Patents

Literature

36results about How to "Improve automated testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

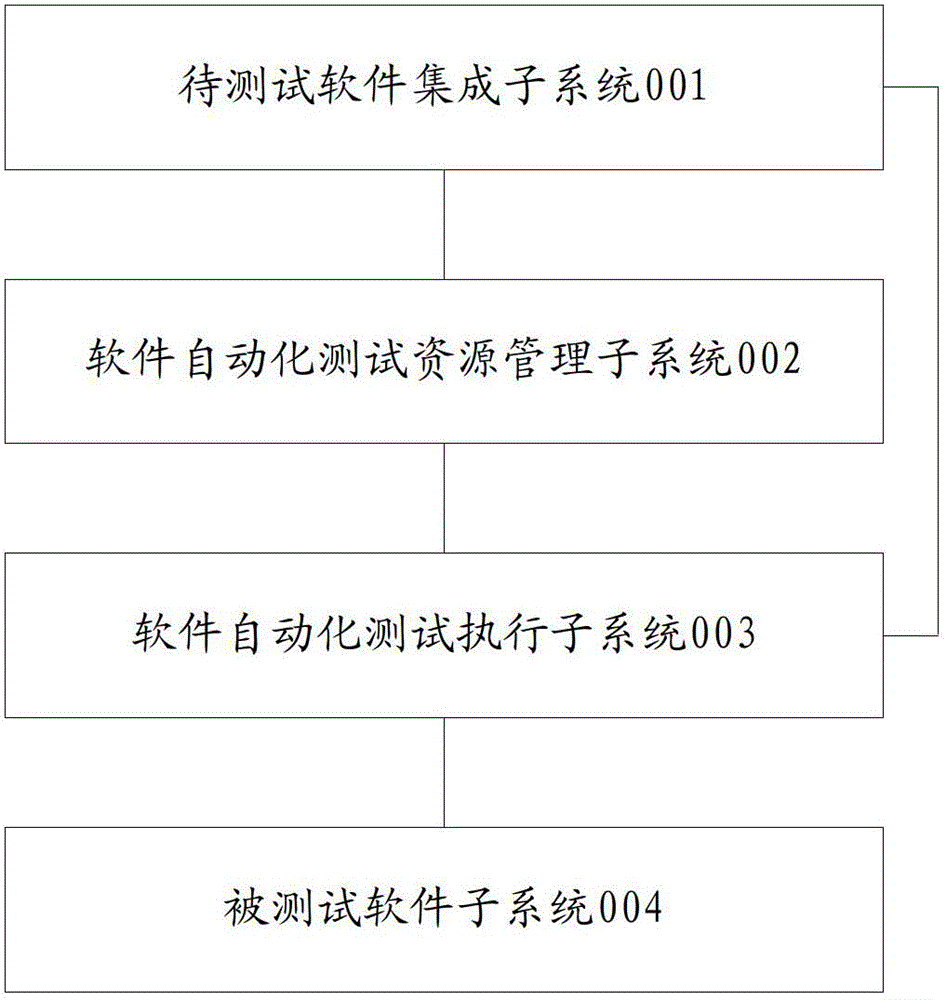

Method and system for realizing automatic software testing

ActiveCN102693183AImprove performanceImprove automated testingSoftware testing/debuggingTest scriptObject code

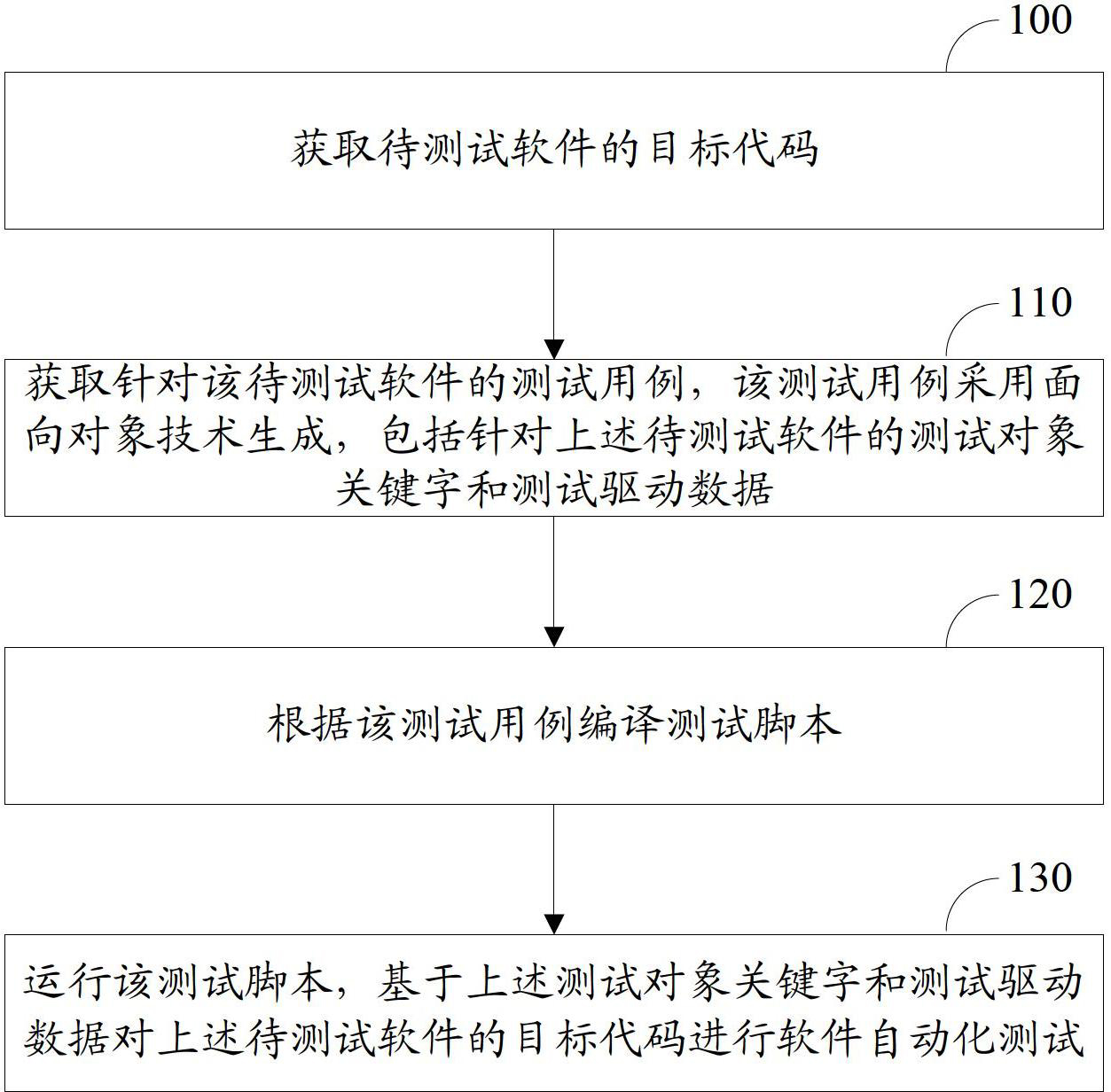

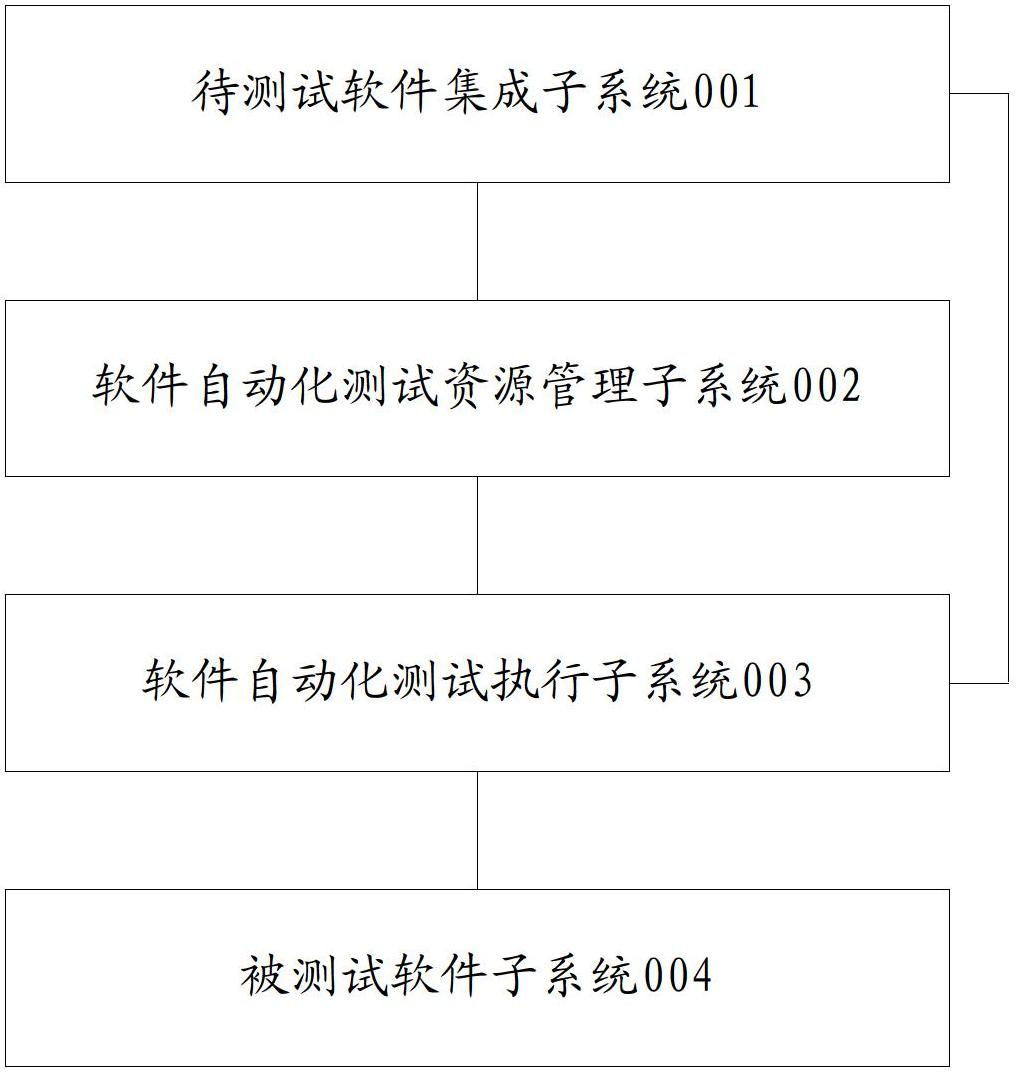

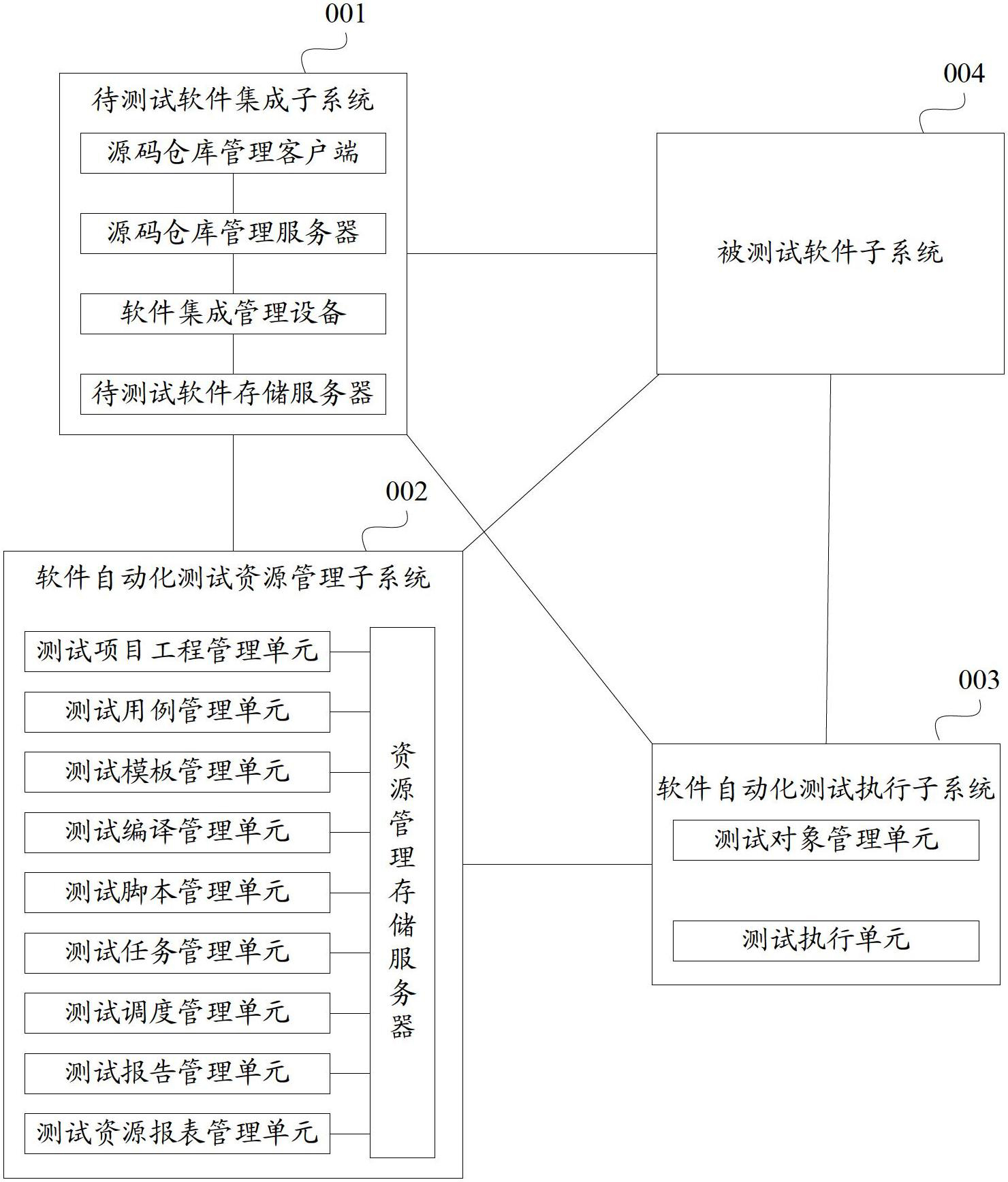

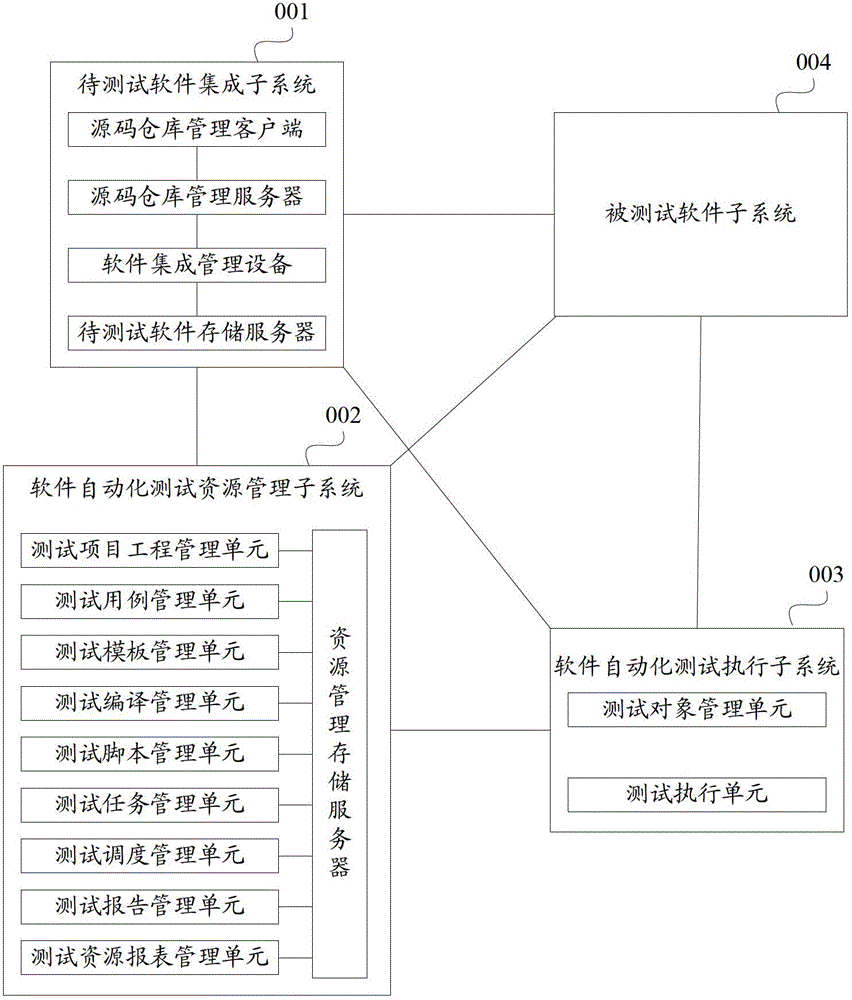

The invention discloses a method and a system for realizing automatic software testing. The method includes the following steps: obtaining the object code of the to-be-tested software; obtaining the test case for the to-be-tested software, wherein the test case is generated by adopting the oriented object technology and includes a test object key word and a test drive data for the to-be-tested software; compiling and saving the test script according to the test case; running the test script, so as to carry out the automatic software testing of the object code of the to-be-tested software based on the test object key word and the test drive data. By adopting the solution of automatic testing and utilizing the object oriented test case to carry out the automatic testing based on the assemblage of the test object key word and the test drive data, the automatic software testing can be realized without the participation of any operator, and the method and the system for realizing automatic software testing are applicable to all the stages of software testing.

Owner:RAISECOM TECH

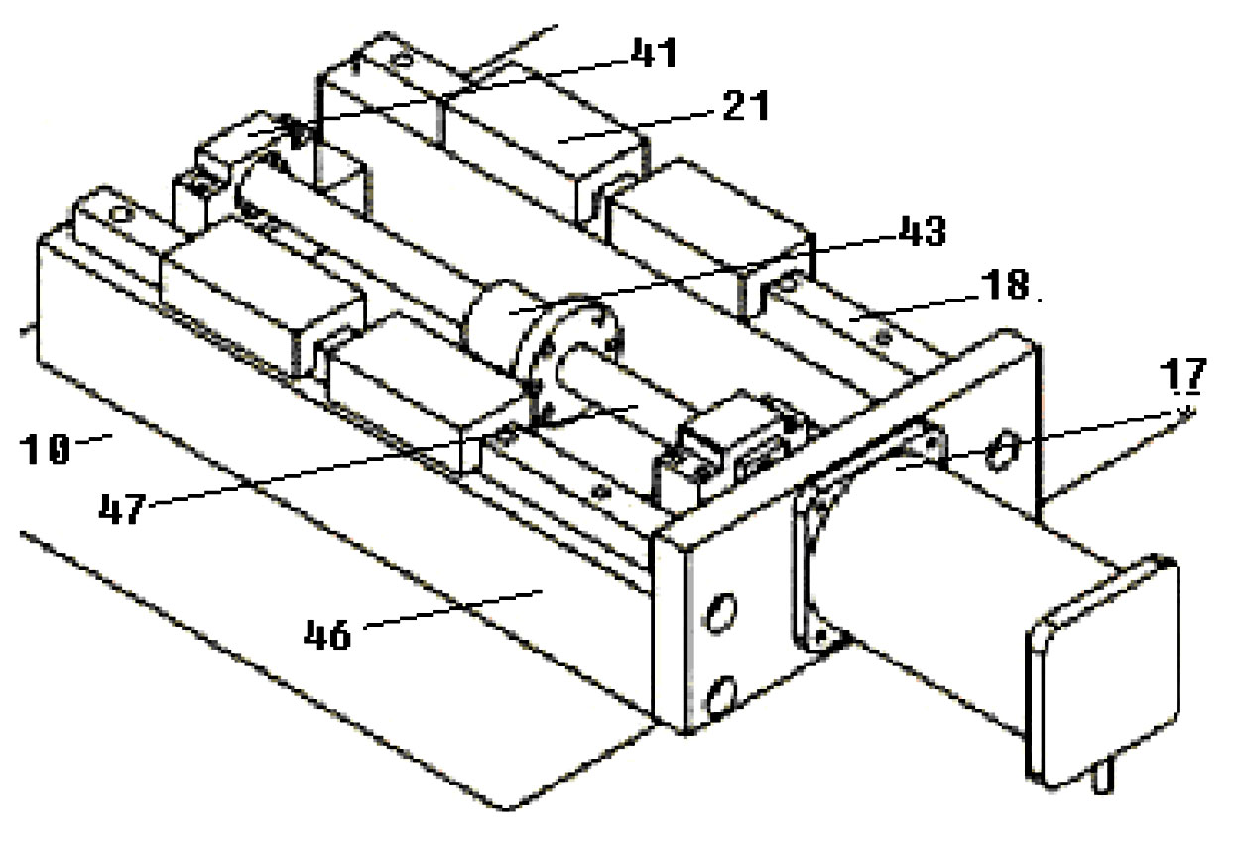

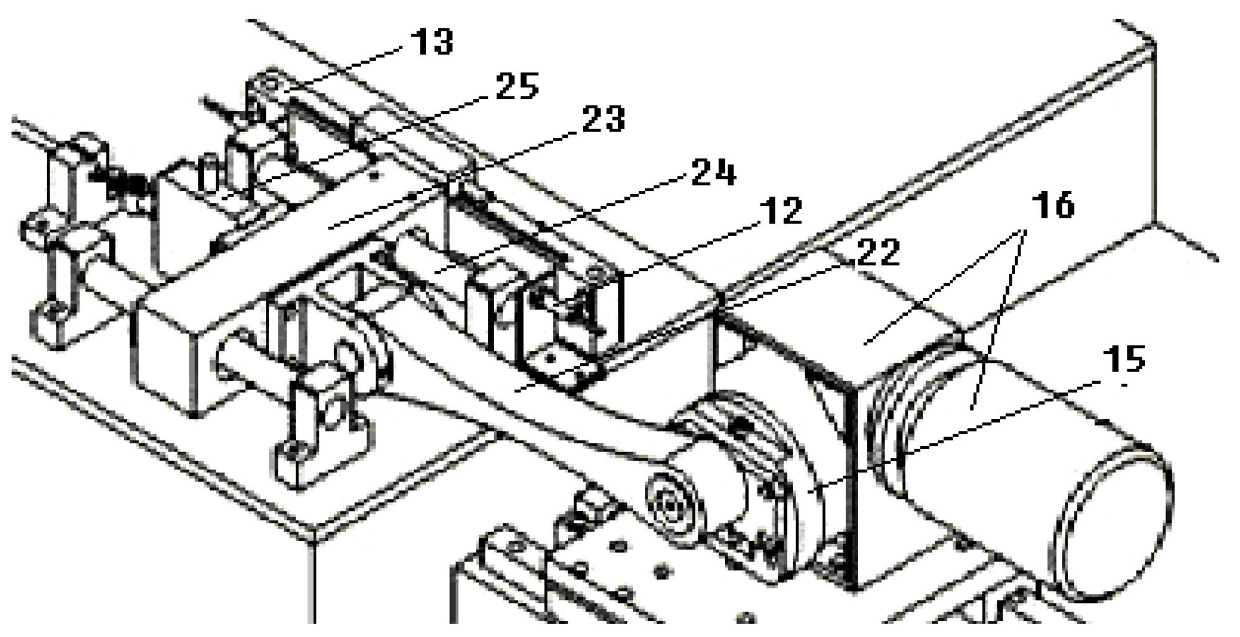

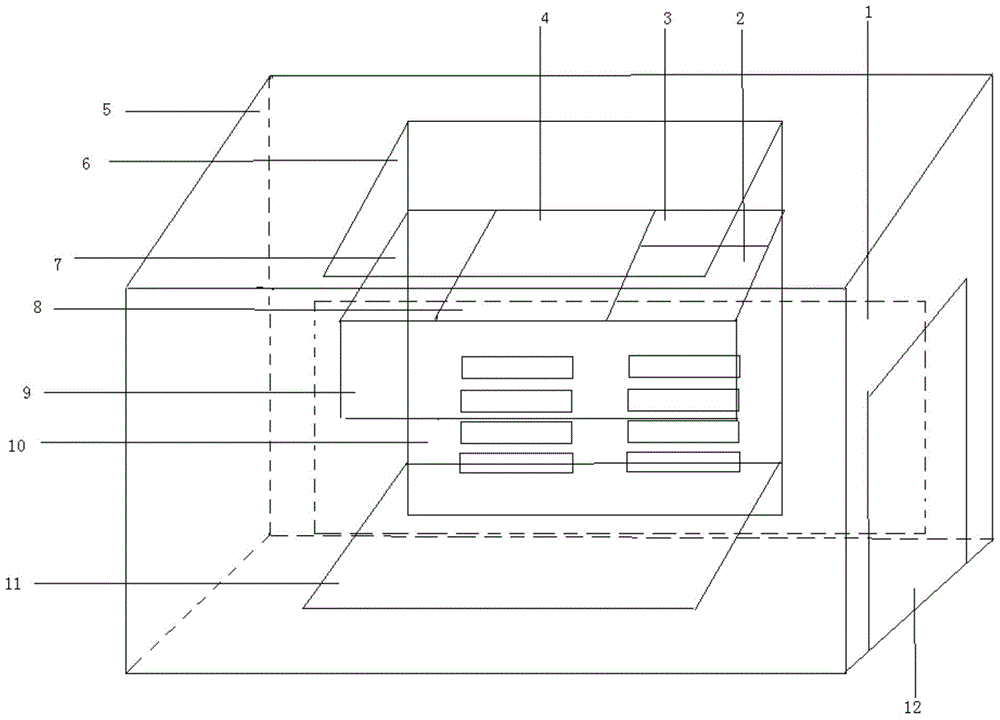

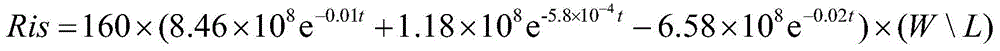

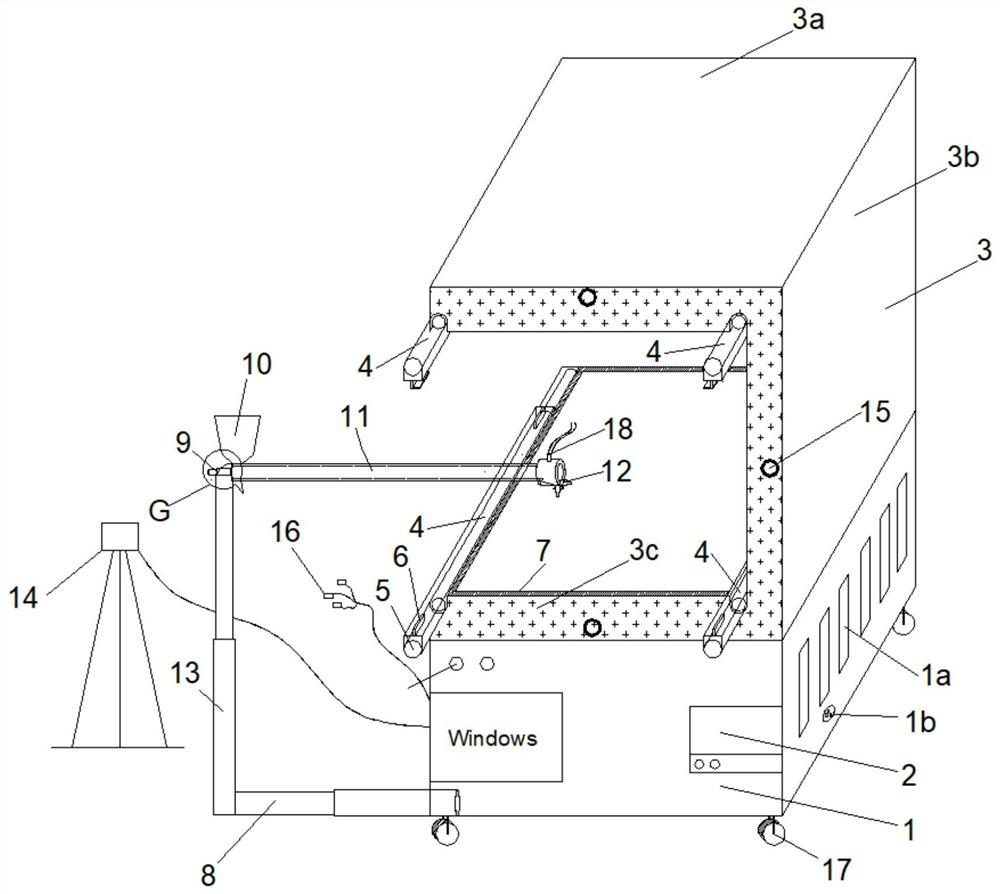

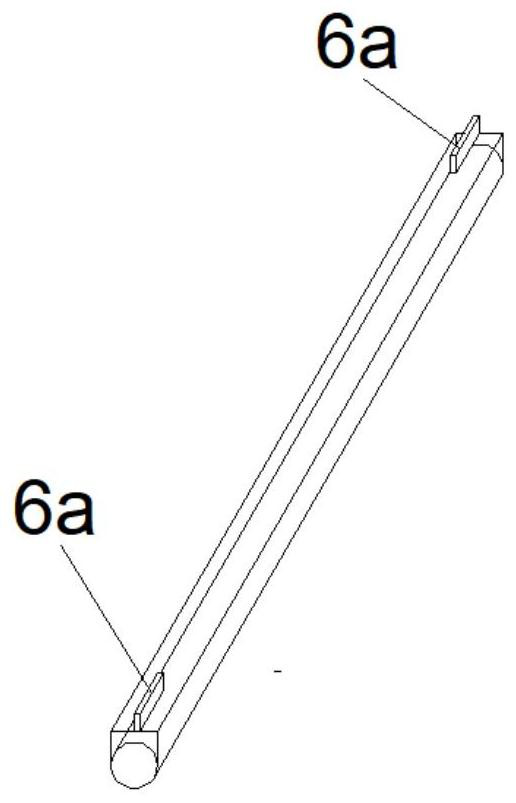

Motorcycle guy cable performance integration test system test bed

InactiveCN101769822AImprove automated testingReduce manual operationsVehicle testingMachine part testingEngineeringElectric control

