Patents

Literature

464results about How to "Improve competitiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for power-saving in a wireless local area network

ActiveUS7412265B2Improve competitivenessPower managementEnergy efficient ICTMedia accessData transmission

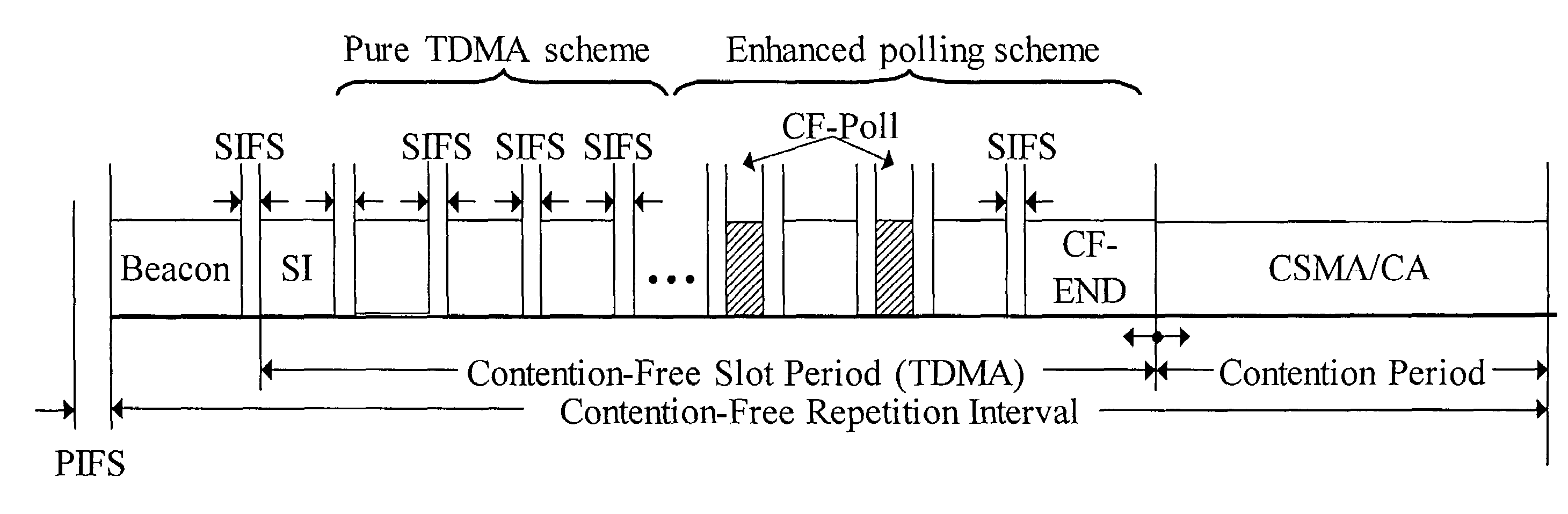

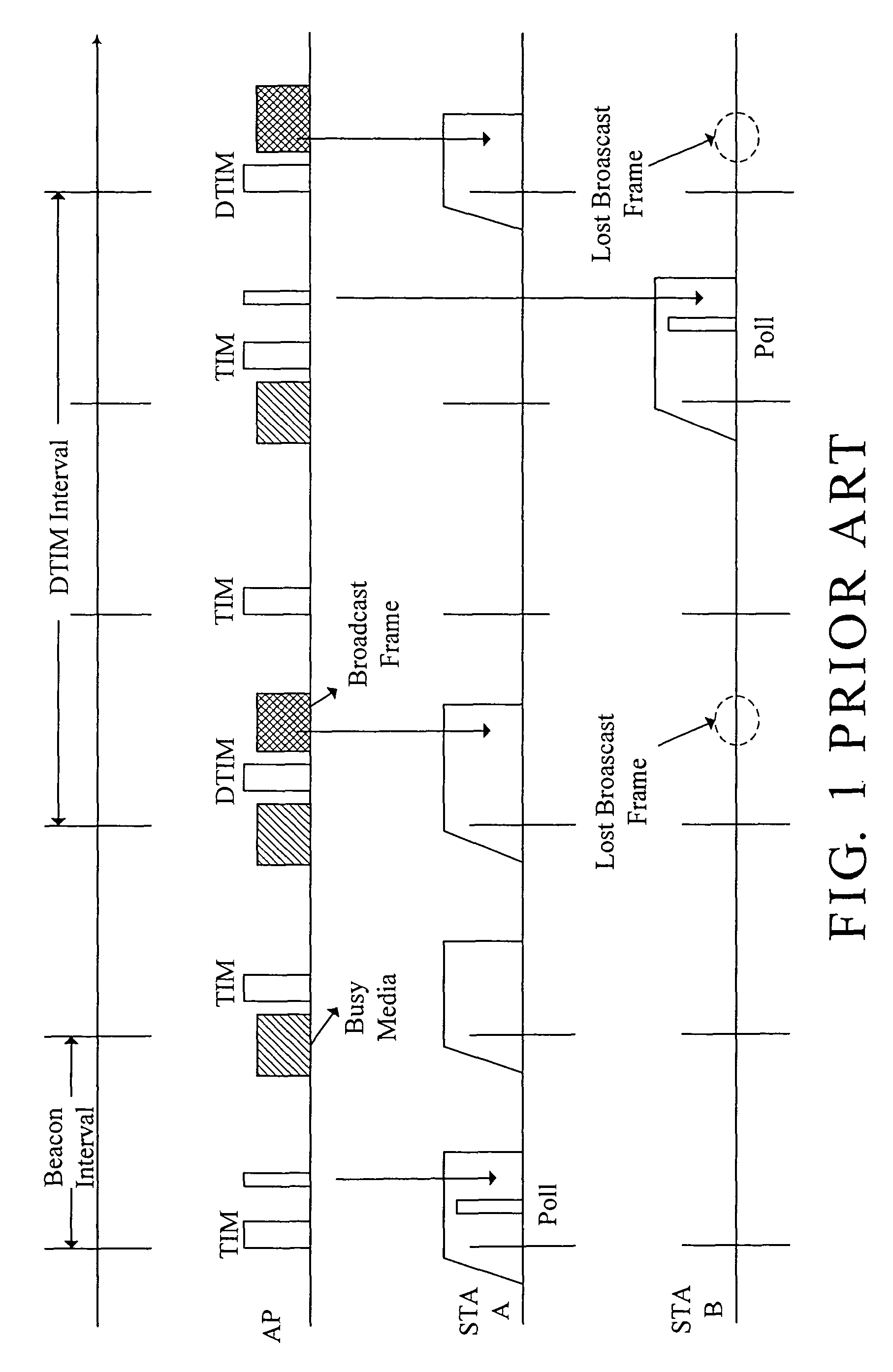

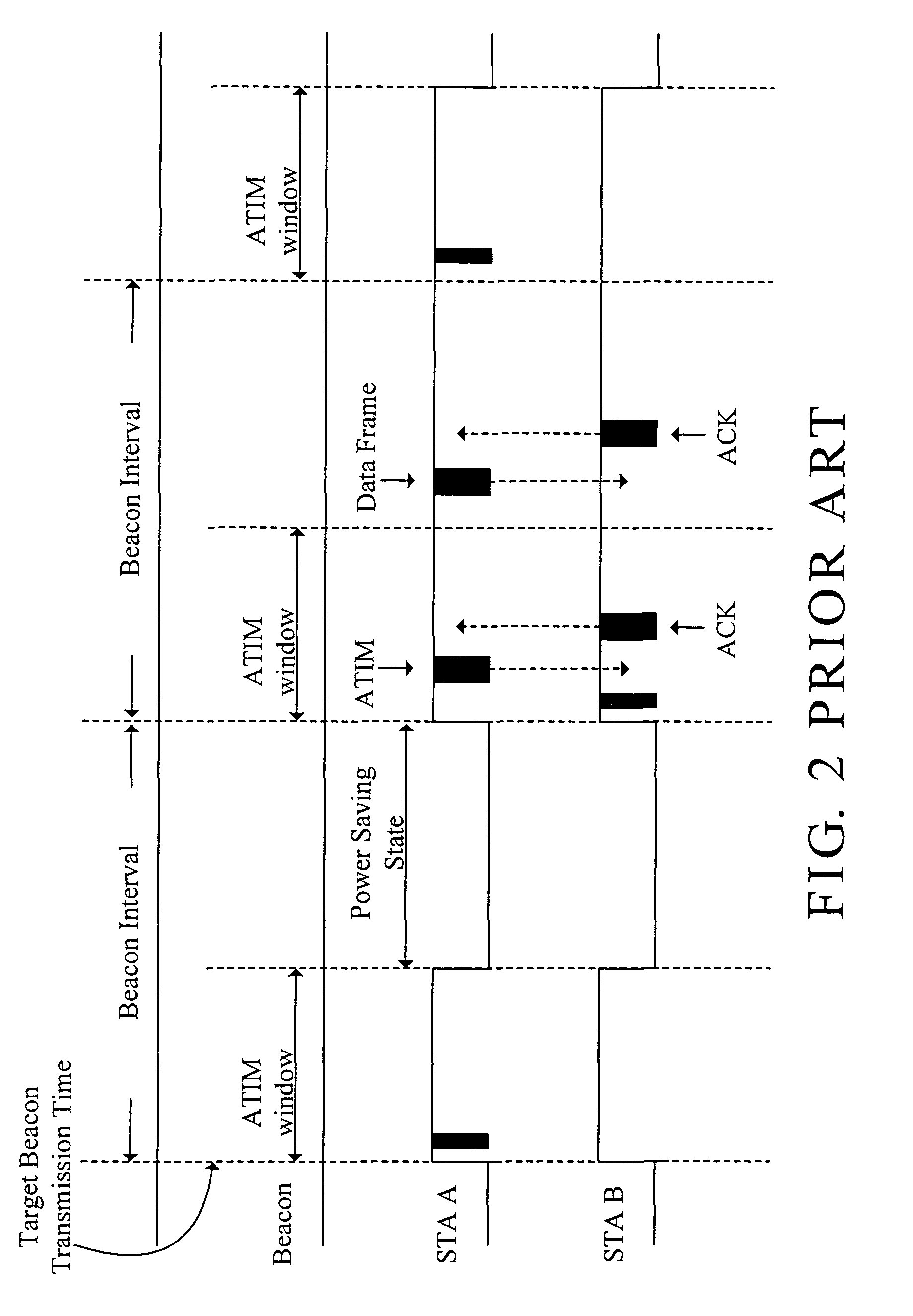

A method and system for power saving in a wireless LAN is disclosed, which uses the method of modifying the beacon frame body or broadcasting the schedule information frame. The medium access behavior of each station during the contention free period (CFP) and the contention period (CP) can be dynamically re-programmed. Therefore, the stations that should access the radio medium can only wake up at the specific access time to send or receive the packet and re-enters its power-saving state after the data transmission.

Owner:IND TECH RES INST

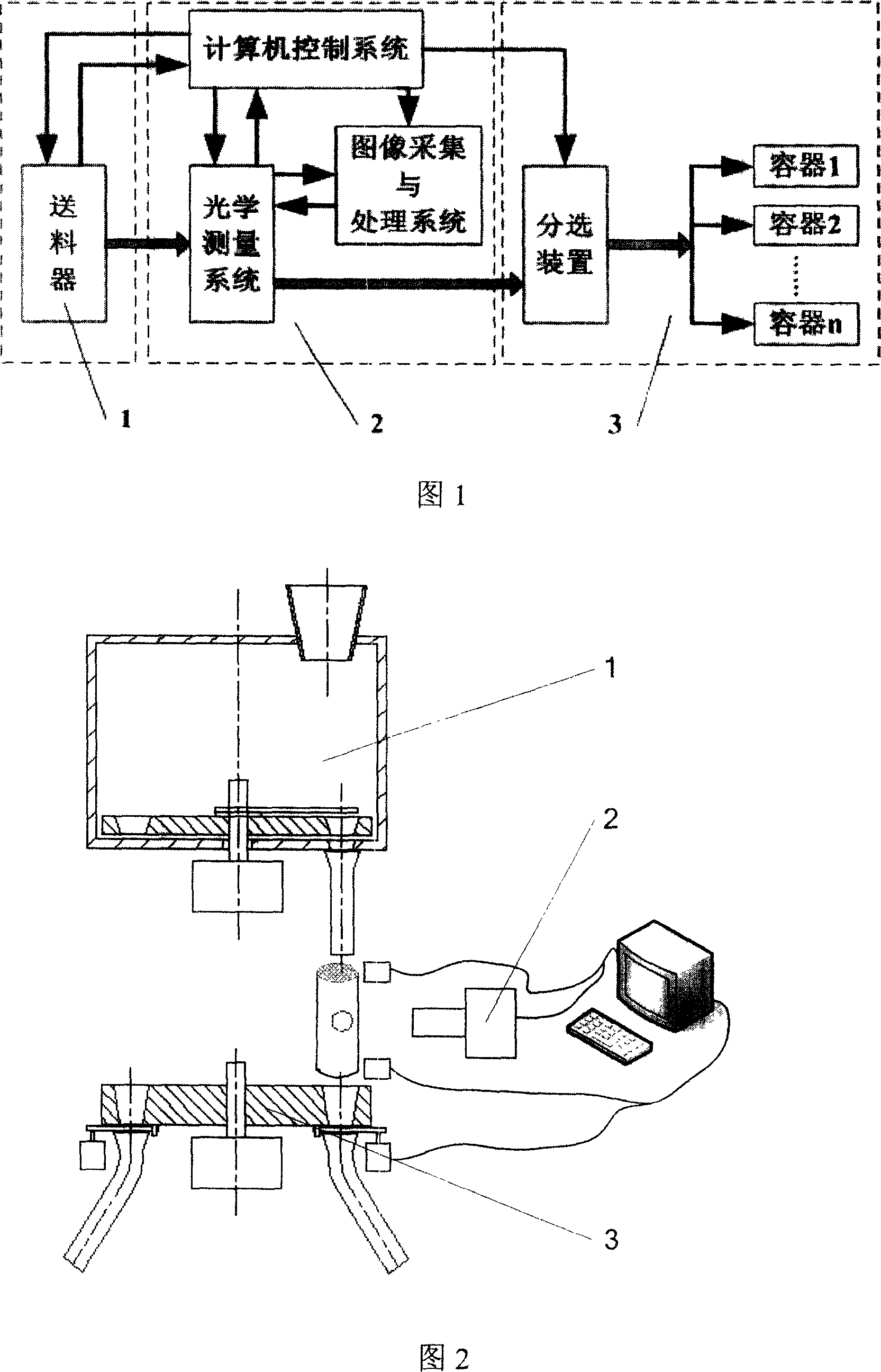

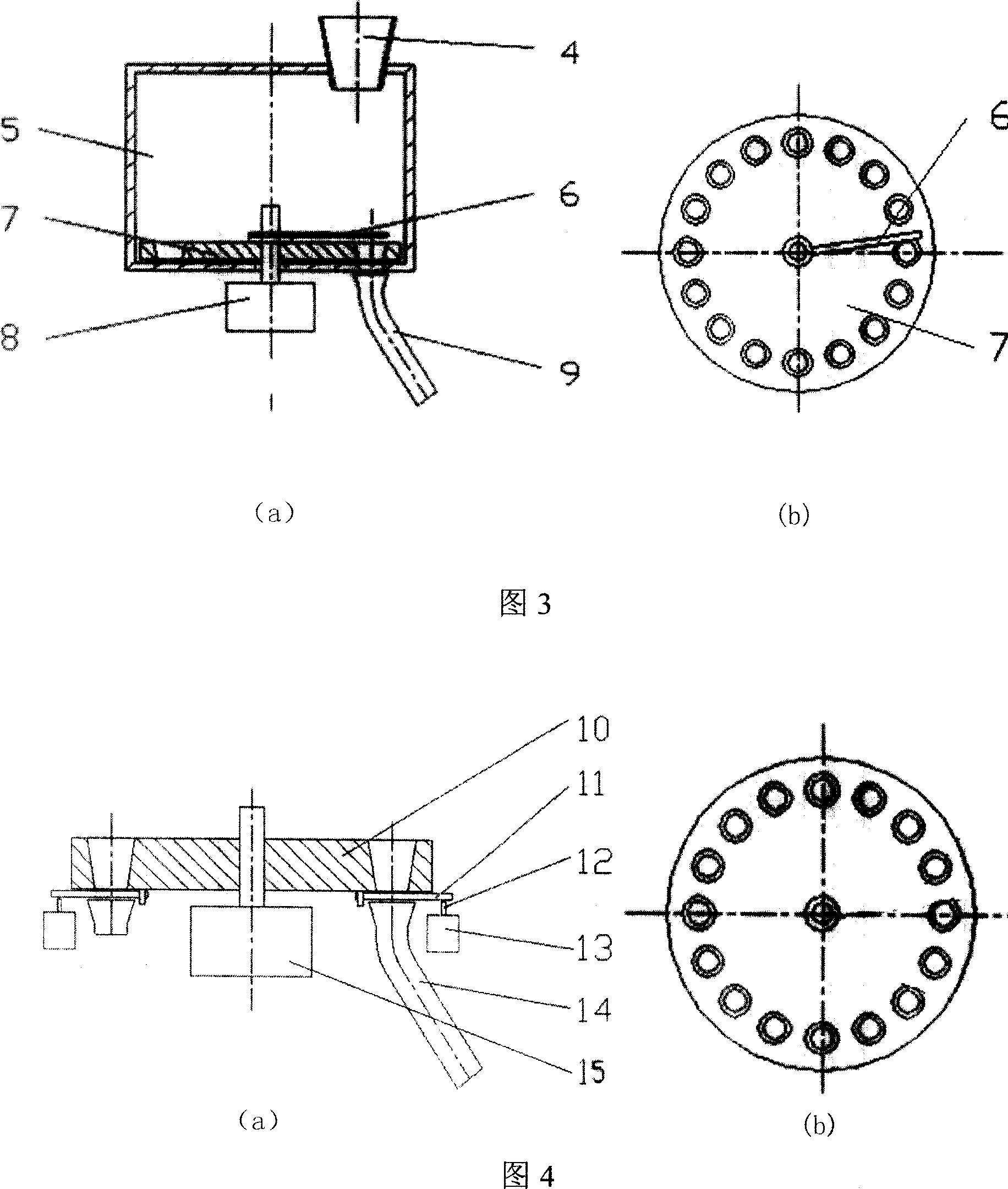

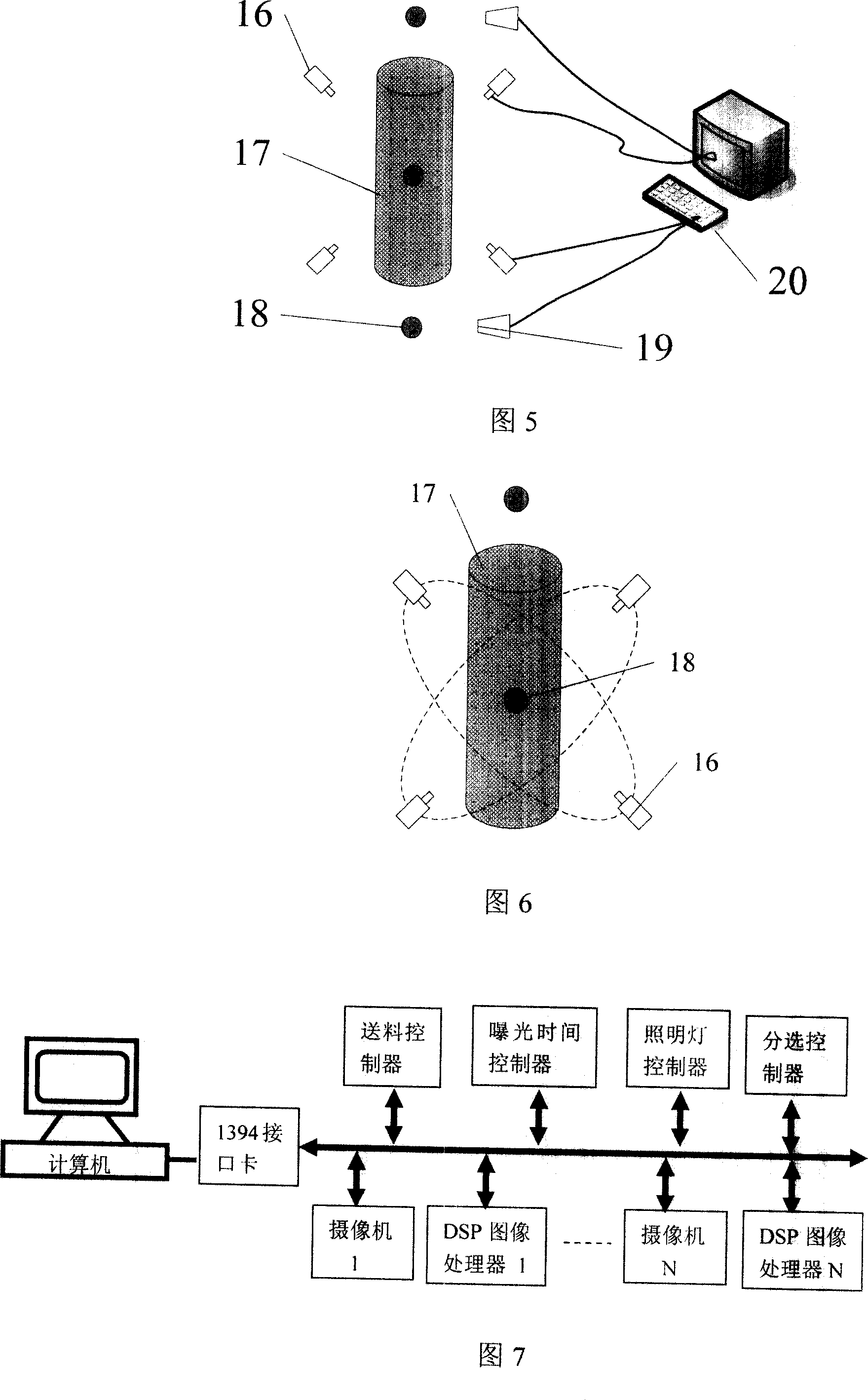

Pearl real time detection and classifying system based on mechanical vision

InactiveCN101007308AAccurate acquisitionEfficient acquisitionPhotogrammetry/videogrammetrySortingFree fallingMachine vision

The invention discloses pearl real-time detection and grading system based on machine vision which includes: computer vision recognition component which is equipped under the charging conduit of pearl charging device, and pearl sorting device is equipped under the computer vision recognition component. Using the computer vision technology, collecting image of sequential free-falling pearl surface, sending the collected image to DSP and computers and other hardware apparatus to dealing, then distinguishing the pearl classification standard instantaneously through the dealing results, last sending the distinguishing information to sorting device to achieving classification of pearl with different characteristics automatically using devices. It can get pearl whole surface image, can complete the testing of whole apparent quality index such as pearl size, shape, smooth, defect and color, etc. simultaneously, achieve the rapid real-time detection and grading. The system can adapt to different classification speed, and the structure is simple, adaptability is strong.

Owner:ZHEJIANG UNIV

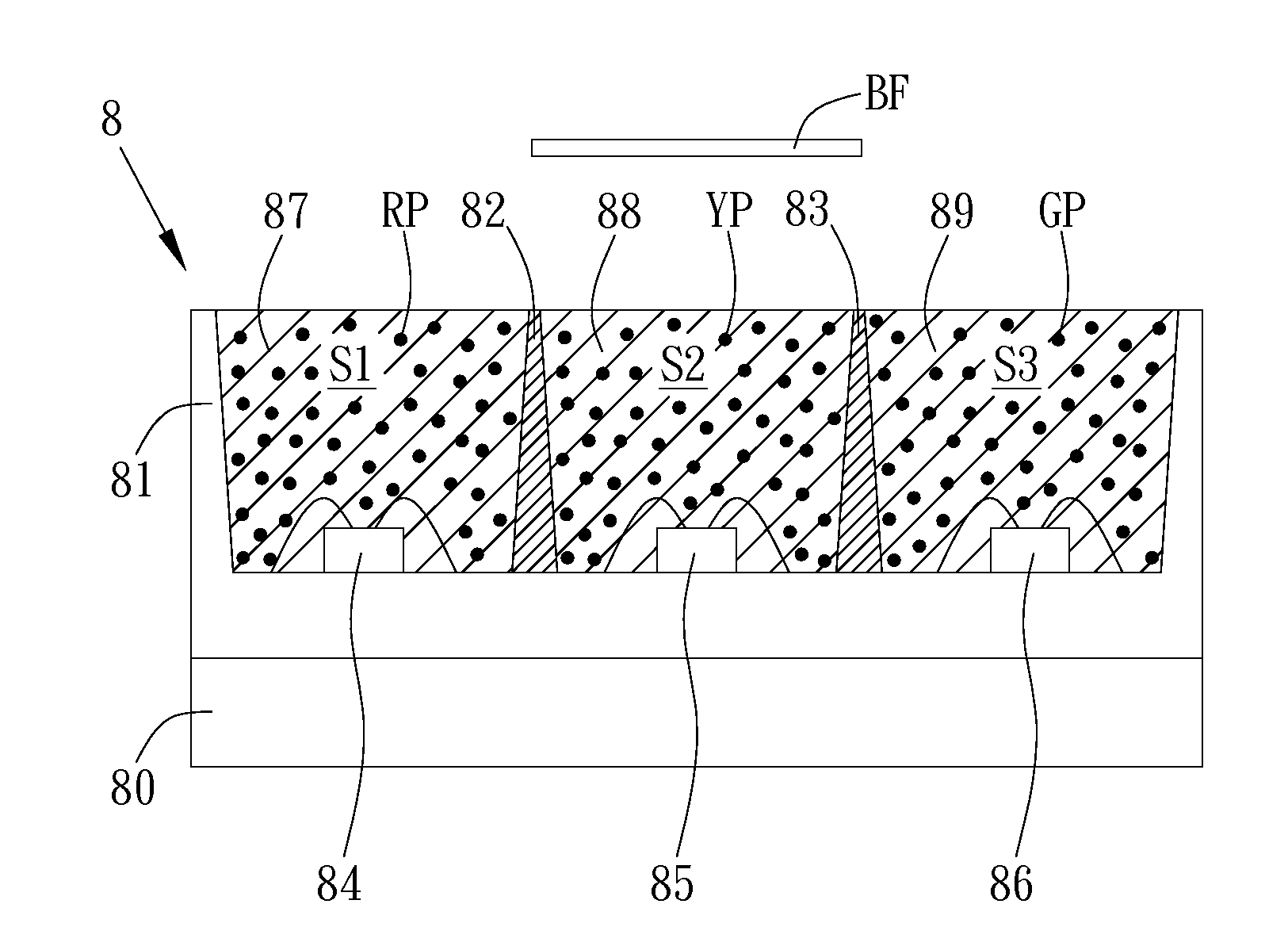

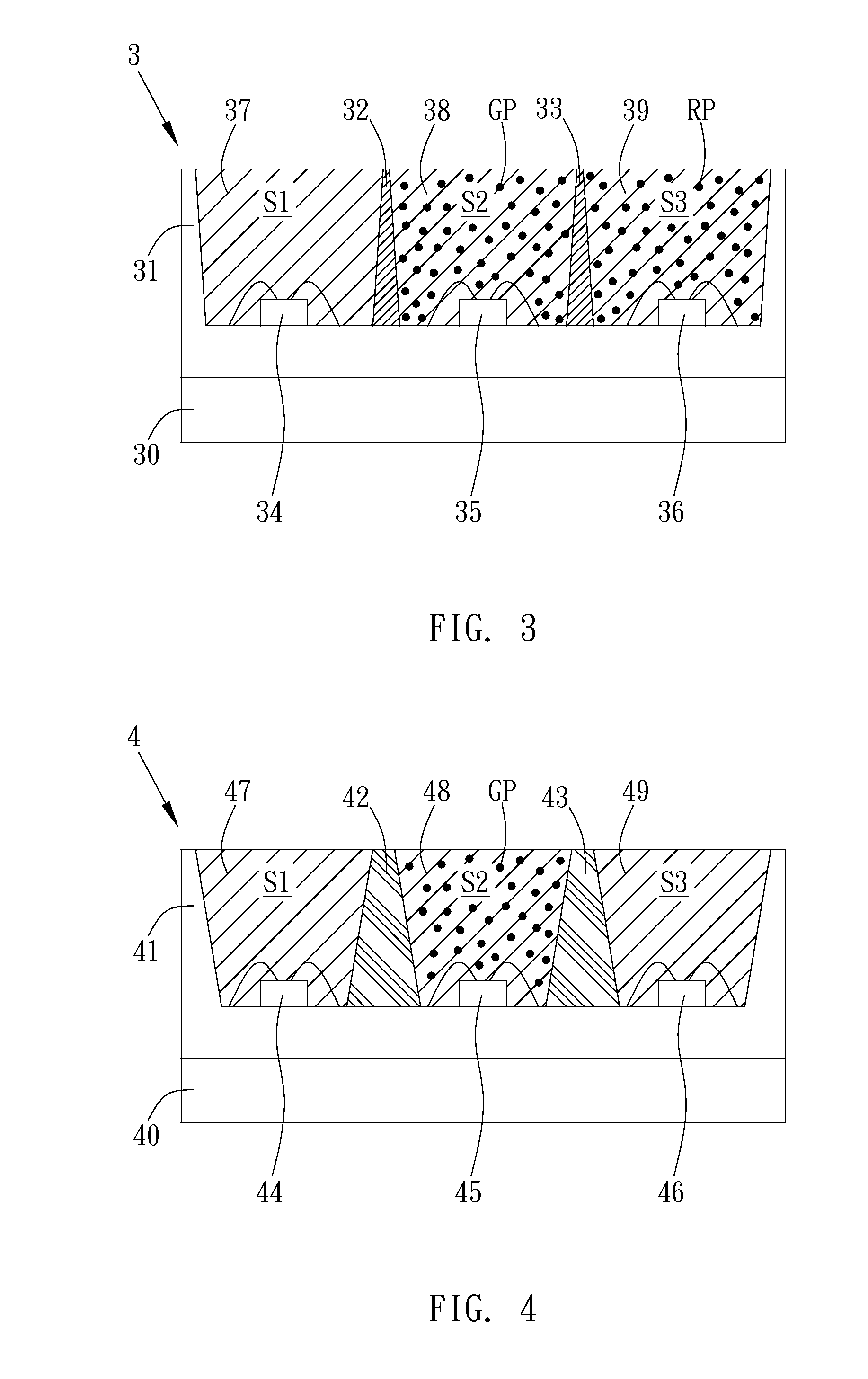

LED Apparatus

InactiveUS20120087108A1Reduce feature differencesImprove efficiencySolid-state devicesIlluminated signsLutetiumEngineering

An LED apparatus is disclosed. The LED apparatus includes a substrate, a cup structure, and a dividing structure. The dividing structure divides a containing space formed by the cup structure into a first region and a second region. A first blue-light chip and a first package colloidal are disposed in the first region and a second blue-light chip and a second package colloidal are disposed in the second region. A green-light phosphor is mixed in the second package colloidal to completely convert a monochromatic emission spectrum of a second blue-light band of the second blue-light chip into a monochromatic emission spectrum of a green-light band. The green-light phosphor is selected from one of silicate, oxynitride, lutetium aluminum oxide, and calcium scandium oxide.

