Patents

Literature

66results about How to "Uniform surface hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

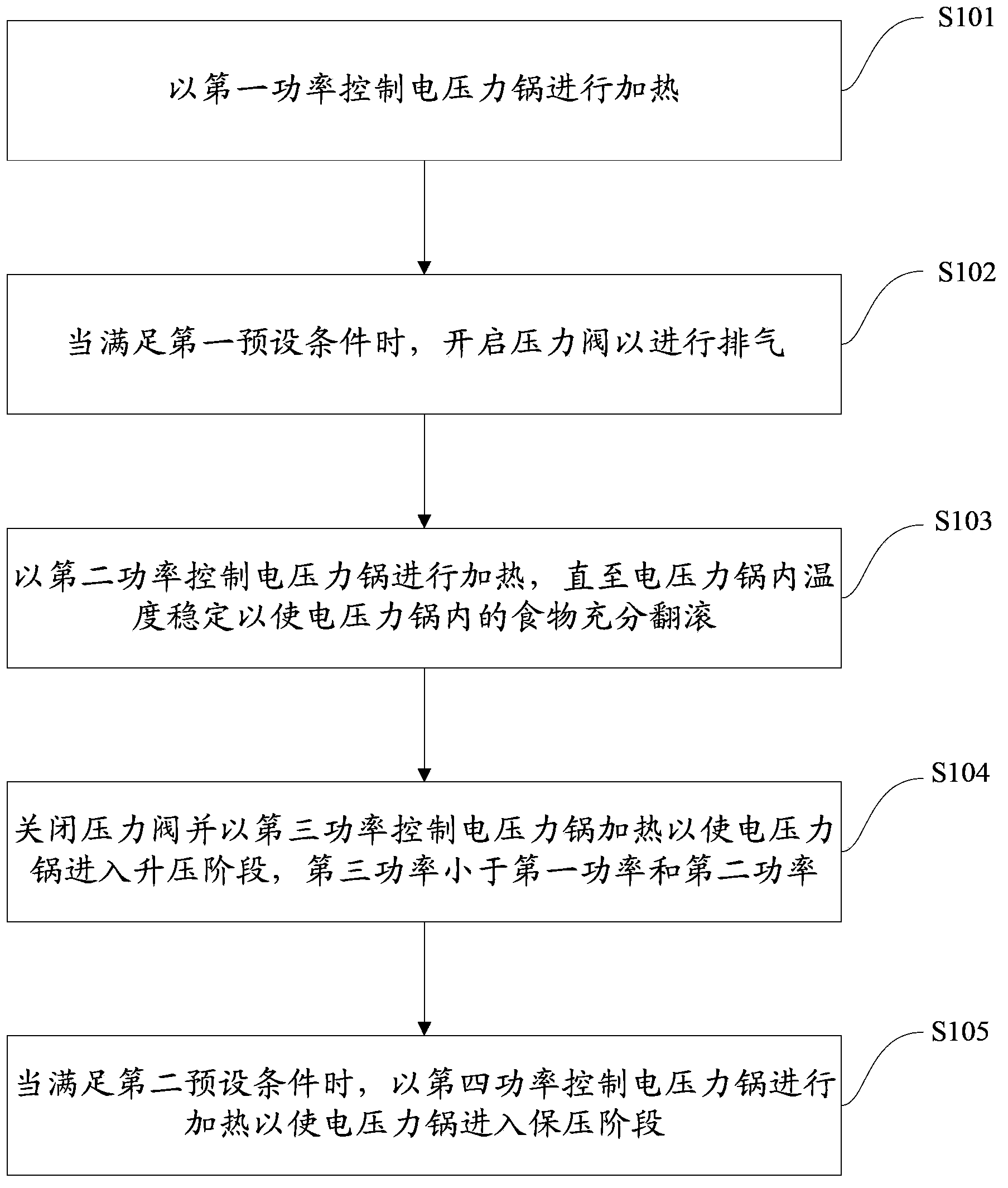

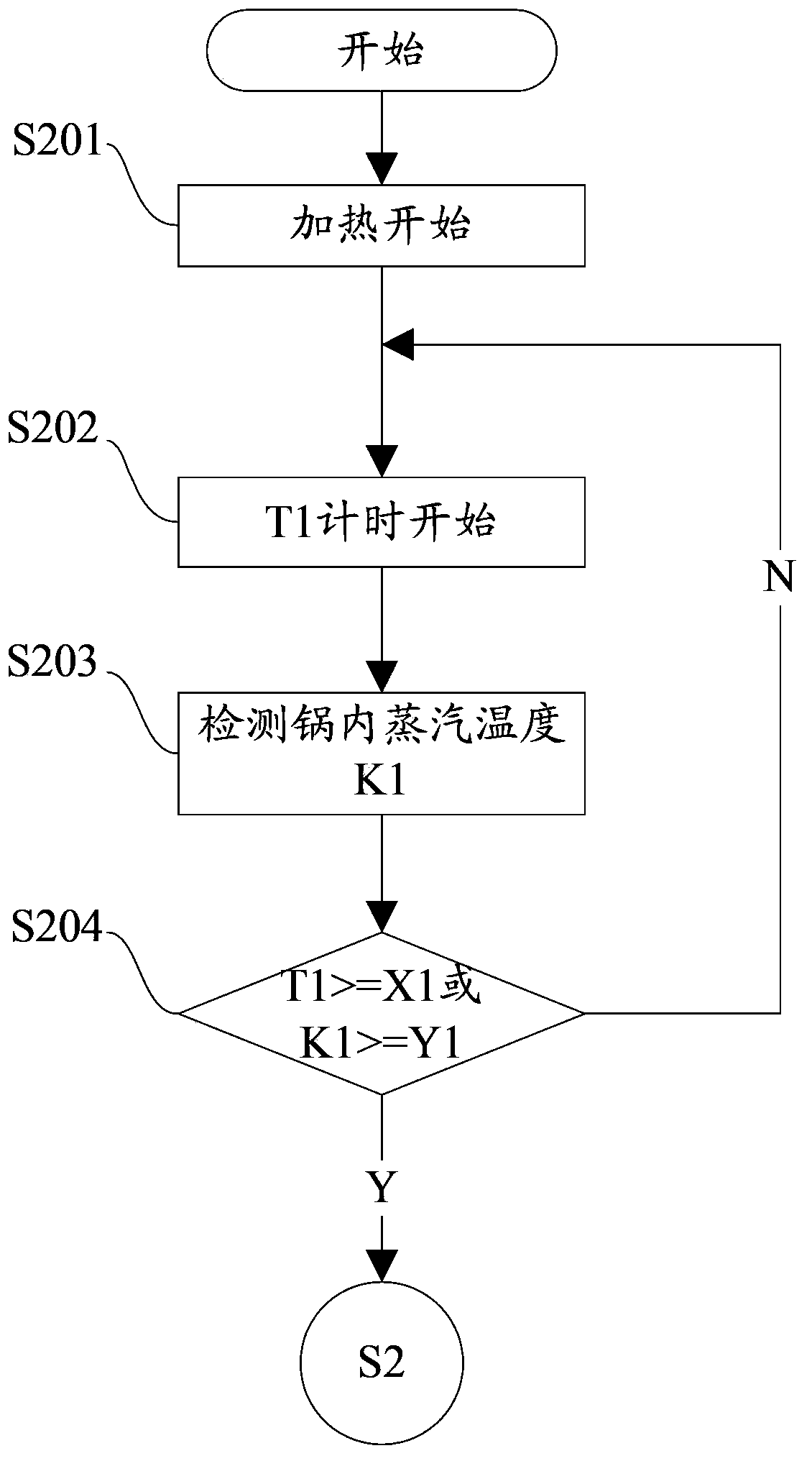

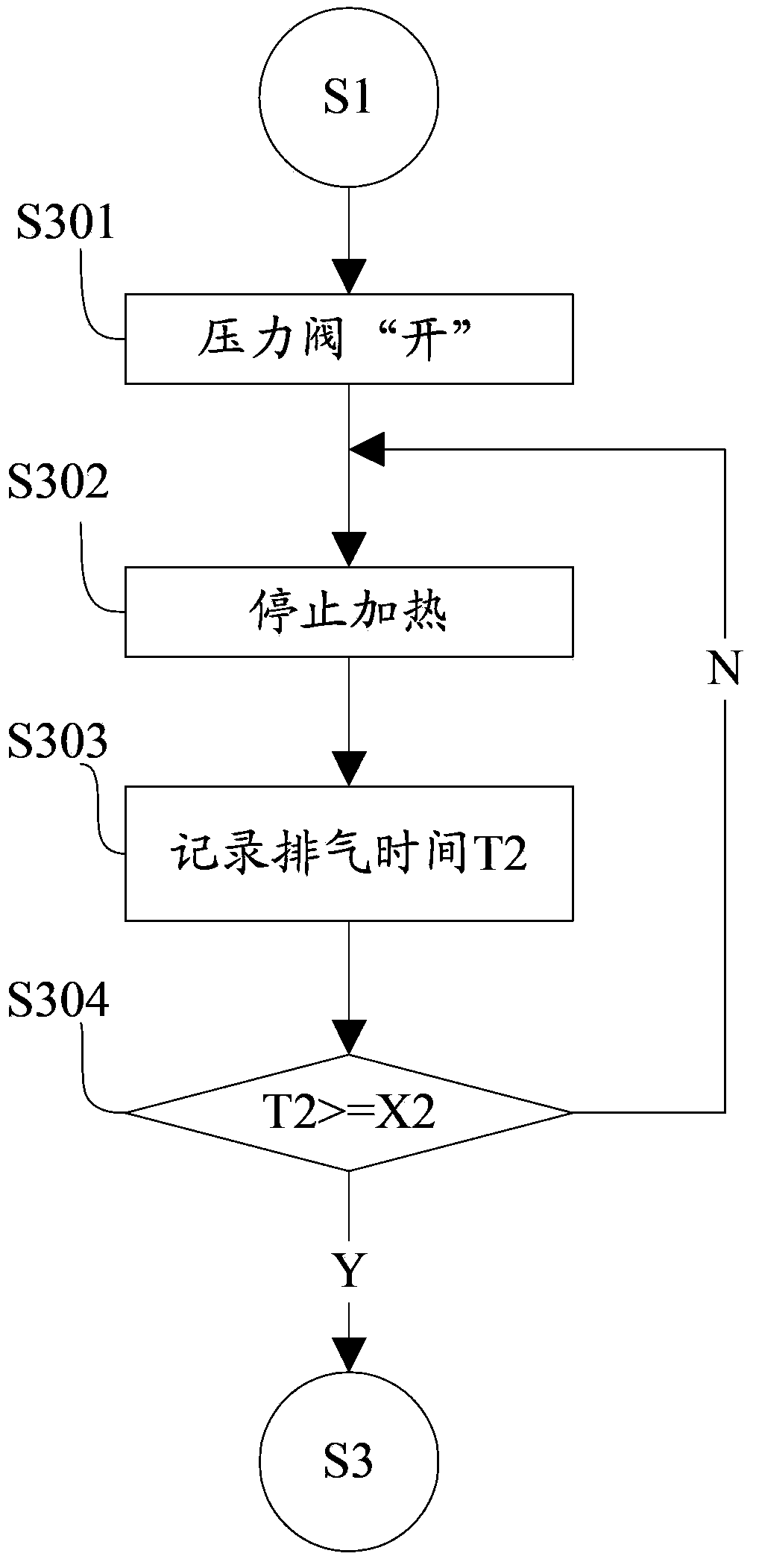

Electric pressure cooker control method and electric pressure cooker

ActiveCN103654373AUniform surface hardnessSufficient flexibilityPressure-cookersEngineeringCooked food

The invention provides an electric pressure cooker control method which comprises the following steps that an electric pressure cooker is controlled to heat with first power; when a first preset condition is met, a pressure valve is opened, so that air is discharged; the electric pressure cooker is controlled to heat with second power until the temperature in the electric pressure cooker is stable and food in the electric pressure cooker is made to be turned over completely; the pressure valve is closed and the electric pressure cooker is controlled to heat with third power, so that the electric pressure cooker enters a boosting stage, and the third power is smaller than the first power and the second power; when a second preset condition is met, the electric pressure cooker is controlled to heat with fourth power, so that the electric pressure cooker enters a pressure maintaining stage. According to the electric pressure cooker control method, the cooked food is complete, moisture is sufficient, the hardness is even, the taste is good, and the cooked food is prevented from pasting the bottom of the cooker and overflowing out of the cooker. The invention further provides the electric pressure cooker.

