Process method and device

A process method and process device technology, applied in the field of semiconductor process control, can solve problems such as difficult operation, poor process stability and repeatability, and achieve the effect of reducing operation difficulty, strong stability and repeatability, and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

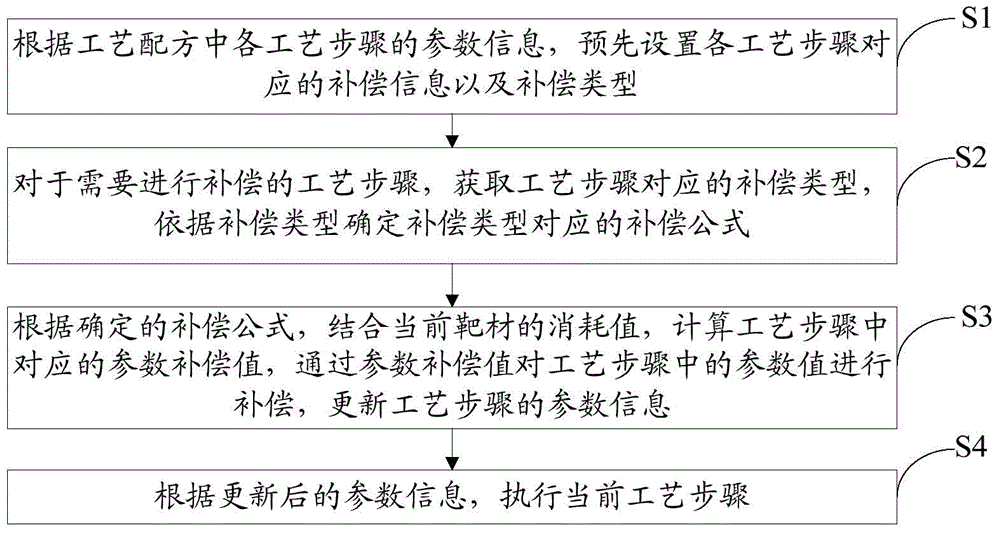

[0029] refer to image 3 , shows a flow chart of steps of a process method in Embodiment 1 of the present invention.

[0030] The processing method of the present embodiment comprises the following steps:

[0031] Step S1: According to the parameter information of each process step in the process formula, preset the compensation information and compensation type corresponding to each process step.

[0032]In this embodiment, first, the process recipe is preset. Specifically, the process recipe is configured with a plurality of process steps for performing a process on the substrate, and parameter information corresponding to the process steps. The parameter information corresponding to the process step can determine whether the target material is needed during the execution of the process step. If a process step requires a target during execution, it is necessary to preset compensation information and compensation type for the process step, and both the compensation informat...

Embodiment 2

[0052] refer to figure 2 , shows a flowchart of steps of a process method in Embodiment 2 of the present invention.

[0053] The processing method of the present embodiment specifically comprises the following steps:

[0054] Step S202: The semiconductor device acquires parameter information corresponding to the current process step in the set process recipe.

[0055] In this embodiment, those skilled in the art need to pre-set the compensation information and compensation type corresponding to each process step according to the parameter information of each process step in the process recipe. Specifically, the process recipe is configured with multiple process steps for processing the substrate and parameter information corresponding to the process steps.

[0056] Wherein, those skilled in the art can determine whether a target is needed during the execution of this process step through the parameter information corresponding to the process step. If a process step require...

Embodiment 3

[0104] refer to Figure 5 , shows a flow chart of steps of a process method in Embodiment 3 of the present invention.

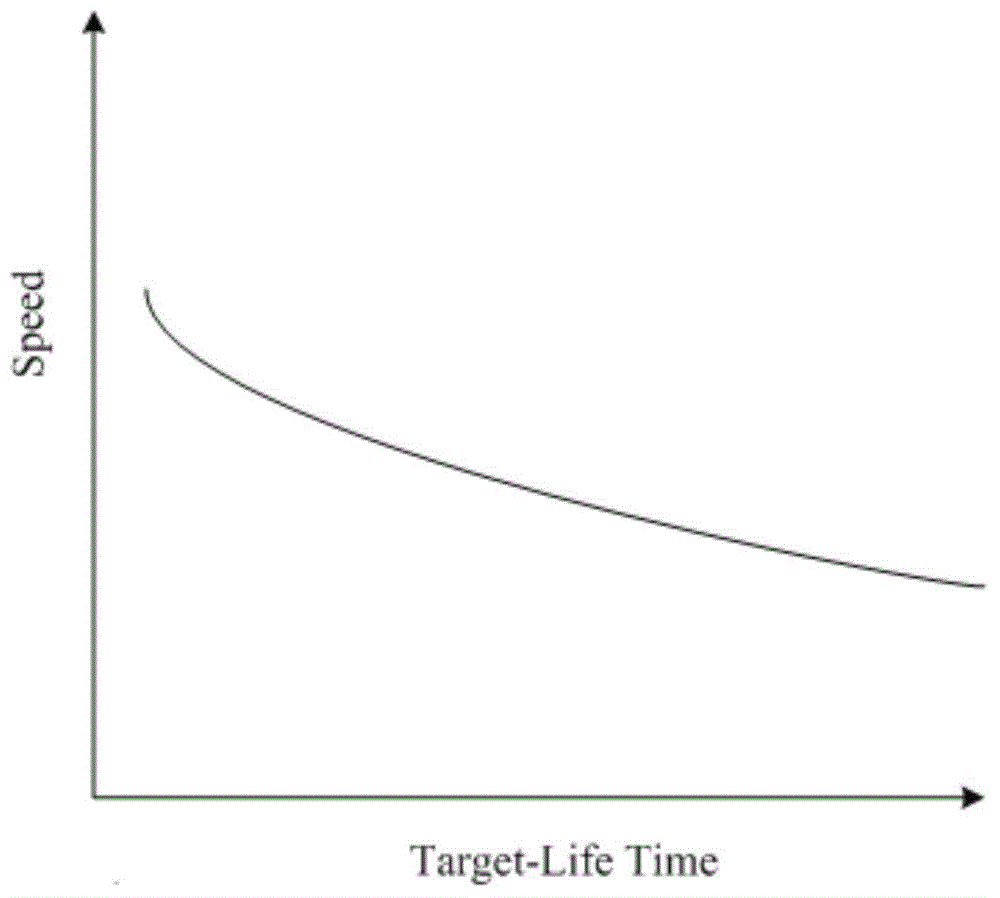

[0105] In this embodiment, the process compensation method of the magnetic control PVD equipment is taken as an example to describe the process compensation method.

[0106] In this embodiment, a counter is set in the magnetron PVD equipment, and the counter is used to record the consumed life of the target. In this embodiment, the historical accumulated work done by the sputtering power supply on the target is used to represent the consumed life of the target. life.

[0107] Simultaneously, the setting format of a kind of preferred process formula is also provided in the present embodiment as shown in table 1:

[0108] Table 1

[0109] name Step1 Step2 …… Time(s) 10 5 …… Power(w) 100 500 …… Compensation Y N …… ComType Time power …… …… …… …… ……

[0110] By setting the above Recipe, that is, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com