Patents

Literature

4290 results about "ModelSim" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ModelSim is a multi-language HDL simulation environment by Mentor Graphics, for simulation of hardware description languages such as VHDL, Verilog and SystemC, and includes a built-in C debugger. ModelSim can be used independently, or in conjunction with Intel Quartus Prime, Xilinx ISE or Xilinx Vivado. Simulation is performed using the graphical user interface (GUI), or automatically using scripts.

A System and Method for Modelling System Behaviour

ActiveUS20170147722A1Reduce the impactReduce impactMedical simulationDesign optimisation/simulationCollective modelModel system

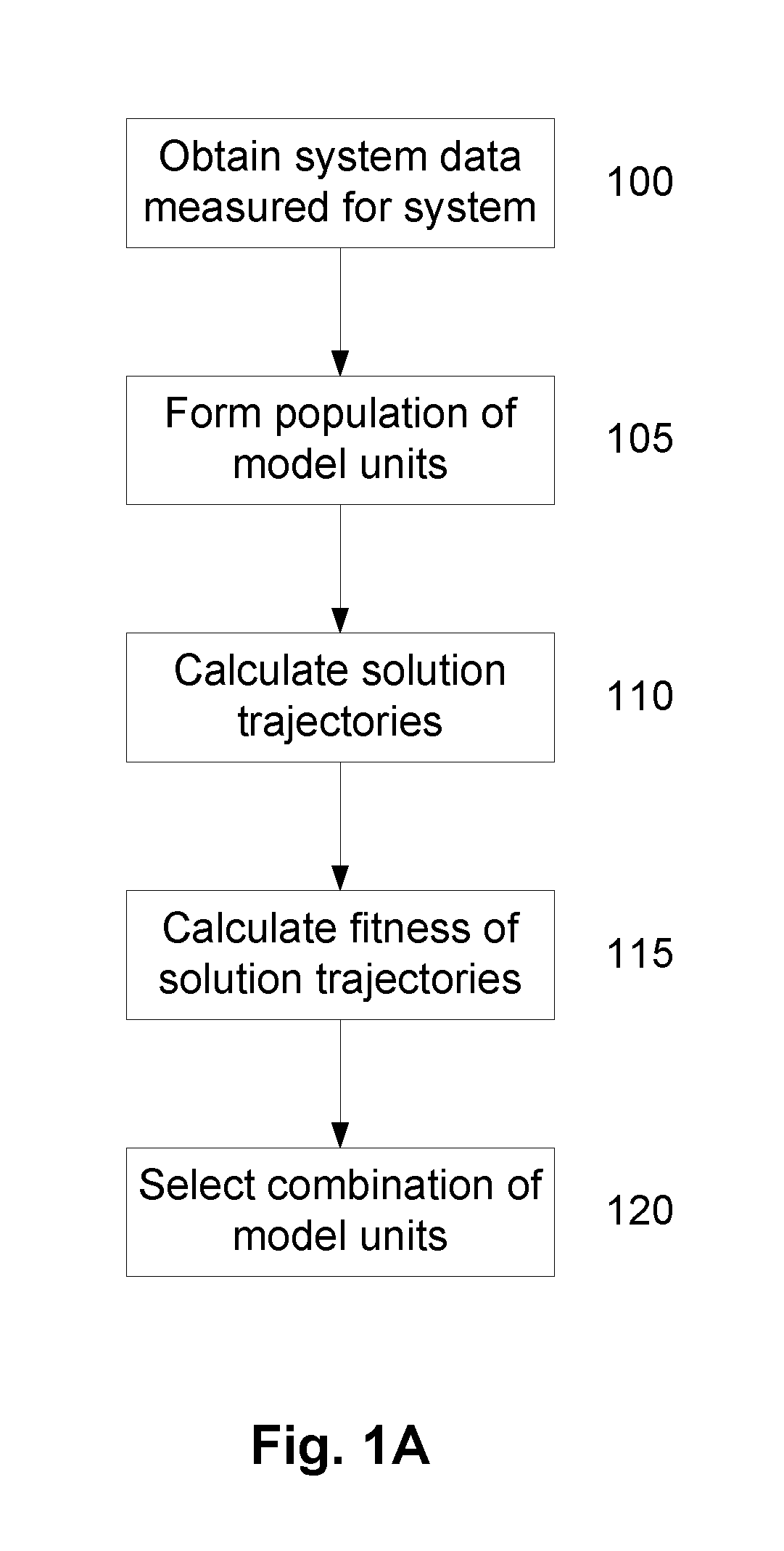

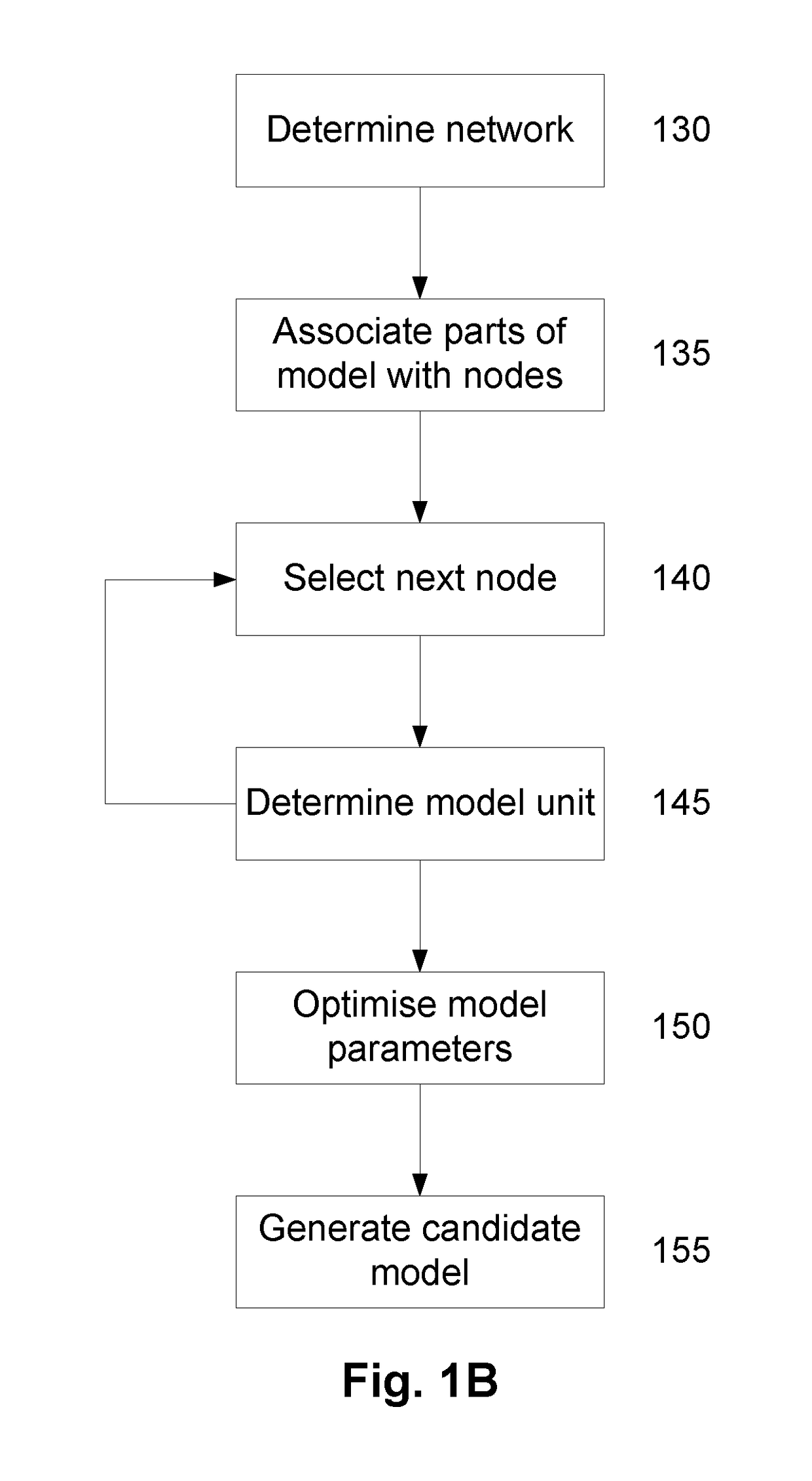

A method of modelling system behaviour of a physical system, the method including, in one or more electronic processing devices obtaining quantified system data measured for the physical system, the quantified system data being at least partially indicative of the system behaviour for at least a time period, forming at least one population of model units, each model unit including model parameters and at least part of a model, the model parameters being at least partially based on the quantified system data, each model including one or more mathematical equations for modelling system behaviour, for each model unit calculating at least one solution trajectory for at least part of the at least one time period; determining a fitness value based at least in part on the at least one solution trajectory; and, selecting a combination of model units using the fitness values of each model unit, the combination of model units representing a collective model that models the system behaviour.

Owner:EVOLVING MACHINE INTELLIGENCE

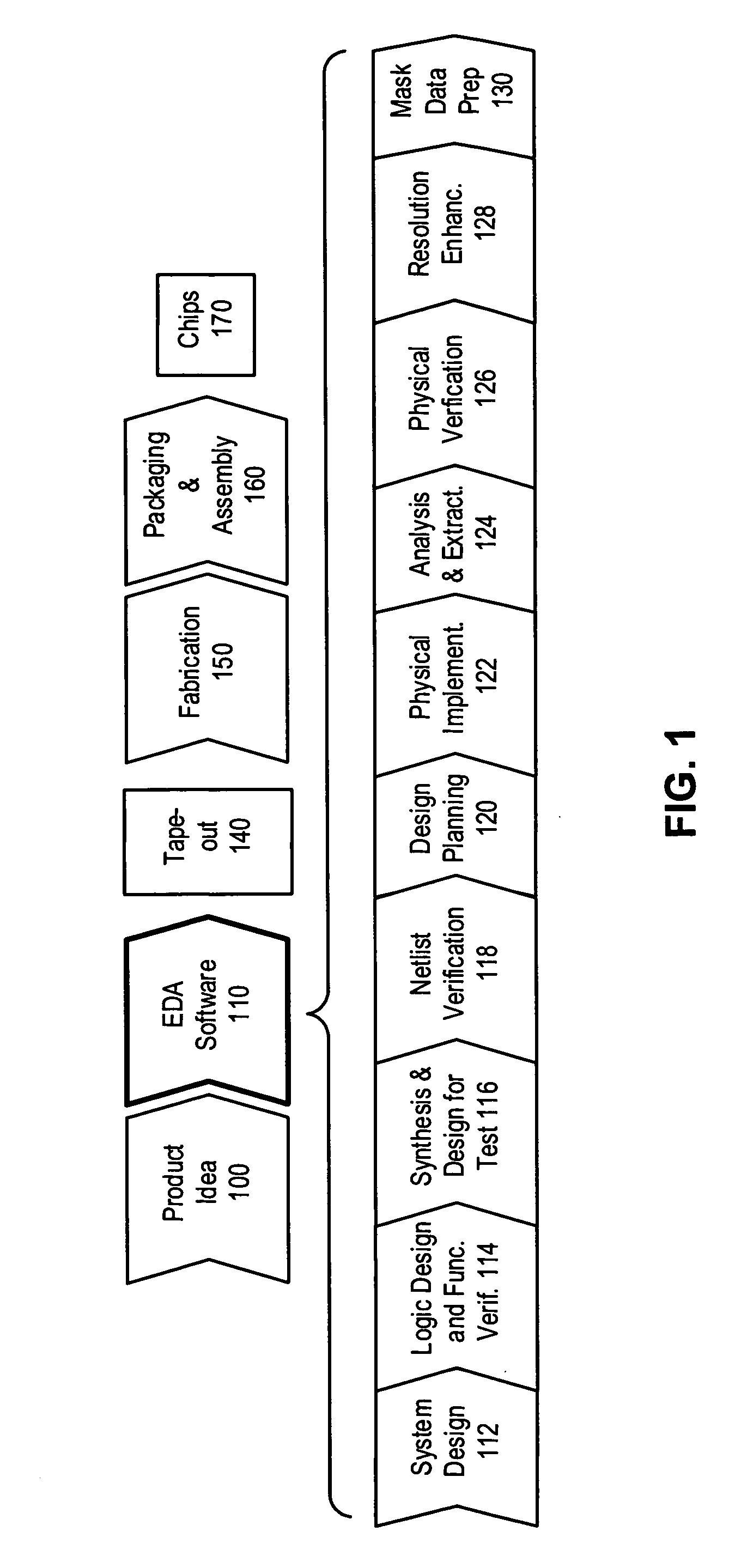

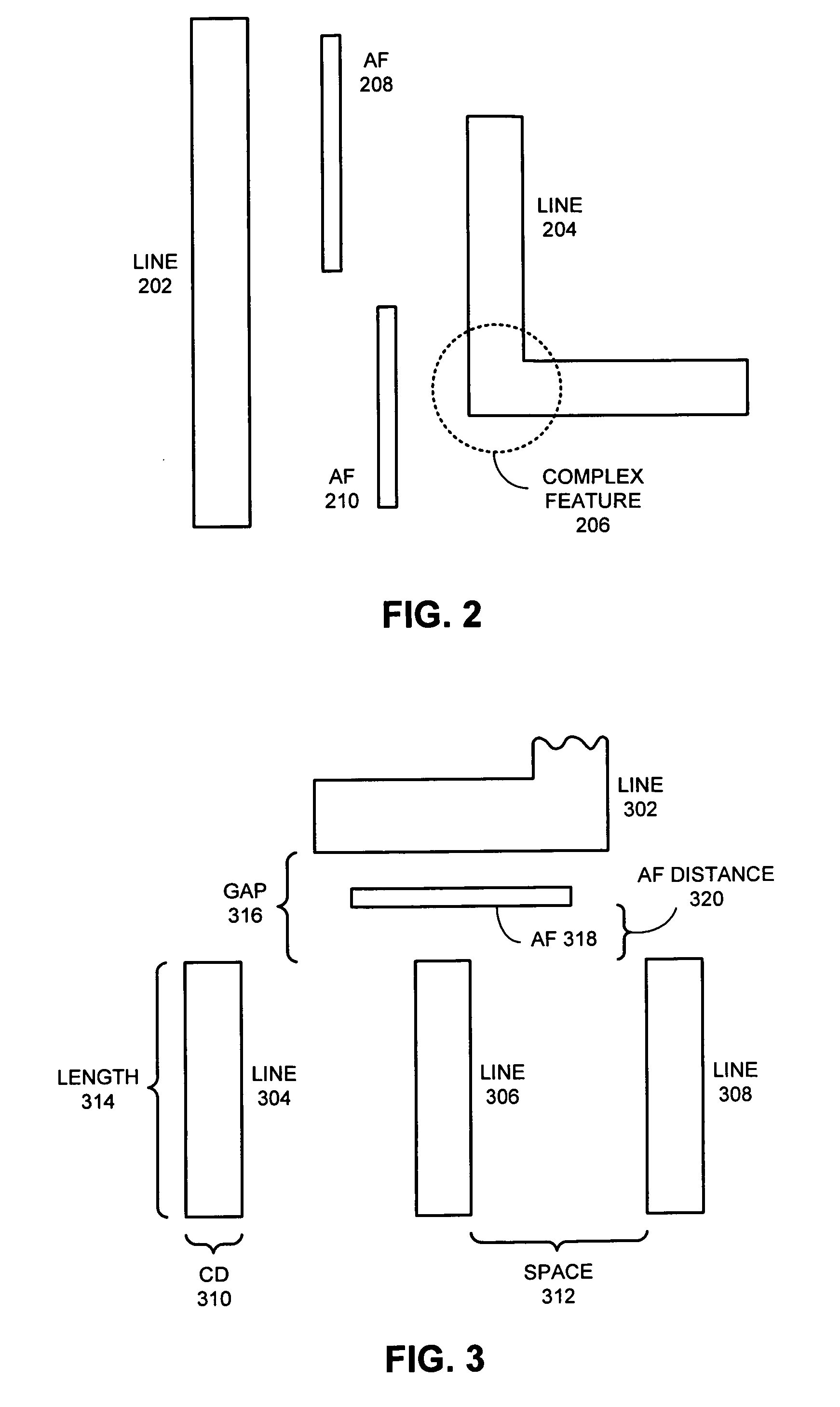

Method and apparatus for quickly determining the effect of placing an assist feature at a location in a layout

ActiveUS20070038973A1Quick effectOptimize locationPhotomechanical apparatusCAD circuit designEngineeringSystem usage

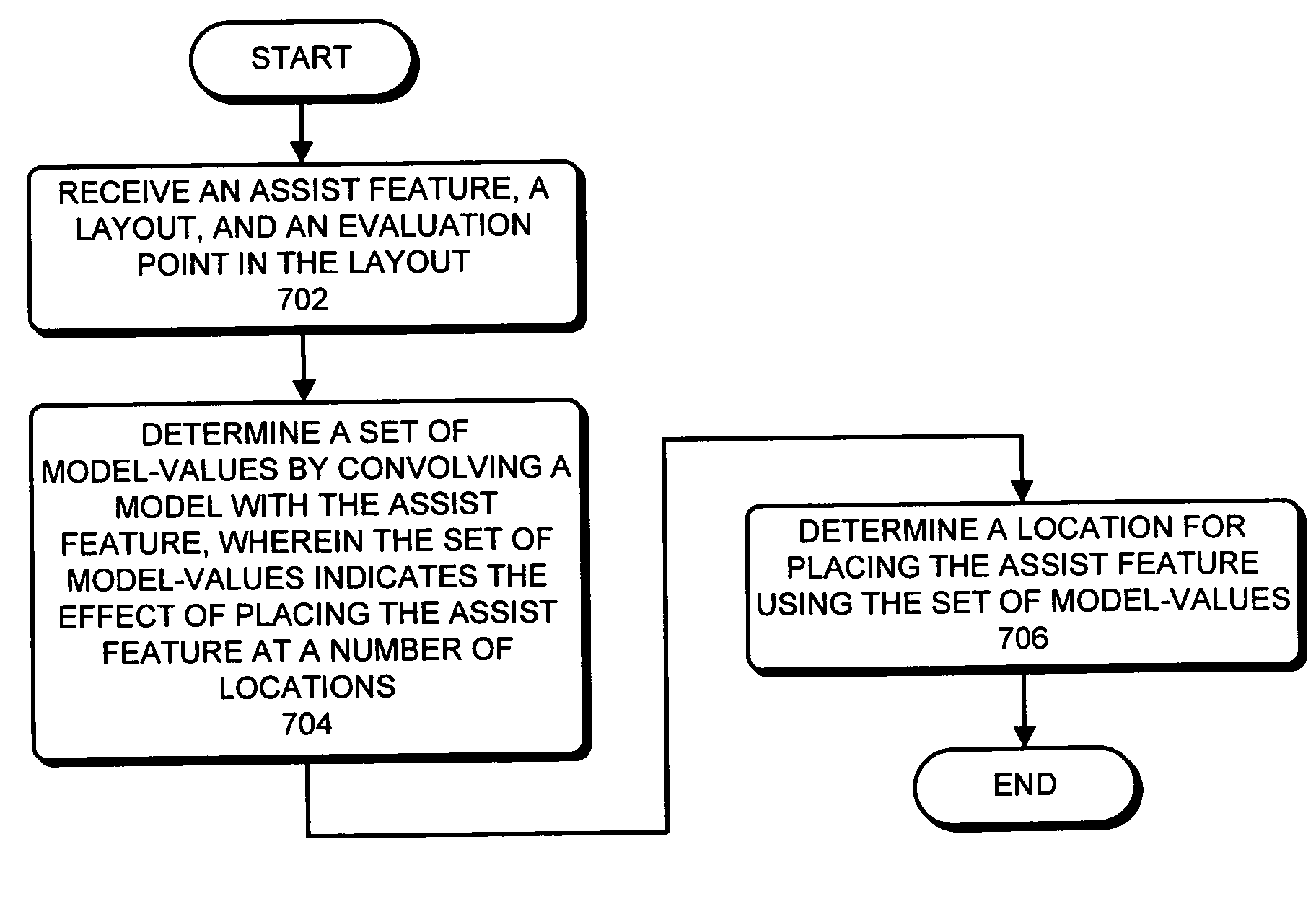

One embodiment of the present invention determines the effect of placing an assist feature at a location in a layout. During operation, the system receives a first value which was pre-computed by convolving a model with a layout at an evaluation point, wherein the model models semiconductor manufacturing processes. Next, the system determines a second value by convolving the model with an assist feature, which is assumed to be located at a first location which is in proximity to the evaluation point. The system then determines the effect of placing an assist feature using the first value and the second value. An embodiment of the present invention can be used to determine a substantially optimal location for placing an assist feature in a layout.

Owner:SYNOPSYS INC

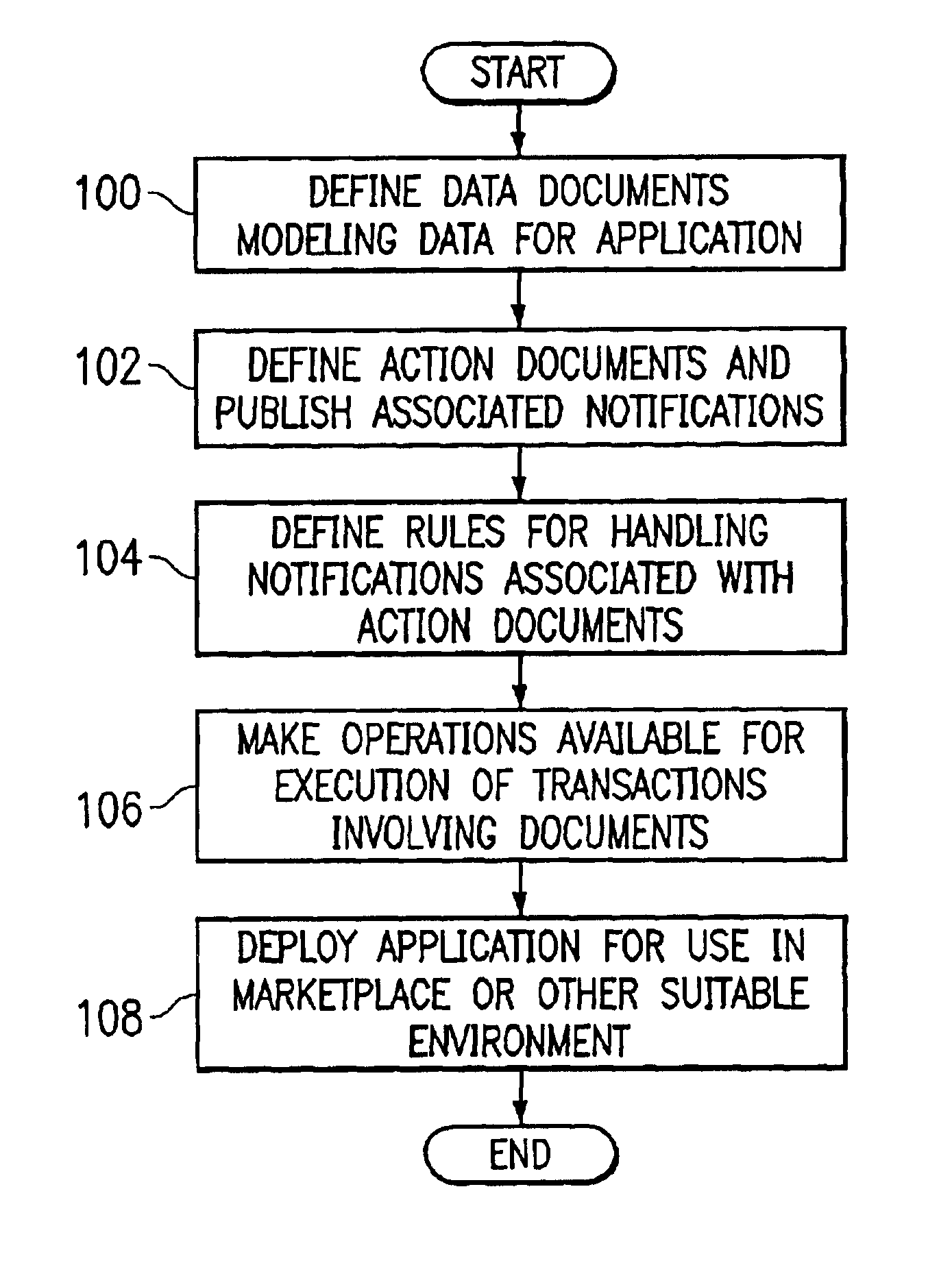

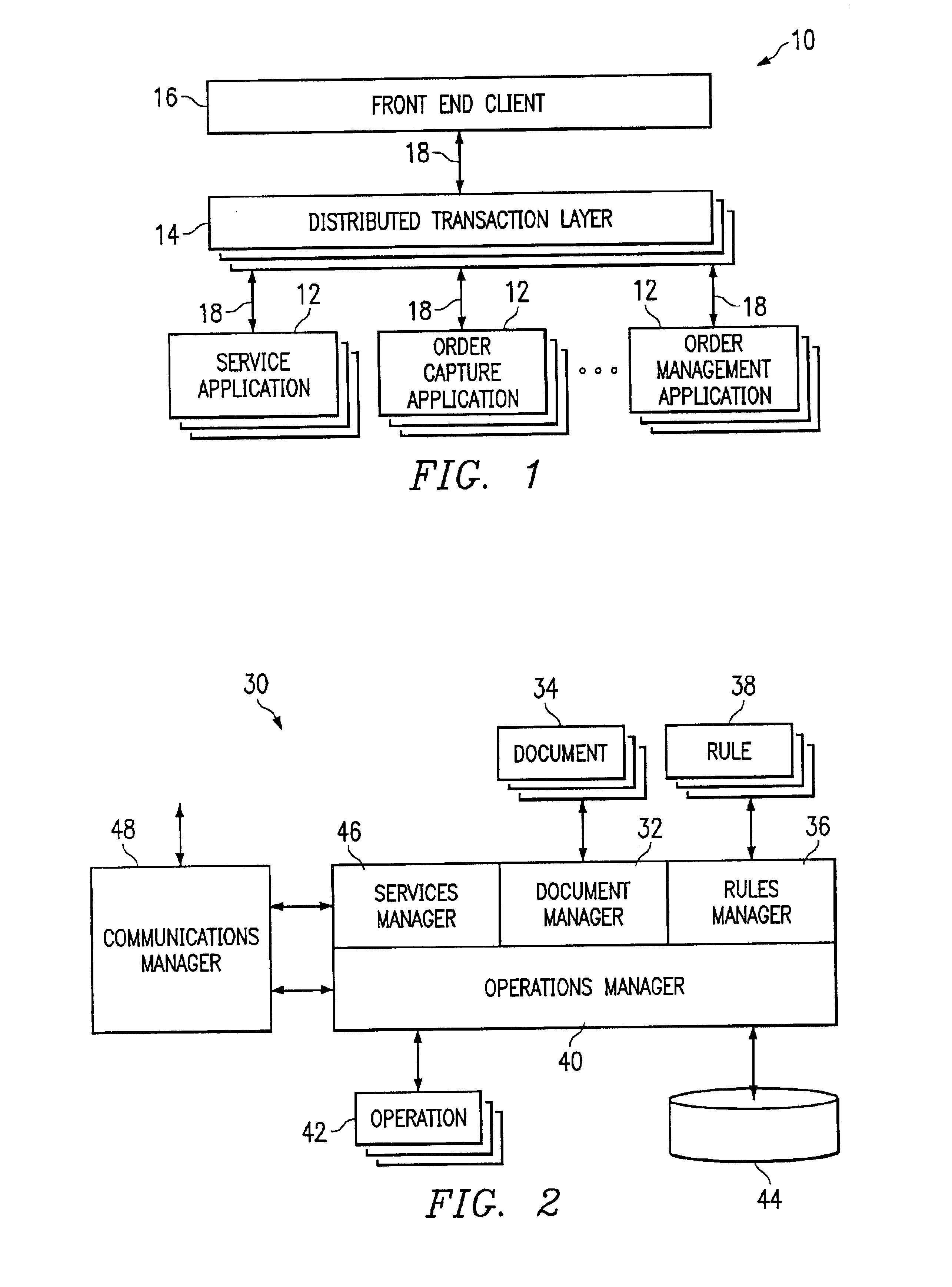

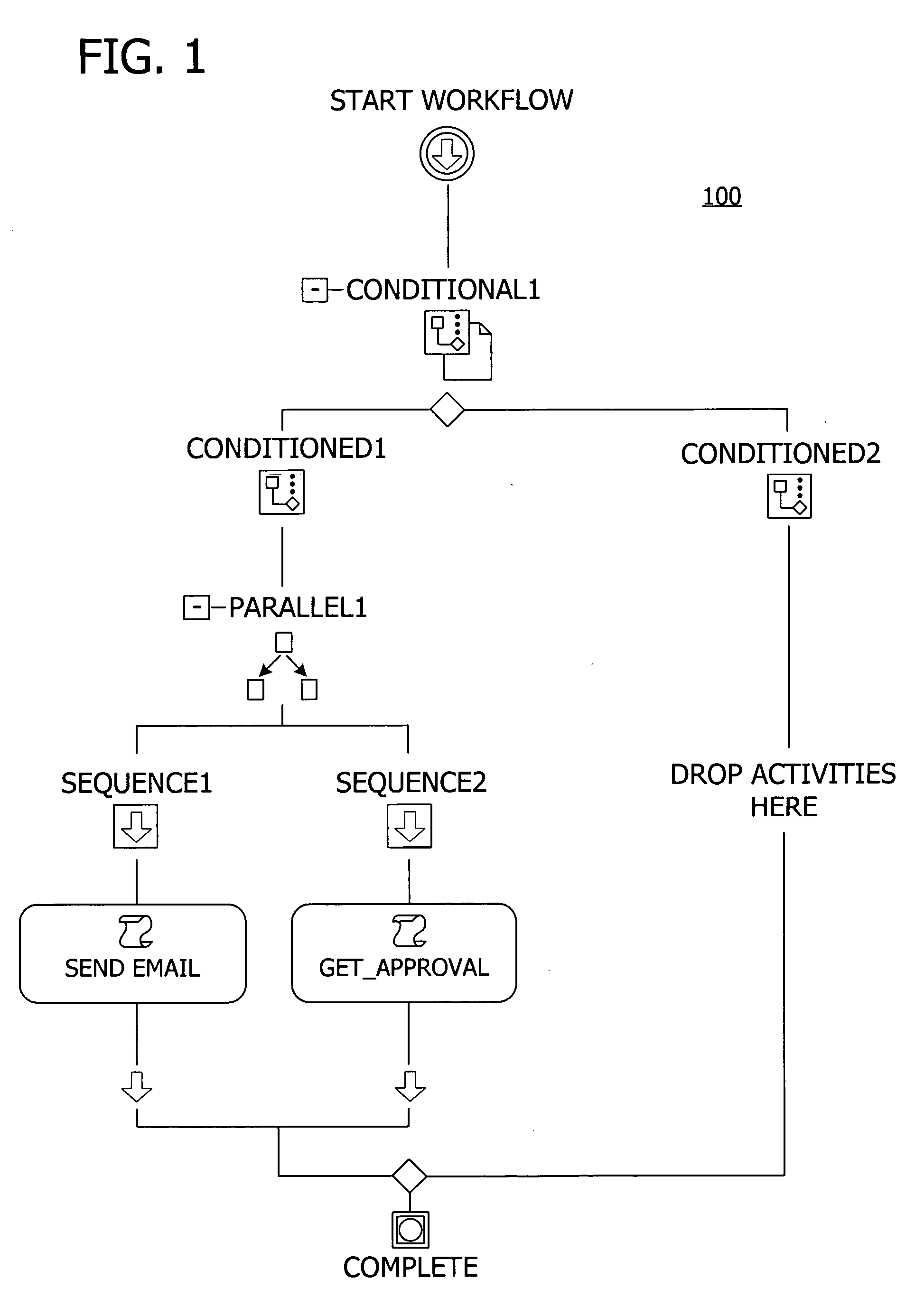

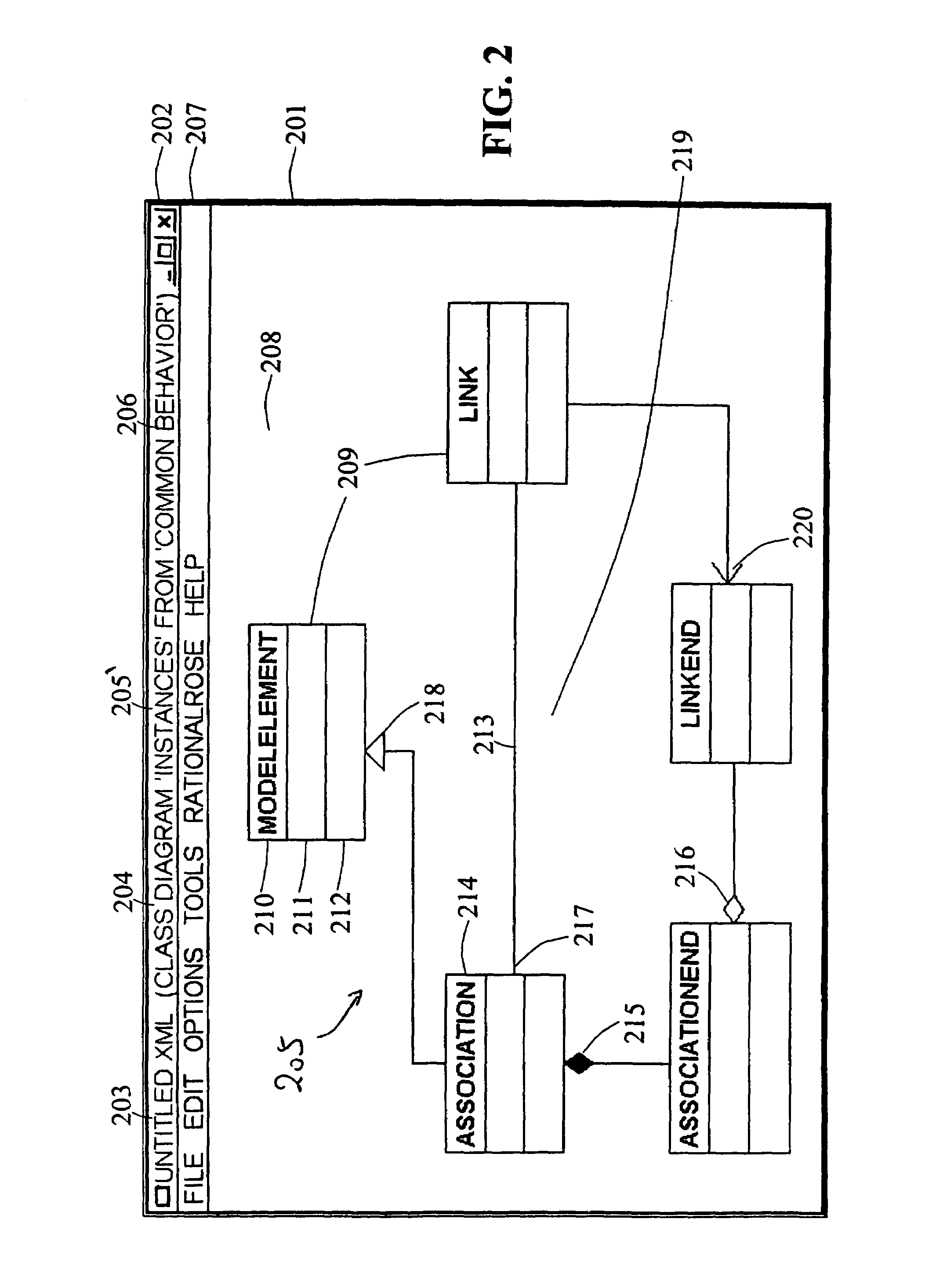

System and method for developing software applications using an extended XML-based framework

InactiveUS6845499B2Developing software applications have been substantially reduced or eliminatedShort development cycleSoftware designSpecific program execution arrangementsRequest - actionSoftware engineering

An XML-based framework (30) for developing software applications (12) includes a document manager (32) to manage activities relating to one or more XML-based data documents (34) associated with an application (12), each data document (34) modeling data associated with the application (12) and representing relationships between the data document (34) and one or more other data documents (34). The framework (30) includes a rules manager (36) to manage rules (38) specifying logic for handling notifications associated with XML-based action documents (34) received at the application (12), the notifications requesting actions involving data documents (34). The framework (30) also includes an operations manager (40) to manage the execution of transactions involving data documents (34) based on operations (42) defined for the application (12) during its development. The framework (30) provides a generic XML-based transaction engine, the application (12) being one of a plurality of distributed applications (12) each being an instance of the generic transaction engine. An electronic marketplace with a distributed transaction layer may include such a plurality of distributed applications (12), where the applications (12) interact with one another using the distributed transaction layer (14) to conduct electronic commerce within the marketplace.

