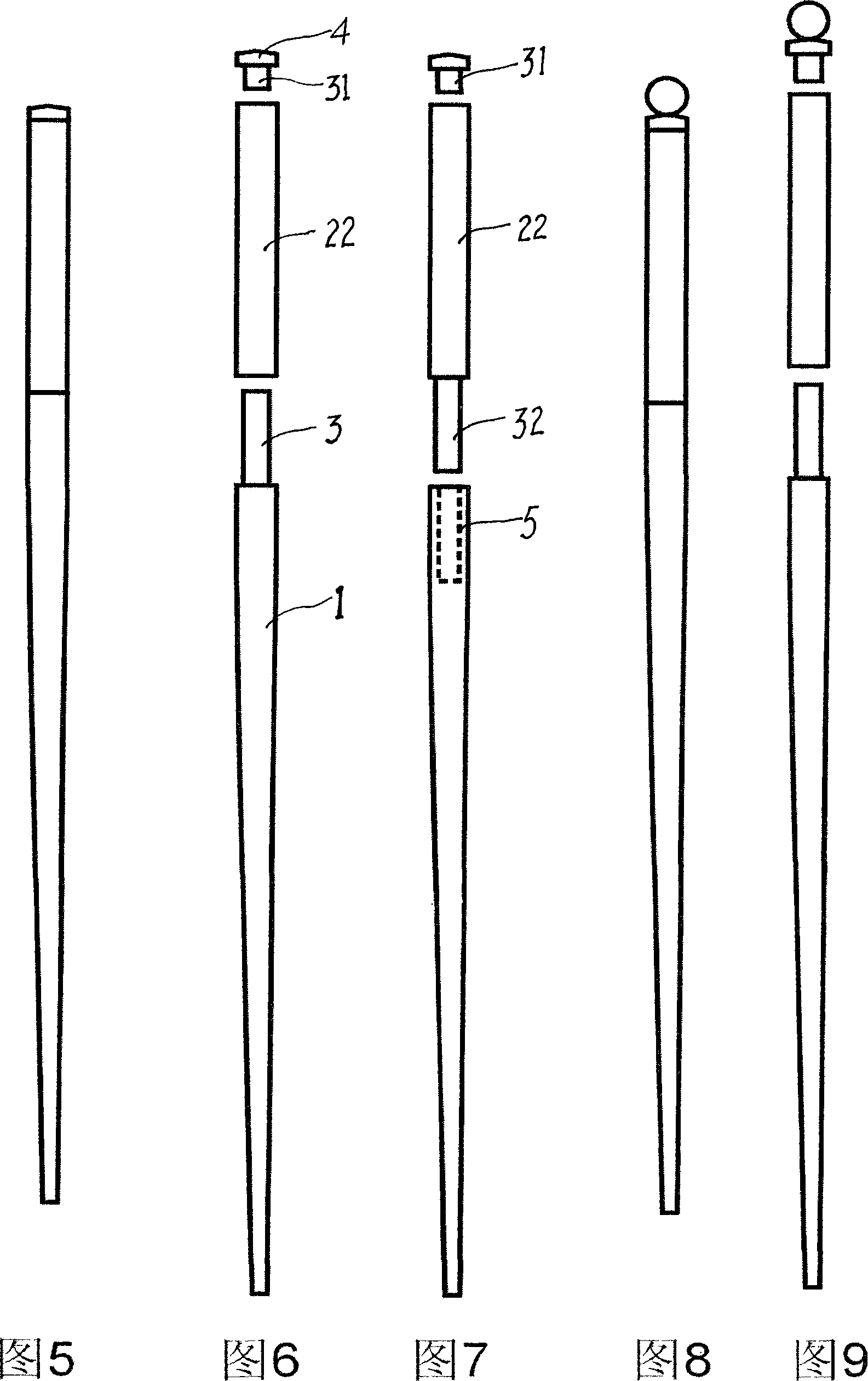

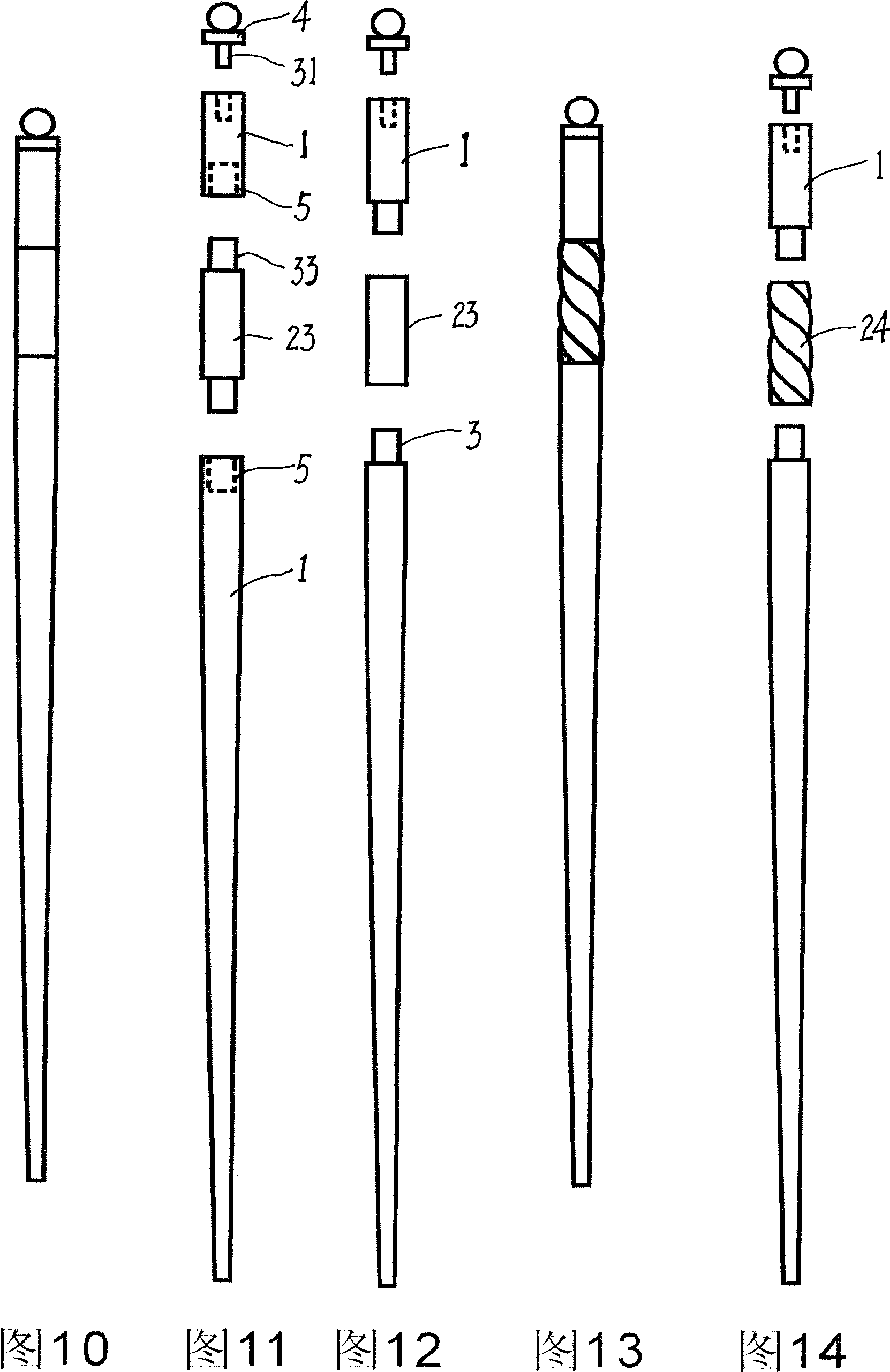

Fastening metal or nonmetal decoration chopstick

The present invention discloses a kind of chopsticks with metal or non-metal ornament. It is characterized by that every chopsticks is formed from chopstick head and chopstick body, on the middle position of chopstick body or on the position above middle portion of chopstick body one section or several sections of metal or non-metal ornaments can be firmly fixed, and the end portion of said chopstick body is equipped with a metal or non-metal chopstick head. Said invention is aimed at saving wood material. Besides, said invention also provides its concrete production method and steps.

Owner:马康

Green palm fan and manufacture method thereof

The invention discloses a green palm fan and a manufacture method thereof. Fresh palm leaves are blanched in boiling water containing zinc sulfate / ferrous sulfate and vitamin C, wherein an aqueous solution of the zinc sulfate / ferrous sulfate and vitamin C comprises following components: 79 parts of clear water, 20 parts of zinc sulfate / ferrous sulfate, and 1 part of vitamin C. Manufacture steps of the green palm fan include: cutting fresh palm leaves in fan shapes; washing and soaking the leaves in the clear water for 1 hour; placing the soaked palm leaves in the boiling water containing 20% zinc sulfate / ferrous sulfate and 1% vitamin C for 15-30 min; washing the blanched palm leaves with the clear water for 5 min; drying at 30-50 DEG C to a water content less than 10% after draining; tying edges with plastic and hemp; packaging. Chlorophyll formation character is stable, and chlorophyll zinc / chlorophyll iron in green color can well protect chlorophyll in the palm leaves so that the palm fan is green in a long time and better in artistic ornamental value.

Owner:罗福仲

Preparation method of honeysuckle tea

The present invention relates to a preparation method of honeysuckle tea. The preparation method includes the following specific steps: initially, honeysuckle buds in the mature period picked when dew is just dry in the sunny morning and selected, and the honeysuckle buds are filled in a bamboo made container; the honeysuckle buds are spread for cooling, de-enzymed, quickly cooled, spread in a baking pan, and continuously baked for three times to make the honeysuckle buds dried quickly, thereby obtaining the dried honeysuckle tea products; and finally, the dried honeysuckle tea products are tested with quality, color and uniformity as quality standards, and qualified honeysuckle tea products are weighed, packaged and put into a cold storage. The honeysuckle tea combines tea fragrance and flower fragrance together so that the tea fragrance induces the flower fragrance and the flower fragrance enhances the tea fragrance, complementing each other. The present invention aims to transform medicines into food so that people can drink the honeysuckle tea every day, playing disease-preventing and body-strengthening effects. The prepared honeysuckle tea is excellent in texture, superior in quality, rich in aroma and unique in shape, and has high economic and artistic appreciation value.

