Method for forming shaped convex surface type high-precision reflection panel with honeycomb sandwich structure

A honeycomb interlayer, high-precision technology, applied in the direction of electrical components, antennas, etc., can solve the problem of panel surface discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

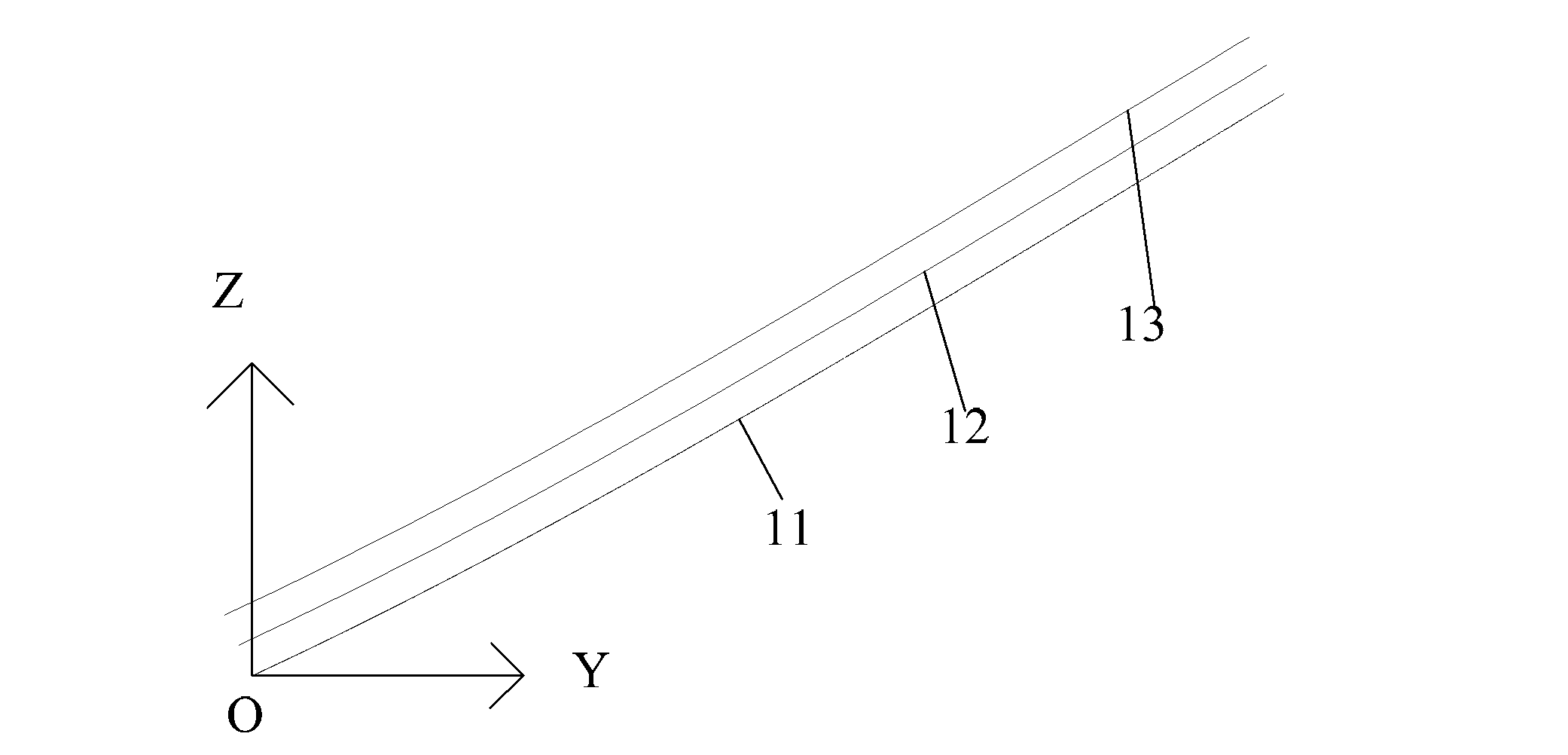

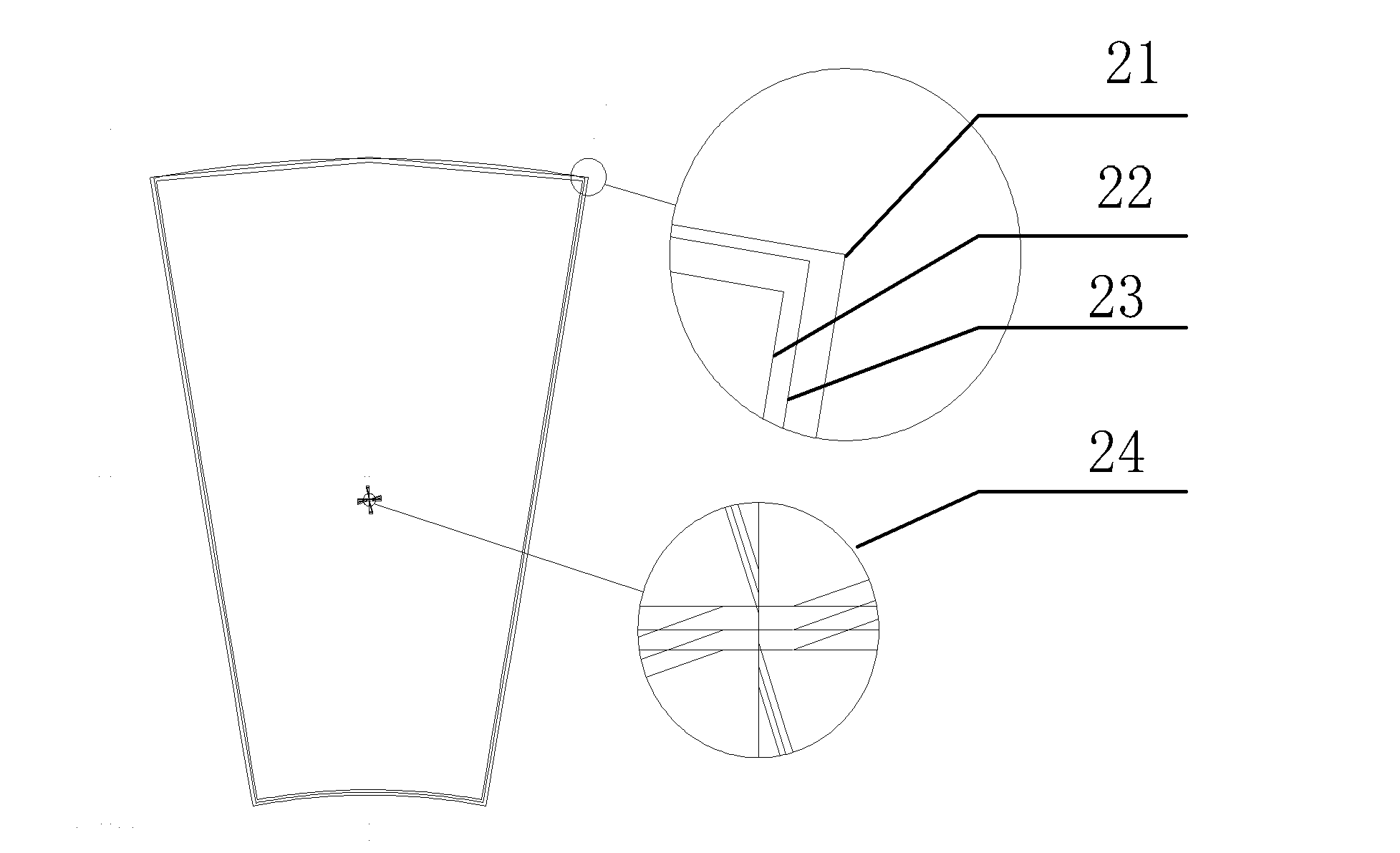

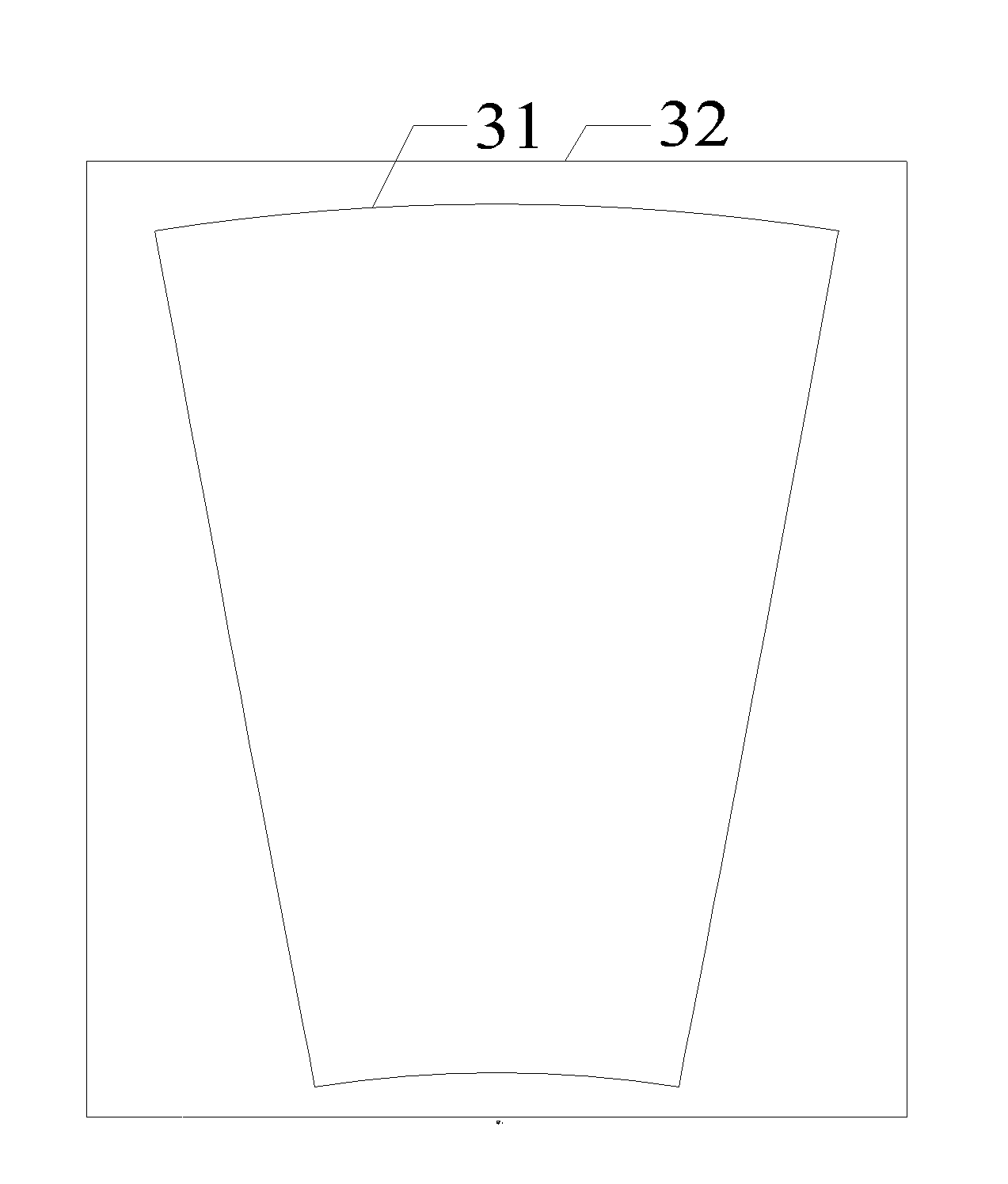

[0053] The invention is a forming method of a high-precision honeycomb sandwich structure reflecting panel with a shaped convex surface. The sandwich structure specifically includes three layers of aluminum plates, two layers of honeycomb cores and several embedded parts for connection; the three layers of aluminum plates are working plates. 1. The intermediate plate 2 and the back plate 3; the forming method includes: three-dimensional modeling of the three-layer aluminum plate with a high-precision honeycomb sandwich structure with a convex surface, spatial geometric expansion of the three-layer aluminum plate, establishment of a process compensation surface, nailing High calculation and positioning of the three-layer board on the high-precision nail bed. Among them, three-dimensional modeling and spatial geometric expansion are the factors that directly affect the profile accuracy of the sandwich panel. The establishment of the process compensation surface and the calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com