Patents

Literature

271results about How to "Shorten production hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

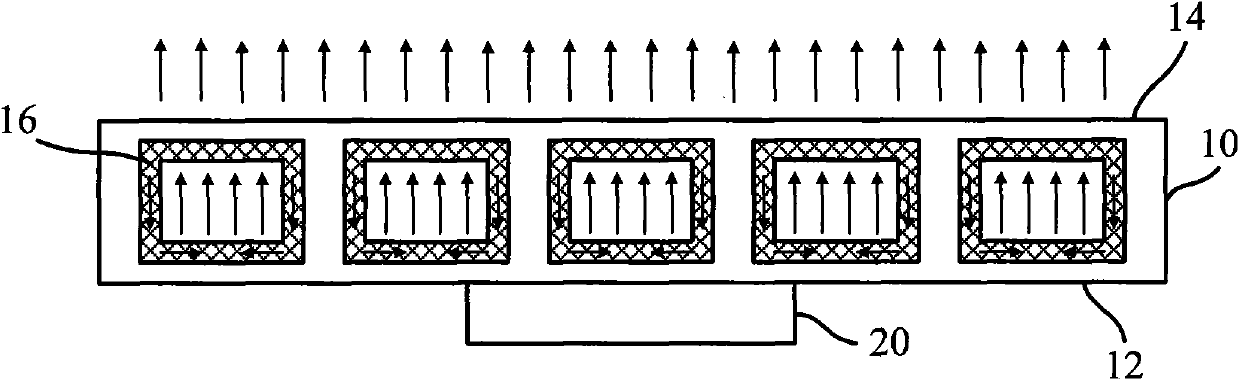

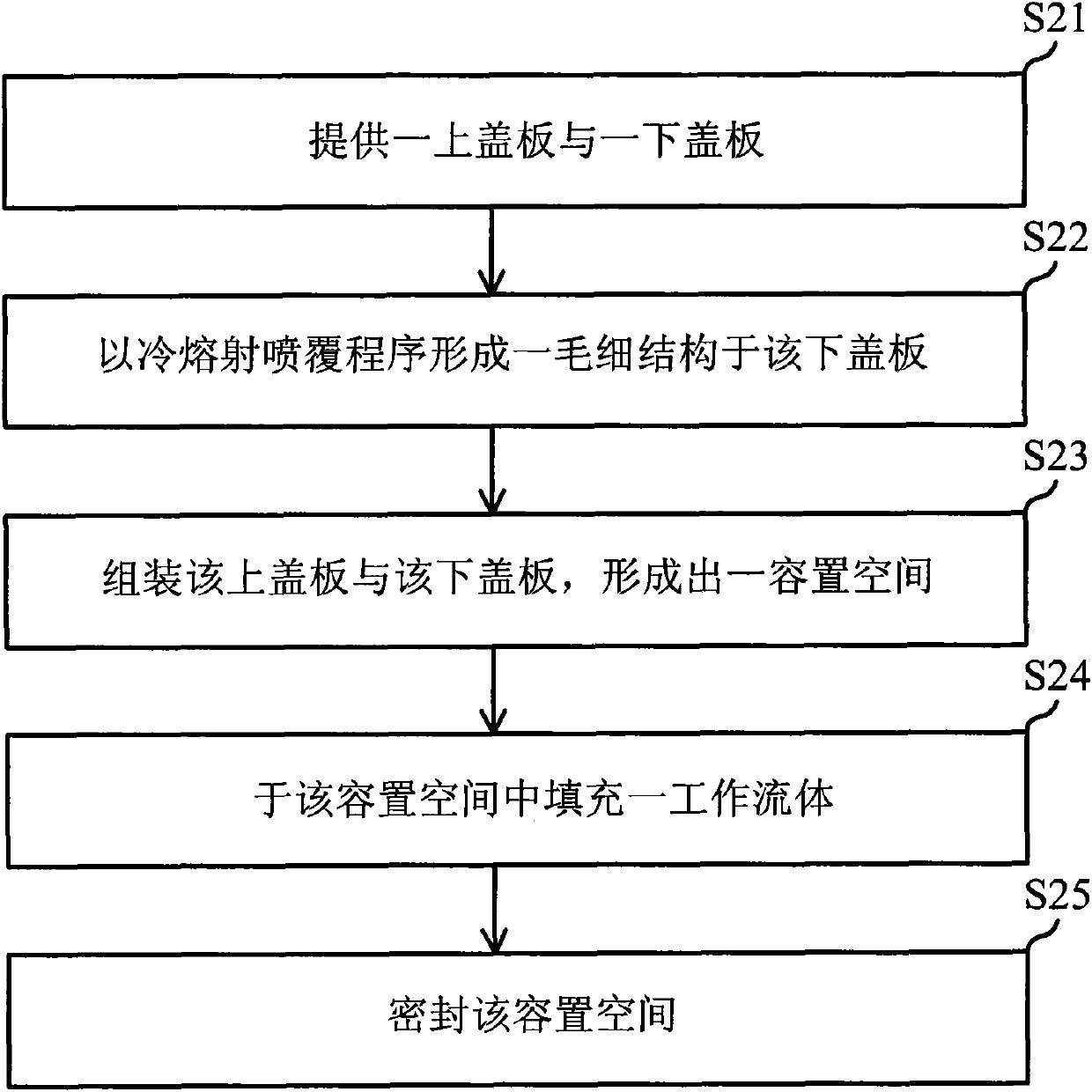

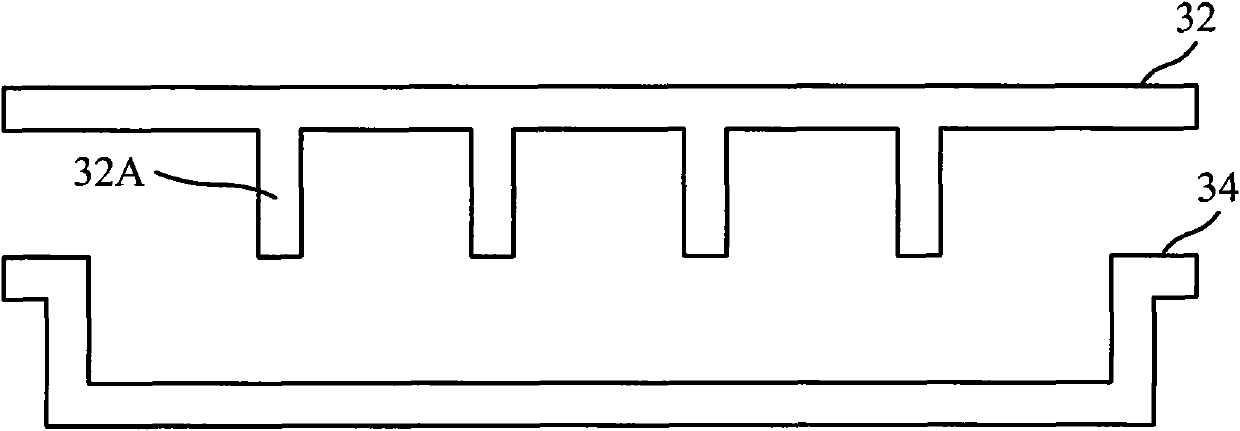

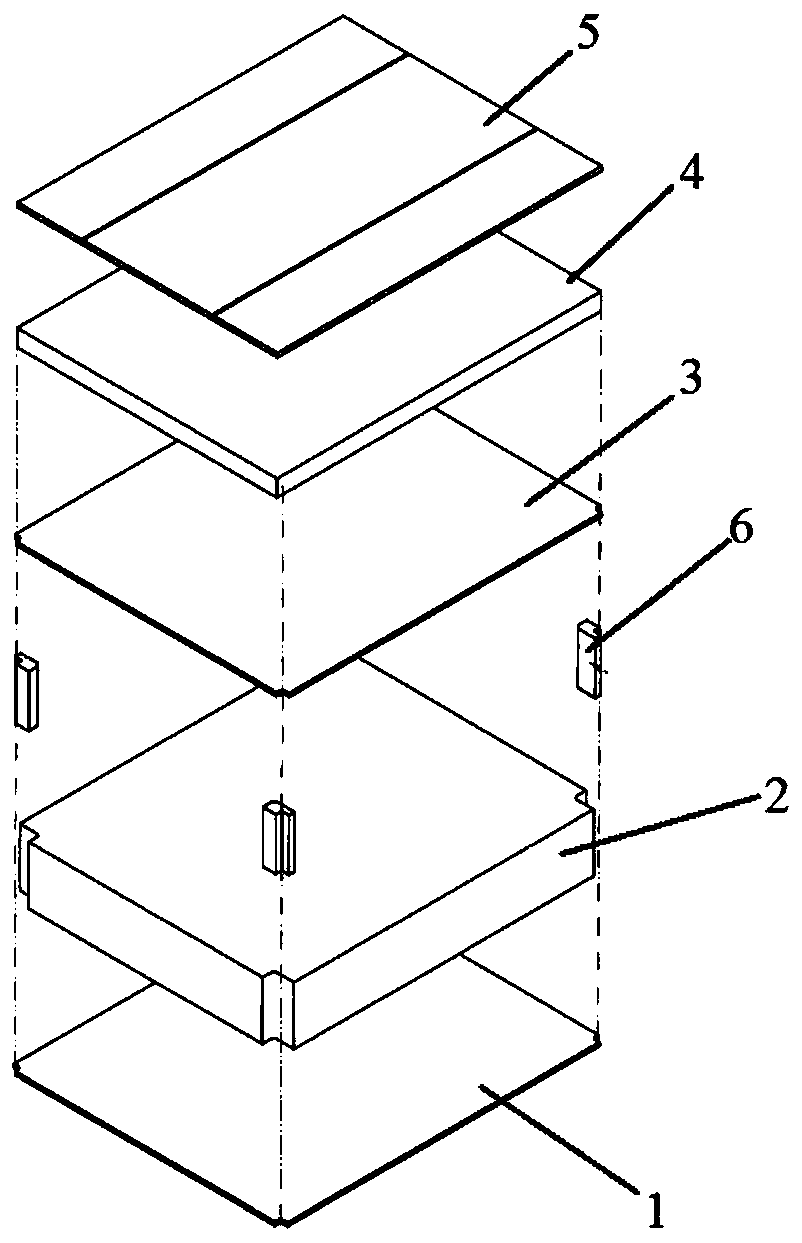

Temperature-equalizing plate and manufacture method thereof

ActiveCN102019543AShorten production hoursIncrease productivityMolten spray coatingSemiconductor/solid-state device detailsWorking fluidEngineering

The invention provides a temperature-equalizing plate and a manufacture method thereof. The manufacture method of the temperature-equalizing plate comprises the following steps of: firstly, providing an upper cover plate and a lower cover plate; secondly, forming a capillary structure on the lower cover plate through a cold-melting spraying procedure; thirdly, assembling the upper cover plate and the lower cover plate to form at least one containing space in which the capillary structure is positioned; and finally, sealing the containing space after filling working fluid in the containing space. Thus, the temperature-equalizing plate manufactured with the manufacture method of the invention comprises a shell, the working fluid and the capillary structure, wherein the containing space is formed in the shell, the working fluid is filled in the containing space, and the capillary structure is formed on the inner wall of the containing wall through the cold-melting spraying procedure.

Owner:PEGATRON

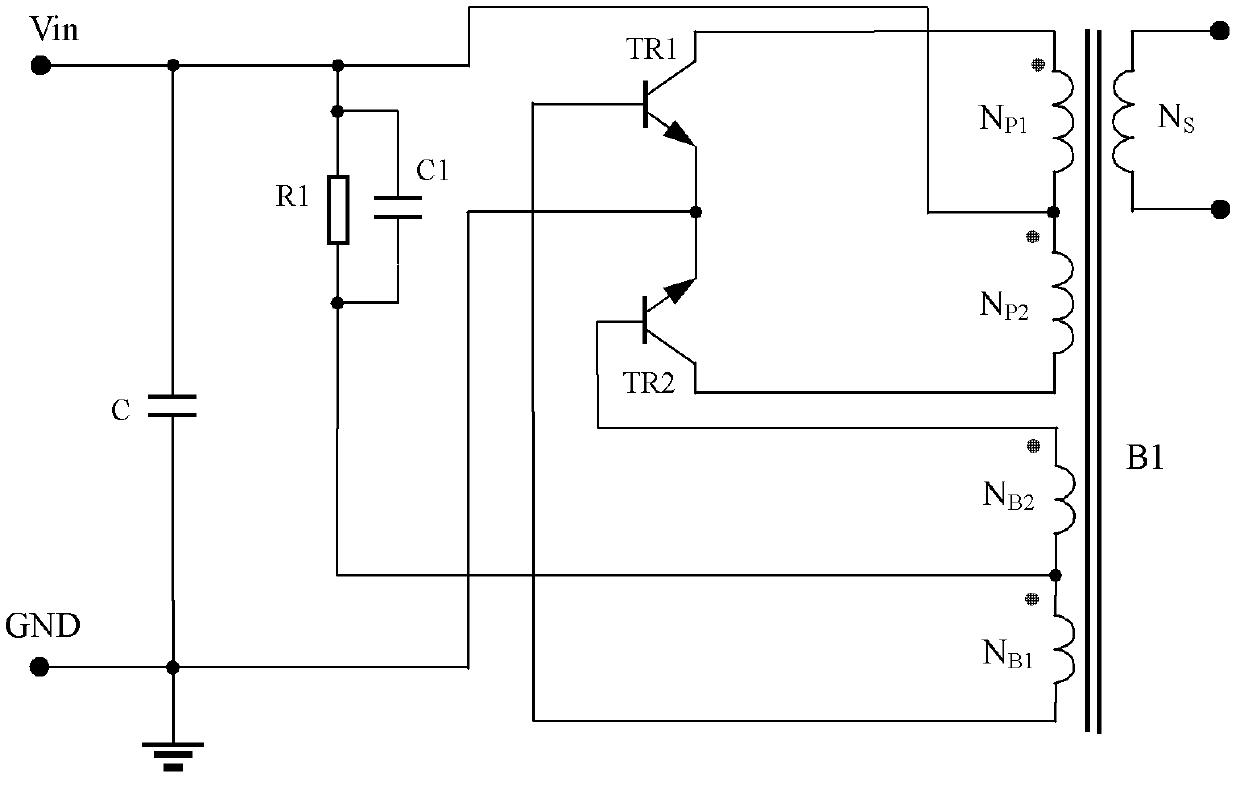

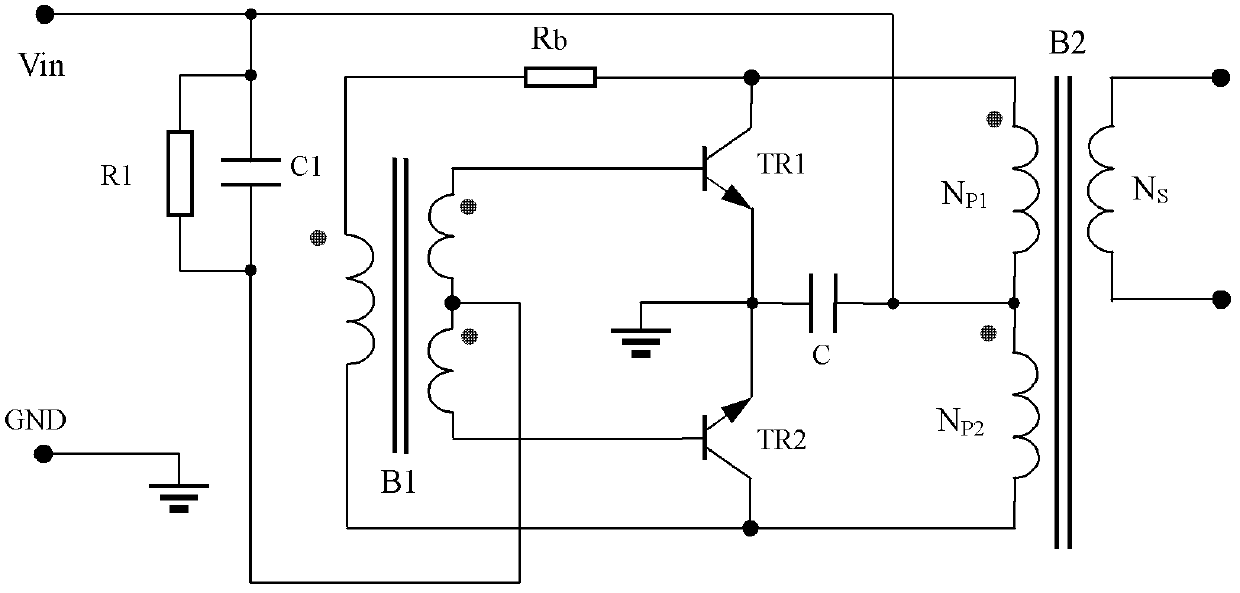

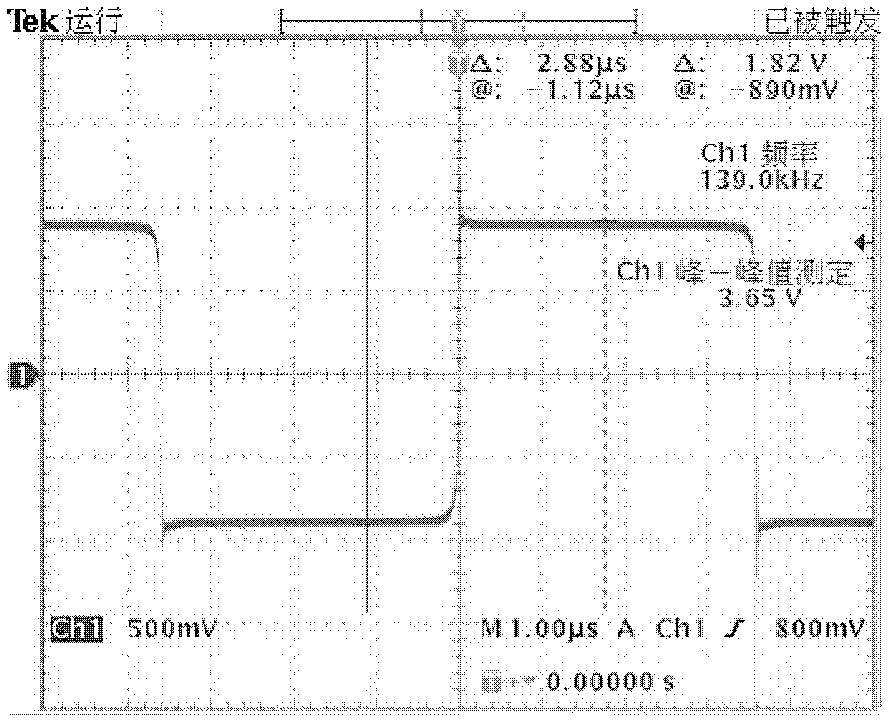

Self-excitation push-pull type converter

ActiveCN102437767AImprove efficiencyReduce power consumptionTransformers/inductances coils/windings/connectionsAc-dc conversionTransformerPush pull

The invention discloses a self-excitation push-pull type converter, comprising a transformer. A closed magnetic core or iron core of the transformer is formed by a main part and a local part, wherein the local part achieves magnetic saturation earlier than the main part under excitation of the same increasing magnetic field. The converter disclosed by the invention can overcome the defects of the traditional self-excitation push-pull type converter, thus efficiency of the self-excitation push-pull type converter is obviously improved when the self-excitation push-pull type converter is in a light load state; when the self-excitation push-pull type converter is in a rated load state, the efficiency is further improved; number of windings of coils on a magnetic saturation transformer in the self-excitation push-pull type converter is reduced; working frequency of the self-excitation push-pull type converter is improved while loss is maintained to be lower; and probability that current peak is produced when the self-excitation push-pull type converter is conducted and closed is reduced, and the efficiency is further improved while output ripple is reduced.

Owner:MORNSUN GUANGZHOU SCI & TECH

Double-component polyurethane coating and production method and construction method

InactiveCN101457120AShorten the coating production cycleHigh fullnessPretreated surfacesPolyurea/polyurethane coatingsLacquerPolyurethane coating

The present invention discloses a bicomponent polyurethane paint and preparation method and execution method thereof, wherein the bicomponent polyurethane paint includes primer, primer fluidifying agent and bicomponent polyurethane PU varnish lacquer that matched with the primer. The bicomponent polyurethane PU paint can be used on HIPS plastic rubber case with complicated structure, and can improve productivity effect and save energy sources, have appearance with high lustrousness and high fullness; the preparation method provides simple producing process and the execution method provides convenient painting.

