Patents

Literature

2580 results about "Start button" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gaming machine

InactiveUS6126541ACard gamesApparatus for meter-controlled dispensingHuman–computer interactionStart button

The invention relates to a gaming machine with at least one display area (2) for a number of game symbols (3) which, after the player has initiated the game by pressing the start button (4), are selected under the control of a computing unit (5) from a multitude of predetermined symbols and presented at positions in the display area (2) for the player to view. The invention calls for a gaming machine (1) to have, preferably in the display area (2) at least one chance-display zone (7,7') in which the computing unit (5), optionally on actuation of a request unit (14), e.g., a request button, by the player, displays and / or increased and / or best-possible win chances, and / or instructions for determining them, which are available for the next game or which, on removal of one or more of the game symbols or game-symbol combinations presented for the next game, apply or could possibly be achieved in the next game.

Owner:NOVOMATIC

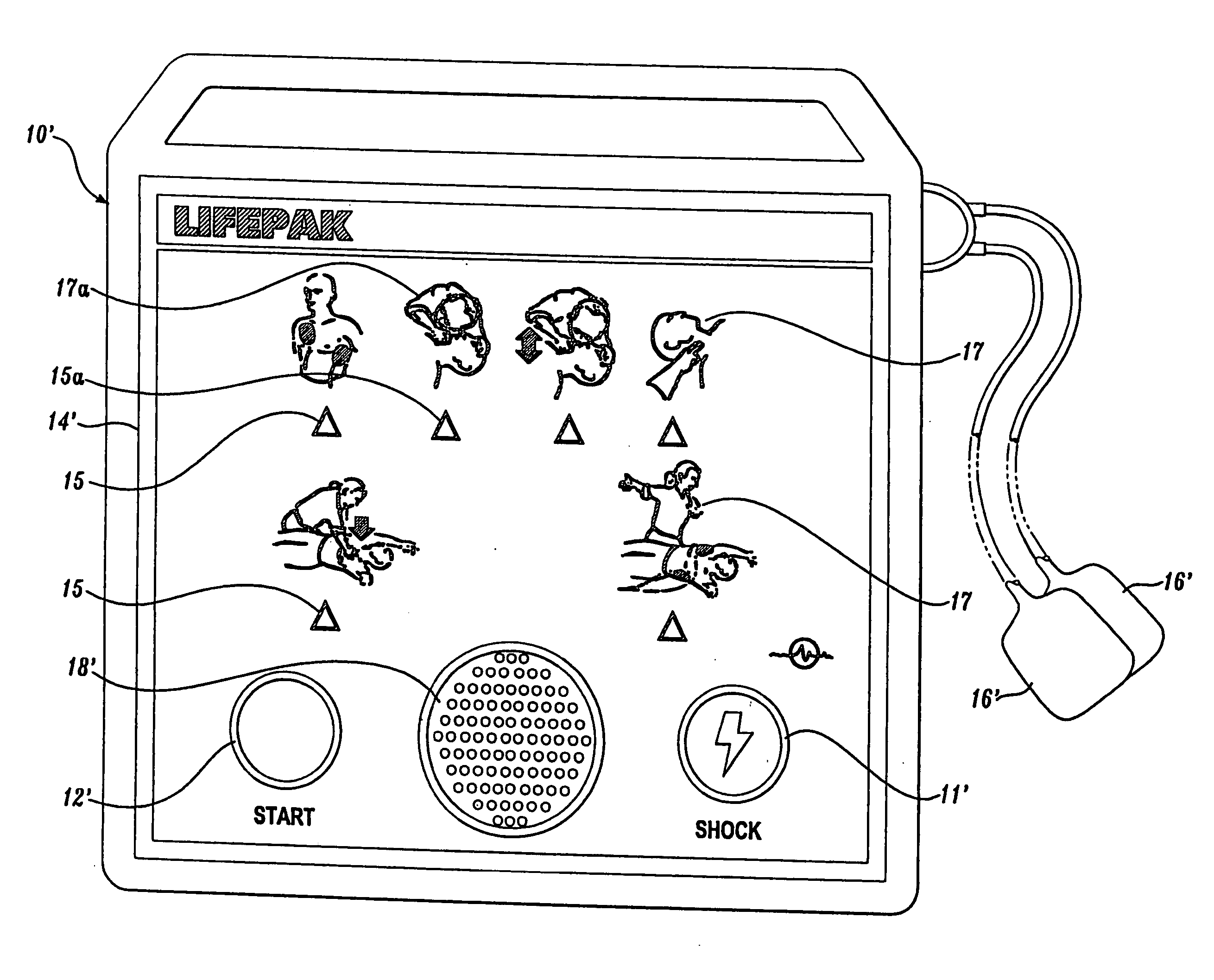

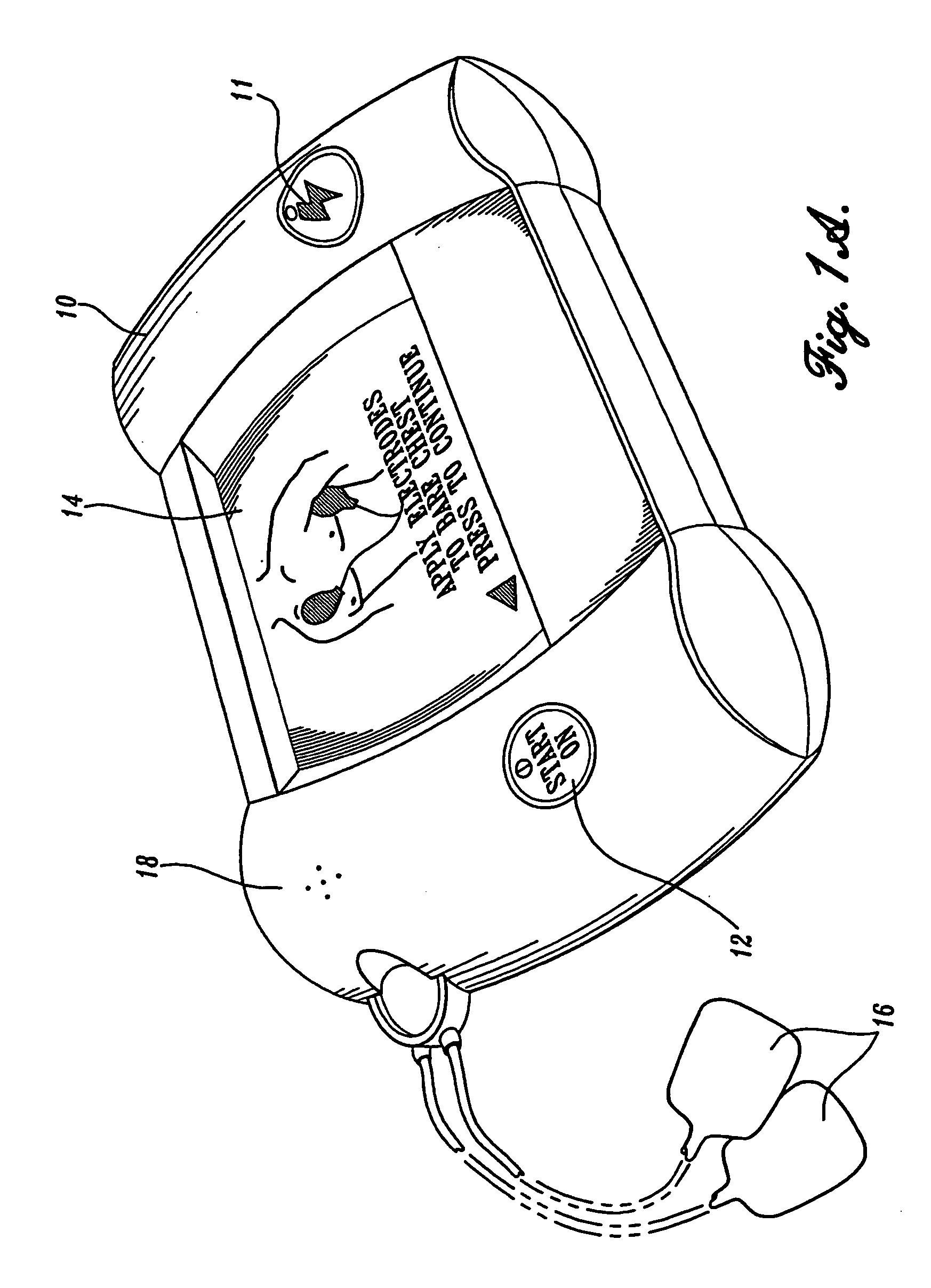

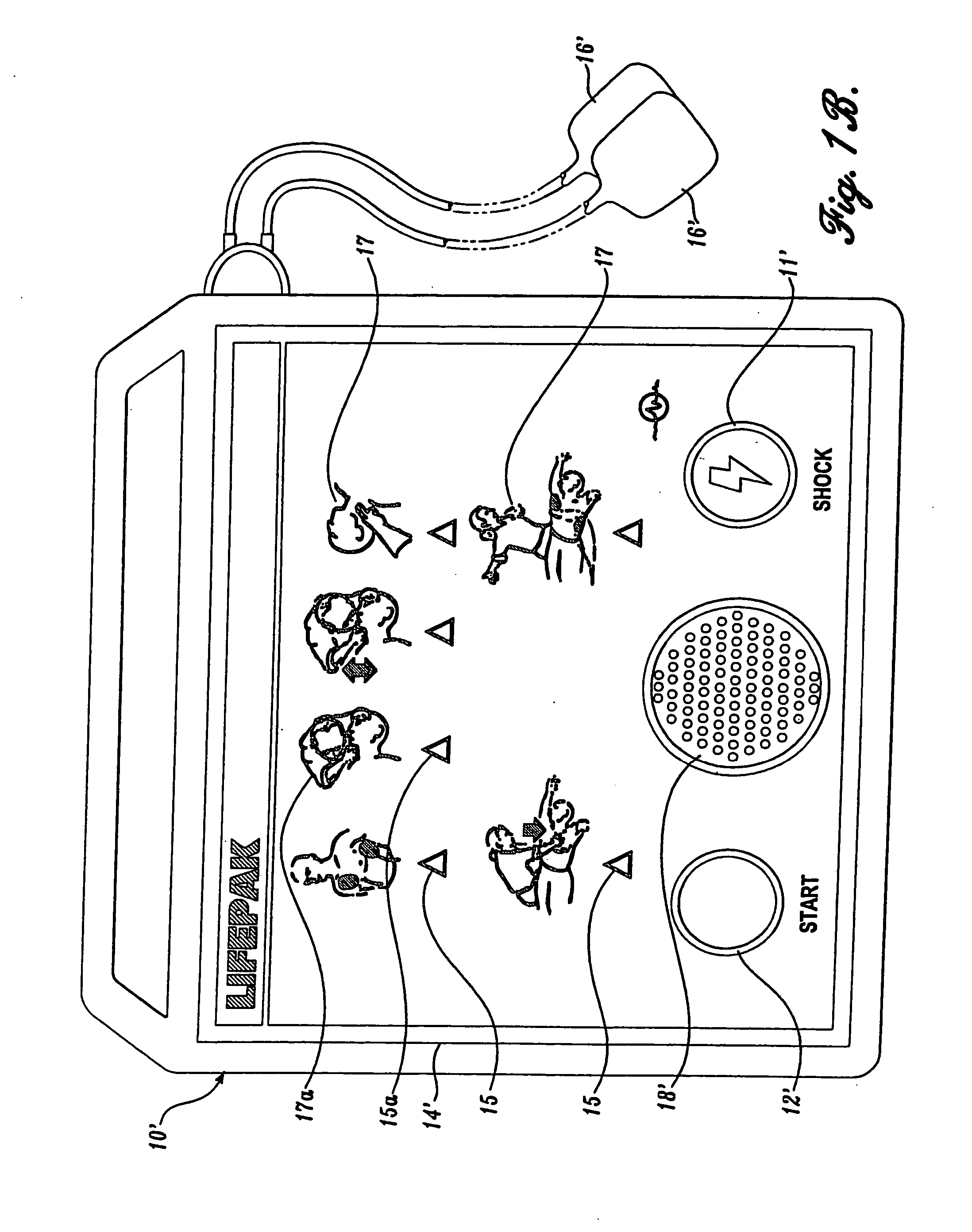

Visual and aural user interface for an automated external defibrillator

An automated external defibrillator (AED) (10) designed for use by a rescuer with minimal or no training during a medical emergency is provided. The AED implements a user interface program (22) which guides the rescuer through operation of the AED and application of CPR and defibrillation therapy to a patient by displaying a series of visual instructions on a graphic display (14) or other visual output device, and by providing additional aural instructions via a speaker (18) or other aural output device. The rescuer merely needs to press a start button (12) to initiate operation of the AED and begin CPR and defibrillation instruction.

Owner:WEST AFFUM HLDG DAC

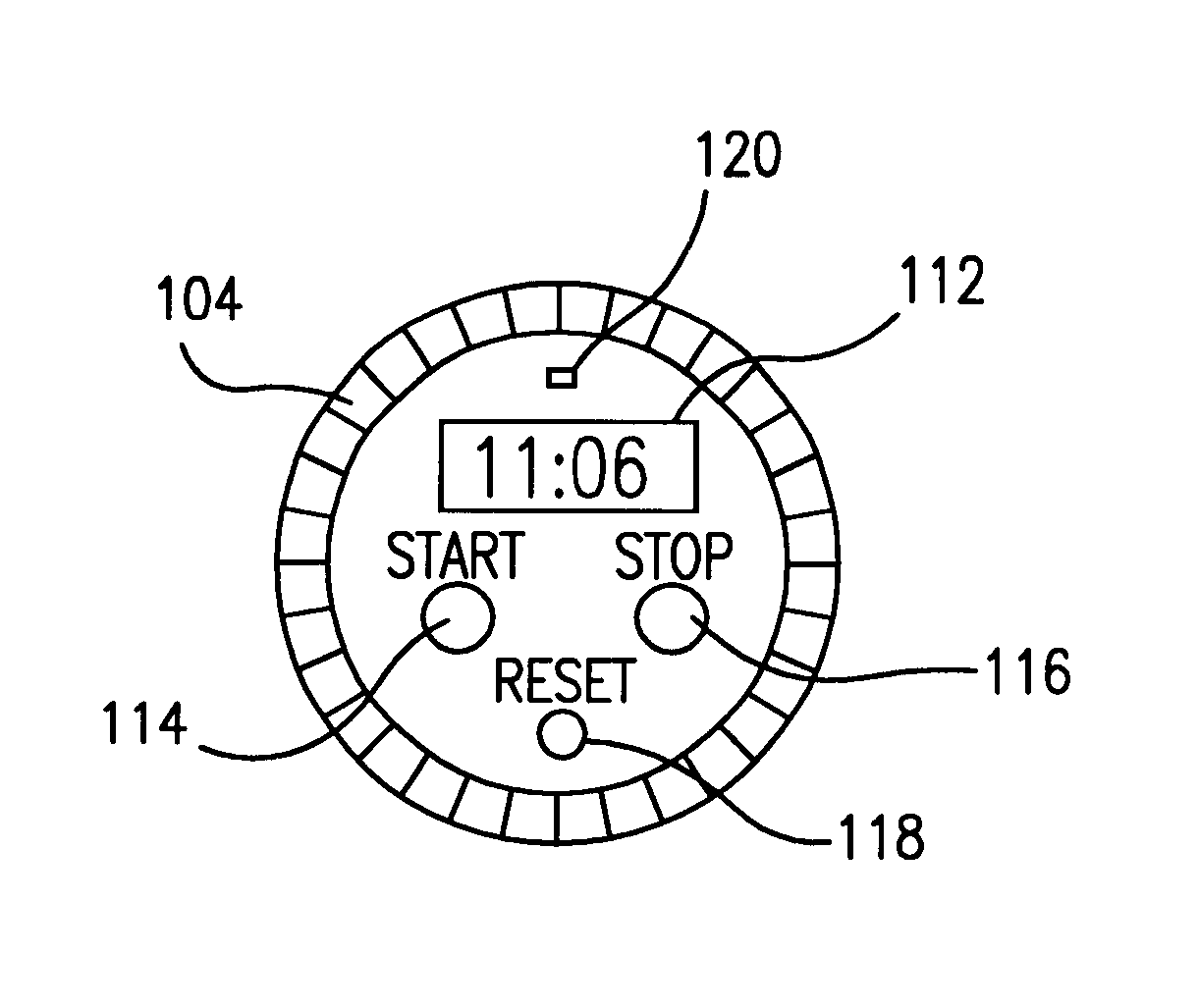

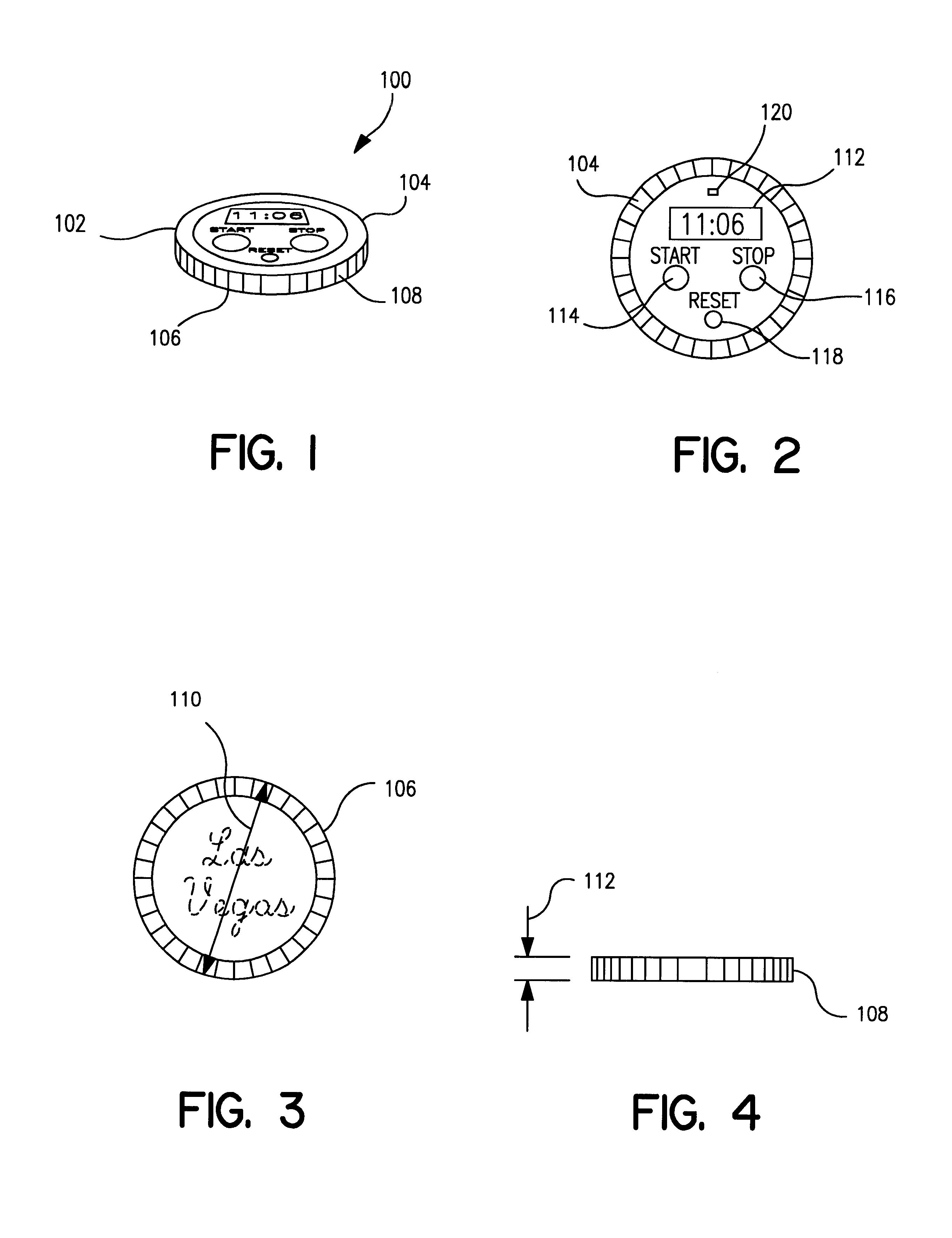

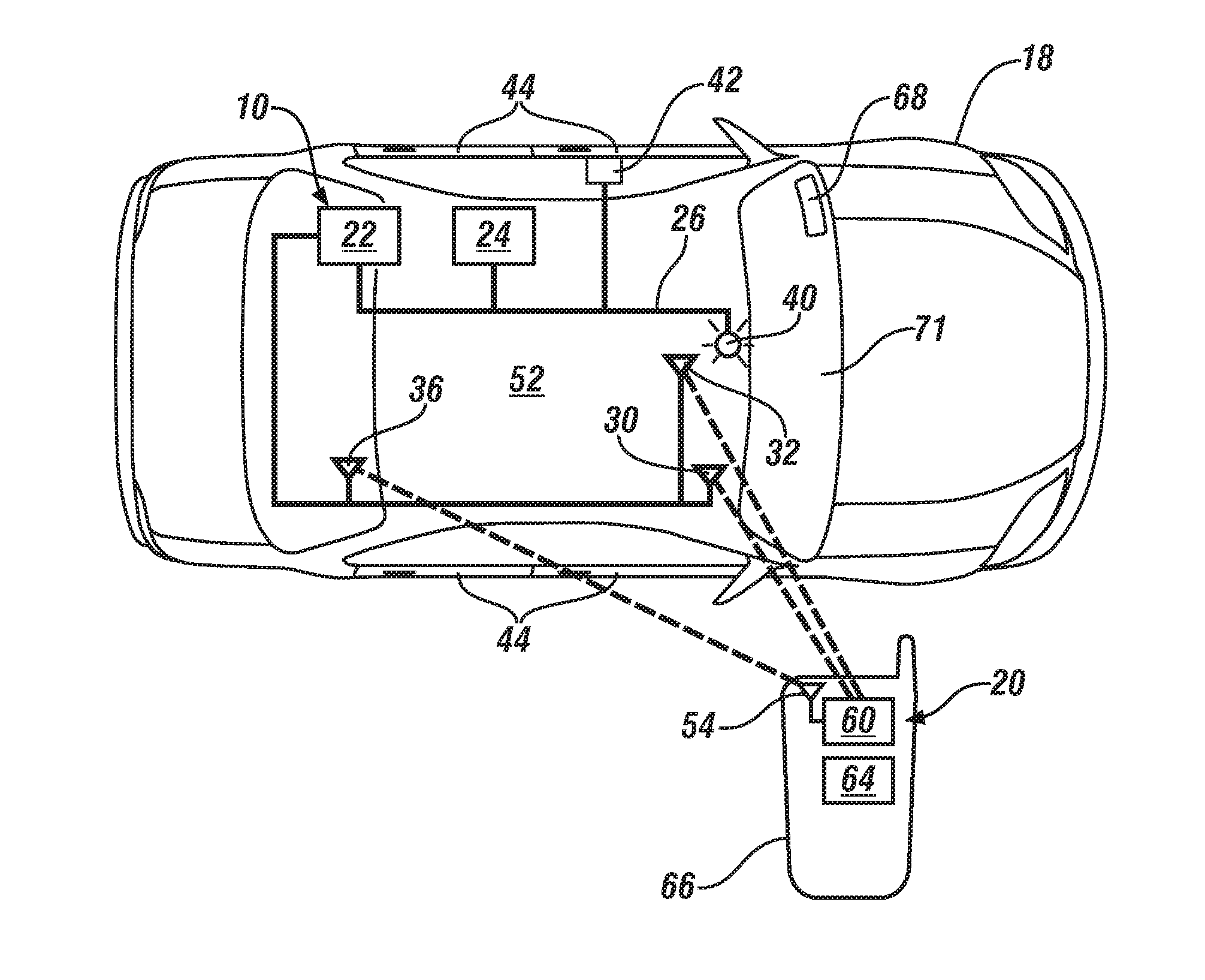

Gaming chip with built-in timer

InactiveUS6357746B1Accurate trackingEasy to storeMechanical clocksElectronic time-piece structural detailsEngineeringTimer

A gaming chip with built-in timer includes a circular cylindrical body with an upper surface, a lower surface, and a continuous sidewall. Additionally, the gaming chip with built-in timer may have a diameter and a thickness that are approximately the same as the diameter and thickness of a standard sized casino gaming chip, which may allow it to be stored in a standard size chip tray. Incorporated into the body of the gaming chip may be a timer, a start button, a stop button, and a reset button. During use, a single gaming chip with built-in timer may be used to mark a seat vacated by a gambler on a break. If more than one gambler vacates his or her seat during a break more than one gaming chip with built-in timer may be used to reserve the empty seats.

