Patents

Literature

42 results about "Tetrabromoethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

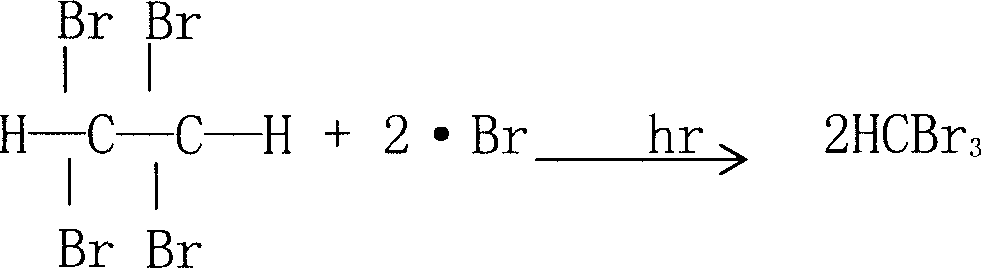

Tetrabromoethane (TBE) is a halogenated hydrocarbon, chemical formula C₂H₂Br₄. Although three bromine atoms may bind to one of the carbon atoms creating 1,1,1,2-tetrabromoethane this is not thermodynamically favorable, so in practice tetrabromoethane is equal to 1,1,2,2-tetrabromoethane, where each carbon atom binds two bromine atoms.

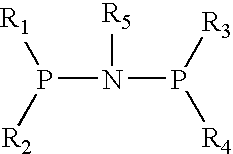

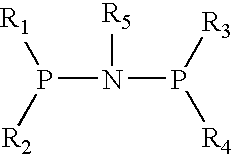

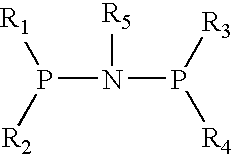

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS7786336B2High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneAluminoxane

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as:in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; the accelerator is selected from the group consisting of 1,1,2,2,-tetrachloroethane, 1,1,2,2-tetrabromoethane, 1,1,2,2-tetrafluoroethane, and compounds having a formula of X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkylene or arylene group; the molar ratio of chromium compound, ligand containing P and N, activator and accelerator is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·ma−1 Cr·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

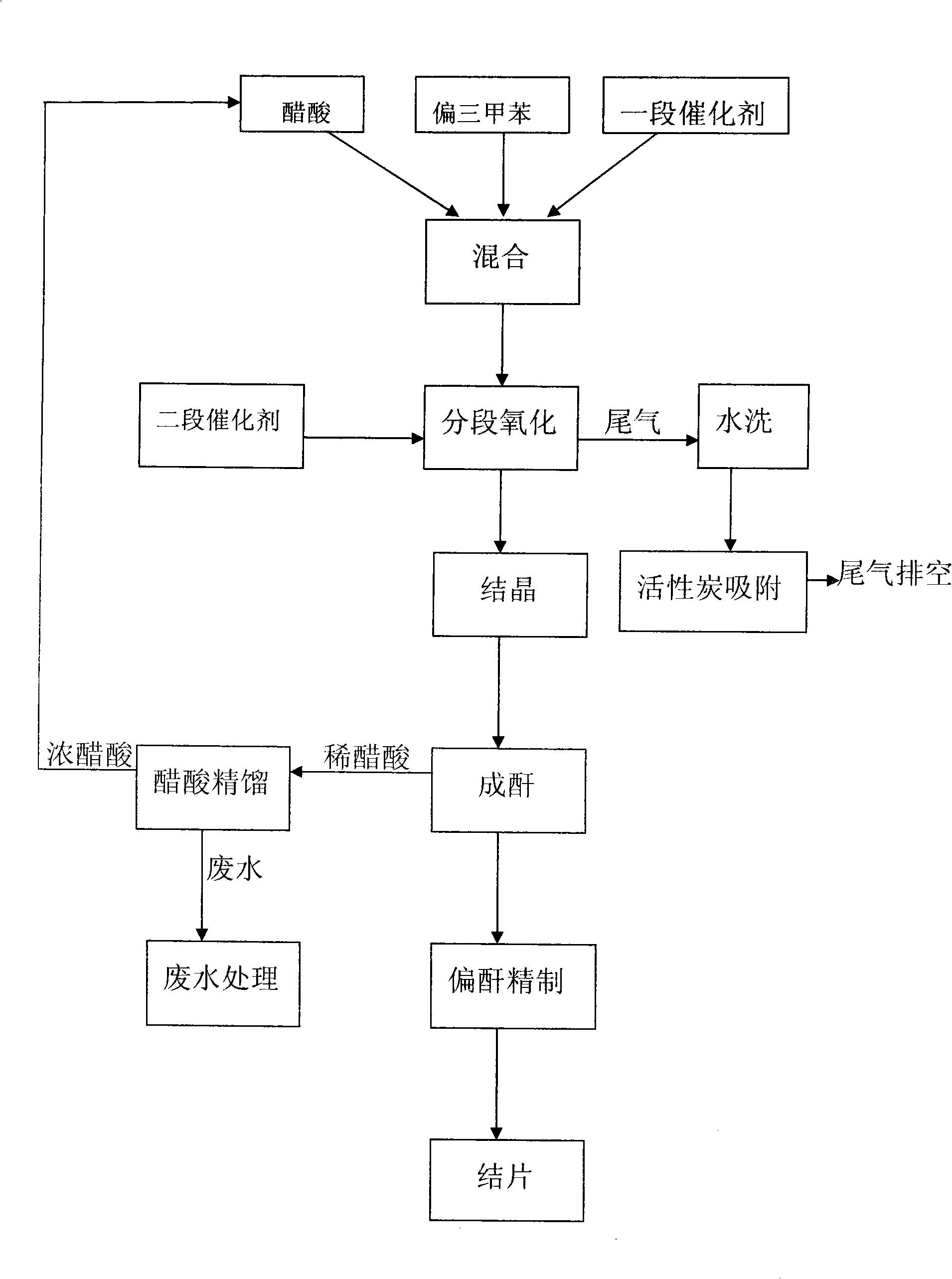

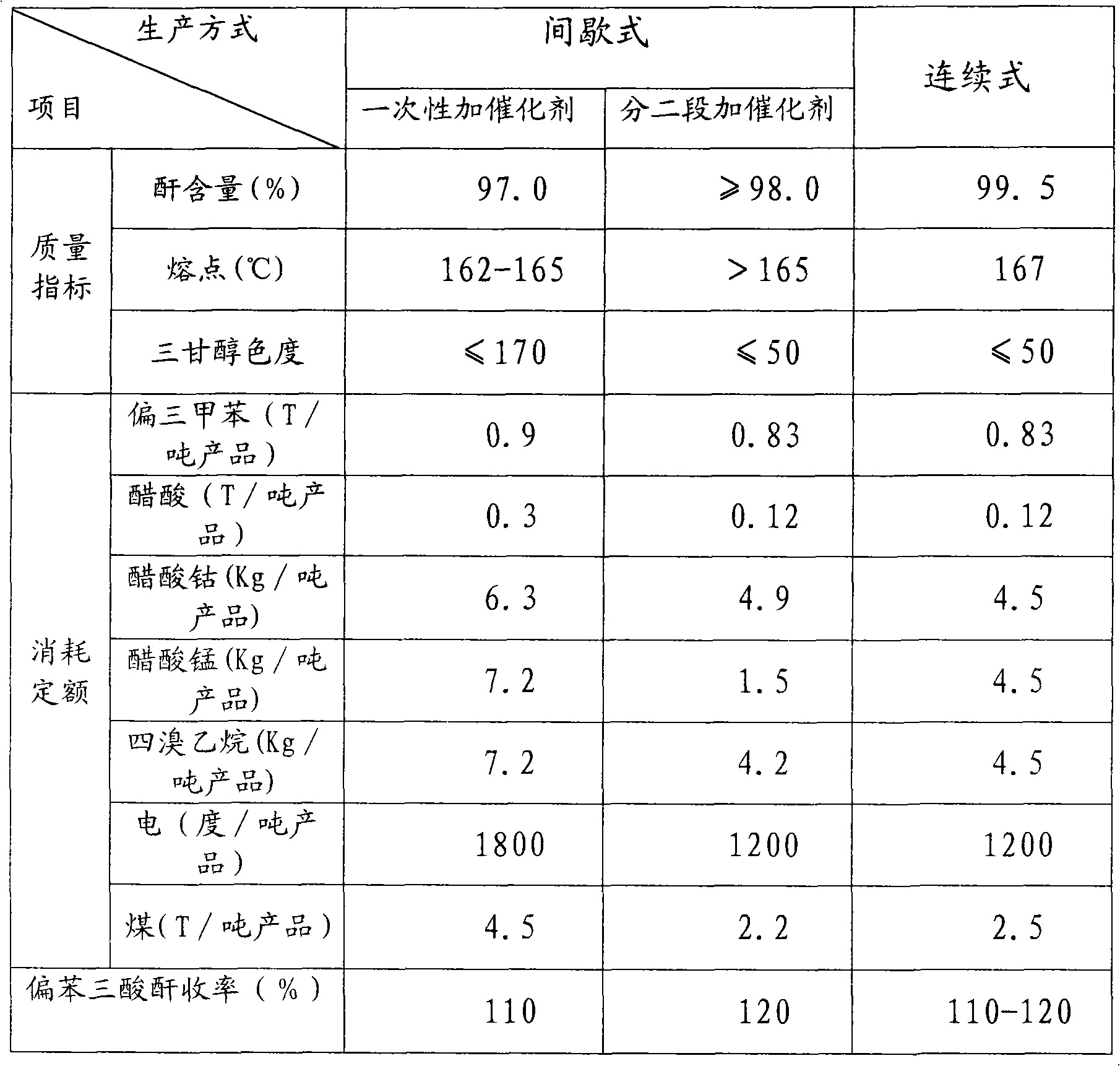

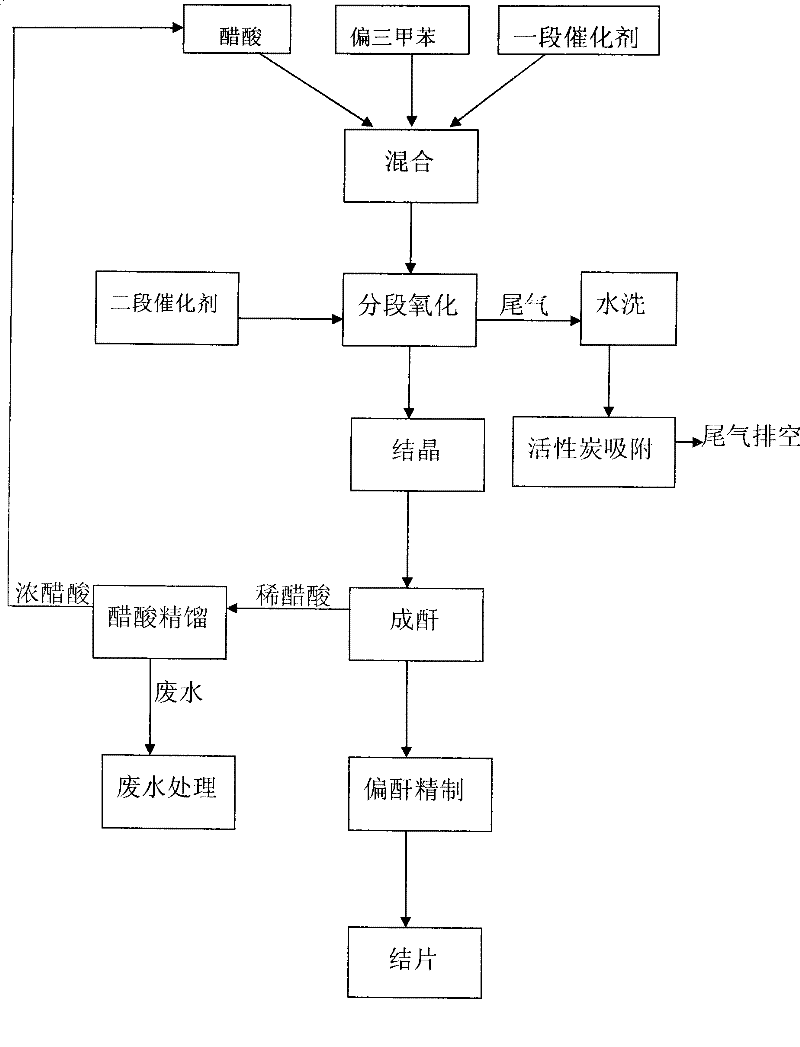

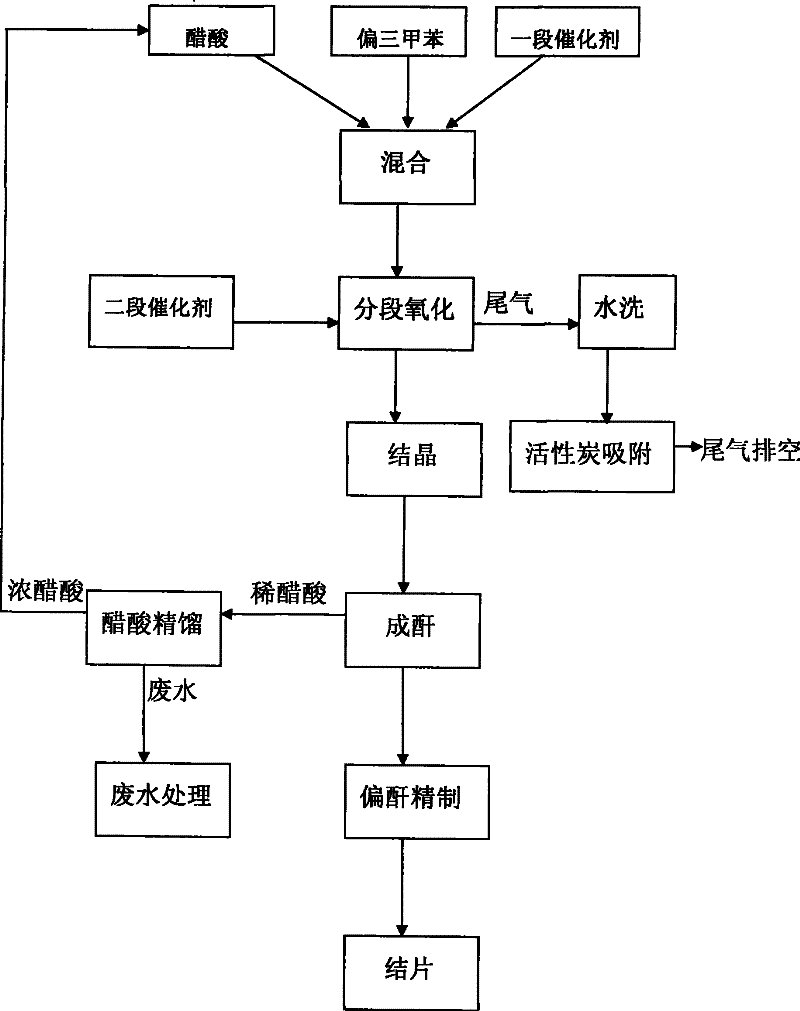

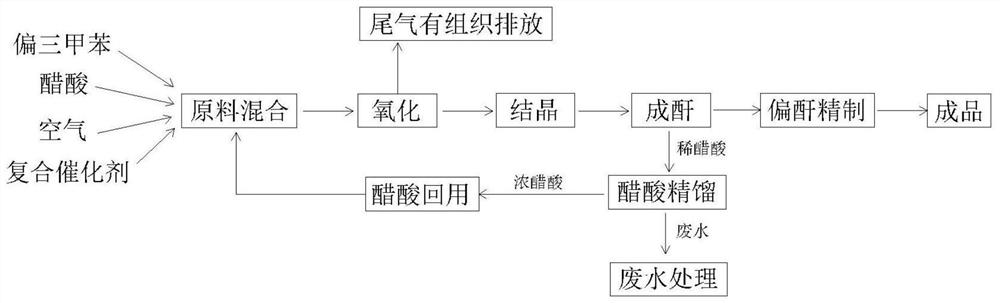

Method for producing trimellitic anhydride with pseudocumene liquid phase air segmenting hydrocarbonylation

The invention relates to a method for producing trimellitic anhydride by using a pseudocumene liquidoid air subsection oxidation method. Pseudocumene is used as a raw material, acetic acid is used as a solvent, and cobalt acetate, manganese acetate, and tetrabromoethane are used as catalysts; the solvent weight ratio of pseudocumene to acetic acid is between 1 to 2.5 and 1 to 10; and the weight ratio of the total catalysts to the pseudocumene is as follows: the ratio of the pseudocumene to the cobalt acetate to the manganese acetate to the tetrabromoethane is 1 to 0.005-0.05 to 0.005-0.05 to 0.005-0.05. The method comprises the following: a step of mixture, in which the pseudocumene and the acetic acid are weighed out according to the proportion, are added with the cobalt acetate and the tetrabromoethane which account for 40 to 60 percent of the total weight at a temperature between 60 and 100 DEG C; a step of subsection oxidation, in which the mixed materials enter the first reaction period which lasts for 30 to 50 minutes from the beginning of the oxidation, at a temperature between 140 and 180 DEG C and at a pressure of between 0.4 and 1.0 Mpa, then enter the second reaction period at a temperature of 180 and 300 DEG C and at a pressure of between 1.0 and 3.0 Mpa, and finally are added with the residual catalysts; a step of anhydride formation; and a step of fine purification. The method effectively solves the problem of self-inhibition in oxidation reaction.