Owner:DONGGUAN JIAZHUOCHENG CHEM TECH

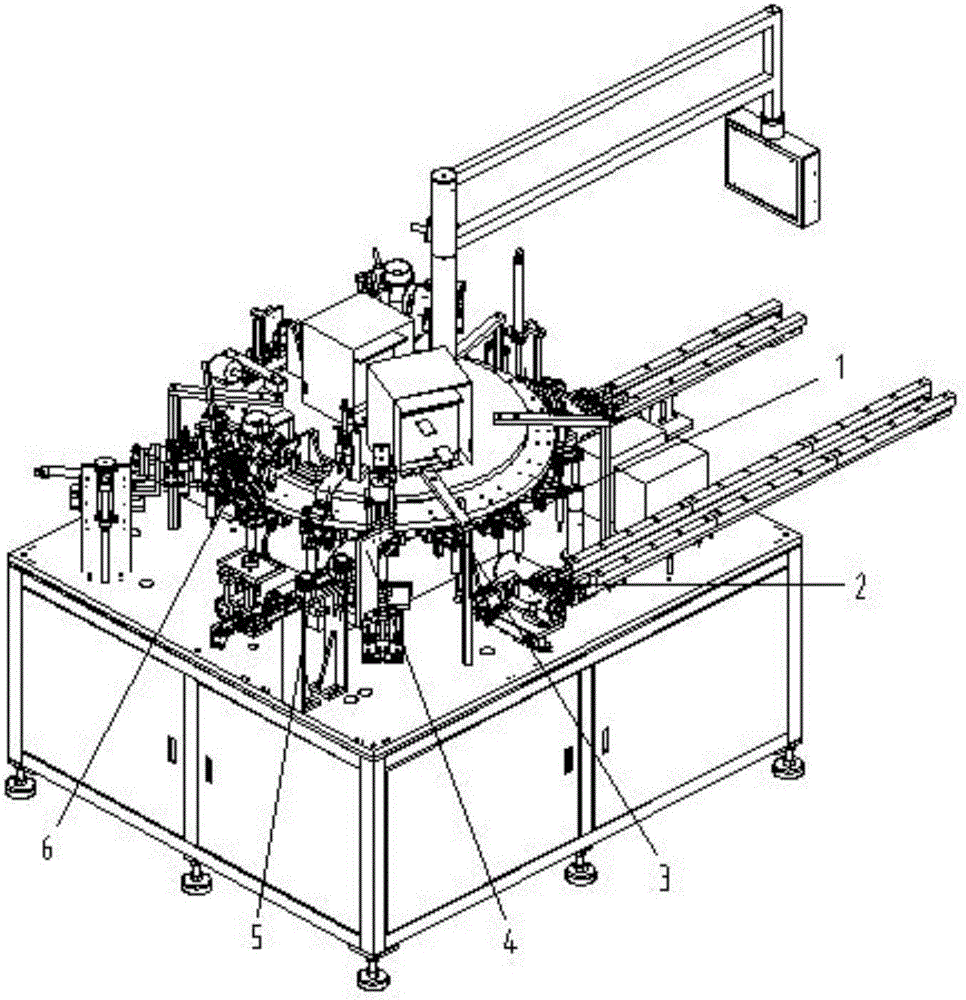

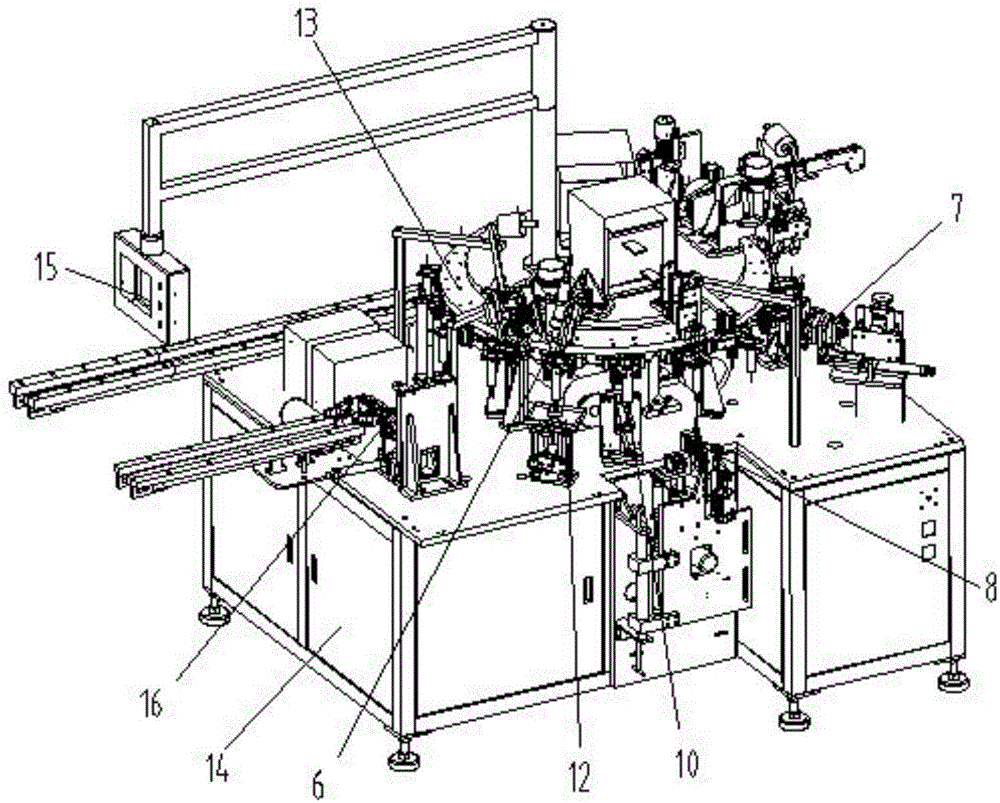

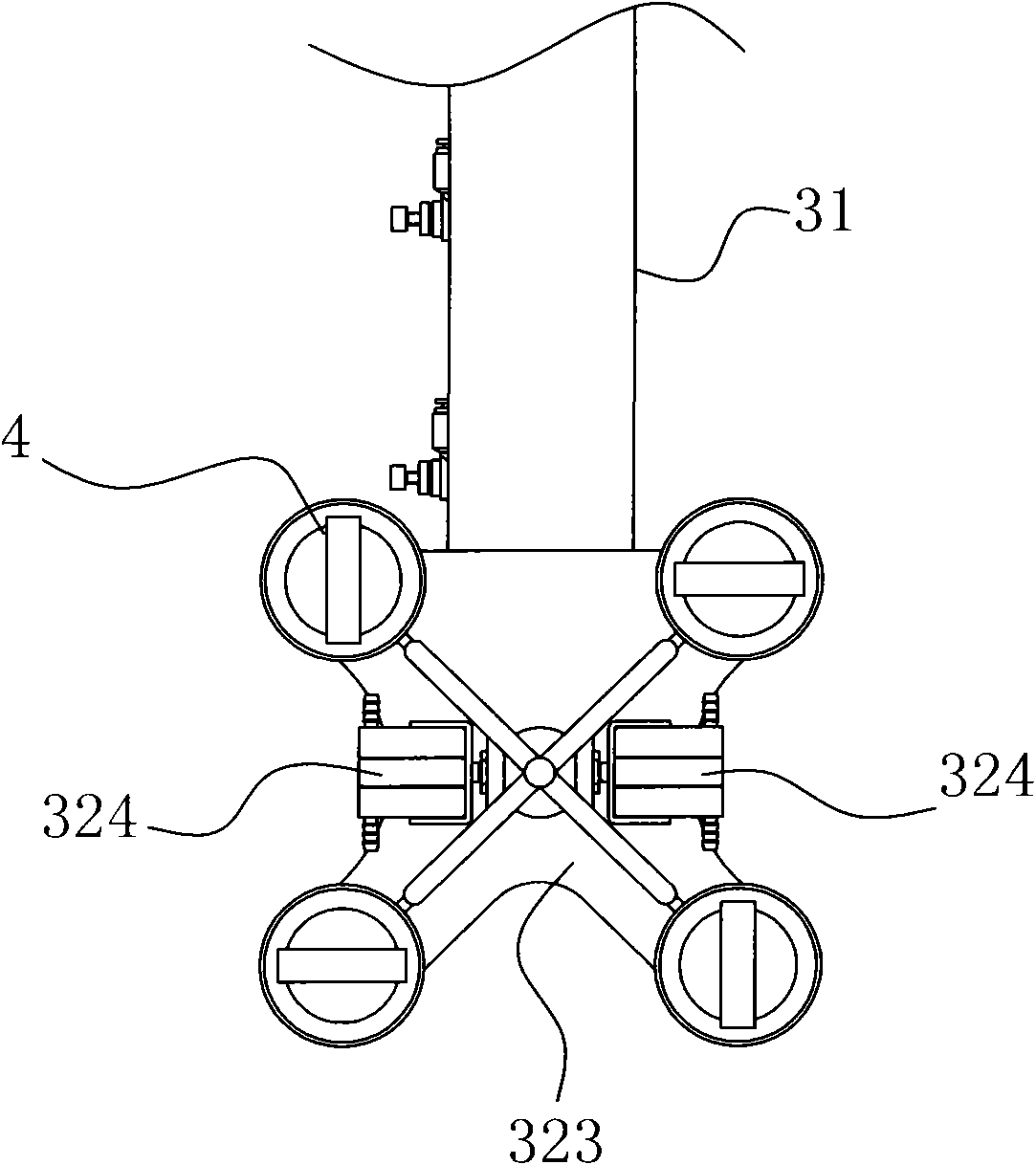

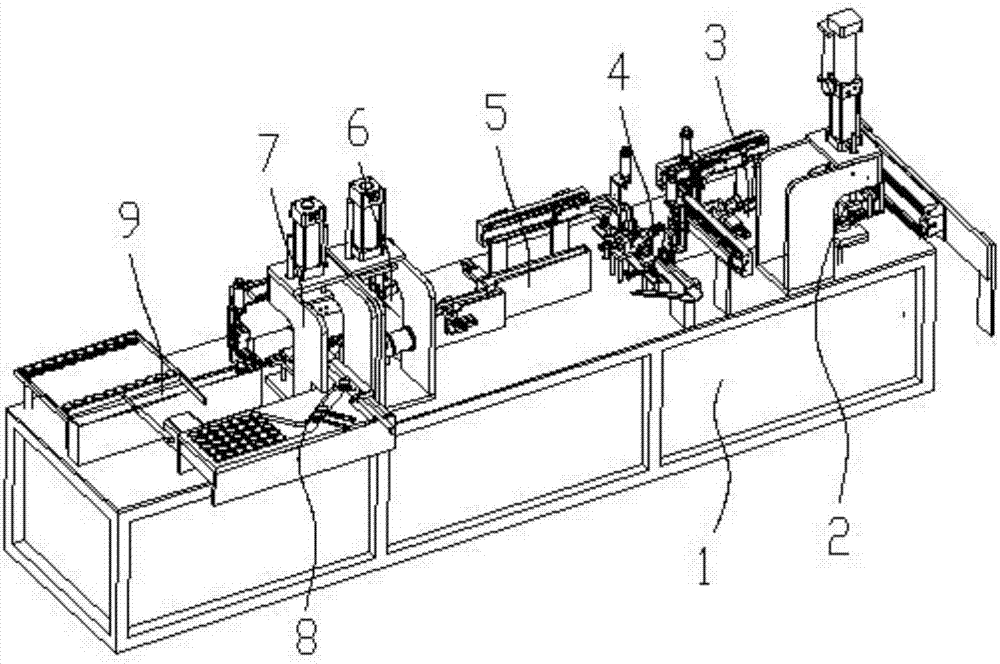

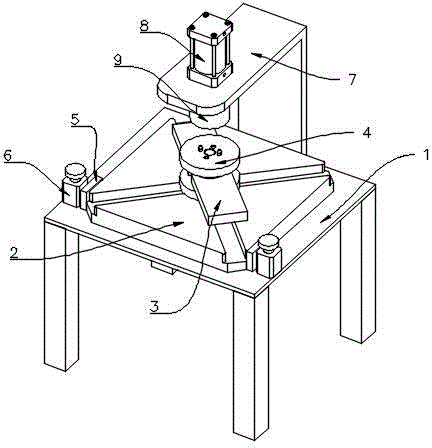

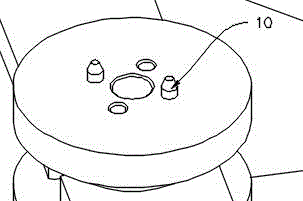

Automatic assembly machine of round capacitor

ActiveCN106847558ARealize automatic flipImprove welding efficiencyTerminal applying apparatusCapacitanceDistribution control

The invention relates to the field of capacitor processing equipment, in particular to an automatic assembly machine of a round capacitor. The machine includes a power distribution control box, a rotary plate and an operation screen, wherein the rotary plate and the operation screen are arranged above the power distribution control box through a bracket and communicated with the power distribution control box; clamps are uniformly arranged along a circle under the rotary plate; a feeding device, a positioning detection device, an upper tin-wire feeding device, a polarity detection device, a first tin-wire welding device, a capacitor turnover device, a lower tin-wire feeding device, a second tin-wire welding device and a discharging device are arranged in sequence on the outer side of the rotary plate in the clockwise direction and connected with the power distribution control box. The automatic assembly machine of the round capacitor has the advantages that automatic operation is adopted from feeding to discharging, the processing accuracy and processing efficiency of the round capacitor are greatly improved, and a large amount of working time is saved.

Owner:天长市中发电子有限公司

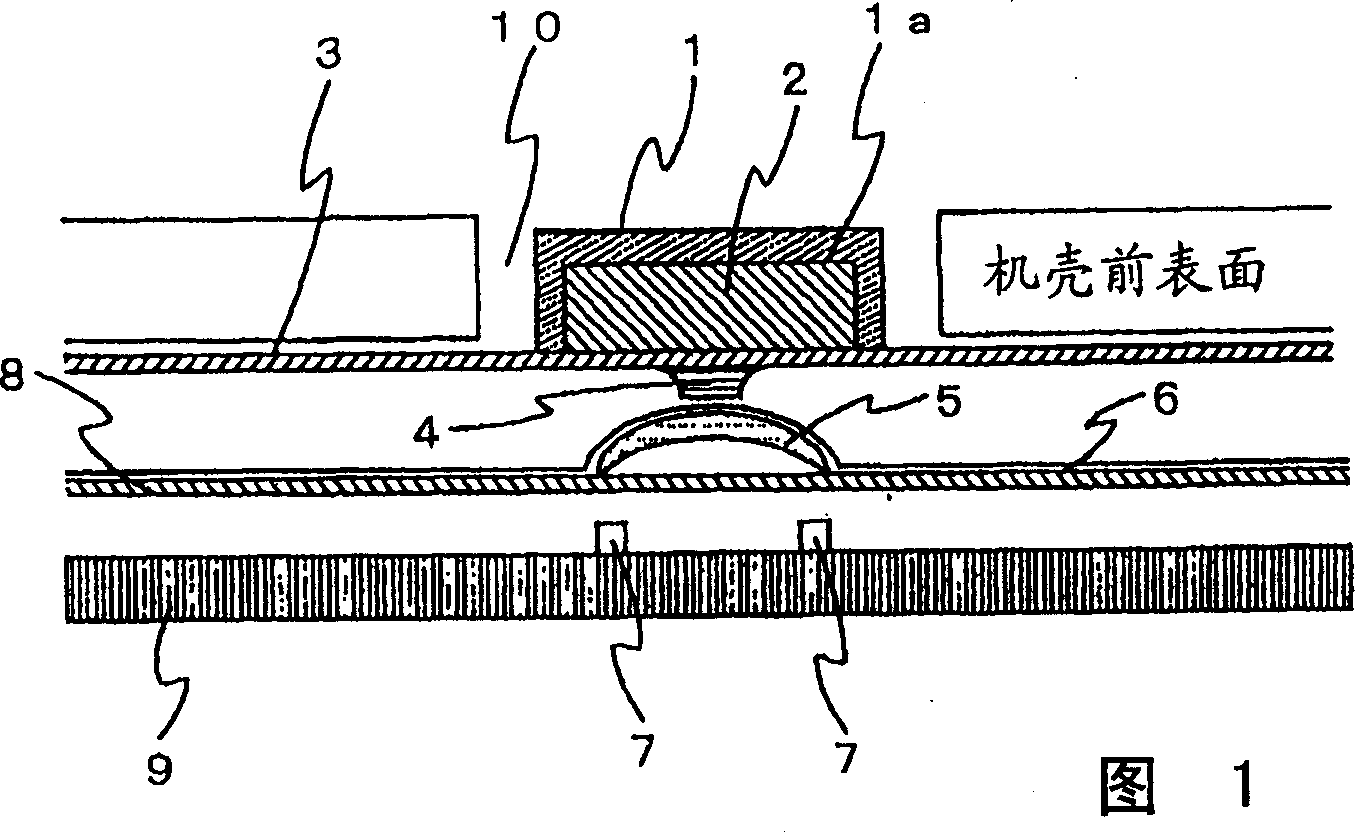

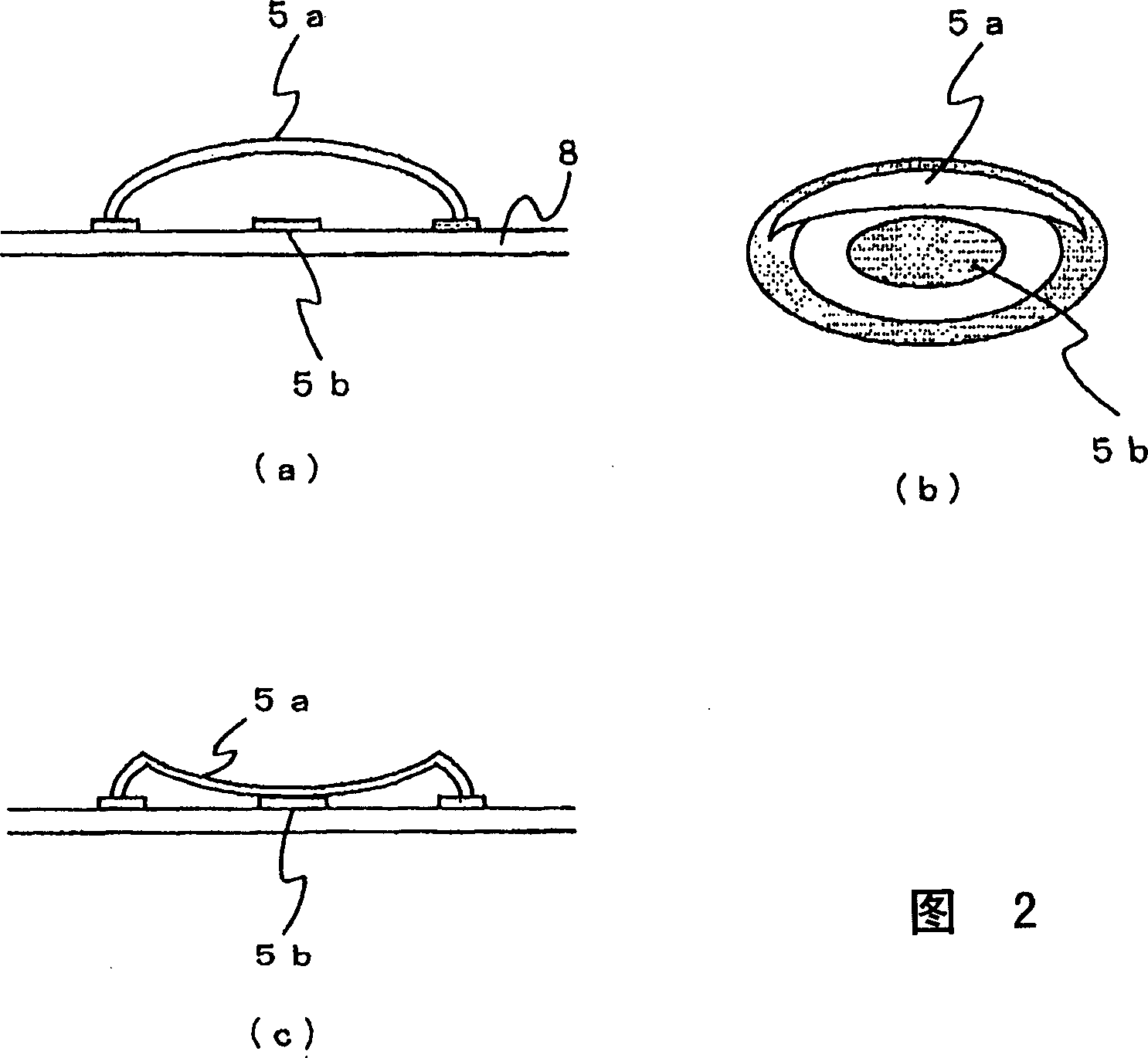

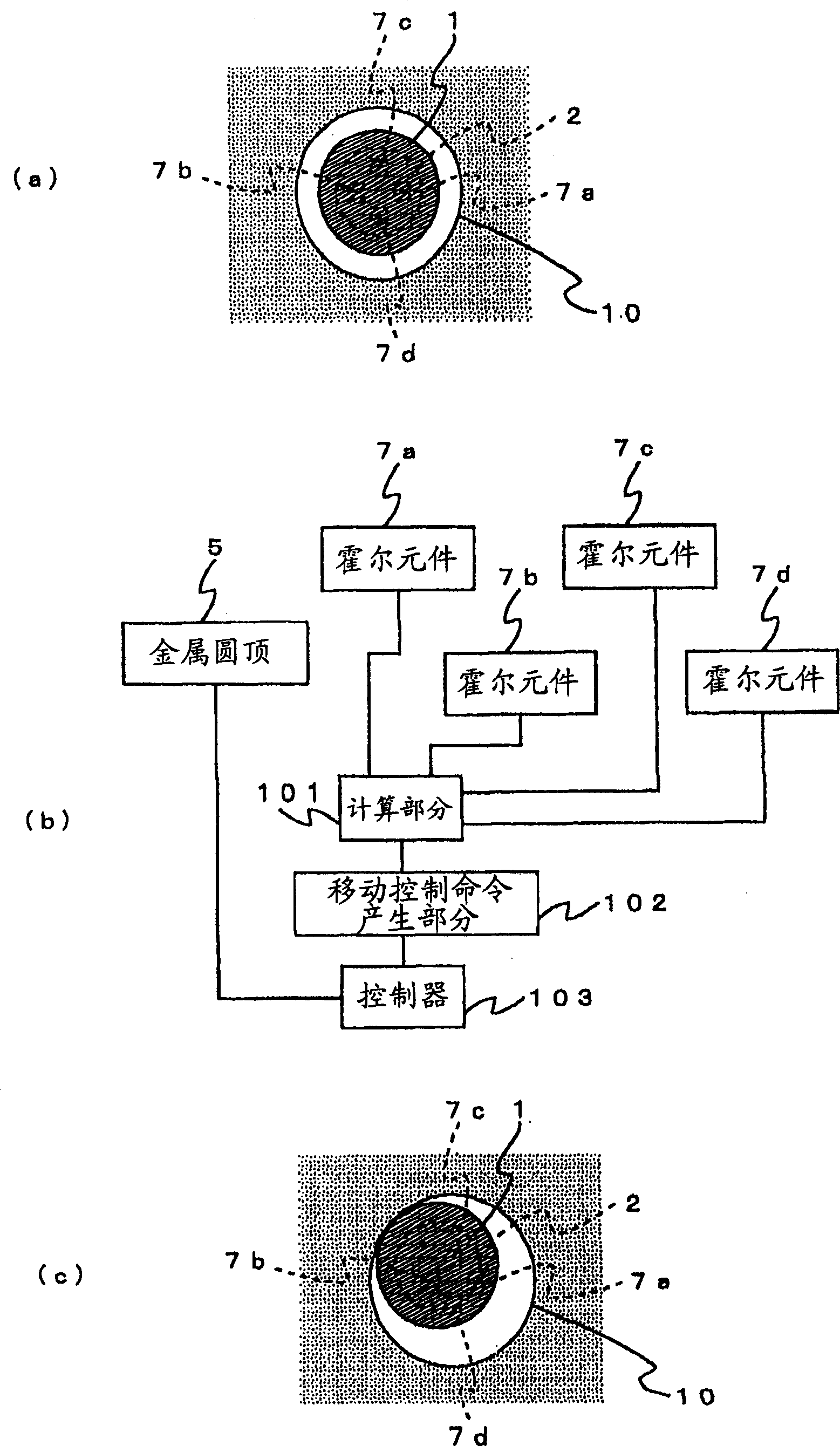

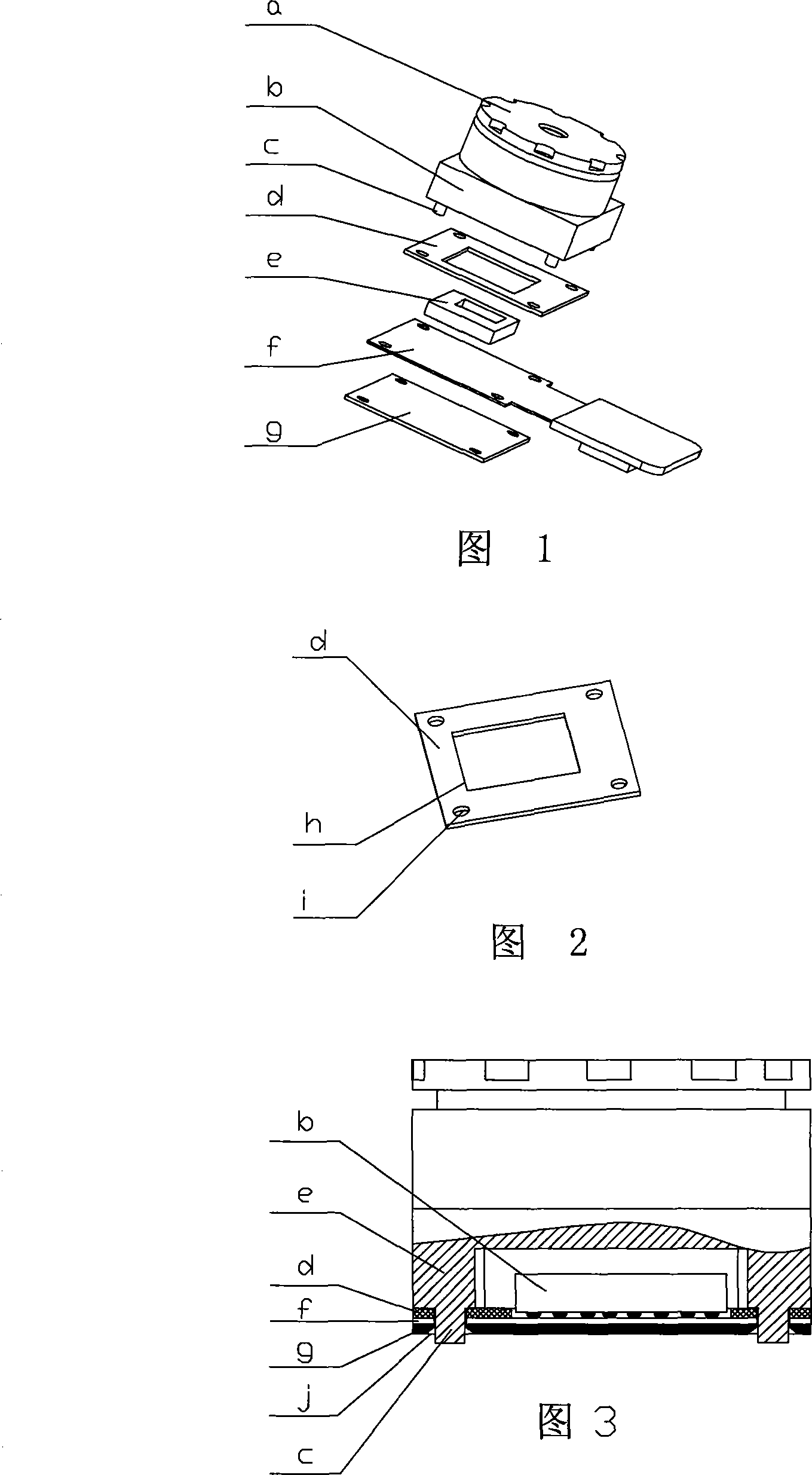

Inputting equipment and mobile terminal

InactiveCN1487766ASmaller and thinnerReduce in quantityEmergency actuatorsEmergency casingsOrthogonal coordinatesControl signal

An inputting device, in which a moving control command to a subject to be controlled is formed on a display in an arbitrary direction and the waterproof and the dustproof are provided and whose structure does not have a part sticking out of the surface of the cabinet or has the part sticking out of the surface of the cabinet as small as possible even if it has the sticking out part and whose structure is also simple, is provided. In this, a plane being about parallel to the front surface of the cabinet is defined as an XY plane in an XY orthogonal coordinate system. The inputting device is disposed in an opening part of a cabinet. The inputting device provides an elastic sheet that is made of a material having elasticity and flexibility or having only elasticity and is disposed inside the cabinet in about parallel to the XY plane in a state that the front surface of the elastic sheet faces the rear surface of the front side of the cabinet, a sliding key that is fixed tightly on the front surface of the elastic sheet so that the sliding key is disposed at an about center of the opening part in a state that the sliding key is possible to move in an arbitrary direction on the XY plane, sensors that at least detect the moved direction of the sliding key on the XY plane, and a first controlling means that generates a first control signal based on the moved direction and the amount of the movement of the sliding key detected by the sensors.

