Patents

Literature

91 results about "Process compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process compensation. Compensation processing allows you to calculate new base compensation amounts for your employees based on equity adjustments, merit increase targets, and performance. This topic covers the basic flow of compensation processing for fixed compensation plans without factoring an employee's performance.

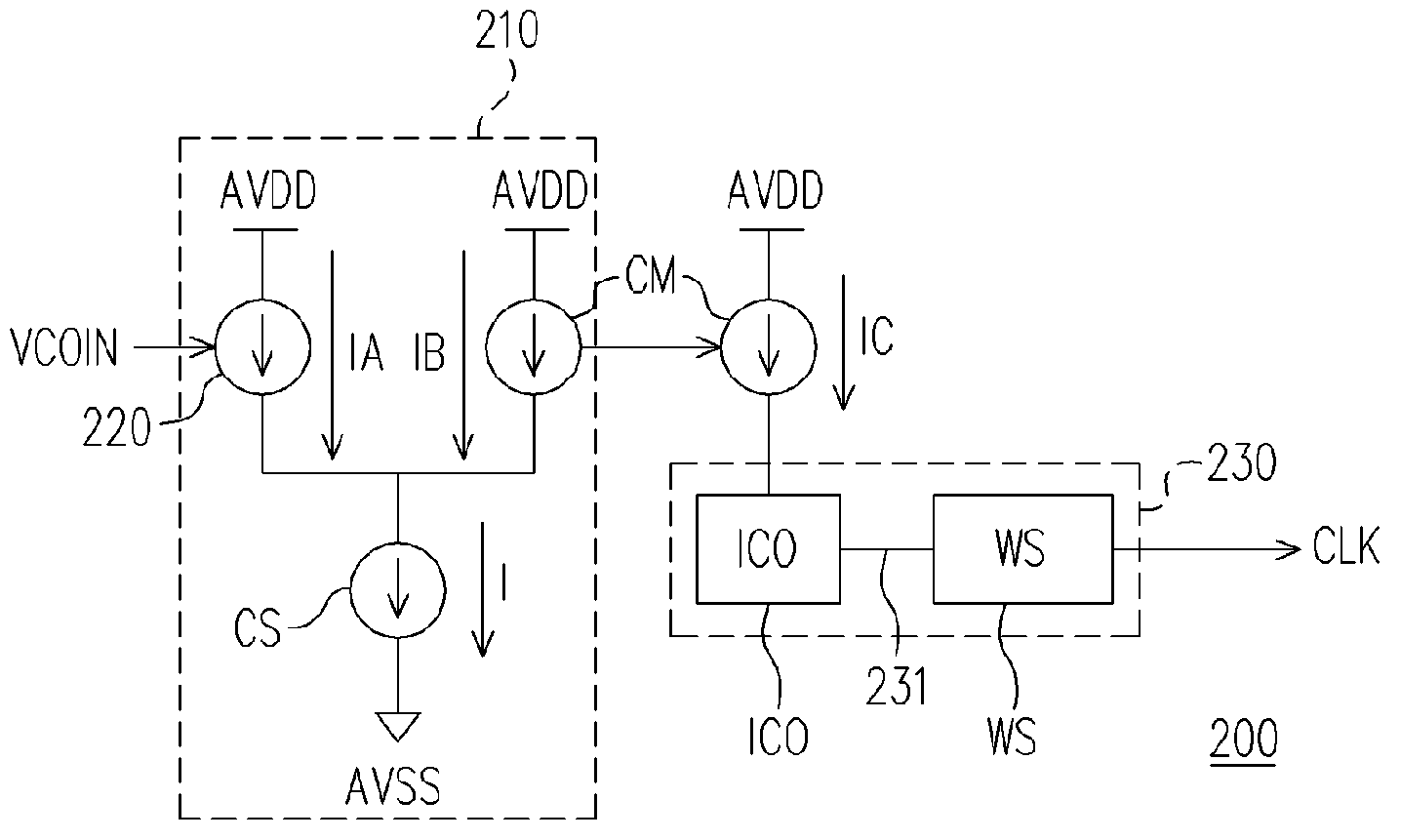

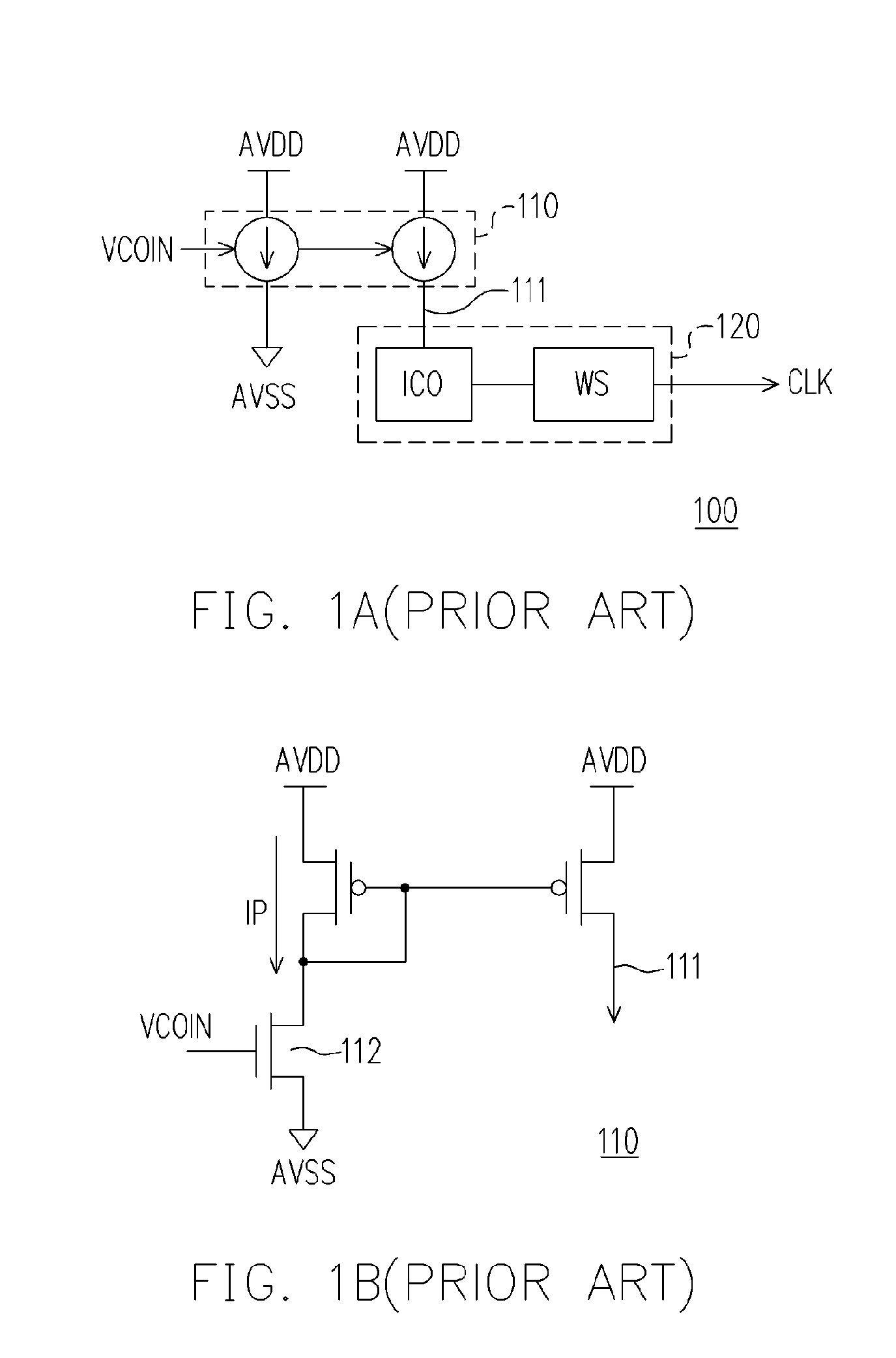

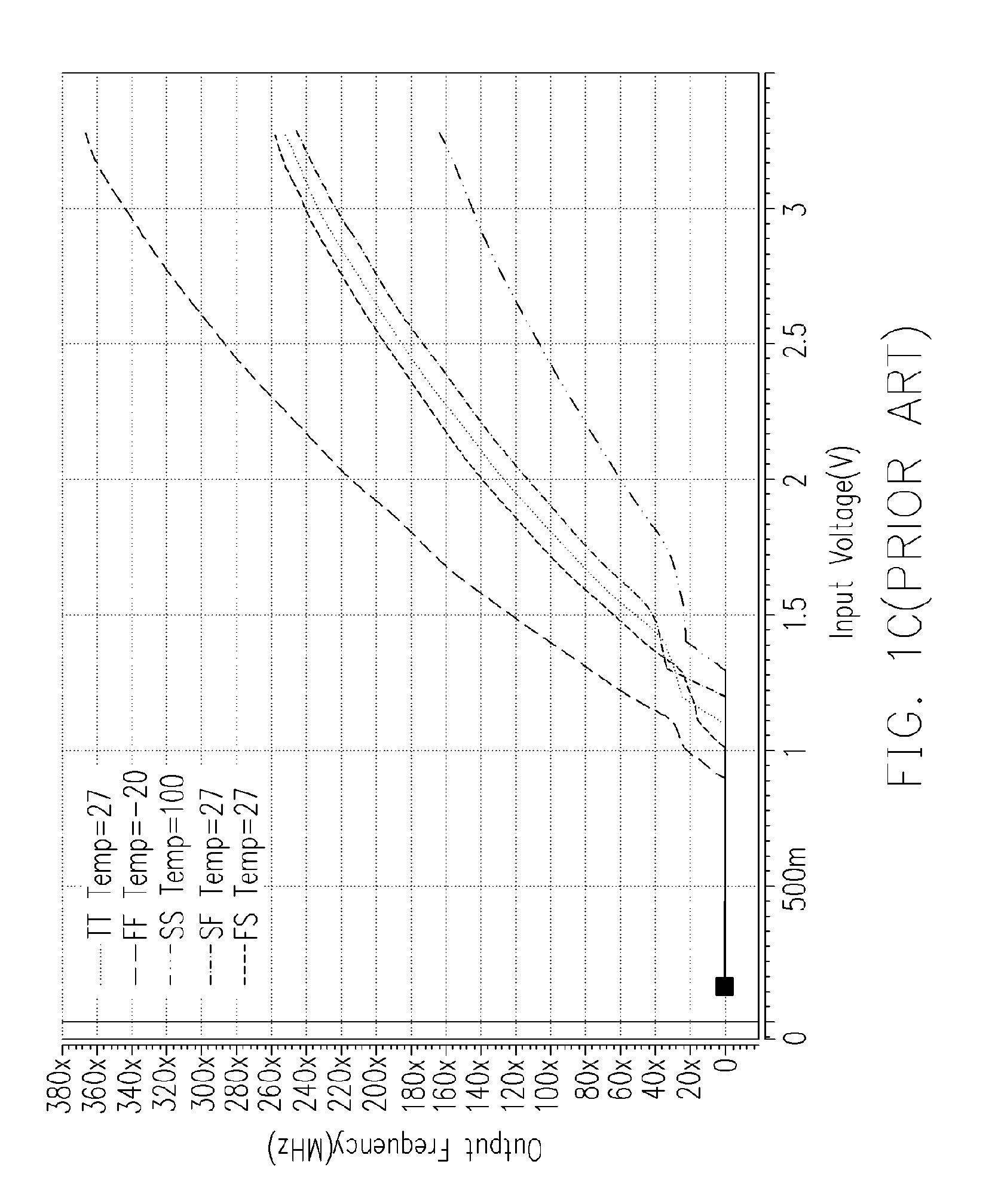

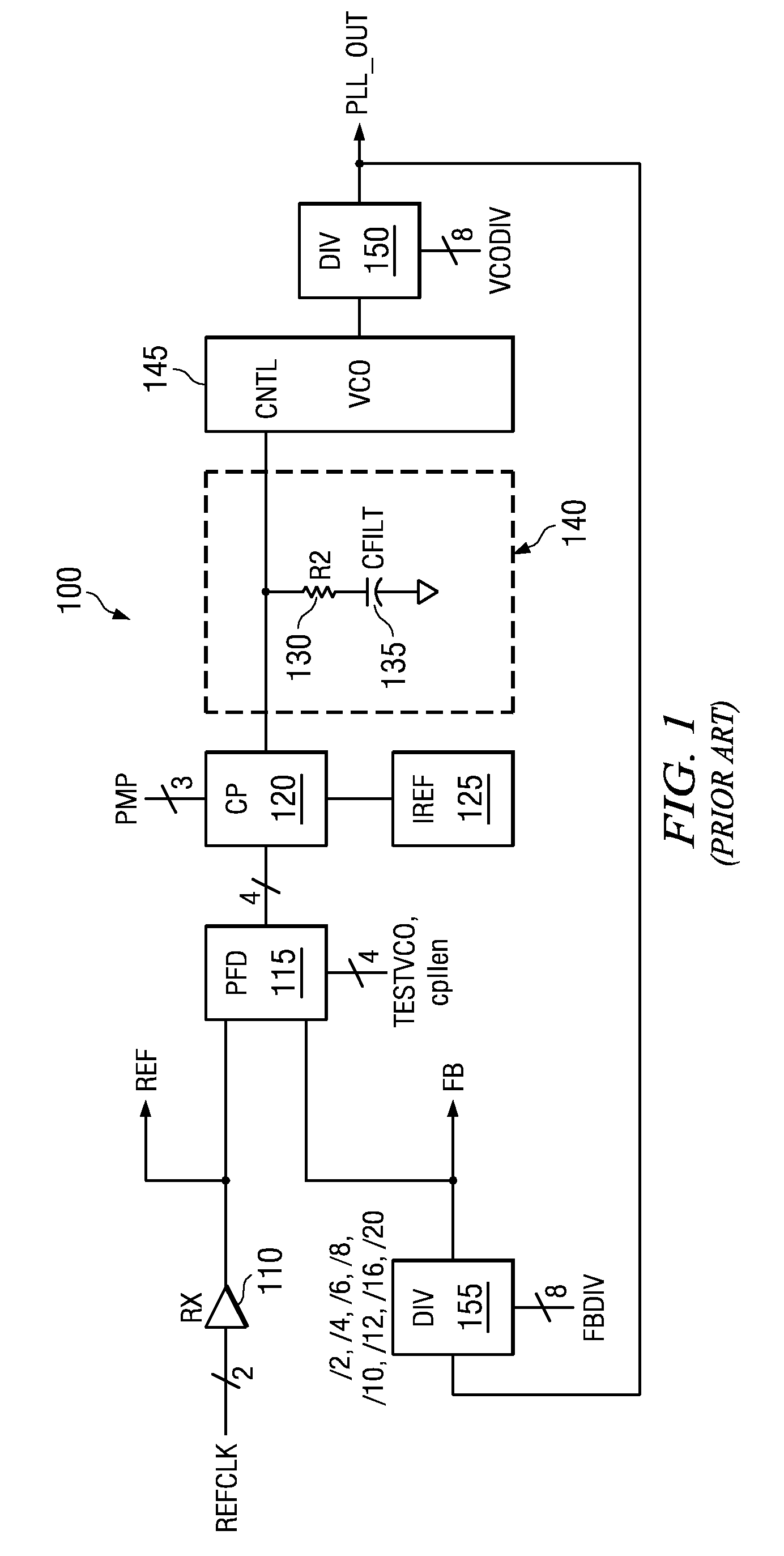

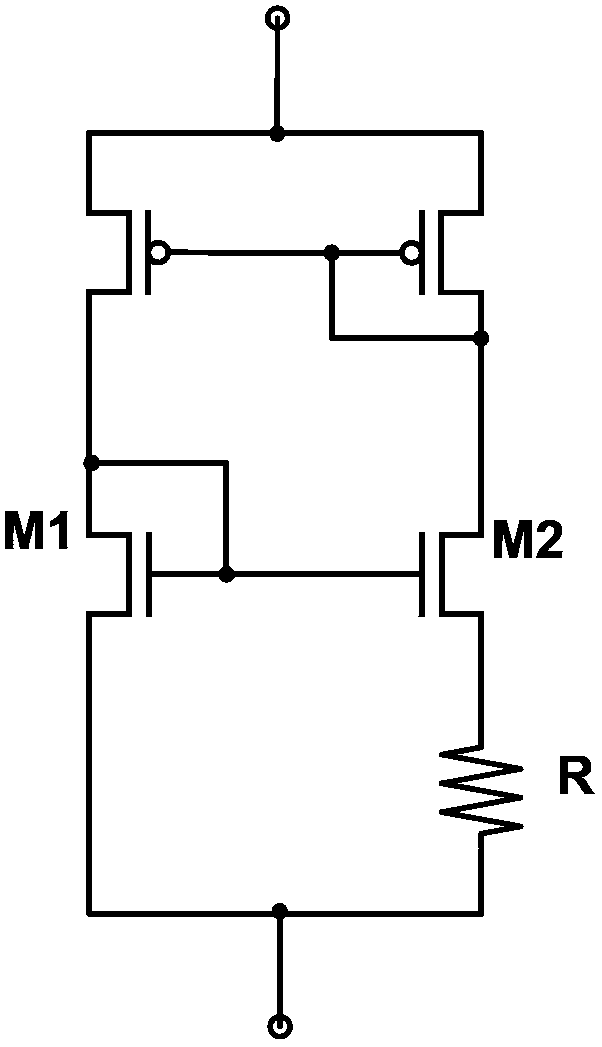

Voltage controlled oscillator with temperature and process compensation

InactiveUS7463101B2Reduce manufacturing costVacuum tubesPulse automatic controlReference currentEngineering

