Quenching tank for large and medium size forging

A large and medium-sized quenching tank technology, applied in the direction of quenching agent, quenching device, furnace type, etc., can solve the unsolved problems such as the temperature uniformity of the quenching liquid, and achieve the effect of simple structure, easy manufacture, and deformation prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

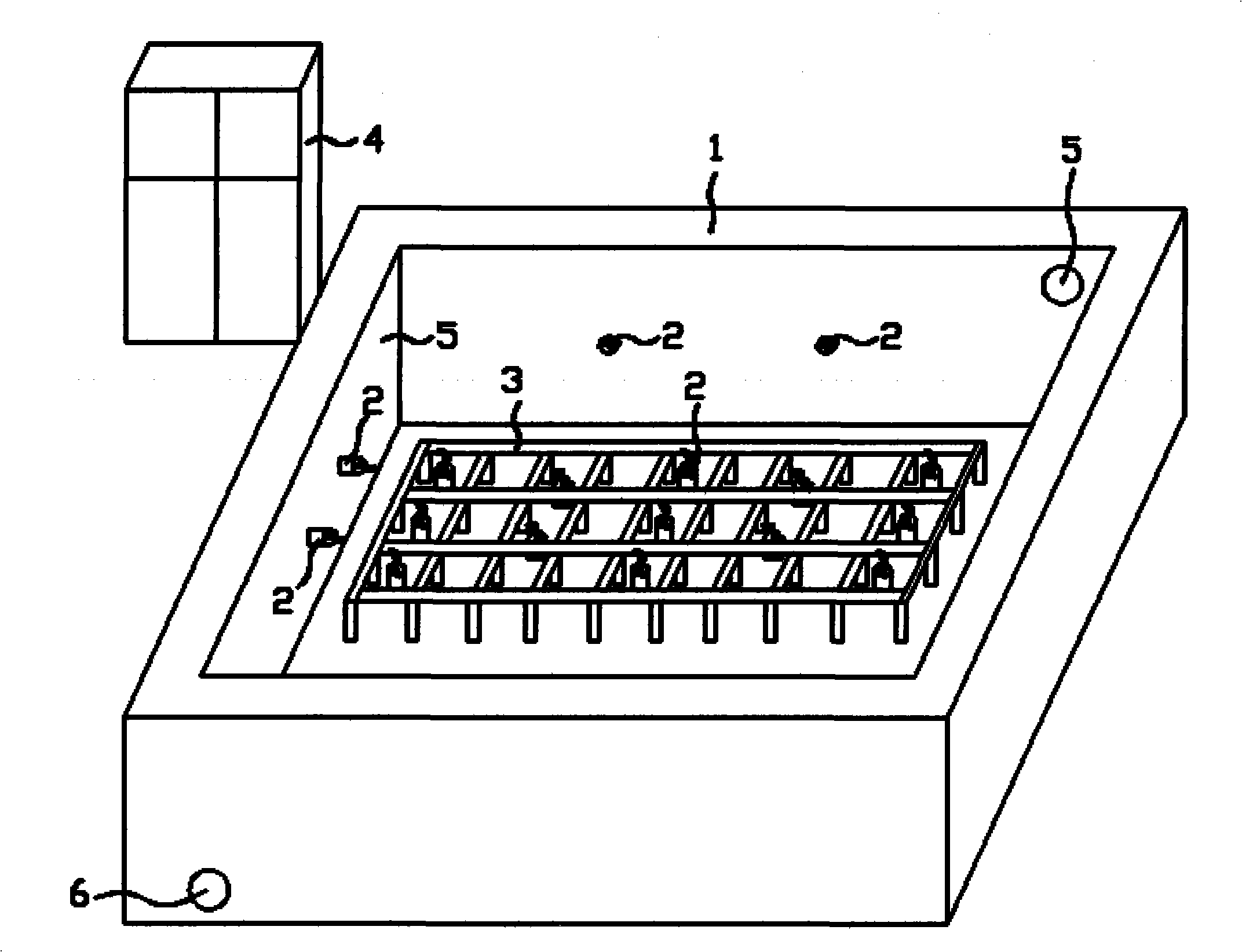

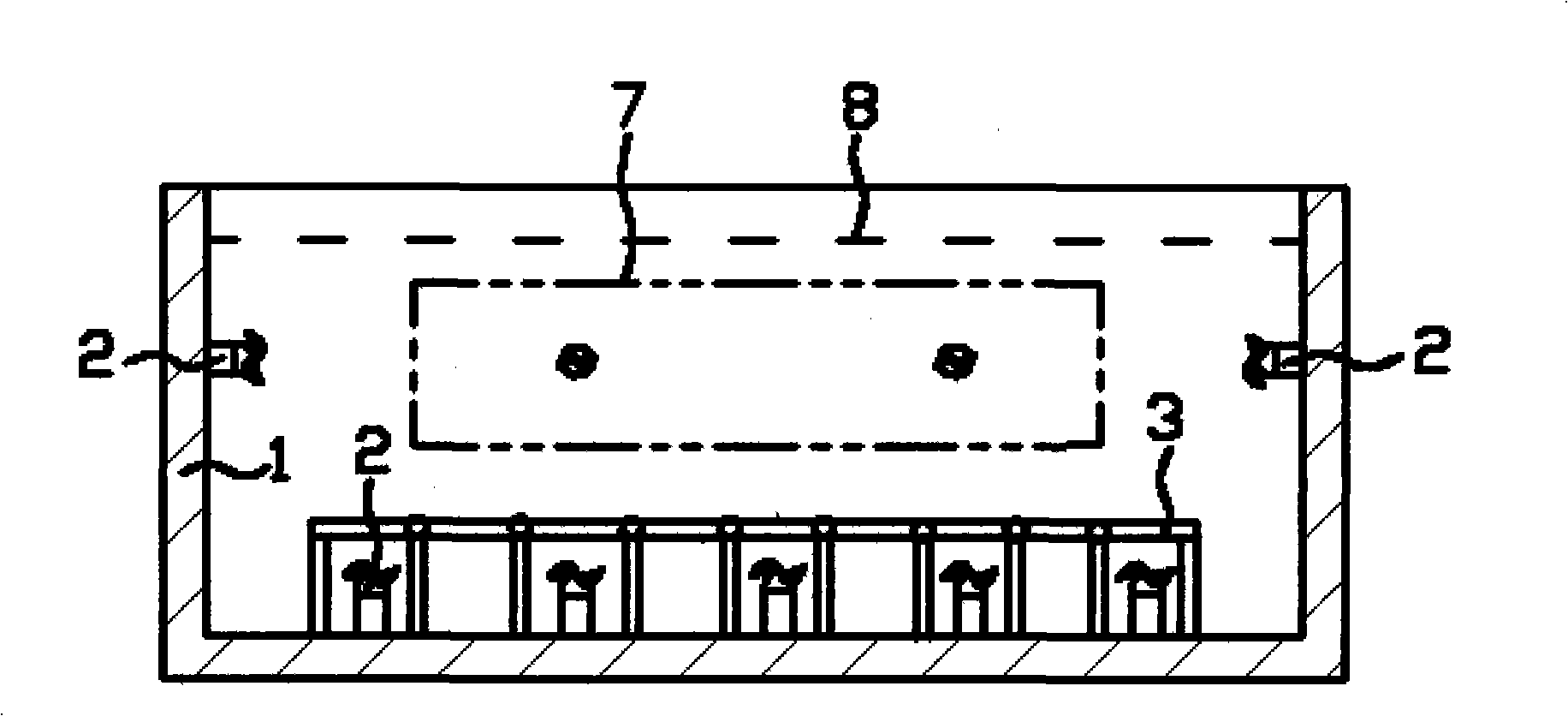

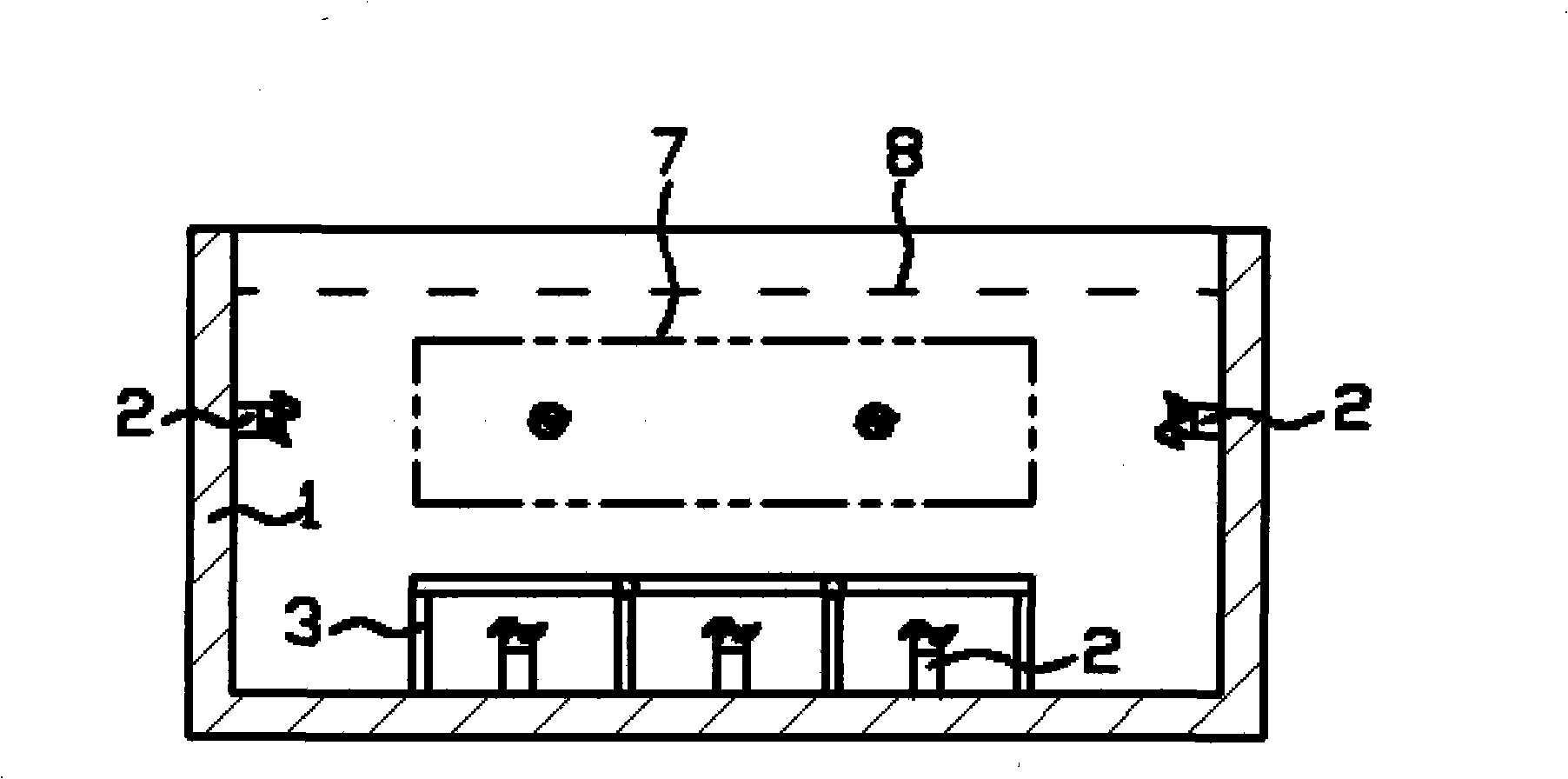

[0017] figure 1 The three-dimensional structure of the quenching tank of the large and medium-sized forgings according to the present invention is shown. The quenching tank is mainly composed of a tank body 1 , a submersible mixer 2 , a protective frame 3 and a frequency conversion controller 4 . The tank body 1 is in the shape of a cuboid tank, and submersible mixers 2 are respectively installed around the inner wall of the tank body 1 and at the bottom.

[0018] Two submersible mixers 2 are respectively installed on each long-side inner wall and wide-side inner wall of the tank body 1, and the submersible mixer 2 is in the middle position in the height direction of the inner wall on each side, and is located on the side in the length direction of the inner wall on each side. Two points in the middle of the trisection distribution of the inner wall.

[0019] 13 submersible mixers 2 are installed on the bottom of the tank body 1 (in order to make the figure clearly visible, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com