Owner:NEC CORP +1

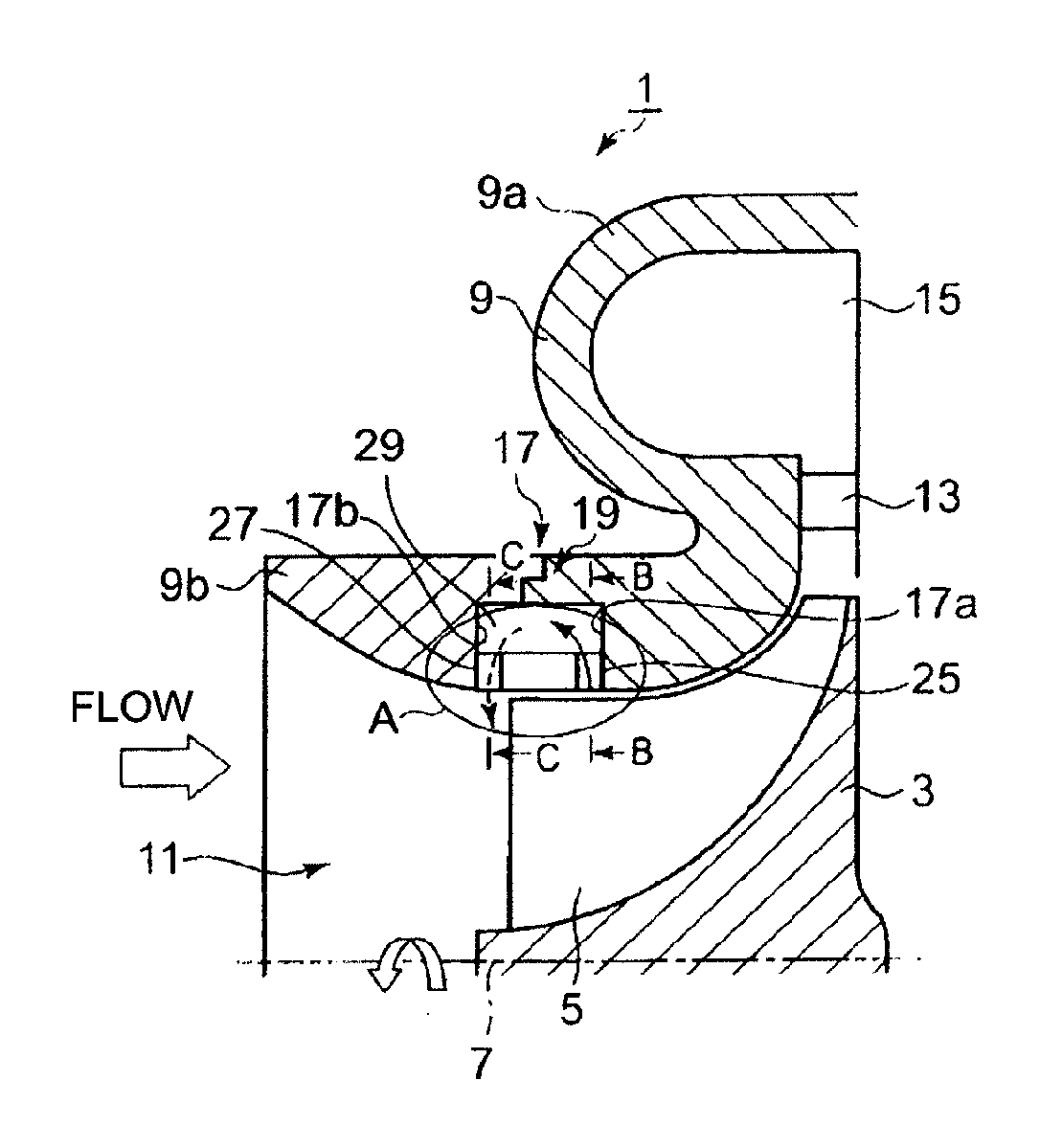

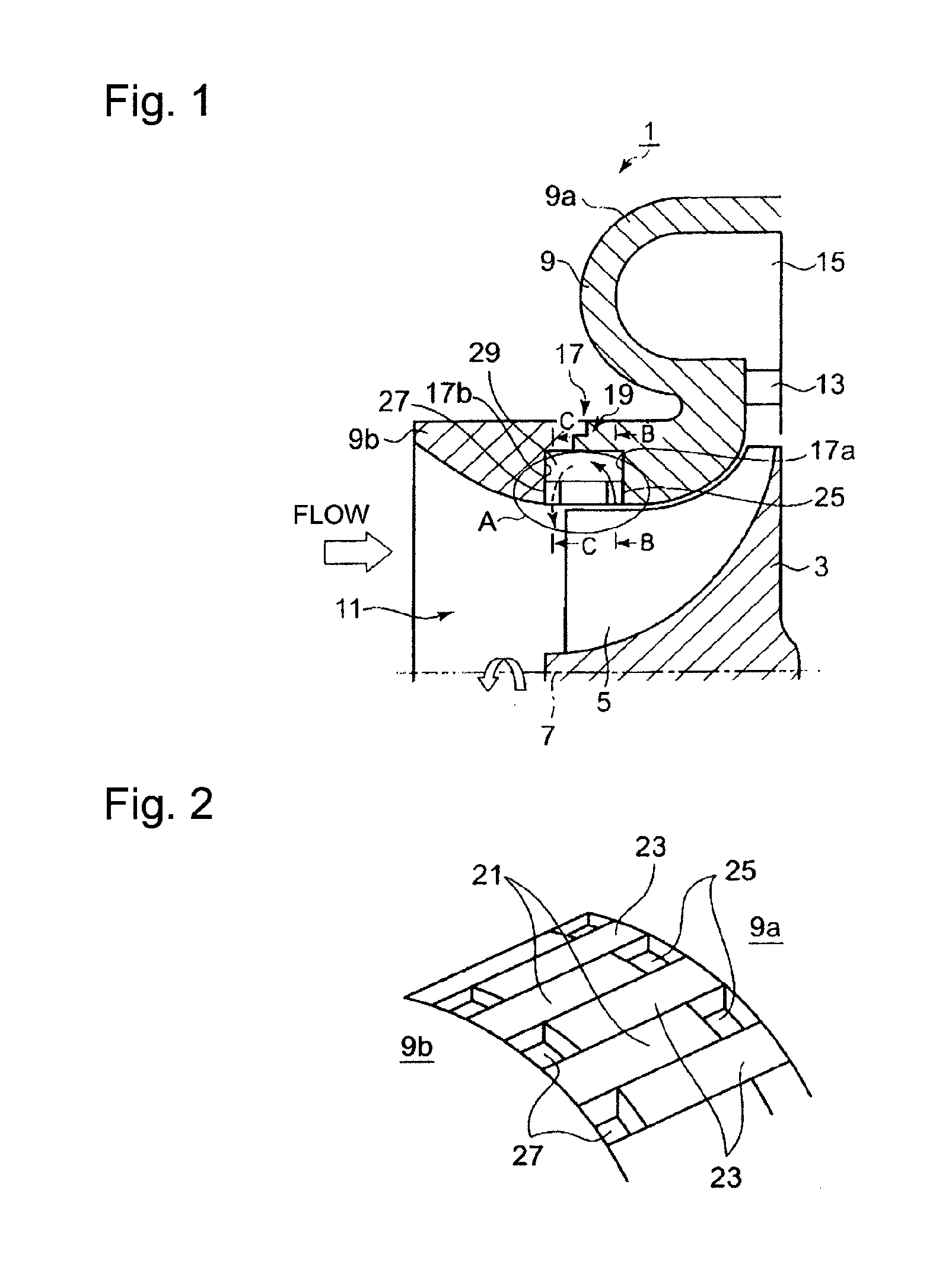

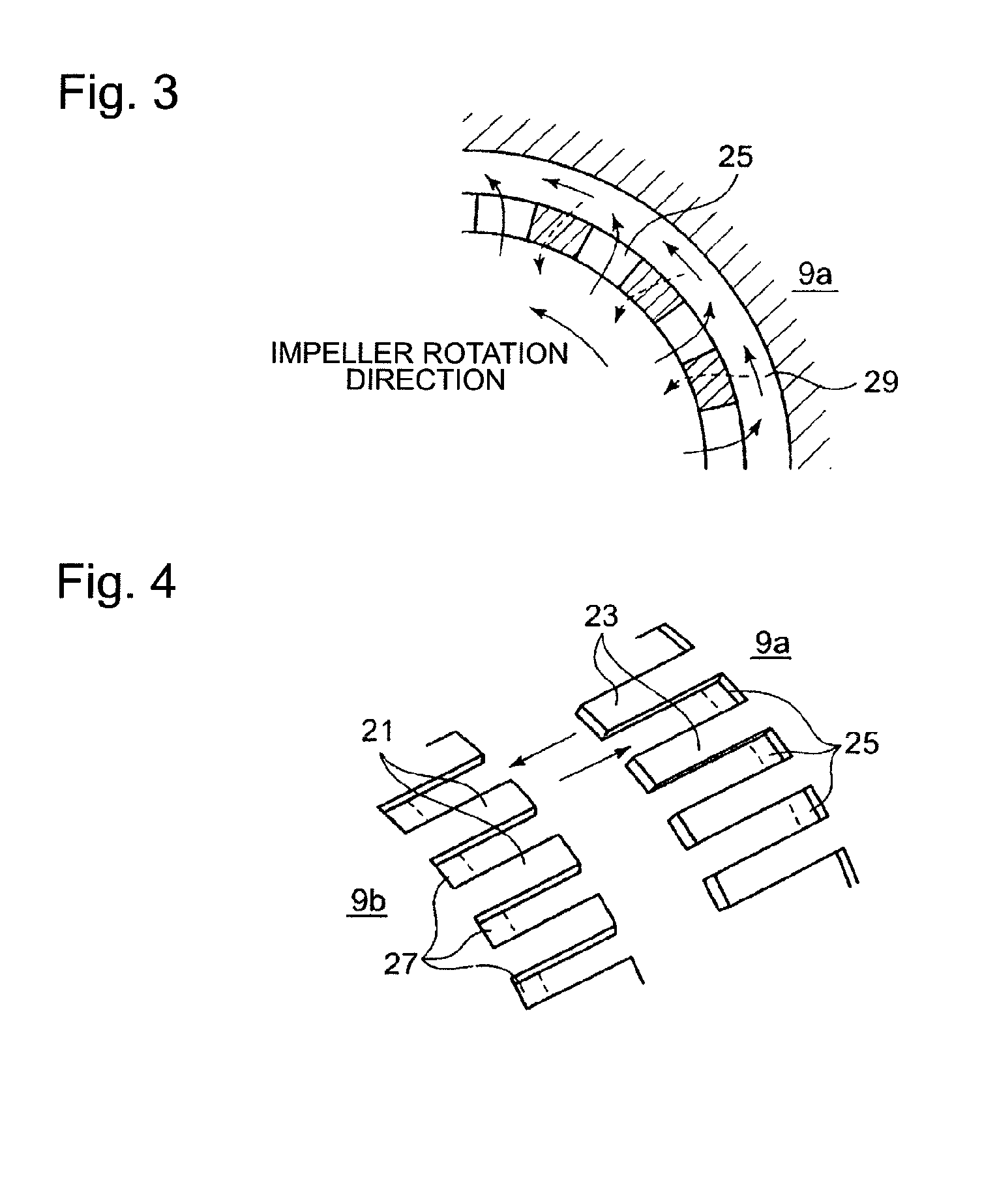

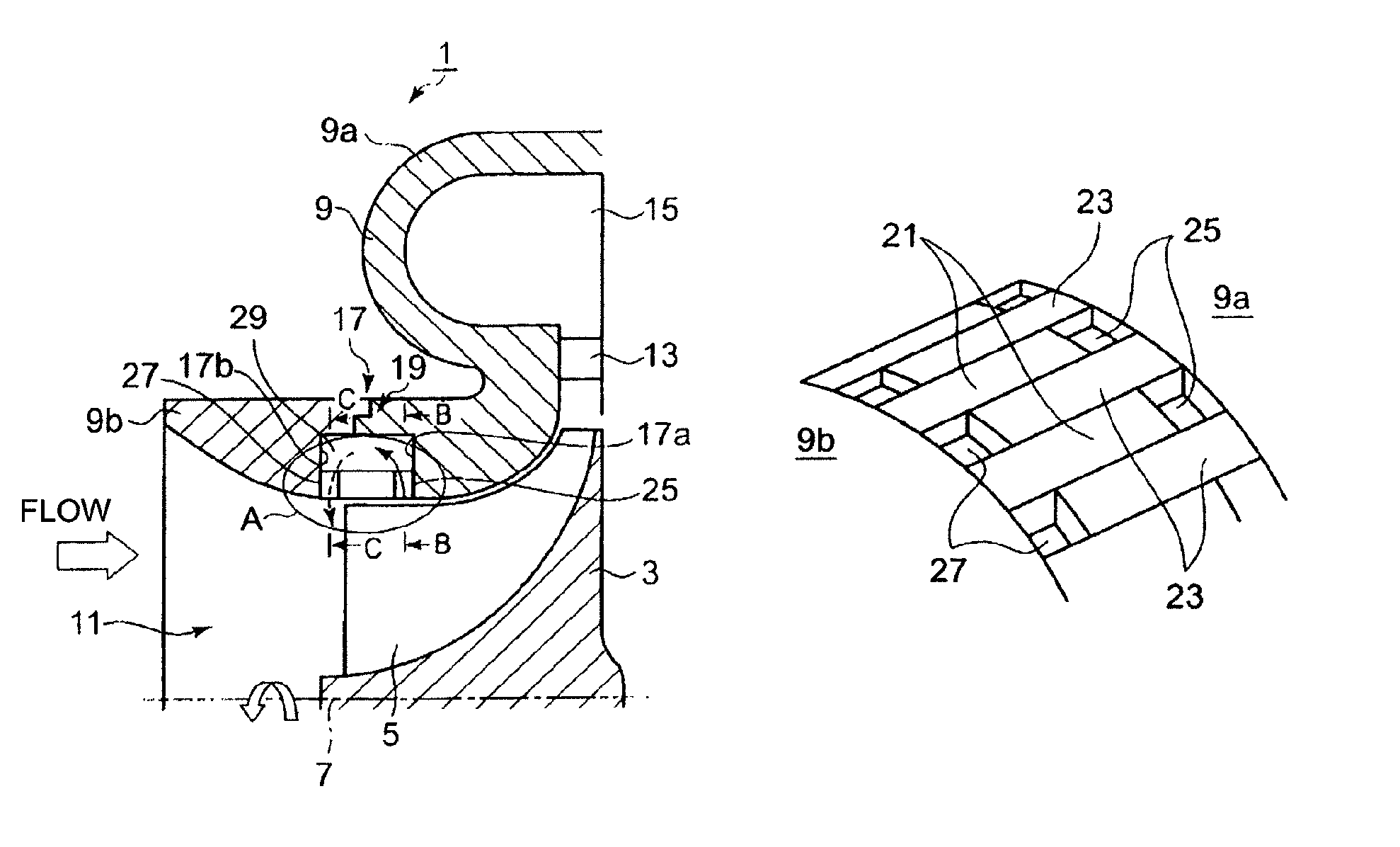

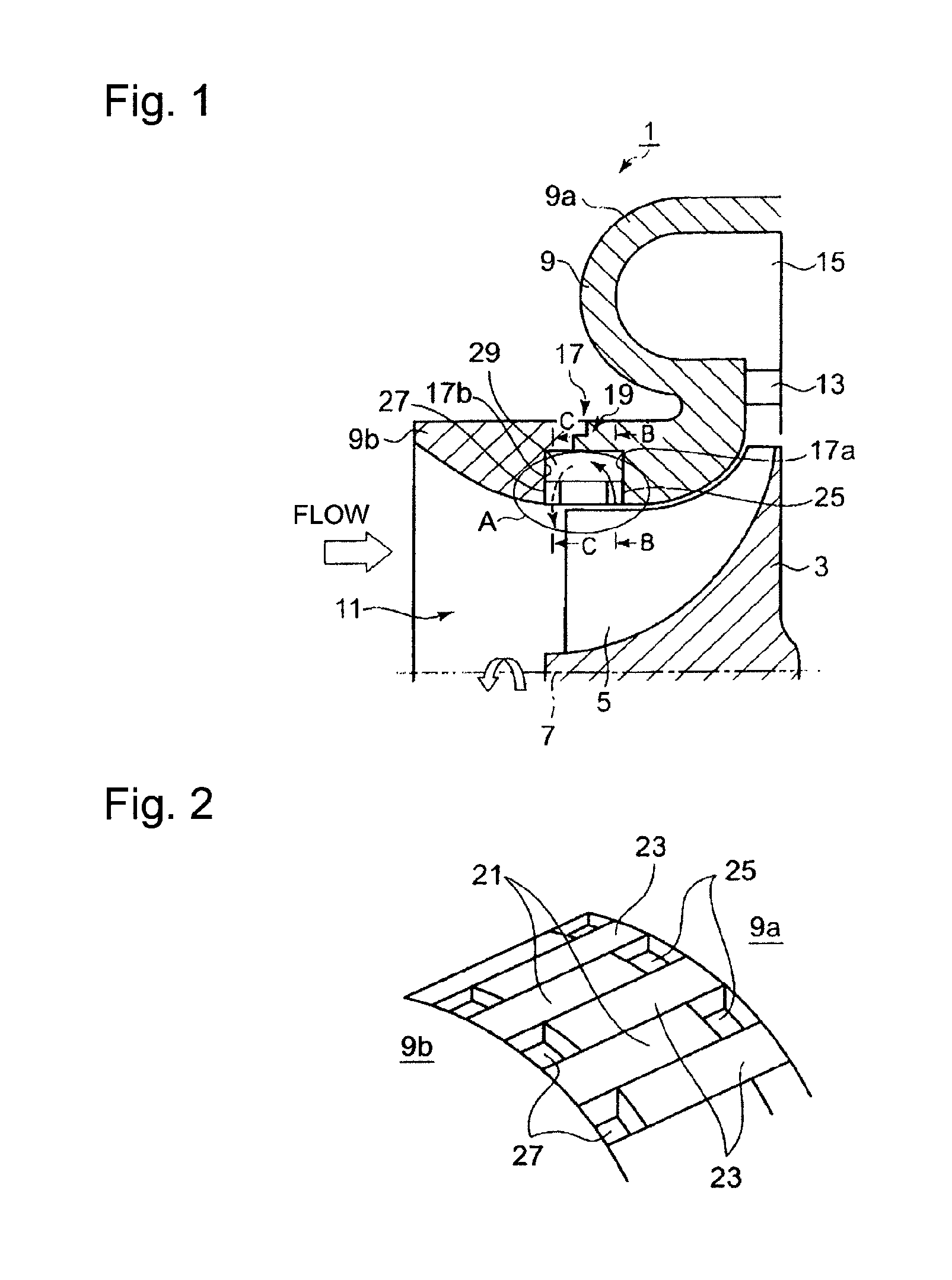

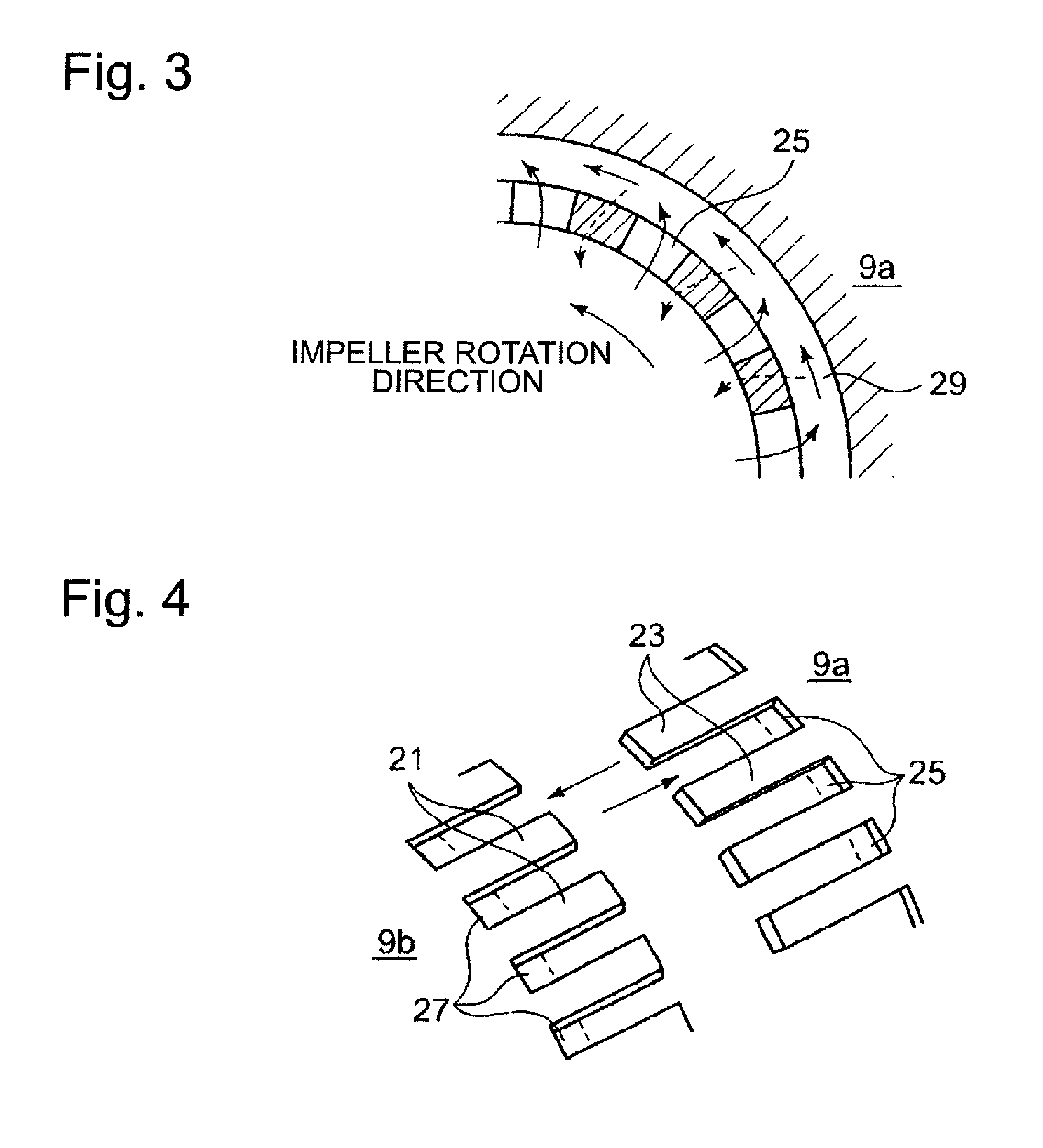

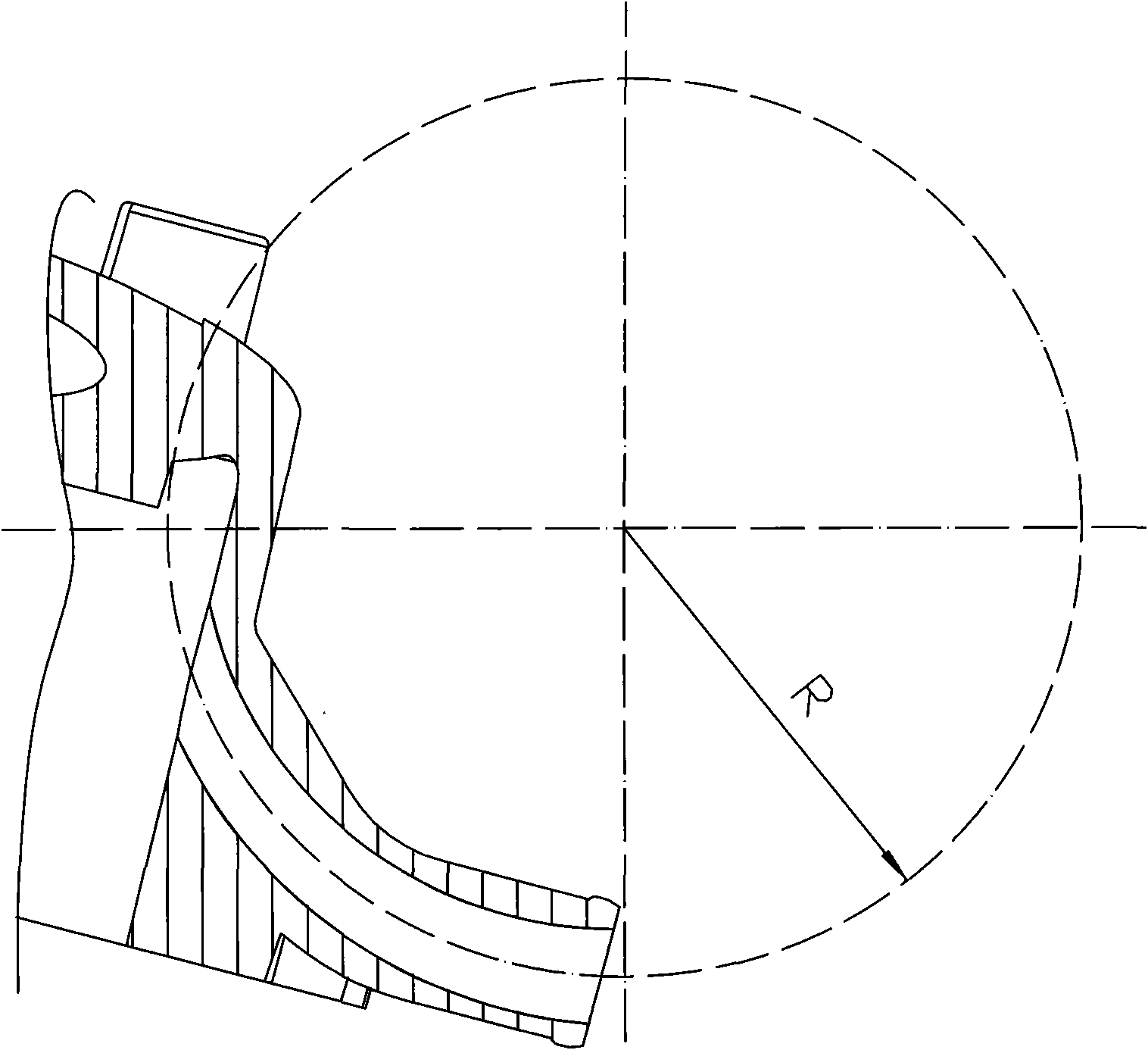

Compressor of exhaust gas turbocharger

ActiveUS20120121400A1Shorten production hoursProduction costPump componentsStatorsImpellerTurbocharger

A compressor of an exhaust gas turbocharger has an inlet slit, an outlet slit and the recirculation passage can formed at the same time when the compressor housing assembled. Ease of assembly and the reduction of the production cost is achieved. The structure of the inlet slit, the outlet slit and the recirculation passage can be compact and can be easily adjusted. Noises generated in the compressor impeller can be reduced without providing a noise insulation cover.

Owner:MITSUBISHI HEAVY IND LTD

Compressor of exhaust gas turbocharger

A compressor of an exhaust gas turbocharger has a compressor housing of a divided type that forms an inlet slit, an outlet slit and a recirculation passage at the same time when the compressor housing is assembled. In the compressor of the exhaust gas turbocharger, mating surfaces of compressor housing members 9a and 9b are formed in the neighborhood of the inlet part of the impeller 5 in the compressor housing 9 that is divided into the compressor housing members 9a and 9b in the direction of the rotation axis of the impeller; and, a space forming the recirculation passage 29, an inlet slit 25 and an outlet slit 27 are formed between the mating compressor housing members 9a and 9b.

