Patents

Literature

116 results about "Bubble column" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

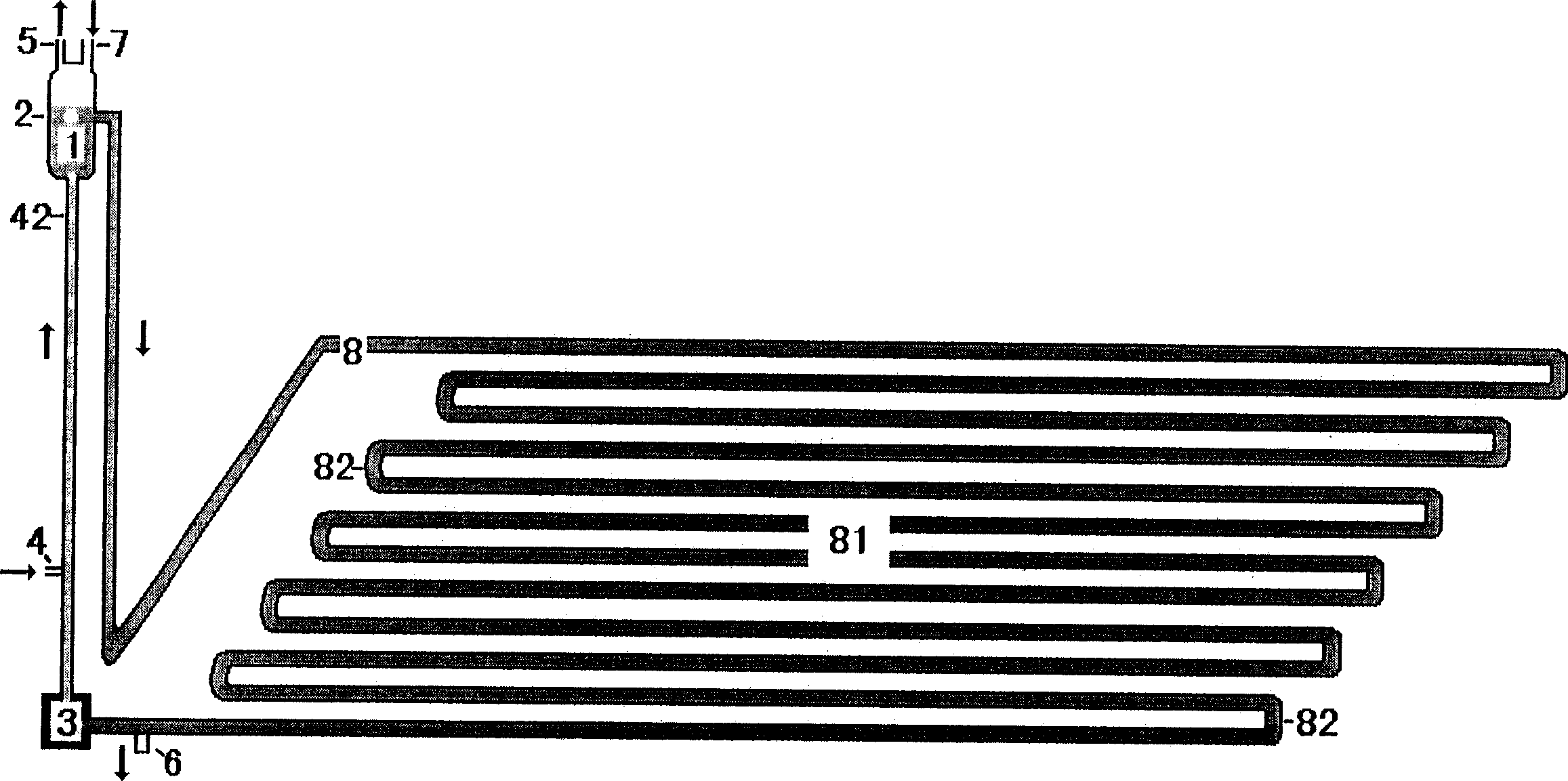

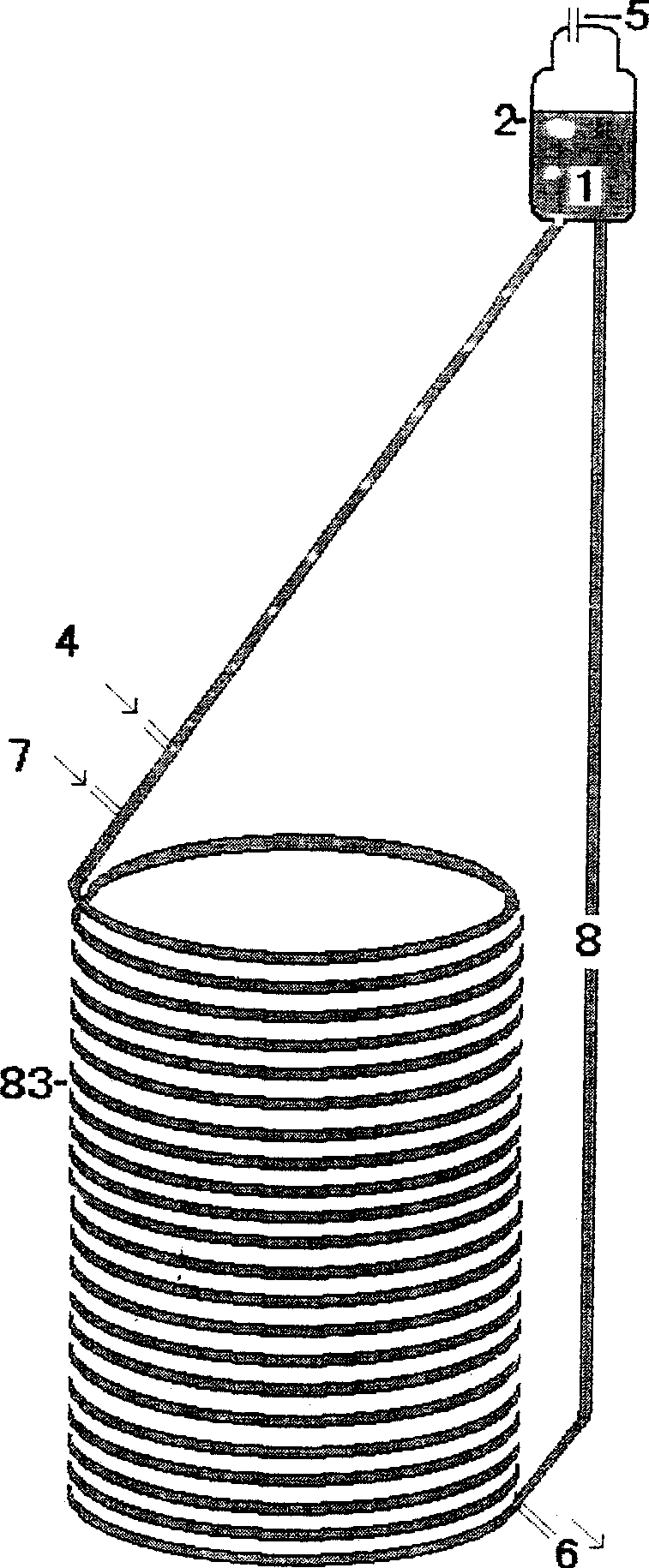

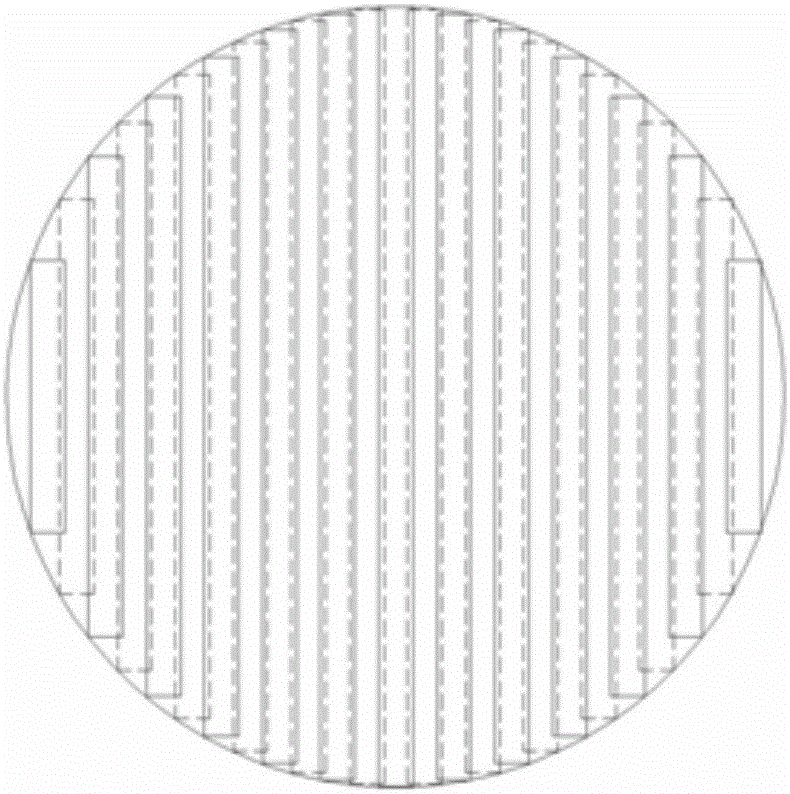

Pipeline photobioreactor for scale culture of microalgae

InactiveCN1721523AOvercome technical difficulties that cannot be scaled up effectivelyFully disinfectedBioreactor/fermenter combinationsBiological substance pretreatmentsBubble columnWater flow

The present invention belongs to the field of micro algae biotechnology, and is especially one kind of closed pipeline optical bioreactor plant for large scale culture of micro algae. The optical bioreactor plant includes transparent pipeline, gas analyzing unit, auxiliary pipe system, culture parameter sensing and controlling unit and economic micro algae. The present invention adopts large gas analyzing unit, parallel connected transparent pipes, mechanically drive water flow, mutual light blocking of cells, etc. to ensure the gas exchange inside the reactor for photosynthetic metabolism, reduce oxidation damage and light damage, replenish CO2 effectively, reduce the blocking of bubble column on water flow, and raise micro algae culturing efficiency and yield. In addition, the optical bioreactor plant may be established in place with sufficient sun light to utilize natural light effectively.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

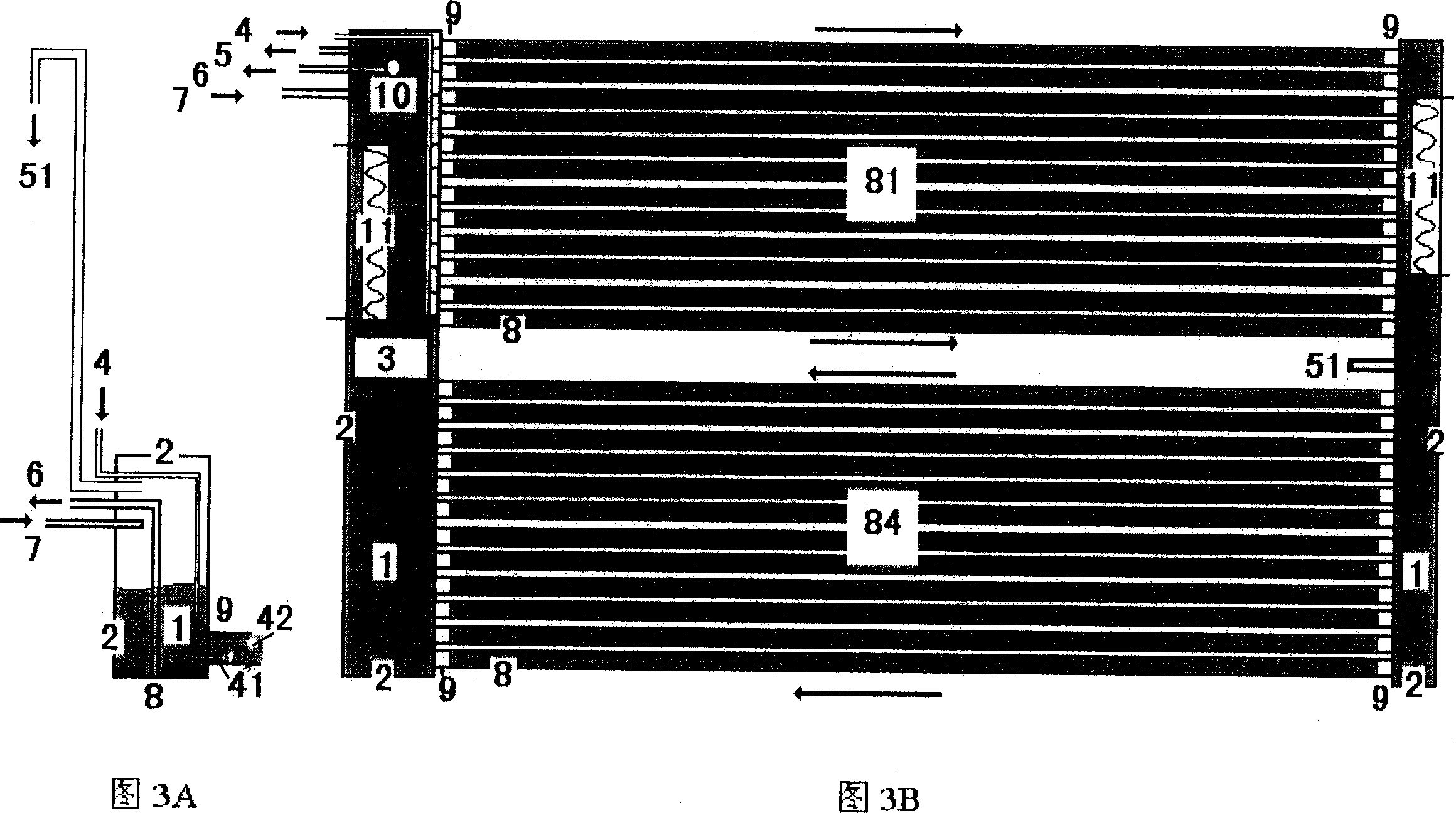

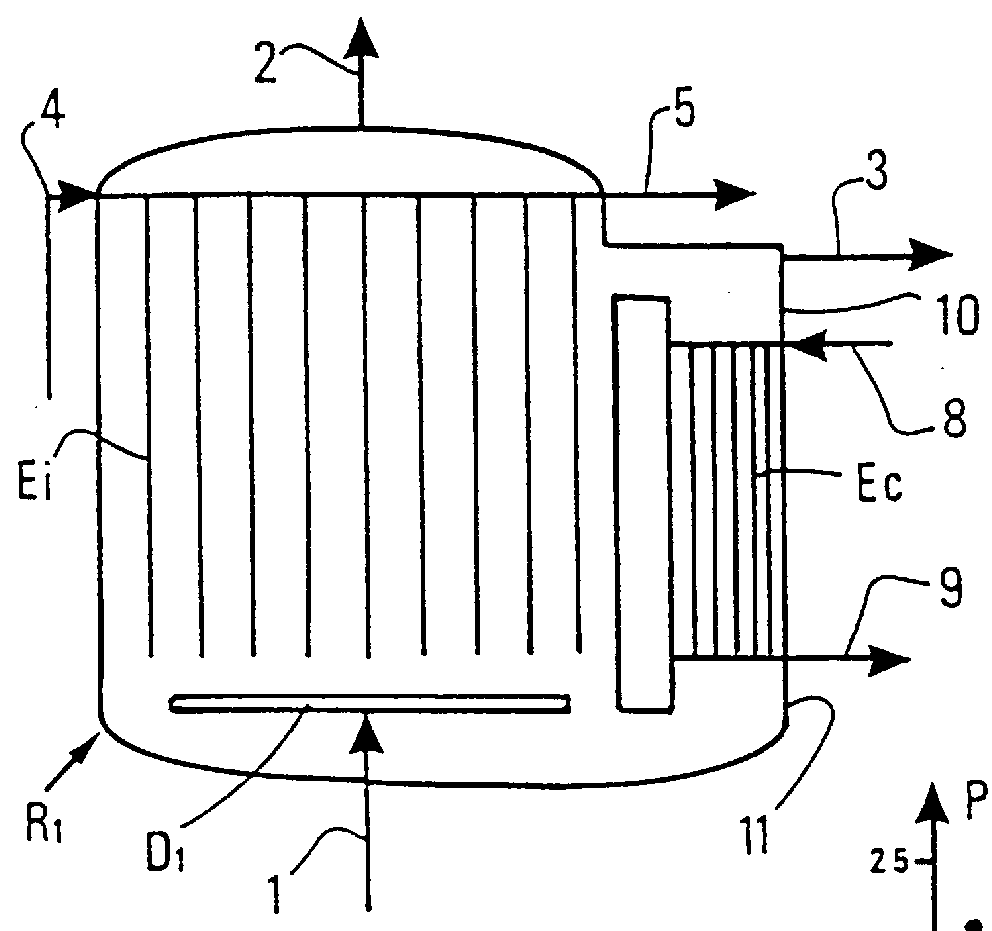

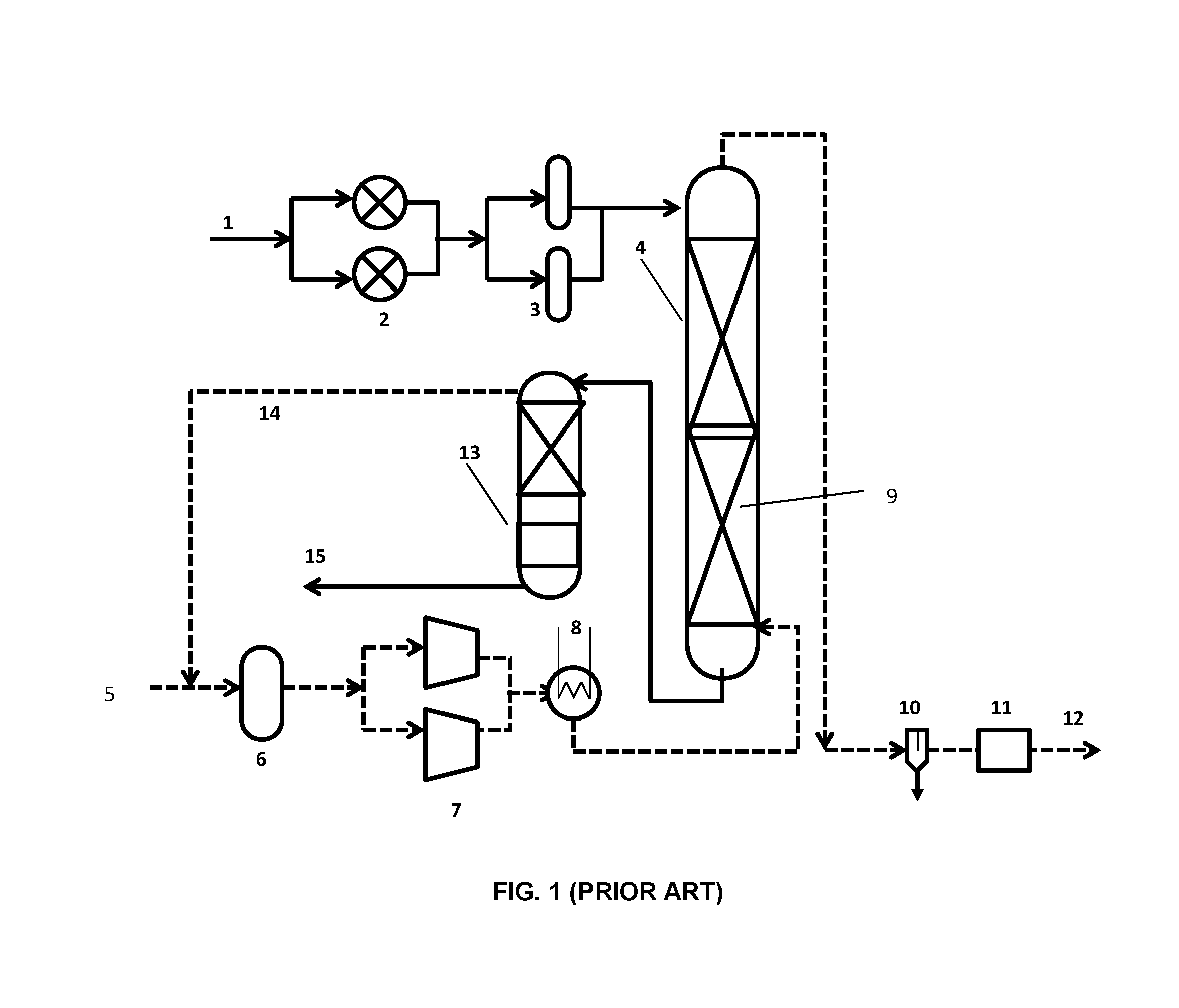

Process and apparatus for operation of a slurry bubble column with application to the fischer-tropsch synthesis

InactiveUS6060524AGuaranteed uptimeAvoid small quantitiesHydrocarbon from carbon oxidesOrganic compound preparationGas phaseBubble column

The invention concerns a process for optimal operation of a slurry bubble column containing a suspension of solid particles in a liquid, characterized in that a gas phase containing the reactant(s) required for the production of the desired products is injected in the form of bubbles close to the lower extremity of said reactor and at least a portion of the liquid fraction and optionally of the solid fraction of said suspension is recirculated, drawn off from close to one extremity of said reactor and reintroduced close to the other extremity of said reactor, with a liquid flow rate U1 in the reactor which is at least equal to and preferably greater than the sedimentation rate Us of the solid particles. The invention also concerns an apparatus for optimal operation of the process. Finally, the invention concerns the use of the process and apparatus in the Fischer-Tropsch synthesis.

Owner:INST FR DU PETROLE +1

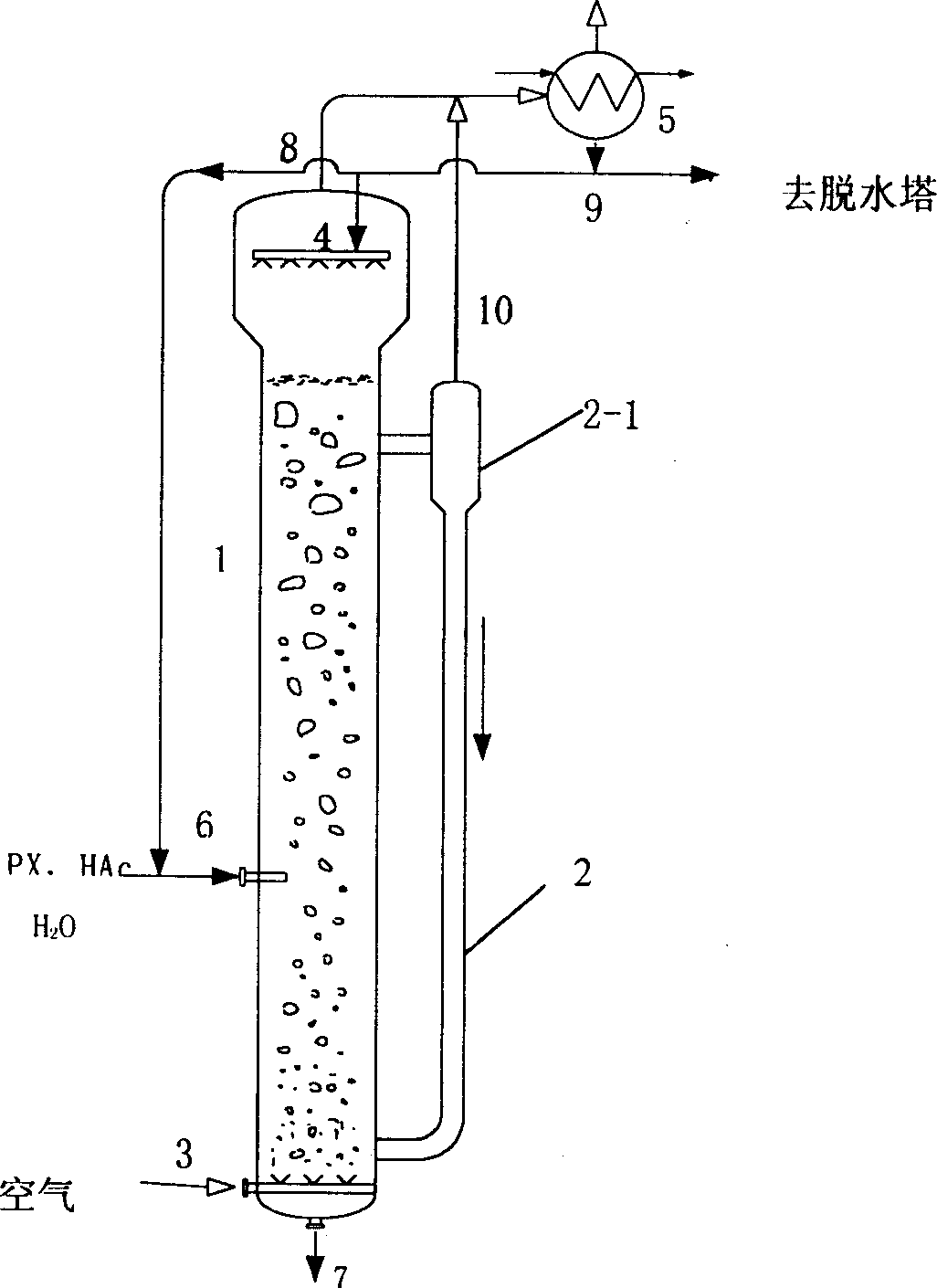

Air lift externally circulating bubble fower oxidation unit for producing terephthalic acid

InactiveCN1486968ASimple structureLow costOrganic compound preparationCarboxylic compound preparationCatalytic oxidationEngineering

The air lift externally circulation bubble tower oxidation apparatus includes cylinder bubble tower with top expanded section, outer circulating pipe, gas distributor, reflux liquid distributor and condensator. The outer circulating pipe has its upper end and lower end communicated with the upper part and the lower part of the bubble tower reaction section separately and is used to lead slurry from the upper part of the tower to the lower part via air lift effect so as to form the fluid circulation in the whole tower and complete the liquid phase catalytic oxidation of xylene. The bubble tower has relatively high height / diameter ratio and thus reinforced gas-liquid mass transfer and the air lift outer circulation pipe improves the temperature distribution and concentraion distribution inside the tower. The tower has no moving part, simple structure and low cost and is suitable for oxidizing xylene to prepare terephthalic acid via different technological processes.

Owner:CHINA TEXTILE IND ENG INST +2

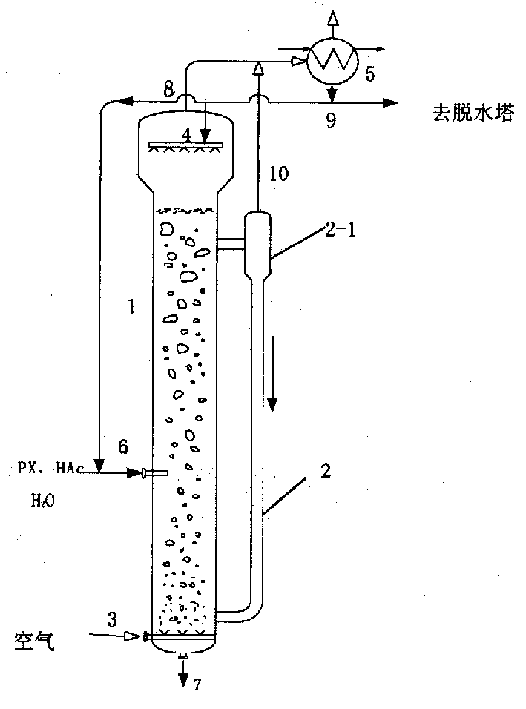

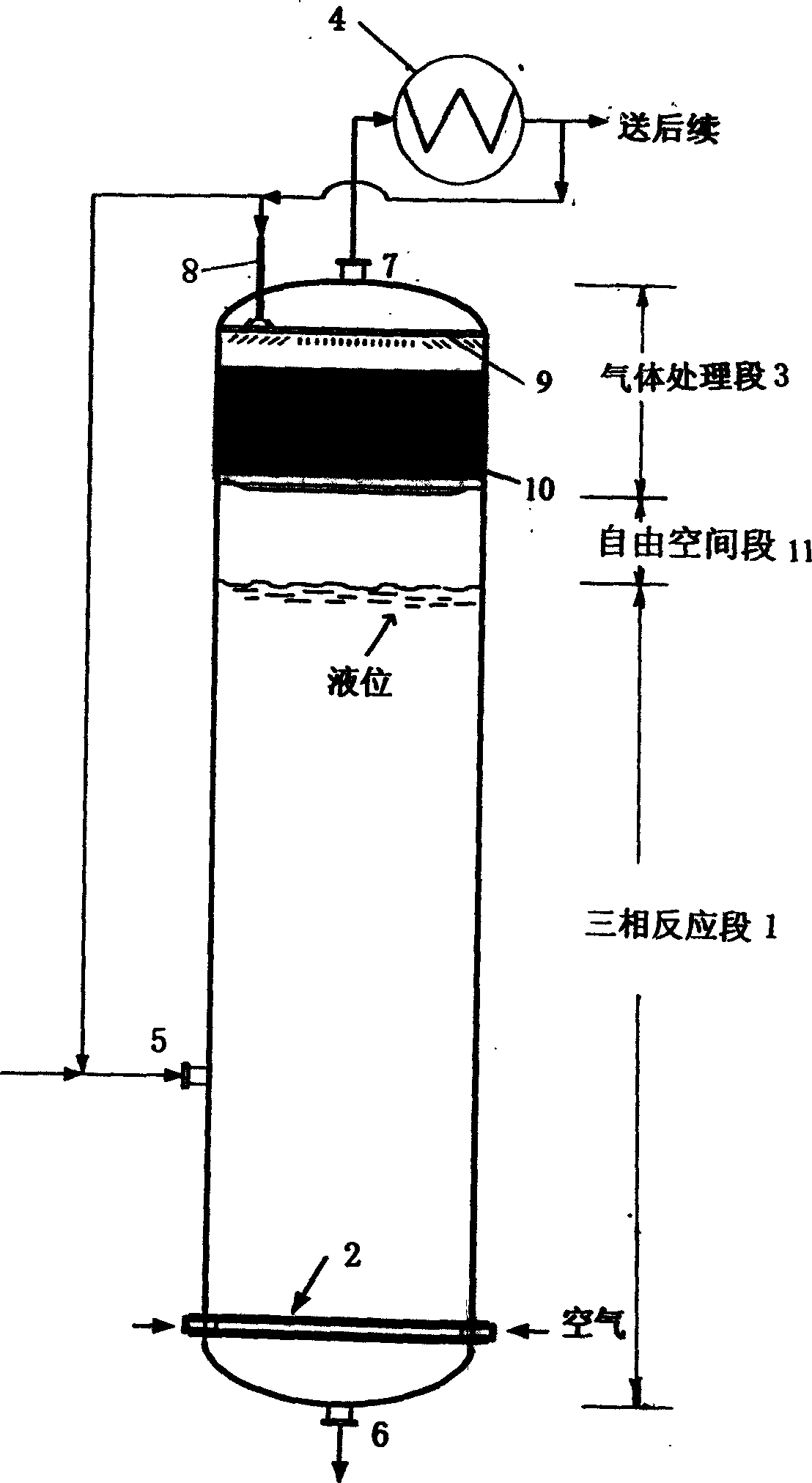

Bubble tower oxidation reaction unit for producing terephthalic acid

InactiveCN1528732ASimple structureLow costOrganic compound preparationCarboxylic compound preparationBubble columnTower

The invention discloses a bubbling column oxidizing reaction device to produce p-phthalic acid, including a uniform straight-cylindrical bubbling column, where there are gas processing segment, free space segment and three phase reaction segment in turn form top to bottom in the bubbling column, there are liquid distributor and filling or liquor-holding board installed in the gas processing segment, there is a gas distributor installed at the bottom of the three phase reaction segment, there is a raw material feeding pipe set at 1 / 4-1 / 2 of the height of reaction segment, there is a discharge pipe set at the bottom of the bubbling column, there is a tail-gas pipe and a liquor condensate reflux pipe on the top of the bubbling column, the inlet of the condenser is linked with the tail-gas pipe, the gas outlet is linked with the follow-up tail-gas processing unit, the liquid outlet of the condenser is linked with raw material feeding pipe, liquor condensate reflux pipe and follow-up dehydration tower. It is applied to the process of preparing p-phthalic acid by high temperature oxidization.