Owner:AU OPTRONICS CORP

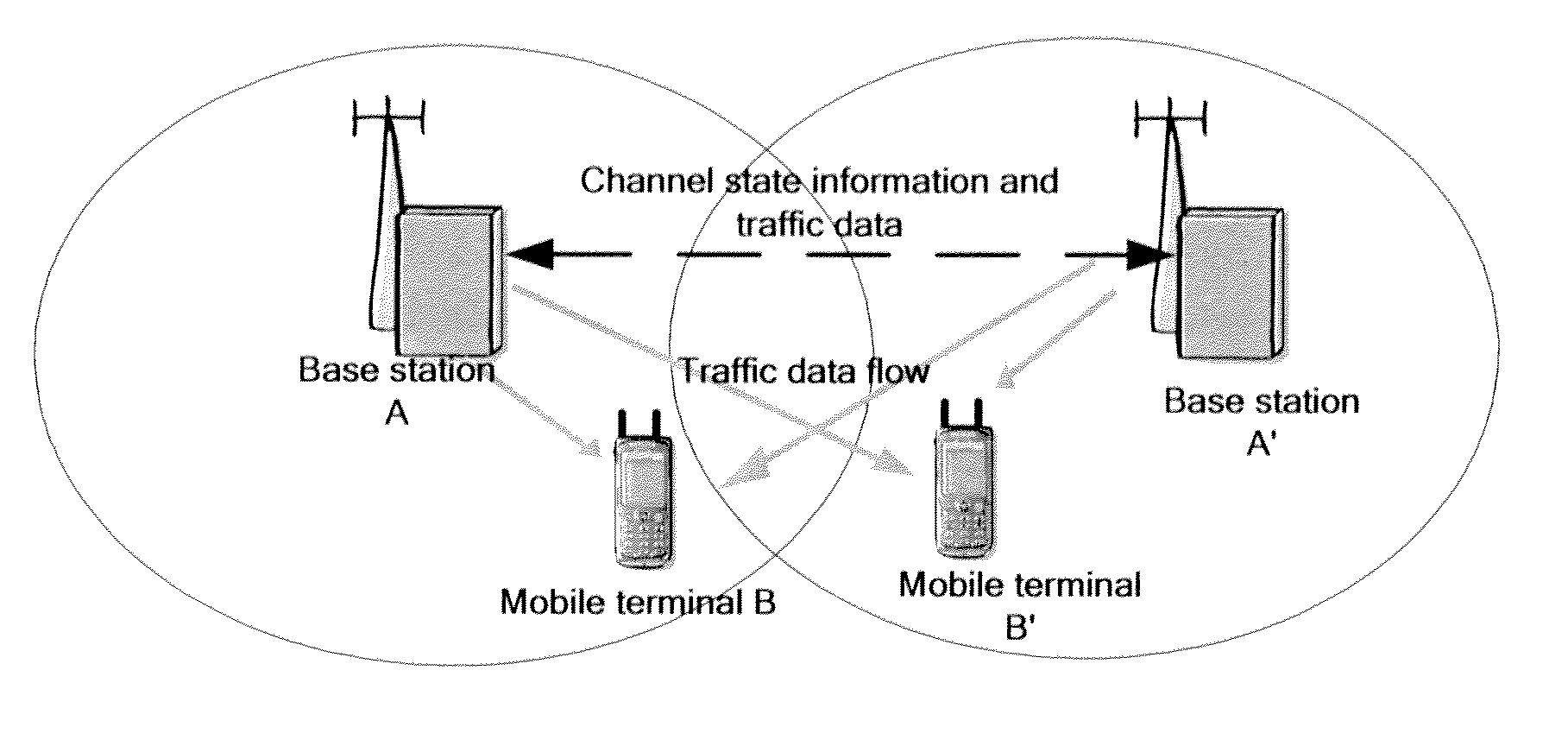

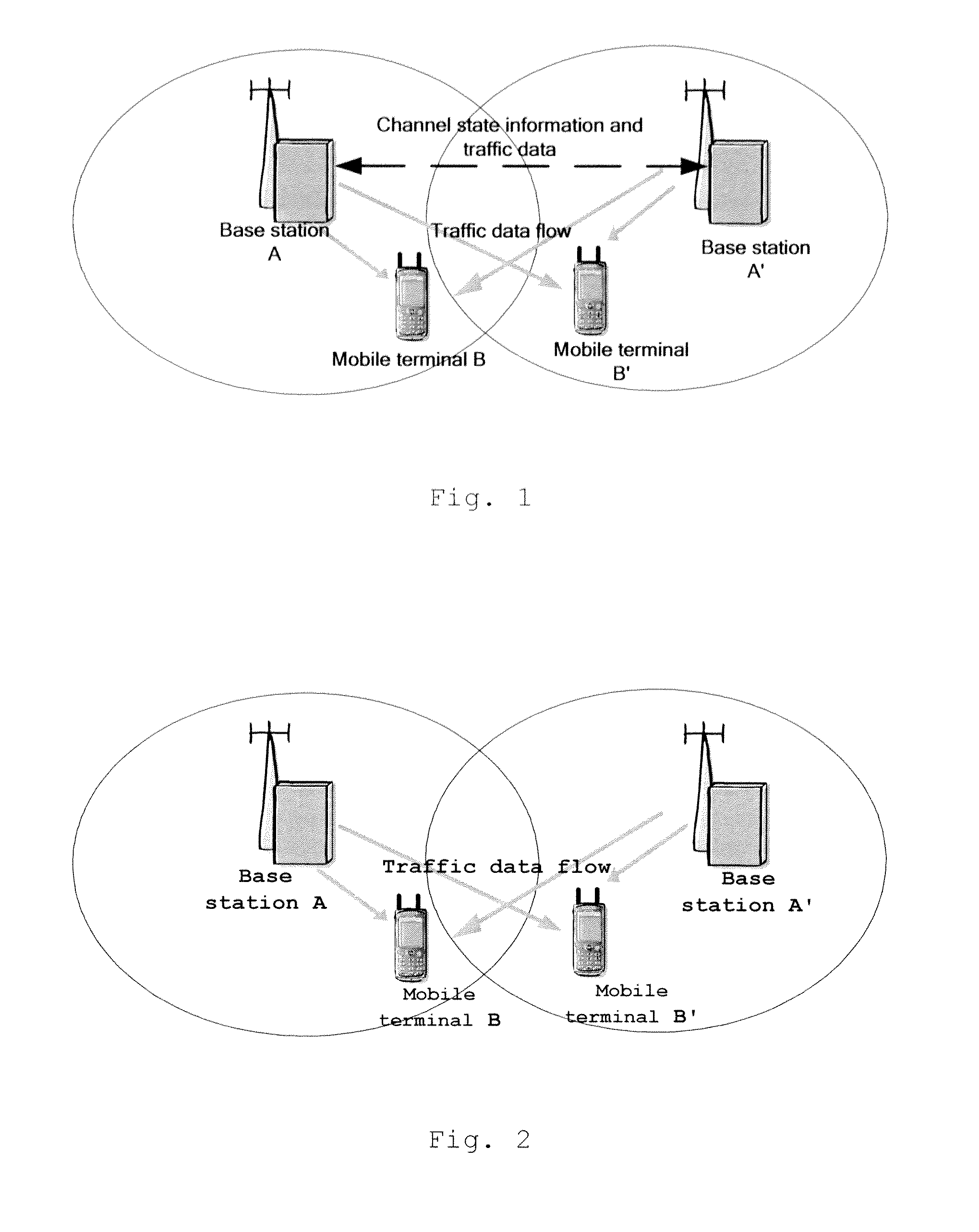

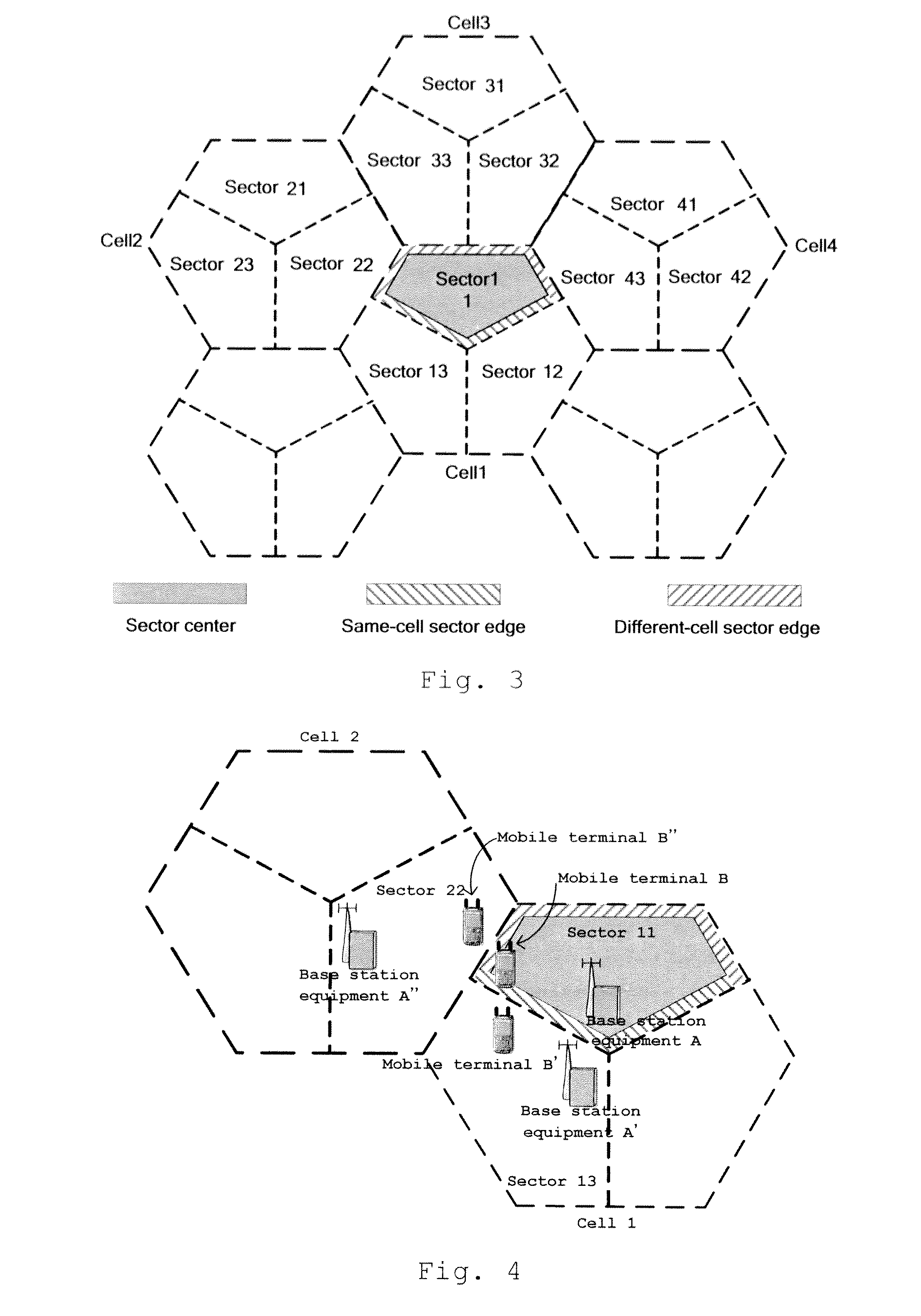

Switching technology for cooperation types in multi-sector cooperative communication

InactiveUS20110207487A1Increase attractionImprove competitivenessInformation formatContent conversionData interchangeThroughput

The current multi-base station cooperative communication technology could only provide one type of cooperative communication fixedly, and this results in that either the amount of data exchange between the base stations is huge and the latency is increased, or the optimum gain can not be obtained. To address this problem, the invention proposes a switching technology for collaboration type in multi-sector cooperative communication. The base station equipment dominating the sector determines one or more cooperating sectors of the mobile terminal, determines the type of the multi-sector cooperative communication provided cooperatively with said one or more cooperating sectors, based on information of said one or more cooperating sectors according to predefined rules, and cooperates with said one or more cooperating sectors and provides, for the mobile terminal, the multi-sector cooperative communication of the corresponding determined type. According to the invention, high speed exchange of the complete channel information and data are conducted between the same-cell sectors, and the cooperative gain is increased; none or few of data backhaul is conducted between the different-cell sectors, which results in decreased backhaul latency of the cooperating information, and increased throughput of the user at sector edge and system performance.

Owner:ALCATEL LUCENT SAS

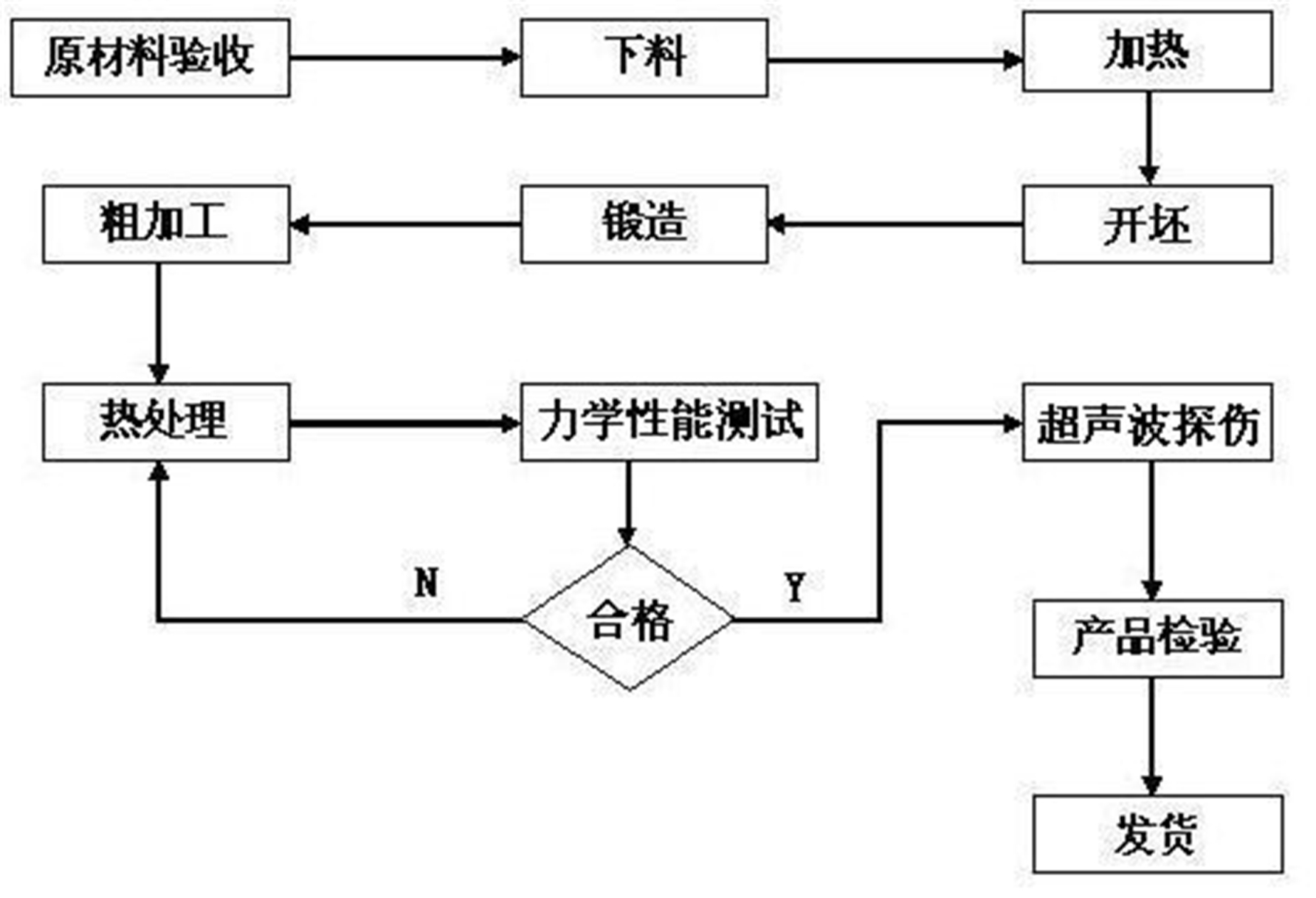

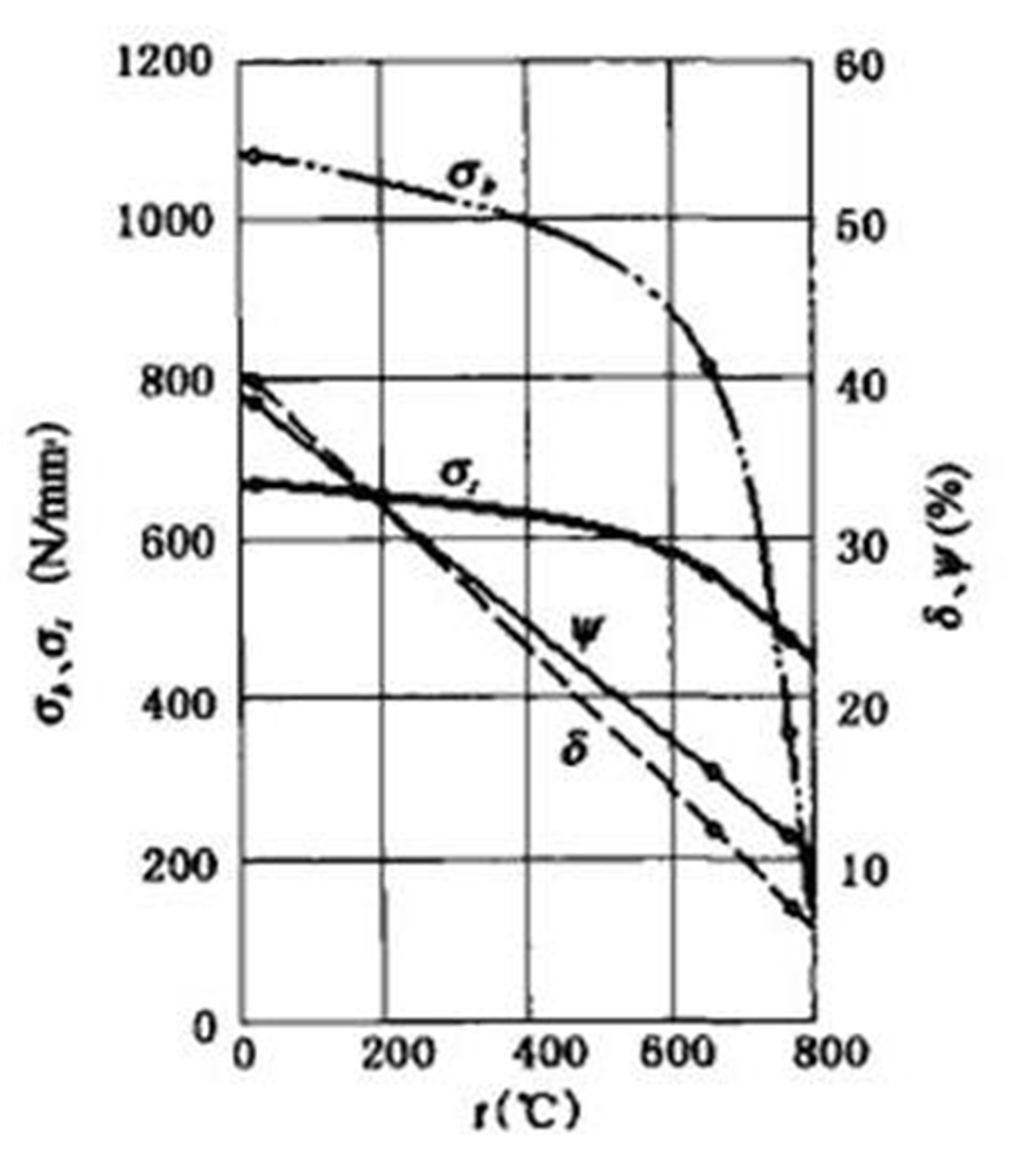

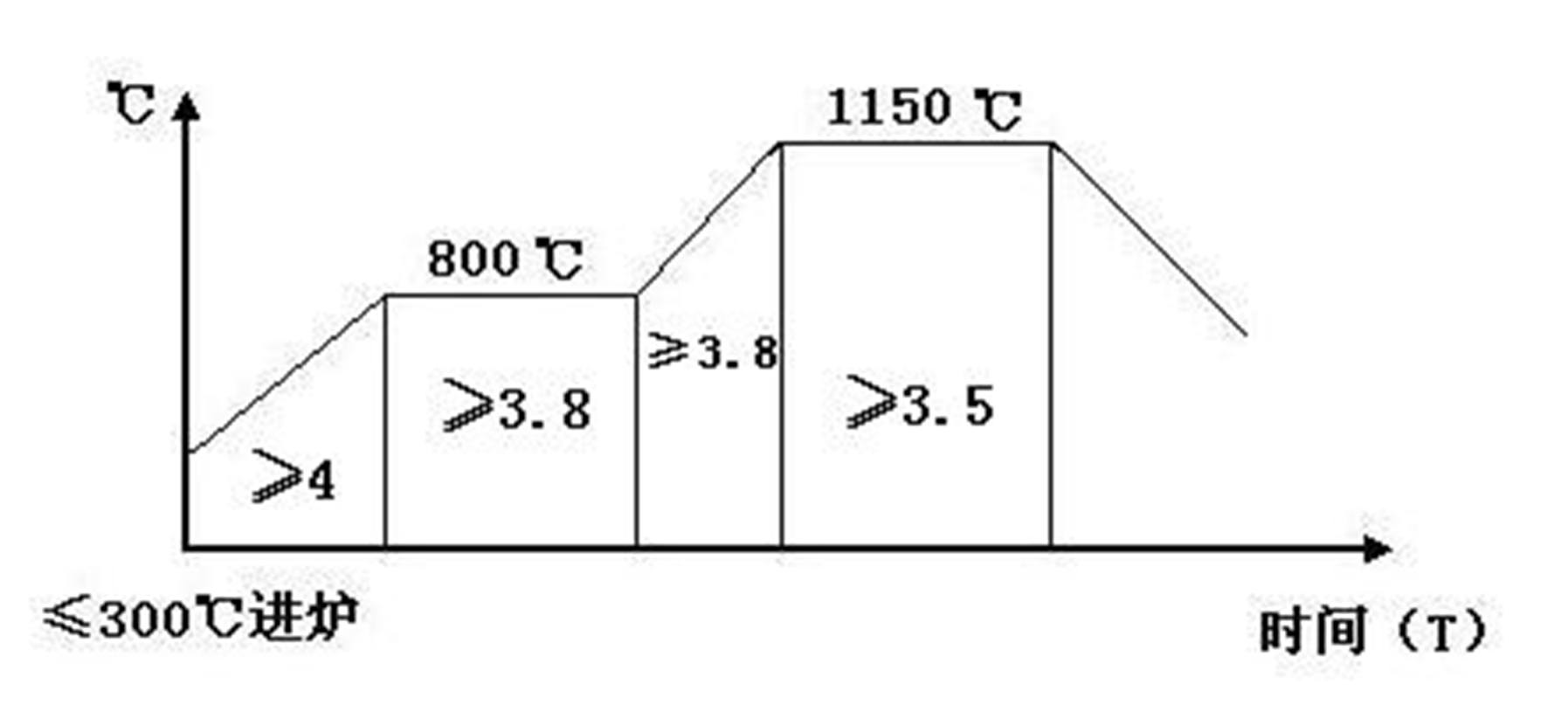

Method for manufacturing nickel-based high-temperature alloy forge piece

InactiveCN102357633AImprove competitivenessReduce mass consumptionMetal-working apparatusChemical compositionForging

The invention relates to the technical field of forge process, and provides a method for manufacturing a nickel-based high-temperature alloy forge piece. The method comprises the following steps of: (1) inspecting nickel-based high-temperature alloy raw materials, including re-inspection of chemical components and inspection of steel ingot surface; (2) blanking by adopting a sawing machine sawing method or a chopper hot chopping method; (3) heating the steel ingot; (4) cogging and performing forge deformation treatment; (5) performing last but one heating number forging and last heating number forging; (6) rough processing; (7) heat treating; (8) testing mechanical performance; (9) detecting faults with ultrasonic wave; and (10) inspecting products. According to the manufacturing method provided by the invention, home-made manufacture of nickel-based high-temperature alloy forge pieces achieves a success, utilization of China to the nickel-based high-temperature alloy is broken through, and the quality and grade of products of China can be improved, the requirement of domestic market for high-quality valve rods and valve discs of a steam turbine, seal rings in various specifications and critical parts in aerospace field can be fulfilled, and the competitive capability of native enterprises in the international market can be improved.