Owner:MITSUBISHI HEAVY IND LTD

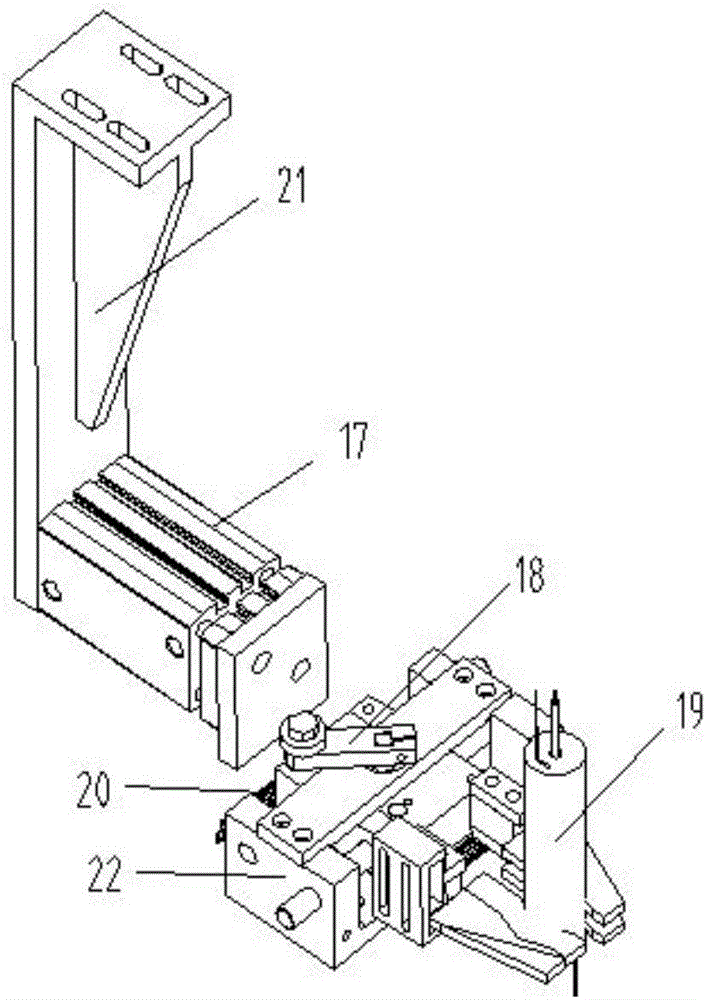

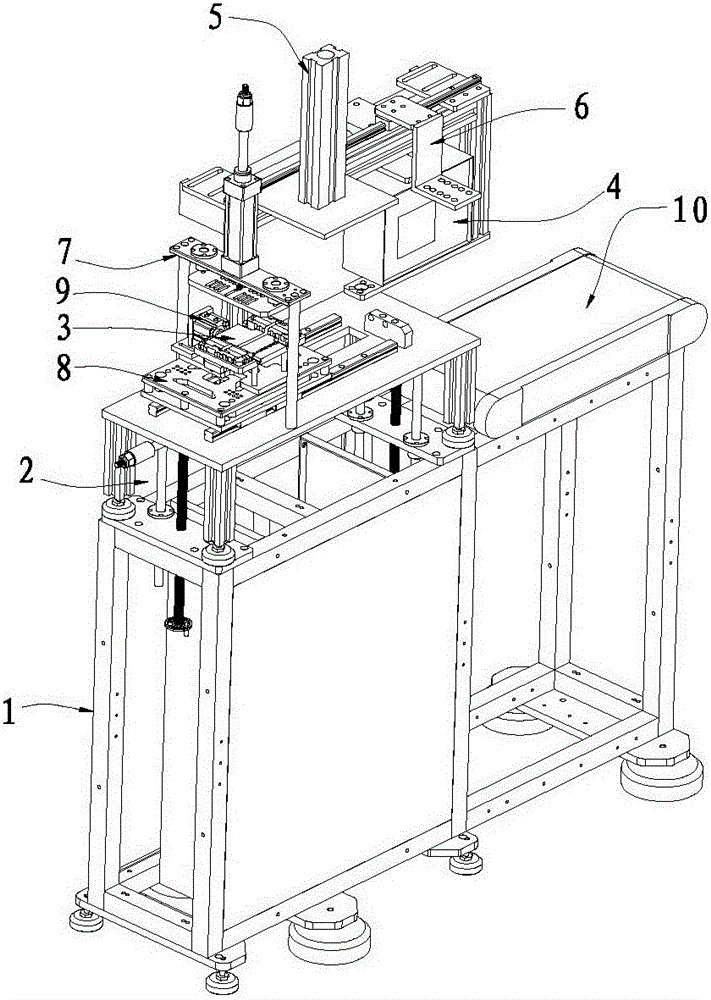

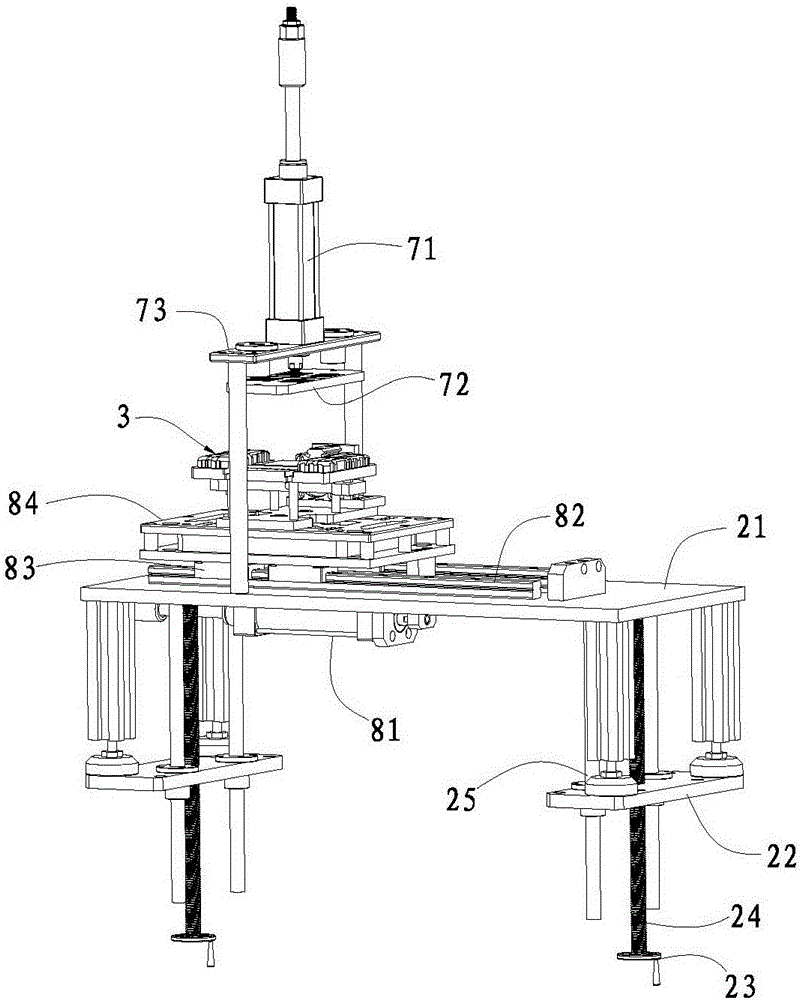

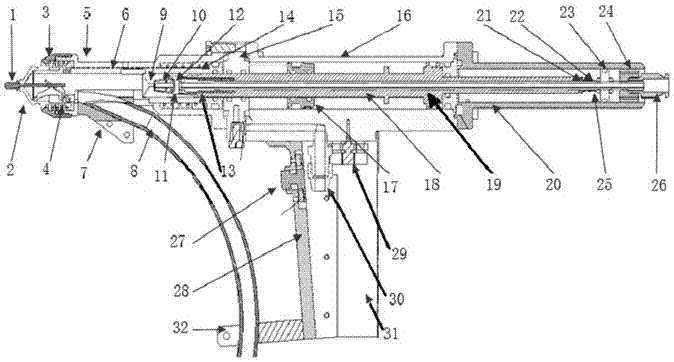

Method for shearing water gap and device for implementing method

The invention discloses a method for shearing water gap, which comprises the following steps: 1) arranging a rack at one side of an injection molding machine; 2) arranging a shearing device which is moveably arranged on the rack and is used for taking out a molded product from a plastic mould, shearing a feed port of the molded product, and then placing the molded product in a finished product area; and 3) arranging a control system which is connected to the shearing device and is used for controlling the working state of the shearing device. The invention also discloses a device for implementing the method. The method for shearing water gap provided by the invention has a simple process, is high in speed, has high efficiency, and can be used for greatly shortening the production time and saving the production cost. The device provided by the invention has a simple and reasonable structure. By matching a shearing mechanism with a manipulator, the effect of shearing water gap is achieved. The feed port and the molded product can be automatically moved to the corresponding positions. The degree of automation is high, the repeated working is avoided, the labor intensity is greatly lowered and the product quality is efficiently ensured.

Owner:DONGGUAN ALFA AUTOMATION TECH CO LTD

Production technology of furan resin for casting

ActiveCN102516482AEmission reductionAvoid pollutionFoundry mouldsFoundry coresFuranUltimate tensile strength

The invention relates to a production technology of furan resin, particularly to a production technology of the furan resin for casting, comprising the following steps: charging, heating up, dehydrating, opening a steam valve, heating up to 80-108 DEG C in 20-30 min, preserving heat for 60-90 min, discharging, packaging, and warehousing. According to the invention, a product with low free formaldehyde and high strength can be provided by the technology, and the production process has no generation of three wastes and is green.

Owner:共享新材料(山东)有限公司

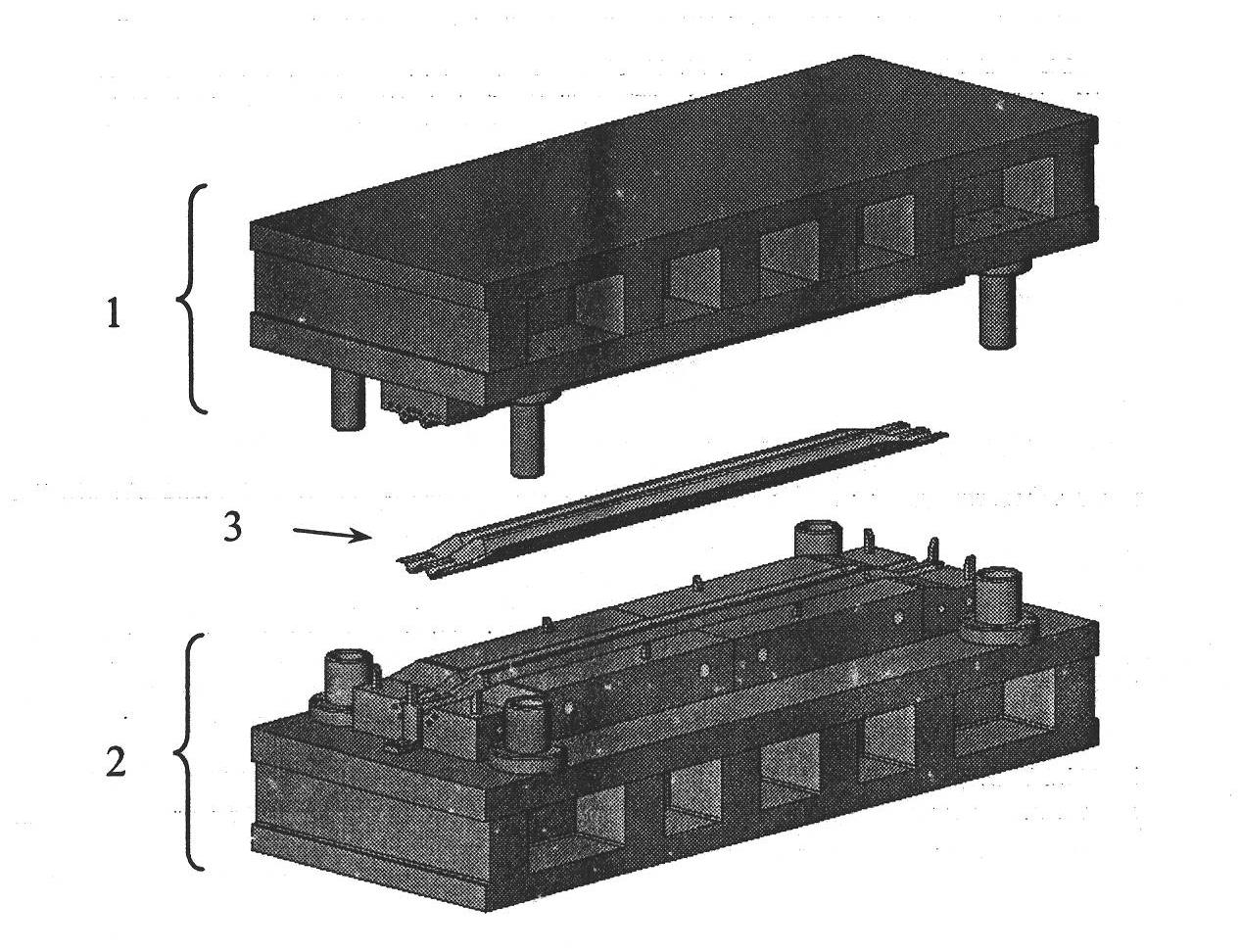

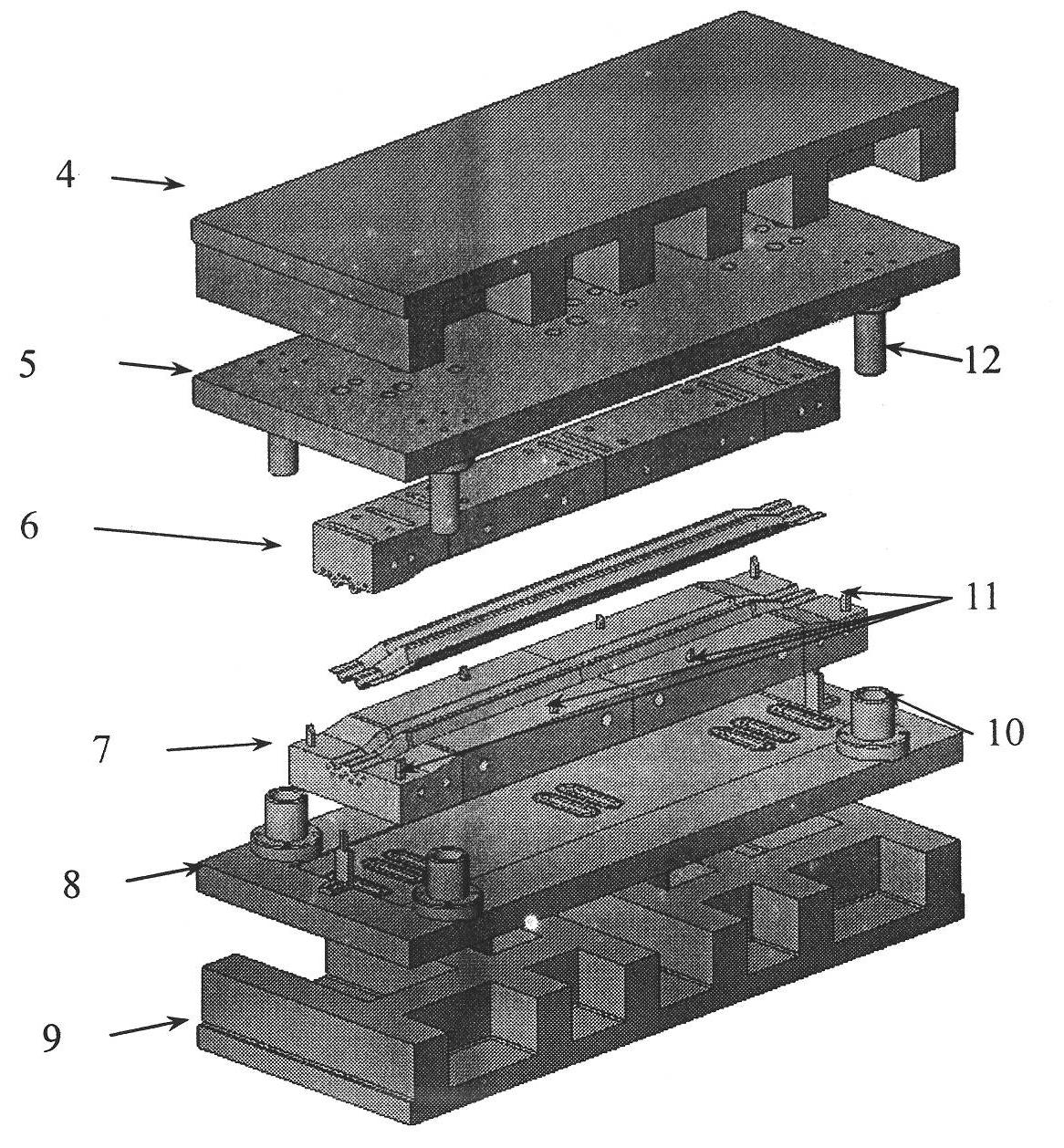

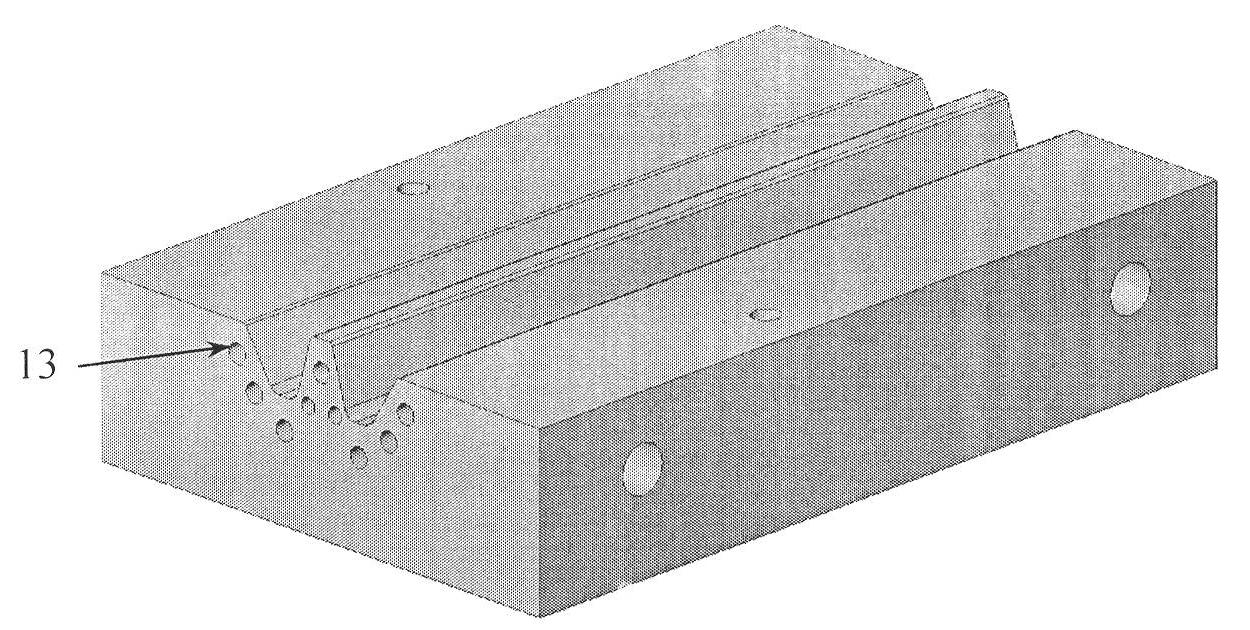

Ultra-high strength steel hot-stamping die for car door anticollision beam

InactiveCN101972814AHigh strengthReduce weightShaping toolsLoad-supporting pillarsHot stampingEngineering

The invention provides a hot-stamping die for an anticollision beam, comprising an upper die and a lower die, wherein the upper and lower dies mainly comprise combined convex / concave dies, cooling systems and a cooling seal ring. The blocks of the combined convex / concave dies avoid the corners and are staggered relatively. The cooling systems adopt drill holes, wherein the diameter of the holes is 8-30mm and the peaks of the holes are 3-10mm distant from the profiles; the two ends of the holes are sealed after hole drilling; runway type water troughs are processed near the places where the block dies are 10-50mm distant from the two end faces; the cooling water enters from one water trough and flows out of the other water trough; and seal grooves are arranged on the cooling water troughs and the cooling water troughs are provided with the seal ring and are externally connected with cooling water pipes.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

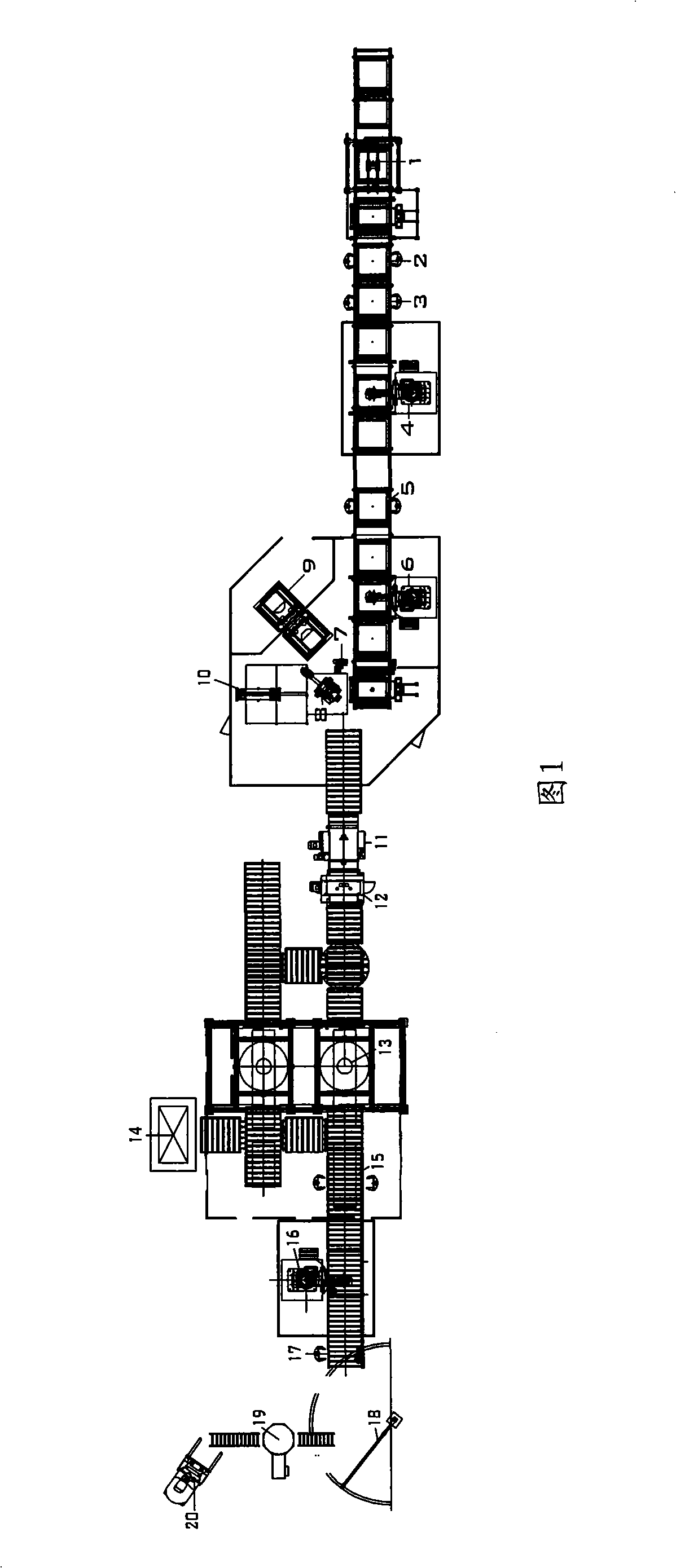

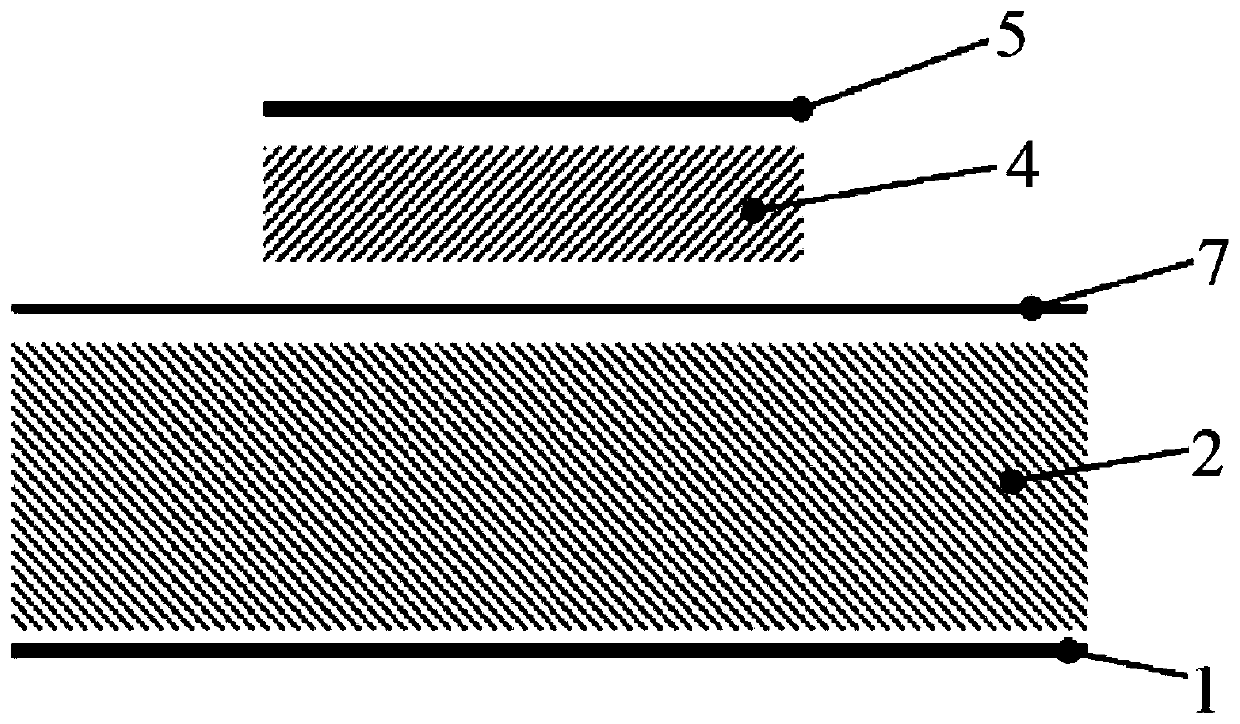

Production method and assembly line of insulation box for liquid natural gas carrier

ActiveCN101319753AAvoid backlogIncrease productivityThermal insulationContainer filling methodsProduction lineVolumetric Mass Density

The invention relates to a method and production line to manufacturing an insulating tank for a liquefied natural gas carrier. The method includes the working procedures of ''mould piggybacking'', ''clapboard assembling'', ''temporary clapboard fixing'', ''clapboard fixing by nailing'', ''roof plate assembling and temporary fixing'', ''roof plate fixing by nailing'', ''bar code affixing'', ''tank body overtuning'', ''double-layer roof plate assembling and temporary fixing'', ''double-layer roof plate fixing by nailing'', ''tank body leveling up'', ''insulating material filling'', ''filling density checking'', ''bottom plate assembling and temporary fixing'', ''bottom plate fixing by nailing'', ''tank body finishing'', ''tank body conveying and cleaning'', ''tank body packaging'' and ''tank body transporting''. By implementing such technical process for producing insulating tanks applied to LNG ships, the labor is largely saved, the production efficiency is improved, and the requirement of high precision of insulation tanks is satisfied.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

