Patents

Literature

126 results about "Composite repairs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite repairs. Composite materials nowadays are used in a wide range of applications in aerospace, marine, automotive, surface transport and sports equipment markets. Damage to composite components is not always visible to the naked eye and the extent of damage is best determined for structural components by suitable Non Destructive Test methods. The concept for composite repair of composite or metallic structures is simple. The bonded repair reduces stresses in the damaged region and keeps the cracks from opening and therefore from growing.

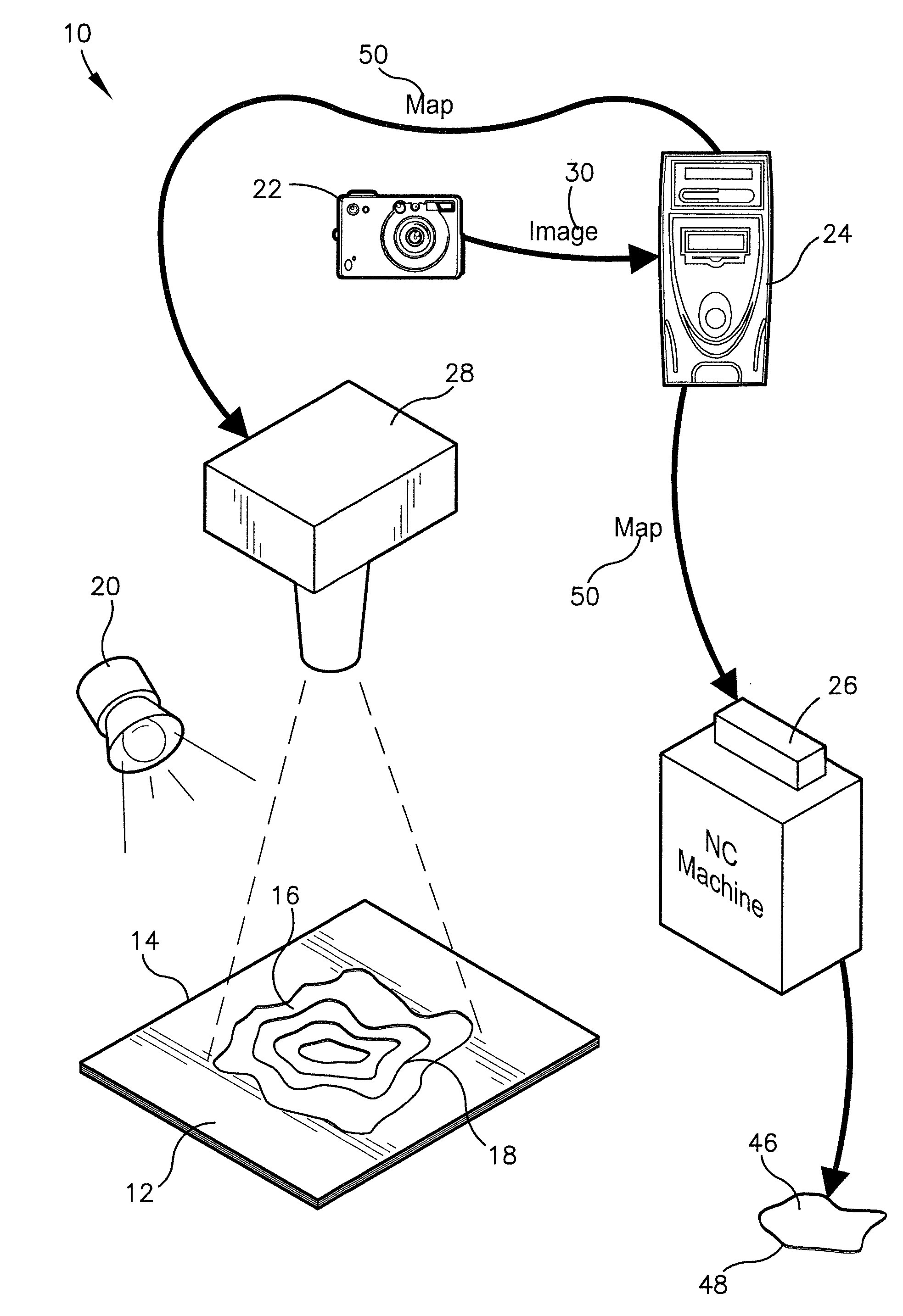

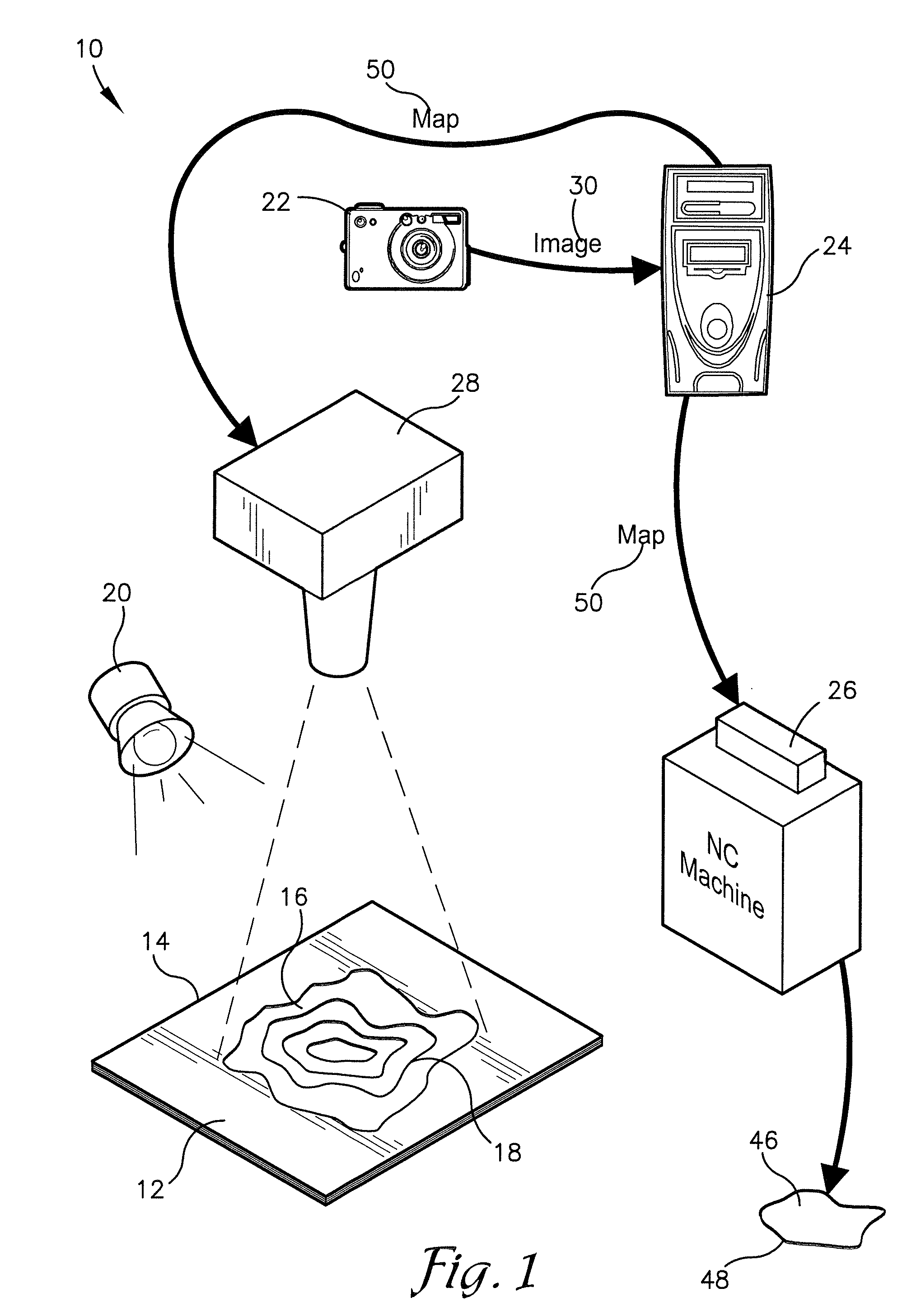

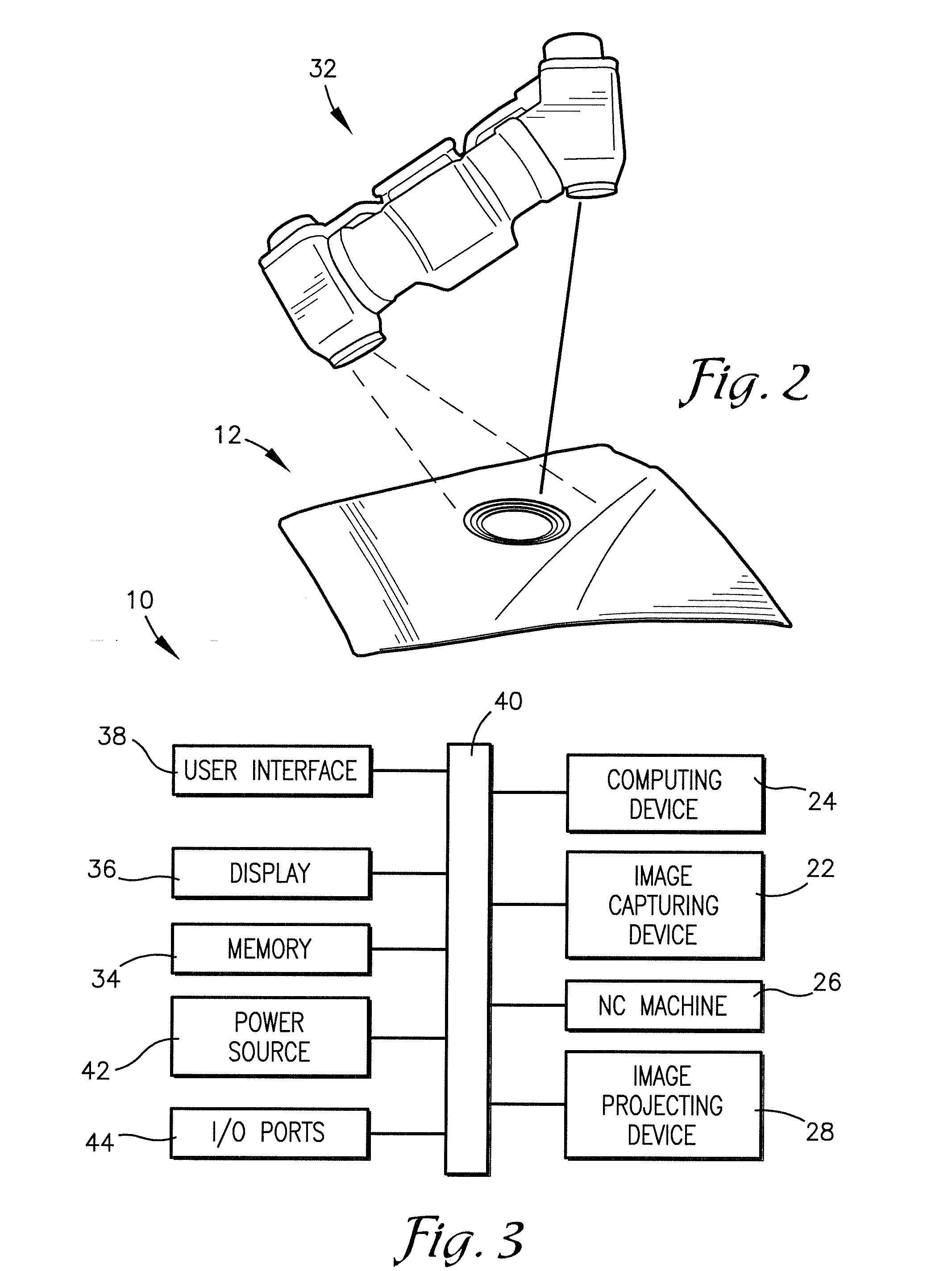

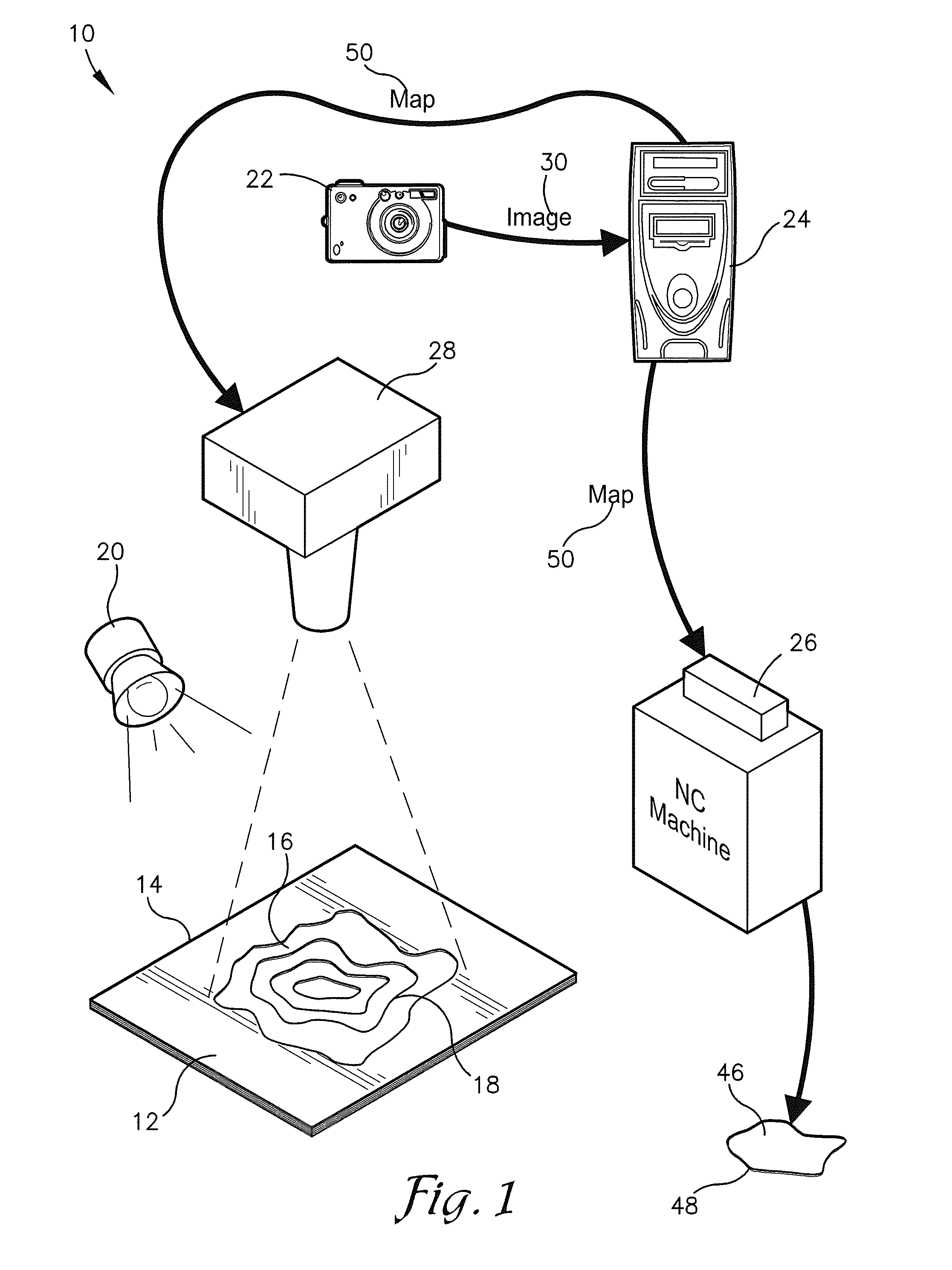

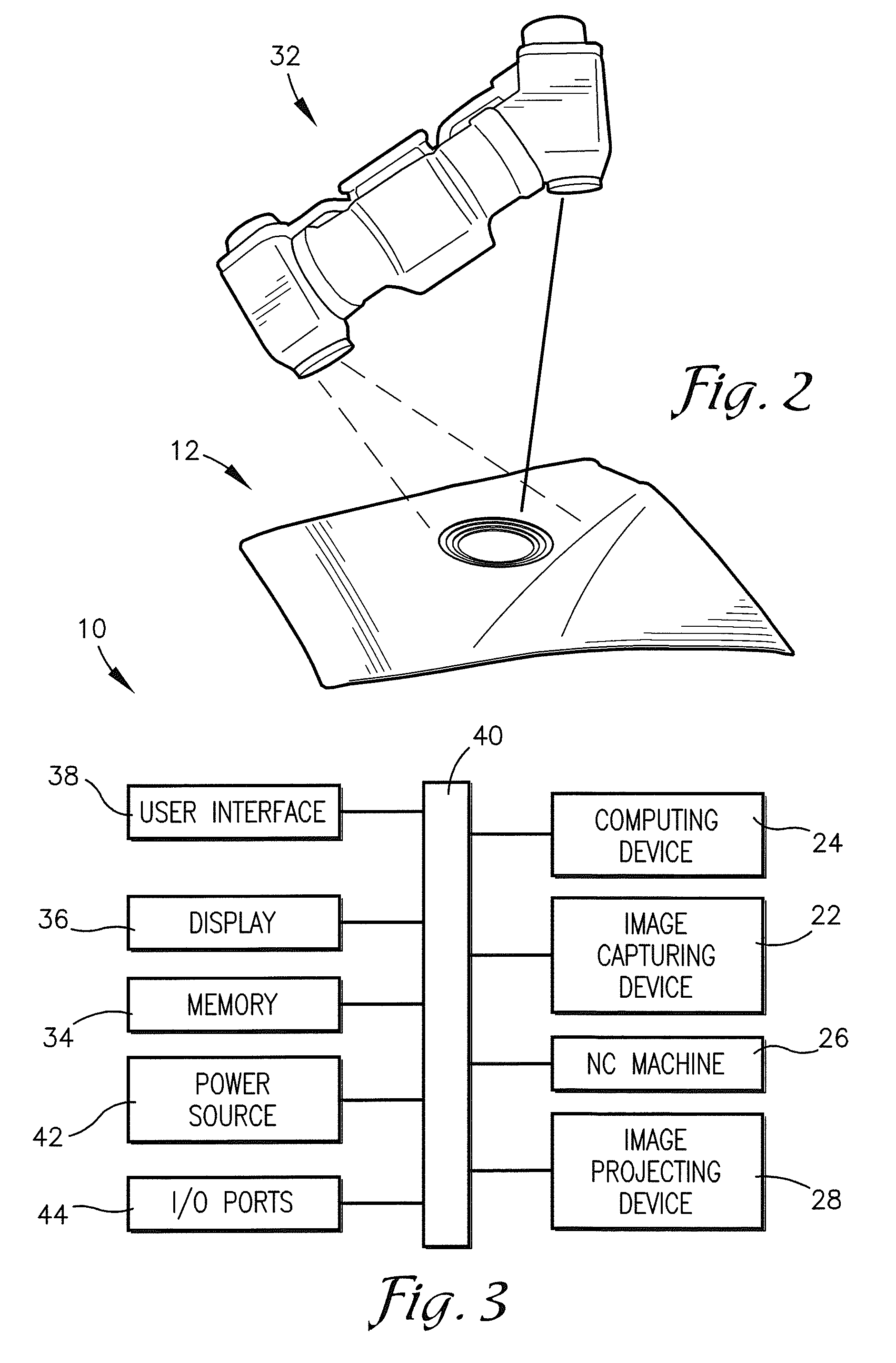

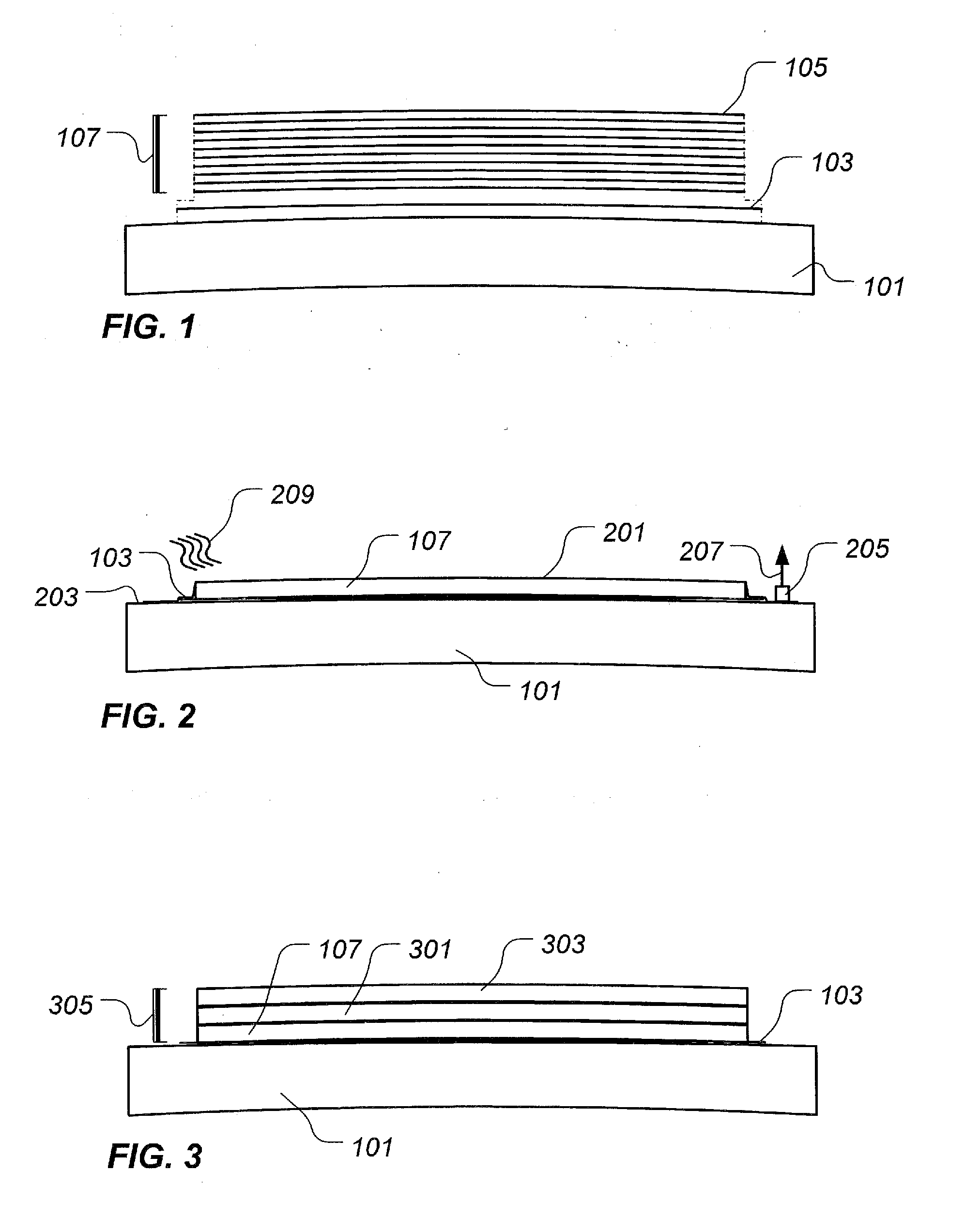

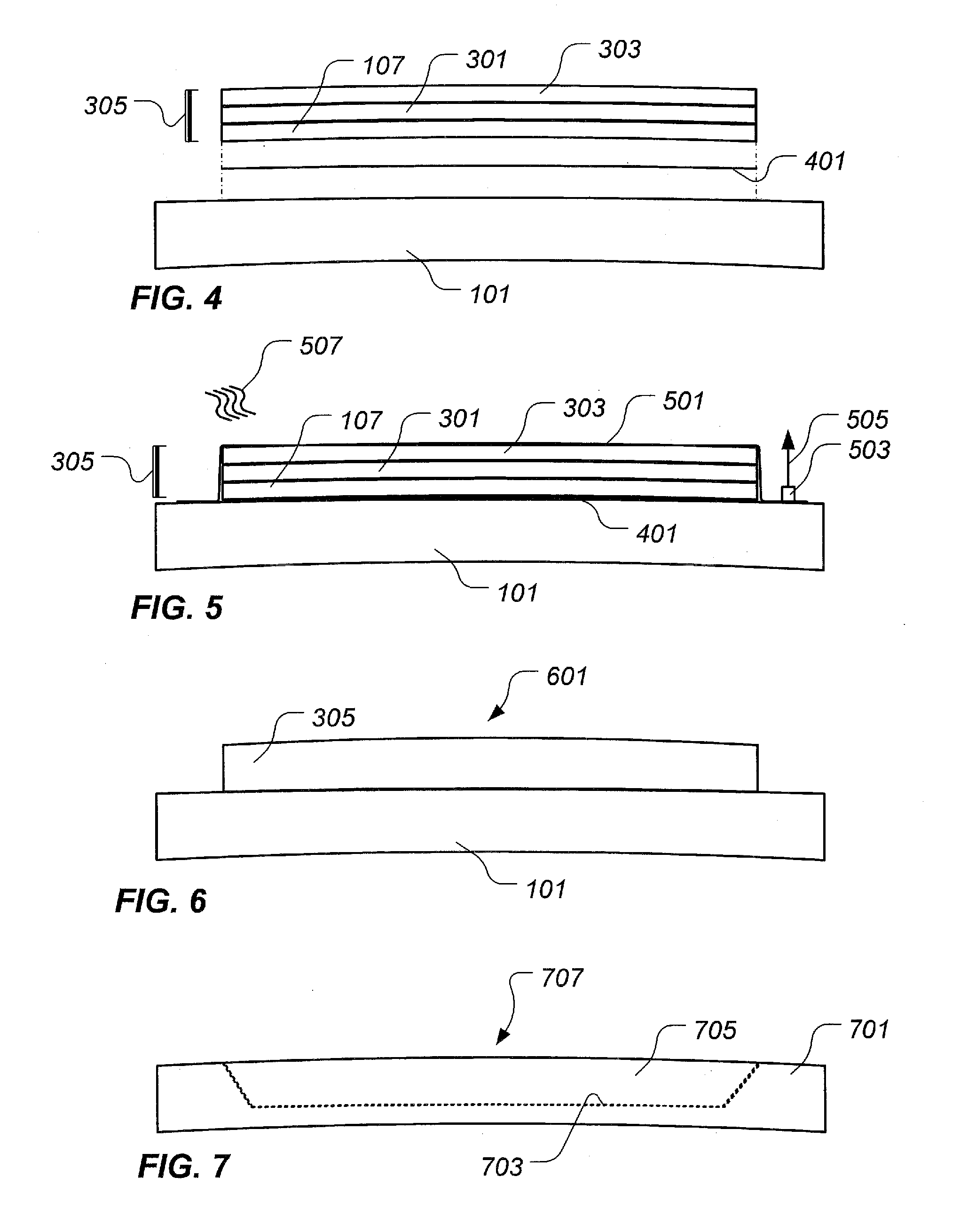

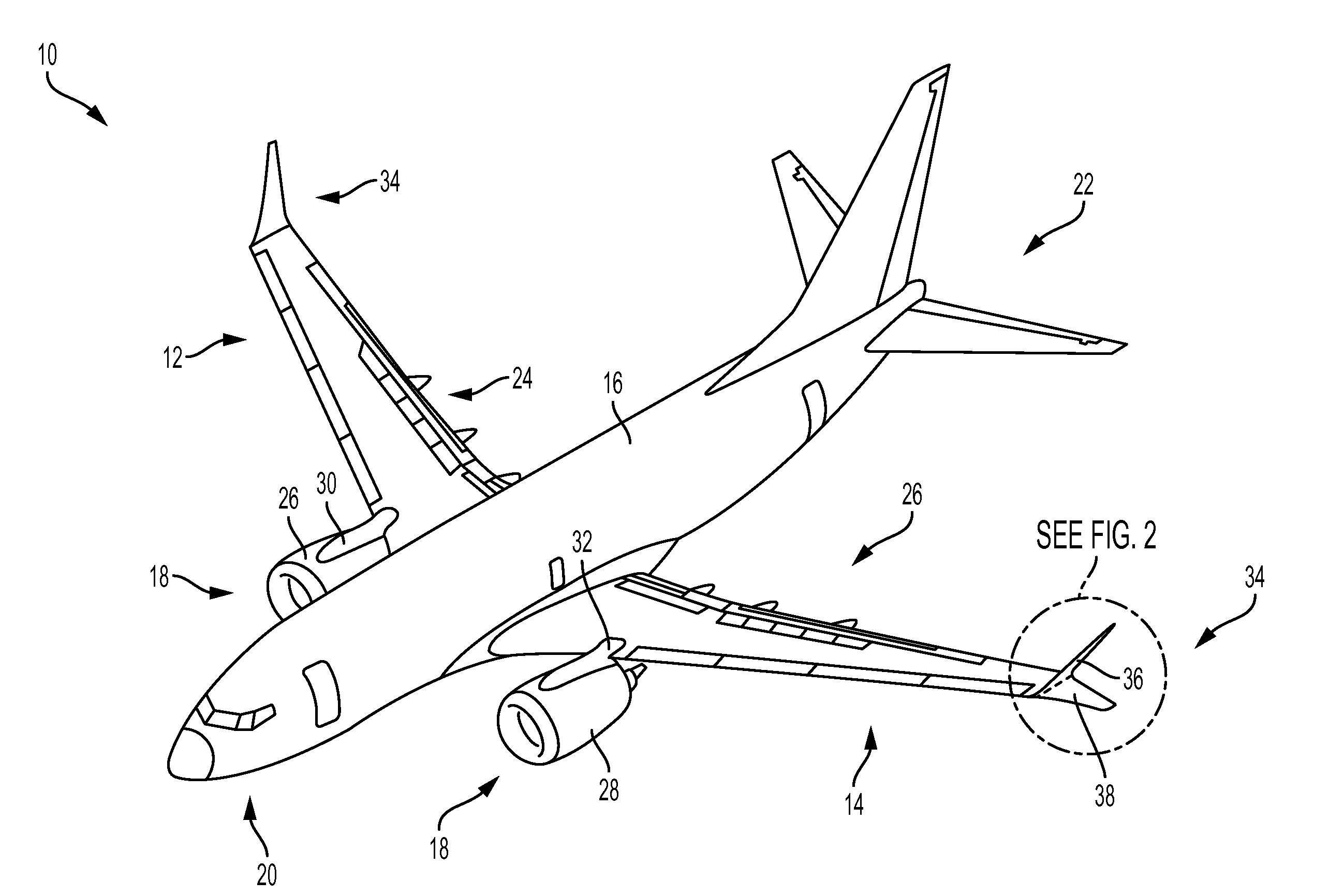

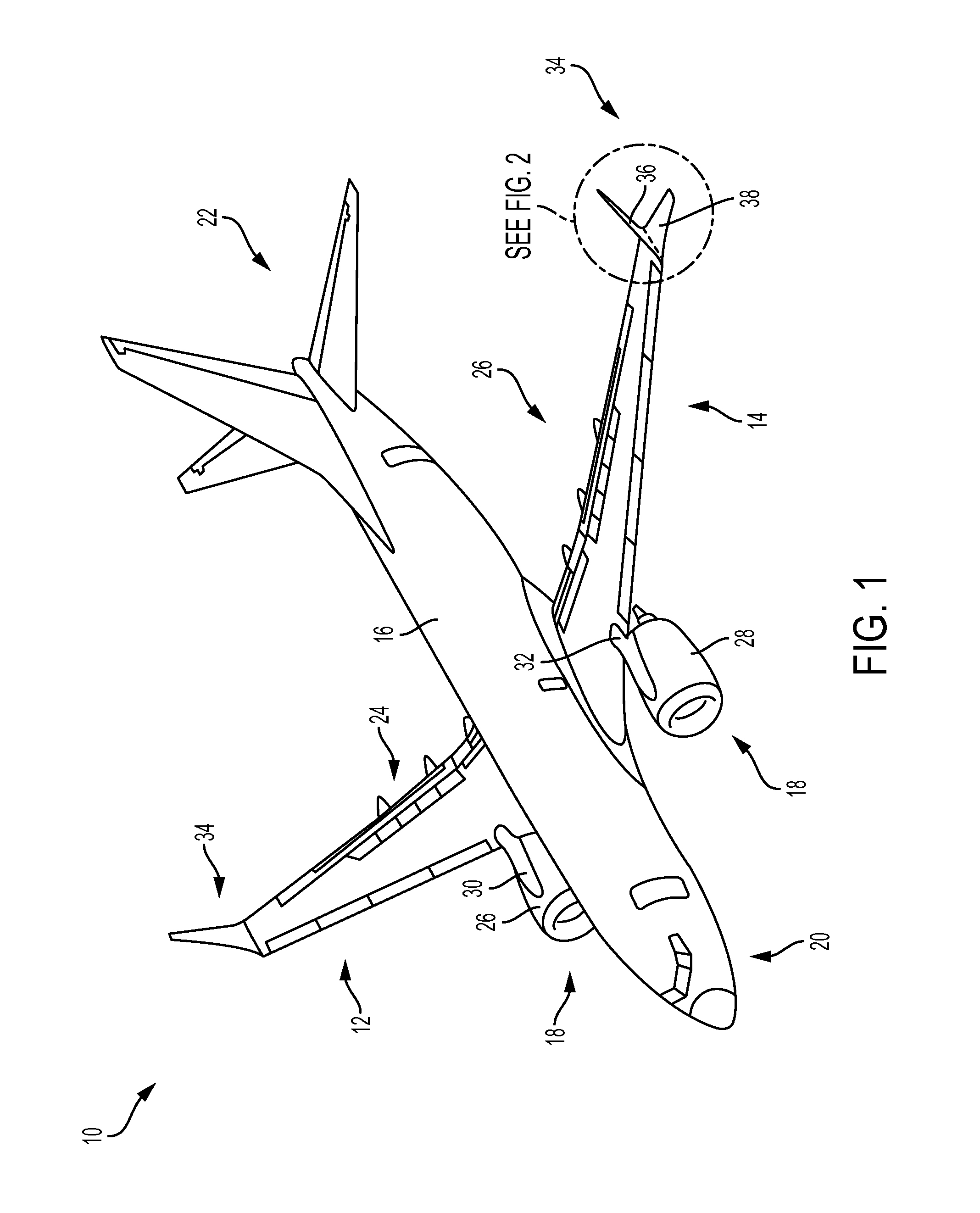

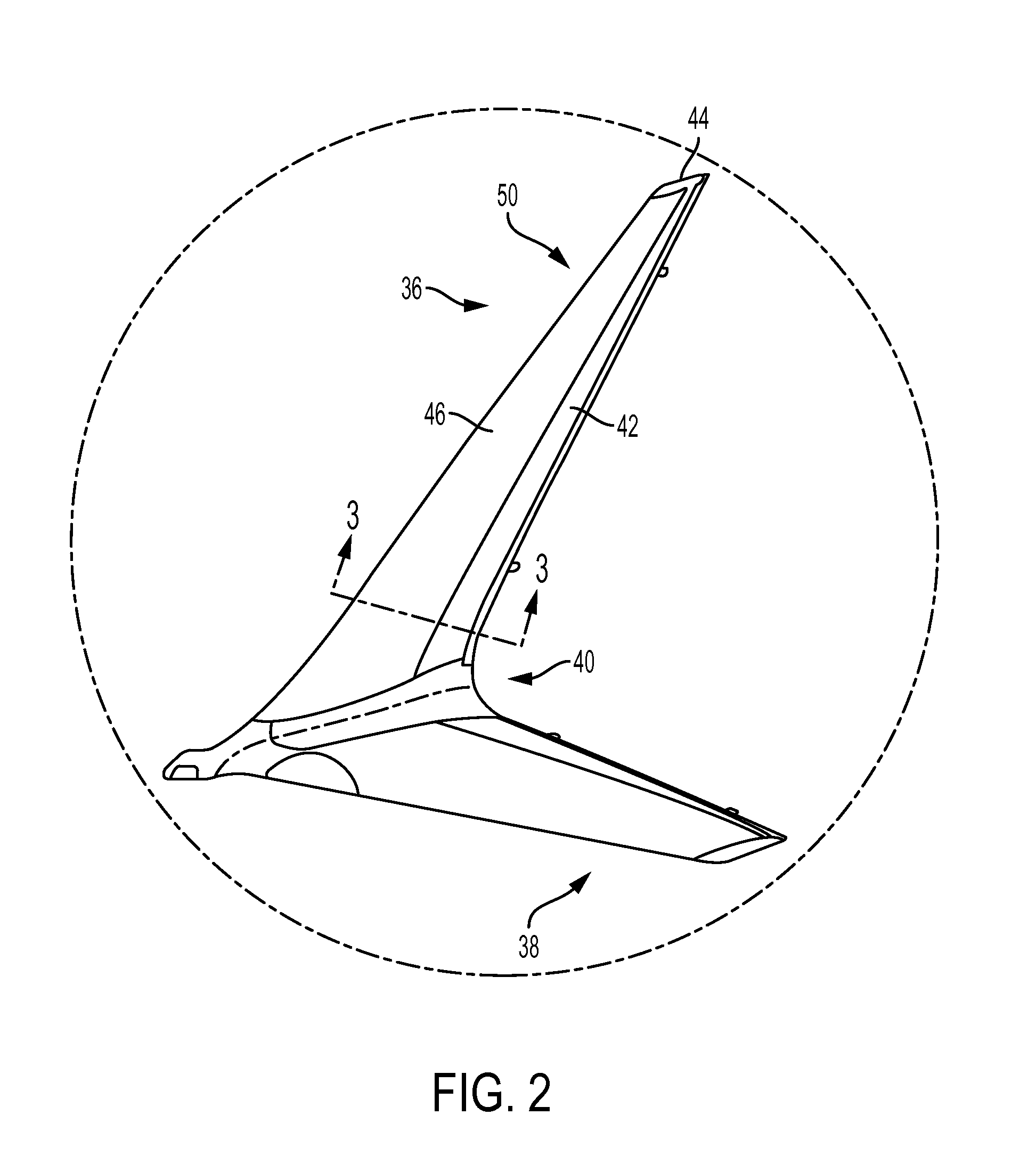

