Patents

Literature

199results about How to "Avoid the impact of product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

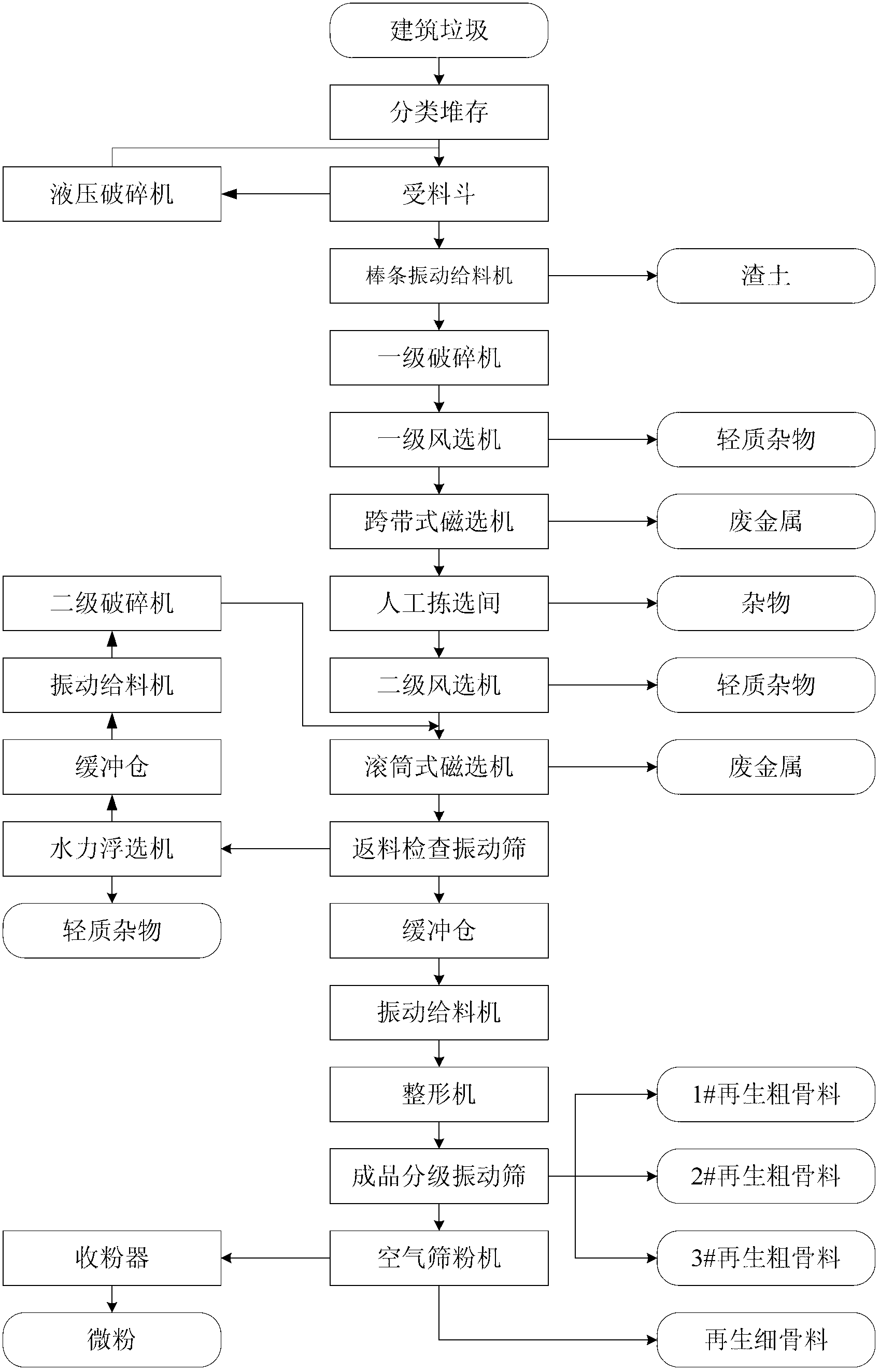

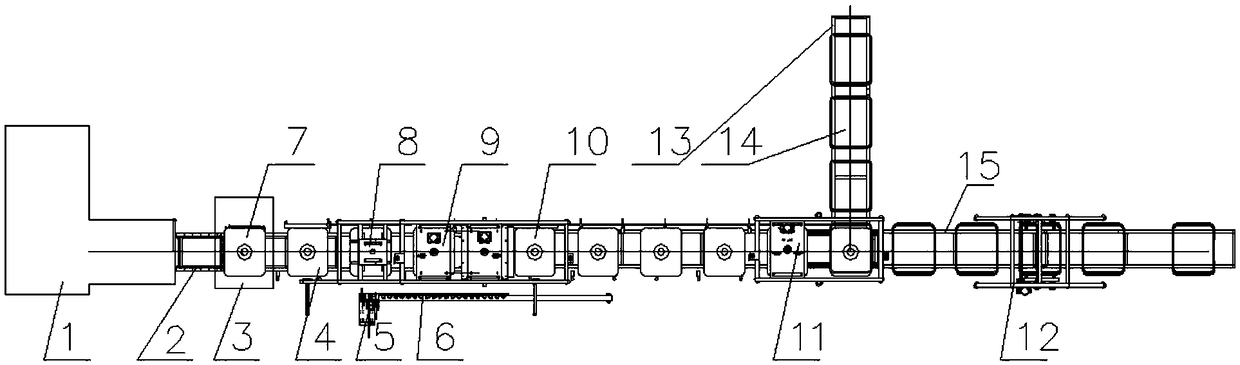

Method and system for treating construction waste

InactiveCN102838307AAchieve pre-separationReduce micronized contentSolid waste managementEngineeringNational standard

The invention discloses a method for treating construction waste, comprising the following steps of: performing feeding and dregs pre-screening, primary crushing, secondary crushing and product screening on a material in sequence; performing sorting and impurity removing treatment on the material subjected to the primary crushing; performing material returning screening on the material subjected to the sorting and impurity removing treatment, performing particle shaping on the material screened down after the material returning screening treatment, and returning the oversize material to the secondary crushing; and combining the material subjected to the secondary crushing with the material in the sorting and impurity removing treatment. The system and method treating construction waste, provided by the invention, have high-efficiency and systemic sorting and impurity-removing functions; the generated construction waste recycled aggregate product meets the requirements of national standard 'recycled coarse aggregate for concrete'(GB / T 25177-2010), 'recycled fine aggregate for concrete and mortar' (GB / T 25176-2010) and other recycled aggregate product raw materials.

Owner:SHOUGANG CORPORATION

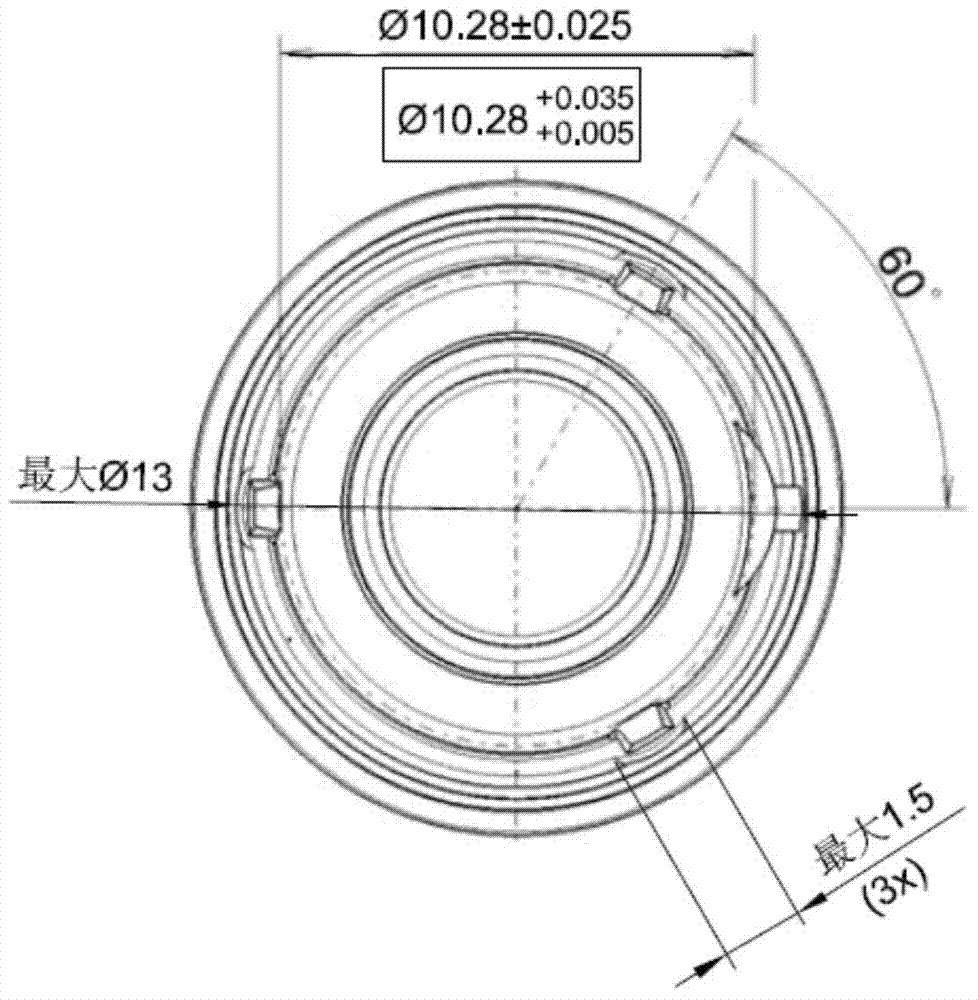

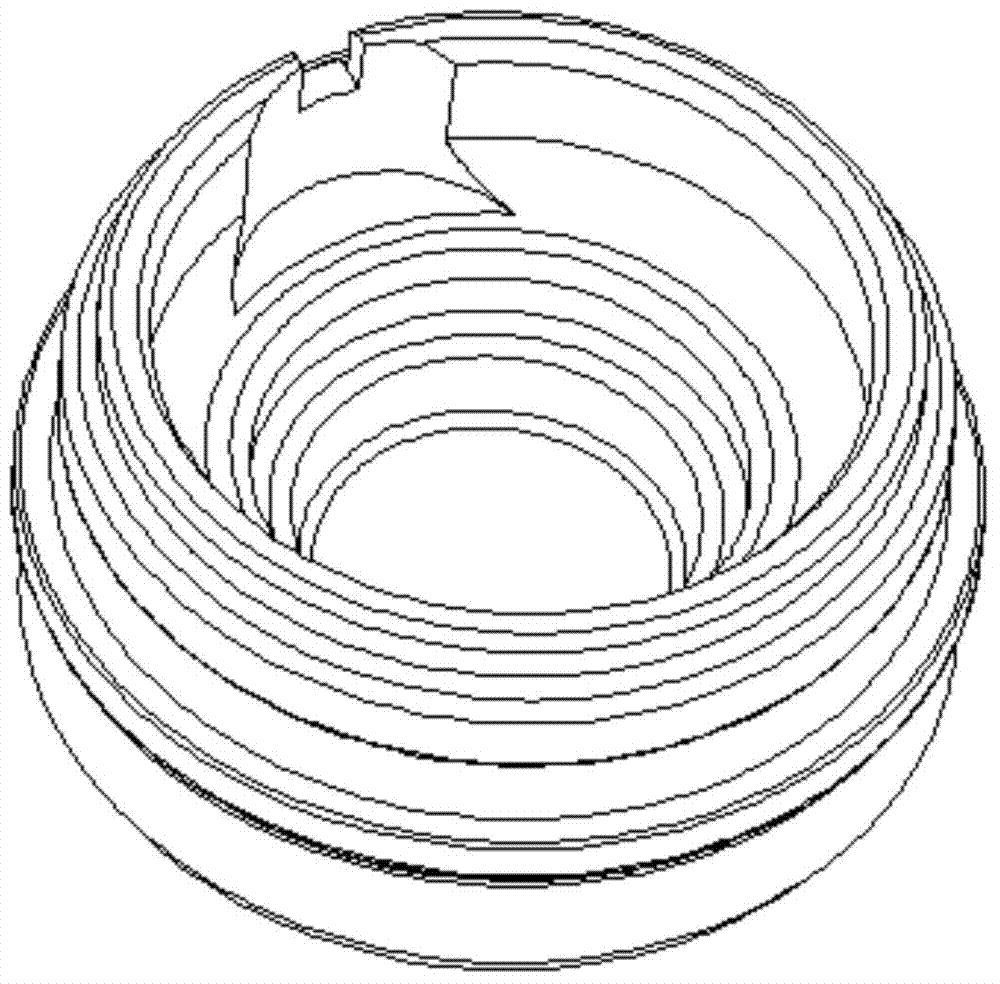

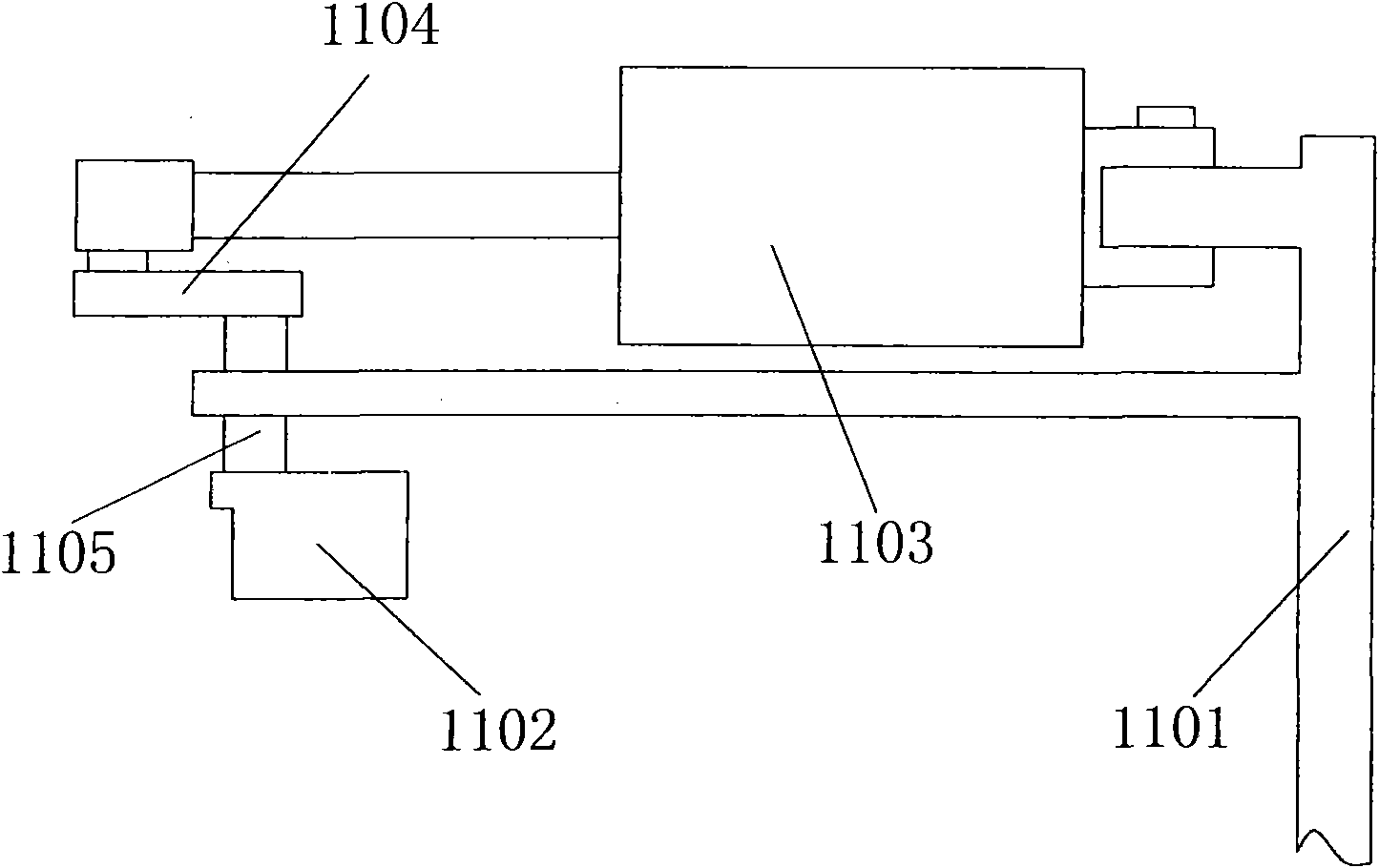

Full-automatic multi-station automobile ABS pile-up valve end cover stamping equipment

The invention relates to full-automatic multi-station automobile ABS pile-up valve end cover stamping equipment which comprises a feeding device, a feeding mechanical arm, a locating device, a salient point stamping die, a salient point stamping mechanism, a transfer mechanical arm, an extrusion rotary table, an unloading mechanical arm, a stamping rotary table, a receiving box, an extrusion die, a salient point extrusion mechanism and a push mechanism. Automatic machining is achieved, work efficiency is high, the quality of the products of an existing manual mode is prevented from being influenced, the number of workers is greatly reduced, production cost is lowered, pushing, feeding, stamping, transfer feeding and discharging and extrusion unloading are automatically completed between all processes, and the technological process is simplified.

