Patents

Literature

139 results about "Comb drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comb-drives are actuators, often used as linear actuators electrostatic forces that act between two electrically conductive combs. Comb drive actuators typically operate at the micro- or nanometer scale and are generally manufactured by bulk micromachining or surface micromachining a silicon wafer substrate. The attractive electrostatic forces are created when a voltage is applied between the static and moving combs causing them to be drawn together.

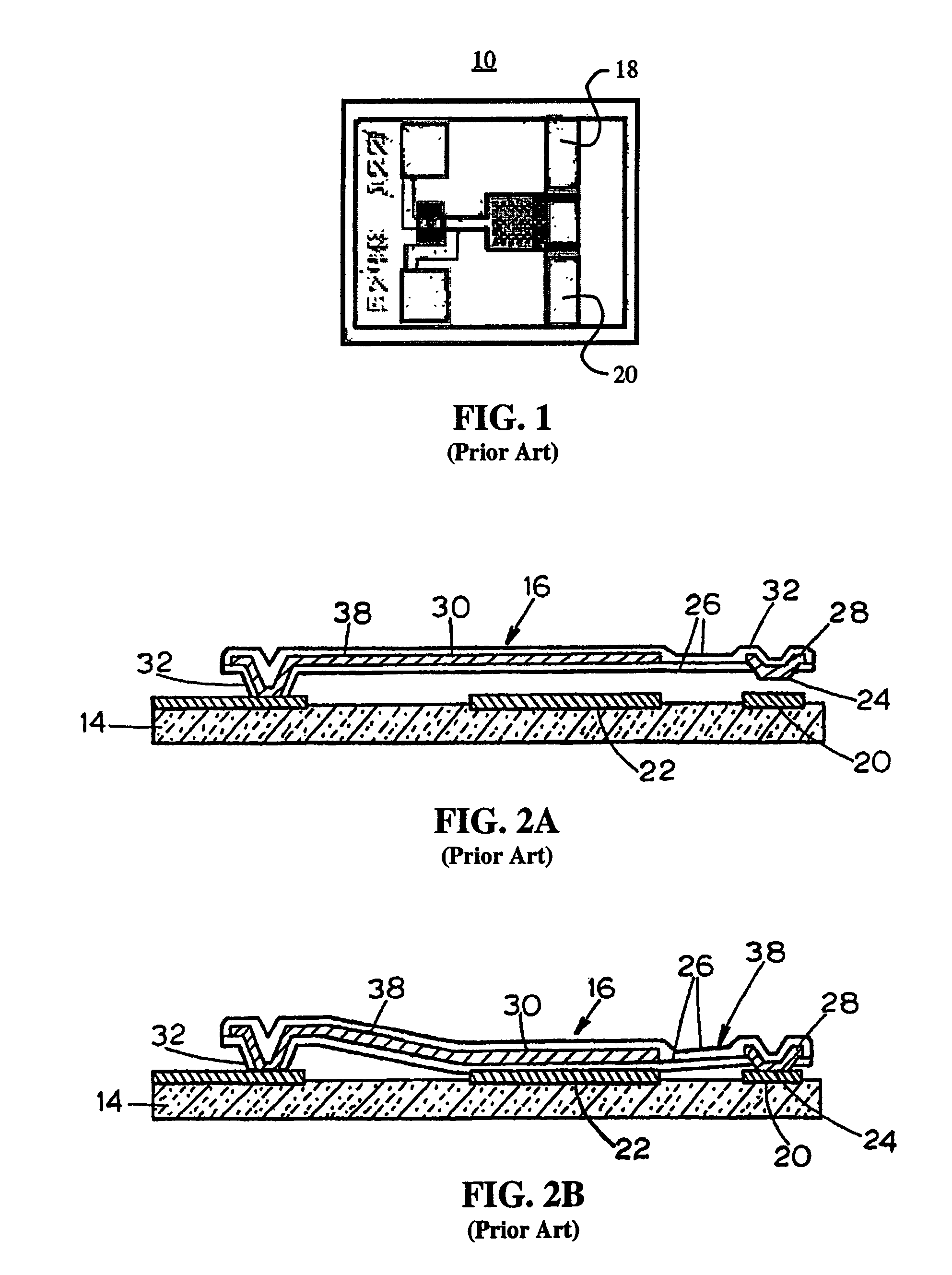

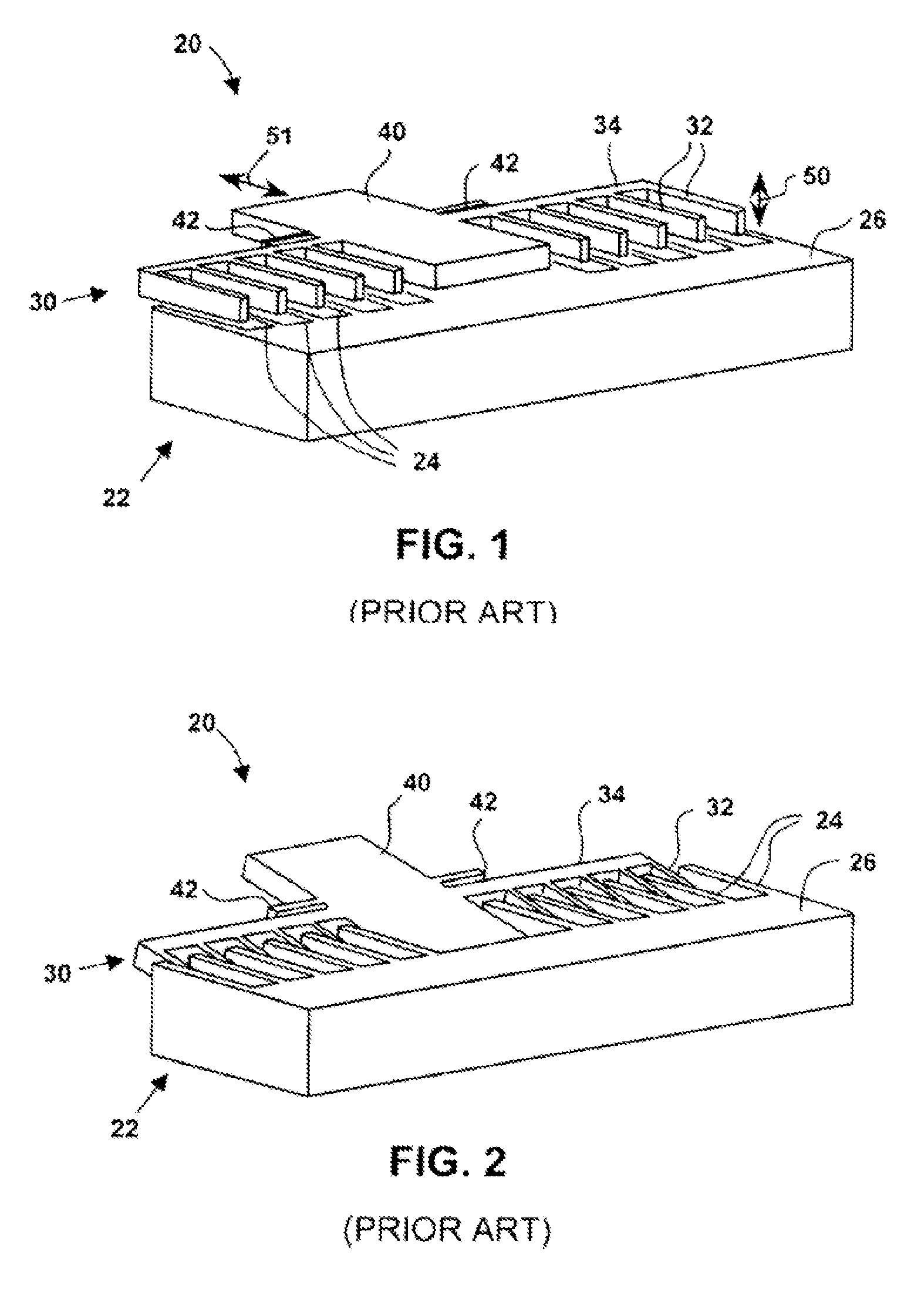

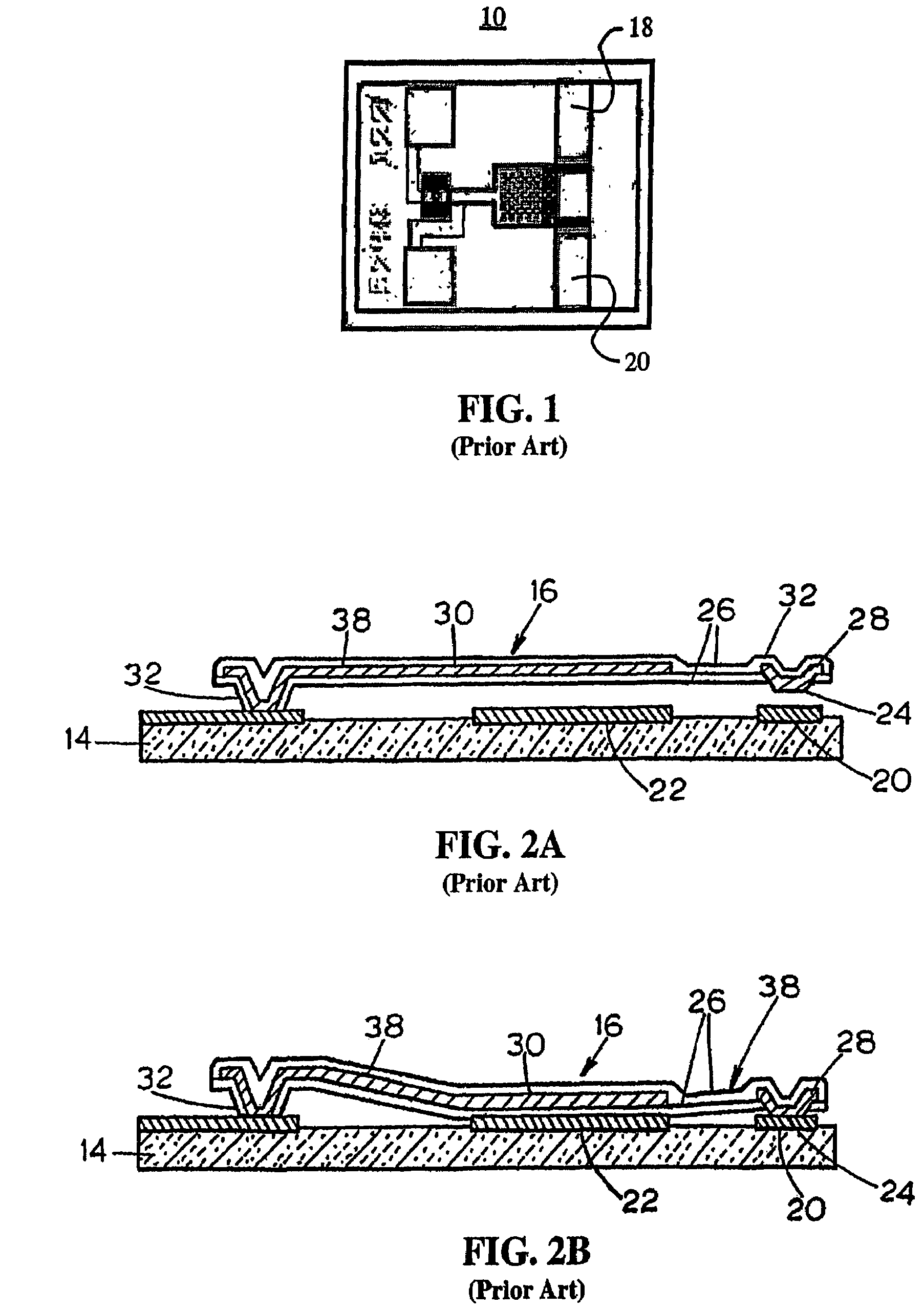

Vertical comb drive actuated deformable mirror device and method

InactiveUS6384952B1Optical waveguide light guideFlexible microstructural devicesPotential differenceComb drive

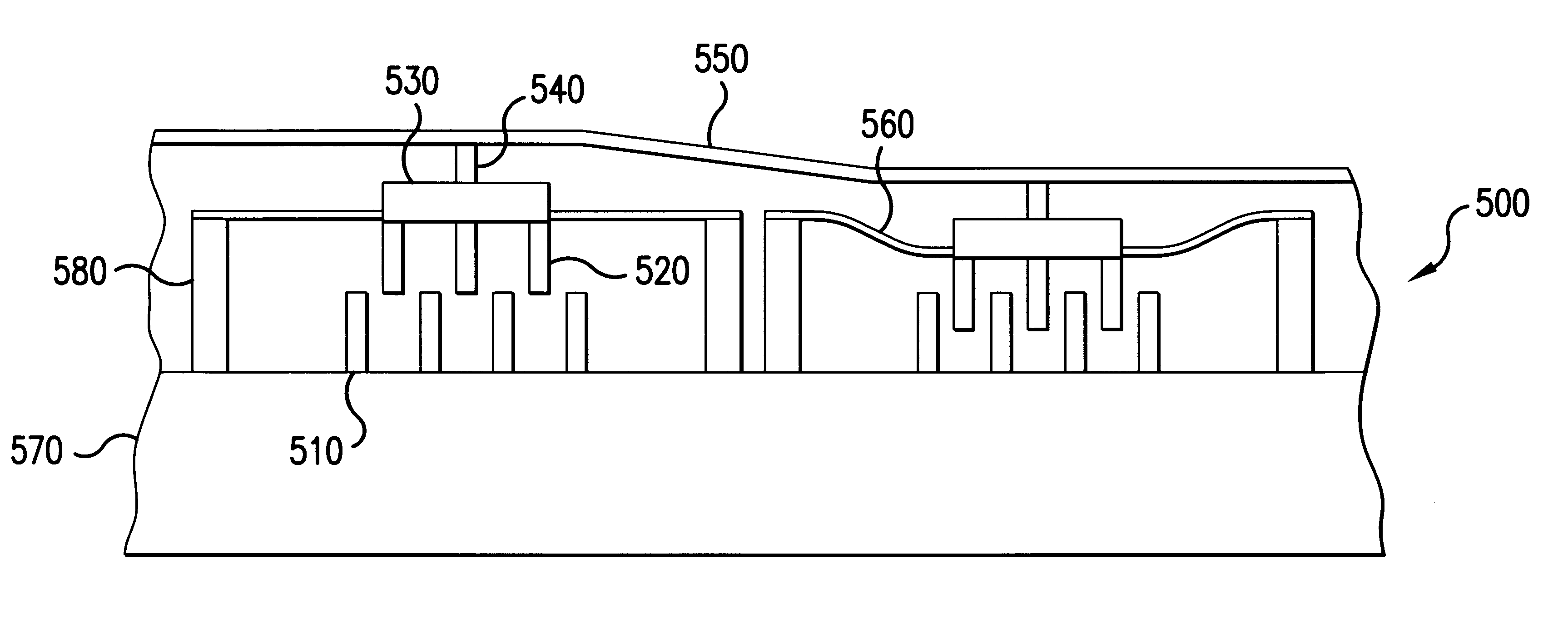

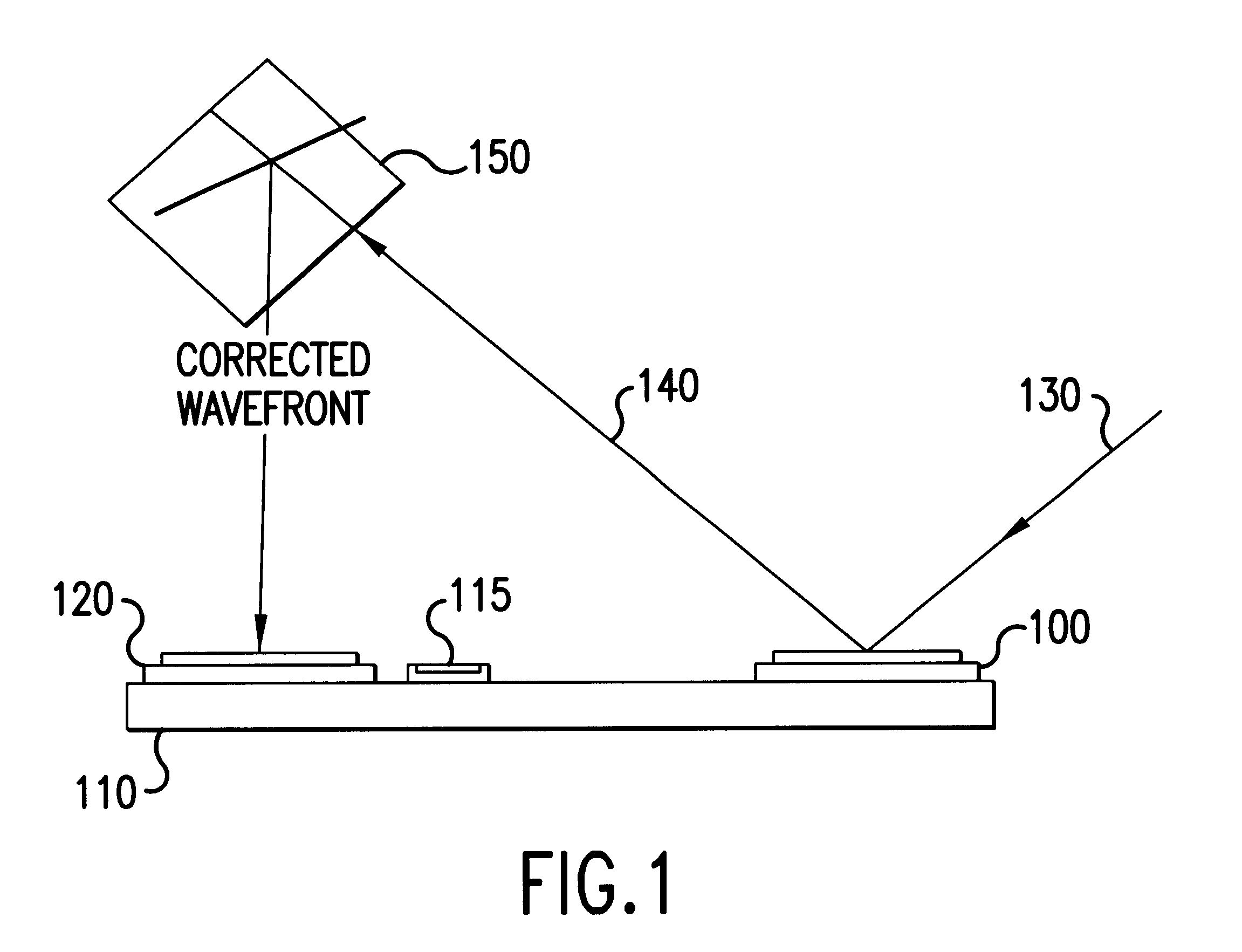

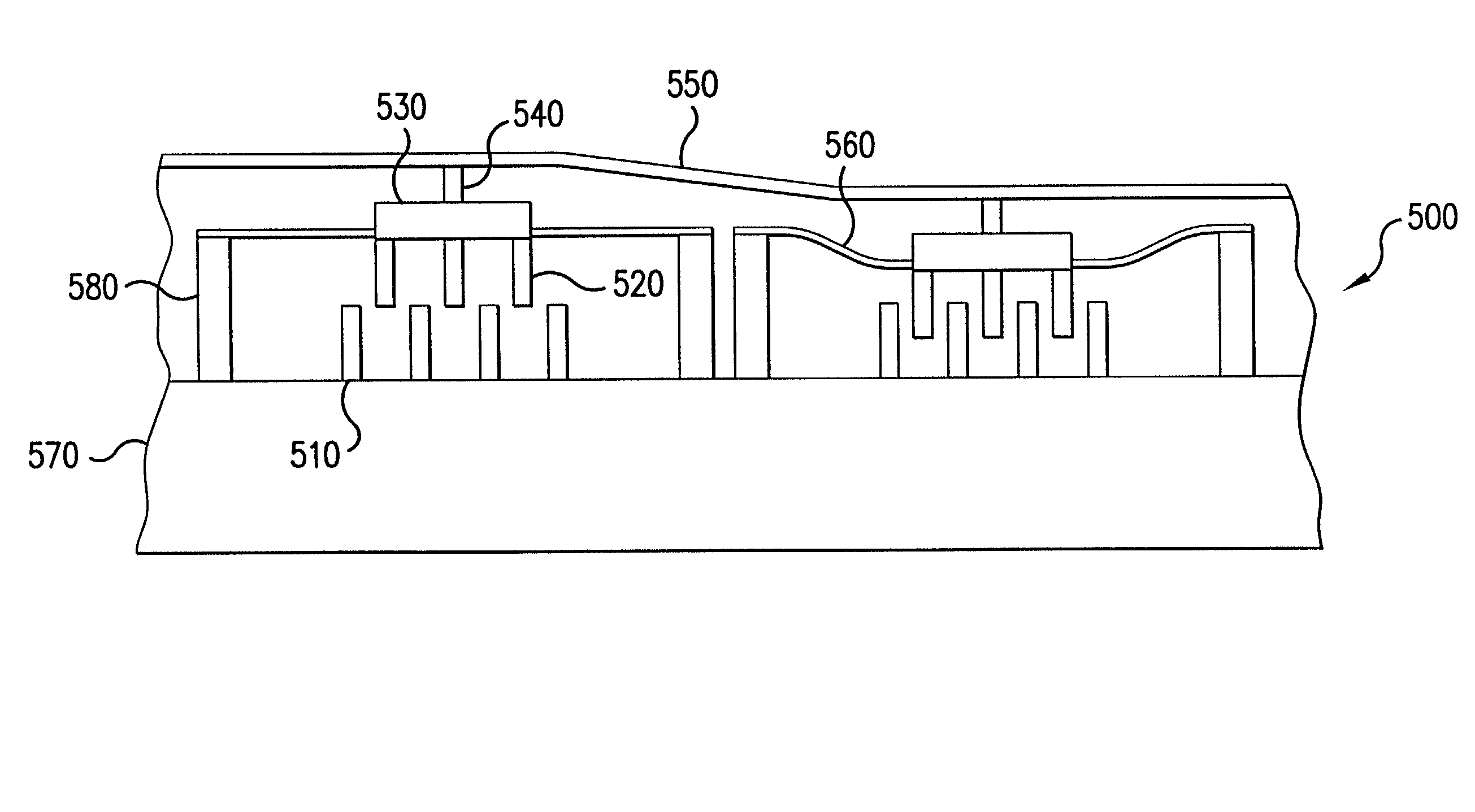

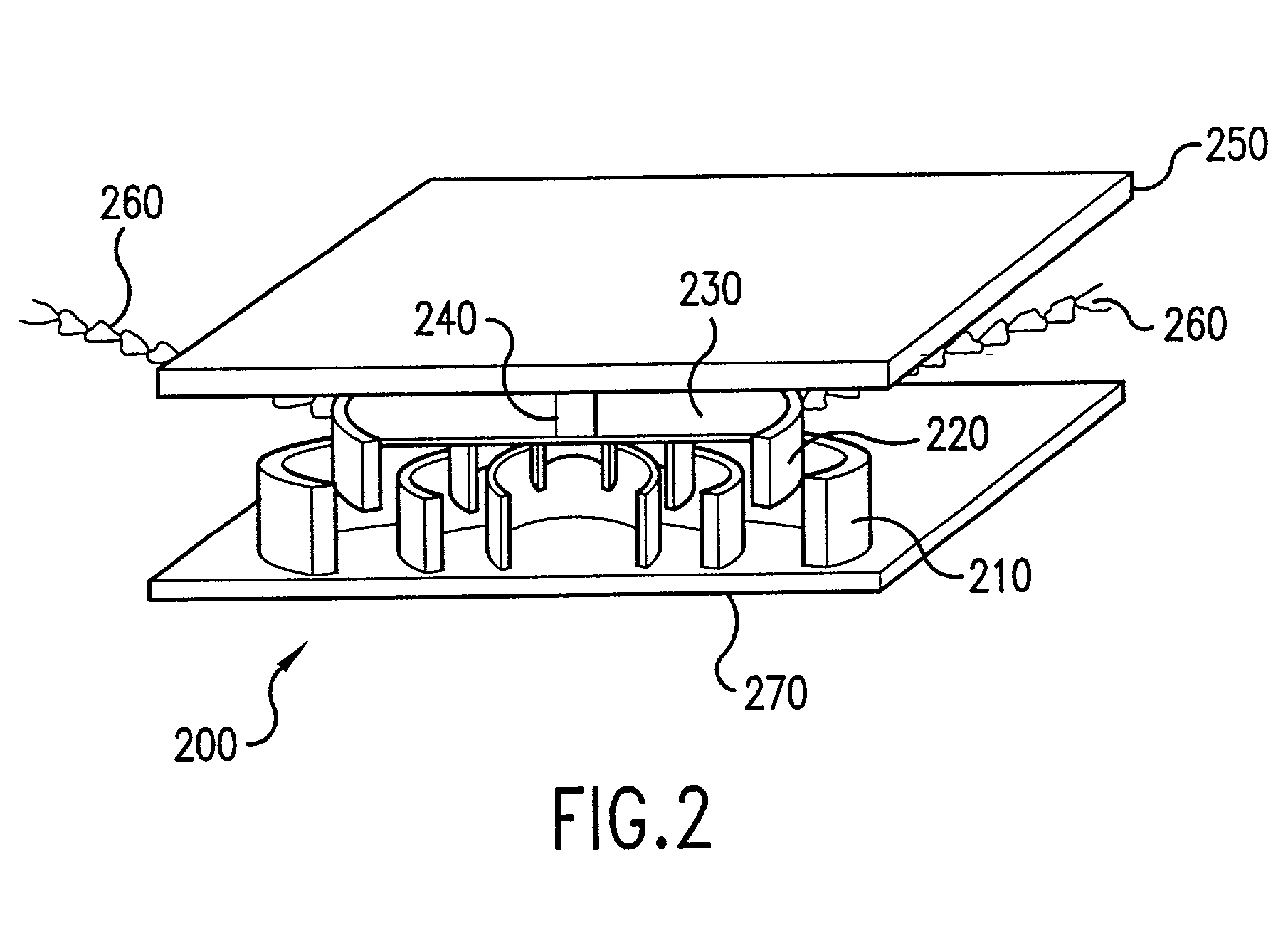

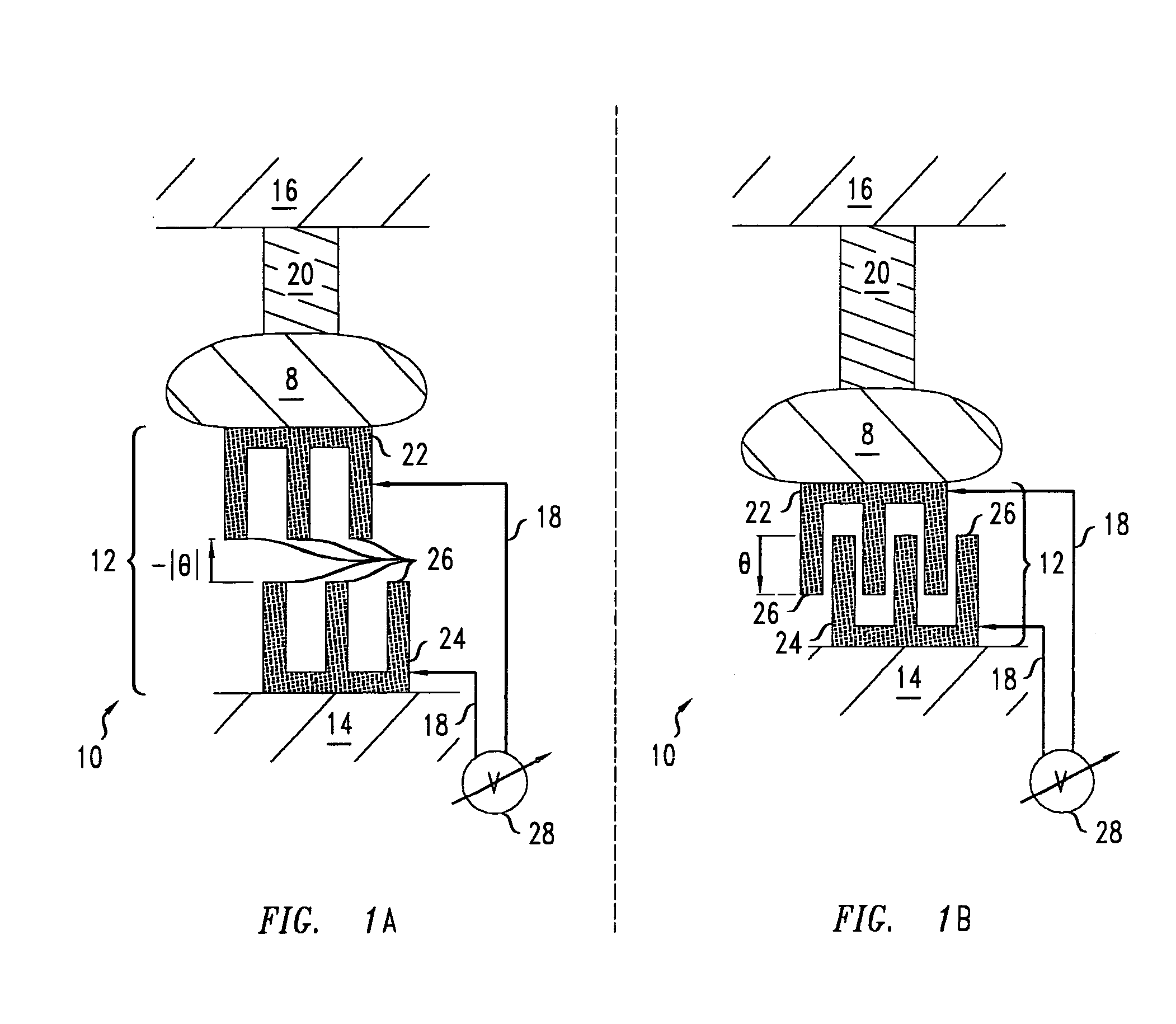

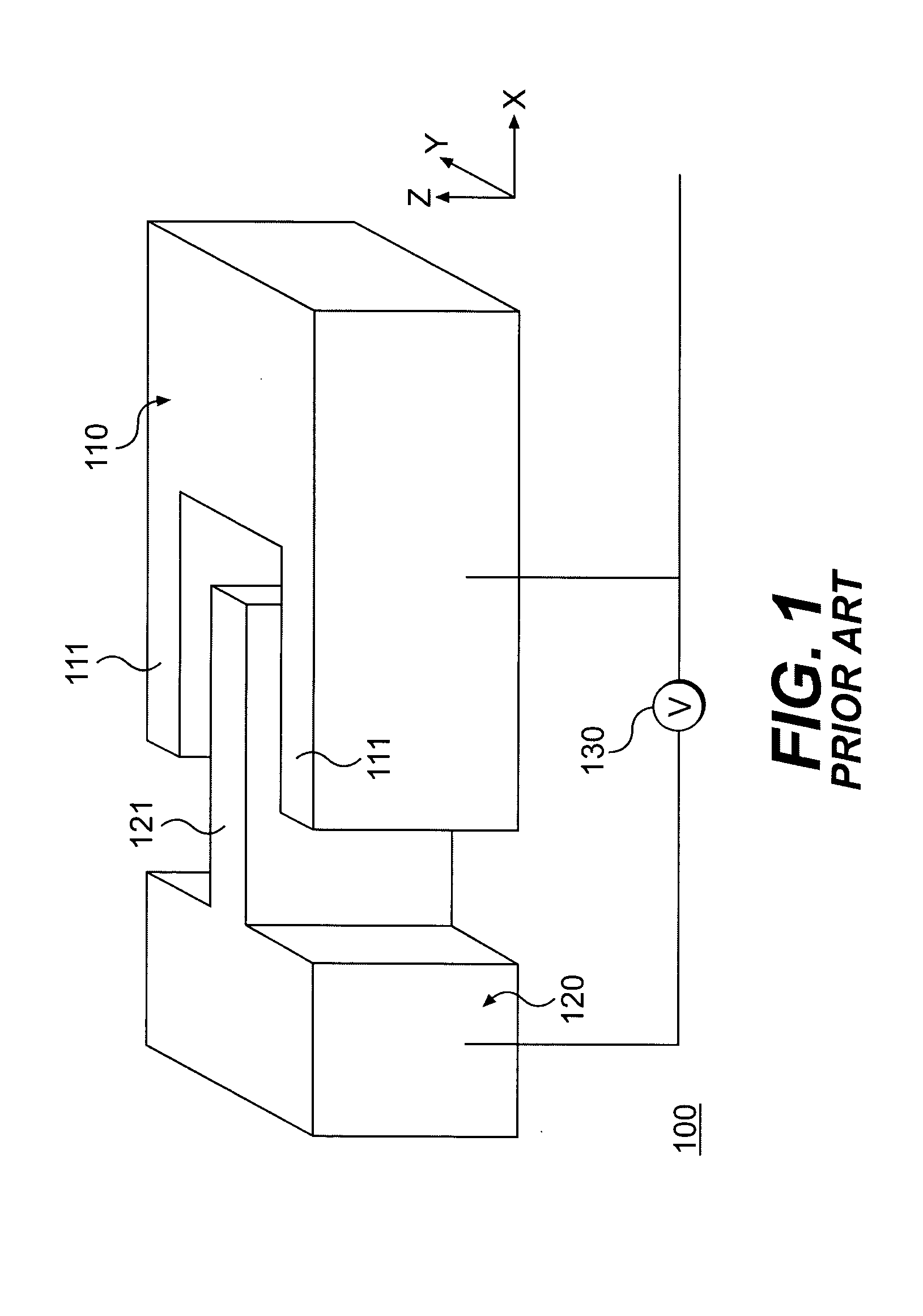

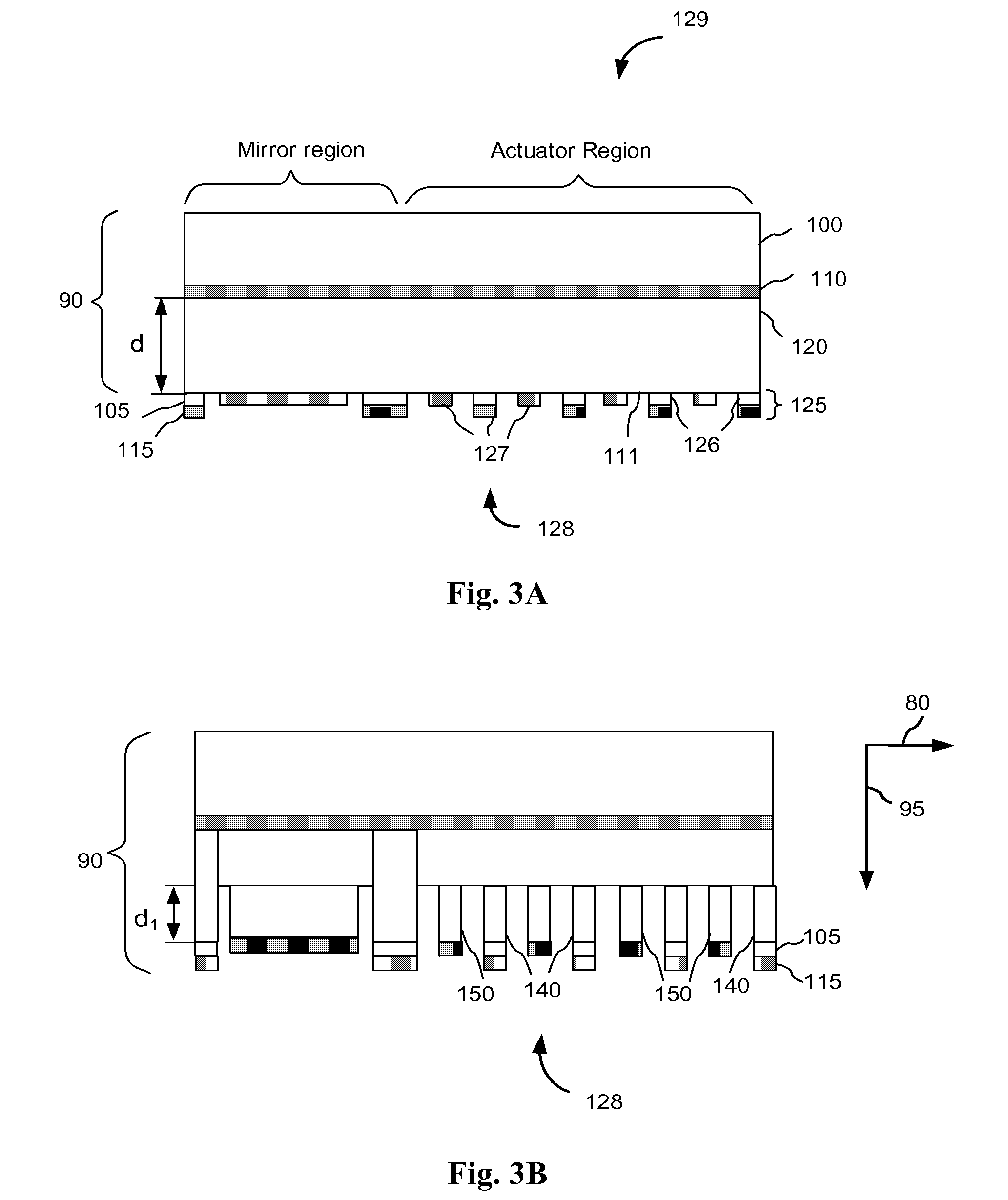

A deformable mirror includes a vertical comb actuator having a reflective surface attached thereto. The vertical comb drive includes stationary elements interspersed with moving elements. When a potential difference is provided between these elements, the moving elements are pulled downward, thereby deforming the reflective surface. The vertical comb drive typically includes a plurality of actuators, which are individually electrically addressed. Each actuator may be an array of interspersed elements or a cavity and corresponding tooth. Springs support the moving elements and bias the reflective surface in an original position. The vertical comb drive provides a large stroke and substantially linear voltage-versus-displacement curve throughout the stroke.

