Patents

Literature

41results about How to "Prevent defects such as cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

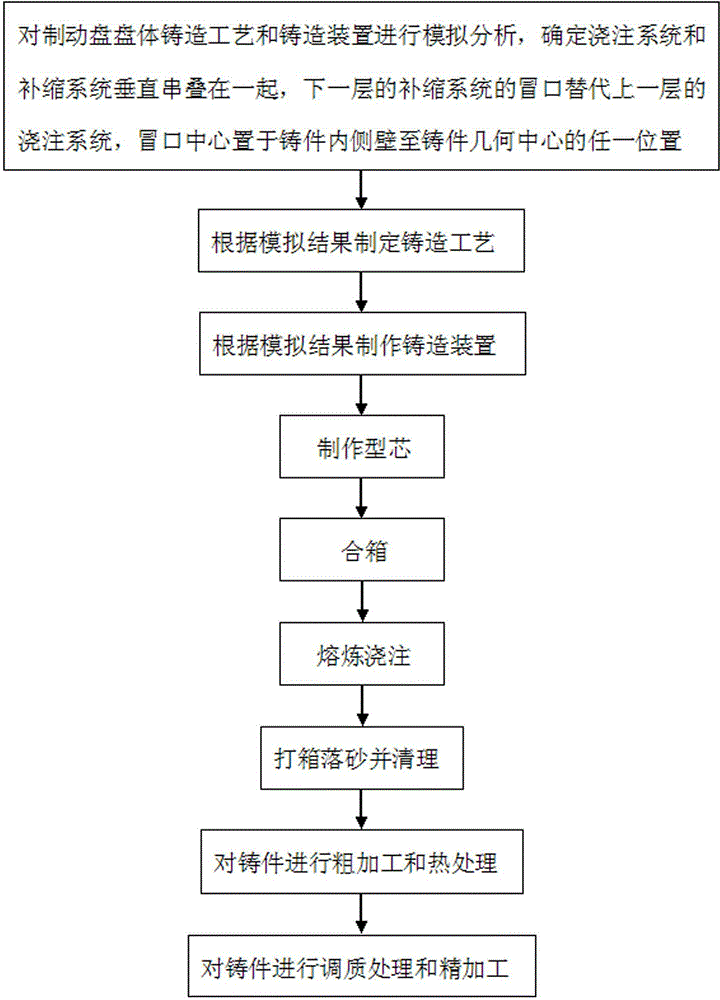

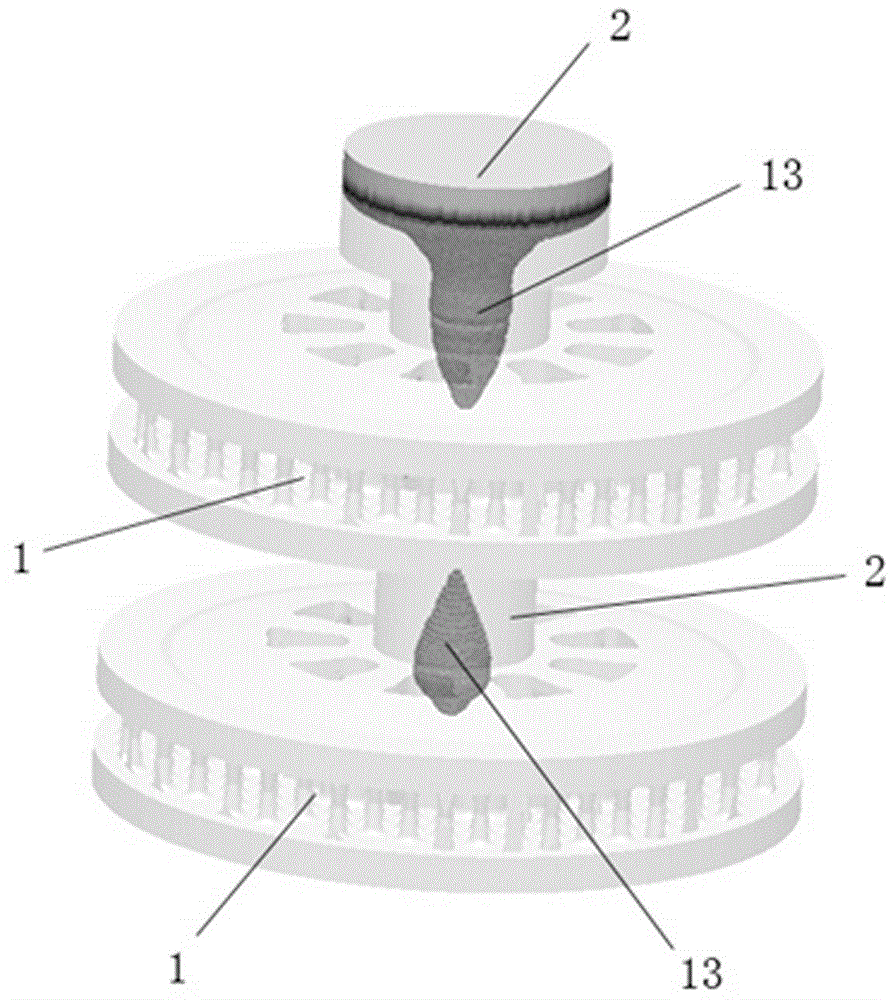

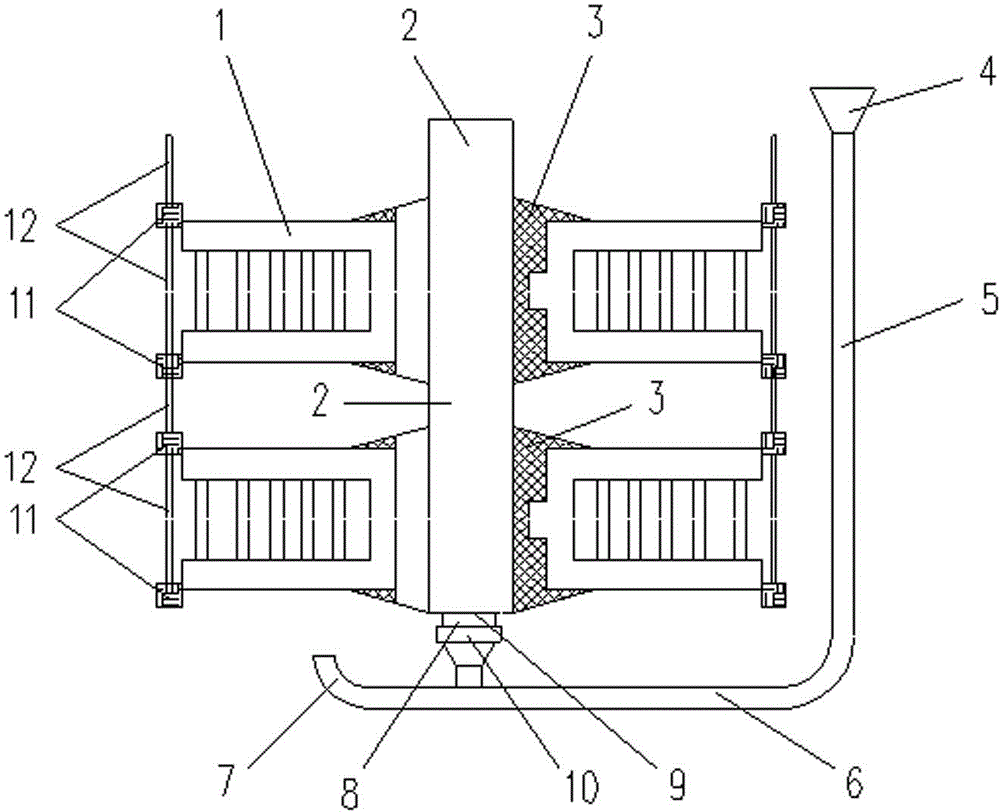

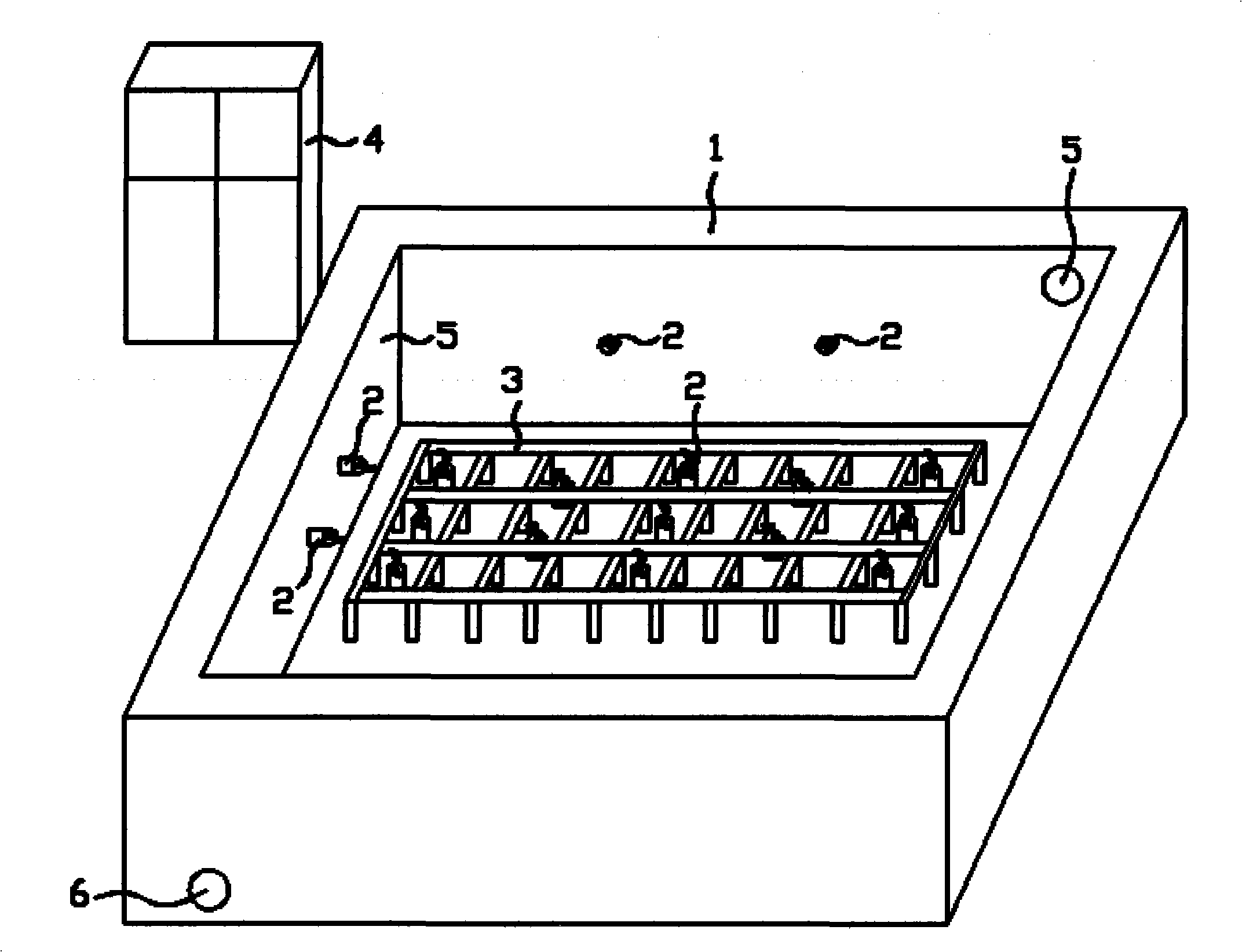

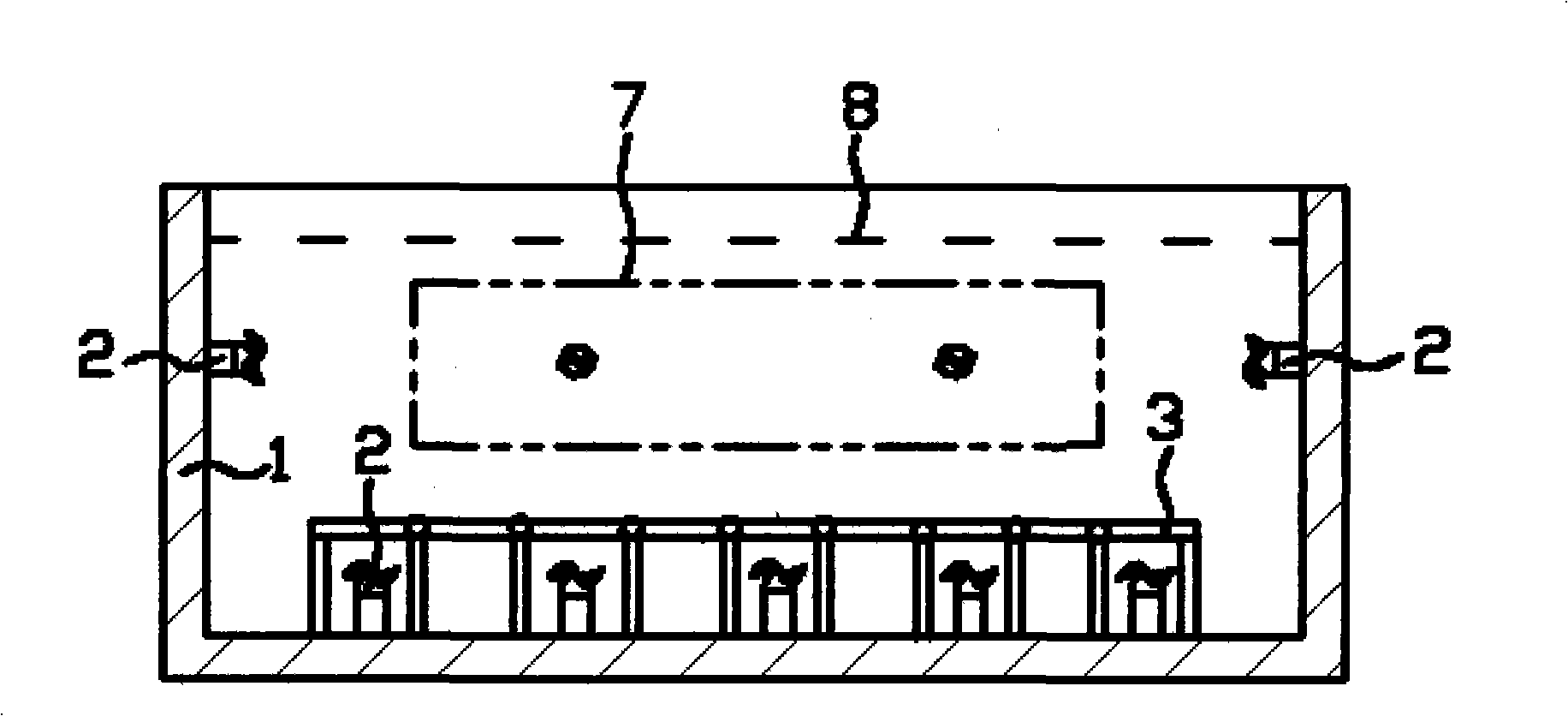

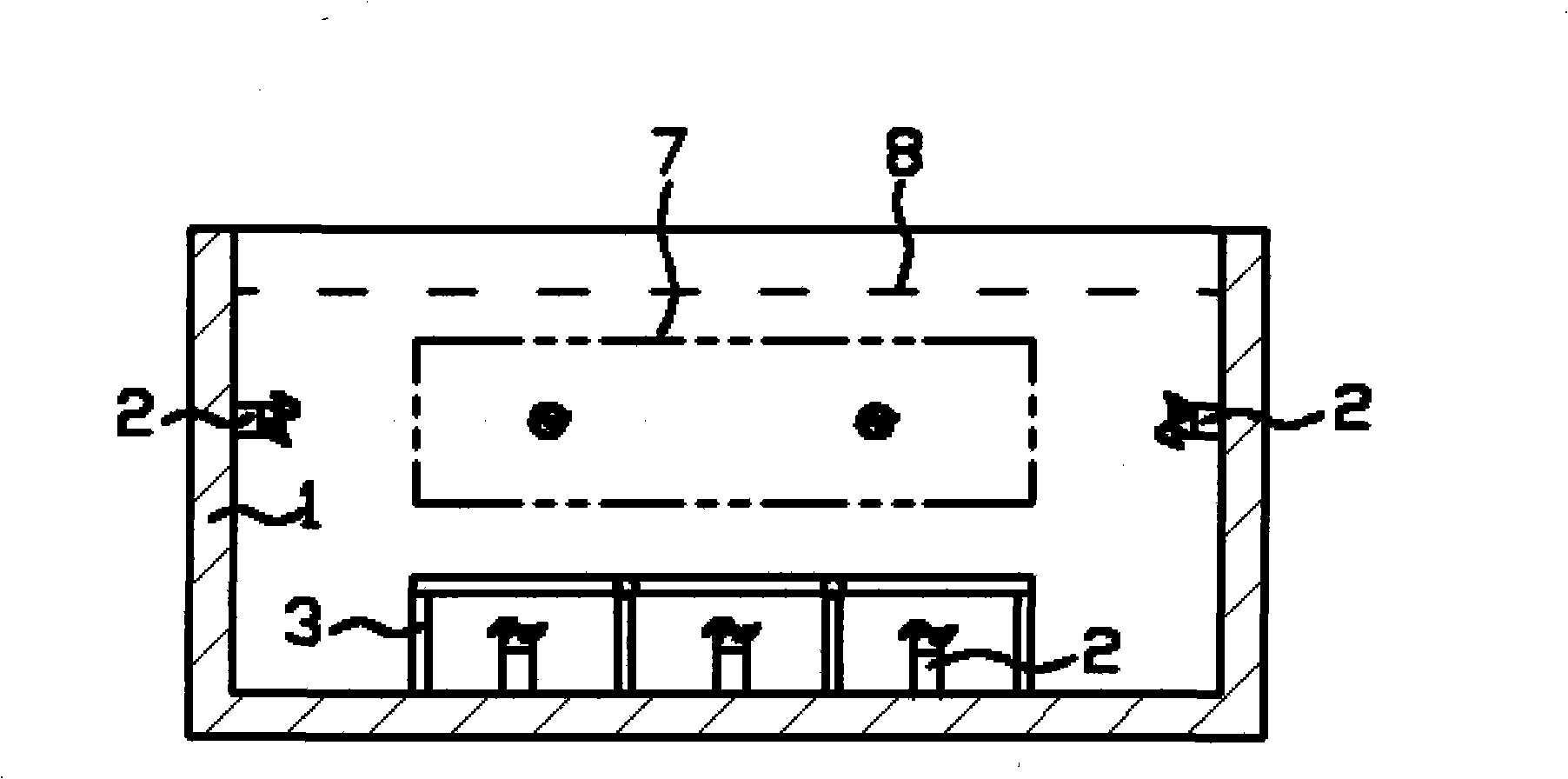

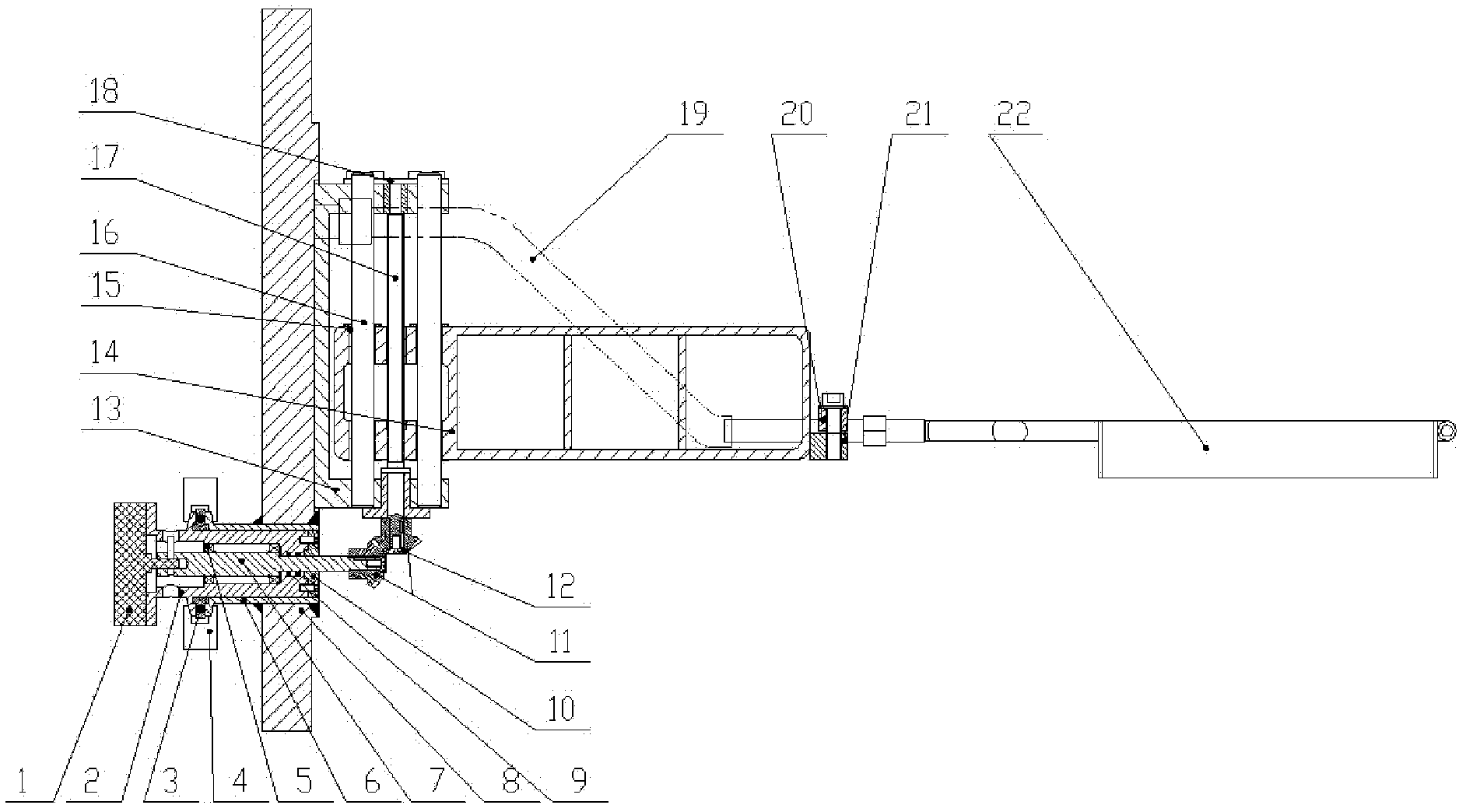

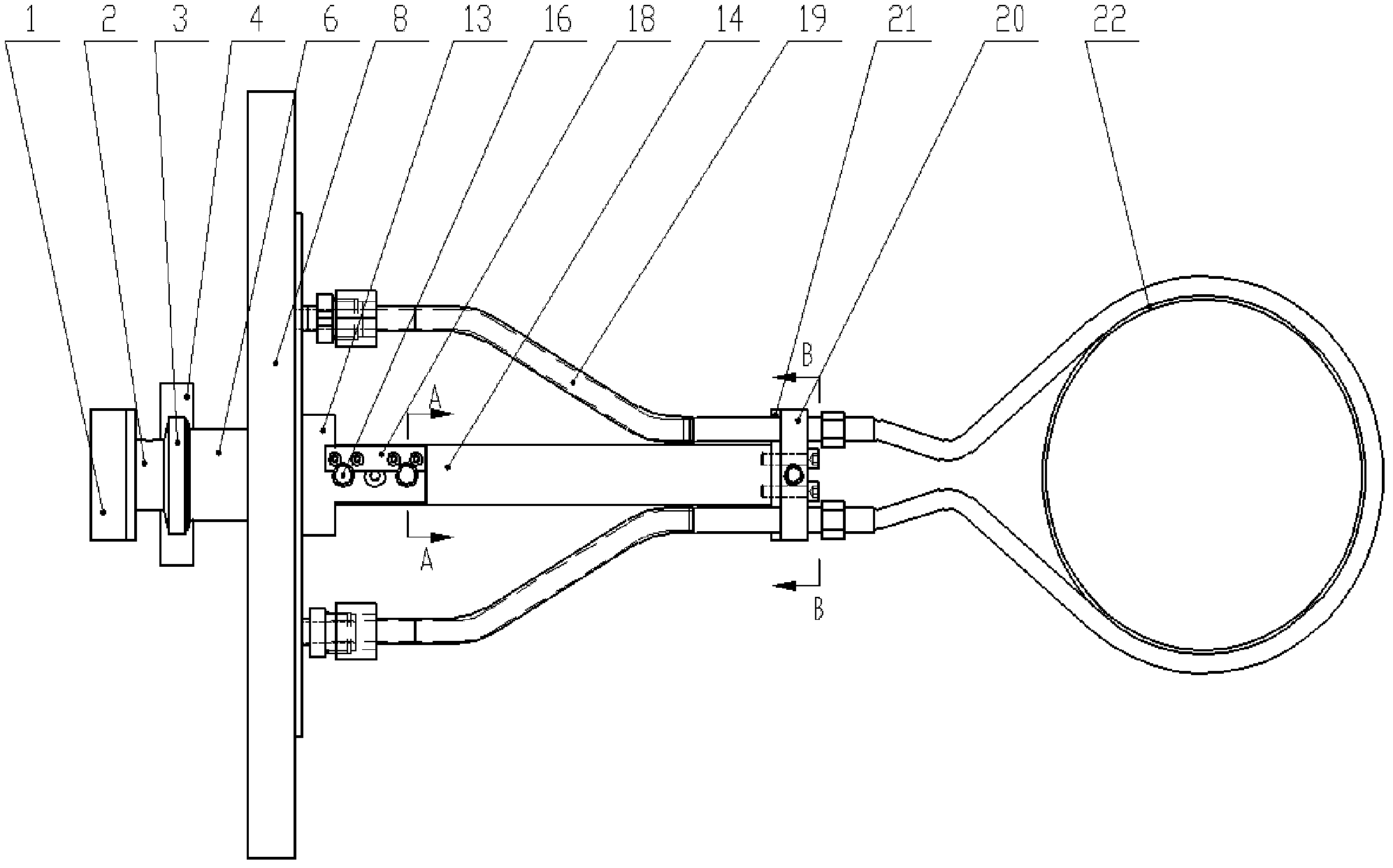

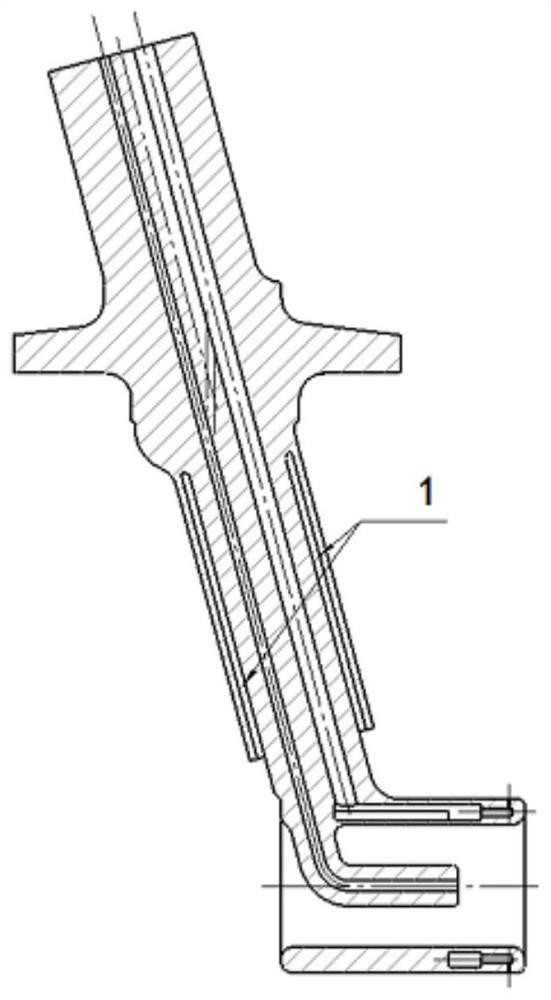

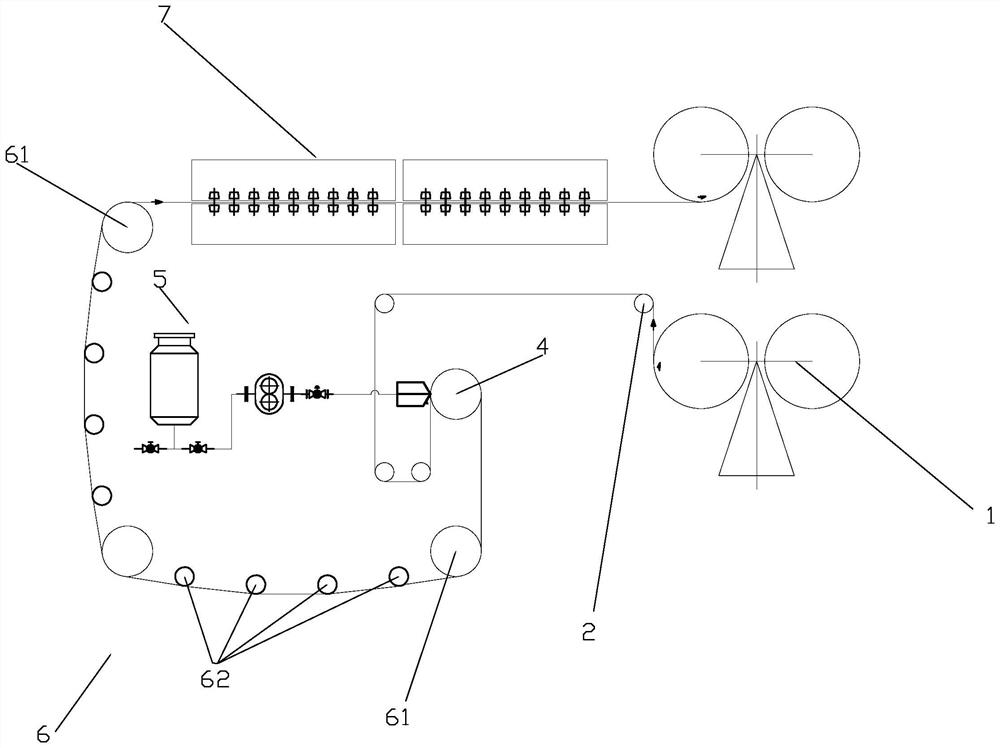

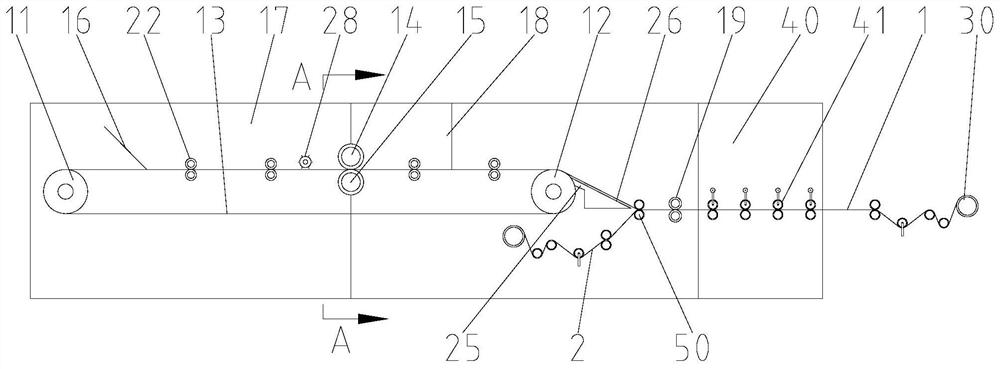

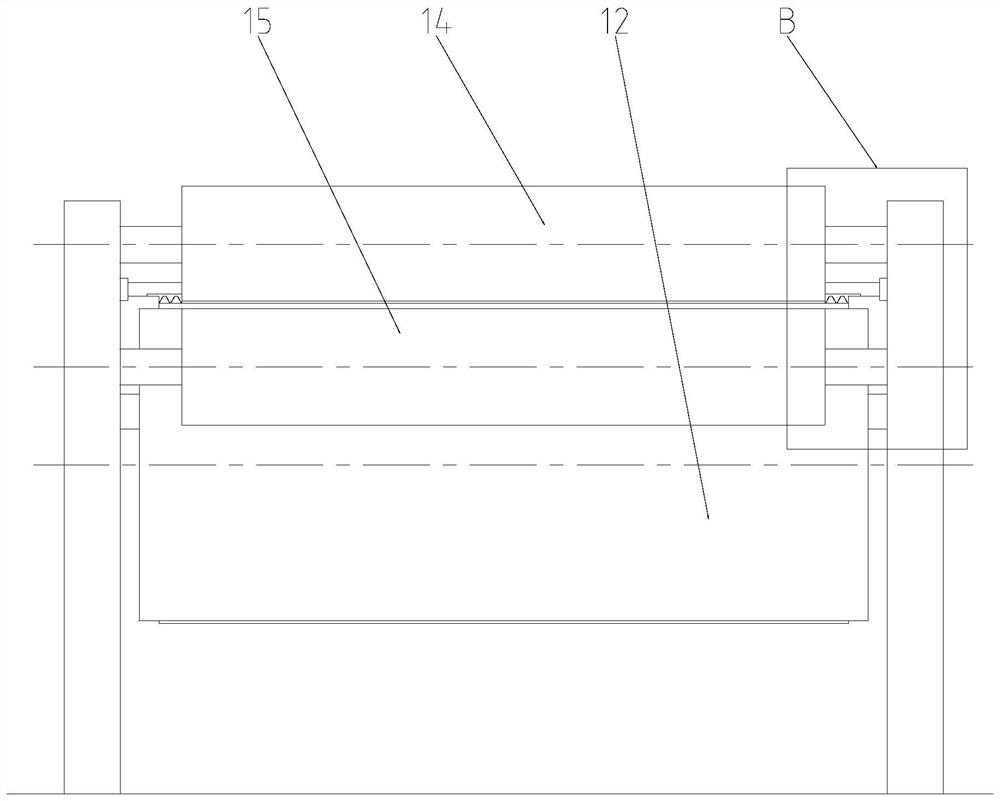

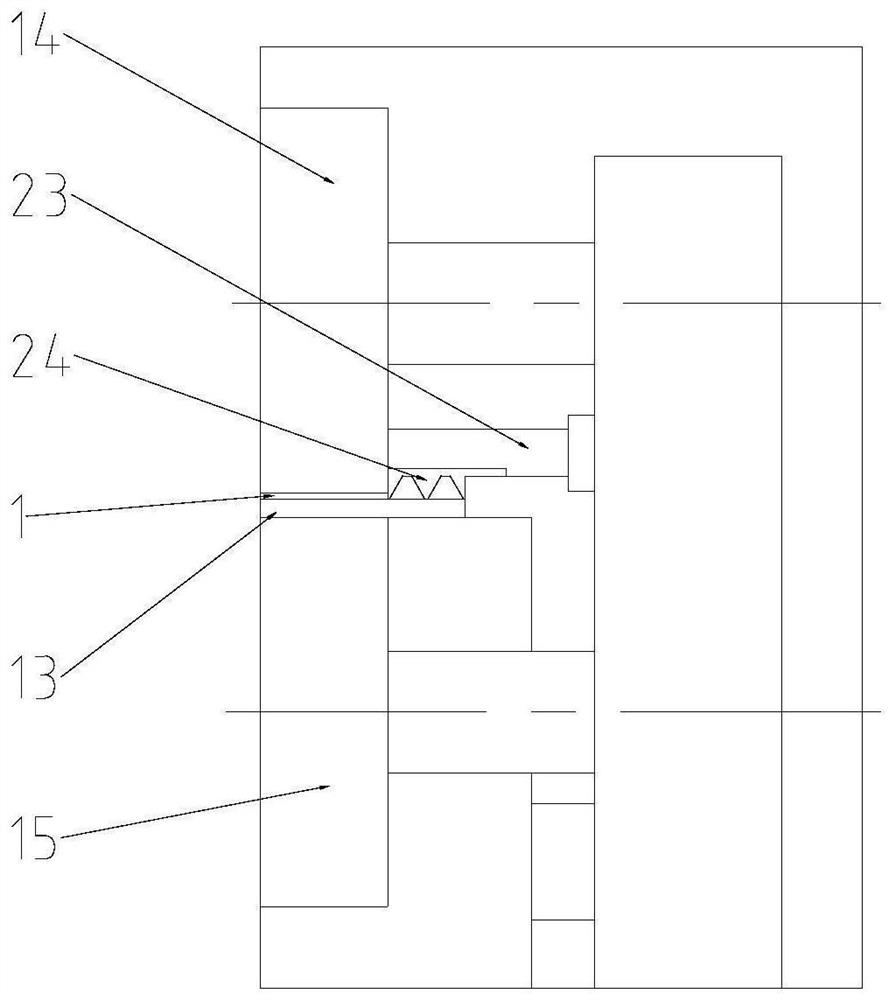

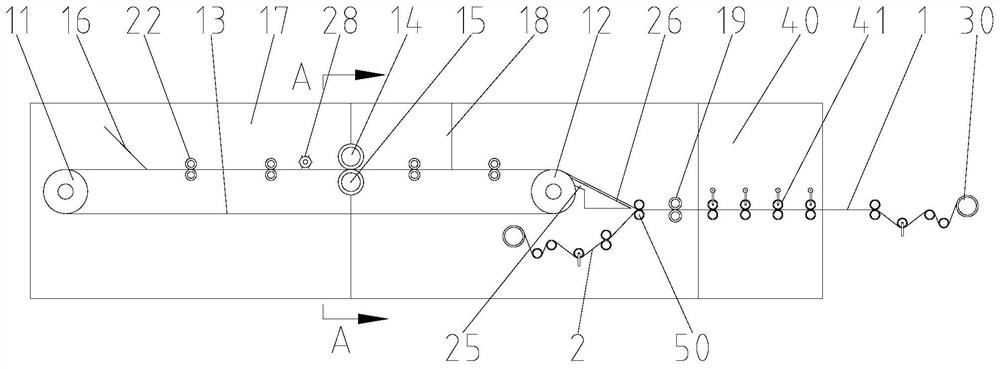

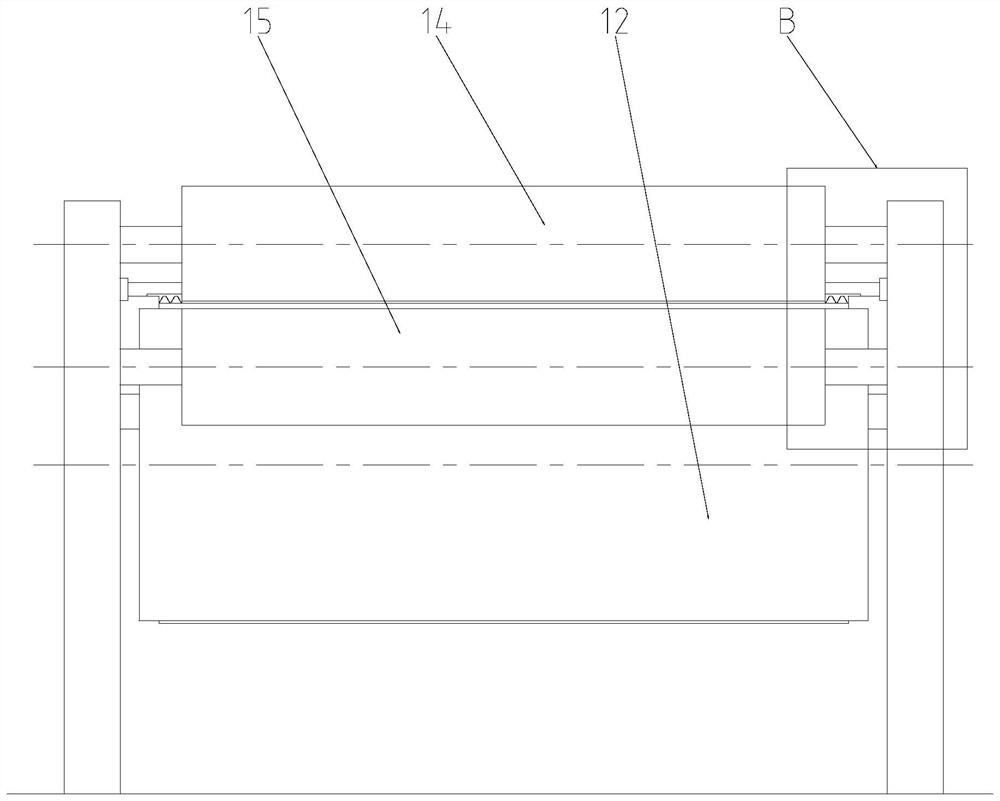

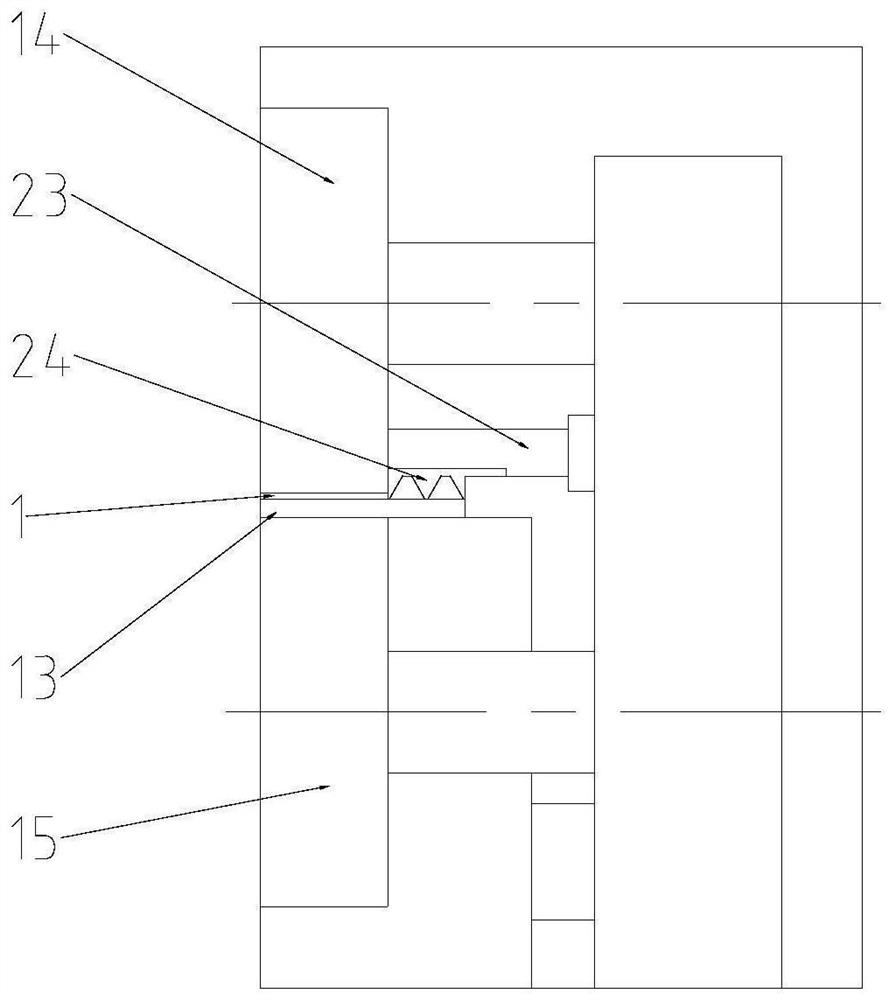

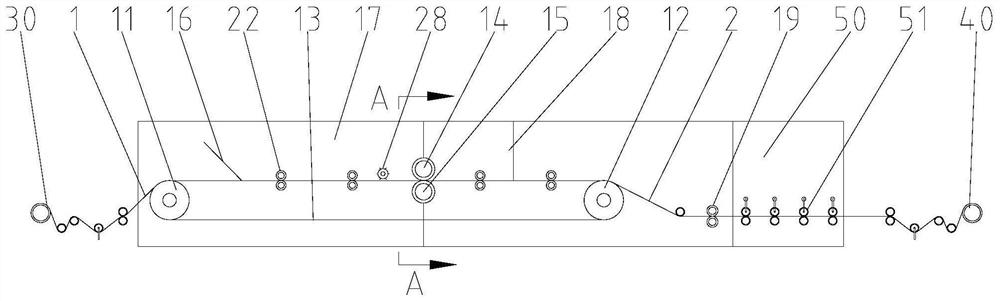

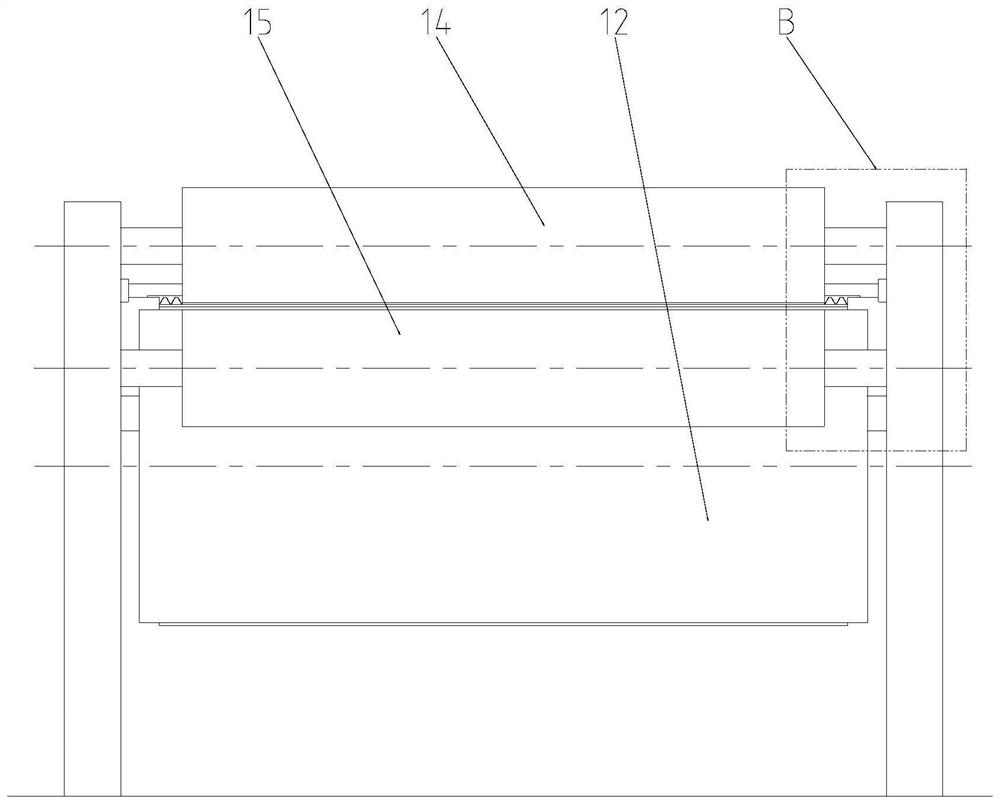

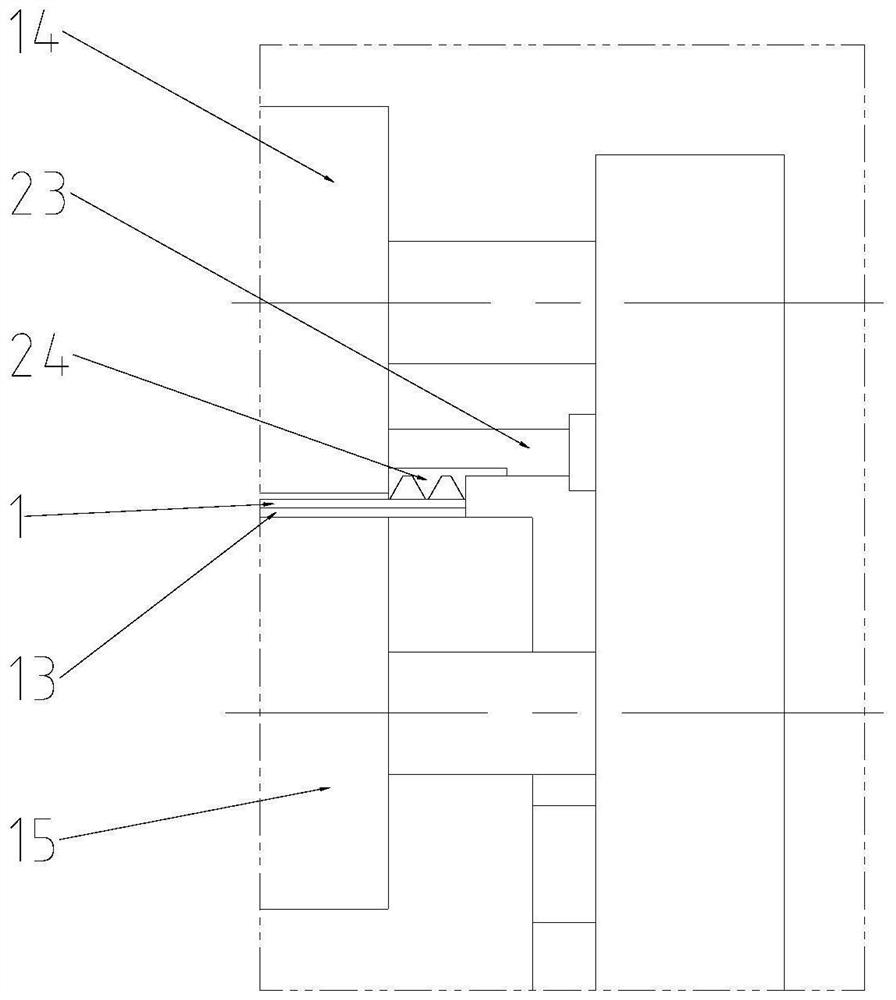

Method and device for casting brake disc body and manufactured brake disc body

ActiveCN104148587AStable and balanced fillingPrevent shrinkageBraking discsFoundry mouldsHigh volume manufacturingSlag

The invention discloses a method and device for casting a brake disc body, and the brake disc body manufactured through the method and device. A casting system and a feeding system are perpendicularly stacked together in a cluster mode, the casting system on the upper layer is replaced with a feeder head on the lower layer, the center of the feeder head is arranged at any position from the inner side wall of a casting to the geometric center of the casting, a mode that metal liquid is introduced in a bottom returning mode is adopted to perform cluster casting, the metal liquid enters a cavity in the upper layer from the bottom of the lower layer, and after the cavity in the upper layer is filled