Owner:JDA SOFTWARE GROUP

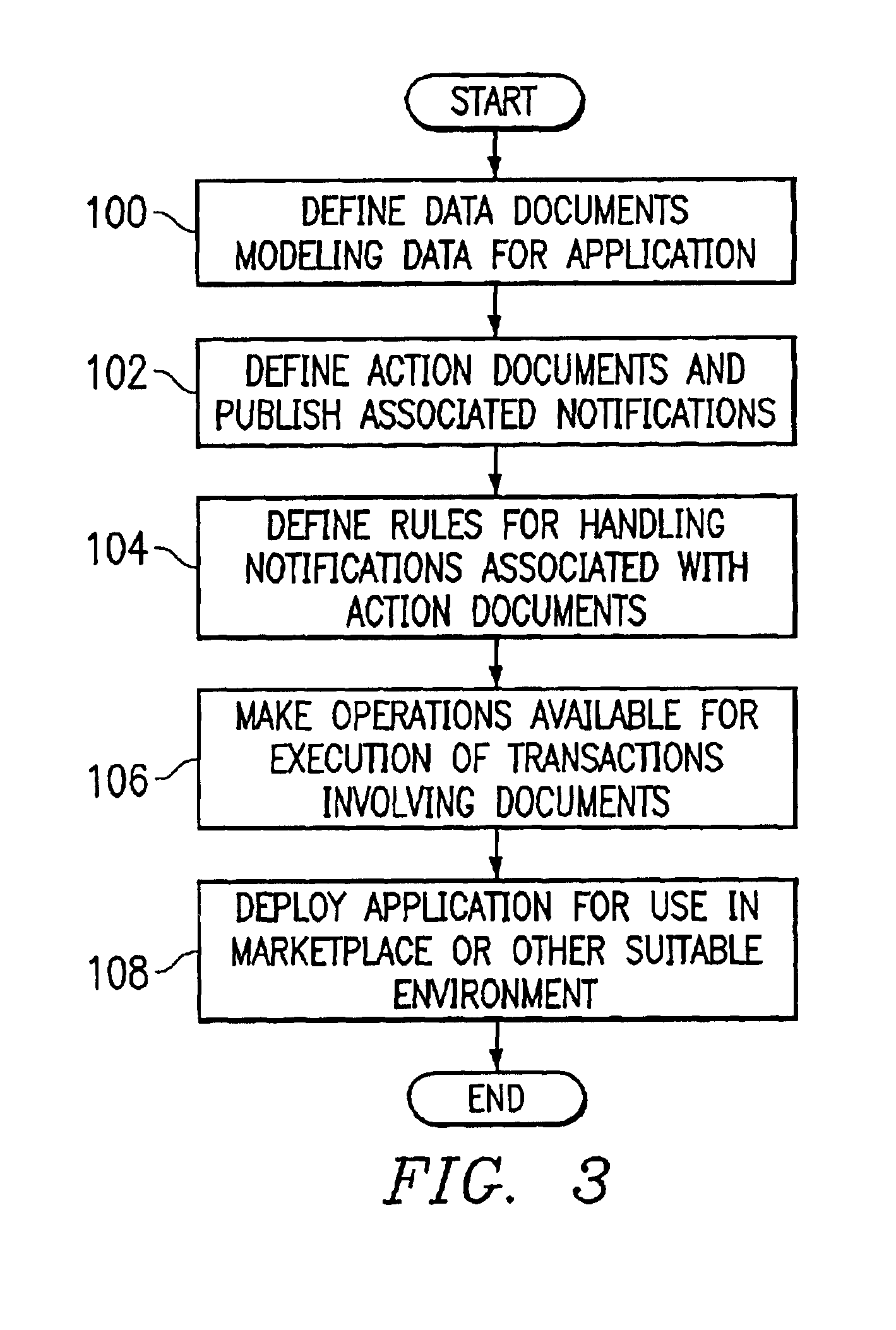

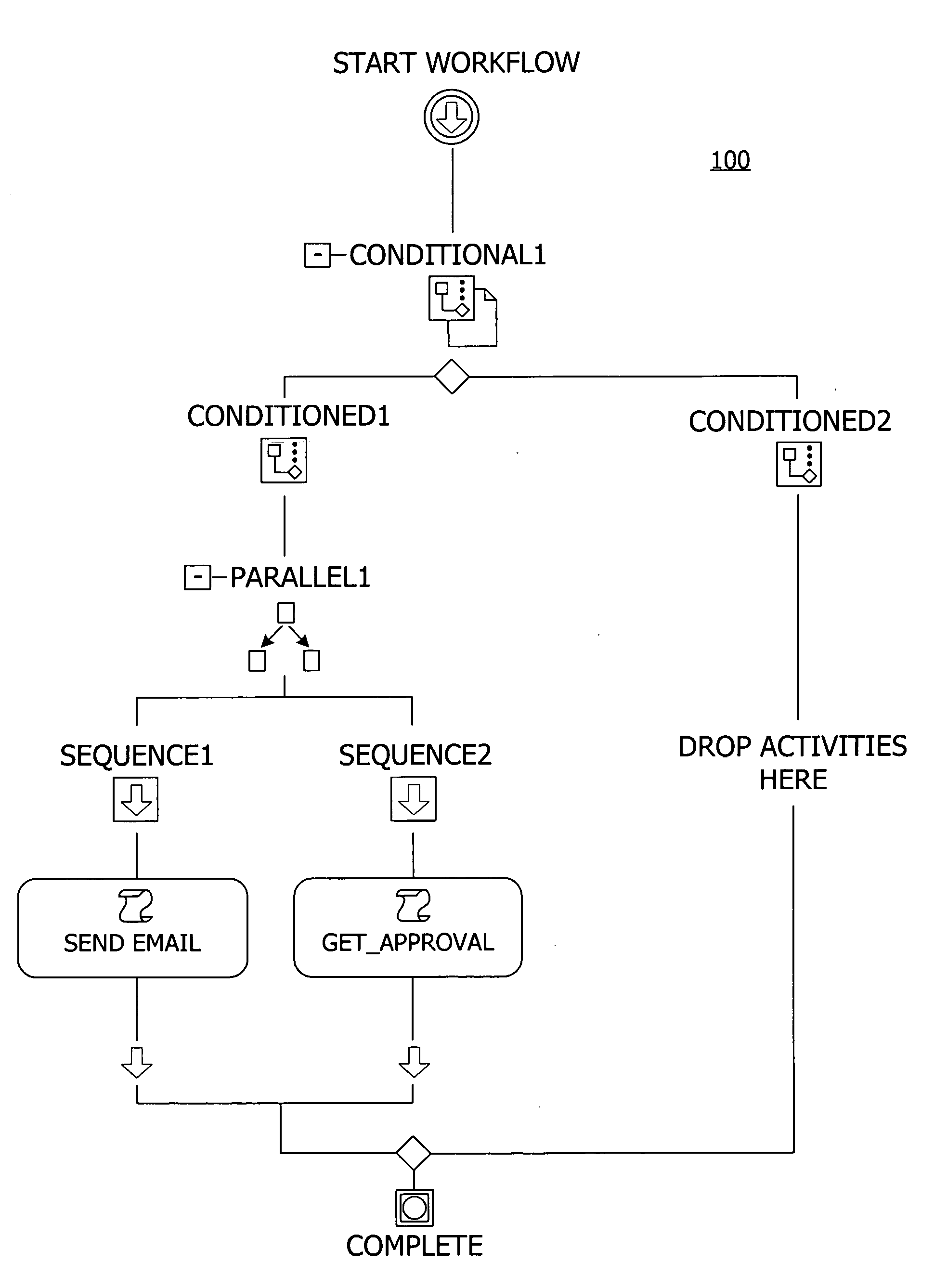

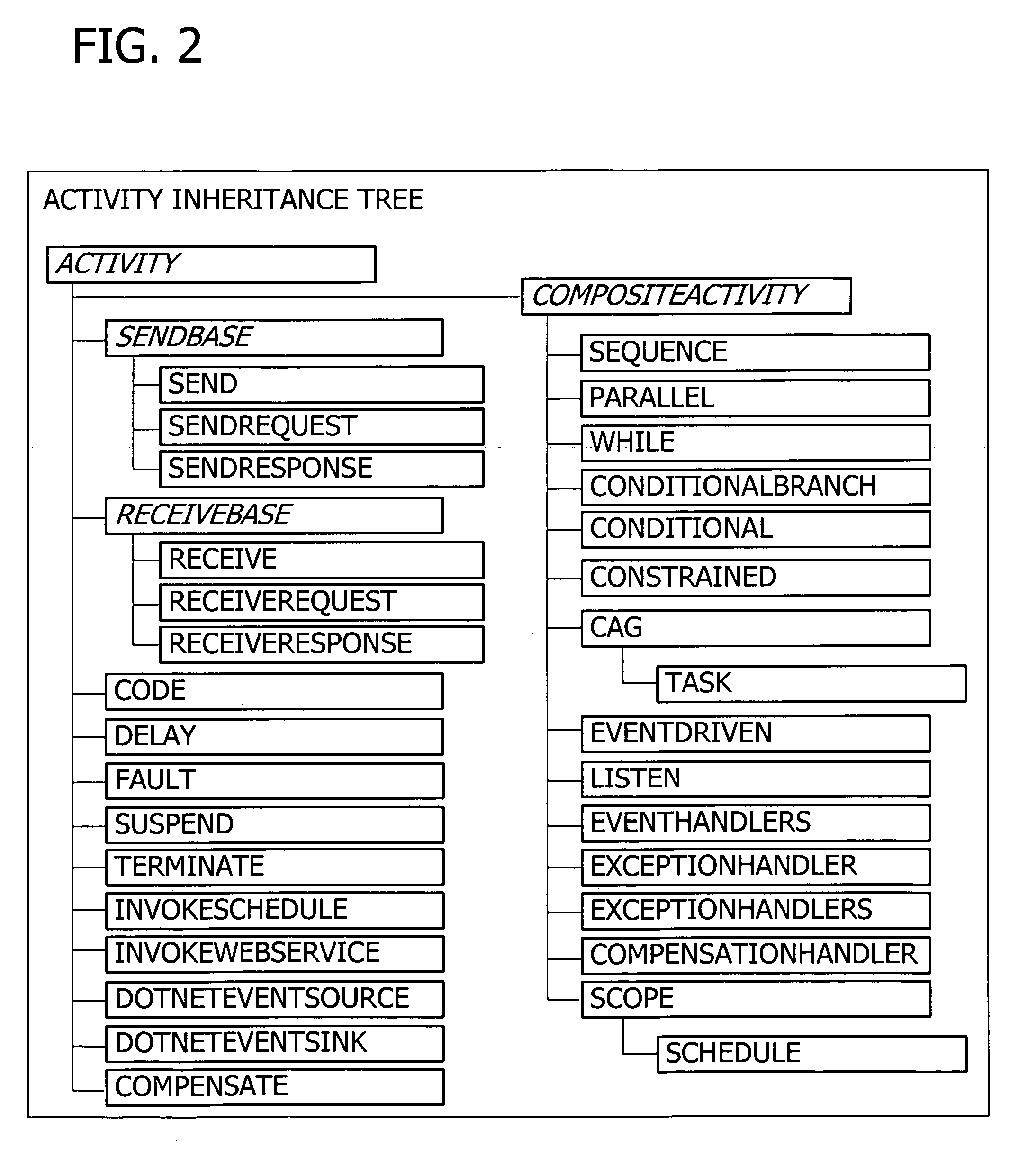

Programming interface for a componentized and extensible workflow model

InactiveUS20060074736A1Increase heightExtend the workflow modelResourcesExecution for user interfacesApplication programming interfaceTime aspect

Building a componentized workflow model via an application programming interface. Each step of the workflow is modeled as an activity that has metadata to describe design time aspects, compile time aspects, and runtime aspects of the workflow step. A user selects and arranges the activities to create the workflow via the application programming interfaces. The metadata associated with each of the activities in the workflow is collected to create a persistent representation of the workflow. Users extend the workflow model by authoring custom activities. Users also compile the workflow via the application programming interface.

Owner:MICROSOFT TECH LICENSING LLC

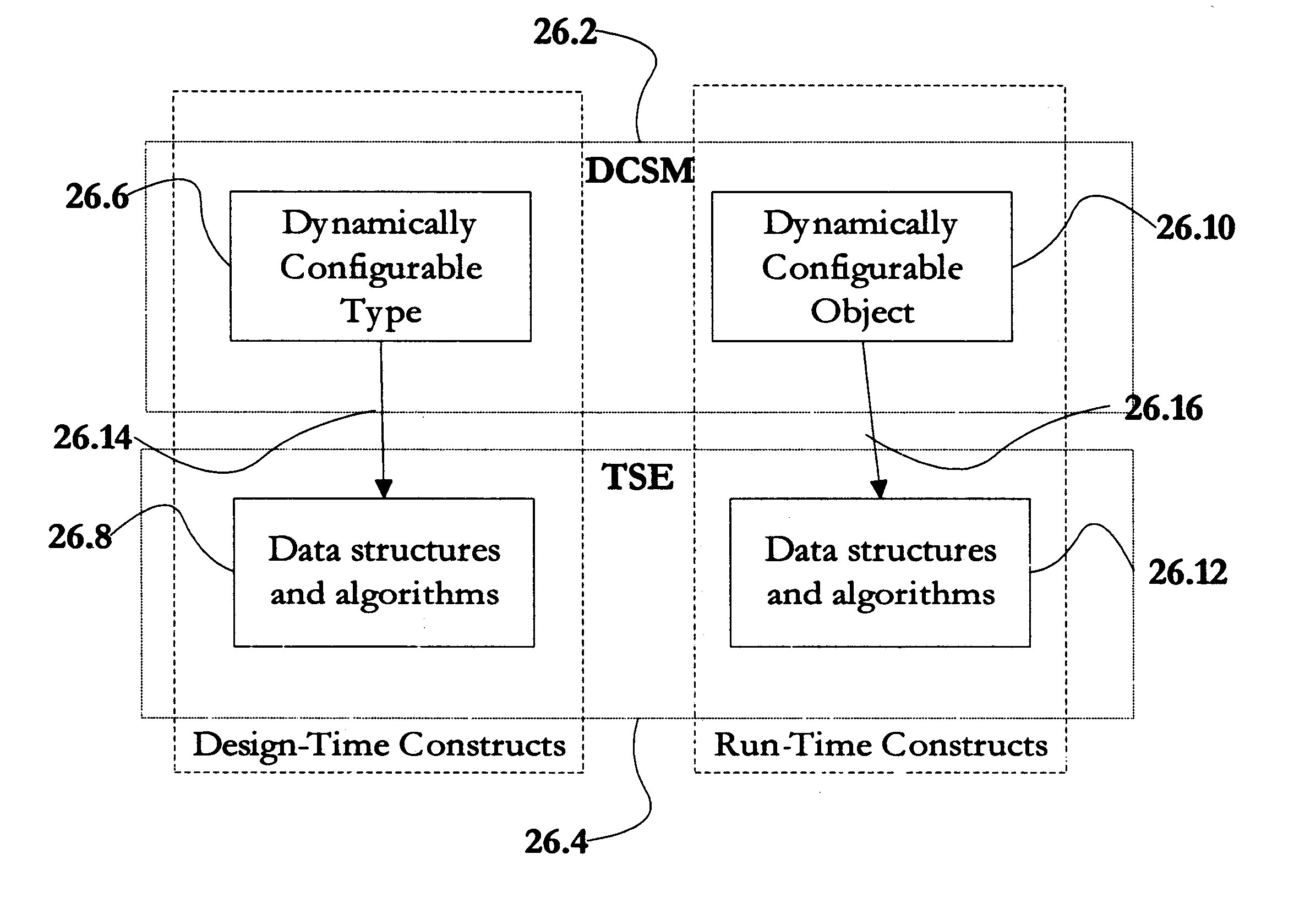

Method and apparatus for the development of dynamically configurable software systems

InactiveUS6269473B1Dynamic configurabilityImprove abilitiesData processing applicationsSoftware designSoftware systemSemantics

A software modeling environment is presented that supports the development and execution of software that can be dynamically configured. This is achieved by introducing a design-time object modeling construct called a dynamically configurable type (DCT) that supports the subdivision of an object into a plurality of subsets of semantics and allows dynamic merging of these semantic subsets together in different combinations in order to allow the resultant object to exhibit different semantics over time to serve different purposes. Specific process modeling constructs are included which take advantage of this semantic merging capability. Also included are other supporting design-time and run-time constructs and services. One embodiment of the present invention allows this software modeling environment to be integrated into a standard software development environment, enhancing the modeling capabilities already present.

Owner:EVOLVE SOFTWARE

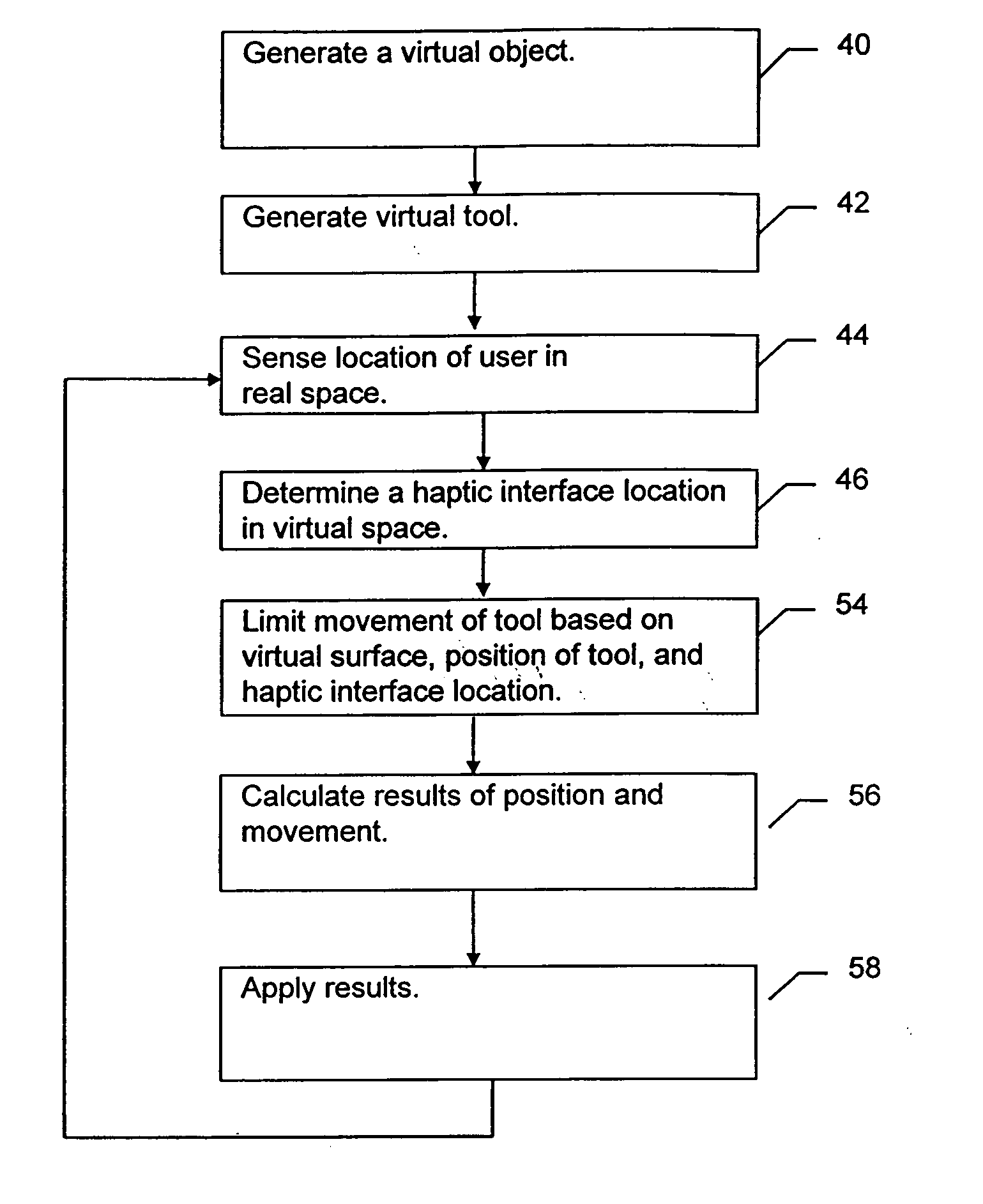

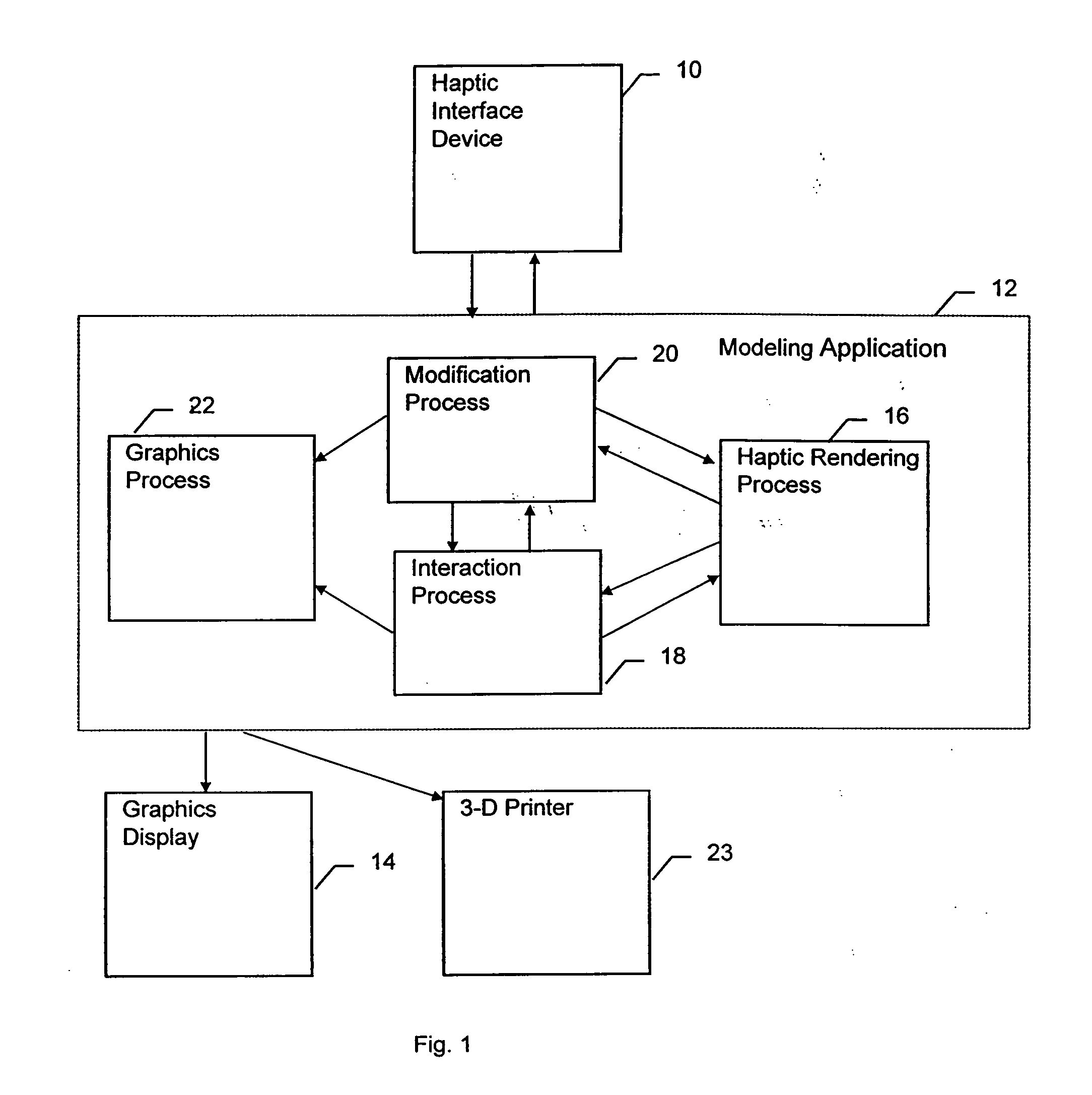

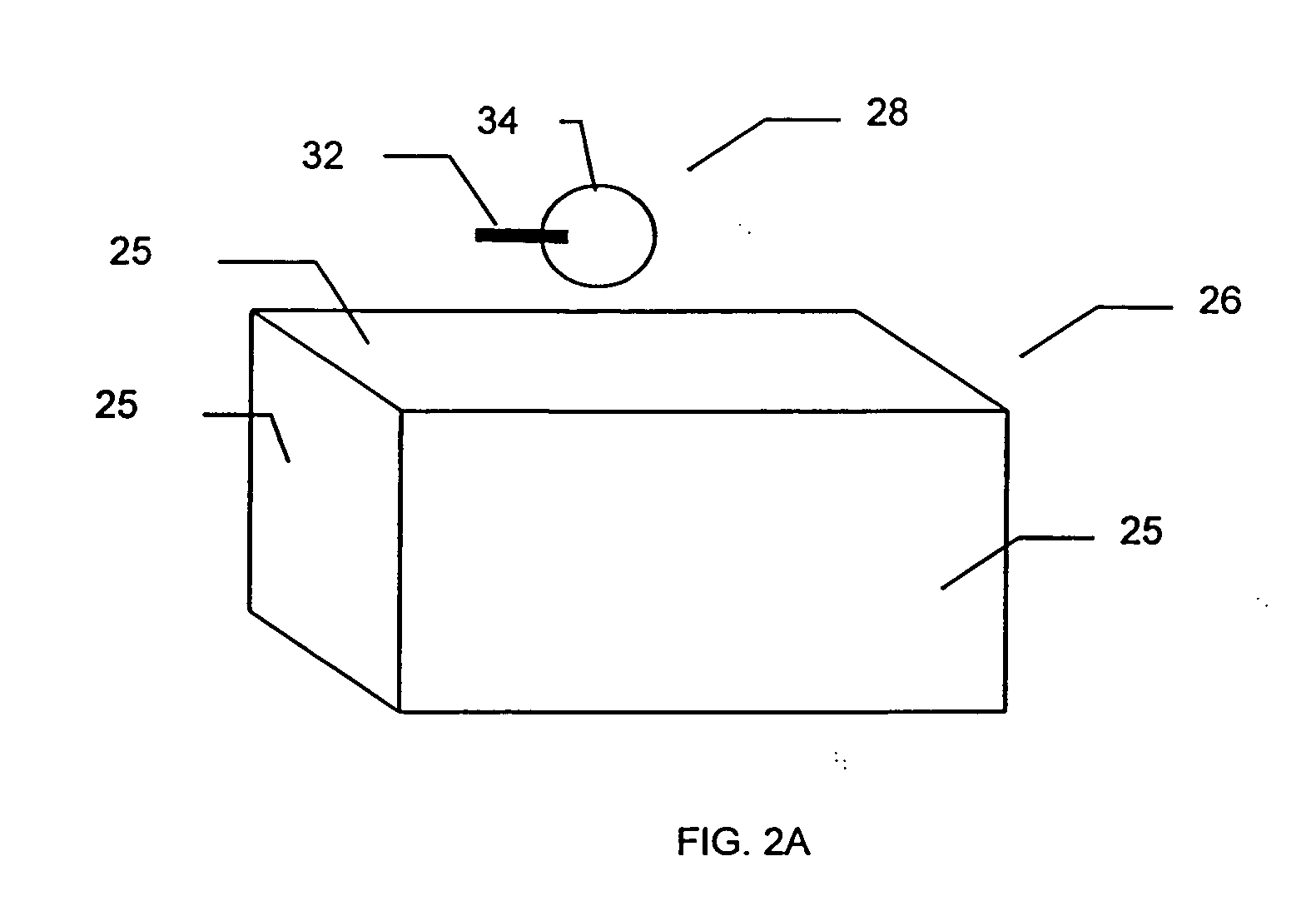

Systems and methods for creating virtual objects in a sketch mode in a haptic virtual reality environment

InactiveUS20050062738A1Ease and expressivenessResolve ambiguityInput/output for user-computer interactionAdditive manufacturing apparatusMirror imageVirtual reality

Owner:3D SYST INC

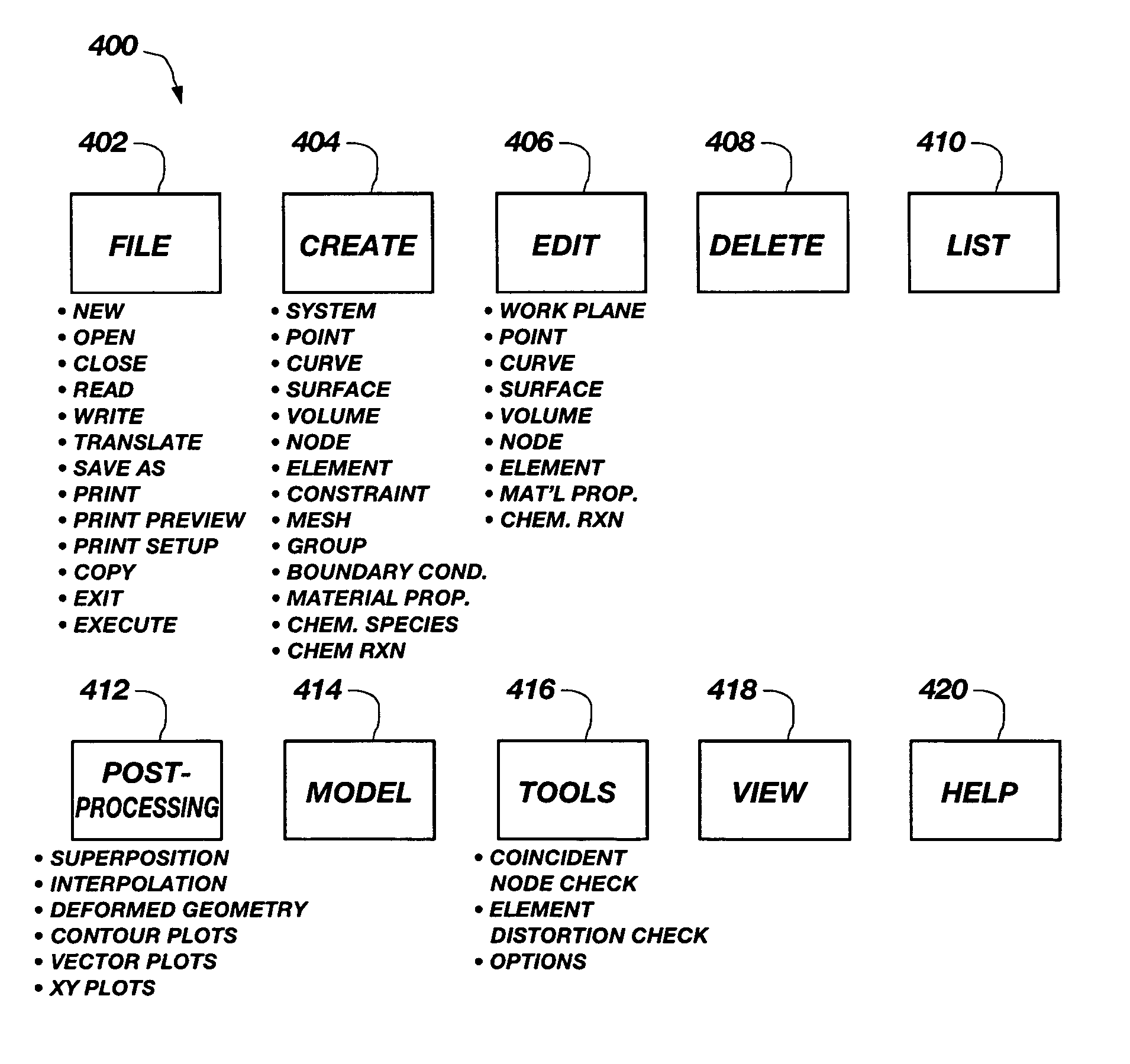

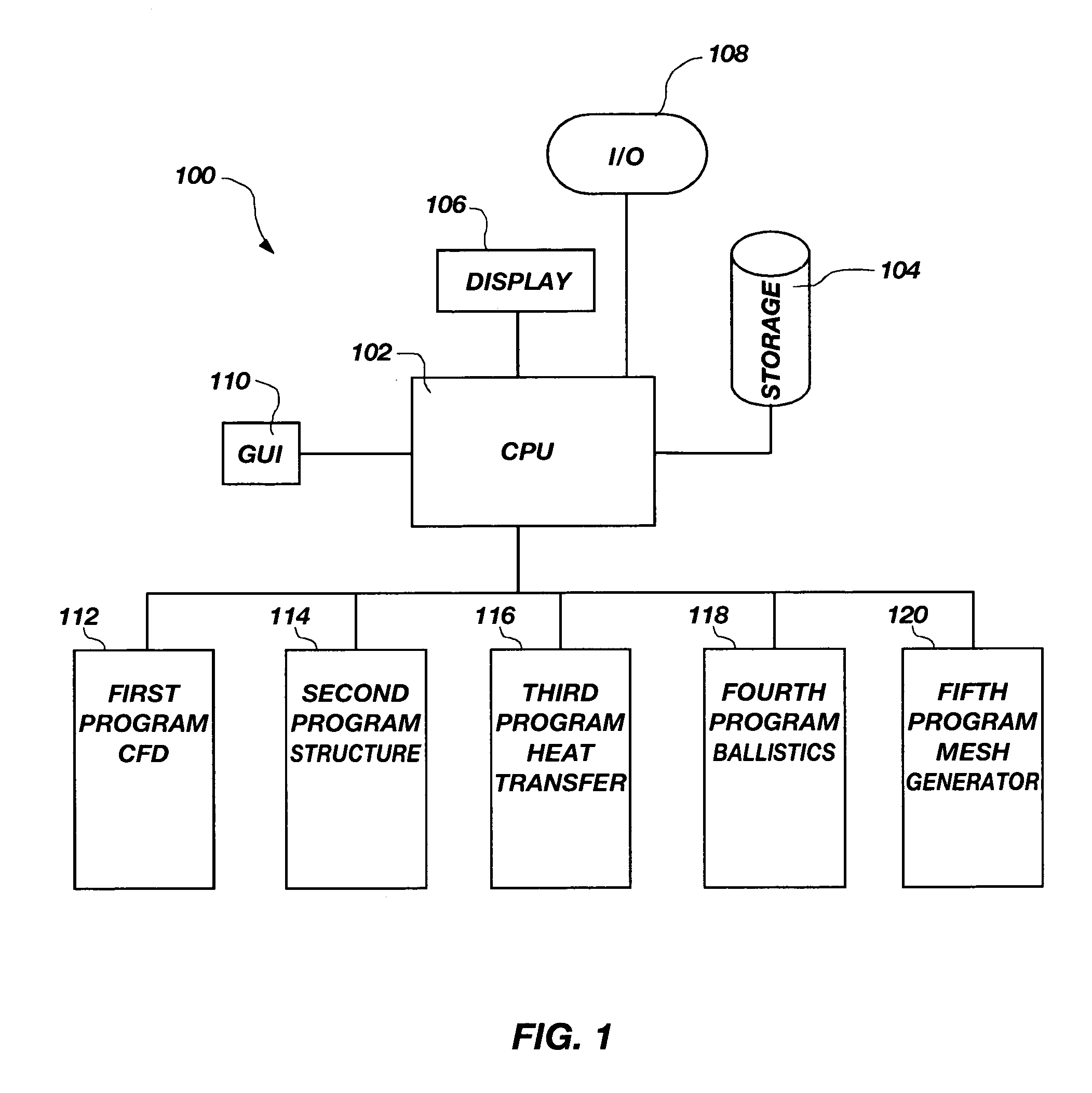

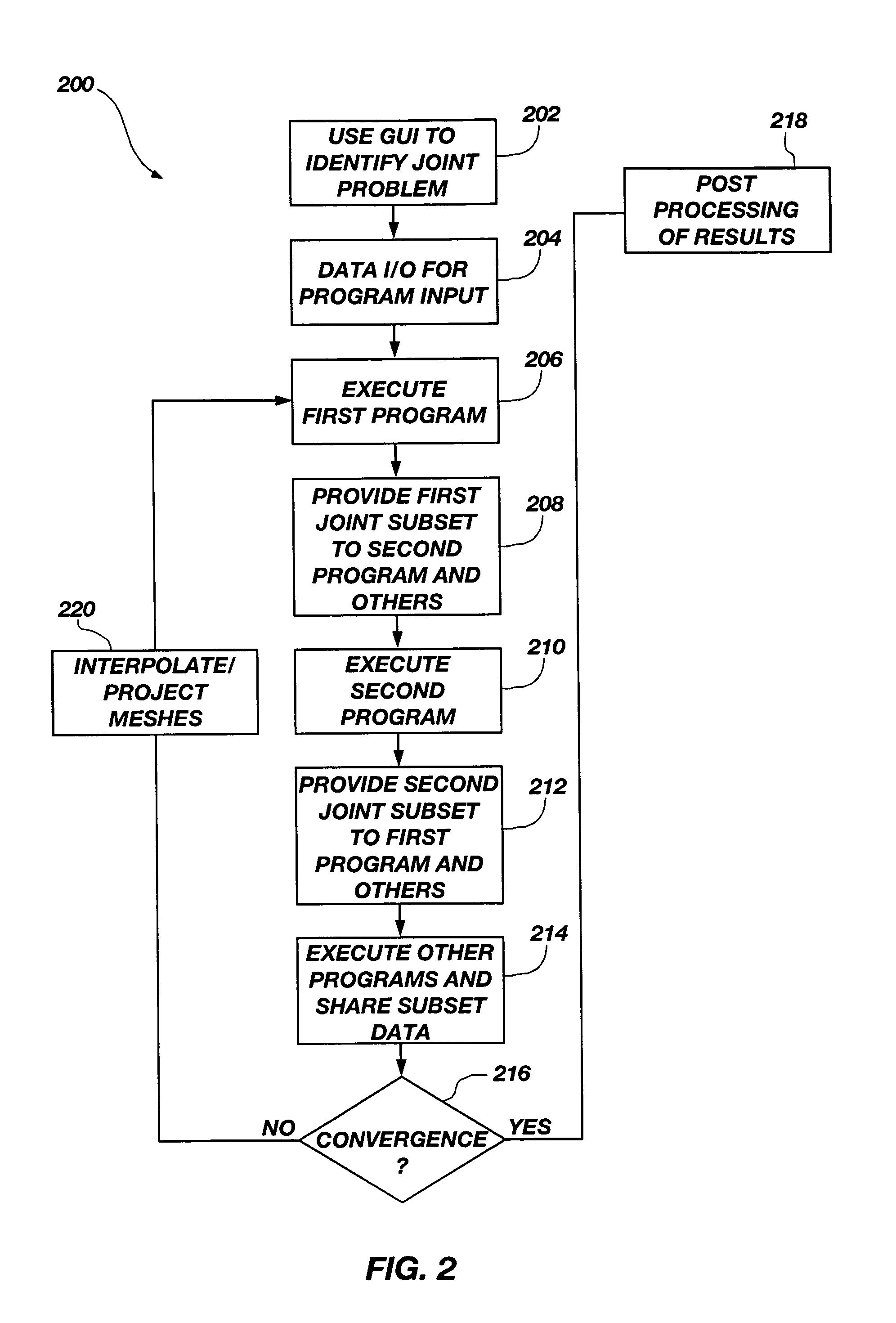

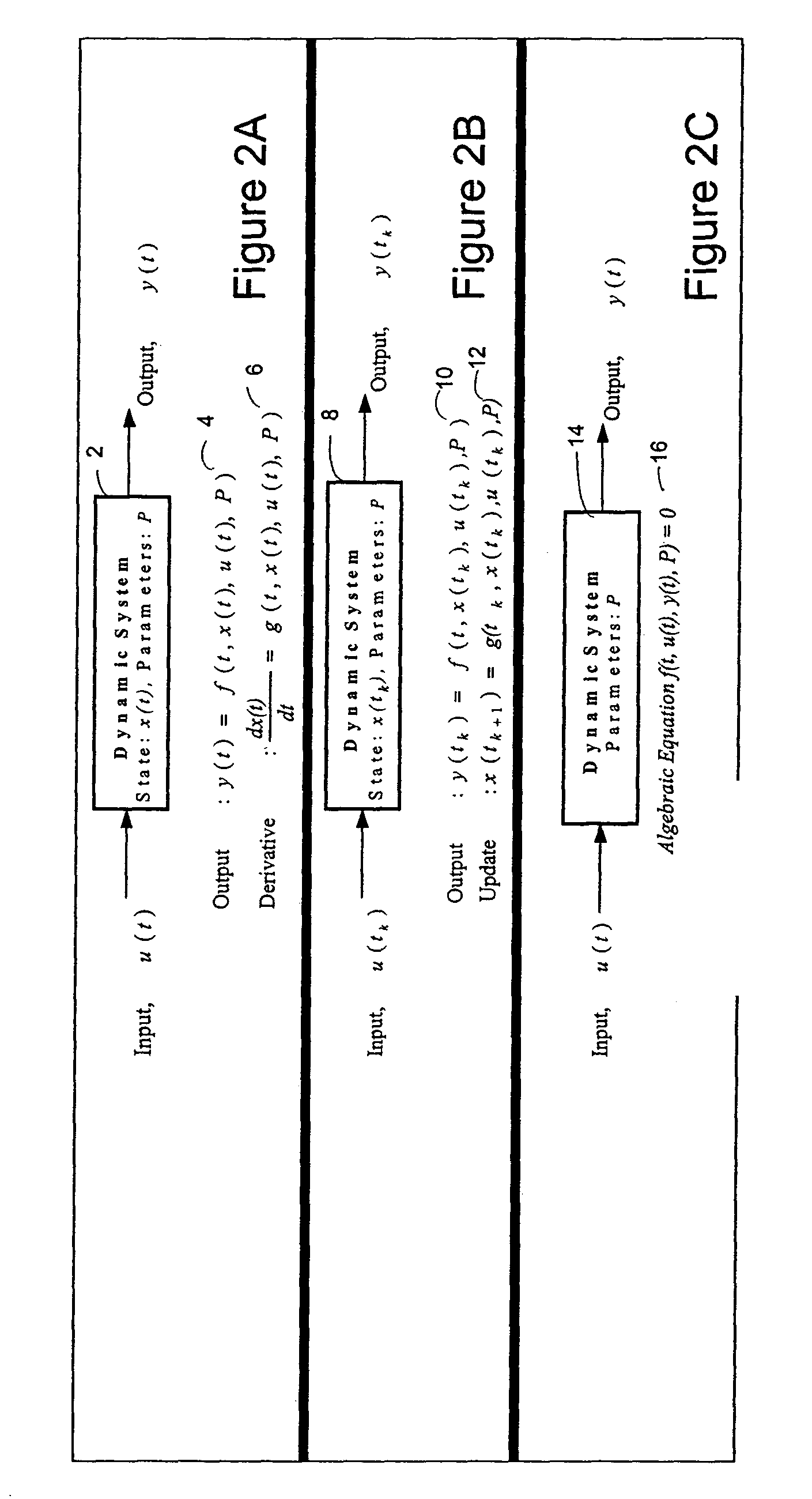

System for performing coupled finite analysis

ActiveUS7127380B1Stay flexibleAccelerated settlementComputation using non-denominational number representationDesign optimisation/simulationComputational scienceGraphics

A graphical user interface, together with a comparable scripting interface, couples a plurality of finite element, finite volume, or finite difference analytical programs and permits iterative convergence of multiple programs through one set of predefined commands. The user is permitted to select the joint problem for solution by choosing program selections. Data linkages that couple the program are predefined by an expert system administrator to permit less skilled modelers access to a comprehensive and multifaceted solution that would not be possible for the less skilled modelers to complete absent the graphical user interface.

