A graphical modeling device and method for an automated test system

A technology for automated testing and graphical modeling, applied in program control devices, electrical testing/monitoring, etc., can solve the problems of increasing complexity of the equipment under test, insufficiency, and difficulty in clearly grasping and managing models, achieving intuitive and efficient automation Test system modeling, reduce design difficulty and workload, and improve the effect of automated testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

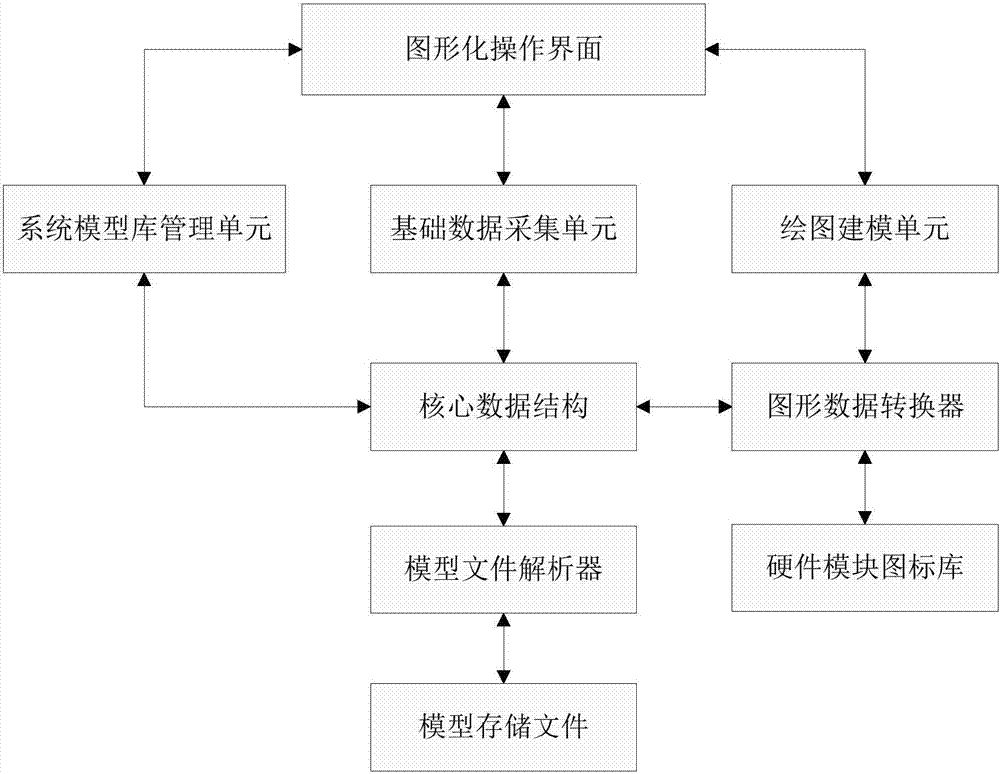

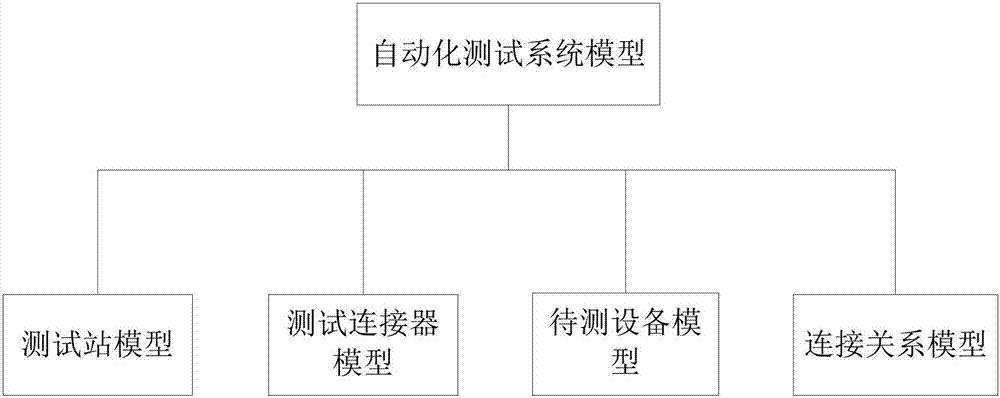

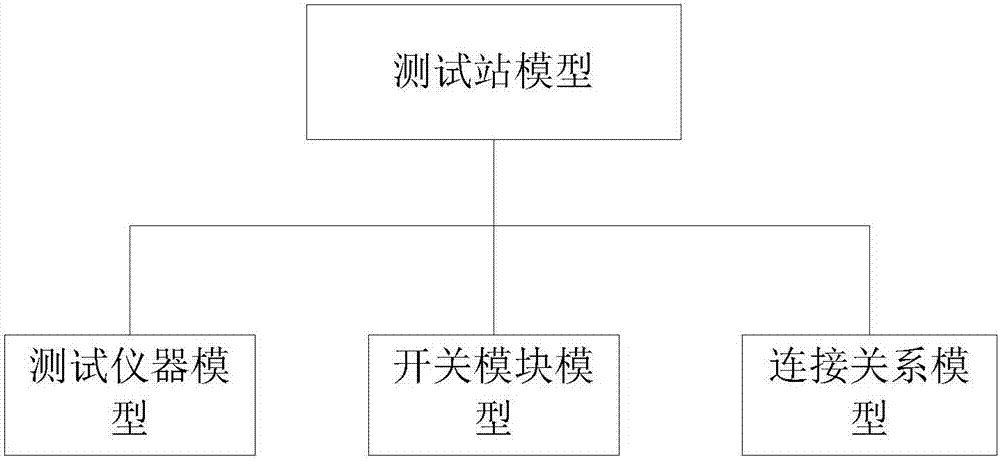

[0048] Such as Figure 1-Figure 3 As shown, a graphical modeling device for an automated test system is used to build an automated test system model, including a graphical operation interface, a system model library management unit, a basic data acquisition unit, a drawing modeling unit, a graphic data conversion unit, a core Data structure, model file parser, model storage file and hardware module icon library;

[0049] The graphical operation interface includes an area for receiving user management instructions, a system module library management area, a module attribute configuration area, and an automated test system module and a connection relationship drawing area, wherein: the system module library management area includes several components that constitute automation Test the hardware modules of the system, and can provide any one or more functions of adding, modifying, and deleting the system modules; the module attribute configuration area is used to configure the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com