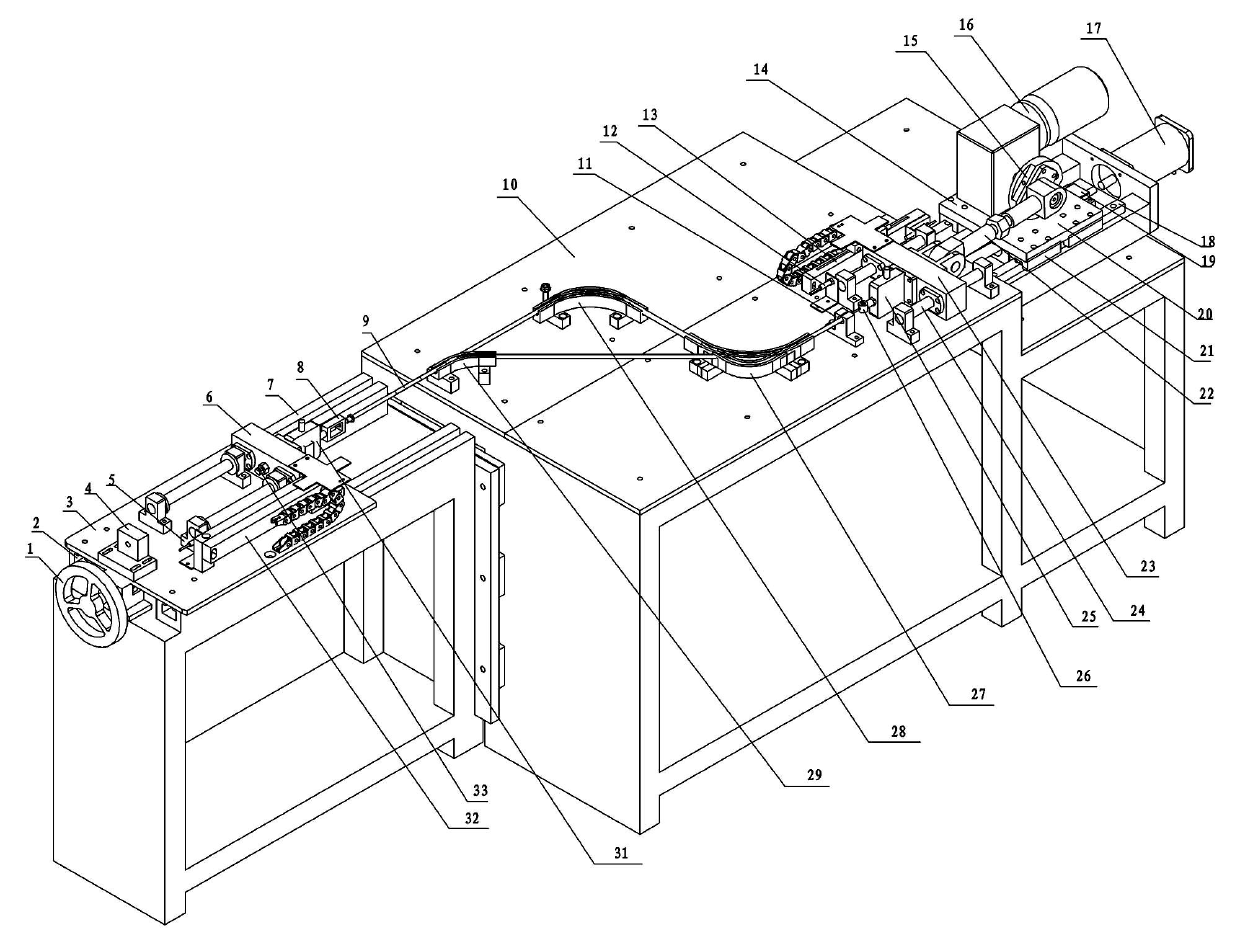

The invention discloses a motorcycle guy cable performance integration test system test bed. The test bed comprises a test system test bed mechanical device for mechanically operating an object to be tested, a test system test bed electric control device for controlling the motion of the mechanical device, a data collecting processing device for collecting and processing test data and a microcomputer. The microcomputer controls the motion of the test bed mechanical device through the connected electric control device, collects various test data through the connected collecting processing device, records, saves and displays the test data and monitors the whole test process. The invention improves the automation test degree, reduces manual operation process, automatically records and saves the test data and displays in a figure or table form, obviously improves the measuring precision and effectively improves the test efficiency. The invention is extensively applied to the safety test of the motorcycle guy cable to be as the motorcycle guy cable performance test experiment platform.

Owner:WUYI UNIV

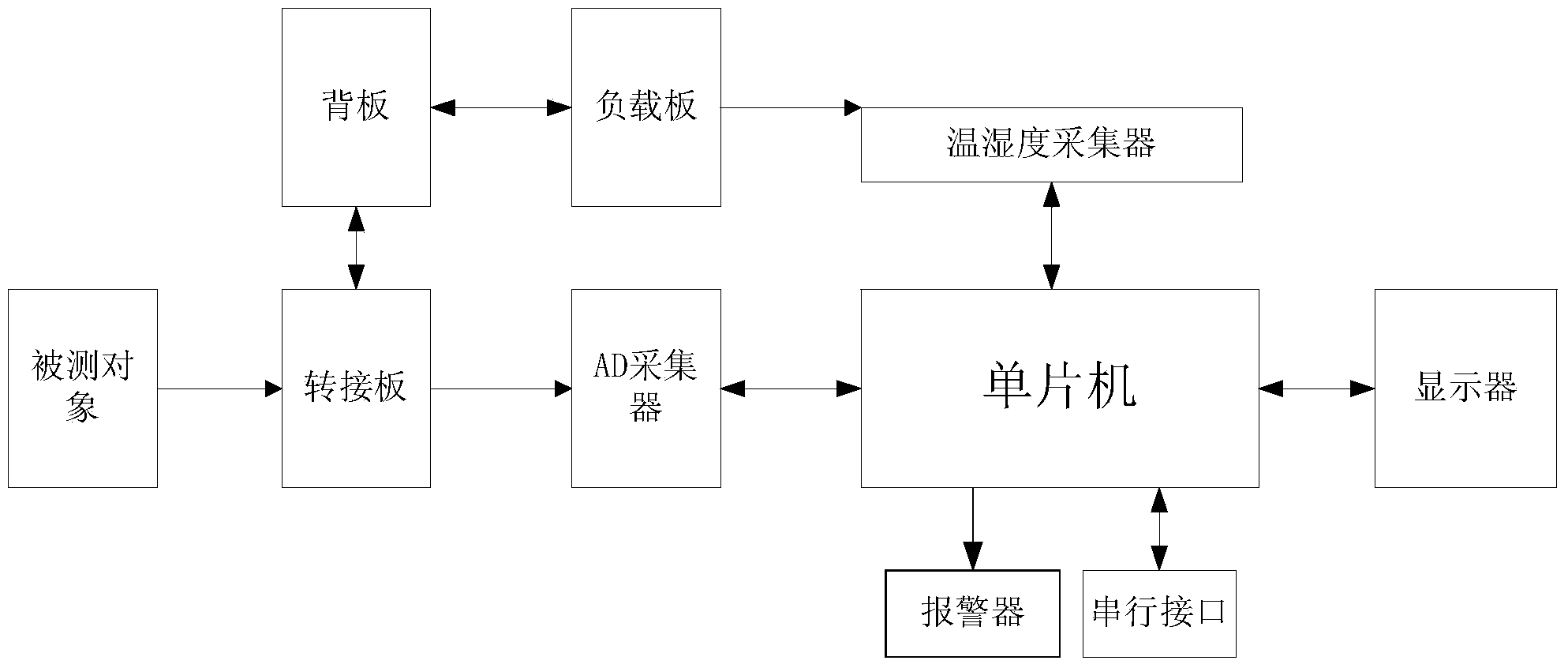

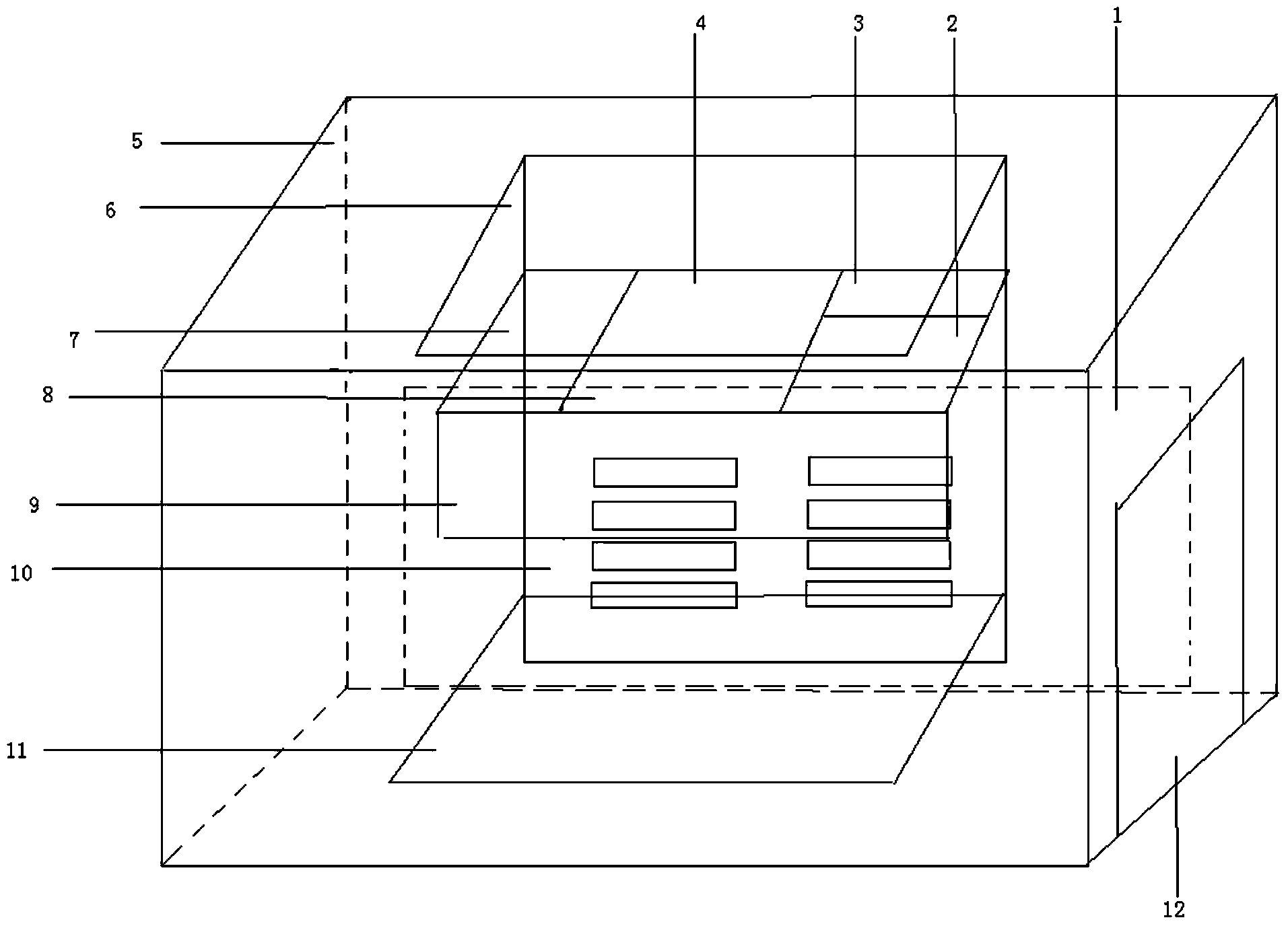

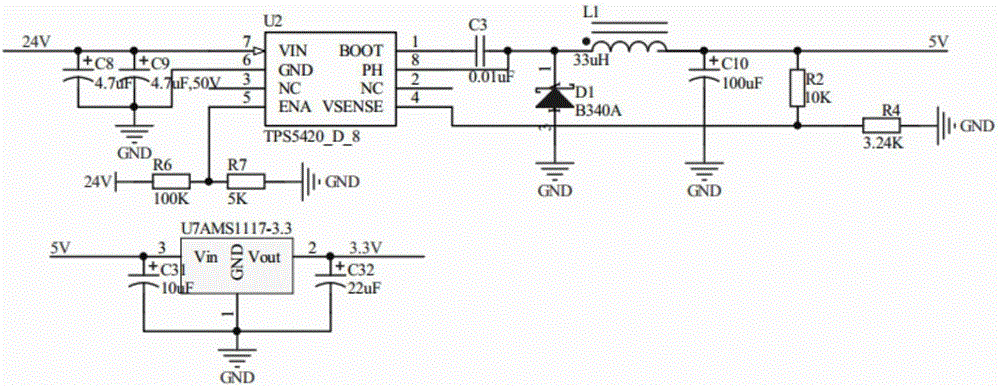

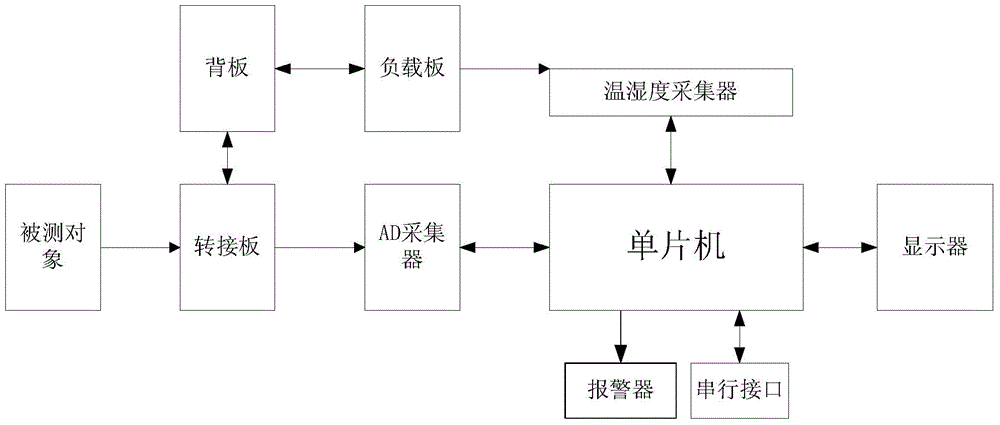

Burn-in detection system

ActiveCN103713265AReduce mistakesExtended service lifePower supply testingMicrocontrollerMicrocomputer

The invention provides a burn-in detection system which can be used for burning different types of power modules by replacing adapting plates, back plates and load plates. The adapting plates enable loads on the load plates to be loaded on objects to be detected through the back plates. An AD collector collects voltage data of the objects to be detected through the adapting plates and sends the data to a single-chip microcomputer. A temperature and humidity collector collects temperature and humidity data of the load plates and sends the data to the single-chip microcomputer. The single-chip microcomputer carries out signal processing on the received temperature and humidity data and the received voltage data to obtain a monitoring result and transmits the result to a display for displaying. In addition, the warning range of the monitoring result is set, and when the result is detected to exceed the warning range, warning inductions are sent out to trigger an alarm. According to the burn-in detection system, manual detection methods before the burn-in detection system is applied are replaced, and efficiency is improved greatly; in addition, the loads can be replaced freely according to needs; voltage signal self-testing and load inner temperature self-testing are added, and the system can give out an alarm immediately when faults happen; human resources are relieved, and uncertain factors caused by manual interference are avoided.

Owner:BEIJING AEROSPACE MEASUREMENT & CONTROL TECH

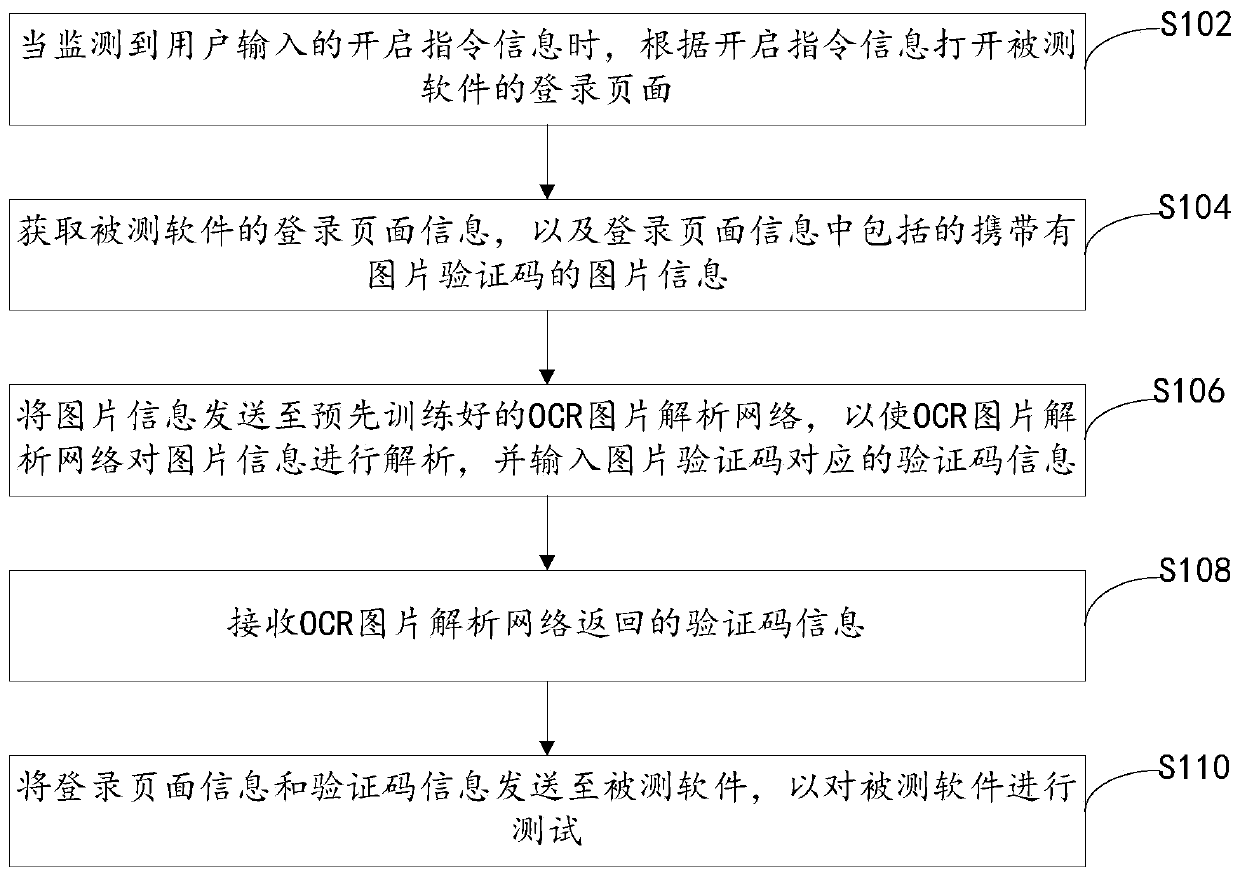

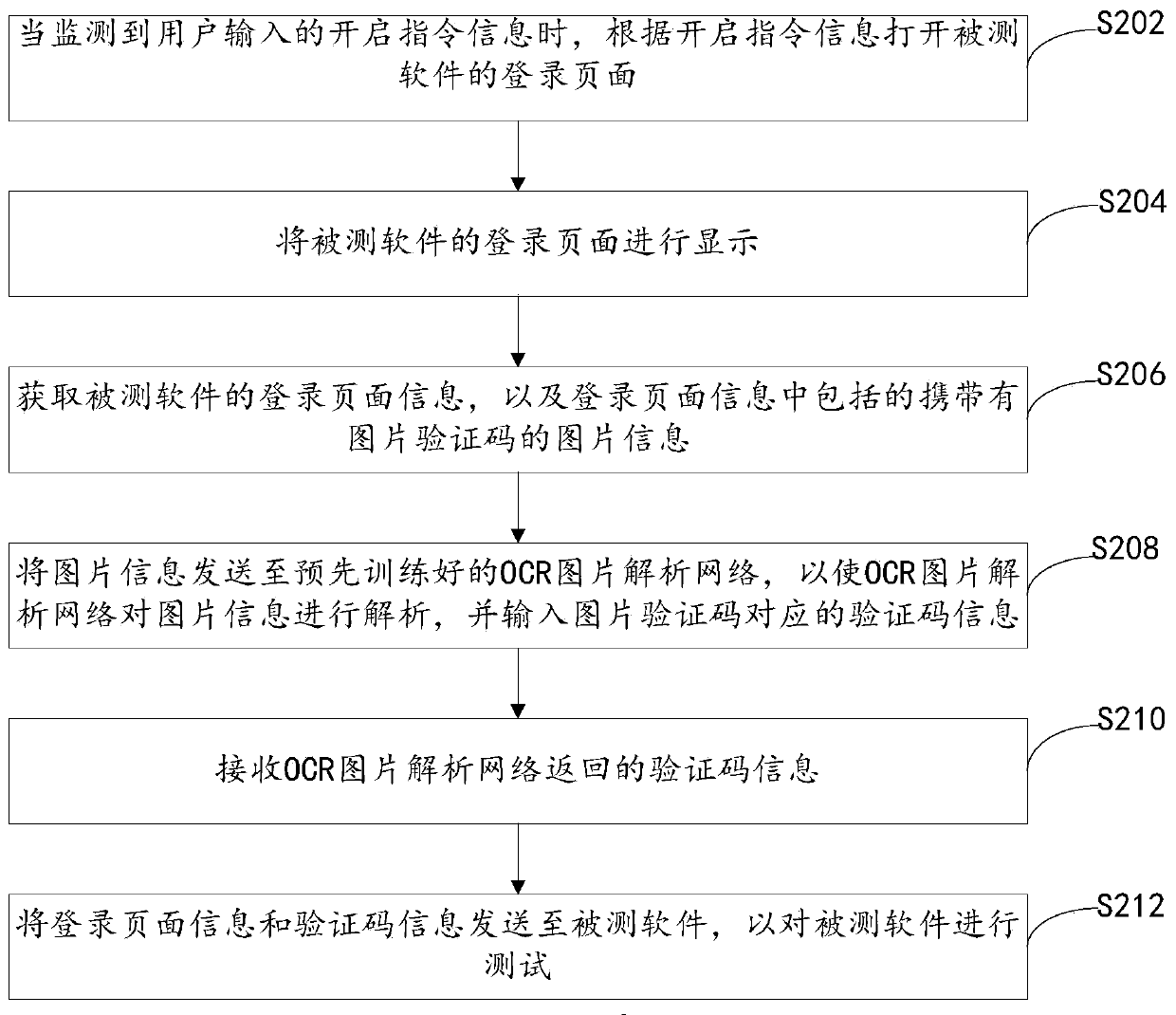

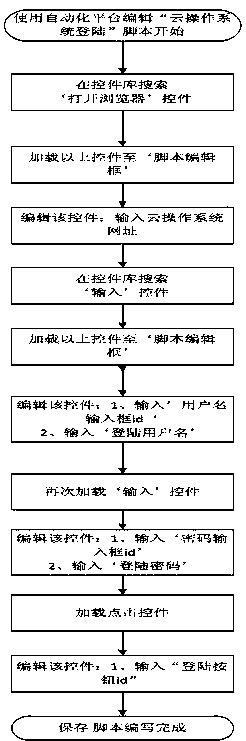

Software automated testing method and device and electronic equipment

PendingCN111143213AImprove automated testingImprove efficiencySoftware testing/debuggingNeural architecturesSoftware engineeringVerification

The invention provides an automatic software testing method and device and electronic equipment, and the method comprises the steps: opening a login page of tested software according to starting instruction information when the starting instruction information inputted by a user is monitored; obtaining login page information of the tested software and picture information carrying a picture verification code and included in the login page information; sending the picture information to a pre-trained OCR picture analysis network, so that the OCR picture analysis network analyzes the picture information and outputs verification code information corresponding to the picture verification code; receiving verification code information returned by the OCR picture analysis network; and sending thelogin page information and the verification code information to the tested software to test the tested software. According to the application, the technical problem that the existing software automation test result is not ideal can be alleviated, the automation test of the software without manual intervention is realized, and the efficiency and precision of the software automation test are improved.