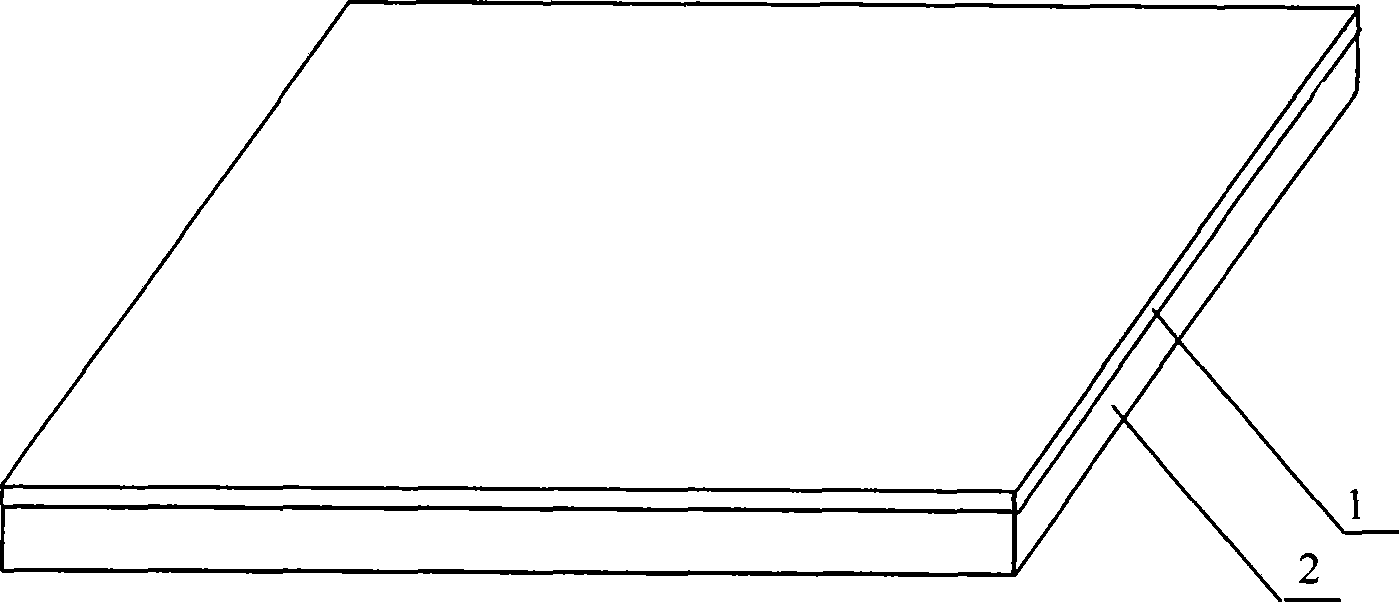

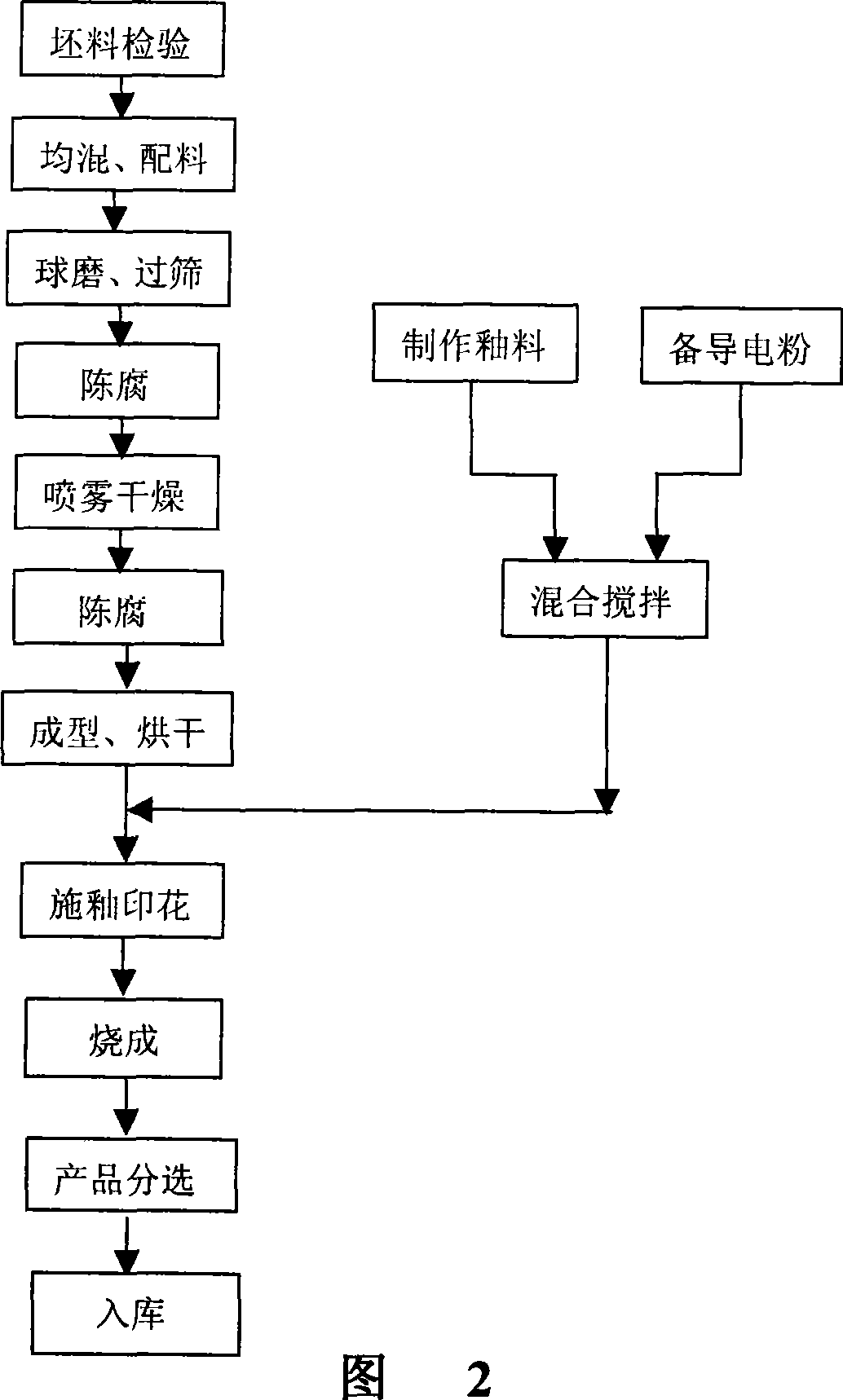

Antistatic ceramic floor and preparing method thereof

The invention discloses an anti-static ceramic floor and a preparation method thereof. The anti-static ceramic floor comprises a body of the ceramic floor, a surface layer of the ceramic floor is baked with a mixed layer of glaze and conductive powder, the conductive powder accounts for 20 to 40 percent of the material weight of the mixed layer, wherein the conductive powder comprises the following compositions in weight percentage: 55 to 90 percent of Sn, 5 to 25 percent of Zn, and 5 to 25 percent of Ti. The preparation method comprises the following steps: the glaze is produced first, and then the conductive powder is added according to the mixing proportion of the glaze and the conductive powder to mix and stir evenly; after a molding process of the ceramic floor is finished, a mixed material of the glaze and the conductive powder is coated on the surface layer of the ceramic floor according to the preset printing proposal; the baking and the separation to finished products are performed to obtain the qualified finished products.

Owner:BEIJING YUNHE INDAL & TRADE

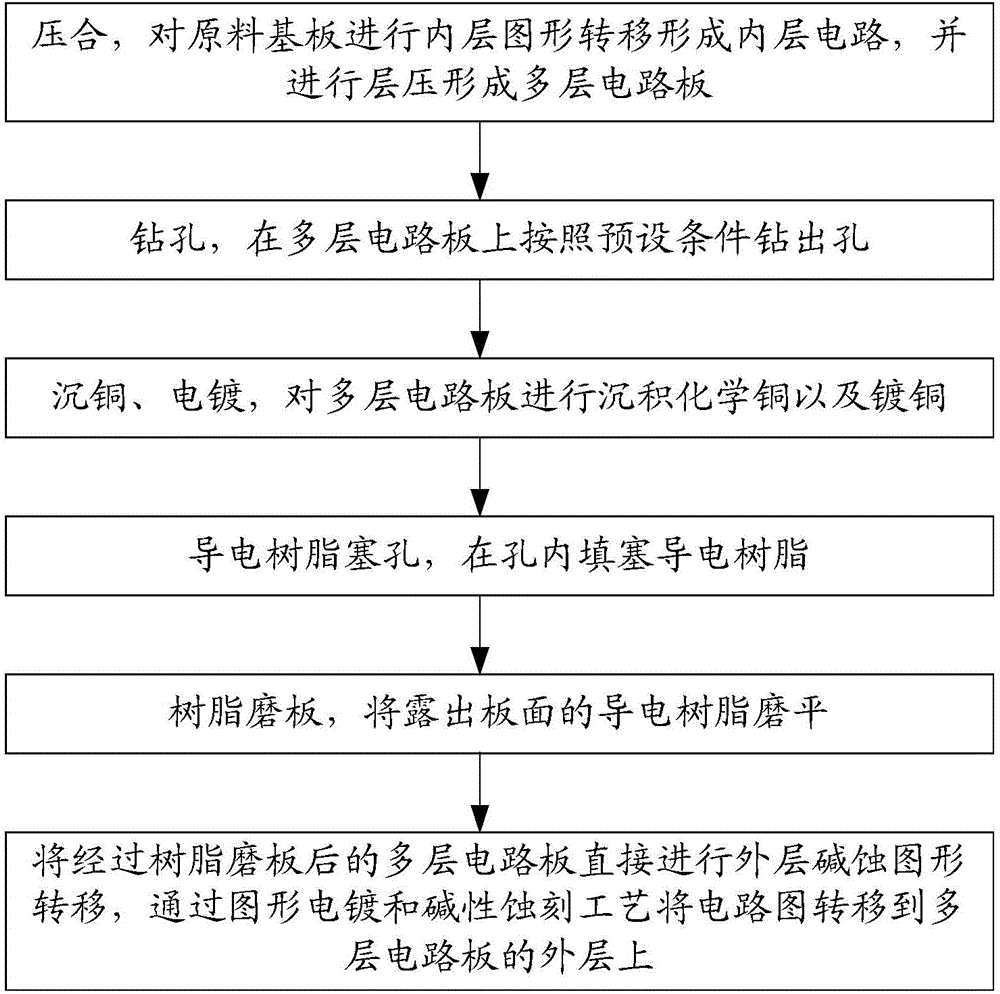

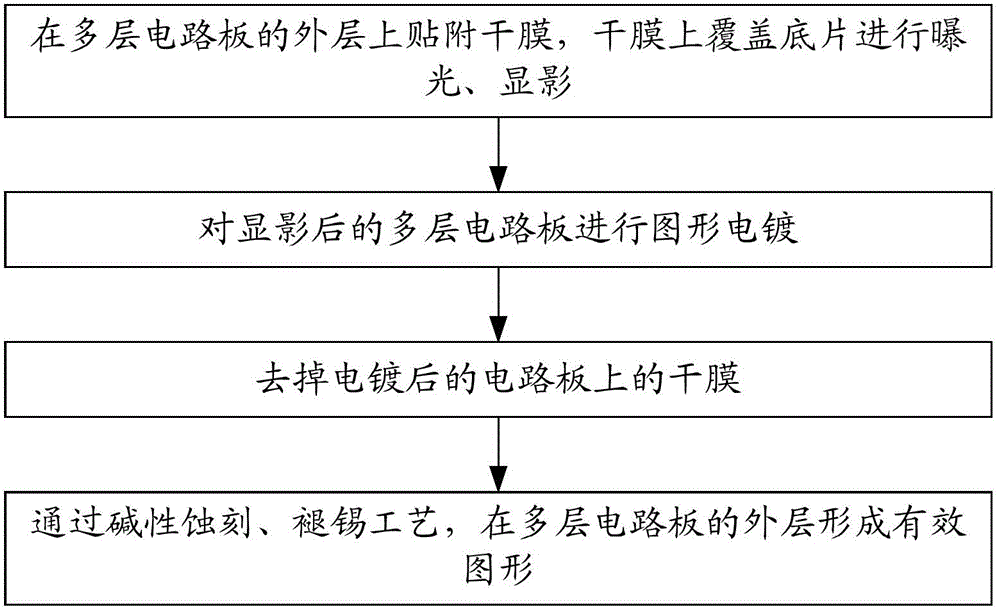

Manufacturing method of circuit board

ActiveCN104602452AEasy to processShorten production hoursPrinted circuit manufactureMachining processAlkaline etching

The invention relates to a manufacturing method of circuit board; the method comprises the following steps: lamination, applying an inner layer pattern transfer to a raw material substrate to form an inner layer circuit, and laminating to form a multi-layer circuit board; drilling, drilling holes on the multi-layer circuit board based on preset conditions; copper deposition and electroplating, depositing chemical copper and plating copper on the multi-layer circuit board; the method further comprises steps of: blocking holes with conduction resin, filling a conductive resin in the holes; resin grinding, grinding the conductive resin exposed out of the board surface; directly applying outer layer alkali etching pattern transfer to the resin-grinded multi-layer circuit board; transferring the circuit pattern on the outer layer of the multi-layer circuit board by pattern electroplating and alkali etching technology. The manufacturing method of circuit board has the following advantages: the technical limitation that alkali etching process cannot be applied in designing and making the outer layer of the board by POFV (Via Filling Plating) is broken through; copper deposition and electroplating are no longer needed after grinding the resin; the positive pattern transfer can be directly implemented; the machining process of the PCB board can be simplified; the production period is shortened; and the production efficiency is increased.

Owner:NEW FOUNDER HLDG DEV LLC +1

VOC (volatile organic compounds)-free ultraviolet curing gravure printing ink and preparation method thereof

The invention discloses VOC (volatile organic compounds)-free ultraviolet curing gravure printing ink and a preparation method thereof. The ink comprises components of a formula in parts by weight as follows: 5-15 parts of unsaturated acrylic resin, 30-70 parts of dispersing monomers, 10-30 parts of dilution monomers, 3-6 parts of a photoinitiator 1173, 2-6 parts of a photoinitiator 369, 5-16 parts of pigment and 2-5 parts of an auxiliary. The preparation method is as follows: the unsaturated acrylic resin, the dispersing monomers, the photoinitiators, the pigment and part of the auxiliary are mixed, stirred at a high speed and pre-dispersed; and the well pre-dispersed material is dispersed and ground to stipulated grain size through combined use of a sand mill and a three-roller machine. The VOC-free ultraviolet curing gravure printing ink and the preparation method have the benefits as follows: the problem of environmental pollution caused by volatilization of a large quantity of VOC in conventional ink and the problems that ink products introduced in conventional related ultraviolet curing gravure printing ink patents are high in viscosity and slow to dry and is not matched with conventional gravure printing or the ink still contains a solvent and is not environment-friendly are solved; and meanwhile, the production process is improved, and the production efficiency is increased.

Owner:杭华油墨股份有限公司

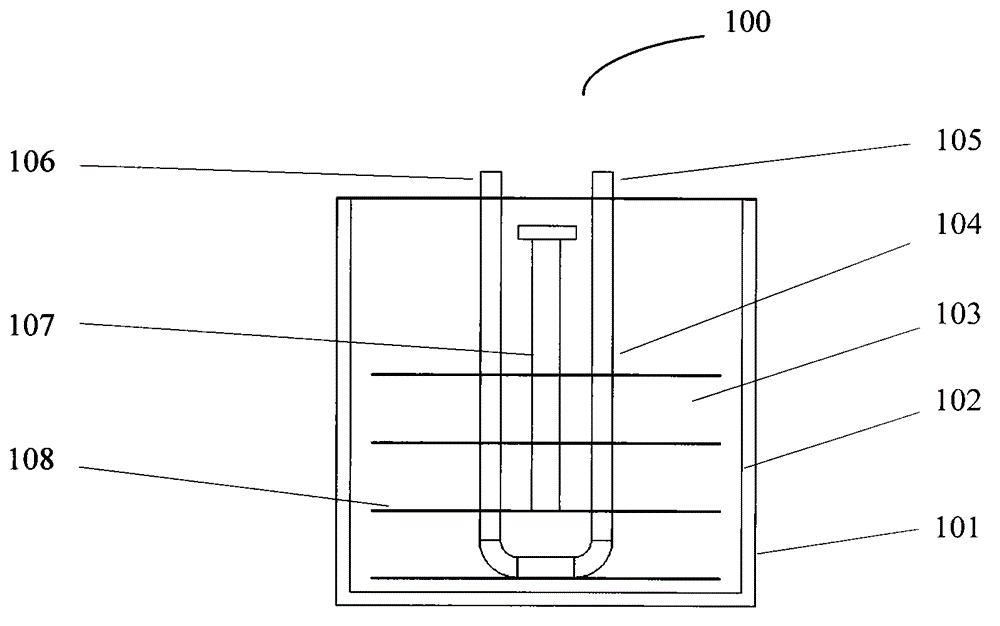

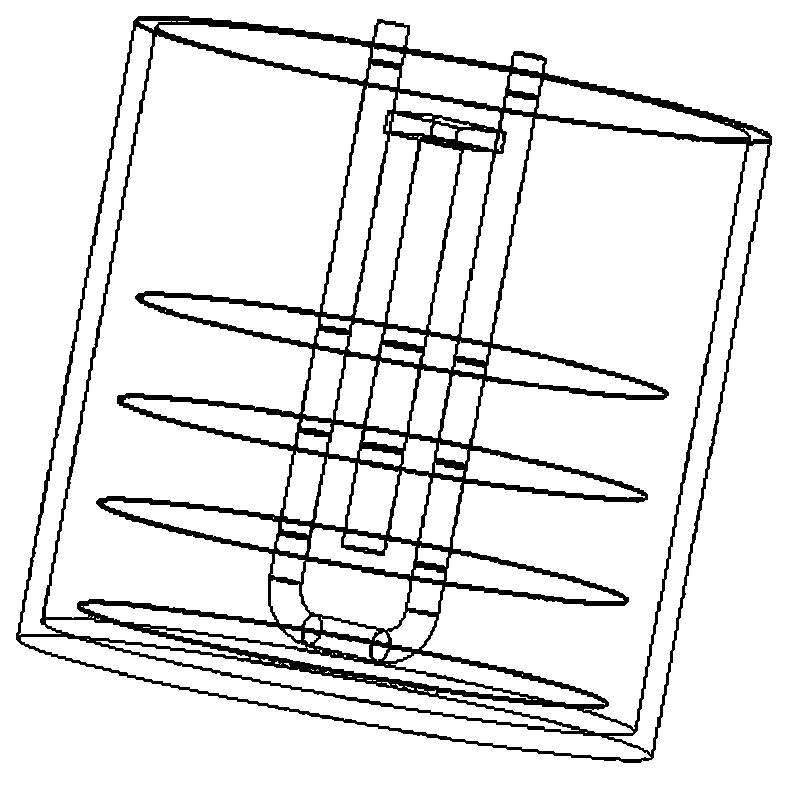

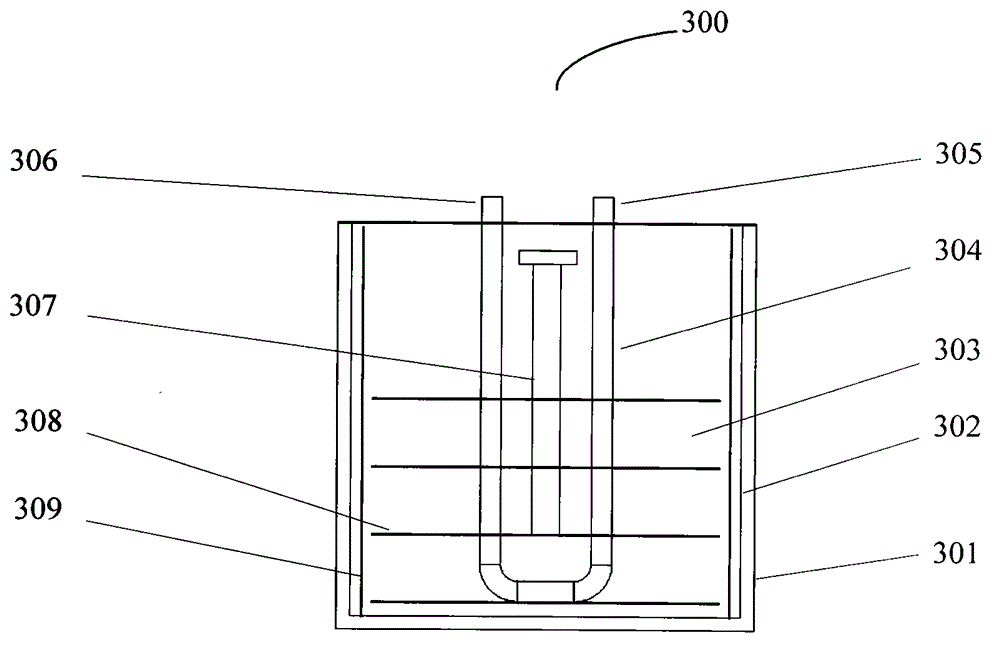

Energy accumulation and heat exchange device and water heater comprising same

InactiveCN105987508ANo fouling problemAvoid security issuesSolar heat devicesChemical industryHigh volume manufacturingEngineering

The invention discloses an energy accumulation and heat exchange device. The energy accumulation and heat exchange device comprises a shell body, a heat preservation separation layer, a heat exchange pipe and a heating part, wherein the heat preservation separation layer is fitted on the inner side of the shell body; the heat exchange pipe and the heating part are arranged in the heat preservation separation layer respectively; the energy accumulation and heat exchange device further comprises an energy accumulation material and a plurality of common fins, wherein the energy accumulation material is filled into the heat preservation separation layer and is used for storing heat of the heating part; a water inlet is connected with one end part of the heat exchange pipe and a water outlet is connected with the other end part of the heat exchange pipe; and all the common fins are immersed into the energy accumulation material and are used for connecting the heat exchange pipe and the heating part. The invention further discloses a water heater comprising the energy accumulation and heat exchange device. The energy accumulation and heat exchange device and the water heater, provided by the invention, are simple in structure, great in energy accumulation amount, high in heat exchange efficiency and easy to produce in a large batch.