Owner:MEMS OPTICAL

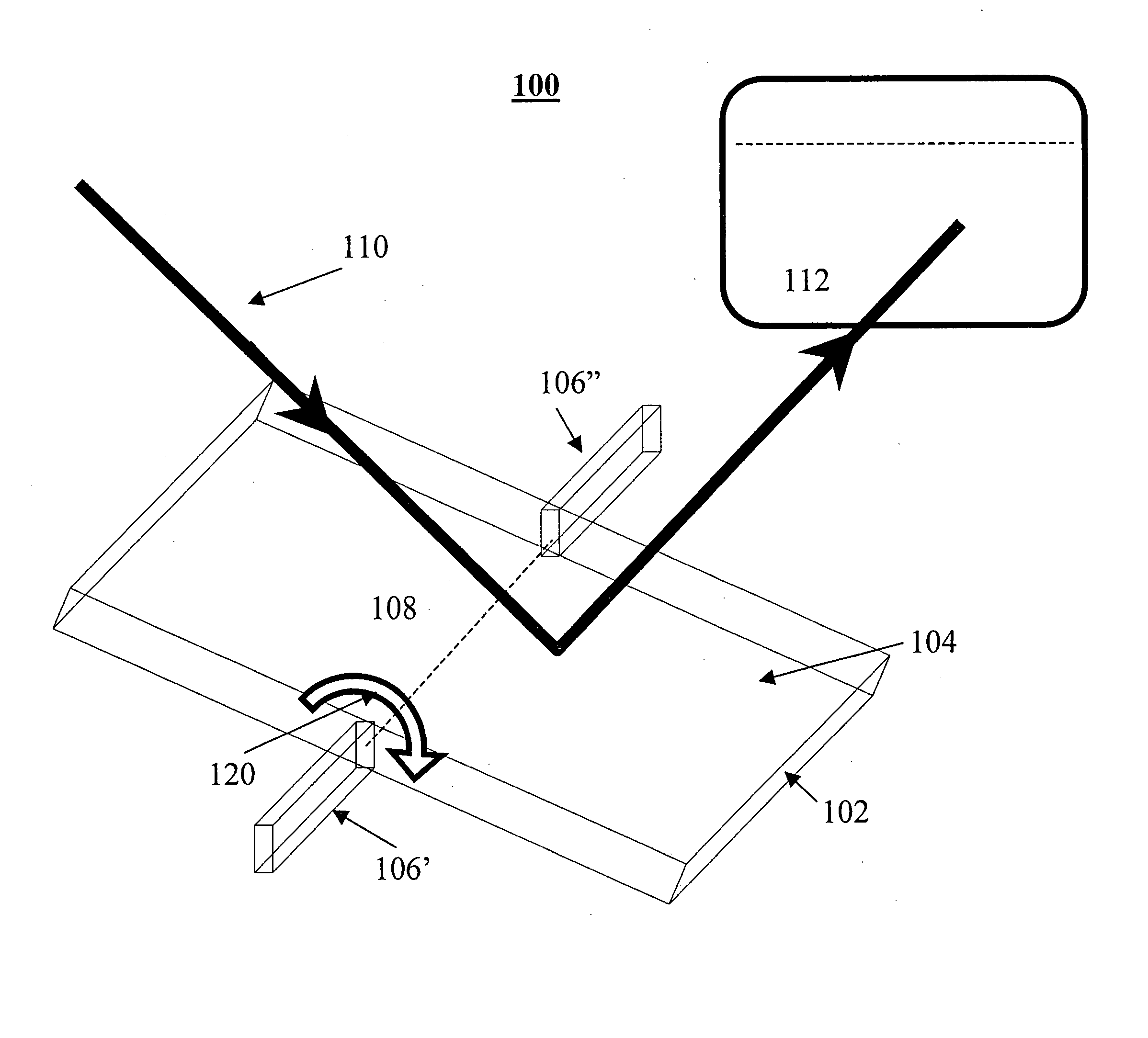

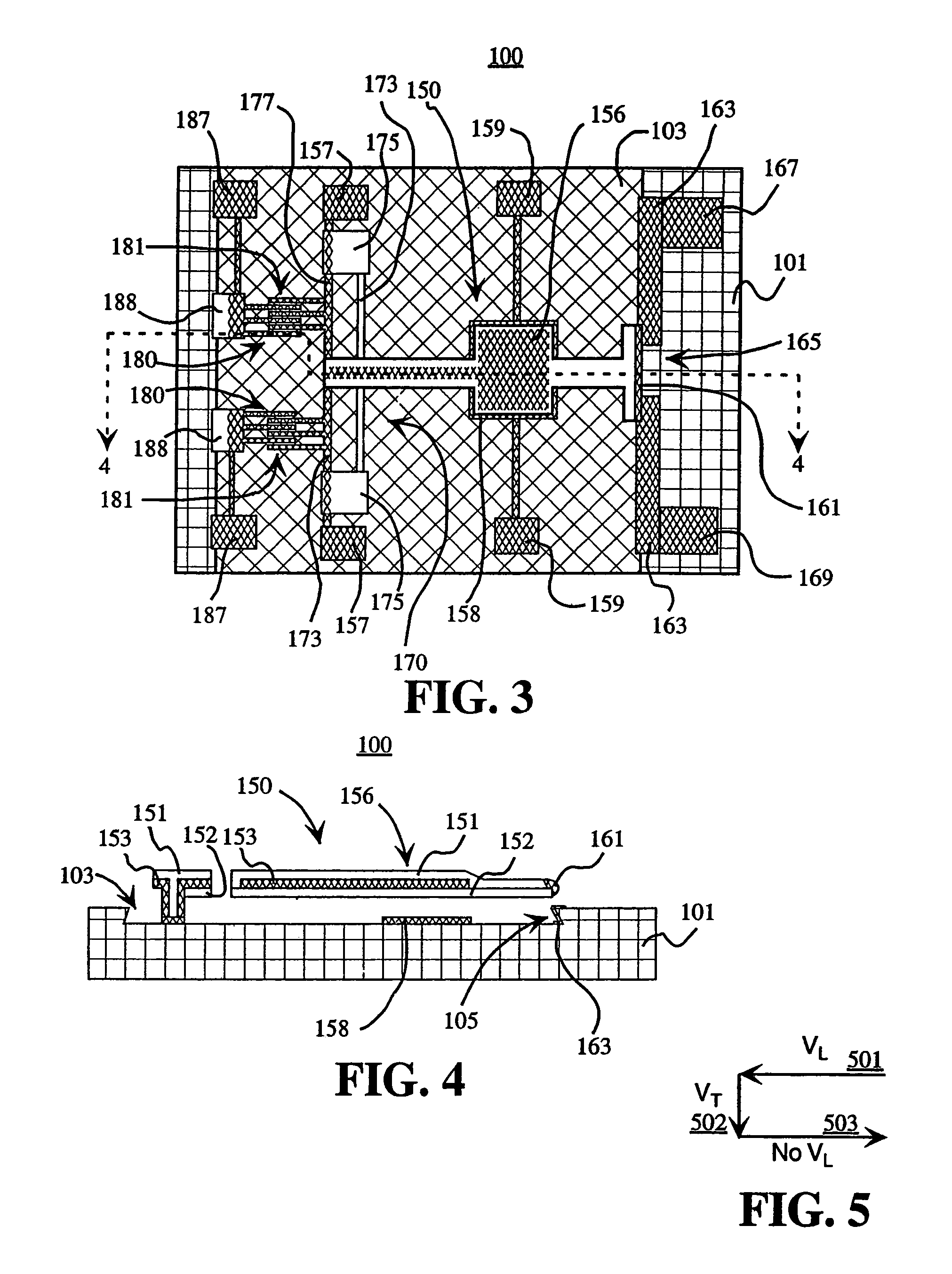

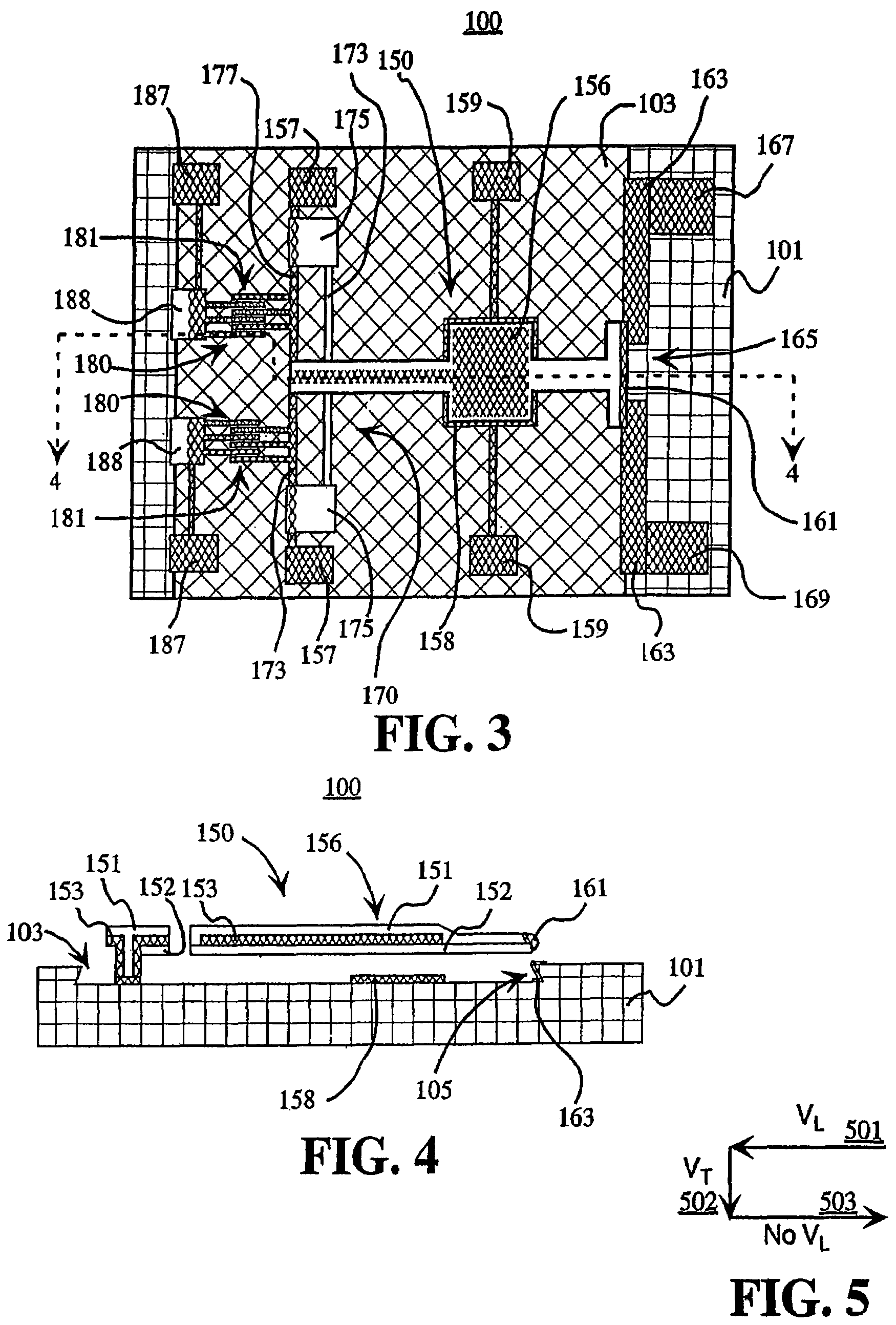

Gimbal-less micro-electro-mechanical-system tip-tilt and tip-tilt-piston actuators and a method for forming the same

