Patents

Literature

50 results about "Joint problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A: The two major categories of joint problems are developmental and degenerative problems. With developmental problems, you have things like hip or elbow dysplasia, where the joint does not develop correctly in a number of different ways. Degenerative problems cover a number of areas.

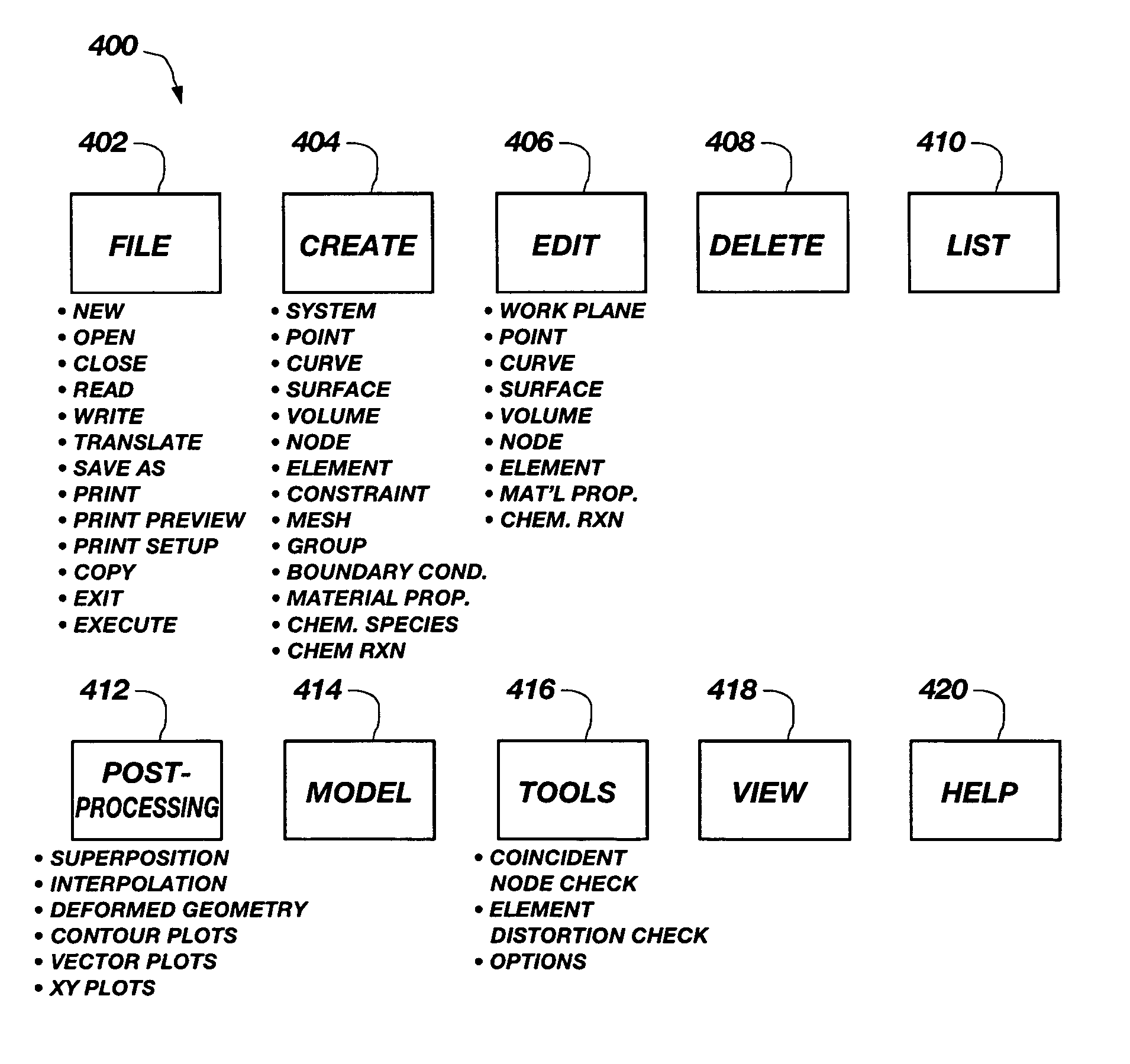

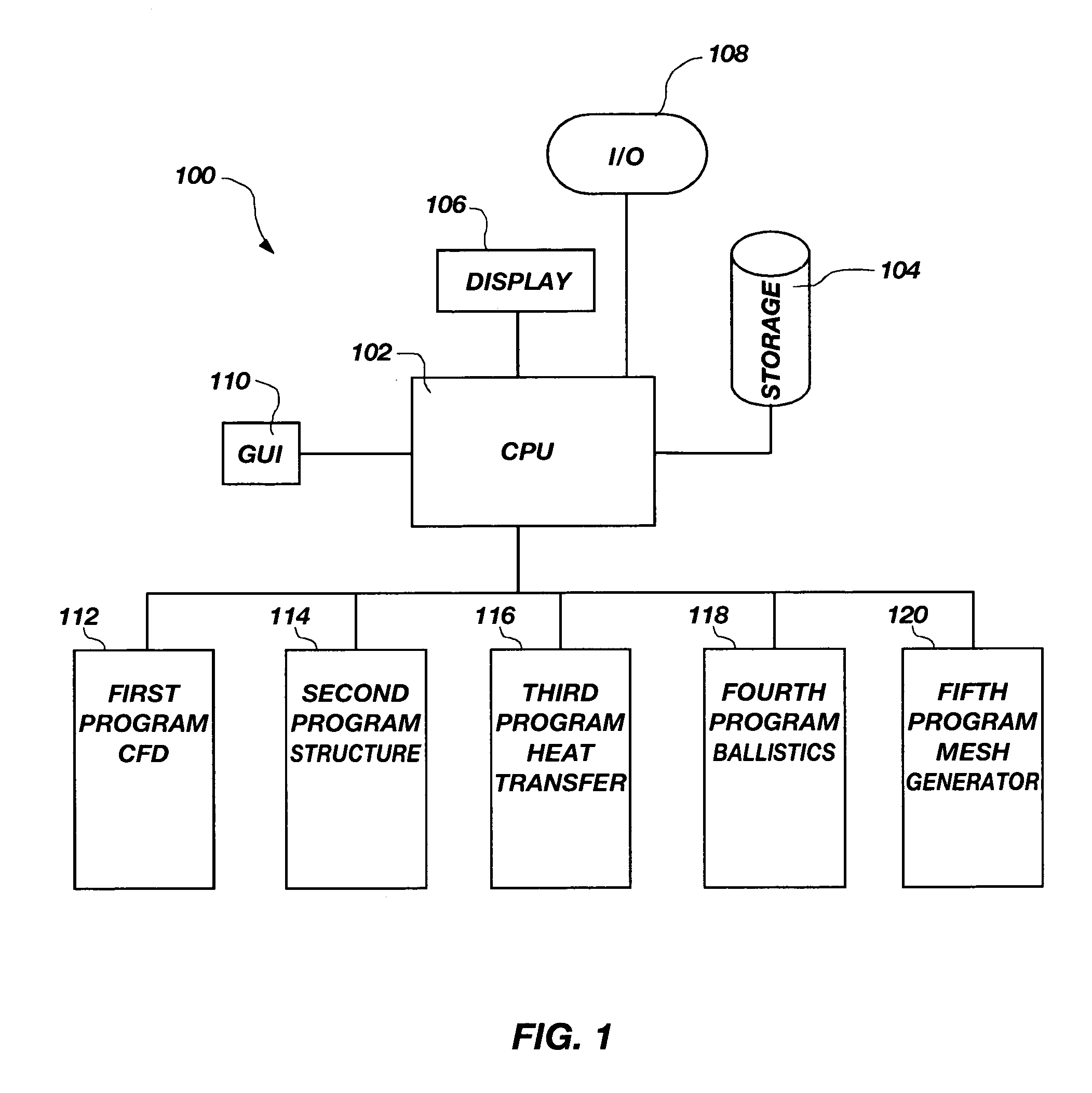