Owner:MIDEA GRP CO LTD

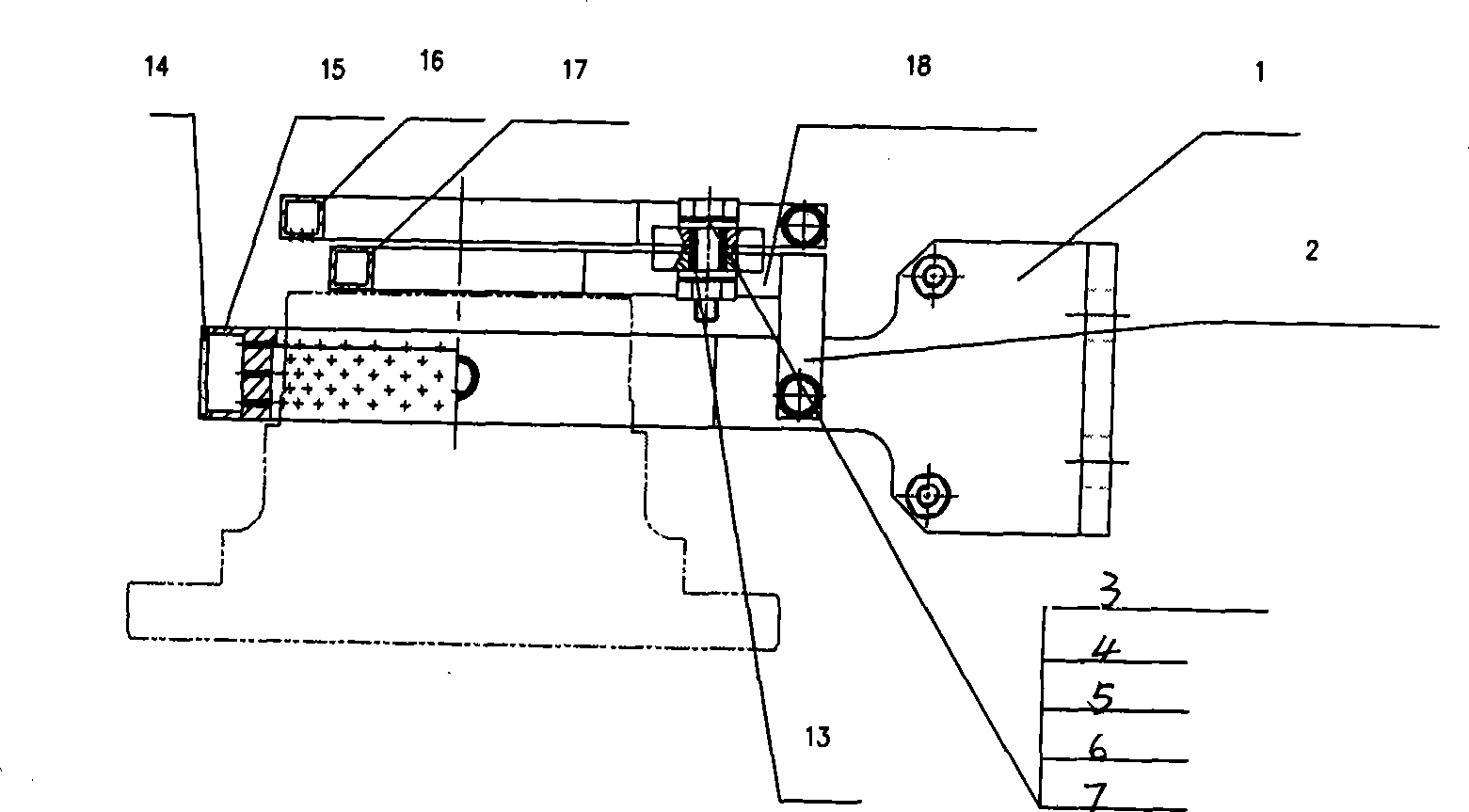

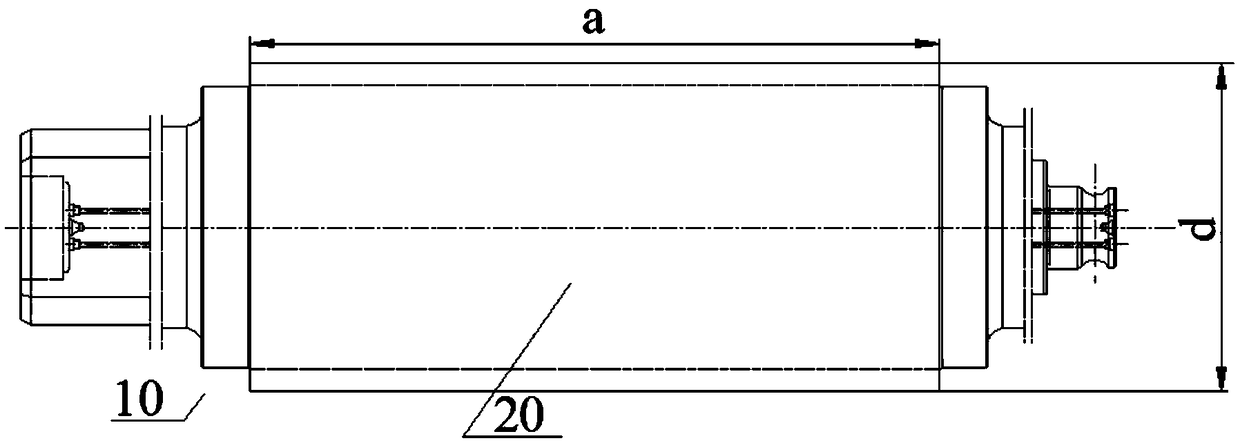

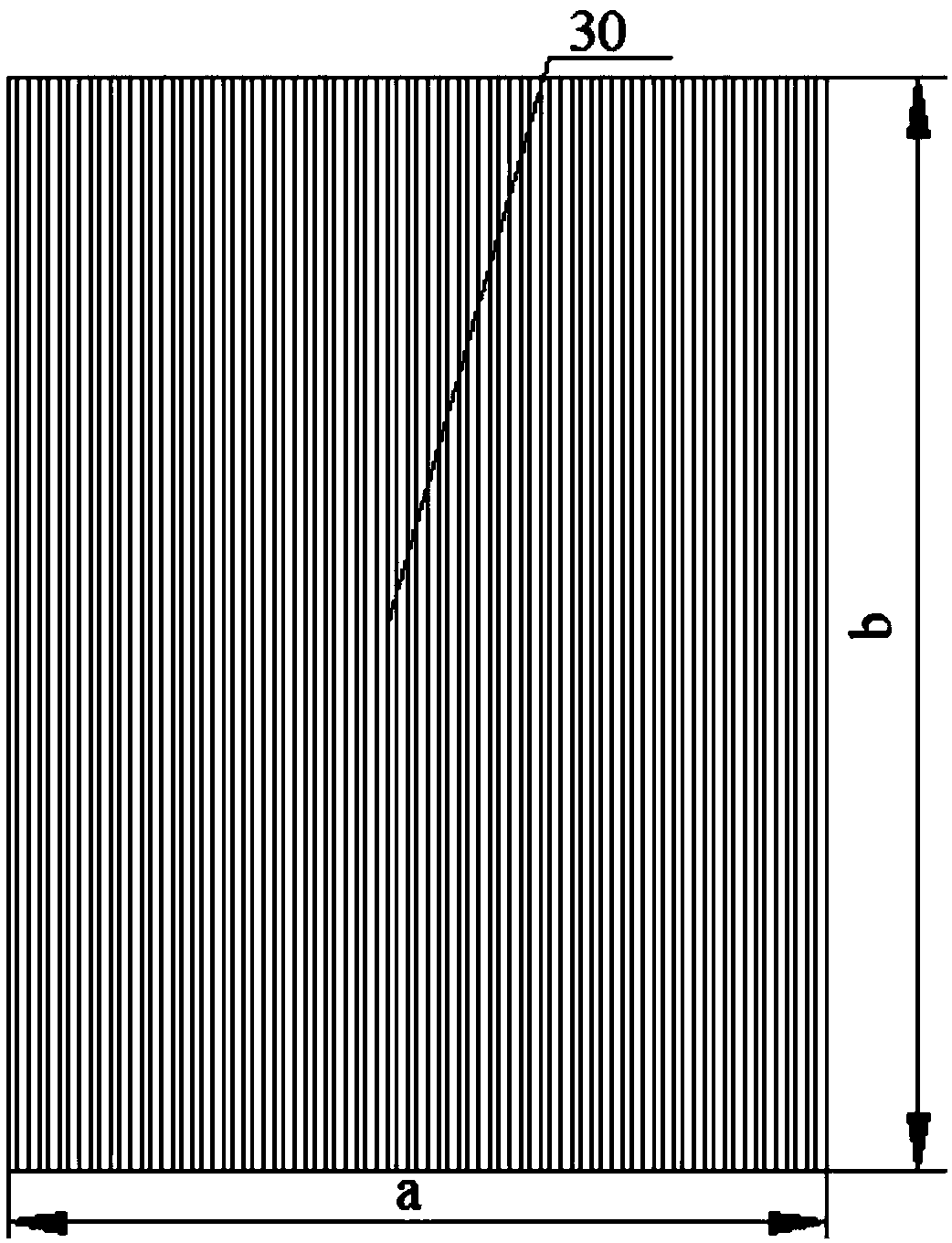

Simultaneous induction quenching technology for flange-output shaft neck and end face

ActiveCN101509061AEvenly distributedEasy loading and unloadingIncreasing energy efficiencyFurnace typesHardnessCooling capacity

The invention relates to a technique for induction-quenching the axle journal and the end surfaces of a flange-output axle simultaneously. The invention is characterized in that the technique comprises the following steps: placing parts to be quenched with end surfaces upward on a rotary base; pressing down a start button to start rotating a workpiece, so that the metal parts adjacent to active wires are heated for 5 seconds; stop heating when the parts are heated to a temperature 50 DEG C higher than the austenitizing temperature of the material; cooling by spraying cooling water; and then, finishing the quenching process of the part by taking the part down from the rotary base when the cooling is finished. The technique ensures that hardening layers can be distributed evenly, prevents the quenching crack from generating, improves the cooling capacity and uniformity during the cooling process in quenching and ensures that the hardness of the quenched surface is even; the invention has the advantages of simple structure, short process time, high production efficiency, energy conservation and low process cost; the hardening layers are continuously distributed from the axle journal to the end surfaces without tempering soft zone, and evenly distributed except for the tip part; and the technique provides convenience for part assembly and disassembly and technique adjustment, so that spraying and part disassembling can be finished at two positions.

Owner:CHINA FIRST AUTOMOBILE

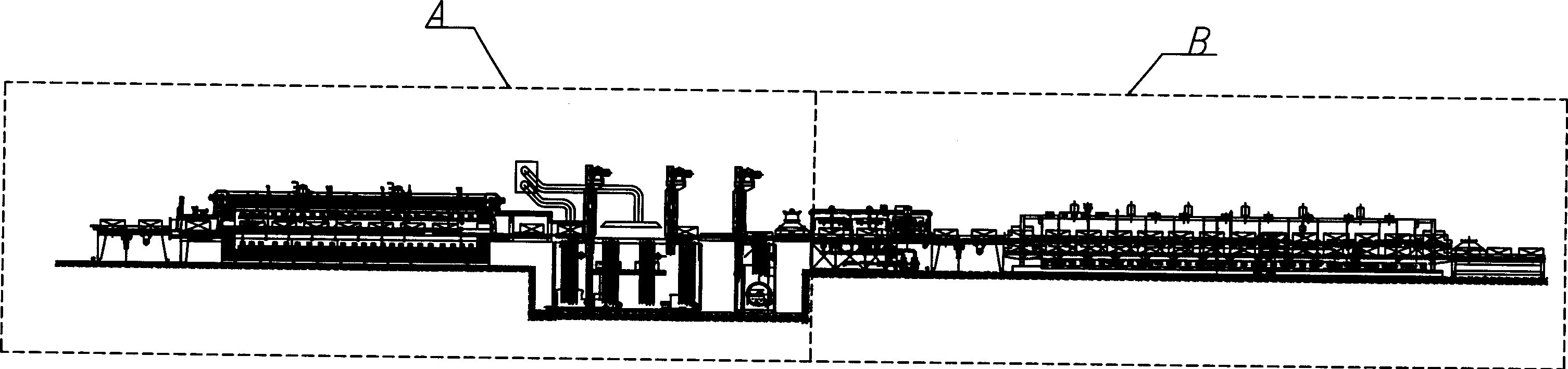

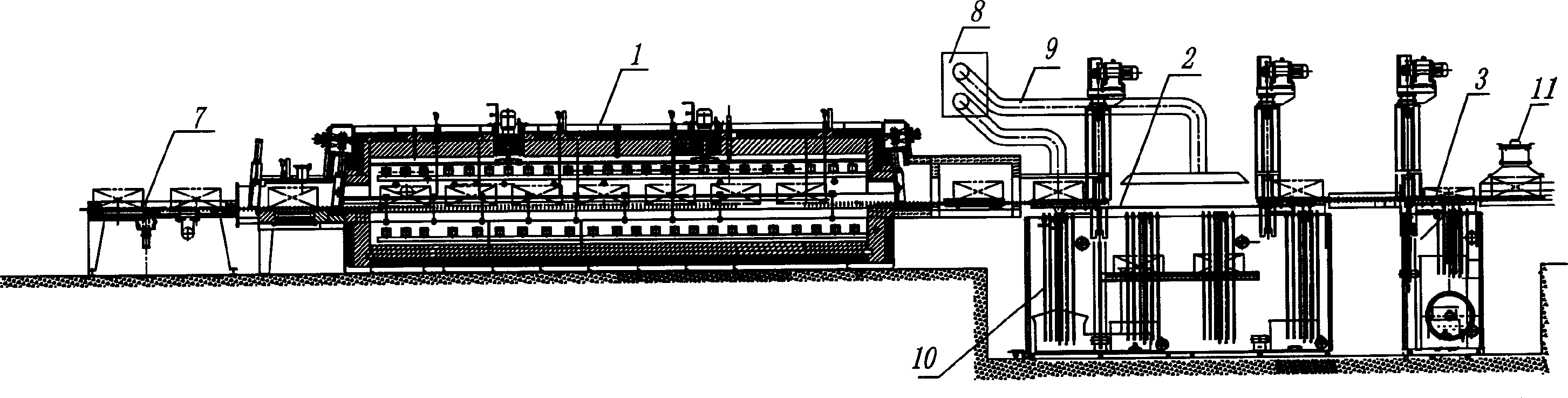

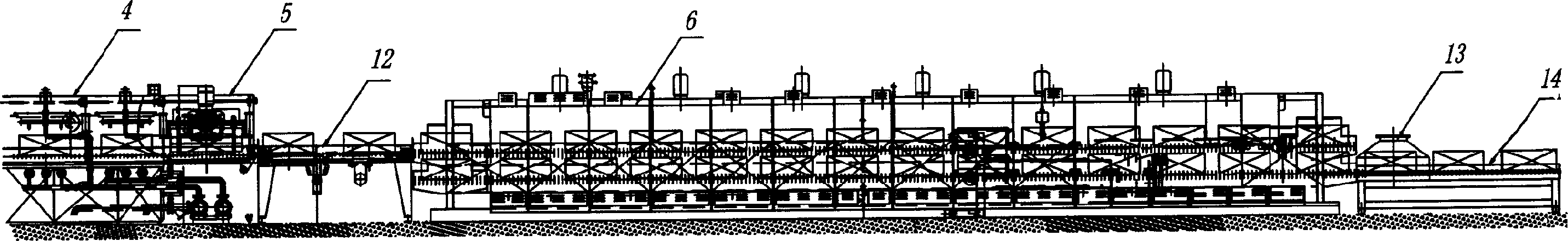

Stepped quenching process and its apparatus suitable for bainite and martensite quenching

InactiveCN1884592ASimple processing methodImprove the quality of heat treatmentQuenching agentsQuenching devicesProduction lineHearth

This invention involves a kind of step quenching process which is suitable for Bainitic and Martensite quenching and the equipment utilizing this step quenching process. The workflow includes: heating, quenching in low-temperature nitrate groove and isothermal; turn to oil grooves to cool down, wash and dry; turn to air furnace for isothermal temper. The above step quenching is performed in roller hearth furnace production line. After adjusting the technology parameter, this production line can undergo Bainitic step quenching and Martensite step quenching. This production line is composed mainly by roller hearth heating furnace, nitrate groove, oil groove, cleaner, dryer and temper furnace. This invention can improve the heat treatment quality; reduce the amount of nitrate and pollution. This production line can undergo normal Martensite quenching, Martensite step quenching and Bainitic step quenching, so to reduce investiment and increase the effeiciency.

Owner:北京时代新人轴承有限公司 +1

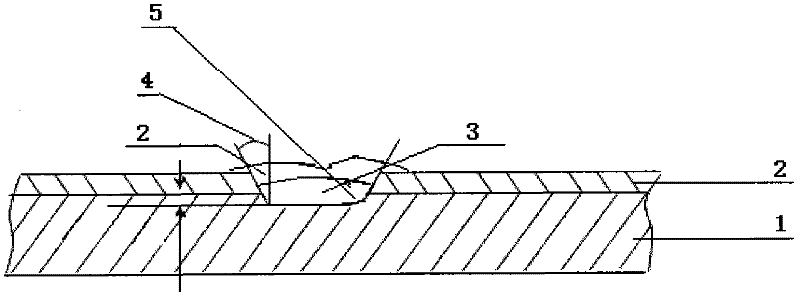

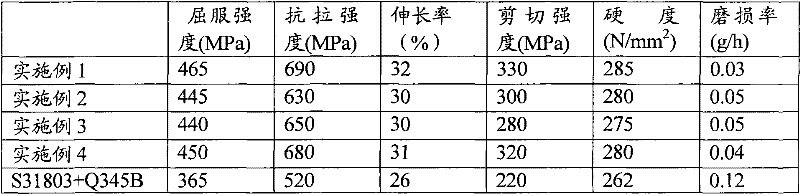

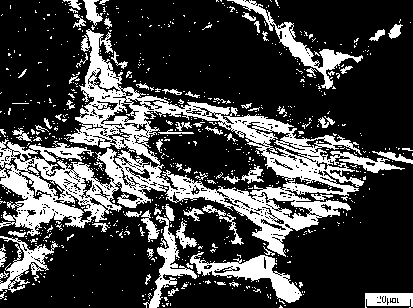

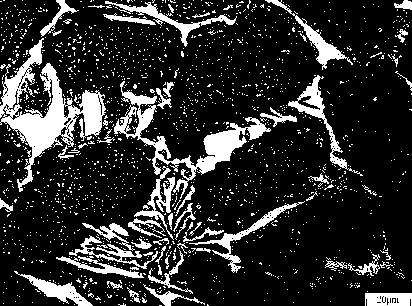

Hydraulic engineering composite plate and preparation method for same

ActiveCN102528265AImprove mechanical propertiesUniform surface hardnessMetal layered productsNon-electric welding apparatusNiobiumNitrogen

The invention relates to a hydraulic engineering composite plate and a preparation method for the same. The composite plate comprises a base plate and a compound plate, and is characterized in that the base plate is a structural carbon steel plate or a vessel plate, the compound plate is a niobium nitrogen austenite stainless steel plate, the base plate and the compound plate are combined to form the composite plate through atoms, and the composite plate is mainly used for a sand washing pipe and a gate. The preparation method for the composite plate includes the steps: firstly treating the surfaces of the base plate and the compound plate; explosively welding the treated base plate and the treated compound plate; additionally welding the composite plate after explosive welding; and performing heat treatment for the composite plate after additional welding. The shear strength of the obtained composite plate ranges from 280MPa to 330MPa, and the surface hardness of the obtained composite plate ranges from 275N / mm2 to 285N / mm2.