with the metal liquid, the metal liquid enters a cavity in the upper layer from the feeder head on the lower layer. According to the casting method, sequential solidification and complete feeding of the casting can be achieved, defects of shrinkage holes, shrinkage porosity, sand holes, air holes, slag holes, cracks and the like are effectively prevented from appearing in the casting process of the casting, isotropy of performance of the casting is ensured, meanwhile, the method is suitable for large-scale production of the high-quality brake disc body under the large-ladle casting, the use rate of metal is improved by 30 percent to 60 percent, the production cost is reduced by 30 percent to 60 percent, and the working efficiency is improved by 40 percent to 60 percent.

Owner:CHINA MACHINERY IND PROD +1

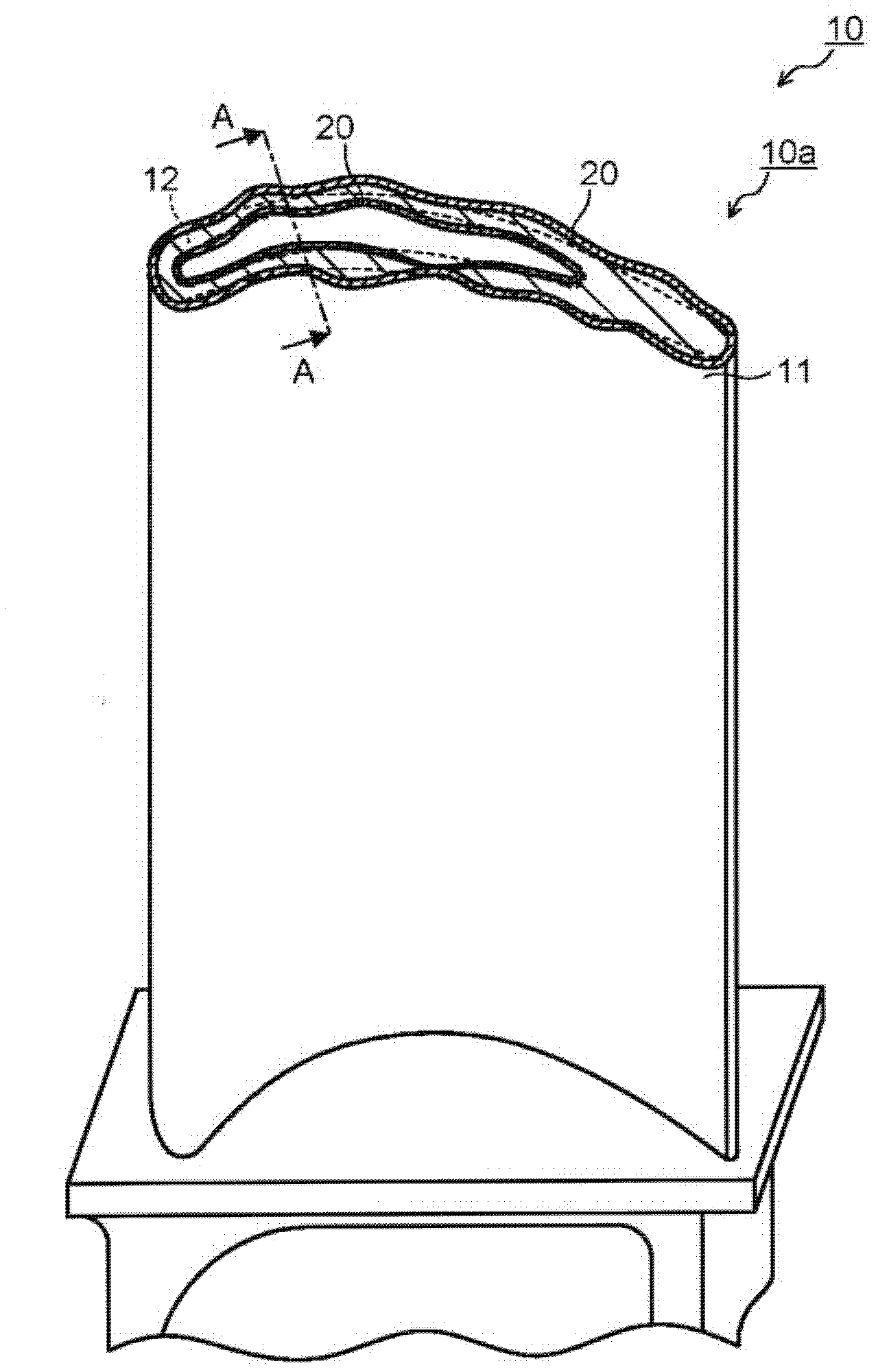

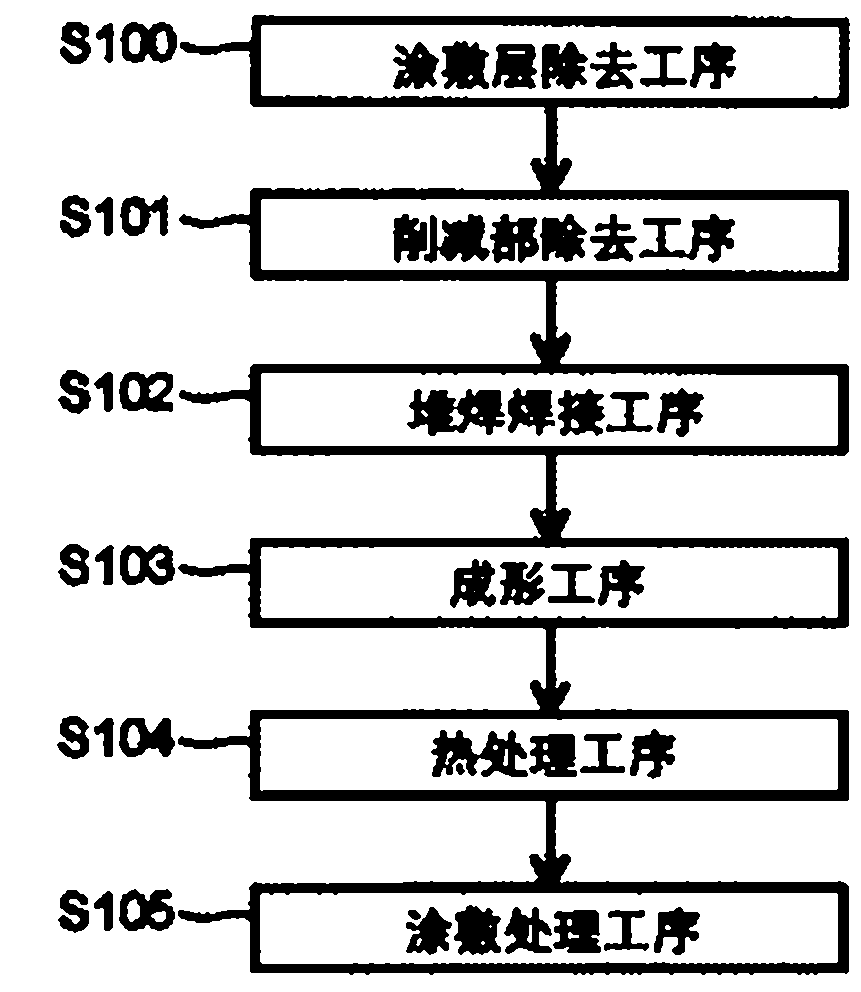

Repair method of gas turbine moving blade and gas turbine moving blade

InactiveCN102275058AImprove reliabilityPrevent defects such as cracks in surfacing weldingBlade accessoriesMachines/enginesDuctilityAerospace engineering

The present invention relates to a method of repairing a gas turbine moving blade capable of preventing defects such as cracks during overlay welding and performing highly reliable repairs when repairing a cut portion of a blade front end of a gas turbine moving blade, and the method for repairing Methods The gas turbine moving blades obtained after repairing. The repair method of the gas turbine rotor blade includes: removing the cut portion at the tip of the blade, and processing the tip of the blade into a flat cut portion removal process; using a laser to make the tip of the blade that is more ductile than the base material constituting the gas turbine rotor blade into a plane. The