Owner:BEIJING BOGONG ANNENG SCI & TECH CO LTD

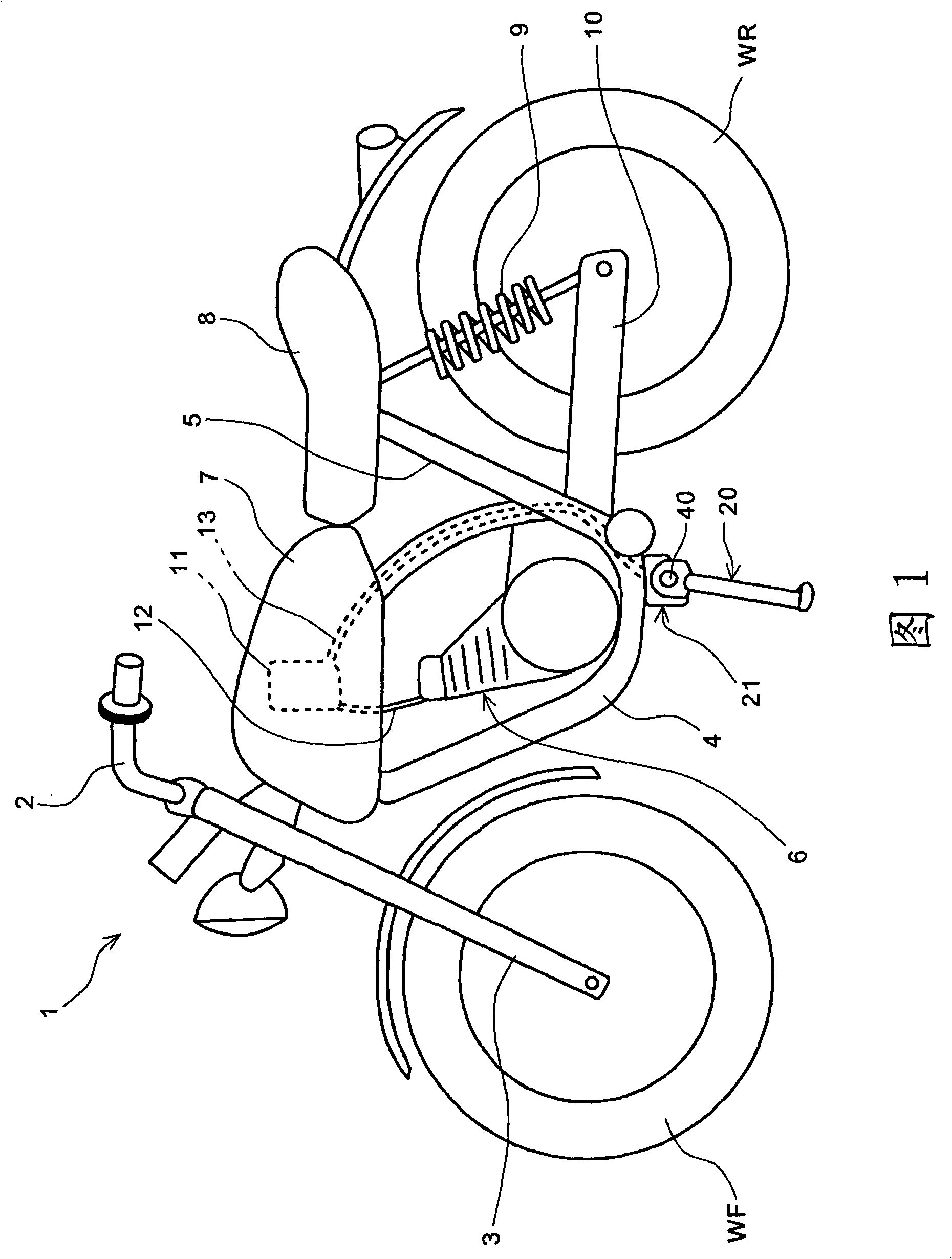

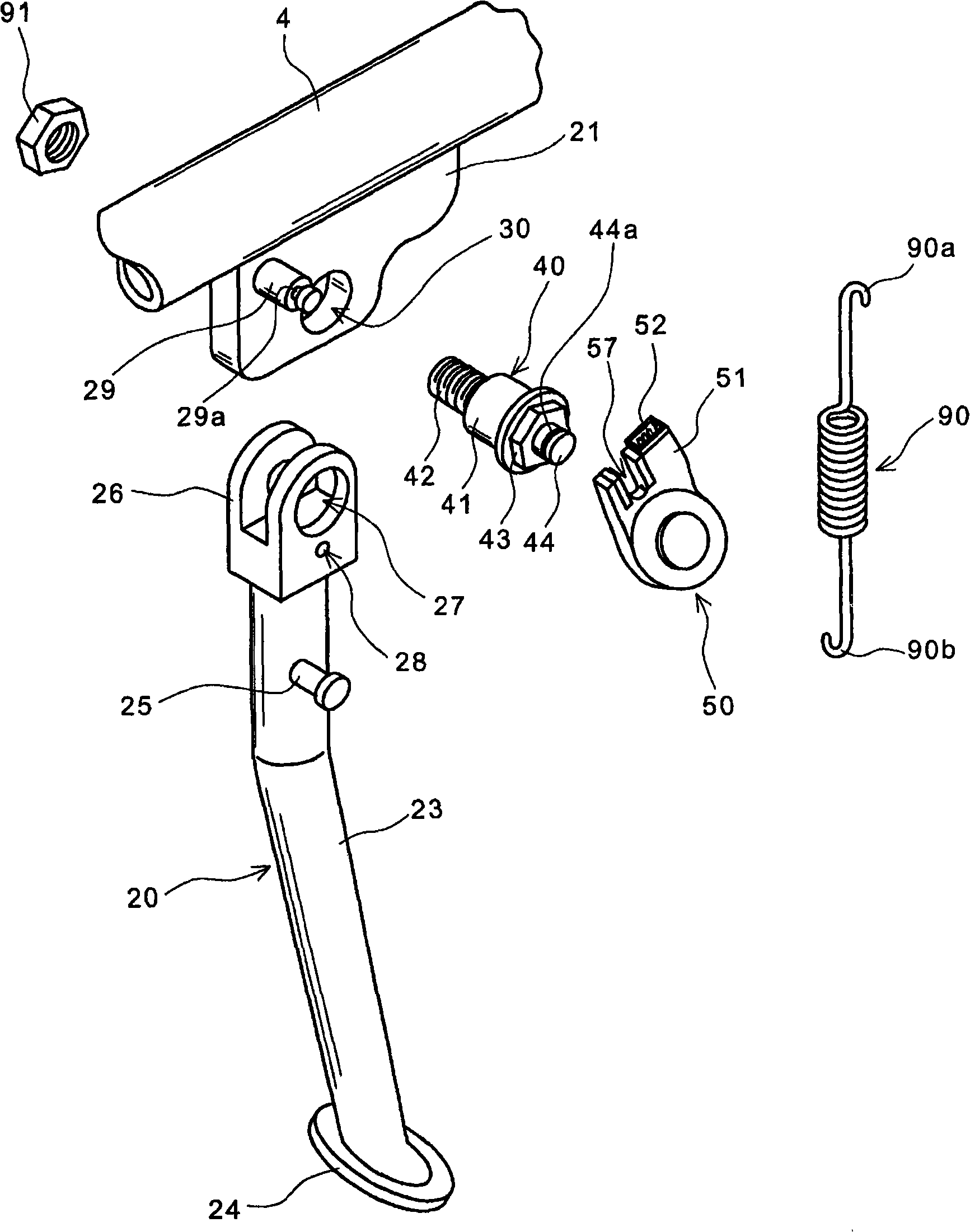

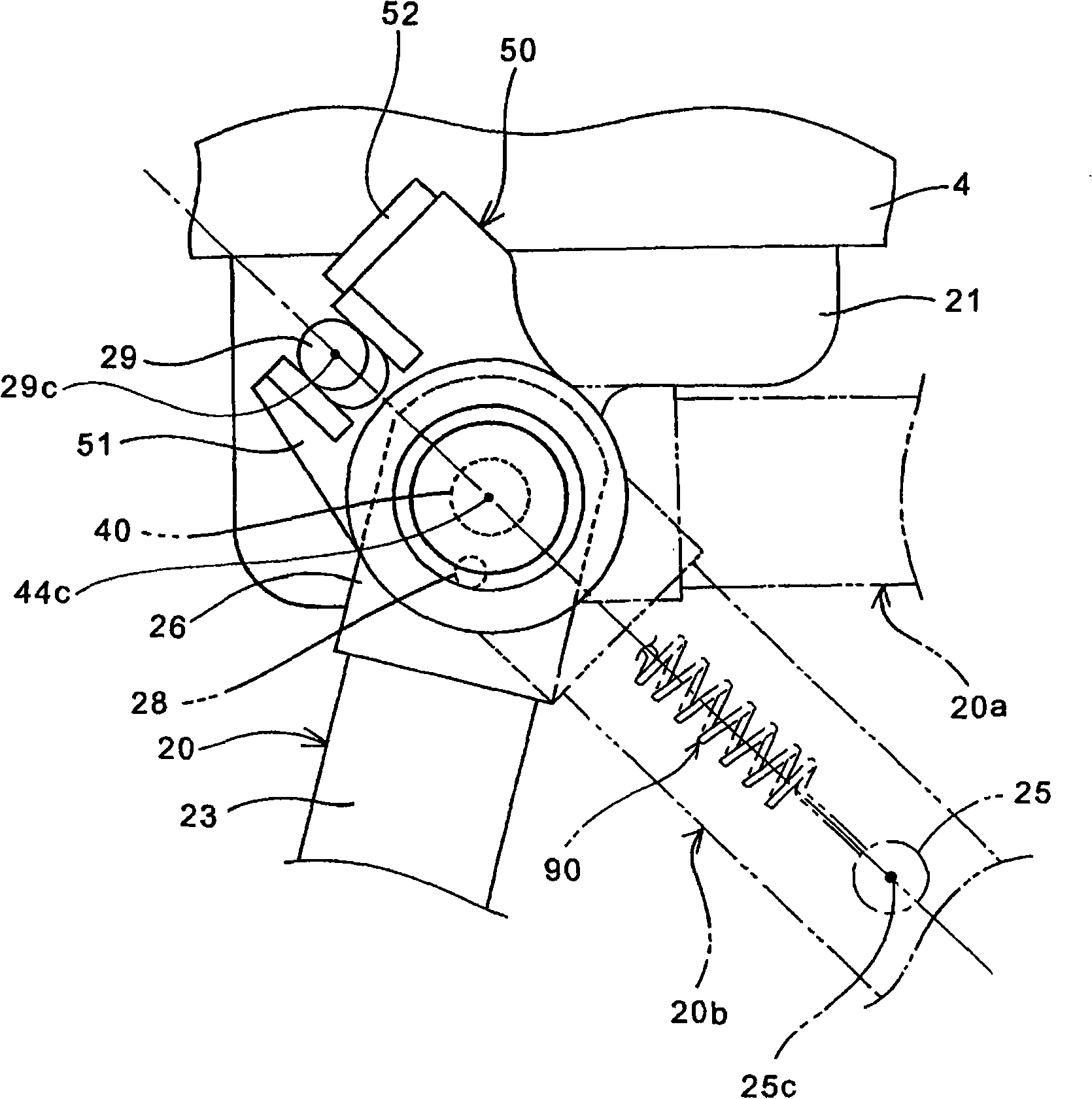

Side stand switch

ActiveCN101356090AReduce the numberImprove the installation effectCycle standsElectric switchesEngineeringMechanical engineering

A side stand switch that has increased assembling easiness, that has reduced number of parts, and that is reduced in weight. A switch unit (50) is attached to a pivot bolt (40) for rotatably supporting a side stand bar (20) at a bracket (21) on the vehicle body side. The switch unit (50) is constructed from a resin base (51) and a rotary (53) and detects the rotational position of the side stand bar (20). A first engagement mechanism (62) constructed from a groove and a ridgeis provided between a tubular section (54) formed at the rotary (53) and an engagement shaft (44), and a second engagement mechanism (63) constructed from a groove and a ridge is provided between the base (51) and the tubular section (54). When a positioning pin (55) formed at one end of the rotary (53) is engaged with a pin hole (28) of a pivot section (26), the rotary (53) to which a movable contact of a sheet spring is attached is rotated integrally with the side stand bar (20) to change a switch output from a connector (52).

Owner:HONDA MOTOR CO LTD

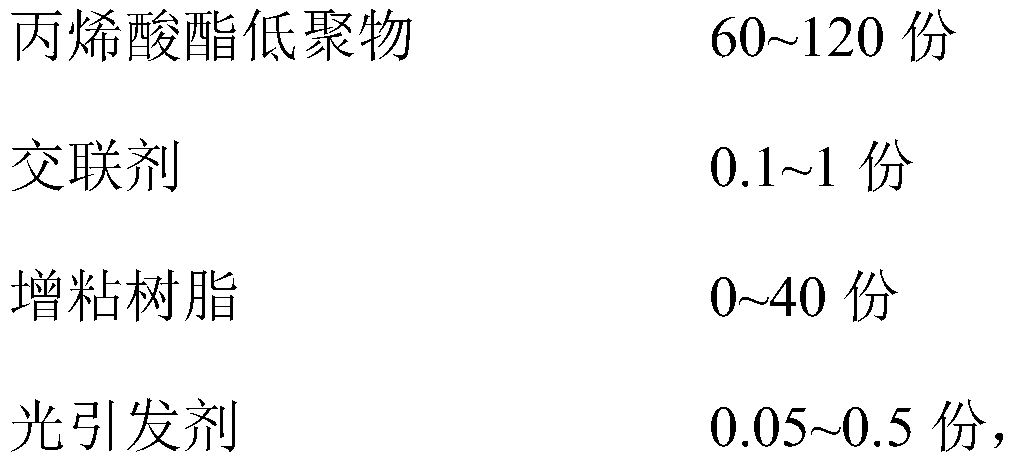

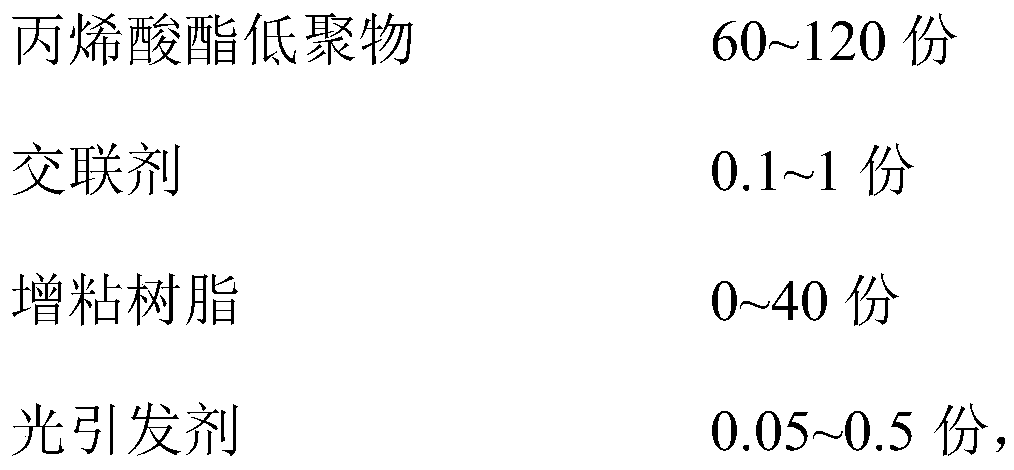

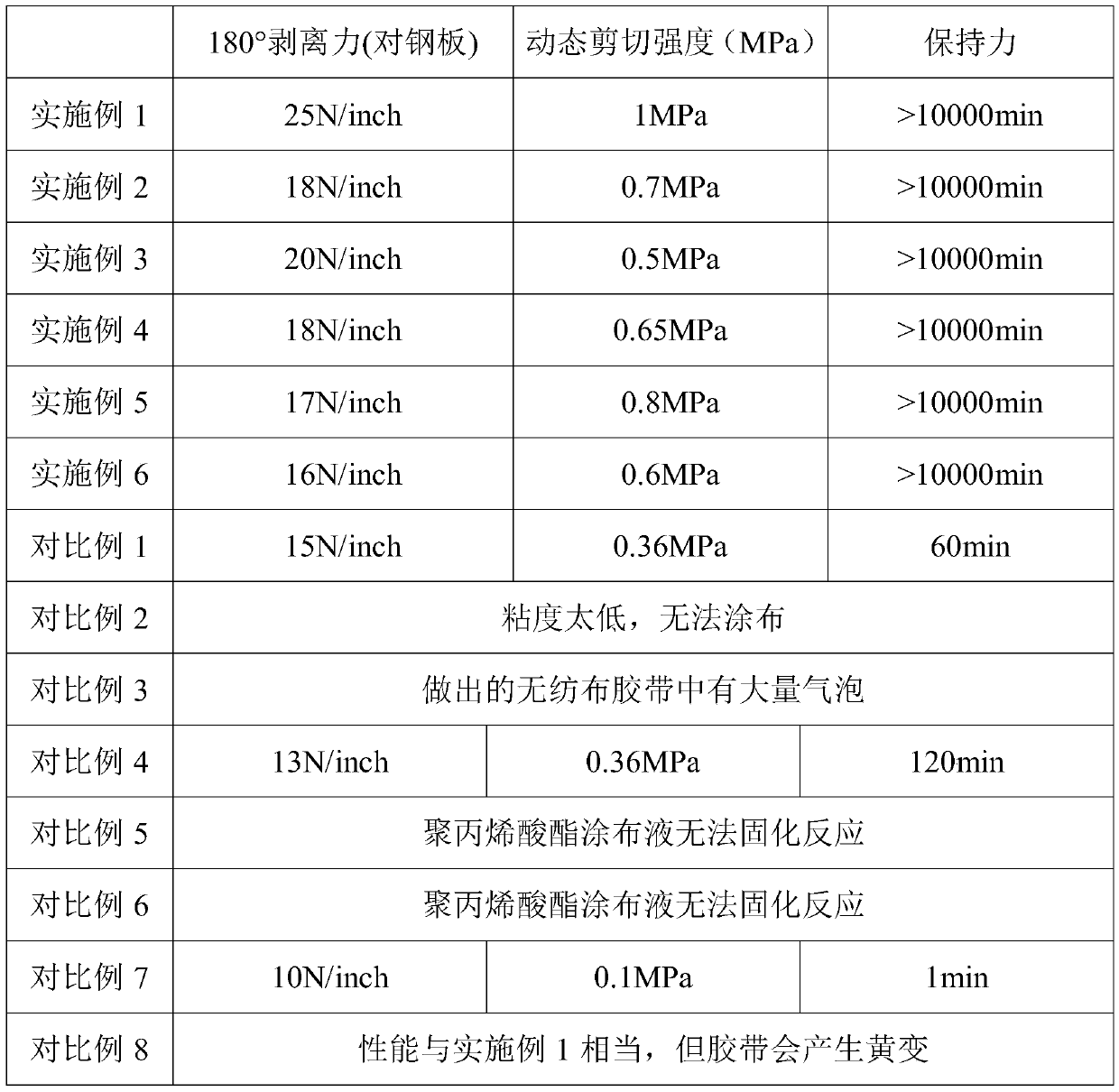

Ultraviolet light curing non-woven adhesive tape and preparation method thereof

PendingCN109810648ATransparent appearanceIncrease stickinessFilm/foil adhesivesOrganic non-macromolecular adhesiveCross-linkOligomer

The invention provides an ultraviolet light curing non-woven adhesive tape and a preparation method thereof. The ultraviolet light curing non-woven adhesive tape is prepared from ultraviolet curing type polyacrylate coating liquid, and the ultraviolet curing type polyacrylate coating liquid is prepared from the following components in parts by weight: 60-120 parts of acrylate oligomers, 0.1-1 partof a cross-linking agent, 0-40 parts of tackifying resin and 0.05-0.5 part of a photoinitiator, wherein the ultraviolet curing type polyacrylate coating liquid does not contain a solvent. The ultraviolet light curing non-woven adhesive tape is coated through a one-step method and prepared by ultraviolet curing, post curing is not required, and production hours are more saved; and the prepared ultraviolet light curing non-woven adhesive tape has a transparent appearance, does not contain the solvent, and is environmentally-friendlier, interlayer damage is not prone to being produced, cohesiveness is good, and viscosity is lasting.

Owner:CYBRID TECHNOLOGIES INC

Automatic drainage opening cutting machine

InactiveCN106273286AIngenious structural designReasonable structural designProduction lineEngineering

The invention discloses an automatic drainage opening cutting machine. The automatic drainage opening cutting machine comprises a machine frame, a horizontal lifting frame, a positioning jig, a PLC, a material collecting mechanical arm, a shifting mechanism, a pressing mechanism, a backward-pulling mechanism, a drainage opening cutting mechanism and a production line conveyer belt, wherein the material collecting mechanical arm, the shifting mechanism, the pressing mechanism, the backward-pulling mechanism, the drainage opening cutting mechanism and the production line conveyer belt are connected with the PLC and are controlled by the PLC. The automatic drainage opening cutting machine is ingenious and reasonable in structural design; a mobile phone injection molding shell subjected to injection molding on an injection molding machine can be clamped and transferred to the positioning jig through the material collecting mechanical arm, the pressing mechanism presses and positions the mobile phone injection molding shell onto the positioning jig, the drainage opening cutting mechanism is started, and thus a drainage opening material can be sheared off by replacing hands of people; and then the pressing mechanism retracts to release the mobile phone injection molding shell, the material collecting mechanical arm grabs and transfers the mobile phone injection molding shell onto the production line conveyer belt so that the next procedure can be performed conveniently. Meanwhile, the PLC can be adopted for controlling, the degree of automation is high, repeated labor is avoided, and labor intensity is effectively relieved. In addition, the material cutting speed is high, and the working efficiency is also high.

Owner:DONGGUAN HUA YING ELECTRONICS PLASTIC CO LTD

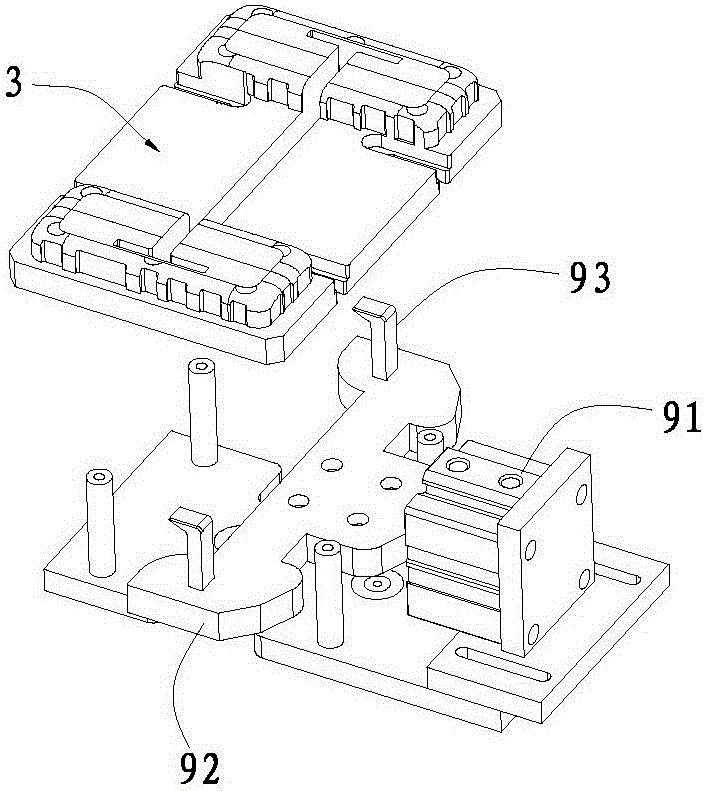

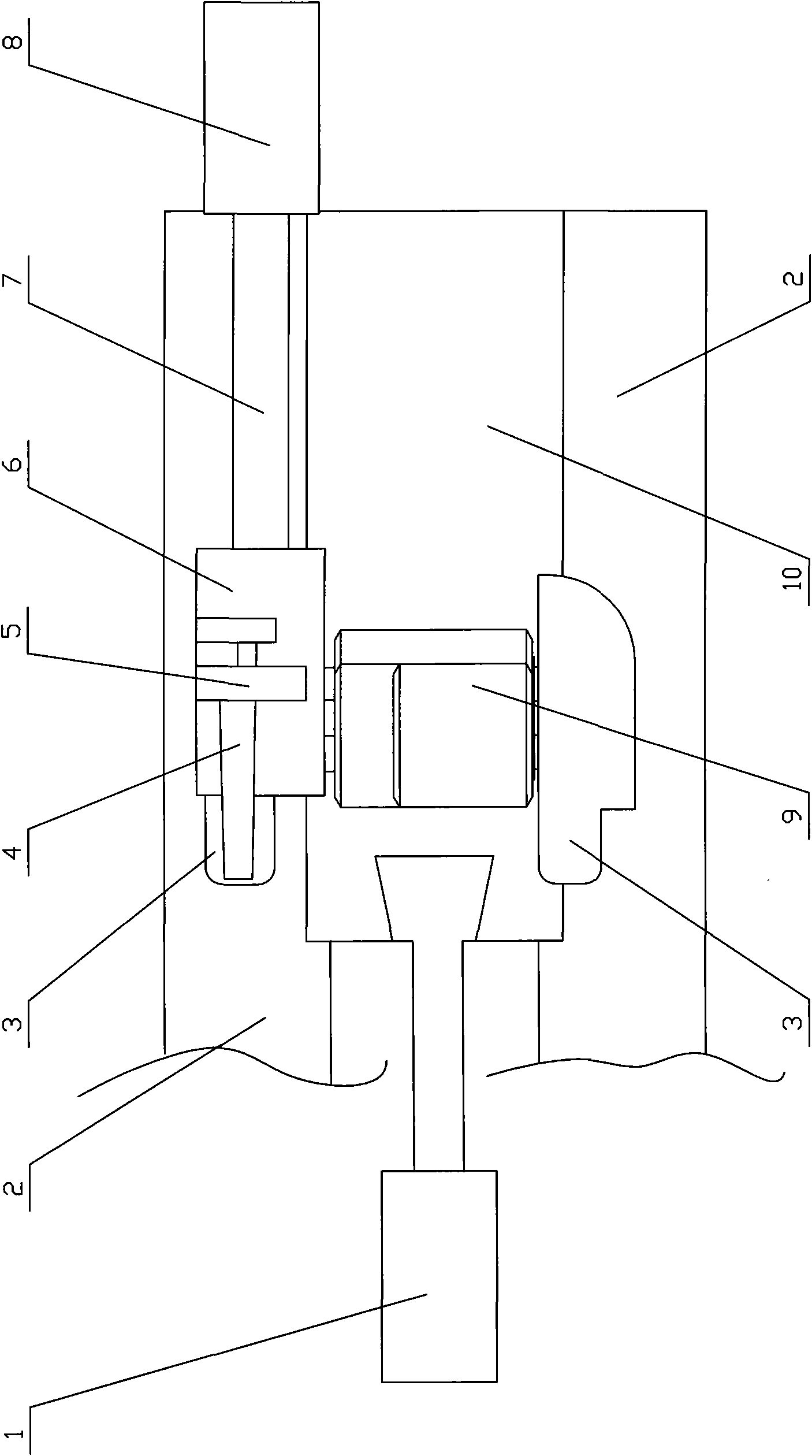

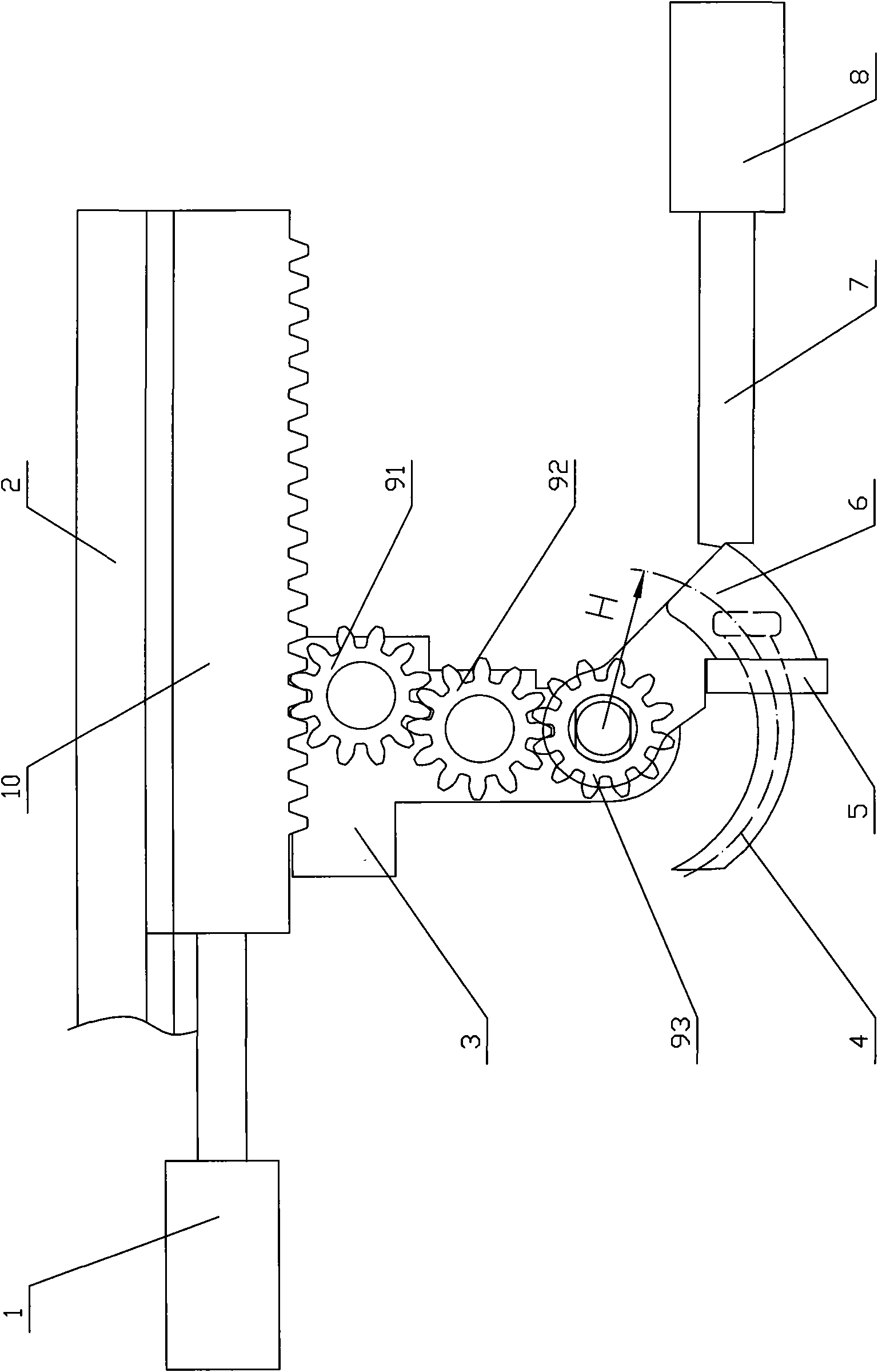

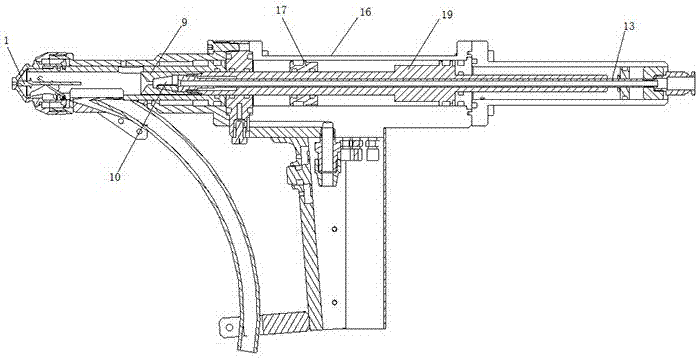

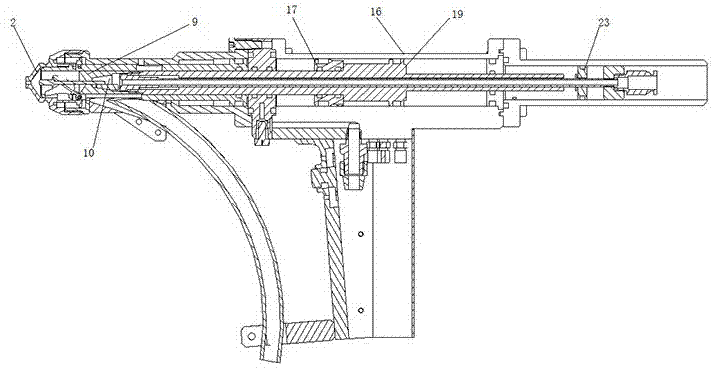

Arc core-pulling device of die-casting mould

The invention discloses an arc core-pulling device of a die-casting mould, which comprises a guide rail (2), a moving oil cylinder (1), a rack (10), gear groups (9) which are positioned on a gear seat(3) and mutually engaged, a connecting block (6) and an arc slide block (4) which is matched with an arc inner hole of a casting, wherein the rack (10) is matched with the guide rail (2) in a slide mode and detachably connected with a piston rod of the moving oil cylinder (1); the gear groups (9) are engaged with the rack (10); and one end of the connecting block (6) is fixedly connected with thegear groups (9), while the other end is fixed connected with the arc slide block (4). After the structure of the arc core-pulling device is adopted, because an arc motion is changed into a linear motion, the mechanical motion avoids larger error caused by manual operations so as to ensure that the size precision of a molded casting is higher. Meanwhile, all the motions of the arc slide block aredriven by a hydraulic oil cylinder, thus the operation is convenient, and production working hours are greatly shortened, thereby greatly improving the production efficiency.