Owner:太原钢铁(集团)有限公司

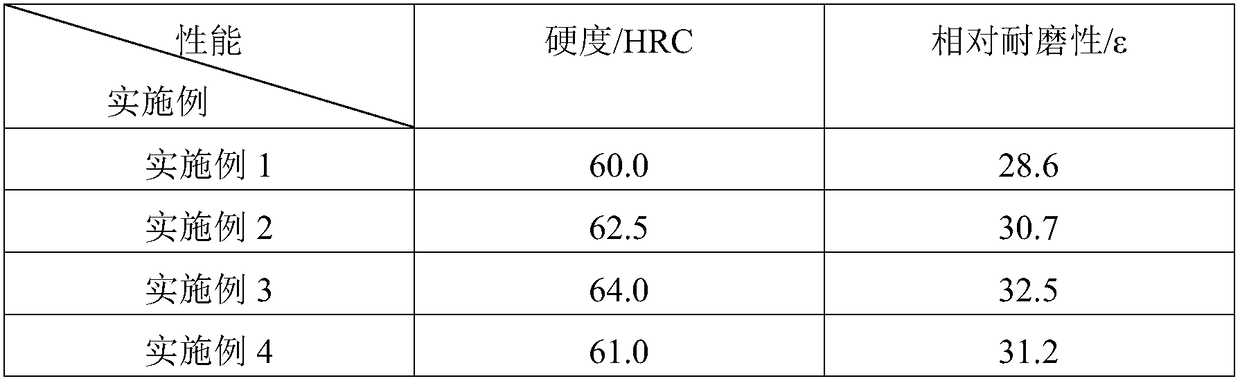

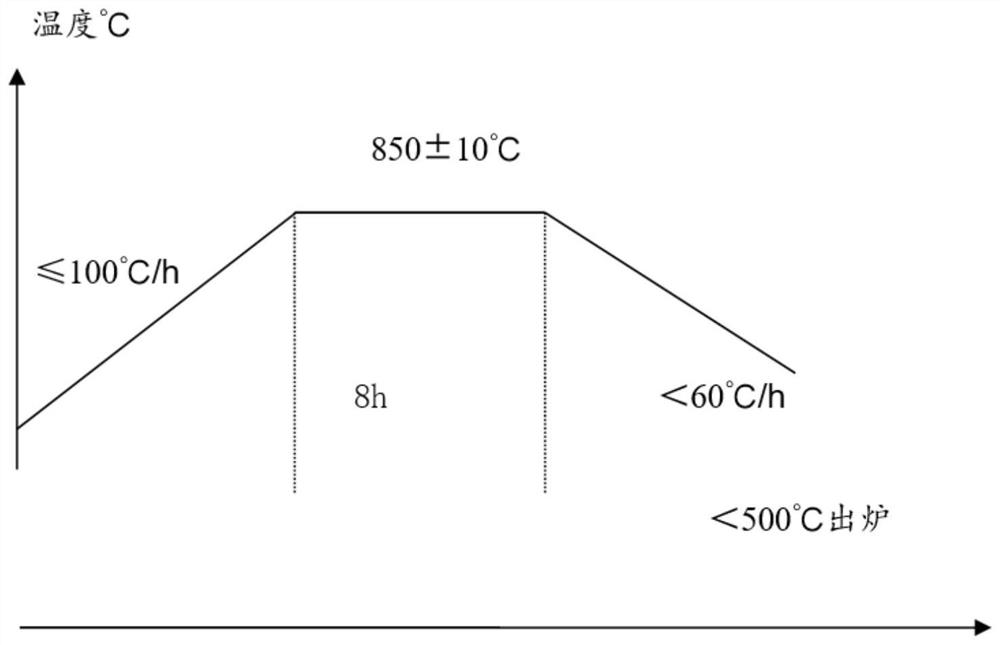

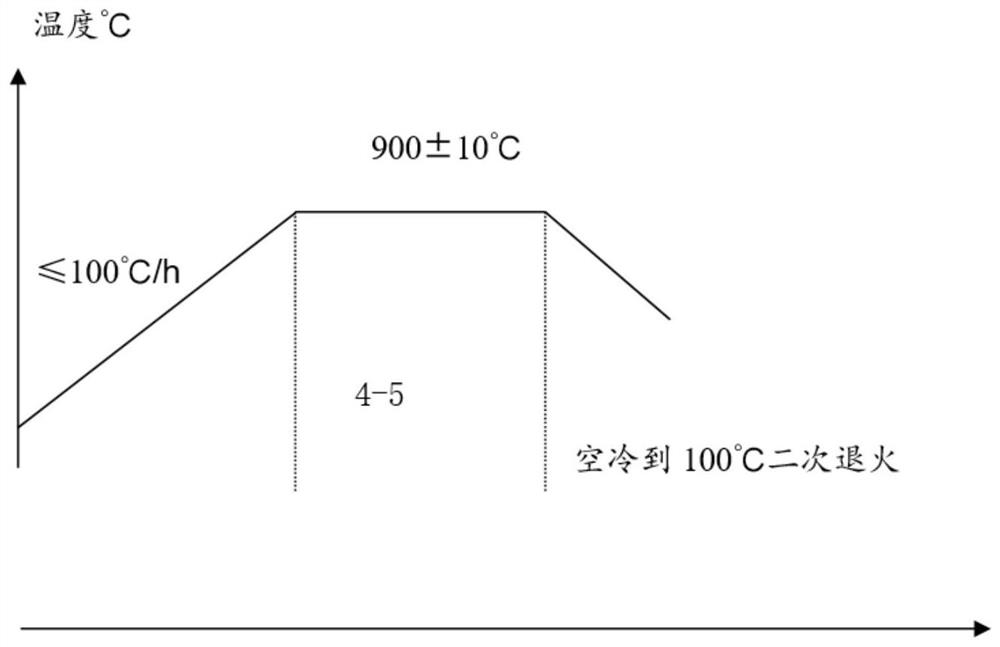

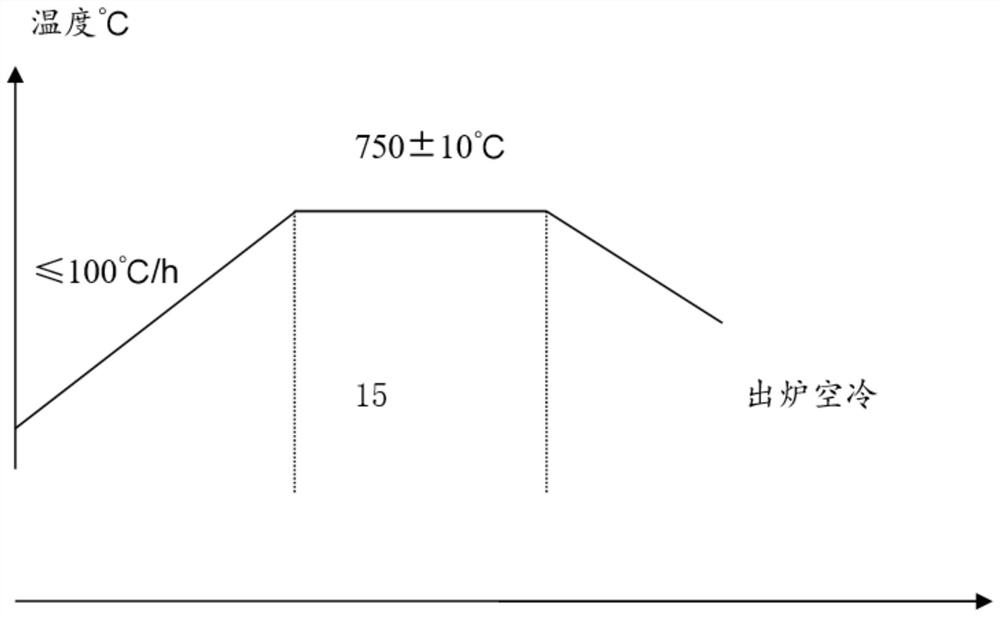

High ferrochrome roller

ActiveCN108018482AImprove mechanical propertiesImprove wear resistanceFurnace typesRollsThick plateFerrochrome

The invention discloses a high ferrochrome roller used for a large-sized wide and thick plate rolling mill. The high ferrochrome roller comprises a roller core, a roller neck and a roller body workinglayer. The roller body working layer comprises, by mass, 2.40%-3.30% of C, 0.60%-1.00% of Si, 0.90%-1.20% of Mn, 15.00%-18.00% of Cr, 1.10%-1.70% of Ni, 0.80%-1.40% of Mo, 0.10%-0.60% of V, 0-0.10% of S, 0-0.05% of P, and the balance Fe and inevitable impurities. By adjusting the heat treatment technology, the mechanical property of the roller is improved, the abrasion resistance and millimeter rolling quantity of the roller are increased, and the service life of the roller is prolonged.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

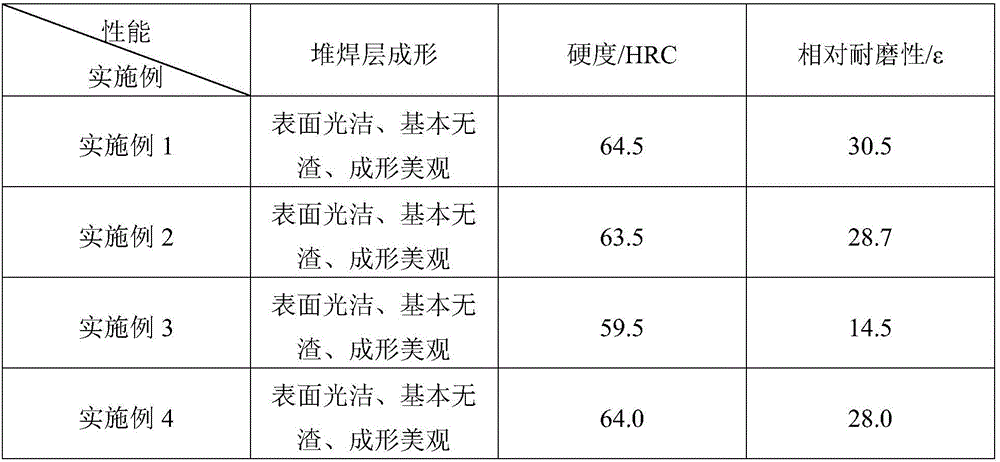

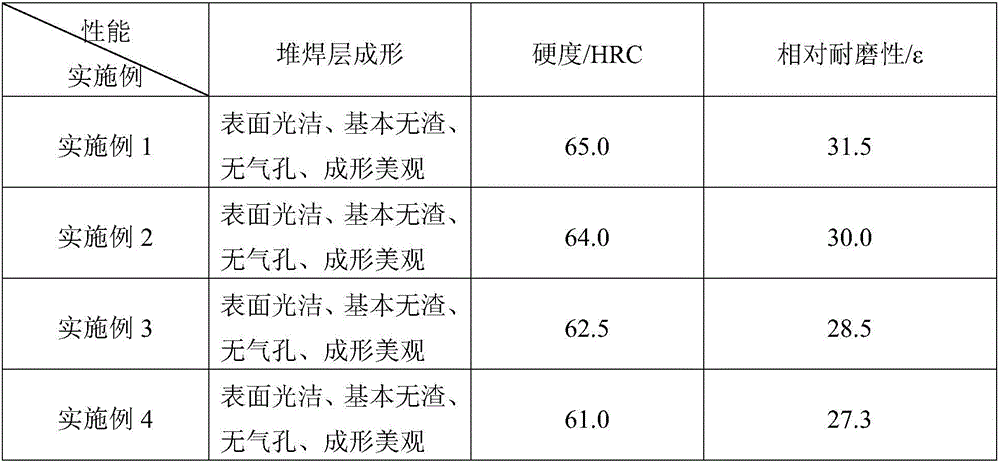

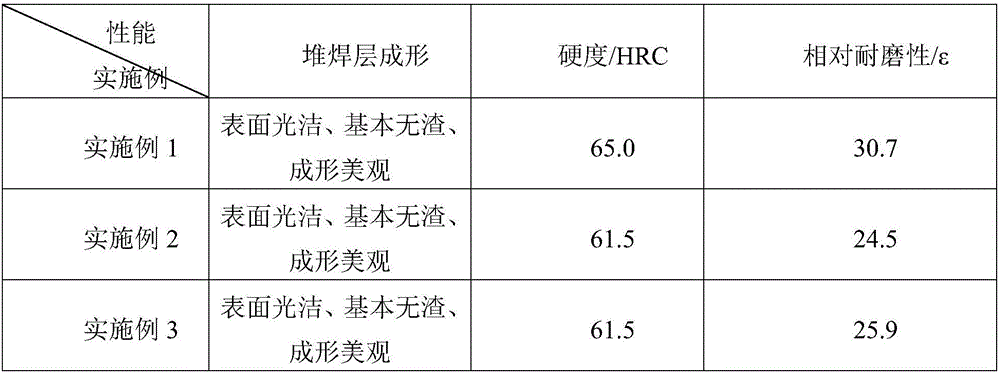

High-efficient energy-saving and surfacing layer well-forming self-shielded flux-cored welding wire and manufacture method thereof

ActiveCN106041356ALow melting pointReduce surface tensionWelding/cutting media/materialsSoldering mediaHigh carbonManganese

The invention discloses a high-efficient energy-saving and surfacing layer well-forming self-shielded flux-cored welding wire. A low-carbon steel belt is an outer skin; and a flux core comprises the following components in percentage by mass: 42-60% of high carbon ferro-chrome with the particle size of 80 meshes, 10-18% of ferrosilicon, 16-25% of ferroboron, 2-8% of rare earth silicon, 2-8% of graphene, 1-4% of aluminum magnesium alloy, 2-5% of manganese powder and the balance of iron powder, wherein the graphene, the aluminum magnesium alloy and the manganese powder are added with two kinds of particle sizes of 60 meshes and 200 meshes, and the weight of the flux core powder accounts for 49-53% of the total weight of the welding wire. According to the welding wire provided by the invention, by adding the flux core components with different particle sizes, good welding technological performance is ensured; and by adding B, Si and other self-fluxing alloy elements simultaneously in the flux core, the fusing point of the welding wire is effectively lowered; a welding process window is expanded; the surfacing efficiency is improved; a high-efficient and energy-saving effect is realized; and the surface tension of a surfacing welding bead is effectively lowered, and the forming of the surfacing welding bead is effectively improved.

Owner:JIANGSU UNIV OF SCI & TECH

Method for preparing high-speed steel composite roll for hot rolling

The invention discloses a method for preparing a high-speed steel composite roll for hot rolling. The method is characterized by comprising the following steps of: firstly, manufacturing a regenerated high-speed steel composite roll collar by adopting an electroslag hollow stripping method; melting low-cost nodular cast iron or plain carbon steel by utilizing an intermediate frequency furnace or an electric arc furnace; manufacturing a roll core by a casting method; and fusing the roll outer collar and the roll core together in the manner of casting to prepare the composite roll for the hot rolling, wherein the working roll collar of the composite roll for the hot rolling is made of high-speed steel, and the roll core is made of the nodular cast iron or the plain carbon steel. The high-speed steel composite roll prepared by the method disclosed by the invention has the characteristics that the outer layer thickness is even, the tissue is fine and compact, and the nodular cast iron or the plain carbon steel is adopted to serve as the material of the roll core. The quality of the working face of the roll is comprehensively improved by utilizing the dual action of rare earth treatment and electroslag refining during a process of manufacturing the roll collar, and the service life is long. A roll body and the roll core are respectively made of the nodular cast iron or plain carbon steel, so that the integrated cost is low. The method disclosed by the invention is suitable for manufacturing the high-speed steel composite roll for the hot rolling and can be widely applied in metallurgical industry and renewable resource industry.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Quenching tank for large and medium size forging

InactiveCN101514385AUniform surface hardnessAvoid deformationFurnace typesHeat treatment process controlFrequency conversionSubmersible mixer

The invention discloses a quenching tank for the large and medium size forging, comprising a body and submersible mixers which are mounted at the periphery and bottom of the inner wall of body. The submersible mixers are positioned at the middle in the height direction of each side of inner wall, at the two middle points of the trisected distribution of the inner wall in the length direction of each side inner wall. Thirteen submersible mixers are mounted at the bottom of the body and in the regular five-row and five-line lineup distribution. Each submersible mixer in the bottom of the body is connected with a frequency conversion controller by a line, the rotating speed of each submersible mixer can be controlled by the frequency conversion controller, thus a uniform temperature area is formed in the quenching solution in the body. The invention has simple structure, easy production, maintenance and use, and is mainly used for the quenching of large and medium size forging.