powder of the surfacing material is melted, and the surfacing is performed in multiple layers to form a surfacing welding process of a predetermined thickness; the shape of the surfacing part is processed into the same shape as the original blade tip before the reduction occurs The forming process; and the heat treatment process to remove the residual deformation caused by laser welding in the surfacing welding process.

Owner:KK TOSHIBA

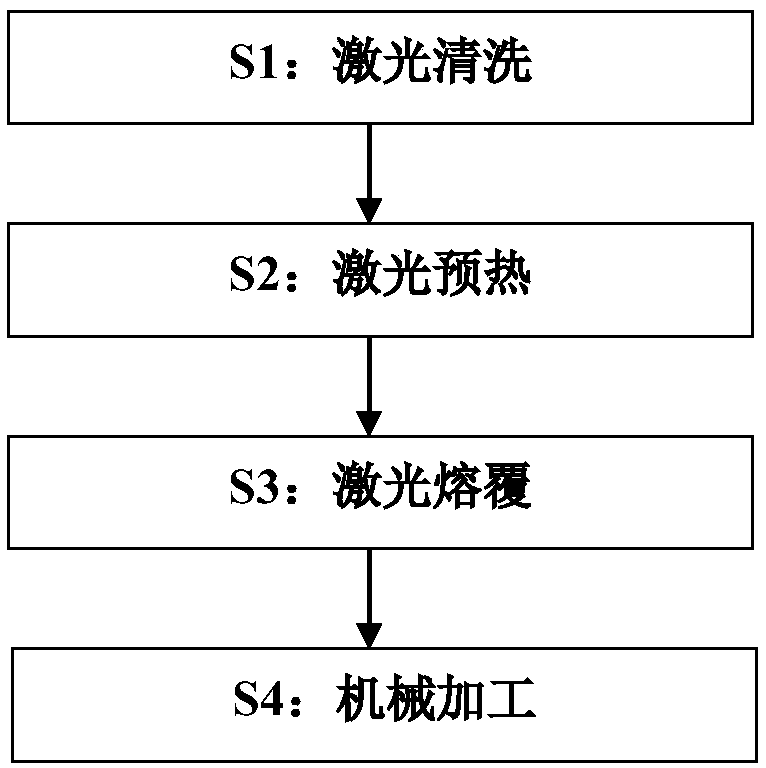

Laser cladding composite repair manufacturing method and application thereof

InactiveCN109385631AEnsure safetyReduce volumeMetallic material coating processesCleaning processes and apparatusOptoelectronicsMachining

The invention relates to a laser cladding composite repair manufacturing method. The method comprises the steps as follows: step 1, laser cleaning; step 2, laser preheating: continuously irradiating the surface of a to-be-repaired workpiece by a laser unit to preheat the to-be-repaired workpiece, marking emergent laser of the laser unit as preheating laser, wherein the spot shape of the preheatinglaser is round or rectangular, the area of preheating spots is 6 mm<2>-20 mm<2> and the scanning speed of the preheating laser spots is 8 mm / s-20 mm / s; step 3, laser cladding: irradiating the preheated to-be-repaired workpiece by cladding laser, wherein the spot shape, spot area and scanning speed of cladding laser are identical with those of the preheating laser; step 4, machining. The inventionalso relates to an application of the laser cladding composite repair manufacturing method. The method can be applied to repair manufacturing of high-carbon steel workpieces and high-alloy steel workpieces; laser is used as machining means, so that the method is clean, efficient, green and environmentally friendly.

