Laser cladding composite repair manufacturing method and application thereof

A technology of laser cladding and composite repair, applied in cleaning methods and appliances, chemical instruments and methods, metal material coating technology, etc., can solve problems such as high cost, air pollution, and water pollution of chemical reagents, and achieve easy storage, Slow temperature rise, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

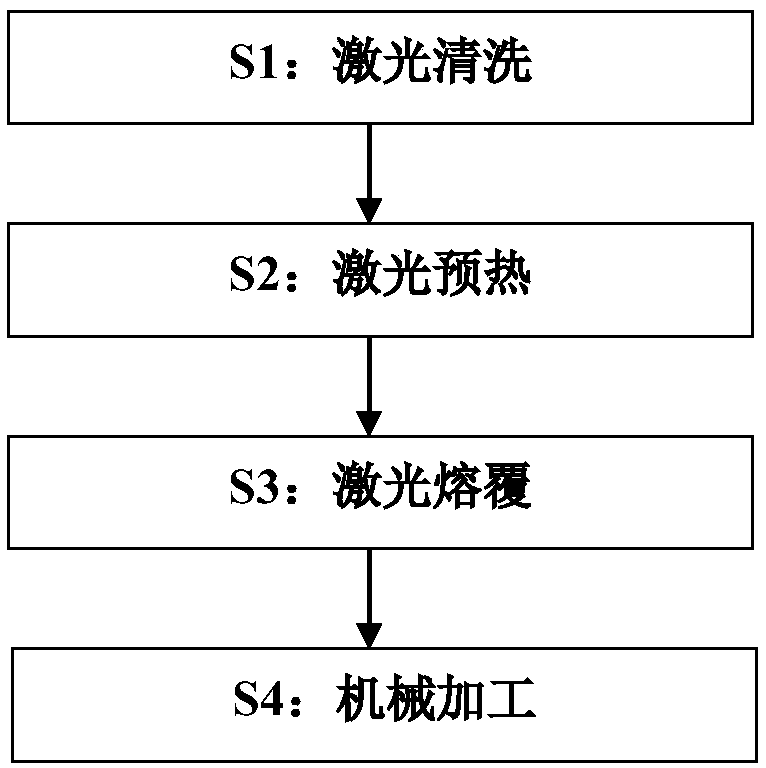

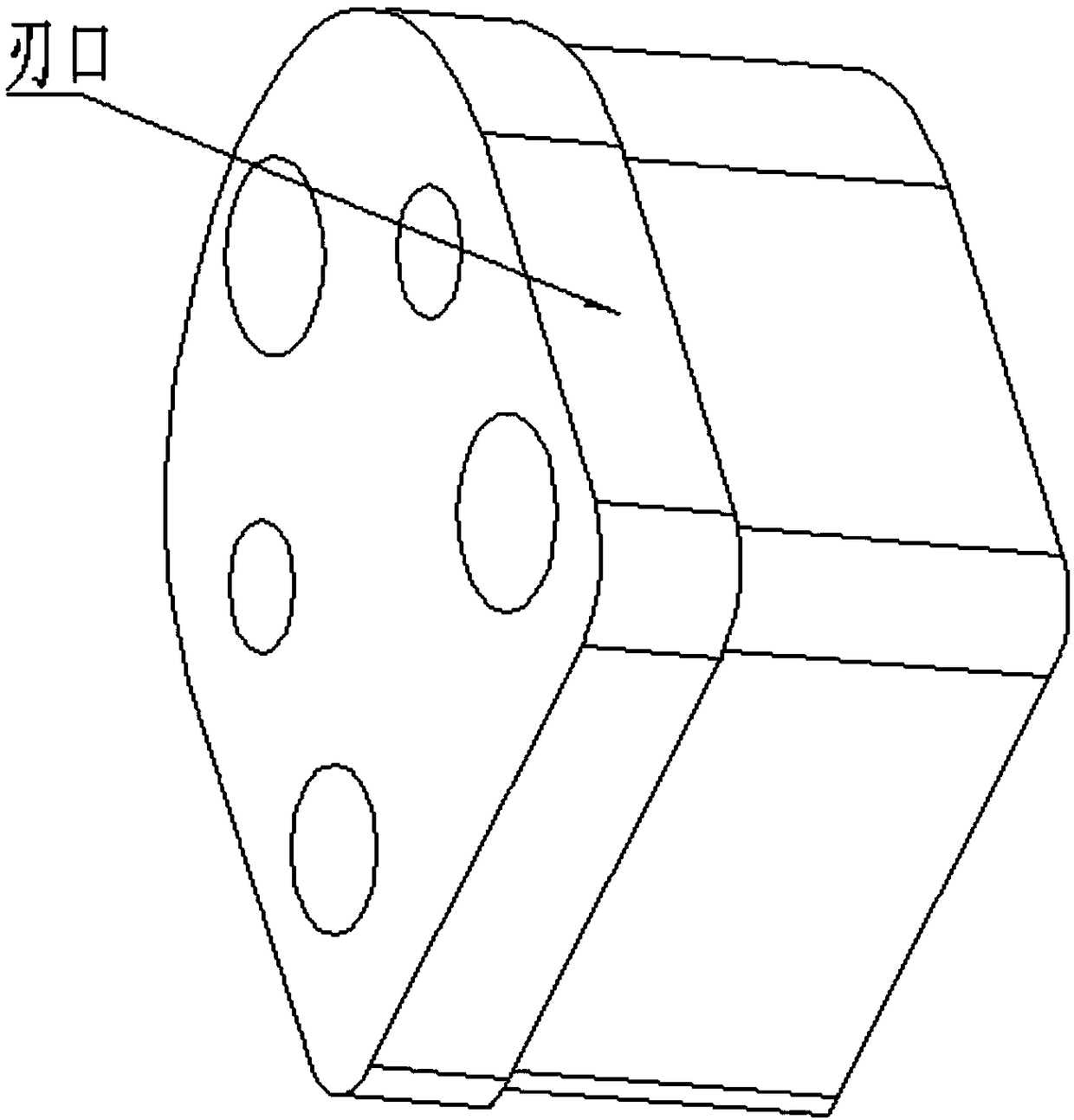

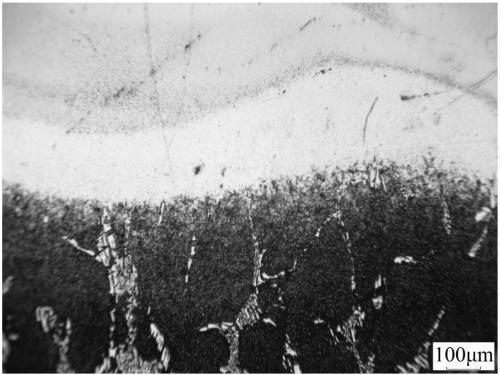

[0036] Such as figure 1 As shown, a laser cladding composite repair manufacturing method, taking the repair of the cutting edge of the Cr12MoV insert of the automobile cold stamping die as an example, as figure 2 As shown, Cr12MoV is a high-carbon high-alloy steel, including the following steps:

[0037] Step 1. At least one laser cleaning, using pulsed laser to clean the cutting edge of the Cr12MoV insert of the automobile cold stamping die, wherein the power of the pulsed laser is 5W-200W, and the cleaning rate is 3cm 2 / min~500cm 2 / min, the repetition frequency is 5Hz~30Hz, and the pulse width of the pulsed laser is 5ns~50ns;

[0038] Step 2, at least 1 laser warm-up;