Owner:ZHEJIANG UNIV

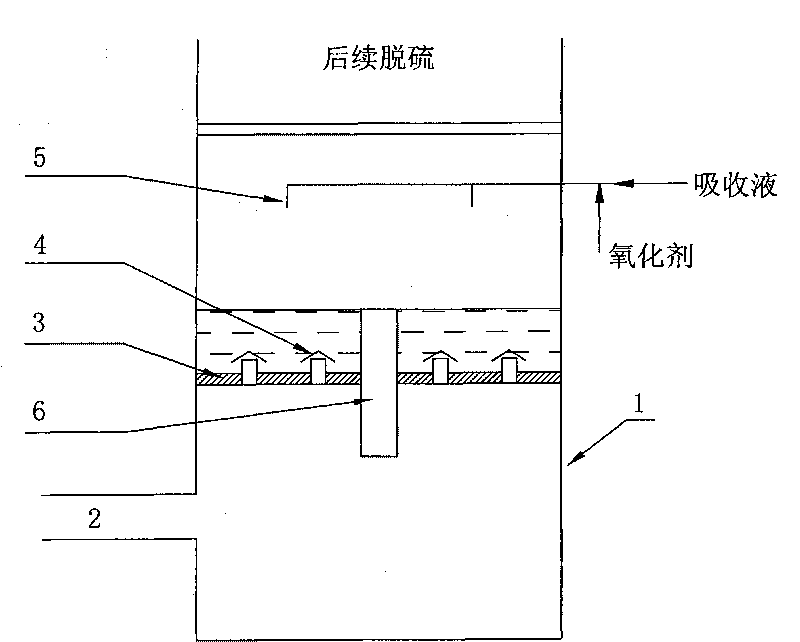

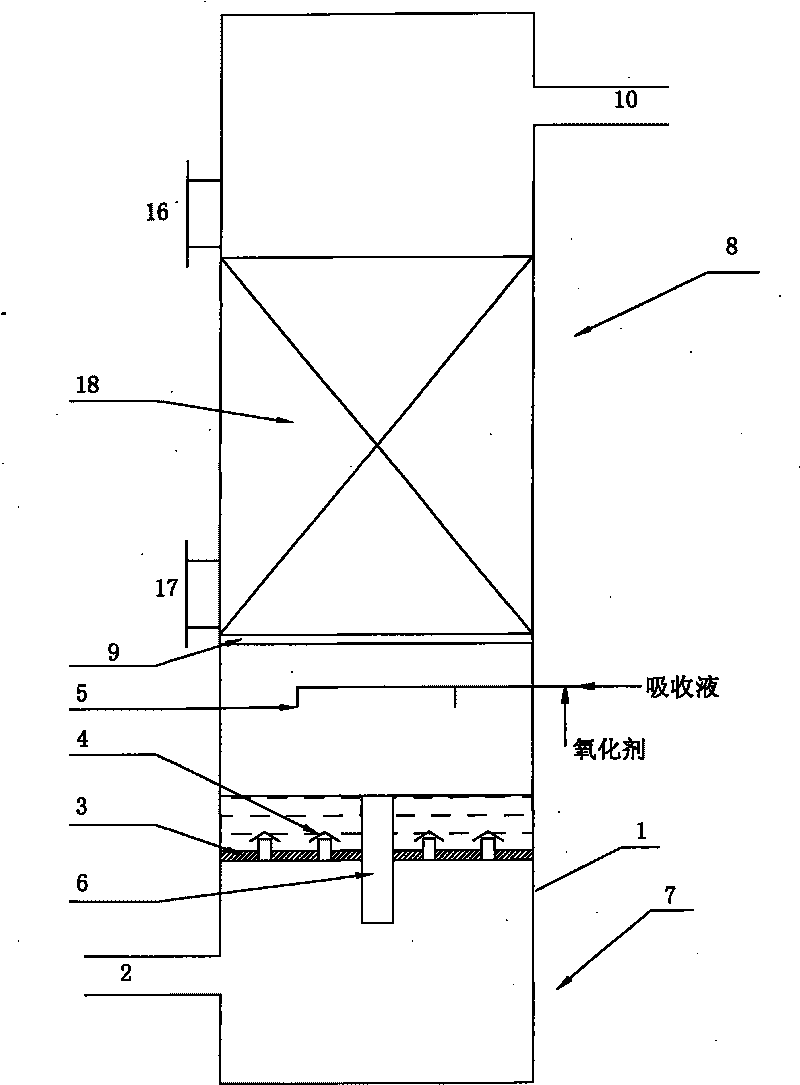

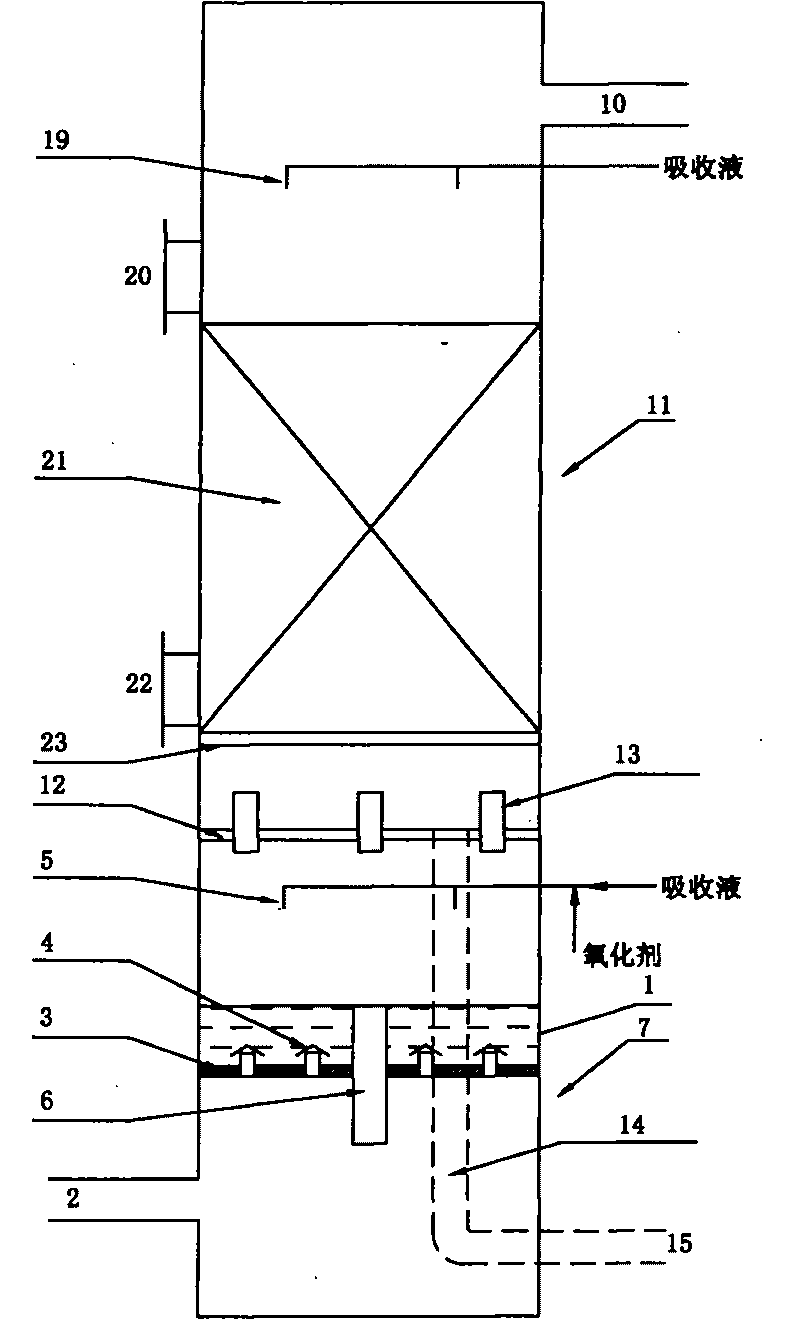

Method for depriving sulfureted hydrogen in biogas and device

The invention provides a method for depriving sulfureted hydrogen in biogas, which is characterized by comprising the following steps: firstly, introducing the biogas into a bubble column plate absorption oxidation device, and absorbing sulfureted hydrogen in the biogas by utilizing sprayed absorption solution containing an oxidant; secondly, controlling the air velocity in a hollow tower of the bubble column plate absorption oxidation device to be 0.2-1.5m / s, wherein the height of the liquid on a plate grid is 0.2-0.8m; and finally sending the biogas absorbed by absorption solution to a subsequent dry-type desulfurizing tower, a wet-type desulfurizing tower or a biological desulfurizing tower for depriving sulfureted hydrogen further. The invention also discloses three devices for depriving sulfureted hydrogen in the biogas by utilizing the combination of the bubble column plate absorption oxidation devices, a desulfuration device using the common dry method and wet method. The invention has simple method, and can effectively and quickly carry out desulfuration at constant pressure.

Owner:NANJING UNIV

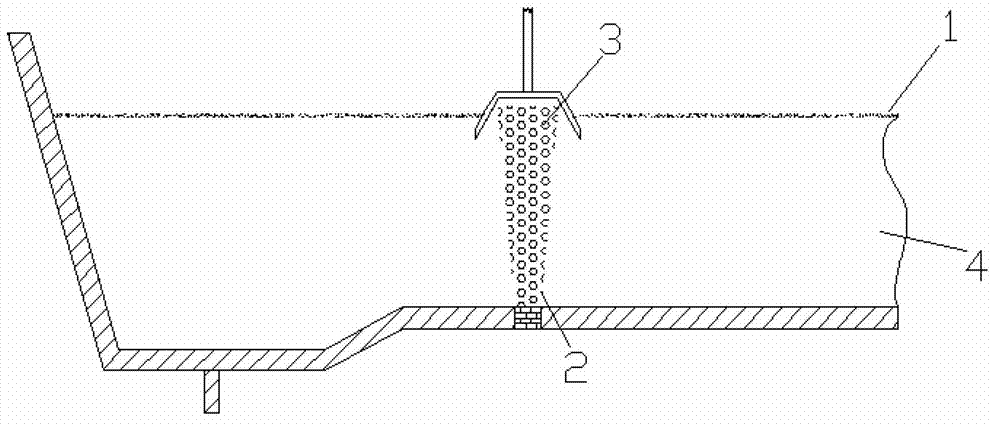

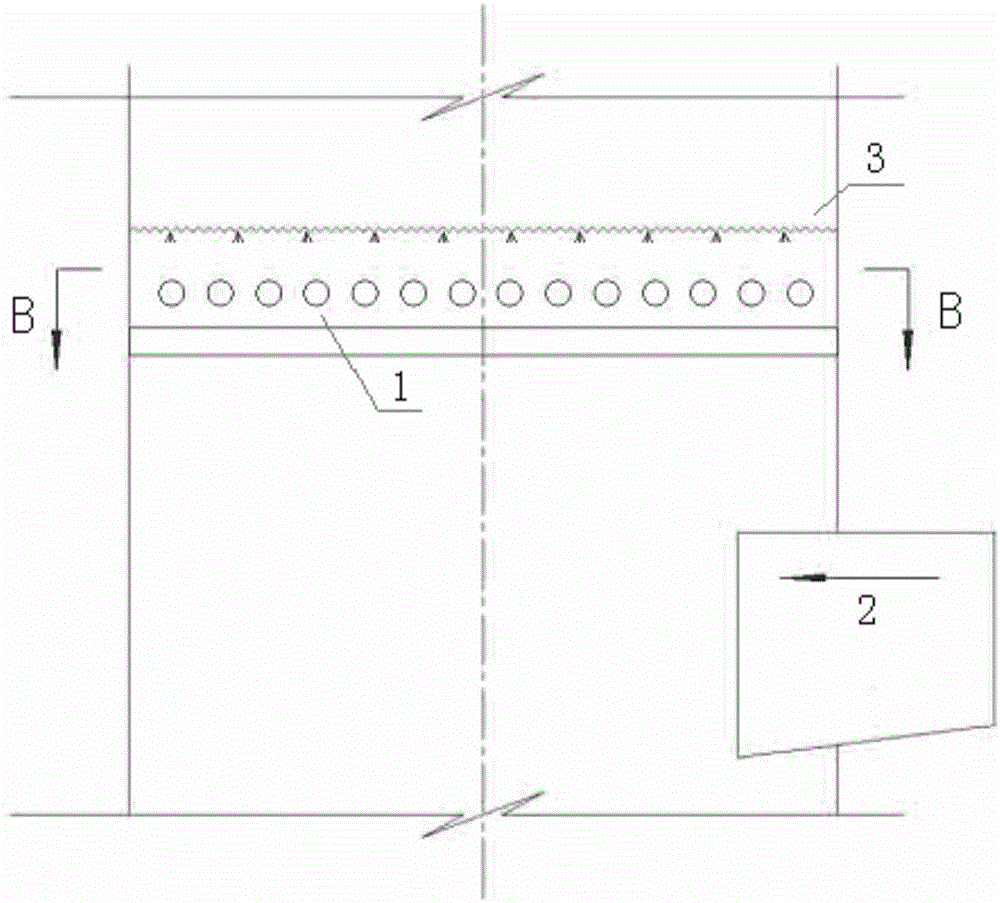

Blowing and refining device and method used for removing tundish molten steel inclusion

The invention discloses a blowing and refining device and method used for removing the tundish molten steel inclusion. The blowing and refining device is characterized by comprising a tundish 1, a blowing device 2 and a dipping cover 3, wherein the tundish comprises a permanent layer and a working layer arranged on the inner surface of the permanent layer; the bottom of the permanent layer is provided with the blowing device; the blowing device comprises an air brick and a ventilating pipe; the air brick comprises a dense layer and a ventilating layer; the middle of the ventilating layer is provided with an air chamber; and the dipping cover is a refractory material cover supported by a steel plate, is connected with an automatic lifting system and is arranged above the blowing device. According to the blowing and refining device, an air curtain retaining wall with a big air flow can be introduced in to form continuous and tight bubble columns, the average residence time of molten steel in the tundish is obviously prolonged, the molten steel flowing behavior is obviously improved, the molten steel can be stirred by a great quantity of tiny bubbles, inclusions with a smaller size can be adsorbed, and meanwhile, steel slag rolling and mixing and the secondary oxidation of the molten steel due to big blowing amount can be avoided.

Owner:UNIV OF SCI & TECH BEIJING

Method and device for reinforcing oil bubble column floatation process of low-order coal

The invention discloses a method and a device for reinforcing an oil bubble column floatation process of low-order coal, and belongs to floatation methods and floatation devices for the low-order coal. The method comprises the following steps: (1) adding a surfactant into a hydrocarbon oil collecting agent proportionally; (2) atomizing hydrocarbon oil mixed with the surfactant into oily mist beads in an atomizer by using air flow provided by an air compressor; (3) heating the air flow of the oily mist beads in a tubular temperature control evaporator until the temperature reaches hydrocarbon oil evaporation temperature to form oil evaporation gas; (4) mixing the heated oil evaporation gas with air, feeding the mixture into a bubble generator, and forming modified oil bubbles by wrapping bubbles with thin surfactant-modified hydrocarbon oil layers under the jet action of the bubble generator; (5) pre-wetting and uniformly mixing the low-order coal in a stirring barrel, and pumping the low-order coal into a floatation column; (6) in the floatation column, mineralizing the modified oil bubbles and low-order coal particles, carrying clean coal to float up by using the modified oil bubbles as carriers, and keeping tailings and high-ash fine silt which are not mineralized in the column to obtain the clean coal and the tailings. The method and the device have the advantages that the consumption of the hydrocarbon oil collecting agent is reduced; the floatation selectivity and the recovery rate of the low-order coal are improved.

Owner:CHINA UNIV OF MINING & TECH

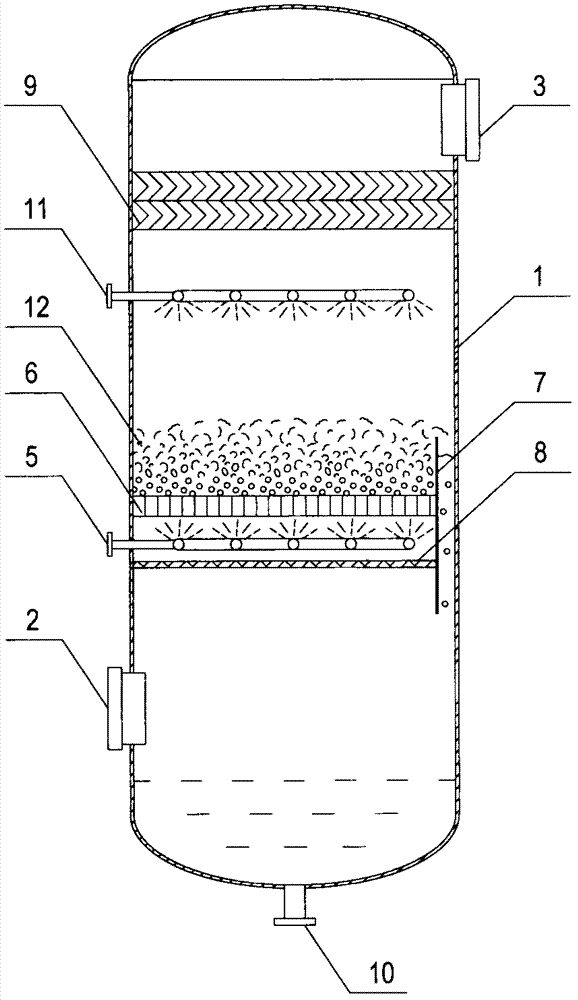

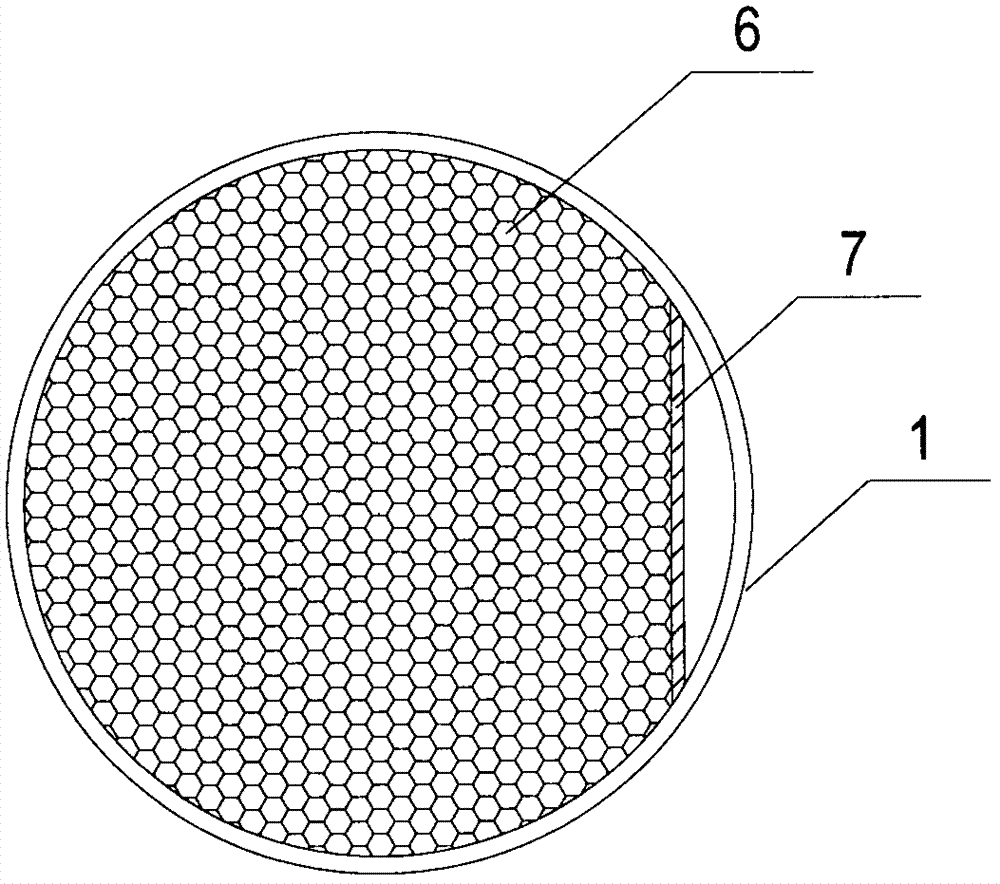

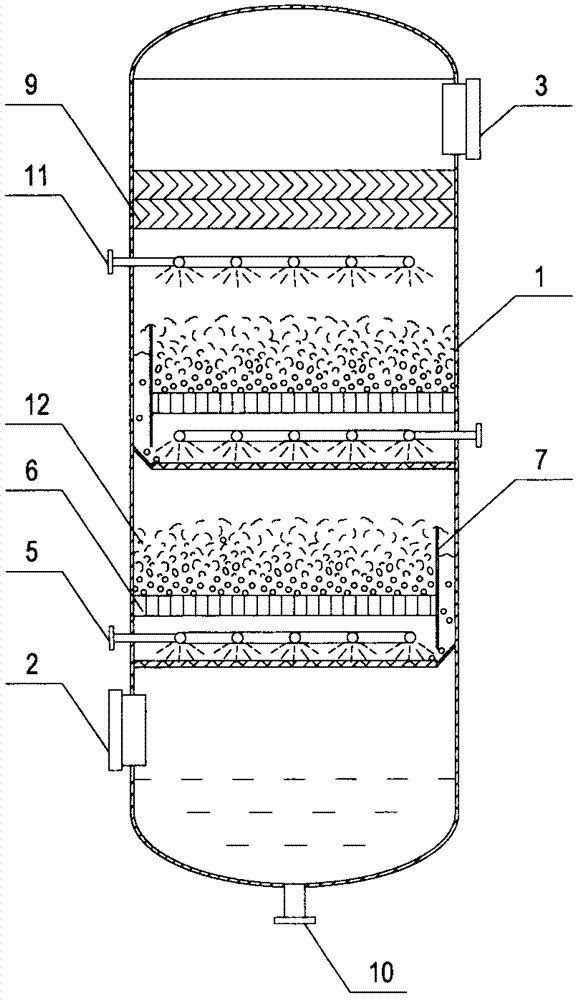

Thin-hole sieve-plate-typed bubble column

InactiveCN104324587ASimple structureImprove mass transfer efficiencyUsing liquid separation agentDistillationBubble column

The invention belongs to gas-liquid mass transfer devices in the technical fields of chemical engineering and environmental protection and is applied in technical processes, such as distillation, absorption, separation, washing, purification and the like. A thin-hole sieve-plate-typed bubble column comprises a cylinder body, a gas inlet, a gas outlet, a micro-channel thin-hole sieve plate, an imbibing breathable net and a downflow apparatus. A liquid phase is fed to the imbibing breathable net and is carried by a gas fed into the bubble column to form a gas-liquid mixture. The gas-liquid mixture passes through the micro-channel thin holes in the sieve plate to form a bubbling layer above a column plate. In the thin-hole sieve-plate-typed bubble column, the micro-channel thin-hole sieve plate and the imbibing breathable net are employed and a method of supplying the liquid from under the plate is employed so that the gas-liquid flow is formed and is passed through the micro channels, thereby significantly increasing a gas-liquid contacting area and enhancing a mass transfer process. The thin-hole sieve-plate-typed bubble column is simple in structure, is stable in operation, is convenient to maintain, is less in pressure loss and liquid consumption amount, and is low in device cost and operation energy consumption.