Owner:SADOWSKI CRAIG

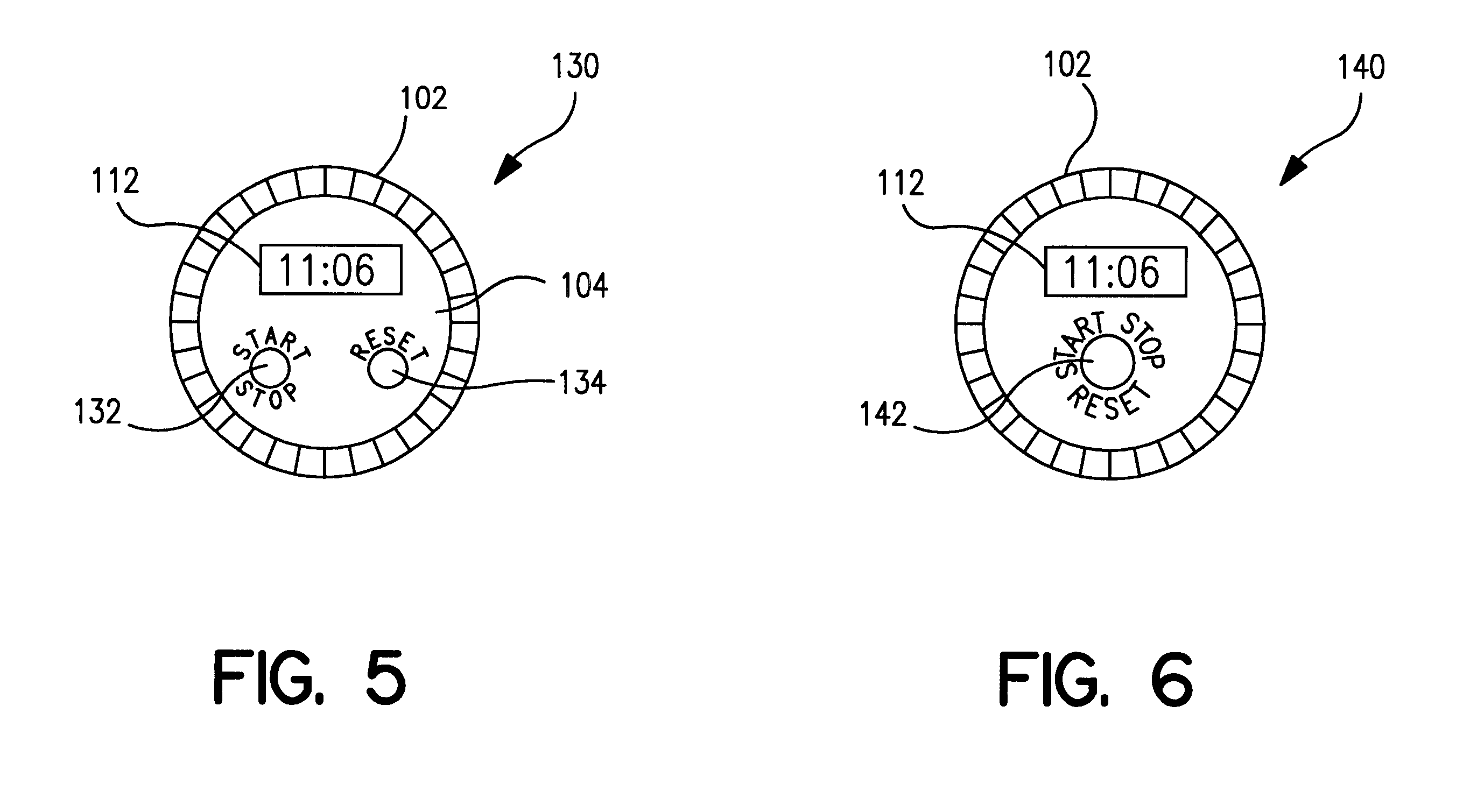

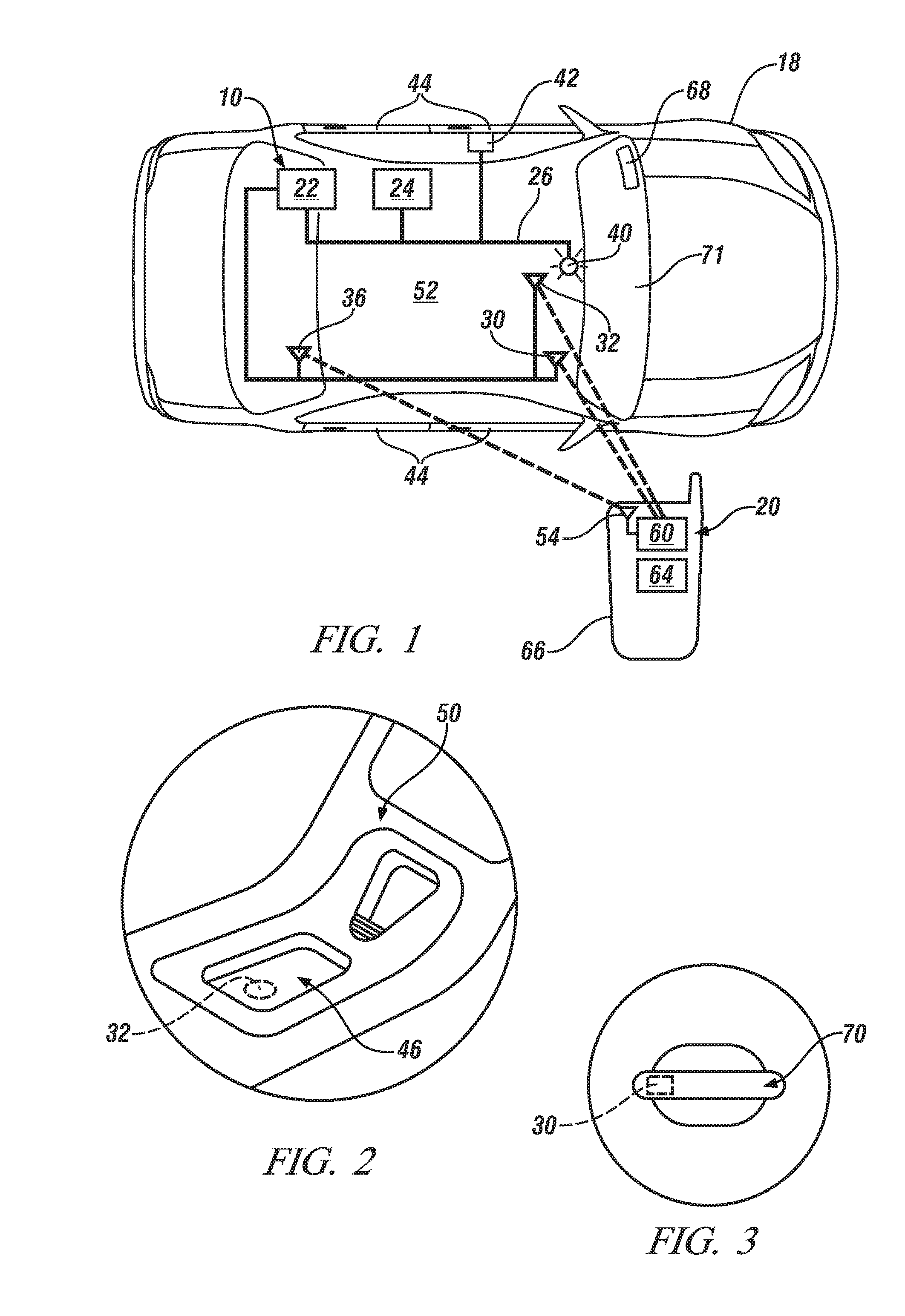

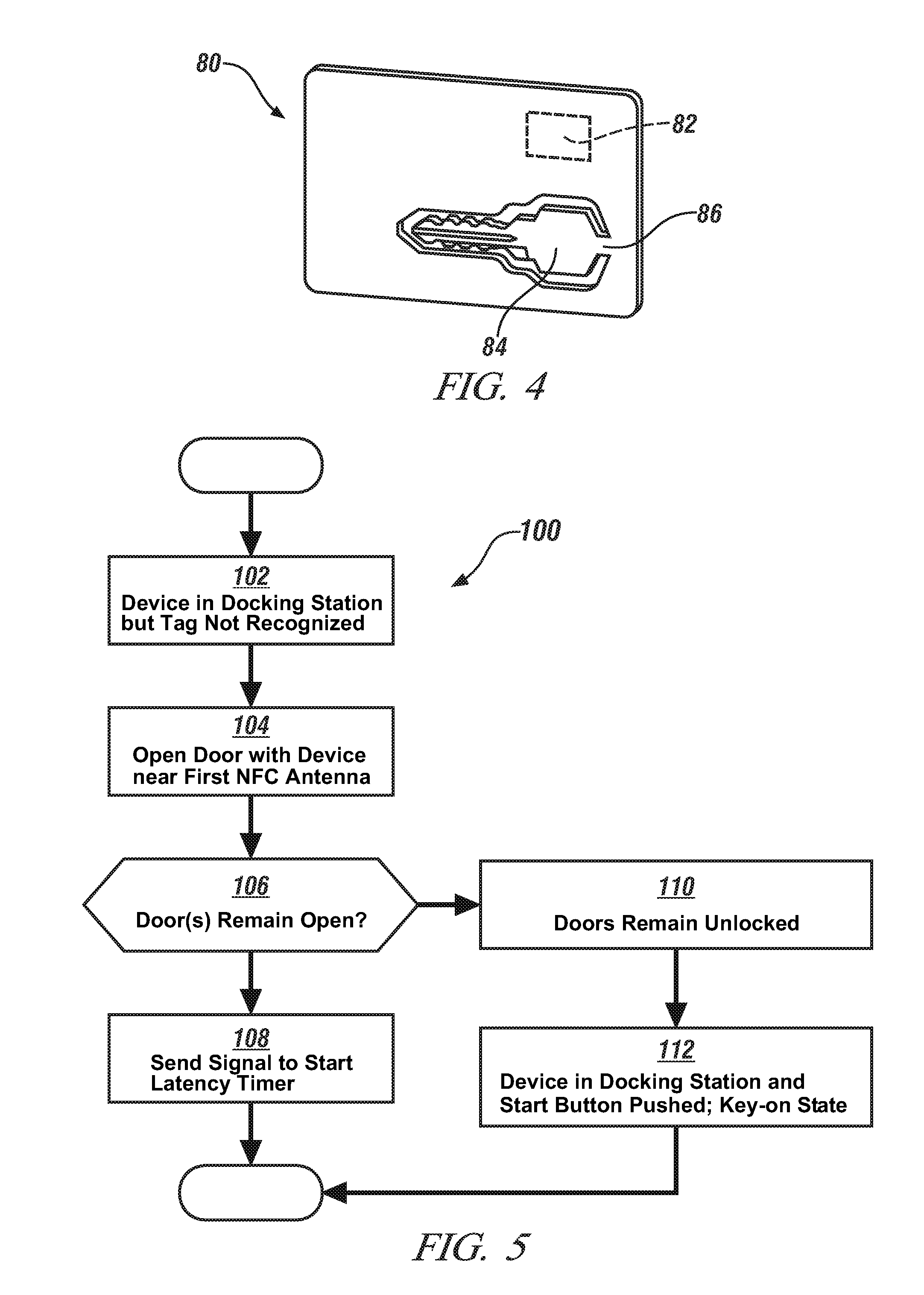

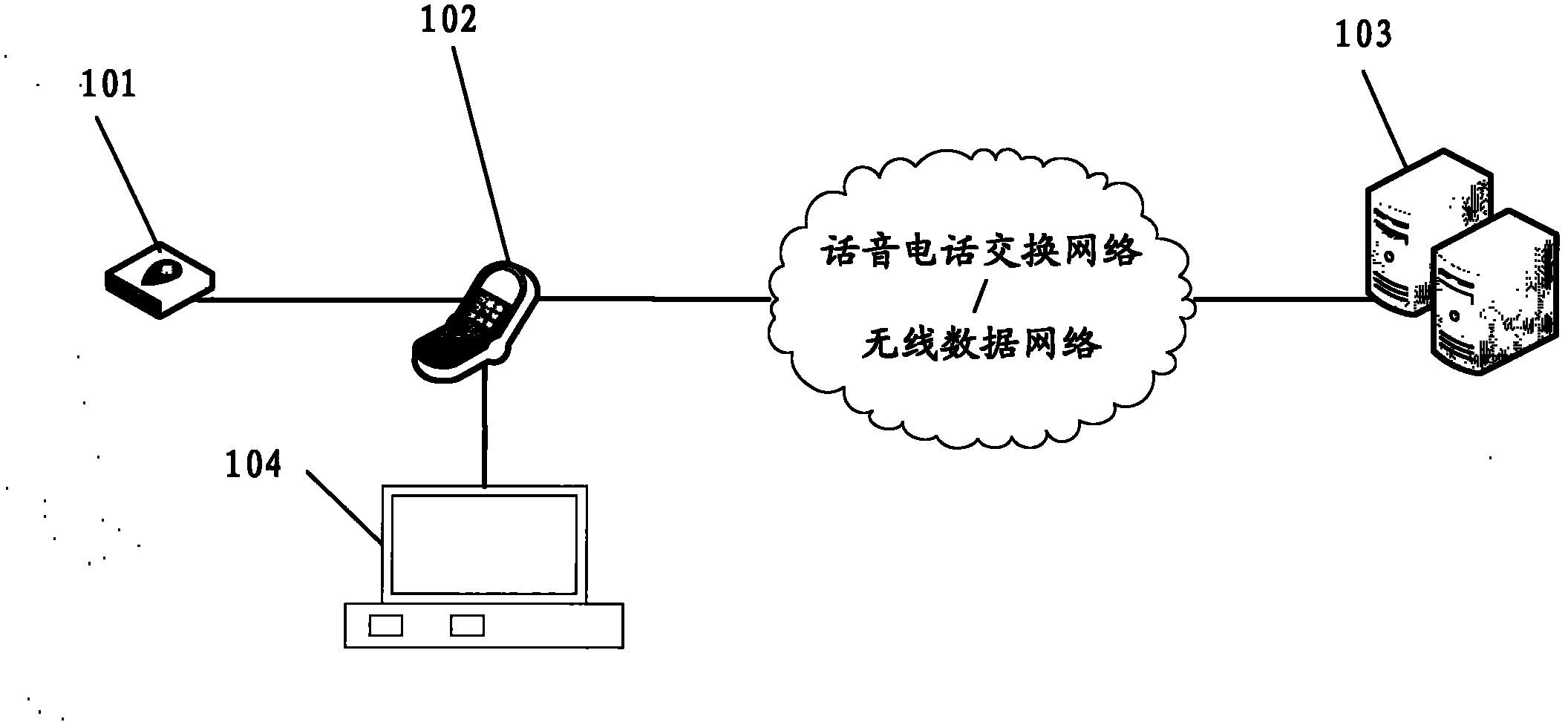

System for passive entry and passive start using near field communication

ActiveUS20140058586A1Near-field transmissionDigital data processing detailsComputer moduleControl logic

A system for activating a vehicle to a key-on state by detecting a presence of a near field communication (“NFC”) tag is provided. The system includes a vehicle bus, a start button in communication with the vehicle bus, an NFC antenna, and a control module. The NFC antenna is positioned to selectively couple with the NFC tag if the NFC tag is within a predetermined distance from the NFC antenna. The control module is in communication with the NFC antenna and the start button. The control module includes control logic for determining if the determining if the NFC antenna is coupled with the NFC tag. The control module includes control logic for determining if the start button has received the input to activate the vehicle to the key-on state. The control module includes control logic for sending a signal through the vehicle bus to activate the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

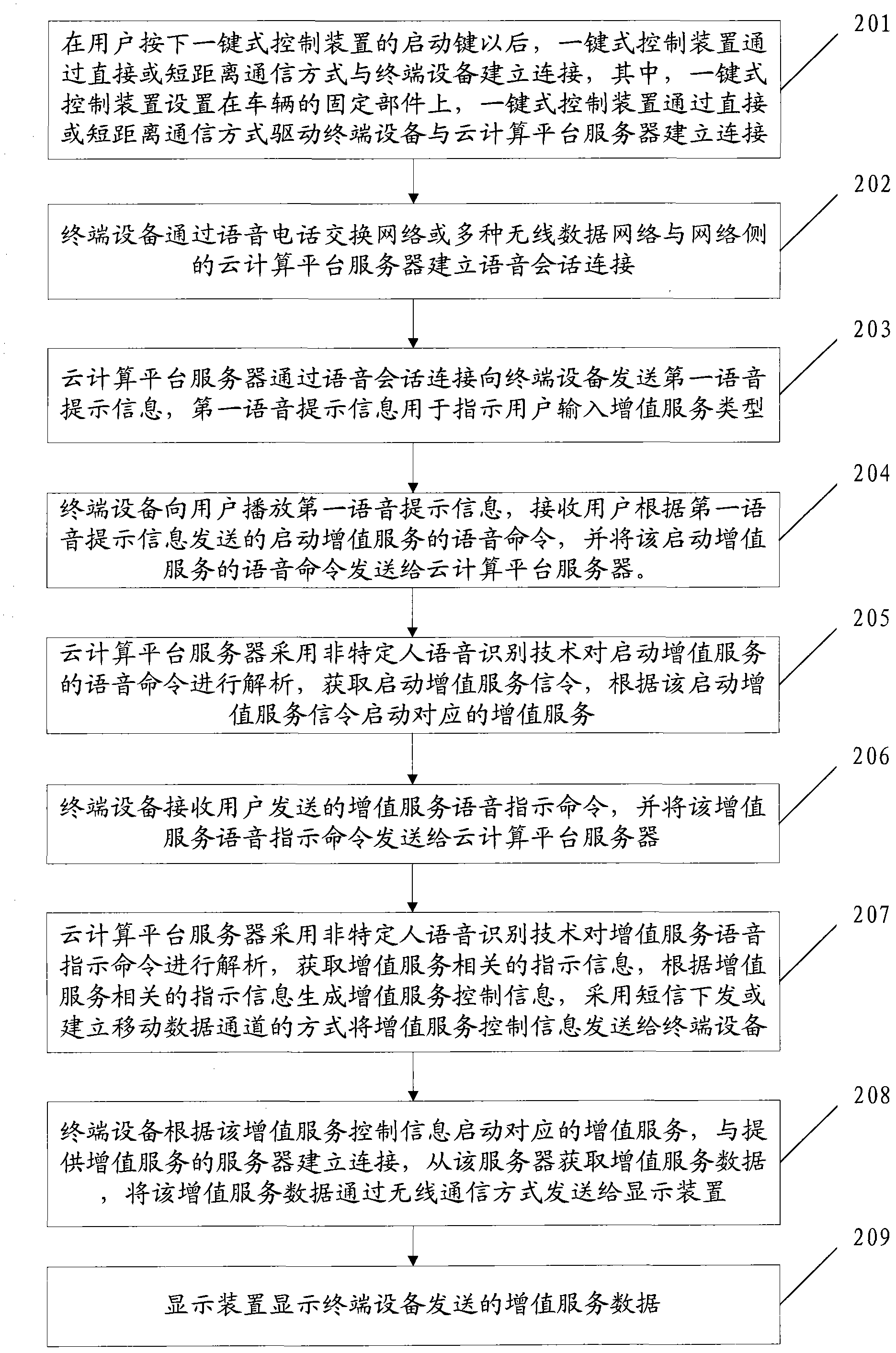

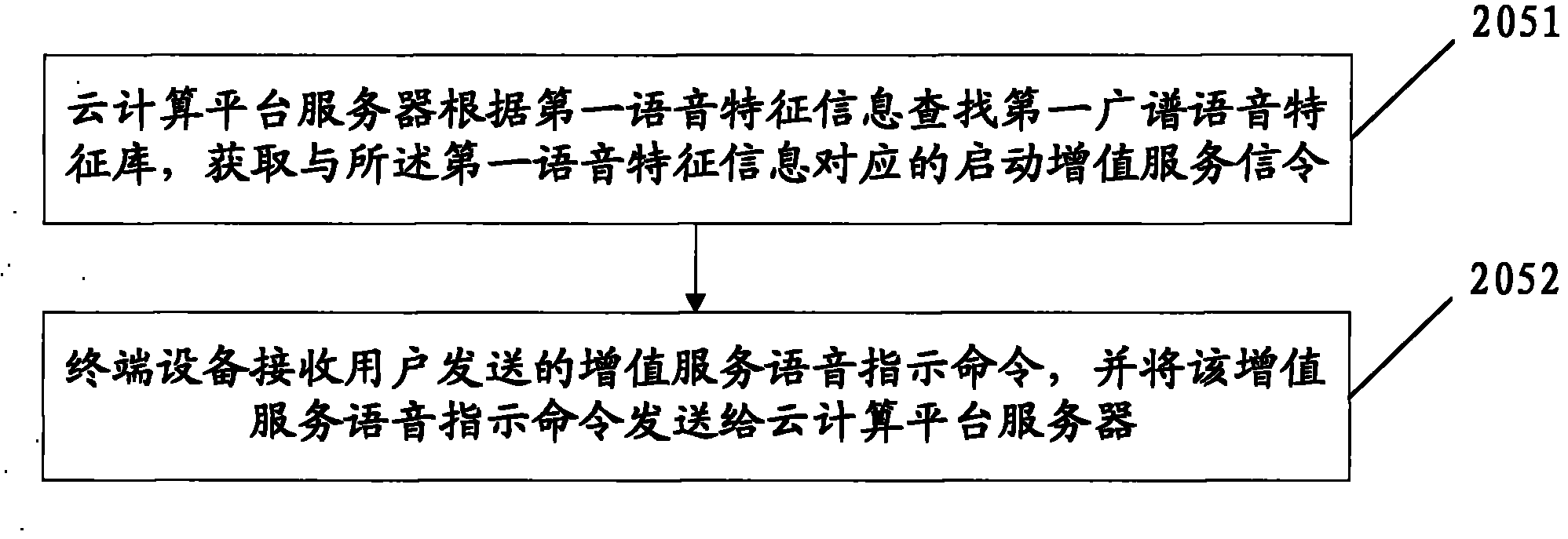

Vehicle-mounted service system and method based on voice command control

ActiveCN102006373AEasy to operateImprove experienceTelephonic communicationMessaging/mailboxes/announcementsDisplay deviceTerminal equipment

The embodiment of the invention discloses a vehicle-mounted service system and method based on voice command control, relating to a vehicle-mounted service technique, which is characterized in that a user is only required to press the start button of a one-button type control device arranged on the fixed device of a vehicle, so that terminal equipment and a cloud computing platform server on the network side are connected through the one-button type control device; the gain service is obtained through a voice control mode; the gain service data is transmitted to a display device for display; and the purposes of simplifying the operation steps of the vehicle-mounted service for the user and enhancing the user experience of the vehicle-mounted service are realized. The technical scheme provided by the embodiment of the invention can be applied to the vehicles such as cars and the like.

Owner:成都车音智能科技有限公司

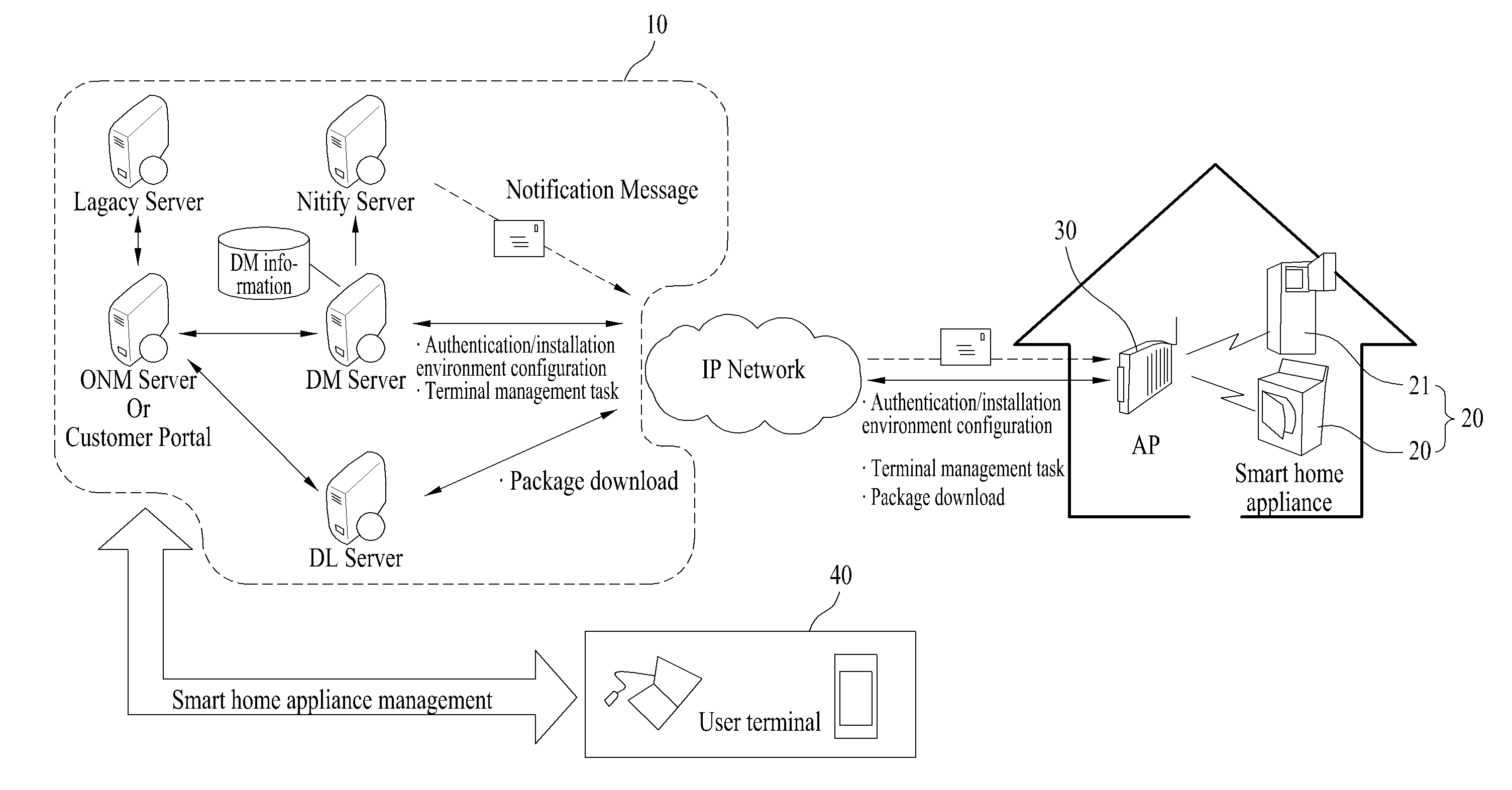

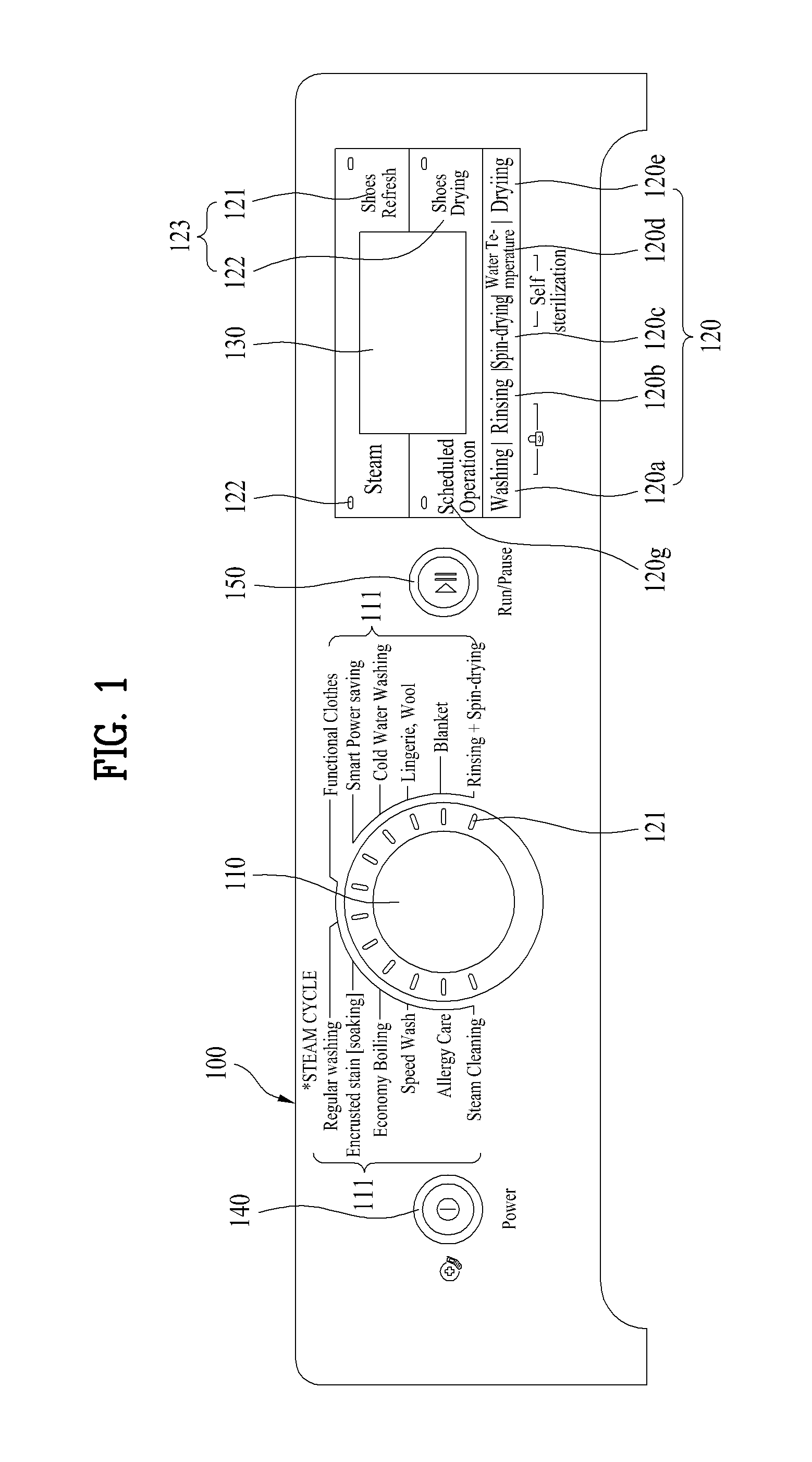

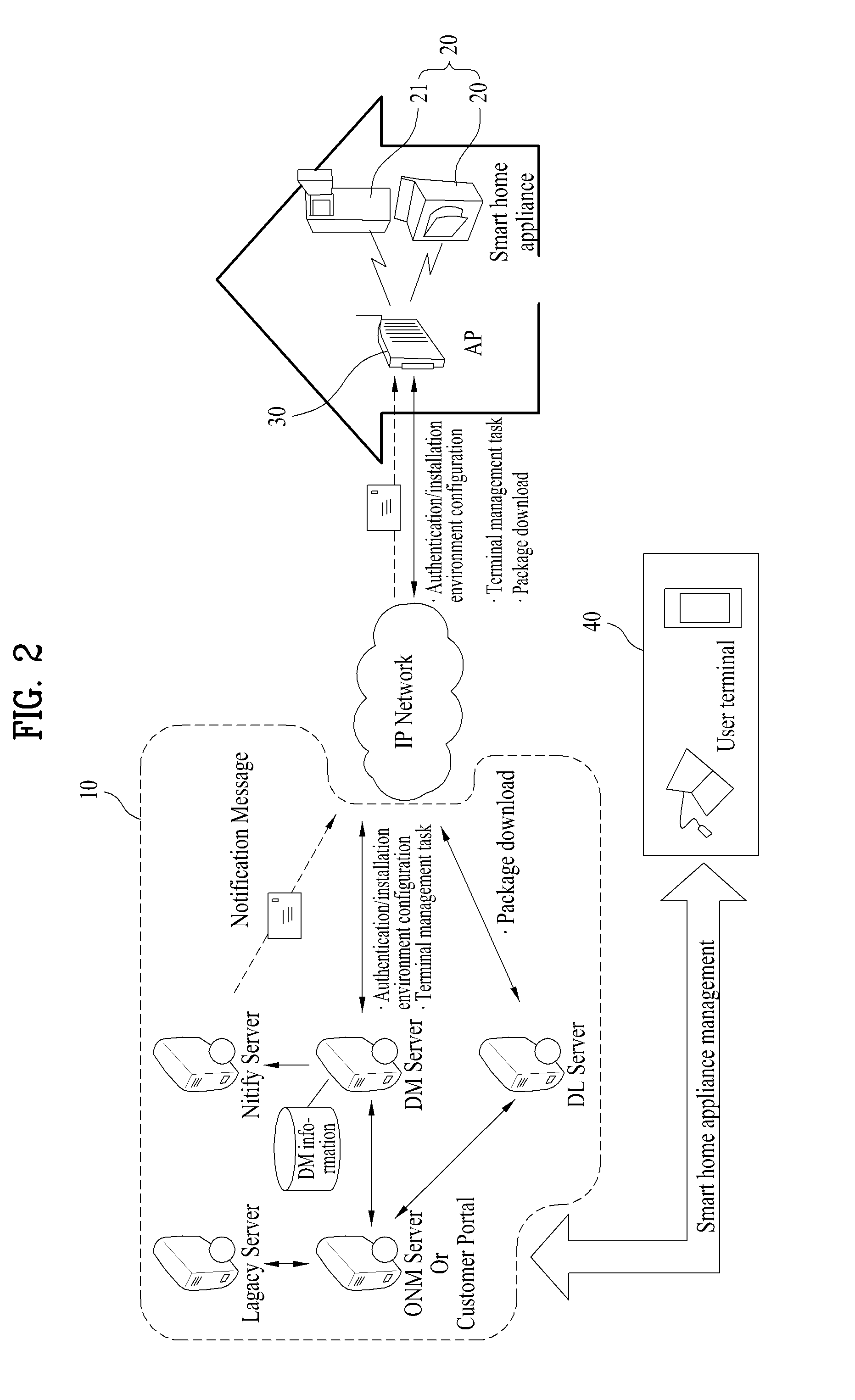

Home appliance and online system including the same

ActiveUS20140067131A1Facilitate communicationEasy to useSampled-variable control systemsWashing controlling processesRemote controlEngineering

An online system, including a smart laundry machine, which is capable of easily and inexpensively using the smart laundry machine is disclosed. A further extended type of a smart home appliance, an online system including the same, and a method of using the online system are also disclosed. A laundry machine communicates with a server, is remotely controlled by an external terminal through the server, and has a control panel for a user interface. The control panel includes a course selection unit, an option selection unit, a start button, a display unit to display state information of the laundry machine, and a remote service activation input unit to set or cancel remote service activation according to user selection. The remote control is performed only in a case in which the remote service activation is set.

Owner:LG ELECTRONICS INC

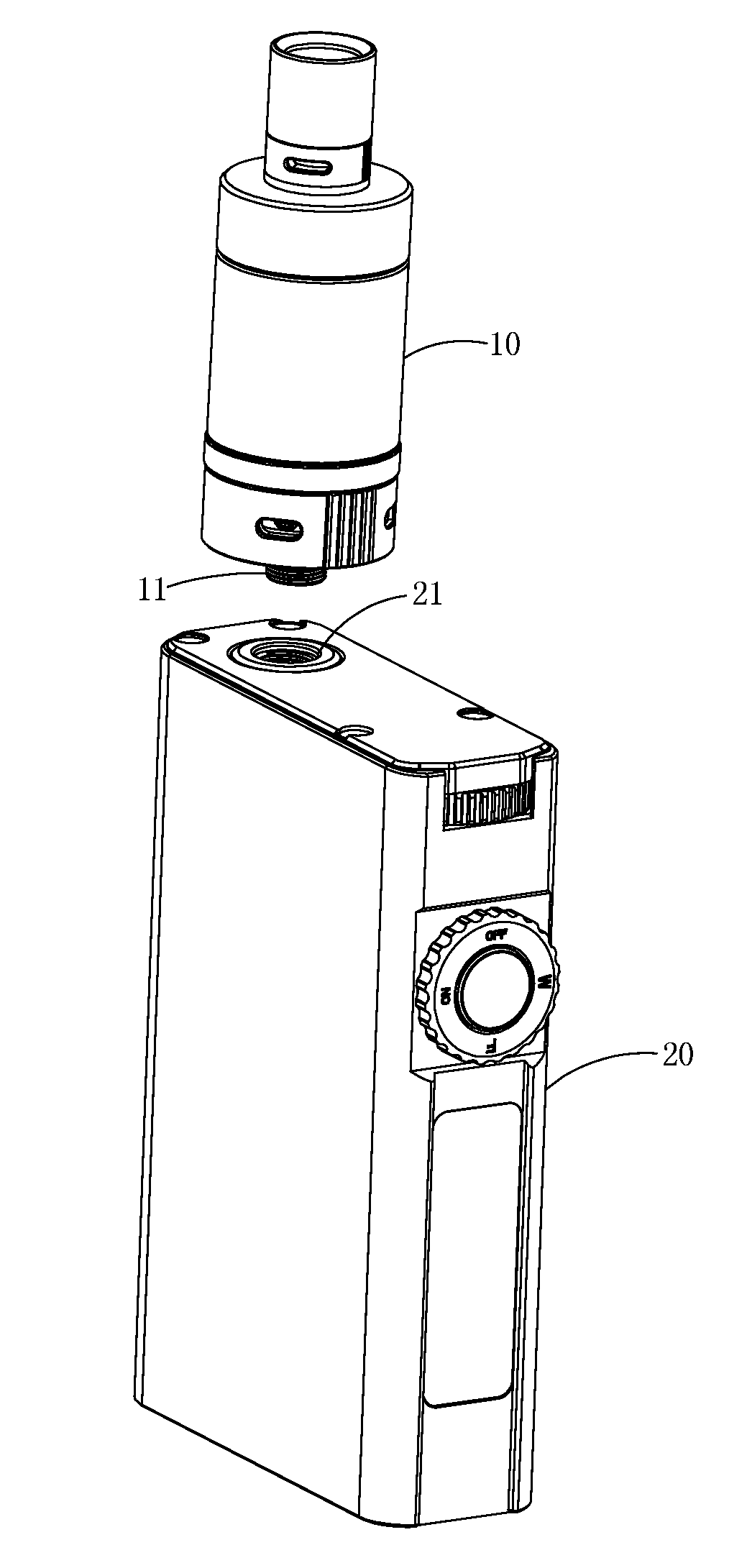

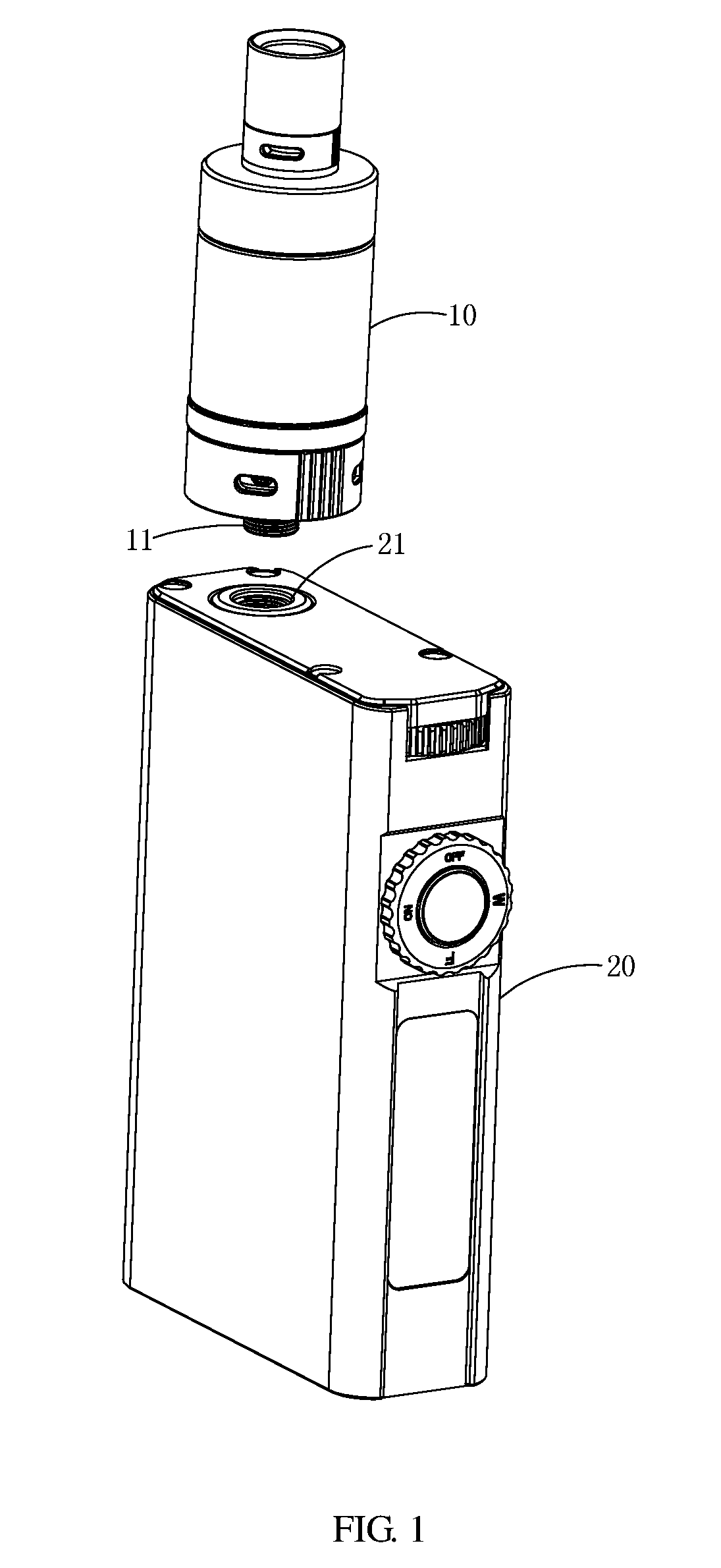

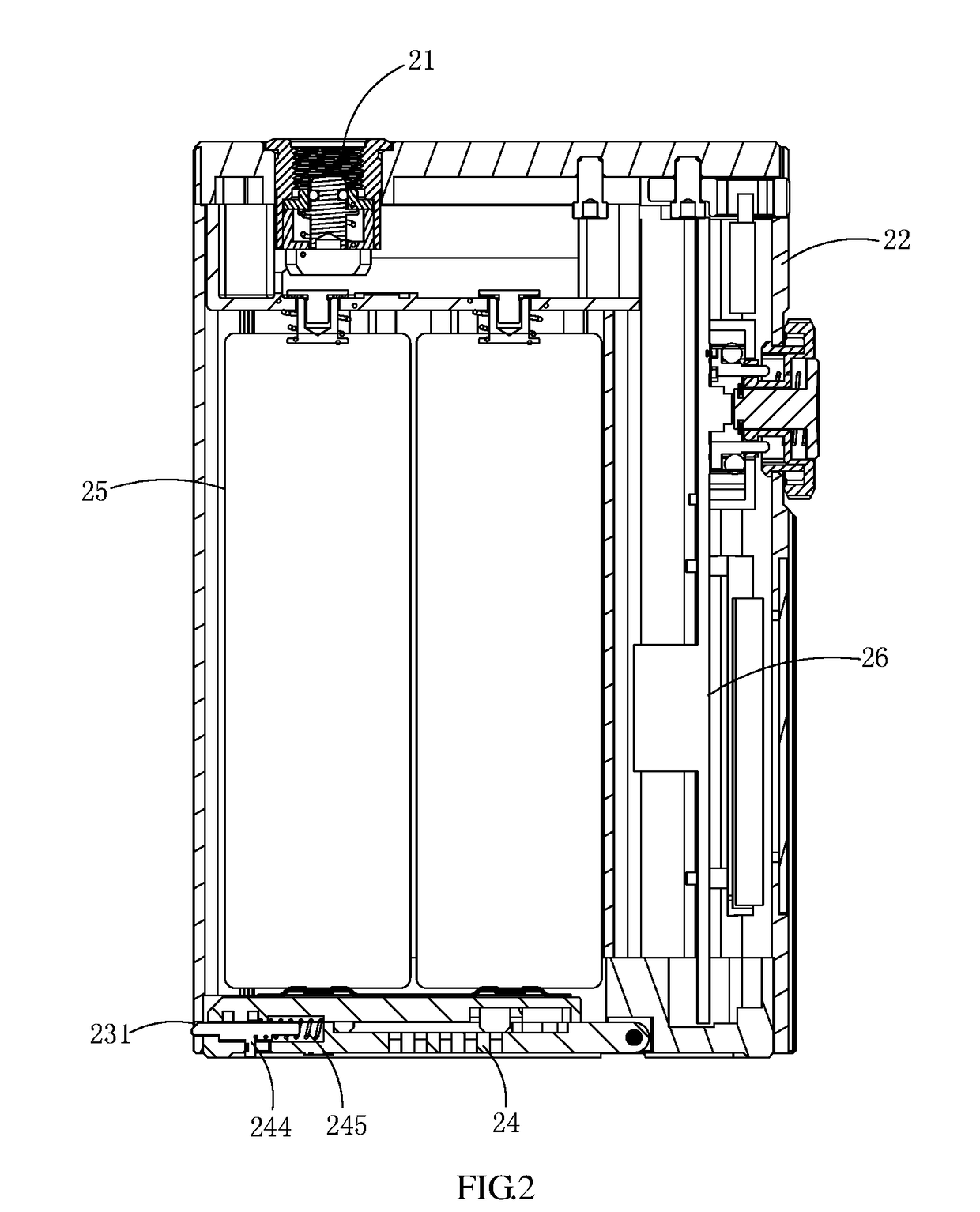

Power supply device for electronic atomizer

InactiveUS20170079327A1Improve technical effectImprove operational convenienceElectric heatingTobacco devicesMicrocontrollerElectricity

Disclosed is a power supply device for electronic atomizer, which includes a housing having a battery compartment formed therein, at least a battery installed in the battery compartment and a control circuit having an input side electrically connected with the battery and an output side electrically connected with an output electrode terminal. The control circuit includes a microcontroller unit, a mode selection module connected with the microcontroller unit for selecting working mode of the electronic atomizer, a regulation module connected with the microcontroller unit for regulating working parameter of the electronic atomizer and a start button connected with the microcontroller unit for controlling whether the electronic atomizer starts up. The mode selection module is a multi-position switch and the microcontroller unit is able to being triggered to start corresponding working modes by switching the multi-position switch to be different positions. The present invention has the advantage of convenient to use.

