Patents

Literature

951 results about "Hybrid device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

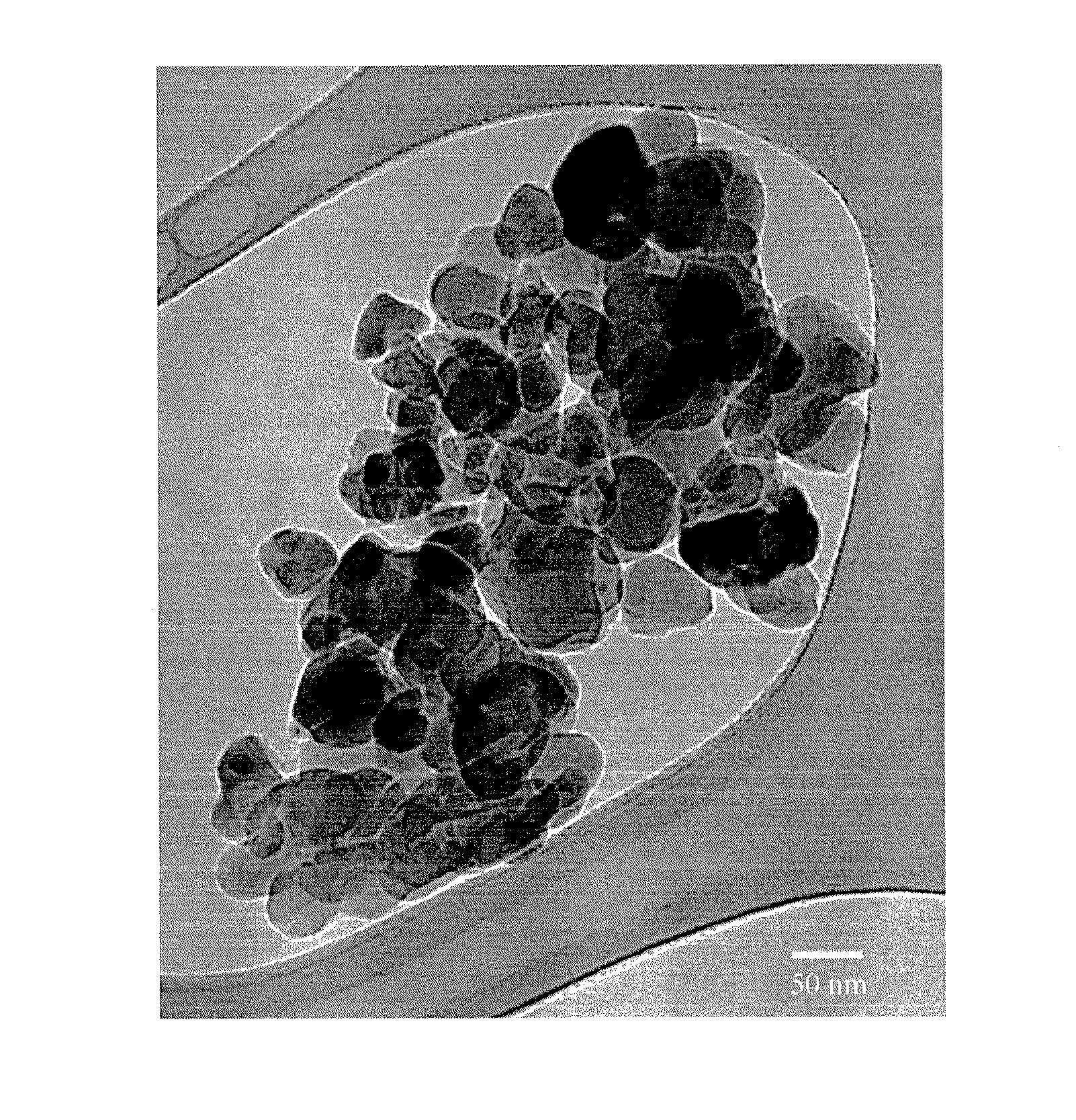

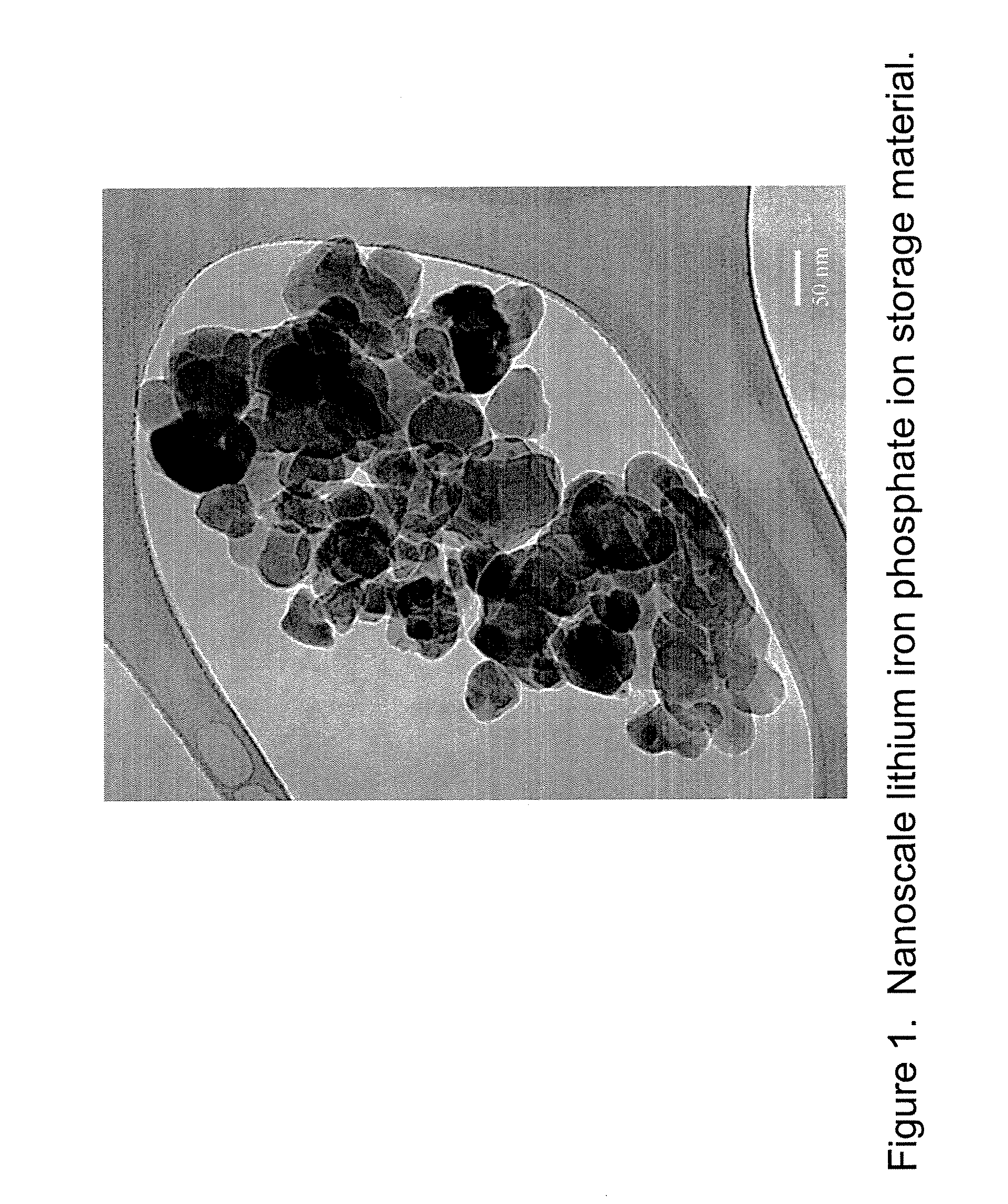

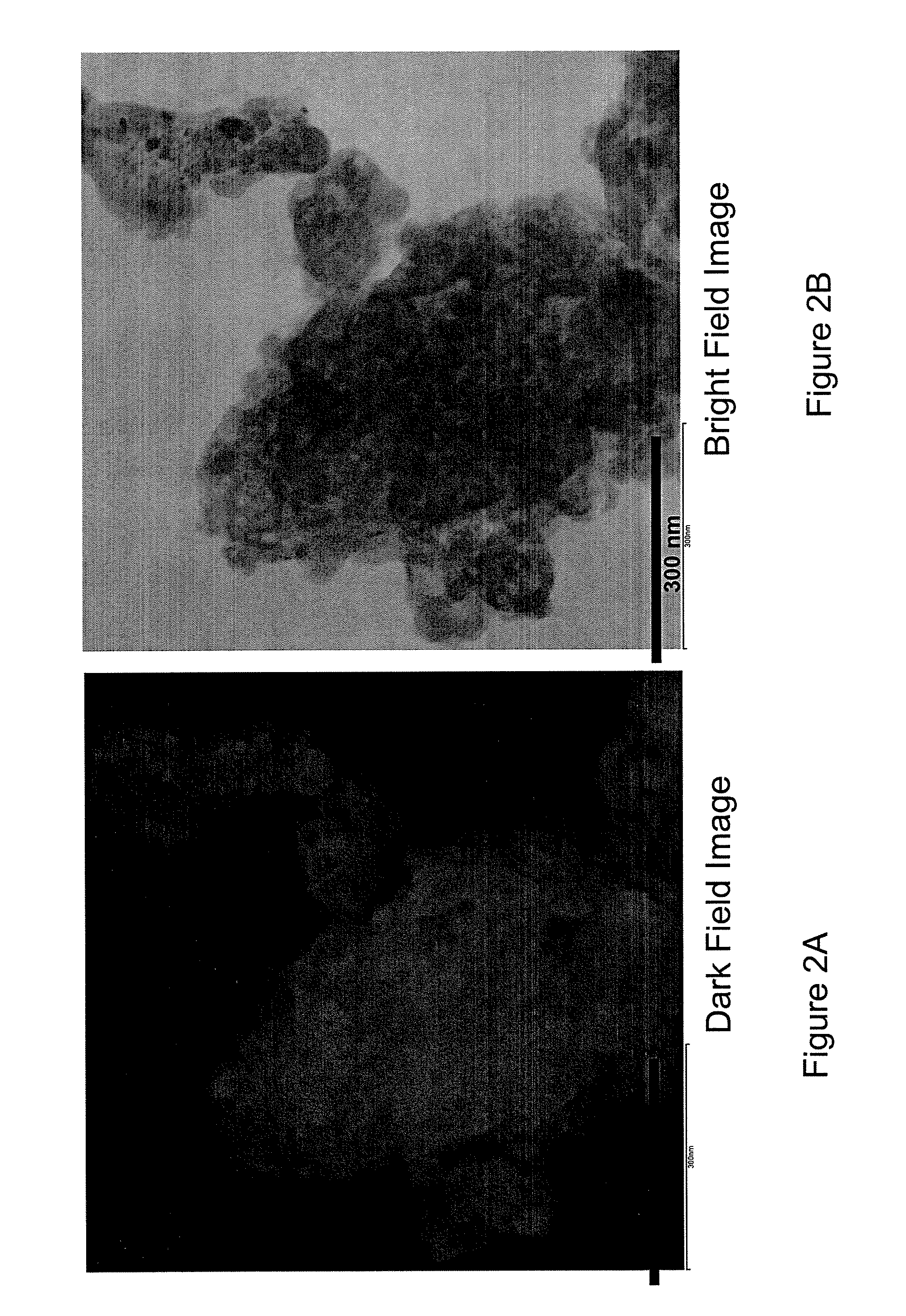

Nanoscale ion storage materials

ActiveUS20070031732A1Improve electronic conductivityImproved electromechanical stabilityMaterial nanotechnologyPhosphatesHigh ratePhosphate

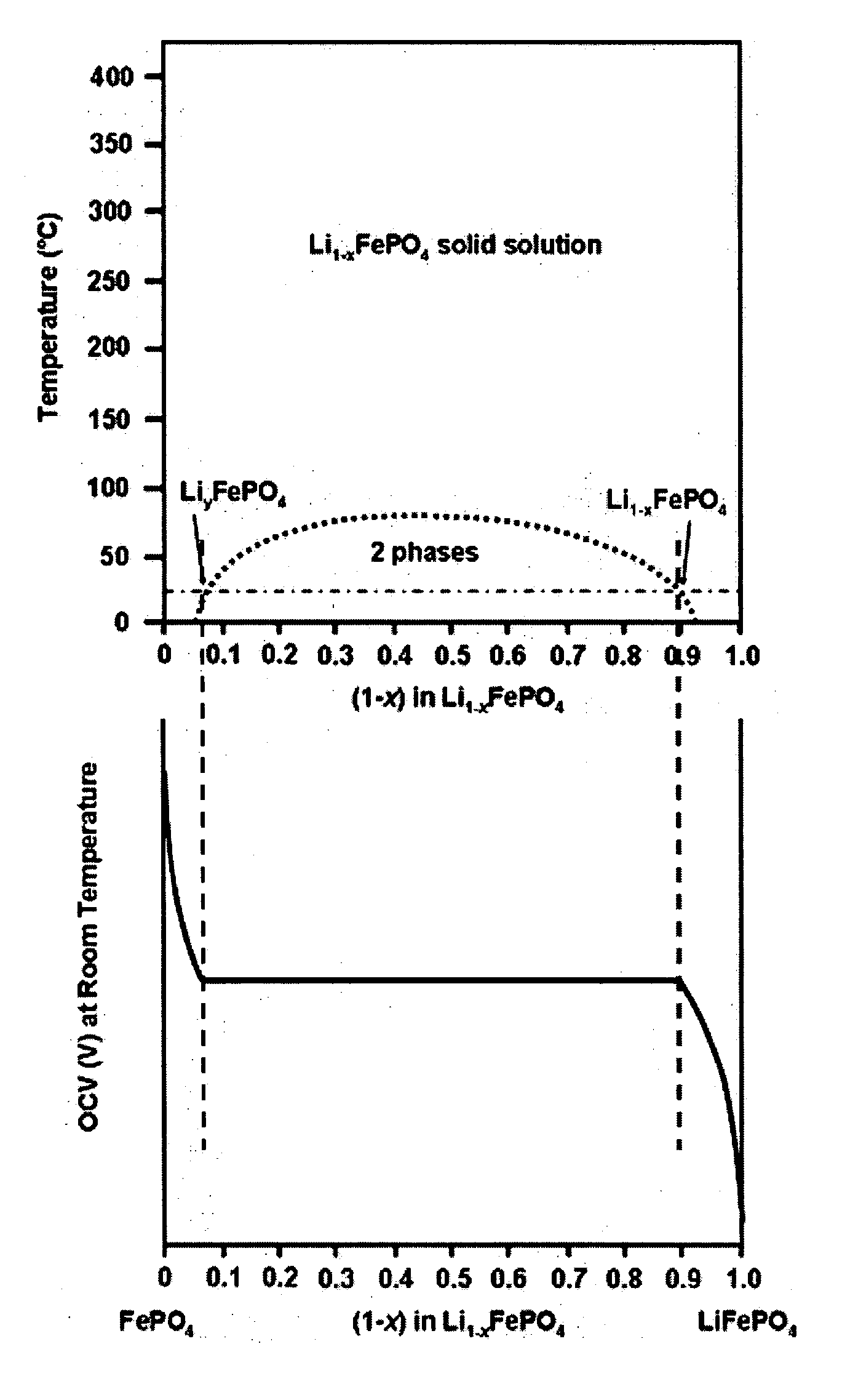

Nanoscale ion storage materials are provided that exhibit unique properties measurably distinct from their larger scale counterparts. For example, the nanoscale materials can exhibit increased electronic conductivity, improved electromechanical stability, increased rate of intercalation, and / or an extended range of solid solution. Useful nanoscale materials include alkaline transition metal phosphates, such as LiMPO4, where M is one or more transition metals. The nanoscale ion storage materials are useful for producing devices such as high energy and high power storage batteries, battery-capacitor hybrid devices, and high rate electrochromic devices.

Owner:RIL USA INC +1

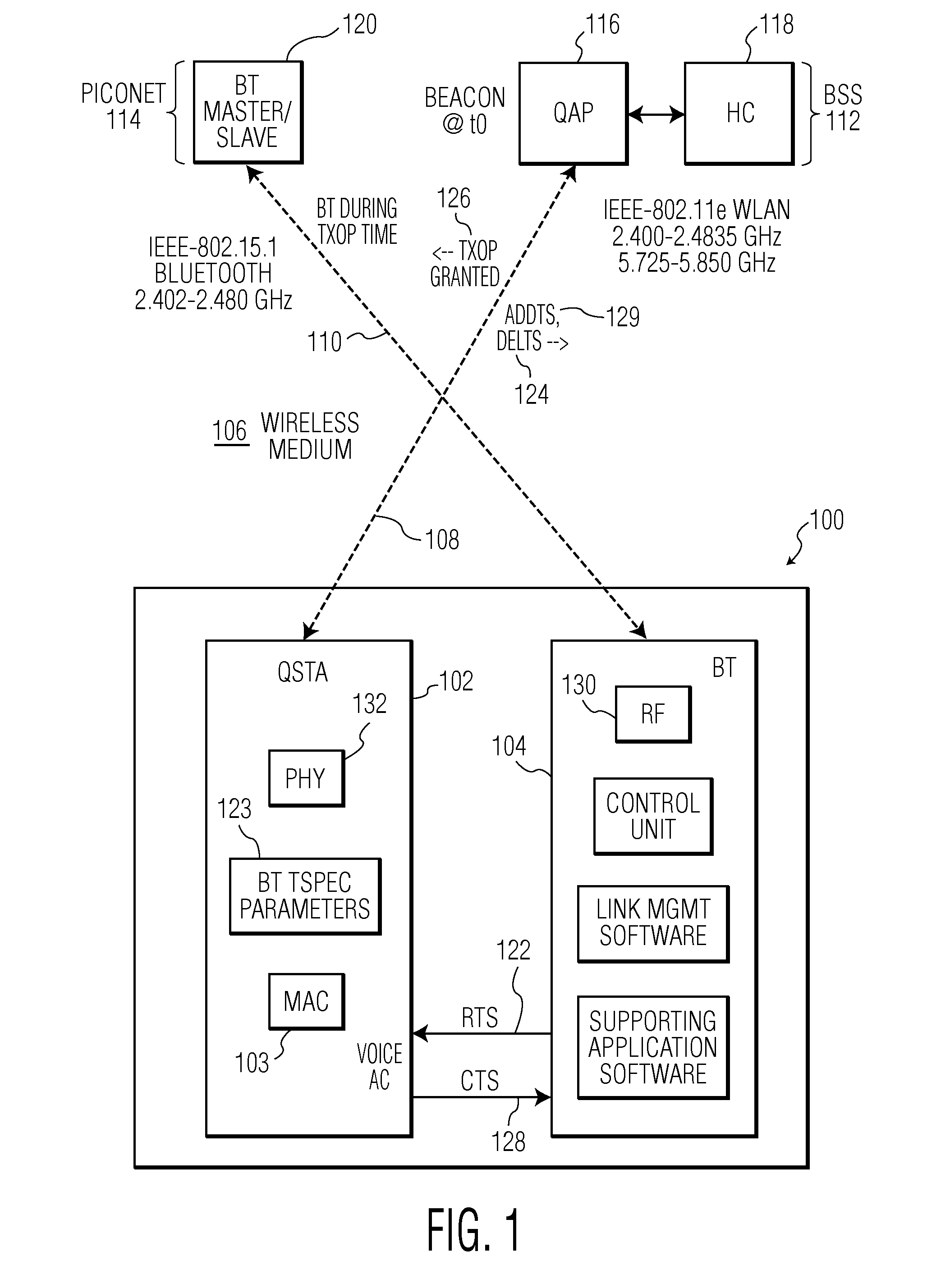

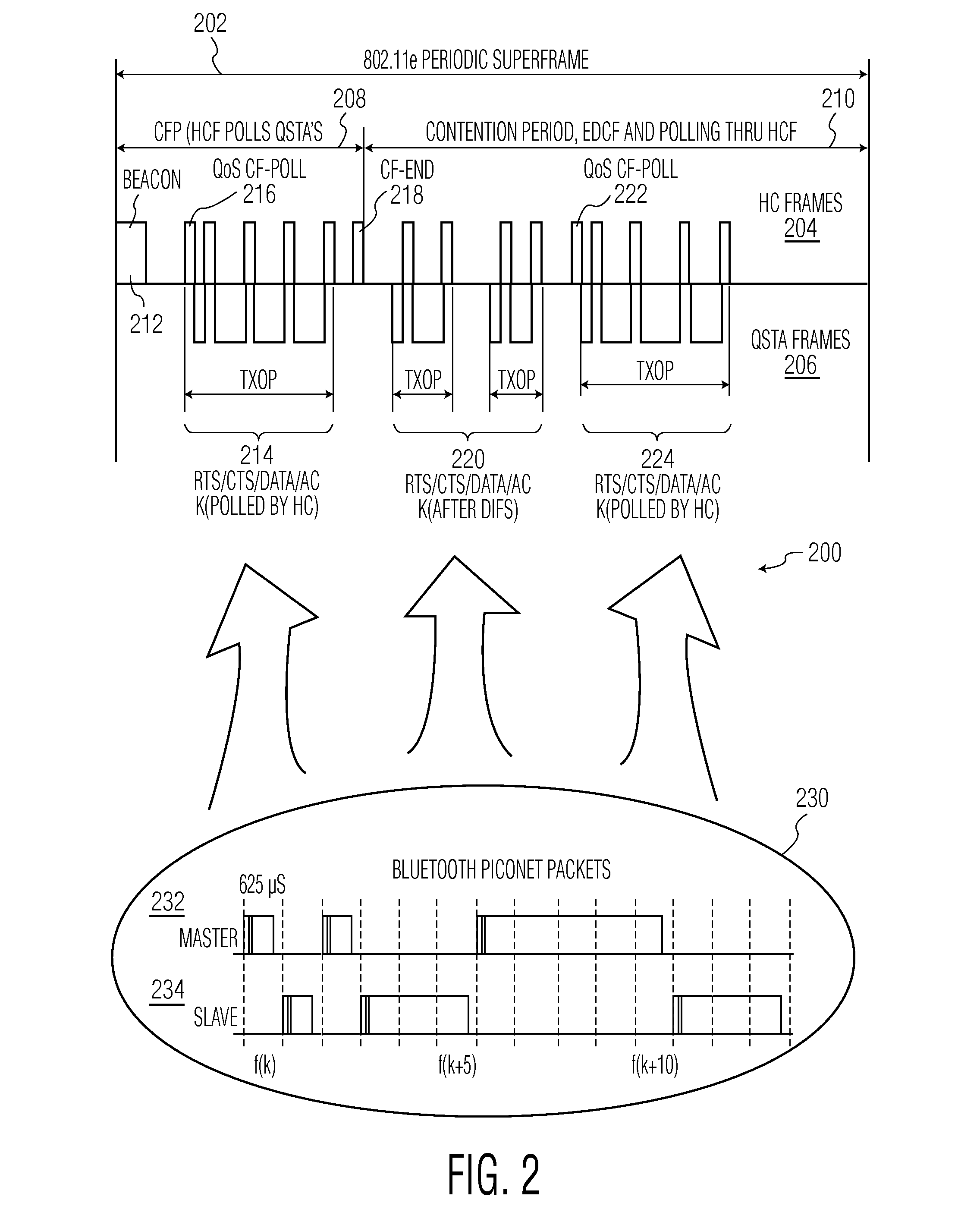

Quality of service for WLAN and bluetooth combinations

ActiveUS20100284380A1Easy to useNetwork topologiesMultiple digital computer combinationsQuality of serviceBluetooth piconets

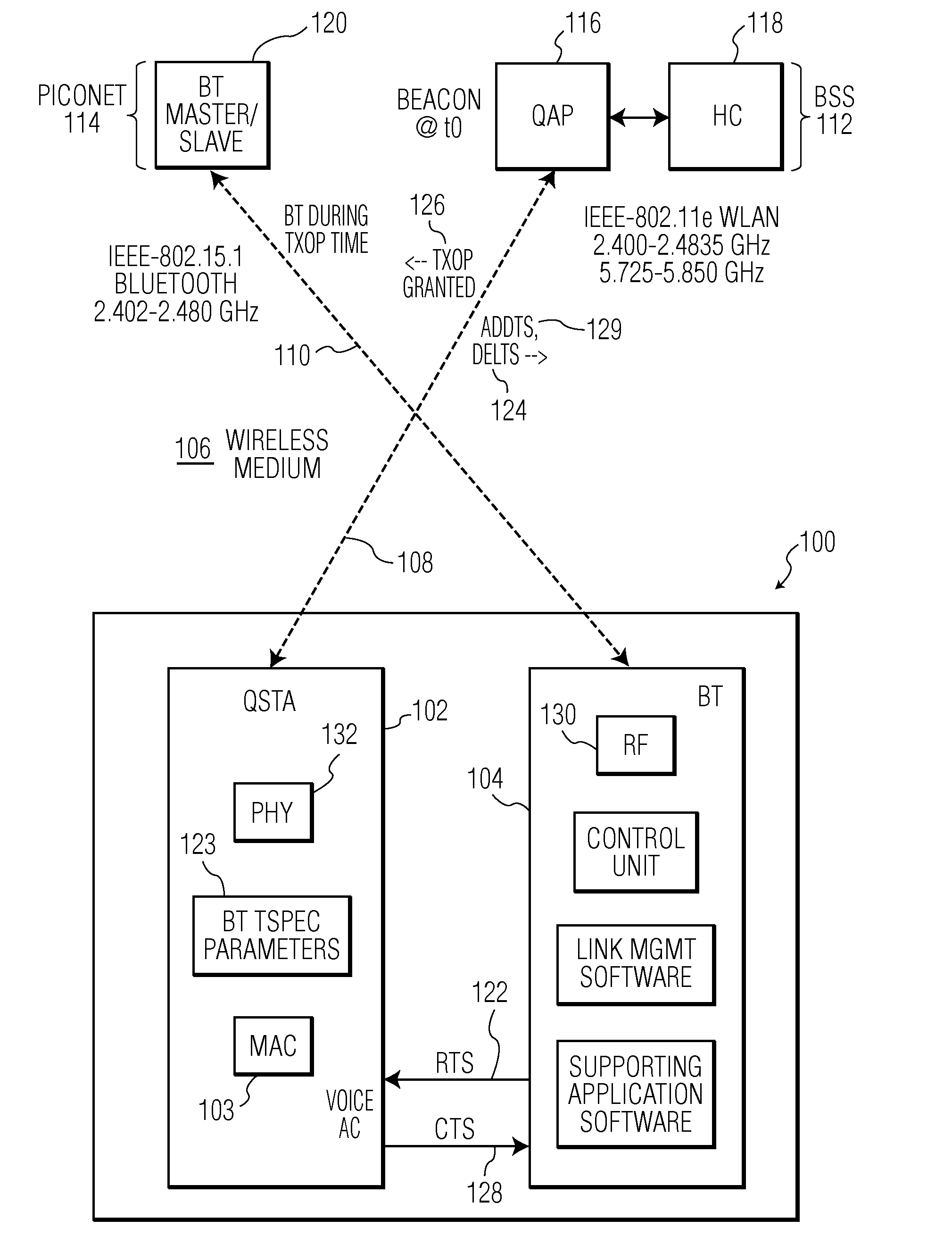

A hybrid device (100) includes both a IEEE-802.11e type WLAN client station (QAP) (102) and a BLUETOOTH piconet unit (104) interconnected such that the BLUETOOTH transmissions are scheduled to occur according to a transmission opportunity (TXOP) (126) that was granted by a quality of service (QoS) access point (QAP) (116) in a basic service set (BSS) (112). Requests for BLUETOOTH traffic are handled by the associated QSTA (102) which generates an add traffic service (ADDTS) (124) to the QAP.

Owner:NXP BV

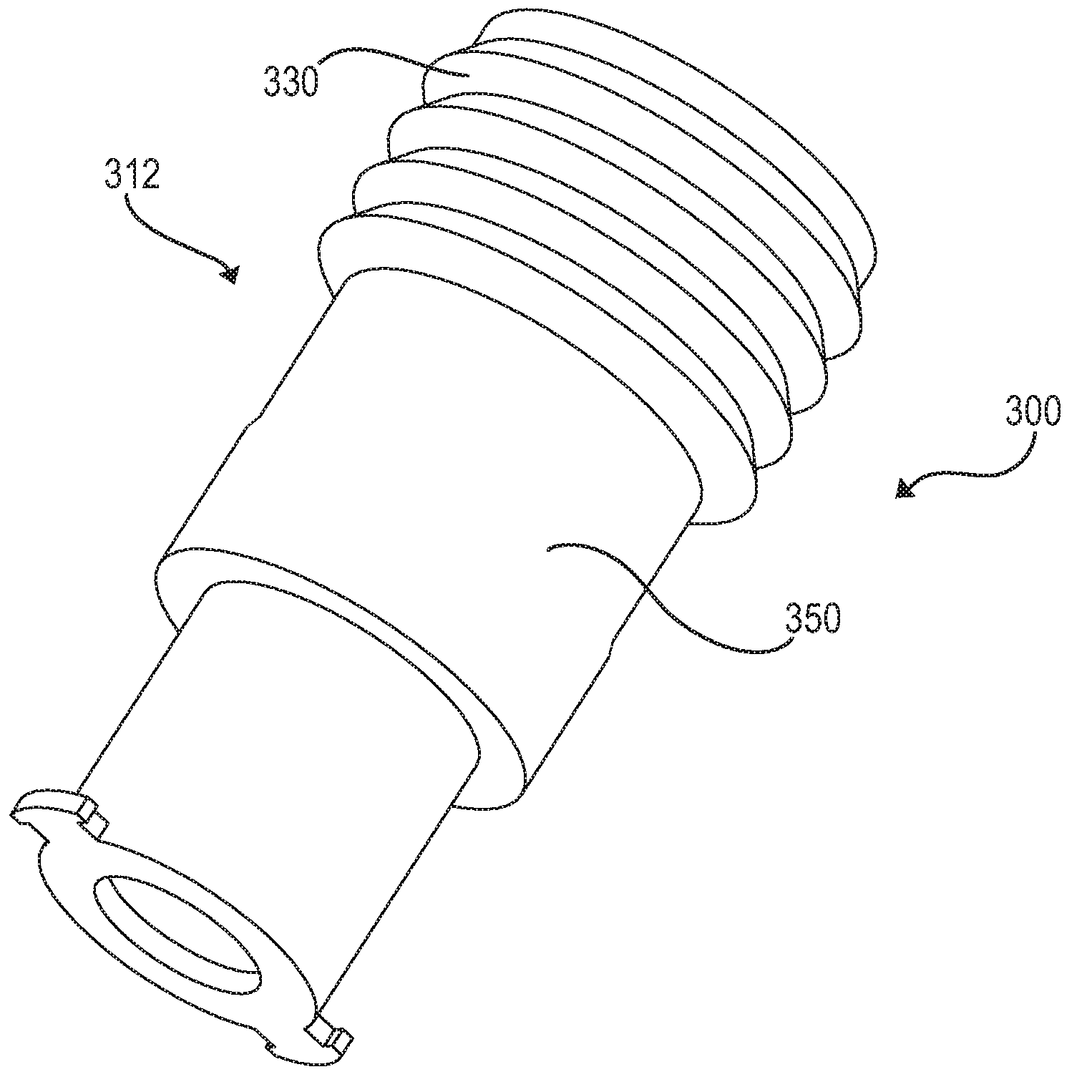

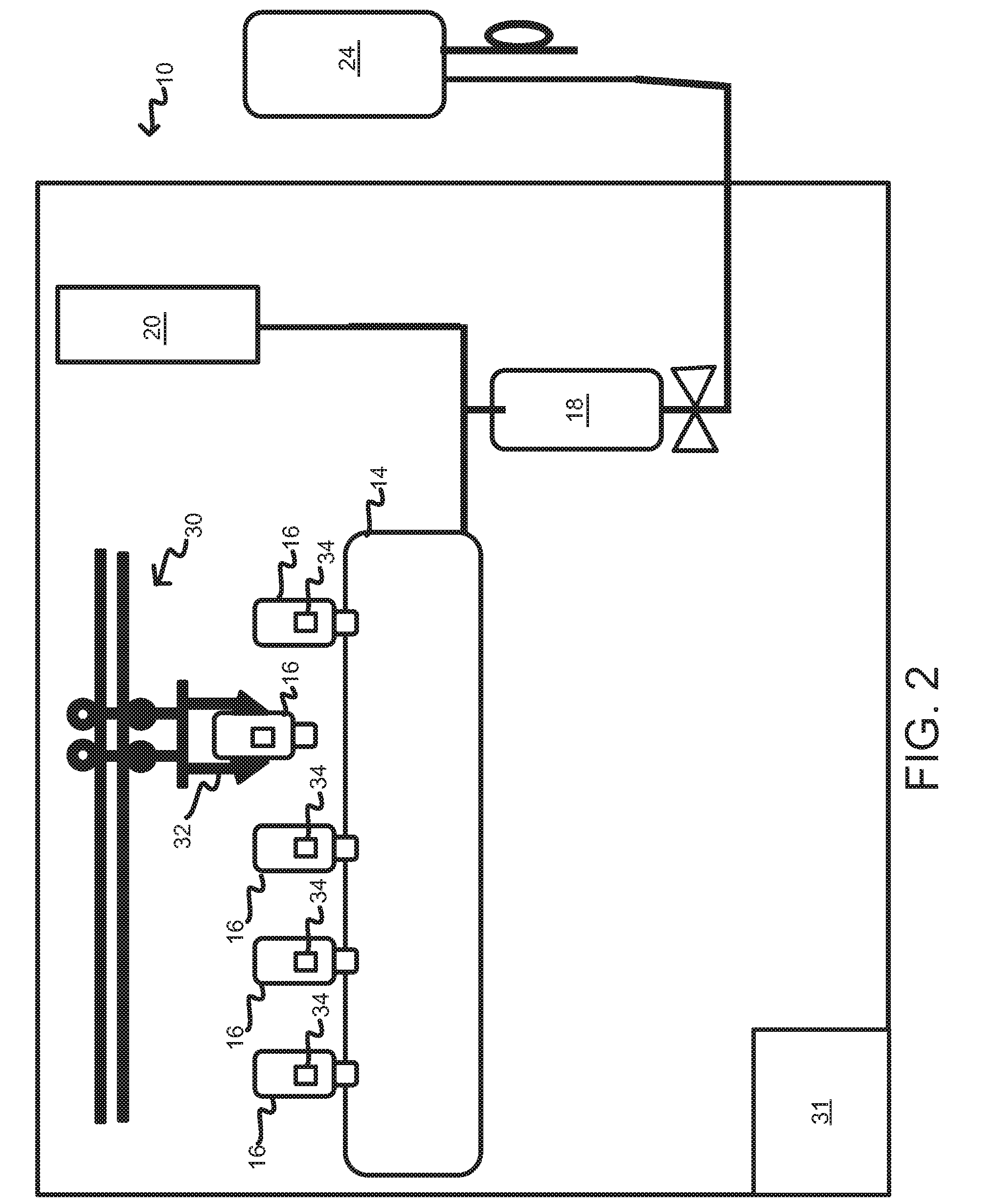

Compounder Apparatus

A containment assembly for enclosing a medication container may comprise a first housing portion or interface portion having a proximal end and a distal end. The interface portion may include a housing wall which defines a channel spanning from the proximal end to the distal end. The channel may be open at the proximal and distal end. The containment assembly may further comprise at least one pierceable septum disposed at least at one of: on the proximal end of the channel and within the channel forming a barrier between the proximal end of the channel and distal end of the channel of the interface portion. The containment assembly may further comprise a variable-volume housing portion having a variable volume chamber. The variable-volume portion chamber of the variable-volume housing portion may be in fluid communication with the distal end of the channel.

Owner:DEKA PROD LLP

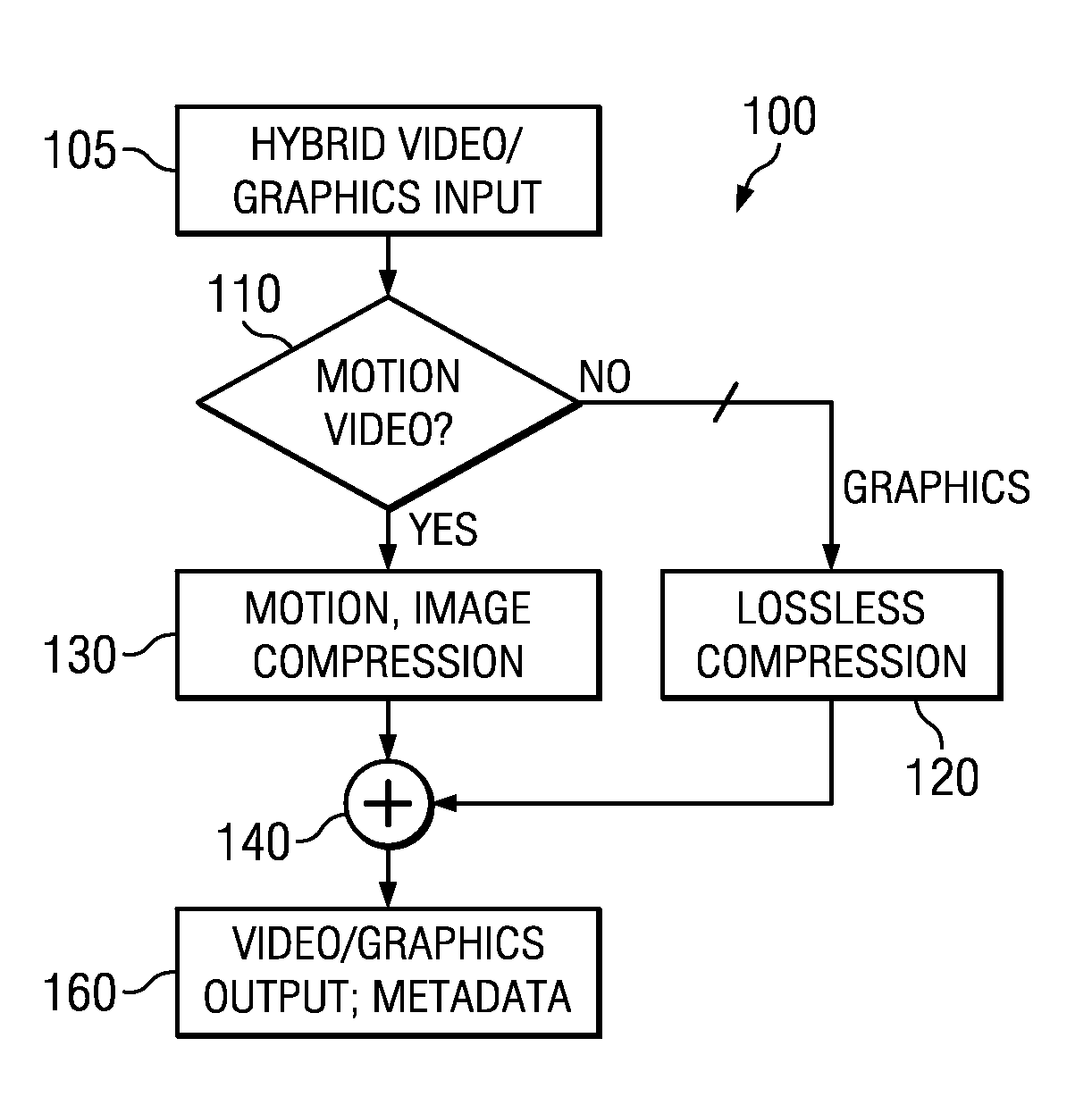

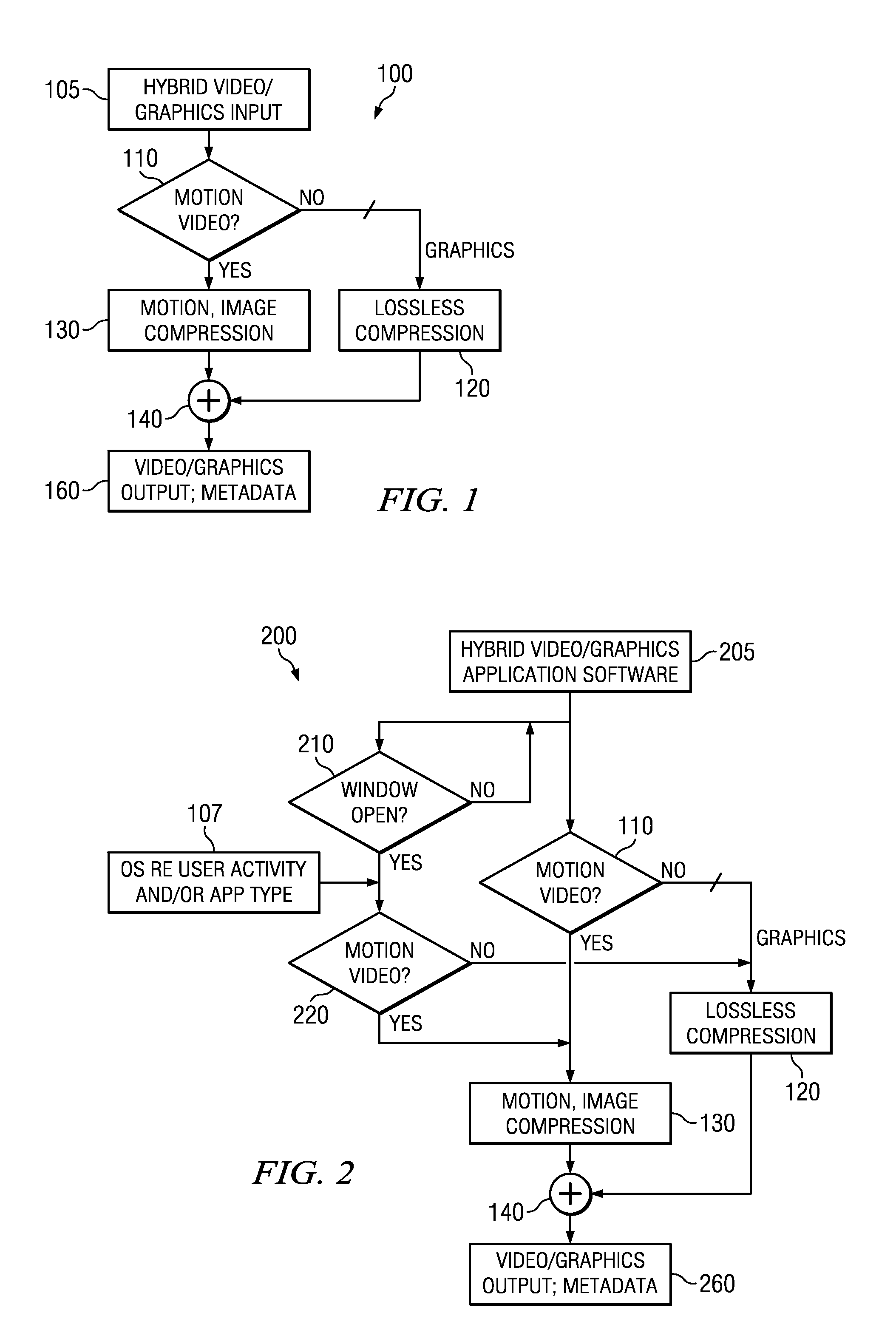

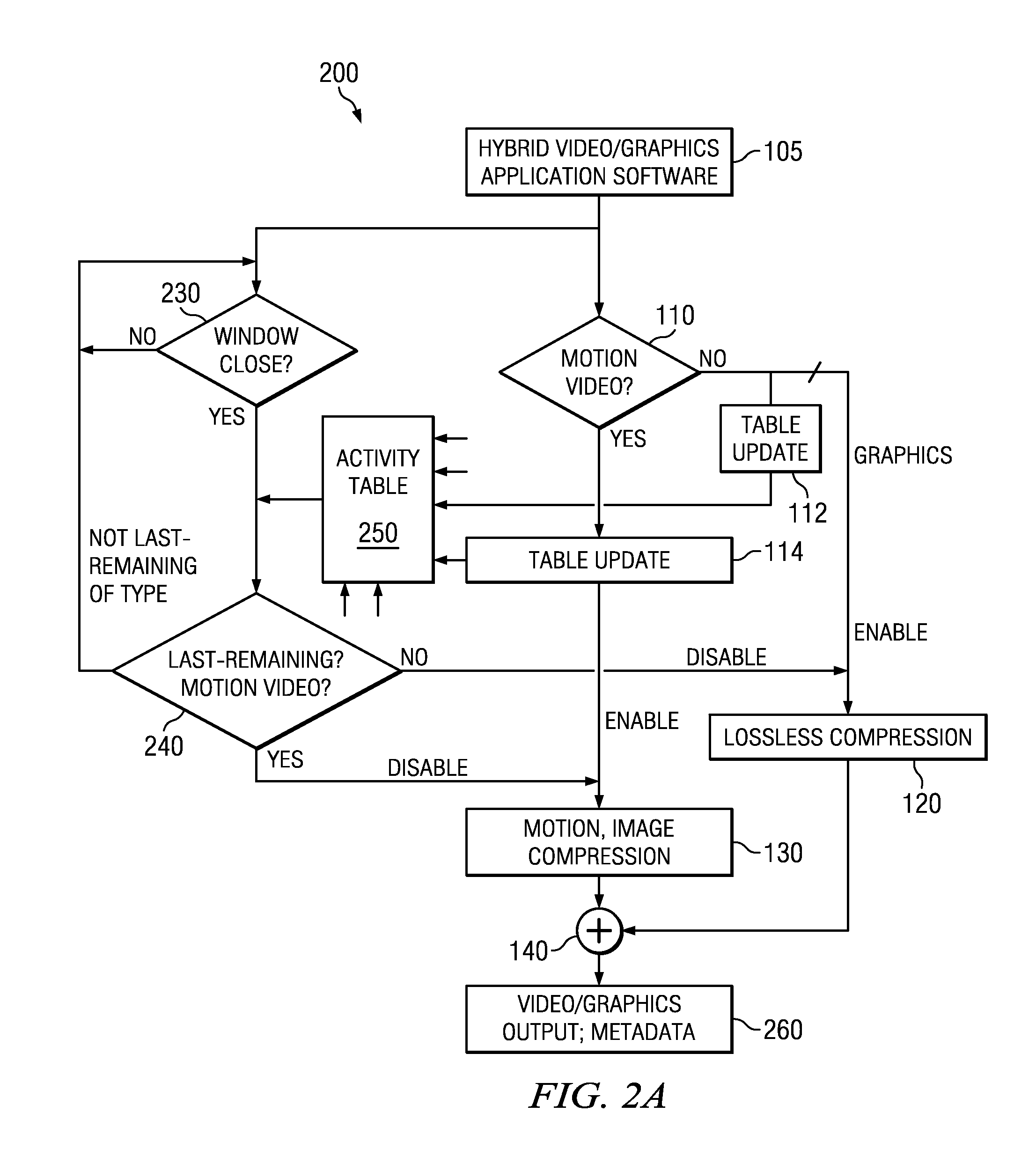

Hybrid video and graphics system with automatic content detection process, and other circuits, processes, and systems

A computing device (300) includes a storage (325) that over time is operable to include video and graphics content and the storage has a first set of instructions representing lossy video compression (130) and a second set of instructions representing lossless compression (120); and a processor (320) coupled with said storage (325), and said processor (320) operable to electronically analyze (110) at least a portion of the content for motion based on magnitudes of motion vectors and, on detection of a significant amount of motion, further operable to activate the first set of instructions (130) to compress at least the motion video, and otherwise to activate the second set of instructions representing lossless compression (120) to compress at least the graphics. Other devices, systems, and processes are disclosed.