Owner:安徽泰达新材料股份有限公司

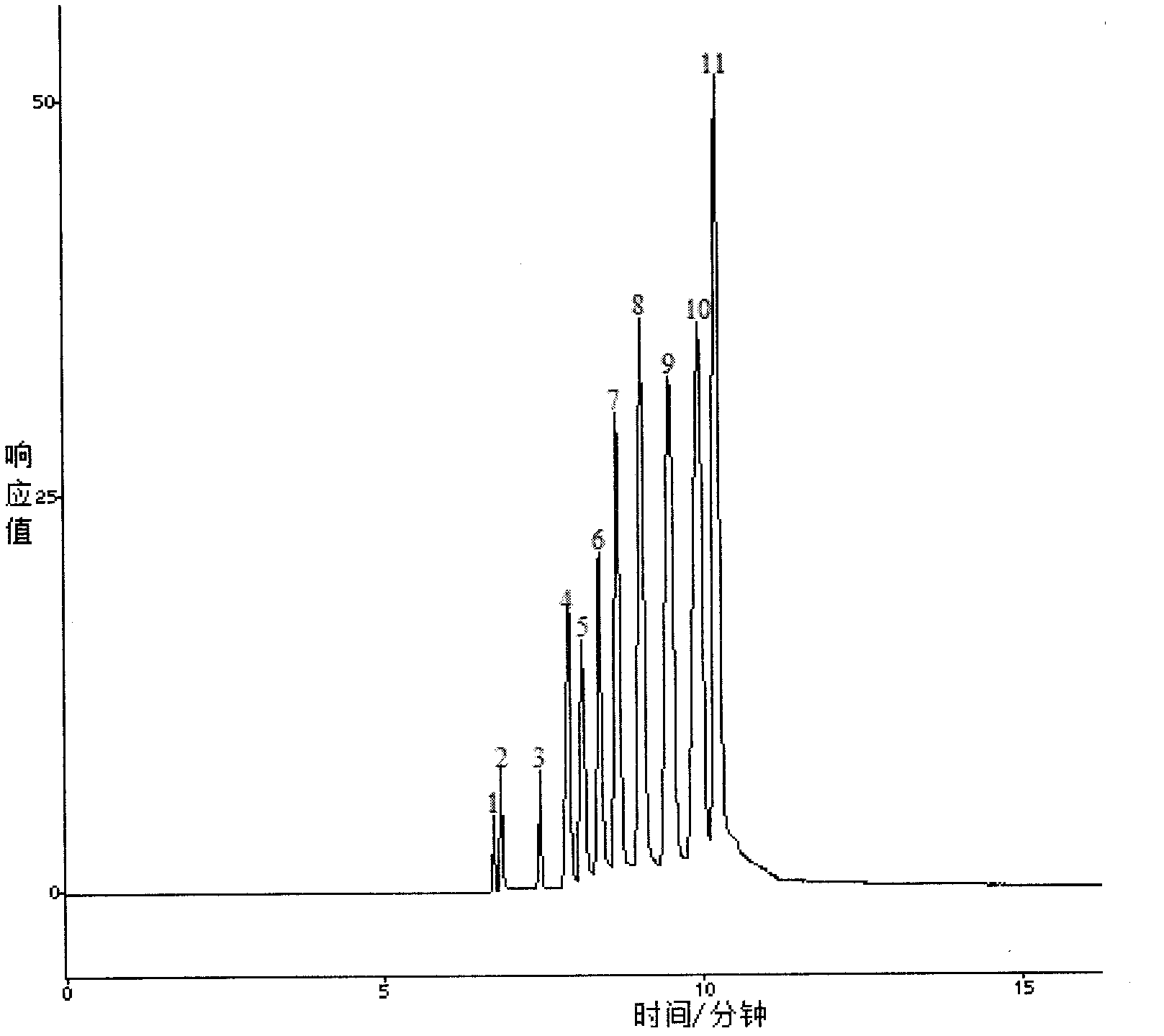

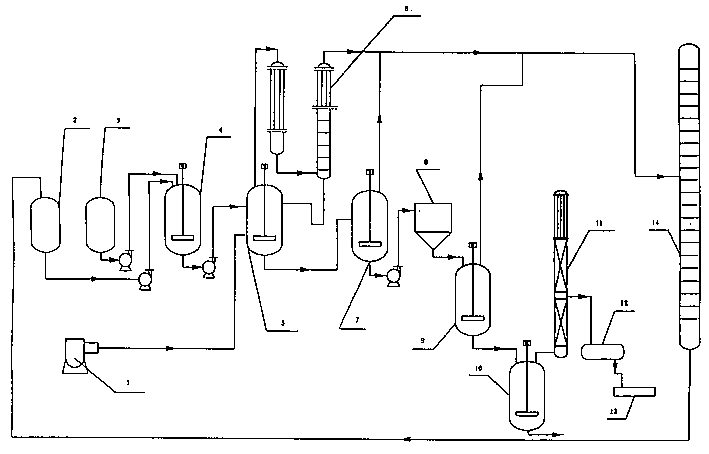

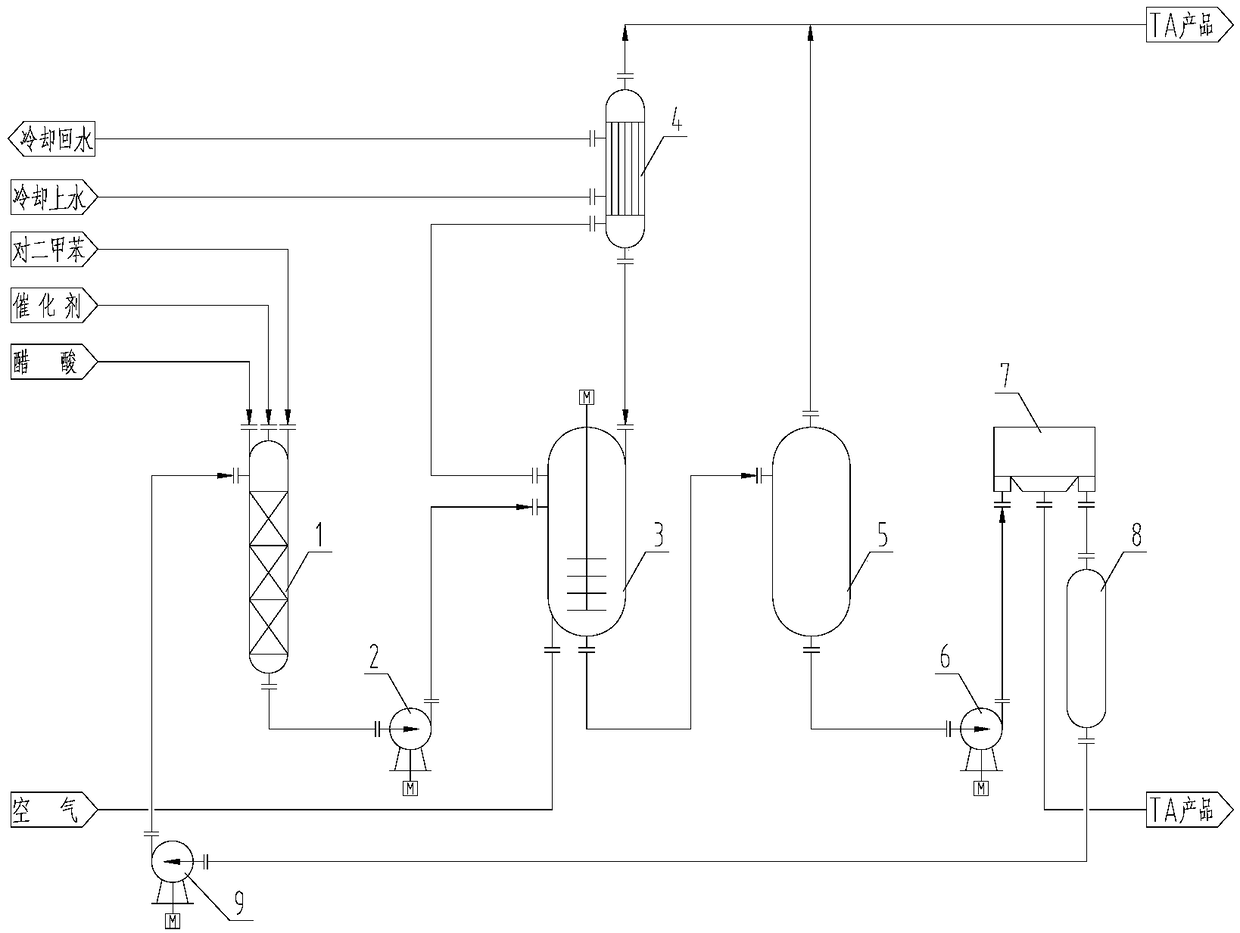

Continuous production method of trimellitic acid

InactiveCN106187739ARealize continuous productionImprove conversion rateOrganic compound preparationCarboxylic compound separation/purificationMANGANESE ACETATEFiltration

The invention discloses a continuous production method of trimellitic acid. The method comprises the following processes of premixing, oxidation, coarse crystallization, filtration and recrystallization, which are sequentially performed, and comprises the following specific processes of (1) performing premixing: mixing raw materials namely unsym-trimethyl benzene, a solvent namely acetic acid, main catalysts namely cobalt acetate and manganese acetate, and a cocatalyst namely tetrabromoethane, and performing preheating to 60-120 DEG C, wherein the mass ratio of the unsym-trimethyl benzene to the acetic acid is 1 to (2-10); (2) performing oxidation: performing 2-4 continuous oxidation stages which are in series connection, and enabling the reaction temperature of the later oxidation stage to be higher than that of the previous oxidation stage; (3) performing coarse crystallization: performing coarse crystallization and then performing centrifugal separation; (4) performing filtration: dissolving crude trimellitic acid in water of 80-100 DEG C, controlling the percentage by mass of the trimellitic acid to be 15-35%, and filtering a hot solution when the solution is still hot; and (5) performing recrystallization: performing recrystallization and then performing centrifugal separation. According to the method disclosed by the invention, the trimellitic acid products with high conversion rate, high yield and high purity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

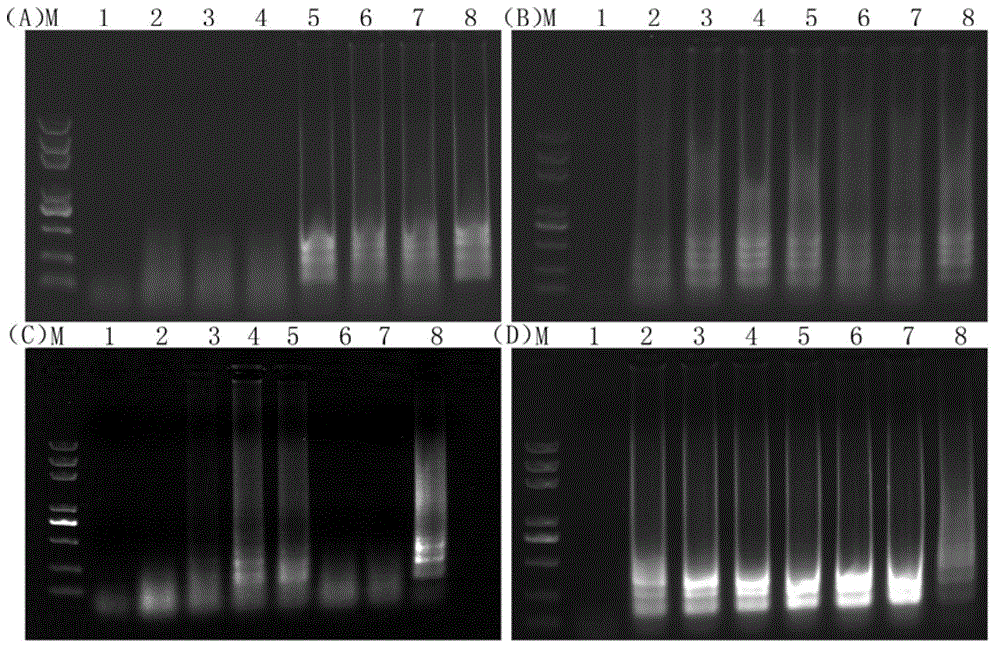

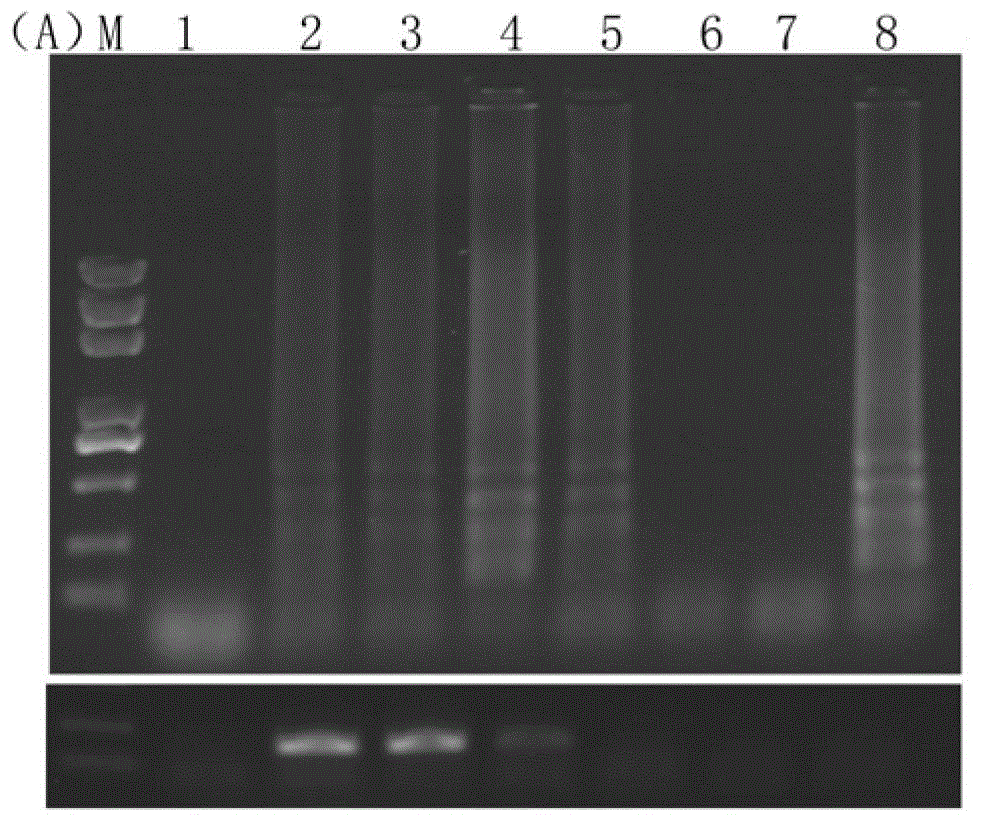

Method for detecting tumor mutant gene in blood

InactiveCN102251046AGuaranteed accuracyGood temperature control systemMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAbnormal tissue growthSingle-strand conformation polymorphism

The invention relates to a method for detecting a tumor mutant gene in blood. The method comprises the following steps of: (1) preparing a polyethylene oxide sieving medium containing TBE (Tetrabromoethane); (2) extracting a genome DNA (Deoxyribonucleic Acid) in a blood sample; (3) amplifying a gene target fragment needing to be detected: performing conventional PCR (Polymerase Chain Reaction) amplification by taking the genome DNA as an amplifying template to obtain a p53 gene PCR amplification sample and a k-ras gene PCR amplification sample; (4) treating the samples: performing denaturation or enzyme digestion on the p53 gene PCR amplification sample and the k-ras gene PCR amplification sample to obtain a denatured sample solution and an enzyme digestion solution respectively; and (5) detecting the samples: adding a 10*SYBR Green I fluorescence dye and the genome DNA into the denatured sample solution and the enzyme digestion solution respectively, uniformly mixing, adding deionized water till a system is 30-50 mu l, automatically filling the polyethylene oxide sieving medium by using a capillary electrophoresis apparatus pressure system and performing CE-SSCP (Capillary Electrophoresis-Single Strand Conformation Polymorphism) detection or CE-RFLP (Capillary Electrophoresis-Restriction Fragment Length Polymorphism) detection respectively. The method is easy to operate, and has high repeatability.