Owner:山东泰利先进制造研究院有限公司

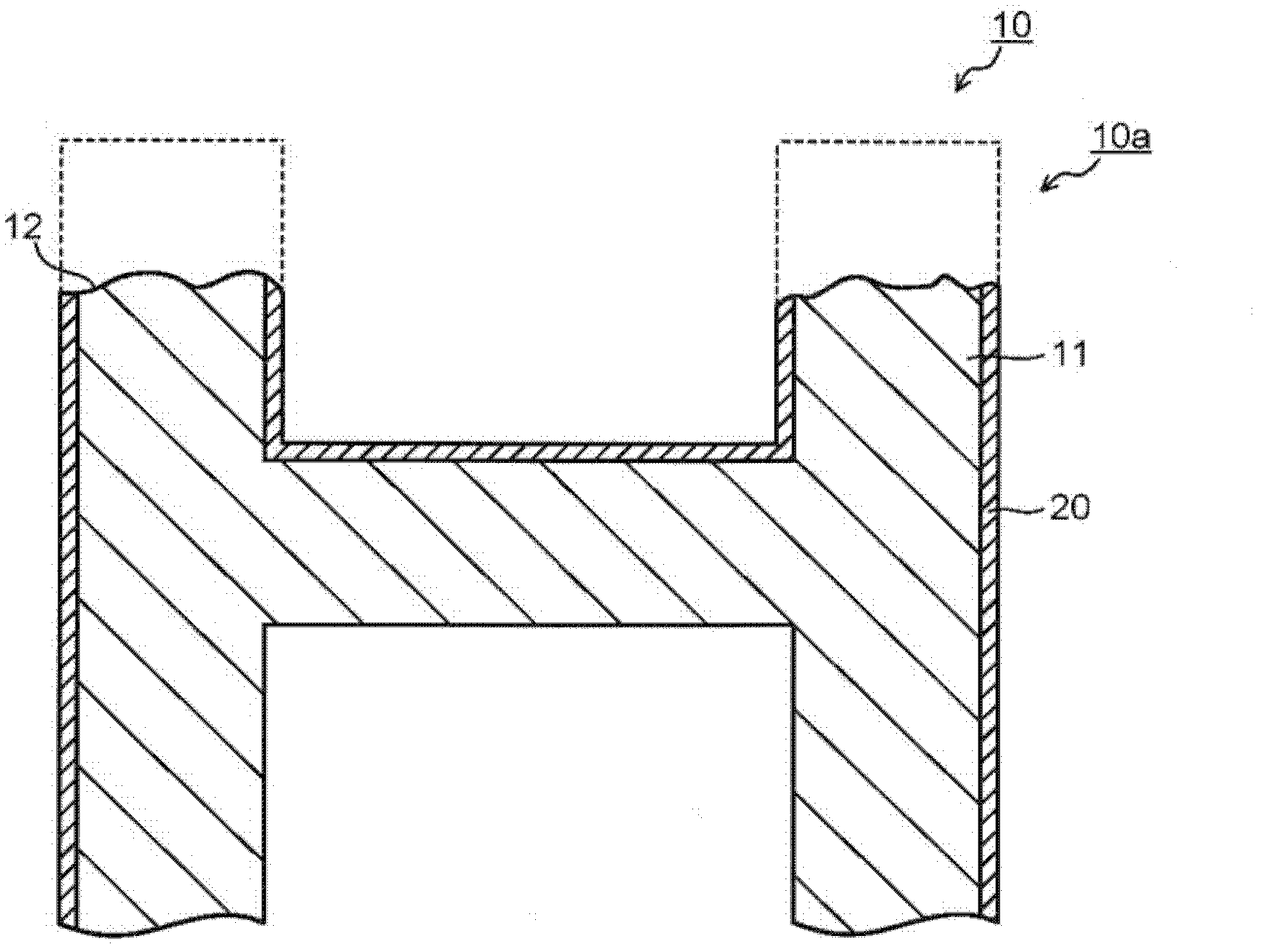

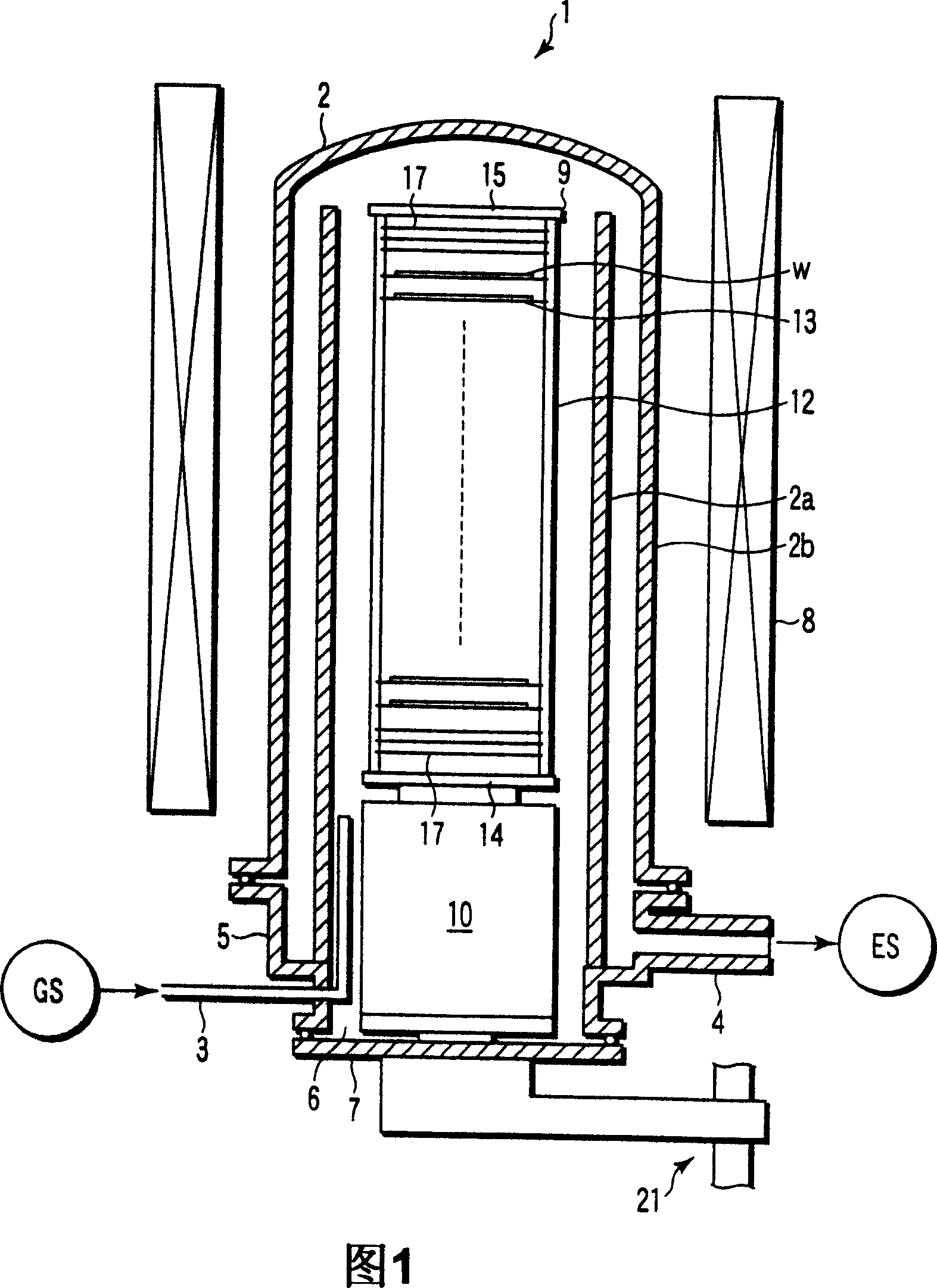

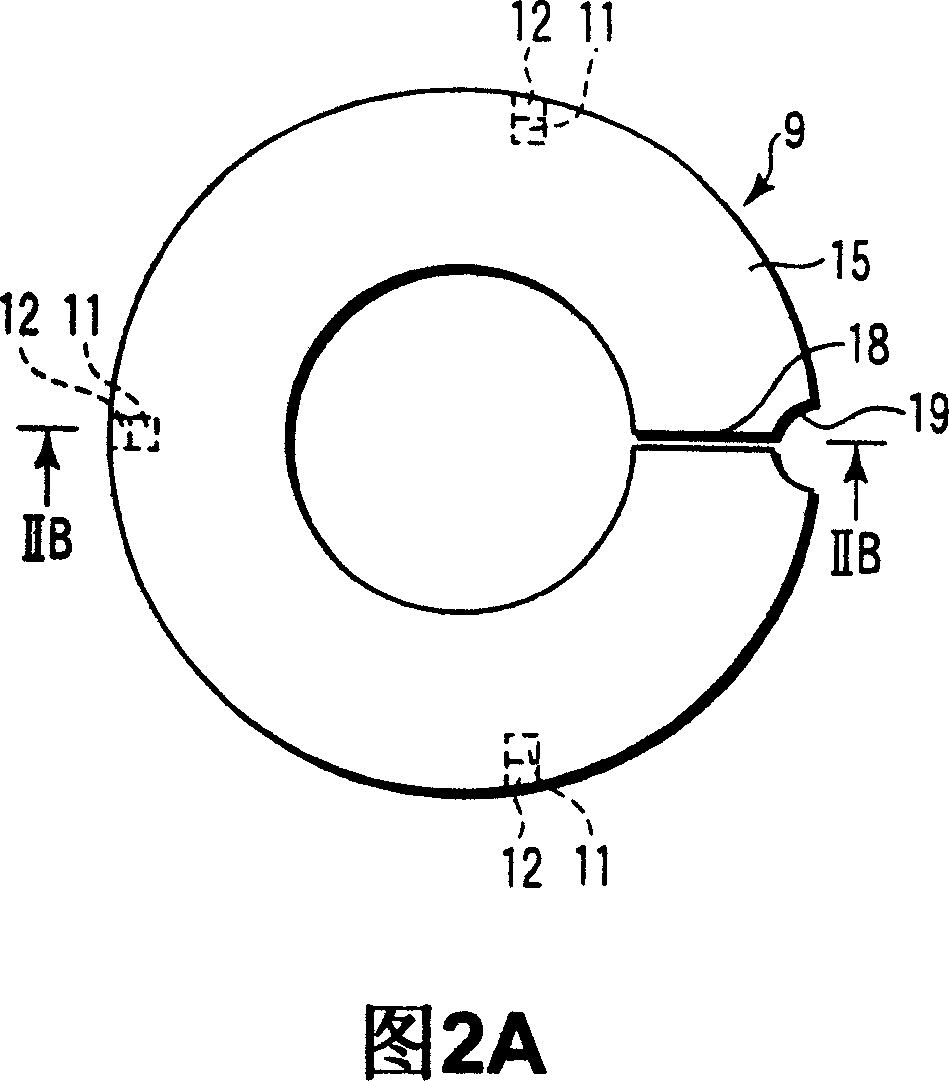

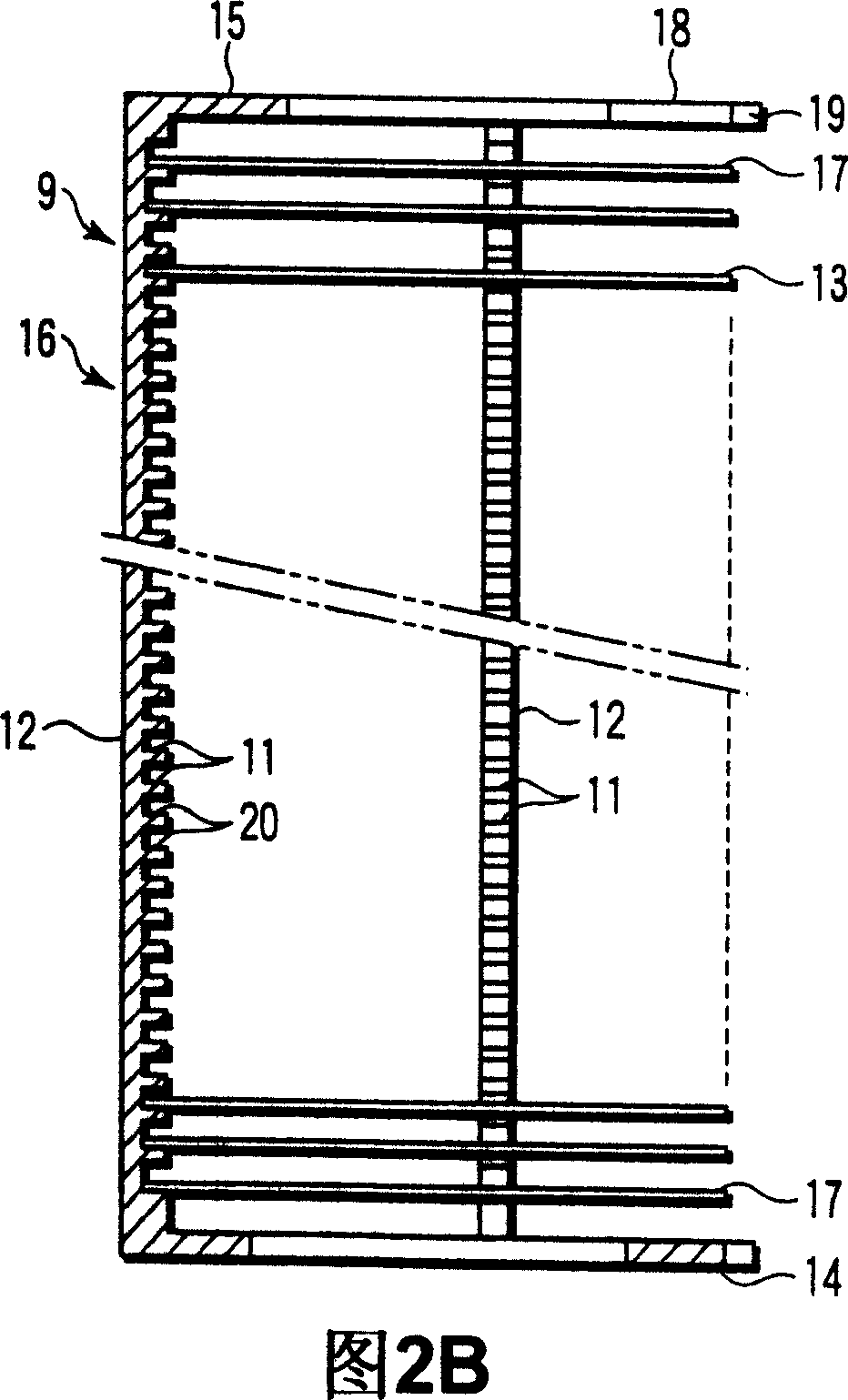

Vertical boat and vertical heat processing apparatus for semiconductor process

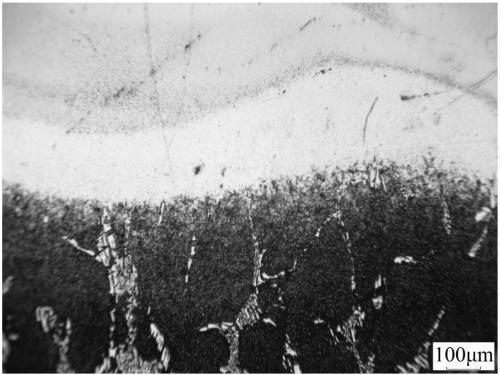

InactiveCN1992192APrevent defects such as cracksCharge supportsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A vertical boat for a semiconductor process is used for supporting target substrates during a heat process performed on the target substrates. The vertical boat includes struts fixed to a fixing member and arrayed at intervals in an annular direction, and fin portions formed on each of the struts at intervals in a vertical direction. Annular support plates are configured to respectively support the target substrates. Each of the annular support plates is held by corresponding fin portions of the struts located at the same height. Each of the annular support plates has an upper surface inclined inwardly downward with inclination set to agree with deformation of a corresponding one of the target substrates caused during the heat process, so that the upper surface comes into plane contact with a bottom of the target substrate during the heat process.

Owner:TOKYO ELECTRON LTD

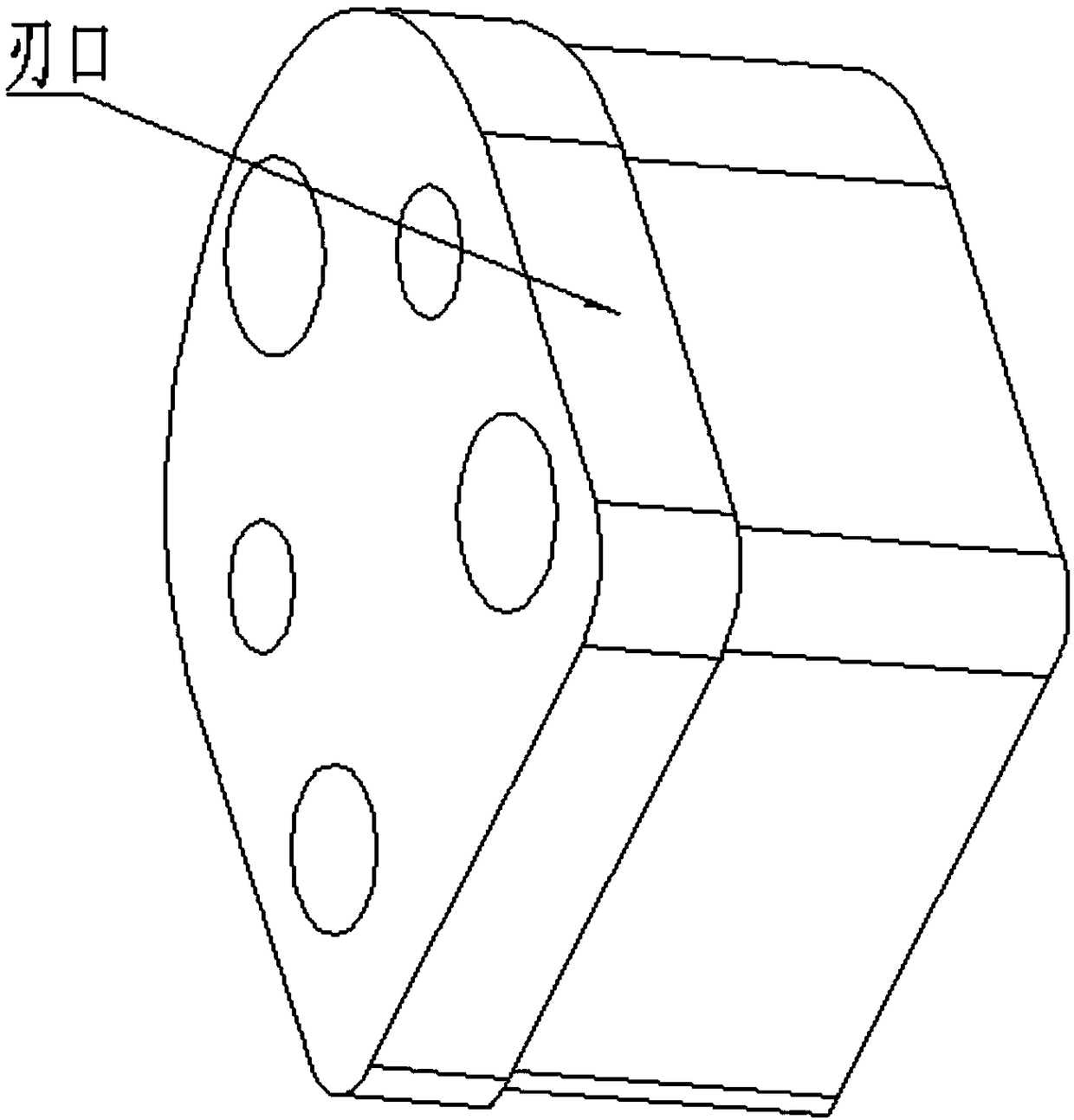

Forging and striking production process for blank with rectangular section

ActiveCN102513483AGuarantee the quality after forgingGuaranteed RegularityForging hammersRadial forgingSquare Shape

The invention discloses a forging and striking production process for a blank with a rectangular section. Equipment adopted in the striking and forging production process comprises two pairs of forging hammers which are mutually vertically distributed, wherein one pair of forging hammers include a first hammer and a second hammer, and the other pair of forging hammers include a third hammer and a fourth hammer; and the section of the blank is forged and struck for seven passes to become rectangular, approximately square, octagonal until circular. Due to the adoption of the technical scheme, a process for forging and striking the blank with the rectangular section to form a circular blank is precisely obtained through simple and effective derivation of equations by utilizing the forging characteristics of a radial forging machine; the forging and striking production process accords with a common forging and striking deformation process, the regularity of the shape of a forged product is ensured through a reasonable deformation step; and each pass reduction is determined through careful calculation, therefore, the quality of the forged blank is ensured, and defects such as folding, cracks and the like are prevented from being caused.

Owner:WUHU XINXING DUCTILE IRON PIPES

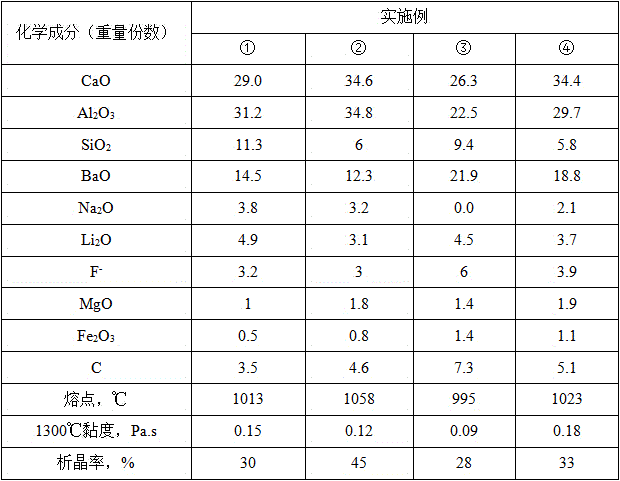

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

Buffering shock-absorbing floor tile and manufacturing method thereof

ActiveCN106760400APlay a protective effectLow costCovering/liningsSynthetic resin layered productsEpoxyFiber

The invention provides a buffering shock-absorbing floor tile and a manufacturing method thereof. A polyurethane buffering layer is arranged on the surface of the floor tile, the floor tile is prepared from a main material, a drilling agent, an additive, reinforcing powder and aluminum fiber filaments through burning, the polyurethane buffering layer is formed by mixing a component A and a component B, the component A is prepared by mixing polyoxypropylene, toluene diisocynate and diphenyl-methane-diisocyanate, and the component B is prepared from polyoxypropylene, epoxy resin, silica sol and modified filler. The polyurethane buffering layer is arranged on the surface of the floor tile and has a protective function compared with a wood floor, the manufacturing price is low, the floor tile of the special structure can absorb and reduce vibration and noise generated by motions, and indoor noise pollution is reduced.