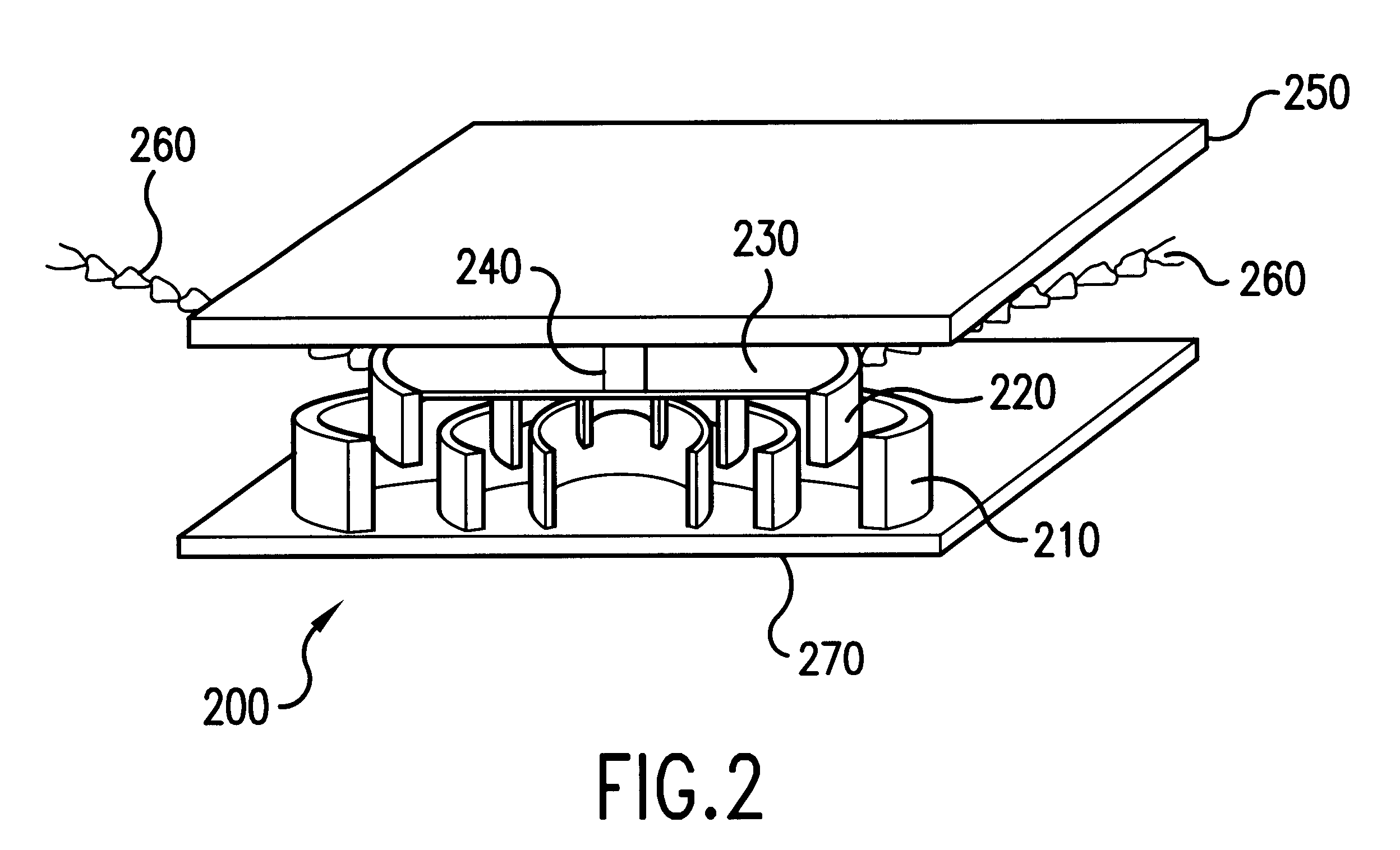

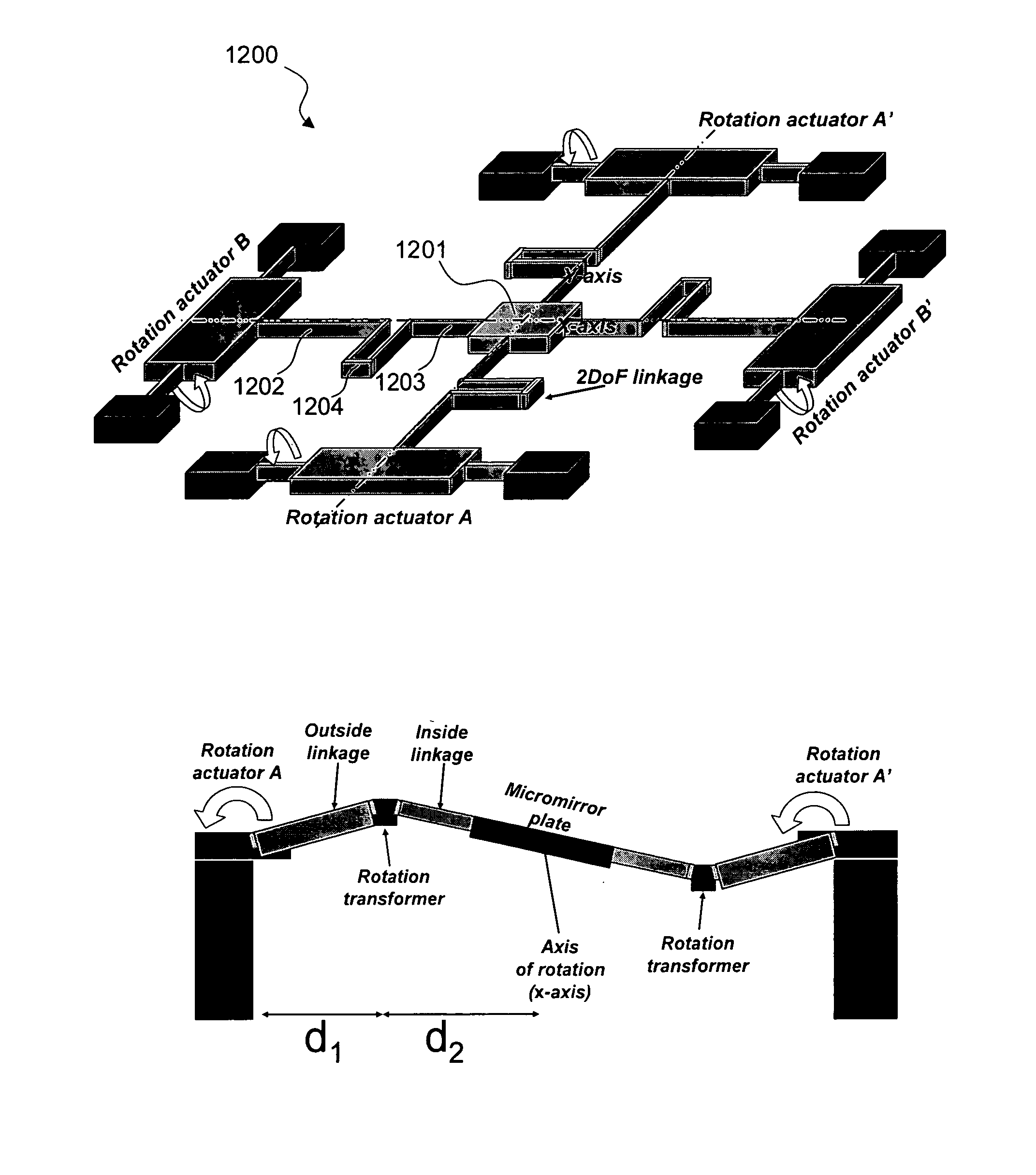

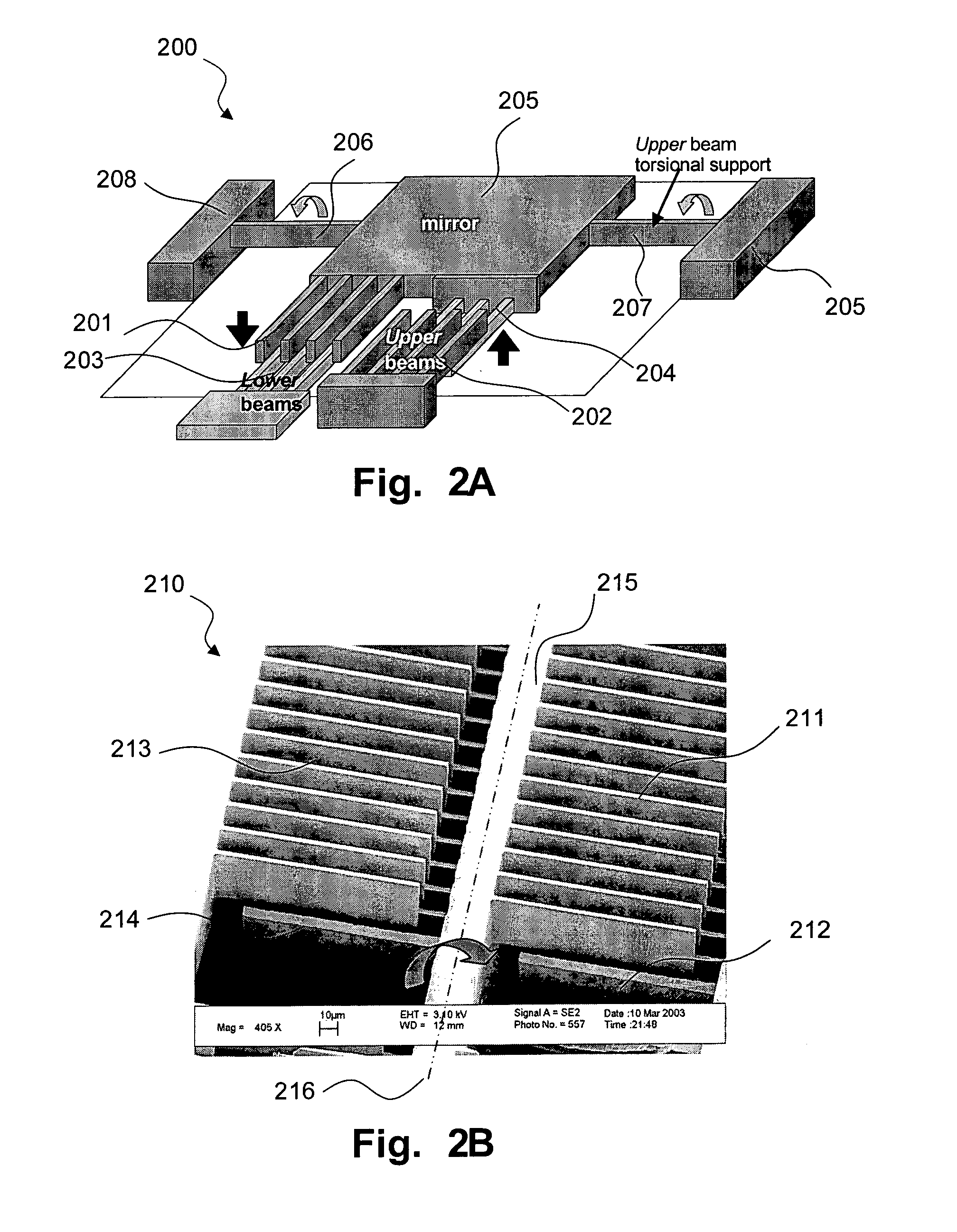

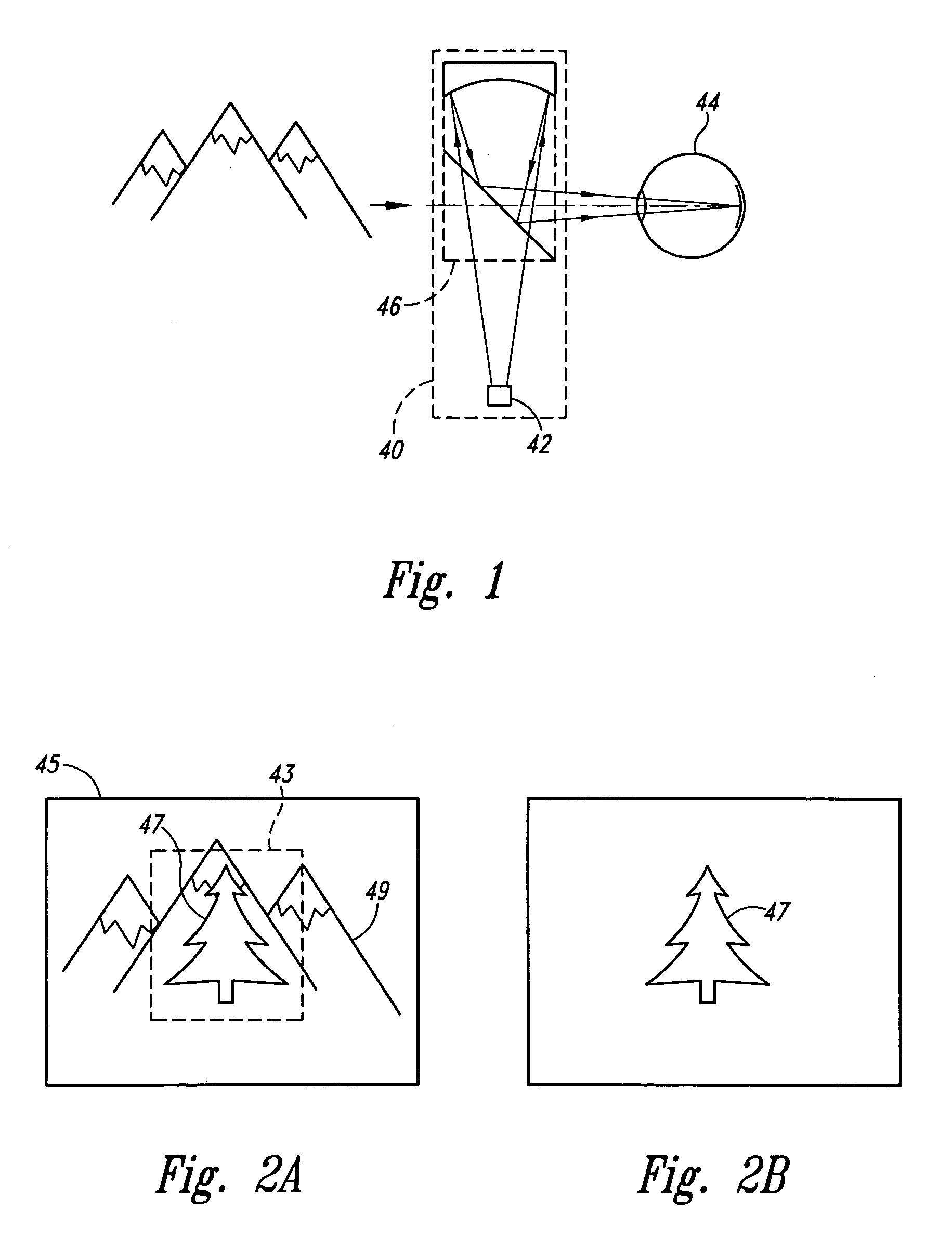

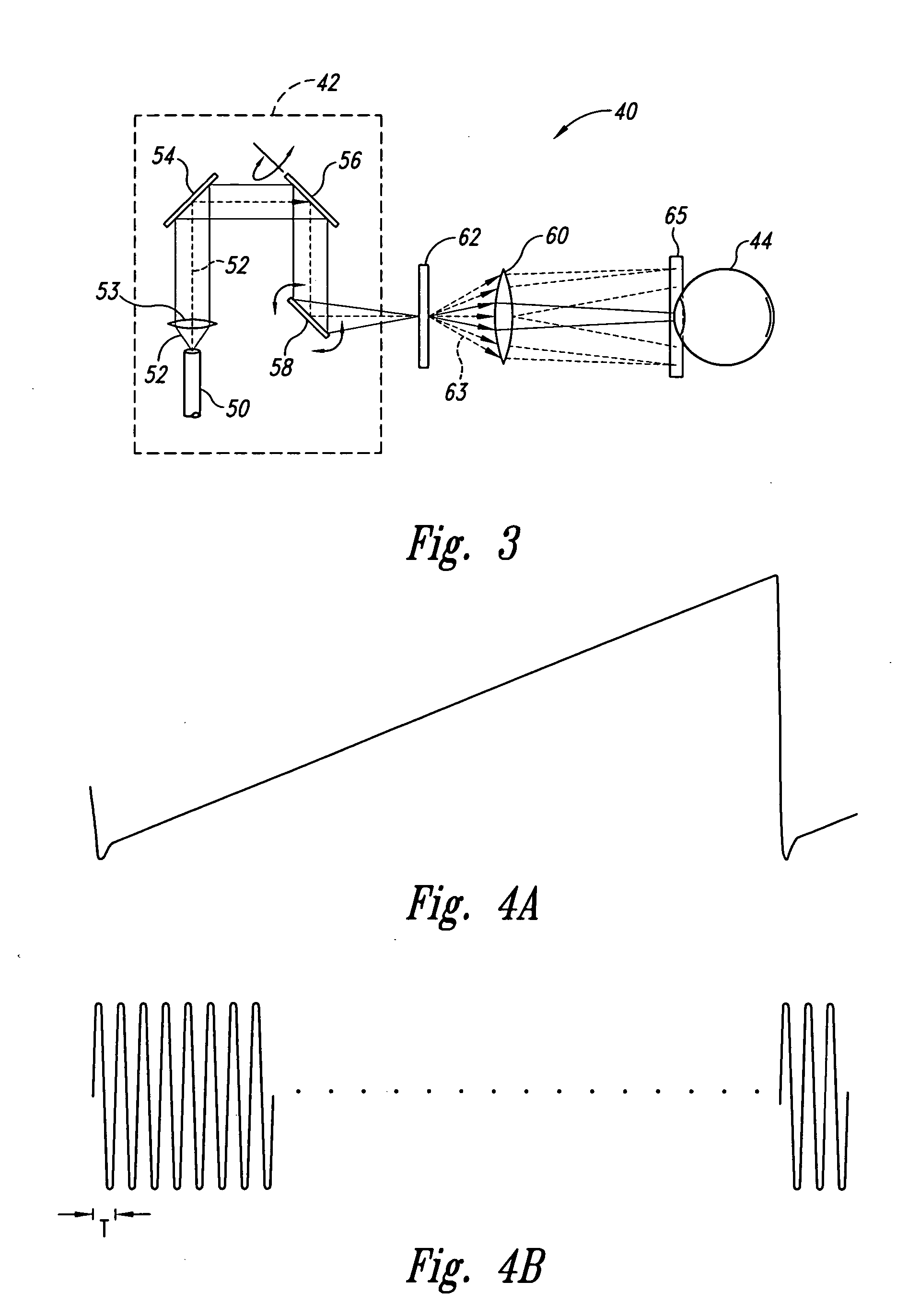

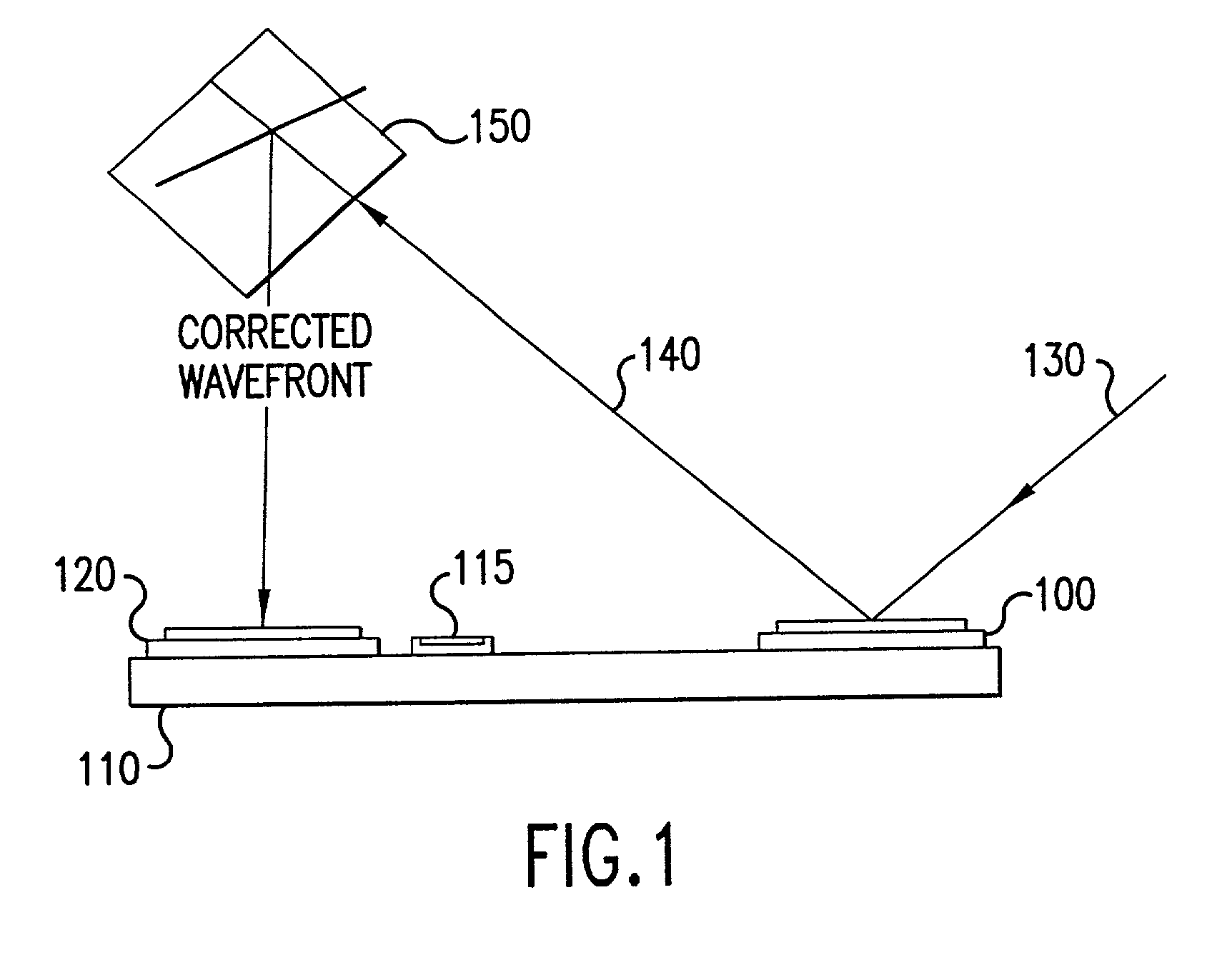

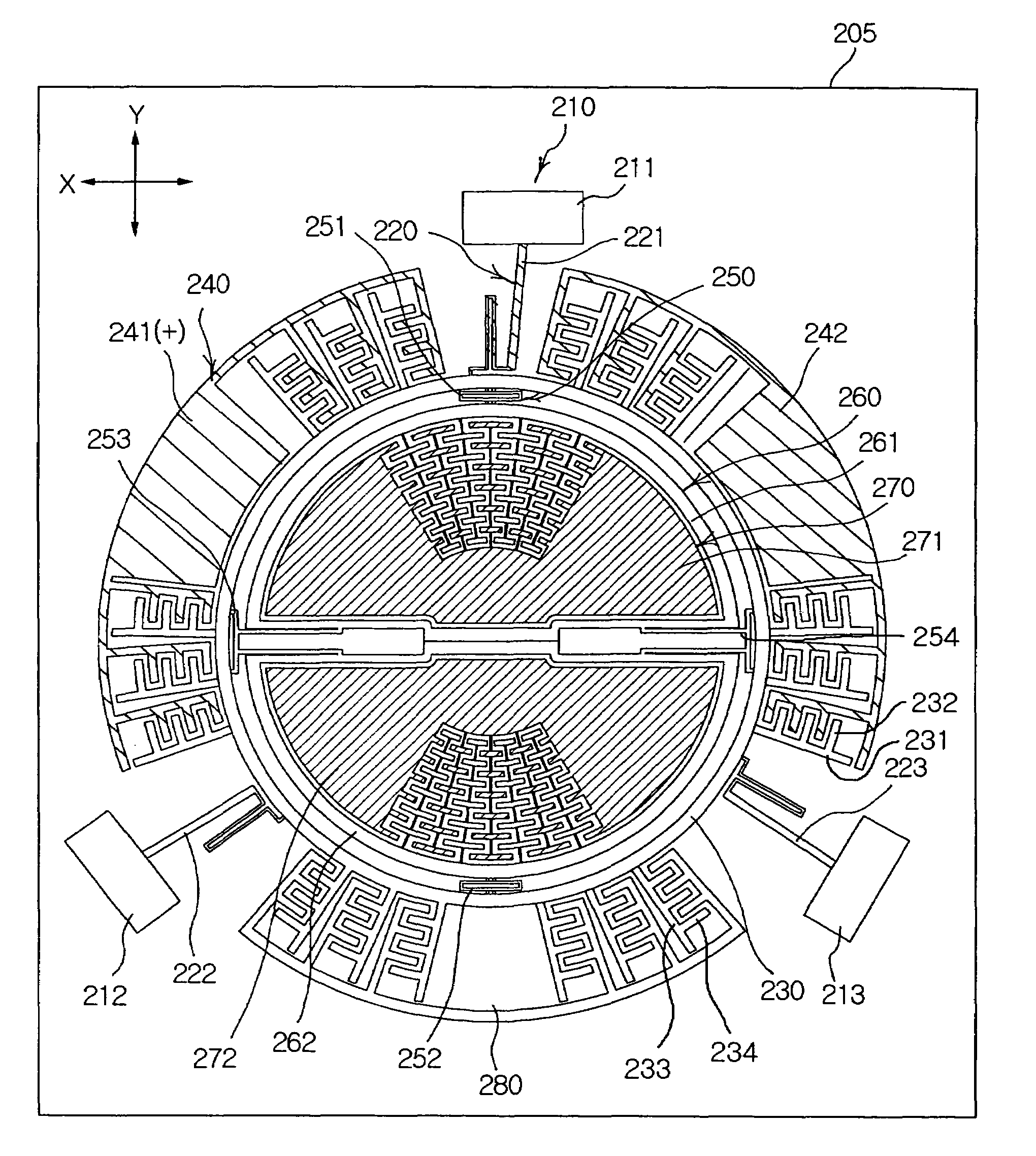

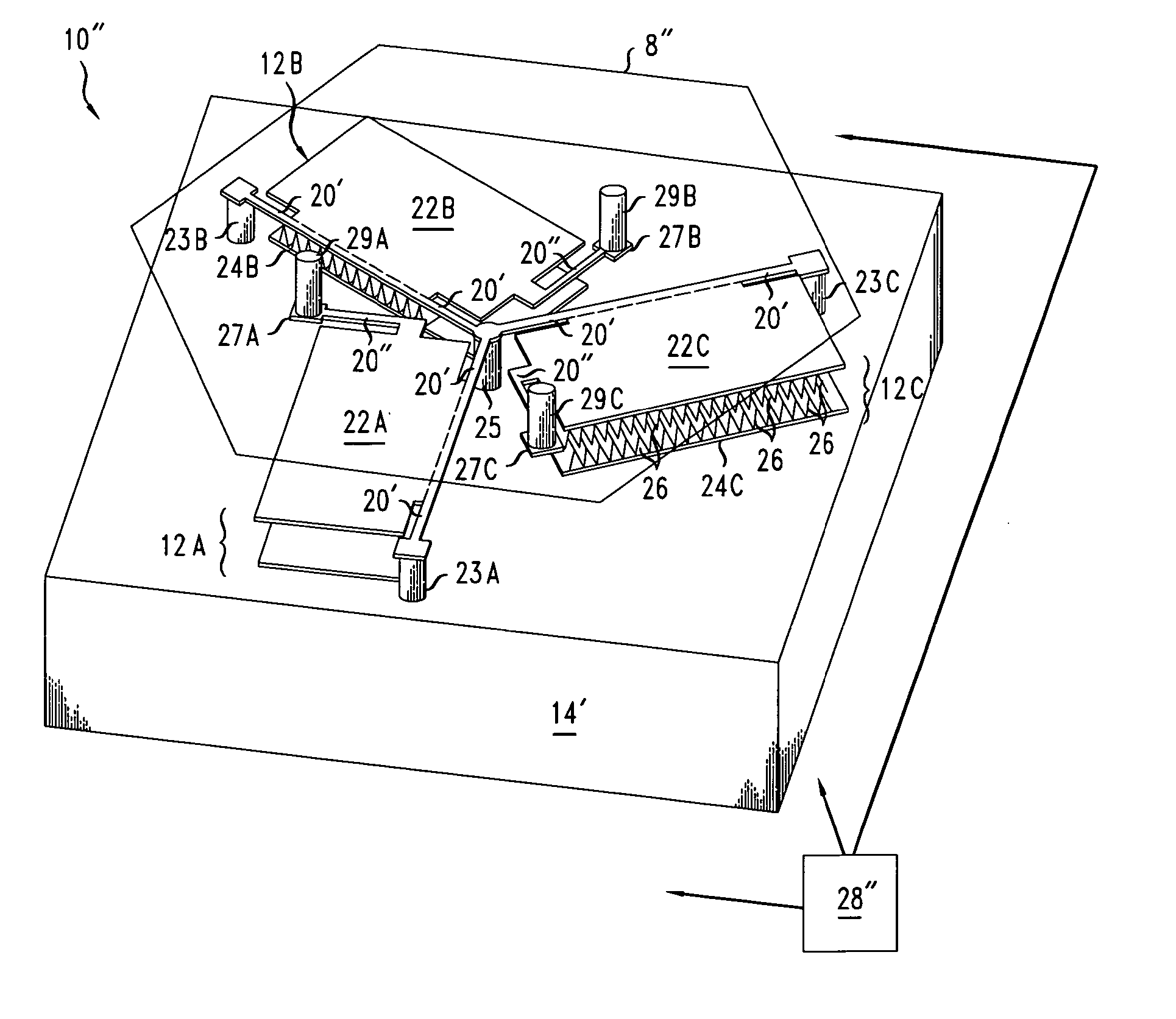

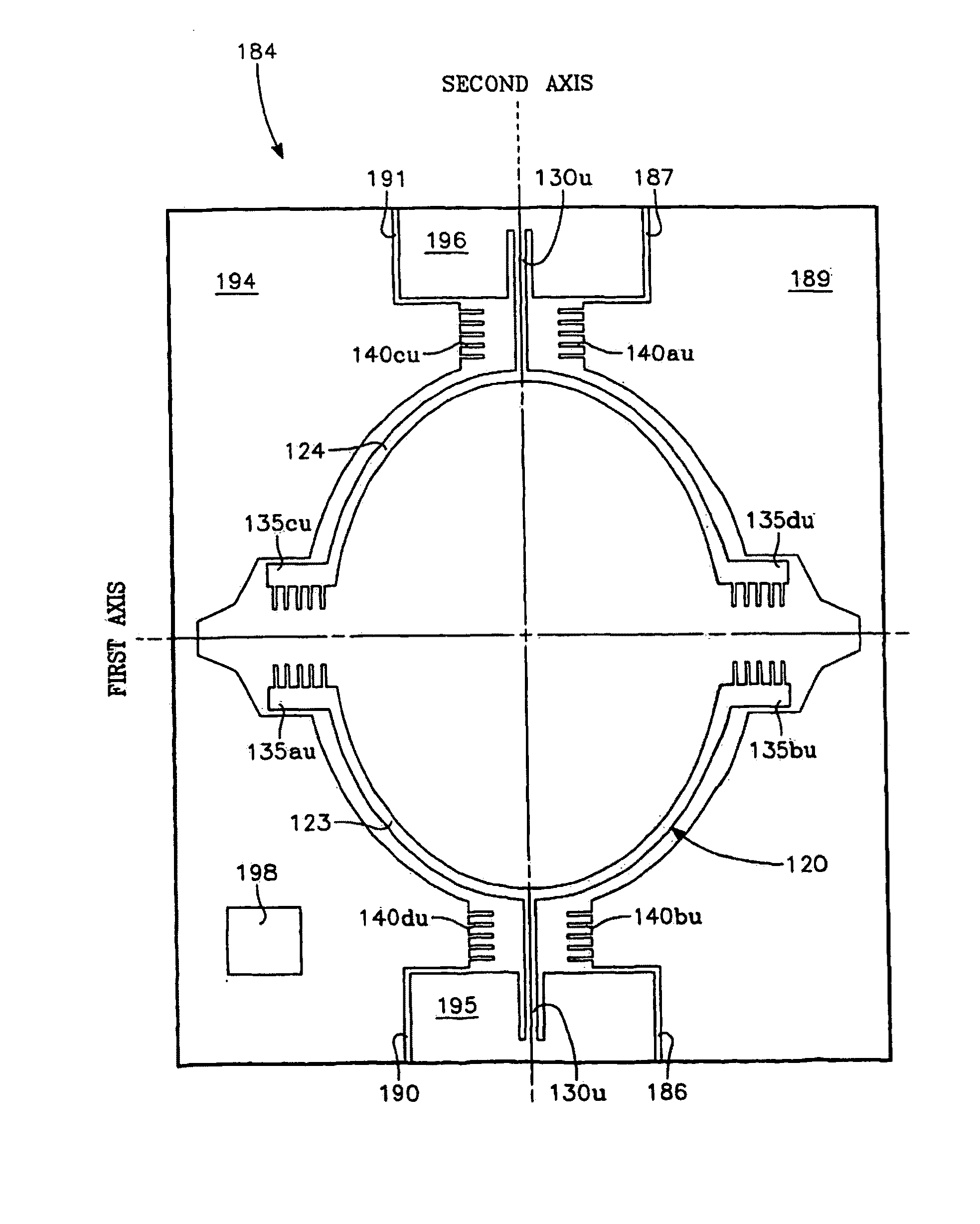

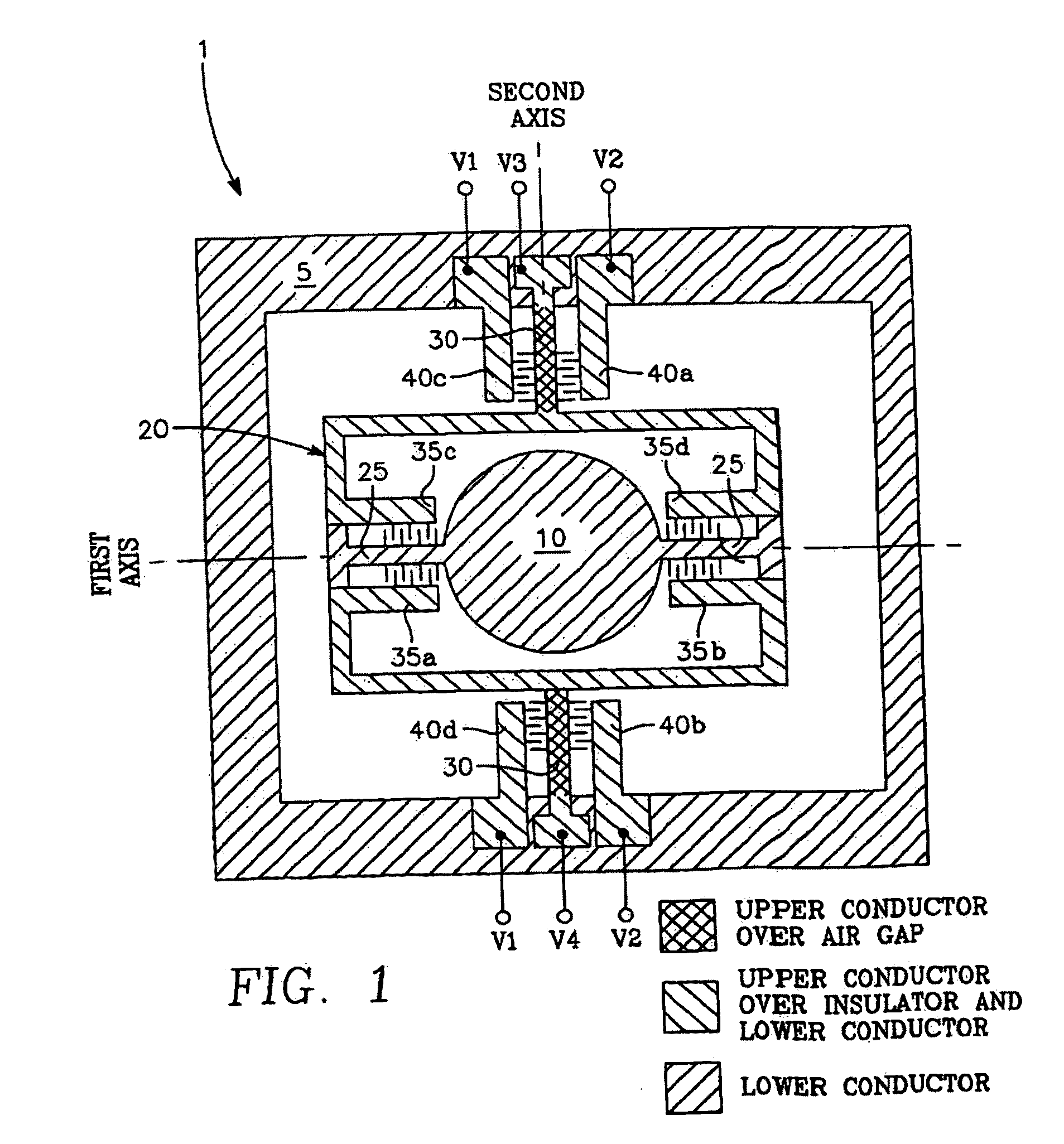

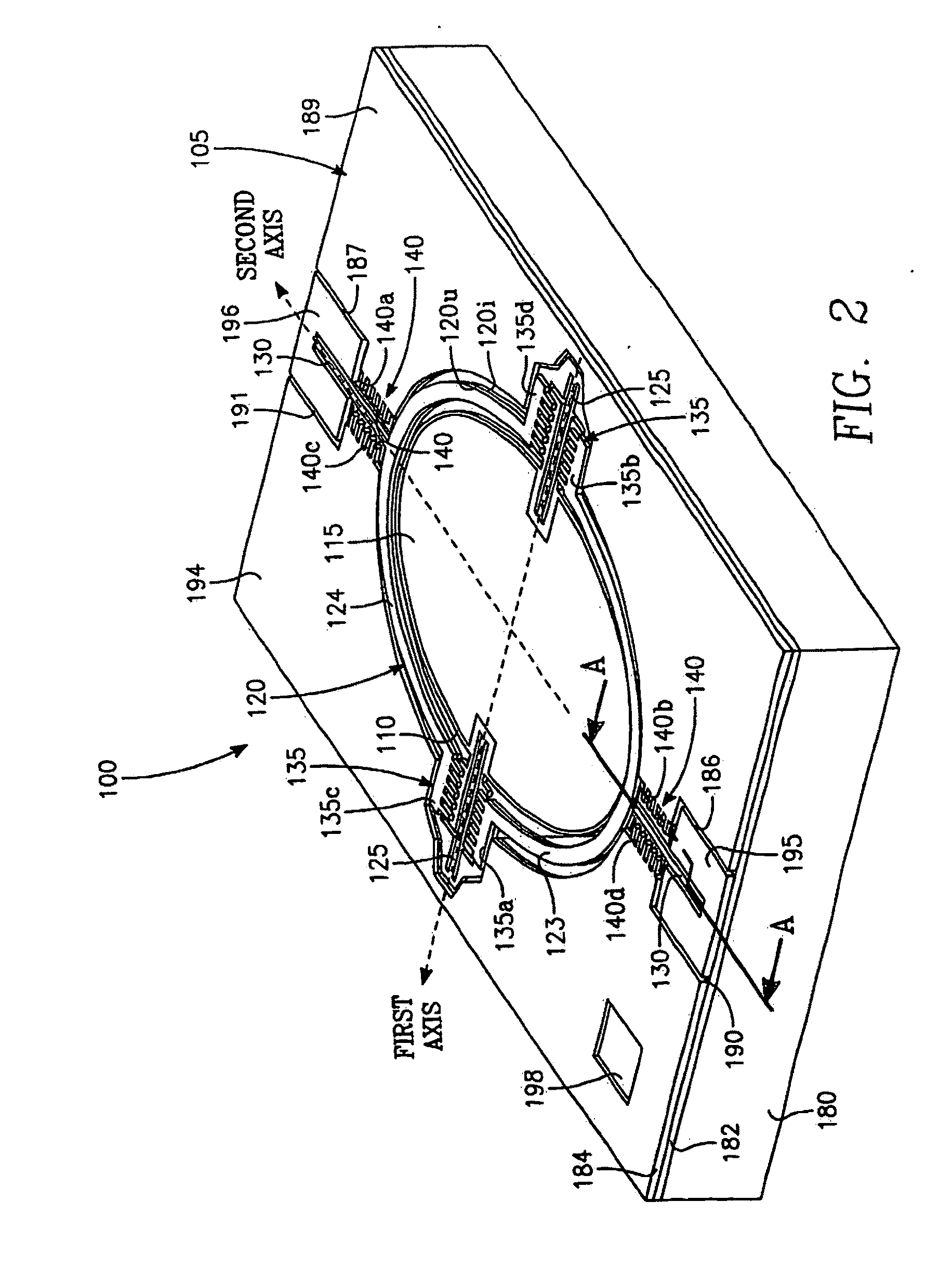

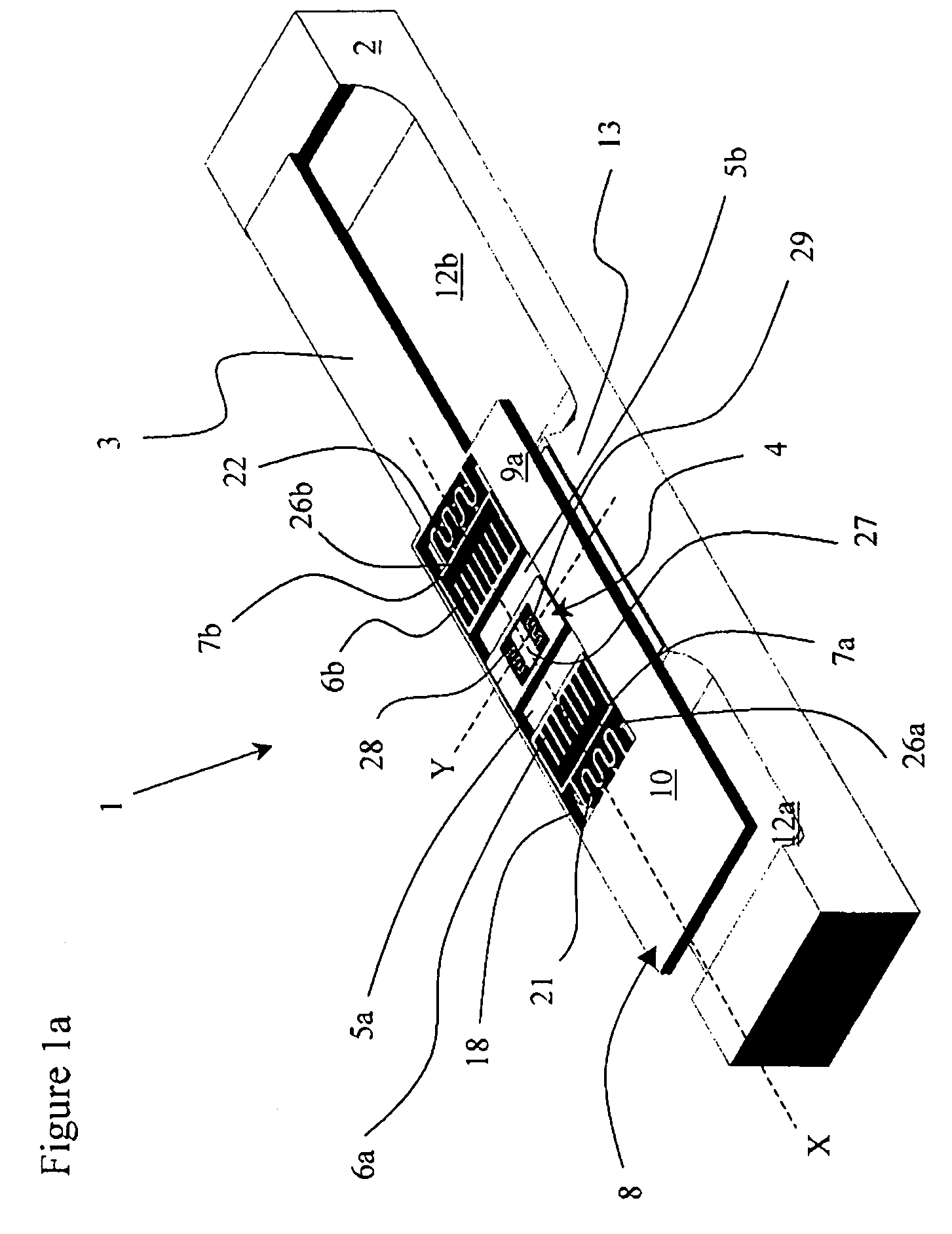

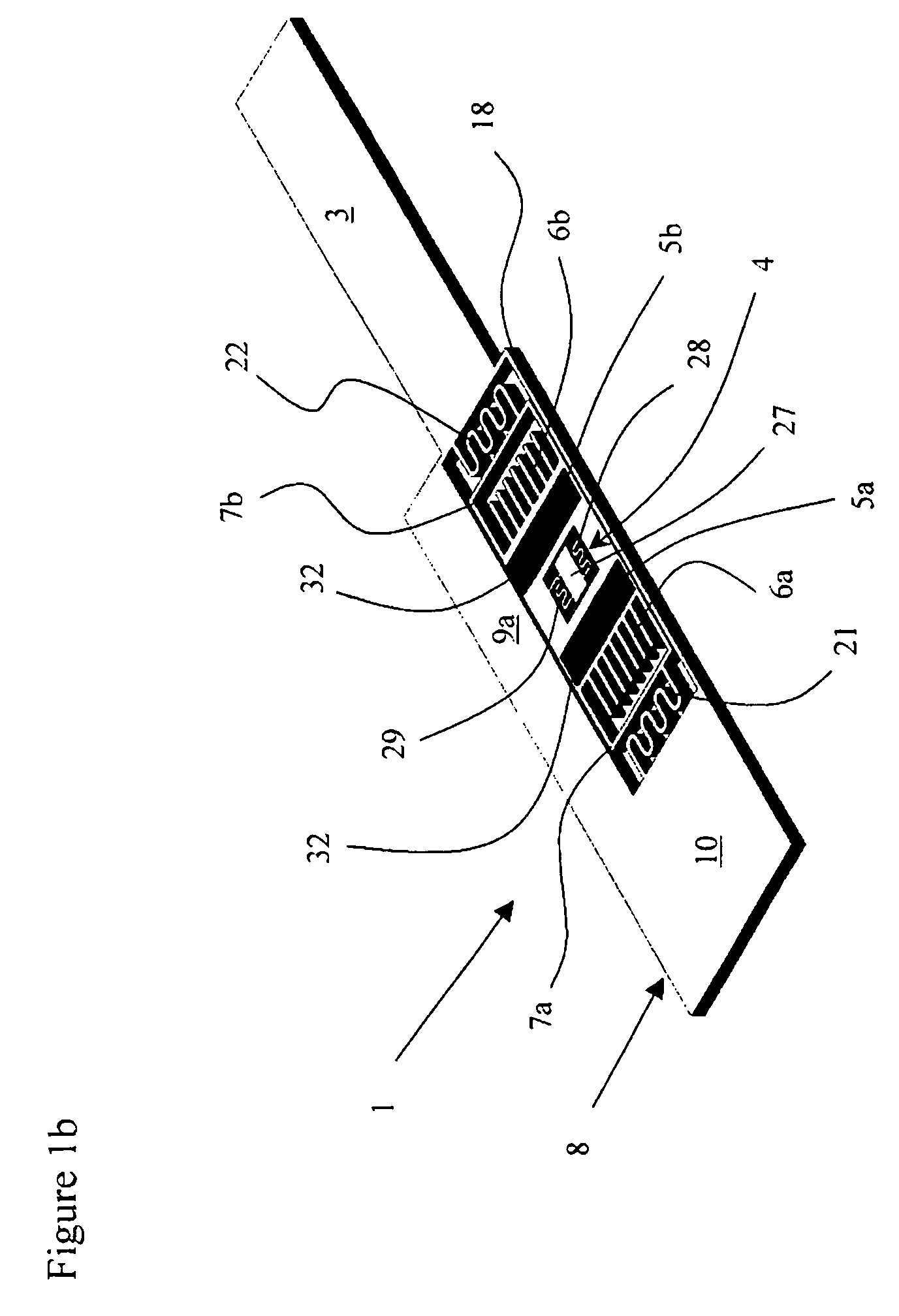

Fully monolithic gimbal-less micro-electro-mechanical-system (MEMS) devices with large static optical beam deflection and fabrications methods are disclosed. The devices can achieve high speed of operation for both axes. Actuators are connected to a device, or device mount by linkages that allow static two-axis rotation in addition to pistoning without the need for gimbals, or specialized isolation technologies. The device may be actuated by vertical comb-drive actuators, which are coupled by bi-axial flexures to a central micromirror or device mount. Devices may be fabricated by etching an upper layer both from the top side and from the bottom side to form beams at different levels, The beams include a plurality of lower beams, a plurality of full-thickness beams, and a plurality of upper beams, the lower, full-thickness and upper beams That form vertical combdrive actuators, suspension beams, flexures, and a device mount.