Owner:SUNPLUS TECH CO LTD

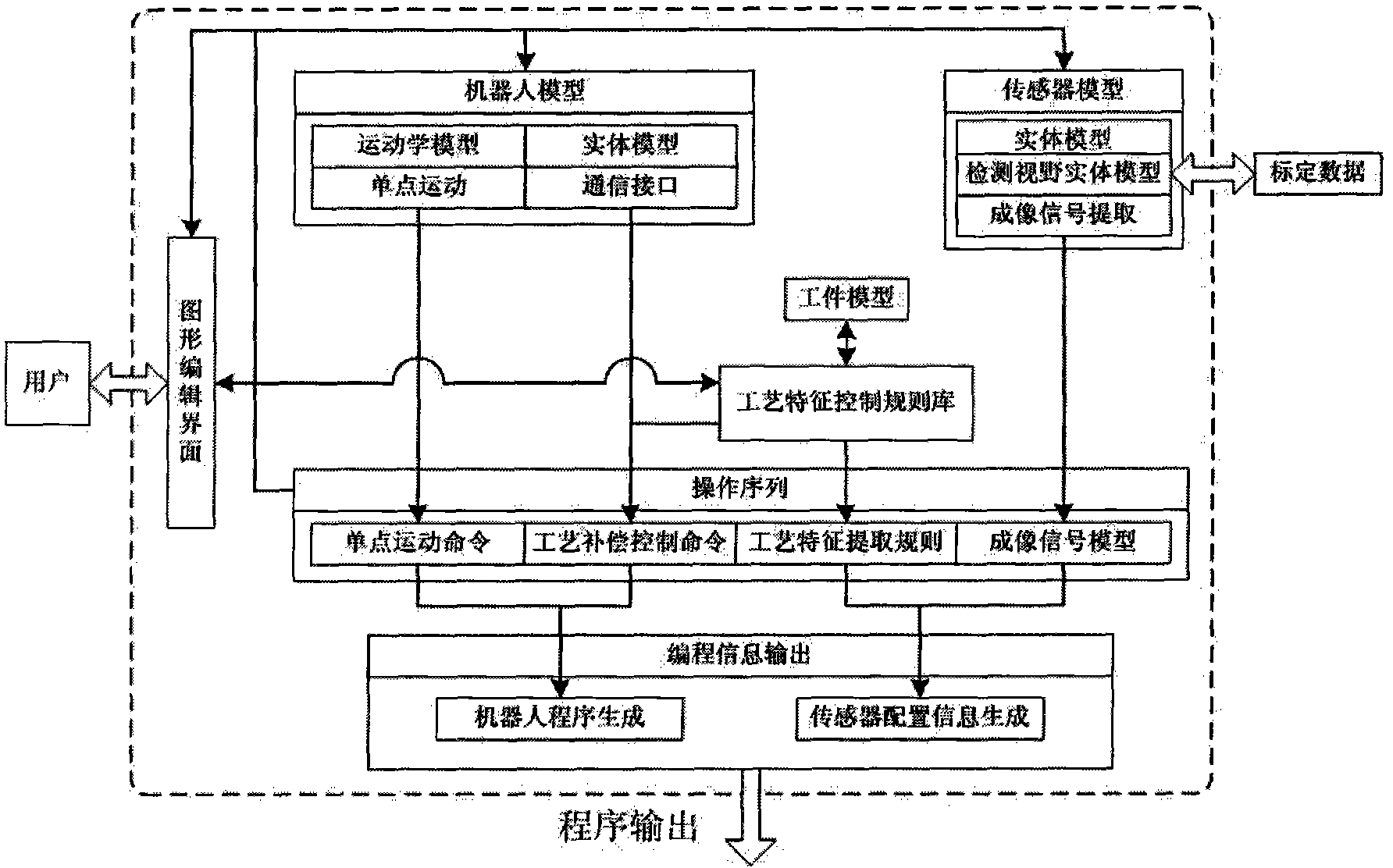

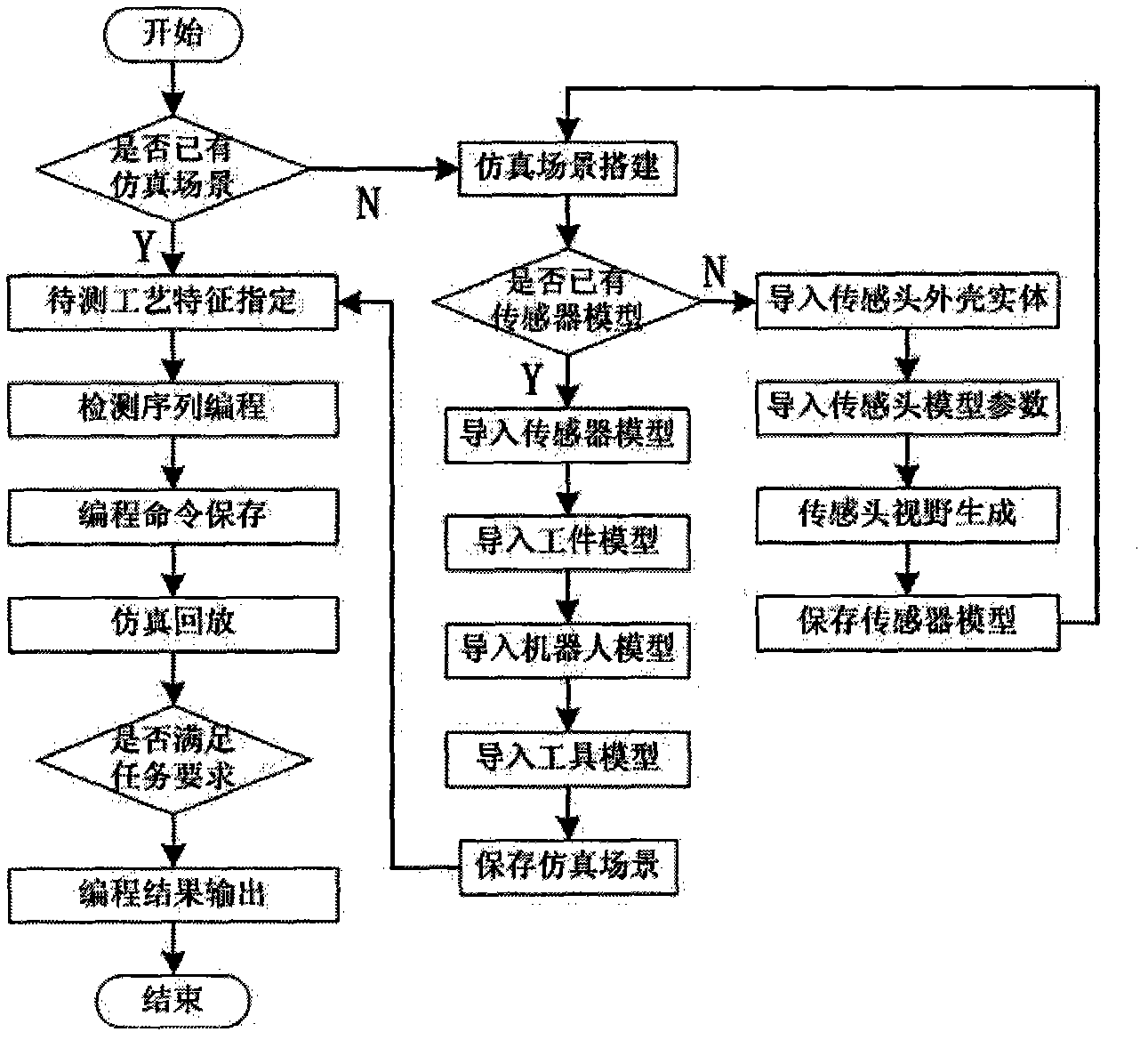

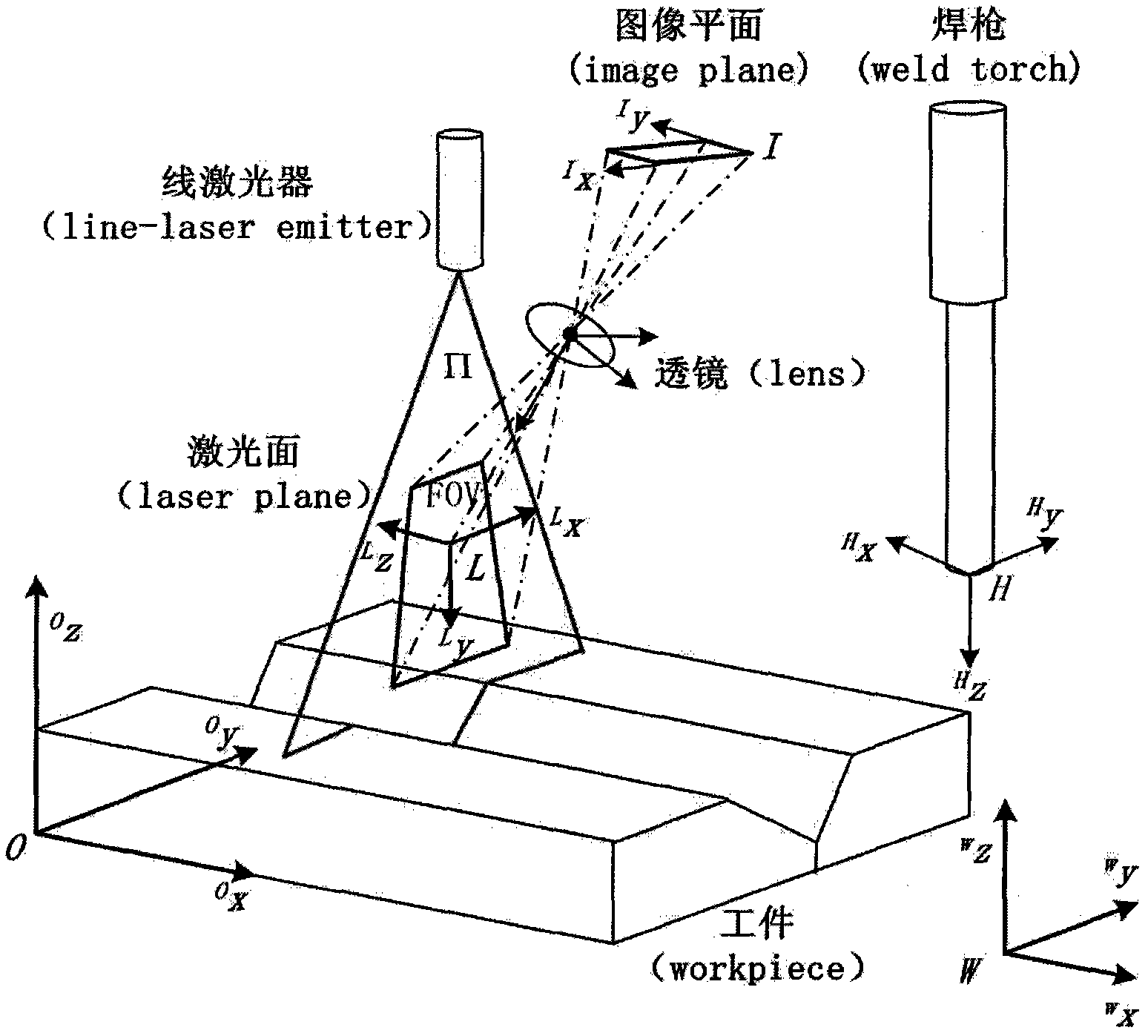

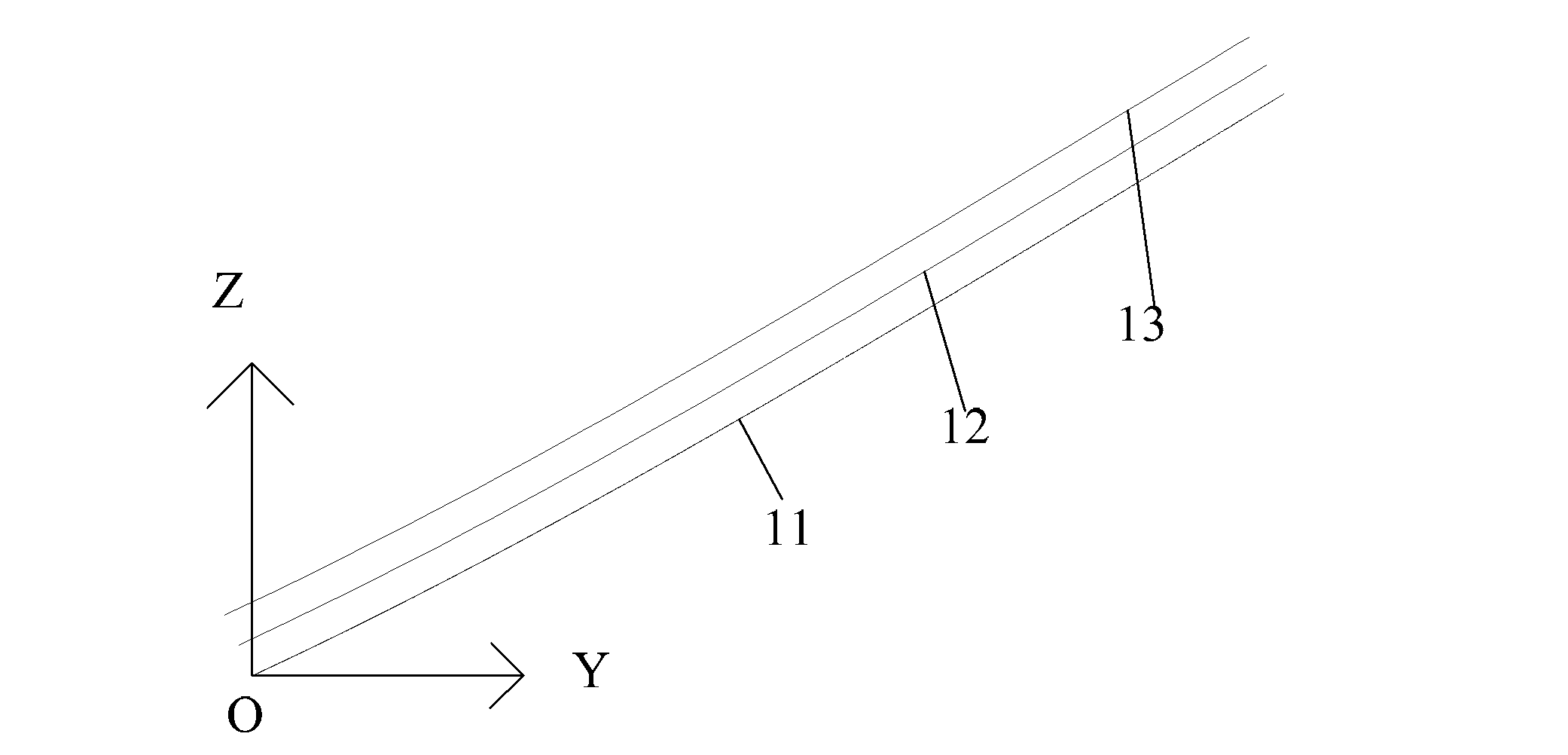

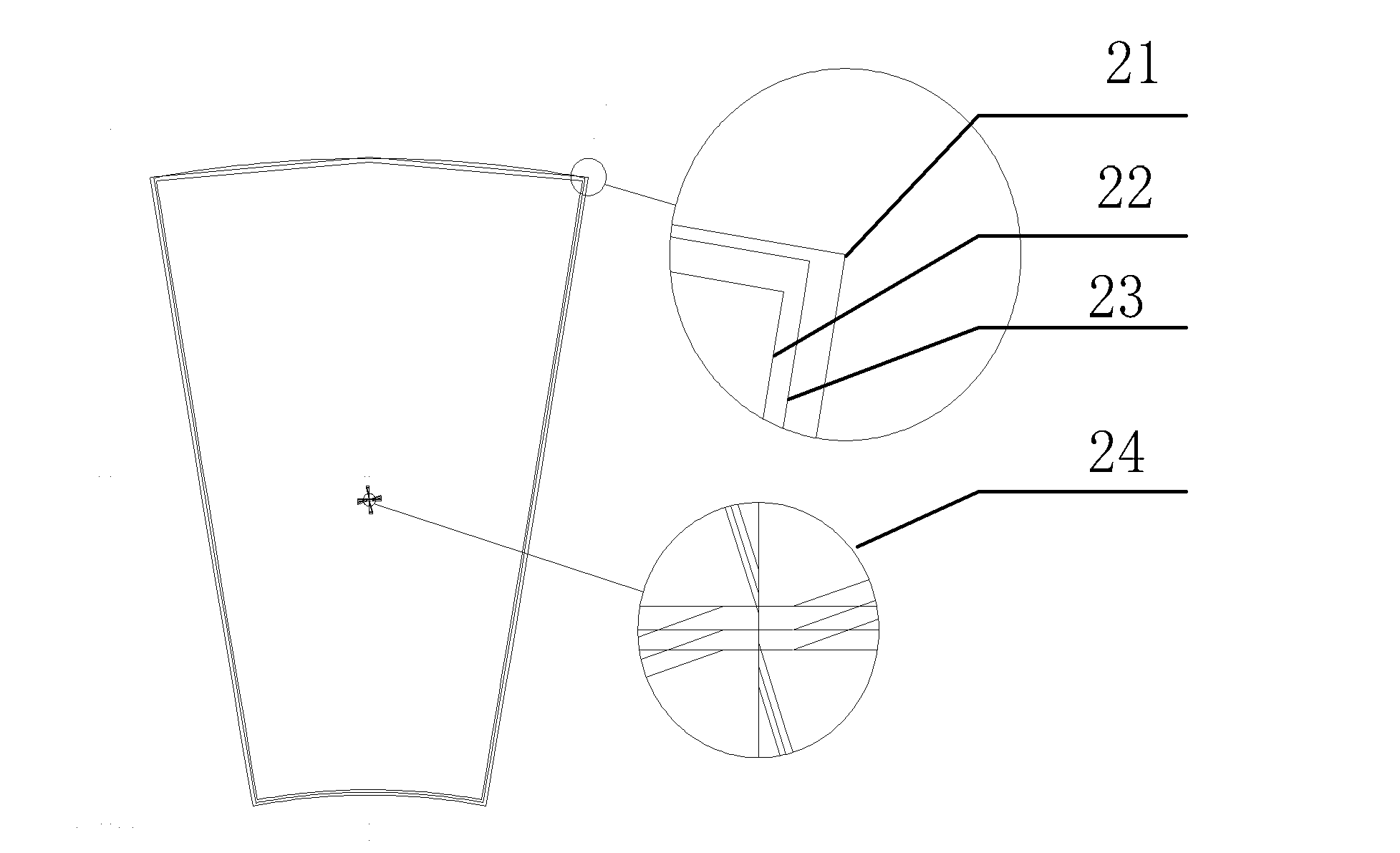

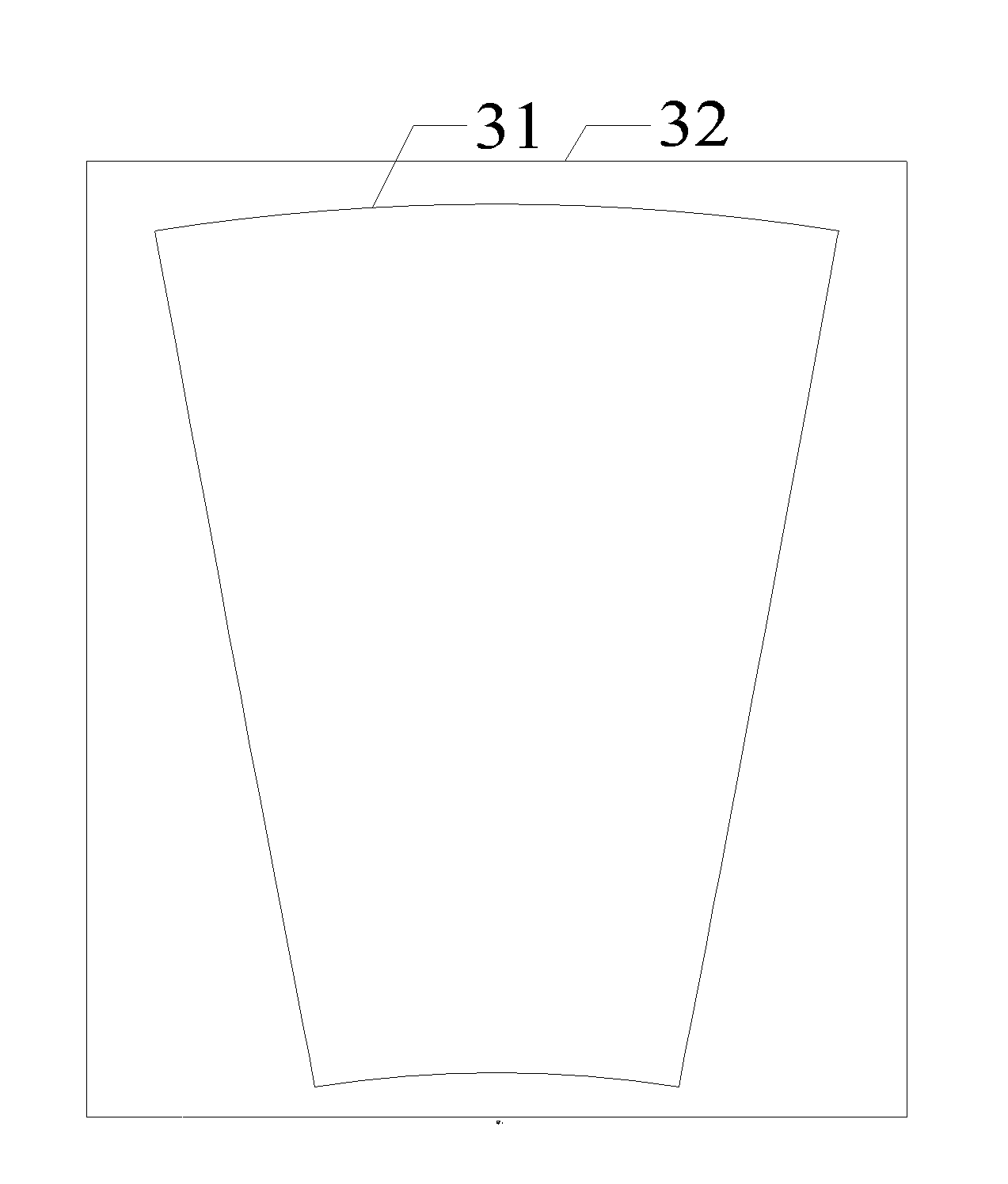

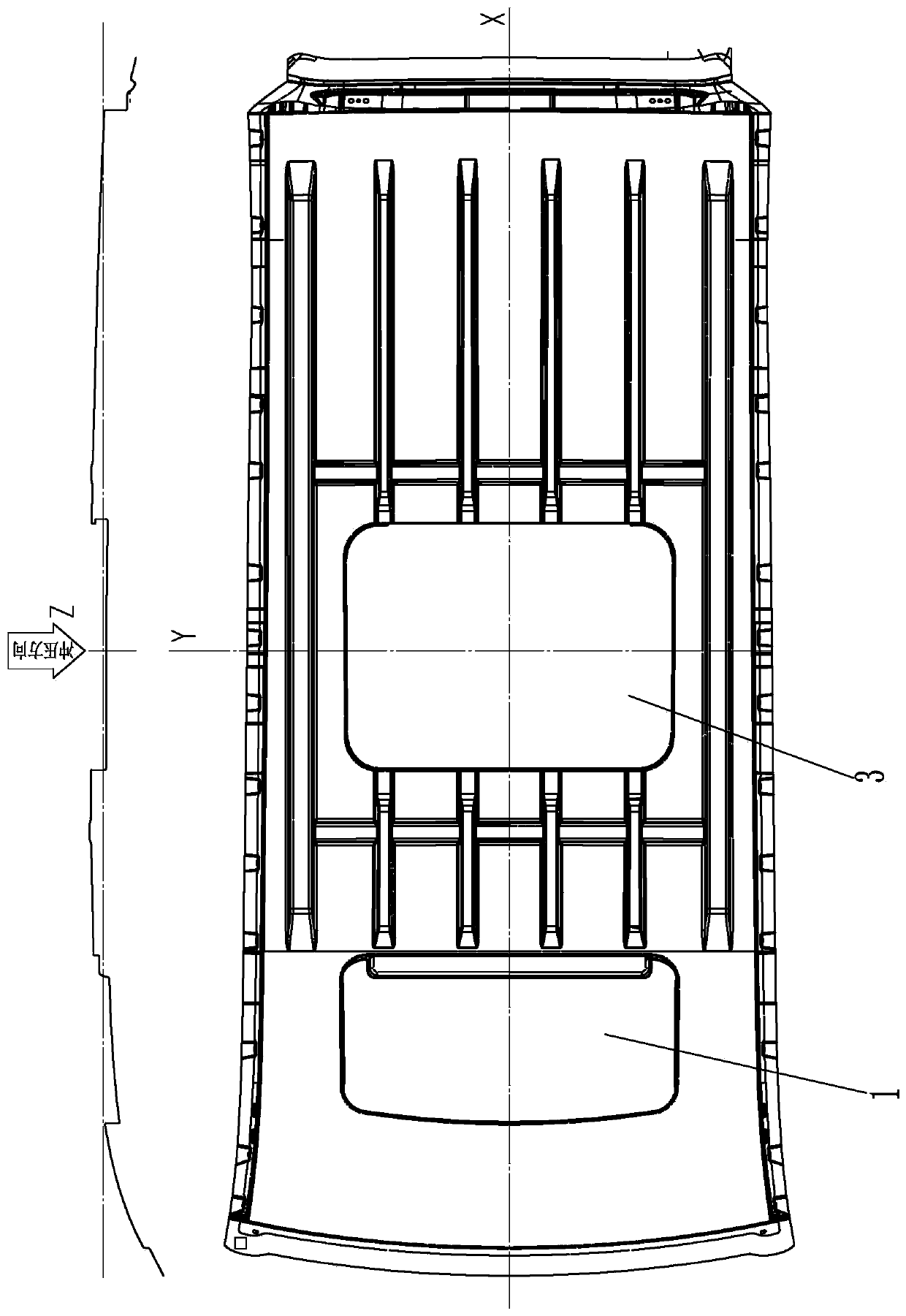

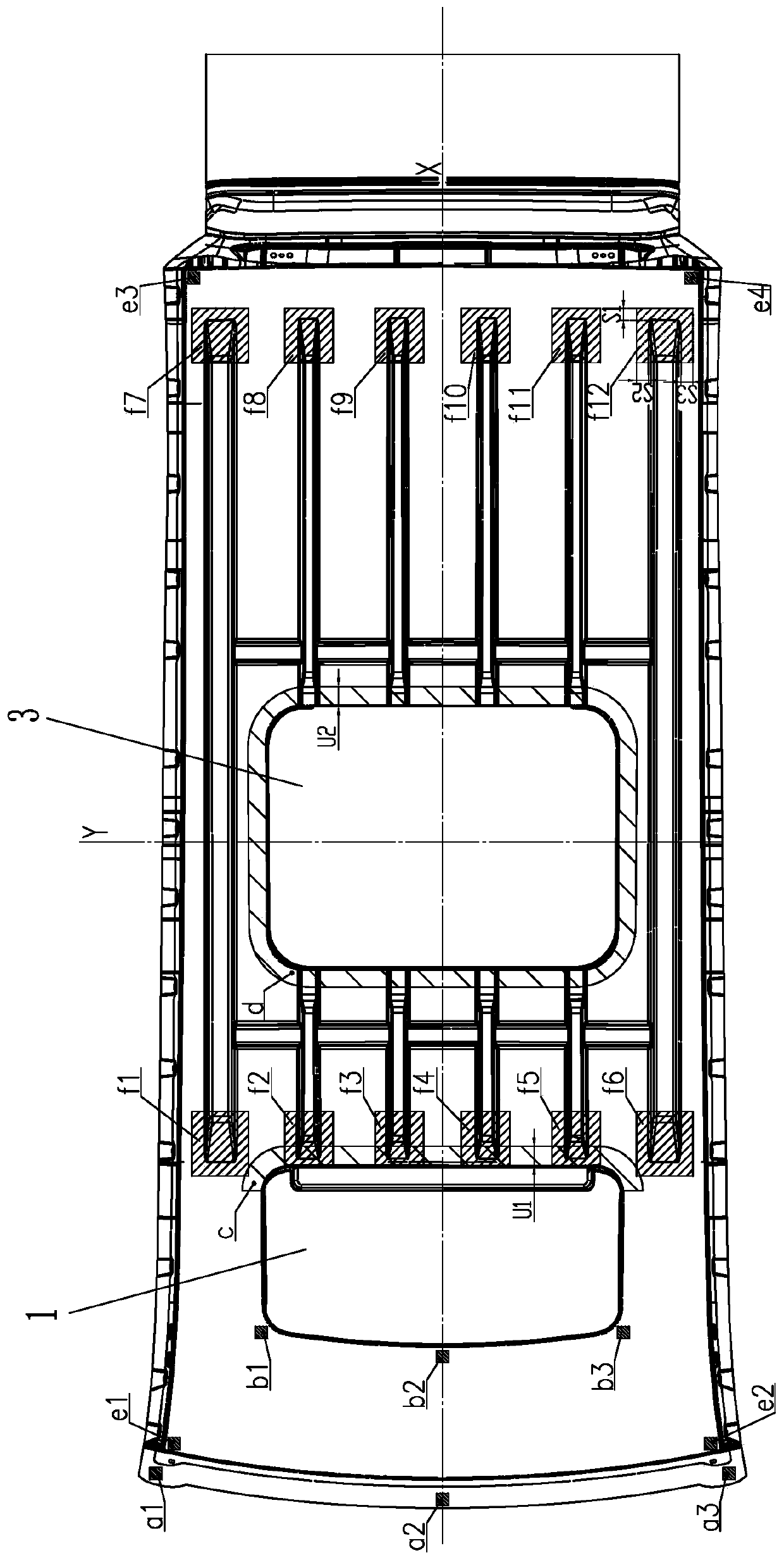

Off-line programming system and method of optical visual sensor with linear structure for welding robot

InactiveCN101973032AIntuitive detection statusIntuitive display of detection statusManipulatorInteractive graphicsSimulation

The invention relates to an off-line programming system and method of an optical visual sensor with a linear structure for a welding robot. The system comprises a sensor model, a robot model, a process control rule base, a graphic editing interface, an operation sequence module and a programming information output, wherein the sensor model is used for simulating a sensor imaging process to acquire a view model and simultaneously completing detection view substantiation to be convenient for user graphic programming; the robot model is used for simulating the single-point motion of the robot and providing communication interface information of connecting sensor input signals; the process control rule base is used for providing process feature extraction rules for different welding tasks andcontrol command related information of processes; the graphic editing interface is used for interactive graphic programming between a user and a system; the operation sequence module is used for saving the information of a series of detection points, wherein the information comprises single-point motion commands, process compensation control commands, process feature extraction rules and imaging signal model information; and the programming information output is used for outputting the program text of the robot and the configuration information text of the sensor system.

Owner:SOUTHEAST UNIV

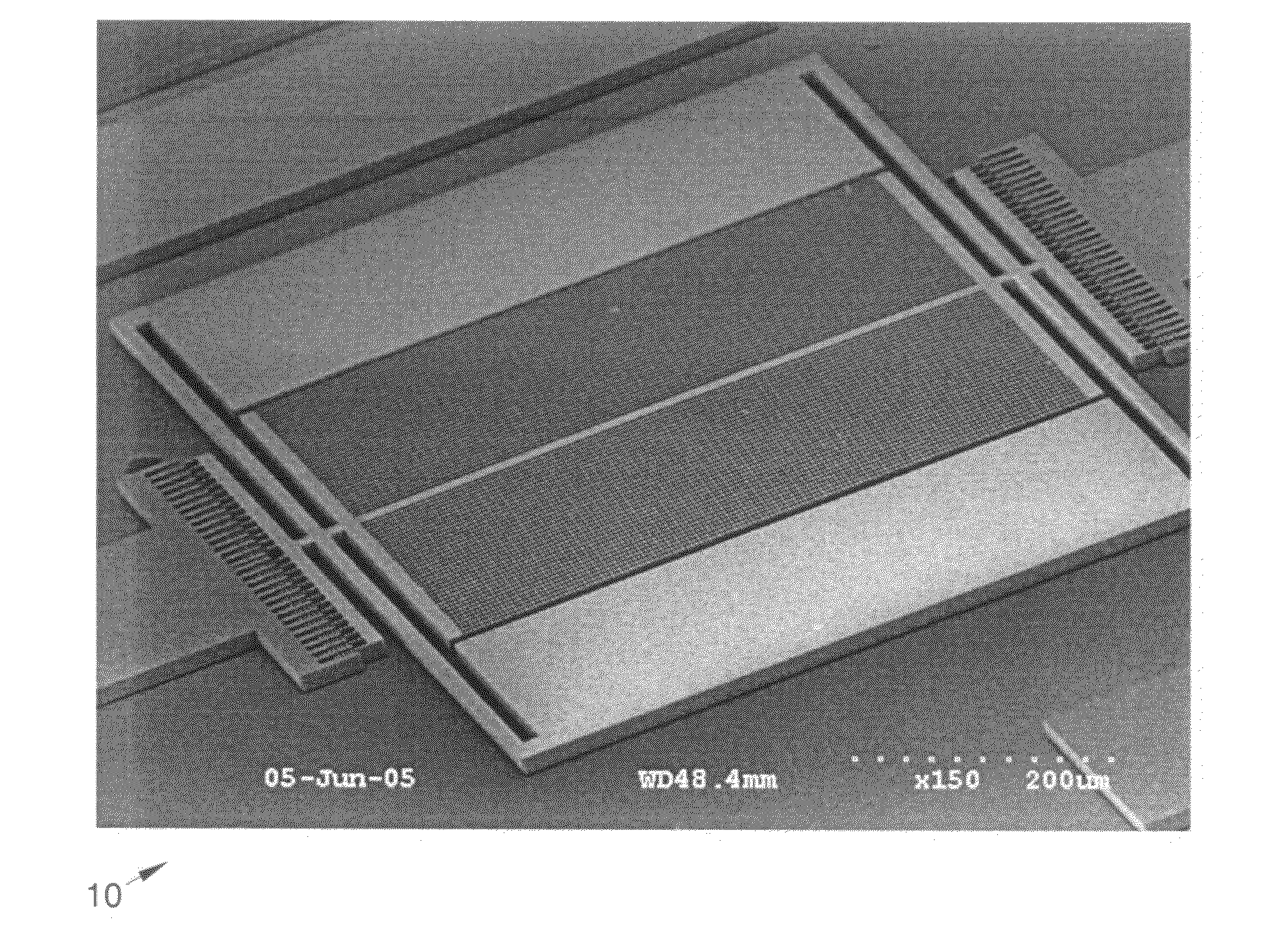

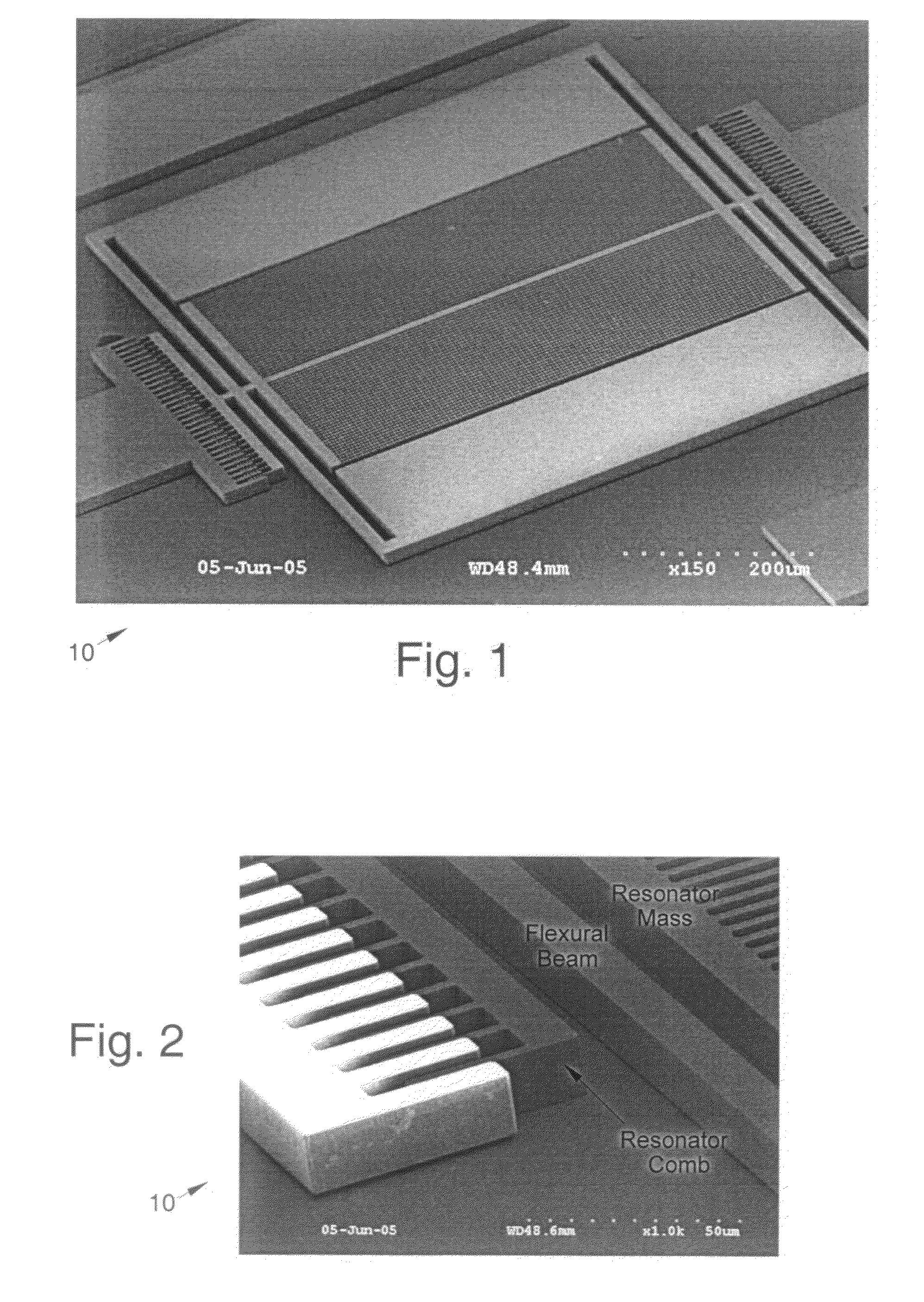

Low frequency process-variation-insensitive termperature-stable micromechanical resonators

Disclosed are micromechanical resonators having features that compensate for process variations and provide improved inherent temperature stability. Exemplary resonators may comprise comb drive resonators or parallel-plate drive resonators. The resonators comprise a (silicon-on-insulator) substrate with resonator apparatus formed therein. The resonator apparatus has one or more anchors connected to the substrate, at least one excitation / sense port that is electrically insulated from the substrate, and a resonator. The resonator comprises one or more flexural members connected to the one or more anchors that are separated from the substrate and separated from the excitation / sense port by gaps. A mass is coupled to flexural members, is separated from the substrate, and comprises a grid. Process compensation is achieved using a resonator mass in the form of a grid of lines that form holes or lines through the mass, wherein widths of lines of the grid are approximately ⅓ the width of the flexural members. Temperature stability is provided using silicon dioxide on at least one of the surfaces of the flexural members.