Owner:GUIZHOU JINGQIANCAO BIOTECH CO LTD

A simulated electric fireplace

ActiveCN104697026BColorfulStrong visual impactDomestic stoves or rangesElectrical heating fuelElectricityEngineering

The invention provides a simulative electric fireplace. The simulative electric fireplace comprises a fireplace bin, the back of the fireplace bin is provided with a stereoscopic flame screen, a dynamic flame generator is arranged behind the stereoscopic flame screen, and a light emitter is arranged at the bottom of the dynamic flame generator; a simulative carbon bed is arranged at the bottom of the fireplace bin and coupled to the stereoscopic flame screen. In the fireplace bin, people can see the completely stereoscopic carbon bed protruding in front of the stereoscopic flame curtain and stereoscopic and multilayer flame, smoke and sparks spurious and elegant behind and above the simulative carbon bed. Images on the stereoscopic flame screen are distinct and bright in color visually and have high vision impact force and looks real, vivid and obvious and quite high artistic appreciation value.

Owner:东莞市智桥电器制造有限公司

Ceramic and production process thereof

The invention discloses ceramic and a production process thereof. A blank is made from, by weight, 10-20 g of lead boron frit, 8-15 g of material soil, 15-28 g of calcite, 30-40 g of albite, 10-20 g of potassium feldspar, 10-20 g of quartz, 5-12 g of iron oxide red and 1-5 g of titanium. The production process includes: smashing the lead boron frit, the material soil, calcite, albite, potassium feldspar, quartz, iron oxide red and titanium in a smasher, and grinding through a ball grinder; using a magnet to remove iron therein, adding an electrolyte, stirring to form grout, and performing slip casting; drying, blank hanging, and drying to obtain the blank; biscuiting, glazing, and firing for 8-10h at high temperature of 1210 DEG C to obtain a finished product. The ceramic and the production process have the advantages that the finished product obtained through the formula and the process is stable in structure, less prone to breakage and uniform in color and luster; resource waste is avoided greatly, and cost saving of enterprises is facilitated; the product has high art appreciation value as artware, so that added value of the product is increased.

Owner:长沙市望城区铜官窑承林陶艺有限公司

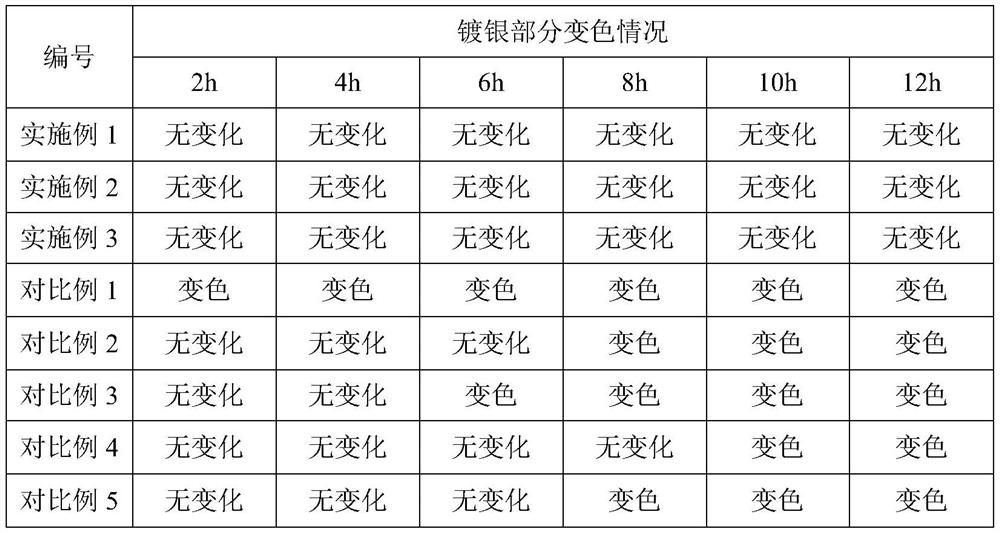

Manufacturing method for silver-plated decorative picture carved in glass

InactiveCN112776525AArt appreciation value is highExpressiveDecorative surface effectsThree-dimensional effectsPrinting inkSilicone tape

The invention discloses a manufacturing method for a silver-plated decorative picture carved in glass. The manufacturing method comprises the following steps of: (1) brushing anti-corrosion printing ink on a part, except for a part needing to be etched, of a glass substrate; (2) immersing the glass substrate into an etching solution for etching; (3) pasting the part with the anti-corrosion printing ink by using an anti-corrosion adhesive tape; (4) plating the etched part with silver; (5) cleaning the silver-plated glass substrate, then soaking the silver-plated glass substrate in a corrosion inhibition solution, and taking out the silver-plated glass substrate for drying; (6) removing the anti-corrosion adhesive tape, and soaking the glass substrate in a sodium hydroxide solution to remove the anti-corrosion printing ink; (7) cleaning and drying the glass substrate; and (8) pasting a picture core on one side, carved and plated with the silver, of the glass substrate, and assembling a picture frame. According to the manufacturing method, the glass substrate subjected to internal carving etching and silver plating is combined with the picture, so that the three-dimensional effect of the decorative picture is improved, the decorative picture is endowed with layering sense, and a product form and the visual effect of the glass decorative picture are enriched.