Owner:王荣

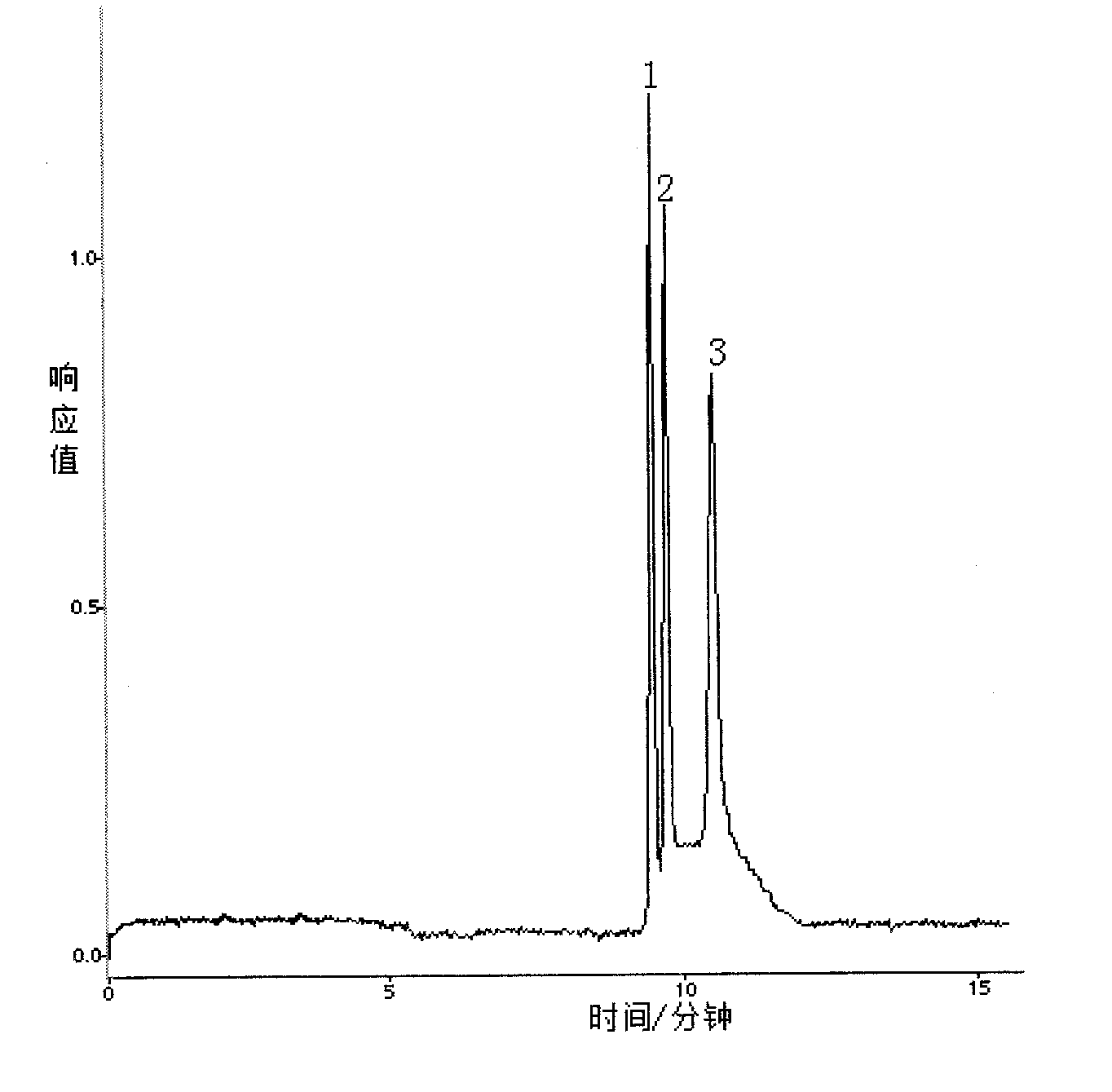

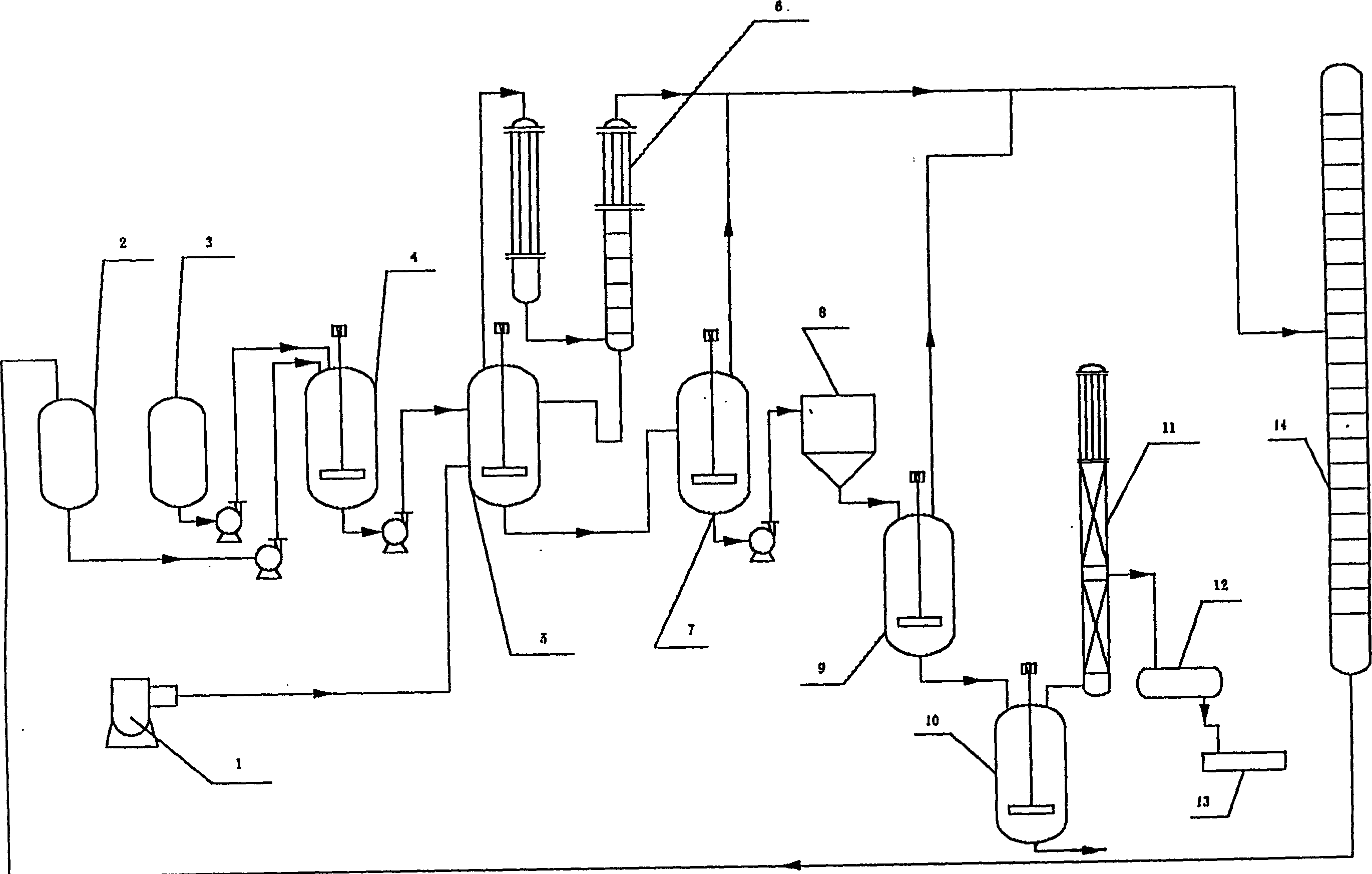

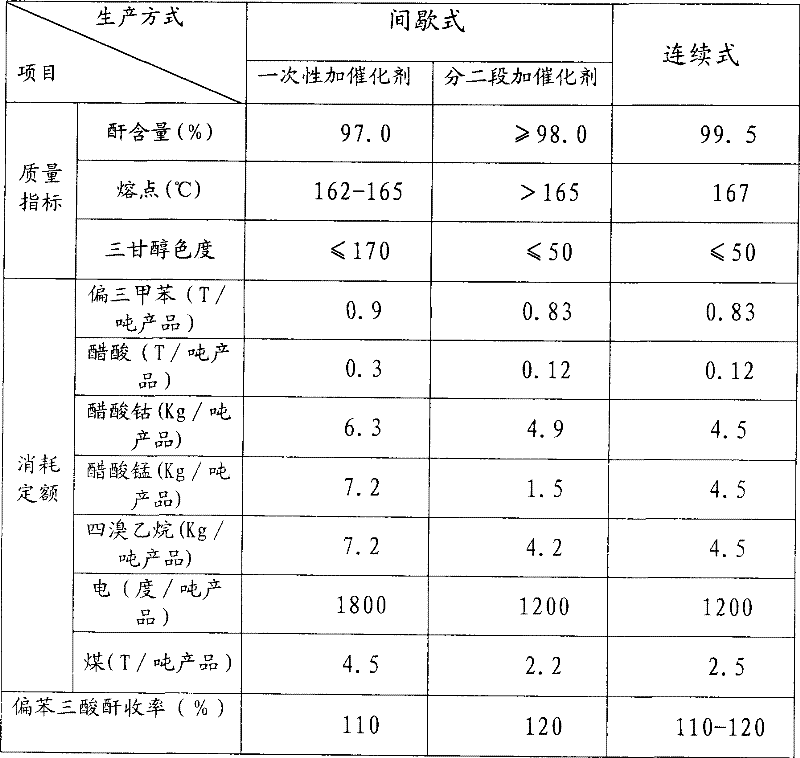

Process for producing trimellitic anhydride by continuous oxidizing process

The invention relates to a method for producing trimellitic anhydride by a continuous oxidation process, which uses trimellitic acid as a raw material, acetic acid as a solvent, and cobalt acetate, manganese acetate, tetrabromoethane or hydrogen bromide as a catalyst. The production process includes the following process: (1) continuous oxidation reaction process of the above mixed material; (2) anhydride forming process; (3) refining process; (4) slicing or granulating process; (5) solvent recovery process. Its advantage is that it adopts continuous oxidation technology and advanced refining technology, so that the yield of the product can reach 120%. Compared with the batch oxidation process, this process has the characteristics of high production safety, complete oxidation reaction, stable product quality, low consumption of raw and auxiliary materials, long service life of equipment, and is suitable for large-scale industrial production. In the production technology, the production scale is small, the product quality fluctuates greatly, the product yield is low, the energy consumption is high, and the service life of the equipment is short. Therefore, the process of the present invention has good promotion value.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

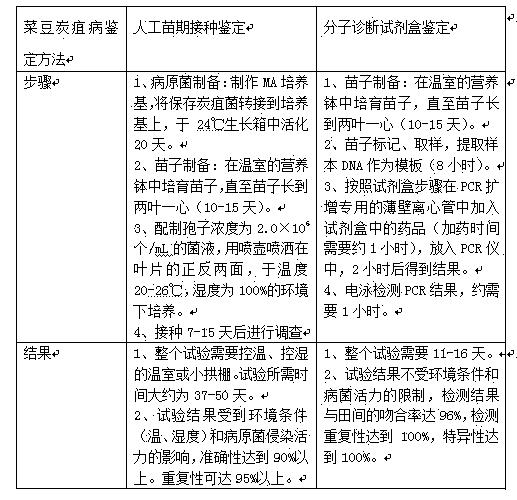

One-step loop-mediated reverse transcription isothermal amplification detection method for soybean mosaic virus

InactiveCN103146845ACheck fastReduce redundant timeMicrobiological testing/measurementMicroorganism based processesFluorescenceTotal rna

The invention discloses a one-step loop-mediated reverse transcription isothermal amplification detection method for soybean mosaic virus. The primer group is used to carry out RT-LAMP (Reverse Transcription Loop-Mediated Isothermal Amplification) reaction; the reaction product is placed to 1% of TBT (Tetrabromoethane) agar gel for electrophoresis or visualization is carried out to the amplification product by using a fluorescent dye SYBR Green I; if the reaction is positive, the soybean mosaic virus exists; if the reaction is negative, the to-be-detected sample does not contain soybean mosaic virus. According to the one-step loop-mediated reverse transcription isothermal amplification detection method for soybean mosaic virus disclosed by the invention, the RNA (Ribonucleic Acid) quick crude extracting method is combined with the RT-LAMP detection, so that the total RNA nucleic acid of the quickly and crudely extracted to-be-detected sample is used as a reaction template of the RT-LAMP, therefore, the redundancy time for the conventional RNA extracting method of the RT-LAMP is saved, the operation process is simplified, the detection speed is improved, and the one-step detection for the soybean mosaic virus is realized.

