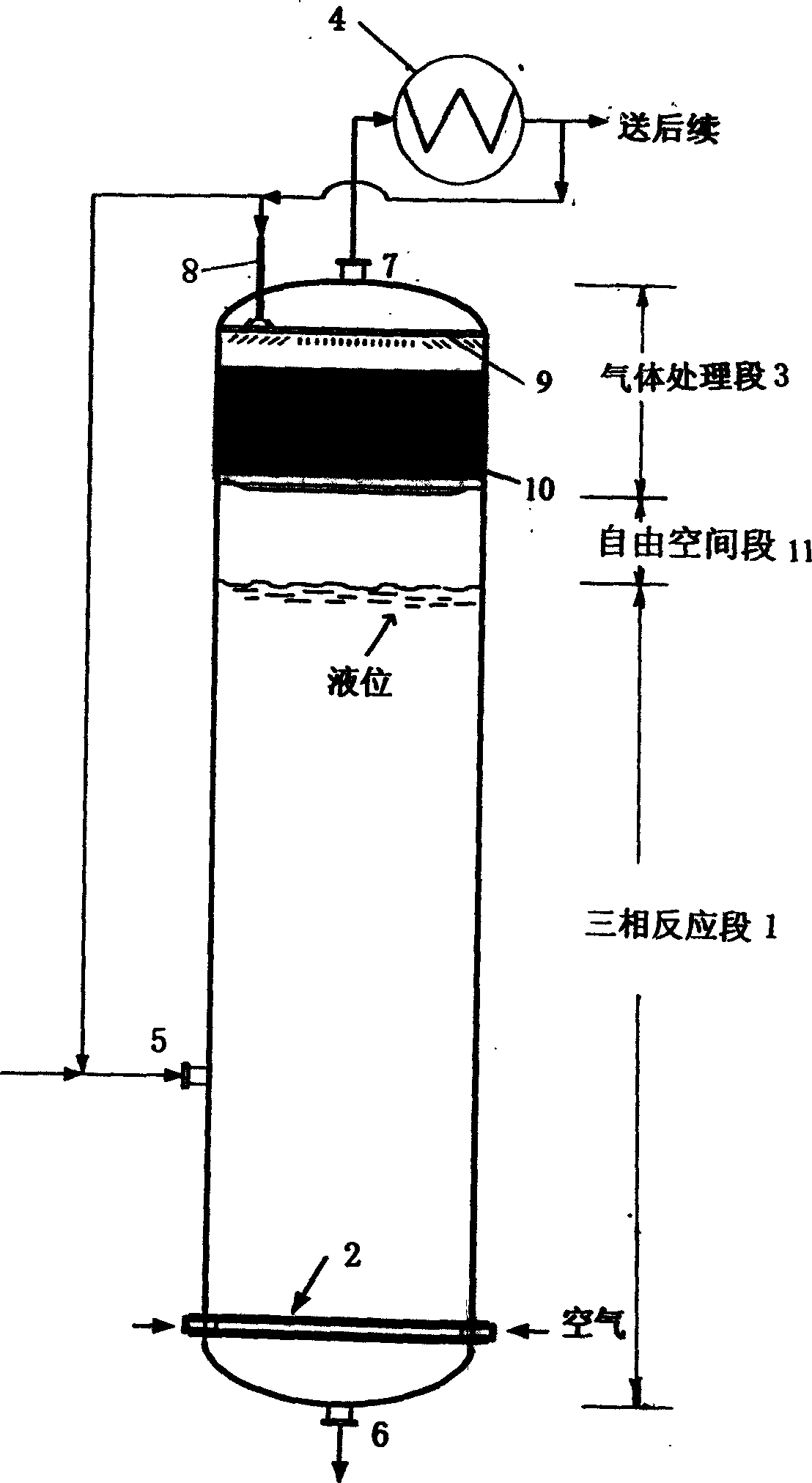

Bubble tower oxidation reaction unit for producing terephthalic acid

A technology of terephthalic acid and oxidation reaction, which is applied in the fields of organic chemistry, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of unfavorable slurry flow and complex structure, and achieves simple structure, low construction cost and low operating cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The medium and high temperature oxidation process is used to produce terephthalic acid. The annual production capacity of a single reaction device is 300,000 tons of TA, and the annual production time is 7600 hours. The reaction conditions are given in Table 1.1.

[0029]

[0030] The structural dimensions of the device are given in Table 1.2.

[0031] diameter (m)

[0032] In the table, D is the diameter of the tower, which is determined according to the production capacity, and H is the height of the reaction section. For a bubble column reactor with an annual output of 300,000 tons of terephthalic acid, when the aspect ratio is selected as 4, D = 4.60m. The reaction results and related indicators are given in Table 1.3.

[0033] PX conversion rate

[0034] PT and 4-CBA given in the table are respectively the liquid phase concentration (=component quality / solvent acetic acid and water quality) of reaction intermediate p-toluic acid and p-...

Embodiment 2

[0036] The high-temperature oxidation process is used to produce terephthalic acid. The annual production capacity of a single reaction device is still 300,000 tons of TA, and the annual production time is 7600 hours. The reaction conditions are given in Table 2.1. The structure and size of the reaction device are shown in Table 2.2, and the output results of the reactor are listed in Table 2.3.

[0037]

[0038] diameter (m)

[0039] PX conversion rate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com