Owner:NORTHROP GRUMMAN SYST CORP

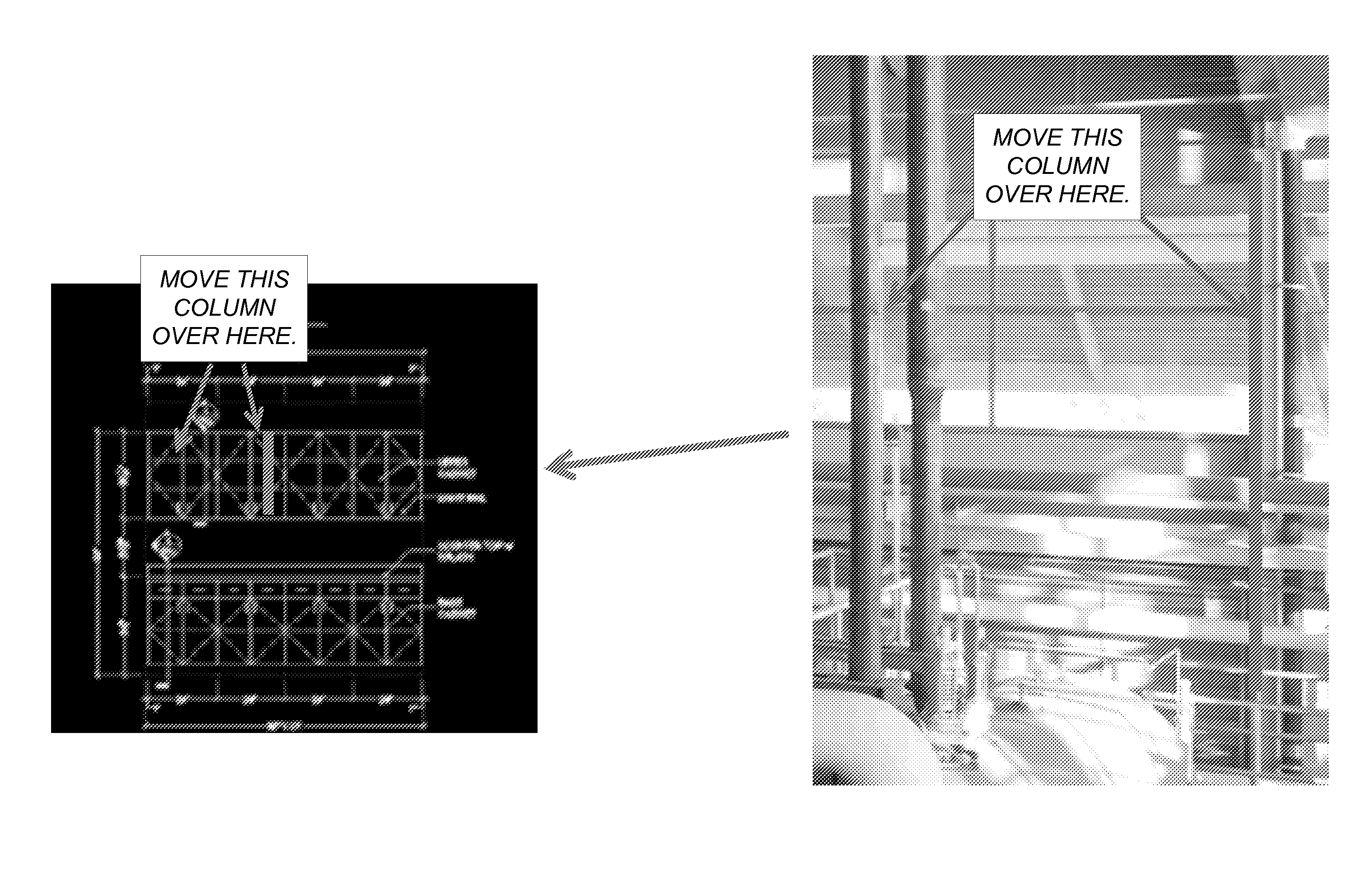

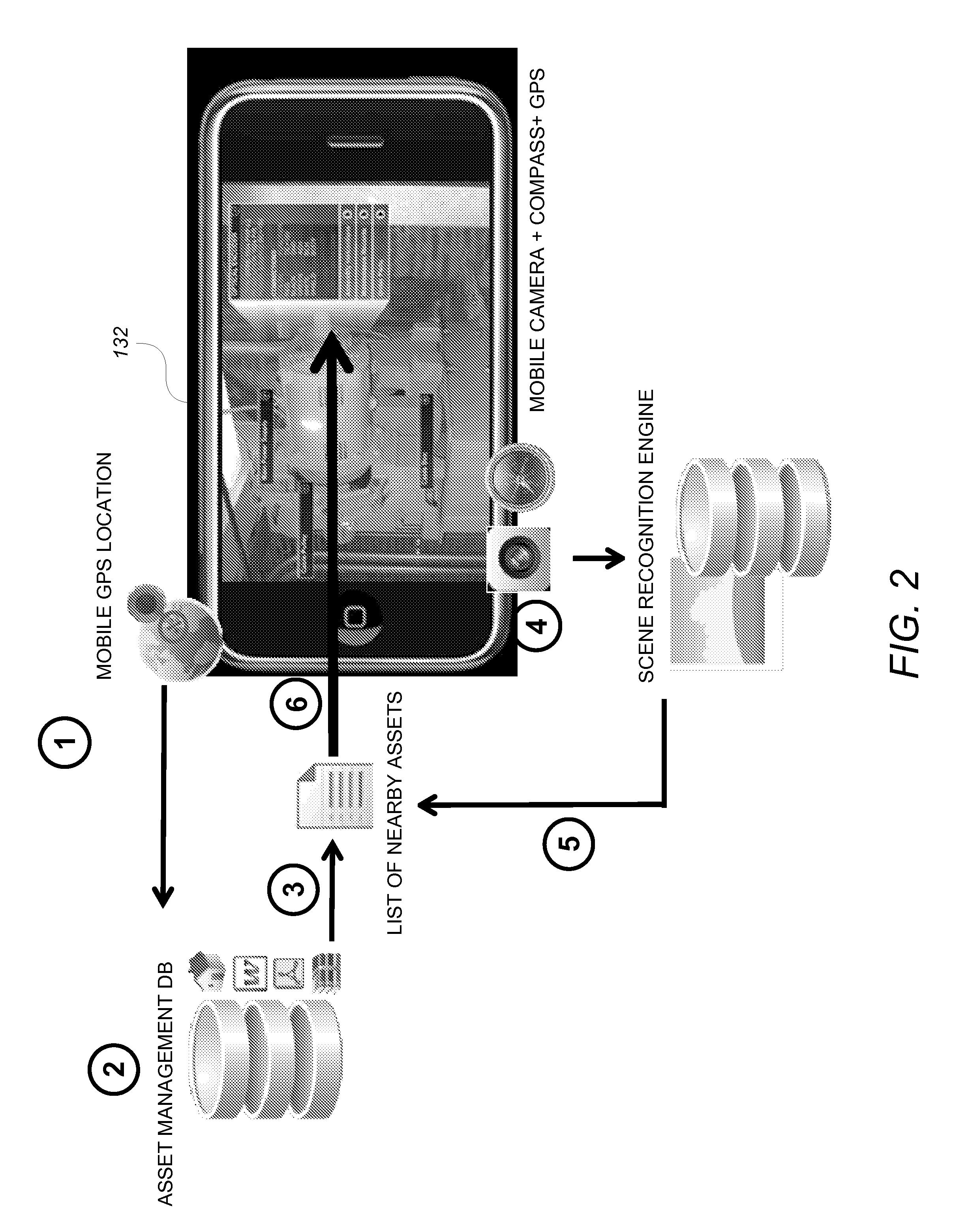

Click to accept as built modeling

A method, system, apparatus, and computer program product provide the ability to augment an as-built model. A CAD drawing of a project as well as a digital representation of a physical implementation of the project are obtained. A relationship that maps the digital representation to the CAD drawing is defined / established. A component of the digital representation is identified based on the relationship (e.g., and a database / catalog). Information about the identified component is transmitted to and displayed on a computer (e.g., a mobile device).

Owner:AUTODESK INC

System and method for enterprise modeling, optimization and control

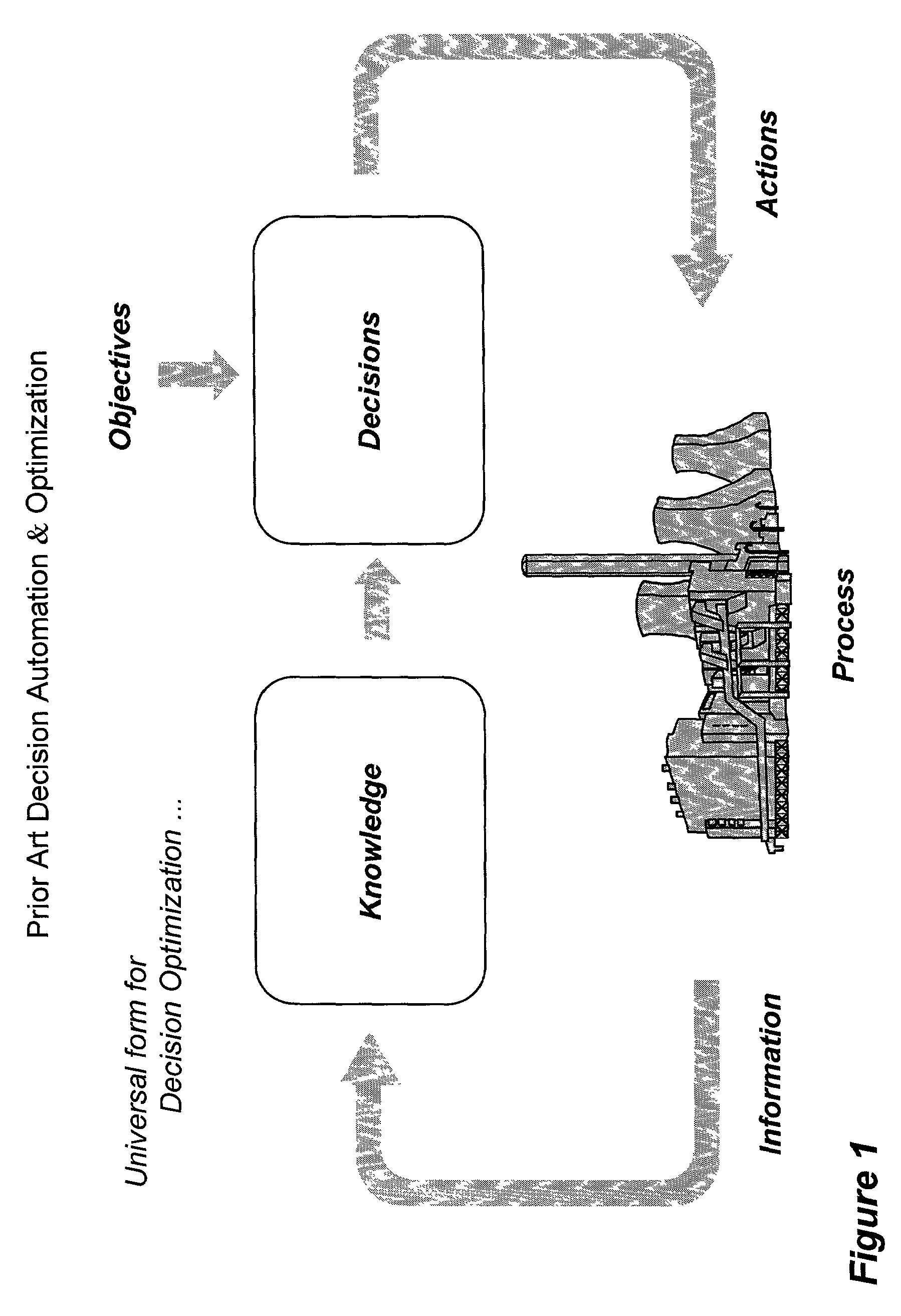

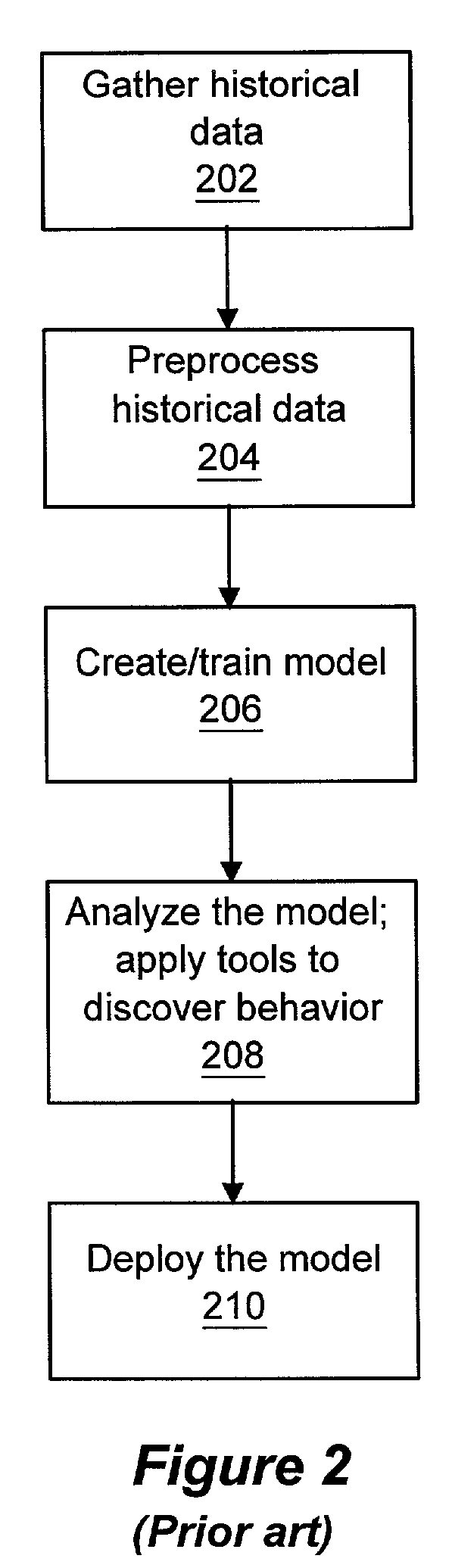

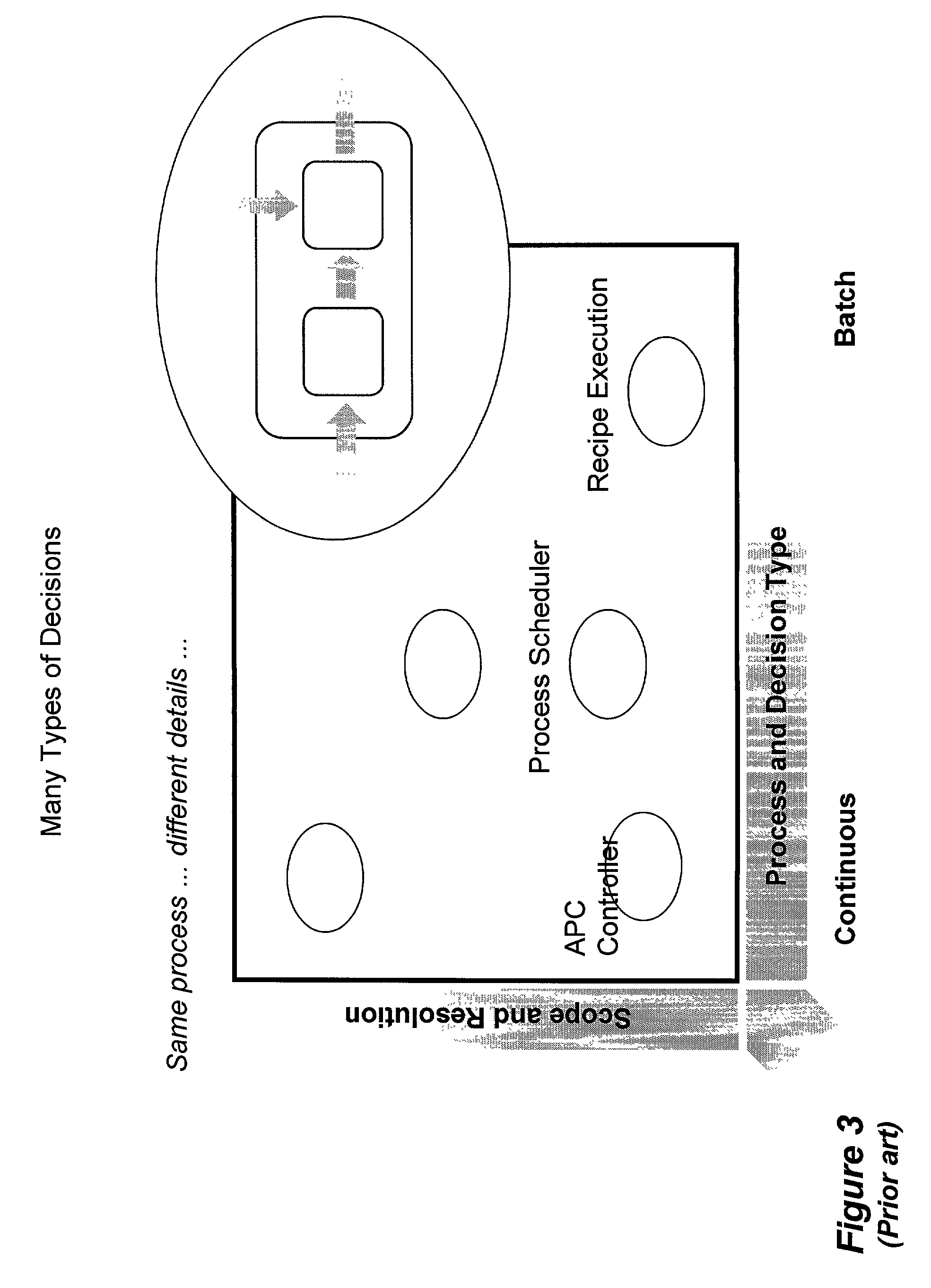

A system and method for performing modeling, prediction, optimization, and control, including an enterprise wide framework for constructing modeling, optimization, and control solutions. The framework includes a plurality of base classes that may be used to create primitive software objects. These objects may then be combined to create optimization and / or control solutions. The distributed event-driven component architecture allows much greater flexibility and power in creating, deploying, and modifying modeling, optimization and control solutions. The system also includes various techniques for performing improved modeling, optimization, and control, as well as improved scheduling and control. For example, the system may include a combination of batch and continuous processing frameworks, and a unified hybrid modeling framework which allows encapsulation and composition of different model types, such as first principles models and empirical models. The system further includes an integrated process scheduling solution referred to as process coordinator that seamlessly incorporates the capabilities of advanced control and execution into a real time event triggered optimal scheduling solution.

Owner:ROCKWELL AUTOMATION TECH

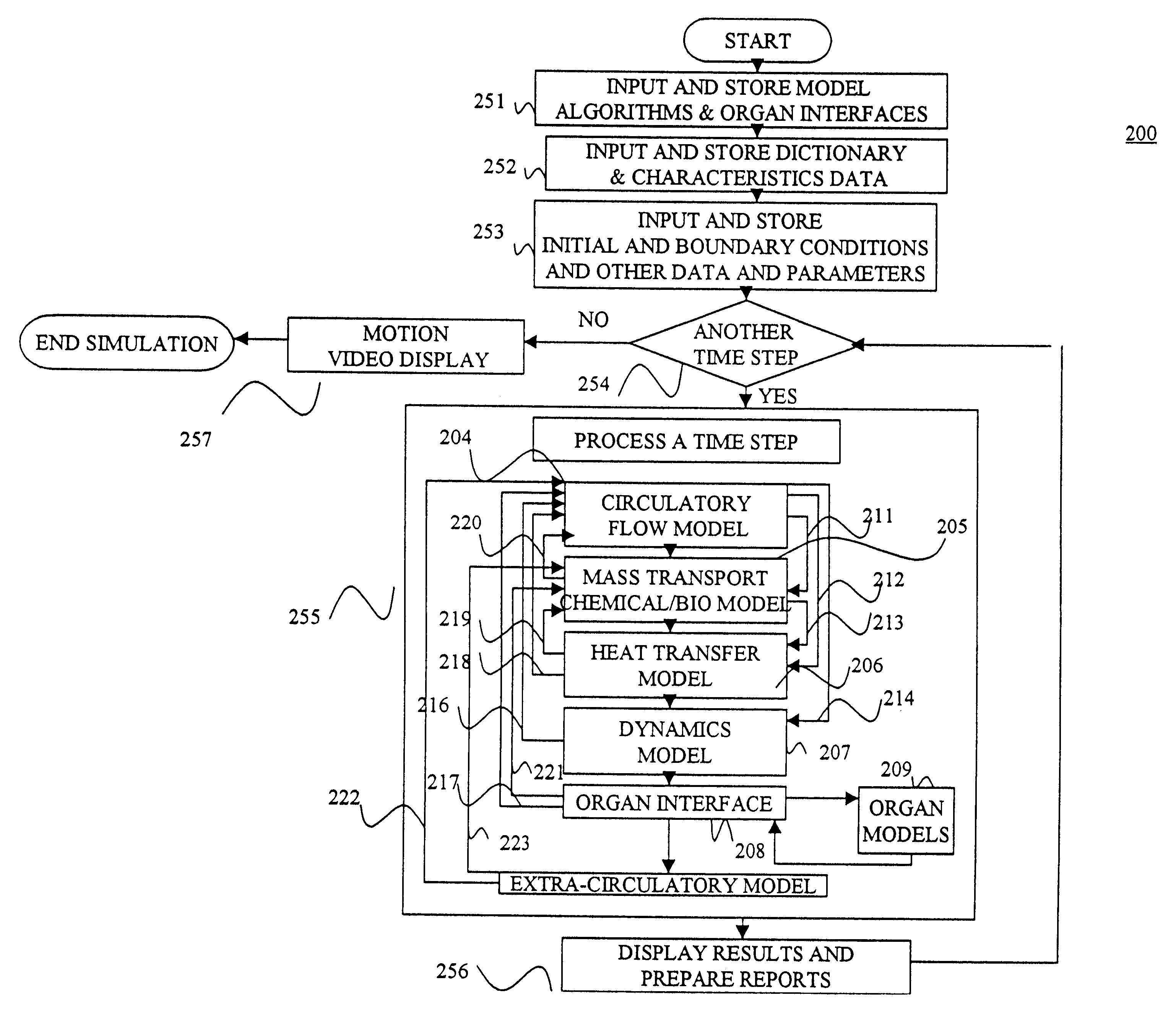

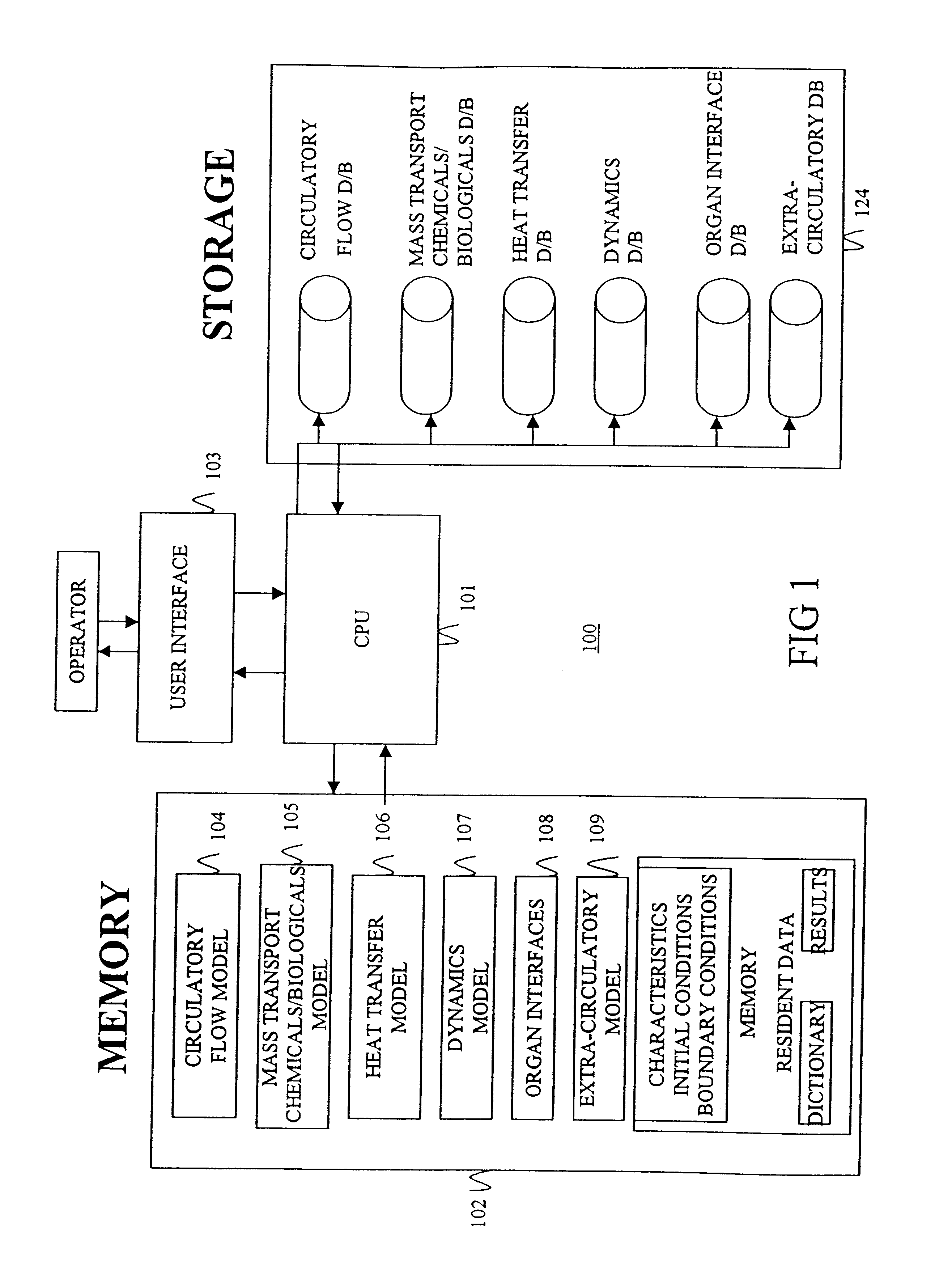

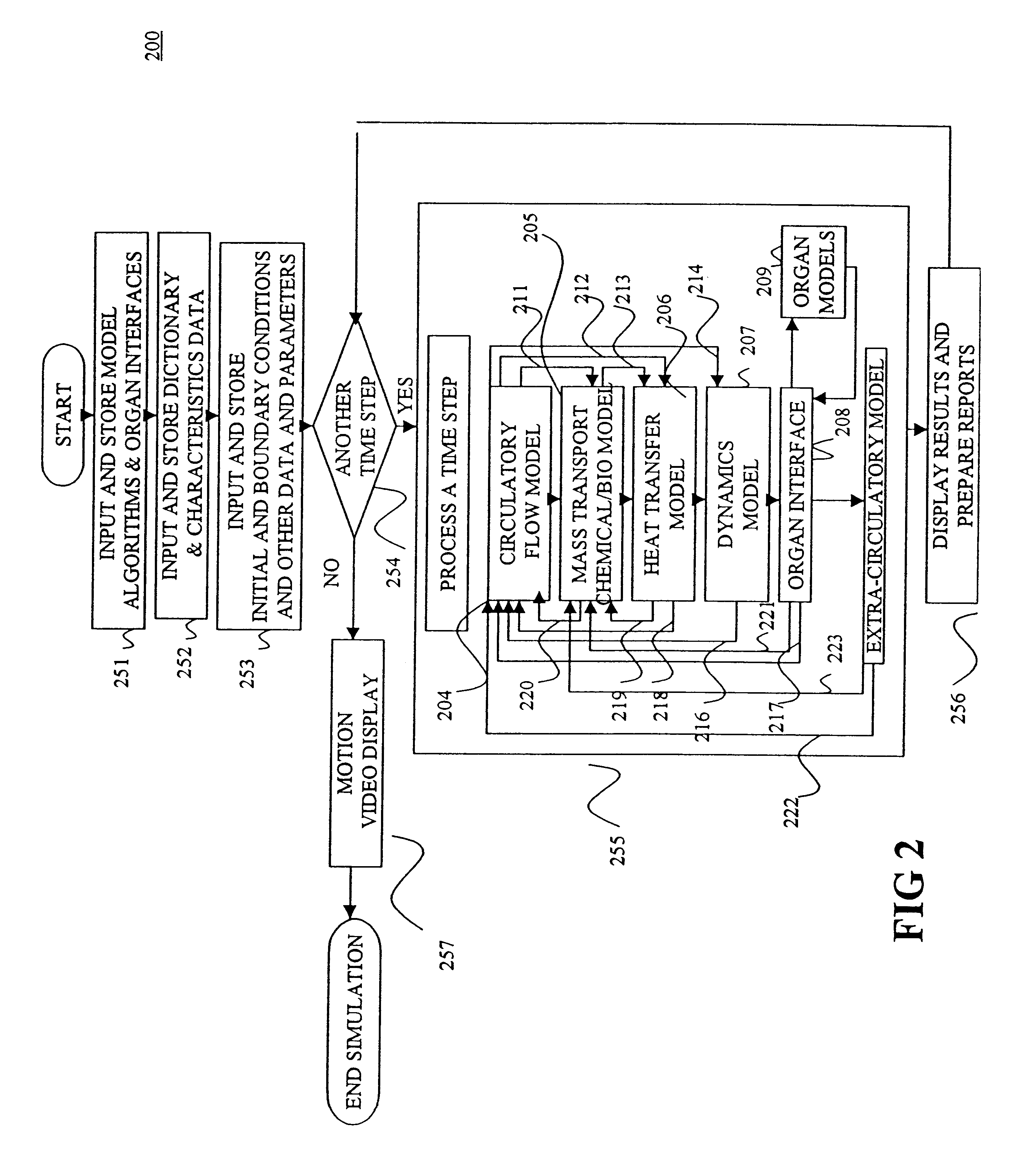

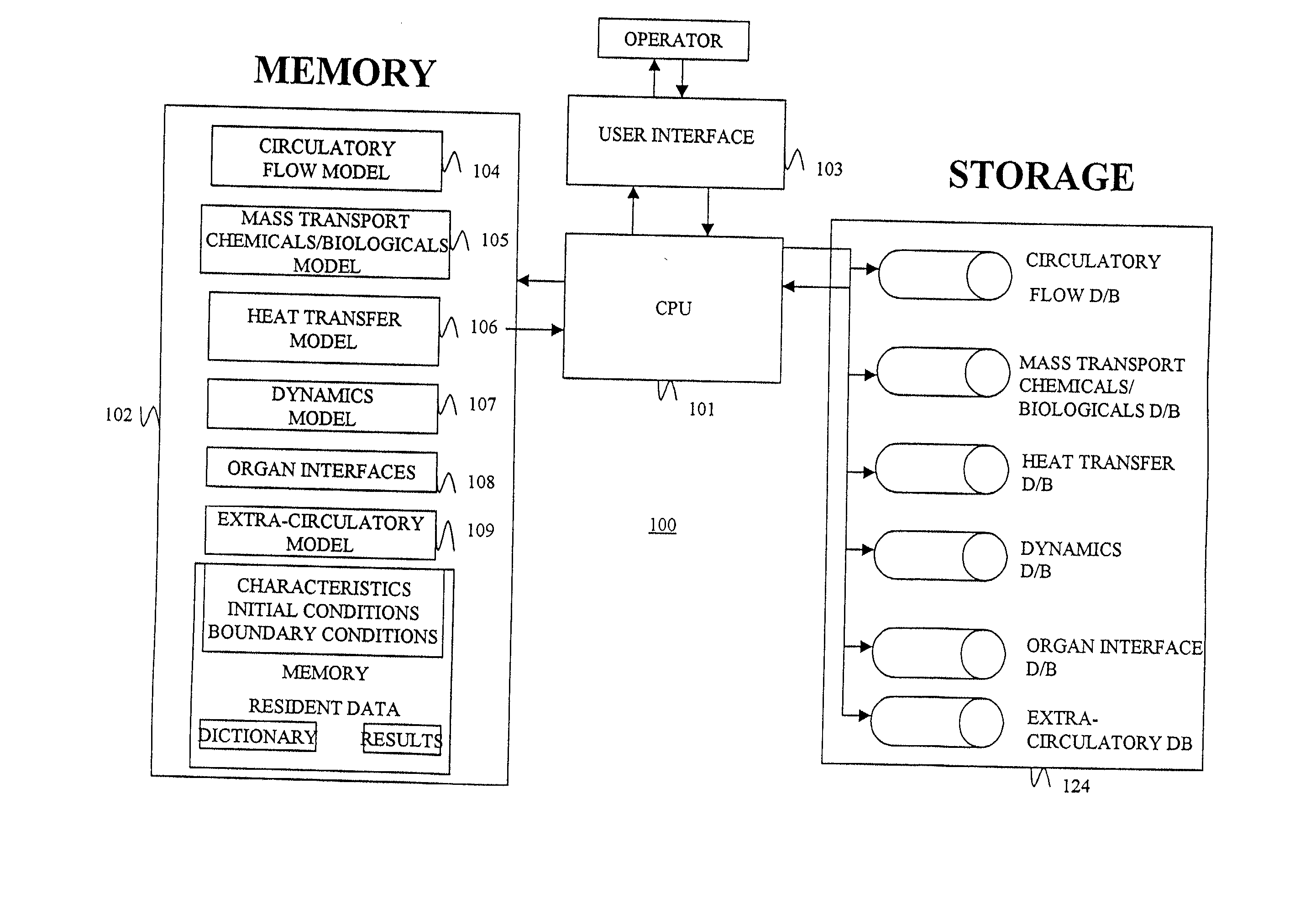

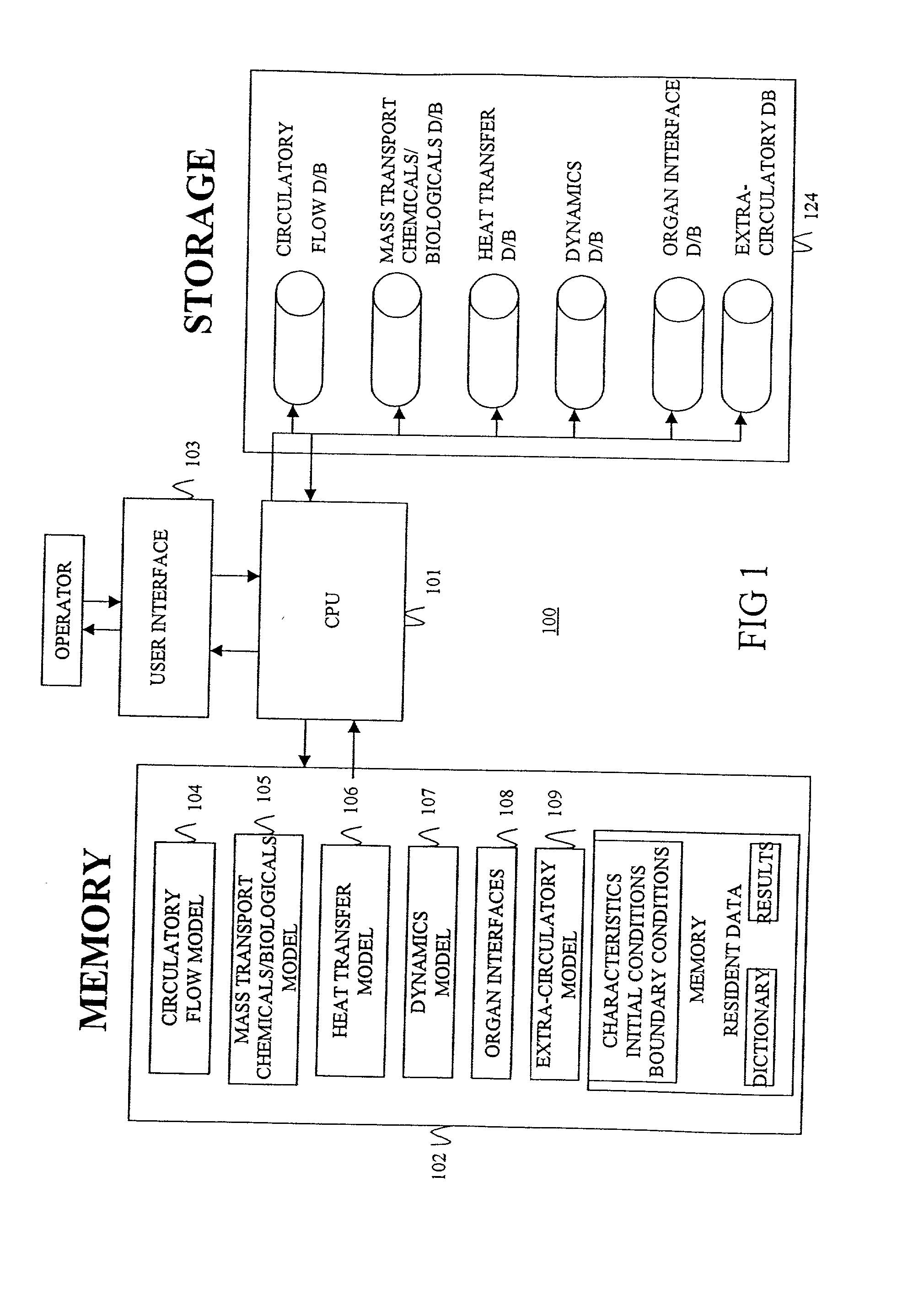

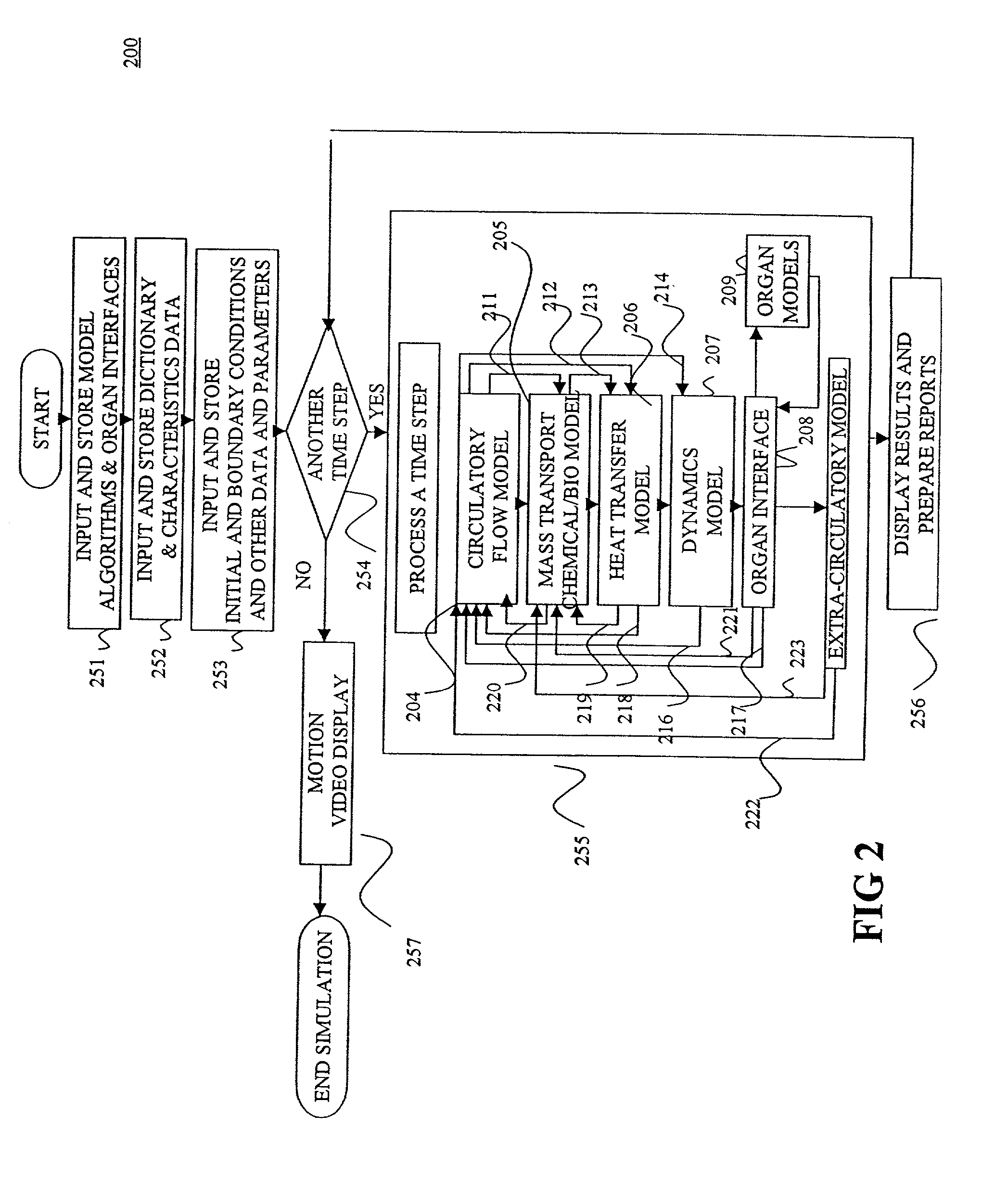

Configurable bio-transport system simulator

InactiveUS6381562B2Easy to customizeSave effortNanoinformaticsAnalogue computers for chemical processesComputational scienceBiological body

A method of simulating a bio-transport system comprising: (a) characterizing one or more elements to represent a bio-transport system of an organism or a portion thereof; (b) constructing one or more mathematical representations that model one or more bio-transport dynamics for each element based on the characterization of the elements to form a configured simulation model; (c) initializing the configured simulation model; (d) executing the configured simulation model to obtain bio-transport dynamics data for one or more elements; and (e) outputting information to a user based on at least a portion of the bio-transport dynamics data.