Owner:NANJING AGRICULTURAL UNIVERSITY

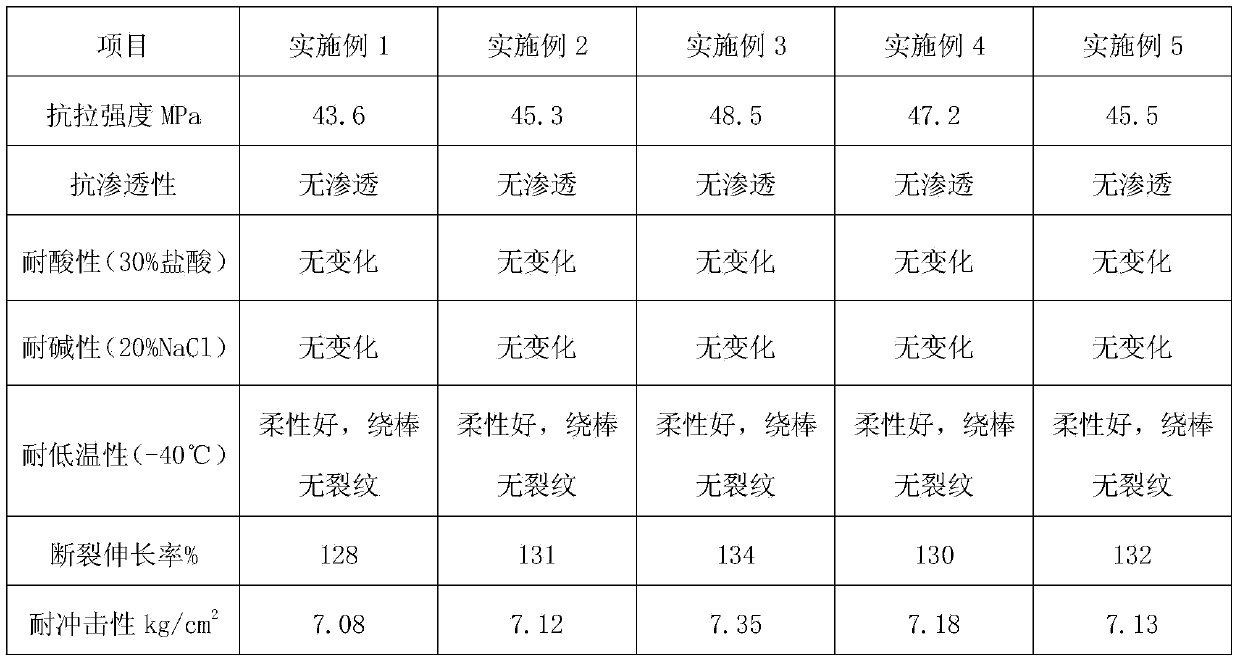

Polyvinyl chloride soft foam plastic coiled material and preparation method thereof

The invention discloses a polyvinyl chloride soft foam plastic coiled material and a preparation method thereof. The polyvinyl chloride soft foam plastic coiled material comprises the following components in parts by weight: 80-90 parts of polyvinyl chloride resin, 20-30 parts of plasticizer, 3-8 parts of foaming agent, 0.5-2 parts of barium stearate, 1-5 parts of butane, 0.5-1 part of zinc oxide and 0.5-2 parts of tetrabromoethane. The preparation method comprises the following steps: stirring and mixing the components in a mixing machine at the stirring speed of 80-100rpm for 15-20 minutes, heating the mixture to 70-80 DEG C, and carrying out foaming reaction, thus obtaining the polyvinyl chloride soft foam plastic. The polyvinyl chloride soft foam plastic disclosed by the invention has the advantages of favorable recovery rate, high tensile strength, high impact resistance and high chemical stability.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

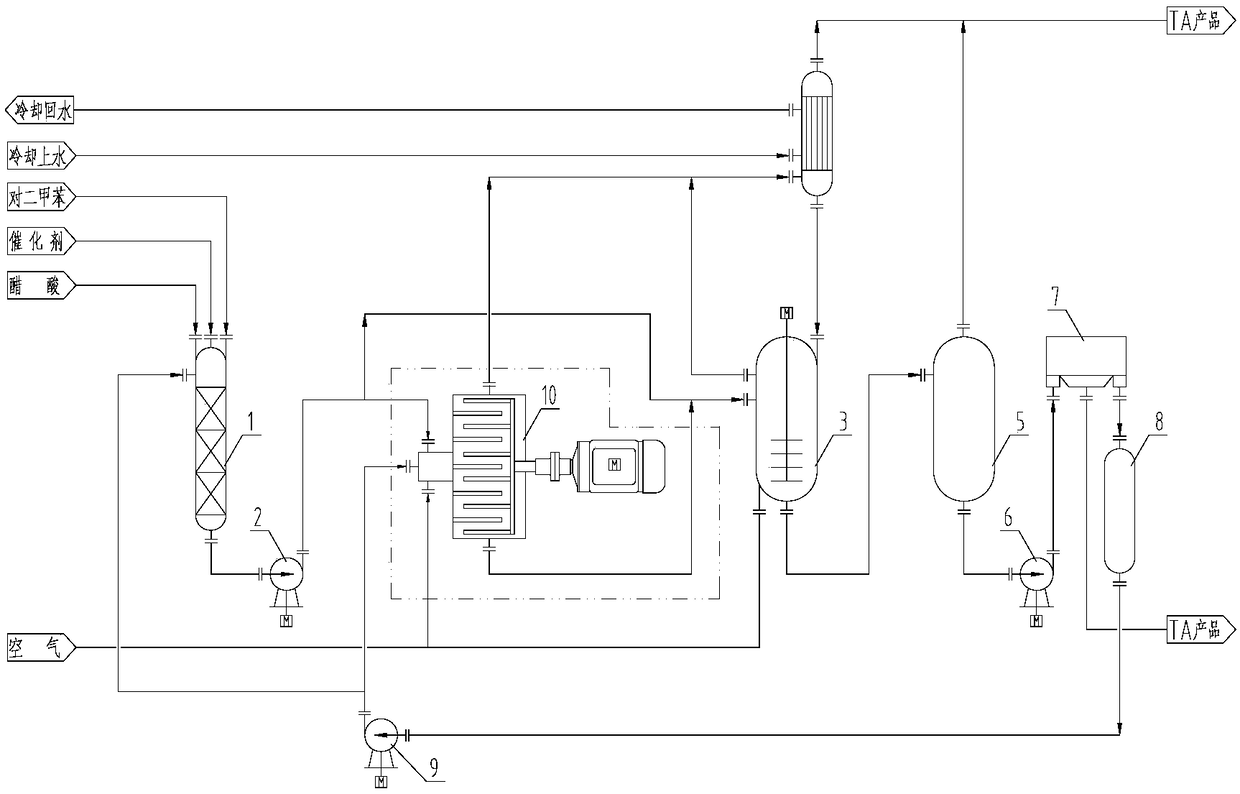

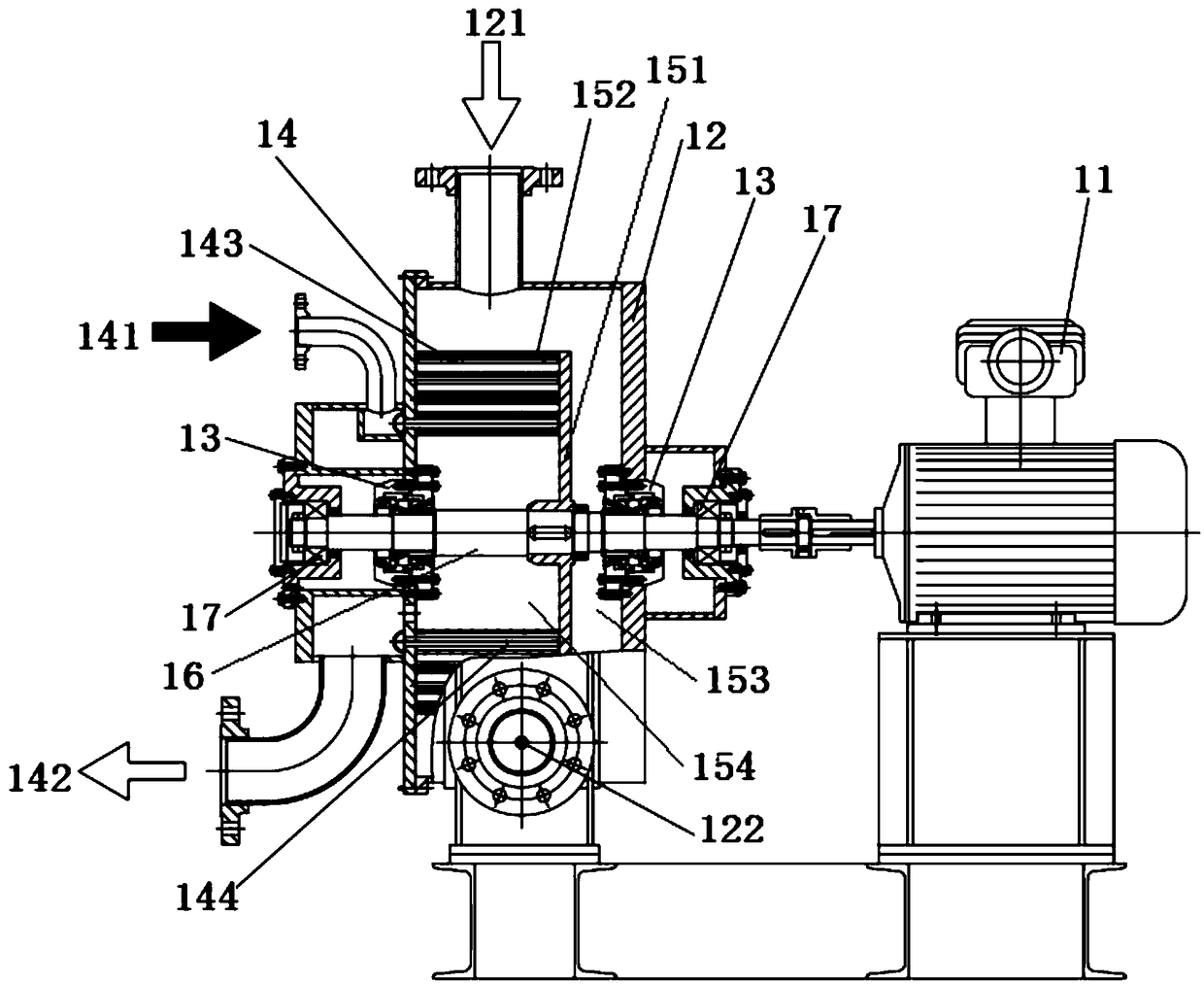

PTA (Pure Terephthalic Acid) energy-saving and consumption-reducing device and homogeneous pre-mixing method before CTA (Crude Terephthalic Acid) oxidation reaction

PendingCN109053412AIncrease the rate of oxidation reactionsIncrease the yield of the main reactionOrganic compound preparationChemical industryMANGANESE ACETATEReaction rate

The invention discloses a PTA (Pure Terephthalic Acid) energy-saving and consumption-reducing device and a homogeneous pre-mixing method before a CTA (Crude Terephthalic Acid) oxidation reaction. A super-gravity homogeneous premixing reactor is added between a feed mixing device and an oxidation reactor, and the super-gravity homogeneous premixing reactor comprises a motor, a housing, an end cap,a rotating shaft, a rotor, a stationary ring, and a feed nozzle. The rotor comprises a rotating disc and a moving ring; the moving ring comprises an inner moving ring, an intermediate moving ring andan outer moving ring which coaxially sleeve the periphery of the rotating shaft from the inside to the outside. Adding the super-gravity homogeneous premixing reactor has two effects on the oxidationreaction process: 1, homogeneously mixing p-xylene, an acetic acid solvent, a catalyst (cobalt acetate, manganese acetate, and an accelerator tetrabromoethane) mixture again, to improve the mixing uniformity; 2, initiating an oxidation reaction by introducing air, to increase the oxidation reaction rate in the oxidation reactor, and to increase the main reaction yield. The heat removal time is shortened, and the evaporation of the acetic acid solvent is reduced.