Owner:SHENZHEN JIESHIBO TECH

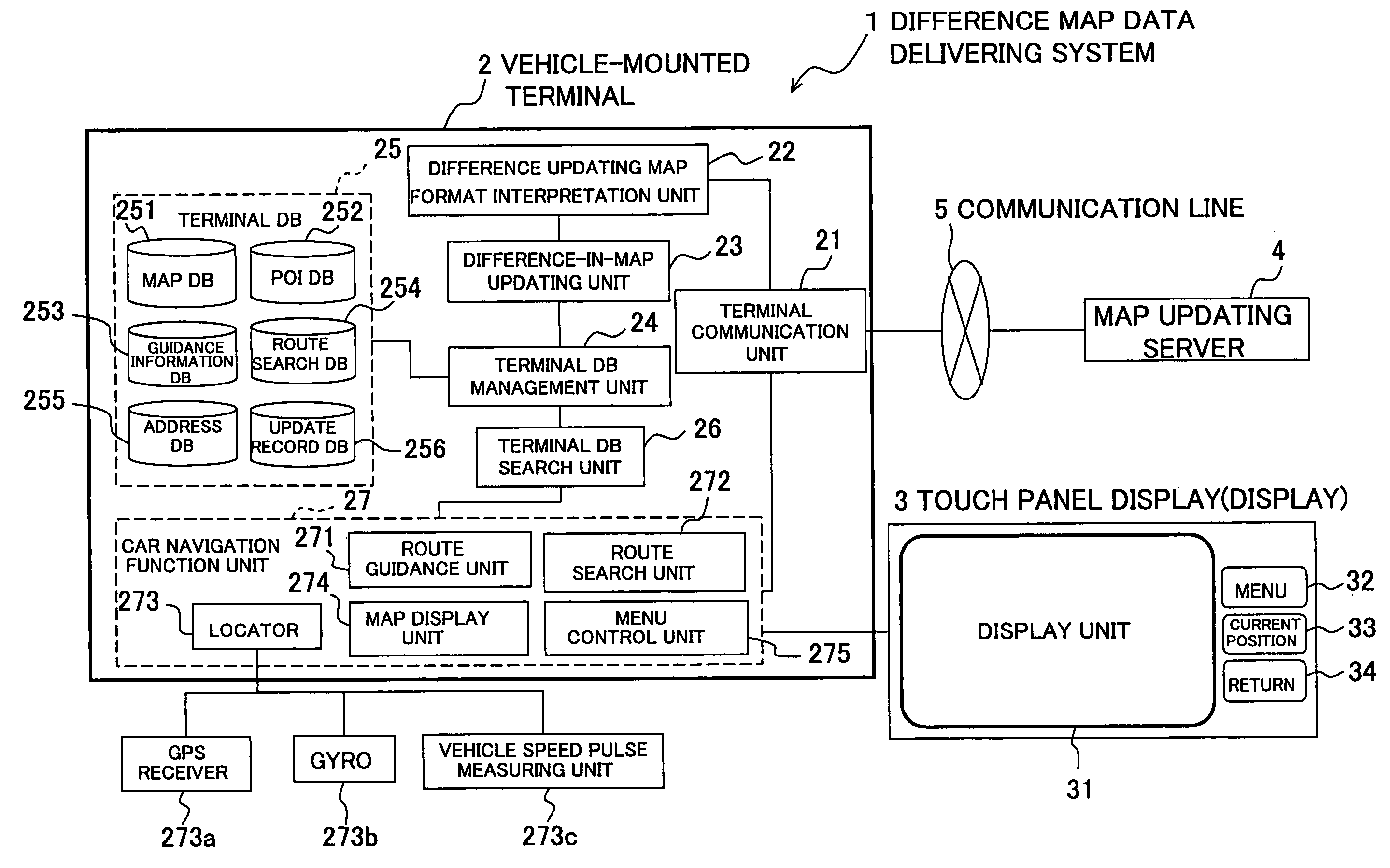

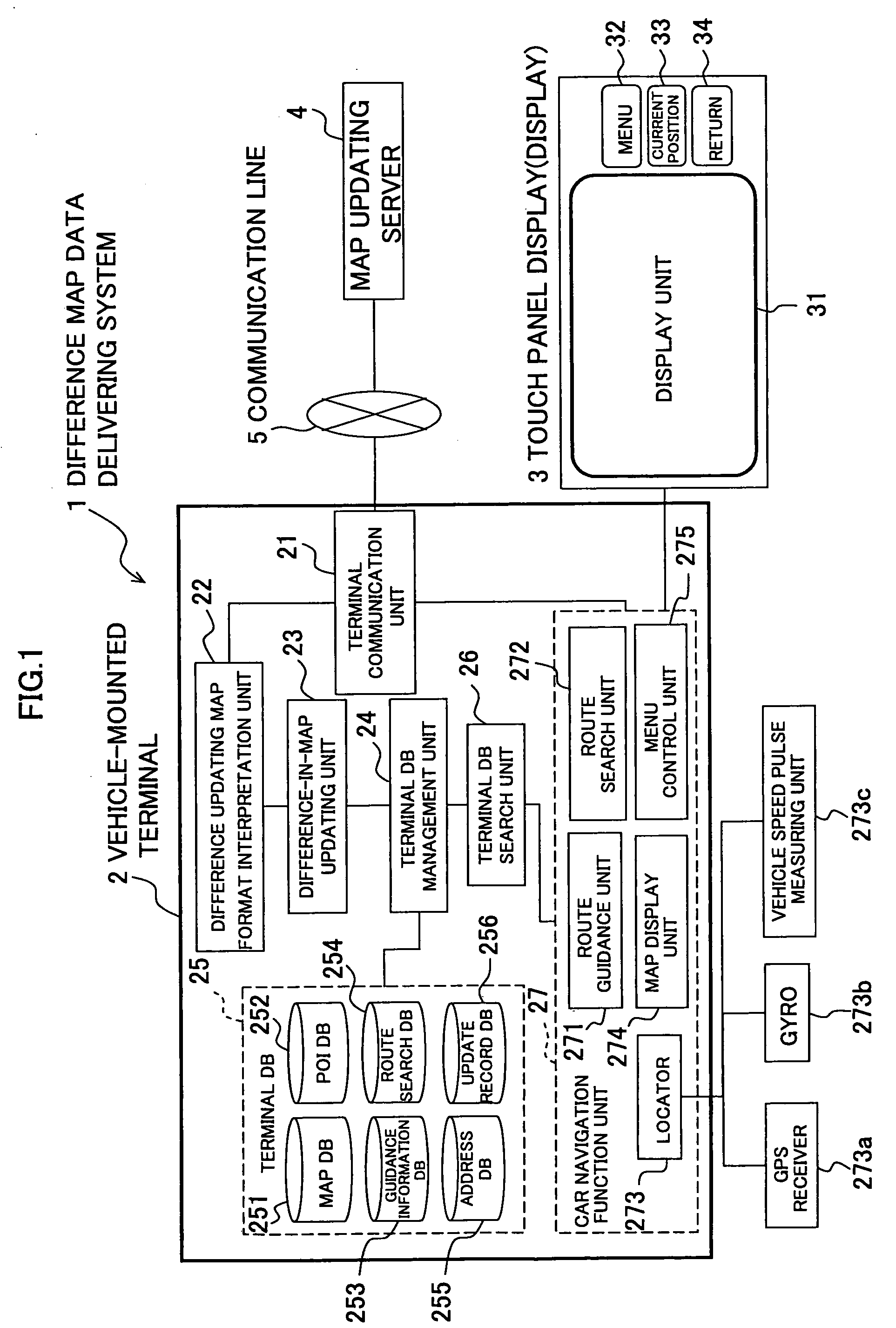

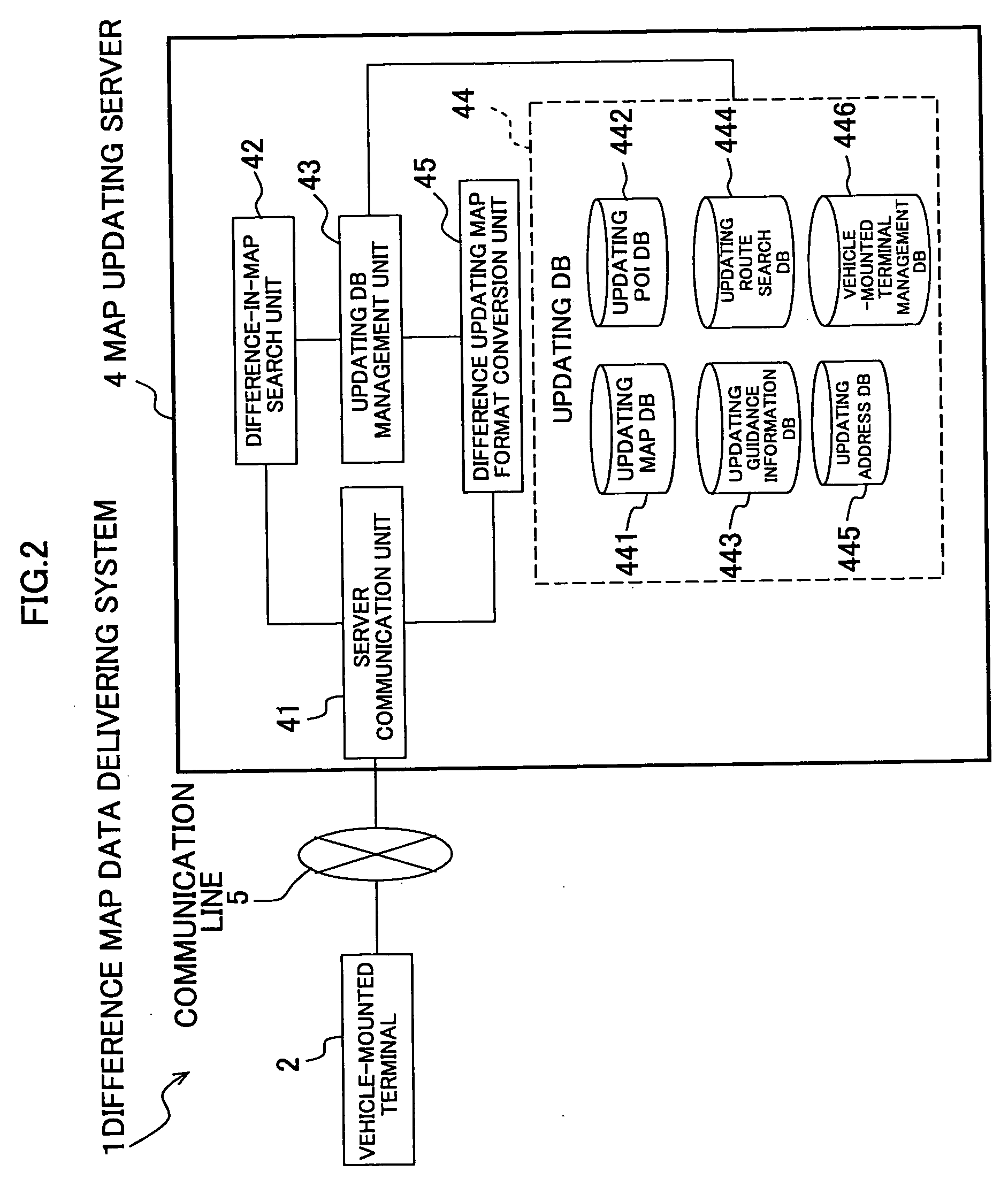

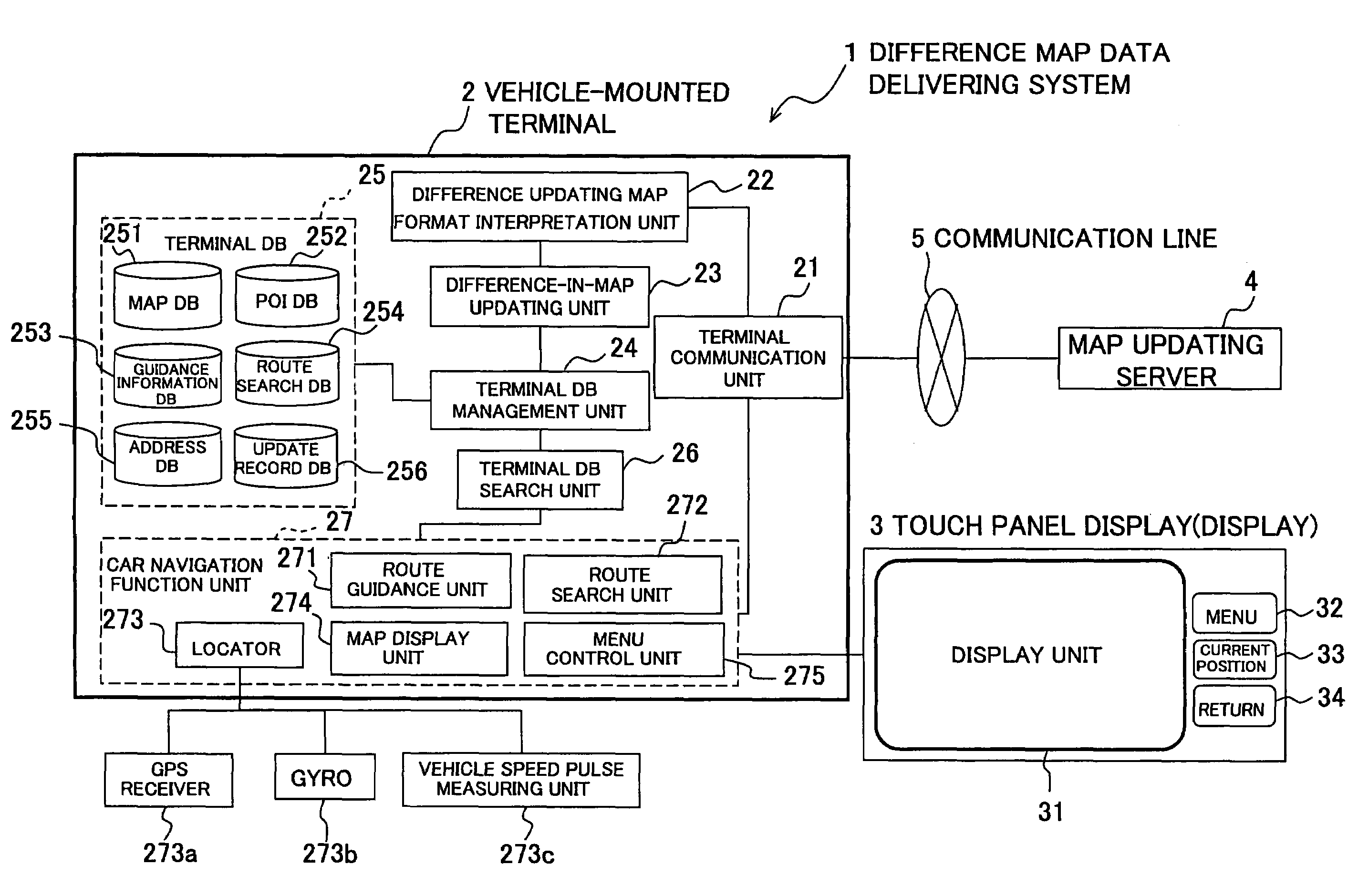

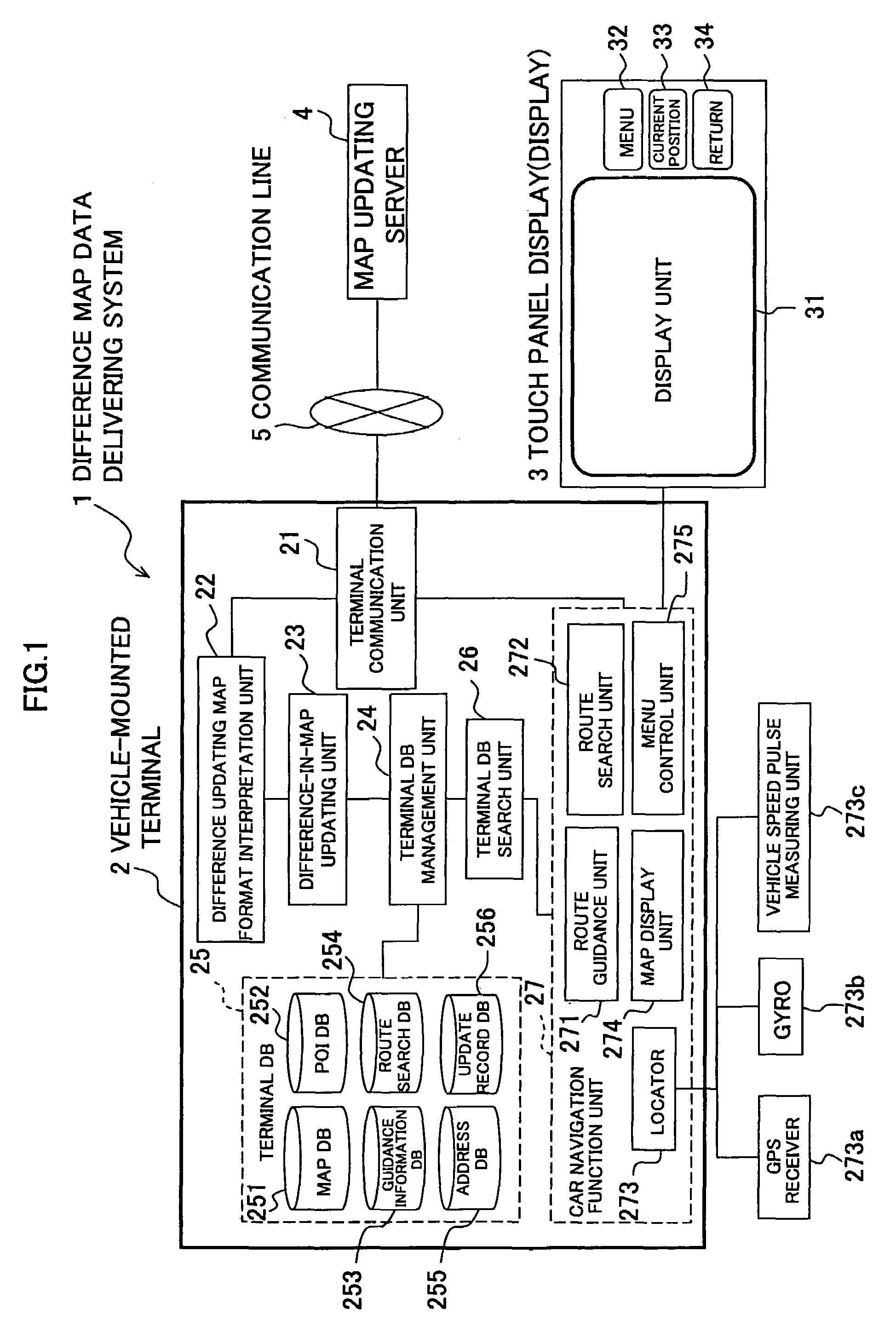

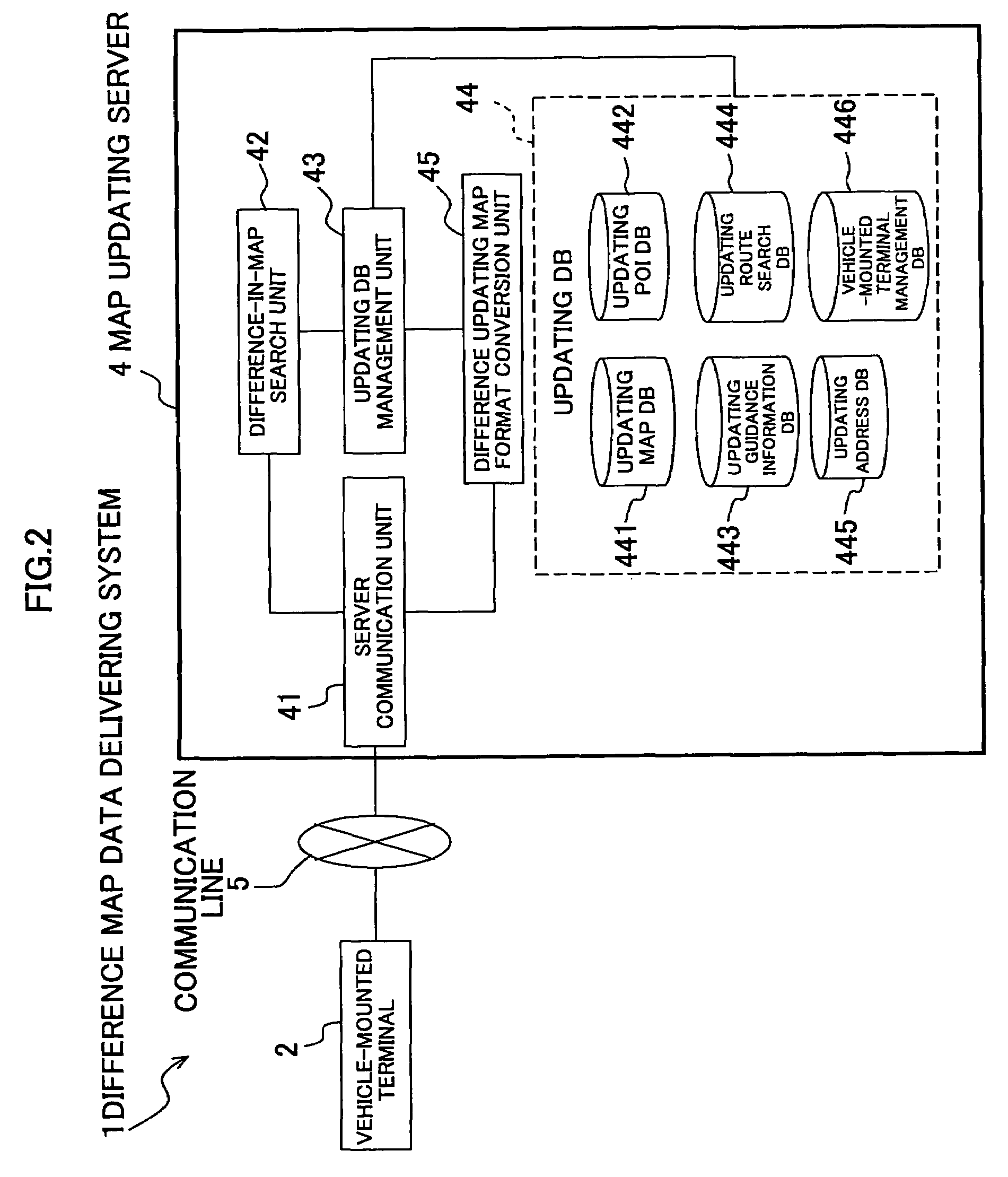

Method of delivering difference map data

ActiveUS20060095202A1Low costShorten the timeInstruments for road network navigationRoad vehicles traffic controlDisplay deviceData storing

The present invention provides, in a car navigation system, a unit of notifying a user of the update contents of map data prior to the downloading of the map data. A vehicle-mounted terminal sets a difference update area in accordance with a selection made by a user and sends a difference update request to a map updating server. If an update mode in this case is “update after outline display”, the vehicle-mounted terminal downloads an outline update map from the map updating server. The outline update map is displayed on a display unit of a display. Here, when a download start button displayed on the display unit is depressed, the vehicle-mounted terminal downloads a detailed update map from the map updating server. The detailed update map is then displayed on the display unit of the display. Furthermore, an updating process is performed on the map data stored in a terminal DB.

Owner:HITACHI LTD

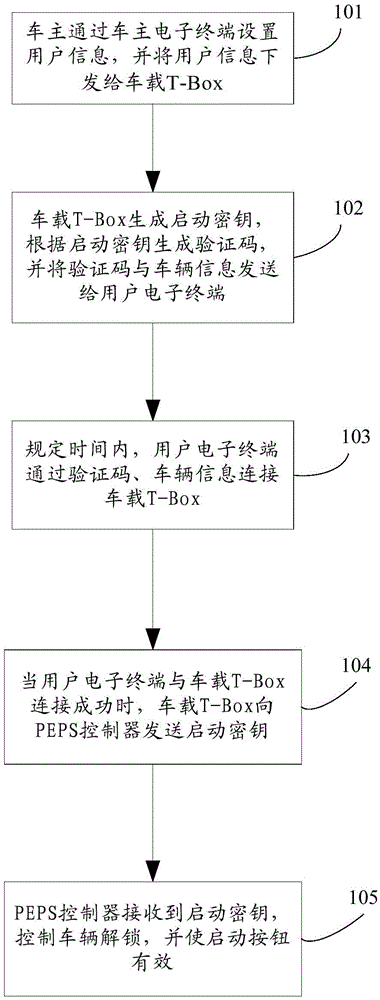

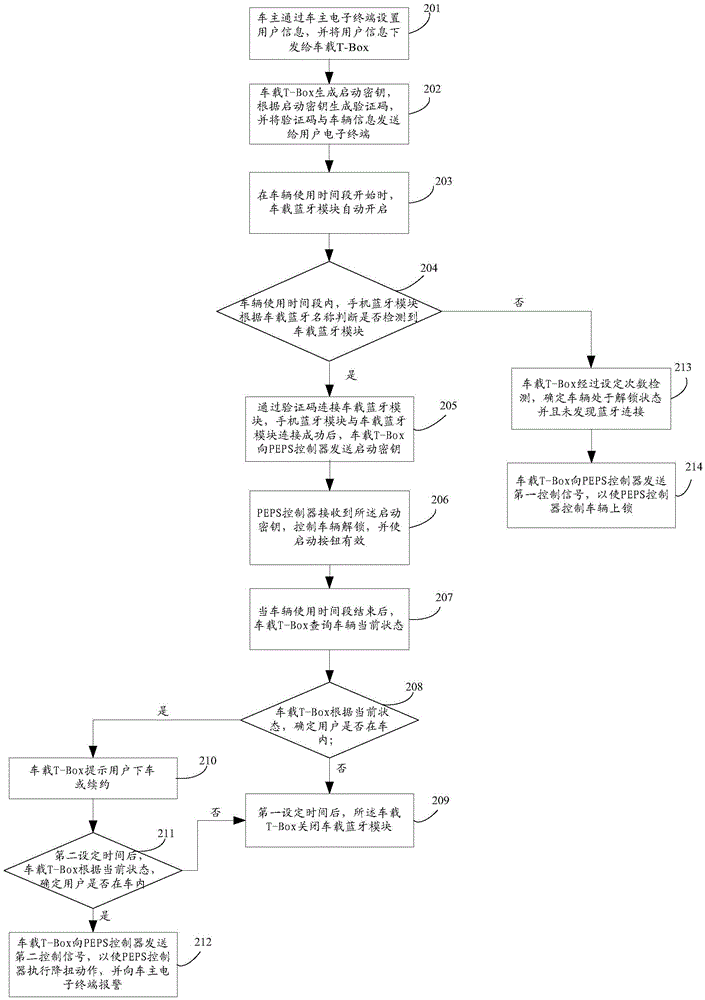

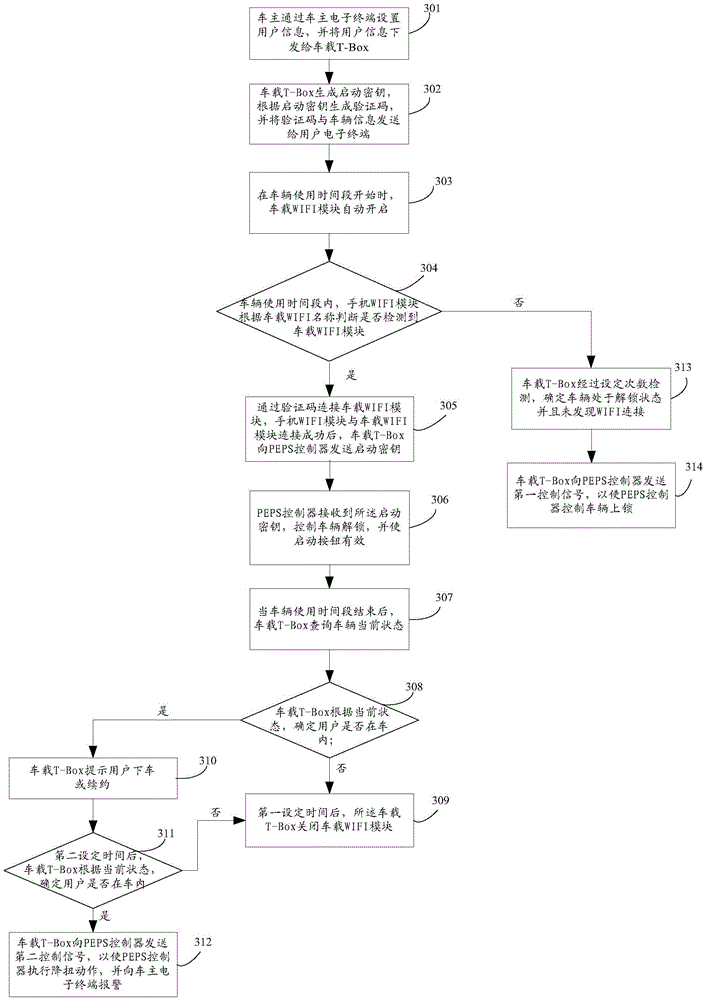

Automobile intelligent key control method and system thereof

ActiveCN105539365AImprove securityImprove convenienceAnti-theft devicesComputer terminalStart button

The invention relates to the technical field of automobile intelligent key control, in particular to an automobile intelligent key control method and a system thereof. The method comprises the steps that an automobile owner sets user information through an owner electronic terminal and sends the user information to a vehicle-mounted T-Box; the vehicle-mounted T-Box communicates with a passive entry & passive start (PEPS) controller according to the set information, generates a startup key, generates a verification code according to the startup key, and sends the verification code and vehicle information to the user electronic terminal; the user electronic terminal is connected with the vehicle-mounted T-Box through the verification code and the vehicle information within the prescribed time; and when the user electronic terminal is successfully connected with the vehicle-mounted T-Box, the vehicle-mounted T-Box sends the startup key to the PEPS controller, so that the PEPS controller controls an automobile to be unlocked, and a start button comes into effect. By the adoption of the automobile intelligent key control method and the system thereof, the using safety and reliability of the automobile intelligent key can be achieved when the automobile is let out.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

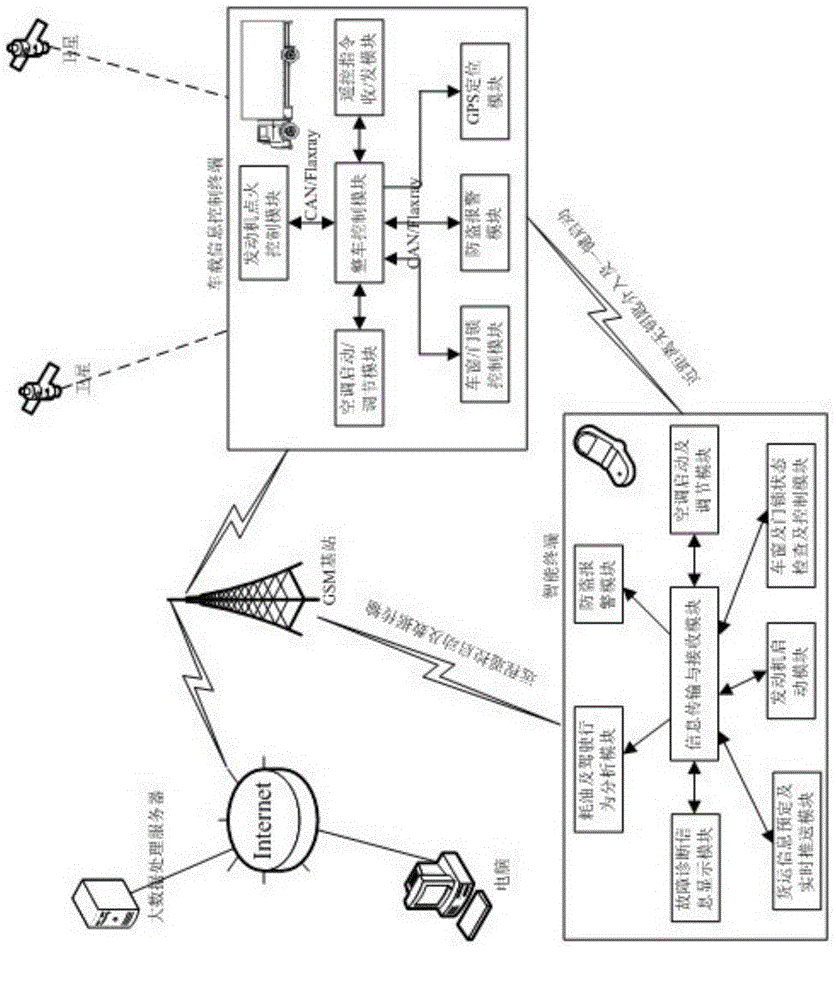

Vehicle interconnected control and data service system based on intelligent terminal

InactiveCN105897809AImprove quick startImprove comfortTransmissionInformation controlData information

The invention provides a vehicle interconnected control and data service system based on an intelligent terminal. A vehicle-borne information control terminal is installed on a vehicle and receives control instruction information of engine start, air conditioner start and temperature regulation sent by the intelligent terminal. At the same time, the vehicle-borne information control terminal sends the state of the vehicle, fault diagnosis and large data information to the intelligent terminal. When the intelligent terminal approaches the vehicle, the vehicle-borne information control terminal starts to search the intelligent terminal in a range and sends corresponding matching information, once the matching is successful, a vehicle door is automatically opened, and entry without a key is realized. If the intelligent terminal is in the cab of the vehicle and the vehicle-borne information control terminal detects that the intelligent terminal is in the cab and a start button is pressed, a controller carries out identity verification of the intelligent terminal, once the verification is successful, the vehicle starts to start, and the one-button start is realized. The intelligent terminal also comprises the functions of vehicle remote positioning, remote viewing of vehicle window and door lock states, anti-theft alarm, vehicle locking and the like.