Owner:河南同伟建材有限公司

Quenching tank for large and medium size forging

InactiveCN101514385AUniform surface hardnessAvoid deformationFurnace typesHeat treatment process controlFrequency conversionSubmersible mixer

The invention discloses a quenching tank for the large and medium size forging, comprising a body and submersible mixers which are mounted at the periphery and bottom of the inner wall of body. The submersible mixers are positioned at the middle in the height direction of each side of inner wall, at the two middle points of the trisected distribution of the inner wall in the length direction of each side inner wall. Thirteen submersible mixers are mounted at the bottom of the body and in the regular five-row and five-line lineup distribution. Each submersible mixer in the bottom of the body is connected with a frequency conversion controller by a line, the rotating speed of each submersible mixer can be controlled by the frequency conversion controller, thus a uniform temperature area is formed in the quenching solution in the body. The invention has simple structure, easy production, maintenance and use, and is mainly used for the quenching of large and medium size forging.

Owner:GUIZHOU ANDA AVIATION FORGING

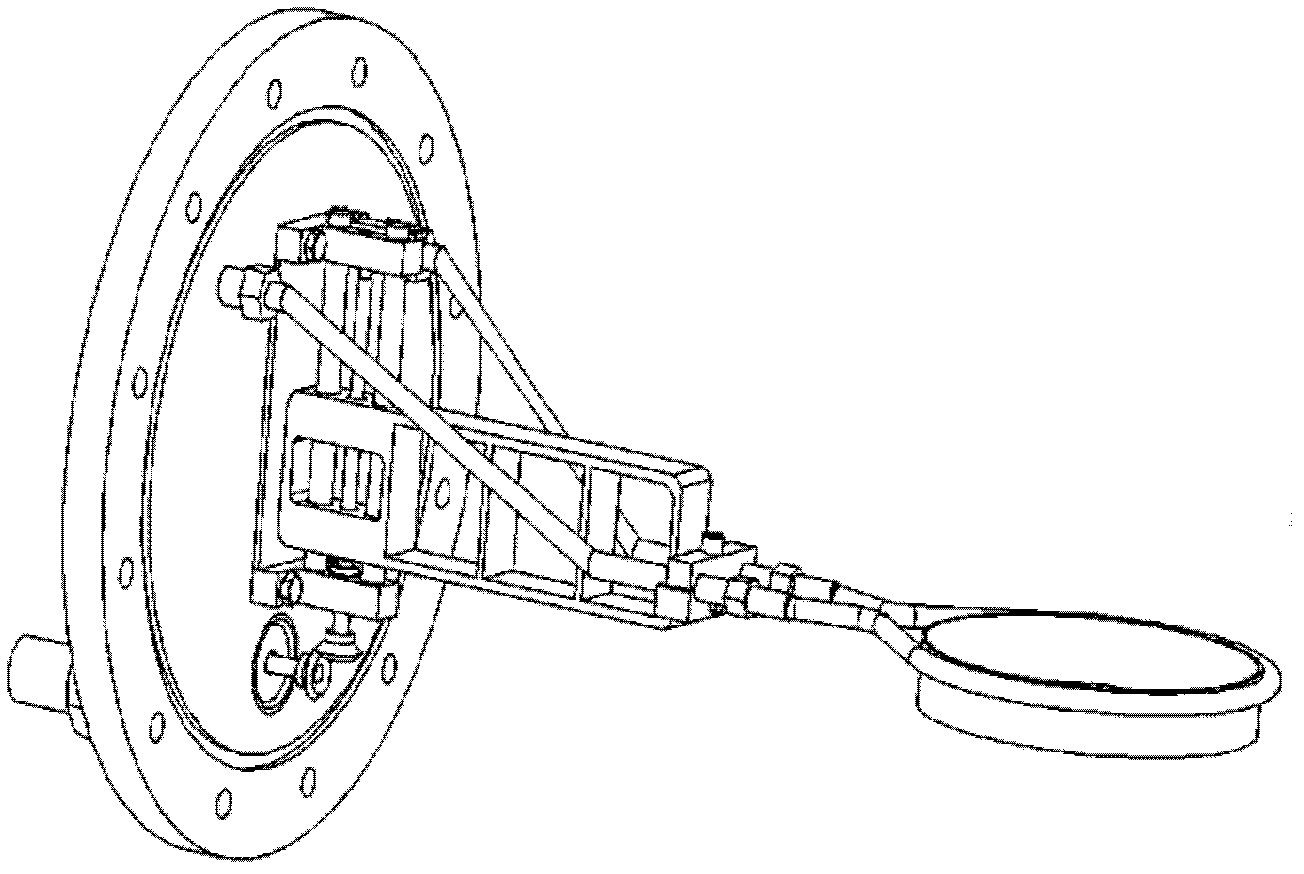

Reflection ring lifting device for improving thermal field of zone-melting single-crystal furnace

ActiveCN102534754ASmooth and reliable movementRealize forward and backward adjustmentBy zone-melting liquidsThermal insulationZone melting

The invention relates to manufacturing equipment for non-mental crystals and aims at providing a reflection ring lifting device for improving the thermal field of a zone-melting single-crystal furnace. The reflection ring lifting device comprises a reflection ring and a window flange of a main furnace chamber; an outer side ring of the reflection ring is provided with a hollow cooling pipe; the two ends of the cooling pipe are connected to metal sealing joints on the window flange; the metal sealing joints are extended out of the outer wall of the window flange to be used as a cooling water inlet and outlet; the cooling pipe is fixed at one end of a support which is positioned on a vertical optical shaft; an engaged vertical lifting lead screw is also arranged on the support; and a transmission shaft is connected with the lifting lead screw through a bevel gear pair. The reflection ring lifting device has the advantages of realizing the lifting movement of the reflection ring in a hearth of the zone-melting furnace, being smooth and reliable in movement, being capable of realizing front and back adjustment, being convenient for aligning the reflection ring and a heating coil and being capable of forming a favorable thermal field in a melting zone, thereby increasing the quality of single crystals. By adjusting the position of the reflection ring, the reflection ring has thermal insulation effect on the single crystals, reduces the thermal stress inside the crystals and prevents detects such as flaws and the like from occurring in the single crystals due to undercooling.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

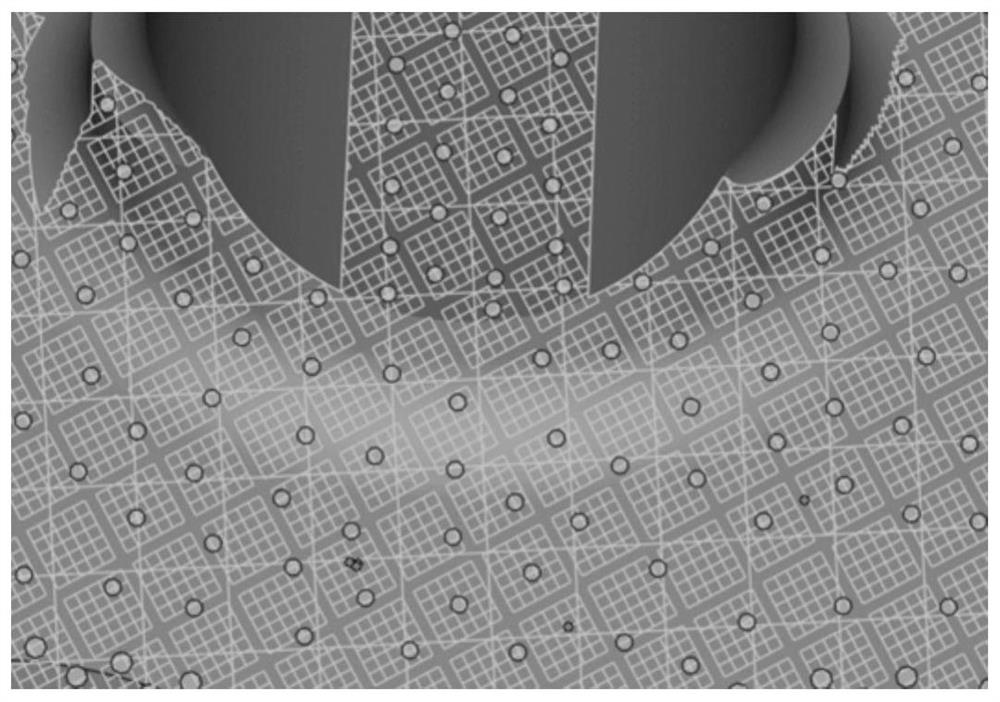

Forming method for selective laser melting forming technology

ActiveCN112496343AReduce porosityReduce defects such as cracksAdditive manufacturing apparatusSelective laser meltingEngineering

The invention discloses a forming method for a selective laser melting forming technology, and belongs to the technical field of additive manufacturing. The forming method comprises the steps of according to the actual design size of a target part, carrying out allowance compensation to optimize a three-dimensional model, and constructing a three-dimensional entity model suitable for selective laser melting forming; according to the obtained three-dimensional entity model, designing and slicing a supporting structure suitable for the target part; after the supporting structure is designed, carrying out process arrangement to form a model file, and slicing the obtained model file; and setting process parameters of the selective laser melting forming technology, and carrying out integrated printing forming, wherein the target part is of a cavity thin-wall structure. Through the forming method, the defect that in the integrated forming process of the part with the cavity thin-wall structure, the part is prone to being scratched by a scraper due to thermal stress can be effectively overcome, and the percent of pass is increased.

Owner:AECC AVIATION POWER CO LTD

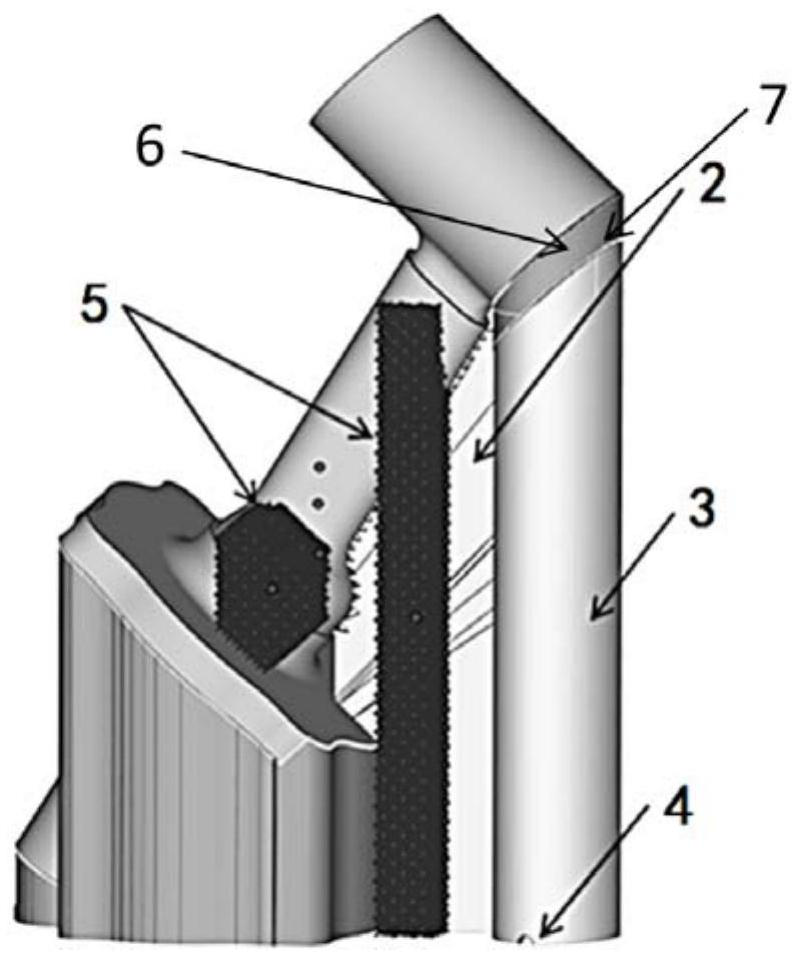

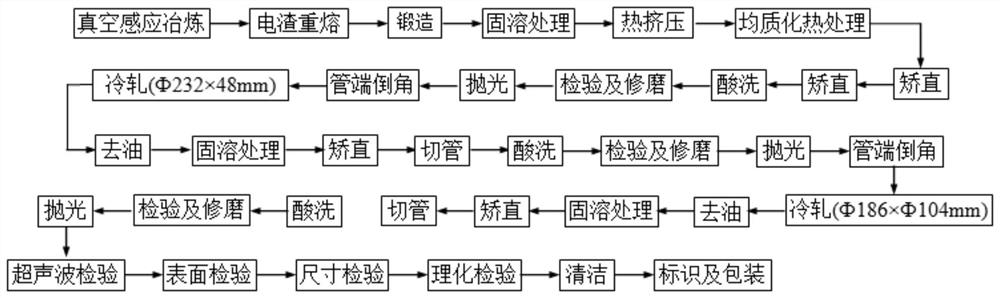

Alloy movable conduit for sodium-cooled fast reactor control rod driving mechanism and manufacturing method

ActiveCN111876690AHigh strengthImprove corrosion resistanceNuclear energy generationNuclear reaction controlChemical compositionNichrome

The invention discloses an alloy movable conduit for sodium-cooled fast reactor control rod driving mechanism and a manufacturing method, and relates to iron-nickel-chromium alloy seamless tubes. Thealloy movable conduit comprises the following chemical components including, by mass, 0.04%-0.09% of C, 1.2%-1.8% of Mn, not more than 0.015% of P, not more than 0.010% of S, not more than 0.20% of Si, 15.0%-17.0% of Cr, 35.0%-37.0% of Ni, 3.0%-3.5% of Mo, not more than 0.05% of Cu, not more than 0.05% of Y, not more than 0.002% of B, not more than 0.05% of Zr, not more than 0.1% of Al, not more than 0.2% of W, not more than 0.03% of N, not more than 0.025% of Co, not more than 0.006% of As, not more than 0.005% of Sb, not more than 0.005% of Bi, not more than 0.006% of Sn, not more than 0.006% of Pb, not more than 0.015% of the sum of As, Sb, Bi, Sn and Pb and the balance Fe and trace elements. The alloy movable conduit has the good structure and mechanical properties, corrosion resistance, dimensional precision and surface quality, and the use requirements of a sodium-cooled fast reactor are met.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

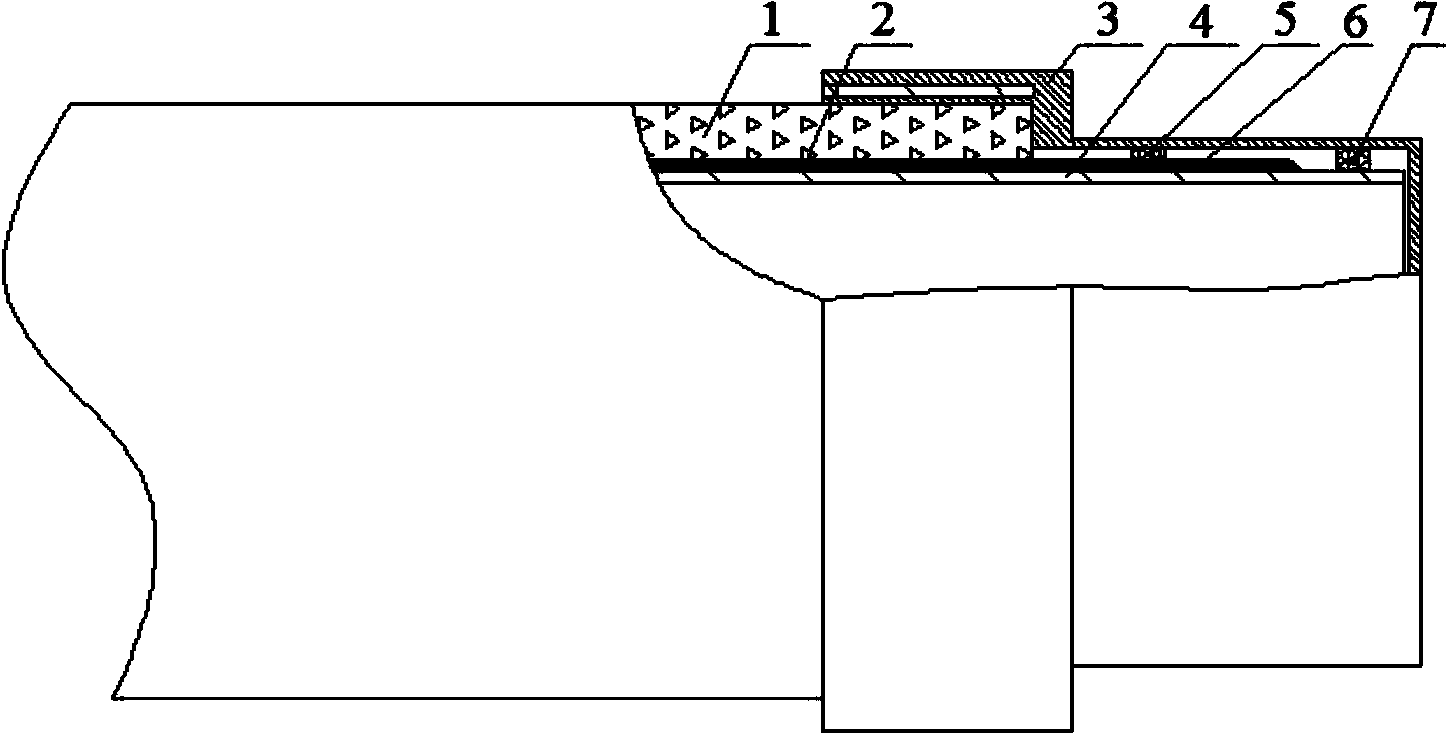

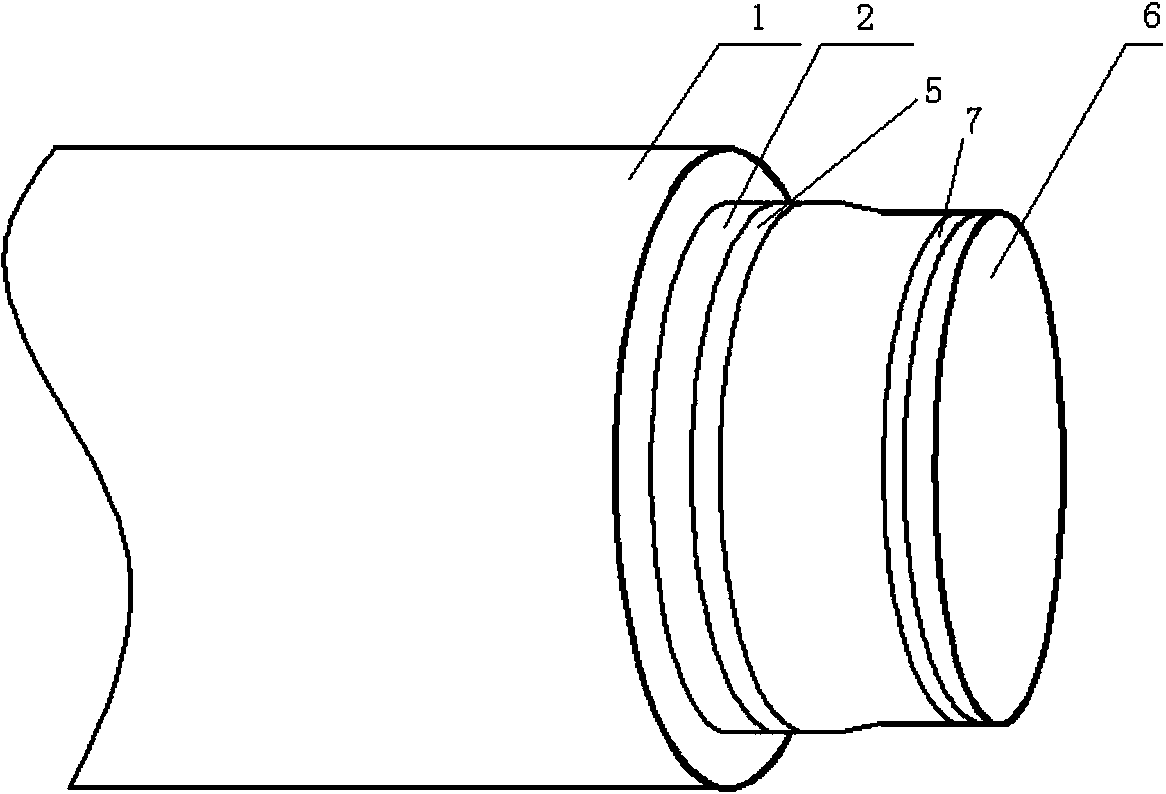

Protecting structure for coated and weighted sea pipe and protecting method

InactiveCN103470911AInhibit sheddingAvoid crackingCorrosion preventionPipe protection against corrosion/incrustationMarine engineeringCorrosion resistant

The invention provides a protecting structure for a coated and weighted sea pipe and a protecting method. The protecting structure comprises a left-end sealing piece, a right-end sealing piece, a left-end protector and a right-end protector; the weighted seat pipe comprises a sea pipe base body, a corrosion-resistant layer and a weighting layer; the outer surface of the sea pipe base body is coated with the corrosion-resistant layer; the outer surface of the corrosion-resistant layer is coated with the weighting layer, wherein the weighting layer is shorter than the corrosion-resistant layer which is shorter than the sea pipe base body in length; the exposed outer surface of the sea pipe base body and the inner wall of the sea pipe base body are coated with anti-rusting coat; the left-end sealing piece seals the left end surface of the sea pipe base body, and then the left end surface is externally and additionally provided with the left-end protector; and the right-end sealing piece seals the right end surface of the sea pipe base body, and then the right end surface is externally and additionally provided with the right-end protector. The protecting structure and the protecting method provided by the invention have the advantages that the storage time of the sea pipe can be effectively prolonged and the quality of the sea pipe can be ensured.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH +1

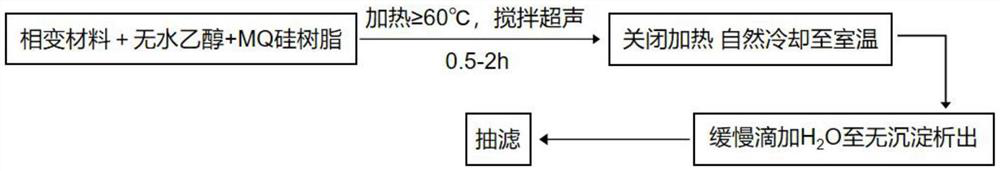

MQ silicon resin coated phase change micro-capsule as well as preparation method and application thereof

PendingCN113694846AImprove compatibilityMitigate leaksMicroballoon preparationMicrocapsule preparationSilicone resinPolymer chemistry

The invention belongs to the technical field of phase change energy storage materials, and particularly relates to an MQ silicon resin coated phase change micro-capsule as well as a preparation method and application thereof. The invention provides an MQ silicon resin coated phase change micro-capsule. The MQ silicon resin coated phase change micro-capsule comprises MQ silicon resin and a phase change material, and the MQ silicon resin coats the phase change material, wherein the MQ silicon resin is of a three-dimensional cross-linked network structure and can well adapt to heat absorption expansion of the phase change material, the defects of cracks and the like of a coating layer are prevented, the matching performance with the thermal expansion rate of the phase change material is improved, leakage caused by volume expansion in the phase change process of the phase change material is relieved, and the anti-leakage performance of the phase change micro-capsule is improved; and according to the MQ silicon resin coated phase change micro-capsule as well as the preparation method and the application thereof, the technical problem that a phase change material in a phase change micro-capsule prepared in the prior art is easy to leak can be solved.