Owner:NINGBO DONGHAO DIE CASTING

Manufacturing method and system of polyurethane insulation box for liquefied natural gas ship

ActiveCN109968700AReduce the impactIncrease productivityPackagingStacking articlesTransport systemMachining process

The invention relates to a manufacturing method and system of a polyurethane insulation box for a liquefied natural gas ship. The manufacturing method includes a gluing and assembling stage, a leveling and output stage, a CNC machining stage and a packaging stage, wherein the gluing and assembling stage comprises a universal gluing and assembling process, a press-fitting process and an aging process; the manufacturing system comprises a universal gluing and assembling area, a MARK III secondary gluing and assembling area, a press-fitting area, an aging area, a leveling and output area, a CNC machining area and a packaging area. Compared with the prior art, the advantage of high efficiency of automatic equipment is utilized, function blocks are set according to properties of machining processes, all stations in the blocks are connected through an automatic logistics conveying line, all the blocks are connected through an intelligent conveying system, and thus the system can operate continuously, efficiently and orderly, the functions of the blocks can be exerted to the maximum extent, the influence of failures of single equipment on the whole production system is lowered, productionefficiency is improved, the production hours are shortened, and the high-precision quality requirement of products is met.

Owner:SHANGHAI JIAO TONG UNIV +1

Method for normal-temperature high-pressure aconine extracting and formulated product thereof

ActiveCN101108826AReduce extraction timeShorten production hoursOrganic active ingredientsOrganic chemistryWater basedAlcohol content

A method for extracting the aconitine under normal temperature and superhigh pressure and the produced preparation are provided, which belongs to the medical technology field. The method is that the traditional Chinese medicinal materials in the aconitine are crushed to coarse powder and are added with the ethanol and soaked under normal temperature after mixing and closing; the mixture is put in a high pressure vessel and extracted by exerting pressure of 100MPa to 1000MPa under normal temperature and filtered after pressure maintaining and pressure relief; the dregs of a decoction are added with water based on the ratio of 1g : 1ml to 30ml between the medicine and solvent and are put in the high pressure vessel after mixing and closing and extracted by exerting pressure under normal temperature and filtered after pressure maintaining and pressure relief; the extracting solution twice is combined and condensed until the alcohol smell does not exist, and filtered after adjusting the pH value and condensed, and added with ethanol to make the alcohol content of 50 per cent to 80 per cent, and put still through night and filtered; the filter liquor is condensed, filtered and added with water for injection to the specified amount, bulked, sterilized to gain the aconitine. The invention has the positive effects of high extraction ratio, short extraction time, low solvent consumption and green environment protection.

Owner:XIUZHENG PHARMA GRP CHANGCHUN HIGH NEW PHARMA CO LTD

Full-automatic rivet gun

The invention discloses a fully automatic rivet gun, which comprises a rivet gun body. The front part of the rivet gun body is provided with an automatic feeding mechanism, the middle part is provided with an automatic riveting mechanism, and the rear part is provided with an automatic material receiving mechanism. Feeding mechanism, automatic riveting mechanism and automatic receiving mechanism, and can be installed on the robot arm or other mechanisms, controlled by PLC signal, complete automatic operation instead of manual operation, reduce the labor intensity of operators, and occupy space It is small and convenient for operation. In addition, since the rivet guide block and the clip are provided, the position of the rivet is consistent each time. During operation, the rivet gun can be positioned accurately, which improves the stability of product quality. There is no restriction on the direction of operation, and it is not affected by the direction of gravity, which greatly improves the production efficiency of continuous operation.

Owner:广州市创效电子设备有限公司

Lens two-sided glue assembly technology for mobile phone camera shooting module group of flexible circuit board

InactiveCN101196605AImprove yieldShorten production hoursRadio/inductive link selection arrangementsMountingsCamera lensSheet film

The invention relates to a production and assembling technique of cellphone camera module, specifically to a dual adhesive tape assembling technique for cellphone camera module lens with flexible circuit wafer. According to the technical solution in this invention, the dual adhesive tape assembling technique for cellphone camera module lens with flexible circuit wafer comprises: A. assembling: to revolve the thread part on lens a into microscope base b; B. patching: to stick the image sensor e on flexible circuit wafer f and make bonding pad in the position; C. attaching the dual adhesive tape: to attach the dual adhesive tape d on the flexible circuit wafer f with image sensor e, and expose the image sensor e in the hollow position in the middle; D. installing the microscope base: to aim the registration mast c of the microscope base b towards the locating hole j on the flexible circuit wafer f, and press the microscope base b and make the microscope b agglutinate with the flexible circuit wafer f; E. hot riveting: to jumping the jut on the registration mast c of the microscope base b and doily g with rivet hot machine. The invention can save production man-hour and increase the one time yield of the production and provide convenient for the possible rework in future.

Owner:无锡凯尔科技有限公司

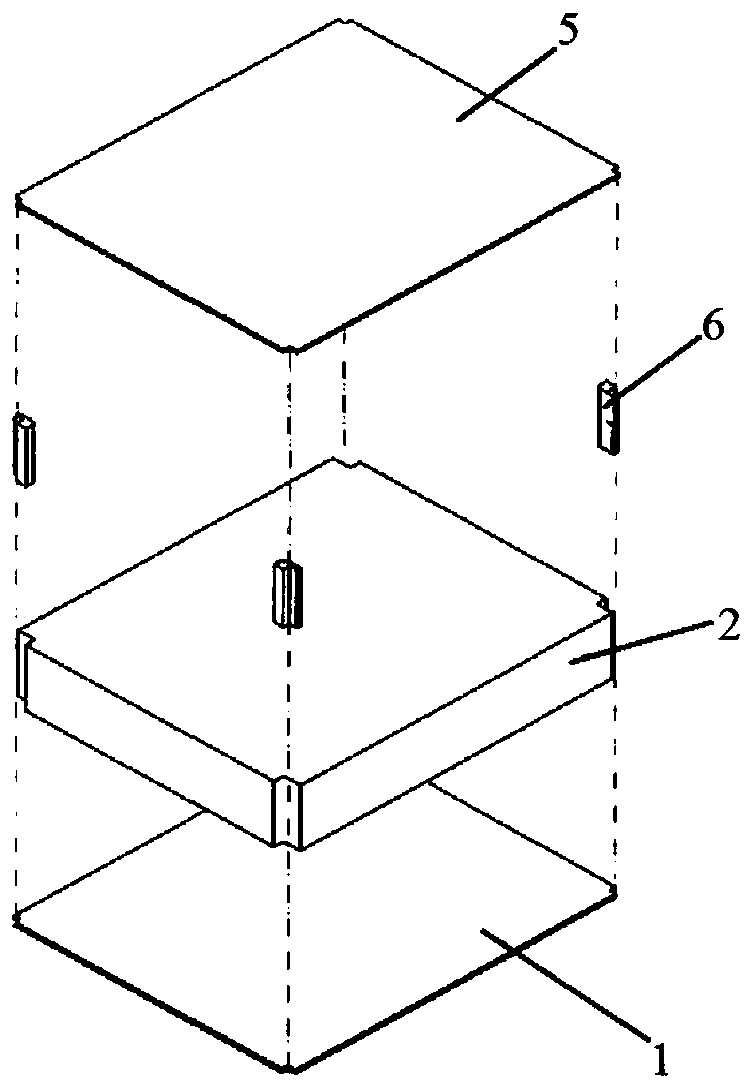

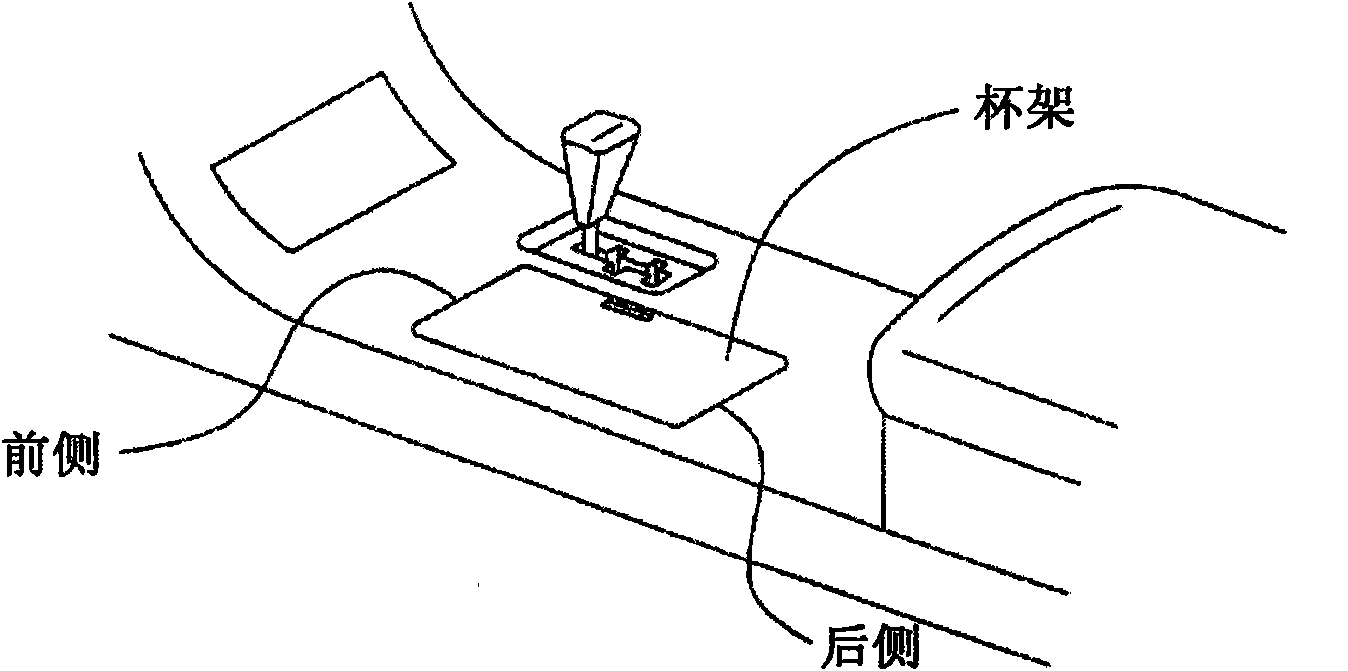

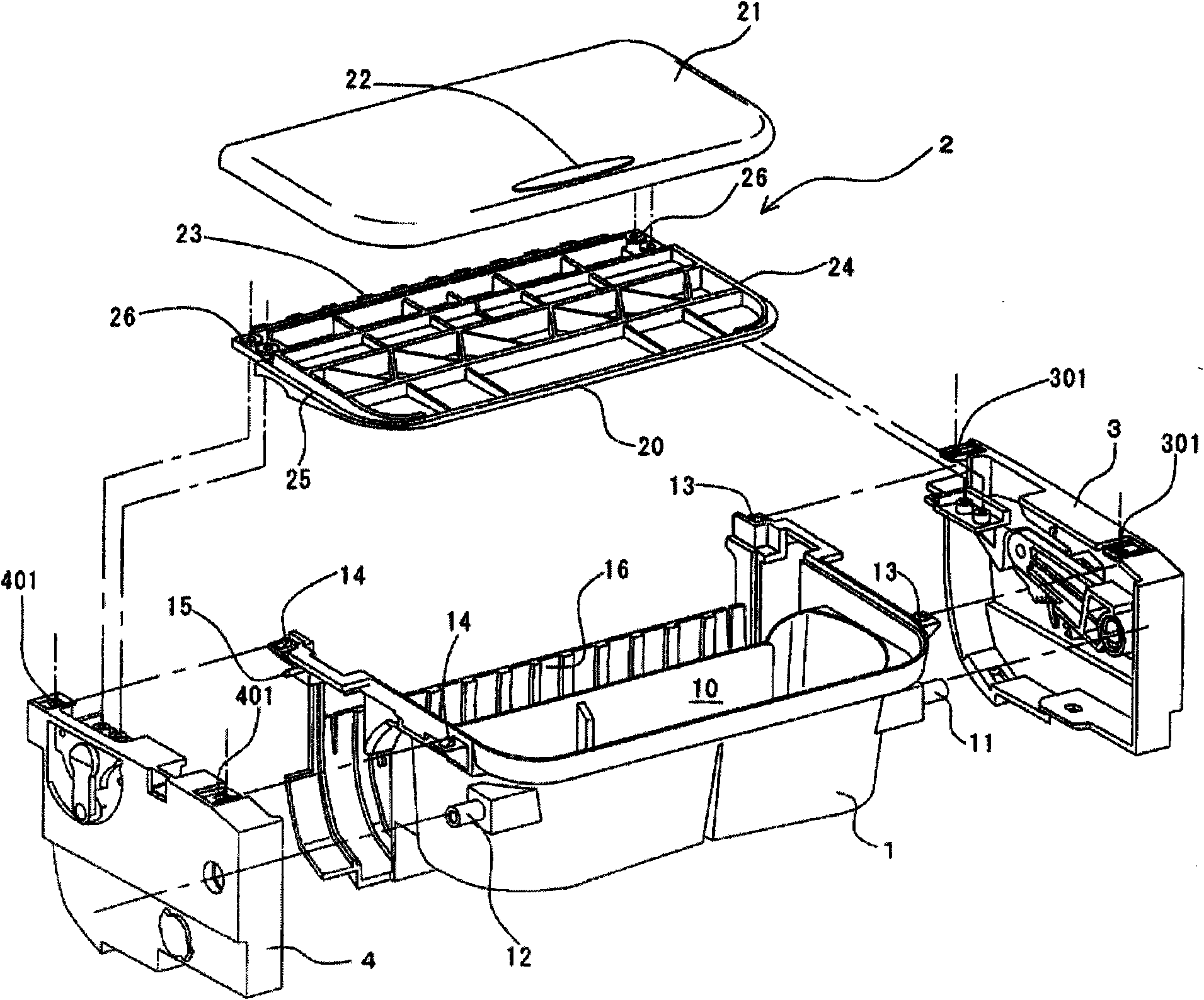

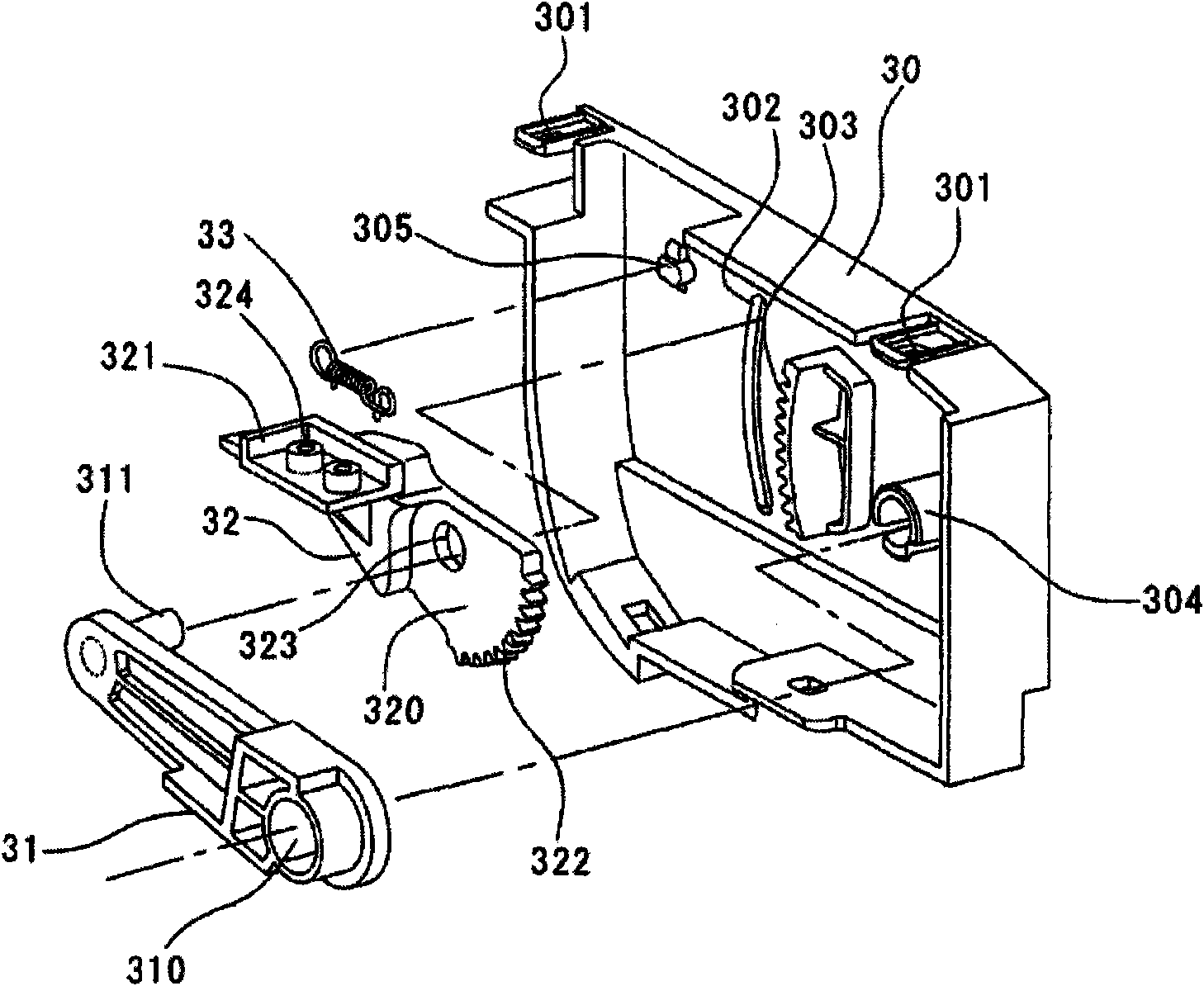

Accommodation device for vehicle use

InactiveCN102133873AShorten production hoursReduce design man-hoursVehicle arrangementsPassenger spaceMan-hourSize change

The invention provides an accommodation device for vehicle use, which contributes significantly to design man-hour decrease and production man-hour decrease even in case of a carrying space or an accommodation container body with a different shape. The accommodation device for vehicle use comprises a pair of rotation adjusting units for fixing guiding mechanisms with a capability of adjusting therotation track on the two ends of the accommodation container body. By fixing the lid on parts of the guiding mechanisms and making the lid rotate relative to the accommodation container body throughthe guiding mechanisms, the lid is thus made capable of opening and closing the opening. Therefore, even in case of size changes of the accommodation container body and the lid, the rotation adjusting unit can be shared.

Owner:TOYODA GOSEI CO LTD

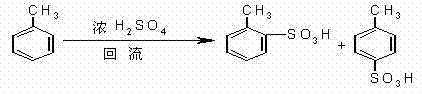

Production method for sulfonic acid curing agent used for casting

InactiveCN102516132AUnique process methodRealize environmentally friendly productionFoundry mouldsFoundry coresAlcoholSteam pressure

The invention relates to a production method for sulfonic acid curing agent and especially to a production method for sulfonic acid curing agent used for casting without generation of three wastes (waste gas, waste water and industrial residue). The method is characterized by comprising the following steps: a, closing a kettle bottom valve, opening a vacuum pump and taking in toluene with a desired weight; b, closing a vacuum valve, opening an air release valve and a sulfuric acid feeding valve, starting a mixer and adding concentrated sulfuric acid with a desired weight; c, opening a steam valve, maintaining steam pressure to be 0.2 to 0.3 MPa, allowing temperature to rise to 100 to 118 DEG C within 40 to 50 min and carrying out insulation for 90 min; d, opening a cooling water valve, allowing temperature to drop to 60 DEG C and slowly adding organic alcohol with a desired weight through an elevated tank; e, slowly adding water with a desired weight through the elevated tank after addition of organic alcohol is finished; and f, after addition of water is finished, allowing temperature to drop to 45 DEG C, adding an aqueous hydrogen peroxide solution with a desired weight, carrying out stirring for 20 min and carrying out inspection by sampling. According to the invention, control of total acidity of the curing agent and free acid is realized, production efficiency is effectively improved, and no discharge of industrial three wastes is realized.

Owner:NINGXIA KOCEL GRP CO LTD +1

Novel air conditioner pipeline perforating device

InactiveCN105618858AAvoid processShorten production hoursLarge fixed membersPunchingDrilling machines

The invention discloses a novel air conditioner pipeline perforating device which comprises a cutting assembly, a punching assembly, a support assembly and a perforating tool, wherein the cutting assembly comprises a clamping cylinder, a cylinder seat, a support shaft, a connecting shaft sleeve, a clamping seat and a tool bit assembly; the clamping cylinder is fixed on the support shaft by the cylinder seat and connects the clamping seat with the tool bit assembly by the connecting shaft sleeve; the other end of the support shaft is fixed with the support assembly for connection; the punching assembly comprises a top punching cylinder and a punching device; the punching device is fixed on the support assembly; and a blade on the tool bit assembly and a tool bit at the front end of the punching device both align with the pipeline perforating tool. The novel air conditioner pipeline perforating device avoids the procedures of chamfering and blowing-out of aluminium skimmings, caused by use of conventional drilling machines for perforating, and production hours are saved and quality risk is reduced.