Owner:SHAANXI AUTOMOBILE GROUP

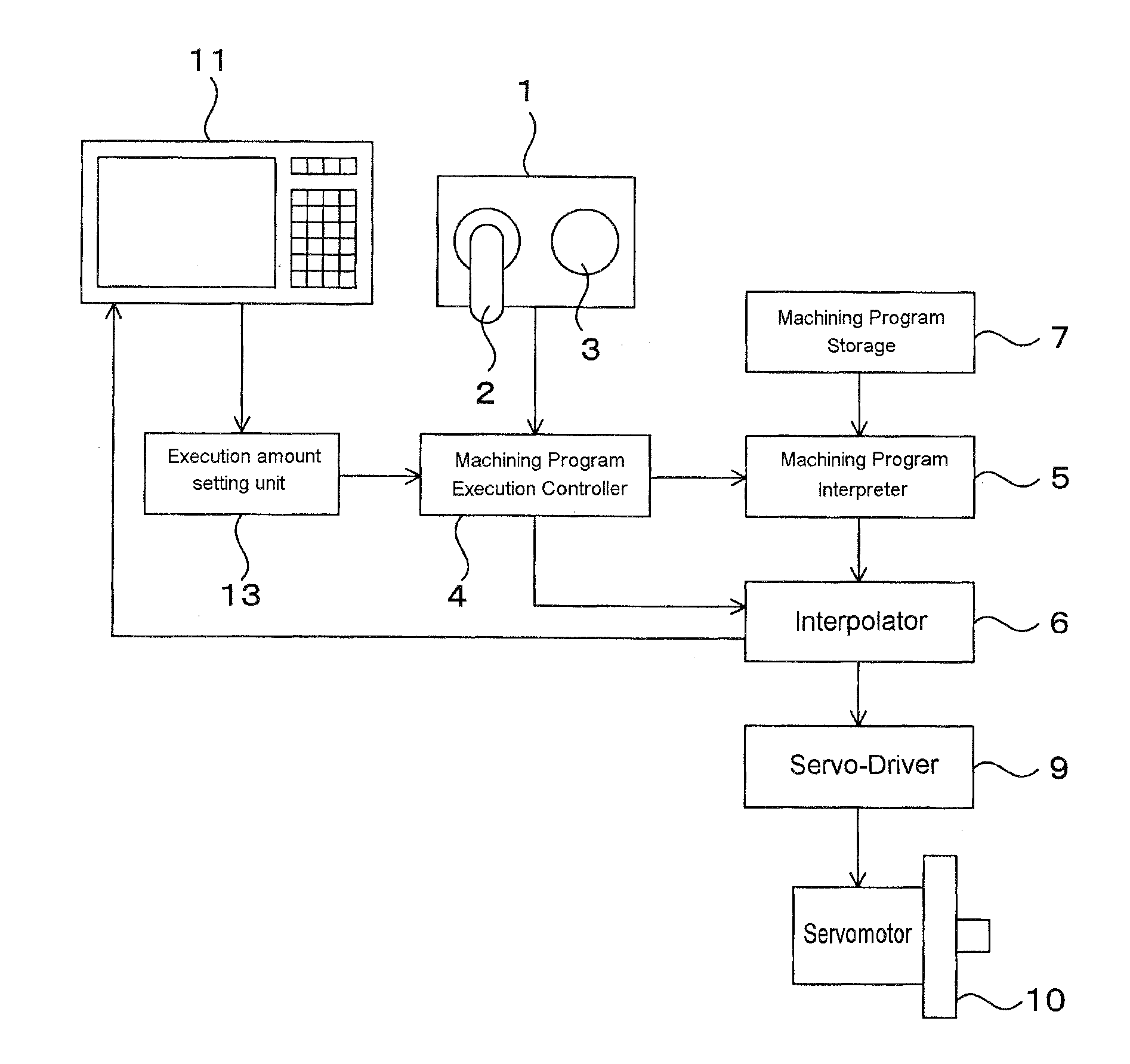

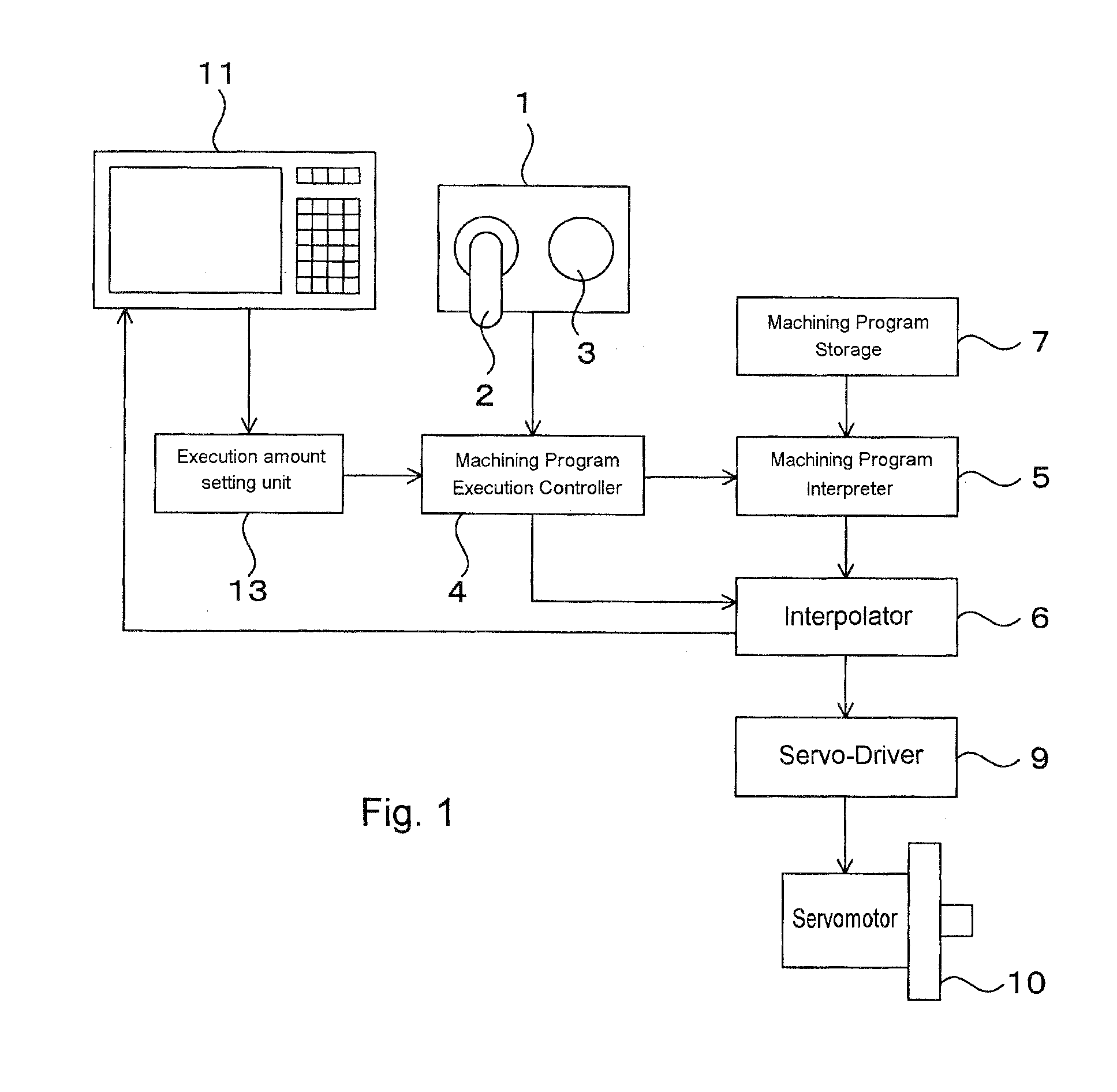

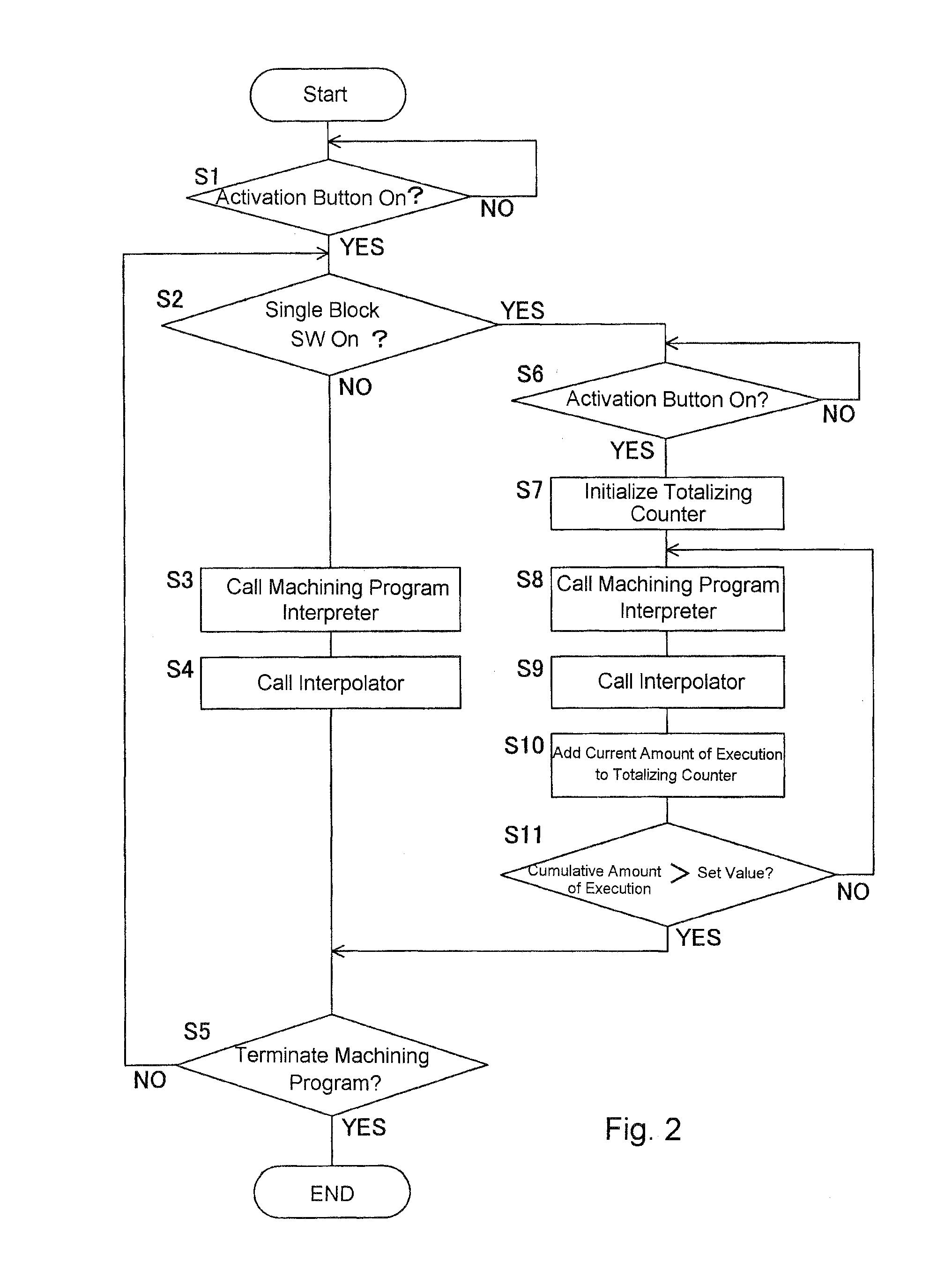

Numerical control unit

InactiveUS20080249653A1Simple and efficient verificationReduce in quantityProgramme controlComputer controlNumerical controlOperating system

A numerical control apparatus with a single block function is provided including a start button (3), an execution amount setting unit (13), and a machining program execution controller (4). Once the amount of execution of the machining program to be executed by a single operation is set in the execution amount setting unit, the machining program execution controller (4) batch executes the blocks included in the set amount of execution upon a single operation, such as a depression, of the start button (3). Additionally, upon detecting a block including a non-cutting command or a command for abruptly changing a machining direction, the machining program execution controller (4) suspends the execution of the machining program as of that block and waits for the start button (3) to be depressed again.

Owner:OKUMA CORP

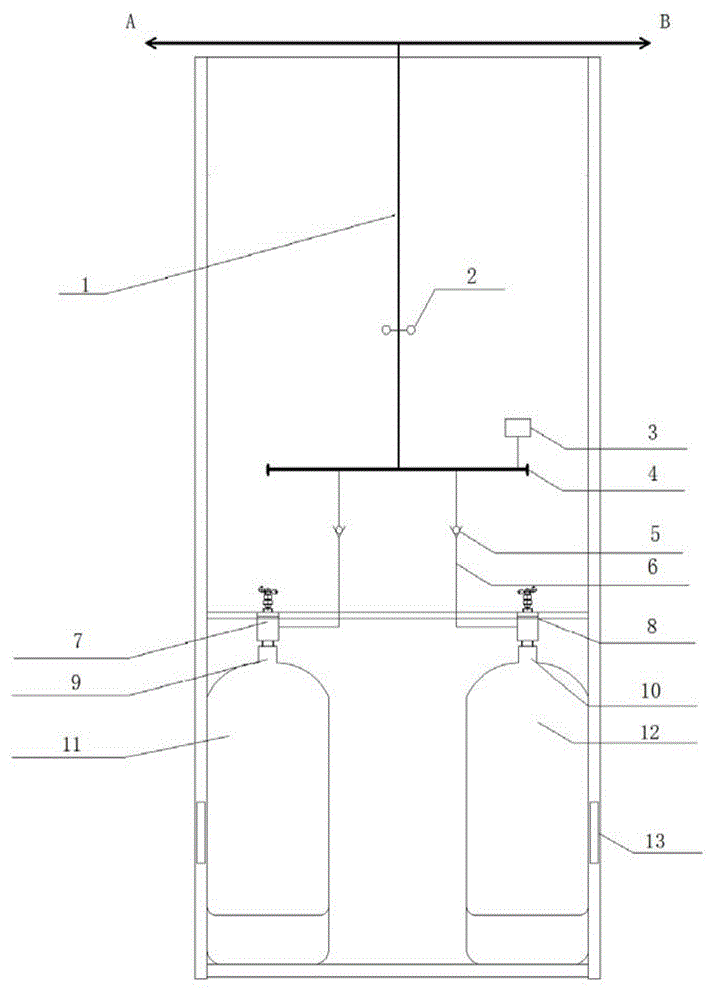

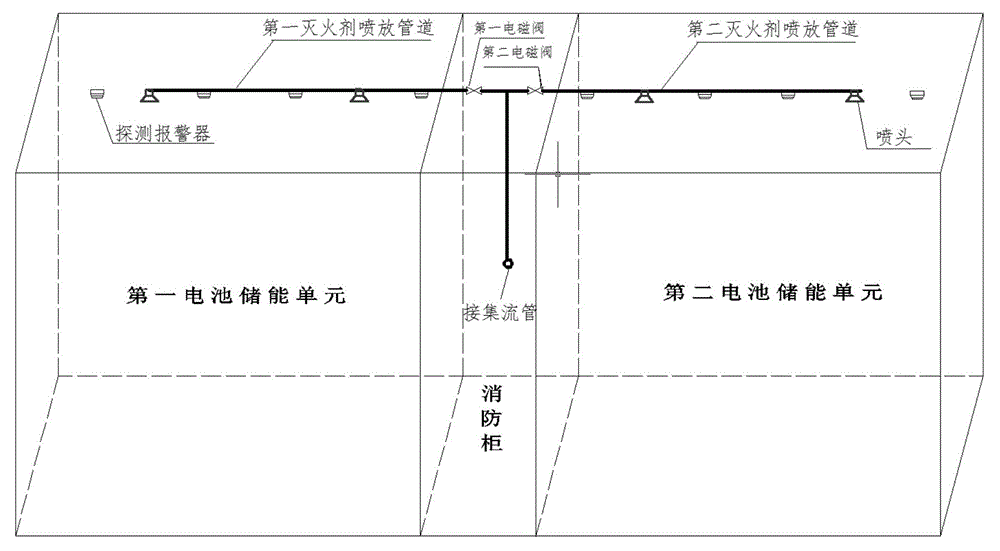

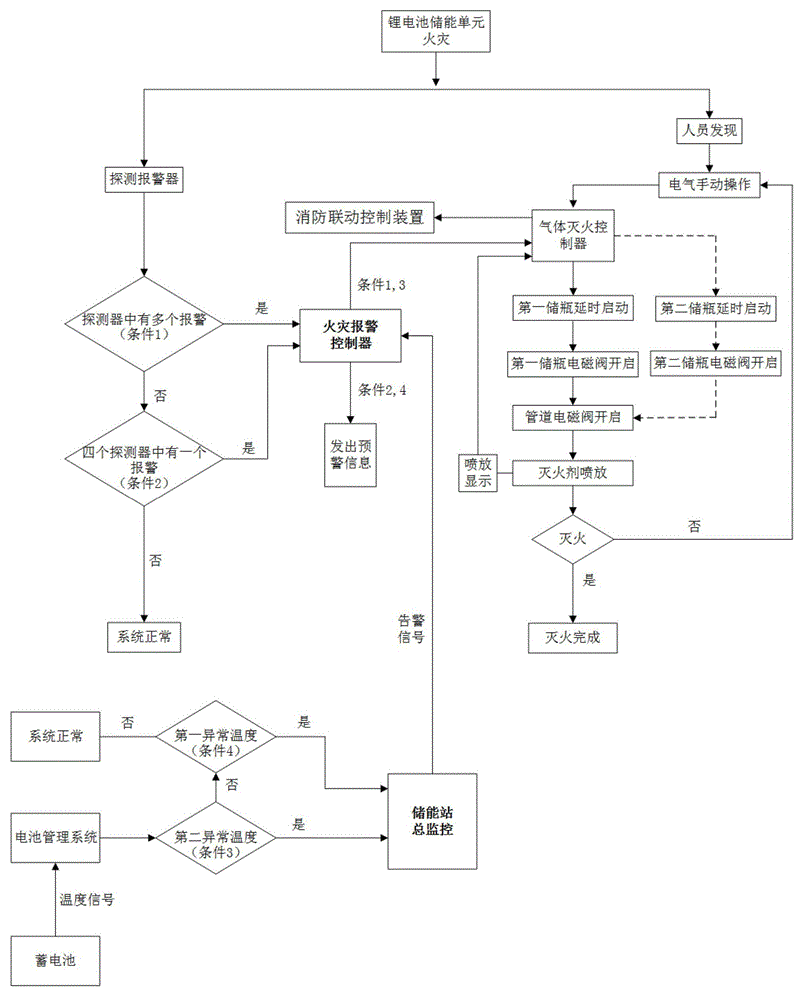

Fire extinguishing system for energy storage units of lithium batteries

ActiveCN103977516AAchieve fire protectionImplement manual operationFire rescueSystems designEngineering

The invention relates to a fire extinguishing system for energy storage units of lithium batteries. The fire extinguishing system mainly comprises an automatic fire alarm system, a gas fire extinguishing system, a fire extinguishing linkage control device, a fire emergent broadcasting and fire extinguishing special telephone device. Fire extinguishing devices of the fire extinguishing system can be automatically or manually started, the automatic starting is triggered mainly by a fire alarm control unit, the fire alarm control unit can receive triggering signals input by a battery management system and a detection alarm, when fire alarm conditions are met, starting signals are output to a gas fire extinguishing controller, and a fire extinguishing device is started to spray a fire extinguishing agent to the energy storage units; when an operator finds fire behavior in a protective zone, a start button outside the protective zone or on the gas fire extinguishing controller can be manually pressed down, and the manual operation of the fire extinguishment system is realized. Specific to multiple fire spraying characteristics of the lithium batteries, the two sets of fire extinguishing devices of the fire extinguishing system share one fire extinguishing cabinet, and the fire extinguishment protection of the two energy storage units of the lithium batteries is realized. The two sets of fire extinguishing devices are independent of each other and spare to each other, and the whole fire extinguishing system has a secondary fire extinguishment function.

Owner:UNIV OF SCI & TECH OF CHINA

Method for detecting defects of cosmetic paper label

PendingCN108548820AAdaptableNo human guard requiredOptically investigating flaws/contaminationSortingChinese charactersRecognition algorithm

The invention provides a method for detecting the defects of a cosmetic paper label. The method judges whether a label is adhered on a correct position or not, whether the Chinese character identification is correct or not, whether the data is printed on a correct position or not, and whether the date identification is correct or not. A Chinese character extraction algorithm and an identificationalgorithm for different color information of a cosmetic label are designed. A pretreatment algorithm and a high precision identification algorithm for machine printed characters on a cosmetic label are designed. The algorithms are stable, thus the maintenance of the system is convenient, in production, the related control parameters are adjusted, then a start button is pressed down, and then the detection is automatically carried out without artificial monitoring.

Owner:ZHEJIANG SCI-TECH UNIV

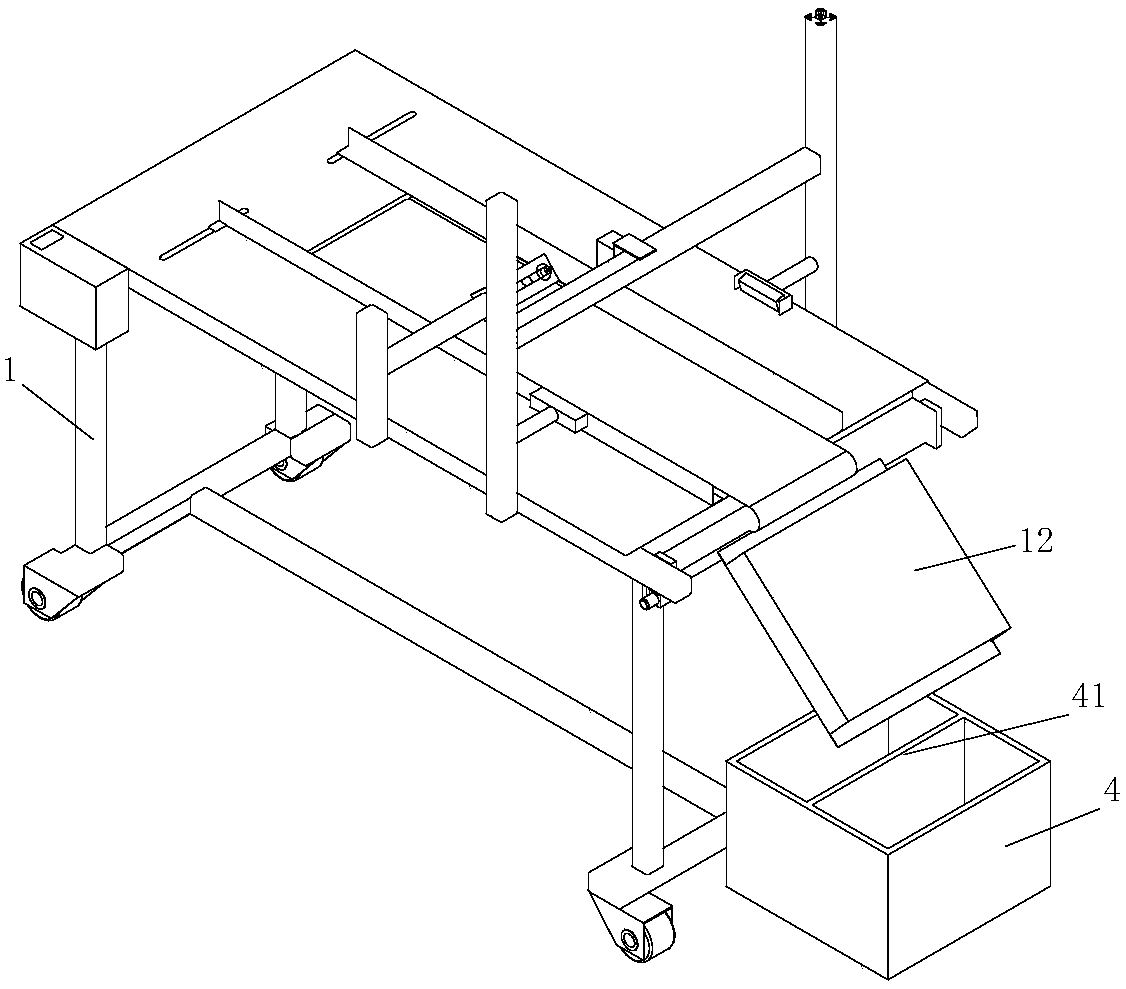

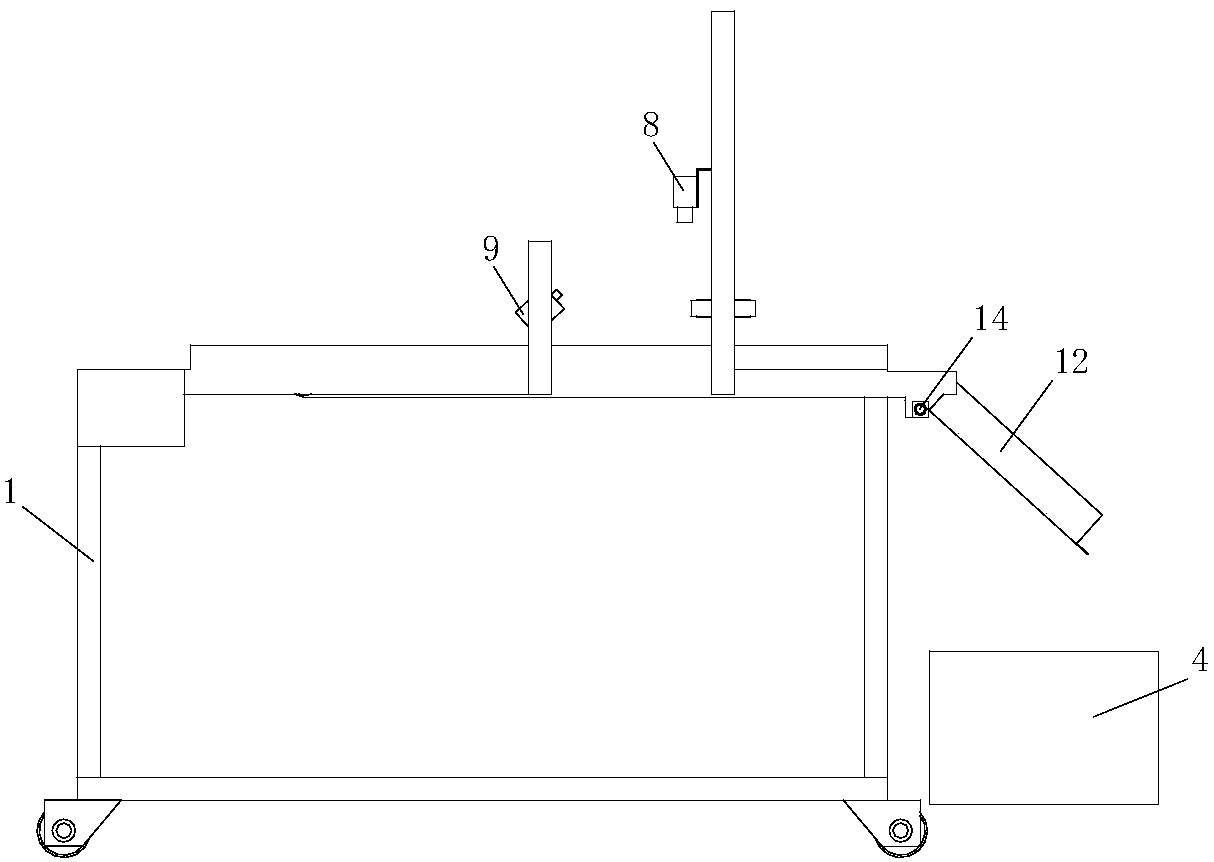

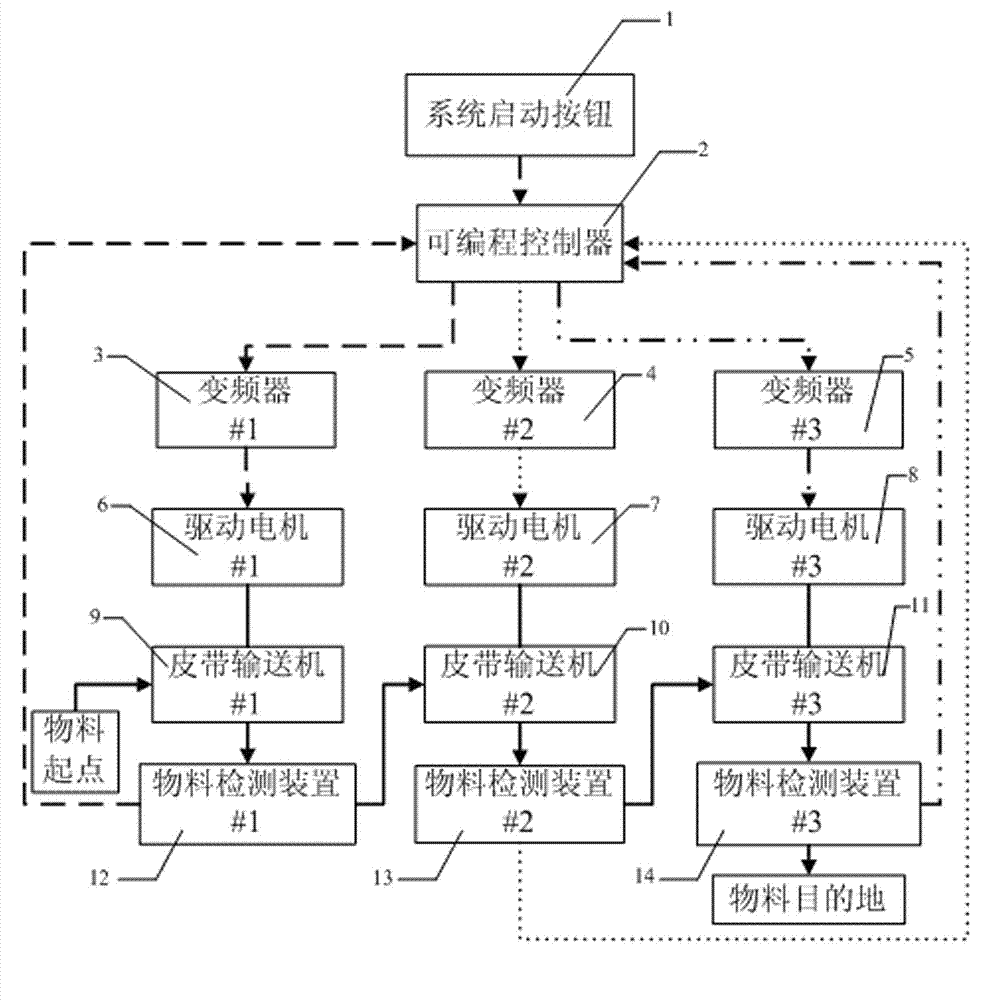

Energy saving system of belt conveyor and energy-saving control method thereof

The invention relates to an energy saving system of a belt conveyor and an energy-saving control method of the energy saving system of the belt conveyor. The energy saving system of the belt conveyor comprises a system starting button, a belt conveyer, a material detection device, a signal transformer, a belt conveyer drive motor, a frequency converter and a programmable controller. The belt conveyer is provided with a conveyer belt and the belt conveyer drive motor. The material detection device is installed right belowunder the conveyer belt and connected with the programmable controller through a signal line. The system starting button is connected with the programmable controller which is connected with the belt conveyer drive motor through the frequency converter by controlling the signal line. The belt conveyer system realizes the automatic control state of ''high speed with materials and low speed without materials''. According to the energy saving system of the belt conveyor and the energy-saving control method of the energy saving system of the belt conveyor provided by the invention, the idle time and idle energy consumption of the belt conveyer can be effectively reduced, so that the system mechanical loss generated in the time is reduced, the work efficiency is remarkably improved, the electric energy loss is reduced, and the purpose of saving energy and reducing consumption is realized.