Owner:GEORGIA TECH RES CORP

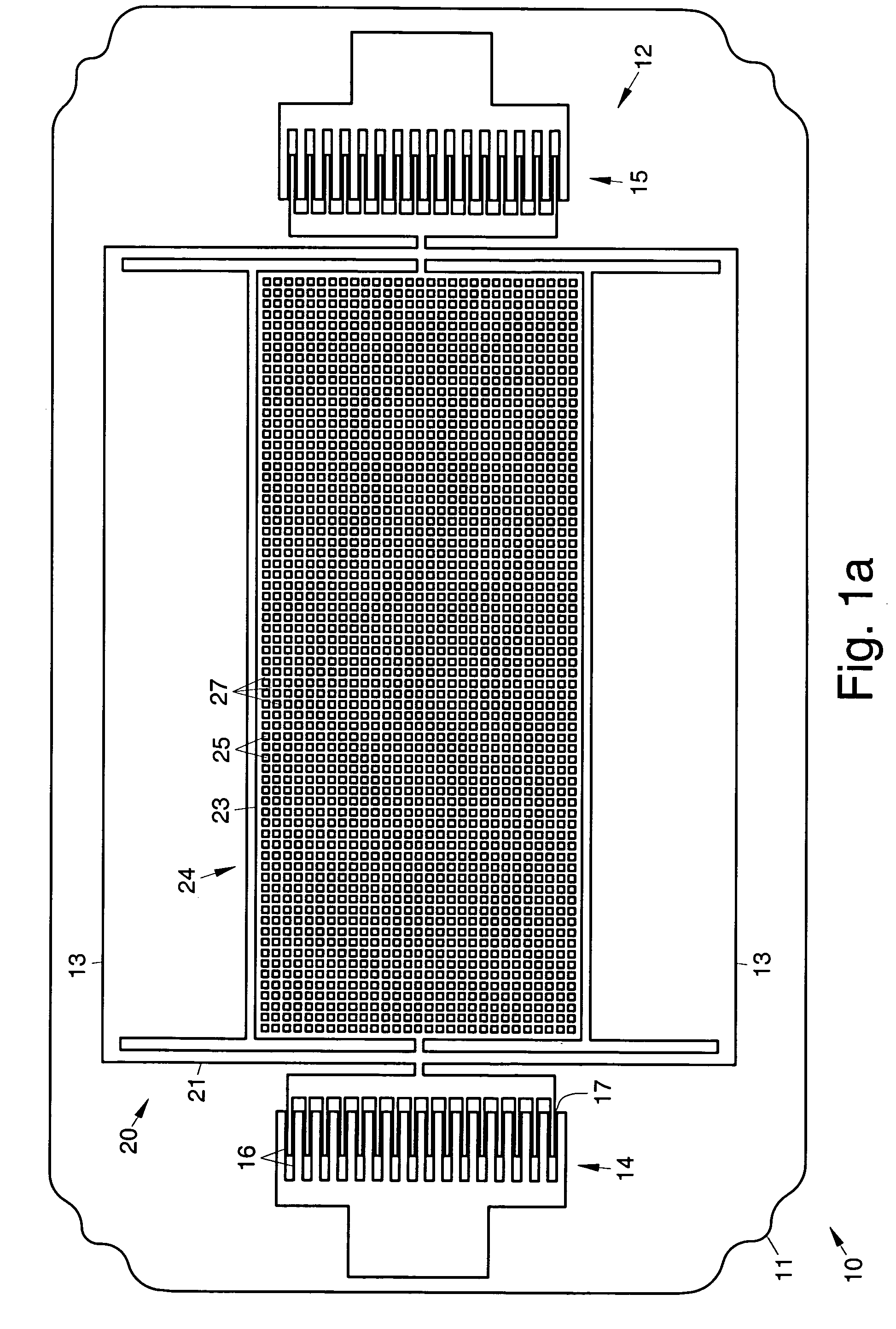

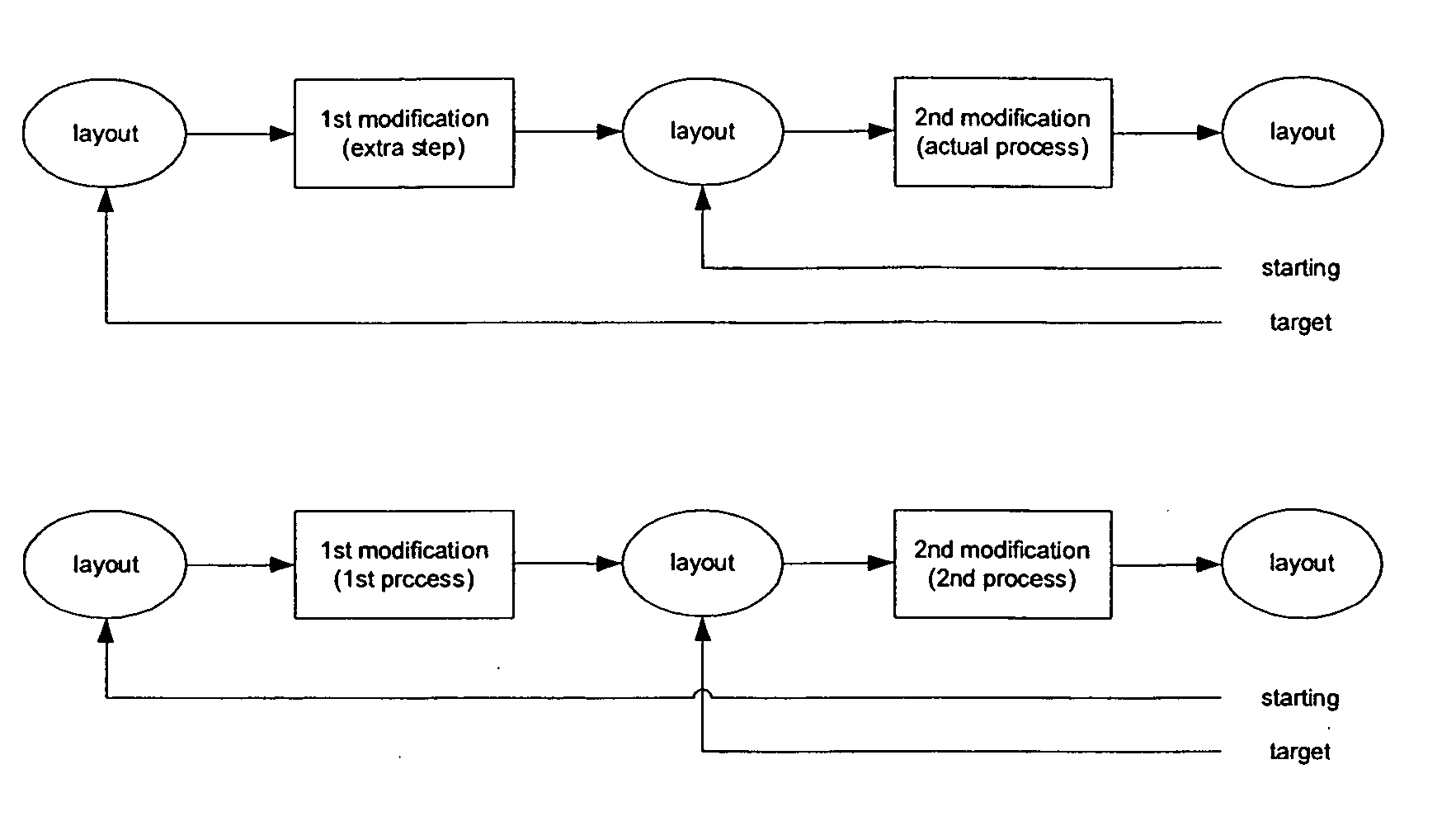

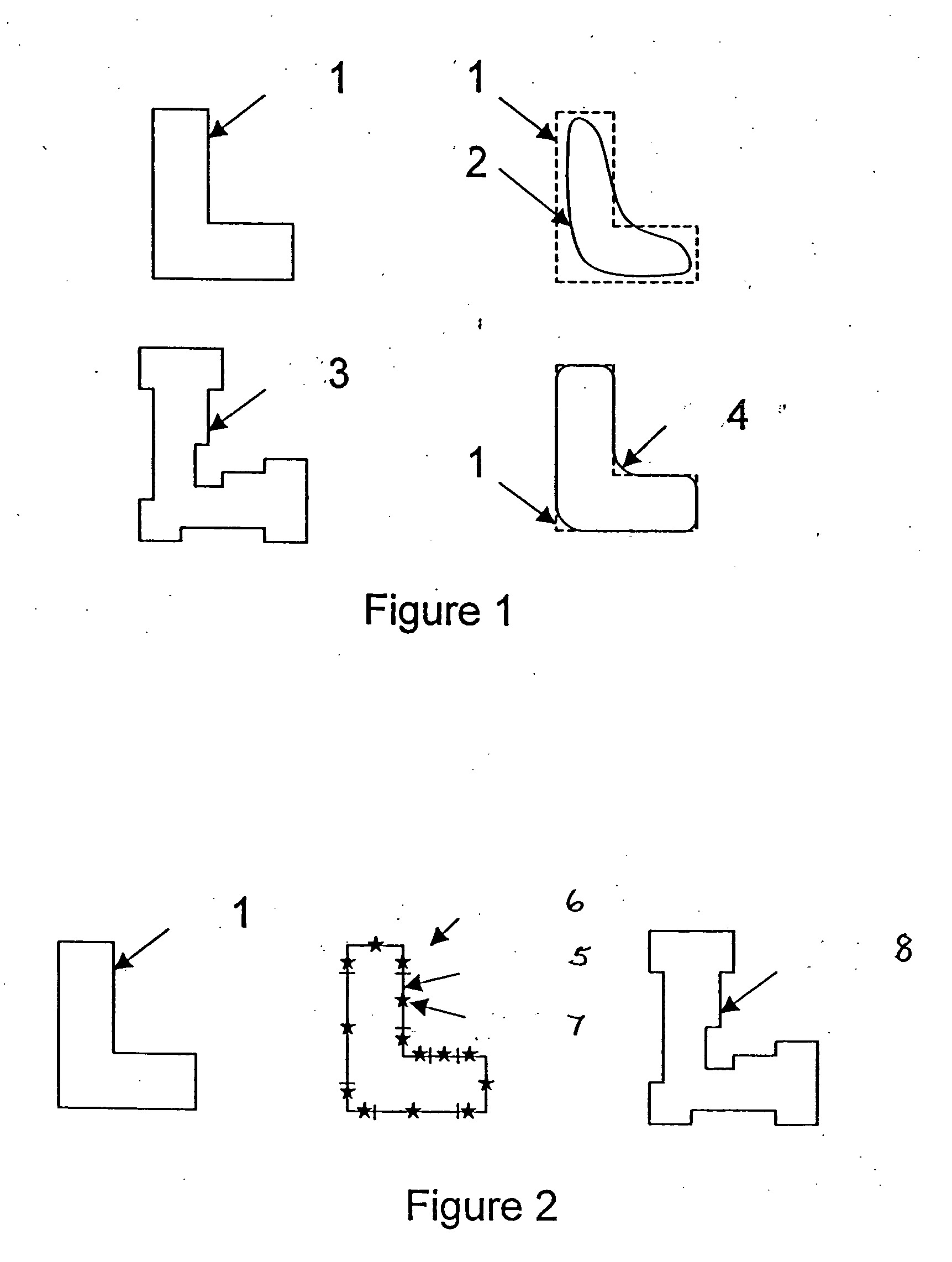

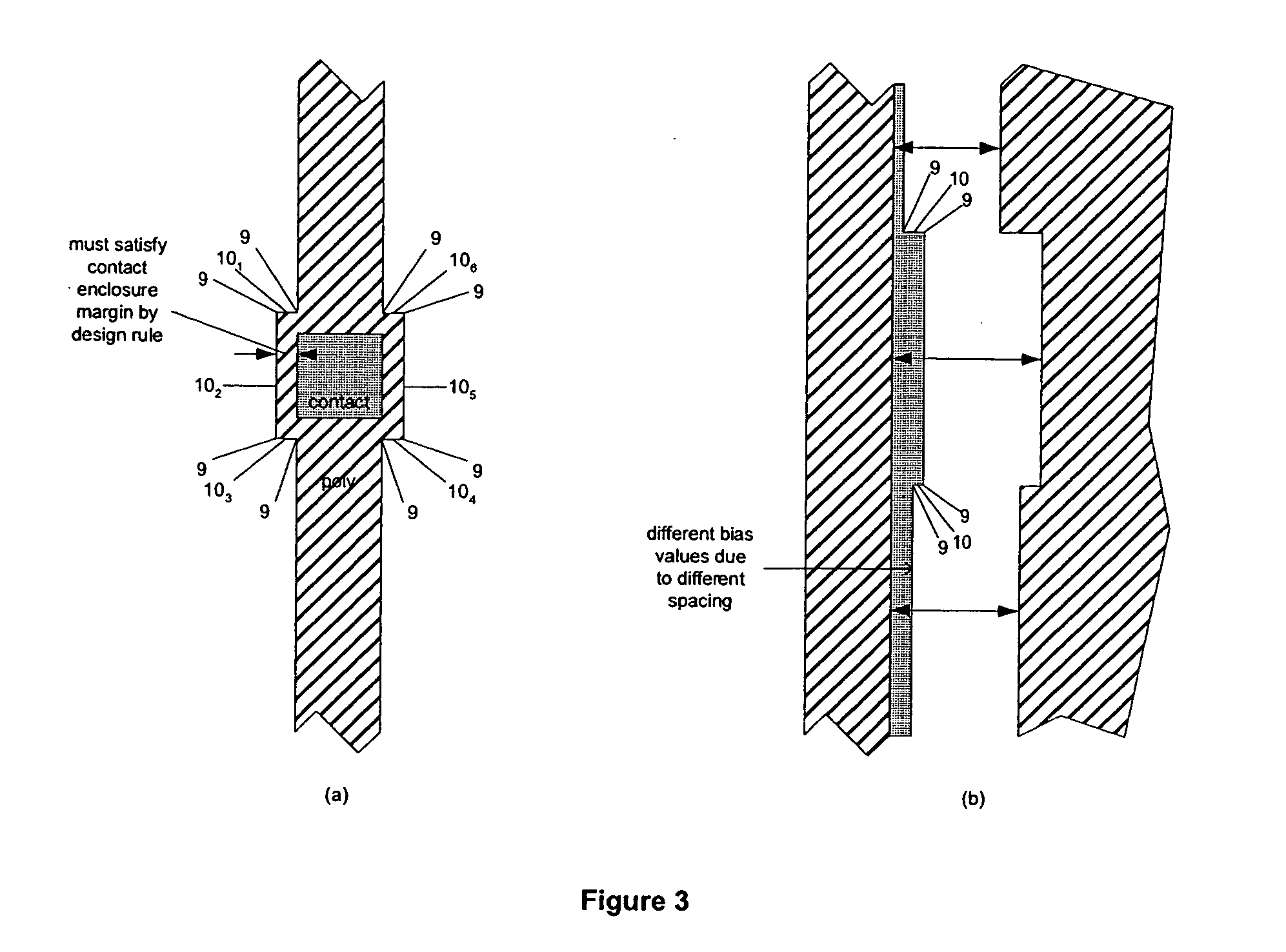

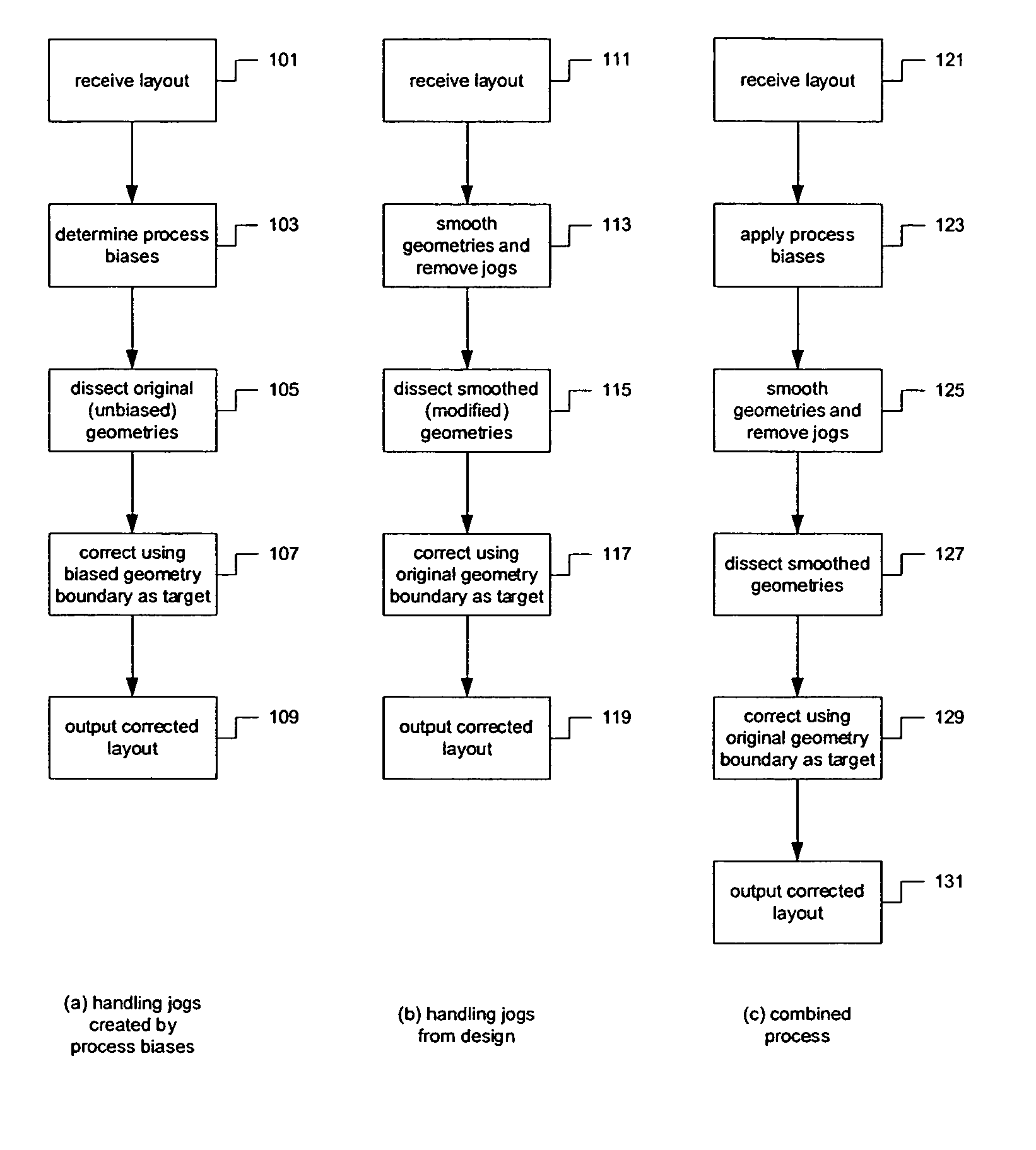

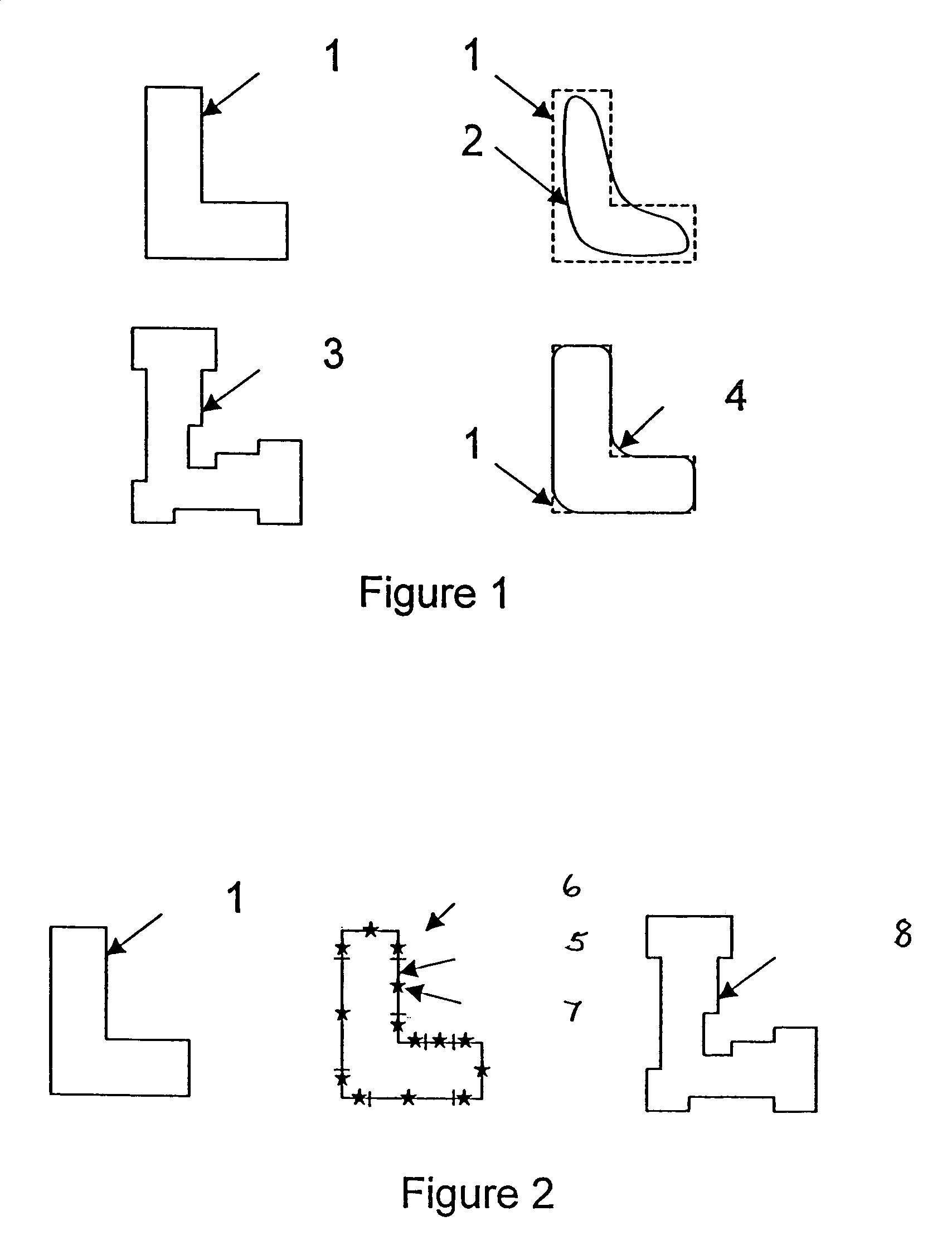

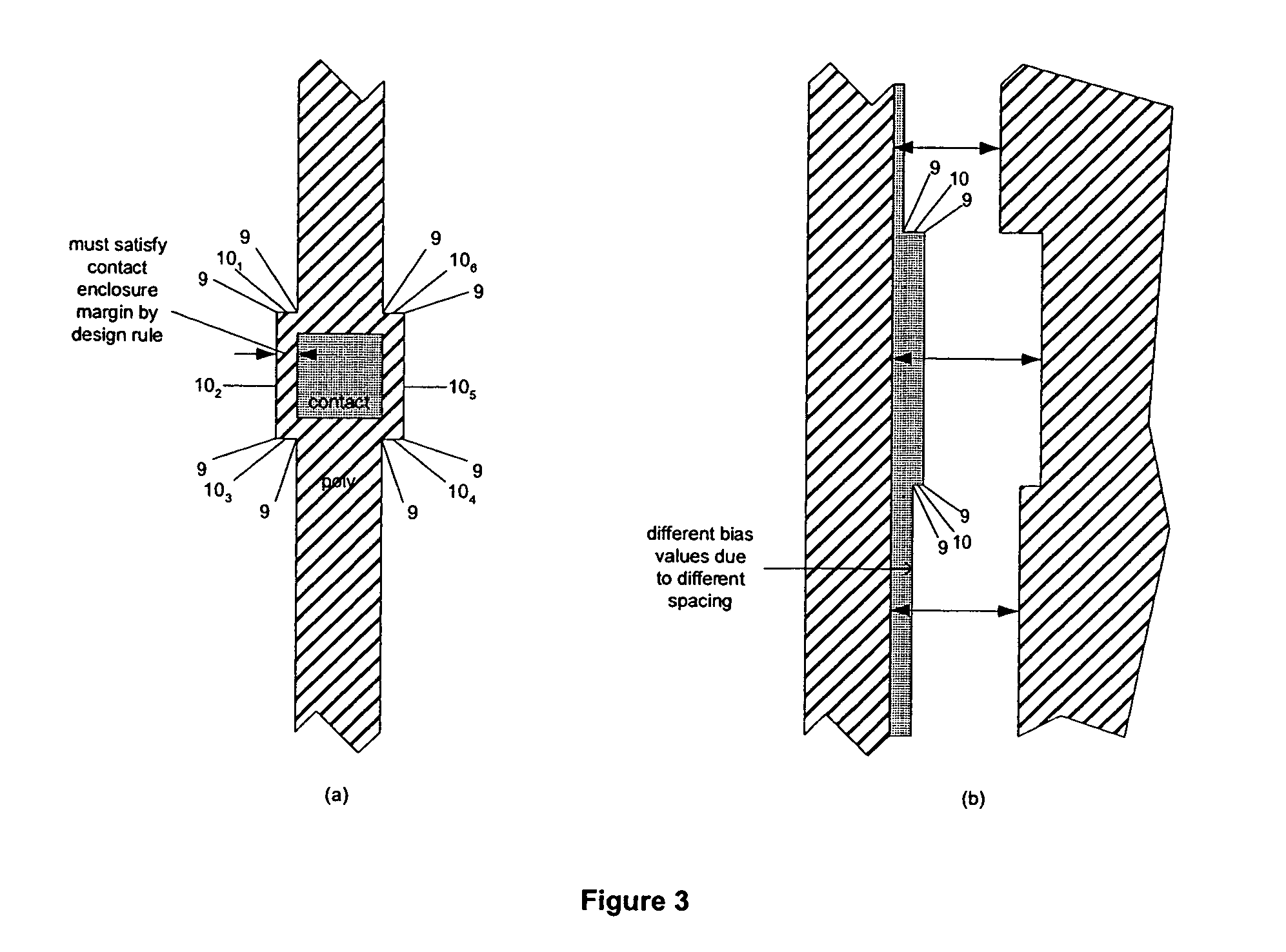

System for simplifying layout processing

ActiveUS20050223350A1Promote generationImprove manufacturabilityComputer aided designTotal factory controlProcess deviationsEngineering

A system and method for integrated circuit design are disclosed to enhance manufacturability of circuit layouts by applying layout processing to handle imperfections such as jogs in integrated circuit design layouts. The layout processing may be applied to jogs in the original integrated circuit design layout or jogs created post-design by process biases, as well as design rule check and Boolean processes or process compensation.

Owner:APPLIED MATERIALS INC

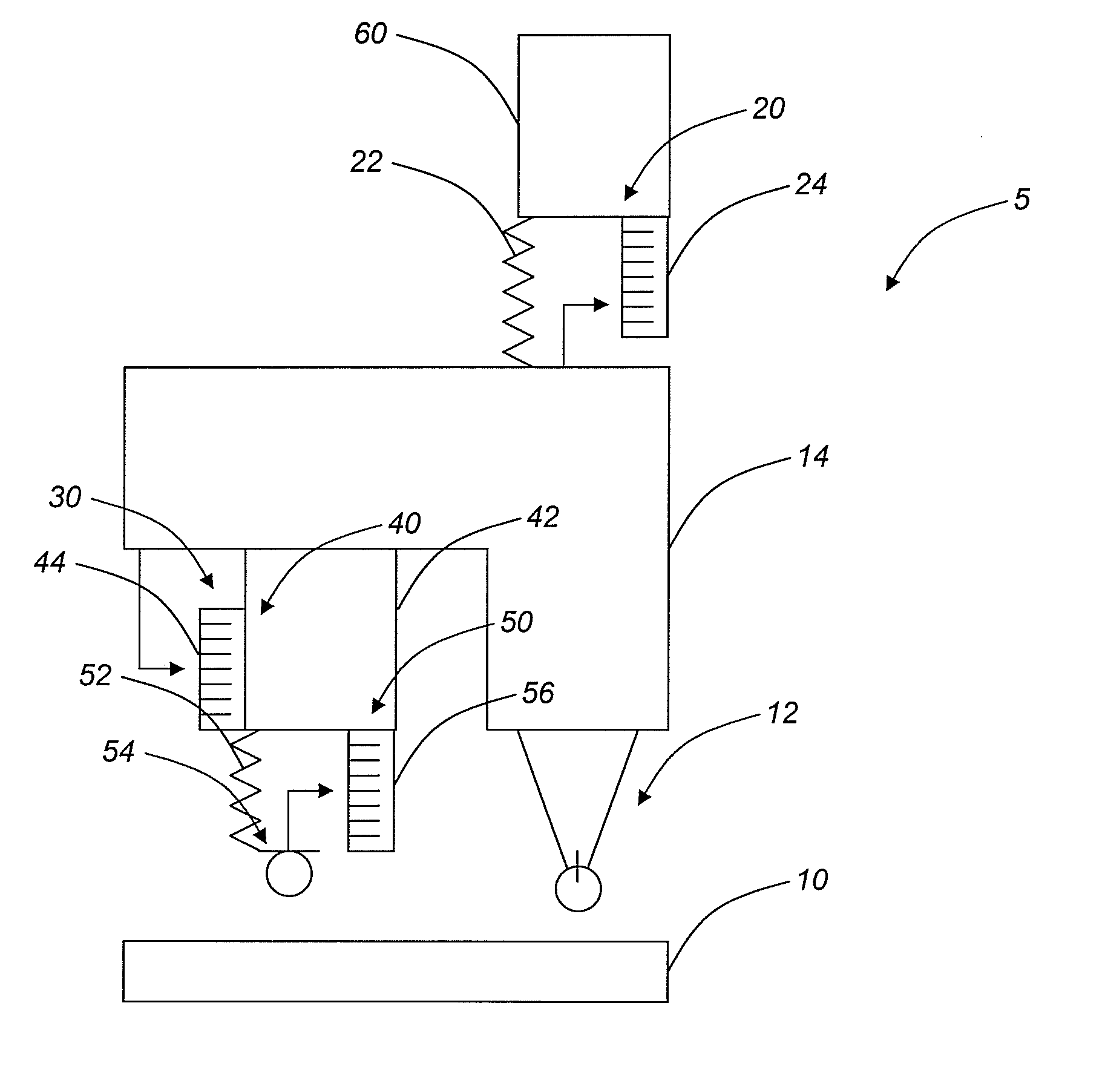

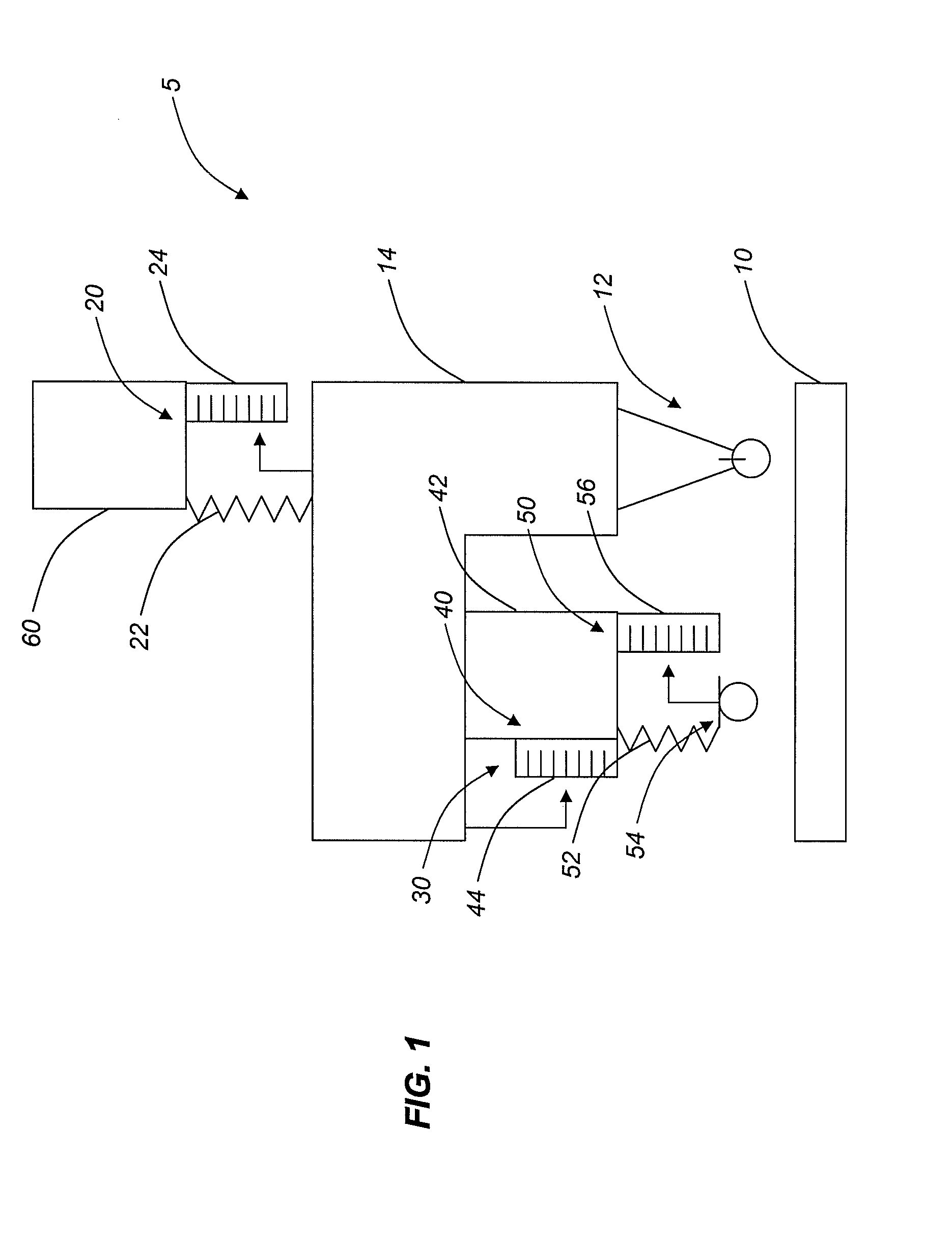

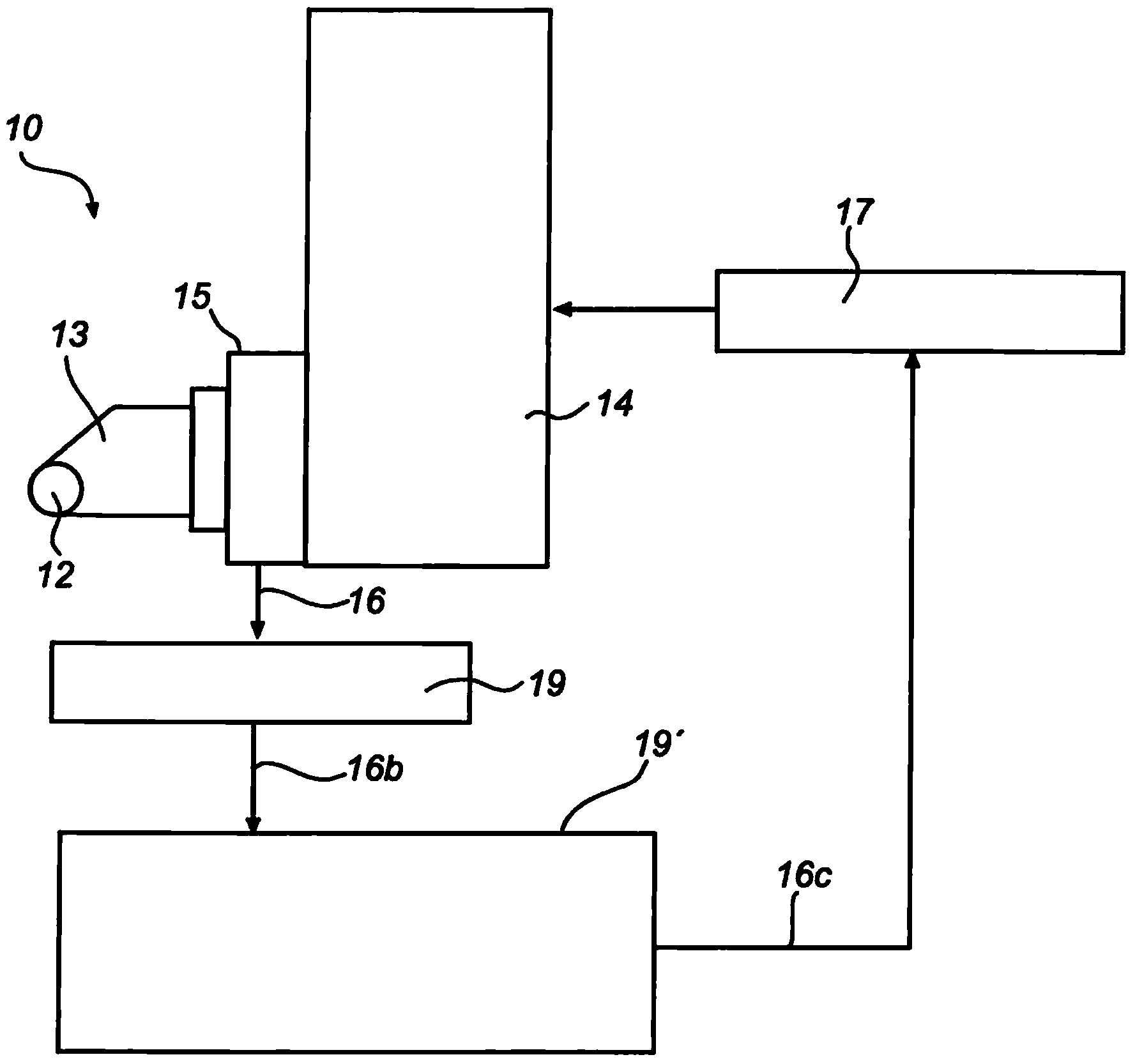

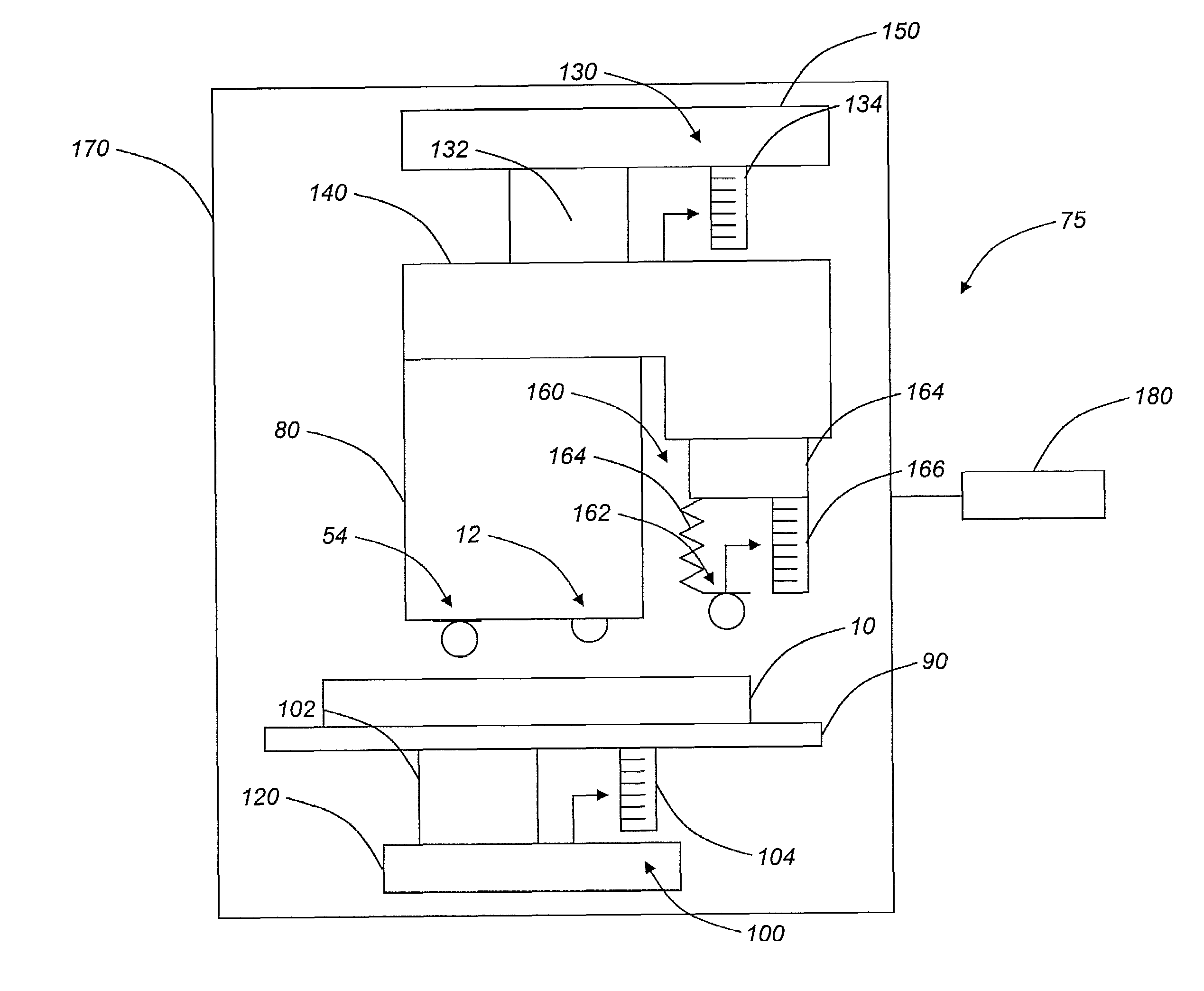

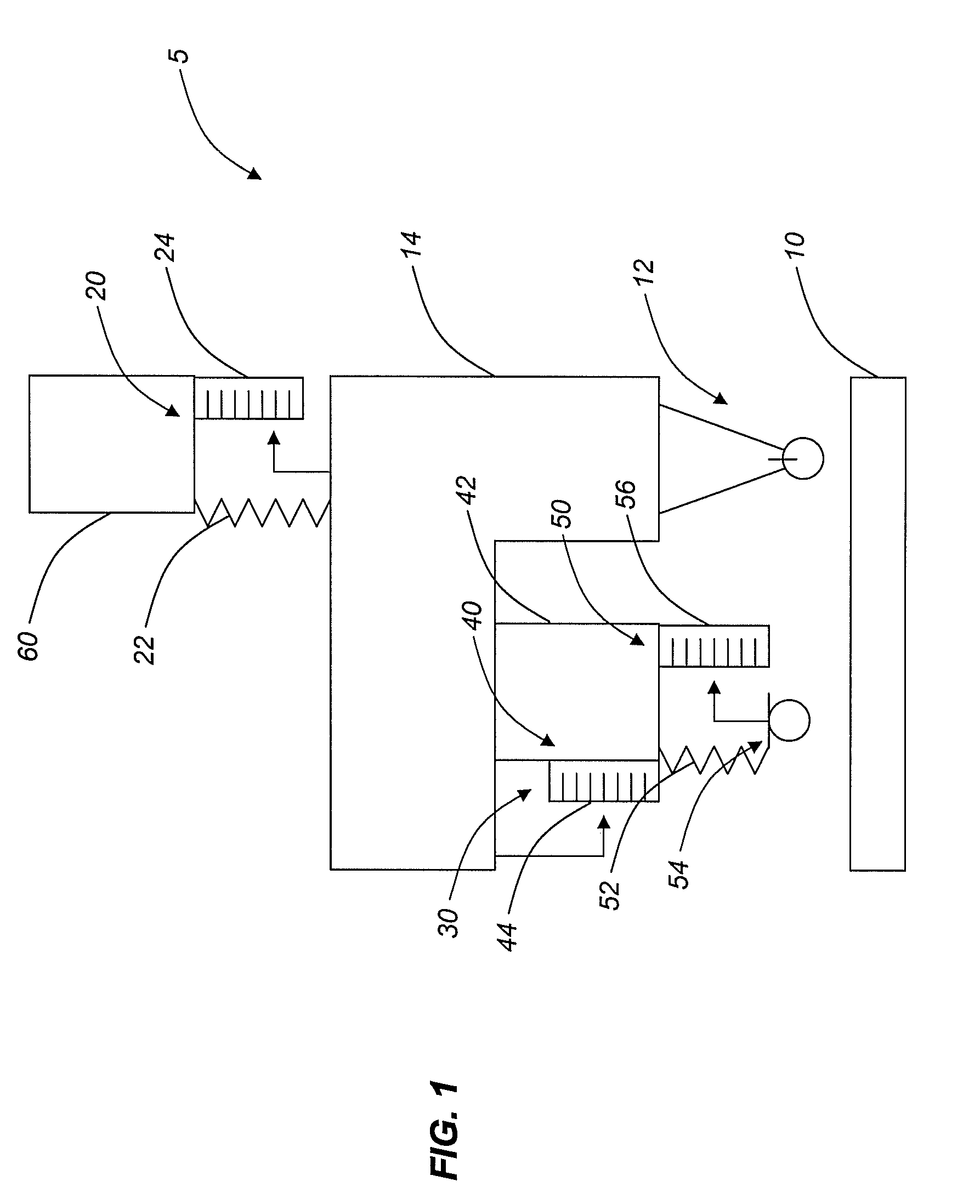

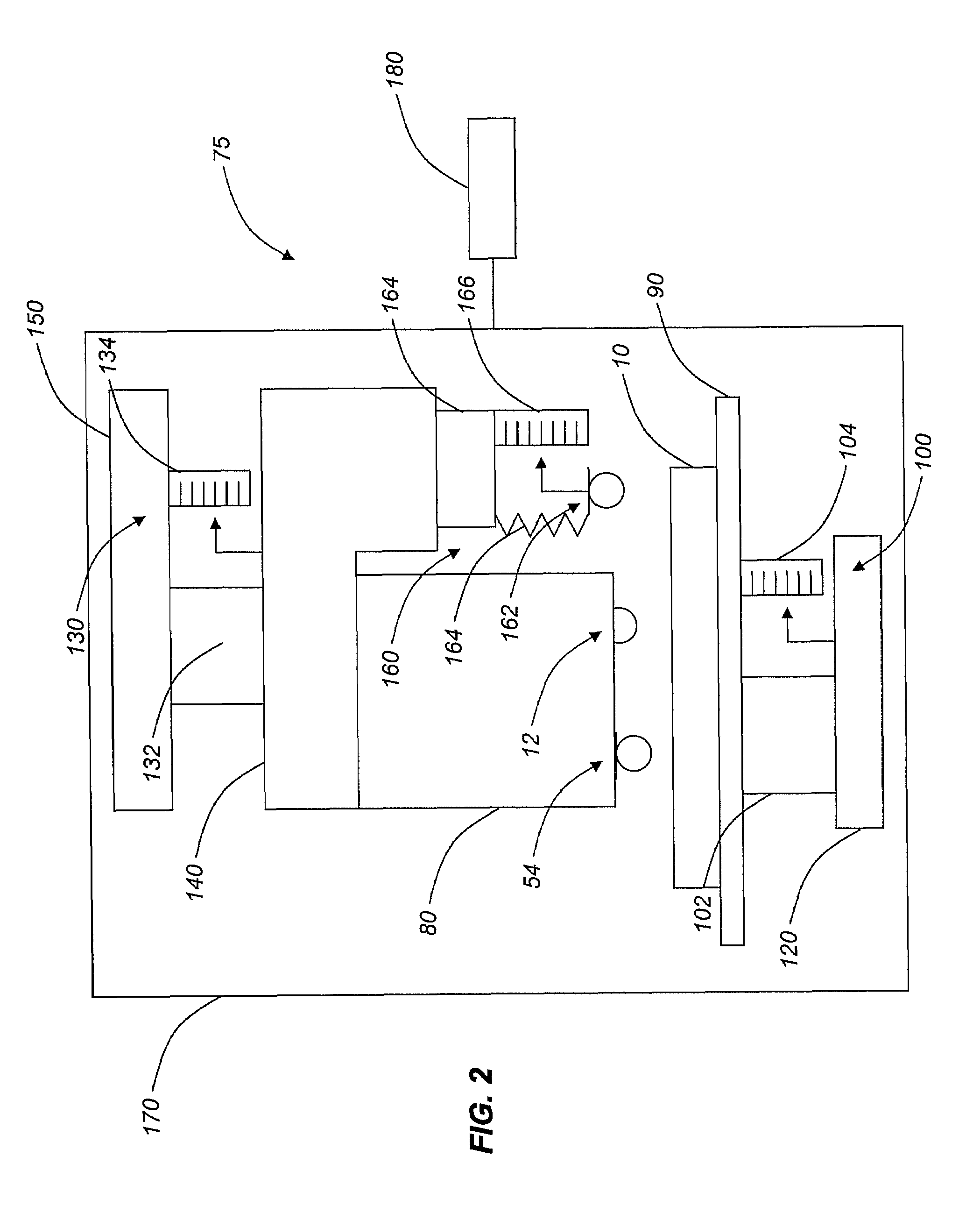

Apparatus and Method For Surface Property Measurement With In-Process Compensation For Instrument Frame Distortion

ActiveUS20080028840A1Reduce dependenceEliminate the effects ofMeasurement/indication equipmentsMaterial strength using single impulsive forceMeasurement deviceHardness

The present invention provides an apparatus and method for performing surface property measurements, such as workpiece hardness and other material property measurements, with in-process compensation for instrument frame distortion and the like. The apparatus includes a substantially rigid base; a stylus coupled to the substantially rigid base, the stylus configured and selectively positioned to interact with a surface of a specimen at points along a central axis of the stylus; a proximity detector sensor coupled to the substantially rigid base, the proximity detector sensor disposed at a predetermined distance from the surface of the specimen and operable for sensing the predetermined distance between the proximity detector sensor and the surface of the specimen; and a proximity detector actuator coupled to the substantially rigid base, the proximity detector actuator operable for maintaining the predetermined distance between the proximity detector sensor and the surface of the specimen as the substantially rigid base and the stylus are moved with respect to the surface of the specimen along the central axis of the stylus.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