Owner:北京数衍科技有限公司

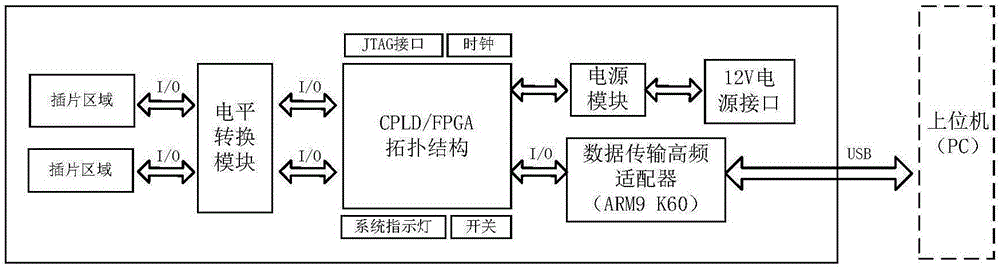

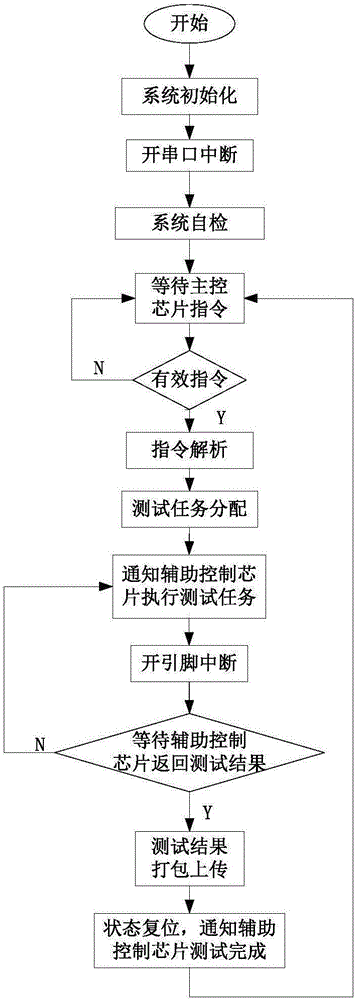

Chip internal logic verify system and method

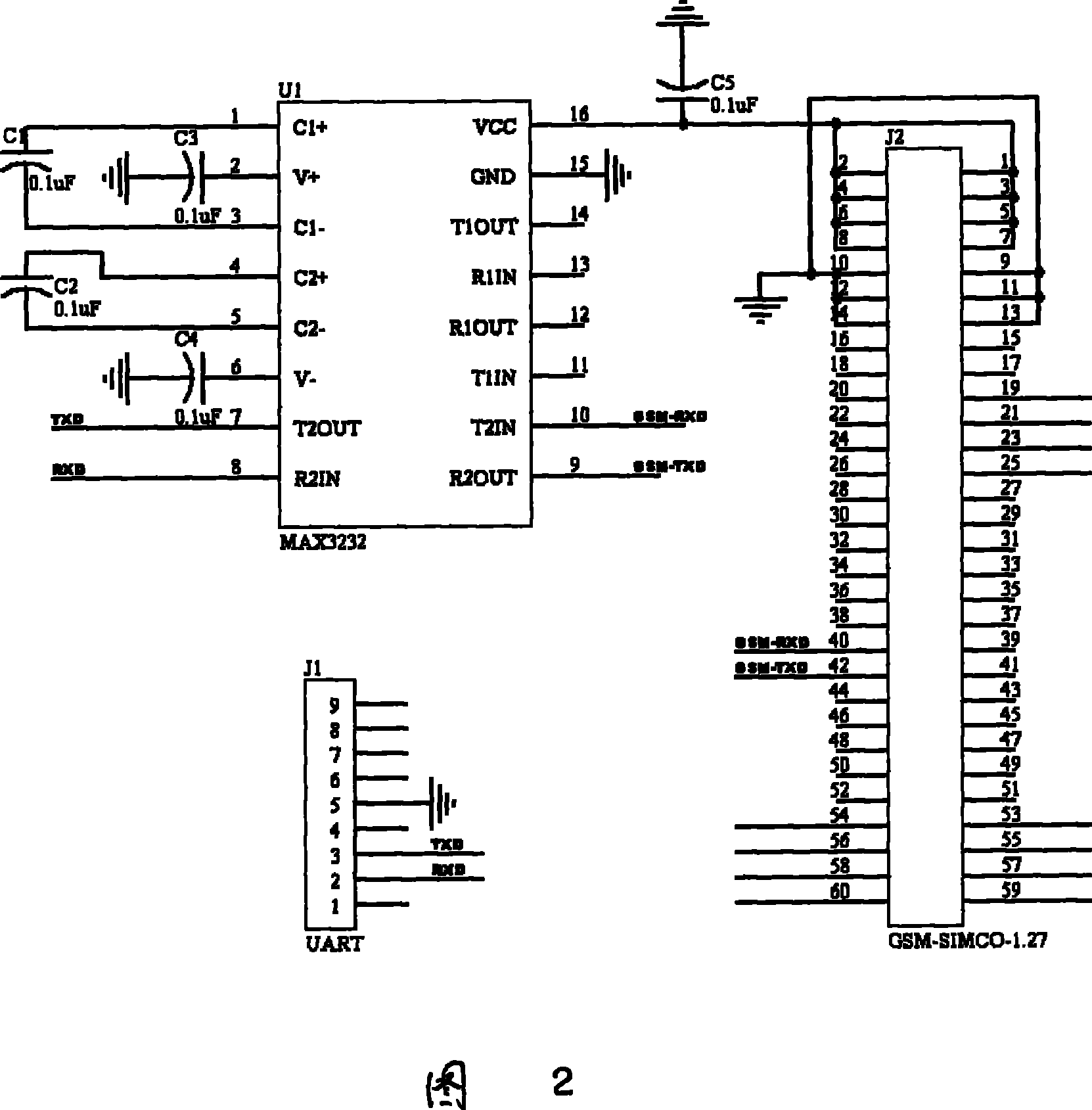

InactiveCN106707143AReduce workloadImprove test efficiencyElectrical testingTest efficiencyControl signal

The invention provides a chip internal logic verify system characterized by comprising the following units: a main control module used for sending a control signal to a tested chip according to a control order and receiving a feedback signal of the tested chip; a level transition module used for carrying out level transition between the tested chip and the main control module; at least one I / O module used for connecting with the tested chip, wherein the I / O module is connected with the main control module through the level transition module. The system and method can test and verify the programmable chip internal logics; the chip internal logic verify system can test and verify chips in batch, thus reducing operation people workload, and improving testing efficiency and test coverage rate.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

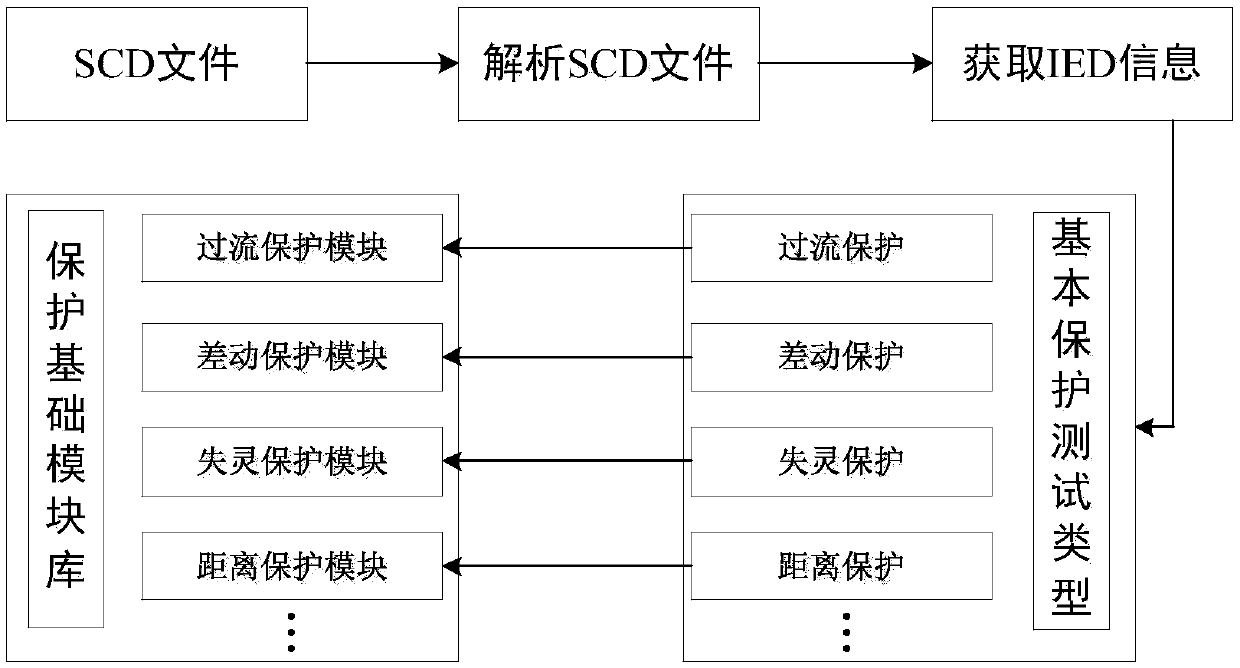

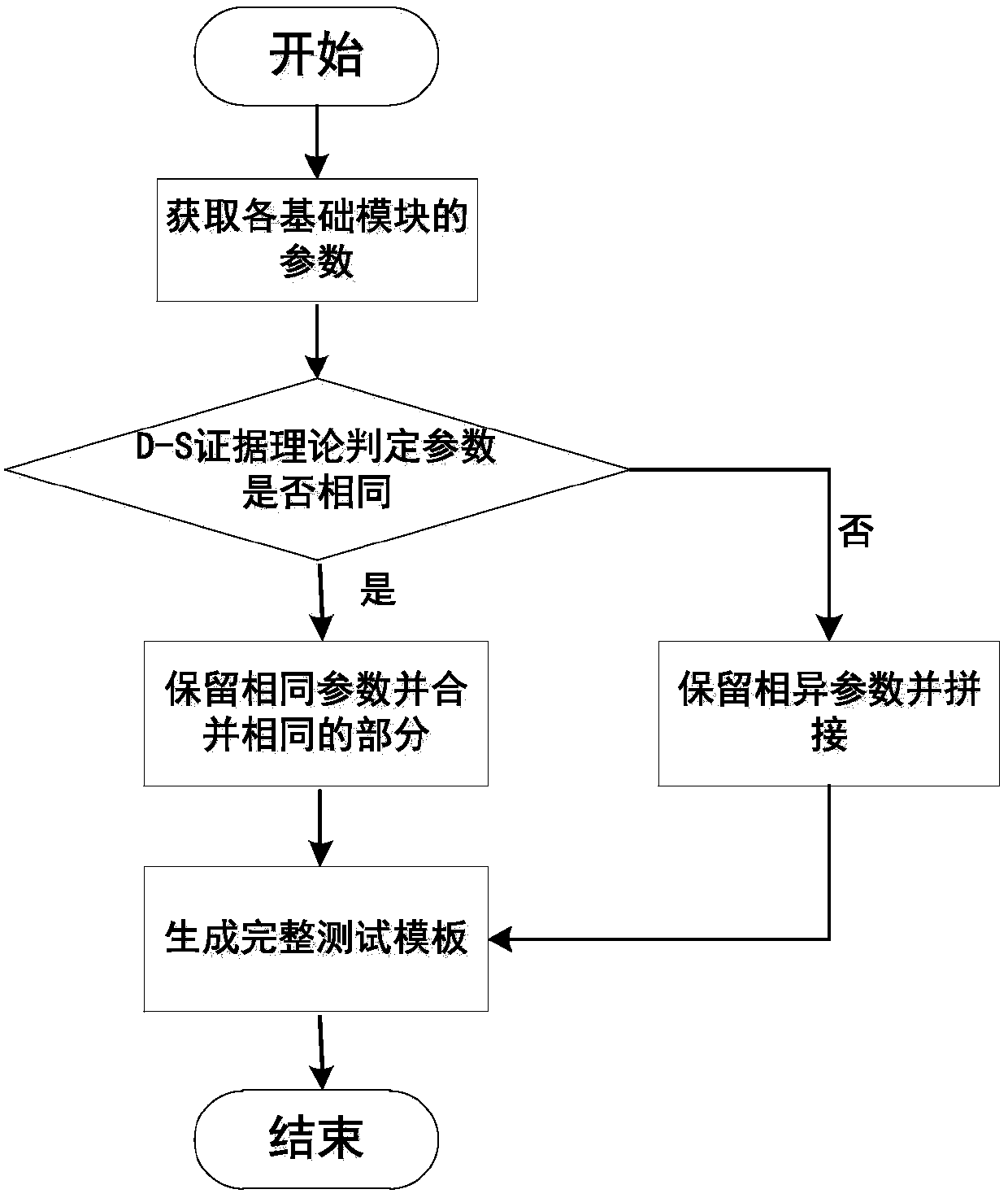

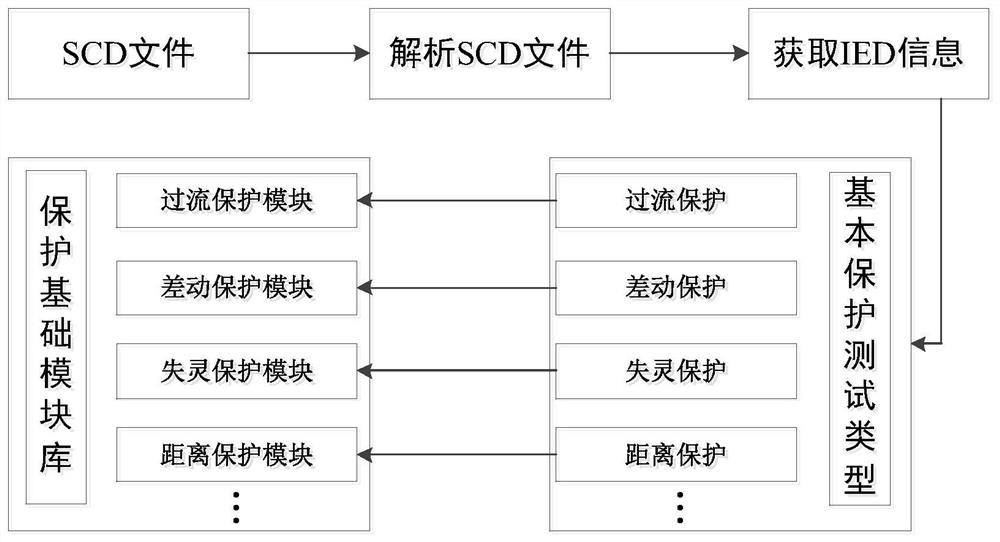

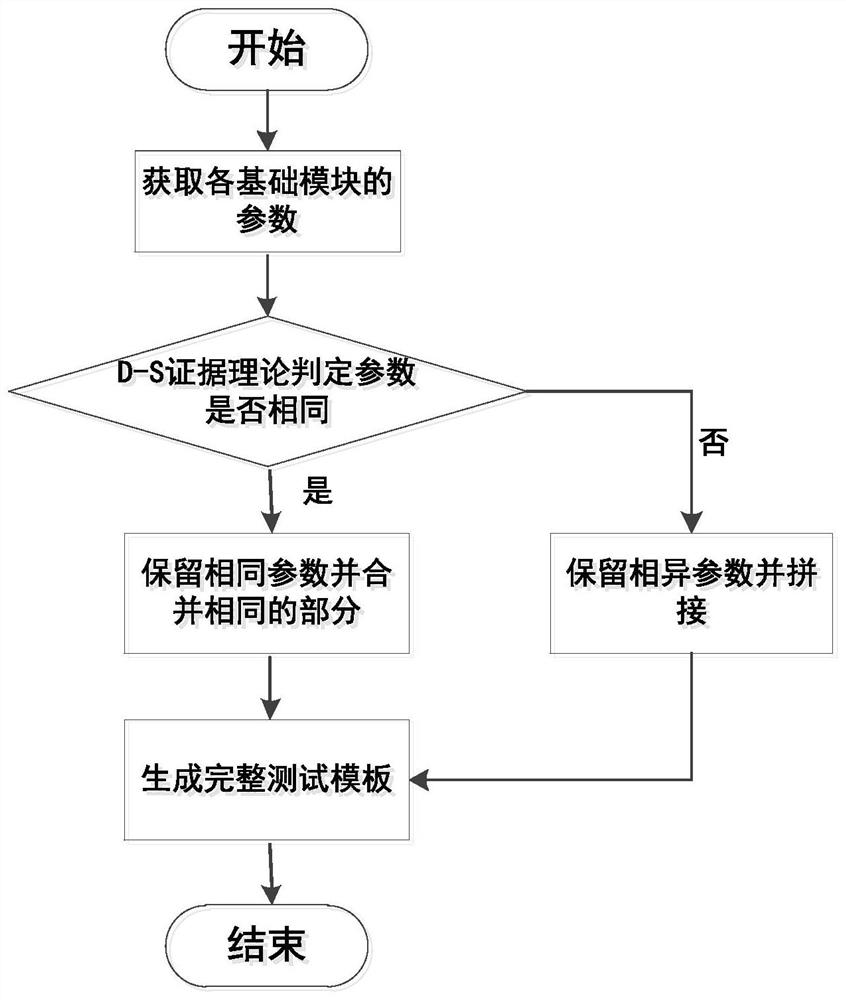

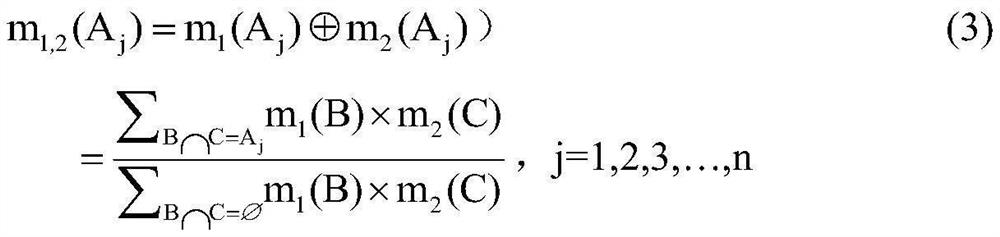

Relay protection device automatic testing template based on D-S evidence theory

ActiveCN108548970AImprove intelligenceAvoid duplication of testsElectrical testingTest efficiencyTemplate based

The invention discloses a relay protection device automatic testing template based on a D-S evidence theory. The method comprises the following steps of (1), in a protection base module database, acquiring the parameter of each protection base module; (2), determining whether the same parameter exists among the base modules according to the D-S evidence theory, if yes, keeping one same parameter and combining the parts with the same parameter; after combination, if no same parameter exists, keeping the respective parameters for performing splicing combination; (3), after splicing, successivelyexpanding the testing items for testing; and (4), after testing, automatically generating a protection testing report. The relay protection device automatic testing template according to the invention is based on module splicing of the D-S evidence theory has advantages of preventing repetitive testing, improving testing efficiency, and laying a basis for intelligentization and automation improvement of the whole set of automatic testing system.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +6