Owner:ADRIATIC RES INST

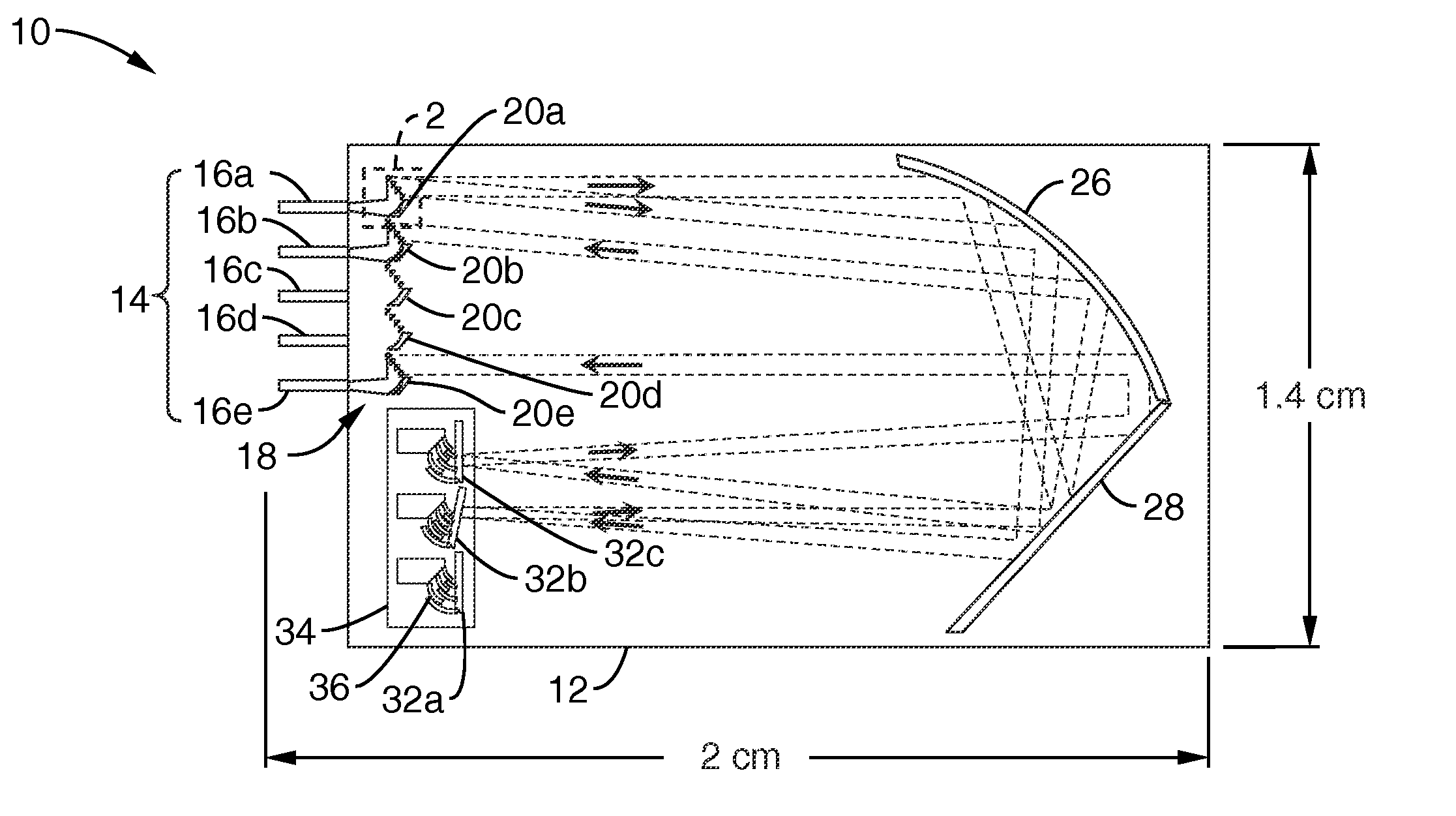

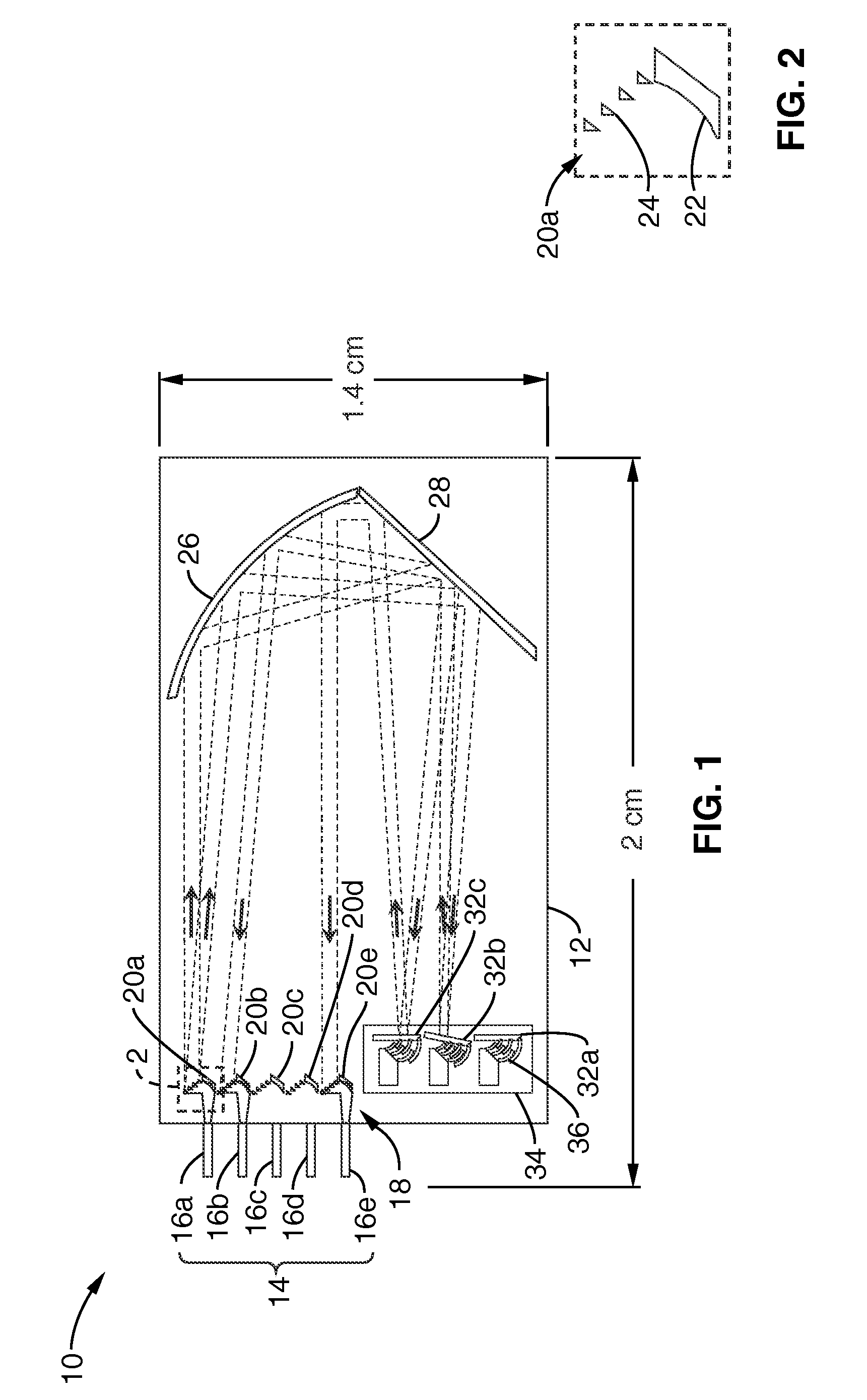

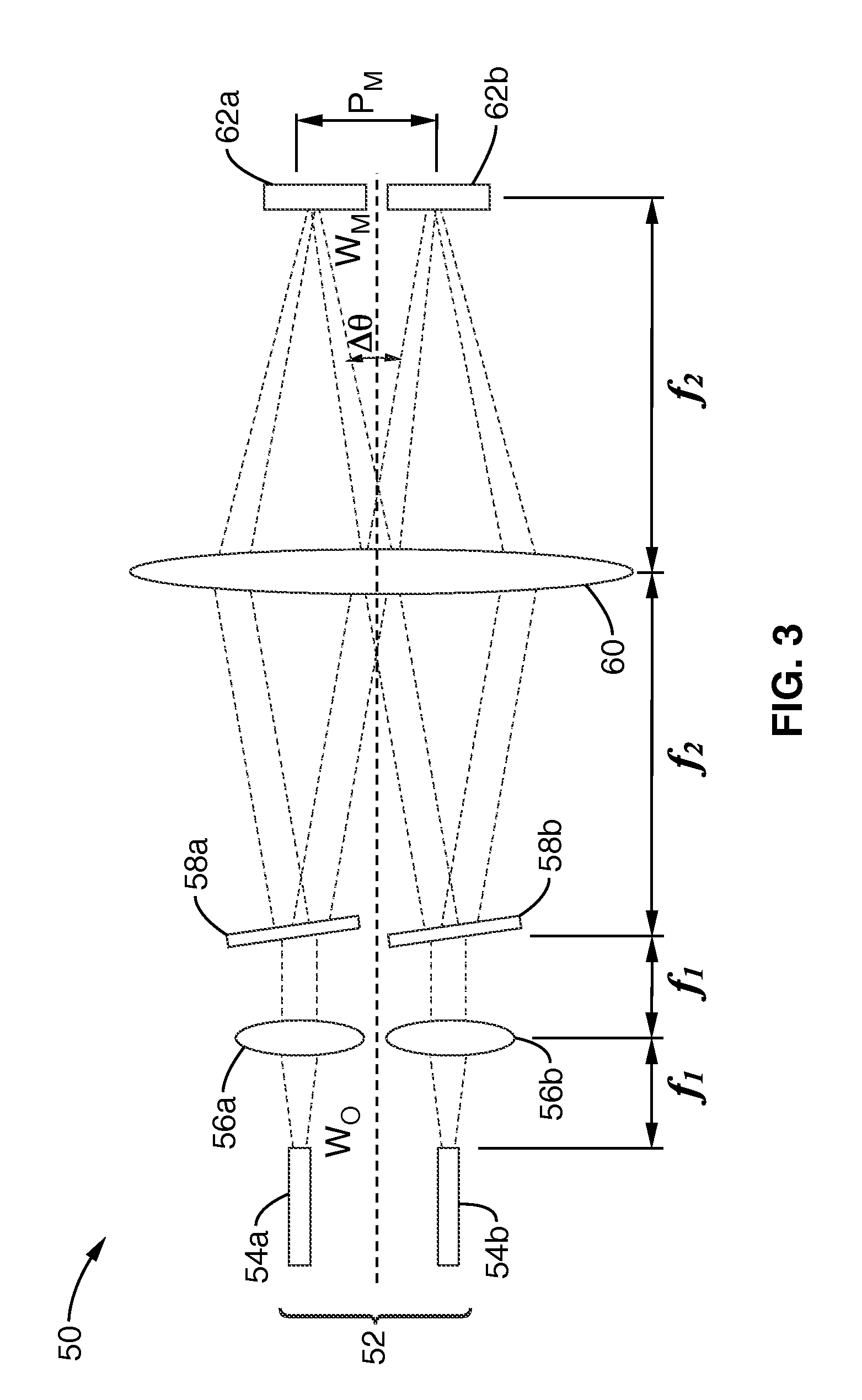

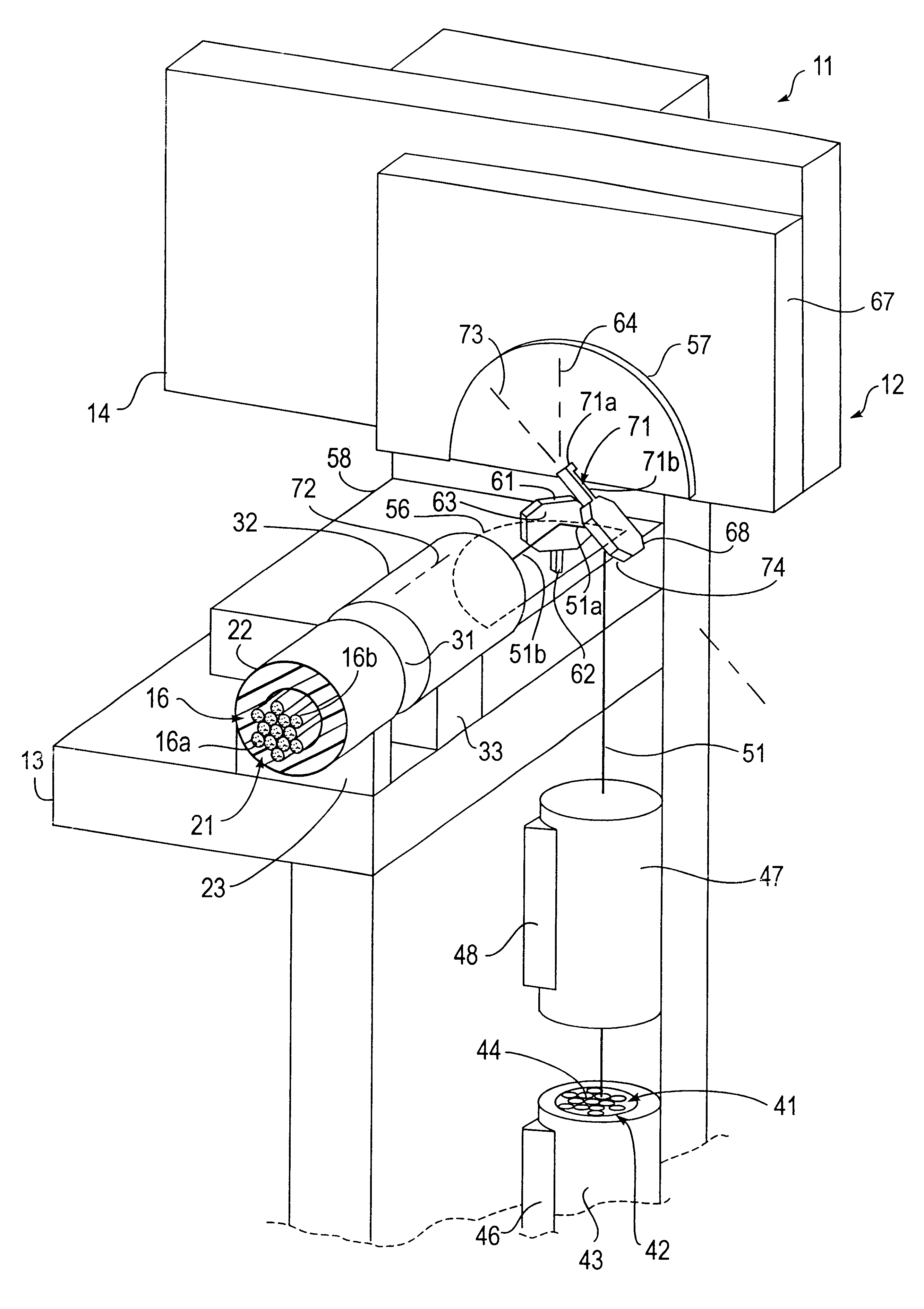

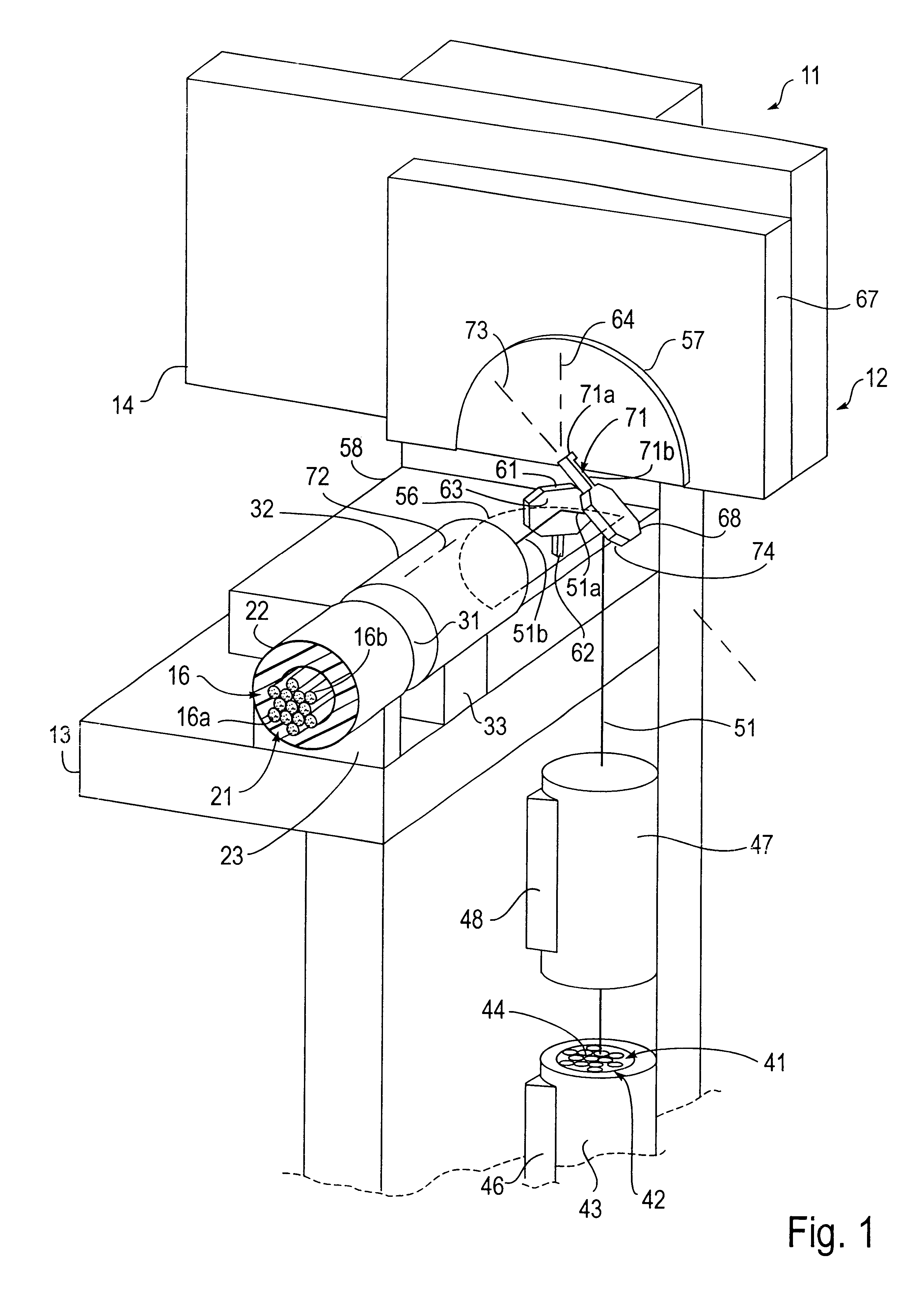

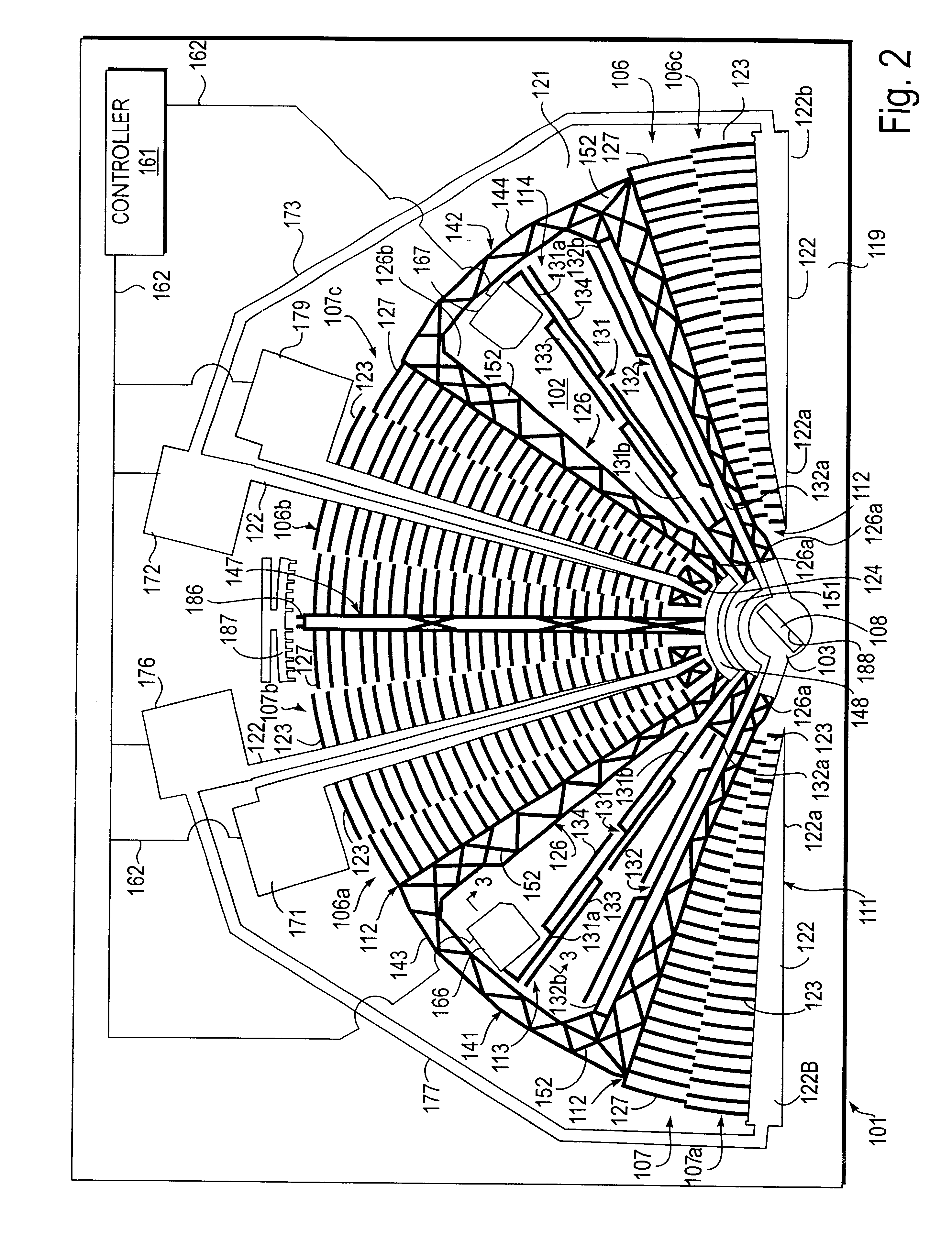

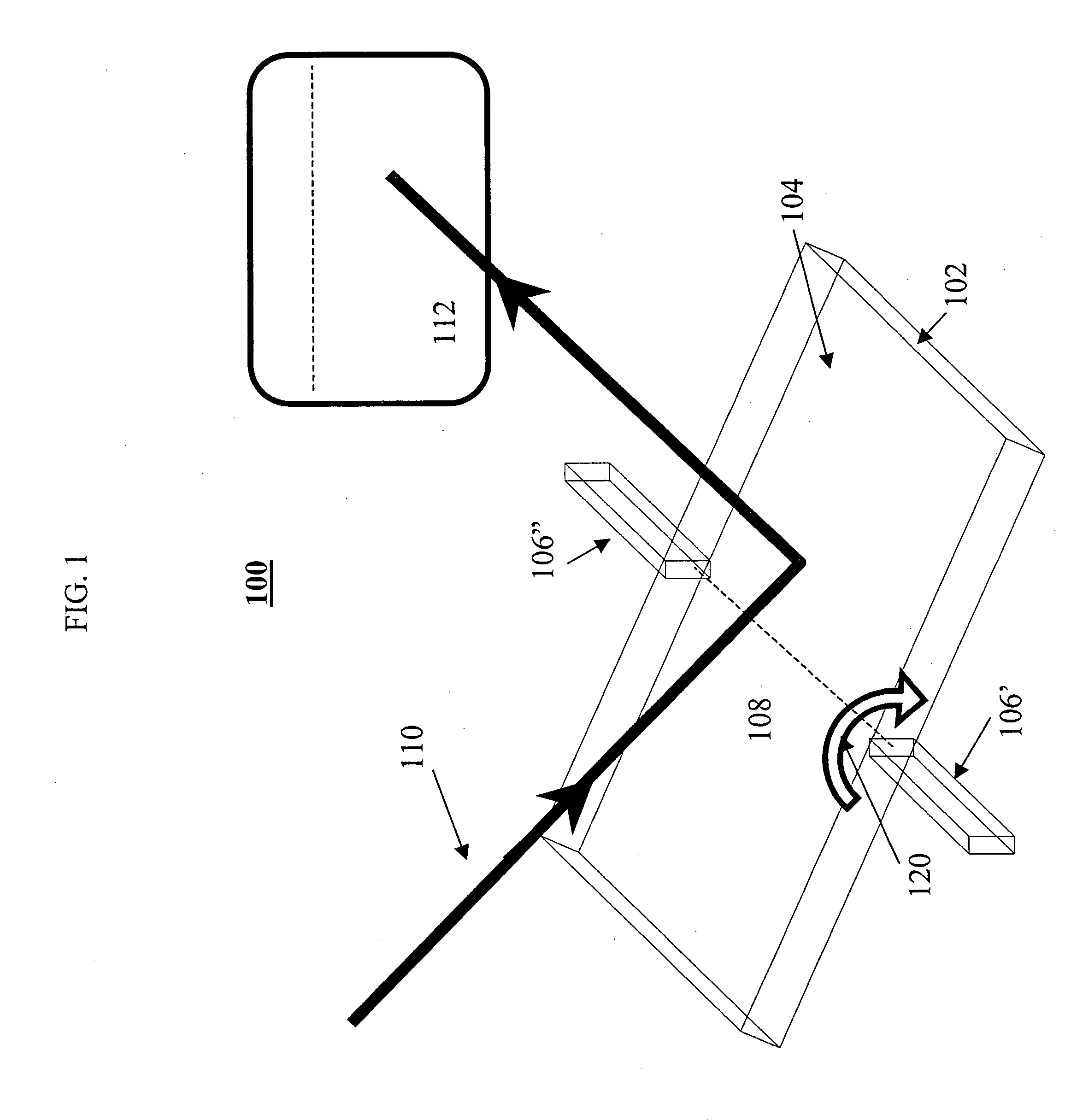

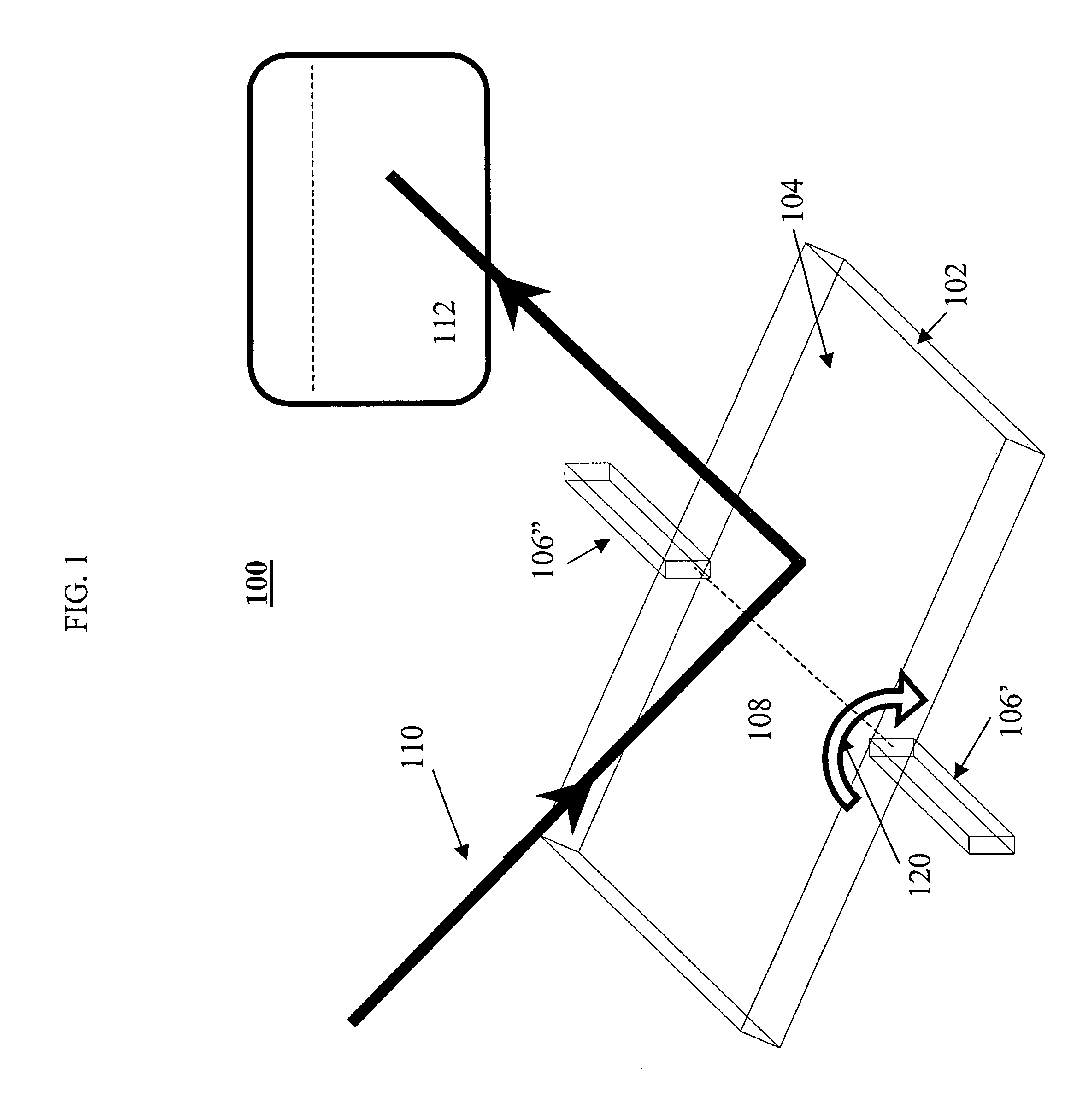

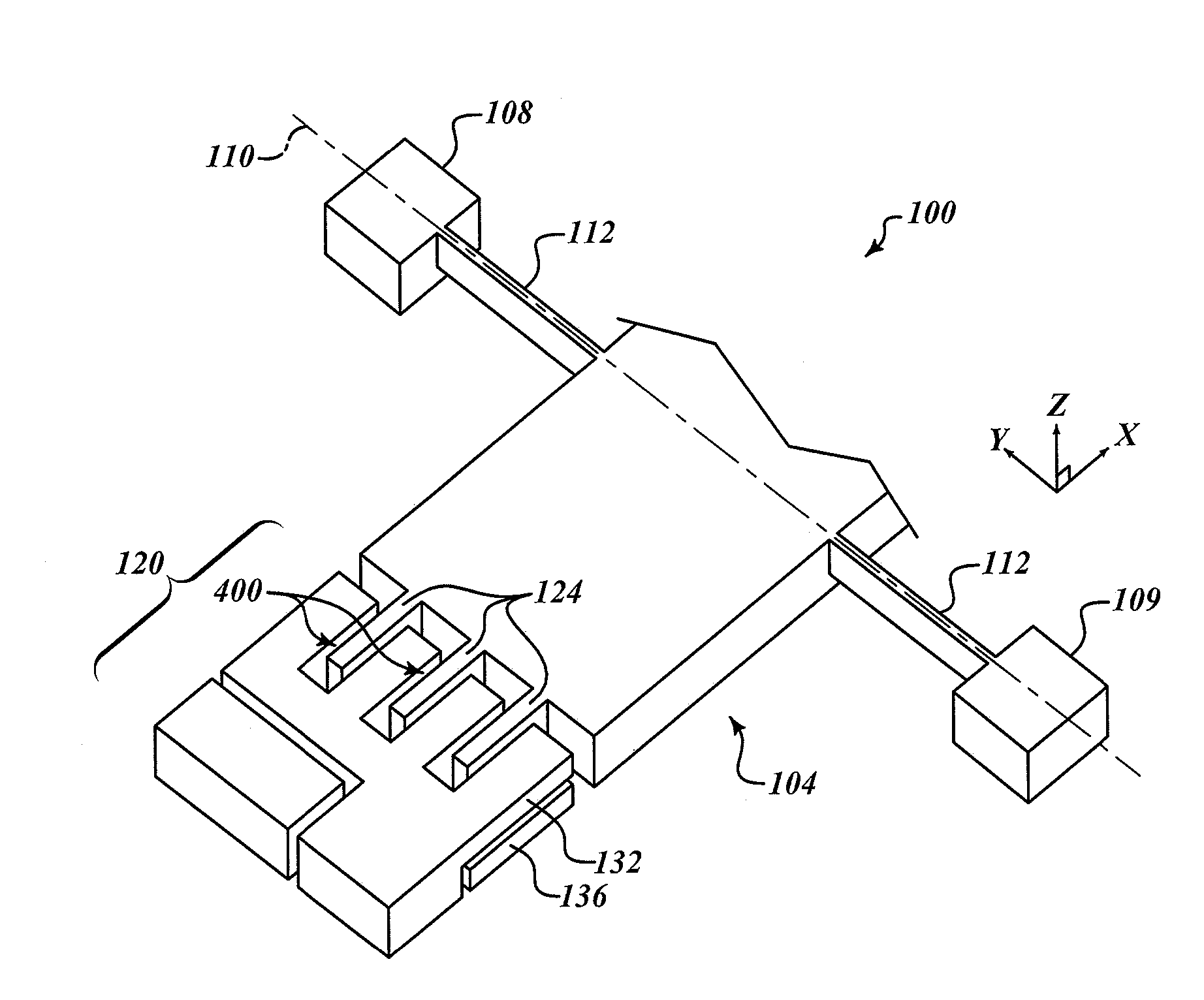

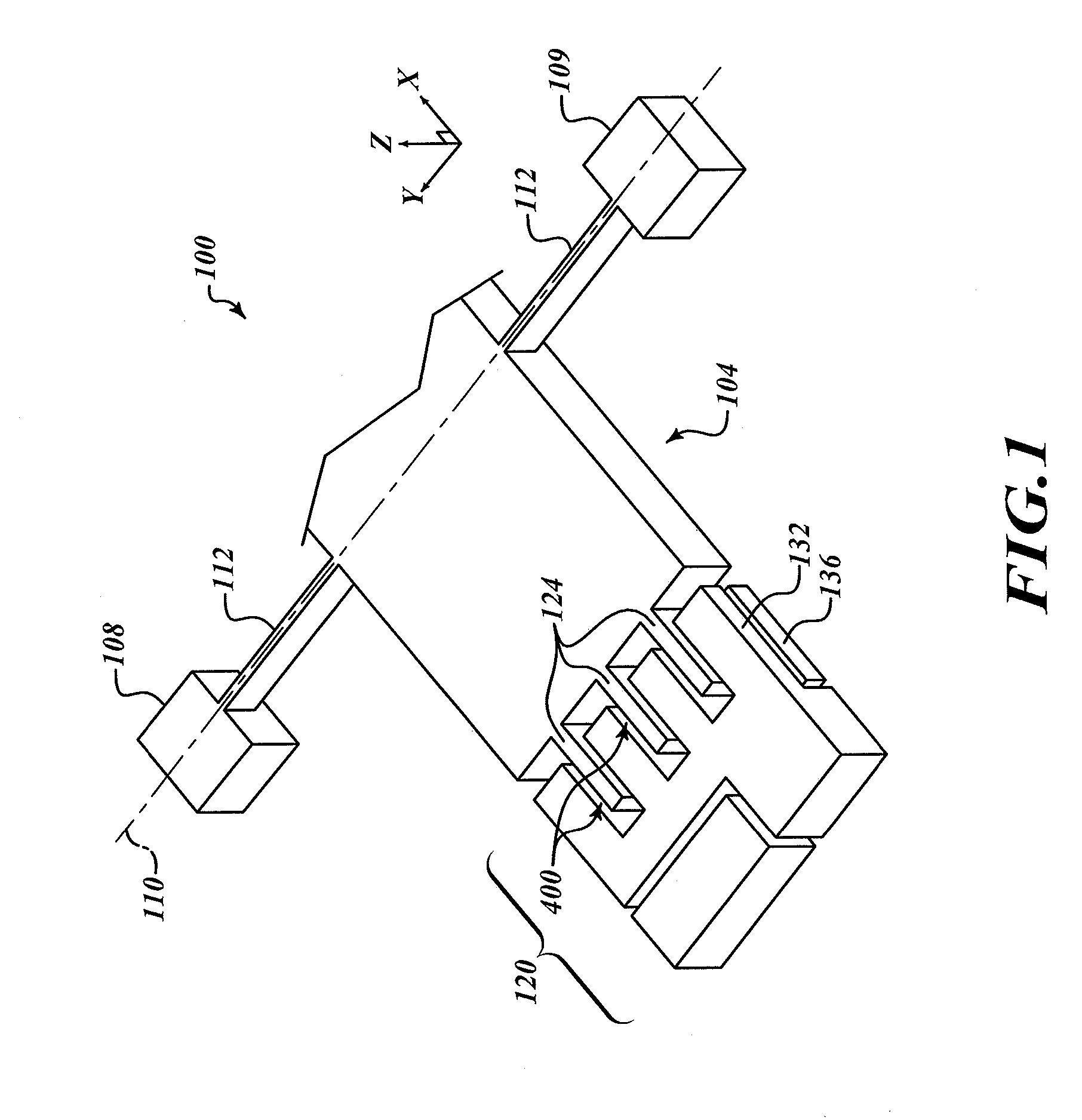

Monolithic mems-based wavelength-selective switches and cross connects

InactiveUS20070160321A1Minimizing insertion lossEliminate needCoupling light guidesCross connectionComb drive

Wavelength-selective 1×N switches (WSSs) and N×N cross-connects (WSXCs) are described which are fabricated as monolithic or hybrid devices. In a preferred embodiment, the optic ports, dispersion elements, and collimating elements are formed on a single monolithic substrate. A micromirror and actuator are either fabricated within the substrate or a separate micromirror is utilized forming a hybrid WSS or WSXC. The optical elements can be formed in an opaque substrate layer (e.g., silicon, SOI, and so forth) or in an optically transparent layer of a PLC material (e.g., silica-on-silicon). Embodiments describe the use of linear and rotary comb drives for actuating front surface mirrors, or solid-immersion micromirrors (SIMs). The switching devices reduce system footprint while reducing or eliminating the need for alignment of the optical elements.

Owner:RGT UNIV OF CALIFORNIA

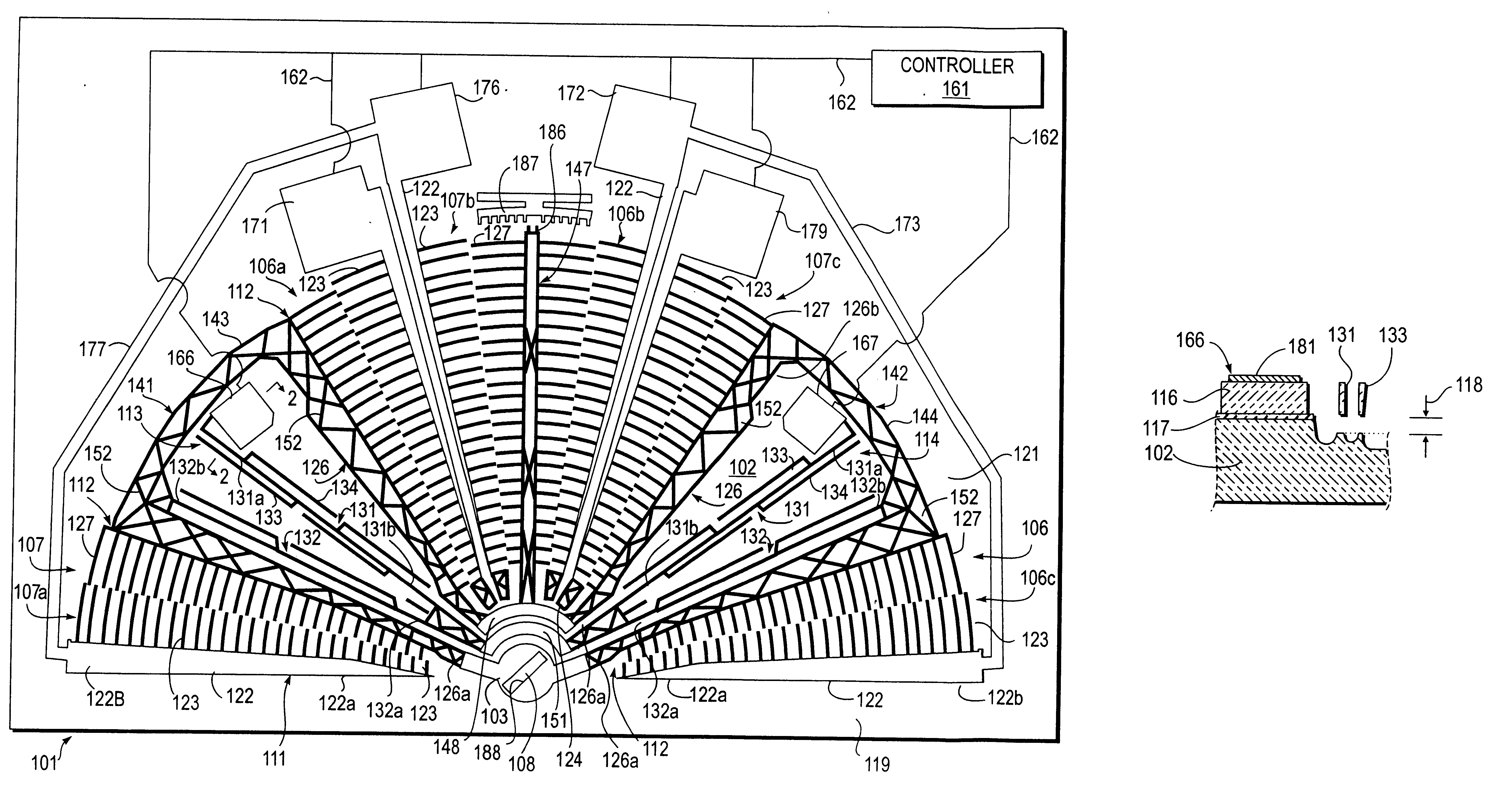

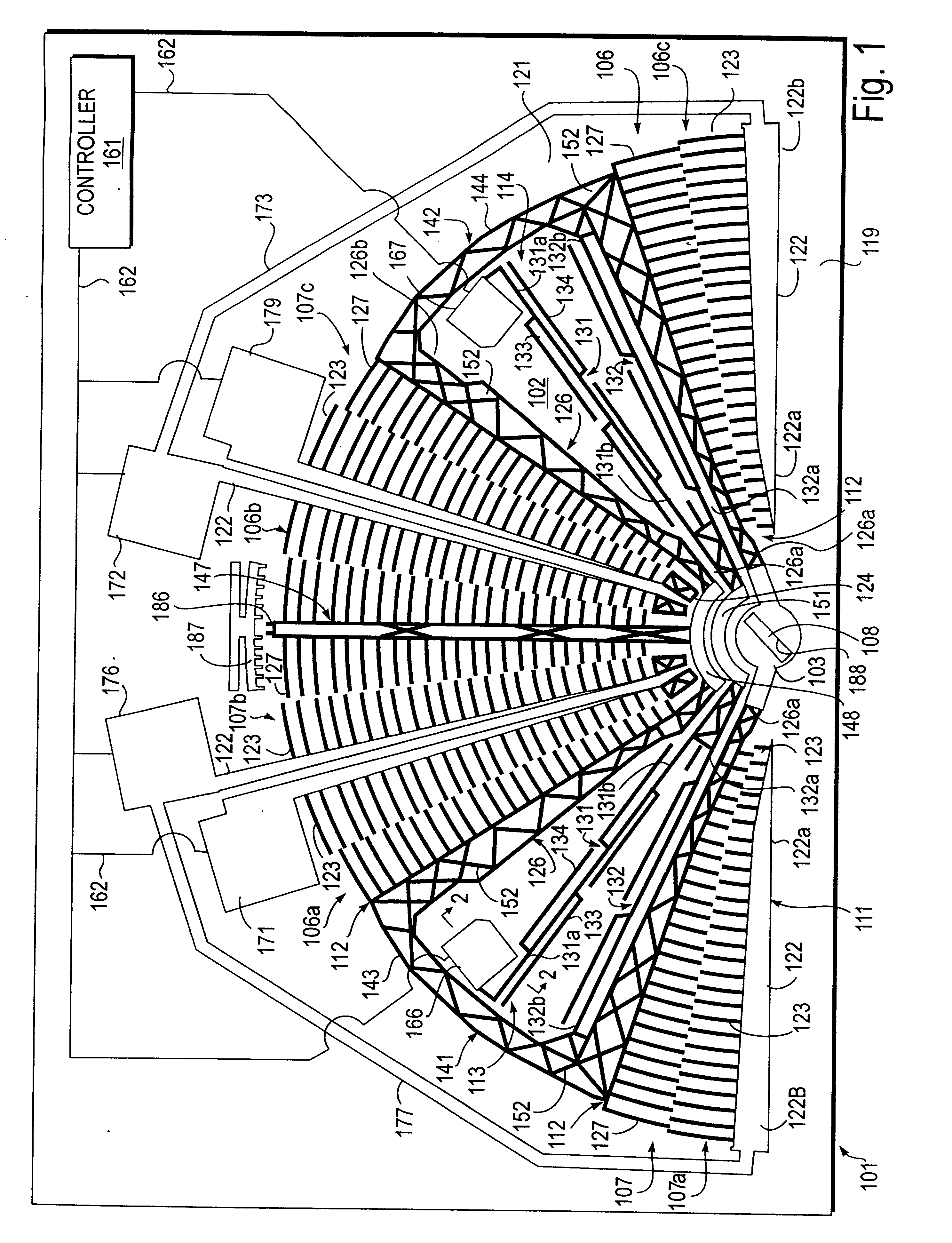

Rotary electrostatic microactuator

InactiveUS6329737B1Improved range of angular motionRecord information storageCoupling light guidesPlanar substrateComb drive

A rotary electrostatic microactuator that includes a substantially planar substrate and a rotatable member overlying the substrate for rotation about an axis of rotation extending perpendicular to the planar substrate. First and second spaced-apart springs and a plurality of comb drive assemblies are included. Each of the comb drive assemblies has a first comb drive member mounted on the substrate and a second comb drive member. Each of the first and second comb drive members are provided with arcuate comb drive fingers. Each of the first and second springs has a first end portion secured to the substrate and a second end portion secured to at least one of the second comb drive members for suspending the second comb drive members and the rotatable member over the substrate. The second comb drive members are movable in a direction of travel about the axis of rotation between a first position in which the comb drive fingers of the first and second comb drive members are not substantially fully interdigitated and a second position in which the comb drive fingers of the first and second comb drive members are substantially fully interdigitated.

Owner:COHERENT INC

MEMS scanner with dual magnetic and capacitive drive

A MEMS scanning device includes more than one type of actuation. In one approach capacitive and magnetic drives combine to move a portion of the device along a common path. In one such structure, the capacitive drive comes from interleaved combs. In another approach, a comb drive combines with a pair of planar electrodes to produce rotation of a central body relative to a substrate. In an optical scanning application, the central body is a mirror. In a biaxial structure, a gimbal ring carries the central body. The gimbal ring may be driven by more than one type of actuation to produce motion about an axis orthogonal to that of the central body. In another aspect, a MEMS scanning device is constructed with a reduced footprint.

Owner:MICROVISION

Magnetic sensor with variable sensitivity

InactiveUS7046002B1Noise minimizationIncrease working frequencyMagnetic field measurement using galvano-magnetic devicesStray field compensationComb driveMicroelectromechanical systems

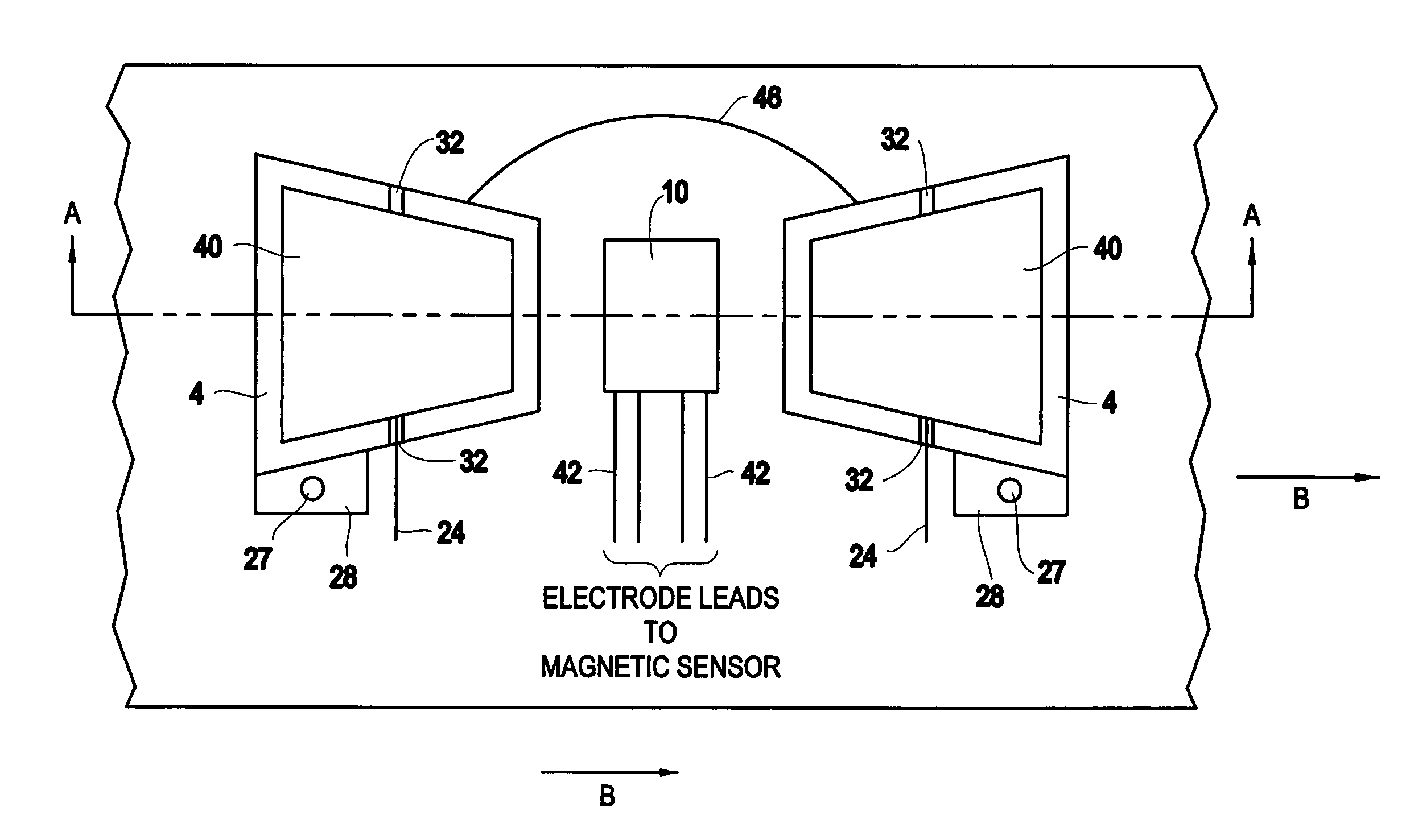

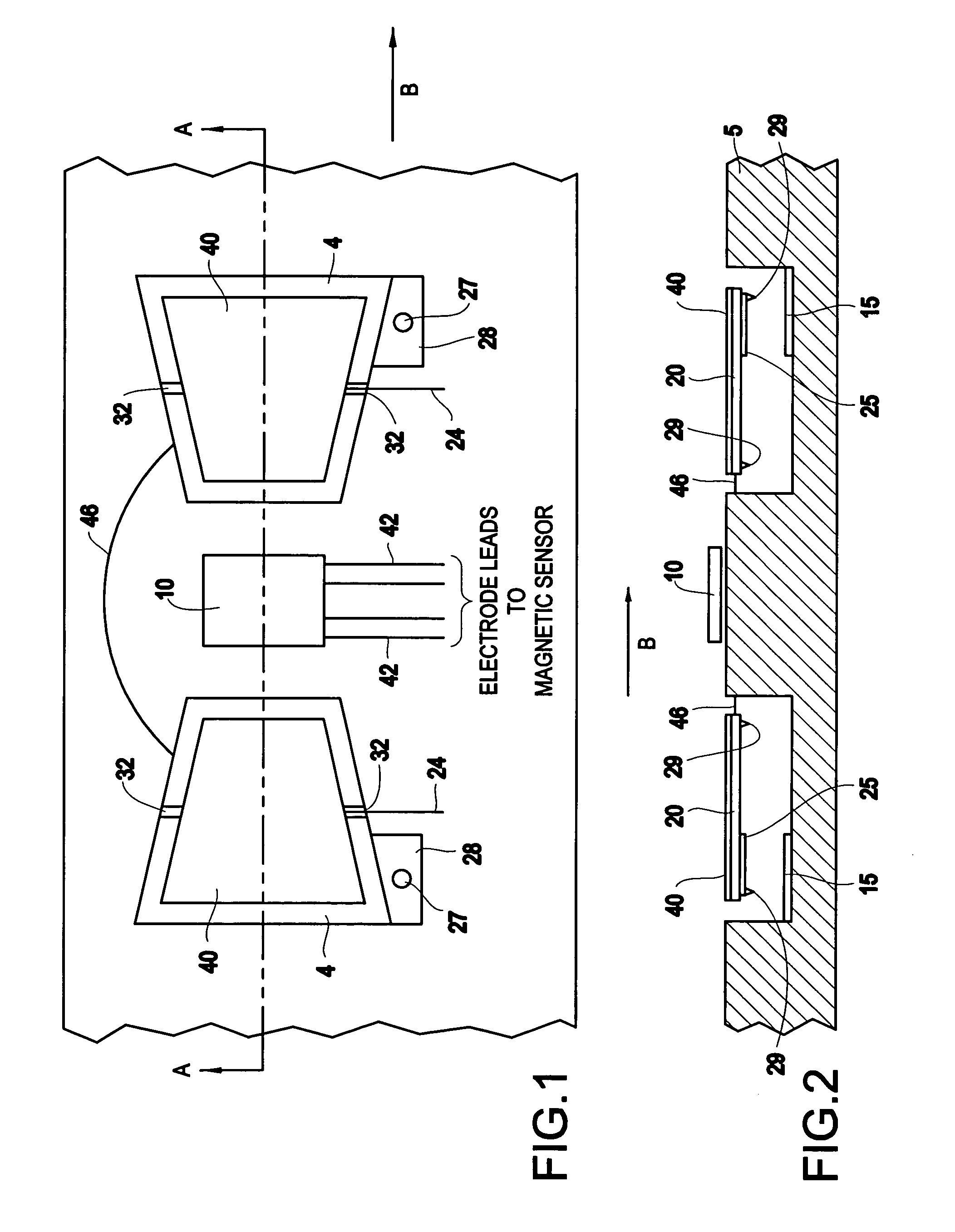

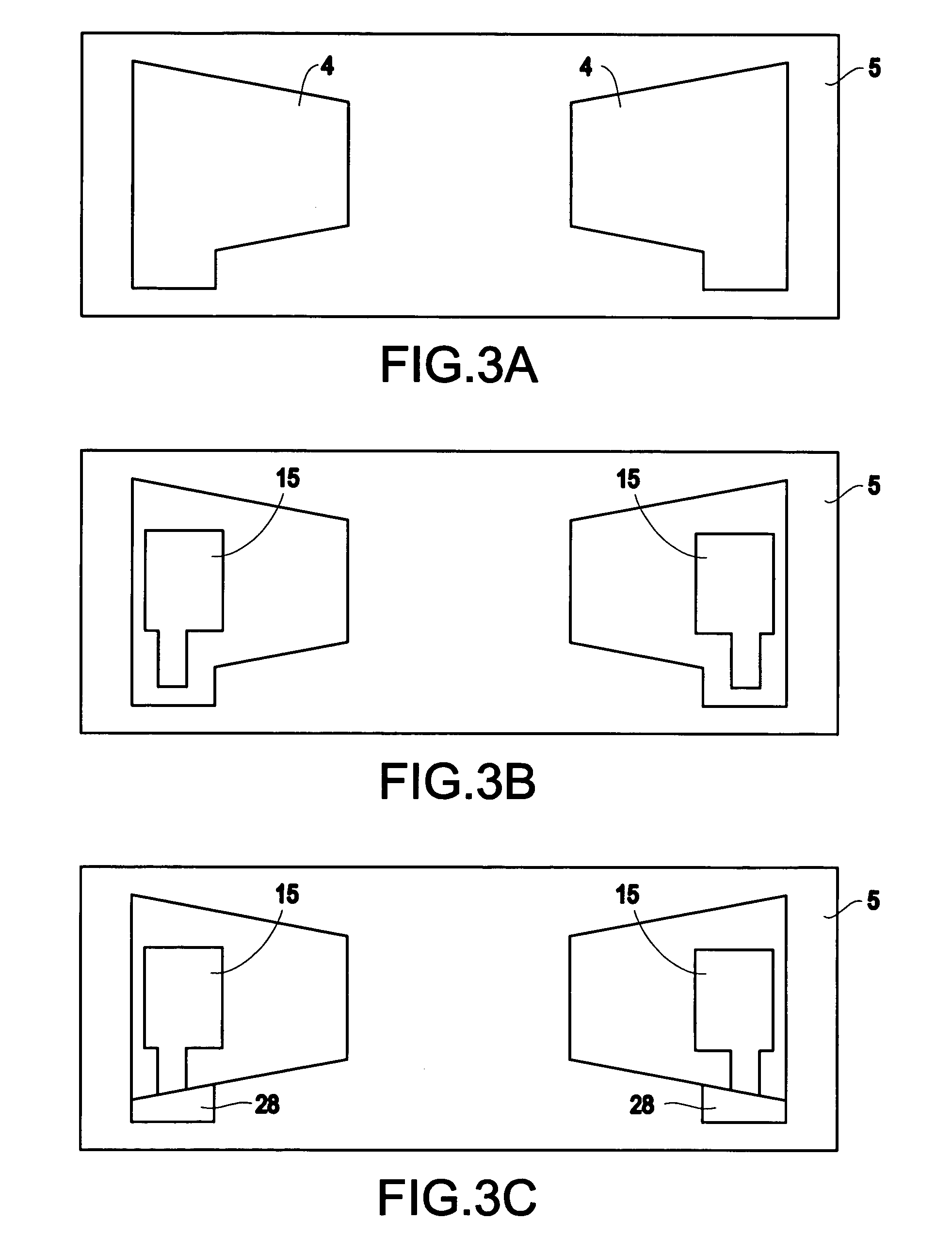

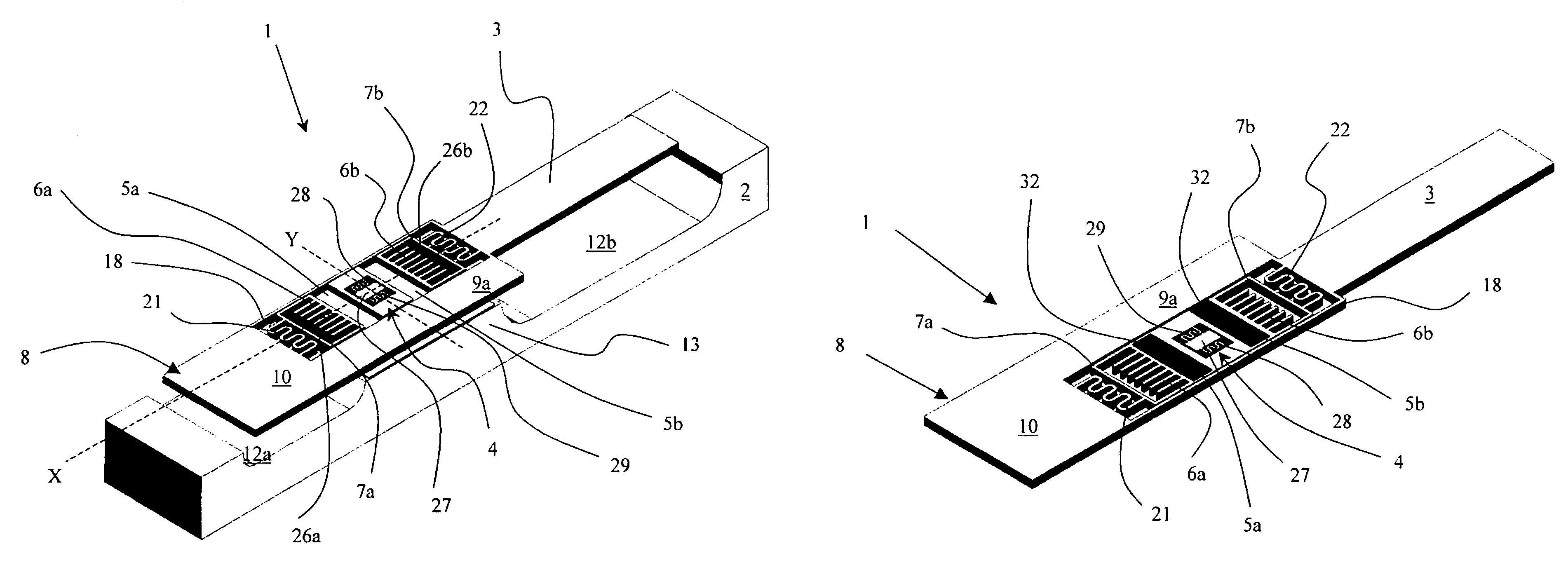

A microelectromechanical system (MEMS) device comprising a base structure; a magnetic sensor attached to the base structure and operable for sensing a magnetic field and allowing for a continuous variation of an amplification of the magnetic field at a position at the magnetic sensor; and for receiving a DC voltage and an AC modulation voltage in the MEMS device; a pair of flux concentrators attached to the magnetic sensor; and a pair of electrostatic comb drives, each coupled to a respective flux concentrator such that when the pair of electrostatic comb drives are excited by a modulating electrical signal, each flux concentrator oscillates linearly at a prescribed frequency; and a pair of bias members (mechanical spring connectors) connecting the flux concentrators to one another.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Vertical comb drive actuated deformable mirror device and method

InactiveUS20020109894A1Optical waveguide light guideFlexible microstructural devicesRelative displacementComb drive

Owner:MEMS OPTICAL

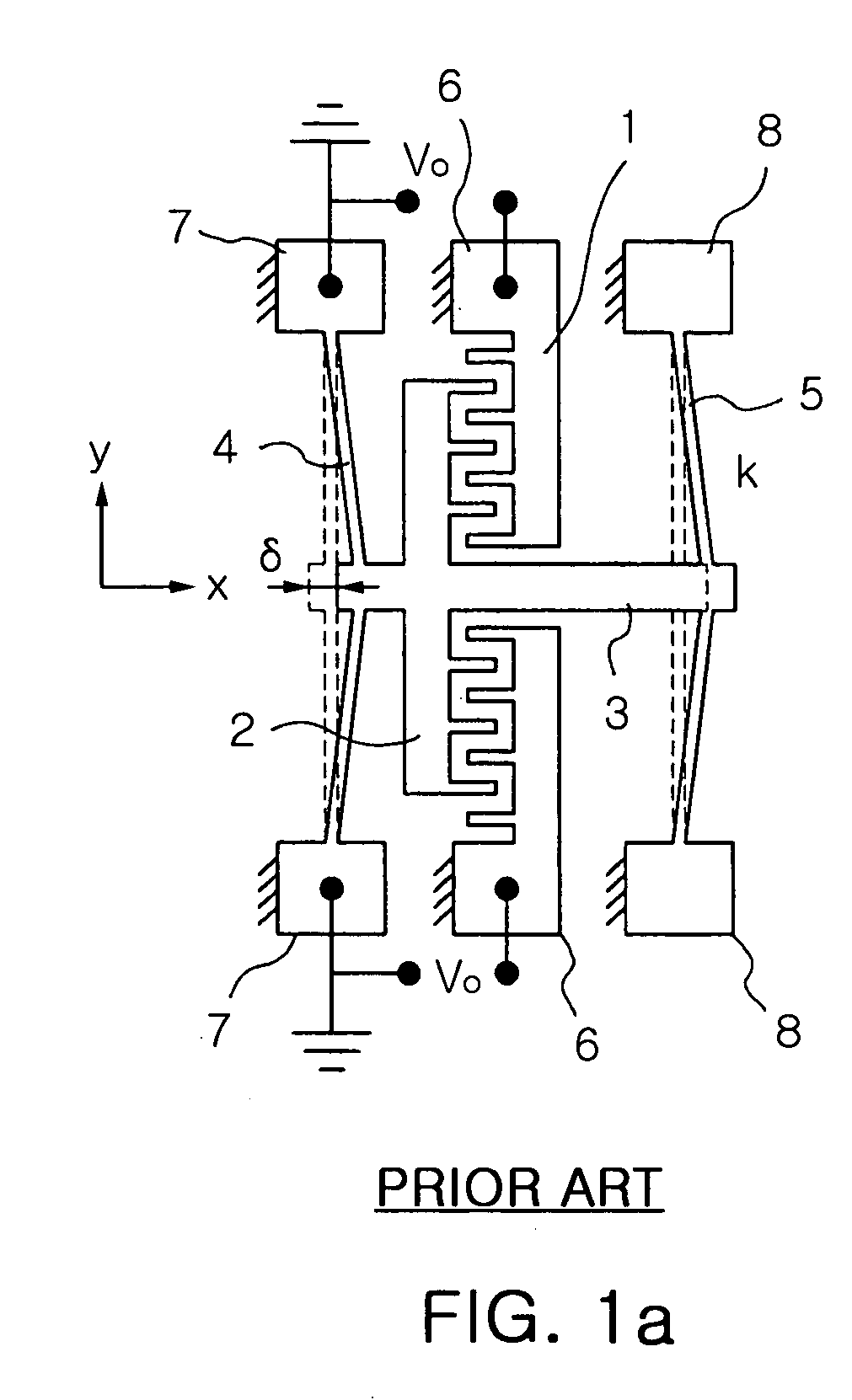

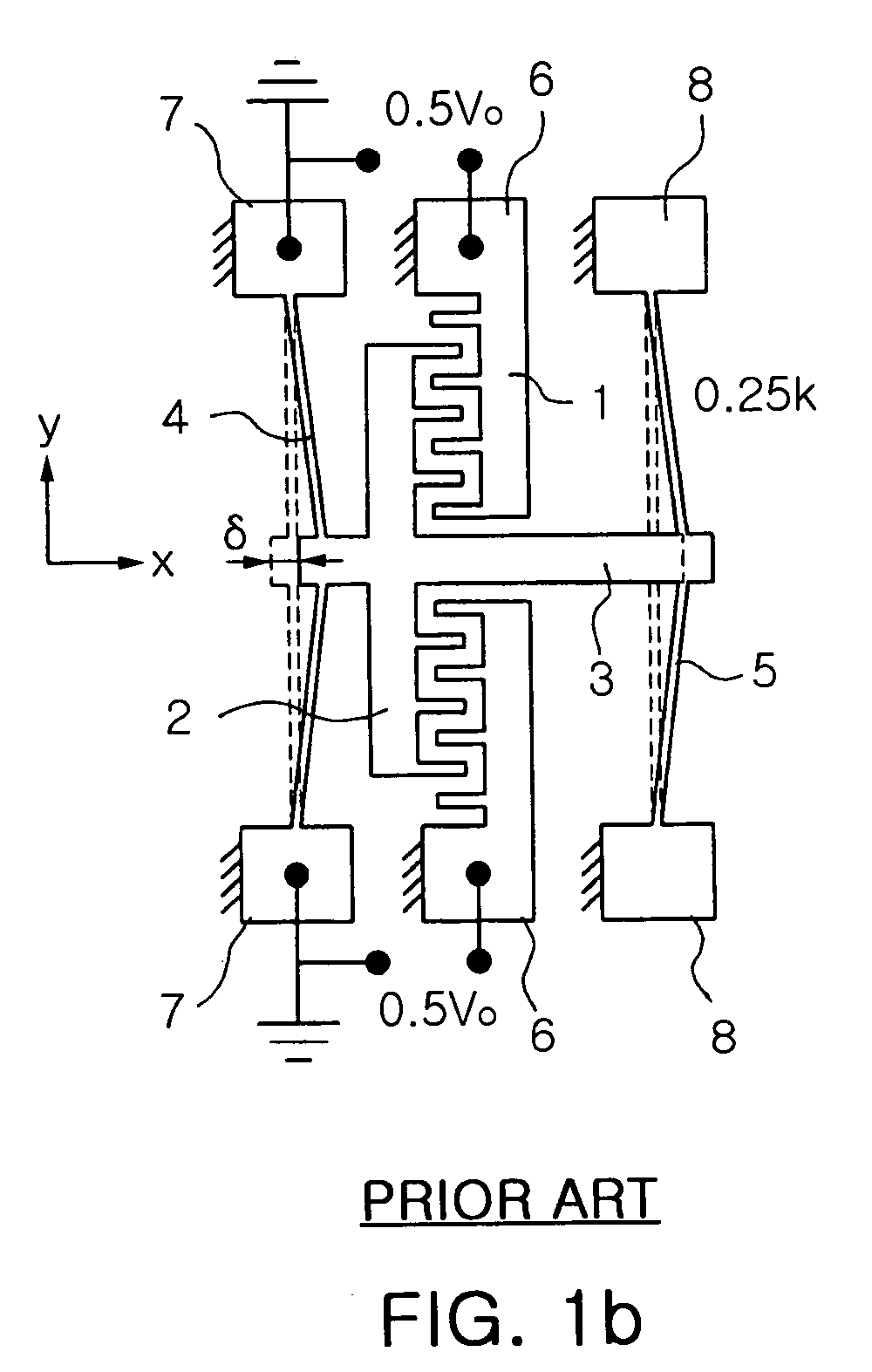

Horizontal and tuning fork vibratory microgyroscope

InactiveUS6918298B2Minimize impactAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkResonance

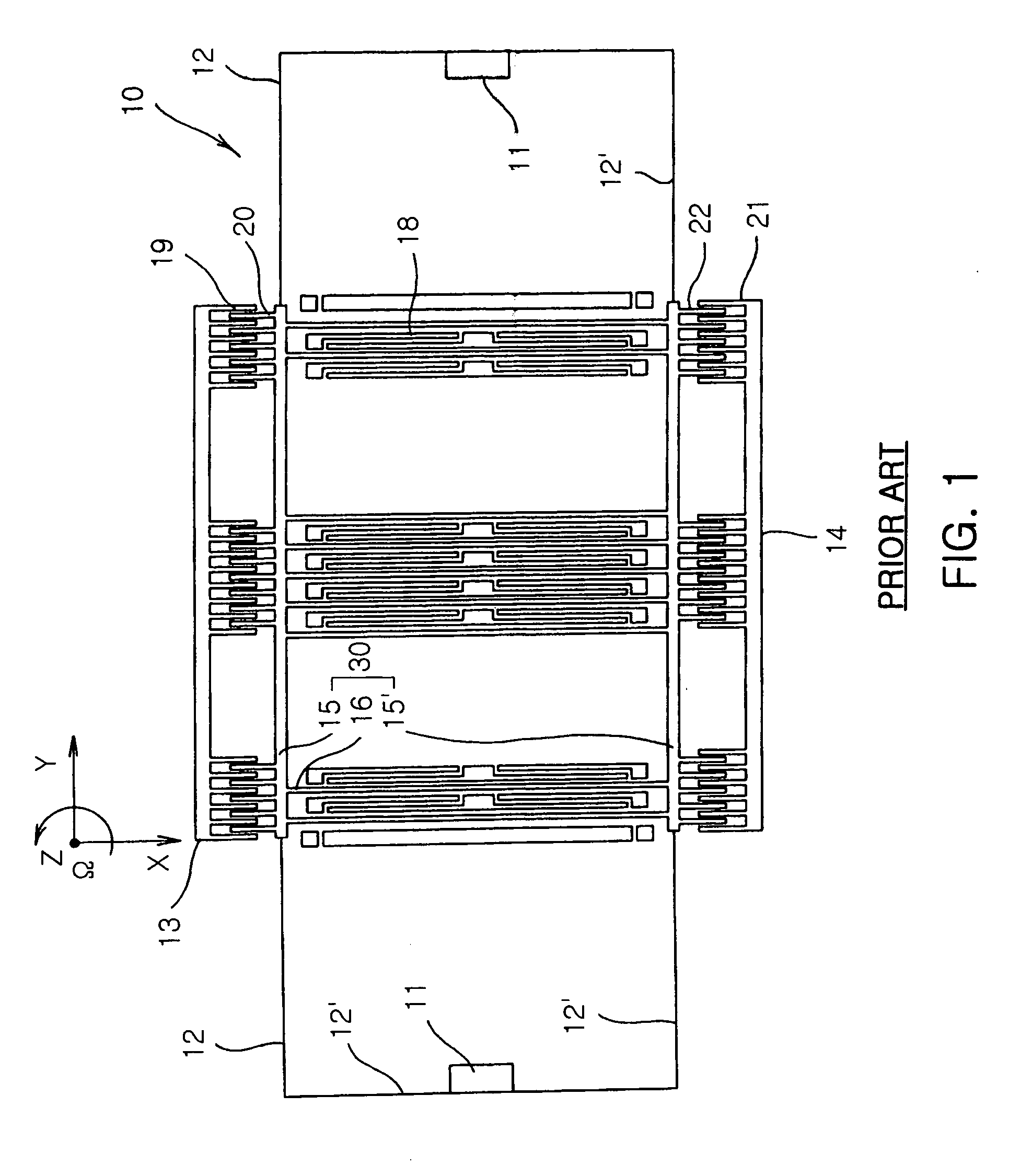

A horizontal and tuning fork vibratory microgyroscope detects angular velocity and angular acceleration of an inertial object when the inertial object is rotated, wherein resonance directions of the microgyroscope are on the same horizontal plane in both sensing and driving modes. The microgyroscope includes a substrate, an anchored pad unit, an outer elastic element unit, an outer frame, a sensing electrode unit, an inner elastic element unit including a plurality of inner elastic elements connected to the inside of the outer frame, an inner weighted element unit including a pair of first and second inner weighted elements each having a driven comb, and a driven electrode unit including a comb drive forming a comb structure.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