Owner:上海宏钢电站设备铸锻有限公司

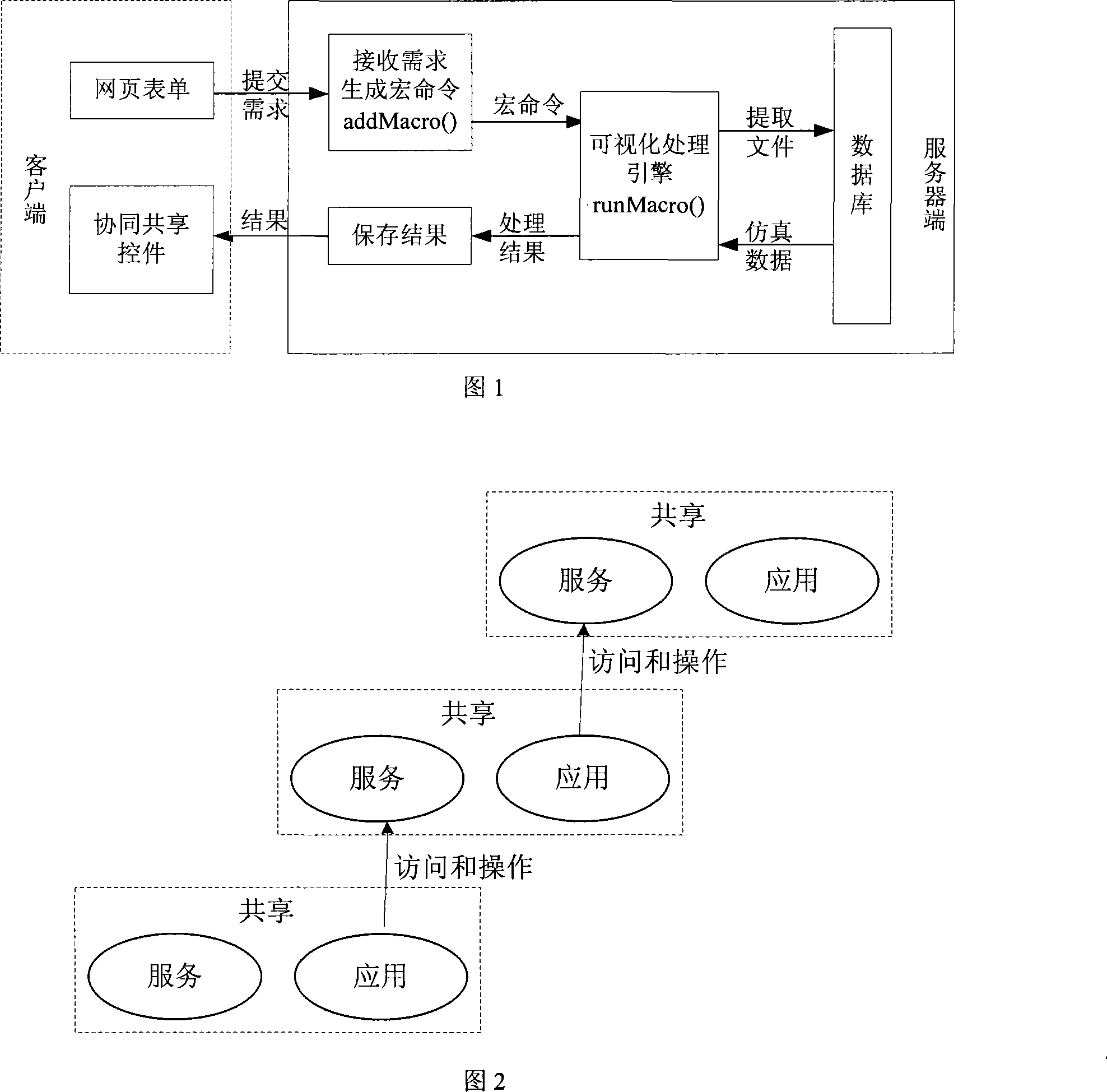

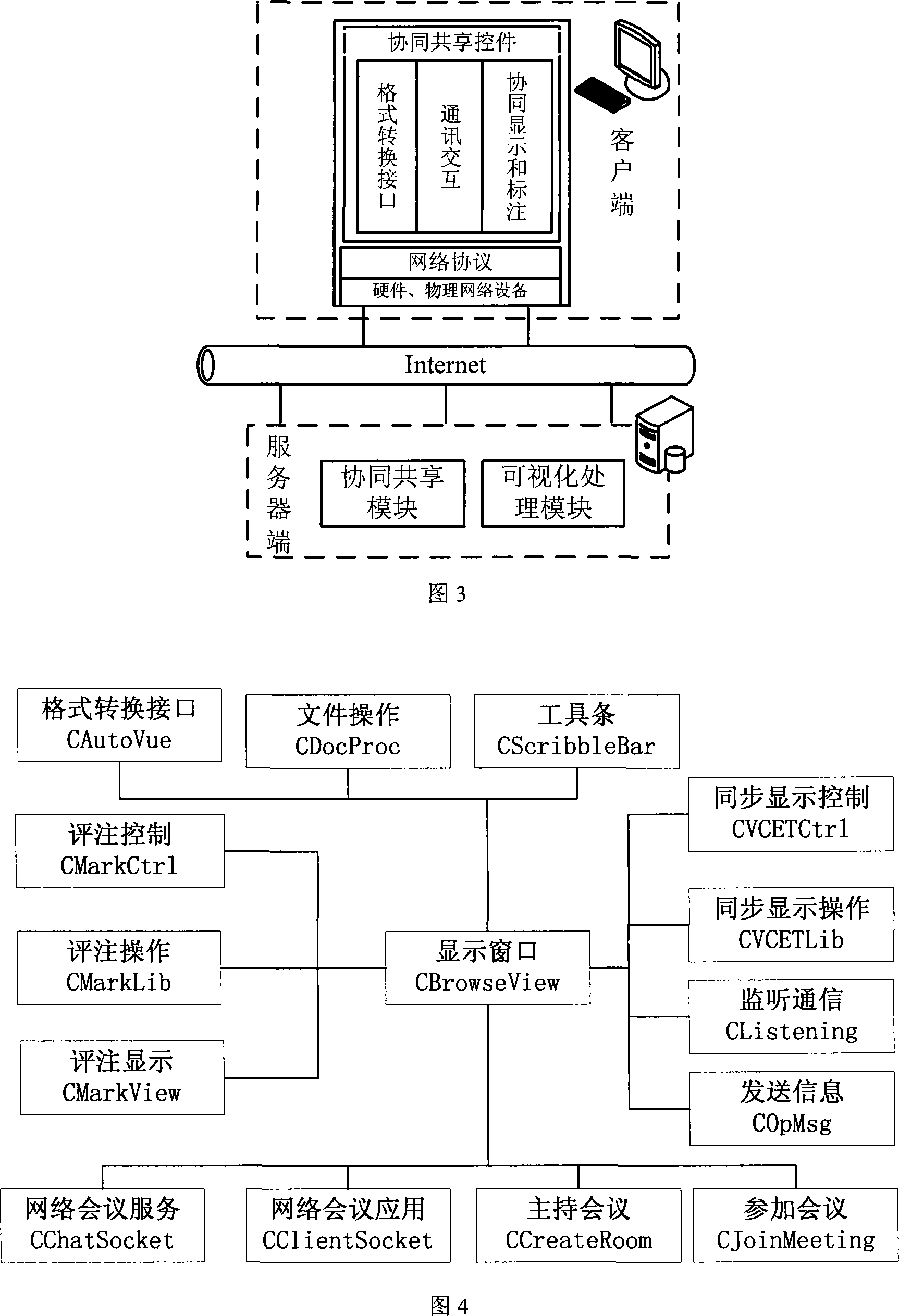

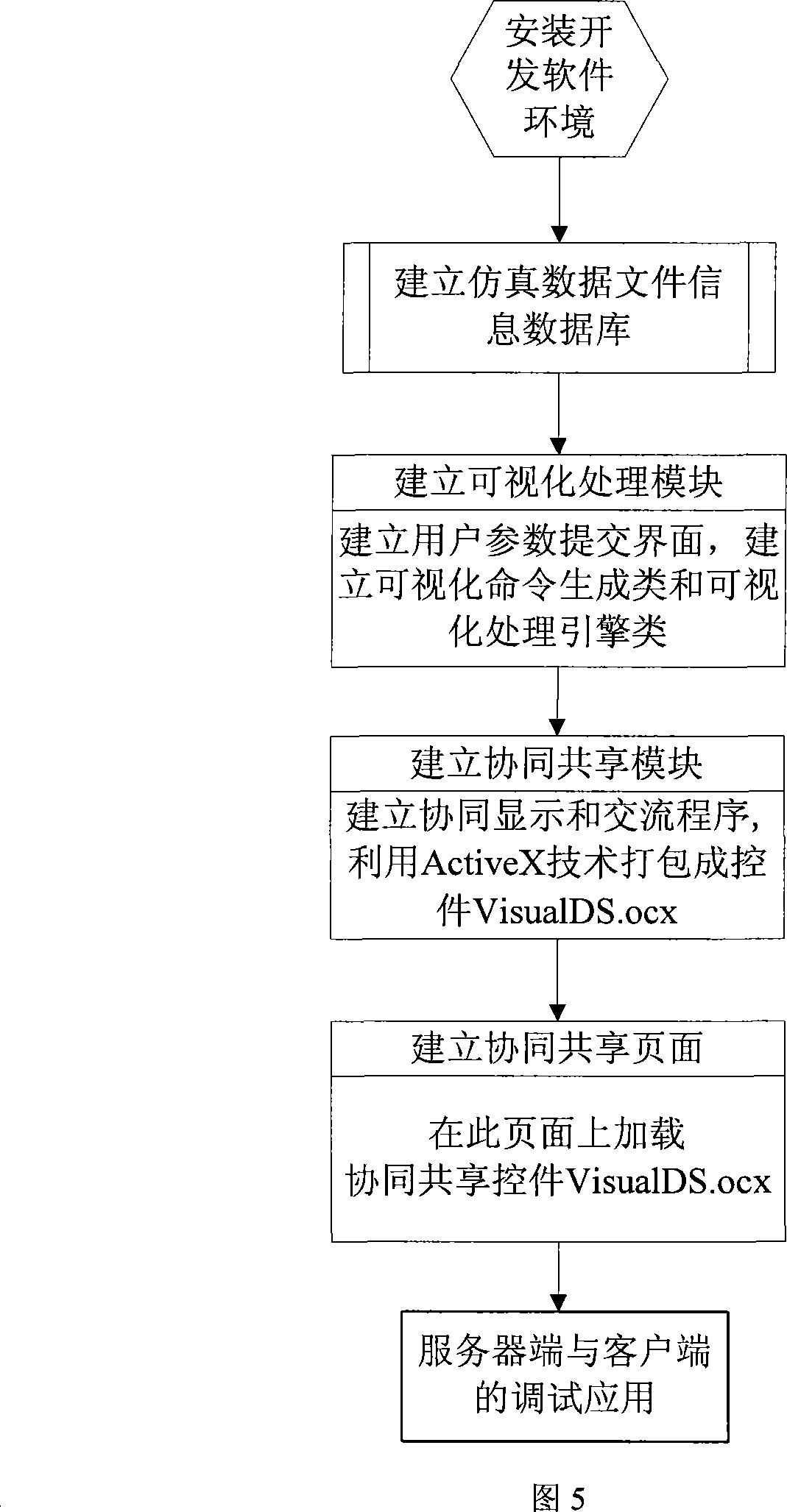

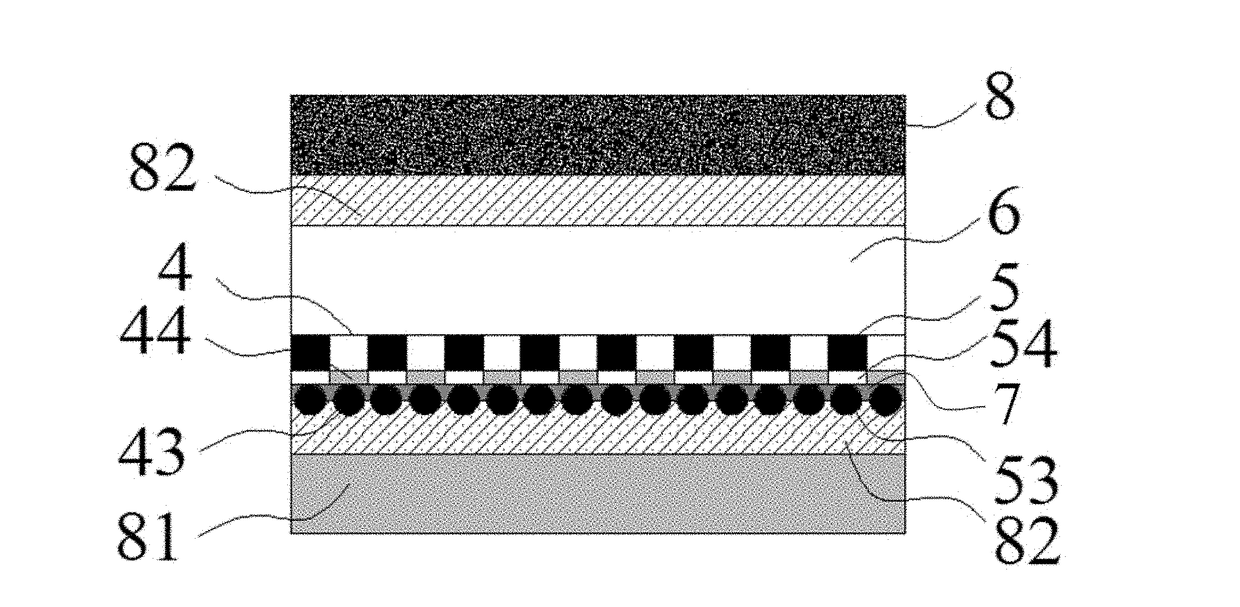

Emulated data visualized and cooperated sharing method

InactiveCN101216846AFix compatibility issuesRealize visualizationSpecific program execution arrangementsSpecial data processing applicationsData visualizationNetwork communication

The invention discloses a visualization cooperative sharing method for simulation data in network environment, belonging to the technical field of data visualization for simulation data network communication. The method is characterized in that a simulation data visualization processing module is created at the server side to provide users a parameter submission interface and a processing engine, thus realizing visualization processing the simulation data document according to the necessary parameters, and a simulation data cooperative sharing module is created to provide users a public virtual environment, thus realizing a remote simultaneous display; a common browser is used at client side to provide an operating interface and the visualization parameters are sent to the business logic class in the visualization processing module for visual processing through the parameter submission interface and the processing result is cooperative displayed and annotated in an end to end model between client sides and between the client side and the server. The invention fills in the blank of simulation data visualization and cooperative sharing in network environment.

Owner:TSINGHUA UNIV

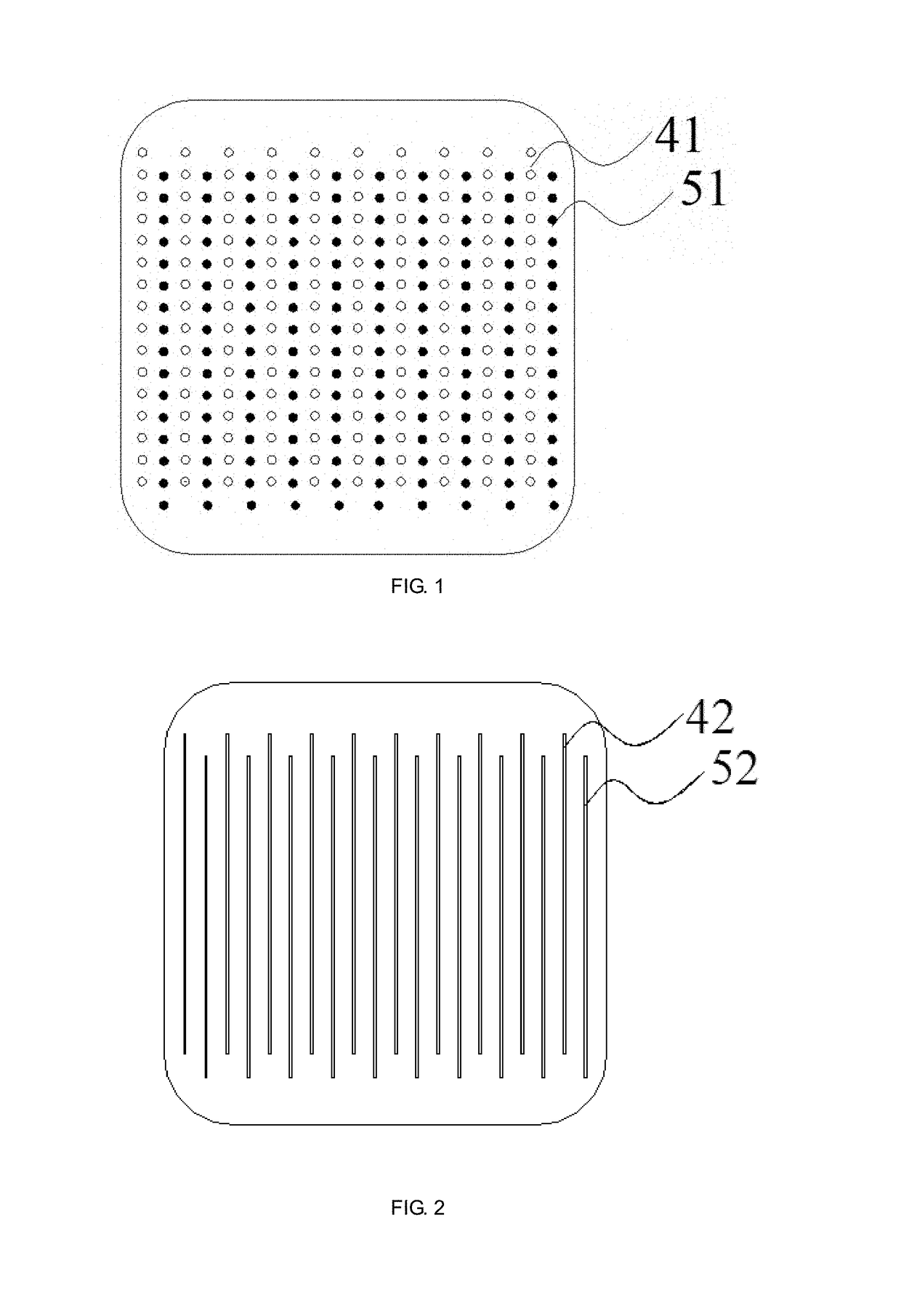

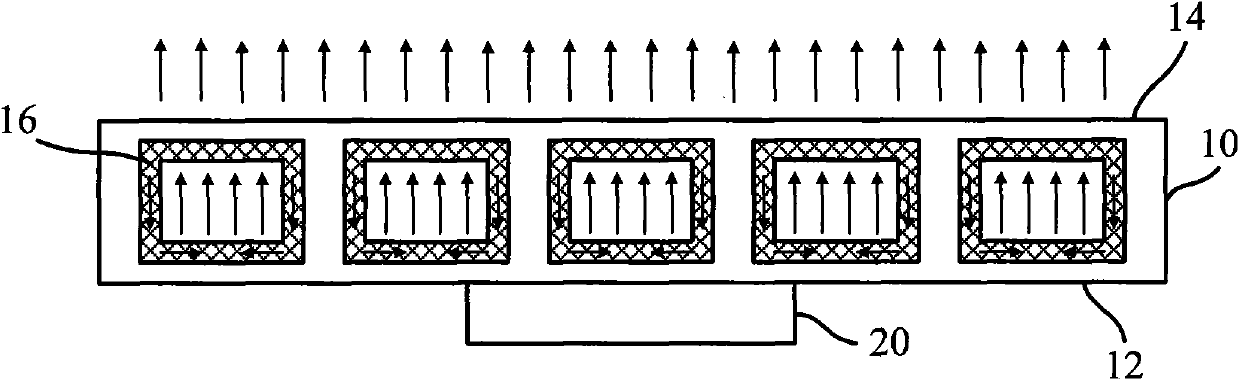

Main-gate-free and high-efficiency back-contact solar cell module, main-gate-free and high-efficiency back-contact solar cell assembly, and preparation process thereof

ActiveUS20170222082A1Reduces electron collection distanceReduced series resistanceFinal product manufacturePV power plantsElectricityCrack resistance

The present invention relates to the field of solar cells, and in particular to a main-gate-free and high-efficiency back-contact solar cell module, a main-gate-free and high-efficiency back-contact solar cell assembly, and a preparation process thereof. The solar cell module, comprising cells and an electrical connection layer, a backlight side of the cells having P-electrodes connected to a P-type doping layer and N-electrodes connected to a N-type doping layer, is characterized in that the electrical connection layer comprises a number of parallel leads each electrically connected to the P-electrodes or the N-electrodes. The present invention has the beneficial effect that a main-gate-free and high-efficiency back-contact solar cell module, a main-gate-free and high-efficiency back-contact solar cell assembly, and a preparation process thereof are provided, which can effectively the short-circuiting of the P-electrodes and the N-electrodes and has the advantages of low cost, high hidden-cracking resistance, high efficiency and high stability.

Owner:JOLYWOOD SUZHOU SUNWATT

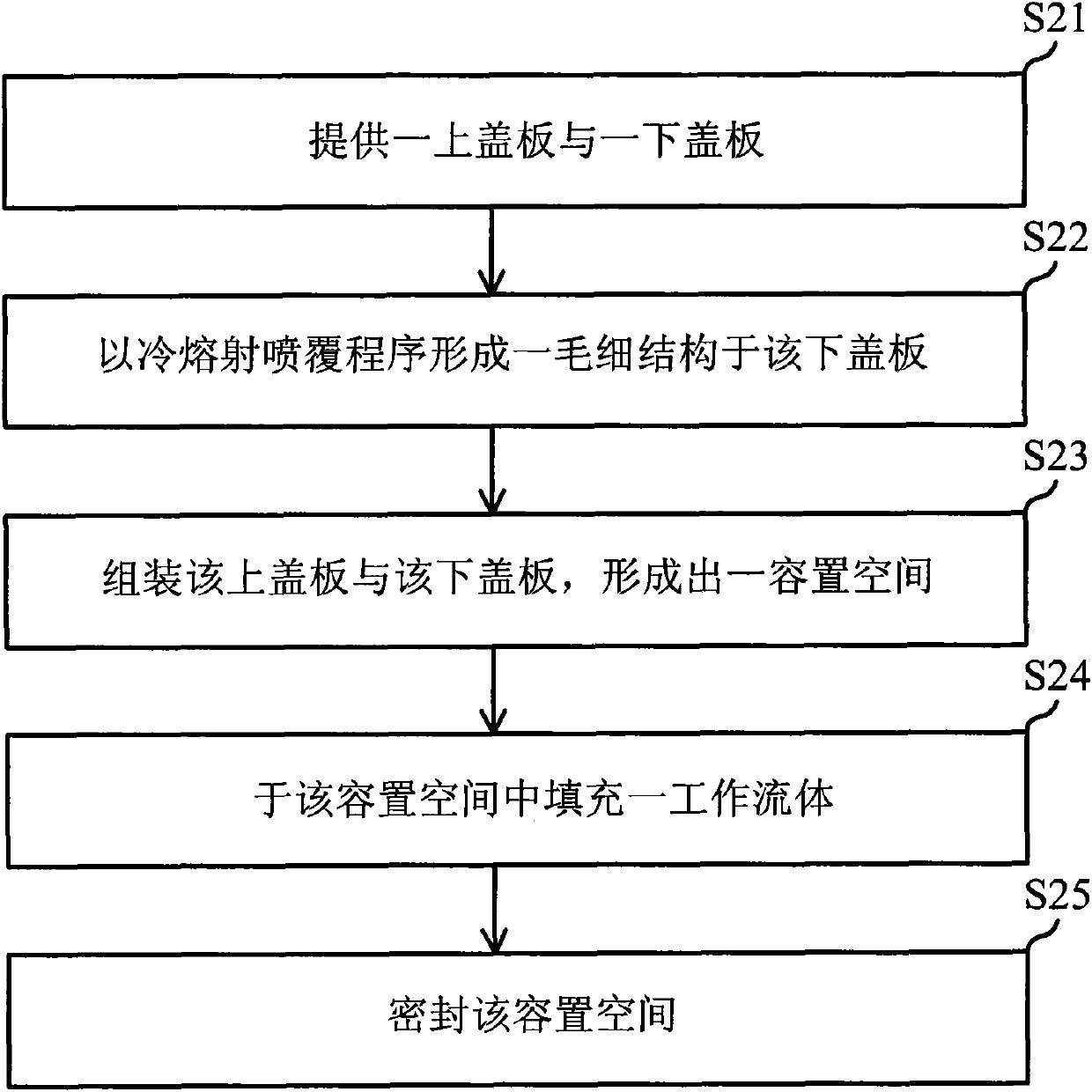

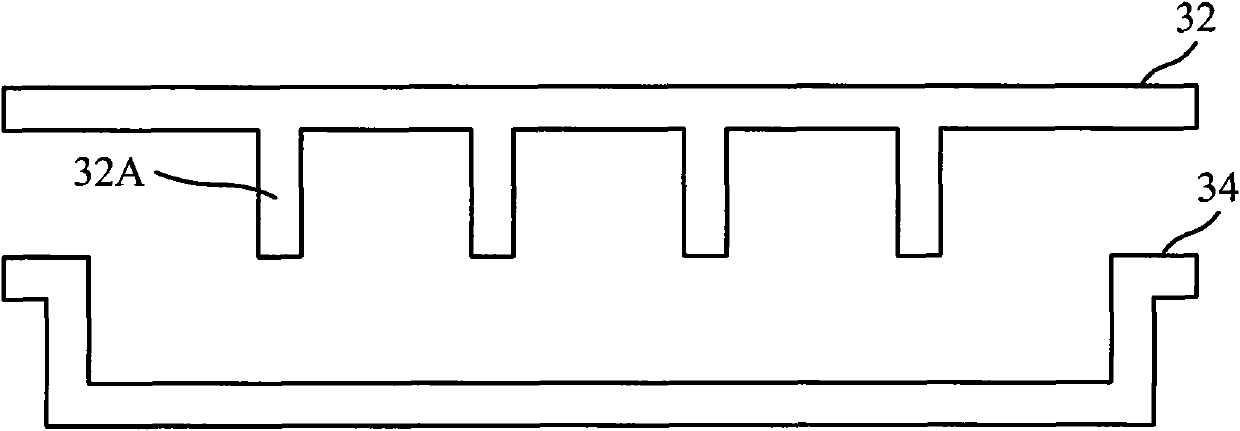

Temperature-equalizing plate and manufacture method thereof

ActiveCN102019543AShorten production hoursIncrease productivityMolten spray coatingSemiconductor/solid-state device detailsWorking fluidEngineering

The invention provides a temperature-equalizing plate and a manufacture method thereof. The manufacture method of the temperature-equalizing plate comprises the following steps of: firstly, providing an upper cover plate and a lower cover plate; secondly, forming a capillary structure on the lower cover plate through a cold-melting spraying procedure; thirdly, assembling the upper cover plate and the lower cover plate to form at least one containing space in which the capillary structure is positioned; and finally, sealing the containing space after filling working fluid in the containing space. Thus, the temperature-equalizing plate manufactured with the manufacture method of the invention comprises a shell, the working fluid and the capillary structure, wherein the containing space is formed in the shell, the working fluid is filled in the containing space, and the capillary structure is formed on the inner wall of the containing wall through the cold-melting spraying procedure.

Owner:PEGATRON

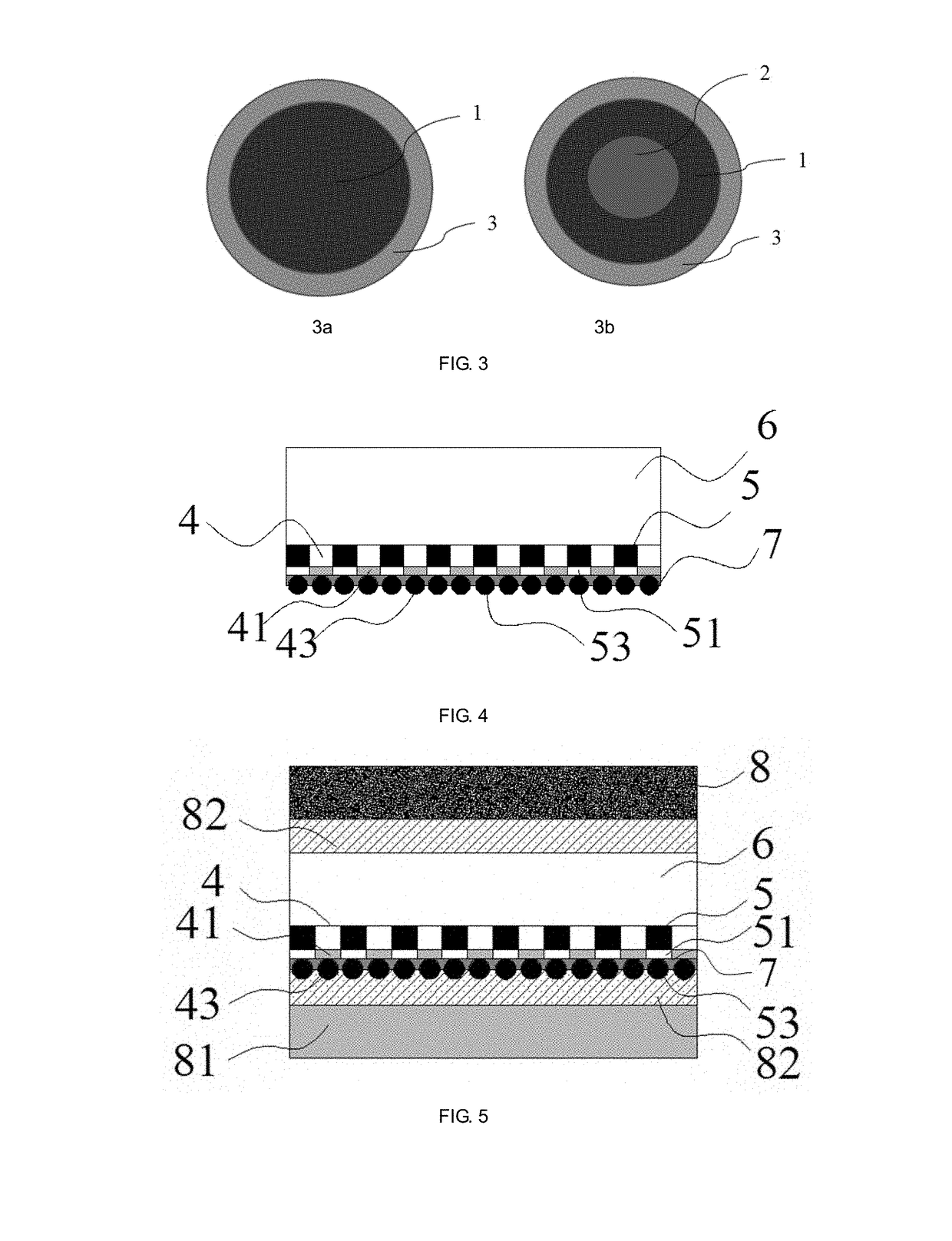

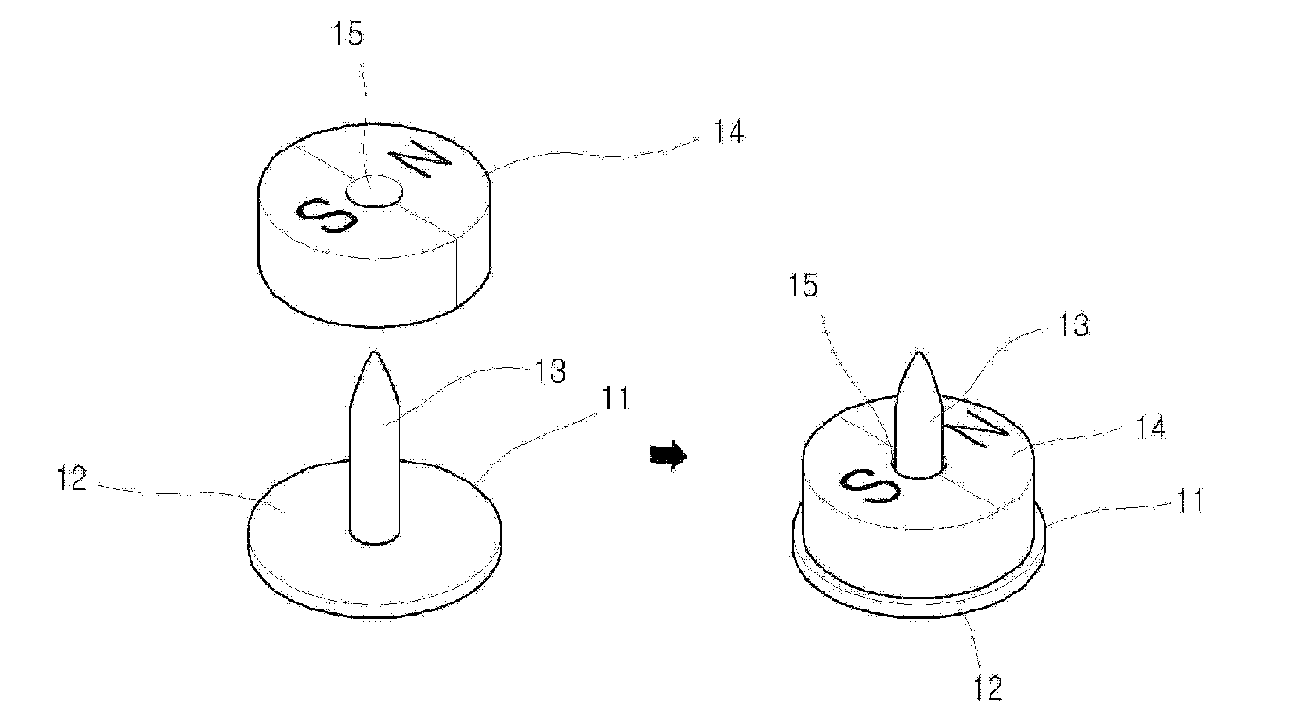

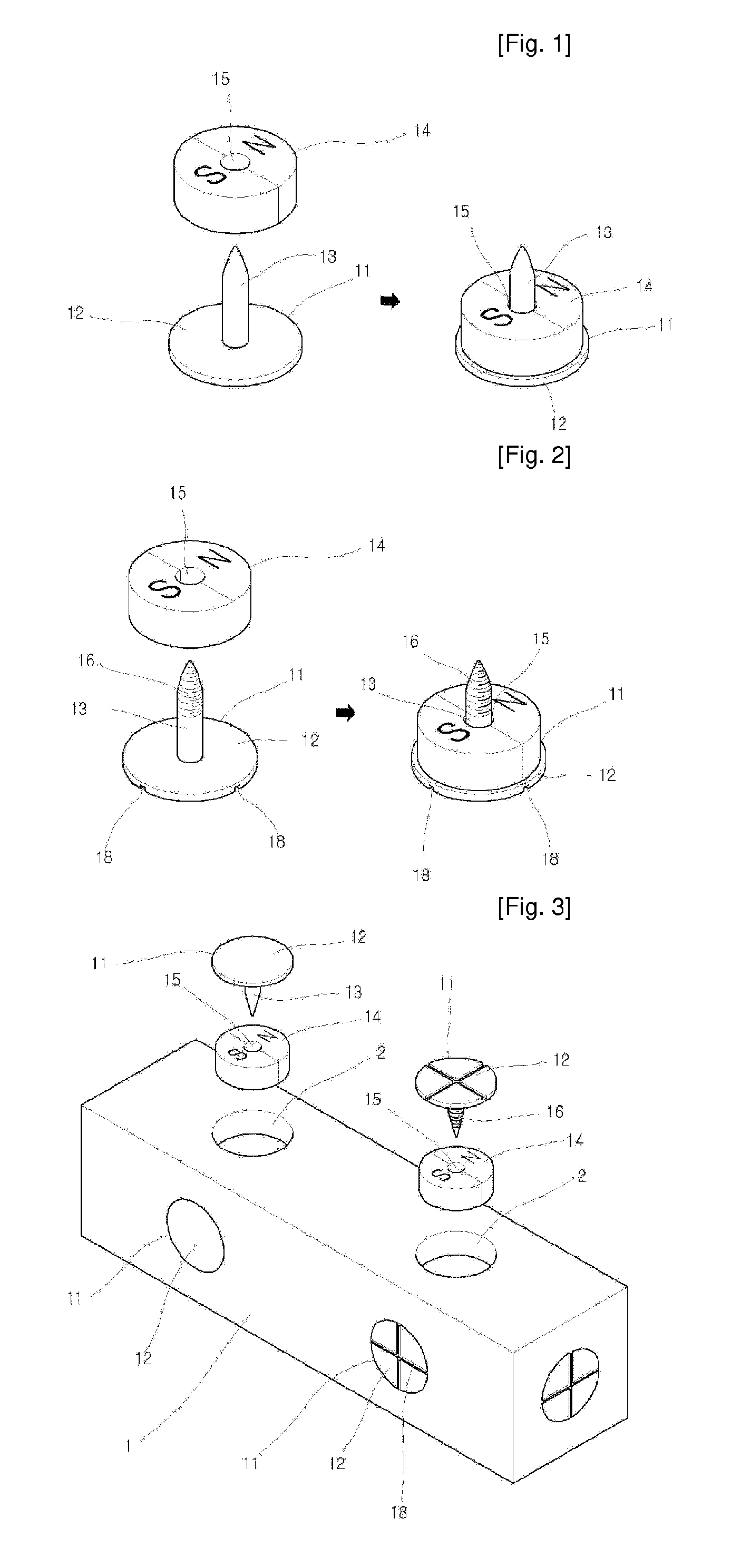

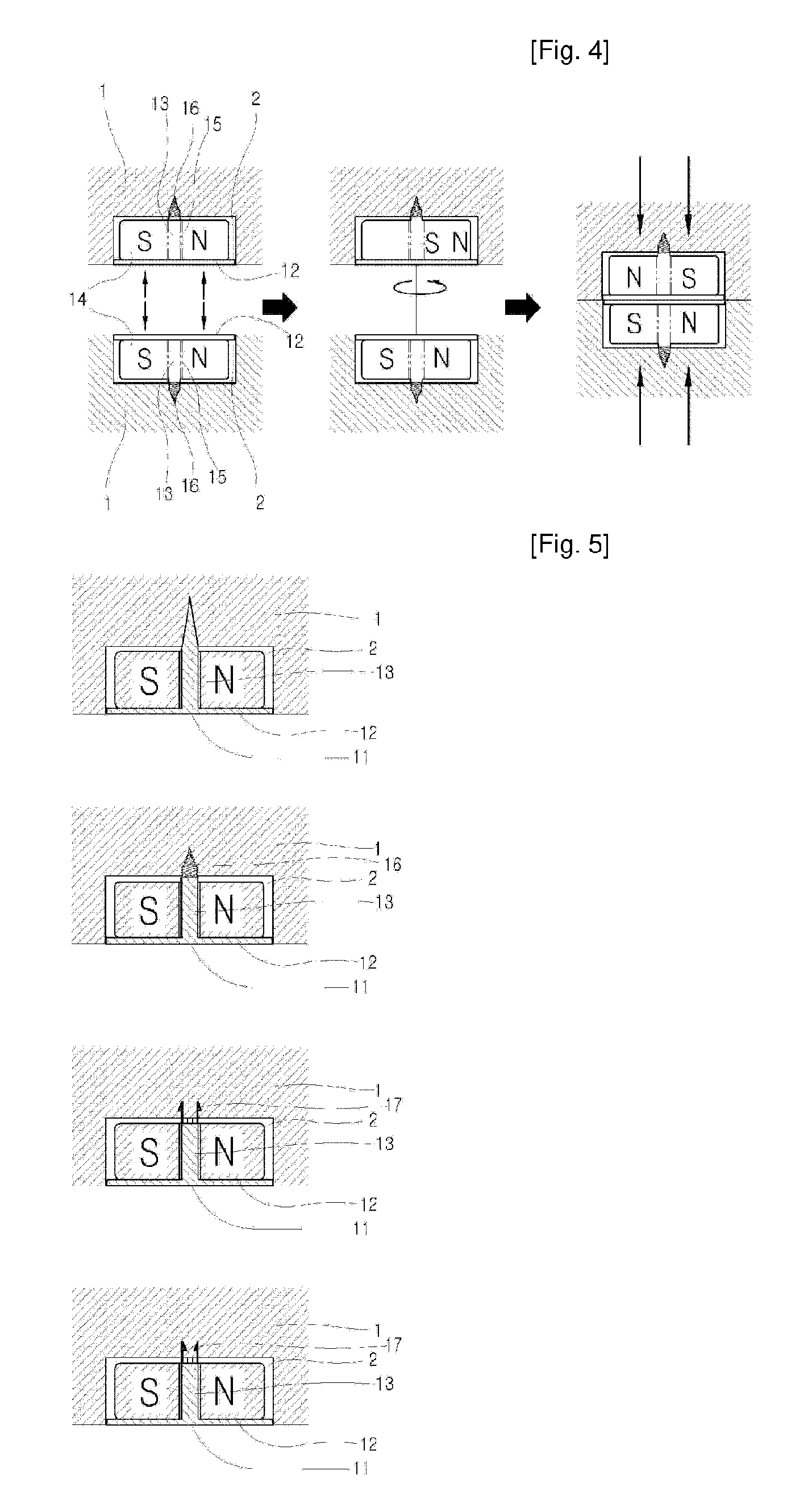

Magnet And Pin for Block Toy

A rotary magnet and a fastening pin for block toys are disclosed. The object of the present invention is to provide a structure such that the production cost can be reduced, the magnet and the pin can be easily installed in a block, and appropriate attractive force can be easily generated between blocks. The fastening pin (11) include a fastening plate part (12), which has a diameter suitable for fitting the fastening plate part into a seating depression (2) of the block (1), and a pin part (13), which has a height greater than that of the rotary magnet (14). The rotary magnet (14) has an N pole and an S pole on the left and right parts thereof. A through hole (15) is formed through the center of the rotary magnet (14), so that the pin part (13) can be inserted into the through hole (15).