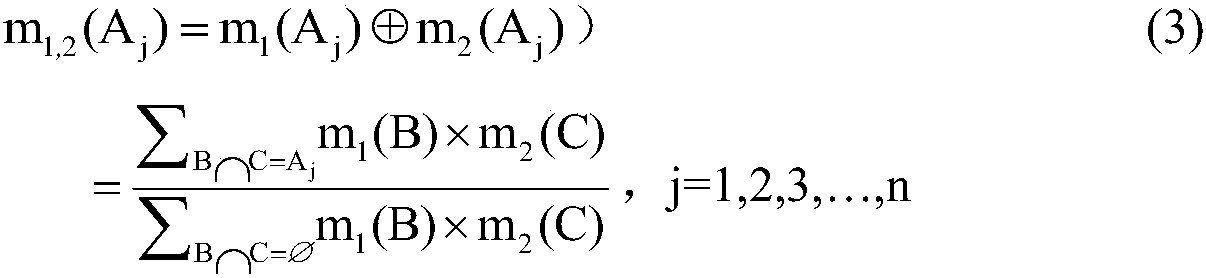

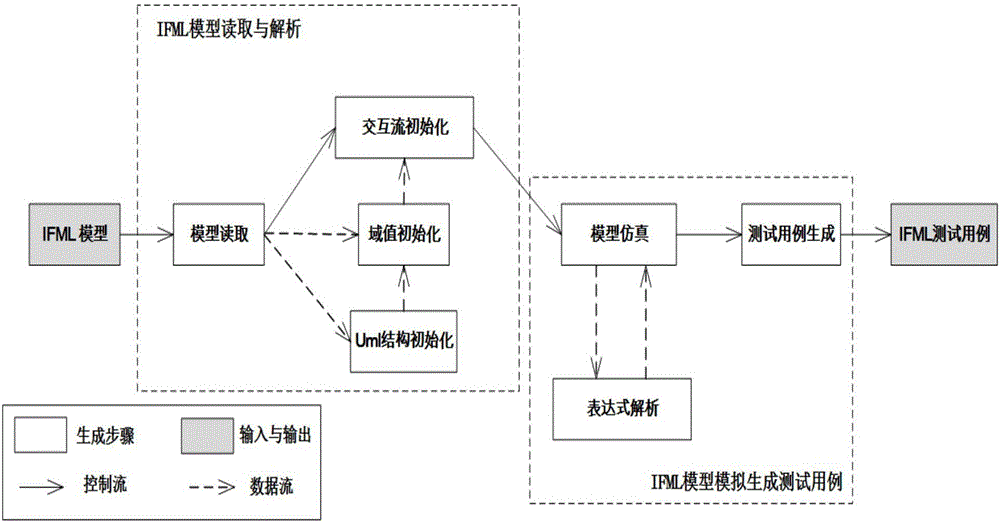

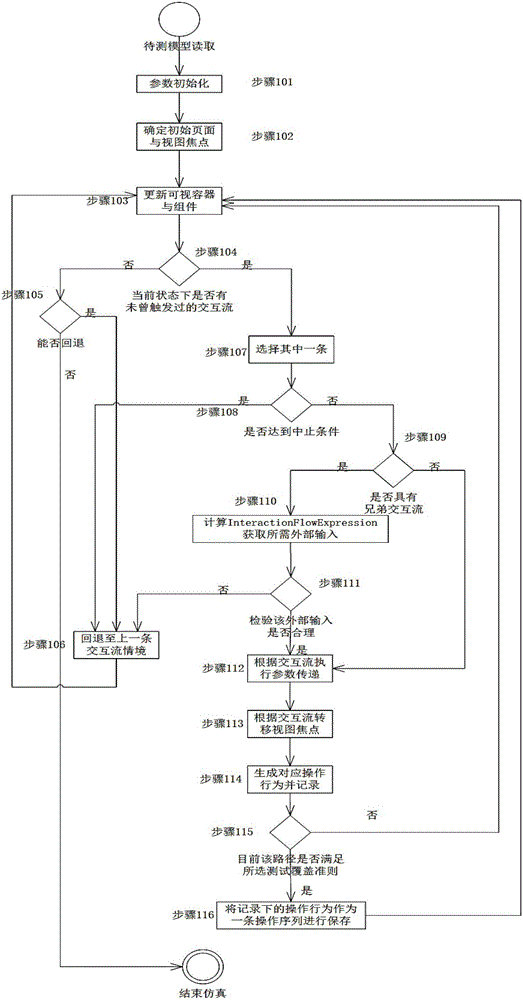

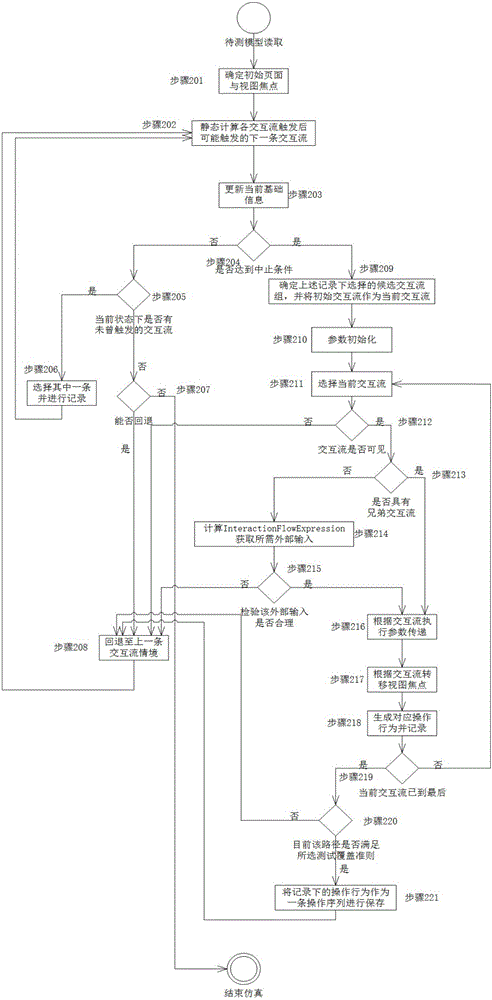

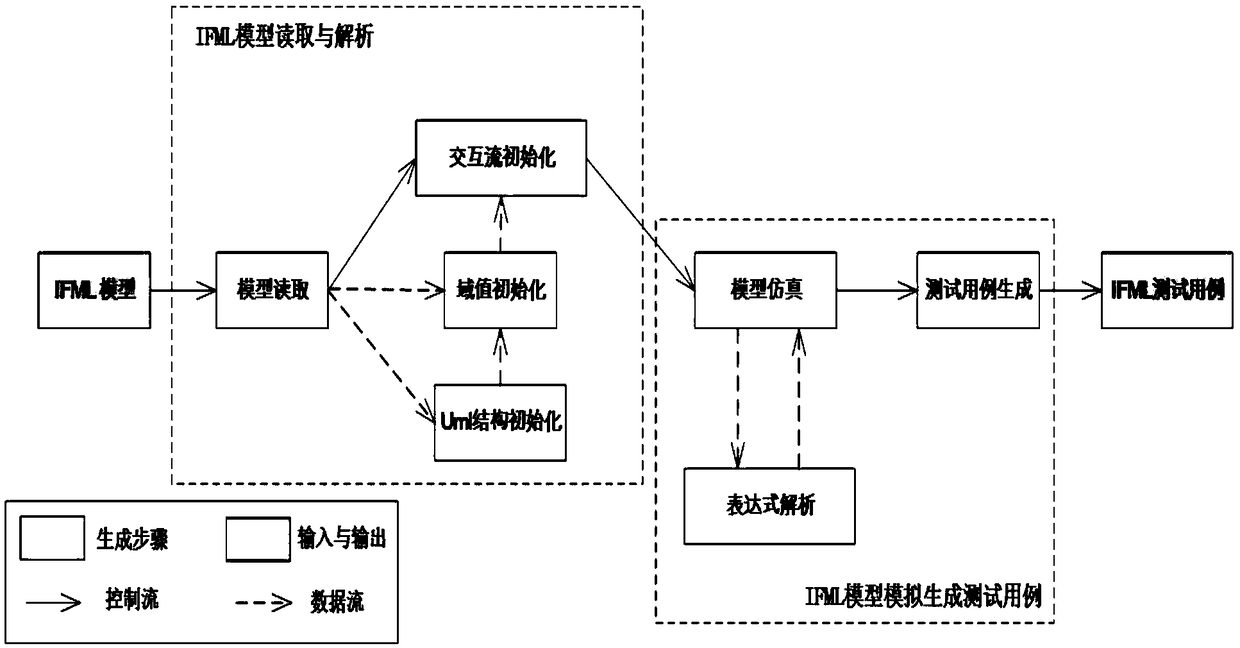

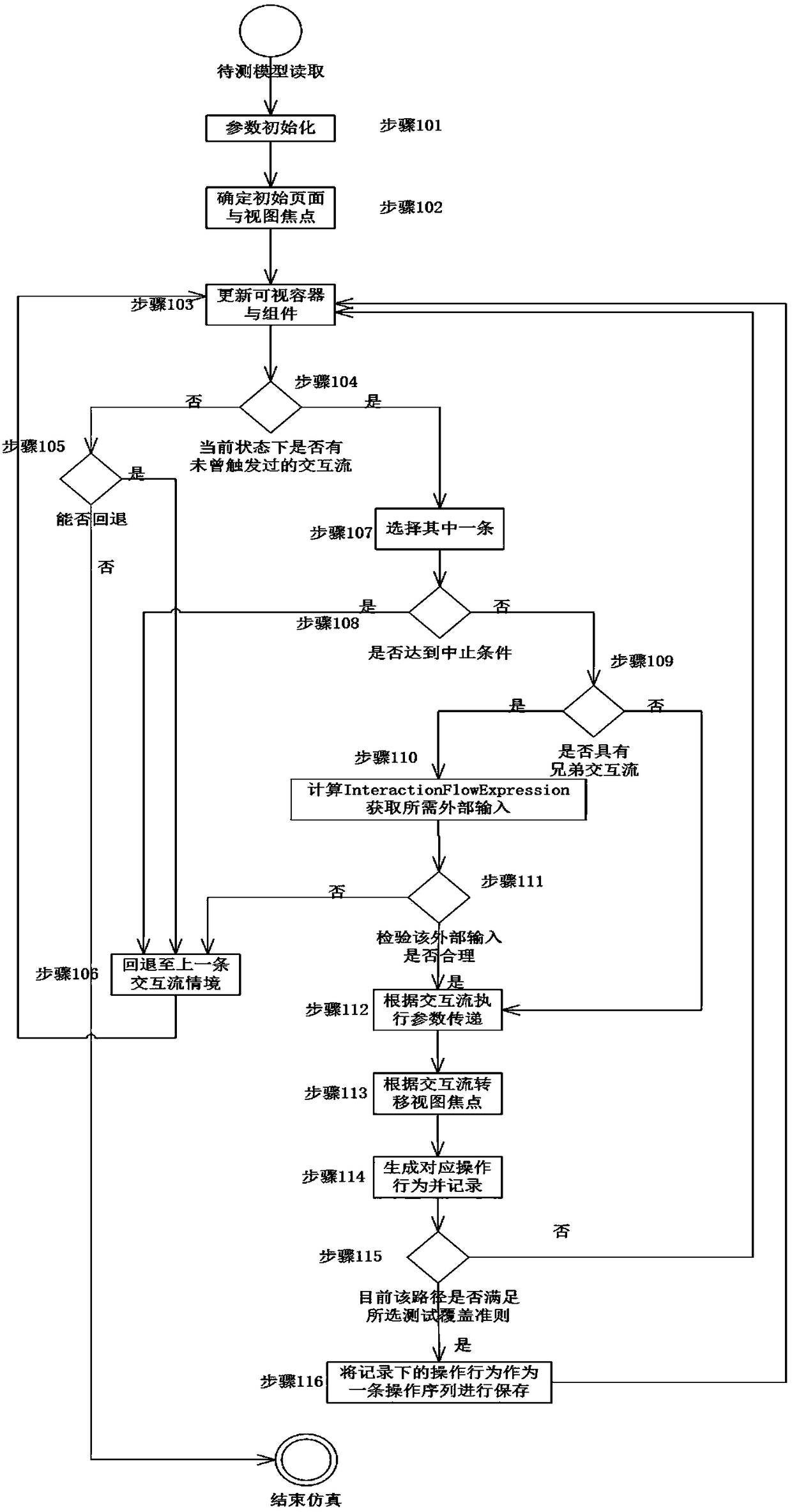

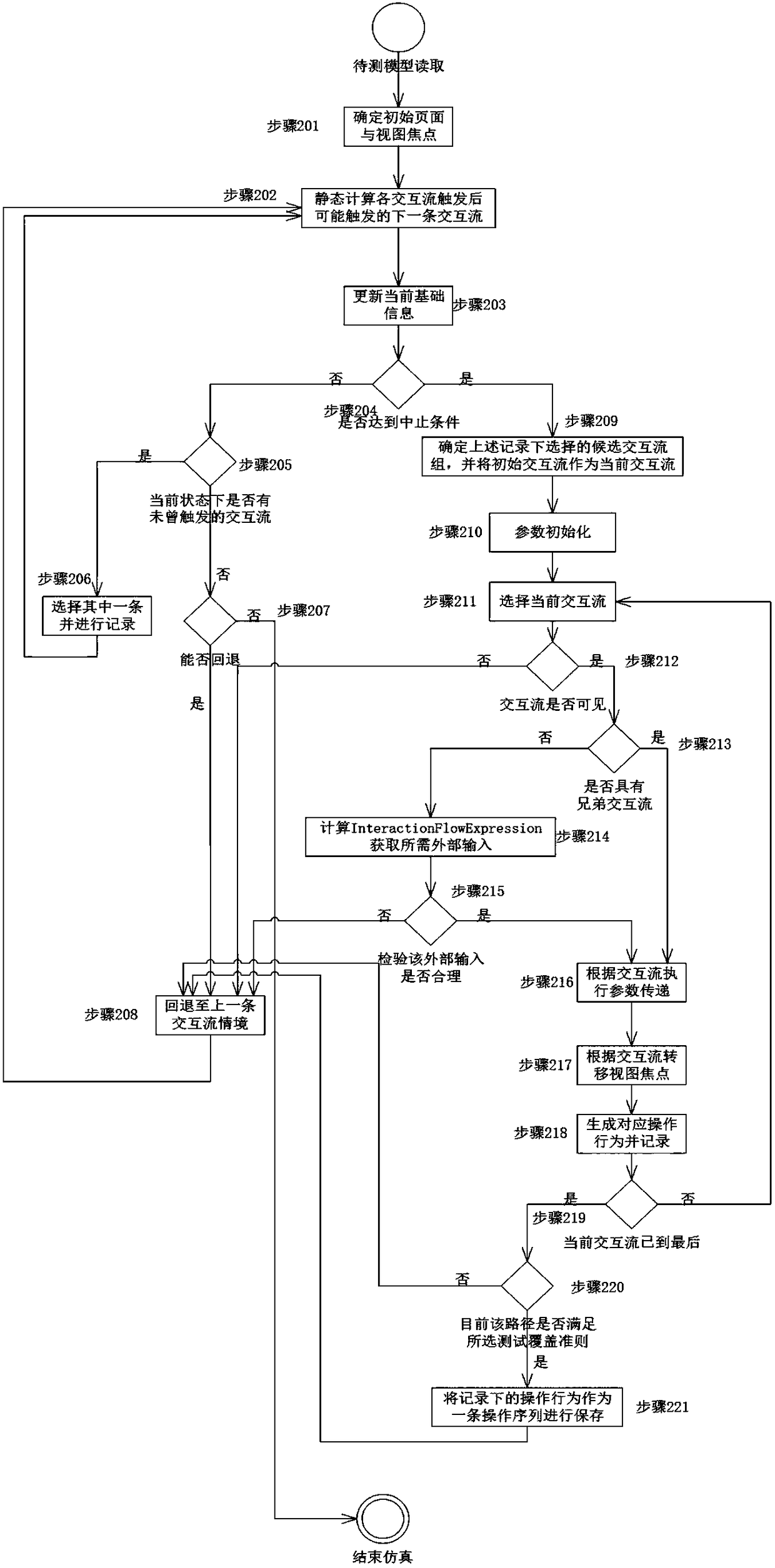

Expansion-based IFML mobile application test case forming method

ActiveCN106227667AImprove readabilityImprove automated testingSoftware testing/debuggingMobile endToolbar

The invention relates to an expansion-based IFML mobile application test case forming method comprising the following steps: building a model, i.e., drawing an IFML model corresponding to a to-be-tested mobile application. Expansion contents aiming at mobile application modeling are added on an original standard IFML so as to form the IFML applied in modeling; the expansion contents comprises the following elements: an expansion subtype toolbar and a screen container are added on a view container; an expansion subtype mobile widget is added on a view assembly; an expansion subtype mobile end system event, a mobile end event and a mobile end behavior activity event are added on an Event; an expansion subtype mobile end behavior activity is added on the behavior activity. The test case complying with requirements can be formed according to selected test coverage criterion.

Owner:NANJING UNIV

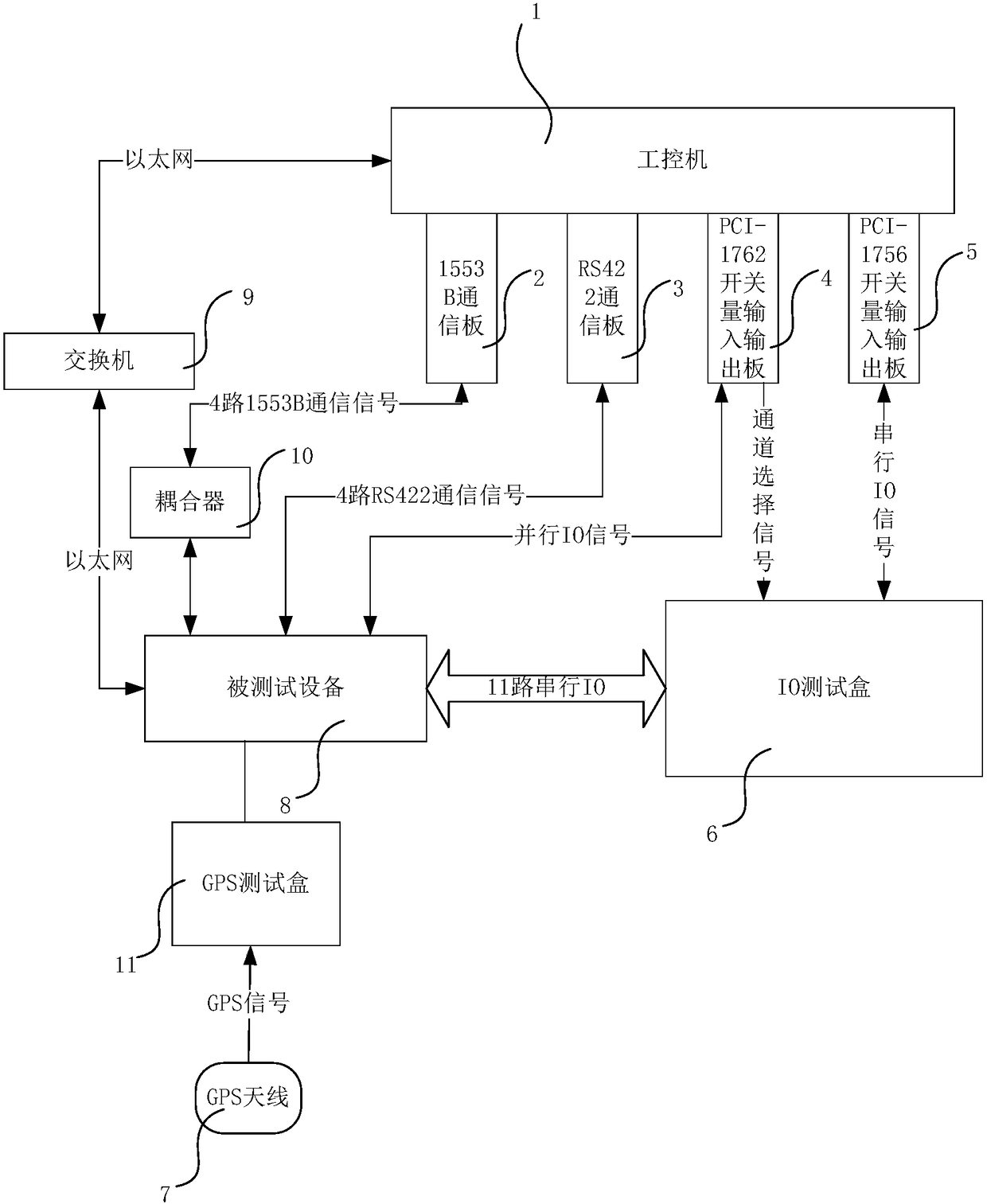

Automatic test equipment

ActiveCN108089952AImprove automated testingImprove test efficiencyDetecting faulty computer hardwareDifferential signalingInput/output

The invention discloses automatic test equipment. According to the equipment, an industrial personal computer is used for sending a network message, controlling to-be-tested equipment to act, to the to-be-tested equipment and receiving feedback data of the to-be-tested equipment; the industrial personal computer sends data to a 1553b interface of the to-be-tested equipment through a 1553b interface, and the data is used for testing the 1553b interface of the to-be-tested equipment 8; the industrial personal computer sends data to an rs422 interface of the to-be-tested equipment through an rs422 interface, and the data is used for testing the rs422 interface of the to-be-tested equipment; the industrial personal computer tests a parallel input / output interface of the to-be-tested equipmentthrough a PCI-1762 switching value input / output board; a one-path serial interface of the industrial personal computer is connected with a corresponding multi-path serial interface of the to-be-testedequipment through an IO test box, and the IO test box switches on the serial interface of the to-be-tested equipment according to an instruction of the industrial personal computer; and a GPS test box converts a GPS signal of a GPS antenna into a differential signal and inputs the differential signal into a second pulse interface of the to-be-tested equipment.

Owner:BEIJING INST OF COMP TECH & APPL

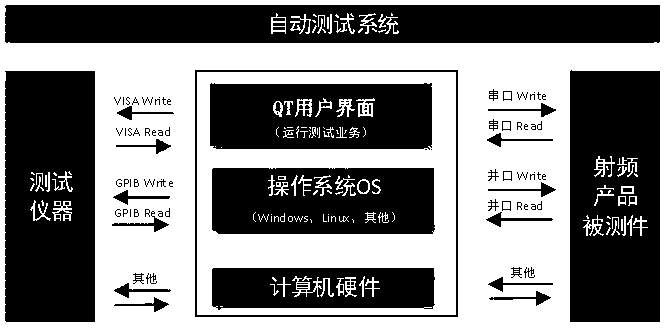

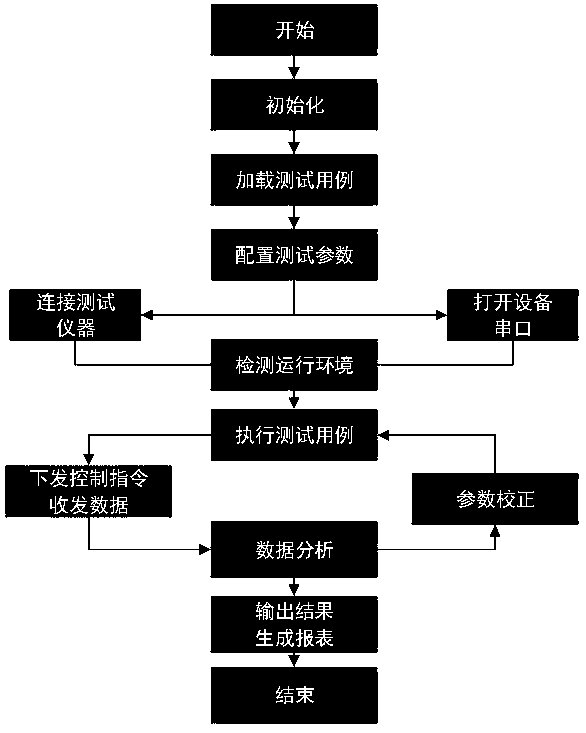

QT-based cross-platform radio frequency index automatic test system and test method

PendingCN110350987AImprove automated testingImprove effective utilizationTransmission monitoringData switching networksLab test methodRadio frequency

The invention discloses a QT-based cross-platform radio frequency index automatic test system and a test method, wherein the system comprises a test instrument which supports the programming control through a programmable instrument standard command; and a main control module which is connected with the test instrument and the radio frequency product to be tested, and is configured in a main control computer for realizing data exchange with the test instrument and the radio frequency product to be tested, and the main control computer executes the test case, stores and records the test data and displays a data report through QT automatic test software capable of running in a cross-platform manner. Through the test instrument and the main control module, the automatic test degree, the testefficiency and the test result accuracy of the radio frequency index can be remarkably improved, the effective utilization rate of test instrument resources is improved, the labor cost and the time cost are reduced, and meanwhile, the operation difficulty can be reduced.

Owner:DFINE TECH

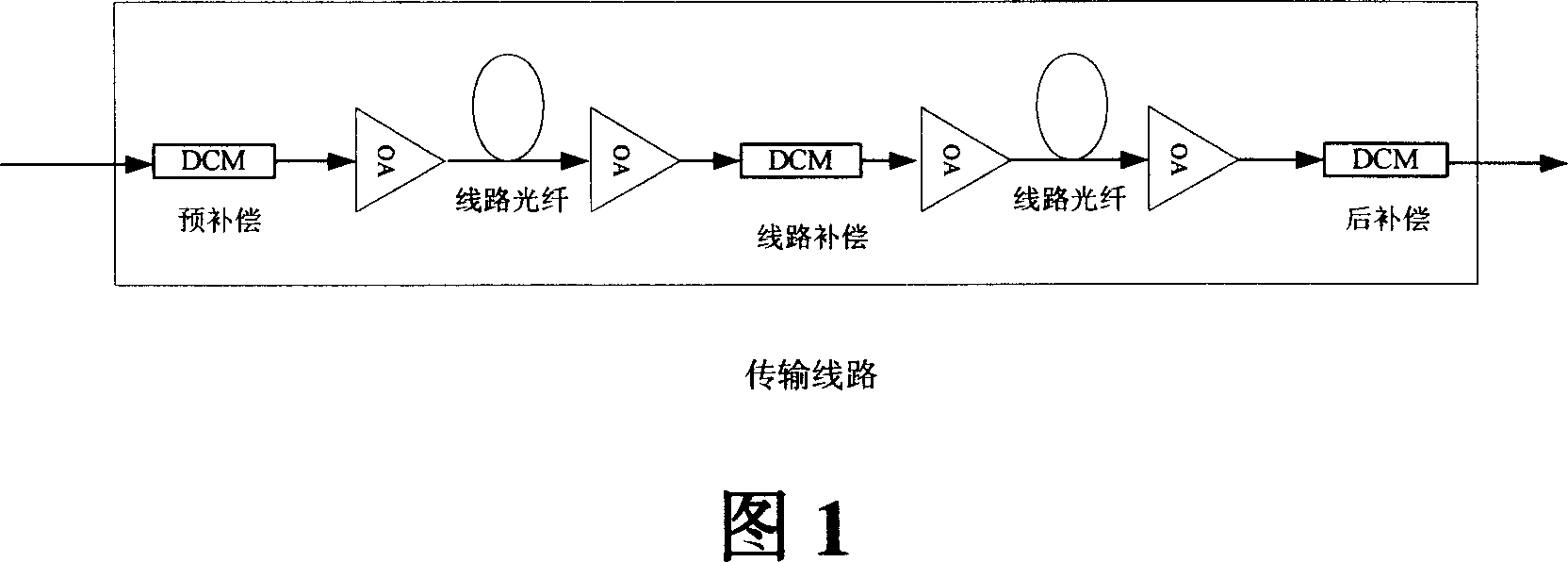

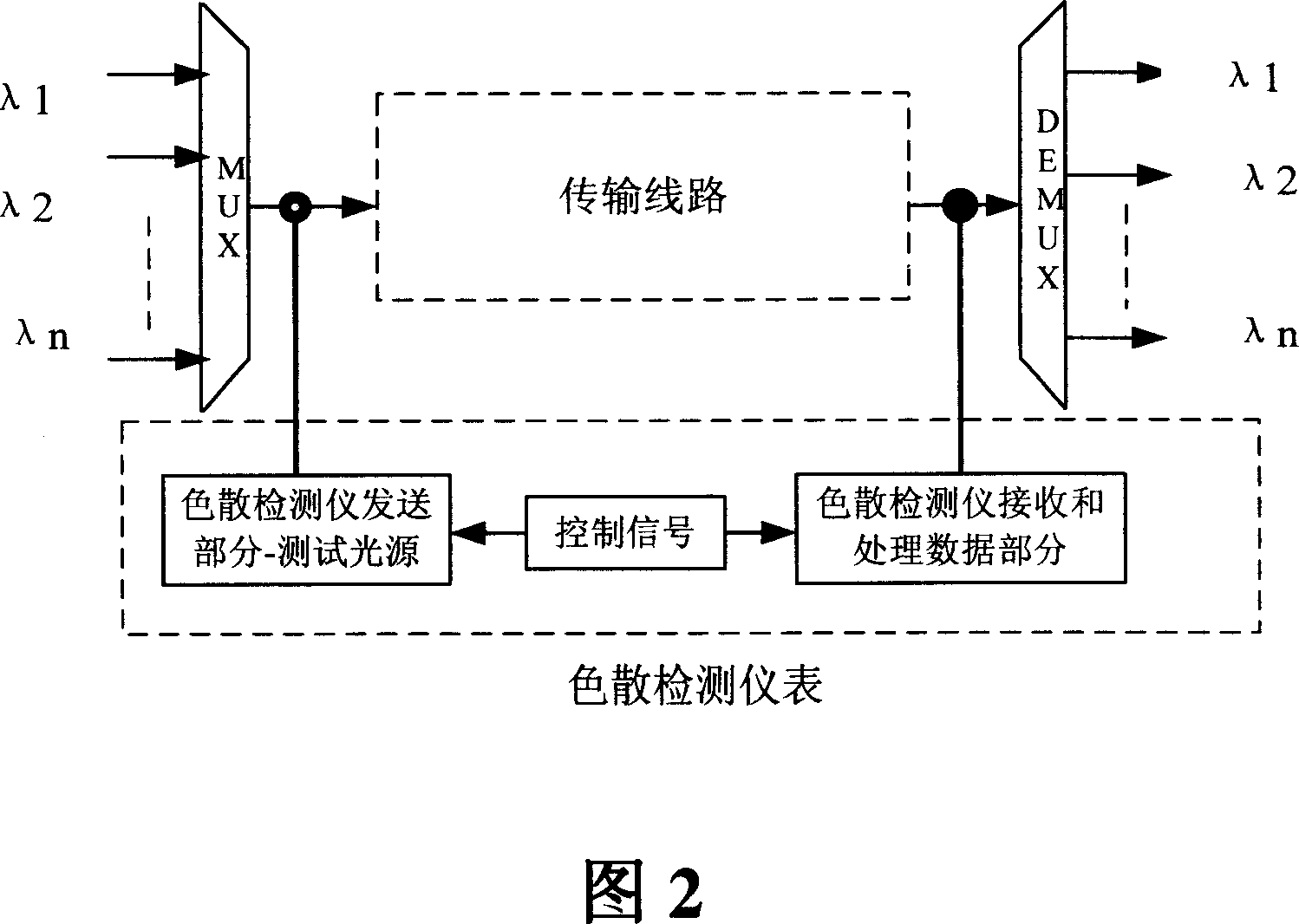

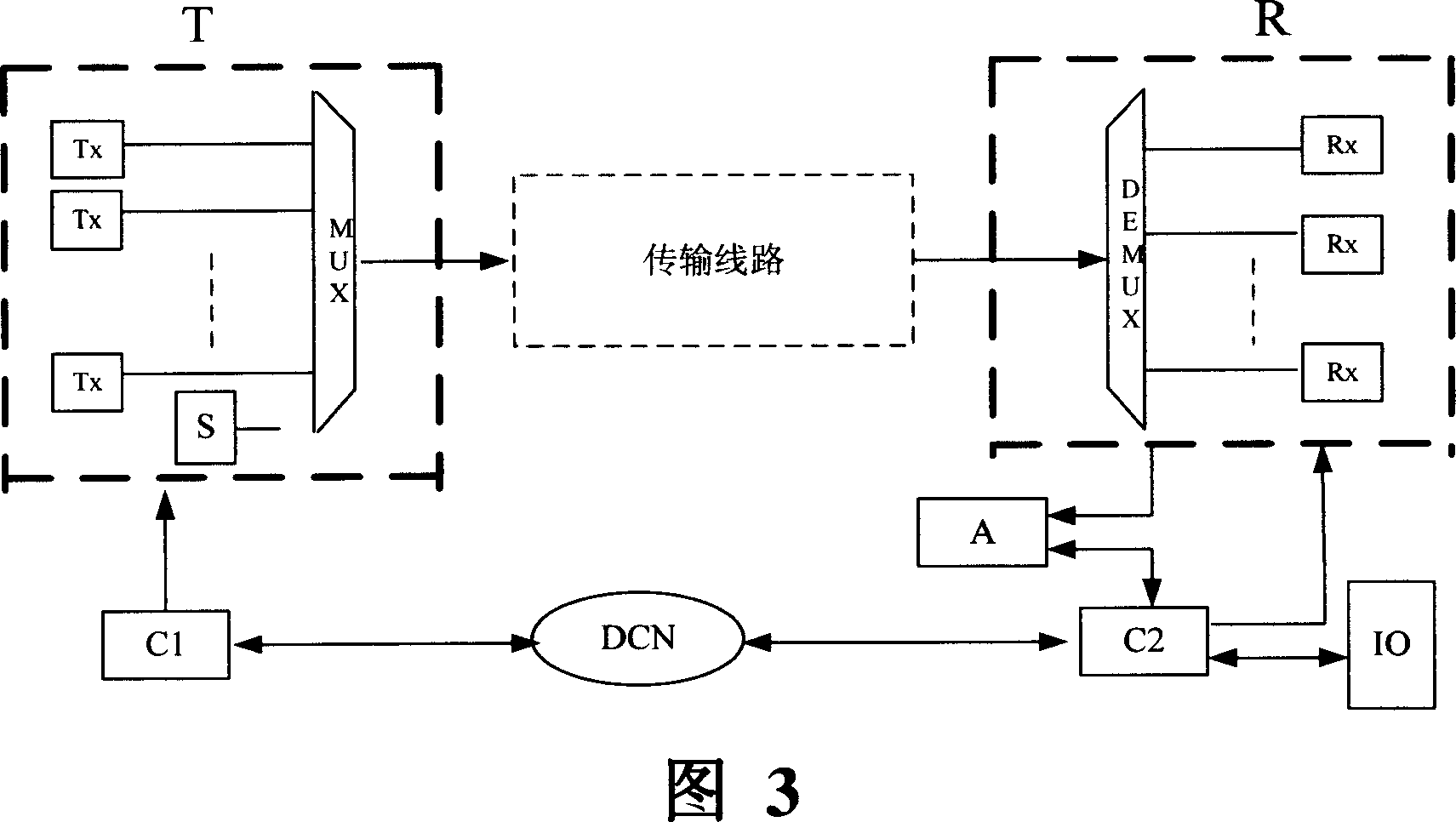

Residual dispersion real-time detection system and method

InactiveCN101047441AImprove automated testingWavelength-division multiplex systemsElectromagnetic transmissionLength waveStart up

A real-time detection system of residual dispersion comprises dispersion test source for outputting test wavelength, dispersion detection-processing unit for carrying out residual dispersion detection on outputted test wavelength, sending end control unit for controlling said test source to output test wavelength, receiving end control unit for sending trigger condition to start up residual dispersion detection and for controlling said detection-processing unit to carry out residual dispersion detection on output of dispersion test source.