Owner:LX PRECISION SHANGHAI CO LTD

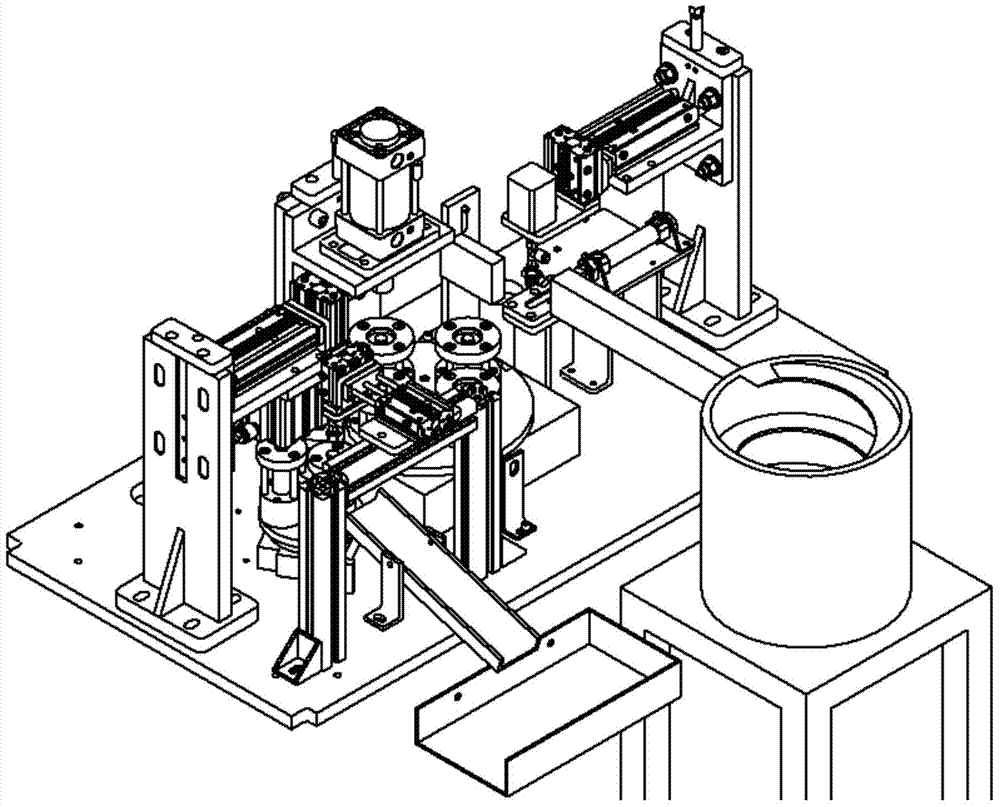

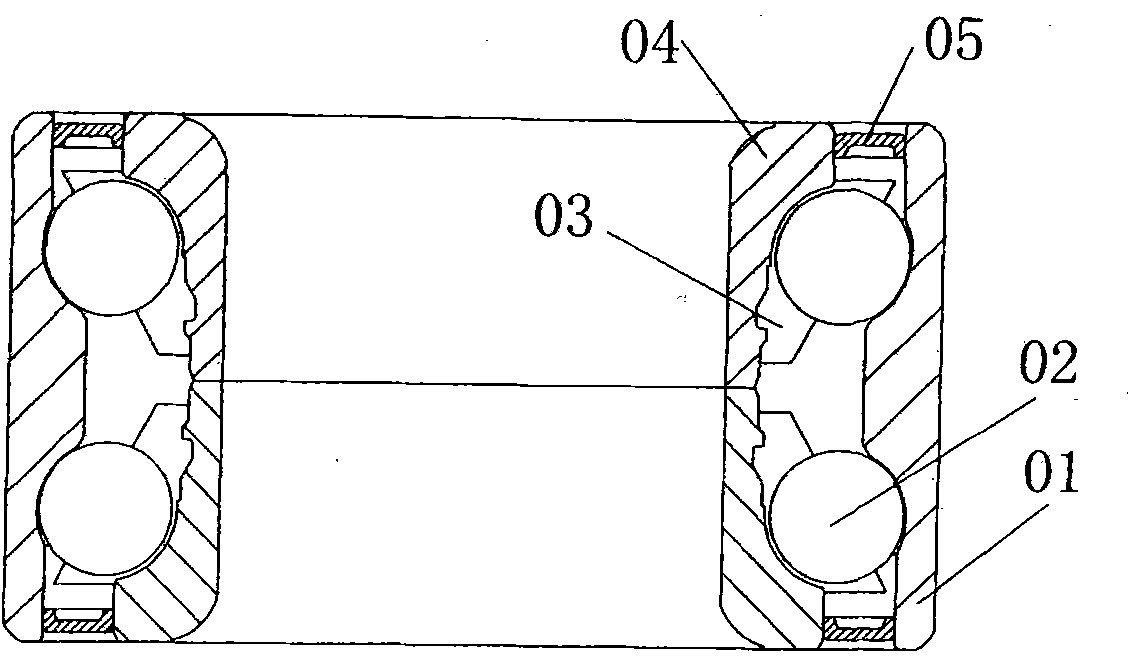

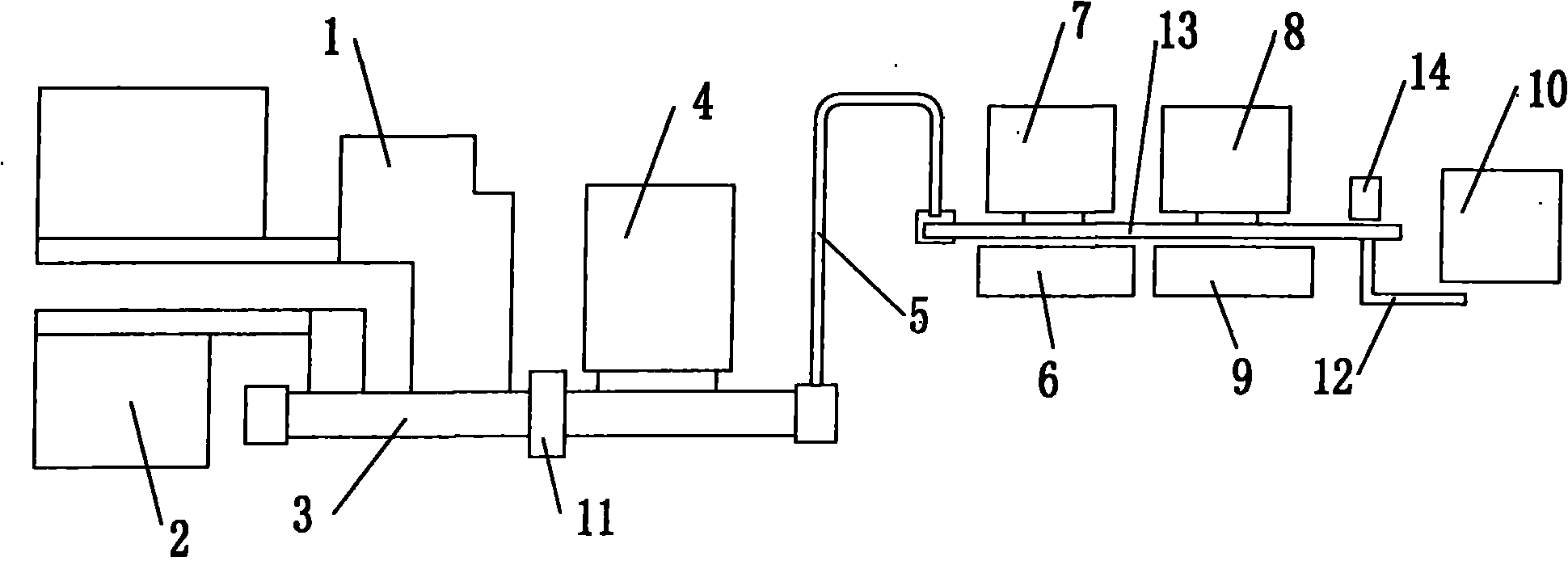

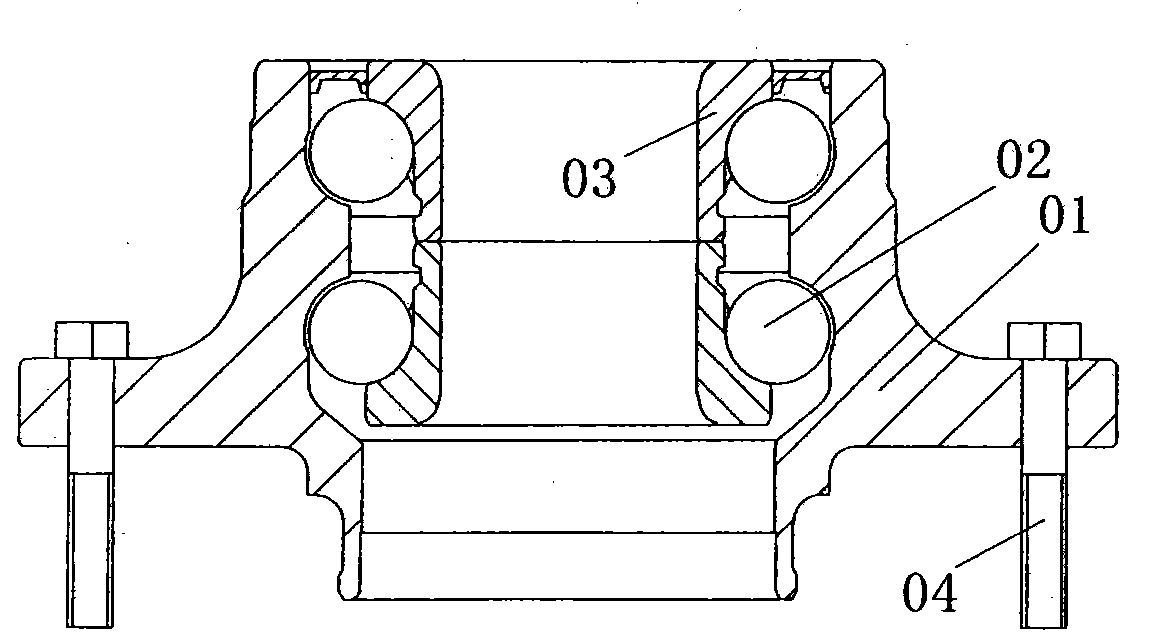

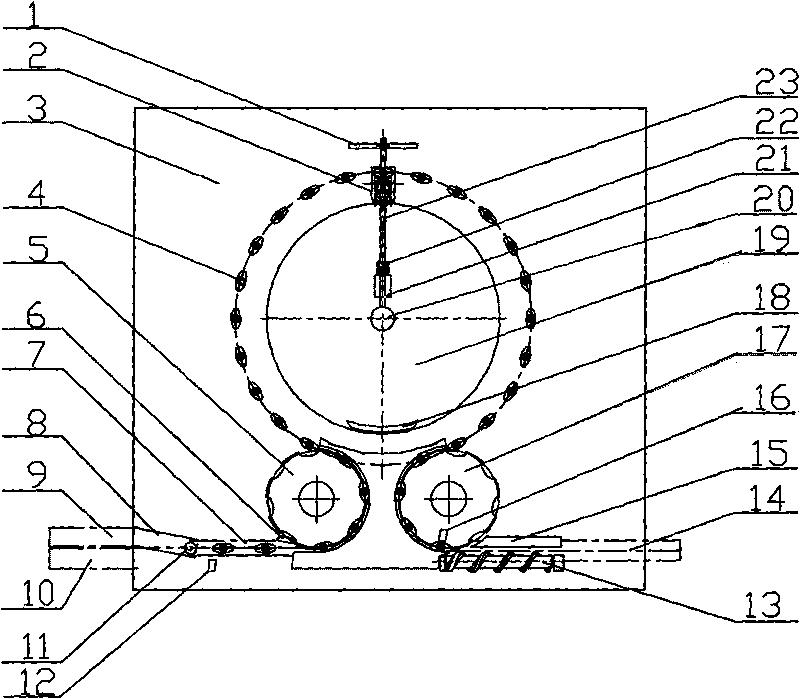

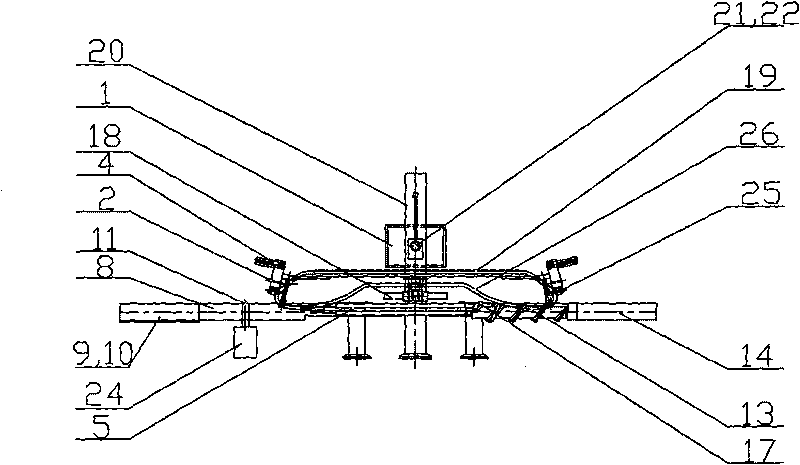

Assembly line for automobile first-generation hub bearing

The invention provides an assembly line for an automobile first-generation hub bearing. The assembly line comprises an inner ring transmission measuring device, an outer ring transmission measuring device, tray conveyor lines, a trap device, a vibration inspecting device, a windage inspecting device and a grease infusion inspecting device, wherein the inner ring transmission measuring device, the outer ring transmission measuring device are connected with the trap device through the tray conveyor lines; the trap device is connected with the vibration inspecting device through a conveyor line, the vibration inspecting device is connected with the windage inspecting device through a sliding table, the tail end of the sliding table is provided with a charging mechanism, and the charging mechanism is connected with the windage inspecting device through an output line; and the front faces of the vibration inspecting device and the windage inspecting device are provided with a transporting device respectively. The invention can finish all the assembly working procedures of the automobile first-generation hub bearing, and realizes automatically inspecting each working procedure and automatically setting parameters; and a PLC is utilized to automatically control the operation of an executing mechanism according to the procedures, thus realizing accurate control and ensuring assembly quality.

Owner:济南易恒技术有限公司

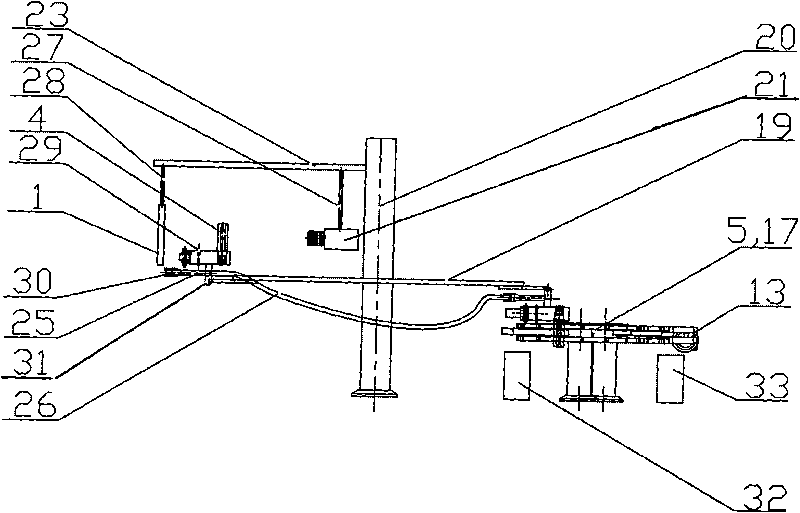

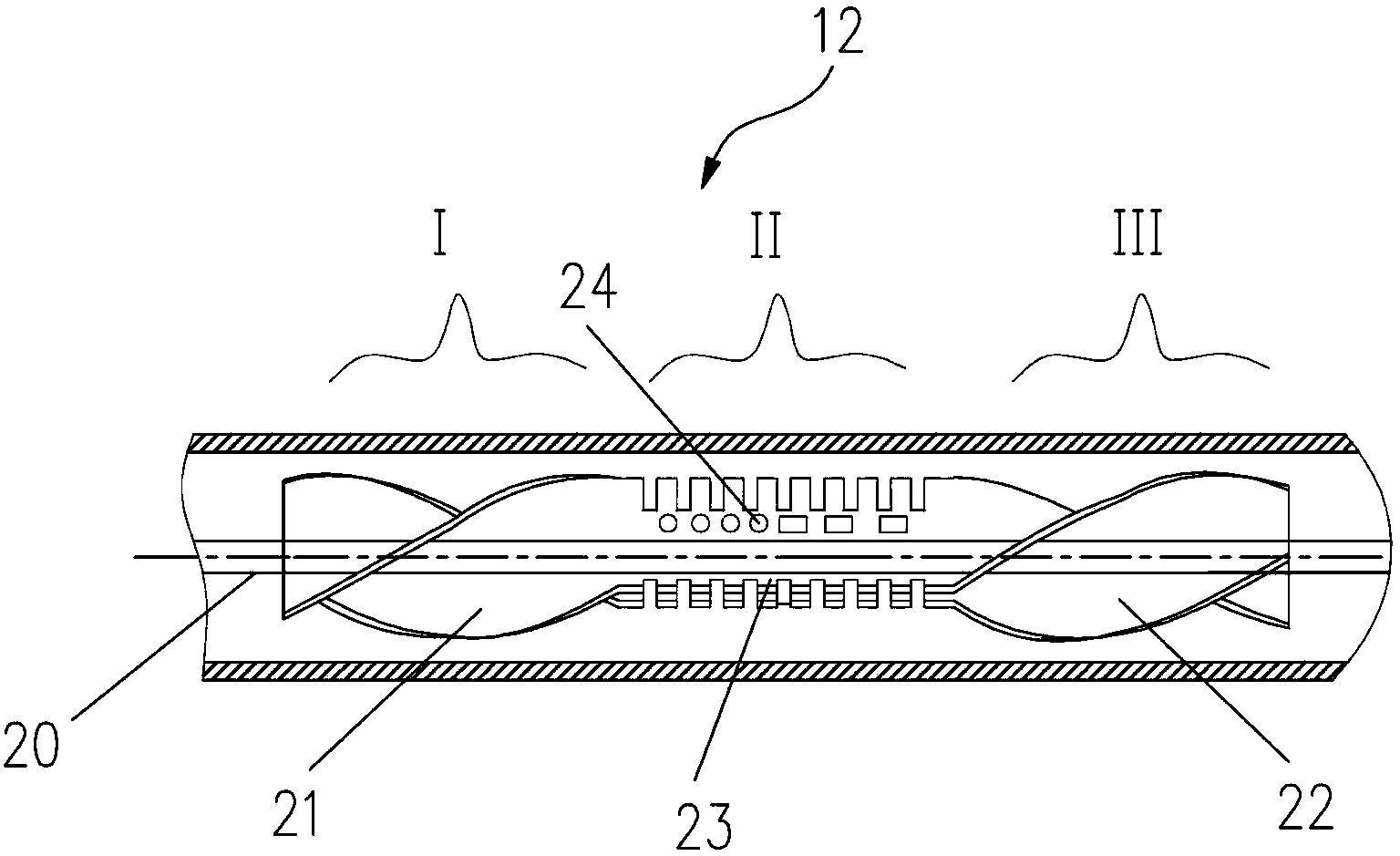

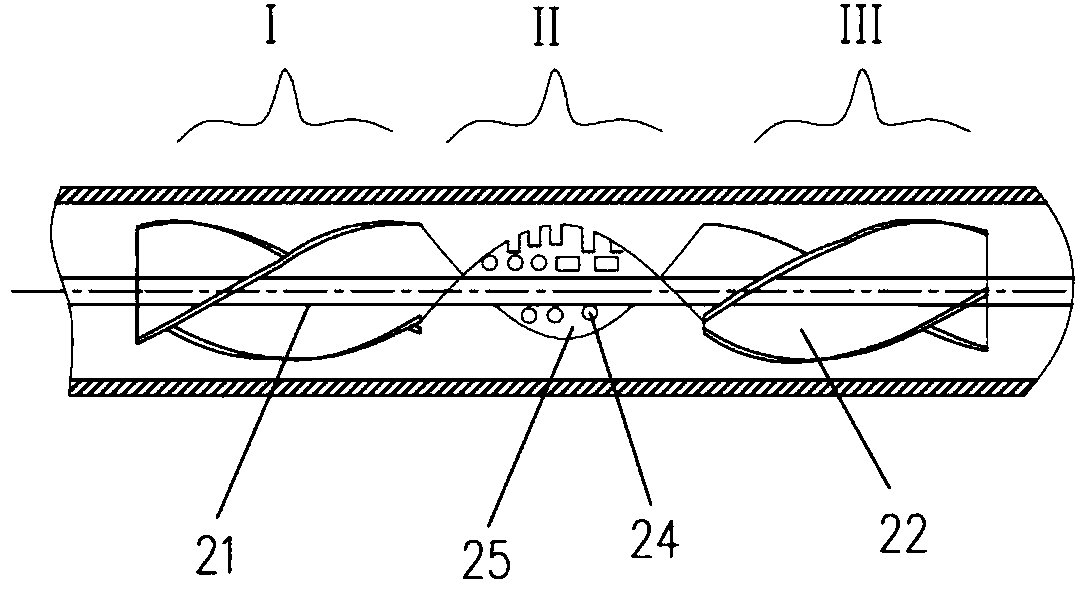

Automobile third-generation hub unit assembly line

ActiveCN101863195AAchieve inflowPrevent inflowWheel assembling toolsAutomatic controlWheel speed sensor

The invention provides an automobile third-generation hub unit assembly line. The assembly line comprises a channel measurement sorting device, a steel ball storage detection device, a flange plate outer ring assembly device, a nut tightener, a vibration detection device, a negative windage detection device, a grease injection and nut riveting device, a bolt tightening and pressing device, a gear ring and sensor pressing device and an ABS wheel speed sensor detection device. The invention can complete all the assembly procedures of the entire automobile third-generation hub unit, realizes automatic detection on each procedure, and prevents unqualified products from flowing into the subsequent procedure. The invention automatically sets parameters and automatically carries out detection, automatically controls the operation of an actuating mechanism by utilizing a PLC according to a program, prevents human factors from affecting the product quality, realizes accurate control and strictly ensures the assembly quality.

Owner:济南易恒技术有限公司

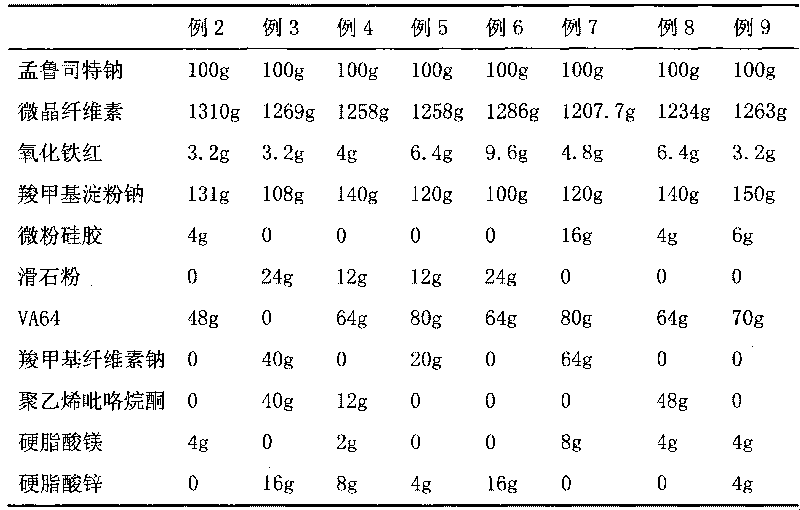

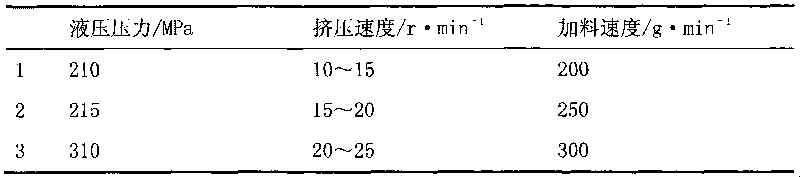

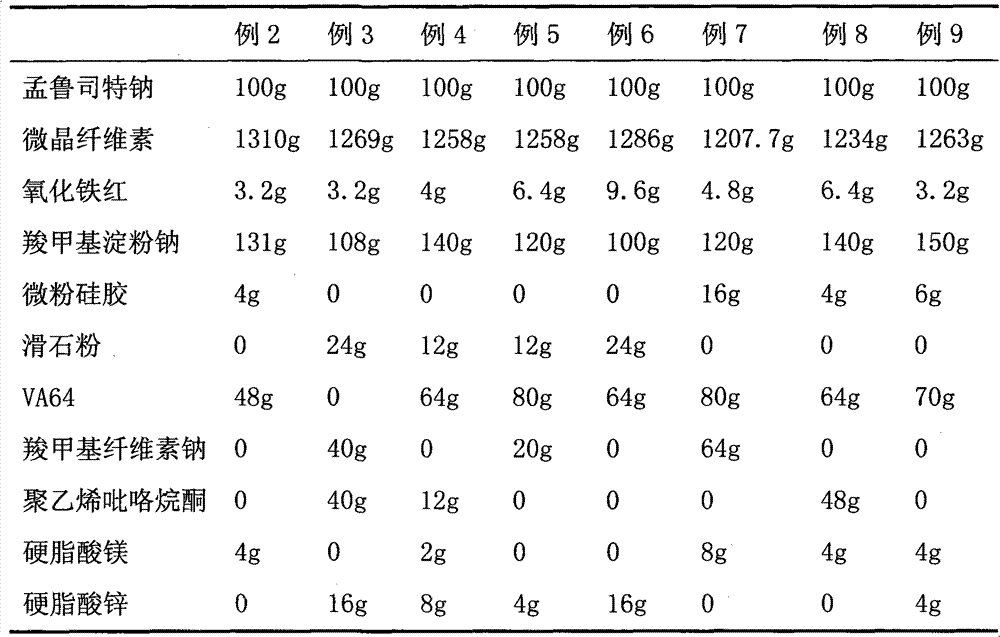

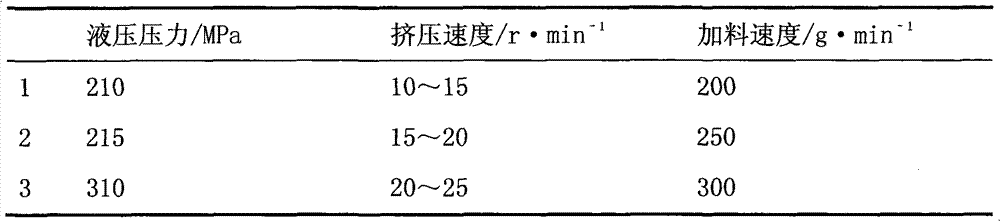

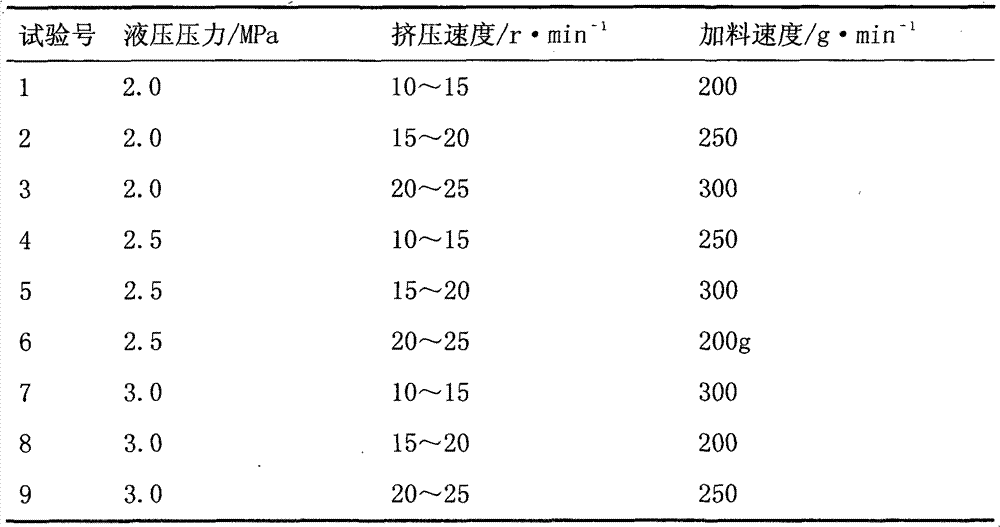

Montelukast sodium tablet and preparation method thereof

ActiveCN101732268AWell mixedSolve production problems that require dark operationPill deliveryPharmaceutical non-active ingredientsTemperature controlAdhesive

The invention belongs to the field of medicine preparations, in particular to a montelukast sodium tablet and a preparation method thereof. Because the montelukast sodium tablet adopts a wet method granulation process and has the problems of long drying time, difficult temperature control and easy causing of content difference, content descent and relevant substance increase between particles, the invention provides the montelukast sodium tablet and the preparation method thereof in order to enhance the stability and the operability of the montelukast sodium tablet. The montelukast sodium tablet provided by the invention comprises montelukast sodium, a filling agent, a disintegrating agent, an adhesive, a colorant, a lubricant and a flow aid. The preparation method of the montelukast sodium tablet provided by the invention adopts direct tabletting after dry method granulation and uses the colorant, the colorant can act as a very good light shielding function in the operational process, the operation is convenient, the influence of a drying process and moist heat to the product quality is avoided, and the product stability is enhanced.