Owner:浙江天画家居用品有限公司

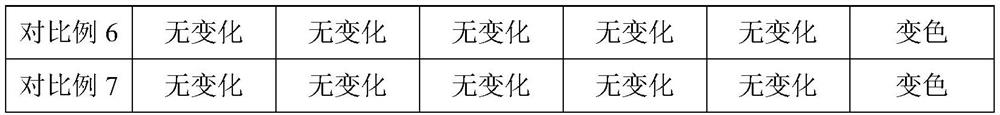

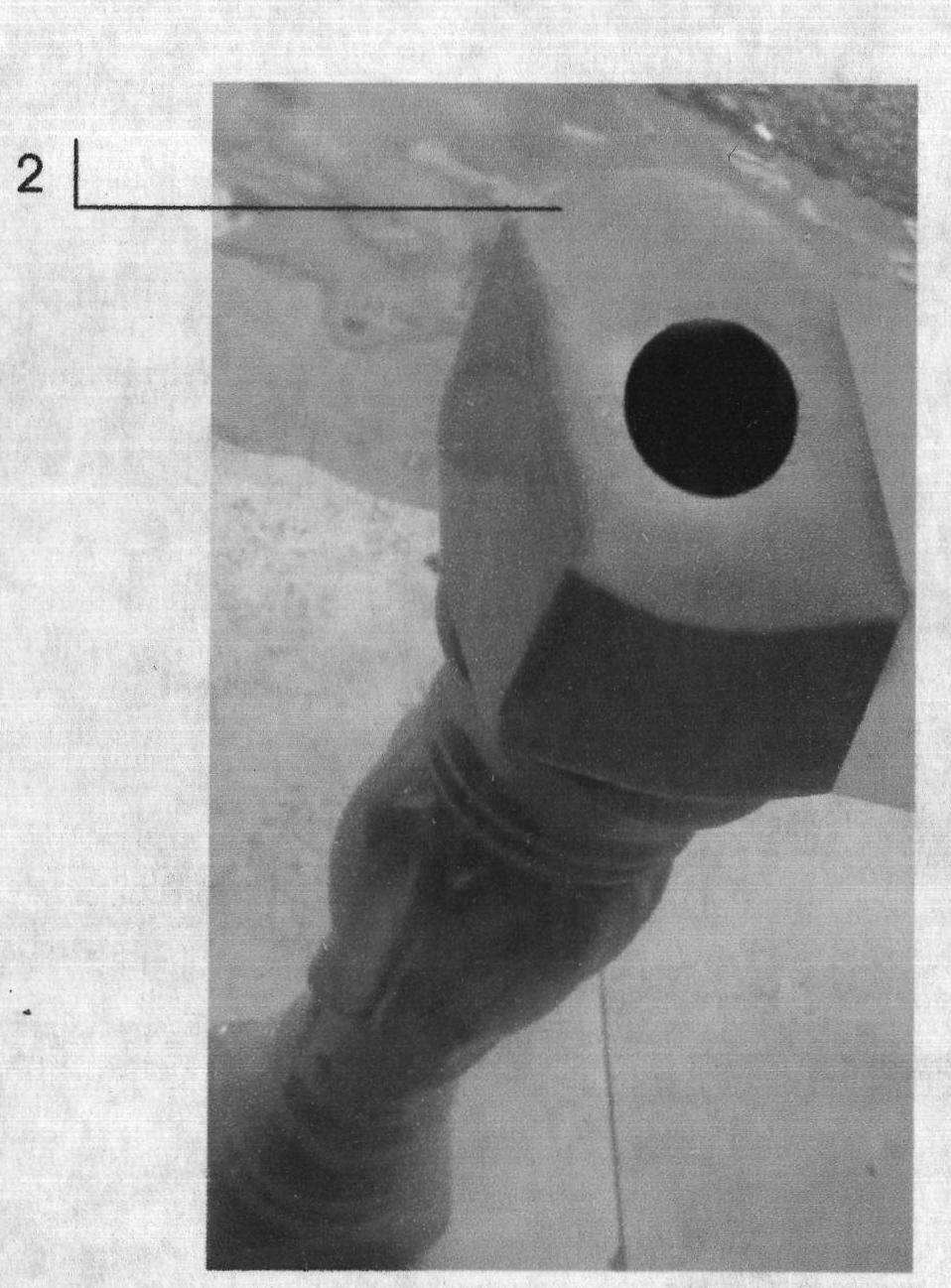

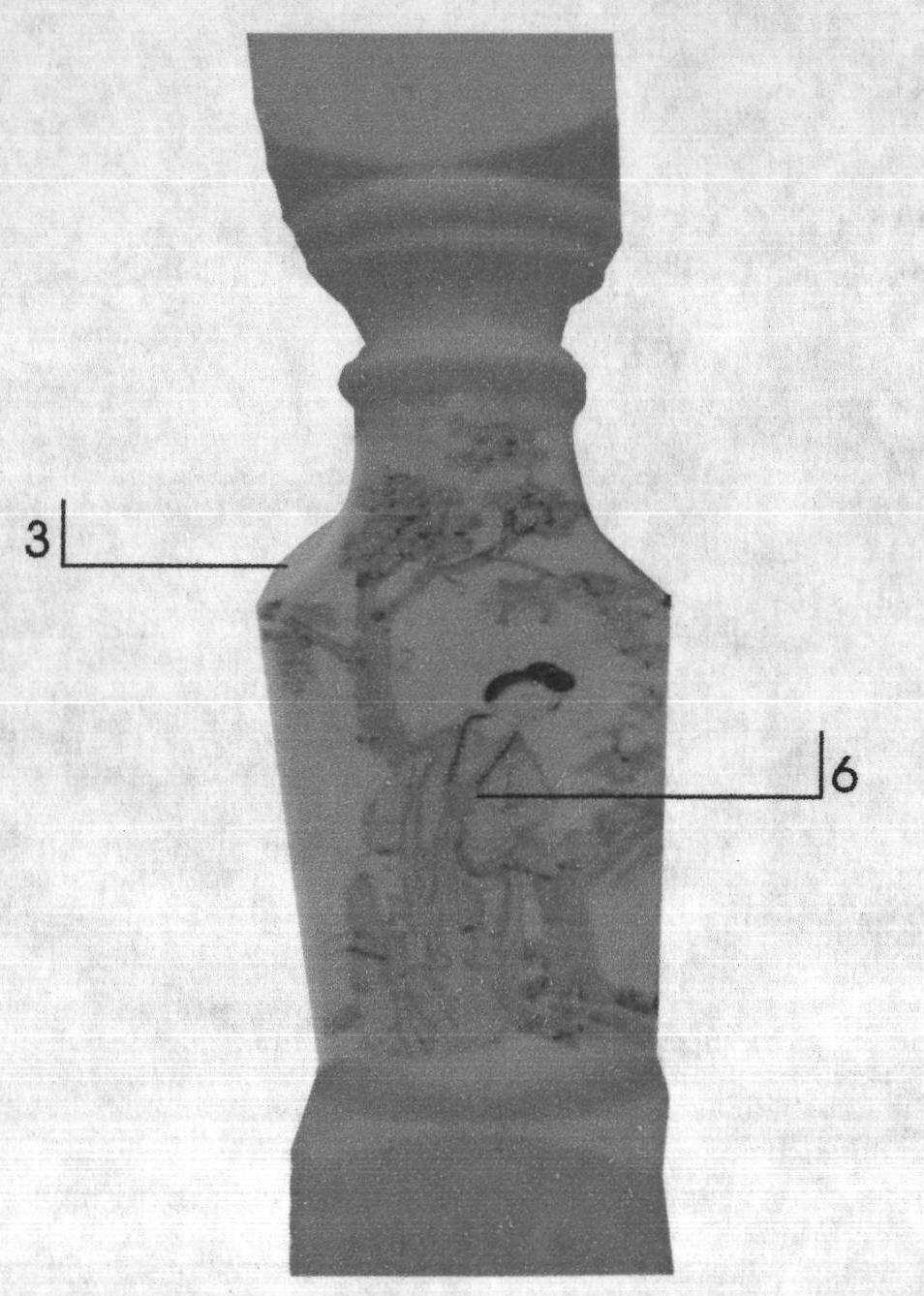

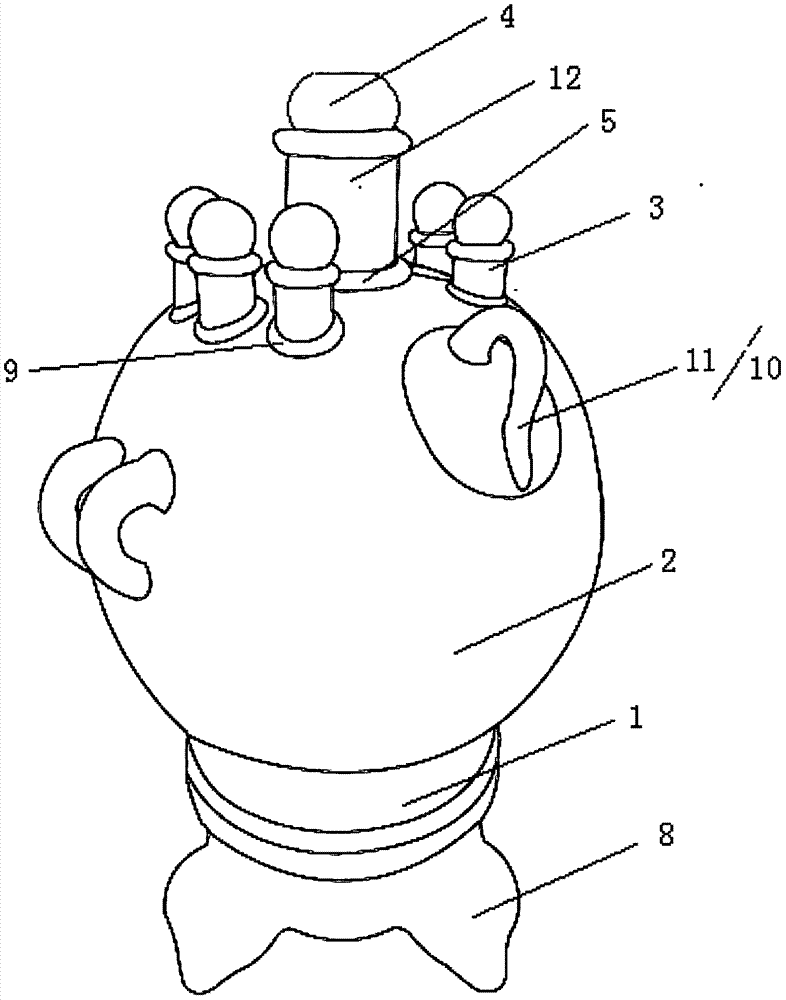

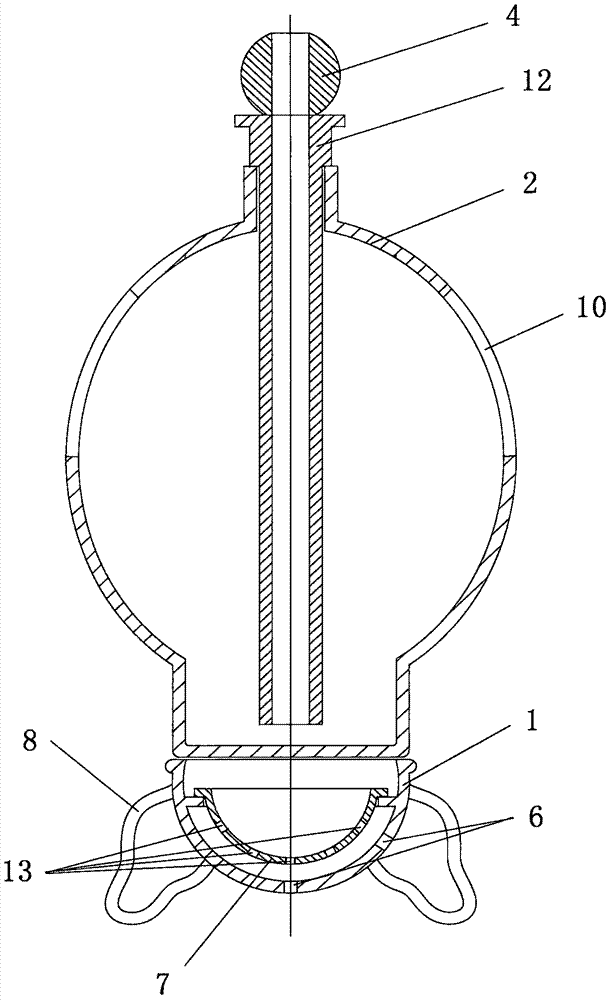

Ceramic rail with balanced compression force and without deformation through calcination

InactiveCN101798859ANovel structureArt appreciation value is highFencingSpecial ornamental structuresTetrahedronMiddle segment

The invention relates to a ceramic rail with balanced compression force and without deformation through calcination. The rail is hollow; the connecting parts at the upper and lower ends of the rail are oblong or square tetrahedron; tetrahedral concave, circular arc-shaped, oblate arc-shaped or square arc-shaped bosses are arranged on the parts connected with the tetrahedron respectively via circular arc-shaped, oblate arc-shaped or square arc-shaped transitional surfaces; the middle end of the ceramic rail is provided with an oblong tetrahedron or is brick-shaped; artistic embossed paintings are sculptured or engraved on the middle end segment; the front middle segment is an oblong tetrahedron; and gambir plant like clouds can be sculptured or engraved at the two sides of the rail for decoration purpose. The embossed paintings can be the embossed figure and scenery paintings such as On the Riverside Scene of Pure Brightness, Eight Immortals Crossing the Sea and Guanyin Song Zi, the embossed animal paintings such as Peacock Spreading its Tail and Rampant Dragon Spiralling up the Columns, embossed flower, bird and insect paintings such as Peony Blooms or embossed landscape paintings such as Qifengjiajing.