Owner:江苏交科能源科技发展有限公司 +1

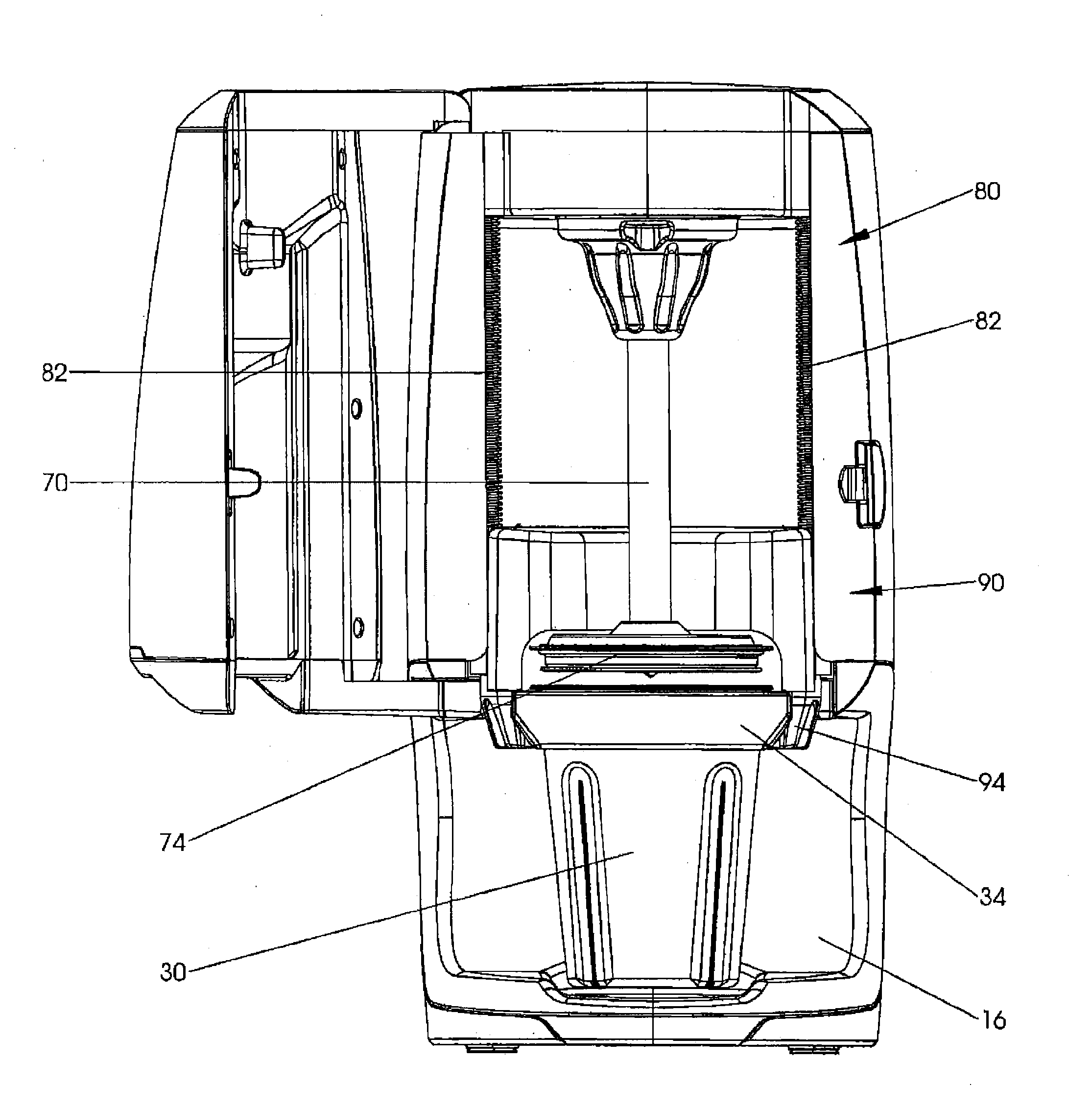

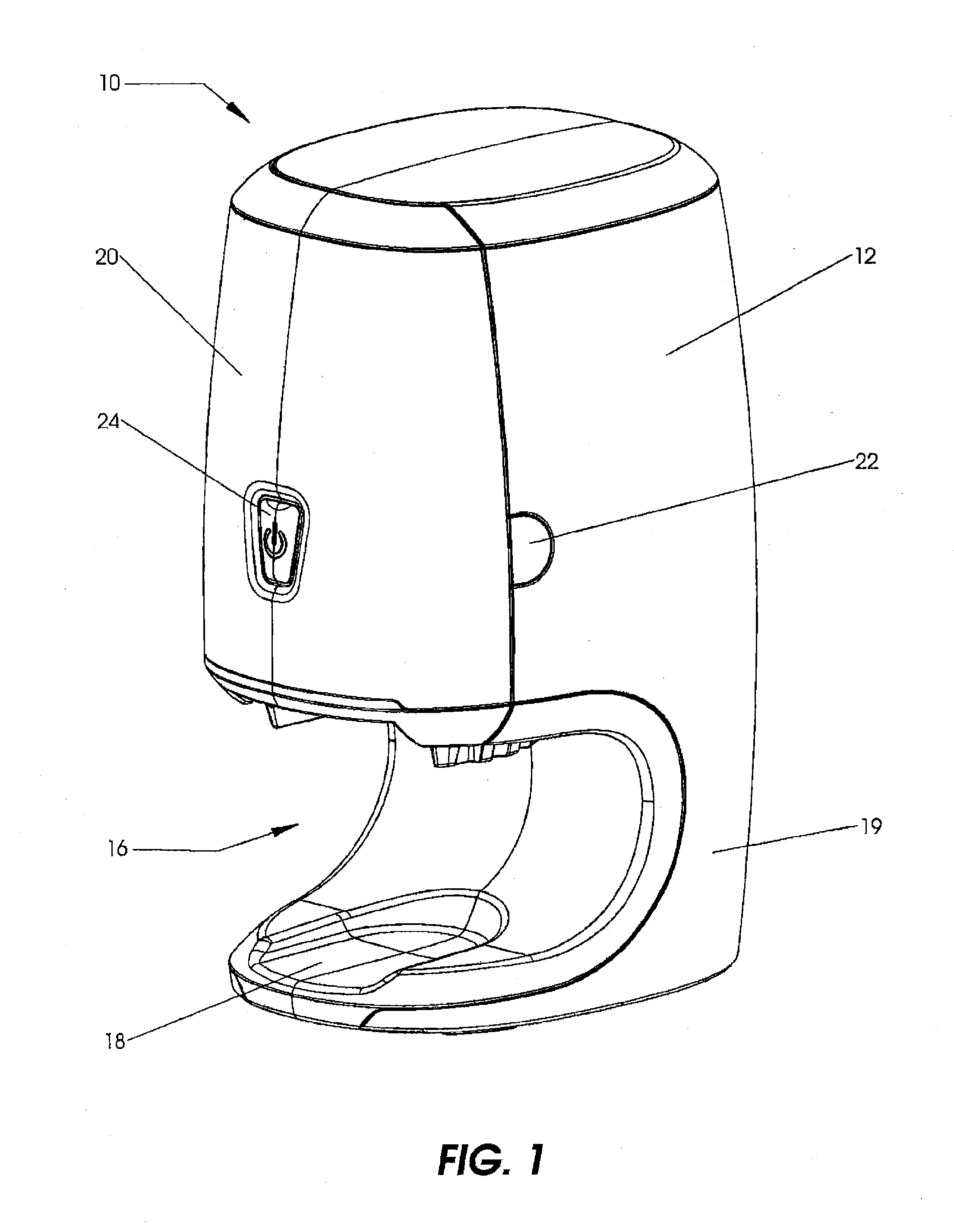

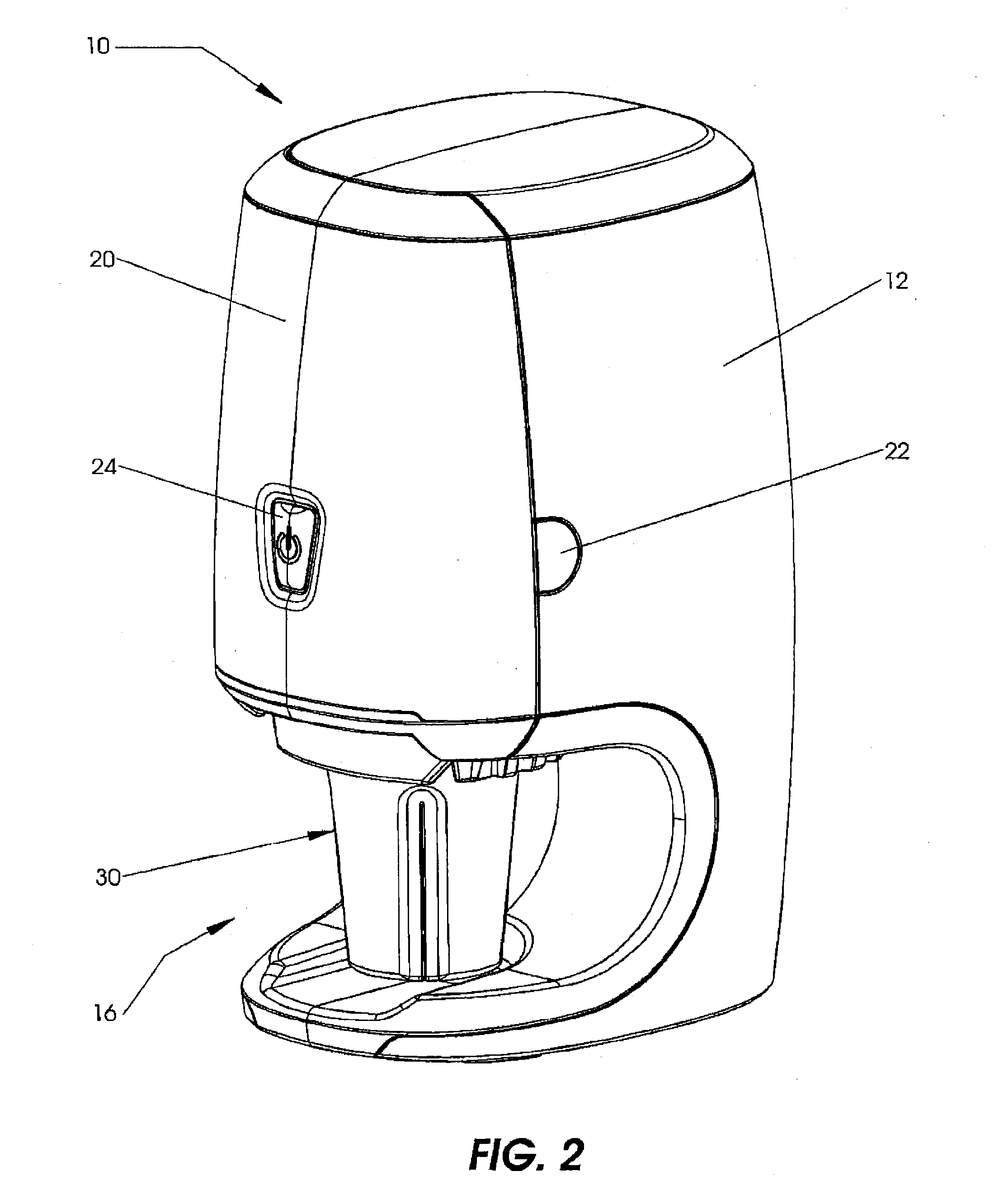

Blender with elevator assembly and removable spindle

ActiveUS20130344221A1Easy to useAvoid injuryRotary stirring mixersLarge containersLinear motionCoupling

A blender for home or commercial use that is rugged enough to blend frozen beverages, simple to use and safe. The blender includes an upper housing with a front housing door that covers the moving blending machinery. The blender also includes a cupholder receiving area which allows the user to safely insert a frozen food or beverage cup inside a cupholder for blending. After the start button is pressed, the cup and cupholder will be lifted together for blending in a balanced, linear motion by an elevator assembly. Dual lead screws or a dual belt drive are preferably used in the elevator assembly to achieve this balanced, linear motion. As the cupholder is lifted upward, a cover will be pressed over the top opening of the inserted cup to prevent spillage during blending. The elevator assembly continues to lift the cupholder upward until the rotating cutter blades of a spindle assembly cut through successive layers of the frozen food or beverage. To facilitate cleaning, the spindle assembly is preferably removable from the blender through use of a quick release coupling mechanism.

Owner:F REAL FOODS LLC

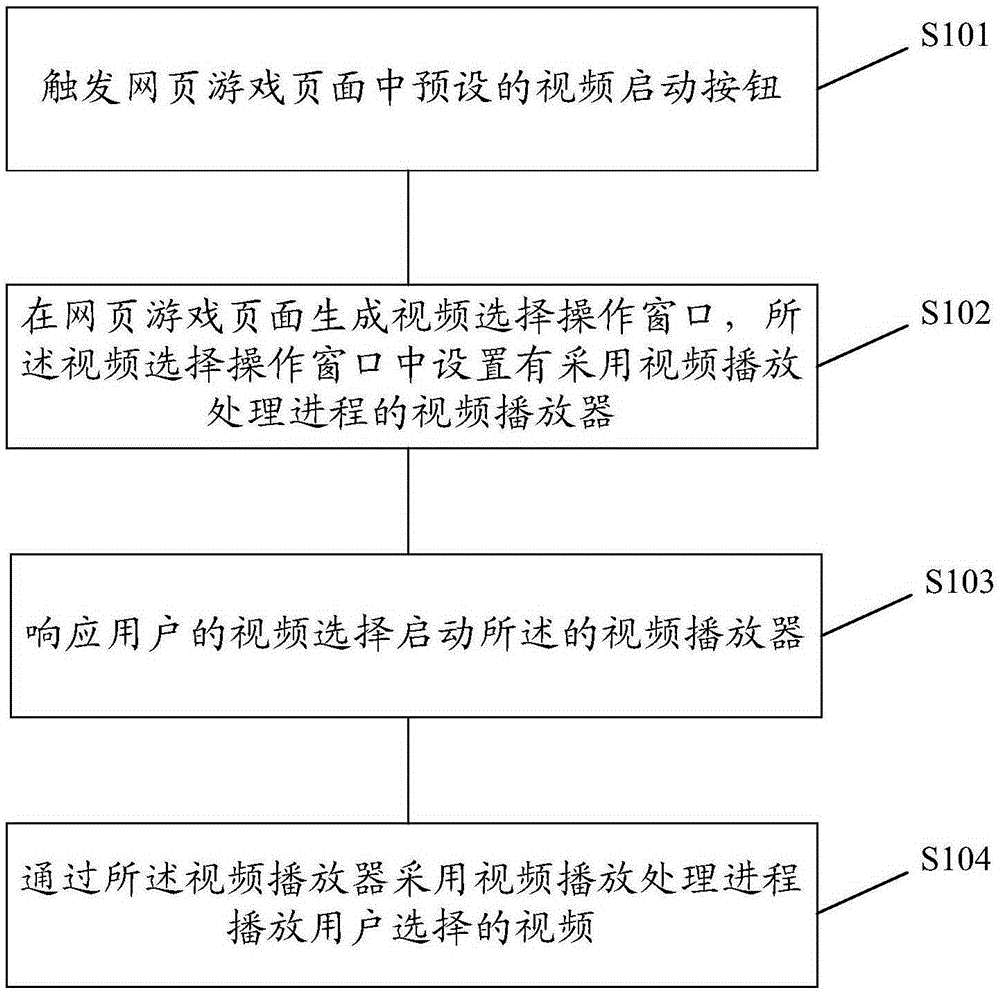

Method and device of playing video in webpage game

InactiveCN105187939AThere will be no problem of taking up too much CPU and causing freezeVideo gamesSelective content distributionVideo playerGame play

The present invention provides a method and device of playing a video in a webpage game. The method comprises the steps of triggering a video starting button preset in a webpage game page; generating a floating video selection operation window in the webpage game page, wherein a video player adopting a video playing processing process is arranged in the video selection operation window; starting the video player in response to the video selection of the users; using the video player to adopt the video playing processing process to play the videos selected by the users. According to the present invention, users can watch the videos while playing the webpage games, and the video playing and the game playing do not influence mutually. Moreover, the video player of executing the video playing adopts the video playing processing process to process, namely, the video playing and the webpage game processing are not in the same process, so that a frame hysteresis problem caused by that one process occupies a central processor excessively does not occur.

Owner:1VERGE INTERNET TECH BEIJING

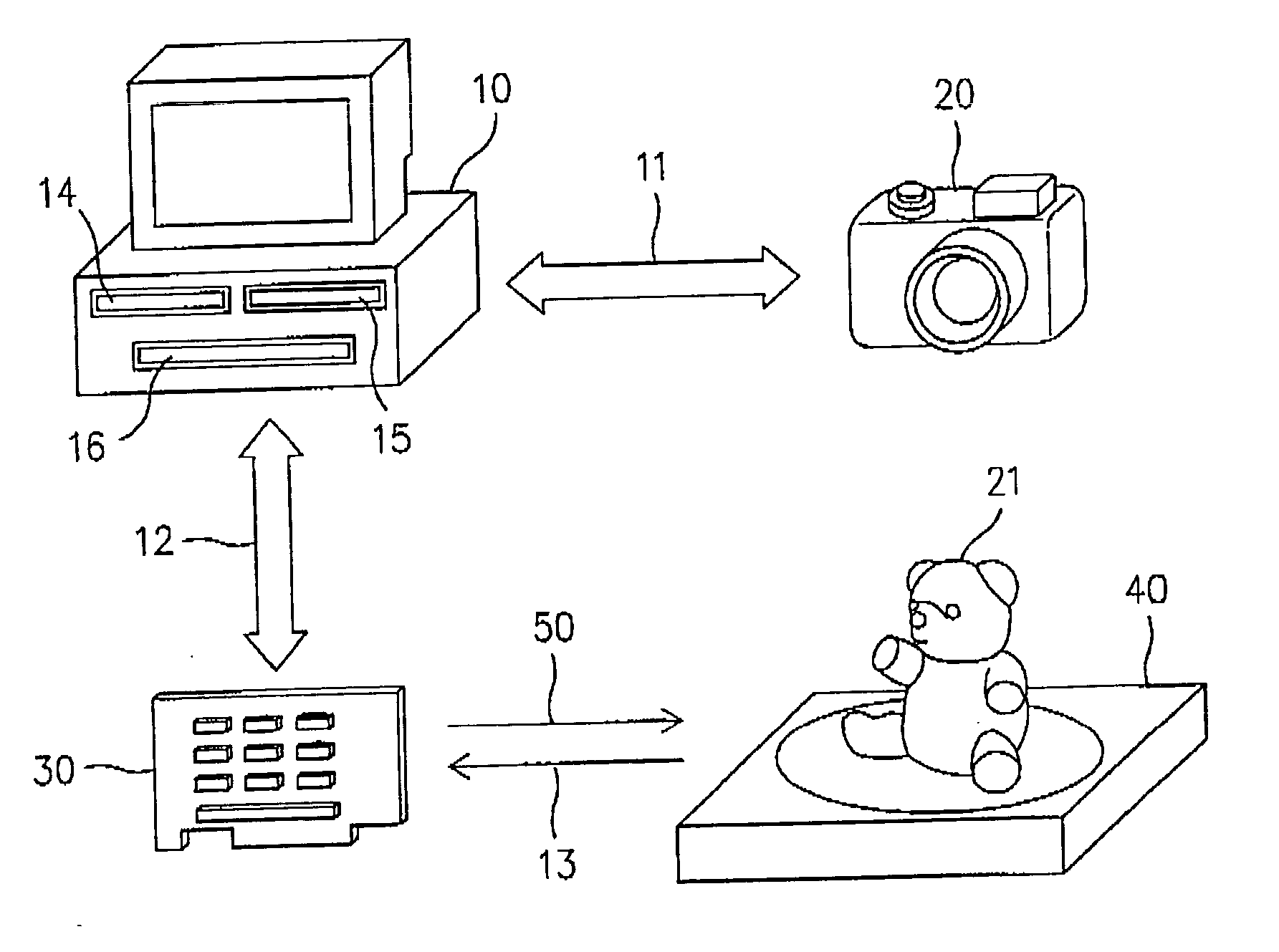

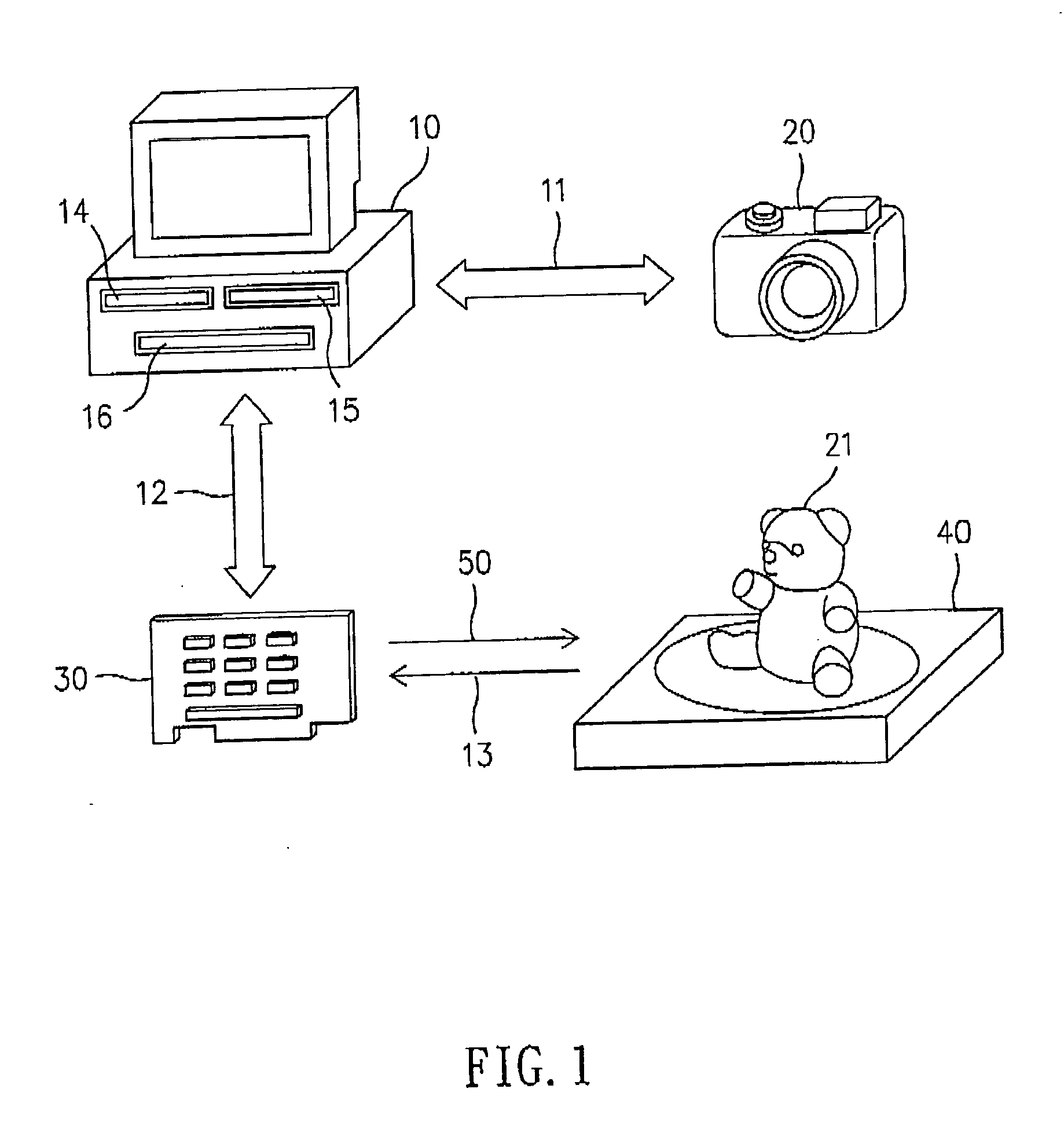

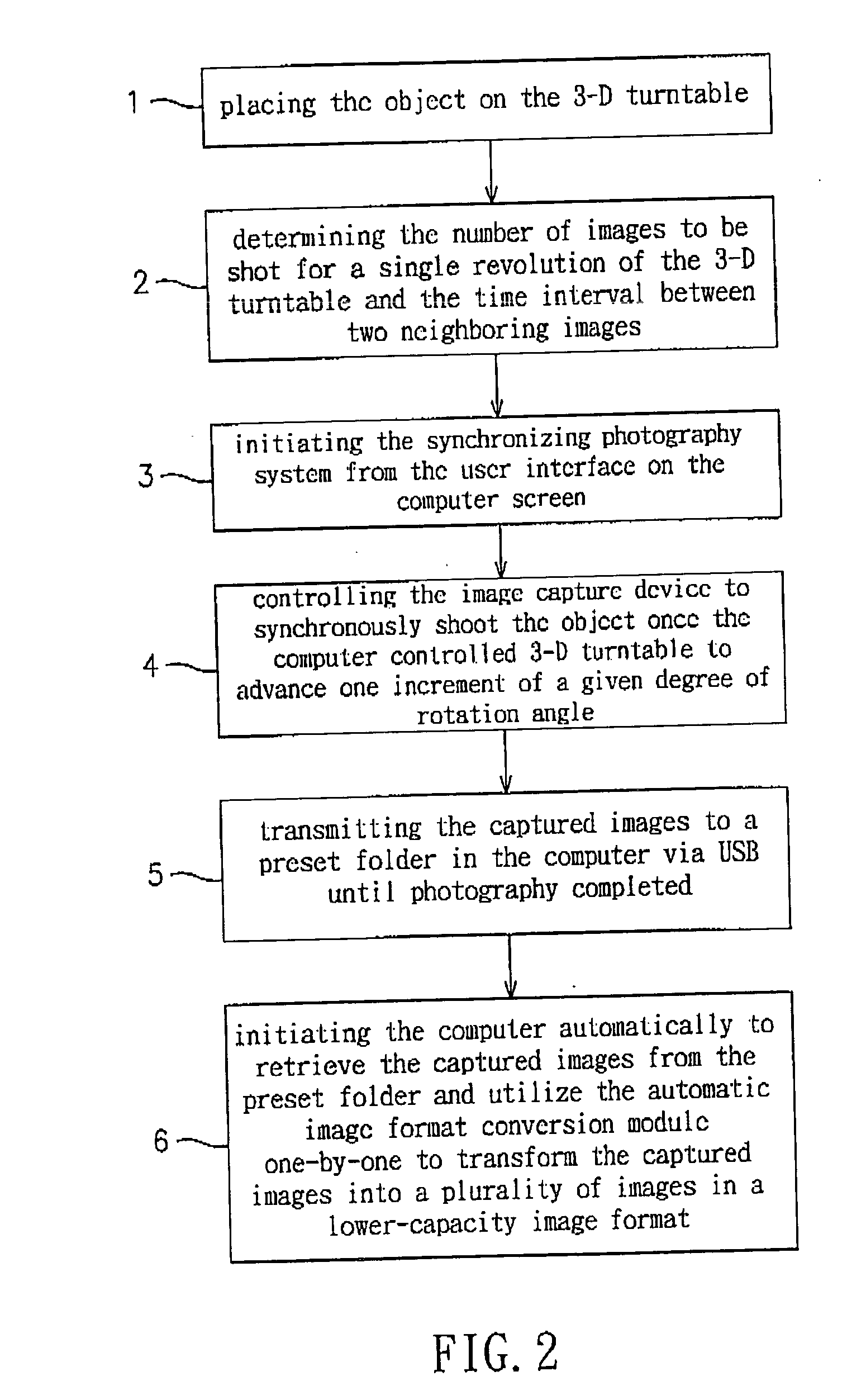

Computer controlled system for synchronizing photography implementation between a 3-D turntable and an image capture device with automatic image format conversion

A computer controlled system for synchronizing photography implementation between a 3-D turntable and an image capture device with automatic image format conversion includes a 3-D turntable, a 3-D turntable control module, an image capture device, an image capture control module and an automatic image format conversion module. A physical object is placed on the 3-D turntable and shot by the image capture device for each increment of a given degree of rotation angle. After a full around of rotation, the images are stored into a designated image folder in the computer and then automatically transformed into displayable format by the automatic image format conversion module. With fully automatic image generation and format conversion, what the user needs to do is only to place the object on the 3-D turntable, determine the number of images to be shot for a single revolution of the 3-D turntable, and press a start button.