Owner:常州友达环保科技有限公司

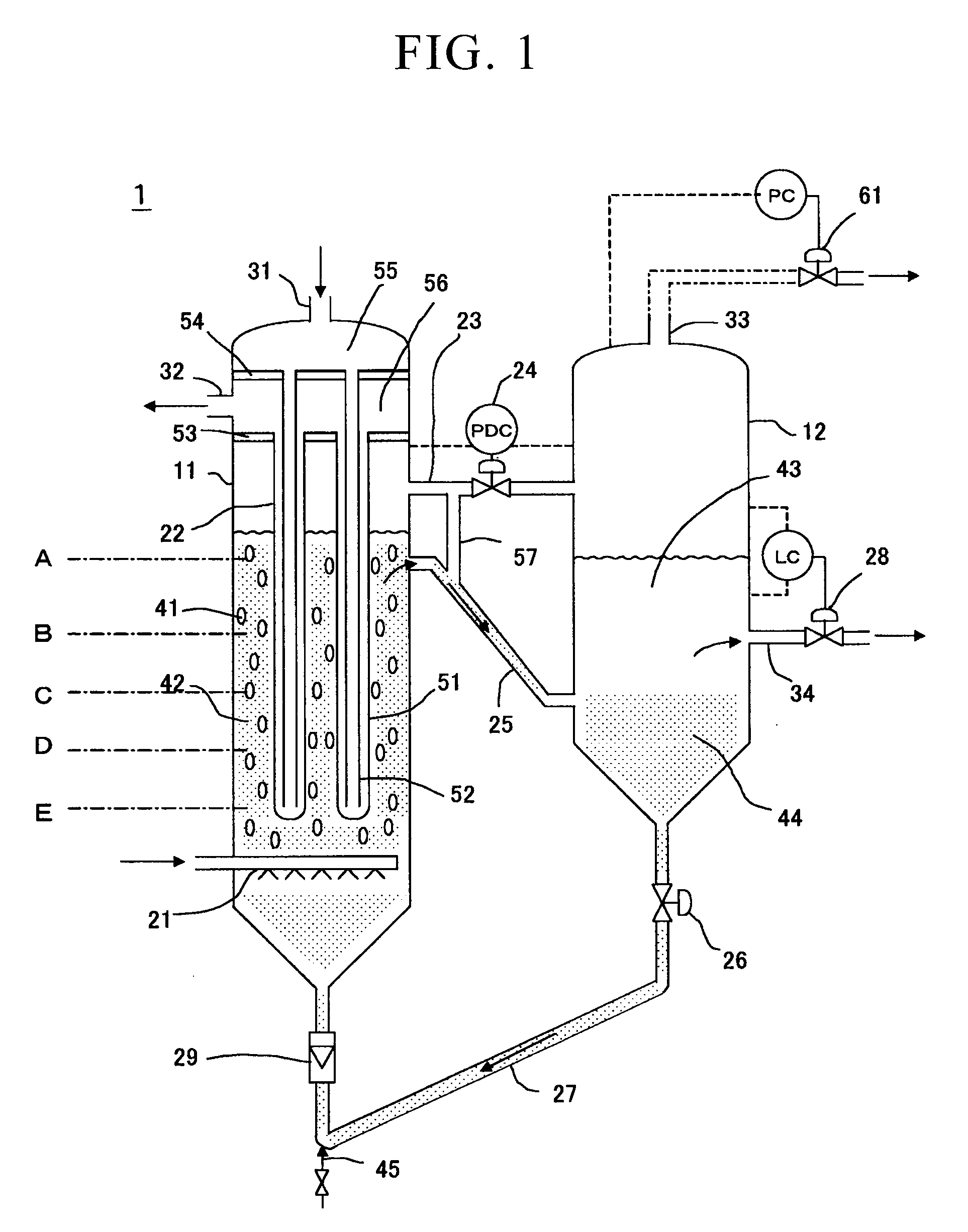

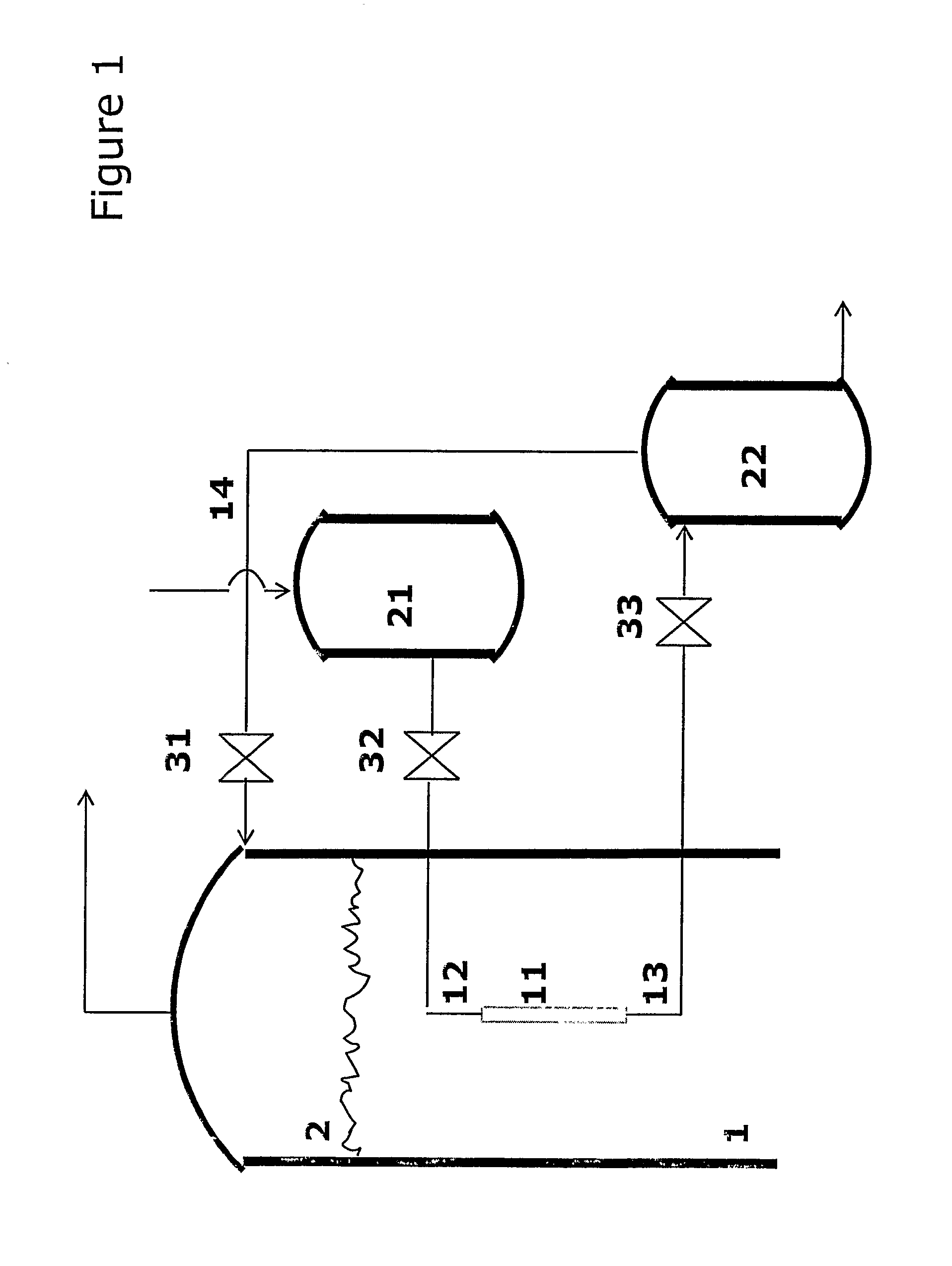

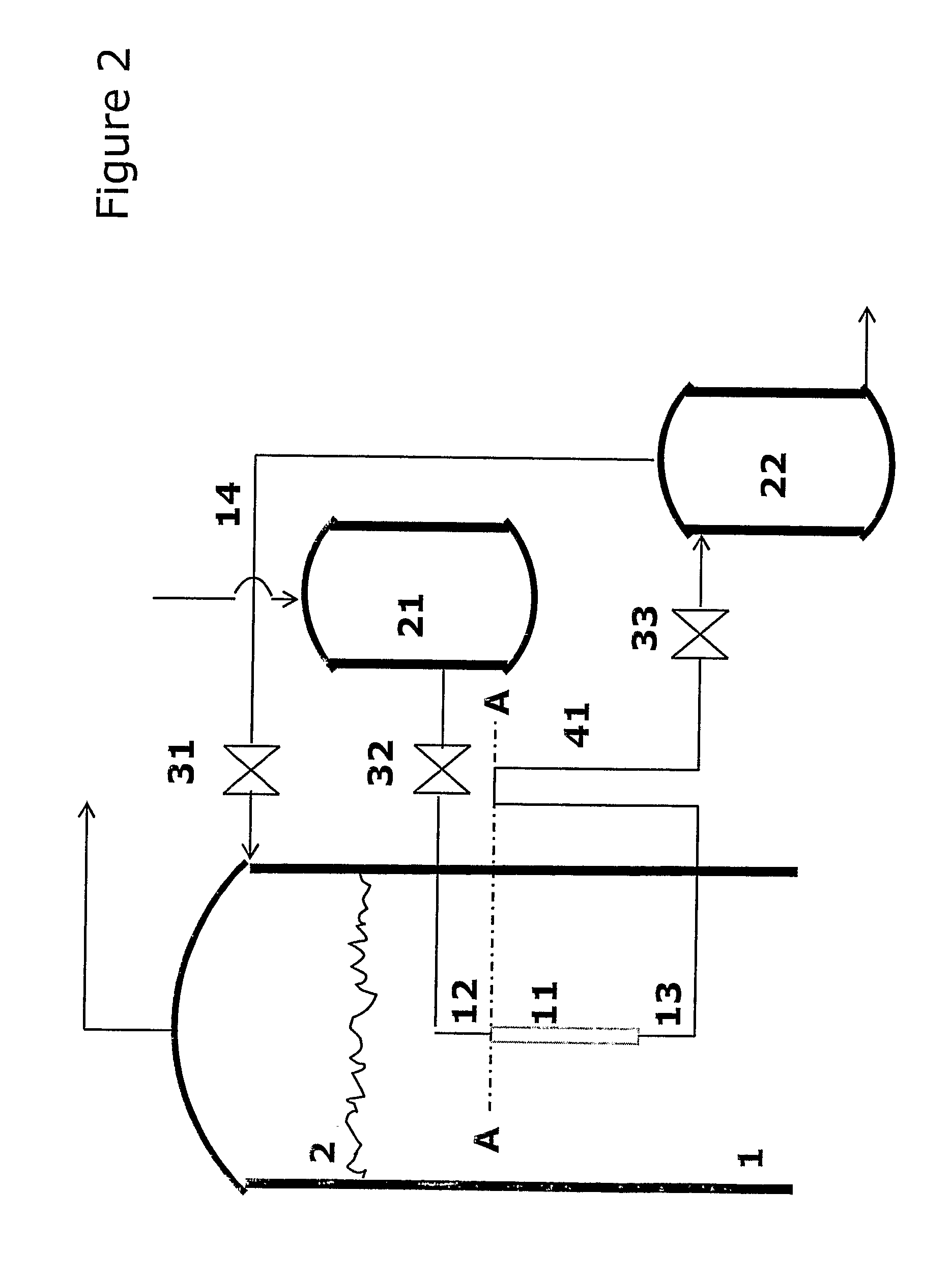

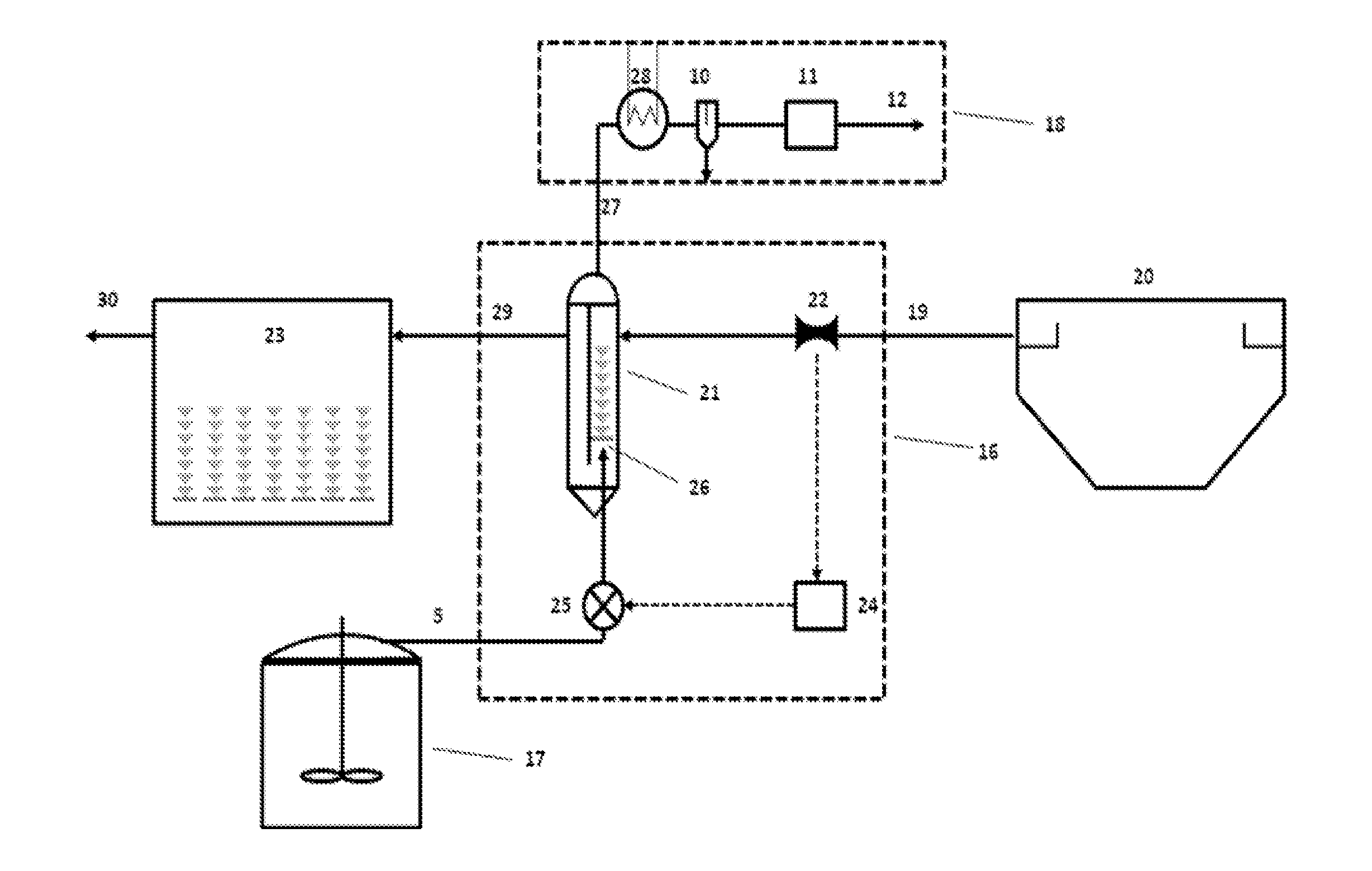

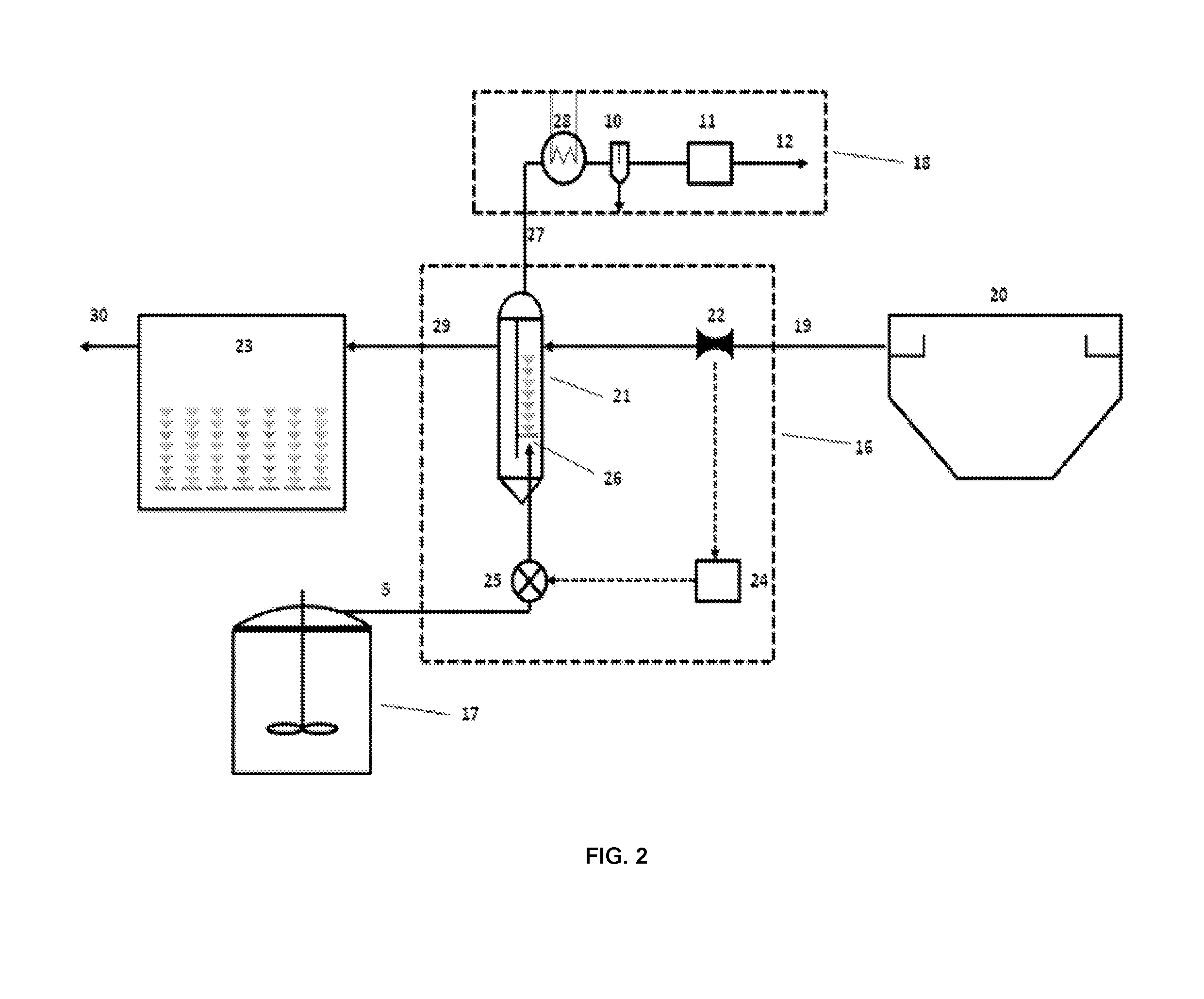

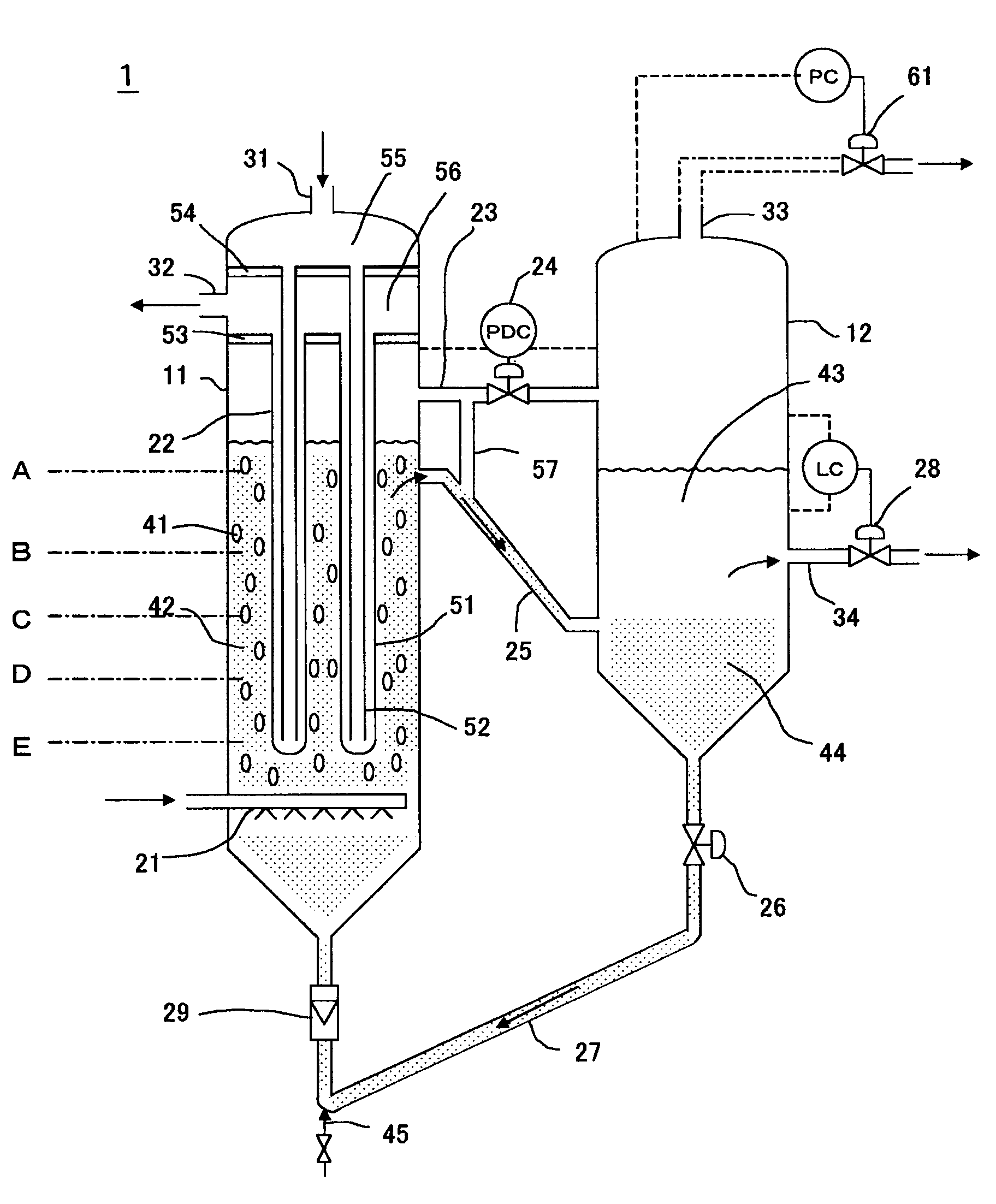

Bubble column-type fischer-tropsch synthesis slurry bed reaction system

InactiveUS20090220389A1Easy to monitorEasy to exportLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesLiquid productSyngas

A bubble column-type slurry bed reaction system is provided in which an operating system, which synthesizes liquid hydrocarbons by the Fischer-Tropsch (FT) synthesis reaction and separates and derives a catalyst and liquid hydrocarbon products from a slurry composed of gas, liquid and solid phases, can be simplified, and deterioration of catalyst particles caused by attrition and so forth can be reduced. In this FT synthesis reaction system, a bubble column-type slurry bed Fischer-Tropsch synthesis reaction process, in which synthesis gas supplied continuously from the bottom of a reactor and suspended catalyst particles are contacted to form liquid hydrocarbons, gaseous hydrocarbons and water, a process in which a slurry of suspended liquid products formed in the Fischer-Tropsch synthesis reaction process and catalyst particles moves from the reactor to the lower portion of a separation vessel through a downwardly inclined transfer pipe to separate the catalyst particles and gaseous products, a process in which the liquid products formed in the Fischer-Tropsch synthesis reaction process is sent to the separation vessel through a horizontal connecting pipe installed above the downwardly inclined transfer pipe and derived from its apex, a process in which liquid products are derived from the separation vessel, and a process in which aslurry in which catalyst particles are concentrated is derived from the bottom of the separation vessel and circulated to the bottom of the reactor, are driven by the driving force of synthesis gas introduced from the bottom of the reactor and which rises through the slurry bed reactor without using an external drive power source for circulation, and the formed liquid hydrocarbon products, gaseous hydrocarbon products and water are separated and derived without using an external drive power source for separation.

Owner:INPEX CORP +4

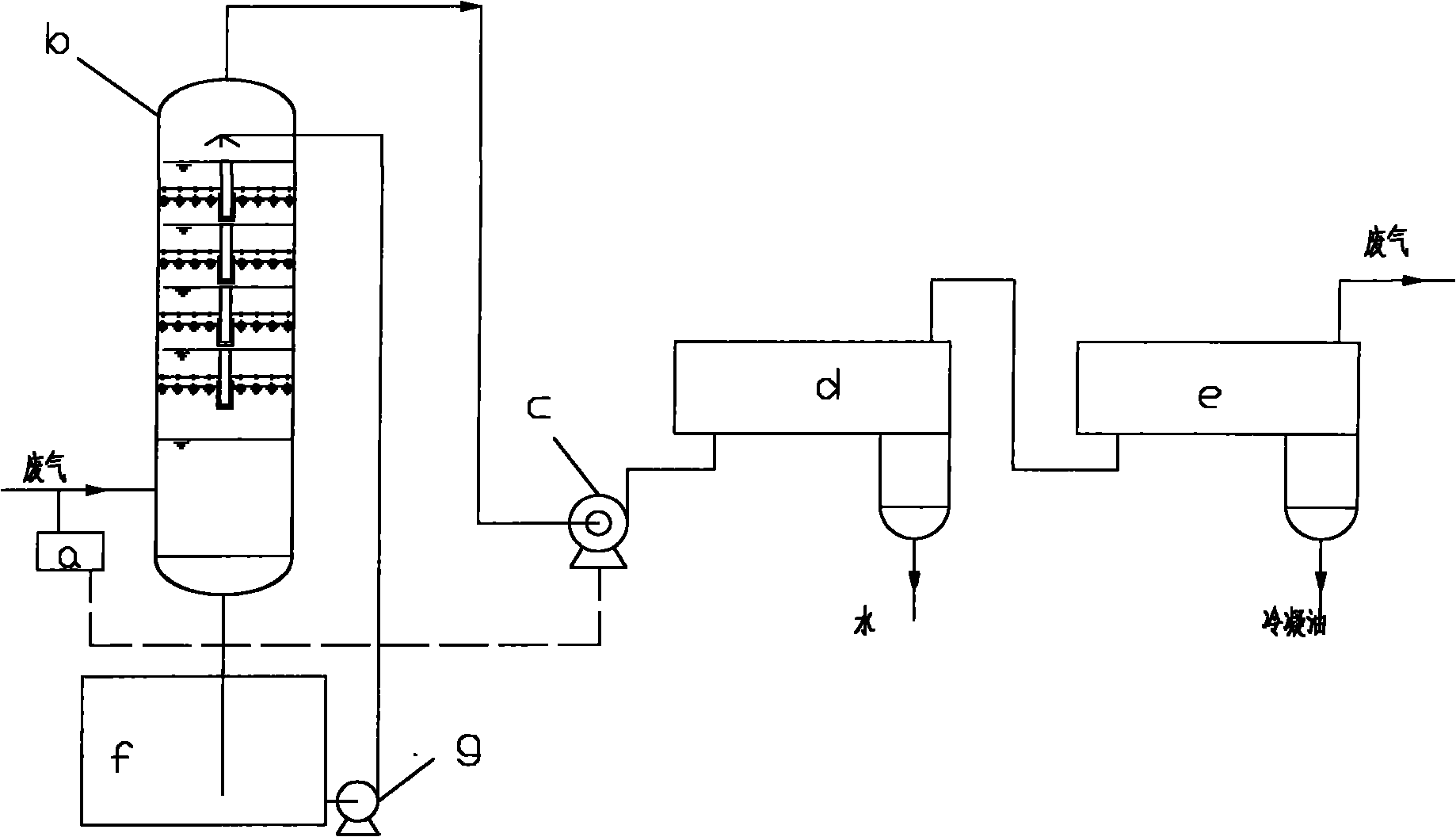

Treatment method of storage tank-dissipating stinking sulfur-containing waste gas

ActiveCN101898079AReduce processingImprove contact effectDispersed particle separationVapor condensationOrganic sulfide compoundGas phase

The invention discloses a treatment method of storage tank-dissipating stinking sulfur-containing waste gas, which comprises the steps that: under the action of a pipeline pressure controller at a waste gas inlet, a fan is started up, with the help of the power provided by the fan, hydrogen sulfide and organic sulfide in the waste gas are purified by using an efficient bubble column, moisture in the waste gas is then removed by preliminary condensation and hydrocarbon components in the waste gas are further condensed and recovered, and in the end, the purifying gas is exhausted; the efficient bubble column is a countercurrent pulse bubble absorption column, and gas phase is dispersed via a nozzle of the absorption column and then subject to contact oxidation together with absorbent in a bubble absorption area in order to absorb sulfur-containing compounds therein, and the nozzle of the bubble absorption column is structured as bubble pulse valve. The method according to the invention has simple flow and high treatment efficiency, can be used for the purification of sulfide and hydrocarbon mixed gas thereof in the process of various productions, and is particularly suitable for the purification of waste gas dissipated from the tanks in oil refining company, such as processing device, waste oil tank, sulfur-containing sewage tank, crude diesel tank, crude gasoline tank, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