Owner:TEXAS INSTR INC

Method and apparatus for cancelling common mode noise occurring in communications channels

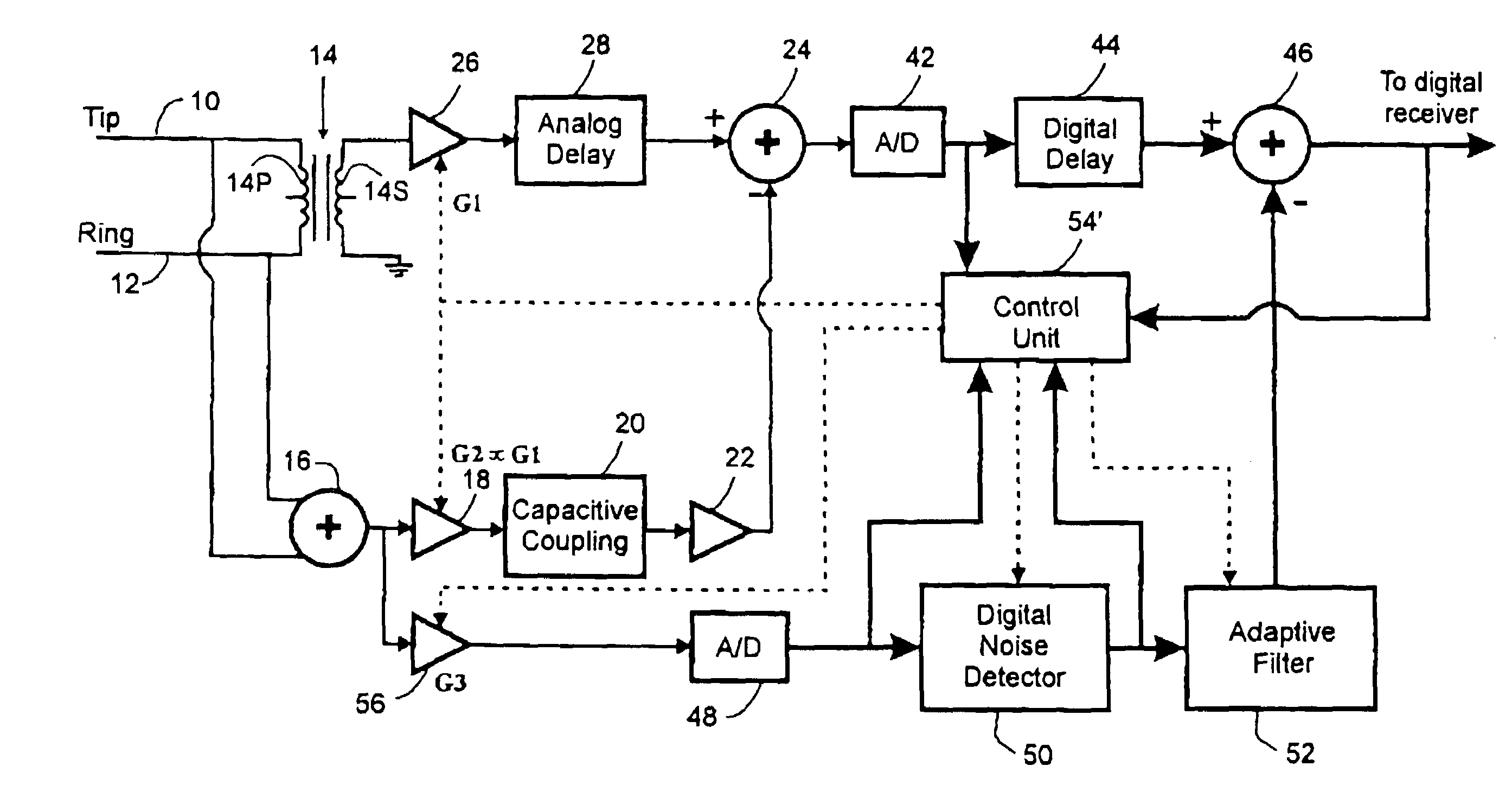

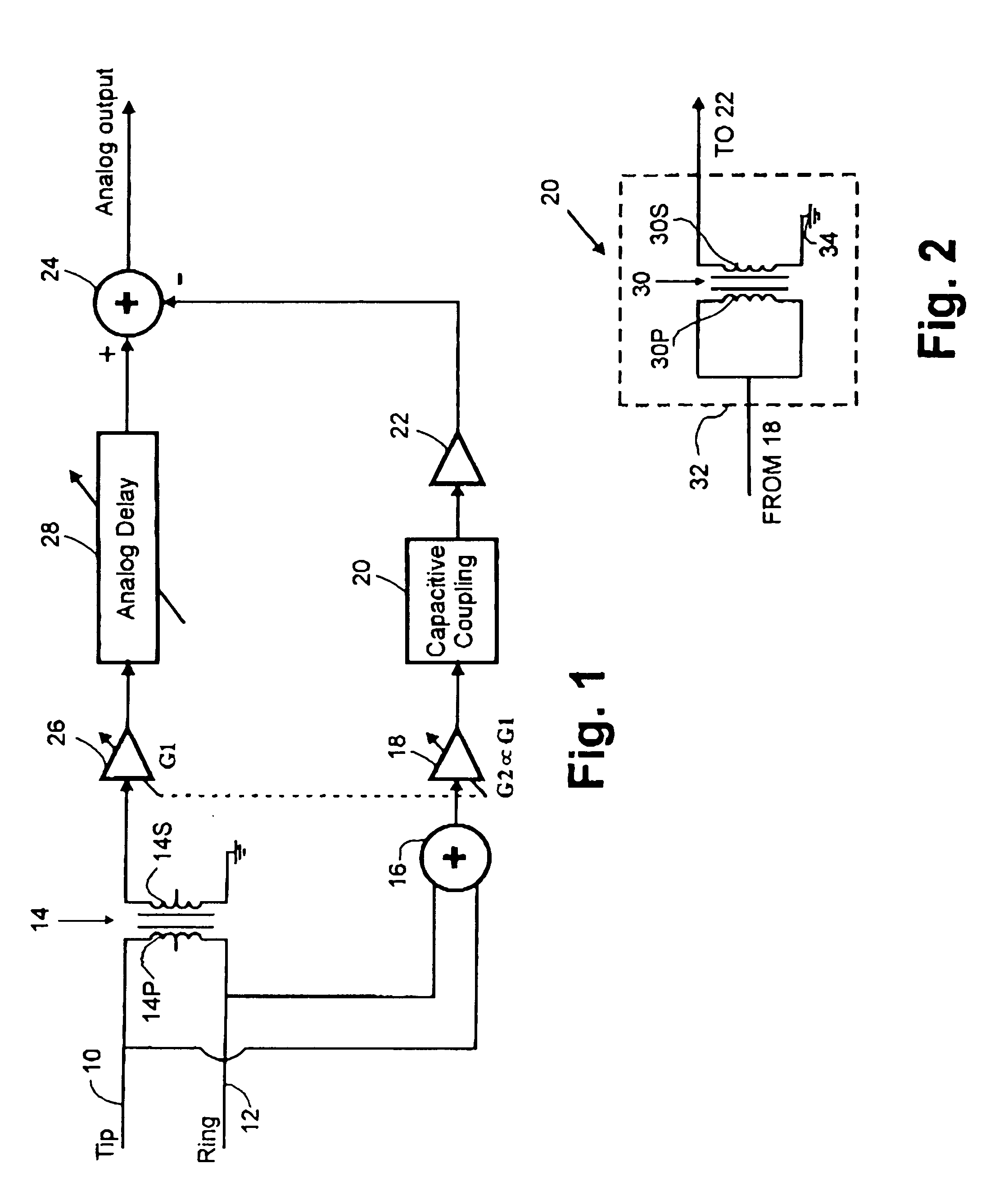

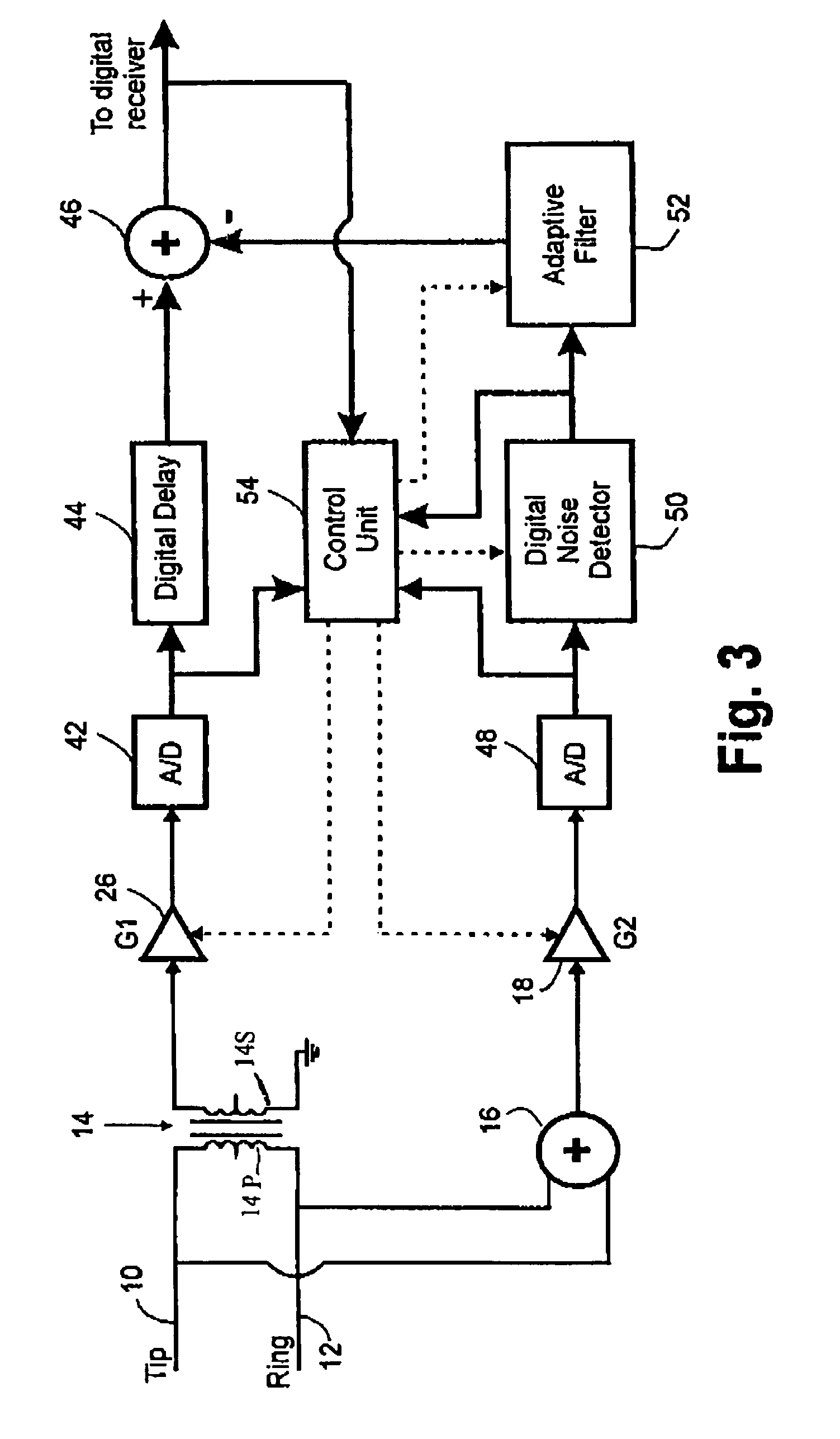

InactiveUS6940973B1Substations coupling interface circuitsInterconnection arrangementsCapacitanceAdaptive filter

In order to overcome problems when using an adaptive filter for cancellation of common-mode noise in digital subscriber loops, caused by a portion of the differential signal being converted to common mode, which degrades the performance of the filter, a noise cancellation technique is proposed which compensates for this cross-coupled signal energy. In particular, a digital noise detector is used to detect one or more noisy frequency bands of the common mode signal and pass only the digitized common mode signal in those detected frequency bands through the adaptive filter to produce a digital common mode noise estimate signal. A control unit adjusts coefficients of the adaptive filter to reduce correlation between the differential signal and common mode signal. It is also proposed to compensate for the effects of stray capacitive coupling across the usual hybrid device by including an equivalent capacitive component in a common mode noise estimation circuit.

Owner:BELL CANADA

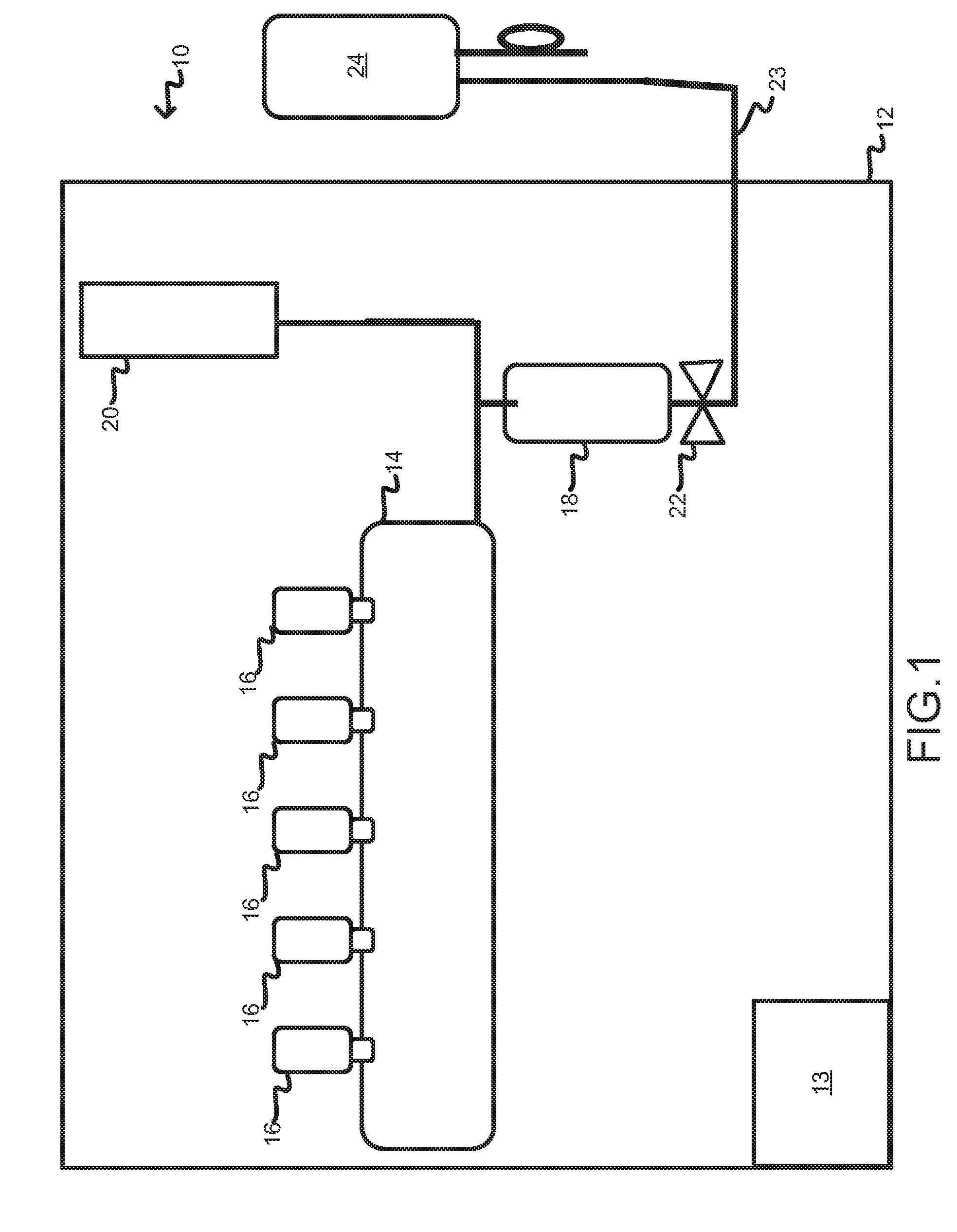

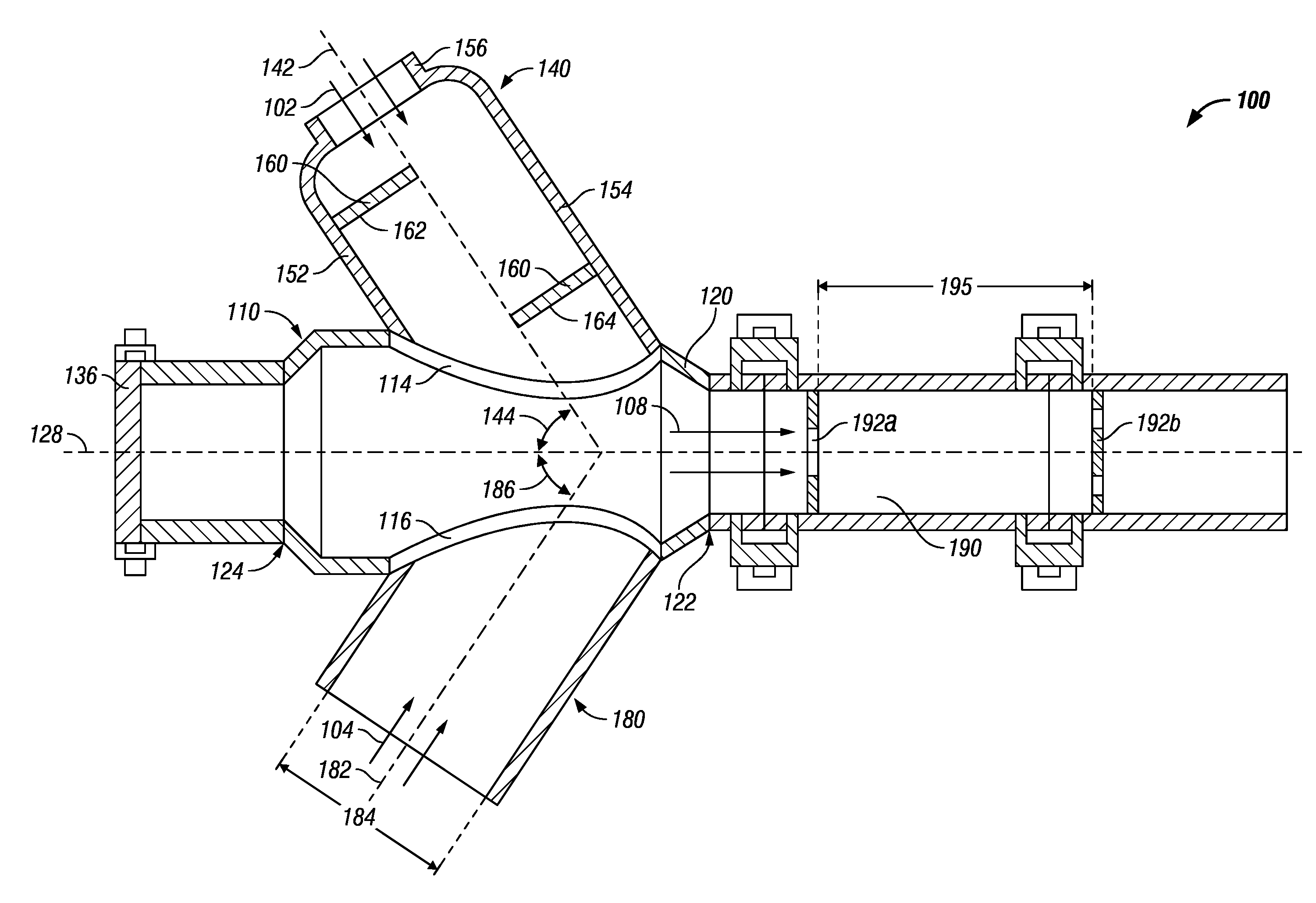

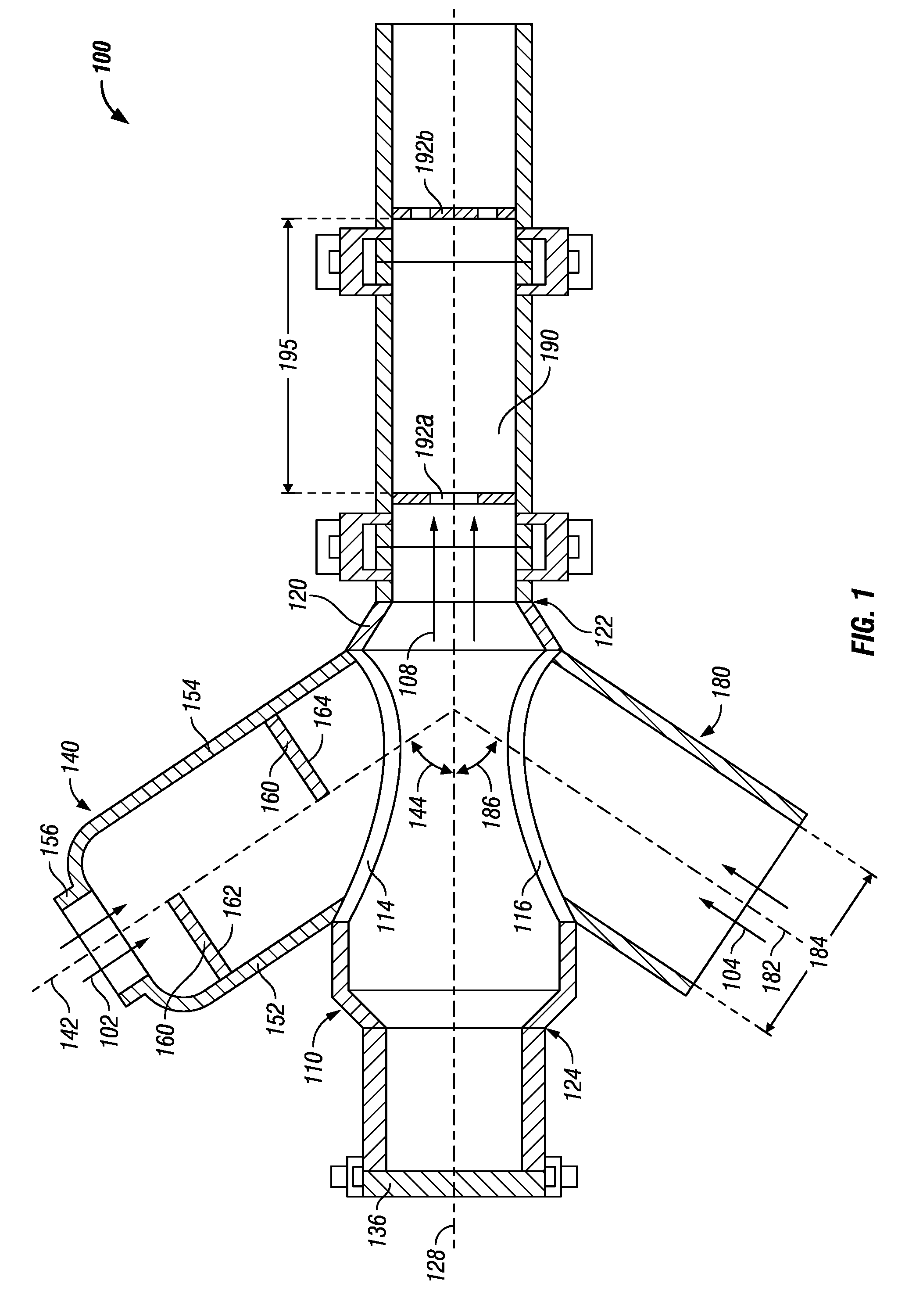

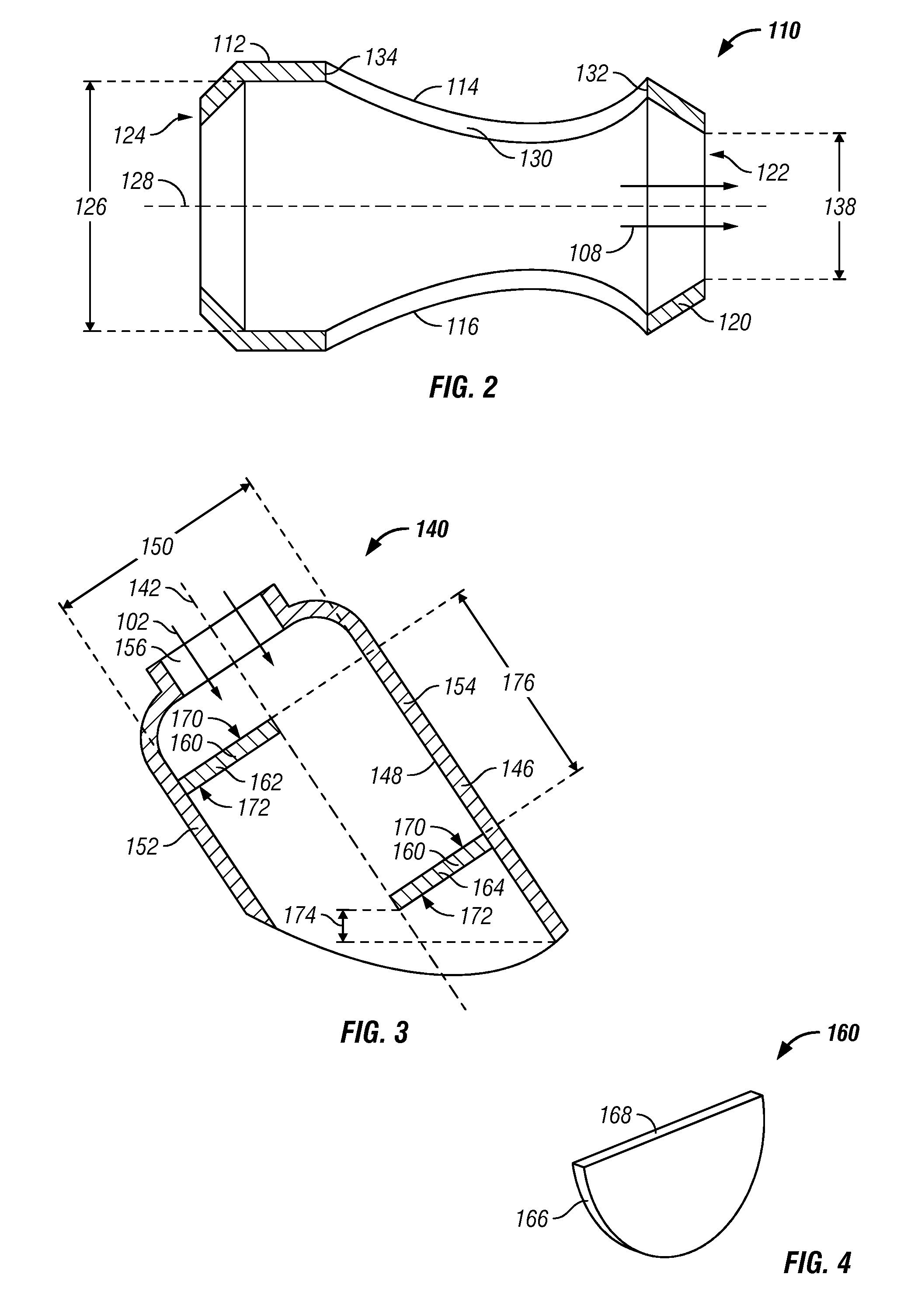

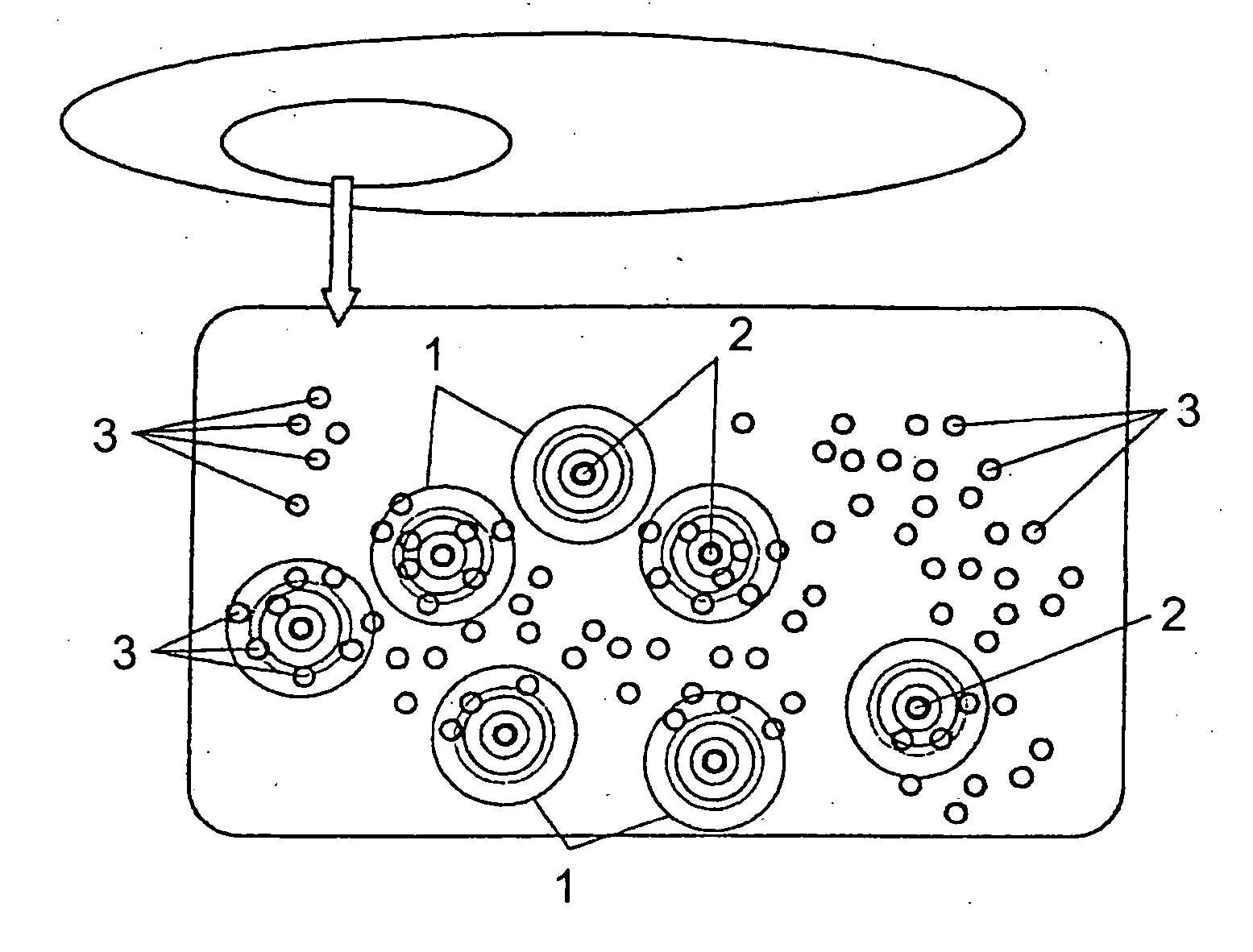

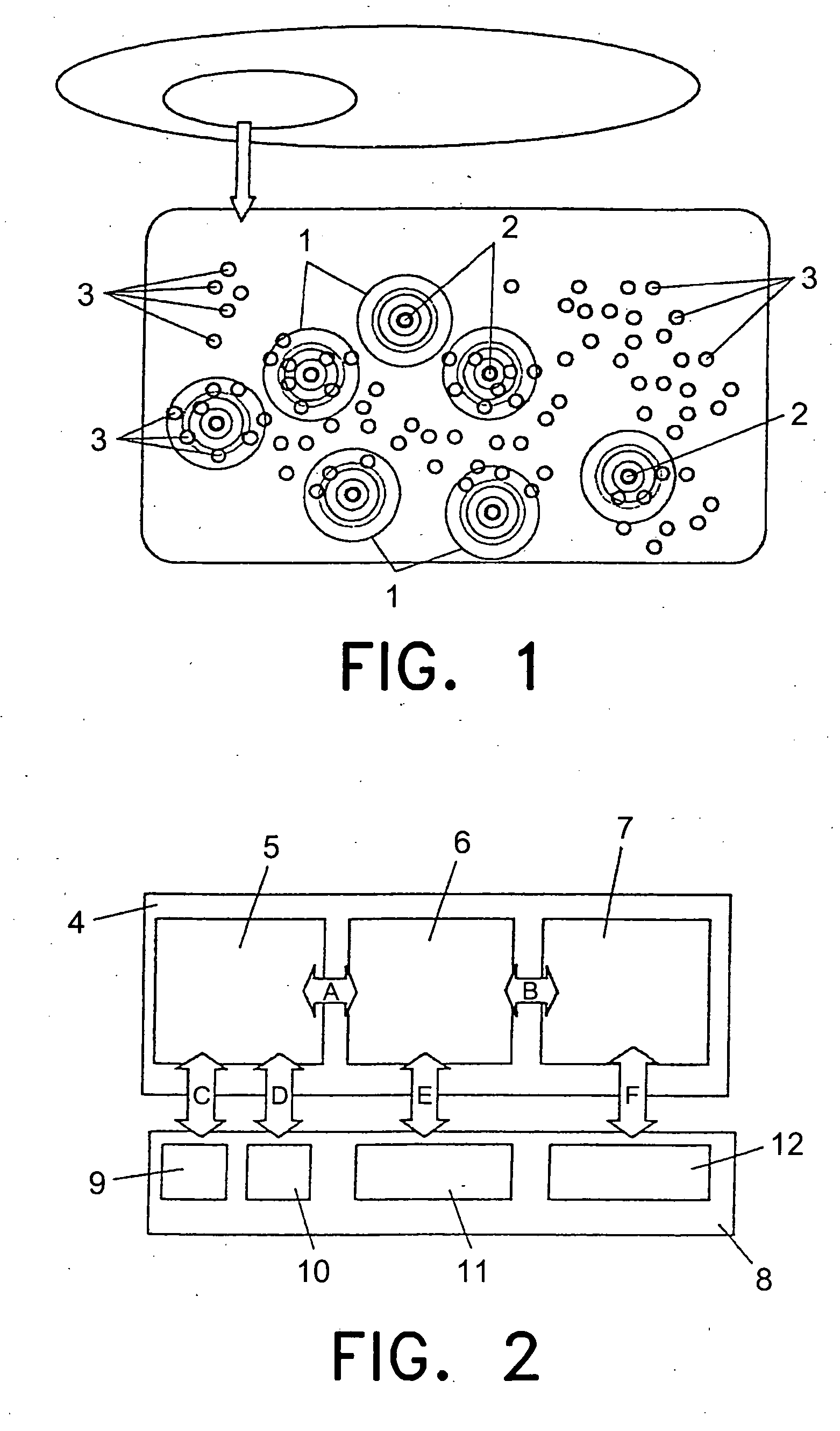

Apparatus for homogenizing two or more fluids of different densities

ActiveUS8079751B2Improve homogenizationFacilitates and improves ability to homogenize two and more fluid rapidlyFlow mixersTransportation and packagingVolumetric Mass DensityEngineering

A blending apparatus for blending a first fluid stream having a first density and a second fluid stream having a second fluid density, the first density being greater than said second density, is discussed. The apparatus includes a first fluid director including a plurality of baffles affixed therein to create turbulence and shear in the first fluid, a cylindrical second fluid director, a primary mixing chamber receiving the first sheared fluid from the first fluid director and receiving the second fluid from the second fluid director, wherein the first fluid and second fluid are mixed in the primary mixing chamber to form a mixed primary fluid stream, and a secondary blending chamber comprising at least one static mixer and coaxially aligned with and receiving the mixed primary fluid stream from the primary mixing chamber.