Owner:NANJING TACHUAN CHEM EQUIP CO LTD

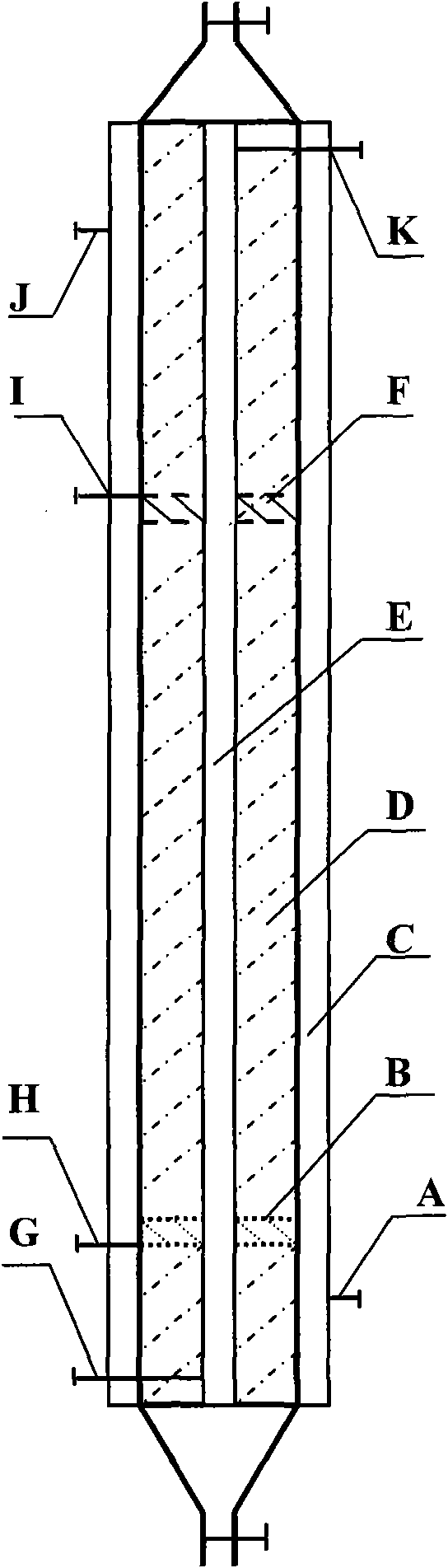

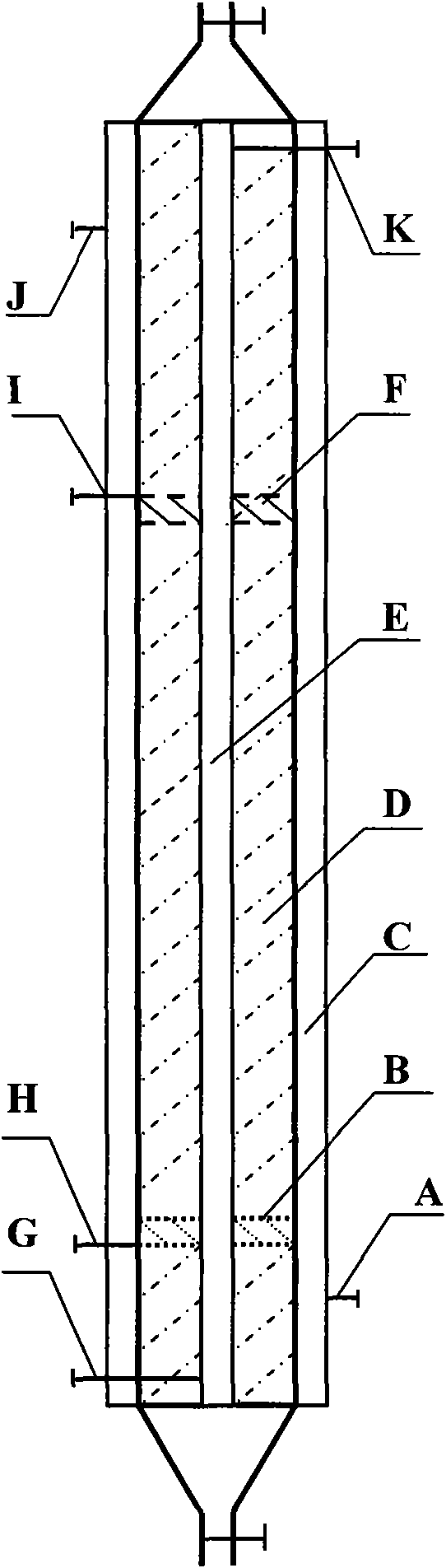

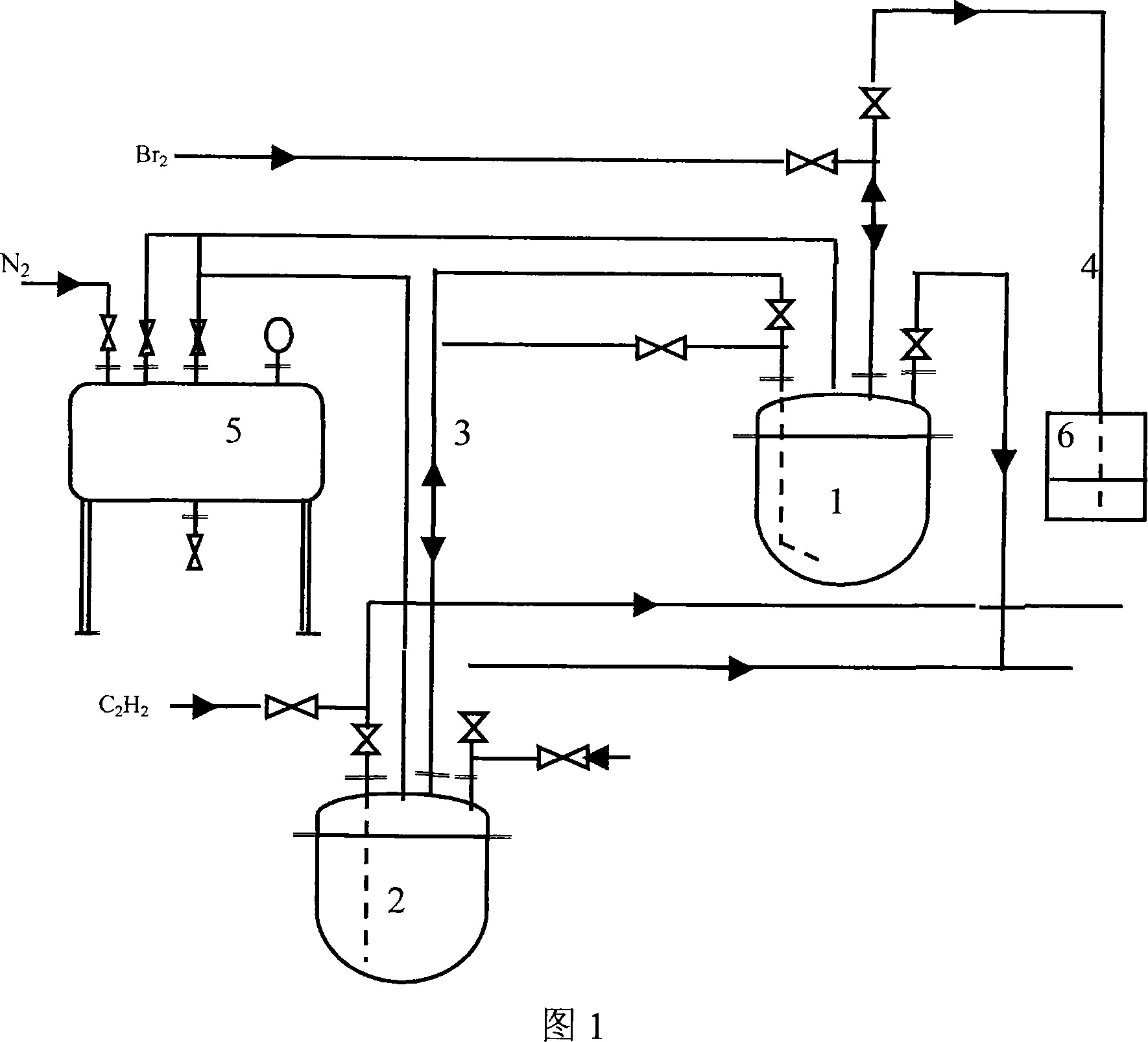

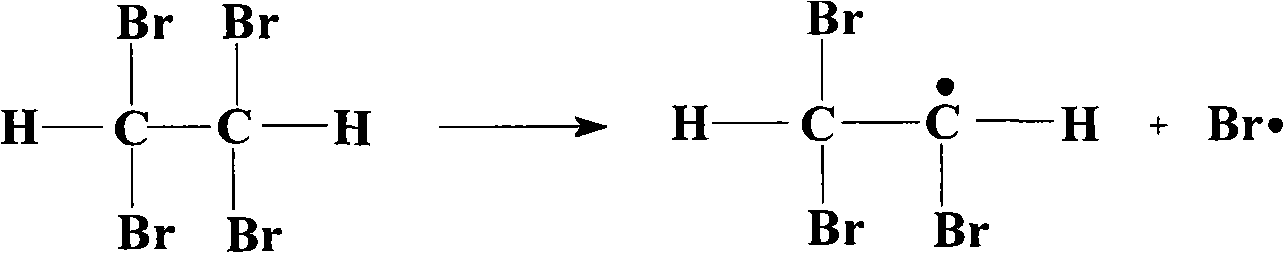

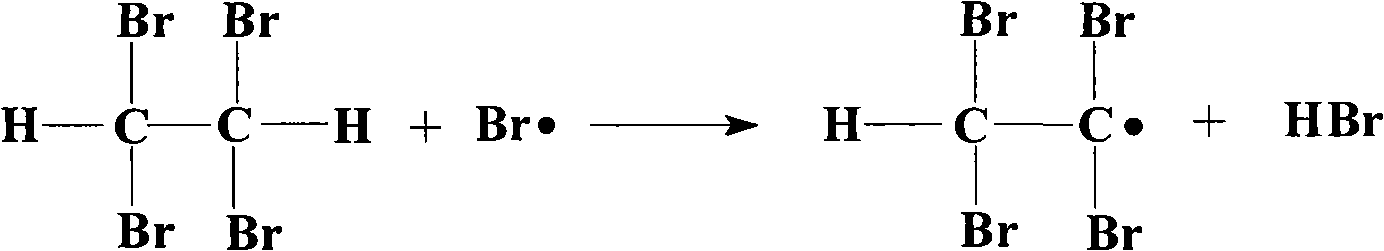

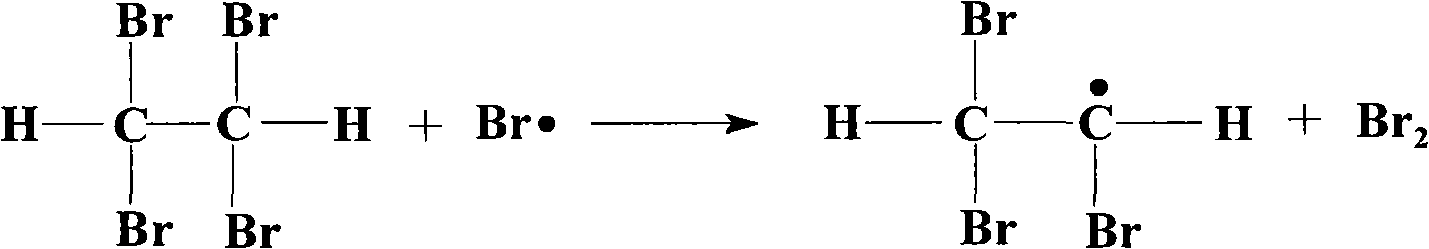

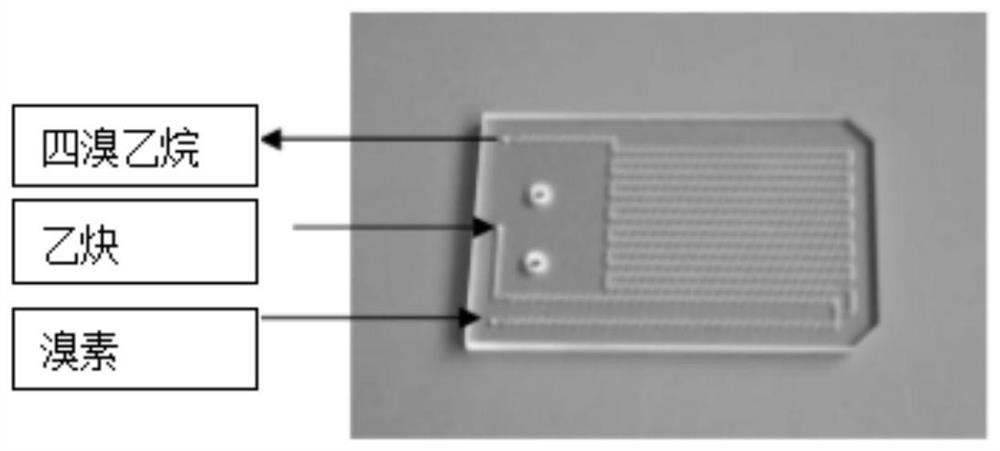

Reactor for preparing tetrabromoethane by addition reaction of bromine and acetylene and synthesis process

InactiveCN101766980AEnables continuous synthesisIncrease productivityGas-gas reaction processesPreparation by halogen additionBromineReaction temperature

The invention relates to a reactor for preparing tetrabromoethane by addition reaction of bromine and acetylene and a synthesis process; the reactor is characterized in that: the reactor is mainly composed of a central cooling pipe, a reaction pipe filled with fillers and an outer cooling pipe; continuous synthesis of the tetrabromoethane is realized by continuous countercurrent contact reaction of the bromine and the acetylene in the reaction pipe, so as to improve the production efficiency; by adjusting the temperature and flow rate of the cooling water in the inner and outer cooling pipes, the addition reaction temperature can be controlled, the problems of safety and more by-products are solved owning to overhigh reaction temperature; by adopting the reactor and the synthesis process, the explosive mixture of acetylene and air is prevented from being formed in the reaction process, so as to improve the reaction safety.

Owner:QILU UNIV OF TECH

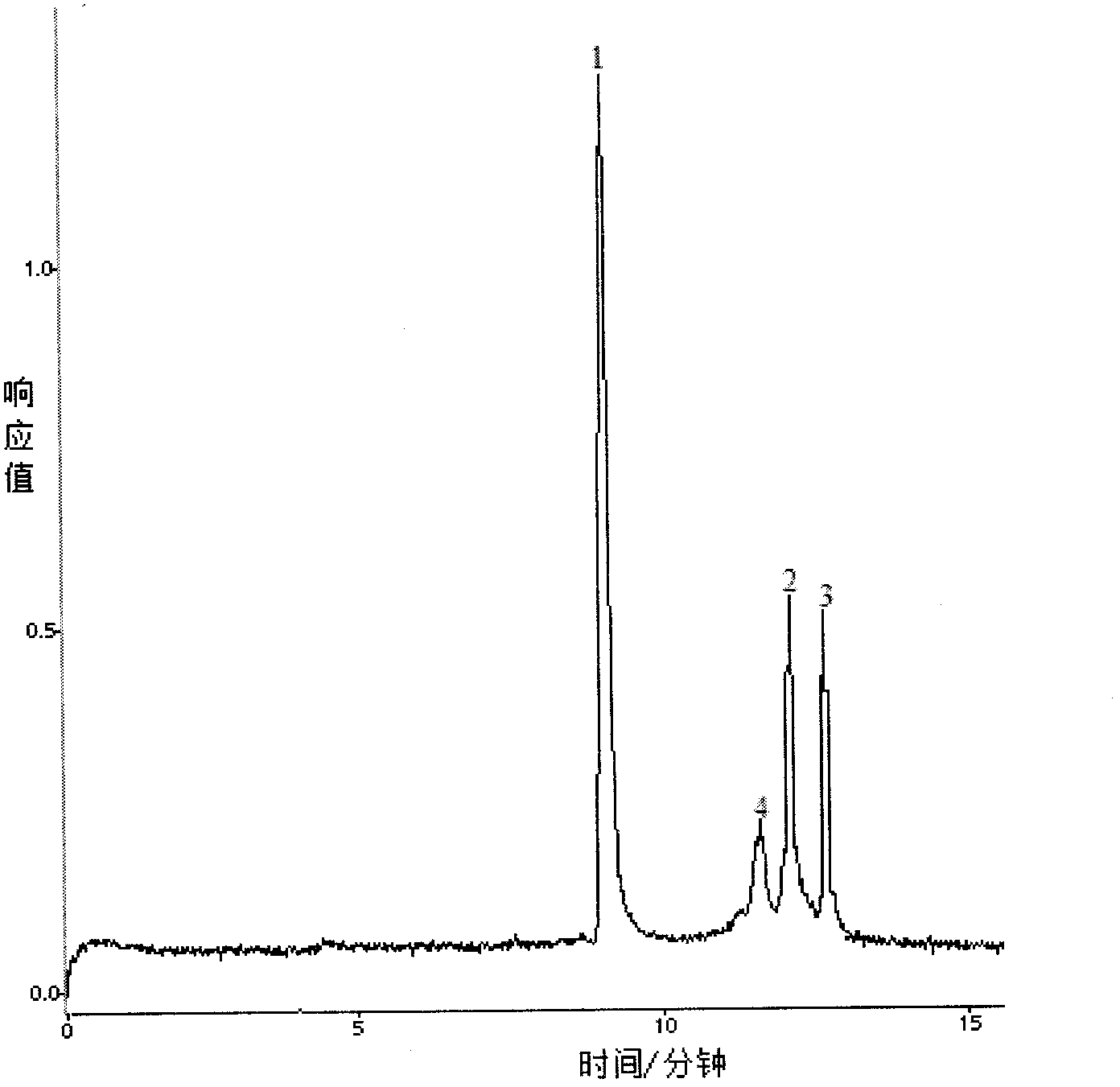

Method for producing trimellitic anhydride with pseudocumene liquid phase air segmenting hydrocarbonylation

The present invention relates to a method for producing trimellitic anhydride by using a pseudocumene liquidoid air subsection oxidation method. Pseudocumene is used as a raw material, acetic acid is used as a solvent, and cobalt acetate, manganese acetate, and tetrabromoethane are used as catalysts; the solvent weight ratio of pseudocumene to acetic acid is between 1 to 2.5 and 1 to 10; and the weight ratio of the total catalysts to the pseudocumene is as follows: the ratio of the pseudocumene to the cobalt acetate to the manganese acetate to the tetrabromoethane is 1 to 0.005-0.05 to 0.005-0.05 to 0.005-0.05. The method comprises the following: a step of mixture, in which the pseudocumene and the acetic acid are weighed out according to the proportion, are added with the cobalt acetate and the tetrabromoethane which account for 40 to 60 percent of the total weight at a temperature between 60 and 100 DEG C; a step of subsection oxidation, in which the mixed materials enter the first reaction period which lasts for 30 to 50 minutes from the beginning of the oxidation, at a temperature between 140 and 180 DEG C and at a pressure of between 0.4 and 1.0 Mpa, then enter the second reaction period at a temperature of 180 and 300 DEG C and at a pressure of between 1.0 and 3.0 Mpa, and finally are added with the residual catalysts; a step of anhydride formation; and a step of fine purification. The method effectively solves the problem of self-inhibition in oxidation reaction.

Owner:安徽泰达新材料股份有限公司

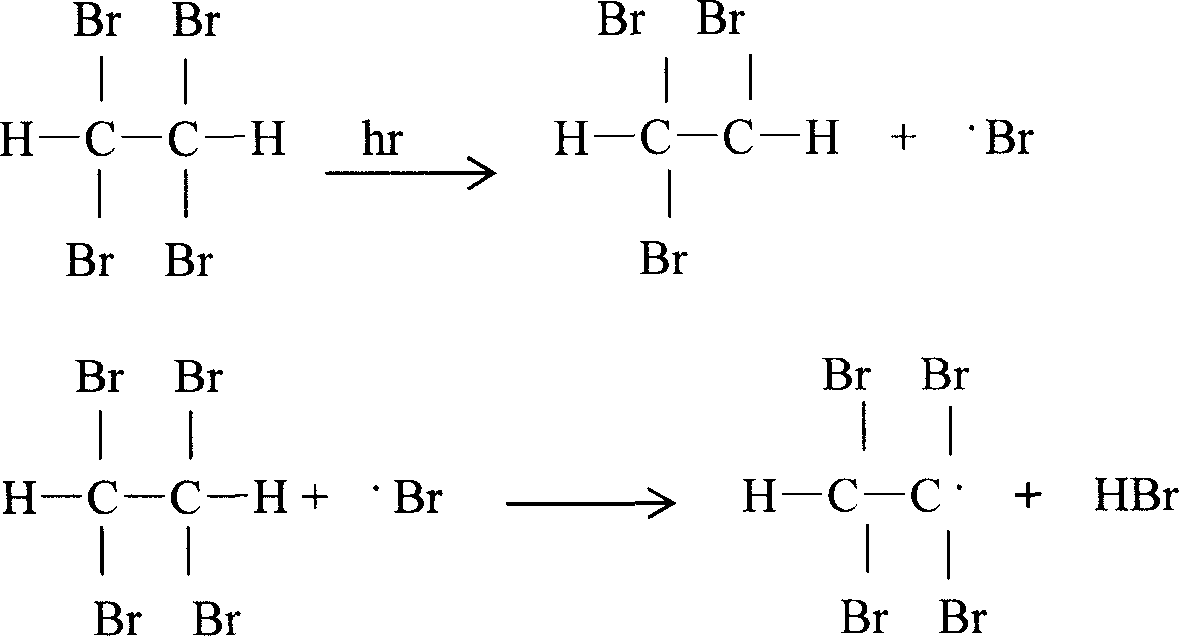

Composite stabilizer for improving stability of tetrabromoethane

ActiveCN1919811AAvoid generatingPrevent discolorationHalogenated hydrocarbon separation/purificationChlorobenzenePolymer science

The invention discloses a composite stabilizer to improve stability of tetrabromoethane, which consists of optical stabilizer and anti-oxidant with weight rate at 1: 1, wherein the optical stabilizer is 2-(3-tertiary-butyl-2-hydroxyl-5-butyl phenylhydrazine)-5-azimido-chlorobenzene; the anti-oxidant is 2, 6-p-tert-butylcatechol or 2, 6-di-tert-butyl-4-butyl-phenol.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

Stabilizer of tetrabromoethane

InactiveCN101723796AExtended storage timeIncrease acidityHalogenated hydrocarbon separation/purificationDehydroacetic acidPhosphorous acid

The invention provides a stabilizer of tetrabromoethane, which is used for improving the storing stability of tetrabromoethane. The stabilizer is prepared by physically mixing a main stabilizer and an auxiliary stabilizer in a mass ratio of 7:3, wherein the main stabilizer is diethylene glycol or triethylene glycol, the auxiliary stabilizer is a mixture prepared by physically mixing diphenyl isooctyl phosphate, zinc stearate or barium stearate and dehydroacetic acid in a mass ratio of 7 to 3 to 1. The stabilizer of tetrabromoethane has the advantages of stabilizing tetrabromoethane for a longtime, prolonging storage time, making free radicals generated in products of tetrabromoethane captured at any time, avoiding oxidizing reaction, neutralizing hydrogen bromide at any time, inhibiting dehydrobromination, inhibiting automatic catalytic action, stabilizing the acidity and color of tetrabromoethane, and preventing the influence of color change and alkalinity acidity change of productson product quality.