Owner:ZTE CORP

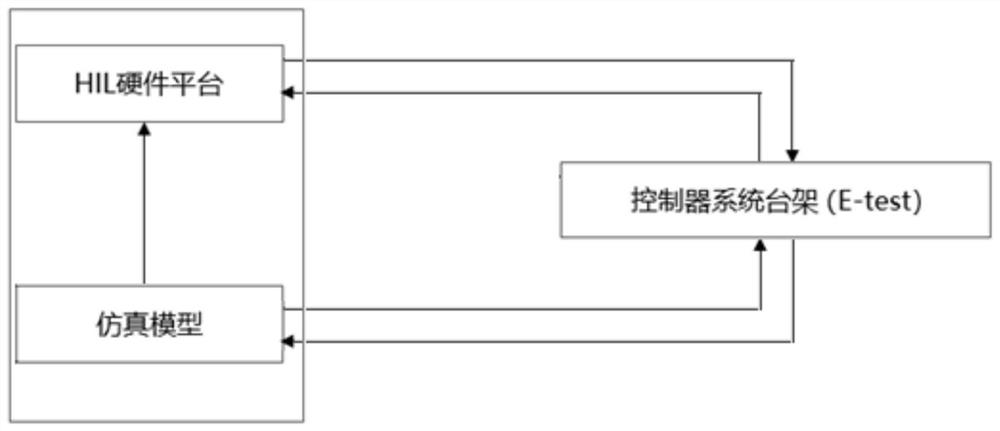

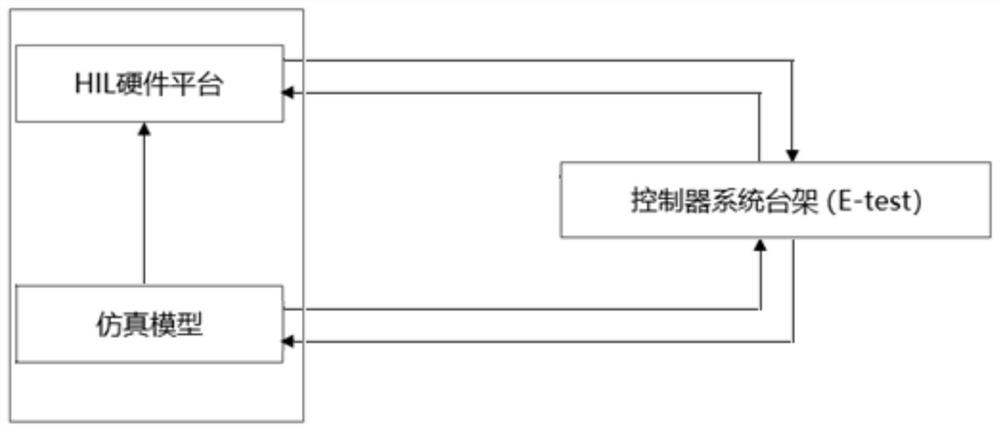

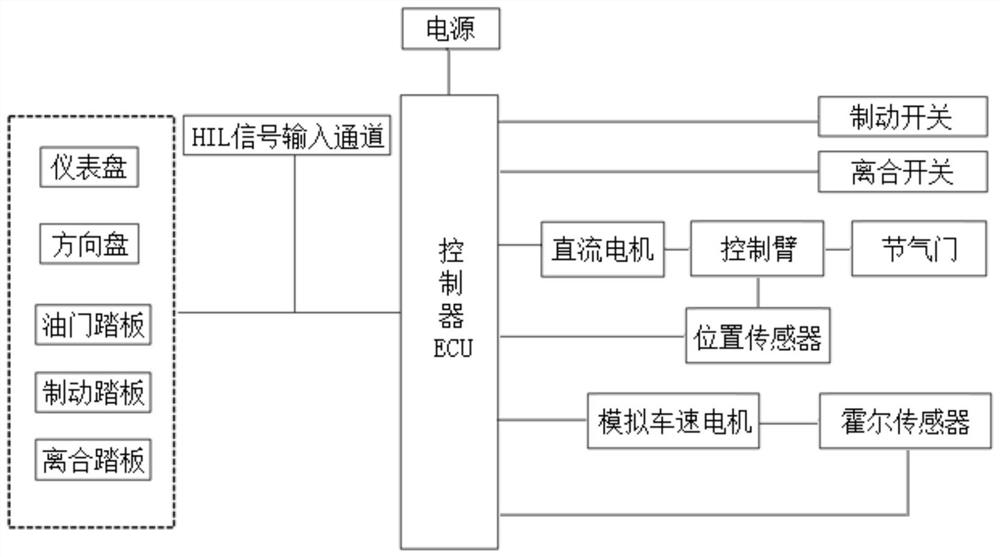

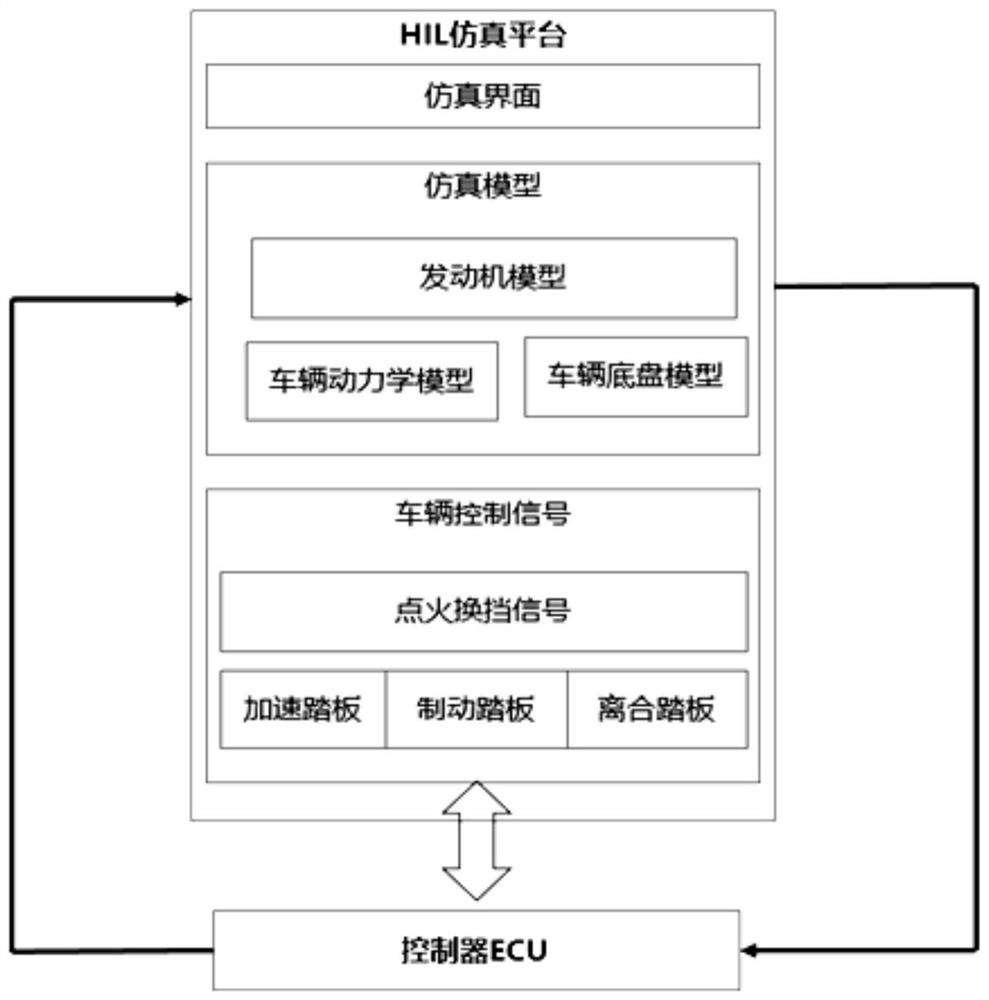

Cruise control test system based on automobile intelligent detection platform and test method thereof

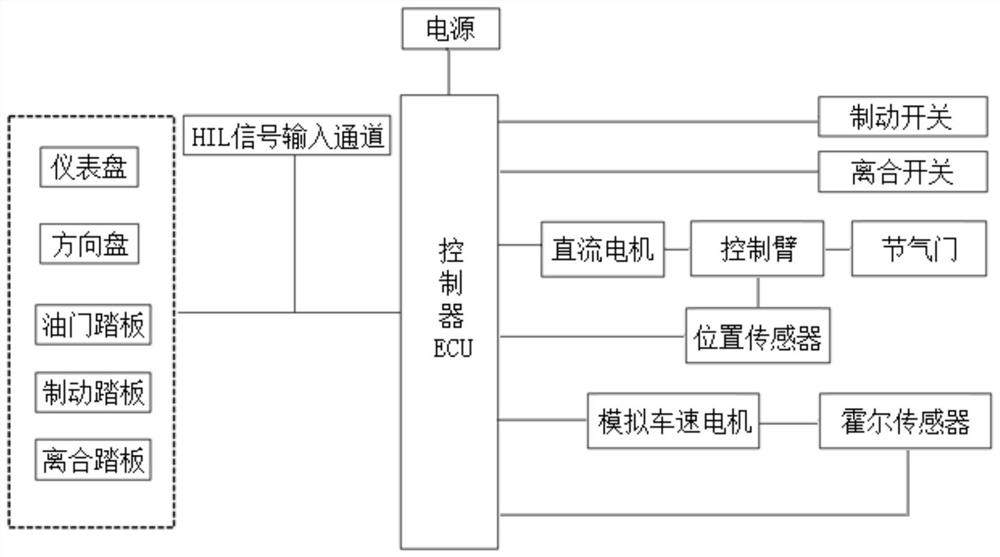

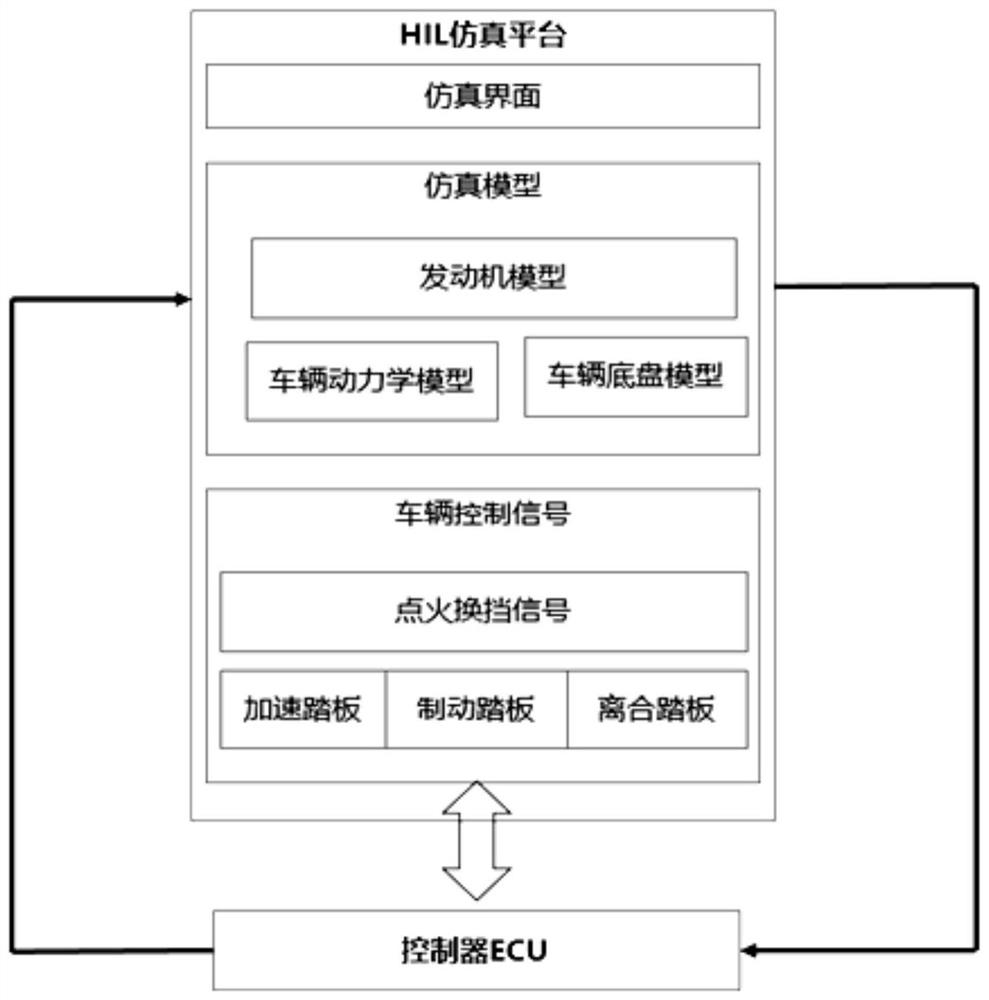

ActiveCN112462733ASolve the problem of low accuracy of manual testingImprove automated testingProgramme controlElectric testing/monitoringSteering wheelCruise control

The invention discloses a cruise control test system based on an automobile intelligent detection platform, which comprises an HIL hardware platform and a controller system rack. The controller systemrack comprises a controller ECU, and an instrument panel, a steering wheel, an accelerator pedal, a brake pedal, a clutch pedal, a power supply, a brake switch, a clutch switch, a simulation vehiclespeed motor, a direct current motor, a Hall sensor and a position sensor which are connected with the controller ECU, and the controller ECU is connected with the HIL hardware platform. The Hall sensor is fixed above the simulated vehicle speed motor rotating shaft magnet and used for measuring the rotating speed of the simulated vehicle speed motor to replace the actual vehicle speed. The position sensor is used for detecting the position information of the throttle valve and transmitting a signal to the controller ECU; the controller ECU is used for receiving signals of the cruise control switch, the Hall sensor and the position sensor on the steering wheel and outputting control signals to drive the direct-current motor to adjust the opening degree of the throttle valve. The design is not only high in test precision, but also high in test automation degree.

Owner:DONGFENG AUTOMOBILE COMPANY

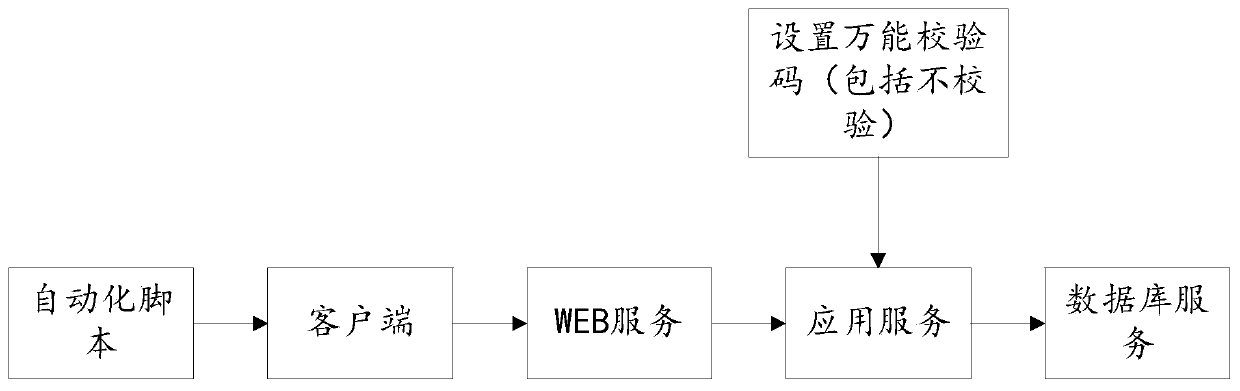

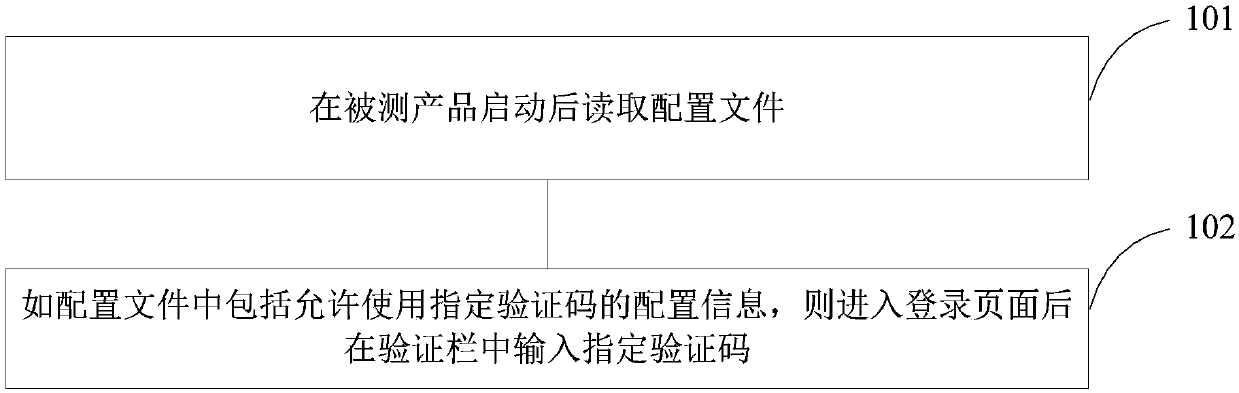

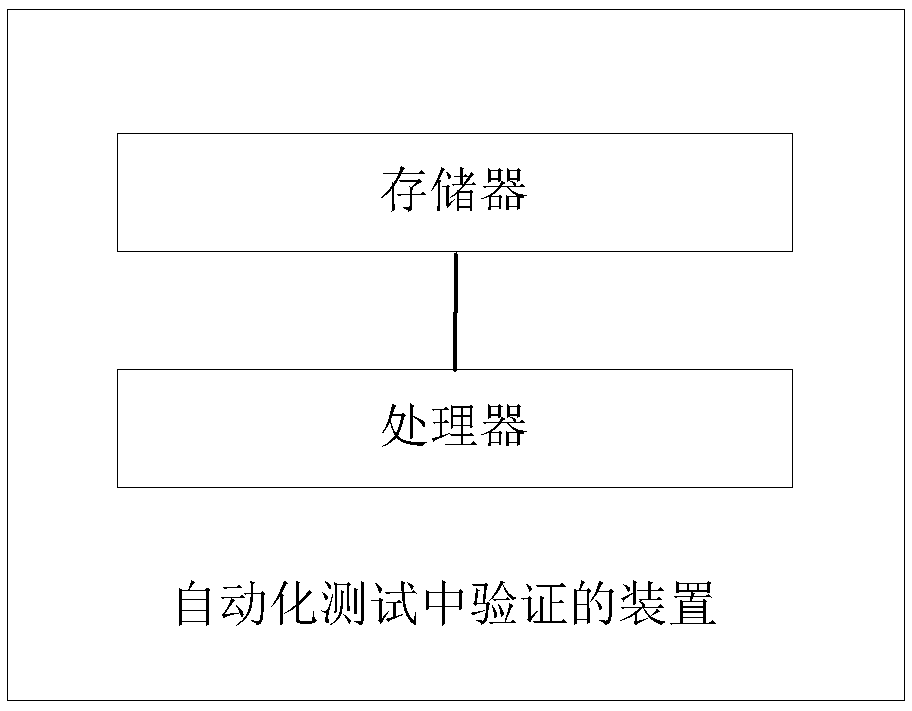

A verification method and device in an automatic test

InactiveCN109635549ASolving inefficienciesImprove automated testingSoftware testing/debuggingDigital data authenticationSoftware engineeringManual testing

The invention discloses a verification method in an automatic test. The method comprises the following steps: reading a configuration file after a tested product is started; And if the configuration file comprises configuration information allowing to use the specified verification code, entering the login page and inputting the specified verification code in the verification bar. The invention further discloses a verification device in the automatic test. The method provided by the embodiment of the invention can be applied to the automatic test of the product, solves the problem of low efficiency caused by verification code identification, can effectively improve the automatic test, can use the universal verification code, does not need to repack the program, and guarantees the consistency of the automatic test and the manual test program.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

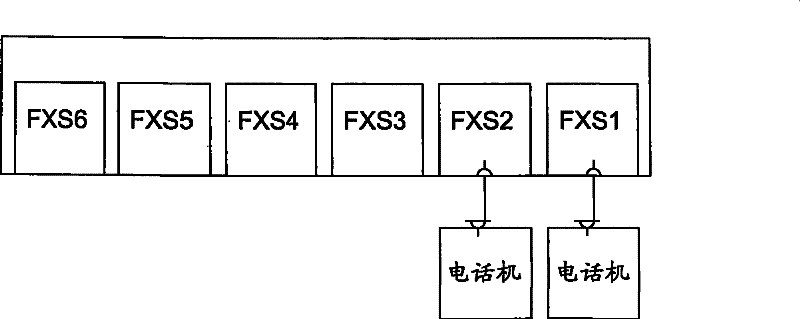

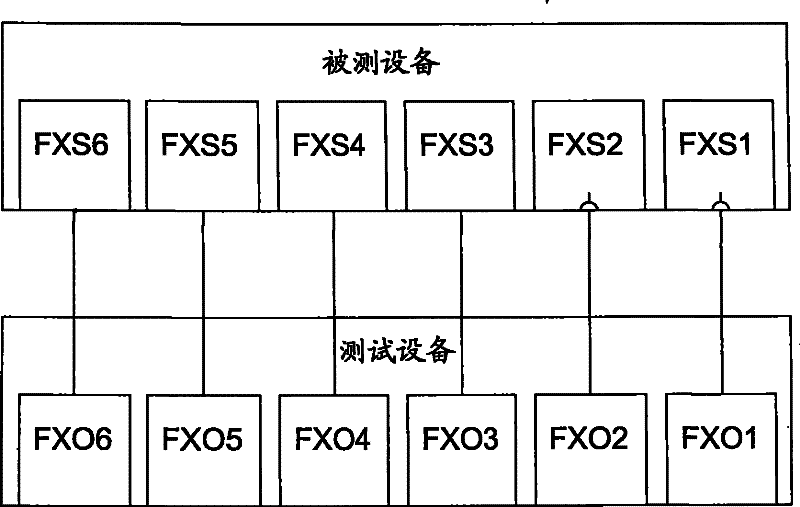

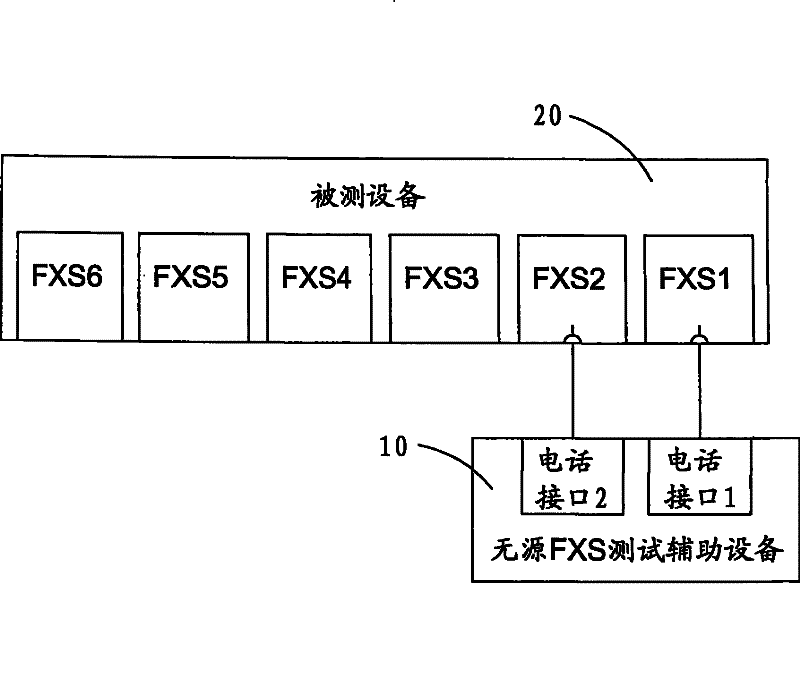

System and method for testing foreign exchange station interface

InactiveCN101662542BReduce testing costsSimple structureData switching networksSoftware engineeringAutomatic testing

The invention provides a system and a method for testing an FXS interface. In the system and the method, passive FXS test auxiliary equipment is provided to connect two interfaces, such as FXS1 and FXS2, in the FXS interface, so that FXS2 is used as test equipment when the FXS1 is tested and the FXS1 is used as test equipment when the FXS2 is tested. Thus, the use of expensive test equipment withan FXO interface is avoided. Then, the test of the FXS interface is automatically completed according to a preset process in software, and each tested FXS interface can realize ringing, off-hook, DTMF signal transmission and DTMF signal reception and other processes. The system and the method have the advantages of reducing signal FXS interface test cost due to the synchronous test of two FXS interfaces by using the FXS interface of the product, improving automatic test degree, avoiding the use of a large amount of human interference, along with simple structure, low cost and suitability for batch production.