Owner:KIM DONG WAN

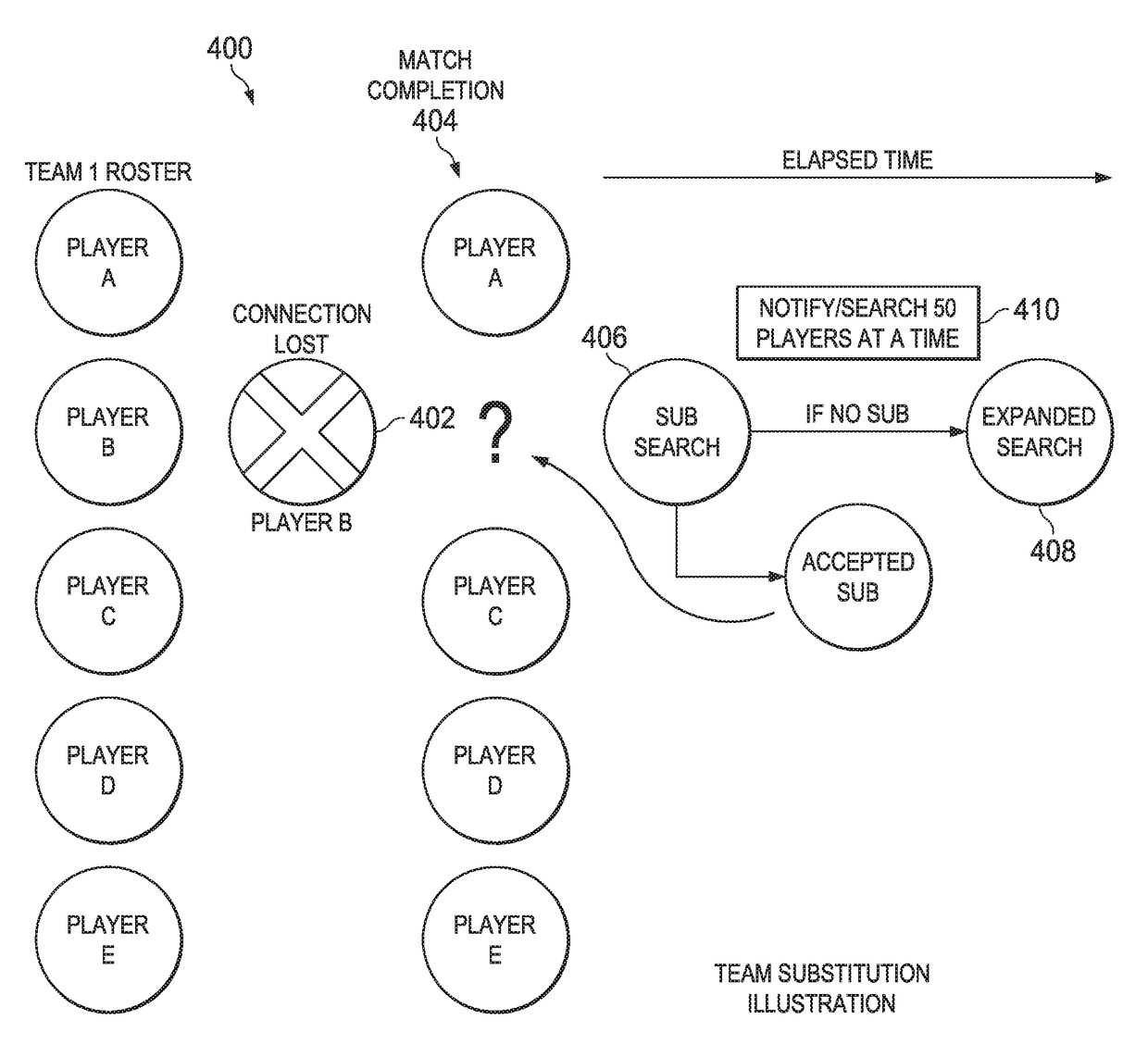

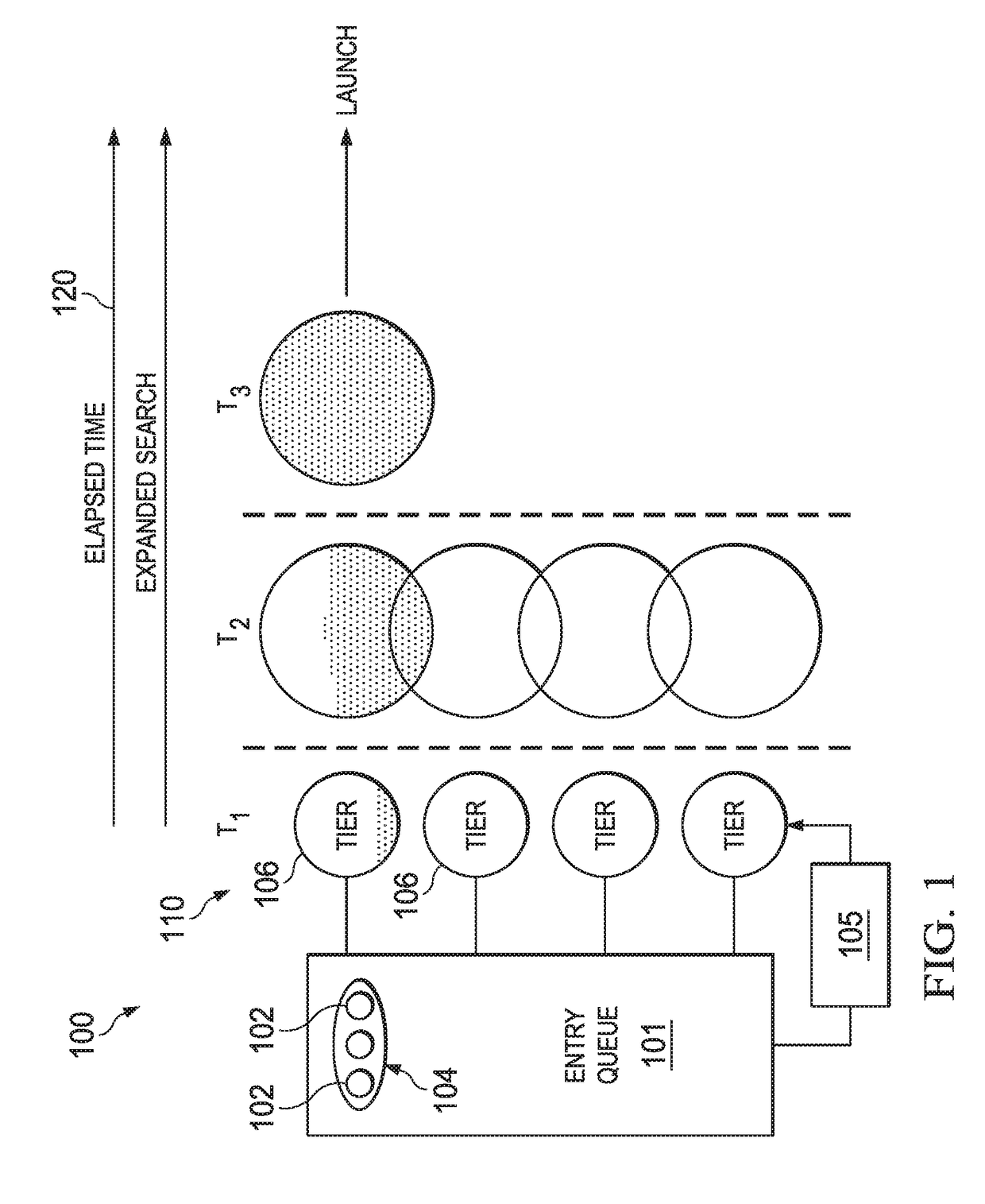

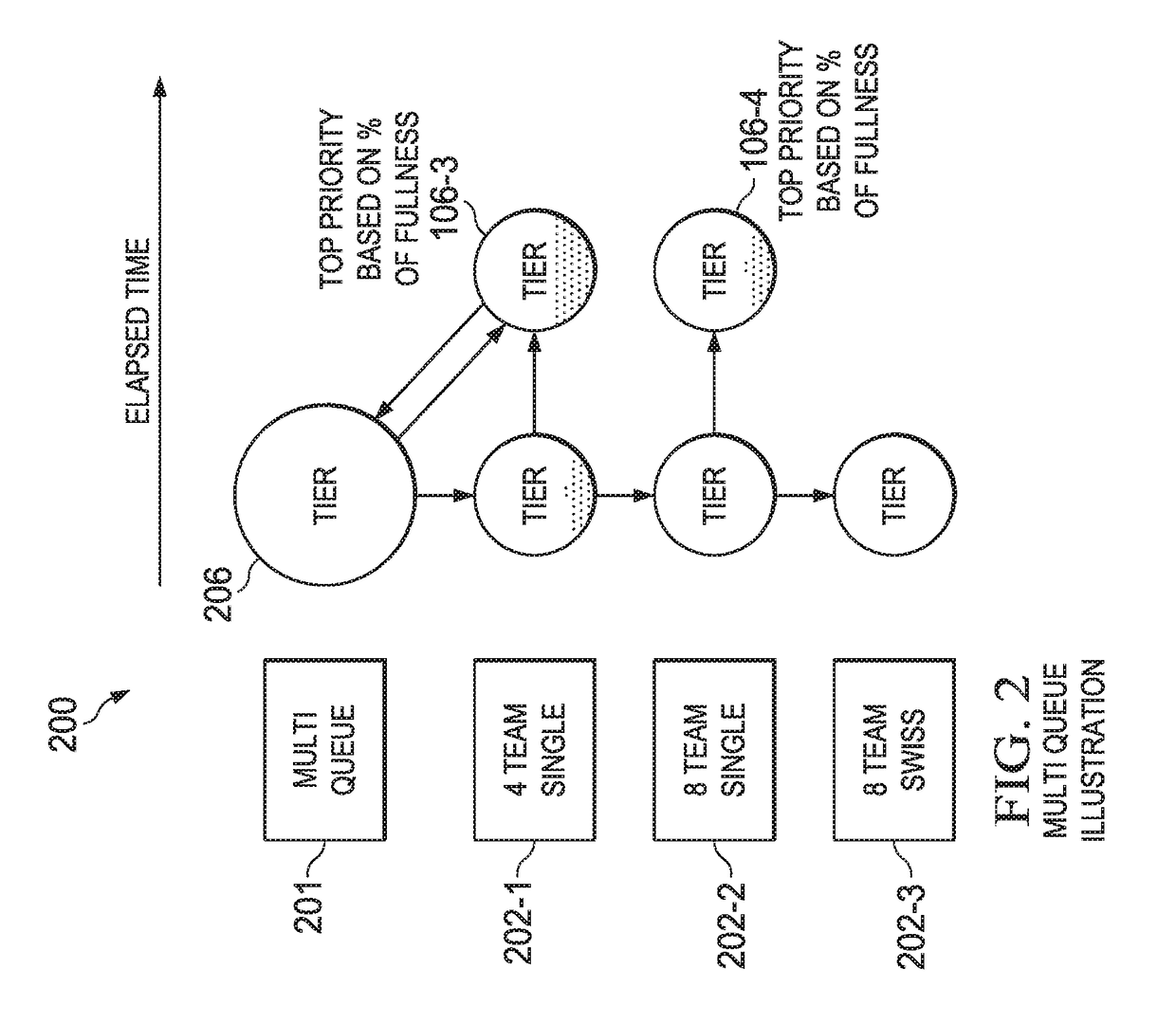

Automated tournament platform for online video games

InactiveUS20170282082A1Improve competitivenessIncrease experienceOffice automationResourcesManagement processSkill sets

An on-line tournament management process includes a team substitution feature suitable when one tournament team loses a player to a disconnection or other unforeseen circumstance. The process may include maintaining roster information for first and second teams. Responsive to detecting a lost connection corresponding to a first player of the first team, performing substitution operations that may include: accessing skill level attributes of the first player, performing a search for a replacement player for replacing the first player in accordance with the skill level attributes and offering at least some eligible standby players, determined in accordance with criteria for matching the skill level attributes of the first player, a substitution spot corresponding to the open roster spot. After monitoring for an acceptance from an eligible player and not receiving an acceptance, additional eligible standby players may be offered the substitution spot. Additional eligible players may be identified by relaxing the degree of matching criteria.

Owner:ATTAQ ONLINE INC

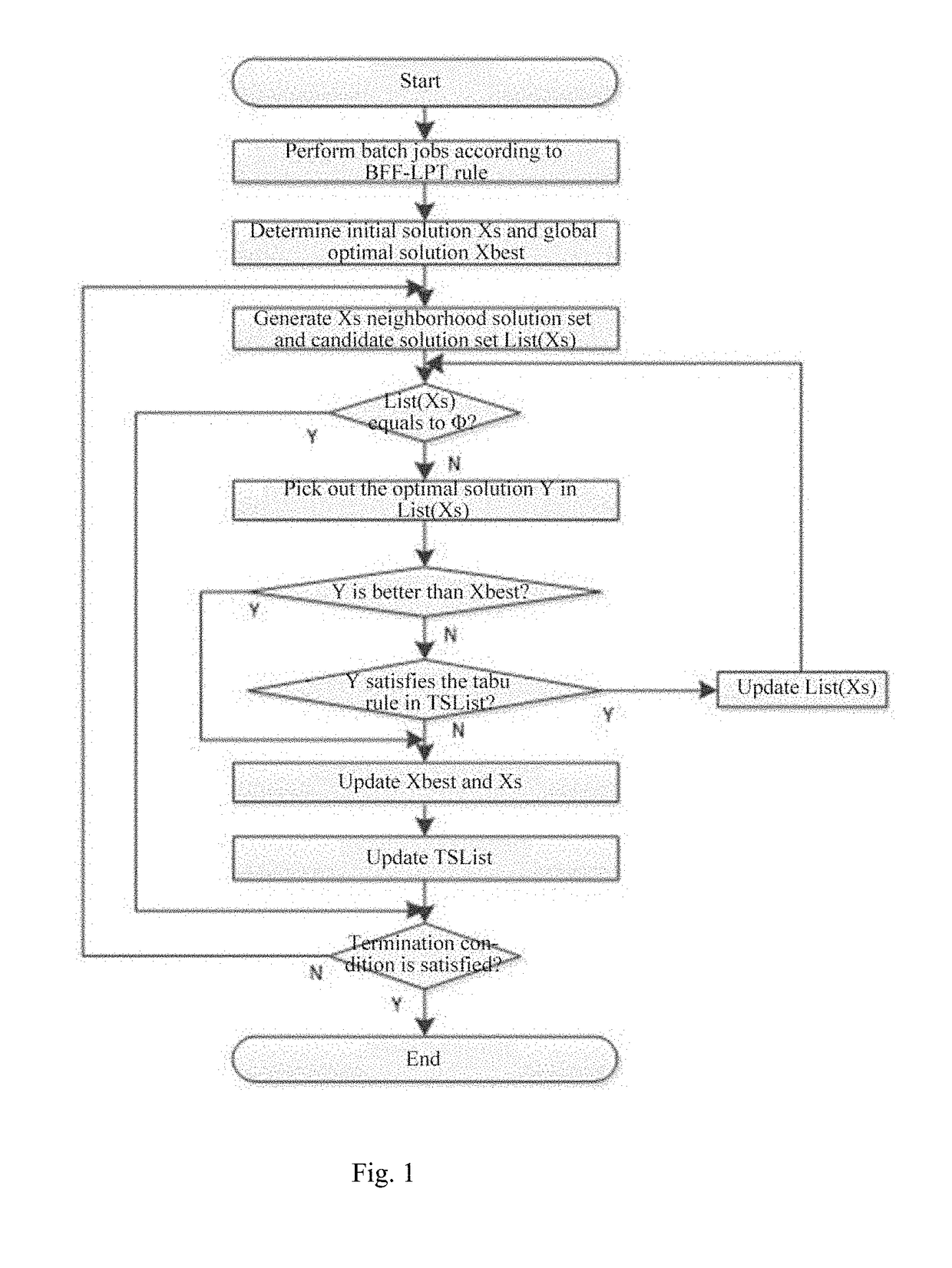

Coordinated Production and Transportation Scheduling Method and System Based on Improved Tabu Search Algorithm

InactiveUS20190080271A1Quality improvementImprove competitivenessRandom number generatorsForecastingTransportation schedulingComputer science

The present invention discloses a coordinated production and transportation scheduling method and system based on an improved tabu search algorithm, and a storage medium. The method includes batching jobs, initializing algorithm parameters, generating an initial solution, generating a neighborhood solution set, performing mutation, crossover and selection on individuals, determining a candidate solution set; calculating a fitness value of an individual, updating the candidate solution set; updating a tabu list, and determining whether an algorithm termination condition is satisfied; if yes, outputting the global optimal solution; otherwise, returning to the step 4. The present invention is mainly aimed at the coordinated production and transportation batch scheduling problem with multiple manufacturers. The whole profit of an enterprise in the production and transportation phases can be maximized, and high quality services can be provided for customers of the enterprise with improved core competitiveness of the enterprise.

Owner:HEFEI UNIV OF TECH

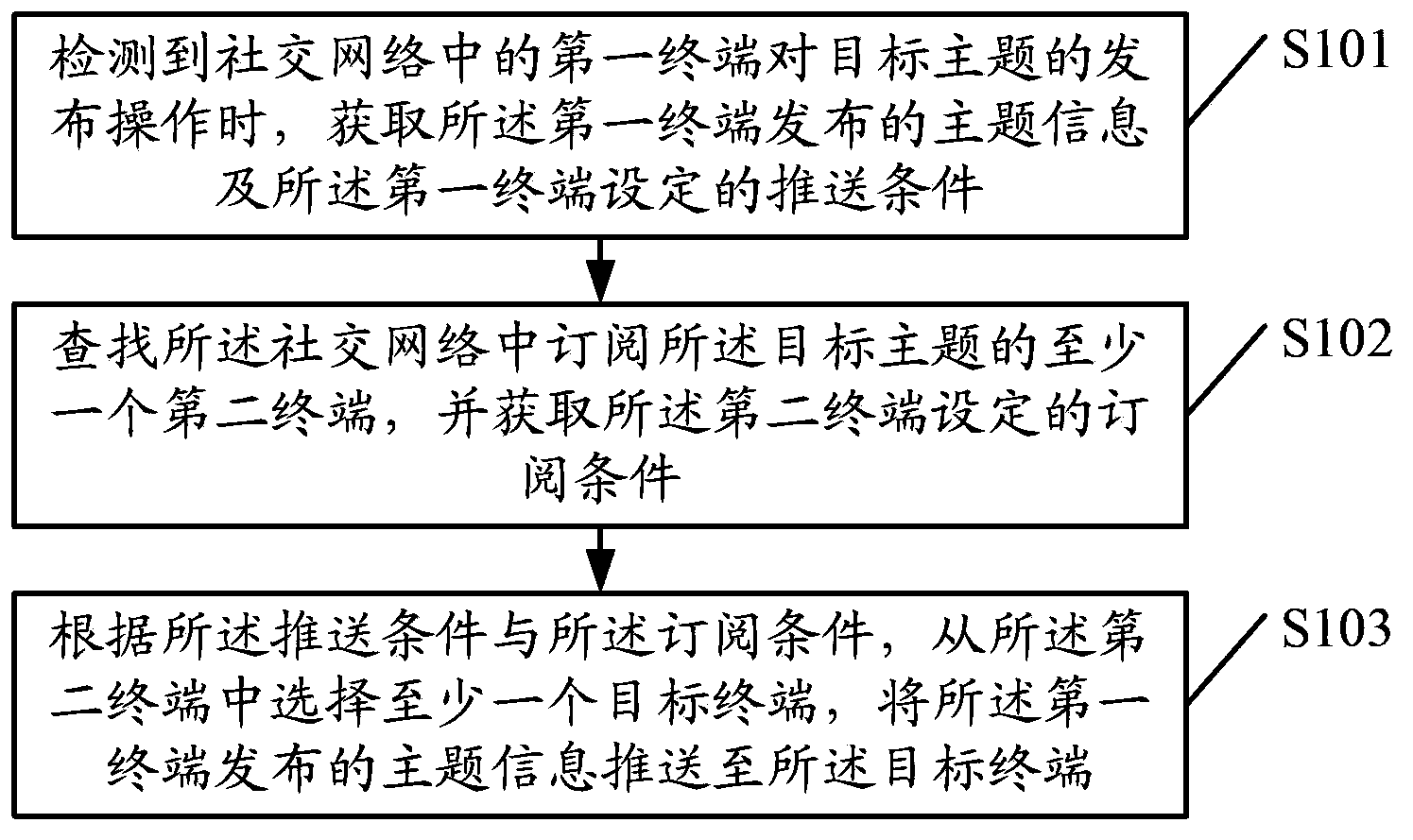

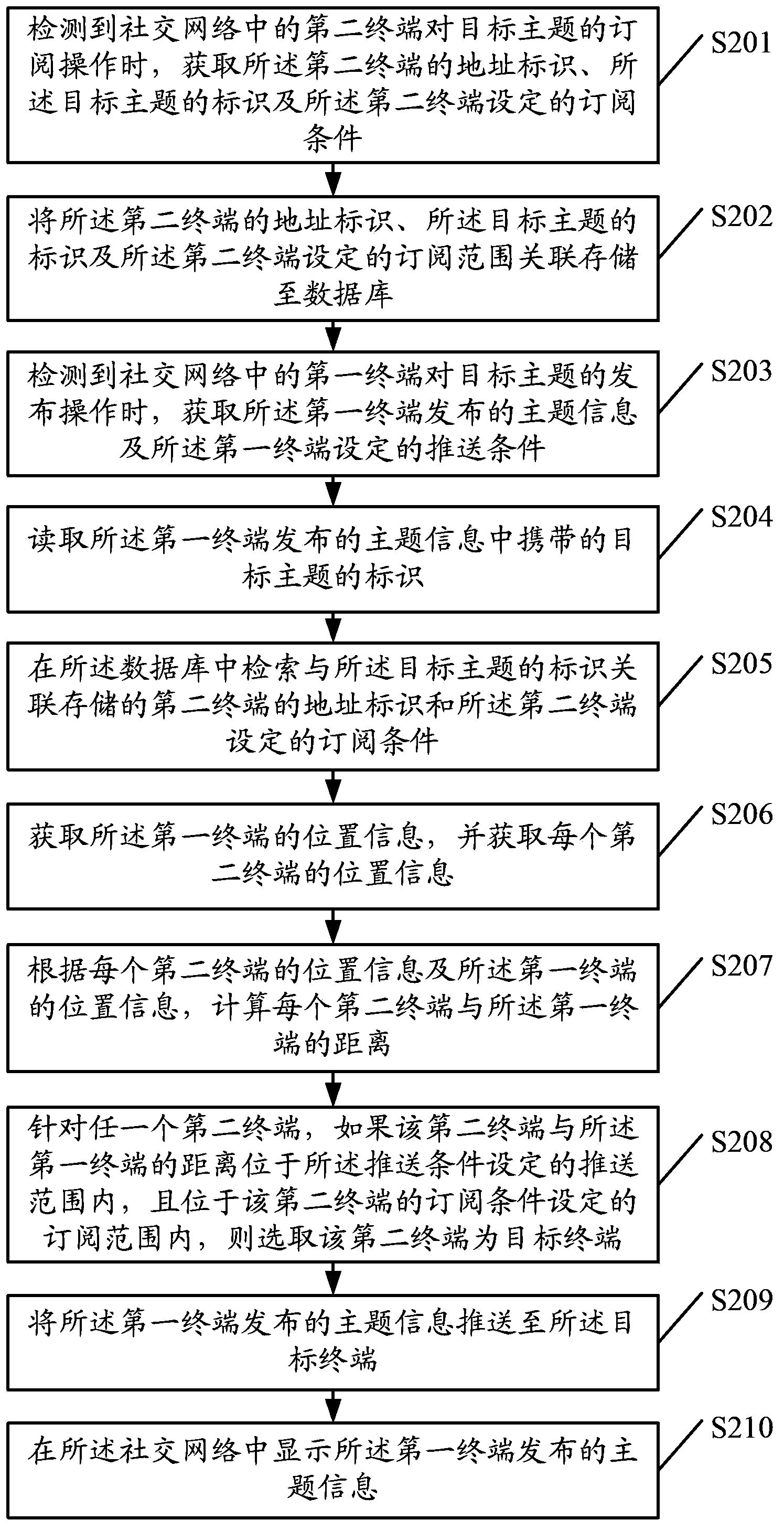

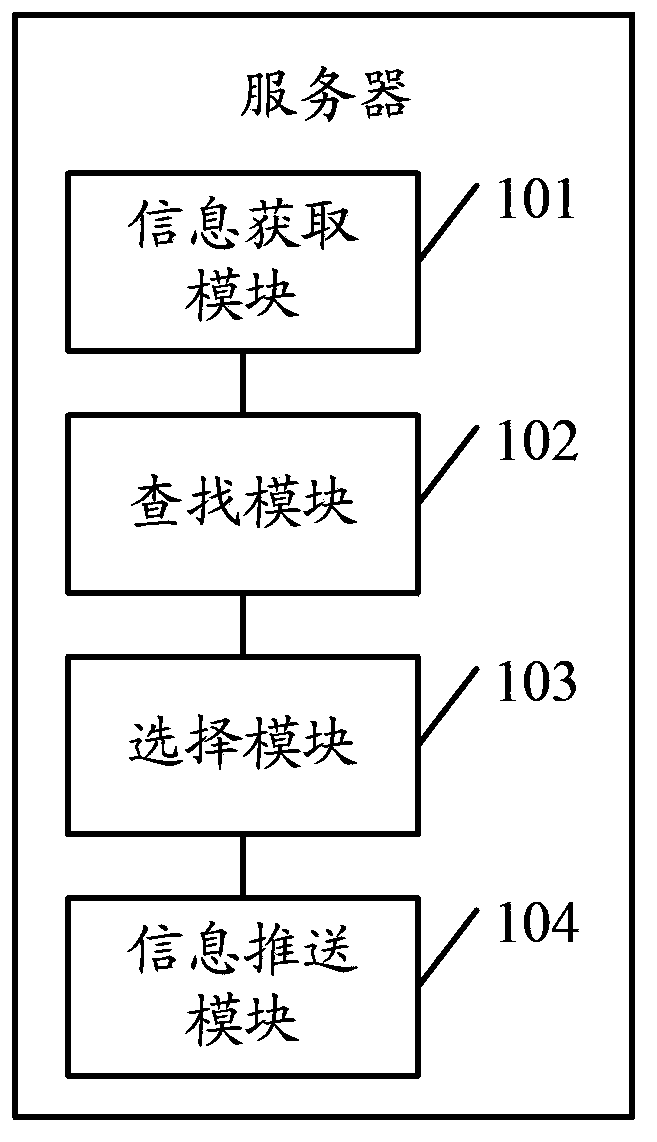

Social network information push method, server and social network

ActiveCN103905471AHigh viscosityFacilitate communicationData switching networksComputer terminalSocial web

The embodiments of the invention provide a social network information push method, a server and a social network. The method can comprise: when it is detected that a first terminal in a social network performs issuing operation on a target theme, obtaining the theme information issued by the first terminal and a push condition set by the first terminal; searching for at least one second terminal subscribing the target theme in the social network, and obtaining a subscription condition set by the second terminal; and according to the push condition and the subscription condition, selecting at least one target terminal from the second terminal, and pushing the theme information issued by the first terminal to the target terminal. According to the invention, specific information push can be carried out, so that the exchange and communication between terminal users can be improved, the intelligence and competiveness in the social network can be improved, and the user stickiness of the social network is enhanced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Local chicken breeding method

InactiveCN103004690APromote egg productionImprove competitivenessAnimal husbandryAgricultureBroiler chick

The invention provides a local chicken breeding method and belongs to the field of agriculture livestock breeding. The method comprises the following steps that 1) local chicken cultivating chambers are managed; 2) local chickens enter the cultivating chambers for carrying out feeding management and disease prevention mangamenet at each stage; 3) a food guide mode is adopted for taking the local chickens into the next field, and in addition, the field expansion is carried out to enter the normal feed management stage. The breeding method has the advantages that the baby chick survival, the adult children growth and meat value and the egg laying of hens are greatly improved, so broiler chicken and eggs have great competitiveness in the market, and in addition, direct economic benefits are generated for farmers.

