Composite repair material for bridging defect nerves and stent made of composite repair material

A composite repair and composite material technology, applied in the composition, preparation and application of composite repair materials and their scaffolds, can solve problems such as lack, achieve the effects of preventing fibrous scars, reducing the difficulty of surgical techniques, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1. Animal Modeling and Evaluation of Nerve Injury

[0029] a. Canine sciatic nerve injury model

[0030] A young Beagle dog was selected and anesthetized by intraperitoneal injection of sodium pentobarbital (30 mg / kg). A longitudinal incision was made at the posterior part of the right thigh, the skin was cut, and the muscle was separated to expose the right sciatic nerve. The sciatic nerve was cut off with a double-sided blade.

[0031] b. Canine spinal cord transection model

[0032] Young Beagle dogs were selected and anesthetized by intraperitoneal injection of pentobarbital sodium (30mg / kg). The skin was incised under sterile conditions, the muscles were separated, and the T9 and T10 spinal lamina were excised, and half-transected at the middle of the T9 lamina The spinal cord (located at the junction of T9 and T10 spinal cord segments), and a 2mm spinal cord tissue block on the right half was excised, and the residual nerve fibers in the injury cavity wer...

Embodiment 2

[0033] The preparation of embodiment 2 different restorative materials

[0034] a. Silk fibroin conduit

[0035] Dissolve the silk in the ternary system of calcium chloride, ethanol and water (the molar ratio is calcium chloride: ethanol: water = 1: 2: 8), heat treatment at 80°C for 5 hours, and fill the dissolved mixed solution into the fiber The plain film bag is dialyzed with distilled water to obtain a silk fibroin solution, which is poured into a mould, dried and then molded. Put the preliminarily formed silk fibroin catheter into methanol and sodium hydroxide solution with a volume ratio of 50:50 for 2 hours, and then wash it successively with 1mol / L sodium hydroxide solution, 50mmol / L phosphate buffer and distilled water , to obtain silk fibroin conduits.

[0036] b. Collagen Scaffold

[0037]Prepare a collagen solution with a concentration of 25 mg / ml, pour it into a mold, and freeze it at -15°C for 80 minutes, then put it in a freeze dryer for 25 minutes in a vacuu...

Embodiment 3

[0043] Embodiment 3 Preparation of silk fibroin-collagen-polymer nerve repair material and scaffold thereof

[0044] a. Preparation of silk fibroin-collagen-PLGA composite scaffold:

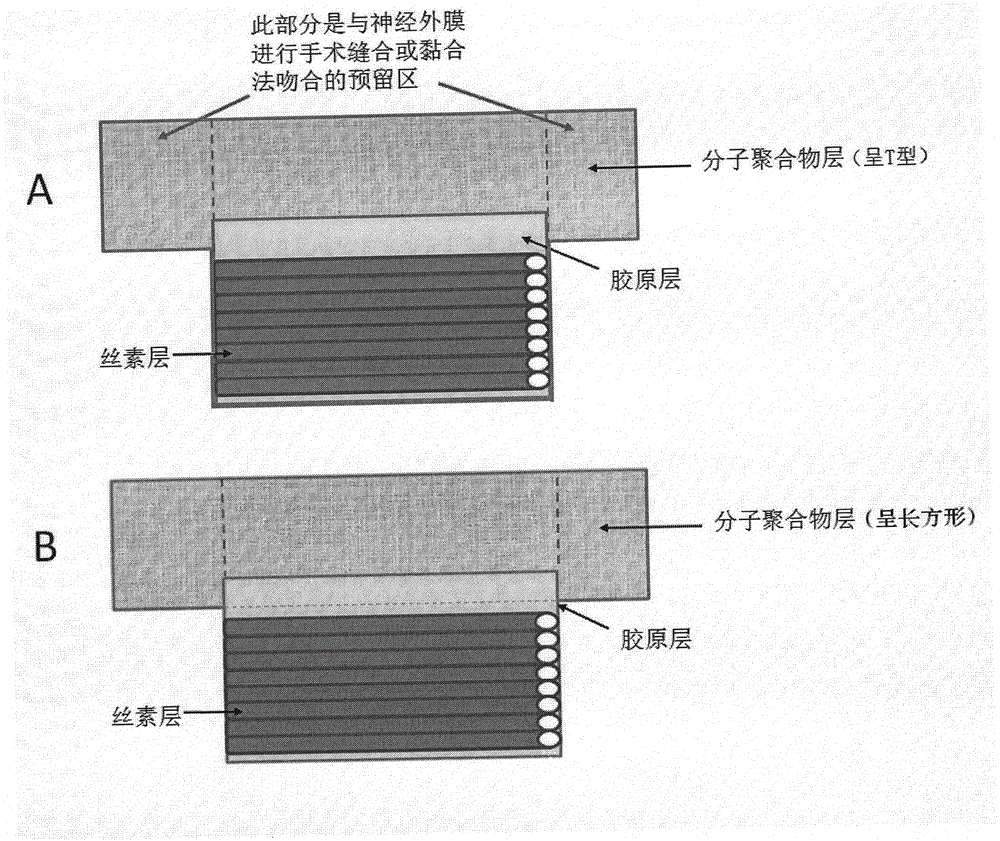

[0045] (1) prepare the PLGA solution that concentration is 0.05g / ml with volatile organic solvent, pour into mold and dry naturally, obtain the PLGA film that the thickness that obtains appearance is T-shaped is 50um;