Owner:QILU UNIV OF TECH

Method for preparing 3,3',4,4'-benzophenone tetra carboxylic acid by liquid phase air oxidation process

InactiveCN101177395AHigh purityUse non-toxicOrganic compound preparationCarboxylic compound preparationAcetic acidCobalt acetate

The invention relates to a liquidoid air oxidation method for preparing 3, 3', 4, 4'-benzophenone tetrabasic carboxylic acid and a preparation method for 3, 3', 4, 4'-benzophenone tetrabasic carboxylic acid. The invention can solve the problems of the prior art such as adoption of toxic purification solvent, difficulty in feeding, low purity and low yield during the process of preparing 3, 3', 4, 4'-benzophenone tetrabasic carboxylic acid. The procedures are as follows: the 3, 3', 4, 4'-tetramethyl hexichol ethane, glacial acetic acid, tetrahydrate cobalt acetate, tetrahydrate manganese acetate and tetrabromoethane are mixed and dissolved according to the mol ratio, and then is arranged into a reaction kettle so as to react under the conditions of pressurizing, heating and stirring, and then the 3, 3', 4, 4'-benzophenone tetrabasic carboxylic acid is obtained through pressure relief, discharge, cooling and centrifugation. The invention has the advantages that: the preparation process of the invention is a weight increment reaction, thereby the yield of the product reaches 100 percent to 140 percent, and the purity of the product can reach 97.5 percent to 99.8 percent.

Owner:HEILONGJIANG INST OF PETROCHEM

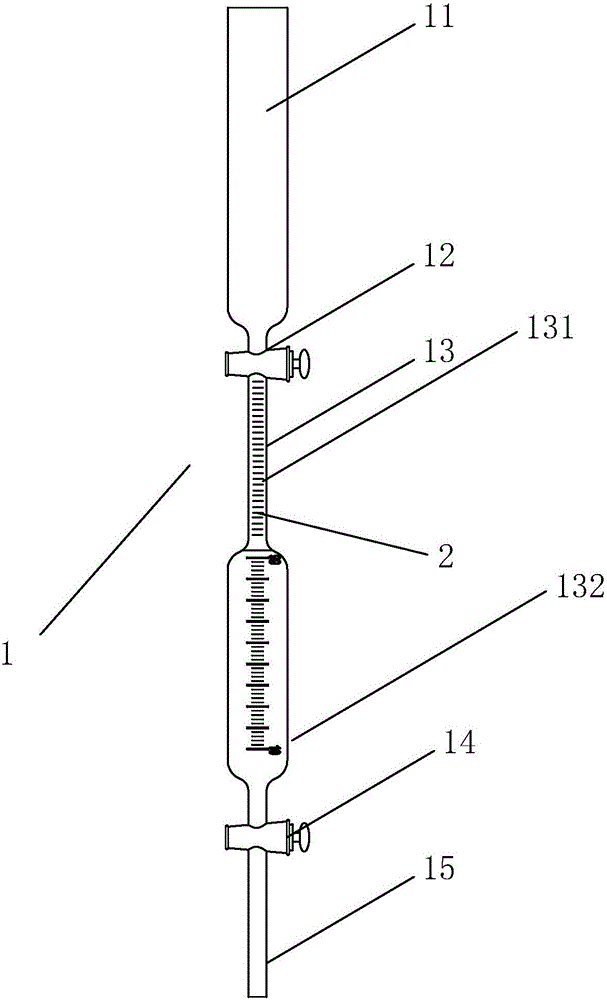

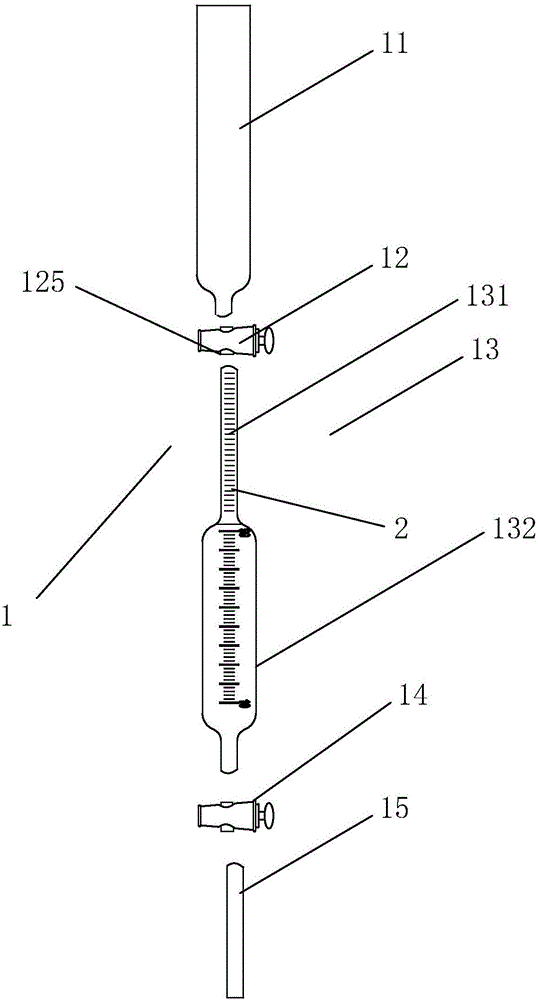

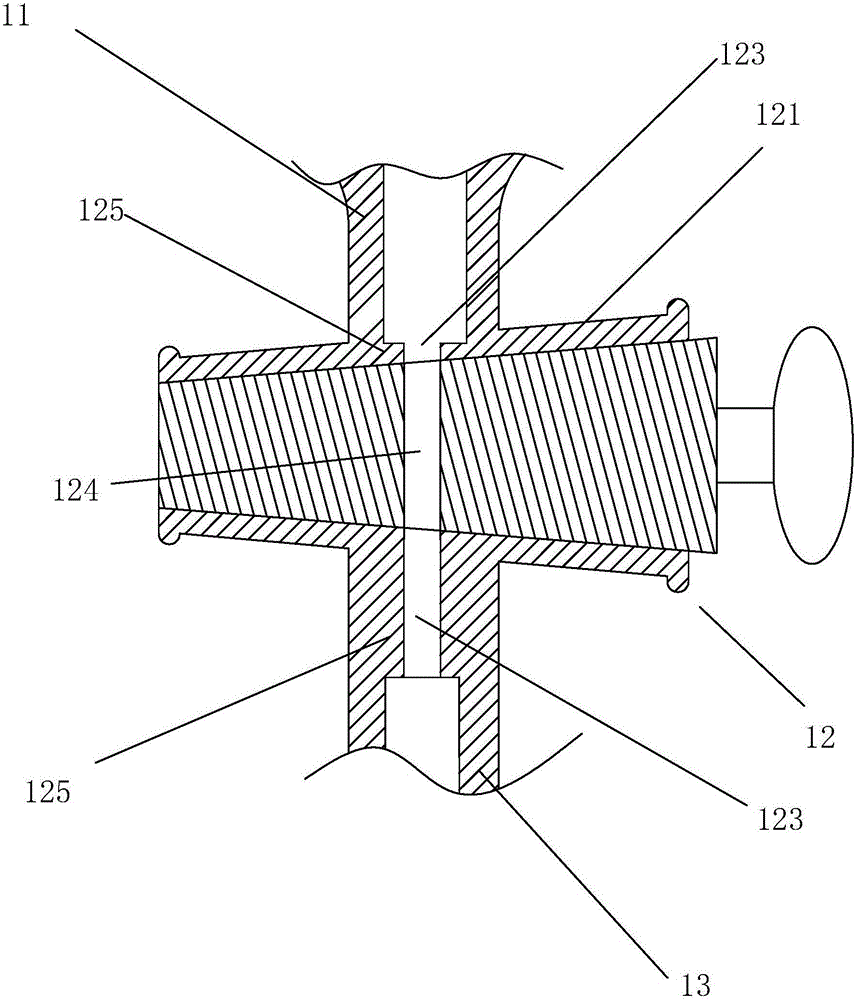

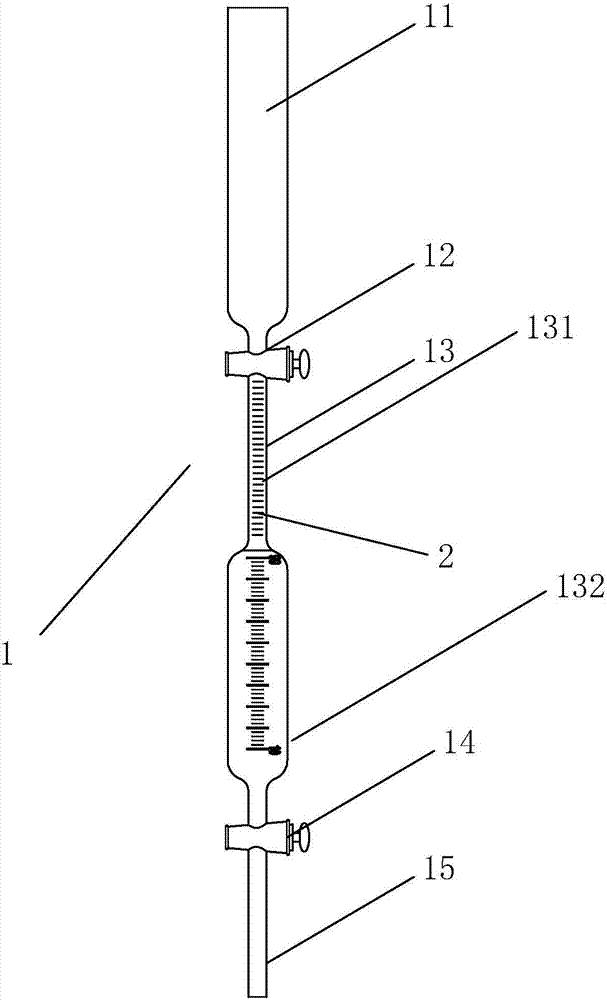

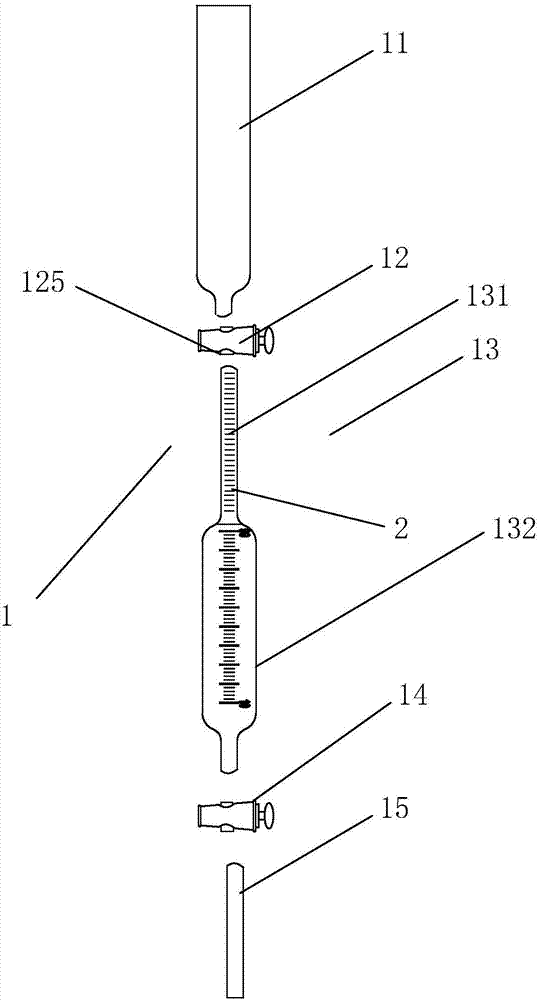

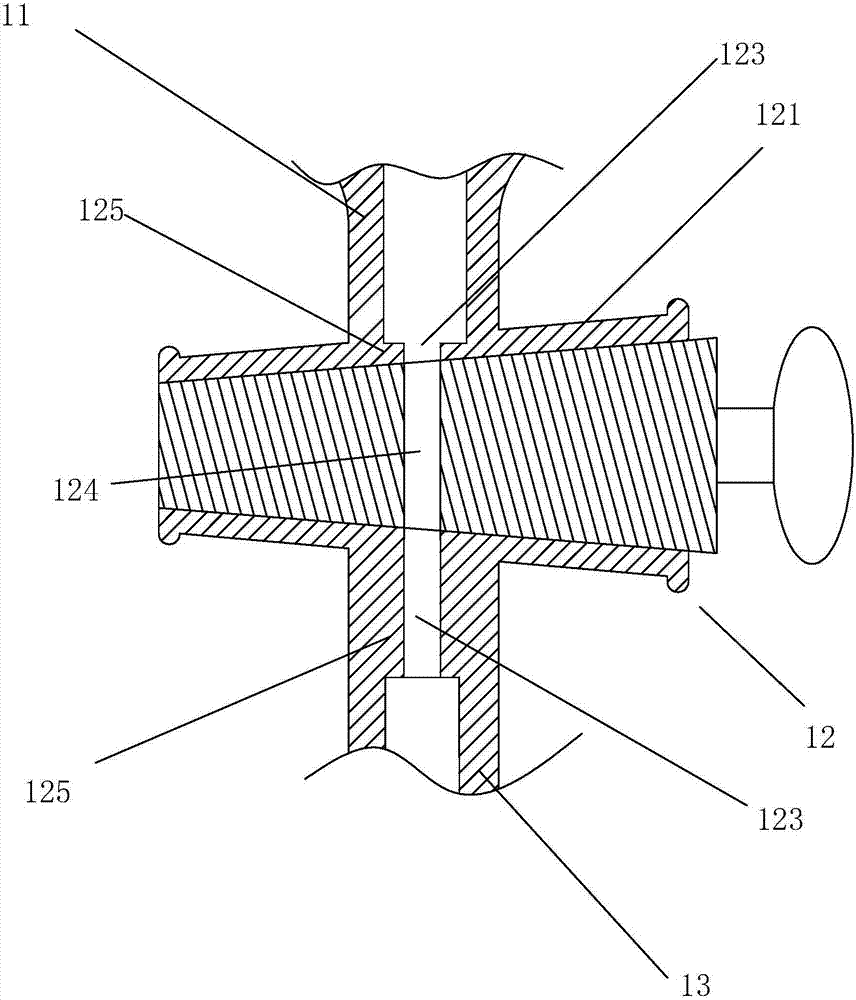

Acetylene gas purity detection device

The invention discloses an acetylene gas purity detection device which comprises a tube body, the tube body sequentially comprises a reaction liquid containing portion, a first plug cock, an absorption tube provided with scales, a second plug cock and a gas inlet tube which can be communicated with one another; the first plug cock comprises a plug cock shell and a valve core rotatably arranged in the plug cock shell, the valve core is provided with a first through hole which enables the reaction liquid containing portion to be communicated with the absorption tube through rotation of the valve core, the plug cock shell is provided with a second through hole matched with the first through hole, and the inner wall of the second through hole above the absorption tube is provided with a protruding block for reducing the radial cross section area of the second through hole. By means of the mode of adding the protruding block, the size of the second through hole can be controlled accurately, the size of the second through hole can be adjusted according to the volume of the absorption tube, and the liquid level of a tetrabromoethane solution is controlled to be lower than the first plug cock.