Owner:袁青松

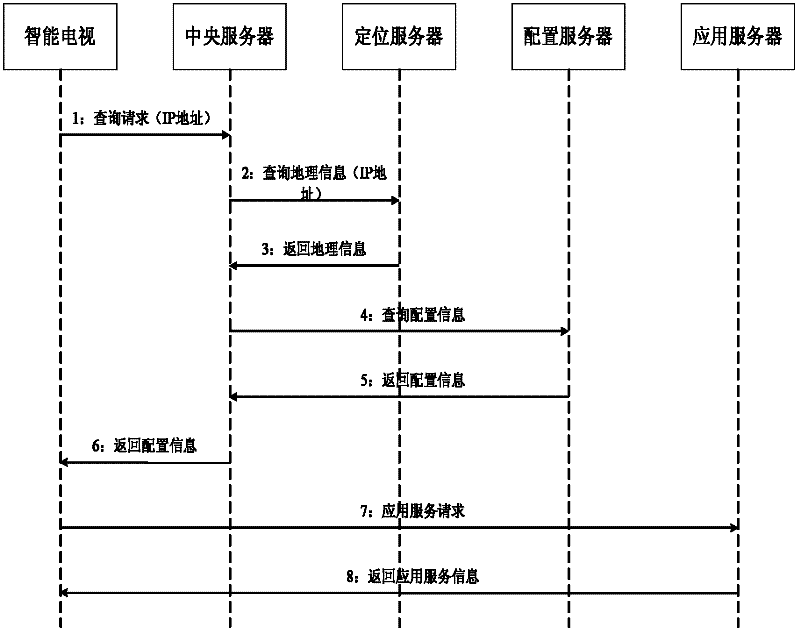

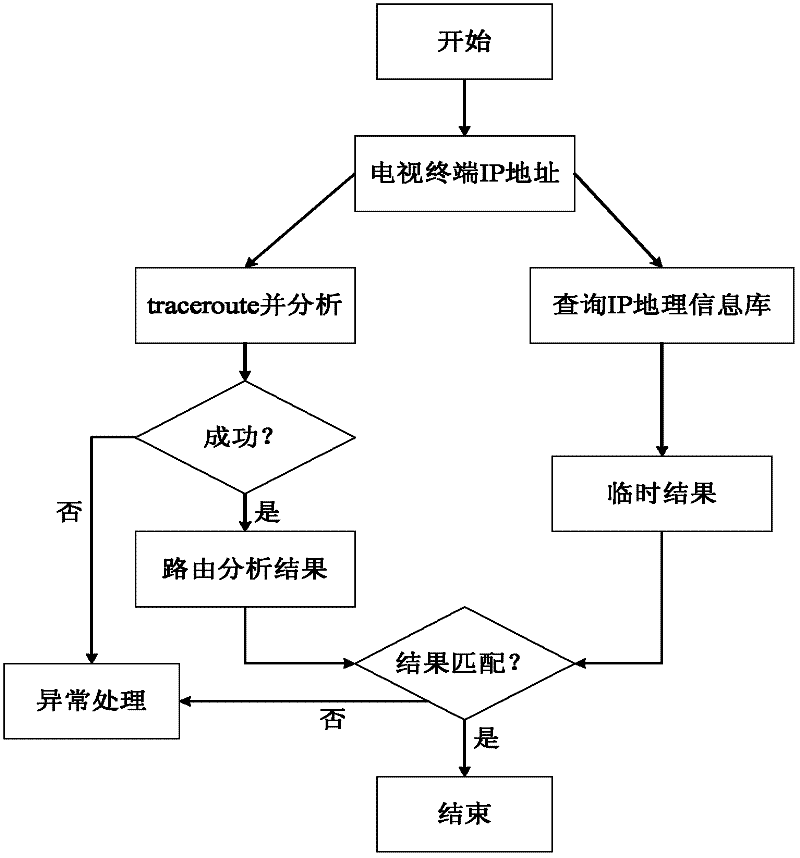

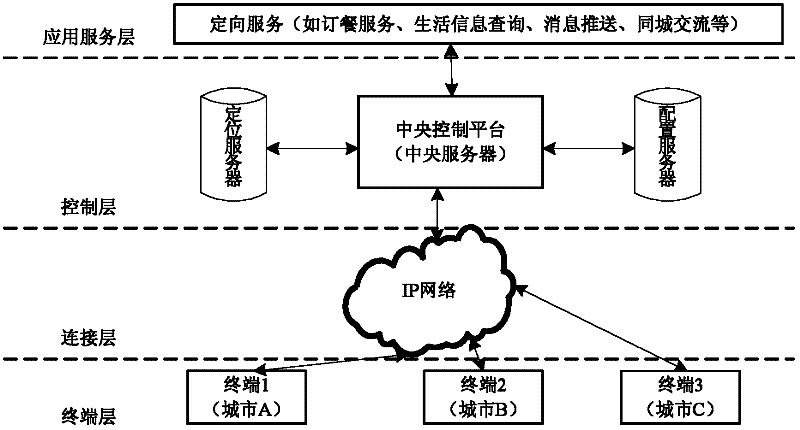

Method and device as well as system for positioning geographic position of television

ActiveCN102595249AEasy to operateMeet different needsTransmissionSelective content distributionInformation repositoryIp address

The invention relates to the technical field of digital televisions and provides a method and system for positioning the geographic position of a television. The method comprises the following steps of: receiving a request of asynchronously inquiring configuration information, which is put forward in the starting-up process of the television; obtaining the IP (Internet Protocol) address of the television from TCP / IP (Transmission Control Protocol / Internet Protocol) connection according to the request; and inquiring on the basis of the IP address of the television to obtain the geographic information showing the current geographic position of the television. According to the technical scheme of the embodiment of the invention, GPS (Global Positioning System) positioning is not needed, and the positioning of the television can be realized by inquiring an IP address information base and / or routing tracking operation, thereby the geographic position of the terminal television can be determined. Simultaneously, the invention can provide directional services for users according to the geographic position of the television so that richer functions are realized under the condition that the cost is not increased.

Owner:HISENSE VISUAL TECH CO LTD

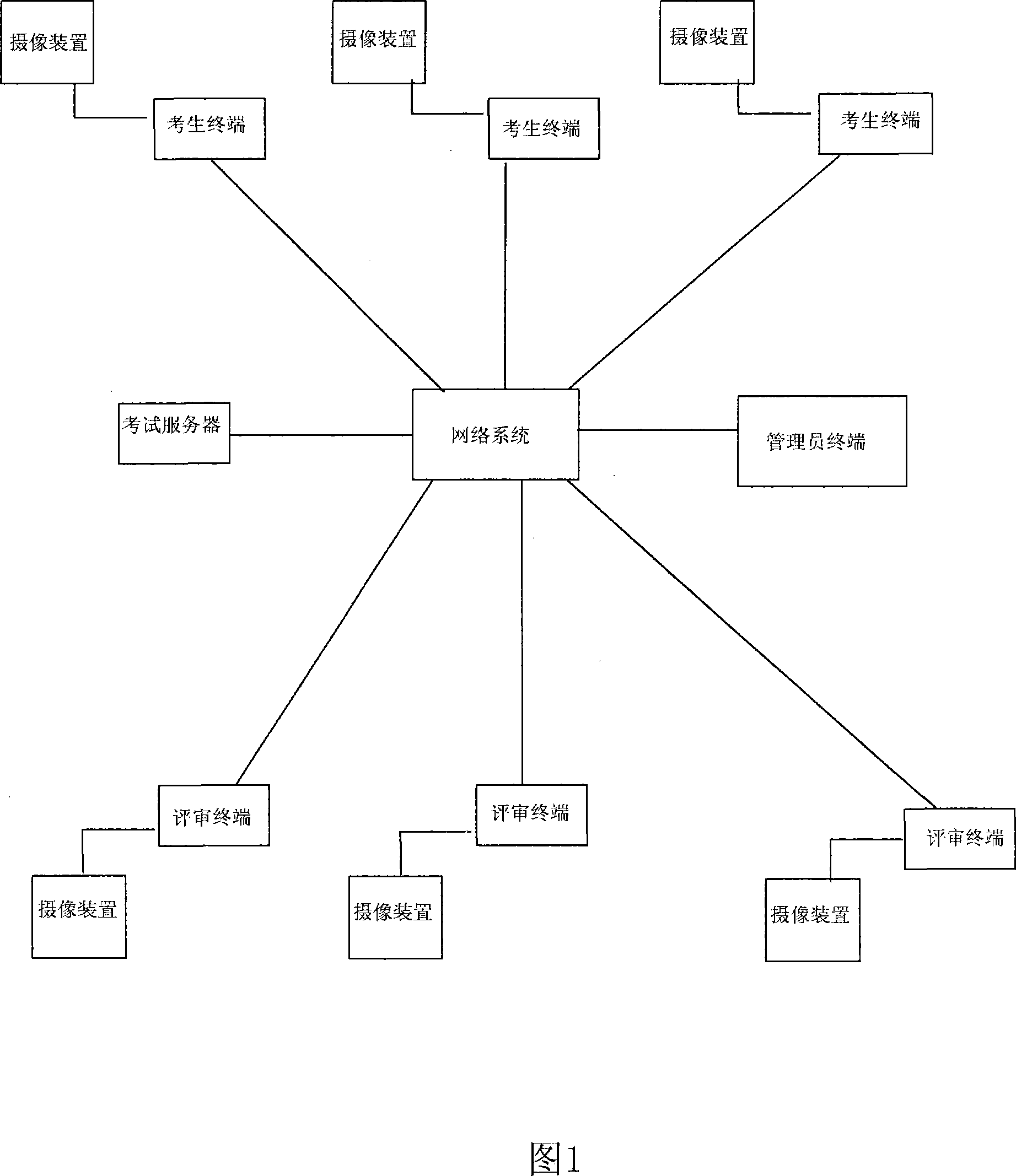

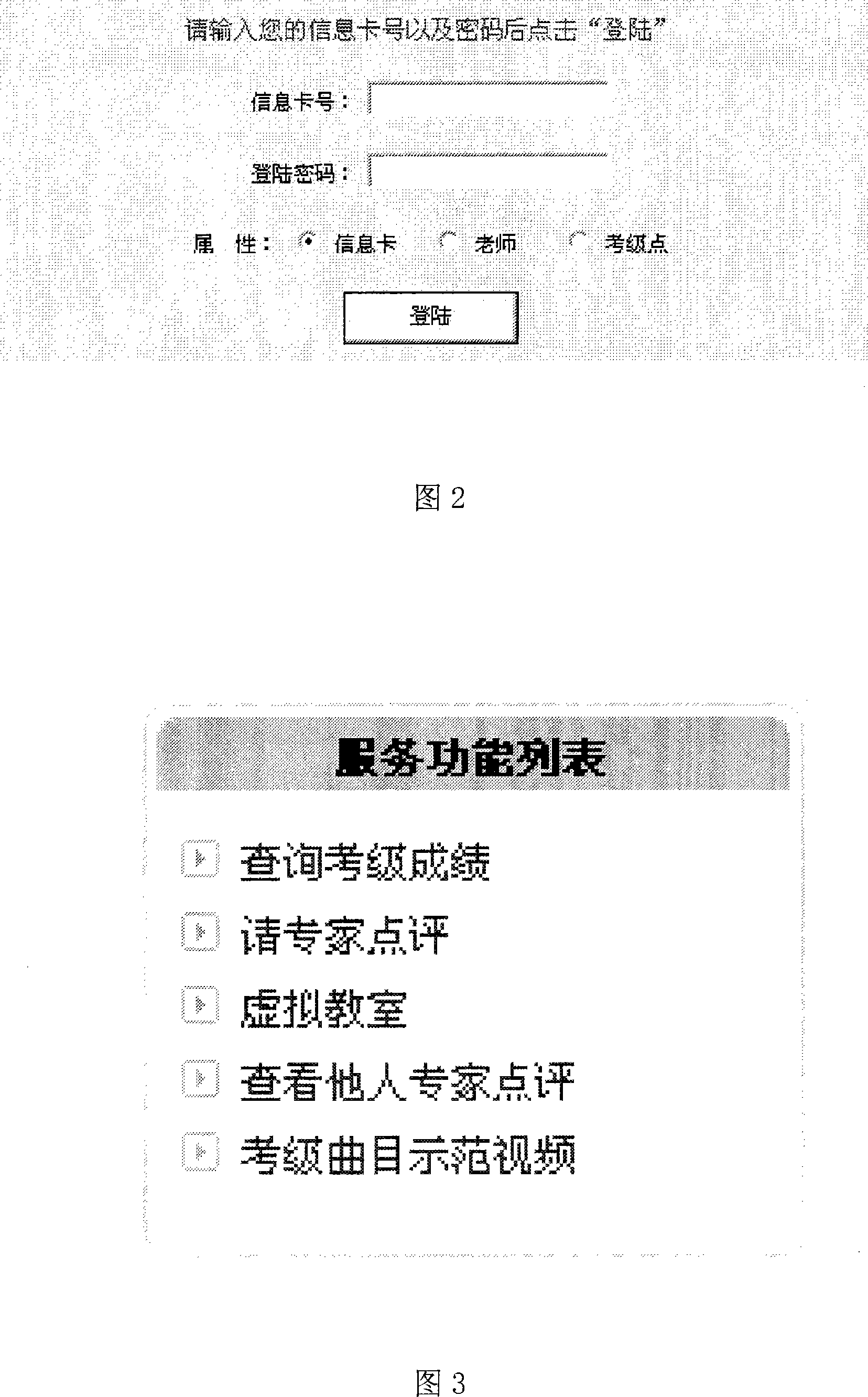

Network video test system for remote test implementing method

InactiveCN101090352ACheck in timeQuick ViewData switching by path configurationTwo-way working systemsComputer hardwareNetworked system

This invention discloses a network video examination system used in remote examinations including: a network system, a server, examinee terminals, an accreditation terminal and a manager terminal. This invention also discloses a realization method for the system: picked-up data at the examinee terminal are processed by software and transferred to digital signals to be transmitted to the server, the accreditiation terminal downloads the video data from the server and plays them to finish the examination, in which, examinees can timely and quickly find out their own results and comments.

Owner:周天行

Method and system for providing service for searching friends

ActiveUS20130275881A1Improve usabilityImprove convenienceKey distribution for secure communicationNetwork topologiesComputer hardwareEncryption

A method of providing a friend search service of a portable terminal is provided. The method includes transmitting, by a first portable terminal, a message for controlling a microphone of a second portable terminal to a contact server through a cellular network, outputting a sound including a first encryption key after transmitting the message, receiving a second encryption key from the second portable terminal through the cellular network, checking the second portable terminals existing in a sound-reaching area by comparing the first encryption key with the second encryption key, and displaying a friends list including the second portable terminals existing in the sound-reaching area.

Owner:SAMSUNG ELECTRONICS CO LTD

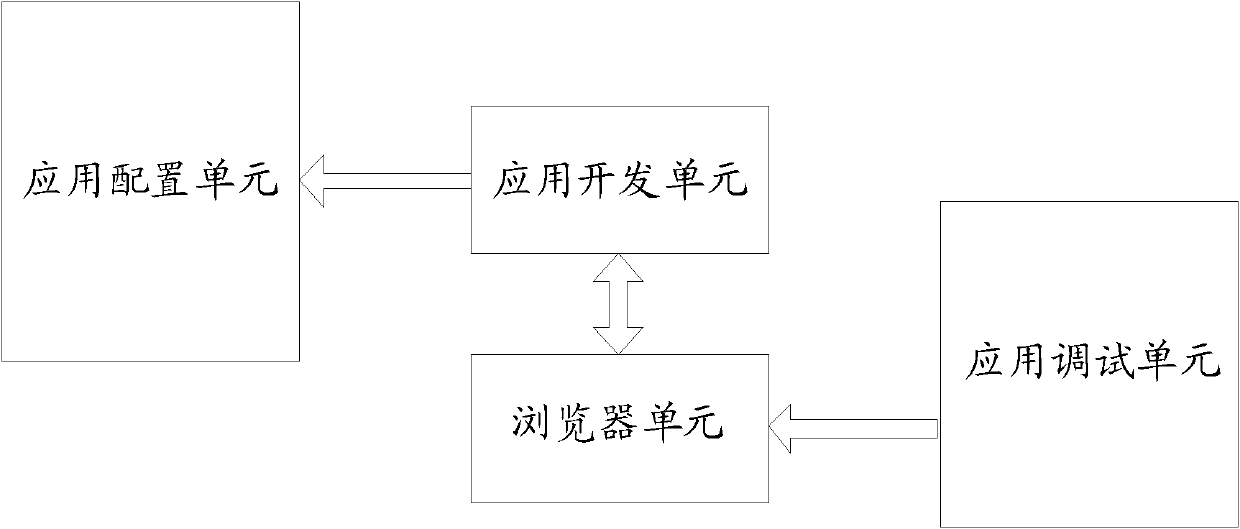

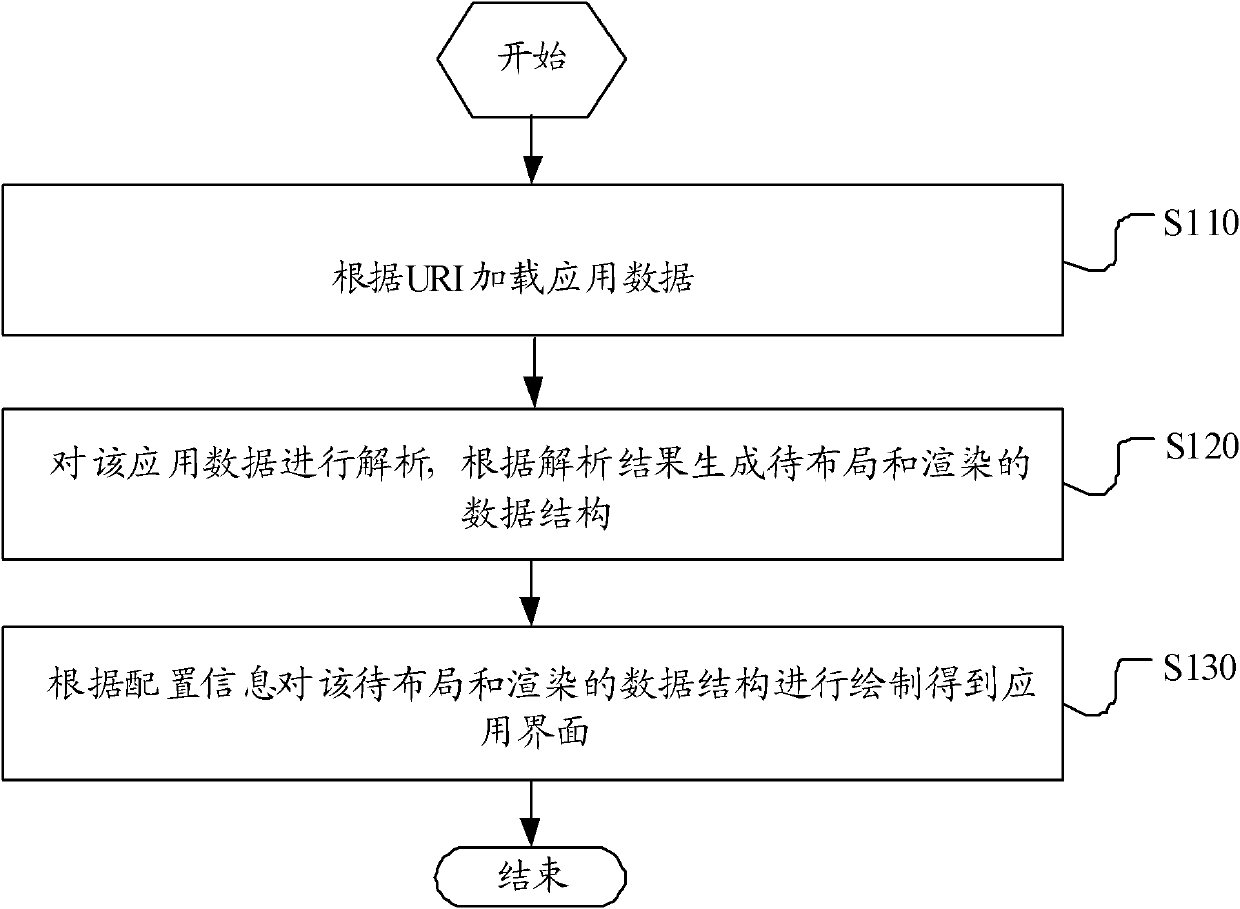

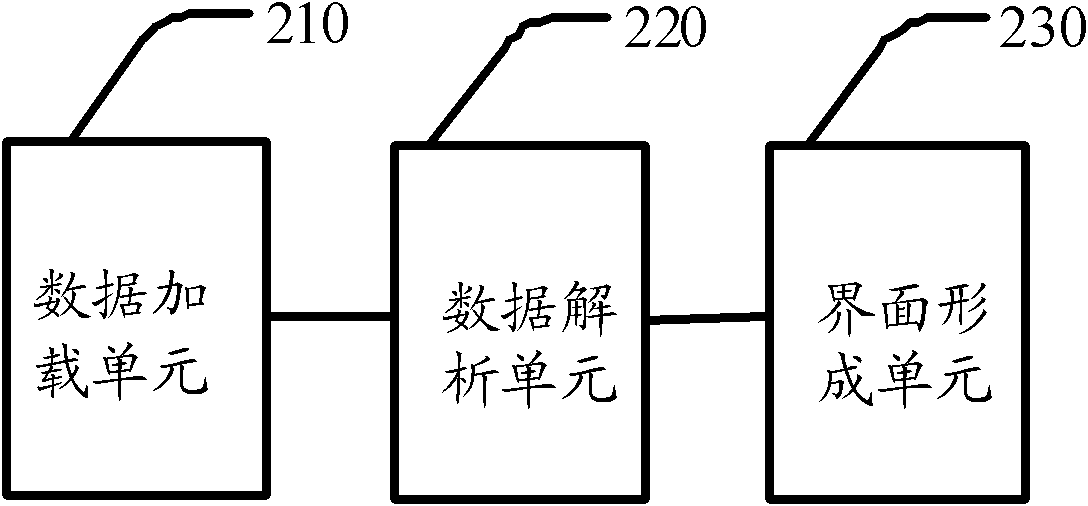

Mobile phone application interface development method and terminal based on browser parsing mode

InactiveCN102323880ASimplify complexityReduce difficultyDigital data information retrievalProgram loading/initiatingMulti platformComputer terminal

The invention relates to a mobile phone application interface development method and a terminal which are based on a browser parsing mode. The method includes the following steps: loading application data according to a universal resource identifier (URI); parsing the application data, and generating a data structure to be laid out and rendered according to a parsing result; and according to configuration information, drawing the data structure to be laid out and rendered to obtain an application interface. The method or the terminal provided by the invention can greatly simplify the complexity of mobile phone application development for users, solve the problem of multi-platform compatibility and decrease the difficulty of general application development for mobile phones and other terminals for users.

Owner:ZTE CORP

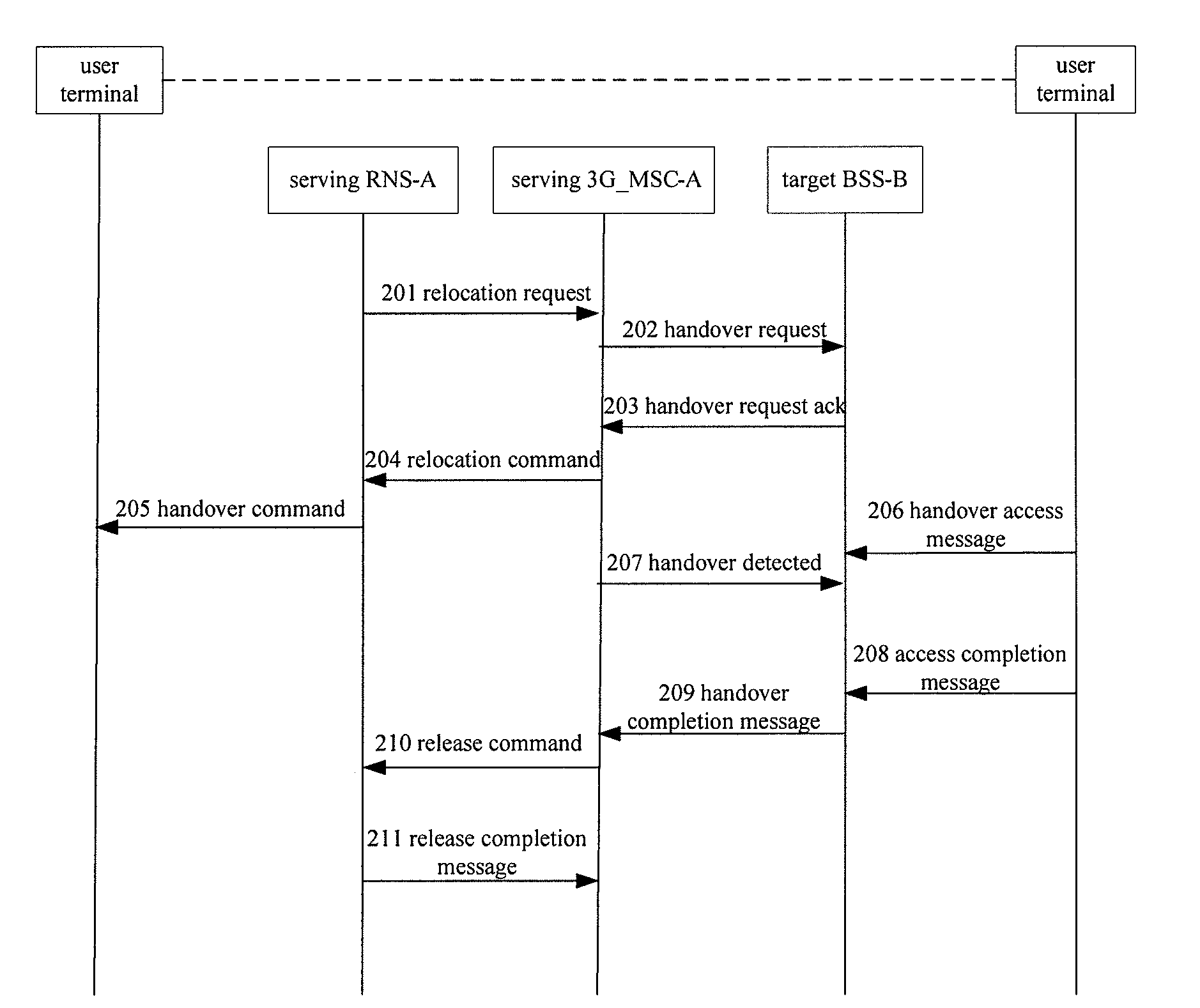

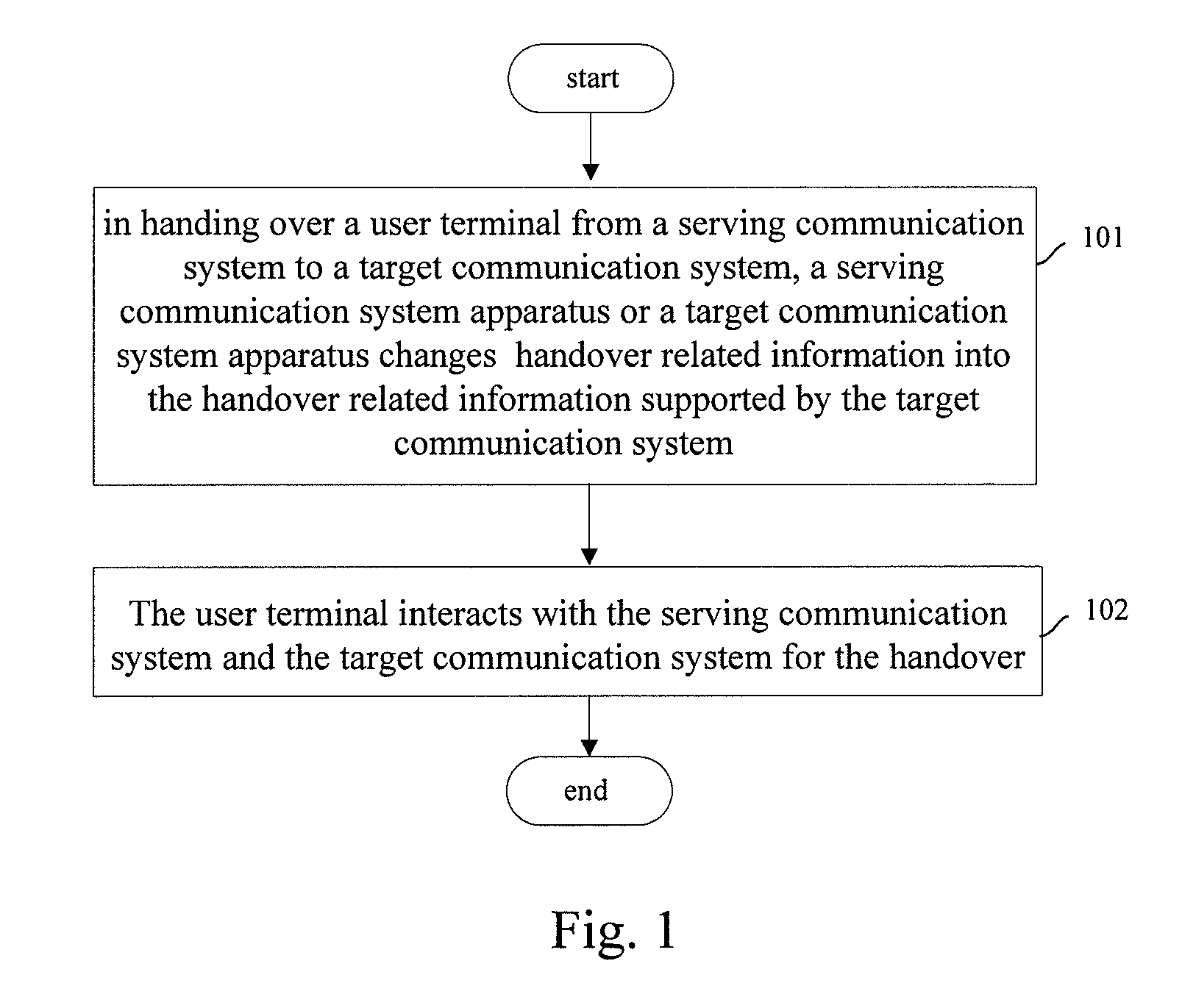

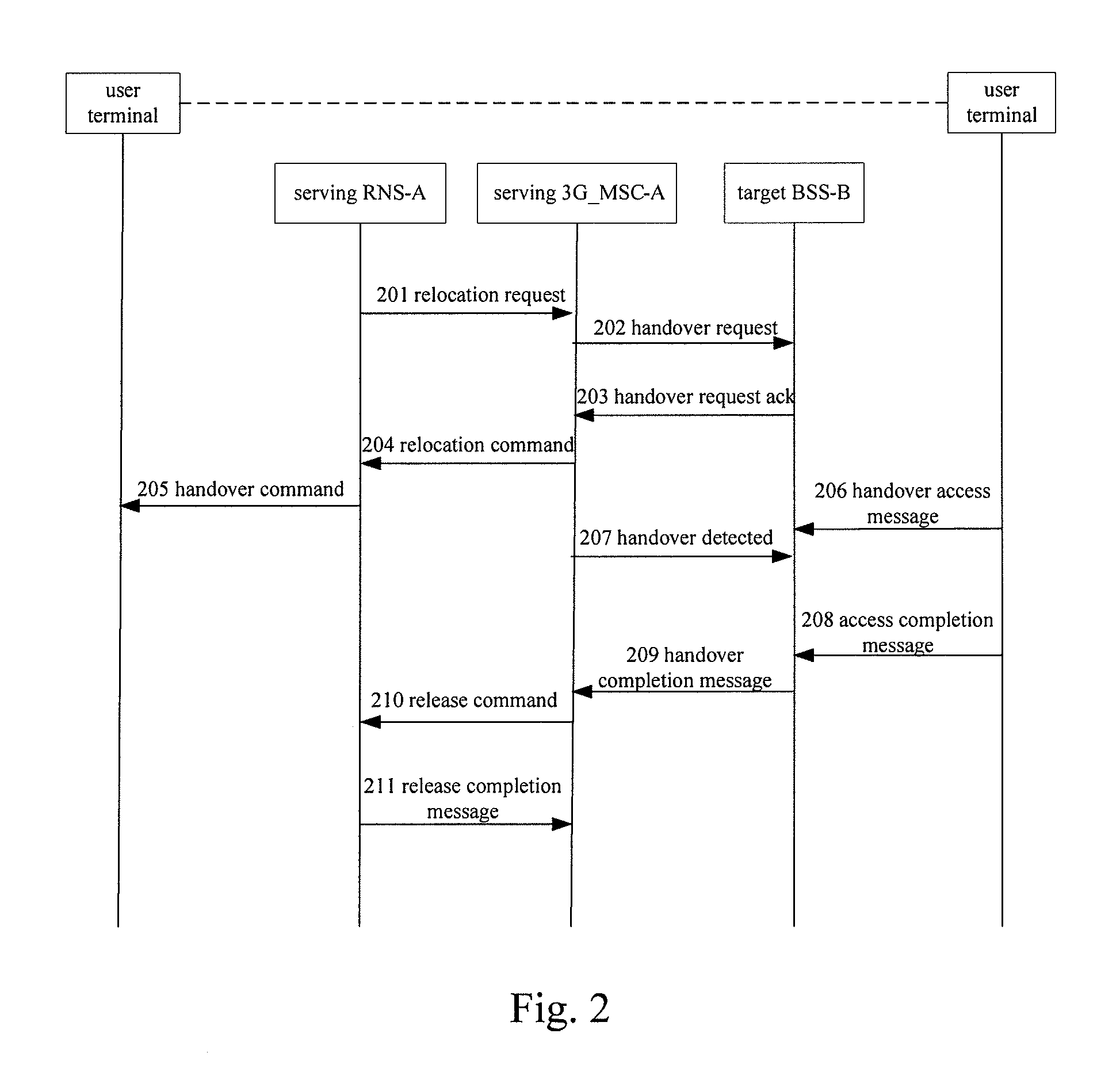

Method for inter-system handover

ActiveUS20080102837A1Improve satisfactionLow costSubstation equipmentRadio/inductive link selection arrangementsCommunications systemHandover

A method for inter-system handover is provided by the present invention, including: changing a first handover-related information into a second handover-related information, wherein the first handover-related information is supported by a serving communication system and the second handover-related information is supported by a target communication system; and handing over the user terminal from the serving communication system to the target communication system based on the second handover-related information. An apparatus for inter-system handover is also provided. The present invention can insure successful handover of user terminals from a serving communication system to a target communication system.