Owner:谢礼荣

Application of noctilucent pattern enamel firing paper to ceramic products manufacture

The invention relates to application of luminated patterns decorating firing paper to the ceramic product manufacture, belonging to the building material technical field. The luminous powder sold in market is added into the paint of the universal printed pattern; 10 to 90 percent by weight percentage of the luminated powder and 10 to 90 percent of the universal printed pattern paint are mixed; the mixed paint is printed into pattern decorating firing paper containing luminous powder by the conventional printing method; the pattern decorating firing paper is stuck on a ceramic product coated by pearl glaze or not coated by pearl glaze, which is the application of the surface pattern of the ceramic product. The application has the advantages that the preparation method is simple, the application of the luminous powder is widened, the product of the luminous powder is used to absorb light and accumulate light during the day and to release the light source naturally at night; and the product not only has novel appearance, gorgeous colors and high artistic appreciation value but also has the illumination function of a midget lamp.

Owner:谢礼荣 +1

Potted landscape apple word sticking technology

InactiveCN100433968CMulti-pattern modelingA variety of multi-pattern shapesDecorative surface effectsCultivating equipmentsFruit treeOrganic fertilizer

Owner:燕兴华

Ceramic and production technology thereof

The invention discloses ceramic and a production technology thereof. Greenware is prepared from, by weight, 25-35 g of lead-boron frit, 10-20 g of red lead, 20-29 g of quartz, 8-15 g of granular soil, 5-15 g of calcite, 30-40 g of iron oxide red and 3-8 g of titanium. Lead-boron frit, red lead, quartz, granular soil, calcite, iron oxide red and titanium are ground by a ball mill after being smashed in a smashing machine, iron in the mixture is removed through a magnet, electrolyte is added to be stirred to form slurry, slurry casting is conducted, the greenware is prepared through drying, greenware hanging and re-drying, then the product is sintered for 8-10 h at the high temperature of 1210 DEG C after biscuiting and glazing, and the finished product is obtained. The method has the advantages that the finished product prepared through the formula and the technology is stable in structure, not easy to damage and uniform in gloss; resource waste is greatly avoided, and cost is reduced for enterprises easily; artistic ornamental value of the product is high as artware, and additional value of the product is increased.

Owner:长沙市望城区学宇陶瓷文化传播有限公司

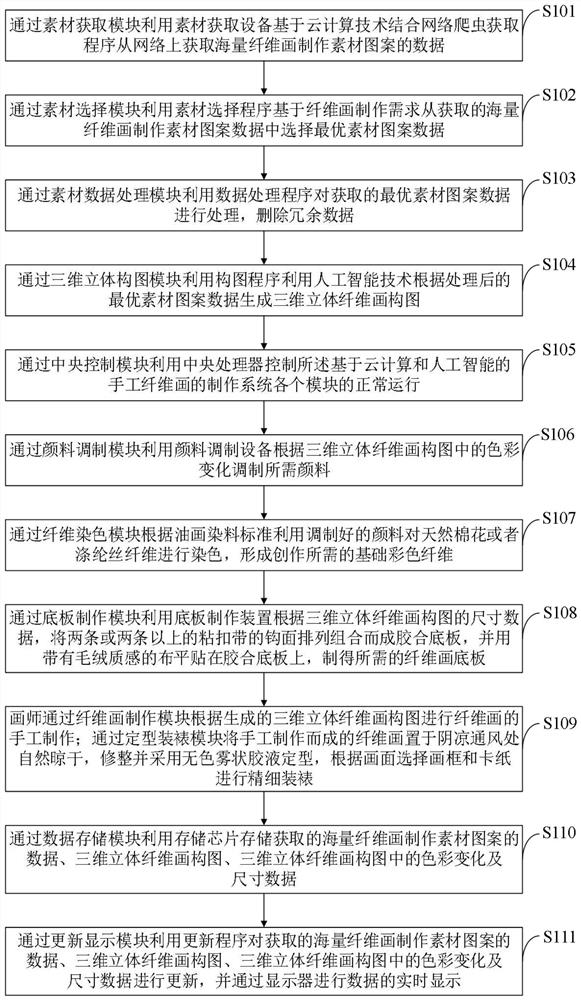

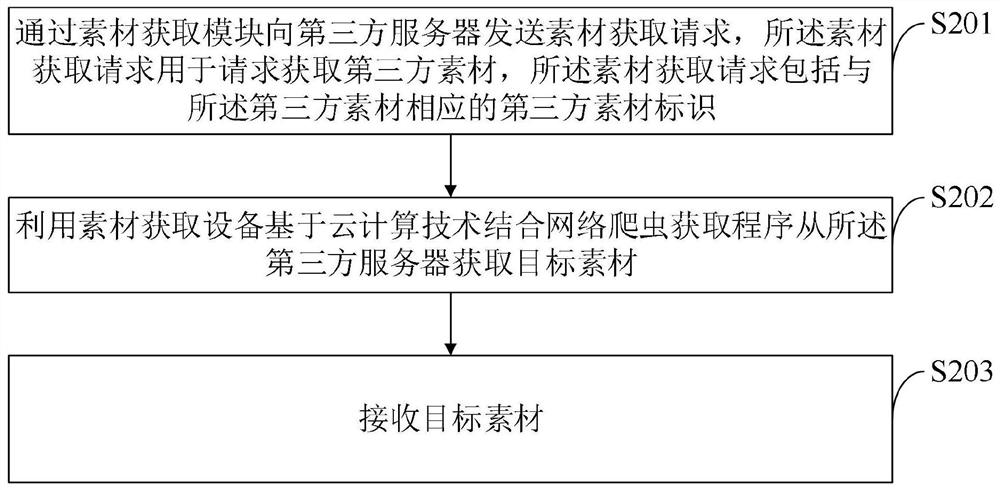

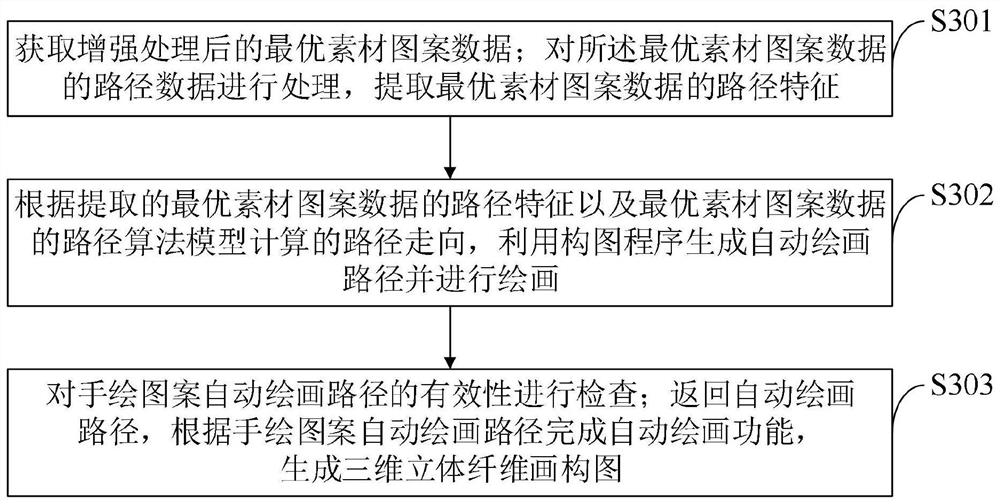

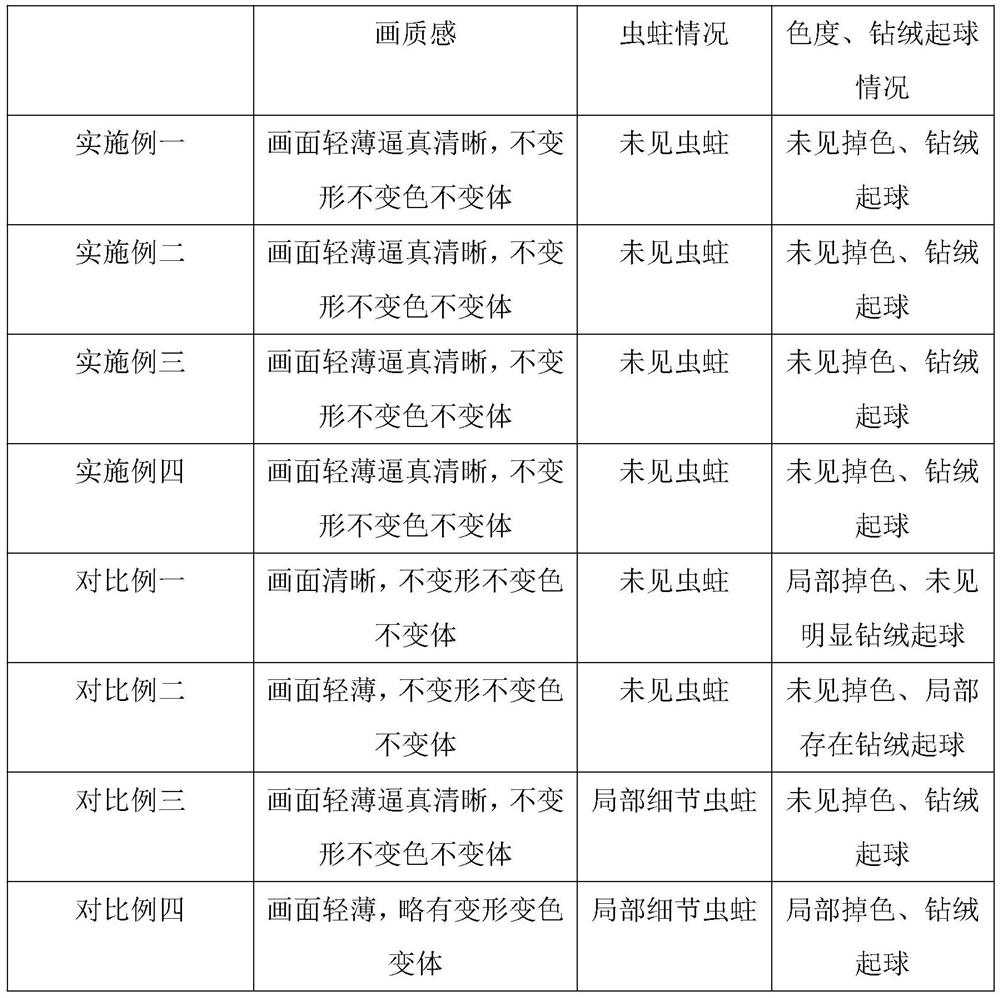

Manufacturing method and manufacturing system of handmade fiber painting, terminal and storage medium

