Composite stabilizer for improving stability of tetrabromoethane

A composite stabilizer, tetrabromoethane technology, applied in the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of reduced pH, turbidity, structural instability, etc., to prevent product discoloration and avoid oxidation reactions , avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The use process of the composite stabilizer for improving the stability of tetrabromoethane of the present invention will be described in conjunction with the accompanying drawings and examples.

[0029] The composite stabilizer for improving the stability of tetrabromoethane of the present invention is formed by physically mixing light stabilizers and antioxidants according to the ratio of 1:1 by weight, and the light stabilizers are 2-(3-tert-butyl -2-Hydroxy-5-butylphenyl)-5-chlorobenzotriazole, the antioxidant is 2,6-di-tert-butyl-p-cresol or 2,6-di-tert-butyl-4- Butylphenol. During use, add 2 to 4 g of the composite stabilizer per 150 kg of tetrabromoethane. It is obtained through experiments that the composite stabilizer can keep tetrabromoethane stable for a long time.

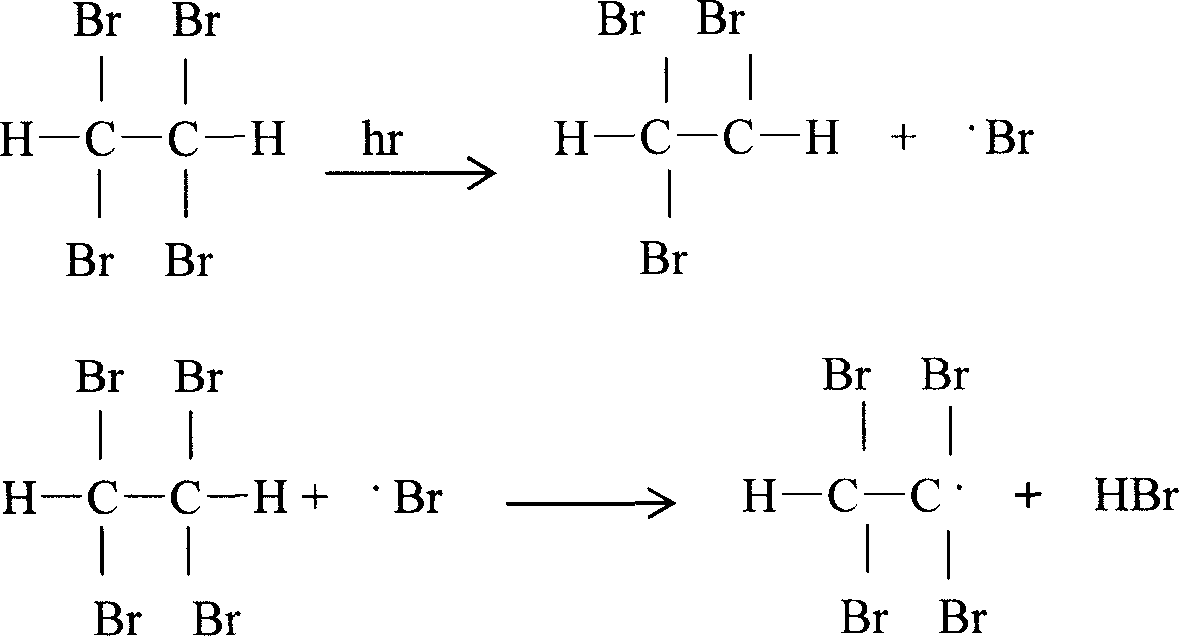

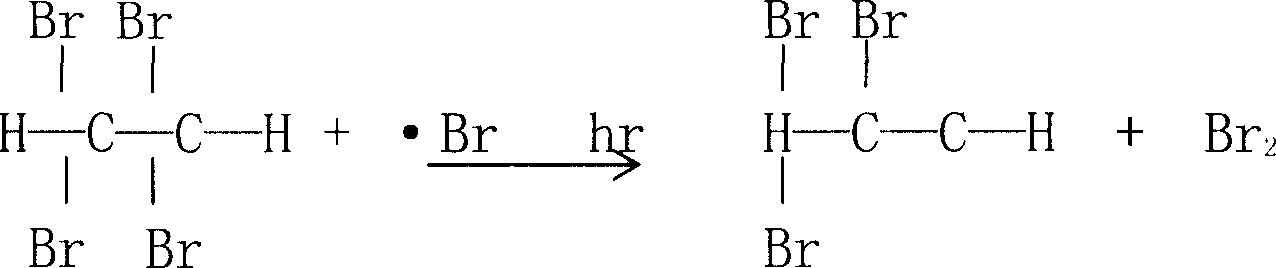

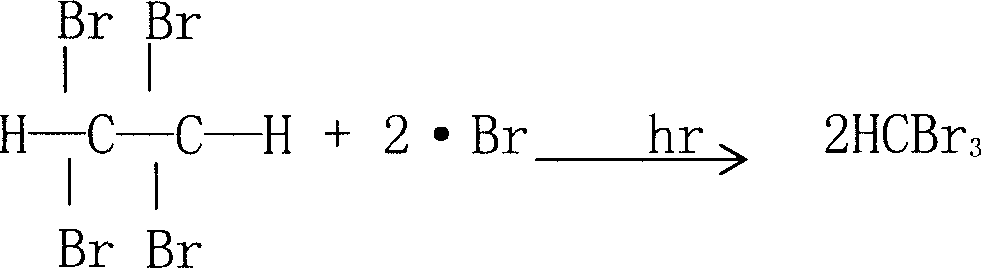

[0030] According to the mechanism of tetrabromoethane deterioration, the composite stabilizer of the present invention controls its stability, on the one hand to suppress the generation of free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com