Owner:HUAWEI TECH CO LTD

Method for removing orange skin by enzyme

ActiveCN1943453AImprove product qualityImprove competitivenessJuice extractionVegetable peelingPectinaseChemistry

A process for peeled citrus by means of ferment is presented and characterized by including washing clean citrus peel, identifying and discarding thread and line covered on citrus segment; putting said above segment into enzymolysis liquid, and through zymolysis on condition of pH 3-10 and temp. 35-60deg.C, mixing and discarding said thread and line, said enzymolysis liquid containing quality density is 0.05-5% of pectinase, 0.05-3% of cellulase, and 0.01- 2.5% of semi- cellulase separately , the rest to be water.

Owner:HUNAN AGRI PRODS PROCESSING INST

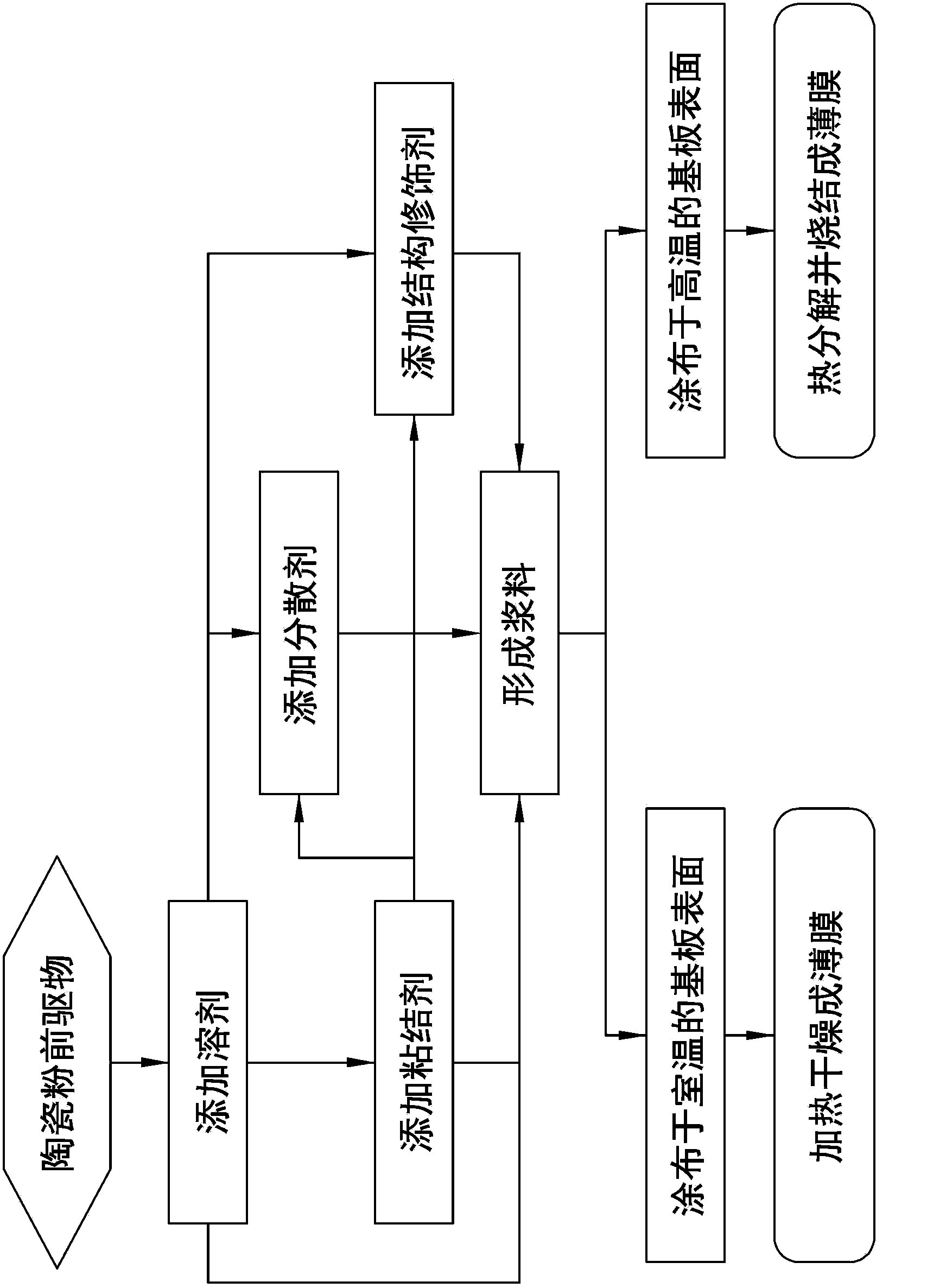

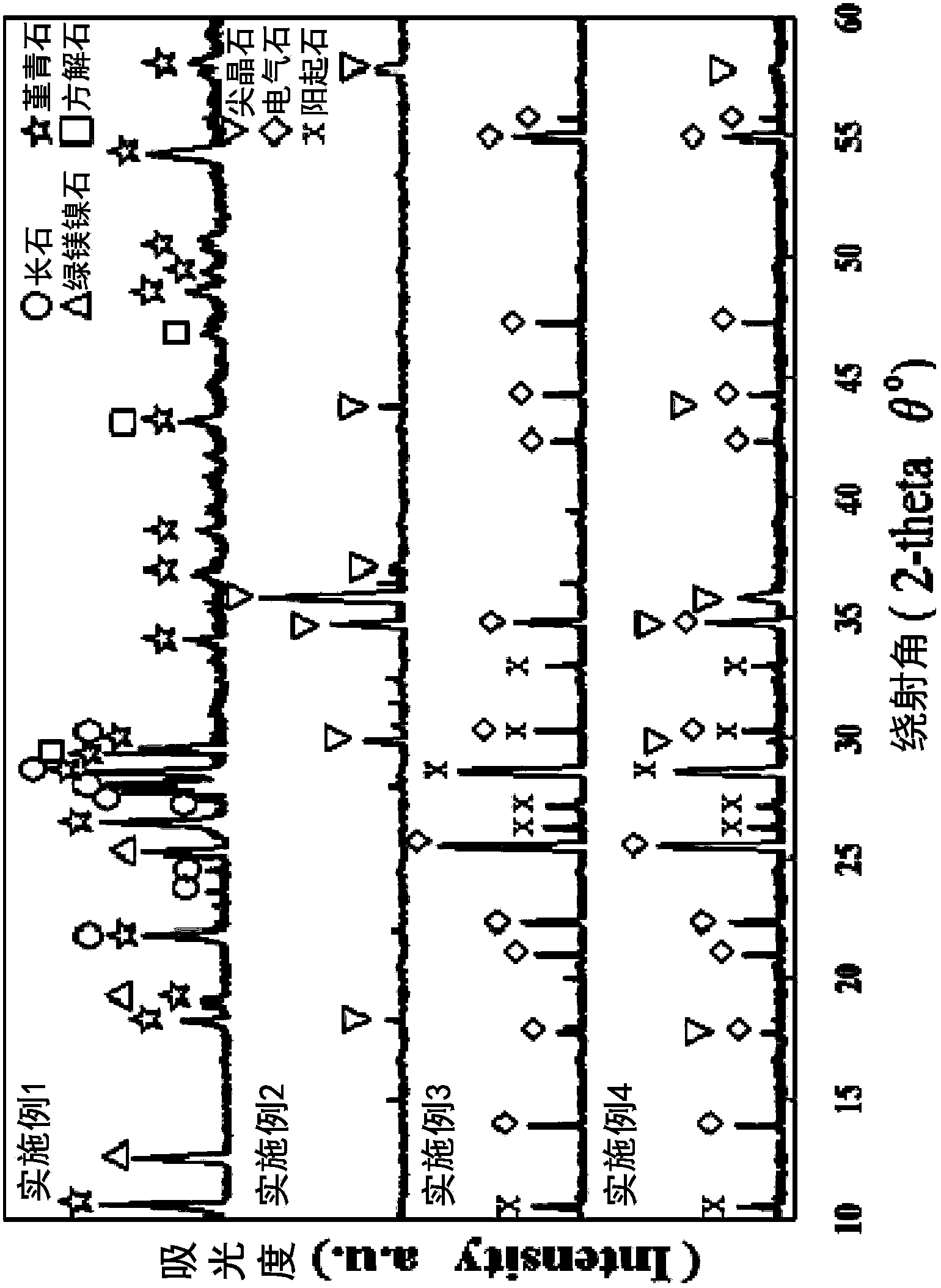

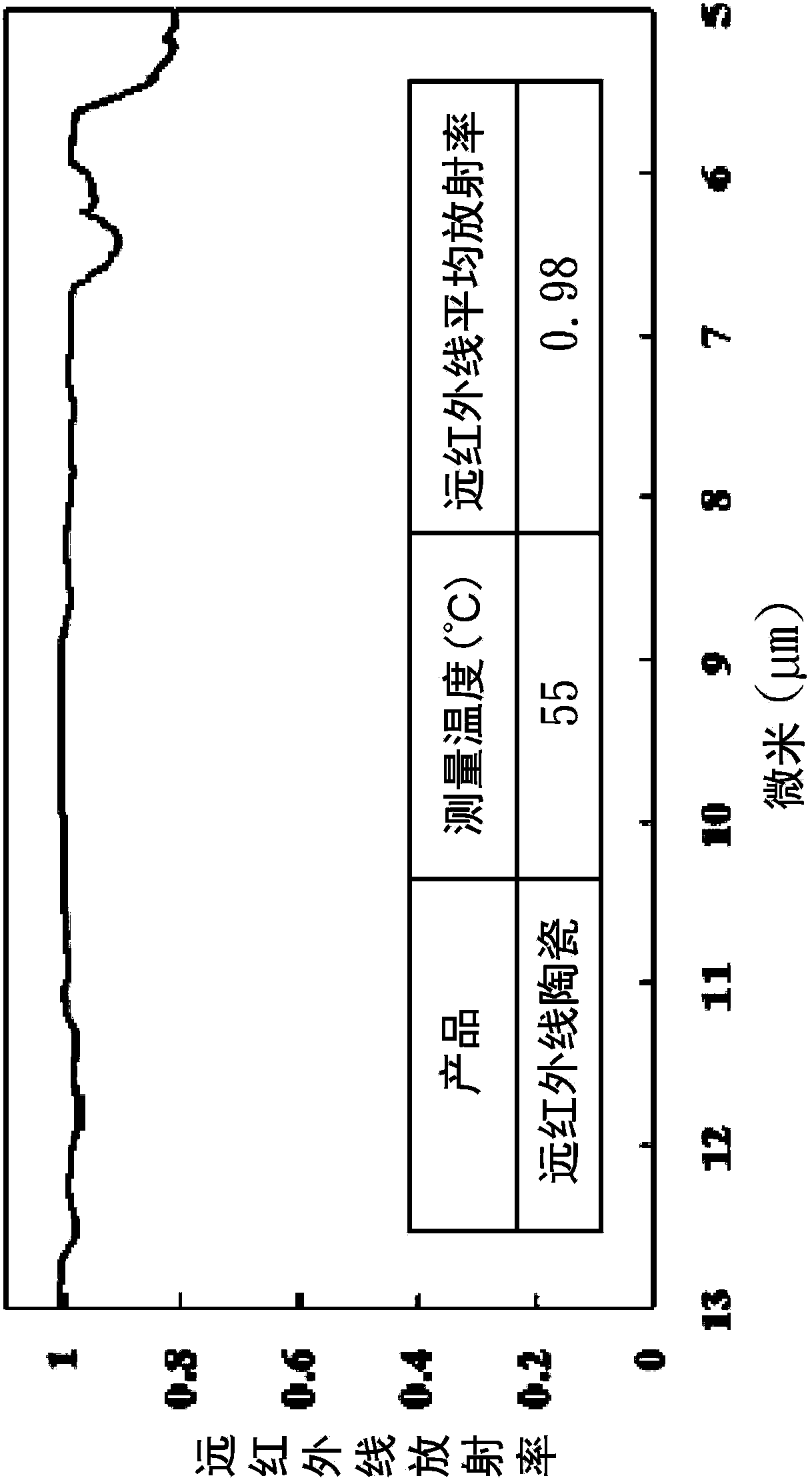

Far infrared heat-radiation ceramic slurry, fiber cloth, thin film and preparation methods thereof

InactiveCN103570360AHigh radiation emissivityLow costMonocomponent polyesters artificial filamentArtifical filament manufactureInfraredFiber

The invention discloses a far infrared heat-radiation ceramic slurry, the far infrared heat-radiation ceramic slurry is prepared by mixing a ceramic powder precursor with a corresponding solvent, a bonding agent, a dispersing agent or a structure modification agent, and the ceramic powder precursor is selected from a composition of salts or oxides of Na, Mg, Ca, B, Al, C, Si, Sn, Mn, Fe, Co, Ni and Cu. A functional ceramic body is obtained by coating the far infrared heat-radiation ceramic slurry on the surface of a substrate or adding the far infrared heat-radiation ceramic slurry into a polymer material, and then heating for drying. The functional ceramic body is a composition or a derivative with at least one or more than one structure of feldspar, olivine, cordierite, chlorite, green magnesium nickel ore, tourmaline, tremolite, actinolite, serpentine, spinel or calcite, has the far infrared radiation rate reaching 0.90-0.98, can rapidly transfer heat energy into radiation waves for spreading to the outside so as to achieve a rapid heat-radiation effect.

Owner:BOSIN TECH

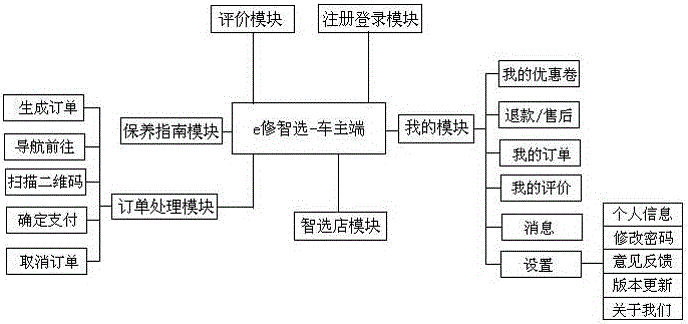

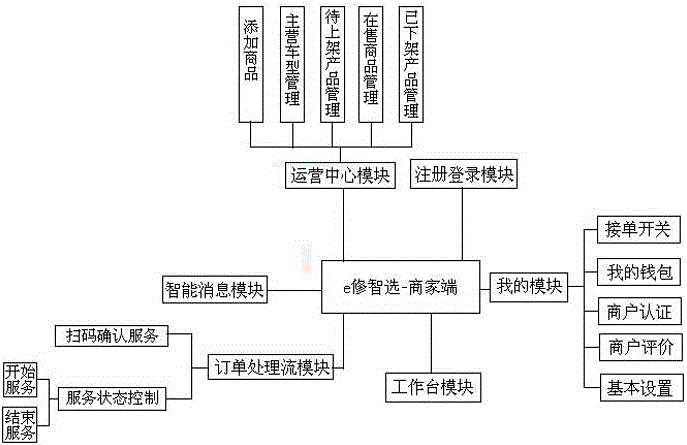

Vehicle precision service platform

InactiveCN105976034AImprove competitivenessMeet maintenance needsData processing applicationsRelational databasesSoftwareClosed loop

The invention provides an e-repair intelligent selection vehicle precision service platform which comprises a client, a server and a database. The database and the server are built together through a public cloud technology. The client is connected with and accesses the server through an interface arranged on the server. The client comprises a merchant and a vehicle owner. The platform provides accurate, fast, efficient, all-round and one-stop after-sales service for a large number of vehicle owners. The services comprise vehicle washing, maintenance, repair, beauty, rescue and many other aspects. The vehicle owner only needs to open the mobile phone application of e-repair intelligent selection. The platform can recommend the best service for the vehicle owner according to vehicle maintenance habits and records of the vehicle owner to meet the vehicle maintenance need of the vehicle owner. After the vehicle owner books a service, the vehicle owner can carry out payment through Wechat payment and alipay, and accepts the service in the near merchant under the guidance of the software. O2O closed-loop is carried out after the whole vehicle is completed.

Owner:趣车网络科技(苏州)有限公司

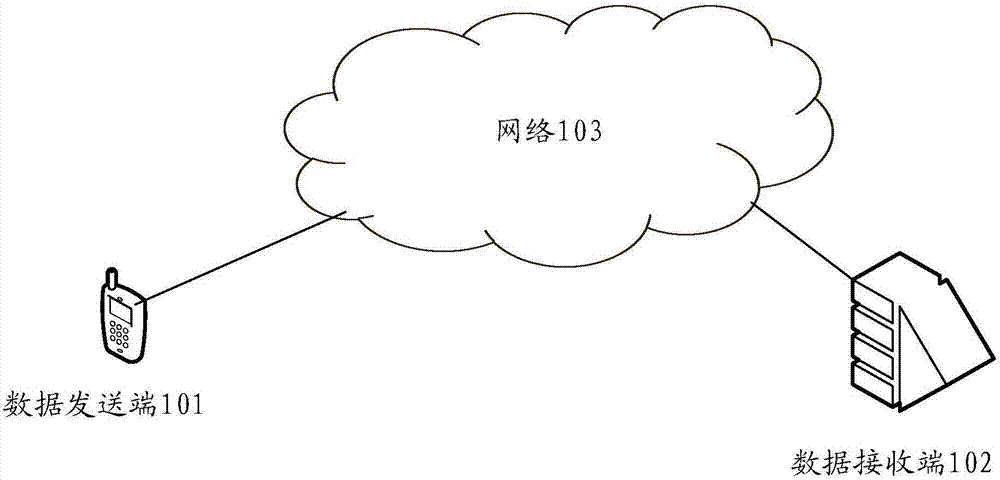

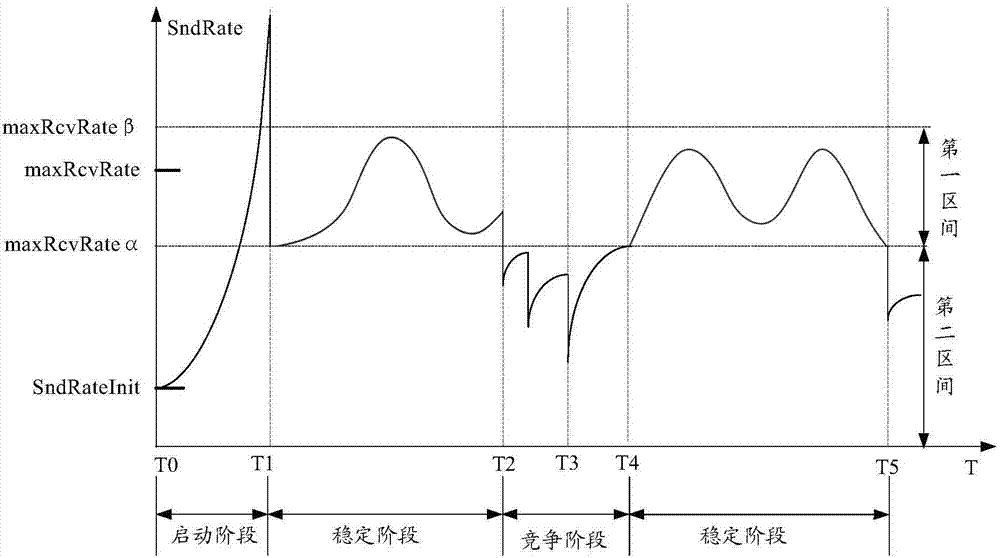

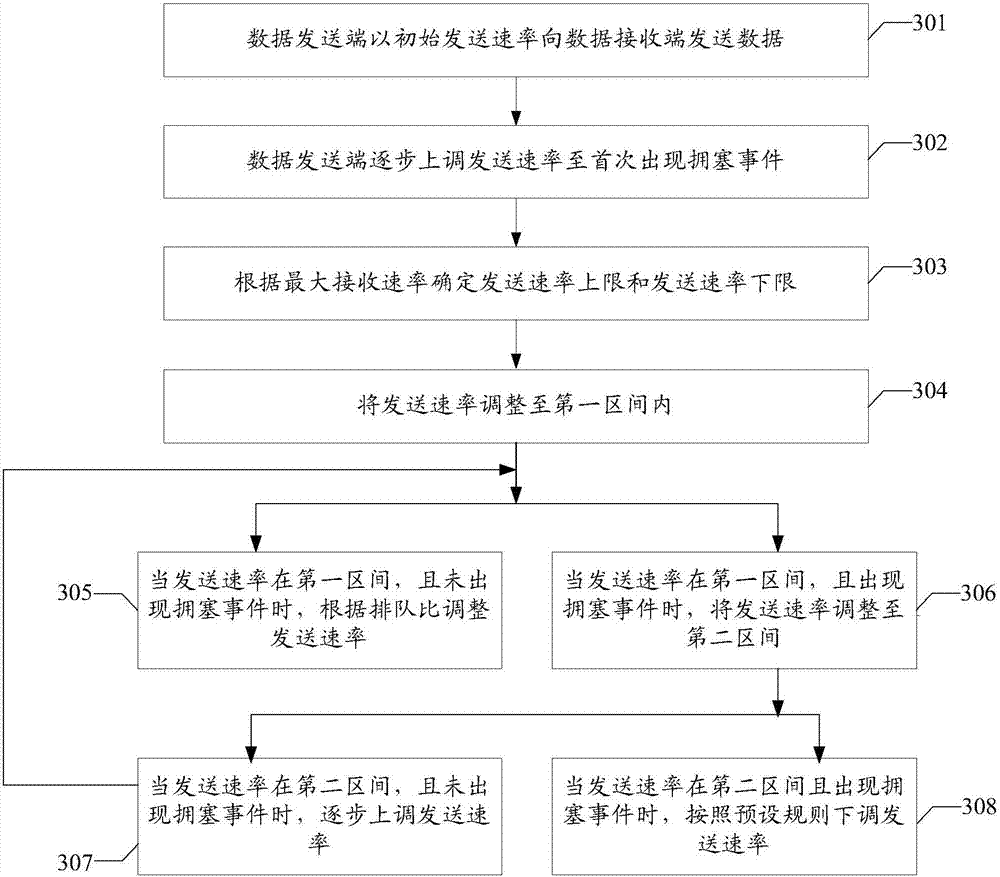

Data transmission method, device and system

ActiveCN107171969AImprove competitivenessIncrease data transfer rateData switching networksData transmissionLower limit

The embodiment of the invention provides a data transmission method, device and system, relates to the field of communication, and can improve the bandwidth pre-empting competitive force of a sending end, and increase the data transmission rate. The specific scheme is as follows: a data sending end sends data to a data receiving end at initial sending rate; furthermore, the sending rate is adjusted according to the maximum receiving rate, the packet loss probability and the round trip time RTT; and the process specifically comprises the steps of: increasing the sending rate step by step till a congestion event occurs for the first time; adjusting the sending rate to the lower limit of the sending rate; when the sending rate is in the first interval, adjusting the sending rate according to the queuing ratio, and furthermore, when the congestion event occurs, adjusting the sending rate to the second interval; and, when the sending rate is in the second interval, increasing the sending rate step by step, and furthermore, when the congestion event occurs, decreasing the sending rate according to a pre-set rule. The data transmission method, device and system provided by the invention are used for data transmission.