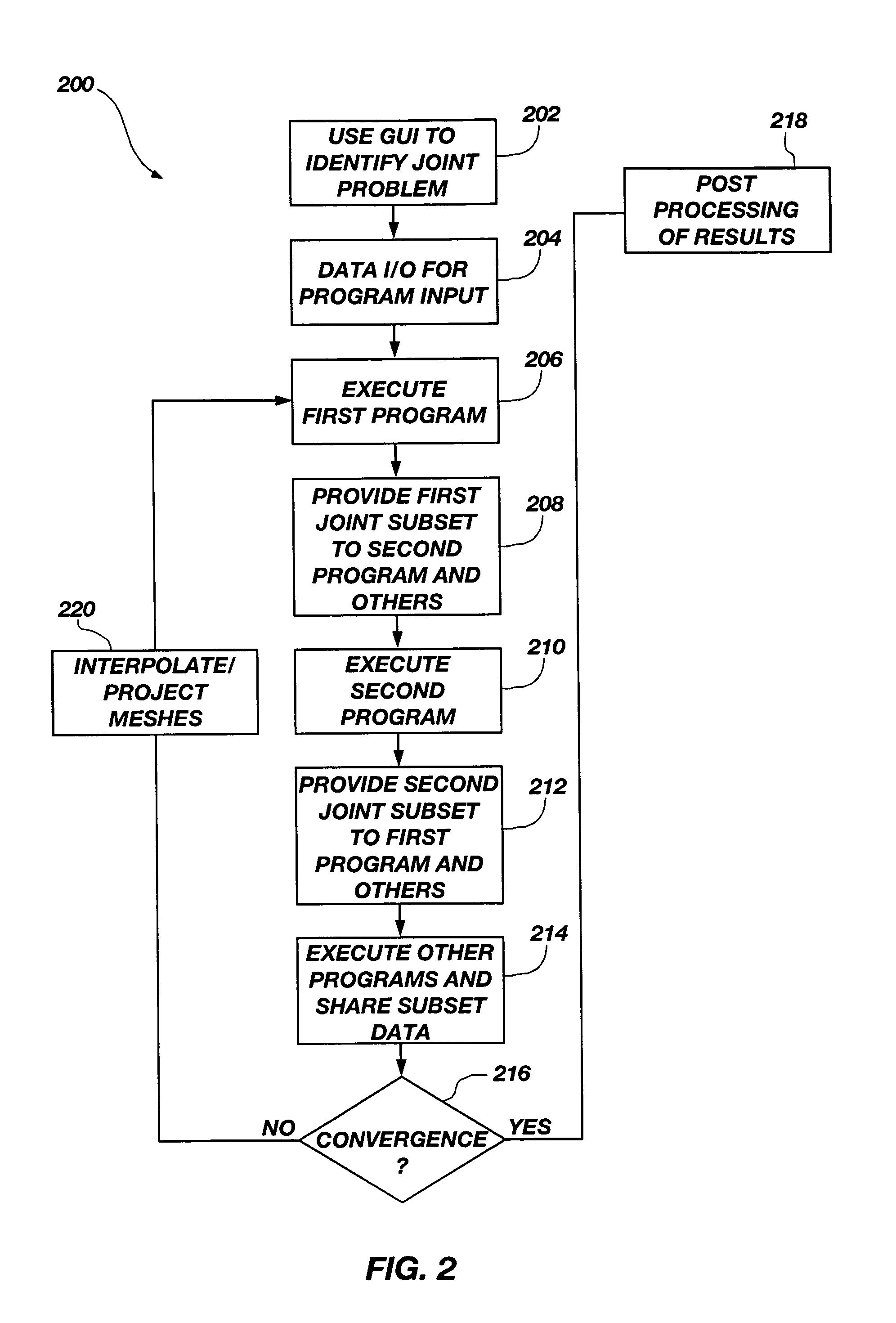

System for performing coupled finite analysis

ActiveUS7127380B1Stay flexibleAccelerated settlementComputation using non-denominational number representationDesign optimisation/simulationComputational scienceGraphics

A graphical user interface, together with a comparable scripting interface, couples a plurality of finite element, finite volume, or finite difference analytical programs and permits iterative convergence of multiple programs through one set of predefined commands. The user is permitted to select the joint problem for solution by choosing program selections. Data linkages that couple the program are predefined by an expert system administrator to permit less skilled modelers access to a comprehensive and multifaceted solution that would not be possible for the less skilled modelers to complete absent the graphical user interface.

