Device for producing vehicle urea aqueous solution and application method of device

A urea aqueous solution and vehicle production technology, which is applied in the production of urea aqueous solution for vehicles and the field of devices for producing urea aqueous solution for vehicles, can solve problems such as product quality fluctuations, low production efficiency, and large floor space, and achieve stable product quality and improved The effect of production efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

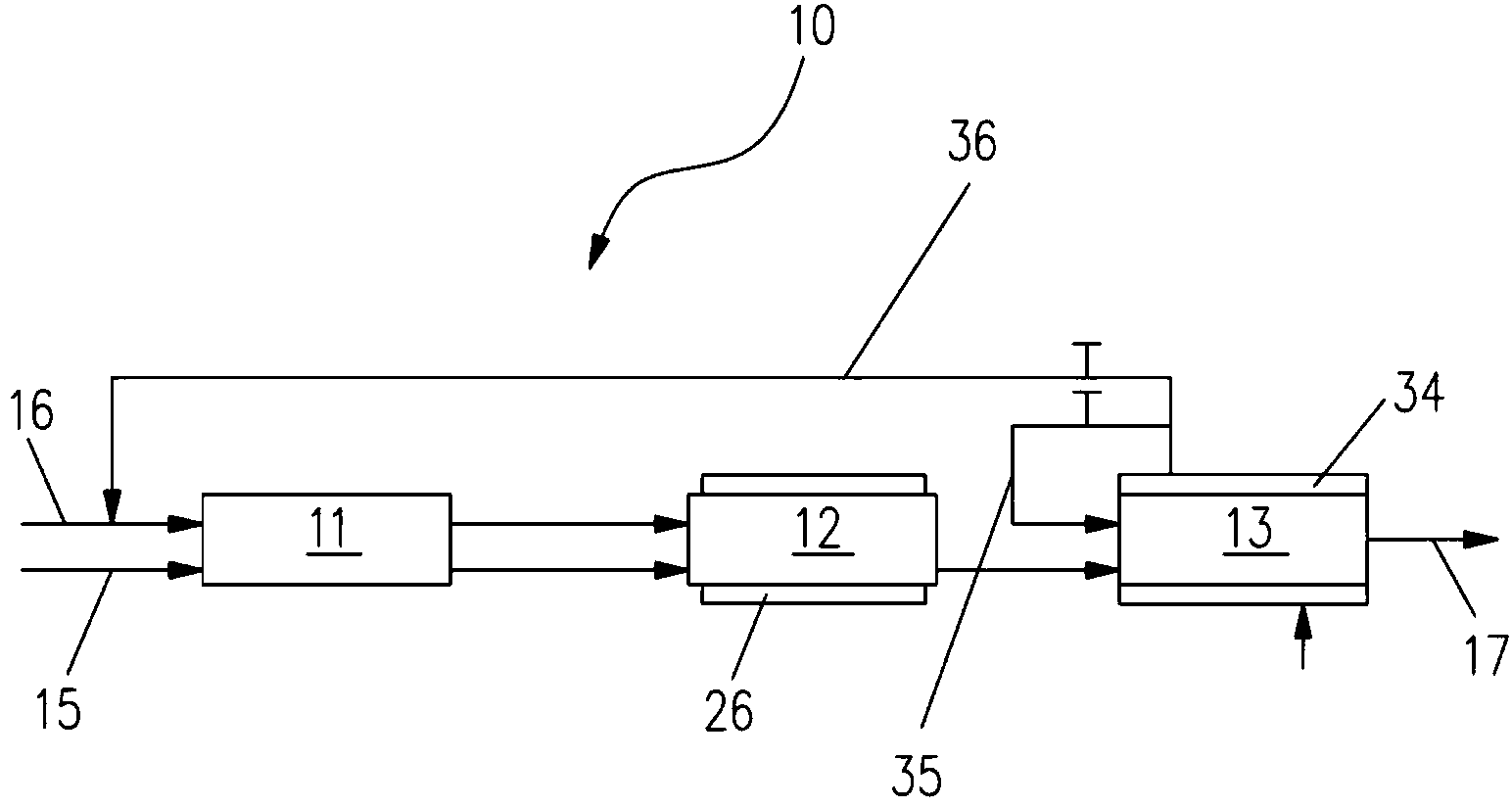

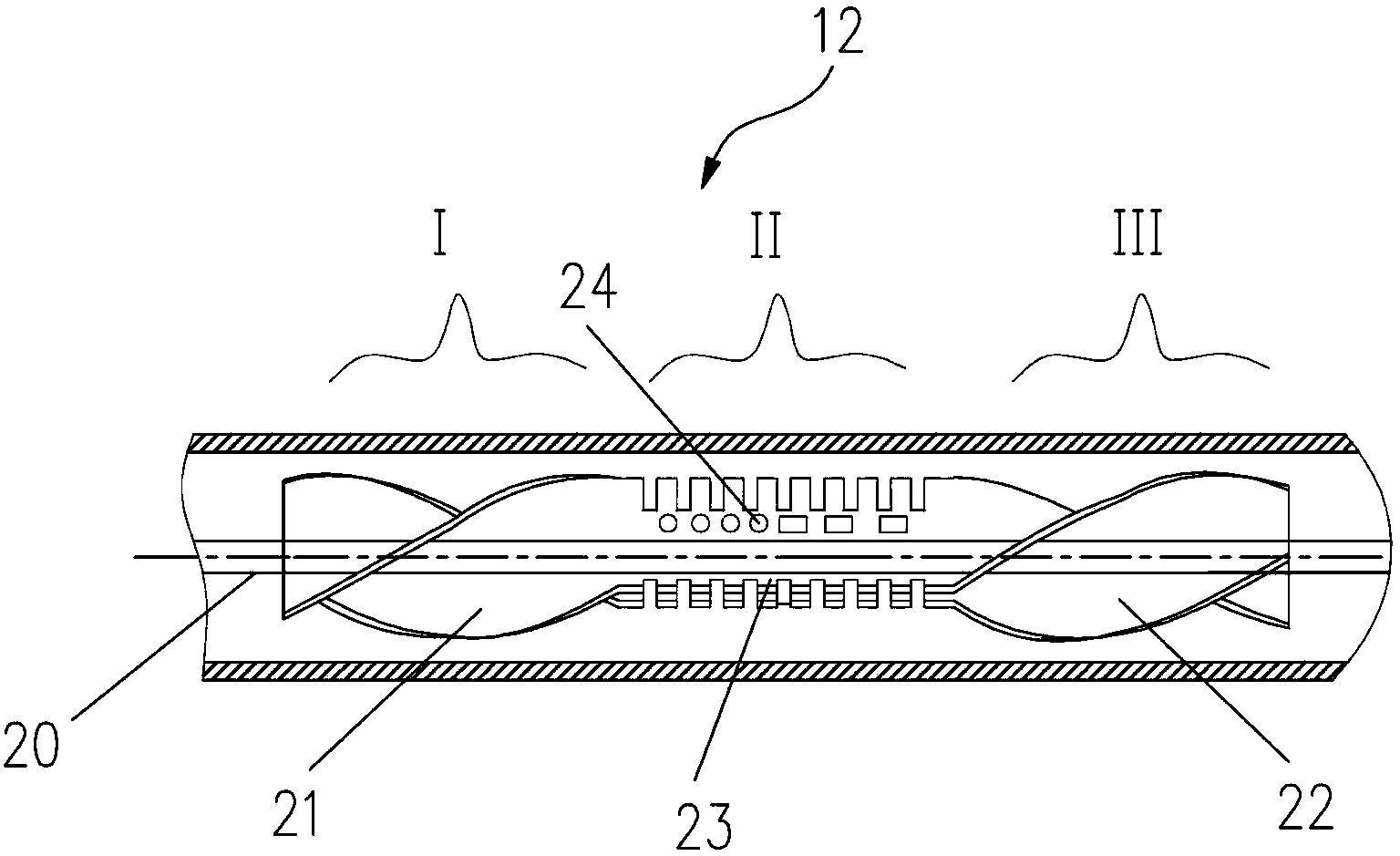

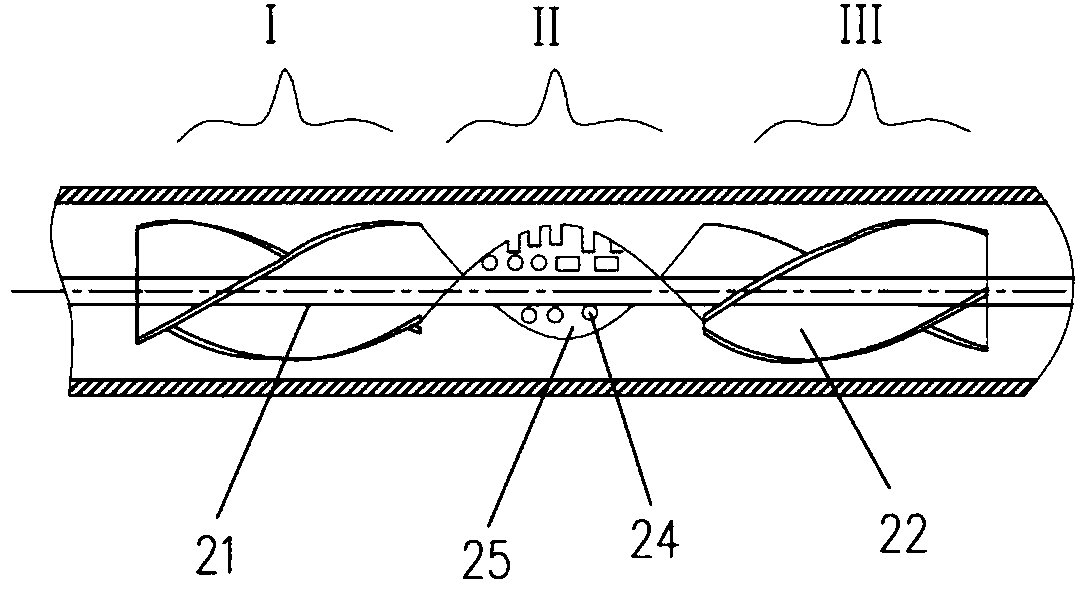

[0045] The deionized water: urea granule weight ratio of 67.5:32.5 deionized water and urea granules were added to the device 10 at the same time from the feeding