Owner:LUNAN PHARMA GROUP CORPORATION

Assembly line for second-generation automobile hub unit

The invention provides an assembly line for a second-generation automobile hub unit. The assembly line comprises inner ring transmission measuring equipment, outer ring transmission measuring equipment, a tray transmission line, a complete set of equipment, vibration detection equipment, play detection equipment, a grease filling detection device and bolt press mounting equipment, wherein, the inner ring transmission measuring equipment, the outer ring transmission measuring equipment and the complete set of equipment are connected by the tray transmission line; the set complete of equipment is connected with the vibration detection equipment by the transmission line; the vibration detection equipment is connected with the play detection equipment by a slipway; an end of the slipway is provided with a feeding mechanism which is connected with the grease filling detection equipment by an outlet line; and the vibration detection equipment and the front of the play detection equipment are both provided with conveyers. The assembly line can complete the whole assembling process of the second-generation automobile hub unit, carry out automatic detection for each procedure and automatic parameter setting, and realize automatically controlling operation of an executive mechanism by a PLC in accordance with procedure, thus achieving accurate control and strictly ensuring assembling quality.

Owner:济南易恒技术有限公司

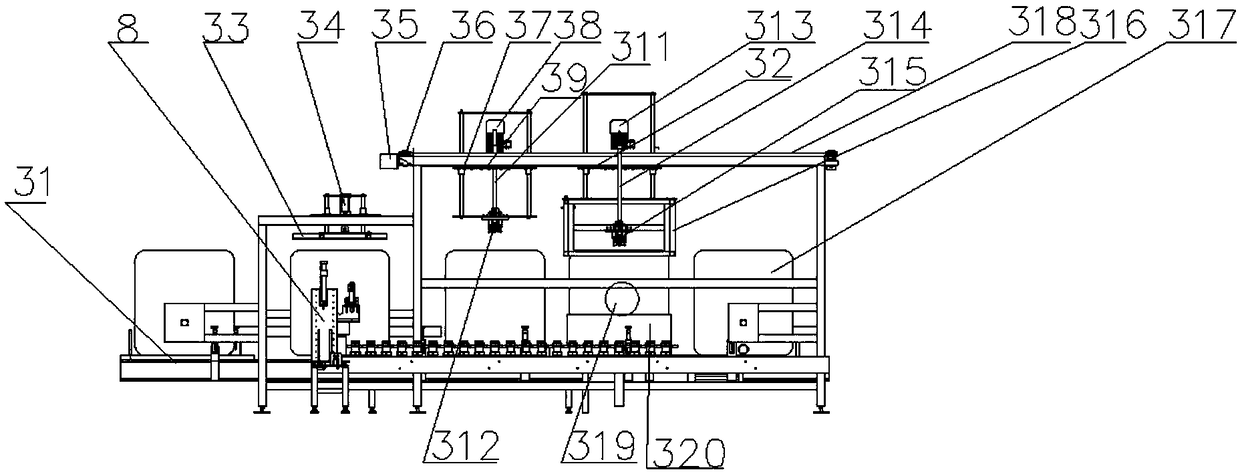

Method and device for automatically detecting impurities in health wine

InactiveCN101692056ALow costSimple structureMaterial analysis by optical meansSortingEngineeringLight source

The invention discloses a method and a device for automatically detecting impurities in a health wine. The device comprises a detection wheel disc, a bottle feeding mechanism, a bottle discharging mechanism, a sorting mechanism for removing inferior health wine bottles, an mechanical arm for clamping and overturning health wine bottles, a detection bracket, a camera to shoot images for health wine bottles, a lens, a light source and a microprocessor. The method comprises the following steps: a health wine bottle is introduced into the detection wheel disc, is clamped and overturned by the mechanical arm; an sequence image of the health wine bottle is acquired when the health wine bottle is in an inverted state and keeps uniform motion; the acquired sequence image is located by a computer; whether impurities exist in the health bottle or not is judged; and the inferior health wine bottles are removed by a control sorting mechanism. The device and the method have the advantages of low cost, rapid detection speed, high reliability and high detection accuracy rate and the like.

Owner:HUNAN UNIV

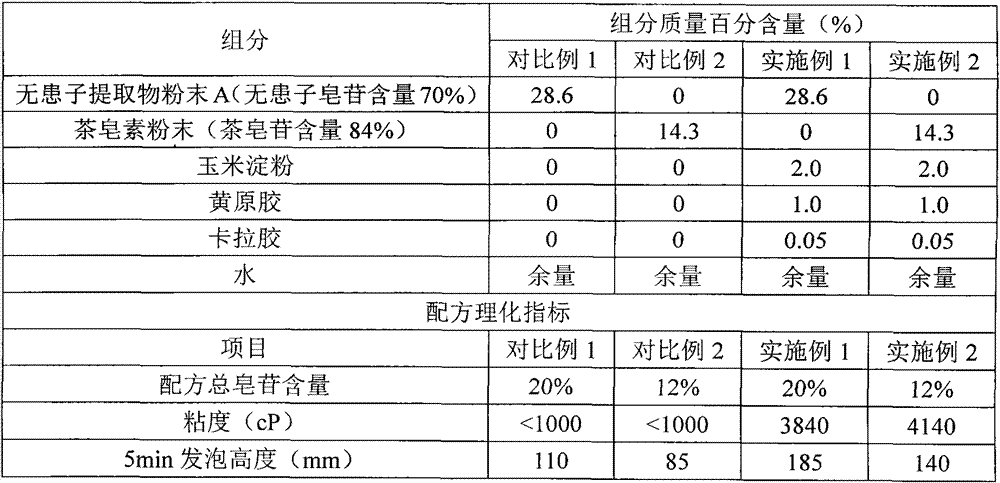

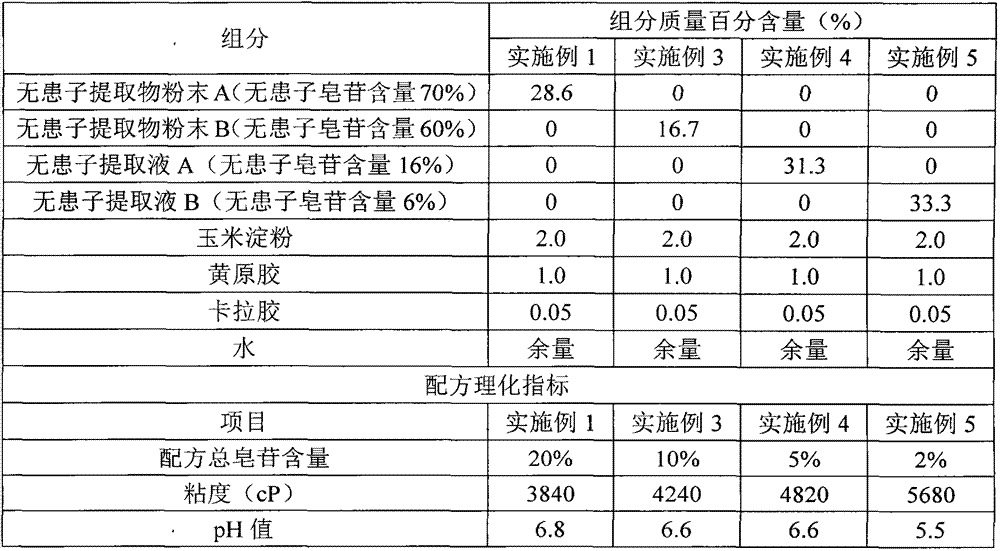

Shampoo containing natural saponin and natural thickener

ActiveCN103479539ALess irritatingEasy to useCosmetic preparationsHair cosmeticsAmyrisChemical synthesis

The invention discloses a shampoo containing natural saponin and natural thickener, which contains natural saponin, natural thickener and water, wherein the natural saponin at least comprises one or mixture of Chinese soapberry saponin tea saponin; and the natural thickener at least comprises one or more of any of natural plant starch, xanthan gum, arabic gum, guar gum, carrageenin and seaweed gel. The natural saponin and natural thickener are matched, so that the shampoo has the viscosity suitable for daily life and can mildly clean the hair without irritating or damaging the scalp. The natural raw materials are adopted to avoid the risk of introducing harmful chemical synthetic substances into the formula.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

Preparation method for alpha-acetyl-gamma-butyrolactone

ActiveCN102229586AEfficient recyclingLow input costOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReaction rateMethyl acetate

In order to solve the problems of a low safety factor, low yield, high cost, environmental pollution and the like existing in the prior art, the invention provides a preparation method for alpha-acetyl-gamma-butyrolactone. In the method, gamma-butyrolactone and methyl acetate are used as reaction raw materials and metallic sodium is used as a catalyst; the final product is prepared through the phases of reaction, separation, neutralization and extraction. According to the invention, methyl acetate is used as the reaction raw material and a reaction solvent, which on one hand enables production cost to be reduced, the reaction rate to be slowed and dashing out of reacting materials to be avoided, and on the other hand avoids environmental pollution and affection on product quality caused by utilization of benzene solvents; preparation of the catalyst into sodium sand can improve reaction efficiency; high purity alpha-acetyl-gamma-butyrolactone can be obtained through neutralization andextraction of the solid resultants alpha-acetyl-gamma-butyrolactone sodium salt of the reaction which have been subjected to solid-liquid separation without underpressure distillation, thereby effectively improving production efficiency and reducing production cost; the acidic neutral solution used in the invention can be used repeatedly, thereby avoiding environmental pollution by the solution.

Owner:山西三维华邦集团有限公司 +1

Method for utilizing waste water during production of stevioside

ActiveCN102649610AAvoid emissionsLow costSugar derivativesMultistage water/sewage treatmentWater savingWastewater

The invention discloses a method for utilizing waste water during production of stevioside. The method comprises the following process steps: (1) adjusting the pH value of acidic and alkaline waste water generated by resin regeneration to be 6 to 8 by using alkali or acid; (2) directly soaking stevia into the waste water with the pH value regulated to obtain extracting solution; (3) flocculating and filtering the extracting solution and adsorbing by using adsorption resin, washing the resin with water after adsorption; (4) analyzing the adsorption resin by using ethanol to obtain analytic solution; (5) desalinating the analytic solution by using strongly acidic cation resin for the first time and decoloring the analytic solution by using strongly alkaline anion resin for the first time; (6) desalinating the analytic solution by using weakly acidic cation resin for the second time and decoloring the analytic solution by using weakly alkaline anion resin for the second time to obtain stevioside solution; and (7) concentrating and spray-drying the stevioside solution to obtain the stevioside product. The method has the characteristics of water saving, environmental friendly, economy and low cost.

Owner:CHENGUANG BIOTECH GRP CO LTD

Ceramic whiteware raw material formula by using shale as main raw material and production process

The invention provides a ceramic whiteware raw material formula by using shale as a main raw material and a production process. The raw material formula comprises 60 to 80 percent of shale, 4 to 6 percent of coal gangue, 8 to 12 percent of industrial coal ash, 8 to 12 percent of high-alumina sand and 4 to 6 percent of potash feldspar. The production process mainly comprises the following steps of: 1, primarily mixing hard raw materials in the formula in the formula ratio, and performing ball milling by using a water mill; 2, after the powder reaches the fineness, removing iron, sieving, putting into a sedimentation tank for sedimentation, removing surface layer water and impurities, and further removing water through a filter press to prepare wet powder; 3, adding the shale and the wet powder into a ball mill for mixed grinding, and performing iron removal and sieving on the slurry; and 4, preparing the prepared slurry into a green body, and firing the green body into a ceramic finished product to achieve the predicted green body whiteness.

Owner:唐兴玲

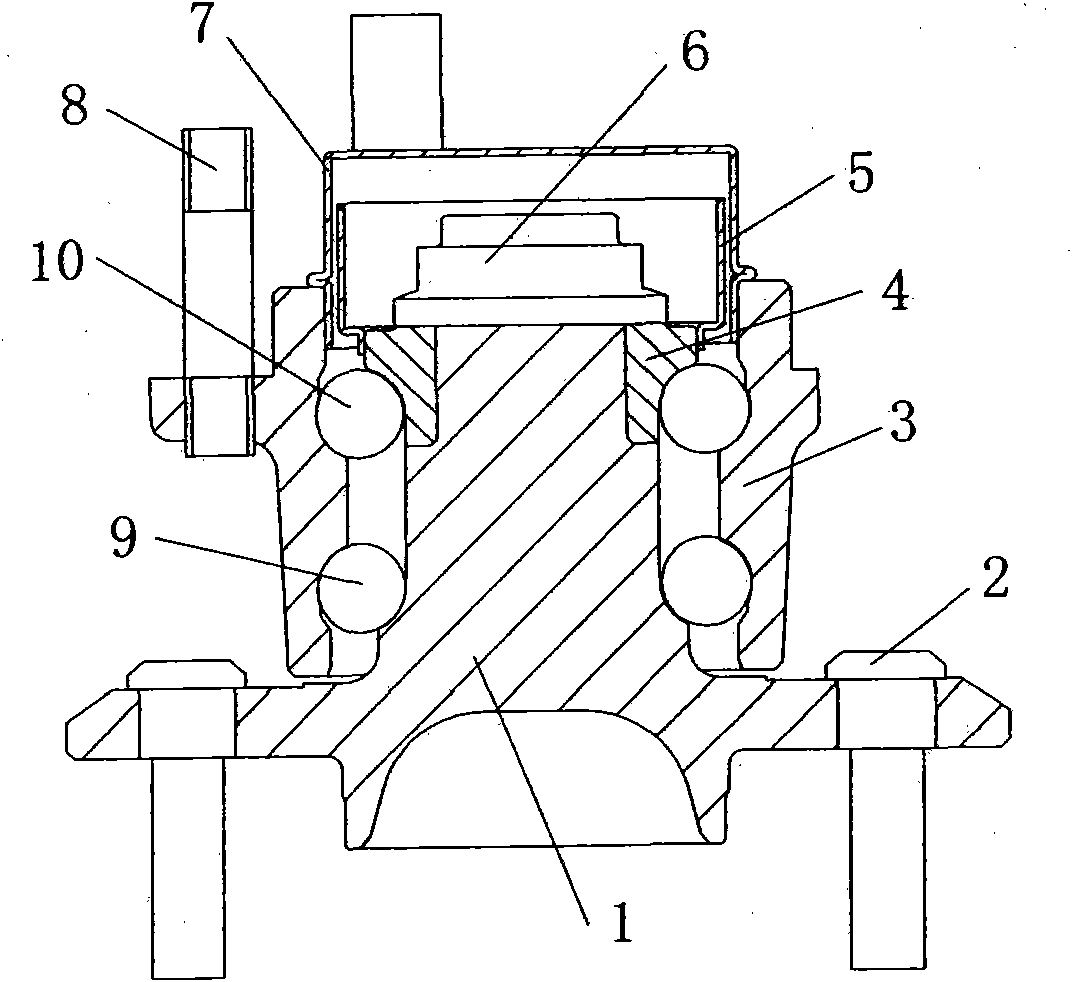

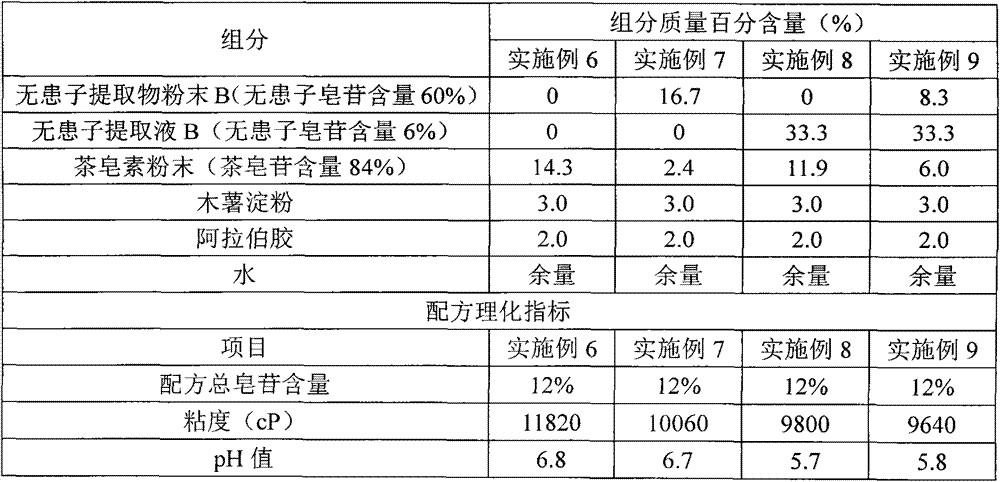

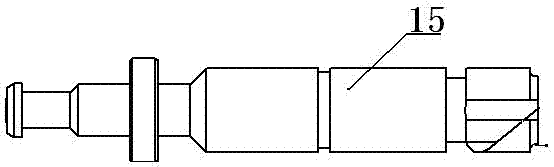

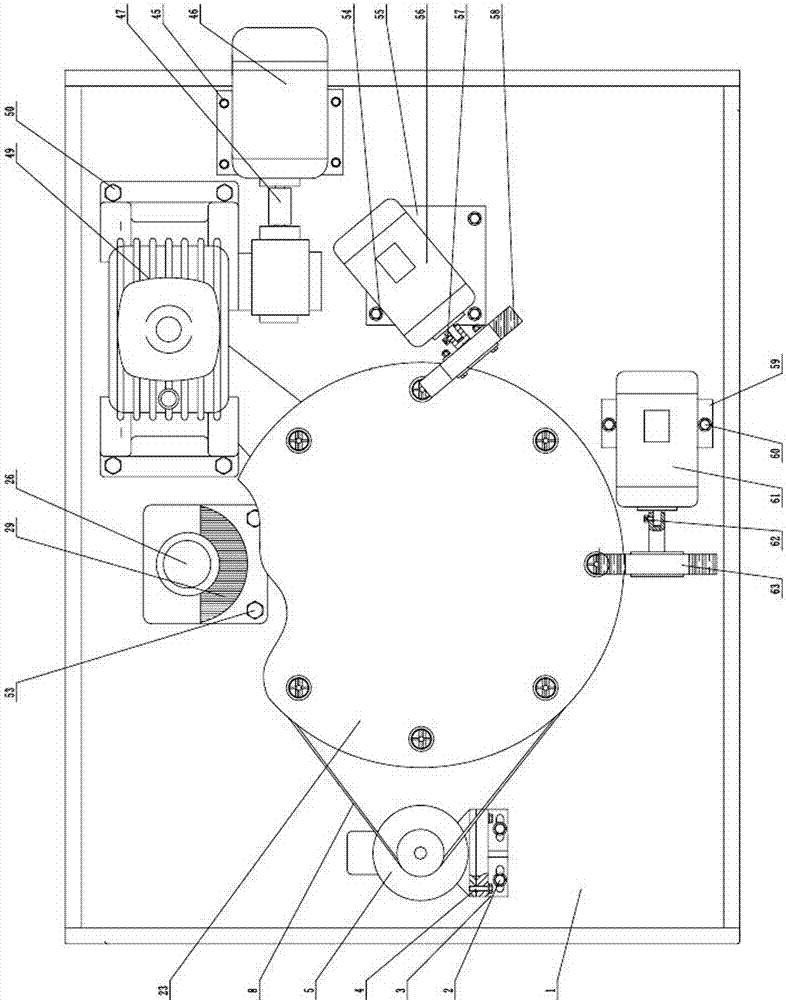

Deburring machine tool

The invention discloses a deburring machine tool which relates to an excricle deburring machine tool of shaft parts, in particular to a machine tool used for deburring a straight flute, a transverse groove, a chute of an excircle of a pillar plunger core inside a plunger and barrel assembly. The deburring machine tool comprises a machine body, a fixture drive motor seat, a first micro motor, a fixture driving pulley, a first synchronous belt, a fixture driven pulley, a first flat key, a draw bar, a first compression spring, a supporting block, a clamping head top block, an elastic clamping head, an elastic clamping head seat, a first plane bearing, a space ring, a first deep groove ball bearing, a lower end cover, a rotary disk, a bush, a combination cap, a second micro motor, a horizontal motor support, a first disk type steel brush, a main shaft, a second flat key, a main shaft belt pulley, a second synchronous belt, a bearing seat, a second deep groove ball bearing, a bush, a space ring, a second plane bearing, a third plane bearing, a nut, a main motor support, a third micro motor, a coupler, a reduction box, a second flat key, a driving pulley, an inclined motor seat, a fourth micro motor, a second disk type steel brush, a vertical motor seat, a ninth outer hexagon bolt, a fifth micro motor and a third disk type steel brush.