Owner:GUIZHOU ANDA AVIATION FORGING

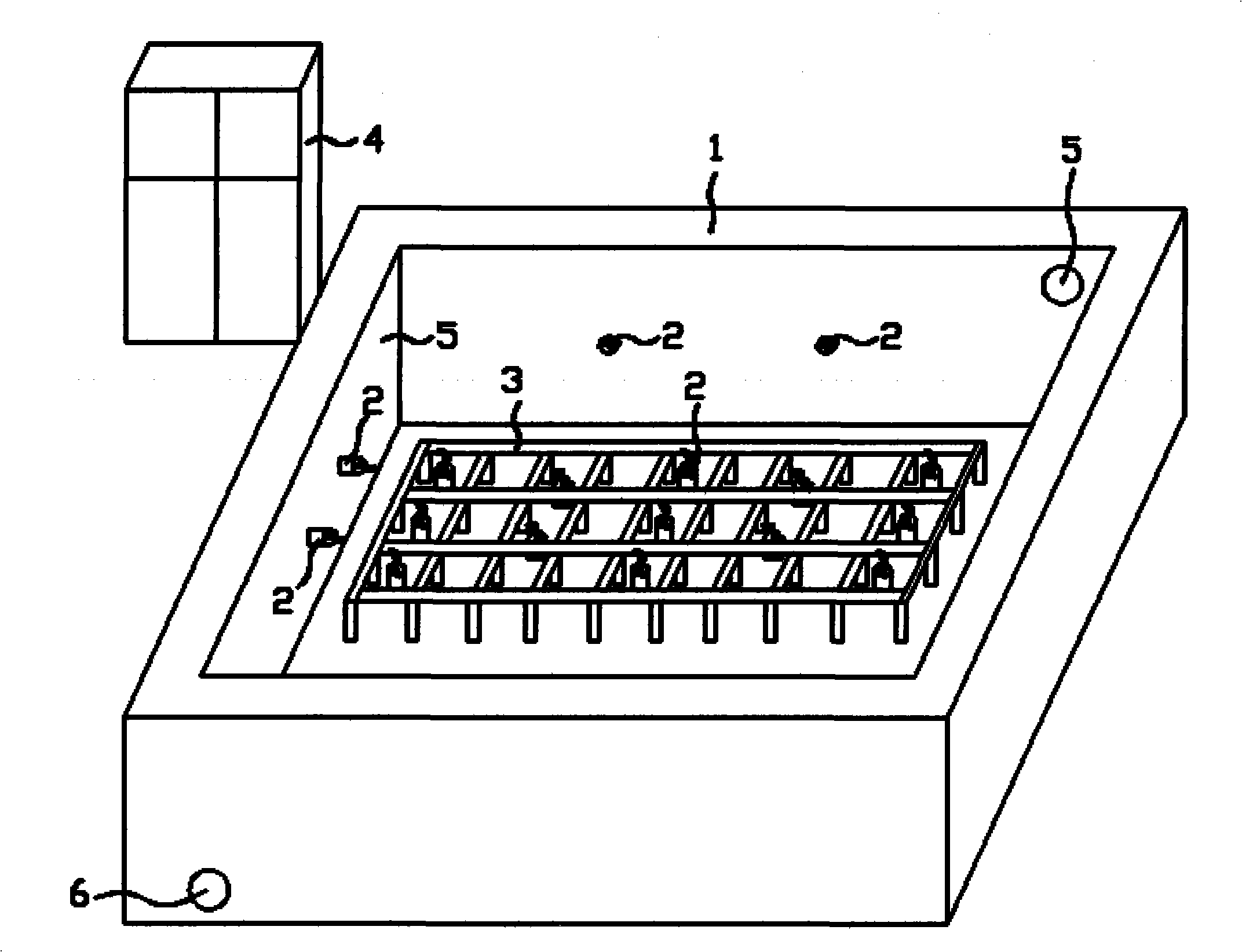

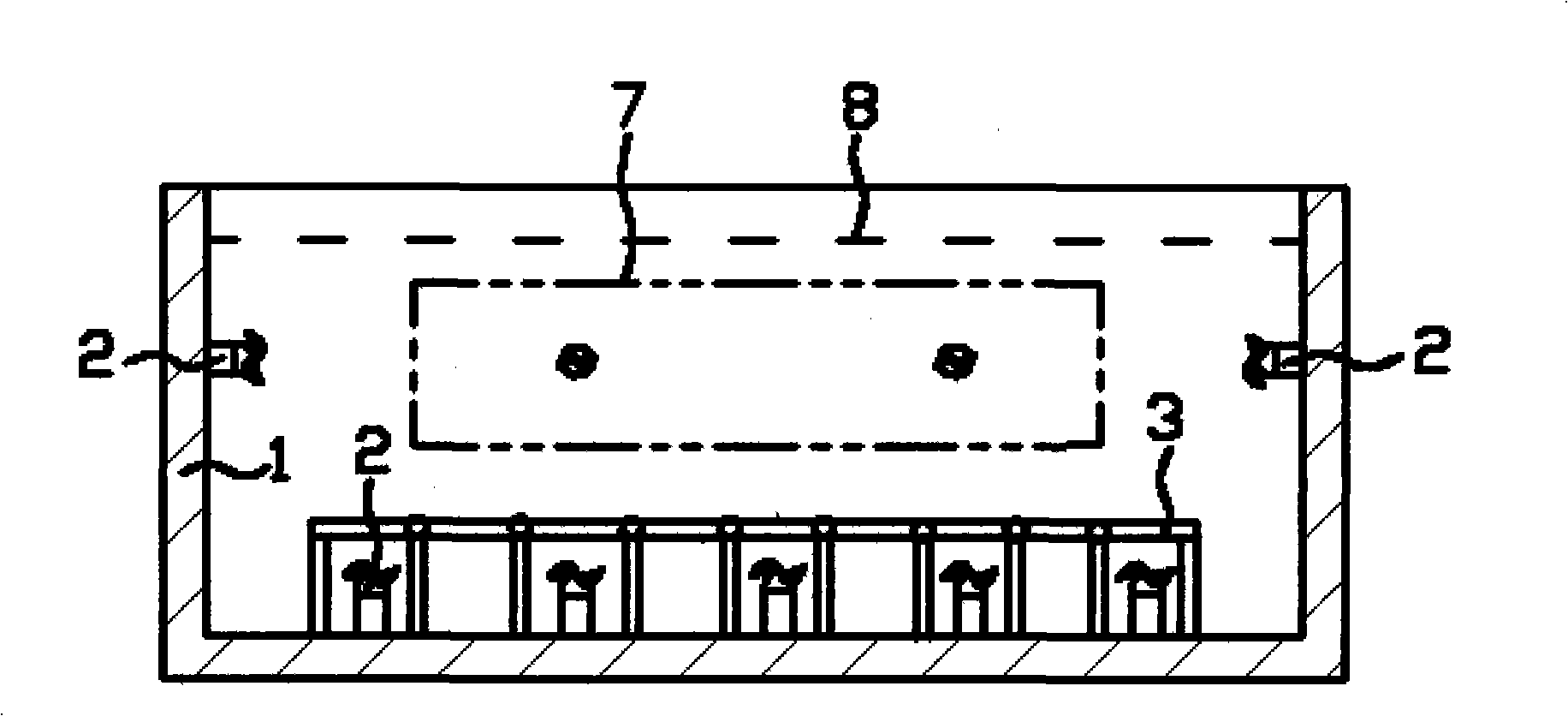

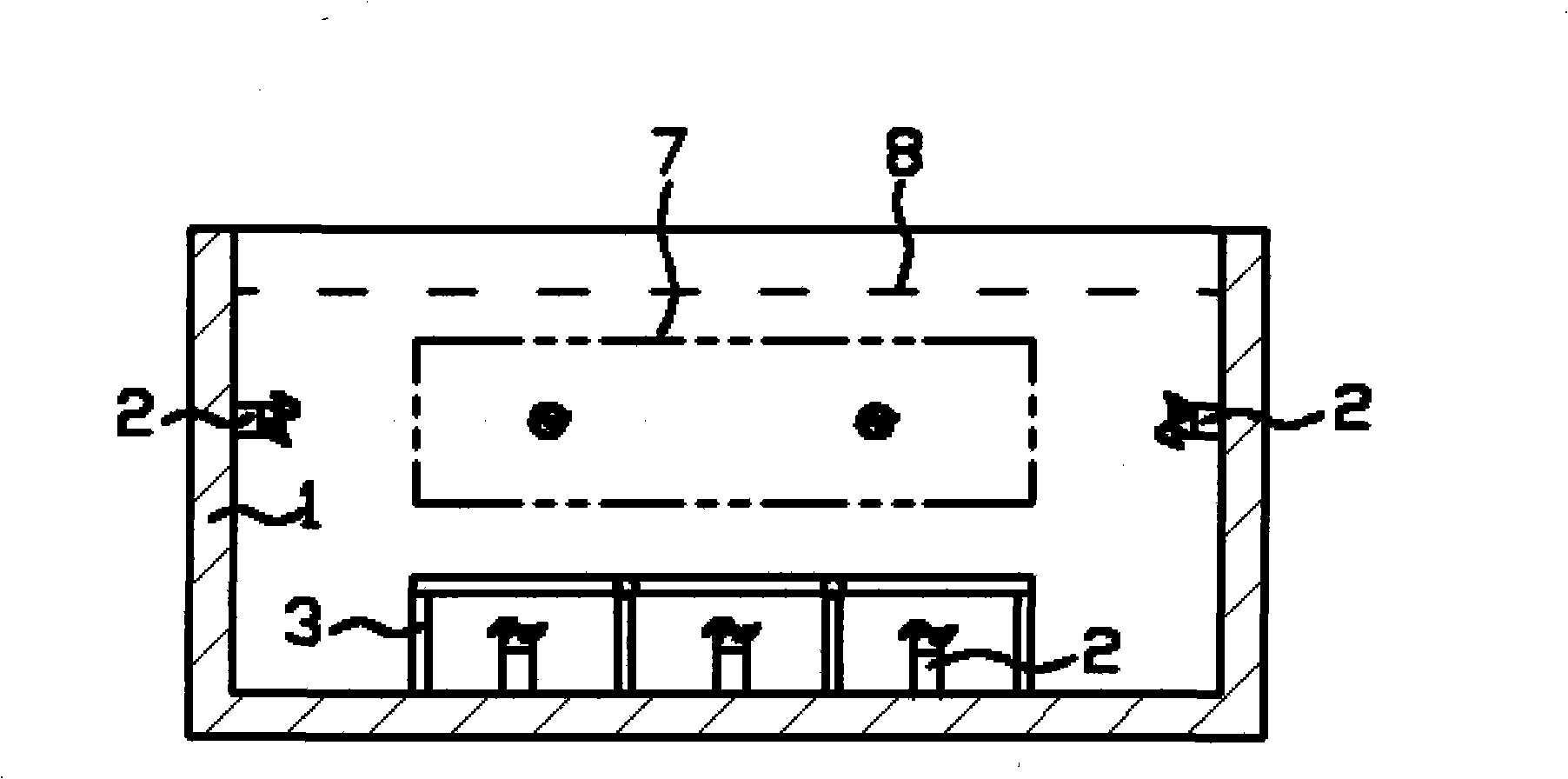

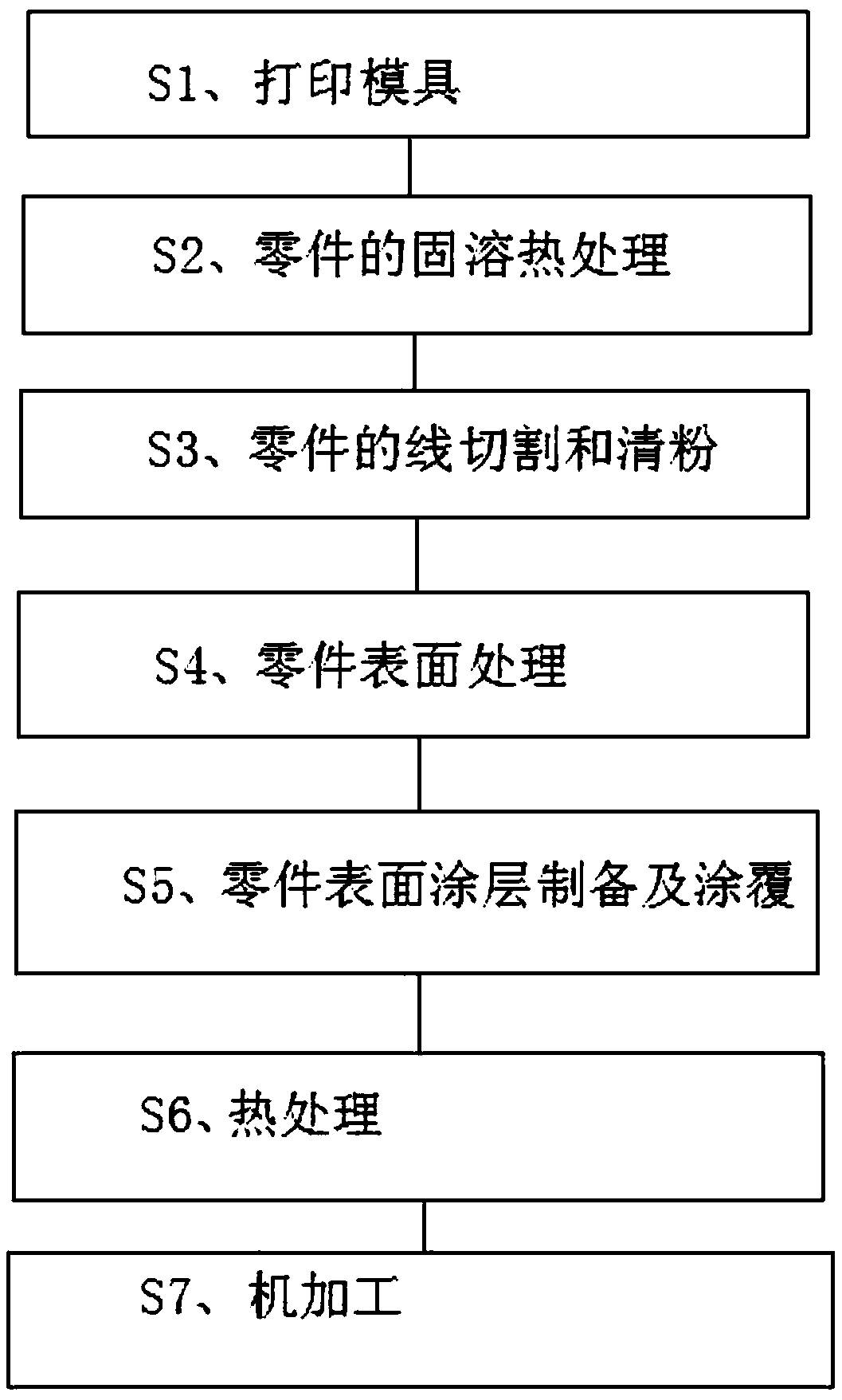

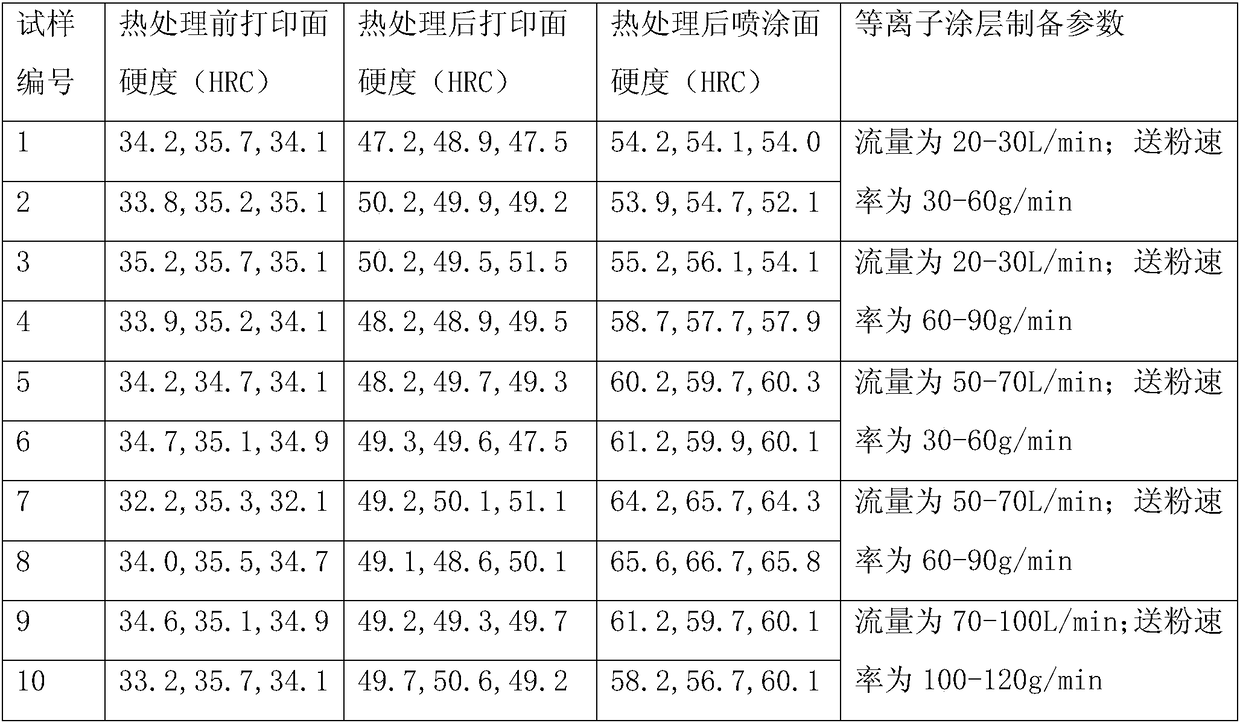

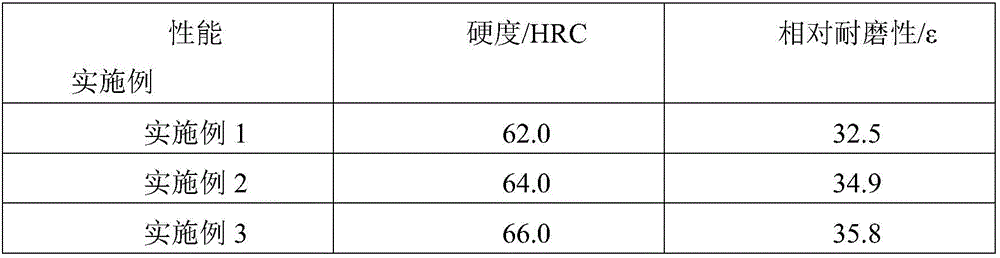

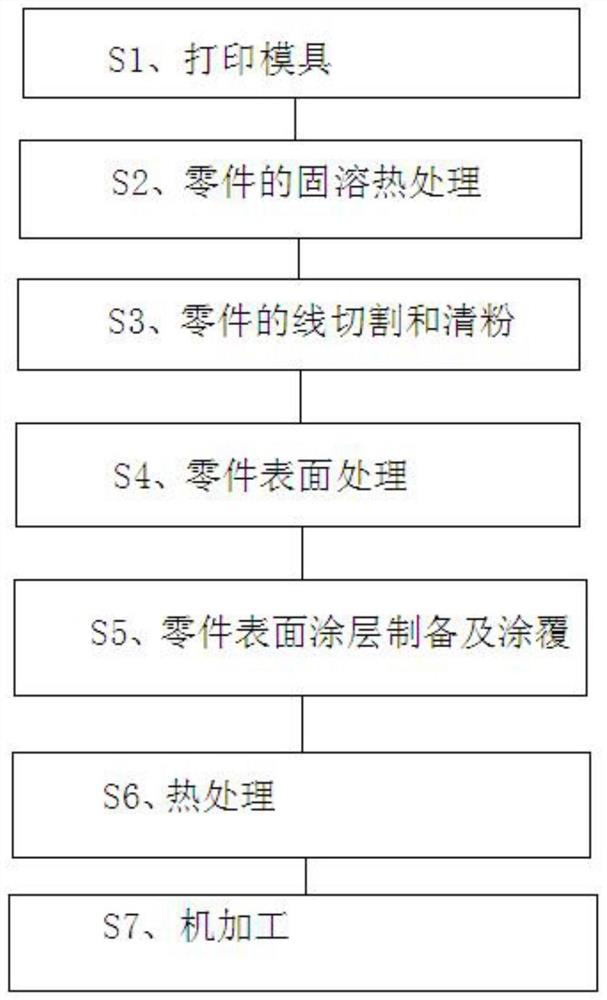

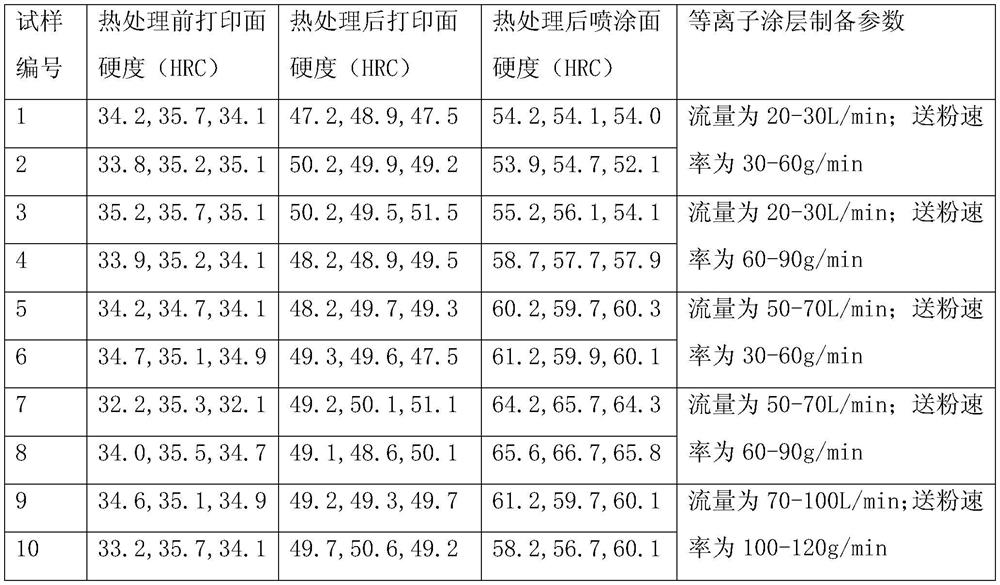

Method for increasing surface hardness of 18Ni300 die steel for metal 3D printing

ActiveCN108950464AUniform surface hardnessUniform internal organizationMolten spray coatingWire cuttingHardness

The invention provides a method for increasing the surface hardness of 18Ni300 die steel for metal 3D printing. The method comprises the following steps that S1, a die is printed; S2, solid-soluble heat treatment of a part is conducted; S3, wire cutting and powder clearing of the part are conducted; S4, parts surface treatment is conducted; S5, part surface coating preparation and coating are conducted; S6, heat treatment is conducted; and S7, machining is conducted, specifically, 0.3-0.5 mm of a part surface coating is removed as machining allowance. According to the method for increasing thesurface hardness of the 18Ni300 die steel for metal 3D printing, an NiCrBSi coating can be evenly applied to the surface of the die part through a plasma spraying process, the surface hardness is uniform, and the surface hardness of the die can reach 56-65 HRC.