Owner:FUJIAN STAR NET COMM

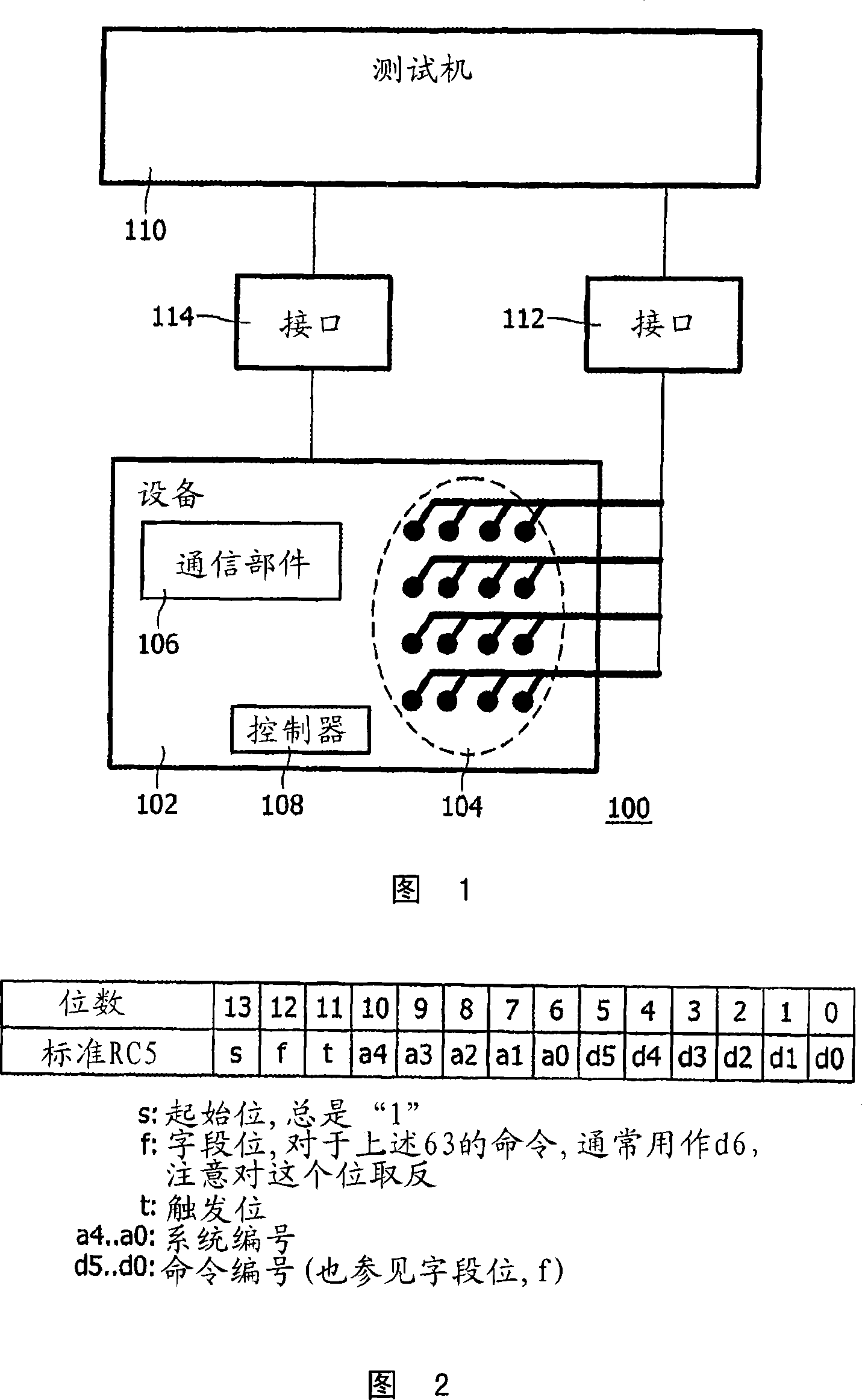

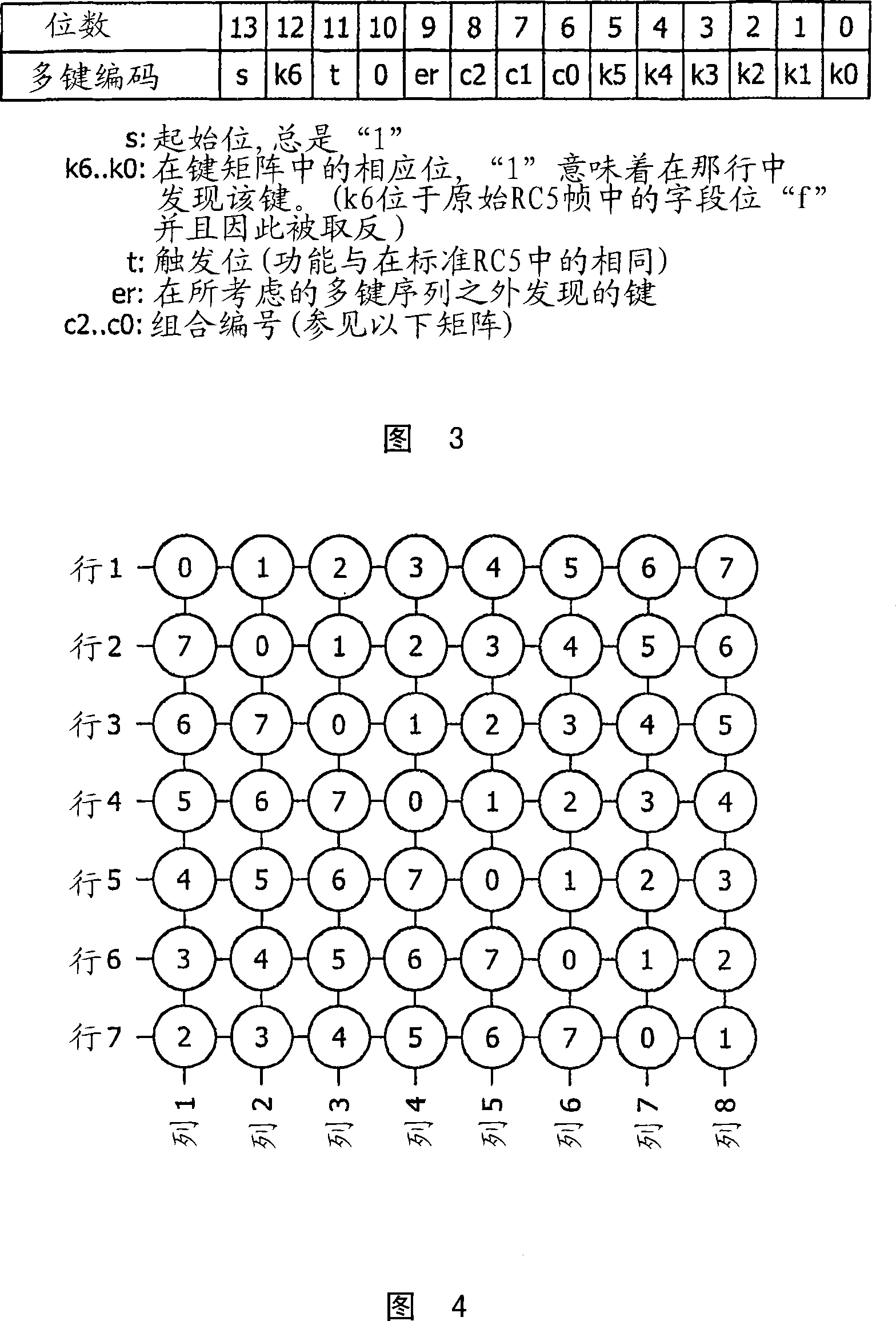

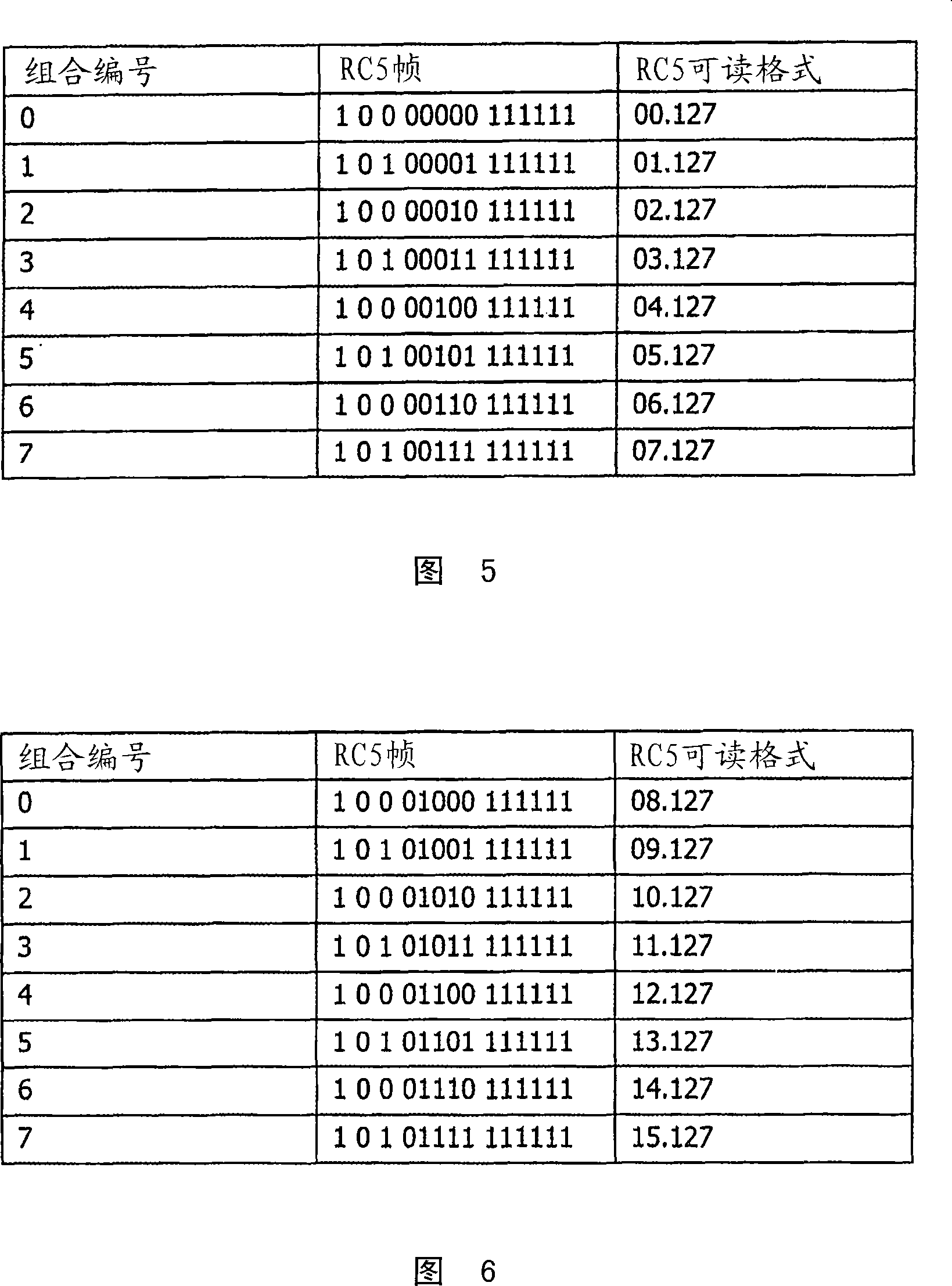

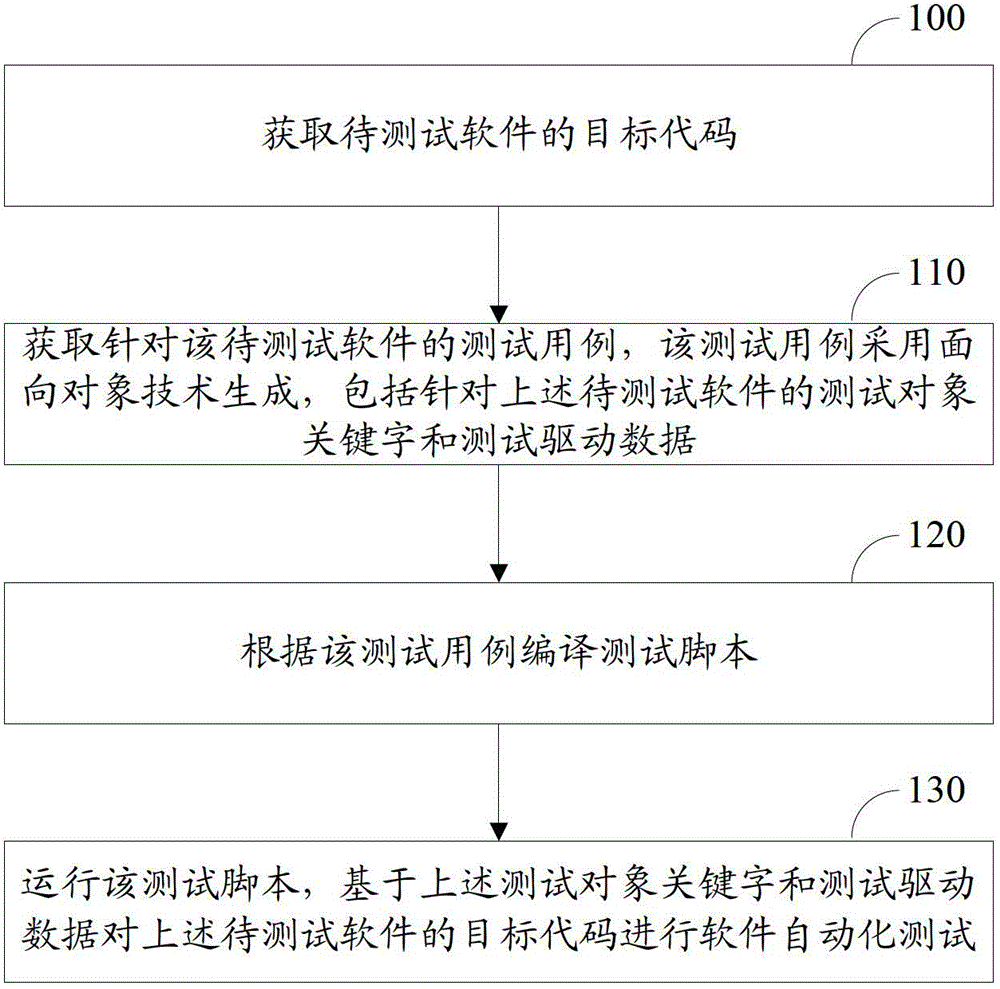

Testing an electronic device having a keypad by simultaneously pressing several keys

InactiveCN101010658AImprove automated testingHigh outputError detection/correctionInput/output processes for data processingComputer hardwareRemote control

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method and system for realizing automatic software testing

ActiveCN102693183BImprove performanceImprove automated testingSoftware testing/debuggingTestwareTest script

The invention discloses a method and a system for realizing automatic software testing. The method includes the following steps: obtaining the object code of the to-be-tested software; obtaining the test case for the to-be-tested software, wherein the test case is generated by adopting the oriented object technology and includes a test object key word and a test drive data for the to-be-tested software; compiling and saving the test script according to the test case; running the test script, so as to carry out the automatic software testing of the object code of the to-be-tested software based on the test object key word and the test drive data. By adopting the solution of automatic testing and utilizing the object oriented test case to carry out the automatic testing based on the assemblage of the test object key word and the test drive data, the automatic software testing can be realized without the participation of any operator, and the method and the system for realizing automatic software testing are applicable to all the stages of software testing.

Owner:RAISECOM TECH

Method for testing product fault-tolerant performance and fault inserting device thereof

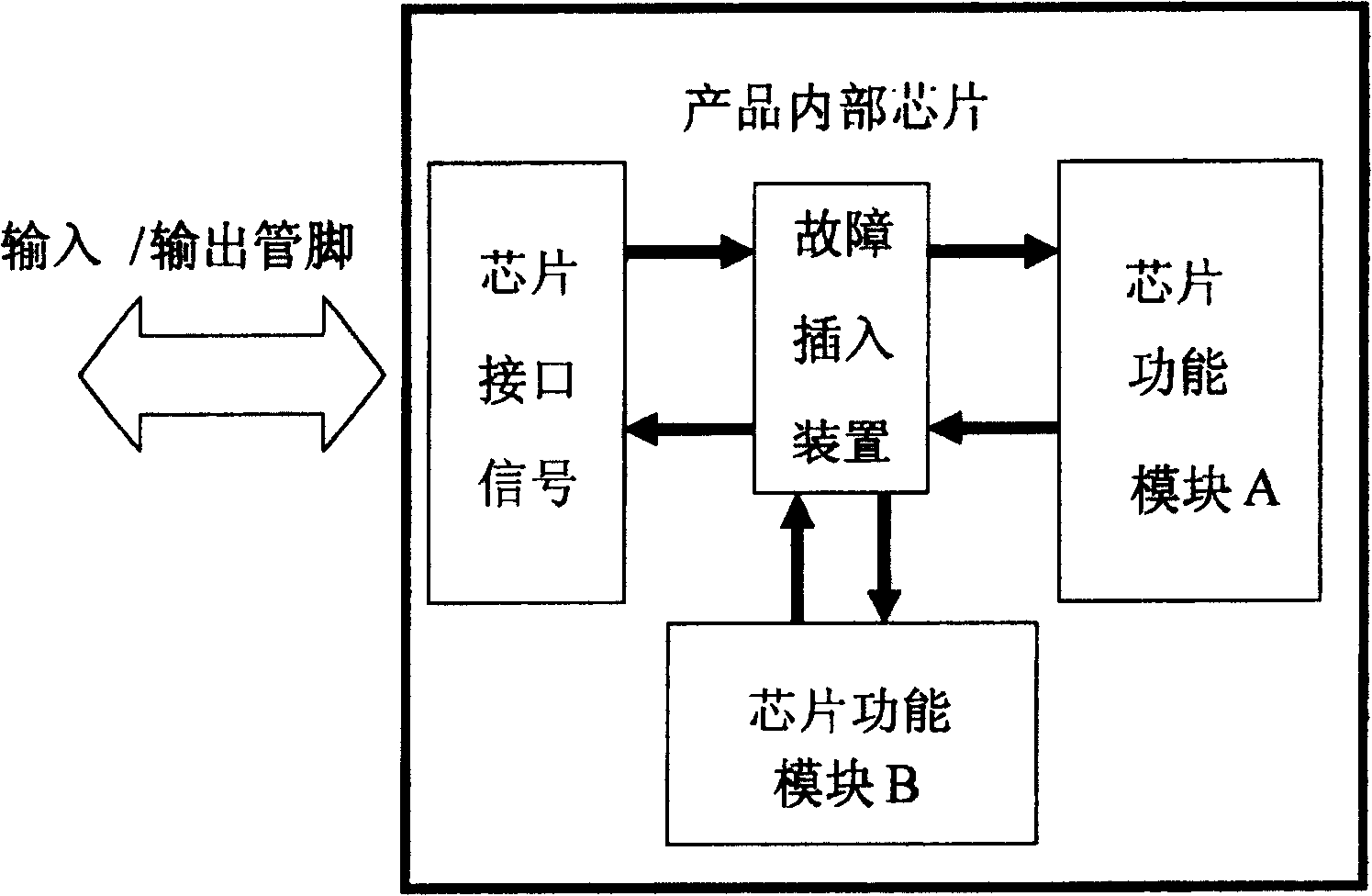

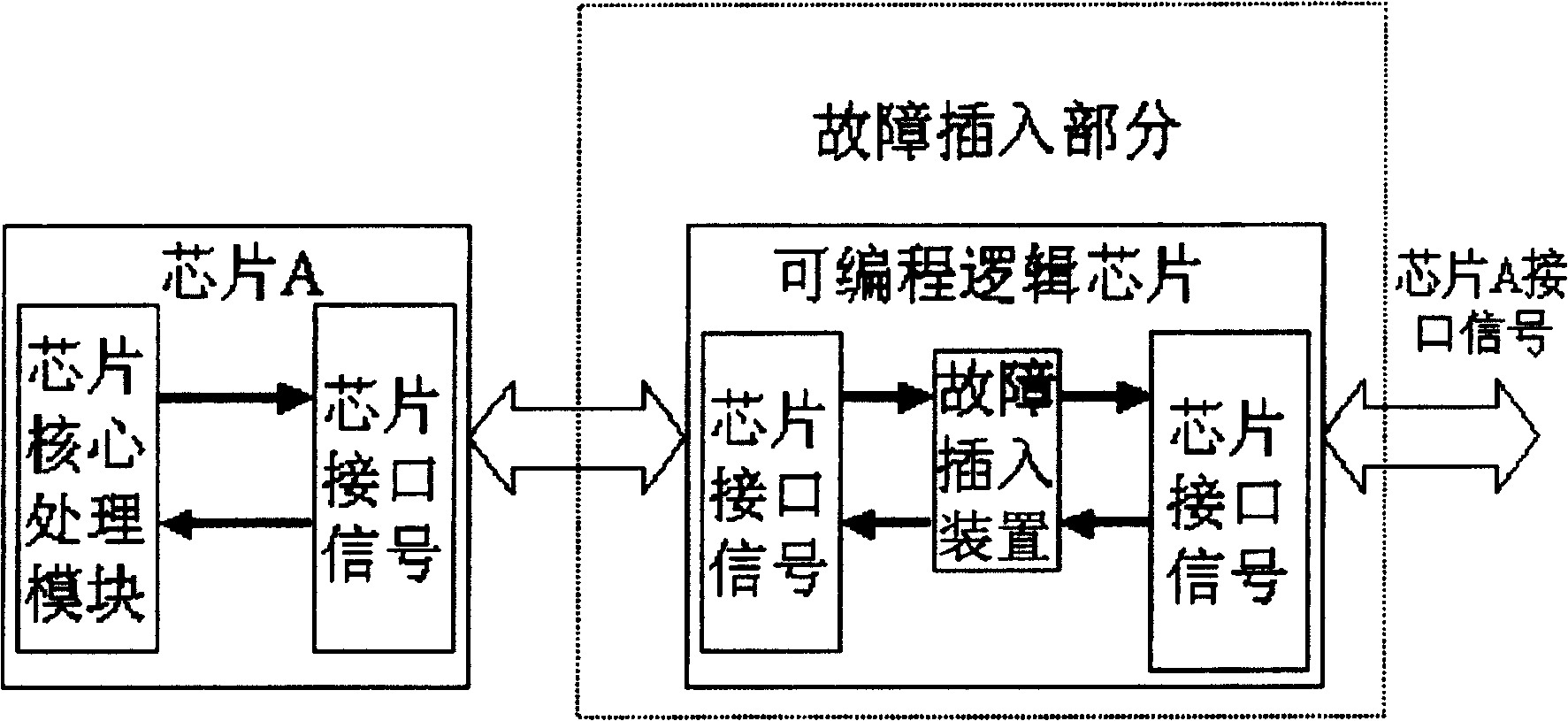

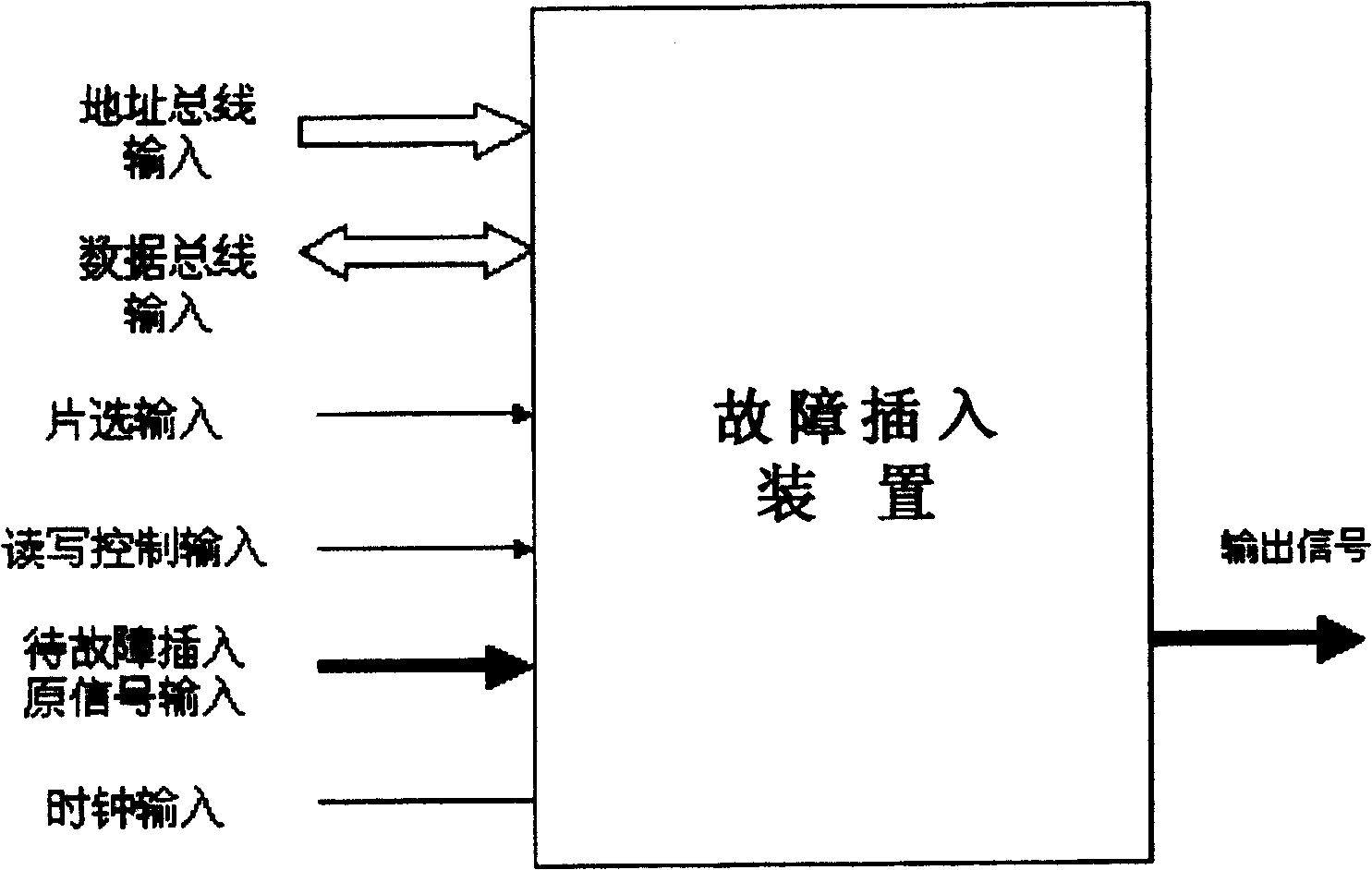

InactiveCN100439930CEasy to controlImproving Reliability Testing EfficiencyElectrical testingFault toleranceControl register

The present invention provides a product fault-tolerance test method and its fault insertion device. Said invention utilizes the production of fault analog signal to implement fault-tolerance test of product. Said method includes the following steps: setting fault insertion device in product interior, utilizing fault insertion device to produce fault analog signal with different types, utilizing CPU control interface of product interior to gate communication control module of fault insertion device, control contents of fault insertion device, control contents of control register of communication control module and selectively make fault analog signal with different types be inserted into arbitrary chip input / output pin or directly inserted into functional module of chip interior so as to simulate partial failure or complete failure of product interior unit.