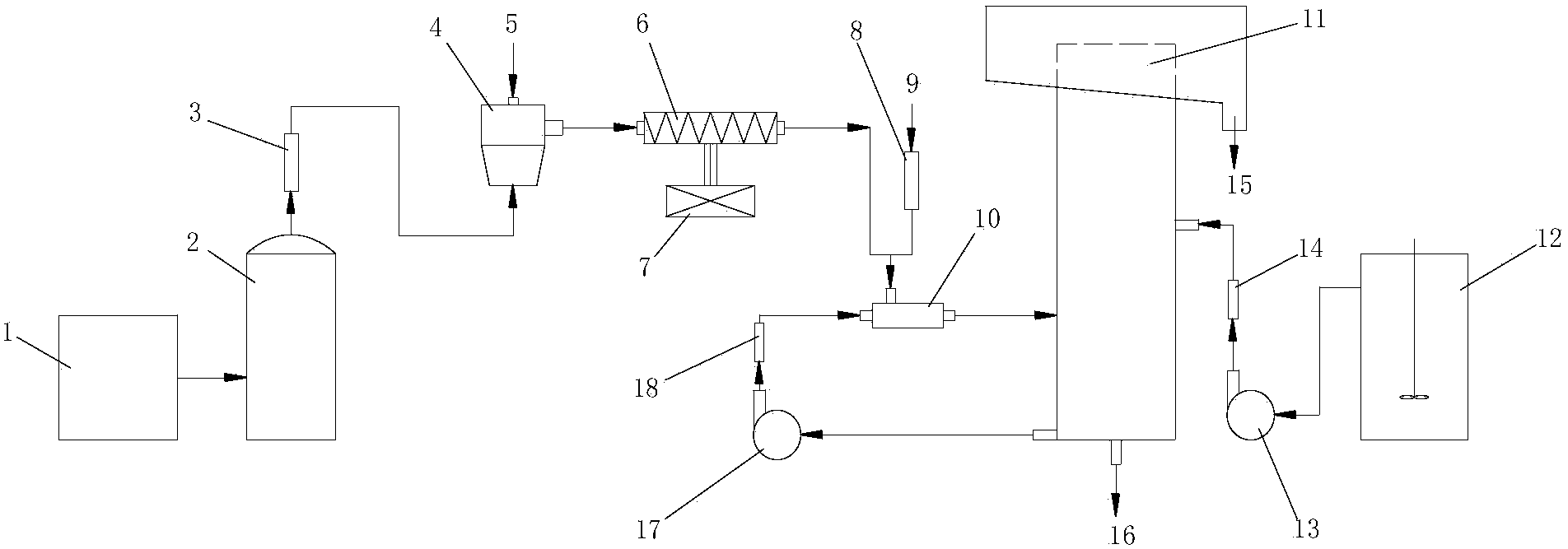

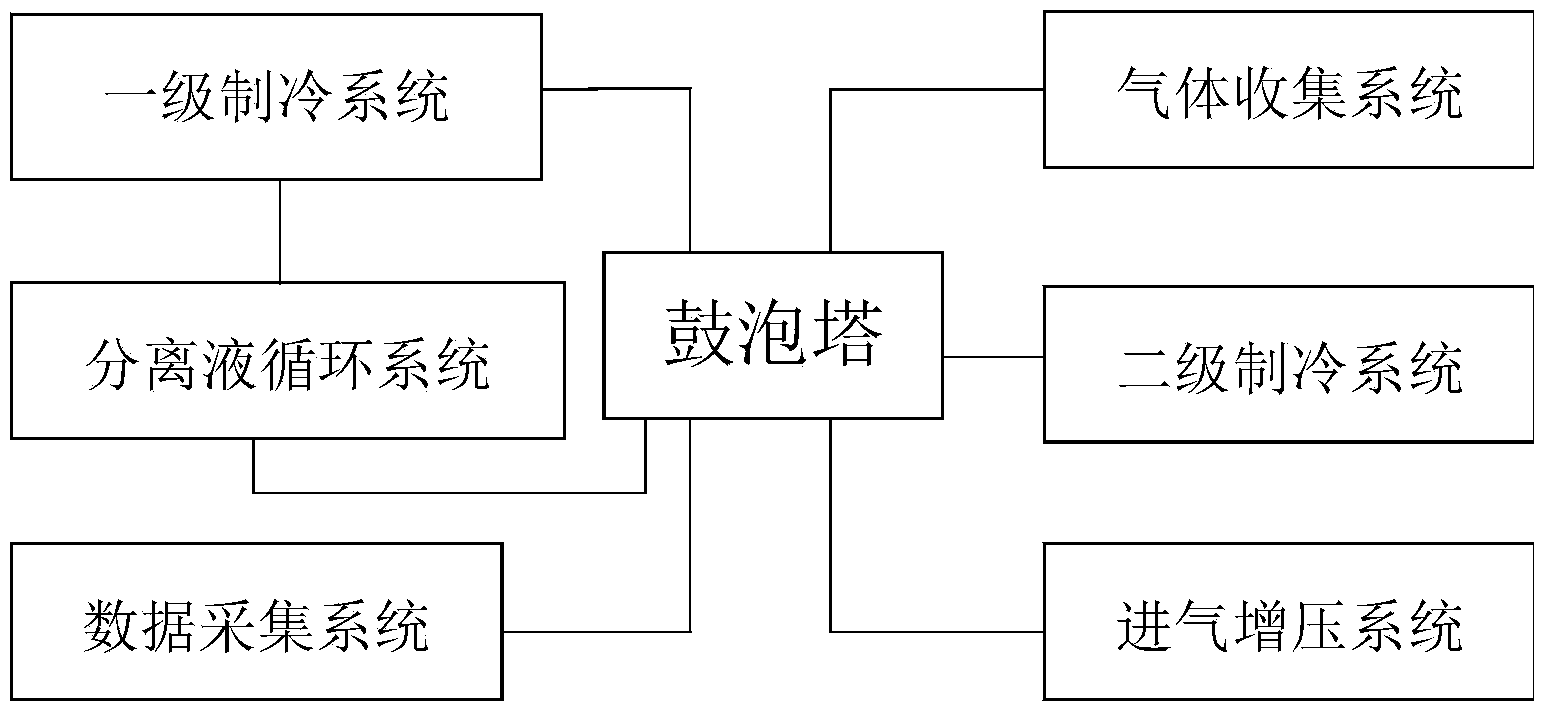

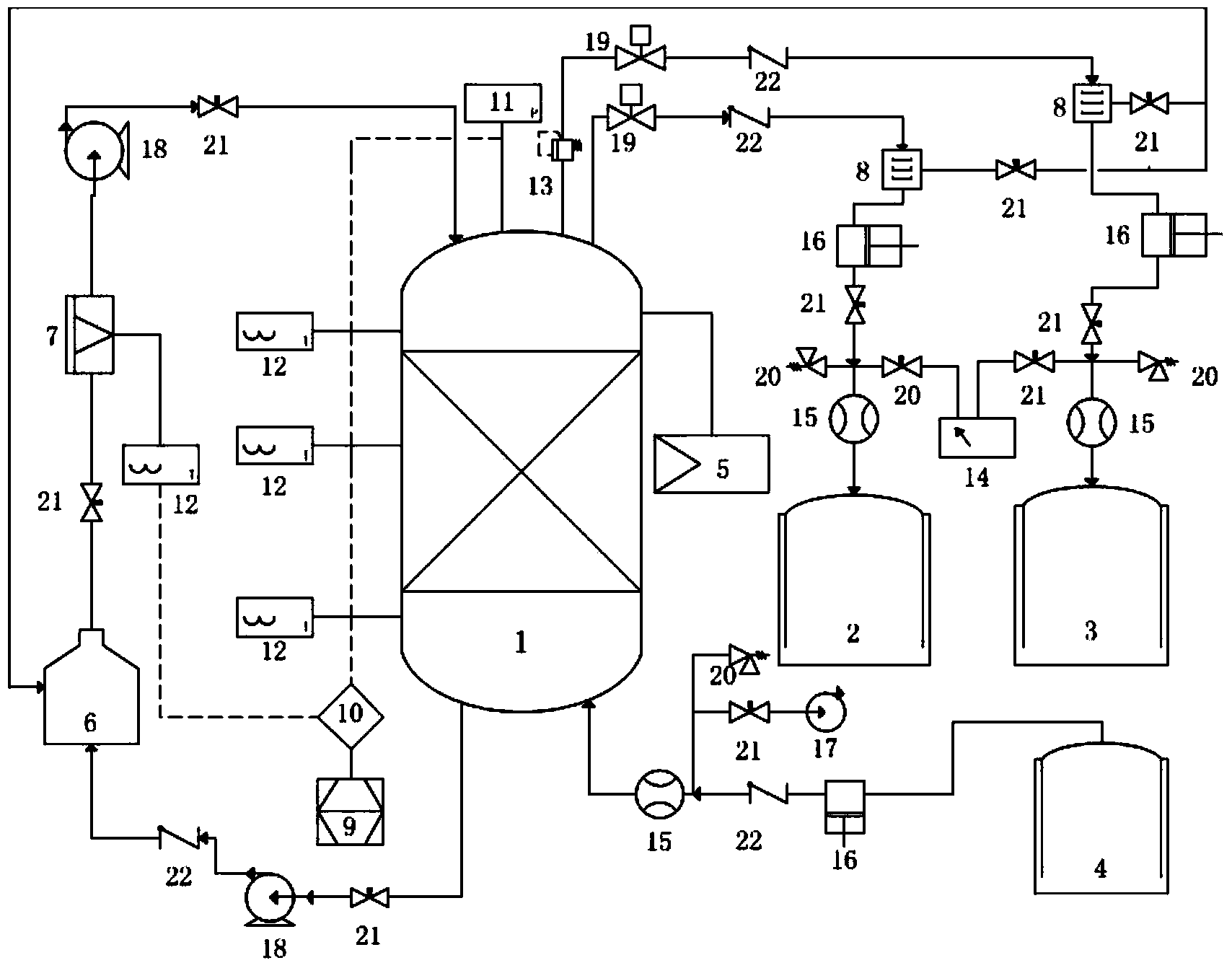

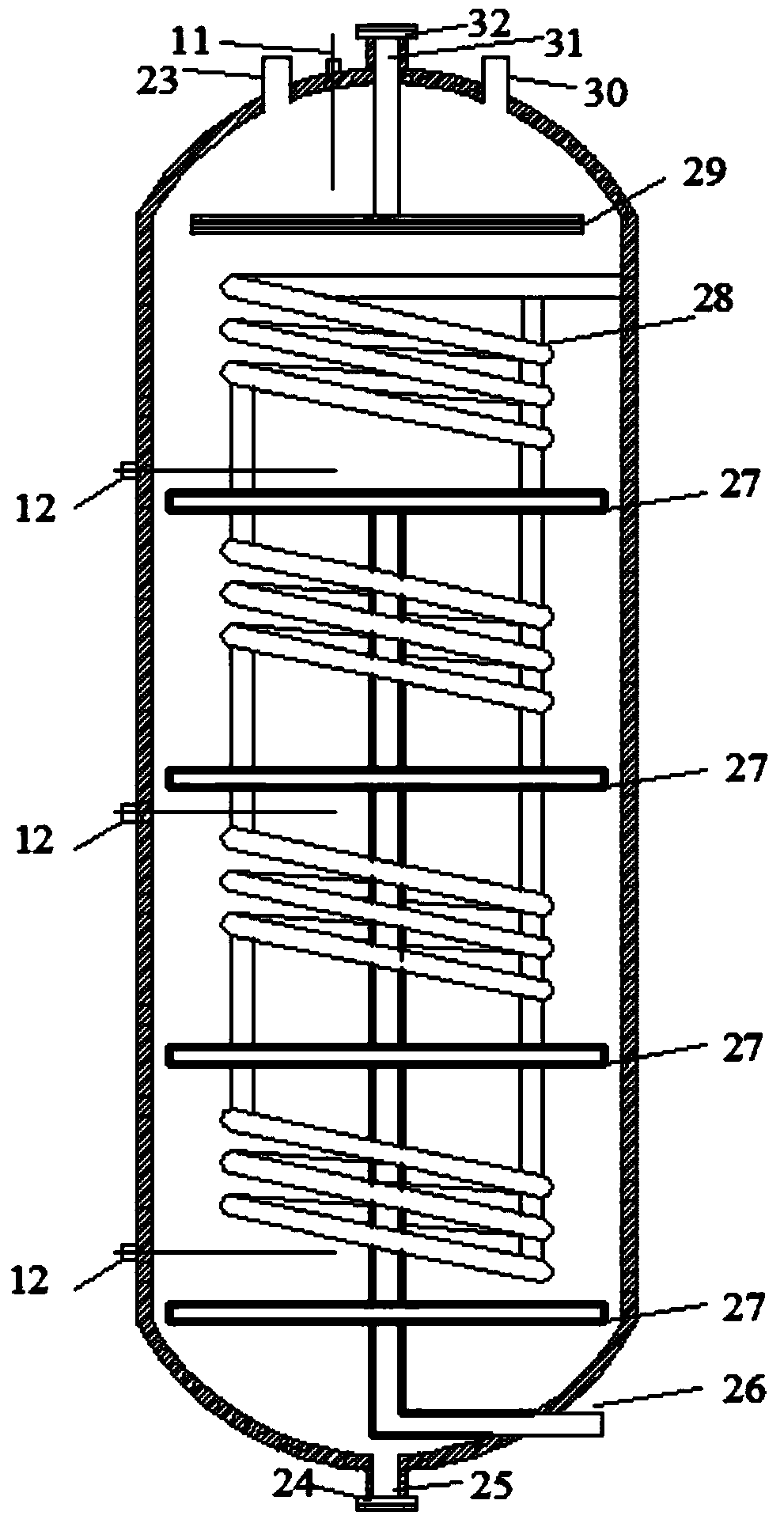

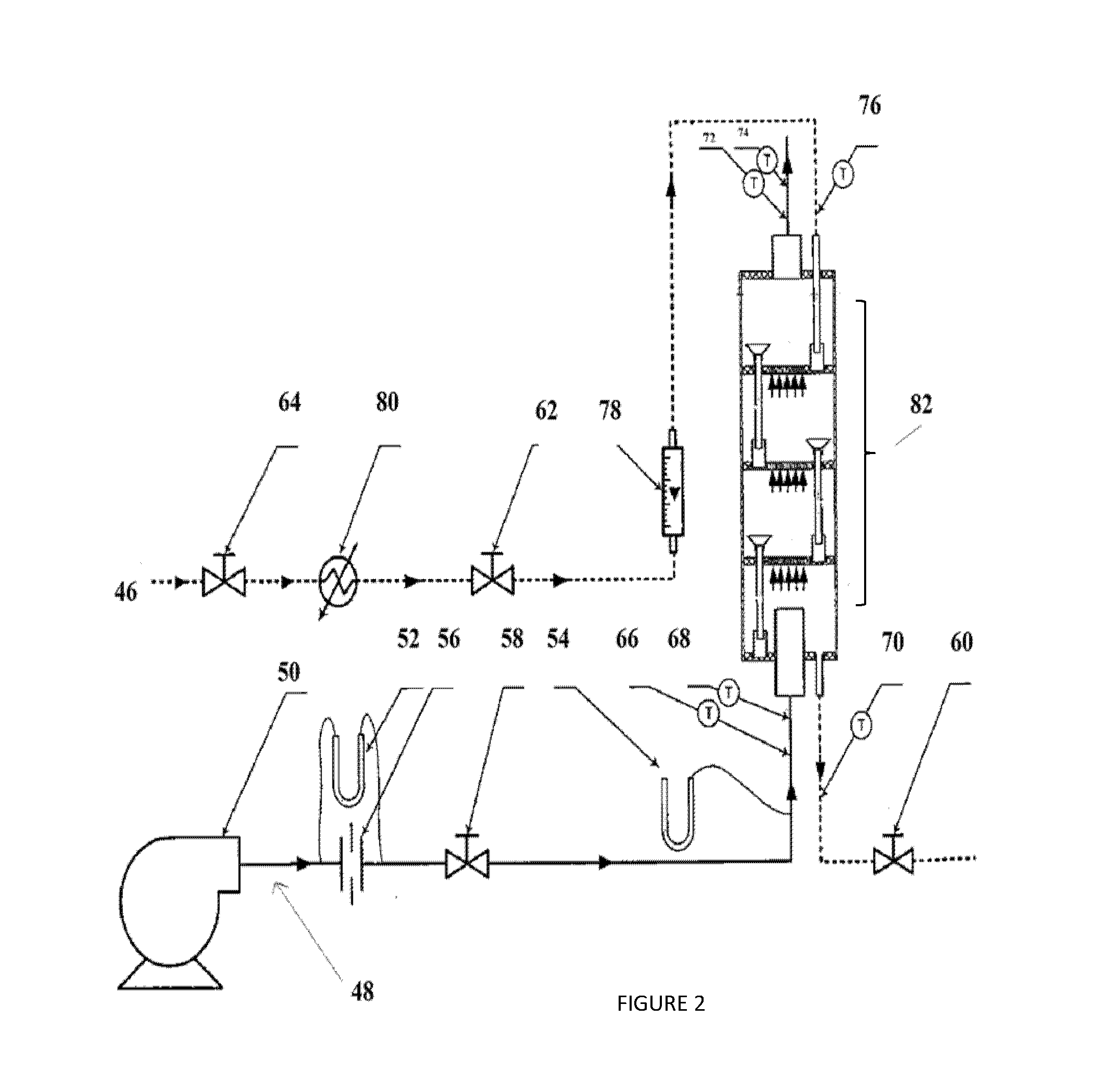

Bubbling type system for gathering carbon dioxide (CO2) by hydrate process

ActiveCN103961989ALower and maintain temperatureAchieve recyclingProductsCarbon compoundsReal time analysisData acquisition

A bubbling type system for gathering CO2 by a hydrate process belongs to the technical field of hydrate application, and comprises a bubble column, a gas intake pressurization system, a dual-refrigerating system, a gas gathering system, a separating medium circulation system and a computer data acquisition system. Mixed gas is conveyed in the bubble column after being pressurized by the gas intake pressurization system, the bubble column is filled with a separating medium, and is introduced into the bubble column after being cooled to the set temperature by the dual-refrigerating system, and CO2 hydrates are generated at low temperature. A reducing valve is arranged outside the bubble column, CO2 is enabled to be separated through a depressurization method, the gas flow after CO2 separation is measured by a flowmeter, gas components are analyzed by a gaschromatograph, the working parameters during the separation process, such as temperature, pressure signal and flow signal, are acquired and analyzed in time by the computer data acquisition system. The device is low in cost, has basic significance in mastering the gas separation technology adopting the hydrate process, and has an important value in the aspects of effective CO2 gathering in a power plant and high-purity utilization of hydrogen energy.

Owner:DALIAN UNIV OF TECH

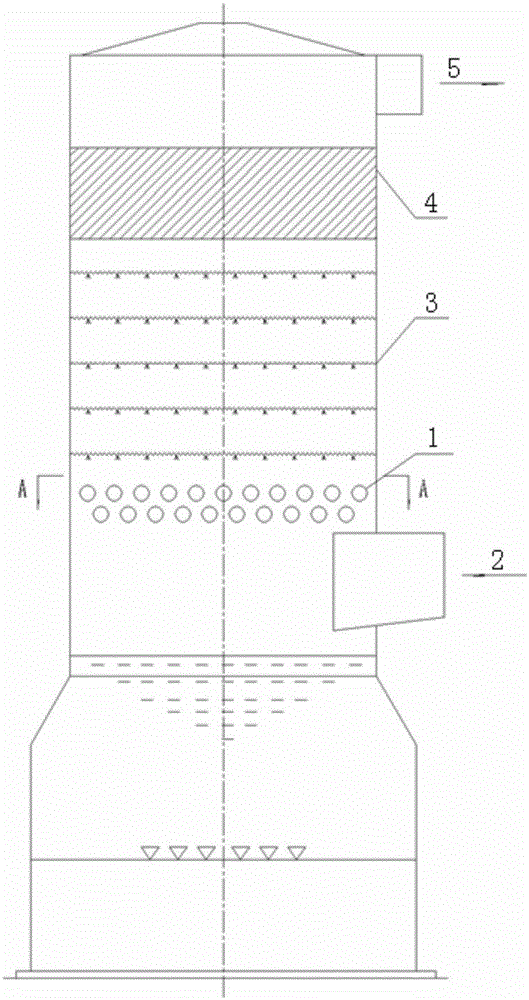

Turbulent tube grid tower capable of improving desulfurization efficiency

InactiveCN105879645ASimple processReduce energy consumptionCombination devicesUsing liquid separation agentManufacturing technologyOperational costs

The invention provides a turbulent pipe-grid tower for improving desulfurization efficiency. By increasing the pipe grid structure to uniformly distribute the flue gas flow field, uniformly spray the slurry, and form a liquid-holding layer on the upper part of the device, the gas-liquid contact area is increased, thereby improving the desulfurization efficiency. At the same time, the liquid-holding layer can also play a certain role in dust removal. And compared with the tray tower and the rotary sink coupling tower, its structure is simple, the manufacturing process is also simplified, the resistance is also greatly reduced, the production and operation costs are reduced, and it is also convenient for maintenance. The technical solution adopted is: a turbulent pipe grid tower for improving desulfurization efficiency, including tower body, flue gas inlet and spray layer; a pipe grid structure is arranged between the flue gas inlet and spray layer, including parallel layered arrangement There are at least two layers of tube arrays; the tube array includes several parallel tubes; the vertical projections of any one tube and the tubes in the adjacent tube arrays of the tube array do not overlap or partially overlap.

Owner:DATANG ENVIRONMENT IND GRP

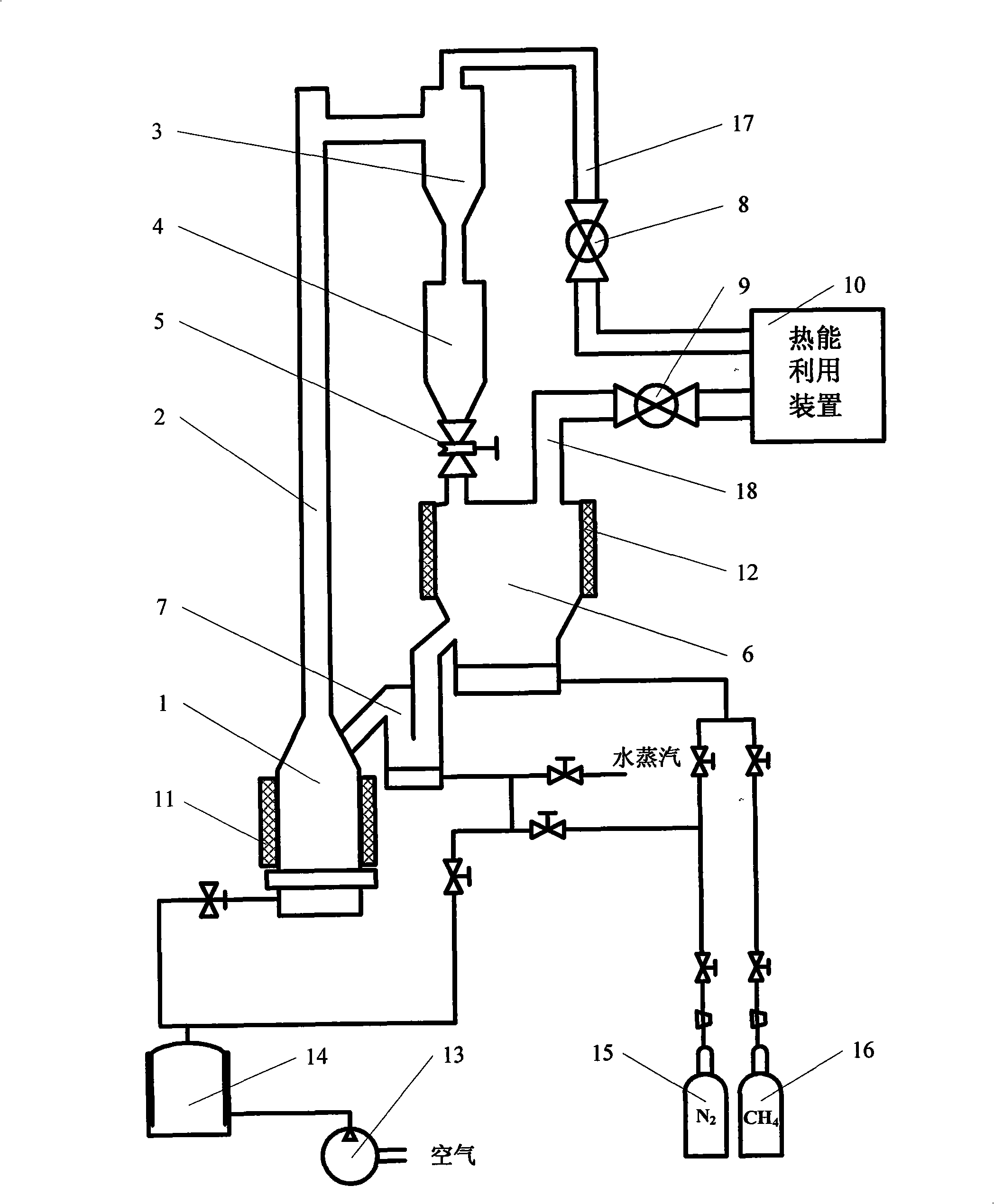

Double-circulating fluid bed system for chemical chain combustion

InactiveCN101349423APrevent leakageReduce usageFluidized bed combustionIndirect carbon-dioxide mitigationBubble columnProcess engineering

The invention relates to the clean-burning and efficient utilization field of fuels, in particular to a double-circulating fluidized bed system used for chemical-looping combustion. The double-circulating fluidized bed system comprises a heat energy utilization device, a bubbling bed, a loop seal, a fast fluidized bed, a lift pipe and a cyclone separating device, wherein the bubbling bed, the loop seal, the fast fluidized bed, the lift pipe and the cyclone separating device are sequentially connected, the cyclone separating device is communicated with the heat energy utilization device through a first exhaust pipe, and the bubbling bed is communicated with the heat energy utilization device through a second exhaust pipe. The double-circulating fluidized bed system is characterized in that an oxygen carrier reservoir and a solid flow control valve are arranged between the outlet of the cyclone separating device and the inlet of the bubble column.

Owner:XI AN JIAOTONG UNIV

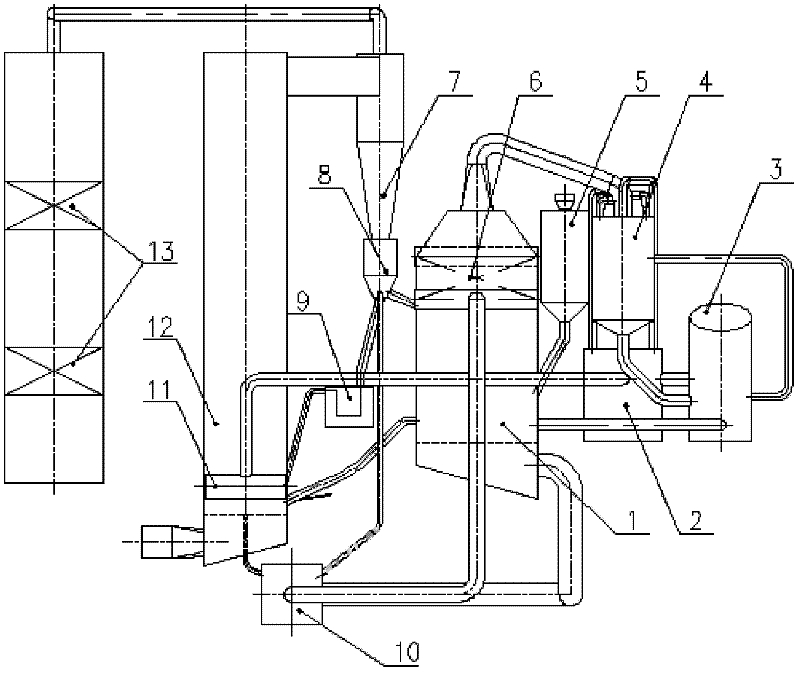

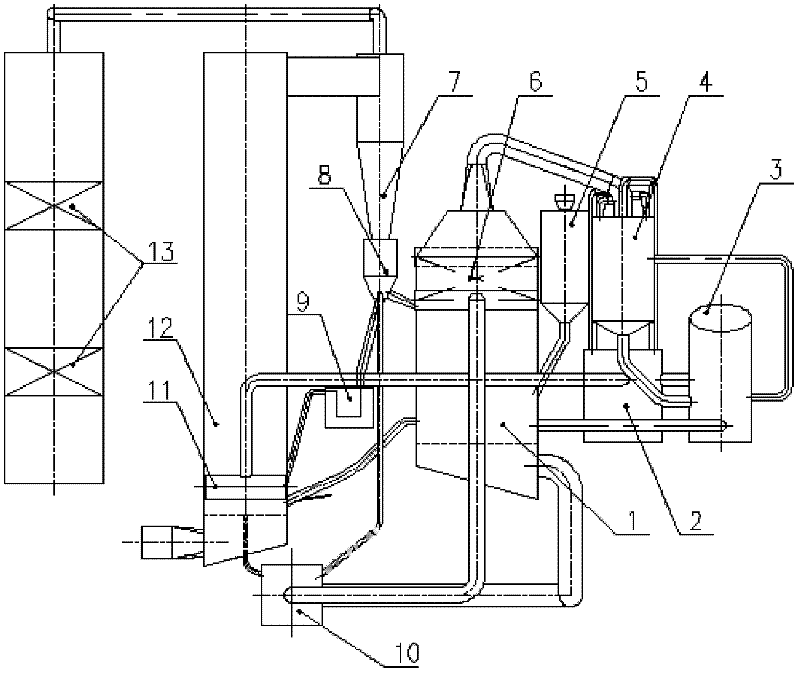

Combination system of oil shale bubbling bed dry distillation and semi-coke circulating fluidized bed combustion

InactiveCN102295941AAchieve oil refiningRealize power generationDirect heating destructive distillationSpecial form destructive distillationHeat carrierAtmospheric air

The invention relates to a combined system of oil shale bubble column dry distillation and semicoke circulating fluidized bed combustion; a bubble column is used as an oil shale dry distillation furnace; a circulating fluidized bed is used as a semicoke combustion utilization device; both hot ash and generated by combustion of the circulating fluidized bed and circulating hot gas are used as a heat carrier of the dry distillation furnace; oil shale particles are heated and decomposed in the bubble column; the generated gaseous substance is separated into gas, shale oil, water and oily sludge through a gas-liquid separator, and a oil-water separator; semicoke discharged from the bottom of the bubble column is directly delivered into the circulating fluidized bed for combustion; the generated high-temperature flue gas is mixed with the high-temperature flue gas discharged from a gas combustor, and then is introduced into a gas-solid separator; the separated fly ash is delivered respectively to the bubble column, a material-returning valve, and an external gas-solid heat exchanger; the flue gas after dedusting passes through a tail heating surface, and finally is discharged into atmosphere; steam generated by the tail heating surface is used for power generation and heat supply. Compared with the prior art, the invention can increase the quality of shale oil and gas, and can effectively reduce the energy loss and environment pollution of the system.

Owner:SHANGHAI JIAO TONG UNIV

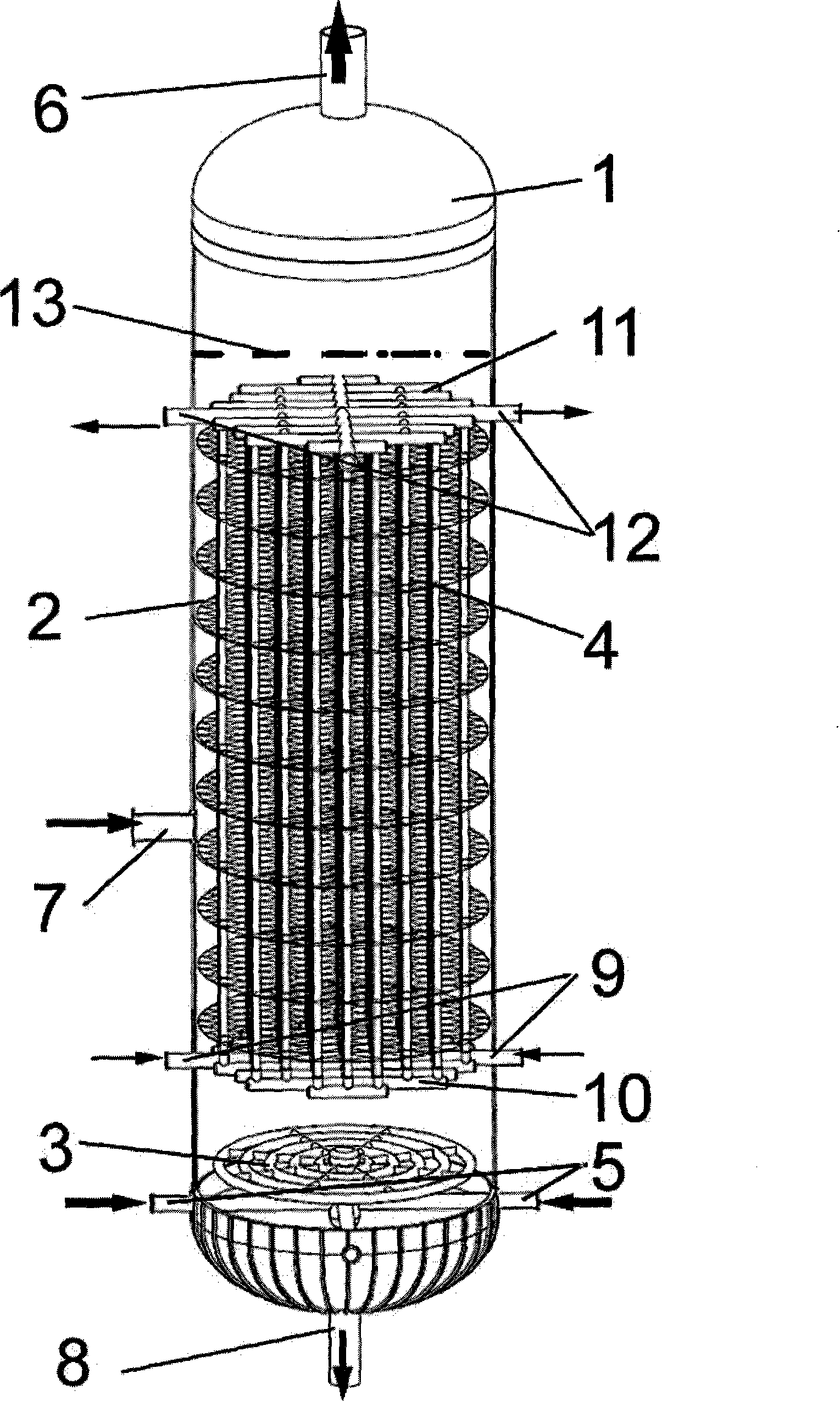

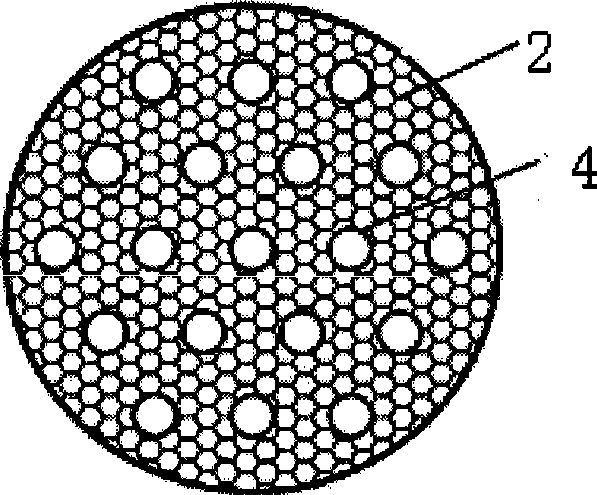

Filtration method and installation

InactiveUS20090261046A1Minimizing transportWater/sewage treatmentLiquid hydrocarbon mixture productionFiltrationBubble column

The invention provides a method for the separation of liquid from a three phase slurry bubble column. The method includes the step of charging the inside of a hollow filter element with a rinsing fluid to clean the inside of the filter for catalyst fines followed by a backflushing step. The invention also provides an installation for the separation of liquid from a three phase slurry bubble column. The installation includes at least one hollow and enclosed filter element and one or more conduits in fluid communication with the internal volume of filter, with at least one conduit being configured or connected for inflow of rinsing fluid and at least one conduit being configured or connected for outflow of rinsing fluid.