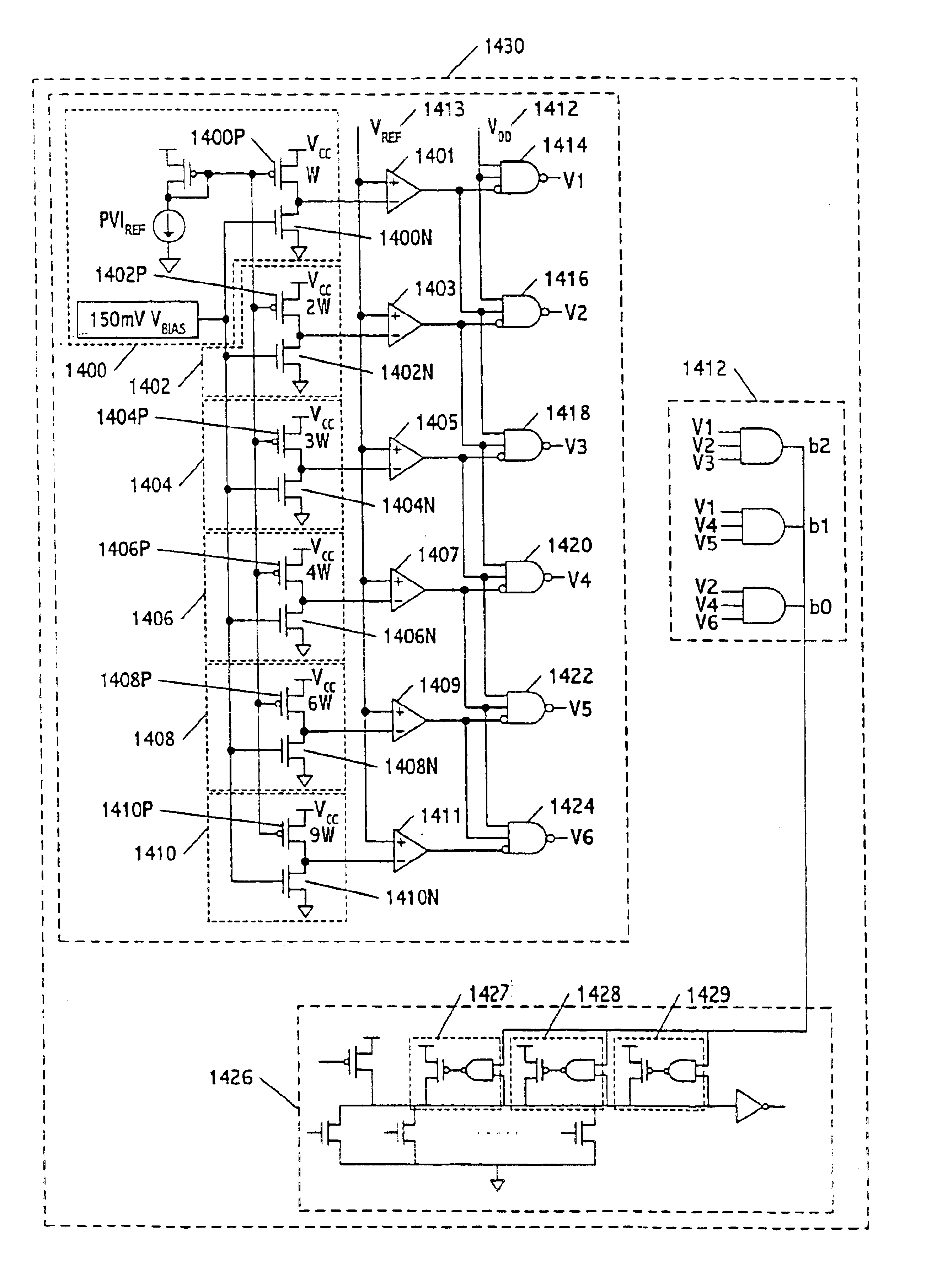

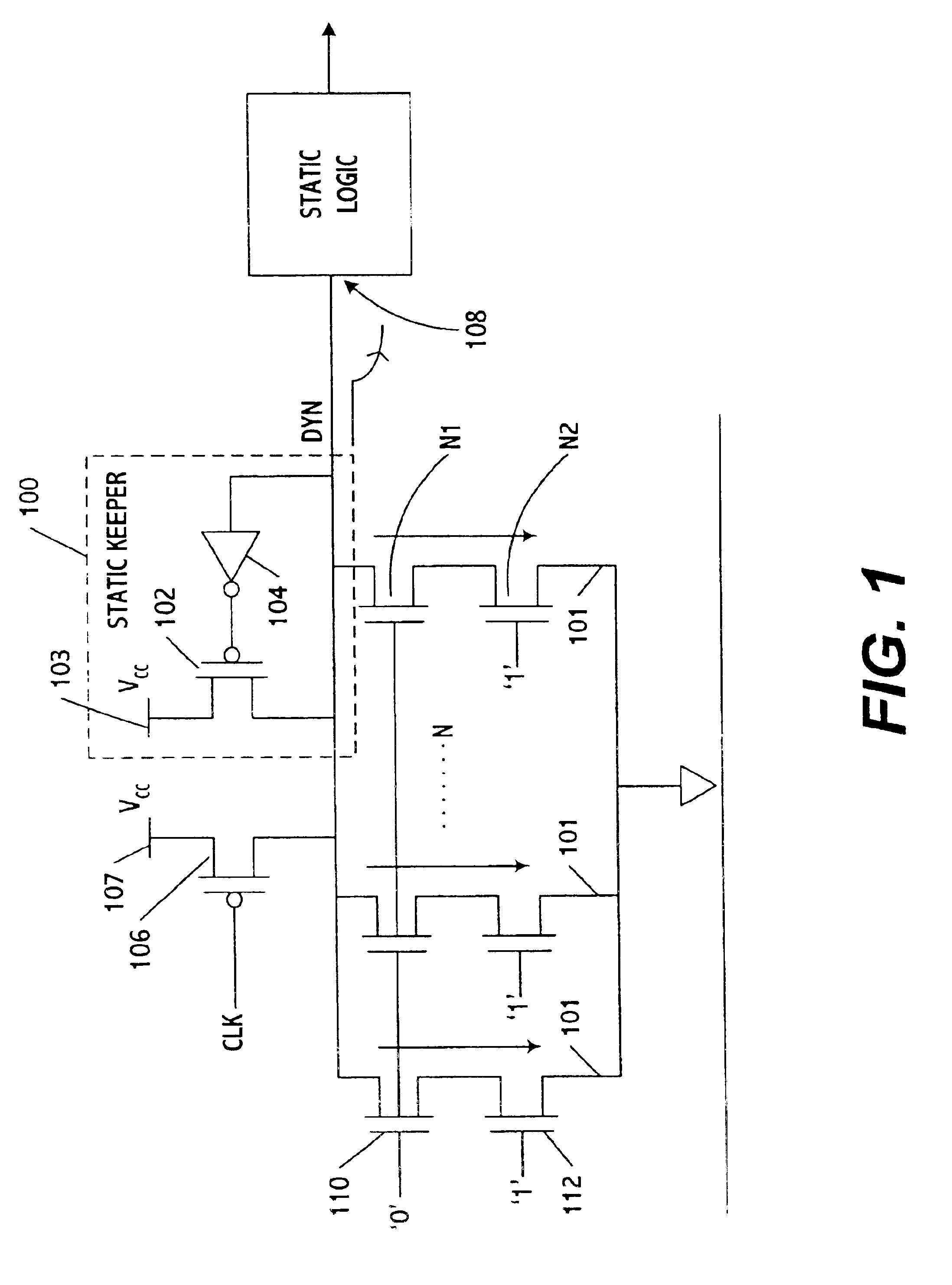

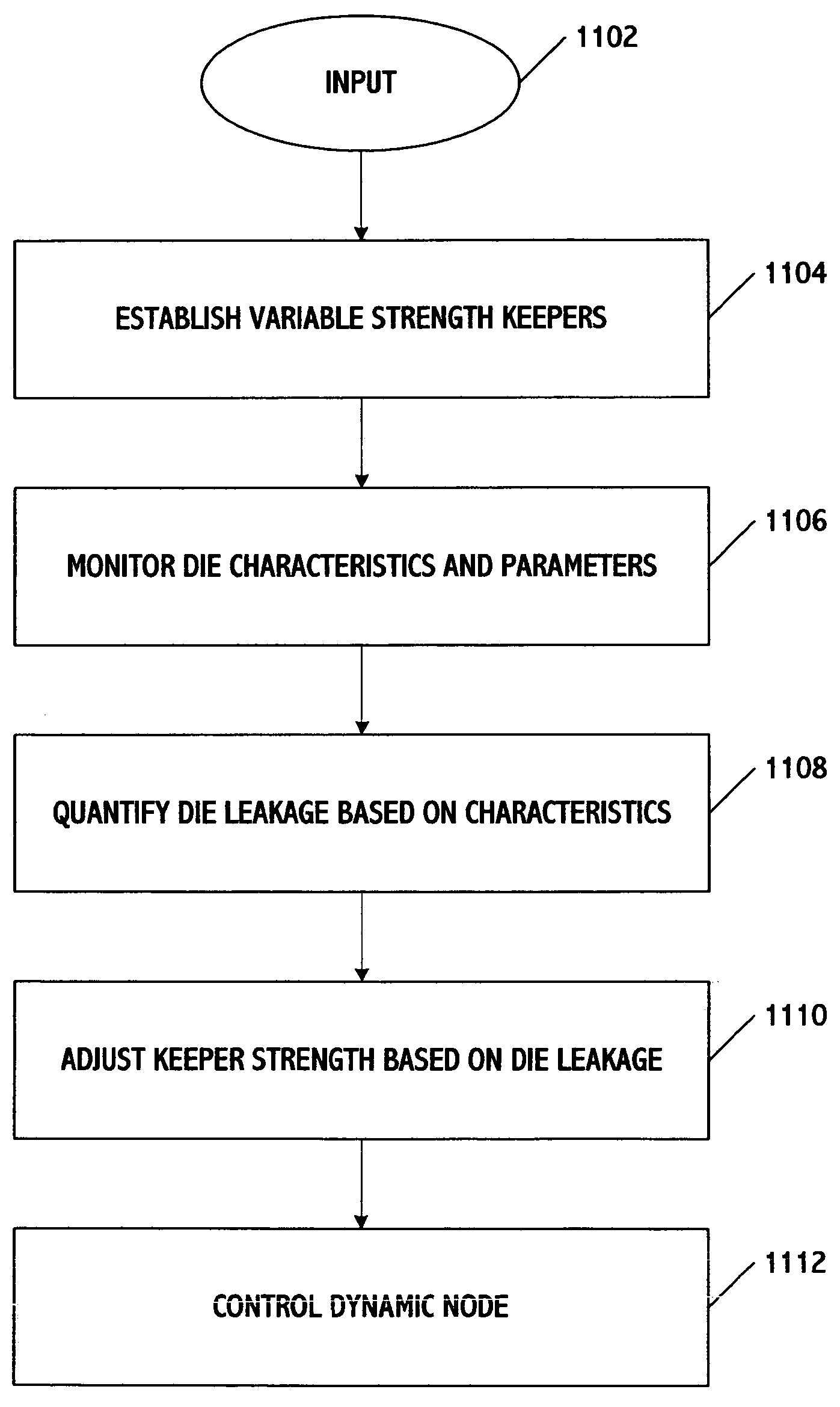

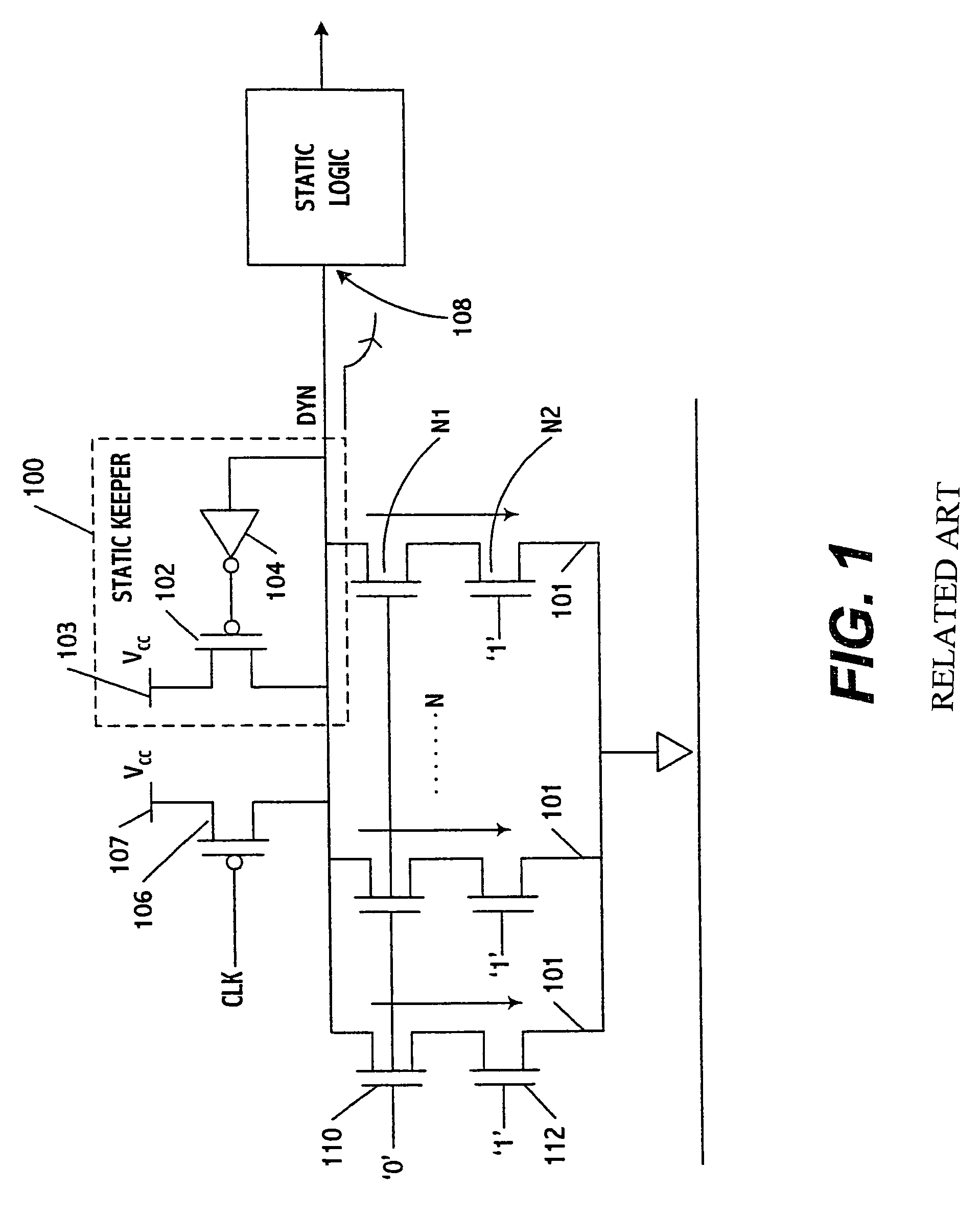

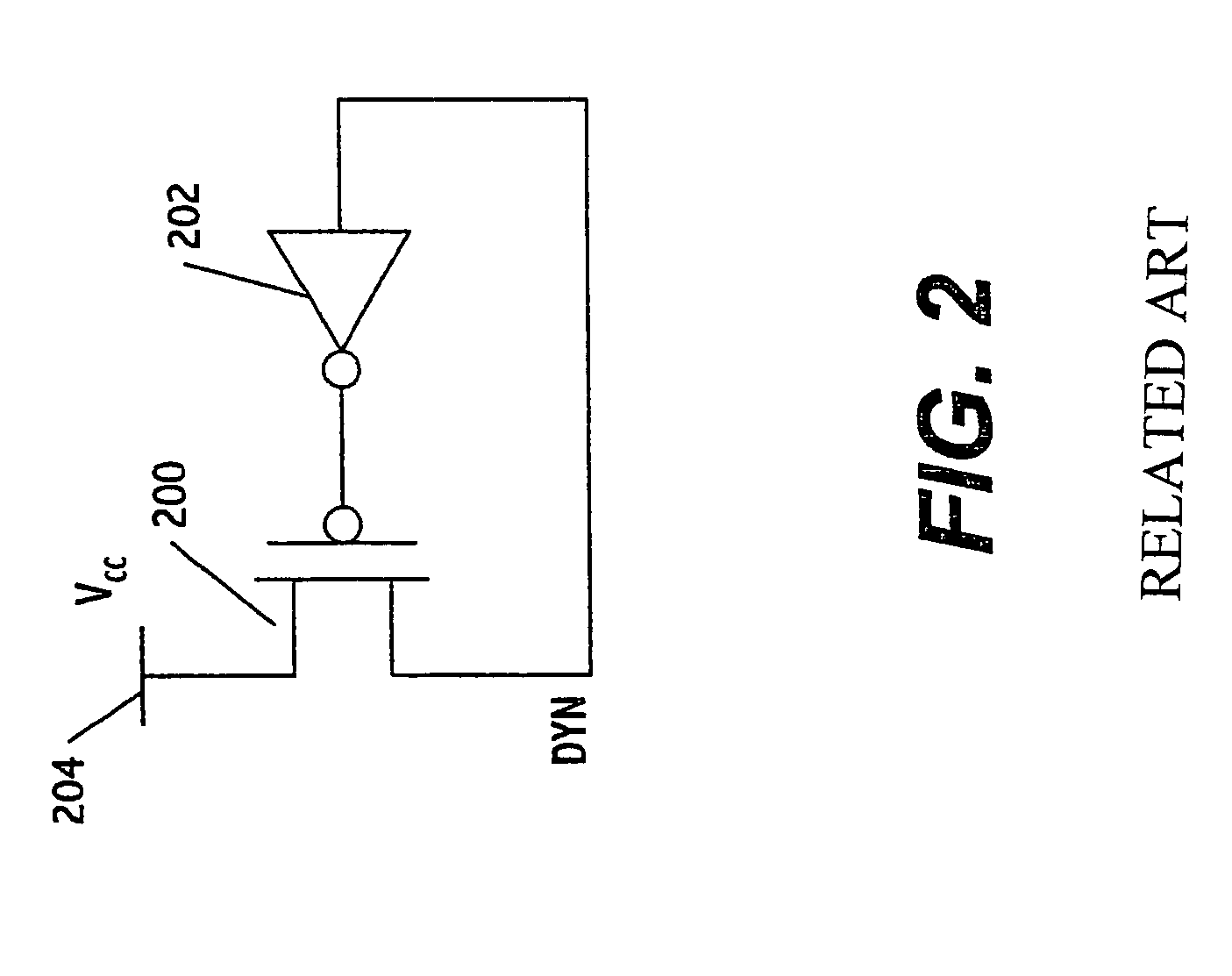

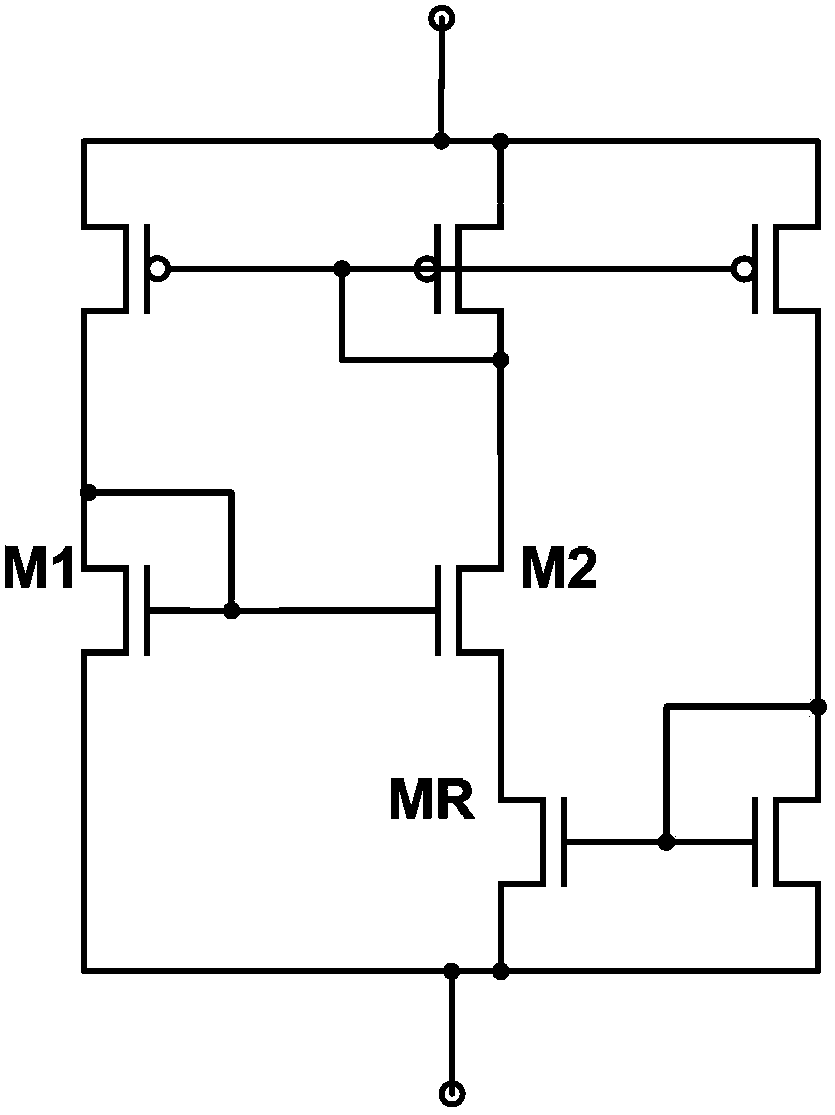

Current mirror based multi-channel leakage current monitor circuit and method

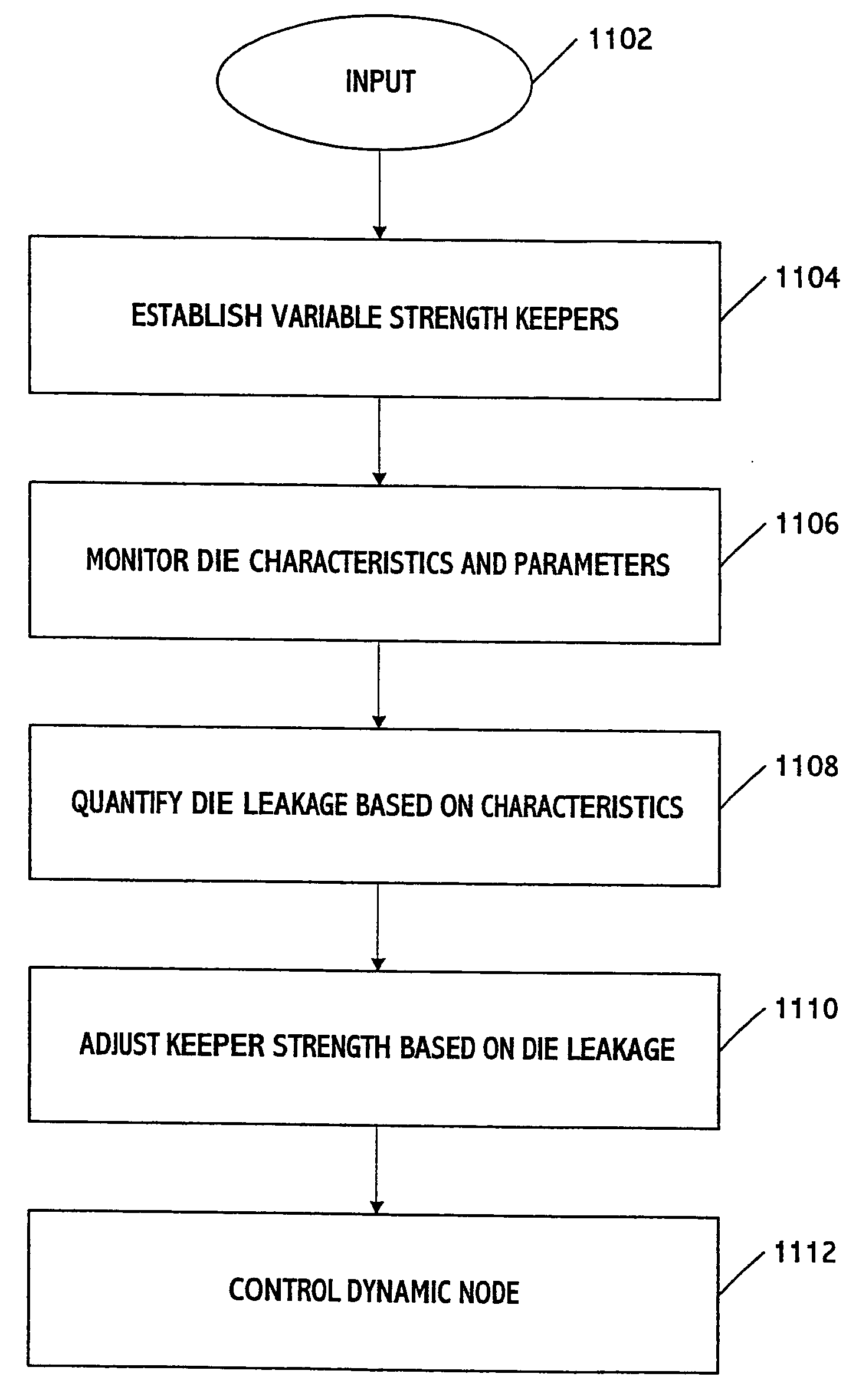

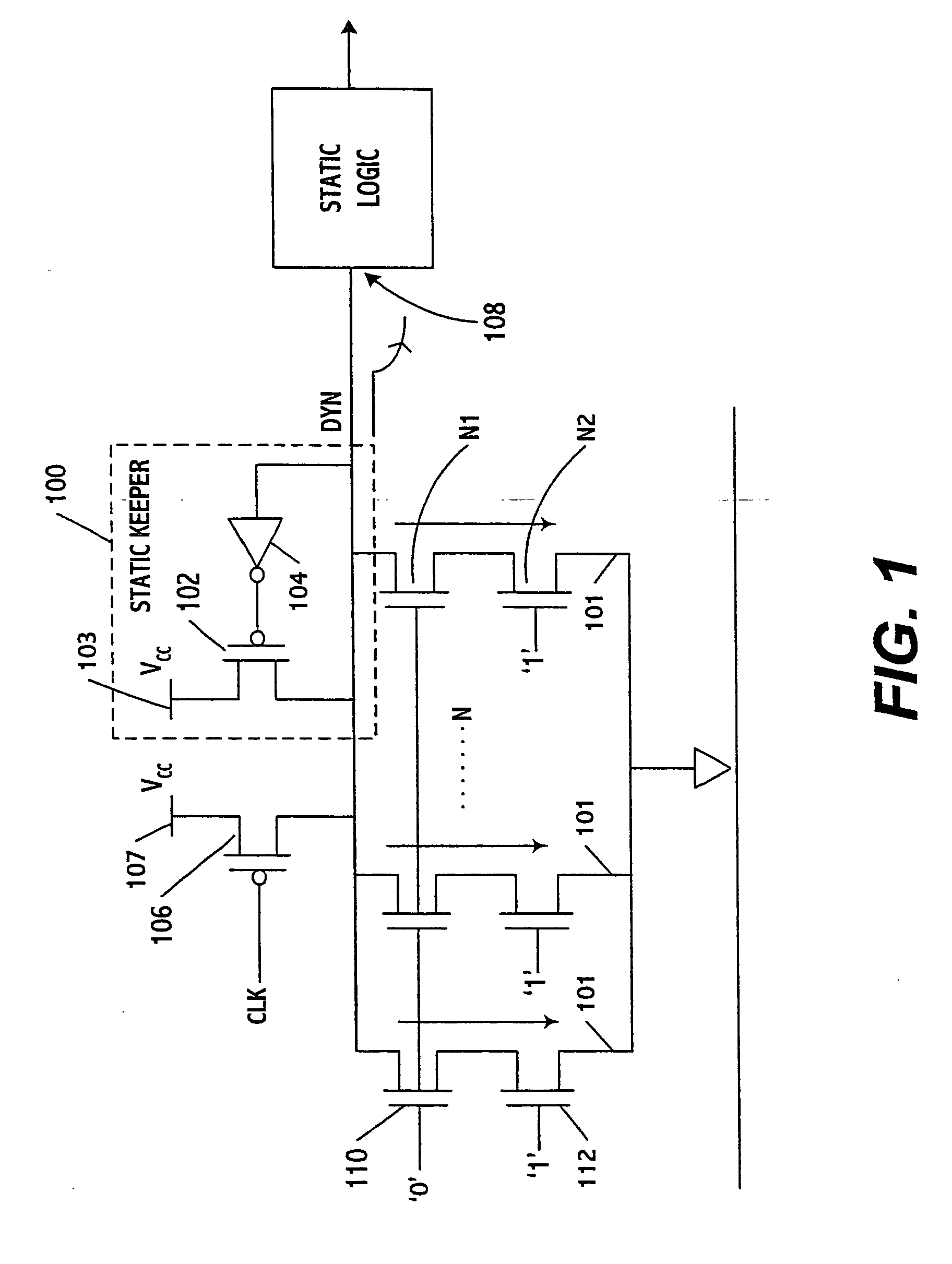

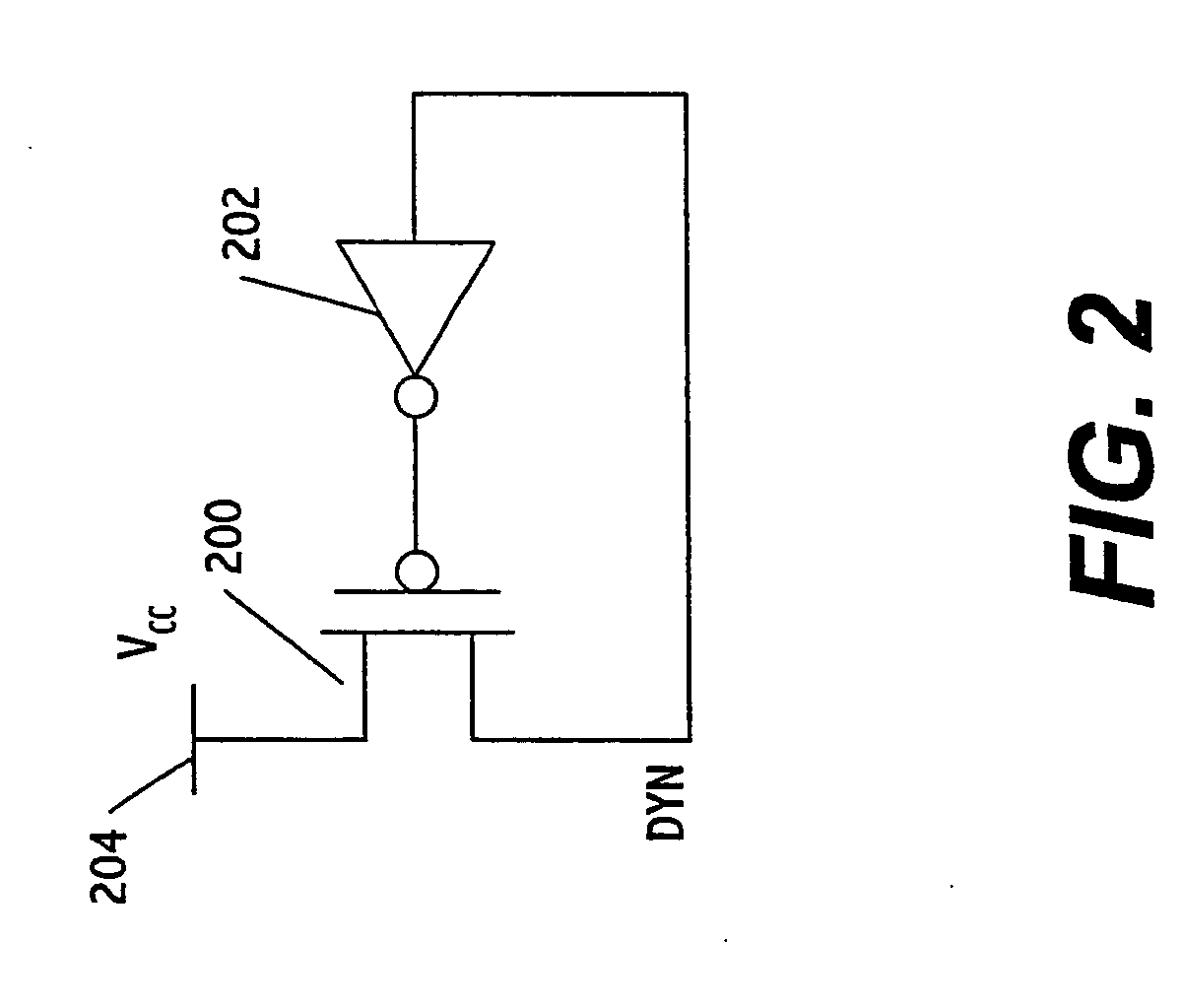

A current mirror multi-channel leakage monitor circuit and method measures die leakage and generates digital keeper control bits to control a process compensated dynamic circuit. The leakage monitor enables high resolution on-chip leakage measurements in multiple locations on a die, thereby saving test time and enabling both die to die and within die process compensation.

Owner:INTEL CORP

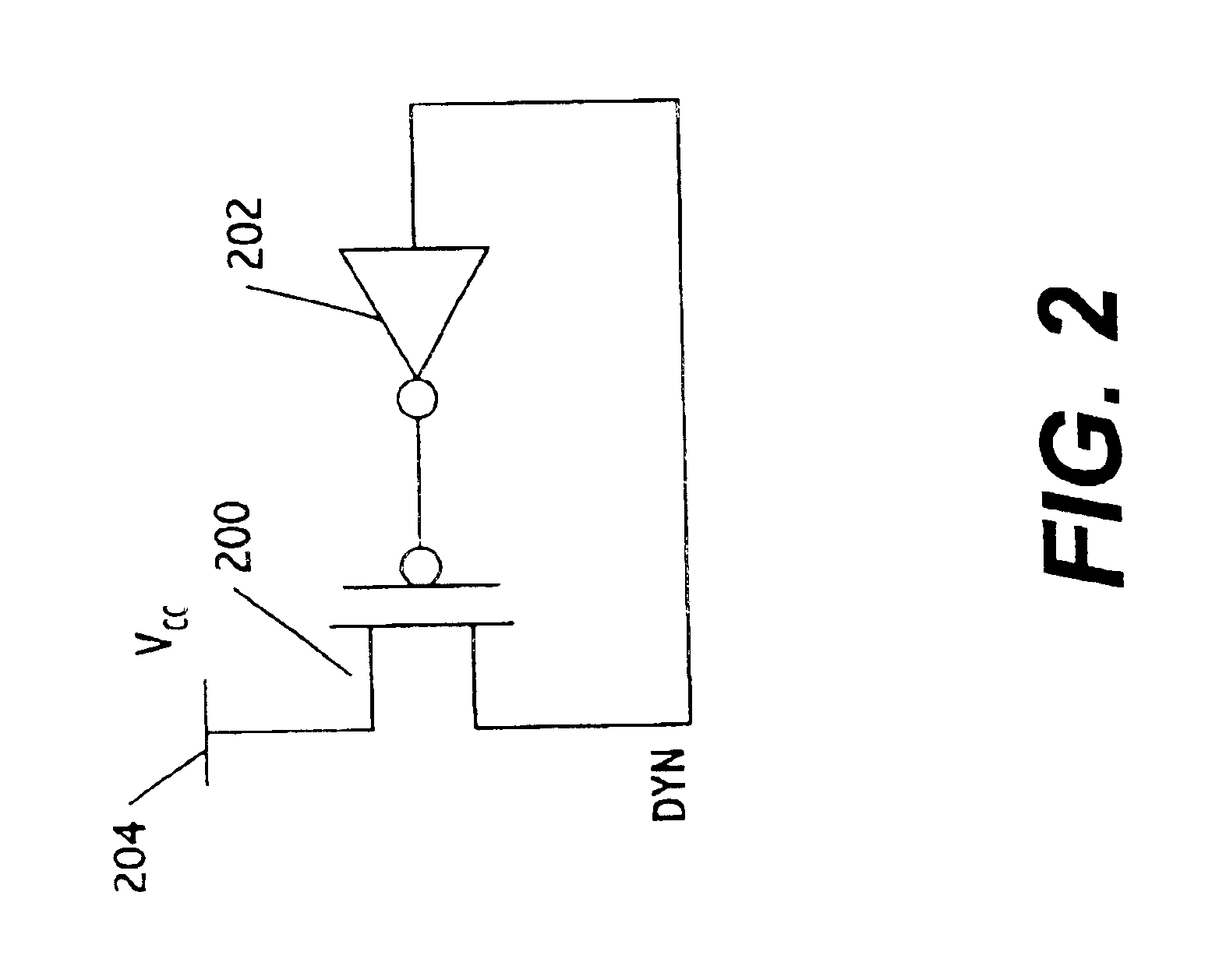

Robust variable keeper strength process-compensated dynamic circuit and method

InactiveUS7002375B2Reliability increasing modificationsLogic circuits characterised by logic functionRobustificationIntrinsics

A variable keeper strength based process-compensated dynamic circuit and method provides a robust digital way to overcome the intrinsic parameter variation present in manufactured die. Using a process-compensated dynamic circuit, the wide robustness and delay distribution becomes narrower which improves performance without sacrificing worst-case robustness. The strength of the keeper is programmed depending on the amount of die leakage. The keeper will have an optimal strength for the best and worst case leakage, allowing better performance with improved worst-case robustness.

Owner:TAHOE RES LTD

System for simplifying layout processing

ActiveUS7487490B2Improve manufacturabilityComputer aided designTotal factory controlIntegrated circuit layoutEngineering

A system and method for integrated circuit design are disclosed to enhance manufacturability of circuit layouts by applying layout processing to handle imperfections such as jogs in integrated circuit design layouts. The layout processing may be applied to jogs in the original integrated circuit design layout or jogs created post-design by process biases, as well as design rule check and Boolean processes or process compensation.

Owner:APPLIED MATERIALS INC

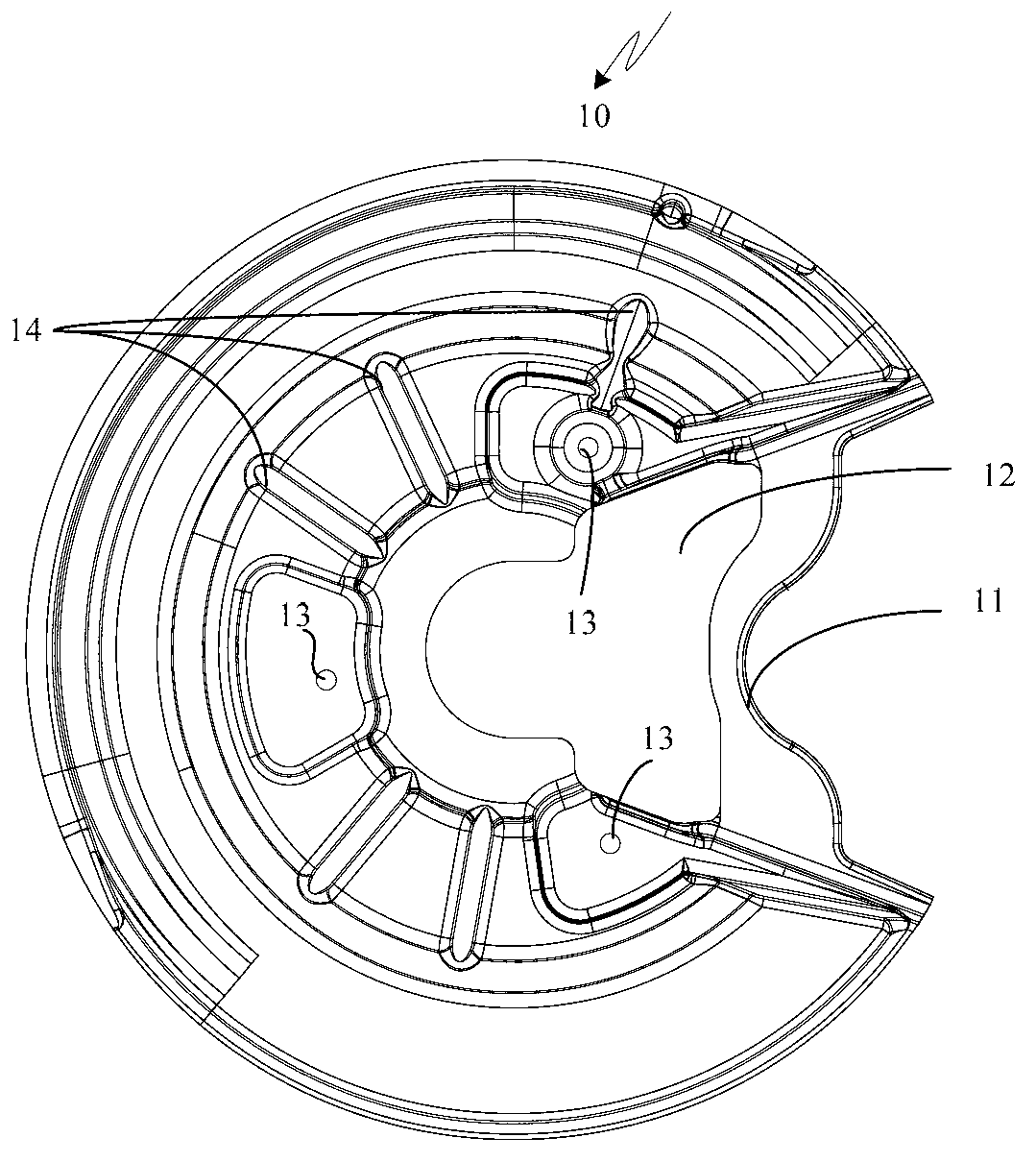

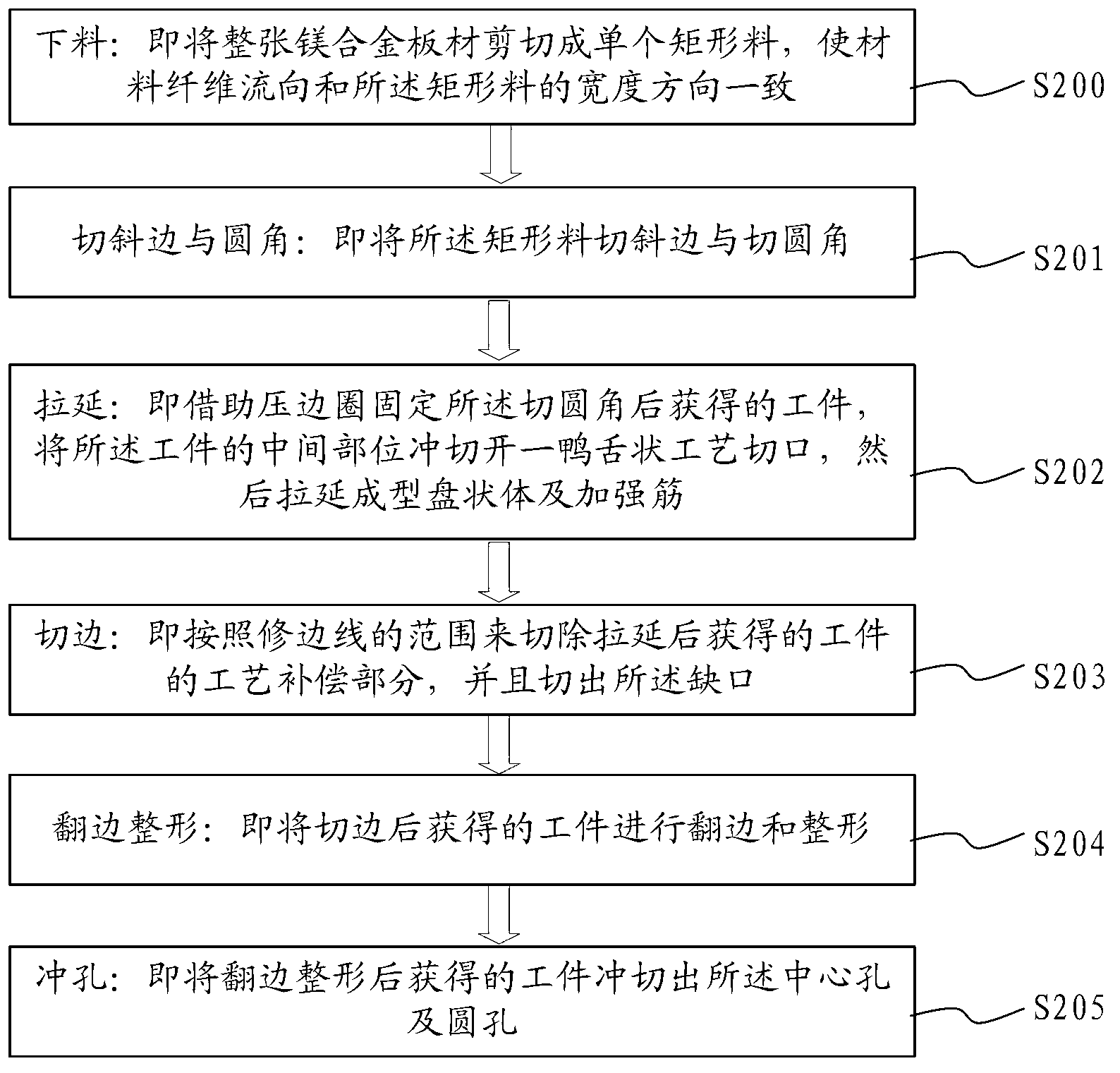

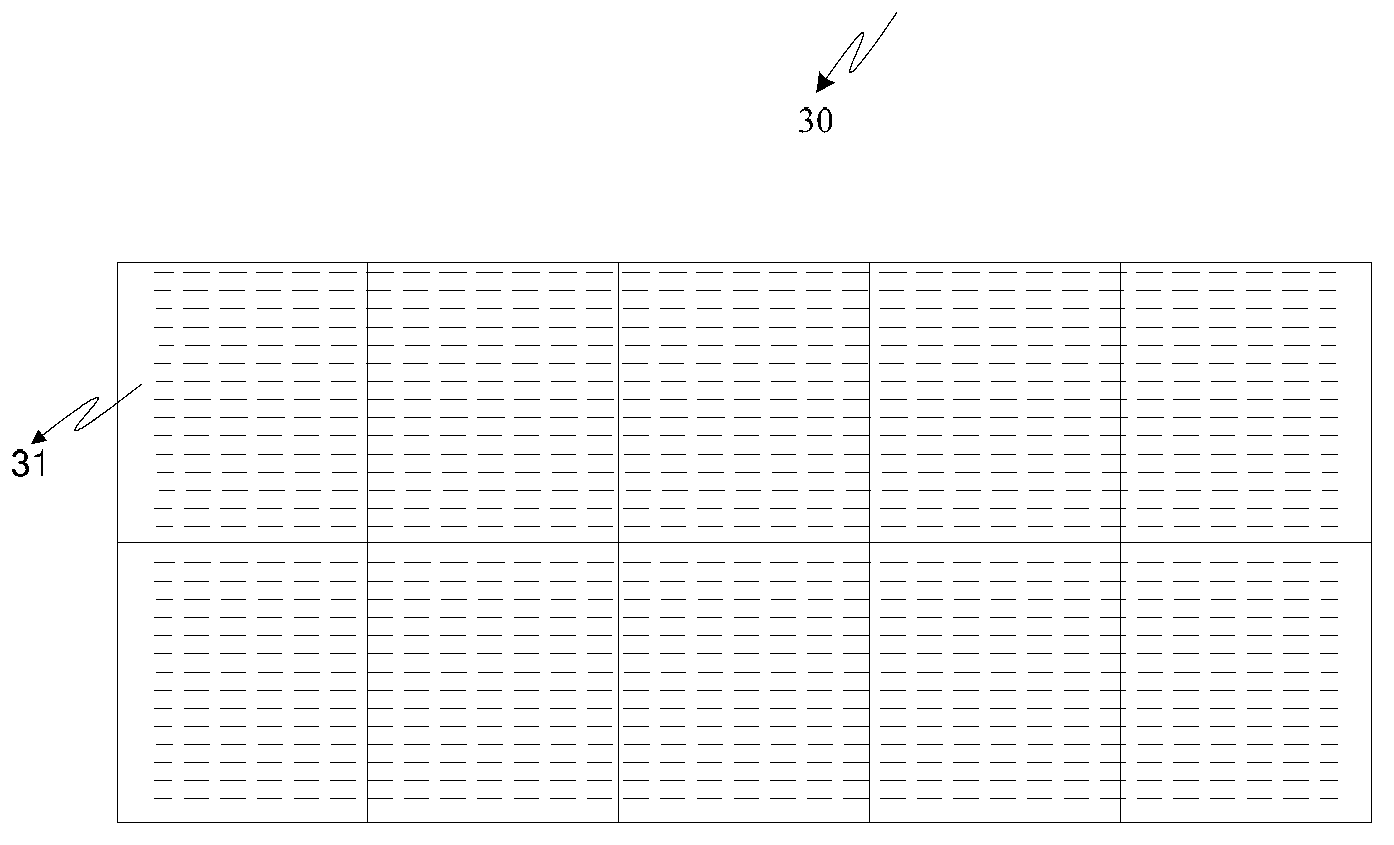

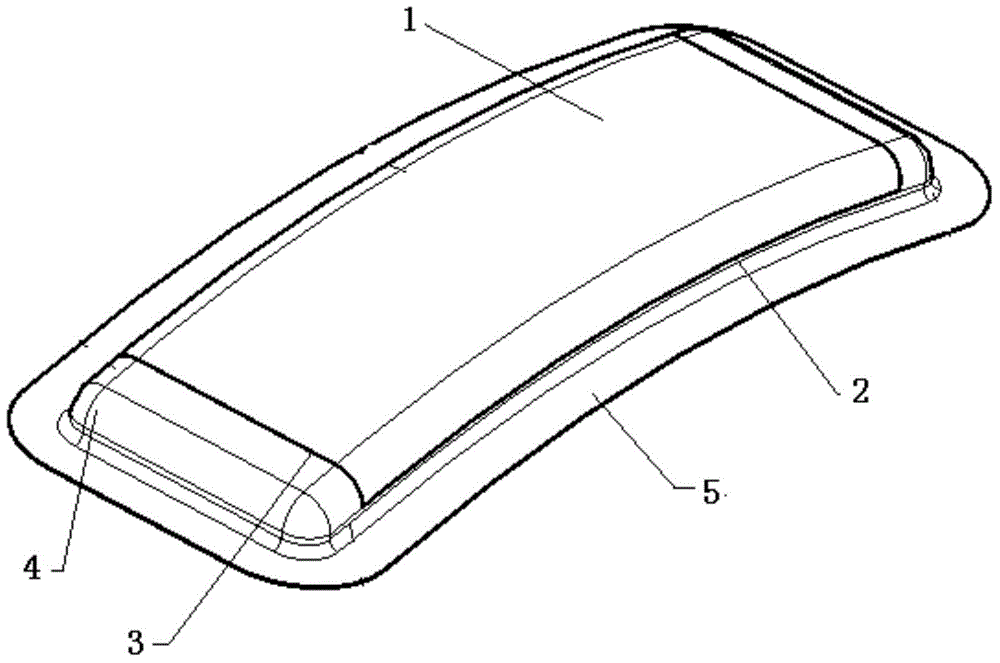

Magnesium alloy cold pressing automobile fender and forming process thereof

InactiveCN102910212ASmall sizePrecise size controlSuperstructure subunitsManufacturing technologyPunching

The invention relates to the technical field of manufacture of automobile parts, and particularly relates to a magnesium alloy cold pressing automobile fender and a forming process thereof. The process comprises the steps that an entire magnesium alloy plate is cut into single rectangular materials; each rectangular material is subjected to chamfering and round cornering; a duck tongue-shaped process cut is punched at the middle position of a workpiece obtained after round cornering by using a blank holder to fix, and then the workpiece is drawn into a plate-shaped body and a reinforcement rib; the process compensation part of a workpiece obtained after drawing is cut according to the range of a trimming line; a workpiece obtained after the cutting of the trimming line is carried out flanging and shaping; and a workpiece obtained after flanging and shaping is punched a central hole and round holes. Therefore, the magnesium alloy cold pressing automobile fender is made by the process, and has the characteristic of lighter weight compared with the fenders made of traditional materials, and solves the problems of easy crinkling and cracking of workpieces during punching and drawing procedures; and meanwhile, the precise control on the dimension, precision and strength of the fender is achieved.