device 11, and the rotating speed of the stirring shaft 20 of the dissolving device 12 was adjusted to 2500 rpm. Fill the heat exchange jacket 34 with deionized water at a temperature of 20° C. to control the temperature of the final automotive urea aqueous solution at 25° C. to obtain the product. The analysis results are shown in Table 1.

Embodiment 2

[0047] The deionized water: urea granule weight ratio of 67.5:67.5 deionized water and urea granules were added to the device 10 at the same time from the feeding device 11, and the rotating speed of the stirring shaft 20 of the dissolving device 12 was adjusted to 3000 rpm. Fill the heat exchange jacket 34 with deionized water at a temperature of 25°C, open the branch 35 at the same time, add deionized water into the mixing chamber 33 to control the temperature of the final aqueous urea solution for vehicles at 30°C, and obtain the product. The results are shown in Table 1.

Embodiment 3

[0049] Deionized water and urea granules with a weight ratio of 67.5:270 of deionized water: urea granules were added to the device 10 at the same time from the feeding device 11, and the rotating speed of the stirring shaft 20 of the dissolving device 12 was adjusted to 3200 rpm. Fill the heat exchange jacket 34 with deionized water at a temperature of 25° C. to control the temperature of the final aqueous urea solution for vehicles at 30° C. to obtain the product. At the same time, the branch 36 was opened, and the deionized water from the heat exchange jacket 34 was added to the feeding device 11 for dissolution. The analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com