Owner:KEANE JOHN A

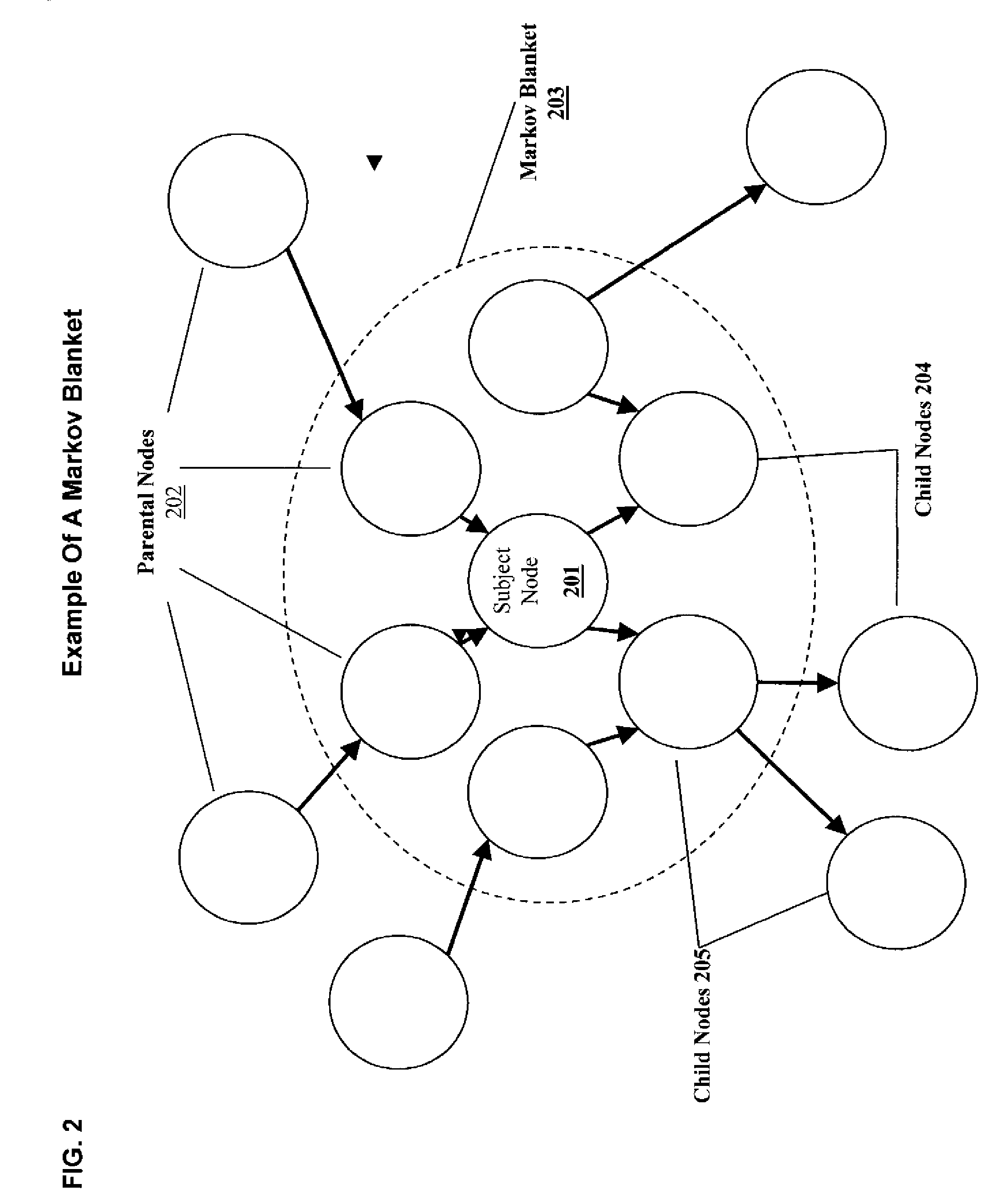

Extensible bayesian network editor with inferencing capabilities

A system for the representation, editing, evaluation, and inference of graphical models is disclosed which can be used to construct and evaluate a graphical model or graphical network and to calculate inference values. An efficient method of updating graphical models is demonstrated, and provides the basis for an improved system for manipulation and evaluation of probabilistic models. The graphical network editor is useful in the construction of graphical modes such as Bayesian Networks. The graphical network and network graphical user interface (GUI) are used in conjunction with each other to model a system wherein failure probabilities and the current state of components are taken into account to monitor the health and progress of a system for an engineer or engineering software to evaluate and monitor. The evaluation is useful in the monitoring of assets and other real systems having multiple, dependent, and independently operating components such as a pump, a manufacturing plant, a production line, an assembly line, where asset health and quality control is a concern. The asset components each influencing some overall outcome of a system or situation. Success or failure or probability of success, probability of failure and health of the system can be monitored and manipulated by altering the values of prior probability and posterior probability values. Failure correlation between components can be evaluated wherein failure rates of asset is unknown. Production and quality can be monitored and altered.

Owner:QUANTUM LEAP RES

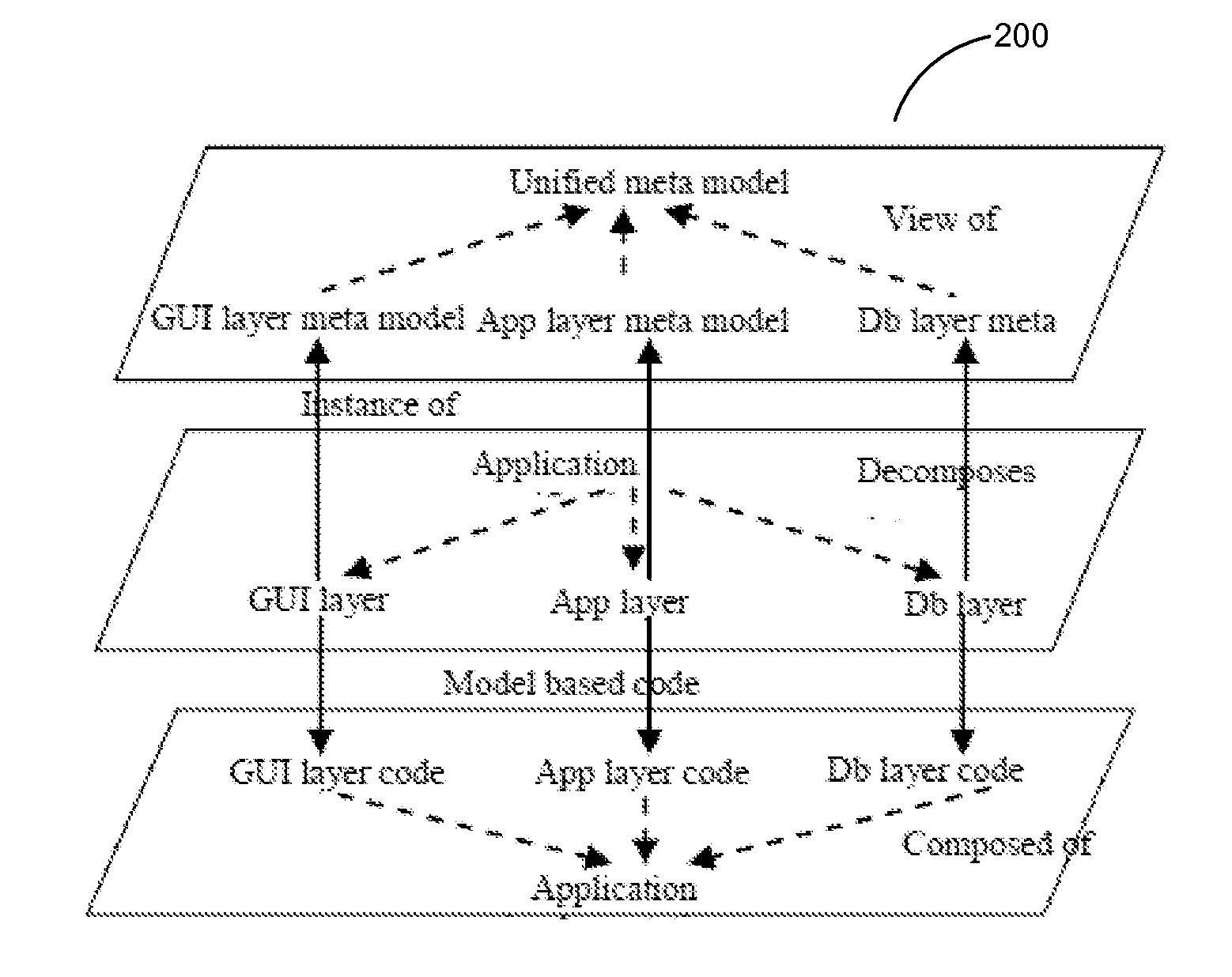

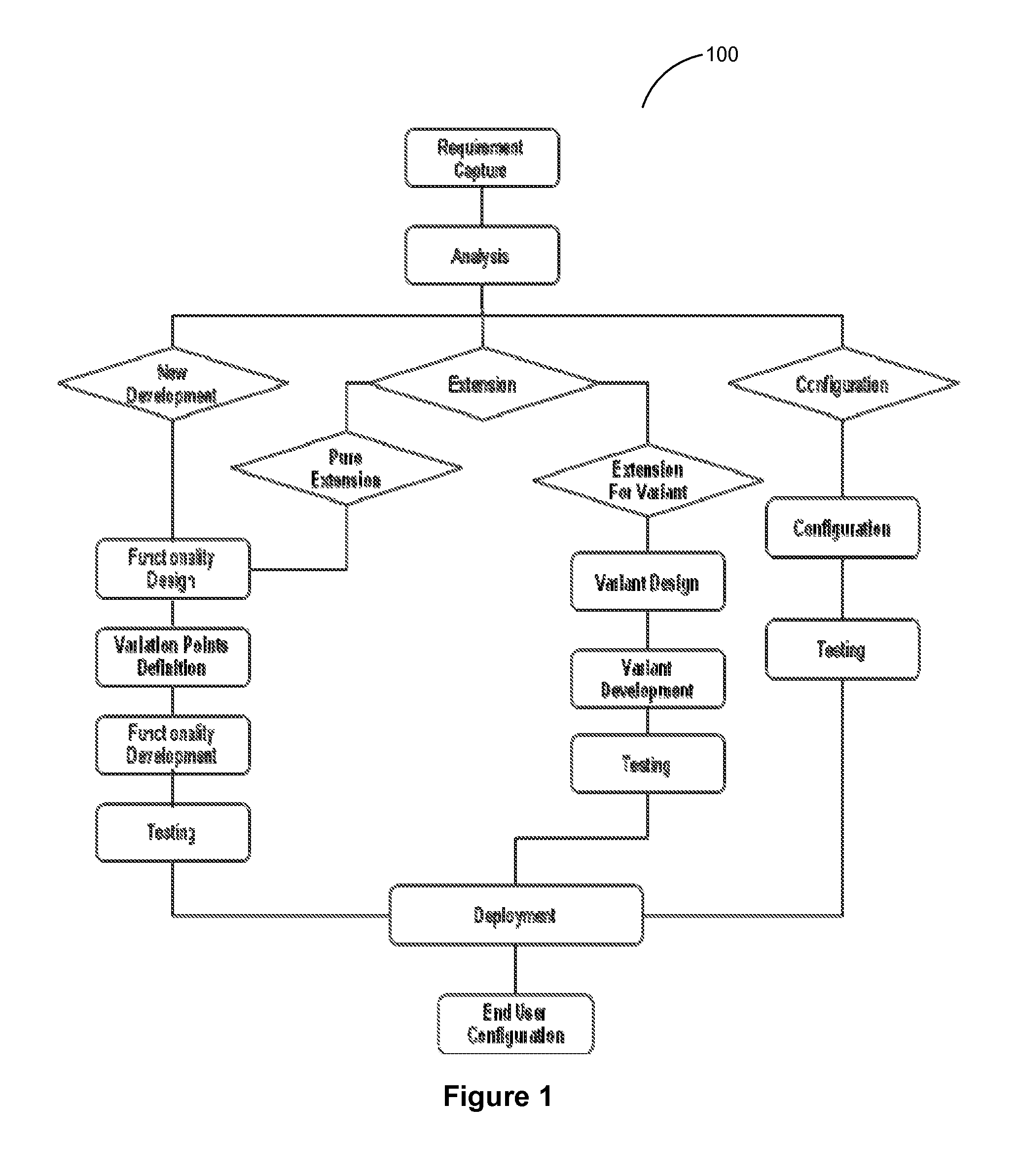

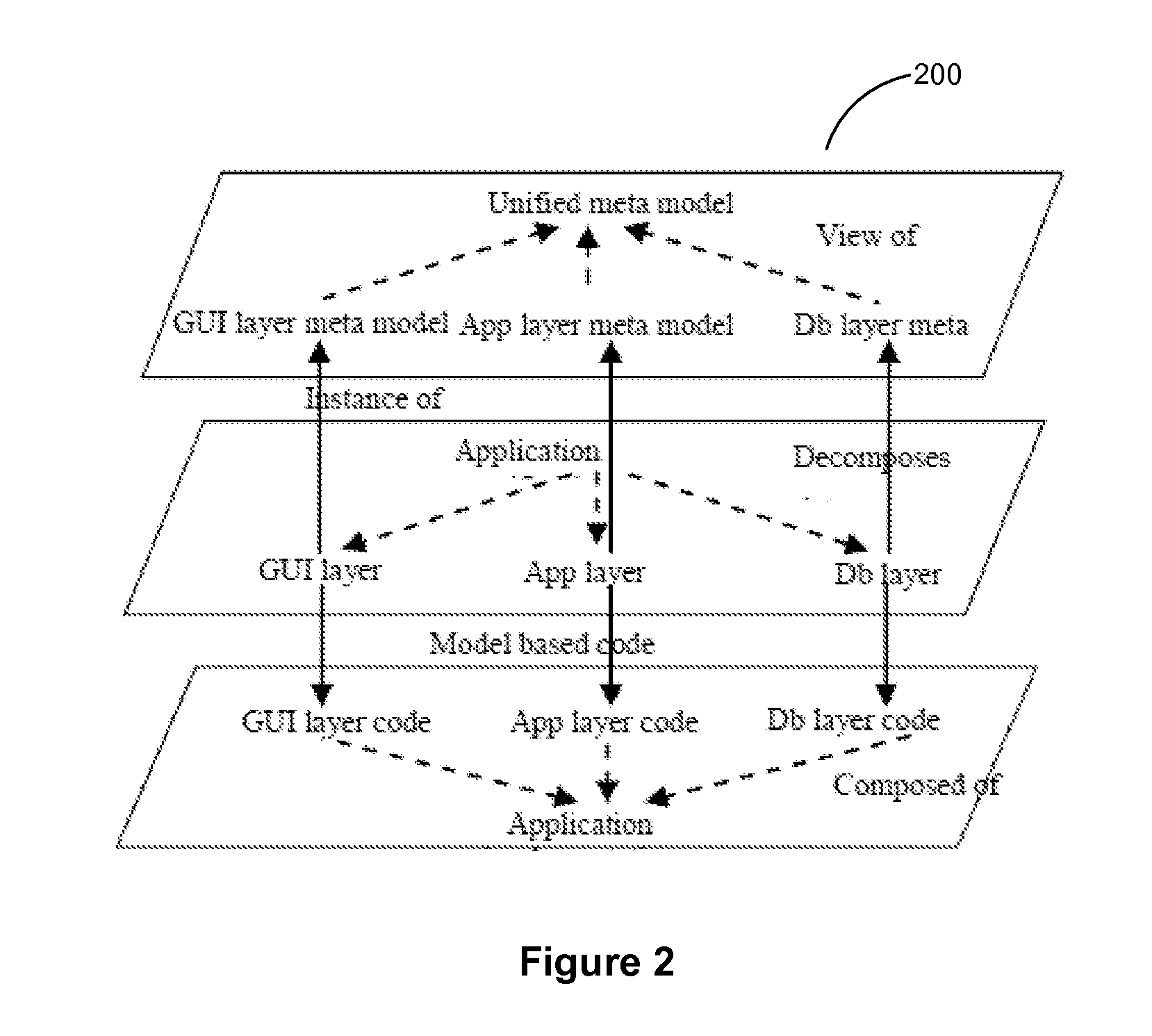

Computationally efficient system for developing configurable, extensible business application product lines using model-driven techniques

ActiveUS20120102451A1Address extensibilityAddress configurabilitySoftware designSpecific program execution arrangementsProduction lineExtensibility

The present invention provides a computationally efficient system for developing configurable, extensible business application product lines using model-driven techniques. The invention enables to create a common business application with a set of pre-defined variants, selection of a suitable variant from the pre-defined set, and composition of the common application with the selected variant into a purpose-specific business application and also provides for modeling of commonality and variability thus leading to a single specification. The invention provides model-based solution to address extensibility and configurability of both structural and behavioral aspects in a functionality dimension of database intensive business application and it supports configuration process at three different stages of application development (i.e. design time, installation time and run time) of database intensive business application. The invention reduces the cost as well as computational time for creating new business applications, and leads to effective maintenance and smooth evolution.

Owner:TATA CONSULTANCY SERVICES LTD

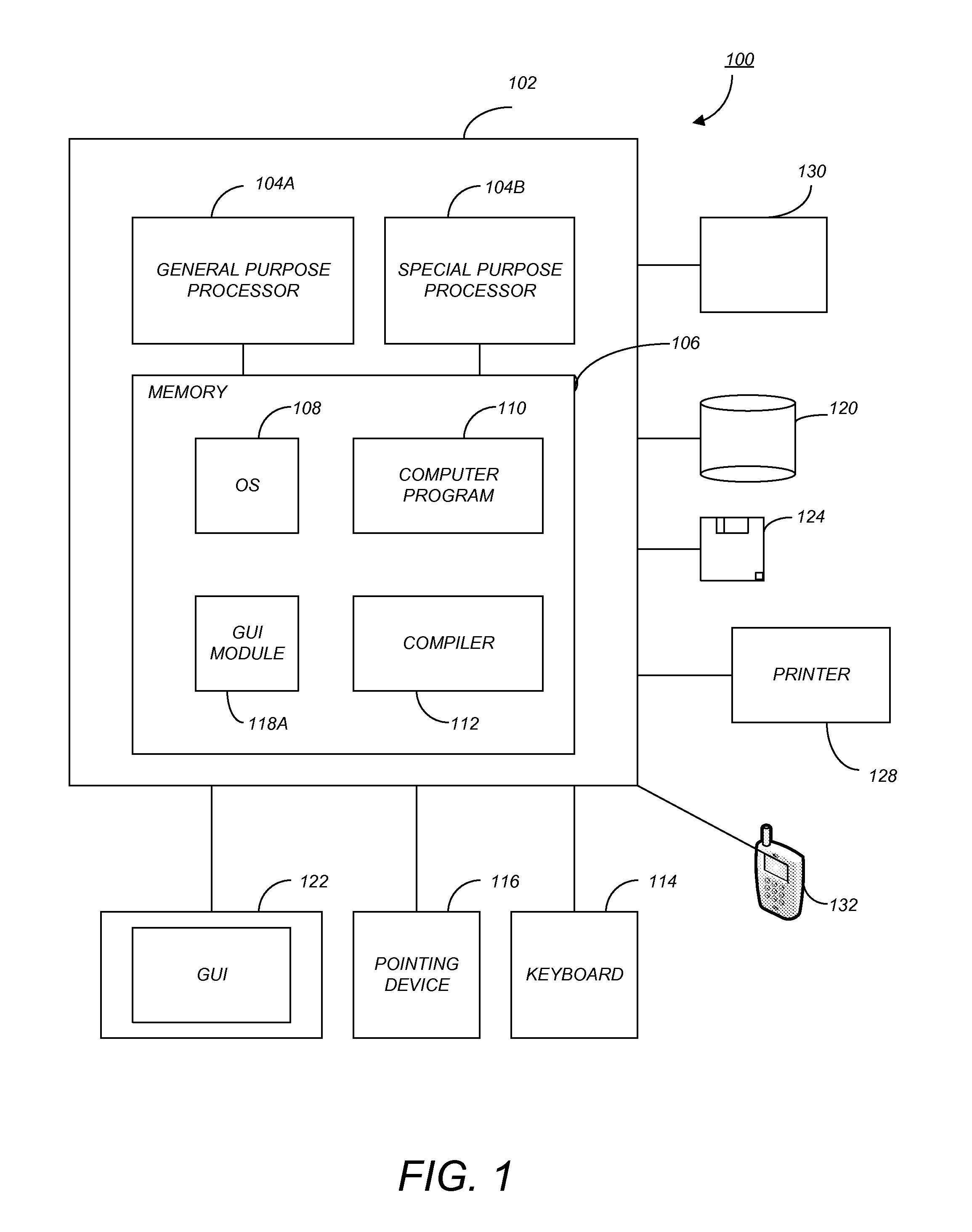

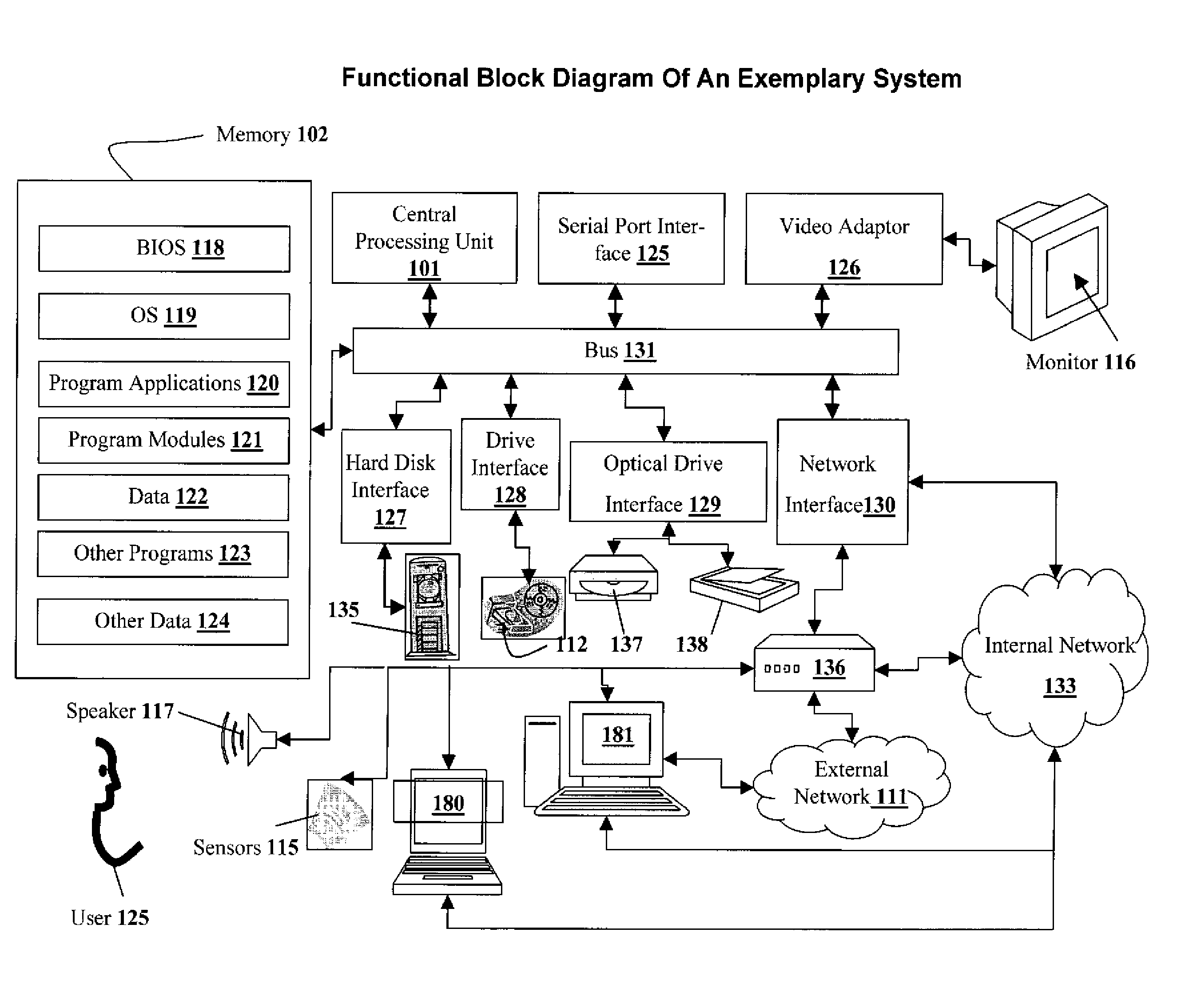

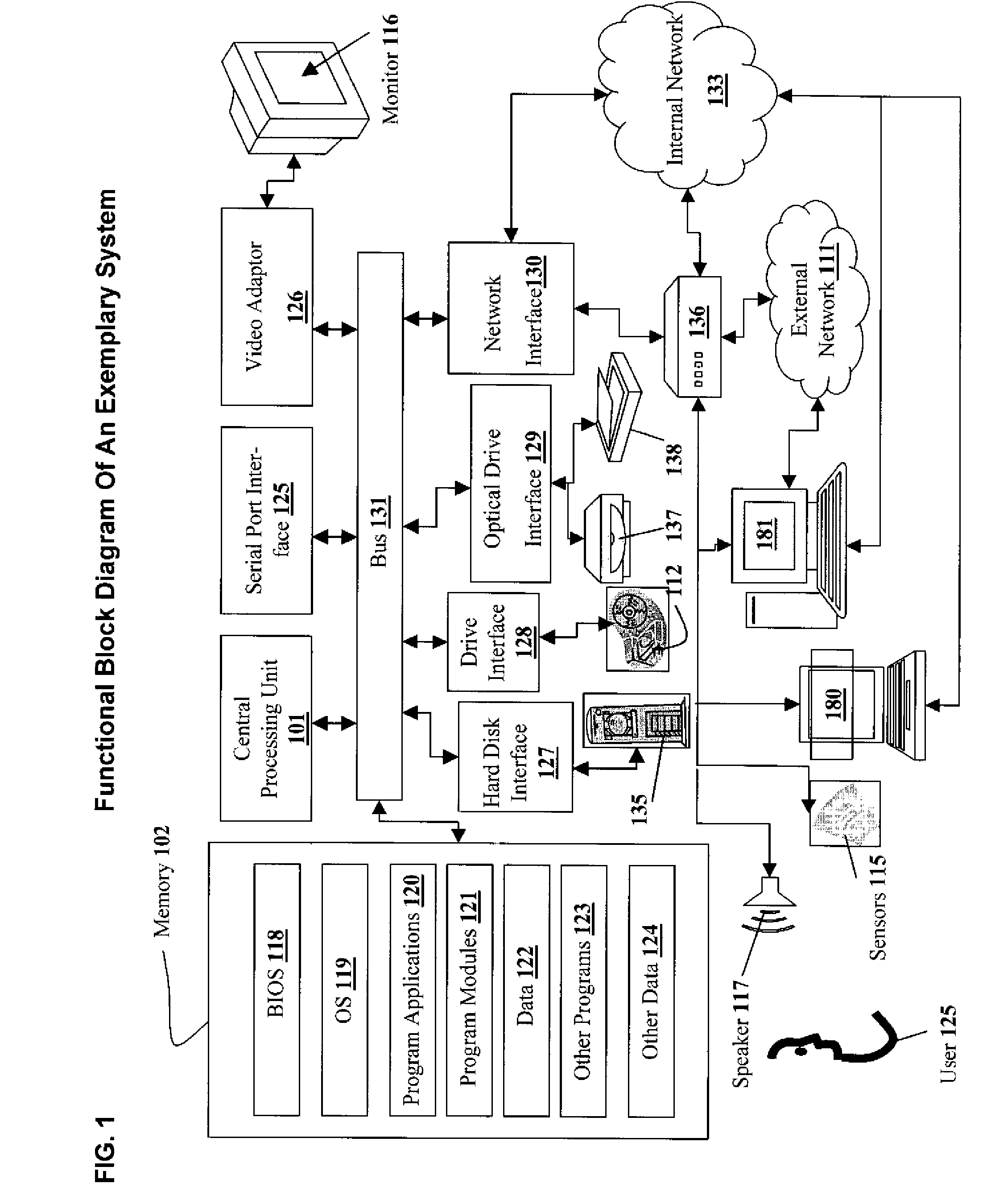

Remote High-Performance Computing Material Joining and Material Forming Modeling System and Method

InactiveUS20100121472A1Arc welding apparatusAnalogue computers for control systemsPerformance computingModelSim

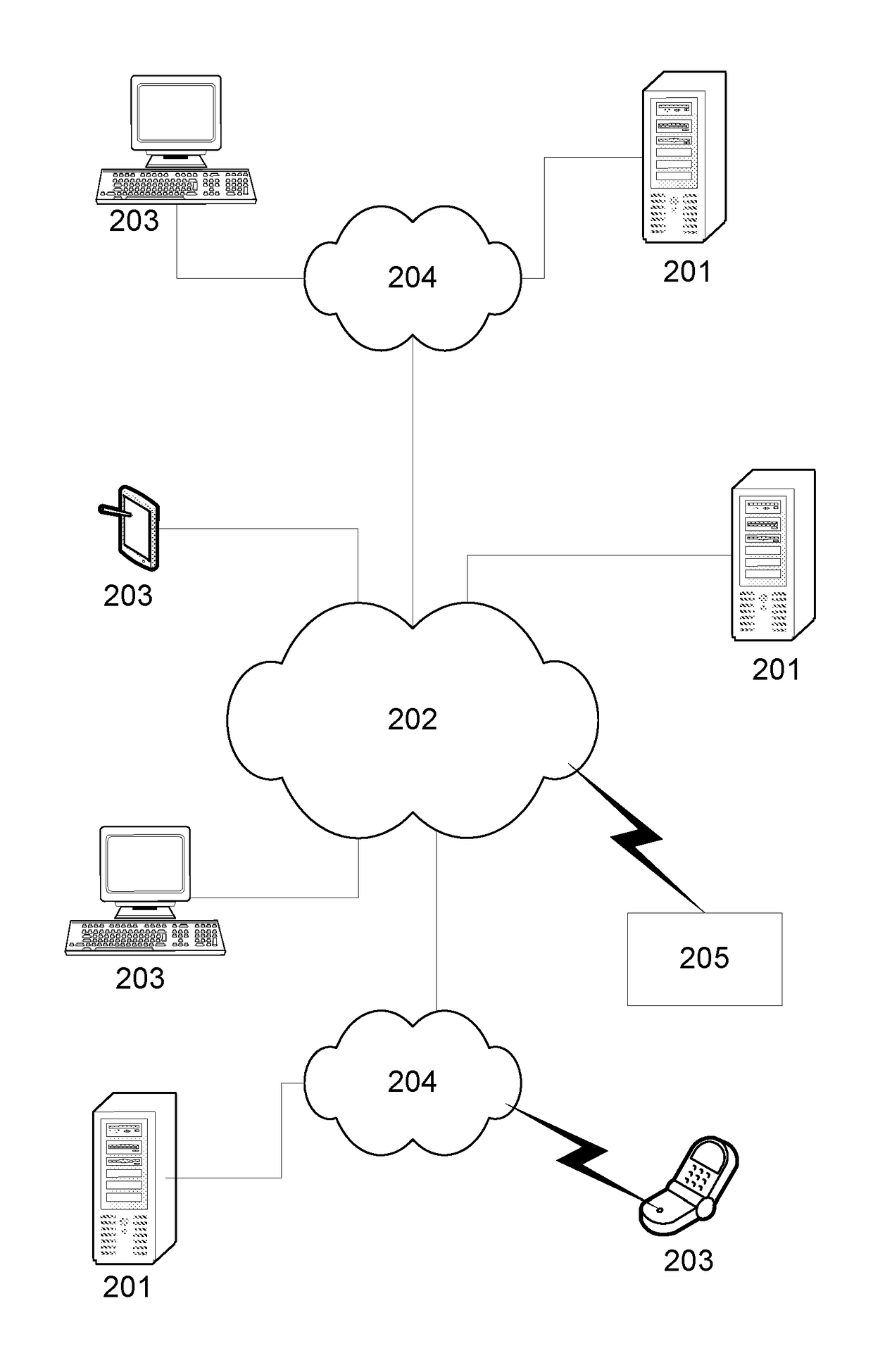

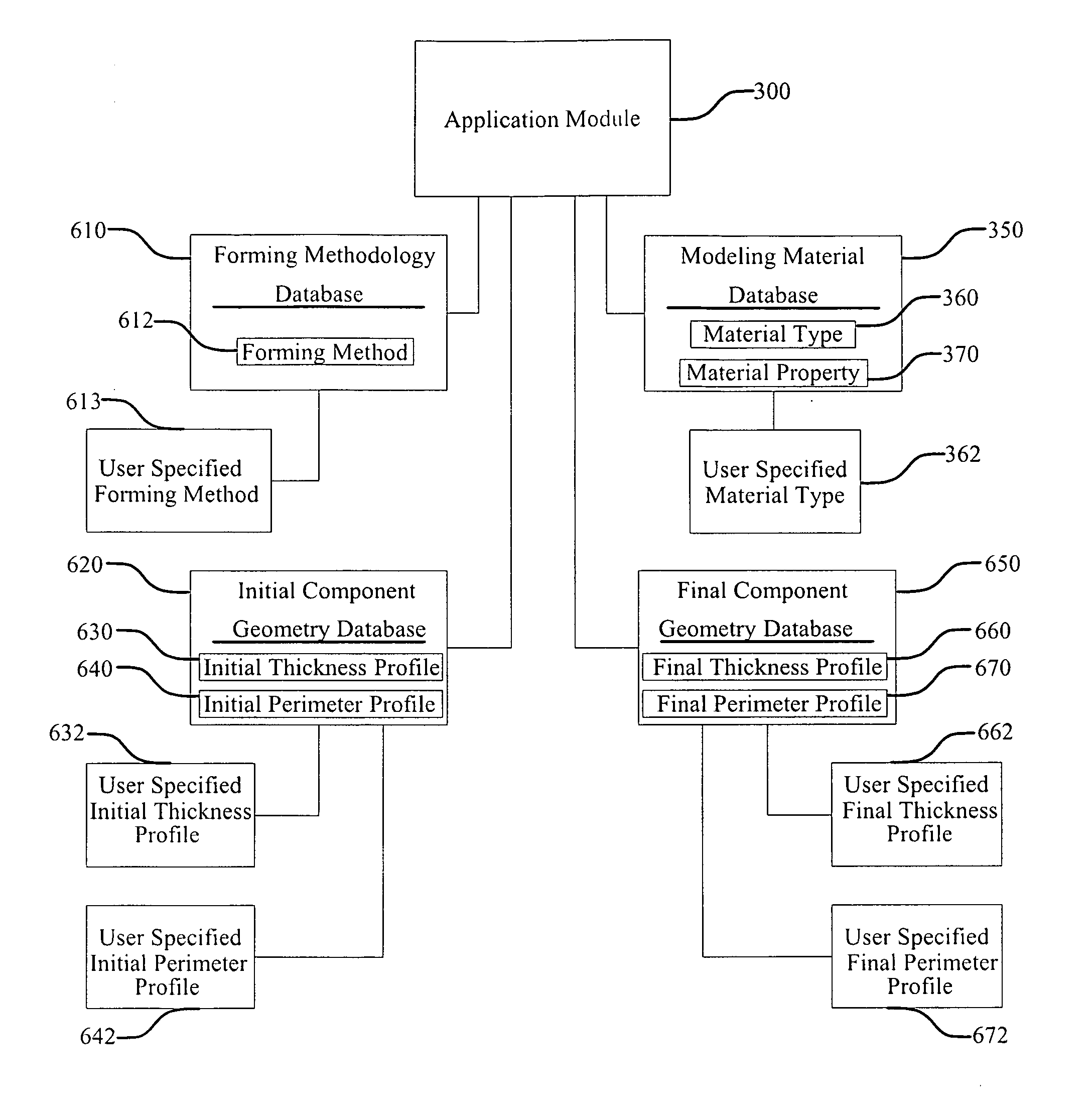

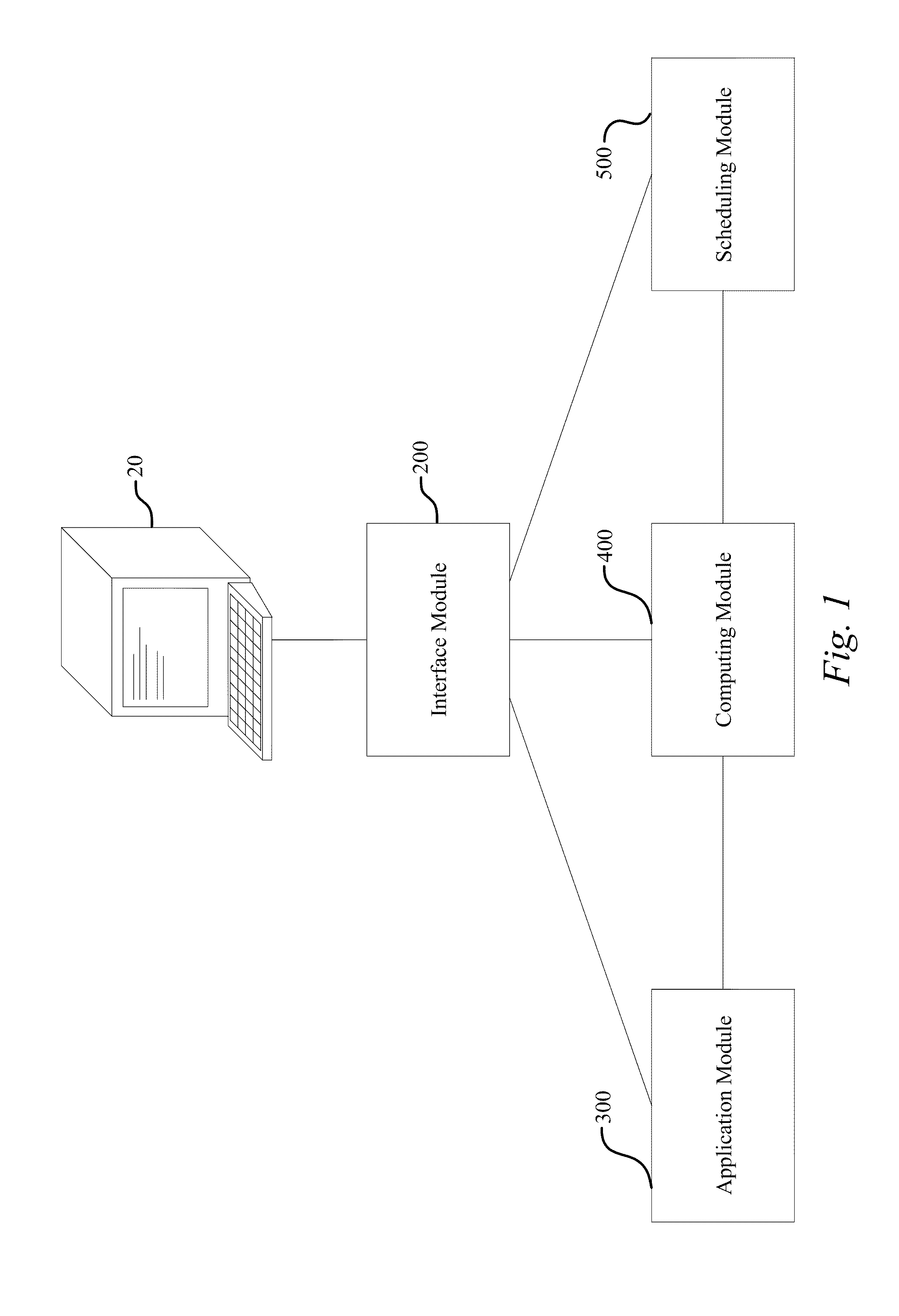

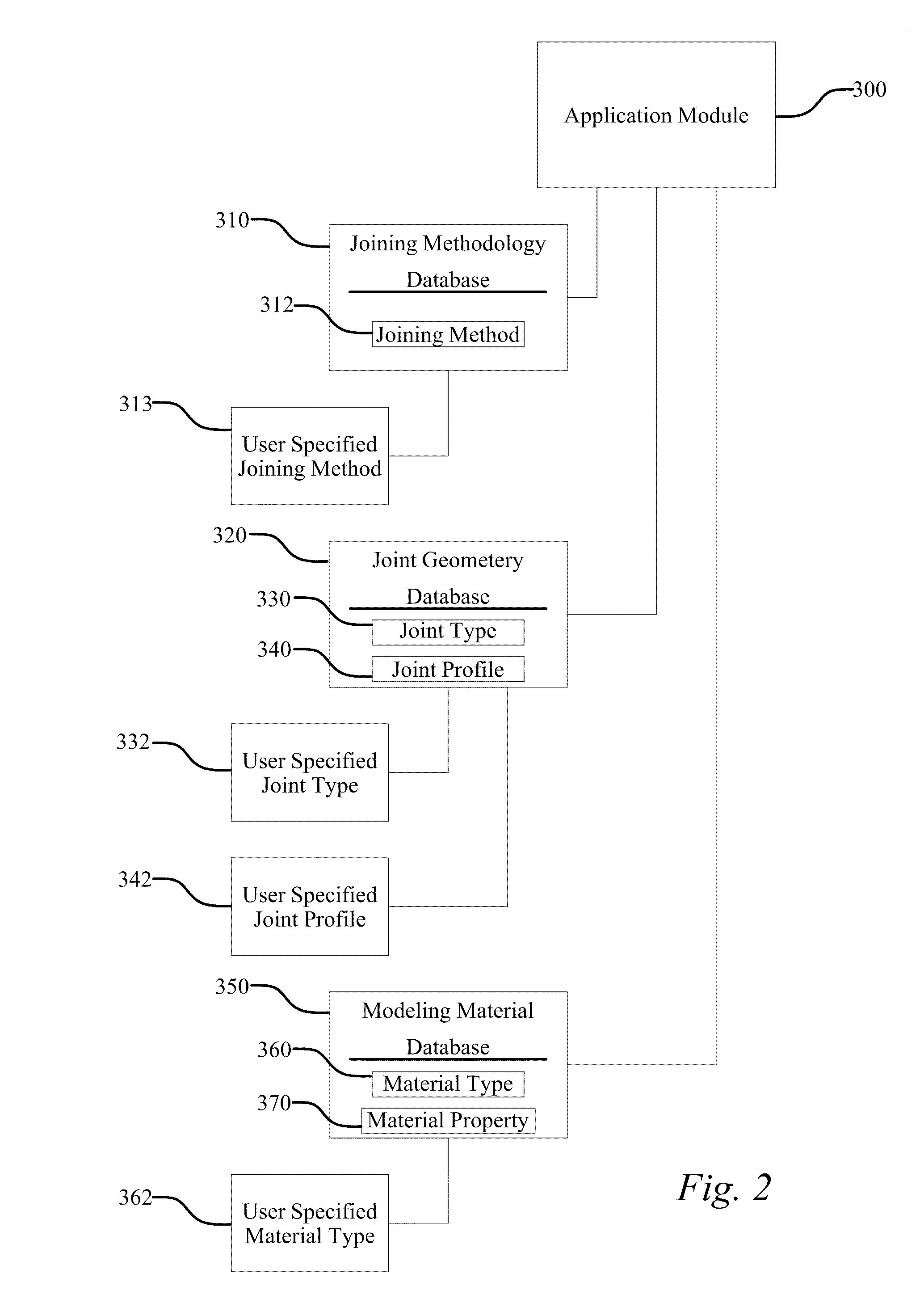

A remote high-performance computing material joining and material forming modeling system (100) enables a remote user (10) using a user input device (20) to use high speed computing capabilities to model materials joining and material forming processes. The modeling system (100) includes an interface module (200), an application module (300), a computing module (400), and a scheduling module (500). The interface module (200) is in operative communication with the user input device (20), as well as the application module (300), the computing module (400), and the scheduling module (500). The application module (300) is in operative communication with the interface module (200) and the computing module (400). The scheduling module (500) is in operative communication with the interface module (200) and the computing module (400). Lastly, the computing module (400) is in operative communication with the interface module (200), the application module (300), and the scheduling module (500).