Owner:NORTHROP GRUMMAN SYST CORP

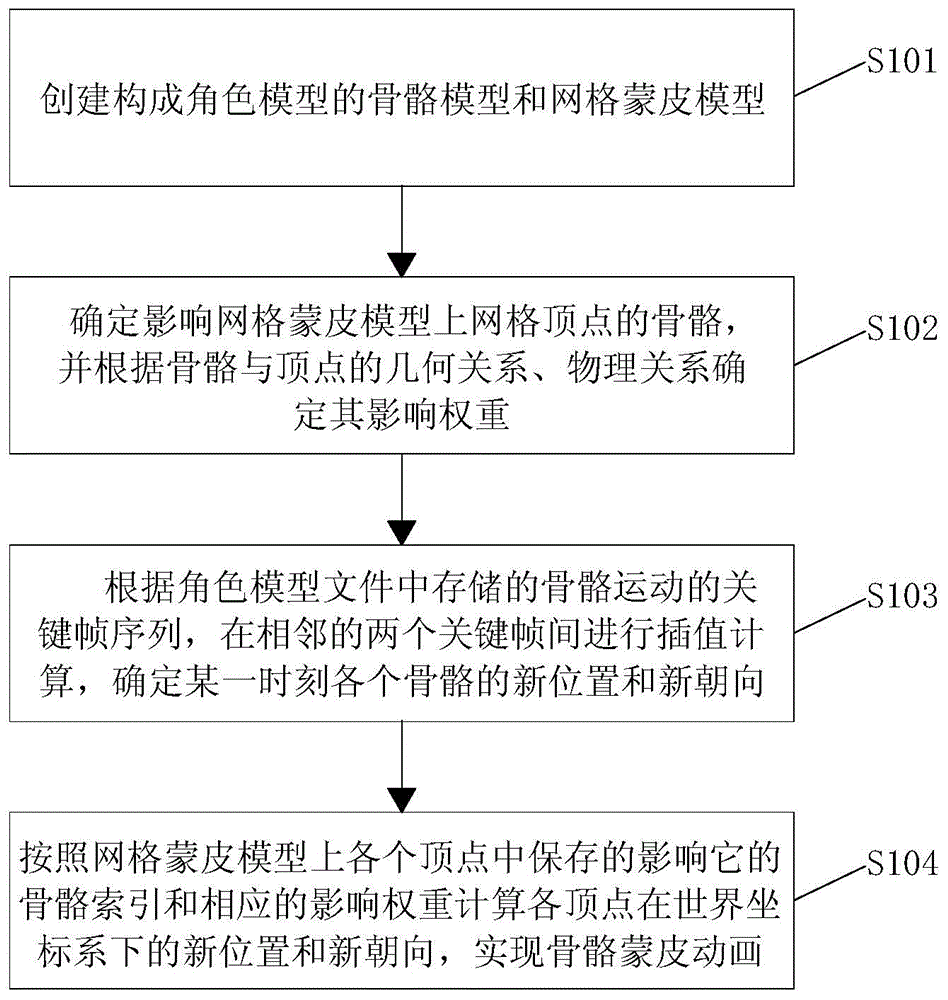

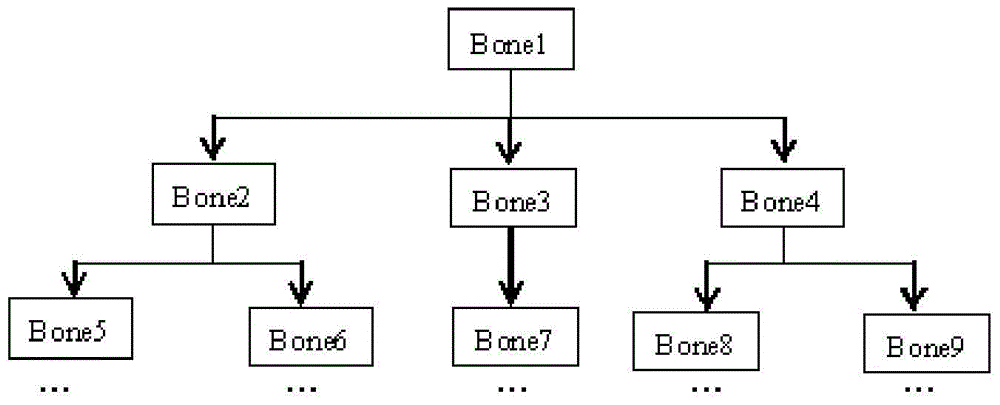

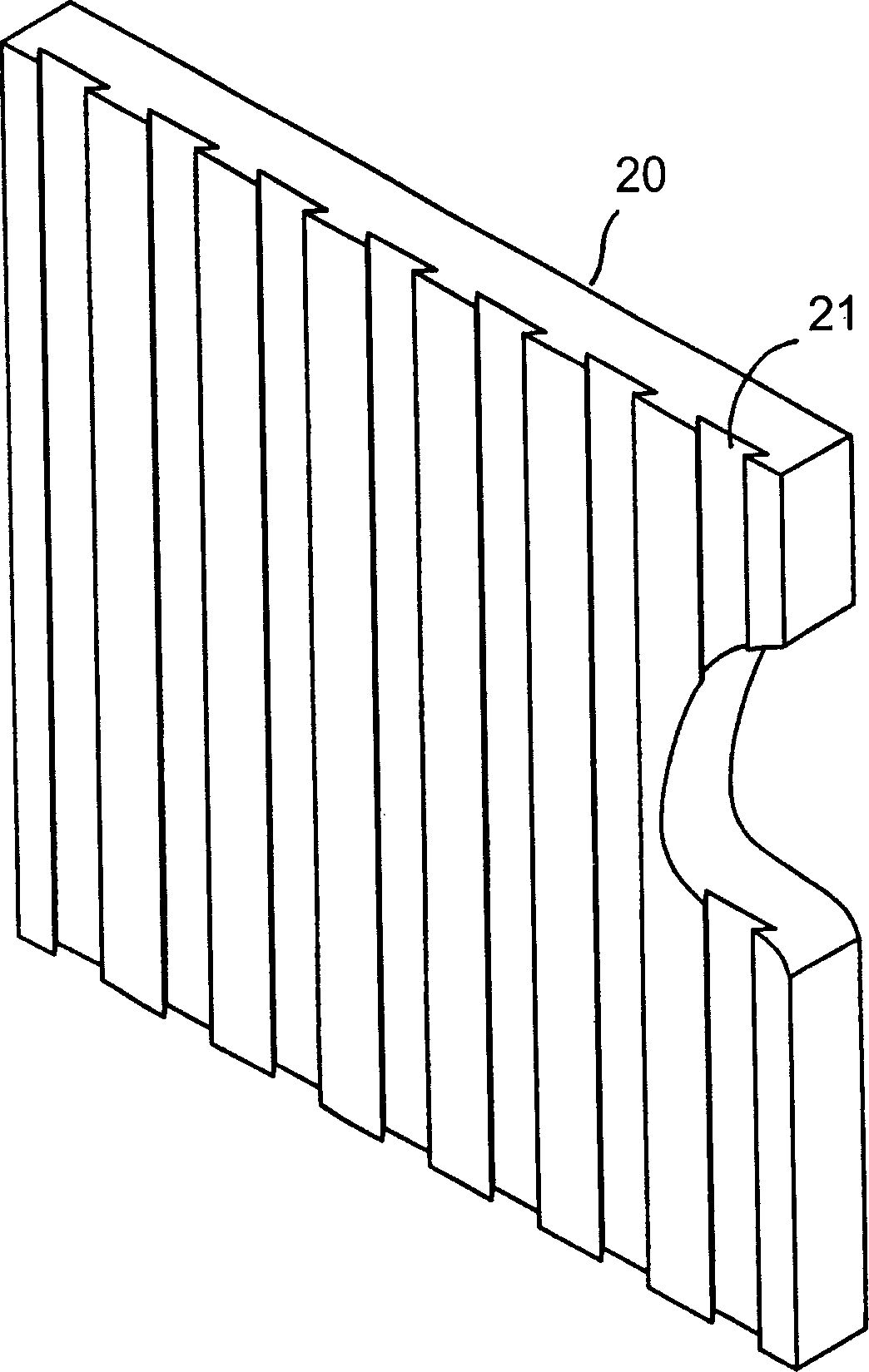