Owner:HUAWEI TECH CO LTD

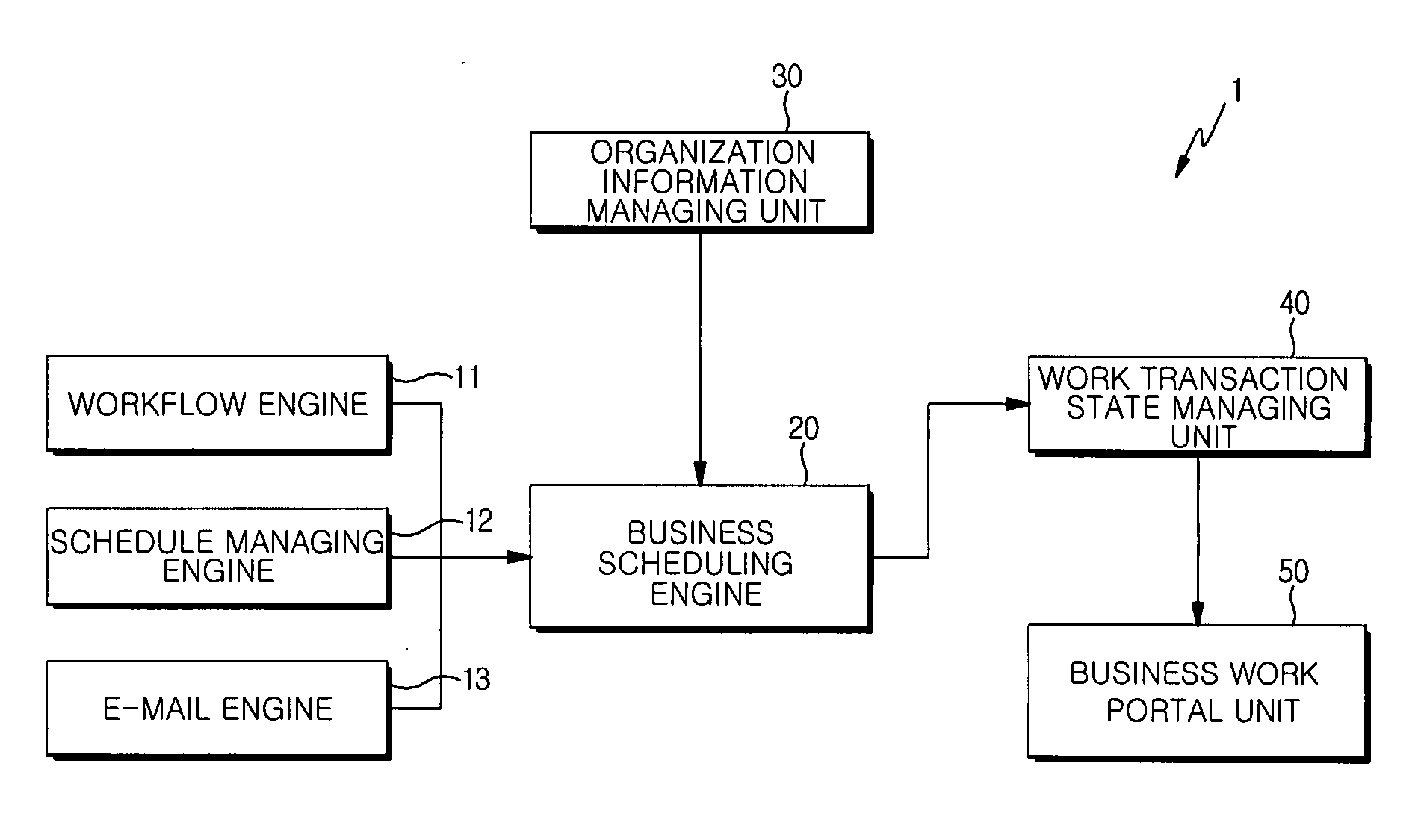

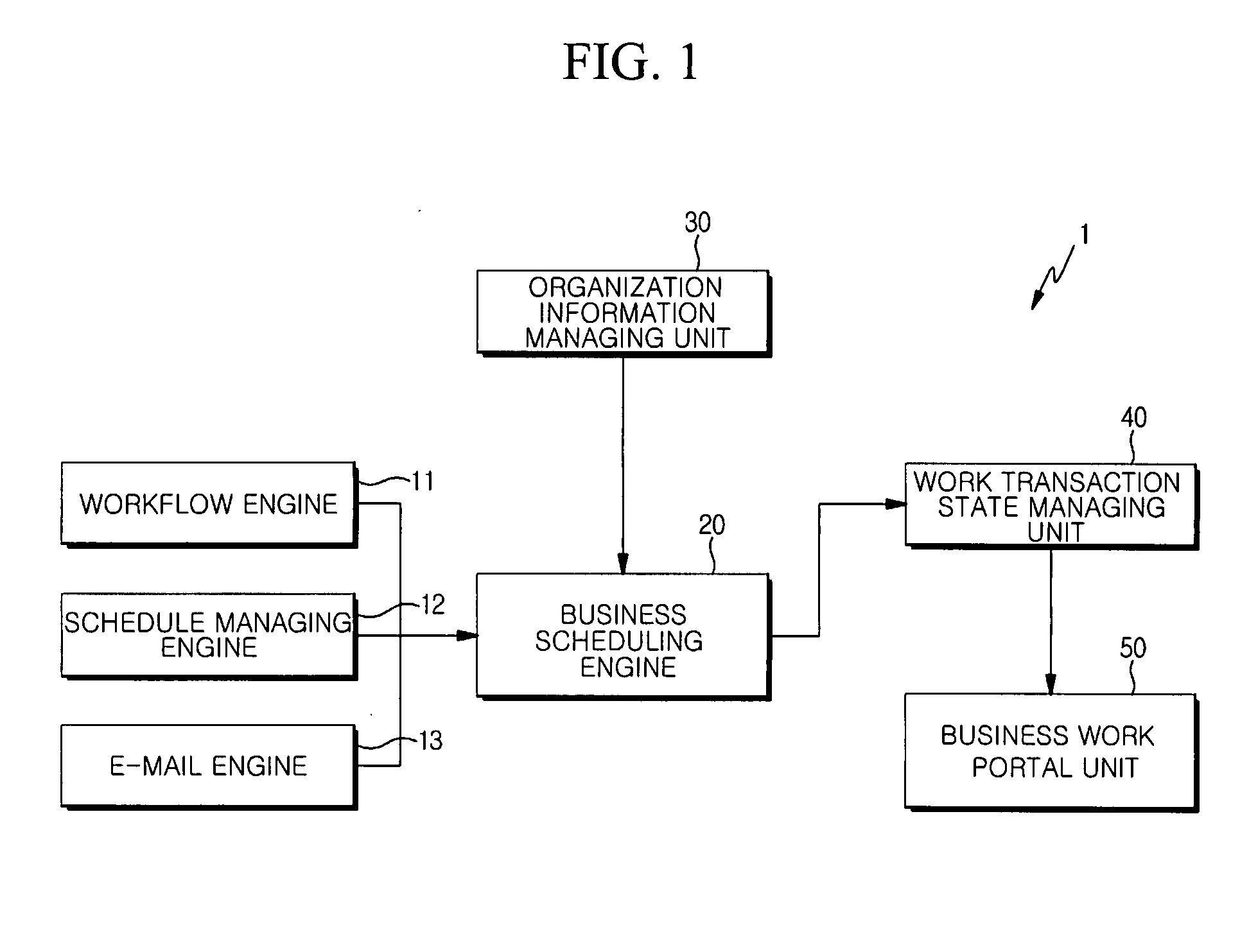

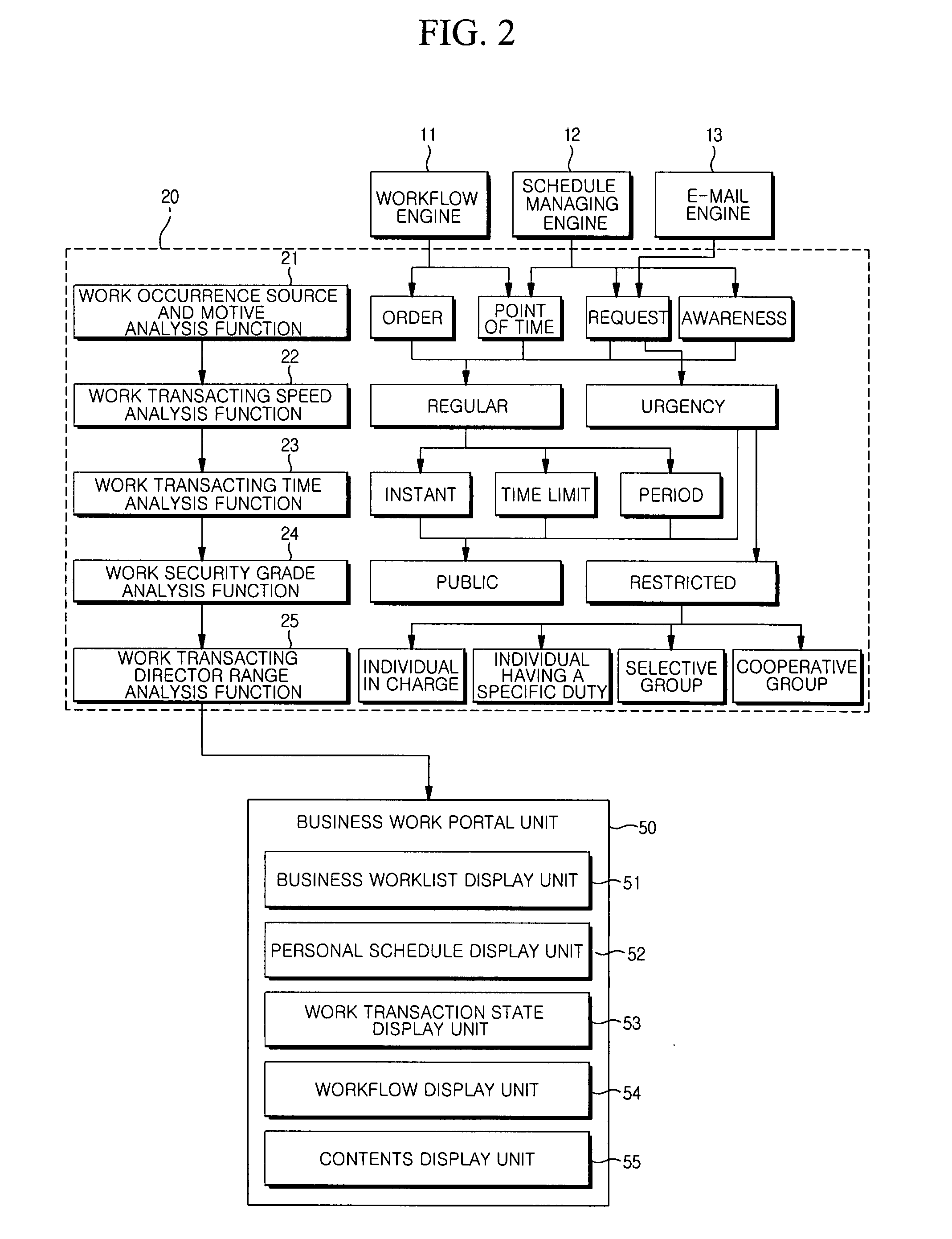

System and method for integrating operation of business software managing execution of business process based on time

InactiveUS20070233535A1Efficient use ofImprove competitivenessResourcesSpecial data processing applicationsSoftwareReal time management

The present invention relates to a system and a method for integrating operation of business software to manage a business process by dividing businesses into unit works (tasks) and managing the tasks based on time. The system includes: an organization information managing unit for inputting and managing at least one of client information, company information, department information and user information; a business scheduling engine for arranging a schedule for carrying out tasks of users and arranging scheduling information including work transaction information with the users in charge of the tasks; a work transaction state managing unit for performing real-time management of work transaction states of the arranged scheduling information; and a business portal unit for generating the scheduling information and the work transaction states in a diary interface composed of visual information and work information, providing the scheduling information and the work transaction states to the users, and providing at least one work-related additional function selected from the group including daily, weekly, and monthly personal schedule management, news search and e-mail transmission.

Owner:KIM GILOONG

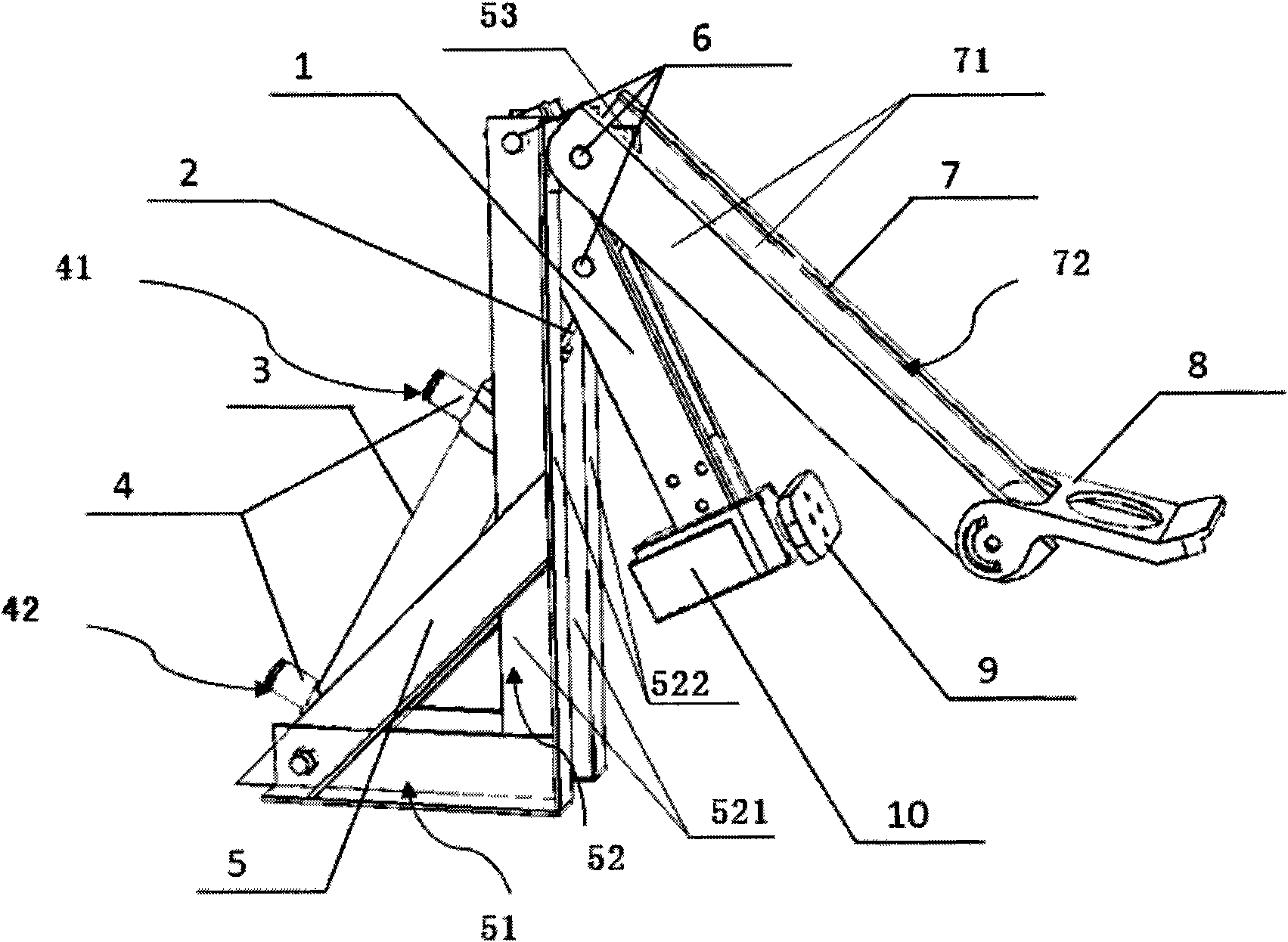

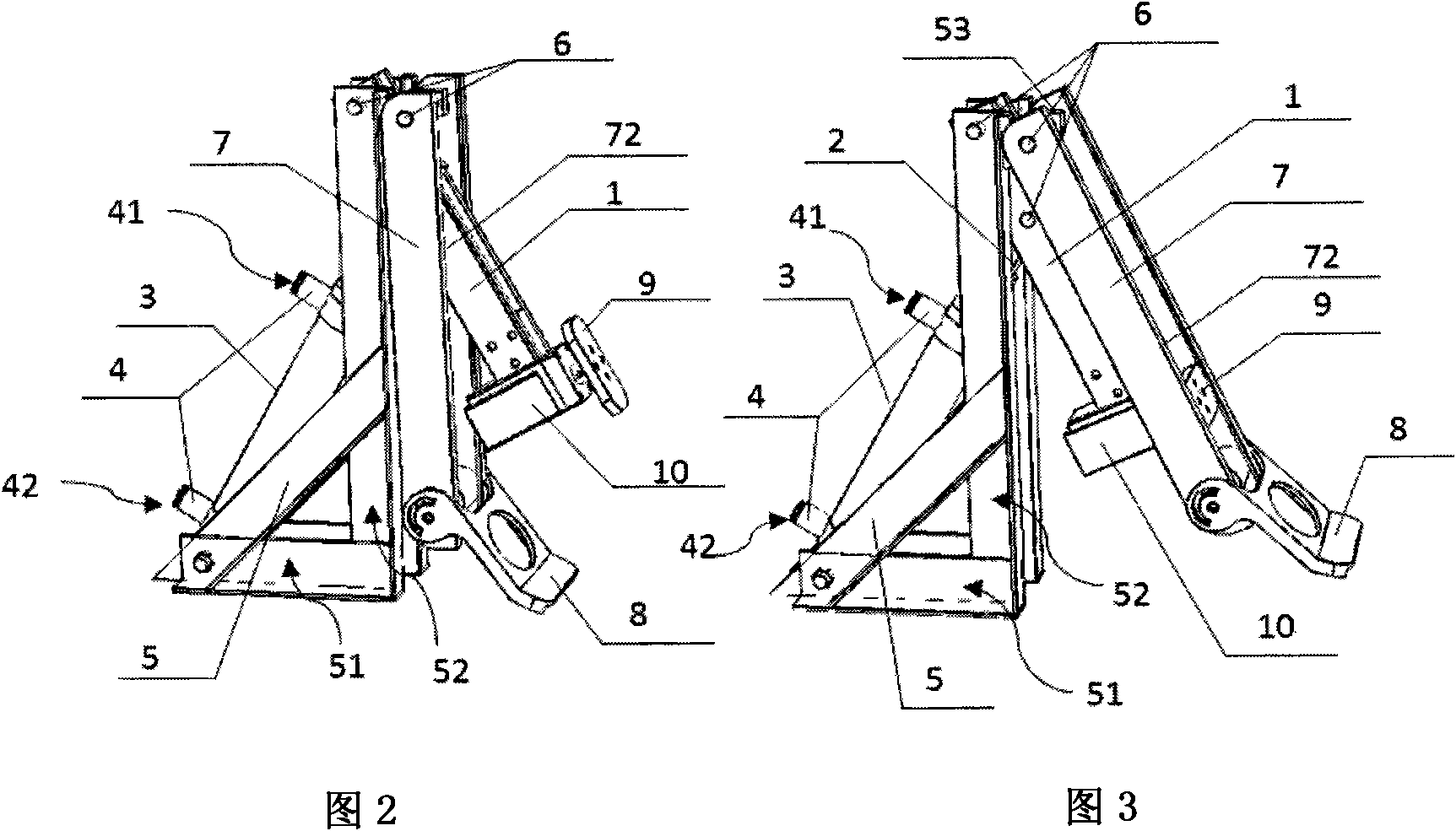

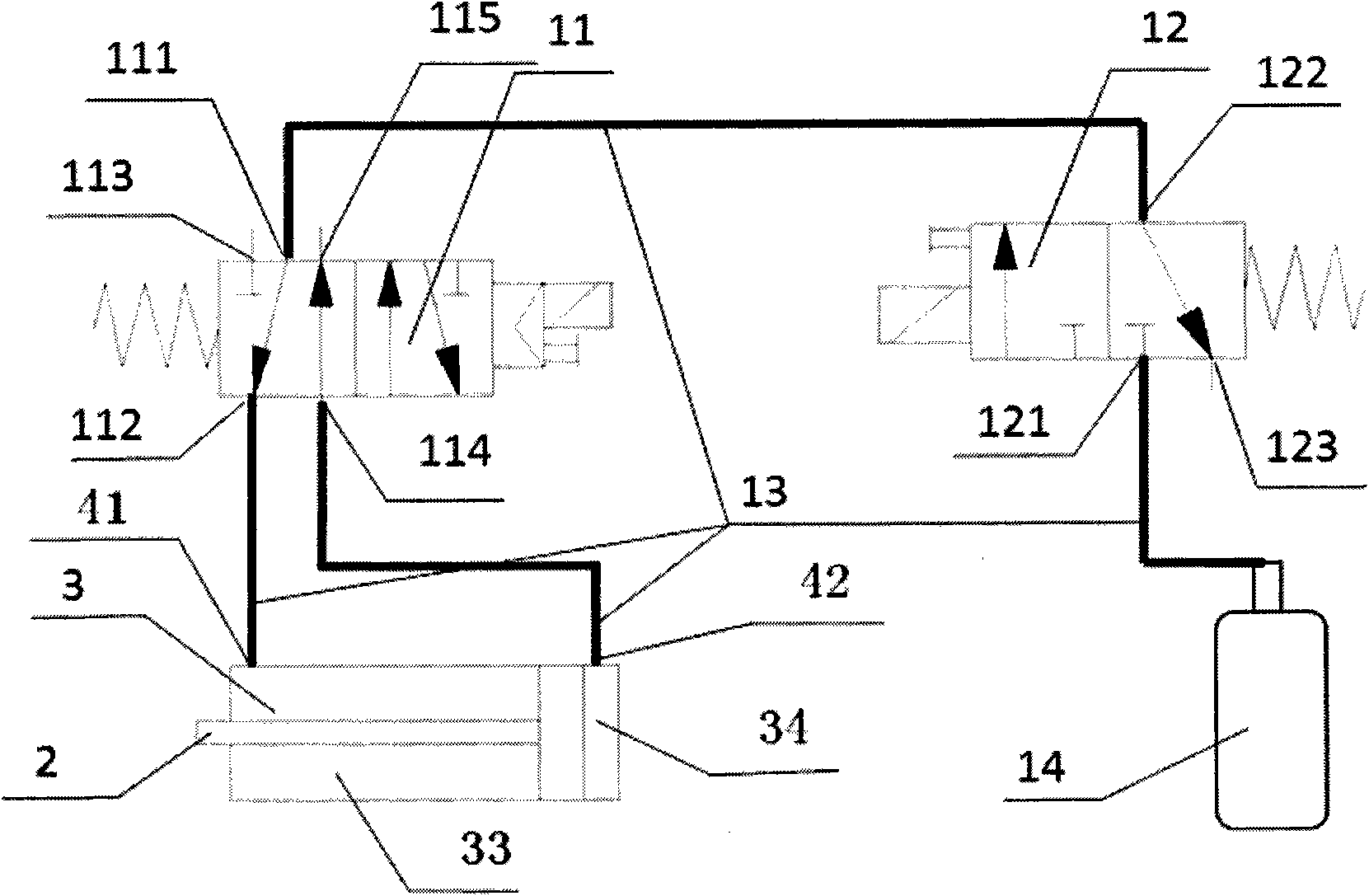

Pneumatic ball kicking system of football robot

InactiveCN101596367AReduce weightImprove competitivenessSelf-moving toy figuresSoccer robotEngineering

The invention relates to a pneumatic ball kicking system of a football robot, comprising a ball horizontally pushing kicking foot, a cylinder output rod, a cylinder, air pipe interfaces, a stand, a connecting rod, a ball lifting kicking foot, a ball lifting kicking foot board, a rotary pushing head and a motor. A pneumatic control loop comprises a cylinder output rod, a cylinder, a two-position five-way electromagnetic valve, a two-position three-way electromagnetic valve and an air storage bottle. The ball kicking system can realize switching between ground ball and air ball by changing the angle of the rotary pushing head. The force of kicking the ball can be regulated by changing duration of electrifying the two-position five-way electromagnetic valve, namely changing the flux of air flowing into the right cavity of the cylinder. The invention realizes a pneumatic ball kicking system which can regulate force of kicking the ball, and can play ground ball and air ball. The invention has simple structure and easy realization, and can greatly improve the competition ability of the football robot, particularly ball kicking ability.

Owner:SHANGHAI JIAO TONG UNIV

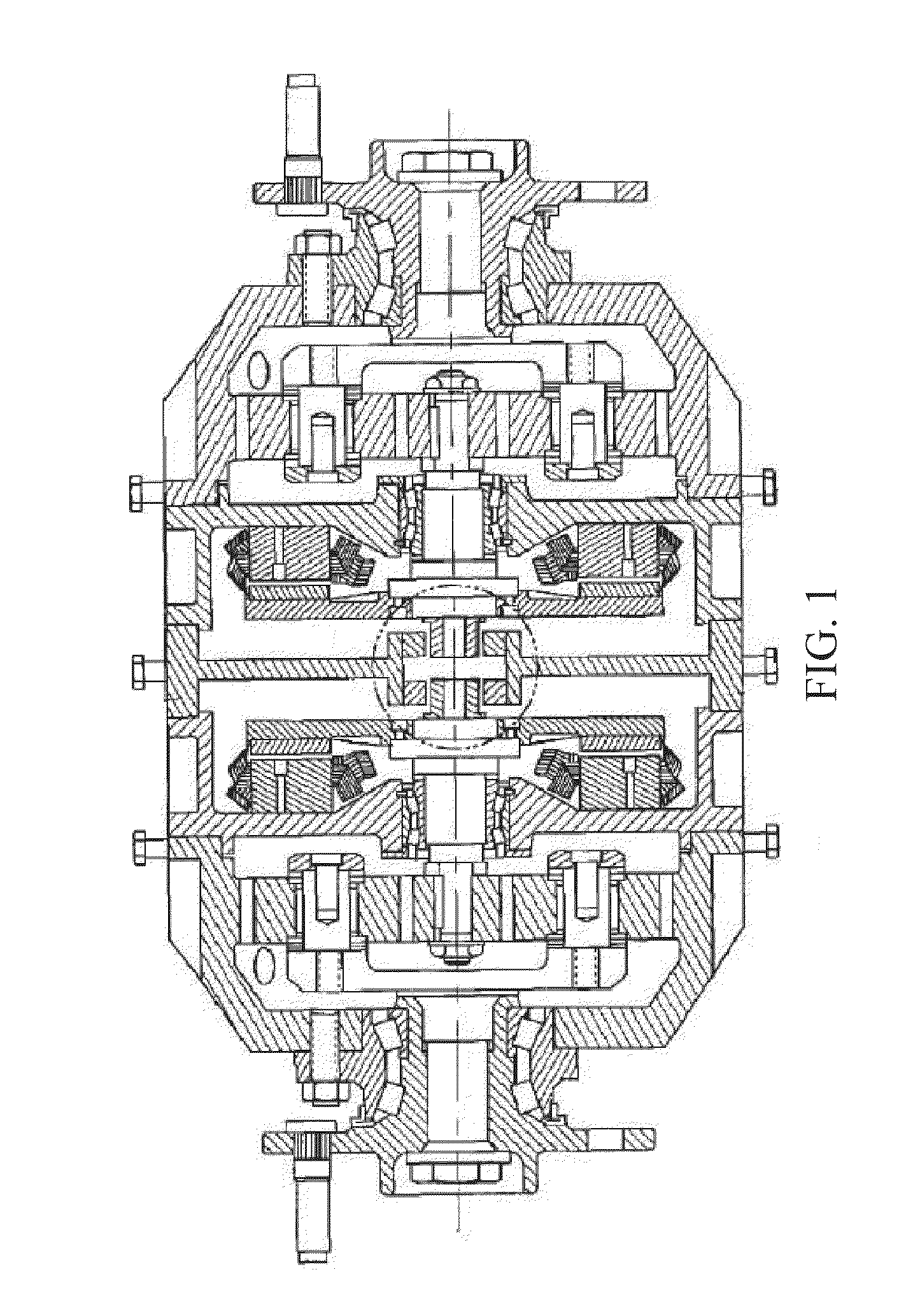

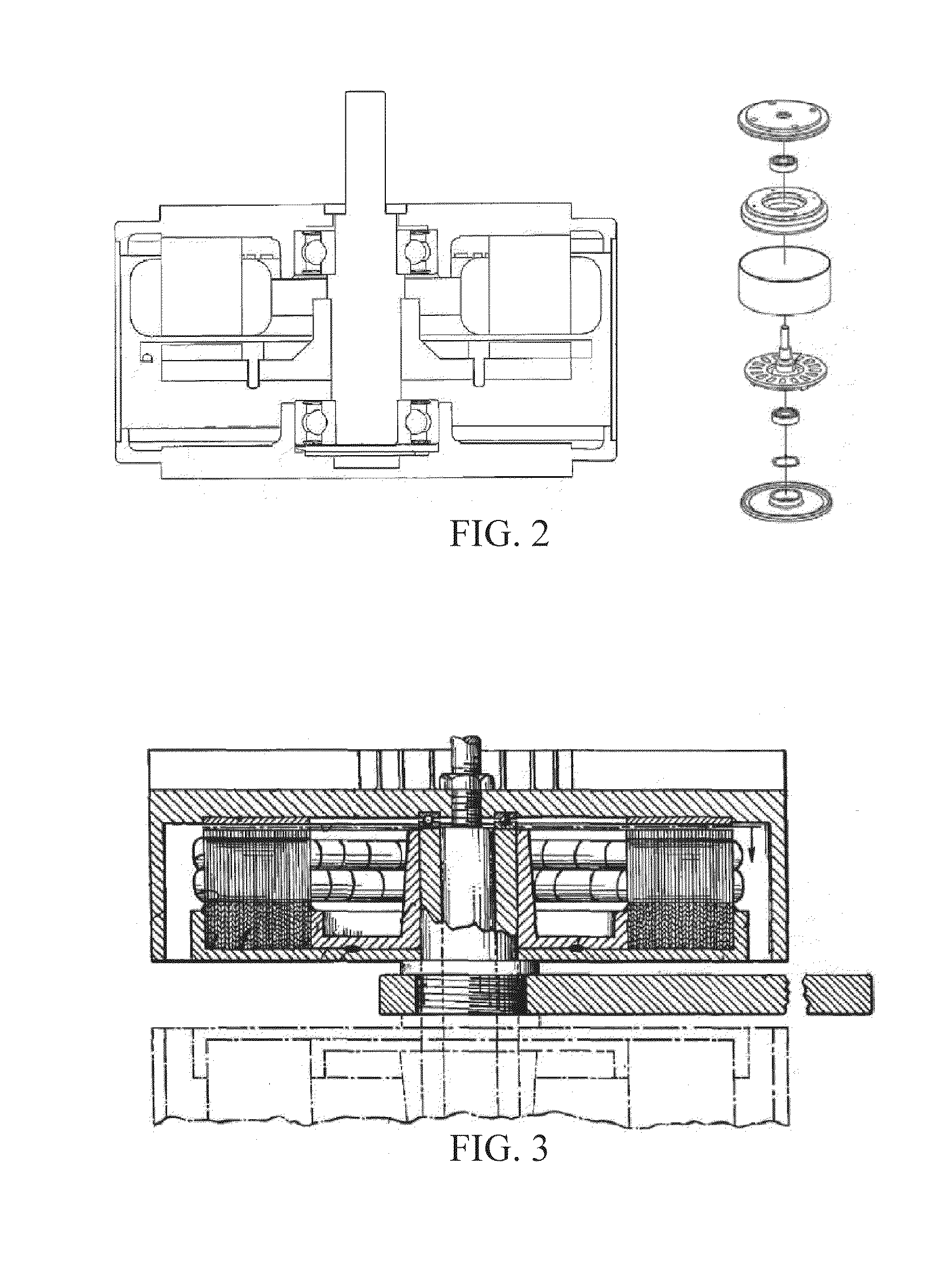

Stator assembly structure for axial flux electric machine

ActiveUS20130140920A1Promote generationImprove competitivenessMagnetic circuit stationary partsManufacturing dynamo-electric machinesElectric machineEngineering

A stator assembly structure for an axial flux electric machine is designed. The back iron for each silicon steel disk stator is formed into a specific structure with tooth-like protrusions for allowing the same to be integrated with the disk-type stator seat, while the disk-type stator seat is made of a material suitable for casting or mold forming. A coil is mounted on the disk stator, and a stator assembly is achieved by integrating the stator, the coil and the stator seat. The stator and the disk-type stator seat of the stator assembly are manufactured by using a one-piece cast or one-piece mold forming method so as to enable the contact surfaces of the stator and the stator seat to engage with each other even more tightly, and consequently enable the heat generated from the coil to be transmitted rapidly from the disk stator to the disk-type stator seat.

Owner:IND TECH RES INST

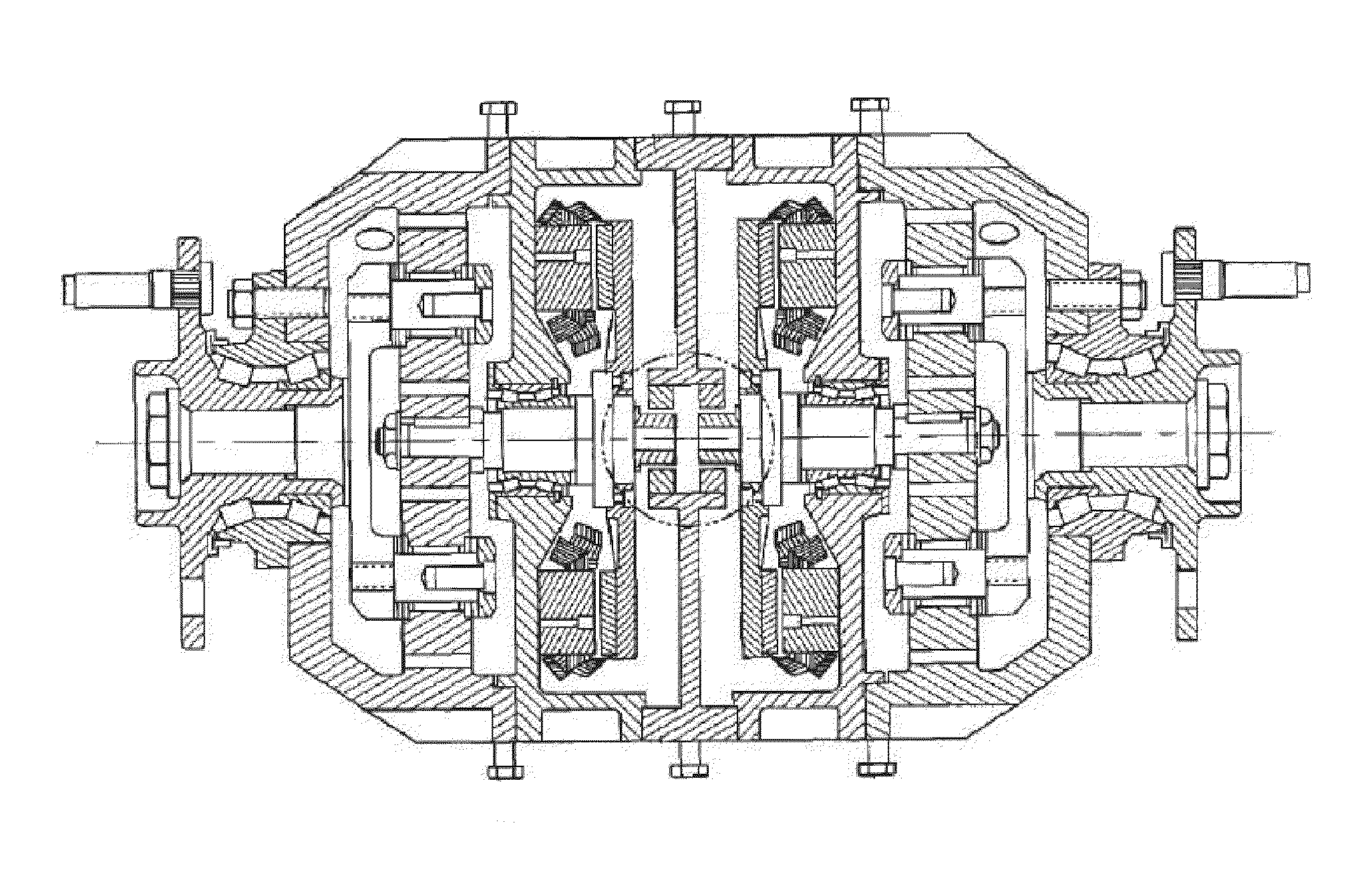

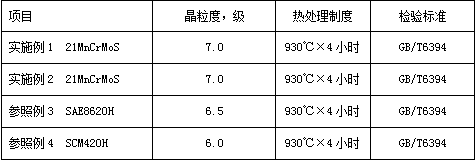

21MnCrMoS steel used for heavy truck transmission gear and manufacturing method for 21MnCrMoS steel

ActiveCN107604250AReduce contentImprove competitivenessProcess efficiency improvementChemical compositionMetallurgy

The invention relates to 21MnCrMoS steel used for a gear. The chemical ingredients comprises 0.17-0.25% of C, 0.10-0.35% of Si, 0.95-1.35% of Mn, 0.25-0.65% of Cr, 0.020-0.050% of S, no more than 0.25% of P, 0.08-0.15% of Mo, no more than 0.10% of Ni, no more than 0.20% of Cu, 0.010-0.050% of Al, no more than 0.0005% of Ca, and the balance being Fe and unavoidable impurities elements. The end hardenability of the steel satisfies the formulas that J5=38-43HRC, J8=30-35HRC, and J13=22-28HRC, and the 21MnCrMoS steel belongs to low-cost carburizing gear type of steel and the producing method. Themanufacturing procedure comprises the steps of electric furnace, refining outside the furnace, VD vacuum degassing, continuous casting, continuous rolling, sawing, reactor cooling, finishing, surfaceand internal flaw detection, and packaging.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

