Electromagnetic valve assembly equipment

A solenoid valve assembly and equipment technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of increasing product scrap rate, increasing production man-hours, increasing production costs, etc., to improve production efficiency, reduce scrap rate, The effect of reducing production man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

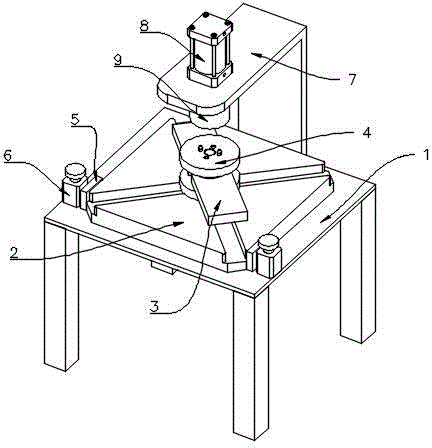

[0014] The present invention is described below in conjunction with accompanying drawing:

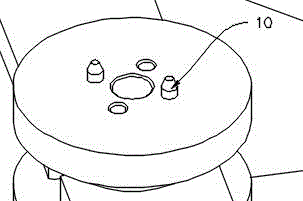

[0015] A solenoid valve assembly equipment, including a frame 1, characterized in that: the fixed base 2 is fixed to the frame 1, the diagonal of the fixed base 2 is provided with a notch for fixing with the clamping positioning block 3, and the middle part of the stamping lower die 4 It is a cylindrical revolving body, the front part of the clamping positioning block 3 is coaxially matched with the middle part of the stamping die 4, the upper part of the stamping die 4 is equipped with a bracket assembly positioning column 10, and the two sides of the fixed base 2 are provided with a fool-proof sensor 5 and a start button 6. The fool-proof sensor 5 is provided with two symmetrically, the start button 6 is symmetrically provided with two, the stamping cylinder fixing plate 7 is connected with the frame 1, the stamping cylinder 8 is connected with the stamping cylinder fixing plate 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com