Owner:GUANGDONG UNIV OF TECH

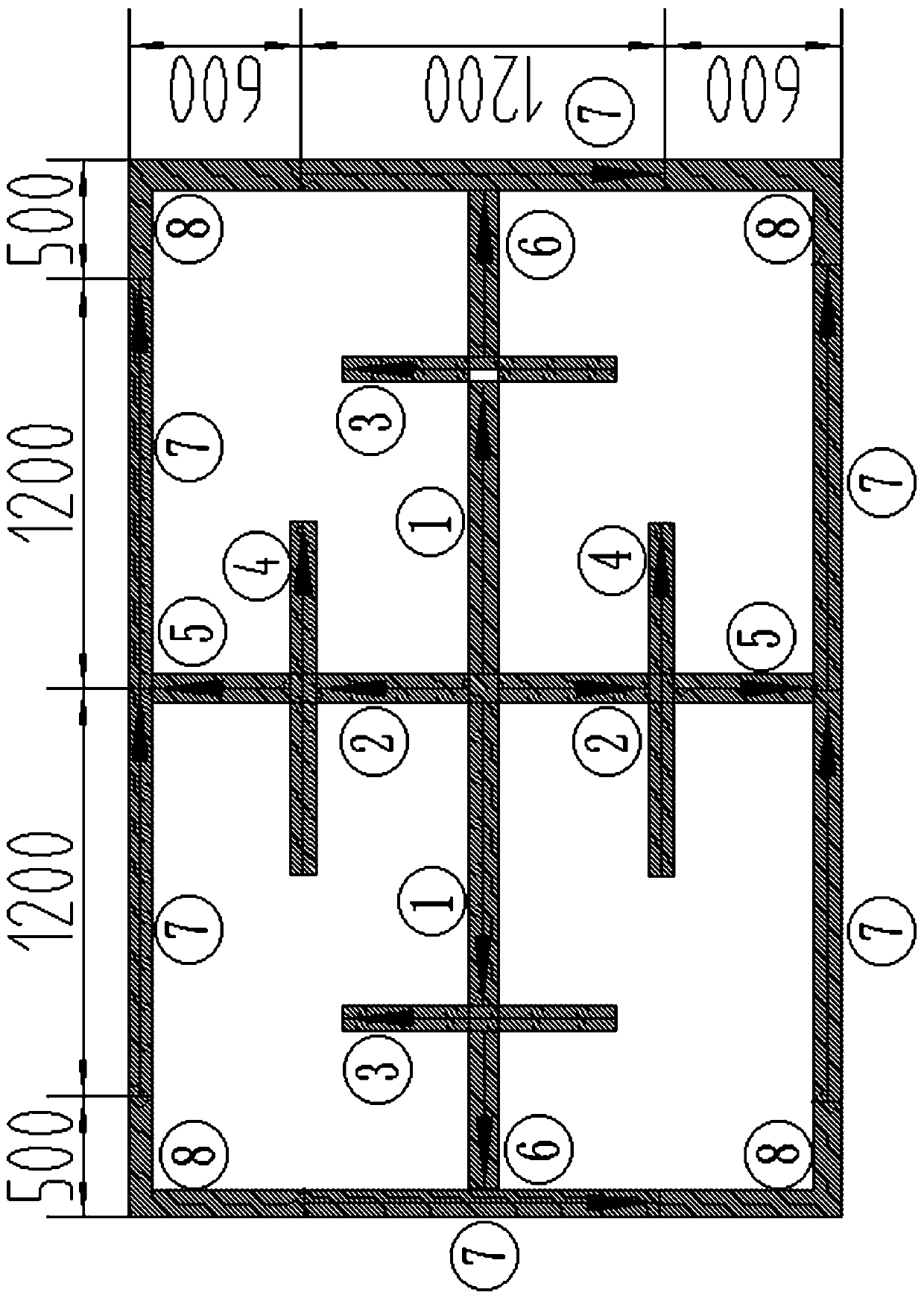

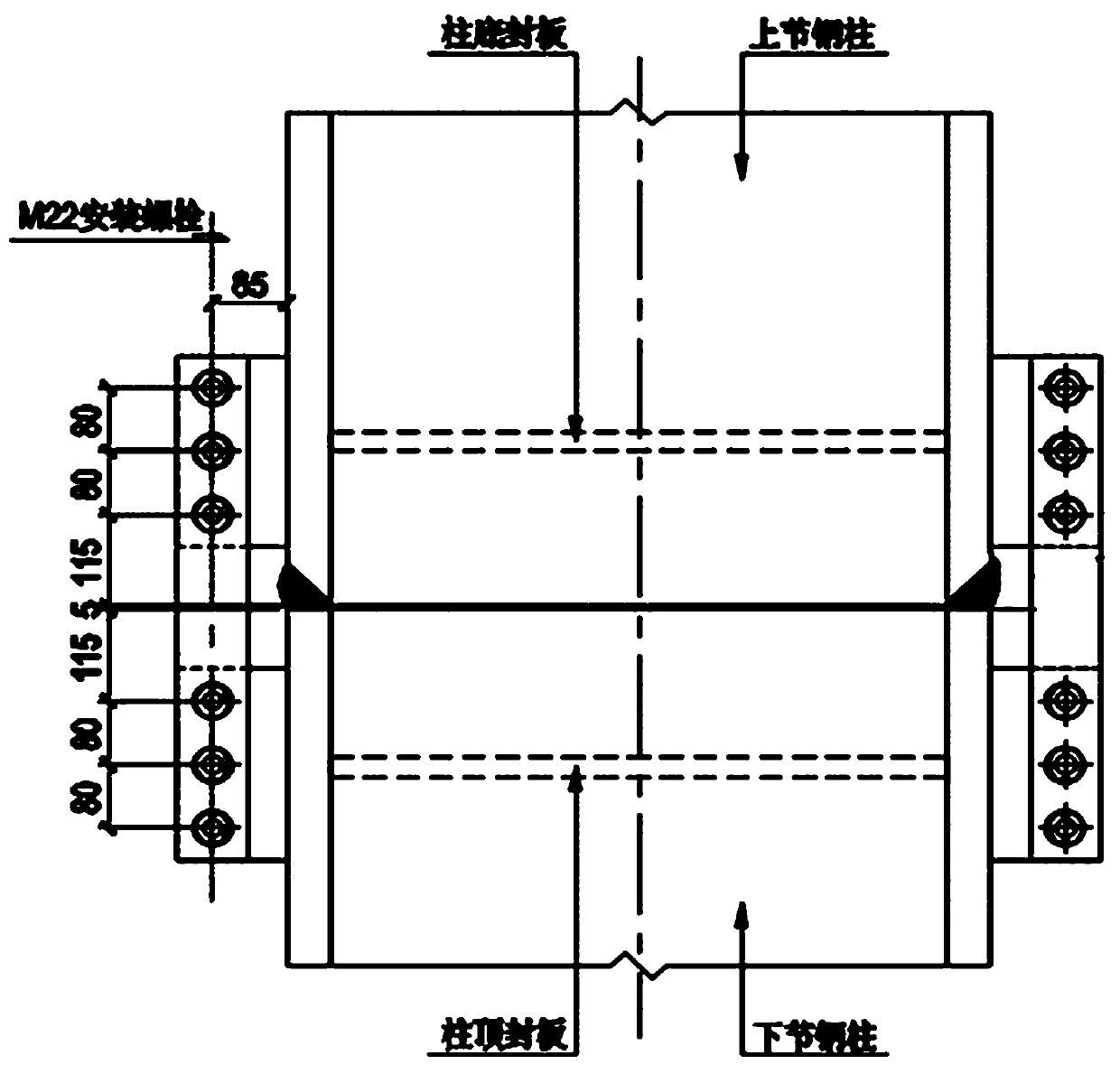

Welding process method suitable for large-section medium-thickness plate box column

PendingCN111168271APrevent defects such as cracksImprove welding qualityWelding/cutting media/materialsSoldering mediaWelding residual stressInternal stress

The invention discloses a welding process method suitable for a large-section medium-thickness plate box column. The same large-section medium-thickness plate box column is subjected to segment-by-segment welding by work shifts, a construction segment is reasonably divided, assembly construction is organized, before the whole-section welding line is closed, inner stress generated by welding is gradually released, in combination with after-welding heat treatment measures, welding residual stress is greatly reduced, the welding process method can effectively release welding stress at proper time, defects of cracks and the like generated by welding can be prevented, the welding quality is improved, the one-time yield of welding quality can be improved, the construction period is shortened, and cost is control is benefited.

Owner:郑州宝冶钢结构有限公司 +1

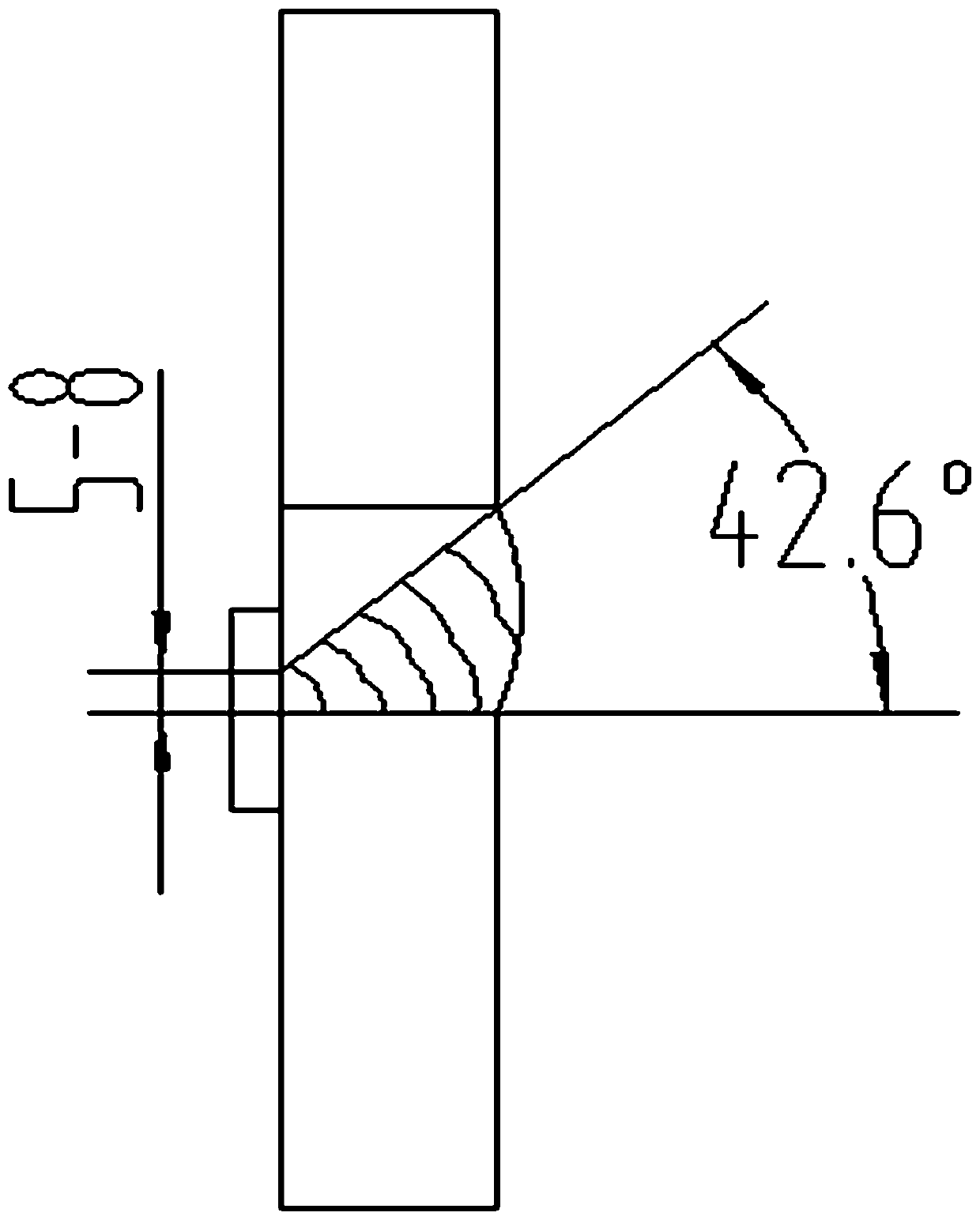

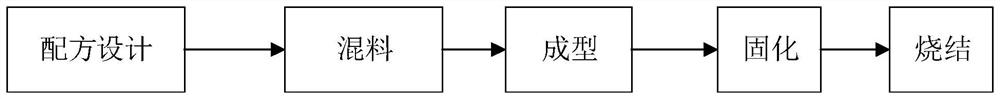

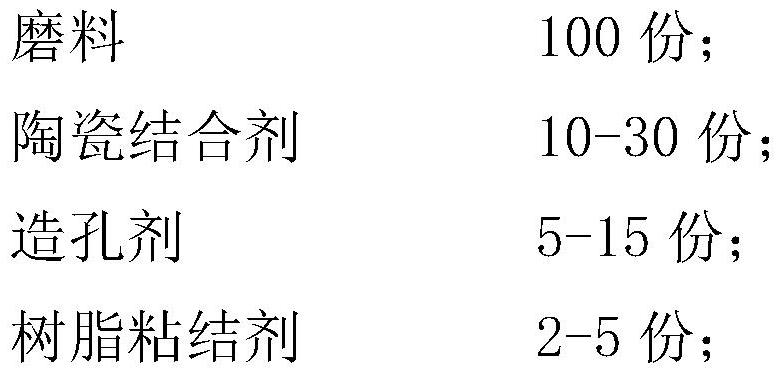

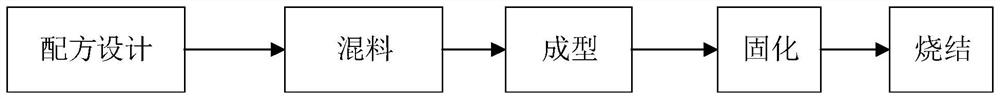

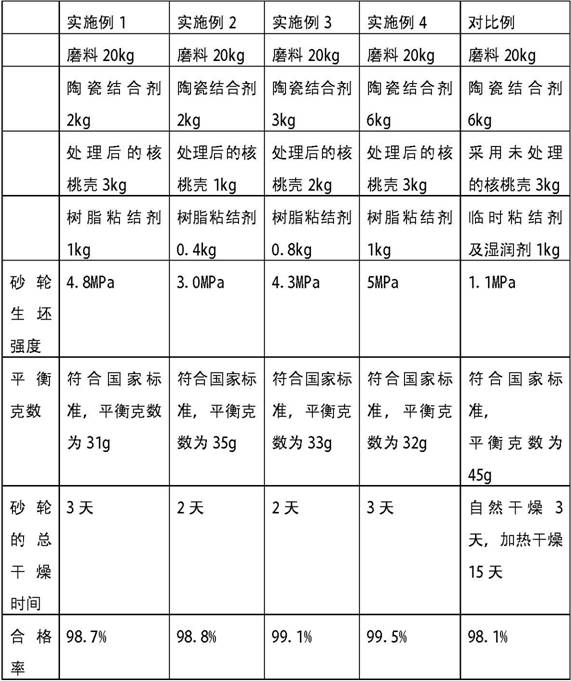

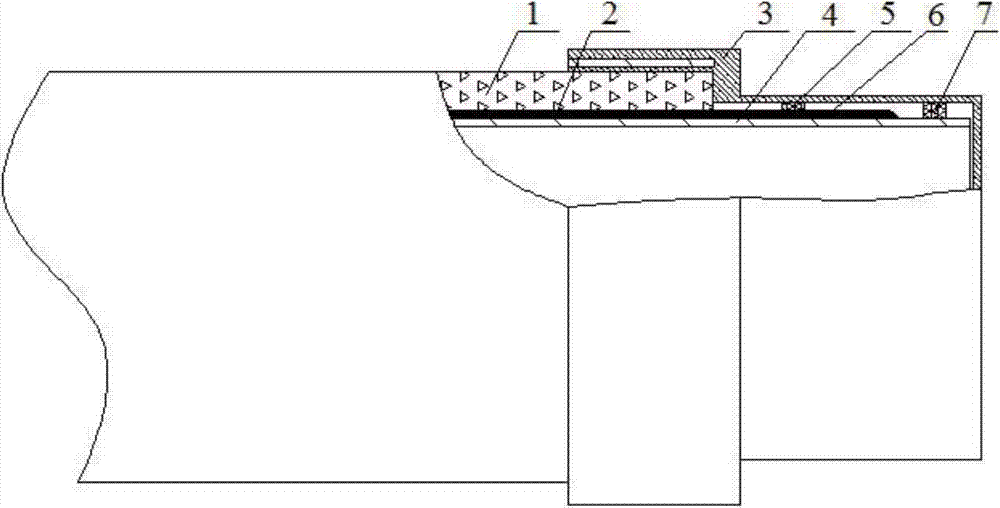

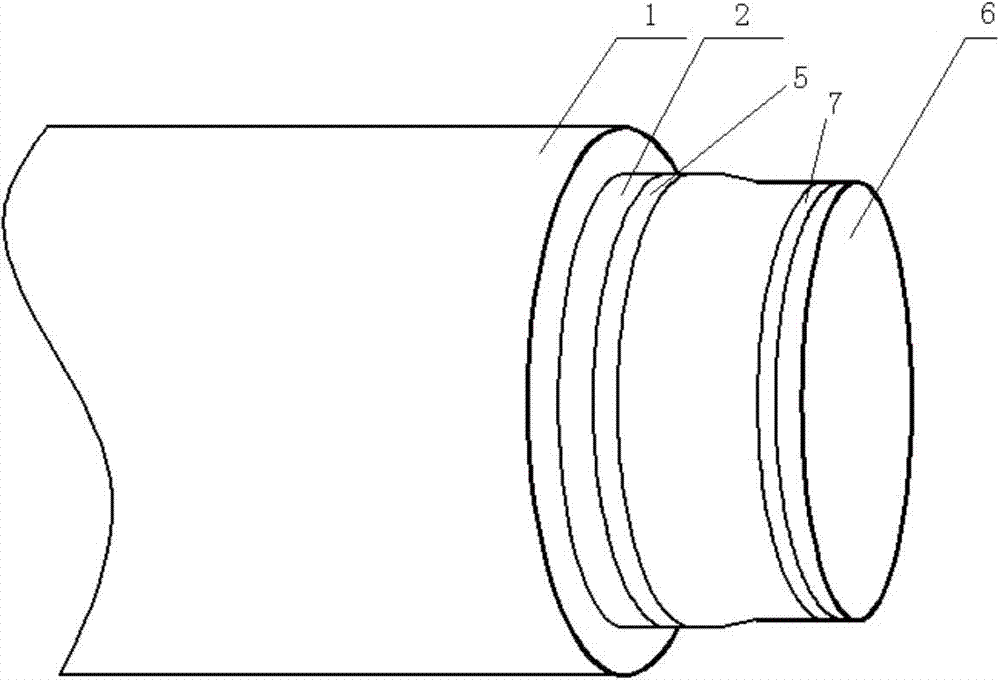

Low-density large-pore ceramic grinding wheel and preparation method thereof

ActiveCN112677059APrevent defects such as cracksCracks and other defects to avoidAbrasion apparatusGrinding devicesCrazingGrinding wheel

The invention relates to a low-density large-pore ceramic grinding wheel. The low-density large-pore ceramic grinding wheel comprises 100 parts of grinding materials, 10-30 parts of ceramic bond, 5-15 parts of pore forming agent, and 2-5 parts of resin binder, wherein the resin binder is a mixture of a resin solution and a diluent, and the ratio of the resin solution to the diluent is 1: 1-1: 4. According to the low-density large-pore ceramic grinding wheel provided by the invention, the modulated resin binder is adopted to replace a temporary binder and a wetting agent in the prior art, so that when the low-density large-pore ceramic grinding wheel is prepared, the strength of a grinding wheel green body is improved, the morphology defect rate generated in the production process is reduced, and the percent of pass of the product quality is increased; and meanwhile, walnut shells subjected to surface treatment reduce the defects of cracks and the like of the ceramic grinding wheel caused by inconsistent and non-uniform volatilization in the drying and sintering process. The pressed grinding wheel green body can be directly cured, the drying time is shortened, and the production efficiency is improved.