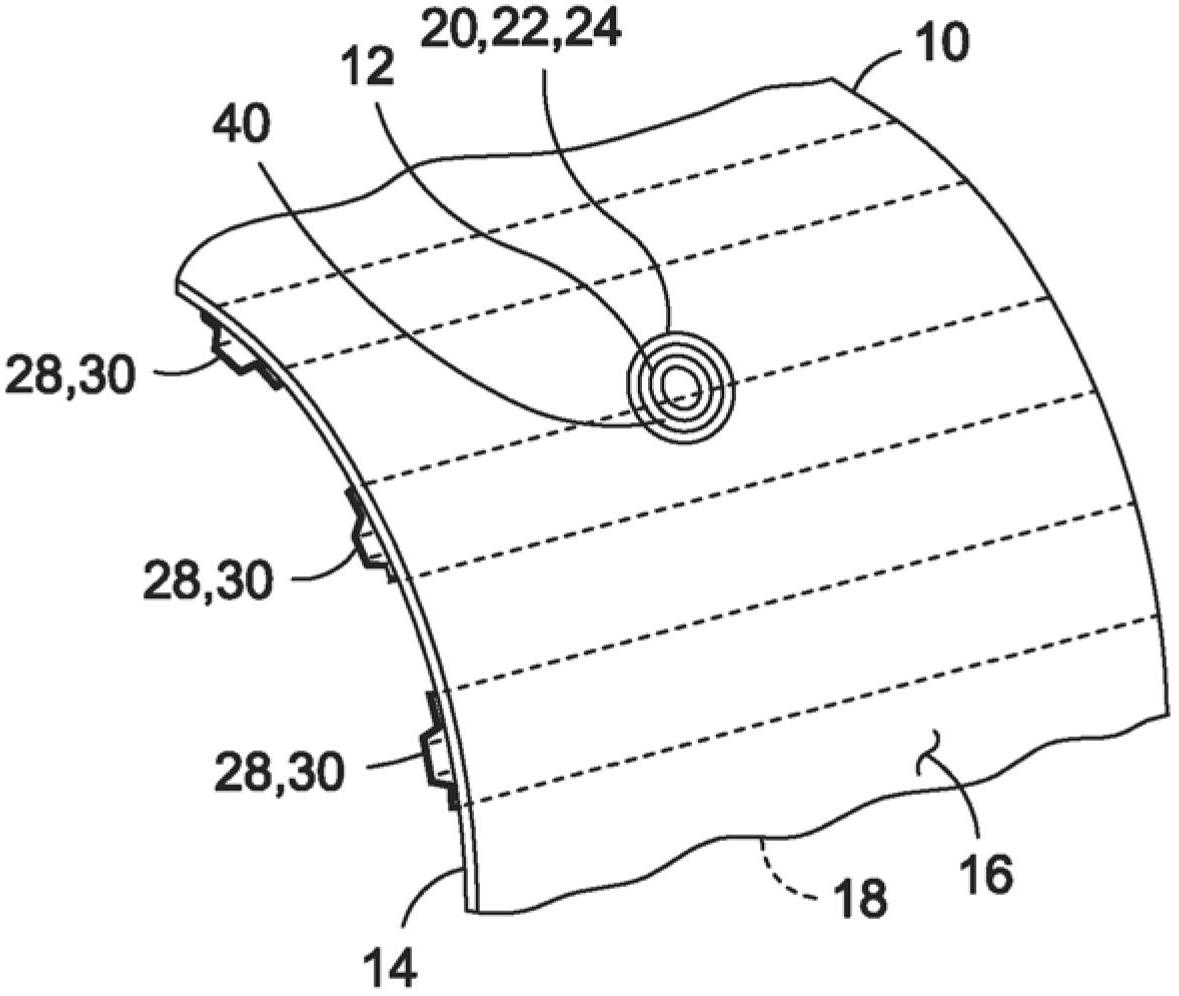

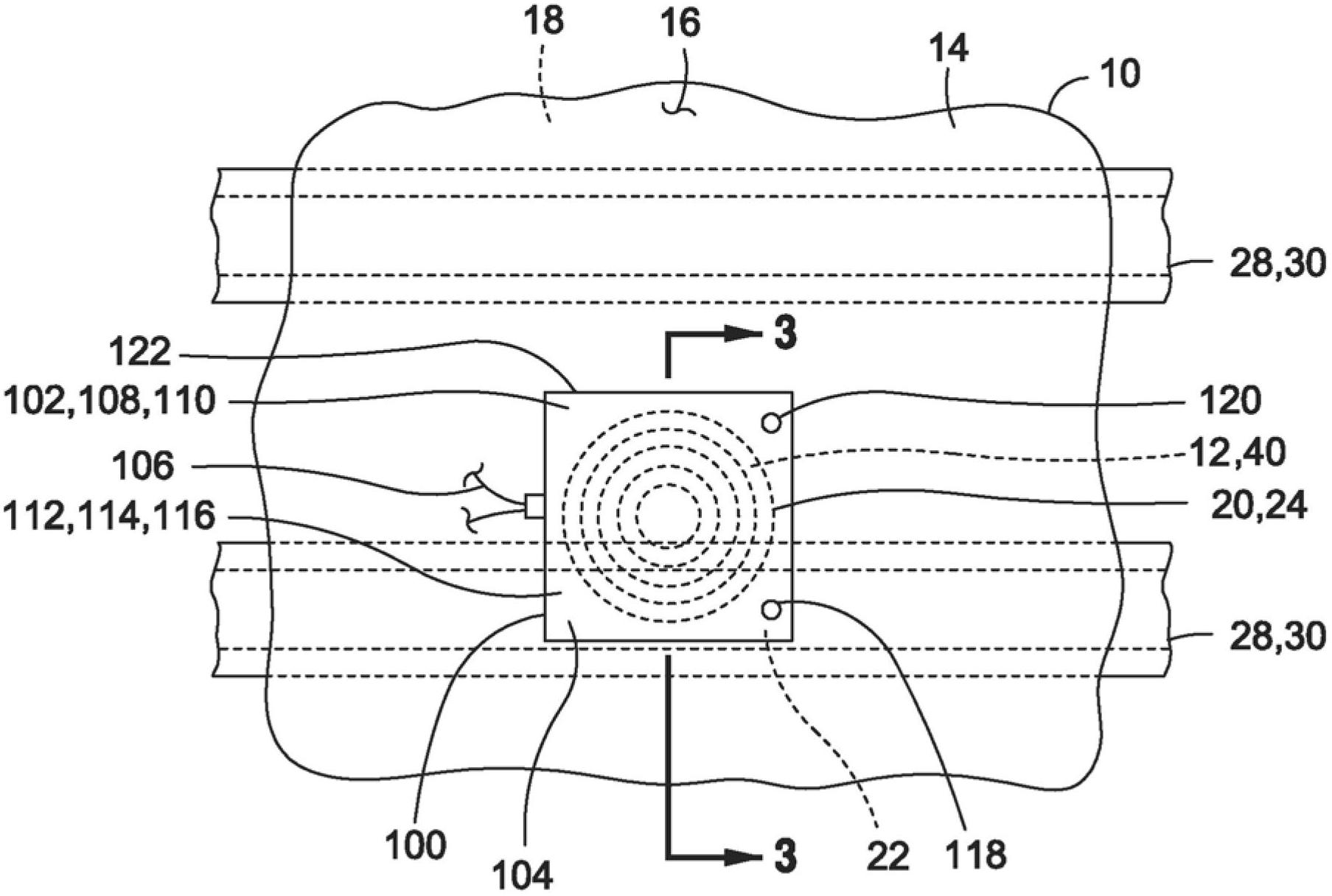

System and method for repairing composite parts

ActiveUS20080281554A1Exact matchPhotomechanical apparatusMaterial analysis by optical meansComputer graphics (images)Edge based

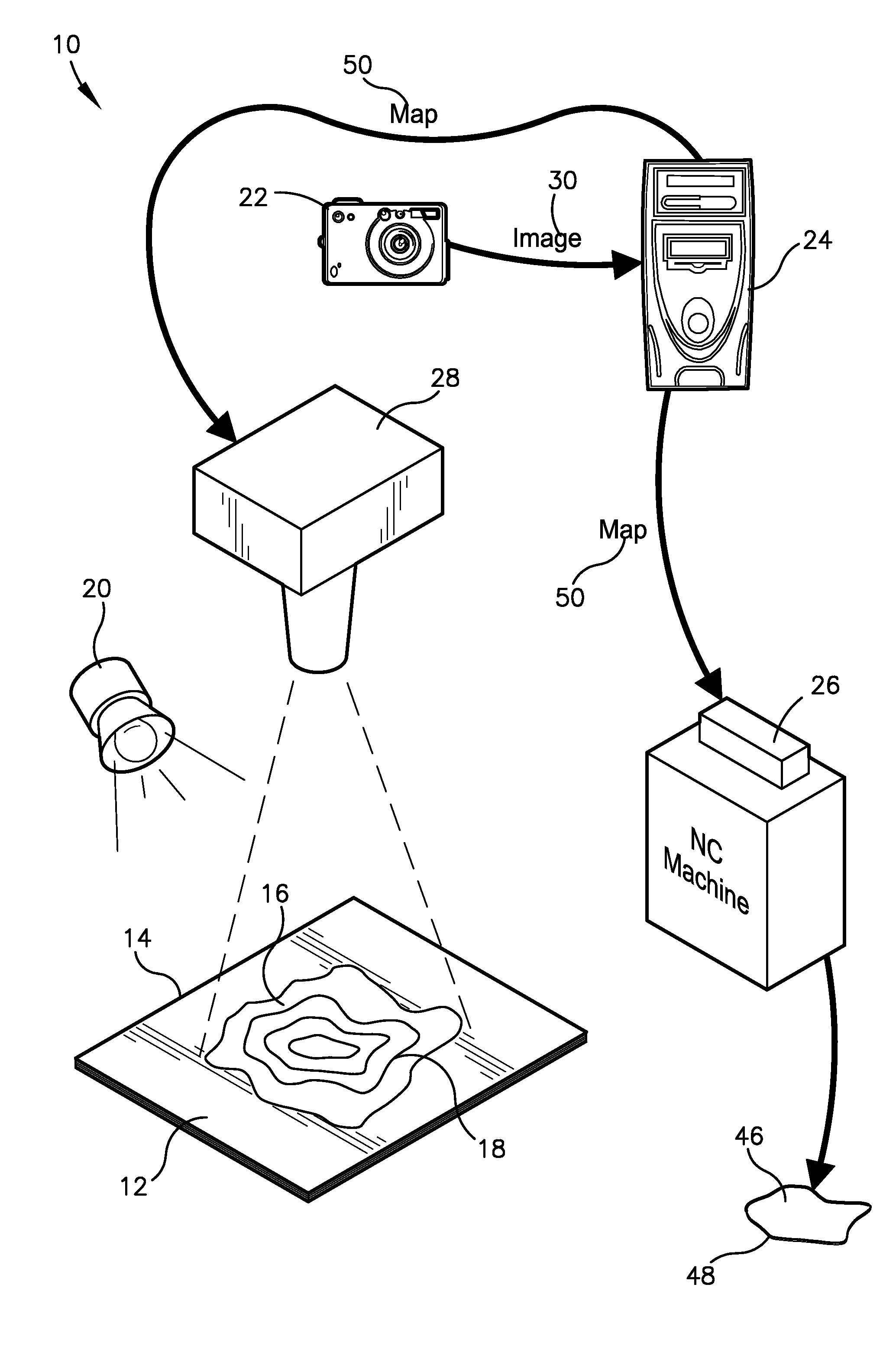

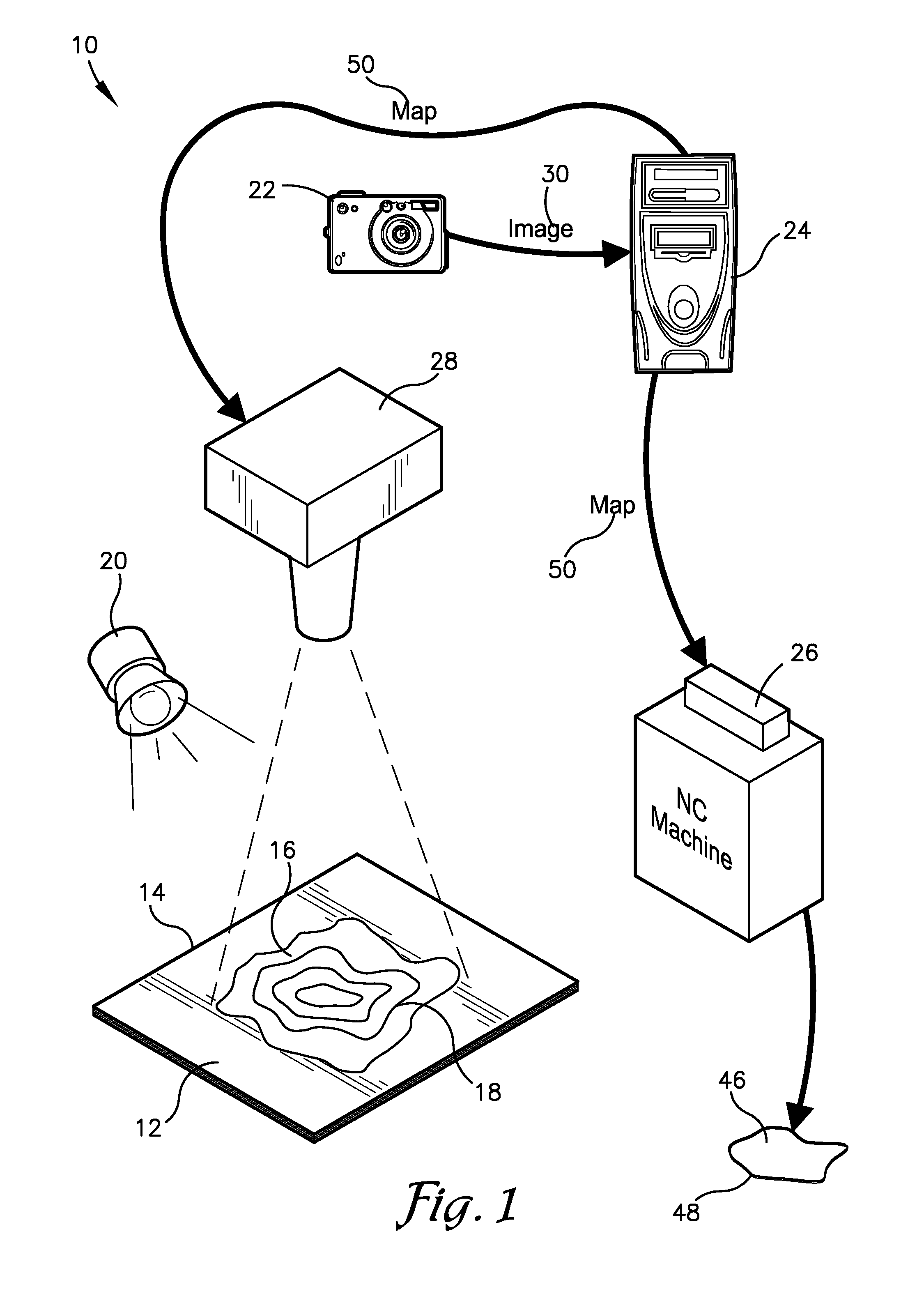

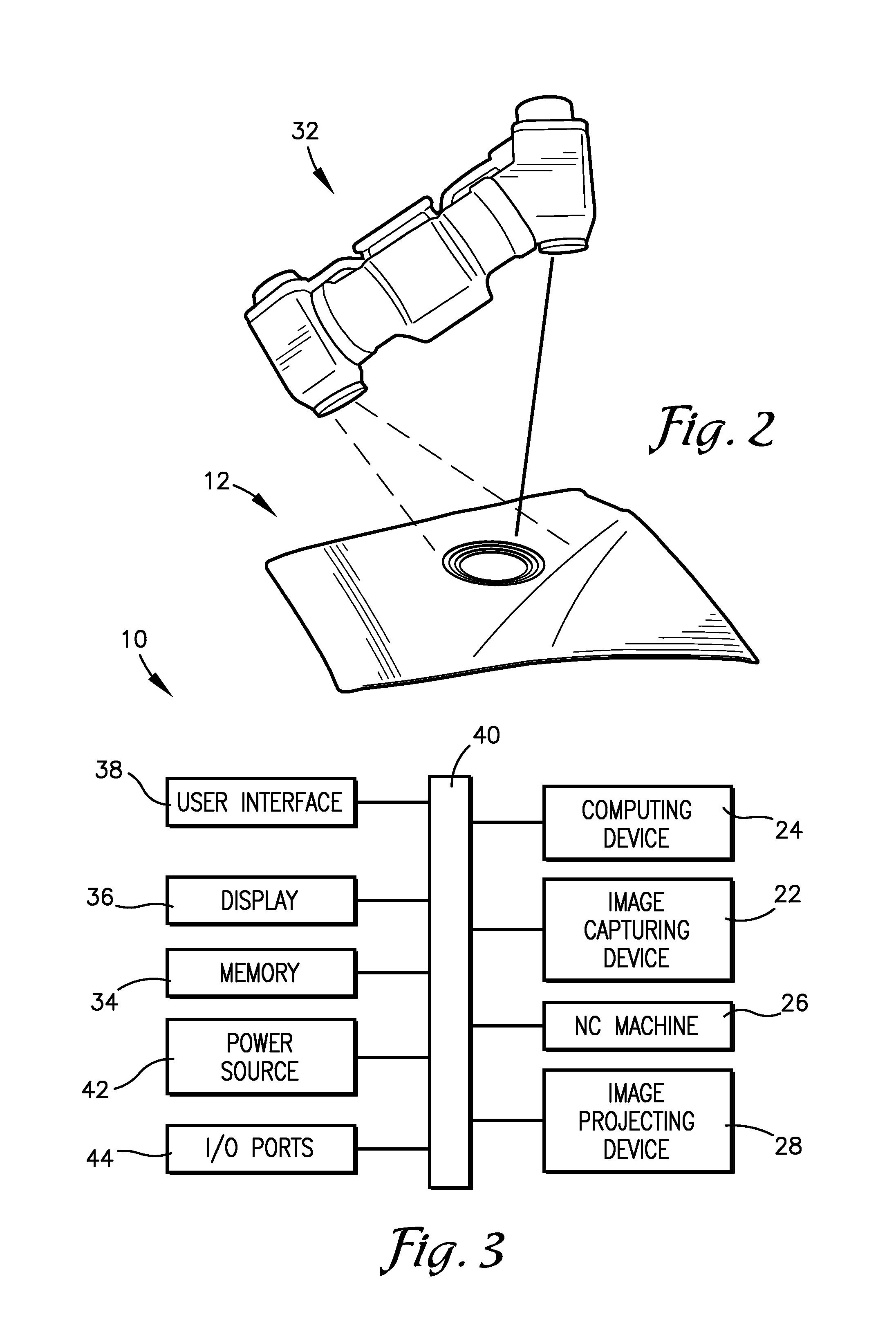

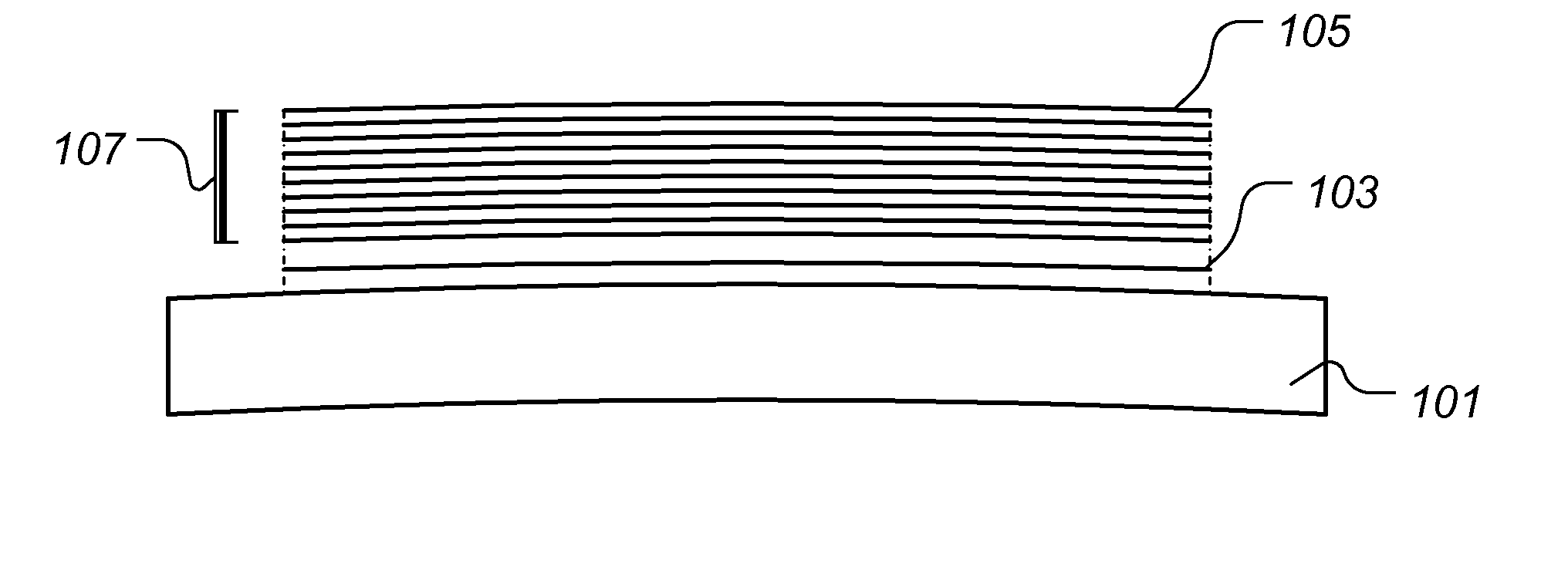

A composite repair system and method for assisting in the repair of a cured composite part in which a damaged portion has been cut out and removed, exposing a plurality of composite plies and their corresponding composite ply edges. The composite repair system may comprise a light source to illuminate the ply edges, an image capturing device to obtain an image of the ply edges, and a computing device for processing the image of the ply edges and creating a map of the ply edges based on the image. The map may be used to manufacture filler plies having peripheral edges shaped to correspond with the composite ply edges for replacing the damaged portion of the composite part.

