Novel spraying manufacturing process of glass bottles

A manufacturing process and glass bottle technology, which is applied in the new spraying manufacturing process of glass bottles, can solve the problems of affecting promotion and application, single imitation pottery products, and low art appreciation value, and achieve high art appreciation value, high simulation degree, The effect of improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

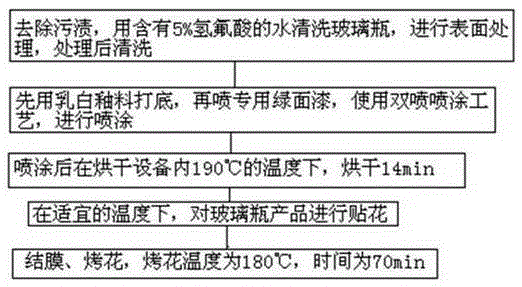

[0020] Such as figure 1 As shown, the production process is as follows:

[0021] 1 Preparation before spraying

[0022] Select semi-finished glass bottles of transparent material with iron content ≤0.055%. After removing the stains on the outer surface of the glass bottle, clean the glass bottles with water containing 5% hydrofluoric acid for the surface treatment. After the treatment is completed Carry out cleaning

[0023] 2Spray semi-finished products

[0024] Choose special milky white and green glazes, first use milky white glaze as a primer, then spray special green topcoat, and use double-spray spraying process to spray;

[0025] 3 drying

[0026] Dry the glass bottles after spraying at a temperature of 190℃ in the drying equipment for 14 minutes;

[0027] 4 decals

[0028] Apply decals to the glass bottle products at a suitable temperature;

[0029] 5 roasted flowers

[0030] After the flowers are pasted, the products are conjunctivated and baked. The baking temperature is 180℃ and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com