Owner:HUAWEI TECH CO LTD

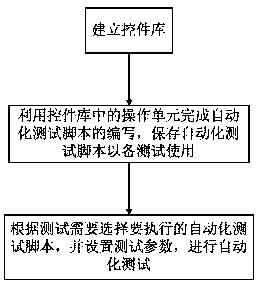

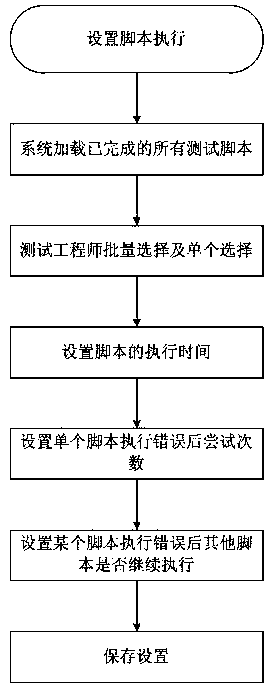

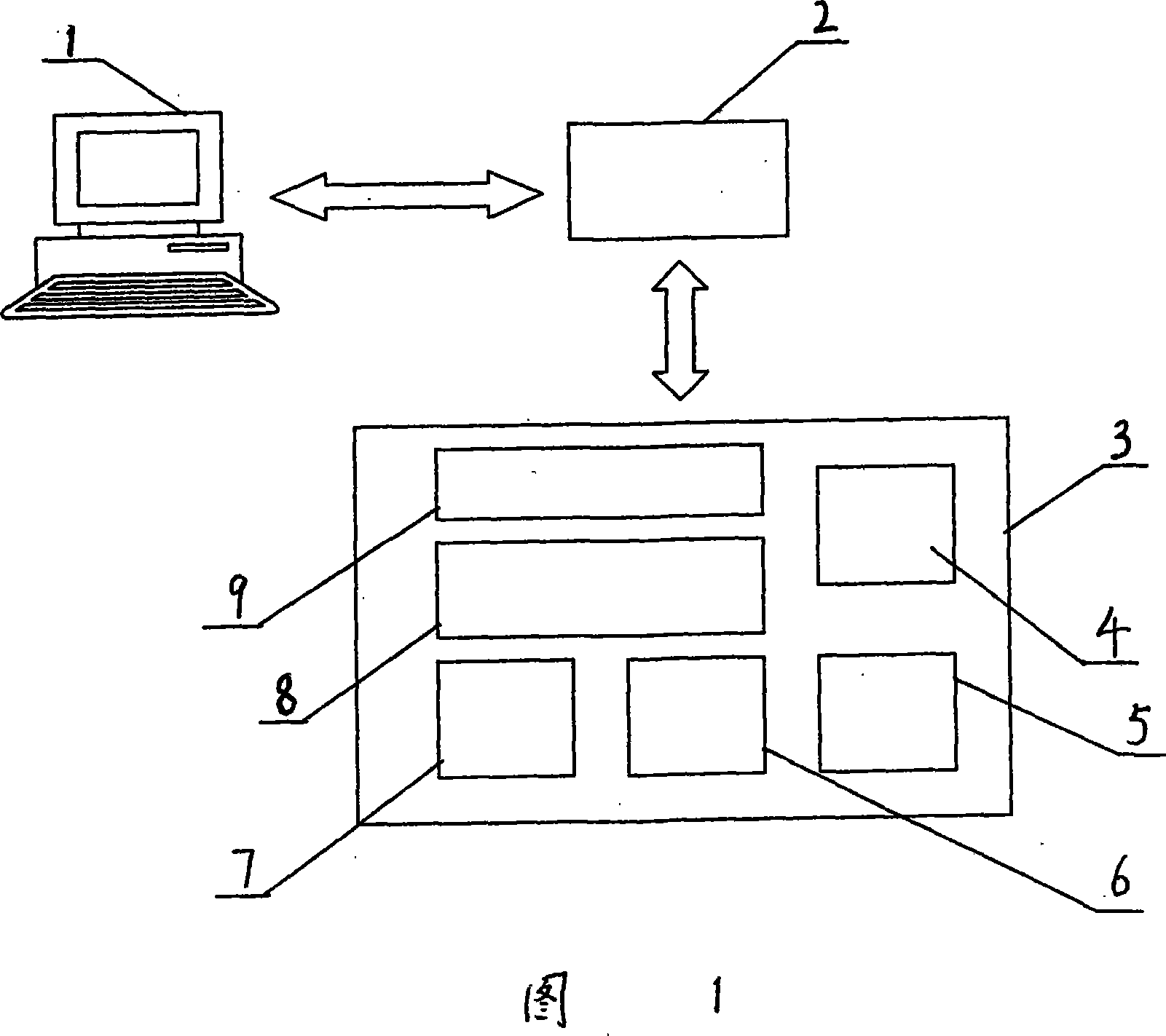

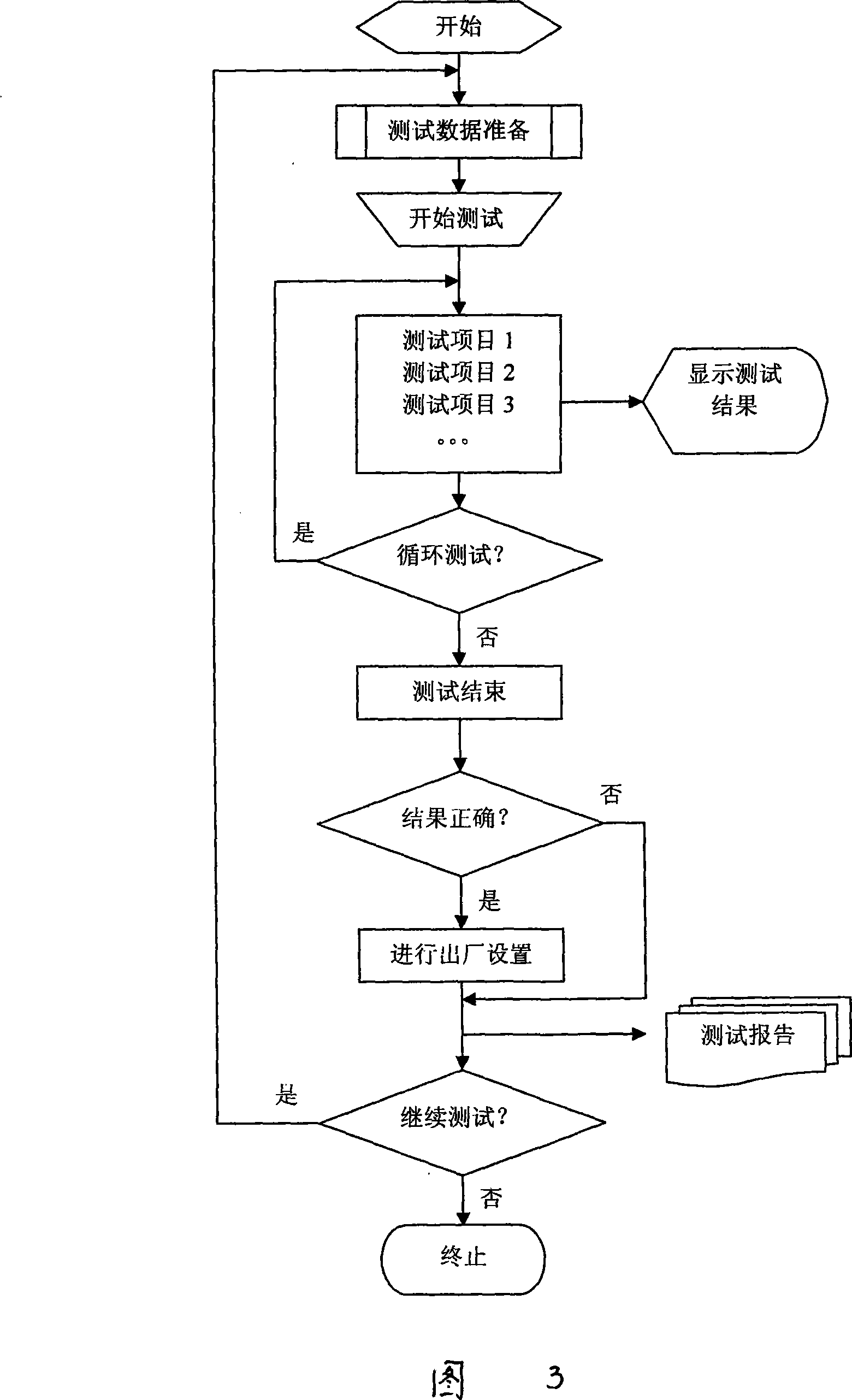

Software automation test method and a test platform

PendingCN109800164AQuick changeImprove automated testingSoftware testing/debuggingTest scriptAutomatic test equipment

The invention provides a software automation test method and a test platform. The software automation test method comprises the following steps: 1) establishing a control library; 2) compiling an automatic test script by using an operation unit in the control library, and storing the automatic test script for test use; And 3) selecting a to-be-executed automatic test script according to test requirements, setting test parameters, and carrying out automatic test. According to the scheme, the automatic script compiling difficulty is simplified by introducing the control, common software testingpersonnel can independently compile the automatic testing script, and therefore even if the software requirement changes, the automatic testing script can be rapidly replaced and put into use, and theeffect of automatic testing in actual testing is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Testing method based on remote control vehicular device

InactiveCN101022634BExtension of timeReduce communication costsVehicle testingTransmission monitoringTest efficiencyEngineering

Owner:YANTAI MIT ELECTRONICS

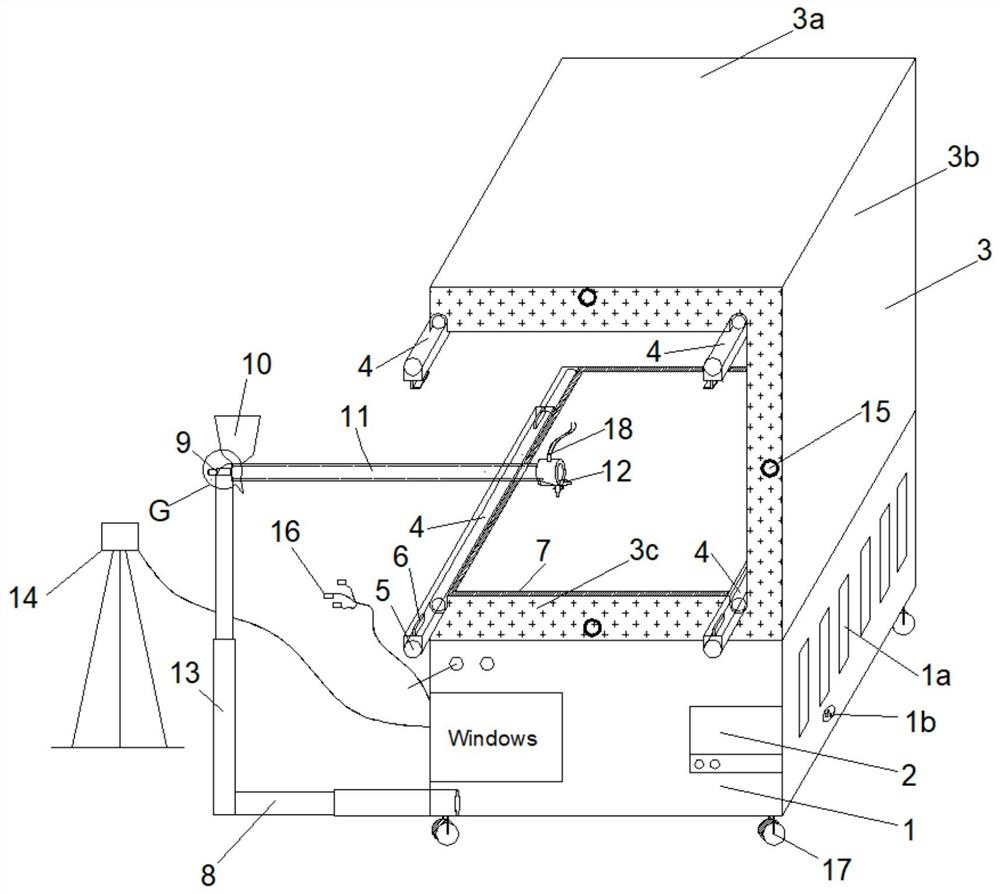

Adjustable electronic temperature-controlled three-dimensional shotcrete performance testing experimental device and method

ActiveCN111795724BImprove automated testingHighly integratedMeasurement devicesShotcreteElectronic temperature

The invention discloses an adjustable electronic temperature-controlled three-dimensional sprayed concrete performance testing experimental device, which includes a control system, a specimen clamping system, a heating system, a spraying system and a testing system. The specimen clamping system includes a A three-sided frame, each of the four corners of the three-sided frame inner cavity is provided with a specimen holder, each specimen holder is equipped with a clamping head, the heating system includes a heating plate and a heater; the injection system includes a second Horizontal hydraulic prop, blower fan, collecting box, feed pipe, rotary nozzle, vertical hydraulic prop and vertical hydraulic push rod, and the test system includes a laser speedometer, an impact force sensor, a stress sensing sheet, and a temperature sensor; the present invention also includes Its experimental method is disclosed. It can simulate the high geothermal environment of the roadway, conduct three-dimensional concrete spraying in the roadway in real time, and perform the performance test of the spraying impact force, rebound rate and initial bond strength of the shotcrete under the influence of high temperature conditions.

Owner:SHANDONG UNIV OF SCI & TECH

A test case generation method for mobile applications based on extended ifml

ActiveCN106227667BImprove automated testingRealize automatic generationSoftware testing/debuggingProgramming languageMobile end

The invention relates to an expansion-based IFML mobile application test case forming method comprising the following steps: building a model, i.e., drawing an IFML model corresponding to a to-be-tested mobile application. Expansion contents aiming at mobile application modeling are added on an original standard IFML so as to form the IFML applied in modeling; the expansion contents comprises the following elements: an expansion subtype toolbar and a screen container are added on a view container; an expansion subtype mobile widget is added on a view assembly; an expansion subtype mobile end system event, a mobile end event and a mobile end behavior activity event are added on an Event; an expansion subtype mobile end behavior activity is added on the behavior activity. The test case complying with requirements can be formed according to selected test coverage criterion.

Owner:NANJING UNIV

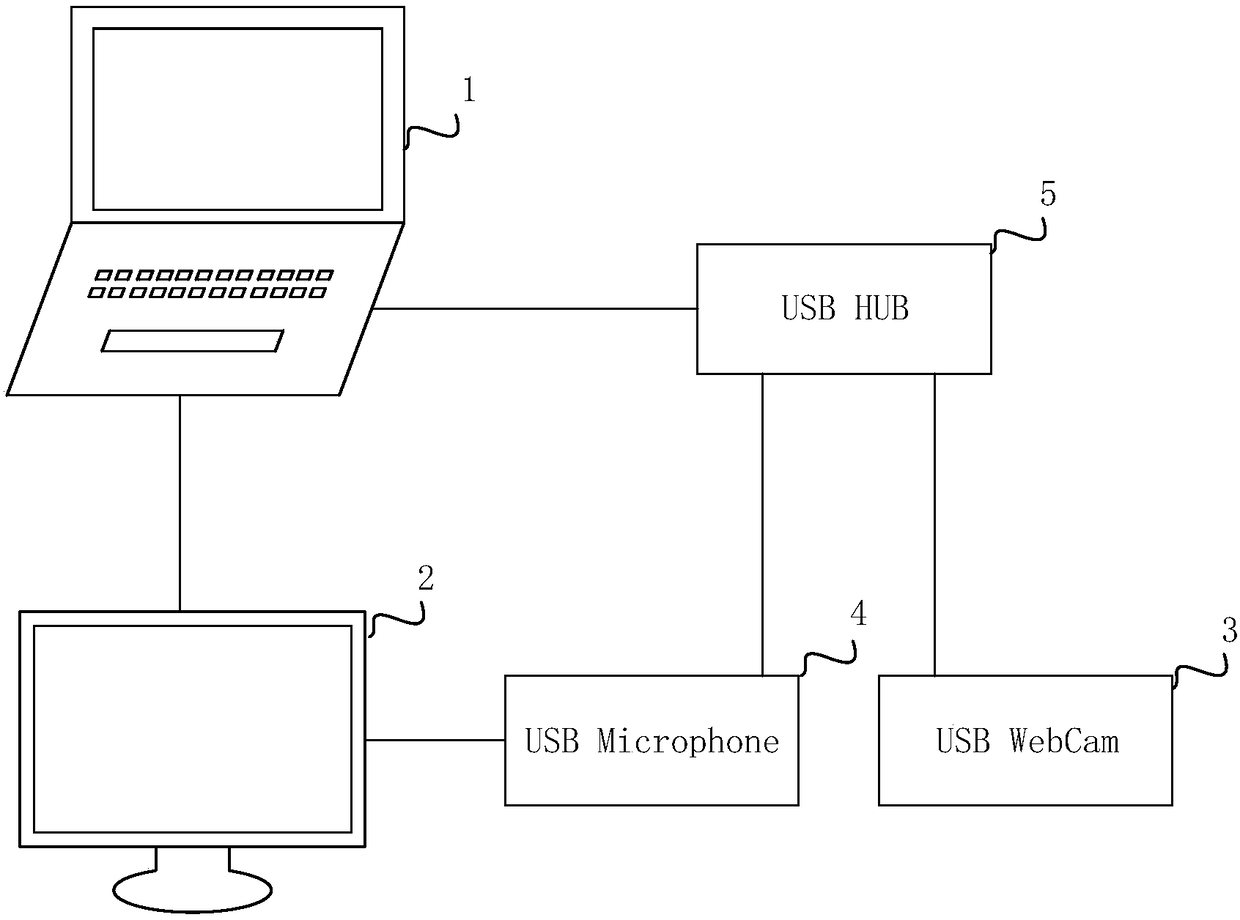

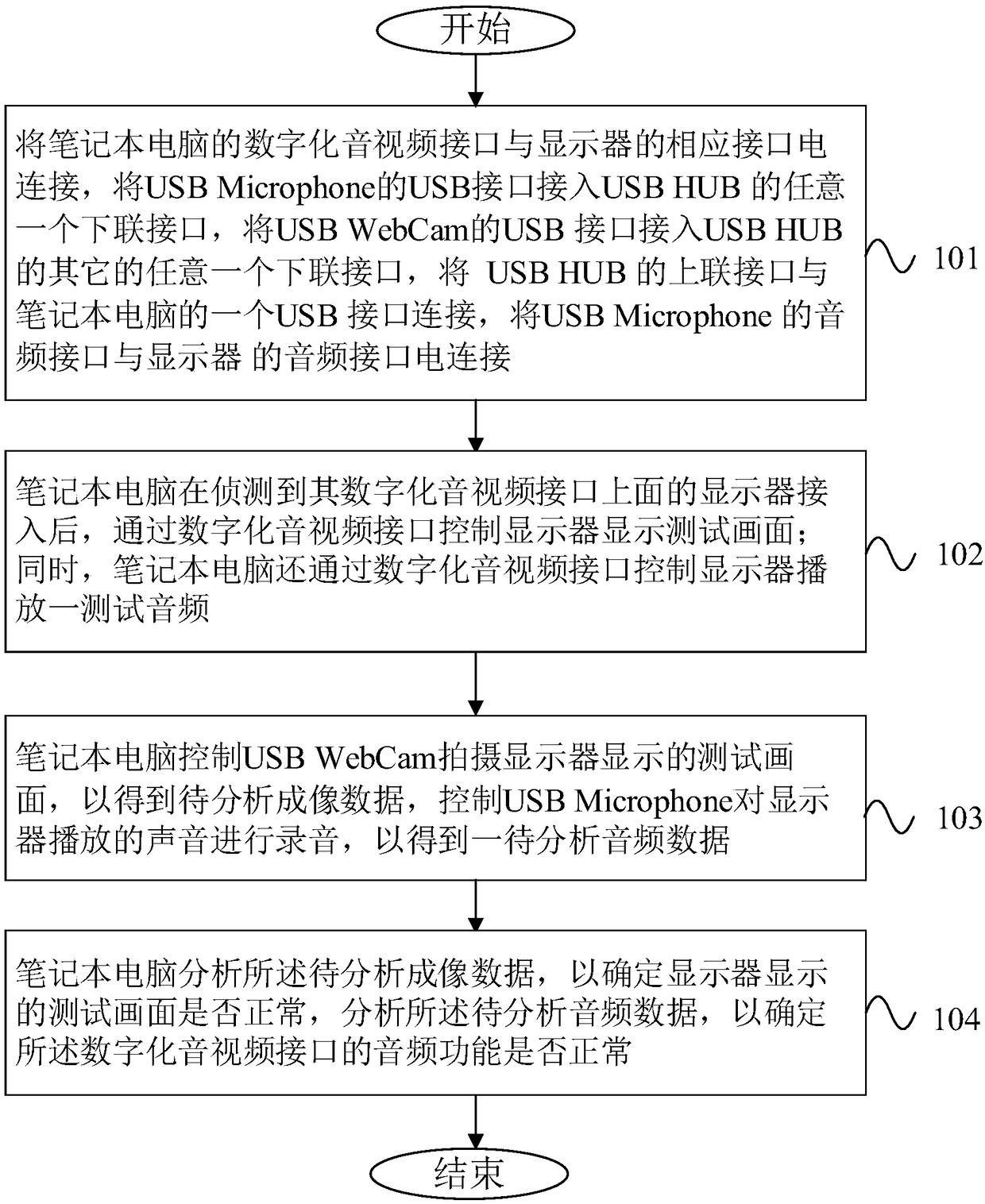

Method and system for testing digital audio-video interface

InactiveCN108347576AReduce stepsReduce labor costsTelevision system detailsColor television detailsElectricityVisual inspection

The invention discloses a method and system for testing a digital audio-video interface. The method comprises the following steps: S1, a digital audio-video interface of to-be-tested equipment is electrically with a testing terminal, and a camera device is electrically connected with the to-be-tested equipment; S2, the to-be-tested equipment controls the testing terminal to display a testing picture through the digital audio-video interface; S3, the to-be-tested equipment controls the camera device to shoot the testing picture displayed by the testing terminal to obtain to-be-analyzed imagingdata; and S4, the to-be-tested equipment analyzes the to-be-analyzed imaging data so as to determine whether the testing picture displayed by the testing terminal is normal. Through the method and system for testing the digital audio-video interface provided by the invention, an operator is unnecessary to check whether the video function is normal through visual inspection, the camera device can automatically accomplish the testing on the video function of the digital audio-video interface through once access, the manpower cost can be reduced, and the automatic testing degree is improved.

Owner:DONGGUAN HUABEL ELECTRONICS TECH

A aging detection system

ActiveCN103713265BReduce mistakesExtended service lifePower supply testingMicrocontrollerMicrocomputer

The invention provides a burn-in detection system which can be used for burning different types of power modules by replacing adapting plates, back plates and load plates. The adapting plates enable loads on the load plates to be loaded on objects to be detected through the back plates. An AD collector collects voltage data of the objects to be detected through the adapting plates and sends the data to a single-chip microcomputer. A temperature and humidity collector collects temperature and humidity data of the load plates and sends the data to the single-chip microcomputer. The single-chip microcomputer carries out signal processing on the received temperature and humidity data and the received voltage data to obtain a monitoring result and transmits the result to a display for displaying. In addition, the warning range of the monitoring result is set, and when the result is detected to exceed the warning range, warning inductions are sent out to trigger an alarm. According to the burn-in detection system, manual detection methods before the burn-in detection system is applied are replaced, and efficiency is improved greatly; in addition, the loads can be replaced freely according to needs; voltage signal self-testing and load inner temperature self-testing are added, and the system can give out an alarm immediately when faults happen; human resources are relieved, and uncertain factors caused by manual interference are avoided.

Owner:BEIJING AEROSPACE MEASUREMENT & CONTROL TECH

Adjustable electronic temperature control three-dimensional shotcrete performance test experimental device and method

ActiveCN111795724AImprove automated testingHighly integratedMeasurement devicesShotcreteElectronic temperature

The invention discloses an adjustable electronic temperature control three-dimensional shotcrete performance test experimental device. The device comprises a control system, a test piece clamping system, a heating system, an injection system and a test system, wherein the test piece clamping system comprises a three-side frame arranged right above a control box, four corners of an inner cavity ofthe three-side frame are respectively provided with a test piece clamping frame, and each test piece clamping frame is provided with a clamping head; the heating system comprises a heating plate and aheater; the injection system comprises a second horizontal hydraulic prop, a fan, a material collecting box, a material conveying pipe, a rotary spray head, a vertical hydraulic prop and a vertical hydraulic push rod; and the test system comprises a laser velocimeter, an impact force sensor, a stress sensing sheet and a temperature sensor. The invention further discloses an experimental method ofthe device. The device can simulate the high-terrestrial-heat environment of the roadway, immediately performs three-dimensional concrete spraying of the roadway, and performs performance test on thejet impact force, the springback rate and the initial bonding strength of sprayed concrete under the influence of a high-temperature condition.

Owner:SHANDONG UNIV OF SCI & TECH

Cruise control test system and test method based on automobile intelligent detection platform

ActiveCN112462733BSolve the problem of low accuracy of manual testingImprove automated testingProgramme controlElectric testing/monitoringSteering wheelCruise control

A constant speed cruise test system based on an automobile intelligent detection platform, including an HIL hardware platform and a controller system platform, the controller system platform includes a controller ECU and an instrument panel connected thereto, a steering wheel, an accelerator pedal, a brake pedal, Clutch pedal, power supply, brake switch, clutch switch, simulated speed motor, DC motor, Hall sensor, position sensor are connected, the controller ECU is connected to the HIL hardware platform, and the Hall sensor is fixed above the magnet of the simulated speed motor shaft for Measure the rotational speed of the simulated vehicle speed motor instead of the actual vehicle speed; the position sensor is used to detect the throttle position information and transmit the signal to the controller ECU; the controller ECU is used to receive the signals from the cruise control switch on the steering wheel, Hall sensor and position sensor , and output a control signal to drive the DC motor to adjust the throttle opening. This design not only has high test precision, but also has high test automation.