Owner:SUZHOU FAR EAST ABRASIVES

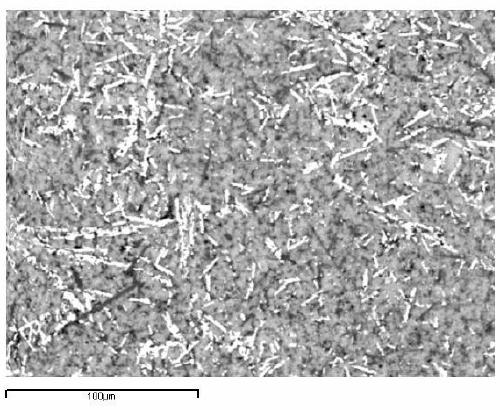

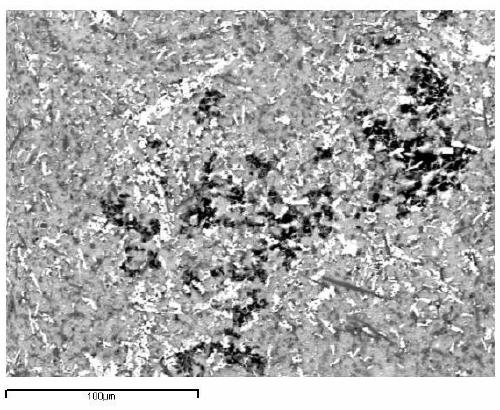

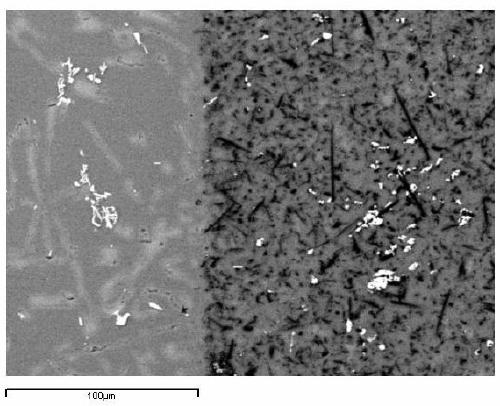

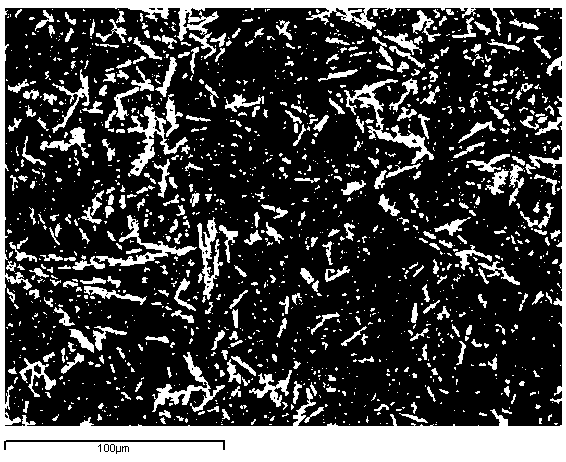

A kind of aluminum borate whisker reinforced zinc-based alloy composite material and preparation method thereof

The invention discloses an aluminum borate whisker reinforced zinc-based alloy composite material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing aluminum borate whiskers, SiO2-Na2O-B2O3 glass granules and then mixing with distilled water; after uniformly stirring, adding PVA (Polyvinyl Alcohol) and 1-hexadecylsulfonic acid sodium salt and stirring; carrying out ultrasonic vibration to obtain mixed slurry; carrying out spheroidization treatment on the mixed slurry to obtain spherical whisker coarse granules; adding the spherical whiskercoarse granules into a rubber mold and extruding through air pressure to obtain a whisker prefabricated body blank; after calcining the whisker prefabricated body blank, naturally cooling to obtain analuminum borate whisker prefabricated body; smelting a zinc-based alloy into zinc-based alloy liquid; pre-heating the aluminum borate whisker prefabricated body and putting the aluminum borate whisker prefabricated body into a metal mold; pouring the zinc-based alloy liquid and closing the mold; pressurizing and keeping pressure until a mixture is cooled and condensed, so as to obtain a product.According to the aluminum borate whisker reinforced zinc-based alloy composite material disclosed by the invention, the defects that the aluminum borate whisker reinforced zinc-based alloy composite material has shrinkage porosity, holes, cracks and the like in a preparation process can be effectively eliminated.

Owner:BINZHOU BOHAI PISTON CO LTD

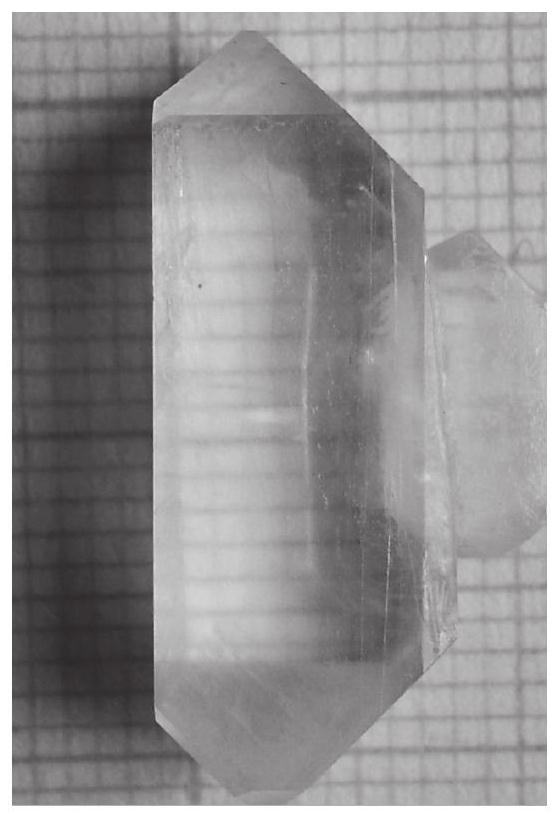

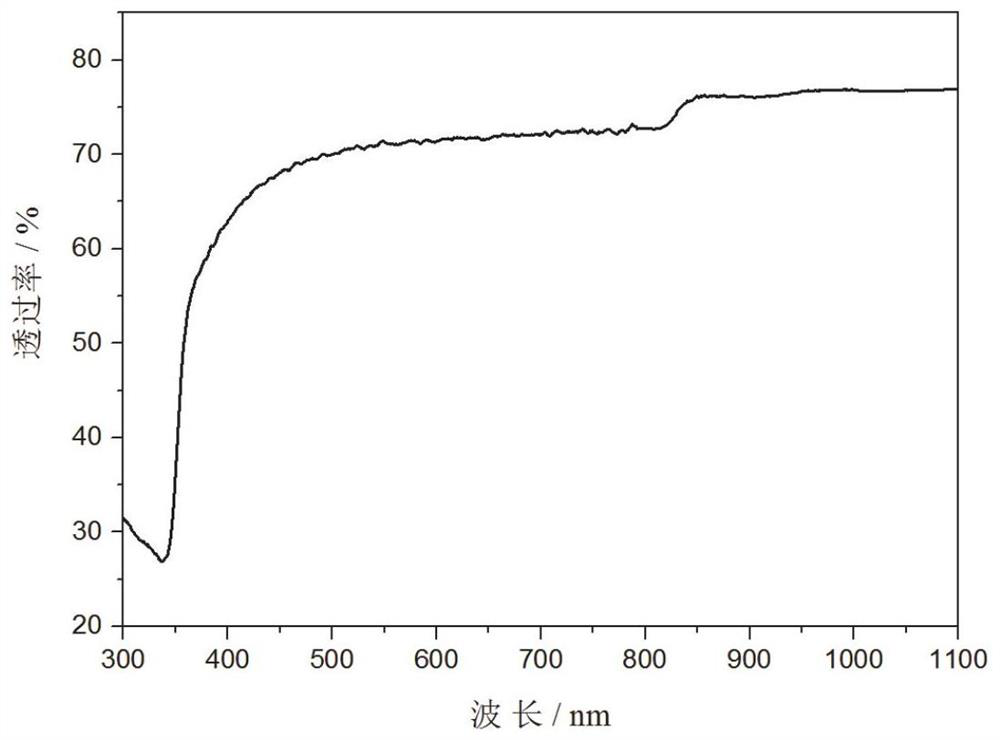

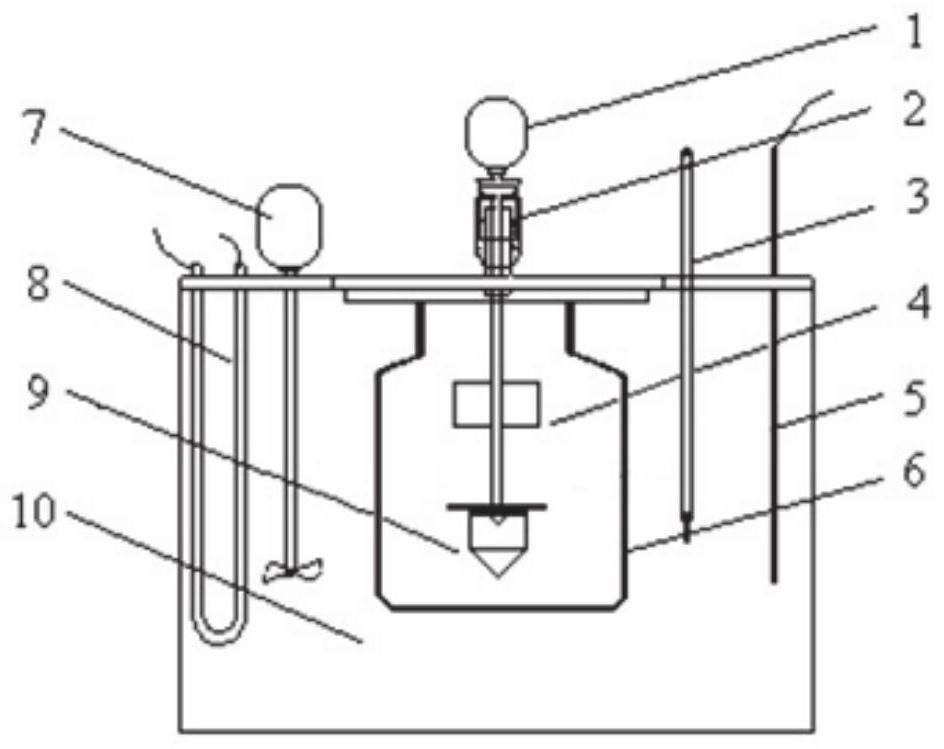

Method and device for preparing thiourea zinc sulfate crystals

PendingCN114016120AHigh transparencyImprove transmittancePolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalSulfate zinc

The invention relates to the technical field of growth and preparation of novel nonlinear optical crystal materials, in particular to a preparation method and device of thiourea zinc sulfate crystals. The preparation method comprises the following steps: preparing a growth solution: presetting the solution saturation point temperature to be 51 DEG C, calculating and weighing thiourea zinc sulfate powder according to a temperature solubility curve of thiourea zinc sulfate, dissolving the thiourea zinc sulfate powder in distilled water at a temperature higher than the saturation point temperature to obtain the growth solution required by crystal growth, and adjusting the pH value of the growth solution; then carrying out purification treatment on the growth solution; preparing a supersaturated thiourea zinc sulfate solution, and performing spontaneous crystallization through a natural cooling evaporation method to obtain small crystals as seed crystals for crystal growth; fixing the seed crystals on a seed crystal rod, immersing the seed crystal rod into the growth solution, performing crystal growth according to a theoretically calculated thiourea zinc sulfate crystal growth cooling curve, and obtaining the thiourea zinc sulfate crystals after growing for a period of time. The prepared crystals are relatively large in size and relatively good in optical quality.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

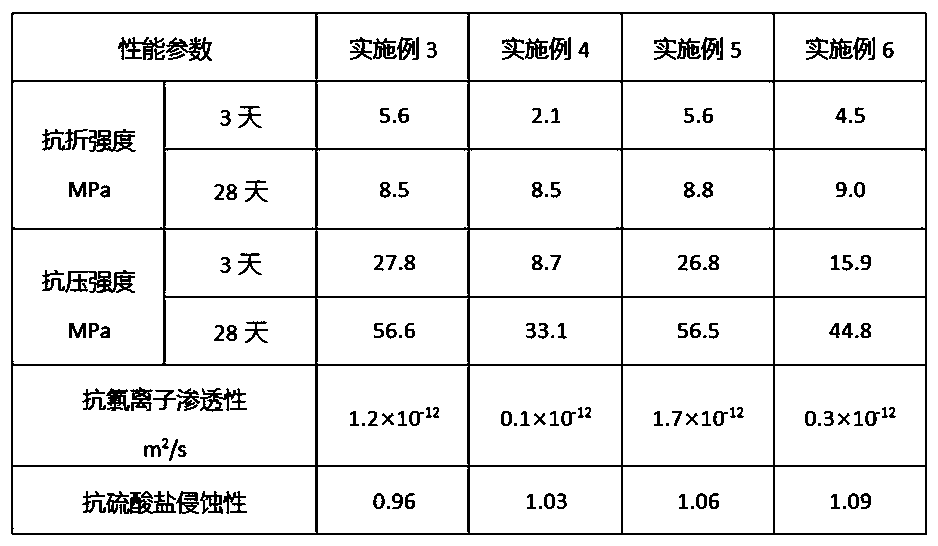

Inorganic cementing material and preparation method thereof

The invention discloses a micro / nano-scale inorganic cementing material with high chloride ion penetration resistance and high sulfate corrosion resistance for marine and hydraulic engineering, and apreparation method of the cementing material. The composition of the cementing material comprises, in parts by weight, 50 to 90 parts of cement, 1 to 10 parts of silicon micro powder, 5 to 30 parts ofmineral slag micro powder, 5 to 10 parts of fly ash, and 1 to 10 parts of mineral fiber. The inorganic cementing material of the invention has a high strength increased by 50% to 70% compared with aconventional material, good chloride ion penetration resistance, excellent sulfate corrosion resistance, high impact resistance and good weather resistance, is a pure inorganic material, is non-toxic,odorless and harmless, and makes up for other defects of existing organic repair materials.

Owner:临沂博泰控股有限公司

Aluminum borate whisker reinforced zinc-based alloy composite material and preparation method thereof

The invention discloses an aluminum borate whisker reinforced zinc-based alloy composite material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing aluminum borate whiskers, SiO2-Na2O-B2O3 glass granules and then mixing with distilled water; after uniformly stirring, adding PVA (Polyvinyl Alcohol) and 1-hexadecylsulfonic acid sodium salt and stirring; carrying out ultrasonic vibration to obtain mixed slurry; carrying out spheroidization treatment on the mixed slurry to obtain spherical whisker coarse granules; adding the spherical whiskercoarse granules into a rubber mold and extruding through air pressure to obtain a whisker prefabricated body blank; after calcining the whisker prefabricated body blank, naturally cooling to obtain analuminum borate whisker prefabricated body; smelting a zinc-based alloy into zinc-based alloy liquid; pre-heating the aluminum borate whisker prefabricated body and putting the aluminum borate whisker prefabricated body into a metal mold; pouring the zinc-based alloy liquid and closing the mold; pressurizing and keeping pressure until a mixture is cooled and condensed, so as to obtain a product.According to the aluminum borate whisker reinforced zinc-based alloy composite material disclosed by the invention, the defects that the aluminum borate whisker reinforced zinc-based alloy composite material has shrinkage porosity, holes, cracks and the like in a preparation process can be effectively eliminated.

Owner:BINZHOU BOHAI PISTON CO LTD

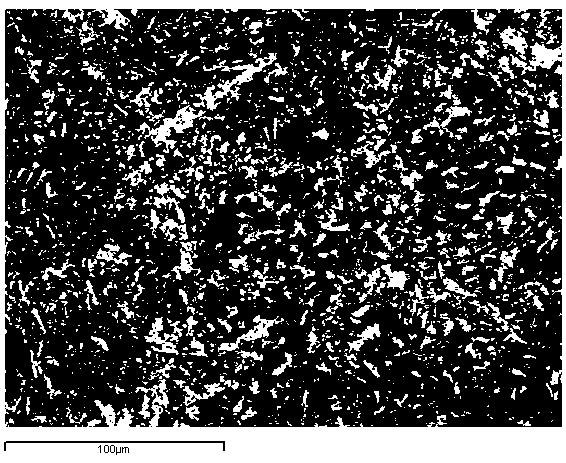

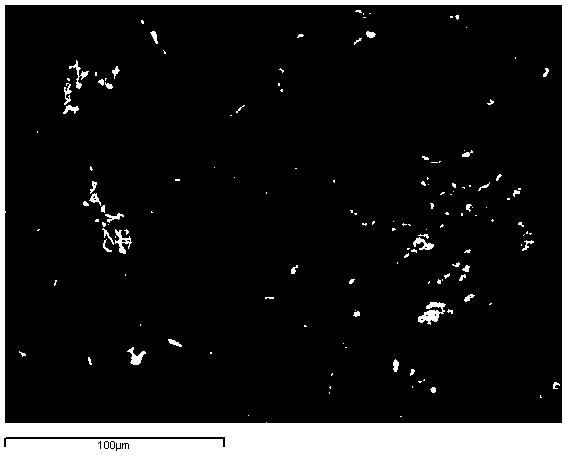

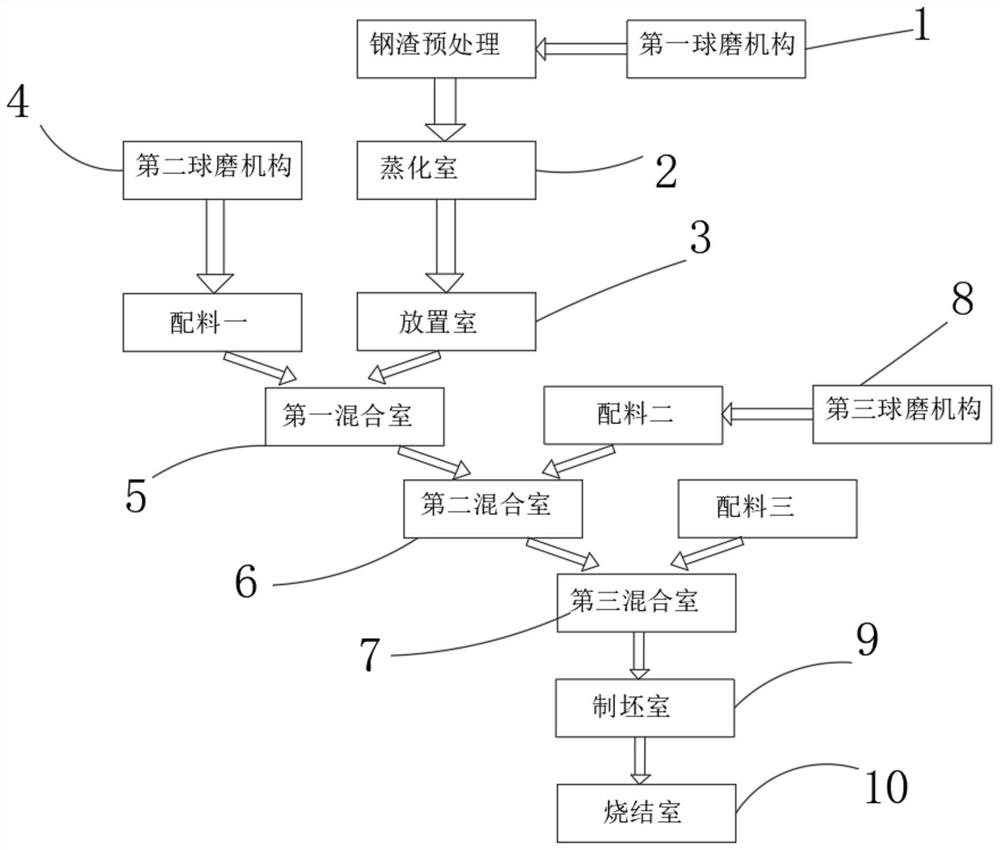

System for preparing steel slag sintered bricks

InactiveCN112979279AHigh strengthNot prone to crush damageCeramic materials productionClaywaresBrickSlag

The invention discloses a system for preparing steel slag sintered bricks. The system is characterized in that: pretreating steel slag through a first ball milling mechanism, grinding the steel slag into steel slag powder with a particle size of smaller than or equal to 0.045 mm, and subjecting the ground steel slag powder to ageing treatment and moisture drying; putting into a placing chamber; and grinding ferric oxide powder in the first ingredient through a second ball milling mechanism, mixing the ground ferric oxide powder and steel slag powder in a first mixing chamber, and then adding silicon powder and argillaceous aggregate. The perfection of ferrite crystallization is further promoted in that the melting point and the dynamic temperature of the mixture are reduced, so that the mass transfer and heat transfer conditions of a liquid phase are improved, the crystallization of minerals such as ferrite and the like can be promoted,the realization of low-temperature sintering of steel slag bricks is facilitated, quicklime is added while the steel slag bricks are mixed and put into a third mixing chamber, and hydration and hardening are promoted to improve the compact strength of brick structure. After the mixture in the third mixing chamber is subjected to blank making and standing for a period of time, the mixture is fed into a calcining kiln to be sintered, and the produced steel slag sintered bricks have the characteristics of high strength and good air permeability.