[0039] Use the laser to continuously irradiate the cutting edge of the Cr12MoV insert of the automobile cold stamping die to preheat it. The laser output from the laser at this time is recorded as the preheating laser. Area is 6mm 2 ~20mm 2 , the preheating laser power is 600W ~ 1000W, the scanning s...

Embodiment 2

[0047] 45 steel spindle journal laser composite repair manufacturing method, including the following steps:

[0048] Step 1. At least one laser cleaning, using pulsed laser to clean the 45 steel spindle journal, wherein the power of the pulsed laser is 5W-200W, and the cleaning rate is 3cm 2 / min~500cm 2 / min, the repetition frequency is 5Hz~30Hz, and the pulse width of the pulsed laser is 5ns~50ns;

[0049] Step 2, at least 1 laser warm-up;

[0050] Use the laser to continuously irradiate the 45 steel spindle journal to preheat it, and record the laser output at this time as the preheating laser. The shape of the preheating laser spot is circular or rectangular, and the area of the preheating spot is 6mm. 2 ~20mm 2 , the preheating laser power is 600W ~ 1000W, the scanning speed of the preheating laser spot is 8mm / s ~ 20mm / s; the temperature of the 45 steel spindle after laser preheating is not higher than 120 ℃, and not lower than 50 ℃;

[0051] Step 3, laser cladding;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com