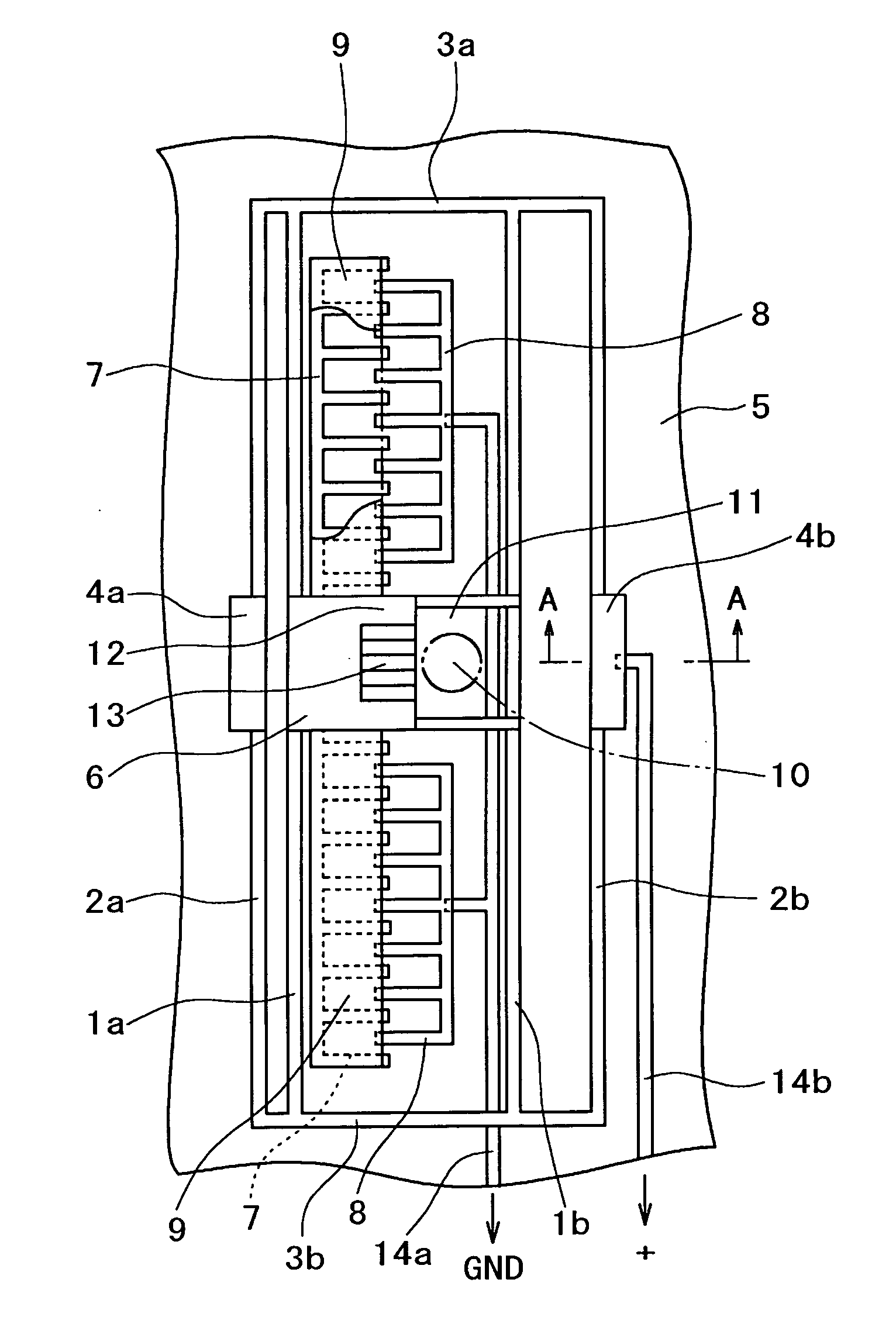

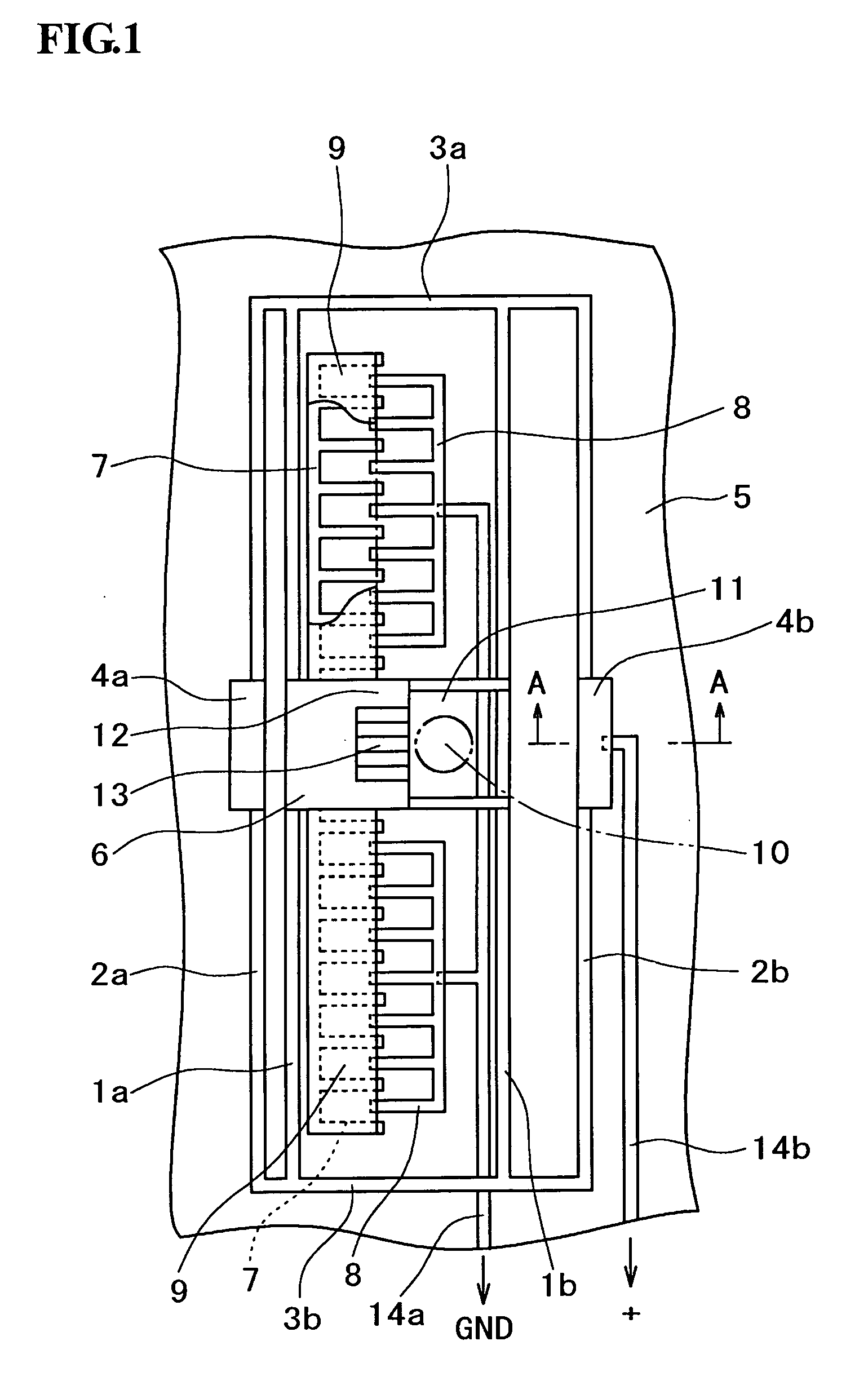

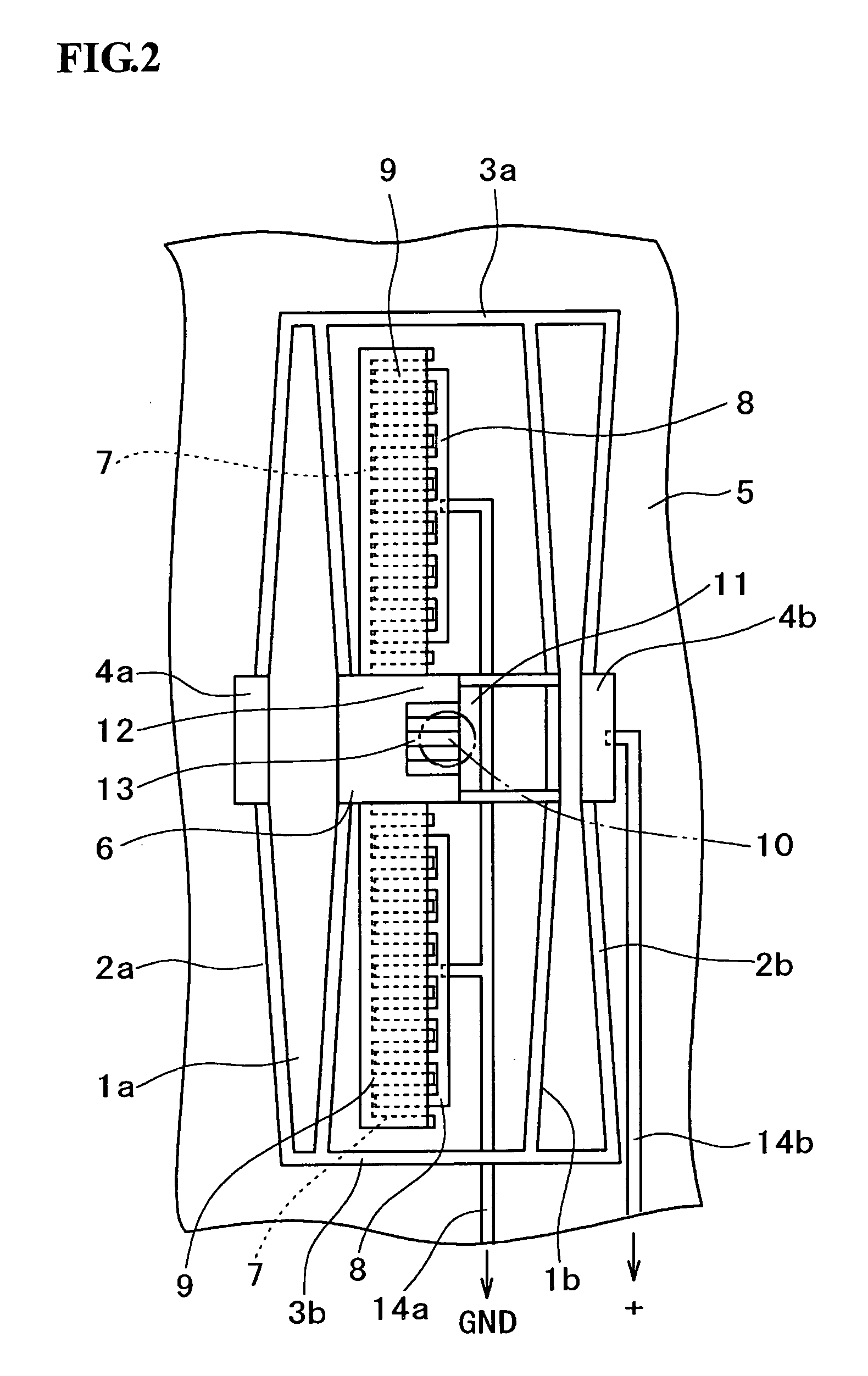

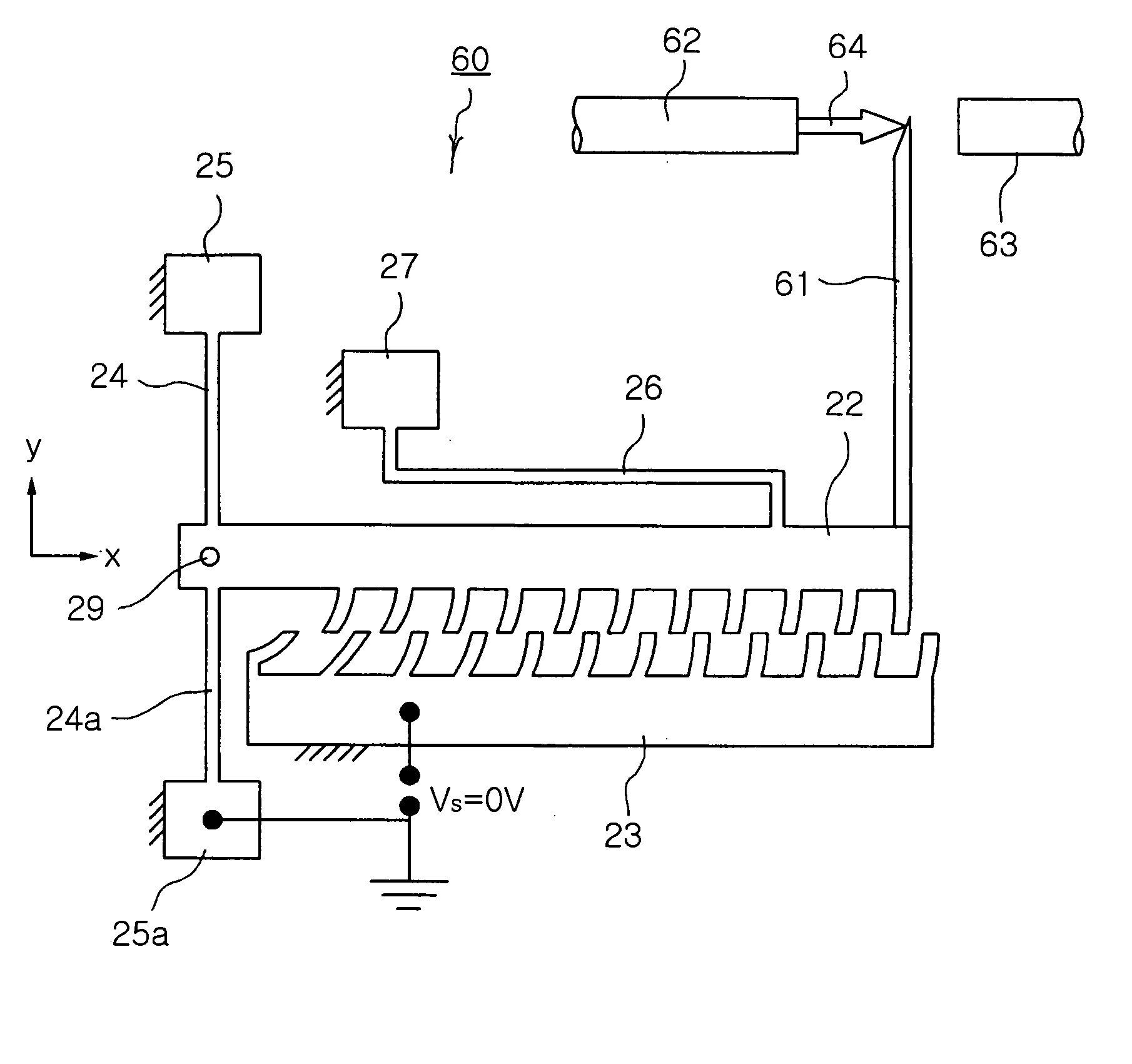

Electrostatic comb drive actuator, and optical controller using the electrostatic comb drive actuator

InactiveUS20050052723A1Preventive effectIncreased bending stiffnessPiezoelectric/electrostrictive devicesFlexible microstructural devicesComb driveEngineering

An electrostatic comb drive actuator, characterized in that plural outer suspended elastic beams 2a and 2b are disposed in parallel to and outside plural inner suspended elastic beams 1a and 1b disposed in parallel to each other; the ends of the inner suspended elastic beams and the outer suspended elastic beams on both sides are connected with end connecting beams 3a and 3b; the outer suspended elastic beams are supported at their centers on a board 5; the inner suspended elastic beams are connected with each other at their centers by means of a working section 6; a movable comb electrode 7 is supported on the working section; and a fixed comb electrode 8 is supported on the board.

Owner:MORITEX CORP +1

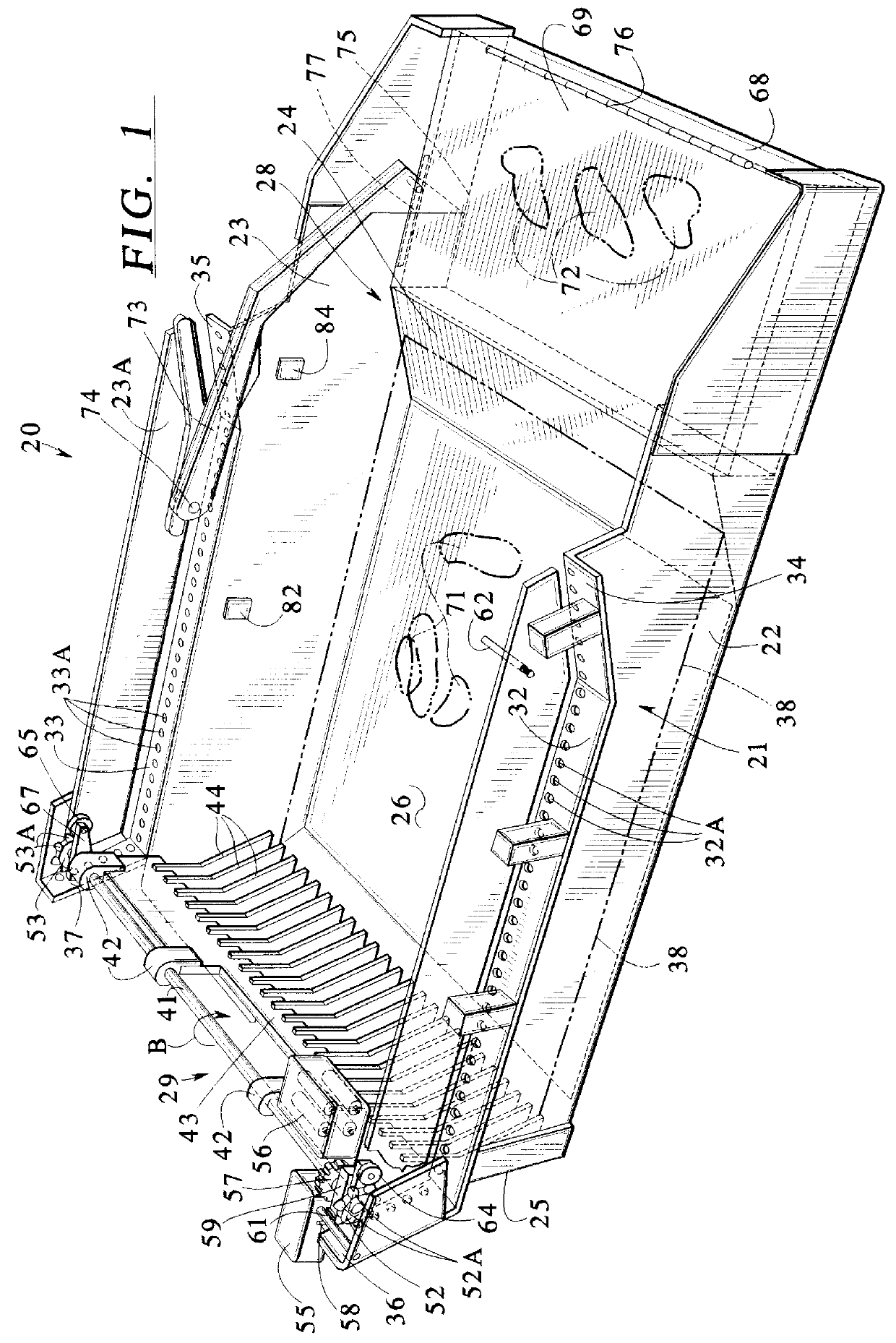

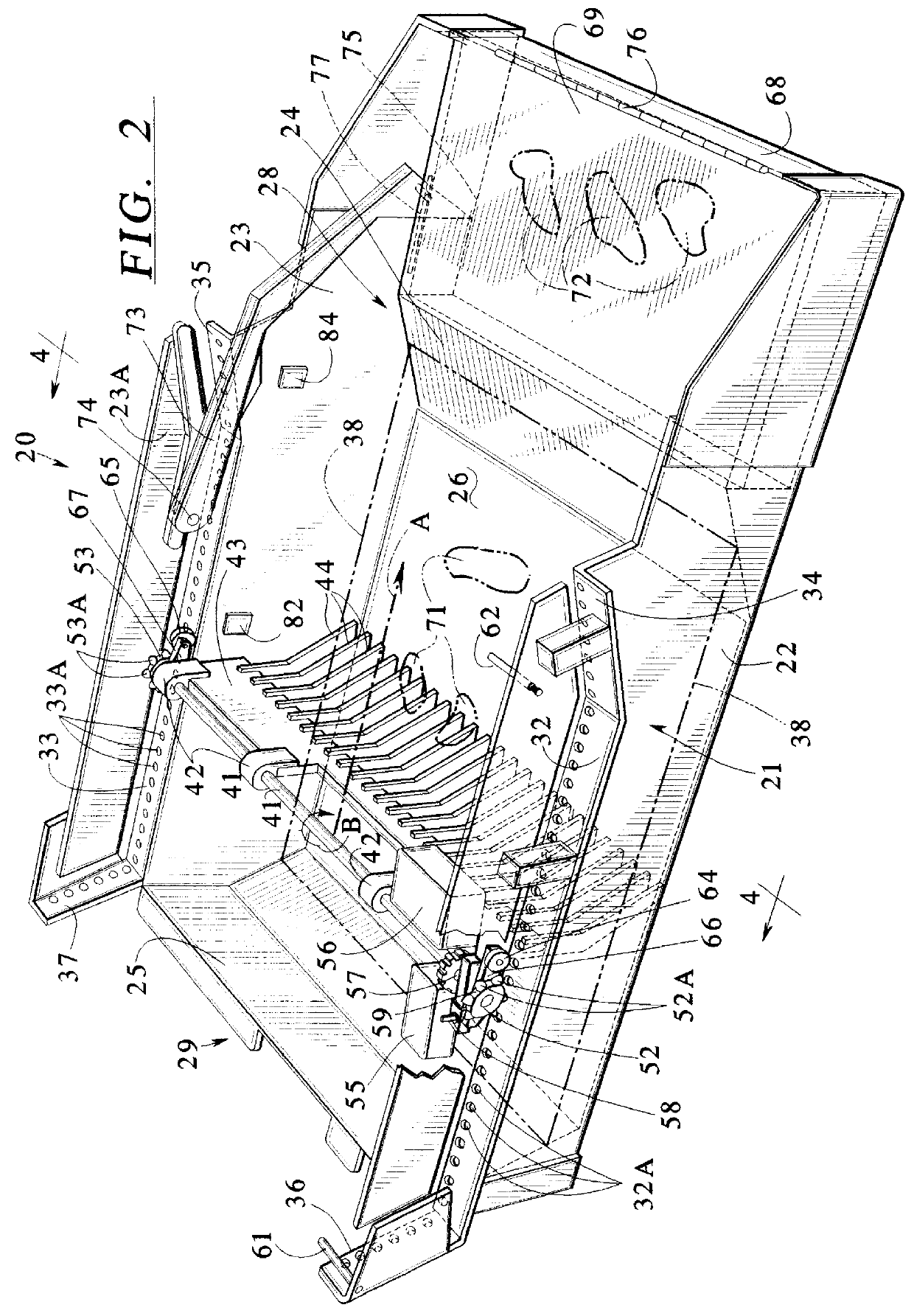

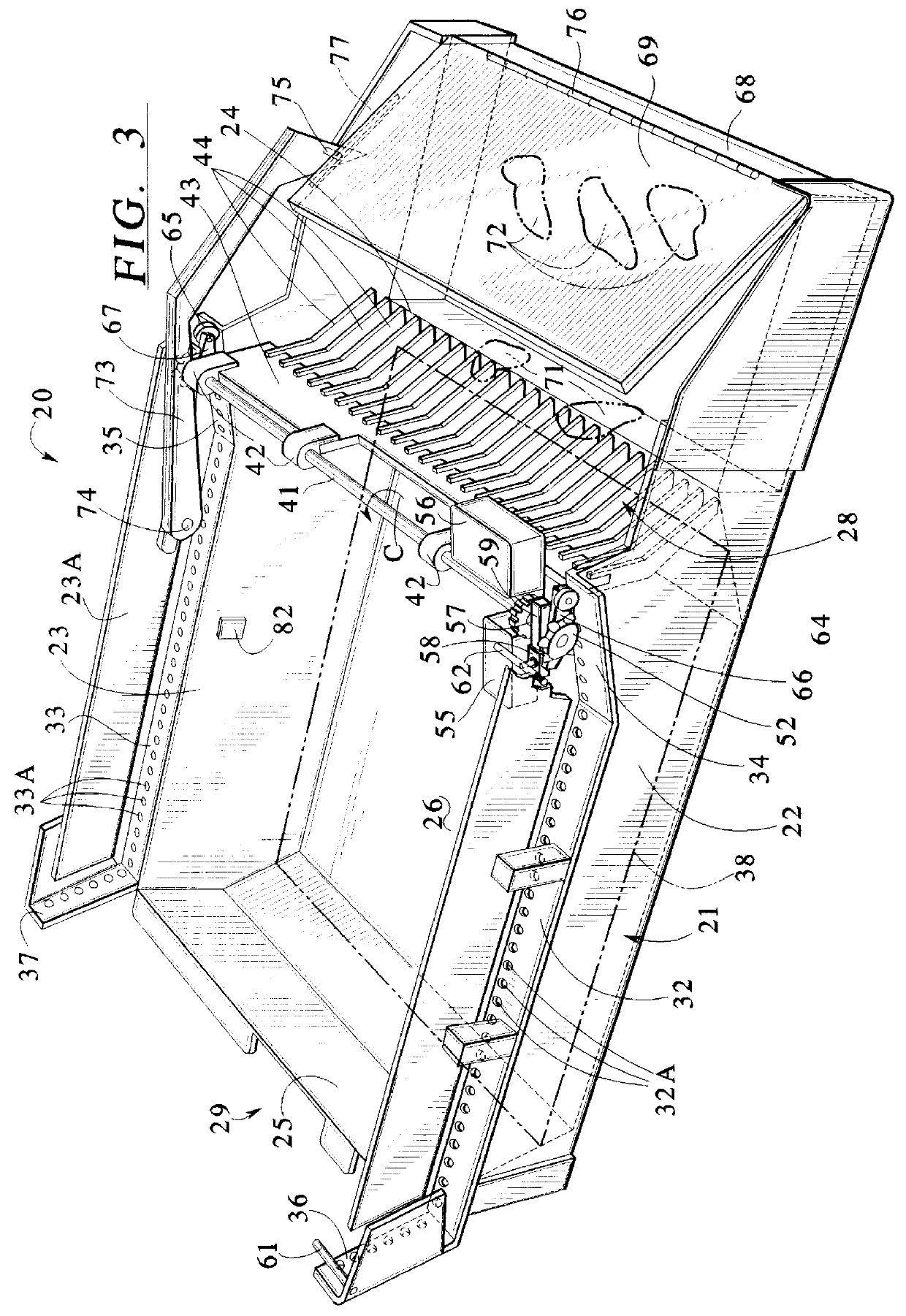

Automated self-cleaning litter box for cats

InactiveUSRE36847E1Simple and economical structureExtended service lifeAnimal housingOther apparatusDrive wheelComb drive

An improved automated self-cleaning litter box for cats, of the kind having a housing defining an upwardly open chamber for storage of a supply of cat litter, accessible to a cat and having path members on opposed side walls defining a comb path from one end of the chamber to the other. A comb, normally stored at the comb storage end of the chamber, is driven forward along the path to the discharge end of the chamber and back to its original storage position. As the comb traverses the chamber forwardly it engages any clumps of waste in the litter and carries them to a disposal receptacle at the discharge end of the chamber. The improvement includes a sensor for sensing the presence of a cat in the litter chamber; a photo electric sensor is preferred, but an infra red, weight, or even an audible sensor can be used. A delay device actuates the comb drive a predetermined time interval after the sensor ceases to sense the presence of a cat in the litter chamber. In the improved construction the comb path includes multi-perforate track members on opposite sides of the litter chamber; those tracks are engaged by rotatable drive wheels connected to the comb. The comb drive includes a reversible electric motor, mounted on the same carriage as the comb. A transparent, biodegradable receptacle is used; alarms for a full receptacle and for an insufficient litter supply are provided.