Owner:ORTERY TECH

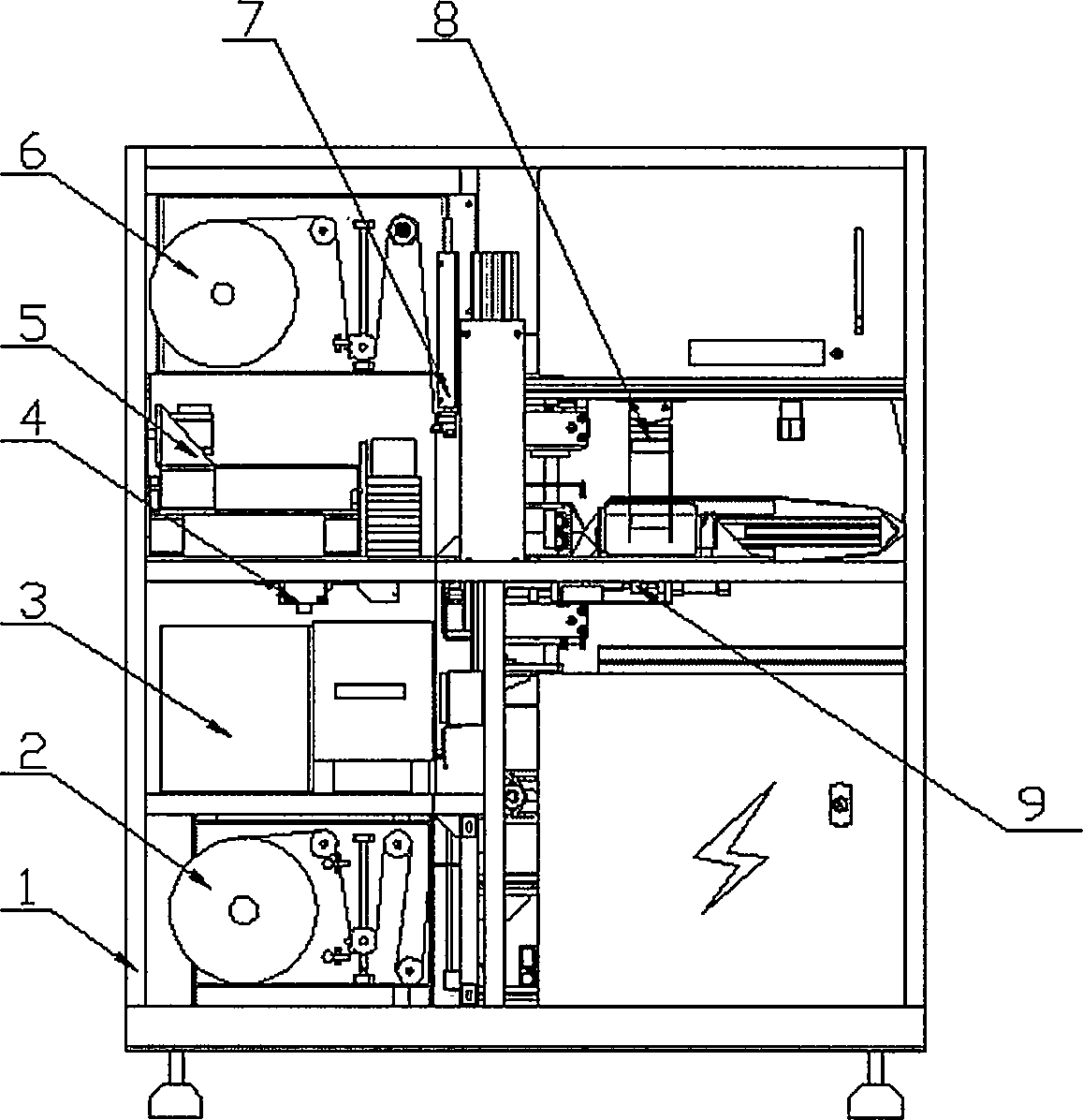

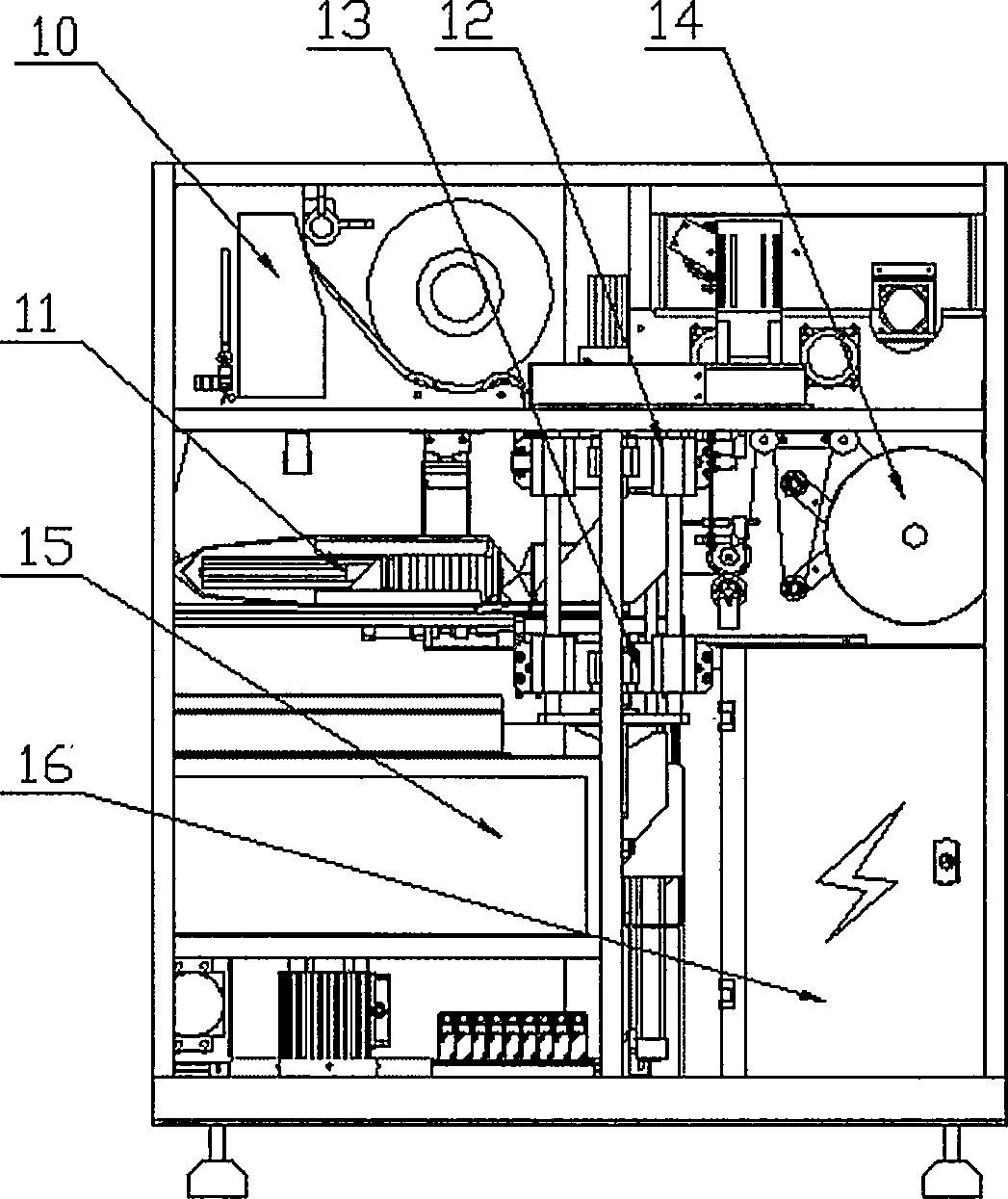

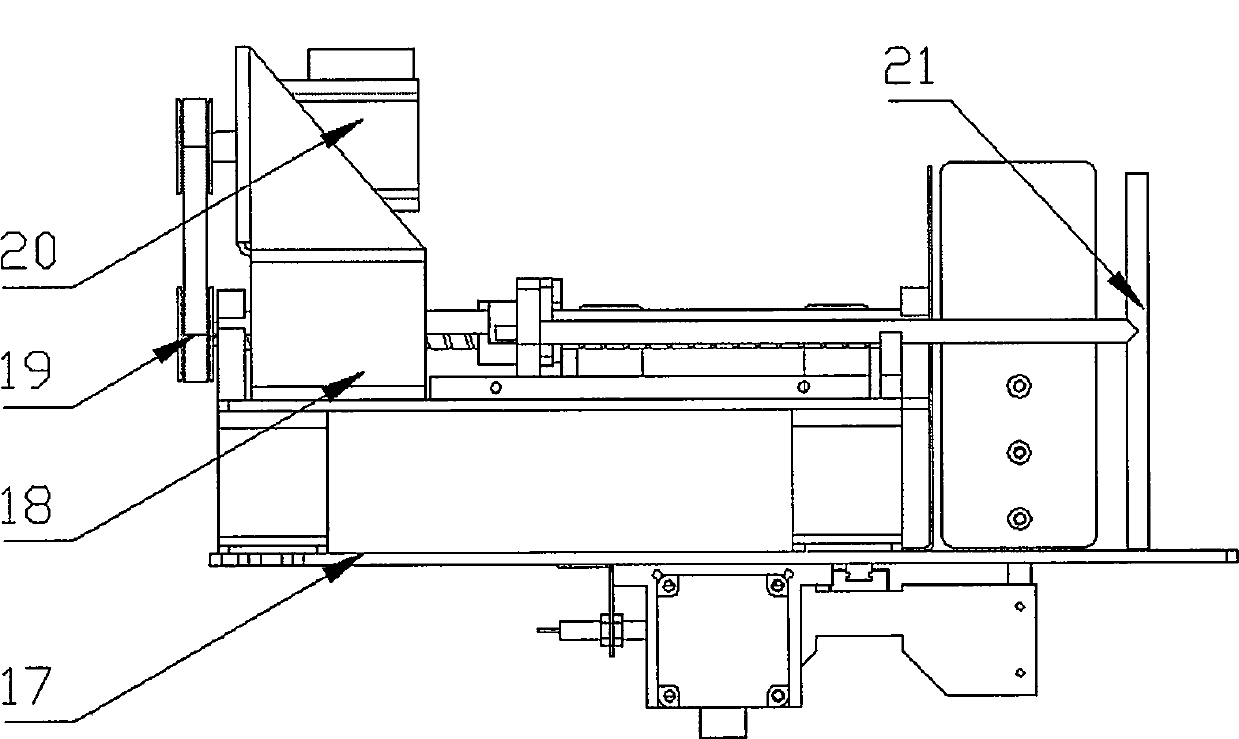

Bundling and plastically-enveloping AIO (all-in-one) machine for paper currency

InactiveCN103738523AMoisture-proofWith dustproofPaper article packagingWrappers shrinkageControl systemProgrammable logic controller

The invention discloses a bundling and plastically-enveloping AIO (all-in-one) machine for paper currency used for automatically bundling and plastically-enveloping the paper currency, aiming at the different face values of paper currency in a financial system. The AIO machine mainly comprises an automatic bundling unit and an automatic plastically-enveloping unit, and is composed of a lower film rolling mechanism, a heat transfer printing printer, a paper currency adjusting mechanism, a primary pushing mechanism, an upper film rolling mechanism, a heat-seal bundling mechanism, a side pushing mechanism, an overturning mechanism, a film plastically-enveloping mechanism, a forming mechanism, a U-shaped sealing mechanism, a lifting mechanism, a material receiving mechanism, a thermoshrinking furnace mechanism and a PLC (Programmable Logic Controller) control system. The working principle of the AIO machine is that a start button is pressed and the primary pushing mechanism is controlled to push the paper current into the bundling mechanism for bundling through the PLC after 10 bundles of paper currency are placed into a paper currency entrance, and the paper currency is sent to a side push position through the overturning mechanism, the paper current is sent into the U-shaped sealing mechanism for plastically enveloping by the side pushing mechanism, and a packaging film is shrunk by the thermoshrinking furnace after the plastic envelope. The AIO machine has the advantages of being reasonable in structure, compact in mechanism, simple to operate, convenient to maintain, and realizing stability and reliability.

Owner:YEE FOO PACKAGING SHENZHEN CO LTD

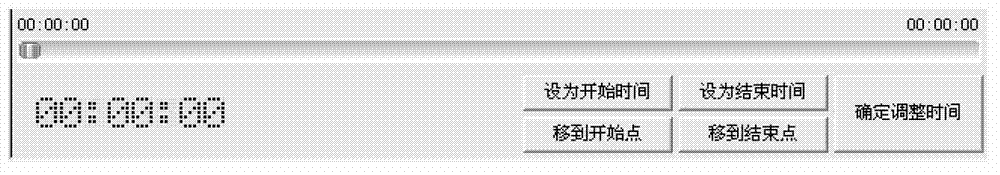

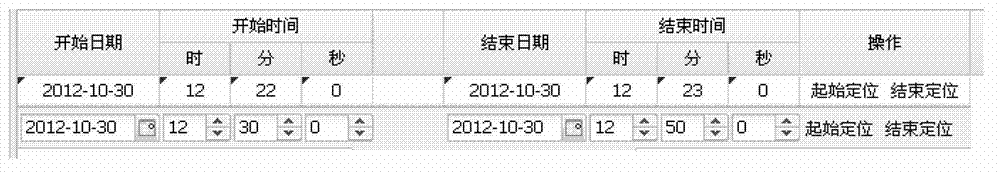

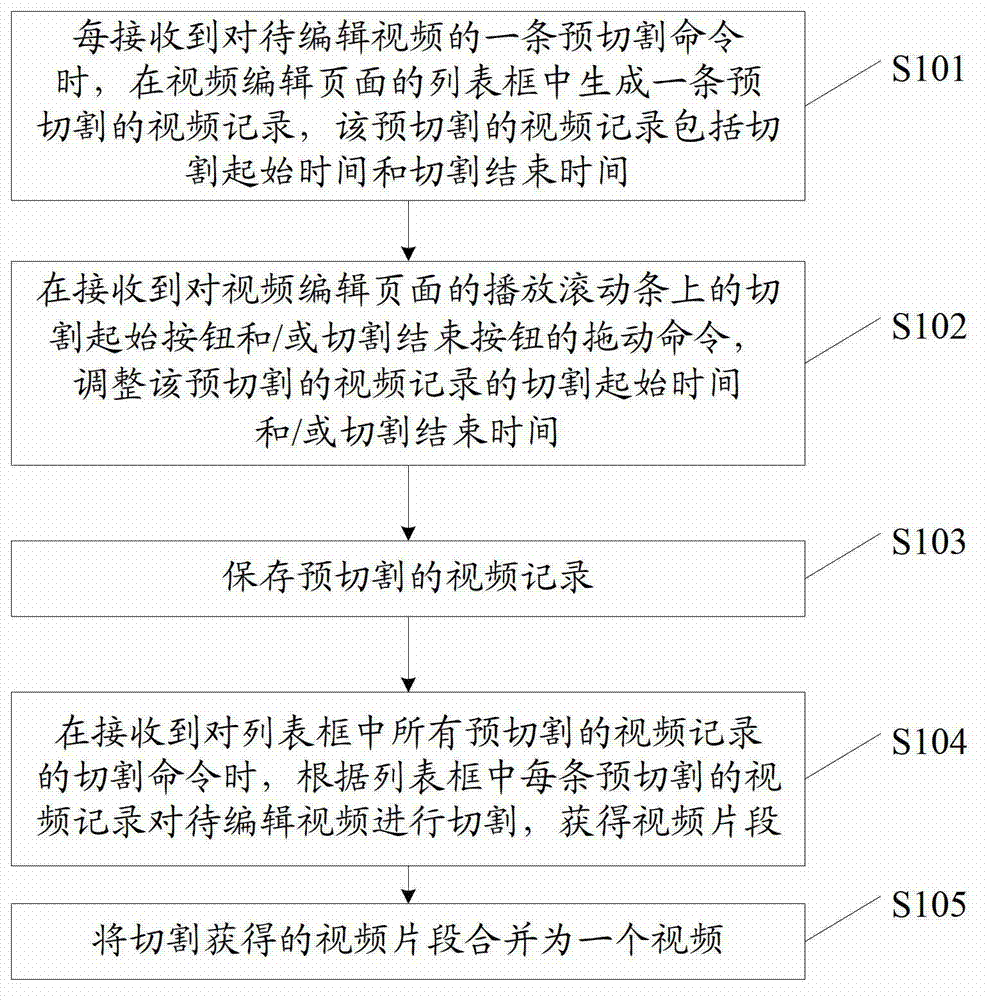

Method and device for video editing

The invention discloses a method for video editing. The method for video editing comprises the steps of generating pre-cutting video records in a list box of a video editing page through pre-cutting of a to-be-edited video, dragging a cutting start button and / or a cutting end button of a play scroll bar of a video editing page, adjusting a cutting start time and / or a cutting end time of each pre-cutting video record, saving adjusted pre-cutting video records, cutting and combining the adjusted pre-cutting video records into one. The method for video editing can achieve cutting of a plurality of video clips and enables the video editing to be more humanized. Besides, the invention further discloses a device for video editing.

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

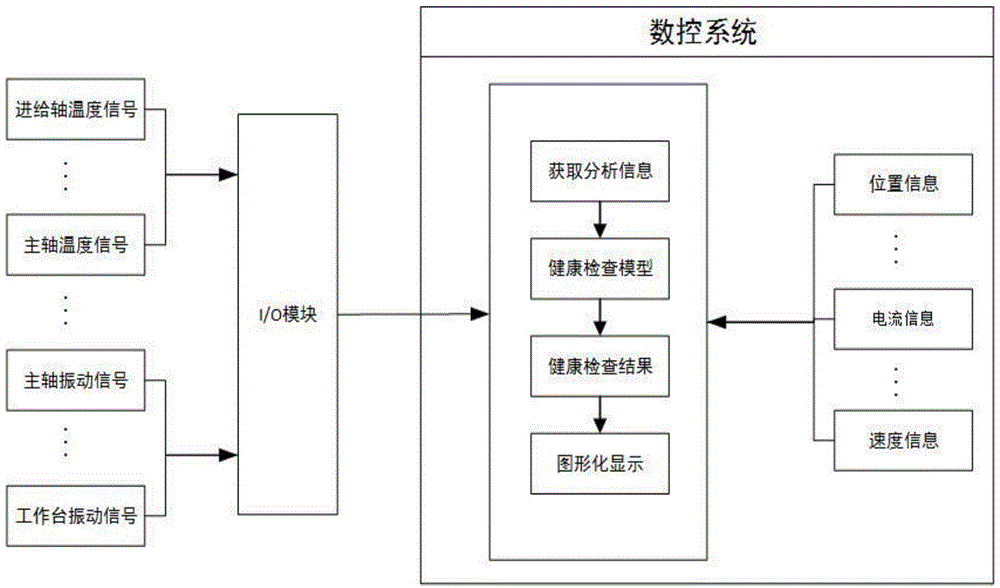

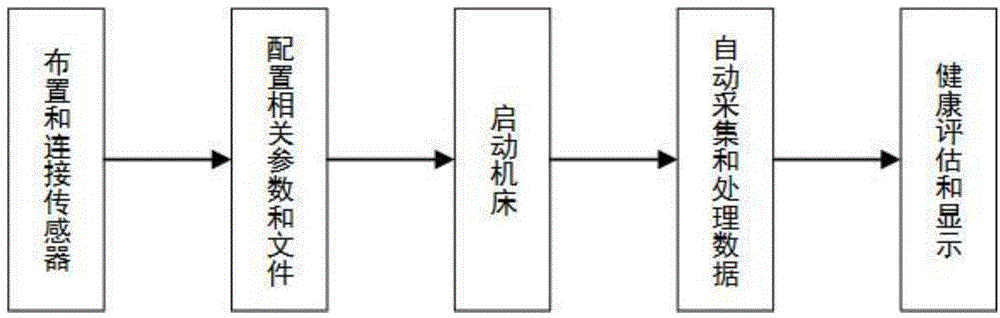

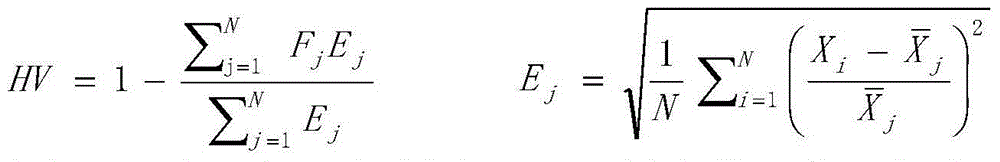

Machine tool health state rapid checking method

ActiveCN104808585AUnderstanding DegradationRealize online collectionProgramme controlComputer controlModelling analysisMachining process

The invention discloses a machine tool health state rapid checking method. According to the method, a HuaZhong HNC-8 numerical control system is utilized, a sensor is arranged into each position that is required to be checked in a machine tool in advance, and then sampling channel information is configured in an oscilloscope sampling interface; health checking parameters are configured in a diagnosis meson interface of the numerical control system; then machining processes are selected, a circulating start button is pressed down to perform on-line sampling, and the system obtains feature values of sampling information by means of a signal analysis method; finally, comprehensive comparison with standard data is performed, health assessment of the machine tool is performed, and a result is displayed in a graphical mode. By means of the machine tool health state rapid checking method, signals of outer sensors are directly transmitted into the numerical control system through a port of the numerical control system, on-line collecting and analysis can be achieved, a mode of traditional external measurement and off-line modeling analysis is changed, and health checking efficiency, practicability and using range of the numerical control machine tool can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH +1

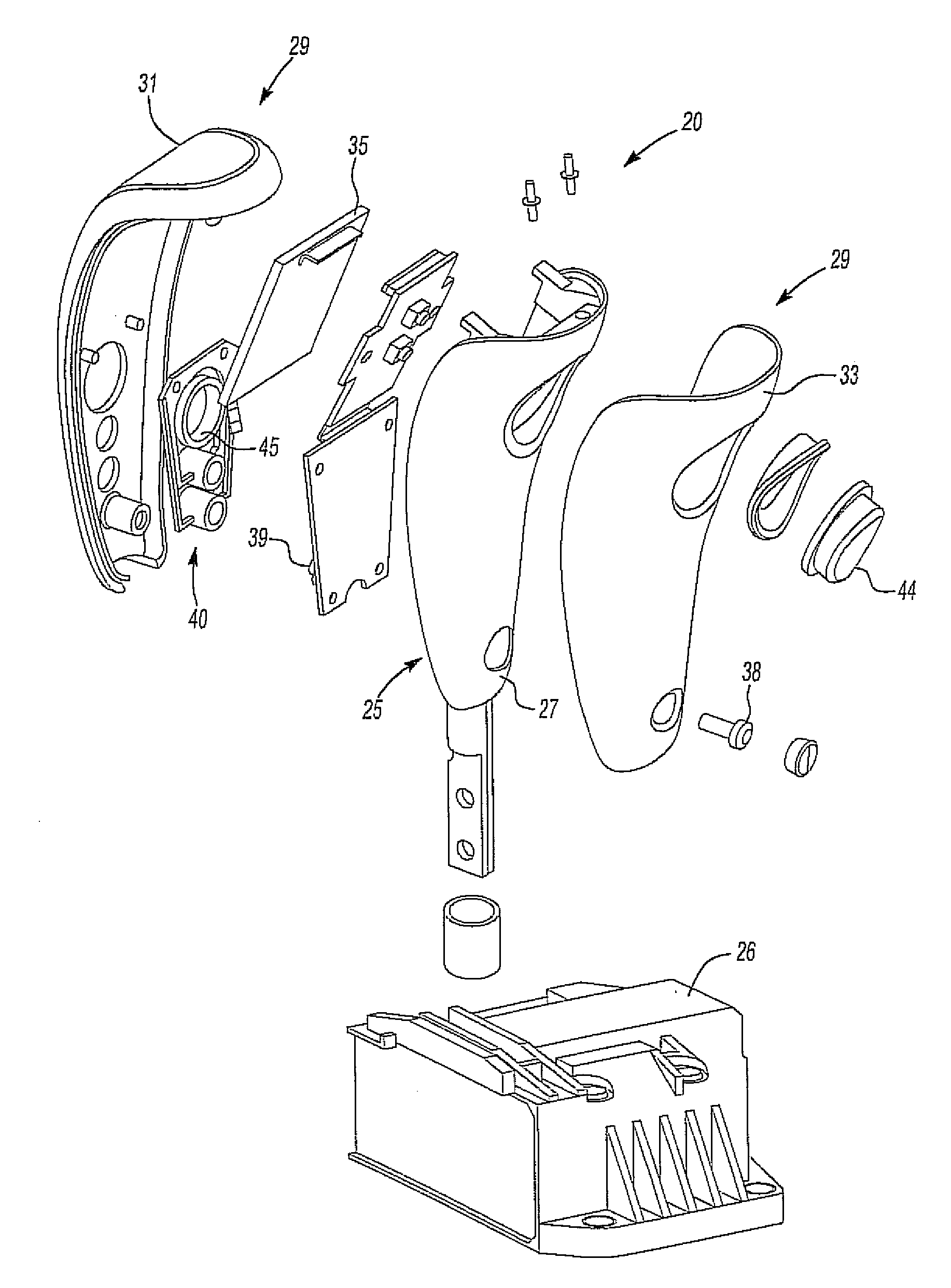

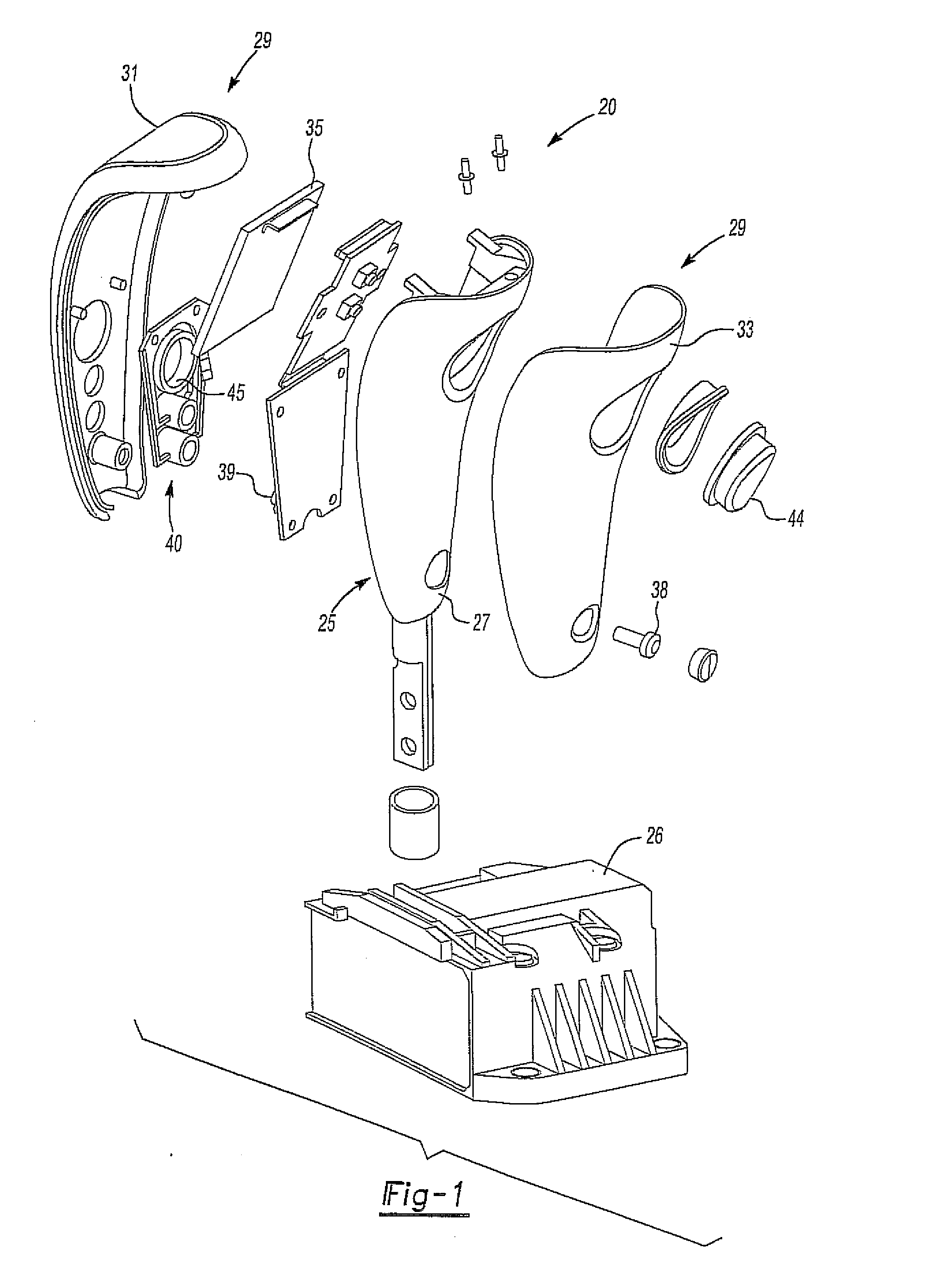

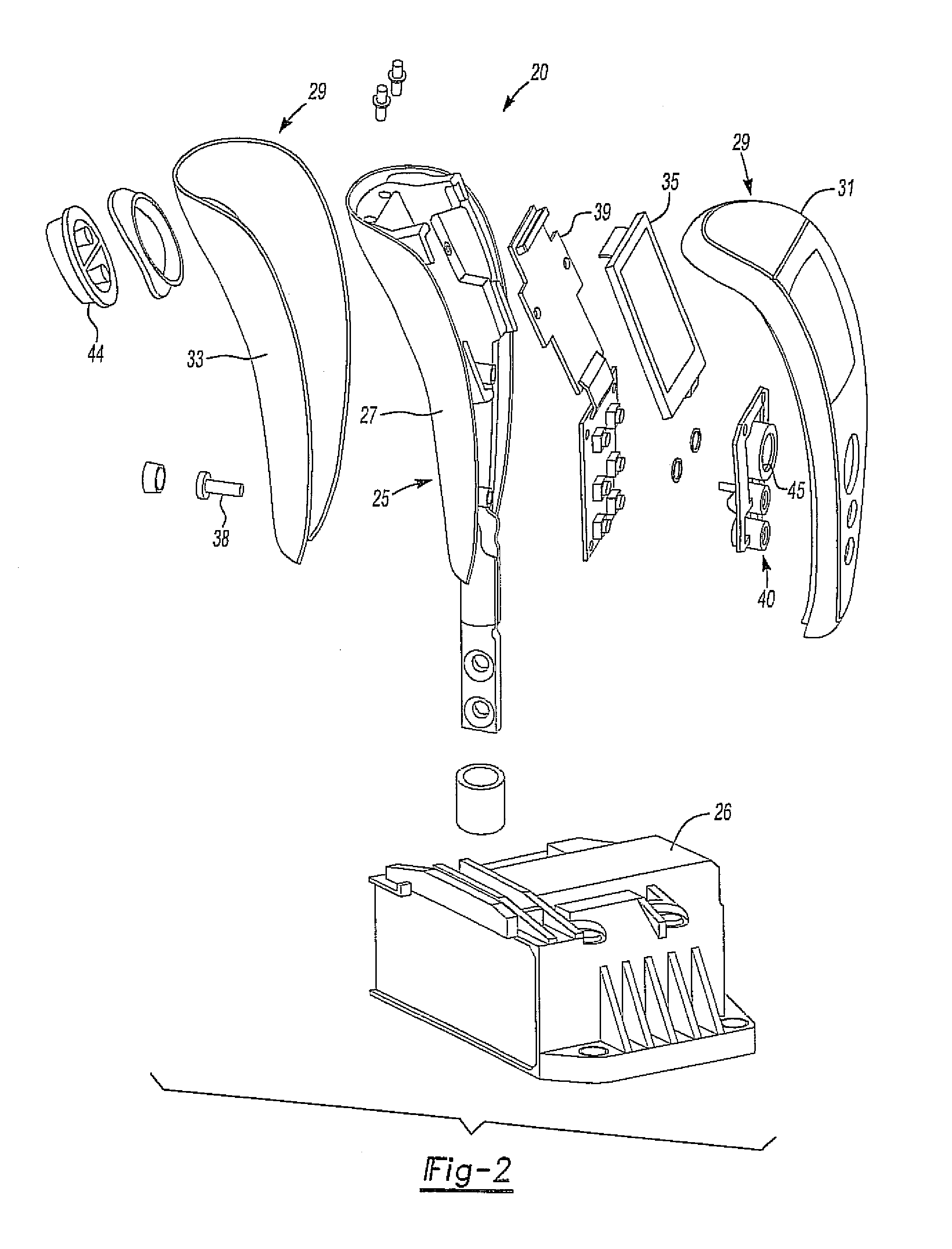

Shifter assembly including display and actuation for driver control

A shifter assembly for a vehicle that includes a shift lever connected to a shifter and in communication with the vehicle and a transmission. A display is positioned on the shift lever indicating data of the vehicle or transmission. A start button is positioned on the shift lever and is linked with an ignition of the vehicle.