Owner:江苏瑞普机床有限公司

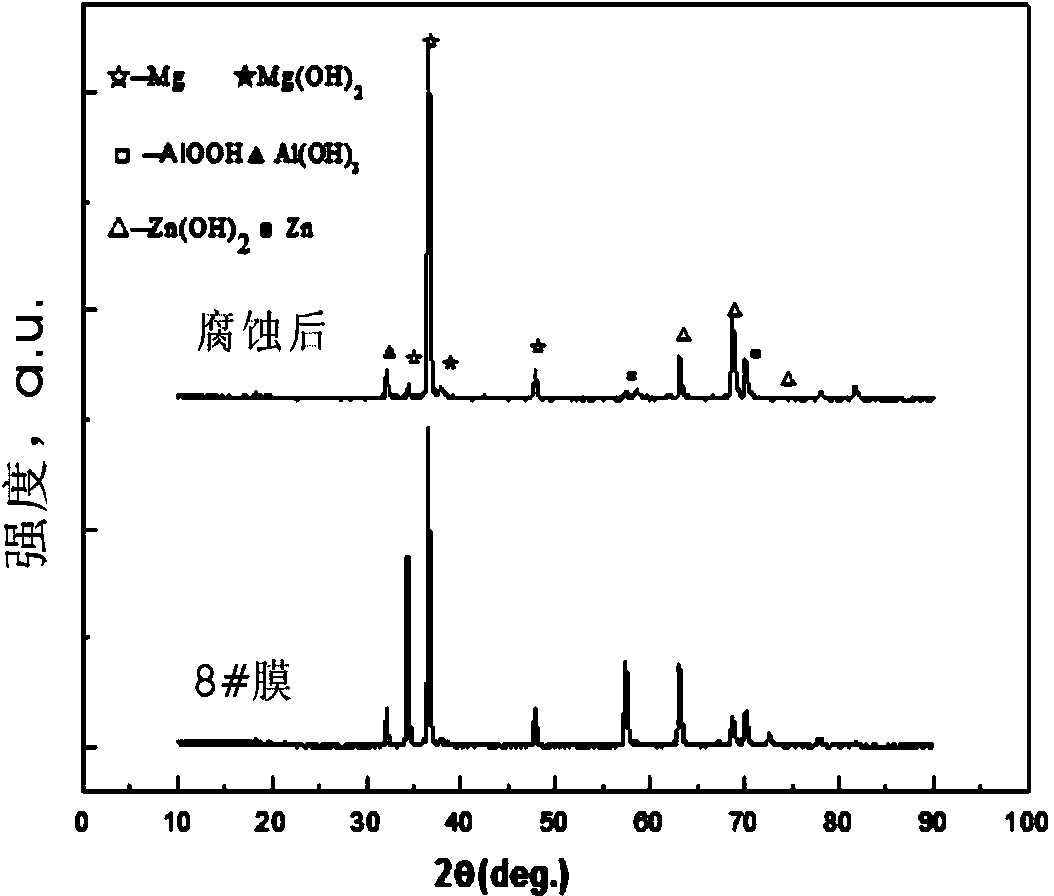

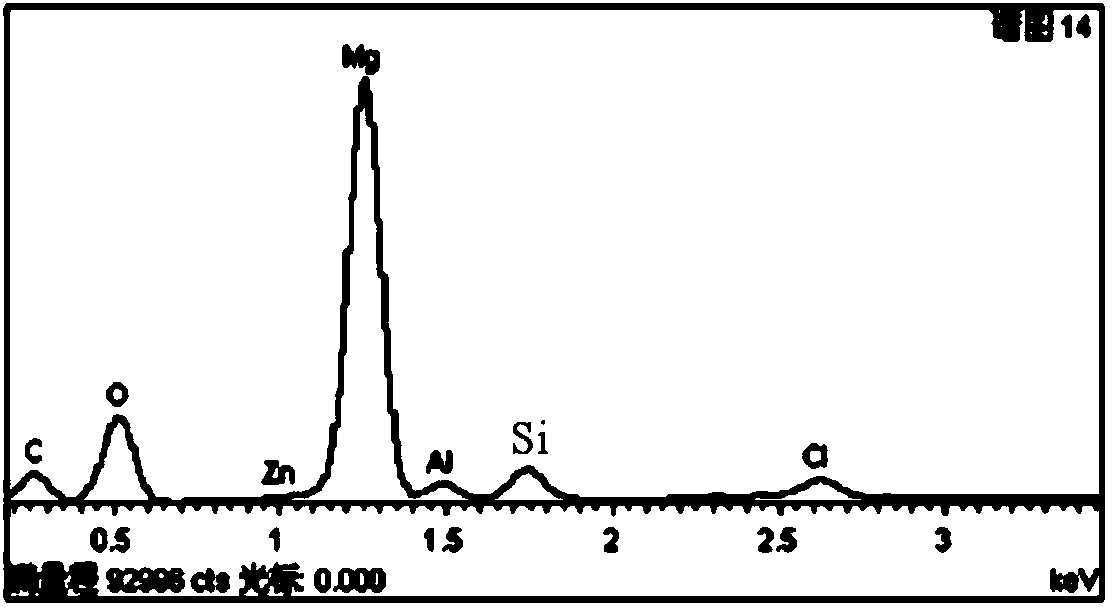

Corrosion resistant film prepared by magnesium alloy surface hydrothermal method and preparation technology thereof

ActiveCN103614717ASmall atomic radiusImprove polarization performanceMetallic material coating processesSolubilityLithium

The invention discloses a corrosion resistant film prepared by a magnesium alloy surface hydrothermal method and a preparation technology thereof, belongs to the technical field of magnesium surface processing, and solves the problem of bad corrosion resistant property of magnesium alloy in the prior art. The technology provided by the invention comprises the following steps: placing a processed magnesium alloy sample into a hydrothermal reactor, then injecting a treating fluid into the reactor according to a certain filling degree, and putting the reactor into a thermotank to maintain the temperature. The treating liquid comprises sodium hydroxide and lithium salt, sodium hydroxide provides a proper alkaline environment for film forming, lithium salt has a large solubility in water, Li+ can hydrolyze in water with a great amount at a certain temperature, so the pH value of the solution is improved so as to promote the film forming reactions on the magnesium alloy surface to move in the positive direction, the obtained film in situ grows on the magnesium alloy surface; the force between the film and the substrate body is excellent, the film is uniform, compact and ultra-thin, and has an excellent corrosion resistant property; the corrosion current density of the conversion film is increased by five magnitude orders compared to that of the substrate body, and reaches 10<-9> A / cm<2> magnitude grade.

Owner:曾荣昌

Minocycline hydrochloride sustained release tablet and preparation method thereof

InactiveCN102772384AReduce rateReduce doseTetracycline active ingredientsPharmaceutical non-active ingredientsSustained Release TabletMedicine

The invention discloses a minocycline hydrochloride sustained release tablet which is prepared from the following components in parts by weight: 40-90 parts of hydrochloride sustained release tablet, 80-120 parts of hydroxypropyl methylcellulose, 200-260 parts of lactose, 3-8 parts of silicon dioxide, 2-6 parts of magnesium stearate and 4-10 parts of coating materials. The invention also discloses a preparation method of the sustained release tablet. According to the minocycline hydrochloride sustained release tablet disclosed by the invention, the known unhealthy acute vestibule events caused by minocyline can be reduced, the tablet is released stably; and the preparation method has the advantages that the concept is ingenious, the flow is simple, the process is stable, the operation is simple and convenient, the production period is short, the product yield and the product stability are increased, and the production cost is lowered.

Owner:SICHUAN BAILI PHARM CO LTD

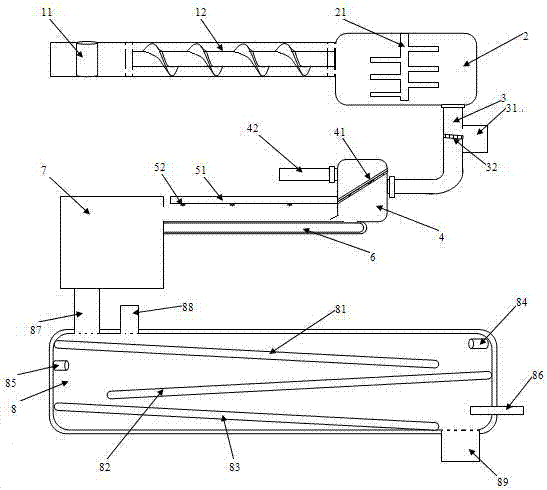

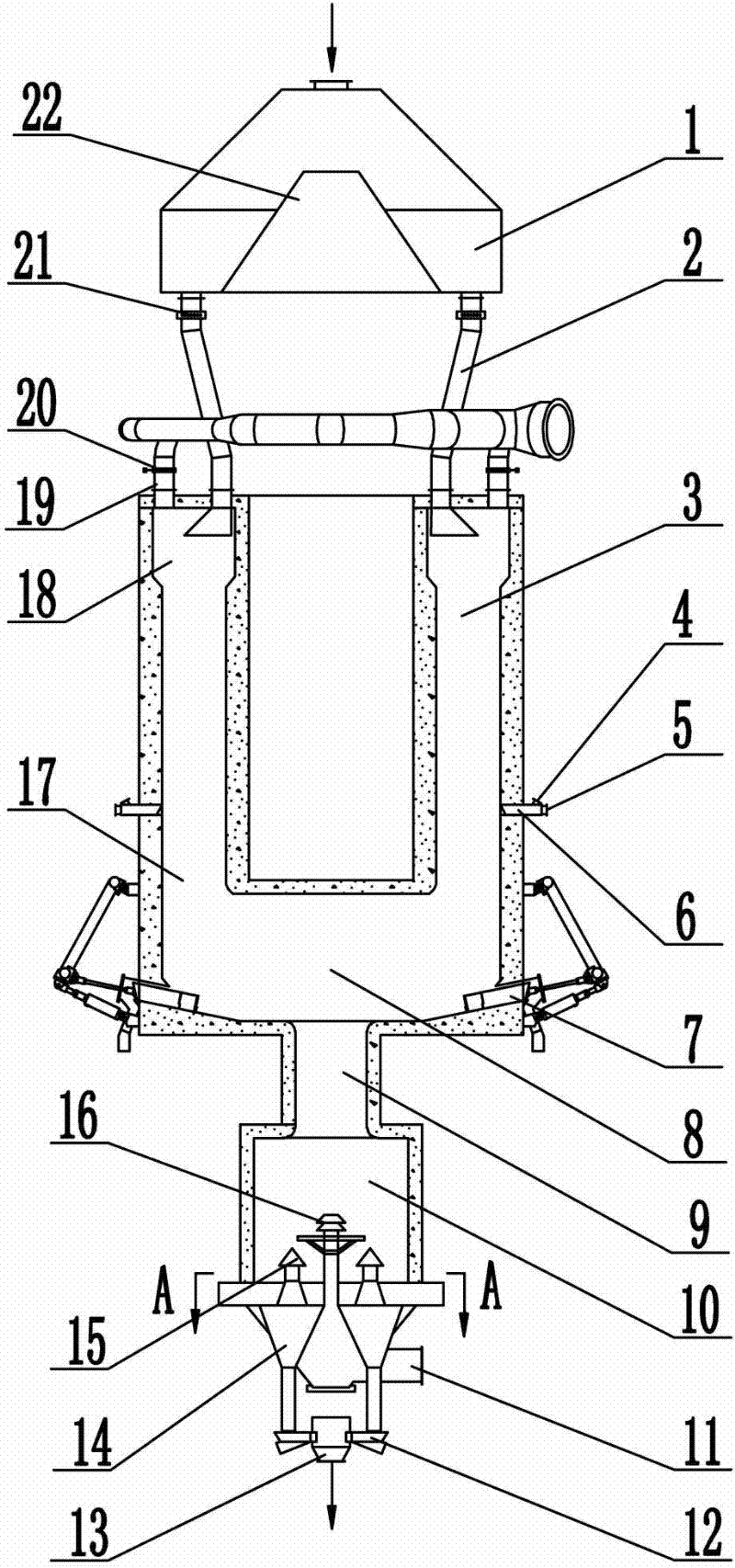

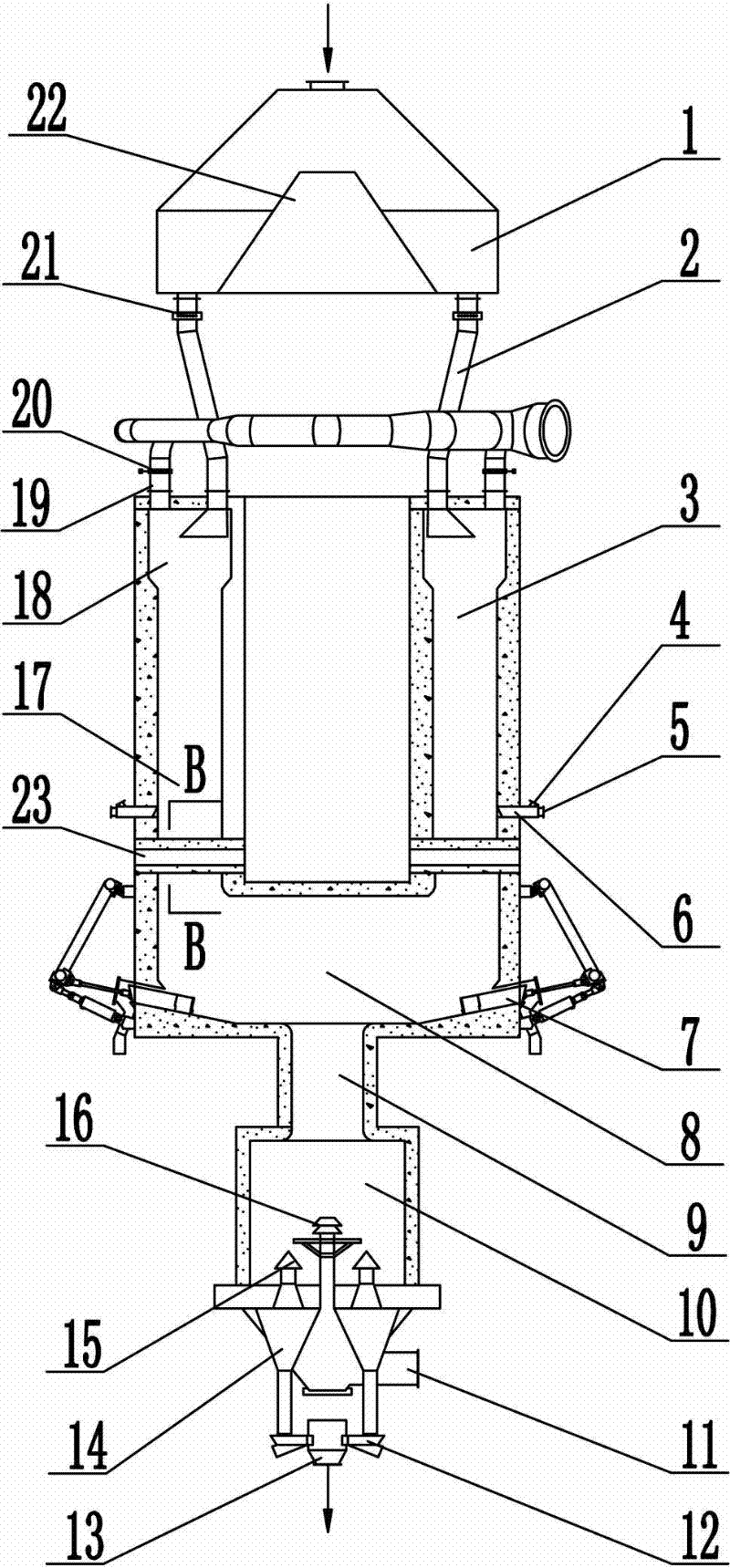

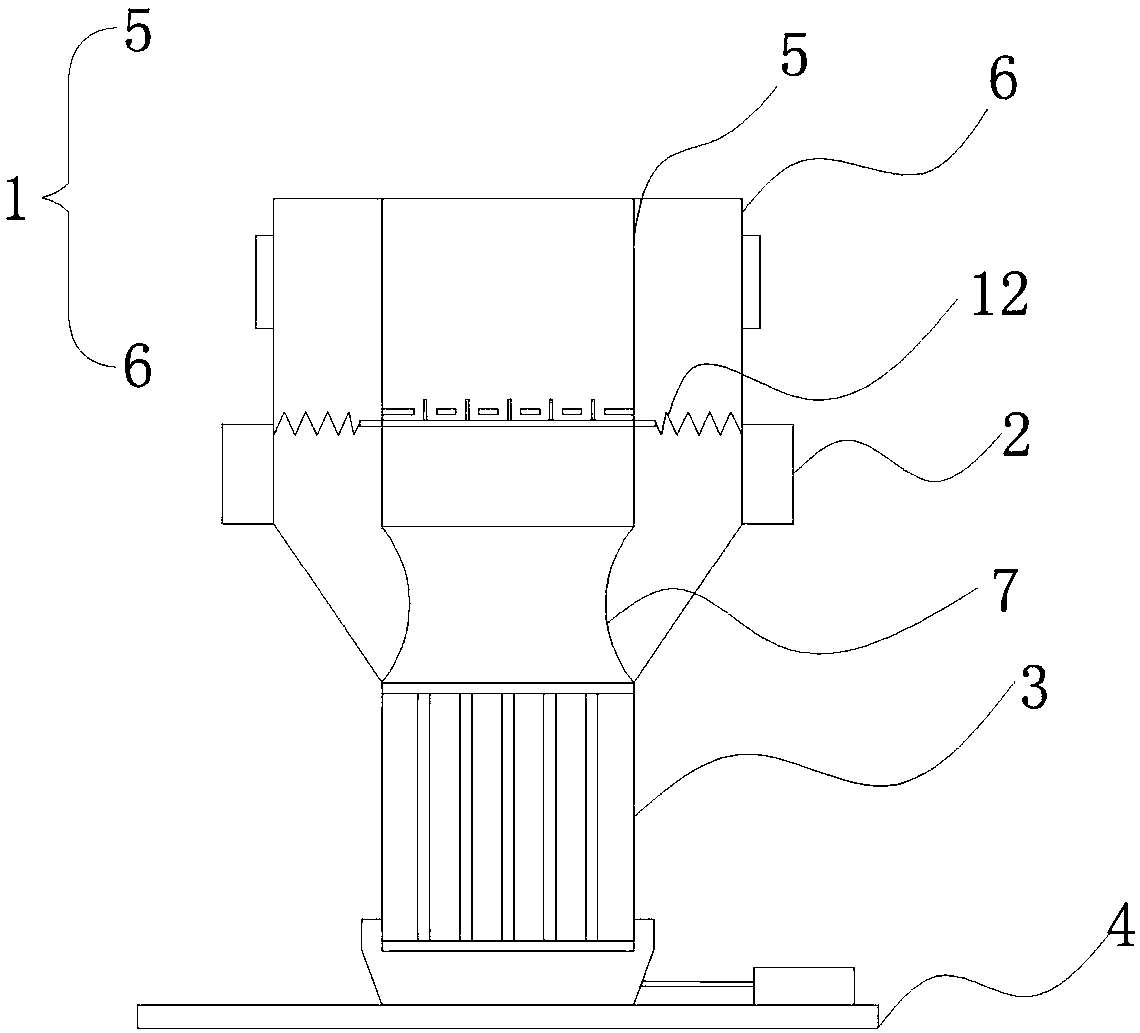

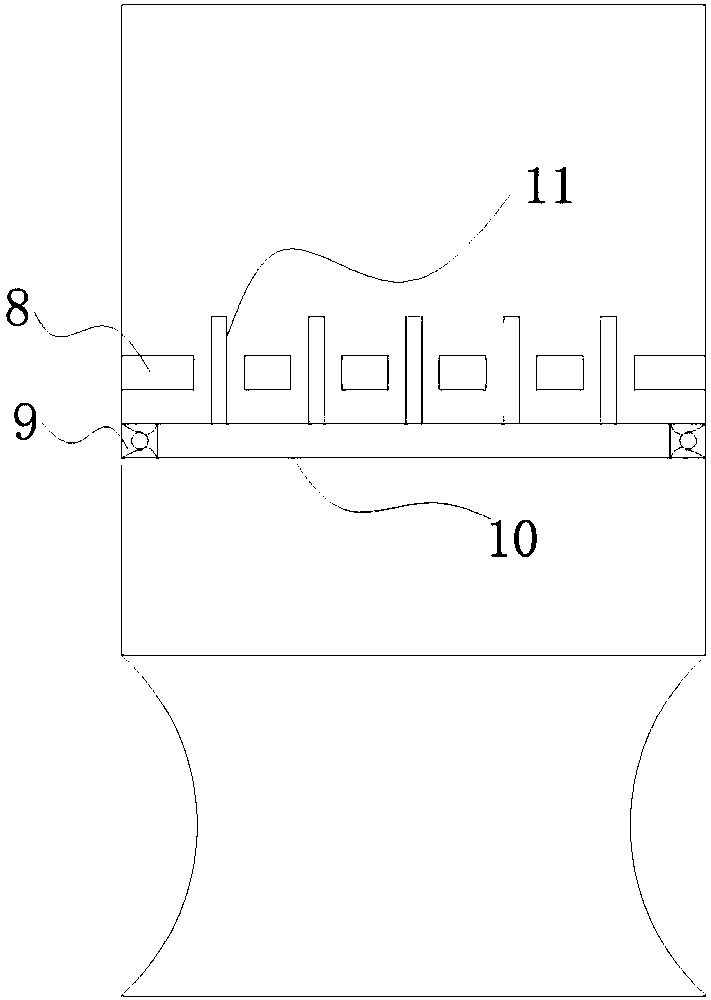

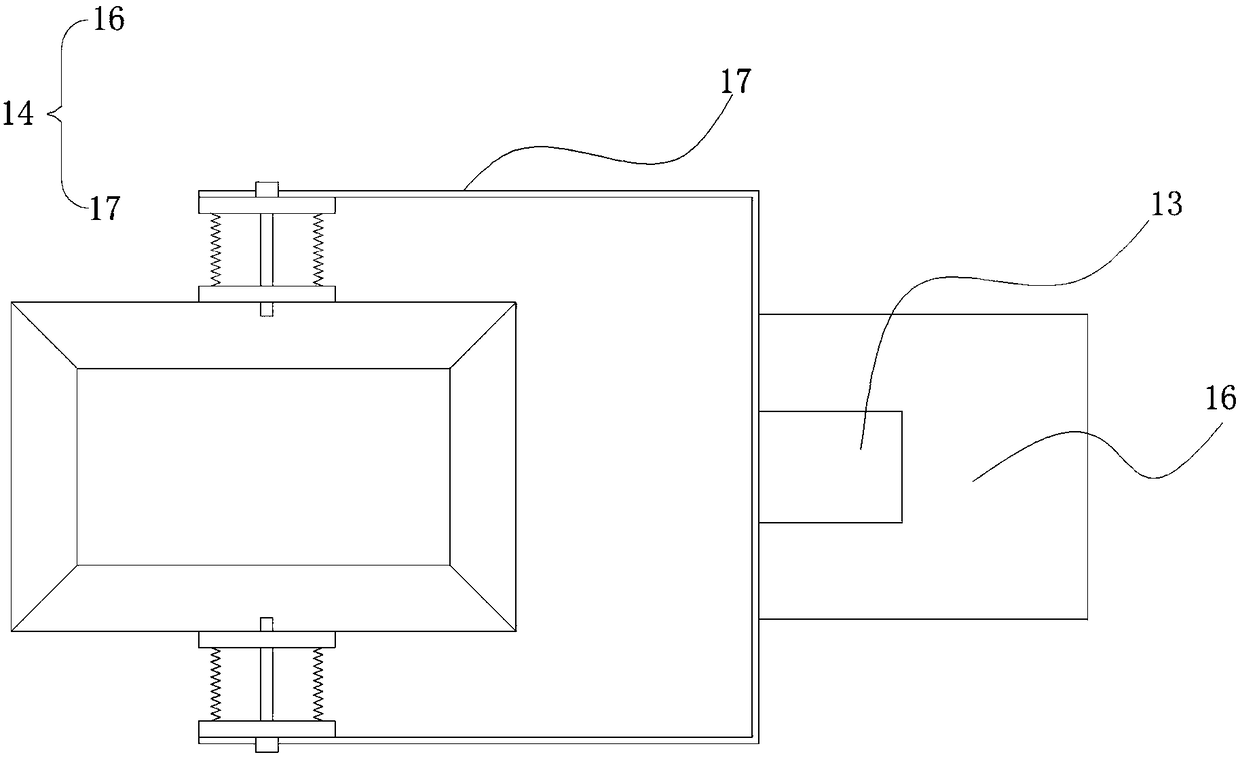

Sludge treatment apparatus for water conservancy project

ActiveCN107381987AAvoid damageAvoid the impact of product qualitySludge treatment by de-watering/drying/thickeningHydraulic engineering apparatusExpanded clay aggregateHydraulic engineering

The invention relates to a sludge treatment apparatus for a water conservancy project. The sludge treatment apparatus comprises a transport apparatus, a stirring chamber, a transport pipeline part, a sludge filter chamber, a sludge mixing and drying part, a mixing and granulating chamber and a ceramsite heating chamber. By arranging various parts, the sludge treatment, the ceramsite preparation from sludge and the ceramsite forming can be continuously carried out, so that not only can the sludge containing heavy metal be removed and the secondary pollution of the sludge to a water body be avoided, but also heavy metal elements are secondarily utilized for the ceramsite, and the harmful sludge can be actually turned into benefit.