Owner:EQUINOR ENERGY AS +1

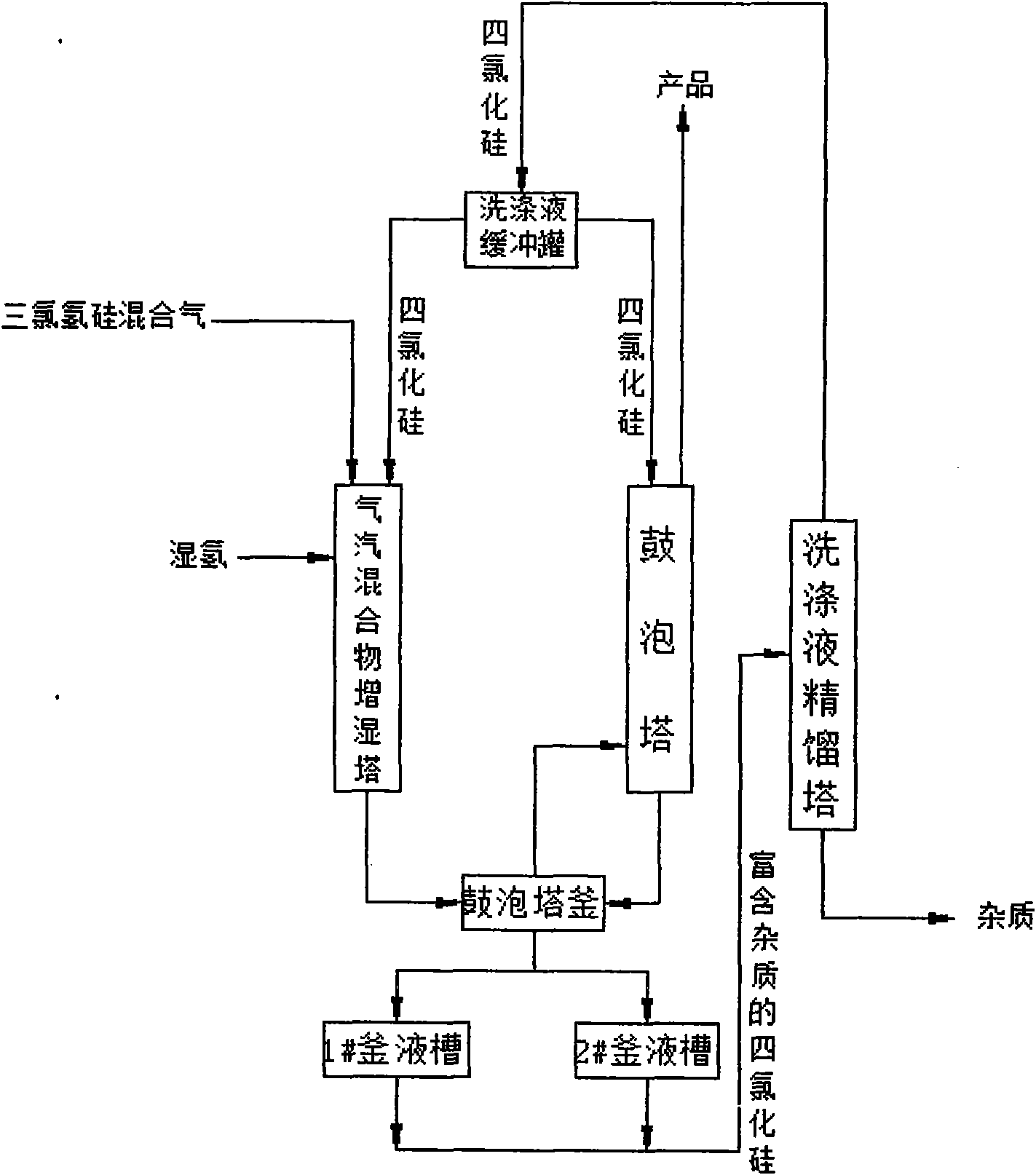

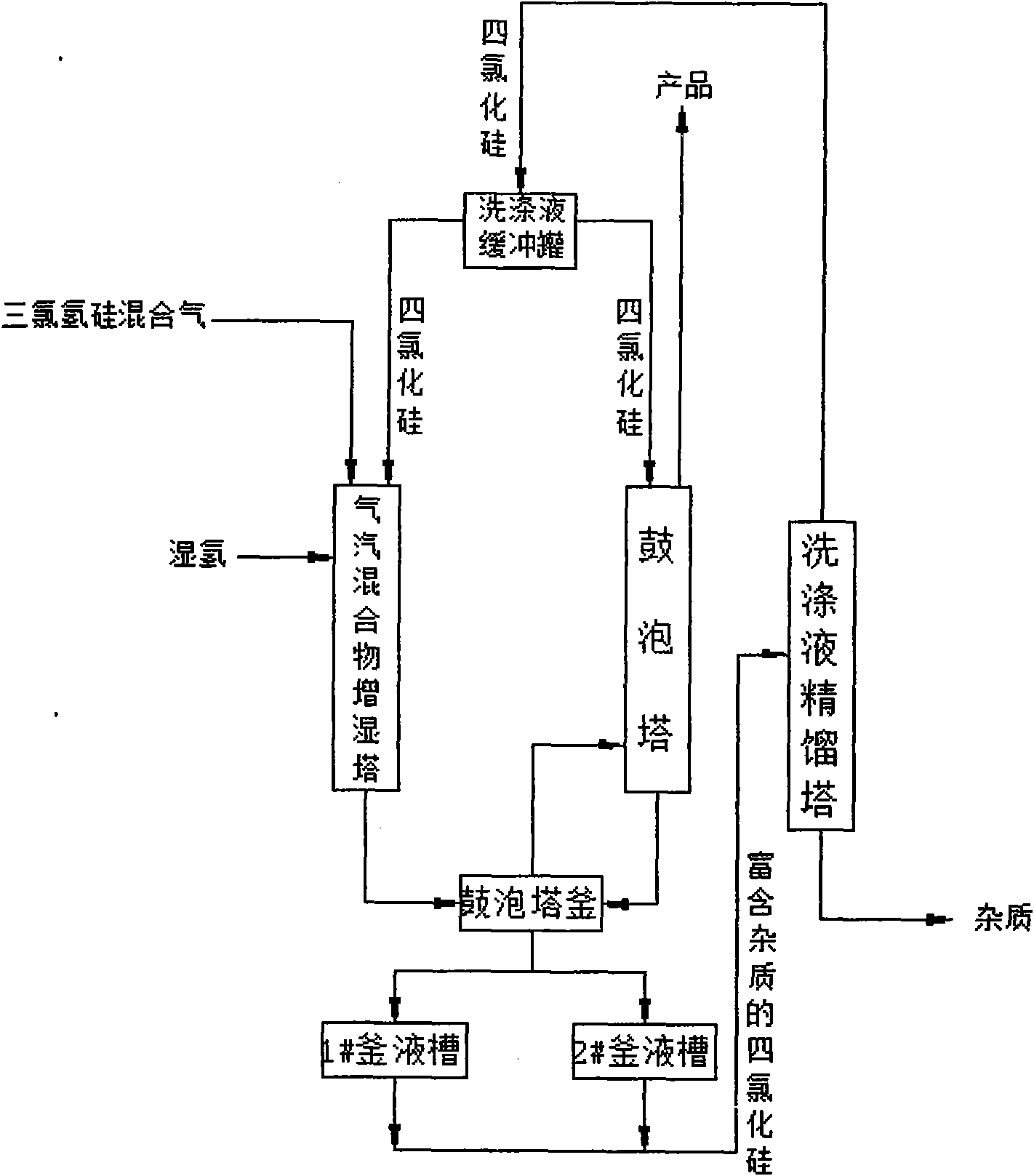

Method and device for removing impurities from trichlorosilane mixed gas

The invention discloses a method and a device for removing impurities from a trichlorosilane mixed gas. The method comprises the steps of: carrying out primary spraying on the trichlorosilane mixed gas in a gas and steam mixture humidifying tower by adopting silicon tetrachloride liquid, absorbing metal chloride and siliceous dust by silicon tetrachloride, introducing wet hydrogen in the trichlorosilane mixed gas to obtain SiO2 through reaction, absorbing boron and phosphorus in the trichlorosilane mixed gas through the SiO2; carrying out secondary spraying on the trichlorosilane mixed gas with the silicon tetrachloride liquid in a bubble column, and further removing the metal chloride to obtain a finished product of a trichlorosilane synthesis gas; and connecting the bubble column used for collecting the silicon tetrachloride obtained by spraying the silicon tetrachloride mixed gas for two times to a washing liquid distilling tower, distilling and purifying the silicon tetrachloride with impurities, and circularly spraying by using the silicon tetrachloride. The impurities are removed by adopting a wet method, the impurities in the trichlorosilane mixed gas can be fully removed to obtain high-quality refined trichlorosilane, the silicon tetrachloride can be circularly utilized, and the purposes of saving energy, reducing consumption and decreasing emission are achieved.

Owner:天威四川硅业有限责任公司

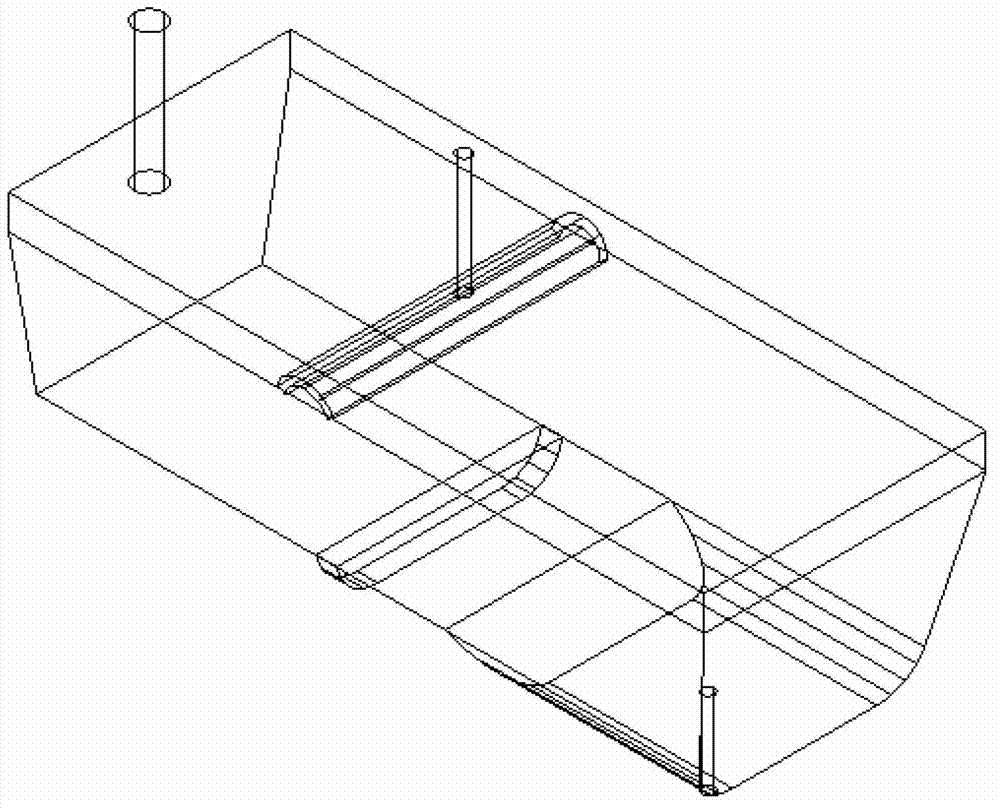

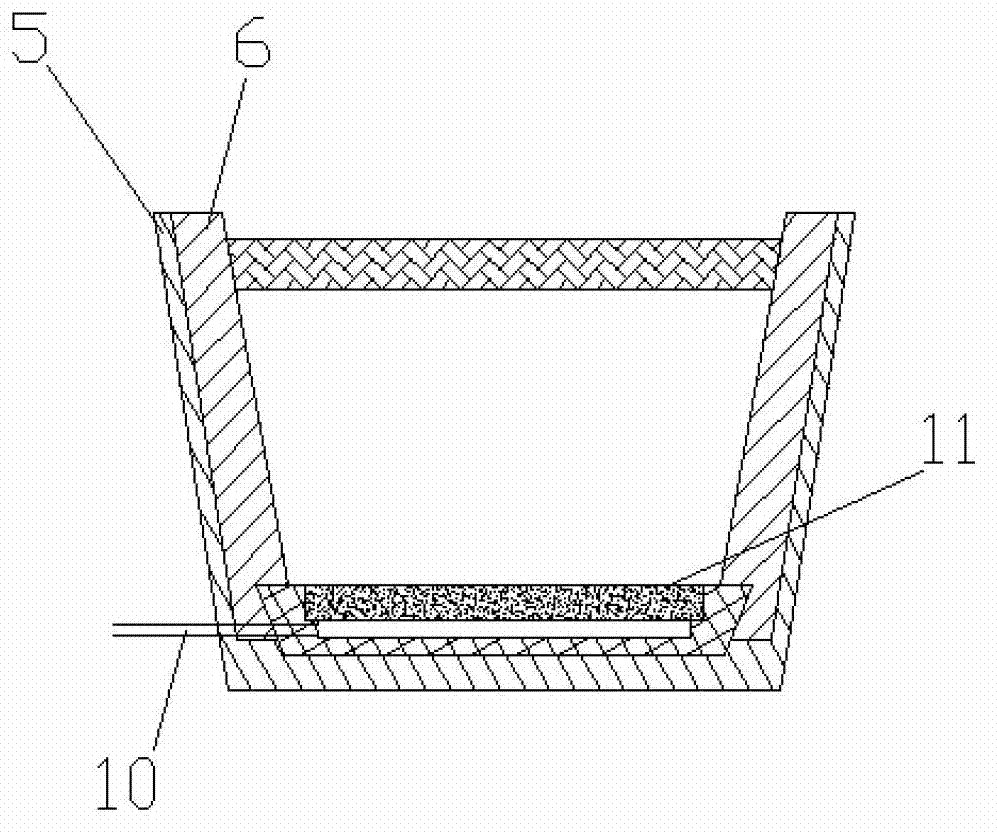

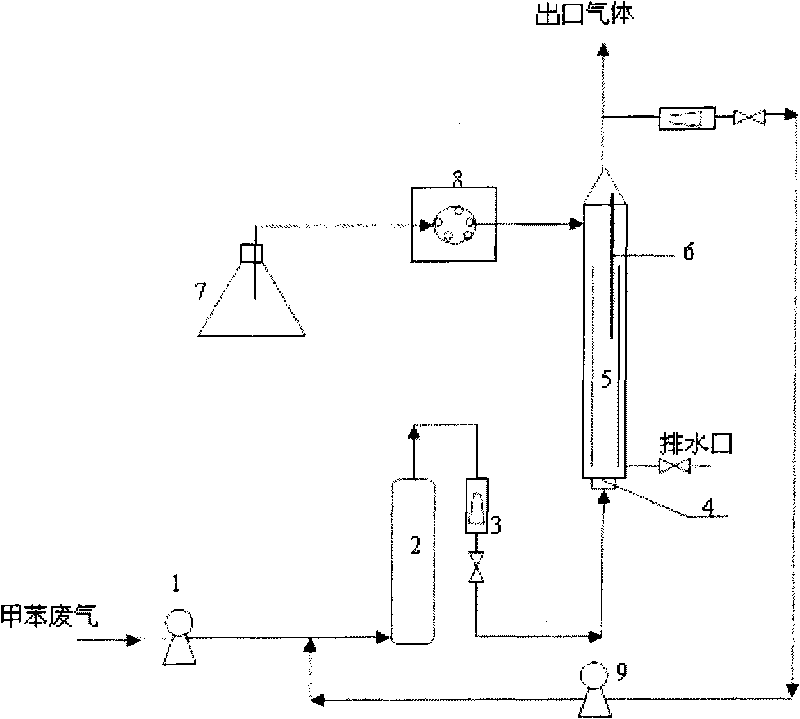

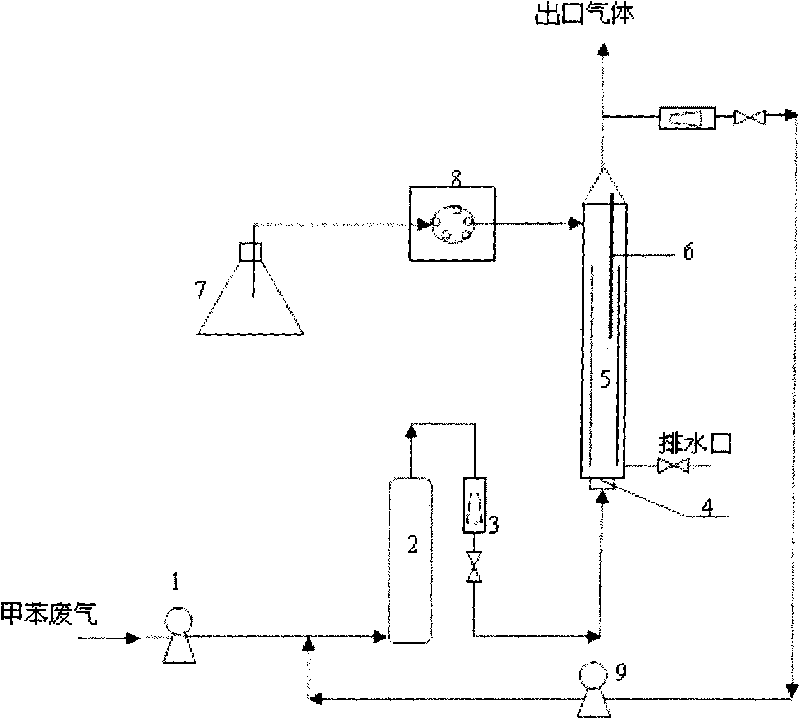

Apparatus and method of airlift three-phase loop bio-reactor for purifying toluene waste gas

InactiveCN101700468AExtended use timeOvercoming key technical defects such as easy clogging and frequent replacement of packingDispersed particle separationAir quality improvementPeristaltic pumpInorganic salts

The invention relates to an apparatus and a method of an airlift three-phase loop bio-reactor for purifying toluene waste gas. The apparatus comprises an airlift three-phase loop bio-reactor, a buffer tank, a flowmeter, an air pump, an inorganic salt medium storage tank, a peristaltic pump and constant-temperature electric heater, wherein the airlift three-phase loop bio-reactor is provided with a square column shaped shell, and the cross section of the shell is a square; the shell is internally provided with a square column shaped guide cylinder and is overlapped with the axle of the guide cylinder; an air distribution plate is arranged in a central position at the bottom of the shell; aperture of the through hole on the air distribution plate is 0.5-4.5mm; and a detachable pysamid shaped seal is arranged at the upper part of the shell. Toluene waste gas is purified by immobilized Pseudomonas putida WQ-03, a liquid phase is the inorganic salt medium, and the reactor is only provided with the guide cylinder. Flow patterns of gas, liquid and solid are normalized and flow circularly. The rising resistance of air is small, and treating effect is good. Therefore, research of using immobilized thallus to purify the toluene waste gas in the bubble column three-phase bio-reactor has important actual application value.

Owner:TIANJIN UNIV

Device and method for simultaneous hydrogen sulphide removal and biogas upgrading

ActiveUS20160250584A1Large water flowMinimizes the methane slip to the atmosphereGas treatmentGaseous fuelsWash waterFlow ratio

A sustainable method and a system for cleaning impurities, mainly hydrogen sulphide, and upgrading of biogas having hydrogen sulphide concentration up to 2% (20,000 ppmv), preferably produced in wastewater treatment plants (WWTPs) to biomethane. The system includes a counter-current, non-pressurized physical absorption bubble column having a high influent liquid-to-gas flow ratio LI / G higher than 1 and preferably equal or higher than 3 and equal or lower than 10, for achieving a simultaneous removal of hydrogen sulphide and carbon dioxide. The system may be inserted for instance on an existing wastewater treatment plant, in such a way that the wash water is the primary treated wastewater of the plant, and preferably the biogas to be upgraded is produced in the anaerobic digesters of the plant itself, and also includes means for regenerating the used wash water by the biological reactor of the plant itself used for the secondary treatment.

Owner:FCC AQUALIA

Bubble-column vortex-induced vibration suppression device of stand pipe under marine environment

InactiveCN102979490AEasy to manufactureLow costFluid removalUnderwater drillingVertical tubeBubble column

The invention provides a bubble-column vortex-induced vibration suppression device of a stand pipe under a marine environment. The whole bubble-column vortex-induced vibration suppression device is composed of one or more bubble-column vortex-induced vibration suppression units (units for short), wherein the units are unequal in height and thickness. Each unit is a gas-filled (liquid-filled) column body and consists of a bracket and a bubble-column, wherein the bracket is used for connecting the bubble-column with the stand pipe and is composed of a base body and a control body, the bubble-column is used for realizing vortex-induced vibration suppression and is composed of a response surface and a response body, wherein the response surface is made of a material capable of bending and deforming along with the stress, and the response body is gas (liquid). The bubble-column vortex-induced vibration suppression device is flexible to manufacture and mount, can be directly sleeved on the stand pipe and can be also machined into a whole together with the stand pipe. The bubble-column vortex-induced vibration suppression device disclosed by the invention has the advantages of suppressing the occurrence of vortex by responding incoming flow and dispersing and eliminating the acting force to the stand pipe, which is formed by movement of flow field near the stand pipe by using the response surfaces and the response bodies.