Owner:TAICANG JINYANG GAS

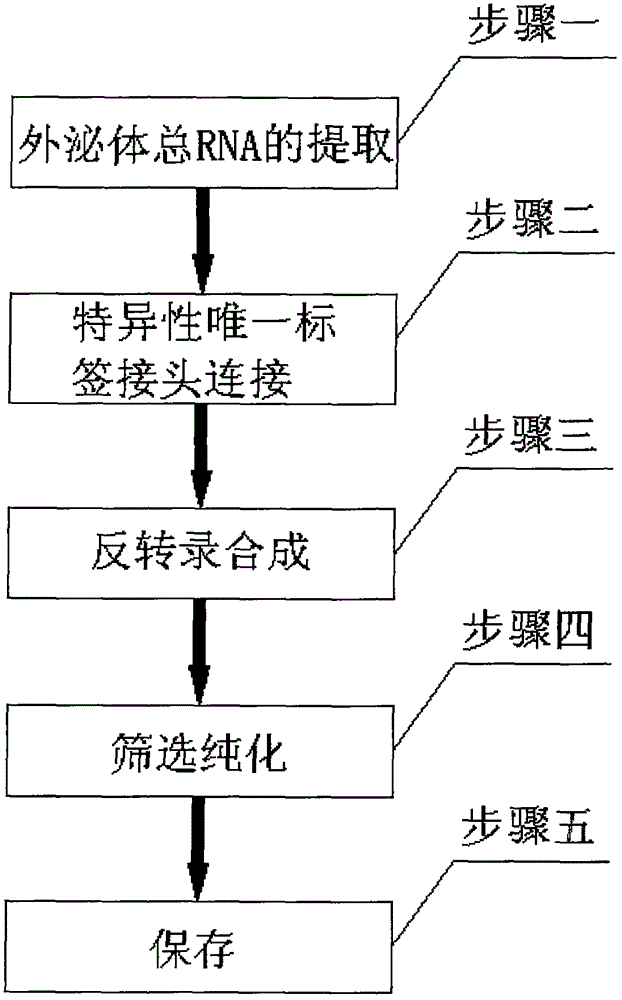

Method for accurately obtaining exosome miRNA (micro Ribonucleic Acid)

InactiveCN106636070AAccurate CountingAvoid preferenceMicrobiological testing/measurementDNA preparationTotal rnaComplementary deoxyribonucleic acid

The invention provides a method for accurately obtaining an exosome miRNA (micro Ribonucleic Acid). The method comprises the following steps: 1) separating the exosome from a sample to be separated; 2) extracting RNA from the exosome, so as to obtain exosome total RNA; 3) connecting a specific unique label connector onto the exosome total RNA, so as to obtain the total RNA with a specific connector; 4) carrying out reverse transcription by taking the total RNA with the specific connector as a template to synthesize cDNA (complementary Deoxyribonucleic Acid), so as to obtain a reverse transcription product; 5) recycling a cDNA fragment of 150bp to 170bp in the reverse transcription product through TBE-PAGE (Tetrabromoethane-Polyacrylamide Gel Electrophoresis) to obtain the miRNA. The method provided by the invention not only avoids preference between molecules in an amplification process, but also effectively realizes accurate counting of the single template; miRNA molecules lower than 10 copies can be accurately detected.

Owner:朱小兰

Preparation method of catalyst of trimellitic anhydride

InactiveCN109499611AHigh yieldGood dispersionOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsManganeseCobalt

The invention relates to the technical field of catalyst preparation, in particular to a preparation method of a catalyst of trimellitic anhydride. The catalyst is prepared from the following components in parts by weight: 15 to 20 parts of acetic acid, 2 to 4 parts of metal ionic liquid, 1 to 1.5 parts of a tetrabromoethane and tetrabutyl ammonium chloride mixed solution, 7 to 9 parts of a stabilizer and 5 to 7 parts of a surfactant. The preparation method of the catalyst comprises the following steps: preparation of the metal ionized liquid: adding at least one of titanium, cobalt and manganese and an acetic acid water solution in a reactor which is provided with a stirrer and a heater, then adding hydrogen peroxide, continuously stirring under the condition that the temperature is 40 to140 DEG C, and controlling the stirring time to be 0.5 to 1.5 hours, thus obtaining the metal ionic liquid for standby use. According to the preparation method of the catalyst of the trimellitic anhydride, provided by the invention, tetrabromoethane and the tetrabutyl ammonium chloride are added on the basis of catalysts of titanium, cobalt and manganese, the yield of the trimellitic anhydride isincreased, and the using quality of the catalyst is increased under the action of the surfactant and the stabilizer.

Owner:黄山利臻新材料科技有限公司

Composite catalyst and method for preparing trimellitic anhydride

InactiveCN113210016AHigh yieldLess side effectsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMANGANESE ACETATEPtru catalyst

A composite catalyst comprises cobalt acetate, manganese acetate, tetrabromoethane and zirconium acetate; and the weight ratio of cobalt acetate to manganese acetate to tetrabromoethane to zirconium acetate in the composite catalyst is 1:(0.3-5):(0.3-5):(0.3-5). A method for preparing trimellitic anhydride takes unsym-trimethylbenzene as a raw material and acetic acid as a solvent, the composite catalyst is used in the method, and air is used as an oxidizing agent; according to the weight ratio of unsym-trimethylbenzene to acetic acid to air of 1:(2.5-10):(0.01-0.08), the preparation method comprises the steps: metering, stirring and mixing the raw materials in a mixing kettle according to the proportion, heating and dissolving; and transferring the mixed material into an oxidation kettle, introducing air to pressurize, controlling the reaction temperature to be 160-220 DEG C and the pressure to be 0.6-2.2 MPa, dehydrating the oxide material into crude anhydride in an anhydride forming kettle, and feeding generated dilute acetic acid into a rectifying kettle to be concentrated and recycled. The invention solves the problem that the appearance and color number of the final product are influenced by more impurities in the obtained finished product due to lower conversion rate of unsym-trimethylbenzene and more side reactions in a traditional production method.

Owner:安徽泰达新材料股份有限公司

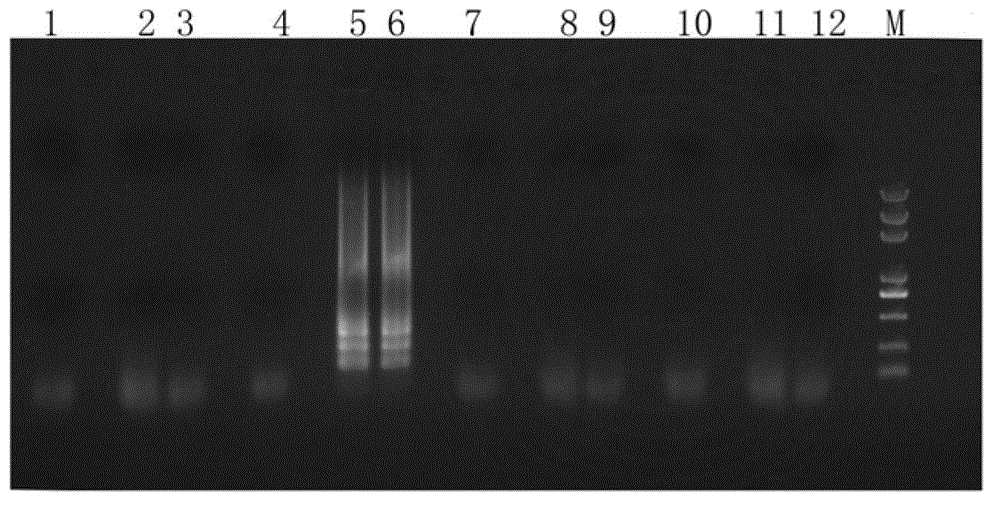

Method for converting monomorphic SSR (Simple Sequence Repeat) marker into polymorphic marker

The invention belongs to the breeding technology field of cotton molecules and particularly relates to a method for converting a monomorphic SSR (Simple Sequence Repeat) marker into a polymorphic marker. The method comprises the following steps: firstly, preparing 8 percent of non-denaturing polyacrylamide gel, ensuring that the proportion of acrylamide and methylene diacrylamide is 25-30:1, adopting 100 ml of 10x TBE (Tetrabromoethane) and then ensuring that the constant volume is 1 L with distilled water; secondly, amplifying the PCR (Polymerase Chain Reaction) of two parents of a mapping population with monomorphic SSR (Simple Sequence Repeat) primers under the conventional electrophoresis conditions, wherein a PCR (Polymerase Chain Reaction) reaction system (10 ul) is a 25 ng of DNA (Deoxyribose Nucleic Acid) template, a 1x Buffer, 2.0 mmol L of 1 MgCI2, 0.25 mmolL of 1 dNTPs (Deoxyribonucleotide Triphosphates), 0.2 umol L of 1 primers and 0.8 U of Taq DNA polymerases, and filling insufficient parts with aseptic double distilled water; thirdly, conducting electrophoresis to an amplified product on the 8 percent of non-denaturing polyacrylamide gradient gel; and fourthly, generating polymorphic SSR primers. The method has low cost and wide application scope, is simple to operate and can effectively convert the monomorphic SSR marker into the polymorphic marker, thereby greatly improving the utilization efficiency of the SSR marker.

Owner:HUAZHONG AGRI UNIV

Technique for manufacturing tetrabromoethane and equipment thereof

The invention provides a process preparing the tetrabromoethane, which solves the problems that explosion may happen due to the mixture of the acetylene and the air in the current process and the tetrabromoethane has low yield coefficient and low quality. The steps are that the bromine liquid is pumped in a tail gas reactor and then pumped in a synthesis reactor; the nitrogen exhausts the air in the synthesis reactor and the tail gas reactor; the acetylene gas is access to the synthesis reactor; the acetylene reacts with the bromine to generate the tetrabromoethane; the tail gas enters the tail gas reactor and the acetylene gas which does not react in the tail gas reacts with the bromine liquid in the tail gas reactor to generate tetrabromoethane, and the tail gas exhausts via a lye absorption bucket.

Owner:南京昂扬新材料有限公司

Door and window sealing waterproof material

The invention discloses a door and window sealing waterproof material. The door and window sealing waterproof material comprises the following raw materials in parts by weight: 70-80 parts of calciumcarbonate, 10-15 parts of three-line dewaxed oil, 10-12 parts of clay, 1.8-2.0 parts of castor oil, 2.5-2.7 parts of rosin, 4-5 parts of red lead, 2.4-2.6 parts of petroleum ether, 5-6 parts of a dicumyl peroxide cross-linking agent, and 0.8-1.2 parts of tetrabromoethane. A preparation method of the waterproof material comprises the following steps: stirring calcium carbonate, the three-line dewaxed oil, clay, castor oil and rosin according to the above weight parts at the temperature of 150-200 DEG C and pressure being 1.2-1.5 MPa for 3-4 h at a rotating speed of 500-600 r / min, preparing a mixed main material, placing the mixed main material and residual raw materials in a centrifugation mixer for centrifugation stirring, wherein the temperature of the centrifugation mixer is kept at 200-260 DEG C, cooling the materials and uniformly dispersing the material to obtain the finished product. The door and window sealing waterproof material combines sealing performance and waterproofness,has the advantages of strong anti-compression capability, long usage life, and better high temperature resistance, can effectively avoid easy oxidation of the door and window sealing waterproof material, and can form integral sealing.

Owner:刘巧云

Anti-anthracnose molecular diagnostic kit for pod bean and application thereof

ActiveCN103146837BSave landSave human effortMicrobiological testing/measurementDNA/RNA fragmentationAnthriscus caucalisPolymerase L

Owner:TIANJIN RES INST OF VEGETABLE

Production process of safe and low-waste tetrabromoethane

PendingCN114315509AReduce generationHigh yieldSemi-permeable membranesHalogenated hydrocarbon separation/purificationDistillationNitrogen gas

The invention relates to a safe and low-waste tetrabromoethane production process, and belongs to the technical field of tetrabromoethane production. The production process comprises the following steps: step 1, adding liquid bromine into a transparent reaction kettle provided with a high-pressure mercury lamp, turning on the high-pressure mercury lamp in a nitrogen atmosphere at a constant temperature of 65-75 DEG C, then introducing acetylene gas, and reacting for 4-5 hours to obtain a reaction solution; step 2, adding ethanol and ethylene glycol glycidyl ether into the reaction liquid in a stirring state to obtain a mixed liquid, and carrying out filter pressing on the mixed liquid by using a modified separation membrane to obtain a permeate liquid; and step 3, recovering ethanol from the permeate through low-temperature distillation, carrying out reduced pressure distillation purification, and finally decolorizing with activated carbon to obtain tetrabromoethane. According to the invention, the reaction of the liquid bromine and the acetylene gas is carried out in the transparent reaction kettle, and the reaction is carried out by raising the temperature under illumination, so that the reaction time is shortened, the generation of reaction byproducts of bromine and the acetylene gas is reduced, and the yield of tetrabromoethane is improved.

Owner:MAANSHAN DEHONG BIOTECH

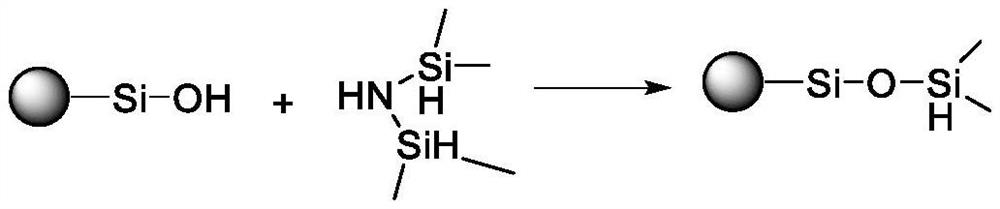

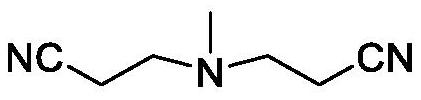

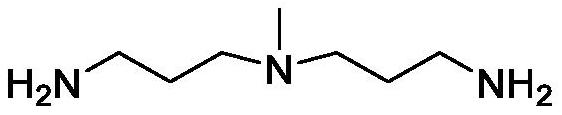

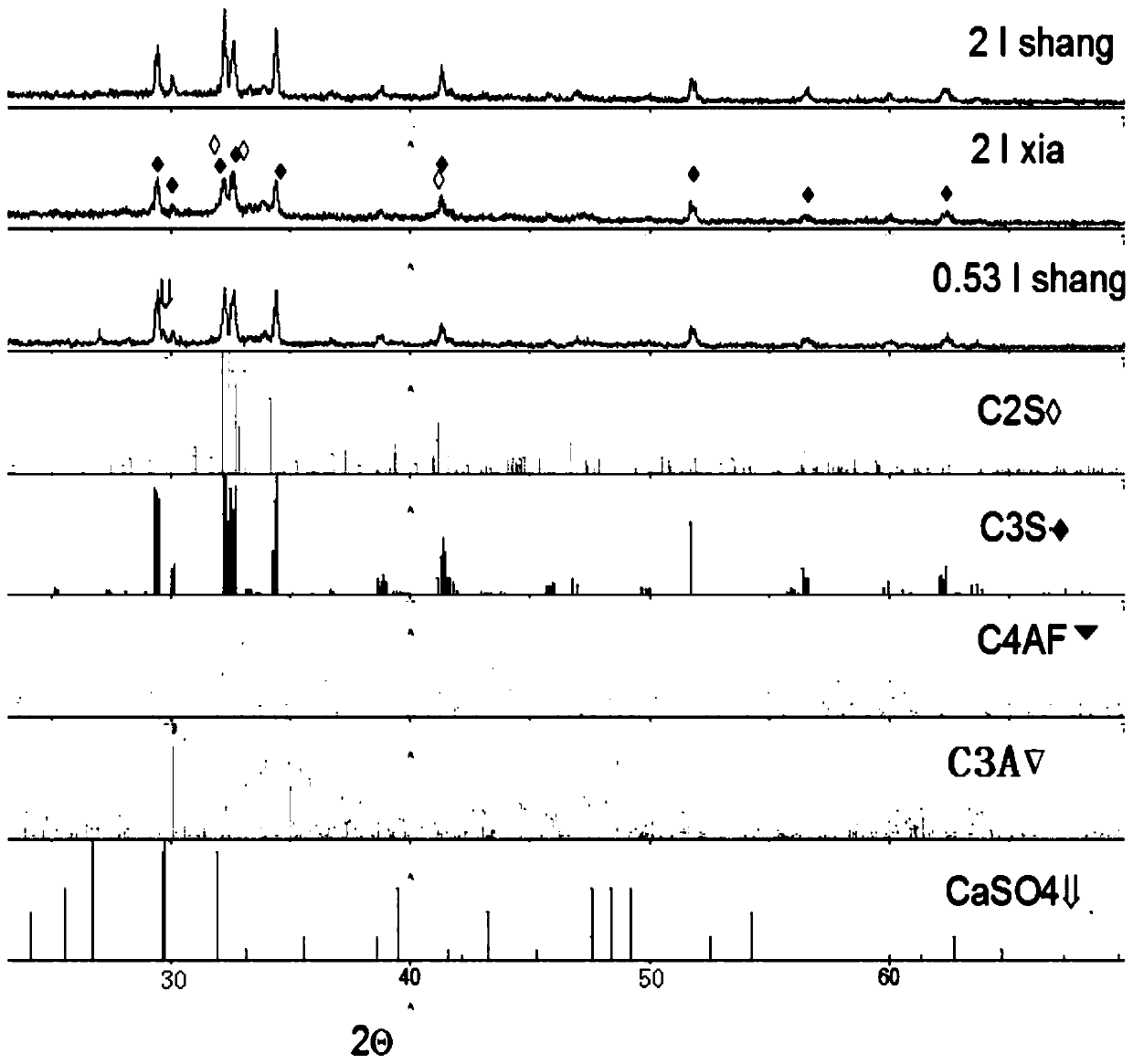

A method for increasing the content of tricalcium silicate in Portland cement powder