Owner:畅庆环保科技(太仓)有限公司

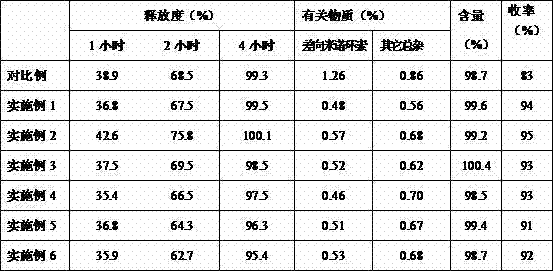

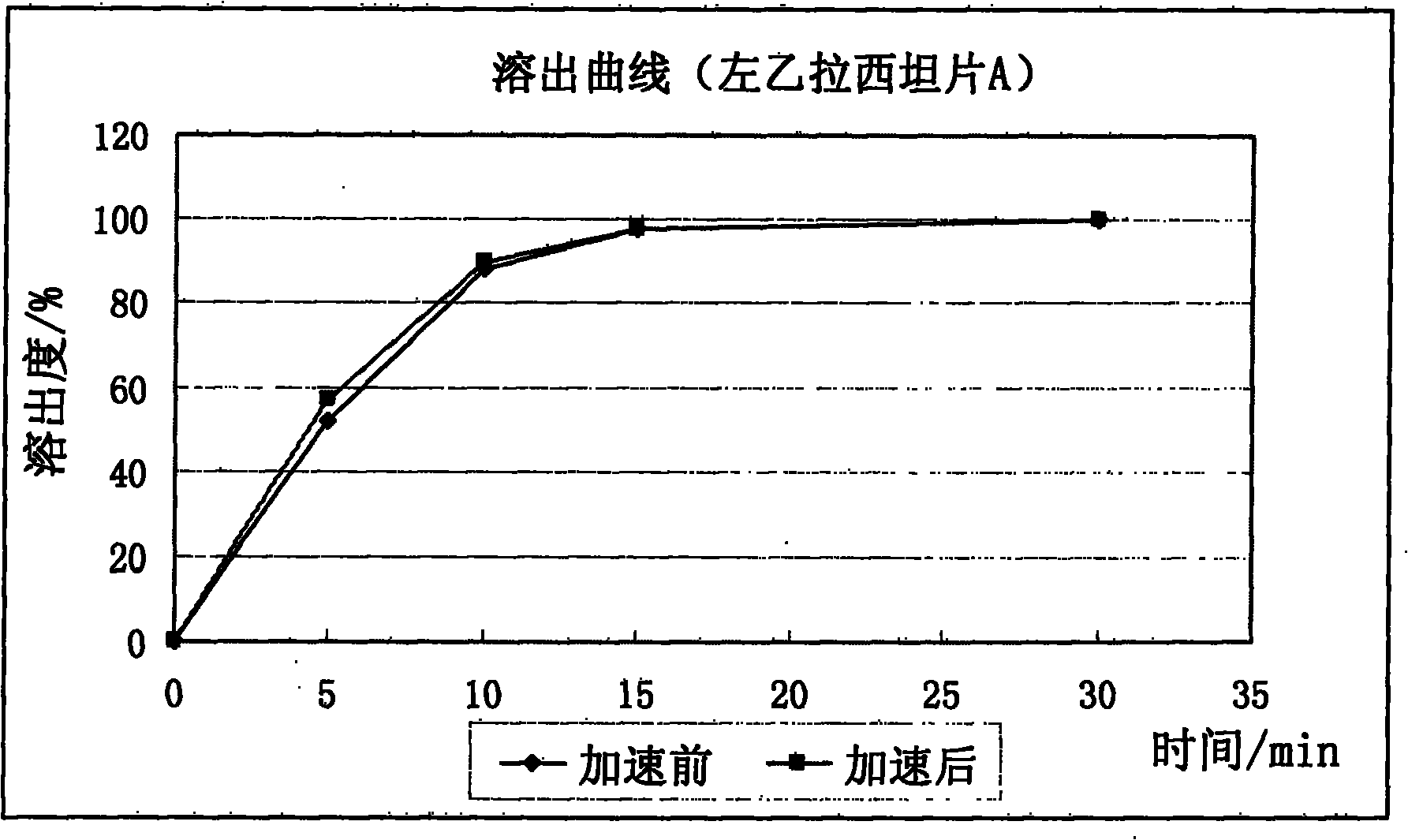

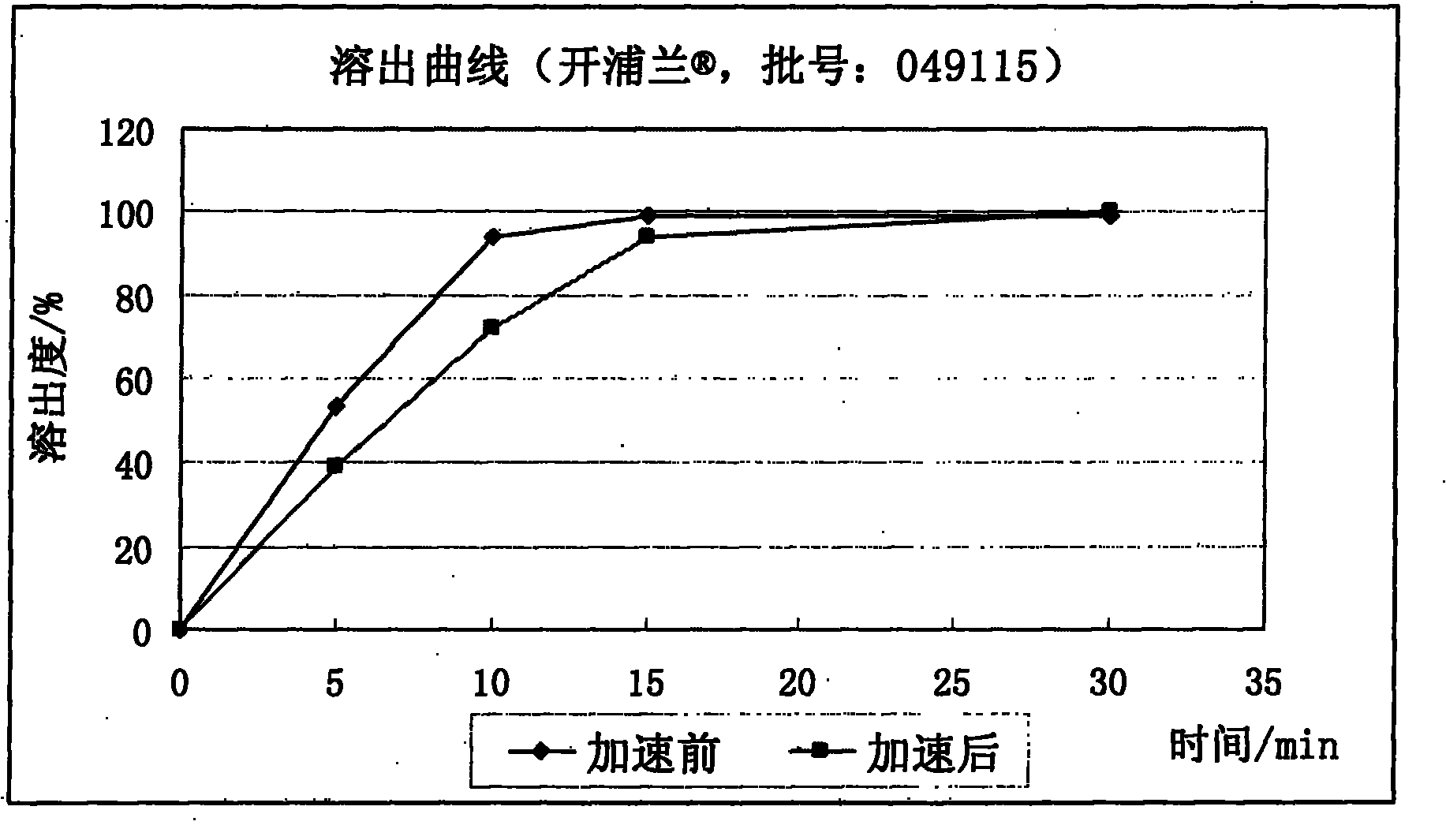

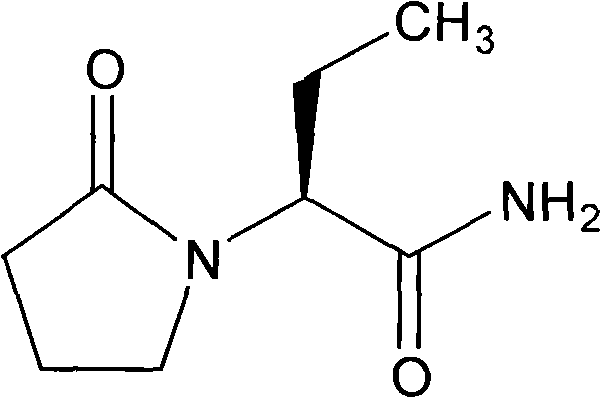

Levetiracetam tablet and preparation method thereof

ActiveCN102038657AEliminate impact on product qualitySimple process controlOrganic active ingredientsNervous disorderActive componentPharmacology

The invention relates to a levetiracetam tablet. The levetiracetam tablet at least comprises levetiracetam used as an active component and a binder accounting for more than 6% of the total weight of the tablet. The invention further relates to a preparation method of the levetiracetam tablet. The improved levetiracetam tablet is simple in production technology and low in cost, and is suitable for commercial production.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

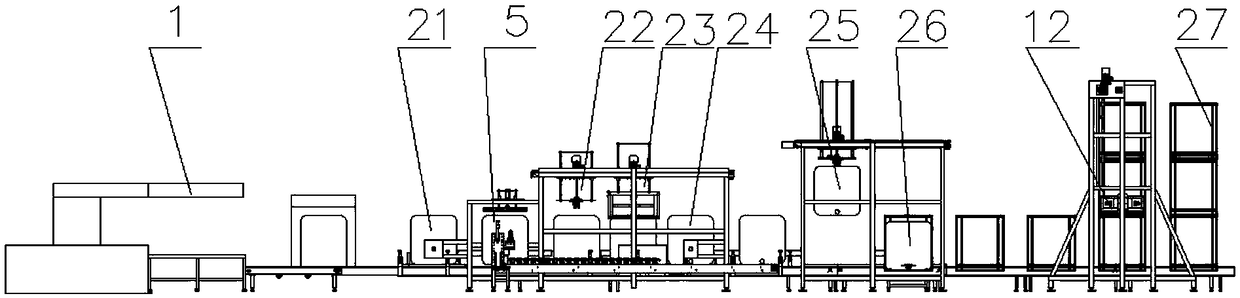

Automatic ton bucket blow molding self-inspection production line

PendingCN108859069AMeet production needsAvoid the impact of product qualityStacking articlesDomestic articlesProduction lineBlow molding

The invention relates to ton bucket production equipment, in particular to an automatic ton bucket blow molding self-inspection production line capable of improving the quality of products without manual intervention. The automatic ton bucket blow molding self-inspection production line comprises an injection molding machine, a plastic internal bladder conveying mechanism, a deflashing mechanism,a conveying line, a weighing and eliminating mechanism, a valve screwing mechanism, a valve screwing manipulator, a valve conveying line, a leakage detection mechanism, a reject eliminating mechanism,a cage loading mechanism and a stacking mechanism which are arranged sequentially from left to right, as well as a controller. The automatic ton bucket blow molding self-inspection production line requires no manual intervention, manpower and material resources are saved, investment in human capital is reduced, the cost is reduced, and the labor productivity is raised greatly when the manpower issaved; secondly, the production line adopts a visual imaging inspection function for performing ton bucket quality detection, so that the influence on the product quality by a human factor is avoided; and the speed of the production line is 1.5 minutes per bucket, so that the production requirements of two injection molding machines can be met at the same time.

Owner:QINGDAO RUNFUDA INTELLIGENT EQUIP CO LTD

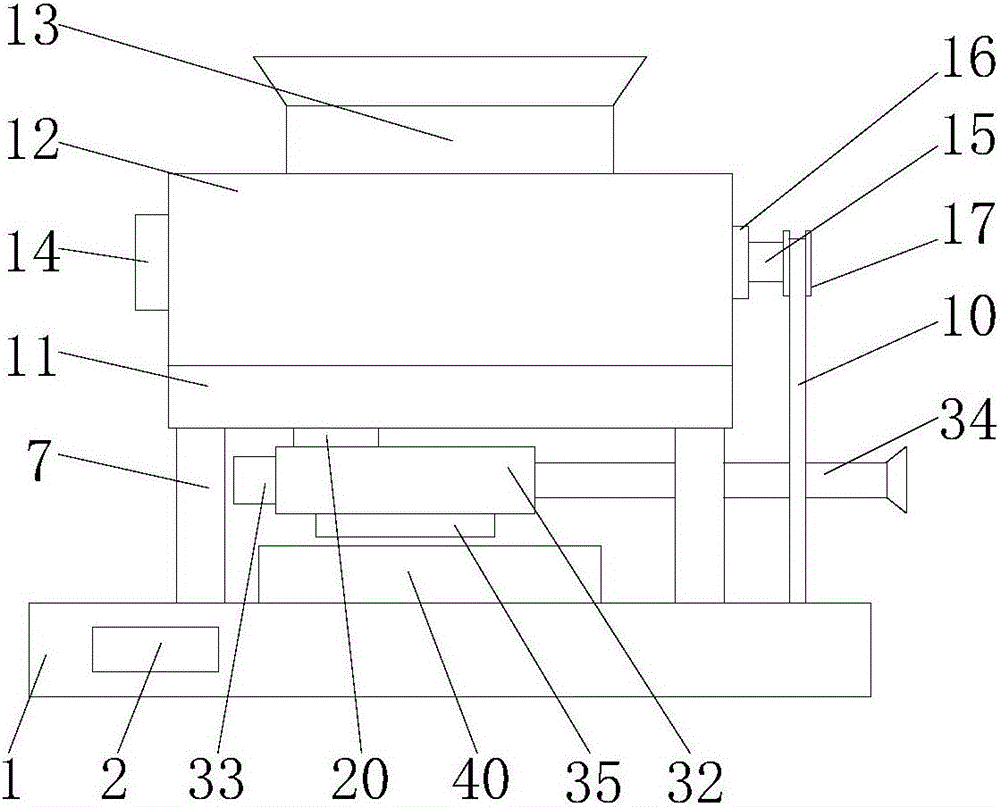

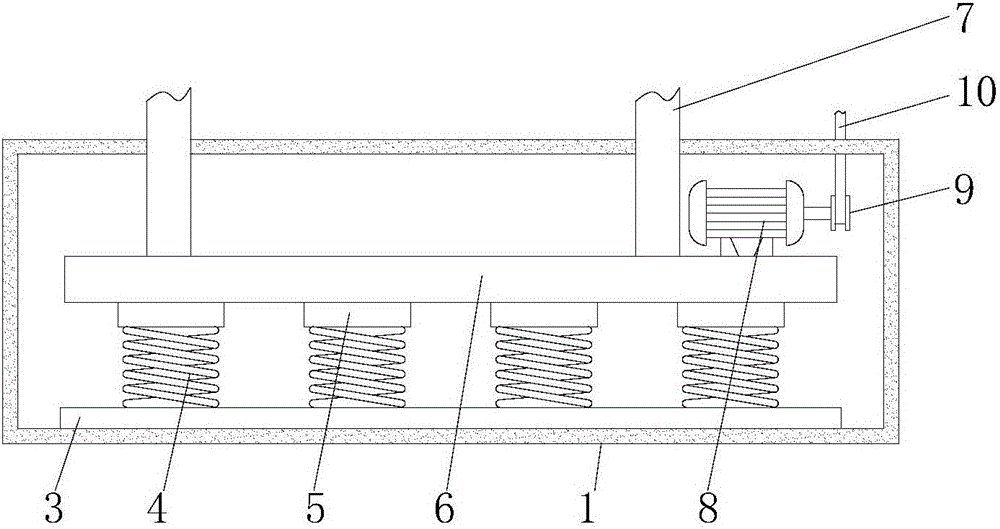

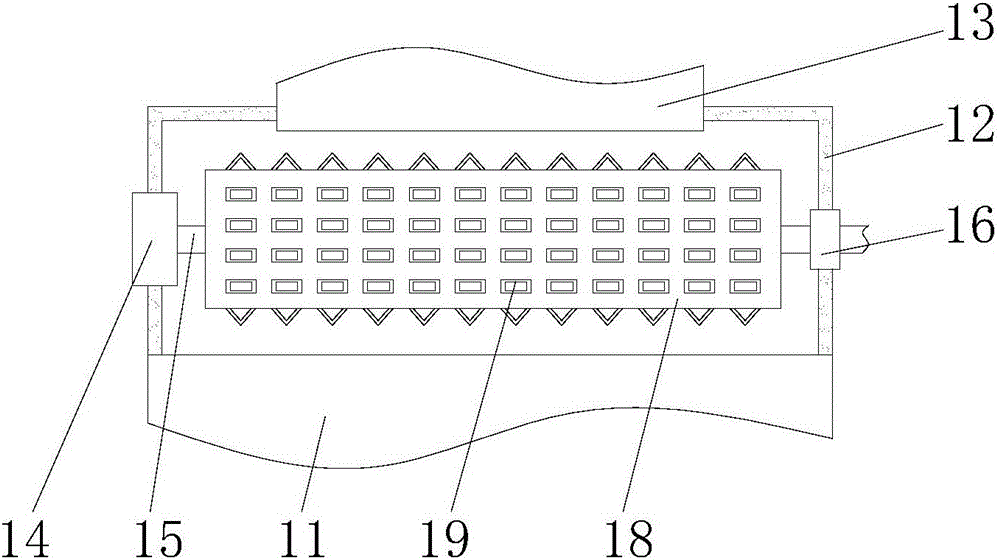

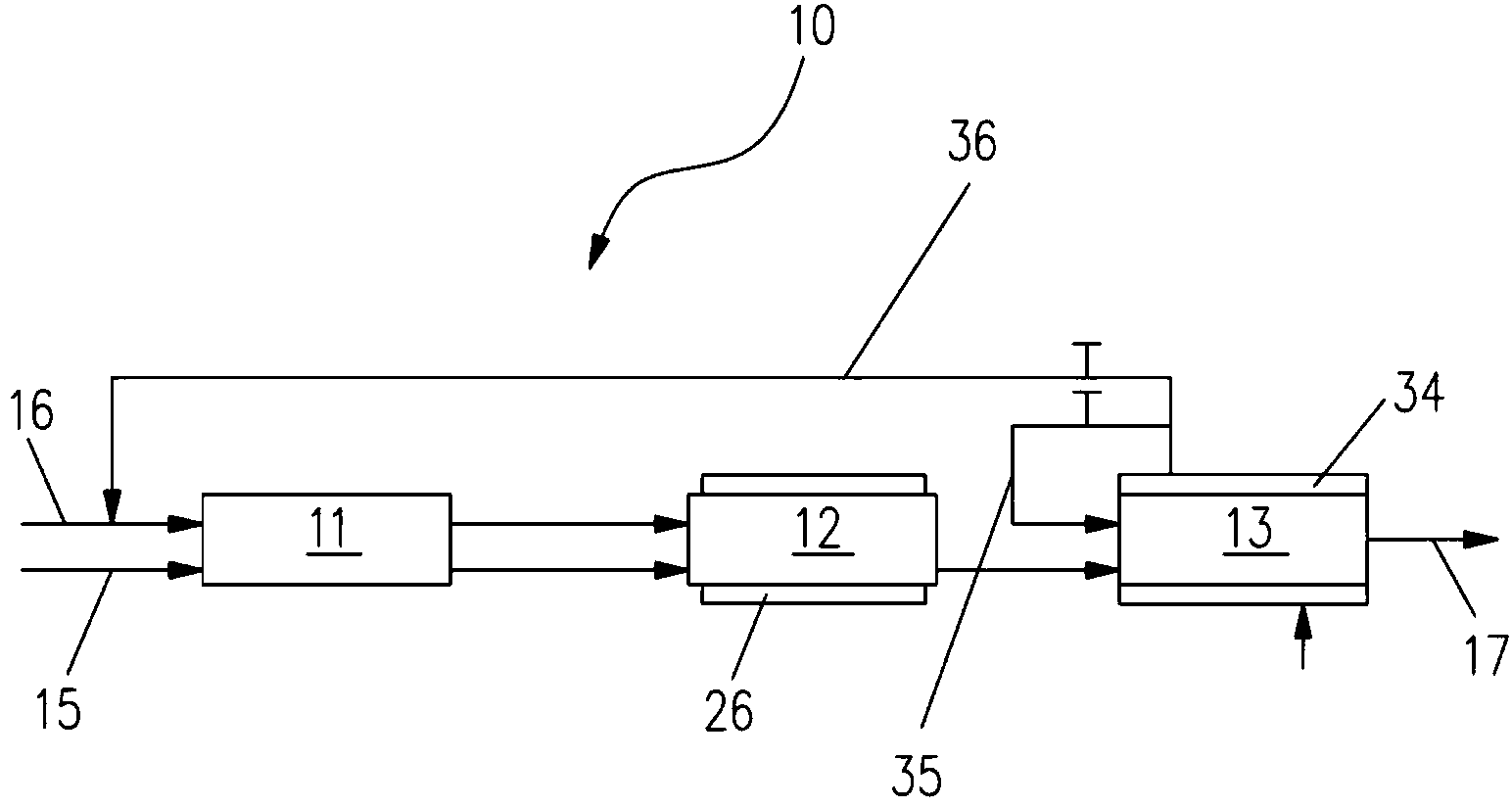

Grain thresher with impurity removing function

The invention discloses a grain thresher with the impurity removing function. The grain thresher comprises a base, a controller is fixedly installed on the front surface of the base, a bottom plate is fixedly installed at the bottom of the inner wall of the base, damping springs are fixedly installed at the top of the bottom plate, cushion blocks are fixedly installed at the tops of the damping springs, a baffle is fixedly installed at the tops of the cushion blocks, two supporting rods and a first motor are sequentially installed at the top of the baffle from left to right, and a belt pulley is fixedly installed on an output shaft of the first motor and provided with a belt. According to the grain thresher with the impurity removing function, as a vibrator, a screen and an impurity box are arranged, grain is fully separated before entering a separating box, impurities in the grain can be effectively removed and prevented from affecting product quality, the grain purity is effectively improved, and production income is increased.

