Powertrain and Method for a Kinetic Hybrid Vehicle

a kinetic hybrid and powertrain technology, applied in the direction of process and machine control, instruments, etc., can solve the problems of inability to meet the needs of kinetic hybrid vehicles, etc., to achieve the effect of reducing energy conversion and conversion losses, reducing energy consumption, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

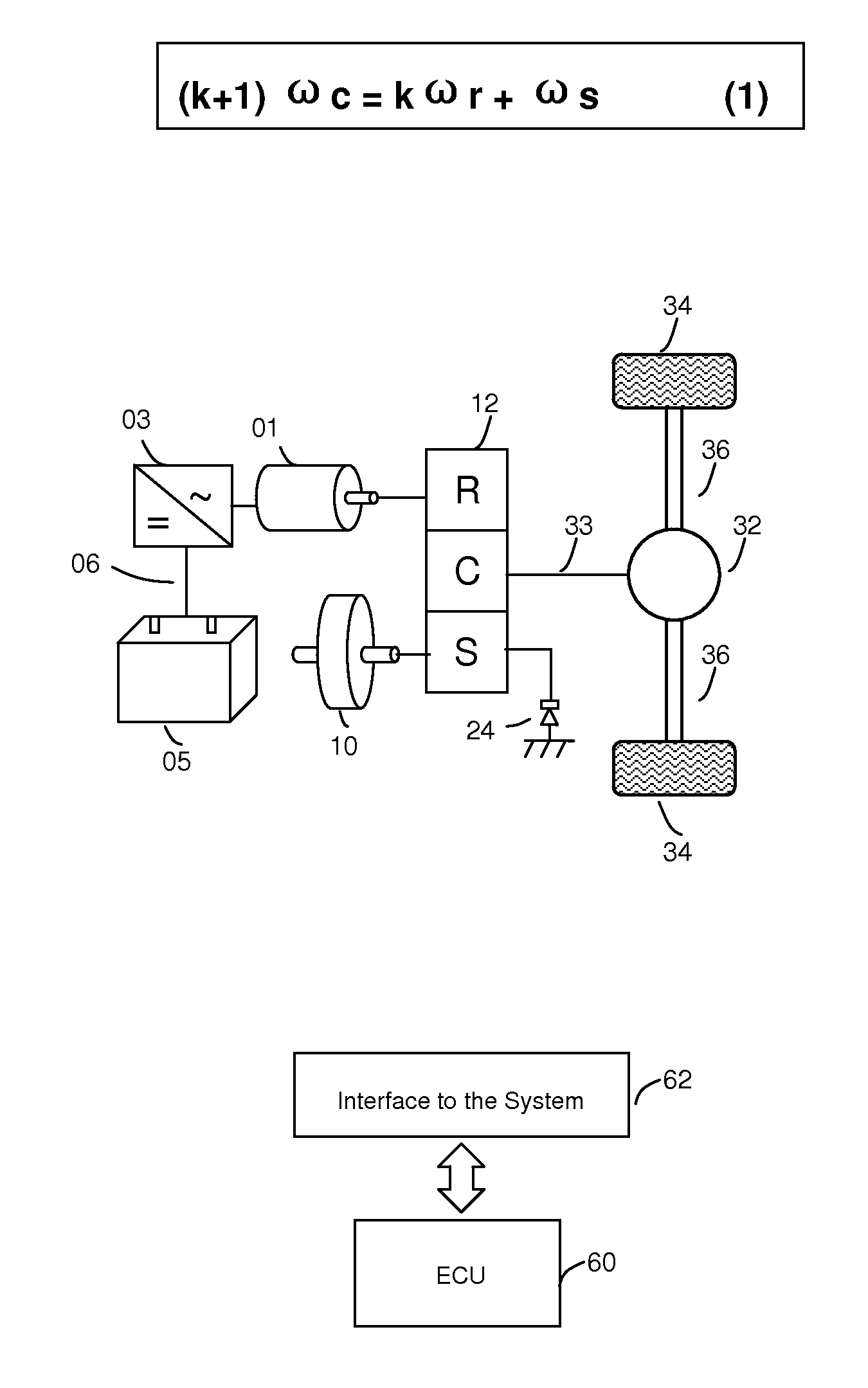

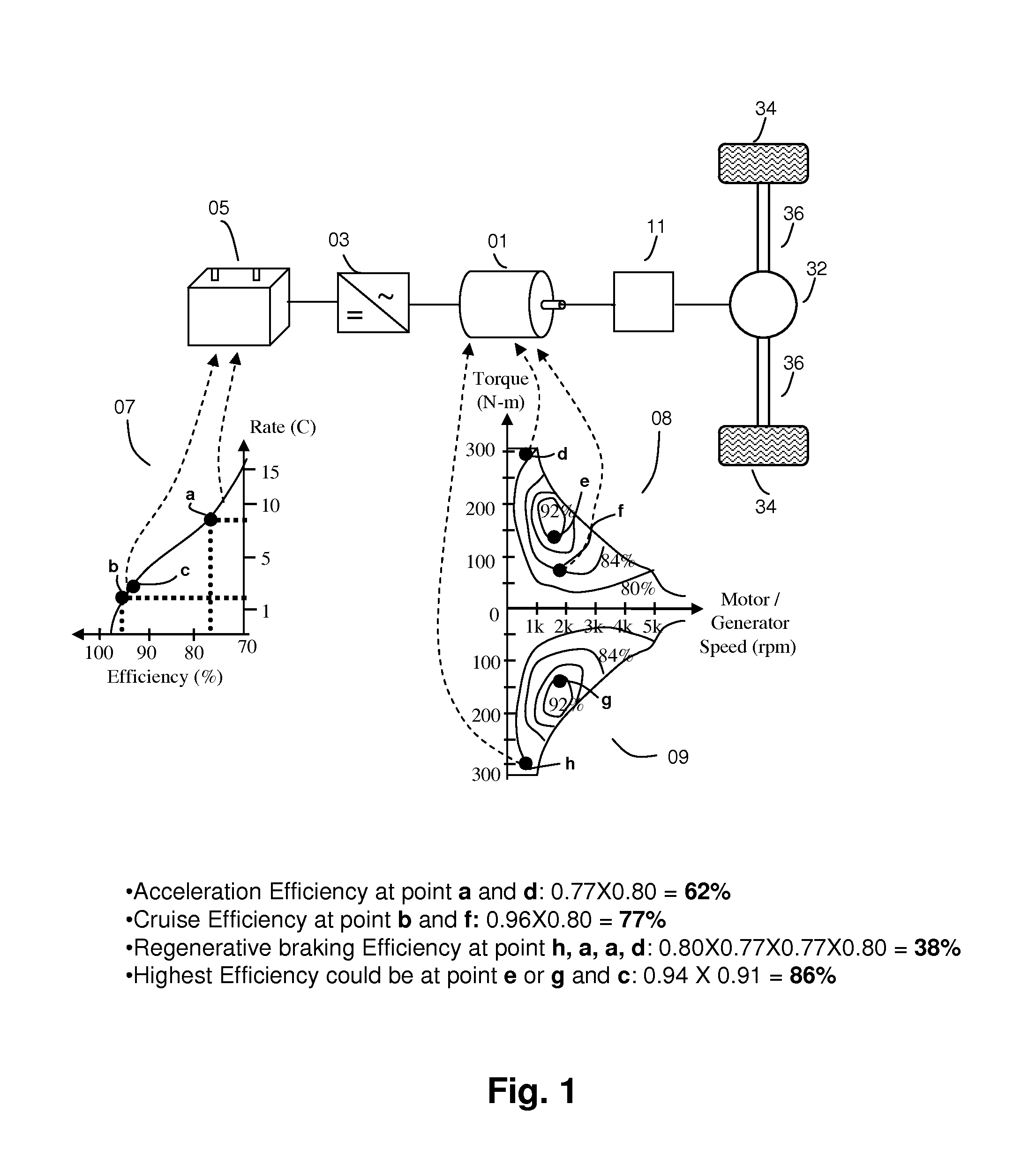

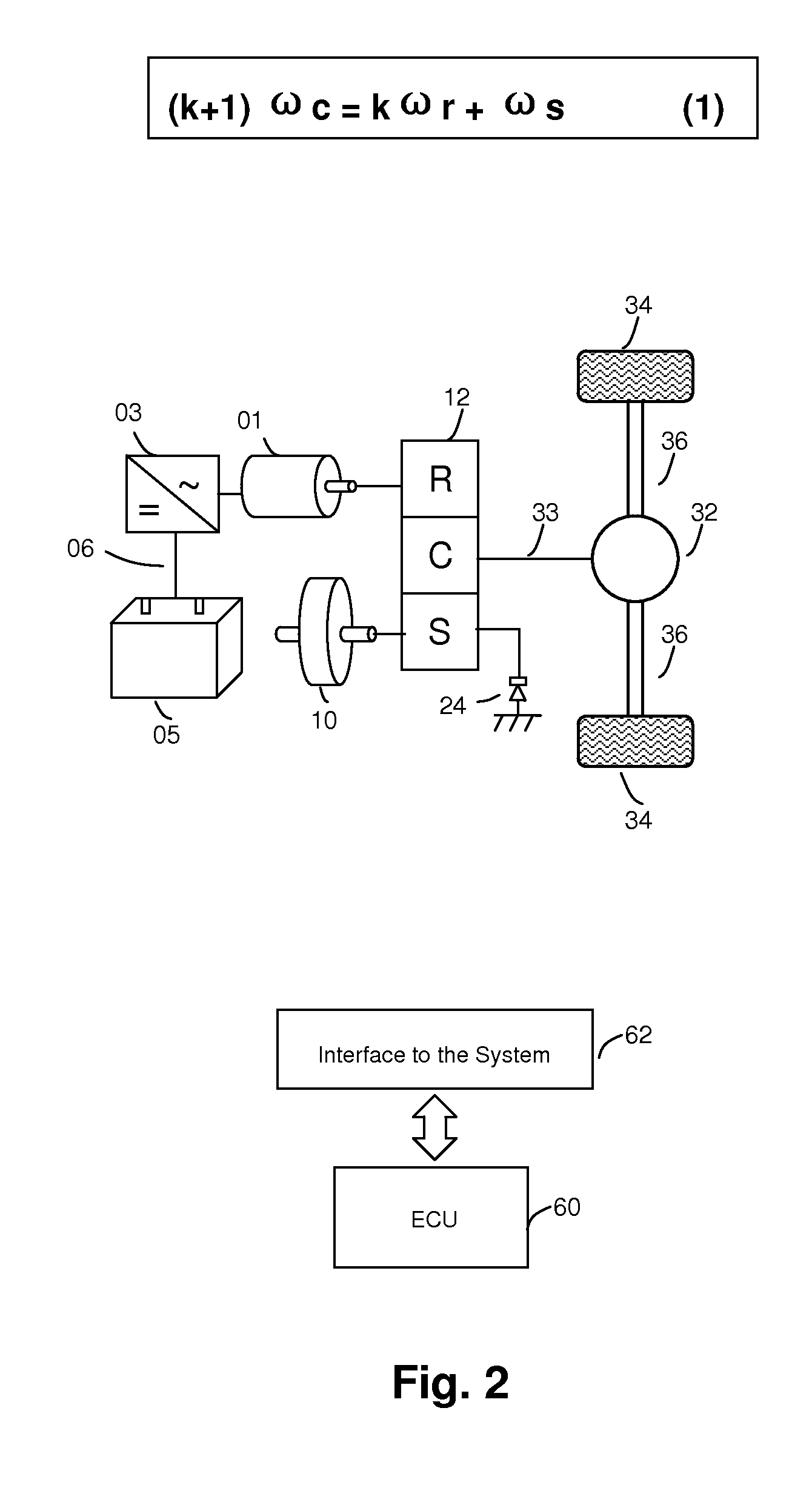

[0057]Embodiment(s) of the present invention are described herein with reference to the drawings. In the drawings, like reference numerals represent like elements.

Current Limitations of Electric Vehicle Propulsion Systems

[0058]Although both fuel efficiency and performance are desired in vehicles, they are conflicting goals in the design of a conventional vehicle powered by an internal combustion engine. High performance vehicles are equipped with large engines but suffer from poor efficiency, whereas fuel efficient vehicles lack performance.

[0059]Gas-electric hybrid vehicle technologies have made considerable advances in resolving the deadlock conflict between fuel efficiency and accelerative performance. These hybrid electric vehicles, or HEVs, rely on a downsized engine that works at a better efficiency converting fuel to mechanical power, while a motor, as a secondary mover, supplements power to compensate for a smaller engine's lack of reserve power for acceleration. In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com