PendingCN112148944AExtensive sources of materialsWide variety of sourcesWeb data indexingSpecial data processing applicationsPolyesterProcess engineering

The invention belongs to the technical field of fiber picture manufacturing, and discloses a manual fiber picture manufacturing method and system, a terminal and a storage medium. The method includes:obtaining data of a mass of fiber painting manufacturing material patterns; selecting optimal material pattern data; processing and deleting redundant data; generating a three-dimensional fiber picture composition; modulating the color change in the generated three-dimensional fiber picture composition to obtain a required pigment; and dyeing natural cotton or polyester silk fibers by using the prepared pigment according to the oil painting dye standard to obtain basic color fibers required by creation. Massive fiber painting manufacturing materials are obtained from a network, the material source is wide, and the selectivity is high; complete drawing of the hand-drawn pattern can be continuously completed through the three-dimensional composition module according to the existing line style and the path trend calculated in the model, and the method is simple and easy to implement; and through the fiber picture manufacturing module, details of the whole picture can be more vivid, and the stereoscopic impression is stronger.

Owner:XIJING UNIV

Manufacturing method of cashmere painting

ActiveCN111942072AClear and light picture qualityEasy to carrySpecial ornamental structuresDyeing processDiammonium phosphateWool

The invention relates to the technical field of cashmere painting manufacturing, in particular to a manufacturing method of a cashmere painting. The method overcomes the defects that in the prior art,the overall picture of the cashmere painting is not smooth, the phenomena of wool leaking and pilling exist, the picture texture is not strong, and the painting is not easy to mount. The method comprises the following steps that a pattern is selected, and meanwhile, 1436 cashmere is selected as a raw material for spinning; plant dyeing is carried out, and diammonium phosphate is added into a dyeing tank after dyeing is completed; silk yarns are utilized as warps and wefts; after the overall manufacturing is completed, embroidering is carried out on the overall picture and detailed parts, andafter completion, triethylene glycol is sprayed to the surface of the picture; and then sewing, crispening, shearing, fulling, wool picking, ironing, painting trimming, and composite working procedurefinishing are carried out, and finally, forming is carried out to obtain the cashmere painting. According to the method, by means of the working procedures of priming, embroidering, sewing, crispening, painting trimming, shearing, fulling, wool picking, ironing, insect prevention, dust removal, painting ironing, compounding, mounting and the like, the problems of picture pilling, wool leaking andthe like are solved, the picture texture is clear, light and thin, and the painting is easy to carry and mount.