Owner:XINING YIGE INTPROP CONSULTING SERVICE

Device for producing vehicle urea aqueous solution and application method of device

ActiveCN103657498AIncrease productivityAvoid the impact of product qualityTransportation and packagingMixing methodsAqueous solutionHybrid device

The invention relates to a device for producing a vehicle urea aqueous solution and an application method of the device. The device comprises a dissolving device, wherein the dissolving device is provided with a stirrer and used for dissolving urea granules; a feeding device is arranged at the upstream of the dissolving device and used for independently introducing the urea granules and deionized water into the dissolving device; a mixing device is arranged at the downstream of the dissolving device and used for regulating property of the urea aqueous solution; the stirrer is provided with one or more stirring shafts with blades. Through the device for producing the vehicle urea aqueous solution, the continuous production can be performed; meanwhile, the quality of the product is stable.

Owner:CHINA PETROLEUM & CHEM CORP

Production method of 5N high-purity alpha alumina powder

InactiveCN104261447AAvoid entrainmentDistillation stableAluminium oxide/hydroxide preparationDistillationImpurity

The invention discloses a production method of 5N high-purity alpha alumina powder. The method comprises the following processing steps: carrying out reaction on 99.996% of high-purity aluminum particles, 5N aluminum isopropoxide as an initiator, and isopropanol to generate aluminum isopropoxide; before reduced pressure distillation, adding zeolite to the aluminum isopropoxide, and preventing liquid from boiling to bring out more impurities; stably distilling the 5N aluminum isopropoxide, hydrolyzing, filtering, drying, roasting and transforming into 5N-purity alpha alumina powder; and finally washing once by using deionized water, and drying to obtain the 5N high-purity alpha alumina powder. According to the method disclosed by the invention, the alpha alumina powder can be ensured to reach 5N purity; the purification difficulty is reduced; the process is simple and convenient, and easy to operate; the production cycle is shortened; meanwhile, the pollution to the environment is also reduced; and popularization and application are facilitated.

Owner:CHENGDU GUANYU TECH

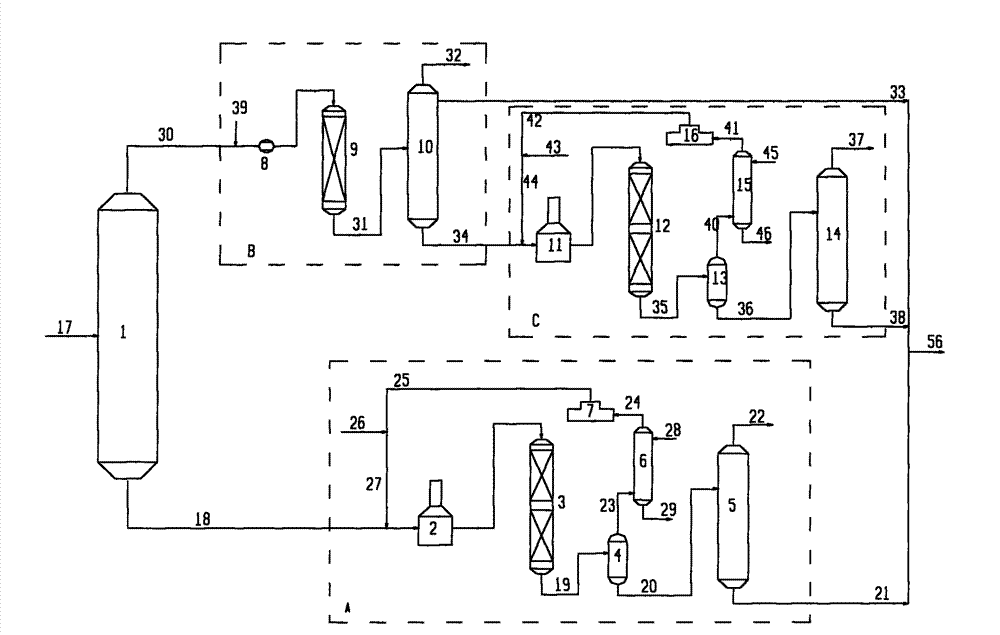

Hydrogenation method for deeply desulfurizing gasoline

ActiveCN103087771AHigh desulfurization depthReduce lossesTreatment with hydrotreatment processesHydrogenation reactionBoiling point

The invention provides a hydrogenation method for deeply desulfurizing gasoline. The hydrogenation method comprises the steps that catalytically cracked gasoline is fractionated into light fractions and heavy fractions; the heavy fractions and hydrogen are mixed and enter into a first hydrogenation reaction zone to react to obtain low-sulfur heavy fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; the light fractions and hydrogen are mixed and enter into a second hydrogenation reaction zone, diene is subjected to hydrogenation saturation to obtain mono-olefin low-boiling sulfides and the mono-olefin low-boiling sulfides are converted to high-boiling sulfides; the hydrogenated light fraction oil enters a light-medium fraction fractionating tower and is divided into light fractions and medium fractions and low-sulfur light fraction oil is obtained; the medium and light fractions and hydrogen are mixed and enter into a third hydrogenation reaction zone to react to obtain low-sulfur medium fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; and the heavy fraction oil, the light fraction oil and the medium fraction oil are mixed to obtain the low-sulfur gasoline product. Aiming to produce the gasoline with sulfur content not more than 10mu g / g, the method provided by the invention has the characteristics of high desulfurization depth, long device running period and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

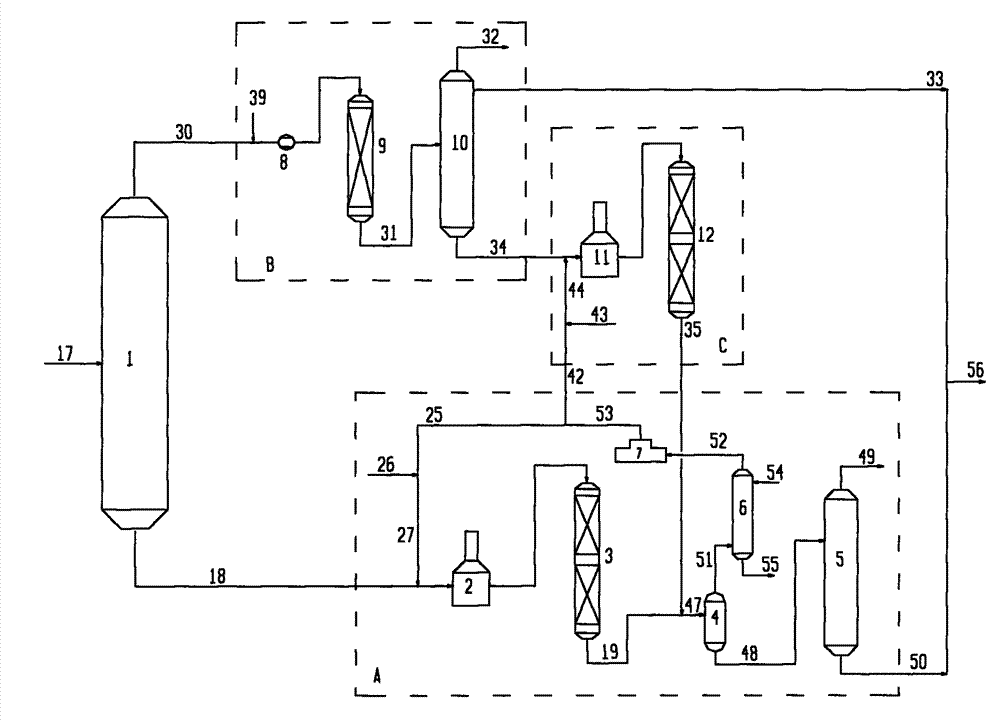

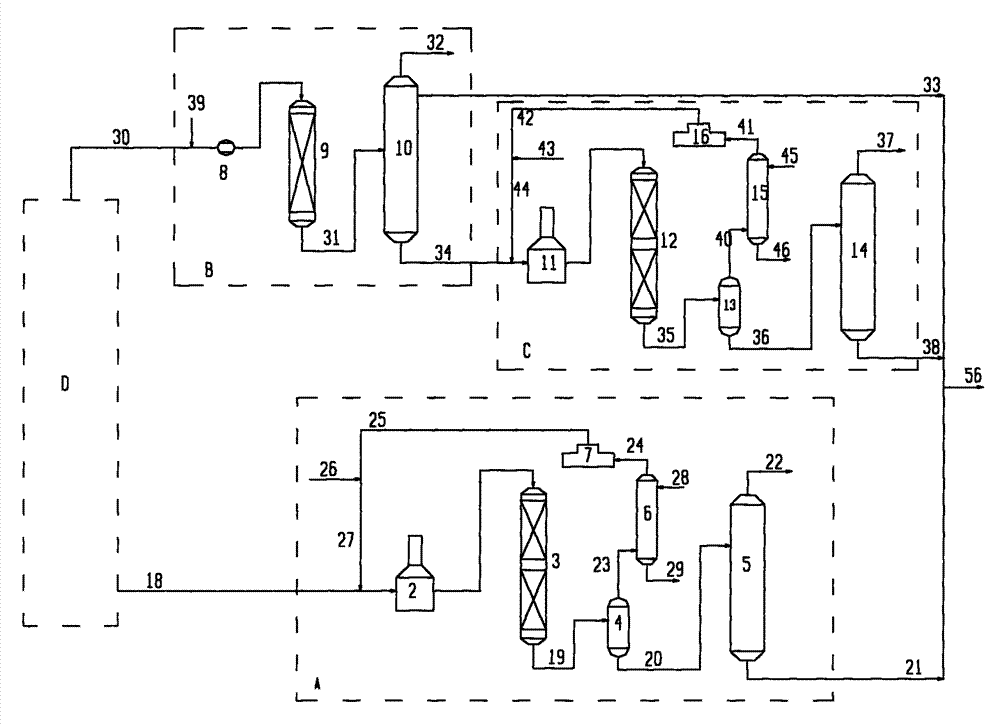

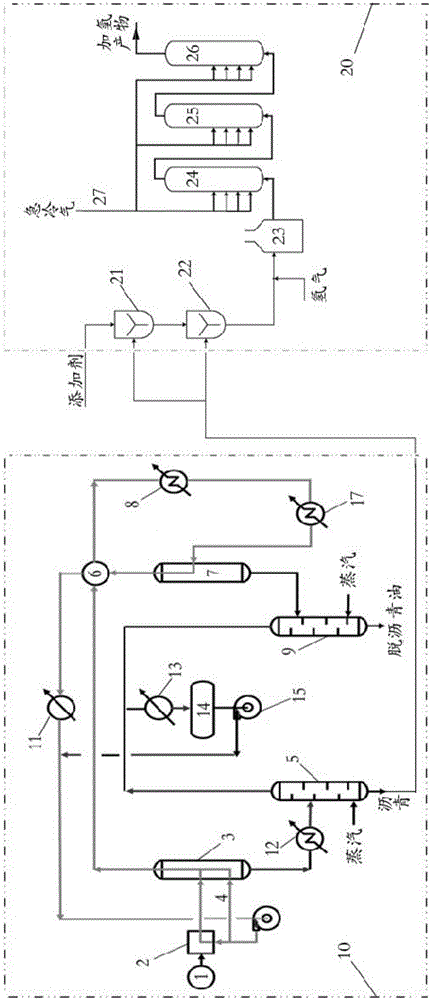

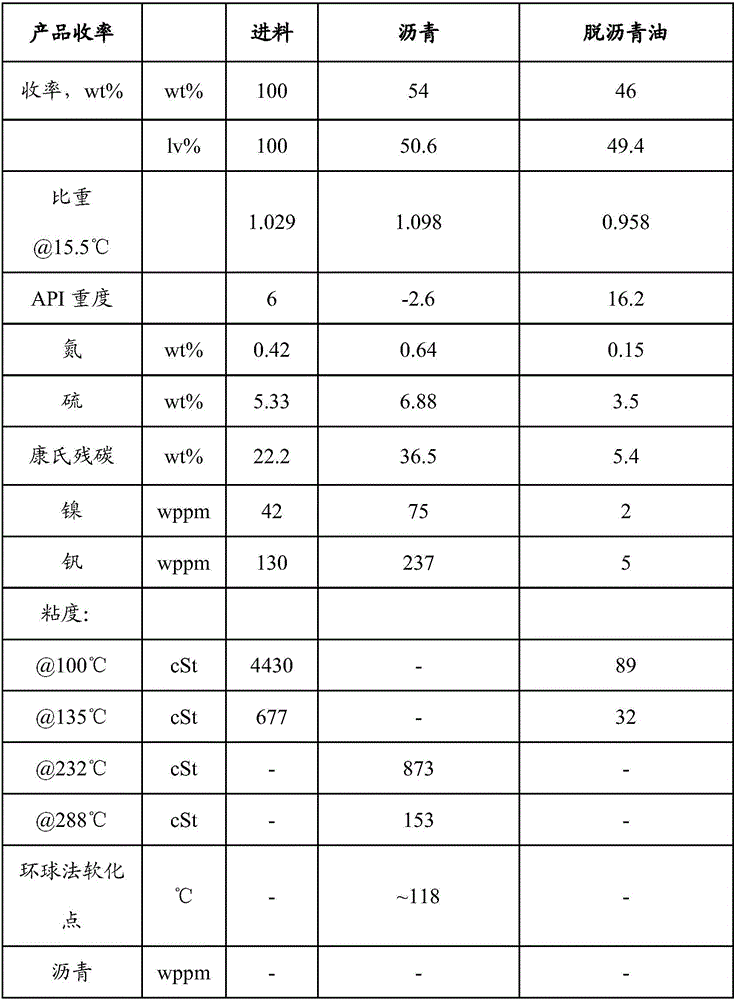

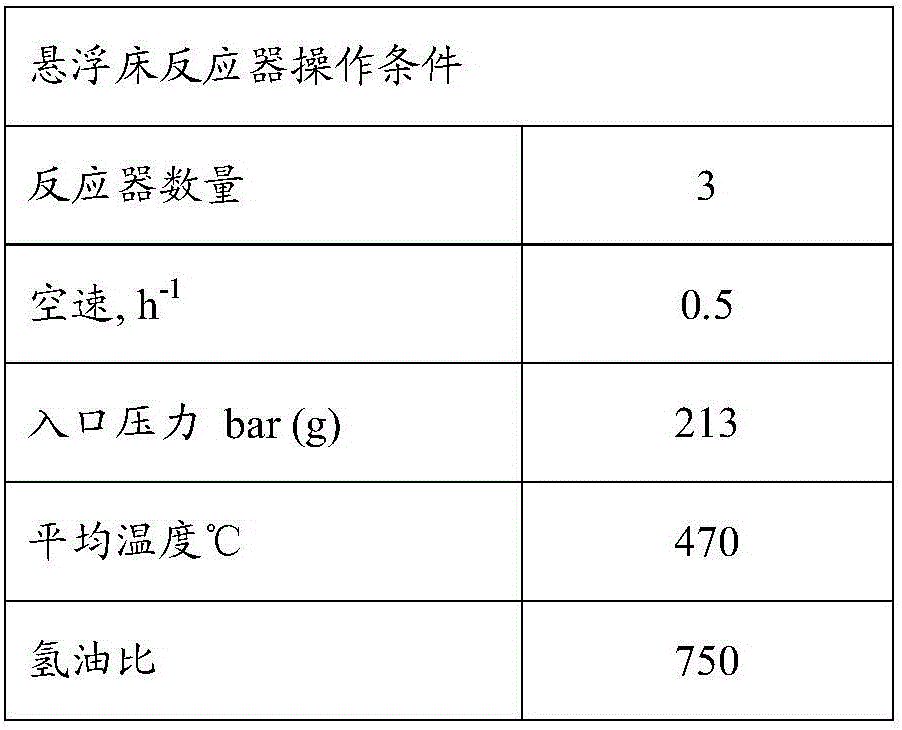

Supercritical extraction and suspension bed hydrogenation combined system for heavy oil raw material and method

ActiveCN107177378AReduce lossesFlexible feedingTreatment with hydrotreatment processesFuel oilAsphaltene

The invention discloses a supercritical extraction and suspension bed hydrogenation combined system for a heavy oil raw material and a method. The combined system comprises a supercritical extraction unit and a suspension bed hydrogenation unit, wherein the supercritical extraction unit is used for extracting and separating the heavy oil raw material so as to separate out an asphaltic product; the suspension bed hydrogenation unit is used for carrying out suspension bed hydrocracking treatment on the asphaltic product coming from the supercritical extraction unit. The supercritical extraction and suspension bed hydrogenation combined system can greatly improve the conversion rate of heavy components of the raw material and asphaltene and reduce the scale of suspension bed unit, thus reducing investment and further greatly reducing the hydrogen consumption.

Owner:北京和利凯石化技术有限公司

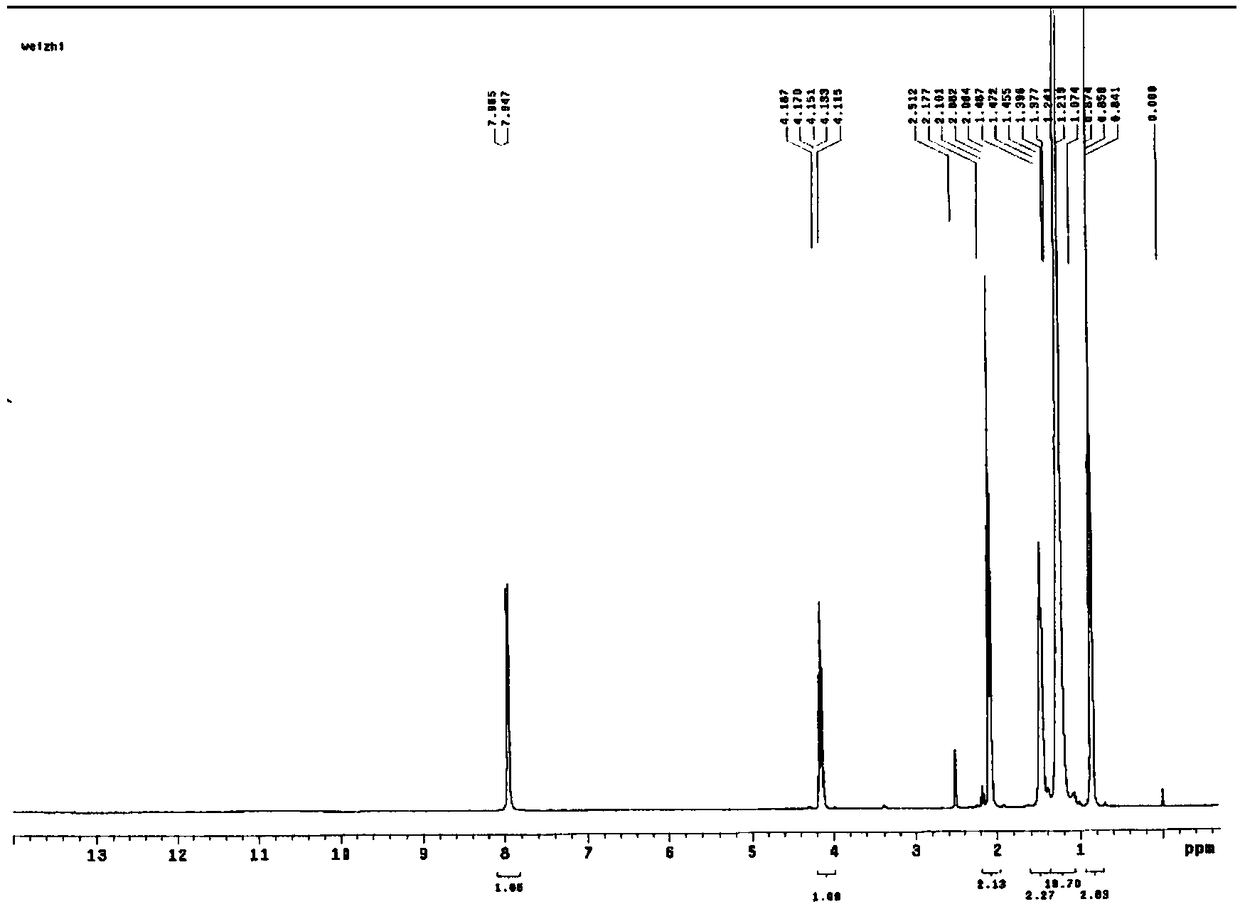

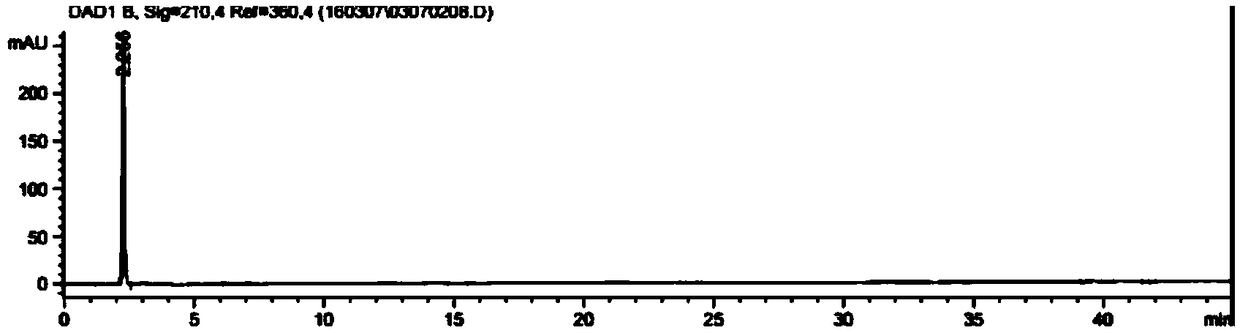

Montelukast sodium tablet and preparation method thereof

ActiveCN101732268BWell mixedSolve production problems that require dark operationPharmaceutical non-active ingredientsPill deliveryTemperature controlAdhesive

The invention belongs to the field of medicine preparations, in particular to a montelukast sodium tablet and a preparation method thereof. Because the montelukast sodium tablet adopts a wet method granulation process and has the problems of long drying time, difficult temperature control and easy causing of content difference, content descent and relevant substance increase between particles, the invention provides the montelukast sodium tablet and the preparation method thereof in order to enhance the stability and the operability of the montelukast sodium tablet. The montelukast sodium tablet provided by the invention comprises montelukast sodium, a filling agent, a disintegrating agent, an adhesive, a colorant, a lubricant and a flow aid. The preparation method of the montelukast sodium tablet provided by the invention adopts direct tabletting after dry method granulation and uses the colorant, the colorant can act as a very good light shielding function in the operational process, the operation is convenient, the influence of a drying process and moist heat to the product quality is avoided, and the product stability is enhanced.