Owner:上海宏昌汽配有限公司

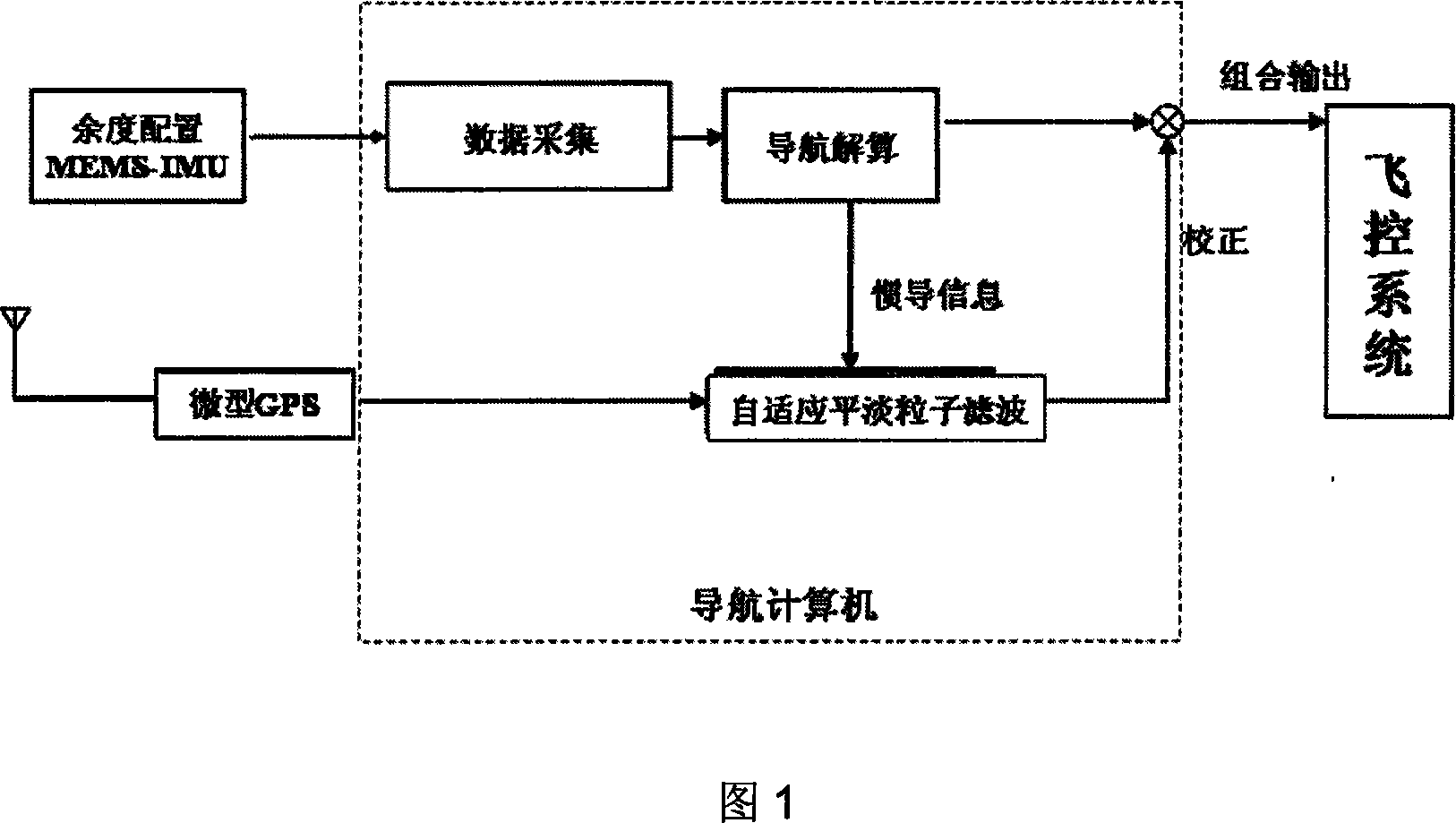

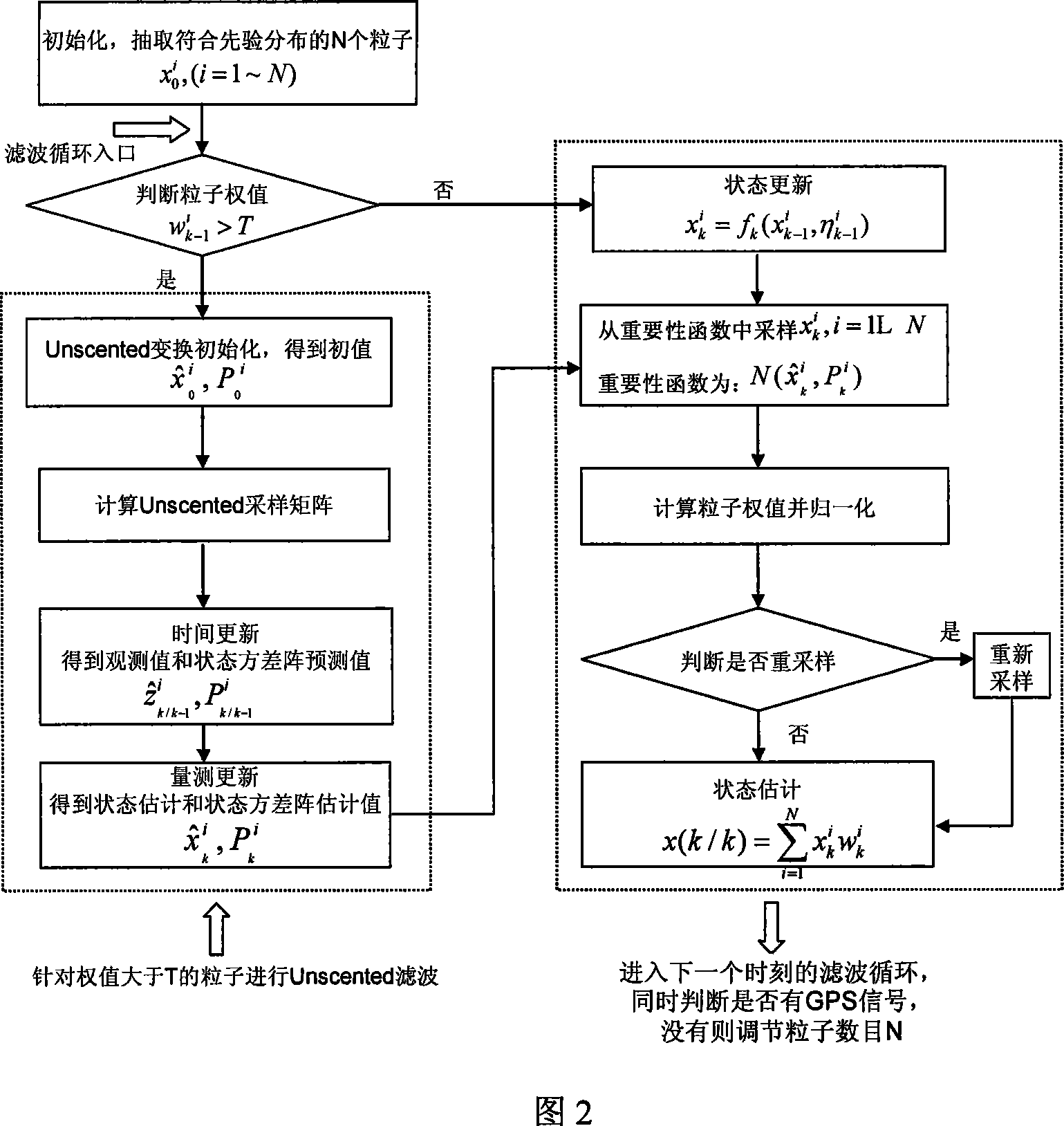

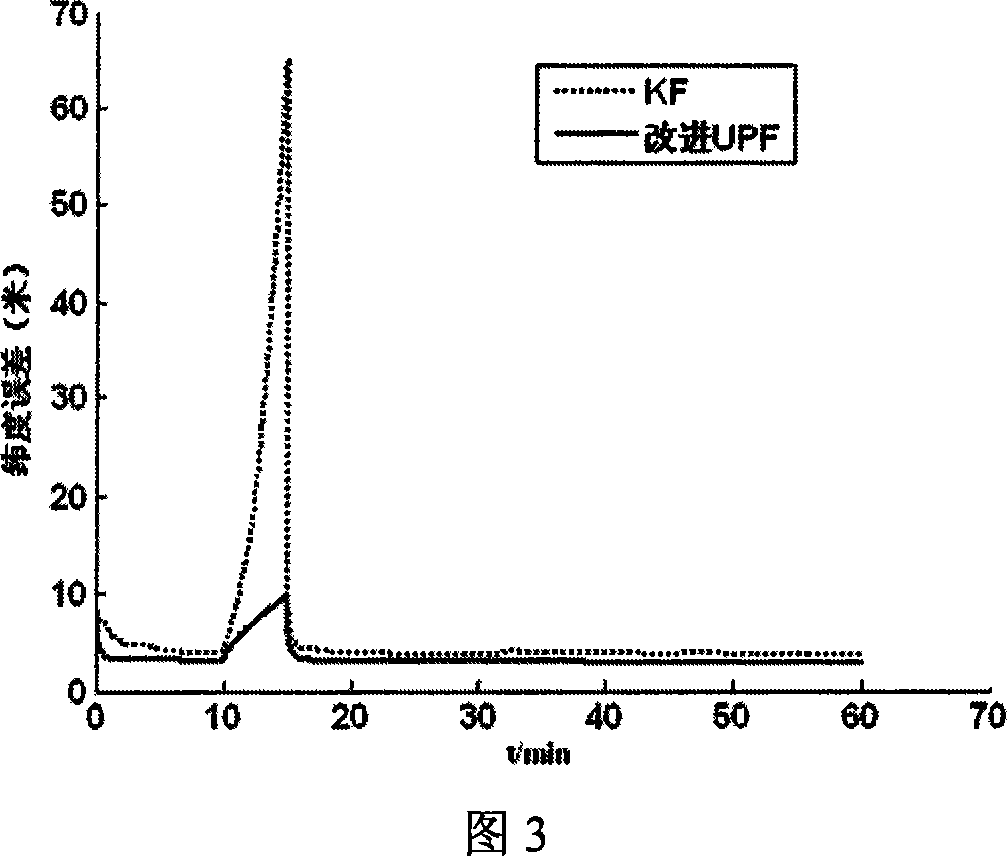

Minitype combined navigation system and self-adaptive filtering method

InactiveCN101059349ASmall amount of calculationHigh precisionNavigation by speed/acceleration measurementsPosition fixationAviationData acquisition

A micro combined navigate system and a relative self-adaptive filter method belong to inertia navigate system, comprising an abundance distribution inertia measuring unit, a micro GPS receiver, and a navigate computer, wherein the navigate computer comprises a data pick-up, navigate calculation, self-adaptive flat particle filter. And the filter method comprises that first designs a system state equation and a measuring equation, generates state sample particles in prior distribution according to the system state and the self-adaptive theory, then based on UKF filter threshold, judges if the standard decide particles enter into UKF filter, while only refreshes time of the particles not entered into UKF filter, refreshes sample weight, judges if needs resample, processes state fusion on the particles to obtain a state evaluated value. The invention can obtain inertia and navigate property, and process compensation in navigate calculation, while the invention avoids large calculation of flat particle filter, improves the accuracy of navigate system, reduces the error of navigate system, to be used in aviation and aerospace fields or the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

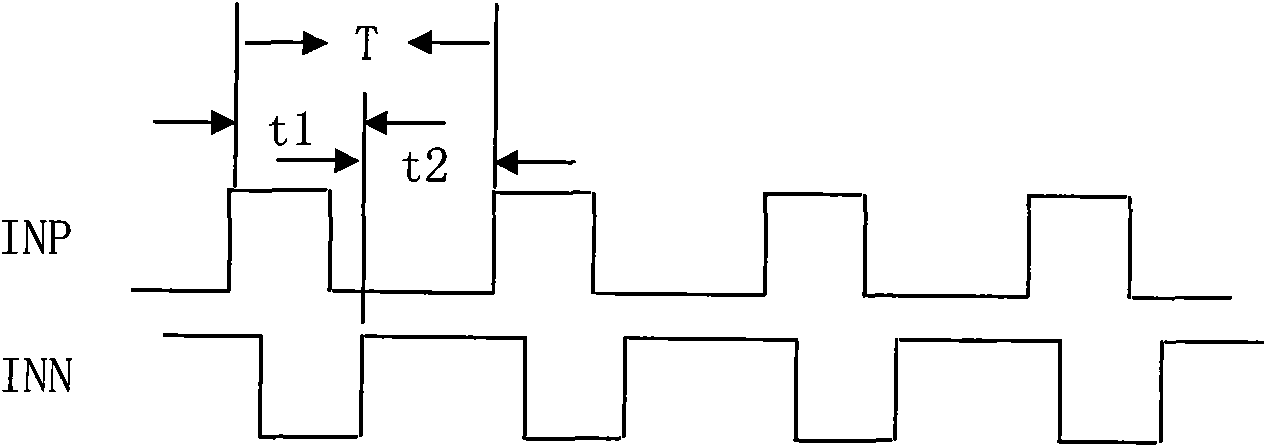

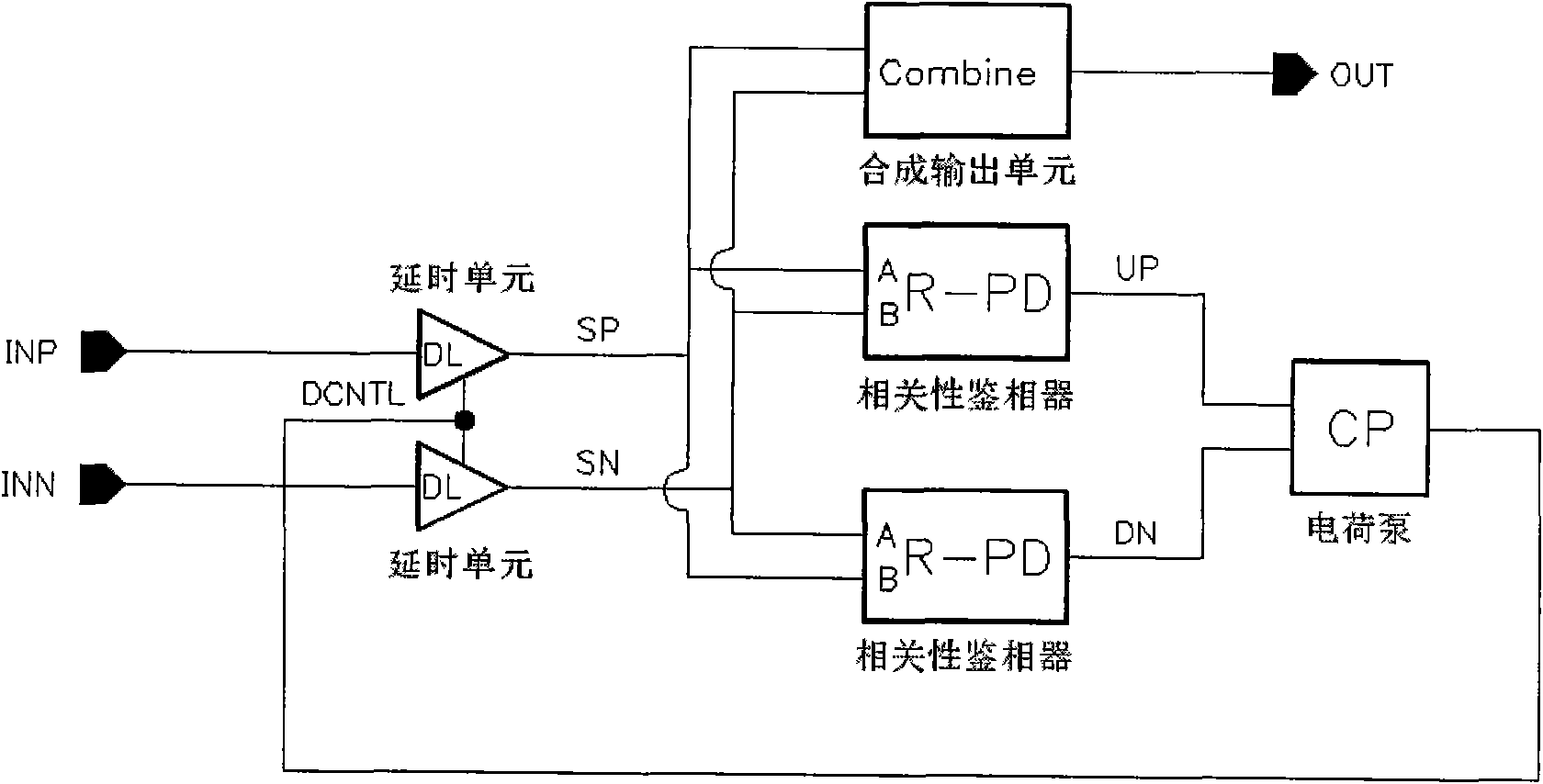

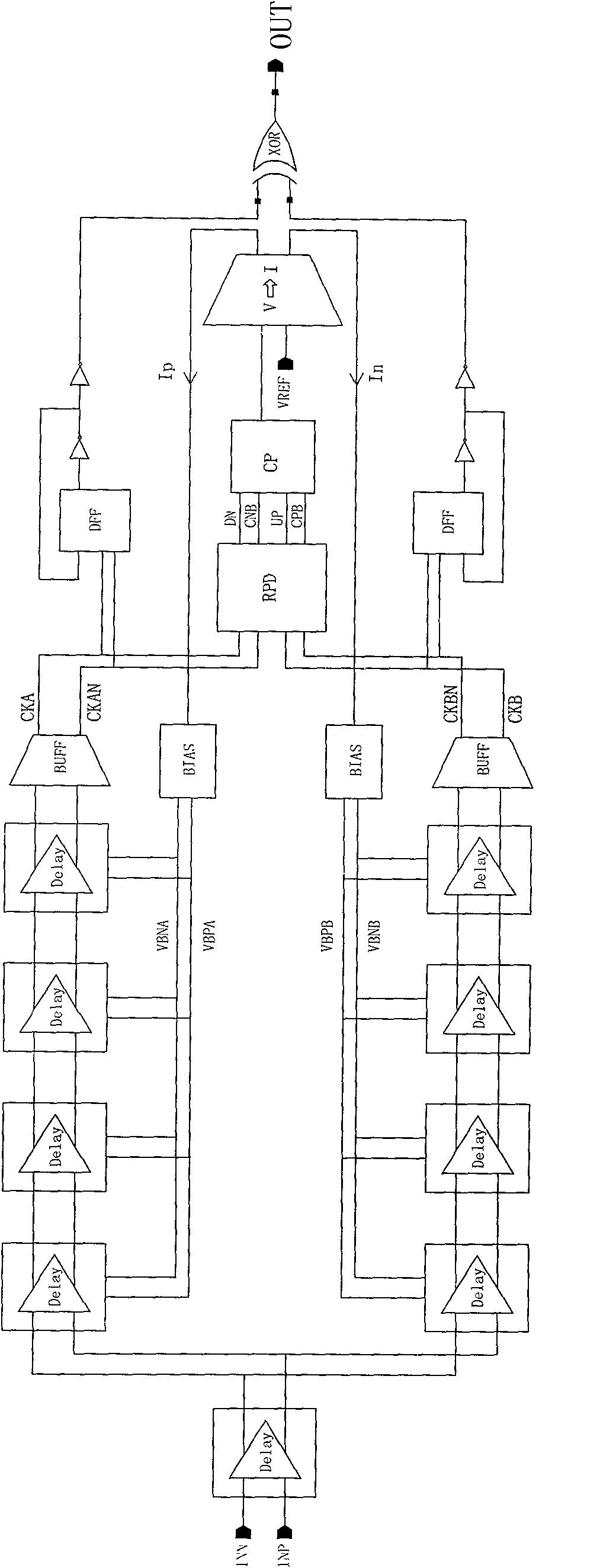

Dutyfactor adjusting method and circuit

InactiveCN101645702ALarge adjustment rangeStructural symmetryPulse automatic controlContinuous to patterned pulse manipulationPhase detectorDifferential signaling

The invention discloses a dutyfactor adjusting method and a circuit. In the invention, two symmetrical delay units with opposite control logic input differential signals INP and INN carry out relativedelay detection on the differential signals, then the delay units are connected with correlation phase detectors, then the correlation phase detectors are connected with a charge pump, the output ofthe charge pump forms a loop with the two relay units, and the dutyfactor is adjusted at last, thereby a signal with the output dutyfactor of an output unit of 1:1 is synthesized. The invention can widen the adjusting scope of the duryfactor, and can theoretically realize the output of random preset dutyfactor; the structure of an implementation circuit is completely symmetrical, and high output precision (namely dutyfactor output signal with high precision) can be realized through favorable matching and process compensation; and an equivalent model of the circuit is a first order pole circuit, and the stability is good.

Owner:IPGOAL MICROELECTRONICS (SICHUAN) CO LTD

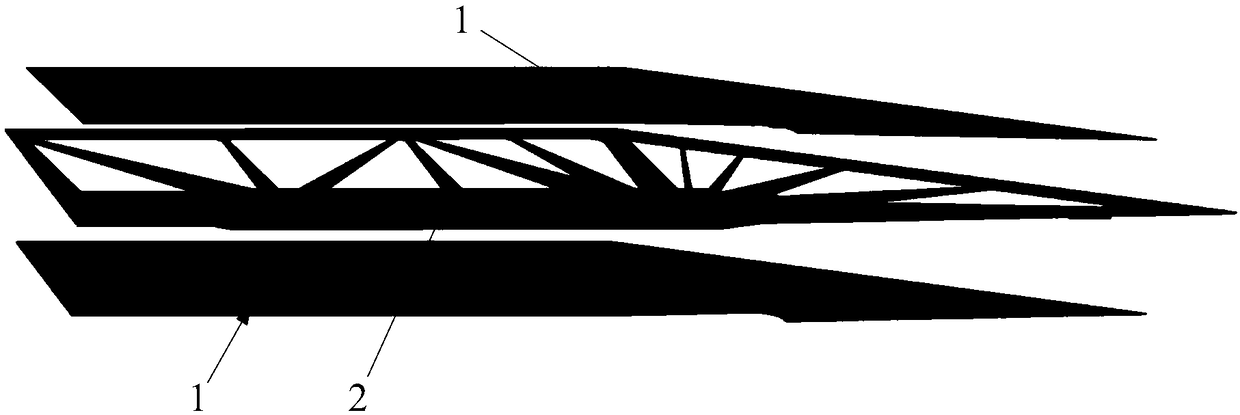

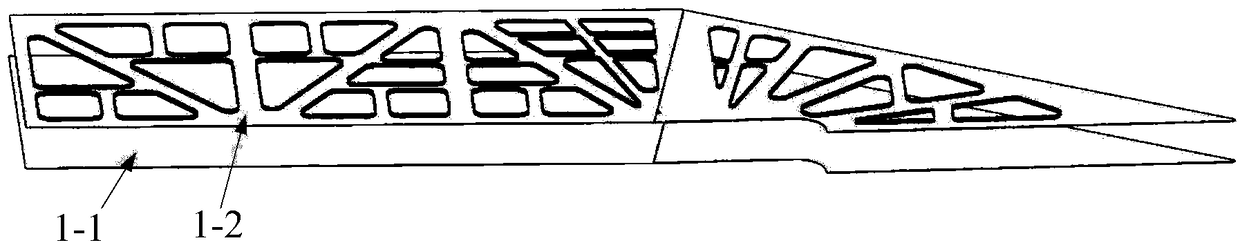

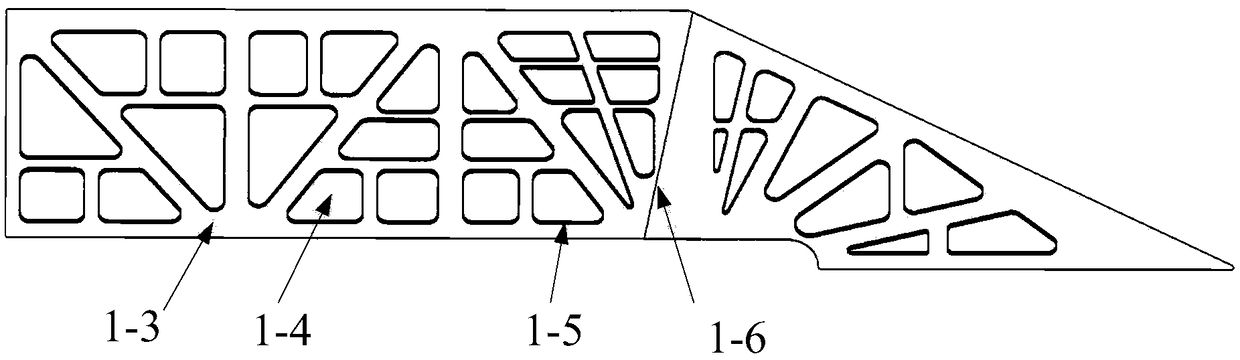

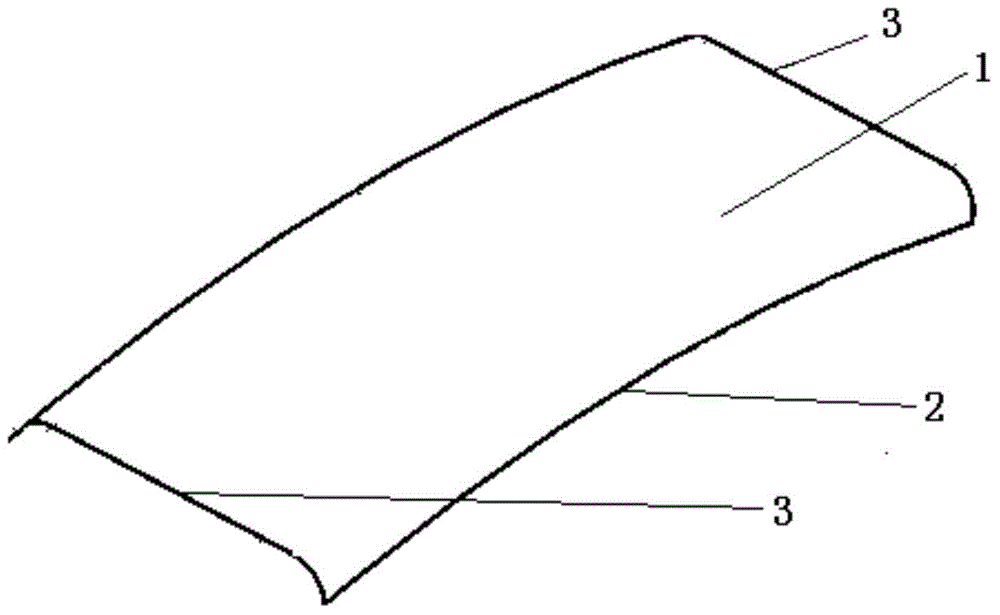

Variable-thickness lightweight elastic wing skin forming method

The invention belongs to the technical field of precision plastic forming, and particularly relates to a variable-thickness lightweight elastic wing skin forming method adopting an integral superplastic diffusion connection method. According to the variable-thickness lightweight elastic wing skin forming method, outer plates and inner plates of two-layer skin are subjected to diffusion connectionand superplastic forming, a process compensation surface formed in the process of forming reinforcing ribs is subjected to wire cutting to remove process allowance, then forming and manufacturing withdifferent thicknesses are realized in different regions of the skin, and a bending angle of a windward surface is subjected to cold bending. The variable-thickness lightweight elastic wing skin forming method is realized through a novel and reasonable design of the variable thickness reinforced structural skin, the combining diffusion connection, the superplastic forming, the wire cutting and thecold bending. According to the variable-thickness lightweight elastic wing skin prepared from the forming method, the structural strength of the skin can be effectively improved while weight reduction of traditional thickness skin is realized, the width of a skeleton rib can be greatly reduced, the weight of a traditional skeleton is greatly reduced, the requirements of future missile models on lightweight bearing structures can be met, the qualification rate and production efficiency of products are improved, and mass production can be realized.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Method for forming shaped convex surface type high-precision reflection panel with honeycomb sandwich structure

The invention provides a method for forming a shaped convex surface type high-precision reflection panel with a honeycomb sandwich structure. The reflection panel particularly comprises three layers of aluminum plates, two layers of honeycomb cores and a plurality of embedded parts for connecting, wherein the three layers of the aluminum plates comprise a work plate, a middle connecting plate and a back plate. The formation method at least comprises the following steps of: three-dimensional modeling of three layers of plates of the shaped convex surface type high-precision honeycomb sandwich structure, space geometric flattening of the three layers of the plates, establishment of a process compensation surface, calculation of a nail height and positioning of the three layers of the plates on a high-precision nail bed; and a process of paving a sandwich structure layer by layer is a main process of manufacturing the shaped convex surface type reflection panel. According to the method provided by the invention, the manufacturing problem of the shaped convex surface type high-precision reflection panel and the manufacturing difficulty of the shaped convex surface type reflection panel with sharp points are solved, thereby realizing a manufacturing target of a shaped convex surface type antenna reflection panel which has the advantages of high precision, large rigidity and light weight.