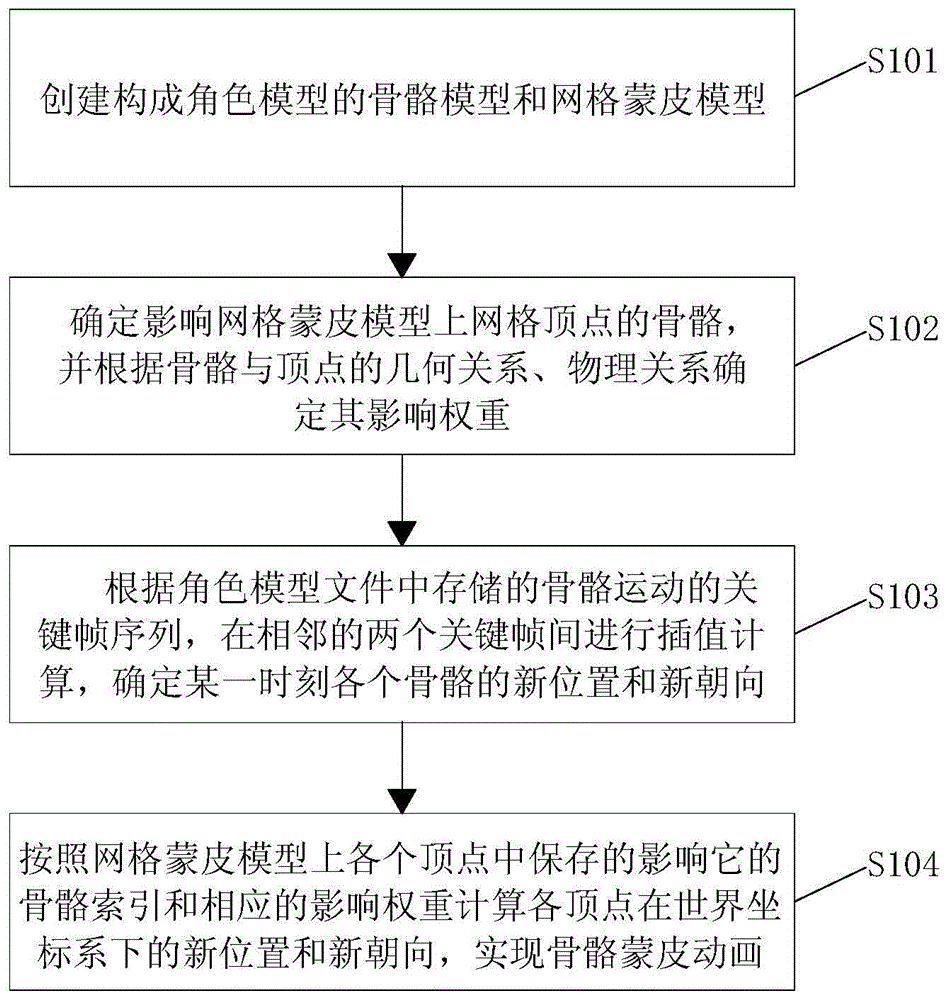

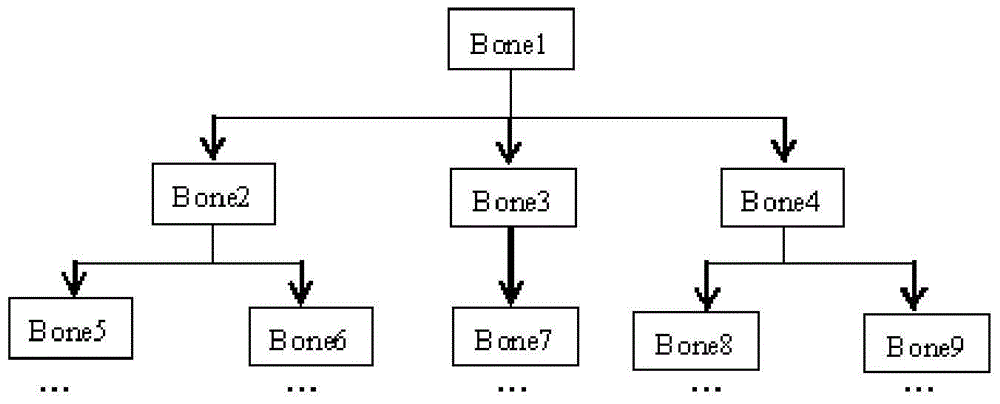

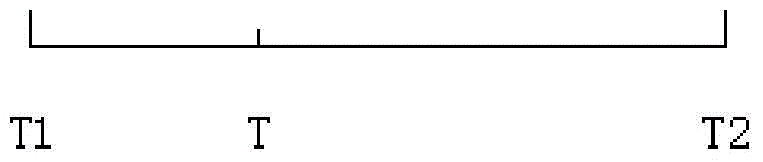

Implementation method of skinned skeletal animation

ActiveCN104021584AOvercoming seam problemsRealistic effectAnimationJoint problemMathematical Calculus