Owner:EDISON WELDING INSTITUTE INC

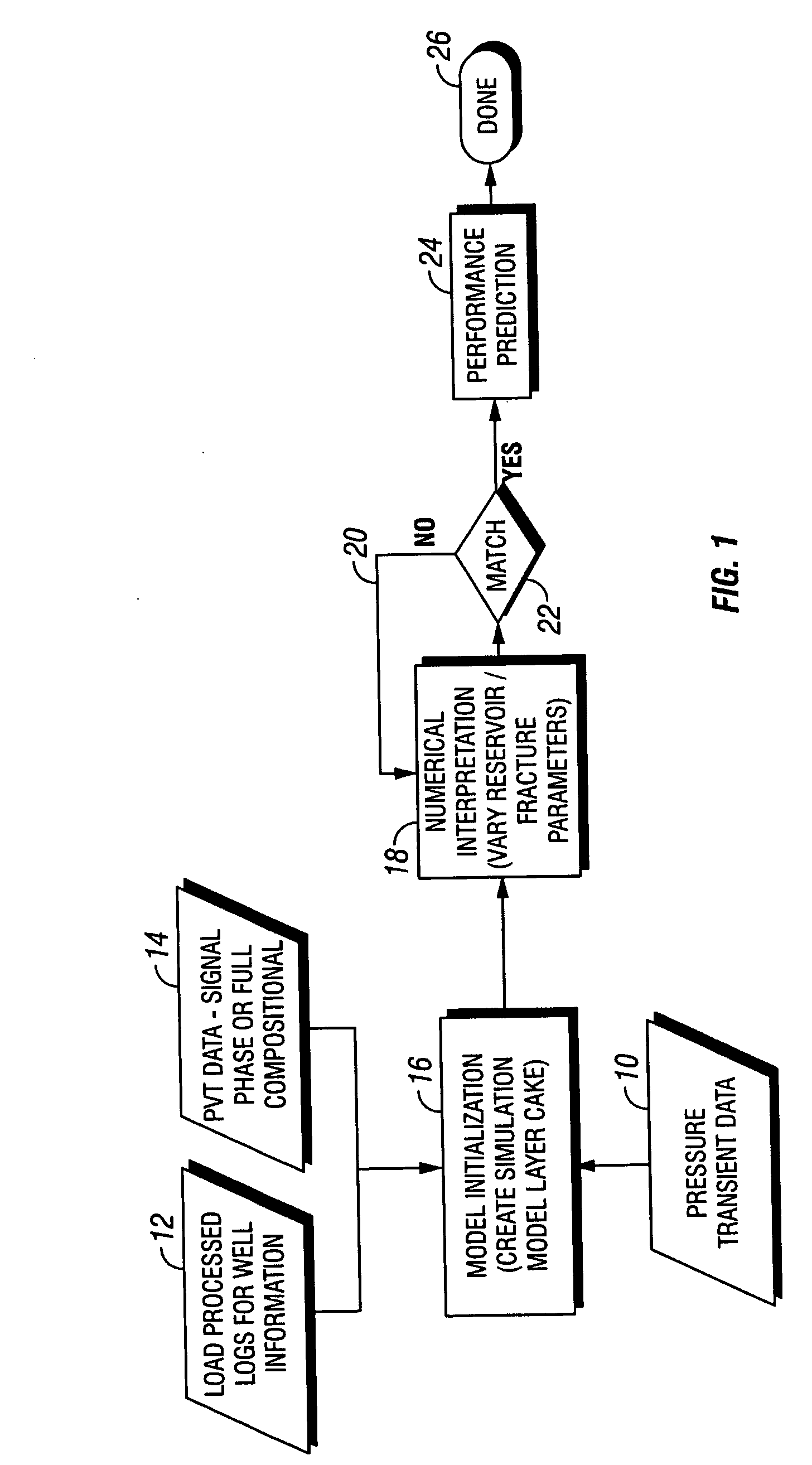

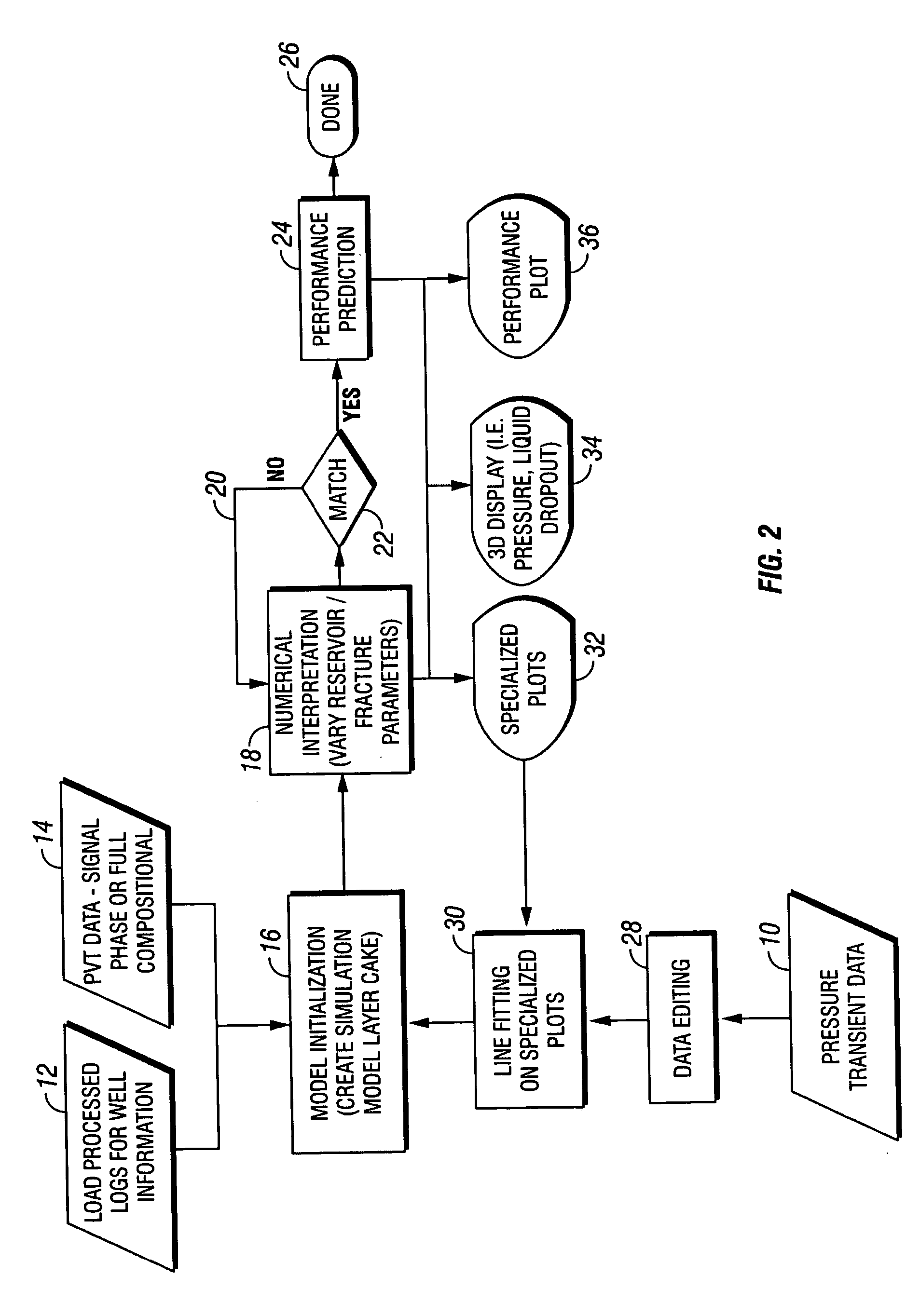

Method for simulation modeling of well fracturing

InactiveUS20060015310A1Reduce ambiguityRemove noiseGeometric CADFluid removalWell loggingModel system

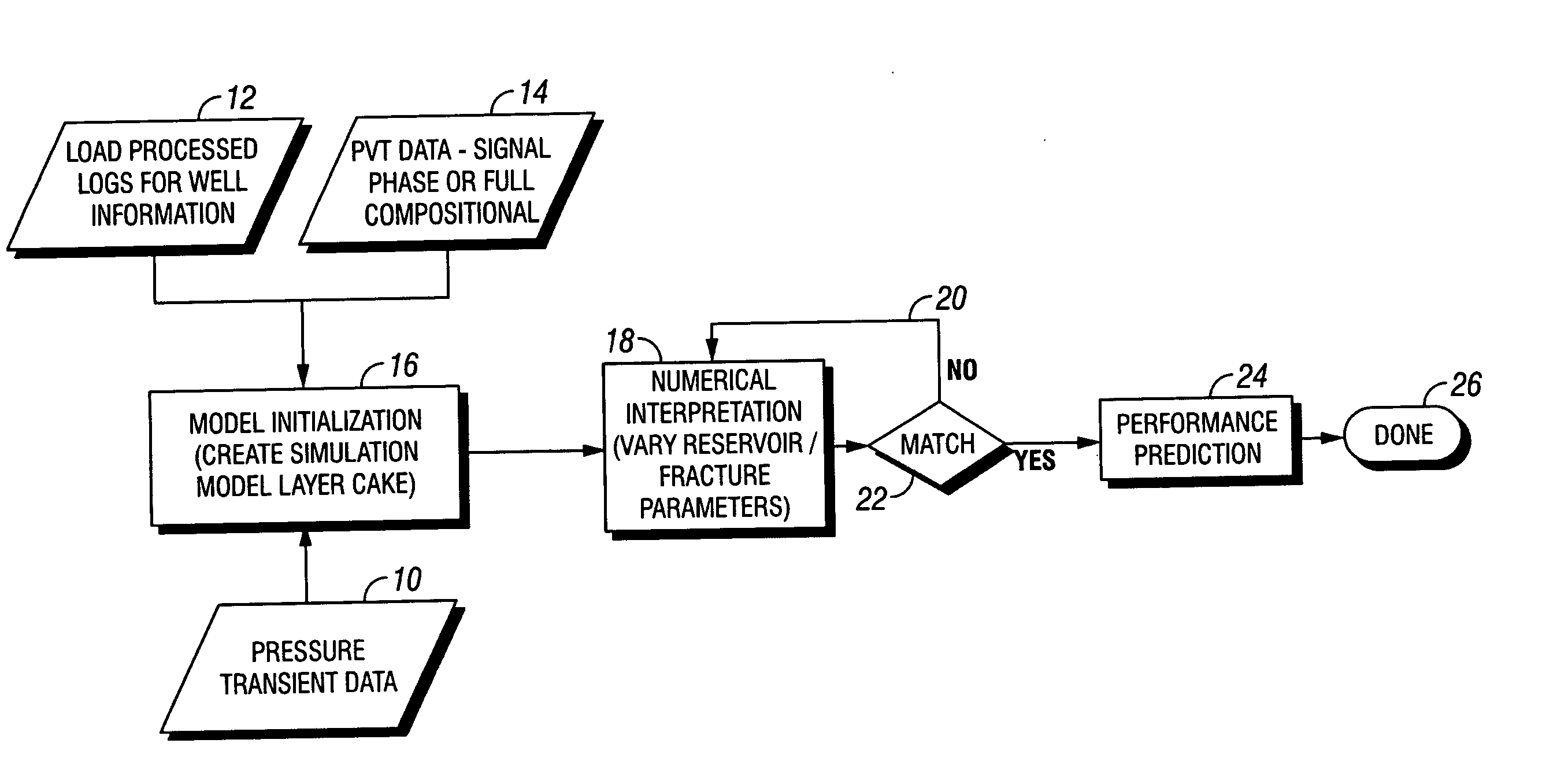

A model system for simulating the performance of a subterranean well, starts with a base model wherein input logging data, pressure transient data and PVT data is introduced into the base model. A numerical interpreter then calculates the predicted performance of the well. A match system compares actual performance data with calculated performance data based on the base model through reiterative loop for modifying the base model to provide a match between the actual performance data and the predicted performance data to optimize the base model. The method for generating the optimized performance data in accordance with the subject invention incorporates the steps of introducing known pressure transient data, well logging data and PVT data for the well into a base model and producing a performance prediction from the base model. These results are compared with actual performance data and the model is modified to generate a performance prediction that matches the actual performance for producing an optimized model. The method is particularly useful because it accounts for and adjusts the performance prediction based on non-Darcy factors effecting the fluid parameters in the well.

Owner:SCHLUMBERGER TECH CORP

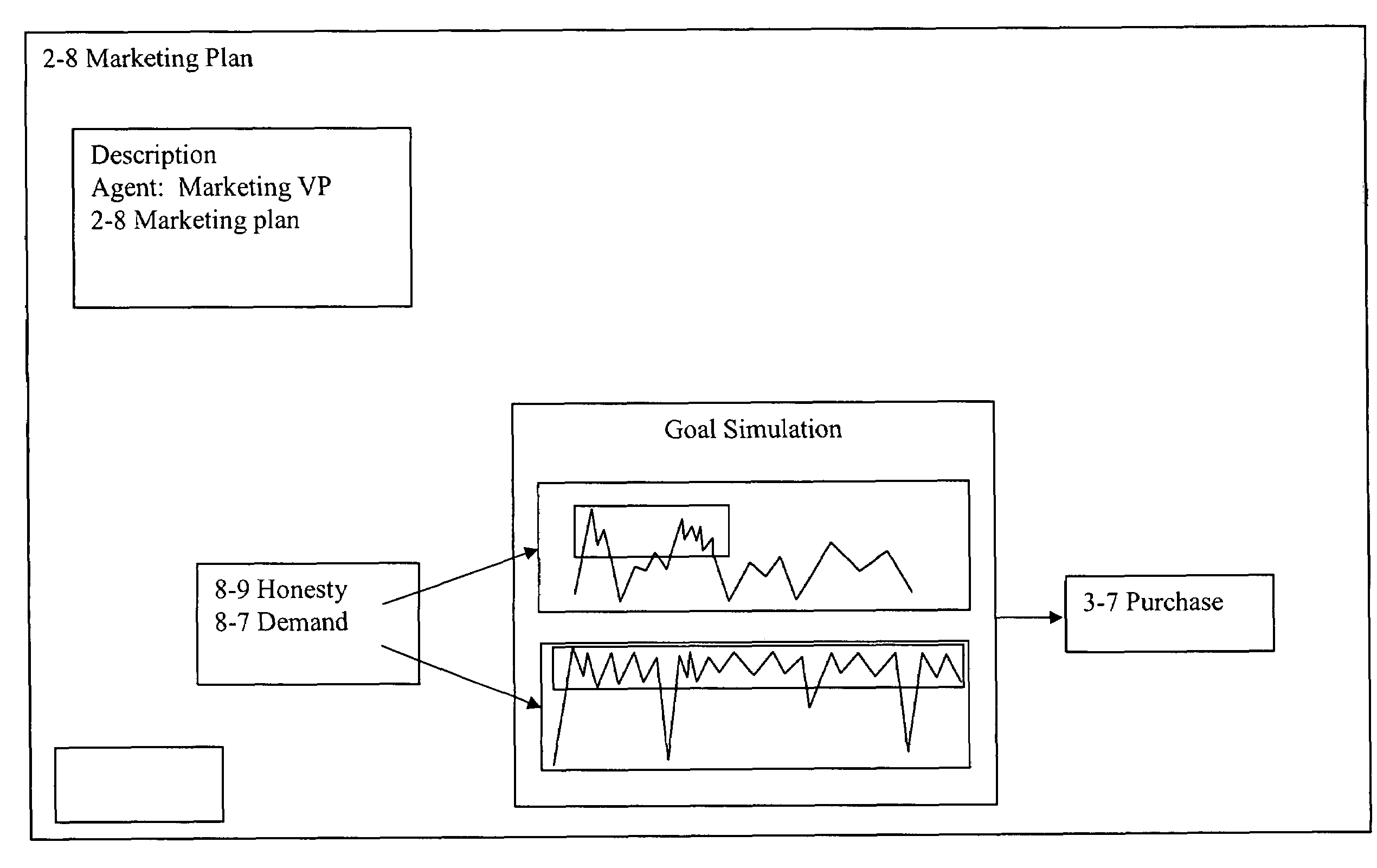

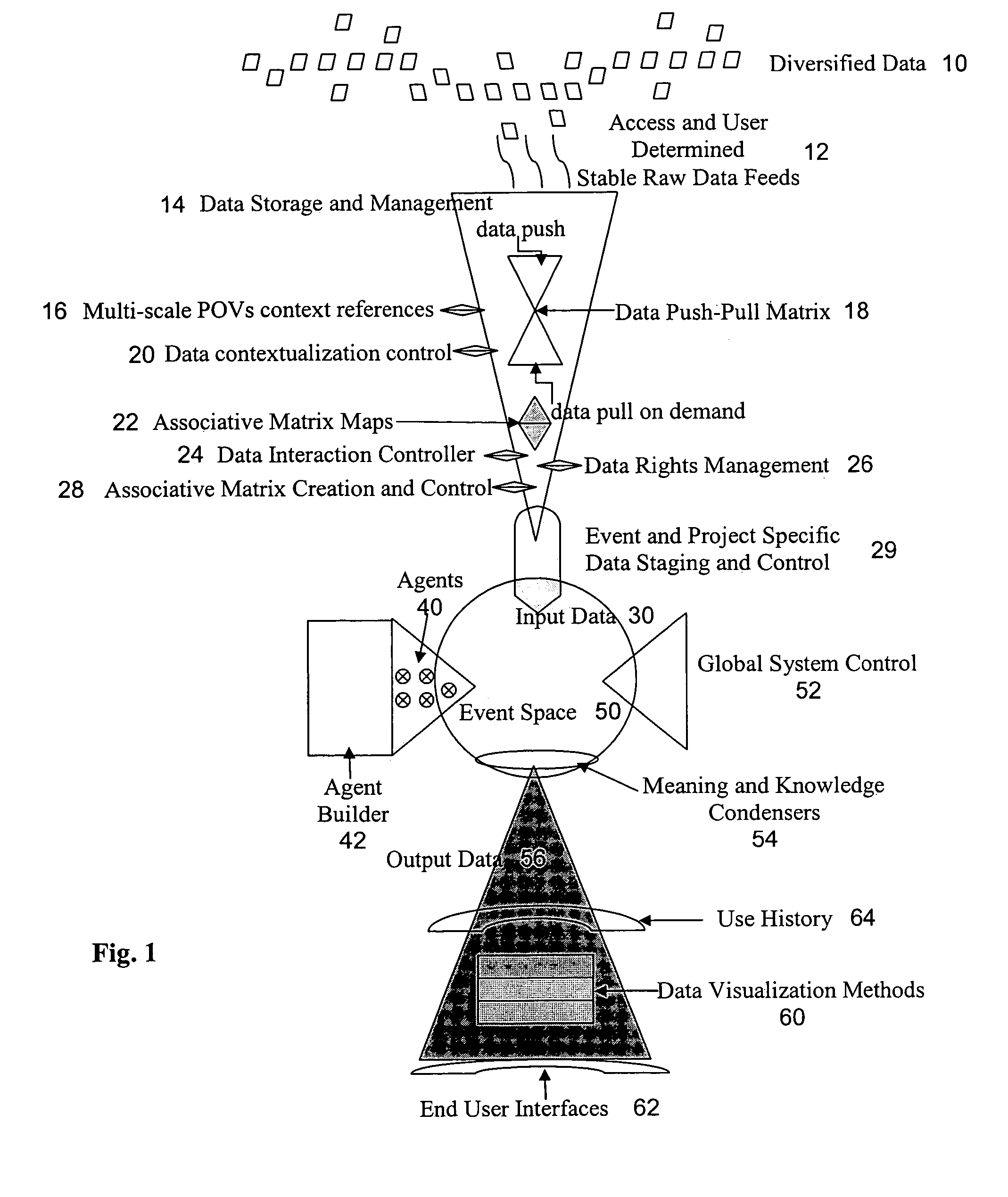

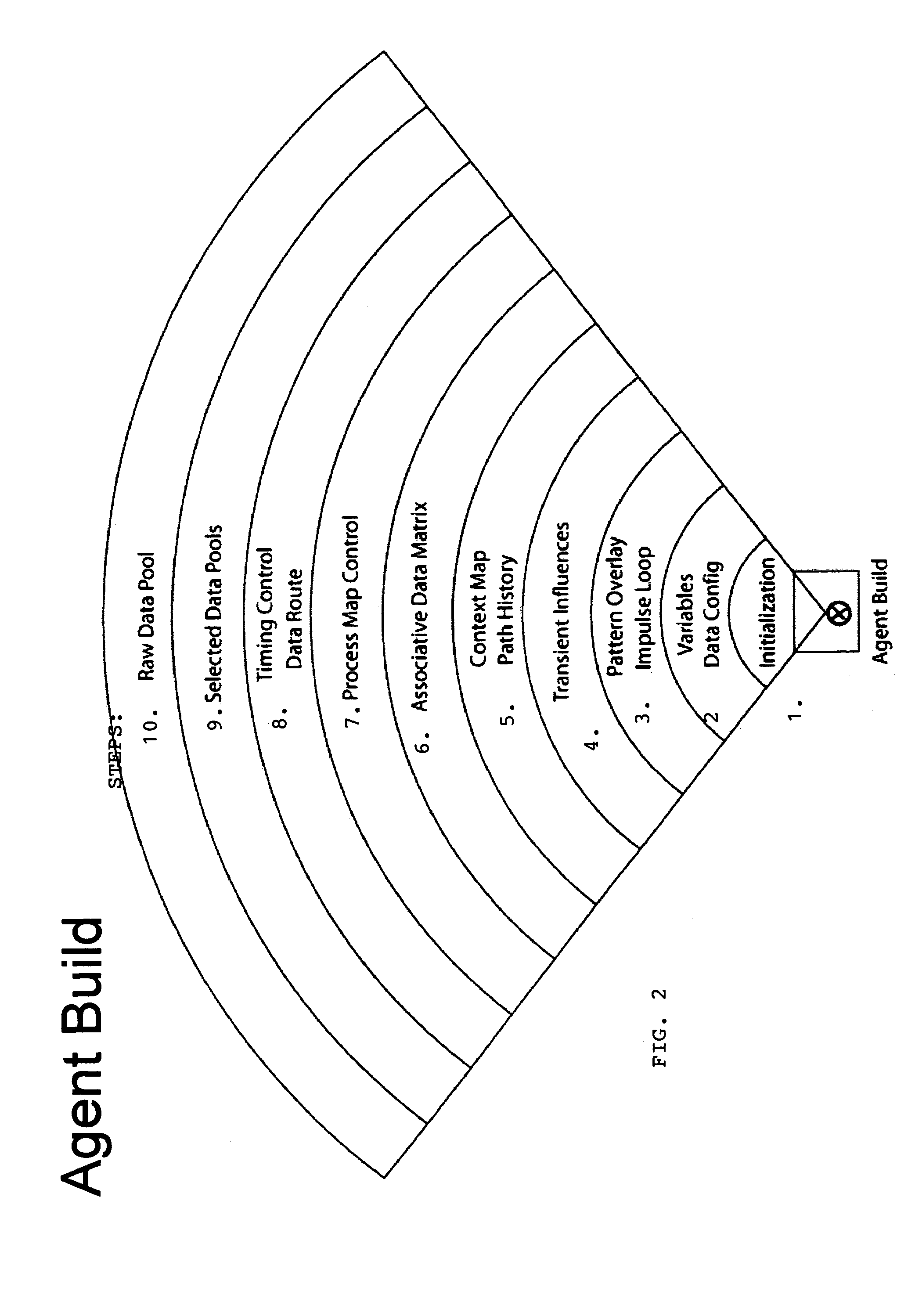

Cultural simulation model for modeling of agent behavioral expression and simulation data visualization methods

ActiveUS7263474B2Accurately indicatedDrawing from basic elementsSpeech analysisData sourceVisual tool

A computer simulation method is provided for modeling the behavioral expression of one or more computerized agents for running a simulation against real-world input data, and providing a visual display identifying elements in the input data corresponding to the modeled agent(s) response(s). Simulations can be run on sources of input data on global networks for agent types of different cultures, societies, and behaviors, such as news feeds, text communications, and reports, in order to identify keywords or phrases therein that correspond to agent behavioral expressions being monitored. Robust new visual tools are provided for discerning patterns and trends in the simulation data, including waveform charts, star charts, grid charts, and pole charts.

Owner:SEASEER R&D

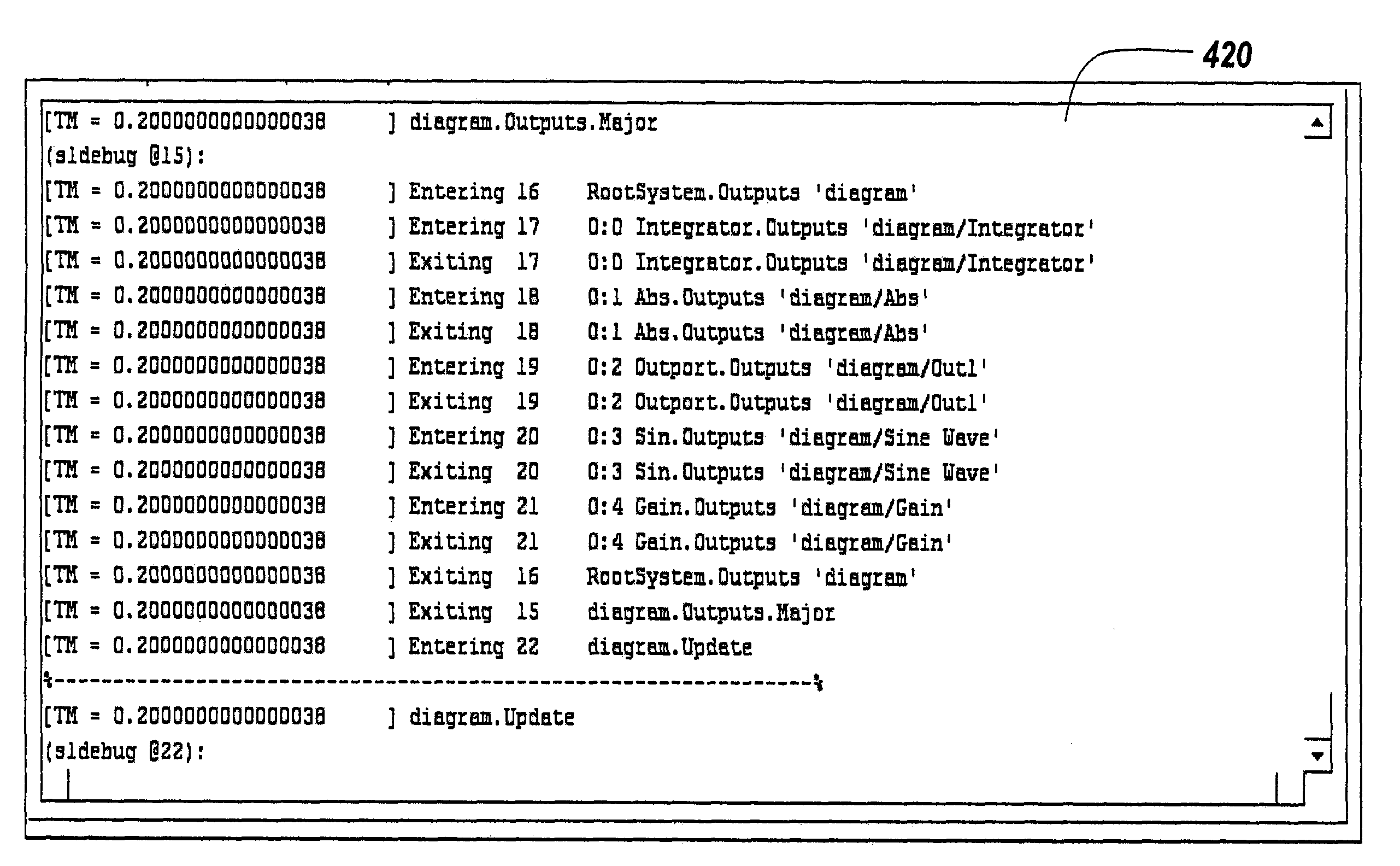

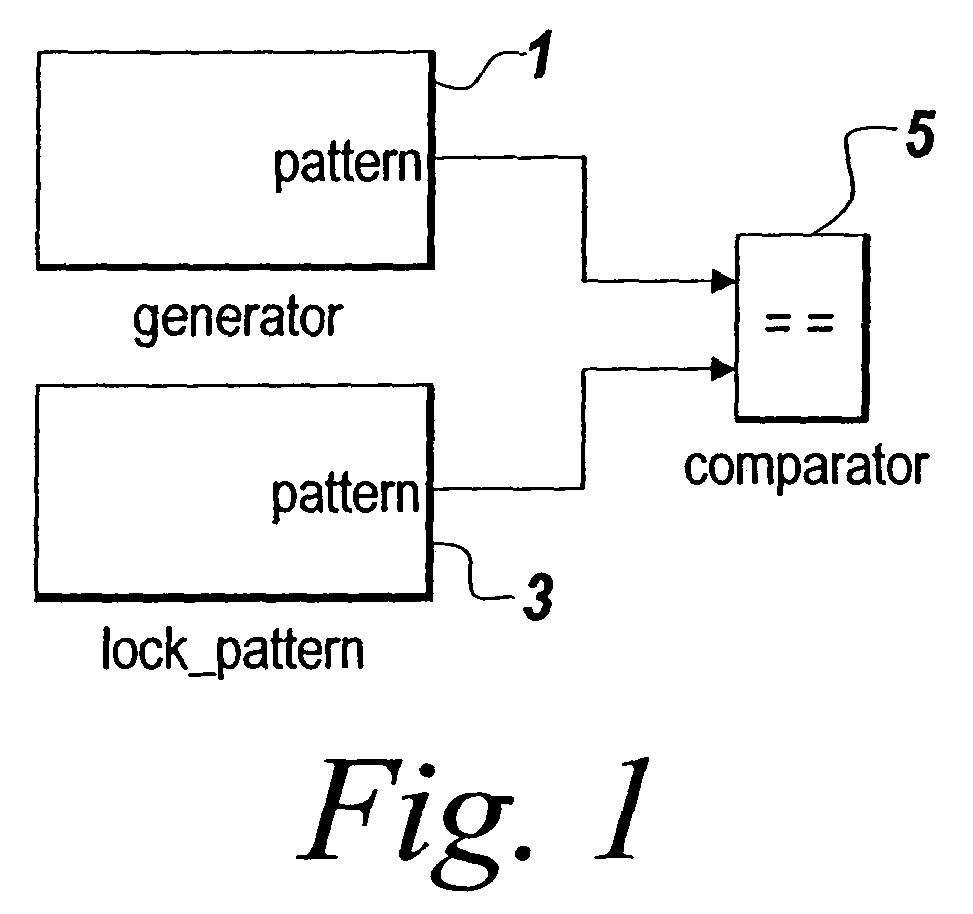

Method for using a graphical debugging tool

InactiveUS7774172B1Detailed informationData processing applicationsError detection/correctionCurrent timeBlock diagram

A system and method of exposing debugging information in a graphical modeling and execution environment is disclosed. The present invention allows a user to view debugging information in the same window as the graphical view of the model being executed. Debugging data is associated with relevant components of the model displayed in the graphical view. A separate execution list view shows the methods called during the execution of the block diagram in the current time step up until the current point in execution. User-set breakpoints and conditional breakpoints may be set in both the model view and the execution list view. Values may be obtained for all of the displayed methods. The debugging tool may be implemented by using it in conjunction with a graphical modeling and execution environment, such as a block diagram environment or state diagram environment.

Owner:THE MATHWORKS INC

A 3D city modeling method based on BIM and GIS

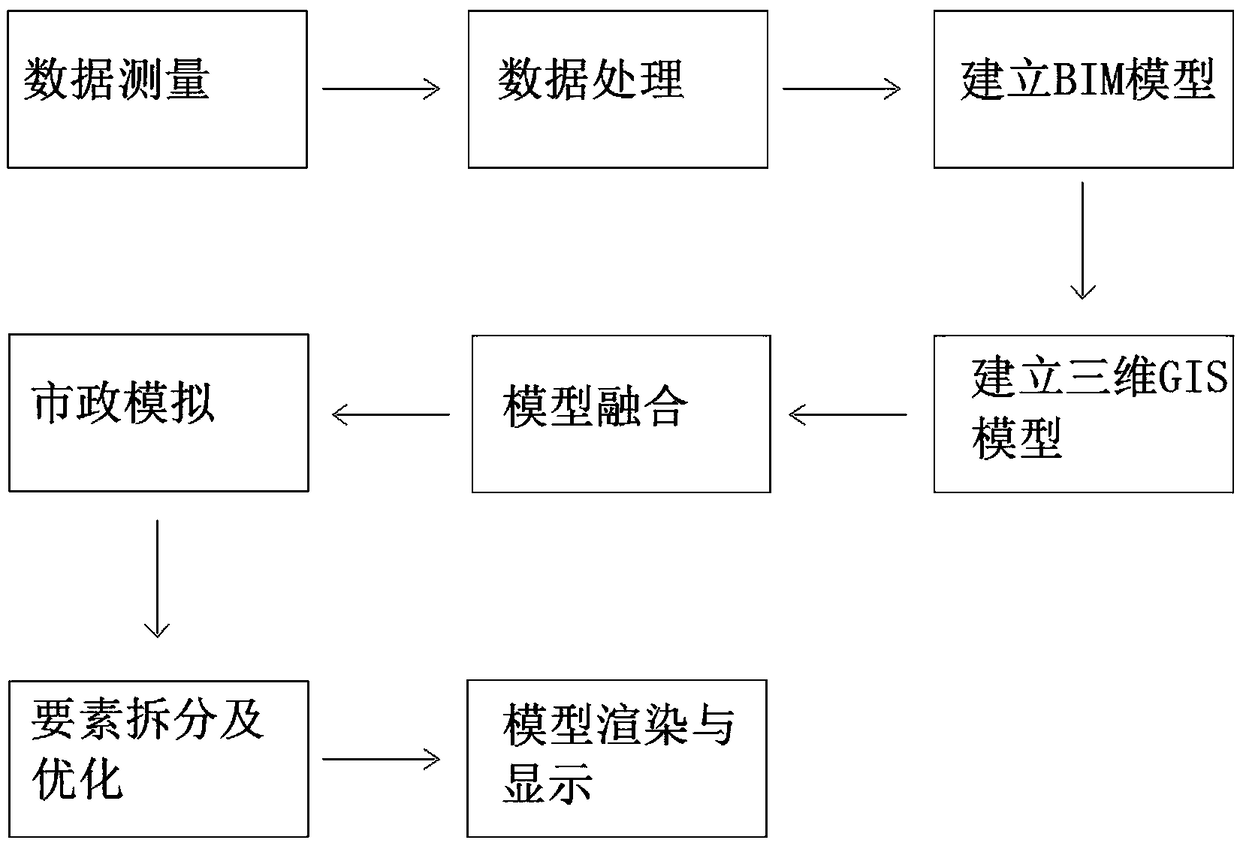

ActiveCN109410327AImprove elevation accuracyLow costDetails involving processing stepsGeographical information databasesInterior spacePoint cloud

The invention discloses a three-dimensional city modeling method based on BIM and GIS, comprising the following steps: data measurement, data processing, establishing BIM model, establishing three-dimensional GIS model, model fusion, municipal simulation, element separation and optimization, model rendering and display; through BIM, the precise height of the building can be easily obtained, appearance size and interior space information, thus through combining BIM and GIS, buildings are modeled first, and then the architectural spatial information is shared with the surrounding geographic environment, and applied to urban 3D GIS analysis, so that the cost of building spatial information can be reduced. At that same time, after the data is collected, point cloud and aerial photograph data are calculated and simulated by data classification comparison, so that the elevation information of the ground object is perfect, the elevation precision of the building model is high, and the roof ismore fine. The invention does not need a large amount of manual interaction modeling, and the data are collected by the unmanned aerial vehicle and the unmanned vehicle, and the efficiency is high, the production period is short, and the timeliness is strong.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

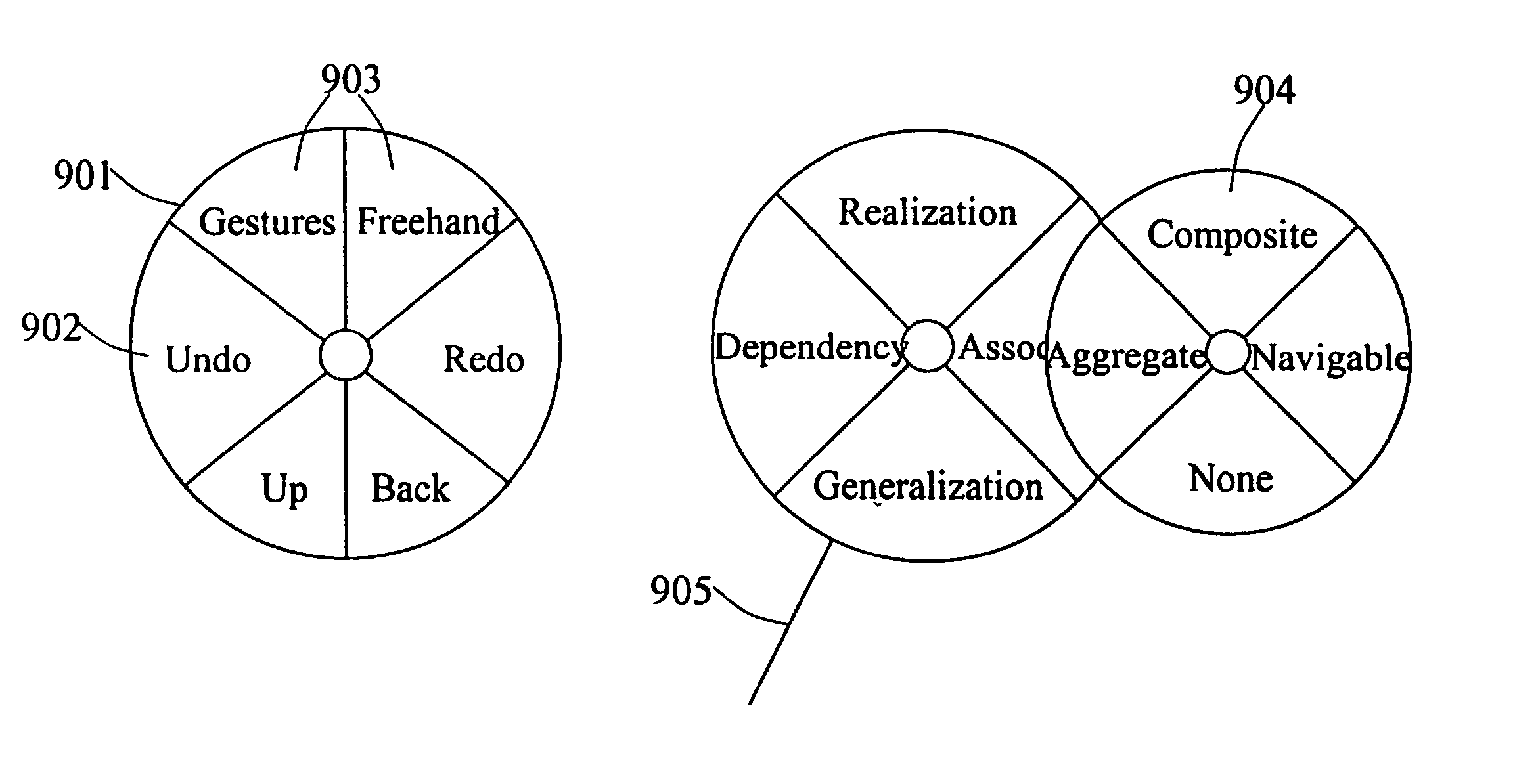

Method for gesture based modeling

InactiveUS7096454B2Specific program execution arrangementsMemory systemsWhiteboardHuman–computer interaction

A computer program based method is described for creating models using gestures. On an input device, such as an electronic whiteboard, a user draws a gesture which is recognized by a computer program and interpreted relative to a predetermined meta-model. Based on the interpretation, an algorithm is assigned to the gesture drawn by the user. The executed algorithm may, for example, consist in creating a new model element, modifying an existing model element, or deleting an existing model element.