Owner:SPIRIT AEROSYSTEMS

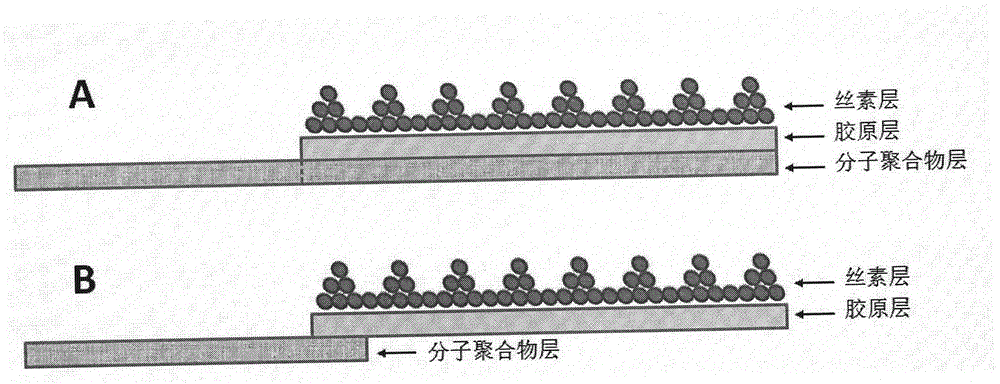

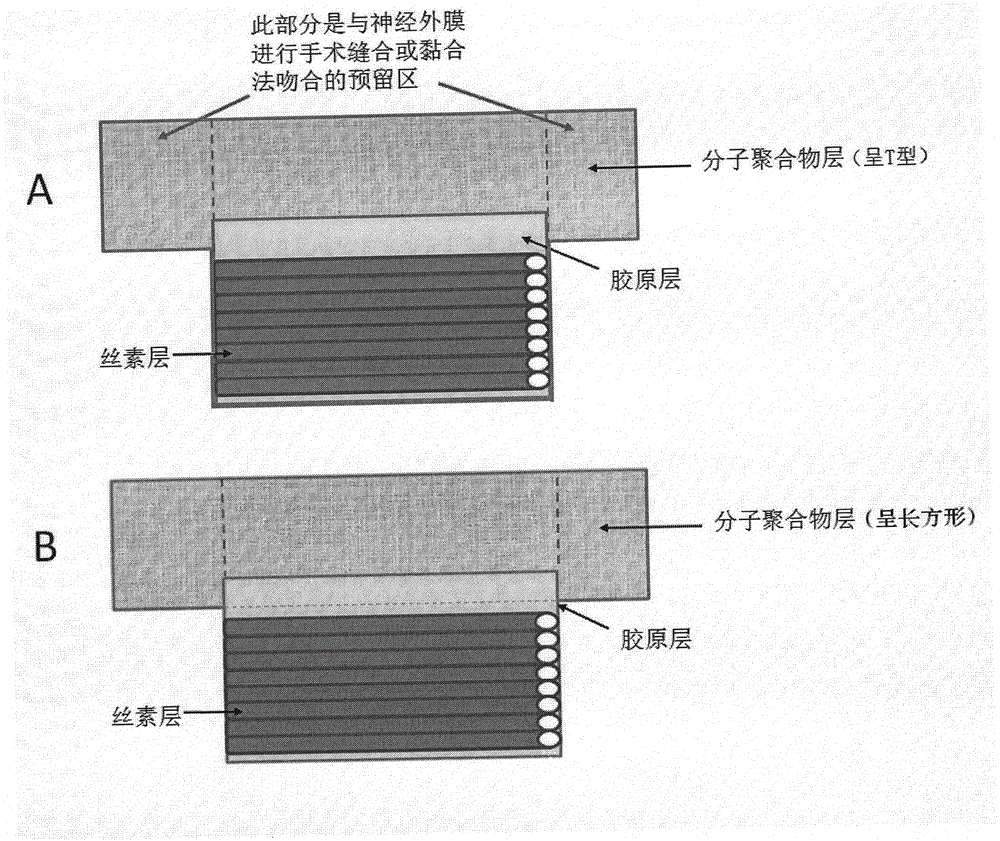

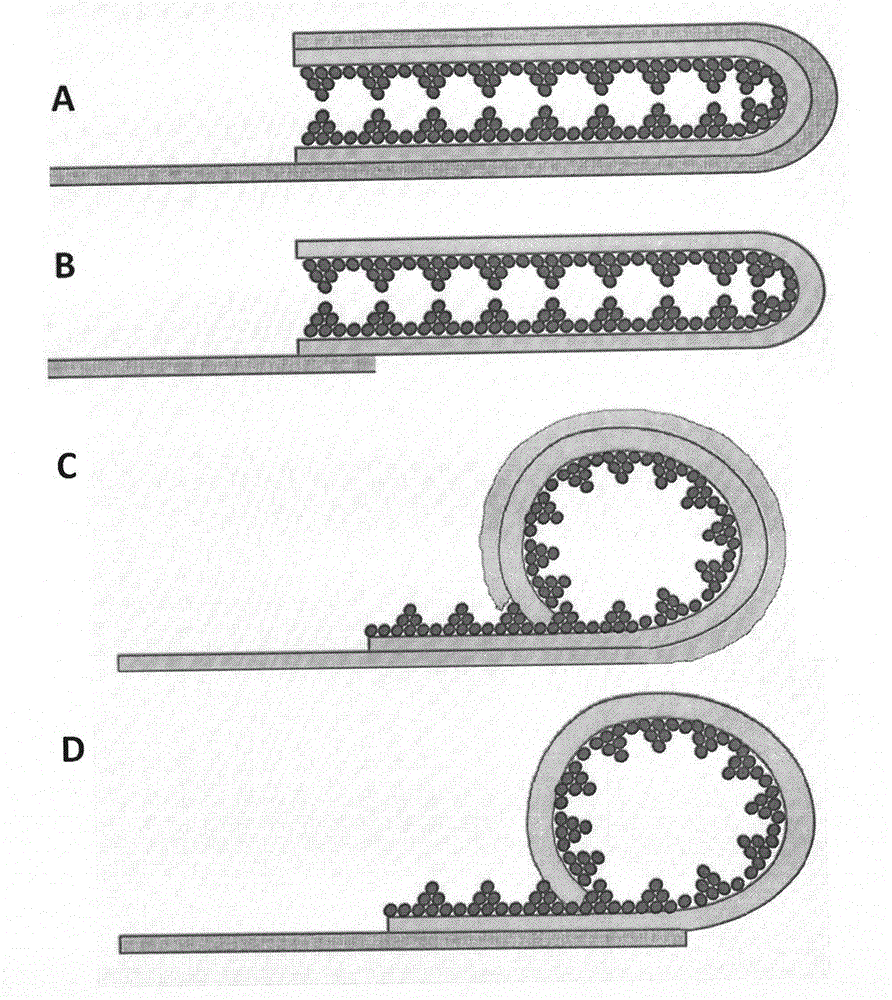

Composite repair material for bridging defect nerves and stent made of composite repair material

The invention provides a composite repair material which facilitates surgical operation and realizes quick defect nerve bridging and composition, preparation and application of a stent made of the composite repair material. The composite repair material consists of a fibroin layer, a collagen layer and a high-molecular polymer layer which are sequentially arranged, and during application, the composite repair material is folded or wound to form the nerve bridging stent taking the fibroin layer as the inner layer, the collagen layer as the middle layer and the high-molecular polymer as the outer layer. The composite repair material and the stent made of the composite repair material adopt the layered arrangement and a specific three-dimensional design to bring the advantages of various repair materials into full play, and meanwhile, make up for the deficiencies of the various repair materials. During surgical operation, only suturing or bonding anastomosis of epineurium is required but not suturing of perineurium, so that the operation time of a defect nerve bridging operation is greatly shortened, the operation technical difficulty is lowered, and the security is improved.

Owner:WENZHOU MEDICAL UNIV

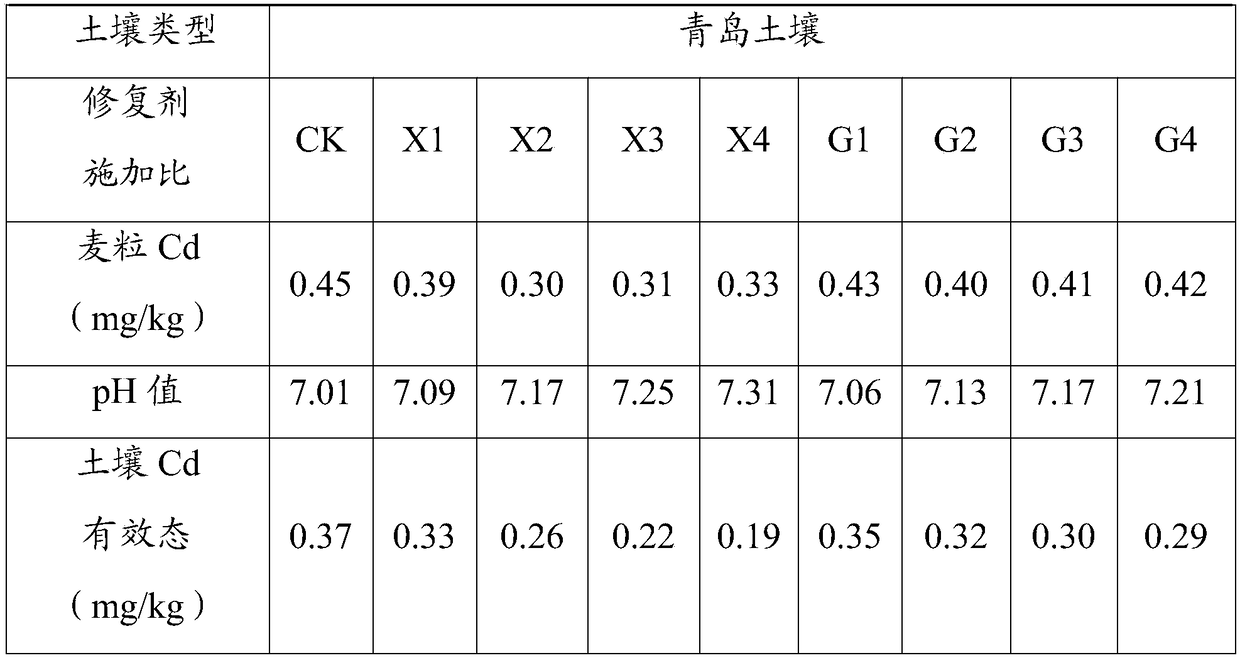

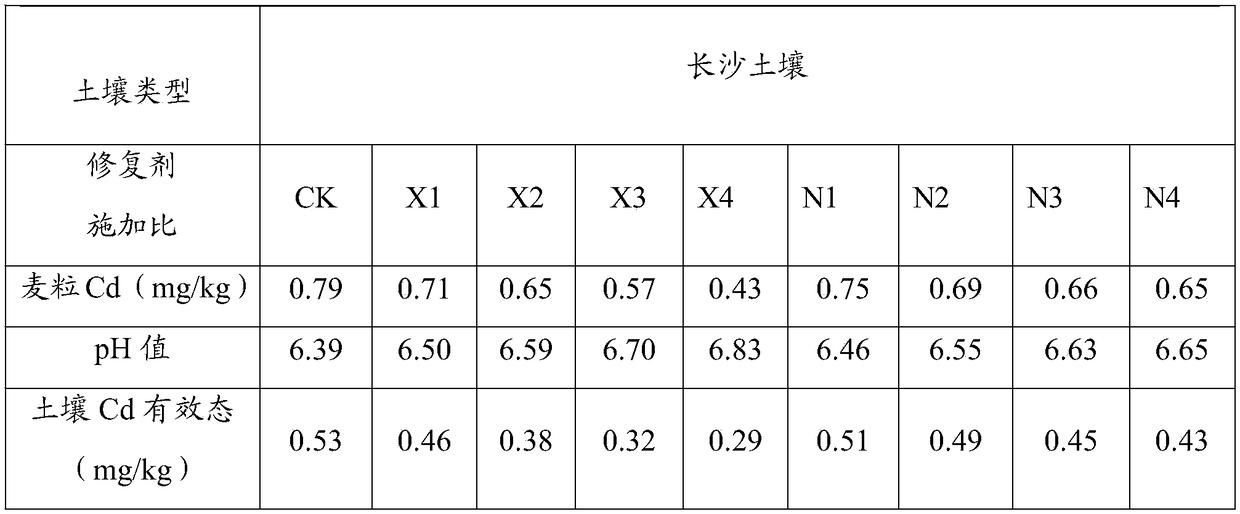

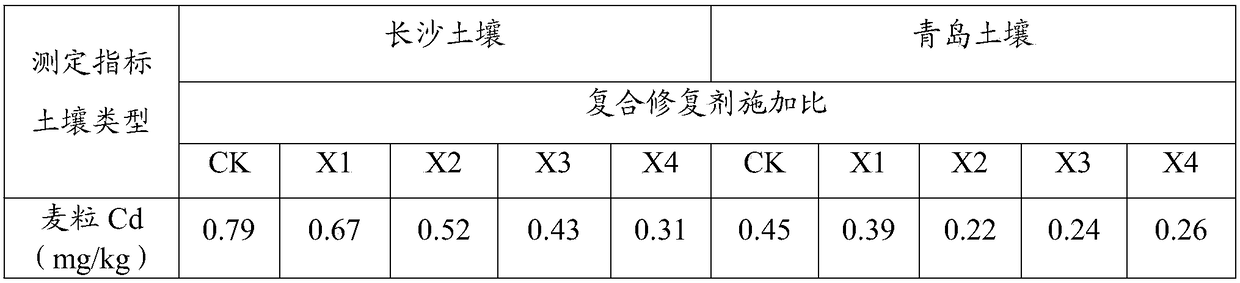

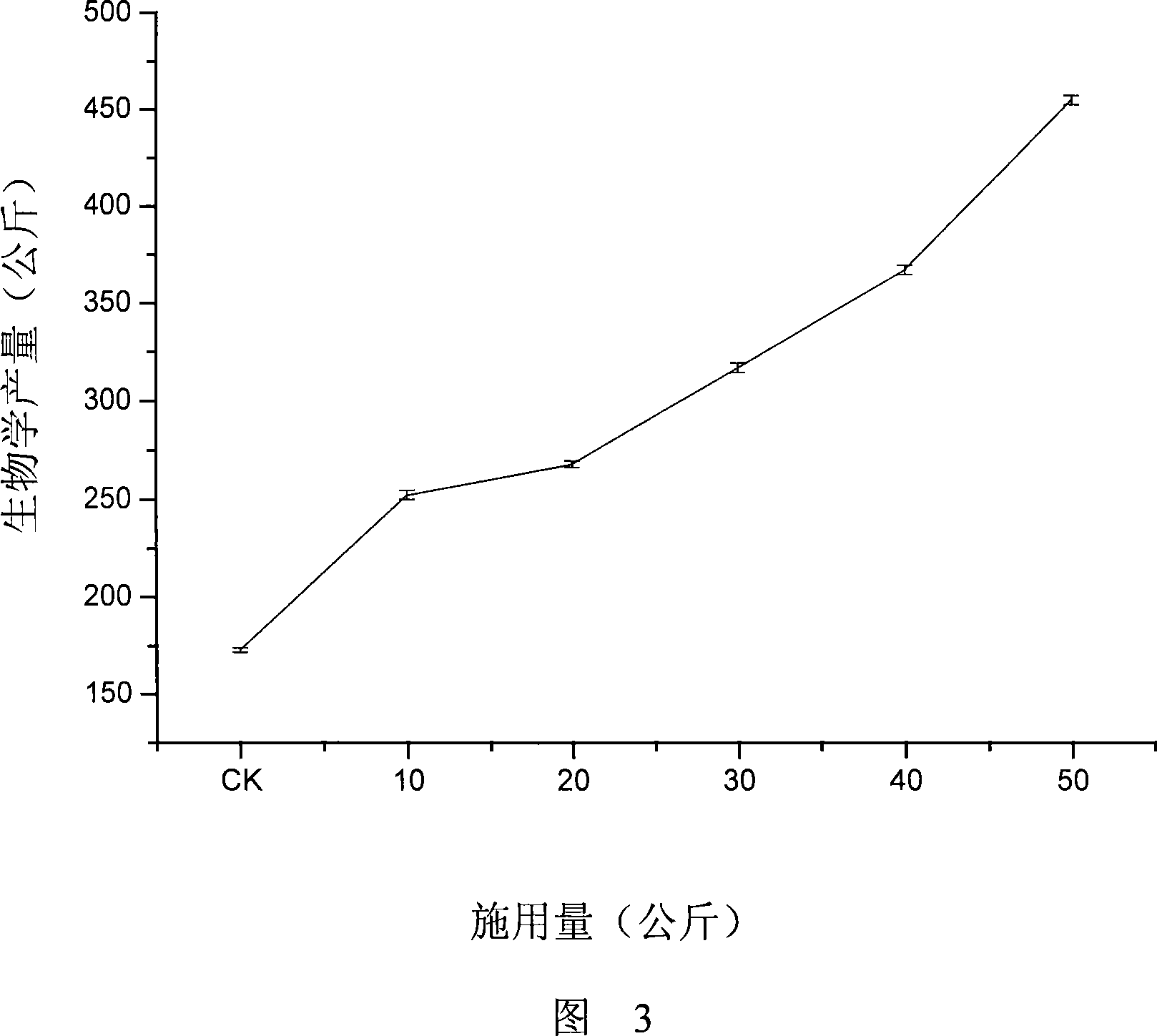

Composite repair agent for soil heavy metal pollution and application thereof

InactiveCN108085010AWide variety of sourcesImprove efficiencyContaminated soil reclamationOrganic fertilisersSodium BentoniteOyster

The invention provides a composite repair agent for soil heavy metal pollution as well as a preparation method and application thereof, and belongs to the technical field of soil improvement and environmental protection. A composite repair agent for soil cadmium pollution is prepared from the following components in parts by weight: 10 to 30 parts of sodium bentonite, 5 to 15 parts of bone powder,5 to 25 parts of chitosan, 5 to 30 parts of oyster shell powder, 10 to 40 parts of graphene-modified crop straw biochar, 10 to 30 parts of bio-organic fertilizer, 15 to 45 parts of sodium silicate, 1to 15 parts of nano-FeO, 1 to 8 parts of carbon nanotubes, and 1 to 10 parts of microbial inoculants. The number of each 10 mg colonies of rhodotorula mucilaginosa OP11 in the microbial inoculum is 2.25*10 <8> to 2.5*10<9> CFU; the preservation number of the rhodotorula mucilaginosa OP11 is CGMCC No. 13540. The application of the composite repair agent is in remediation of heavy metal contaminated soil.

Owner:QINGDAO AGRI UNIV +1

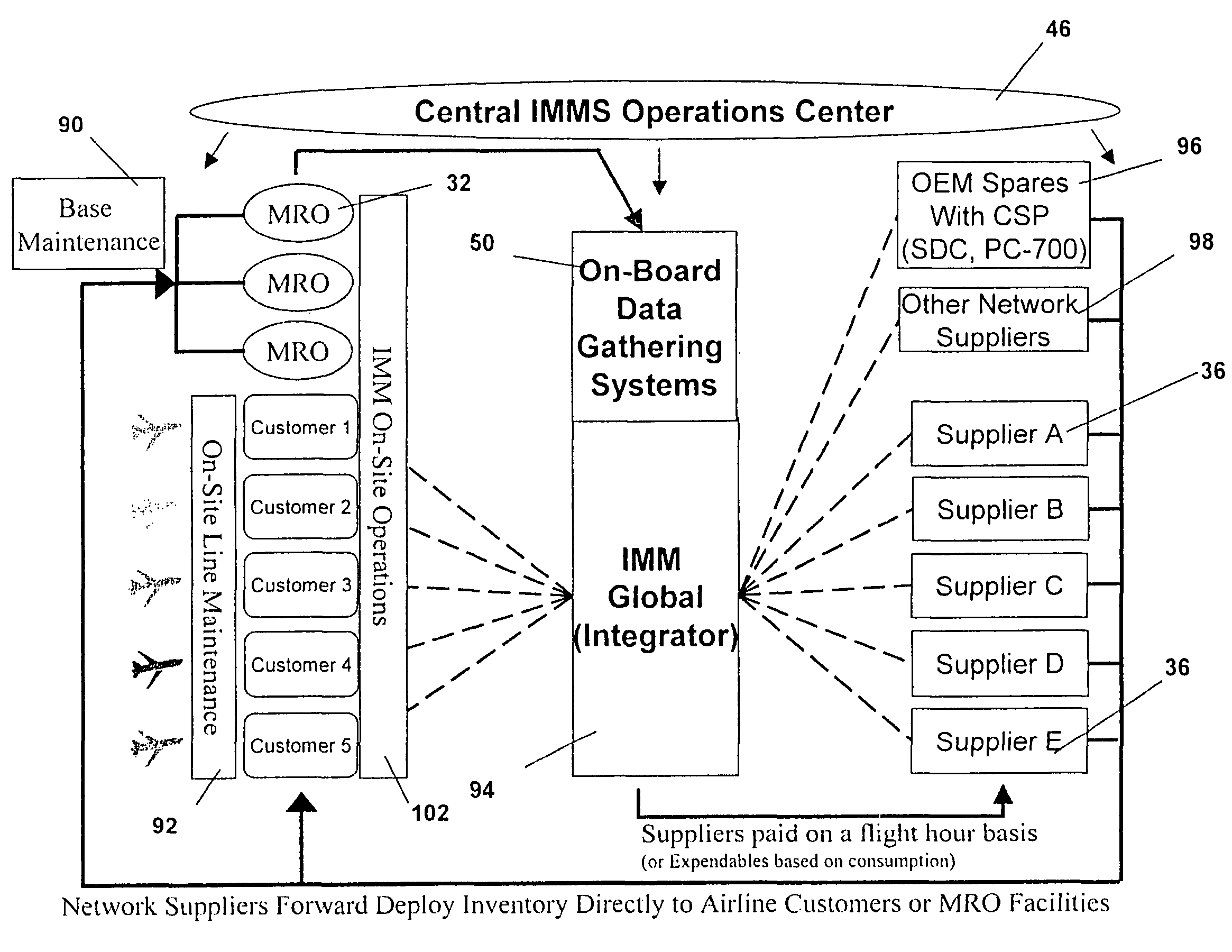

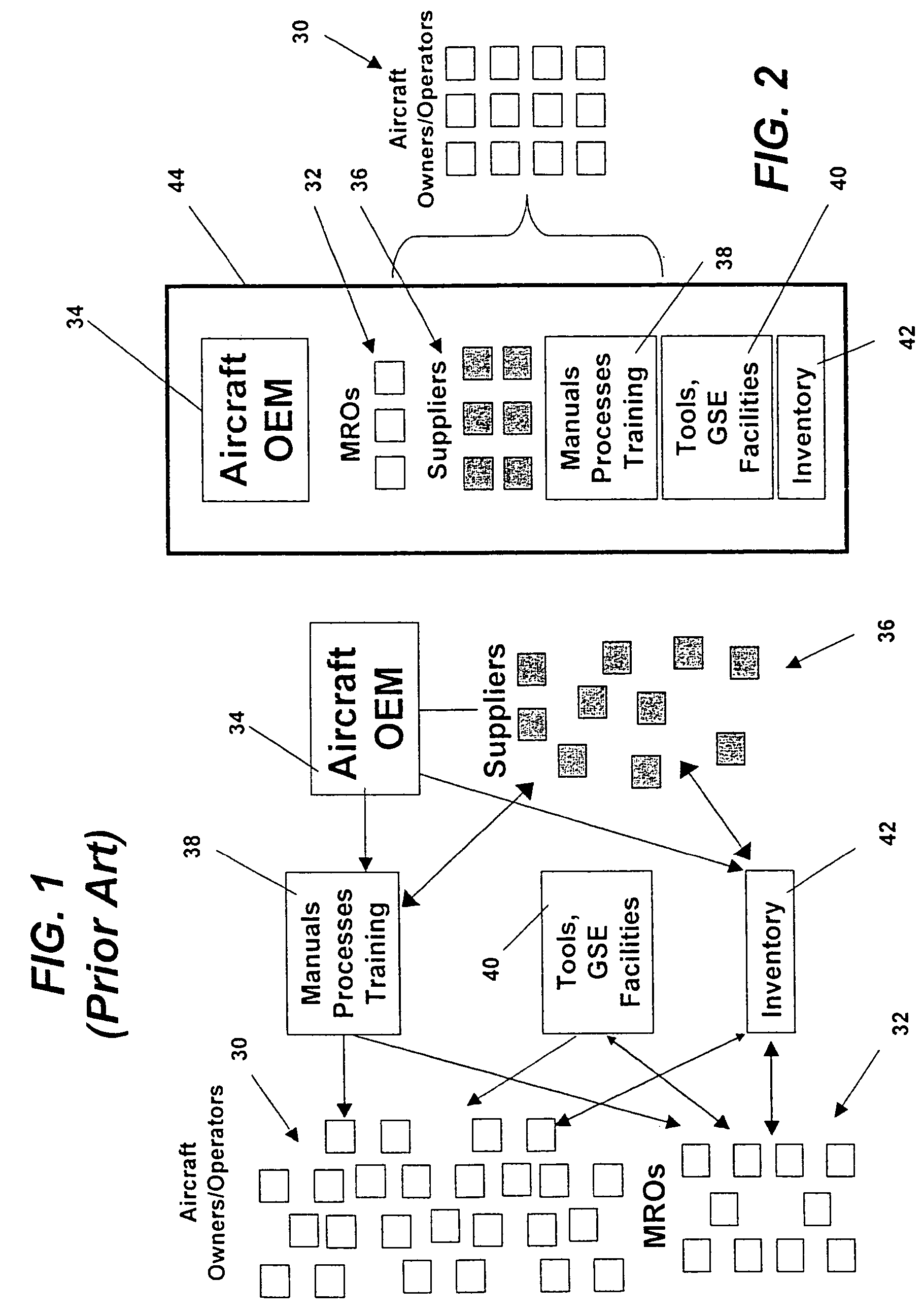

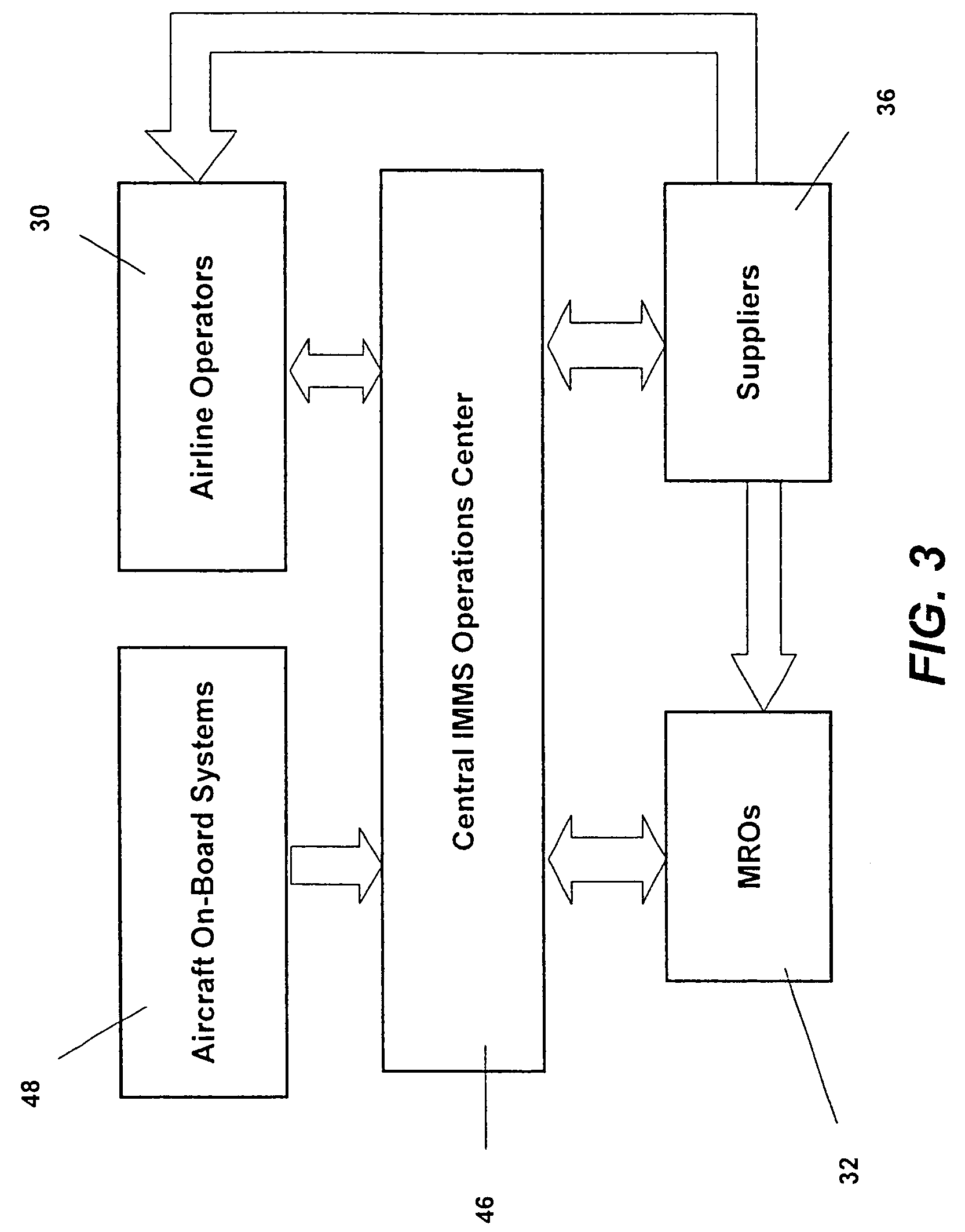

Integrated maintenance and materials services for fleet aircraft using aircraft data to improve maintenance quality

ActiveUS7761201B2Improve efficiencyLow costVehicle testingRegistering/indicating working of vehiclesMaintenance planningOn board

Owner:THE BOEING CO

System and method for repairing composite parts

ActiveUS20130294644A1Exact matchProgramme controlCharacter and pattern recognitionEngineeringImage capture

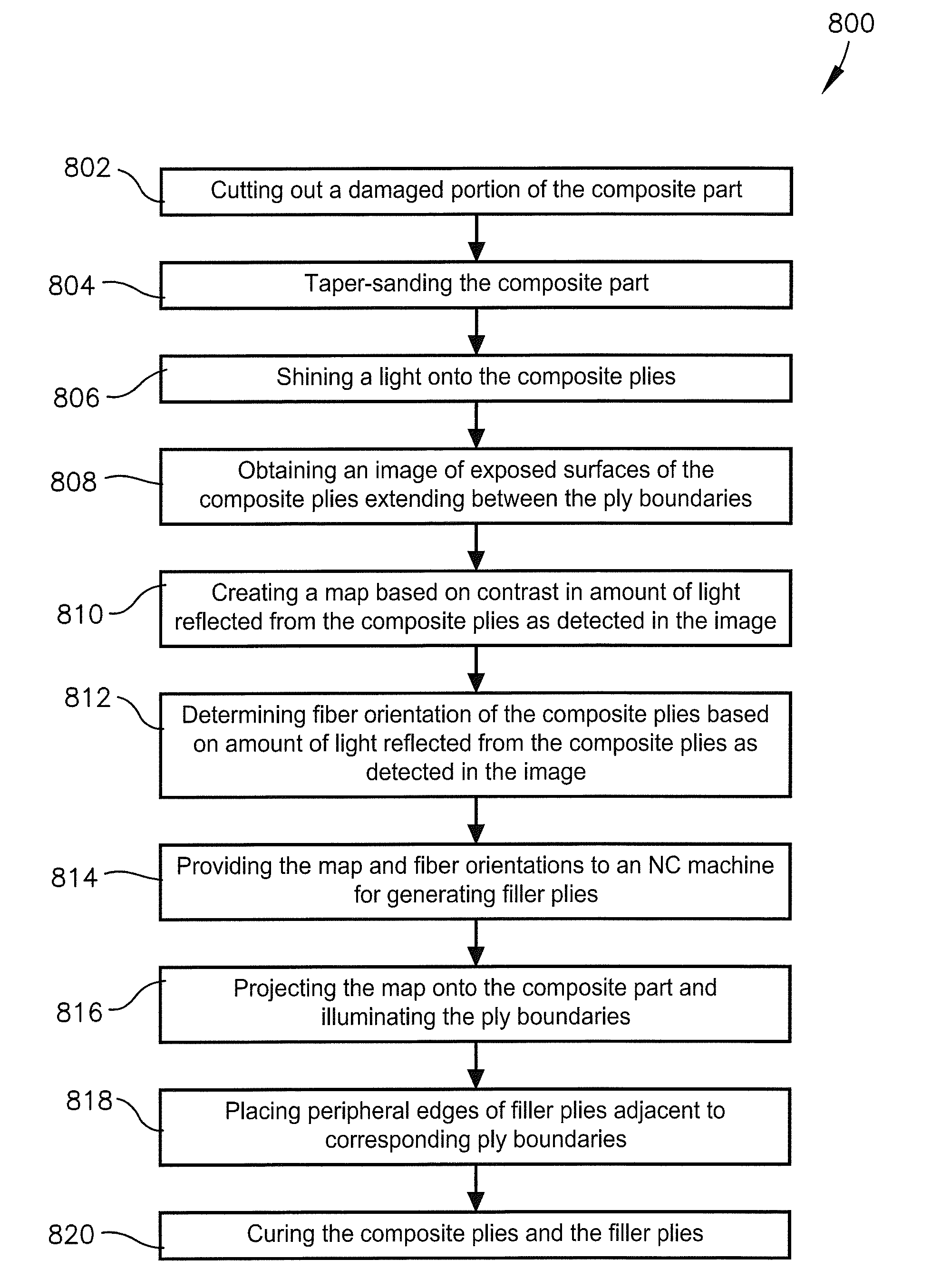

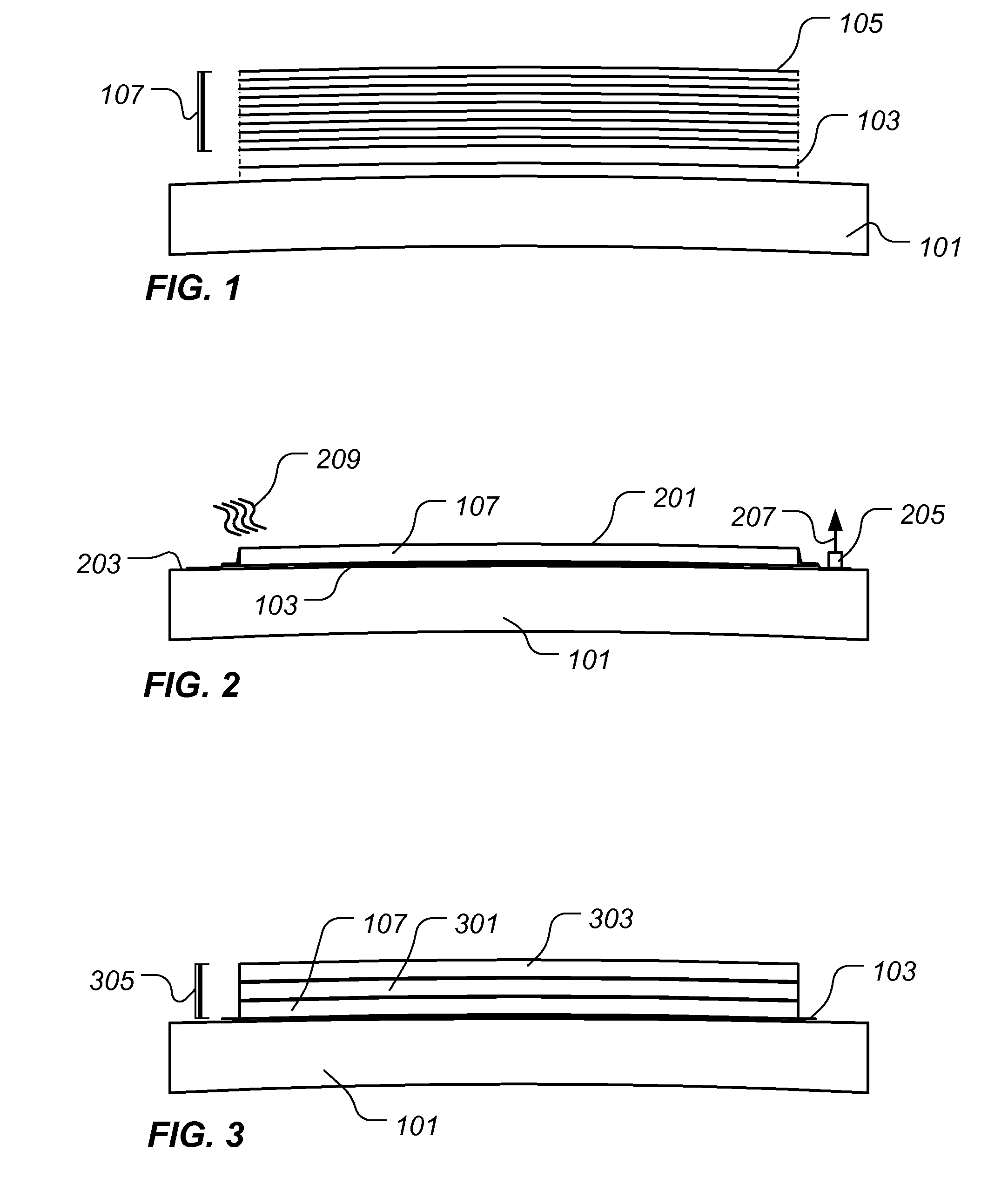

A composite repair system and method for assisting in the repair of a cured composite part in which a damaged portion has been cut out and removed, exposing a plurality of composite plies and their cut edges, which are then taper sanded to expose a plurality of taper-sanded surfaces and their corresponding ply boundaries. The ply boundaries may be traced by a user with a marking device. The composite repair system may comprise an image capturing device to obtain an image of the traced ply boundaries and a computing device for processing creating a map of the traced ply boundaries based on the image. The map may be used to manufacture filler plies having peripheral edges shaped to correspond with the ply boundaries for replacing the damaged portion of the composite part.