Owner:DONGFENG AUTOMOBILE COMPANY

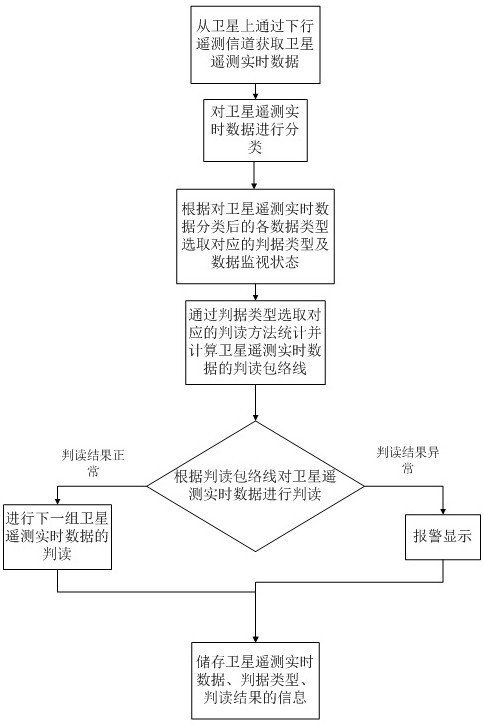

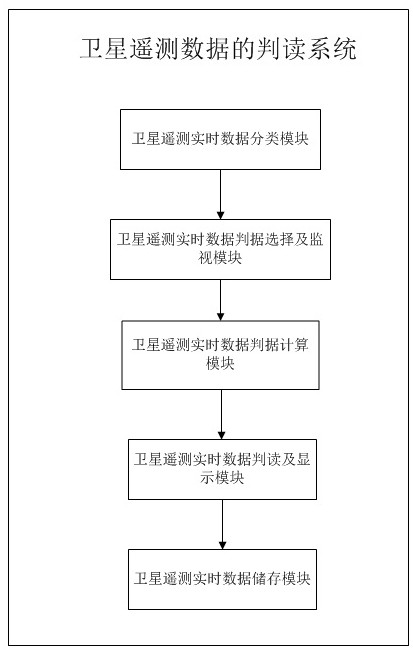

Interpretation method, system, electronic equipment and storage medium of satellite telemetry data

ActiveCN113205162BImprove automated testingImprove efficiencyCharacter and pattern recognitionComplex mathematical operationsSatellite dataEngineering

The invention provides a satellite remote measurement data interpretation method, system, electronic equipment and storage medium. The method includes: obtaining satellite telemetry real-time data from the satellite through the downlink telemetry channel and classifying it; selecting corresponding criterion types and data monitoring status according to the data types after the classification of satellite telemetry real-time data; The corresponding interpretation method counts and calculates the interpretation envelope of the satellite telemetry real-time data; interprets the satellite telemetry real-time data according to the interpretation envelope; When the telemetry real-time data interpretation result is abnormal, the alarm will be displayed. With the application of the invention, the corresponding interpretation method can be independently selected according to the type of satellite telemetry, which plays a better role in helping satellite data interpretation and status monitoring, reduces the burden of satellite testers, and increases the efficiency of satellite automatic testing and interpretation.

Owner:耕宇牧星(北京)空间科技有限公司

An automatic test template of relay protection device based on d-s evidence theory

ActiveCN108548970BImprove intelligenceAvoid duplication of testsElectrical testingTest efficiencyAlgorithm

The invention discloses a relay protection device automatic testing template based on a D-S evidence theory. The method comprises the following steps of (1), in a protection base module database, acquiring the parameter of each protection base module; (2), determining whether the same parameter exists among the base modules according to the D-S evidence theory, if yes, keeping one same parameter and combining the parts with the same parameter; after combination, if no same parameter exists, keeping the respective parameters for performing splicing combination; (3), after splicing, successivelyexpanding the testing items for testing; and (4), after testing, automatically generating a protection testing report. The relay protection device automatic testing template according to the invention is based on module splicing of the D-S evidence theory has advantages of preventing repetitive testing, improving testing efficiency, and laying a basis for intelligentization and automation improvement of the whole set of automatic testing system.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +6

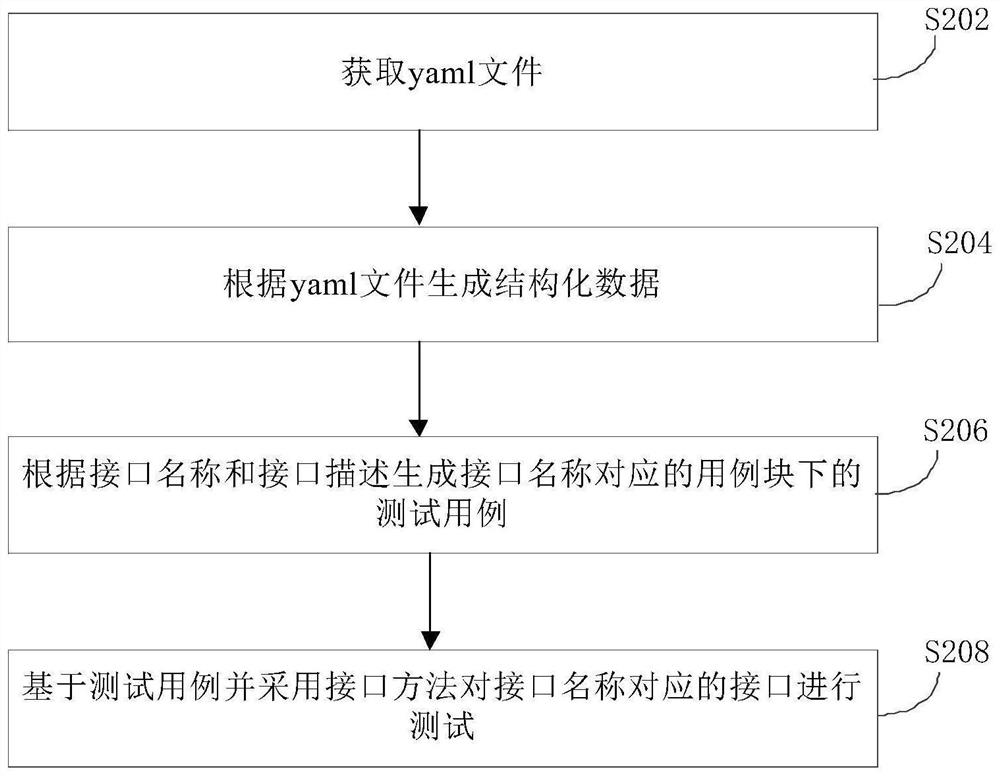

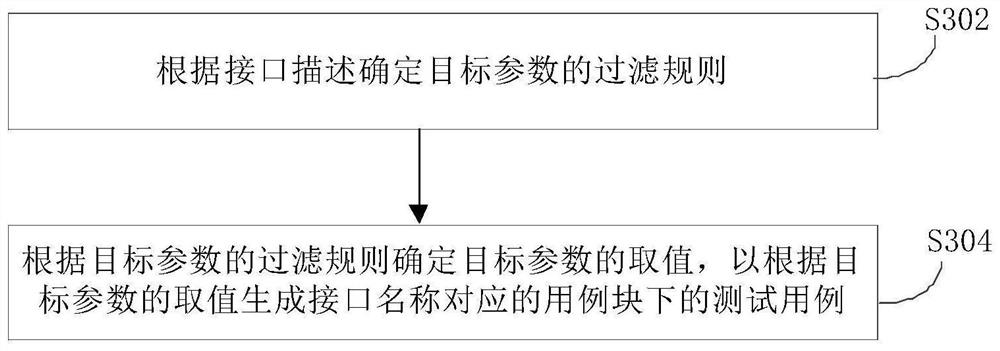

Automatic generation and test method and device of use case, electronic equipment and readable medium

PendingCN114168477AImplement the generate methodImplement the test methodSoftware testing/debuggingData packTest quality

The embodiment of the invention provides a use case automatic generation and test method and device, electronic equipment and a computer readable medium, and the method comprises the steps: obtaining a yaml file which comprises an interface name; generating structured data according to the yaml file, wherein the structured data comprises an interface name, an interface method and an interface description; generating a test case under a case block corresponding to the interface name according to the interface name and the interface description; and testing the interface corresponding to the interface name by adopting the interface method based on the test case. According to the automatic generation and test method and device of the use case, the electronic equipment and the computer readable medium provided by the embodiment of the invention, the use case set with comprehensive coverage can be efficiently and automatically generated, and the test quality is improved.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

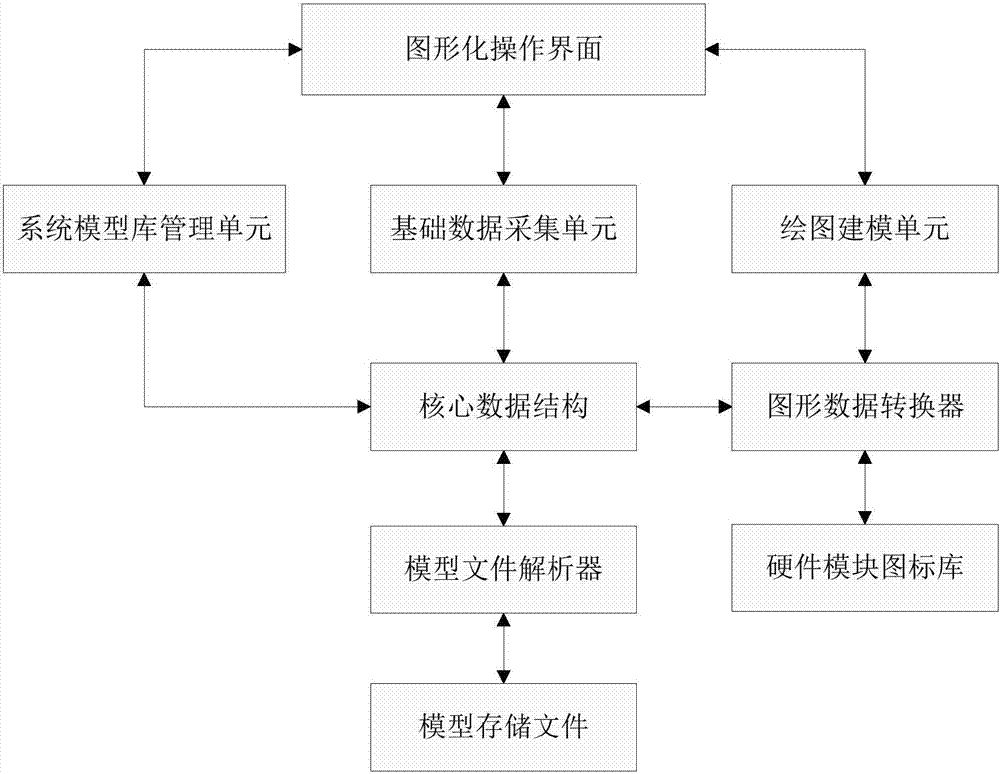

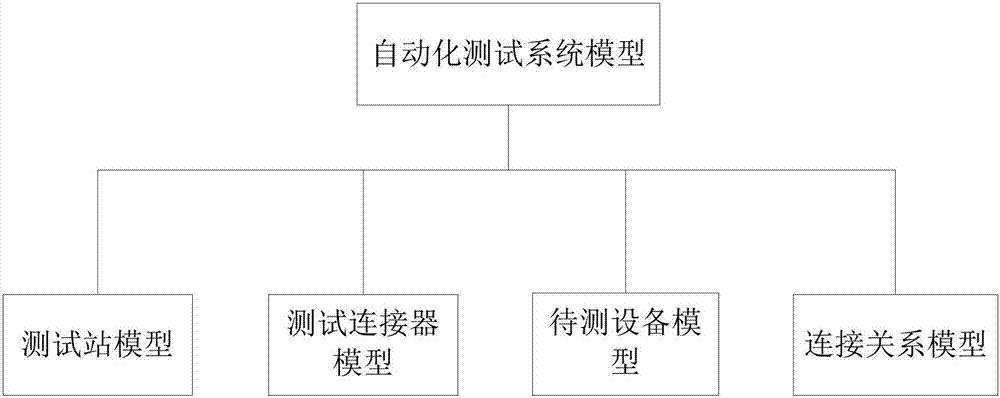

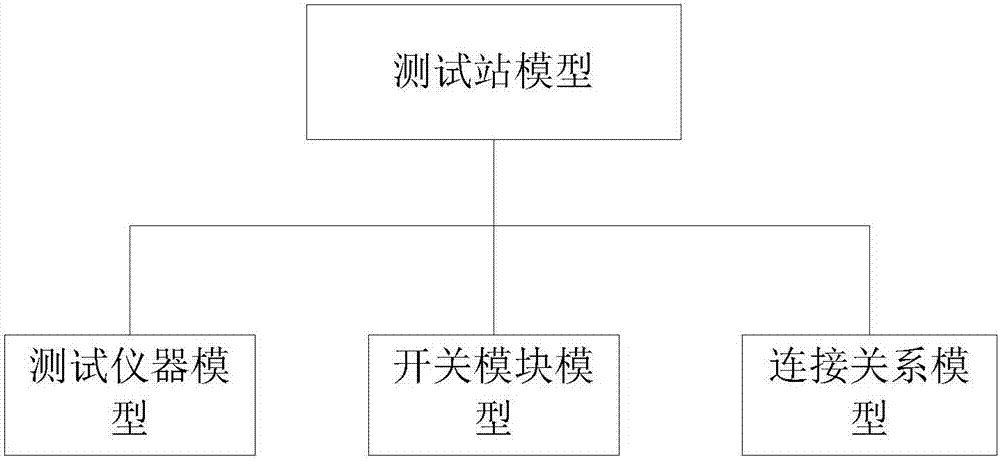

A graphical modeling device and method for an automated test system

ActiveCN104484166BIntuitive and efficient designSimple designElectric testing/monitoringSpecific program execution arrangementsHardware modulesGraphical data

The invention relates to a graphical modeling device and method for an automated test system, belonging to the field of automated testing, including: a graphical operation interface, a system model library management unit, a basic data acquisition unit, a drawing modeling unit, a graphic data conversion unit, Core data structure, model file parser, model storage file and hardware module icon library, the invention allows users to design and optimize the model composition and signal path scheme of the automated test system in a graphical way before building the physical automated test system, and realize The intuitive and efficient automated test system simulation design reduces development costs and improves development efficiency, and stores model data in a formatted manner to provide support for the execution of automated tests.

Owner:SHANDONG UNIV OF SCI & TECH

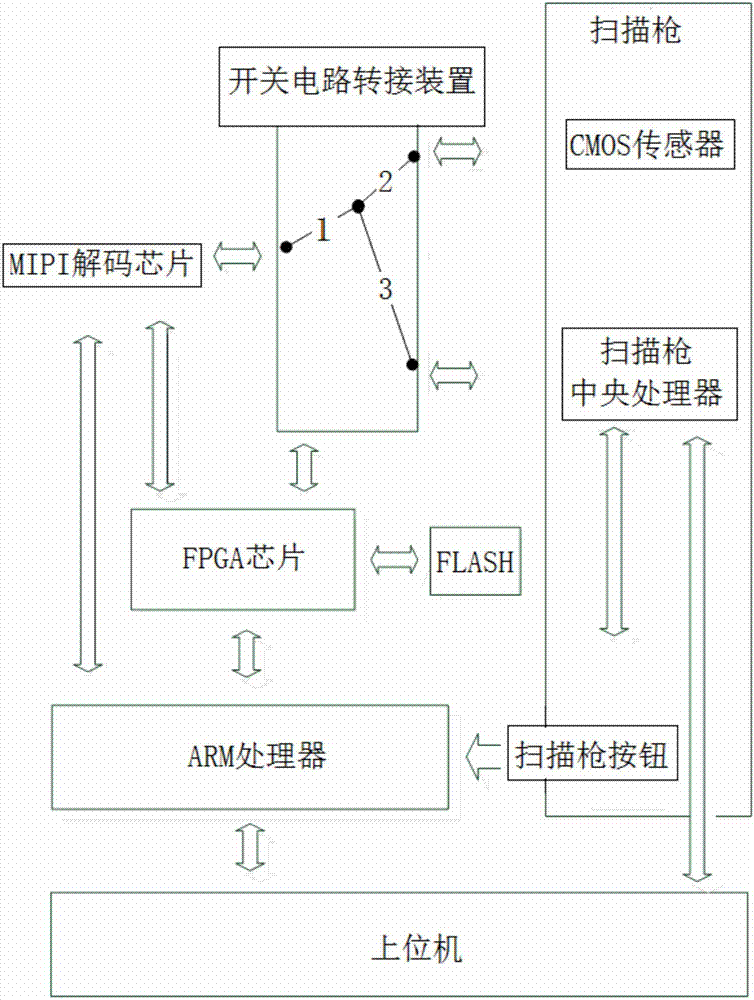

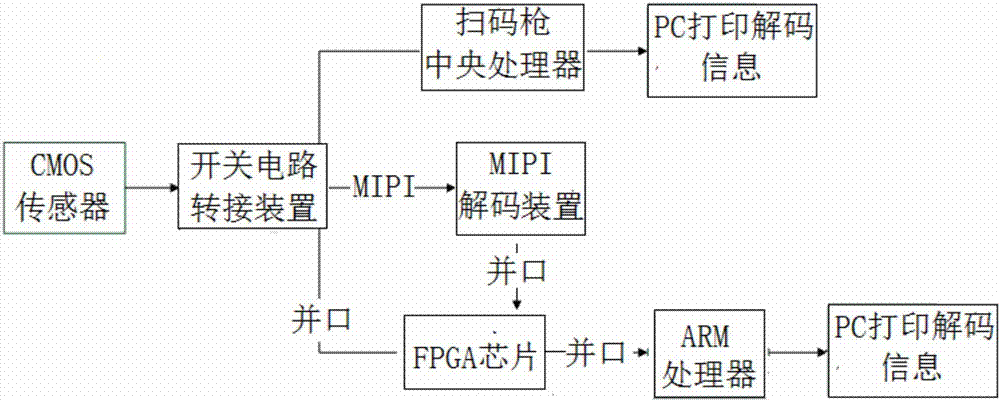

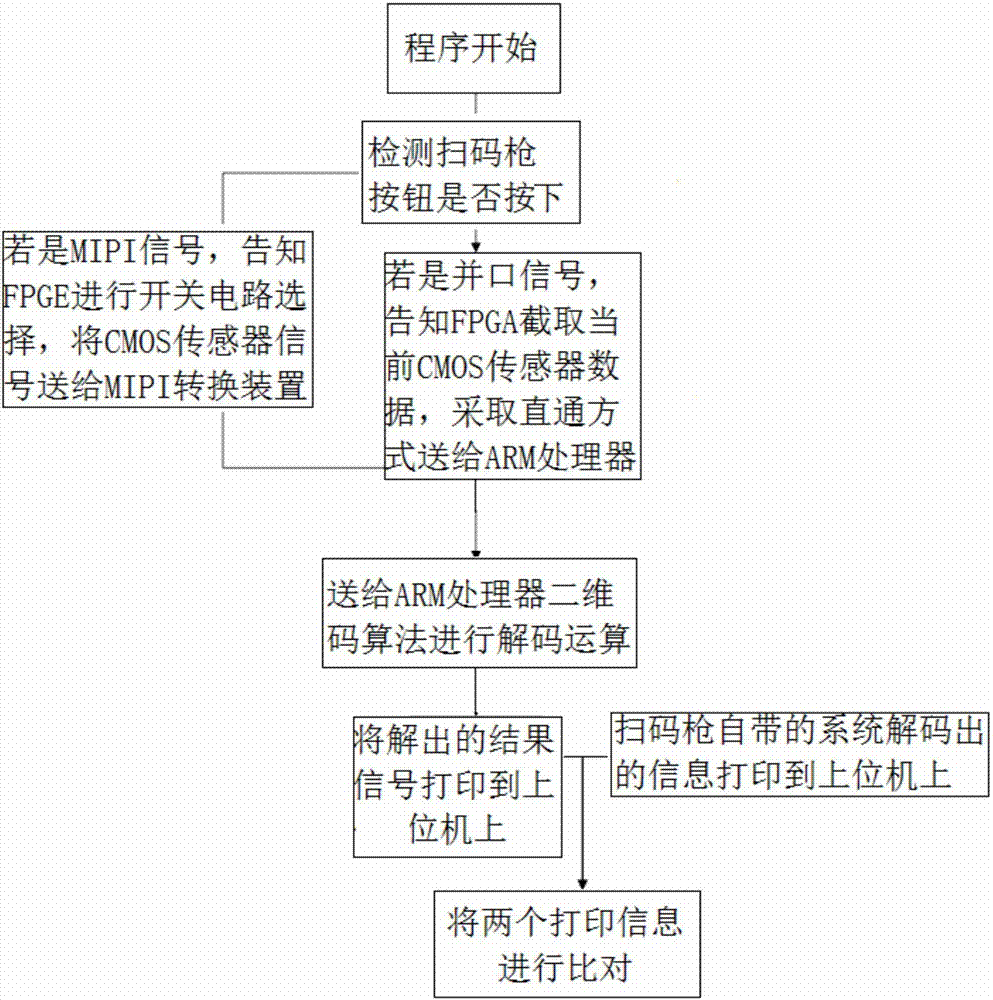

Two-dimensional code decoding algorithm comparison verification method

ActiveCN106971125AImprove identityImprove accuracySensing by electromagnetic radiationCoding decodingFpga chip

The present invention relates to a two-dimensional code decoding algorithm comparison verification method. The method aims to solve the technical problems of low accuracy of comparison results and complicated operation in the prior art. According to the two-dimensional code decoding algorithm comparison verification method of the invention, a scanning gun, a switching circuit change-over device connected with the scanning gun, an ARM processor and an upper computer are adopted; the switching circuit change-over device is also connected with an MIPI decoding device and an FPGA chip; the ARM processor is connected with the MIPI decoding device, the upper computer and the FPGA chip; and the MIPI decoding device is connected with the FPGA chip. The method includes the following steps that: an oscilloscope is adopted to detect early-stage parameters; hardware circuits are connected; the scanning gun is adopted to align a two-dimensional code picture so as to collect two-dimensional code picture data, a scanning gun central processing unit and the ARM processor decode and process the acquired data respectively so as to convert the data into data of a corresponding format; and a result is printed to the upper computer. With the two-dimensional code decoding algorithm comparison verification method provided by the technical schemes of the invention adopted, problems can be well solved. The method can be applied to the actual design of a two-dimensional code algorithm.

Owner:义乌好耶网络技术有限公司

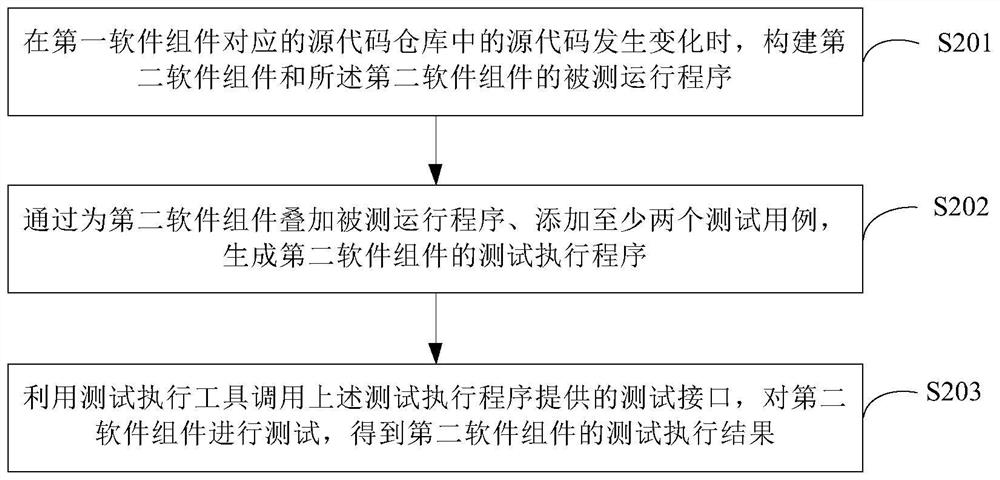

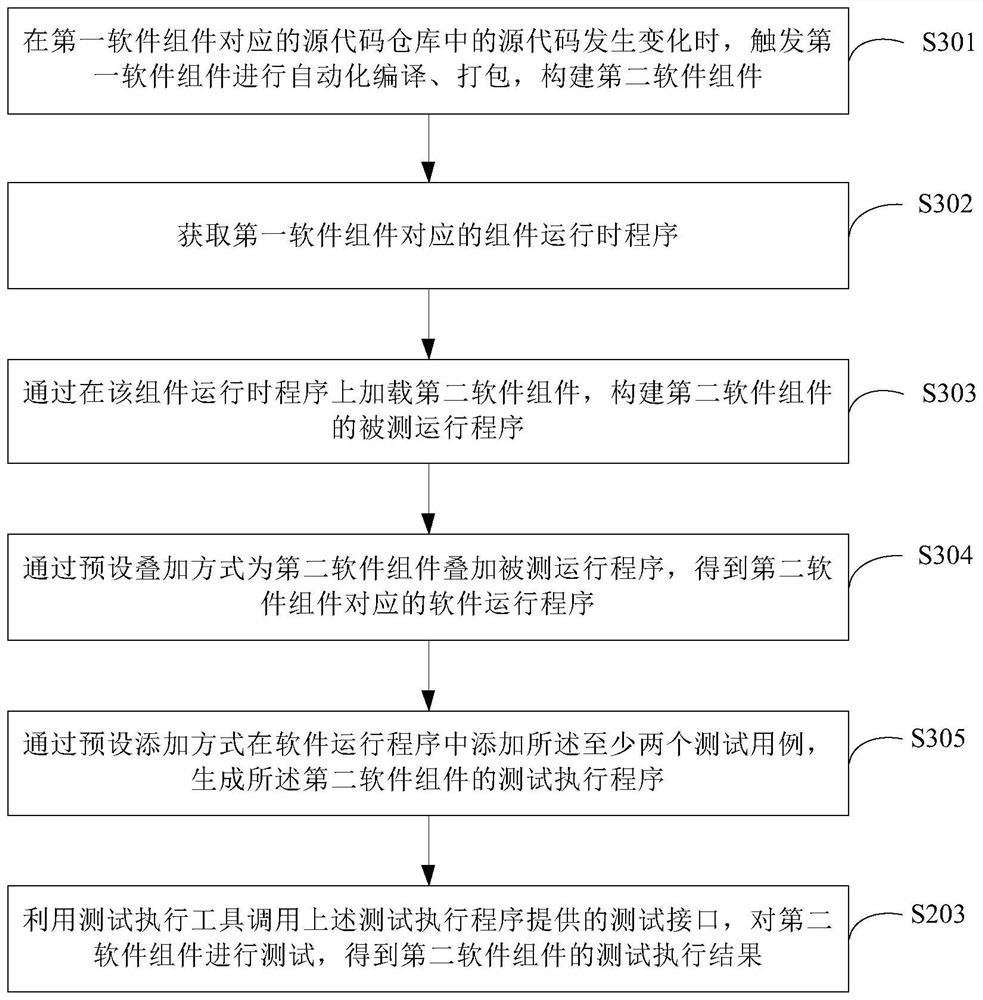

Software component testing method and device, equipment and storage medium

PendingCN114238144AReliable automated testingImprove automated testingSoftware testing/debuggingTest qualityTest execution

The invention provides a software component testing method and device, equipment and a storage medium, when a source code in a source code warehouse corresponding to a first software component changes, a second software component and a tested running program of the second software component are constructed, the second software component is a software component after the first software component is updated, and the tested running program of the second software component is updated. The method comprises the following steps: superposing a tested running program for a second software component, adding at least two test cases, generating a test execution program of the second software component, and finally calling a test interface provided by the test execution program by utilizing a test execution tool to test the second software component to obtain a test execution result of the second software component. According to the technical scheme, the software component can be automatically tested in a brand-new, reliable and efficient mode, the automatic testing degree is high, the testing quality can be guaranteed, and the testing accuracy is high.

Owner:AGRICULTURAL BANK OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com