Owner:TYRSTED MANAGEMENT

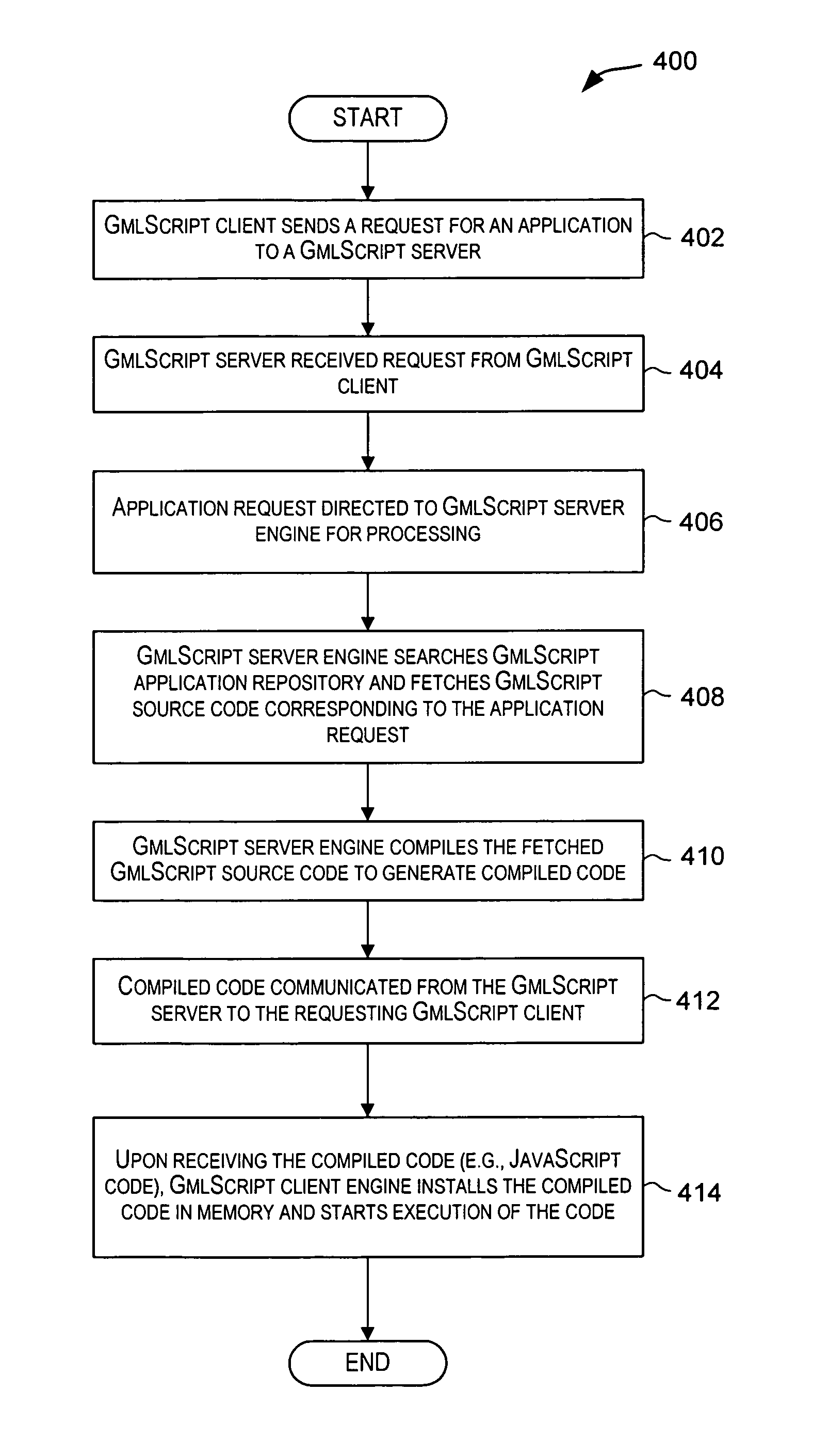

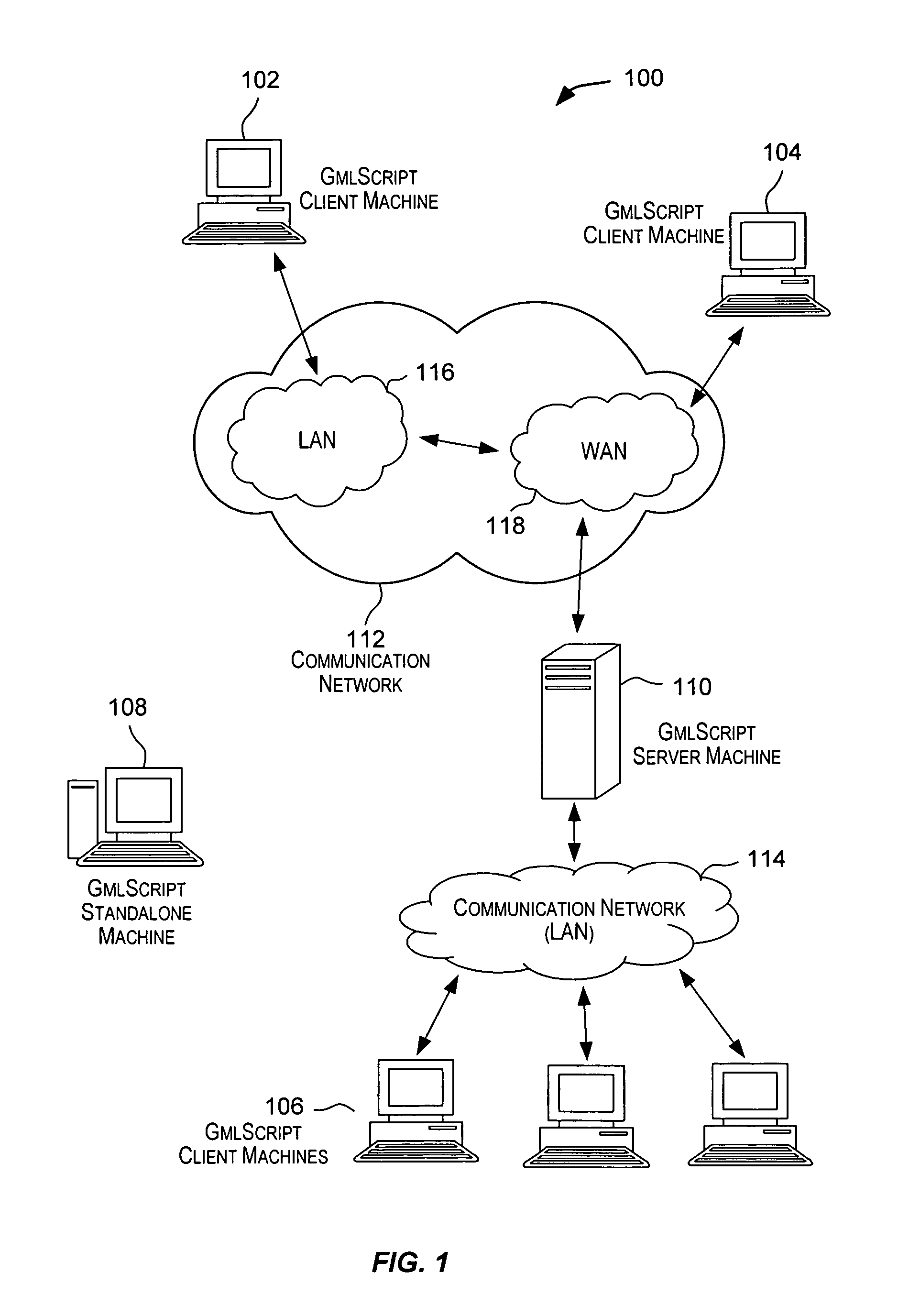

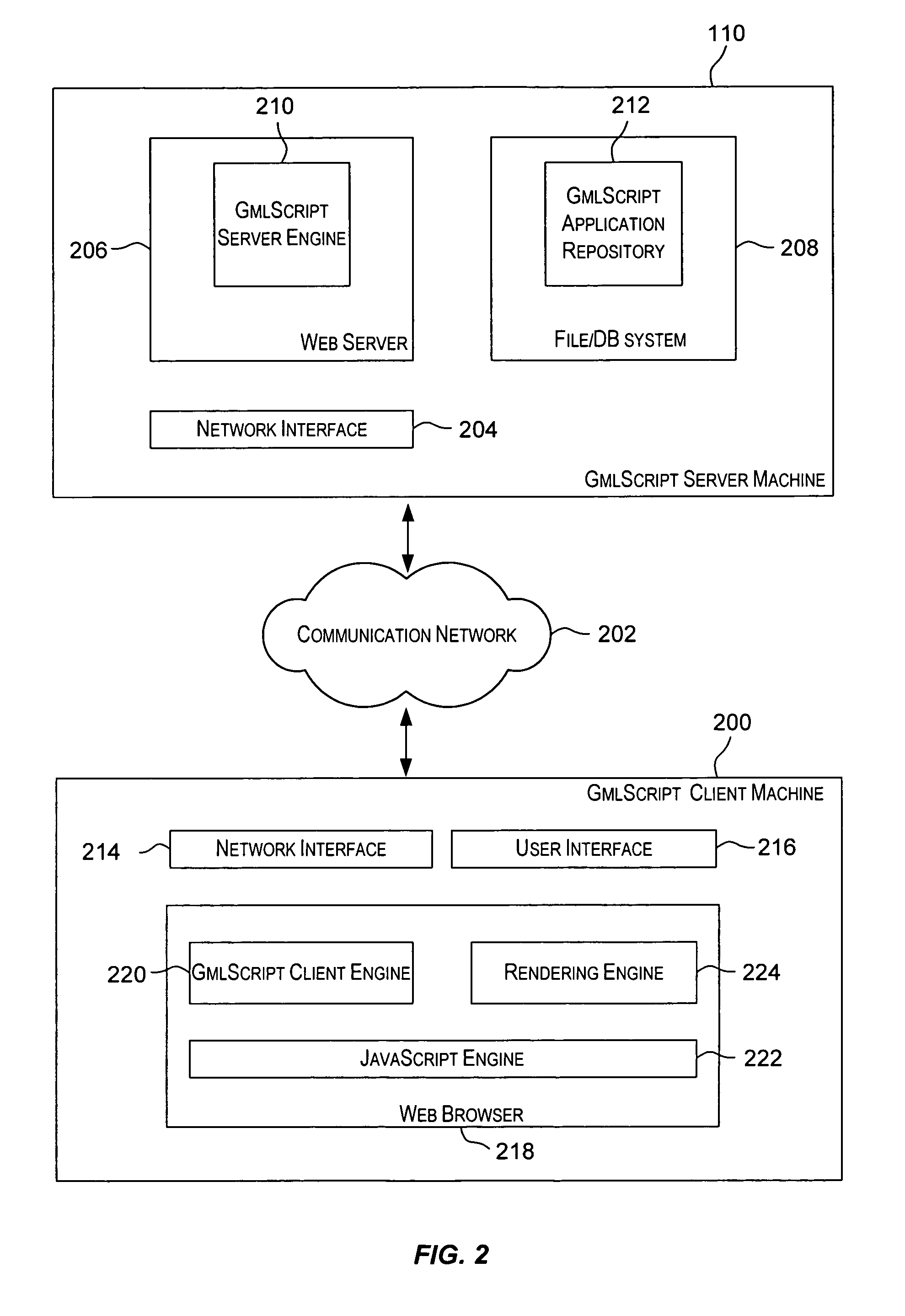

Programming language techniques for client-side development and execution

ActiveUS7971194B1Promote application developmentSoftware designRequirement analysisSoftware engineeringComponent (UML)

Techniques that facilitate development of applications that may be executed by a client program. The client program may be a modeling framework that may be hosted by a browser or other client-side program. A programming language (referred to as “GmlScript”) is provided for developing the applications. In one embodiment, the programming language provides various features such as object-oriented programming, client-side scripting, self-contained components, aspect-oriented programming, namespaces and self-contained components (kits), classes, methods, and properties, prototypes for multiple inheritance, events and listeners for implementing dynamics and constraints, transactions for ensuring model consistency and for undo / redo operations, objects persistency, dynamic loading, introspection, self documentation, preprocessing pragmas, and other features.

Owner:SAP PORTALS ISRAEL

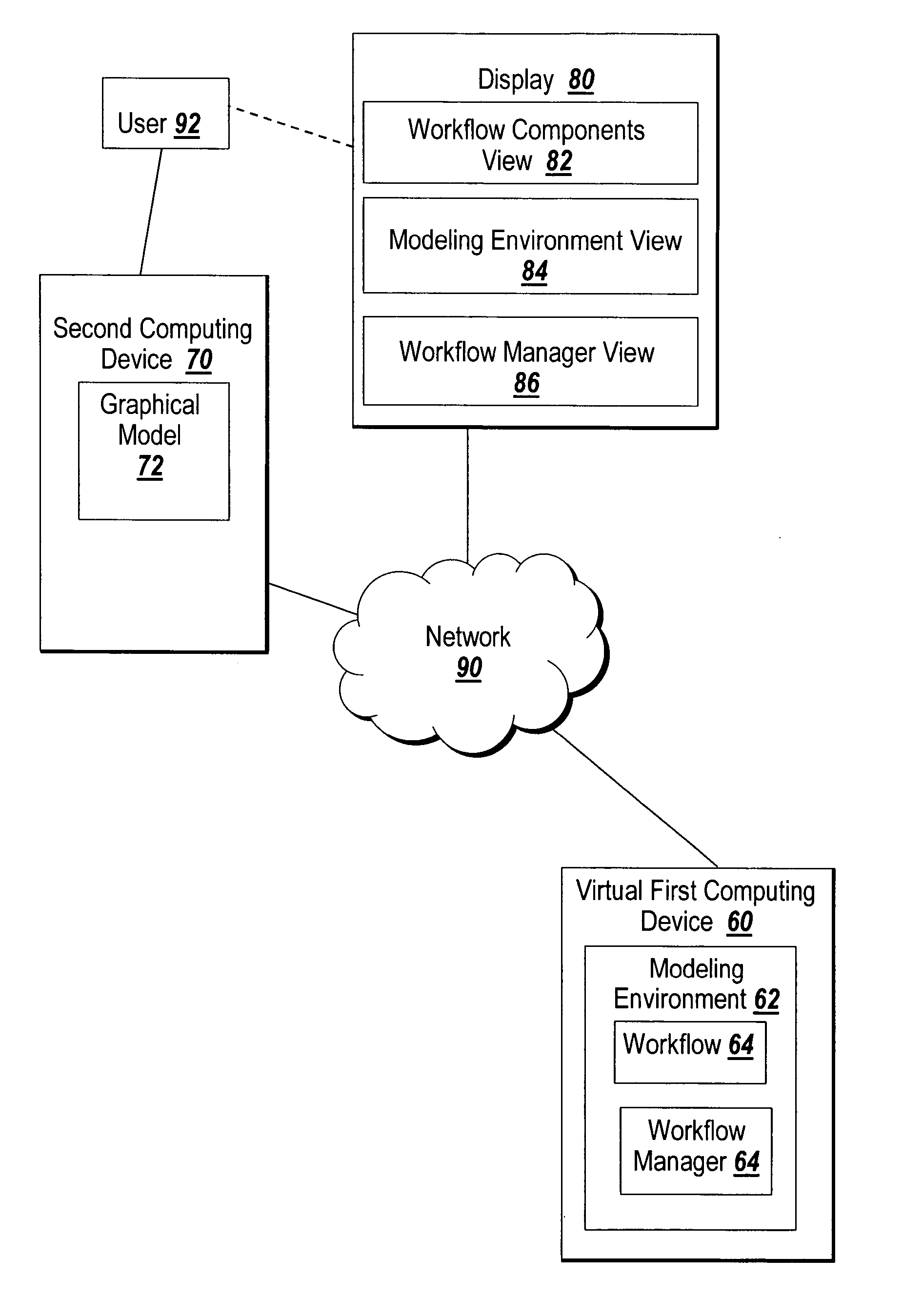

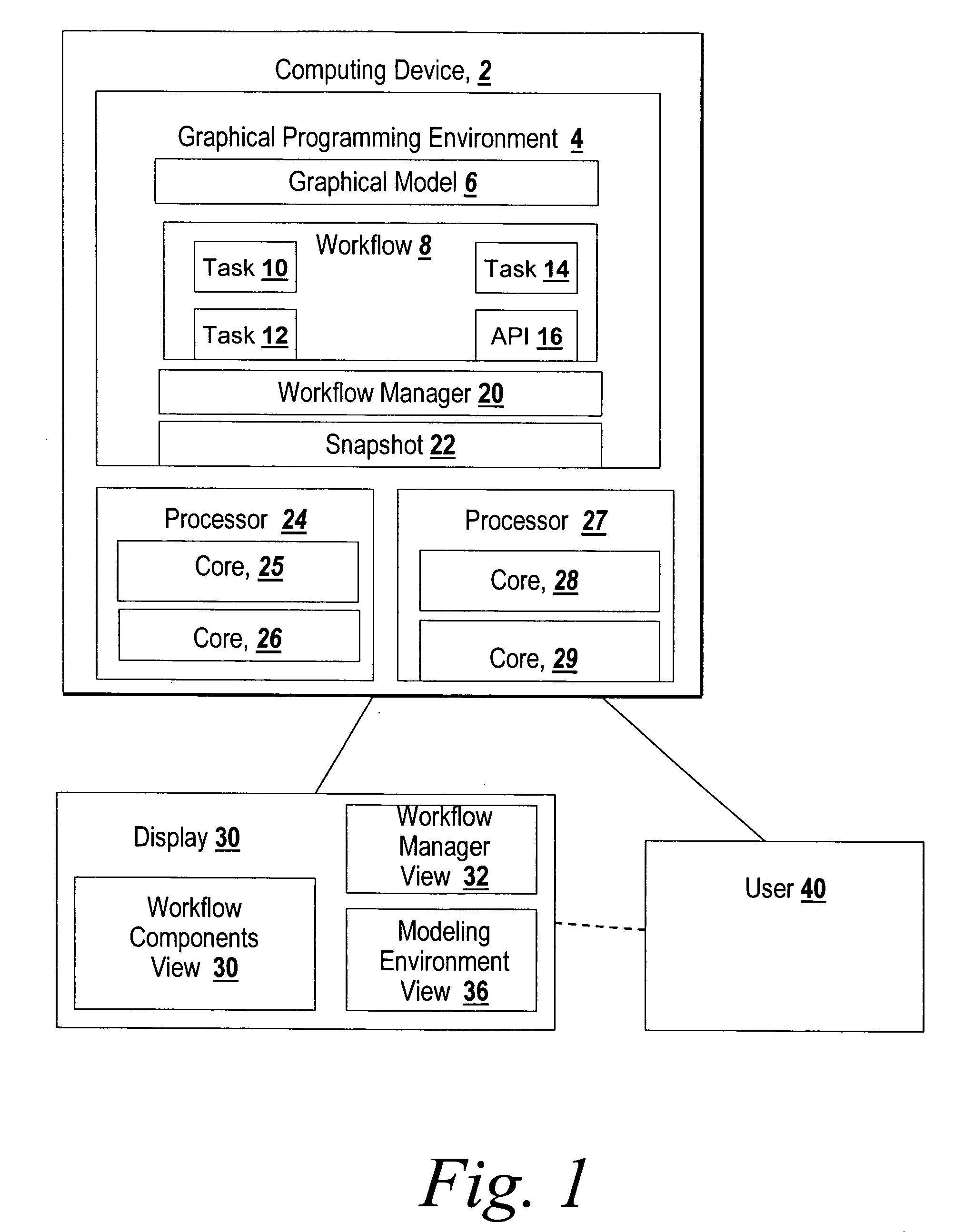

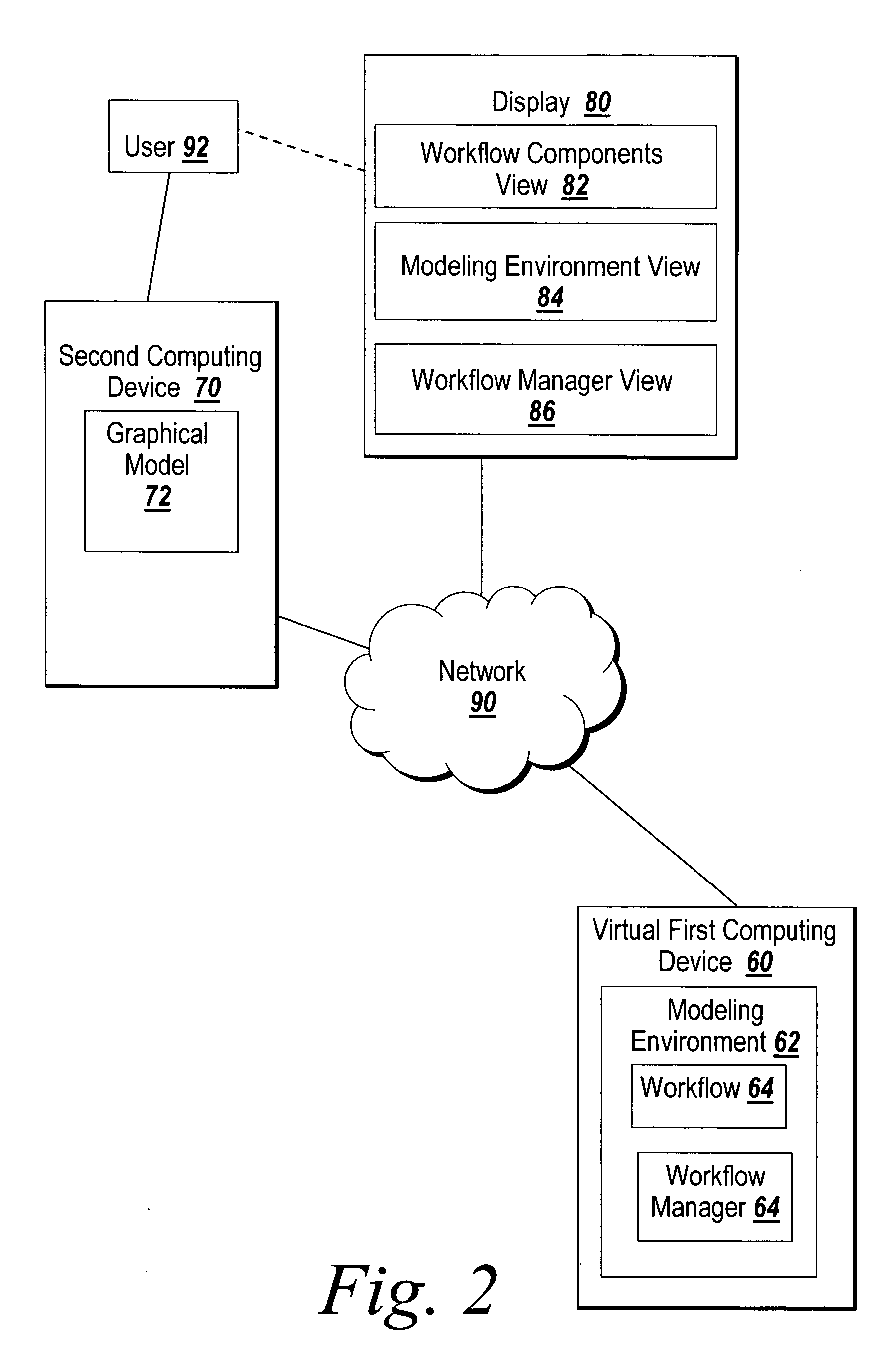

System and method for synchronized workflow management

A workflow manager that offers structure and control over the graphical modeling environment so that the graphical modeling environment is reconfigured in a manner appropriate for a particular workflow is disclosed. The workflow manager of the present invention provides hierarchical task management that is synchronized to the graphical modeling environment. The workflow manager also allows a model designer to navigate a series of steps required to achieve the goal of a particular workflow. An API allows the steps to be customized as required by the end user.

Owner:THE MATHWORKS INC

Configurable bio-transport system simulator

InactiveUS20020120431A1Easy to customizeSave effortNanoinformaticsAnalogue computers for chemical processesComputational scienceBiological body

A method of simulating a bio-transport system comprising: (a) characterizing one or more elements to represent a bio-transport system of an organism or a portion thereof; (b) constructing one or more mathematical representations that model one or more bio-transport dynamics for each element based on the characterization of the elements to form a configured simulation model; (c) initializing the configured simulation model; (d) executing the configured simulation model to obtain bio-transport dynamics data for one or more elements; and (e) outputting information to a user based on at least a portion of the bio-transport dynamics data.