Owner:BEIJING E PLUS 3D TECH CO LTD

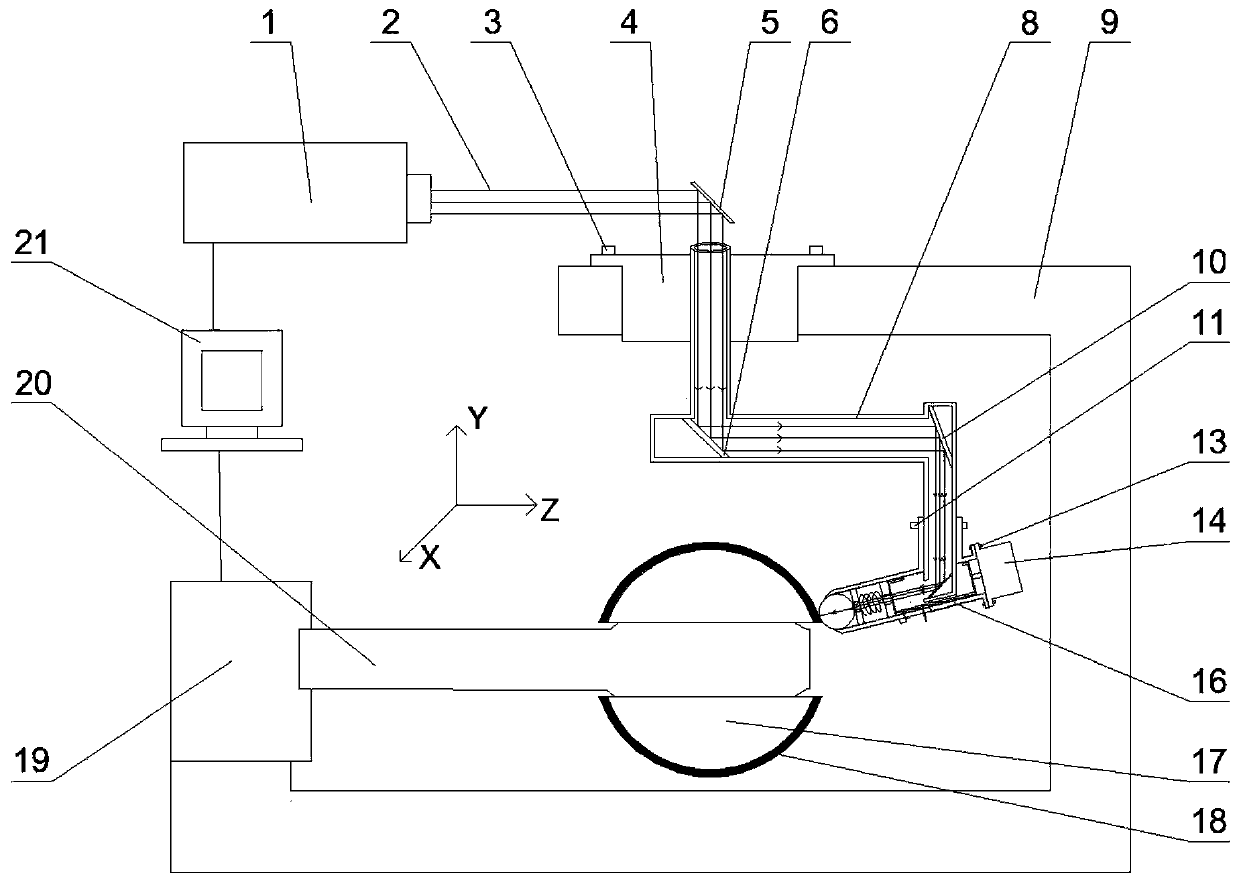

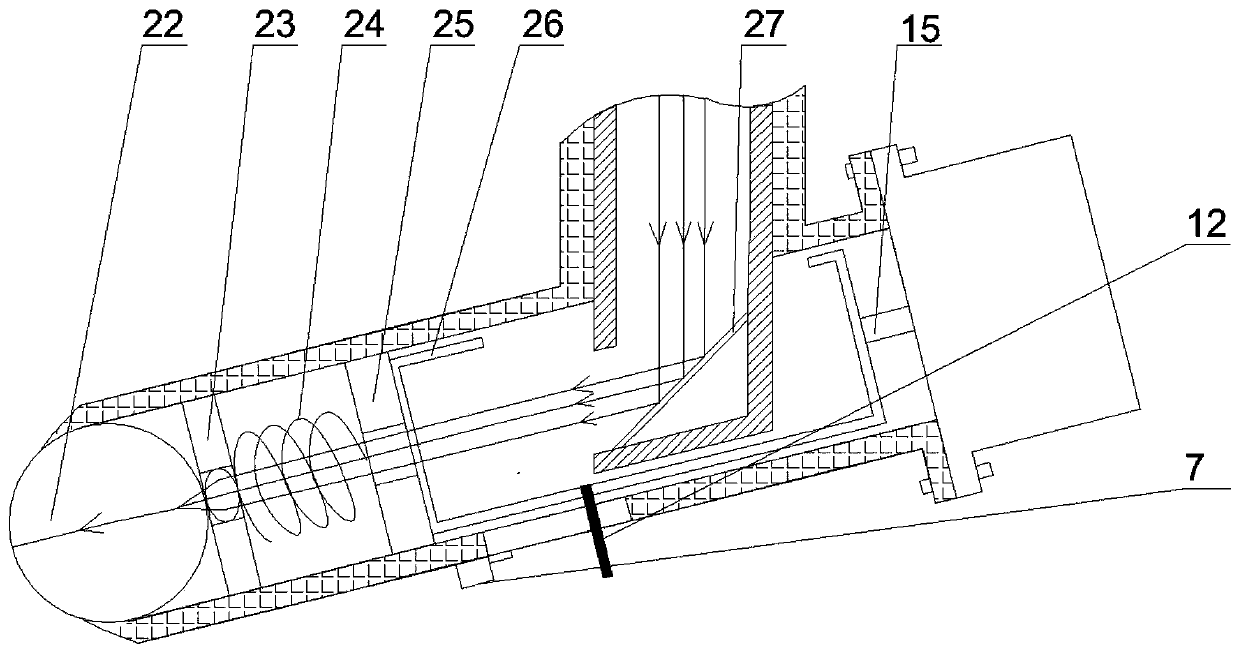

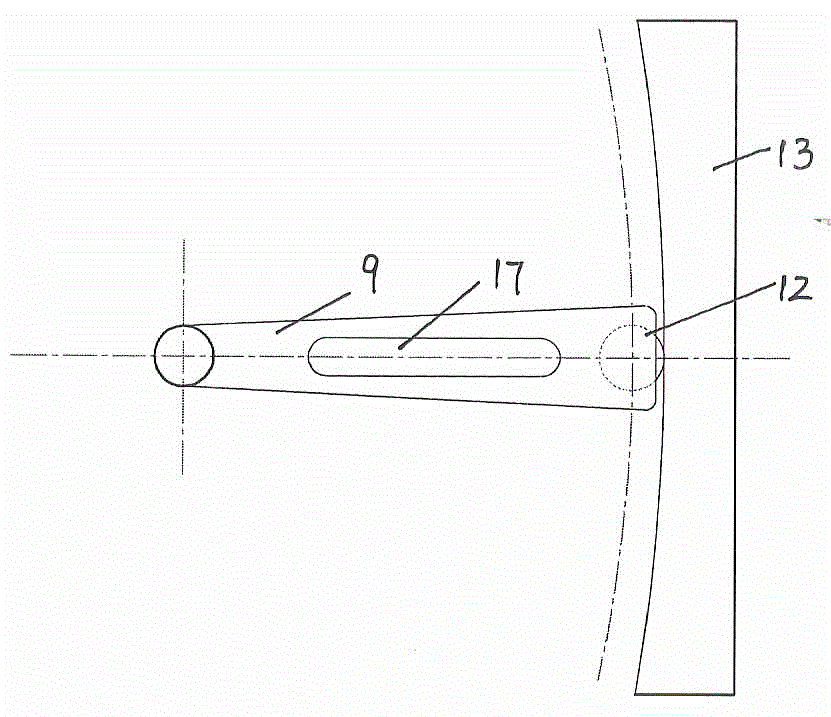

Laser shot blast-rolling reinforcement compound device of rotary body and method thereof

The invention provides a laser shot blast-rolling reinforcement compound device of a rotary body and a method thereof. The laser shot blast-rolling reinforcement compound device comprises a laser emitting device, a light path conveying device, a numerical control platform and a rolling head; the laser emitting device is used for generating laser beams; one end of the light path conveying device isused for inputting the laser beams, the other end of the light path conveying device is provided with the rolling head, and the rolling head is in contact with the rotary body and used for carrying out rolling reinforcement on the surface of the rotary body while the laser beams are enabled to penetrate through the rolling head so as to perform laser shot blast on the surface of the rotary body;the rotary body is fixed by the numerical control platform through a first rotating device; and the numerical control platform is used for fixing the light path conveying device through a second rotating device, which is used for enabling the rolling head to rotate around the rotary body. According to the laser shot blast-rolling reinforcement compound device of the rotary body and the method thereof, a pressure spring in the rolling head is adjusted to obtain the required rolling load, a laser is guided through the light path system, automatic focusing of the laser shot blast process is realized, and compound surface reinforcement of a complex curved surface can be accurately realized.

Owner:JIANGSU UNIV

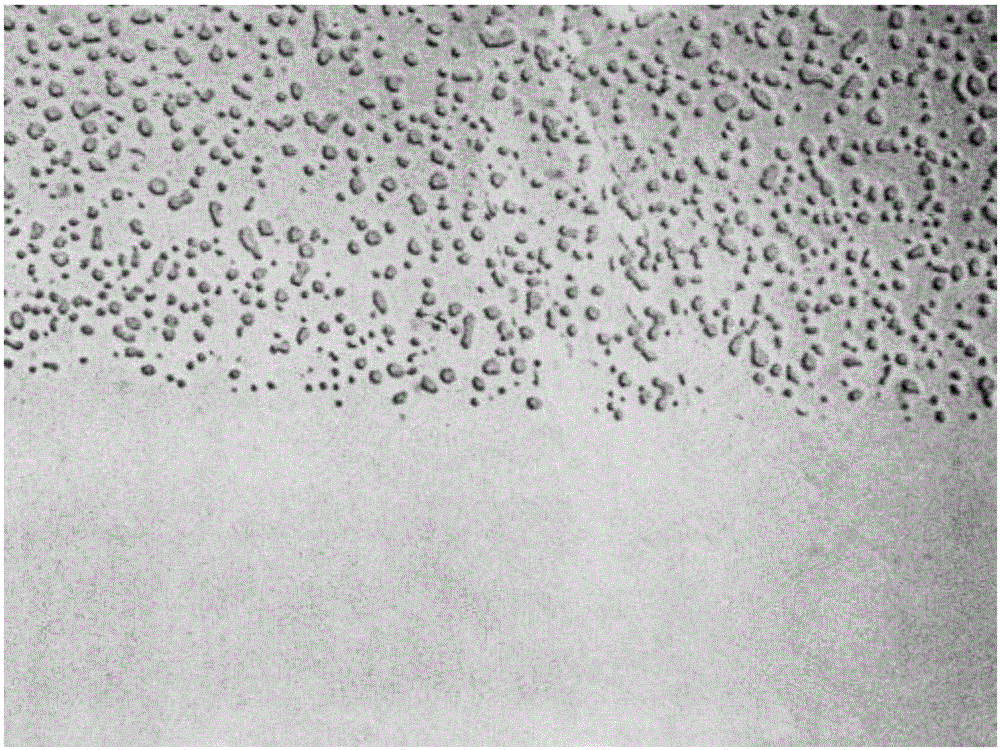

Modified hardfacing self-shielded flux-cored wire doped with multi-boride and preparation method of modified hardfacing self-shielded flex-cored wire doped with multi-boride

ActiveCN106141495AHigh hardnessImprove thermal stabilityWelding/cutting media/materialsSoldering mediaBorideIron powder

The invention discloses a modified hardfacing self-shielded flux-cored wire doped with multi-boride and a preparation method of the modified hardfacing self-shielded flex-cored wire doped with the multi-boride. The modified hardfacing self-shielded flux-cored wire doped with the multi-boride comprises a low-carbon steel strip and a flux core, wherein the flux core comprises, by mass percentage, 45-55 wt% of high carbon ferro-chrome, 6-16 wt% of B4C, 3-9 wt% of TiB2, 3-9 wt% of ZrB2, 1-3 wt% of graphite, 0.5-1 wt% of cellulose powder with the mesh being 60, 0.5-1 wt% of cellulose powder with the mesh being 200, 1-3 wt% of an aluminum-magnesium alloy with the mesh being 60, 0.5-2 wt% of an aluminum-magnesium alloy with the mesh being 200, 2-7 wt% of an silicon-manganese alloy with the mesh being 60, 1-4 wt% of an silicon-manganese alloy with the mesh being 200 and the balance iron powder, and the flux core accounts for 50-54 wt% of the total mass of the flux-cored wire. According to the flux-cored wire, through addition of the flux core components of different grain sizes, the good welding process performance is guaranteed; through the addition of the multi-boride component, the multi-boride is dispersed and extracted in the welding process; and the flux-cored wire has the beneficial effects of being high and uniform in hardness, good in wear resistance and the like, and few residues are left on the surface of a weld bead, and slag removal is not needed in multi-layer welding.