The invention relates to a method for increasing tricalcium silicate content of Portland cement powder. The method comprises the following steps: adding the Portland cement powder into a heavy fluid 1, uniformly mixing, centrifuging, and taking a lower-layer sample after centrifugation, wherein the heavy fluid 1 is obtained by blending diiodomethane and tetrabromoethane according to a volume ratio of 0.53: 1; adding a heavy fluid 2 into the lower-layer sample, uniformly mixing, centrifuging, and taking an upper-layer sample after centrifugation as the Portland cement powder with high tricalcium silicate content, wherein the heavy fluid 2 is obtained by blending diiodomethane and tetrabromoethane according to a volume ratio of 2: 1. The method is simple in process; increase in tricalcium silicate in cement clinker is achieved by changing improvement in the cement clinker calcining process into physical sorting after calcining; and the method is insusceptible to dosing and calcining process factors and the like.

Owner:CHANGAN UNIV

Method for preparing 3,3',4,4'-benzophenone tetracarboxylic acid by liquid phase air oxidation process

InactiveCN100567248CHigh purityUse non-toxicOrganic compound preparationCarboxylic compound preparationAcetic acidCobalt acetate

A method for preparing 3,3',4,4'-benzophenone tetracarboxylic acid by liquid-phase air oxidation method, which relates to a preparation method of 3,3',4,4'-benzophenone tetracarboxylic acid . It solves the problems of using a highly toxic purification solvent, difficulty in adding materials, low purity and low yield in the process of preparing 3,3',4,4'-benzophenone tetracarboxylic acid in the prior art. The method step is to mix 3,3',4,4'-tetramethyldiphenylethane, glacial acetic acid, cobalt acetate tetrahydrate, manganese acetate tetrahydrate and tetrabromoethane in molar ratio, dissolve and add to the reaction In the kettle, react under the conditions of pressurization, heating and stirring, and then release the pressure, discharge, cool and centrifuge to obtain 3,3',4,4'-benzophenone tetracarboxylic acid. The preparation process of the invention is a weight gain reaction, the product yield is as high as 100-140%, and the product purity is 97.5-99.8%.

Owner:HEILONGJIANG INST OF PETROCHEM

Stabilizer of tetrabromoethane

InactiveCN101723796BExtended storage timeIncrease acidityHalogenated hydrocarbon separation/purificationDehydroacetic acidPhosphorous acid

The invention provides a stabilizer of tetrabromoethane, which is used for improving the storing stability of tetrabromoethane. The stabilizer is prepared by physically mixing a main stabilizer and an auxiliary stabilizer in a mass ratio of 7:3, wherein the main stabilizer is diethylene glycol or triethylene glycol, the auxiliary stabilizer is a mixture prepared by physically mixing diphenyl isooctyl phosphate, zinc stearate or barium stearate and dehydroacetic acid in a mass ratio of 7 to 3 to 1. The stabilizer of tetrabromoethane has the advantages of stabilizing tetrabromoethane for a longtime, prolonging storage time, making free radicals generated in products of tetrabromoethane captured at any time, avoiding oxidizing reaction, neutralizing hydrogen bromide at any time, inhibiting dehydrobromination, inhibiting automatic catalytic action, stabilizing the acidity and color of tetrabromoethane, and preventing the influence of color change and alkalinity acidity change of productson product quality.

Owner:QILU UNIV OF TECH

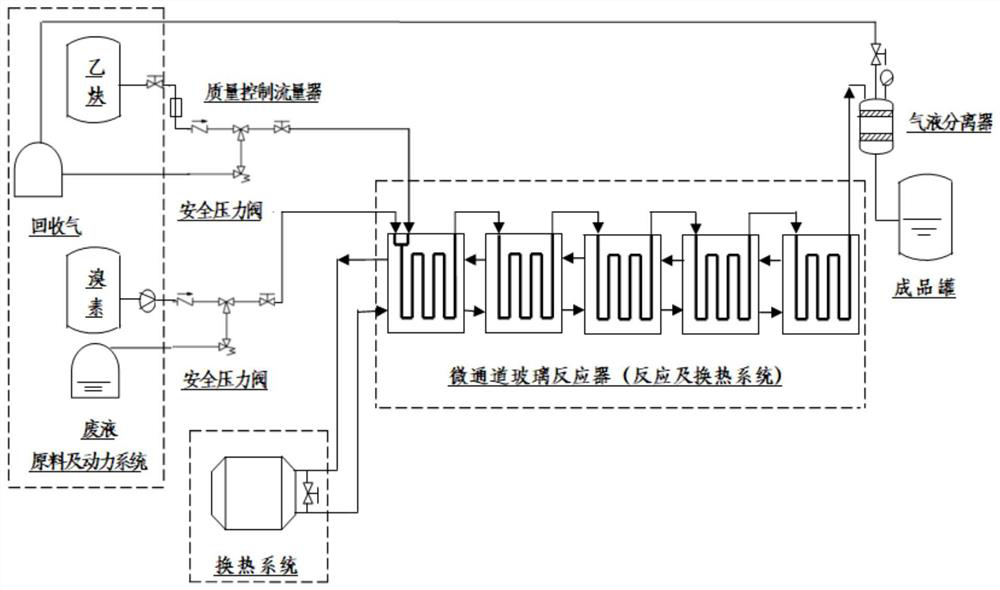

A kind of production technology that utilizes microchannel reactor to prepare tetrabromoethane

ActiveCN110437027BNo wasteIncrease productivityPreparation by halogen additionVapor–liquid separatorBromine

The invention discloses a production process for preparing tetrabromoethane by utilizing a microchannel reactor. The raw material bromine is continuously fed into the microchannel reactor driven by the power system; the acetylene is continuously fed into the microchannel reactor through the gas mass flow controller; the introduced acetylene and bromine are fully mixed in the microchannel reactor, Reaction; through the heat exchange system, the temperature of the reactant is controlled; after the reaction process is completed, the product is collected through the gas-liquid separator; after the collected product is analyzed and qualified, a stabilizer is added and packaged into a product. The production process of the present invention can realize the uniform distribution of acetylene and bromine in the microchannel reactor, make acetylene and bromine fully contact, improve production efficiency and yield, improve the utilization rate of raw material acetylene; avoid the formation of acetylene and air explosive Mixture, improve safety; shorten the process flow, greatly reduce the generation of waste water, waste gas and eliminate by-products.

Owner:MAANSHAN DEHONG BIOTECH

Acetylene gas purity detection device

The invention discloses an acetylene gas purity detection device which comprises a tube body, the tube body sequentially comprises a reaction liquid containing portion, a first plug cock, an absorption tube provided with scales, a second plug cock and a gas inlet tube which can be communicated with one another; the first plug cock comprises a plug cock shell and a valve core rotatably arranged in the plug cock shell, the valve core is provided with a first through hole which enables the reaction liquid containing portion to be communicated with the absorption tube through rotation of the valve core, the plug cock shell is provided with a second through hole matched with the first through hole, and the inner wall of the second through hole above the absorption tube is provided with a protruding block for reducing the radial cross section area of the second through hole. By means of the mode of adding the protruding block, the size of the second through hole can be controlled accurately, the size of the second through hole can be adjusted according to the volume of the absorption tube, and the liquid level of a tetrabromoethane solution is controlled to be lower than the first plug cock.

Owner:TAICANG JINYANG GAS

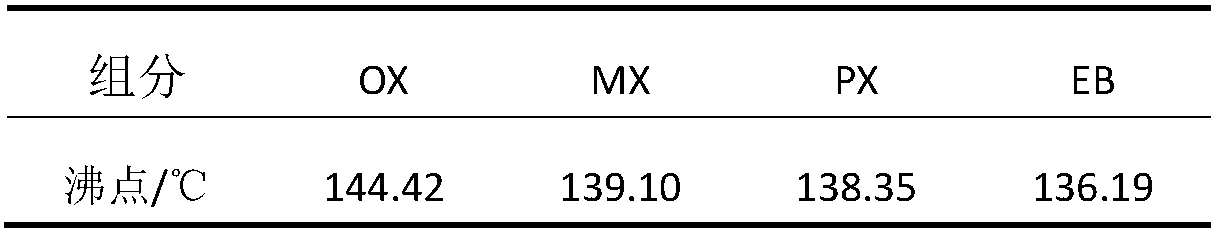

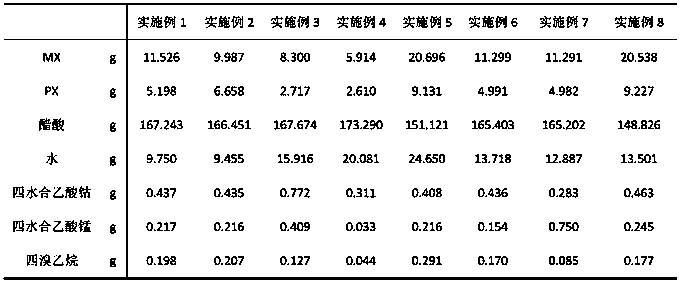

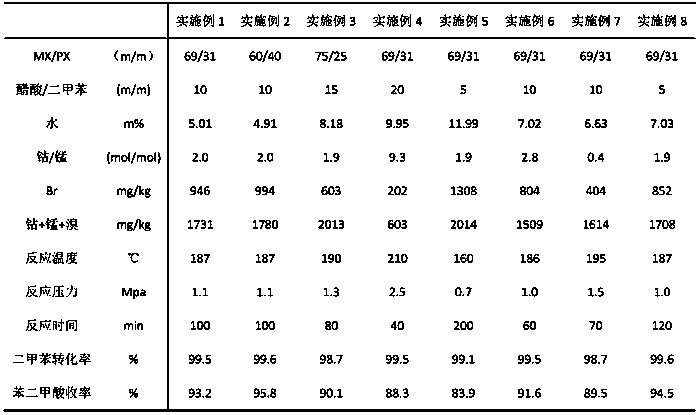

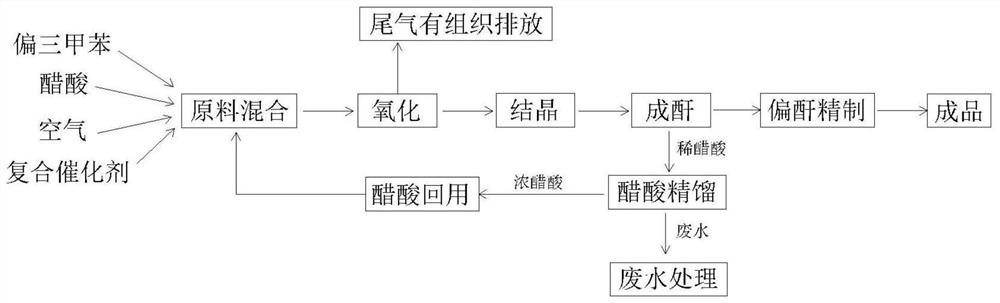

Method for preparing phthalic acid from m-xylene and p-xylene through mixing and oxidation

InactiveCN108299182AHigh yieldEasy to separatePhysical/chemical process catalystsOrganic compound preparationMass ratioSolvent

The invention relates to a method for preparing phthalic acid from m-xylene and p-xylene through mixing and oxidation. The method comprises the following steps: putting a mixed xylene raw material ofMX / PX (M-Xylene / P-Xylene) in a ratio of 60-40 to 75-25, an acetic acid solvent in a mass ratio of 5-1 to 20-1 to the mixed xylene, and a Co-Mn-Br three-way catalyst into an oxidation reactor, introducing air, enabling the components to react for 40-200 minutes under conditions that the air speed is 2000-3000mL / minute, the temperature is 160-210 DEG C and the pressure is 0.5-2.5MPa so as to obtainslurry with mixed benzol dioctyl phthalate, and performing separation and refining. Due to mixing and oxidation of MX and PX, the separation cost of MX and PX can be reduced; a small amount of the catalyst is used, a small amount of tetrabromoethane is used as a bromide, and equipment corrosion can be alleviated; the obtained mixed oxide is relatively high in yield; the market competitiveness of the product can be improved.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of velvet foaming mattress

The application discloses a preparation method of a velvet foaming mattress. The preparation method comprises the step of weighing velvet, triethylamine, polyether triols, methane dioxide, purified water, an AC foaming agent, silicone oil, ethylenediamine polyether, white oil, barium stearate, petroleum jelly, methylbenzotriazole, tetrabromoethane, butane and phenolsulfonic acid; the velvet foaming mattress has the characteristics that the relative density is low, the compressive strength is 290 to 330 MPa, the tear strength is 5 to 9 N / cm and the low-temperature resistance is realized; in addition, the velvet foaming mattress has the disability of 60 to 80 percent, and the product is soft, high in durability, low in possibility of collapse and deformation, high in bearing performance andlow in water absorption; the elongation is 260 to 440 percent, and the product has the advantages of antibacterial property, mildew resistance, good process stability, long service life, low possibility of worm damage and off-fire self-extinguishing; furthermore, the product has no change when being put into a high temperature-resisting oven at the temperature of 150 DEG C for 8 to 12 hours, the tensile strength is 460 to 480 MPa, and the bonding strength is 340 to 440 MPa.

Owner:苏州市苏真床垫有限公司

Composite catalyst and method for preparing trimellitic anhydride

InactiveCN113813997AHigh yieldLess side effectsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMANGANESE ACETATEPtru catalyst

The invention discloses a composite catalyst and method for preparing trimellitic anhydride. The composite catalyst comprises cobalt acetate, manganese acetate, tetrabromoethane and zirconium acetate, the weight ratio of cobalt acetate to manganese acetate to tetrabromoethane to zirconium acetate in the composite catalyst is 1: (0.3-5): (0.3-5): (0.3-5). According to the method for preparing trimellitic anhydride, pseudocumene is taken as a raw material and acetic acid is taken as a solvent, the composite catalyst is used in the method, and air is used as an oxidizing agent; the weight ratio of pseudocumene to acetic acid to the composite catalyst is 1: (2.5-10): (0.01-0.08), the preparation method comprises the following steps: metering and mixing the raw materials in a mixing kettle according to the proportion, heating and dissolving; transferring the mixed material into an oxidation kettle, introducing air to pressurize, controlling the reaction temperature to be 160-220 DEG C and the pressure to be 0.6-2.2 Mpa, dehydrating the oxide material into crude anhydride in an anhydride forming kettle, and feeding generated dilute acetic acid into a rectifying kettle to be concentrated and recycled. The invention solves the problem that the appearance and color number of the final product are influenced by more impurities in the obtained finished product due to lower conversion rate of pseudocumene and more side reactions in the traditional production method.

Owner:安徽泰达新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com