Owner:SPIRIT AEROSYSTEMS

System and method for repairing composite parts

ActiveUS8218852B2Exact matchPhotomechanical apparatusMaterial analysis by optical meansComputer graphics (images)Edge based

A composite repair system and method for assisting in the repair of a cured composite part in which a damaged portion has been cut out and removed, exposing a plurality of composite plies and their corresponding composite ply edges. The composite repair system may comprise a light source to illuminate the ply edges, an image capturing device to obtain an image of the ply edges, and a computing device for processing the image of the ply edges and creating a map of the ply edges based on the image. The map may be used to manufacture filler plies having peripheral edges shaped to correspond with the composite ply edges for replacing the damaged portion of the composite part.

Owner:SPIRIT AEROSYSTEMS

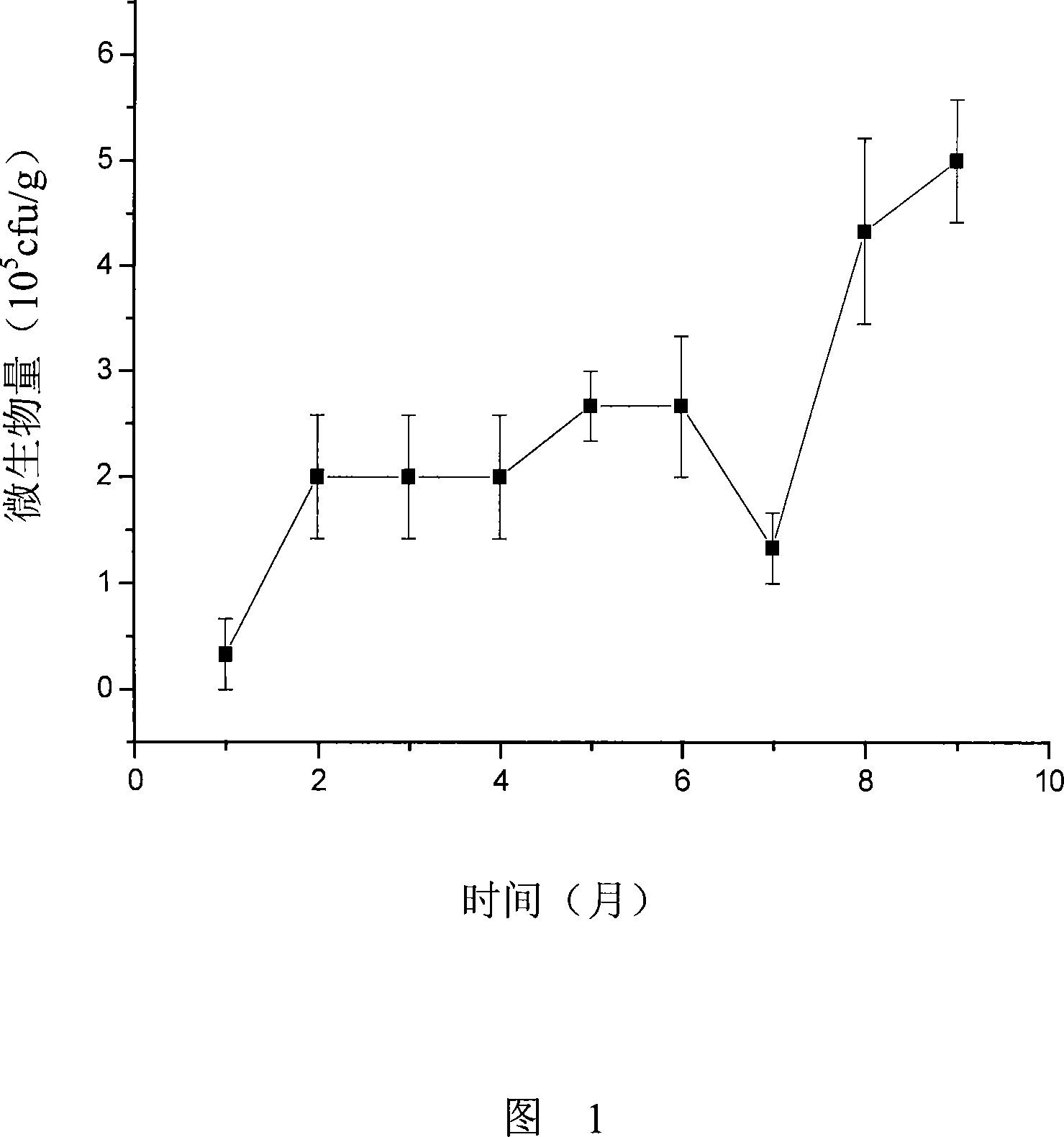

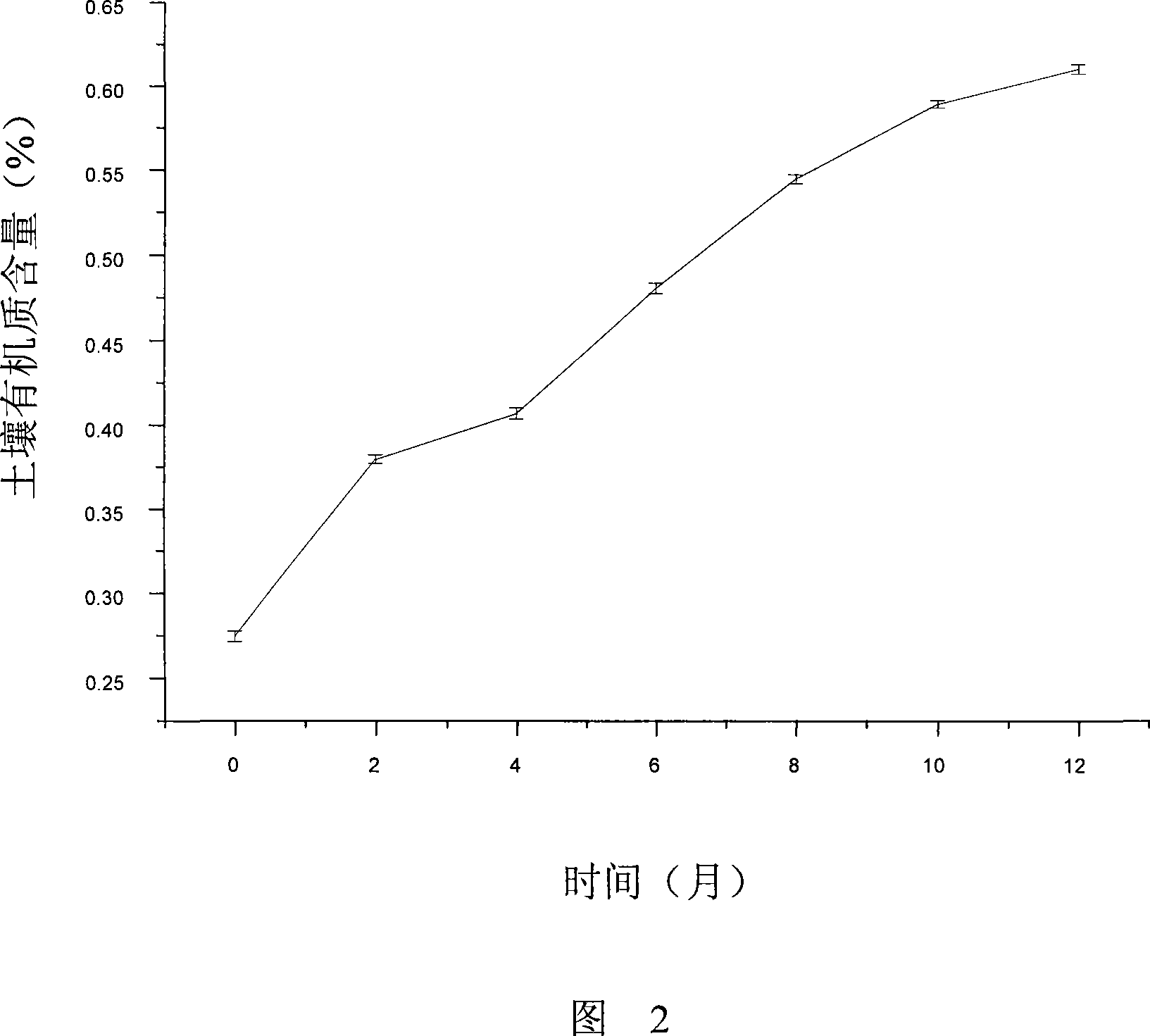

Biological modification method for sand desertification soil

InactiveCN101182418AIncrease diversityHigh organic contentAgriculture tools and machinesOrganic fertilisersSummer seasonMicrobial agent

The invention discloses a method for biological improvement of sand degraded soil. The method adopts the soil restoration preparation compounded by humic acid and microbial agent, which is covered and applied to the degraded sandy soil where licorice is planted after the beginning of spring and before the arrival of summer, and is managed in the field for 1 to 2 years. The invention can rapidly increase the organic matter content of the soil, increase the types and quantities of microorganisms in the soil, thereby improving the ecological environment of the soil, and achieving the purpose of improving sand degraded soil.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

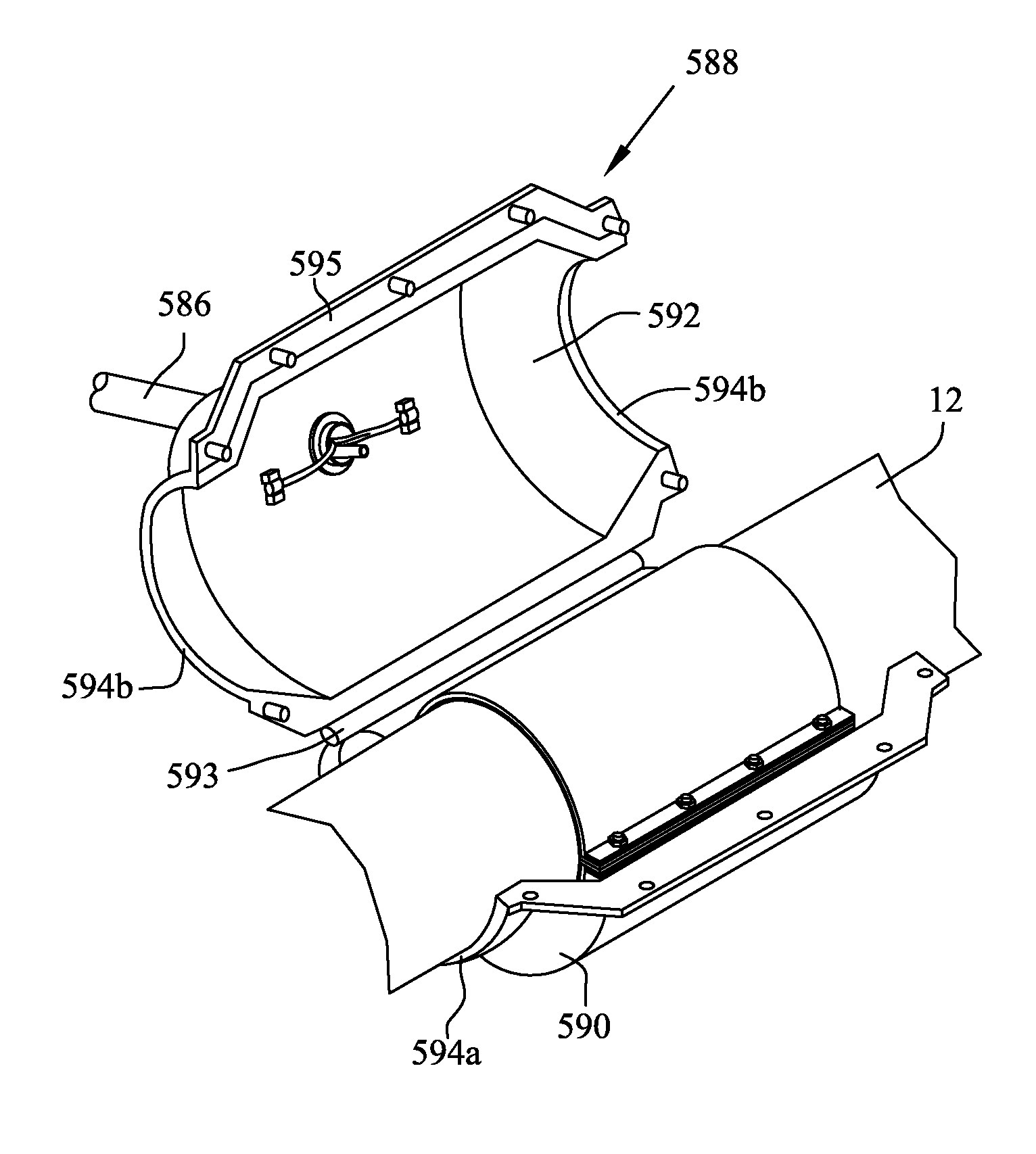

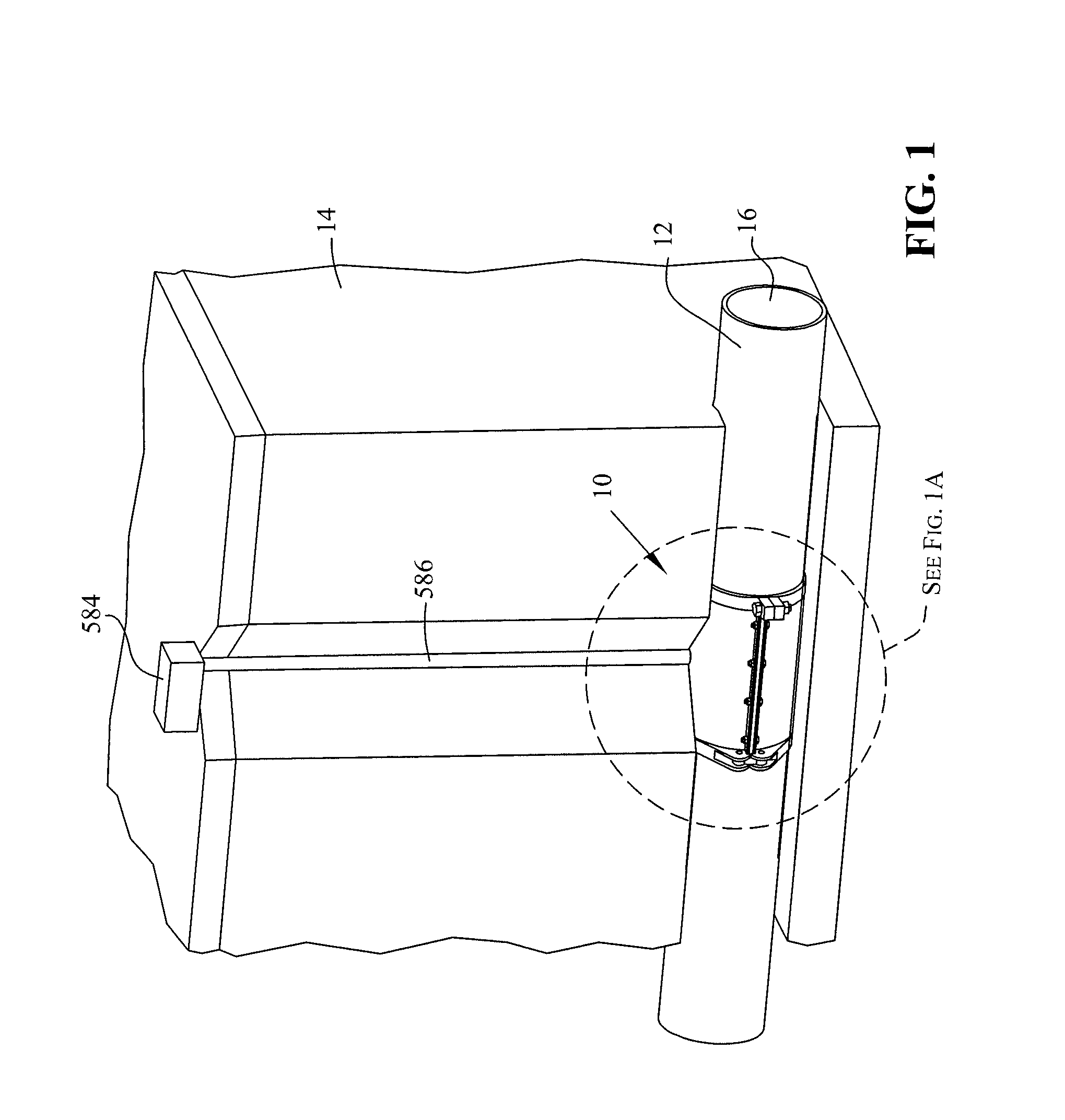

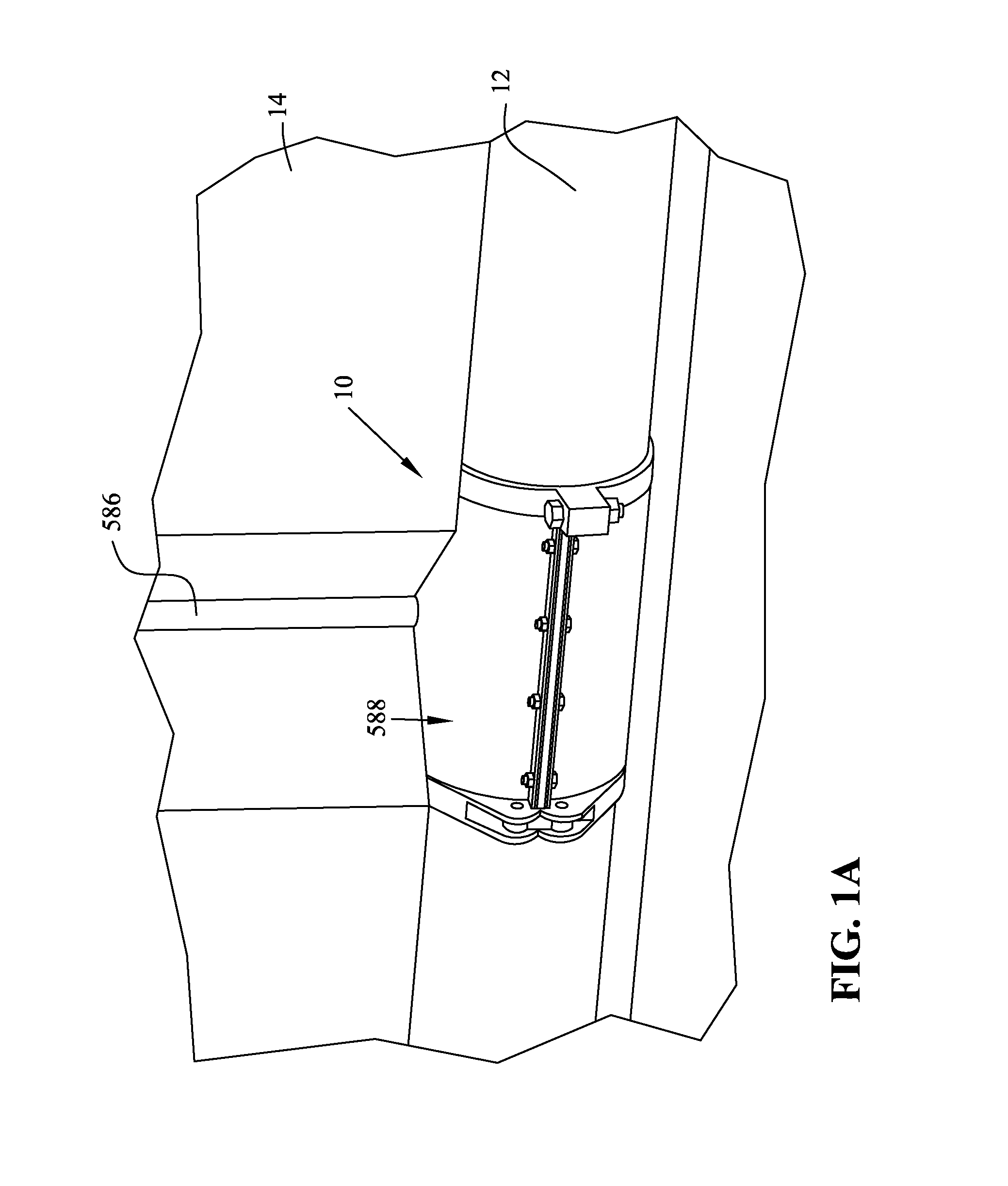

Composite repair for pipes and monitoring assembly

InactiveUS8631829B1Good dispersionHigh densityDetection of fluid at leakage pointPipe elementsMonitoring systemFluid - substance

A method and assembly for monitoring at least one condition outside of a containment device containing a gaseous or fluid substance and an inlet and outlet attached to the containment device. The method includes the steps of providing a monitoring system having a housing surrounding the containment device extending an inlet and outlet through openings in the housing; sealing the housing and sealing around the inlet and outlet so that a cavity internal to the housing is sealed from the exterior environment; providing at least one sensor located in the cavity between the containment device and the housing; connecting the sensor to a unit for monitoring the sensor; sensing at least one parameter indicative of a leak or potential leak of the containment device or attachment of the containment device to the inlet or outlet; and providing alerts of the leak or potential leak.