Owner:JIANGSU UNIV OF SCI & TECH

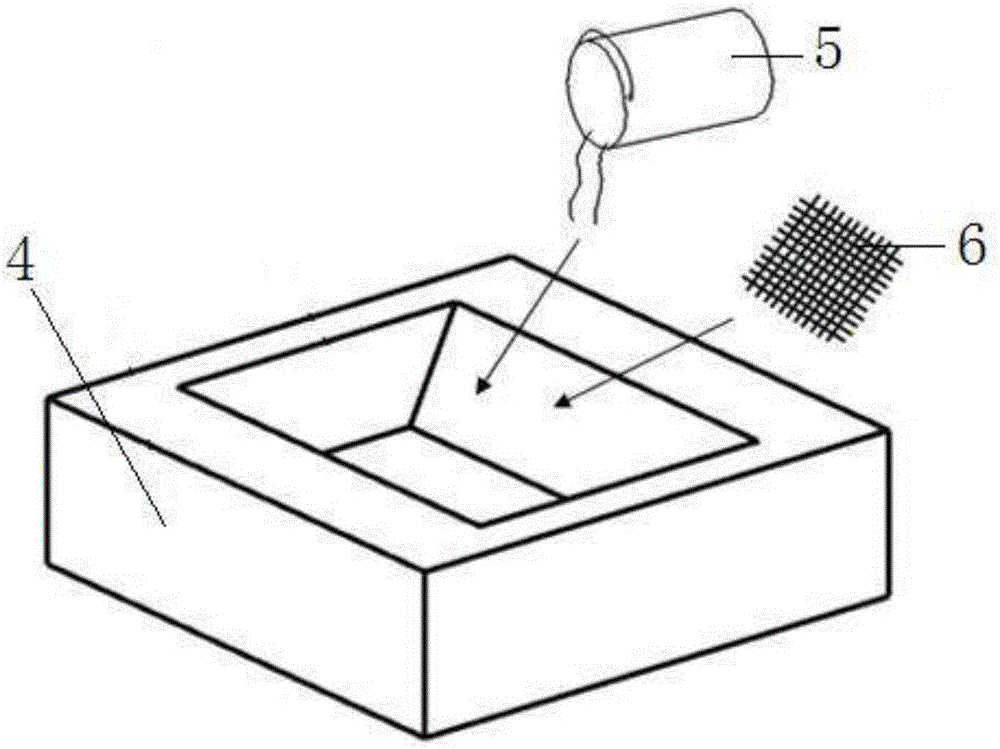

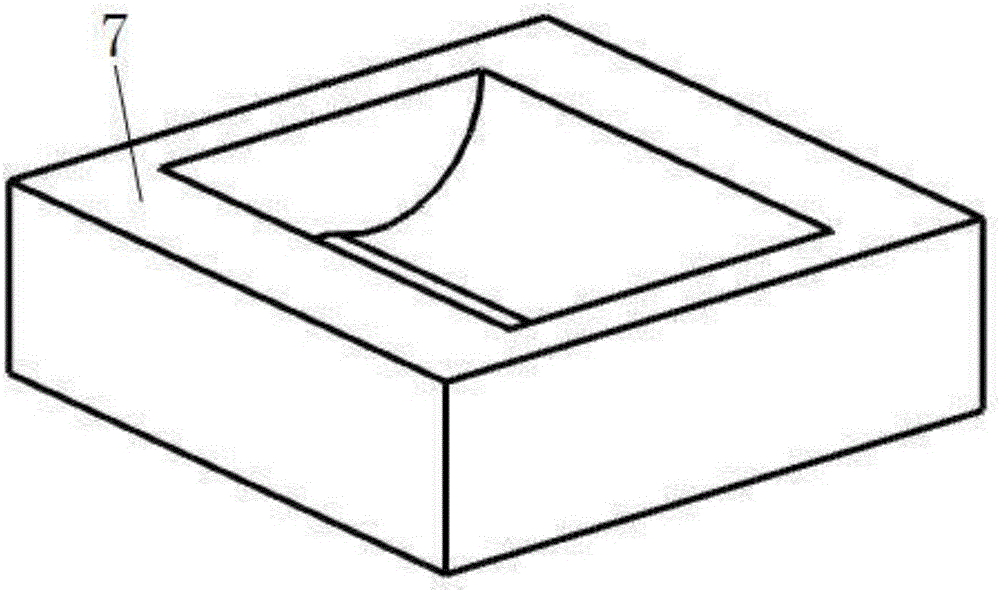

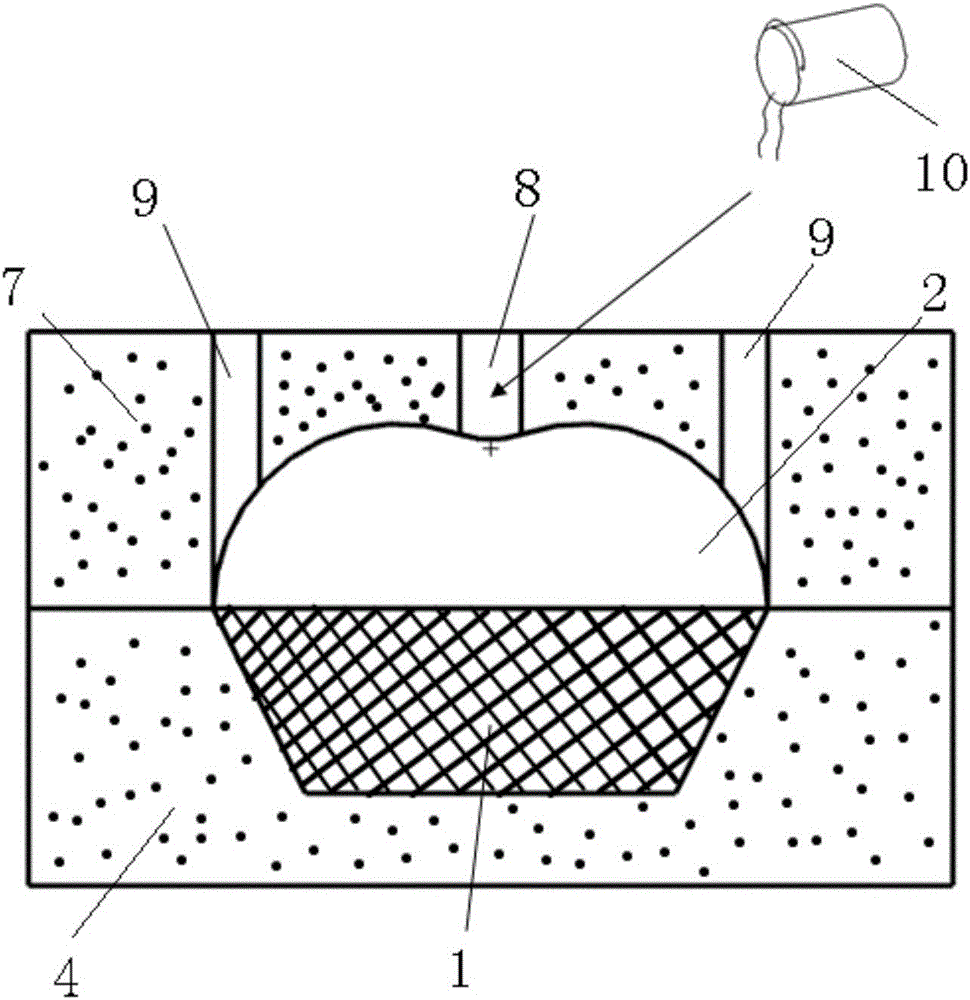

Manufacturing method for airplane part stretch-forming mold made of resin matrix composite

ActiveCN105945159AWith self-lubricating functionUniform surface hardnessShaping toolsNumerical controlResin matrix

The invention discloses a manufacturing method for an airplane part stretch-forming mold made of a resin matrix composite and mainly aims to solve the problems that existing molds are large in manufacturing difficulty, hard to store and large in weight and cannot be repaired. The provided manufacturing method for the airplane part stretch-forming mold made of the resin matrix composite comprises the steps that a matrix and a surface are manufactured with the resin matrix composite; and then the airplane part stretch-forming mold is machined and manufactured through a numerical control machine tool. By means of the manufacturing method, the mold using rate is increased, especially, the part productivity is improved, the mold manufacturing cost is reduced, and the mold manufacturing period is shortened.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

In-situ synthesis WC and W6C type carbide self-protection strengthening build-up welding flux-cored wire and preparation method thereof

ActiveCN106041358AImprove wear resistanceSimple welding processWelding/cutting media/materialsSoldering mediaHigh carbonSlag

The invention discloses an in-situ synthesis WC and W6C type carbide self-protection strengthening build-up welding flux-cored wire. A low carbon steel strip is used as an outer cover; a flux core comprises the following components in percentage by weight: 6-12% of high-carbon ferromanganese, 50-60% of tungsten powder, 6-12% of electrolytic manganese powder, 8-12% of graphite, 1-3% of ferroboron, 1-3% of an aluminum magnesium alloy, 1-3% of silicomangan and the balance iron powder, wherein the ferroboron, the aluminum magnesium alloy and the silicomangan are added in two particle sizes including 60 meshes and 200 meshes; and the weight of the flux core accounts for 50-55% of the total weight of the flux-core wire. According to the welding flux-cored wire provided by the invention, components of the flux core in different particle sizes are added, so that favorable welding process performance is guaranteed; through an appropriate compounding ratio with other alloy powder, an eutectic crystal consisting of first-separated WC carbide, W6C and part of martensite is formed in the build-up welding alloy structure; the hardness of a build-up welding layer is as high as 62-66HRC, so that the in-situ synthesis WC and W6C type carbide self-protection strengthening build-up welding flux-cored wire disclosed by the invention is good in abrasion resistance, favorable in welding process performance, and high in depositing efficiency, and multilayer welding is free from removing slags.

Owner:JIANGSU UNIV OF SCI & TECH

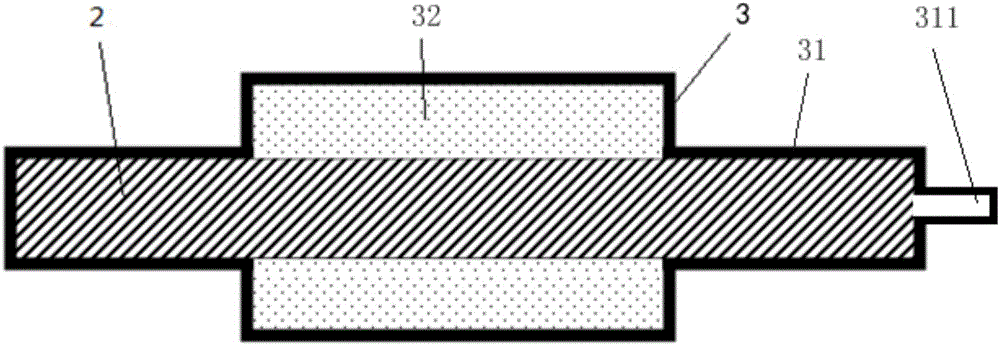

Roller production method and roller produced by using method

InactiveCN105108148AExtended service lifeHigh bonding strengthTurbinesOther manufacturing equipments/toolsNon-metallic inclusionsCarbide

The invention relates to a roller production method. The roller production method comprises the following steps: (S1) a cover having an air port is arranged outside a mandrel; and alloy powder is filled in the cover while setting; (S2) air is extracted from the air port of the cover to degas the alloy powder in the cover; (S3) the air port is sealed to form a transition part; (S4) the hot isostatic pressing treatment is performed for the whole cover containing the mandrel inside, so that the alloy powder is sintered to form a roller sleeve; and (S5) the cover is disassembled and machined to form a roller with size and surface quality accordant with requirements. In the roller obtained by the roller production method, the bonding place between the mandrel and the roller sleeve is a metallurgical bonding interface; the bonding is tight; no carbide is separated out from the bonding place; and the content of nonmetal inclusions in the roller sleeve is low. The tissue in the bonding place is free of segregation; the component distribution is more uniform; the surface hardness of the roller sleeve is uniform; the product surface quality is greatly improved; and finally, the service life of the roller is largely prolonged.

Owner:飞而康快速制造科技有限责任公司

Flux-cored wire capable of enhancing welding partition continuous self-protection effect and preparation method thereof

ActiveCN106001994AGood deoxidation self-protection abilityBeautiful shapeWelding/cutting media/materialsSoldering mediaHigh carbonFerrochrome

The invention discloses a flux-cored wire capable of enhancing the welding partition continuous self-protection effect and a preparation method thereof. A low-carbon steel strip serves as a skin. A flux core is prepared from 70-85wt% of high-carbon ferrochrome, 1-3.5wt% of ferroboron, 8.5-18.5wt% of a deoxidizing agent, 1-5wt% of an arc stabilizing agent and the balance ferrous powder. By the total weight of the flux core, the deoxidizing agent is prepared from 3-6wt% of 230-mesh silicomanganese alloy, 3-6wt% of 50-mesh graphite, 2-4.5wt% of 50-mesh aluminum powder and 0.5-2wt% of 50-mesh magnesium powder. The arc stabilizing agent is a mechanical mixture formed by sodium potassium silicate and sodium carbonate, and the flux core accounts for 54-59wt% of the mass of the wire. The wire can effectively enhance the self-protection effect of various partitions (at the melting stage, the globular transfer stage and the molten pool stage) of the wire, an arc is stable, the manufacturability is good, and a surfacing layer is attractive in shape, high in hardness and good in wear resistance.

Owner:JIANGSU UNIV OF SCI & TECH

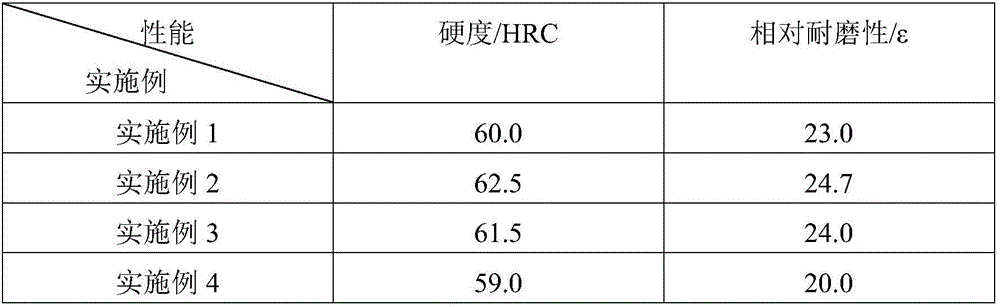

Medium manganese steel lining material for ball mill and preparing method of material

InactiveCN107974630AImprove mechanical propertiesImprove hardenabilityGrain treatmentsPressure castingNiobium

The invention relates to a medium manganese steel lining material for a ball mill and a preparing method of the material, and belongs to the technical field of wear-resisting materials. The medium manganese steel lining material for the ball mill is composed of components including, by mass percent, 0.2 to 0.6% of carbon, 5.0 to 8.0% of manganese, 0.1 to 0.3% of silicon, not larger than 0.015% ofphosphorus, not larger than 0.015% of sulphur, 0.01 to 0.05% of niobium, 0.3 to 0.8% of chromium and the balance iron. According to the medium manganese steel lining material for the ball mill, methodof vacuum smelting and pressure casting is adopted for preparing. The mechanical property and the wear-resisting performance of the medium manganese steel lining material for the ball mill are excellent, the anti-bending strength reaches 821 MPa, the hardness reaches 55HRC, the impact power of a V-shaped sample reaches 30J, and the service life is prolonged by more than 25% compared with a traditional high manganese steel lining plate.

Owner:HENAN UNIV OF SCI & TECH

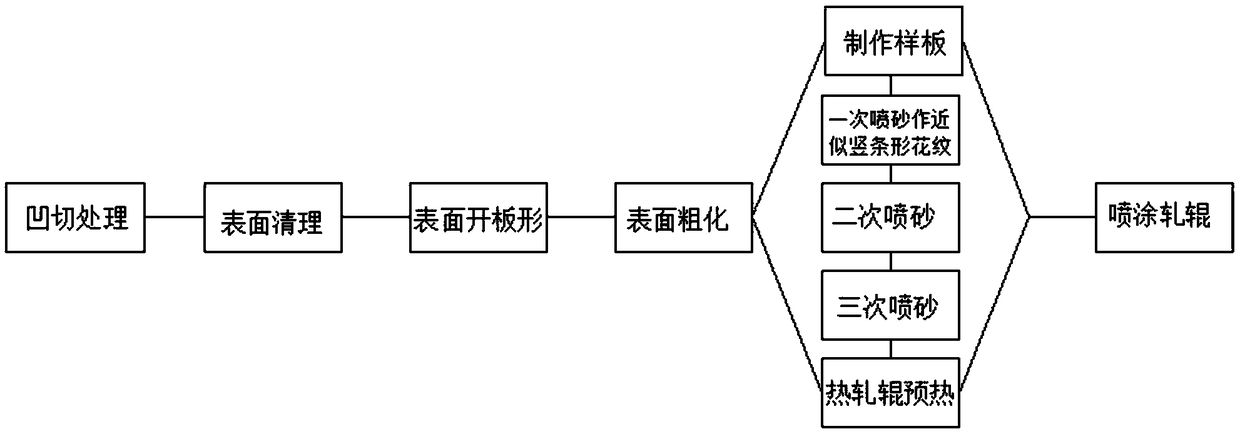

Hot roller supersonic spraying surface repair pretreatment method

ActiveCN108842127AHigh bonding strengthExtended service lifeMolten spray coatingPre treatmentShape formation

The invention discloses a hot roller supersonic spraying surface repair pretreatment method. The hot roller supersonic spraying surface repair pretreatment method comprises specific procedures of 1) concave cutting treatment, 2) surface cleaning, 3) surface plate shape formation and 4) surface roughening, wherein the surface roughening specifically comprises the following steps: (1) similar vertical strip patterns are formed through primary sand blasting; and the roughness is controlled within Ra 2.5-3.2; (2) a roller is stopped rotating; two sample plates are fixed on the surface of the roller after primary sand blasting; a sand blasting gun blasts sand in a spiral gap between the two sample plates; and the roughness is controlled within Ra 5.5-6.5; (3) the two sample plates are overturned and fix on the surface of the roller after secondary sand blasting; the sand blasting gun blasts sand in the spiral gap between the two sample plates; and the roughness is controlled within Ra 5.5-6.5; and (4) the hot roller is preheated. The method can obtain a supersonic spraying layer with high bonding strength and higher wear resistance, prolongs the service life of the roller, and reduces the production cost.

Owner:ANHUI HENGYI HARD FACE ENG CO LTD

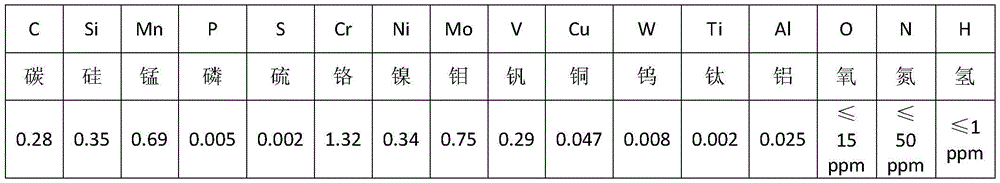

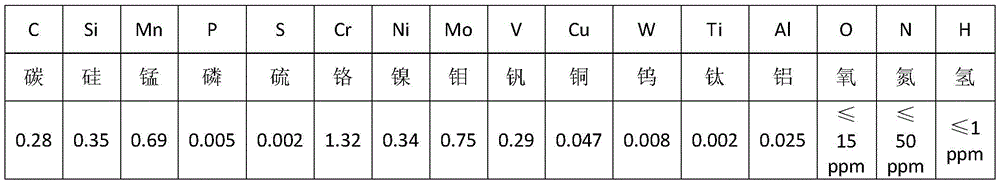

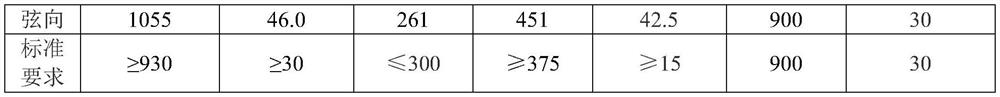

Hot rolling alloy steel for train brake disc

InactiveCN105463331AGuaranteed mechanical propertiesImprove wear resistanceBraking discsManganeseHardness

The invention discloses hot rolling alloy steel for a train brake disc. The hot rolling alloy steel comprises C, Si, Mn, Cr, N, Mo, V and Fe. C, Si, Mn, Cr, Ni, Mo and V are evenly doped and distributed in a steel base body according to the specific proportion, and the abrasion resistance of a material is greatly improved while the mechanical performance of the material is guaranteed. The material has good forming performance, the braking disc close to the final shape can be prepared, and later machining of a traditional preparing method is reduced. By means of control over the content range of C and Mn, the material cooling speed is increased, and the material strength and surface hardness are improved.