Owner:LUNAN PHARMA GROUP CORPORATION

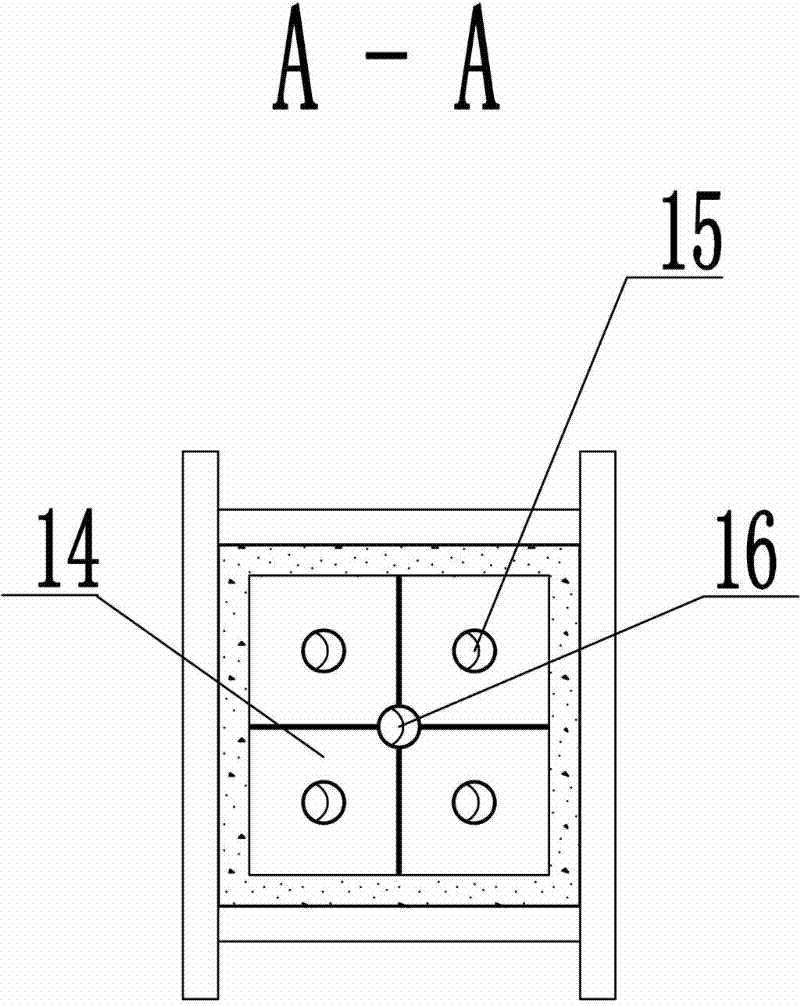

Calcinating shaft kiln comprehensively utilizing heat energy unit temperature field

InactiveCN102374769AReasonable structural designEven air distributionVertical furnacesAirflowEngineering

The invention provides a calcinating shaft kiln comprehensively utilizing heat energy unit temperature field and solves the problems of the existing shaft kiln that product quality is low and heat consumption is high. The calcinating shaft kiln comprises a feeding bin, a feeding pipe, a calcinating chamber and a cooling chamber. According to the technical key points of the invention, each discharge port of a top loop shunting feeding bin is connected with the feed inlet of the respective independent unit temperature field material calcinating activate chamber through a feed air lock pipe; each chamber is internally provided with one unit temperature field combustor, the bottom of each chamber is communicated with a material integrative energy integration chamber, and is communicated with the proportion gas flow strengthening cooling chamber through a material diffusing heat exchange region, the lower part of the balance gas flow strengthening cooling chamber provided with a center cooling nozzle button and a chamber cooling nozzle button is connected with the discharging air lock device. The calcinating shaft kiln has reasonable structure design, and can be controlled accurately in material preheating, calcination and cooling process; each unit temperature field has the advantages of small calcinating region, strong flame ejection penetrating power, uniform temperature distribution in the temperature field, good product quality and low heat rate.

Owner:鞍山市华杰石灰工业设计研究有限公司

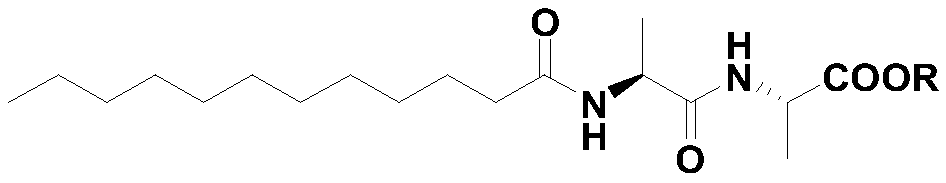

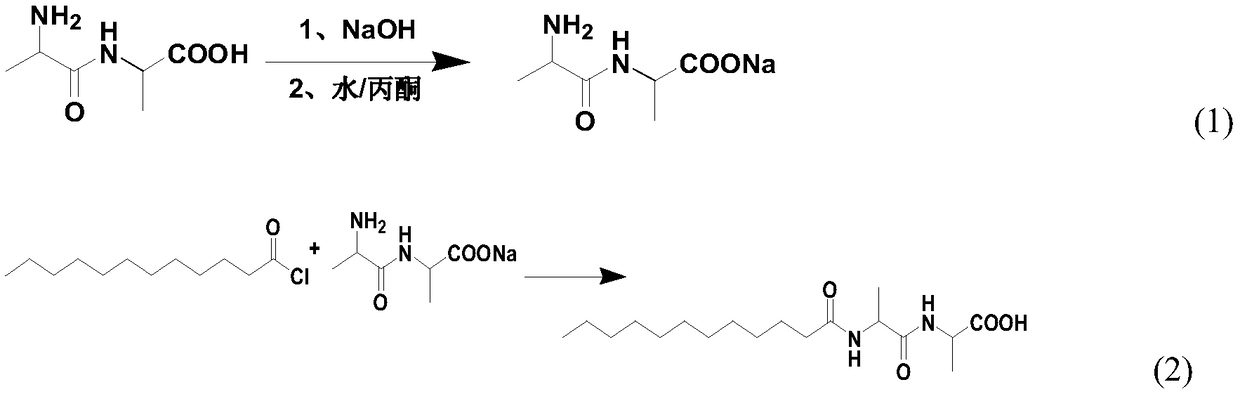

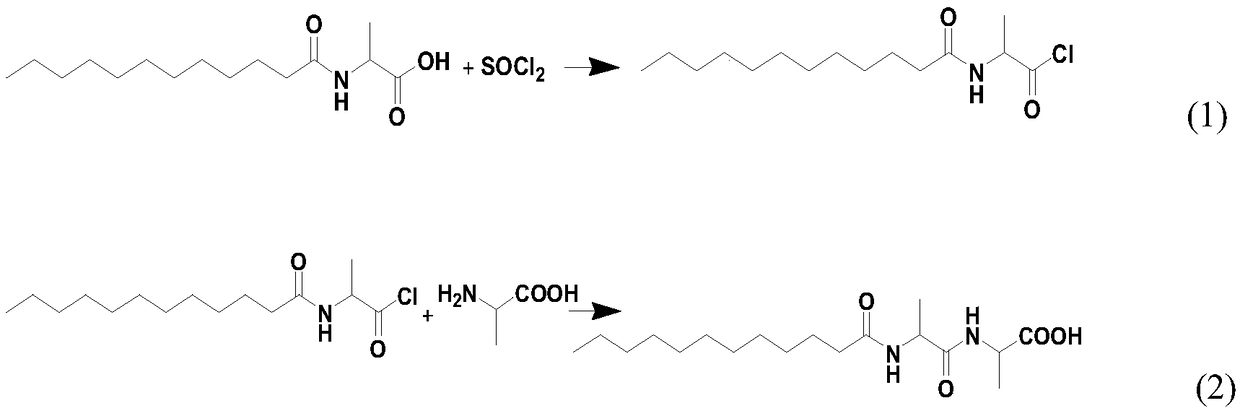

Preparation method and application of N-lauroyl-L-alanine

ActiveCN108752228ABeneficial technical effectThe process steps are simpleOrganic compound preparationTransportation and packagingL-alanosineN-lauroyl-L-alanine

The invention discloses a preparation method of N-lauroyl-L-alanine. The preparation method comprises the following steps: preparing L-alanine salt, preparing pasty N-lauroyl-L-alanine salt, and preparing an N-lauroyl-L-alanine crude product and the like. The invention further provides application of amino acid in the daily chemical field and industries such as agriculture and medicines. The aminoacid provided by the invention has high performance, and has an obvious effect in the aspects of bacterium inhibition, pesticide removal, peculiar smell elimination and the like.

Owner:SUZHOU OULIT BIOPHARM CO LTD

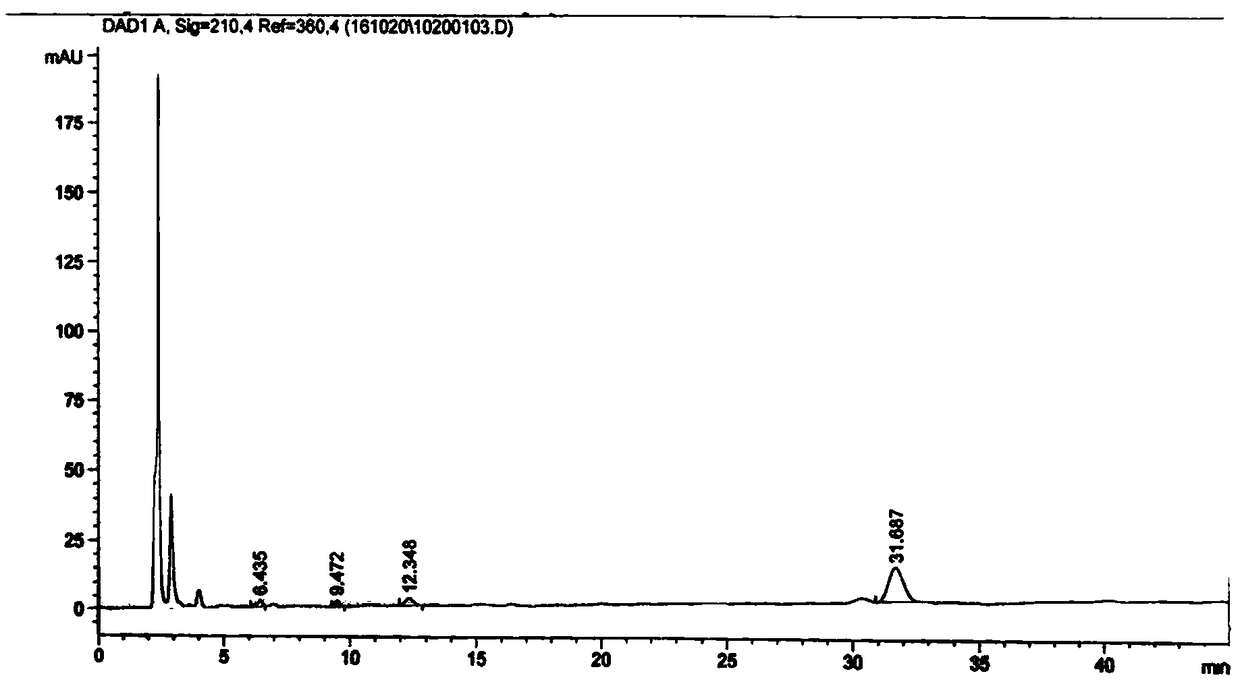

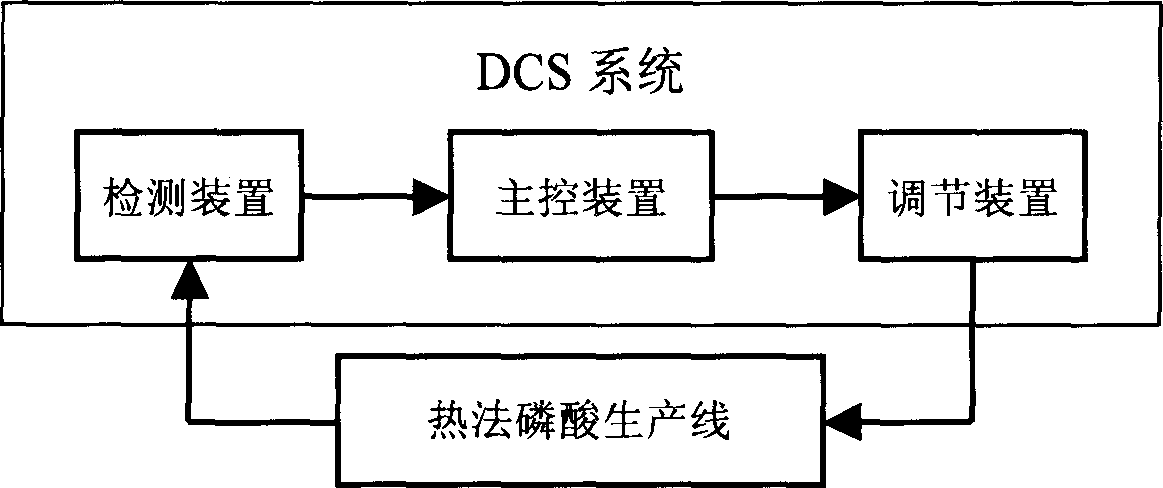

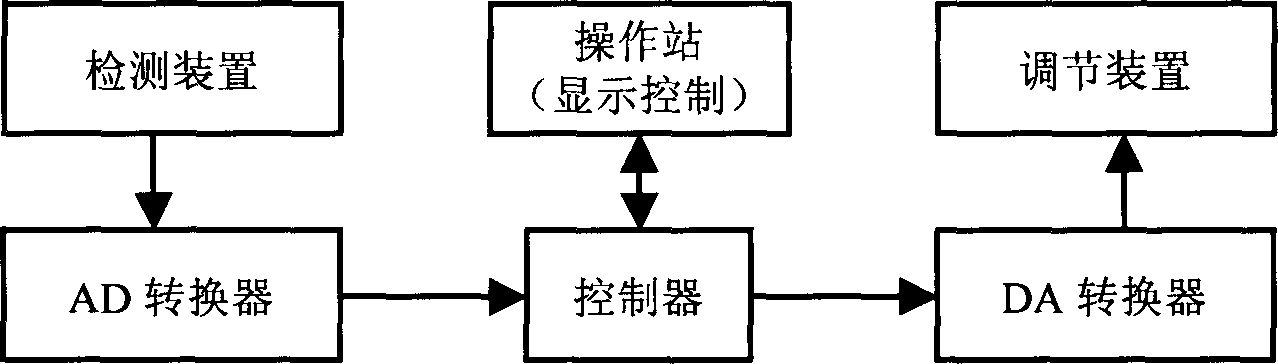

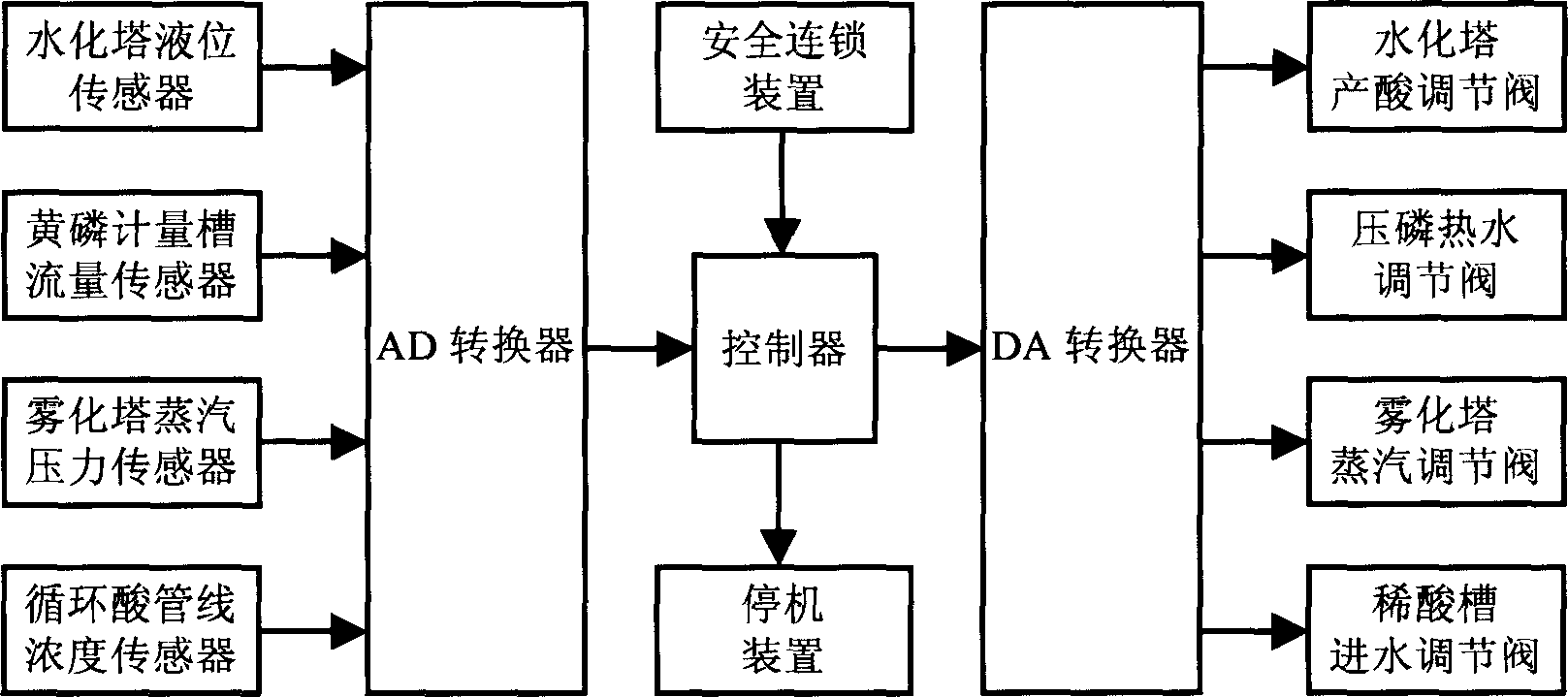

Phosphoric acid production system

InactiveCN1803588AImprove detection accuracyHigh control precisionPhosphoric acidProduction lineAutomatic control

The invention relates to a computer DCS in phosphoric acid manufacture technique, which comprises a thermal phosphoric acid process line and a connected DCS system. This invention overcomes the problems of large parameter control quantity, manual error and unstable production quality in prior art, realizes automatic control for key process, and fit to reconstruction for current process line.