Owner:BEIHANG UNIV

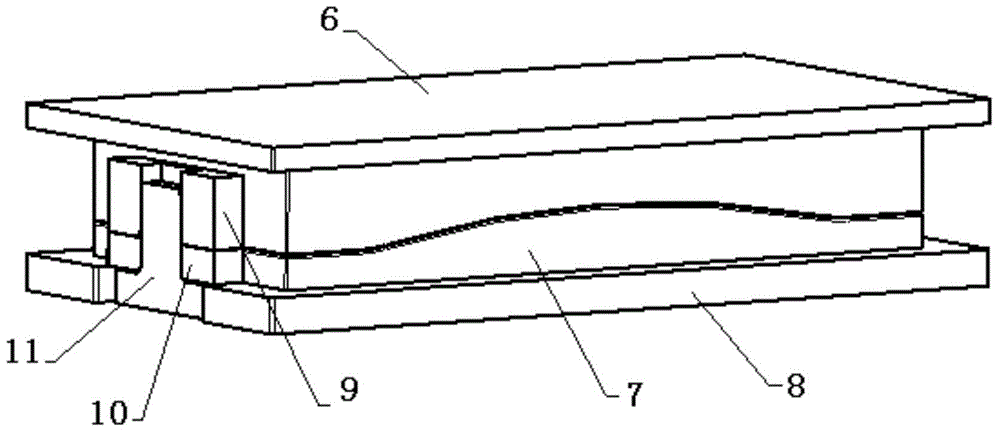

Bulging draw forming method for variable-camber half flat tube part

ActiveCN104438537ASolving Elasticity ProblemsSolve wrinkleShaping toolsEngineeringProcess compensation

The invention provides a bulging draw forming method for a variable-camber half flat tube part. A process model for bulging draw forming of the part is set up according to a theoretical model of the part, the process model is used for carrying out process compensation on the theoretical model of the part to enable the theoretical model to become a cavity with a circular bead process end, an annular flange edge is arranged on the bottom face of the cavity, unfolded blank materials and a bulging draw forming die for part machining are manufactured according to the process model, and the plate blank materials to be formed are subjected to pressing and draw forming under the effect of external force.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

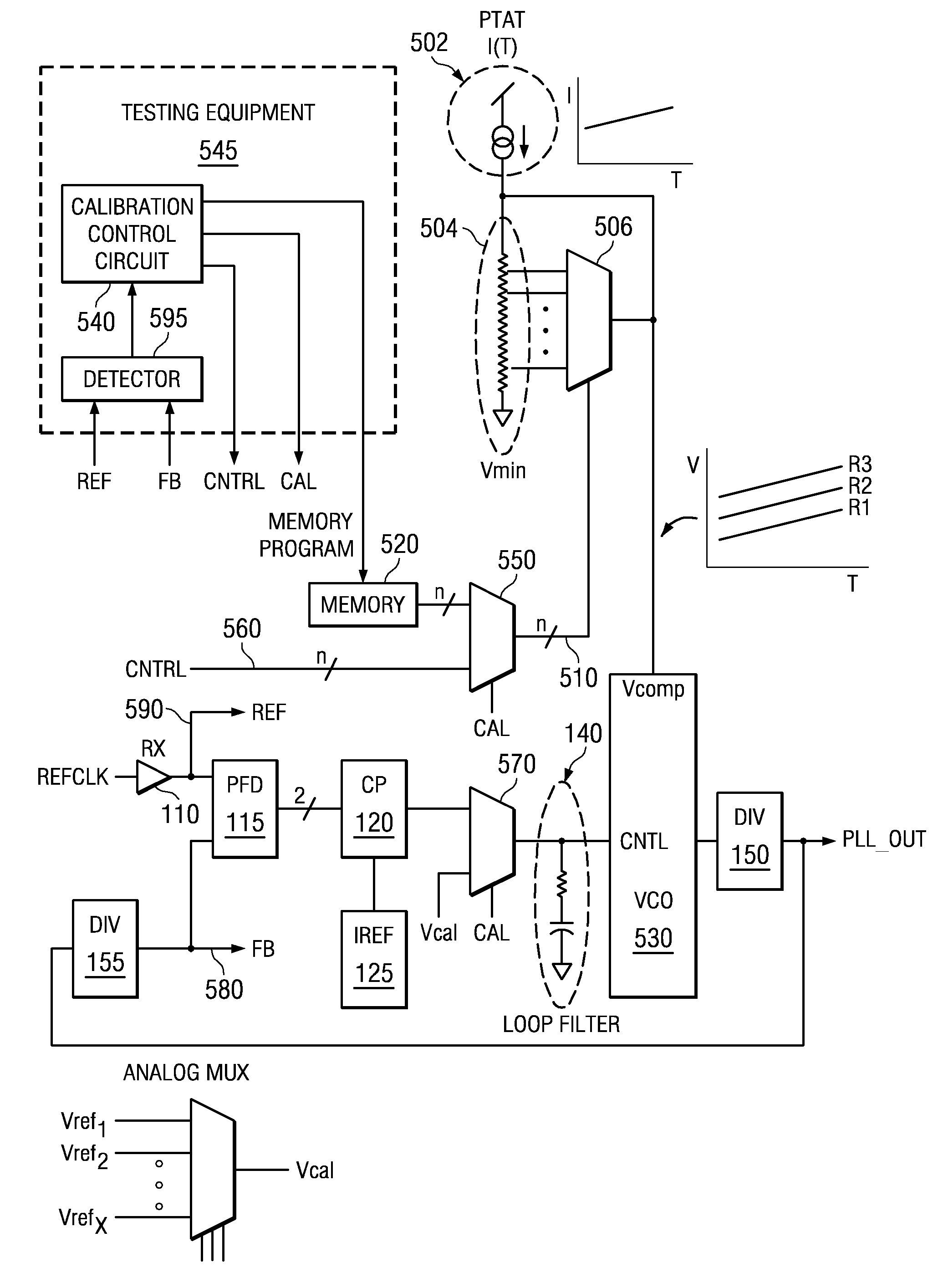

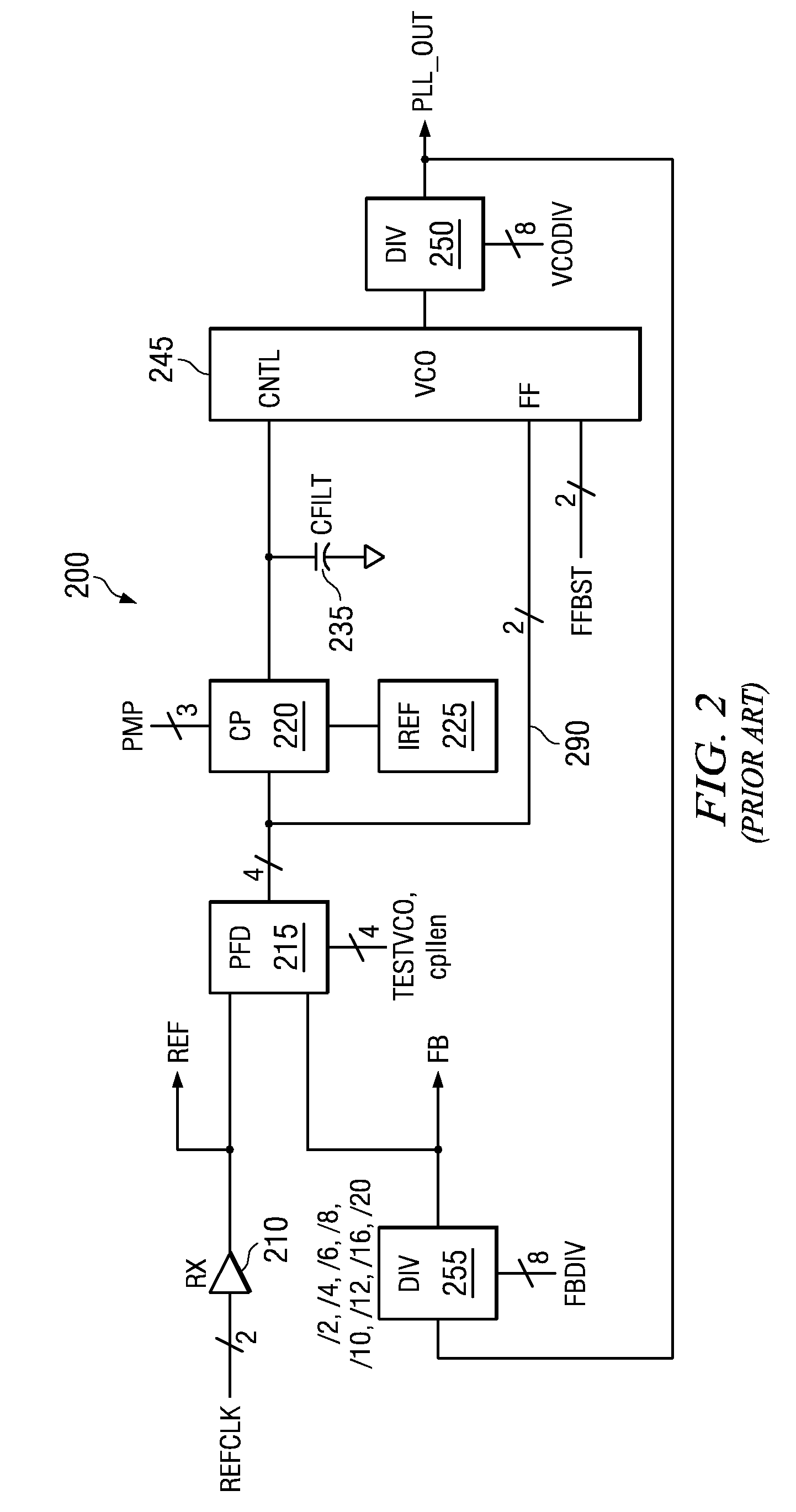

Phase Locked Loop with Temperature and Process Compensation

InactiveUS20090285344A1Pulse automatic controlGenerator stabilizationProcess compensationPhase-locked loop

Mechanisms are provided for compensating for process and temperature variations in a circuit. The mechanisms may select at least one resistor in a plurality of resistors in the circuit to provide a resistance value for generating a calibration voltage input to the circuit to compensate for variations in process. A reference signal may be compared to a feedback signal generated by the circuit based on the calibration signal. A determination is made as to whether the feedback signal is within a tolerance of the reference signal and, if so, an identifier of the selected at least one resistor is stored in a memory device coupled to the circuit. The circuit may be operated using the selected at least one resistor based on the identifier stored in the memory device. An apparatus and integrated circuit device utilizing these mechanisms are also provided.

Owner:GLOBALFOUNDRIES INC +2

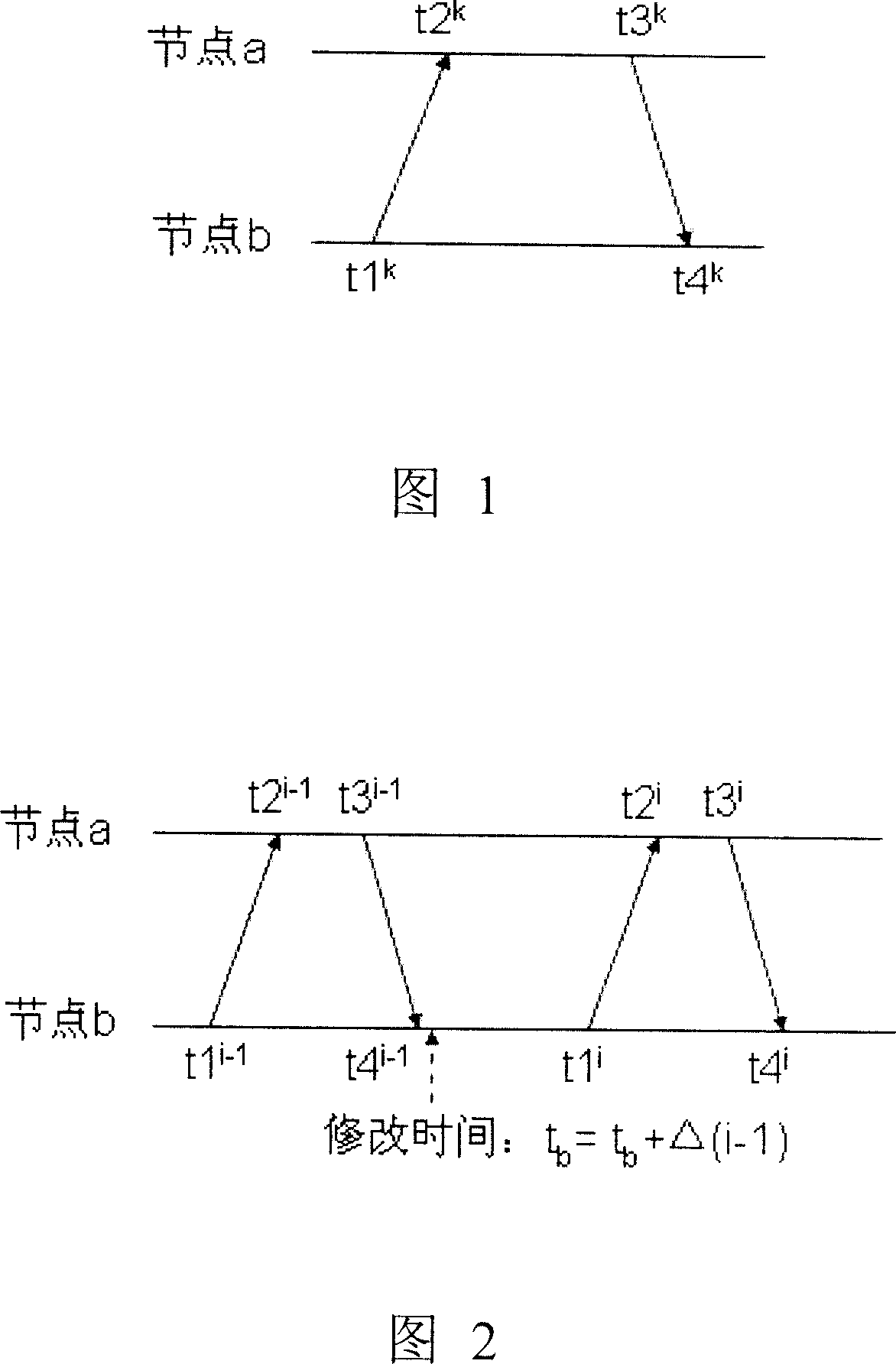

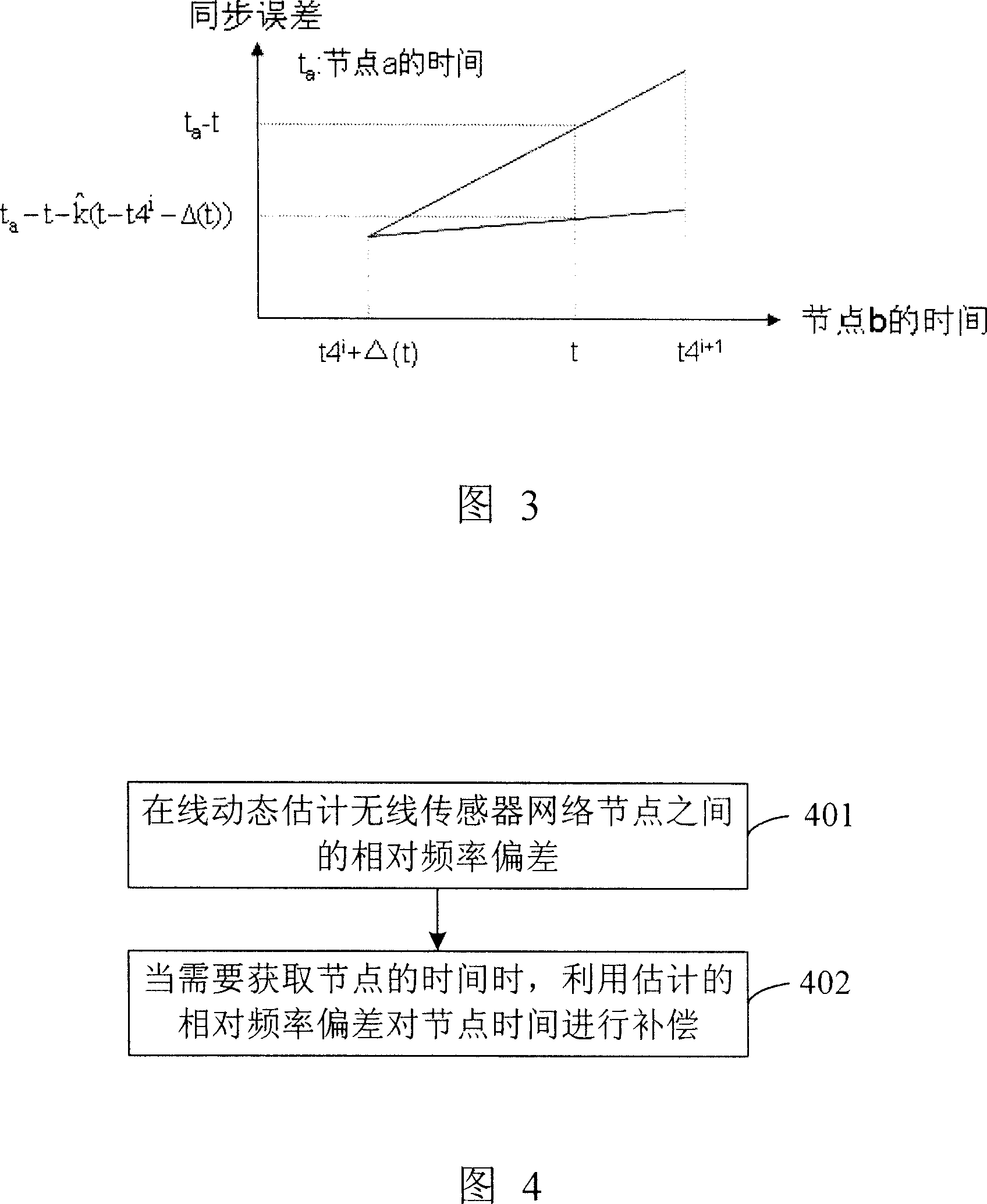

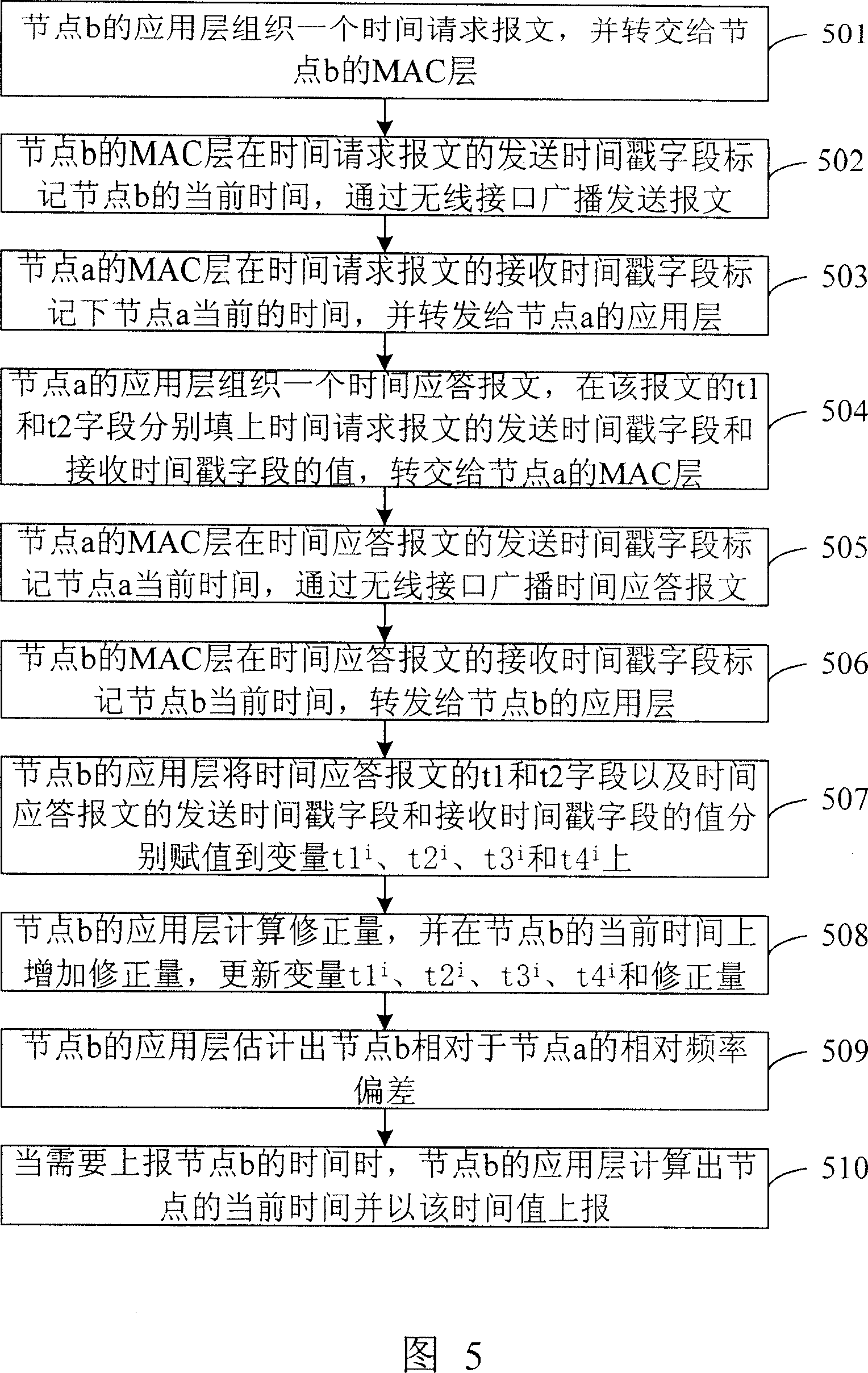

A method for improving wireless sensor network time synchronization precision

This invention relates to wireless sensor network technique and discloses one method to improve wireless sensor network time simultaneous accuracy, which comprises the following steps: a, online dynamic estimating wireless sensor network joints relative frequency bias; b, in need of point time, using estimated frequency bias to compensate point time. This invention can process compensation by use of estimation relative frequency bias.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

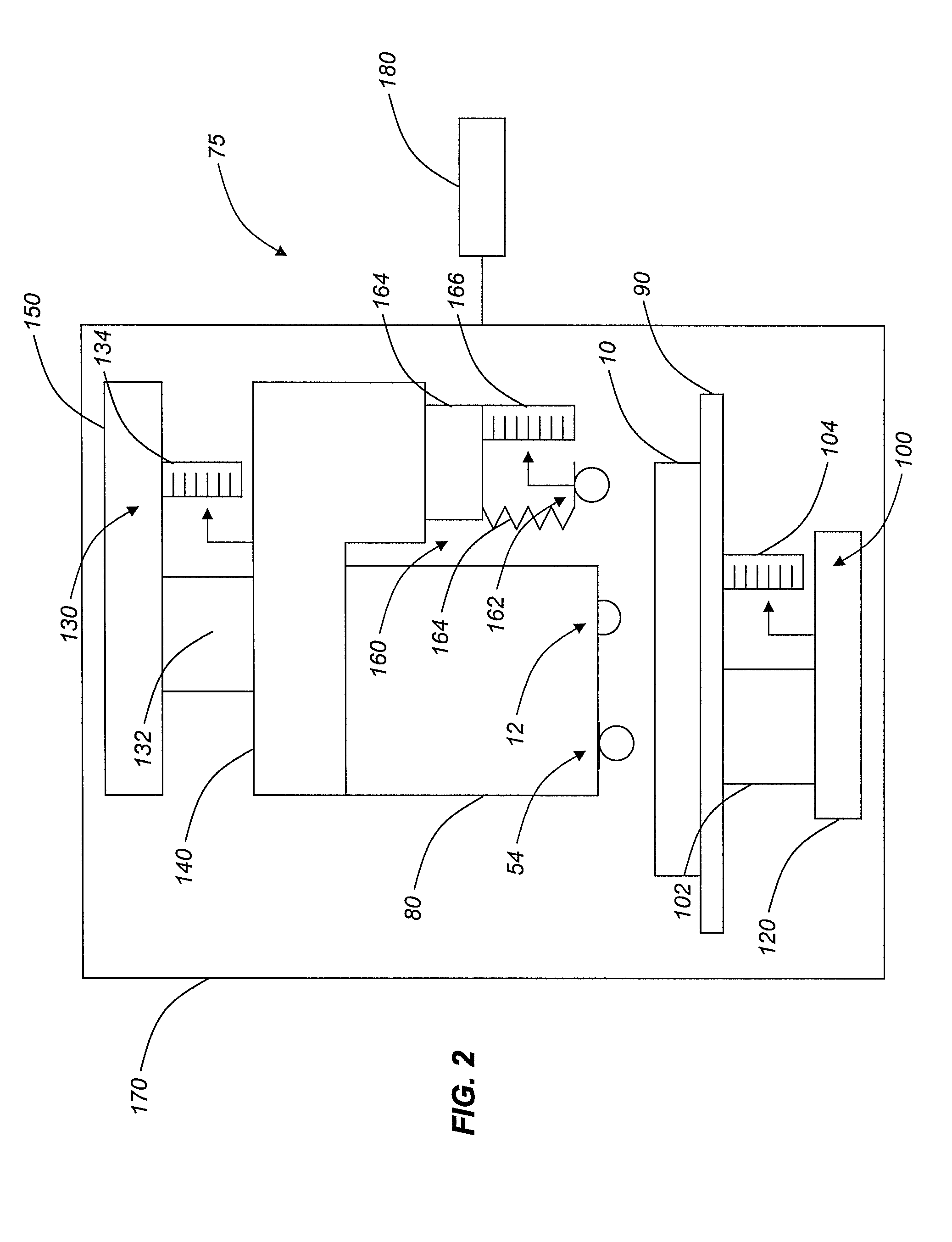

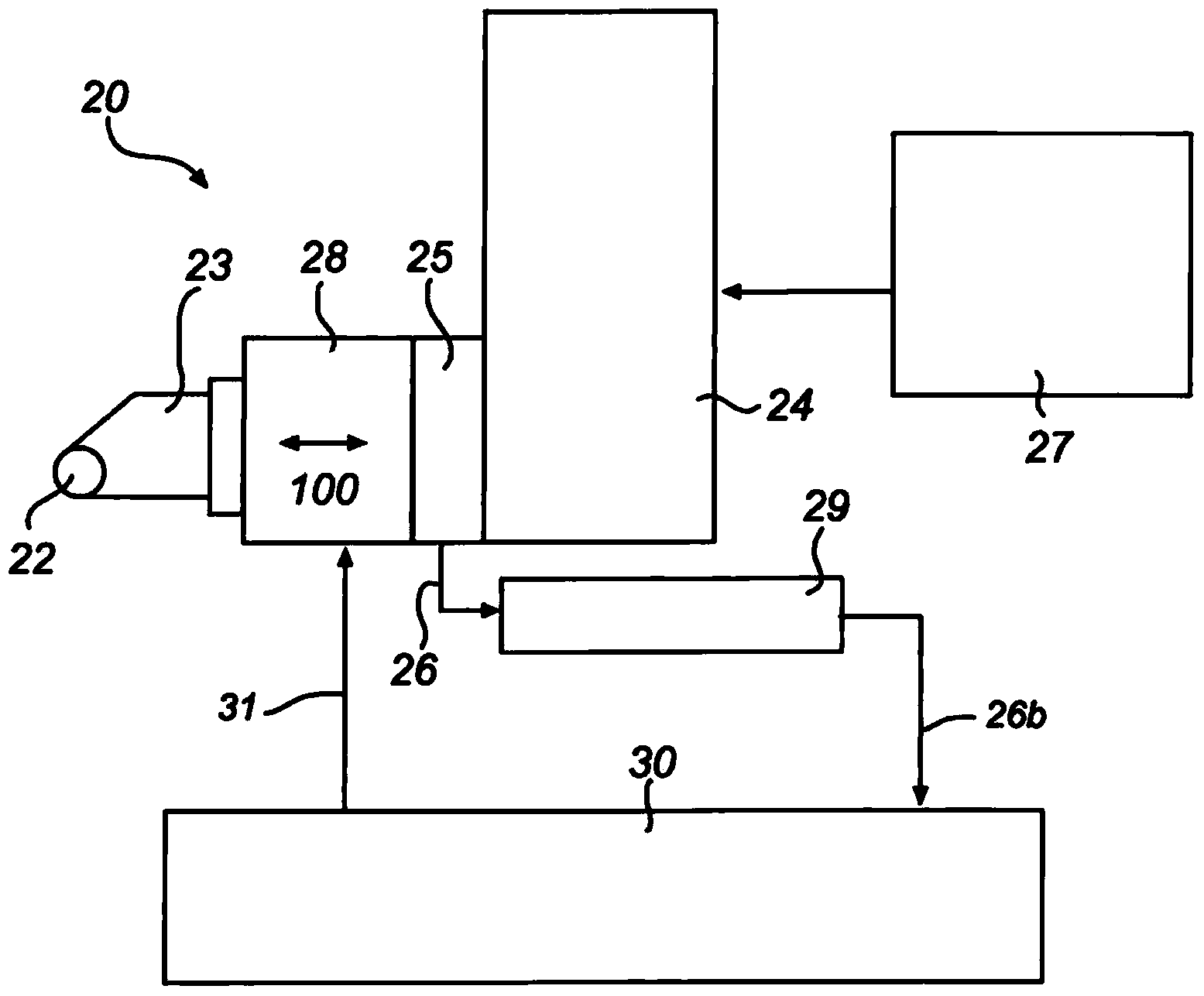

In-process compensation of machining operation and machine arrangement

The present invention relates to a method for performing in-process compensating a machining operation on a workpiece, wherein the compensation process comprises generating a control signal representative of magnitude of a contact force exerted on a cutting tool in a normal direction in relation to a machining surface of the workpiece, determining a compensation parameter value based on the control signal, and compensating the machining operation based on the compensation parameter value. The present invention also relates to corresponding machine arrangement for performing machining operation on a workpiece, such as a hard turning process.

