Manufacturing method of cotton flock picture

A production method and technology of cotton velvet, applied to the special technology of art painting, special decorative structure, decorative art, etc., can solve the problems that the production process is not ordinary people, only one cotton painting can be made, and the production cost is rising. Achieve the effects of high artistic appreciation value, delicate picture and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

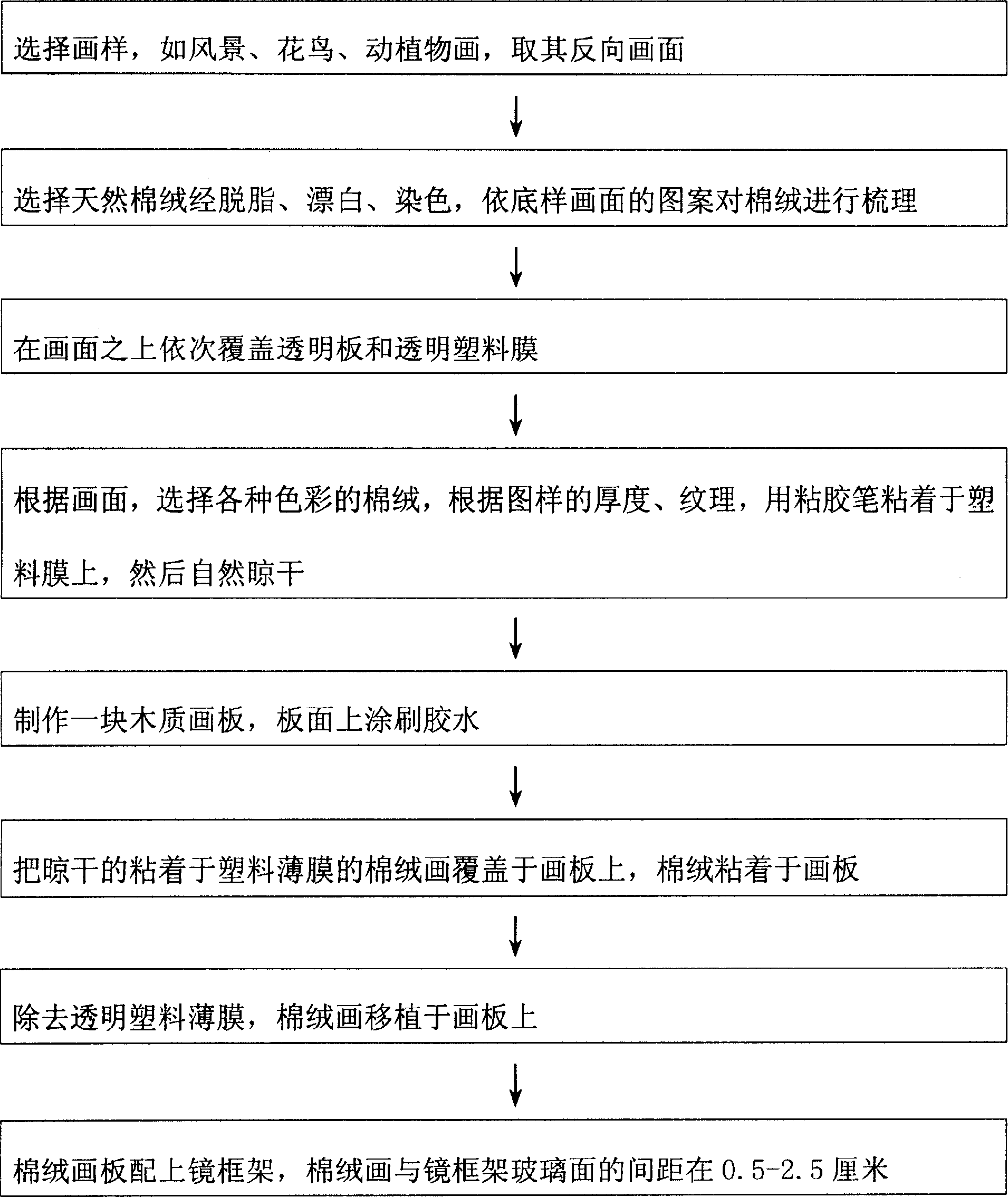

Method used

Image

Examples

Embodiment Construction

[0018] Take the production of a cotton wool craft painting of a tiger as an example, the production steps are as follows:

[0019] 1. Choose a picture of a tiger, scan it into the computer, and use a color printer to print it into a reverse picture;

[0020] 2. Prepare natural lint: the lint is selected, degreased, bleached, and dyed into various colors required for the tiger painting, and then the lint is combed;

[0021] 3. Place the reverse drawing in step 1 on the workbench, cover it with a transparent glass plate, and then cover the glass plate with a layer of transparent plastic film. The reverse drawing, glass plate and plastic film are clamped with fixing clips so that they do not move, which is convenient for drawing; mix thin glue, the volume ratio of water and glue is 1000-1500:1, according to the tiger drawing Dip the velvet into thin glue and paste it on the plastic film layer from the close-up to the long-range, so that the tiger painting is completely "copied" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com