Owner:SOUTHWEST PETROLEUM UNIV

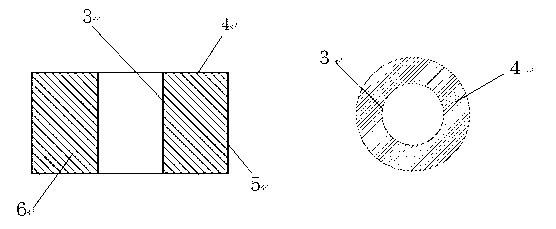

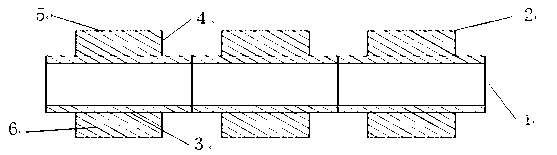

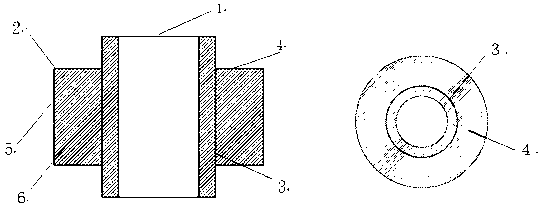

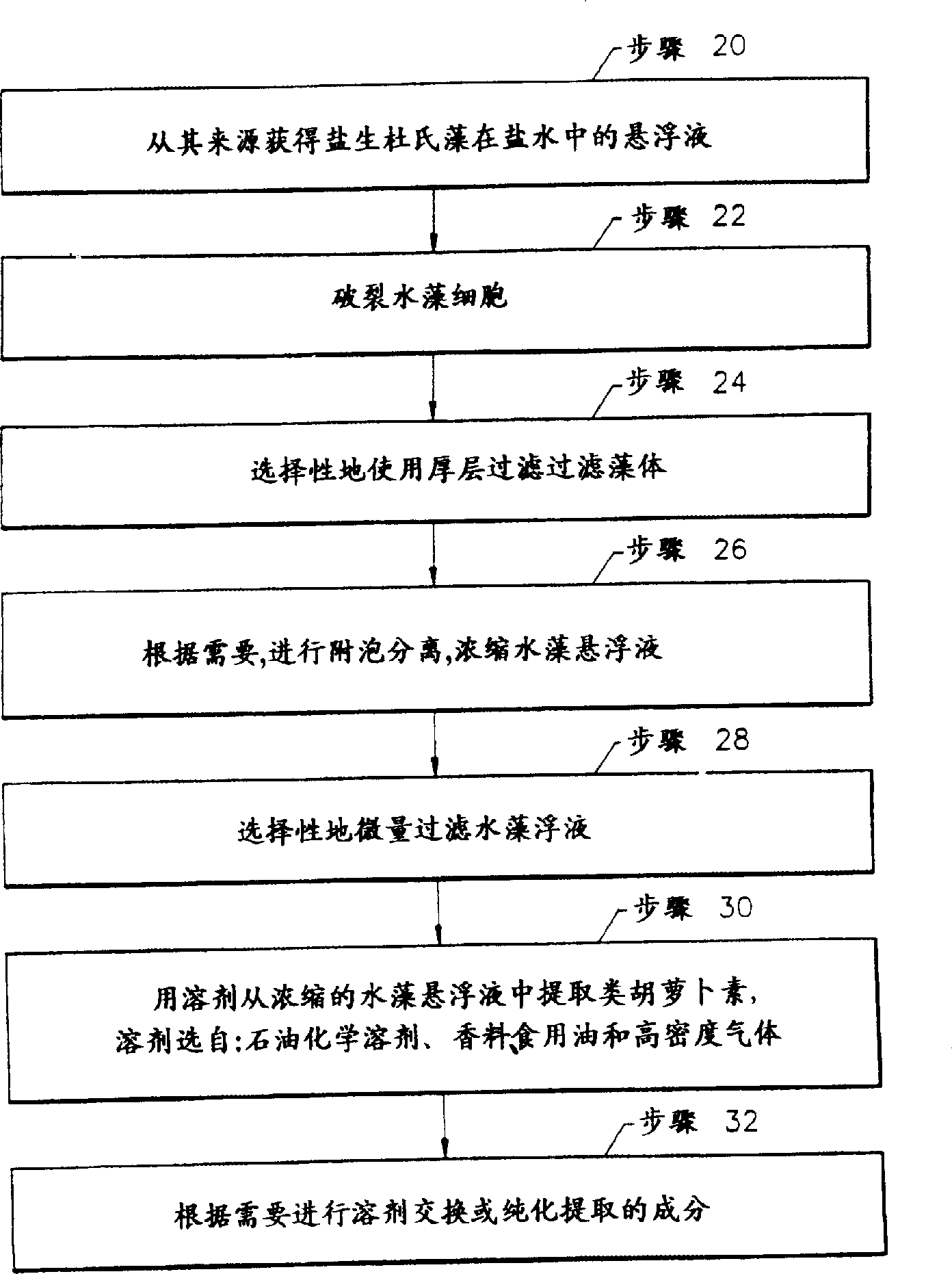

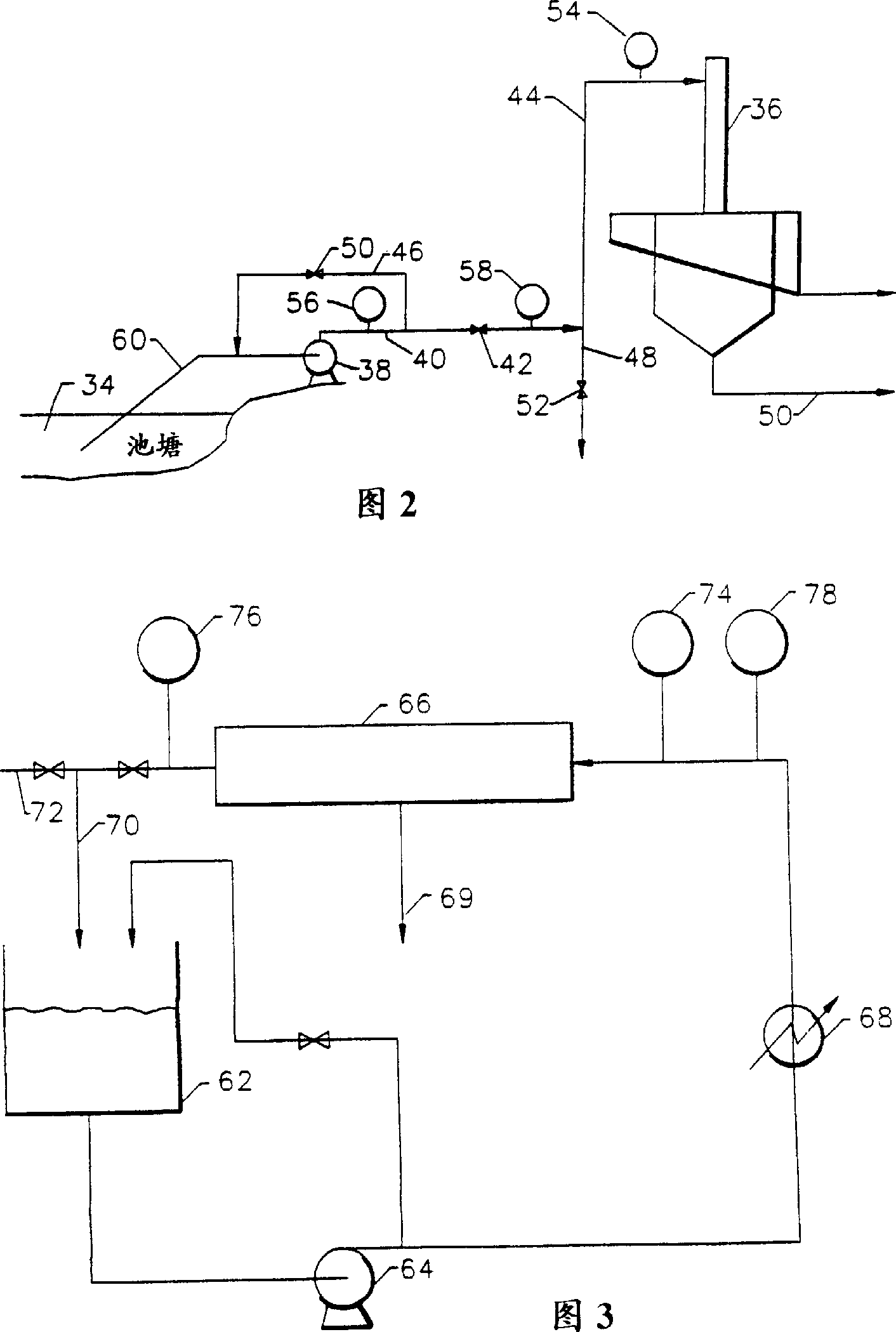

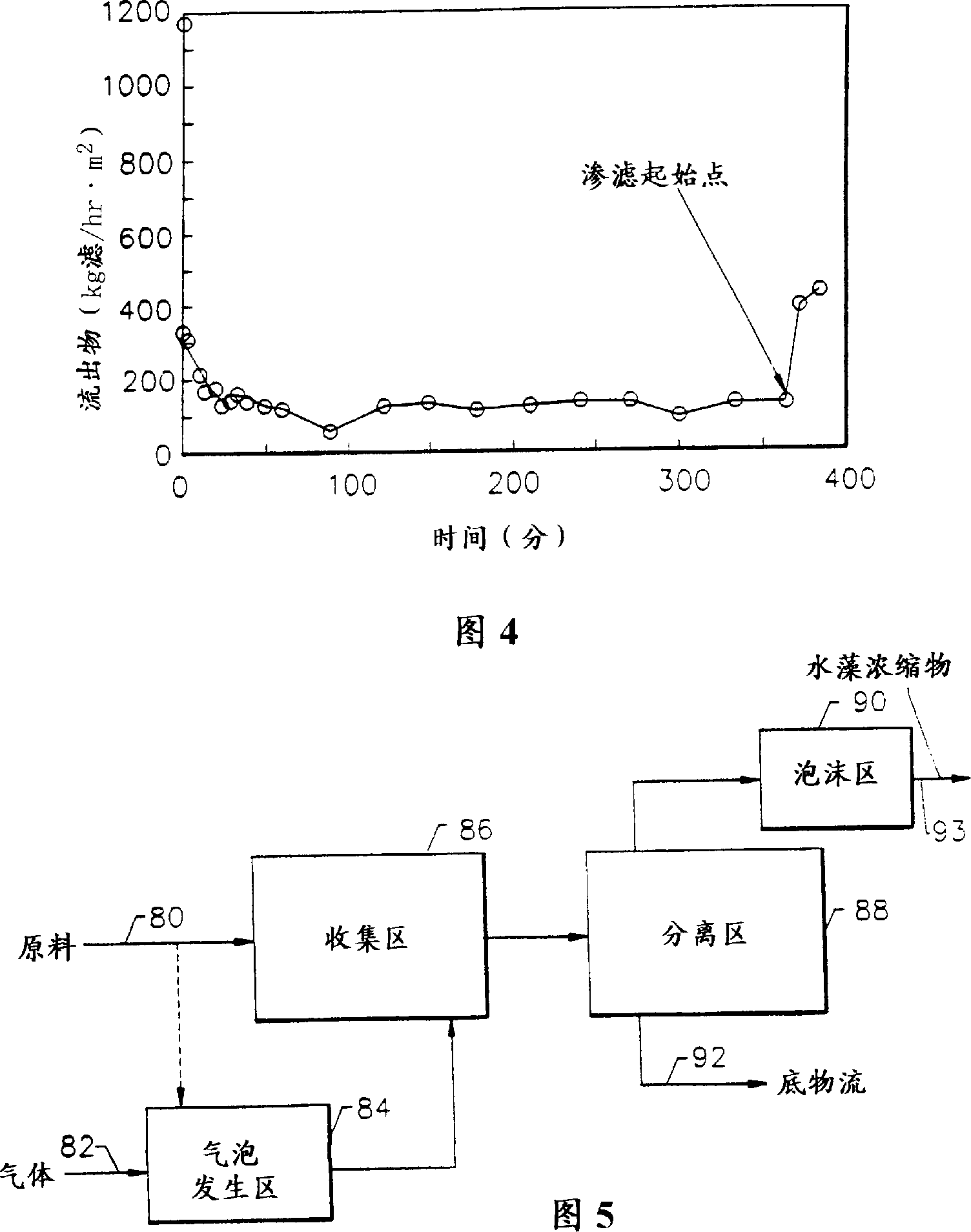

Method for dewatering microalgae with bubble column

InactiveCN1241148ABioreactor/fermenter combinationsBiological substance pretreatmentsSaline waterDunaliella salina

A process for dewatering an aqueous suspension of microalgae is disclosed in which the aqueous suspension of the algae is introduced into a bubble column or a modified bubble column for generating a froth of bubbles and adsorbed algal cells that can be separated from the aqueous suspension. In one advantageous embodiment, the bubble column is a multi-stage loop-flow flotation column that has three loop-flow zones, each of which is defined by a draft tube concentrically mounted in the column to divide each loop-flow zone into a riser and the downcomer. Fine bubbles of gas and brine are in cocurrent upward flow in the riser and in cocurrent downward flow the downcomer. A higher gas holdup is promoted in the riser than in the downcomer, thereby circulating the brine in loop-flow upwardly through the riser and downwardly through the downcomer. Liquid communication between adjacent loop-flow zones is substantially eliminated. A froth enriched in algae is generated that can be separated from the aqueous suspension. The process has application in the recovery of mixed carotenoids from Dunaliella salina.

Owner:EASTMAN CHEM CO

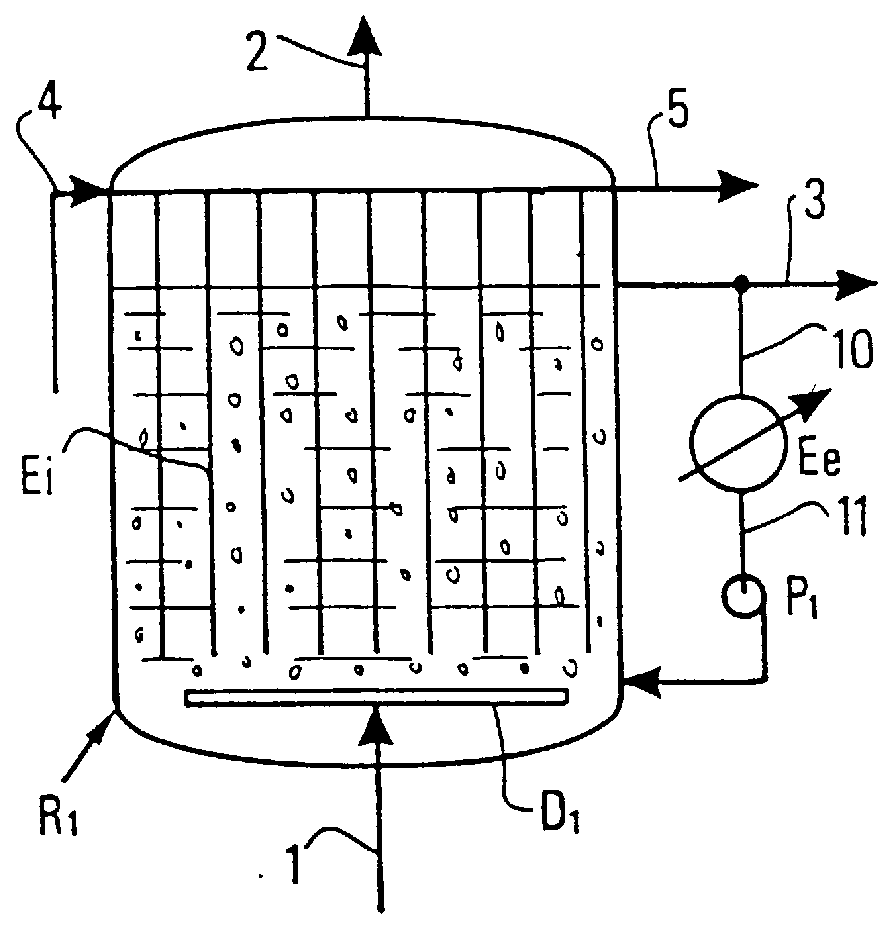

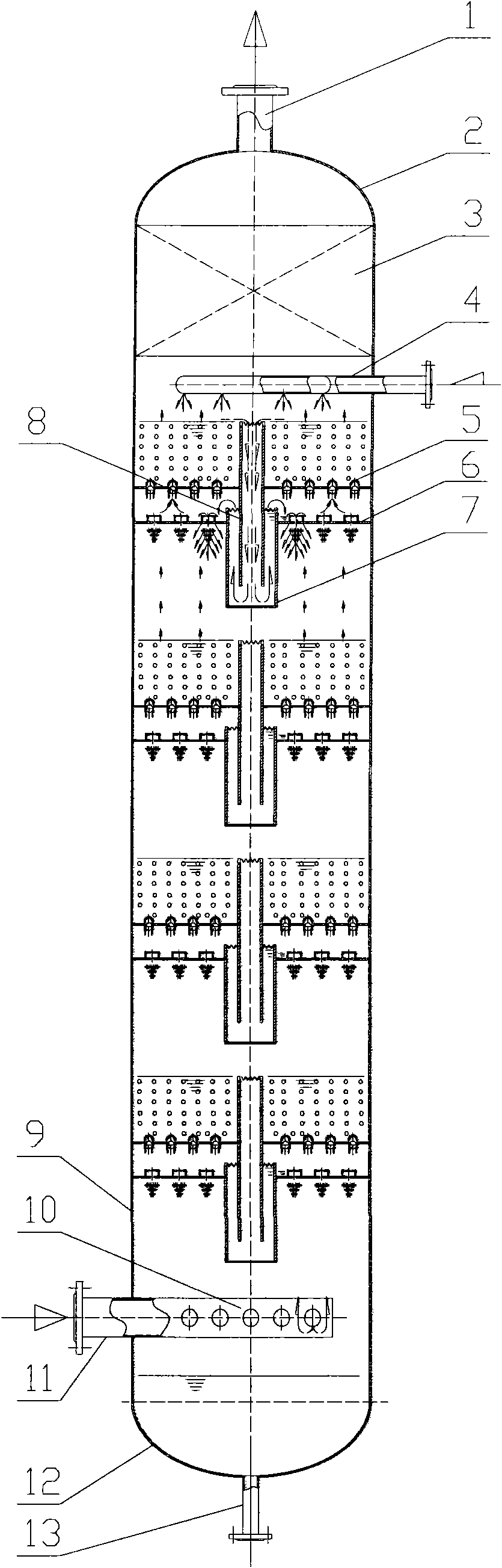

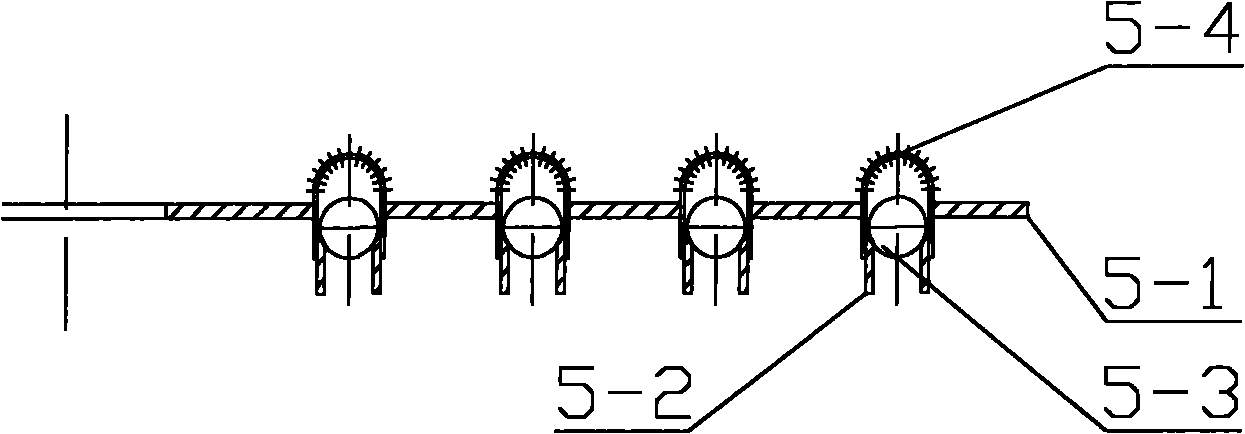

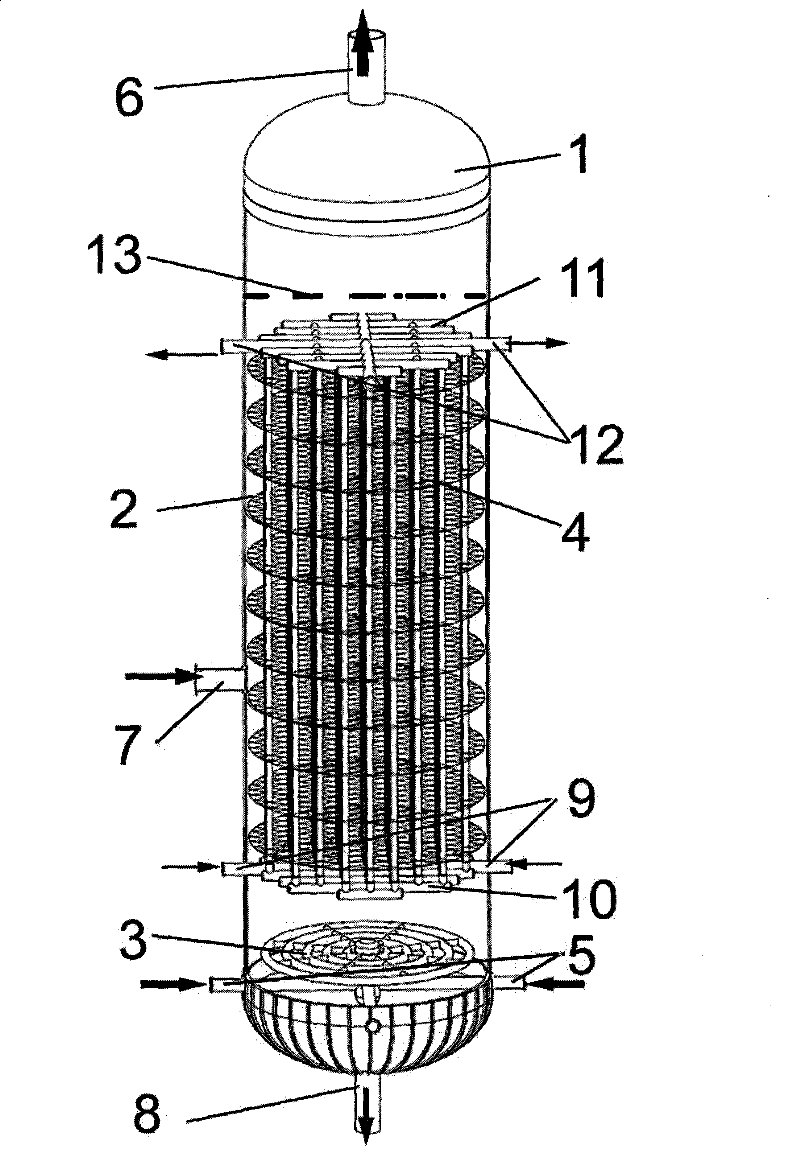

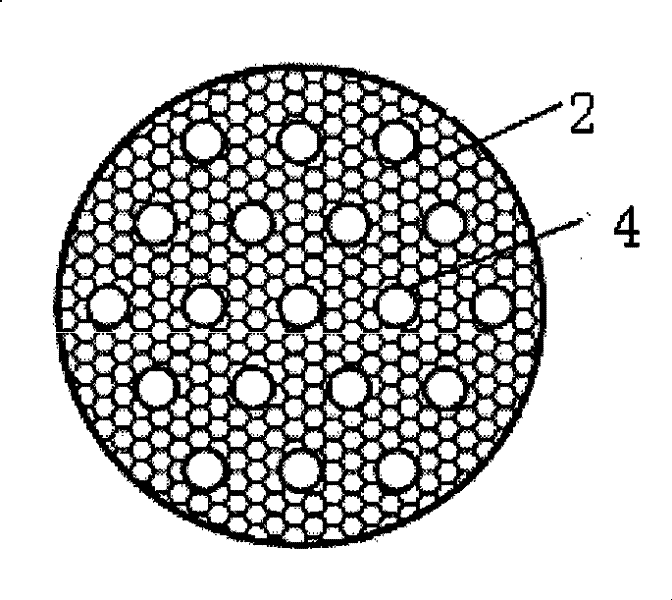

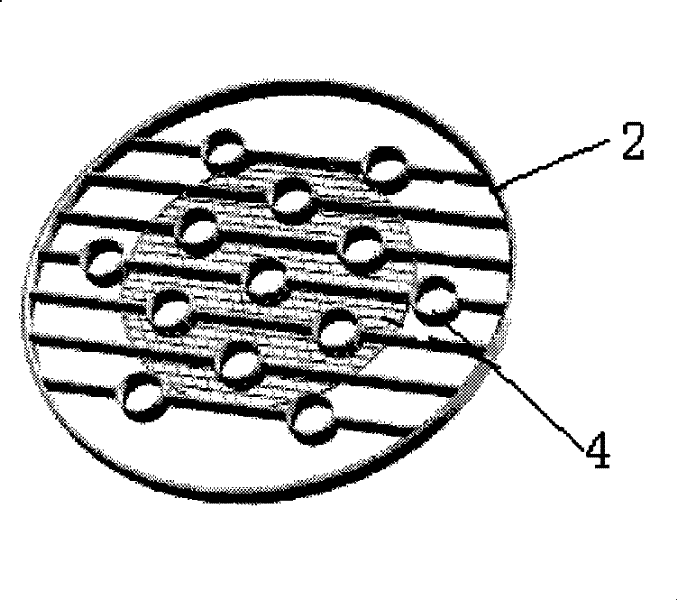

Method and device for improving flow character of gas liquid bubble column with row tubes

InactiveCN101417220AImprove flow characteristicsImprove responseLiquid-gas reaction processesSlurry reactorBubble column

The invention discloses a method and a device used for improving the flowing characteristic of the slurry bubble tower with row tubes; the device comprises a tower body, a gas distributor and a vertical heat exchanging row tube bundle; the lower end of the vertical heat exchanging tube bundle is connected with a liquid distributor which is fixed at the lower part of the tower body and the upper end thereof is connected with a liquid collector which is fixed at the upper part of the tower body; a plurality of layers of horizontal grid-typed damp internal components are arranged between the liquid distributor and the liquid collector; the heat exchanging row tube bundle vertically passes through the horizontal grid-typed damp internal components; each layer of the grids is fixed on the tower wall and the row tubes; and by arranging the horizontal grid-typed damp internal components in the slurry bubble tower which is provided with vertical row tube bundles; and the horizontal damp internal components block the flowing of the slurry and air bubbles in the tower, inhibit the flowing craggedness effect caused by the row tube bundle, and reduce the returned mixing of the fluid, thus improving the flowing characteristic of the slurry reactor.

Owner:ZHEJIANG UNIV

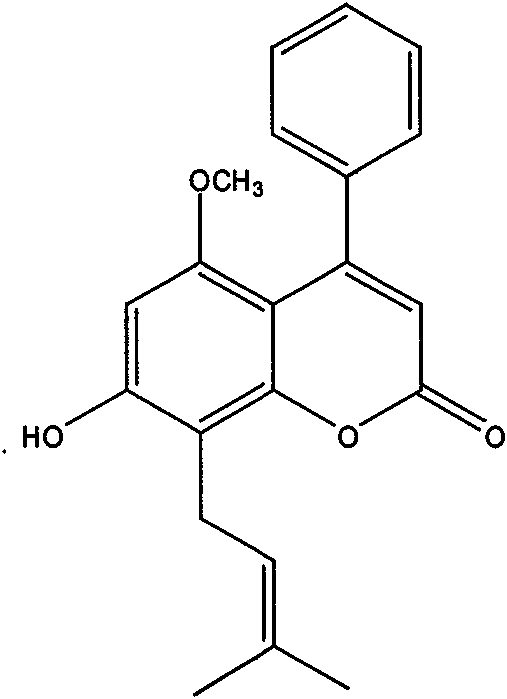

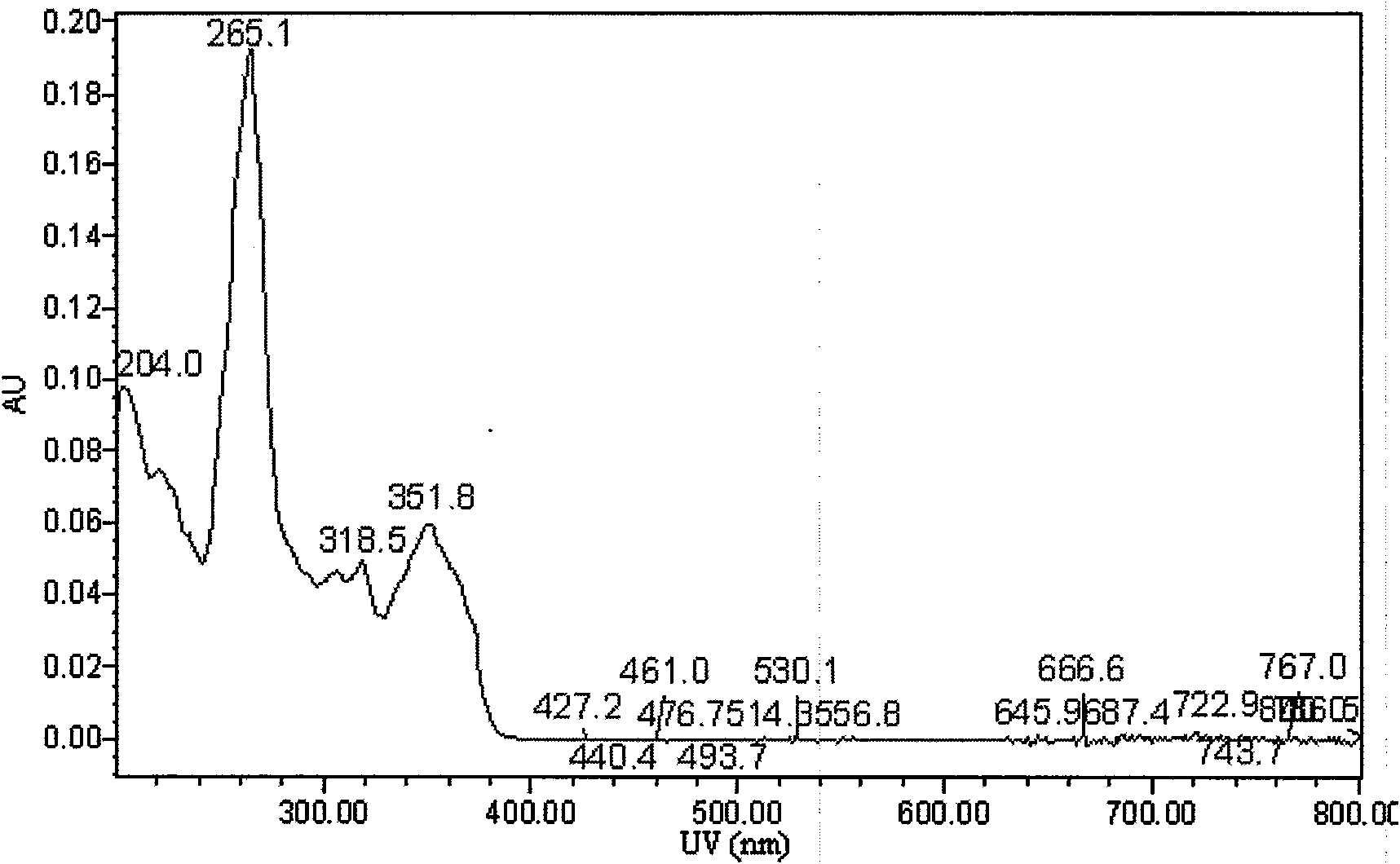

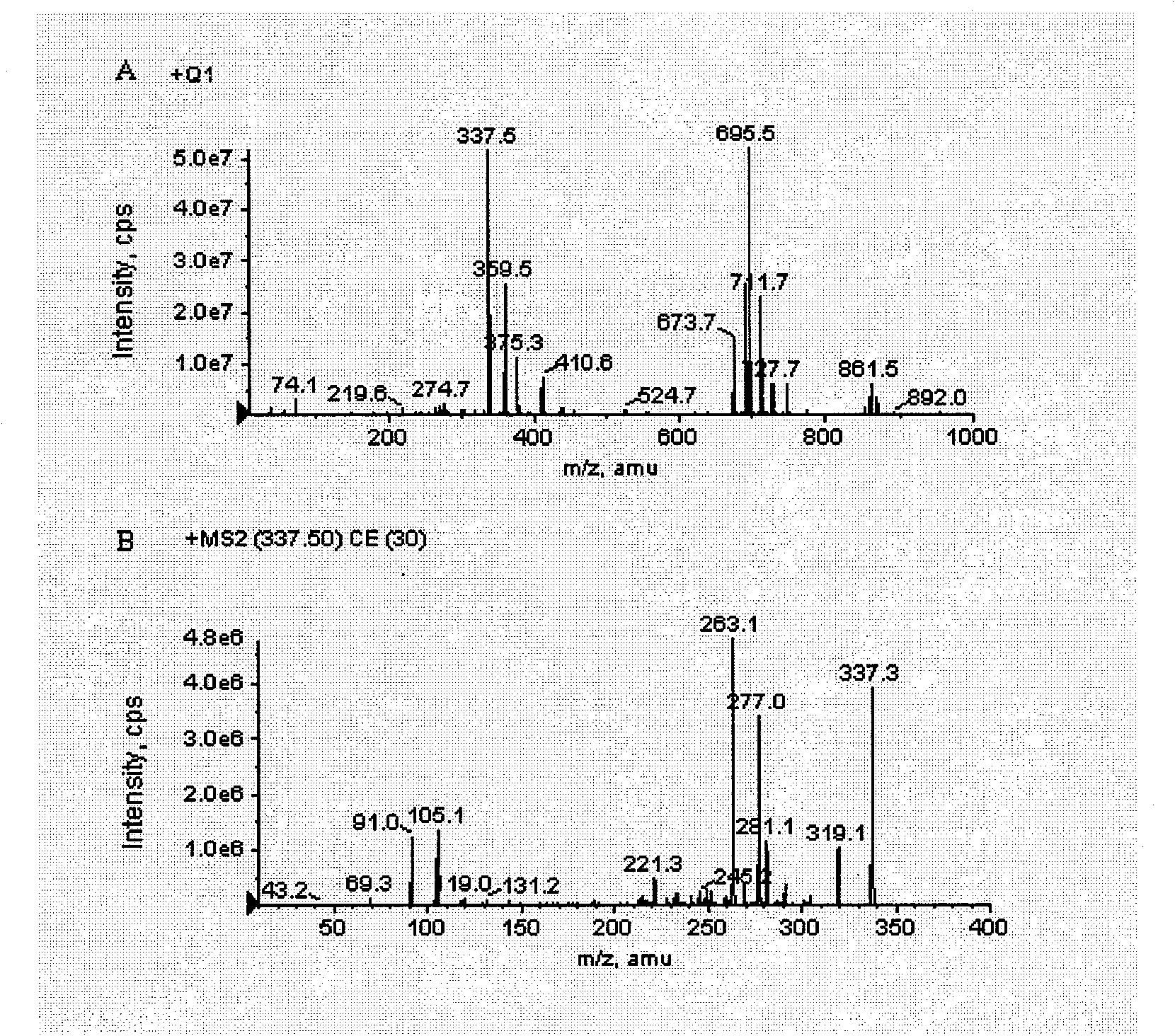

New coumarin active content, preparation method and application thereof

ActiveCN101619054AStrong free radical scavenging activityHigh activityNervous disorderOrganic chemistrySolventPlatelet inhibition