Owner:ODYSSIAN TECH

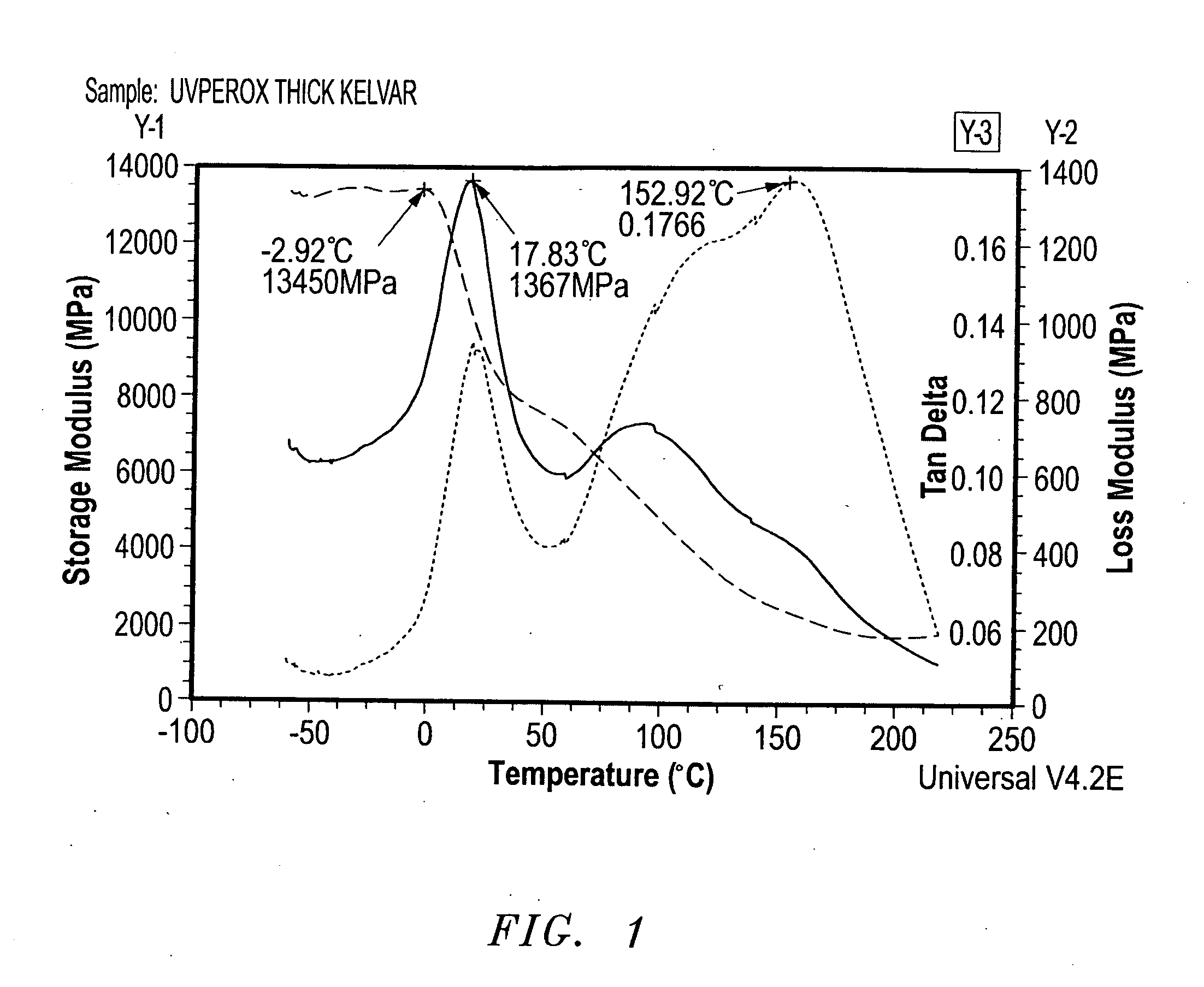

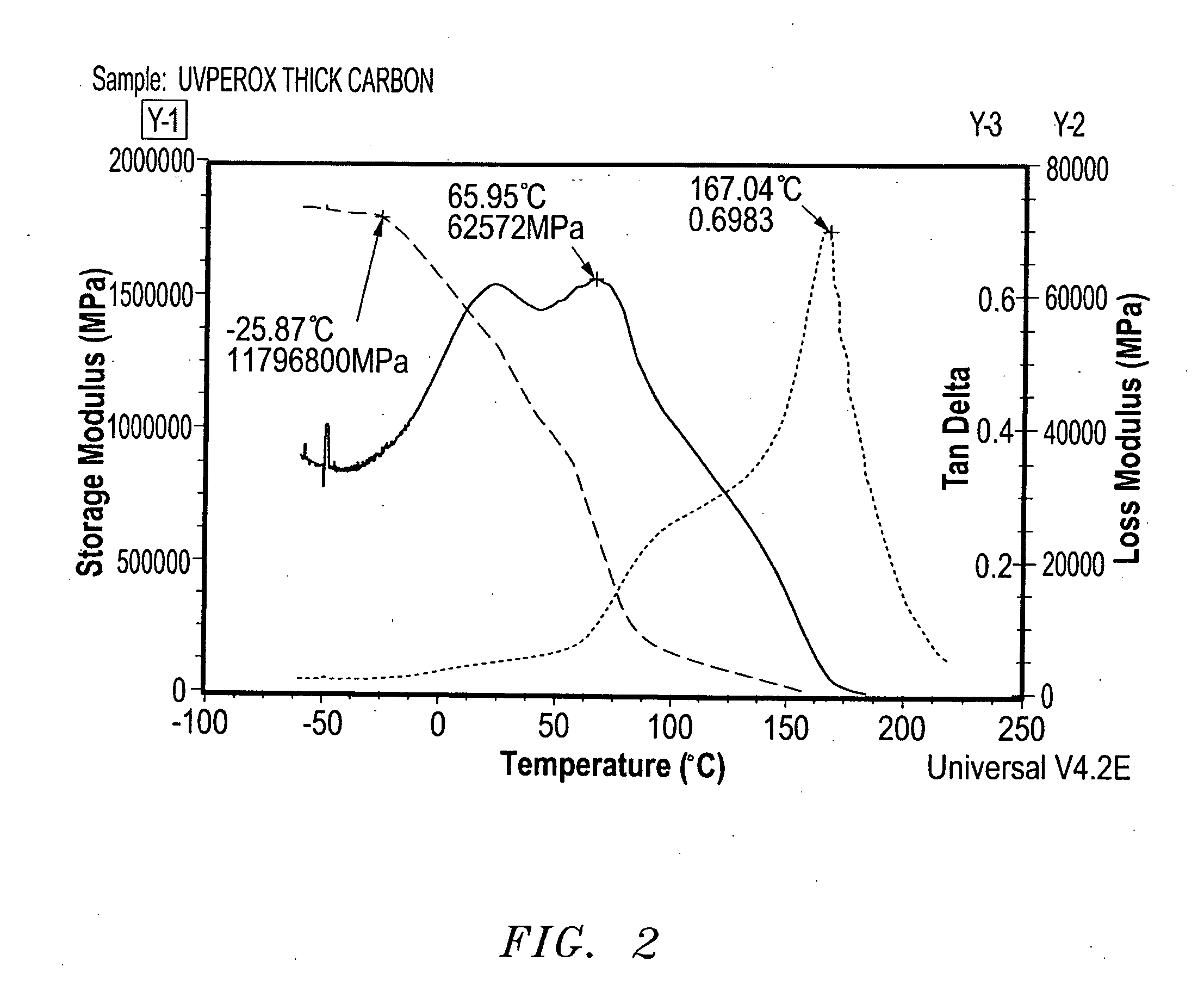

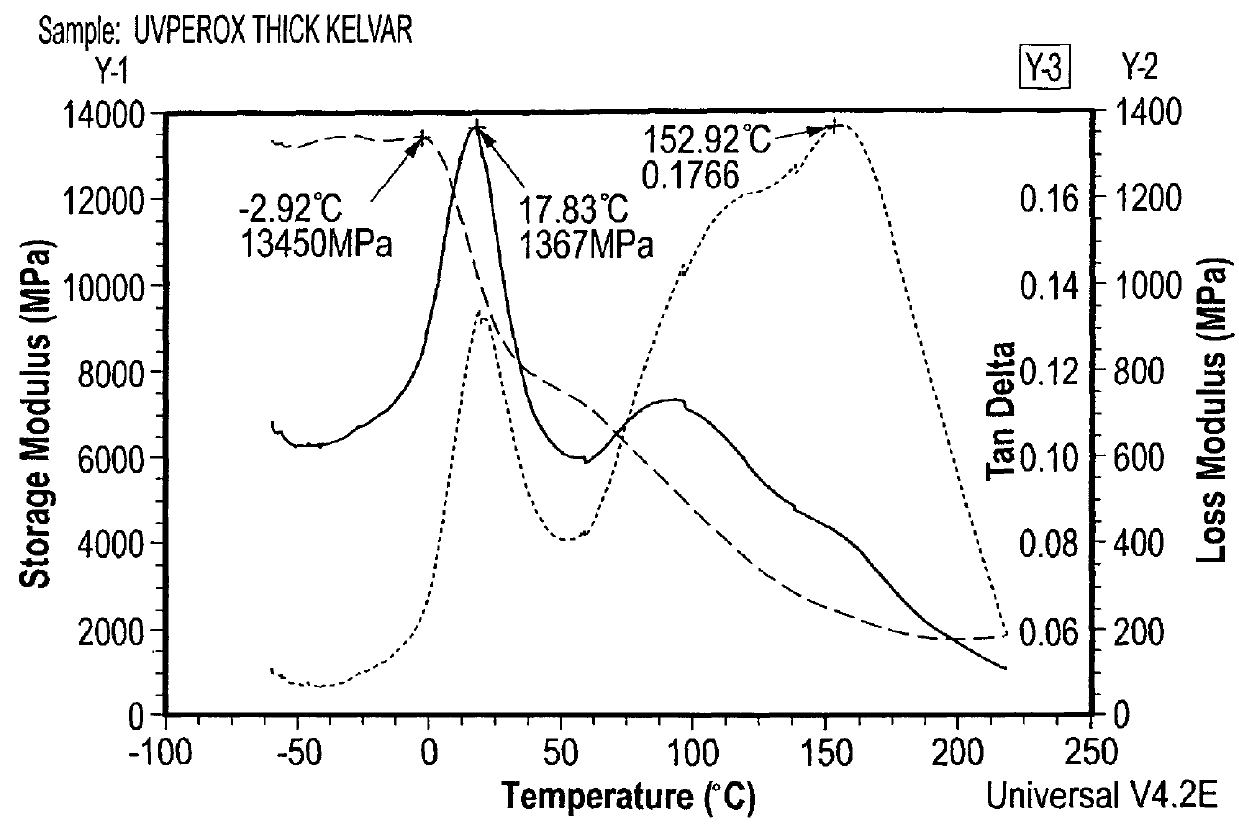

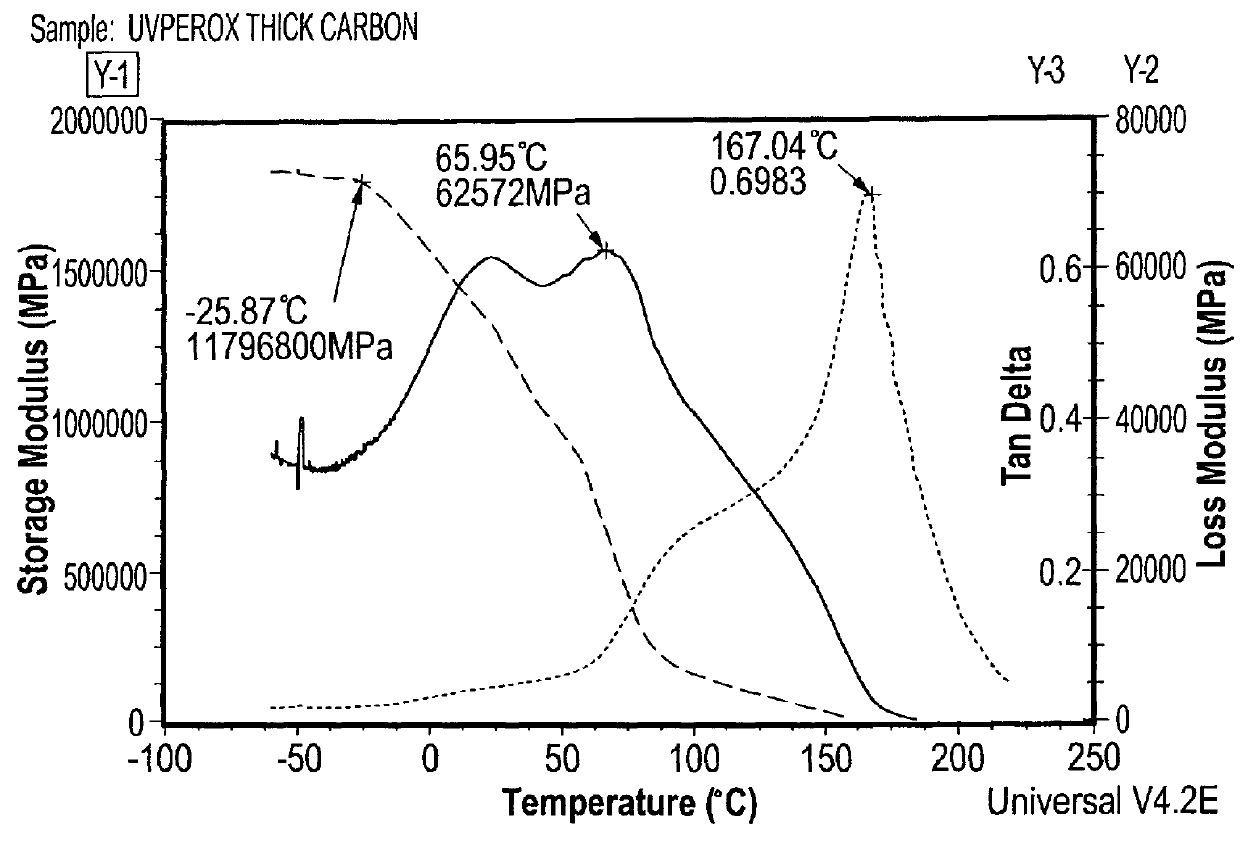

Ultraviolet light curing compositions for composite repair

Methods and compositions concerning an ultraviolet light curable formulation useful for repairing composite materials including the repair of a hole in the exterior of an airplane. The formulation may contain an acrylic oligomer, an acrylic monomer, an organic peroxide, a dialkylaniline promoter, a photoinitiator. The formulation can include a filler such as carbon fabric or Kevlar fabric.

Owner:TEXAS RES INT

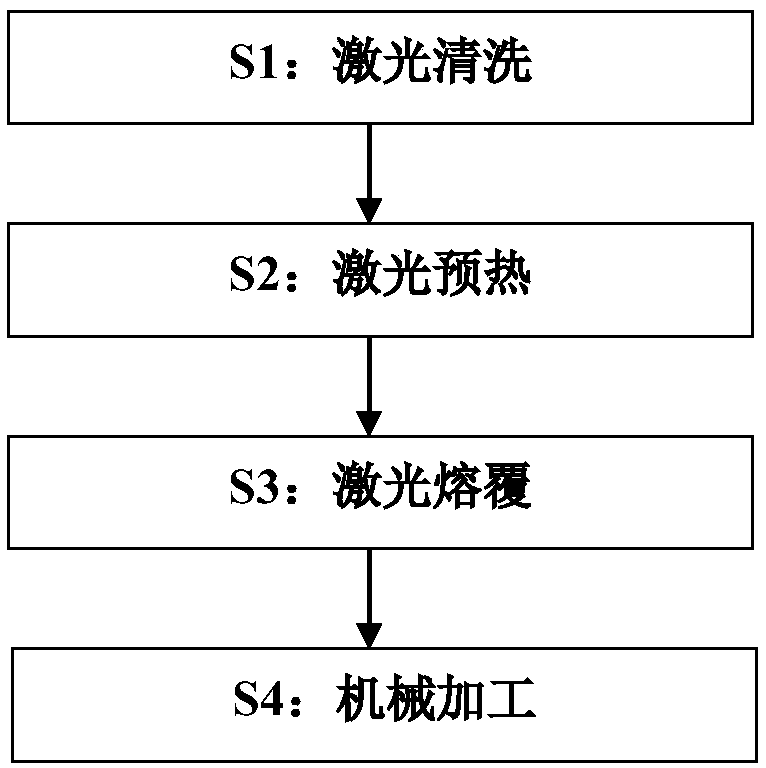

Laser cladding composite repair manufacturing method and application thereof

InactiveCN109385631AEnsure safetyReduce volumeMetallic material coating processesCleaning processes and apparatusOptoelectronicsMachining

The invention relates to a laser cladding composite repair manufacturing method. The method comprises the steps as follows: step 1, laser cleaning; step 2, laser preheating: continuously irradiating the surface of a to-be-repaired workpiece by a laser unit to preheat the to-be-repaired workpiece, marking emergent laser of the laser unit as preheating laser, wherein the spot shape of the preheatinglaser is round or rectangular, the area of preheating spots is 6 mm<2>-20 mm<2> and the scanning speed of the preheating laser spots is 8 mm / s-20 mm / s; step 3, laser cladding: irradiating the preheated to-be-repaired workpiece by cladding laser, wherein the spot shape, spot area and scanning speed of cladding laser are identical with those of the preheating laser; step 4, machining. The inventionalso relates to an application of the laser cladding composite repair manufacturing method. The method can be applied to repair manufacturing of high-carbon steel workpieces and high-alloy steel workpieces; laser is used as machining means, so that the method is clean, efficient, green and environmentally friendly.

Owner:山东泰利先进制造研究院有限公司

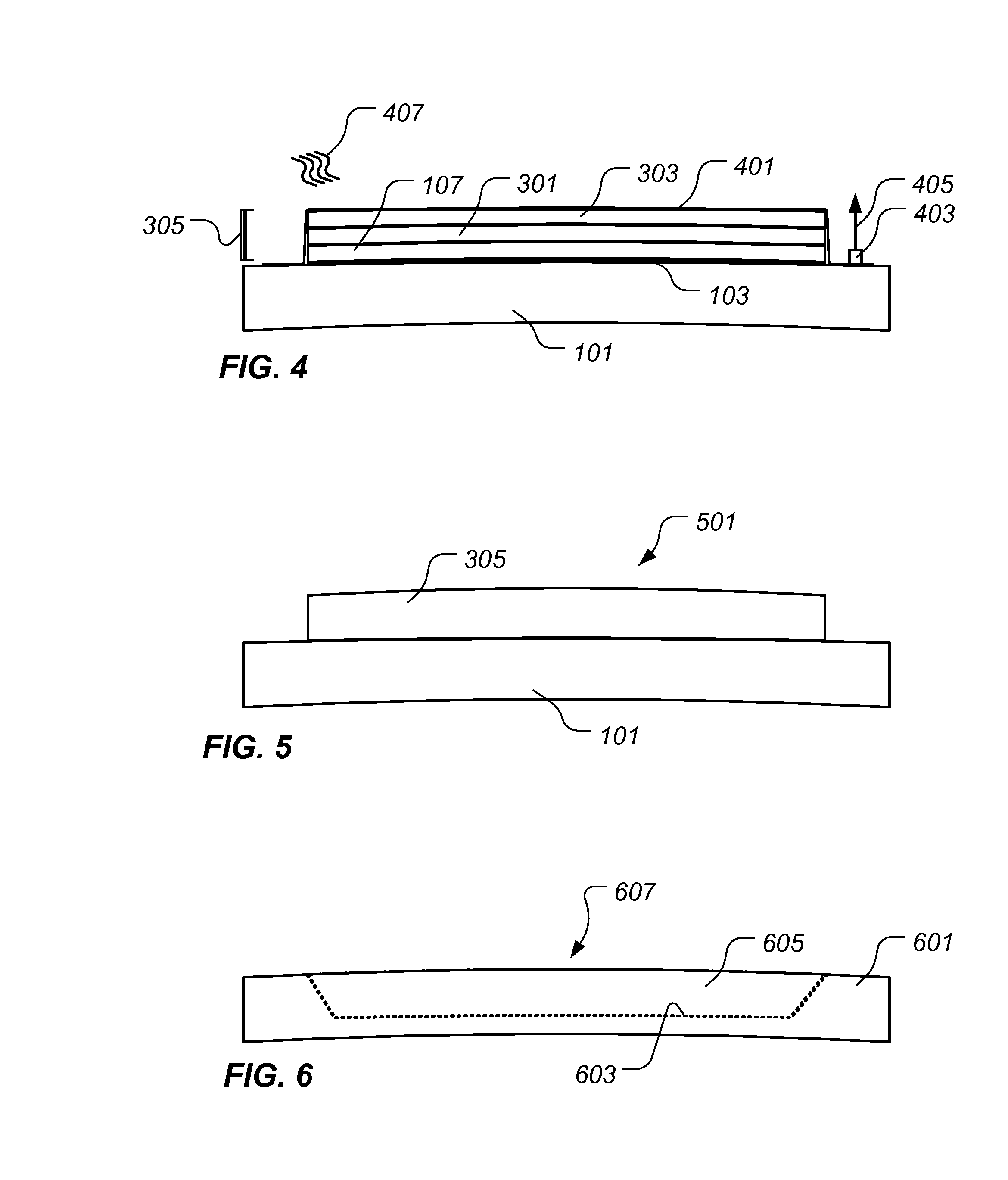

Multi-Stage Debulk and Compaction of Thick Composite Repair Laminates

A method for fabricating a repair laminate for a composite part having an exposed surface includes applying a release film to the exposed surface and forming an uncured ply stack assembly on the release film. The uncured ply stack assembly is formed by forming and compacting a series of uncured ply stacks. The release film and ply stack assembly is then removed from the exposed surface. A bonding material is then applied to the exposed surface, and the uncured ply stack assembly is applied to the bonding material. The ply stack assembly and bonding material are then cured.

Owner:TEXTRON INNOVATIONS

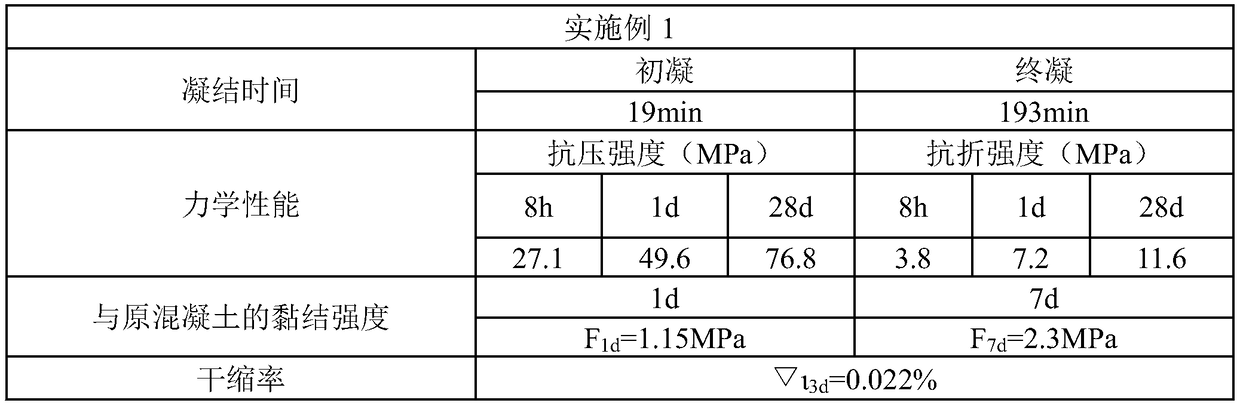

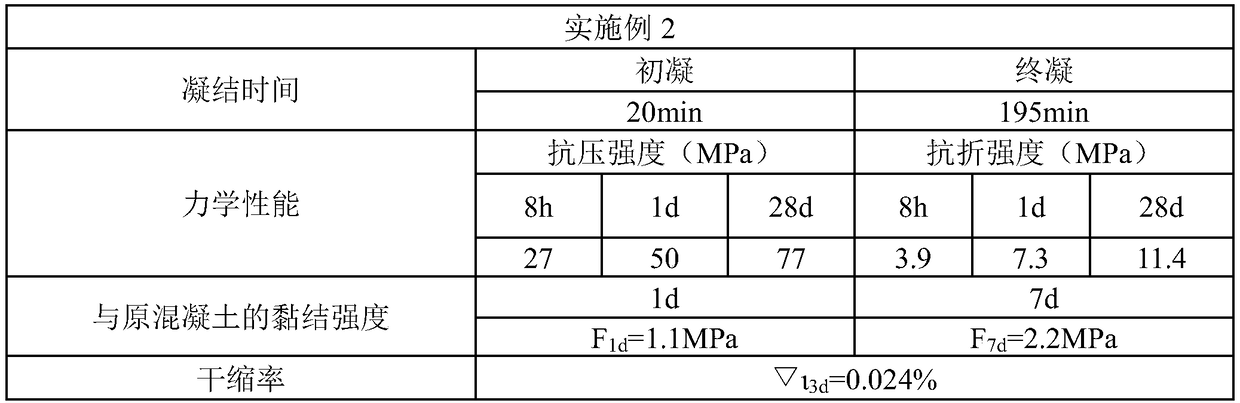

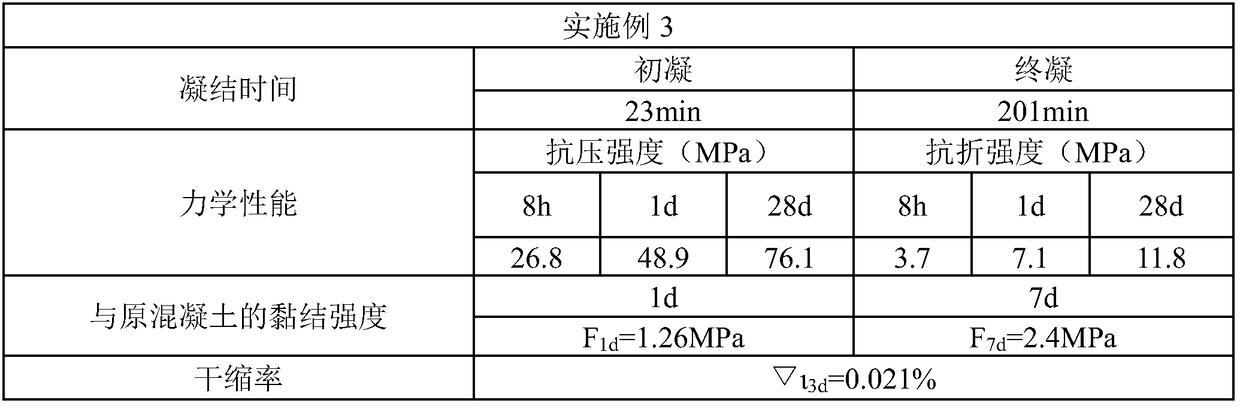

Cement-based rapid repair material with high early strength, and preparation method thereof

The invention discloses a cement-based rapid repair material with high early strength, wherein the cement-based rapid repair material is prepared from the following raw materials by mass: 500-650 parts sulphoaluminate cement, 200-400 parts of ordinary Portland cement, 800-900 parts of quartz sand, 4.5-9.0 parts of nanometer silicon dioxide, 0.25-0.6 part of a dispersing agent, 1.1-10.8 part of a water reducing agent, 0.045-0.160 part of a retarder, 0.10-0.25 part of a defoaming agent and 315-360 parts of water. The invention further provides a preparation method of the cement-based rapid repair material with improved early strength. According to the invention, the field preparation is convenient and easy, sulphoaluminate cement and Portland cement are compounded so as to ensure the early strength and the later strength, the microstructure of the composite repair system is obviously improved through the nanometer material, the early mechanical property of the cement-based material is remarkably improved, the driving quality and the driving safety of the repaired pavement are ensured, the repair cost is low, and the practicability is high.

Owner:GANSU ELECTRIC POWER DESIGN INST

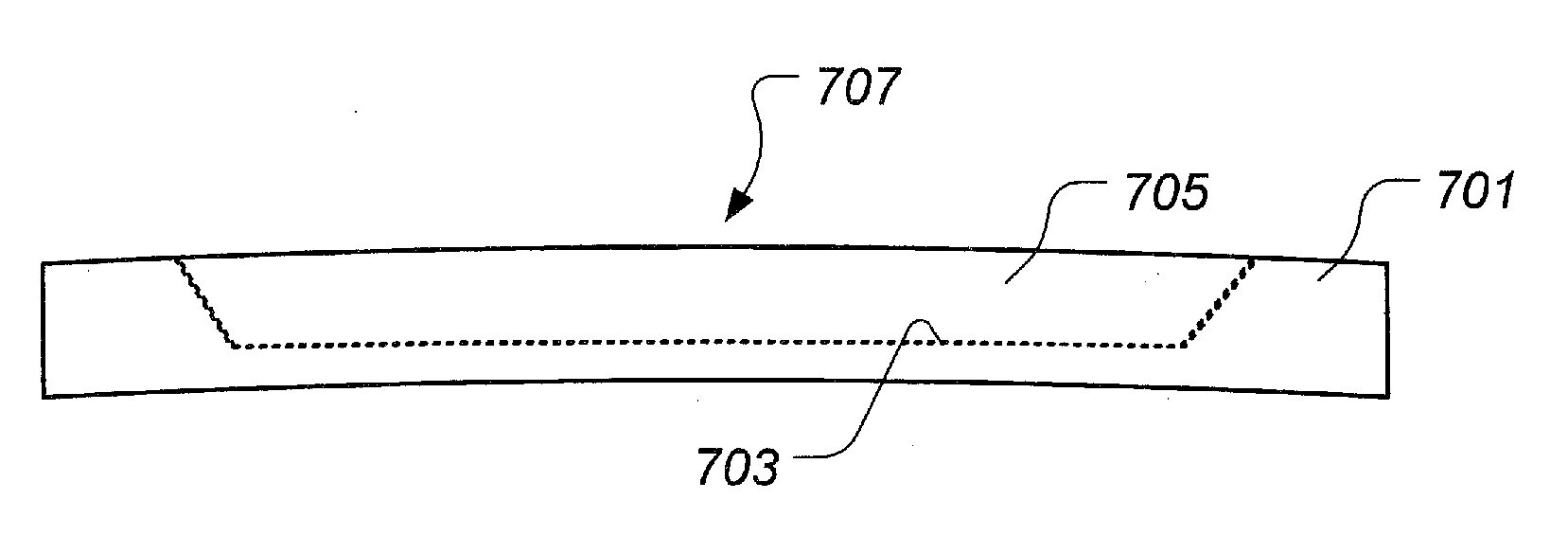

Repairing a contoured composite panel

Owner:THE BOEING CO

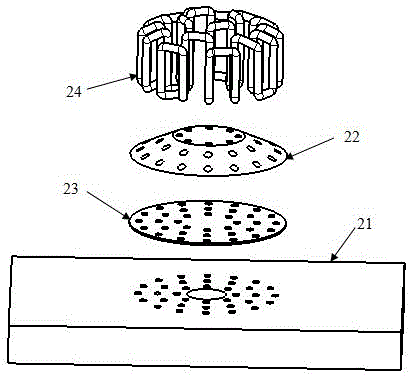

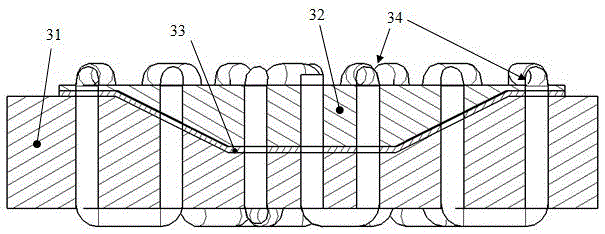

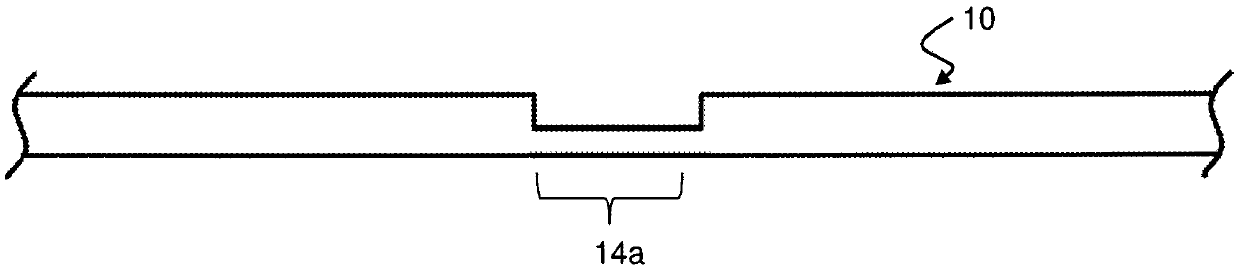

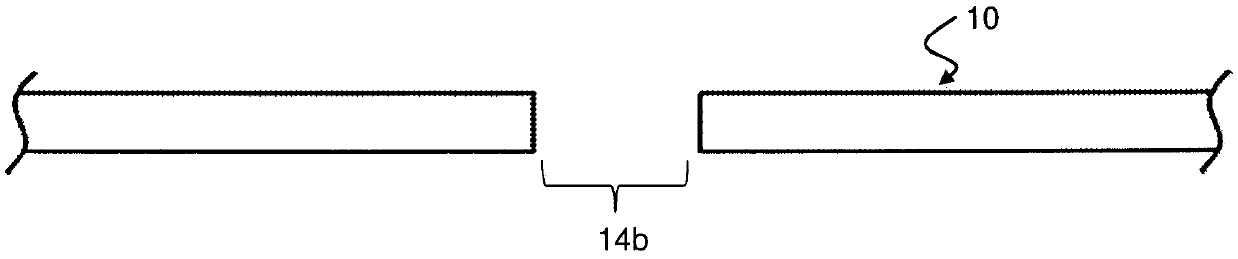

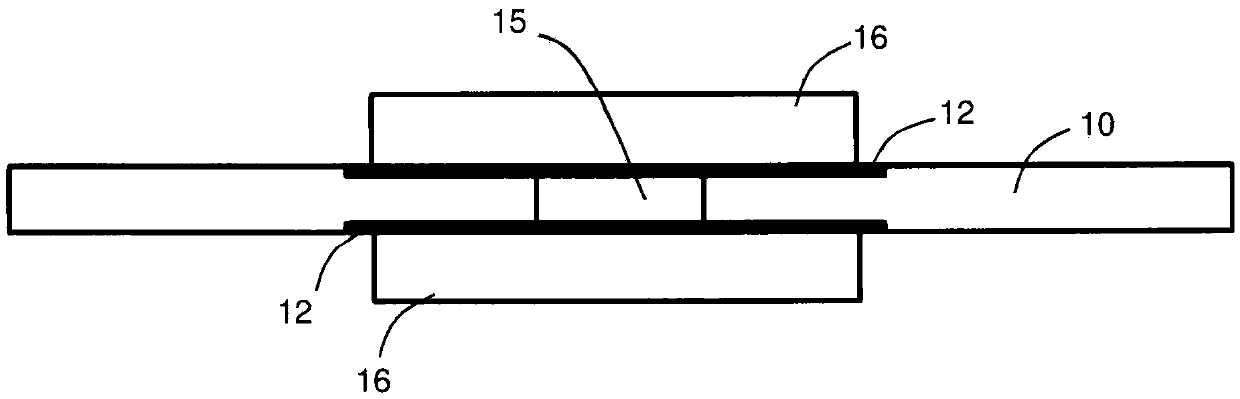

Repairing structure with composite repairing piece and method for forming repairing structure

InactiveCN105153950AReduce the risk of useLittle impact on performanceAdhesive processes with surface pretreatmentAdhesive processes with adhesive heatingPosterior compositesMechanical property

The invention discloses a repairing structure with a composite repairing piece and a method for forming the repairing structure and belongs to the technology of composite repairing. The repairing structure is composed of a repaired damaged composite structure, the composite repairing piece, glue between the composite repairing piece and the composite structure, and a sewing thread steeped with a cementing compound. Firstly, small holes penetrating through the repairing piece, the damaged composite structure and a glue layer between the repairing piece and the damaged composite structure are machined in a repairing piece repairing part; secondly, the sewing thread steeped with the cementing compound sequentially penetrates into the small holes; lastly, curing is carried out at the regulated temperature and pressure, so that the sewing thread are bonded to the repairing piece around the sewing thread and the damaged composite structure together, and thus the repairing structure with the repairing piece is formed. By means of the repairing structure formed through the method, the influence on the performance in a composite laminated plate face is small, the environmental sensitivity is reduced, and the weight of the structure is slightly increased; in addition, the bonding effect between the composite repairing piece and the repaired structure can be improved, so that the mechanical property and the reliability of the repairing structure with the composite repairing piece are improved, and the use risk of the repaired composite structure is lowered.

Owner:刘龙权

Fast hardening early strength type composite repair mortar

The invention belongs to the technical field of a building material, and provides fast hardening early strength type composite repair mortar. The mortar is prepared from the following ingredients in percentage by weight: 5 to 10 percent of water, 20 to 30 percent of cement, 1 to 5 percent of silicon ash, 1 to 5 percent of fly ash, 50 to 70 percent of quartz sand, 0.4 to 0.5 percent of compound early strength agents, 0.06 to 0.1 percent of water reducing agents, 1 to 5 percent of rubber powder and 0.06 to 0.8 percent of hybrid fiber, wherein the composite early strength agent is prepared from an ingredient A and an ingredient B; the ingredient A is lithium carbonate; the ingredient B is a mixture of triethanolamine and aluminum sulfate; the quartz sand consists of coarse sand, medium sand and fine sand; and the hybrid fiber consists of basalt fiber and polypropylene fiber. The fast hardening early strength type composite repair mortar solves the problems of reduced strength, high dry shrinkage rate and low bonding strength of the repair mortar in the prior art.