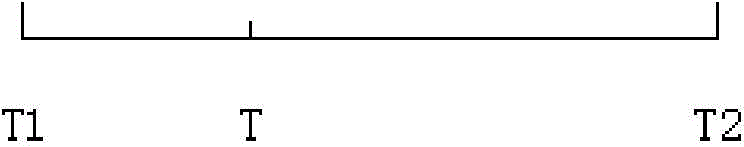

The invention discloses an implementation method of skinned skeletal animation. The implementation method comprises the following steps: A, constructing a skeleton model and a skinned mesh model which constitute a role model; B, determining a skeleton which influences the mesh vertexes on the skinned mesh model, and determining the influence weight according to a geometrical relationship and a physical relationship between the skeleton and the vertexes; C, carrying out calculus of interpolation between each two adjacent key frames according to a key frame sequence of skeleton movement, which is stored in a role model file, and determining new position and new orientation of each skeleton at certain moment; and D, calculating new position and new orientation of each vertex under a world coordinate system according to skeleton index and corresponding influence weight which influence each vertex and are stored in each vertex on the skinned mesh model, and thus achieving skinned skeleton animation. According to the implementation method disclosed by the invention, the joint problem in skeletal animation is solved, the effect is real and vivid, and is more flexible compared with that of vertex animation, and little memory space is occupied while a favorable animation effect is finished; the skinned skeletal animation can be constructed more easily and rapidly.