Owner:AB SKF

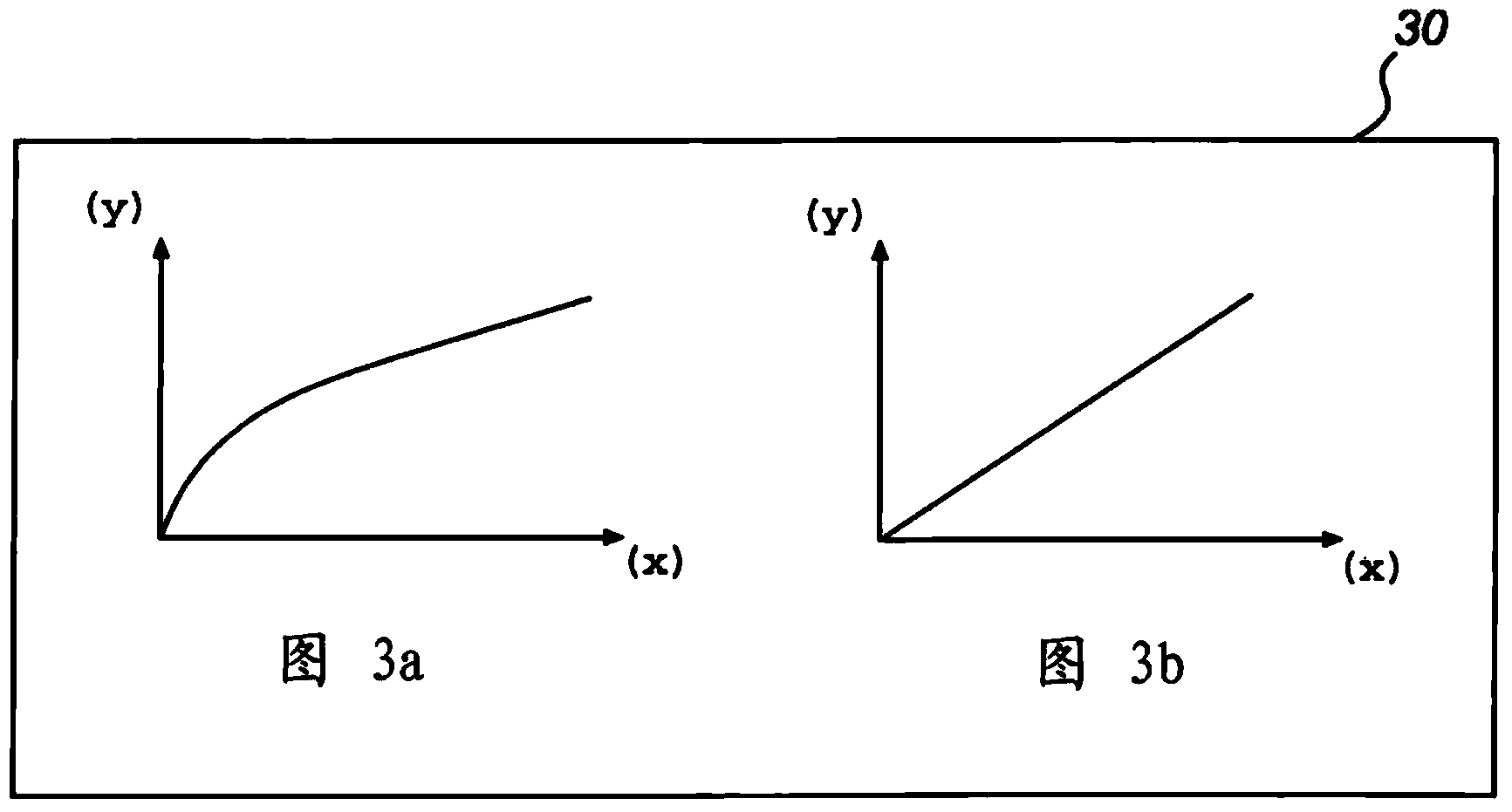

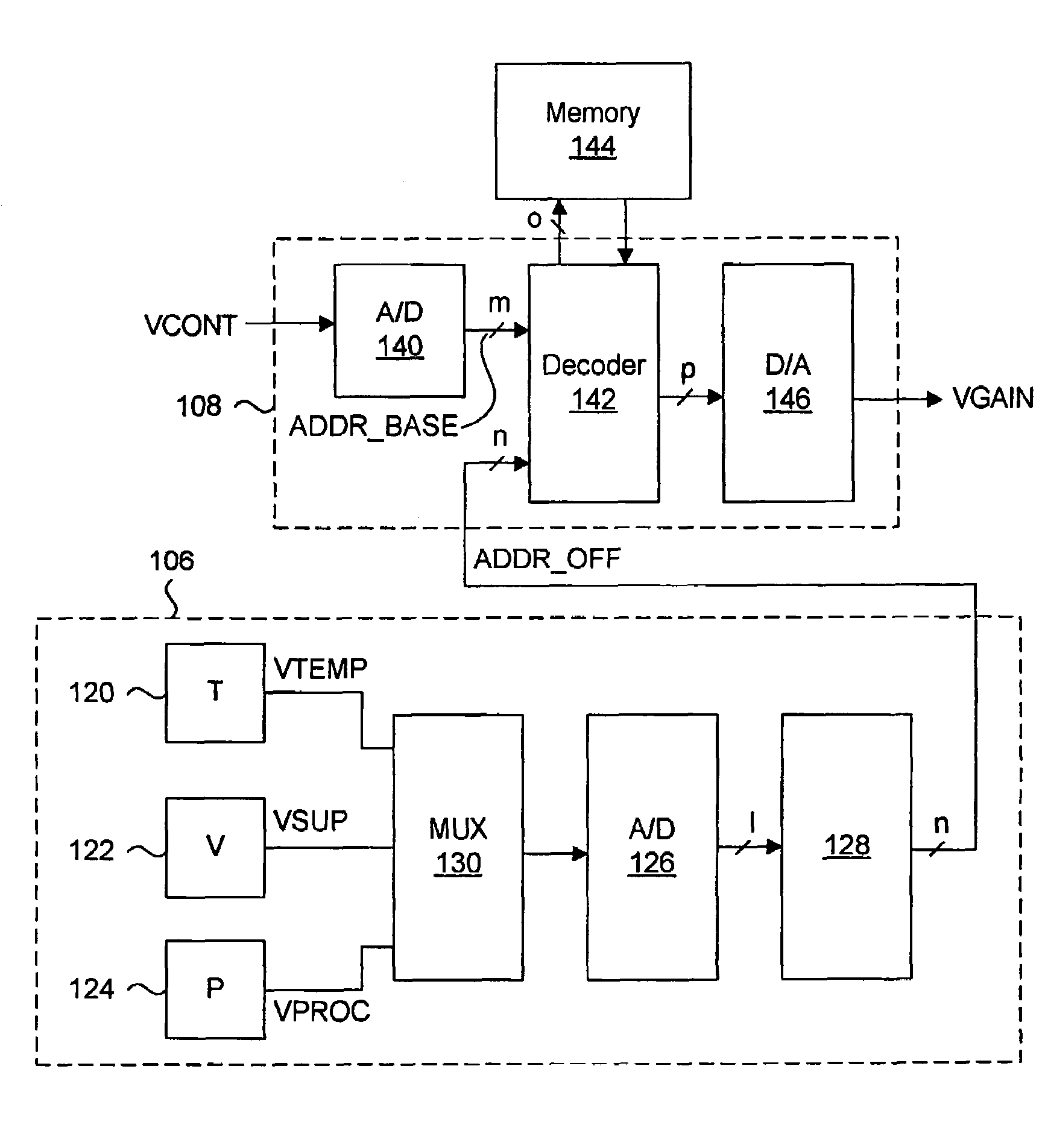

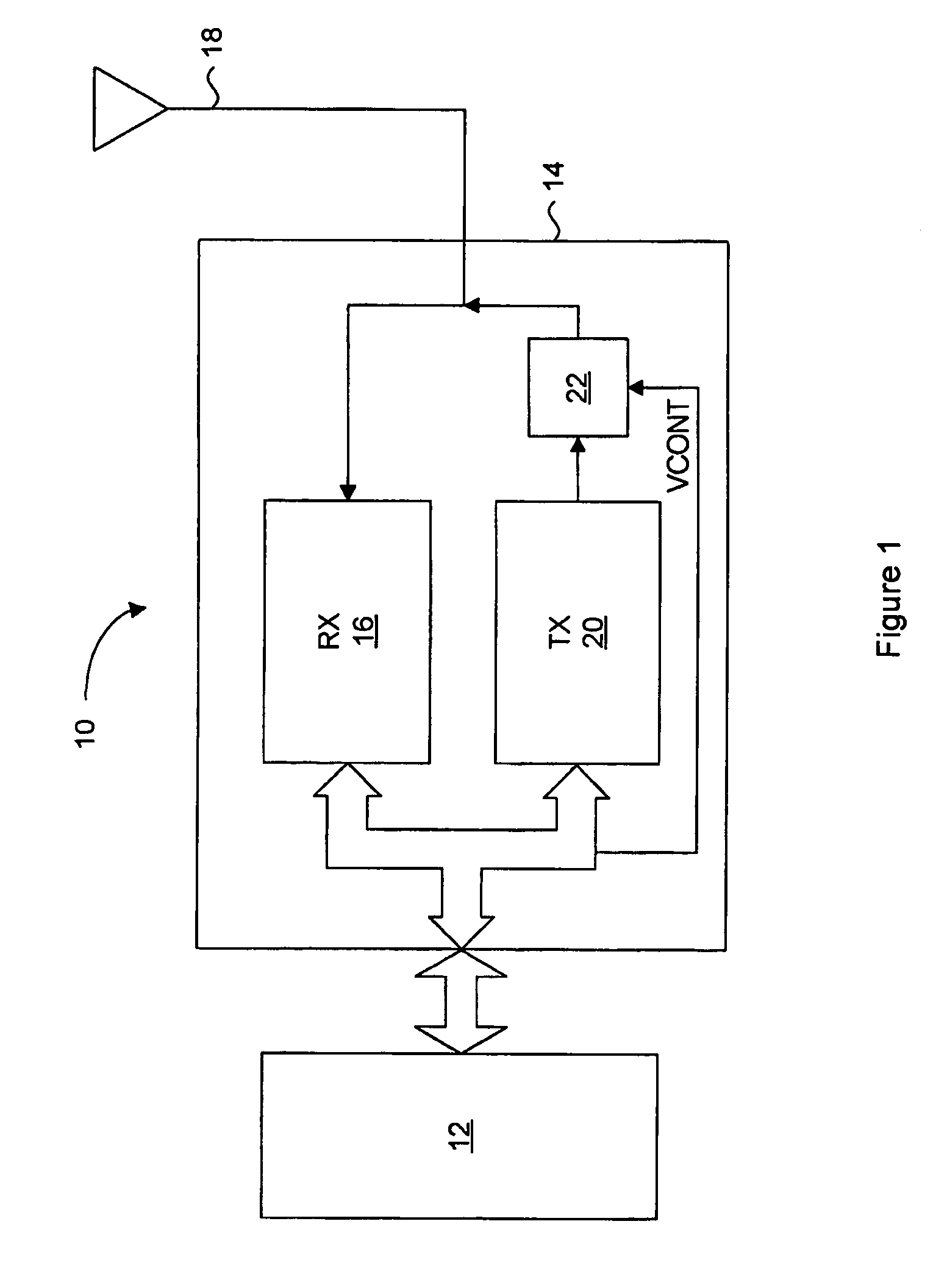

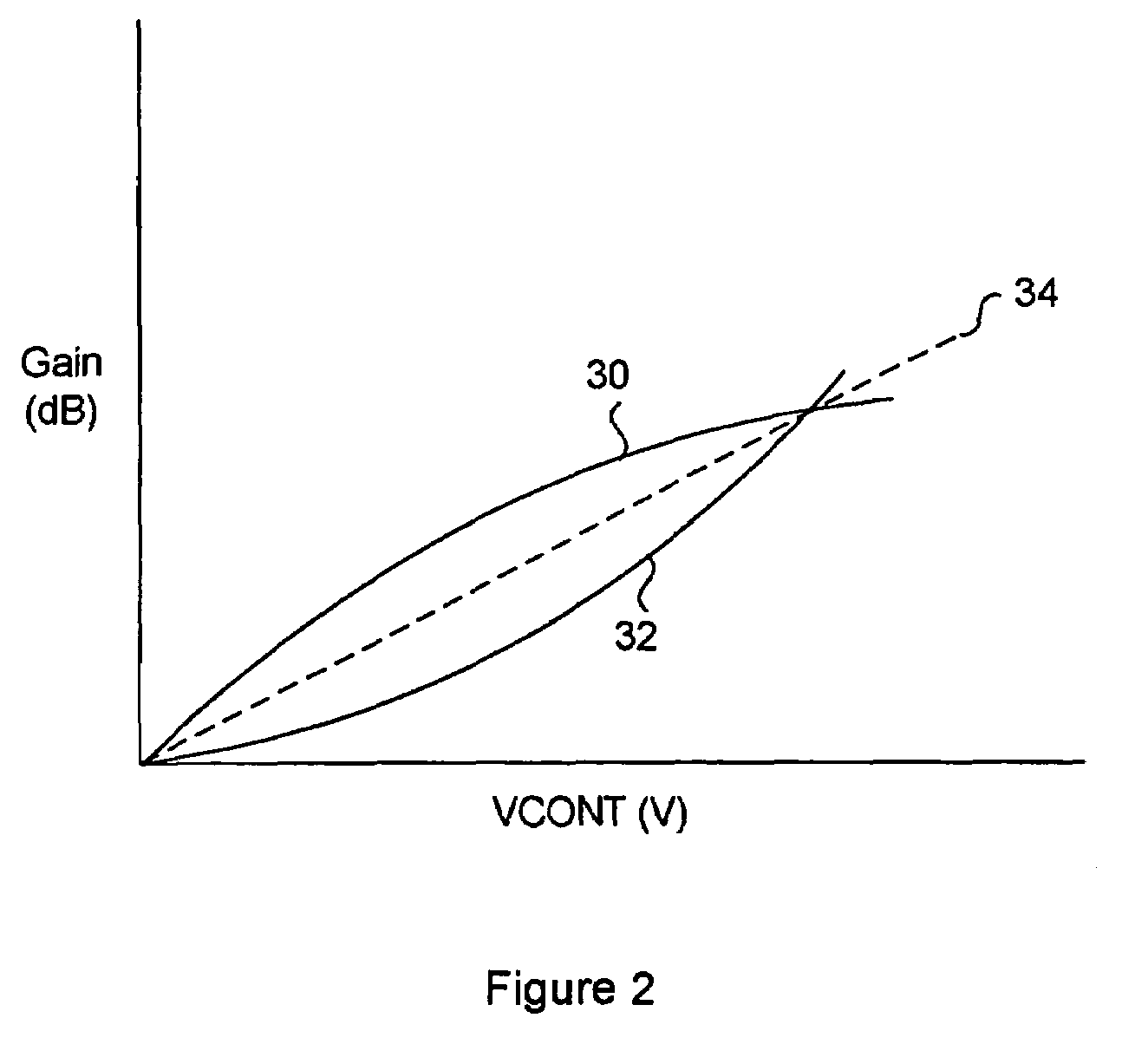

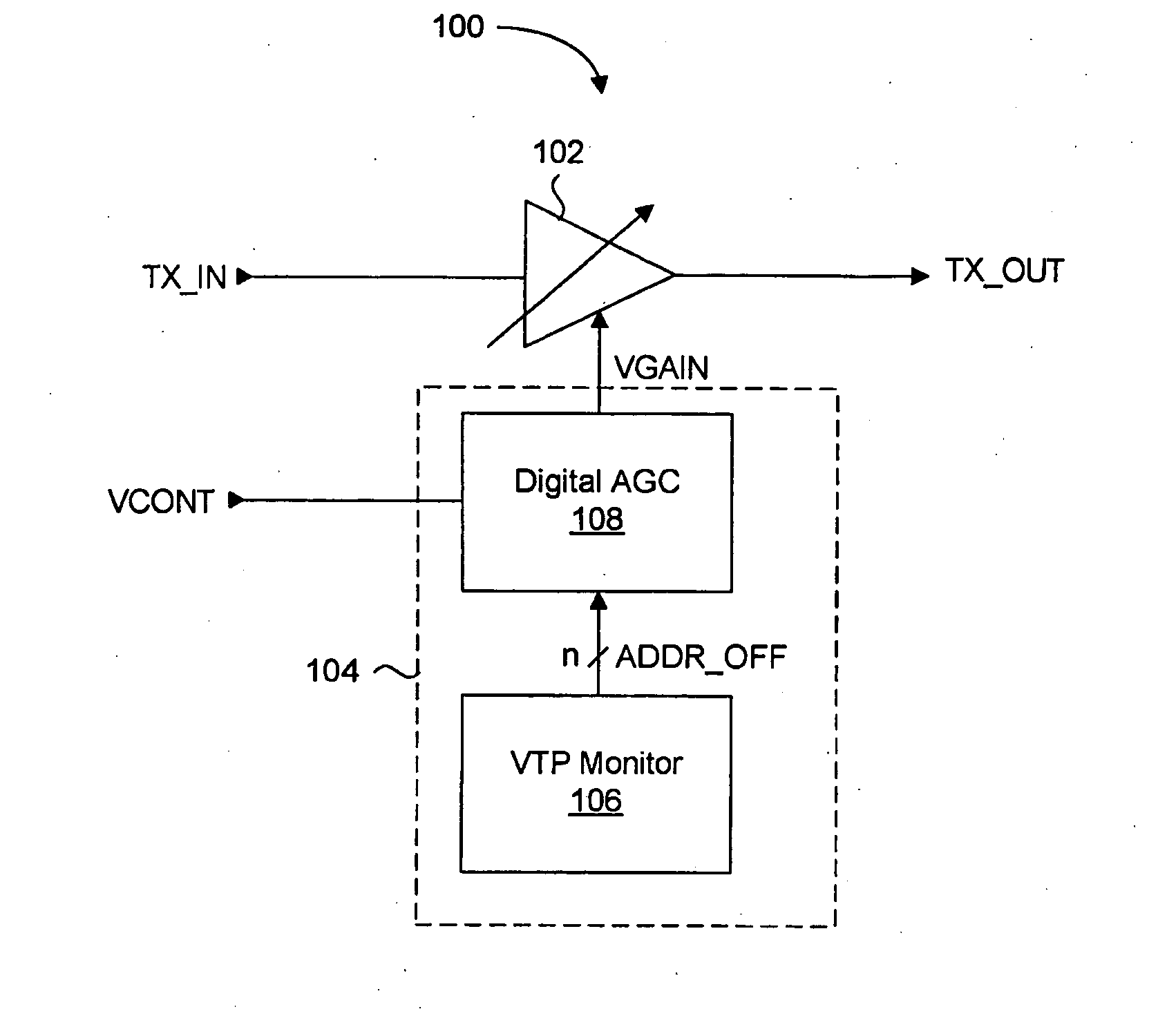

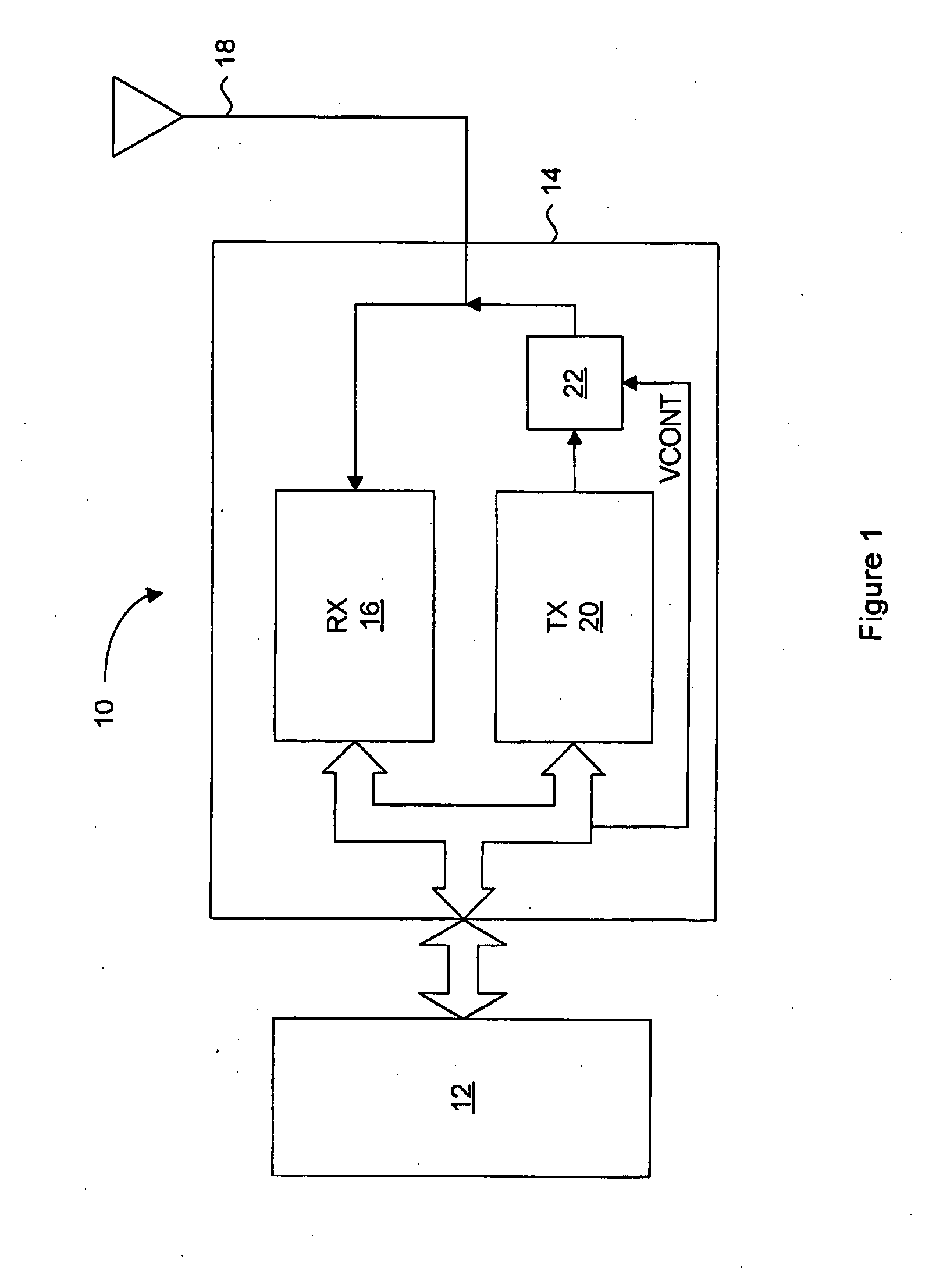

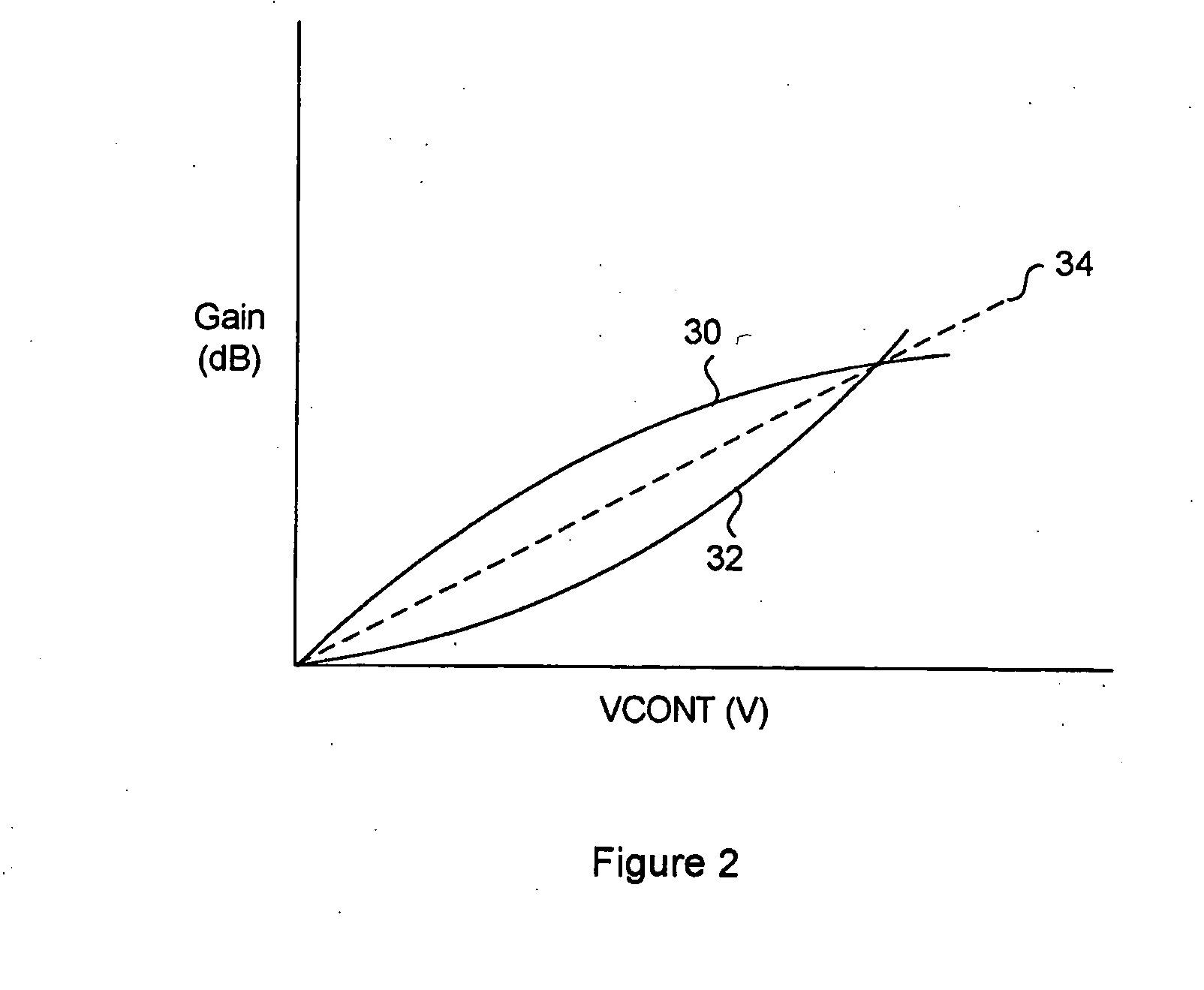

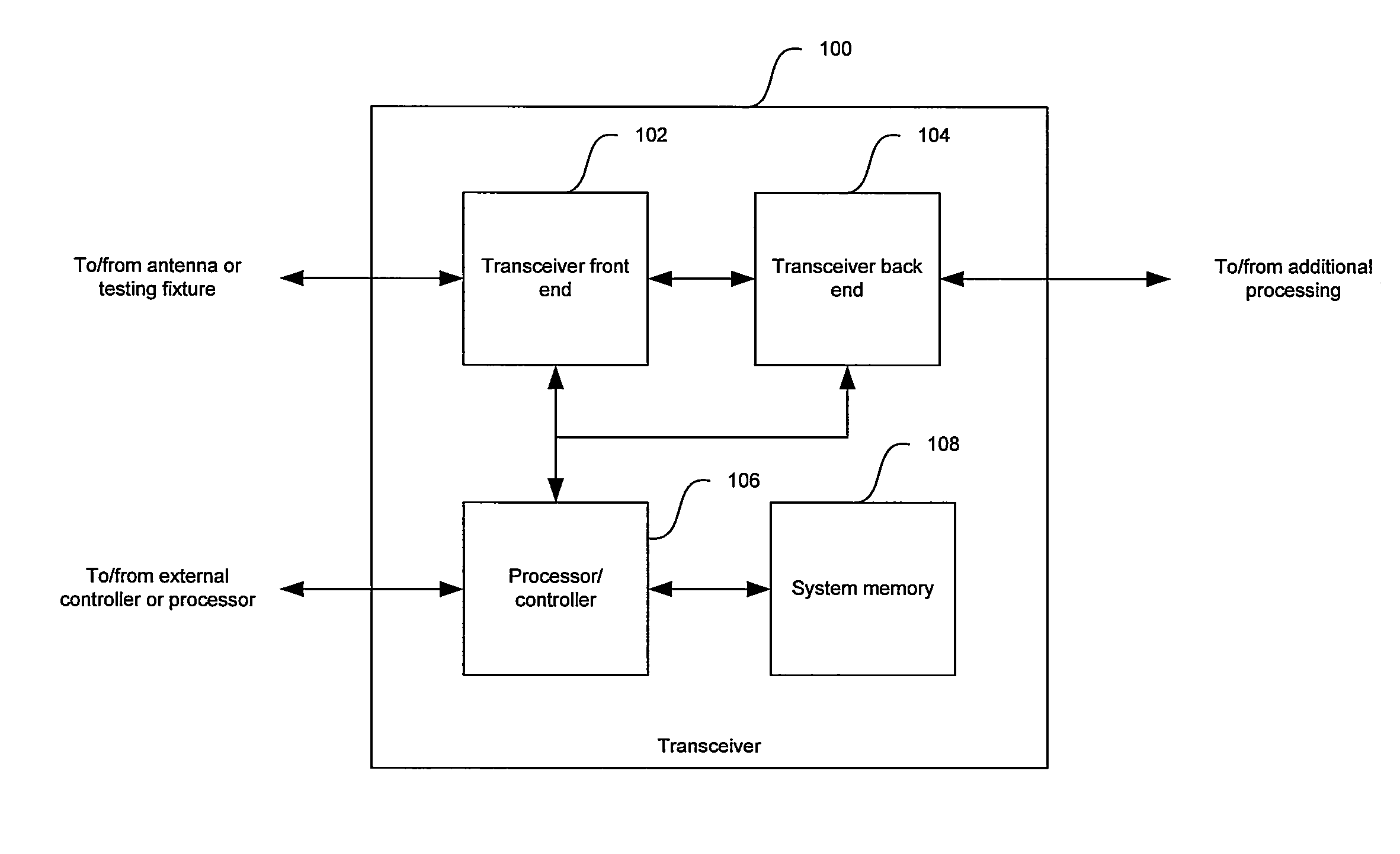

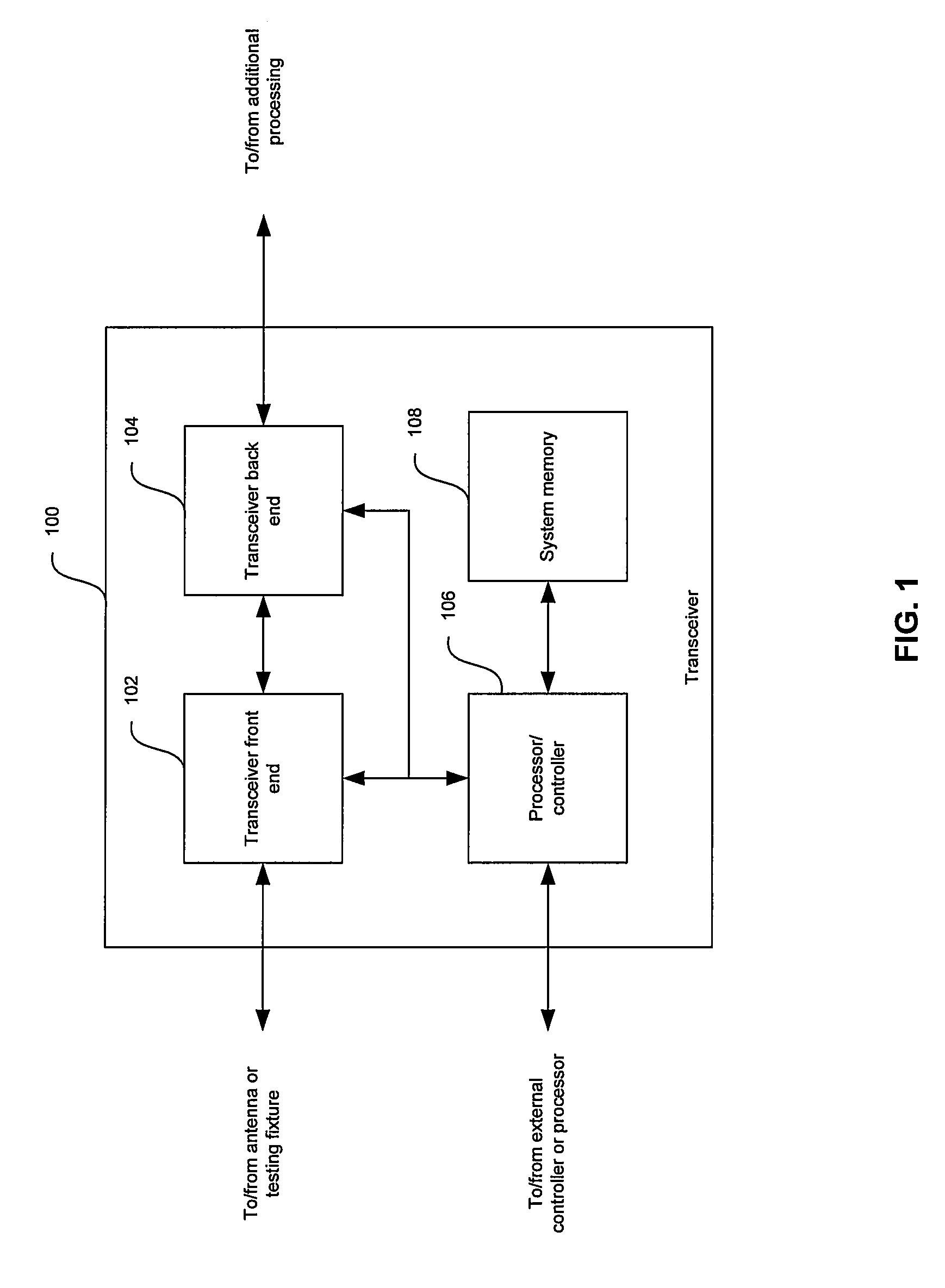

Circuit and method for automatic gain control

A system for generating a supply voltage, temperature and process compensated gain control voltage from a digital data word. In particular, the compensated gain voltage control voltage maintains a linear relationship between a change in gain in response to an input gain control voltage for a gain circuit of a transmitter circuit. A monitor circuit senses at least one of the supply voltage, temperature and process parameters, and generates a first set of digital signals corresponding to the sensed parameter. A digital compensator circuit converts the input gain control voltage into a second set of digital signals, and decodes the combined first and second set of digital signals to provide a data word. The data word is converted into an analog voltage representing the compensated gain voltage control voltage. The digital compensator circuit includes a table of compensation values, each accessible by a distinct combination of the first and second set of digital signals.

Owner:ICERA CANADA ULC

Circuit and method for automatic gain control

A system for generating a supply voltage, temperature and process compensated gain control voltage from a digital data word. In particular, the compensated gain voltage control voltage maintains a linear relationship between a change in gain in response to an input gain control voltage for a gain circuit of a transmitter circuit. A monitor circuit senses at least one of the supply voltage, temperature and process parameters, and generates a first set of digital signals corresponding to the sensed parameter. A digital compensator circuit converts the input gain control voltage into a second set of digital signals, and decodes the combined first and second set of digital signals to provide a data word. The data word is converted into an analog voltage representing the compensated gain voltage control voltage. The digital compensator circuit includes a table of compensation values, each accessible by a distinct combination of the first and second set of digital signals.

Owner:ICERA CANADA ULC

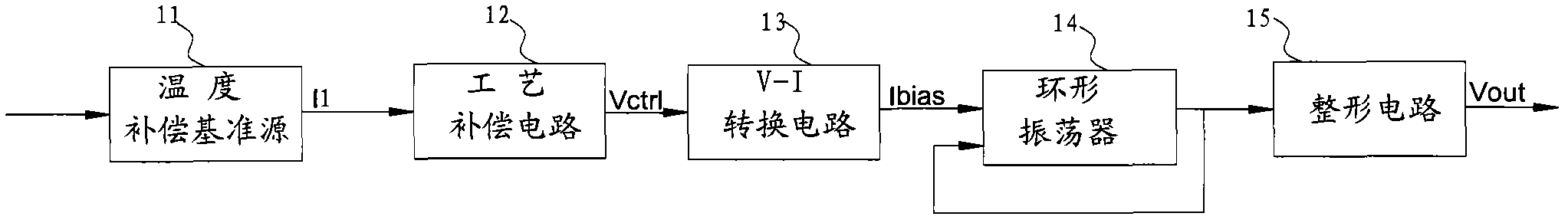

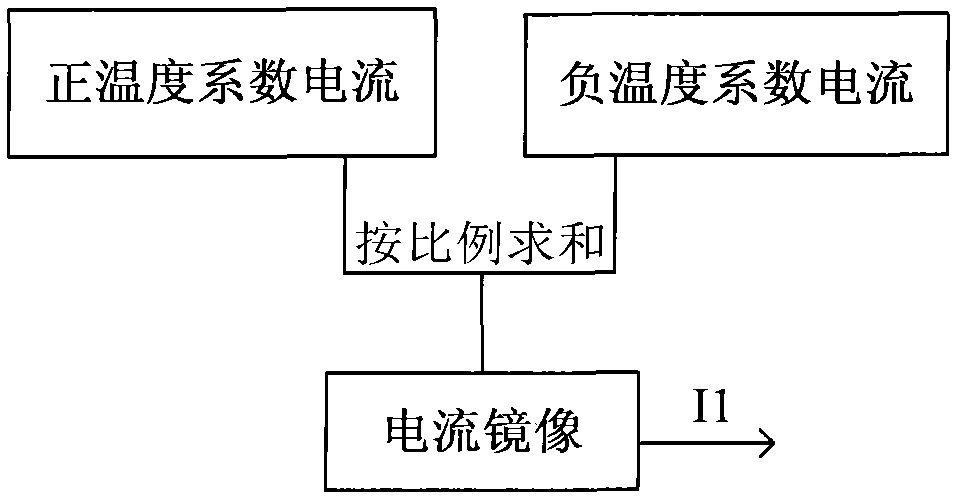

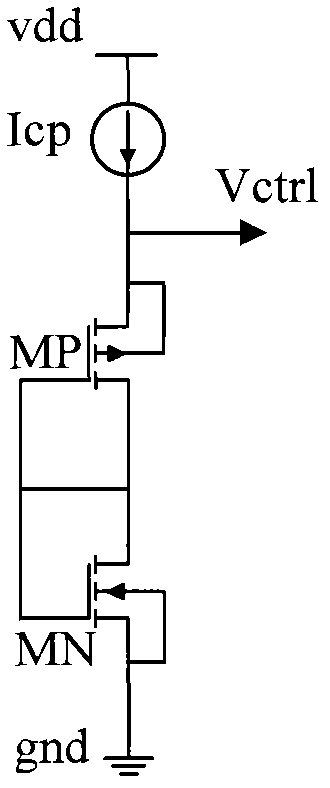

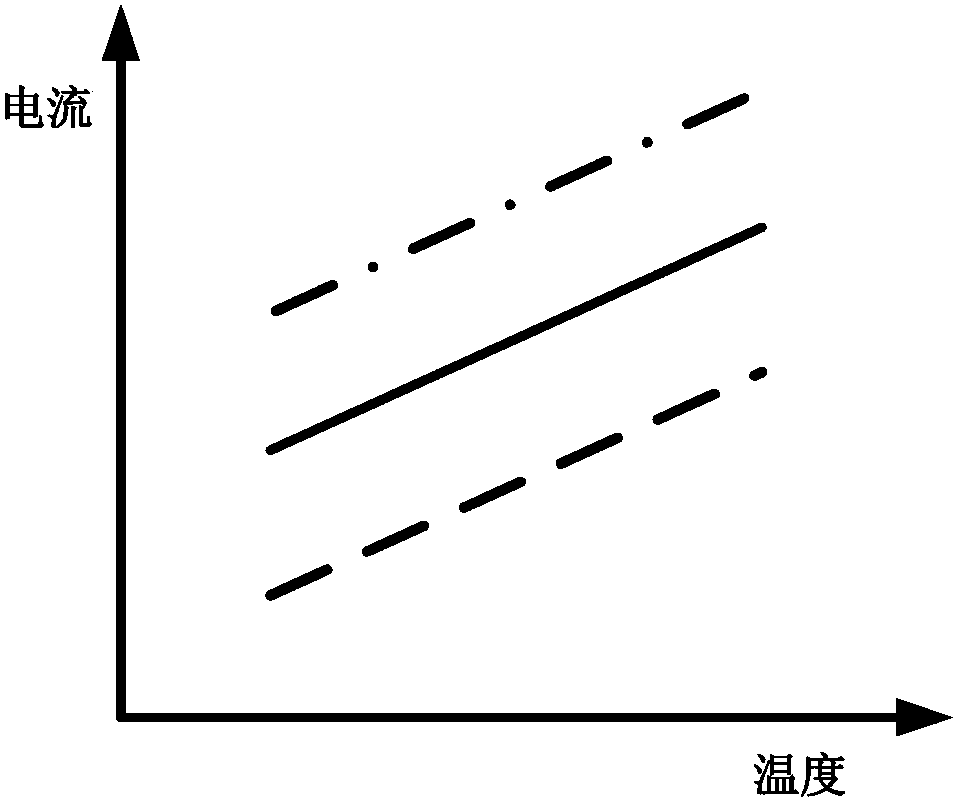

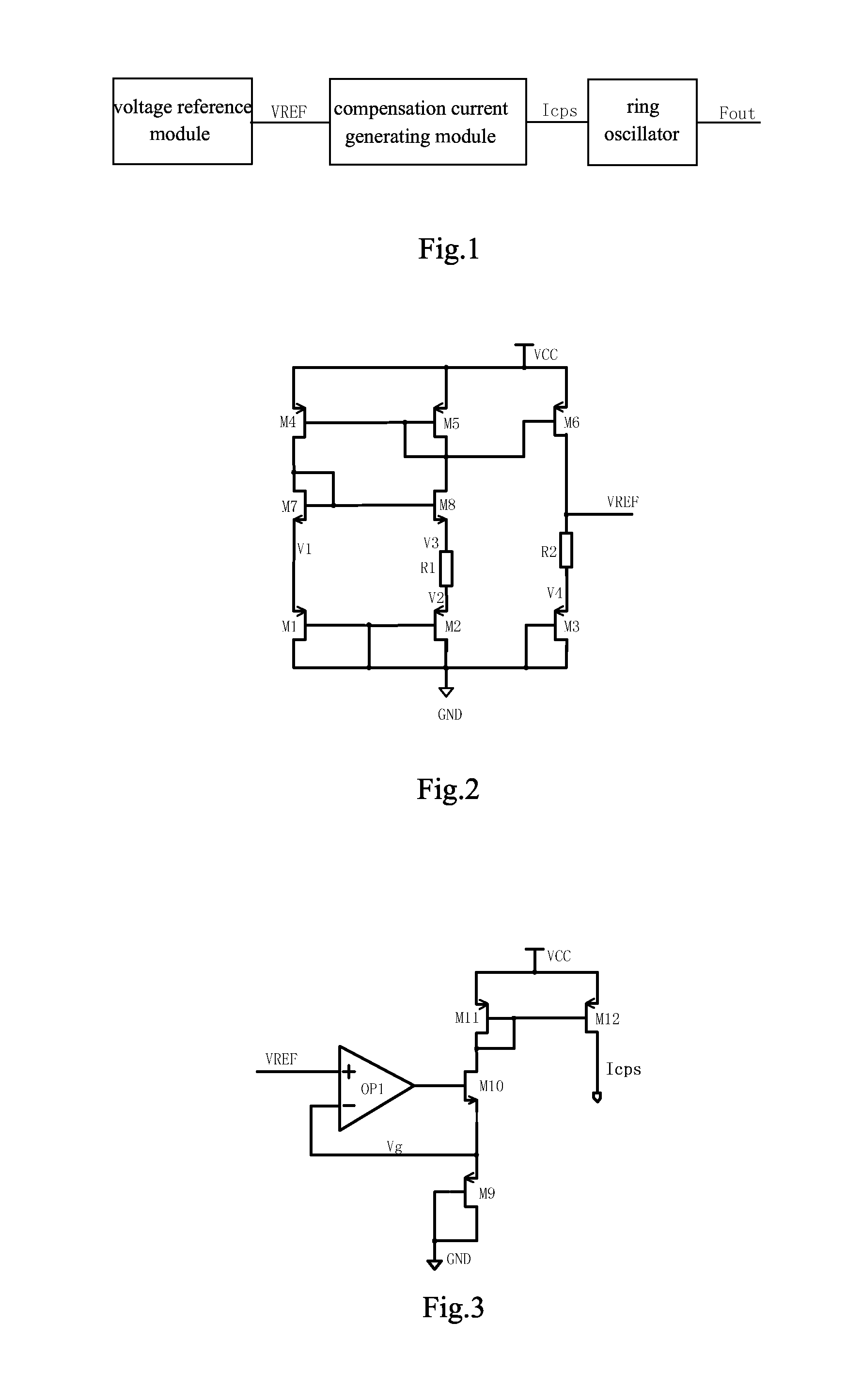

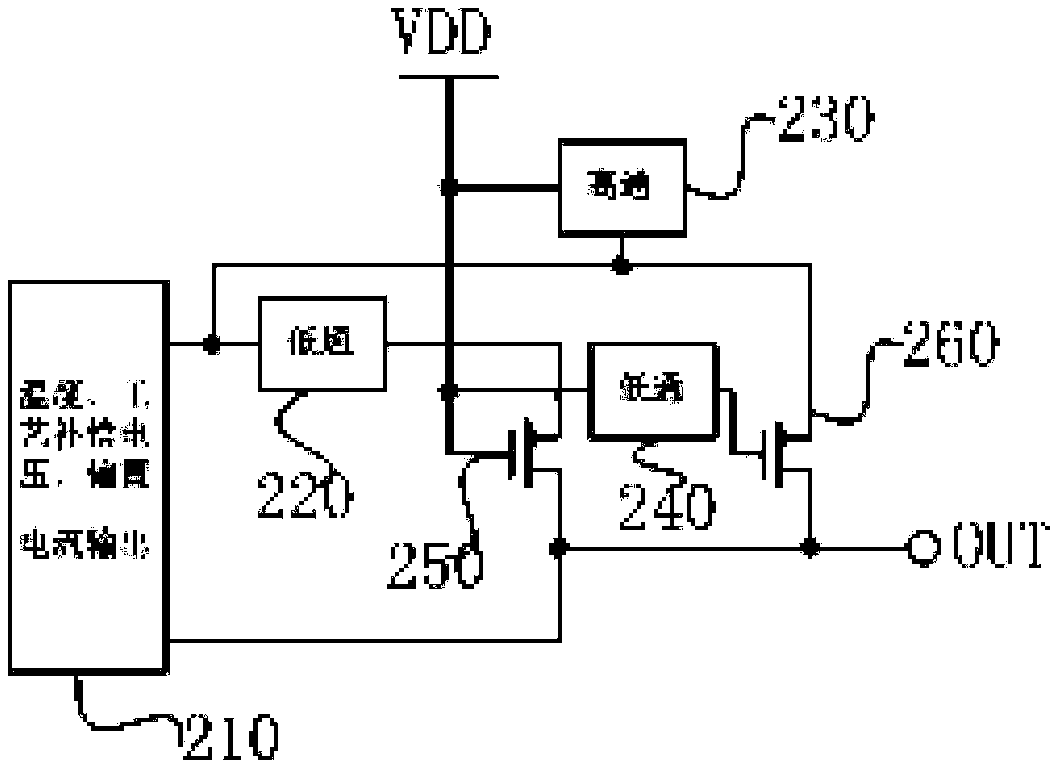

All-silicon clock generator realized on basis of complementary metal oxide semiconductor (CMOS) process

InactiveCN102064801ASimple structureImprove clock accuracyElectric pulse generatorElectric variable regulationPower flowEngineering

The invention relates to an all-silicon clock generator realized on the basis of a complementary metal oxide semiconductor (CMOS) process. The all-silicon clock generator comprises a temperature compensation current source, a process compensation circuit, a V-I conversion circuit, a loop oscillating circuit and a shaping circuit the output ends of which are sequentially connected, wherein the temperature stabilizing current source is used for providing current after temperature compensation; the process compensation circuit is used for providing voltage for reducing the deviation of the CMOS process; the V-I conversion circuit is used for converting the compensated voltage to current output; the loop oscillating circuit generates clock signals with the corresponding frequency according tothe magnitude of the received current; and the shaping circuit is used for shaping the clock signals and outputting after frequency division. The invention adopts the temperature and process compensation circuits, thus ensuring that the CMOS clock circuit has favorable temperature and process stabilities and also has stronger power-supply rejection capacity. Besides, the circuit structure is simple, and the clock accuracy is high, so that the CMOS clock circuit can be substituted for a quartz crystal oscillator, a ceramic resonator and other circuits and used as a clock source.

Owner:SUZHOU R&D CENT OF NO 214 RES INST OF CHINA NORTH IND GRP

Reference current source

ActiveCN103425177AReduce the impact of accuracyReduce power consumptionElectric variable regulationPower flowReference current

The invention discloses a reference current source comprising a current source core circuit, a current bias circuit, an offset voltage circuit and an output stage unit. The reference current source is characterized in that a fifth end and a sixth end of the current source core circuit are respectively connected to a first relative voltage and second relative voltage outside, and the difference between the first relative voltage and the second relative voltage serves as offset voltage which maintains constantly while the temperature changes and which is reserved to carrier mobility along the process changing tendency. According to the reference current source, the temperature coefficient of the voltage of two end of an MOS (metal oxide semiconductor) resistor can be changed by guiding in the offset voltage in the current source core circuit and can compensate mutually with that of the carrier mobility, and output current with zero temperature coefficient can be realized. The reference current source further has the advantages of process compensation, and influences on current source accuracy by process variations can be reduced.