Owner:JILIN JIANZHU UNIVERSITY

Heavy metal polluted soil composite repair agent and soil repair method thereof

InactiveCN109575929AImplement resourcesAchieve recyclingContaminated soil reclamationOrganic fertilisersSorbentSludge

The invention discloses a heavy metal polluted soil composite repair agent and a soil repair method thereof, and belongs to the technical field of soil repairing. The invention provides the heavy metal polluted soil composite repair agent. The heavy metal polluted soil composite repair agent is prepared by the following method: heating sludge in high-temperature vacuum, and washing and drying thesludge to obtain sludge biochar; heating forestry and agricultural residues in high-temperature vacuum, and washing and drying the forestry and agricultural residues to obtain forestry and agricultural residue biochar; mixing the sludge biochar with the forestry and agricultural residue biochar; and mixing the mixed biochar with a sodium citrate solution, performing oscillating reaction, and washing and drying the solution at the end of the reaction to obtain the heavy metal polluted soil composite repair agent. According to the heavy metal polluted soil composite repair agent and the soil repair method thereof, the sludge and the forestry and agricultural residues are used as the raw materials; the two biochars are mixed in different proportions, so that the ash content and the carbon content of the composite adsorbent are increased; and by use of the sodium citrate solution for modification, the activity of the biochar is improved, so that the content of heavy metal elements in a biological use state in the soil is effectively reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

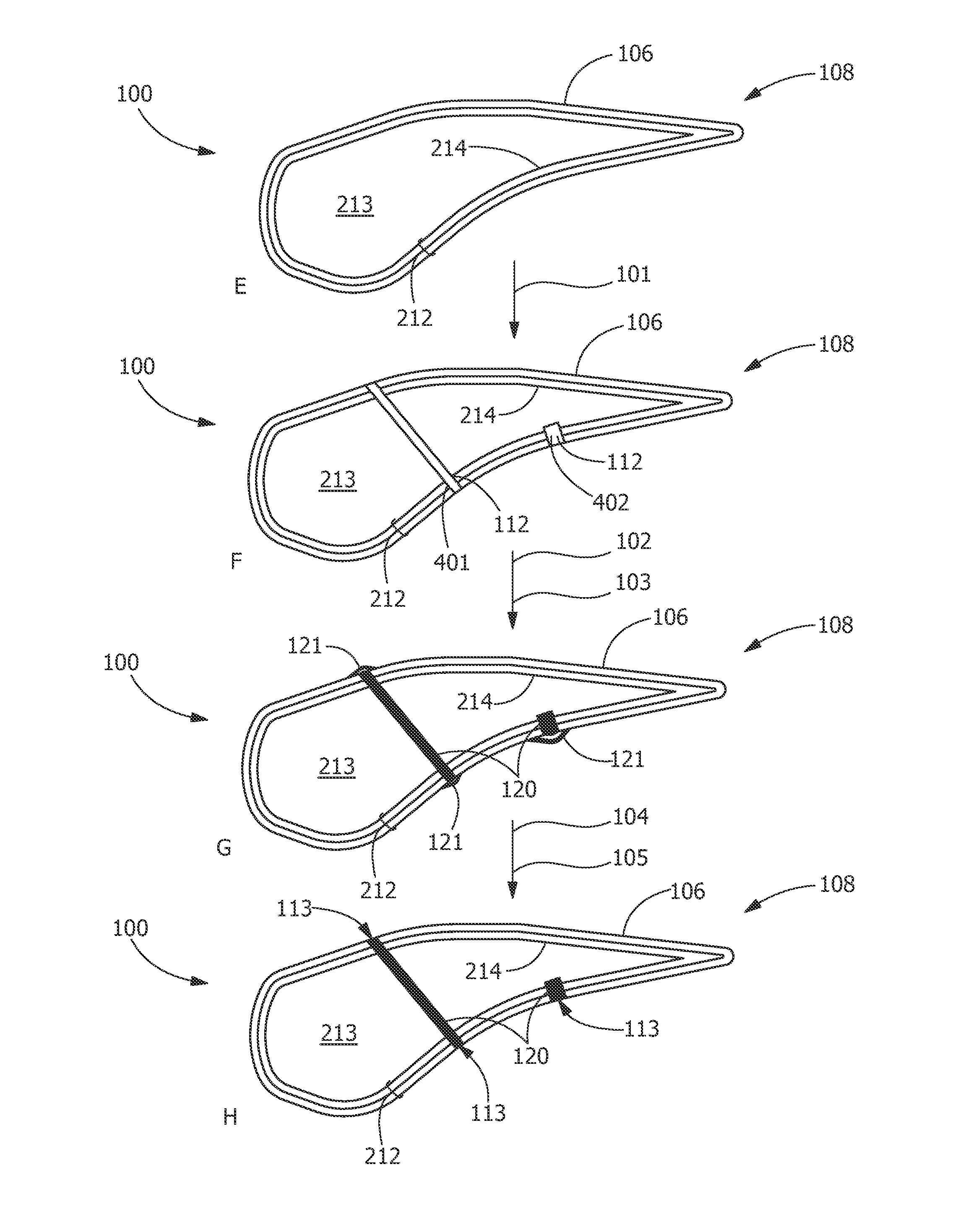

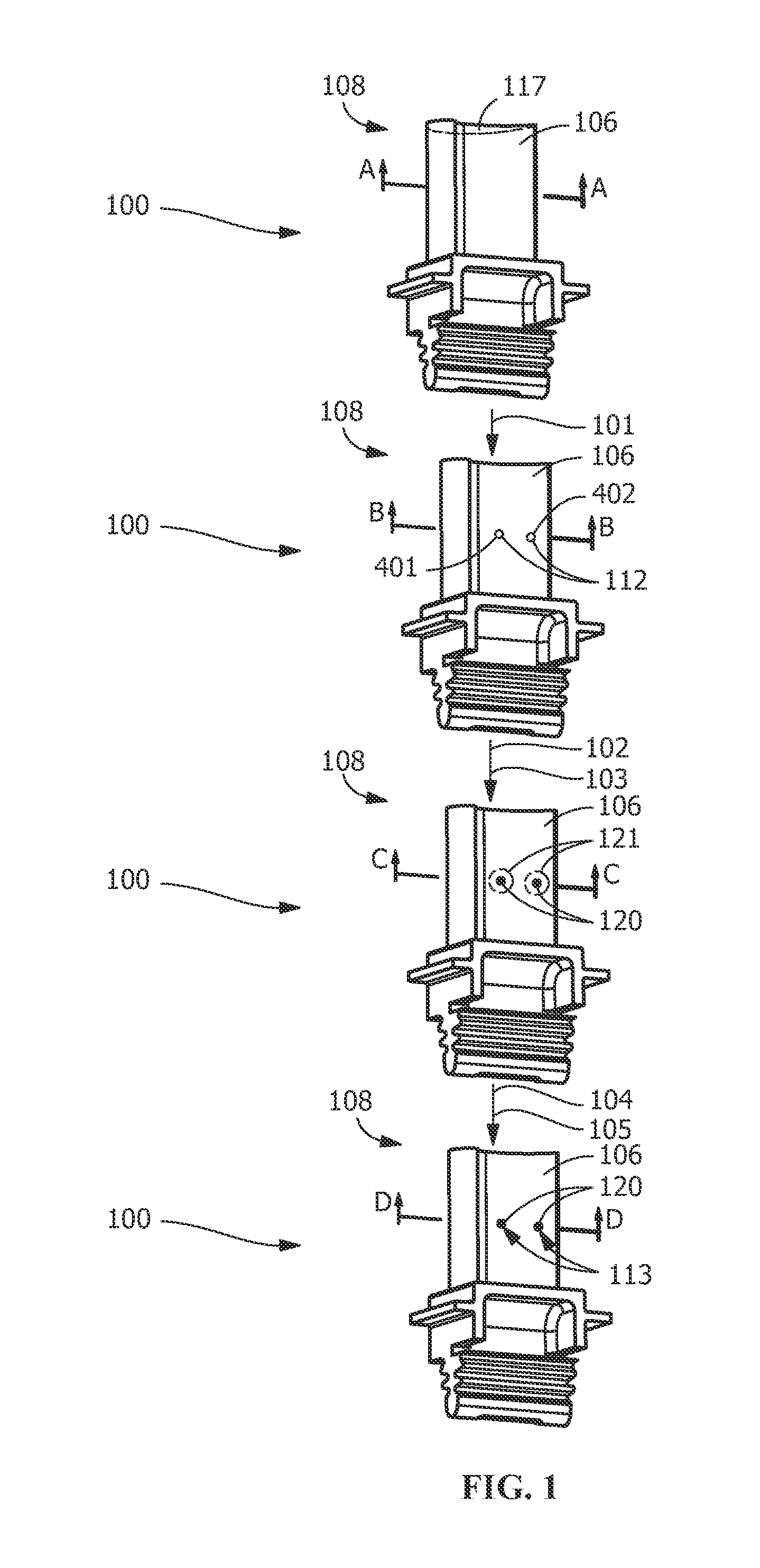

Mechanical interlocking realized through induction heating for polymeric composite repair

A method of repairing a polymeric composite workpiece. The method comprises identifying a localized area of the polymeric composite workpiece having a defect. A plurality of three dimensional interface structures are aligned adjacent at least a portion of the localized area. The method includes applying a polymeric composite patch to the localized area such that the interface structures are disposed between the polymeric composite workpiece and the polymeric composite patch. An alternating electromagnetic field may be introduced to selectively induce localized heating of the interface structures. The localized heating softens regions of the polymeric composite workpiece and the polymeric composite patch adjacent the interface structures, causing the interface structures to penetrate a distance into the respective polymeric composite workpiece and the polymeric composite patch.

Owner:GM GLOBAL TECH OPERATIONS LLC

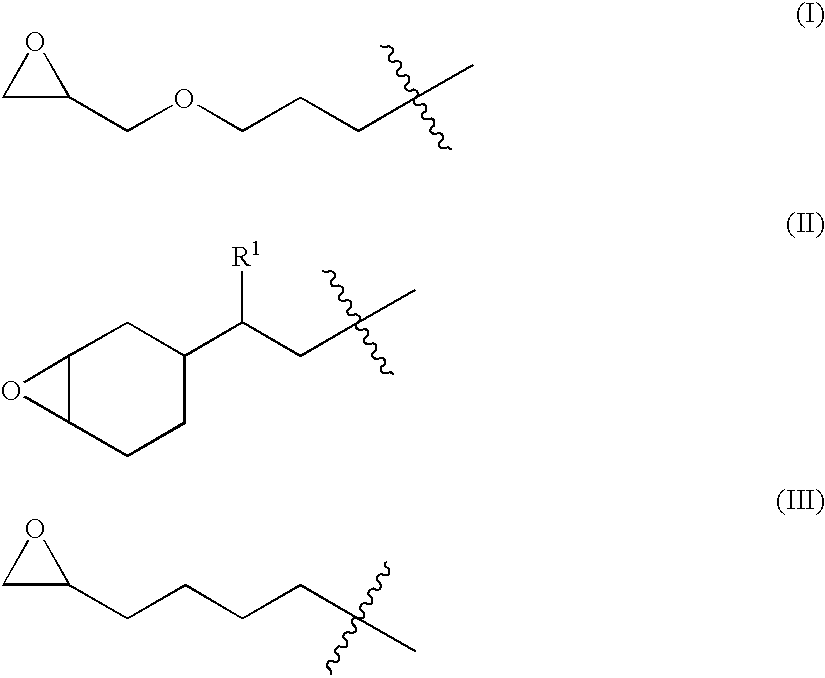

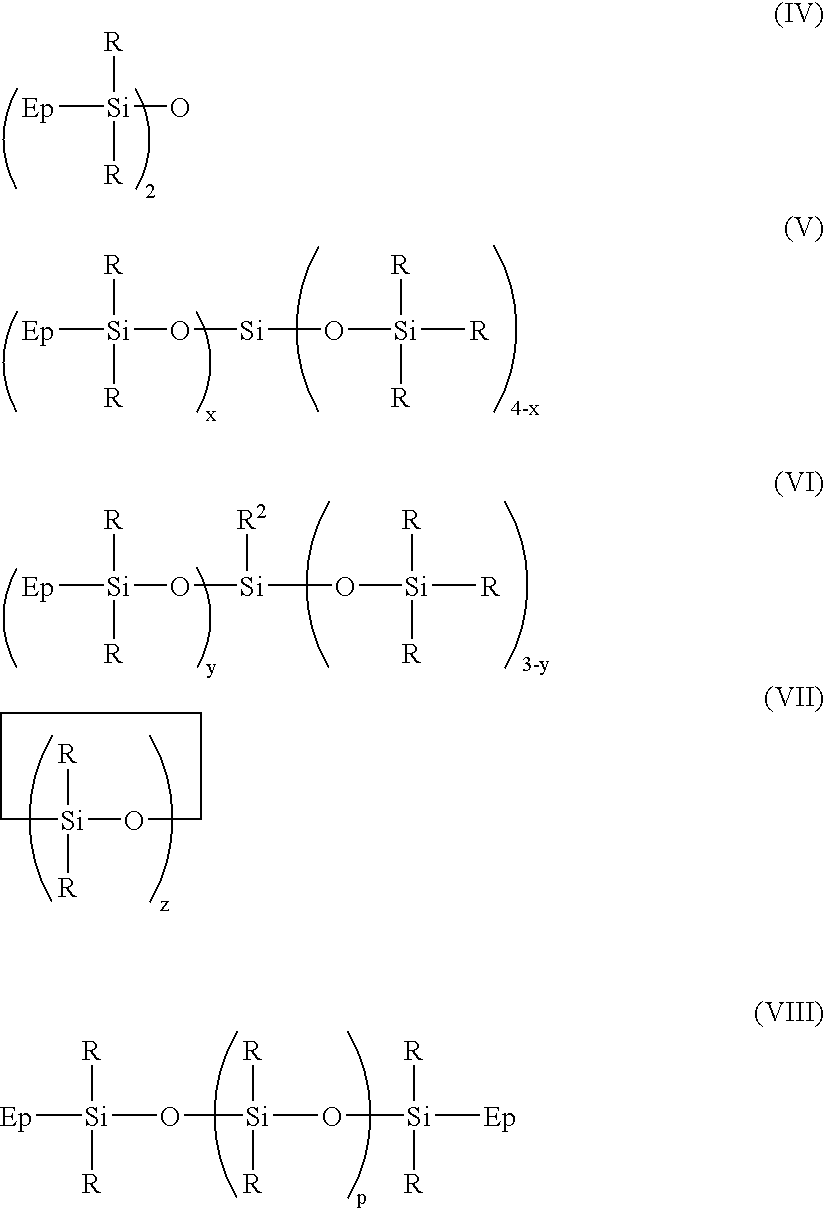

Thermally curable compositions and method

Disclosed are thermally curable compositions comprising at least one cyclic ether, an initiator selected from the group consisting of an iodonium salt, a sulfonium salt, an acylium salt, a tropylium salt, an oxonium salt, and combinations thereof, and a catalyst having structure Pd(Q)2, wherein Q is at least one ligand selected from the group consisting of a carboxylate, a halide, a ketoester, an ester, a ketone, an hydroxyl, and combinations thereof. Disclosed also are methods of curing the thermally curable compositions, and articles made therefrom. Curing methods comprise heating the composition to a suitable temperature for a period of time. Articles may comprise coated articles, shaped articles or shaped components. Compositions and methods may also be used for composite repair applications.

Owner:GENERAL ELECTRIC CO

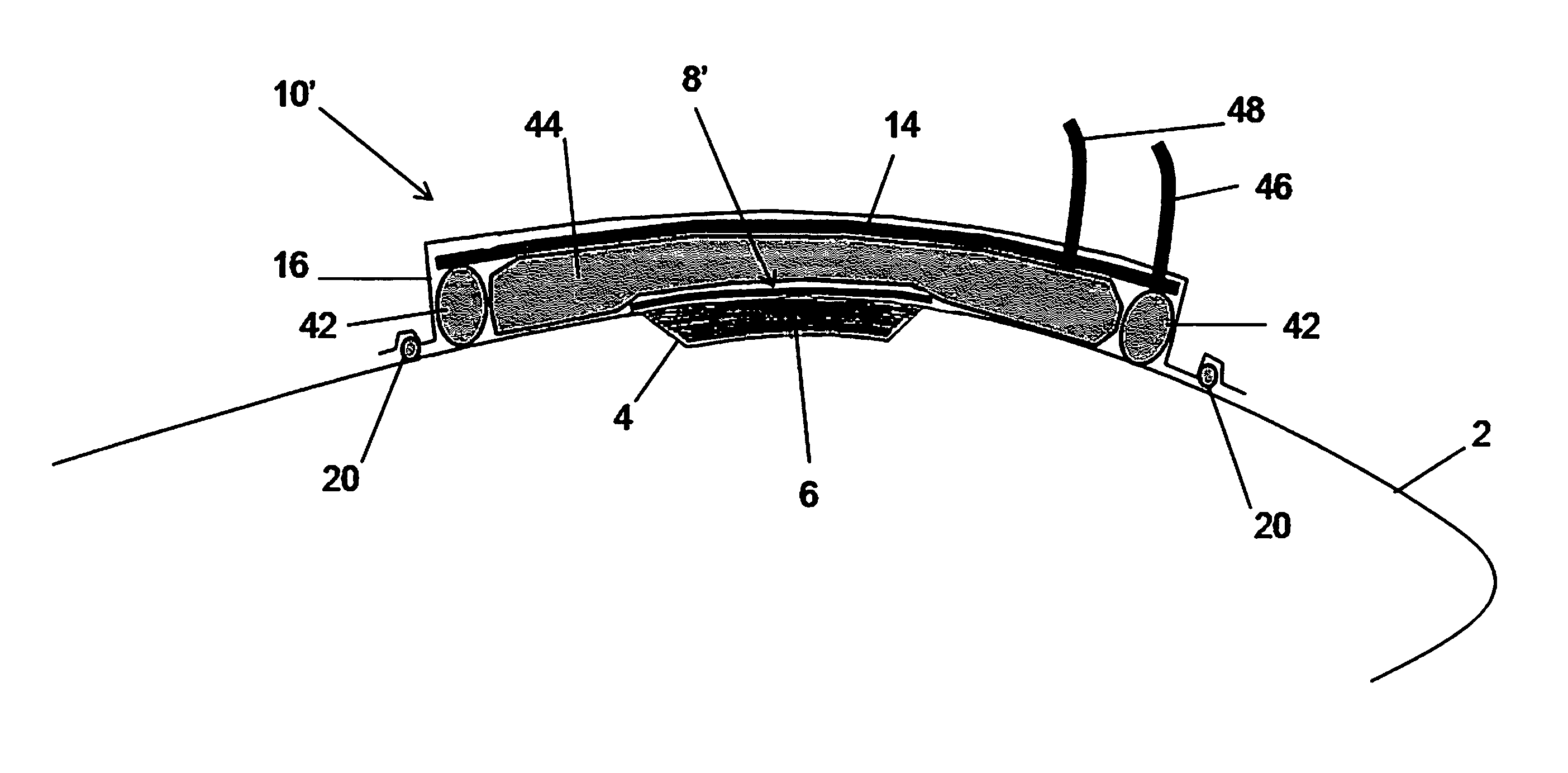

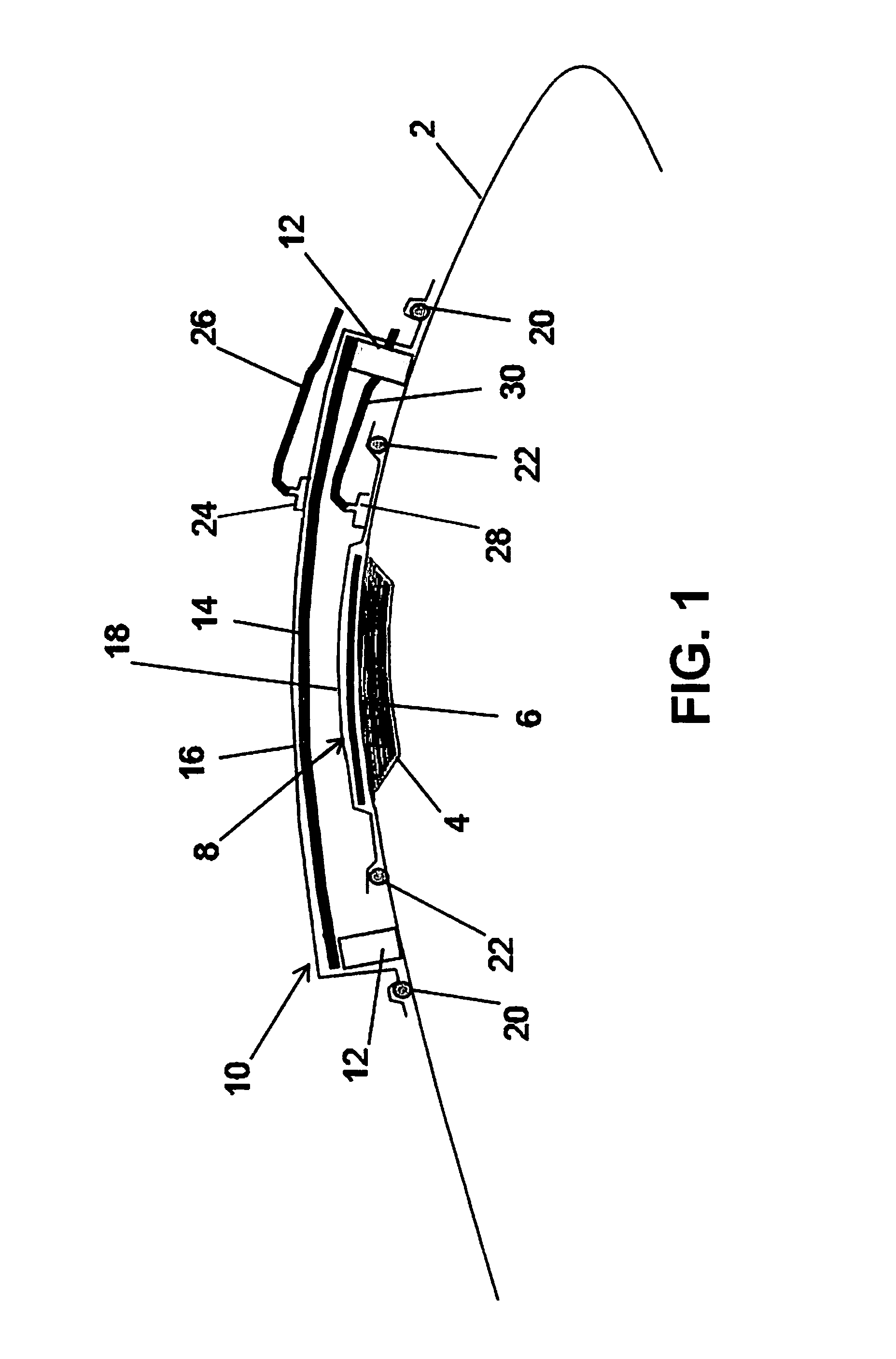

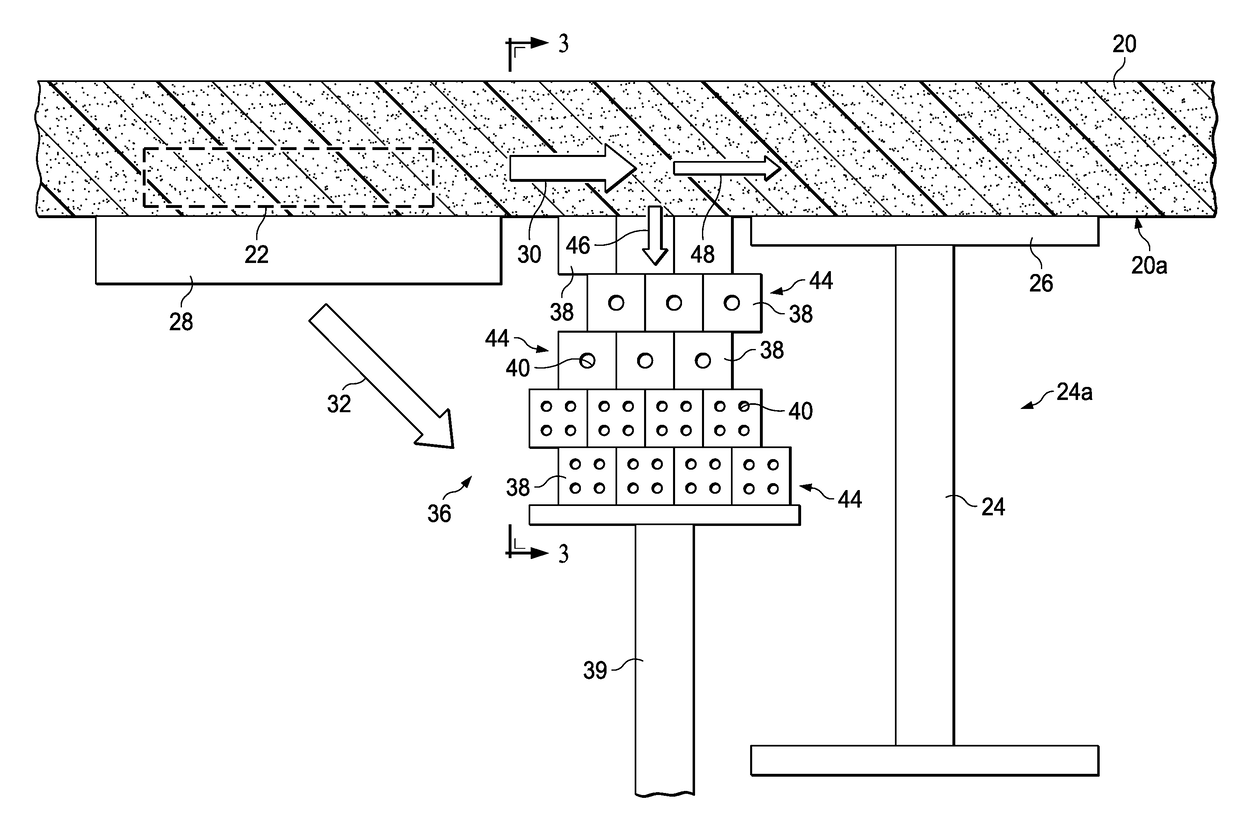

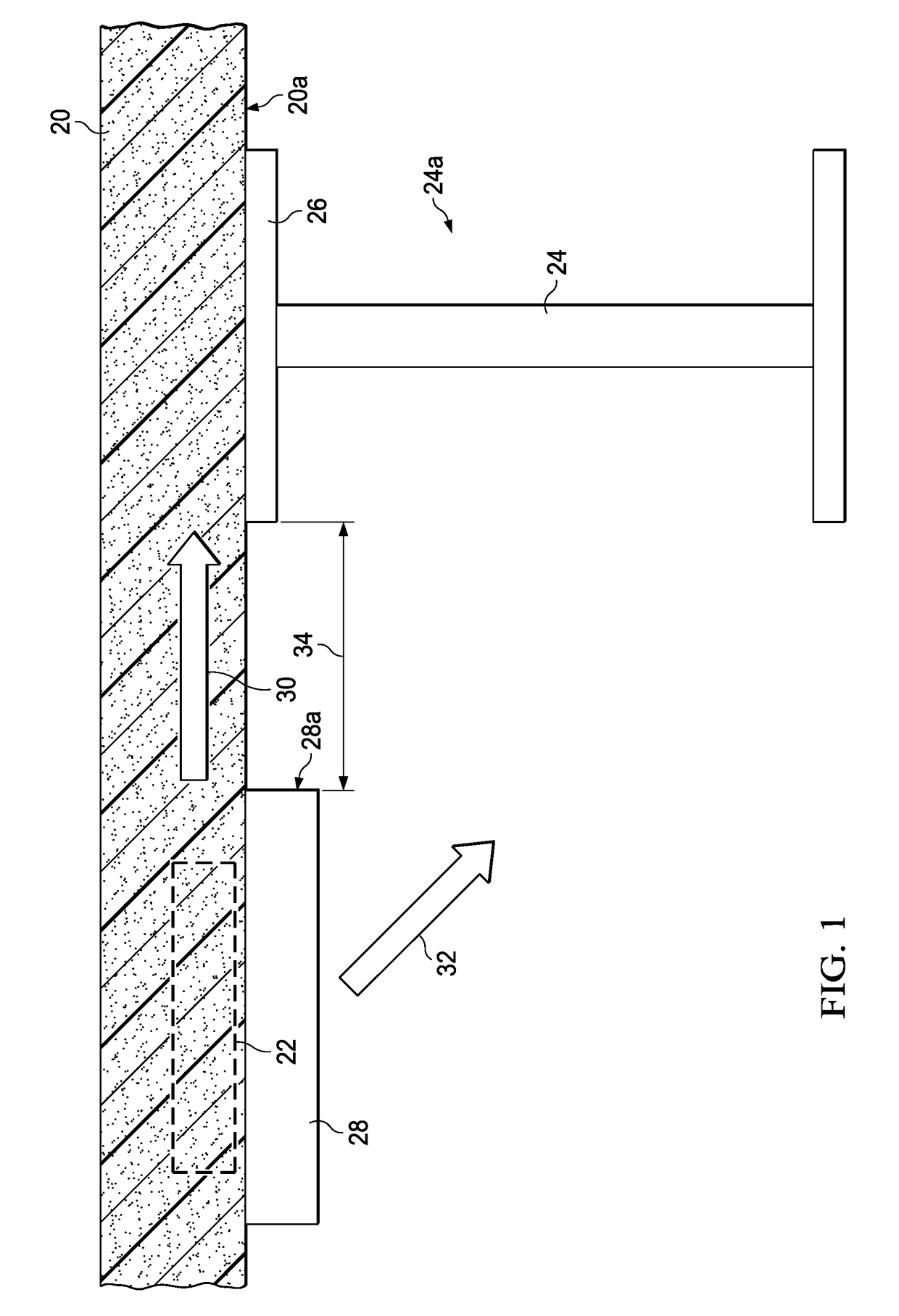

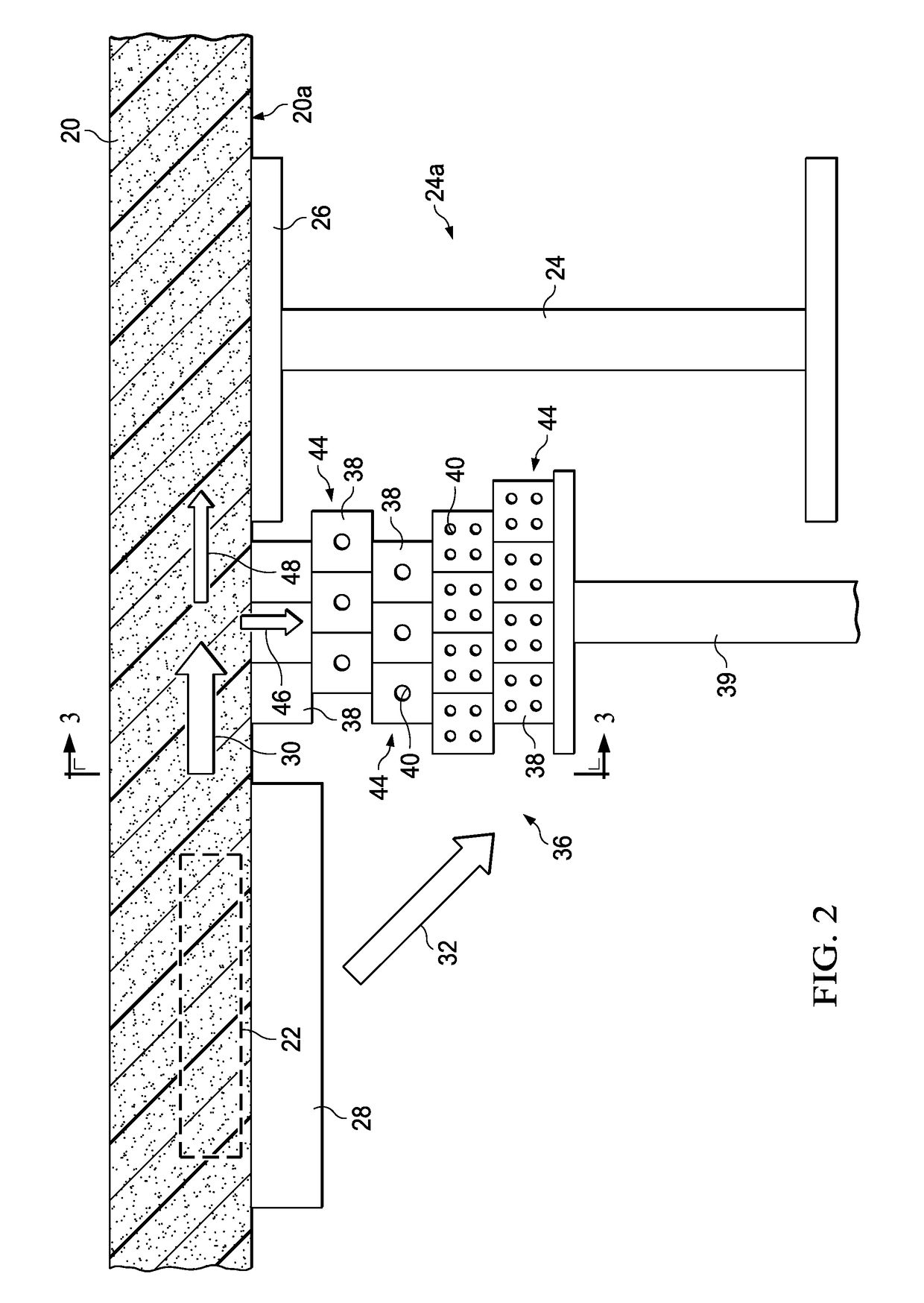

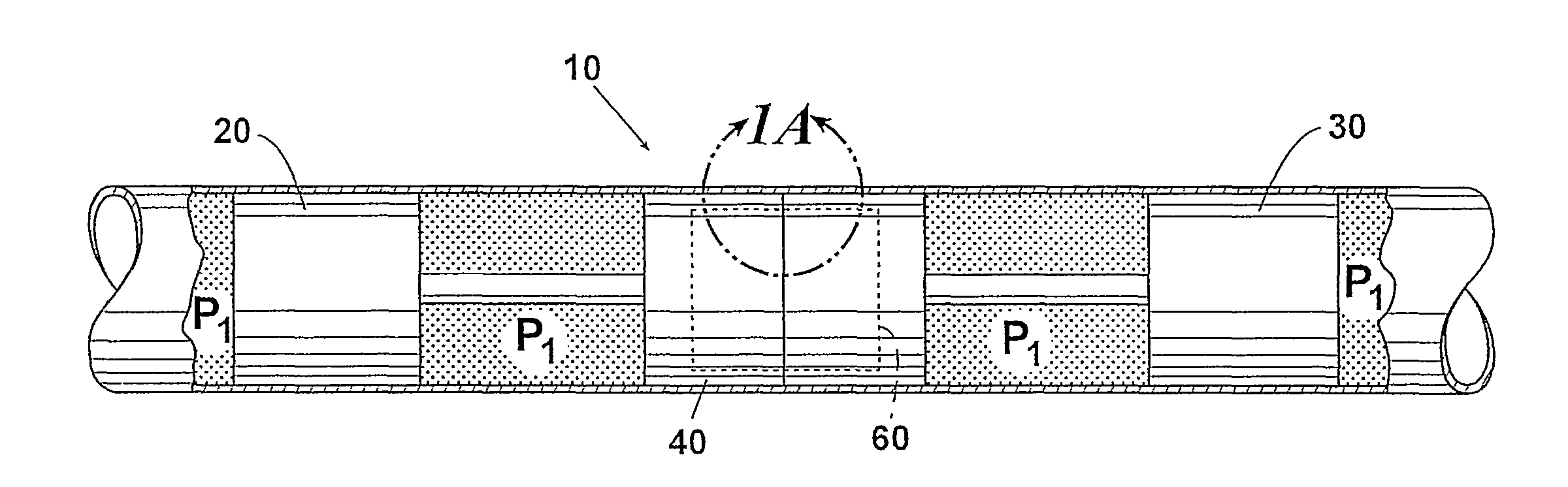

Systems and methods for on-aircraft composite repair using double vacuum debulking

InactiveUS8986479B2Eliminate processingIncrease probabilityConfectionerySweetmeatsRepair siteVacuum pressure

An in-situ double vacuum debulk (DVD) composite repair system designed to produce partially or fully cured autoclave-quality hot-bond composite repairs on contoured structures. The system provides vacuum pressure for hot bond repairs to be performed on flat and contoured structures using one set-up capable of debulking (partially curing) and then fully curing composite repairs on composite and metallic aircraft structures. The use of in-situ DVD also eliminates handling of the patch / adhesive when transferring from an off-aircraft DVD chamber to the repair site on the aircraft. This can increase the probability of successful repairs because the possibility of contaminating and misaligning the adhesive and repair patch are eliminated.