Owner:MI

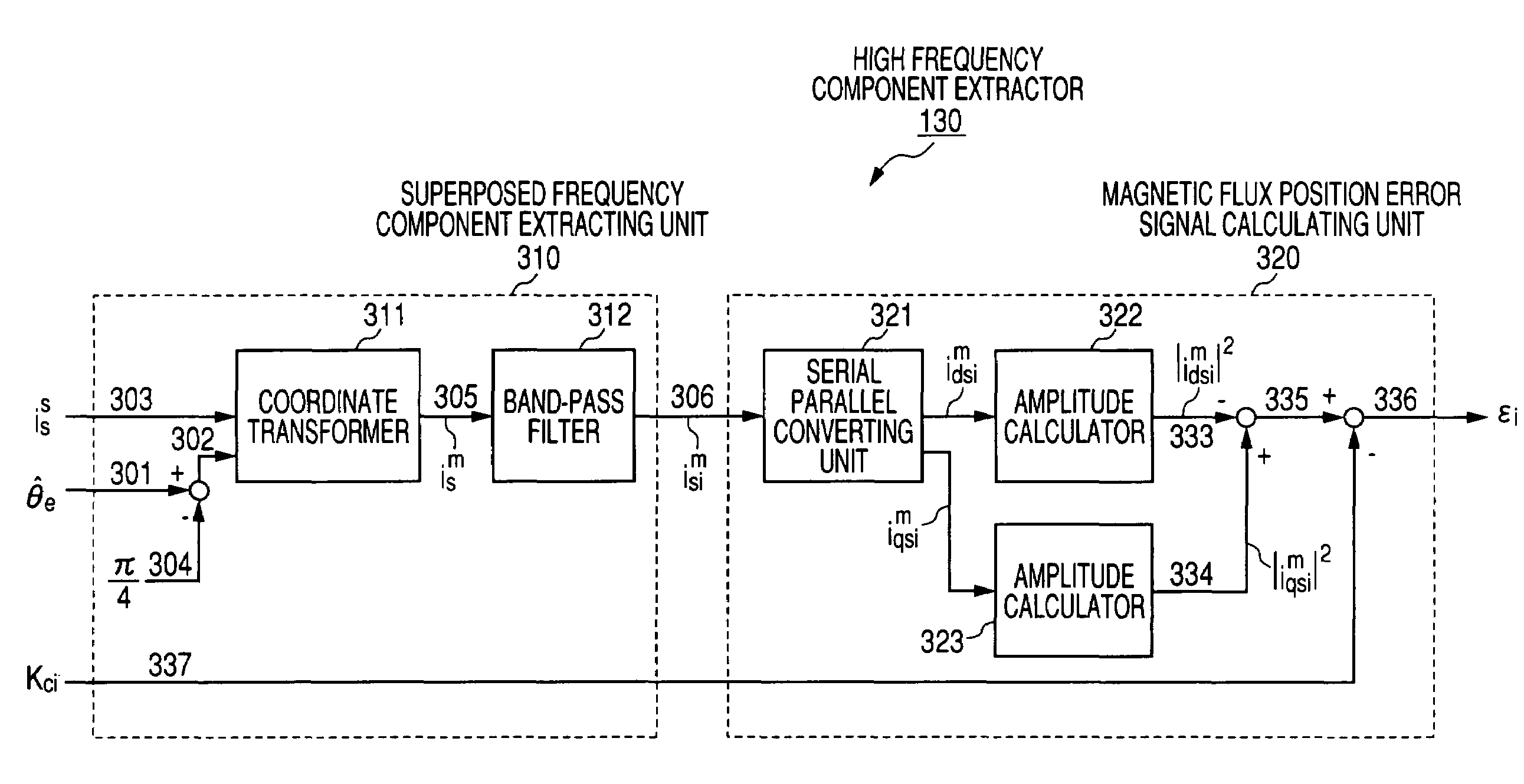

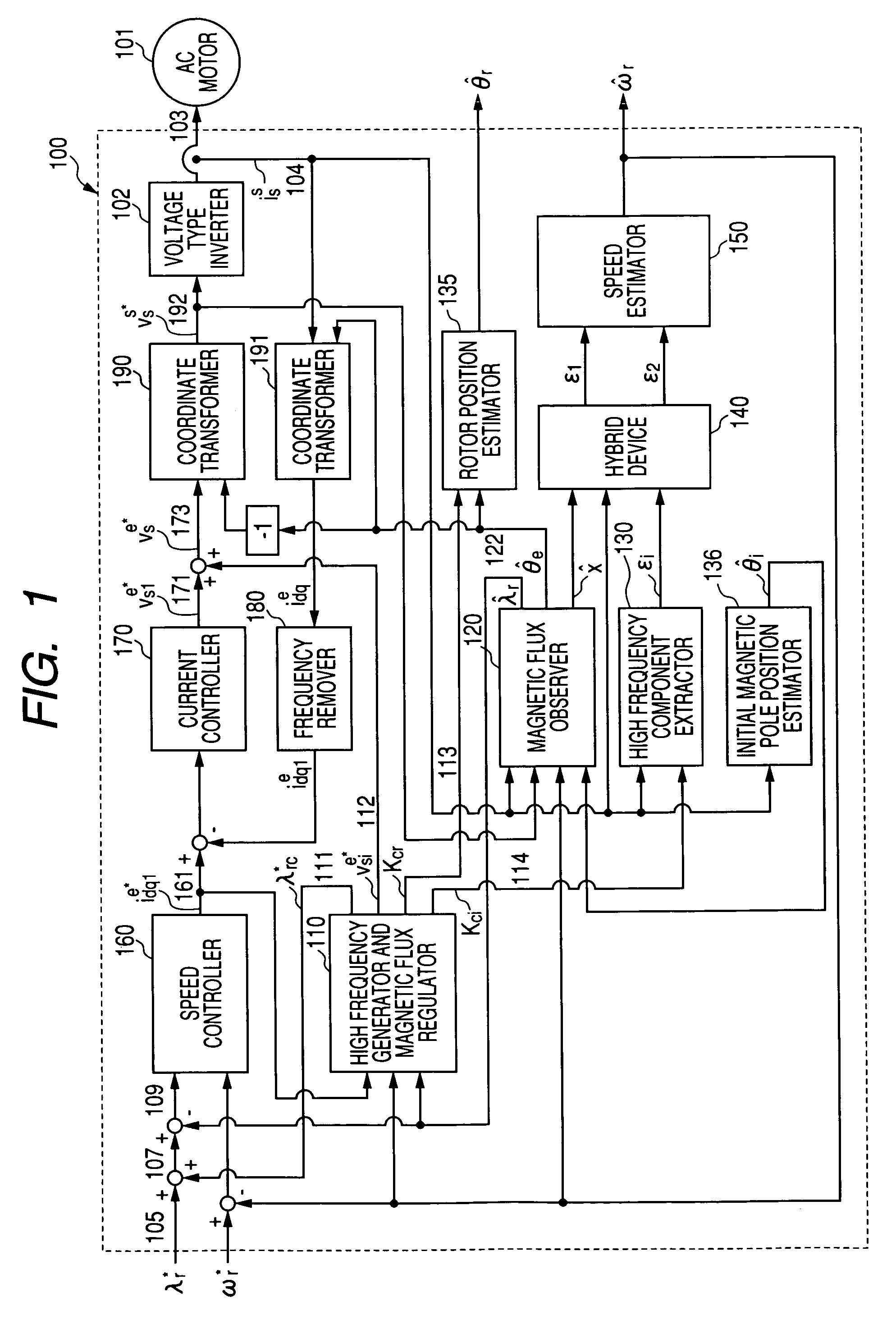

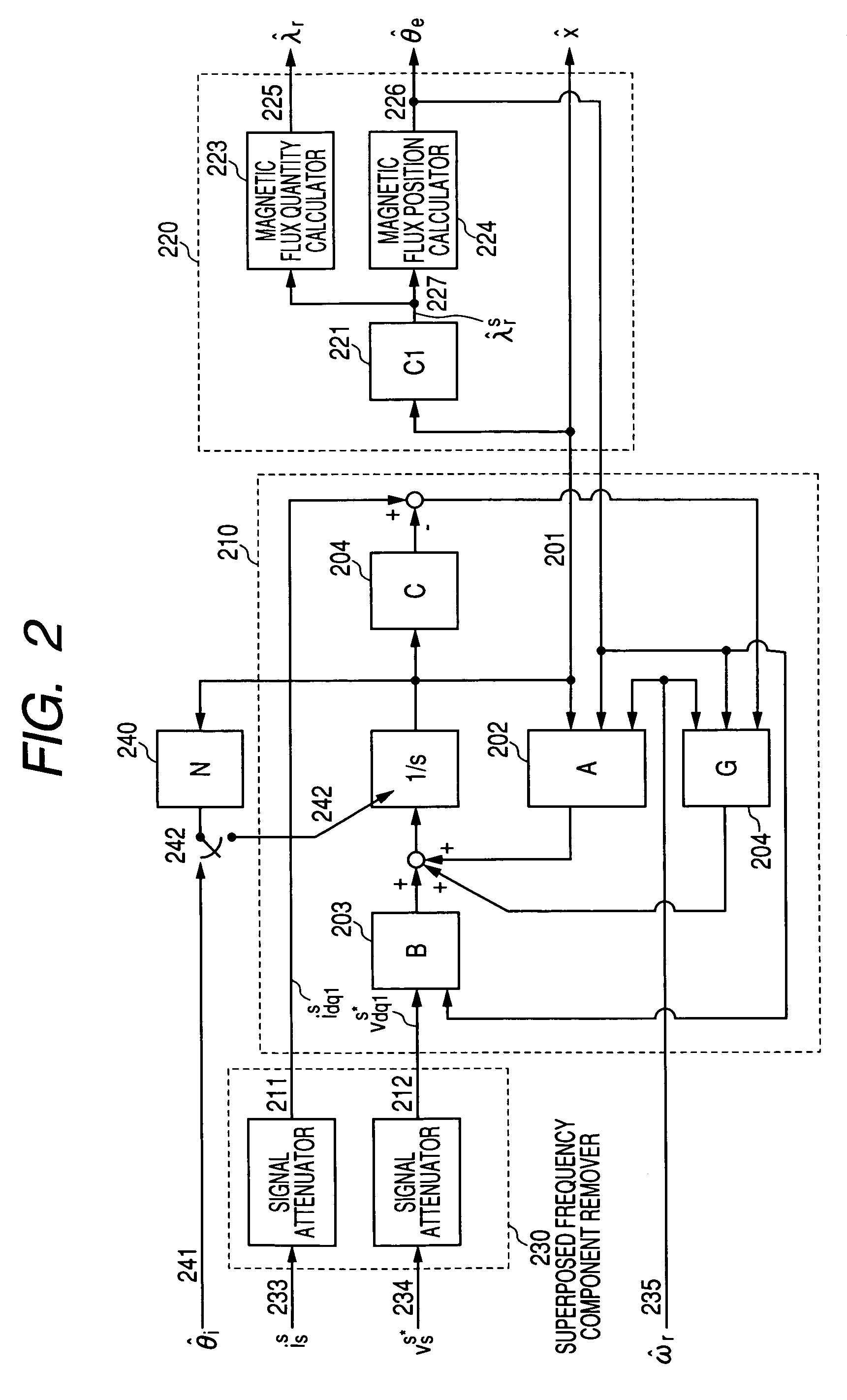

Sensorless controller of AC motor and control method

InactiveUS7045988B2Improve efficiencyMagnetic saliency at the high frequency is reducedVector control systemsSingle motor speed/torque controlLow speedSignal on

Owner:YASKAWA DENKI KK

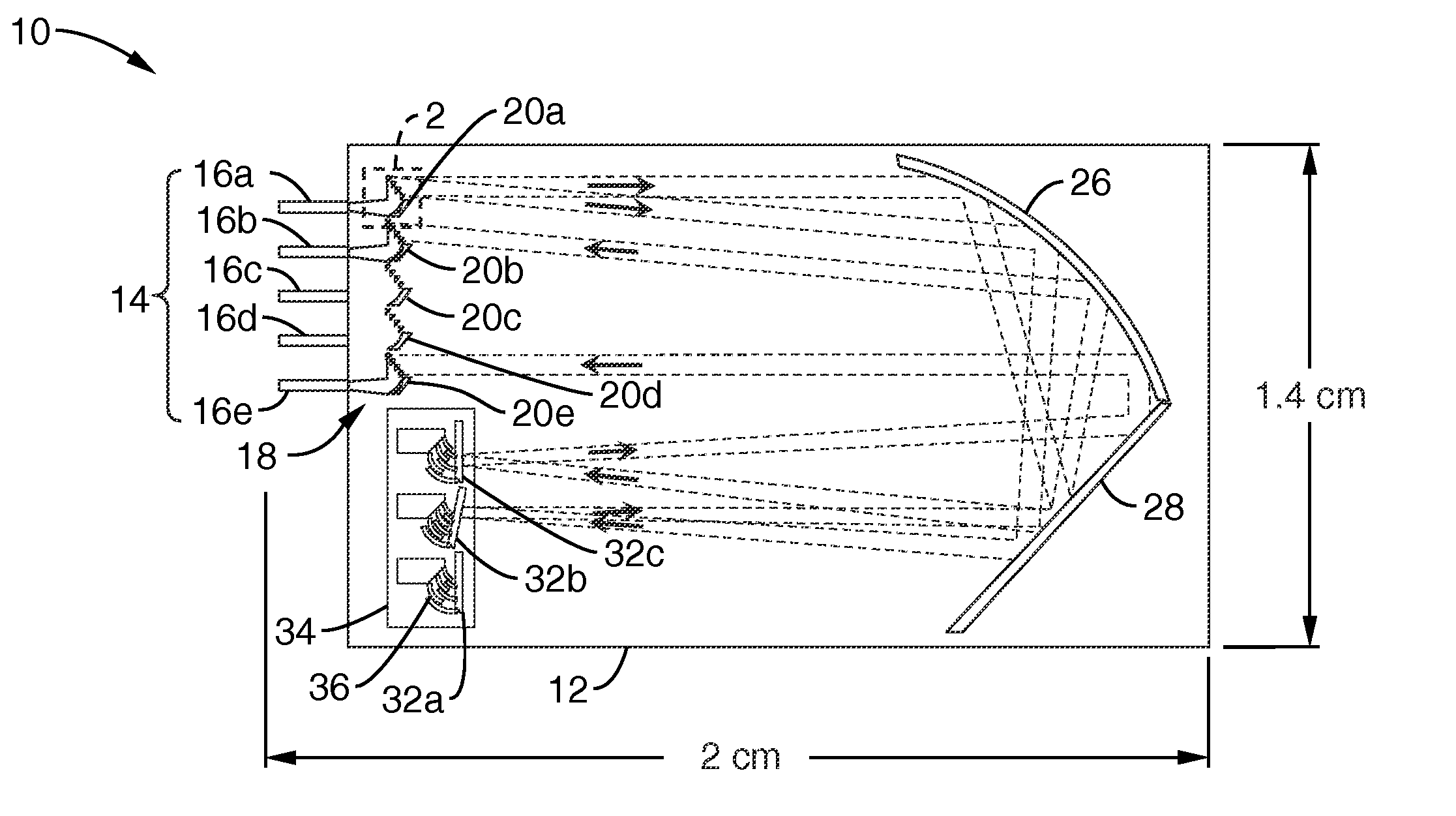

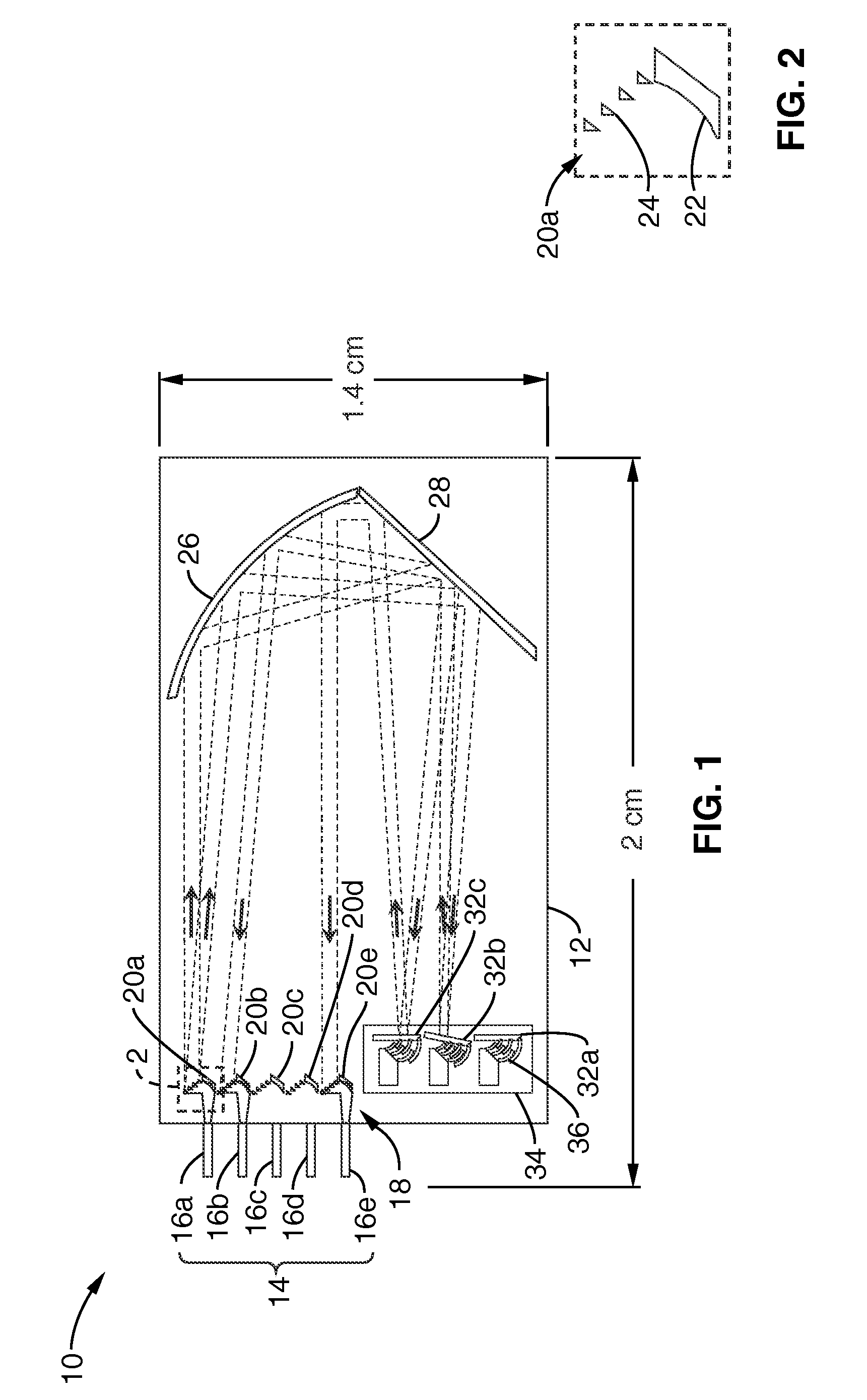

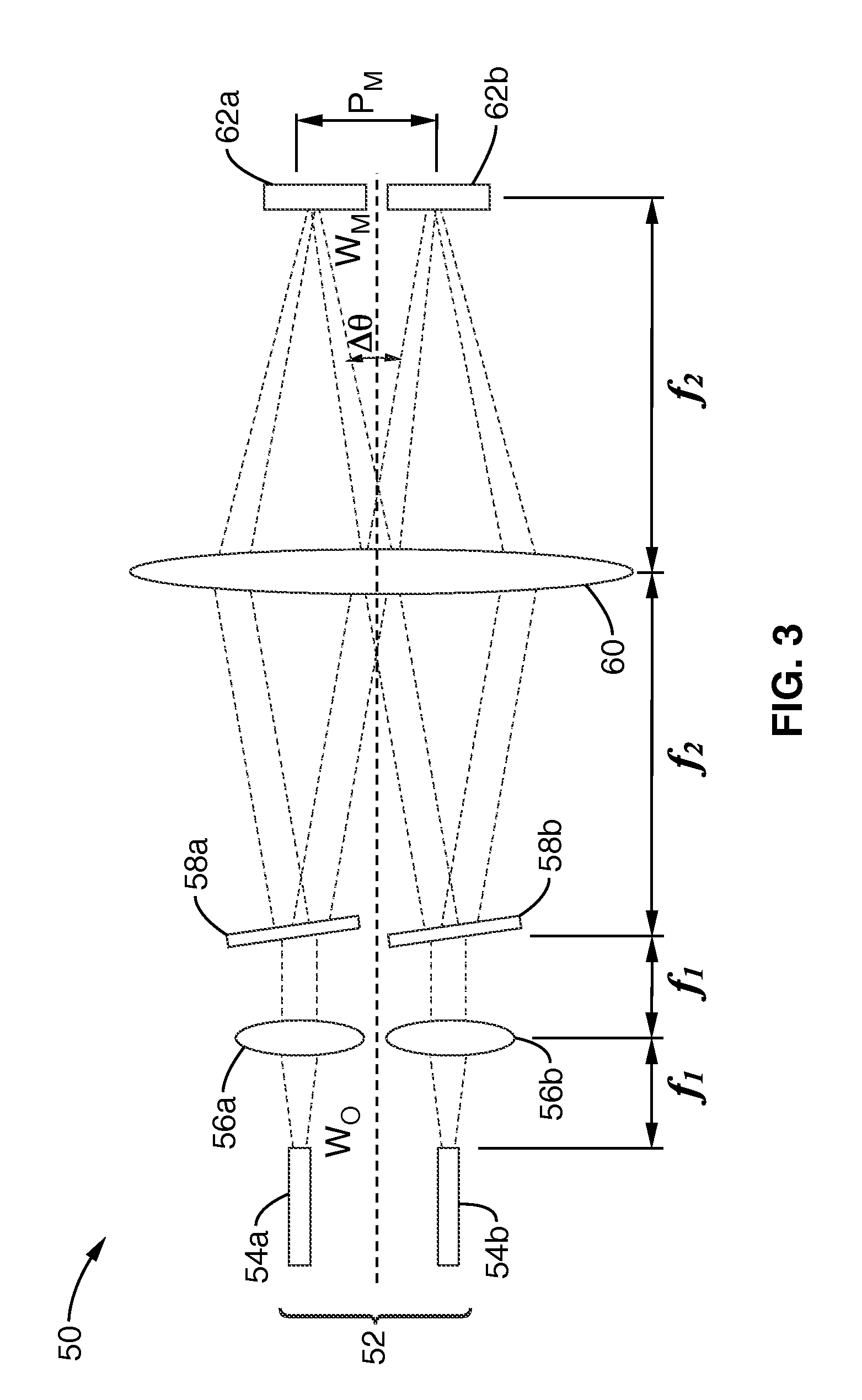

Monolithic mems-based wavelength-selective switches and cross connects

InactiveUS20070160321A1Minimizing insertion lossEliminate needCoupling light guidesCross connectionComb drive

Wavelength-selective 1×N switches (WSSs) and N×N cross-connects (WSXCs) are described which are fabricated as monolithic or hybrid devices. In a preferred embodiment, the optic ports, dispersion elements, and collimating elements are formed on a single monolithic substrate. A micromirror and actuator are either fabricated within the substrate or a separate micromirror is utilized forming a hybrid WSS or WSXC. The optical elements can be formed in an opaque substrate layer (e.g., silicon, SOI, and so forth) or in an optically transparent layer of a PLC material (e.g., silica-on-silicon). Embodiments describe the use of linear and rotary comb drives for actuating front surface mirrors, or solid-immersion micromirrors (SIMs). The switching devices reduce system footprint while reducing or eliminating the need for alignment of the optical elements.

Owner:RGT UNIV OF CALIFORNIA

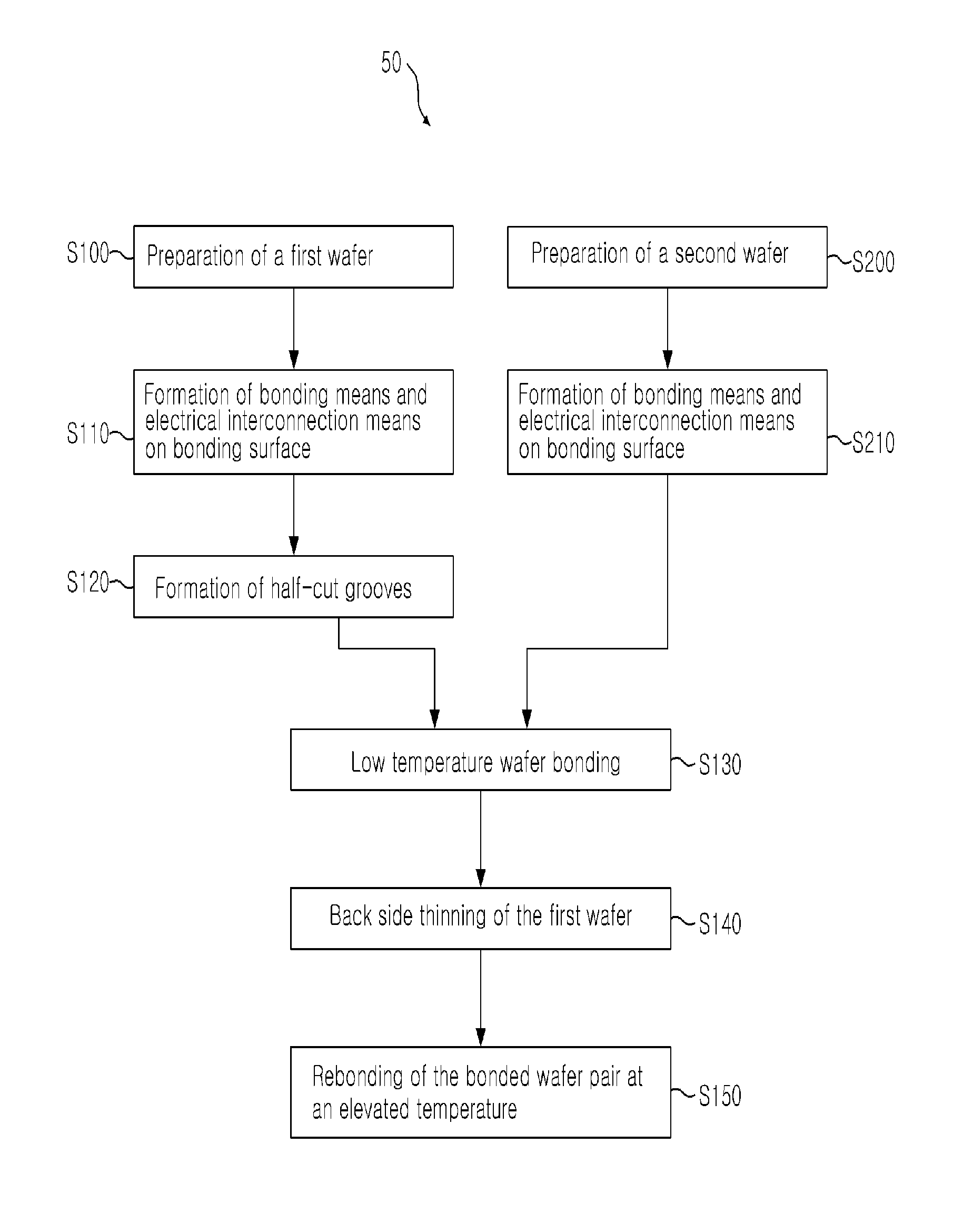

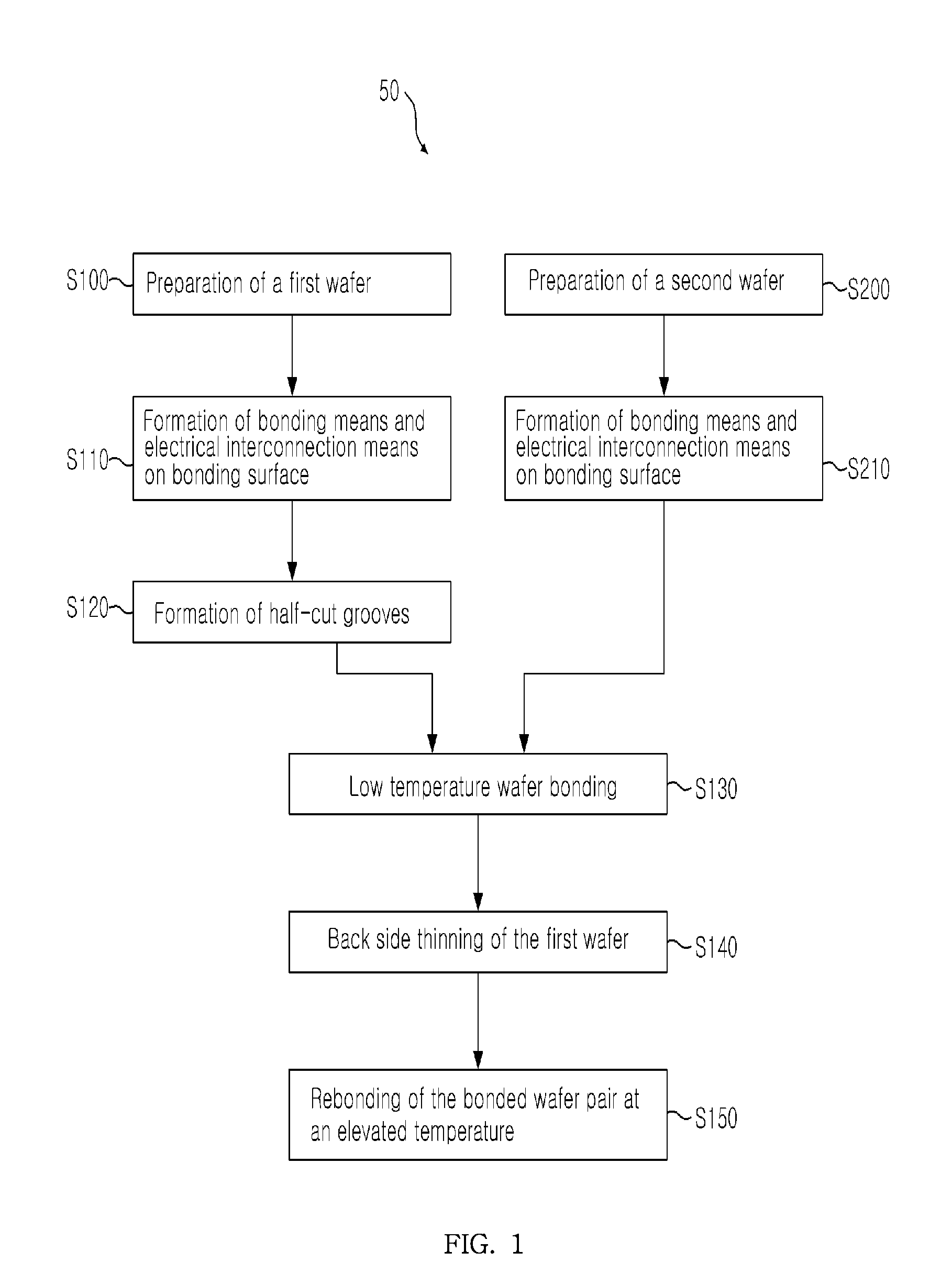

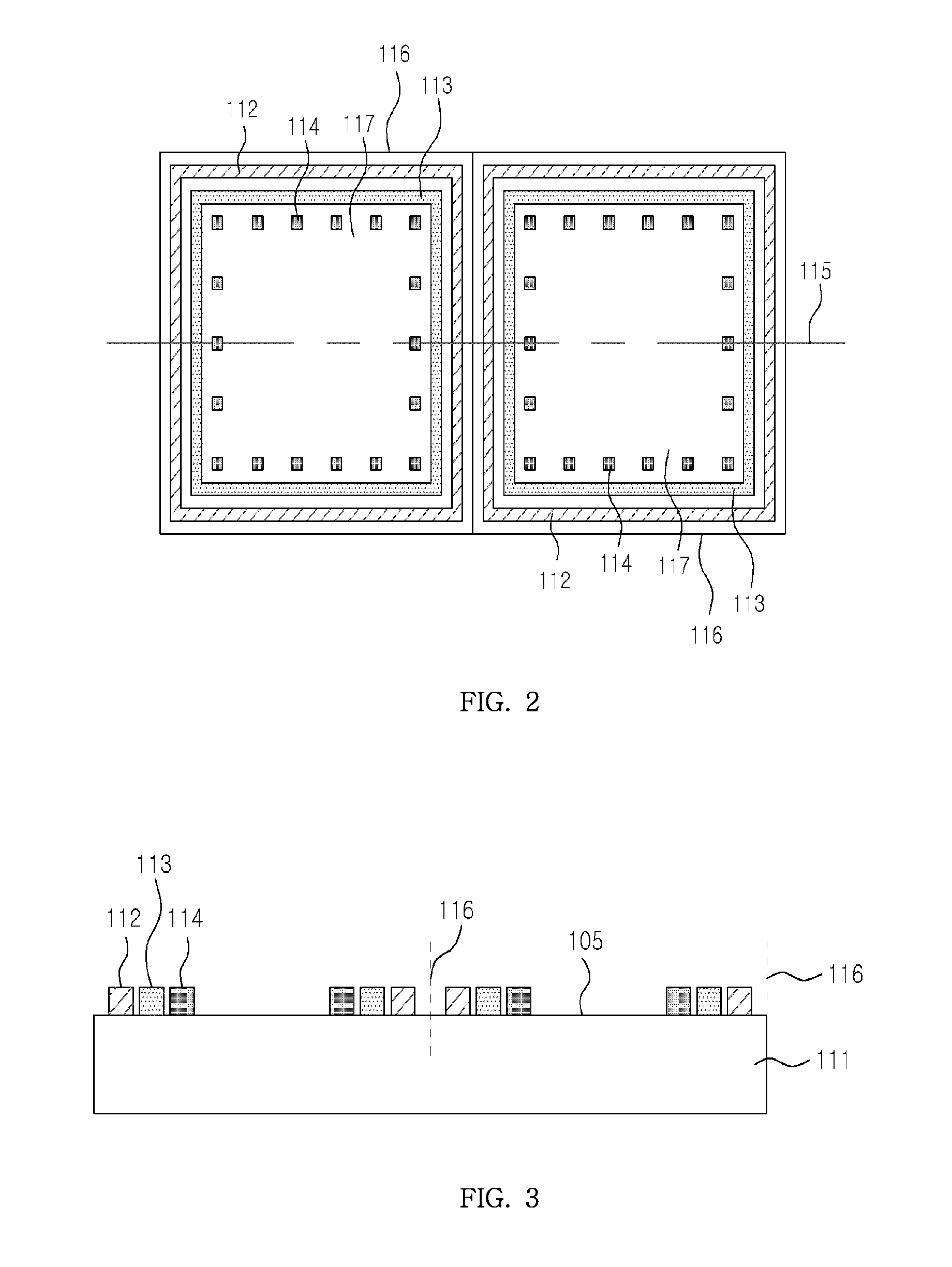

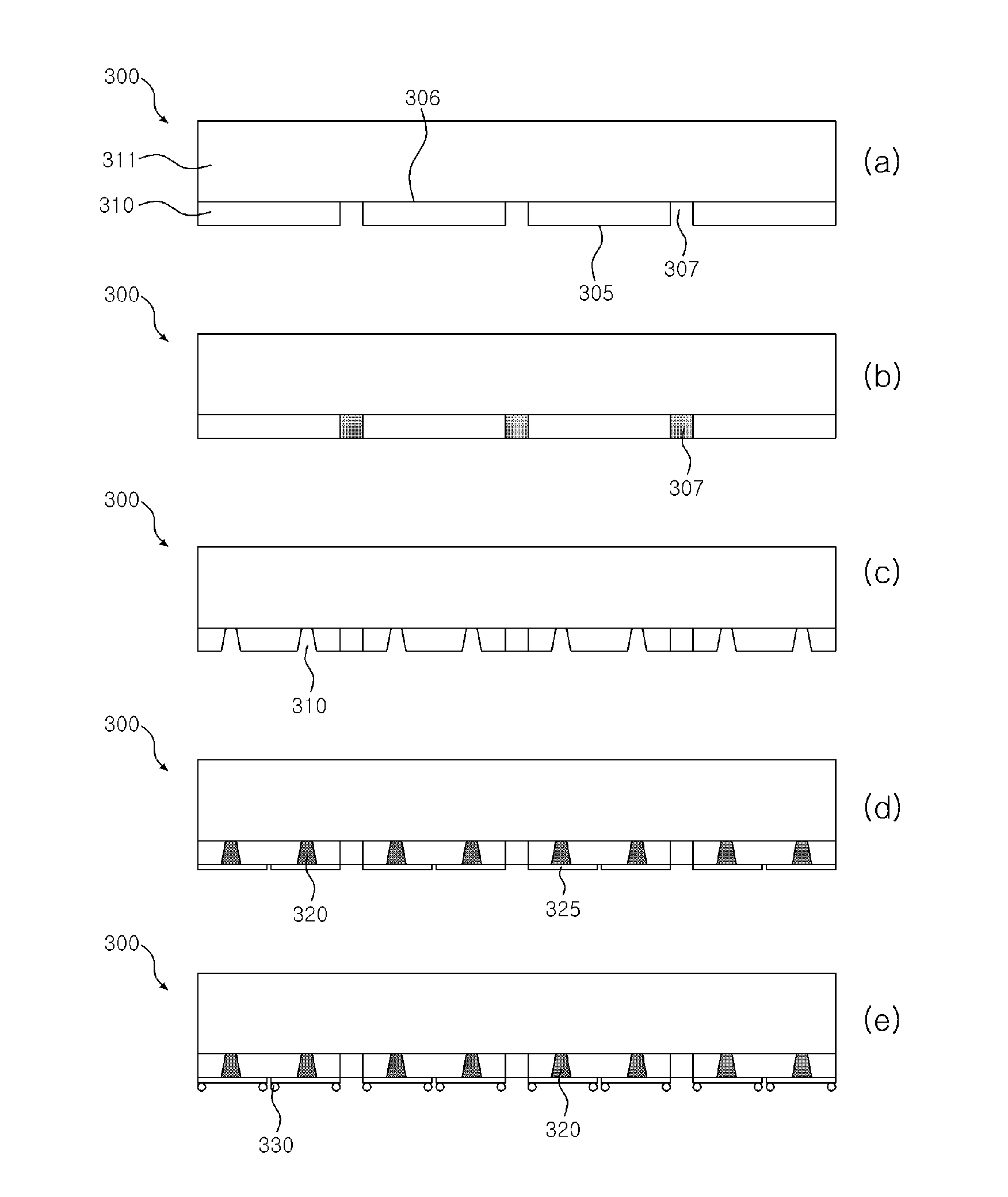

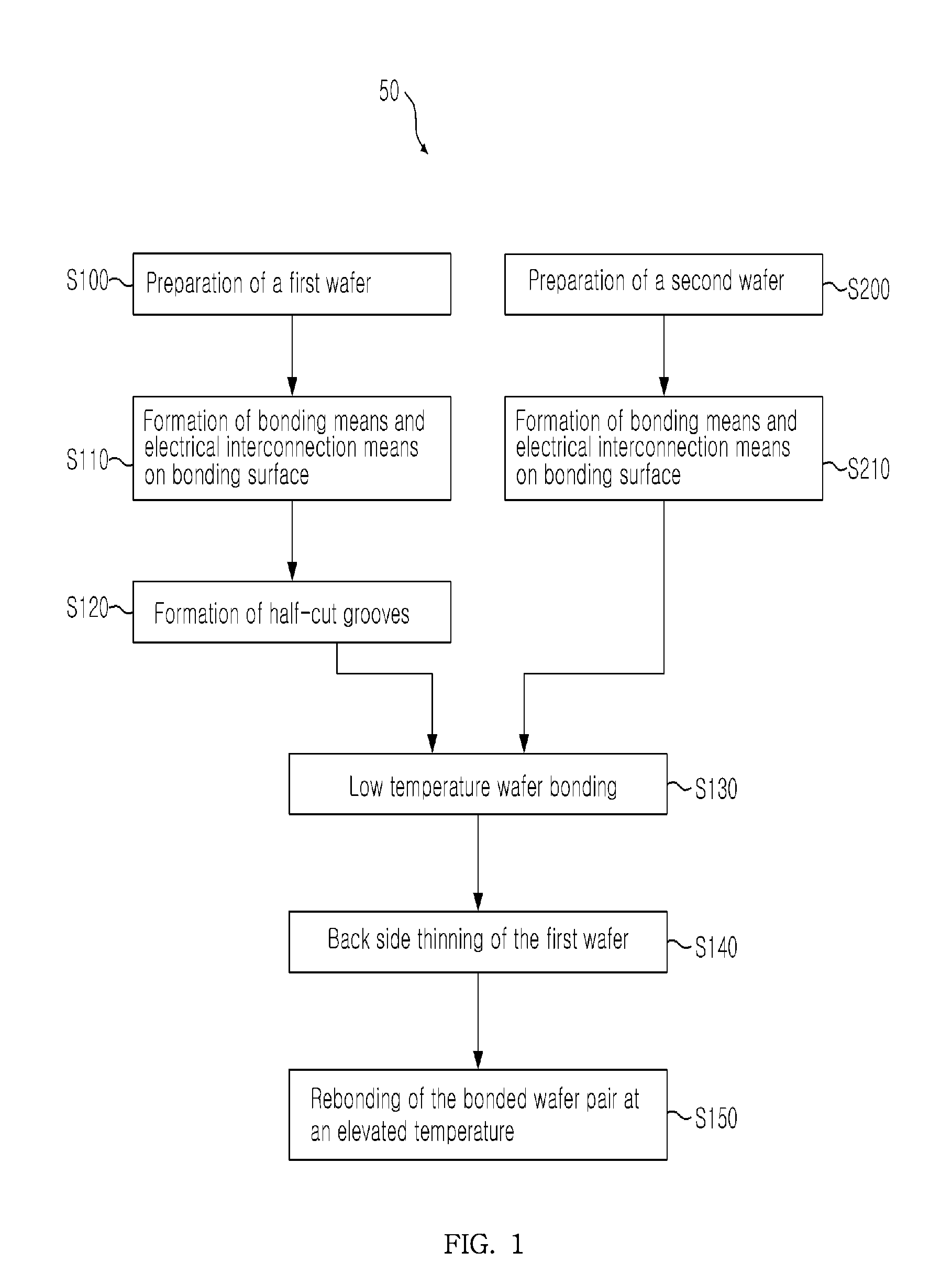

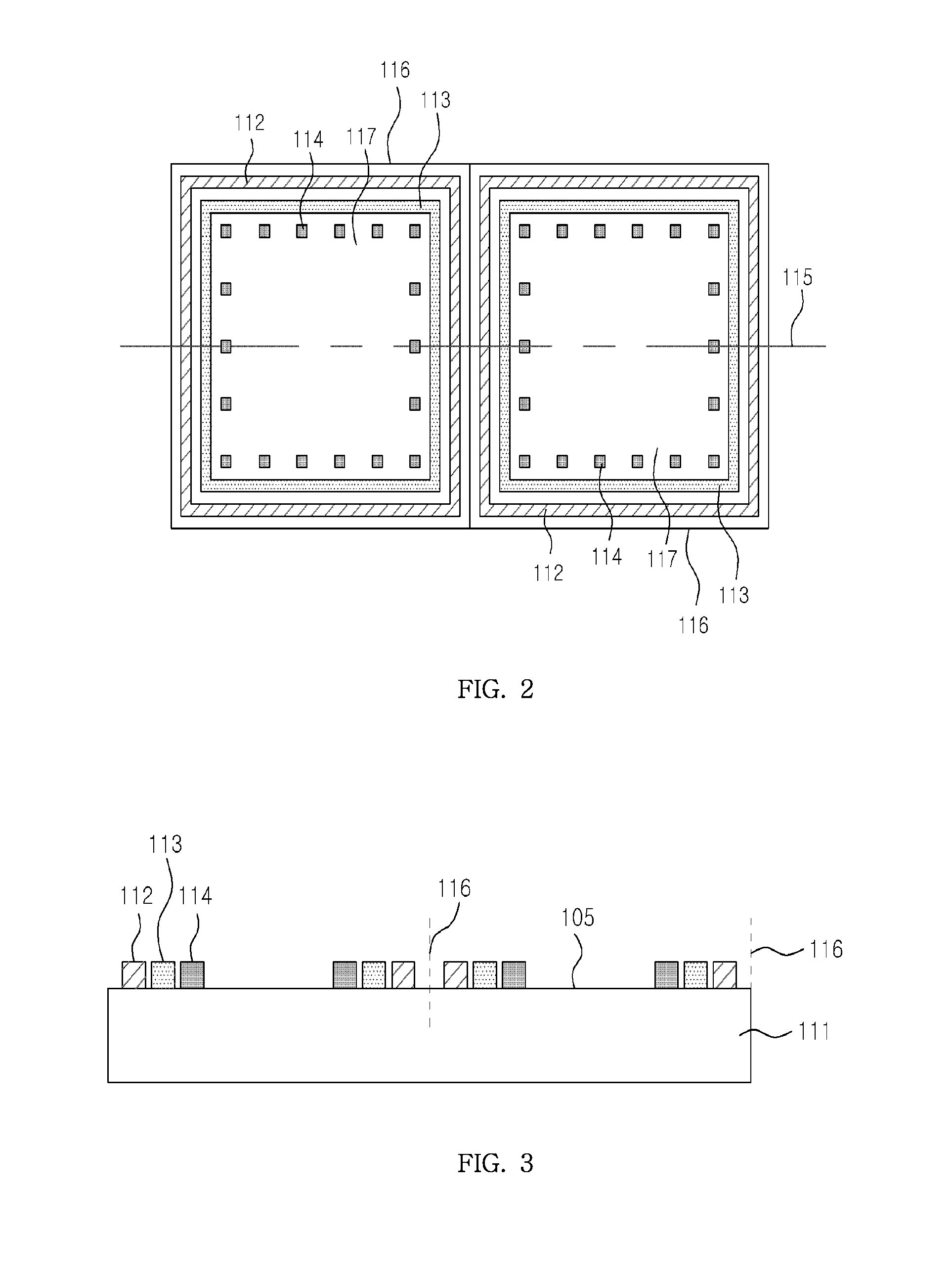

Method for manufacturing hetero-bonded wafer

InactiveUS8241961B2Low costGood adhesionSemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

A method for manufacturing a hetero-bonded wafer having a large mismatch of thermal expansion coefficient comprises forming a wafer bonding means and an electrical interconnection means on at least one bonding surface of two wafers to be bonded with each other, forming grooves in the bonding surface of one wafer along dicing lines with an interval between the grooves being equal to or an even multiple of a die width, bonding the two wafers at a temperature less than 200° C., thinning a back side of the grooved wafer such that at least a portion of the grooves is exposed, and rebonding the bonded wafer pair at an elevated temperature higher than the first bonding temperature. The method for manufacturing a hetero-bonded wafer can avoid wafer level bow / warp and also reduce debonding and cracking in individual segments induced by thermal stress due to a mismatch of thermal expansion coefficient. Embodiments of the method are useful for wafer level packaging and the fabrication of hybrid devices by heterogeneous wafer bonding.