Owner:KEANE JOHN A

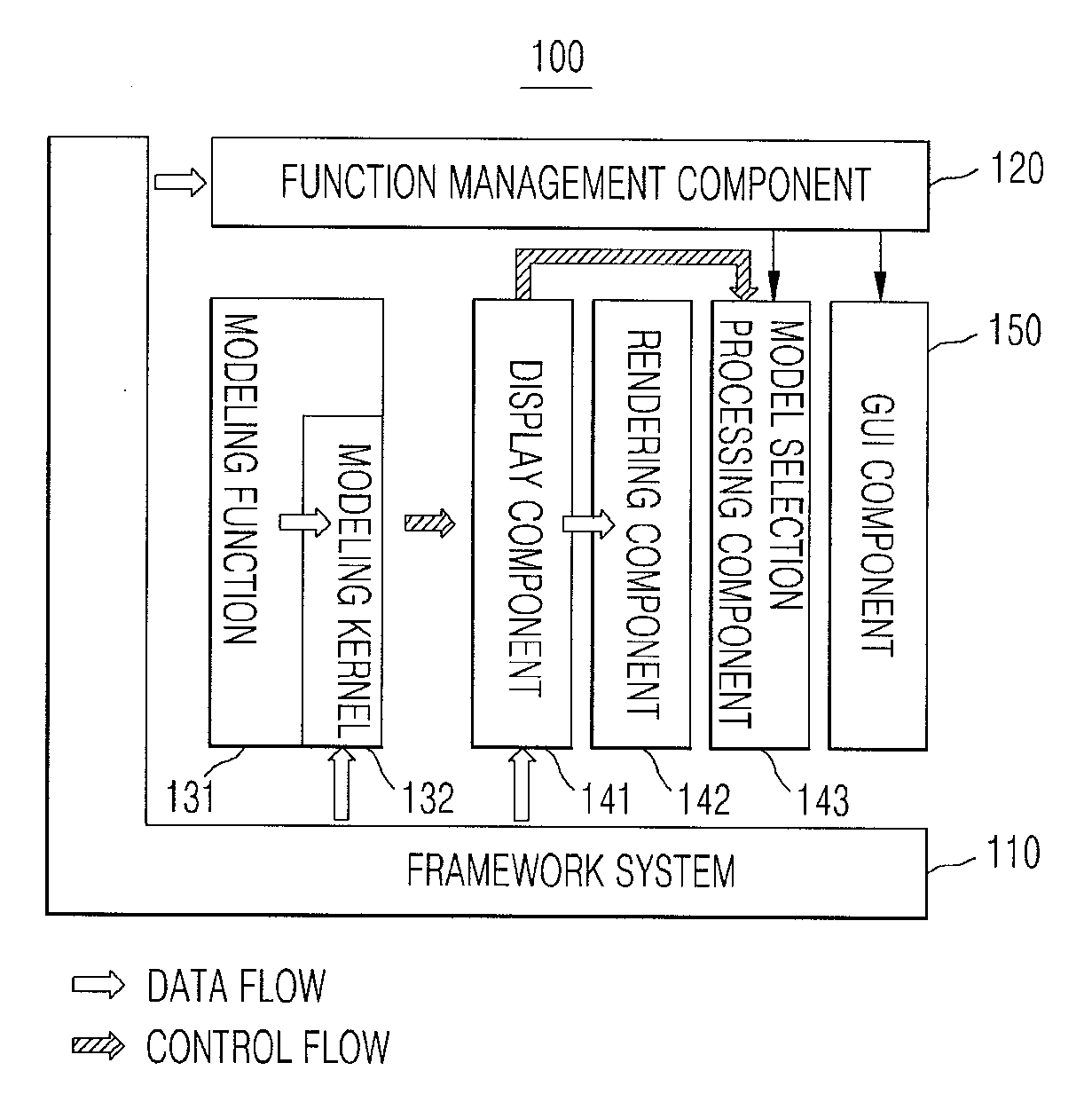

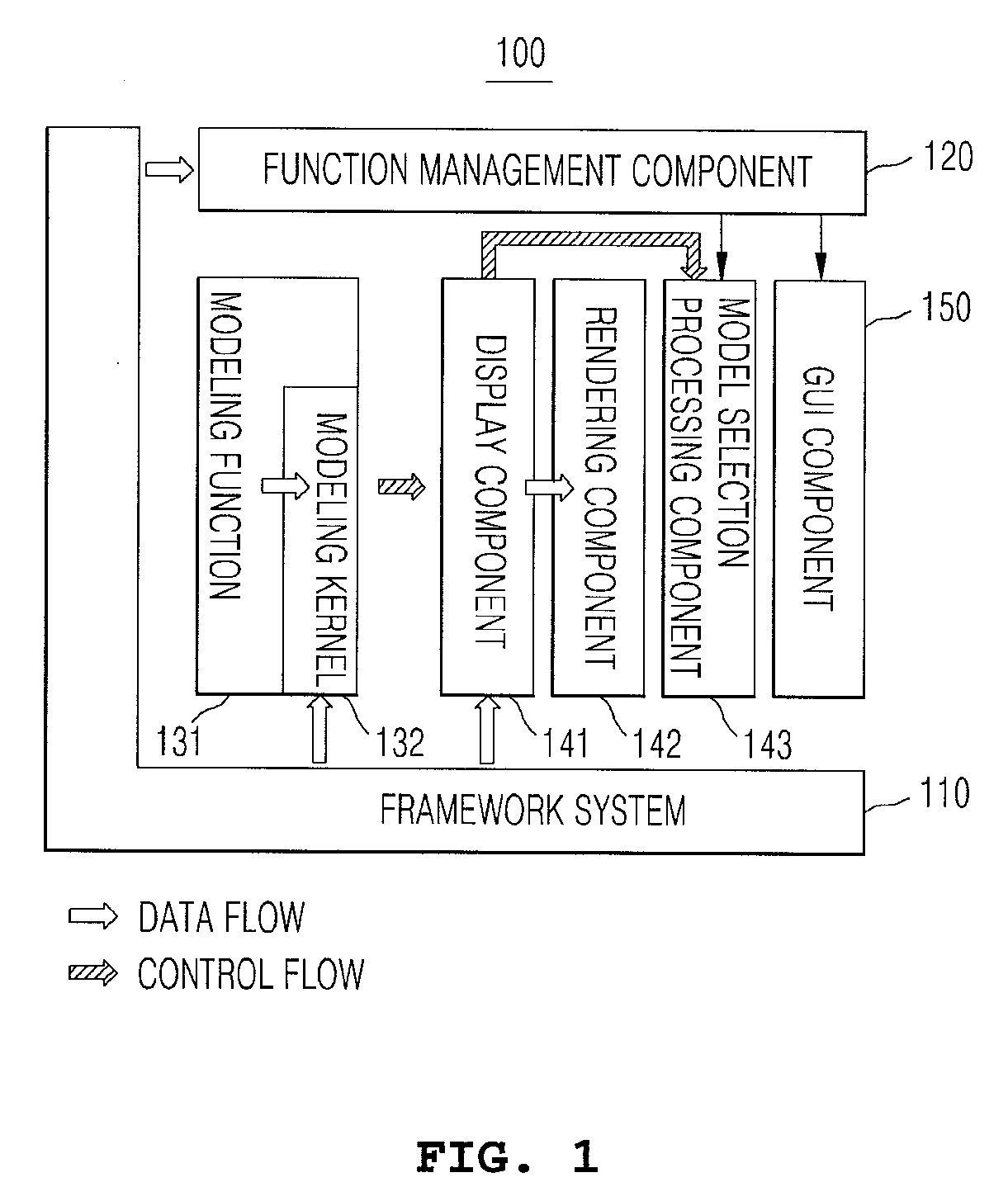

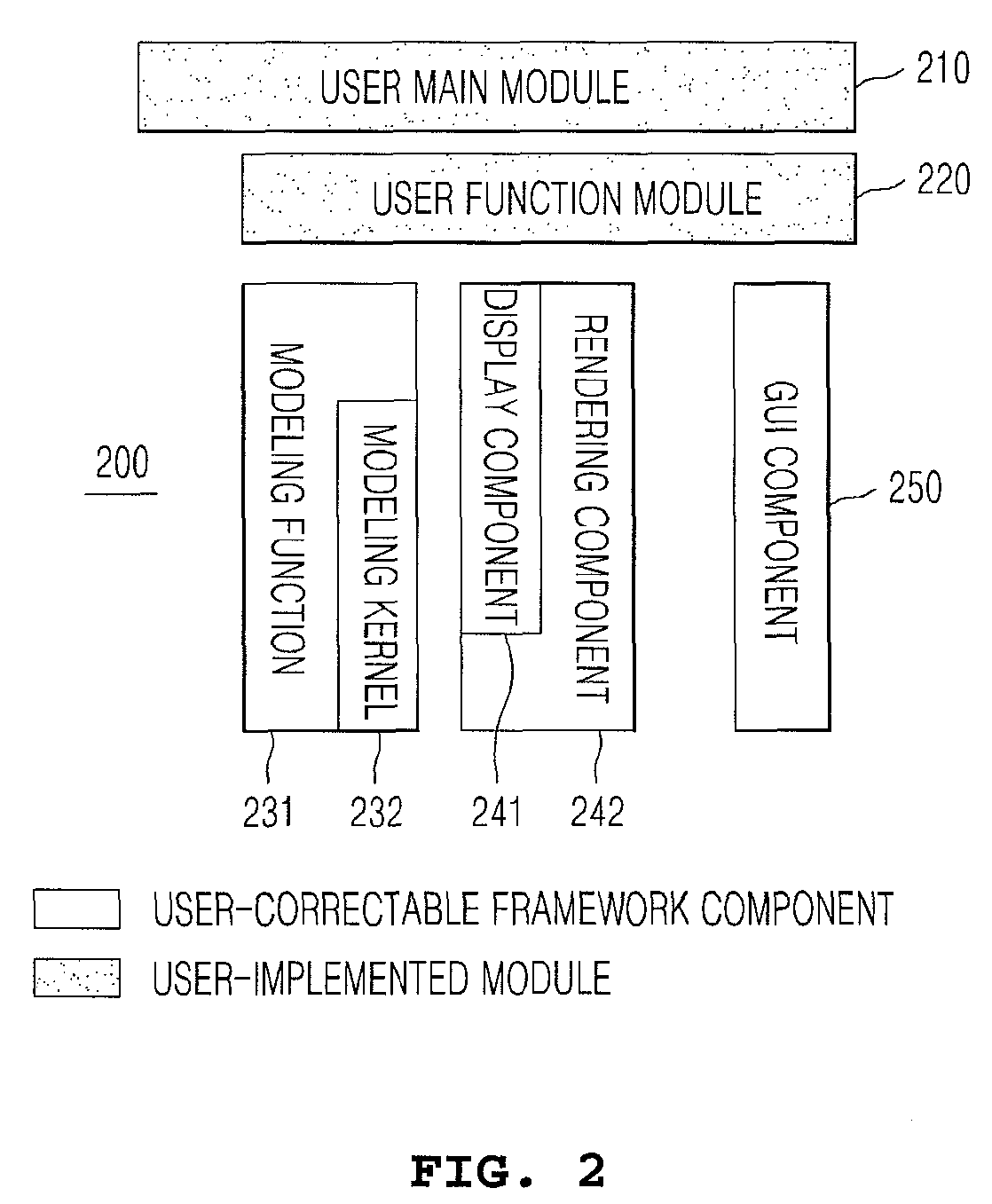

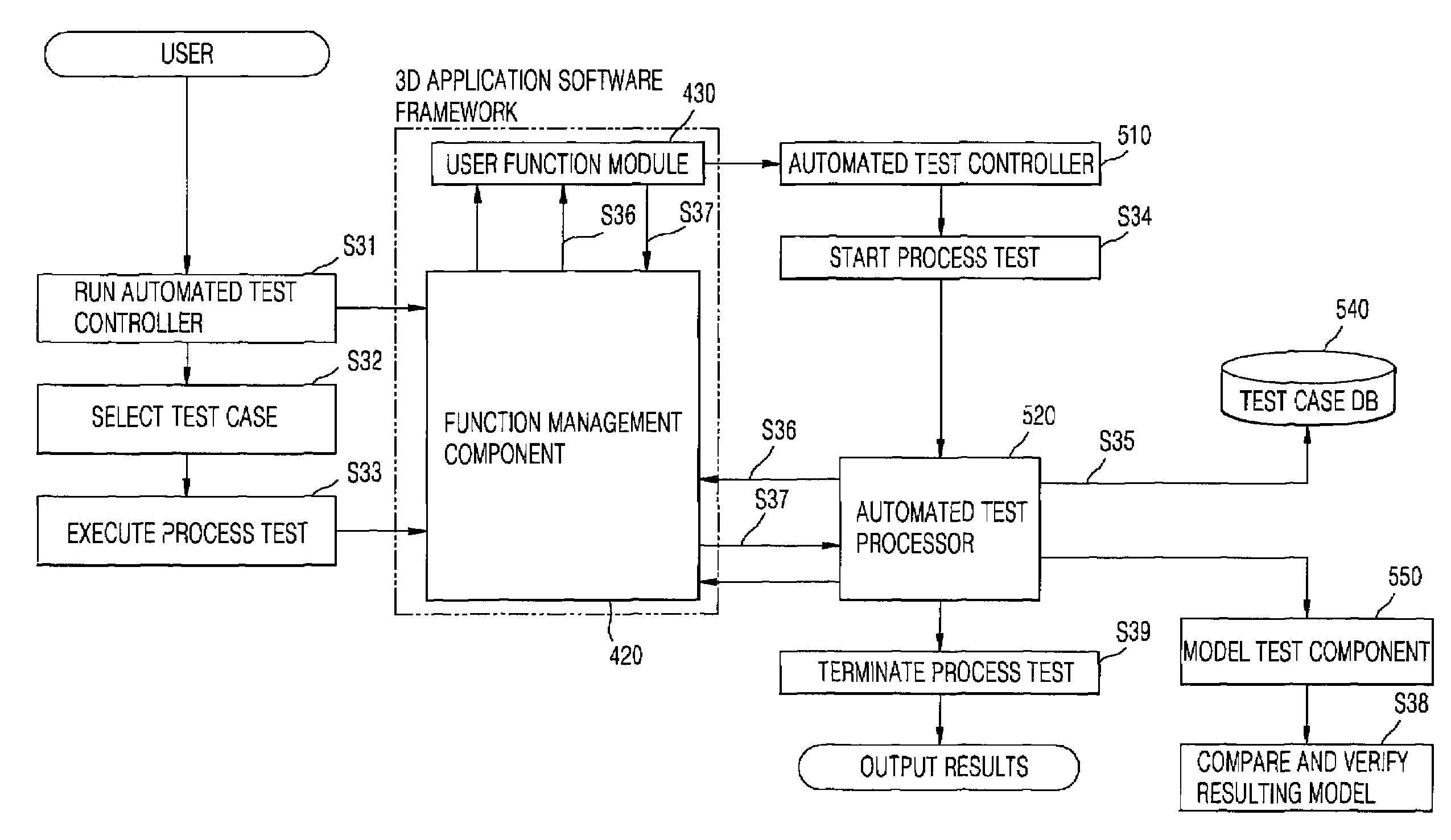

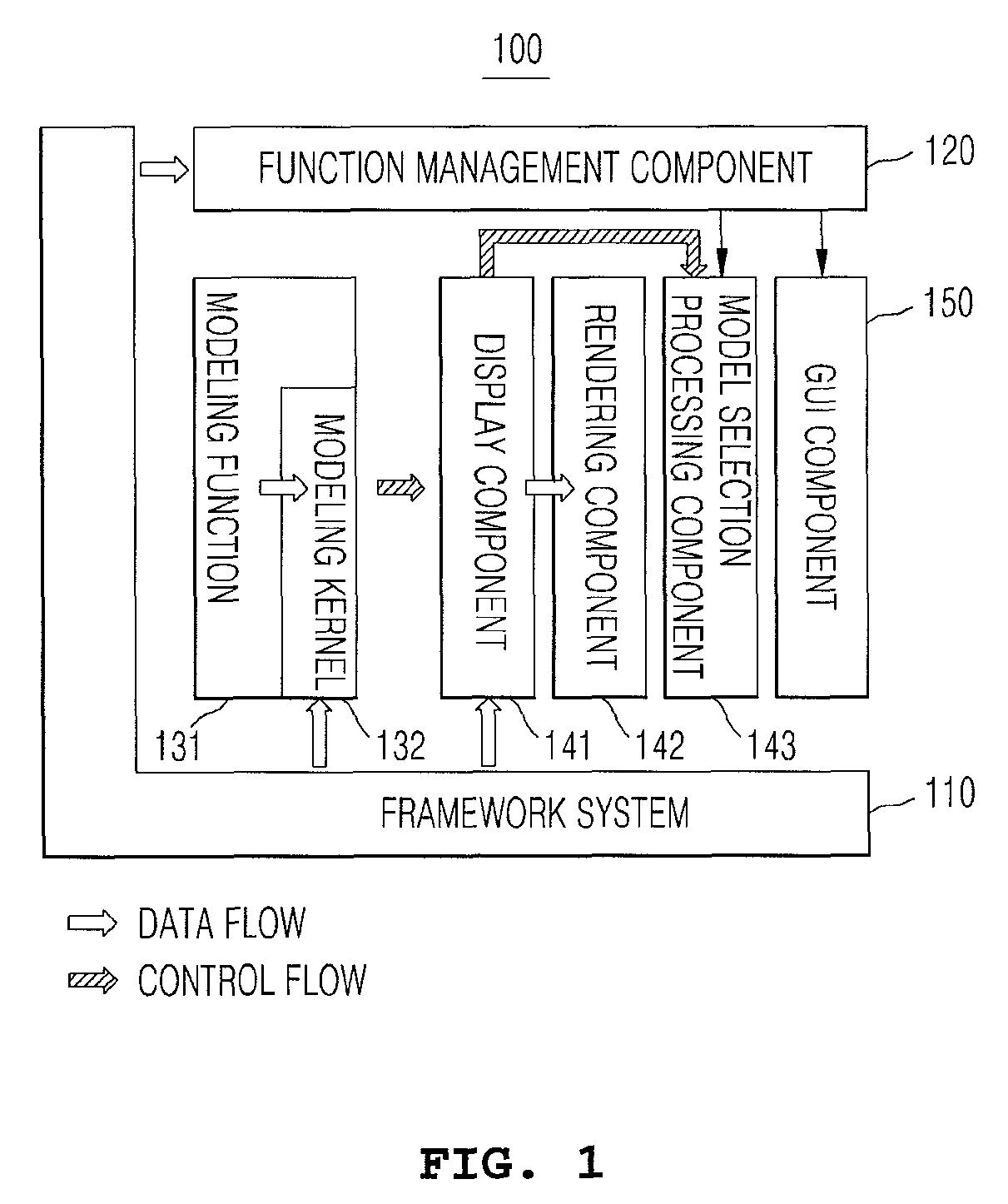

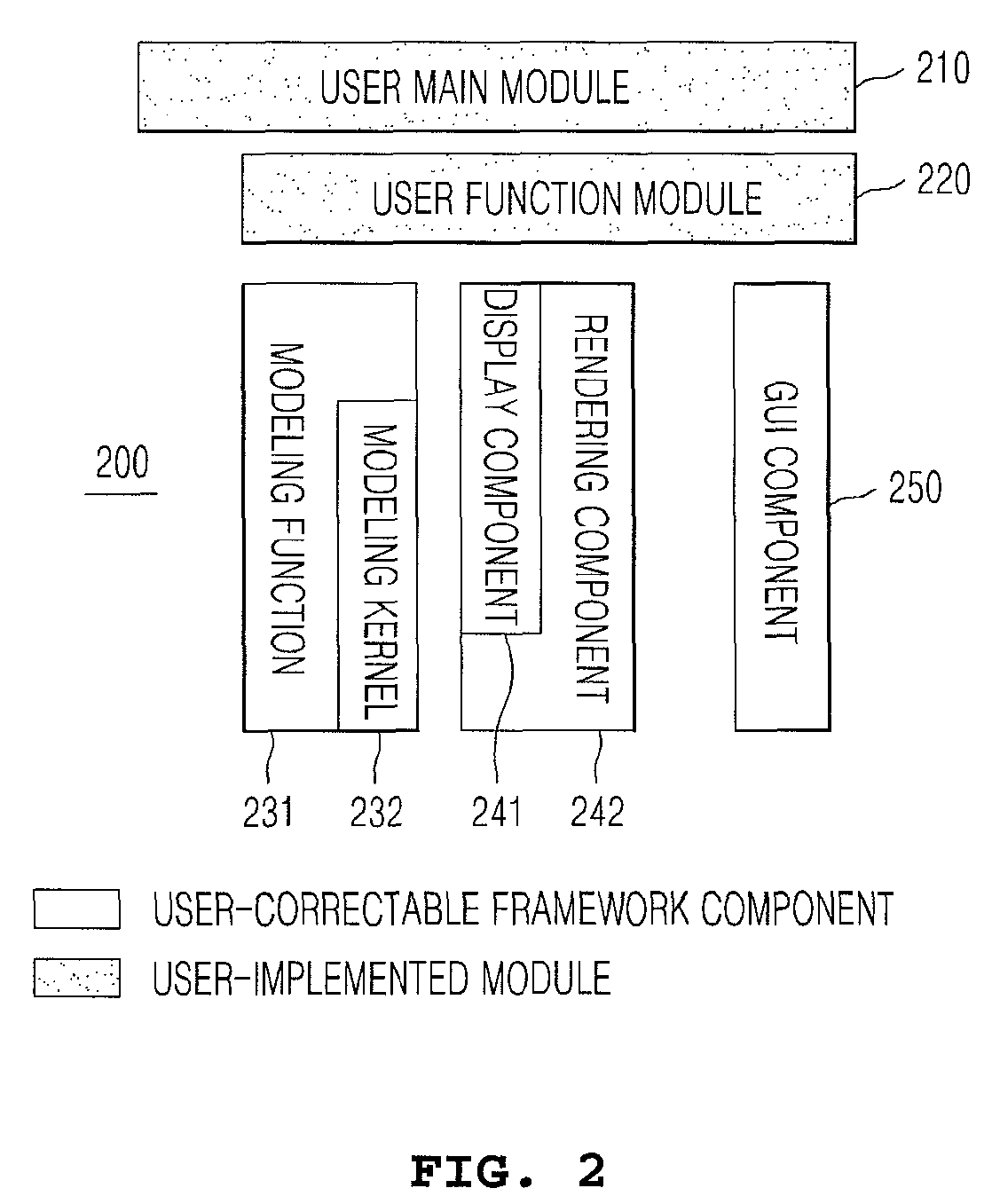

Three-dimensional application program framework structure and a method for implementing an application program based on the same, and an automatic testing system based on a three-dimensional application software framework and a method therefor

InactiveUS20110125448A1Ensure stable executionMaintain relatively stableError detection/correctionElectrical measurementsGraphicsFrame based

A three-dimensional application program framework structure; a method for implementing an application program based on the same; and an automatic testing system based on a three-dimensional application software framework and a method therefor. The three-dimensional application program framework structure provides a framework comprising functions and management of the environment of the system and events to be implemented by the user (developer), and the developer can easily expand the graphic user interface (GUI) and an actual modeling function as required, and user model. In addition, by using an automatic test system based on the framework, it is possible to record the function-execution history of the user and to automatically generate a test case, and to thereby test the functioning of the application software through the use of the test case regardless of changes in the source code and the GUI.

Owner:CODESE

System for and Method of Capturing Performance Characteristics Data From A Computer System and Modeling Target System Performance

ActiveUS20080244533A1Satisfy demand flexibilitySatisfy speedError detection/correctionDigital computer detailsModelSimParallel computing

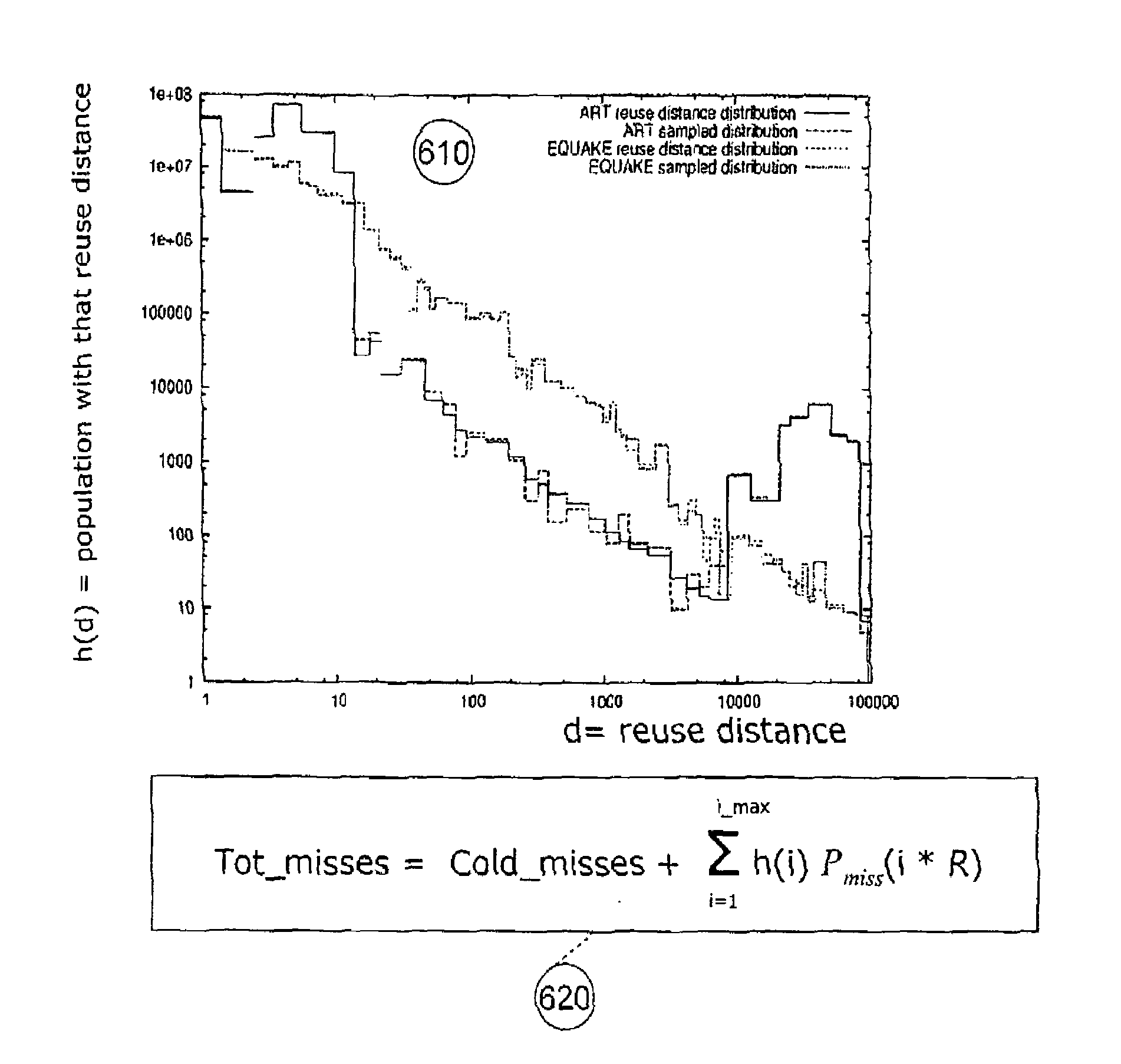

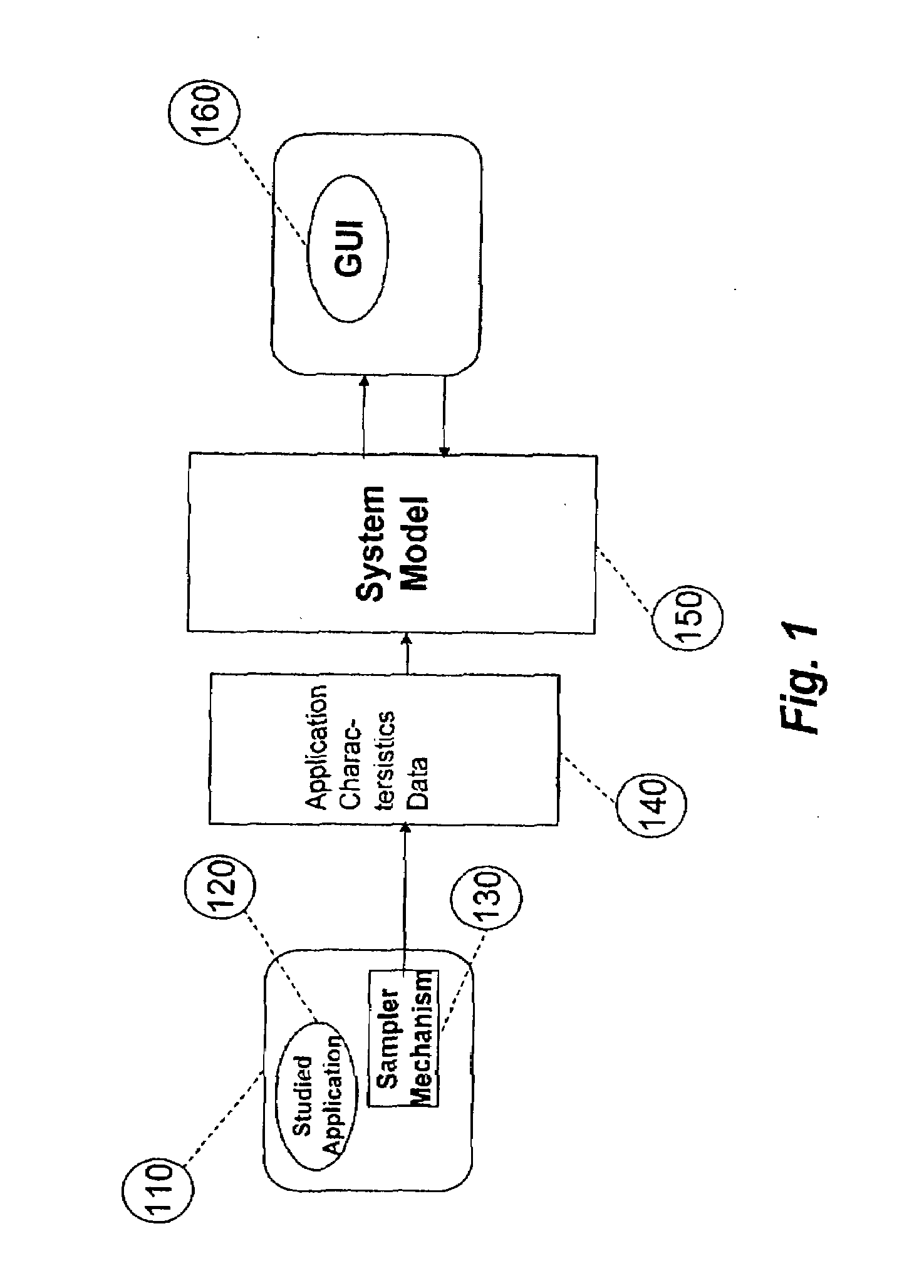

A system for, method of and computer program product captures performance-characteristic data from the execution of a program and models system performance based on that data. Performance-characterization data based on easily captured reuse distance metrics is targeted, defined as the total number of memory references between two accesses to the same piece of data. Methods for efficiently capturing this kind of metrics are described. These data can be refined into easily interpreted performance metrics, such as performance data related to caches with LRU replacement and random replacement strategies in combination with fully associative as well as limited associativity cache organizations. Methods for assessing cache utilization as well as parallel execution are covered.

Owner:ROGUE WAVE SOFTWARE

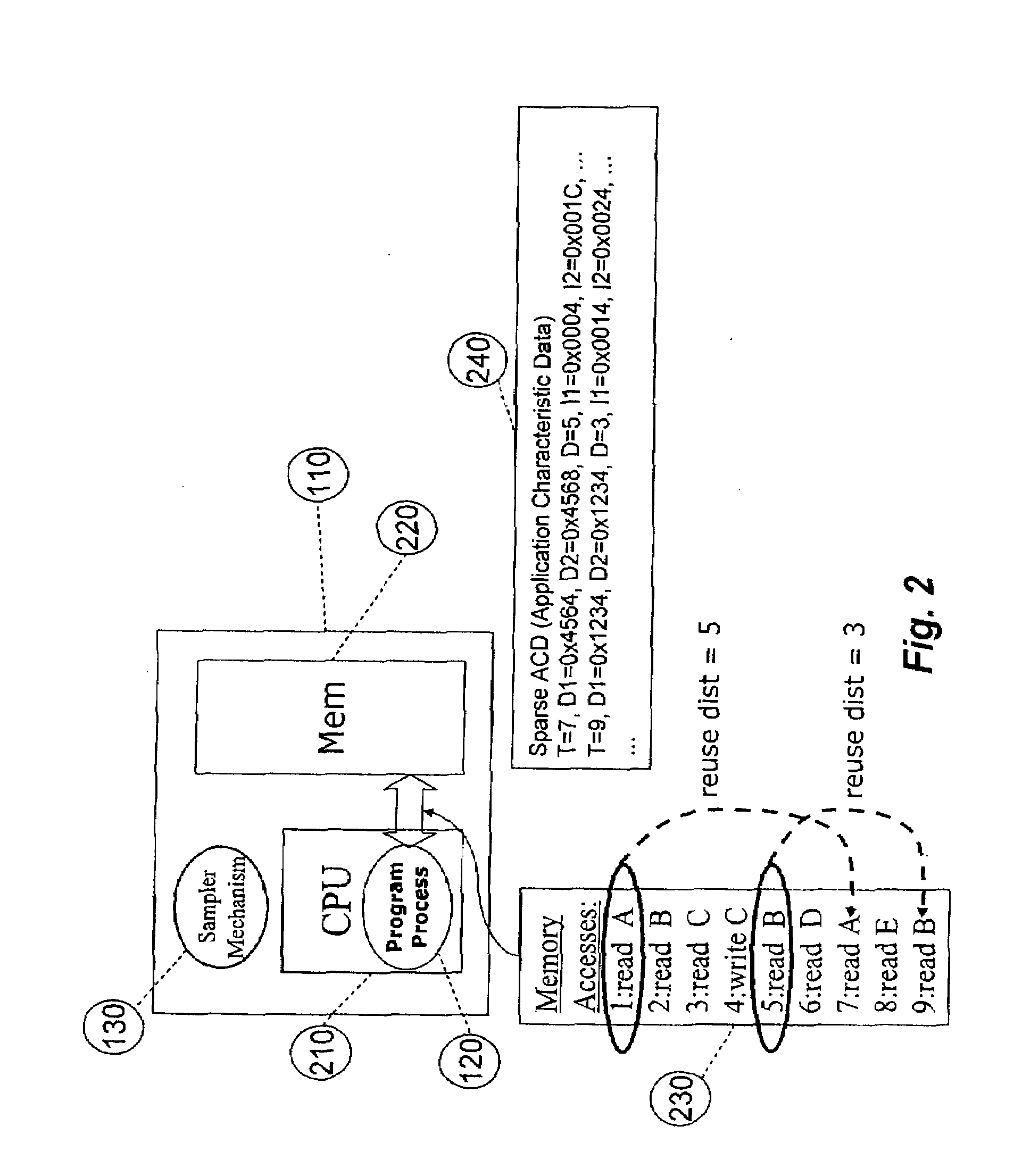

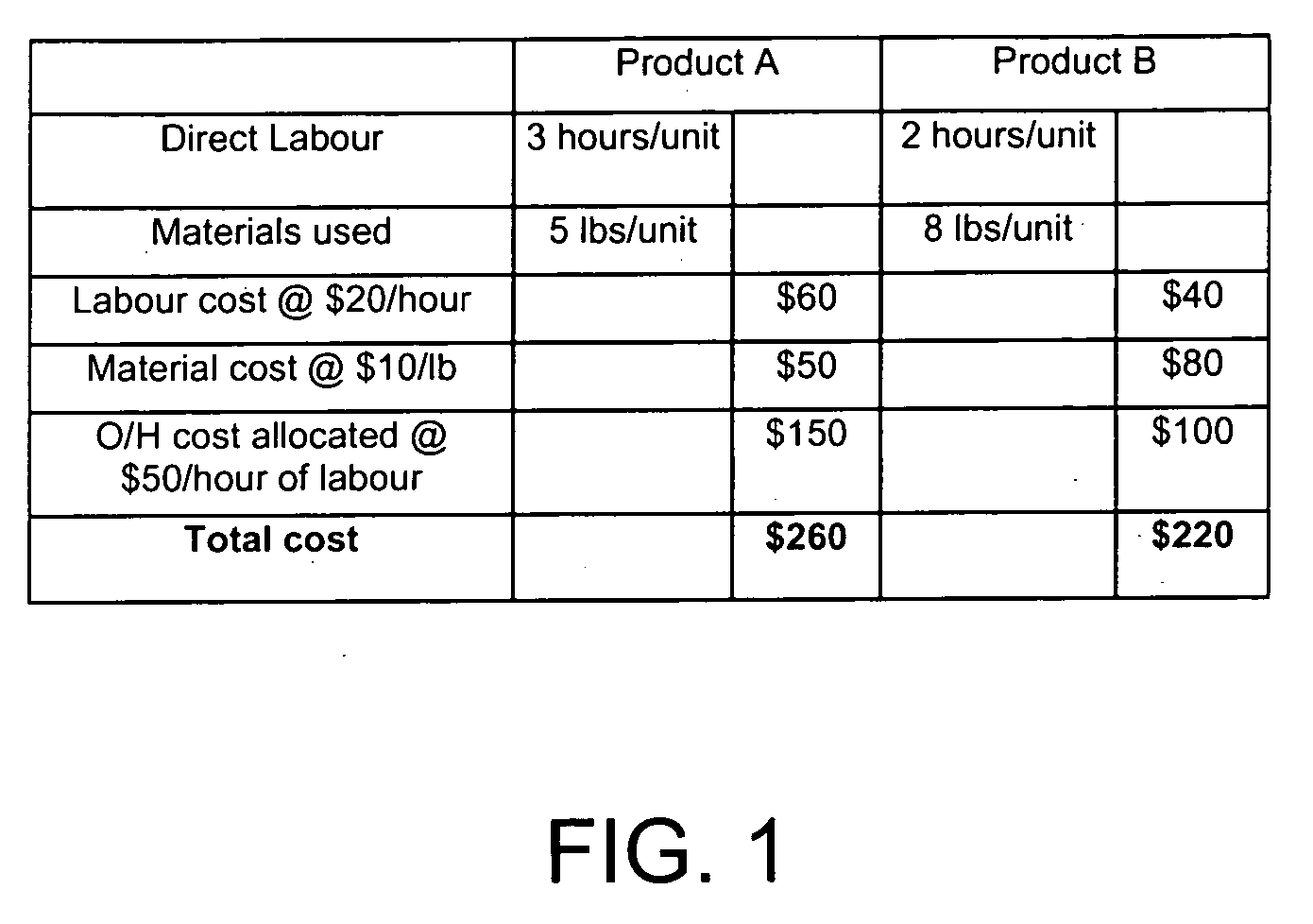

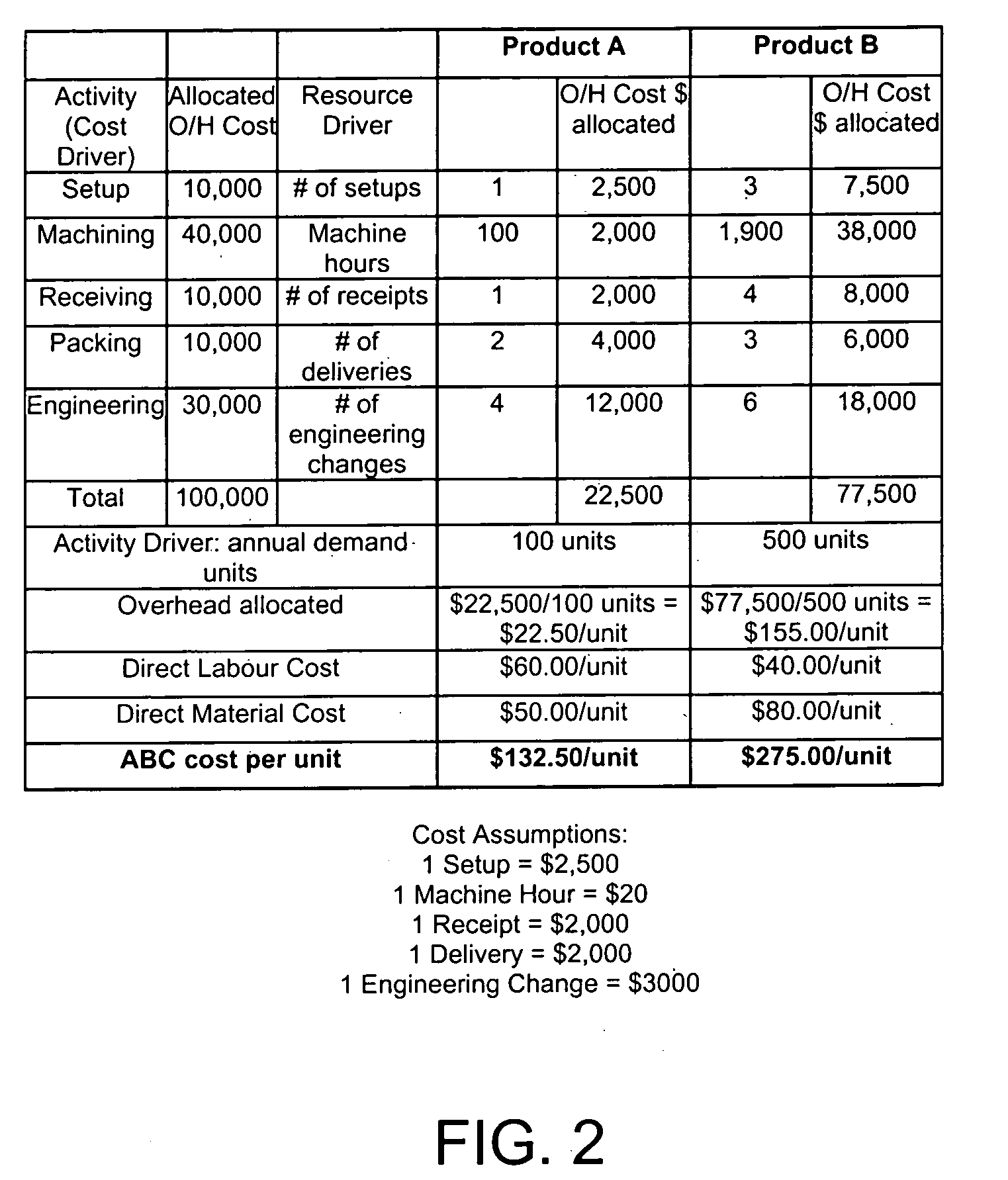

System, computer program product, and method for enterprise modeling, temporal activity-based costing and utilization

A method of temporal, activity-based cost modeling for an organization is provided. The method includes the steps of (a) determining a plurality of data types contributing to costs related to one or more activities of the organization; (b) capturing data elements corresponding to the data types; (c) Creating an ontological enterprise model based on the data elements, by applying a Temporal Activity Based Costing Model to the organization; testing the applicability of the Temporal Activity Based Costing Model to the organization; and adjusting the Temporal Activity Based Costing Model to the organization, based on the testing; and (d) configuring a computer system to apply the ontological enterprise model to the data elements on an ongoing basis, such that the ontological enterprise model yields information about the costs of the activities for defined periods of time. The method enables derivation of cost knowledge from the cost information, by operation of a profit knowledge utility. A series of sub-methods are also provided to enable the application of the Temporal Activity Based Costing Model. A computer system and computer program is also provided for implementing the temporal, activity-based cost modeling of the invention for an organization. The invention also provided for temporal, activity based billing, and generation of real time temporal cost information.

Owner:NULOGY CORP

Automated test system based on three-dimensional application software framework and a method thereof

InactiveUS8676723B2Ensure stable executionMaintain relatively stableError detection/correctionDigital computer detailsGraphicsFrame based

Owner:CODESE

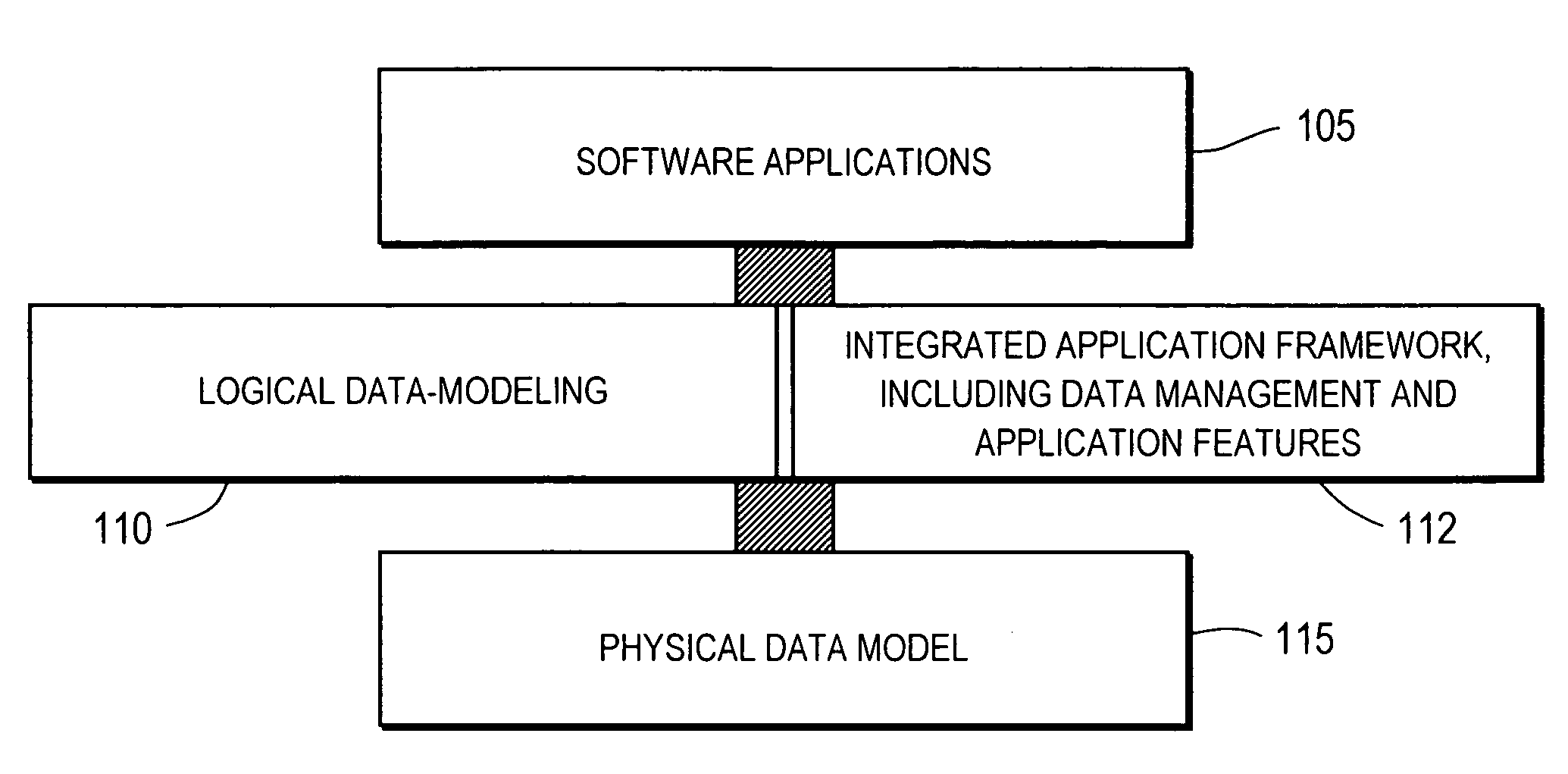

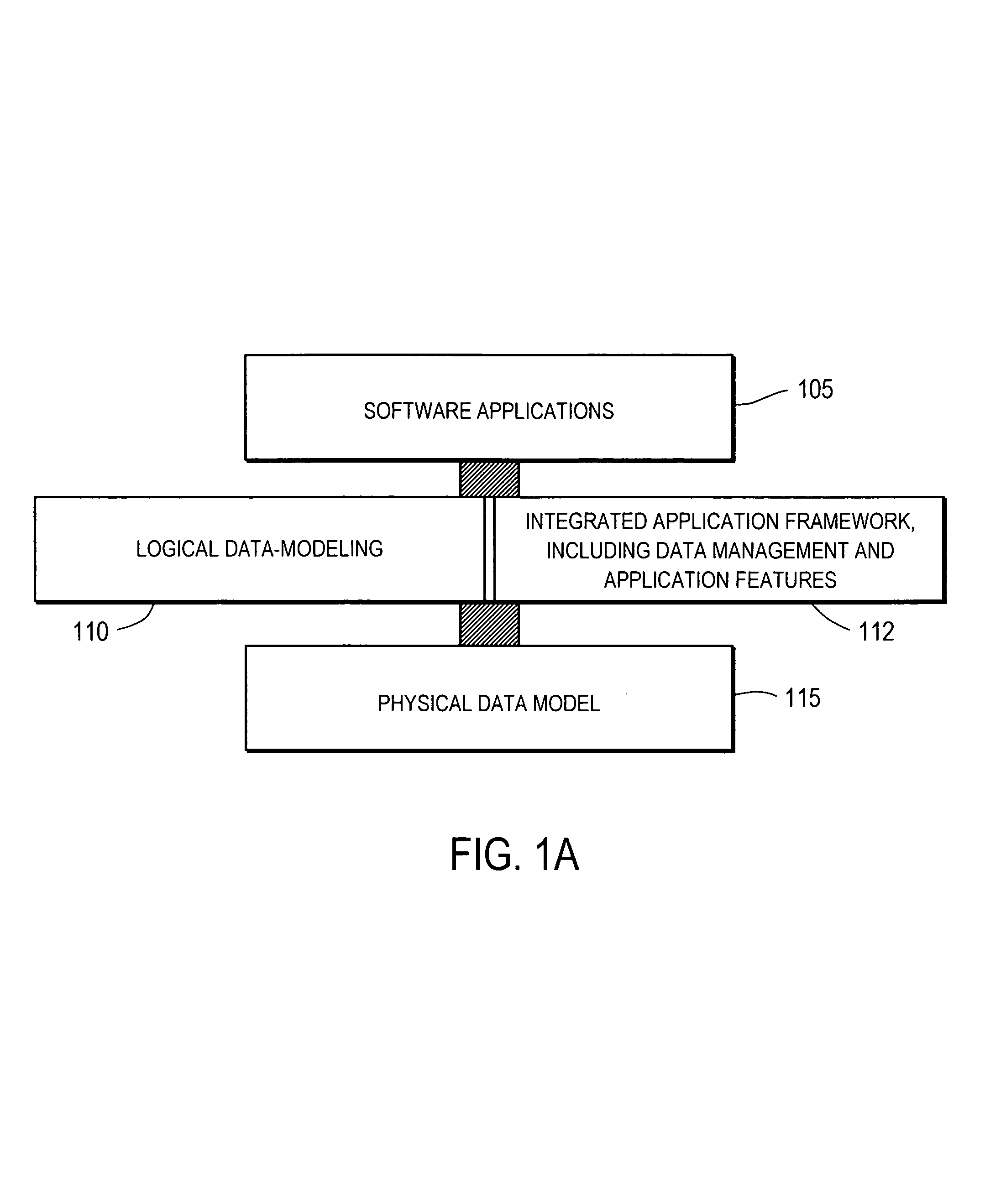

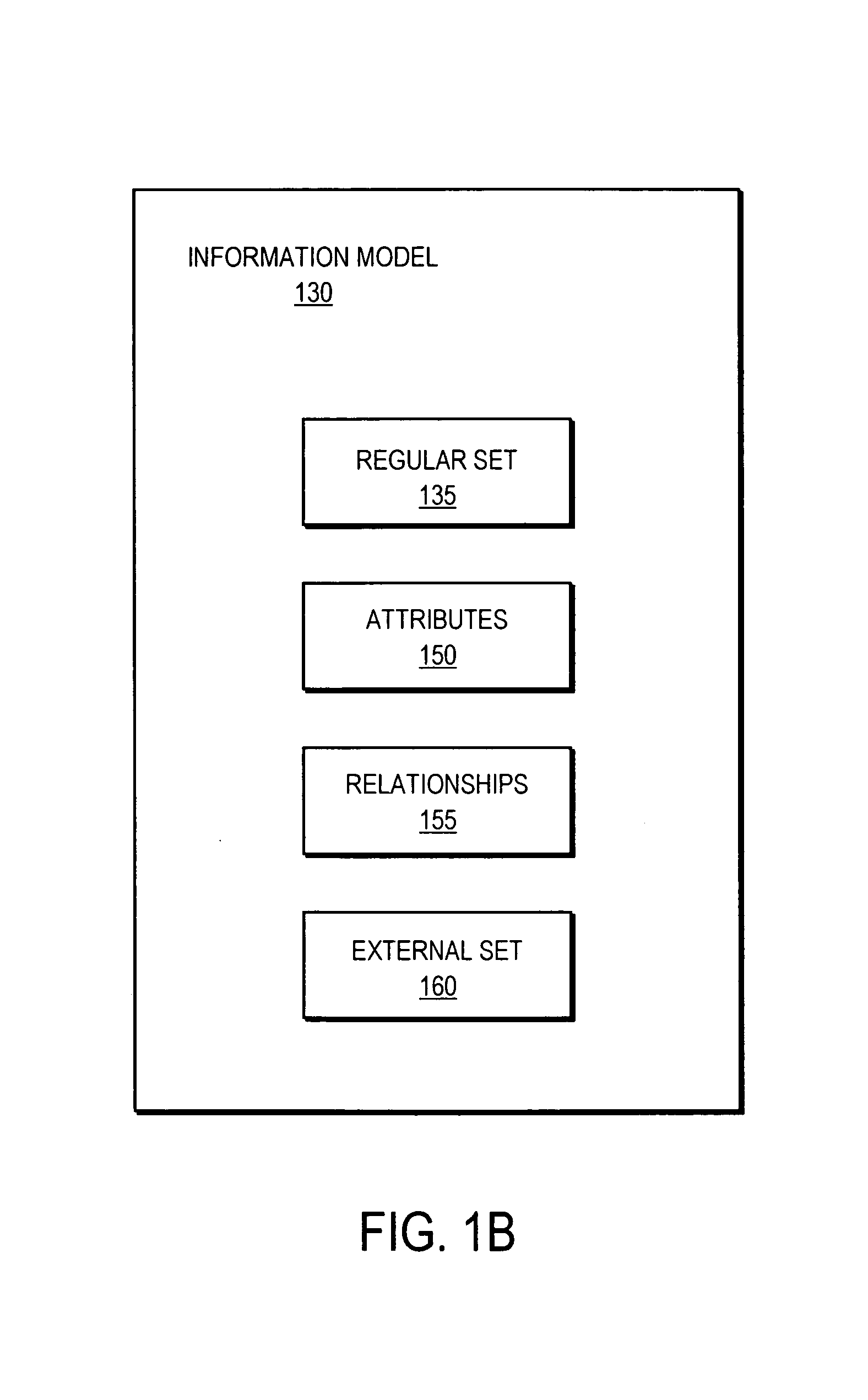

Logical data modeling and integrated application framework

ActiveUS7185317B2Visual/graphical programmingSpecific program execution arrangementsTheoretical computer scienceEngineering

A logical data model is defined using a data-modeling framework. The data-modeling framework enables a user to define the logical data model using a series of graphical user interfaces (GUI) or an application-programming interface (API). The data-modeling framework dynamically translates the logical data model into a corresponding physical data model. The logical data model can be changed using the GUI or API and the physical data model is automatically adjusted to accommodate the changes to the logical data model. The logical data model extends capabilities of the physical data model and automatically allows these capabilities to be available to software developers using an application framework integrated with the data-modeling framework. The application framework enables the developer to configure various application features and data management operations using GUI or API. The application framework is tightly coupled with the data-modeling framework such that changes in the logical data model is automatically reflected in the applications.