Owner:康兰

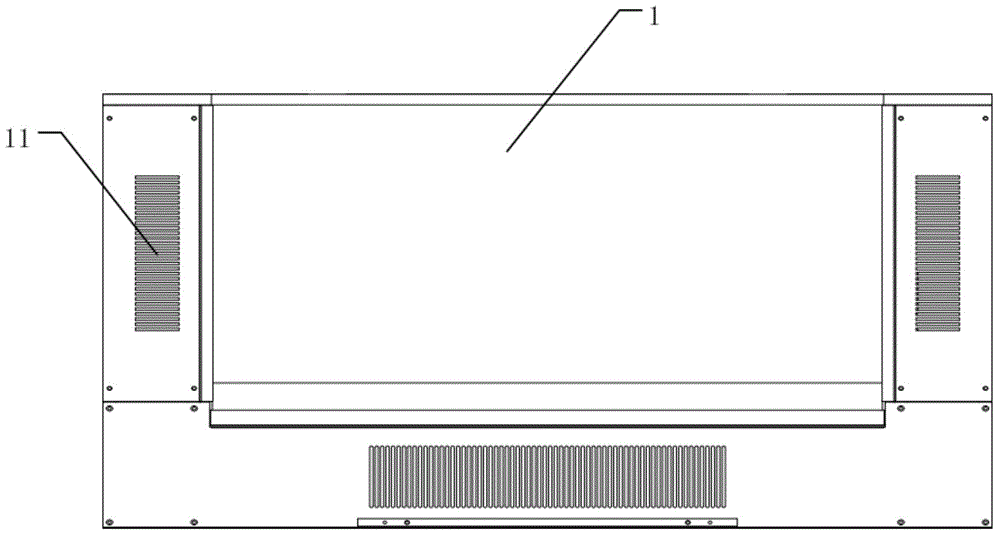

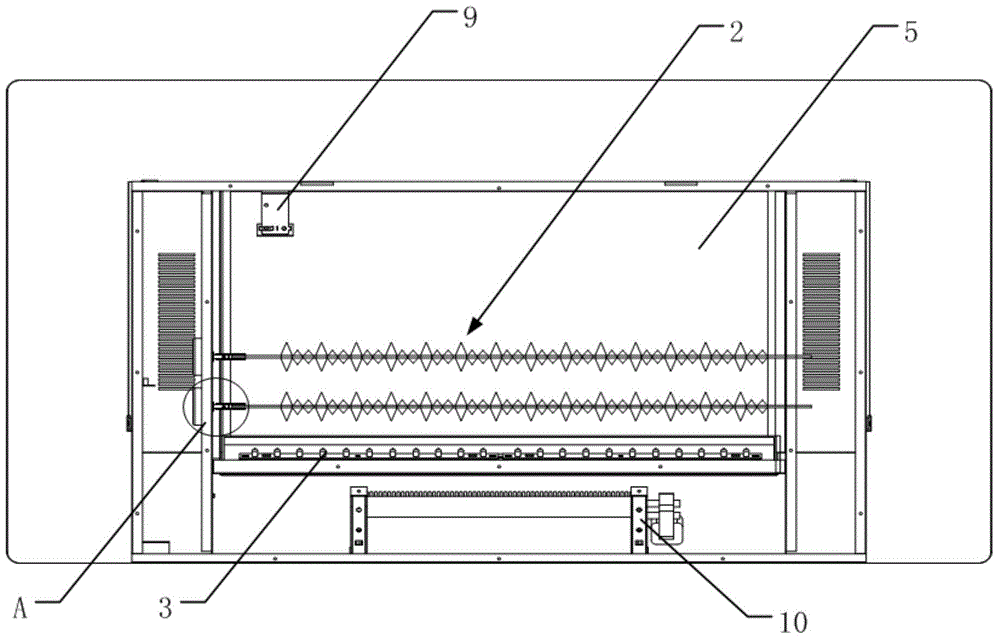

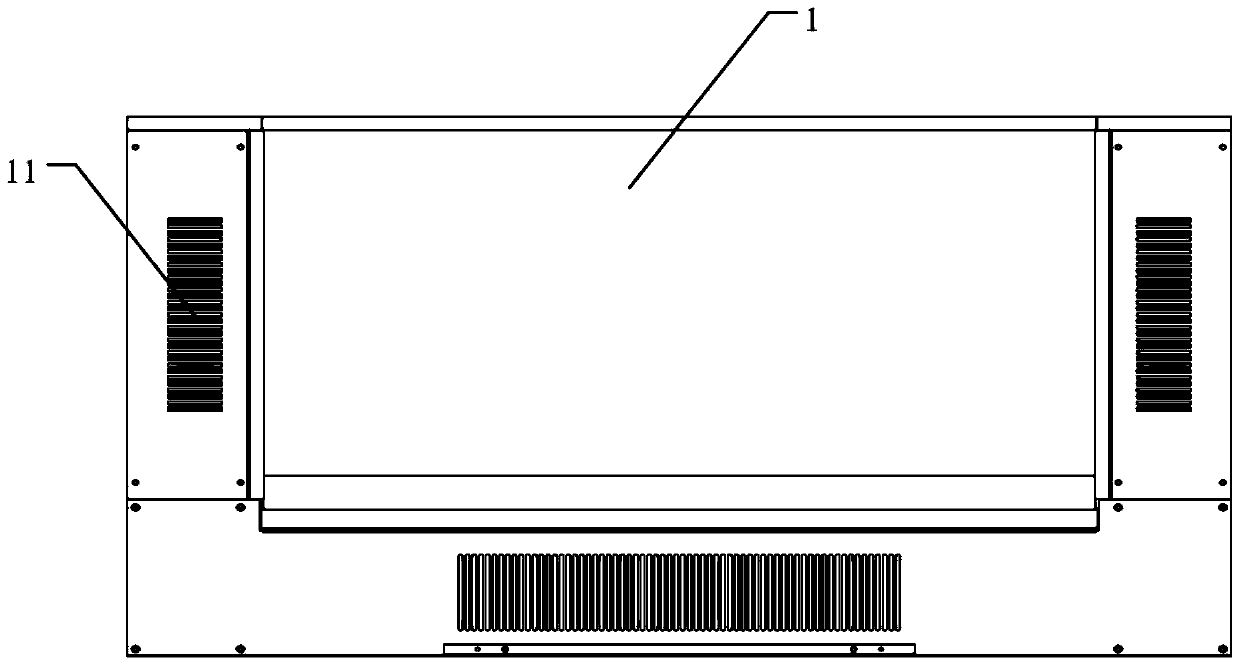

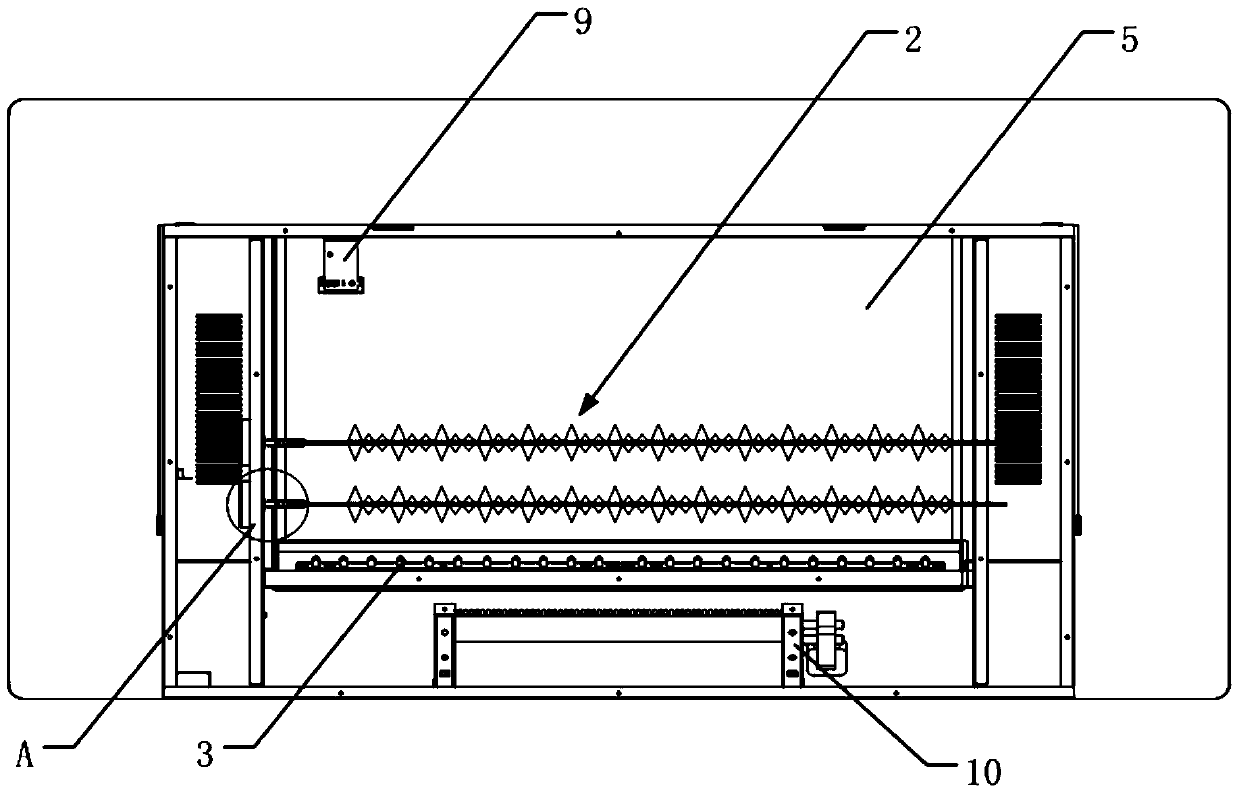

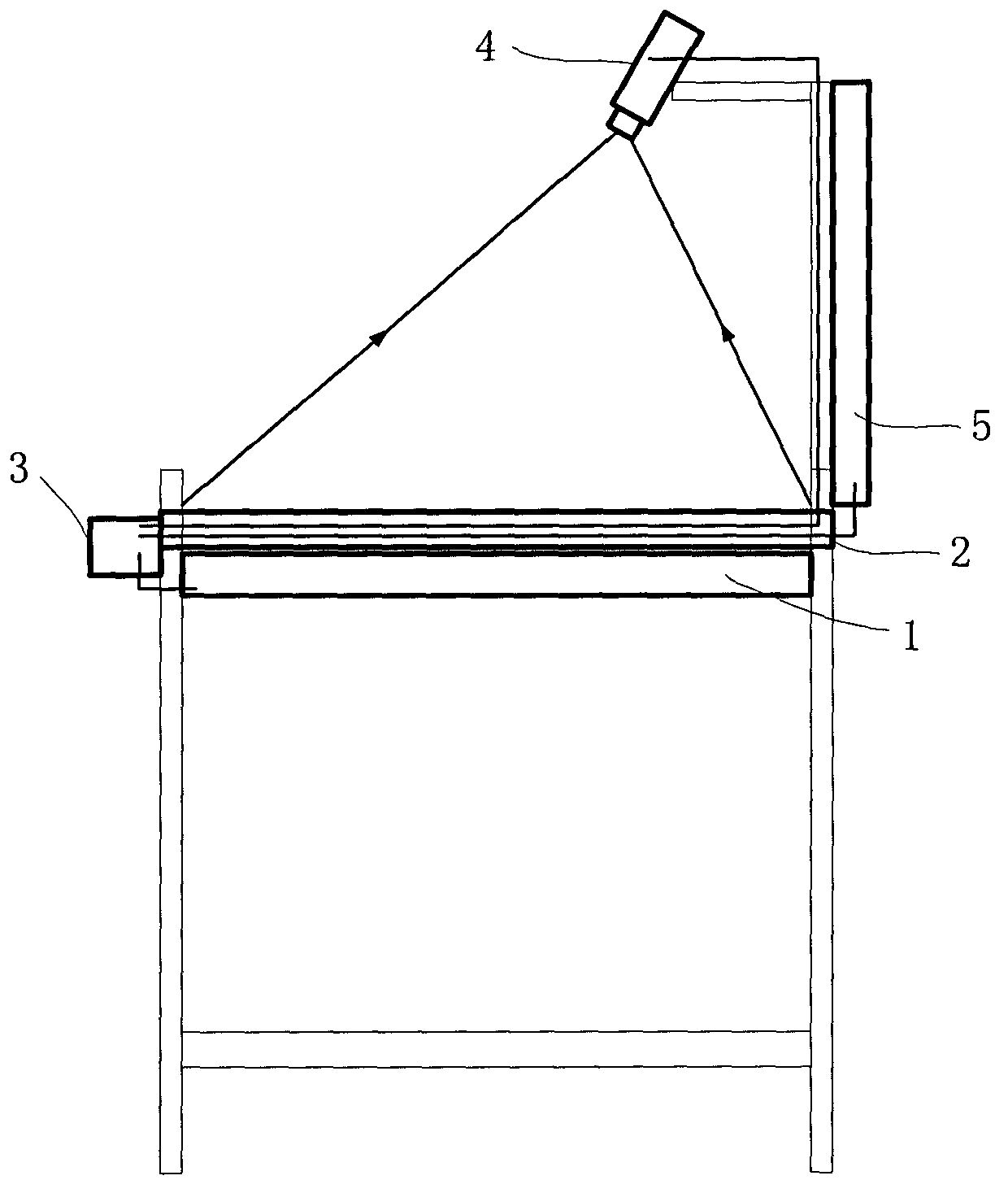

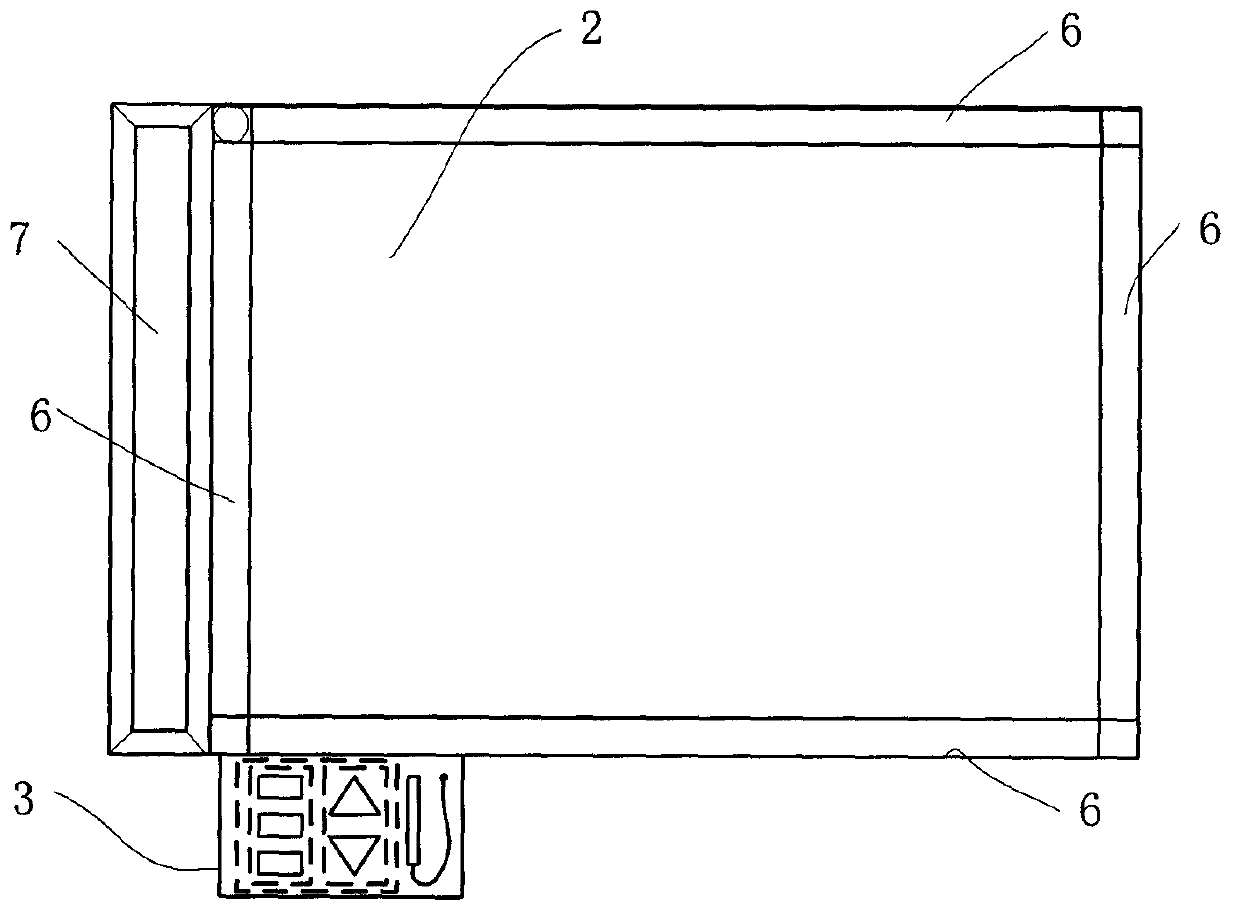

