Simultaneous induction quenching technology for flange-output shaft neck and end face

An induction quenching and output shaft technology, applied in the direction of quenching agent, furnace type, furnace, etc., can solve the problems of affecting the performance of parts, low production efficiency, long process route, etc., to avoid quenching cracks, high production efficiency, and process time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

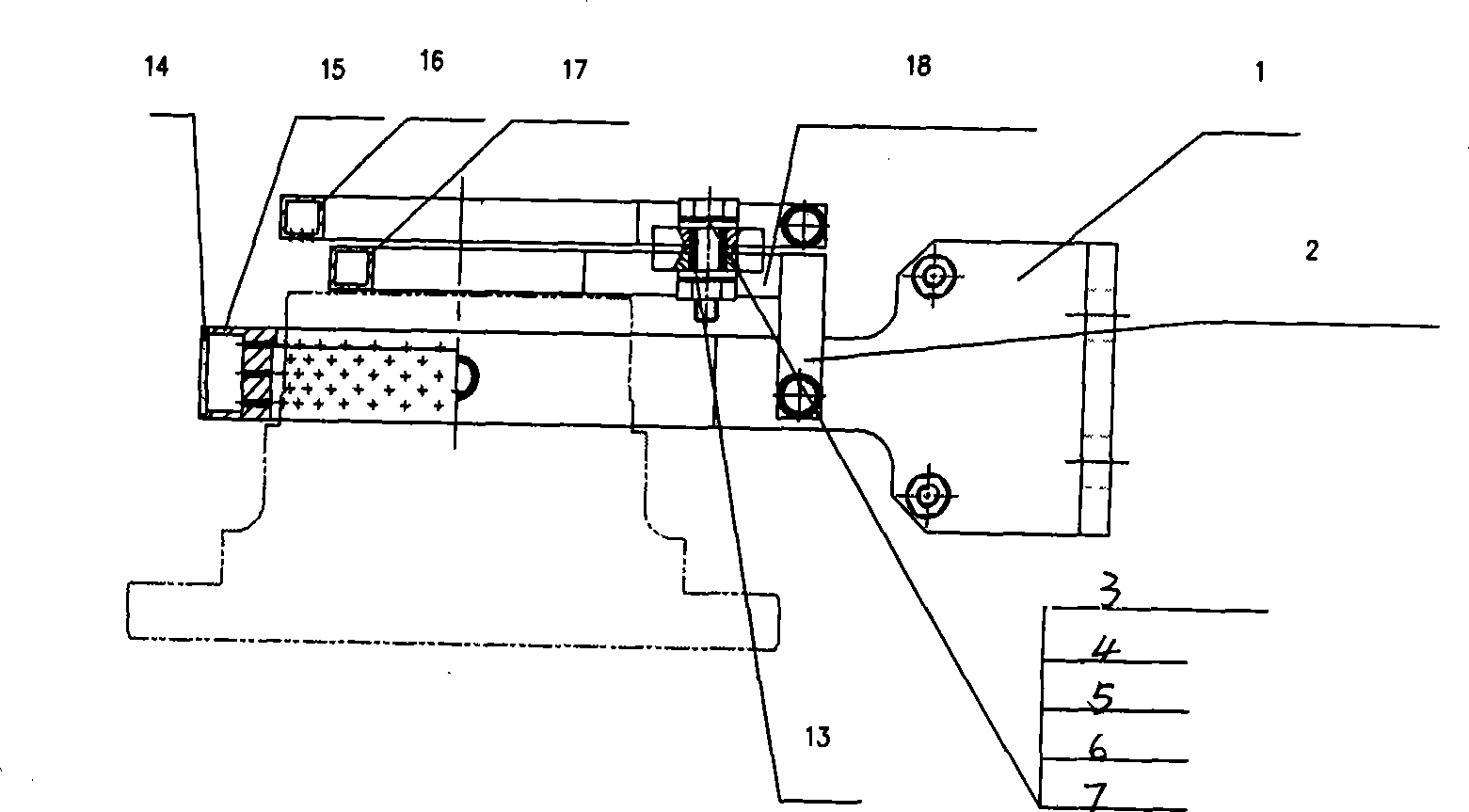

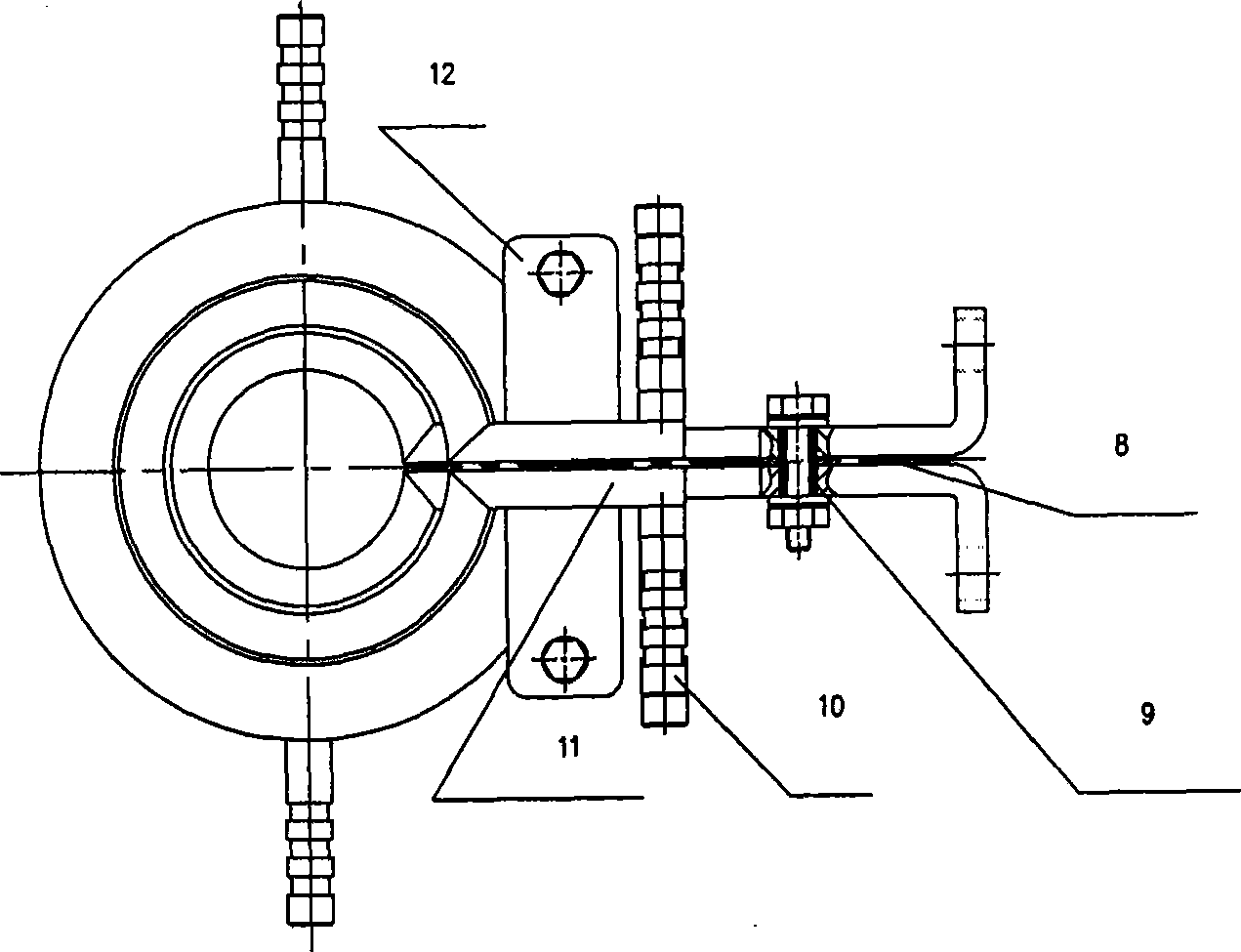

[0010] Below in conjunction with accompanying drawing, the present invention is further described: flange-output shaft journal and end face induction hardening technology simultaneously, it is characterized in that: (A) the contact plate of inductor is fastened together with the quenching transformer of quenching lathe; Under the condition that the cooling water and quenching water channel are guaranteed to be unobstructed, place the parts on the rotating base of the quenching machine tool, and place the parts to be quenched on a rotating base with a stop that fits with the gap; (B) press Press the start button, the workpiece starts to rotate, and the inductor quickly descends to the position where the part needs to be heated to start heating. A magnetic field is generated nearby, and under the action of an alternating magnetic field, an induced current (eddy current) is generated in a metal part placed near the effective wire to heat the part, and the heating time is 5 seconds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com