Owner:南京东电检测科技有限公司

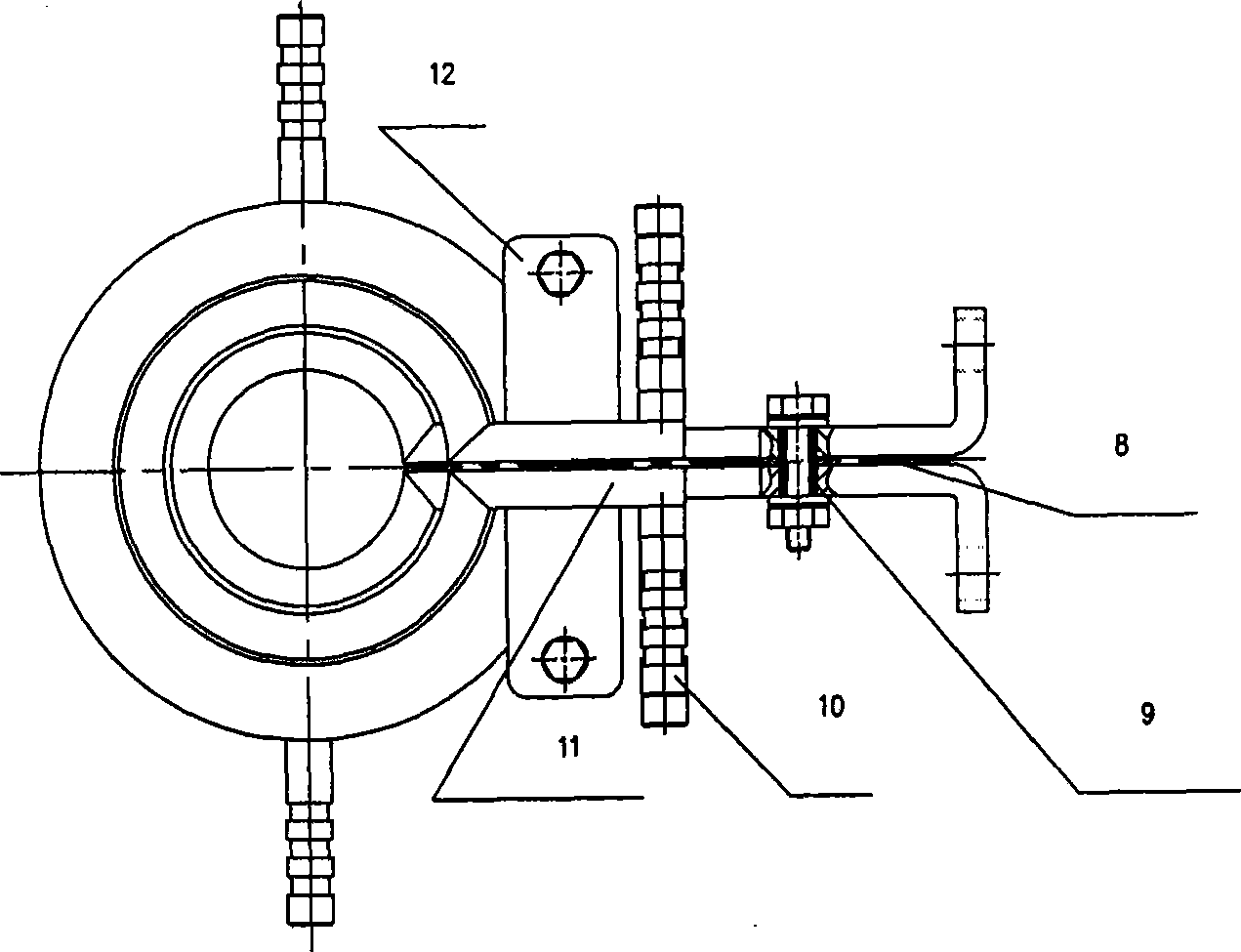

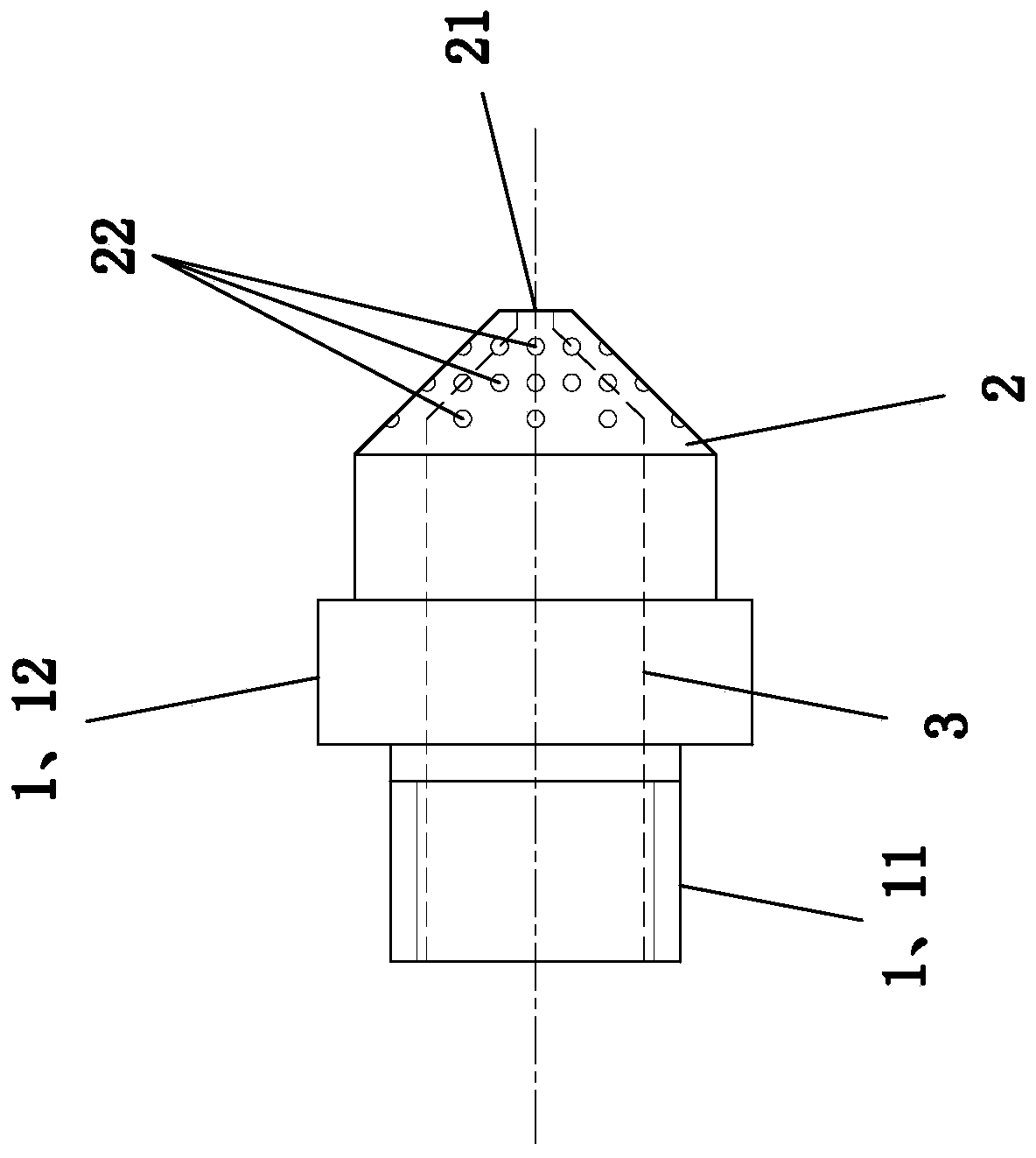

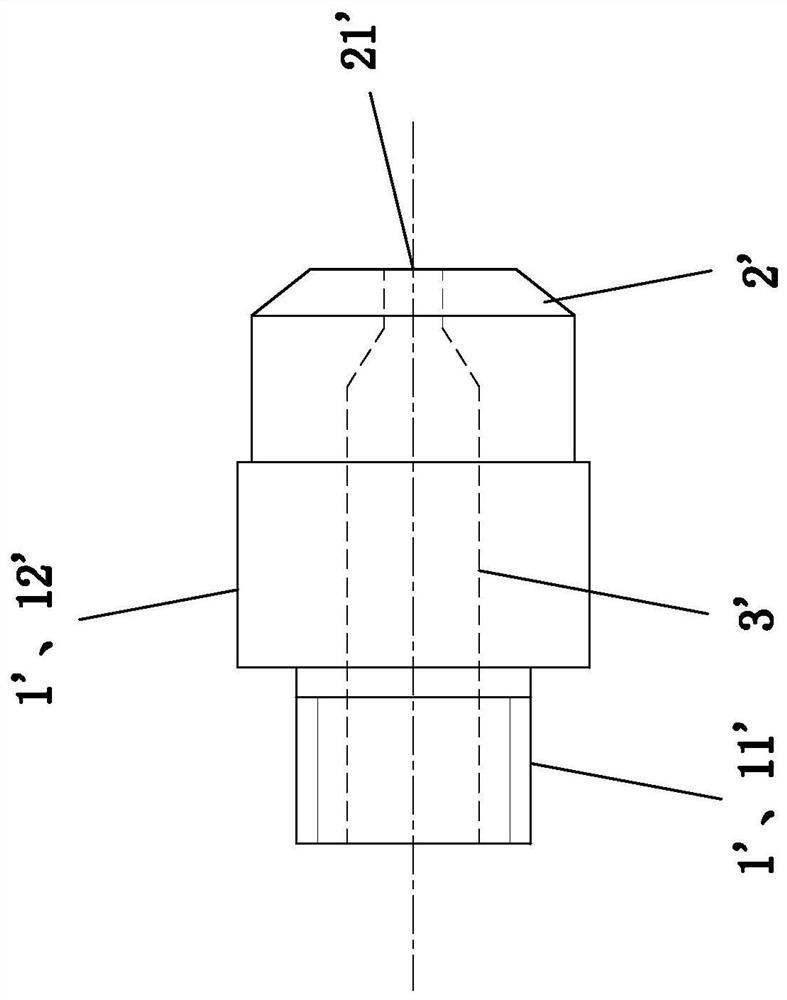

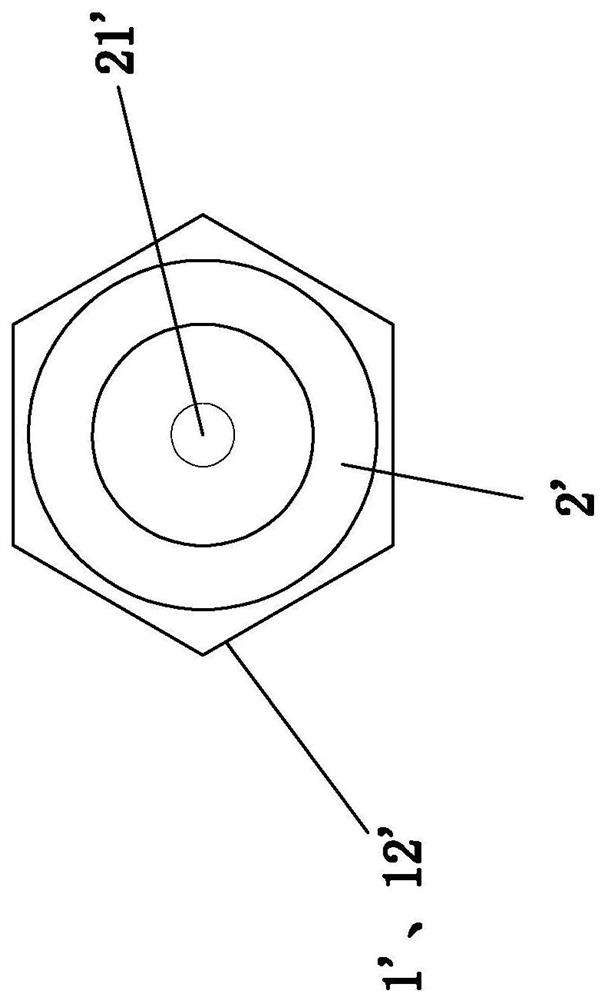

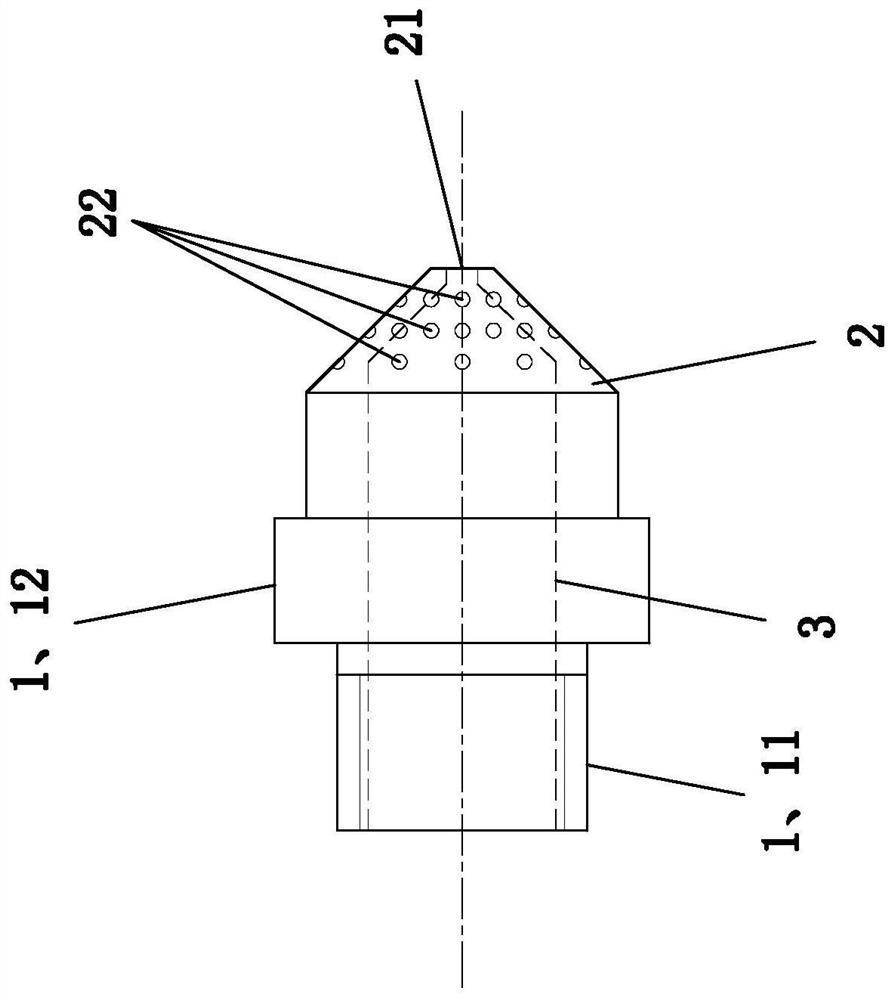

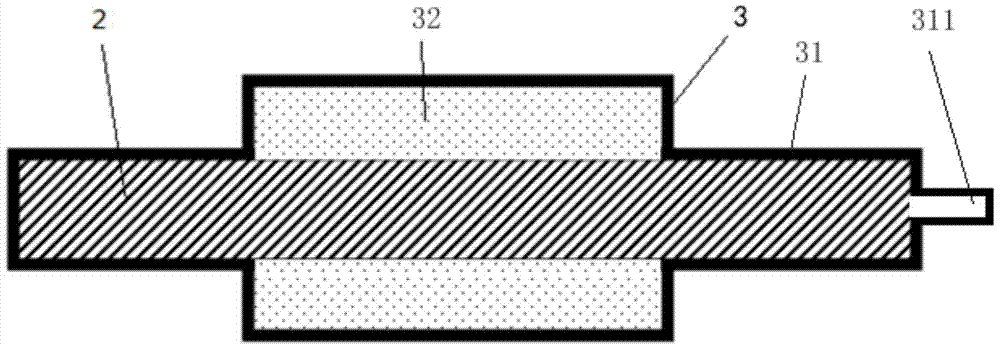

Forged steel cold rolling roller cryogenic treatment method and novel nozzle adopted by same

ActiveCN110684890AReduce cloggingUniform surface hardnessFurnace typesHeat treatment furnacesCryogenic treatmentMaterials science

The invention discloses a forged steel cold rolling roller cryogenic treatment method and a novel nozzle adopted by the same. The nozzle is provided with a mounting part and a nozzle head, wherein thenozzle head is provided with a large nozzle port with the diameter of 0.8 mm to 1.2 mm and a plurality of small nozzle ports provided with the diameters of 0.4 mm to 0.6 mm and arranged on the periphery of the large nozzle port. The cryogenic treatment method comprises the following steps that (1) a forged steel cold rolling roller is placed in a cryogenic box, and the cryogenic box is closed; (2) liquid nitrogen is sprayed into the cryogenic box from the nozzle, and the temperature in the cryogenic box is lowered to -160 DEG C to -120 DEG C through 1 h to 2 h; (3) the temperature is kept for 2 h to 5 h at the temperature; and (4) after keeping of the temperature is finished, the cryogenic box is opened, and the forged steel cold rolling roller is placed under a room temperature environment to be naturally restored to the room temperature. According to the forged steel cold rolling roller cryogenic treatment method and the novel nozzle adopted by the same, the novel nozzle is designed, and the corresponding cryogenic treatment method is adopted for matching so that the sprayed liquid nitrogen can be more dispersed and more uniform, so that the surface hardness of the forged steelcold rolling roller is more uniform, the hardness uniformity of the finished product is improved, and the blockage phenomenon of the nozzle is also greatly reduced.

Owner:BAOSTEEL ROLL SCI & TECH

Low-cost self-protection flux-cored wire containing multi-granularity deoxidizing agent and preparation method of low-cost self-protection flux-cored wire containing multi-granularity deoxidizing agent

ActiveCN106112305AImprove self-protection performanceSimple welding processWelding/cutting media/materialsSoldering mediaHigh carbonSlag

The invention discloses a low-cost self-protection flux-cored wire containing a multi-granularity deoxidizing agent and a preparation method of the low-cost self-protection flux-cored wire containing the multi-granularity deoxidizing agent. A mild-carbon steel strip serves as a skin, and a flux core is prepared from 62 wt% to 75 wt% of high carbon ferro-chrome, 10% to 25% of the deoxidizing agent and the balance iron powder. The deoxidizing agent is a mechanical mixture formed by graphite, cellulose powder, an aluminum-magnesium alloy and a silicon-manganese alloy, the graphite, the cellulose powder, the aluminum-magnesium alloy and the silicon-manganese alloy are each composed of at least two different granularities, and the flux core accounts for 52 wt% to 56 wt% of the mass of the flux-cored wire. According to the flux-cored wire, deoxidization is full in the whole welding stage, the welding processing property is remarkable, a bead weld layer has the beneficial effects of being high in hardness, good in wear resistance and the like, the surface of a weld bead is basically free of slag, slag removal is not needed during multilayer welding, and the manufacturing cost of the flux-cored wire is low.