Owner:KIM YOUNG HAE

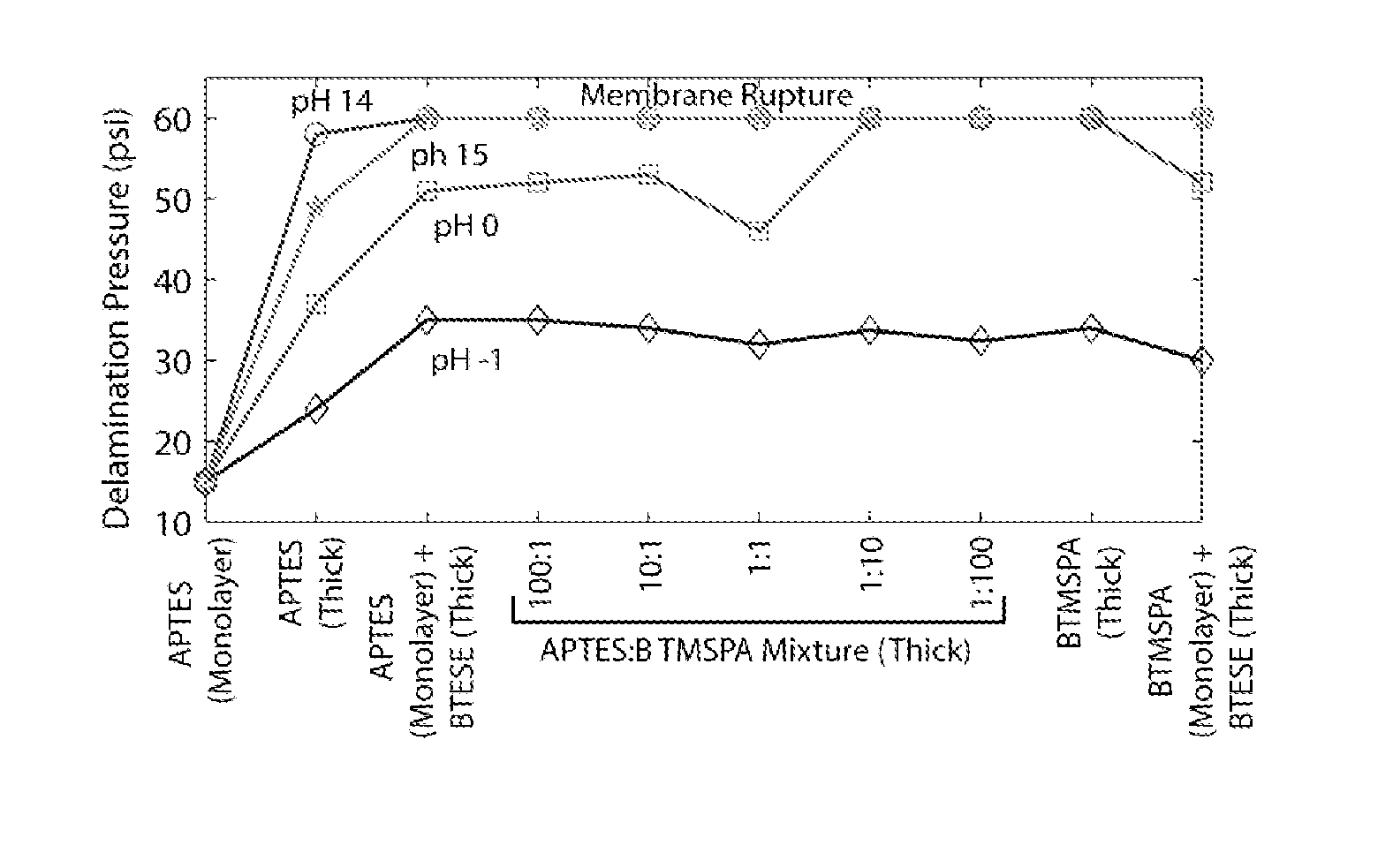

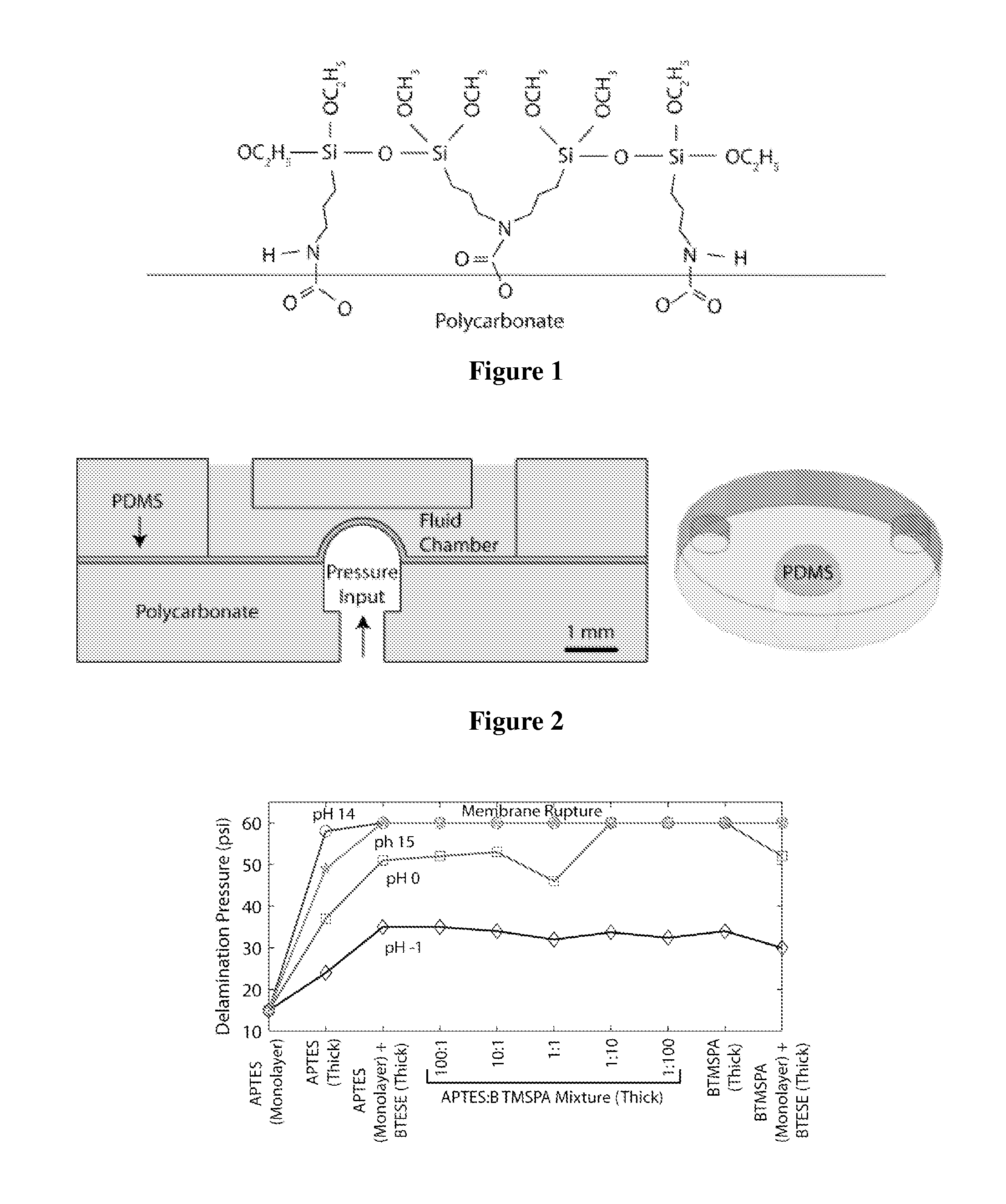

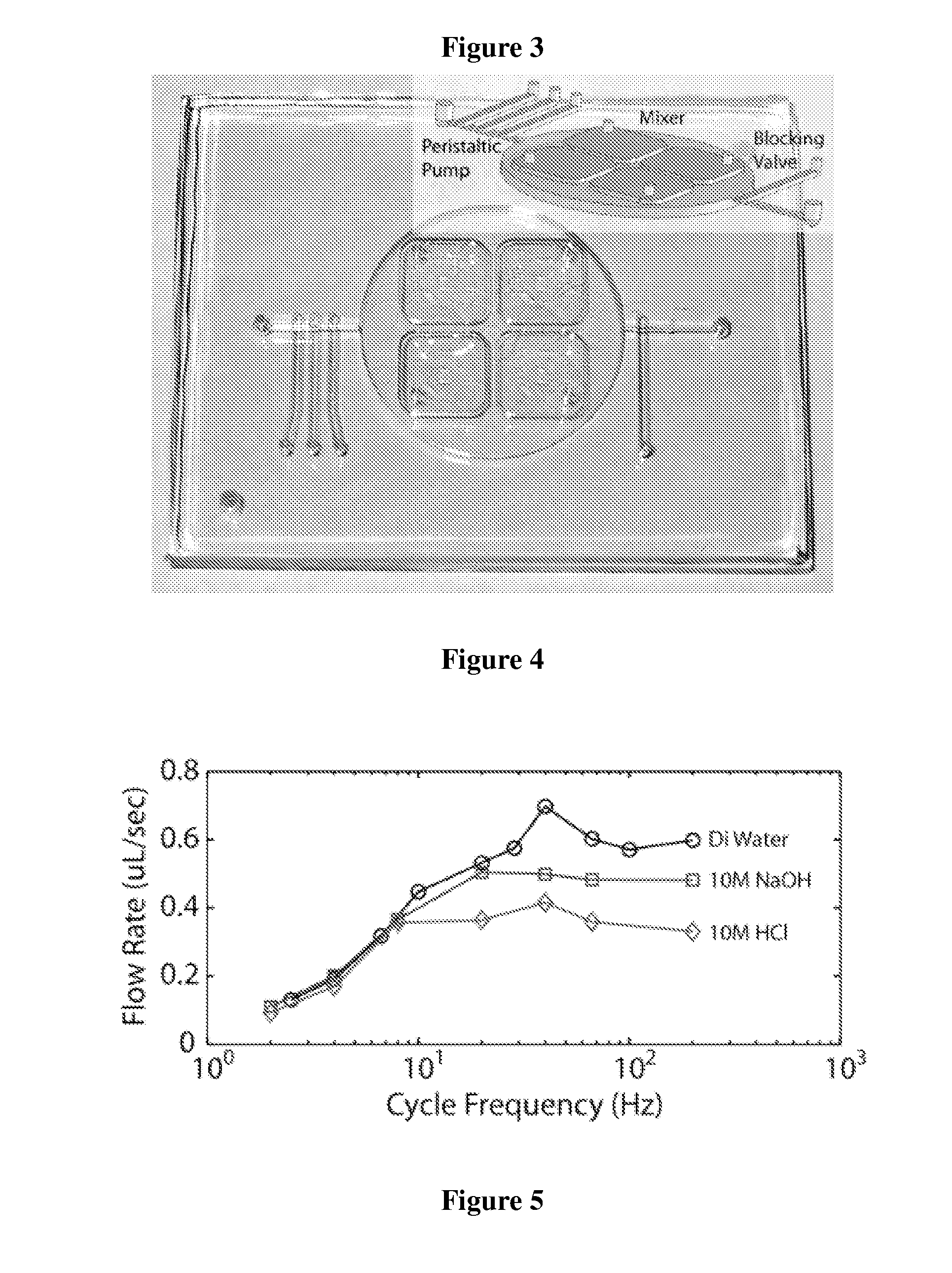

Method of hydrolytically stable bonding of elastomers to substrates

ActiveUS20110195260A1Hydrolytic stabilityAdhesive processesLaboratory glasswaresElastomerPeristaltic pump

Active devices such as pumps and mixers have been fabricated in plastic-PDMS hybrid devices. By utilizing functionalized bis-silane primers, bond strength between Polycarbonate or PMMA and PDMS improved in dry and aqueous environments. Plastic-primer-PDMS layers exposed to acid and base solutions at 70° C. for 2 hours showed no signs of delamination at 30 psi for pH −1 to 15 and 60 psi for pH 0 to 15. A peristaltic pump fabricated in polycarbonate achieved consistent flow rates up to peristaltic cycle frequencies of 10 Hz in water, 1OM HCl, and 1OM NaOH solutions.

Owner:MASSACHUSETTS INST OF TECH

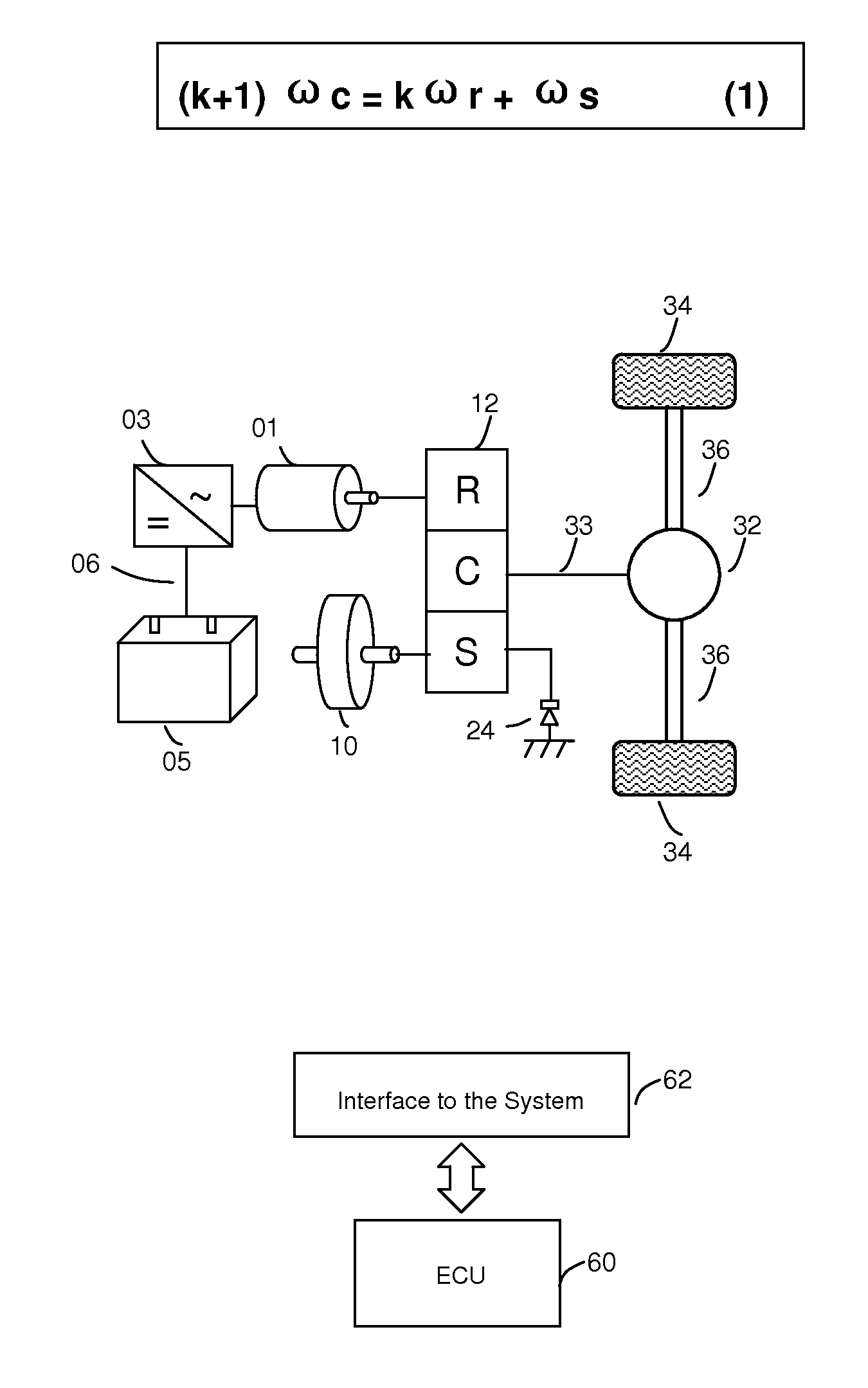

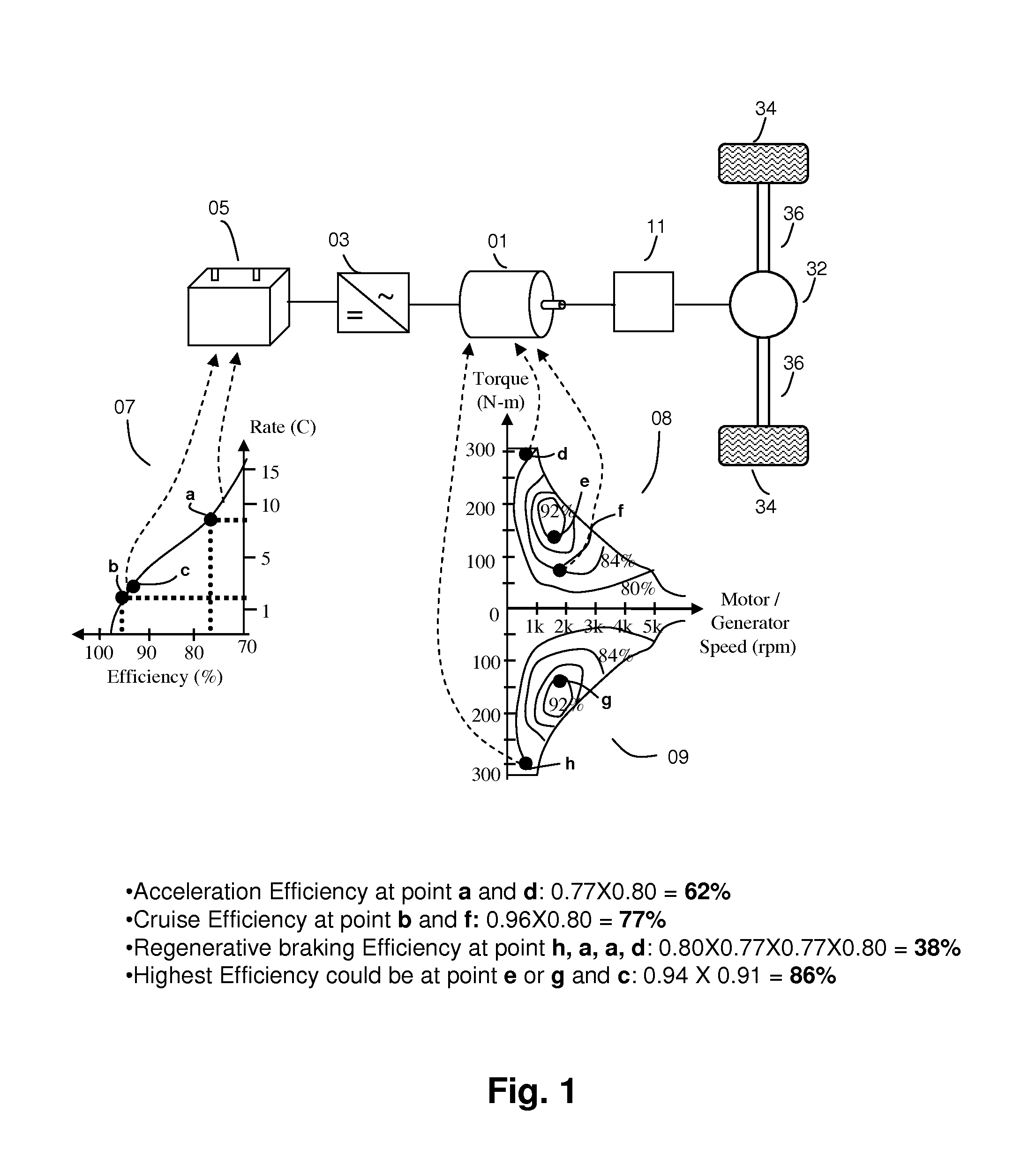

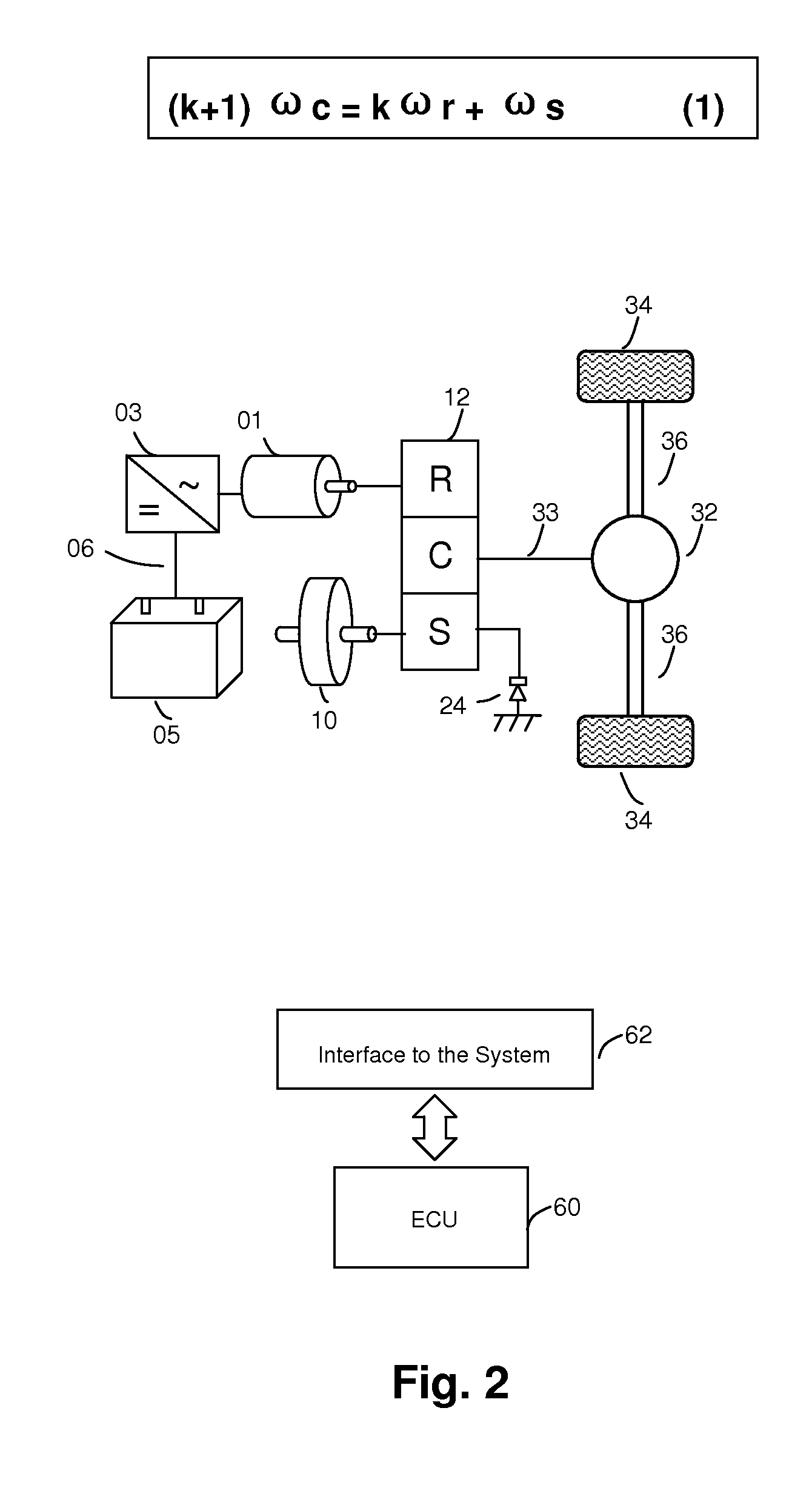

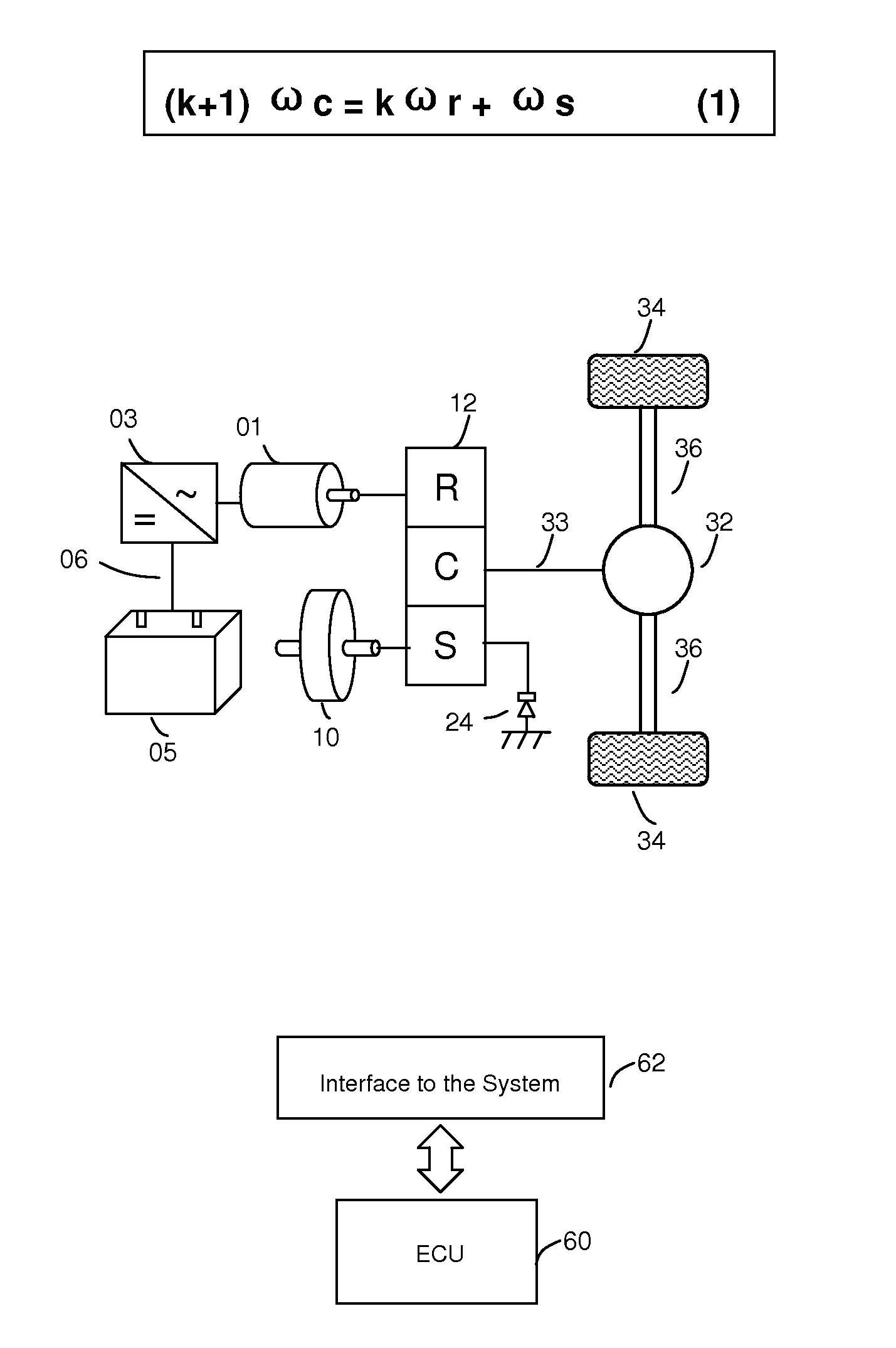

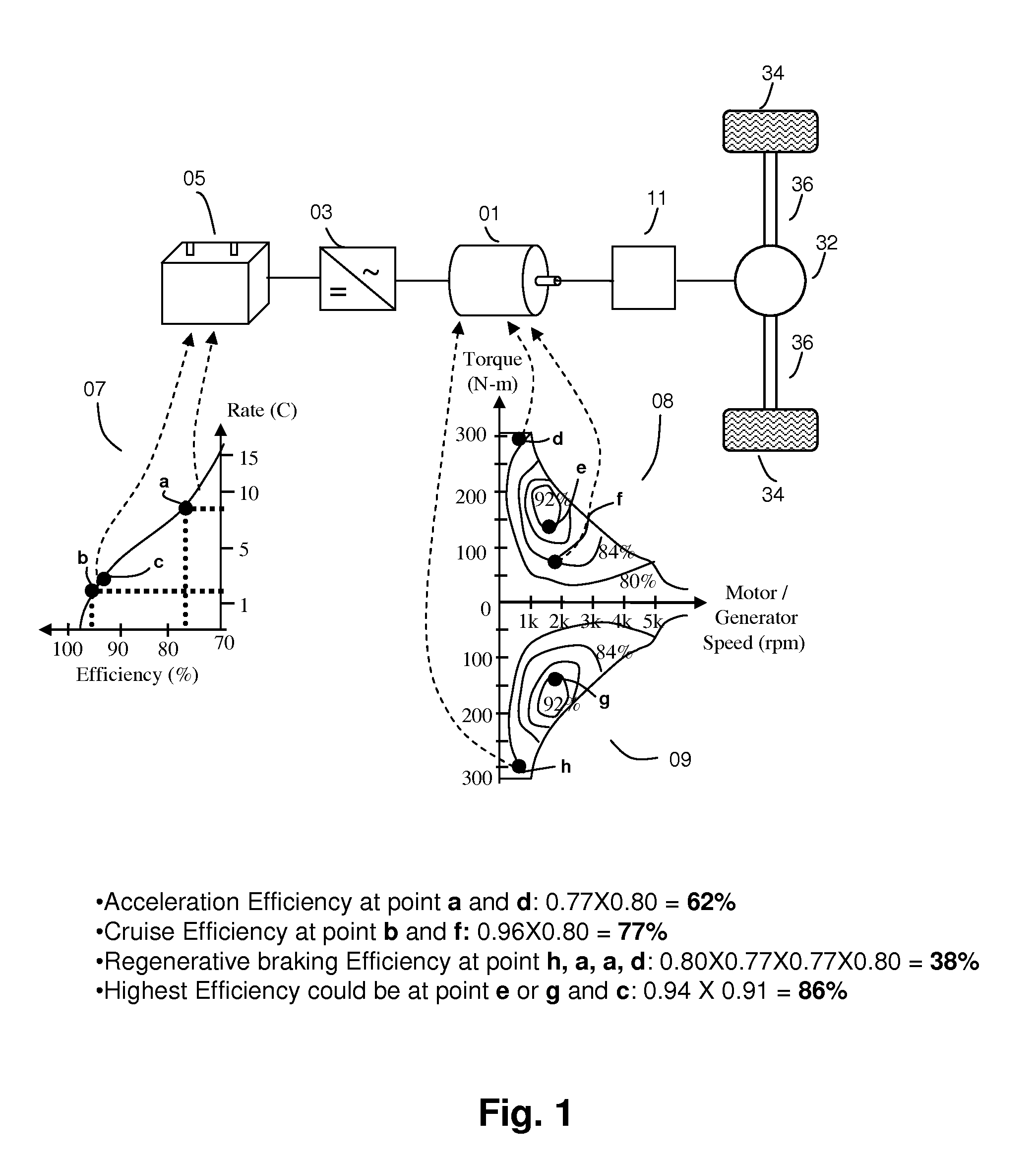

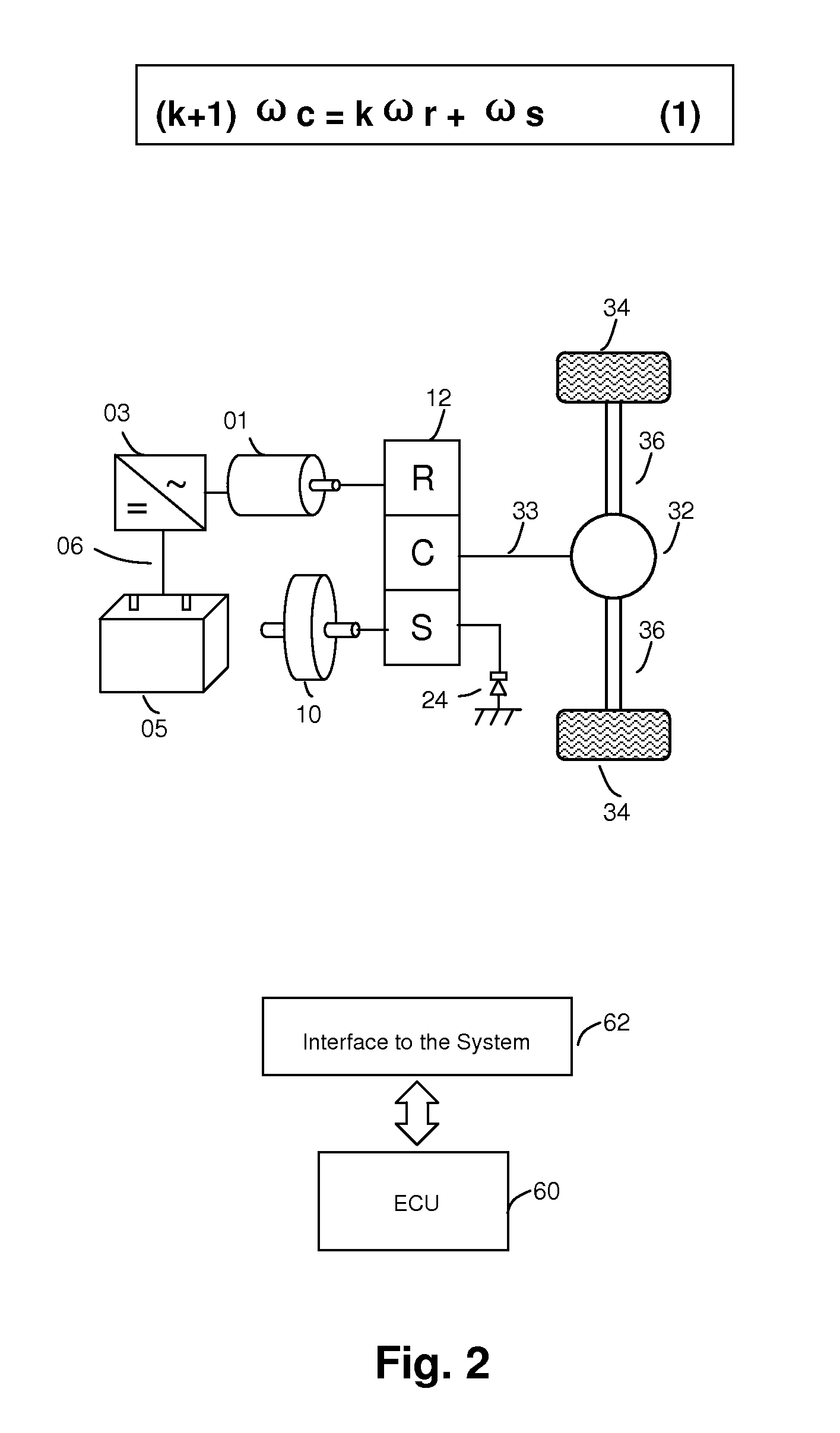

Powertrain and Method for a Kinetic Hybrid Vehicle

InactiveUS20120197472A1Minimal energy conversion and conversionImprove performanceDigital data processing detailsToothed gearingsGear systemFlywheel

A kinetic hybrid device and method for a vehicle may include a planetary gear system configured as a continuously variable transmission comprised of three or four ports. The kinetic hybrid device and method may include a flywheel connected to a first port of the system, a final drive connected to a second port of the system, and the variator for the flywheel connected to a third or fourth port of the system. The prime mover and / or other power sources may share a port with the flywheel, but do not share a port with the final drive.

Owner:HE JING +1

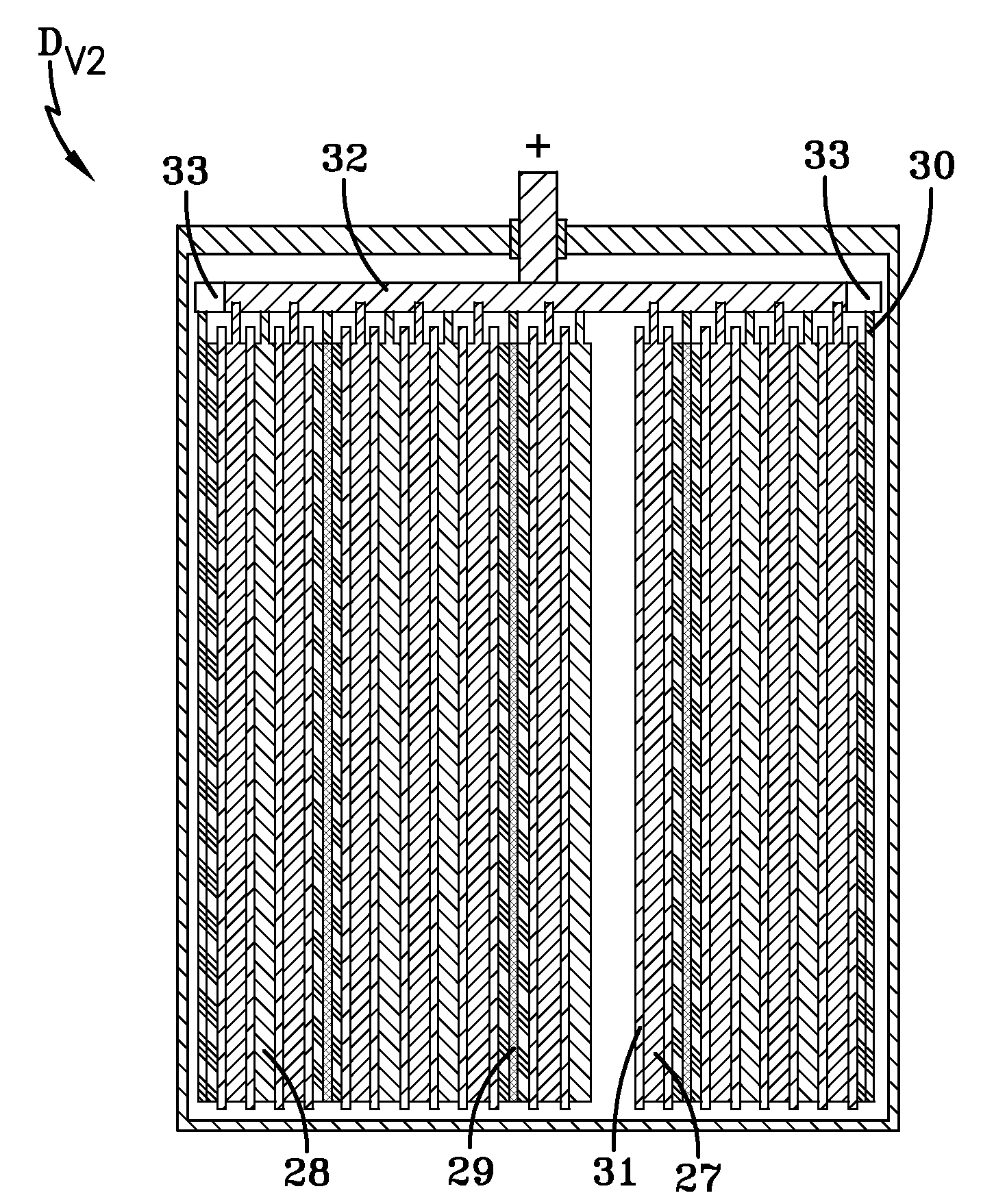

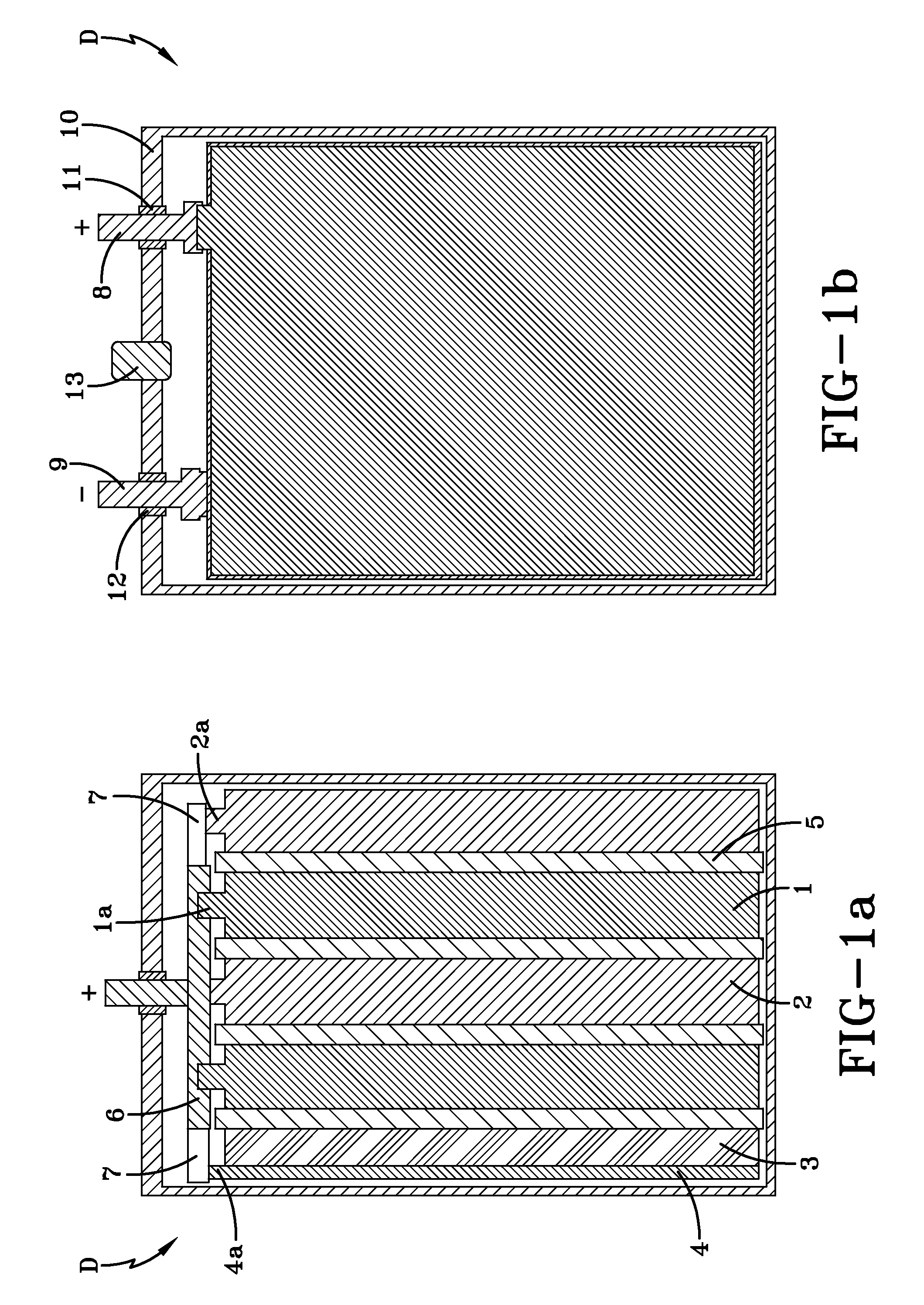

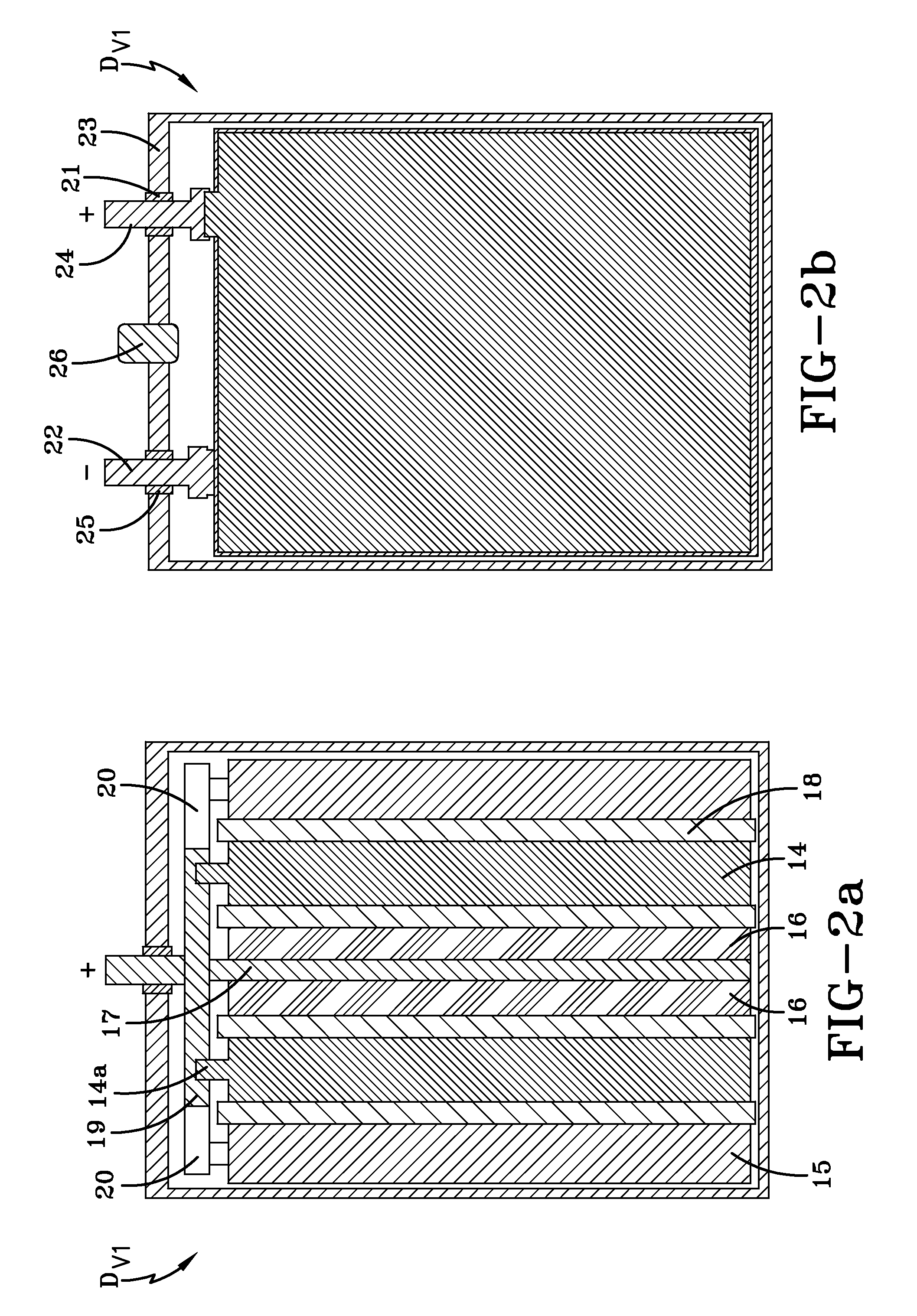

Electrochemical supercapacitor/lead-acid battery hybrid electrical energy storage device

InactiveUS20080199737A1Low costHybrid capacitor electrolytesCapacitor and primary/secondary cellsEngineeringElectrochemistry

A hybrid lead-acid battery / electrochemical capacitor electrical energy storage device. The lead-acid battery and electrochemical capacitor reside in the same case and are electrically connected. Preferably, a hybrid device of the present invention includes at least one non-polarizable positive electrode, at least one non-polarizable negative electrode, and at least one polarizable electric double layer negative electrode. Separators reside between the electrodes and the separators and electrodes are impregnated with an aqueous sulfuric acid electrolyte. A hybrid device of the present invention exhibits high power characteristics.