Owner:HEFEI JIANGHUAI AUTOMOBILE PIPE

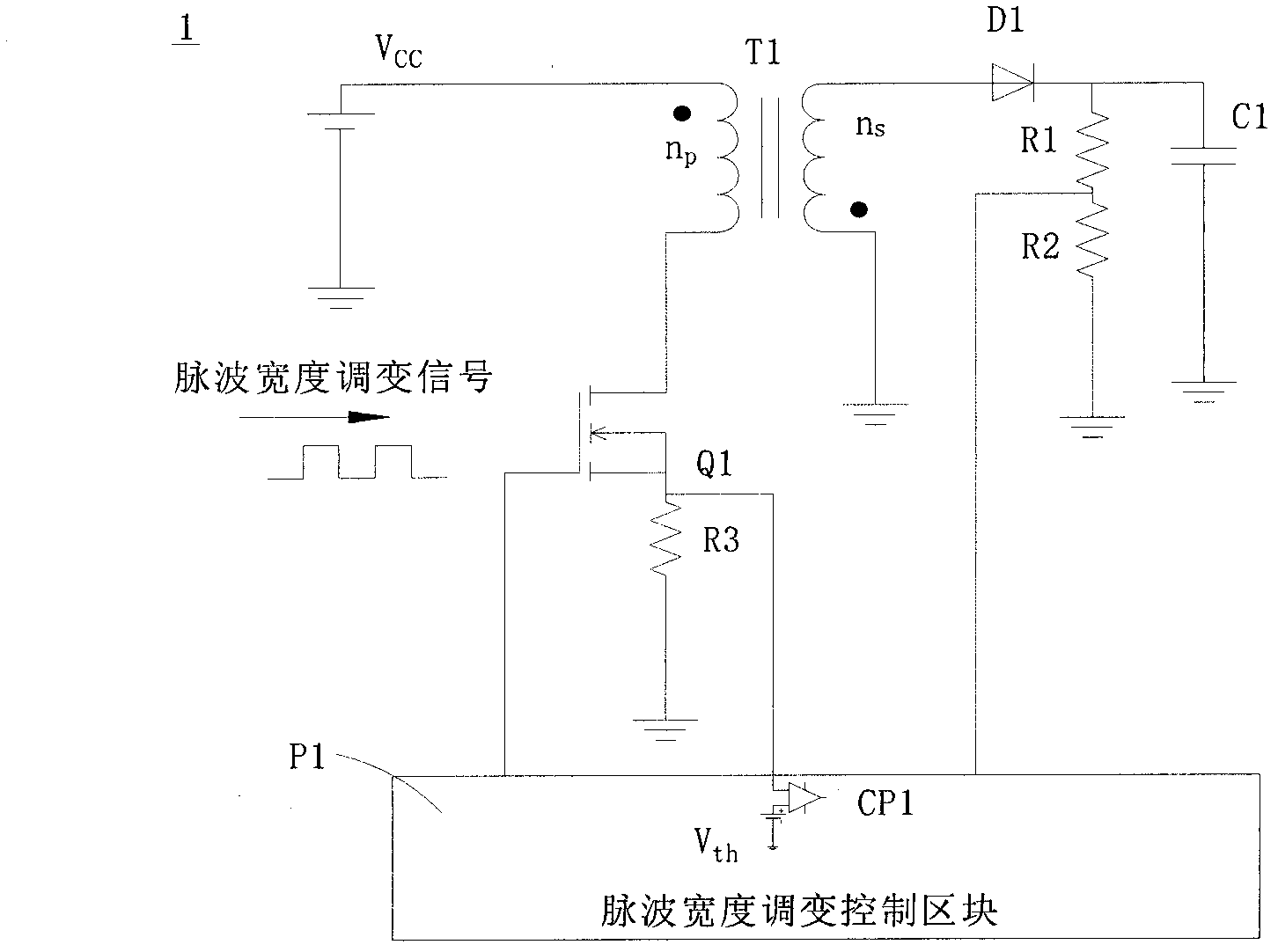

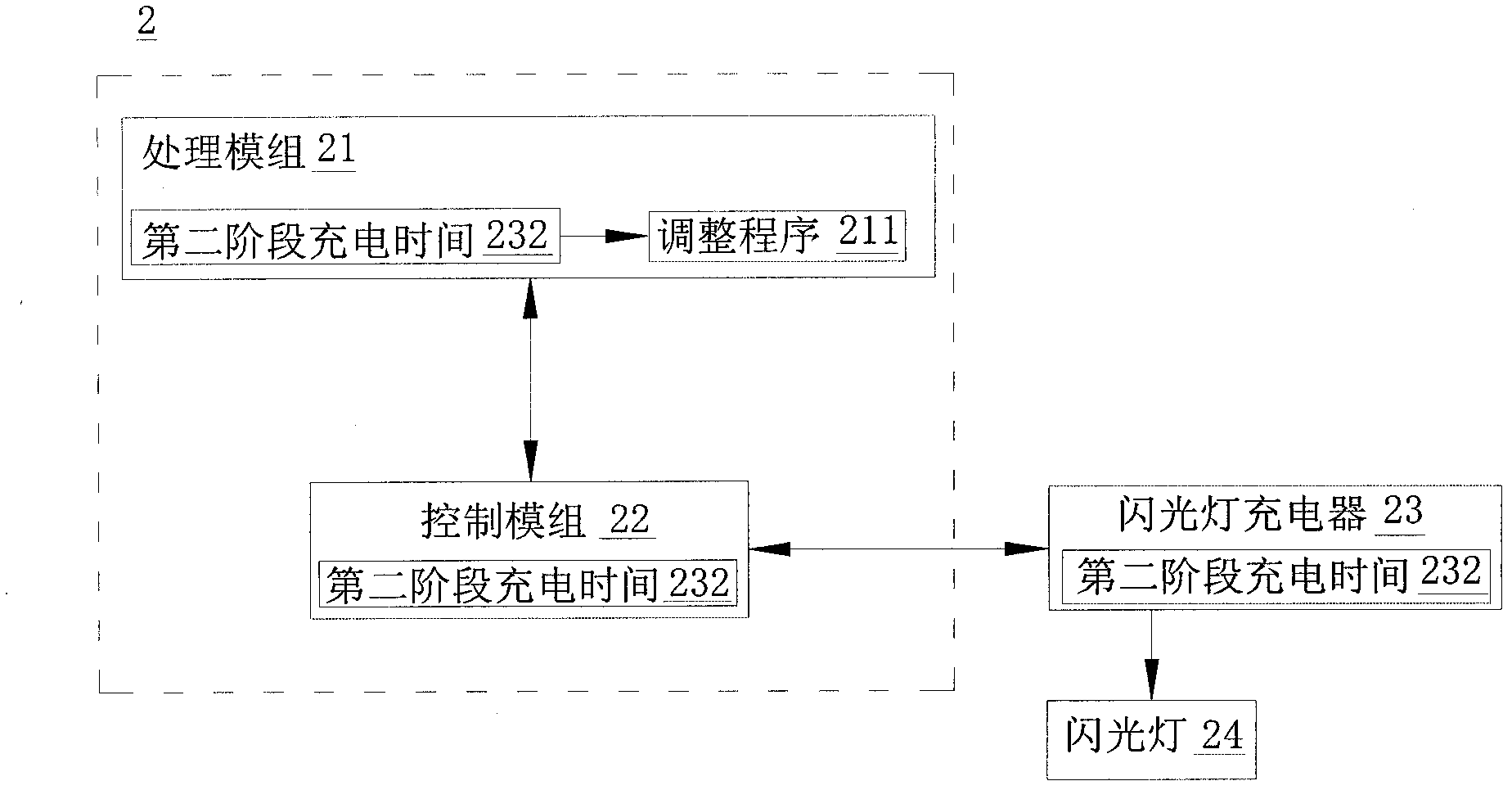

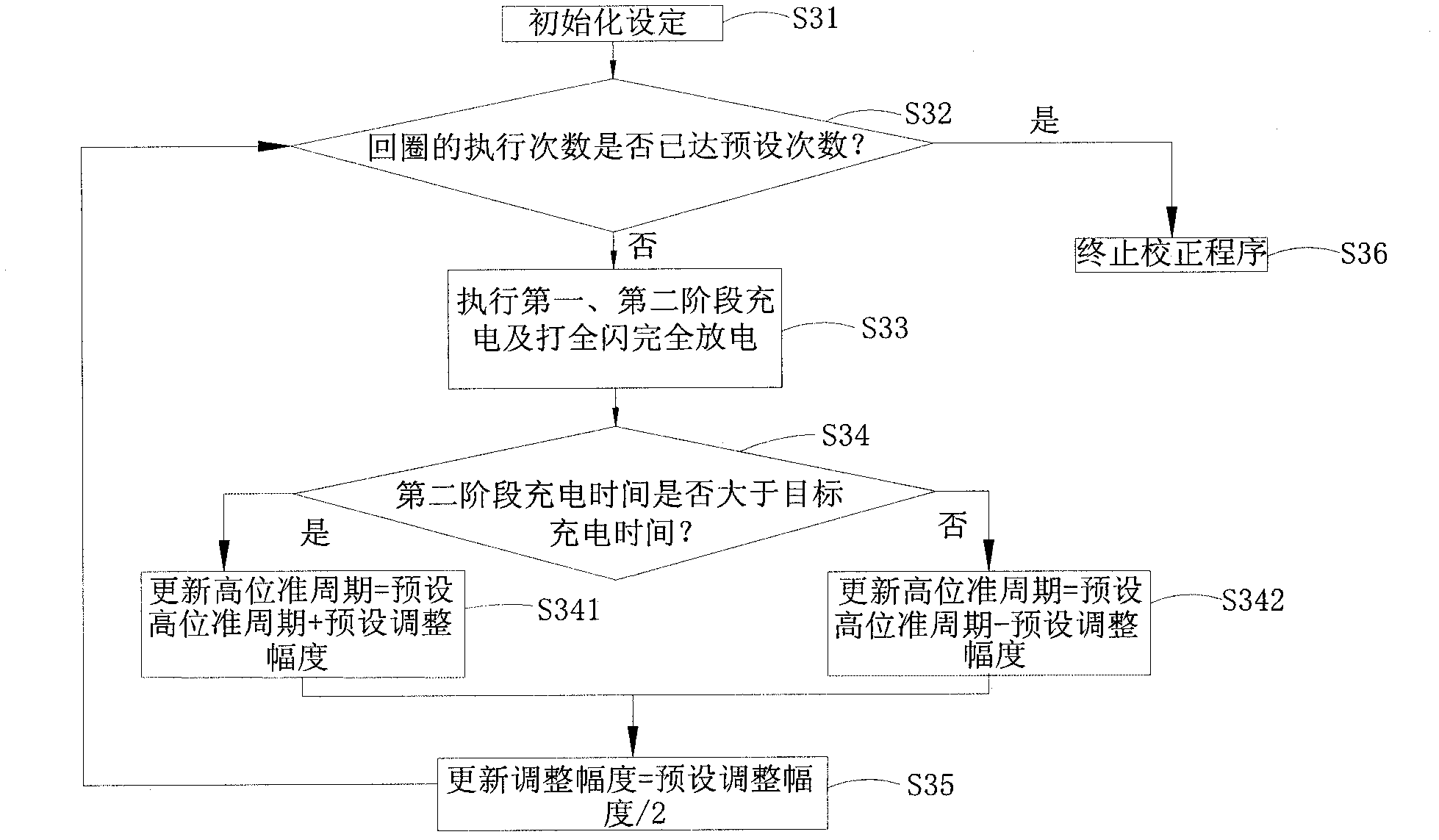

Charger calibration device and charger calibration method

InactiveCN103036262ALow manufacturing costShorten production hoursBatteries circuit arrangementsElectric powerCorrection methodElectrical and Electronics engineering

The invention discloses a charger calibration device and a charger calibration method. The charger calibration device comprises a control module and a processing module. The control module controls a charger needed to be calibrated to carry out a first stage charging and a second stage charging to an electrical device. The processing module carries out a adjustment process according to the second stage charging time, so that high level quasi-periodicity of a pulse width modulating signal in a charging circuit of the charger need to be calibrated is adjusted. A preset high level quasi-periodicity is added or subtracted a preset adjustment range by the adjustment process, so that an updated high level quasi-periodicity is generated, then the preset adjustment range is reduced by half to generate an updated adjustment range, a calibration loop is repeated to preset times, and a calibration procedure is terminated.

Owner:ALTEK CORP

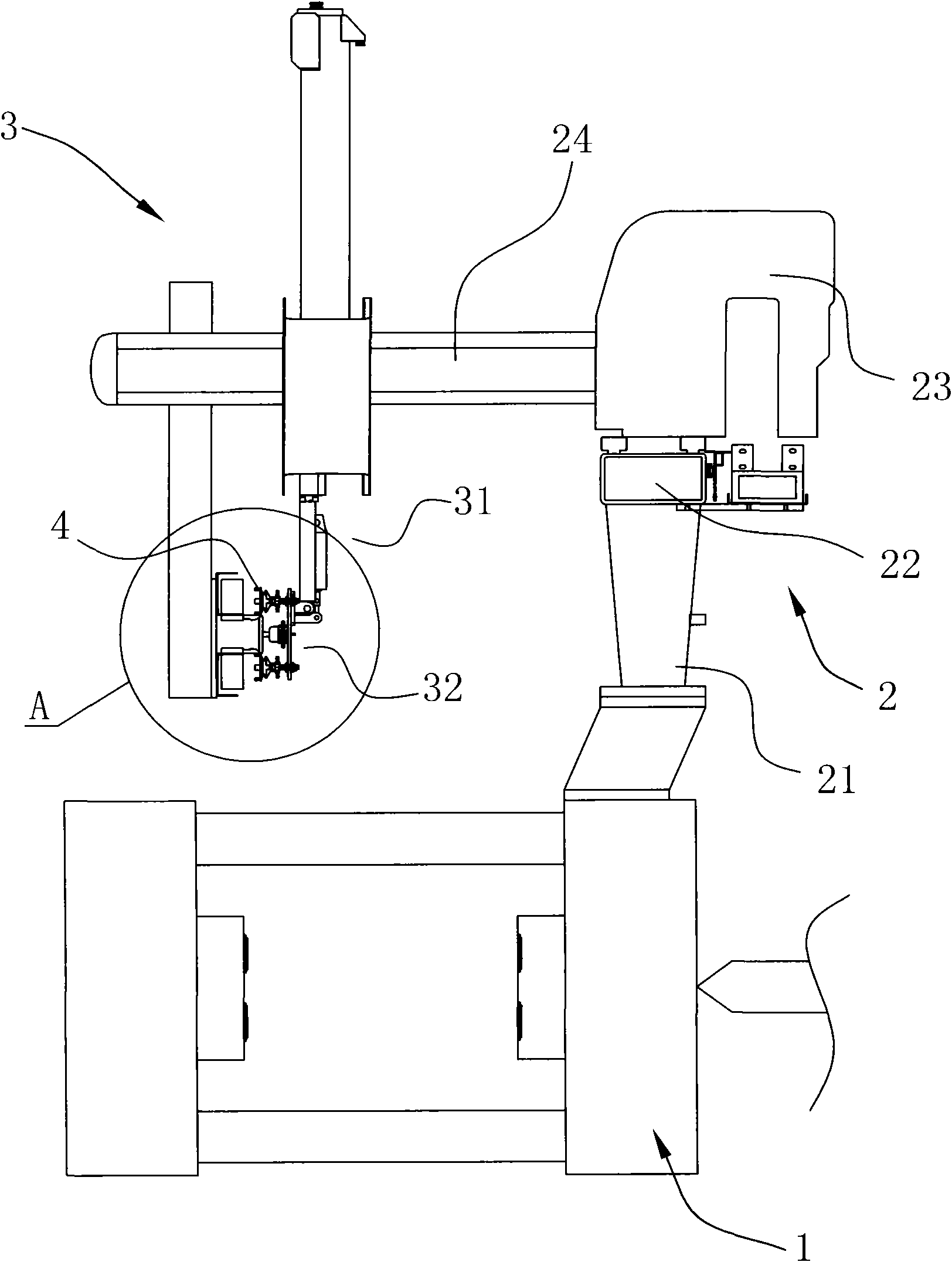

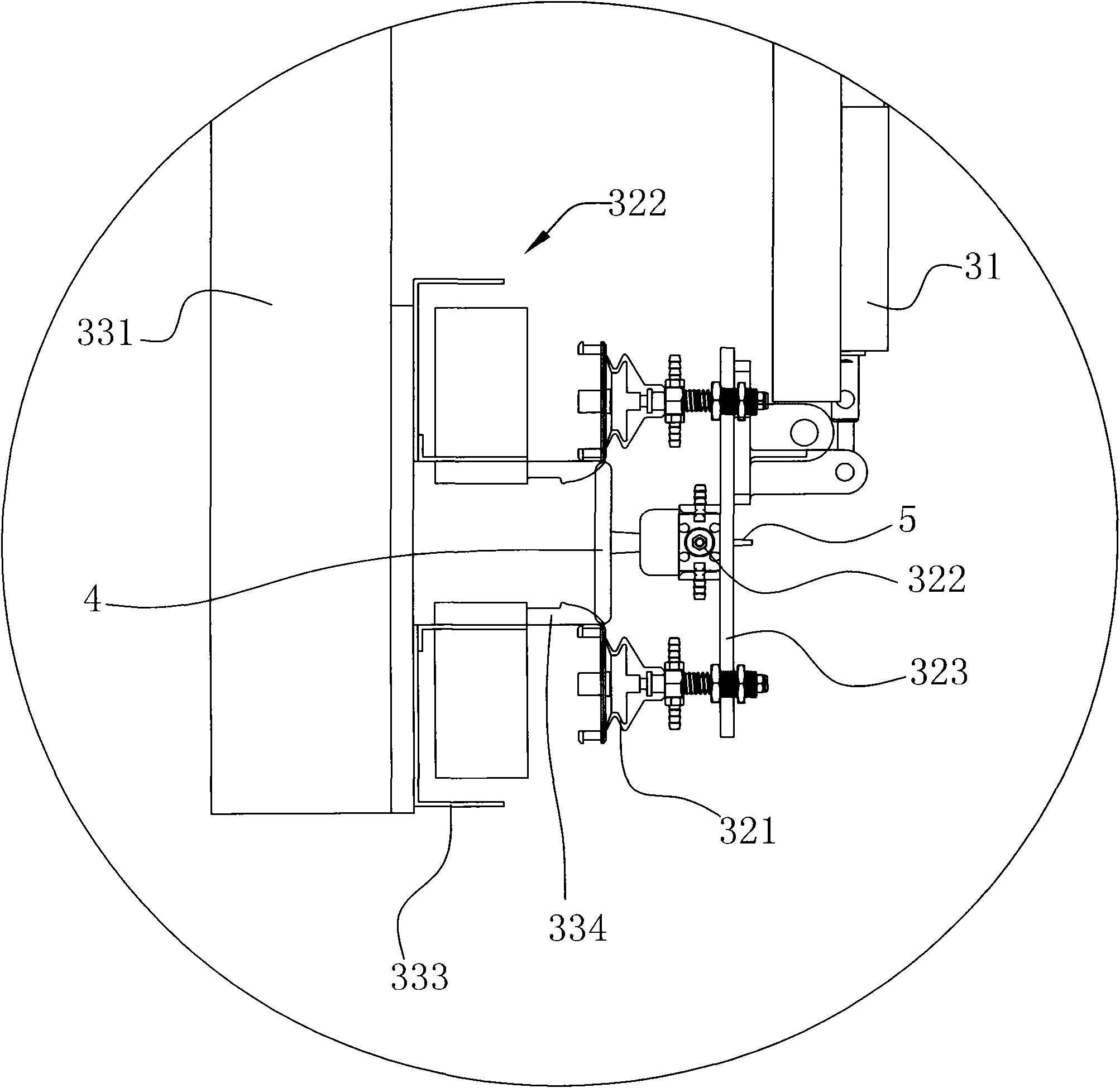

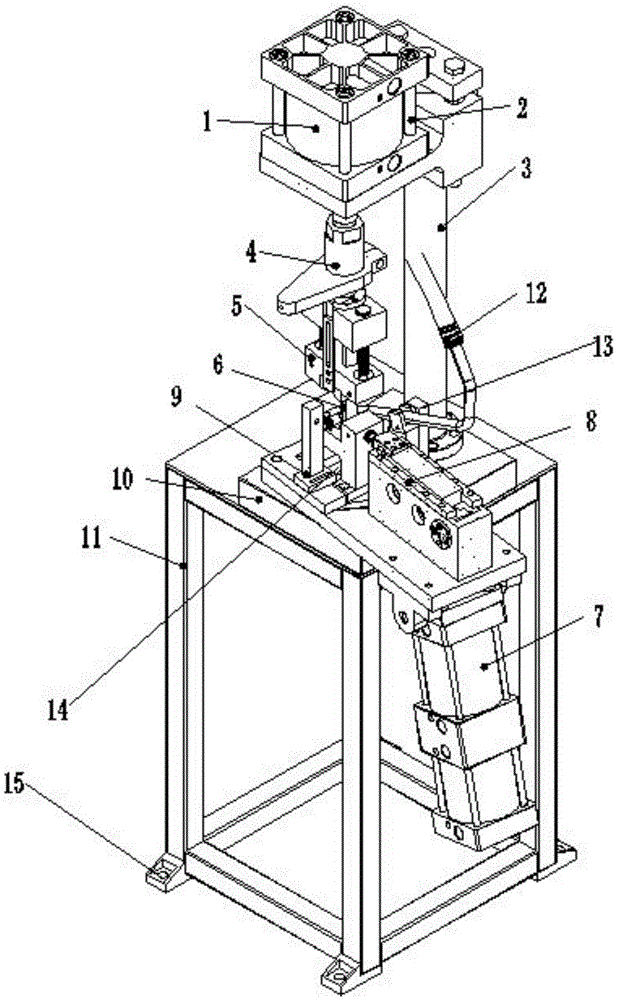

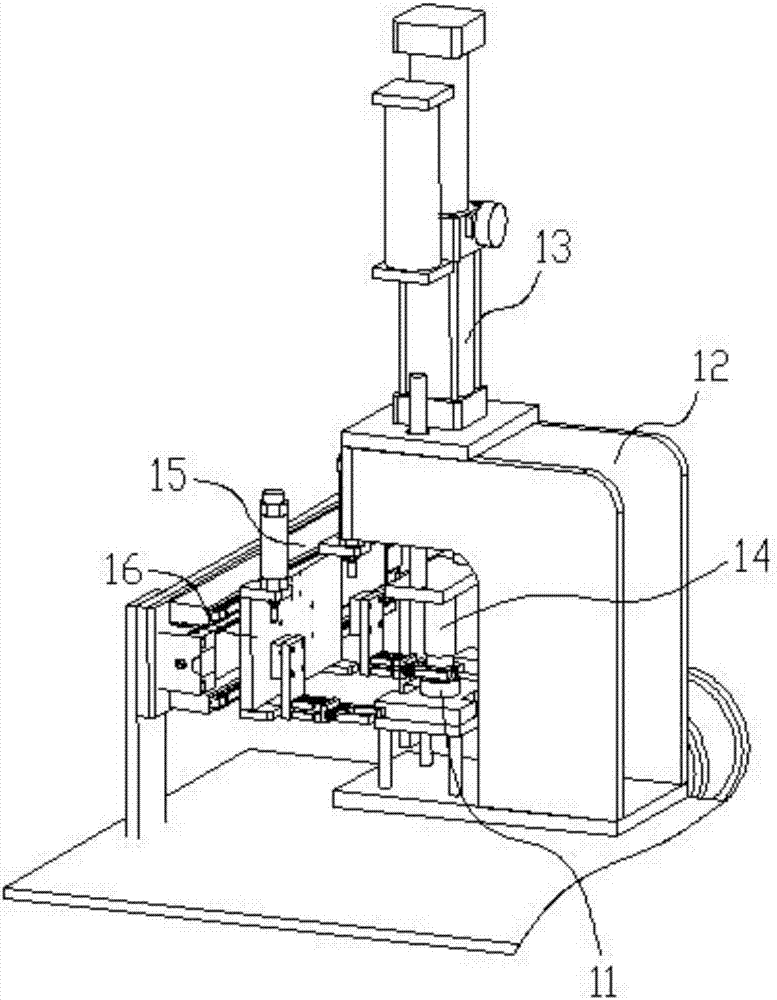

Automatic assembling machine for anode parts

ActiveCN106862930AComply with welding wire requirementsShorten production hoursOther manufacturing equipments/toolsMetal working apparatusDistribution controlEngineering

The invention relates to an automatic assembling machine for anode parts. A riveting device is arranged on the right portion of a power distribution control box. A welding wire device and a pressing sleeve device are arranged on the left portion of the power distribution control box. A conveying device is arranged between the riveting device and the welding wire device. The riveting device and the welding wire device are both matched with the conveying device through a grab mechanical hand. The conveying device comprises a conveying groove. The conveying groove is provided with two right-angle corner parts. The two right-angle corner parts are provided with two overturning devices in the opposite overturning directions respectively. Each overturning device comprises an overturning base arranged on the outer wall of the conveying groove, wherein the overturning base is provided with an overturning air cylinder, and the overturning air cylinder is provided with an overturning push block. Material picking is carried out through the grab mechanical hand, riveted parts are conveyed to a welding wire station through the conveying device, the conveying device is provided with the two overturning devices, thereby being capable of being turned by 180 degrees, the welding wire requirements of the welding wire station are directly met, the production hours are greatly shortened, and production efficiency is improved.

Owner:天长市捷俊精密模具有限公司

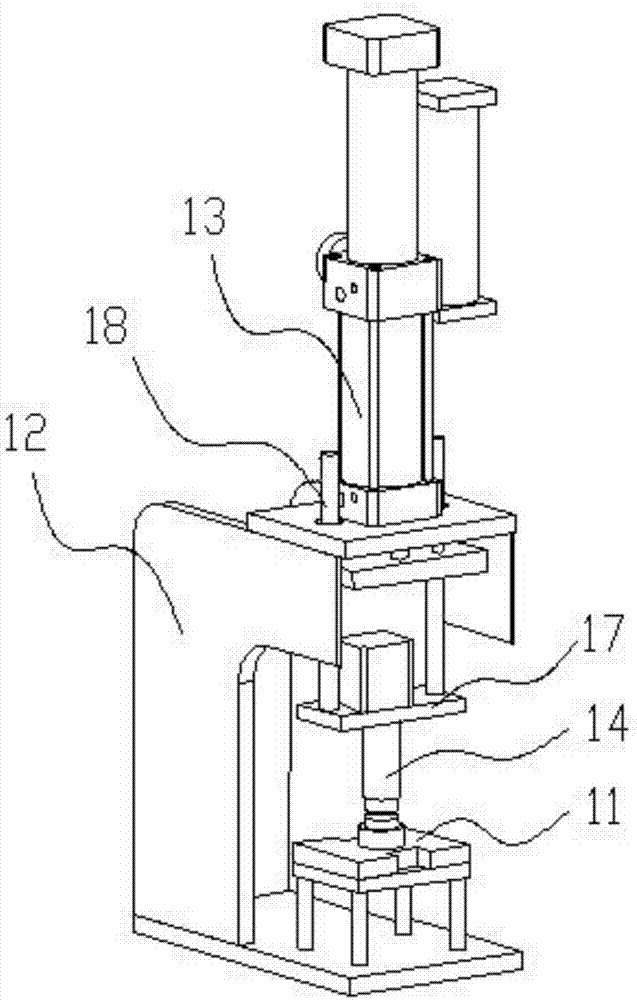

Electromagnetic valve assembly equipment

InactiveCN104889714AReduce manufacturing costGuaranteed accuracyMetal working apparatusPunchingEngineering

The invention discloses electromagnetic valve assembly equipment. The electromagnetic valve assembly equipment comprises a frame, and is characterized in that a fixed base is fixed with the frame, wherein a notch for fixing a clamping positioning block is formed in a diagonal line of the fixed base; the middle part of a punching lower mold is a cylindrical revolving body; the front part of the clamping positioning block coaxially fits the middle part of the punching lower mold; a bracket assembly positioning column is mounted at the upper part of the punching lower mold; a fool-proof sensor and a starting button are arranged at the two sides of the fixed base; a punching cylinder fixed plate is connected with the frame; a punching cylinder is connected with the punching cylinder fixed plate; and the head part of the punching cylinder is connected with a punching upper mold. The electromagnetic valve assembly equipment has the beneficial effects of simple structure, operation safety, adoption of the cylinder to act so as to greatly improve the production efficiency and to shorten the production time, and possession of the positioning column to guarantee the bracket assembly precision, to largely reduce the rejection rate and to reduce the enterprise production cost.

Owner:奥可利电子(昆山)有限公司

Anti-aging composition containing hydroxypropyl tetrahydropyrantriol and fermentation product and application of anti-aging composition

PendingCN113975220ACombined application has good anti-aging and anti-wrinkle effectEasy to prepareCosmetic preparationsToilet preparationsBiotechnologyButanediol

The invention discloses an anti-aging composition containing hydroxypropyl tetrahydropyrantriol and a fermentation product and application of the anti-aging composition. The anti-aging composition is prepared from the following components in parts by weight: 0.1 to 20 parts of hydroxypropyl tetrahydropyrantriol, 0.1 to 20 parts of bifida ferment lysate fermentation product lysate, 0.1 to 20 parts of lactobacillus fermentation filtrate, 1 to 30 parts of saccharomycetes / rice fermentation product filtrate, 1 to 20 parts of butanediol and 20 to 70 parts of deionized water. According to the invention, the anti-aging composition containing the hydroxypropyl tetrahydropyrantriol and the fermentation product can be applied to various skin care dosage forms such as essence water, essence, emulsion, cream and the like; and the anti-aging composition complements each other on the action mechanism, and has the anti-aging effects of promoting collagen synthesis, scavenging free radicals, accelerating the skin renewal speed and repairing the skin barrier through combined application.

Owner:湖北省麦诗特生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com