Owner:UNITED PET GRP INC

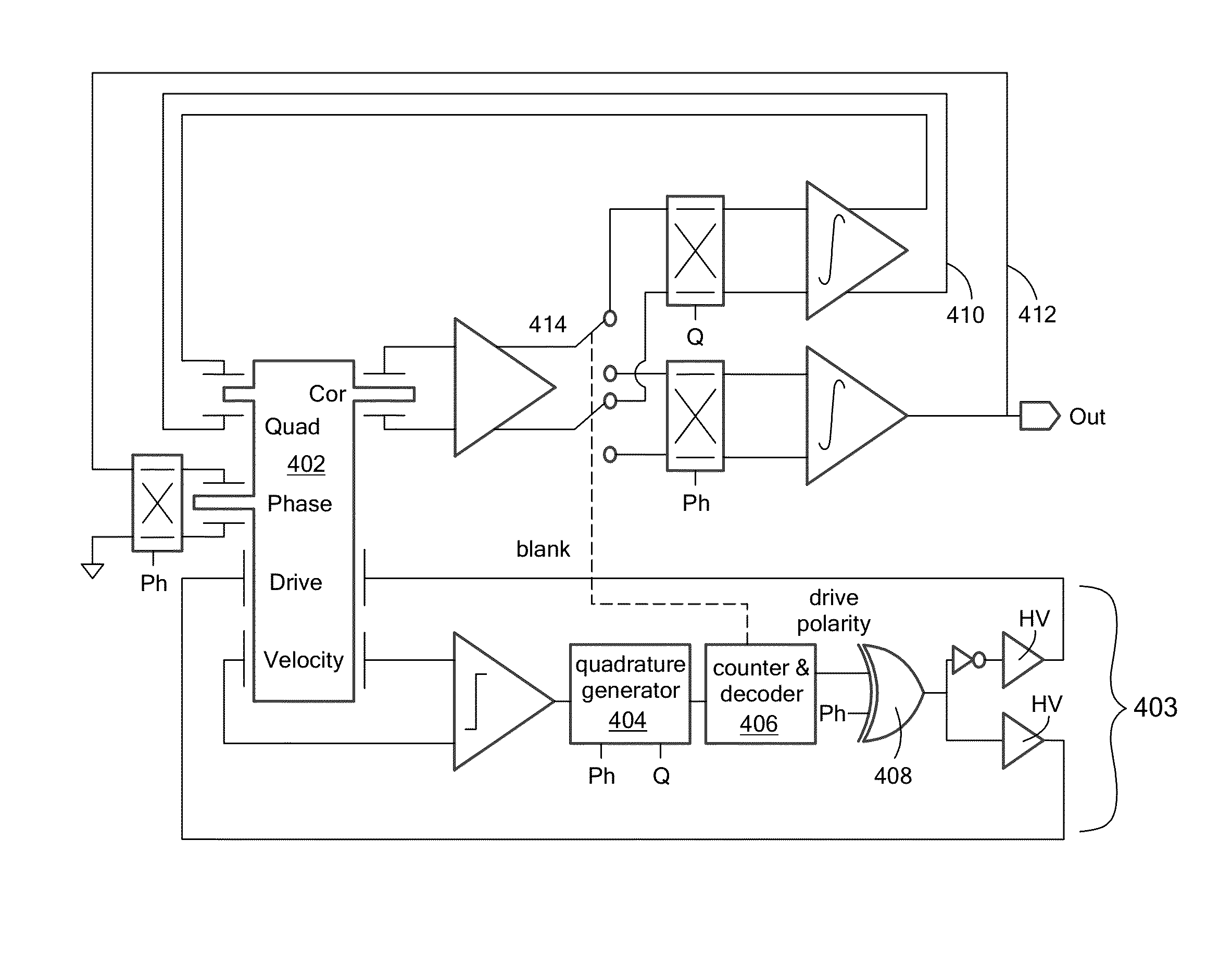

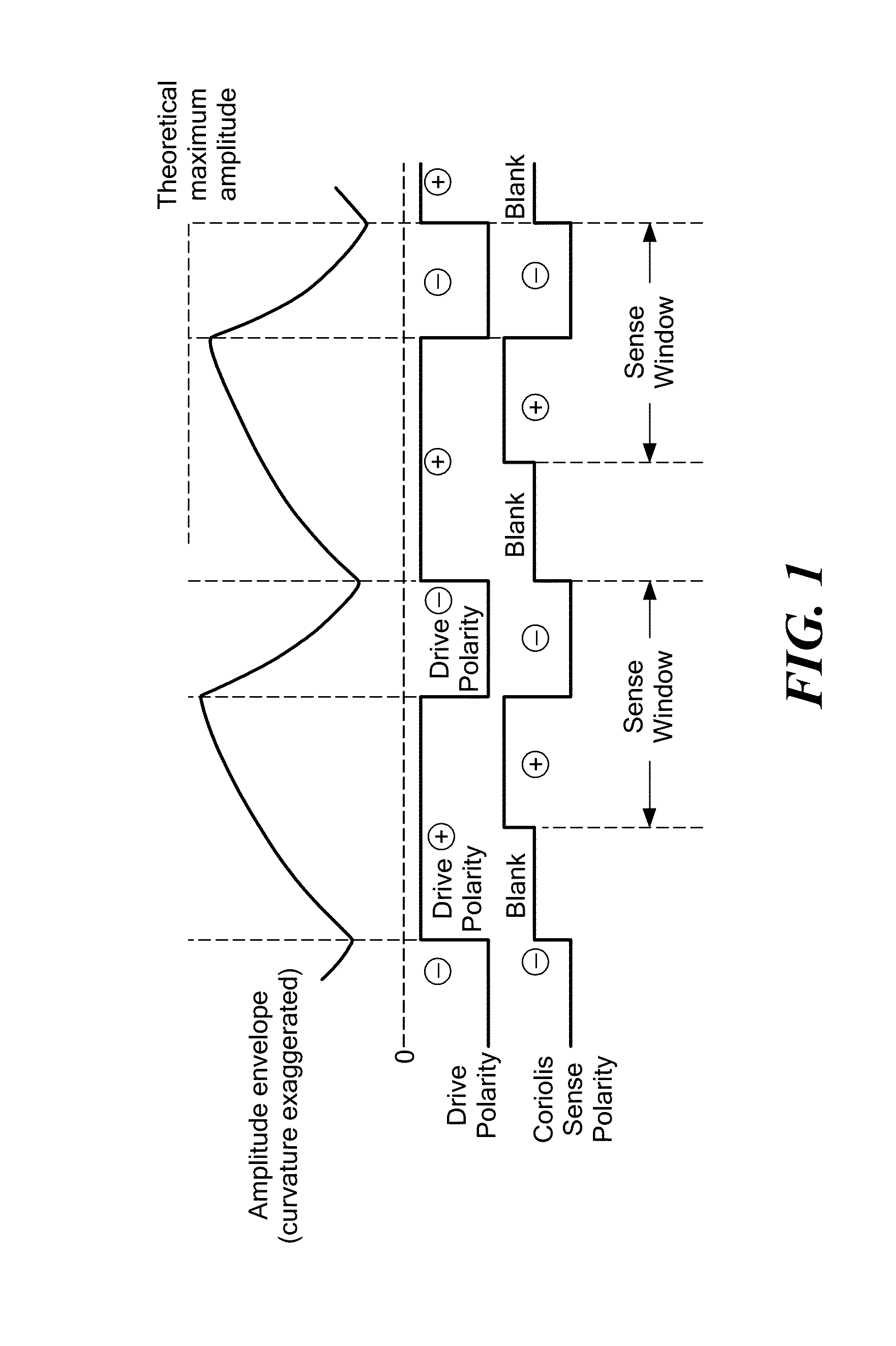

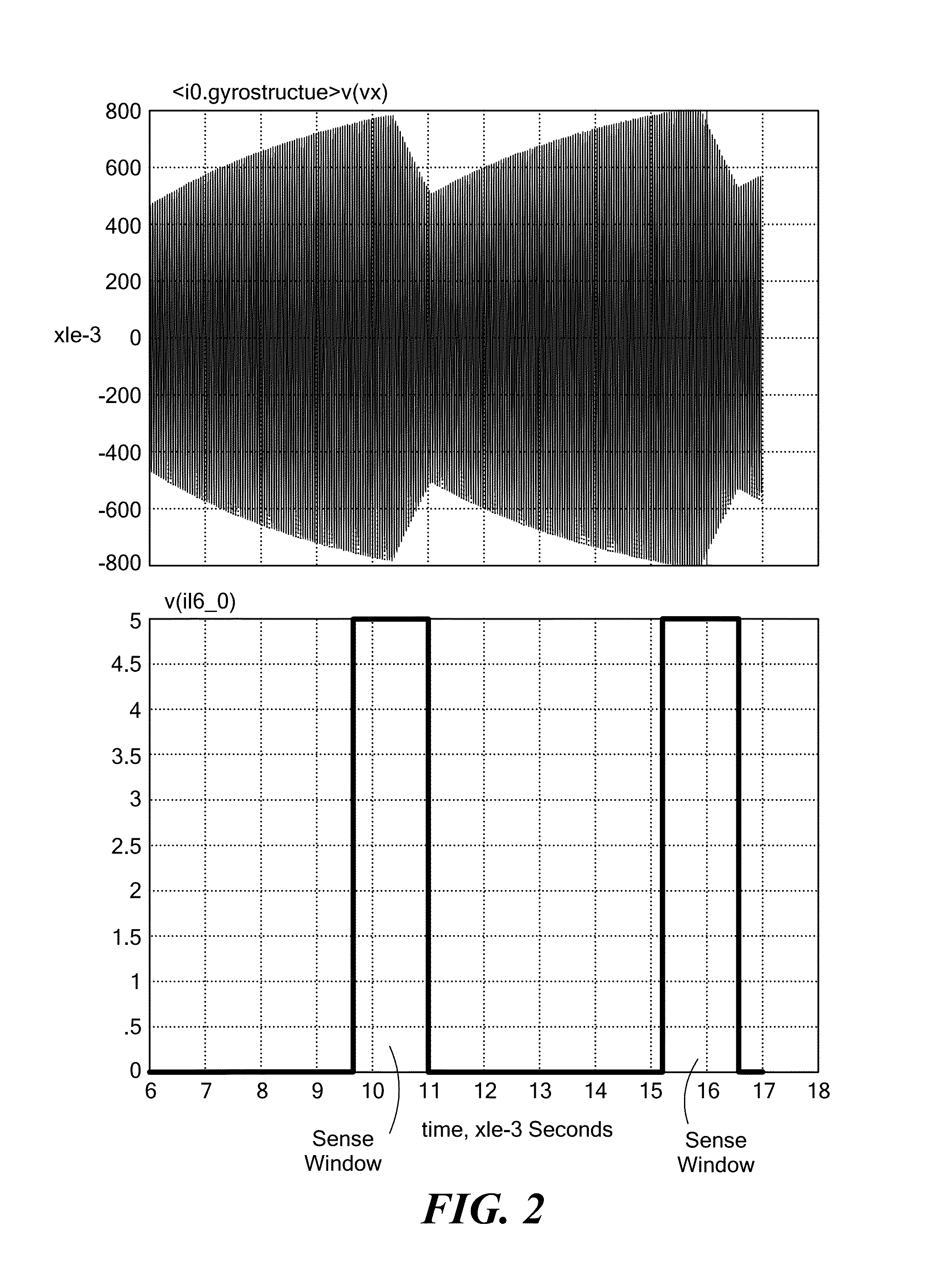

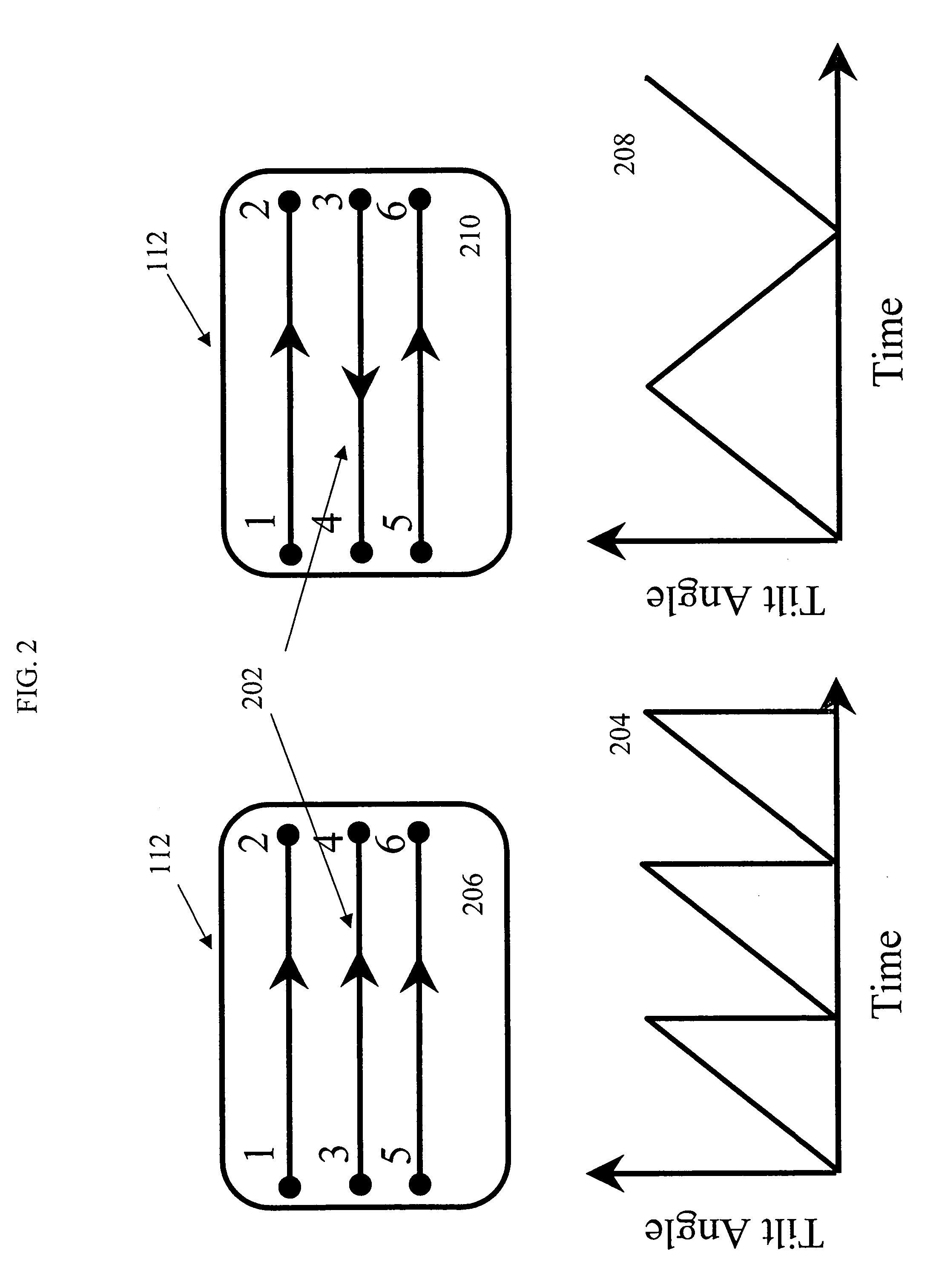

MEMS gyroscopes with reduced errors

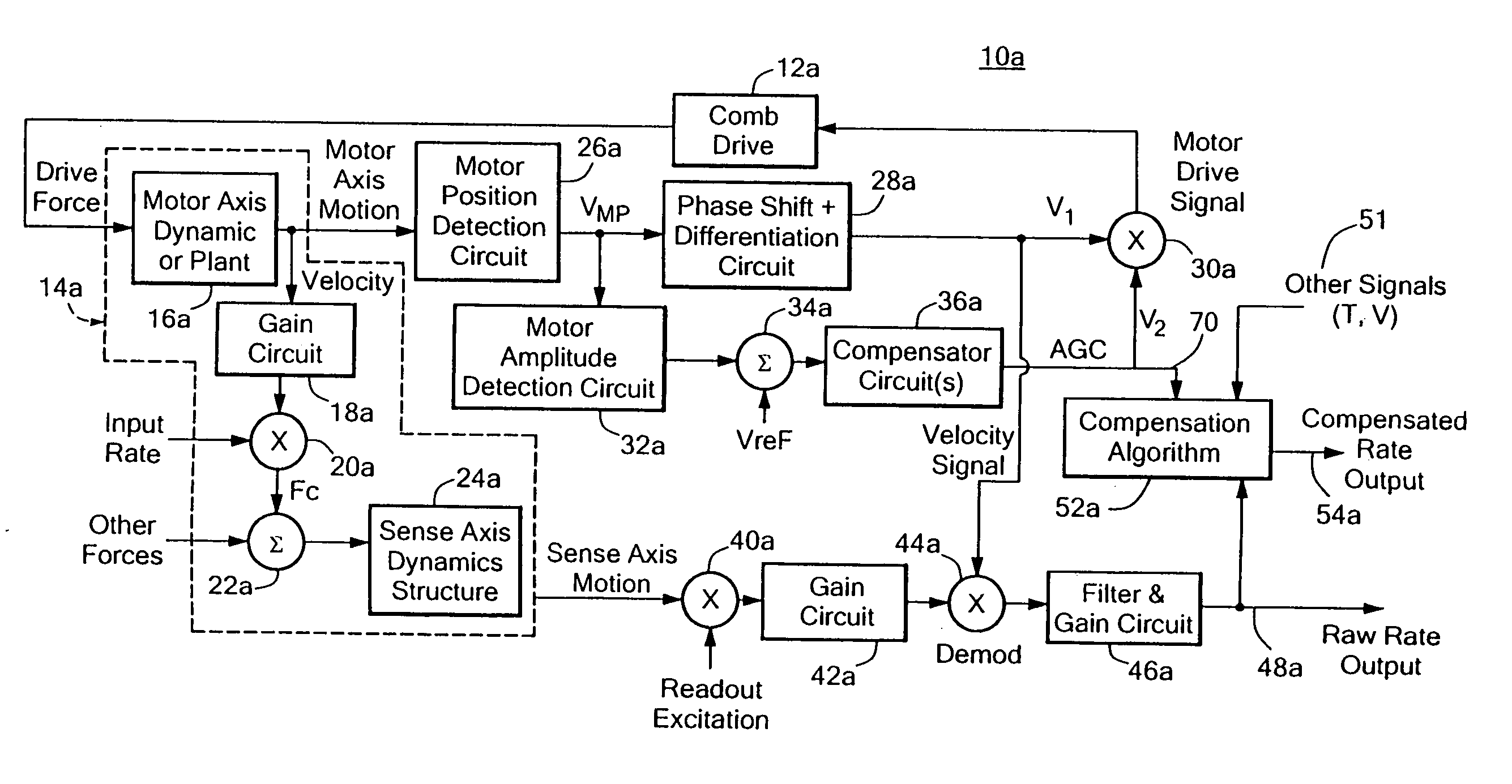

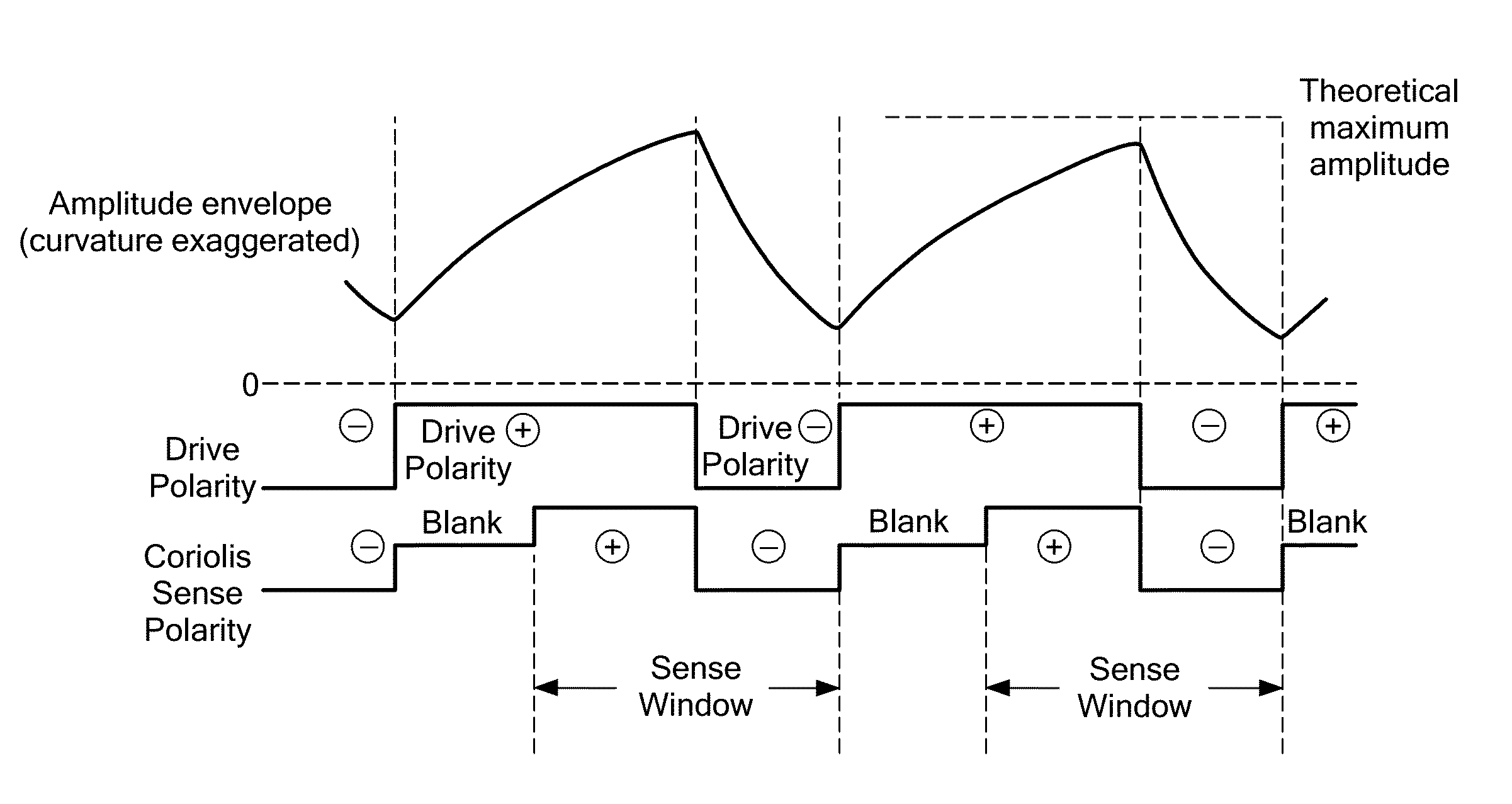

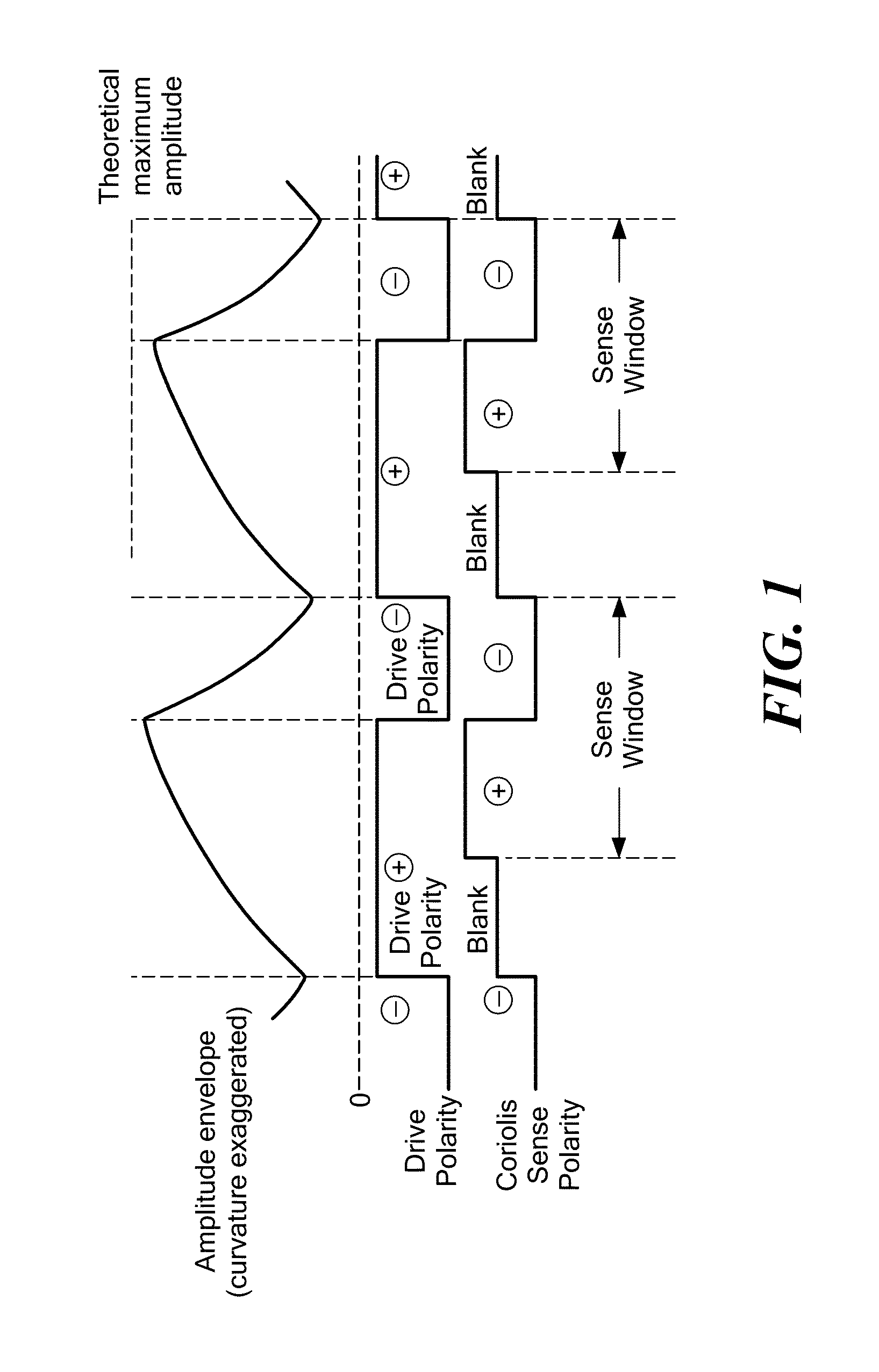

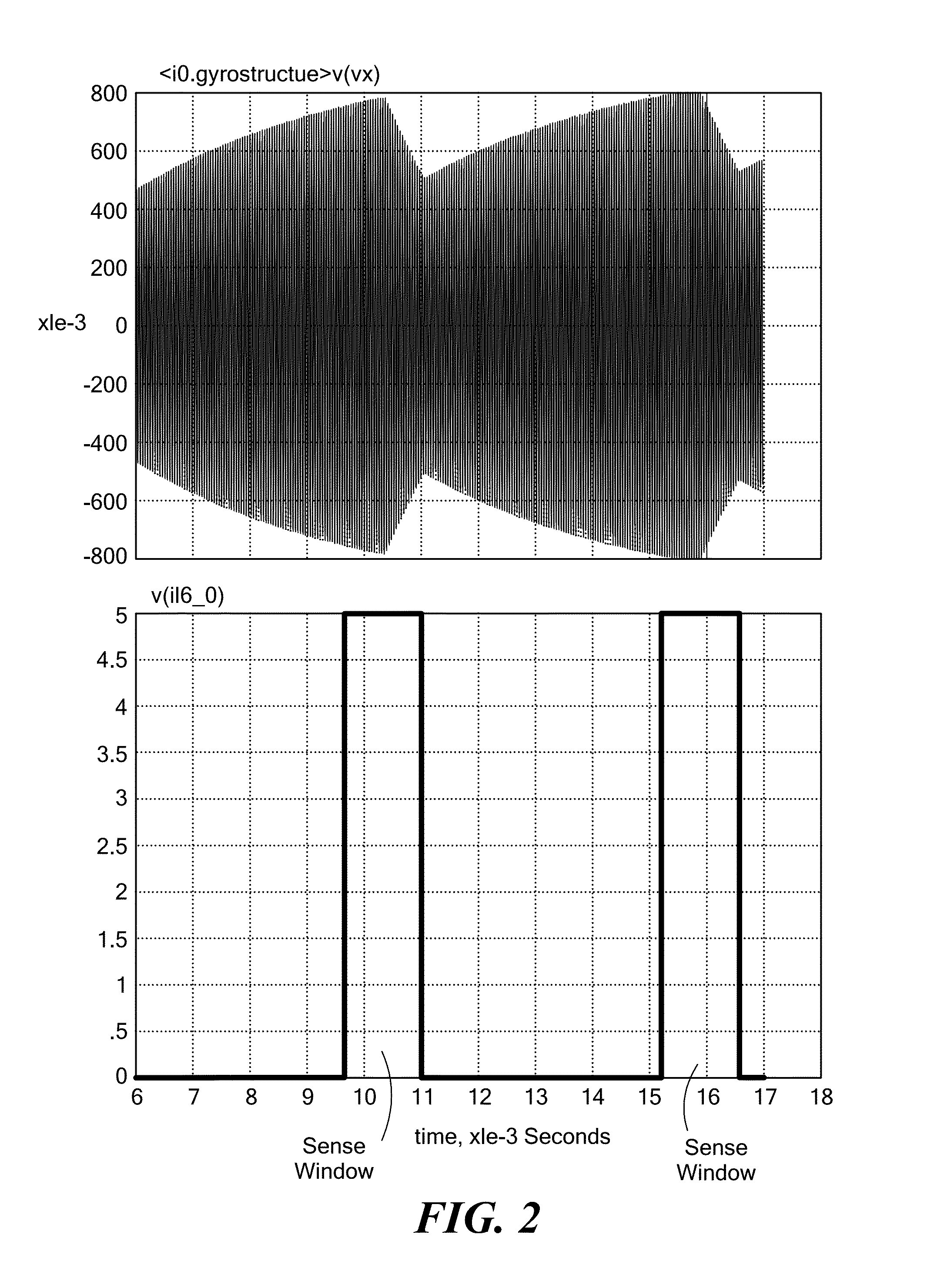

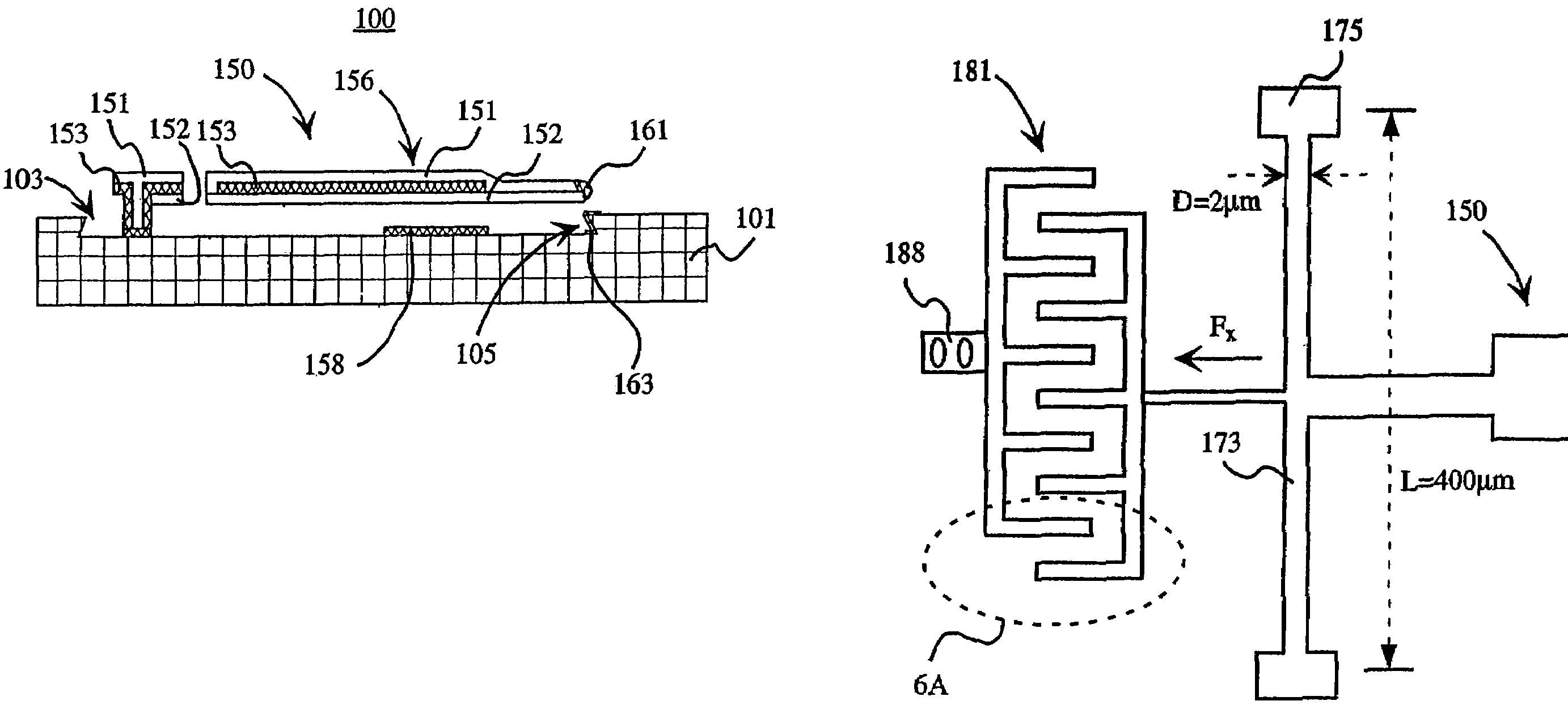

ActiveUS20130283908A1Reducing drive-induced Coriolis accelerometerReducing drive-induced Coriolis accelerometer offsetAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeAccelerometer

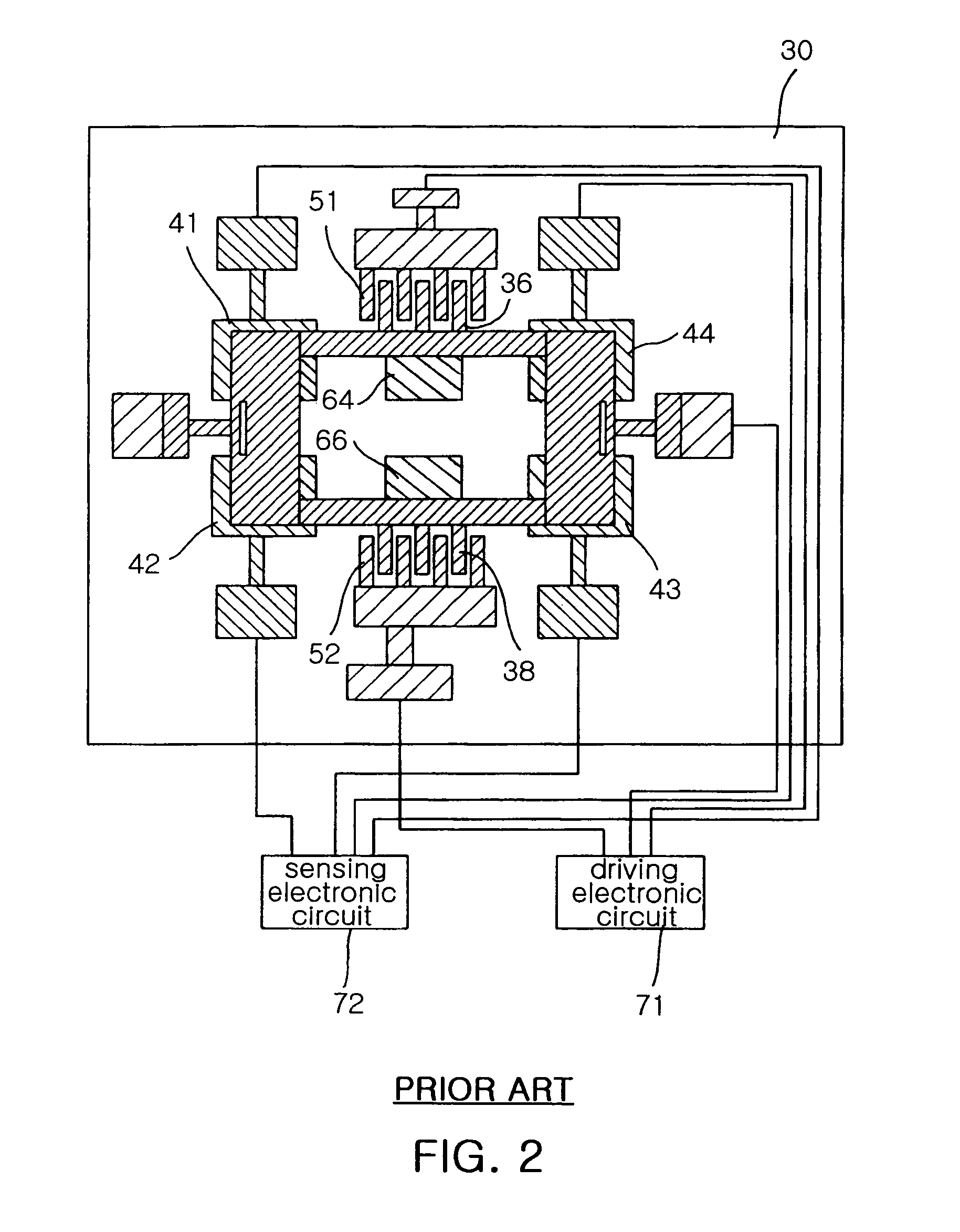

In comb drive vibratory gyroscopes, drive-induced Coriolis accelerometer offset is effectively canceled by demodulating the output during equal times of in-phase and anti-phase drive of the shuttle with respect to the velocity signal used for angular rate demodulation. This reduces or eliminates the corresponding thermal and die-stress effects otherwise needing calibration.

Owner:ANALOG DEVICES INC

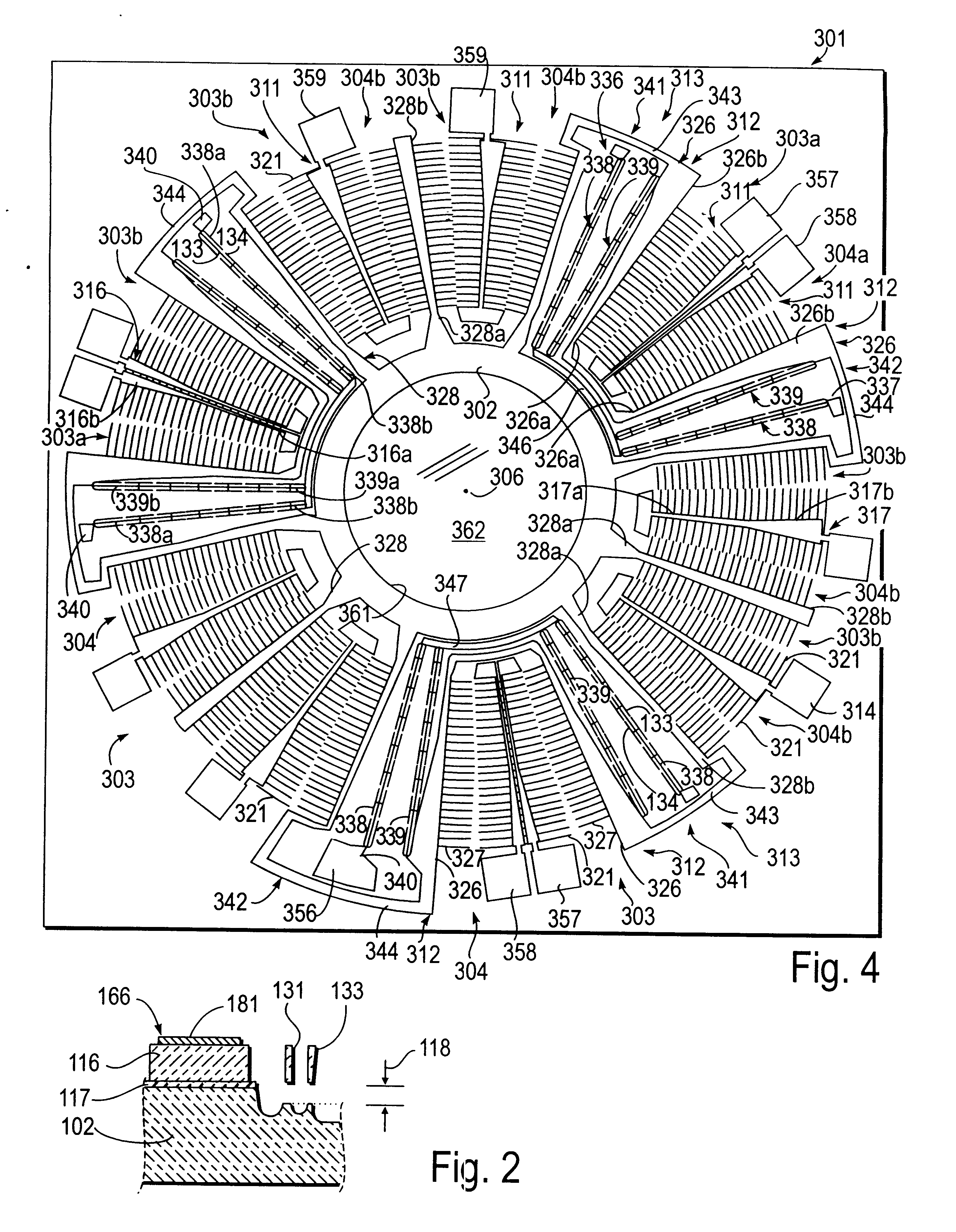

Optical microswitch with rotary electrostatic microactuator

InactiveUS6301403B1Reduce transmission lossFast switching timeOptical flying-type headsOptical beam sourcesFiberIn plane

An optical microswitch comprising a support body and first and second output fibers carried by the body. A rotary electrostatic microactuator is carried by the body and extends in plane. A micromirror is disposed out of the plane. The microactuator has a mirror holder coupled to the micromirror and at least one comb drive assembly coupled to the mirror holder for driving the micromirror about an axis of rotation extending perpendicular to the plane between a first position for reflecting a laser beam to the first output fiber and a second position for reflecting the laser beam to the second output fiber.

Owner:COHERENT INC

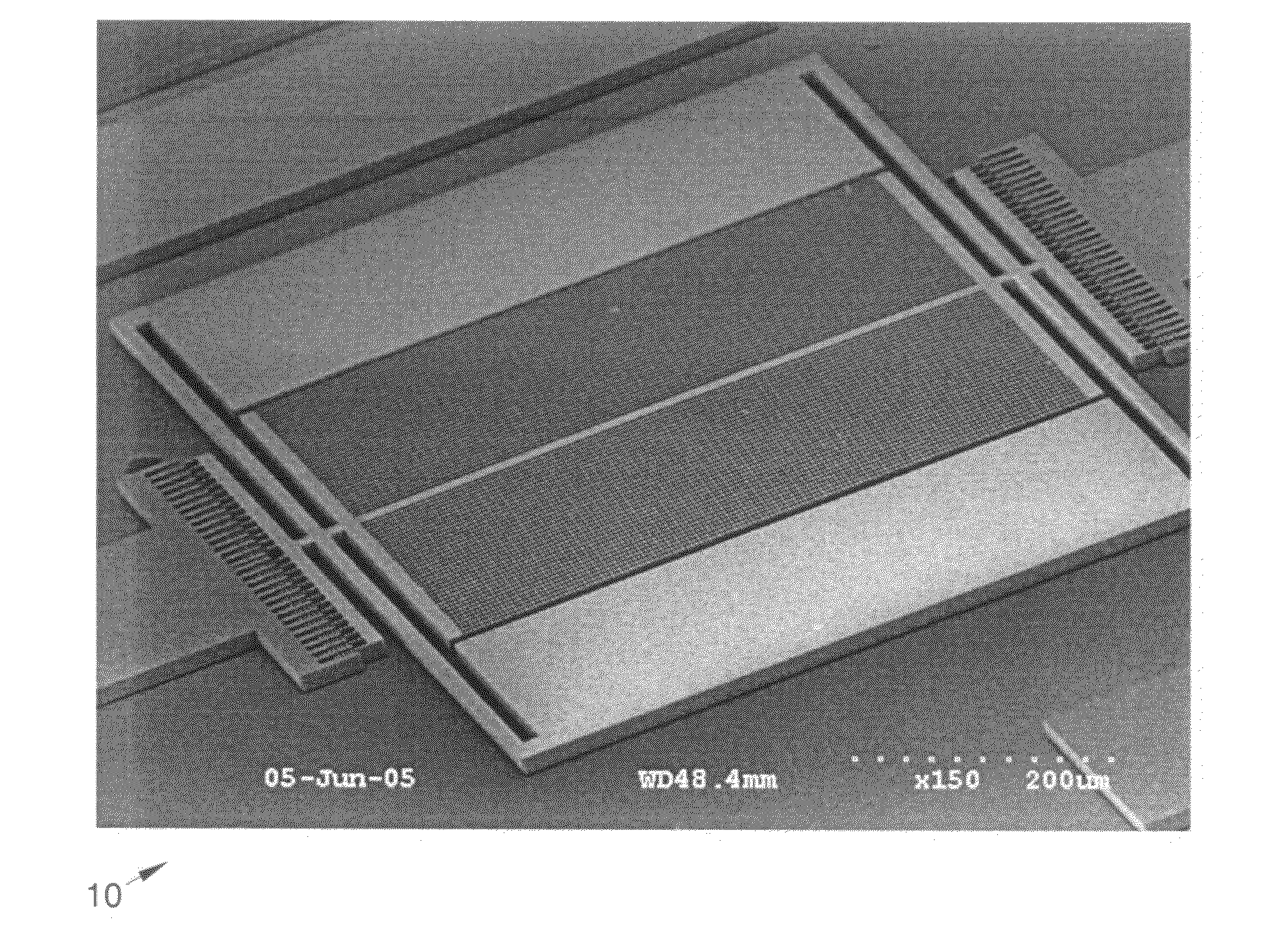

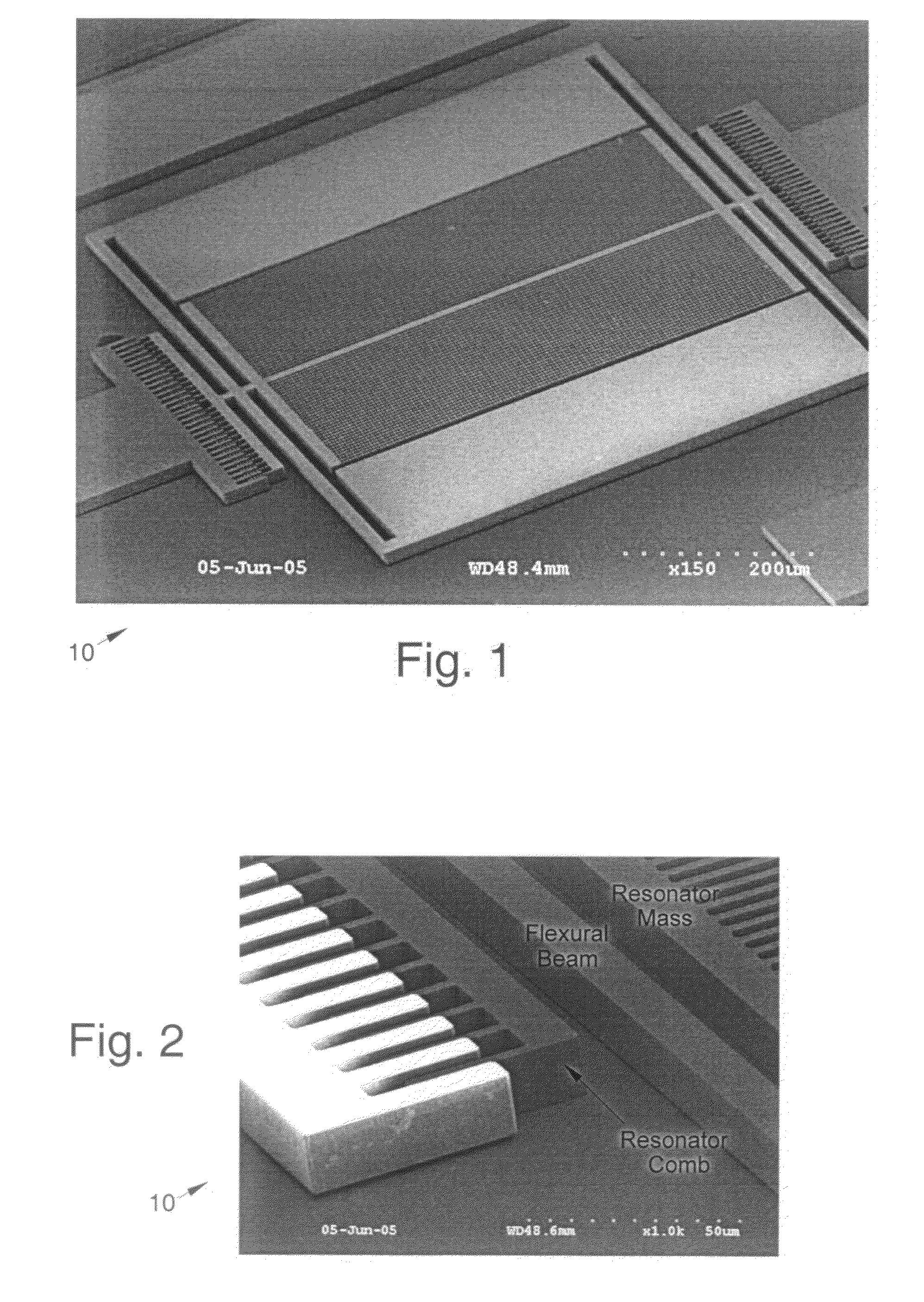

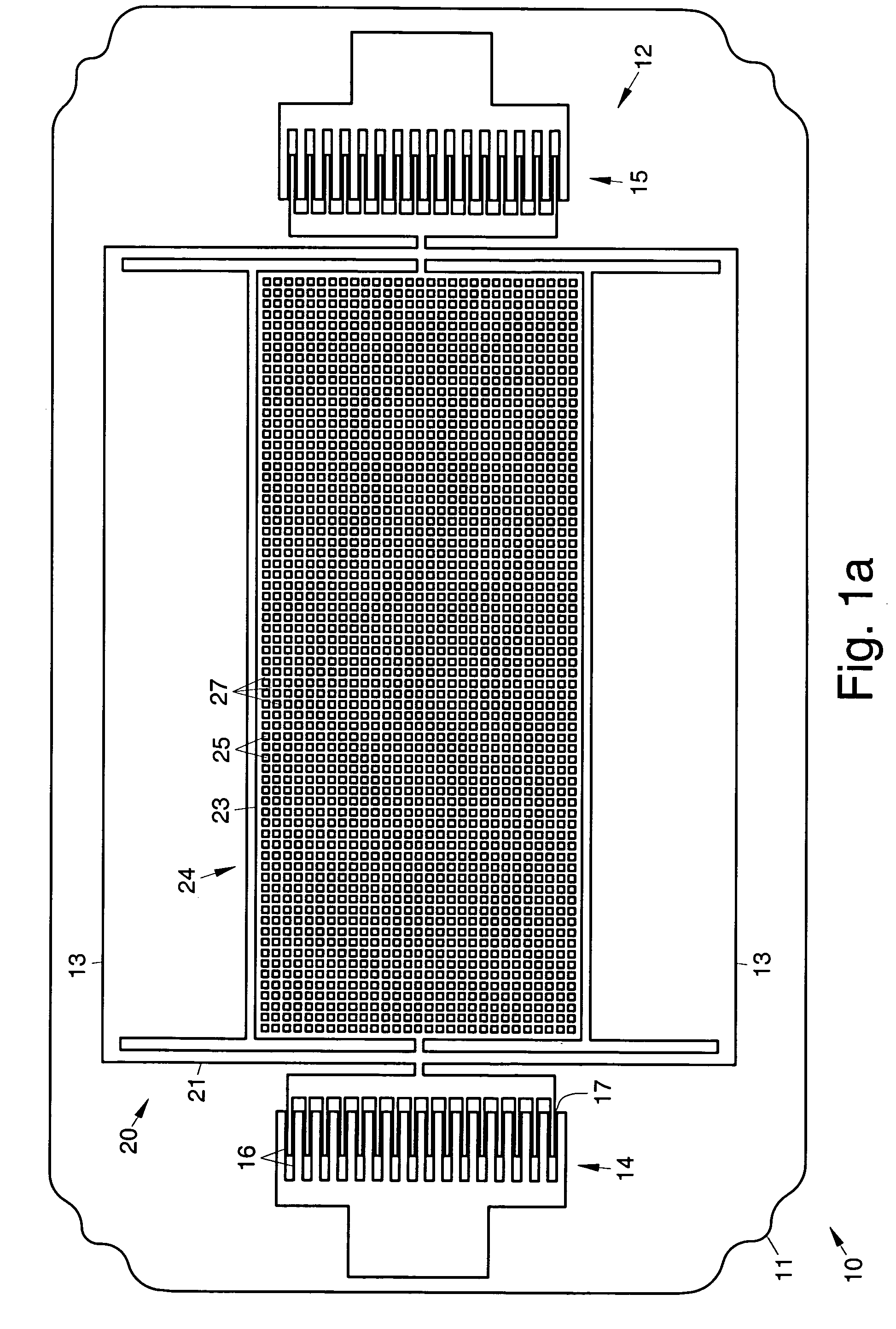

Low frequency process-variation-insensitive termperature-stable micromechanical resonators

Disclosed are micromechanical resonators having features that compensate for process variations and provide improved inherent temperature stability. Exemplary resonators may comprise comb drive resonators or parallel-plate drive resonators. The resonators comprise a (silicon-on-insulator) substrate with resonator apparatus formed therein. The resonator apparatus has one or more anchors connected to the substrate, at least one excitation / sense port that is electrically insulated from the substrate, and a resonator. The resonator comprises one or more flexural members connected to the one or more anchors that are separated from the substrate and separated from the excitation / sense port by gaps. A mass is coupled to flexural members, is separated from the substrate, and comprises a grid. Process compensation is achieved using a resonator mass in the form of a grid of lines that form holes or lines through the mass, wherein widths of lines of the grid are approximately ⅓ the width of the flexural members. Temperature stability is provided using silicon dioxide on at least one of the surfaces of the flexural members.