Owner:DUS OPERATING INC

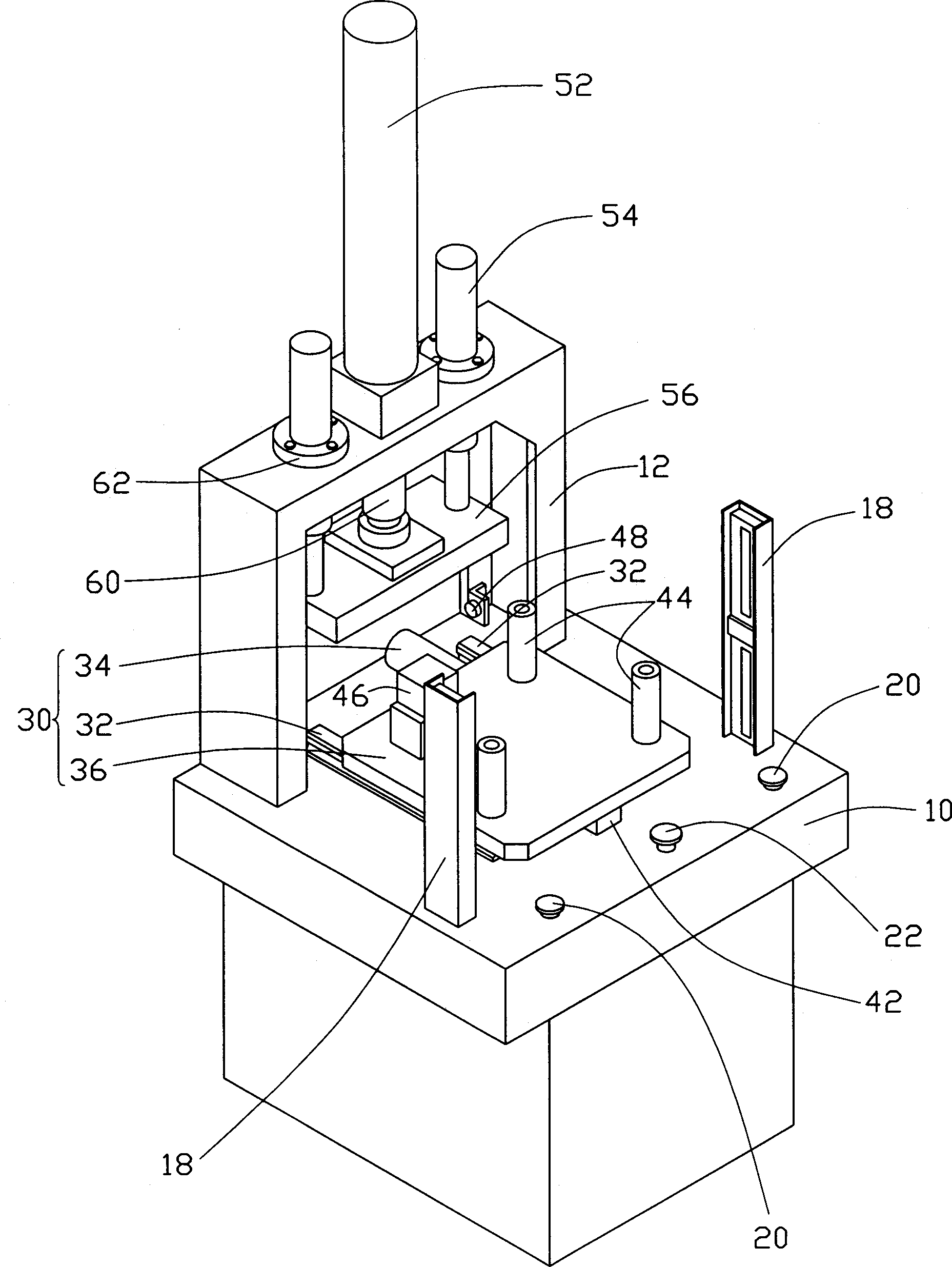

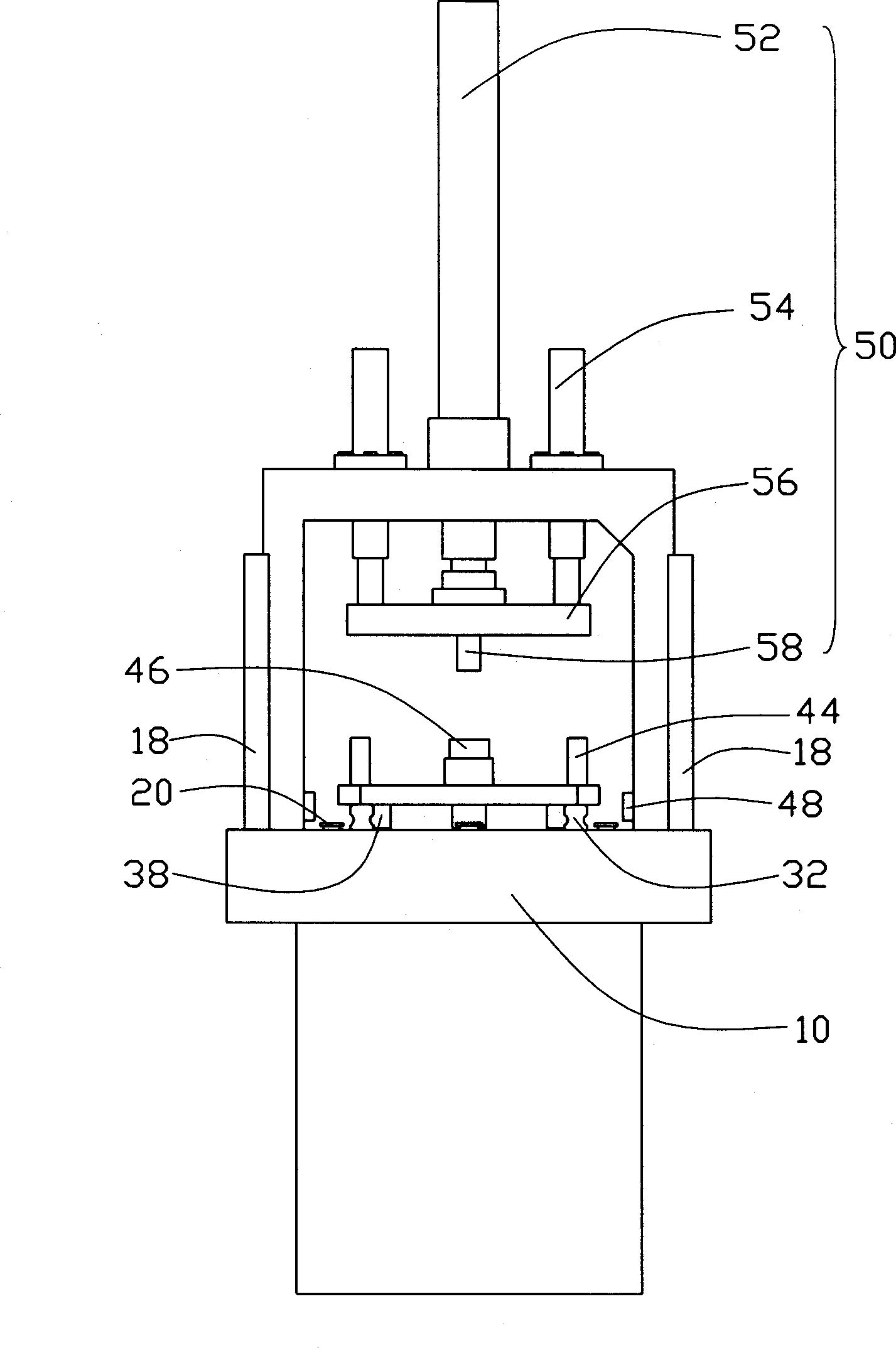

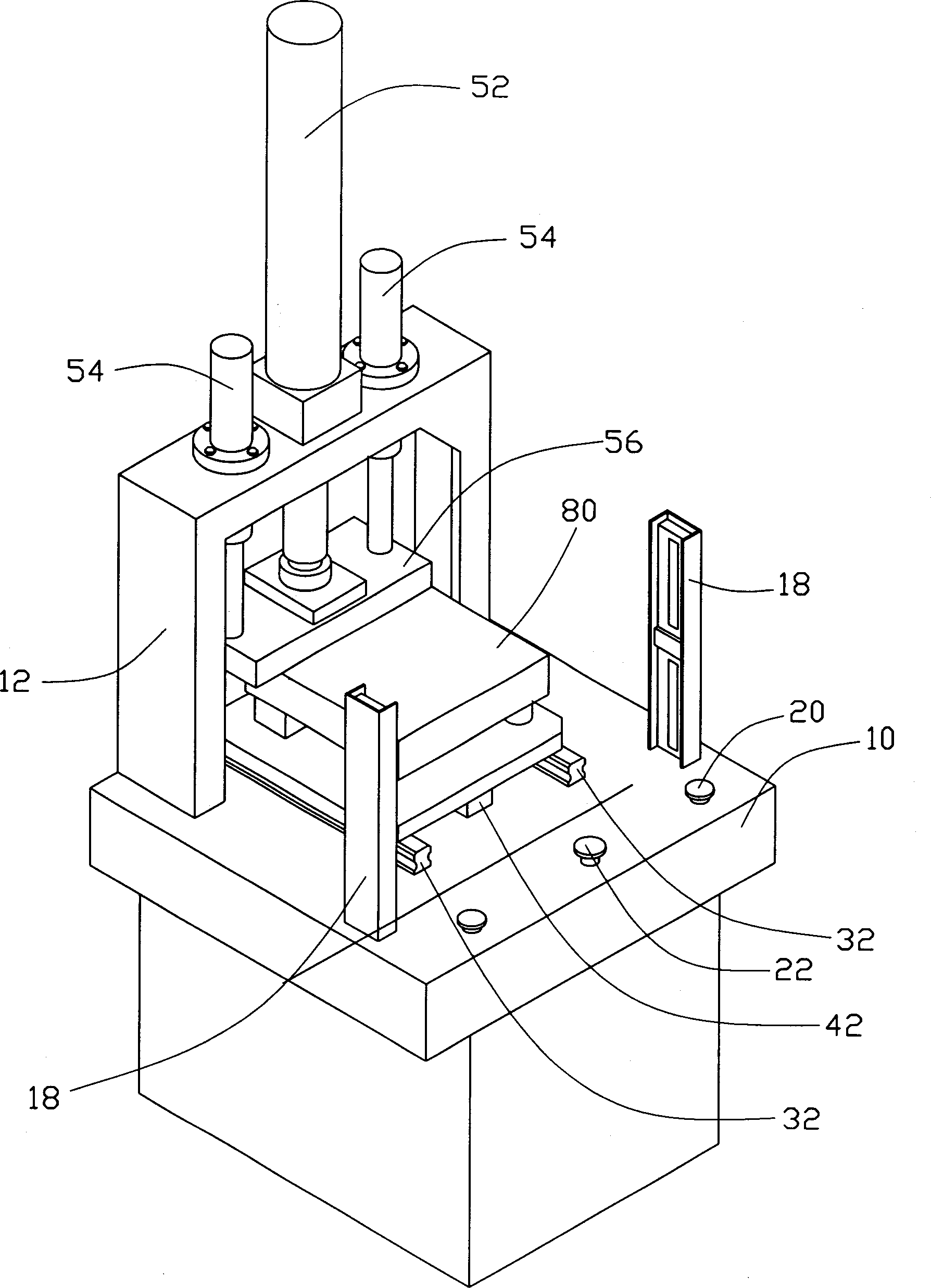

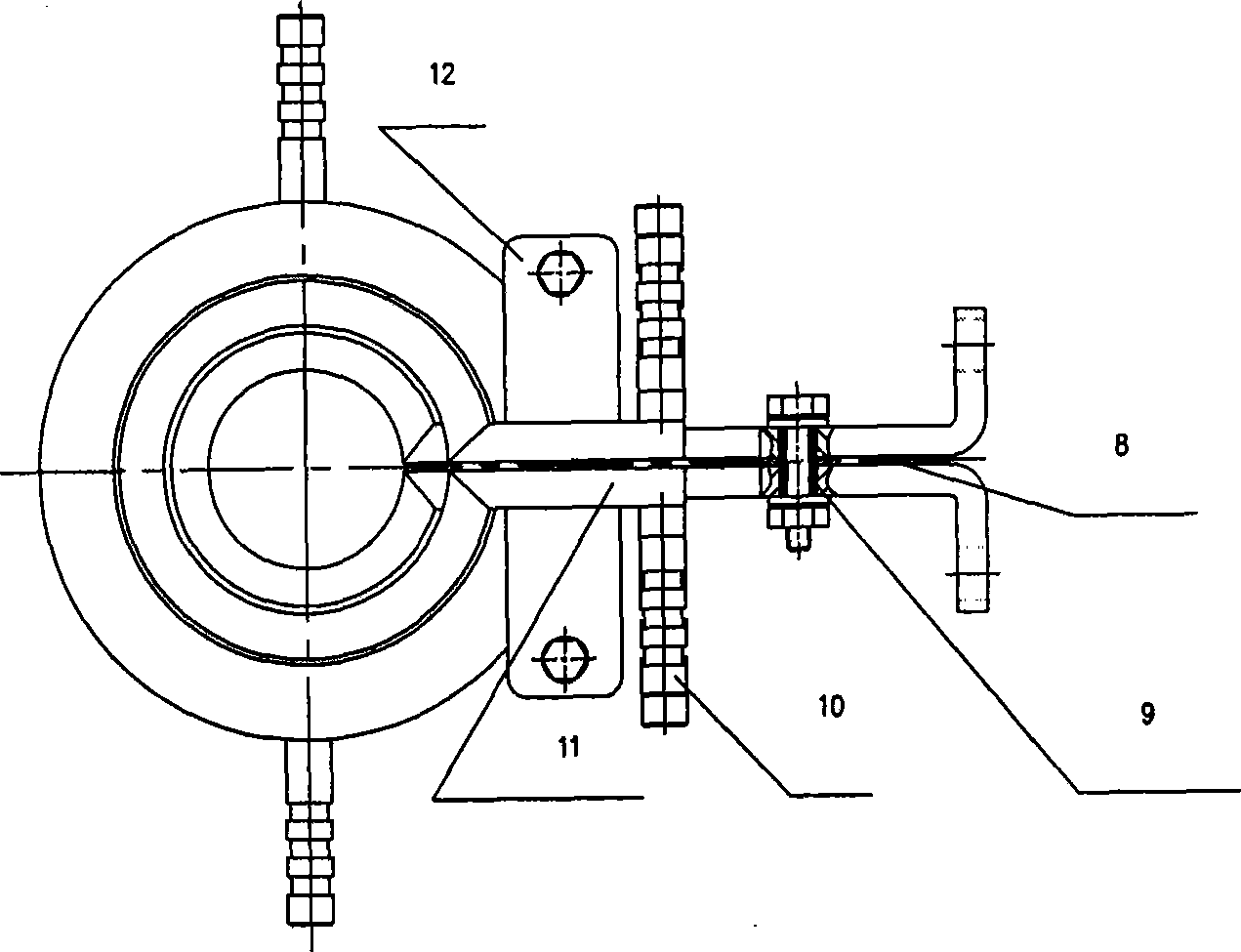

Automatic feeding riveter

The automatic feeding riveter includes one base, one feeding mechanism and one riveting unit. On the base, there is a portal support installed vertically, two photoelectric relays on two sides of front part, two start buttons and one emergency stop button. The feeding mechanism includes two parallel slide racks, one small cylinder between the two slide racks and one lower template capable of sliding along the slide racks and one connecting block fixed to the end of piston rod of the small cylinder. One photoelectric contact is set on the inner wall of the portal support. The riveting unit includes one large cylinder, two guide columns, one connecting board and one riveting head connected together.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

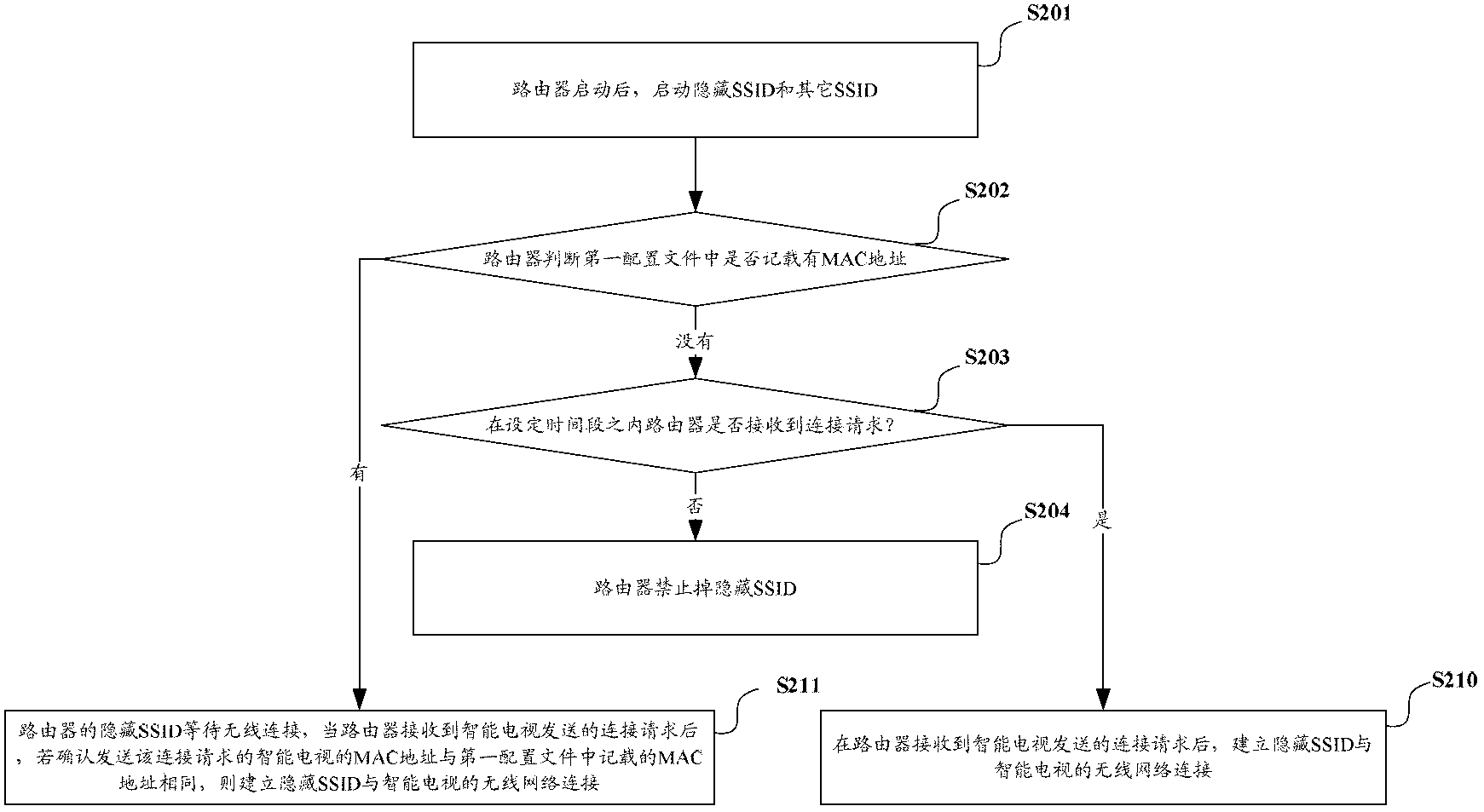

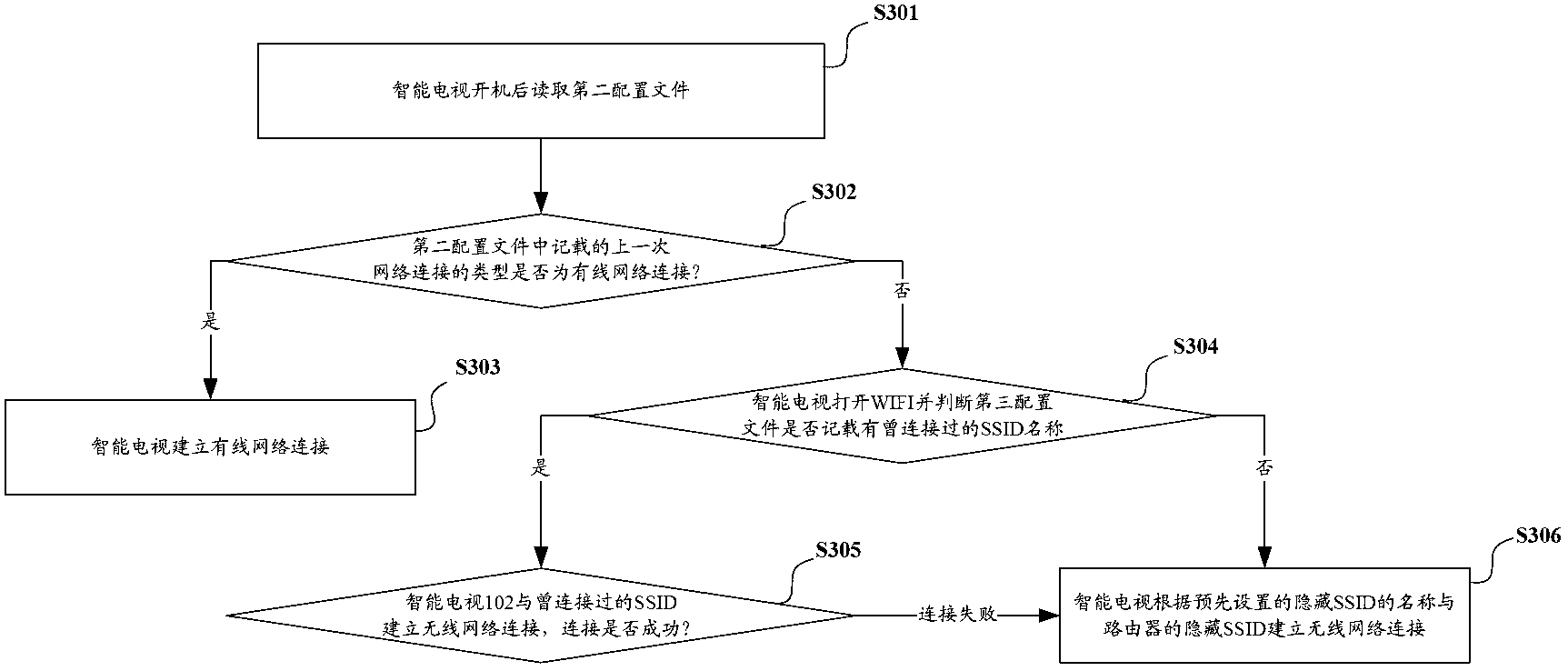

Method and system for automatically connecting wireless network and smart television

InactiveCN102711215AAvoid occupyingGuaranteed reliabilityAssess restrictionSelective content distributionStart buttonCable television

The invention discloses a method and a system for automatically connecting a wireless network and a smart television. The system comprises a router and a smart television, wherein the router is used for starting a hidden SSID (service set identifier) for waiting for wireless connection after starting; and the smart television is used for actively connecting the hidden SSID of the router after starting according to a preset name of the hidden SSID to establish wireless network connection with the hidden SSID of the router. Because the name of the hidden SSID of the router is preset in the smart television, the wireless network connection with the hidden SSID can be actively established by the smart television according to the name of the hidden SSID, so that a user does not need to carry out complicated operations of manual setting and searching and only needs to press a start button of the television like operating a traditional smart television, and the wireless network connection can be automatically established between the smart television and the router.

Owner:HISENSE

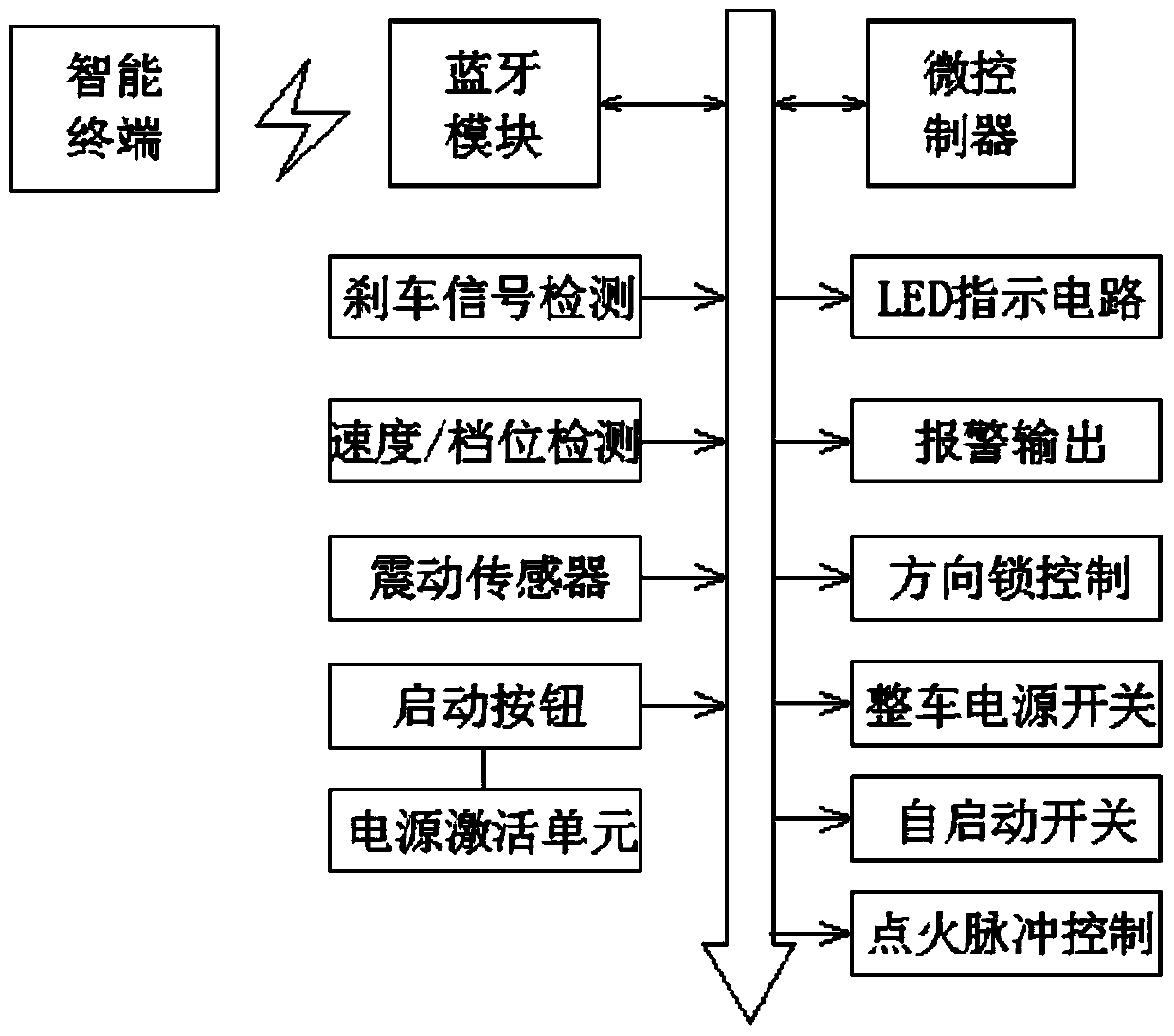

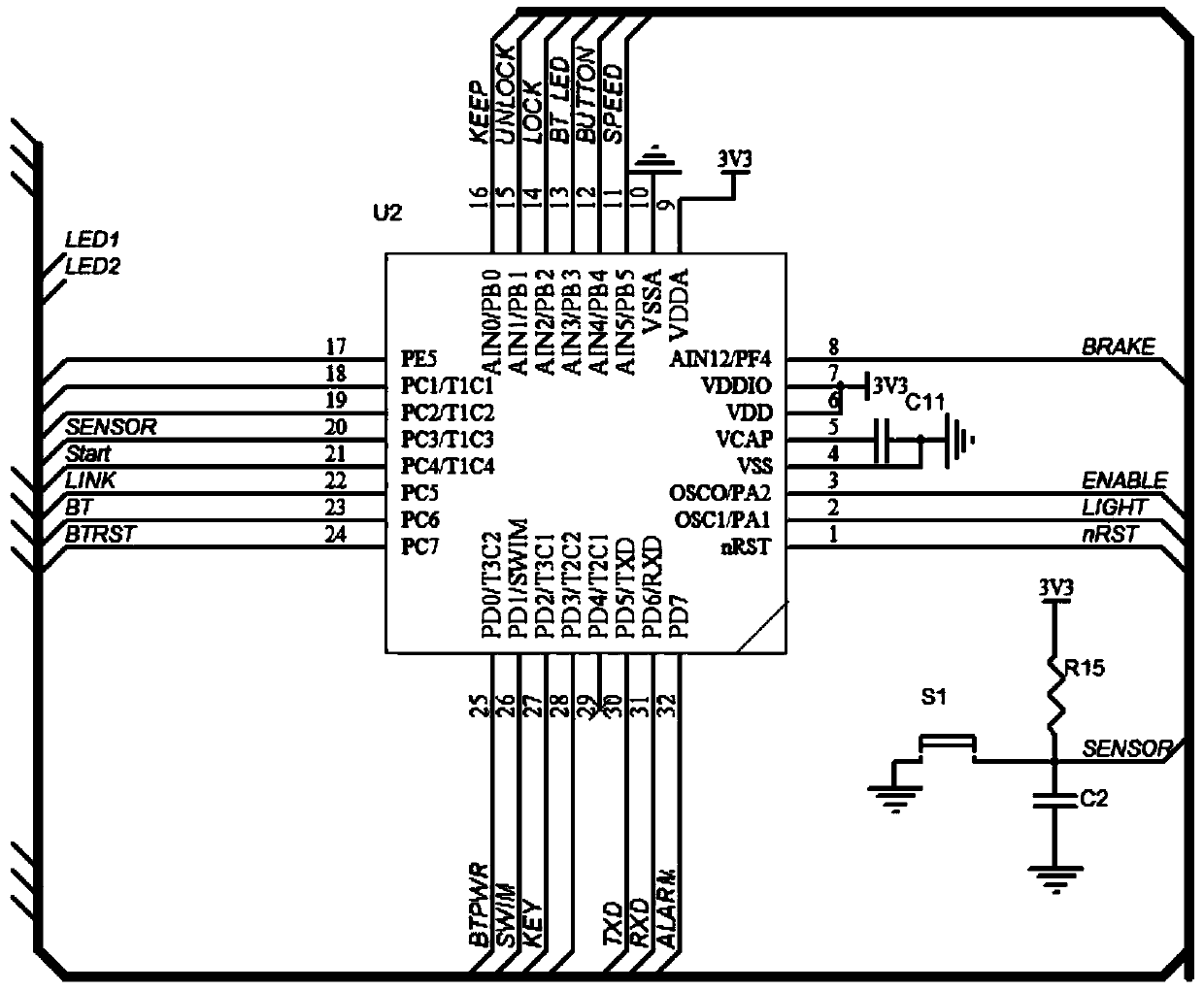

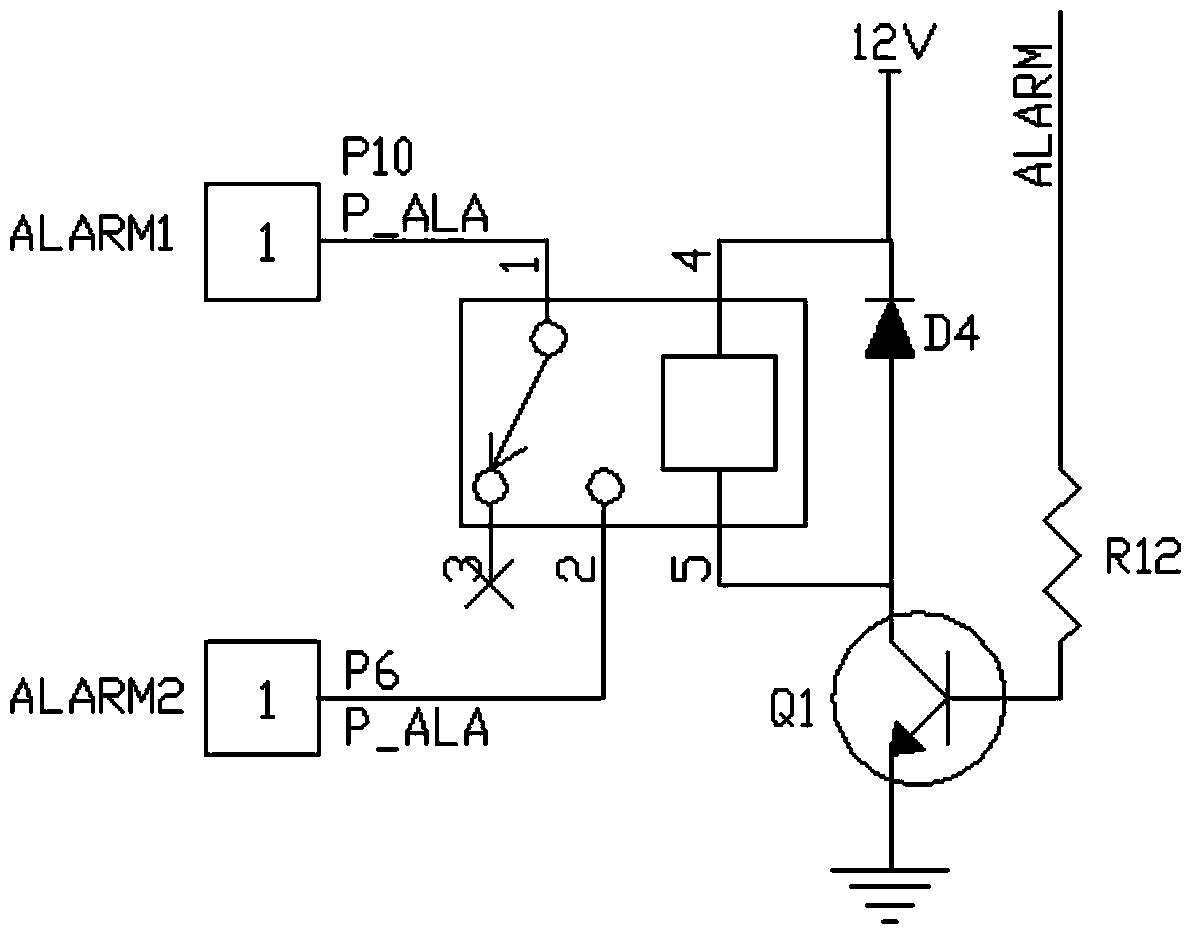

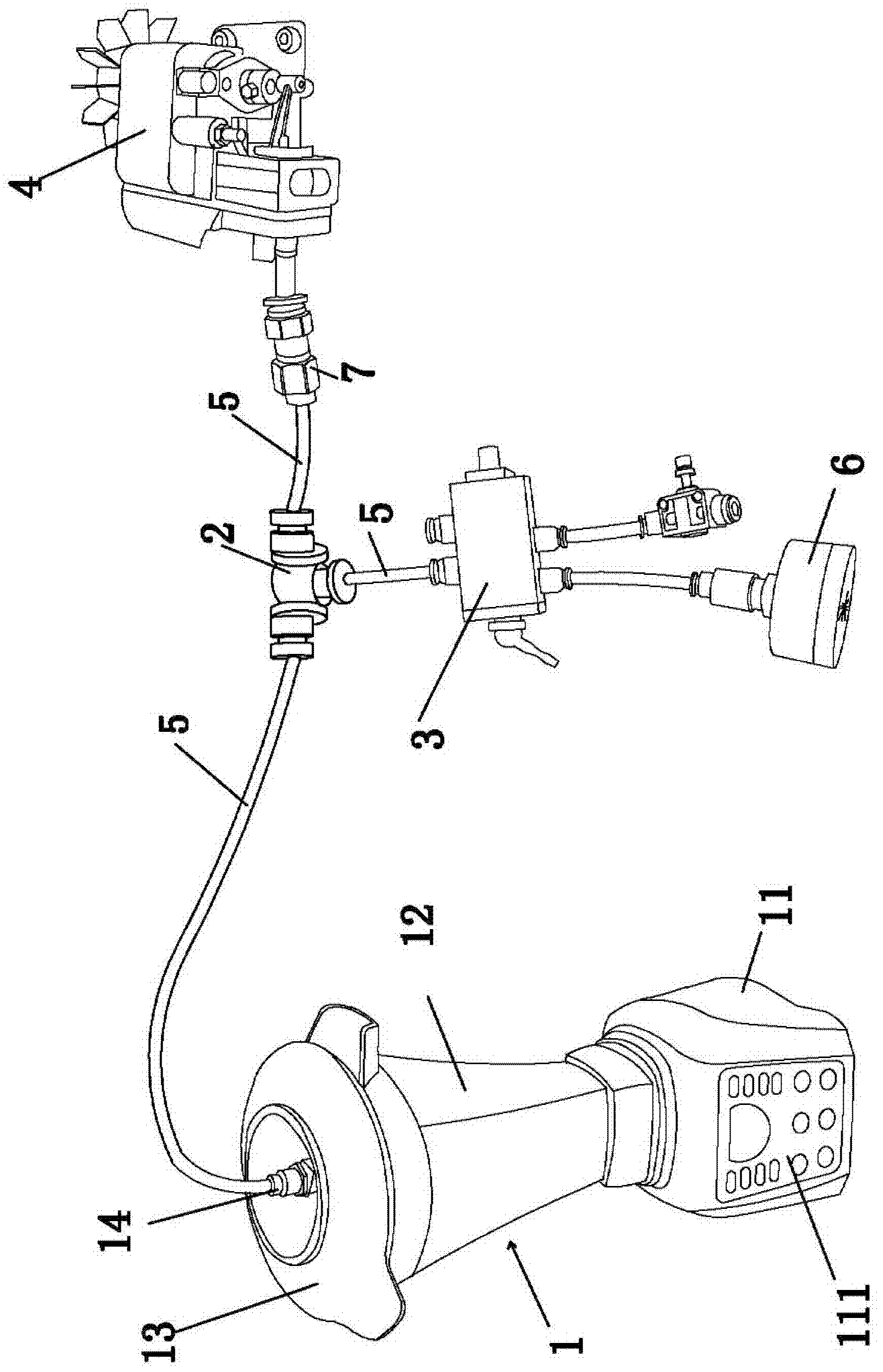

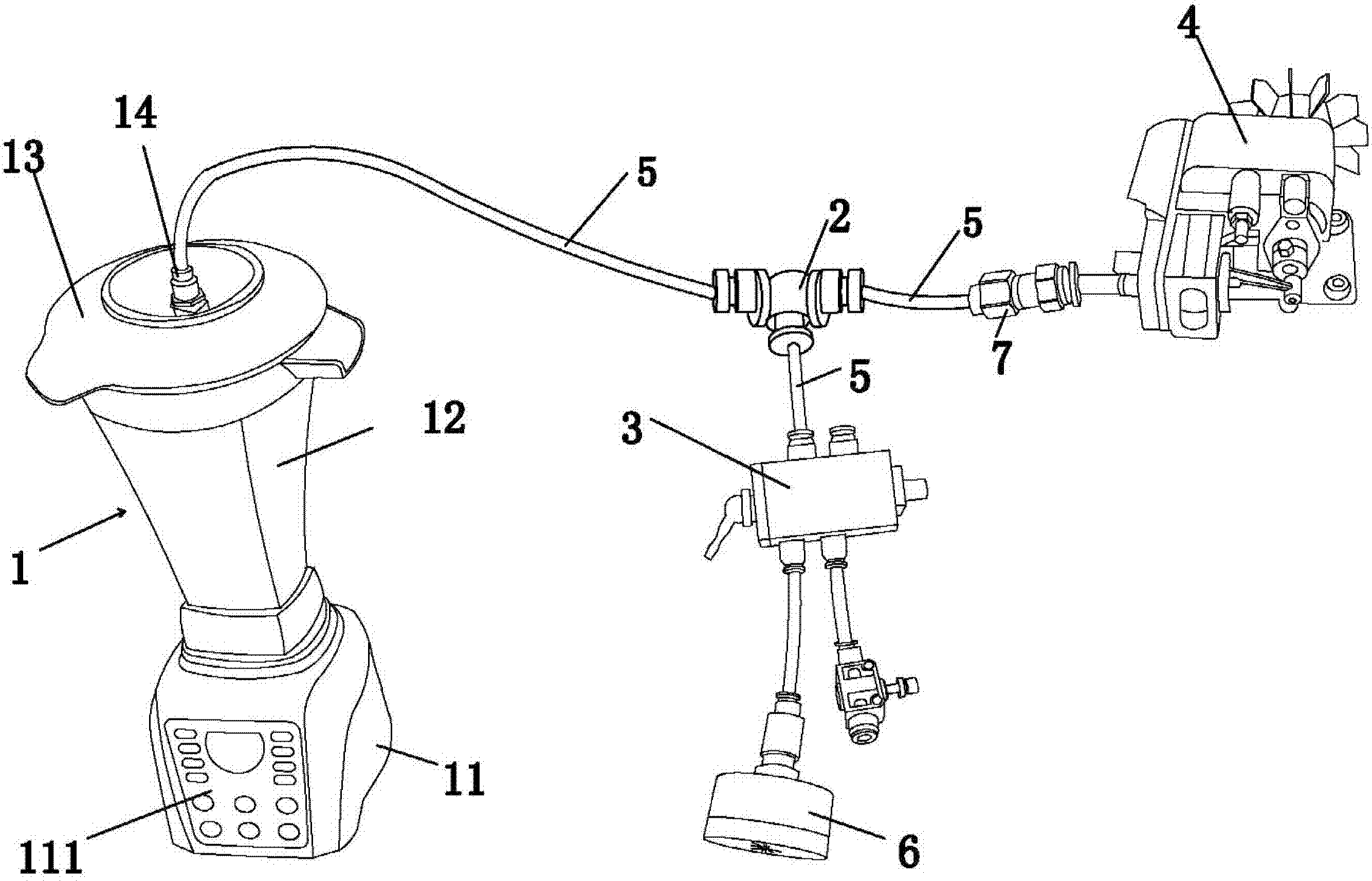

Intelligent motorcycle starting system with Bluetooth transmission and control method of intelligent motorcycle starting system

ActiveCN104192093ASimple structureEasy to installAnti-theft cycle devicesAnti-theft devicesMicrocontrollerPower switching

The invention discloses an intelligent motorcycle starting system with Bluetooth transmission and a control method of the intelligent motorcycle starting system. The intelligent motorcycle starting system is provided with a microcontroller, the microcontroller is communicated with an intelligent terminal through a Bluetooth module, an input end of the microcontroller is connected with a speed / gear detecting circuit, a vibration sensor circuit, a starting button circuit and a power source activating circuit, the output end of the microcontroller is connected with an alarm output circuit, a direction lock control circuit, an integral motorcycle power supply switch circuit and a self-starting switch circuit, and the system is set with a dormant state, a lock-out state and an unlocking state. The intelligent motorcycle starting system has the advantages that the circuits are simple in structure and convenient to mount, a Bluetooth unlocking mode and a single-key button emergency unlocking mode are integrated in the intelligent terminal, and single-key button emergency unlocking can be realized by a starting button of a motorcycle in case of abnormality of the intelligent terminal; meanwhile, speed signals and vibration signals are combined, so that the intelligent motorcycle starting system is capable of automatically locking and starting, good in antitheft effect, high in intelligentization level and energy saving.