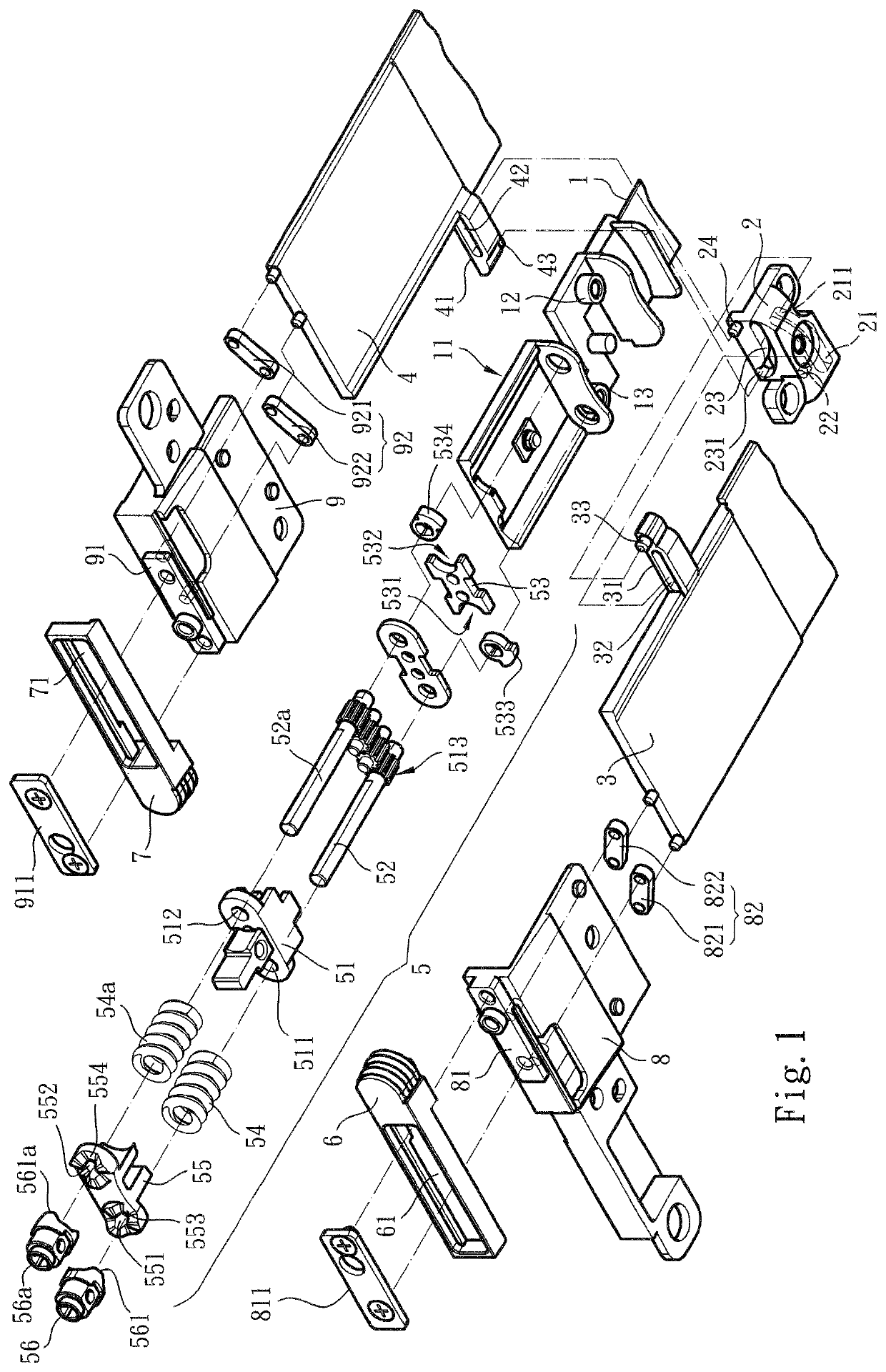

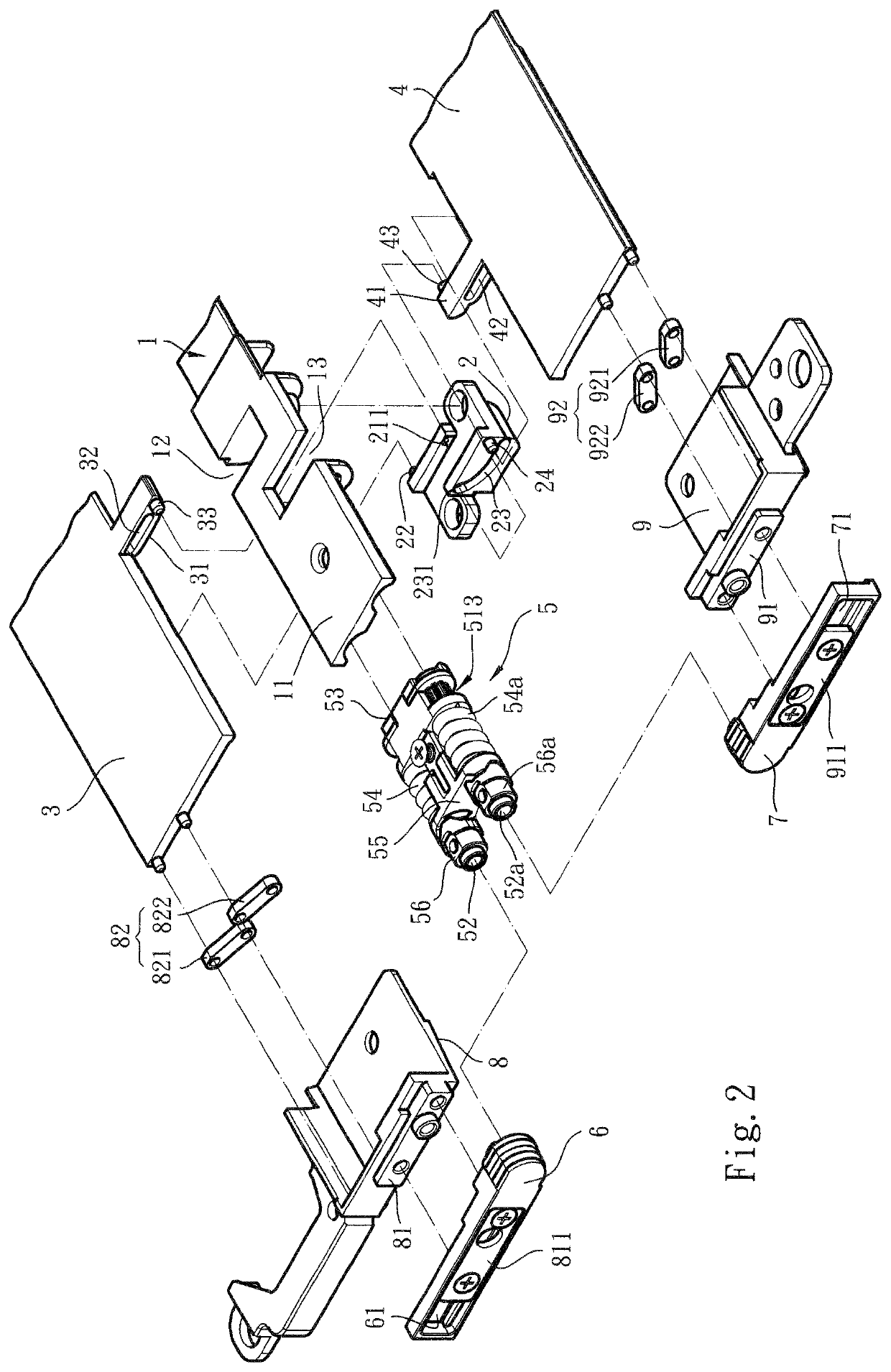

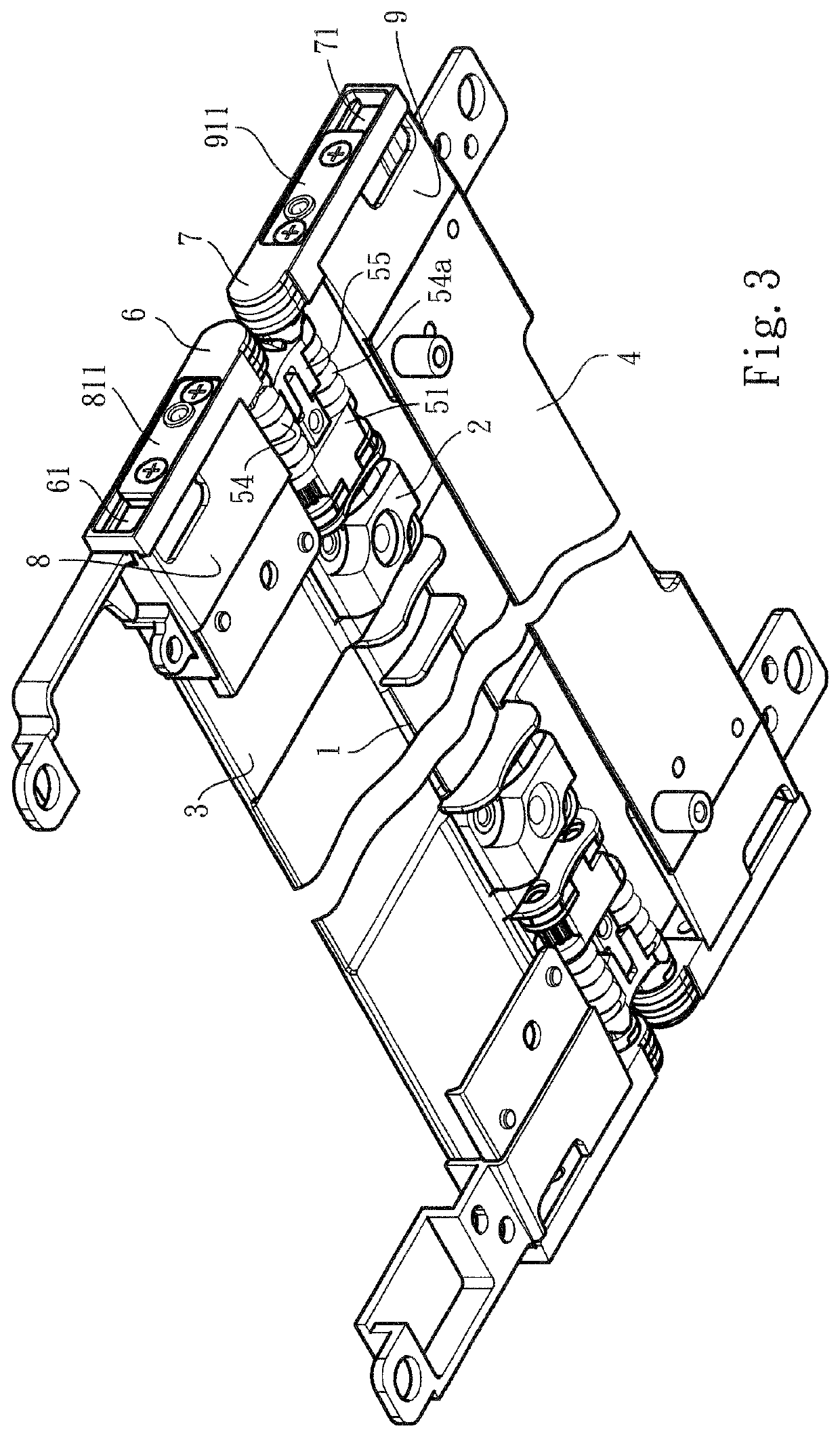

Folding shaft structure of flexible display screen

ActiveUS10824197B1Simple structureLess componentsDetails for portable computersEngineeringStructural engineering

A folding shaft structure of a flexible display screen includes an intermediate bracket, a pivot seat, and two movable seat panels. Two sides of an intermediate bracket each have an open groove. The pivot seat is disposed between the two open grooves. Two sides of the pivot seat, facing the two open grooves, are each provided with a curved guide groove and a guide pin. One end of the curved guide groove, away from an opening of the open groove, is a curved tilted end. Each guide pin is disposed close to one end of the curved guide groove away from the curved tilted end. Each movable seat panel has a protruding portion inserted in the open groove. One side of the protruding portion is provided with a protruding pin inserted into the curved guide groove and a guide groove for insertion of the guide pin.

Owner:FIRST DOME

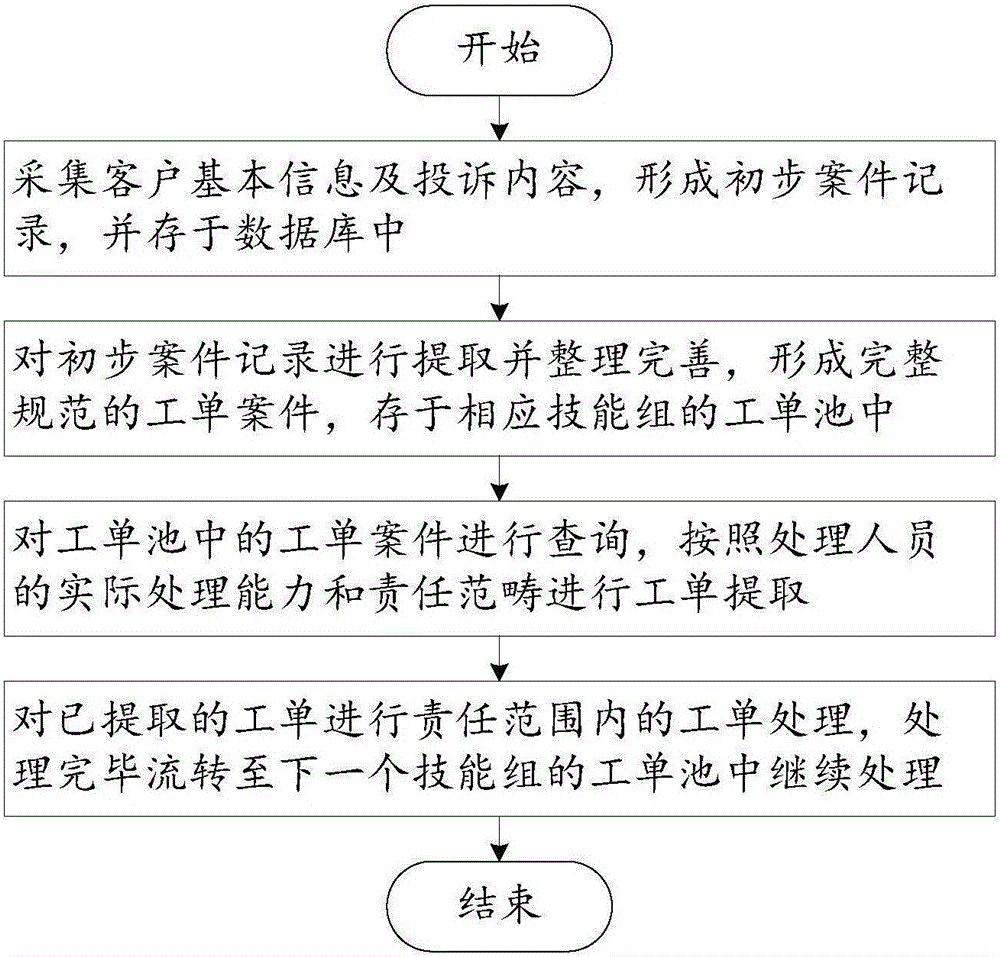

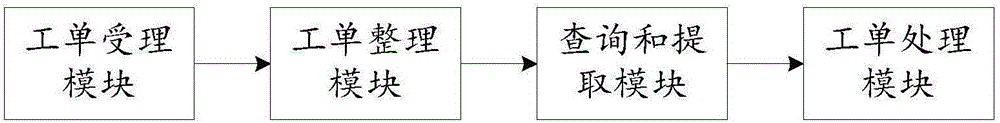

Customer complaint solving method based on B/S framework work order flow and customer complaint solving system thereof

The invention relates to a customer complaint solving method based on B / S framework work order flow and a customer complaint solving system thereof. The method comprises the steps that customer basic information and complaint content are acquired so that a preliminary case record is formed and stored in a database; the preliminary case record is extracted and compiled and completed so that a complete and standard work order case is formed and stored in a work order pool of the corresponding skill group; the work order case of the work order pool is inquired, and work order extraction is performed according to the actual processing capacity and the responsibility range of processing personnel; and work order processing within the responsibility range is performed on the extracted work order and then flows to the work order pool of the next skill group to perform processing continuously after completion of processing. Solving of the complaint issues is realized by adopting the mode of combination of the B / S work order flow and skill group employee configuration, and all the flow nodes are flexibly configured so that user complaint solving time can be shortened, issue solving efficiency can be enhanced, user satisfaction can be enhanced and the competitiveness and the advantages of the method in the similar industries can be enhanced.

Owner:北京思特奇信息技术股份有限公司

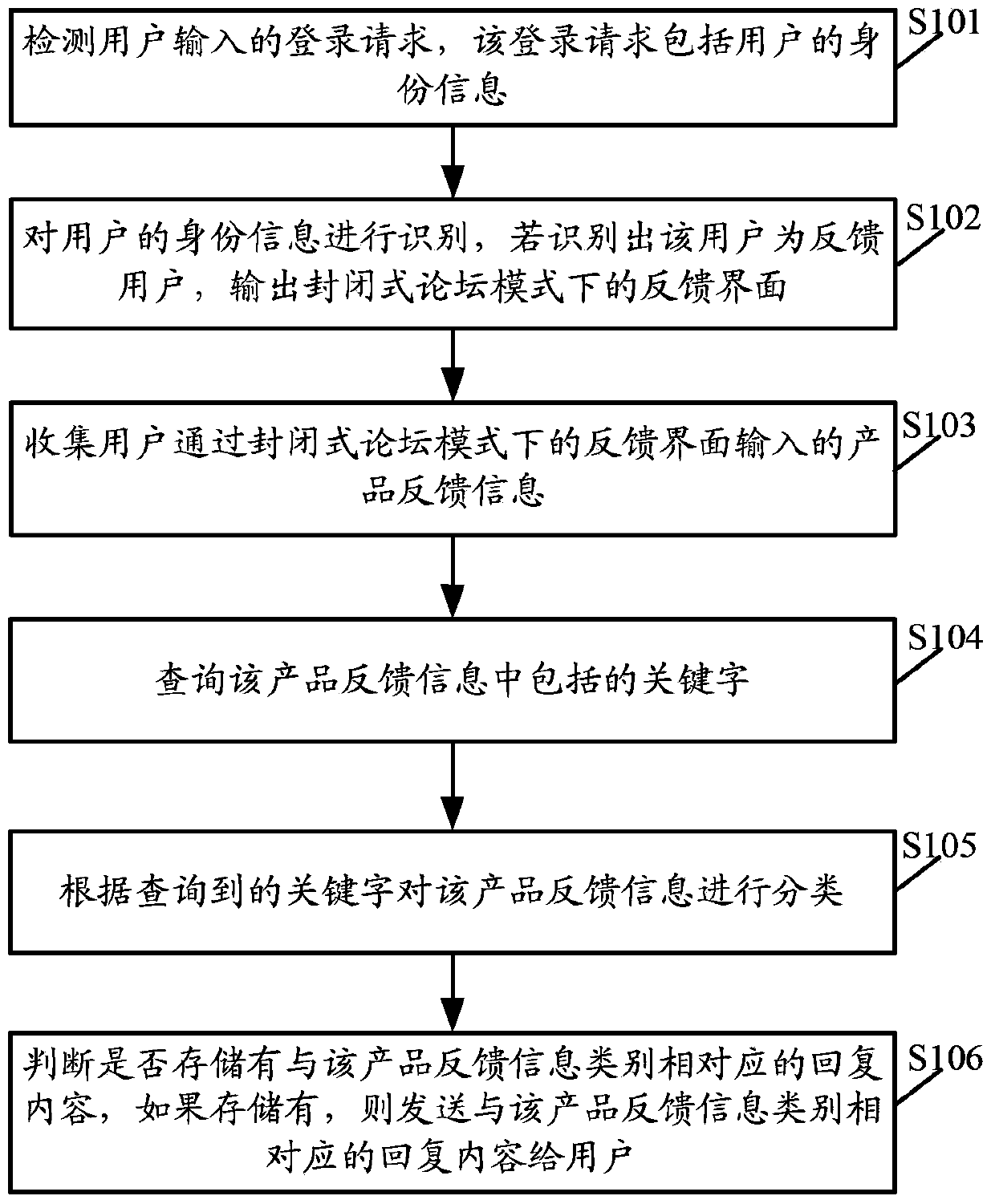

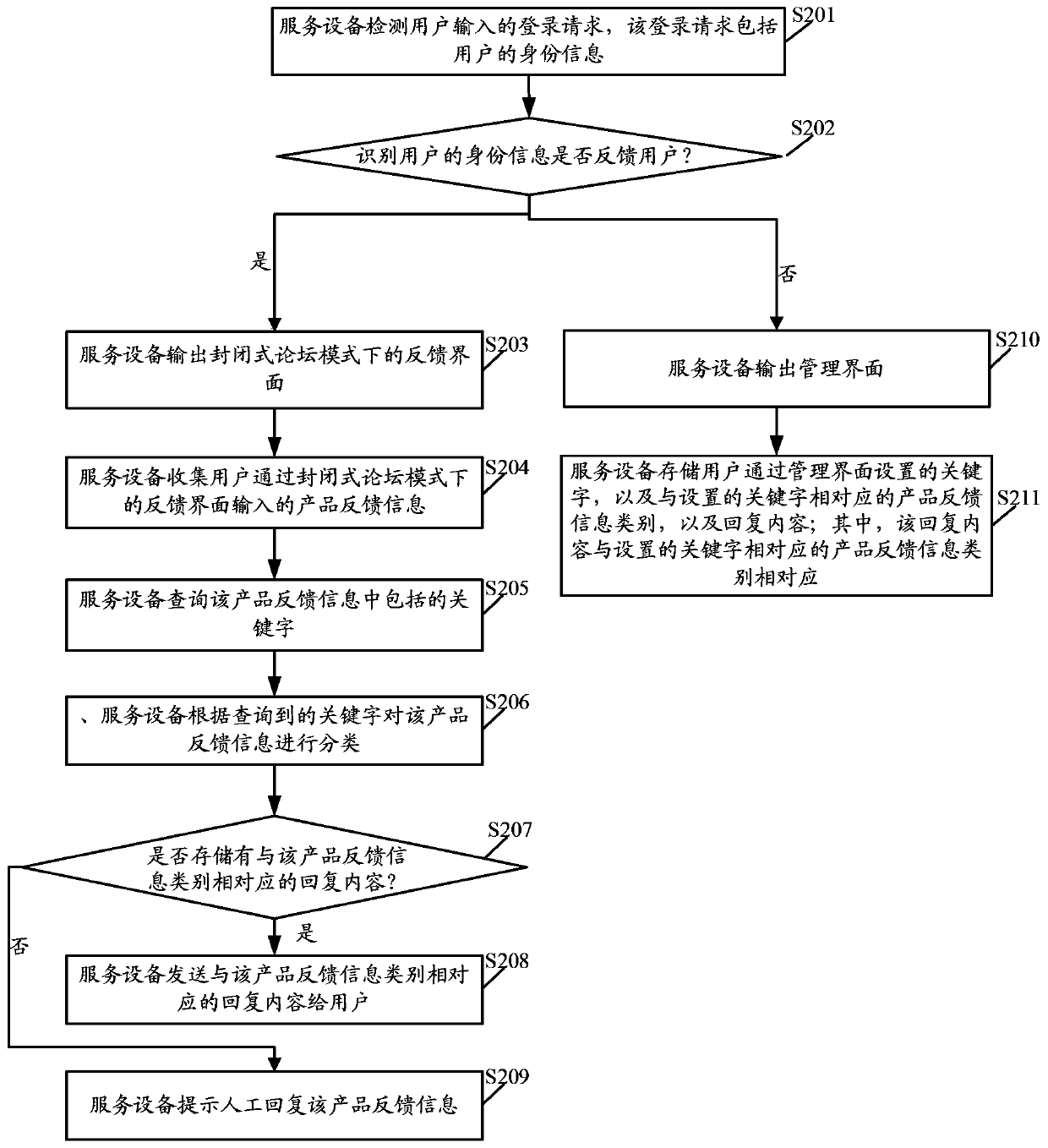

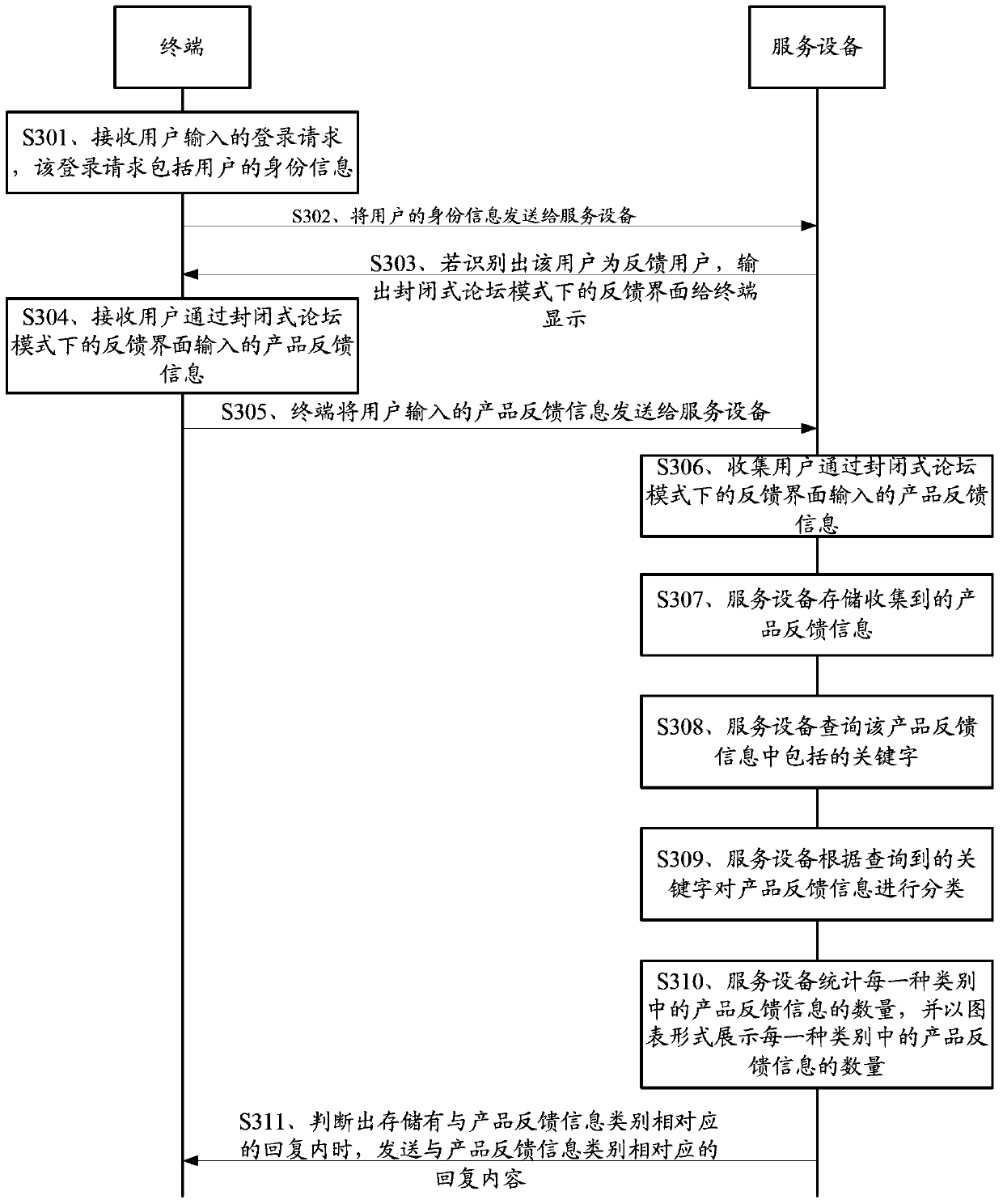

Feedback information processing method and system and service apparatus

ActiveCN104184763AImprove response efficiencyImprove competitivenessTransmissionSpecial data processing applicationsInformation processingThe Internet

The invention relates to the technical field of Internet, and discloses a feedback information processing method and system. The method comprises: detecting a registration request input by a user, wherein the registration request comprises user identity information; identifying the user identity information, if the user is the feedback user, outputting the feedback interface in the mode of an enclosed forum; collecting product feedback information input through a feedback interface in the mode of the enclosed forum; querying keywords included in the product feedback information; classifying the product feedback information according to the queried keywords; determining whether being stored with reply content corresponding to the product feedback information, if true, transmitting the reply content corresponding to the product feedback information category to the user. According to the embodiment of the invention, replying efficiency of the feedback information can be effectively increased, and competitive strength of the product is lifted.

Owner:TENCENT TECH (SHENZHEN) CO LTD

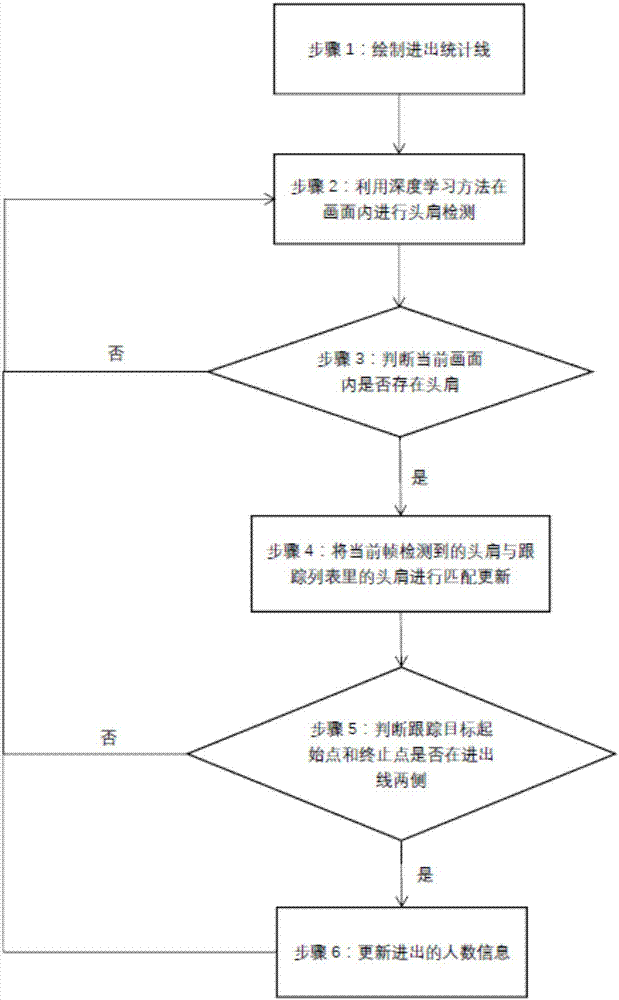

Passenger flow counting method based on deep learning in vertical visual angle

ActiveCN107103279AImprove competitivenessImprove scienceImage enhancementImage analysisLearning abilitiesConvolution

The invention provides a passenger flow counting method based on deep learning in a vertical visual angle. According to the method, passenger flow statistics is performed in the vertical visual angle. Compared with an oblique photographing visual angle, the visual angle realizes easier coping with conditions such as market, supermarket and subway with high passenger density. The method provides head and shoulder detection by means of deep learning. Strong learning capability of deep learning is utilized. Background modeling and foreground extraction on a video are not required, and passenger cutting on the foreground is not required. Head information and shoulder information can be more accurately detected with higher robustness. A deep convolutional characteristic is utilized for performing matched tracking. Compared with manually designed characteristics such as HOG and LBP, the deep convolutional characteristic has better expression capability and can better cope with various scenes. The passenger flow counting method directly use the deep convolutional characteristic of a certain layer for matching, thereby preventing repeated characteristic calculation and realizing high time saving effect.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com