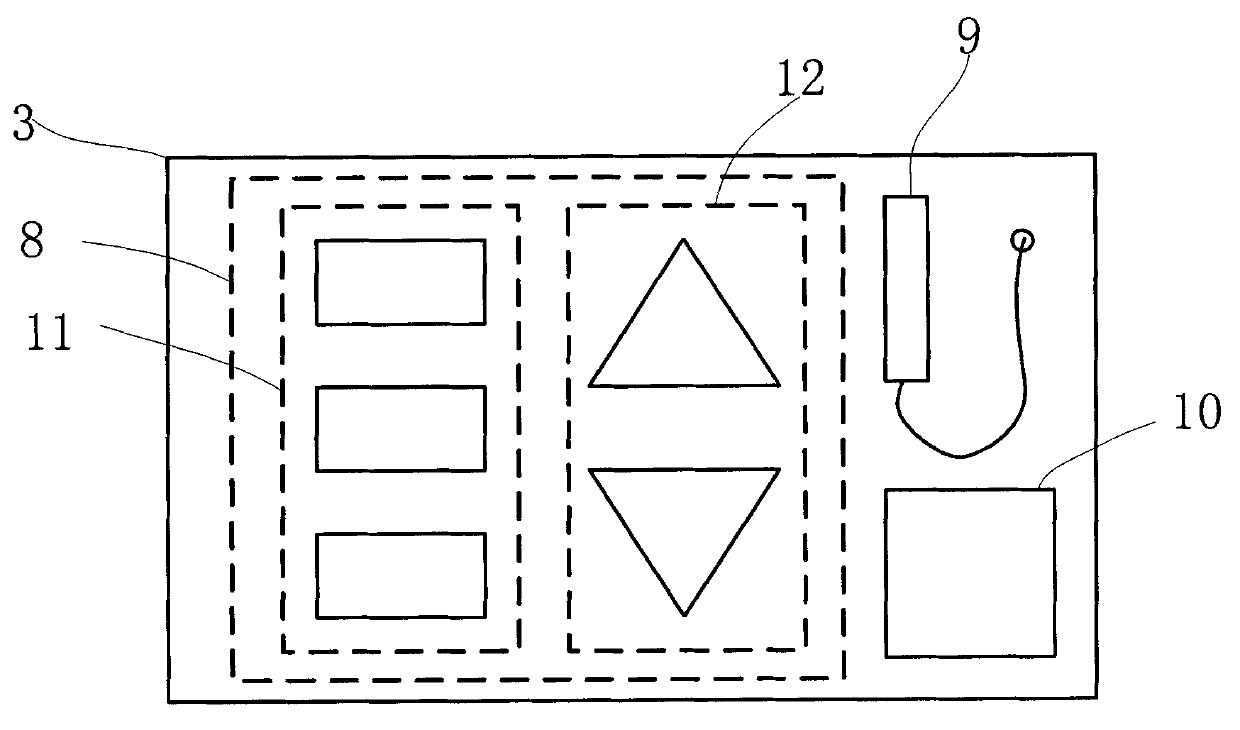

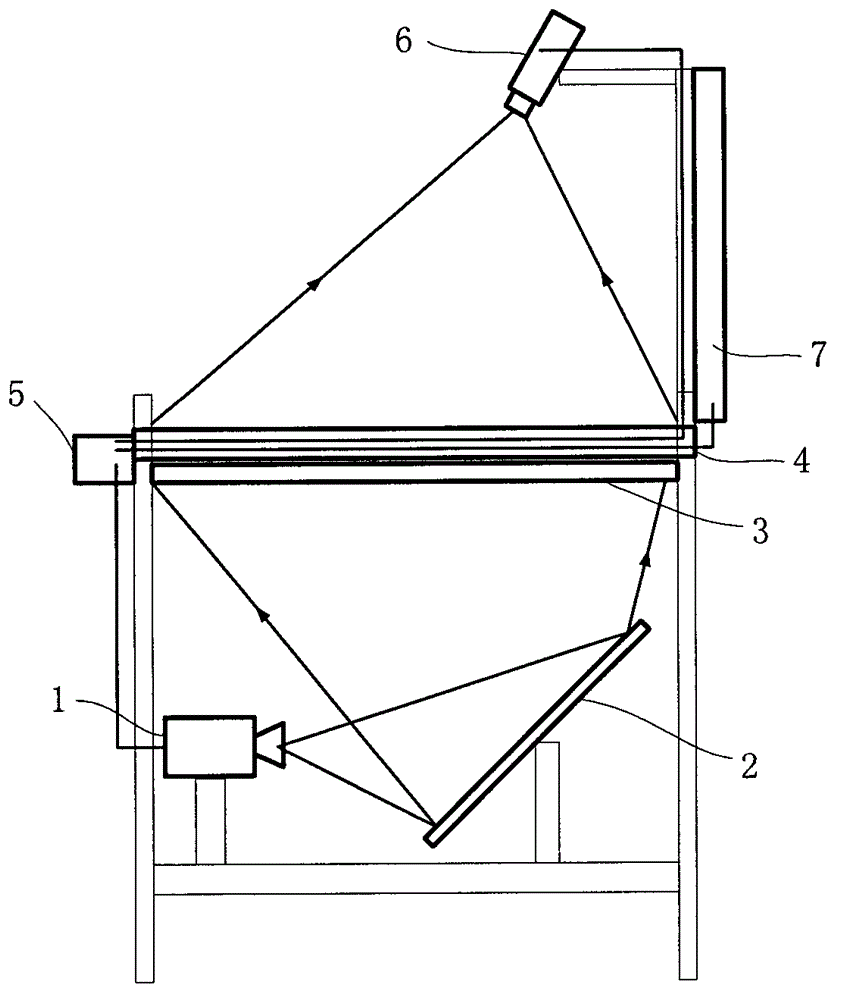

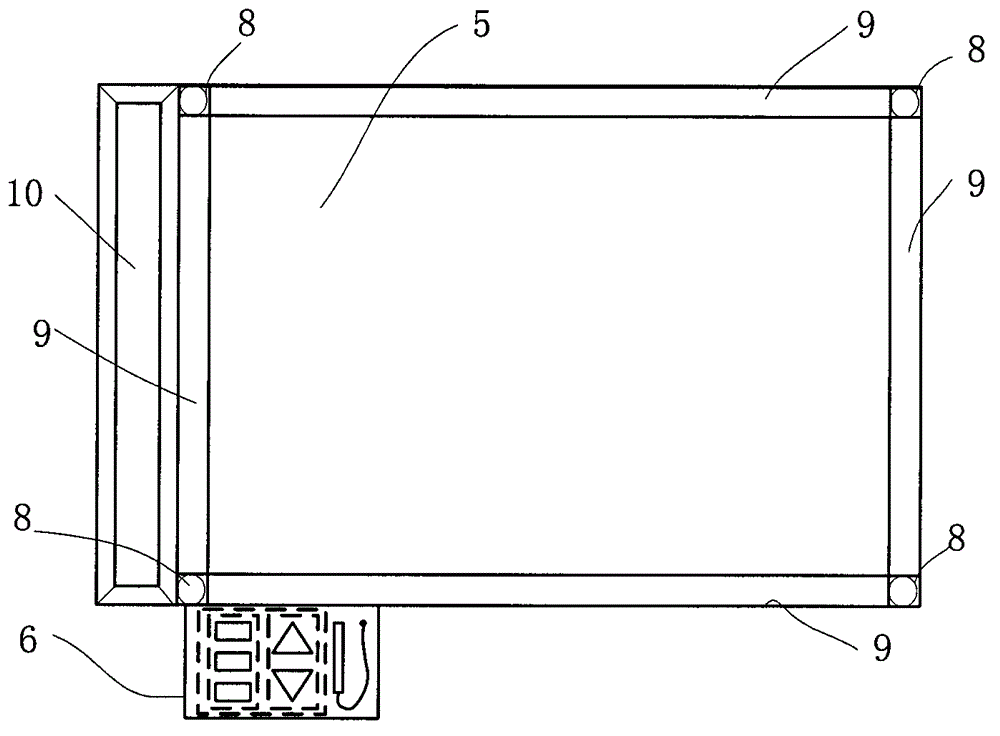

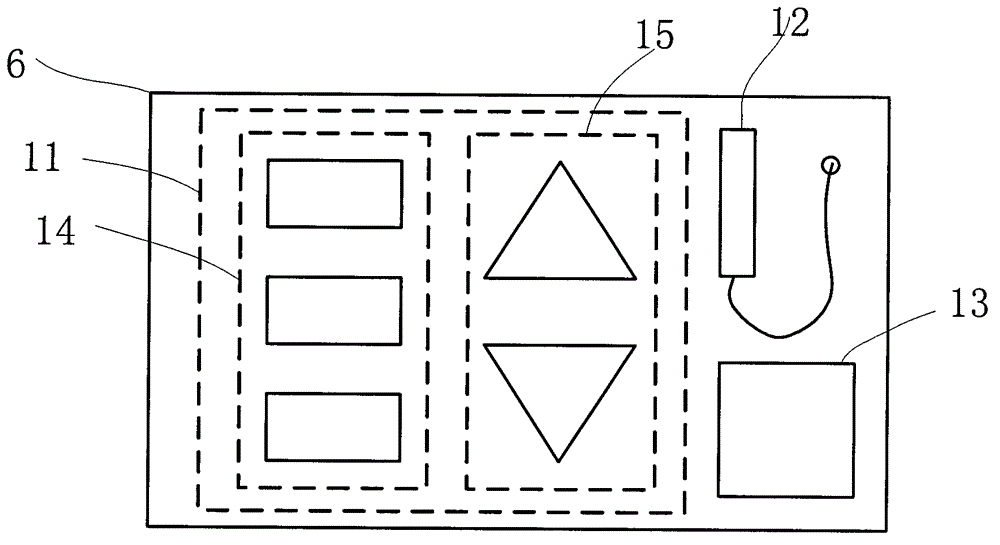

Sand painting device based on liquid crystal displayer and capable of adjusting colors