Owner:UNIVERSAL SUPERCAPACITORS LLC

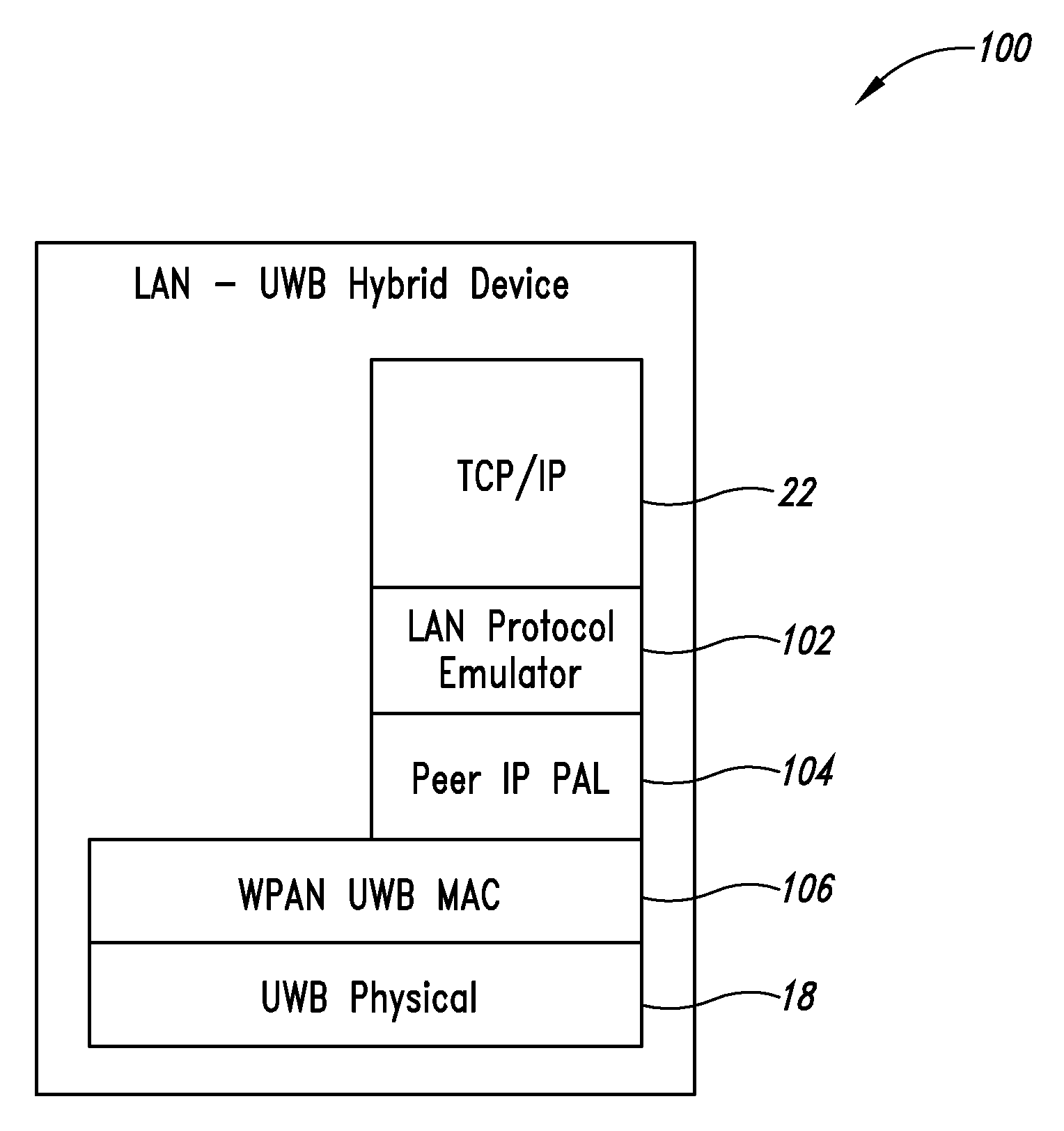

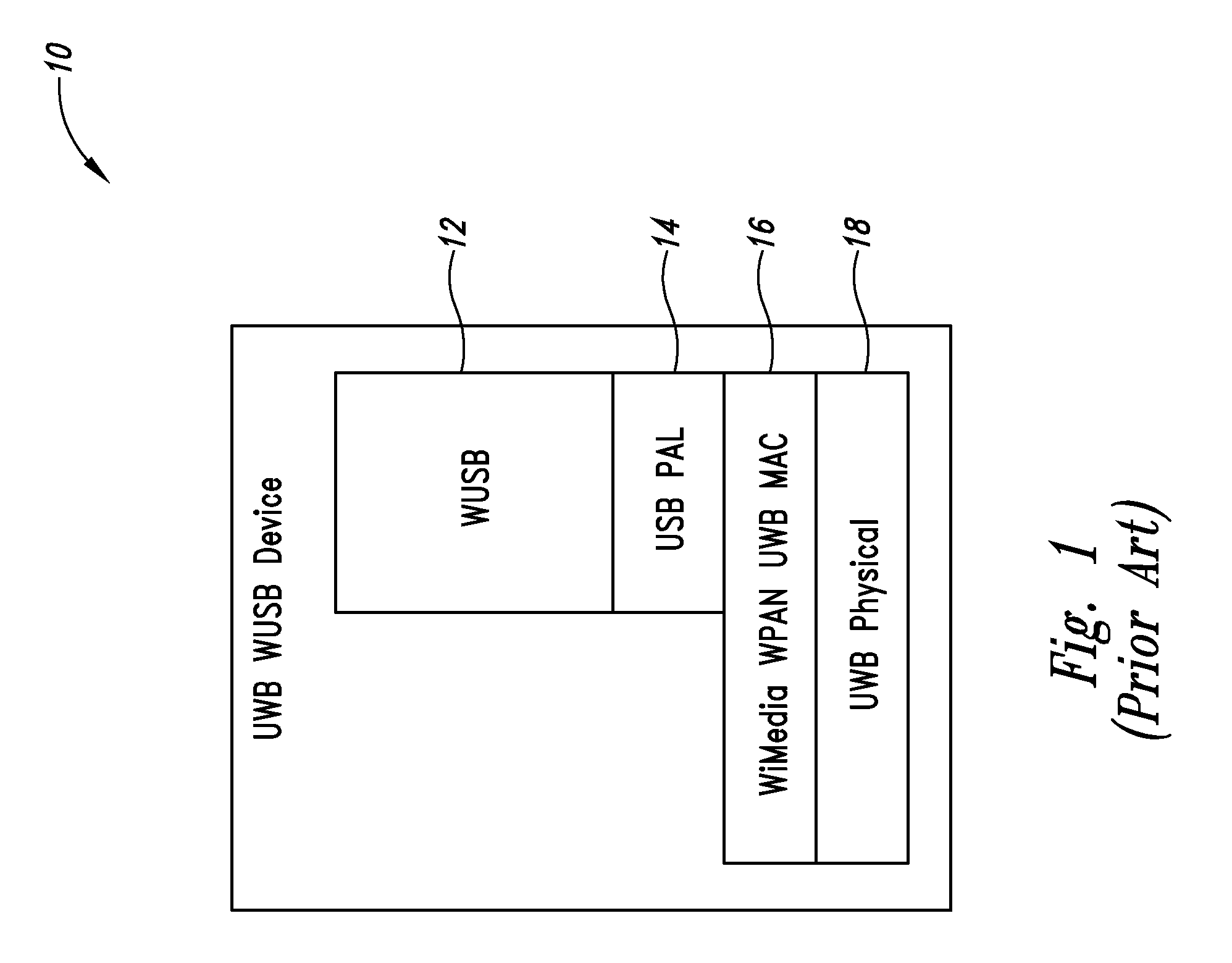

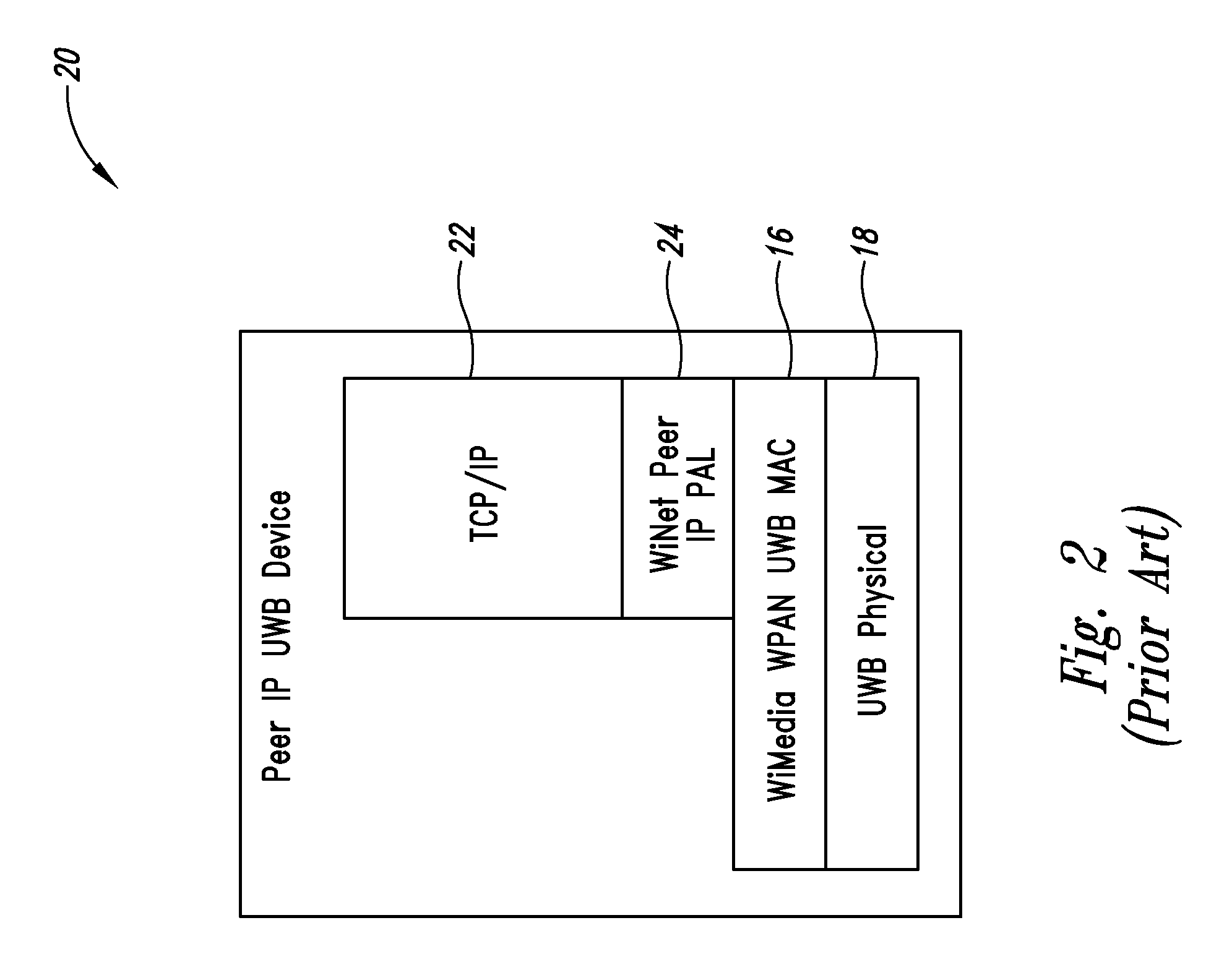

LAN by ultra-wideband system and method

An ultra-wideband (UWB) system and method provide a local area network (LAN) and / or LAN access. LAN access versions of the UWB system includes an emulator layer and bridge that allow data to be transmitted between a LAN-UWB hybrid device and a LAN network switch, such as an IEEE 802 network switch, through in part a UWB node of a UWB WPAN that can receive UWB super-frames from the LAN-UWB hybrid device. In some implementations the LAN-UWB hybrid device uses WiFi protocol layers above the emulator layer and a WiNet Peer IP PAL layer below the emulator layer.

Owner:FREESCALE SEMICON INC +1

Information broadcasting and support system using mobile devices

InactiveUS20060172697A1Broadcast transmission systemsFile transfer between terminalsSupporting systemMediaFLO

A system to provide media to broadcast informational advertising or any other kind of ad campaign by using portable devices carried by users, such as mobile telephones, PDA devices, hybrid devices and, in general, any device that permits a multimedia reproduction of content received in the device, either in the form of a call or in the form of a message. The system provides for the implementation of an application in the mobile device, whose application involves a call management and campaign broadcast module, a configuration and storage management module, and server data communication modules. The interrelationships between the application modules and the modules in the mobile device are done through interfaces. The system allows users to configure parameters and also incorporates point generating media depending on the broadcast performed.

Owner:GALLEGO FERNANDO PLANAS +2

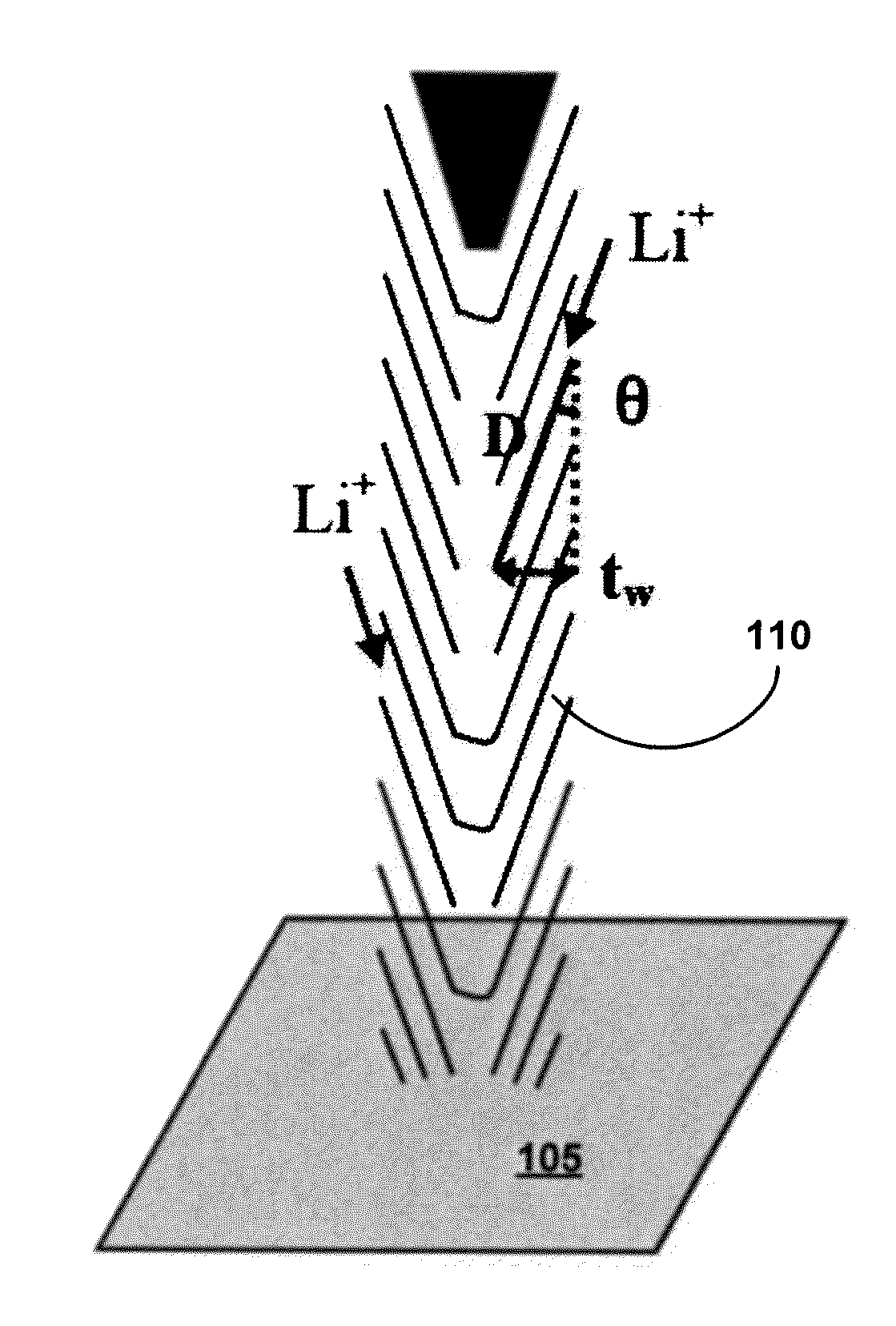

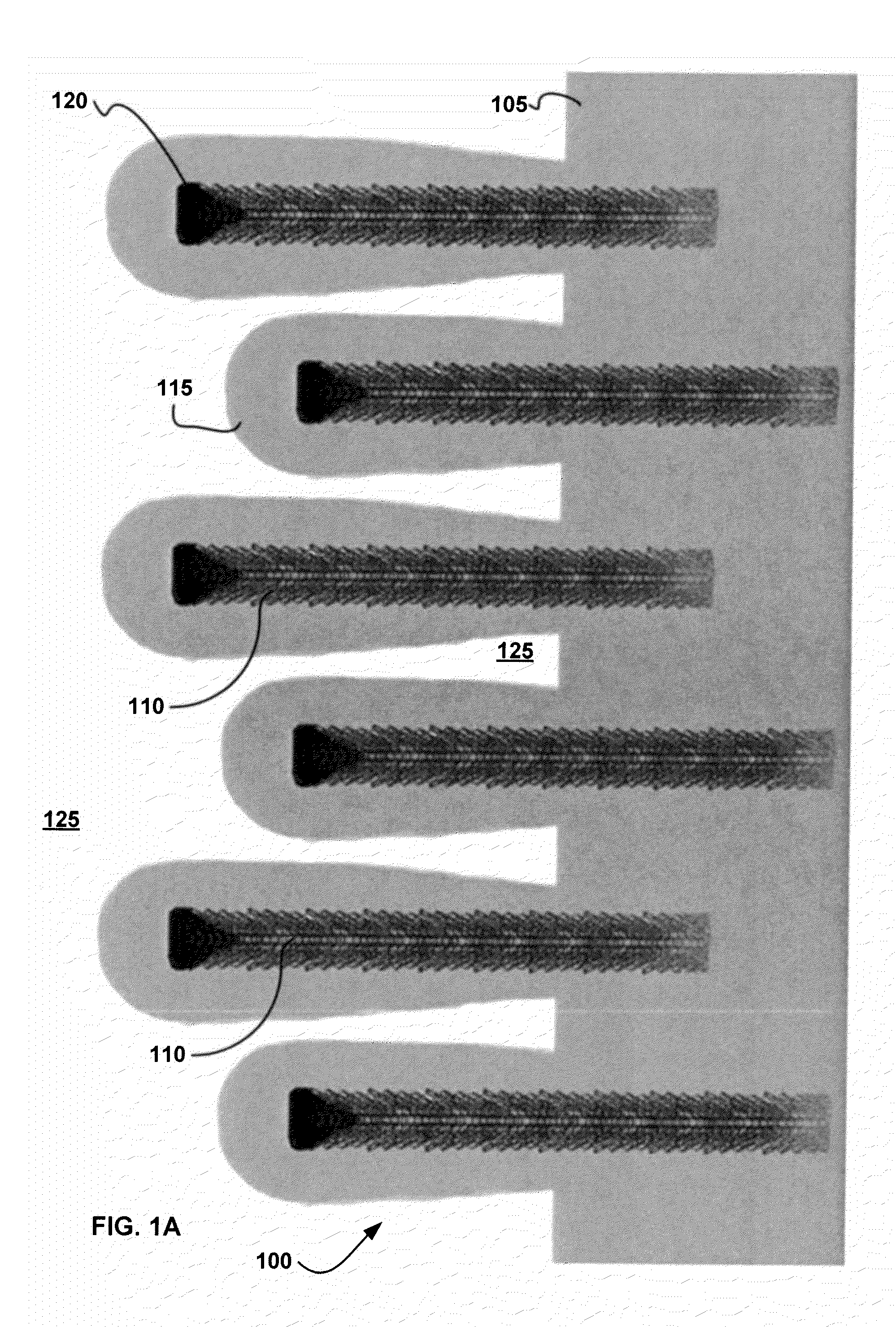

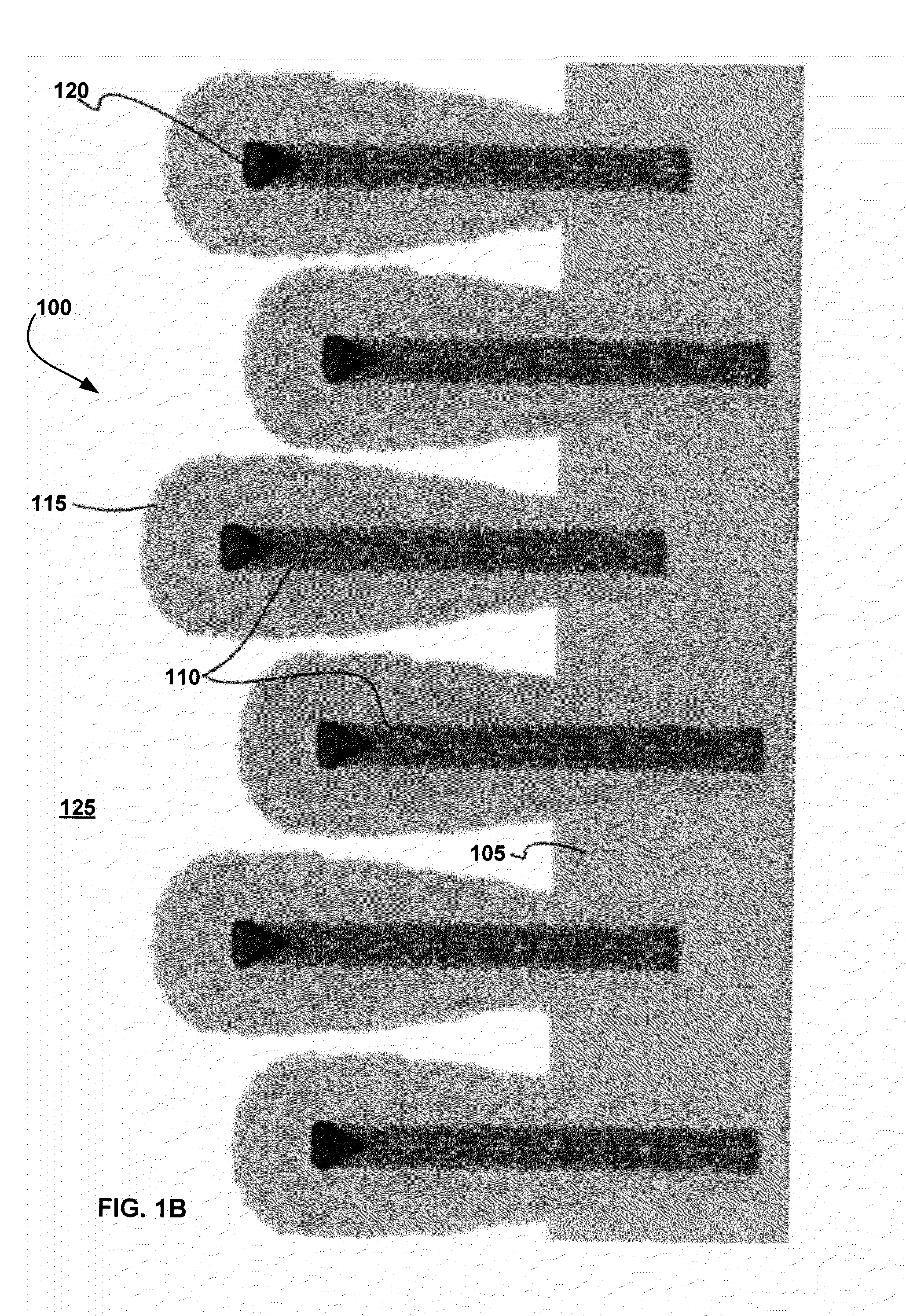

Hybrid Energy Storage Device Charging

A novel hybrid lithium-ion anode material based on coaxially coated Si shells on vertically aligned carbon nanofiber (CNF) arrays. The unique cup-stacking graphitic microstructure makes the bare vertically aligned CNF array an effective Li+ intercalation medium. Highly reversible Li+ intercalation and extraction were observed at high power rates. More importantly, the highly conductive and mechanically stable CNF core optionally supports a coaxially coated amorphous Si shell which has much higher theoretical specific capacity by forming fully lithiated alloy. Addition of surface effect dominant sites in close proximity to the intercalation medium results in a hybrid device that includes advantages of both batteries and capacitors.

Owner:CF TRAVERSE LLC

Method for Manufacturing Hetero-Bonded Wafer

InactiveUS20100308455A1Increase first bonding strengthInhibit thermal stressSemiconductor/solid-state device detailsSolid-state devicesEngineeringInterconnection

A method for manufacturing a hetero-bonded wafer having a large mismatch of thermal expansion coefficient comprises forming a wafer bonding means and an electrical interconnection means on at least one bonding surface of two wafers to be bonded with each other, forming grooves in the bonding surface of one wafer along dicing lines with an interval between the grooves being equal to or an even multiple of a die width, bonding the two wafers at a temperature less than 200° C. thinning a back side of the grooved wafer such that at least a portion of the grooves is exposed, and rebonding the bonded wafer pair at an elevated temperature higher than the first bonding temperature. The method for manufacturing a hetero-bonded wafer can avoid wafer level bow / warp and also reduce debonding and cracking in individual segments induced by thermal stress due to a mismatch of thermal expansion coefficient. Embodiments of the method are useful for wafer level packaging and the fabrication of hybrid devices by heterogeneous wafer bonding.

Owner:KIM YOUNG HAE

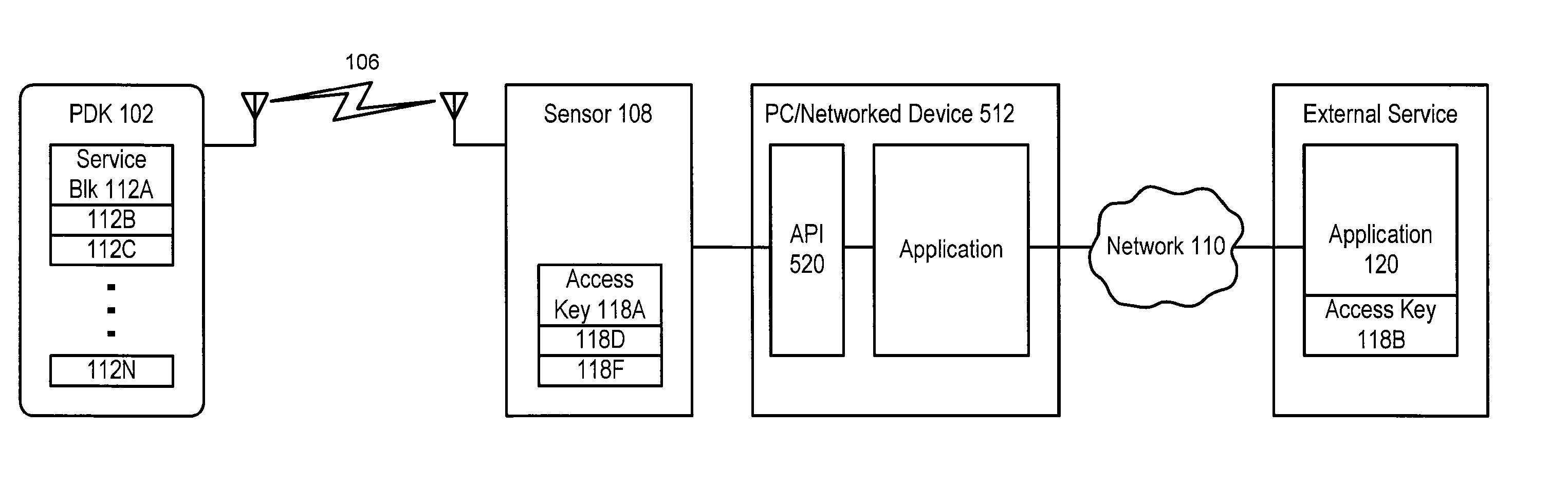

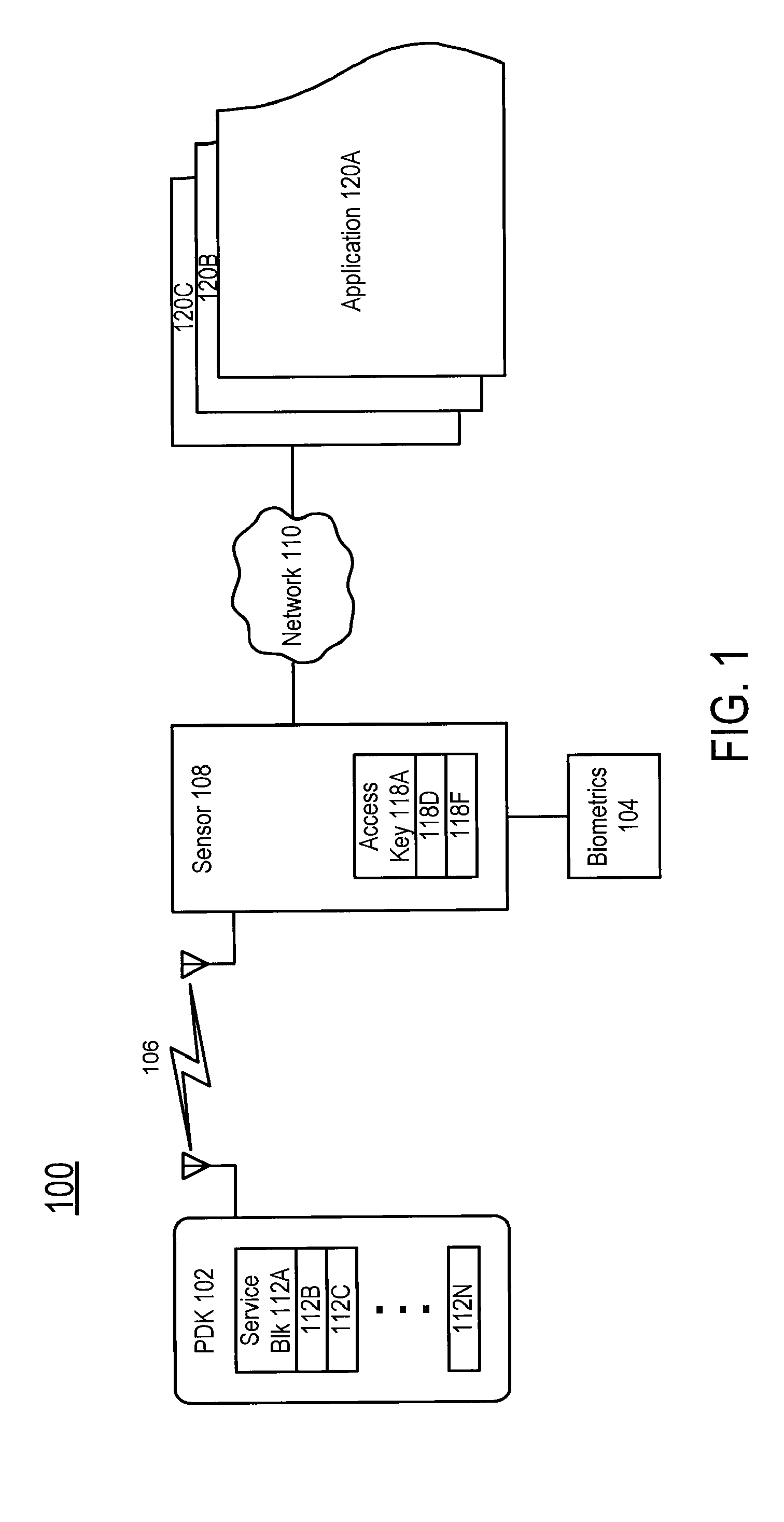

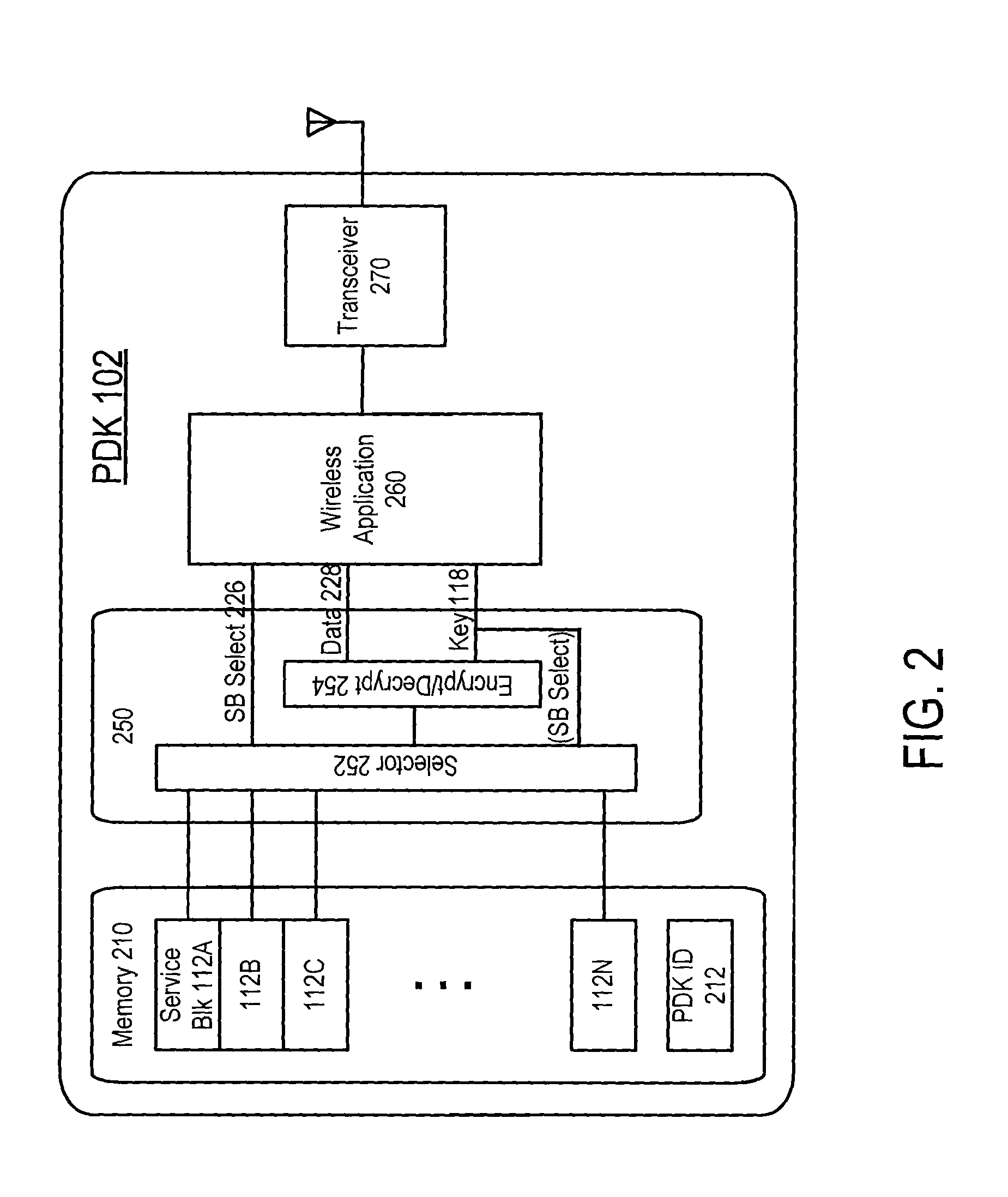

Hybrid device having a personal digital key and receiver-decoder circuit and methods of use

ActiveUS8171528B1Automatically featureOvercomes drawbackDigital data processing detailsMultiple digital computer combinationsControl signalEngineering

A hybrid device includes a personal digital key (PDK) and a receiver-decoder circuit (RDC). The PDK and RDC of the hybrid device are coupled for communication with each other. In one embodiment, the hybrid device also provides a physical interconnect for connecting to other devices to send and receive control signals and data, and receive power. The hybrid device operates in one of several modes including, PDK only, RDC only, or PDK and RDC. This allows a variety of system configurations for mixed operation including: PDK / RDC, RDC / RDC or PDK / PDK. The present invention also includes a number of system configurations for use of the hybrid device including: use of the hybrid device in a cell phone; simultaneous use of the PDK and the RDC functionality of hybrid device; use of multiple links of hybrid device to generate an authorization signal, use of multiple PDK links to the hybrid device to generate an authorization signal; and use of the hybrid device for authorization inheritance.