The invention relates to a new coumarin active content, i.e. pigeon pea lactone extracted and separated from cajan leaves, an extraction and separation method and an application thereof. The structure of the compound is shown as a figure 1. The invention adopts the technical scheme that agricultural waste of cajan leaves is used as raw material which is extracted by a solvent; the extracting solution is concentrated and dispersed in water; an ultrasonic oscillation flocculation technology, a bubble column extraction technology and a column chromatography separation technology in positive-phase silica gel are adopted and combined with a low-temperature crystallization and recrystallization technology to obtain the content with the purity higher than 95 percent; and the anti-oxidation activity and the action of the chemical content on cardiovascular diseases are detected by a DPPH model, a beta-renieratene-linoleic acid model, an in-texture SOD enzyme model, a platelet aggregation model induced by ADP in corpora and an aorta systole model induced by phenylephrine. Results show that the active content has favorable free radical scavenging activity, anti-oxidation activity in corpora and in vitro, platelet aggregation restraining action in corpora and a certain hemangiectasis action. Meanwhile, the preparation method of the pigeon pea lactone in the invention is easy and practical and can obtain a product with high purity high yield and high added value in a short period which is suitable for industrialized production and application, can be further developed and researched into a new antioxidant as an additive for medicines, foods and cosmetics.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

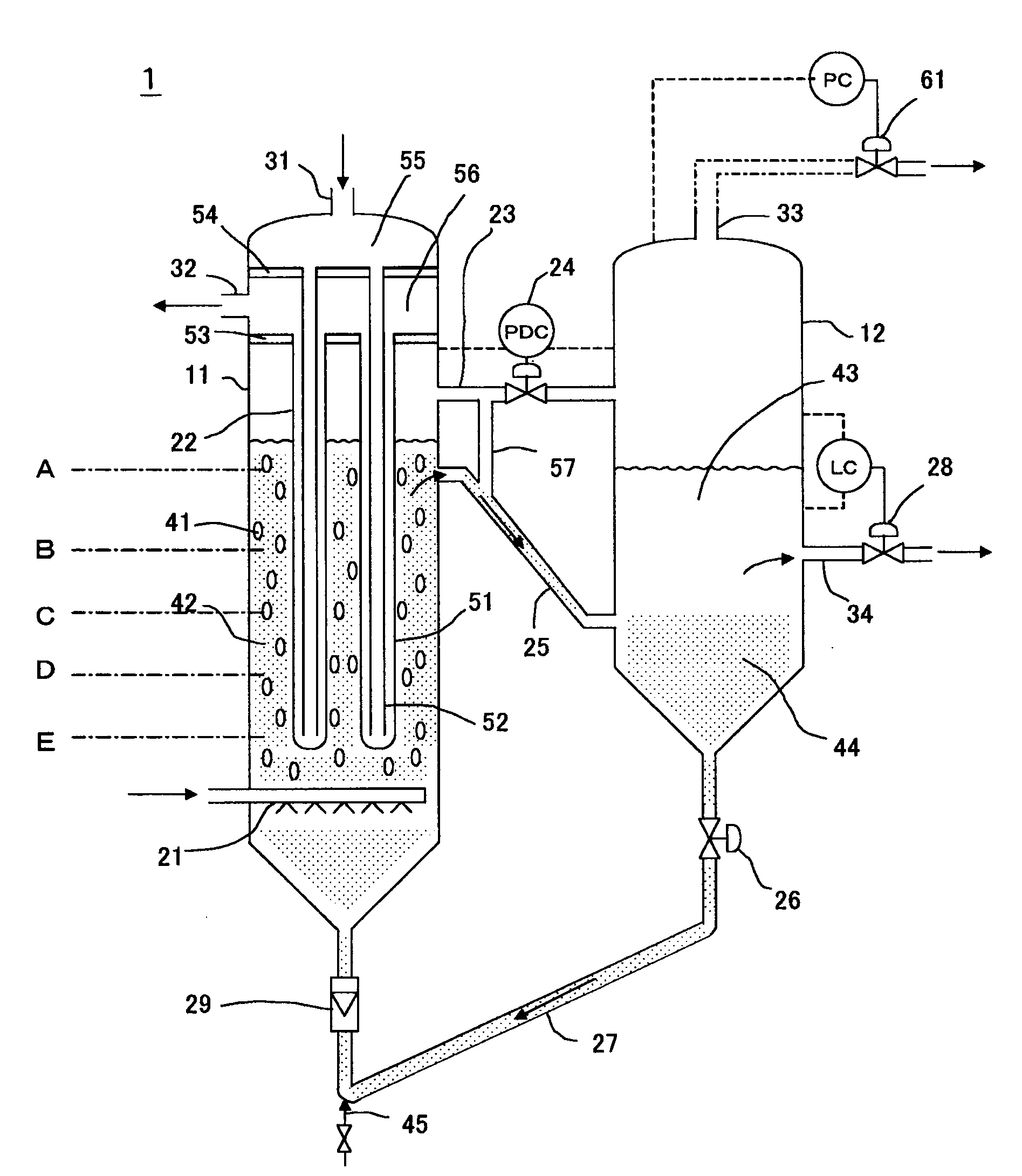

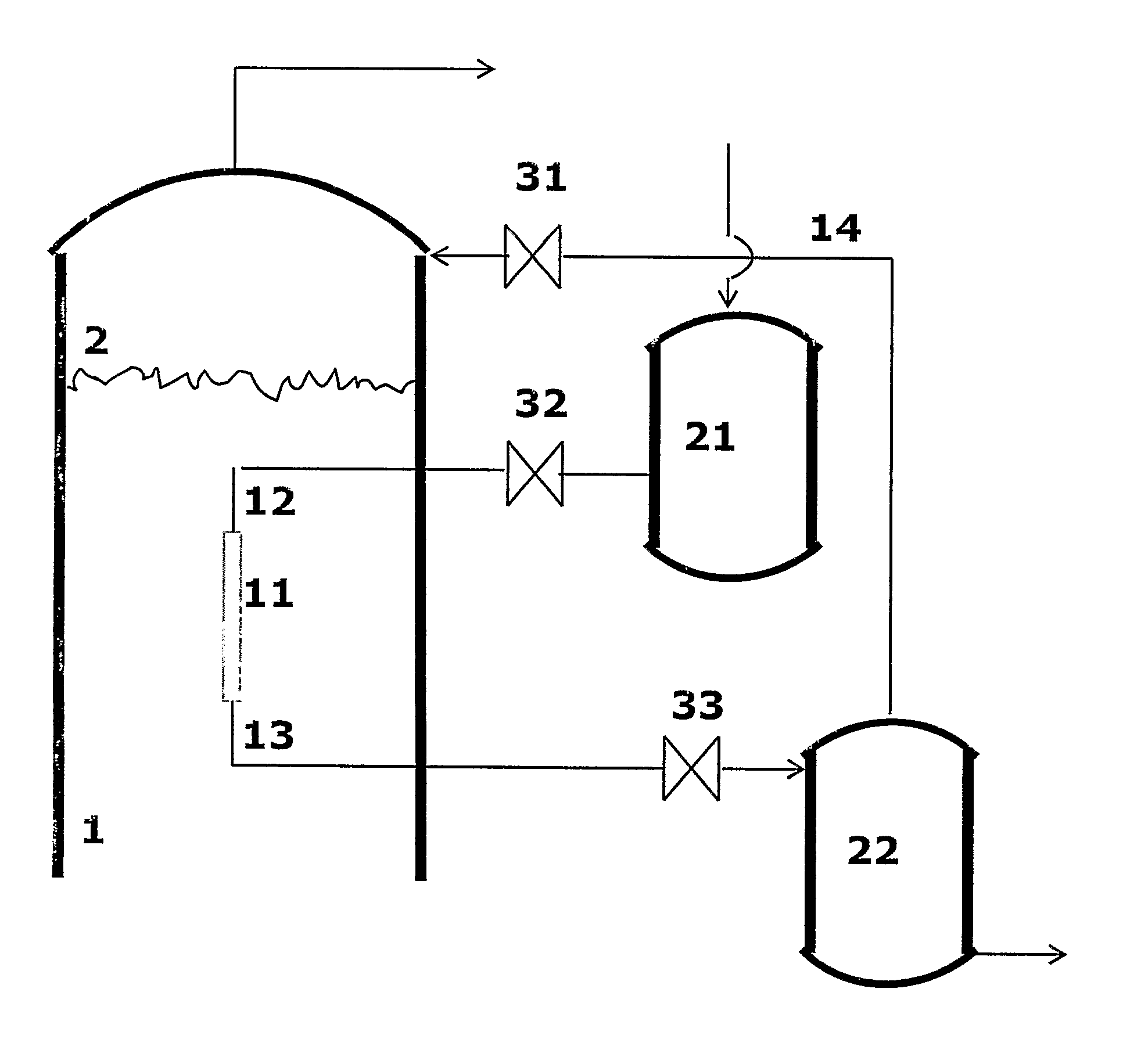

Bubble column-type Fischer-Tropsch synthesis slurry bed reaction system

InactiveUS8057744B2Easy to operateReduce deteriorationLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesLiquid productBubble column

According to an exemplary embodiment, a bubble column-type slurry bed Fischer-Tropsch synthesis reaction process can be provided, in which synthesis gas supplied continuously from the bottom of a reactor contacts suspended catalyst particles to form liquid hydrocarbons, gaseous hydrocarbons and water. Additionally, a slurry of suspended liquid products and catalyst particles can move from the reactor to the lower portion of a separation vessel to separate the catalyst particles and gaseous products. Further, a process can be provided in which the liquid products formed are sent to the separation vessel a process in which liquid products can be derived. Additionally, a process can be provided in which a slurry in which catalyst particles are concentrated is derived from the bottom of the separation vessel and circulated to the bottom of the reactor, are driven by the driving force of synthesis gas without using an external drive power source.

Owner:INPEX CORP +4

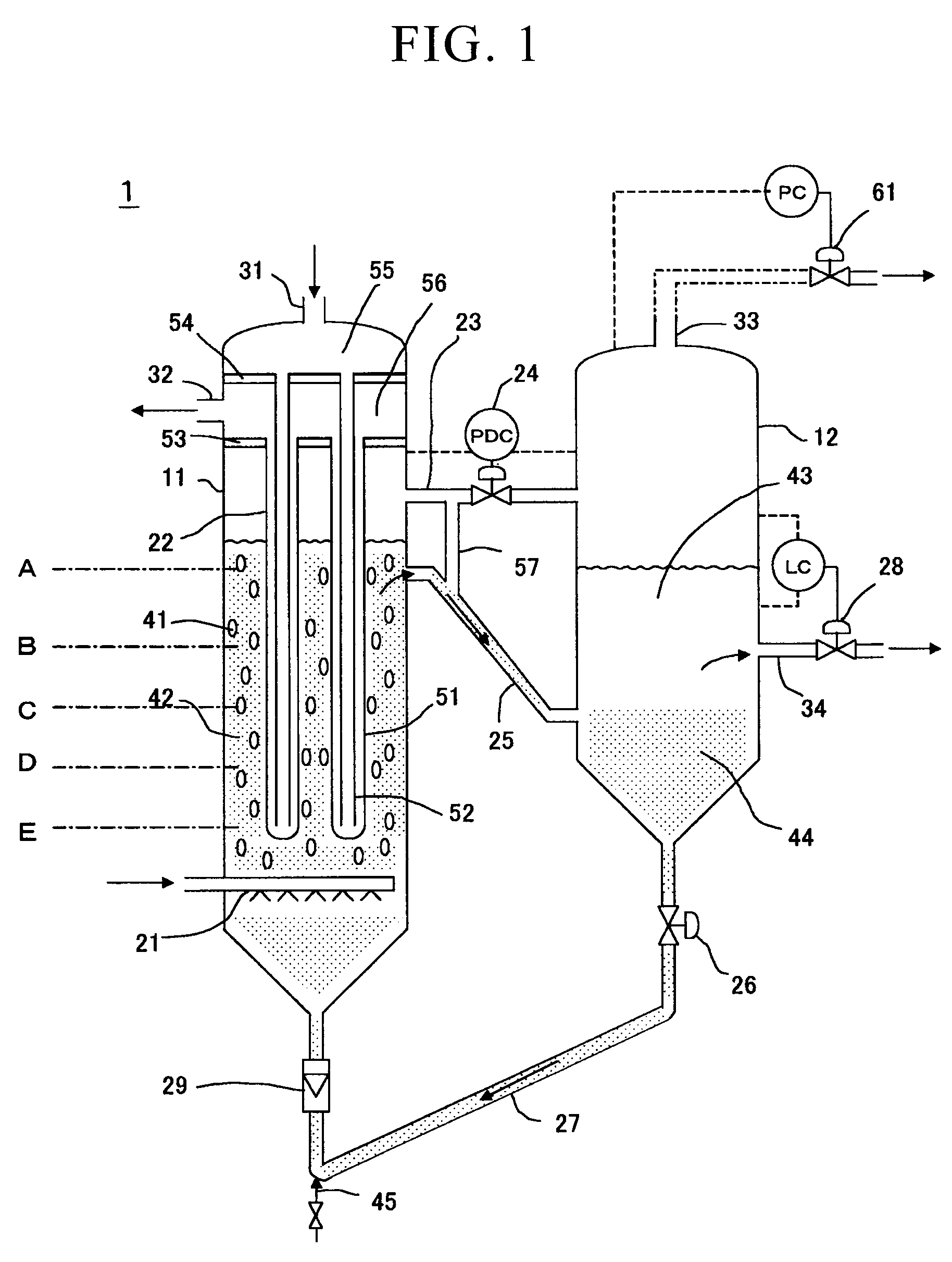

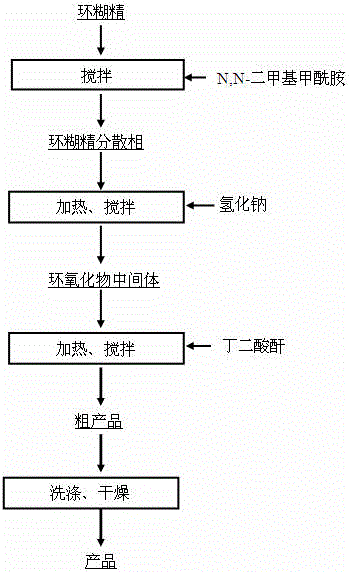

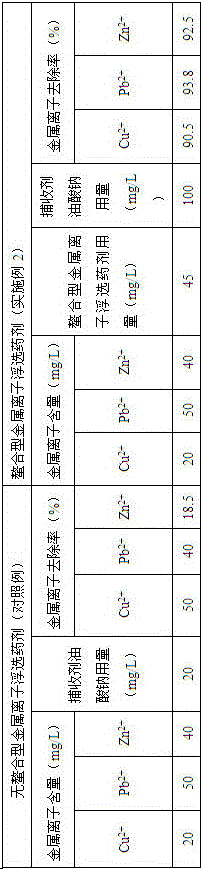

Chelate type metal ion flotation reagent, and preparation method and application method thereof

ActiveCN106238010AReduce consumptionWide adaptabilityOther chemical processesMultistage water/sewage treatmentCyclodextrinSodium hydride

The invention provides a chelate type metal ion flotation reagent, and a preparation method and application method thereof, belonging to the technical field of mineral processing. The chelate type metal ion flotation reagent is prepared from cyclodextrin, sodium hydride and succinic anhydride through two steps. The preparation method comprises the following steps: allowing sodium hydride to act on cyclodextrin so as to convert cyclodextrin into an epoxide intermediate; and subjecting the epoxide intermediate and succinic anhydride to crosslinking so as to obtain the chelate type metal ion flotation reagent. The application method for the chelate type metal ion flotation reagent comprises the following steps: adding the chelate type metal ion flotation reagent into waste water with a metal ion concentration of 50 to 500 mg / L; and carrying out stirring, aeration and bubbling and flotation, wherein the usage amount of the chelate type metal ion flotation reagent is 10 to 200 mg / L. The chelate type metal ion flotation reagent is especially applicable to removal of metal pollutants in mineral processing wastewater via a fine bubble column ion floatation method, has the advantages of low consumption of the reagent and wide adaptability and facilitates environmental protection and recovery of metal resources.

Owner:ZHENGZHOU UNIV

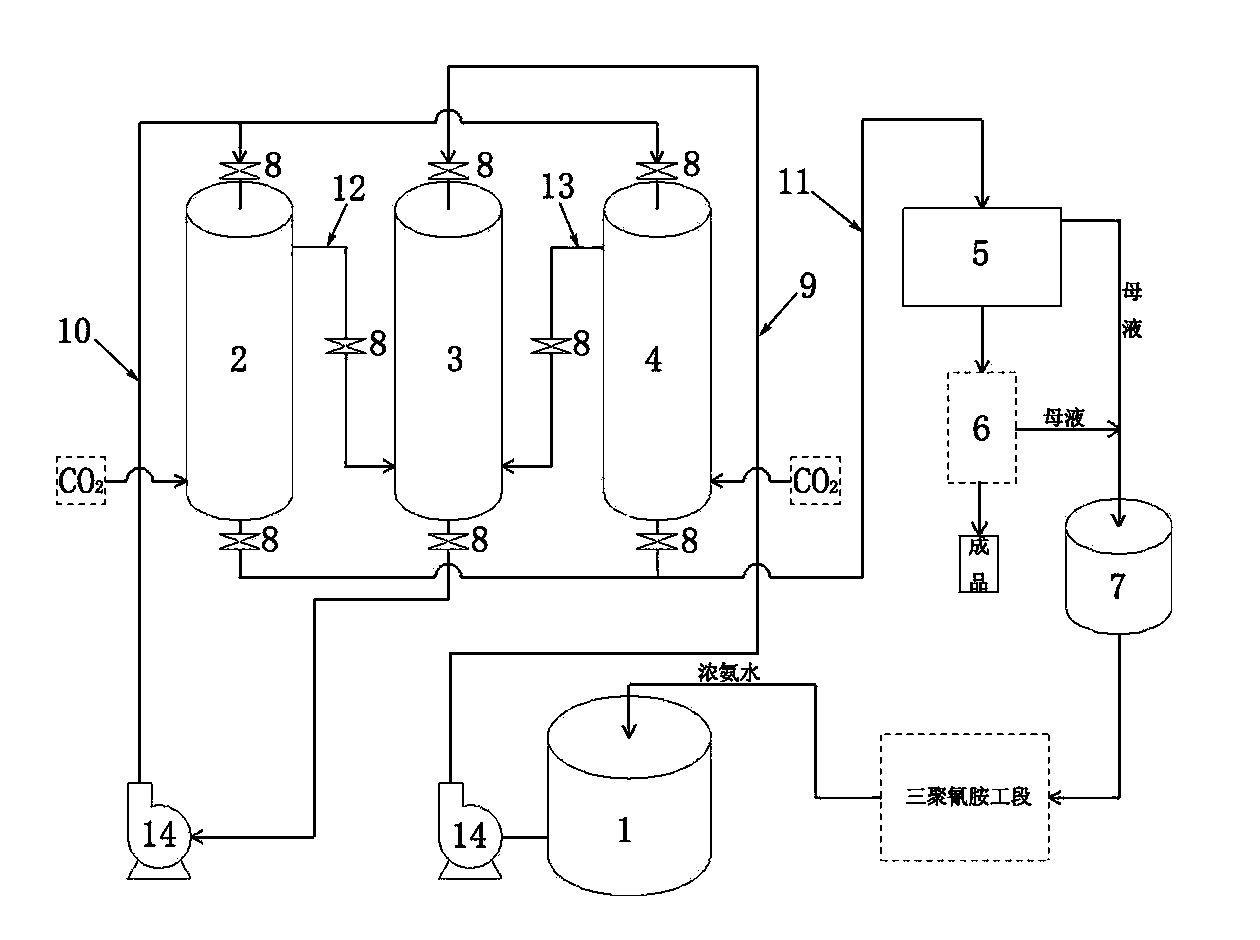

Technological method for co-production of ammonium bicarbonate through melamine tail gas

InactiveCN103523799ASimple structureReasonable designAmmonium carbonates/bicarbonatesMaterial balanceBubble column

The invention provides a technological method for co-production of ammonium bicarbonate through melamine tail gas and solves the problems that material balance is difficult, gas purification is substandard, the technology fluctuation range is large, and the like in a conventional production technology. The technological method comprises a co-production system formed by an ammonia tank, a main carbonizing tower, an auxiliary carbonizing tower, a bubble column, a thickener, a centrifugal machine and a mother liquor tank. The main carbonizing tower, the auxiliary carbonizing tower and the bubble column are operated, the temperature in the bubble column is kept to be 40-45 DEG C, and the tower boiling times are decreased; and the CO2 content in stronger ammonia water in the main carbonizing tower is controlled to be 120-124 mol / L, the yield of ammonium bicarbonate is determined according to the amount of the CO2, and materials are balanced, so that balance is achieved. According to the technological method, the main carbonizing tower, the auxiliary carbonizing tower and the bubble column are operated, the temperature in the bubble column is kept to be 40-45 DEG C, the yield of ammonium bicarbonate is determined according to the amount of the CO2 at the same time, and materials are balanced, so that balance is achieved. According to the technological method, an expected purpose is achieved, and carbonization process influences are relieved, so that an ammonia synthesis system can operate more stably.

Owner:SHANXI YANGMEI FENGXI FERTILIZER IND GRPCO

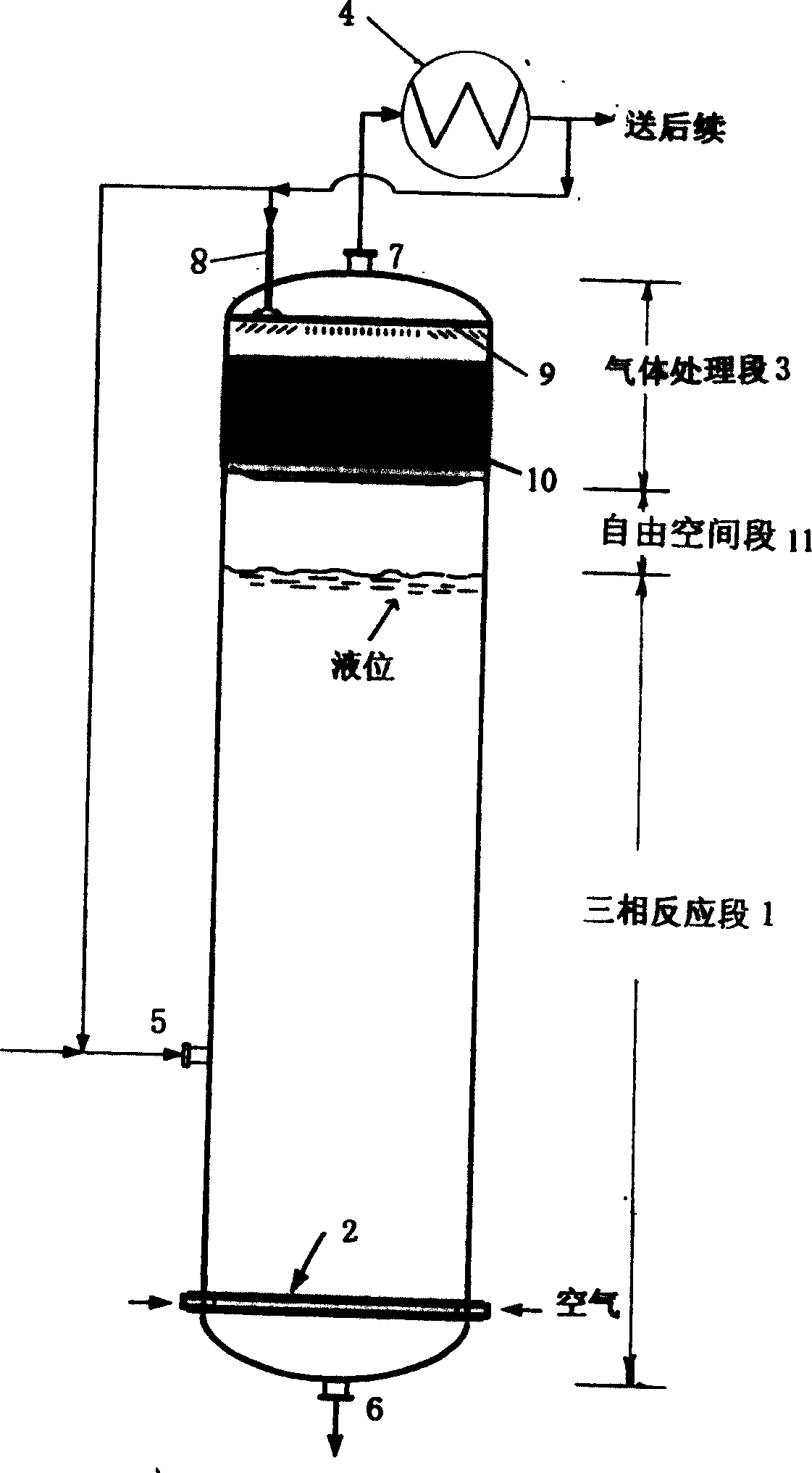

Bubble tower oxidation reaction unit for producing terephthalic acid

InactiveCN1228302CSimple structureLow costOrganic compound preparationCarboxylic compound preparationBubble columnTower

The invention discloses a bubbling column oxidizing reaction device to produce p-phthalic acid, including a uniform straight-cylindrical bubbling column, where there are gas processing segment, free space segment and three phase reaction segment in turn form top to bottom in the bubbling column, there are liquid distributor and filling or liquor-holding board installed in the gas processing segment, there is a gas distributor installed at the bottom of the three phase reaction segment, there is a raw material feeding pipe set at 1 / 4-1 / 2 of the height of reaction segment, there is a discharge pipe set at the bottom of the bubbling column, there is a tail-gas pipe and a liquor condensate reflux pipe on the top of the bubbling column, the inlet of the condenser is linked with the tail-gas pipe, the gas outlet is linked with the follow-up tail-gas processing unit, the liquid outlet of the condenser is linked with raw material feeding pipe, liquor condensate reflux pipe and follow-up dehydration tower. It is applied to the process of preparing p-phthalic acid by high temperature oxidization.