Owner:THE BOEING CO

Configurable Cooling Assembly and Cooling Method

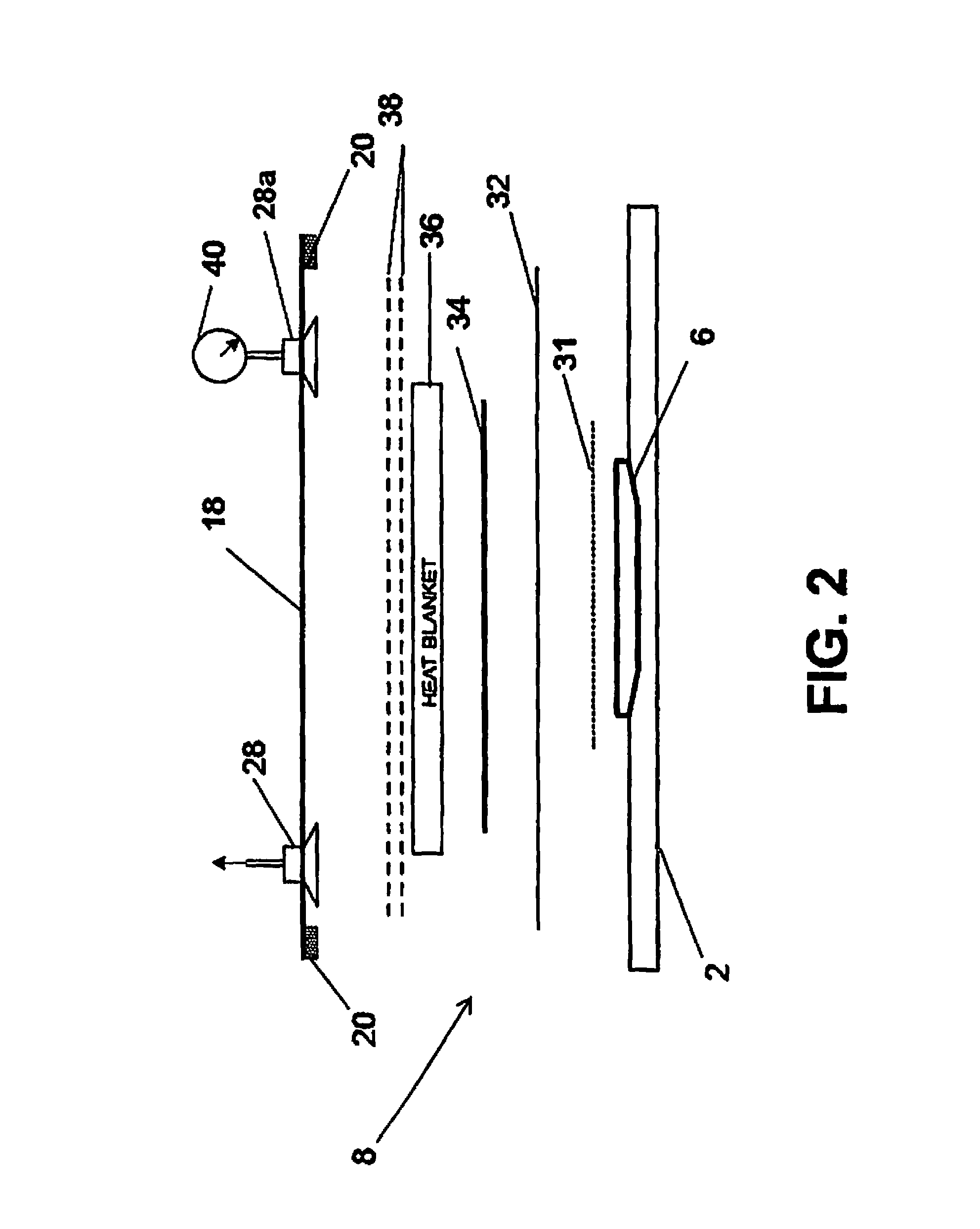

InactiveUS20180147800A1OptimizationAvoid the needLayered product treatmentSynthetic resin layered productsNuclear engineeringHeat sensitive

An assembly of thermally conductive cooling blocks is configured to be placed against a composite skin between a heating blanket used to thermally cure a composite repair patch and a structure formed of a heat sensitive material. The cooling block assembly conducts heat away from the skin to prevent overheating of the heat sensitive material.

Owner:THE BOEING CO

Ultraviolet light curing compositions for composite repair

ActiveUS9248468B2Shorten the curing timeImprove usabilityPretreated surfacesInksPolymer scienceCarbon fibers

Methods and compositions concerning an ultraviolet light curable formulation useful for repairing composite materials including the repair of a hole in the exterior of an airplane. The formulation may contain an acrylic oligomer, an acrylic monomer, an organic peroxide, a dialkylaniline promoter, a photoinitiator. The formulation can include a filler such as carbon fabric or Kevlar fabric.

Owner:TEXAS RES INT

Surrogate patch for composite repair process

ActiveCN102686386ALayered productsMaterial analysis by electric/magnetic meansEngineeringMoisture sensor

A surrogate patch assembly for a rework area of a structure comprises a surrogate patch body which may be formed of a material for drawing moisture from the rework area. The patch assembly may include a sensor mounted to the surrogate patch body. The sensor may comprise a thermal sensor for sensing the temperature of the rework area and the surrogate patch body. The sensor may comprise a moisture sensor for sensing moisture drawn into the surrogate patch body.

Owner:THE BOEING CO

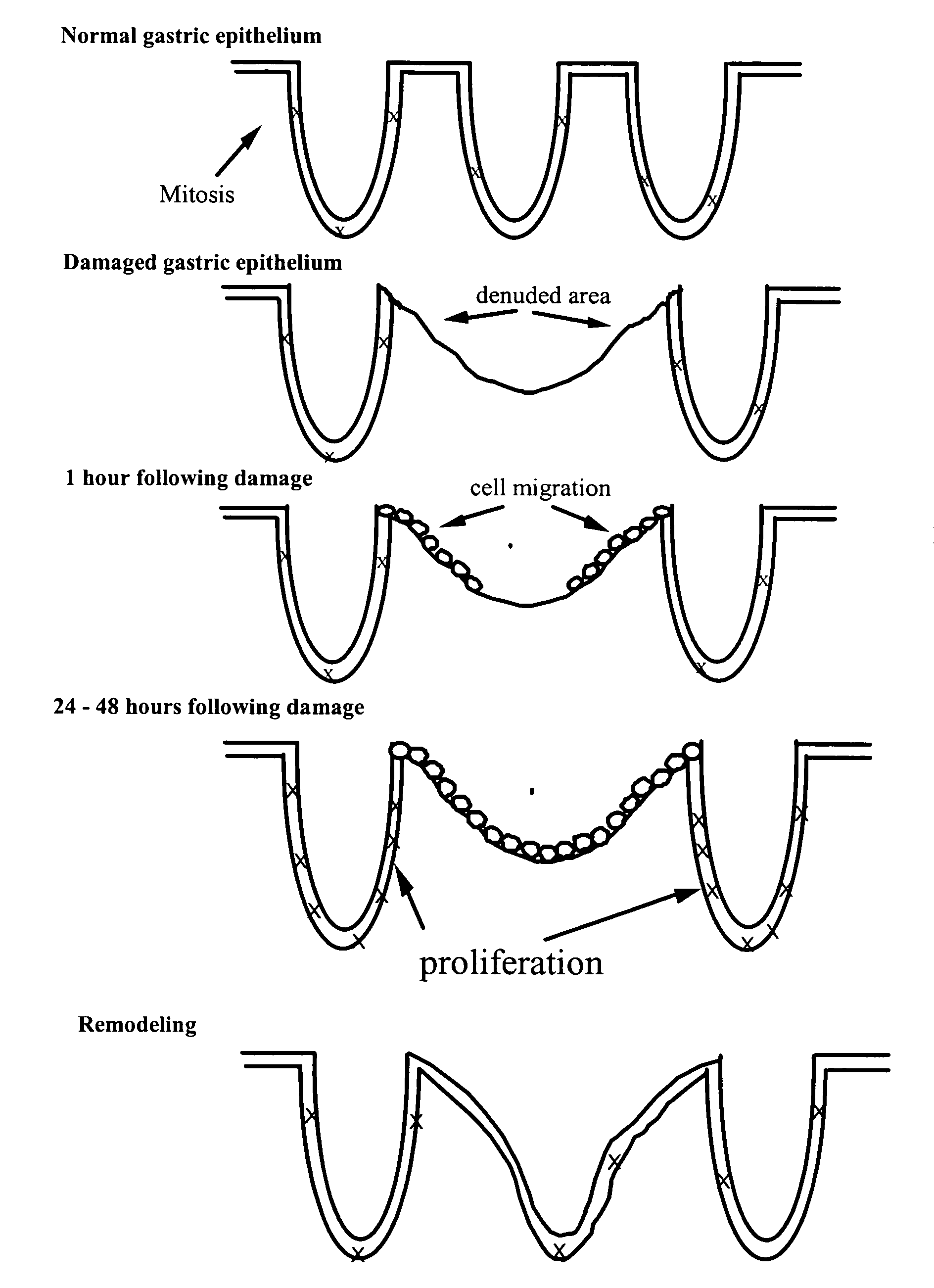

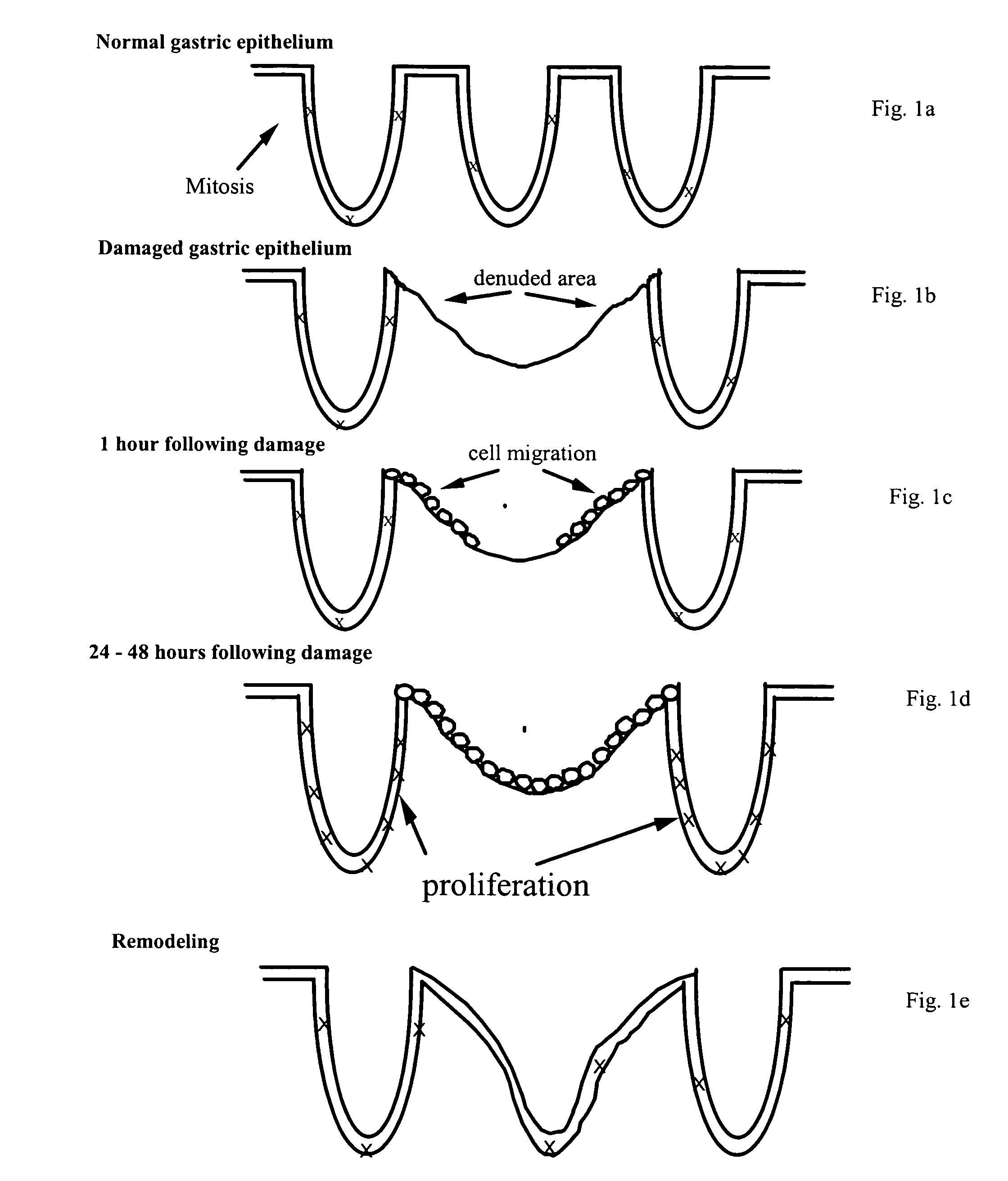

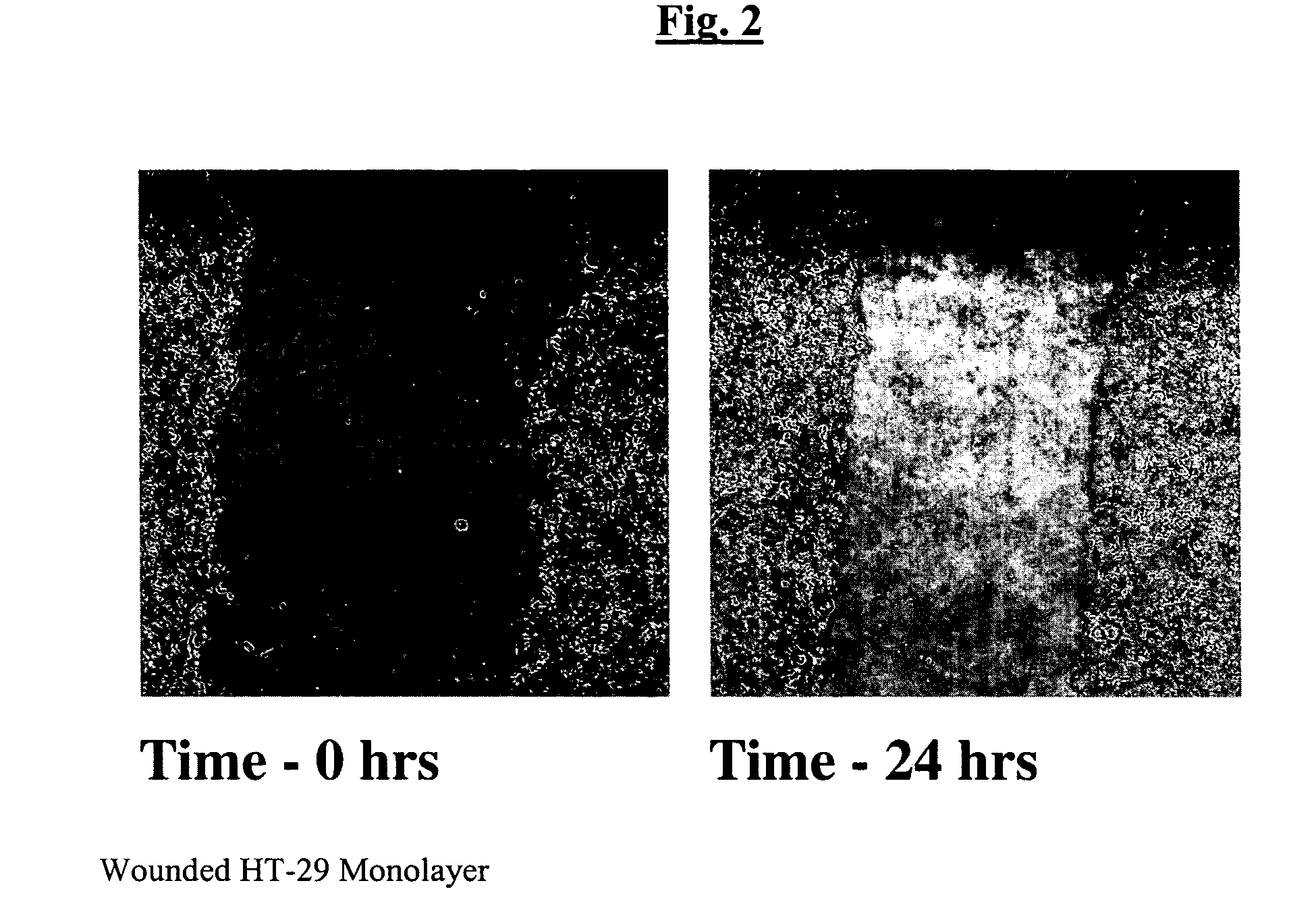

Repair and protection factor scoring method for bioactive agents

InactiveUS7426440B2Increased proliferationPromote repairTissue cultureComputation using non-denominational number representationSun protection factorBiology

A method of scoring the biological activity of bioactive agents like colostrum comprising conducting separate bioassays for cell restitution and cell proliferation on the bioactive agent, a comparative growth factor stimulating agent, and (preferably) a negative baseline control sample containing the cells and growth medium alone. These values are then plugged into the equations provided in this application to calculate a Restitution Score (“RS”), Proliferation Score (“PS”), and a composite repair and protection factor score (“RPF”). In this manner, the bioactivity of compositions that enhance the repair and / or proliferation of mammalian cells, or act as additives to growth media used to maintain and grow laboratory cell cultures can be quickly and reproducibly obtained. This invention may be applied to a wide variety of bioactive agents used to treat a large assortment of functional cells in organ tissues.

Owner:NUTRITIONAL BIOSCI

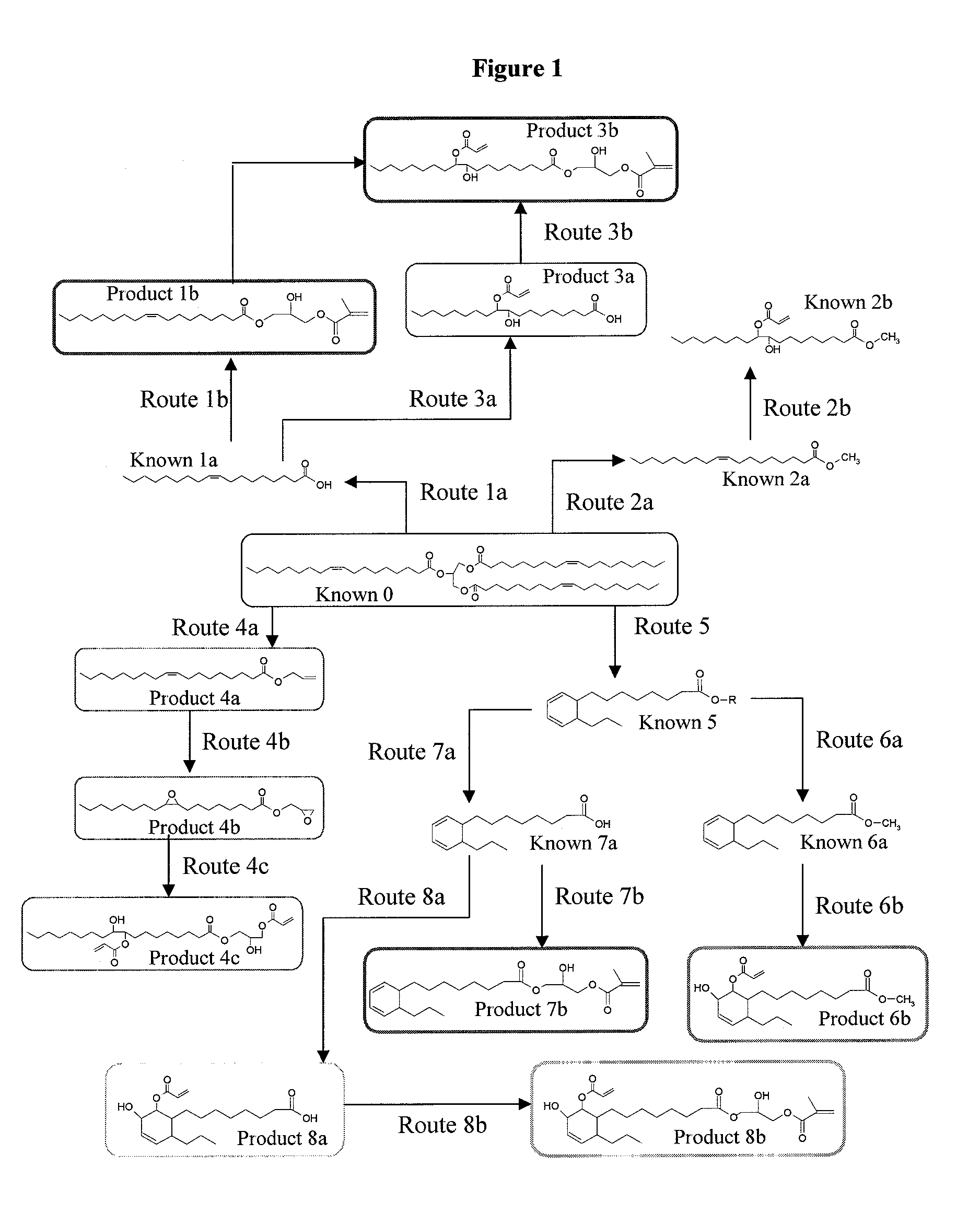

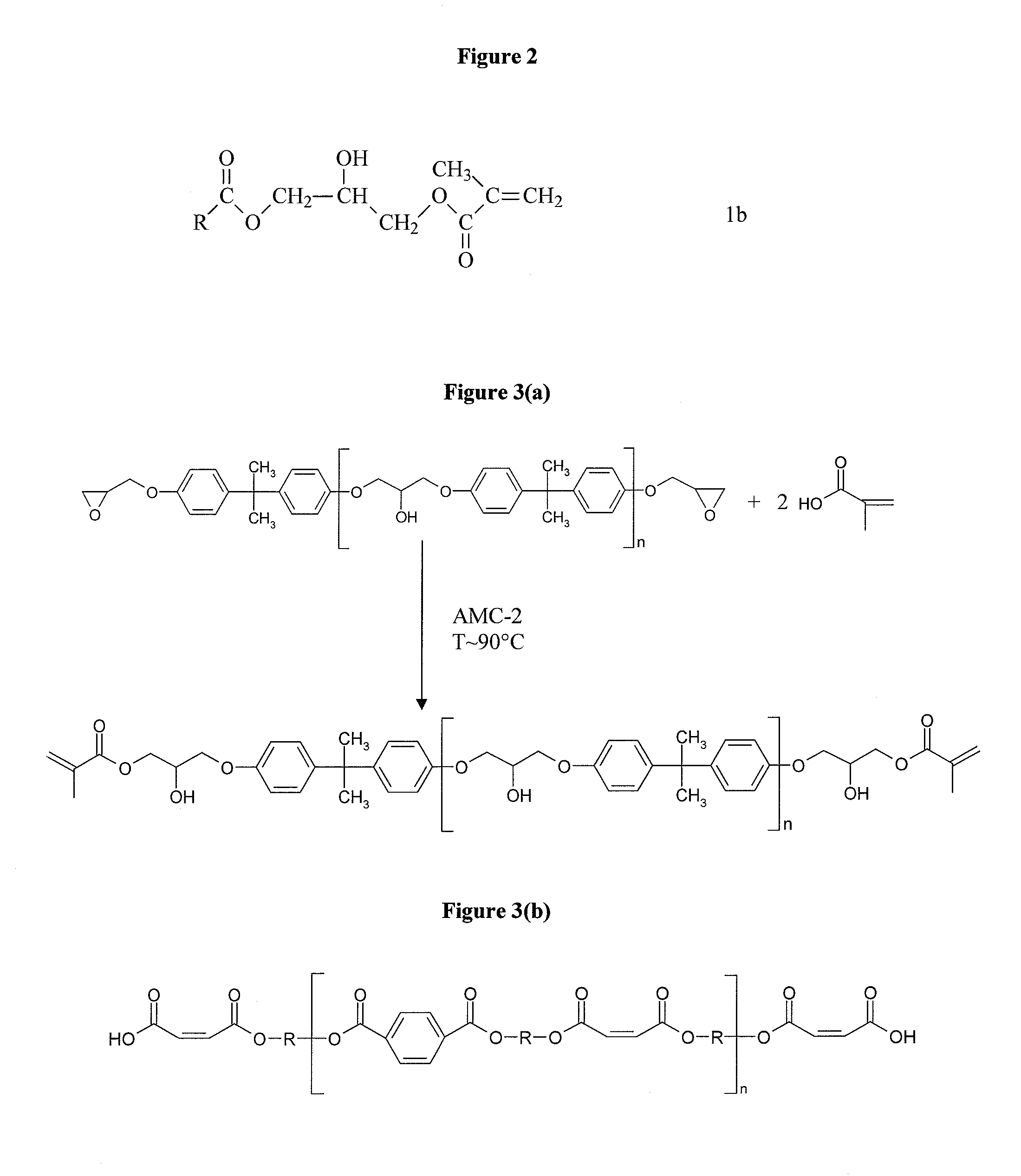

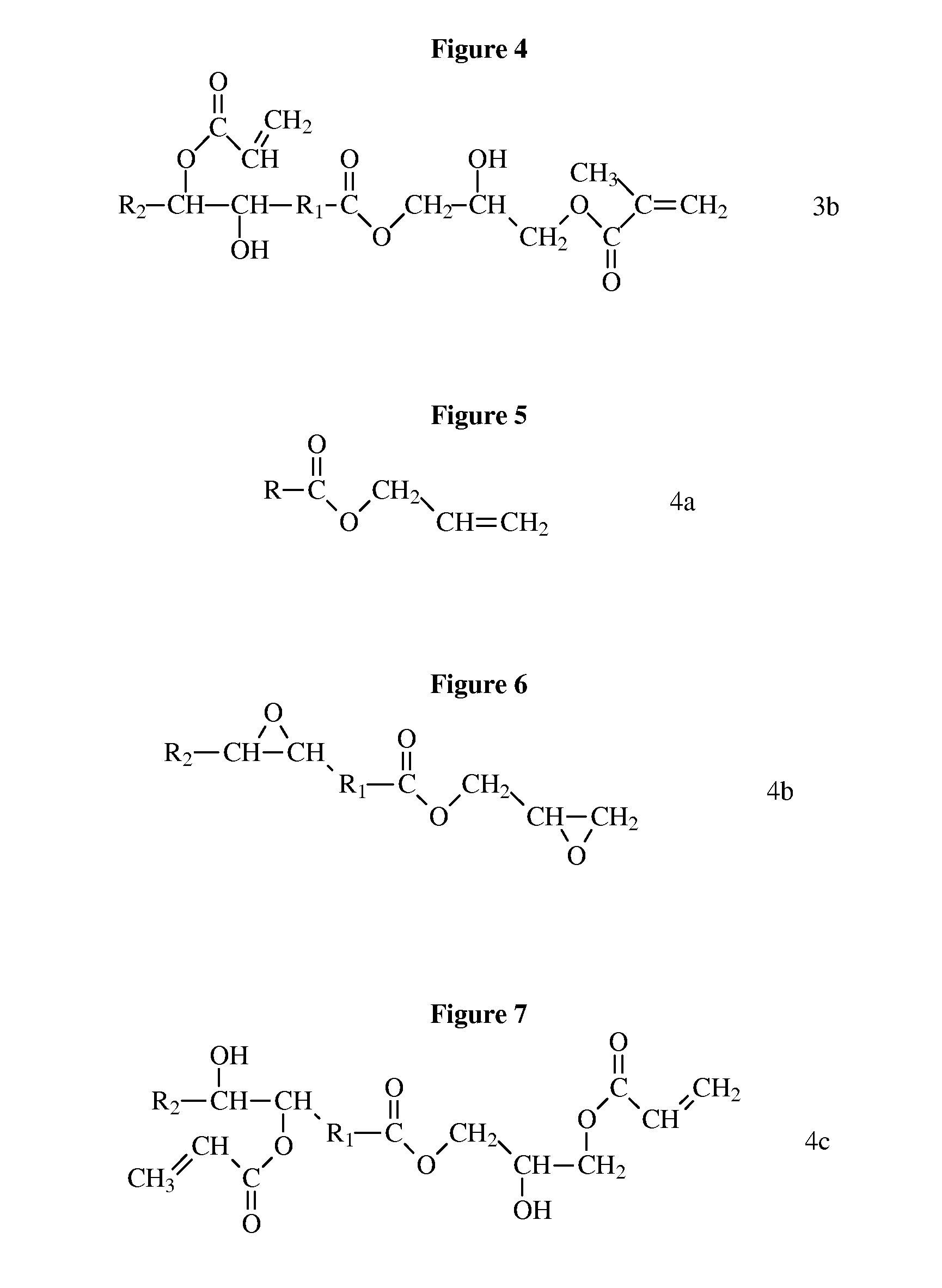

Composite repair resins containing minimal hazardous air pollutants and volatile organic compound

The present invention relates to a composition and method for fabricating composite resins that produce either reduced or zero volatile organic compound (VOC) and zero hazardous air pollutant (HAP) emissions. The non-volatile reactive diluents of the composite resin, fatty acid monomers, enhance the stability, shelf-life, flexibility and strength of the composite resin. The resins incorporating fatty acid monomers may be used to repair military equipment or for any commercial repair purposes.