Owner:PROXENSE

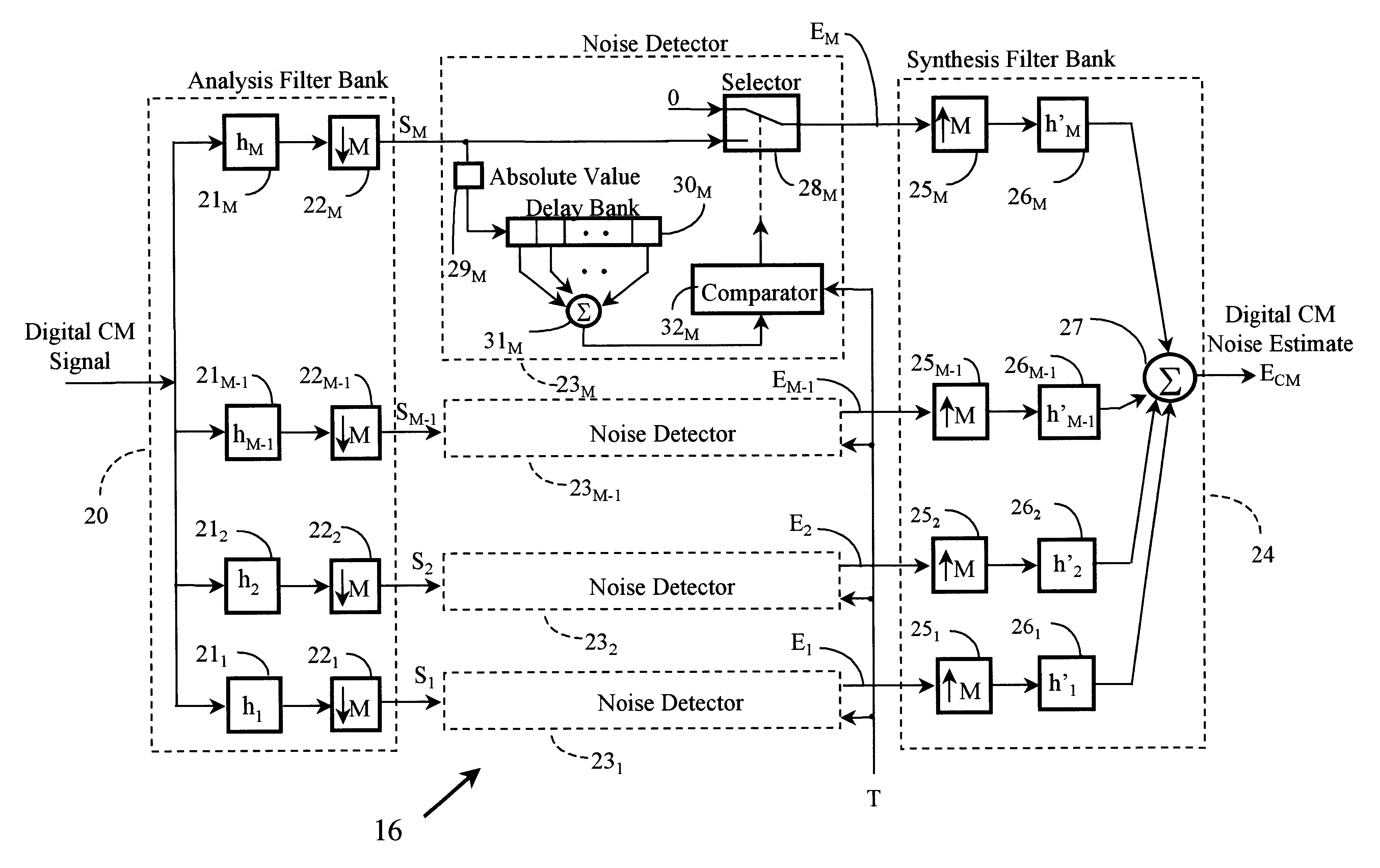

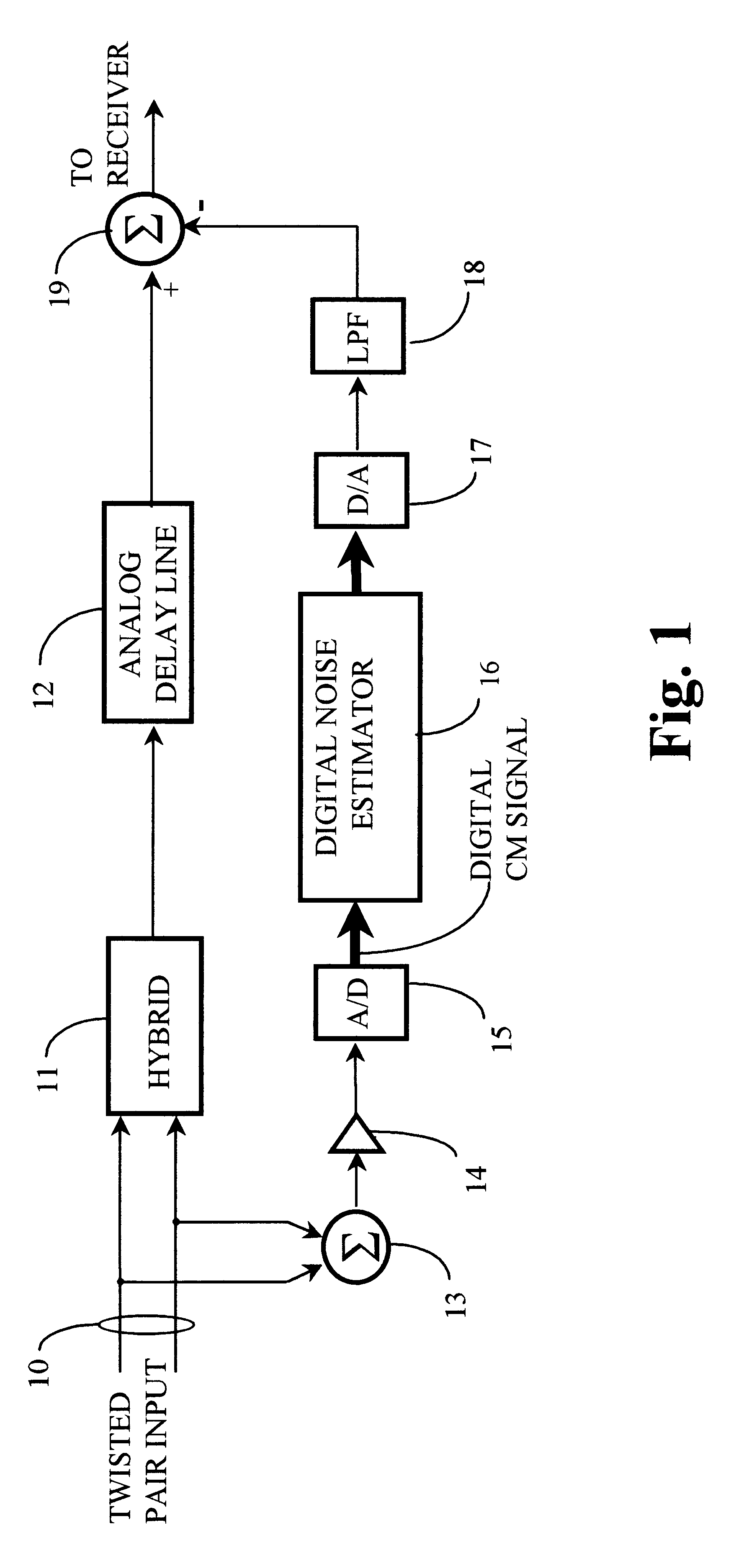

Suppression of radio frequency interference and impulse noise in communications channels

InactiveUS6546057B1Error preventionUnbalanced current interference reductionDifferential signalingEngineering

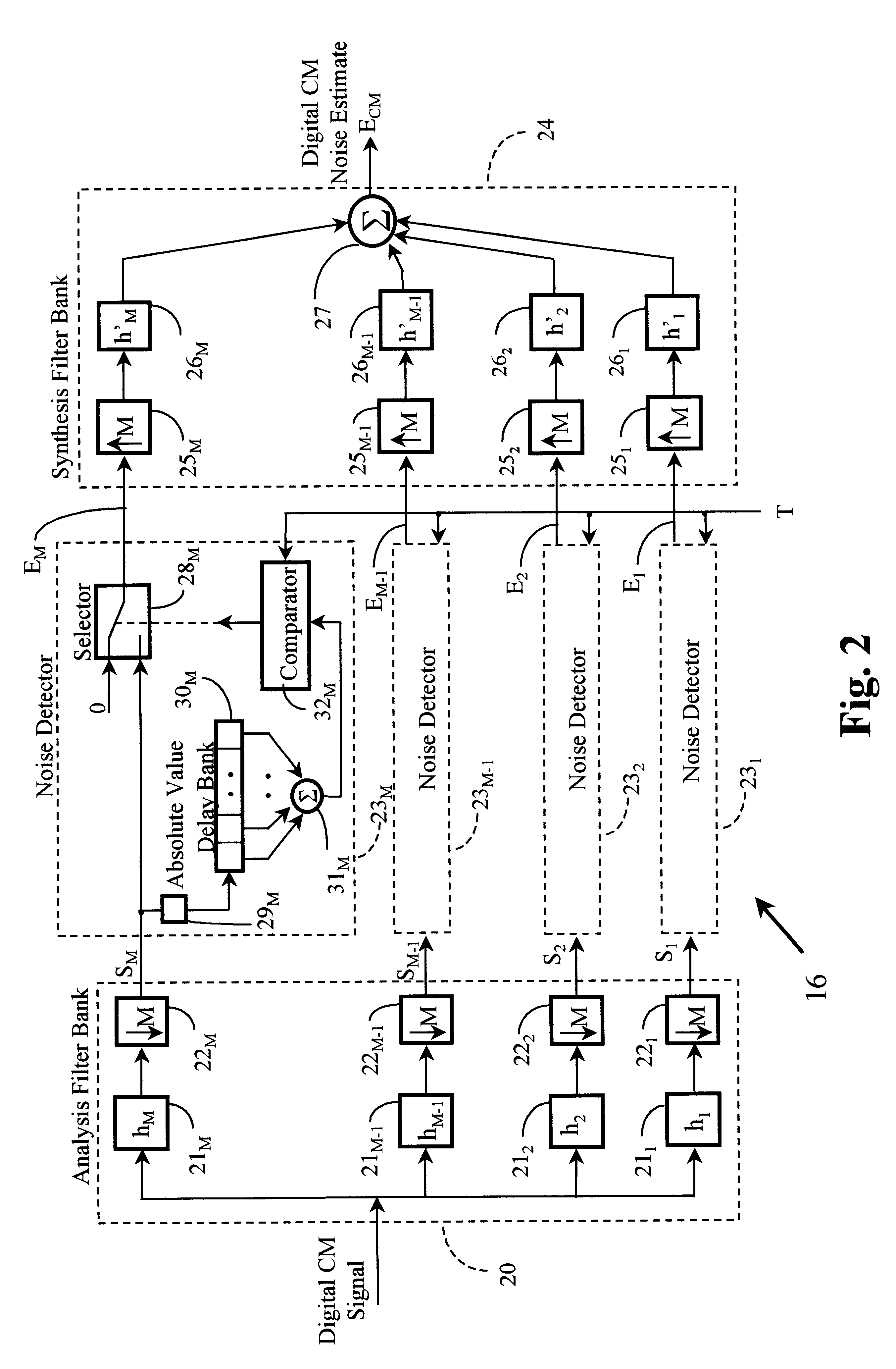

A noise suppression circuit for a communications channel (10) comprises a hybrid device (11) coupled to the channel for providing a differential output signal corresponding to a received signal. A delay unit (12) delays the differential signal by a suitable amount to allow for the generation and subtraction of a noise estimate. A summing device (13) extracts a digital common mode signal from the channel, and a noise estimation unit (16) provides a common mode noise estimate signal in dependence upon a history of the common mode signal over a predetermined period of time and over a plurality of frequency bands. The common mode noise estimate signal is combined subtractively (19) with the delayed differential signal to cancel common mode noise elements of the delayed differential signal. The noise estimation unit may comprise an analysis filter bank (20) for producing a plurality of subband signals (S1-SM), each at a different one of a plurality of different frequencies, a plurality of noise detection circuits (231-23M), each for processing a respective one of the plurality of subband signals to provide a component of the common mode noise estimate signal, and a synthesis filter bank (24) for processing the common mode noise signal components to provide the noise estimate signal.

Owner:BELL CANADA

Disposable sanitary mixing apparatus and method

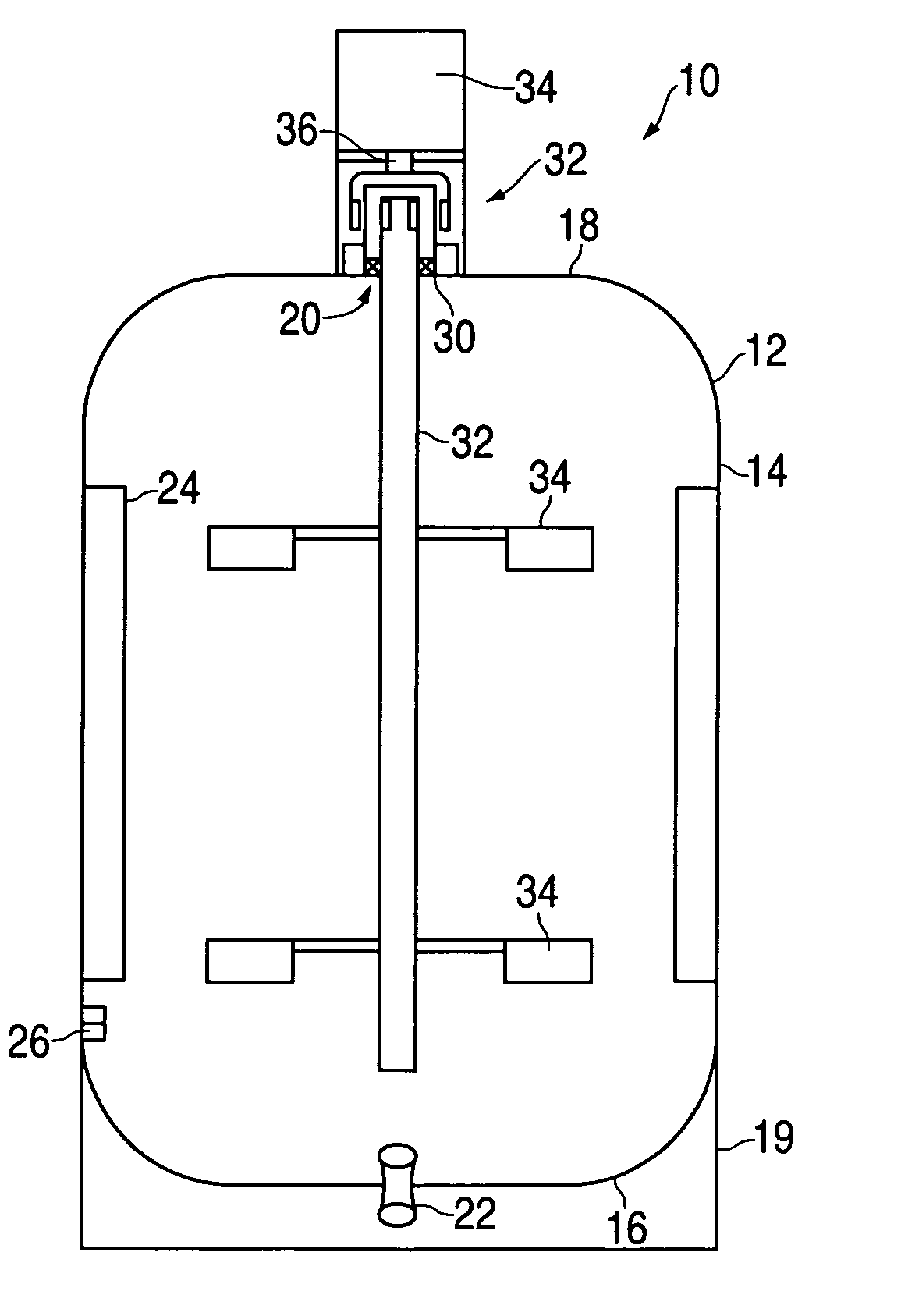

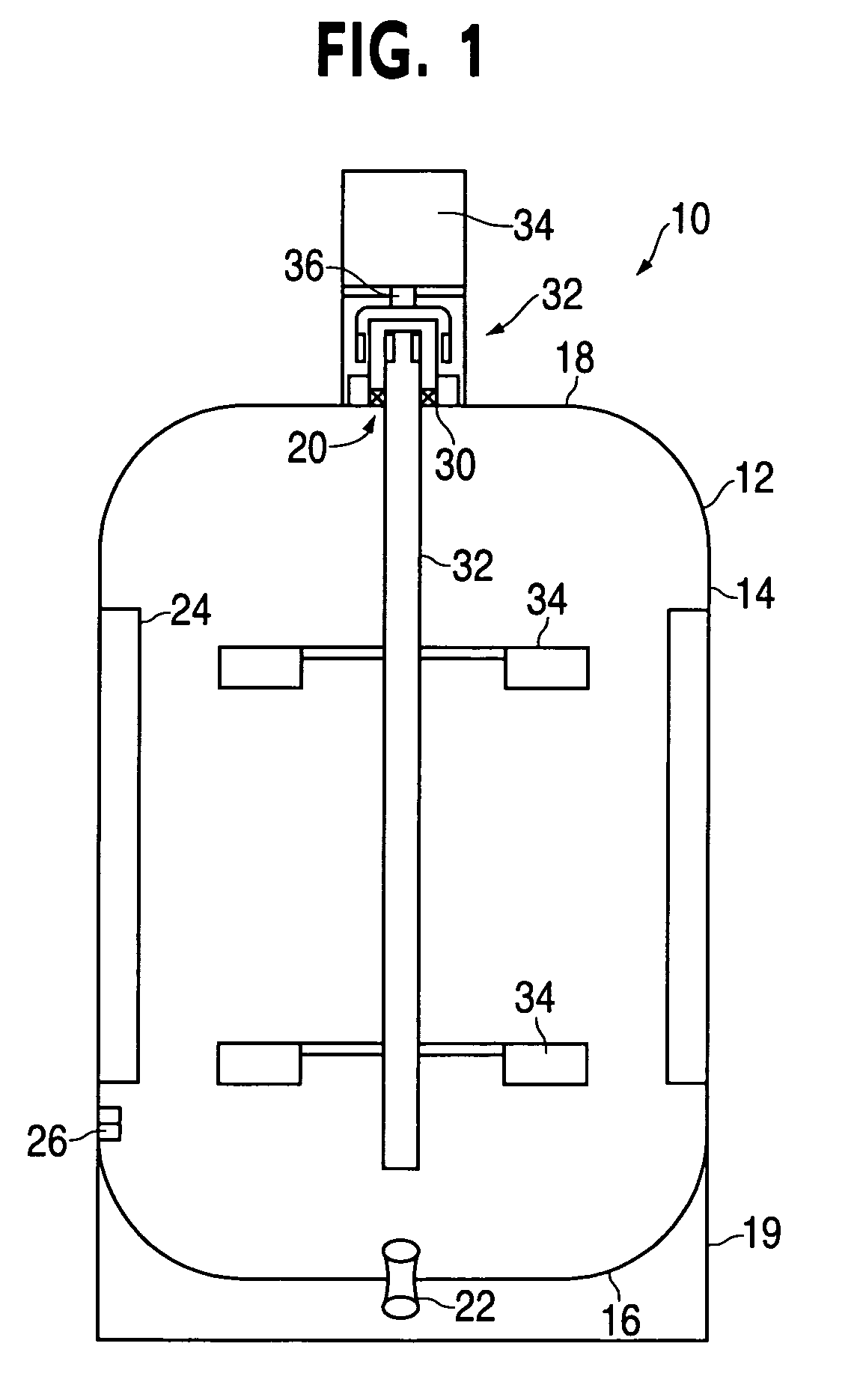

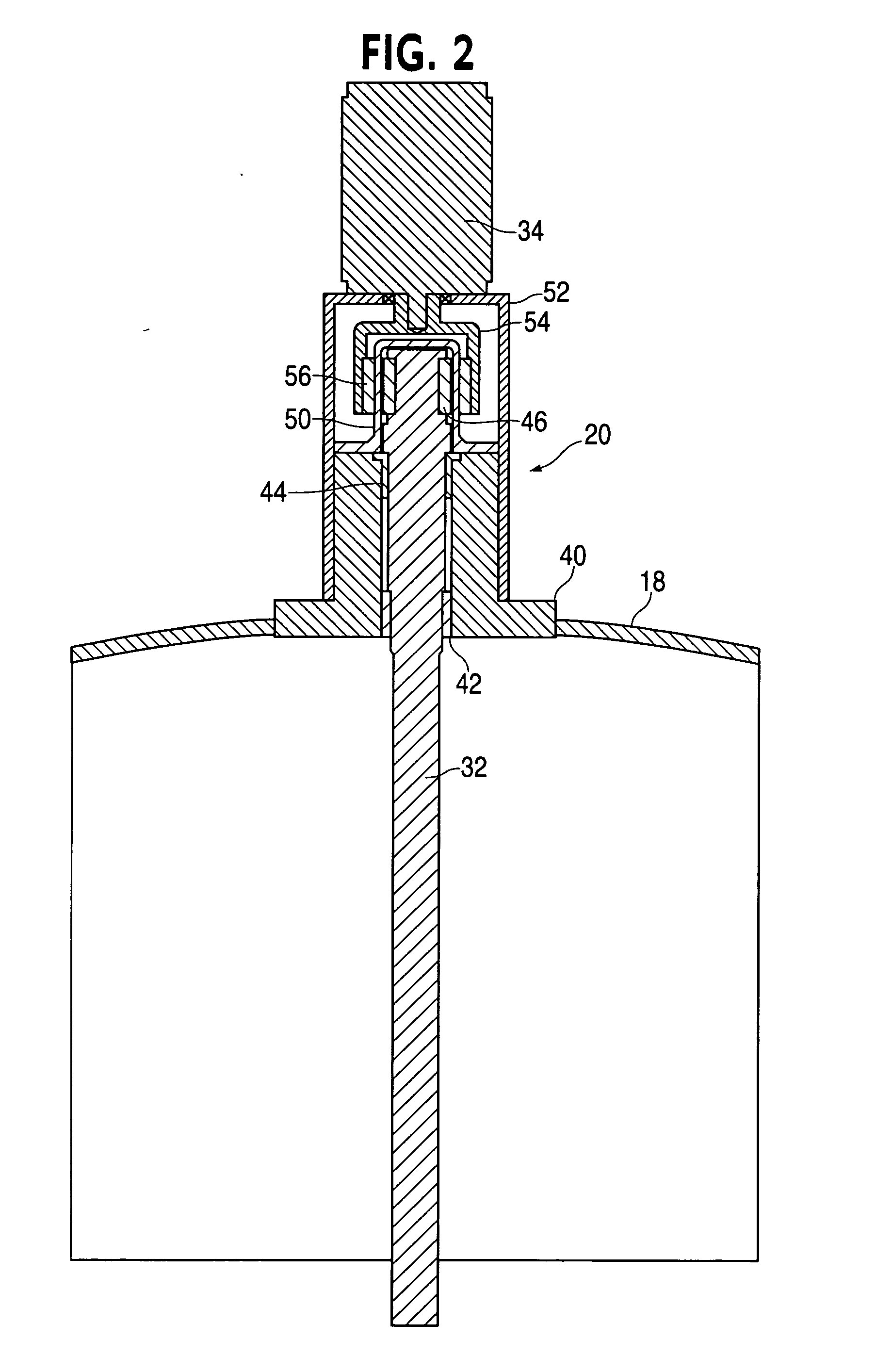

ActiveUS20070053238A1Highly clean and sterile internal environmentConvenient and practical to useRotary stirring mixersTransportation and packagingRotational axisImpeller

A mixing apparatus and method uses a disposable assembly including a closed vessel with a rotating shaft supported in the vessel. The shaft has radially extending impellers. The shaft is driven via an external magnetic drive system. The vessel can be cleaned during manufacture and discarded after use.

Owner:SPX FLOW INC

Nanoscale ion storage materials

ActiveUS20070190418A1Improve electronic conductivityImproved electromechanical stabilityPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh ratePhosphate

Nanoscale ion storage materials are provided that exhibit unique properties measurably distinct from their larger scale counterparts. For example, the nanoscale materials can exhibit increased electronic conductivity, improved electromechanical stability, increased rate of intercalation, and / or an extended range of solid solution. Useful nanoscale materials include alkaline transition metal phosphates, such as LiMPO4, where M is one or more transition metals. The nanoscale ion storage materials are useful for producing devices such as high energy and high power storage batteries, battery-capacitor hybrid devices, and high rate electrochromic devices.

Owner:LITHIUM WERKS TECH BV

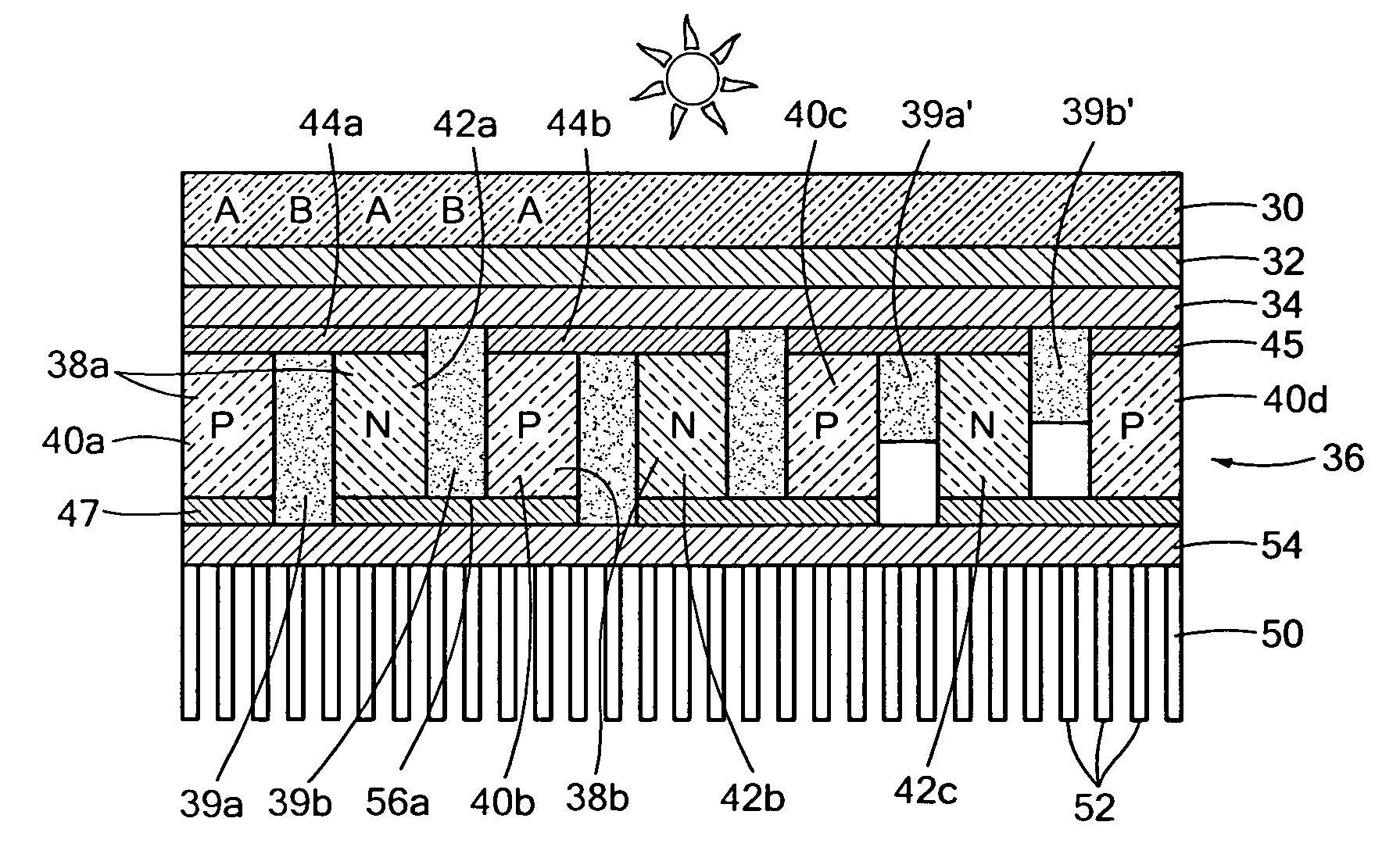

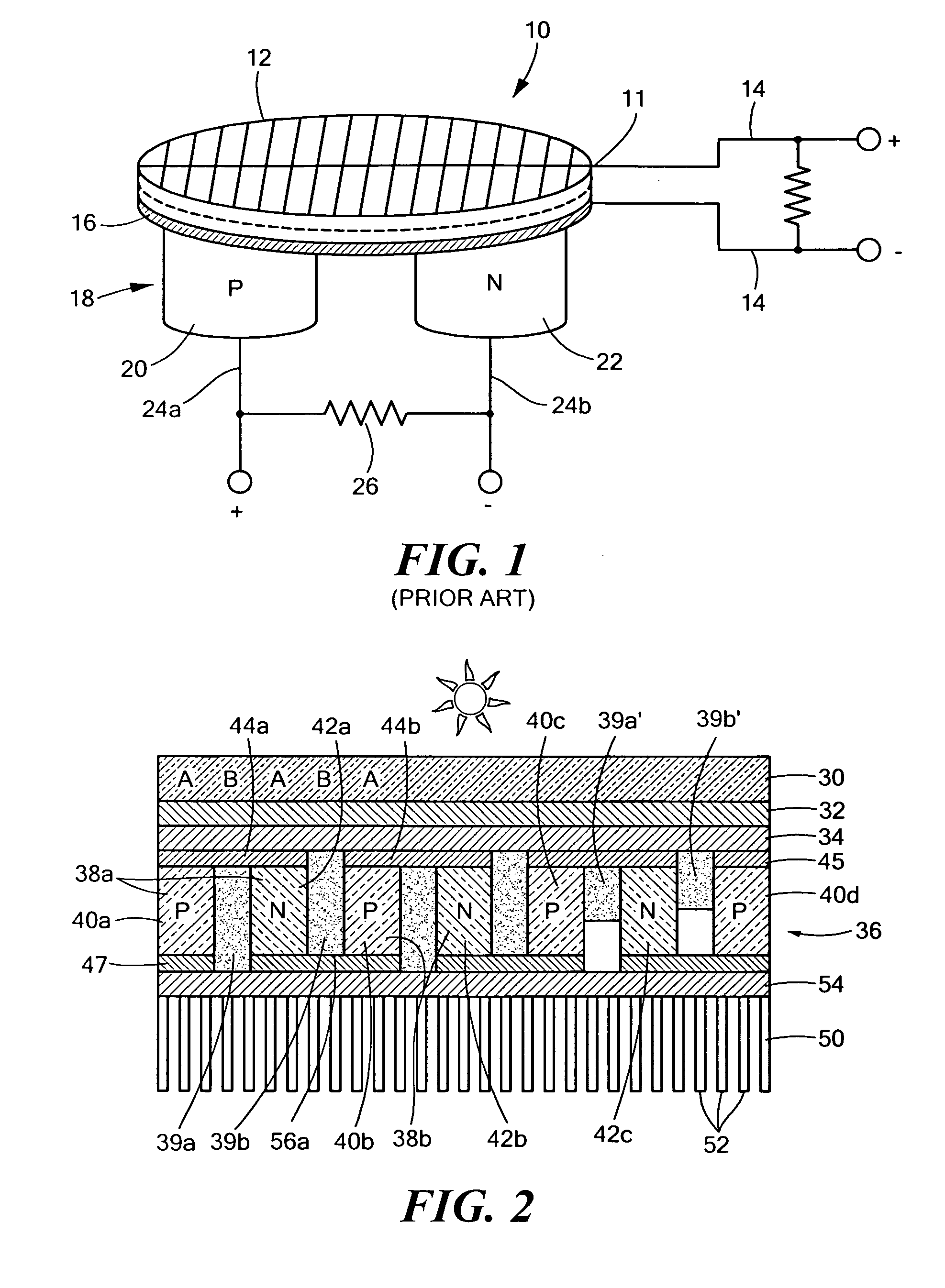

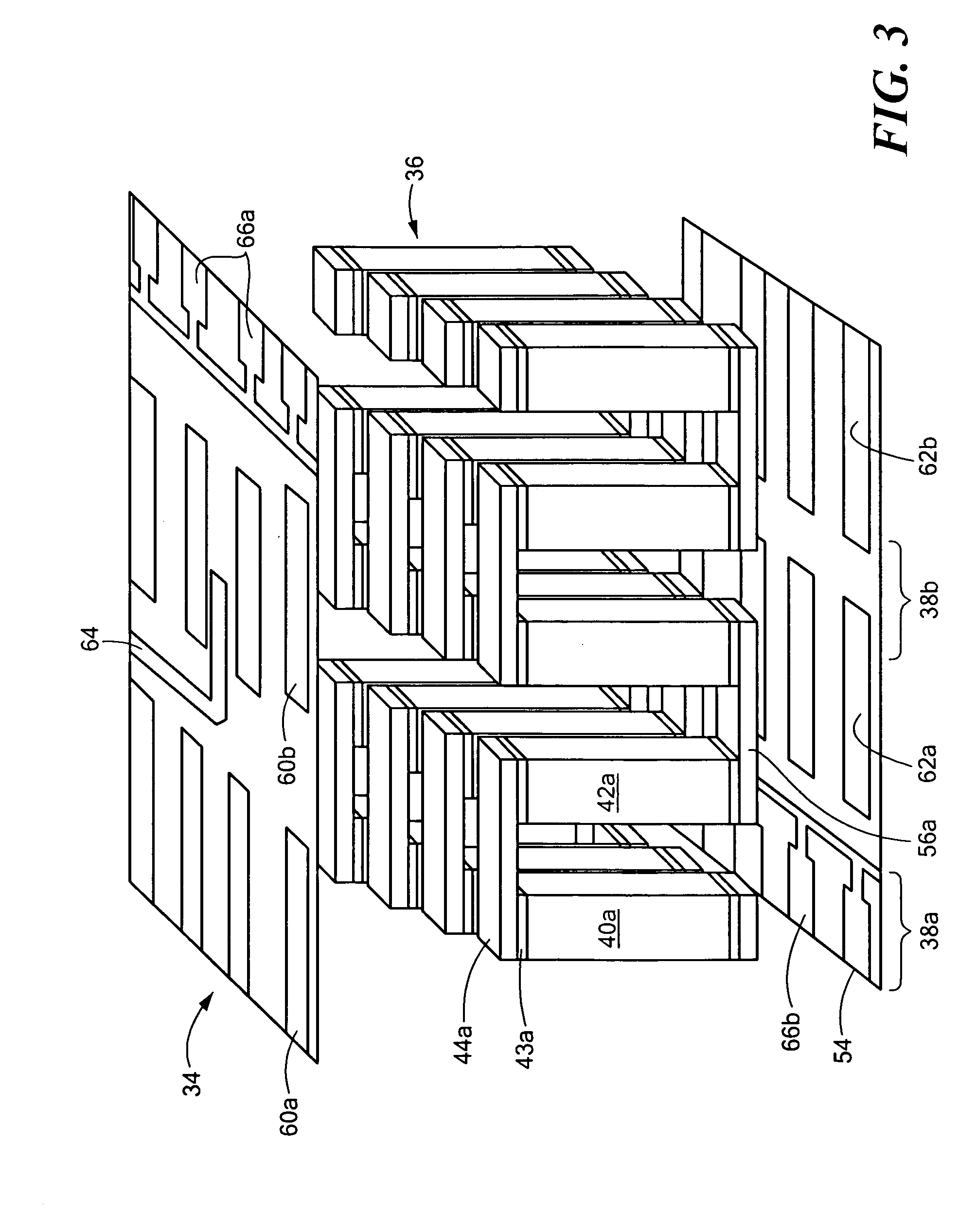

Combined thermoelectric/photovoltaic device for high heat flux applications and method of making the same

InactiveUS20110048489A1Improve photovoltaic efficiencyCost-effective manufacturingThermoelectric device with peltier/seeback effectPV power plantsEngineeringHeat spreader

A combined thermoelectric / photovoltaic device features a photovoltaic cell with a common electrode, an electrically insulative, thermally conductive layer applied to the common electrode, and an array of thermoelectric couples each including a p-type semiconductor element and an n-type semiconductor element. There is an electrically conductive bridge for each thermoelectric couple formed on the electrically insulative thermally conductive layer. Methods of making such a hybrid device also including a heat sink are also disclosed.

Owner:RAYTHEON CO

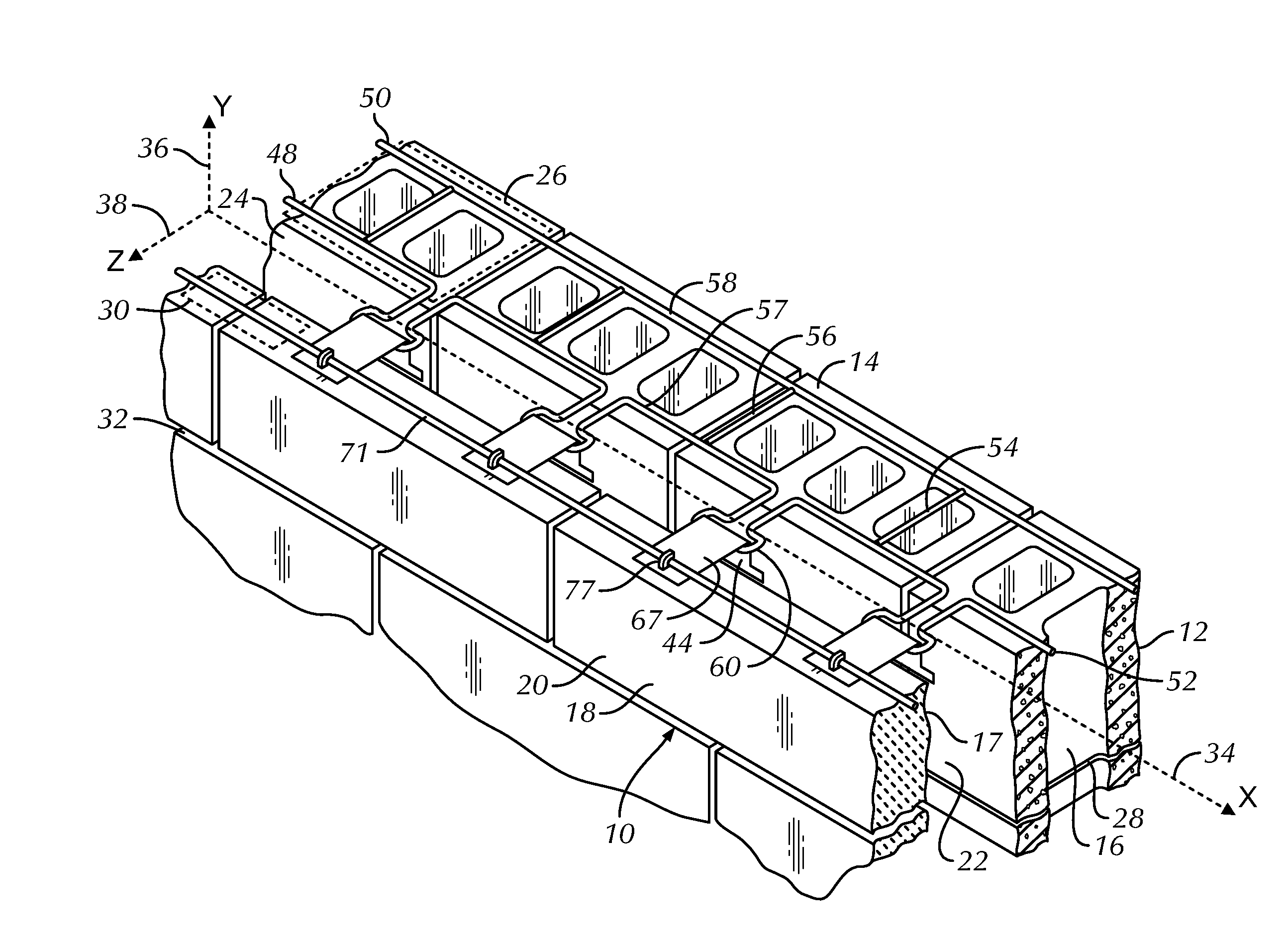

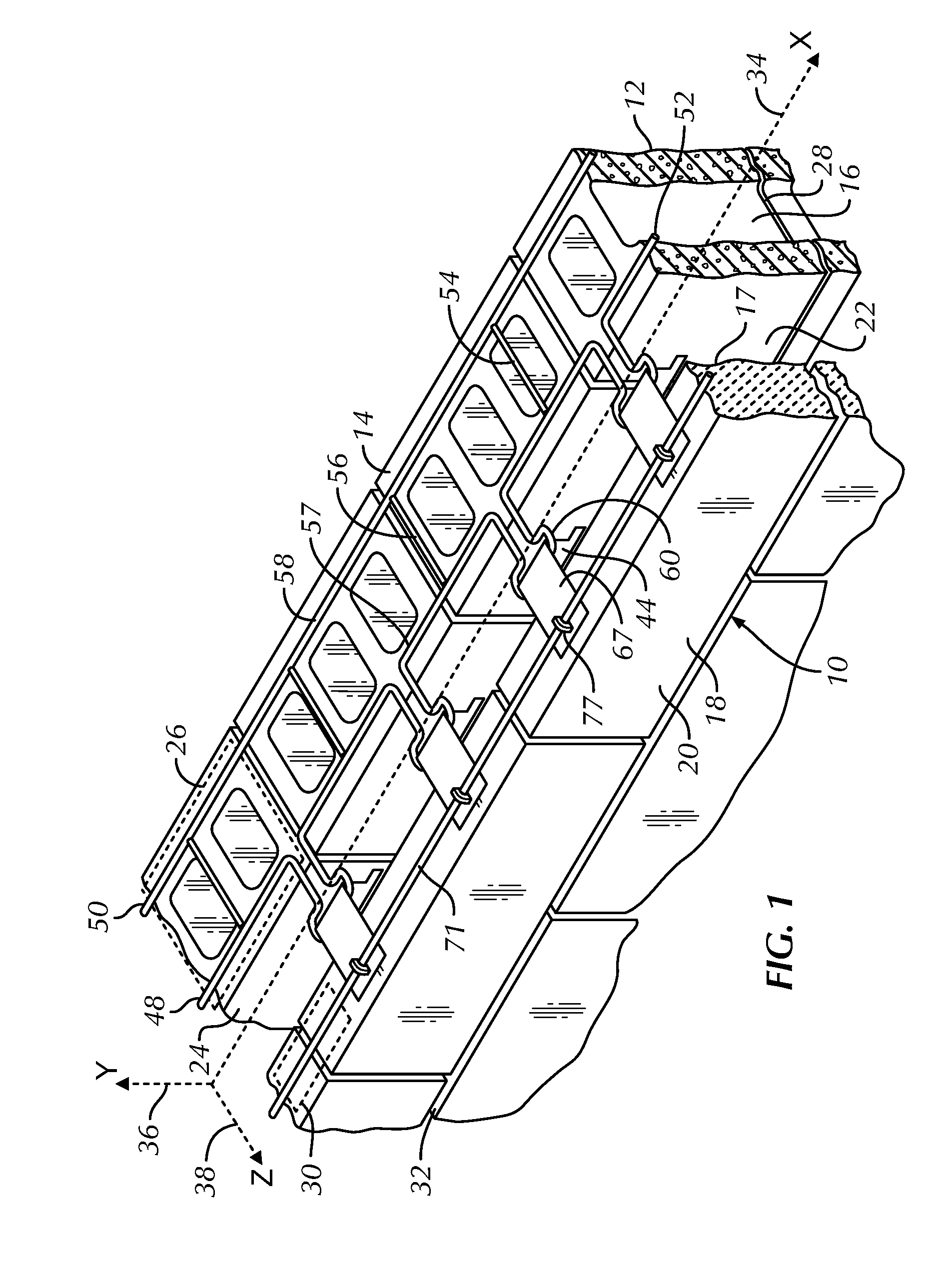

Backup wall reinforcement with t-type siderail

InactiveUS20130232893A1Improve protectionReduce manufacturing costStrutsWallsEarthquake resistant structuresStructural engineering

A backup wall reinforcement with T-type siderail anchoring system is described for use in masonry cavity walls. The reinforcement and integral anchor is hybrid device installed within the backup wall and interlocked with novel veneer ties. The novel veneer ties are manually connected through swinging or twisting the veneer ties until the veneer ties are interlocked with the anchor. Once interlocked, lateral and vertical veneer tie movement is limited strengthening the cavity wall structure. The inclusion of a reinforcement wire within the veneer ties and the exterior wall provides a seismic structure.