Owner:江西联达冶金有限公司

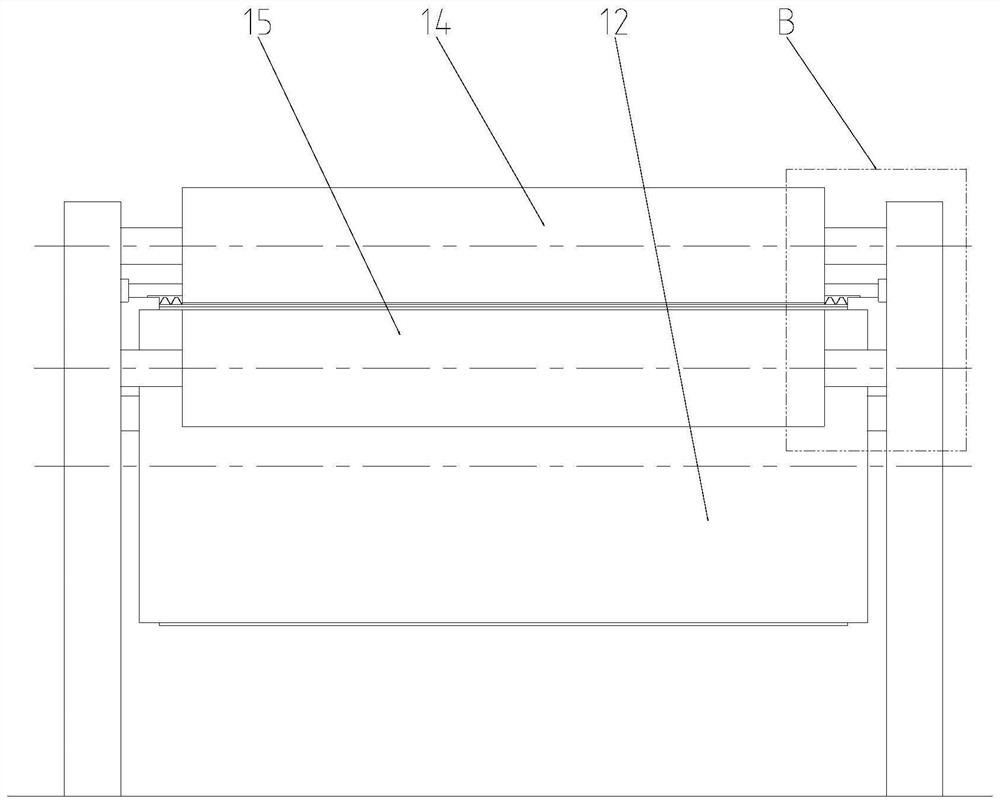

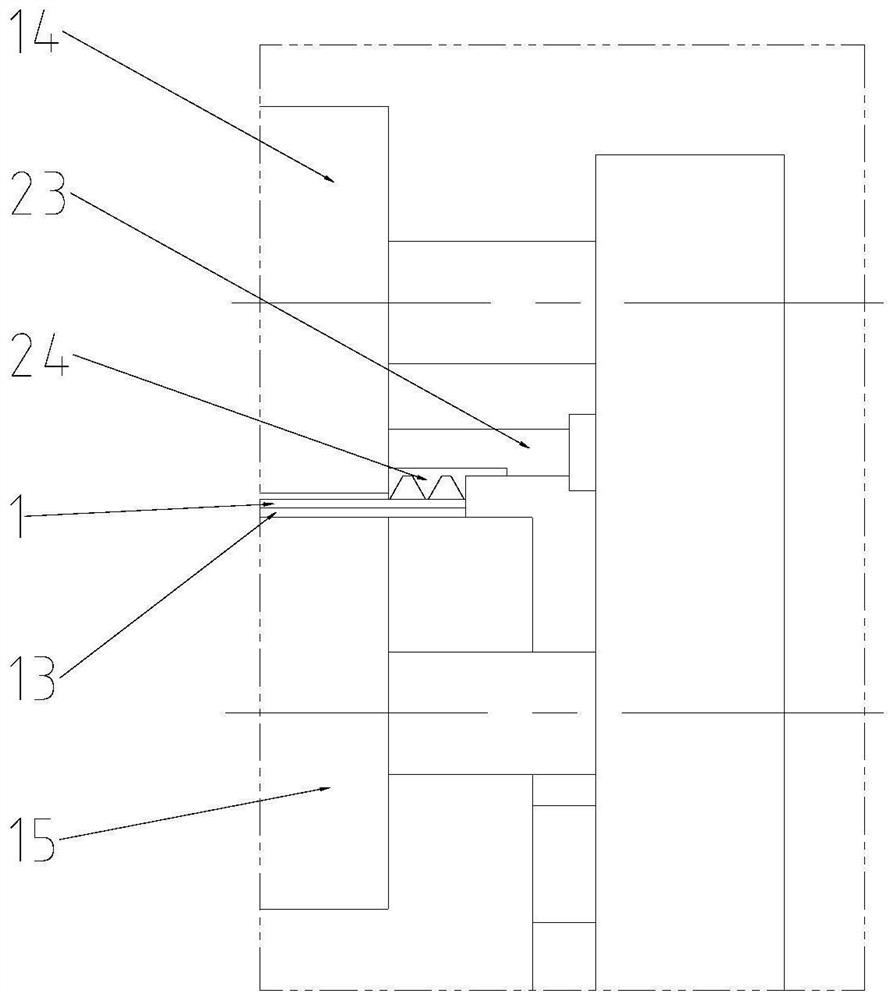

A production method of continuous casting and rolling composite metal strip

ActiveCN112439786BReduced tensile strength requirementsHigh bonding strengthRoll mill control devicesWork cooling devicesMetal stripsMetallic materials

The invention discloses a production method of continuous casting and rolling composite metal strip. The strip is uncoiled and the strip is moved synchronously with the transmission belt. Liquid metal is added to the feeding side of the control roller group. The high temperature zone on the material side keeps the liquid metal liquid and fluid, the thickness of the liquid metal is controlled by the control roller group, and the liquid metal located on the strip is cooled and shaped into a composite on the belt by the cooling zone set on the discharge side of the control roller group. The metal material layer on the material is obtained to obtain a composite metal belt. The production method of the continuous casting and rolling composite metal strip of the present invention can precisely control the thickness of the metal material layer, that is, the thickness can be thinner to meet the use requirements of the energy storage electrode, and the bonding force is also better.

Owner:QINGDAO NINEX NEW ENERGY TECH CO LTD

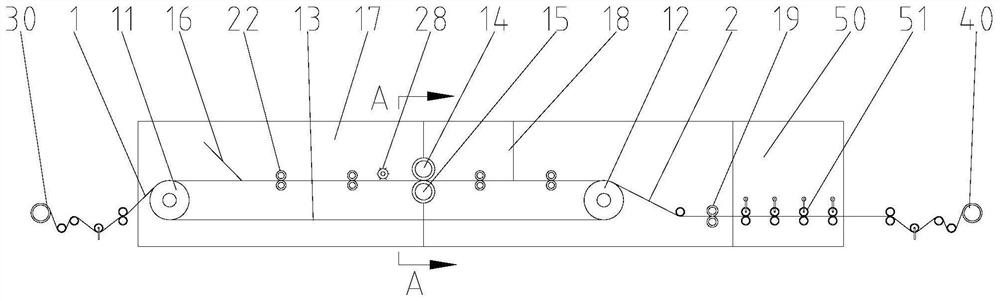

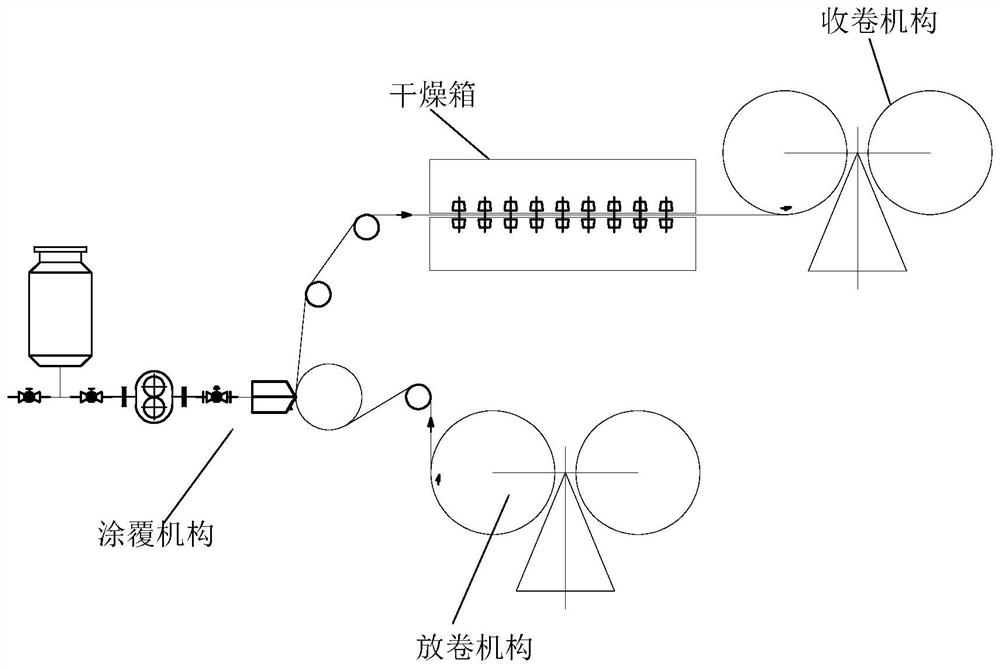

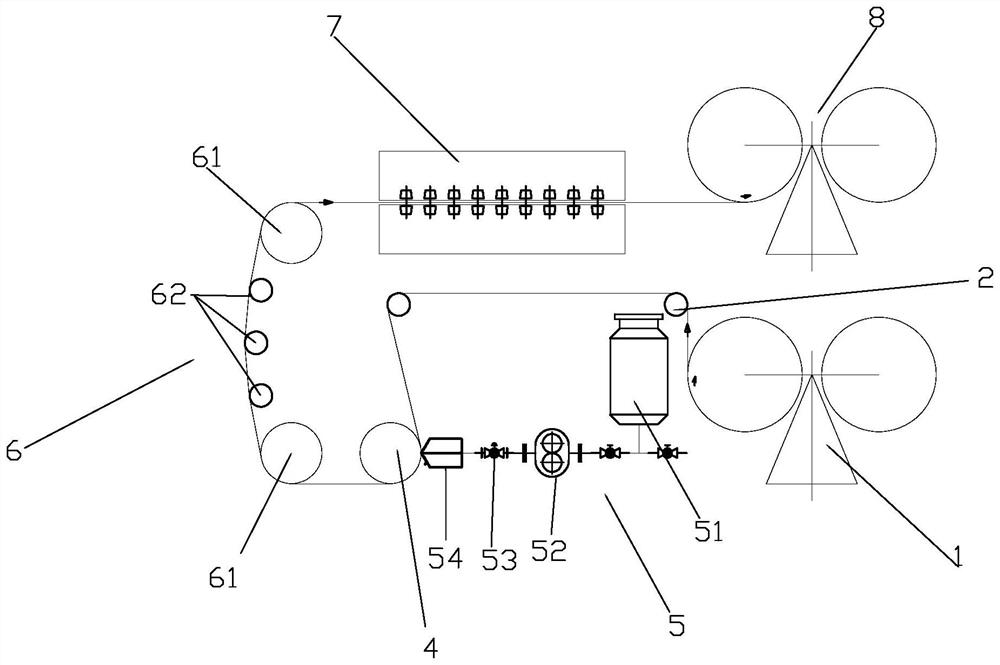

Lithium battery pole piece coating heating process and equipment

ActiveCN114367414AEvenly heatedImprove yieldElectrode thermal treatmentPretreated surfacesMetallurgyPhysical chemistry

The invention relates to the technical field of coating, in particular to a lithium battery pole piece coating heating process and equipment, and the process specifically comprises the steps of S1, slurry coating, S2, base material back face preheating and S3, base material drying, by preheating the base material back face, the production efficiency of lithium battery pole piece coating is improved, the yield of products is improved, and defects such as cracks of a coating are prevented.

Owner:江阴市乐事康工业设计有限公司

A kind of production method of continuous casting and rolling metal strip

The invention discloses a production method of continuous casting and rolling metal strips. Liquid metal is added to the feeding side of the control roll group, and the liquid metal is kept liquid and fluid by utilizing the high temperature zone arranged on the feeding side of the control roll group. The control roller group controls the forming thickness of the liquid metal, and the liquid metal on the transmission belt is cooled and shaped into a metal belt by using the cooling zone arranged on the discharge side of the control roller group. In the production method of the continuous casting and rolling metal strip of the present invention, the thickness of the liquid metal is controlled by the control roller group, and the liquid metal moves to the cooling zone on the discharge side of the control roller group under the joint action of the control roller group and the transmission belt, and is cooled The metal strip is obtained after cooling and shaping in the zone. Due to the high fluidity of the liquid metal, the thickness of the liquid metal can be controlled to be very thin. When the composite metal strip is used as an energy storage electrode, it can meet the application requirements.

Owner:QINGDAO NINEX NEW ENERGY TECH CO LTD

A kind of preparation method of low-density macroporous ceramic grinding wheel

ActiveCN112677059BPrevent defects such as cracksCracks and other defects to avoidAbrasion apparatusGrinding devicesPorosityCrazing

The invention relates to a low-density macroporous ceramic grinding wheel, comprising 100 parts of abrasive material; 10-30 parts of vitrified bond; 5-15 parts of pore-forming agent; 2-5 parts of resin binder; wherein the resin binder is resin liquid Mixture with diluent, the ratio of resin liquid to diluent is 1:1 to 1:4. The low-density macroporous ceramic grinding wheel provided by the present invention adopts the modulated resin binder to replace the temporary binder and wetting agent in the prior art. When preparing the low-density macroporous grinding wheel, the strength of the green body of the grinding wheel is improved and the The appearance defect rate produced in the production process is improved, and the qualified rate of product quality is improved; meanwhile, the surface-treated walnut shell reduces defects such as cracks on the ceramic grinding wheel caused by inconsistency and inhomogeneity in volatilization during the drying and sintering process; The grinding wheel blank can be solidified directly, which shortens the drying time and improves the production efficiency.

Owner:SUZHOU FAR EAST ABRASIVES

Protective structure and protective method of coated counterweight sea pipe

InactiveCN103470911BInhibit sheddingAvoid crackingCorrosion preventionPipe protection against corrosion/incrustationMarine engineeringCorrosion resistant

The invention provides a protecting structure for a coated and weighted sea pipe and a protecting method. The protecting structure comprises a left-end sealing piece, a right-end sealing piece, a left-end protector and a right-end protector; the weighted seat pipe comprises a sea pipe base body, a corrosion-resistant layer and a weighting layer; the outer surface of the sea pipe base body is coated with the corrosion-resistant layer; the outer surface of the corrosion-resistant layer is coated with the weighting layer, wherein the weighting layer is shorter than the corrosion-resistant layer which is shorter than the sea pipe base body in length; the exposed outer surface of the sea pipe base body and the inner wall of the sea pipe base body are coated with anti-rusting coat; the left-end sealing piece seals the left end surface of the sea pipe base body, and then the left end surface is externally and additionally provided with the left-end protector; and the right-end sealing piece seals the right end surface of the sea pipe base body, and then the right end surface is externally and additionally provided with the right-end protector. The protecting structure and the protecting method provided by the invention have the advantages that the storage time of the sea pipe can be effectively prolonged and the quality of the sea pipe can be ensured.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH +1

Production method of continuous casting rolled metal strip

The invention discloses a production method of a continuous casting rolled metal strip. The production method comprises the following steps: adding a liquid metal into a feeding side of a control roller set; keeping the liquid metal in a liquid state and in a flowable state by means of a high-temperature area arranged on the feeding side of the controller roller set; controlling a forming thickness of the liquid metal by means of the control roller set; and cooling and sizing the liquid metal on a transmission belt to the metal strip by means of a cooling area arranged on a discharging side ofthe control roller set. According to the production method of the continuous casting rolled metal strip, the thickness of the liquid metal is controlled by the control roller set, the liquid metal moves to the cooling area on the discharging side of the control roller set under joint action of the control roller set and the transmission belt, and the metal is cooled and sized by the cooling areato obtain the metal strip. As a result of high flowability of the liquid metal, the thickness of the liquid metal can be controlled very thin. When a compound metal strip is used as an energy-storingelectrode, a using demand can be met.

Owner:QINGDAO NINEX NEW ENERGY TECH CO LTD

Industrial production process of high-strength copper-tin alloy contact wire

ActiveCN114480894AImprove mobilityUniform compositionApparatus for heat treatmentConductive materialElectrically conductiveGunmetal

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

A shock-absorbing floor tile and its manufacturing method

ActiveCN106760400BPlay a protective effectLow costCovering/liningsSynthetic resin layered productsEpoxyFiber

The invention provides a buffering shock-absorbing floor tile and a manufacturing method thereof. A polyurethane buffering layer is arranged on the surface of the floor tile, the floor tile is prepared from a main material, a drilling agent, an additive, reinforcing powder and aluminum fiber filaments through burning, the polyurethane buffering layer is formed by mixing a component A and a component B, the component A is prepared by mixing polyoxypropylene, toluene diisocynate and diphenyl-methane-diisocyanate, and the component B is prepared from polyoxypropylene, epoxy resin, silica sol and modified filler. The polyurethane buffering layer is arranged on the surface of the floor tile and has a protective function compared with a wood floor, the manufacturing price is low, the floor tile of the special structure can absorb and reduce vibration and noise generated by motions, and indoor noise pollution is reduced.

Owner:河南同伟建材有限公司

Production method of continuous casting and rolling composite metal strip

ActiveCN112439786AReduced tensile strength requirementsHigh bonding strengthRoll mill control devicesWork cooling devicesMetal stripsLiquid state

The invention discloses a production method of a continuous casting and rolling composite metal strip. The production method comprises the following steps: unwinding a strip, synchronously moving thestrip along with a transmission belt, adding liquid metal to the feeding side of a control roller set, keeping the liquid metal in a liquid state and fluidity through a high-temperature area arrangedon the feeding side of the control roller set, controlling the thickness of the liquid metal by using the control roller set, cooling and shaping the liquid metal located on the strip into a metal material layer compounded on the strip through a cooling area arranged on the discharging side of the control roller set, and obtaining the composite metal strip. According to the production method of the continuous casting and rolling composite metal strip, the thickness of the metal material layer can be accurately controlled, in other words, the thickness can be smaller so as to meet the use requirement of an energy storage electrode, and the binding force is better.

Owner:QINGDAO NINEX NEW ENERGY TECH CO LTD

A kind of production method of alkali phenolic curing agent for casting

ActiveCN104190856BUnique methodChange hardening speedFoundry mouldsFoundry coresGlycerolDicarboxylic acid

The invention relates to a production method of a curing agent, in particular to a production method of an alkali phenolic curing agent for casting. Propylene ester, 30%-70% glyceryl triacetate, 10%-30% 1,4 butyrolactone and 0%-30% dibasic carboxylate, after adding, continue stirring for 30-40 minutes, The material is discharged, measured and packaged, and the content of the above-mentioned raw materials is a percentage by weight; the method of the invention is unique, can effectively prevent defects such as air holes and cracks in steel castings, and the performance of the process product is good.

Owner:共享新材料(山东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com