Owner:GEORGIA TECH RES CORP

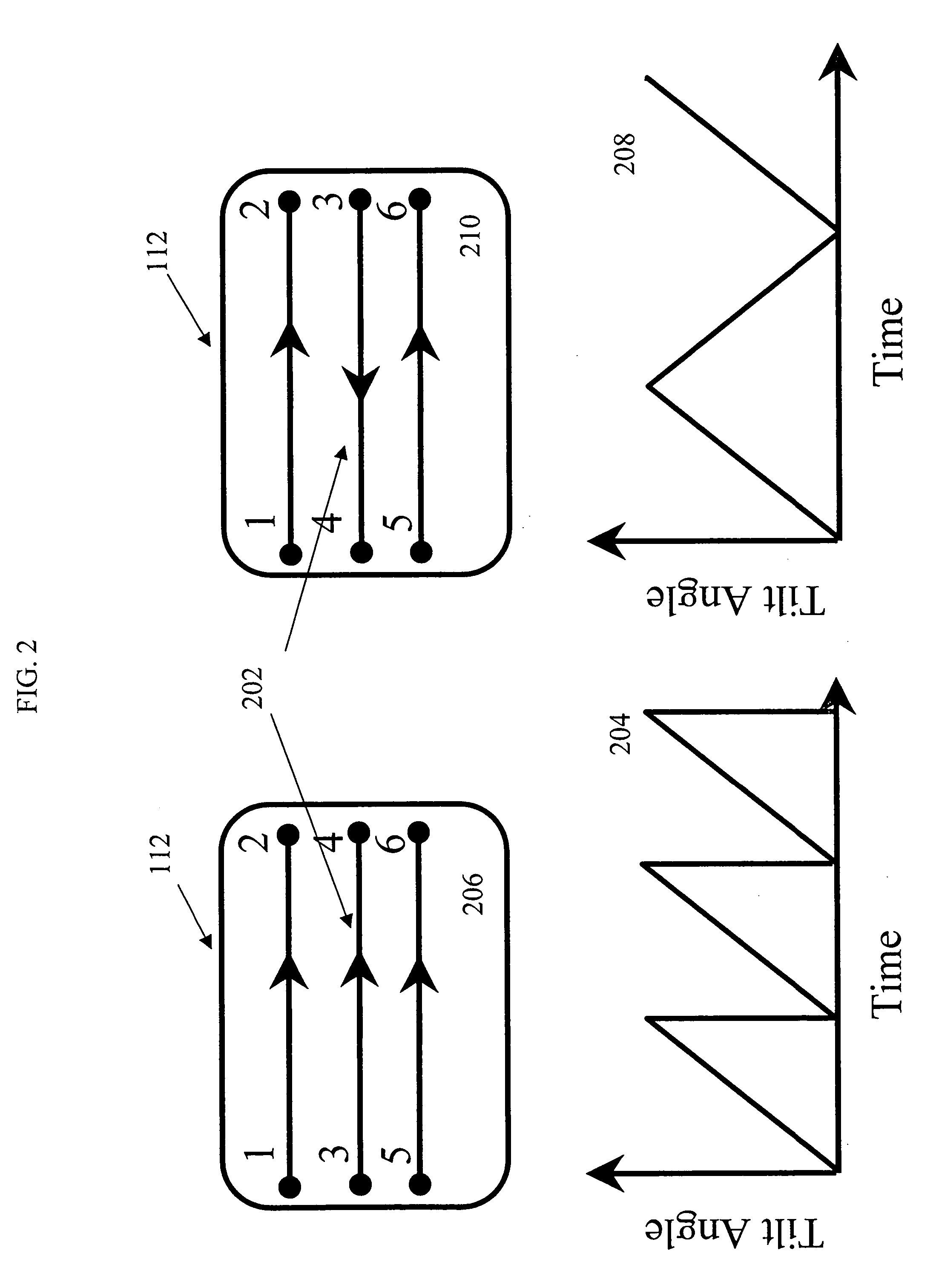

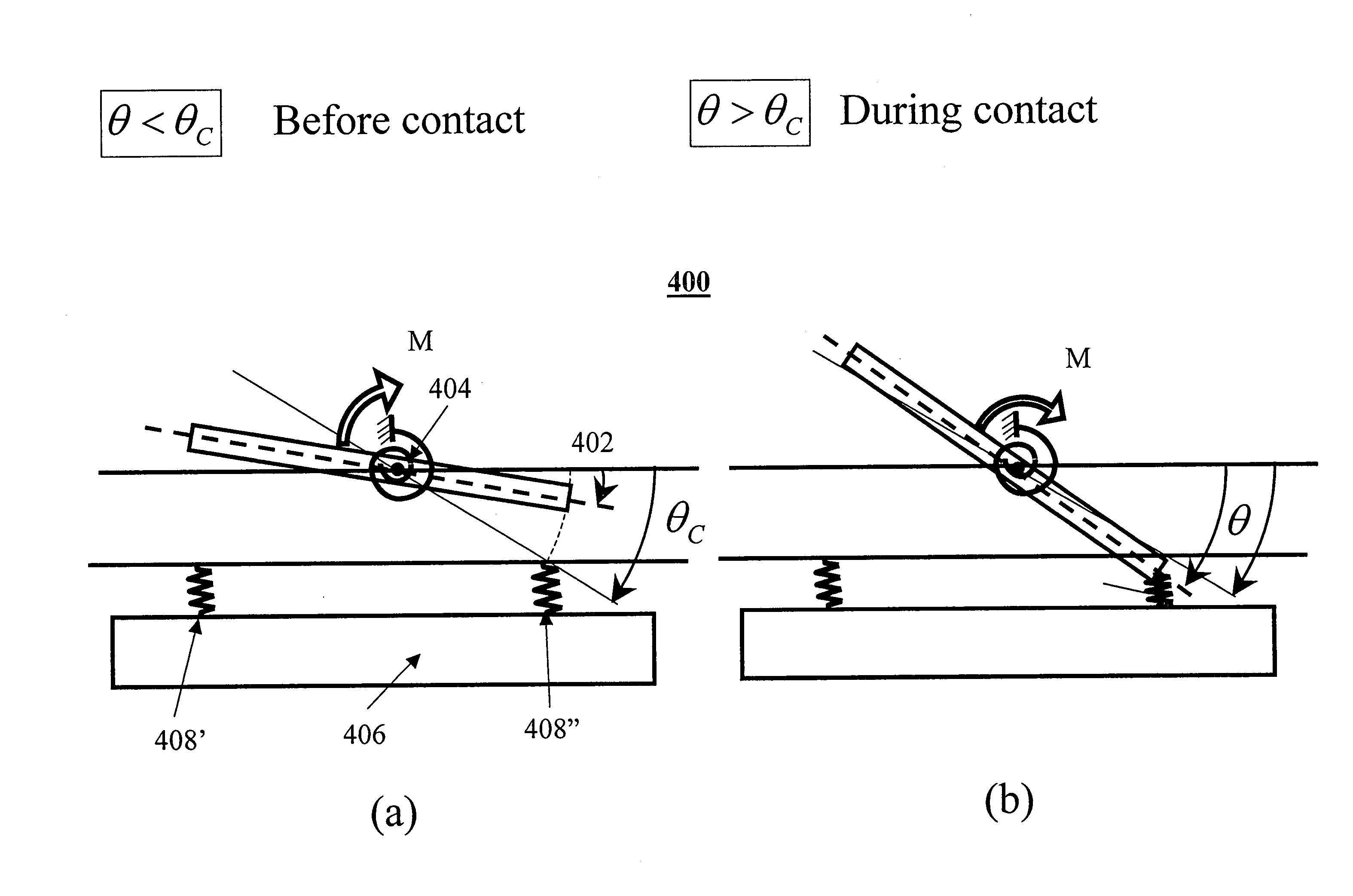

Bouncing mode operated scanning micro-mirror

ActiveUS20050219677A1Good scan effectImprove linearityNon-linear opticsOptical elementsRotational axisComb drive

A MEMS apparatus for scanning an optical beam comprises a mirror operative to perform a rotational motion to a maximum rotation angle around a mirror rotation axis formed in a double active layer silicon-on-insulator (SOI) substrate. The apparatus may include a bouncing mechanism operative to provide a bouncing event and to reverse the rotational motion. The bouncing event provides the mirror with a piecewise linear response to actuation by intrinsically nonlinear electrostatic forces. In a particular embodiment, the bouncing mechanism includes a vertical comb drive stator built in the same active layer of the double active layer SOI substrate, while actuator comb drive stators are built in a different active layer.

Owner:STMICROELECTRONICS INT NV +1

Bouncing mode operated scanning micro-mirror

ActiveUS7177063B2Good scan effectLow costNon-linear opticsFlexible microstructural devicesRotational axisComb drive

A MEMS apparatus for scanning an optical beam comprises a mirror operative to perform a rotational motion to a maximum rotation angle around a mirror rotation axis formed in a double active layer silicon-on-insulator (SOI) substrate. The apparatus may include a bouncing mechanism operative to provide a bouncing event and to reverse the rotational motion. The bouncing event provides the mirror with a piecewise linear response to actuation by intrinsically nonlinear electrostatic forces. In a particular embodiment, the bouncing mechanism includes a vertical comb drive stator built in the same active layer of the double active layer SOI substrate, while actuator comb drive stators are built in a different active layer.

Owner:STMICROELECTRONICS INT NV +1

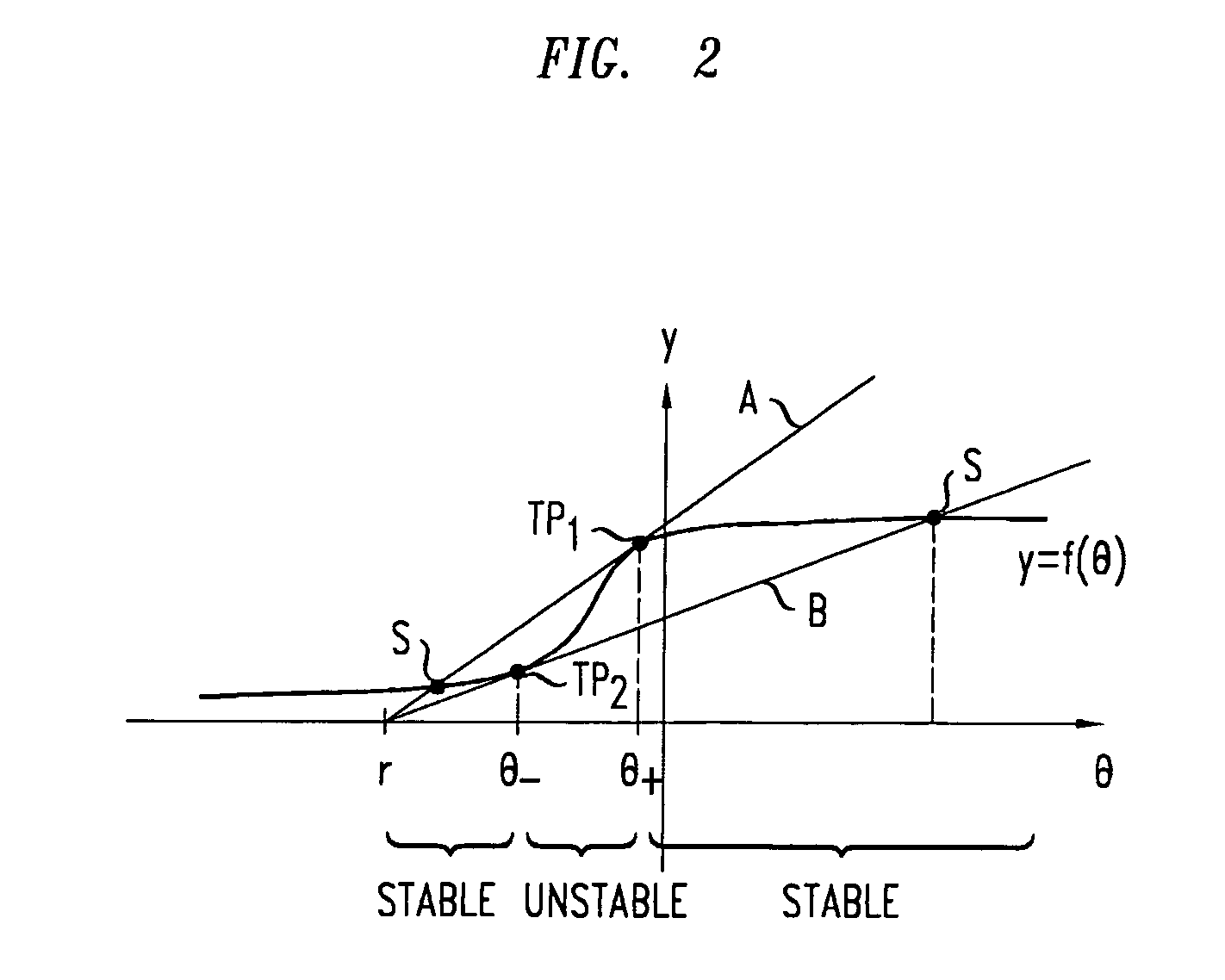

Stable electro-mechanical actuators

An electro-mechanical actuator includes a comb drive and a deformable connector. The comb drive has a first capacitor plate and a second capacitor plate. The capacitor plates have teeth capable of inter-digitating. The deformable connector is configured to apply a mechanical restoring force to the first capacitor plate. The deformable connector is configured to restore the first capacitor plate to be at an equilibrium rest position in response to no control voltage being applied across the capacitor. The comb drive is more engaged at the equilibrium rest position than at a mechanical stability threshold of the comb drive. The capacitor plates are disengaged at the equilibrium rest position.

Owner:ALCATEL-LUCENT USA INC

Process for fabricating MEMS devices

InactiveUS20110136283A1Semiconductor/solid-state device manufacturingElectrostatic motorsSemiconductor materialsComb drive

A process for fabricating a MEMS device with movable comb teeth and stationary comb teeth. A single mask is used to define, during a series of processing steps, the location and width of both movable comb teeth and stationary comb teeth so as to assure self alignment of the comb teeth. MEMS devices are fabricated from a single multi-layer semi-conductor structure of semiconductor material and insulator material. In a preferred embodiment the process is employed to provide a MEMS mirror device having a movable structure, a movable frame, a first set of two torsional members, a first set of at least four comb drives, an outer fixed frame structure, a second set of two torsional members, and a second set of at least four comb drives.

Owner:CROSSFIBER +1

Stepping electrostatic comb drive actuator

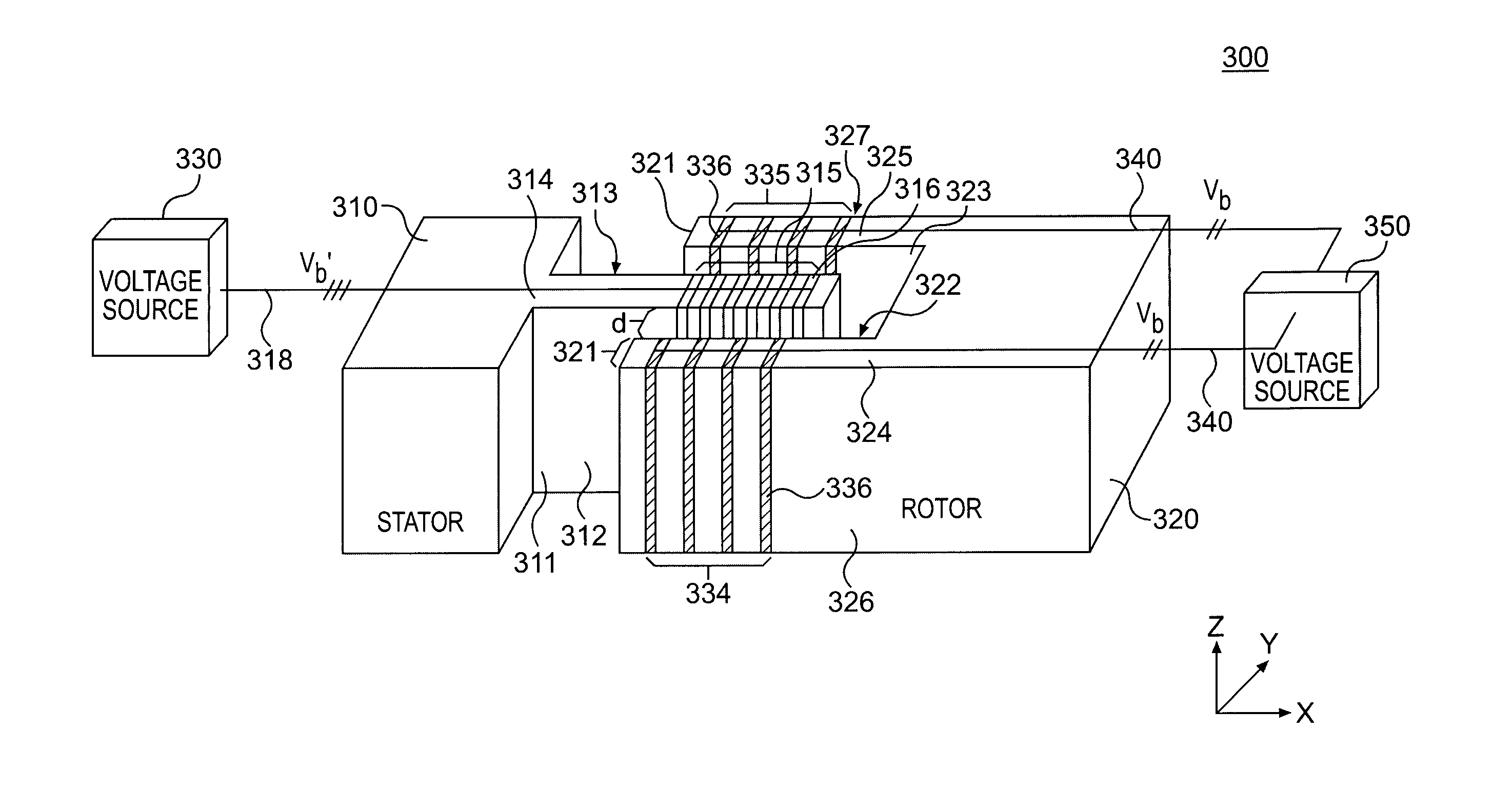

An electrostatic stepping comb drive actuator has a first tooth and a second tooth. Each tooth has a first surface, with the first surface of the first tooth opposite the first surface of the second tooth, first conductors, and a first electrode array located on the first surfaces. The first electrode array includes first electrodes in first electrode groups. The comb drive actuator further includes a second member having a third tooth interdigitated with the first tooth and the second tooth such that relative motion is possible between the third tooth and the first and second teeth. The third tooth includes a second surface disposed opposite each of the first surfaces, second conductors, and a second electrode array located on the second surfaces. The second electrode array includes second electrodes in second electrode groups. The second electrodes in each second electrode group are electrically connected to the same one of the second conductors.

Owner:AGILENT TECH INC

Force compensated comb drive

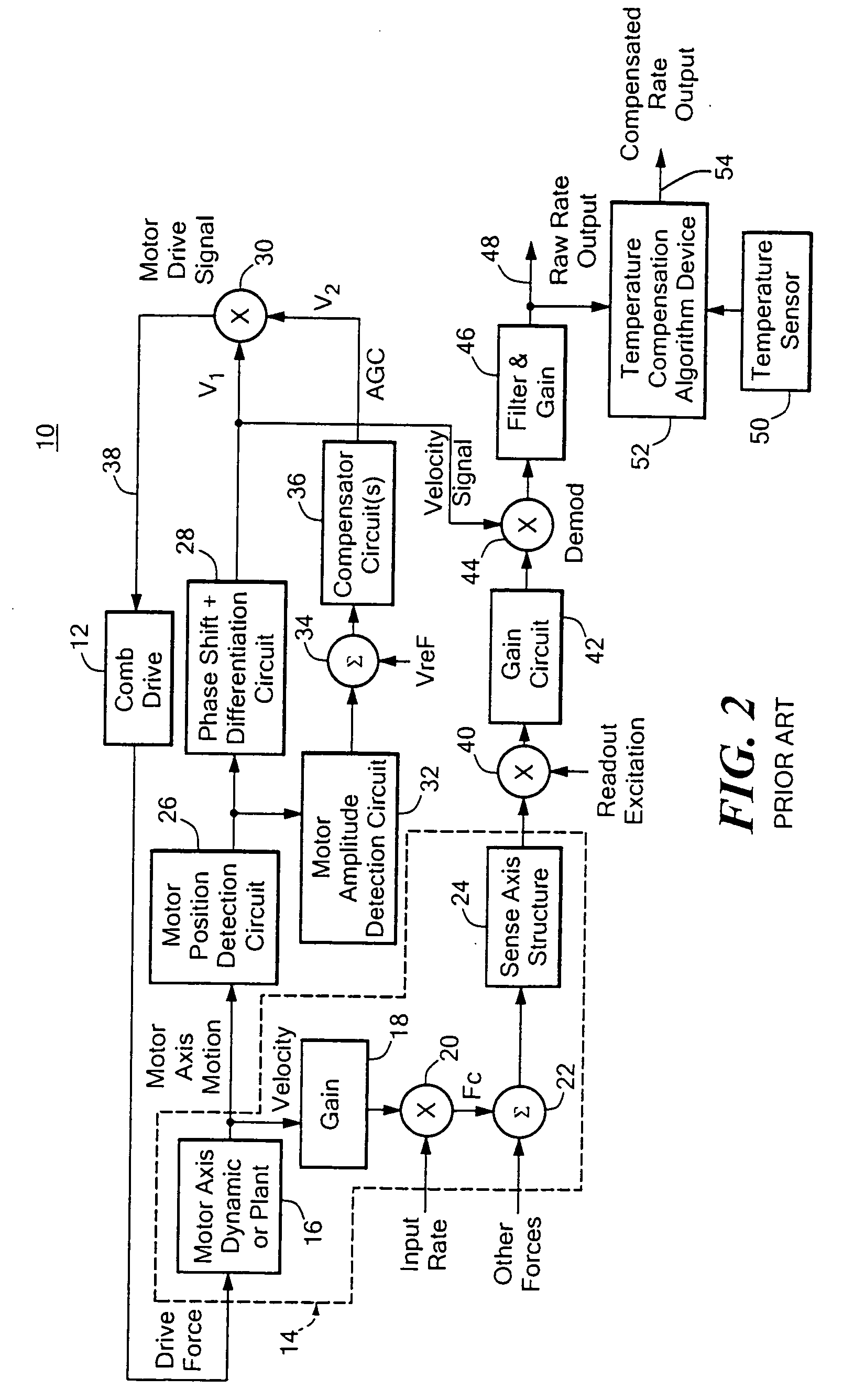

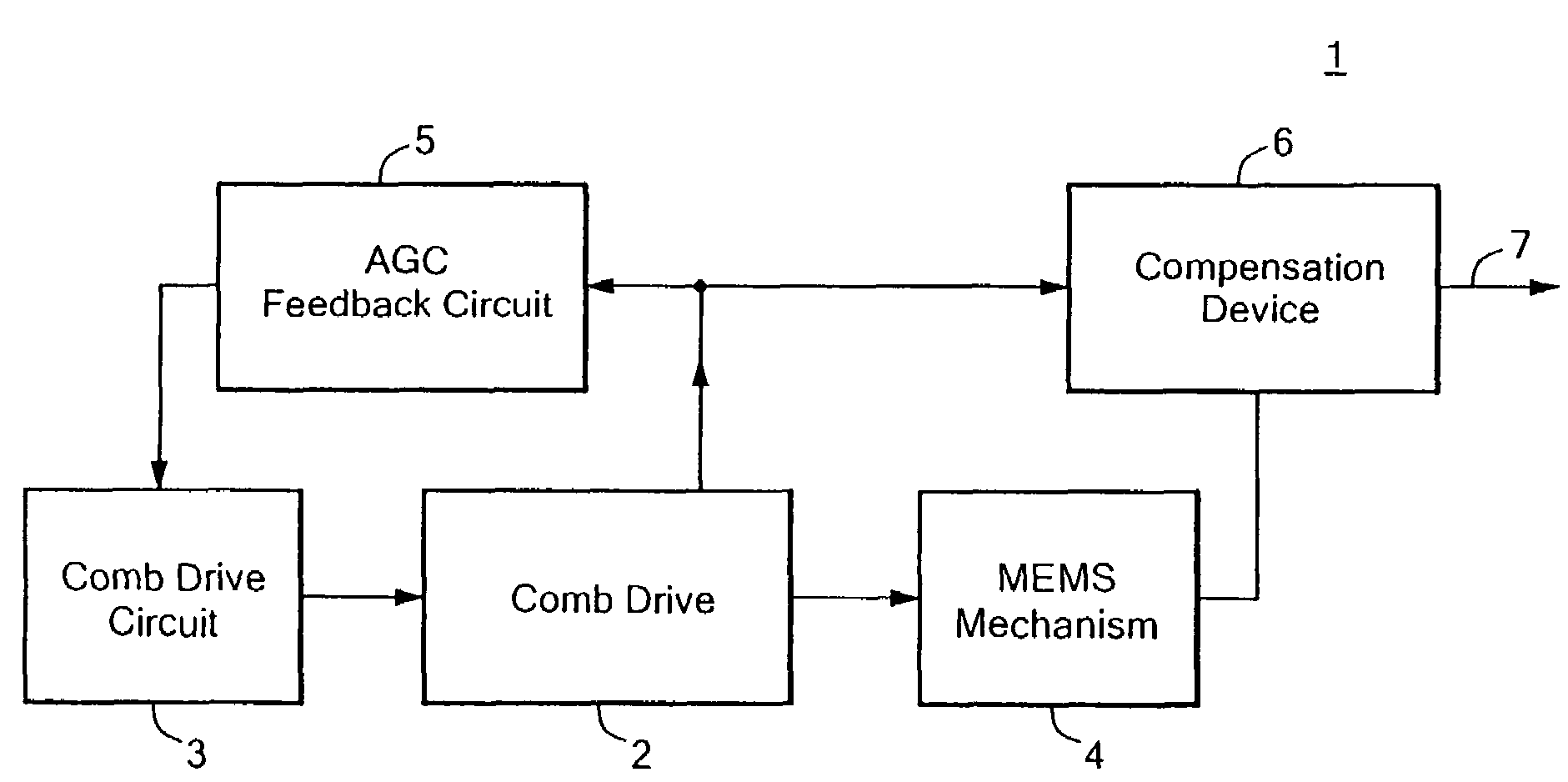

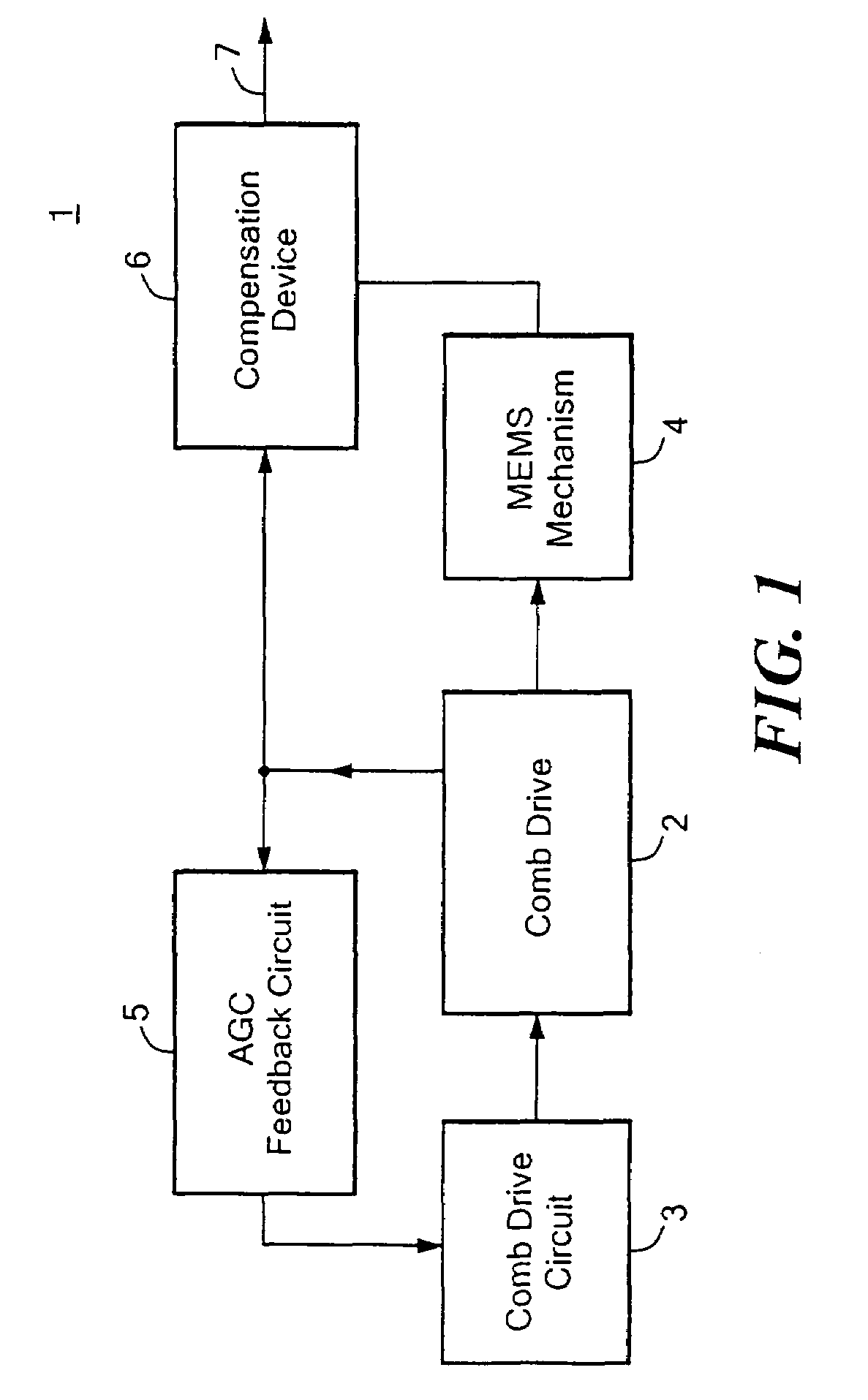

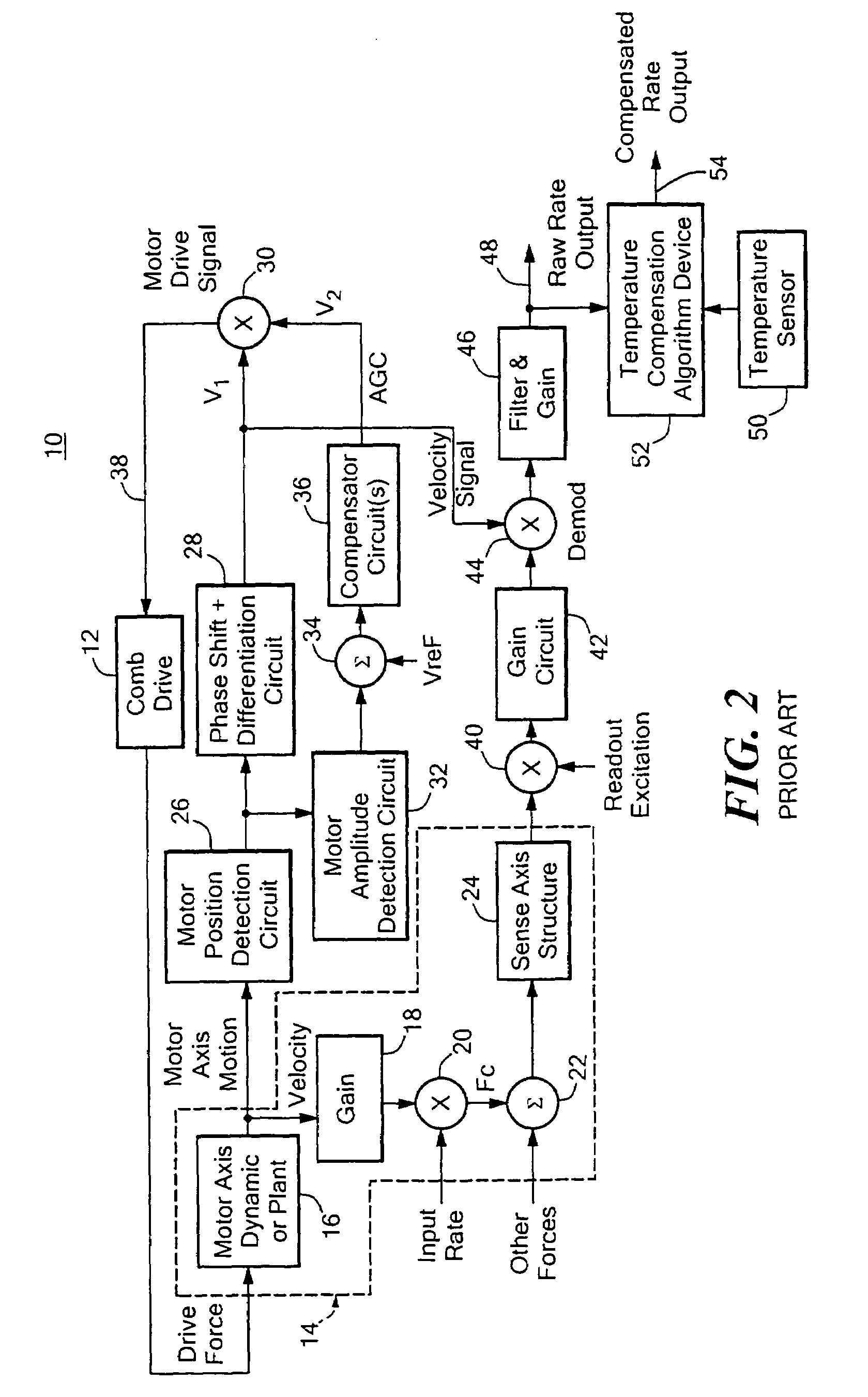

ActiveUS20060201250A1Eliminates thermal propagation errorHigh strengthAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsDriver circuitComb drive

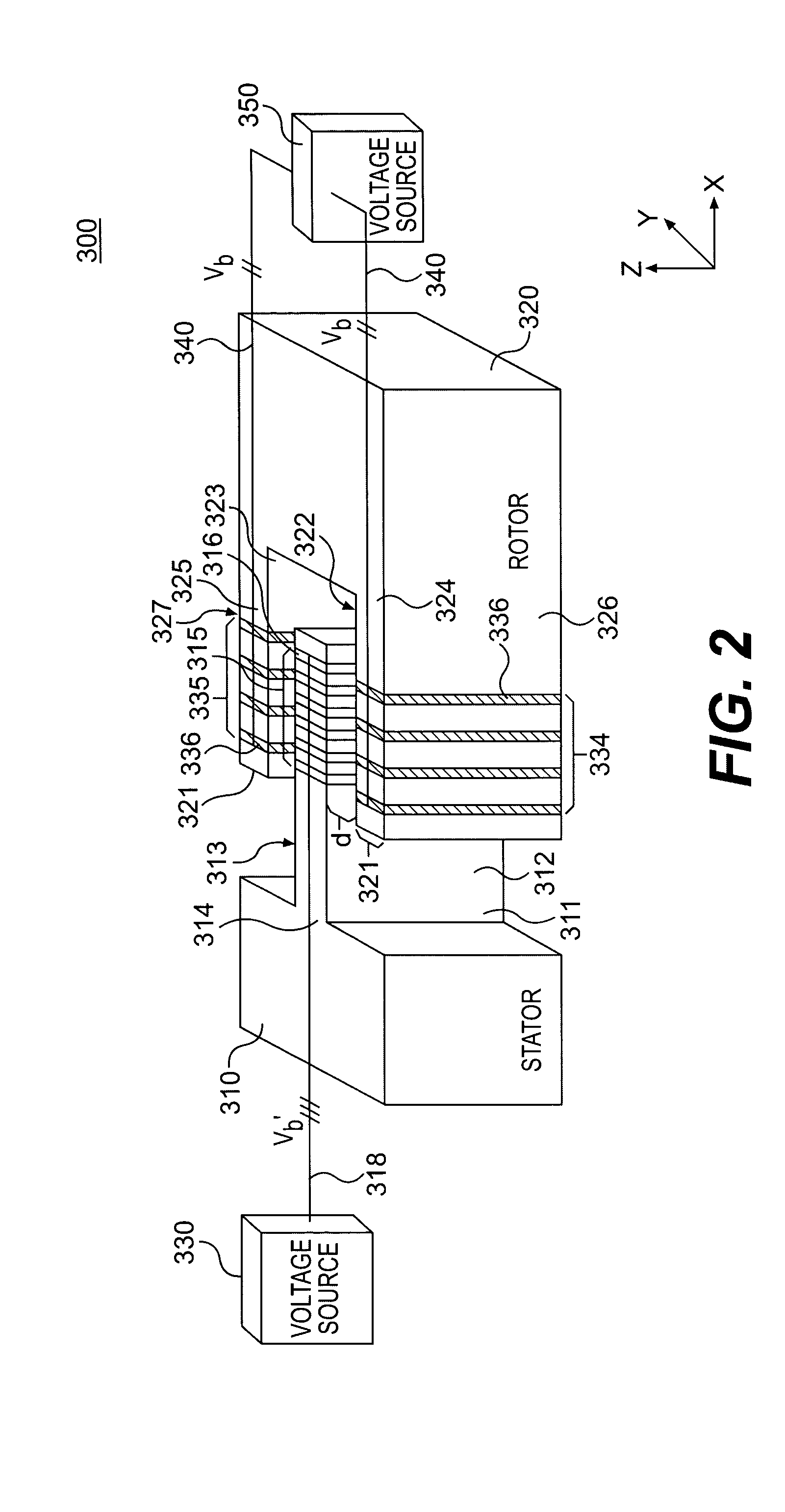

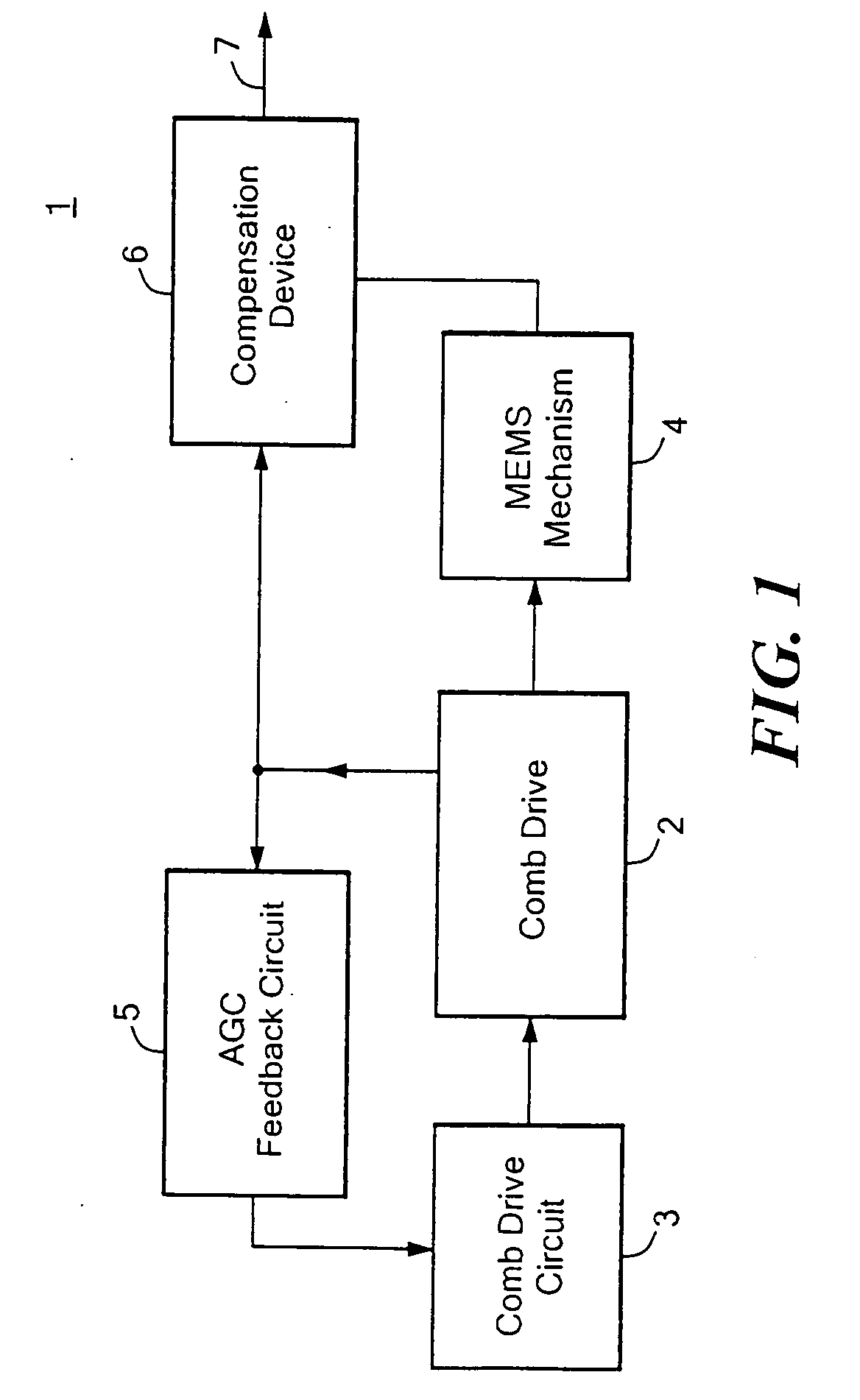

A force compensated comb drive for a microelectromechanical system includes a MEMS mechanism for providing an output signal representative of a physical quantity; a comb drive for actuating the MEMS mechanism; a comb drive circuit for providing a drive signal to the comb drive for developing a predetermined displacement applied by the comb drive to the MEMS mechanism; an automatic gain control responsive to a change in the force to provide a correction signal to the comb drive circuit to maintain the predetermined motion; and a compensation device responsive to the correction signal for adjusting the output signal of the MEMS mechanism to compensate for errors in the output signal due to a change in the predetermined force.