Owner:JIANGSU UNIV OF SCI & TECH

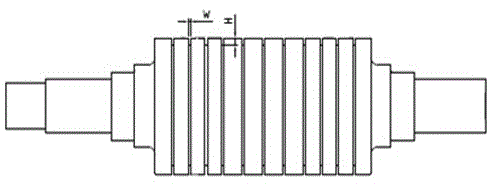

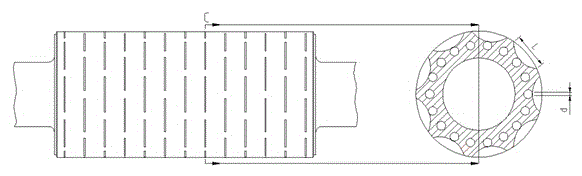

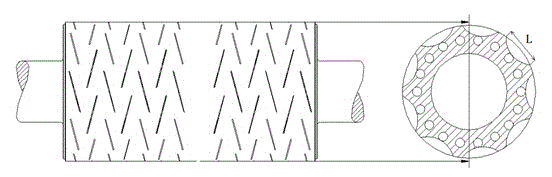

Machining method and manufacturing method of air suction grooves of corrugated roller

The invention discloses a machining method of air suction grooves of a corrugated roller. The machining method includes the first step of earlier-stage processing specifically involving the processes of a matrix modulation, b primary machining, c tooth punching and d multiplex heat treatment which are conducted on the corrugated roller in sequence, the second step of grinding of the air suction grooves, and the third step of turning of the air suction grooves. The machining method has the beneficial effects that the surface hardness of the roller reaches above HRC62, and the wear life of the roller is prolonged by 30%; the corrugated roller is uniform in surface hardness and free of soft zones; in the using process, neither pocking marks nor concave pits occur; due to the fact that hardening treatment is conducted at first and then the grooves are cut, the hardness of groove openings is consistent with the hardness of other positions, and the defect that poor gluing of paper boards is caused by quick abrasion to the groove openings, tooth breakage and other reasons is avoided in the using process.

Owner:SHANGHAI DASONG CORRUGATING ROLL IND

Gradient centrifugal casting process for large-diameter furnace rollers

InactiveCN101602098AImprove distribution ratioImprove compactnessFurnace typesHeat treatment furnacesRoom temperatureHardness

The invention discloses a gradient centrifugal casting process for cold-rolling heat treatment of large-diameter furnace rollers in the metallurgical industry. The process comprises the steps of adopting a steel-forging die for casting, finishing casting, coating the inner wall of a furnace roller with an insulating layer to lower the temperature of the furnace roller sequentially from outside to inside and cooling to between 100 and 120 DEG C within 10 to 15 minutes. As the furnace roller is cooled sequentially from outside to inside in the cooling process, the distribution ratio of columnar grains to equiaxed grains is improved, and the compactness of crystallization structure is increased so as to improve the high-temperature creep strength and oxidation resistance of materials. The large-diameter furnace rollers centrifugally cast are high in strength, free from deformation and uniform in surface hardness, have tensile strength Rm greater than or equal to 460 N / mm at room temperature, have yield strength RP0.2 greater than or equal to 240 N / mm, and have elongation A after fracture greater than or equal to 15 percent.

Owner:孙立彬

A method to improve the surface hardness of metal 3D printing 18ni300 mold steel

ActiveCN108950464BUniform surface hardnessImprove toughnessMolten spray coatingWire cuttingMachining

The invention provides a method for increasing the surface hardness of 18Ni300 die steel for metal 3D printing. The method comprises the following steps that S1, a die is printed; S2, solid-soluble heat treatment of a part is conducted; S3, wire cutting and powder clearing of the part are conducted; S4, parts surface treatment is conducted; S5, part surface coating preparation and coating are conducted; S6, heat treatment is conducted; and S7, machining is conducted, specifically, 0.3-0.5 mm of a part surface coating is removed as machining allowance. According to the method for increasing thesurface hardness of the 18Ni300 die steel for metal 3D printing, an NiCrBSi coating can be evenly applied to the surface of the die part through a plasma spraying process, the surface hardness is uniform, and the surface hardness of the die can reach 56-65 HRC.

Owner:BEIJING E PLUS 3D TECH CO LTD

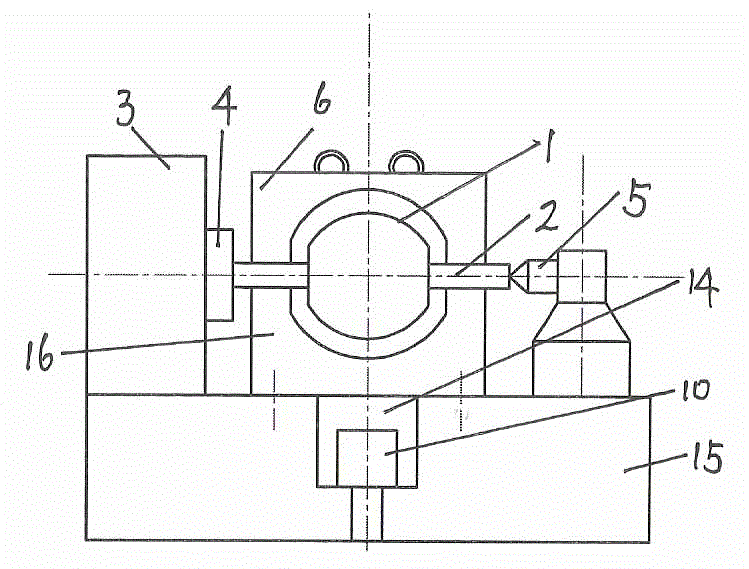

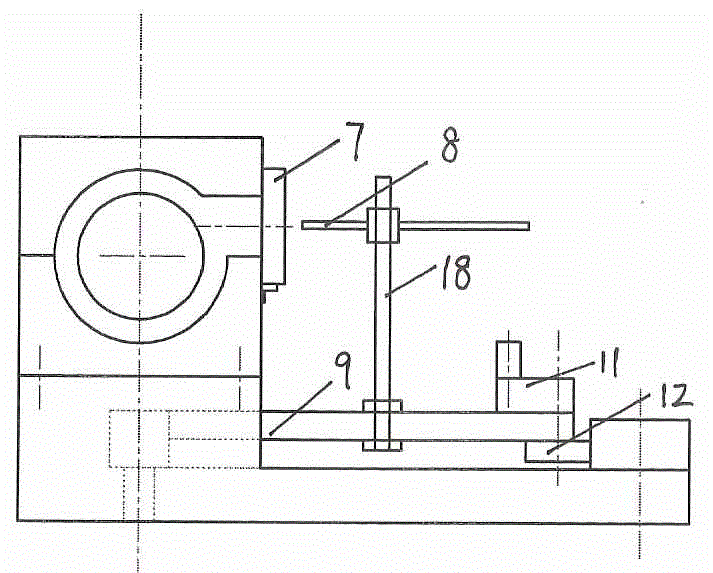

Ball surface spray welding device for ball valve

ActiveCN104178723BImprove working environmentReasonable structureMolten spray coatingTemperature controlWorking environment

The invention discloses a spray welding device for a ball body surface of a ball valve. A temperature control box comprises an upper box body and a lower box body, wherein a spray gun gate is arranged on the upper box body or the lower box body; the upper box body covers on the lower box body; a cavity for accommodating a ball body is formed in the temperature control box, an elastic-form mandrel passes through a hole of the ball body and is tightly matched with the ball body; the two ends of the mandrel prop against a tail frame by virtue of a chuck at the front end of a gearbox respectively; a spray gun is arranged on the outer side of the spray gun gate, the spray gun is connected with a spray gun swinging mechanism. The spray welding device is reasonable in structure, capable of enabling a sprayed piece to be integrally preheated in the temperature control box, high in heating efficiency, uniform in temperature, high in combination compactness and small in stress on a combined surface; the sprayed piece is integrally re-molten in the temperature control box, so that the surface of the sprayed piece is completely and sufficiently bonded in a metallurgical manner, and thus, a peel-off phenomenon is avoided; the spray welding device is cooled along with the box, so that the hardness of all surfaces is uniform, the processing efficiency is high and the quality is good. And besides, the working environment of the staff is improved, and the labor intensity of the staff is relieved.

Owner:JIANGSU SHENTONG VALVE

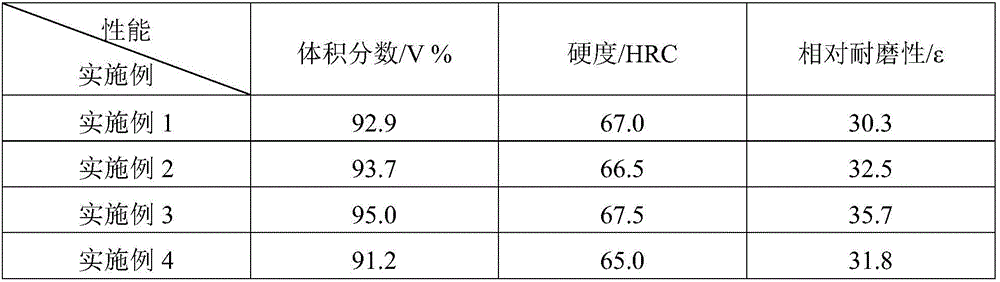

Self-generated wear-resistant surfacing self-protected flux-cored wire reinforced by boron carbide with great volume fraction and preparation method for self-generated wear-resistant surfacing self-protected flux-cored wire

ActiveCN106141483AImprove thermal stabilitySimple welding processWelding/cutting media/materialsSoldering mediaHigh carbonWear resistant

The invention discloses a self-generated wear-resistant surfacing self-protected flux-cored wire reinforced by boron carbide with great volume fraction and a preparation method for the self-generated wear-resistant surfacing self-protected flux-cored wire. By taking a low-carbon steel belt as skin, the flux-cored wire consists of the following components in percentage by mass: 52-62% of high carbon ferro-chrome, 2-6% of chromium powder, 22-30% of ferroboron, 2-4% of graphite, 1-3% of an aluminum-magnesium alloy, 4-8% of a silicon-manganese alloy, and the balance iron powder; the graphite, the aluminum-magnesium alloy and the silicon-manganese alloy are added with grain sizes being 60 meshes and 200 meshes; and the flux core powder accounts for 55-60% of the total weight of the flux-cored wire. According to the flux-cored wire provided by the invention, flux core components with different grain sizes are added, so that good welding process performances are guaranteed; the flux core components are reasonably proportioned with other flux core components, so that boron carbide with mass fraction being 90% or more, namely (Cr, Fe)7(C, B) 3 and (Cf, Fe)3(C, B), is obtained in a surfacing alloy structure, hardness of a surfacing layer is as high as 65-68 HRC, and wear resistance of abrasives resistant to low stress is extremely good; and the welding process performances are good, deposition efficiency is high, and multi-layer welding is carried out while slag does not need to clear.

Owner:JIANGSU UNIV OF SCI & TECH

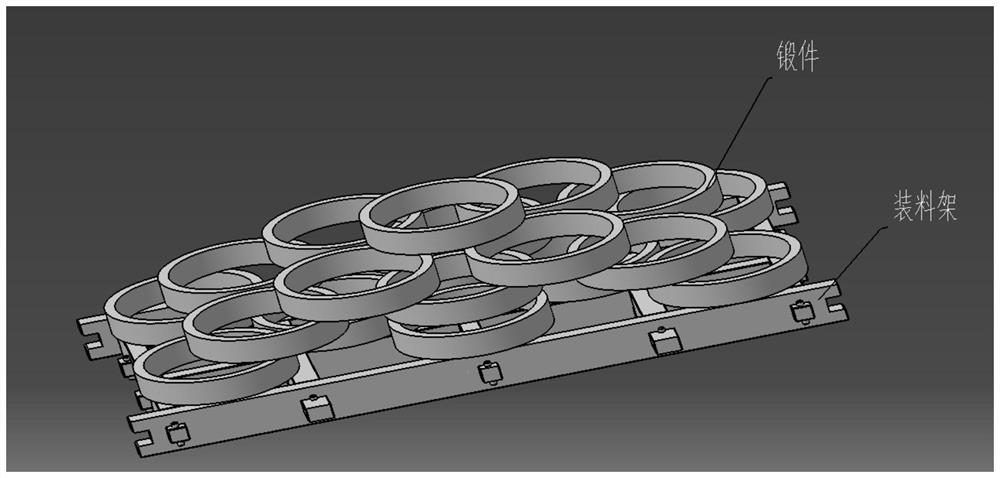

Heat treatment method for GH99 alloy annular forgings

PendingCN114231866AHeating and cooling evenlyMinimize the difference in cooling ratesHeat conservationForging

The invention belongs to the technical field of heat treatment of high-temperature alloy forgings, and discloses a heat treatment method for GH99 alloy annular forgings, which comprises the following steps: heating the forged GH99 alloy forgings to 1100 DEG C, preserving heat for 1-3 hours, carrying out air cooling and precooling on the forgings for 1-5 minutes after discharging, and then carrying out water cooling. Compared with a conventional GH99 alloy heat treatment method, layered staggered placement is adopted for heat treatment charging of the annular forge piece, it is guaranteed that each face of the forge piece is cooled uniformly, the treated forge piece is uniform in structure, and the hardness of the surface and the core of the forge piece is uniform; according to the method, after solid solution heat preservation is finished, the cooling mode that air cooling and pre-cooling are conducted firstly, and then water cooling is conducted is adopted for cooling, so that the difference between the surface cooling rate and the core cooling rate of the forge piece is reduced, the hardness HB (d) of the treated forge piece is within the range of 3.6-3.9 mm, the strength surplus amount is large, and the delivery and use requirements are met.

Owner:SHAANXI HONGYUAN AVIATION FORGING

A silicon-toughened high-chromium cast iron type self-shielding flux-cored welding wire and its preparation method

ActiveCN106392361BImprove wear resistanceSimple welding processWelding/cutting media/materialsSoldering mediaHigh carbonSlag

The invention discloses a silicon annealed high-chromium cast iron type self-protection flux-cored wire. A mild-carbon steel strip serves as the skin. A flux core is composed of, by mass, 60-75% of 80-mesh high-carbon ferro-chrome, 12-16% of 80-mesh silicon iron, 0.5-1% of 60-mesh graphite, 1-2% of 200-mesh graphite, 1-5% of 60-mesh ferro-boron, 1-3% of 200-mesh ferro-boron, 1-2% of 60-mesh aluminum magnesium alloy, 1-2% of 200-mesh aluminum magnesium alloy, 1-2% of 60-mesh manganese powder, 1-3% of 200-mesh manganese powder, and the balance 80-mesh iron powder. According to the wire provided by the invention, excellent welding technological performance is guaranteed by adding flux core components with different particle sizes; a proper amount of Si is added into the flux core, (Cr,Fe)7C3 carbide in the surfacing alloy high-chromium cast iron type hypereutectic structures is refined, the Fe3Si phase is formed, the toughness of a surfacing layer is remarkably improved, and the abrasion resistance is good; and in addition, the welding technological performance is excellent, the melting efficiency is high, slag removal is not needed during multilayer welding, and the manufacturing cost of the wire is low.

Owner:JIANGSU UNIV OF SCI & TECH

Method for eliminating color differences of machined surface of electroslag martensite circle forging machine

ActiveCN113265512ANo color differenceUniform surface hardnessFurnace typesProcess efficiency improvementMachined surfaceMartensite

The invention discloses a method for eliminating color differences of a machined surface of an electroslag martensite circle forging machine. According to the method, the mechanism of electroslag steel forging circle color difference generation is researched according to the personalized requirements of a user for surface color differences, besides normal electroslag process control, the forging circle heat treatment process is optimized and improved with post-forging heat treatment process optimization as a thinking starting point, and two annealing processes are formulated. The problem of the color differences after machining of the electroslag martensite round forging surface is solved, and user requirements are met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Cryogenic treatment method of forged steel cold rolling roll and its new nozzle

ActiveCN110684890BReduce cloggingUniform surface hardnessFurnace typesHeat treatment furnacesEngineeringCryogenic treatment

The invention discloses a cryogenic treatment method for forged steel cold rolling rolls and a novel nozzle adopted therefor. The nozzle has a mounting part and a nozzle head, and the nozzle head is provided with a large nozzle with a diameter of 0.8-1.2 mm and several nozzles arranged in large nozzles. There are small nozzles with a diameter of 0.4 to 0.6mm around the nozzle; the cryogenic treatment method is as follows: ①Put the forged steel cold roll in the cryogenic box and close the cryogenic box; ②Spray liquid nitrogen from the nozzle into the cryogenic box, and Reduce the temperature in the cryogenic box to ‑160 to ‑120°C for 1 to 2 hours; ③ keep warm at this temperature for 2 to 5 hours; ④ after the heat preservation is over, open the cryogenic box and place the forged steel cold roll at room temperature , naturally returned to room temperature. By designing a new type of nozzle and matching the corresponding cryogenic treatment method, the present invention can make the ejected liquid nitrogen more dispersed and more uniform, so that the surface hardness of the forged steel cold rolling roll is more uniform, and the hardness of the finished product is uniform, and the phenomenon of nozzle clogging is also decrease very much.

Owner:BAOSTEEL ROLL SCI & TECH

Roll production method and roll produced by the method

InactiveCN105108148BExtended service lifeHigh bonding strengthTurbinesOther manufacturing equipments/toolsNon-metallic inclusionsCarbide

The invention relates to a production method of a roll, comprising: S1: setting a sheath with a gas port outside the mandrel, and loading alloy powder into the sheath when setting; S2: extracting gas from the gas port on the sheath to The alloy powder in the sheath is degassed; S3: seal the gas port to form a transition piece; S4: hot isostatically press the whole sheath containing the mandrel inside, so that the alloy powder is sintered to form a roller sleeve; S5 : Remove the sheath and perform machining to form a roll that meets the required size and surface quality. For the roll obtained by the roll production method of the present invention, the joint between the mandrel and the roll sleeve is a metallurgical joint interface, the joint is tight, no carbide is precipitated at the joint, and the content of non-metallic inclusions in the roll sleeve is low. There is no segregation in the structure of the roller sleeve, and the composition distribution is more uniform. At the same time, the surface hardness of the roller sleeve is uniform, and the surface quality of the product is greatly improved. Finally, the service life of the roll is greatly improved.

Owner:飞而康快速制造科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com