Owner:DREXEL UNIV +1

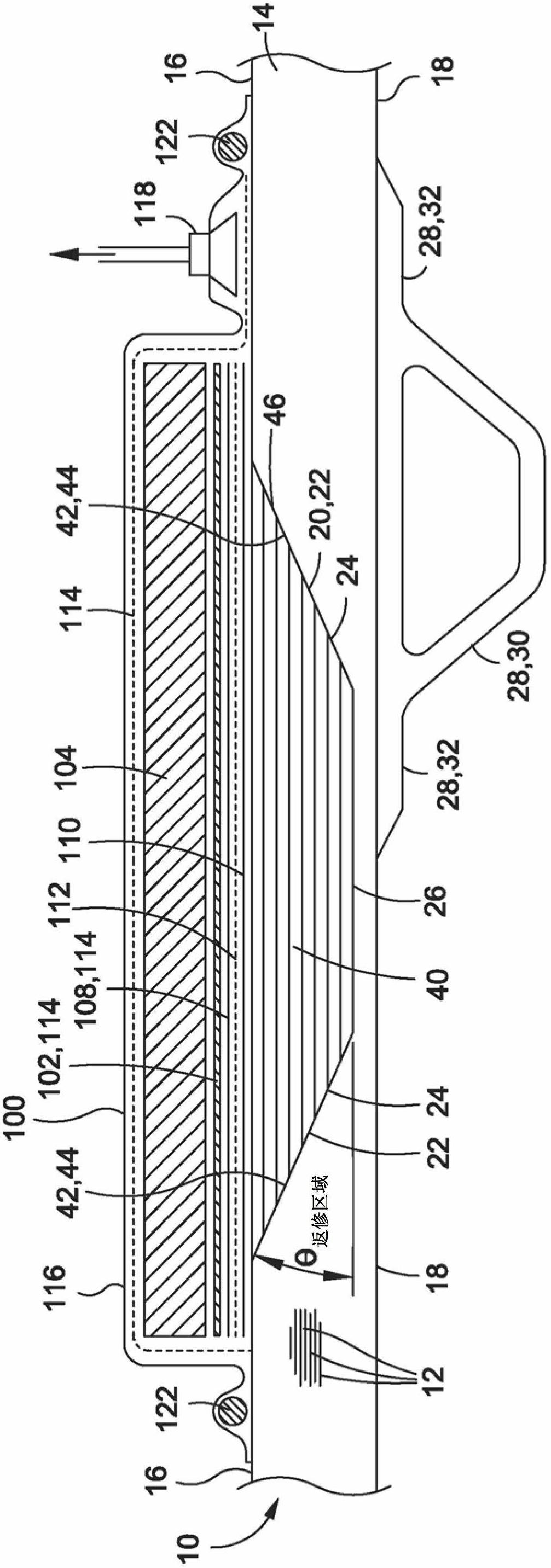

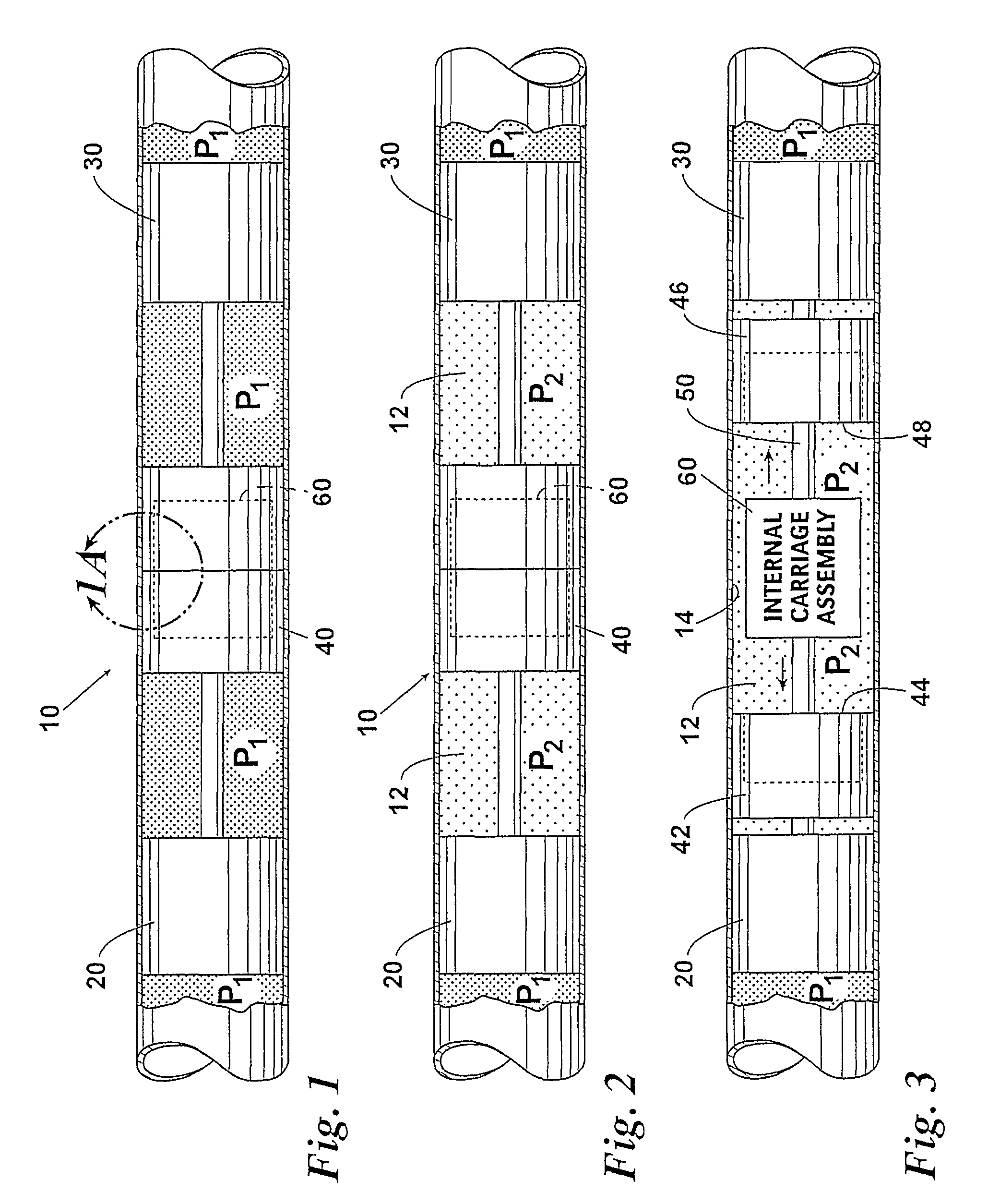

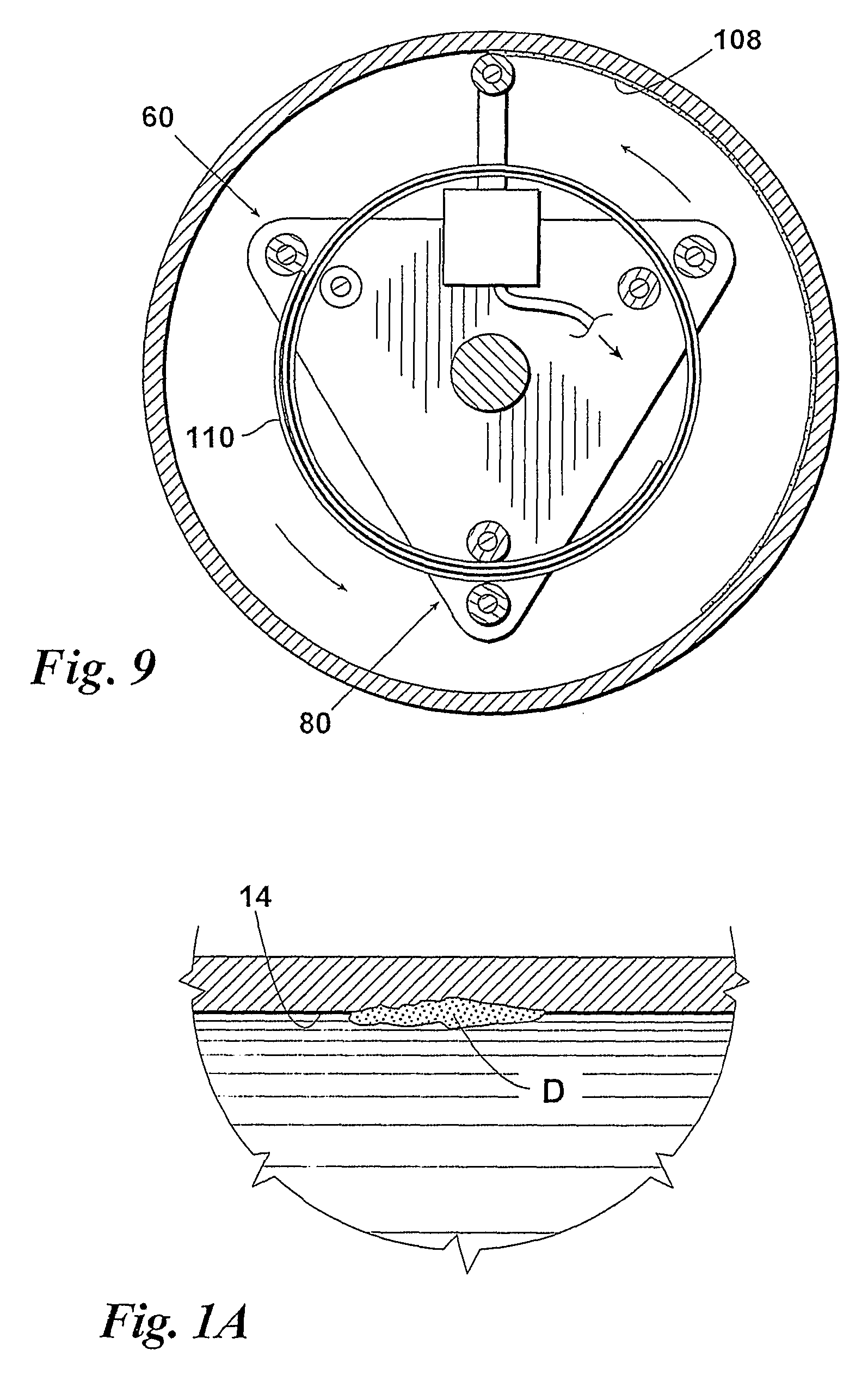

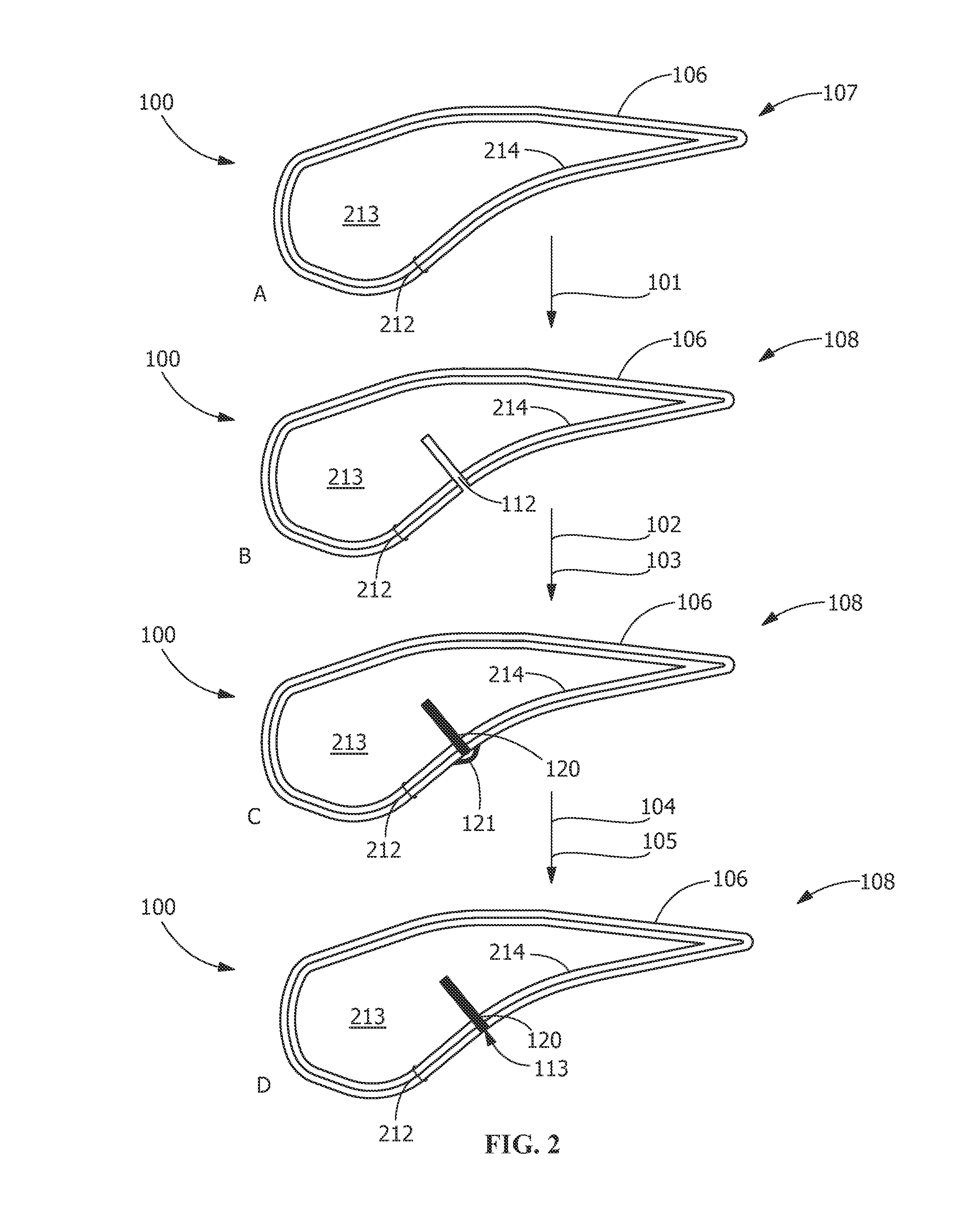

Internal composite repair apparatus

A repair device and method for its use includes plugs that pressure isolate an internally damaged pipeline section and an hermetically sealed housing that contains a length of composite material and a means for controllably releasing the composite material. In a preferred embodiment, the composite material is a pre-cured composite plank and the releasing means is a rotatable carriage assembly. The carriage assembly includes pairs of rollers that maintain the composite material in its coiled state and provide for its controlled release onto the interior wall of the pipeline. The carriage assembly also includes a nozzle for injecting an adhesive into a roller. The roller applies the adhesive onto the interior wall surface and then presses the composite material into the adhesive as the carriage assembly rotates and the composite material uncoils. A pneumatic or electric motor may be used to power the carriage assembly.

Owner:TDW DELAWARE INC

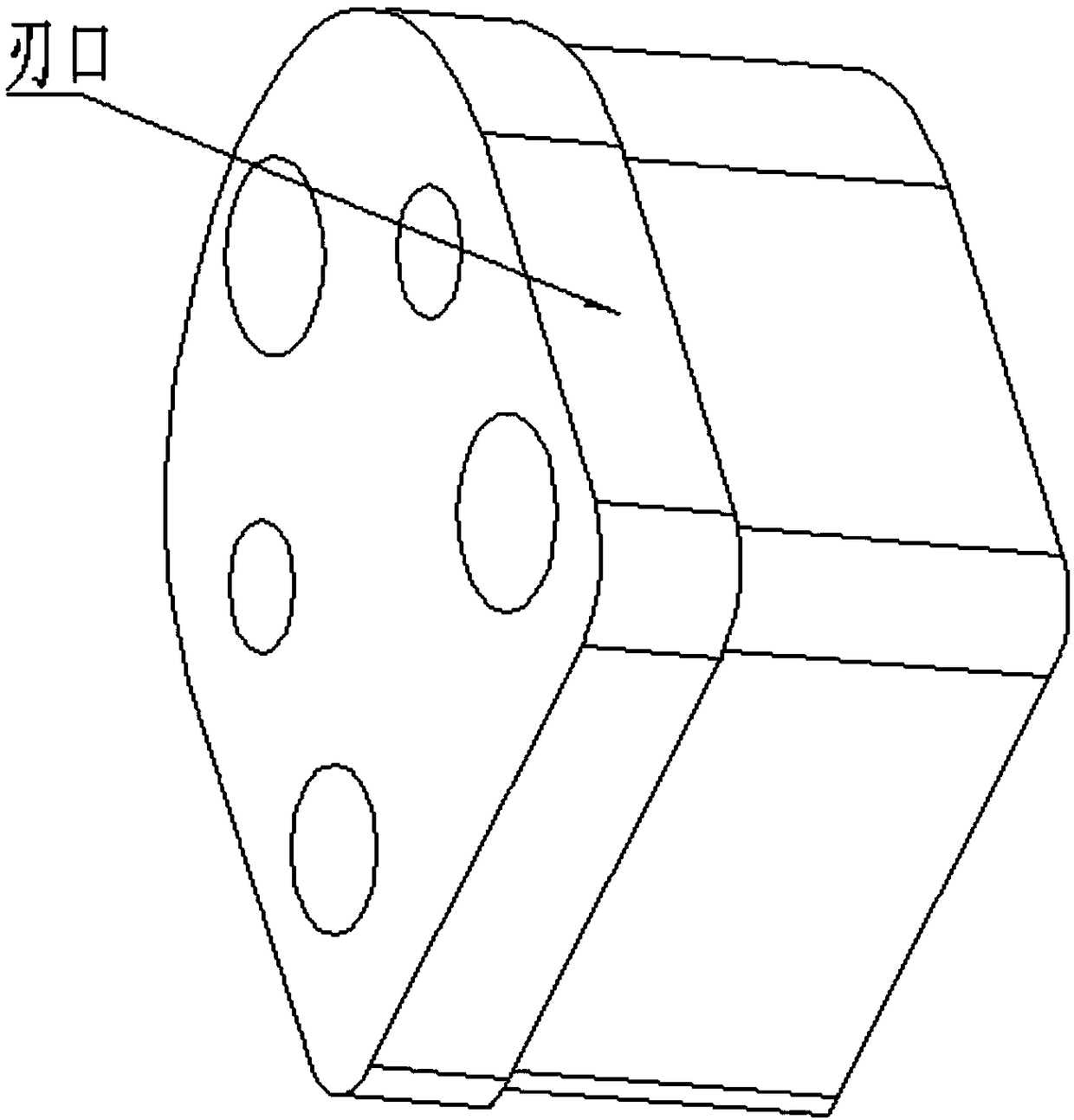

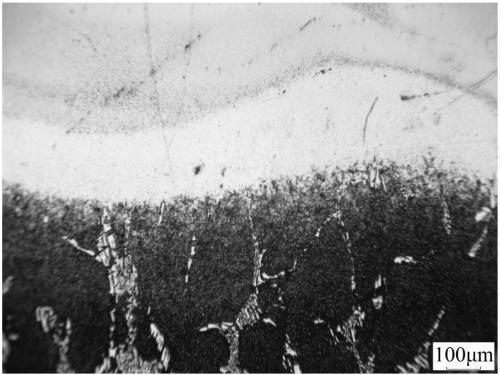

CMT and laser cladding composite repair method for inner hole of flat head sleeve of rolling mill spindle

ActiveCN110102878AOvercome thermal deformationImprove wear resistanceLaser beam welding apparatusMachined surfaceImpurity

The invention discloses a CMT and laser cladding composite repair method for an inner hole of a flat head sleeve of a rolling mill spindle. The composite repair method comprises the following steps ofcutting the inner hole of the flat head sleeve to be repaired; removing a wear fatigue layer; cleaning the machined surface and removing impurities on the machined surface; using a CMT process to surfacing a transition layer on the machined surface; detecting the defects of a CMT welding layer, such as cracks; preparing alloy powders and cladding with a CW fiber laser, and coloring the surface ofa laser cladding layer to detect the detects, such as the cracks; and machining the laser cladding layer surface to obtain the flat head sleeve, specifically, the size, the tolerance and the surfacefinish of the flat head sleeve meet the requirements of a drawing. According to the CMT and laser cladding composite repair method for the inner hole of the flat head sleeve of the rolling mill spindle, a CMT welding process and a laser cladding process are organically combined, so that the purposes of low cost and agile repair are achieved; and the hardness and alloy compositions of the laser cladding layer can be quickly adjusted according to the change of working conditions, so that the service performance of a product is significantly improved and the service life of the product is significantly prolonged, and the service life is prolonged by more than two times

Owner:YANSHAN UNIV

Repair process and a repaired component

Matrix composite component repair processes are disclosed. The matrix composite repair process includes applying a repair material to a matrix composite component, securing the repair material to the matrix composite component with an external securing mechanism and curing the repair material to bond the repair material to the matrix composite component during the securing by the external securing mechanism. The matrix composite component is selected from the group consisting of a ceramic matrix composite, a polymer matrix composite, and a metal matrix composite. In another embodiment, the repair process includes applying a partially-cured repair material to a matrix composite component, and curing the repair material to bond the repair material to the matrix composite component, an external securing mechanism securing the repair material throughout a curing period, In another embodiment, the external securing mechanism is consumed or decomposed during the repair process.

Owner:GENERAL ELECTRIC CO

In-Situ, Multi-Stage Debulk, Compaction, and Single Stage Curing of Thick Composite Repair Laminates

A method for fabricating a repair laminate for a composite part having an exposed surface includes applying a bonding material to the exposed surface and forming an uncured ply stack assembly on the bonding material. The uncured ply stack assembly is formed by forming and compacting a series of uncured ply stacks. The ply stack assembly and bonding material are then cured.

Owner:TEXTRON INNOVATIONS

Soil composite repair agent and applications of soil composite repair agent in removal of heavy metals from soil

InactiveCN106479507ALow toxicityChemically stableAgriculture tools and machinesContaminated soil reclamationAntioxidantMaterials science

The present invention discloses a soil composite repair agent, which contains a biodegradable macromolecule material, a filler, a plasticizer, a lubricant and an antioxidant. According to the present invention, the soil composite repair agent can efficiently activate the beneficial indigenous microorganisms in the soil, and the microorganisms can provide effects of adsorption, precipitation, oxidation-reduction, and the like for heavy metals, such that the toxicity of heavy metals in the contaminated soil can be reduced; and the microorganisms can react with the heavy metals in the soil to make the heavy metals form the stable chemical forms, such that the environmental migration and diffusion of the heavy metals can be prevented, and the poisoning degree of the heavy metals in the environment can be reduced.

Owner:ZHEJIANG AVOCADO ENVIRONMENTAL PROTECTION TECH CO LTD

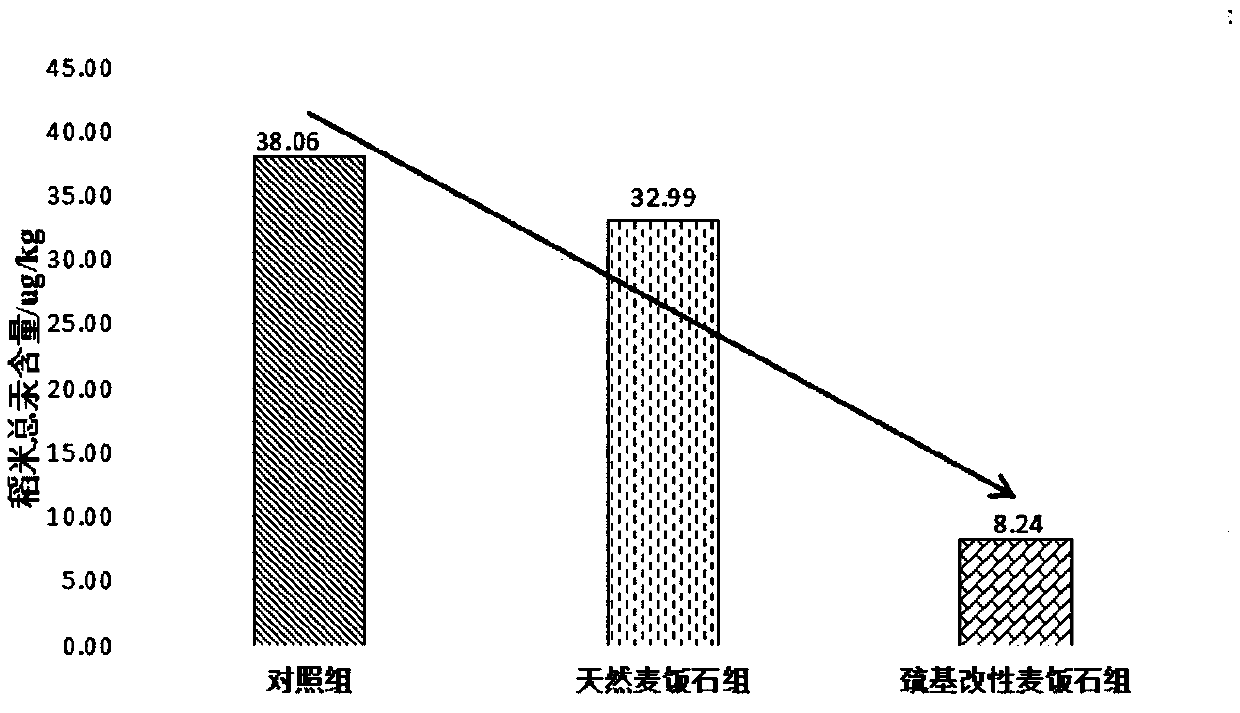

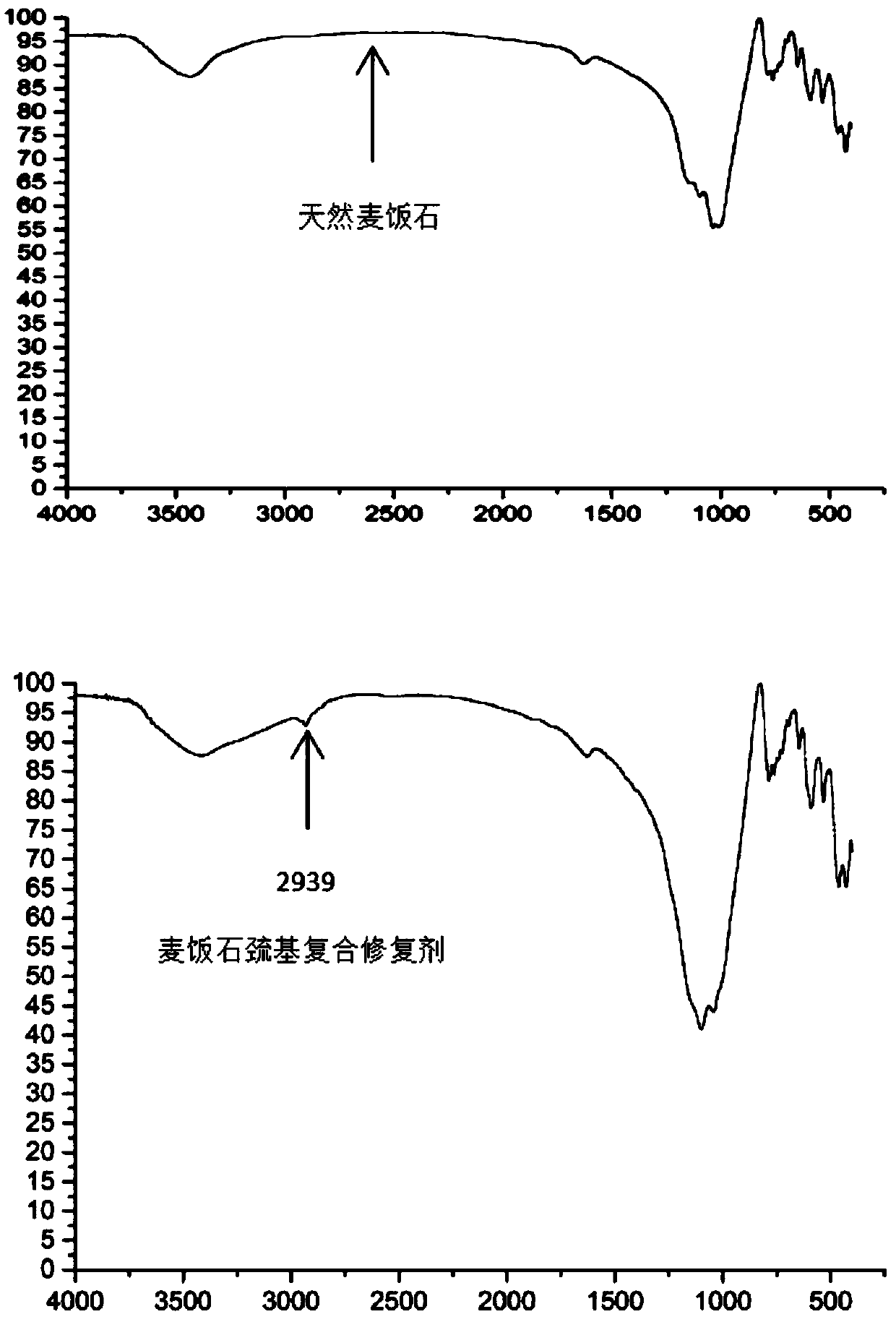

Medical stone sulfenyl repairing agent for treating soil mercury pollution and preparation method thereof

InactiveCN109621909AAbundant resourcesLarge specific surface areaOther chemical processesContaminated soil reclamationMedicineAcid activation

The invention discloses a medical stone sulfenyl repairing agent for treating soil mercury pollution and a preparation method thereof. The medical stone sulfenyl repairing agent is a composite repairing agent material obtained by modifying medical stone obtained after acid activation treatment through a sulfenyl-containing complex; the medical stone sulfenyl repairing agent is prepared from, by weight, 10-12 parts of medicine stone and 11-14 parts of a sulfenyl complex. The medical stone sulfenyl repairing agent has the advantages that the remarkable repairing effect on mercury polluted soil is achieved, the concentration of mercury in rice can be effectively lowered, the technological flow process is simple and reliable, the cost is low, use is safe, no secondary contamination is caused,the medical stone sulfenyl repairing agent is of a great actual and economic significance in mercury polluted soil repairing, and the repairing agent meets the national agricultural sustainable requirement.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com