Owner:CHARLES STARK DRAPER LABORATORY

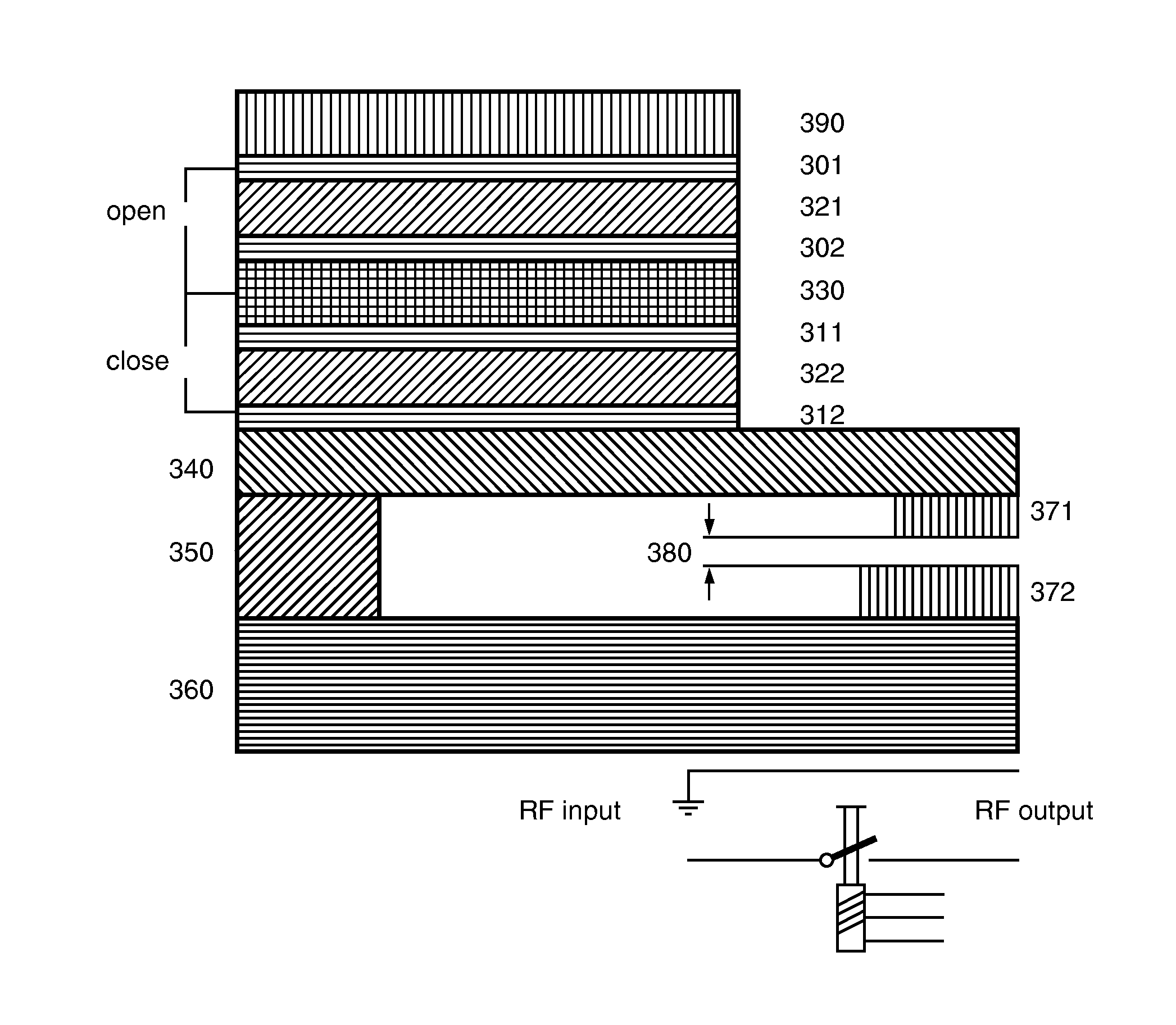

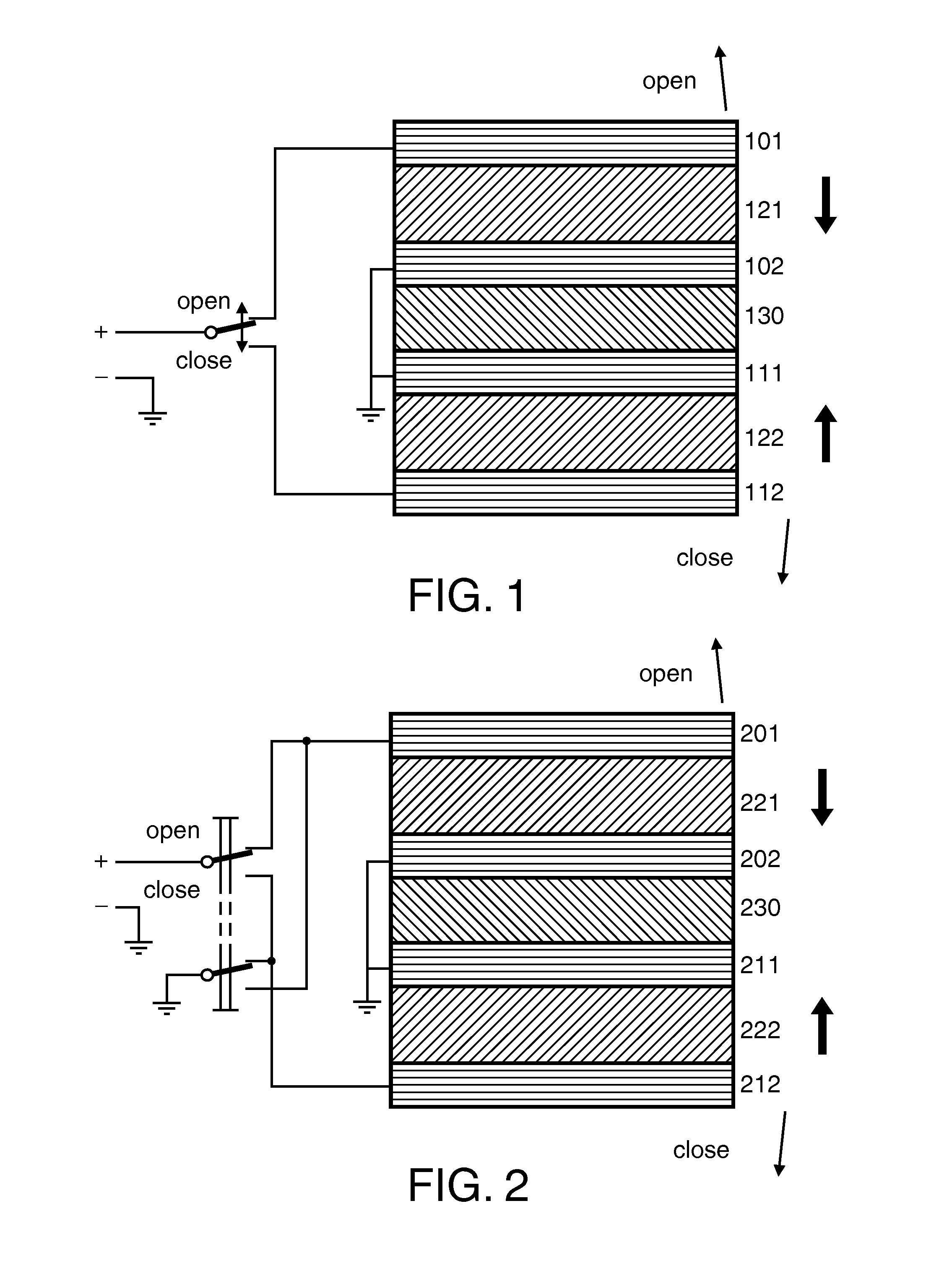

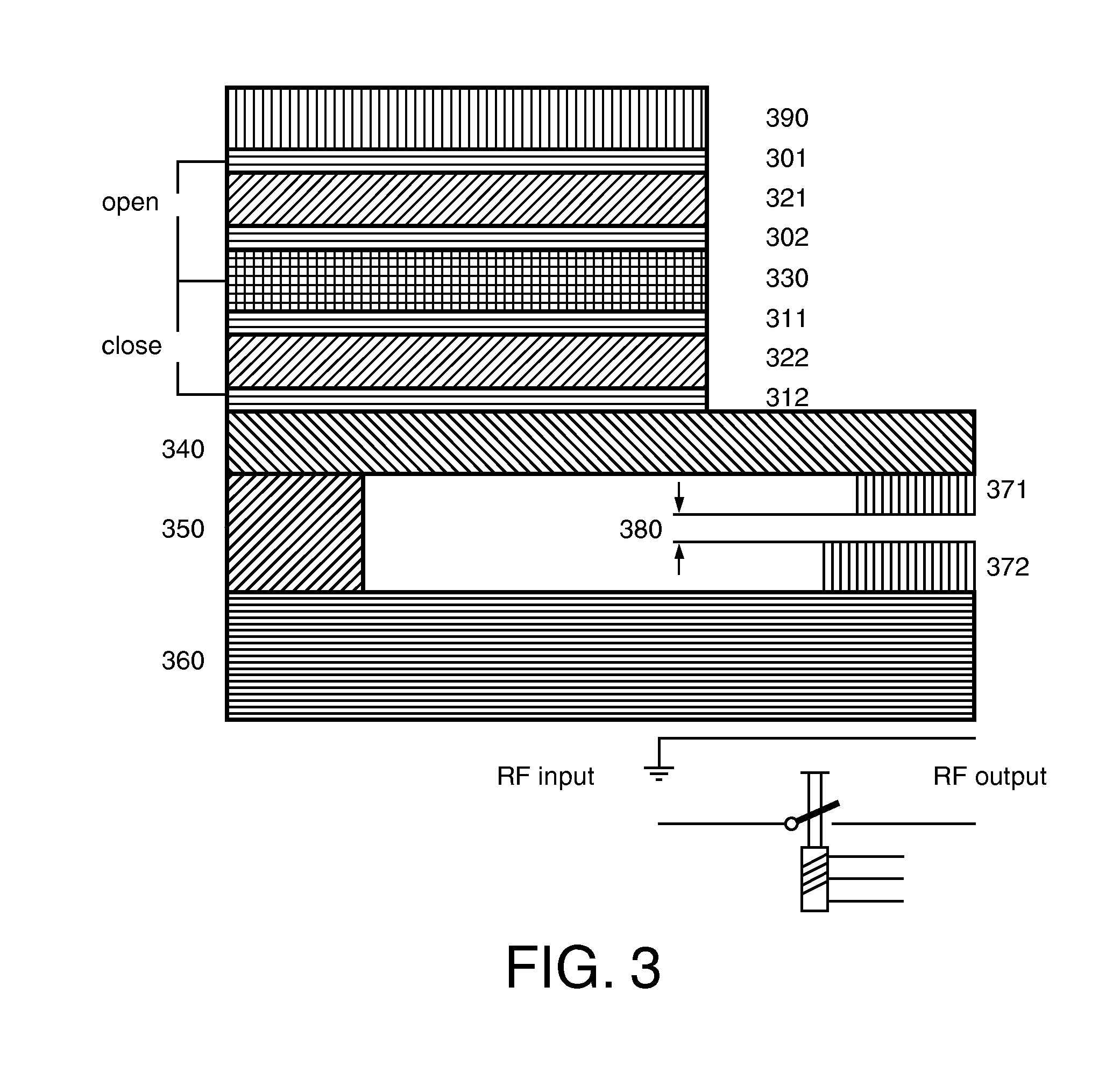

Piezoelectric bimorph switch

ActiveUS20110120843A1Enhance resilienceIncrease probabilityPiezoelectric/electrostrictive/magnetostrictive devicesElectrostrictive/piezoelectric relaysEngineeringMaterials science

The present invention relates to a piezoelectric bimorph switch, specifically a cantilever (single clamped beam) switch, which can be actively opened and closed. Piezoelectric bimorph switch are known from the prior art. Such a switch may be regarded as an actuator. Actuators are regarded as a subdivision of transducers. They are devices, which transform an input signal (mainly an electrical signal) into motion. Electrical motors, pneumatic actuators, hydraulic pistons, relays, comb drive, piezoelectric actuators, thermal bimorphs, Digital Micromirror Devices and electroactive polymers are some examples of such actuators. The switch of the invention comprises piezoelectric stack layers (121, 122), which form a symmetrical stack, wherein an electric field is always applied in the same direction as the poling direction of the piezoelectric layers.

Owner:NXP BV

Comb drive and leaf spring camera actuator

ActiveUS20150350499A1Television system detailsColor television detailsElectrical conductorComb drive

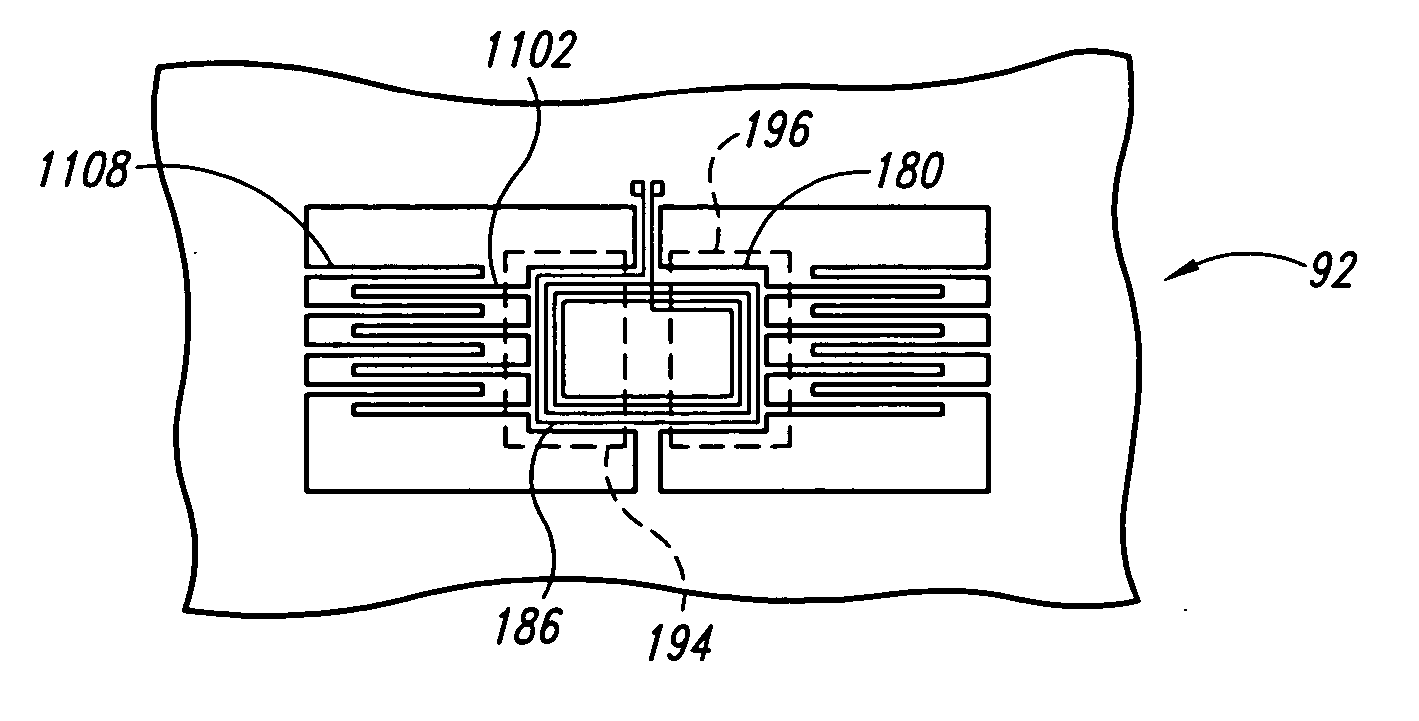

An actuator package includes a base frame member and an image sensor. The actuator package further includes a plurality of comb drive actuators affixed to the base frame member by a plurality of respective electrically conductive leaf spring flexures. The respective electrically conductive leaf spring flexures provide an electrical current conductive path between the image sensor and conductors mounted on the base frame member, and the plurality of comb drive actuators is arranged to control the motion of the image sensor in multiple degrees of freedom relative to the fixed structure. Each of the plurality of comb drive actuators includes at least two independent comb drive array portions. At least one of the comb drive array portions generates force tending to move the image sensor out of a plane of the base frame member.

Owner:APPLE INC

RF MEMS switch with spring-loaded latching mechanism

Apparatus for a micro-electro-mechanical switch that provides for latching switching action. The switch has a cantilever arm disposed on a substrate that can be moved in orthogonal directions for latching and unlatching. To latch the switch, the cantilever arm is moved back by a comb-drive actuator and then pulled down by electrodes disposed on the substrate and the cantilever arm. The comb-drive actuator switch is then released and the cantilever arm moves forward to be captured by a dove-tail structure on the substrate. When the voltage to the electrodes on the substrate and the cantilever arm is removed, the cantilever arm is held in place by the dove-tail structure. The switch is unlatched by actuating the comb-drive actuator to move the cantilever arm away from the dove-tail structure. The cantilever arm will then pop up once it is released from the dove-tail structure.

Owner:HRL LAB

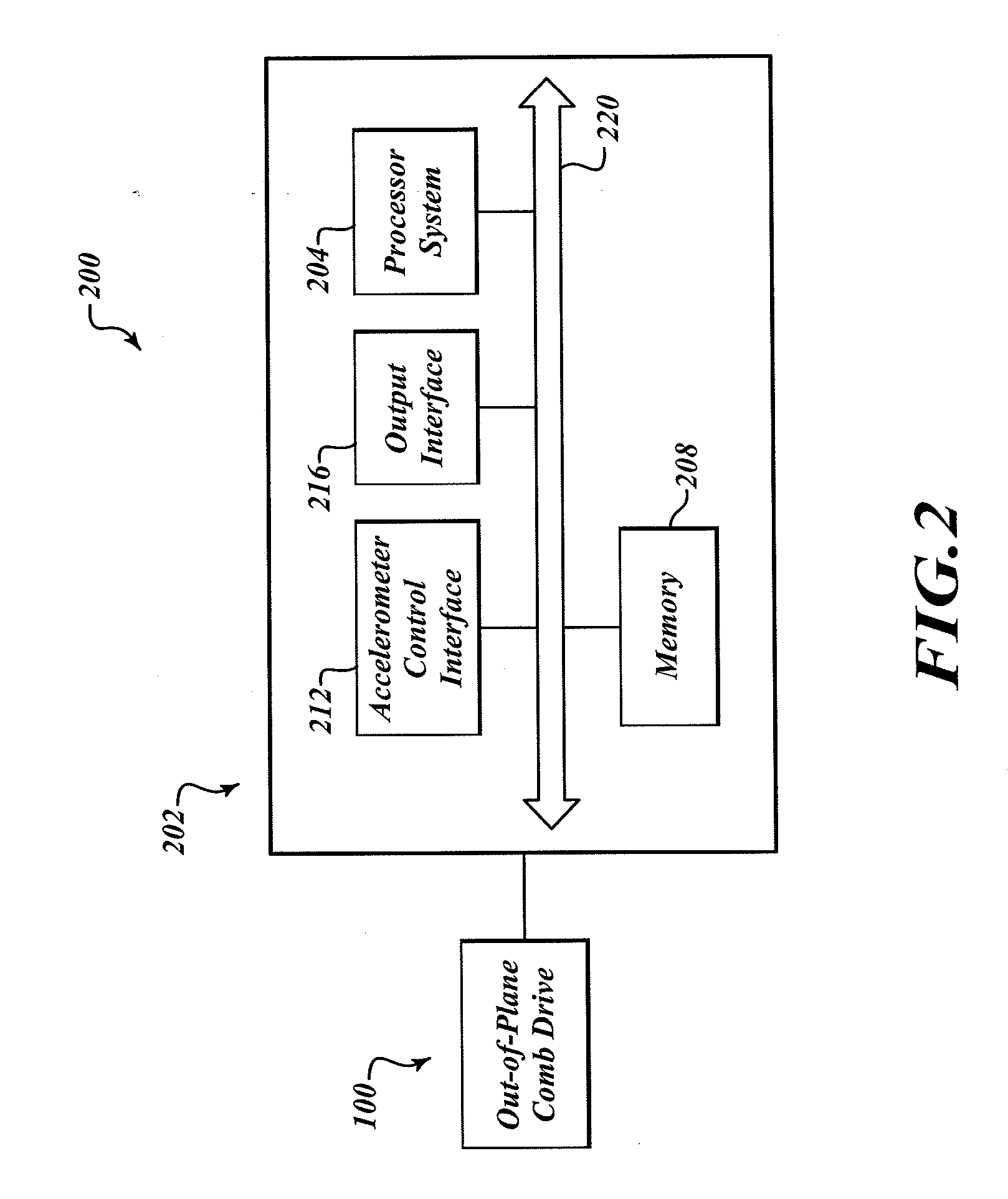

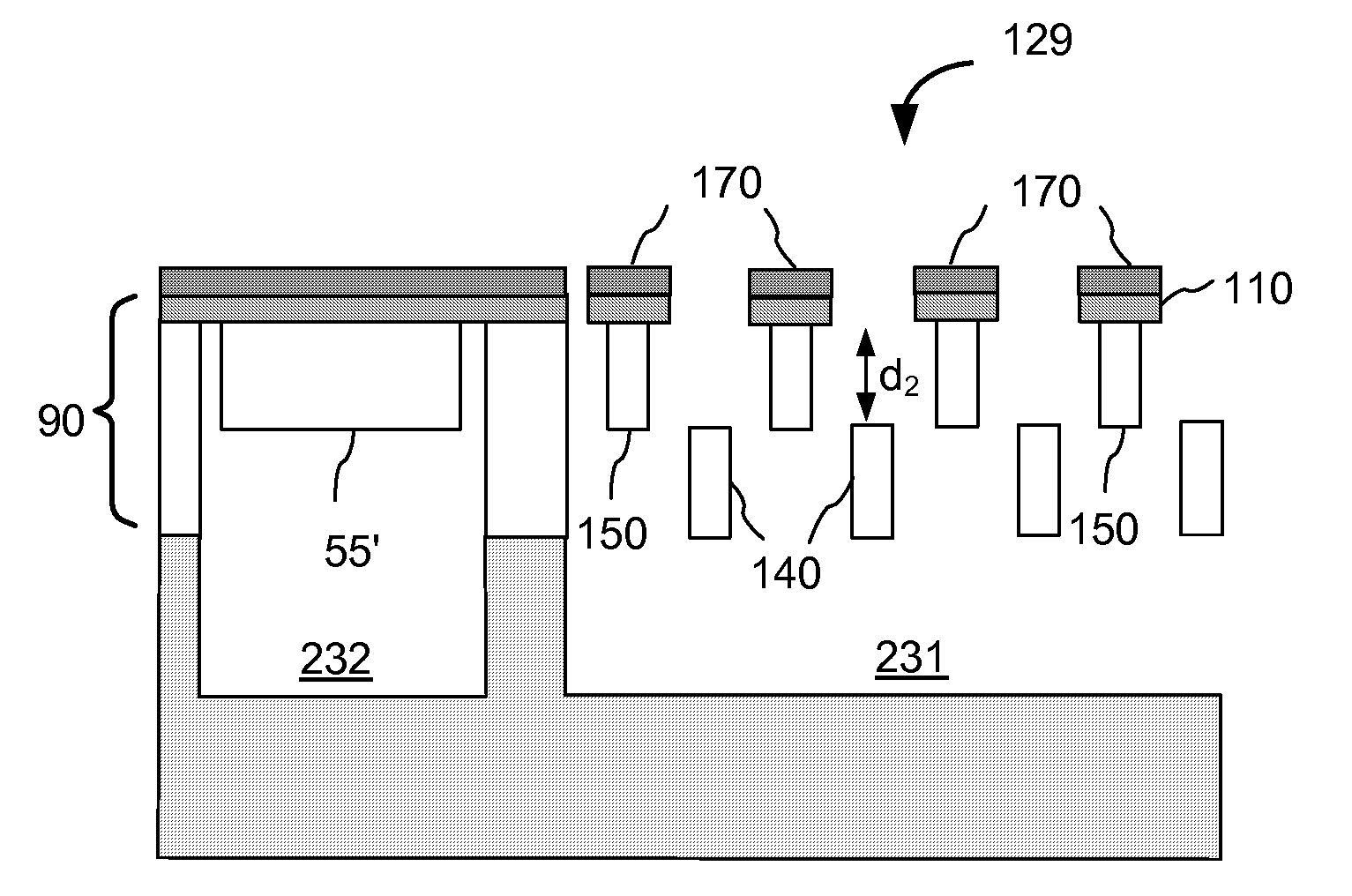

Bidirectional, out-of-plane, comb drive accelerometer

ActiveUS20100326191A1Acceleration measurement using interia forcesManufacturing dynamo-electric machinesAccelerometerComb drive

A bi-directional, out-of-plane electrostatic comb drive apparatus including two electrically independent sets of stator comb tines; and a method for fabricating an out-of-plane comb drive with stacked sets of stator comb tines. A first set of stator comb tines is offset from a second set of stator comb tines. A set of rotor comb tines interleaves with both sets of stator comb tines. A first voltage applied to the first set of stator comb tines operates to pull the rotor tines toward the first set of stator comb tines. A second voltage applied to the second set of stator comb tines operates to pull the rotor tines toward the second set of stator comb tines, enabling bi-directional operation. A fabrication method is disclosed that enables fabrication of the first and second sets of stator comb tines that are mechanically and electrically independent and interleaved by the rotor comb tines.

Owner:HONEYWELL INT INC

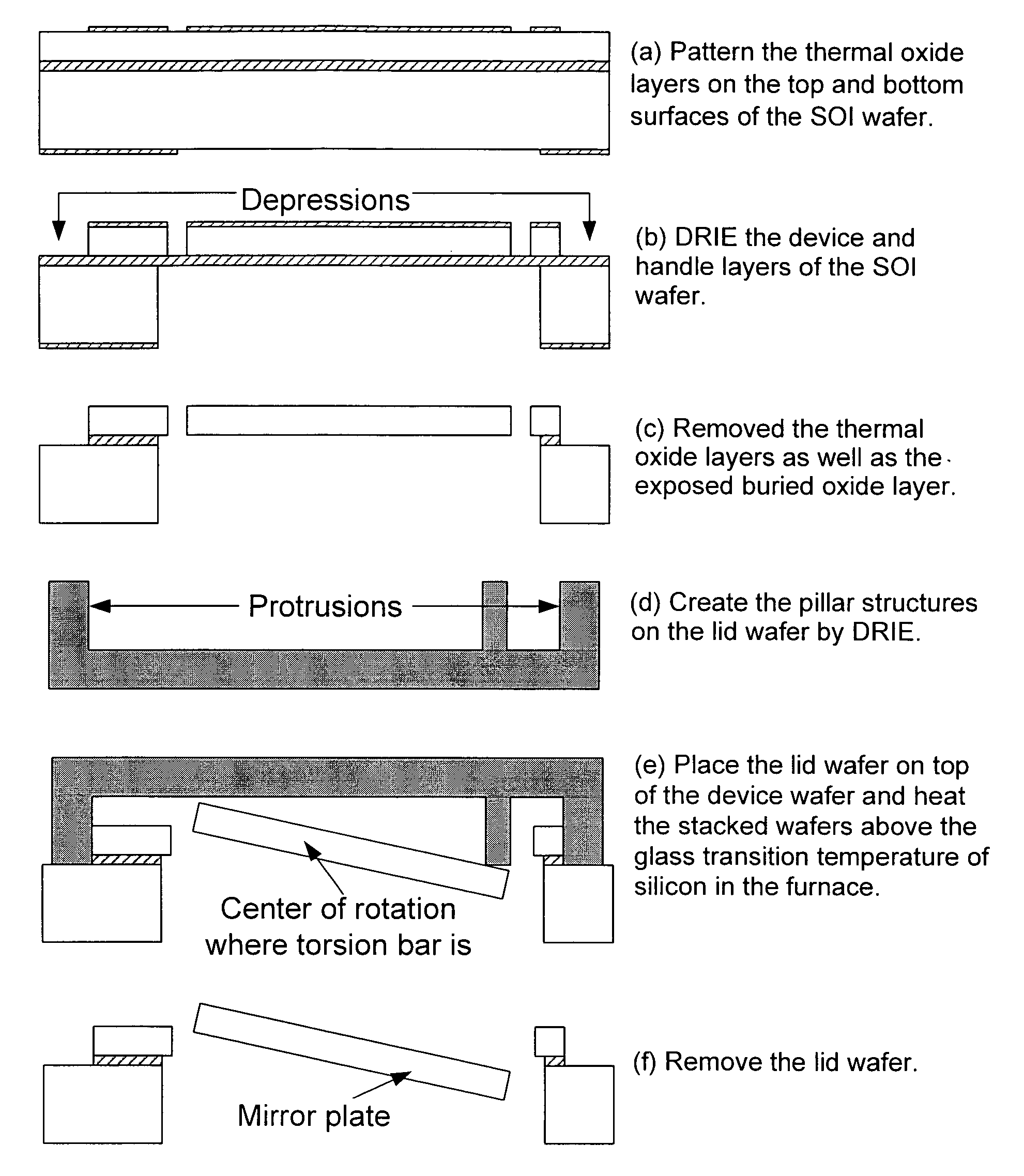

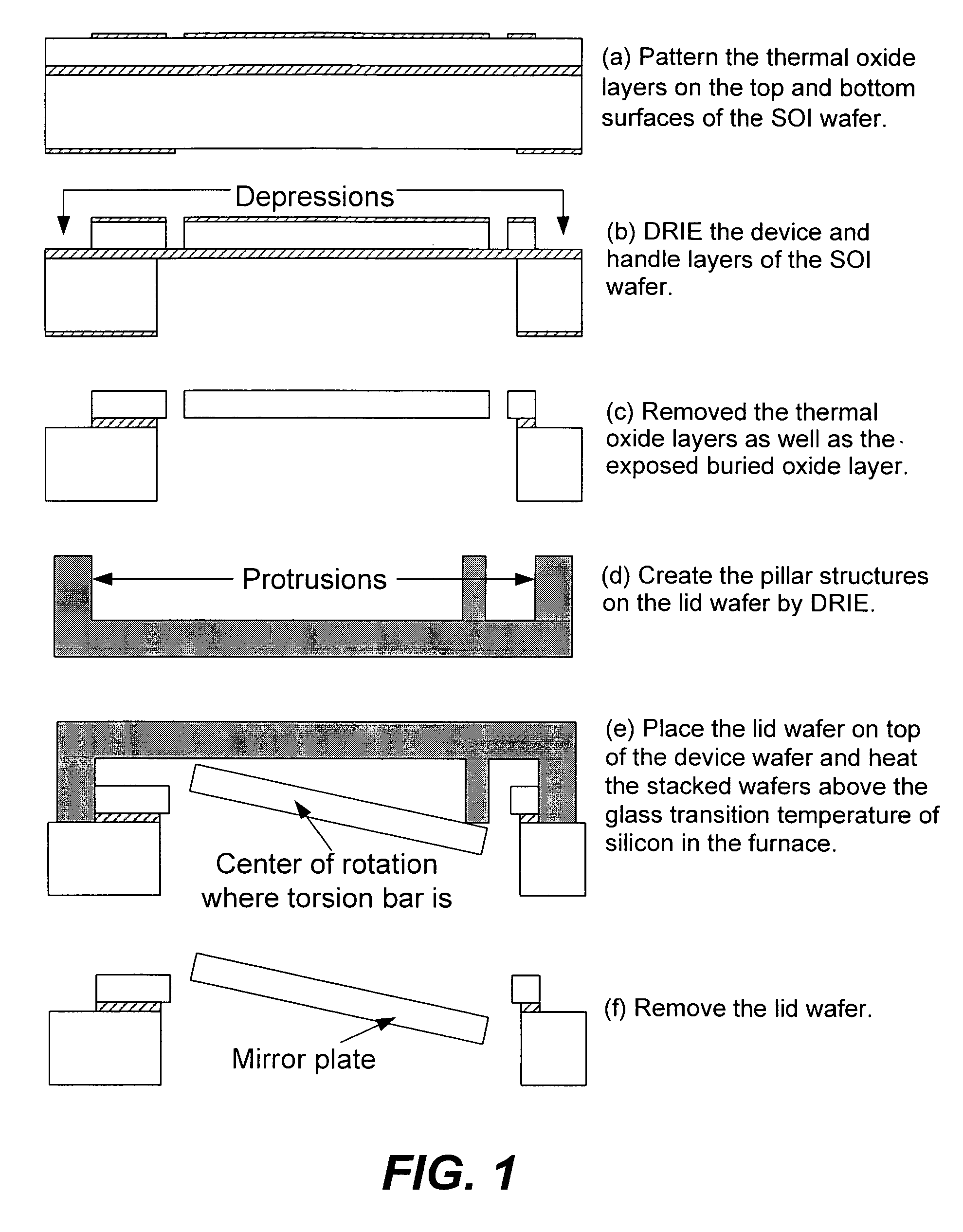

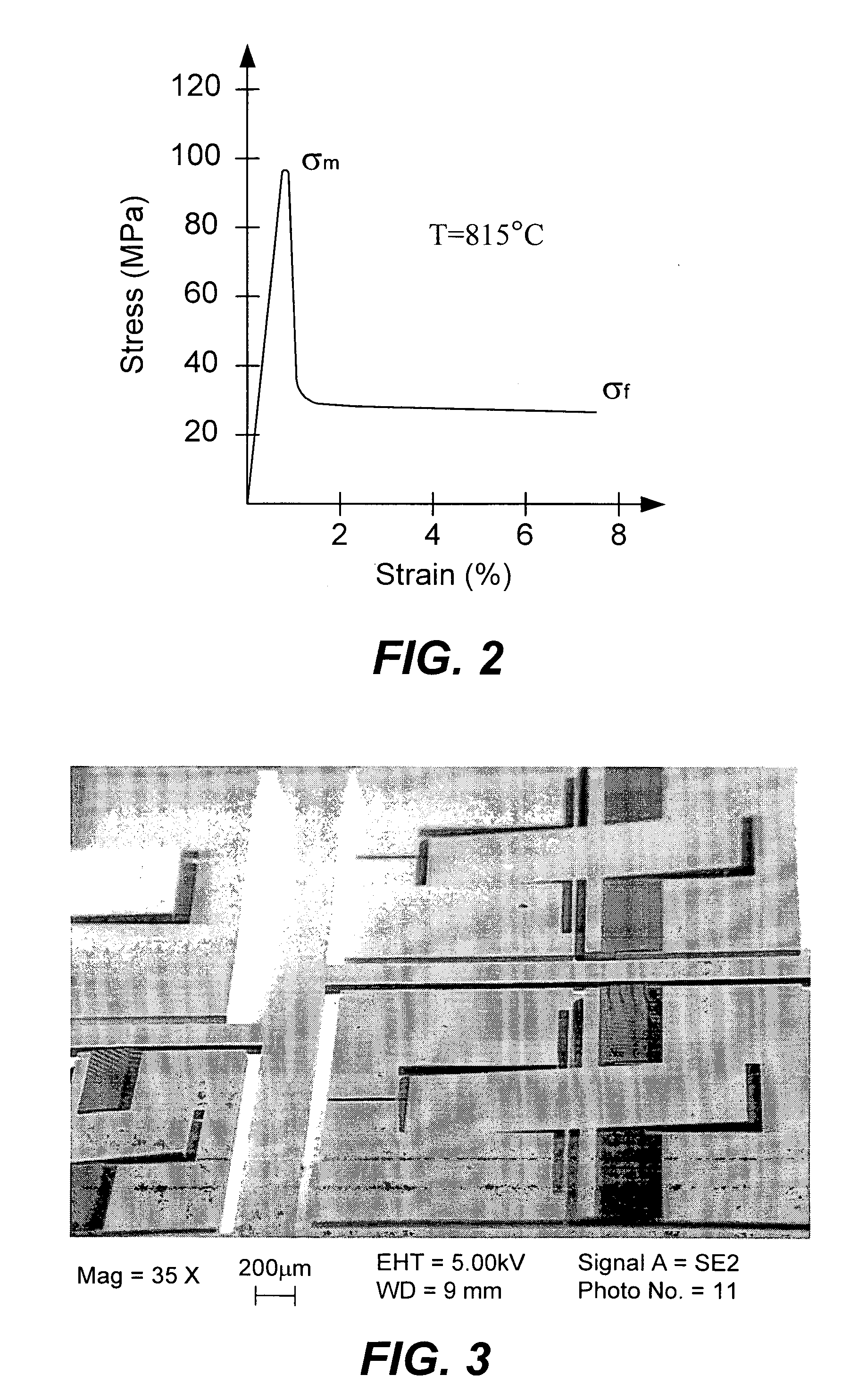

Microfabricated vertical comb actuator using plastic deformation

A microfabricated actuator of the vertical comb-drive (AVC) type or staggered vertical comb-drive type for torsional or linear applications includes torsion springs which permit self-aligned deformation of the device (micromirror) structure of the actuator through the heating of the torsional springs to plasticity. The torsional springs can include perpendicular-beam springs or double folded beams which allow axial movement of the spring when heated. Heating of the springs can be by bulk heating of the actuator structure or by Joule heating to the torsional springs by passing an electrical current therethrough.

Owner:RGT UNIV OF CALIFORNIA

Force compensated comb drive

ActiveUS7302848B2Eliminate errorsMany errorAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsDriver circuitComb drive

A force compensated comb drive for a microelectromechanical system includes a MEMS mechanism for providing an output signal representative of a physical quantity; a comb drive for actuating the MEMS mechanism; a comb drive circuit for providing a drive signal to the comb drive for developing a predetermined displacement applied by the comb drive to the MEMS mechanism; an automatic gain control responsive to a change in the force to provide a correction signal to the comb drive circuit to maintain the predetermined motion; and a compensation device responsive to the correction signal for adjusting the output signal of the MEMS mechanism to compensate for errors in the output signal due to a change in the predetermined force.

Owner:CHARLES STARK DRAPER LABORATORY

MEMS device with an angular vertical comb actuator

ActiveUS7817331B2Acceleration measurement using interia forcesSemiconductor/solid-state device manufacturingComb driveActuator

A vertical comb electro-static actuator for rotating a micro-electro-mechanical micro-mirror device about a tilt axis or rotation. The rotor comb fingers of the comb drive extend from a sub-frame of the micro-mirror, which includes a prestressed layer for bending the rotor comb fingers at an angle to the substrate and mirrored platform, enabling the platform, the hinges, the rotor comb fingers and the stator comb fingers to be formed in the same layer, i.e. the same etching step.

Owner:LUMENTUM OPERATIONS LLC

Staggered Vertical Comb Drive Fabrication Method

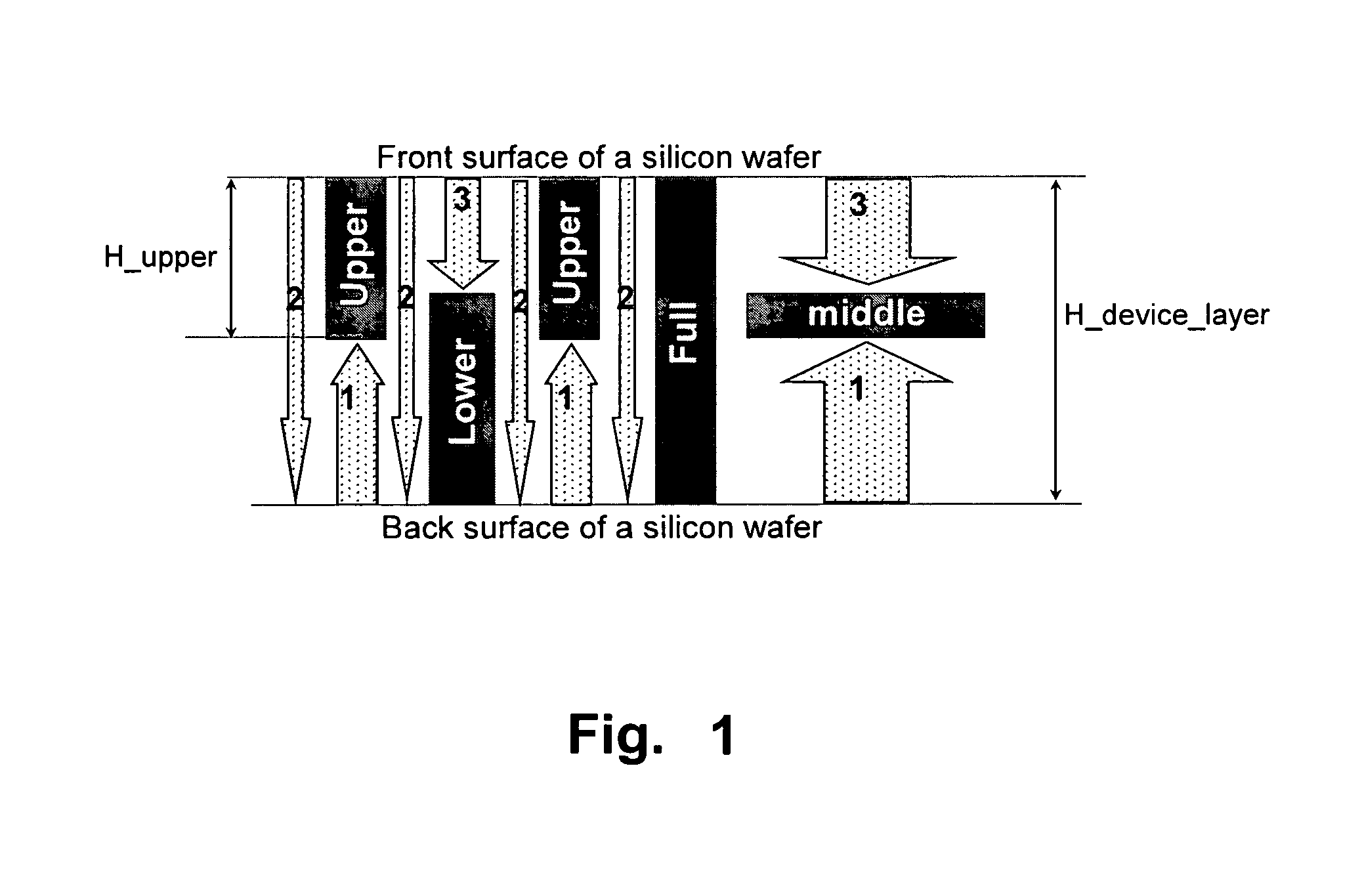

The invention relates to a method of fabrication of staggered vertical comb drive actuators with relaxed lateral alignment tolerances. A device layer of a wafer is first etched from a front side using a self-aligned two-layer mask to define interdigited fingers of both moving and stationary combs. A second etch step is used for vertically thinning one of the two sets of fingers by selectively removing their top portions. The front side of the wafer is then bonded to a carrier wafer. The wafer is then selectively etched from the back side of the device layer so as to remove lower portions of the second set of fingers, thereby forming interdigited moving and stationary combs having vertically offset fingers.

Owner:LUMENTUM OPERATIONS LLC

Rotary-type comb-drive actuator and variable optical attenuator using the same

InactiveUS20050264131A1Reduce the driving voltageRequired driving distanceCoupling light guidesPiezoelectric/electrostrictive device detailsComb driveEngineering

The present invention relates to an actuator and optical attenuator using the actuator. The rotary-type comb-drive actuator includes a substrate, a movable electrode, a drive electrode, one or more vertical springs, one or more vertical spring anchors, a horizontal spring and a horizontal spring anchor. The movable electrode is arranged on a plane of the substrate to be movable in parallel to the substrate plane, and formed to have a predetermined length so as to have a comb-shaped electrode comprised of a plurality of fingers. The drive electrode is formed to have a length corresponding to that of the movable electrode, and formed to have a comb-shaped electrode that is comprised of a plurality of fingers and arranged to be interdigitated with the comb-shaped electrode of the movable electrode. The vertical springs are arranged in parallel to the substrate, and connected to be perpendicular to the movable electrode on both sides of a first end of the movable electrode. The vertical spring anchors are connected to the vertical springs to support the vertical springs. The horizontal spring has a main part connected in parallel to a longitudinal direction of the movable electrode. The horizontal spring anchor is connected to the horizontal spring to support the horizontal spring, and fixed on the substrate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

MEMS gyroscopes with reduced errors

ActiveUS9212908B2Reducing drive-induced Coriolis accelerometer offsetAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeAccelerometer

In comb drive vibratory gyroscopes, drive-induced Coriolis accelerometer offset is effectively canceled by demodulating the output during equal times of in-phase and anti-phase drive of the shuttle with respect to the velocity signal used for angular rate demodulation. This reduces or eliminates the corresponding thermal and die-stress effects otherwise needing calibration.

Owner:ANALOG DEVICES INC

Method of fabricating an RF MEMS switch with spring-loaded latching mechanism

ActiveUS7653985B1Contact member manufacturingElectrostatic/electro-adhesion relaysComb driveEngineering

Disclosed are methods for fabricating a micro-electro-mechanical switch. The switch has a cantilever arm disposed on a substrate that can be moved in orthogonal directions for latching and unlatching. For latching, the cantilever arm is moved back by a comb-drive actuator and then pulled down by electrodes disposed on the substrate and the cantilever arm. The comb-drive actuator switch is then released and the cantilever arm moves forward to be captured by a dove-tail structure on the substrate. When the voltage is removed, the cantilever arm is held in place by the dove-tail structure. The switch is unlatched by actuating the comb-drive actuator to move the cantilever arm away from the dove-tail structure. The cantilever arm will then pop up once it is released from the dove-tail structure.

Owner:HRL LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com