Owner:四川电子科技大学教育发展基金会

Apparatus and method for surface property measurement with in-process compensation for instrument frame distortion

ActiveUS7568381B2Reduce dependenceEliminate the effects ofInvestigating material hardnessHardnessEngineering

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

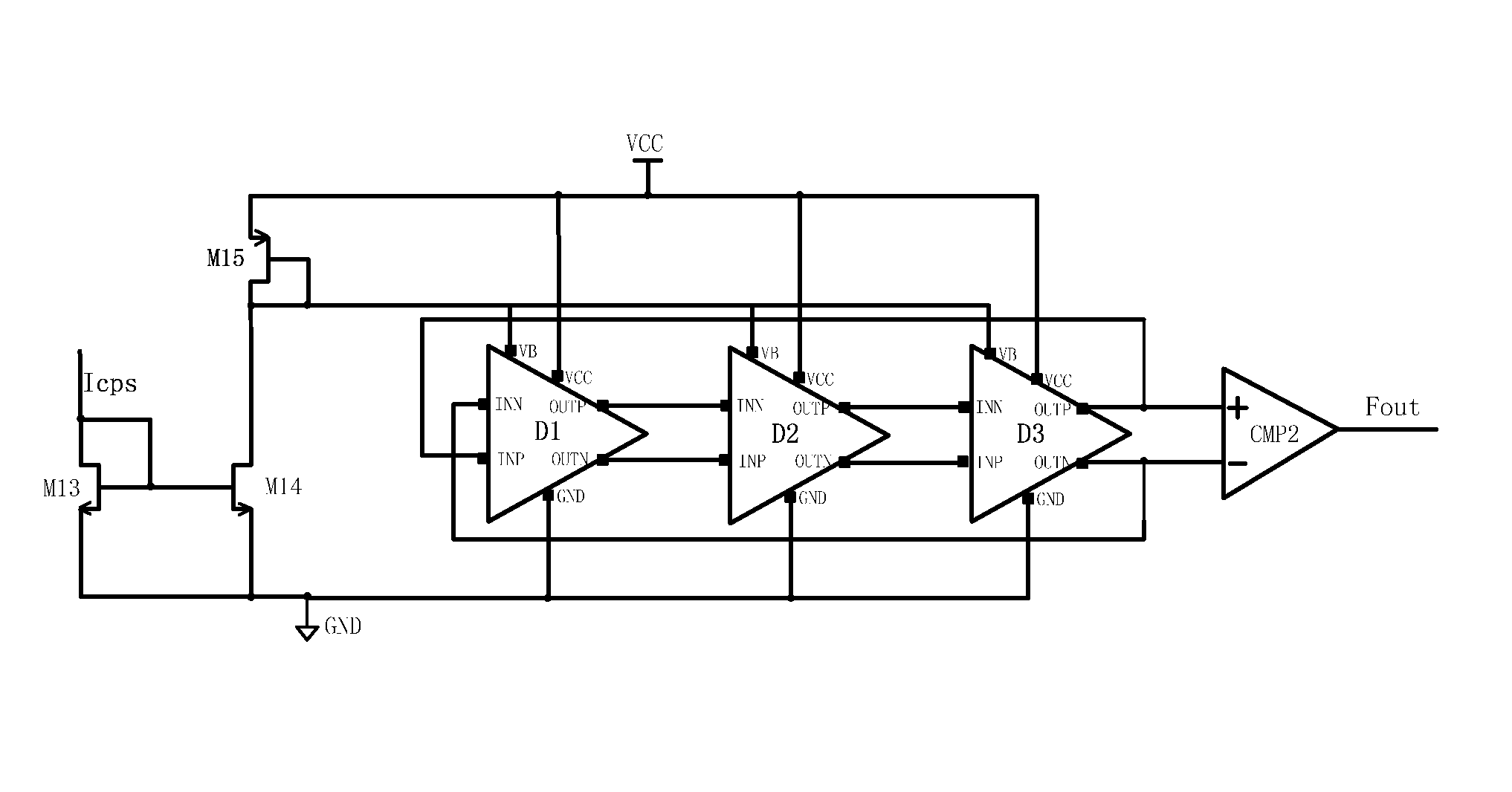

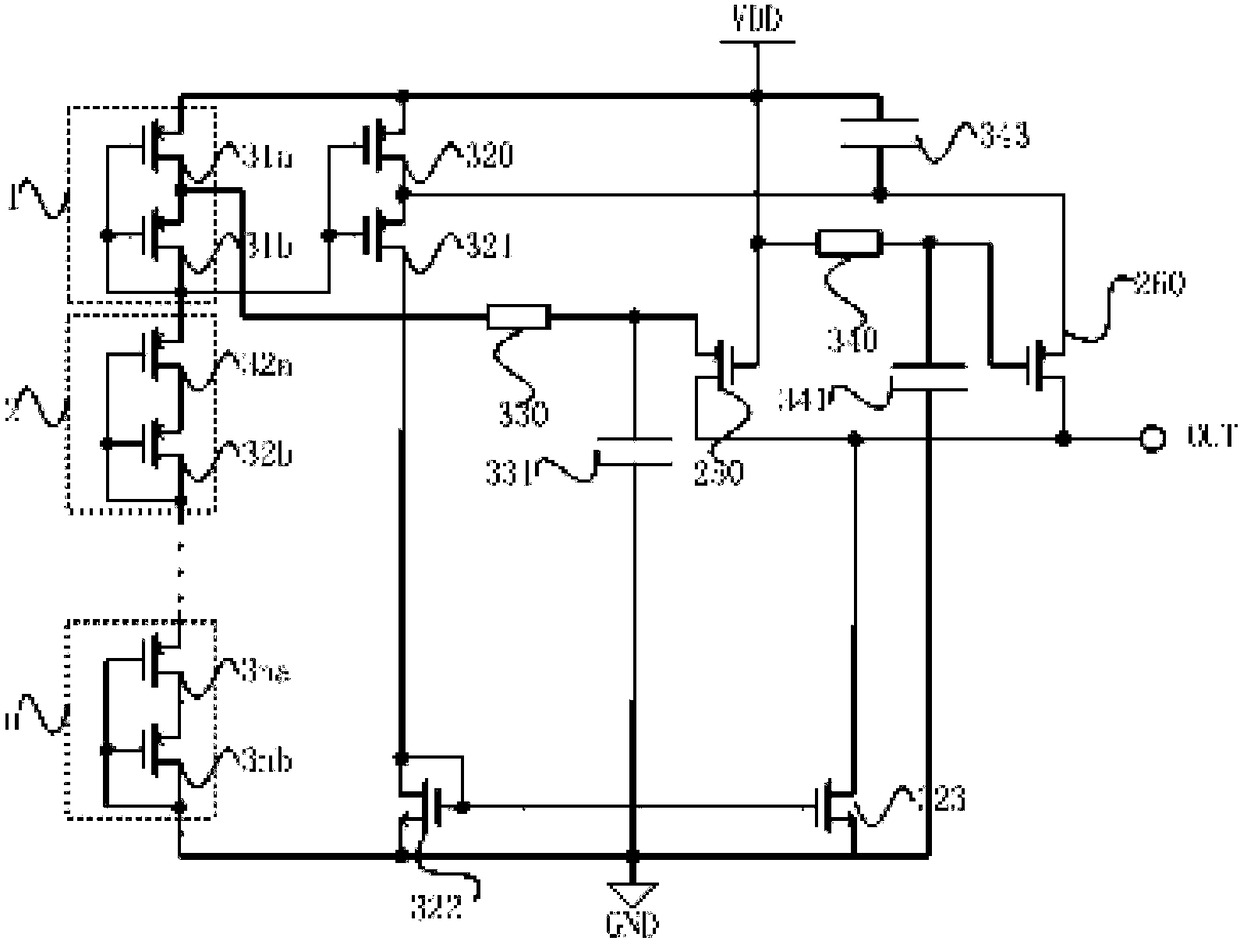

High-precision oscillator

InactiveUS20150137897A1Outputted clock is improvedHigh precisionGenerator stabilizationPulse generation by logic circuitsVoltage referenceEngineering

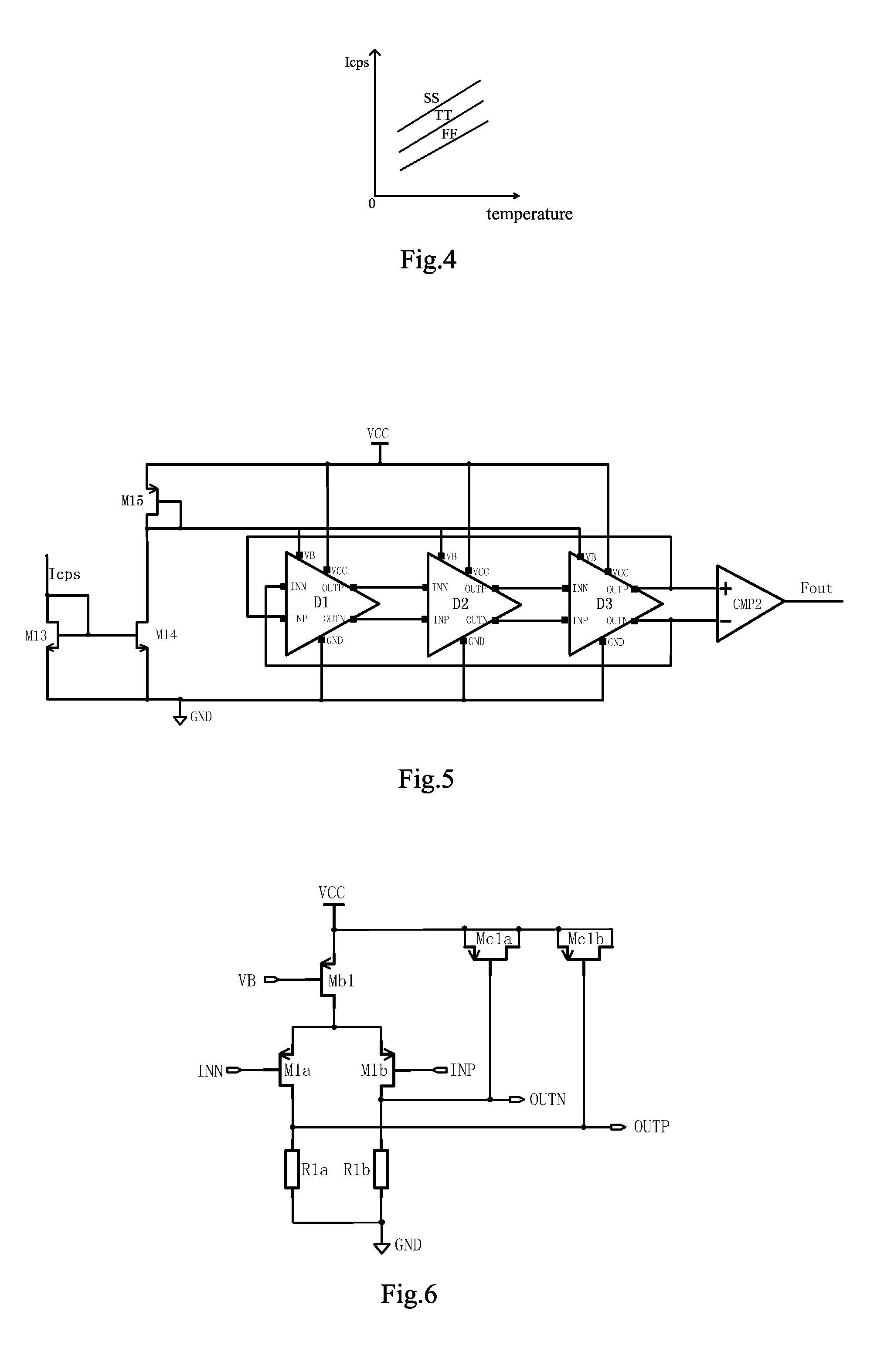

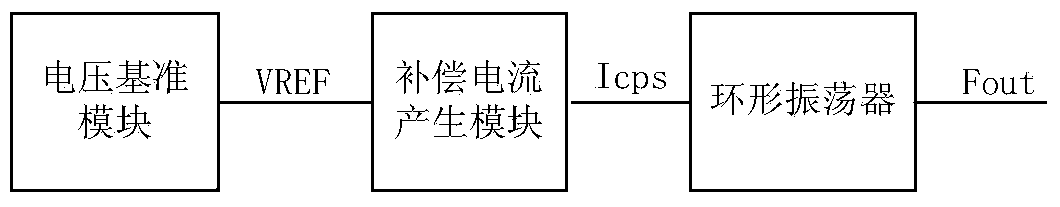

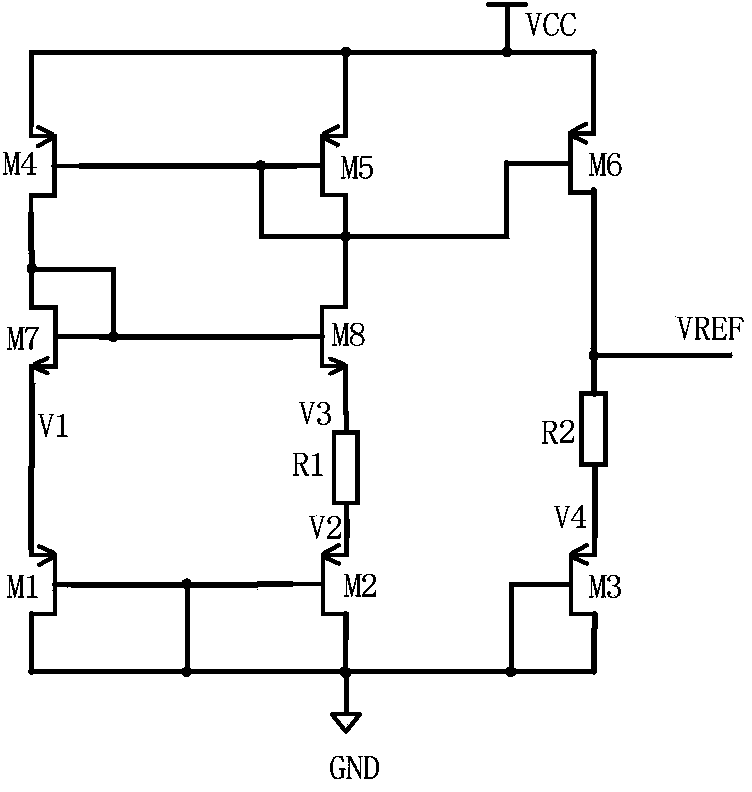

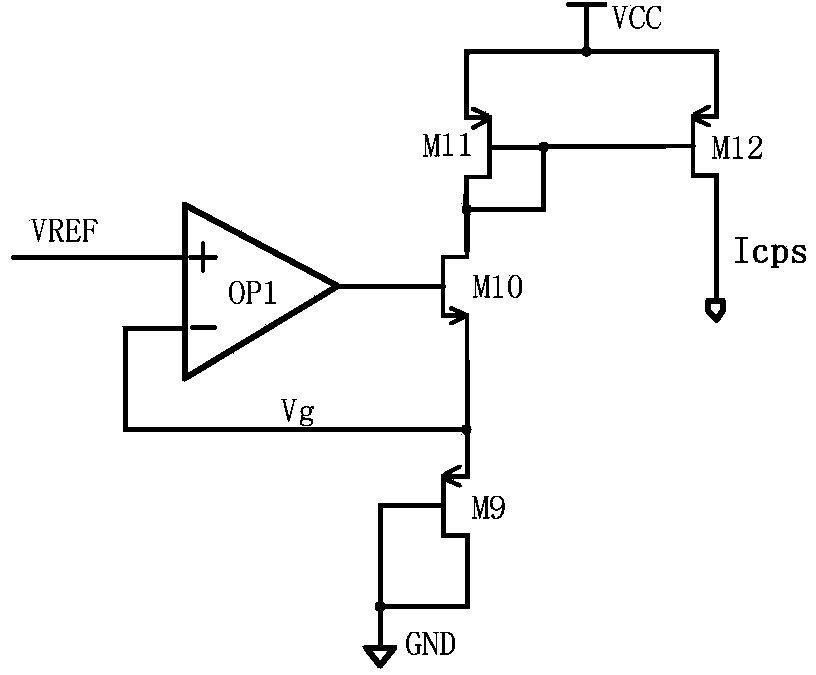

A high-precision oscillator includes a voltage reference module which includes multiple measured Field Effect Transistors and arranged for detecting process corners for the measured Field Effect Transistors to generate a reference voltage containing process corner information of the measured Field Effect Transistors, a compensation current generating module which is arranged for receiving the reference voltage, making a temperature compensation for the reference voltage, and generating a compensation current which includes both the process compensation and temperature compensation, and a ring oscillator which is arranged for receiving the compensation current and outputting a clock with stable frequency. The high-precision oscillator designs the process compensation and the temperature compensation separately, which are adjustable due to one of them will not be influenced by the other; and frequency of its outputted clock is not influenced by process and temperature, thereby precision of the outputted clock is improved.

Owner:IPGOAL MICROELECTRONICS (SICHUAN) CO LTD

High-accuracy oscillator

ActiveCN103595402AHigh precisionEasy to adjustGenerator stabilizationElectric pulse generatorFrequency stabilizationPower flow

The invention discloses a high-accuracy oscillator. The high-accuracy oscillator comprises a voltage reference module, a compensating current generating module and an annular oscillator; the voltage reference module comprises a plurality of detected field-effect tubes, process corner detection is conducted on the detected field-effect tubes to generate reference voltage comprising process corner information of the detected field-effect tubes, and the reference voltage is input into the compensating current generating module; temperature compensation is conducted on the reference voltage by the compensating current generating module, currents having process compensation and temperature compensation are generated, and the compensating current generating module inputs the generated currents into the annular oscillator; the annular oscillator receives the currents generated by the compensating current generating module, and clocks having stable frequency are output according to the currents. According to the high-accuracy oscillator, process compensation and temperature compensation are designed independently and do not affect each other, and regulation is facilitated; in addition, frequency of the output clocks is not affected by the process and the temperature, and accuracy of the output clocks is improved.

Owner:IPGOAL MICROELECTRONICS (SICHUAN) CO LTD

Current mirror multi-channel leakage current monitor circuit and method

A current mirror multi-channel leakage monitor circuit and method measures die leakage and generates digital keeper control bits to control a process compensated dynamic circuit. The leakage monitor enables high resolution on-chip leakage measurements in multiple locations on a die, thereby saving test time and enabling both die to die and within die process compensation.

Owner:INTEL CORP

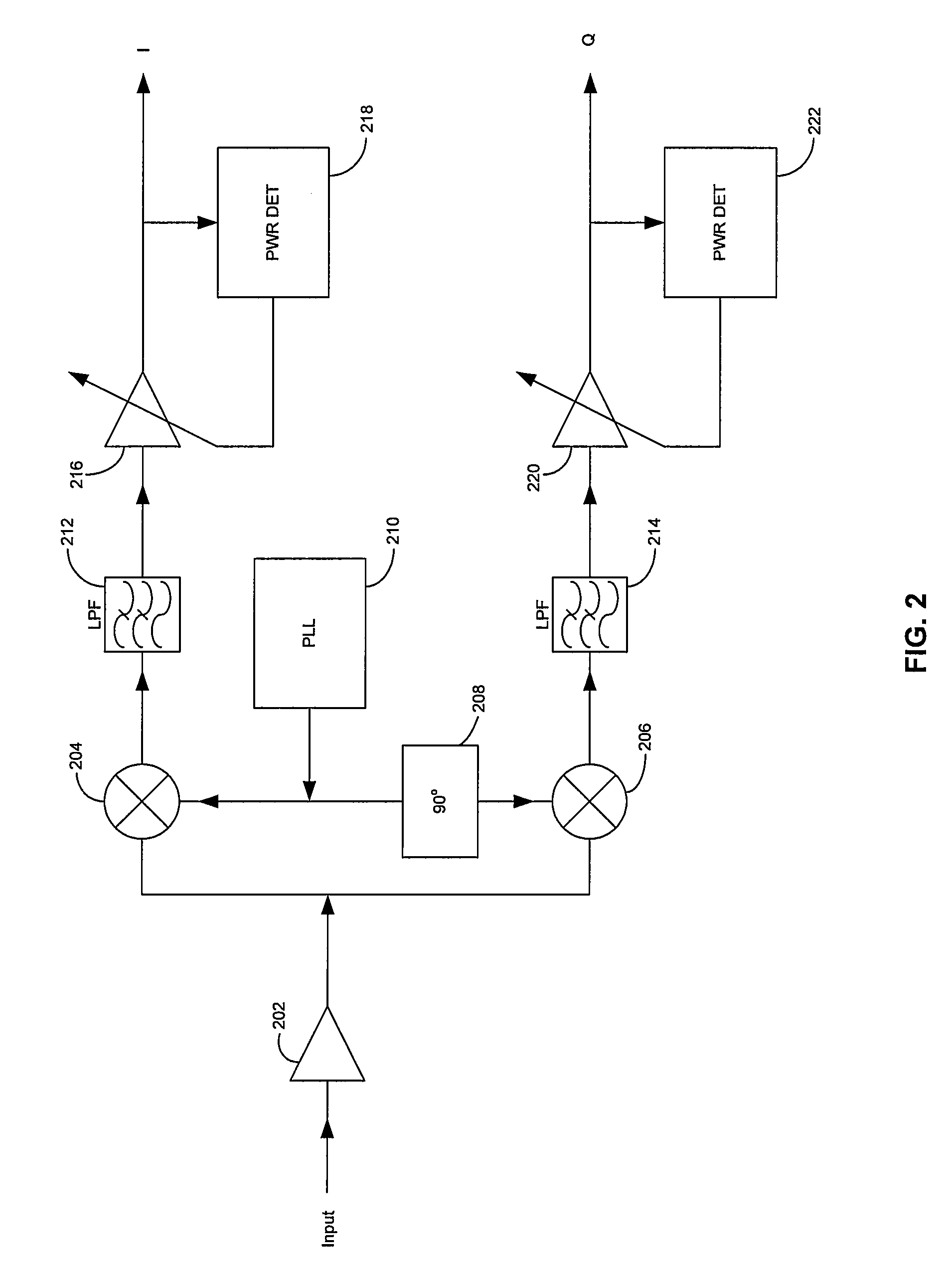

Method and System for RC-CR Quadrature Generation with Wideband Coverage and Process Compensation

InactiveUS20080137785A1Error preventionLine-faulsts/interference reductionSeries compensationProcess compensation

Certain aspects of a method and system for RC-CR quadrature generation with wideband coverage and process compensation may include determining an amplitude mismatch between an in-phase (I) component and a quadrature (Q) component of a signal generated in a radio frequency (RF) transmitter or receiver. A variation in resistance of a quadrature network associated with the I component and Q component may be determined. The determined amplitude mismatch and the determined variation in the resistance of the quadrature network may be compensated by adjusting a resistance of a portion of the quadrature network associated with the I component and a resistance of a portion of the quadrature network associated with the Q component.

Owner:AVAGO TECH INT SALES PTE LTD

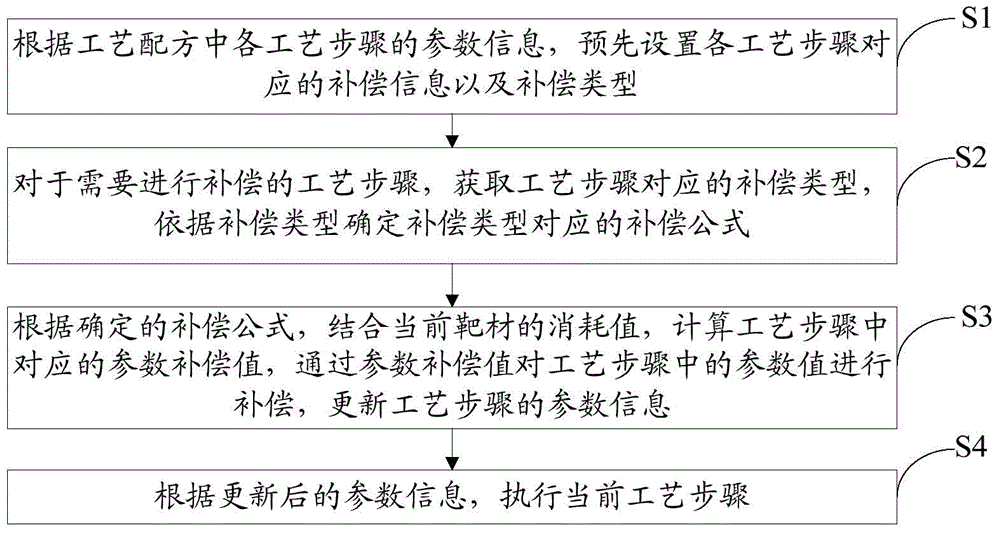

Process method and device

InactiveCN106328550AReduce manual operationsSave human resourcesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringProcess compensation

The embodiment of the invention provides a process method and device. The method comprises the following steps of 1, setting compensation information and a compensation type which are corresponding to each process step in advance according to parameter information, in a process formula, of each process step; 2, acquiring the compensation type corresponding to the step with regard to the step needed to be compensated, and determining a compensation formula corresponding to the compensation type according to the compensation type; 3, calculating a parameter compensation value corresponding to the step by combining a current target consumption value according to the compensation formula, compensating the parameter value in the step according to the parameter compensation value, and updating the parameter information of the process step; and 4, executing the process step according to the updated parameter information. Through the process scheme provided by the embodiment of the invention, the process compensation is performed in real time by semiconductor equipment according to the configuration demand of the formula, and thus, the operation difficulty can be greatly reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

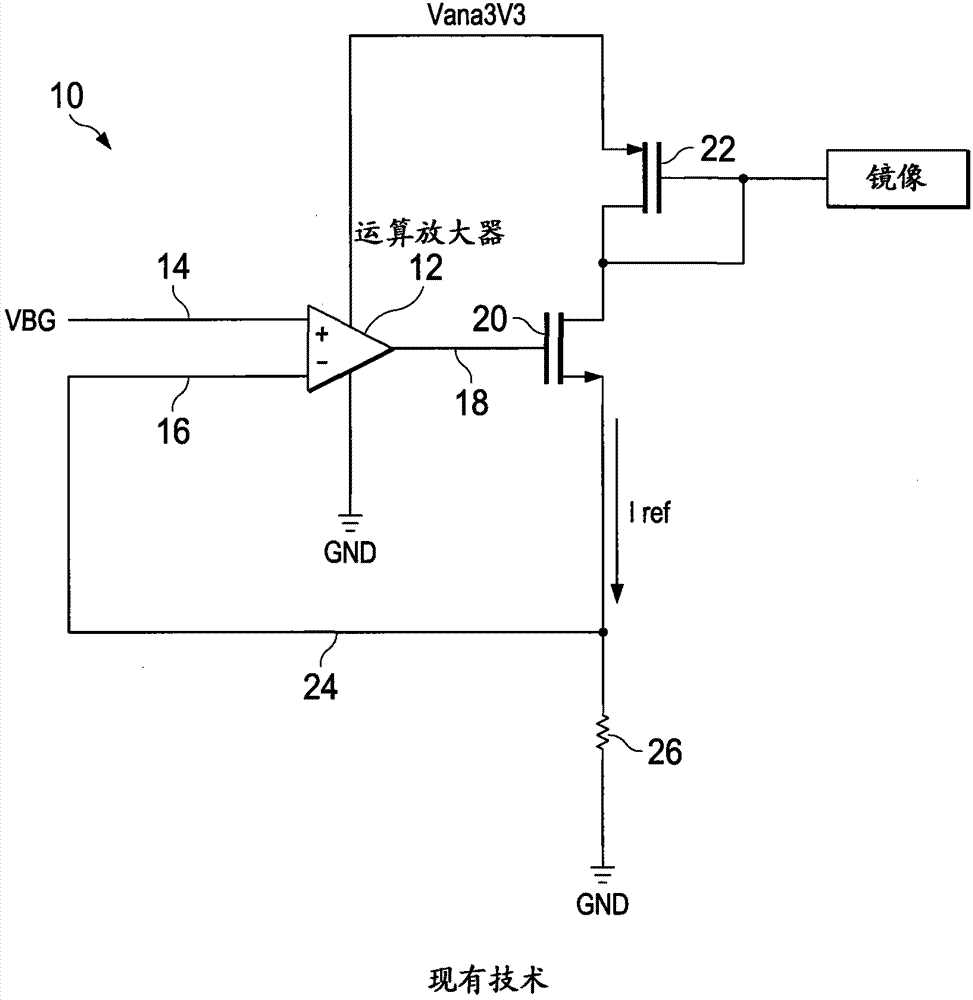

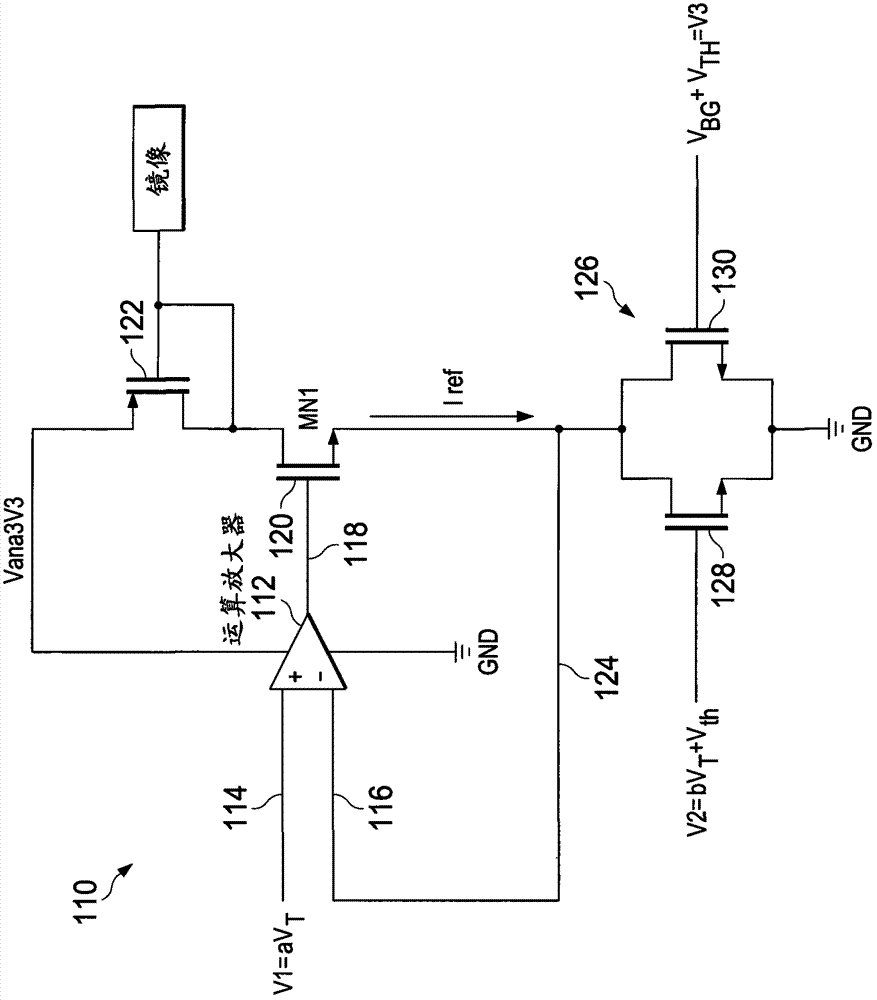

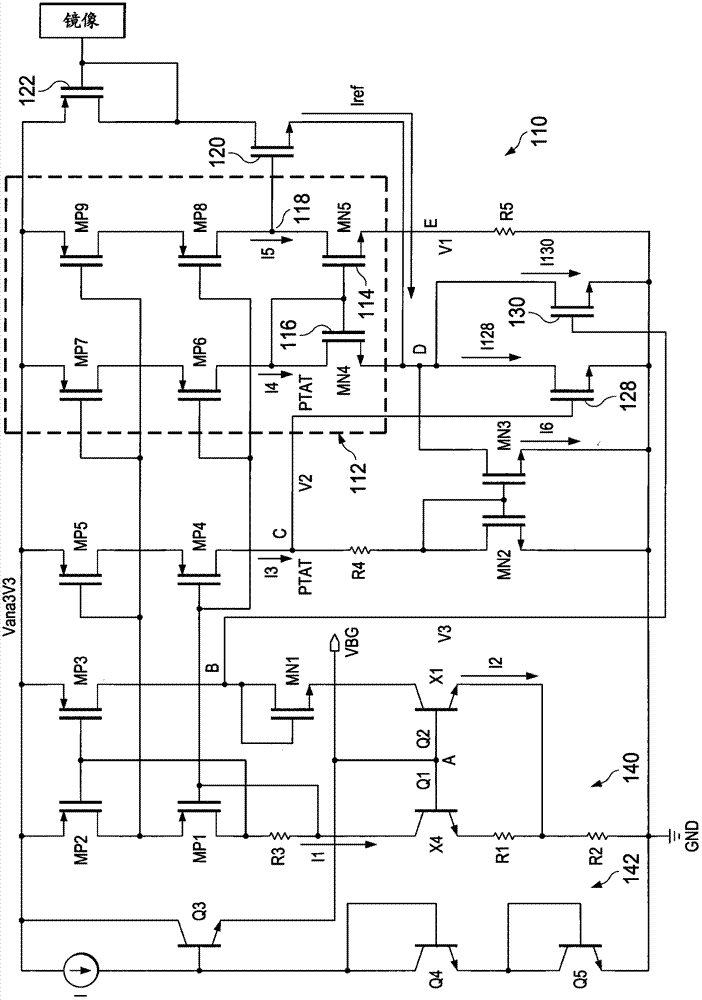

Current reference circuit for temperature and process compensation

A reference current path carries a reference current. A first transistor is coupled to the reference current path. A second transistor is also coupled to the reference current path. The first and second transistors are connected in parallel to carry the reference current. The first transistor is biased by a first voltage (which is a bandgap voltage plus a threshold voltage). The second transistor is biased by a second voltage (which is a PTAT voltage plus a threshold voltage). The first and second transistors are thus biased by voltages having different and opposite temperature coefficients with a result that the temperature coefficients of the currents flowing in the first and second transistors are opposite and the reference current accordingly has a low temperature coefficient.

Owner:STMICROELECTRONICS (SHENZHEN) R&D CO LTD

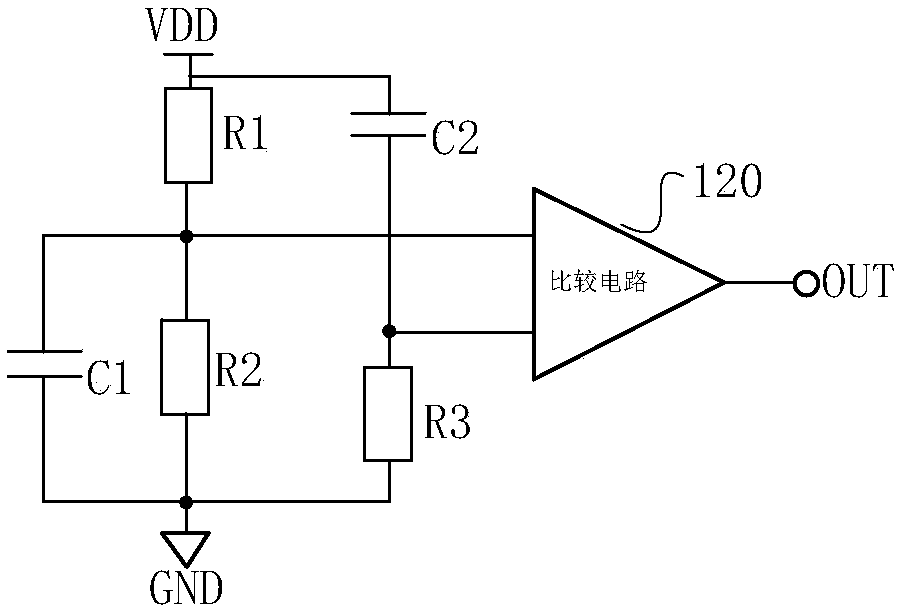

Burr detection circuit with temperature and process compensation functions

ActiveCN108169694ASimple structureWork reliablyCurrent/voltage measurementPower supply testingProcess deviationsCompensation effect

The invention discloses a burr detection circuit with temperature and process compensation functions. The compensation voltage generated by a temperature process compensation voltage generation circuit and output by a bias current generation circuit is connected with the input end of a first low-pass filter circuit, the output end of a high-pass filter circuit and the source electrode of a fourthPMOS tube, and the bias current generated by the temperature process compensation voltage generation circuit and output by the bias current generation circuit is connected with the drain electrodes ofthe third PMOS tube and the fourth PMOS tube and serves as an output signal; the output end of the first low-pass filter circuit is connected with the source electrode of the third PMOS tube, the grid electrode of the third PMOS tube is connected with the input end of the power supply VDD and the input end of the second low-pass filter circuit; the source electrode of the fourth PMOS tube is further connected with the high-pass filter circuit, the high-pass filter circuit is connected with the power supply VDD, and the grid electrode of the fourth PMOS tube is connected with the second low-pass filter circuit. The device is simple in circuit structure and stable and reliable in work, the temperature and process deviation can be well compensated, and the application range is wide.

Owner:成都三零嘉微电子有限公司

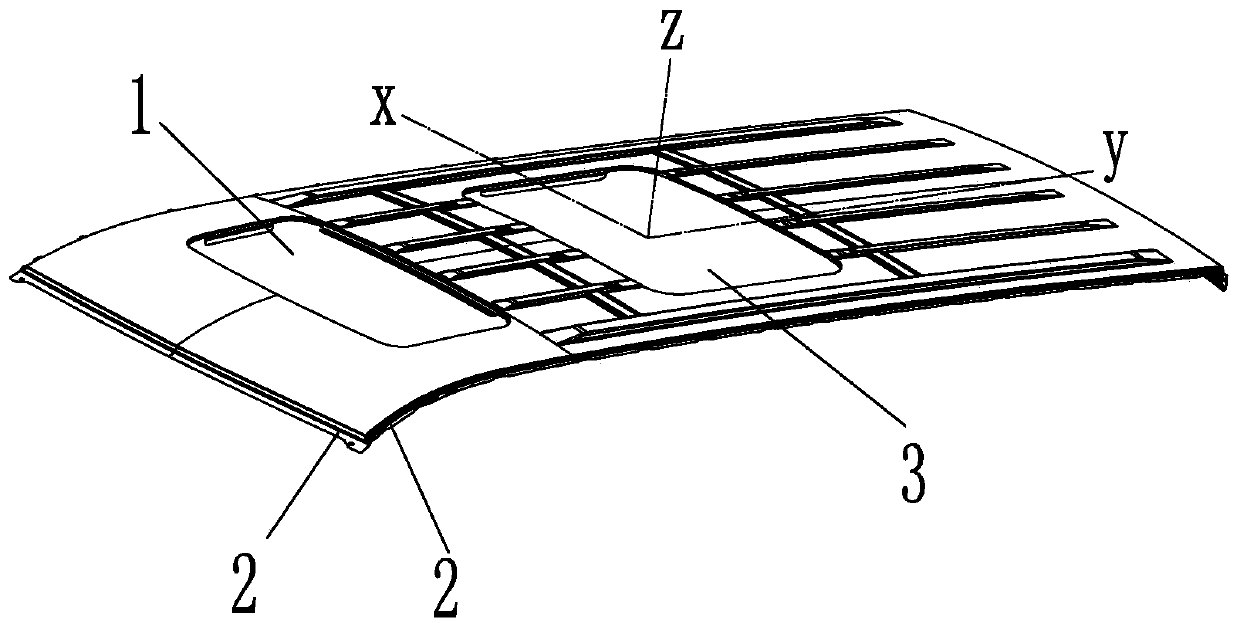

Stamping process profile compensation method for vehicle roof cover with sunroof

The invention discloses a stamping process profile compensation method for a vehicle roof cover with a sunroof. A stamping process for the vehicle roof cover with the sunroof comprises the following four procedures: 1. drawing; 2. trimming, punching and side shaping; 3. trimming, flanging and shaping; 4. trimming, punching, side punching, side shaping and upward flanging. As for the stamping process profile compensation method, die profiles from the first procedure to the third procedure are compensated. Through the method of the invention, the stamping process profiles are compensated by thepreliminary CAE analysis, and the process compensation scheme is formulated at the process design stage, thereby greatly reducing the die debugging workload, shortening the die forming cycle of complicated panel dies such as the roof cover, reducing die development costs, and improving the quality of the large panel dies.

Owner:柳州业泰汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com