Owner:ZHEJIANG UNIV

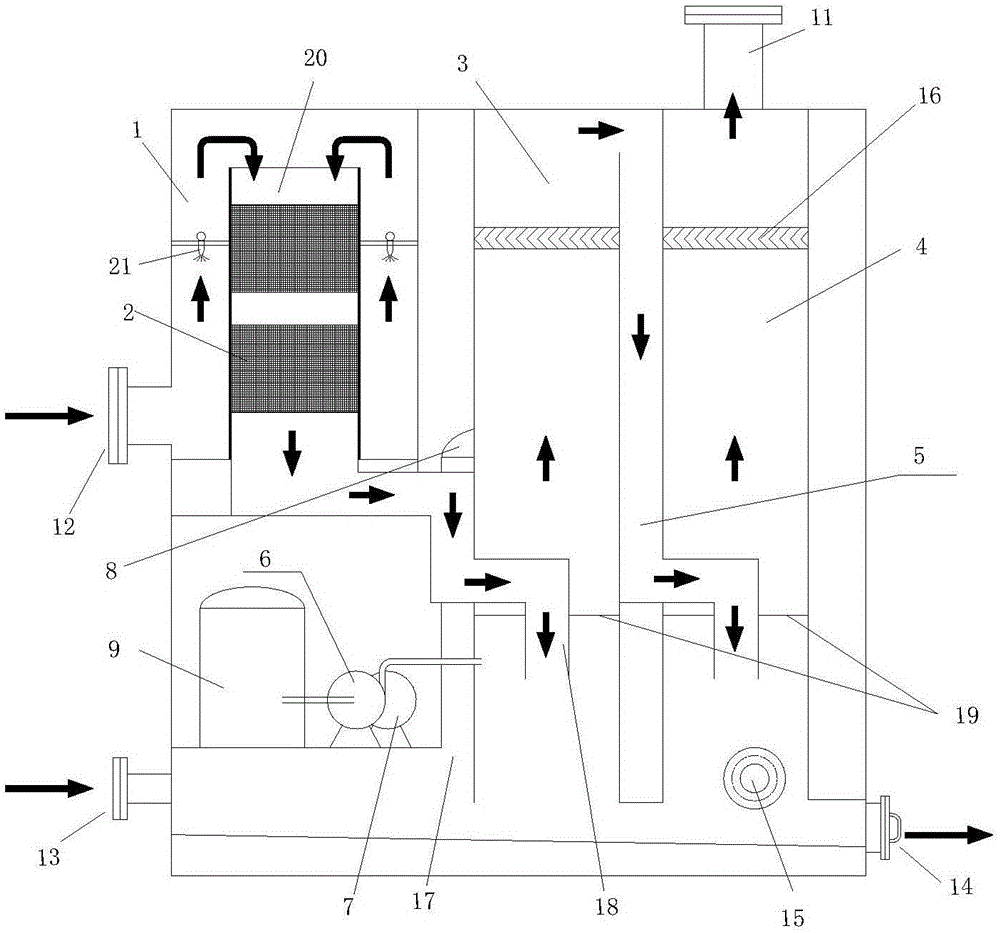

Integrated marine diesel engine exhaust-gas treatment apparatus

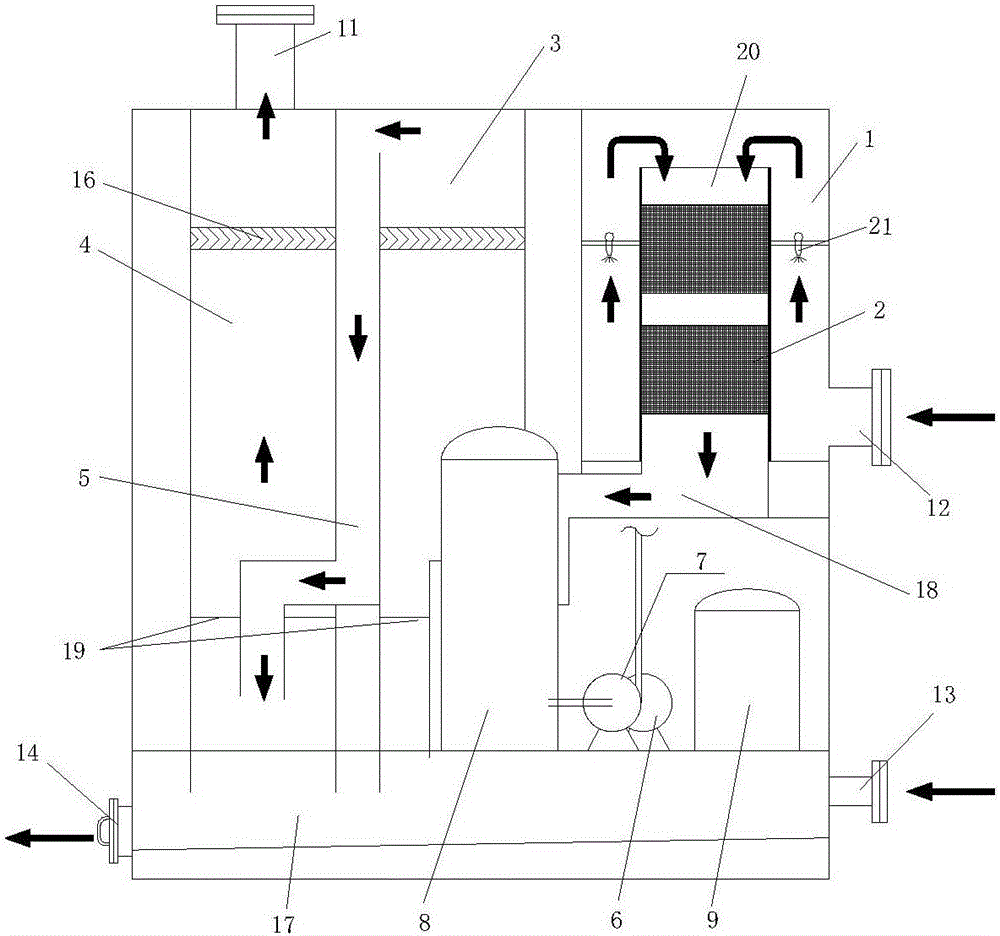

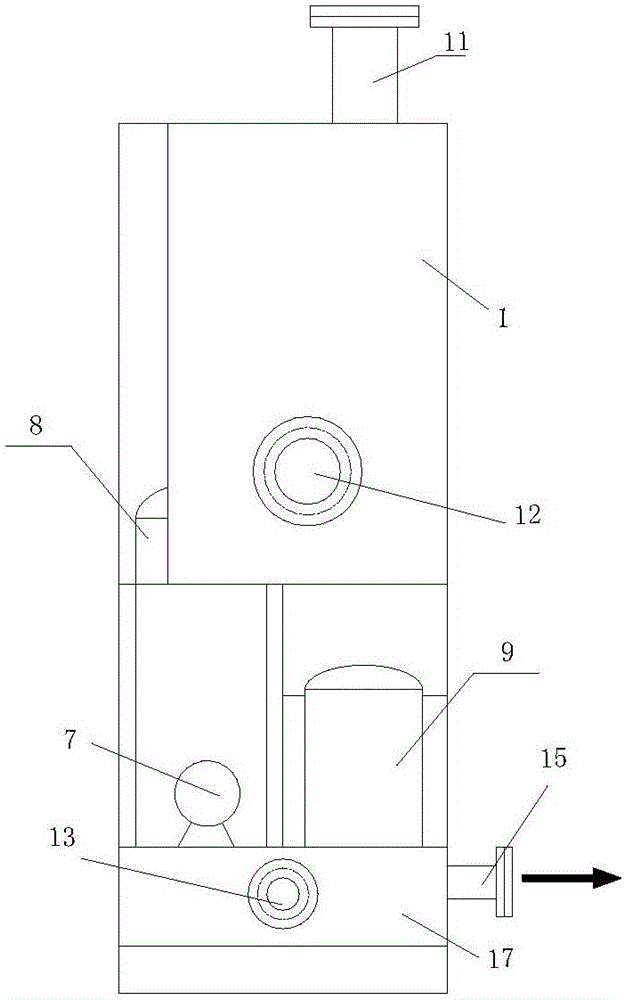

InactiveCN106166446AImprove denitrification efficiencyImprove purification effectCombination devicesGas treatmentBubble columnProcess engineering

The invention relates to an integrated marine diesel engine exhaust-gas treatment apparatus, which comprises a box. A SCR denitration reactor, a urea solution conveying device, an alkali lye conveying device, a seawater storage groove and a bubble column are arranged inside the box. The SCR denitration reactor is arranged at the upper part of the left side inside the box. The urea solution conveying device and the bubble column are both disposed at the right side of the SCR denitration reactor. The bubble column is mounted in front of the urea solution conveying device. The seawater storage groove is arranged at the bottom of the box and positioned right below the bubble column. An atomizing nozzle and a catalyst module are arranged inside the SCR denitration reactor. A demister is mounted inside the bubble column. The alkali lye conveying device is communicated with the bubble column. By the design of the integrated structure, all equipment is arranged inside the box. The structural design is ingenious, and the structure is closely linked and is simple. Thus, floor area is greatly reduced, and floor space is saved. The integrated marine diesel engine exhaust-gas treatment apparatus is applicable to ships with small space.

Owner:山东格润内泽姆环保科技有限公司

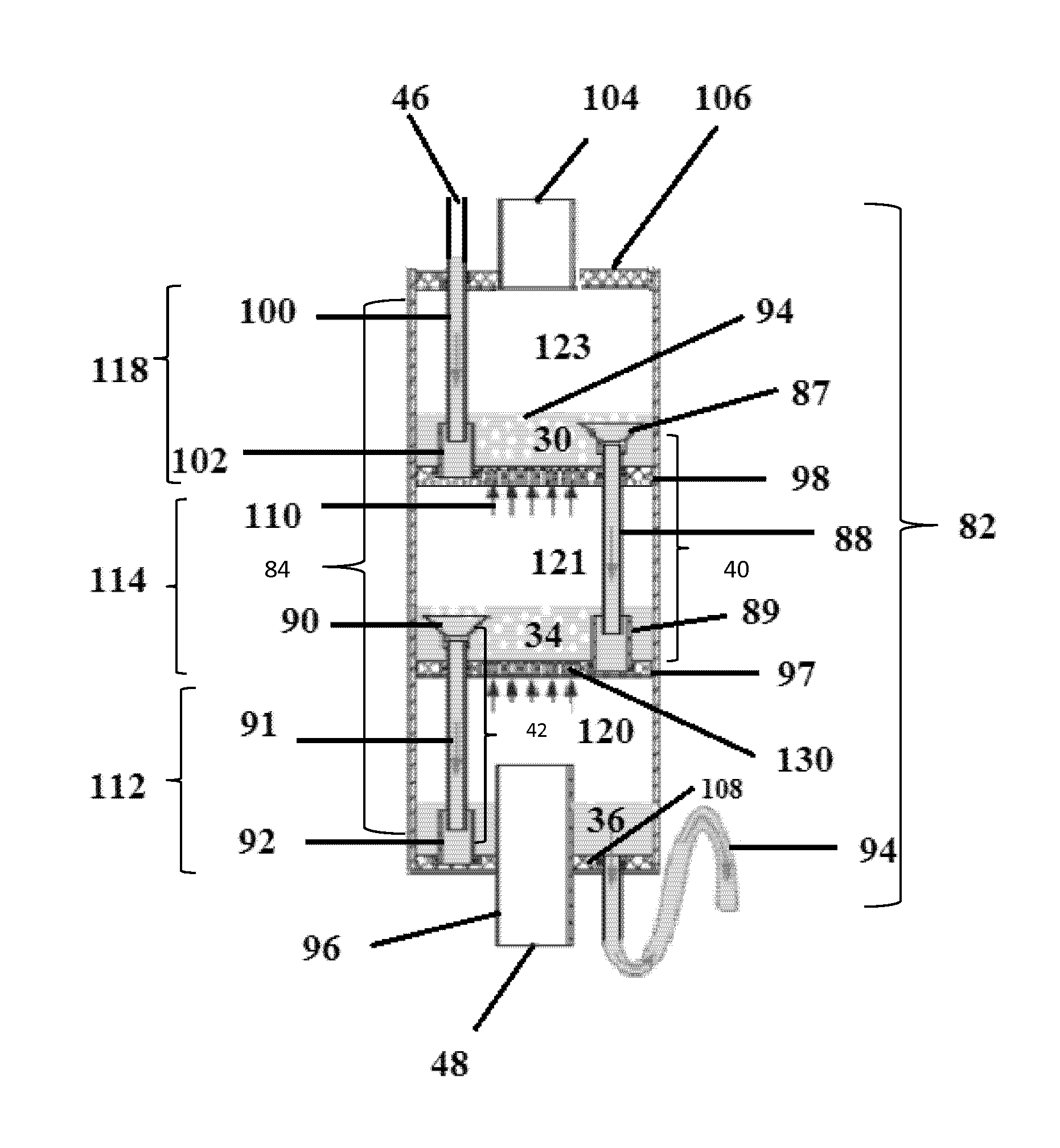

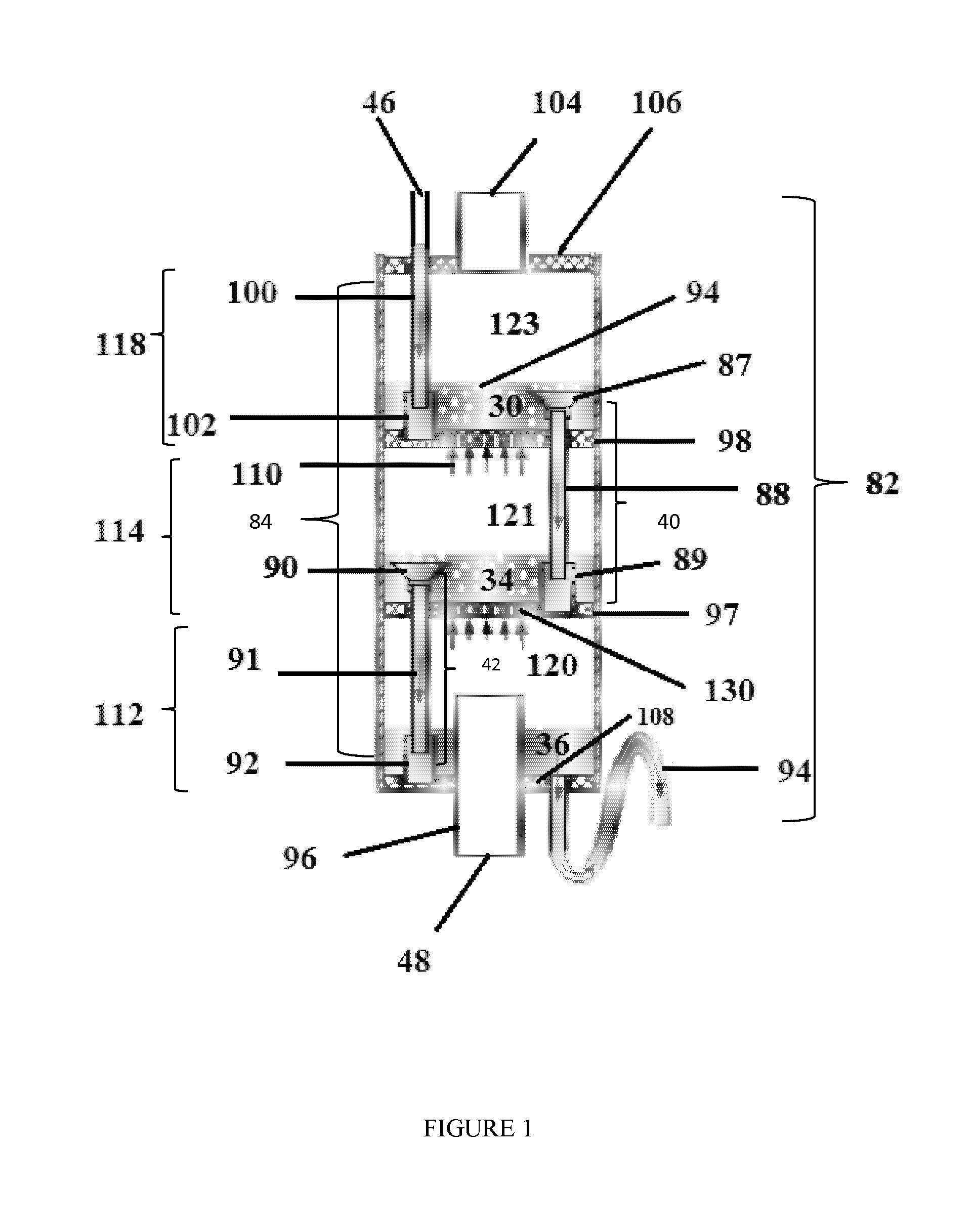

Multi-stage bubble column humidifier apparatus

InactiveUS20160288013A1Easy to replaceGuaranteed ease of adjustmentWaste water treatment from quariesSeawater treatmentBubble columnStream flow

A downcomer apparatus for use in a multi-stage bubble column humidifier. The humidifier comprises at least a first, second and third stage, wherein each of said stages includes an inlet, an outlet and a chamber defined by said stage, in fluid communication with the inlet and the outlet. In the humidifier, a heated liquid fluid stream flowing downwardly exchanges mass and heat with a cooler carrier gas stream flowing upwardly through the bubble column. A bubble generator comprising a perforated plate, or sparger, passes the carrier gas, such as air, from a lower chamber to form bubbles in a fluid, such as water, forming a bath on an upper chamber. An off-set arrangement of downcomer apparatuses, wherein said apparatus comprises a funnel, a watergate, and a downcomer, is used to prevent a recirculation of humid bubbles from the upper chamber to the lower chamber, thus preventing the air stream from circumventing the bubble generator in the form of the humid bubbles. This arrangement assures the maximum possible performance of the humidifier, as the entire air stream is forced to move through the bubble column, thus maximizing the air-water surface interface for an efficient mass and heat exchange.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Method and device for improving flow character of gas liquid bubble column with row tubes

InactiveCN101417220BImprove responseReduce the difficulty of zooming inLiquid-gas reaction processesSlurry reactorBubble column

The invention discloses a method and a device used for improving the flowing characteristic of the slurry bubble tower with row tubes; the device comprises a tower body, a gas distributor and a vertical heat exchanging row tube bundle; the lower end of the vertical heat exchanging tube bundle is connected with a liquid distributor which is fixed at the lower part of the tower body and the upper end thereof is connected with a liquid collector which is fixed at the upper part of the tower body; a plurality of layers of horizontal grid-typed damp internal components are arranged between the liquid distributor and the liquid collector; the heat exchanging row tube bundle vertically passes through the horizontal grid-typed damp internal components; each layer of the grids is fixed on the tower wall and the row tubes; and by arranging the horizontal grid-typed damp internal components in the slurry bubble tower which is provided with vertical row tube bundles; and the horizontal damp internal components block the flowing of the slurry and air bubbles in the tower, inhibit the flowing craggedness effect caused by the row tube bundle, and reduce the returned mixing of the fluid, thus improving the flowing characteristic of the slurry reactor.

Owner:ZHEJIANG UNIV

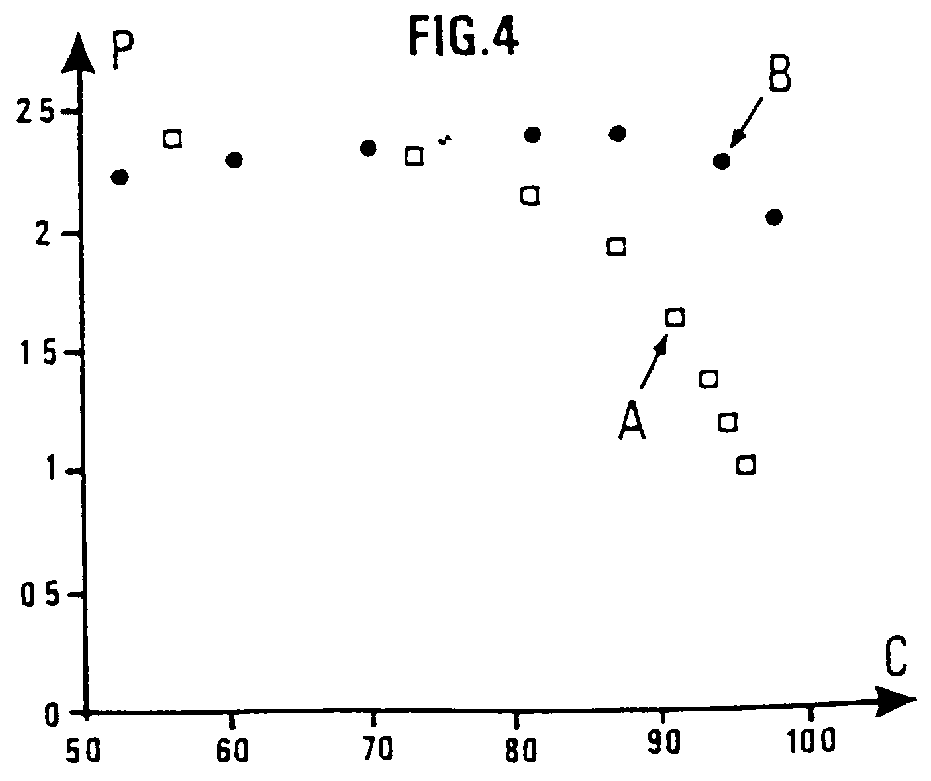

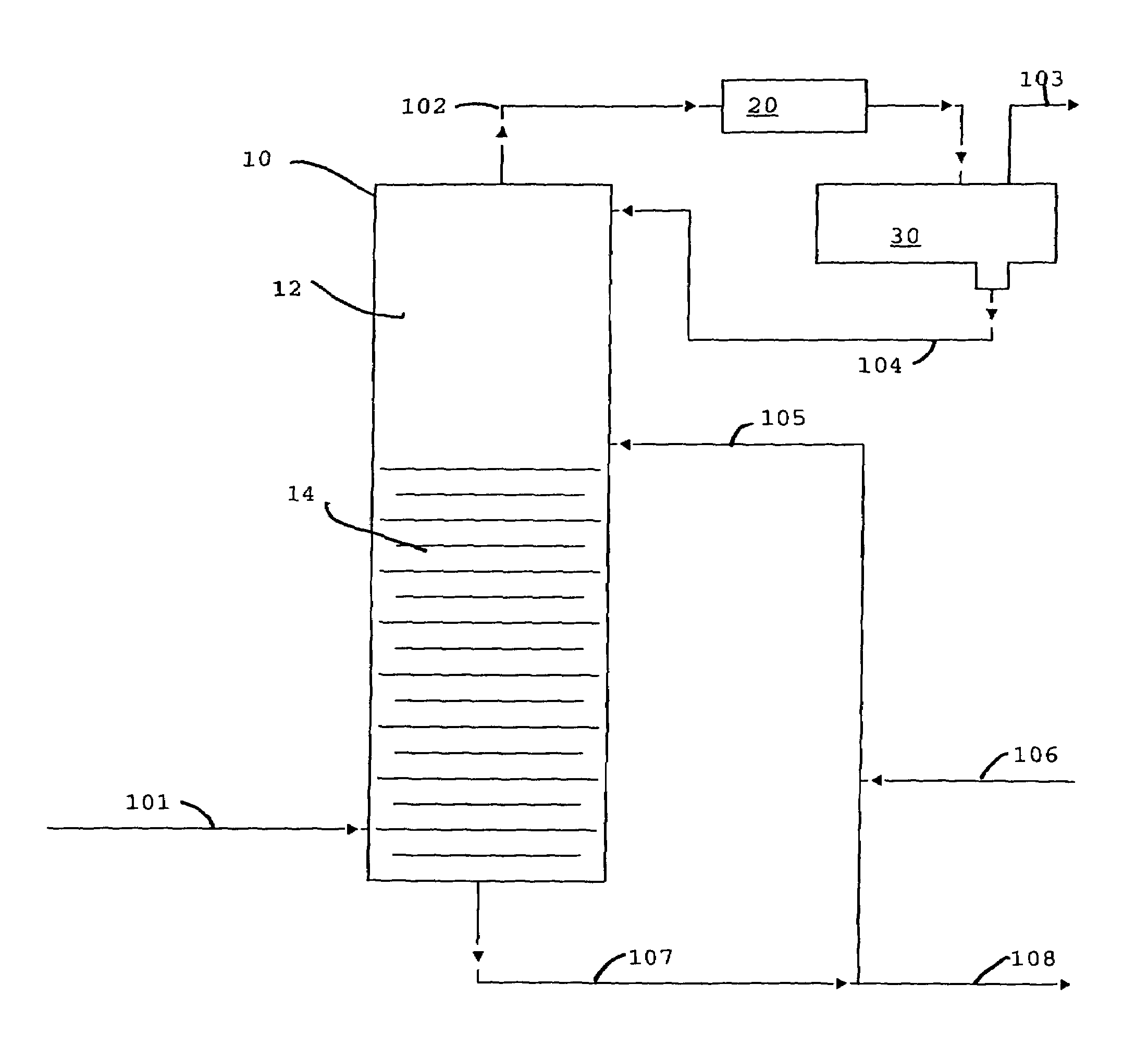

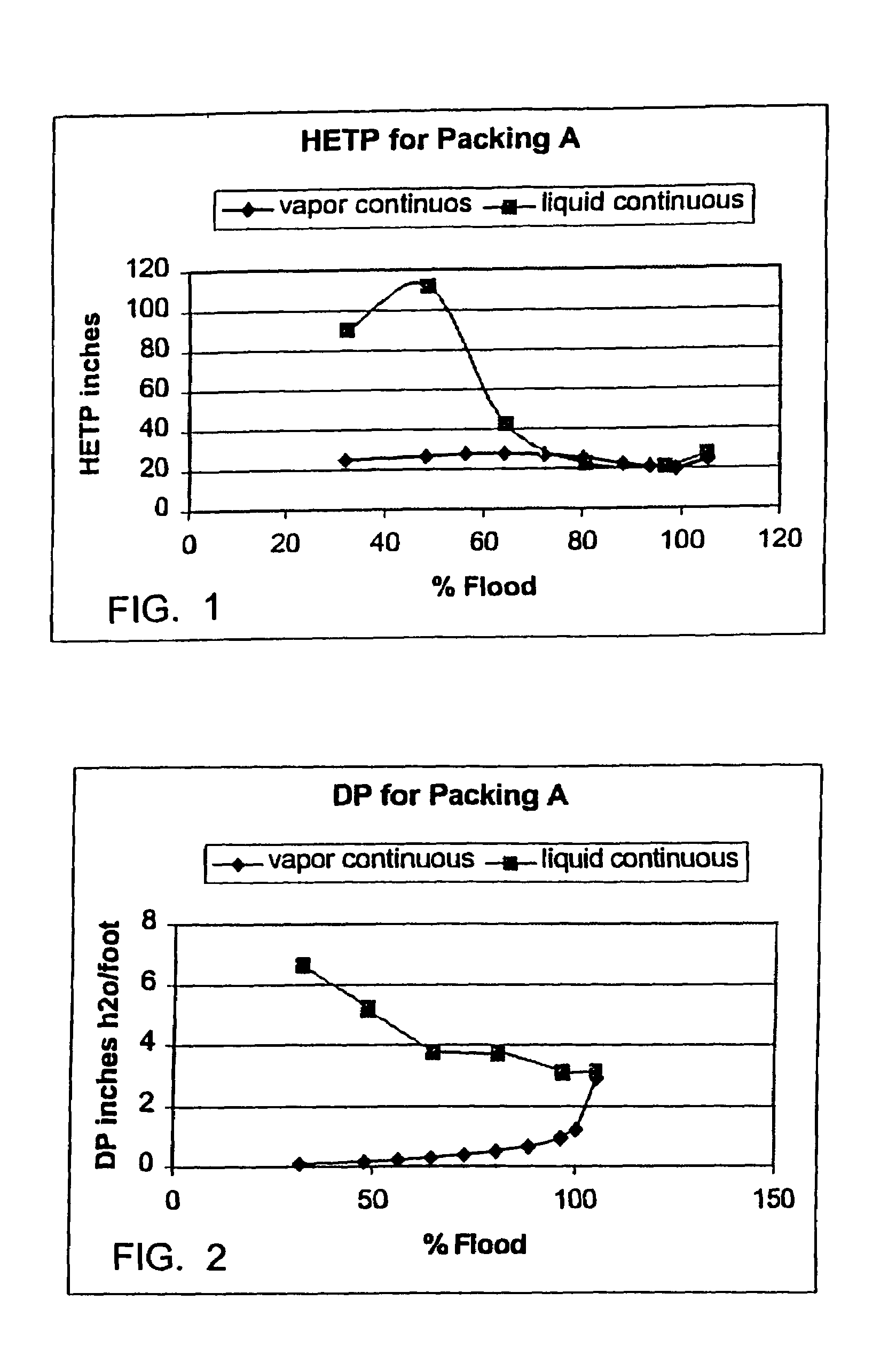

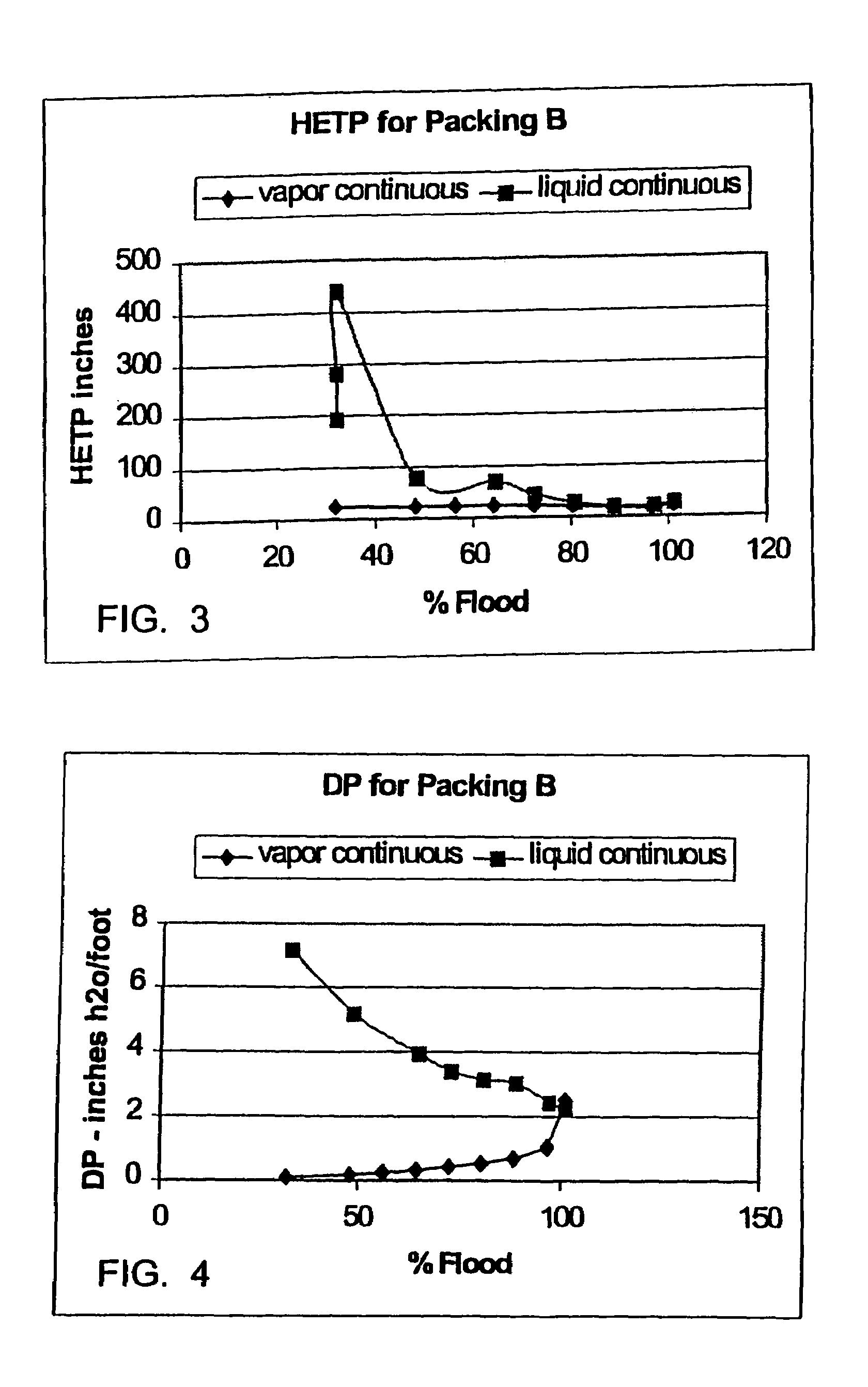

Liquid-continuous column distillation

InactiveUS7091252B2Organic compounds purification/separation/stabilisationOrganic compound preparationVapor liquidBubble column

Bubble columns fractionate with vapor-liquid mass transfer efficiencies approaching that of distillation towers when vapor velocities in excess of 50% of jet flood are used. If the vapor velocities are pushed above about 70% of jet flood then the distillation performance of a given column packing becomes similar for both liquid continuous operation (bubble column mode) and vapor continuous operation (ordinary distillation tower mode).

Owner:CHEM RES & LICENSING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com