Owner:MITEK HLDG INC

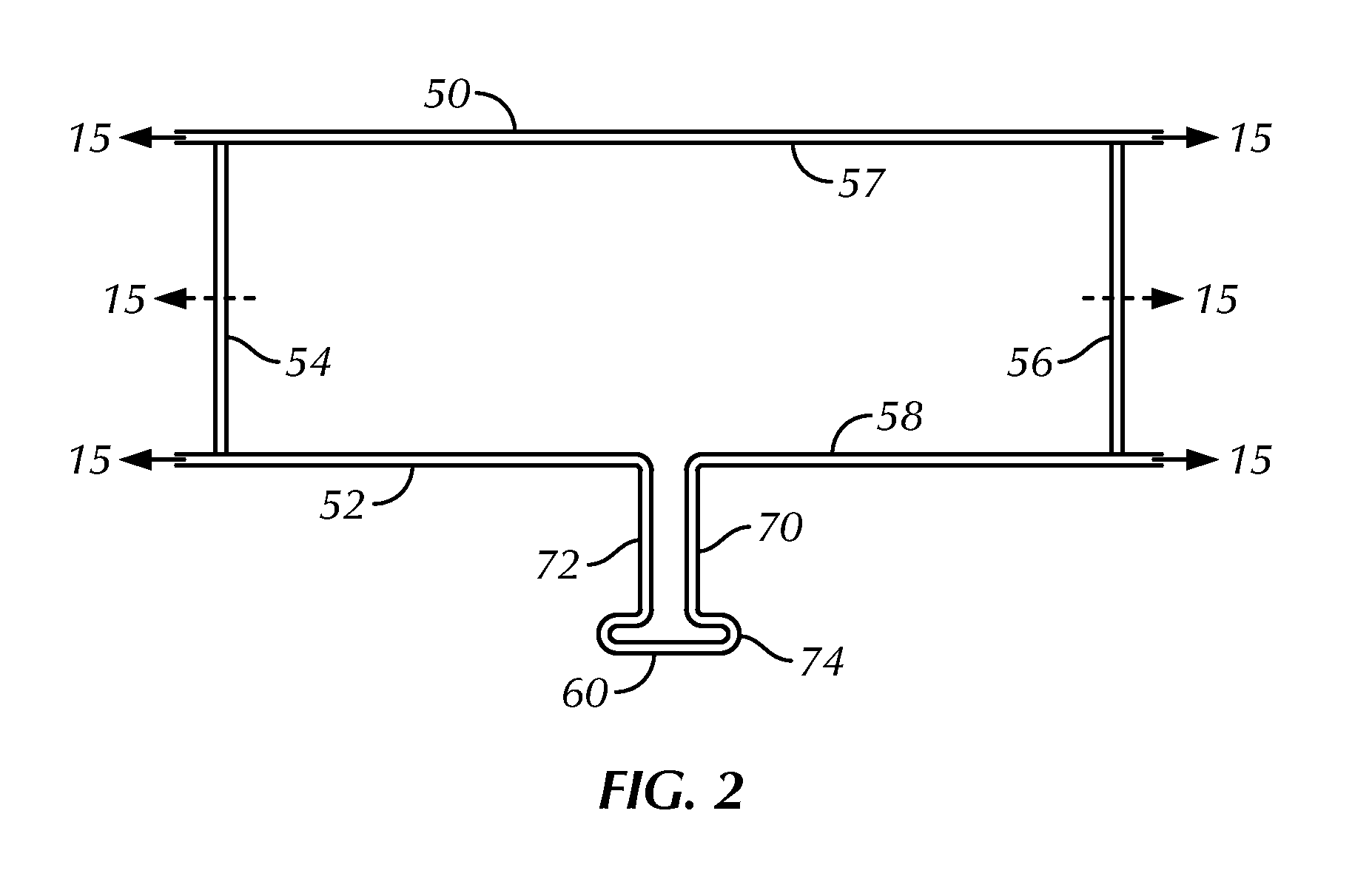

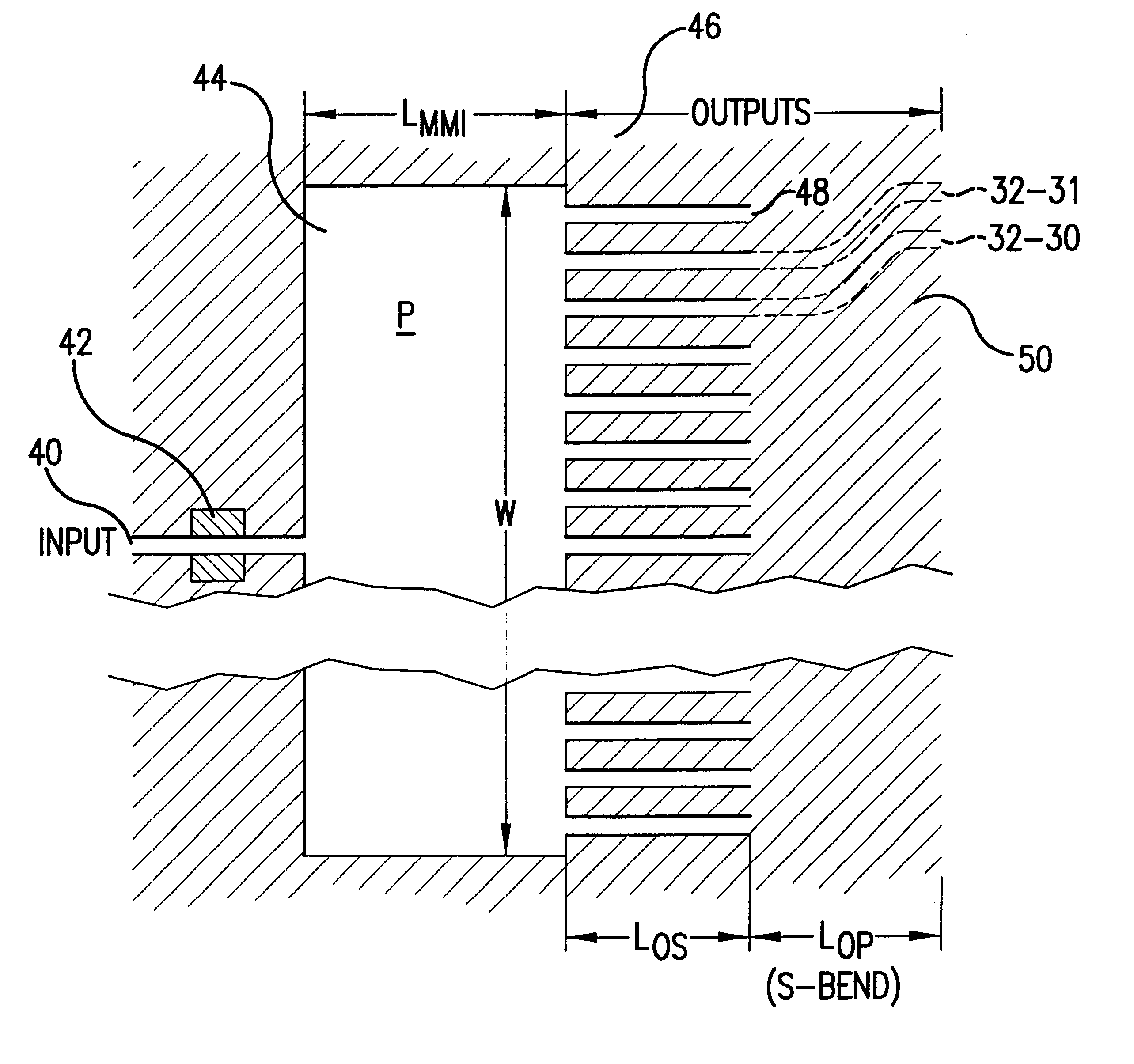

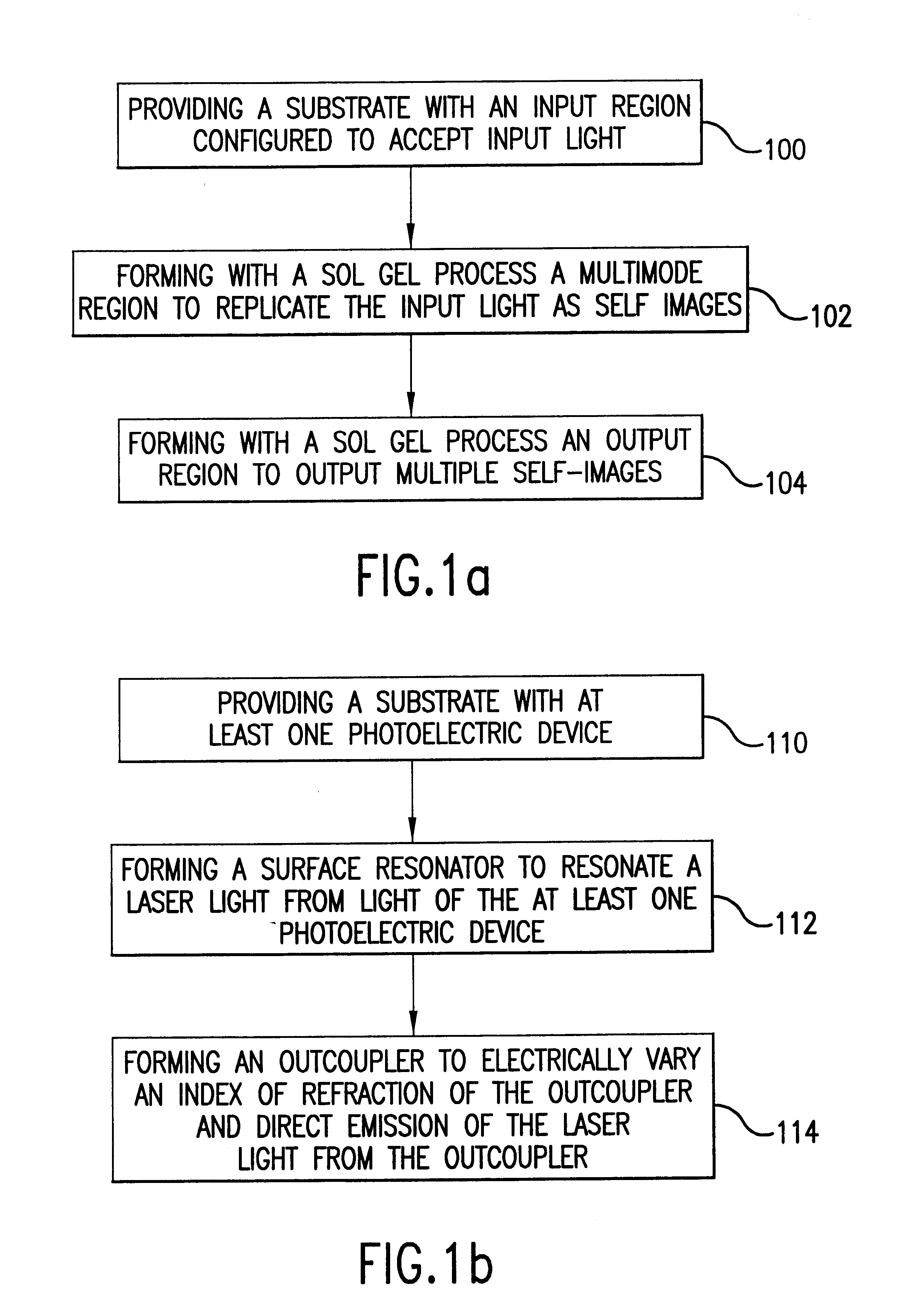

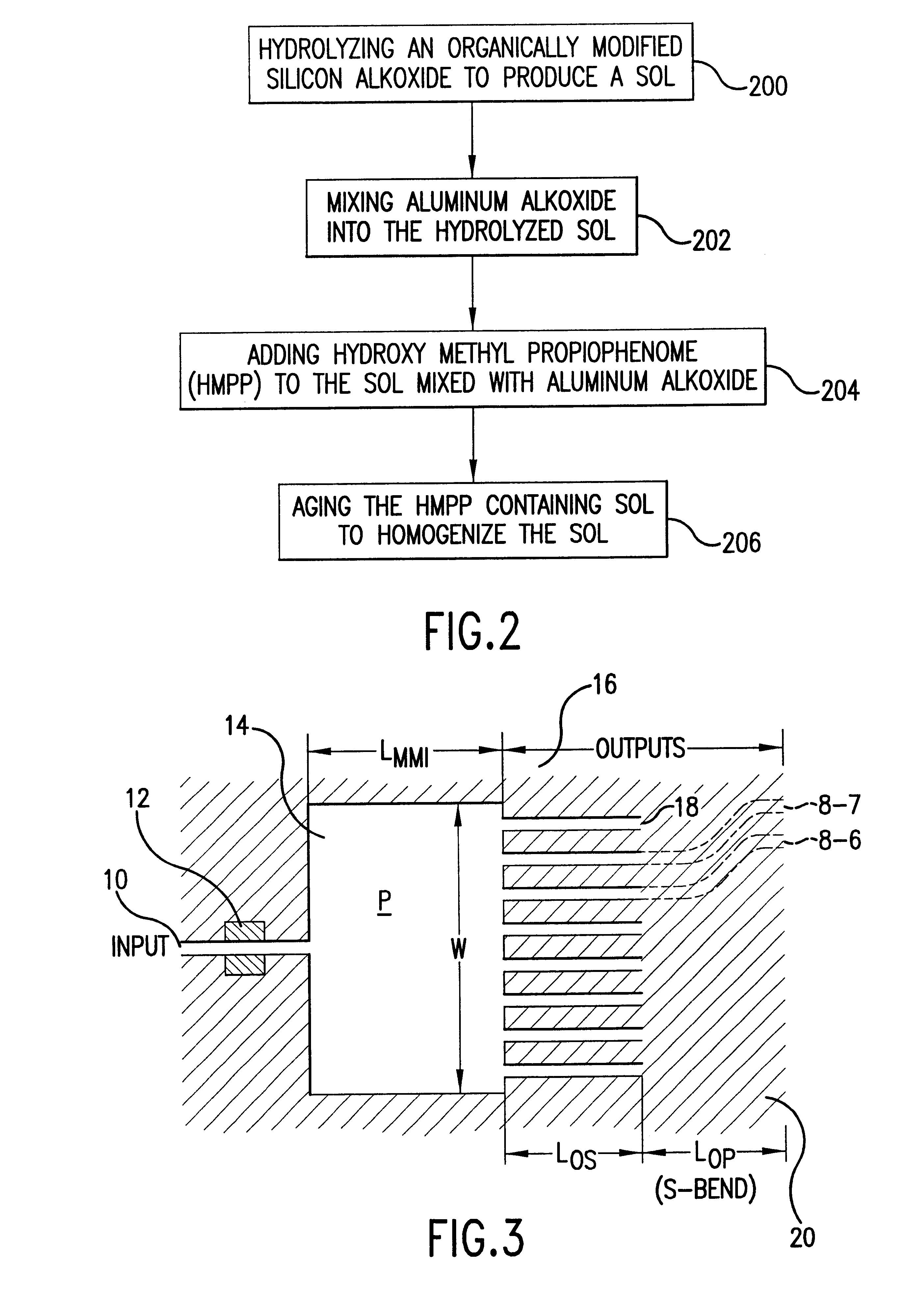

Integrated hybrid optoelectronic devices

InactiveUS6436613B1Low costLow internal lossOptical wave guidanceLaser detailsGratingMultimode interference

A hybrid optoelectronic device and method of producing the hybrid device in which the hybrid device includes a substrate with an input region configured to accept input light, a sol-gel glass multimode interference region coupled to and contiguous with the input region and configured to accept and replicate the input light as multiple self-images, and a sol-gel glass output region contiguous with the multimode region and configured to accept and to output the multiple self-images. Alternatively, the hybrid optoelectronic device includes a substrate with a photoelectronic device, a surface resonator including a light-emitting part of the photelectronic device and configured to resonate light from the photoelectronic device to produce a laser light, and a grating outcoupler contiguous with the surface resonator and configured to diffract the laser light outward from the grating outcoupler and to electrically vary an index of refraction of the outcoupler and change a direction of the diffracted laser light.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Powertrain and Method for a Kinetic Hybrid Vehicle

InactiveUS20120196713A1Minimal energy conversionMinimal conversion lossToothed gearingsEngine controllersGear systemFlywheel

A kinetic hybrid device and method for a vehicle may include a planetary gear system configured as a continuously variable transmission comprised of three or four ports. The kinetic hybrid device and method may include a flywheel connected to a first port of the system, a final drive connected to a second port of the system, and the variator for the flywheel connected to a third or fourth port of the system. The prime mover and / or other power sources may share a port with the flywheel, but do not share a port with the final drive.

Owner:HE JING +1

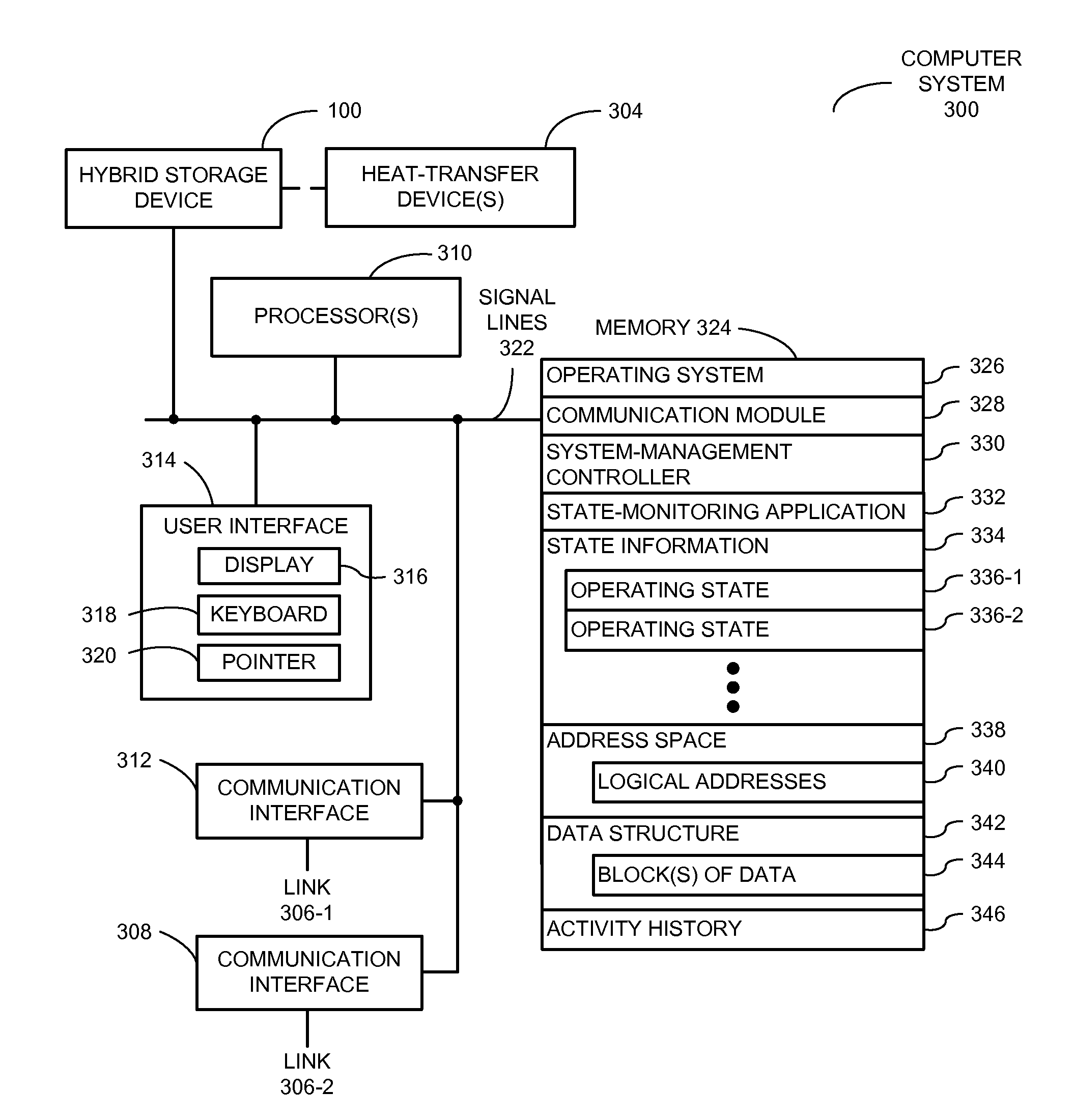

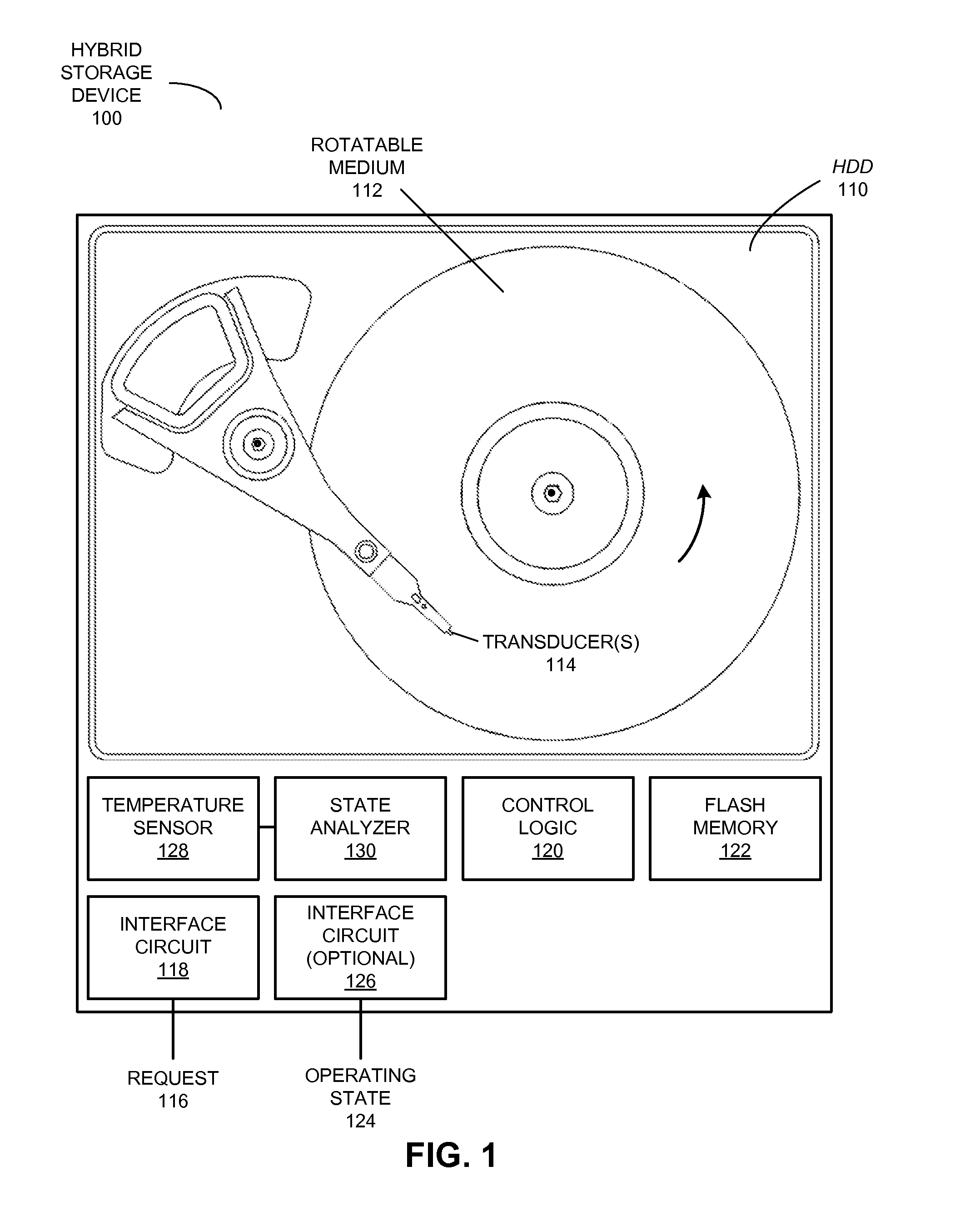

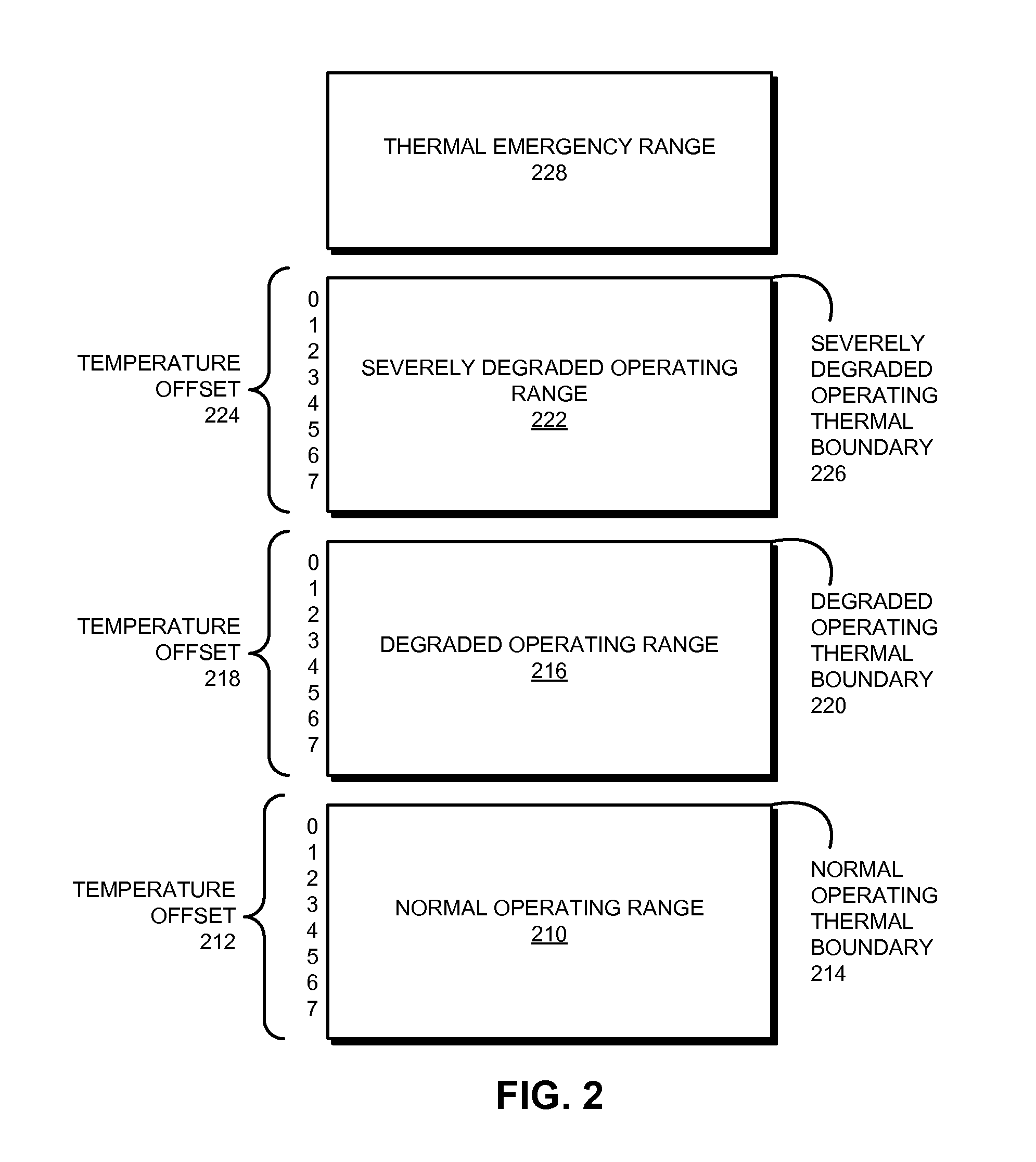

Hybrid-device storage based on environmental state

ActiveUS20110238887A1Memory adressing/allocation/relocationRecord information storageHard disc driveControl logic

A hybrid storage device that includes a hard-disk drive (HDD) and a flash memory is described. When control logic in the hybrid storage device receives a request from an external device to write a block of data to a logical address in a first portion of an address space that maps to the HDD, the control logic writes the block of data to the HDD. However, if there is a change in environmental state information of the hybrid storage device during the write operation, the control logic writes at least a portion of the block of data to a logical address for the block of data in a second portion of the address space which maps to the flash memory. Note that the address space may be common to the external device and the hybrid storage device.

Owner:APPLE INC

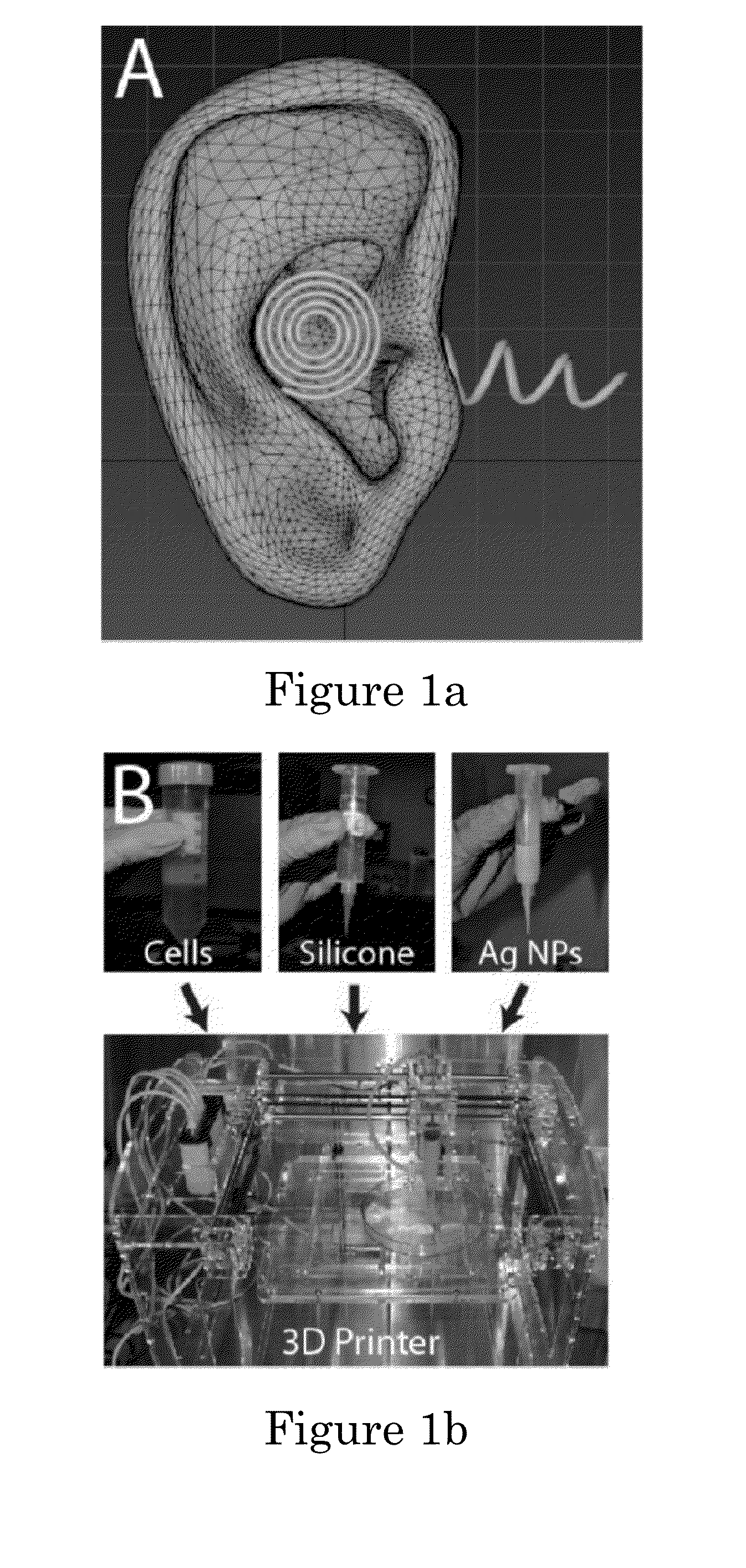

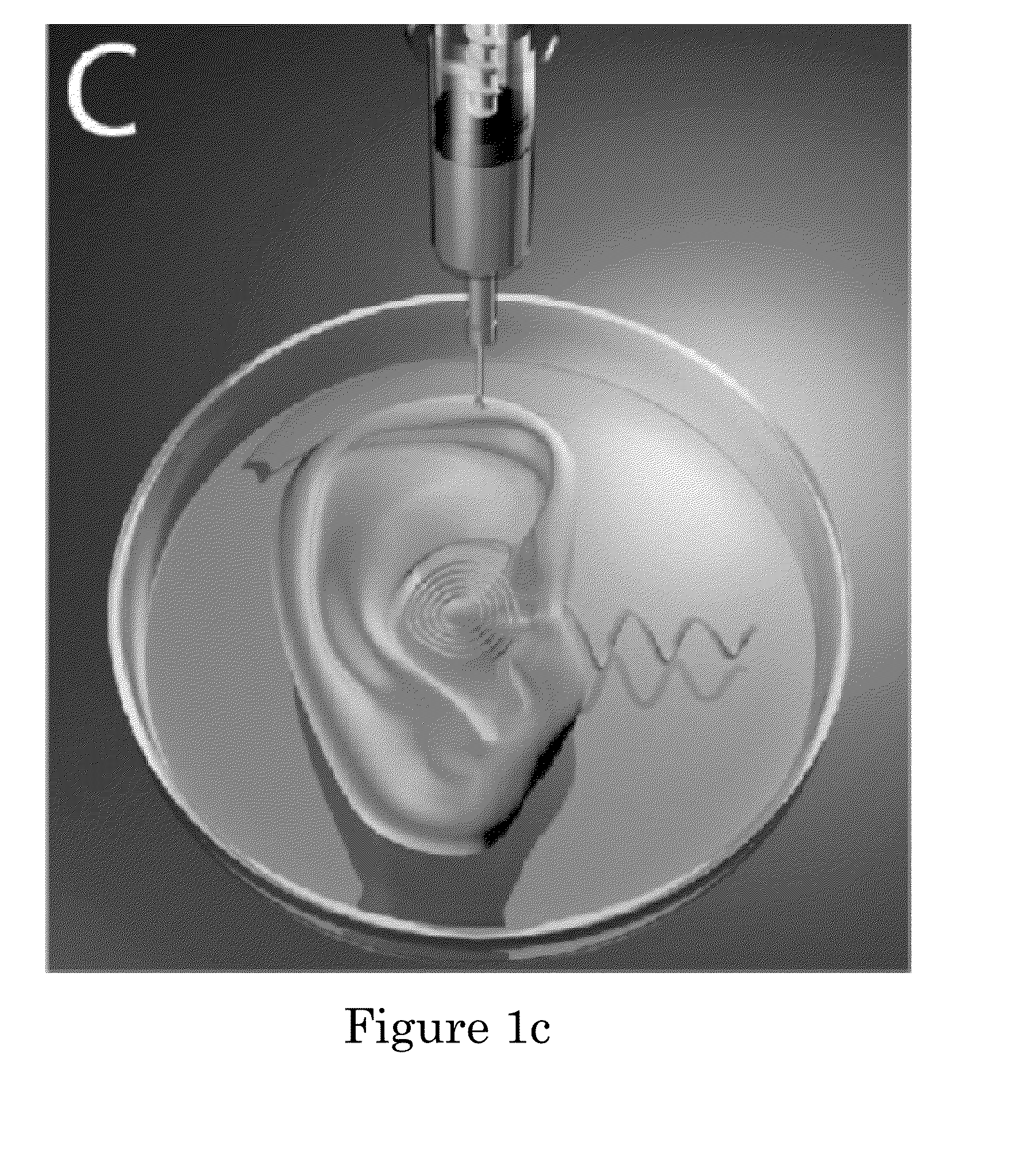

Multi-functional hybrid devices/structures using 3D printing

A bioelectronic device and method of making is disclosed. The device includes a scaffold formed via 3D printing. The device also includes a biologic and an electronic device formed via 3D printing, the biologic and electronic device being interweaved with or coupled to the scaffold. The electronic component may e.g., include at least one of hard conductors, soft conductors, insulators and semiconductors. The scaffold may be formed of at least one of synthetic polymers and natural biological polymers. The biologic may include at least one of animal cells, plant cells, cellular organelles, proteins and DNA (including RNA).