Owner:重庆特斯联智慧科技股份有限公司

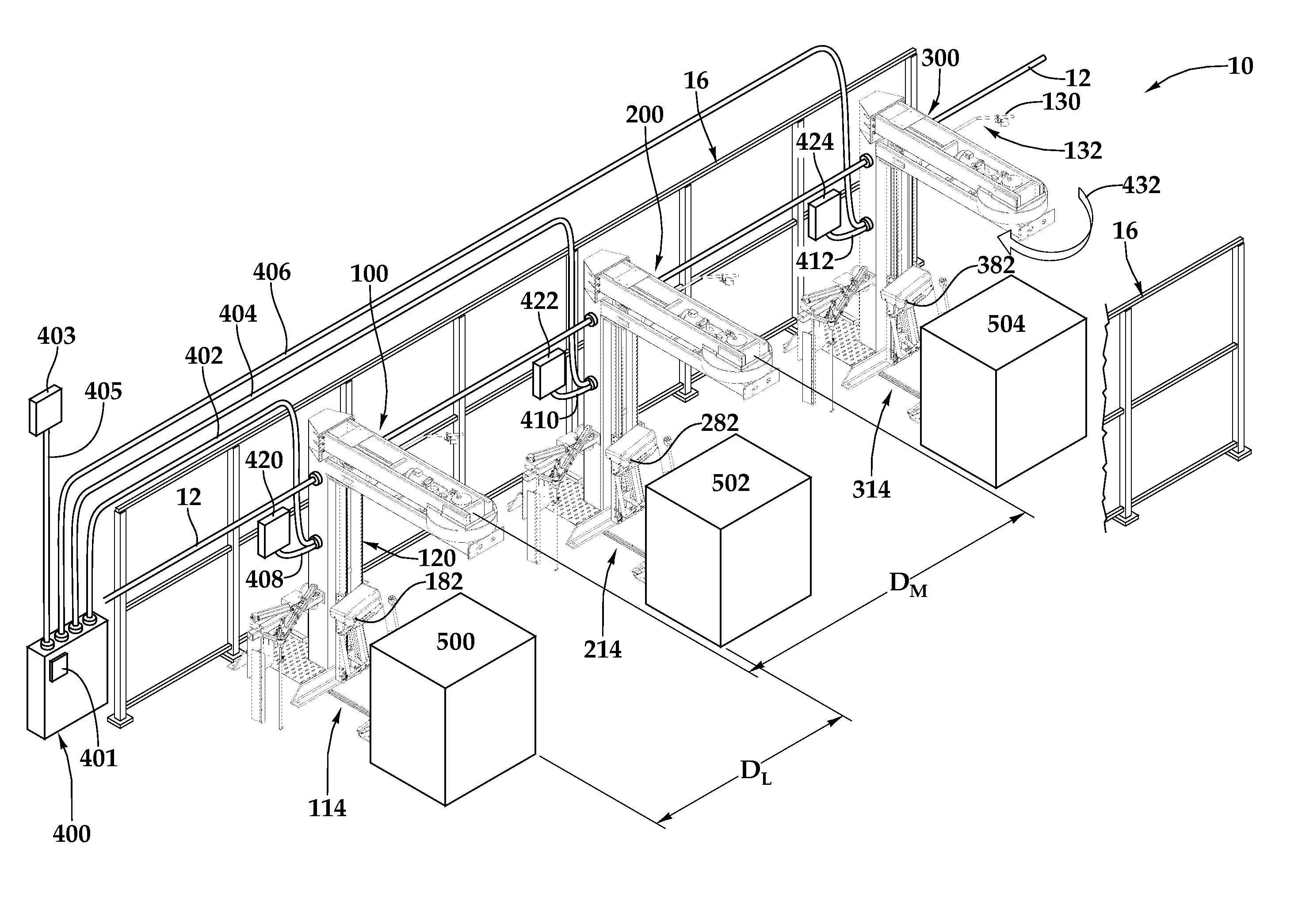

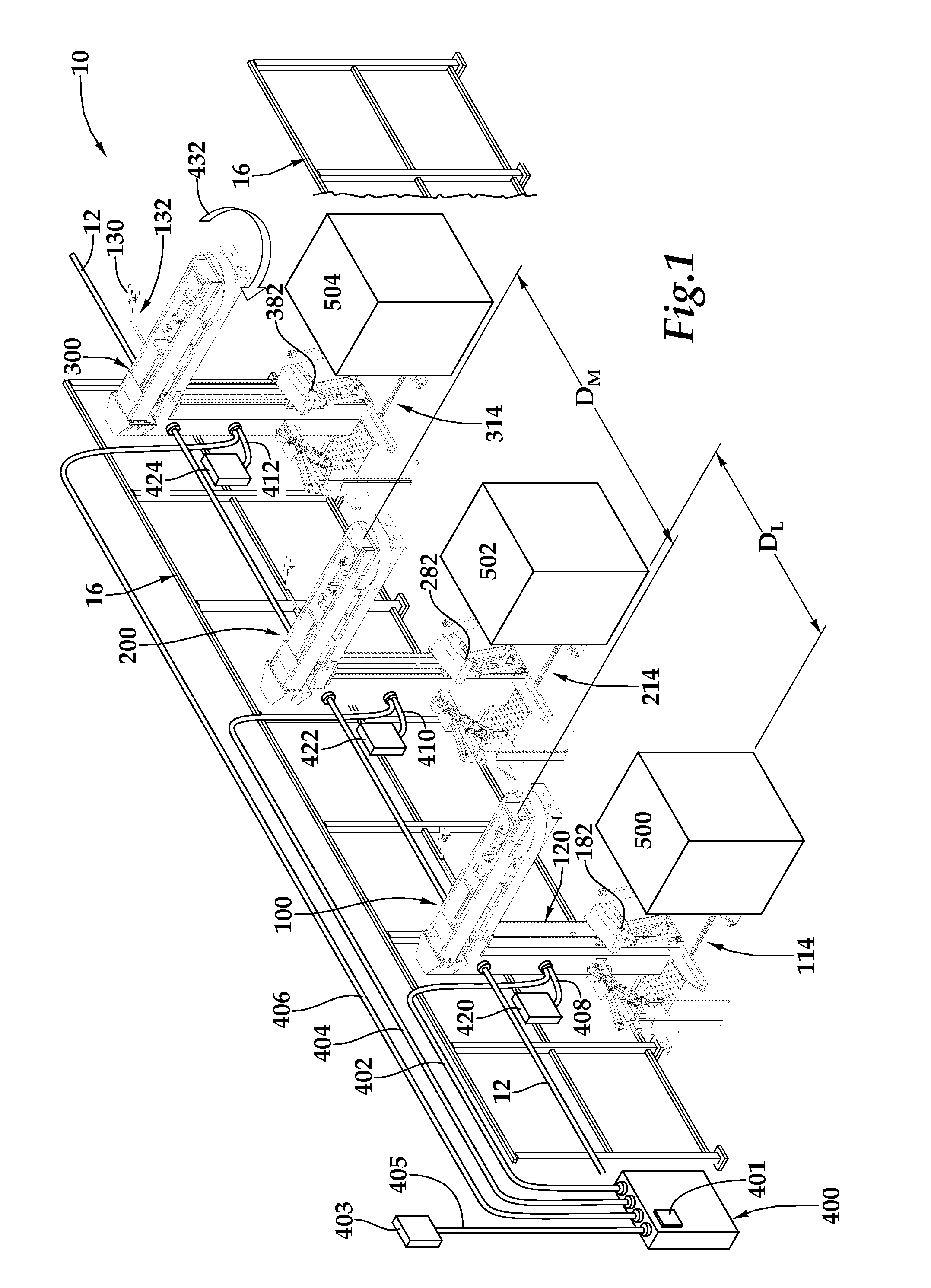

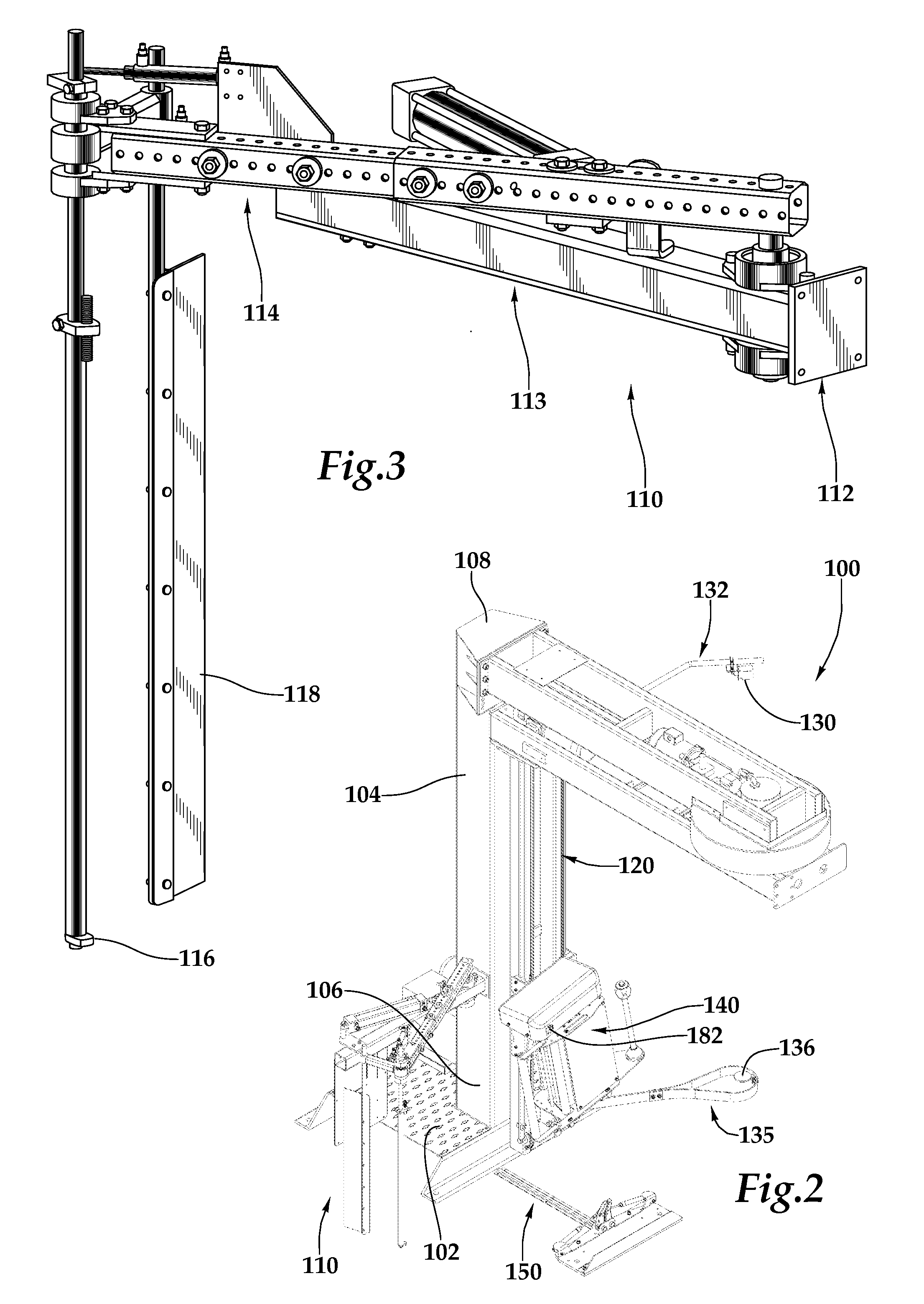

Stretch Wrapping System and Process

In one aspect, a stretch wrap system configured to separately wrap a plurality of loads in film comprising a plurality of stretch wrapping machines, each machine comprising at least one sensing mechanism configured to sense the presence of a load, and a control box electrically coupled to sensing mechanisms, the control box comprising a start button configured to start the machines when sensing mechanisms detect load. In another aspect, a process of operating a system for stretch wrapping comprising positioning at least one load to be wrapped in front of at least one of a first and second machine wherein the first machine includes a sensing mechanism electrically coupled to a control box and wherein the second machine includes a second sensing mechanism electrically coupled to the control box, inputting a start signal through the control box, transmitting a signal from the control box to each of the sensing mechanisms, determining the presence or absence of a load within an operational space of each of the plurality of stretch wrapping machines and wrapping each present load using a respective one of the plurality of stretch wrapping machines.

Owner:BEST PACKAGING

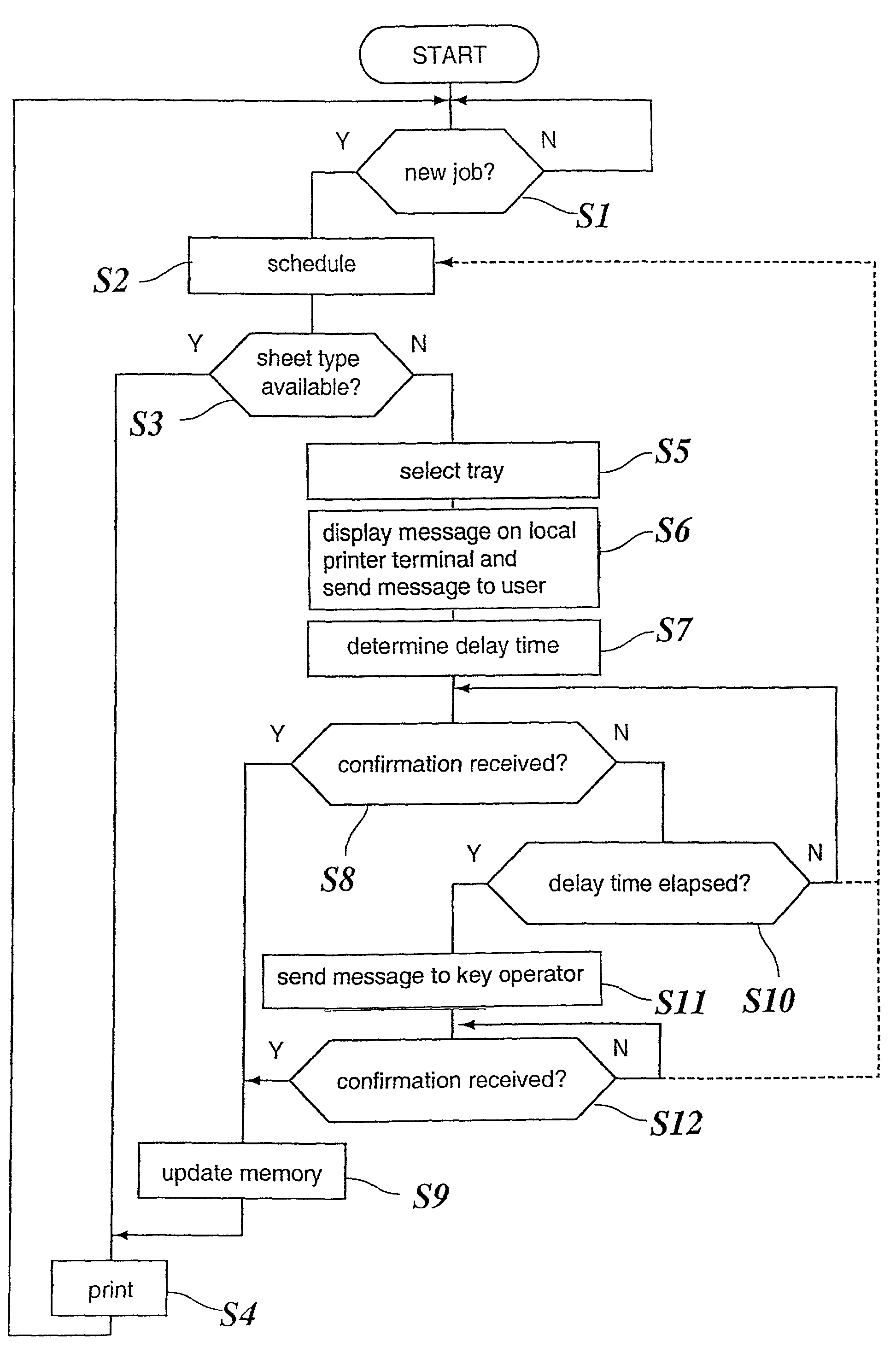

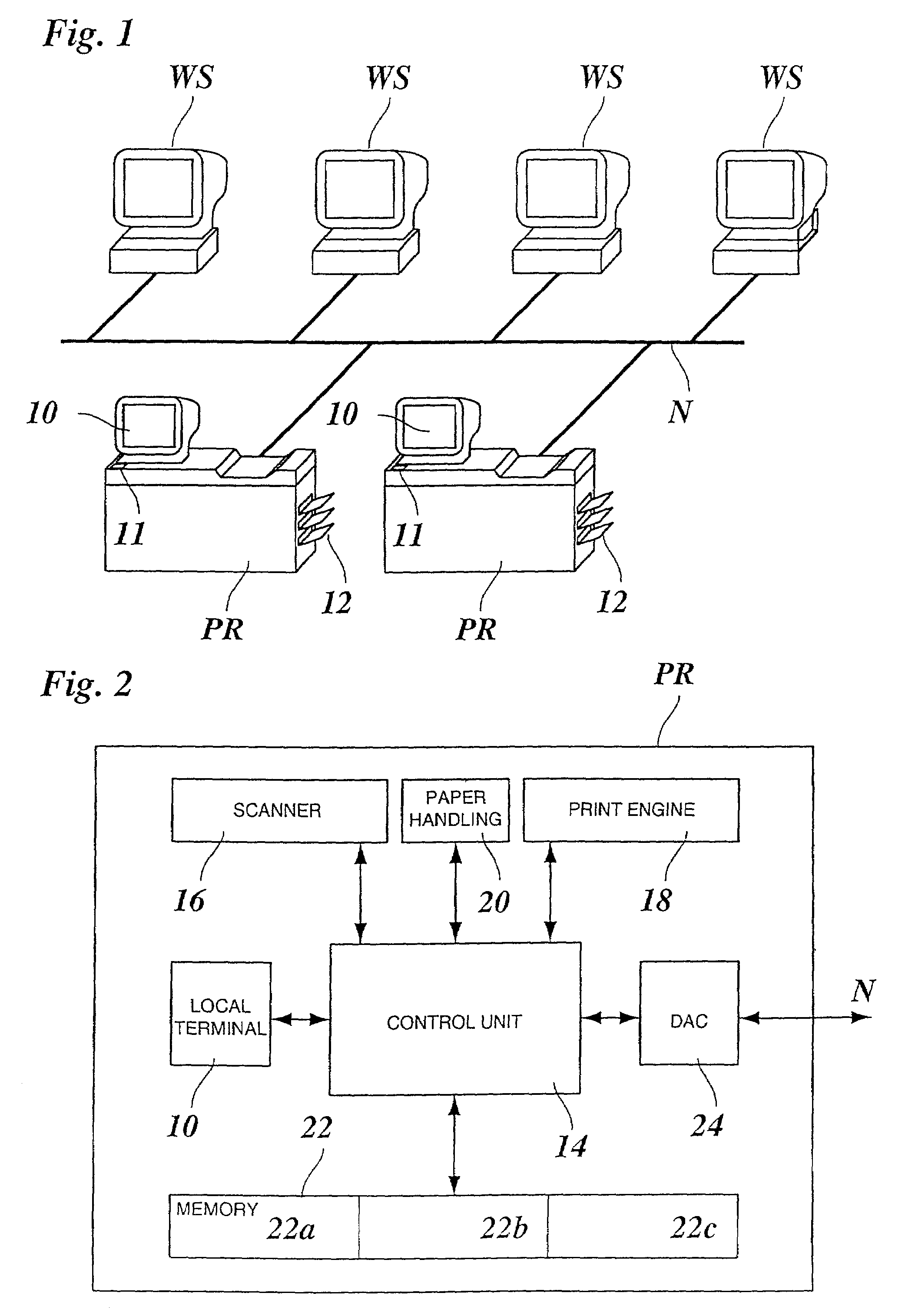

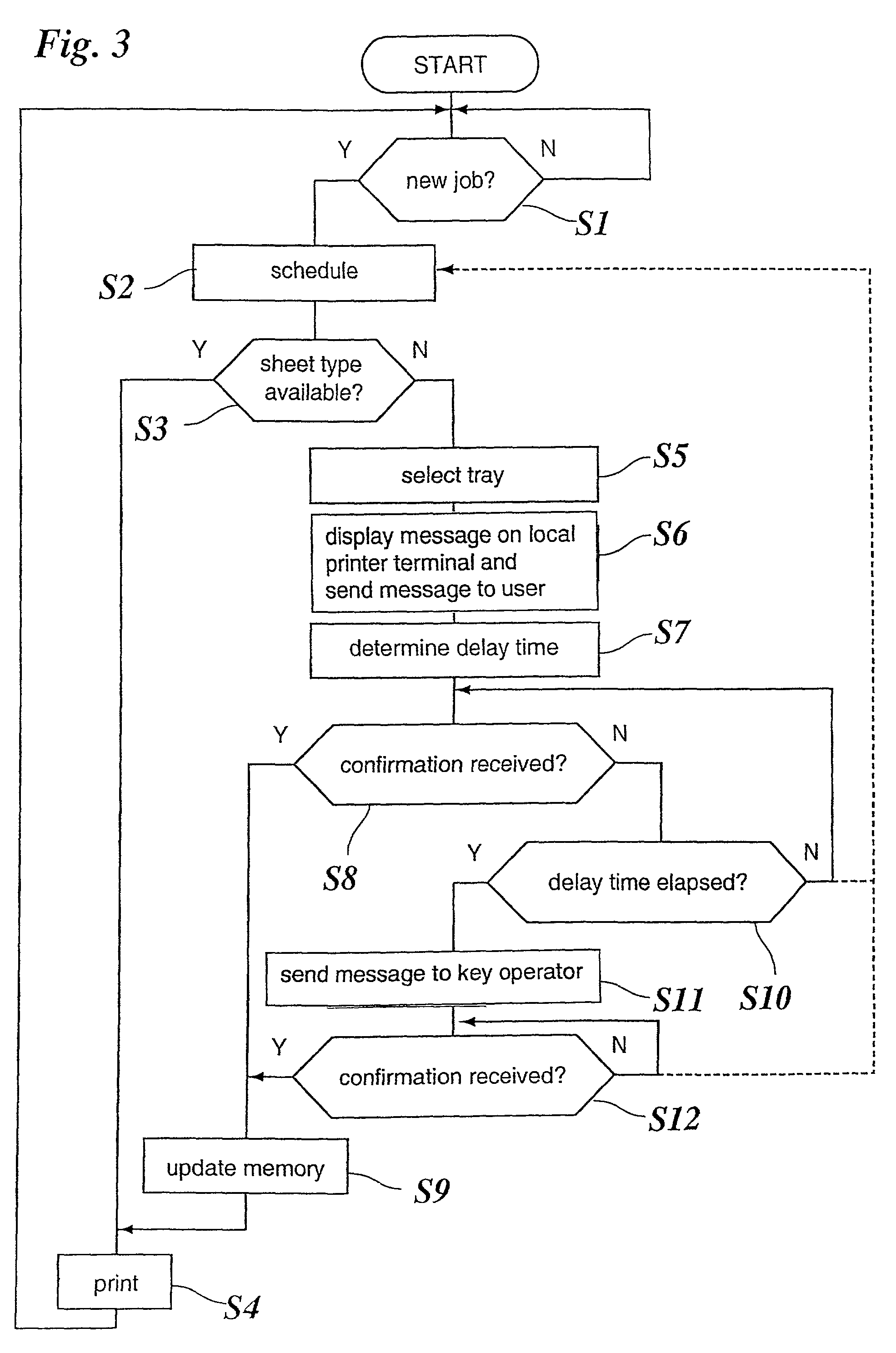

Recording material management in a copier or printer

InactiveUS7355733B2Simplifying and speeding up the process of loading the required type of recording sheetsSimple processDigitally marking record carriersDigital computer detailsControl systemElectronic control system

Disclosed is a digital image production apparatus comprising: a print engine having a plurality of trays each of which is capable of accommodating different types of recording sheets; a user interface; and an electronic control system controlling print processing, including control of supply of recording sheets from the trays in accordance with sheet specifications of print jobs. Such a control system has access to a memory which stores for each tray the type of recording sheets presently accommodated therein, and when the type of recording sheet required for a job is not available in any of the trays, indicates, through the user interface, the required type of recording sheet and invites an operator to place recording sheets of the required type in a specific tray. In response to a confirmation signal which simply confirms that the operator has completed the requested action, the control system automatically stores information specifying the required type of recording sheet in a location of the memory associated with said specific tray. Such a confirmation signal would e.g. be generated when the operator presses the start button. Alternatively, the control system may leave the selection of a tray to the operator, in which case the confirmation signal should include an indication of the tray the operator has chosen.

Owner:OCE TECH

Simultaneous induction quenching technology for flange-output shaft neck and end face

ActiveCN101509061AEvenly distributedEasy loading and unloadingIncreasing energy efficiencyFurnace typesHardnessCooling capacity

The invention relates to a technique for induction-quenching the axle journal and the end surfaces of a flange-output axle simultaneously. The invention is characterized in that the technique comprises the following steps: placing parts to be quenched with end surfaces upward on a rotary base; pressing down a start button to start rotating a workpiece, so that the metal parts adjacent to active wires are heated for 5 seconds; stop heating when the parts are heated to a temperature 50 DEG C higher than the austenitizing temperature of the material; cooling by spraying cooling water; and then, finishing the quenching process of the part by taking the part down from the rotary base when the cooling is finished. The technique ensures that hardening layers can be distributed evenly, prevents the quenching crack from generating, improves the cooling capacity and uniformity during the cooling process in quenching and ensures that the hardness of the quenched surface is even; the invention has the advantages of simple structure, short process time, high production efficiency, energy conservation and low process cost; the hardening layers are continuously distributed from the axle journal to the end surfaces without tempering soft zone, and evenly distributed except for the tip part; and the technique provides convenience for part assembly and disassembly and technique adjustment, so that spraying and part disassembling can be finished at two positions.

Owner:CHINA FIRST AUTOMOBILE

Method of delivering difference map data

ActiveUS7428460B2Low costShorten the timeInstruments for road network navigationRoad vehicles traffic controlDifference-map algorithmDisplay device

The present invention provides, in a car navigation system, a unit of notifying a user of the update contents of map data prior to the downloading of the map data. A vehicle-mounted terminal sets a difference update area in accordance with a selection made by a user and sends a difference update request to a map updating server. If an update mode in this case is “update after outline display”, the vehicle-mounted terminal downloads an outline update map from the map updating server. The outline update map is displayed on a display unit of a display. Here, when a download start button displayed on the display unit is depressed, the vehicle-mounted terminal downloads a detailed update map from the map updating server. The detailed update map is then displayed on the display unit of the display. Furthermore, an updating process is performed on the map data stored in a terminal DB.

Owner:HITACHI LTD

Bubble-free high-speed fruit juice/food vacuum stirring method and stirrer thereof

The invention discloses a bubble-free high-speed fruit juice / food vacuum stirring method and a stirrer thereof, relating to the field of stirrers. The stirring method disclosed by the invention comprises the following steps of: feeding articles to be stirred to a stirring cup and powering on a power supply; sealing the stirring cup and connecting a vacuum ducting; pushing a start button; beginning to test air pressure in the stirring cup by a system; starting operating a vacuum pump; when the air pressure in the stirring cup is lower than 300mbar, starting stirring; finishing stirring and stopping the vacuum pump; opening an air intake valve to enable air to return to the stirring cup; and ending stirring. According to the invention, the stirring process is carried out under a vacuum condition, and no bubbles or fewer bubbles occur, so that the condition that a large amount of bubbles are mixed in fruit juice / food is avoided. The bubble-free high-speed fruit juice / food vacuum stirring method and the stirrer thereof disclosed by the invention have the advantages of being capable of producing health beverages with abundant fibers and smooth mouthfeel and further reducing oxidation between air and food / fruit juice heated under high speed.

Owner:杨志文

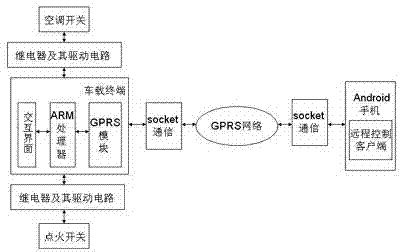

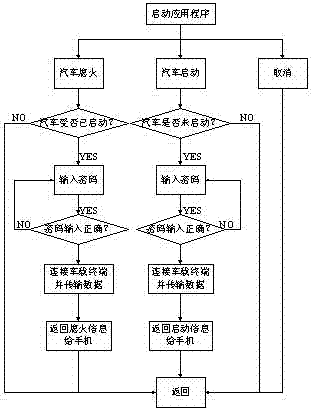

Device for remotely controlling automobile by mobile phone and control method

InactiveCN102891885ATelephonic communicationMessaging/mailboxes/announcementsGeneral Packet Radio ServiceIn vehicle

The invention provides a device for remotely controlling an automobile by a mobile phone and a control method, so that an automobile owner can remotely start the automobile and switch on an air conditioner. The device for remotely controlling the automobile comprises the mobile phone, a vehicle-mounted terminal, a relay and a driving circuit of the relay, wherein the vehicle-mounted terminal comprises a general packet radio service (GPRS) module, an advanced RISC machine 11 (ARM11) processor and a human-machine interaction interface; the mobile phone is an Android intelligent mobile phone and transmits data to the vehicle-mounted terminal through a socket communication mode of a transmission control protocol (TCP); and the vehicle-mounted terminal is connected with the relay through an input / output port. The control method for remotely controlling the automobile by the mobile phone comprises the following steps that: the vehicle-mounted terminal regularly sends a connection request to the mobile phone; a user clicks a starting button to receive the connection request by using a mobile phone application program and sends a corresponding instruction to the vehicle-mounted terminal; and the vehicle-mounted terminal operates the relay connected to a corresponding IO port according to a resolved instruction content. Therefore, the aim of controlling an ignition switch and an air conditioner switch of the automobile is fulfilled.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com