Owner:THOMSON REUTERS ENTERPRISE CENT GMBH

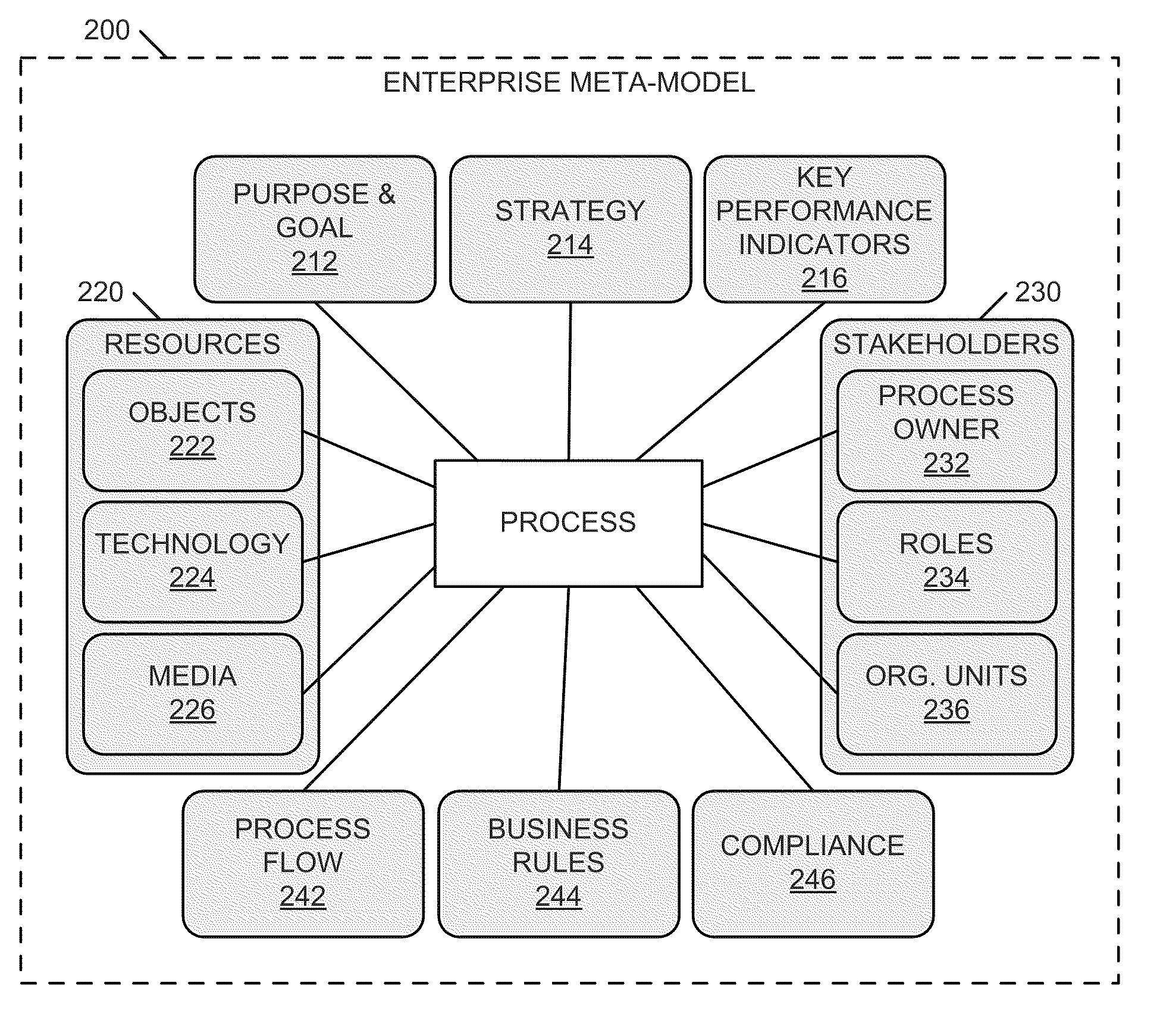

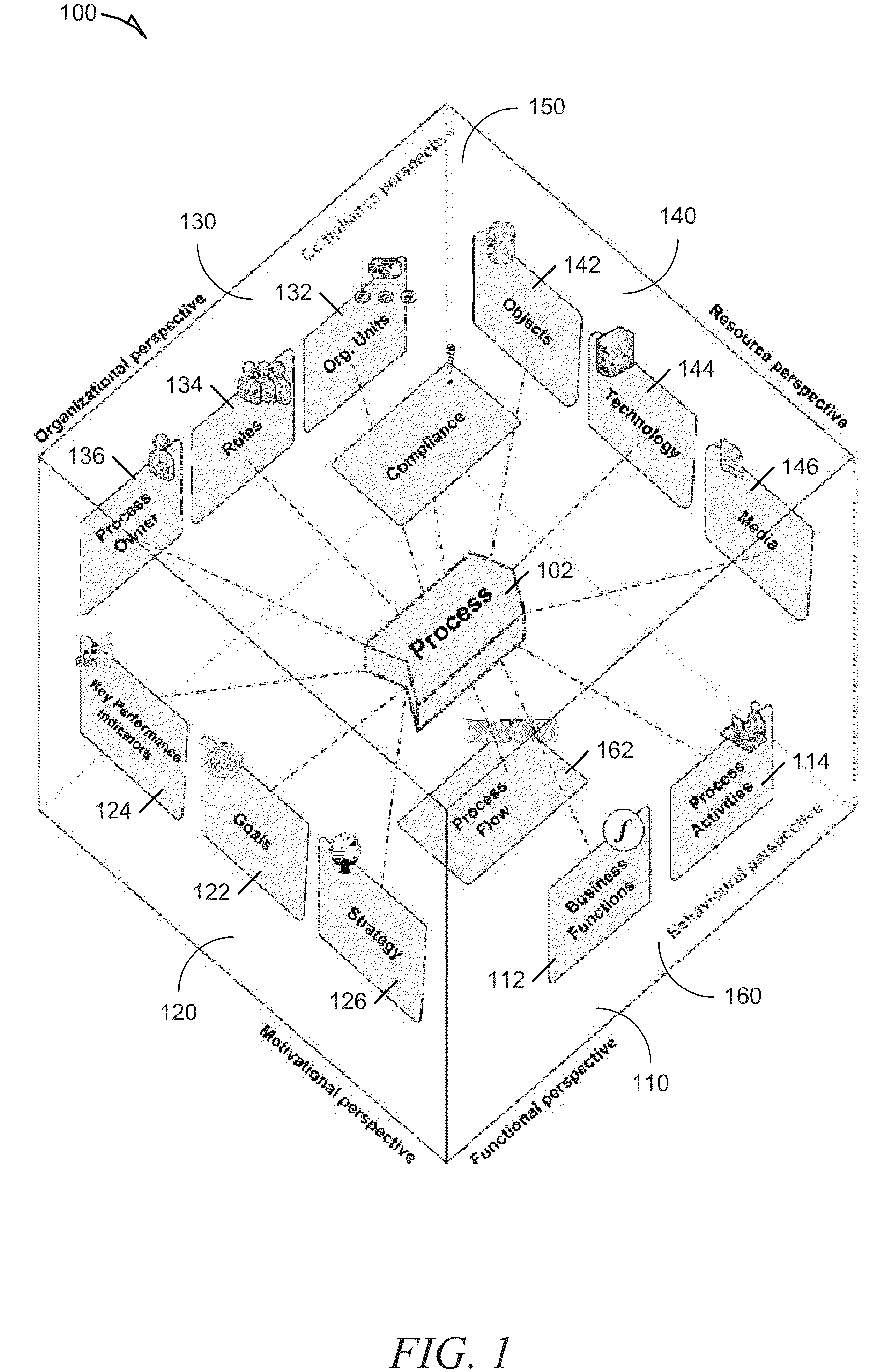

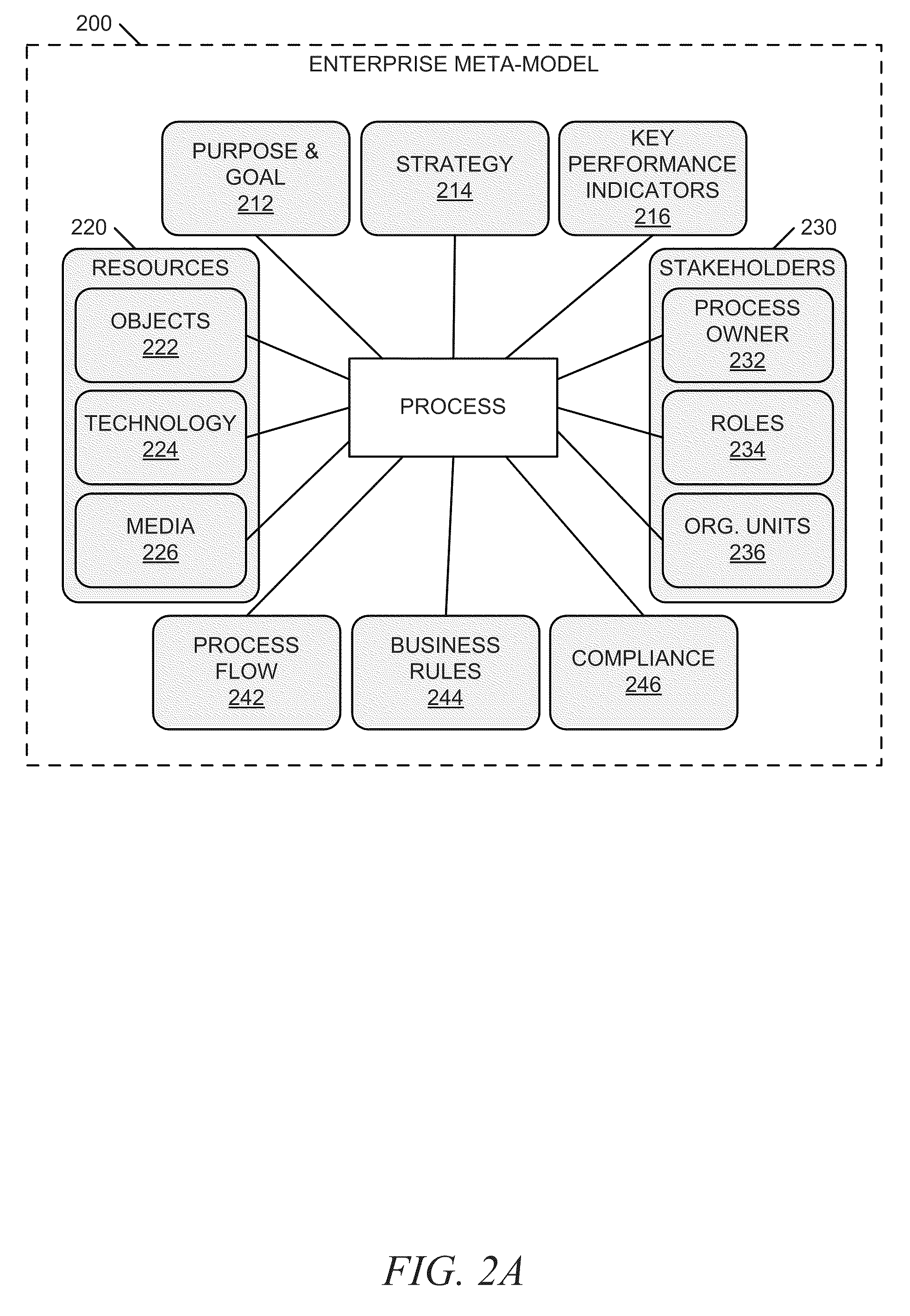

Systems and methods for integrating process perspectives and abstraction levels into process modeling

ActiveUS20110029947A1Office automationSpecific program execution arrangementsAbstraction layerEnterprise modelling

Methods and systems for integrating process perspectives and abstraction levels into business process modeling are described. In one example embodiment, modeling business processes for an enterprise can include selecting a segmented view of an enterprise meta-model. The segmented view is associated with a business process to be modeled. The enterprise meta-model is a machine-readable representation of business rules and policies for the enterprise. A business process model is created using a set of visual modeling tools, which are limited by the segmented view. A business policy having some relevance to the process being modeled can be selected for annotation to the business process. Once completed, the business process model is transformed into a machine-readable representation and stored in a repository.

Owner:SAP AG

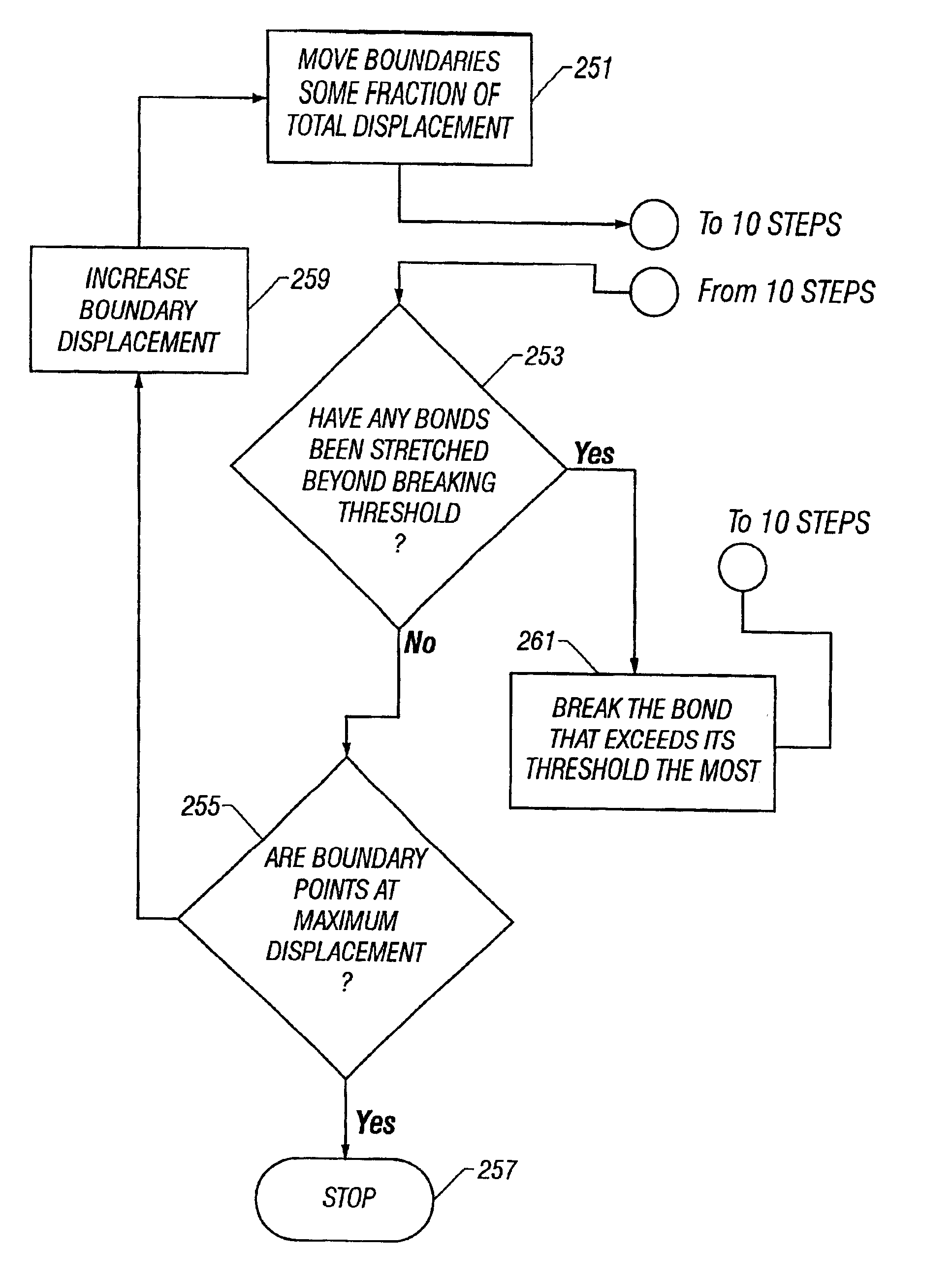

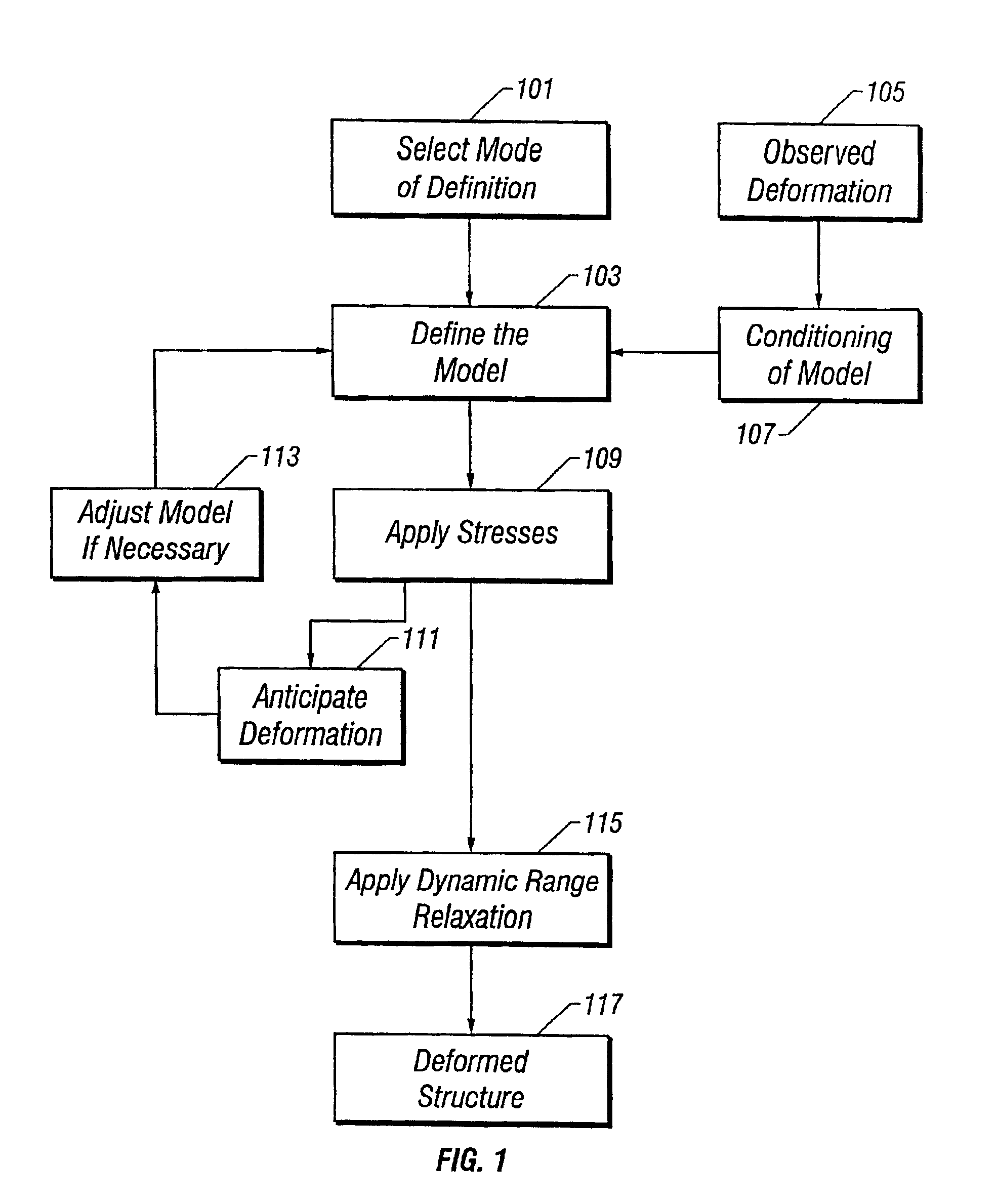

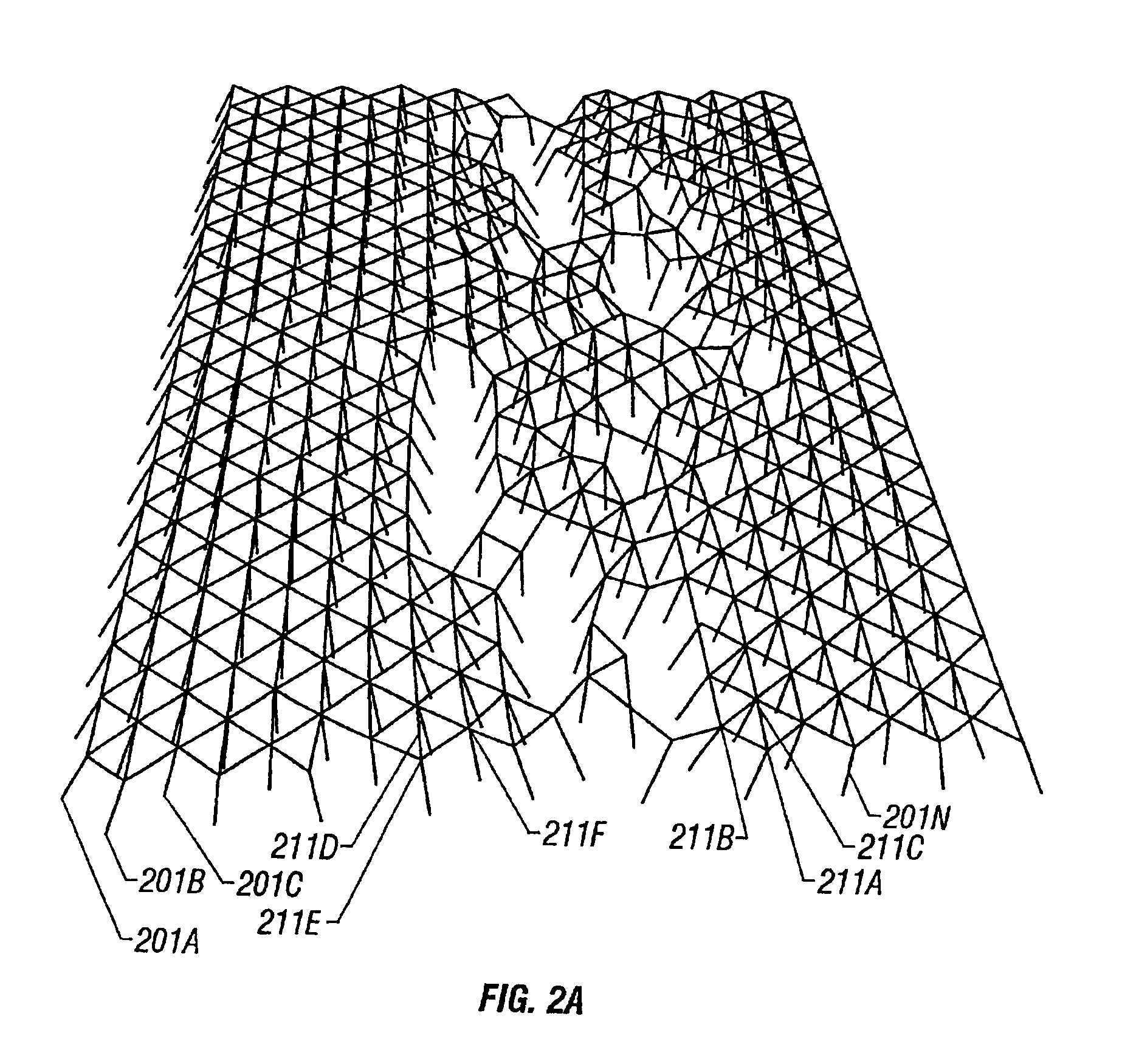

Method of modeling of faulting and fracturing in the earth

InactiveUS7089166B2Computation timeElectric/magnetic detection for well-loggingComputation using non-denominational number representationGravity modelingModelSim

A computer implemented method for modeling of faulting and fracturing uses “small scale rules” to produce large-scale results. One part of the method is a user interface for inputting deformations, preexisting faults and fractures, and material rock properties. The second part of the software is the code that solves the motion of each point or node in the subsurface volume defined by the user interface. The model may be defined in one of three modes: an aerial mode, in which the model is 2-dimensional with the material and a substrate on a horizontal plane; a cross-sectional mode similar to the aerial mode except that the nodes are in a vertical cross section and gravity is included in the model; and a 3-D model that is an extension into a third dimension of the 2-D model and deformation may be applied to the bottom and four sides of the material region.A modified over-relaxation approach, wherein the over-relaxation is concentrated in those nodes where the greatest movement occurs, is used to solve for the deformation. This significantly speeds up the computation time. The model is “conditioned” to increase the likelihood that the deformation pattern resulting from the simulation of the deformation will at least duplicate an observed large-scale deformation. As an aid to the simulation, an “anticipate” step provides a quick solution to the deformation without including the effects of faulting.

Owner:CONOCO INC +1

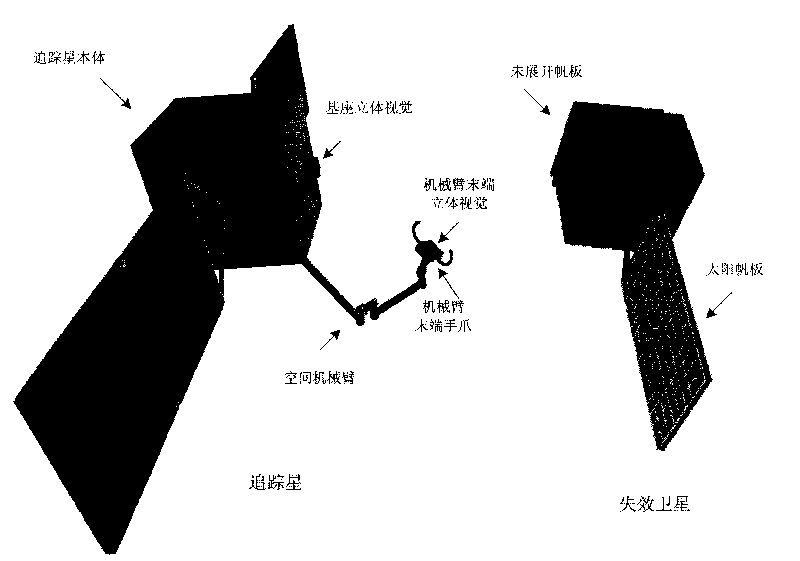

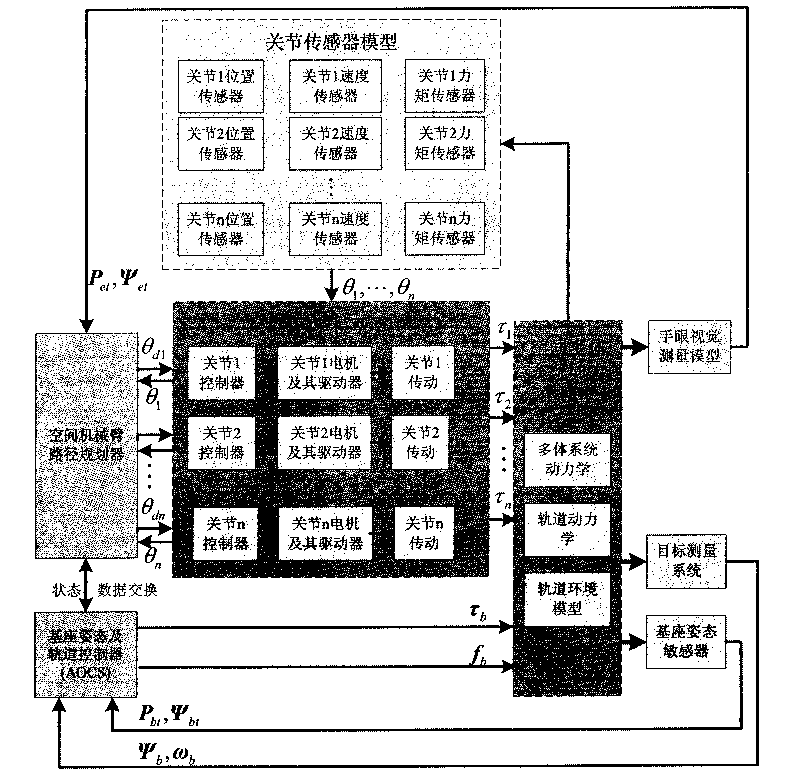

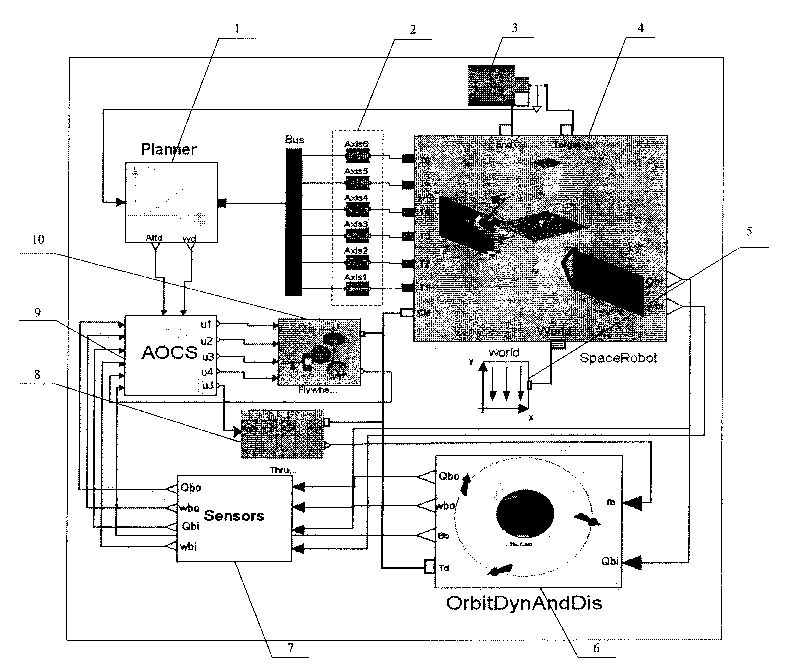

Multidomain uniform modeling and emulation system of space robot

InactiveCN101733749AGood reusabilityGood module reusabilityProgramme-controlled manipulatorToolsRobot handMulti disciplinary

The invention relates to a multidomain uniform modeling and emulation system of a space robot, comprising a space robot path planer (1), a joint shaft module (2), a space robot hand and eye cameral measuring module (3), a space robot mechanism module (4), a world coordinate and centerbody gravitational field (5), a track dynamics and space environment module (6), a space robot base sensor module (7), a propulsion module (8), a counteractive flywheel assembly (10) and a space robot base posture track control module (9). Model libraries are developed by adopting multidomain physical system modeling language Modelica, thereby seamless integration and data switching among models in different domains, such as machinery, electric, software, control and the like, are thoroughly realized, and the target of multidisciplinary optimization design is realized. Based on the modeling and emulation system, the invention can conveniently realize the modeling and emulation of single-arm and multi-arm space robots under the modes of free flying and free floating.

Owner:HARBIN INST OF TECH

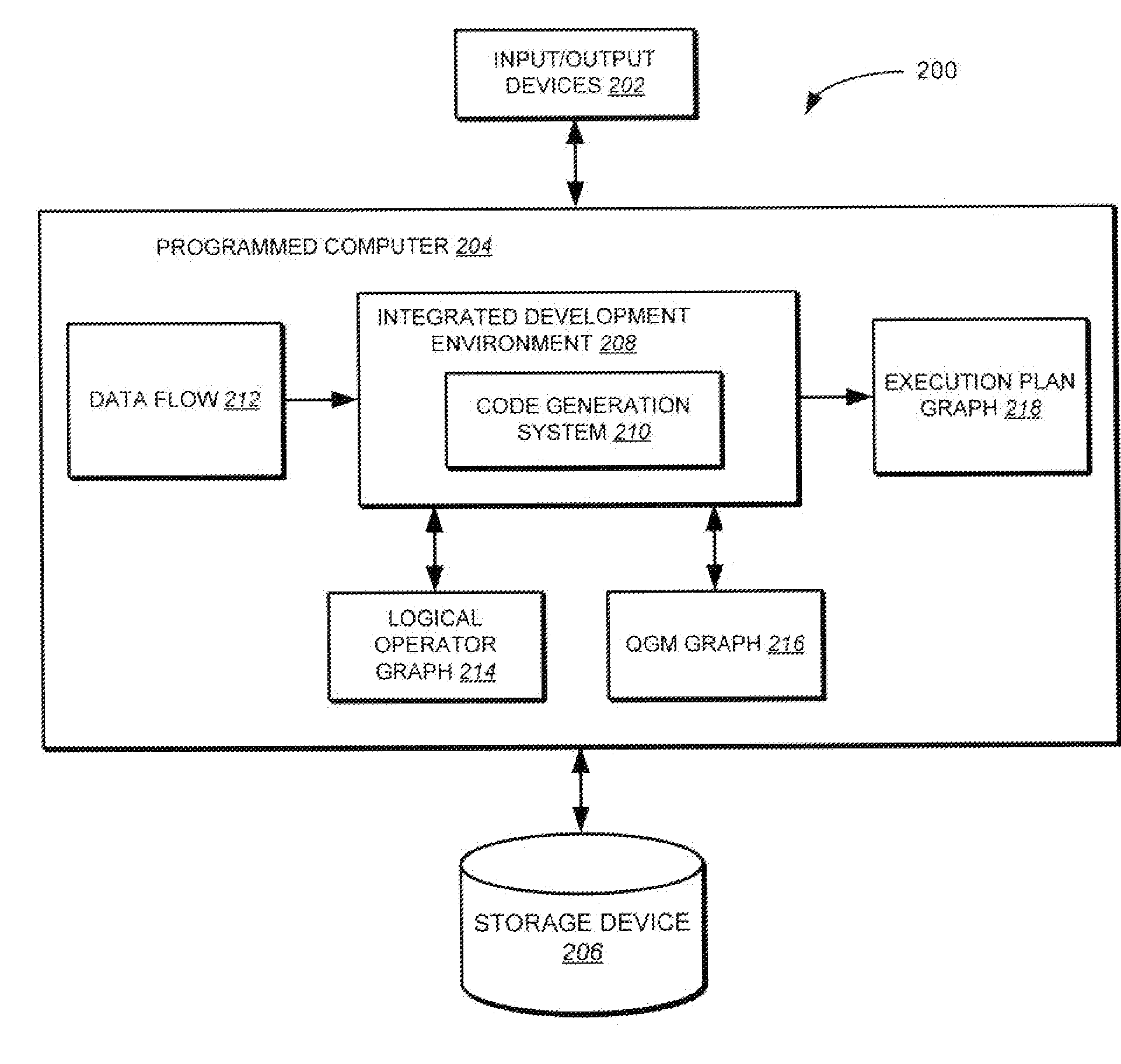

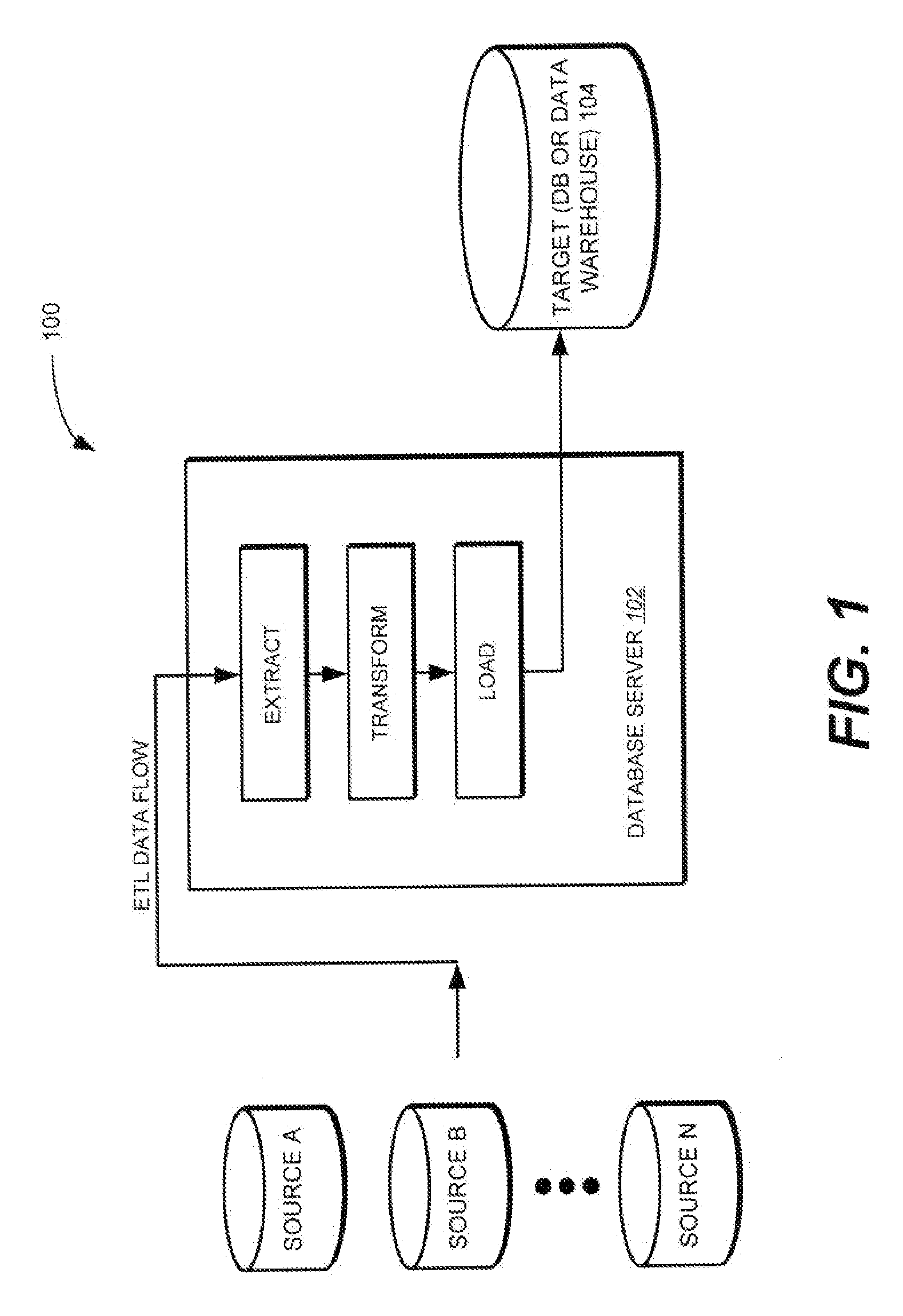

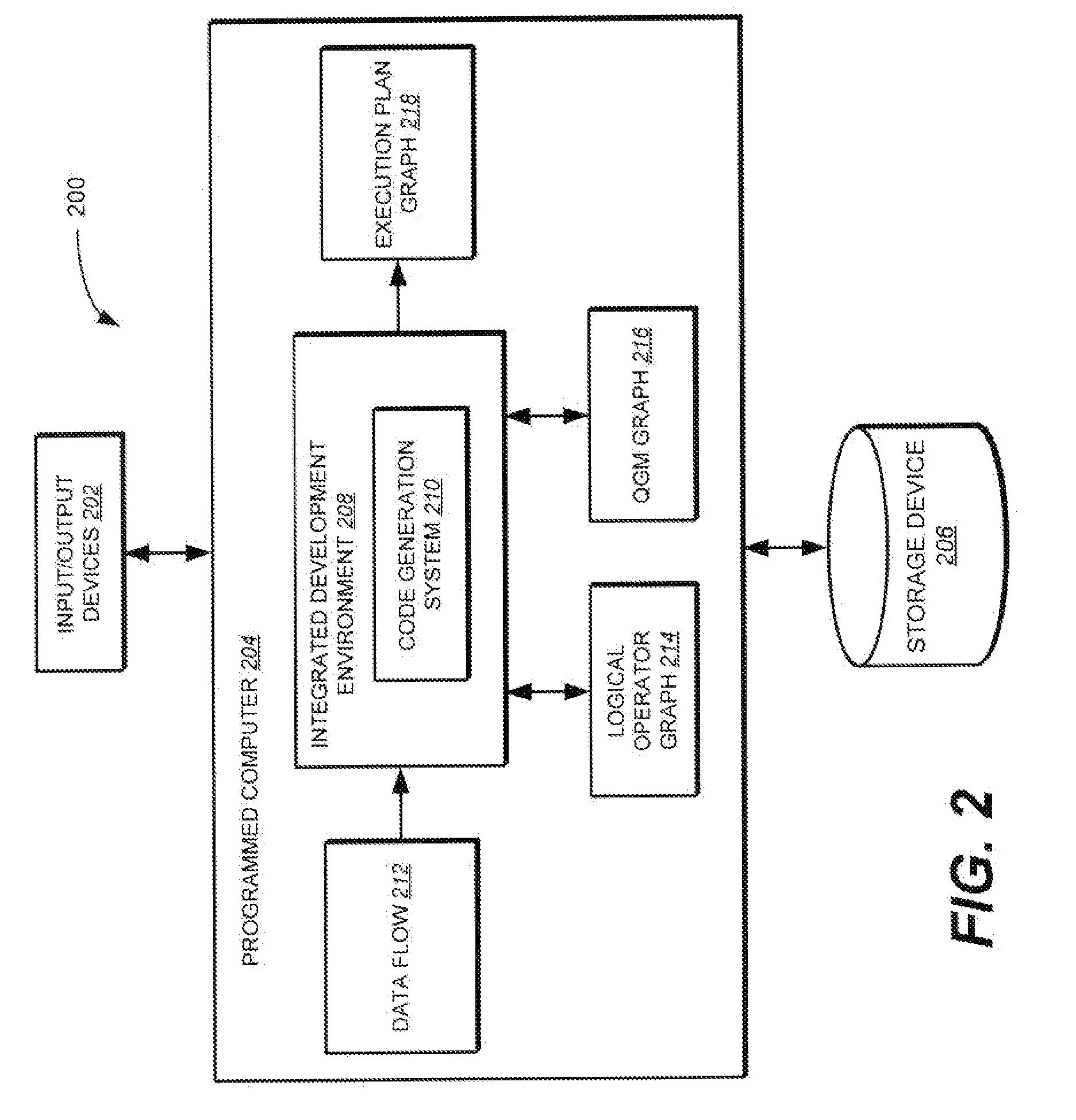

Method and apparatus for modelling data exchange in a data flow of an extract, transform, and load (ETL) process

InactiveUS20080168082A1Good performanceEase of recoveryDigital data processing detailsSoftware designData conversionData exchange

Methods, systems, and computer program products for generating code from a data flow associated with an extract, transform, and load (ETL) process. In one implementation, the method includes identifying a data exchange requirement between a first operator and a second operator in the data flow. The first operator is a graphical object that represents a first data transformation step in the data flow and is associated with a first type of runtime engine, and the second operator is a graphical object that represents a second data transformation step in the date flow and is associated with a second type of runtime engine. The method further includes generating code to manage data staging between the first operator and the second operator in the data flow. The code exchanges data from a format associated with the first type of runtime engine to a format associated with the second type of runtime engine.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com