Owner:YIBIN TIANYUAN GRP CO LTD

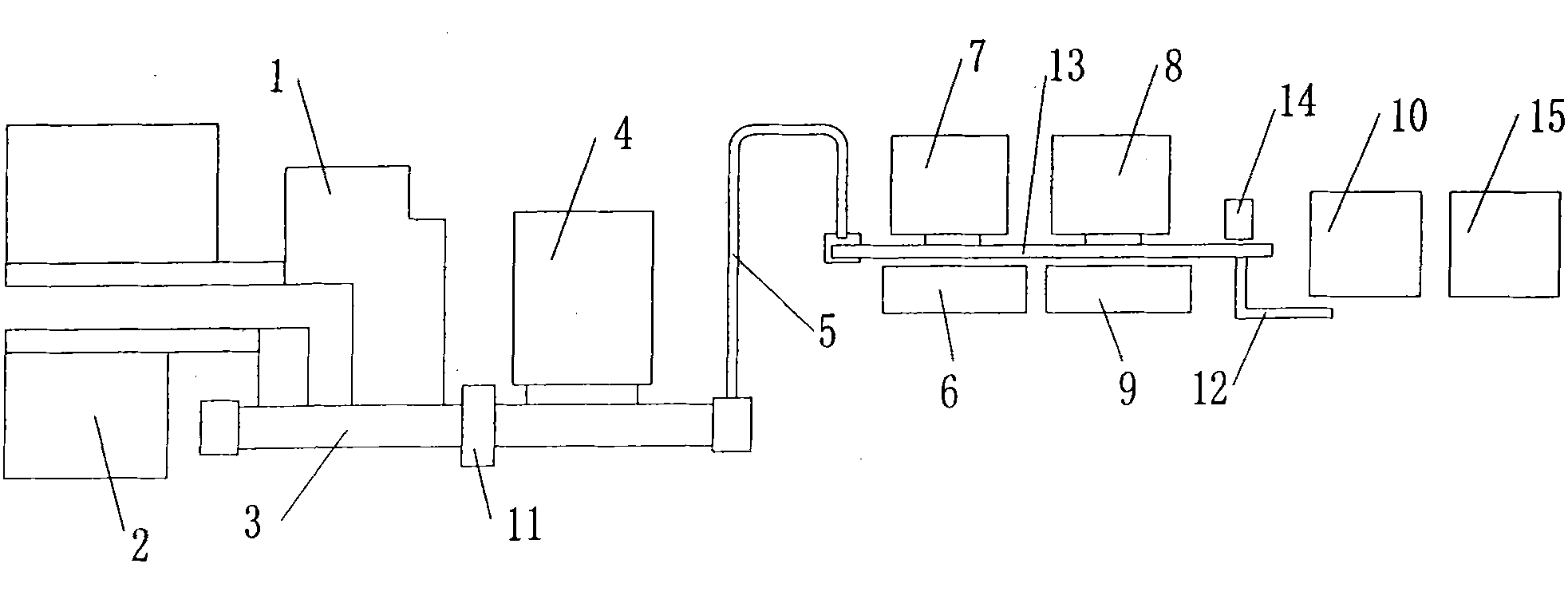

Feeding device of powder coating extruder

PendingCN108284576AImprove qualityImprove the phenomenon of arching and blockingReciprocating motionEngineering

The invention provides a feeding device of a powder coating extruder. The feeding device is characterized by comprising a hopper, a vibration device, a square discharging pipe and a base, and the hopper comprises an inner-layer hopper and an outer-layer hopper; the vibration device comprises a vibration motor, a force transmission frame and an elastic adjusting piece, wherein a magnetic support isarranged in the square discharging pipe; and the base comprises a bottom frame, a sliding guide rail, an interface, a driving air cylinder, a telescopic baffle and a limiting plate. The feeding device of the powder coating extruder is novel in structural design; the inner-layer hopper and the outer-layer hopper are adopted, and the vibration device is combined with the reciprocating motion of thedriving air cylinder of the base, so that the phenomenon that the hoppers are blocked is greatly improved; a filter screen of the inner-layer hopper avoids the collapse phenomenon of materials, andthe materials can be uniformly discharged; and the magnetic support in a square material storage pipe can effectively remove iron-containing impurities in the materials, and greatly improves the quality of powder coating.

Owner:BAZHOU JINCHANG ENVIRONMENTAL PROTECTION MATERIALS CO LTD

Compound as well as preparation method and application thereof

ActiveCN108752420AThe process steps are simpleMild reaction conditionsTransportation and packagingPeptide preparation methodsPotassiumStereochemistry

The invention discloses a compound. The compound is N-lauroyl-L-alanyl-L-alanine or salts of N-lauroyl-L-alanyl-L-alanine, wherein the salts include N-lauroyl-L-alanyl-L-sodium alanine and N-lauroyl-L-alanyl-L-potassium alanine. The compound discloses by the invention has effective effects of bacteriostasis, pesticide removal and the like, and can be widely applied to daily use chemical, agriculture and medicine industry. The invention also discloses three methods for preparing the compound. The product obtained by the method has high yield and is suitable for industrial production.

Owner:SUZHOU OULIT BIOPHARM CO LTD

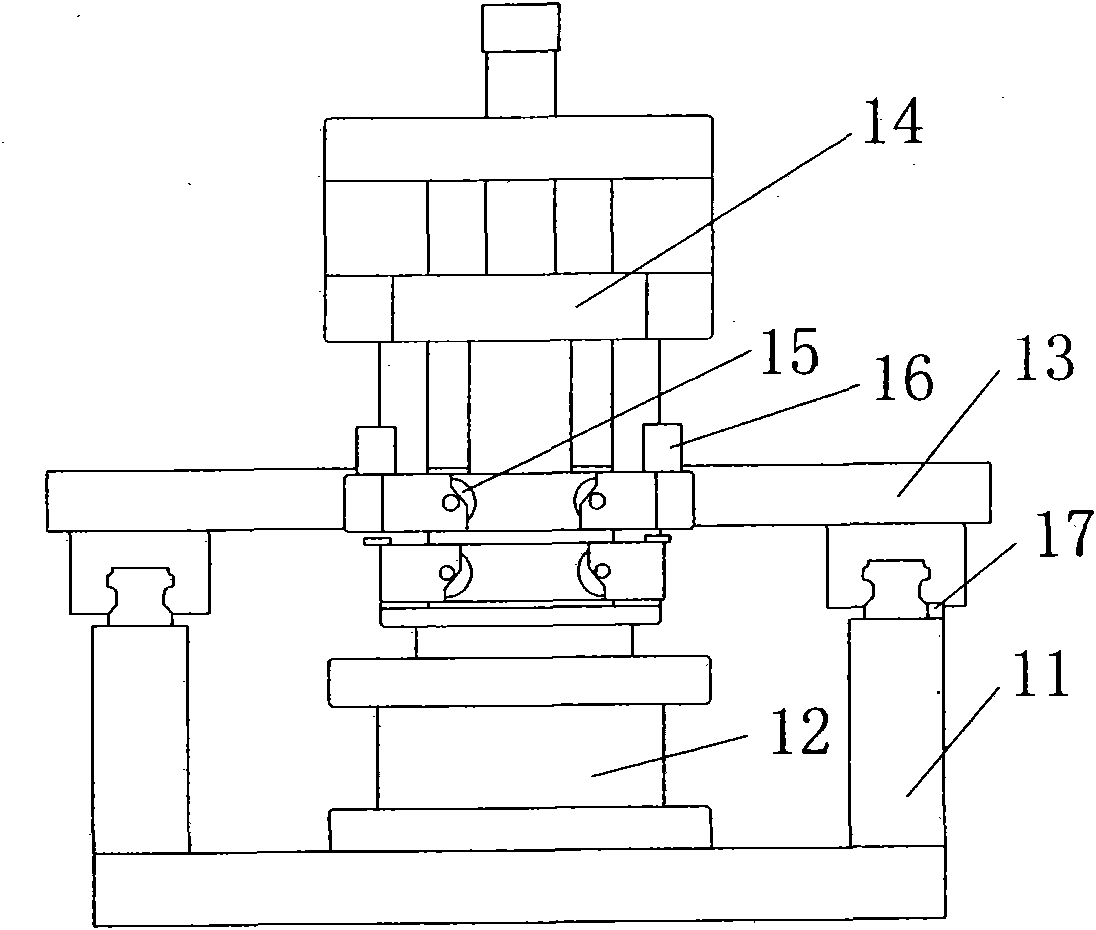

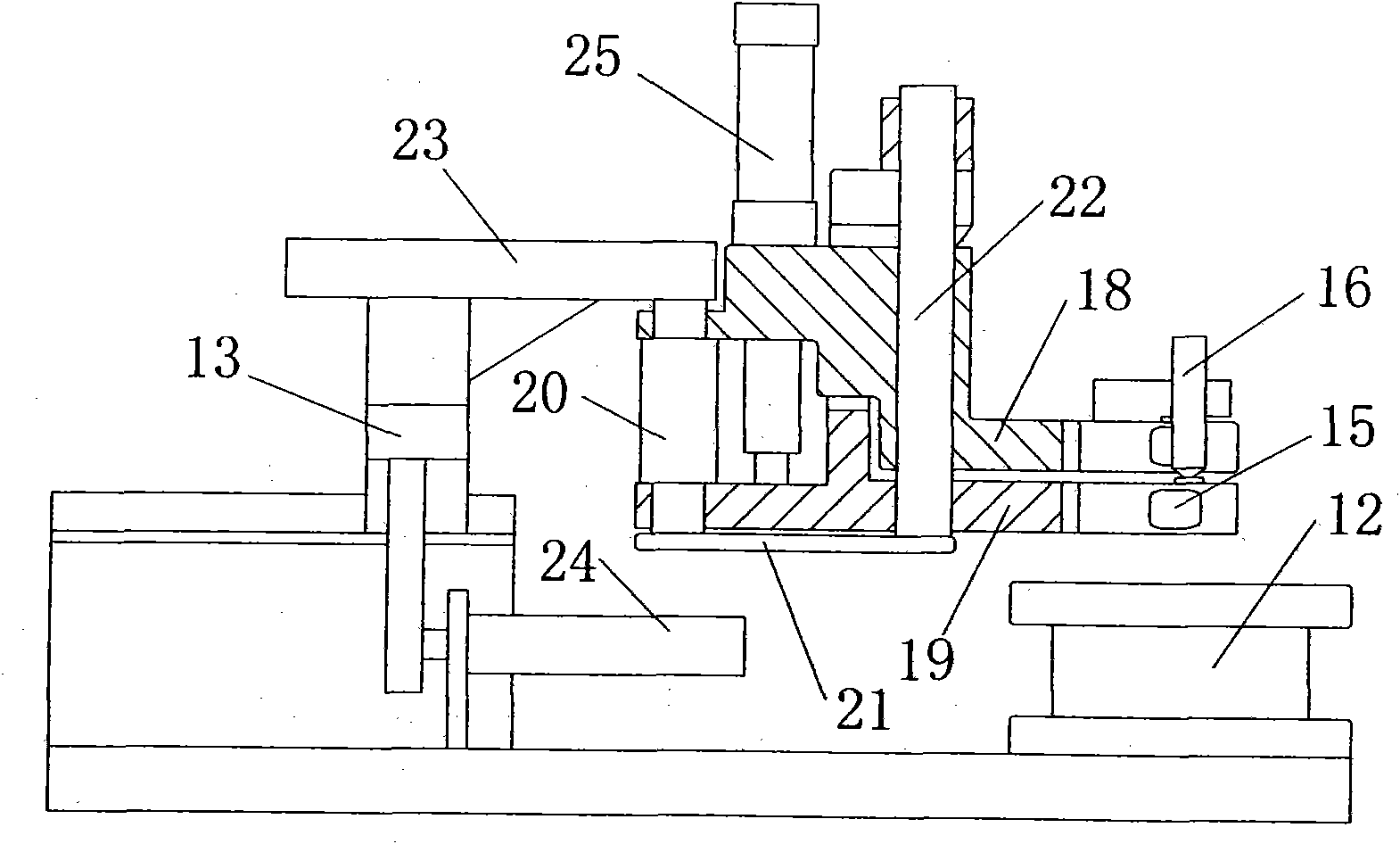

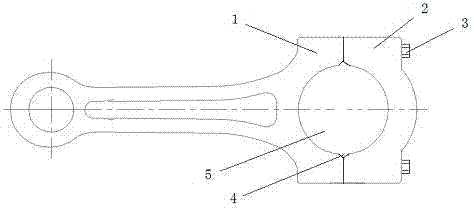

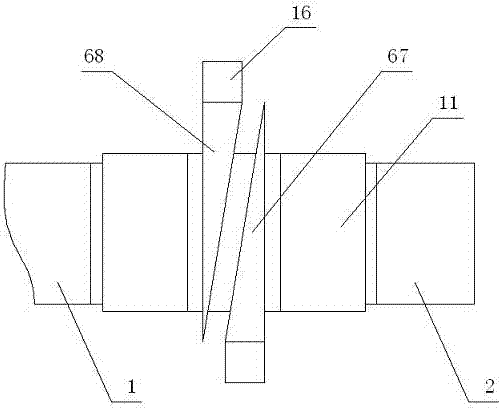

Cracking method machining technology of engine connecting rod

The invention relates to a cracking method machining technology of an engine connecting rod. A large-end hole machined in a connecting rod blank is a round hole; the connecting rod blank where the large-end hole is machined is separated into a connecting rod body and a connecting rod cover in a cracking manner; the joint faces of the connecting rod body and the connecting rod cover are cracking faces which are not subjected to cutting machining; and connecting and locating between the connecting rod body and the connecting rod cover are achieved through engagement of the joint faces of the connecting rod body and the connecting rod cover. A connecting rod cracking device for connecting rod cracking comprises a vertical rack and a workbench mounted on the vertical rack, and further comprises an upper machine head and a lower machine head. The upper machine head is provided with an upper wedge part and an upper cracking pushing force mechanism used for driving the corresponding wedge part to move up and down, and the lower machine head is provided with a lower wedge part and a lower cracking pushing force mechanism used for driving the corresponding wedge part to move up and down. Extrusion force formed by opposite movement of the upper edge part and the lower wedge part is used for achieving connecting rod cracking. By means of the method of the technology, the cracking difficulty is reduced, the quality of the connecting rod obtained after cracking is guaranteed, production procedures and manufacturing cost are reduced, and good economical benefits are achieved.

Owner:BEIJING BEINEI DIESEL ENGINE

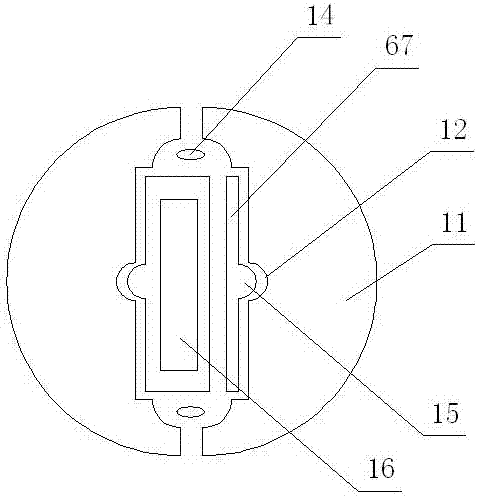

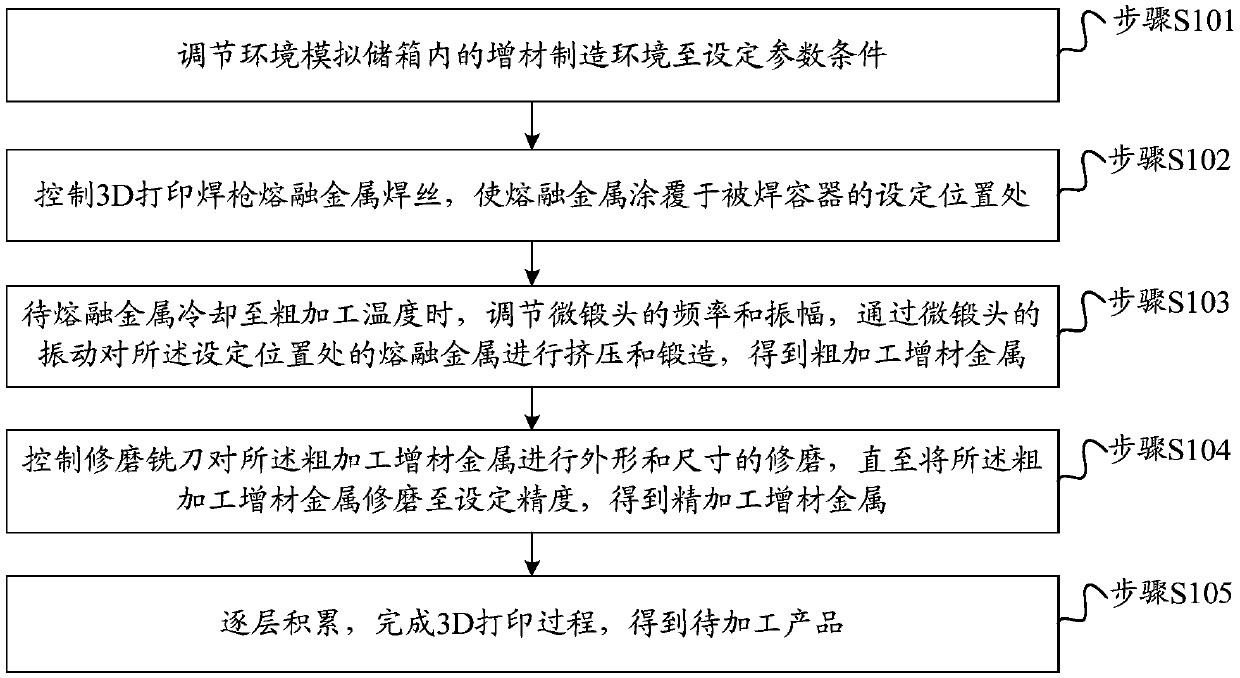

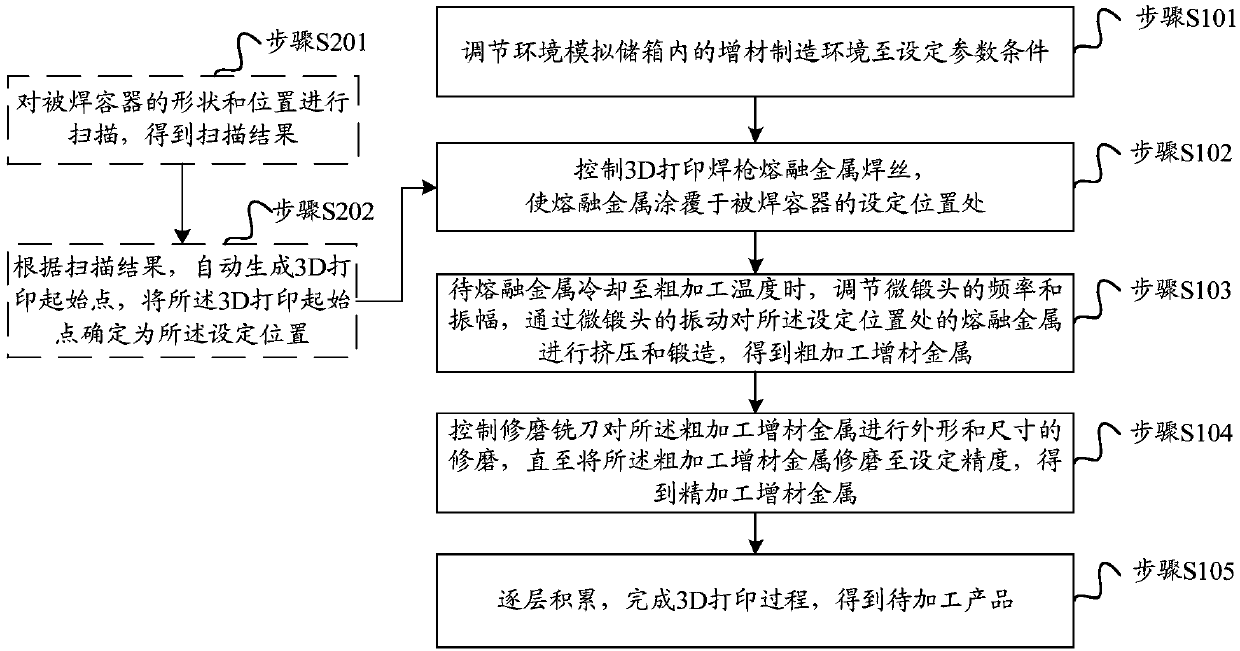

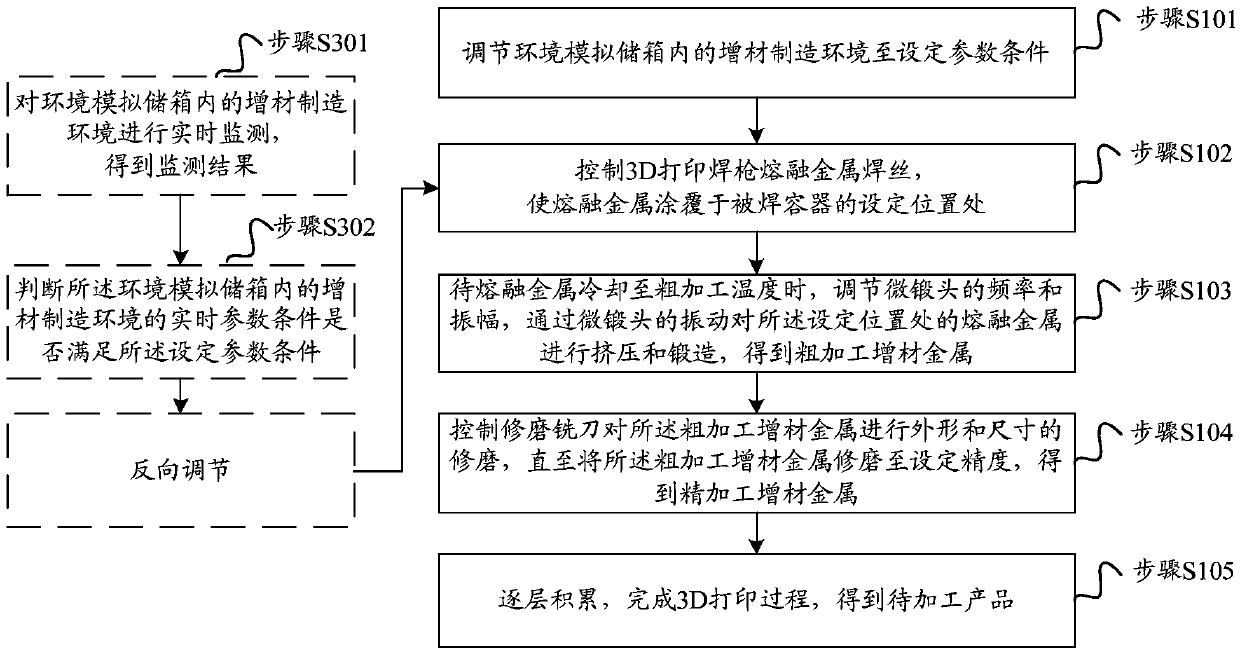

Method and device for manufacturing metal lining of 3D printing composite material space pressure vessel

InactiveCN109590678AGuaranteed printing effectTo achieve the printing effectOther manufacturing equipments/toolsMilling cutterEnvironmental simulation

The invention discloses a method and device for manufacturing a metal lining of a 3D printing composite material space pressure vessel. The manufacturing method comprises the steps that an additive manufacturing environment of an environmental simulation storage tank is adjusted to a set parameter condition; a 3D printing welding gun is controlled to fuse a metal welding wire, and molten metal iscoated to a set position of the welded vessel; after the molten metal is cooled to the rough machining temperature, the frequency and the amplitude of a micro forging head are adjusted, the molten metal at the set position is pressed and forged through vibration of the micro forging head, and rough machining additive metal is obtained; a grinding milling cutter is controlled to conduct appearanceand size grinding on the rough machining additive metal until the rough machining additive metal is ground to the set accuracy, and finish machining additive metal is obtained; and layer-by-layer accumulation is carried out, the 3D printing process is completed, and a product to be processed is completed. According to the method and device, the fusing-forging integration process is used for producing the lining of the pressure vessel or a thin-walled pressure vessel, influences of machining like welding on the product quality are reduced, and the precision and the tissue performance of the molded product are improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com