Owner:THE TRUSTEES FOR PRINCETON UNIV

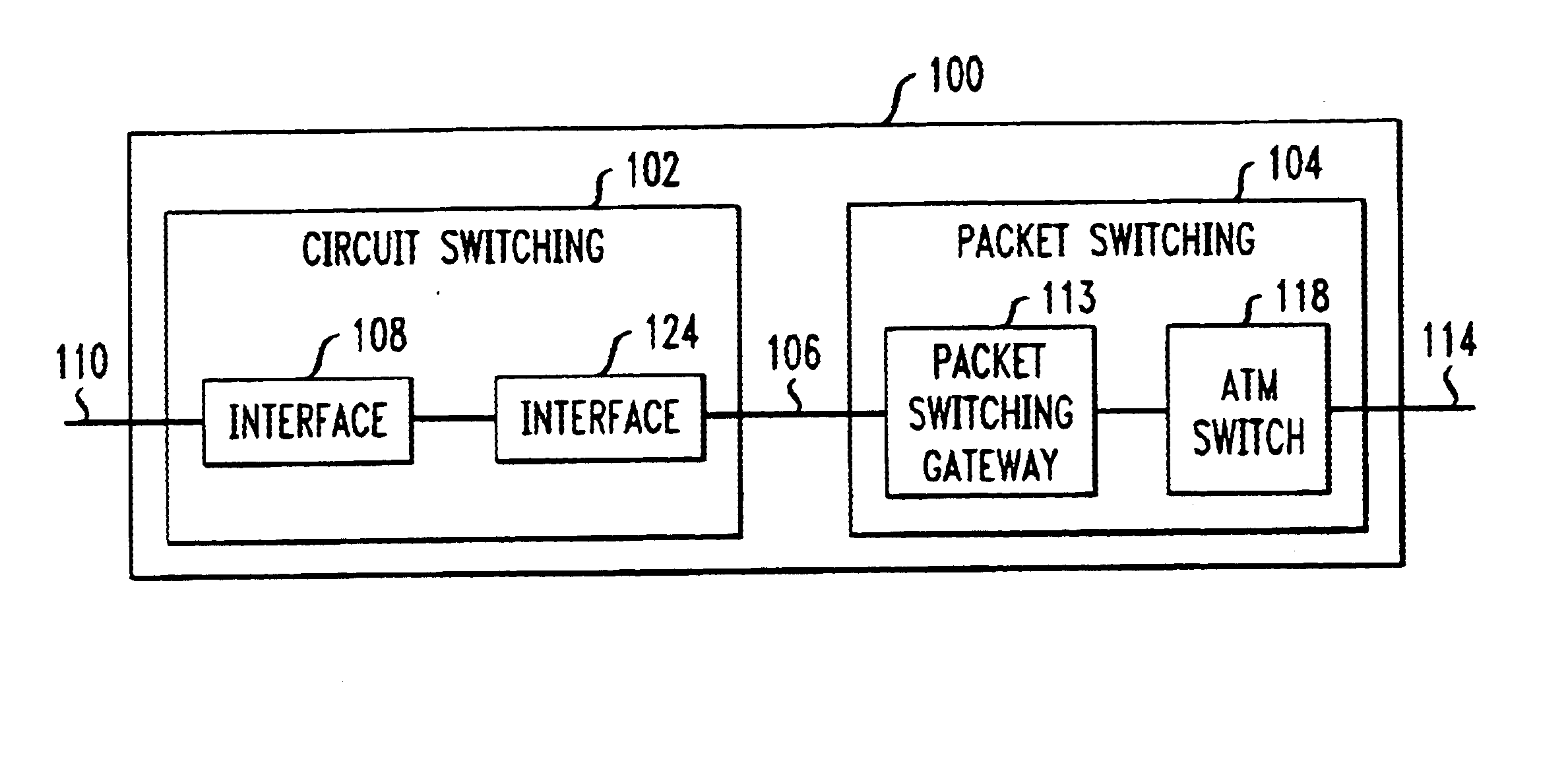

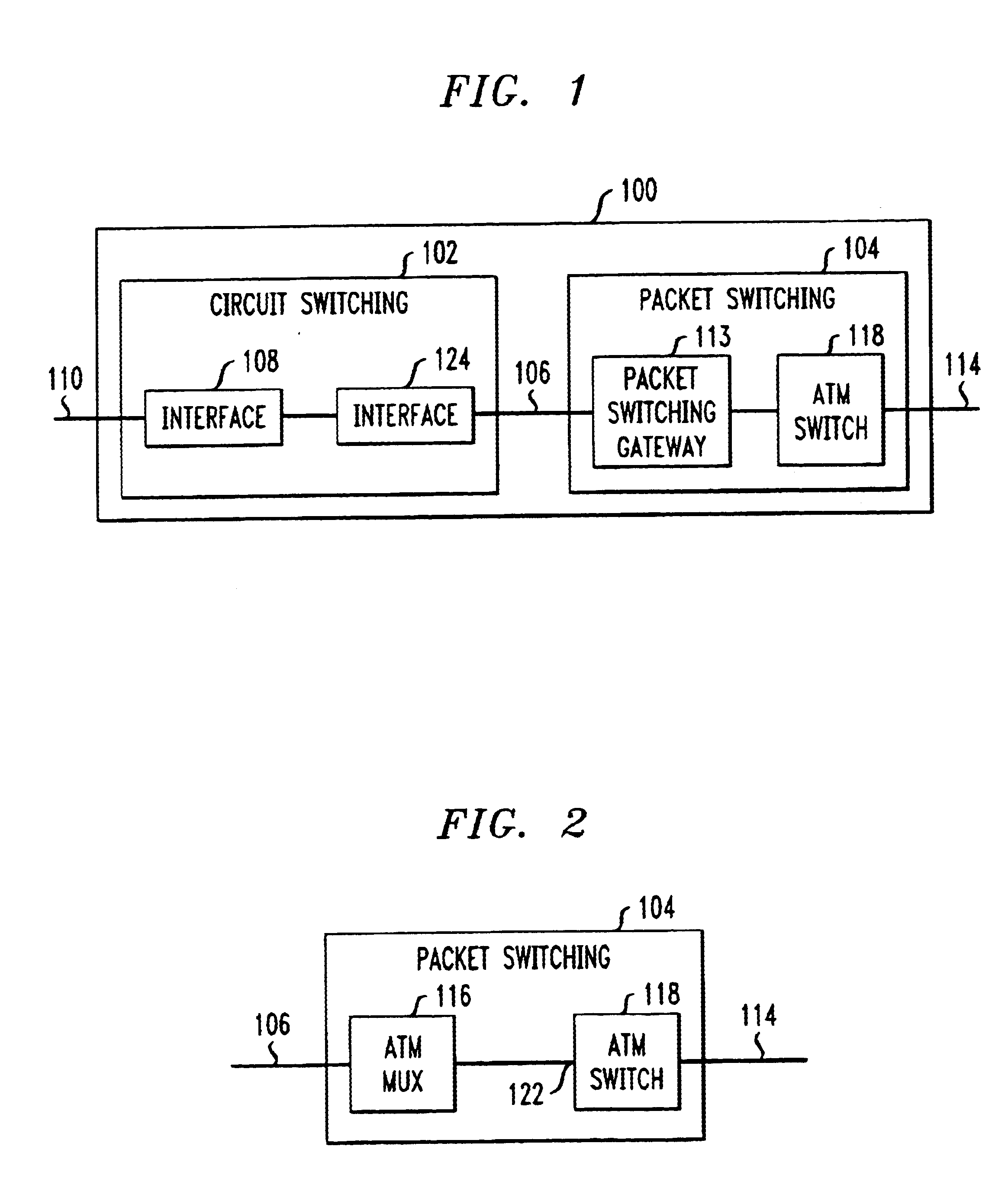

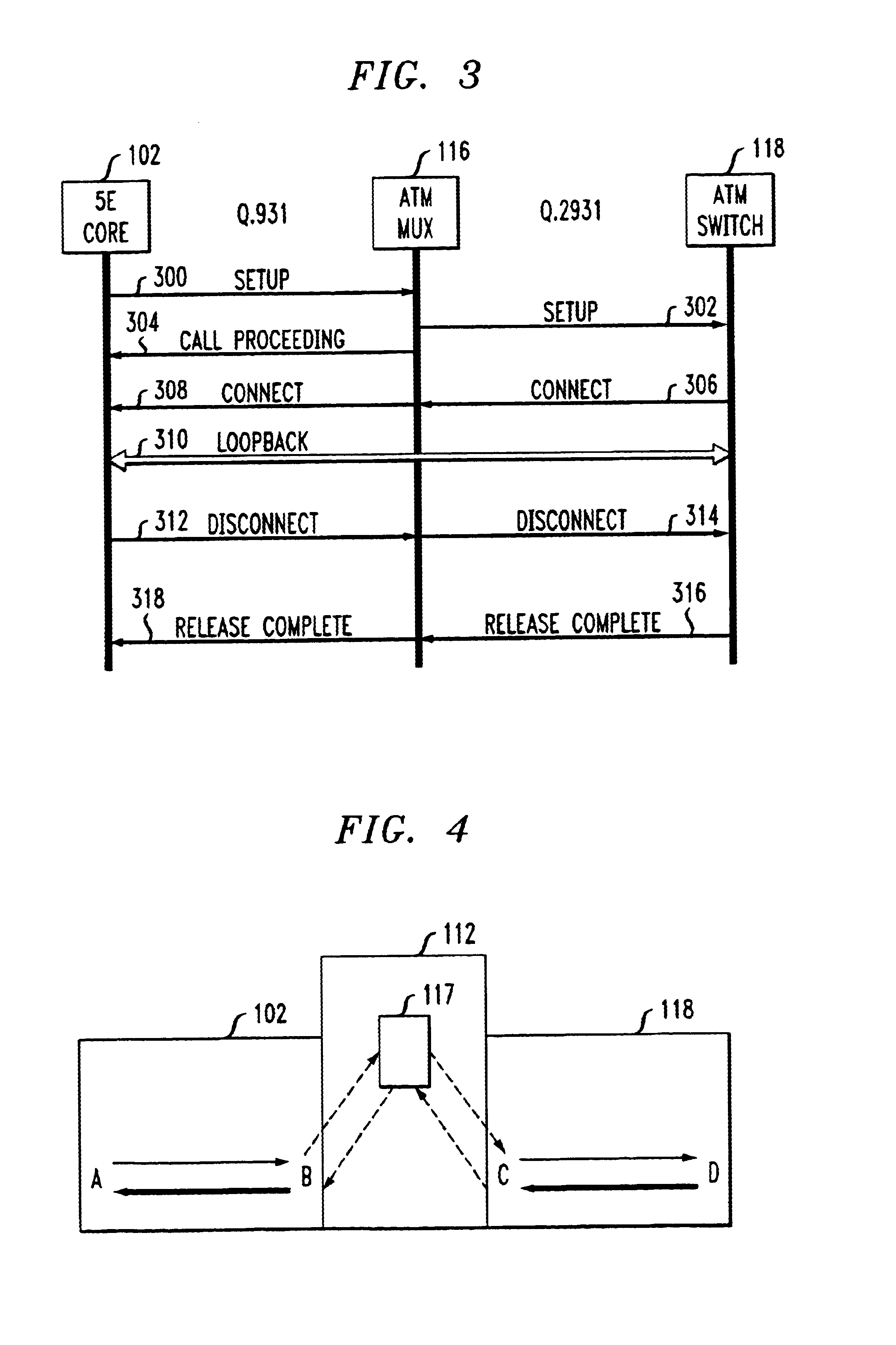

Apparatus and method for error isolation in hybrid communications systems

InactiveUS6873599B1Error preventionFrequency-division multiplex detailsHybrid systemCommunications system

A hybrid telecommunications component in accordance with the principles of the present invention affords loopback test capabilities across boundaries between circuit switched and packet switched components. A loopback test which encompasses at least a portion of the packet switched side of a hybrid system may be initiated from the circuit switched side of the hybrid device. Additionally, a loopback test which encompasses at least a portion of the circuit switched side of a hybrid system may be initiated from the packet switched side of the hybrid device. In an illustrative embodiment, when a loopback test of the circuit switched side is initiated by the packet switched side, the loopback test is carried out by the circuit switched side, with the results being reported by the circuit switched side to the packet switched side.

Owner:LUCENT TECH INC

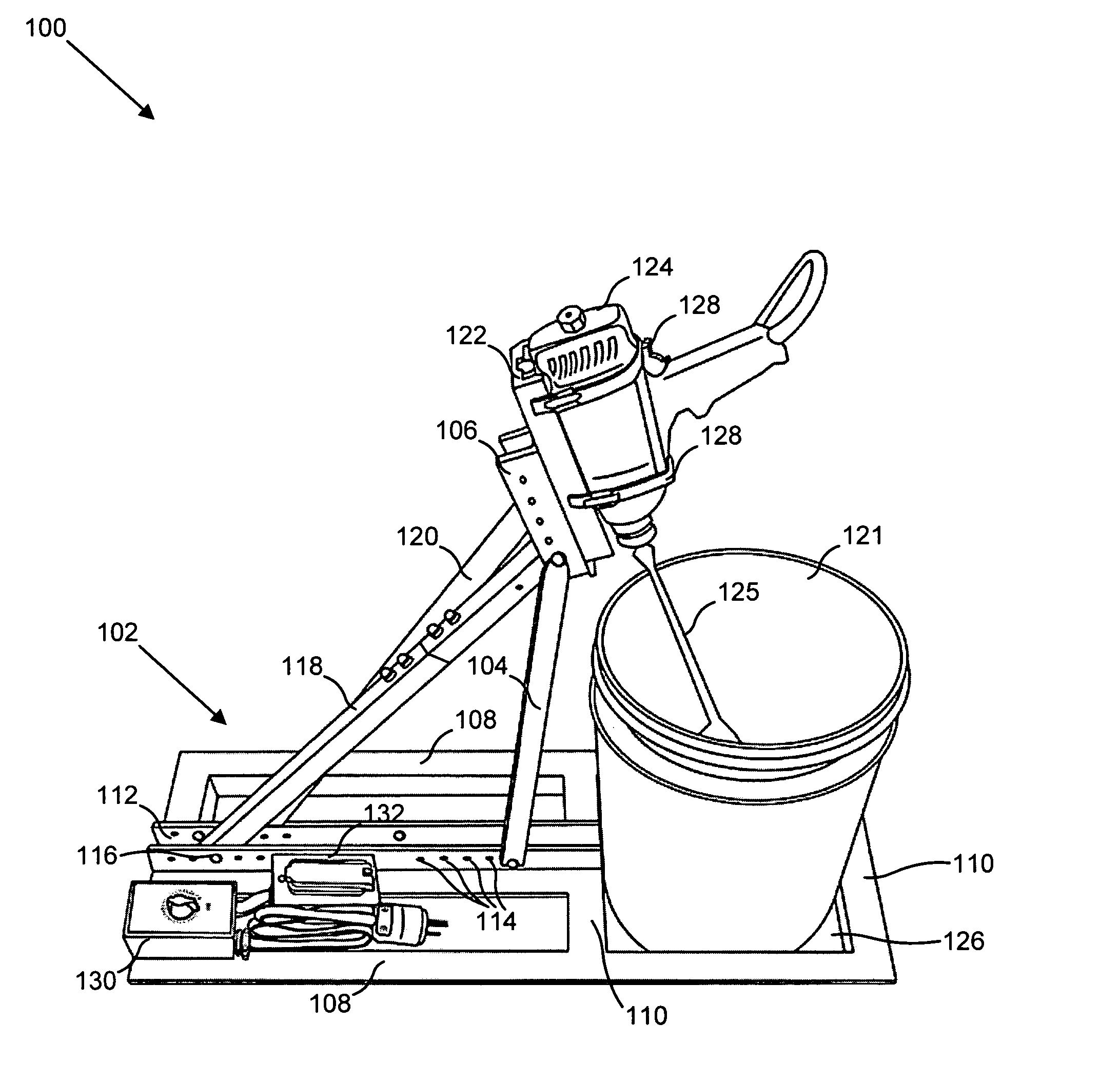

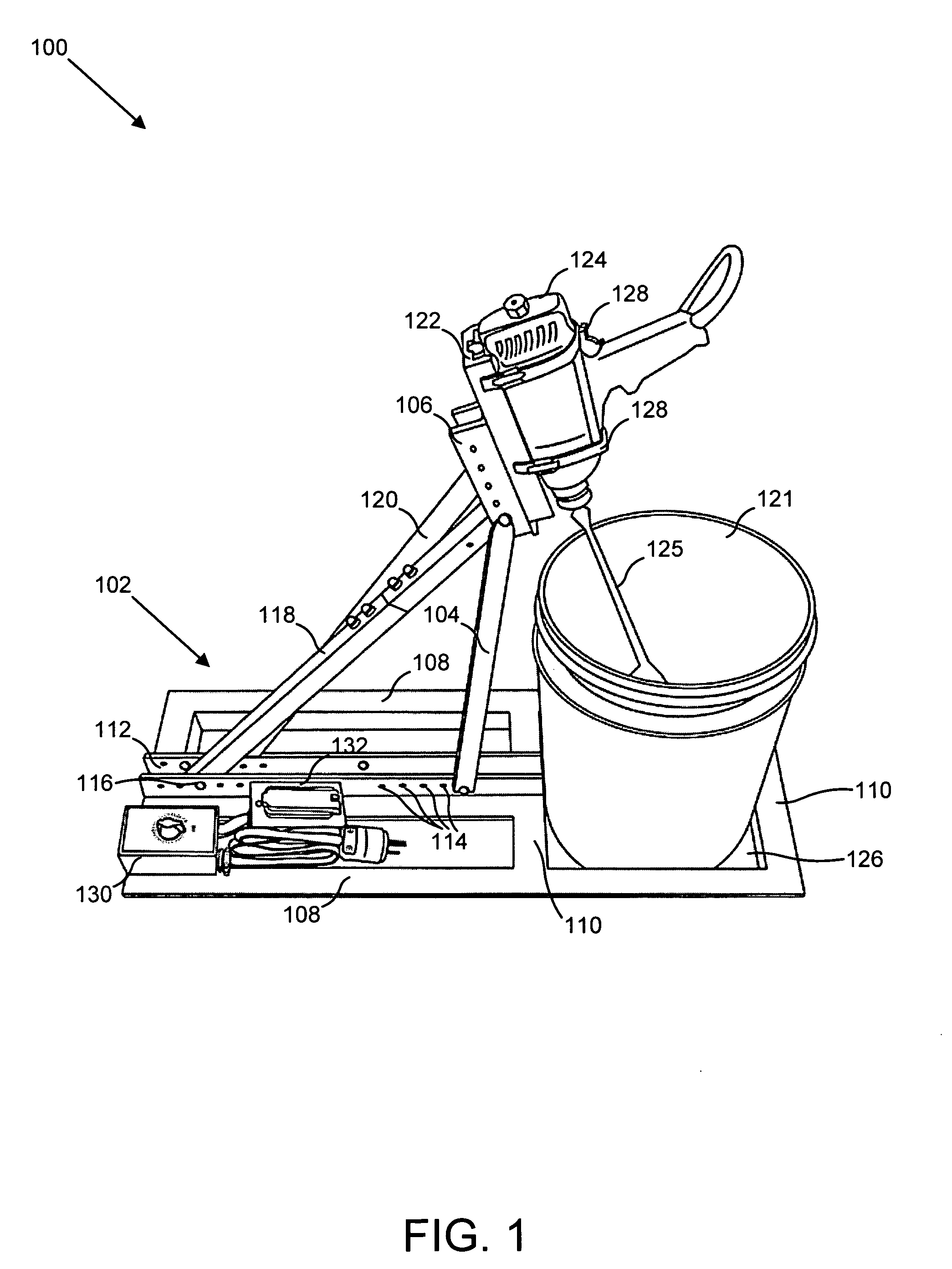

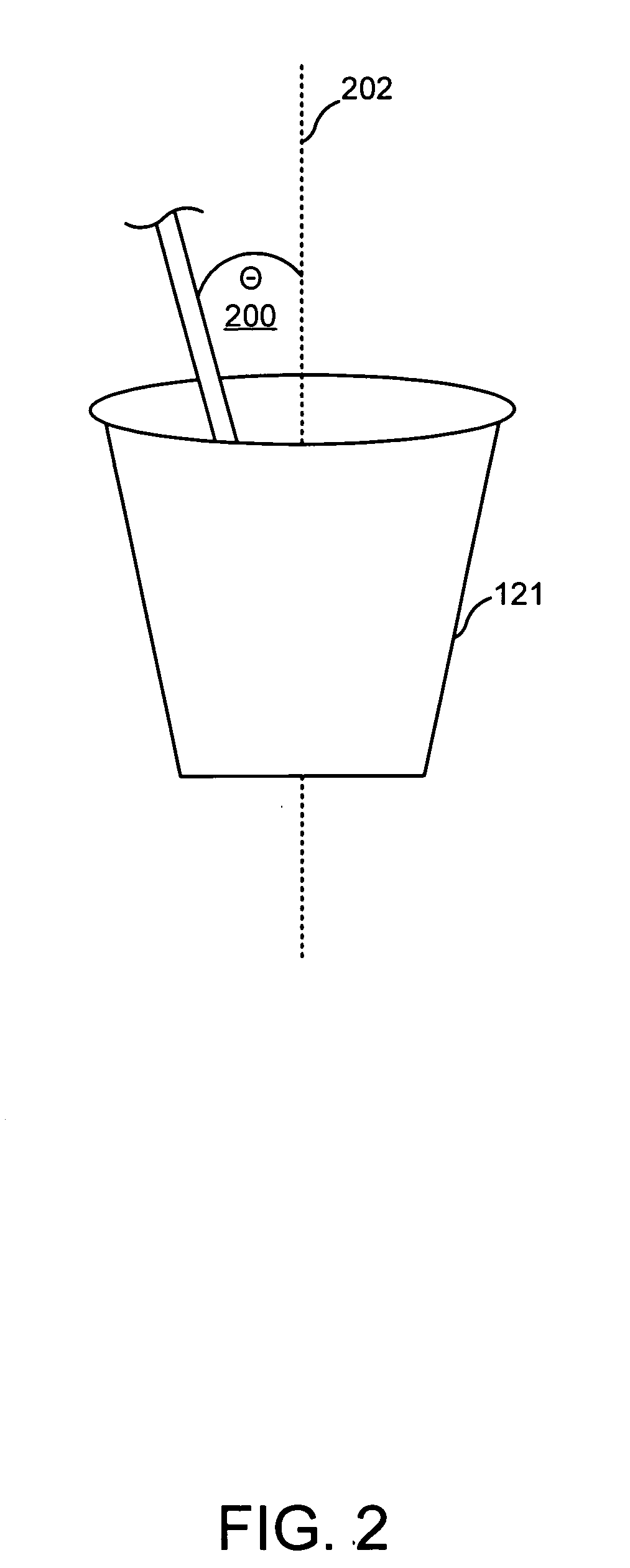

Apparatus and method for mixing materials

An apparatus and method are disclosed for mixing materials using a portable mixing apparatus. The portable mixing apparatus includes a base, a support stand coupled to and extending upward from the base, and an opening disposed to one side of the base and configured to receive a container. The mixing apparatus may also include a timer for terminating power to the handheld power tool upon reaching a predefined time value. The method includes providing a base, providing a support stand coupled to and extending upward from the base, and providing an opening disposed to one side of the base for receiving a container. A mixing paddle is also included with a central portion having a first end having a bend in a first direction, a second end having a second bend in an opposing direction, and a flexible portion coupled to a bottom surface formed by the central portion.

Owner:ORTON MARK B

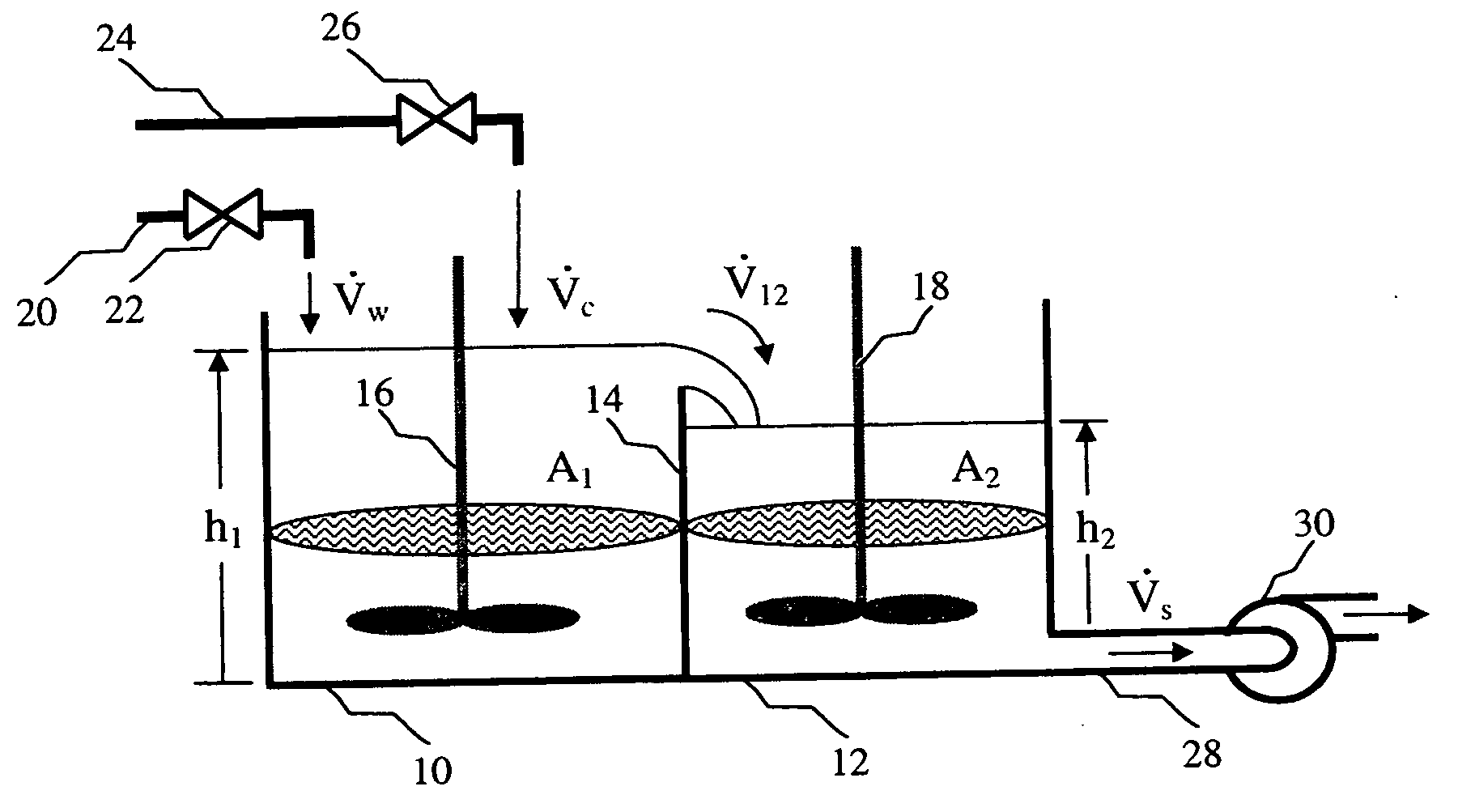

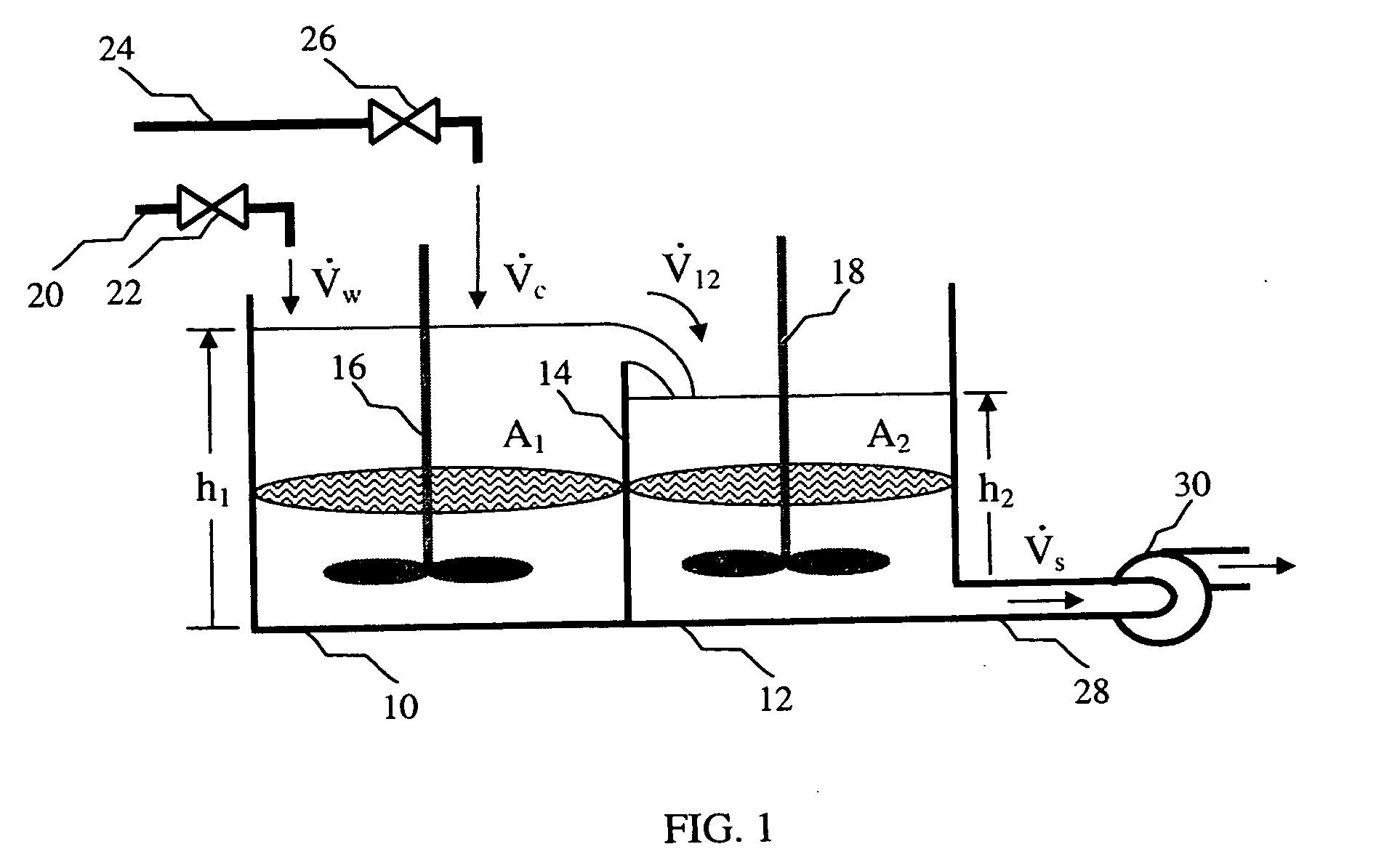

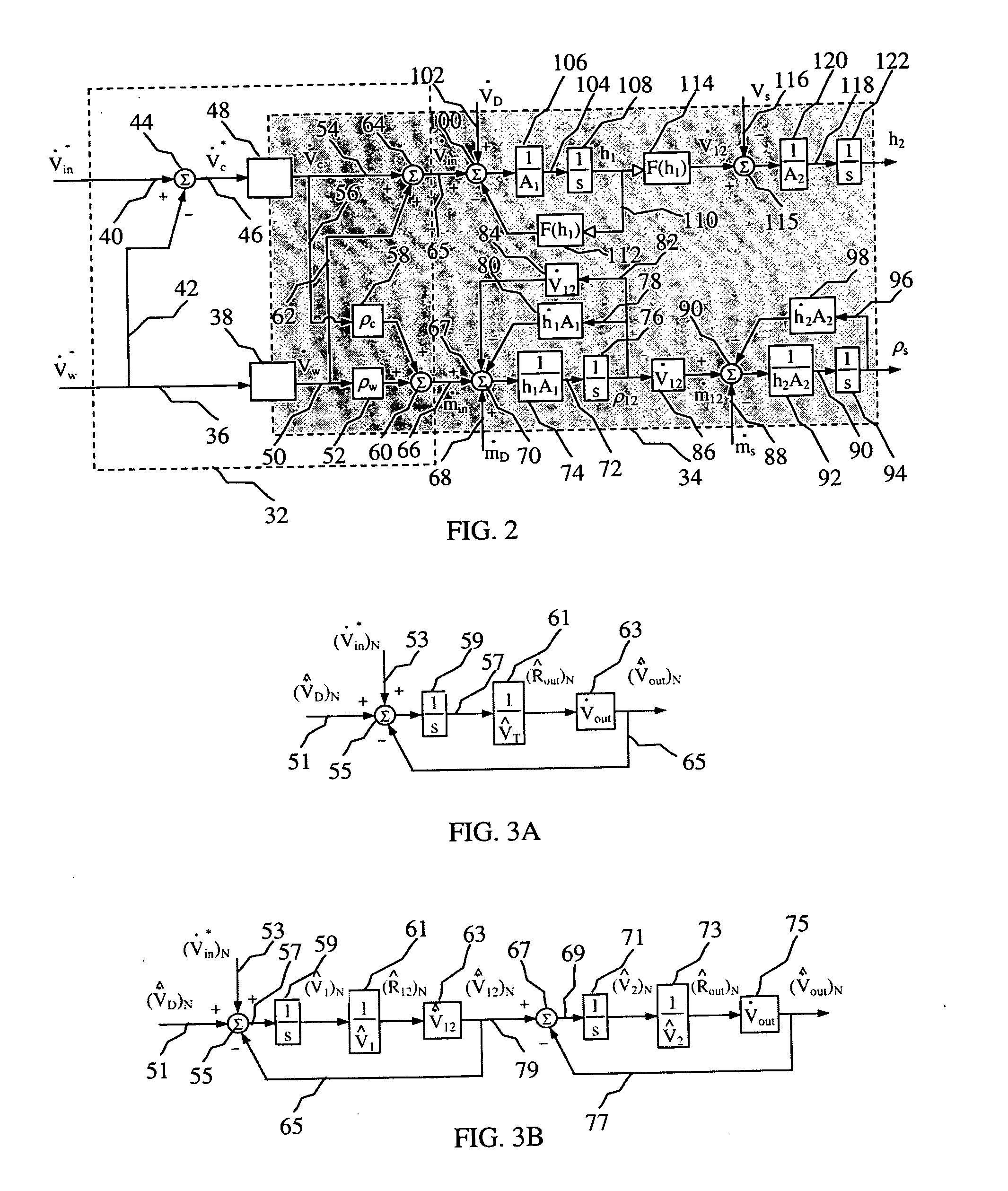

Methods for volumetrically controlling a mixing apparatus

ActiveUS20070153622A1Good estimateStrict controlSampled-variable control systemsControlling ratio of multiple fluid flowsControl theoryStreamflow

Methods of controlling a volumetric ratio of a material to total materials in a mixing vessel are provided. In various embodiments, the methods may comprise: estimating the volumetric ratio of the material to the total materials in the mixing vessel and an output flowrate of the material from the mixing vessel using a volumetric ratio observer; dynamically recomputing the commanded input flowrate of the material based on outputs of the volumetric ratio observer using a flow regulator; and adjusting an input valve of the material based on the commanded input flowrate of the material using a flow modulator. The mixing vessel may include a first mixing vessel partially separated from a second mixing vessel. In this case, a height of the total materials in the second mixing vessel may be estimated using a height observer.

Owner:HALLIBURTON ENERGY SERVICES INC

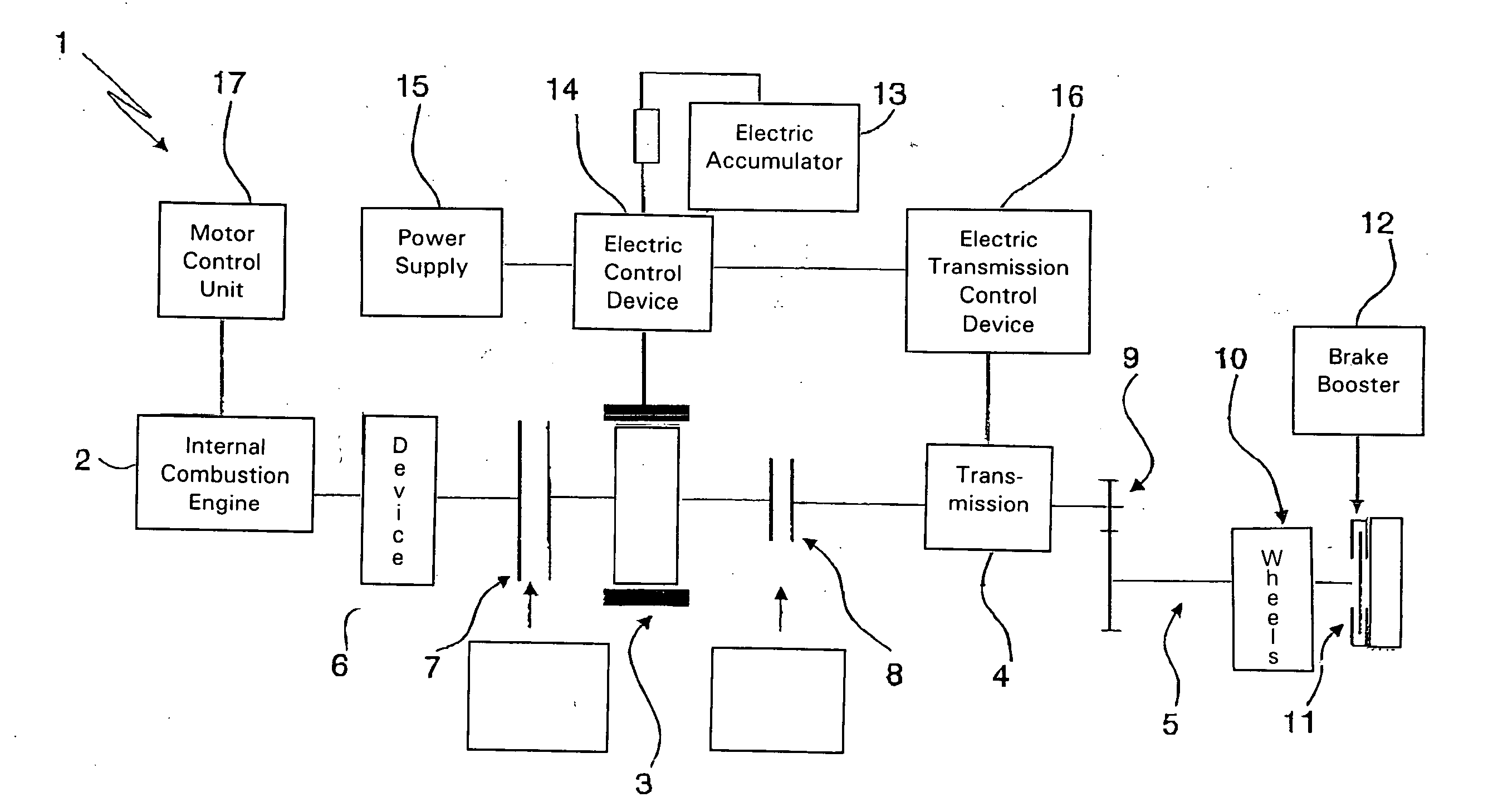

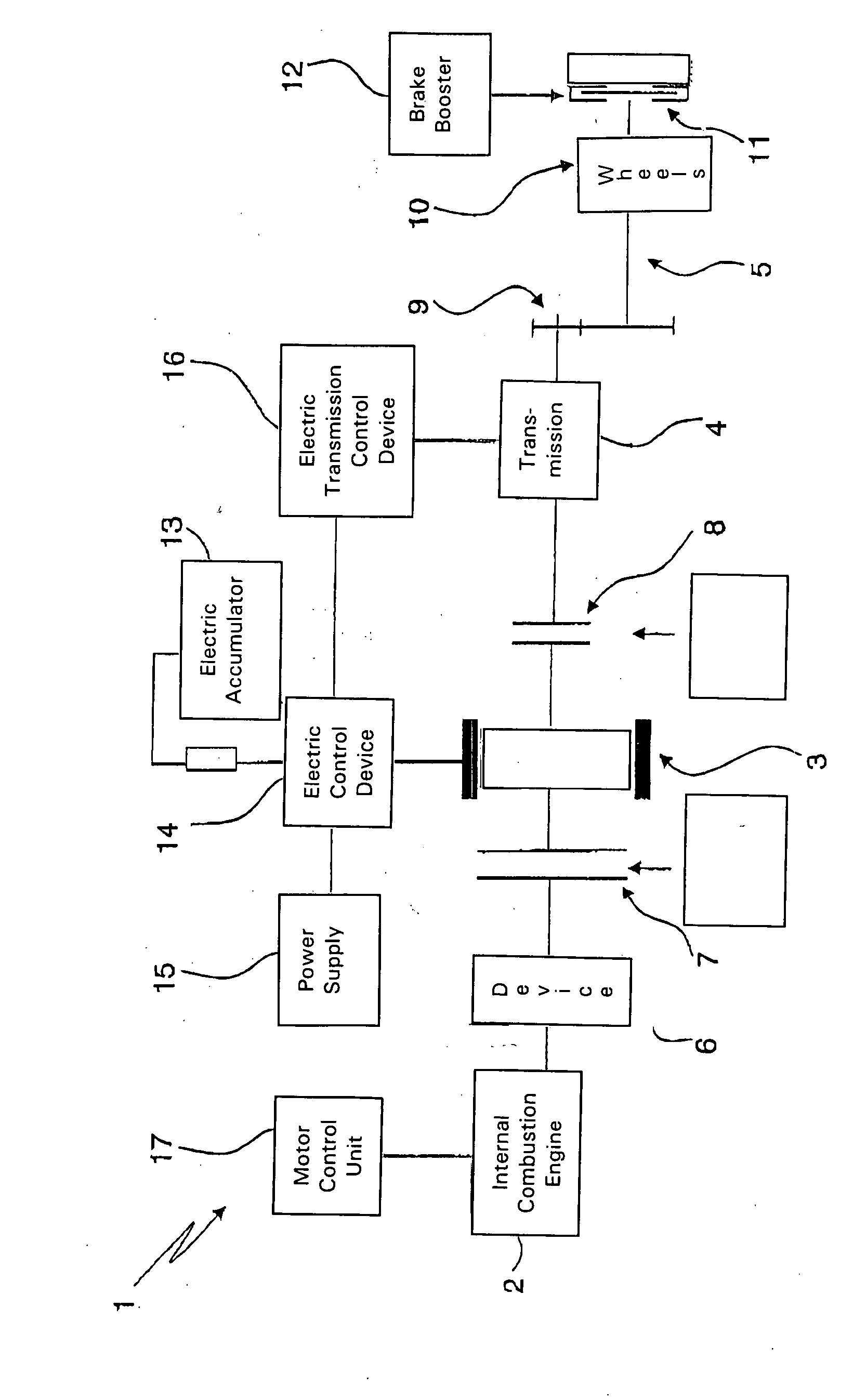

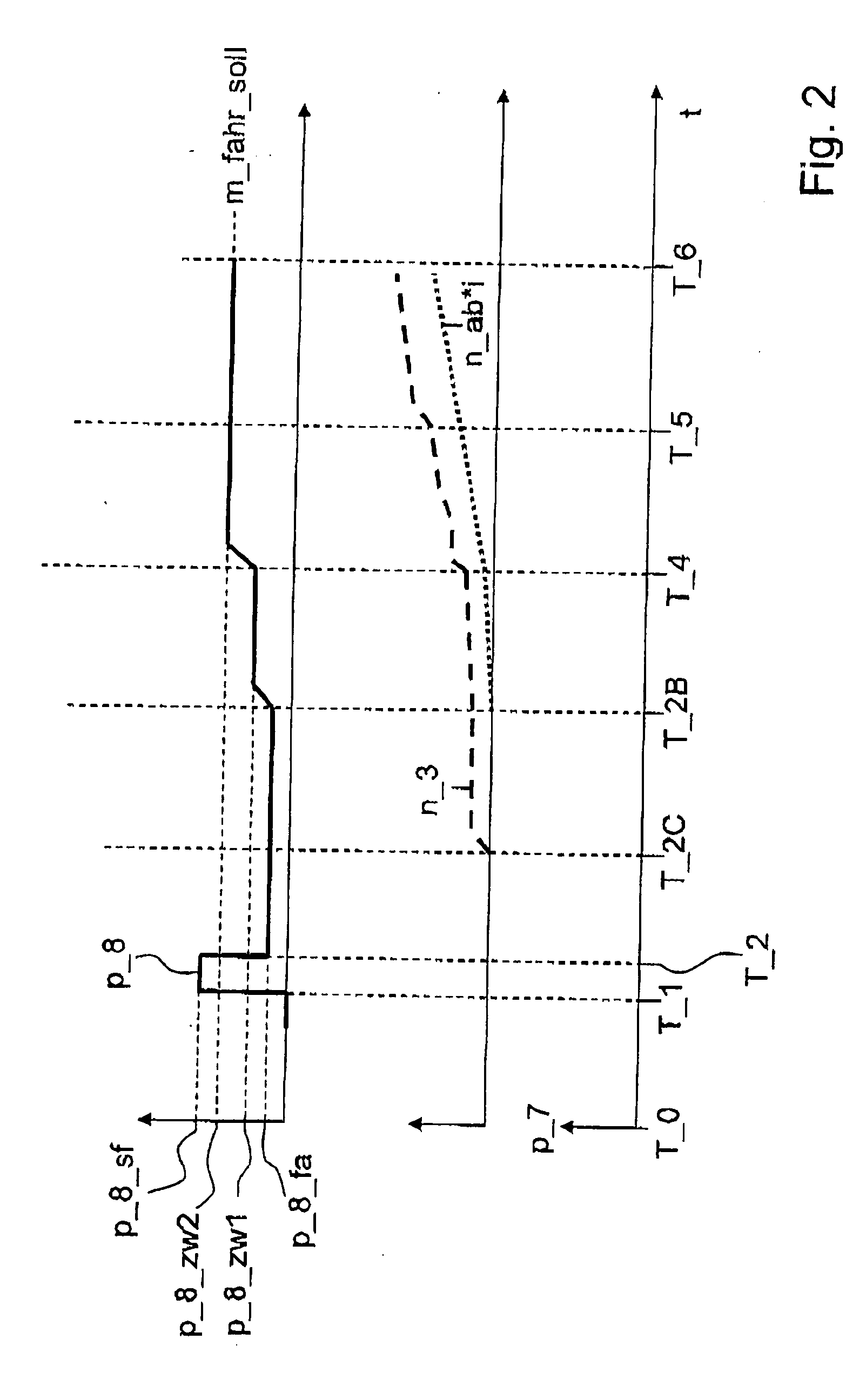

Method for operating a parallel hybrid drive train of a vehicle

InactiveUS20070207892A1Easy to adaptReduce slippagePropulsion using engine-driven generatorsGas pressure propulsion mountingControl theoryHybrid device

A method is described for operating a parallel hybrid device train (1) of a vehicle having an internal combustion engine (2), an electric engine (3) and an output (5) wherein the electric engine (3) is disposed in the power train between the output (5) and the internal combustion engine (2) and both between the internal combustion engine (2) and the electric engine (3) and between the electric engine (3) and the output (5) is respectively provided a frictionally engaged shifting element (7, 8). In addition, a nominal output torque abutting on the output (5) can be adjusted according to the transmitting capacity of the first shifting element (8) located between the electric engine (3) and the output (5). According to the invention, the transmitting capacity of the first shifting element (8) is adjusted under control according to the nominal input torque required so that the first shifting element (8) has a transmitting capacity needed for producing the nominal output torque on the output (5). Furthermore, an input rotational speed of the electric engine (3) is adjusted under regulation during a starting process of the internal combustion engine (2) in order to keep the first shifting element in slip operation at least during the starting process of the internal combustion engine (2) and to produce the nominal output torque on the output (5).

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com