InactiveCN103273794AEasy to operateRich color expressionLight effect designsSpecial artistic techniquesColor imageLiquid-crystal display

A sand painting device based on a liquid crystal displayer and capable of adjusting colors comprises a first displayer (1), a sand painting workbench (2), a control panel (3), a camera system (4) and a second displayer (5). The first displayer (1) is located below the sand painting workbench (2), displays color images, and casts color light rays towards the sand painting workbench (2), and the color light rays are blocked by sand on the sand painting workbench (2), so that sand painting works in different colors are presented on the sand painting workbench (2). A user can change emergent light rays of the first displayer (1) through the control panel (3) so that brightness and colors in different areas on the sand painting workbench (2) can be adjusted, and the sand painting works in different colors are achieved. Meanwhile, the camera system (4) shoots the painting process and the works so as to enable the painting process and the works to be displayed on the second displayer (5) for appreciation of audience. The sand painting device enables the sand painting works to present different colors, brings great convenience for a designer and brings visual experience of high art value for the audience.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Processing method for forming uniformly distributed smooth textures on surface of willow product

ActiveCN112045805AArt appreciation value is highClear textureWood treatment detailsPretreatment apparatusOrganic chemistryWood product

The invention discloses a processing method for forming uniformly distributed smooth textures on the surface of a willow product, and relates to the technical field of wood treatment, and the processing method specifically comprises the following steps: S1, pretreating the willow product; S2, pretreating the metal oxide nano wire bundle; S3, preparing willow product treatment liquid; and S4, forming smooth lines on the surface of the willow product. Smooth and uniform textures formed by arranging the composite nano wire bundles are formed on the surface of the willow product, and the compositenano wire bundles of large-size structures are arranged on the wood product, so that the textures on the surface of the wood product are clearer, concave-convex patterns are well-proportioned, the surface of the wood product is more layered, the appearance of the wood product is more attractive, and the artistic appreciation value of the wooden product is improved.

Owner:阜南县中信柳木工艺品有限公司

Ceramic rail carved with craft embossed painting

The invention relates to a ceramic rail carved with craft embossed painting. The new product of the invention is in the structure that: the rail is a hollow body, the two ends of the rail is a rectangular cube or a rectangular half round cube, the part connected with the cube by arc or oblate arc transition face is respectively provided with one or a plurality of arc or oblate arc bosses, the middle end of the ceramic rail is designed into two faces in flat shape or drum shape, the flat body at the middle end section is carved with craft embossed painting, and the two sides of the front flat shape can be carved with uncaria clouds for achieving ornament effect. The embossed painting can be 'Riverside Scene at Qingming Festival', 'The Eight Fairies' and 'Children-sending Guanyin' figure and scenery embossed paintings, 'Proud as a Peacock' animal embossed painting, 'Fortune Comes with Blooming Flowers' flower bug bird embossed painting and 'picturesque peak lovely scene' landscape scene embossed painting.

Owner:谢礼荣

Application of pearl glaze in preparing ceramic handrail

The invention relates to application of pearl glaze, glisten glaze or pearl powder during the production of ceramic railing and pertains to the technical field of building material. Pearl glaze and turpentine are mixed according to the ratio of 1:2, glisten glaze and turpentine are mixed according to the ratio of 1:0.5 and pearl powder and hand drawing oil are mixed according to the ratio of 1:1, all applied to the treatment raw materials of the surface of the ceramic railing. Then the raw materials are respectively coated on the ceramic railing on normal way, the ceramic railing coated with the raw materials is put in a normal curing device, cured for 3-4h under the temperature of 700-800 DEG C and cooled, then ceramic railing with pearl glaze, glisten glaze or pearl powder is obtained. The method has the advantages of simple preparation, broadening the application of pearl glaze, glisten glaze or pearl powder and endowing the product with novel appearance, various colors and more artistic appreciation value. The invention can be widely applied to ceramic railing of various structures.

Owner:谢礼荣

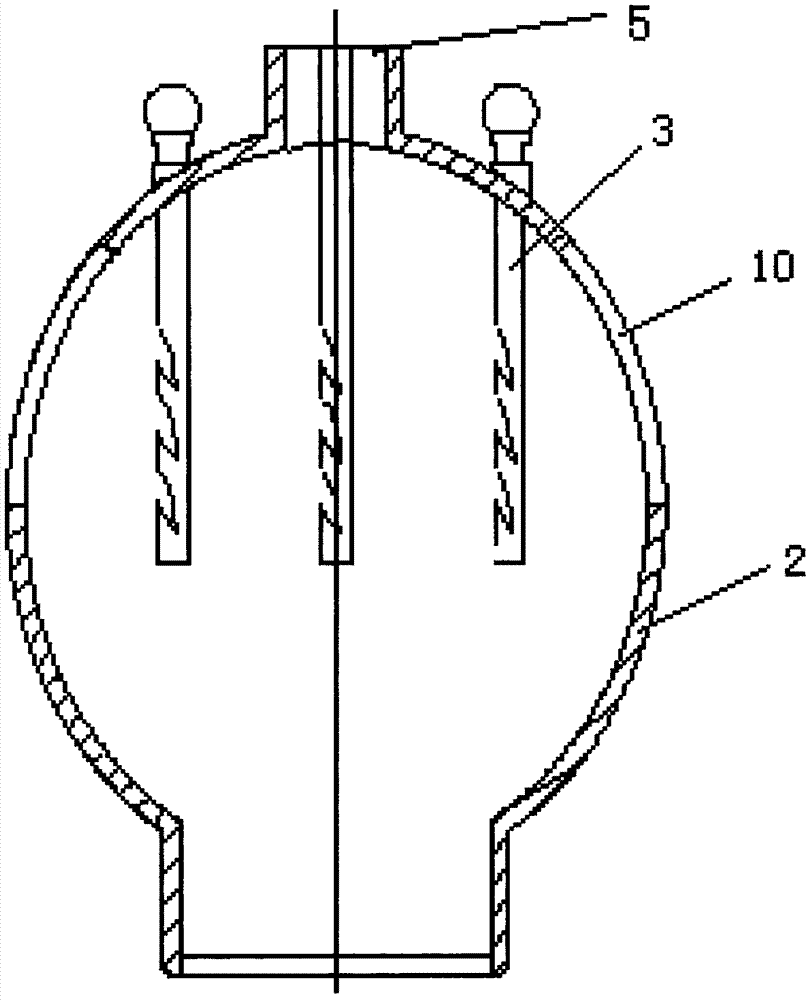

Multifunctional ceramic baking oven

InactiveCN107367167AImprove breathabilityArt appreciation value is highFurnace typesCircular discCooking & baking

The invention provides a multifunctional ceramic baking oven. The multifunctional ceramic baking oven is composed of an upper baking chamber and a lower heat source chamber, wherein the upper baking chamber and the lower heat source chamber are of a split type structure and are both ceramic bodies. A smoke outlet is formed in the top of the upper baking chamber. Air holes are formed in the left side and the right side of the smoke outlet. Ceramic adjustment suspension rods are mounted in the air holes. Two baked article inlets / outlets are formed in the middle of the upper baking chamber. The bottom of the lower heat source chamber is of a double-layer structure, the outer layer of the lower heat source chamber is a hemispherical shell and is provided with three supporting legs, and the inner layer of the lower heat source chamber is a disc; air inlets are formed in the two sides and the bottom of the outer layer, disc through holes are formed in the bottom surface of the disc on the inner layer; and a heat source is arranged in the disc. The multifunctional ceramic baking oven has the beneficial effects that the multifunctional ceramic baking oven integrates the baking function and the beautifying and ornamenting function and is suitable for being placed in any places; the exhaust capacity and the baking atmosphere of the upper baking chamber can be adjusted freely; and the multifunctional ceramic baking oven is convenient to clean, environmentally friendly, capable of saving energy, easy to operate, and convenient to use.

Owner:邢良坤

Projector-based sand painting platform device with adjustable color

InactiveCN103273795BEasy to operateRich color expressionHand artistic toolsOther artistic work equipmentsDisplay deviceVisual perception

Owner:ZHEJIANG FORESTRY UNIVERSITY

A processing method for forming evenly distributed smooth texture on the surface of willow wood products

ActiveCN112045805BArt appreciation value is highClear textureWood treatment detailsPretreatment apparatusBotanyAgronomy

The invention discloses a processing method for forming evenly distributed smooth textures on the surface of willow wood products, relates to the technical field of wood treatment, and specifically comprises the following steps: S1, pretreatment of willow wood products; S2, pretreatment of metal oxide nanowire bundles; S3, preparation of willow product treatment solution; and S4, formation of smooth lines on the surface of willow product. In the present invention, a smooth and uniform texture composed of composite nanowire bundles is formed on the surface of willow wood products, and the composite nanowire bundles with a large-scale structure are arranged on the wood product, so that the texture on the surface of the wood product appears clearer, and the unevenness is well-arranged. It makes the surface of wooden products more layered and enhances the artistic appreciation value of wooden products.

Owner:阜南县中信柳木工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com