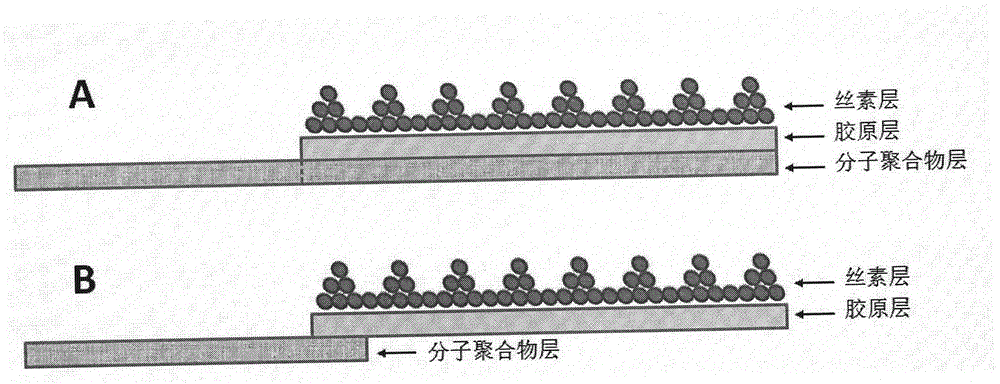

[0046] (2) Prepare a collagen solution with a concentration of 5 mg / ml, pour it on the glass slide of the PLGA membrane, and let it dry naturally to obtain the attached collagen solution. figure 2 Type A collagen-PLGA bilayer membrane;

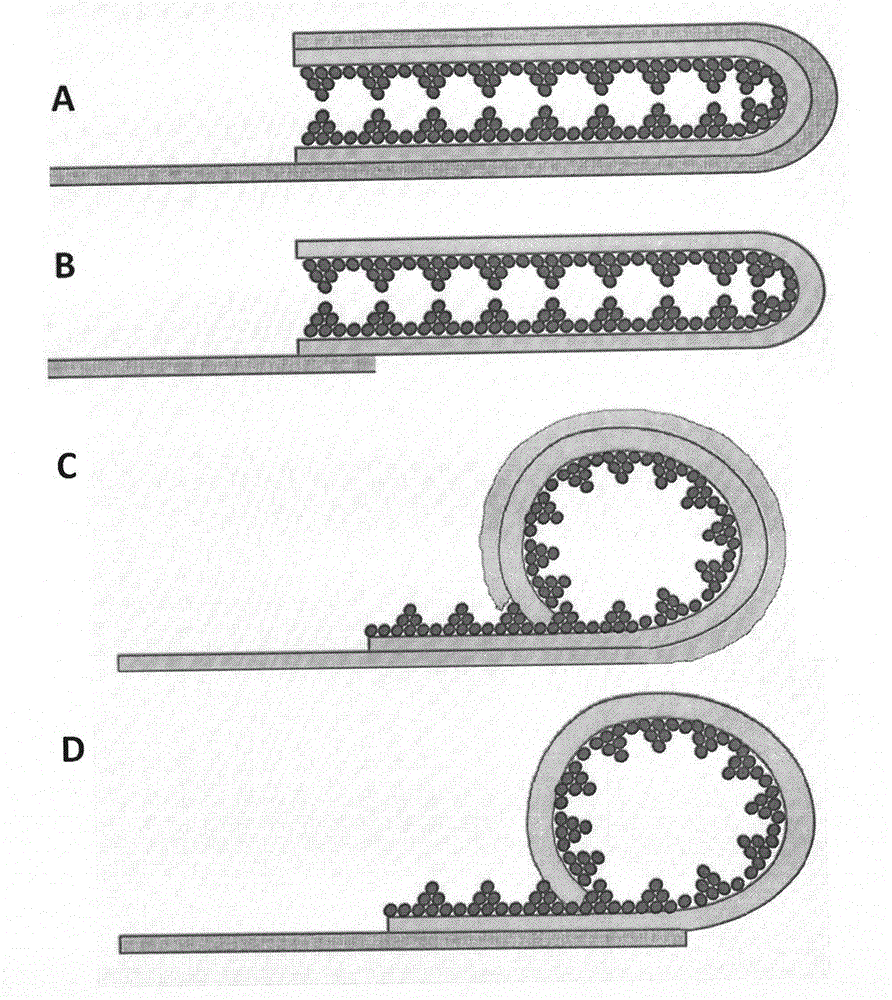

[0047] (3) silk is dissolved in the ternary system of calcium chloride, ethanol and water (molar ratio is calcium chloride: ethanol: water=1: 2: 8), heat treatment at 80 ℃ for 5 hours, the mixed solution of dissolving Put it into a cellulose film bag, and dialyze it with distilled water to obtain a silk fibroin solution. Use three-dimensional p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com