Owner:WUXI FANTIAN INFORMATION TECH

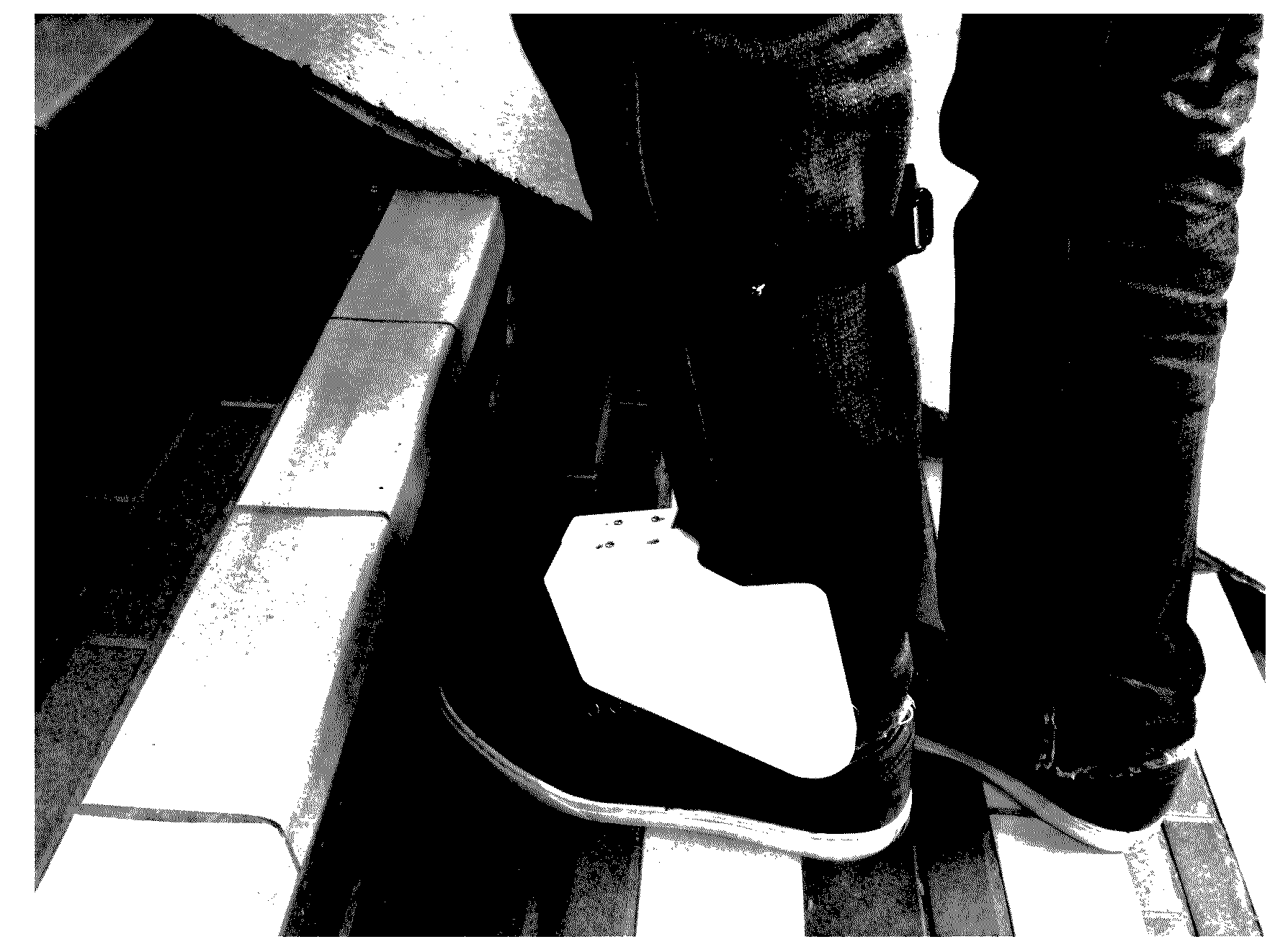

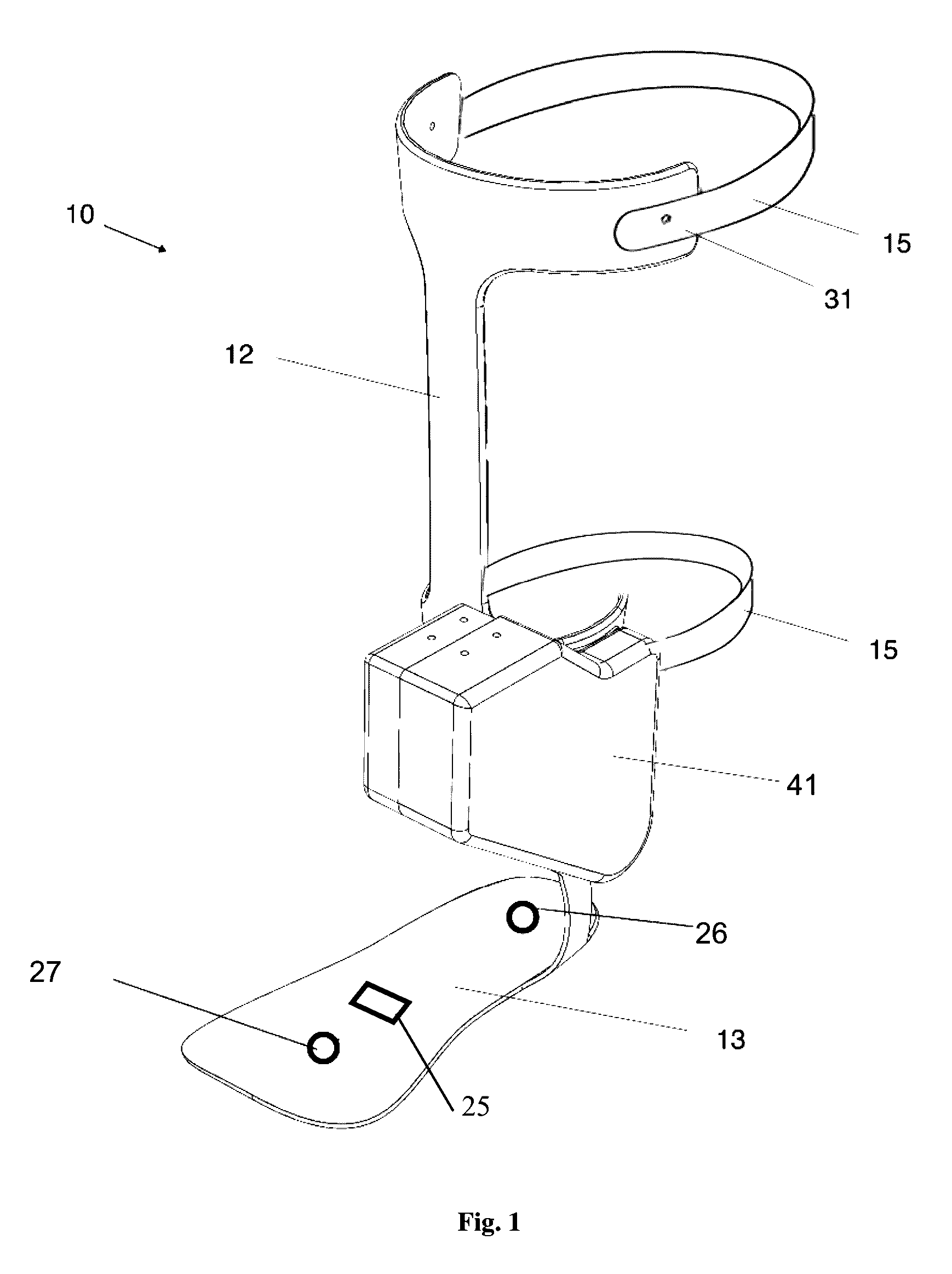

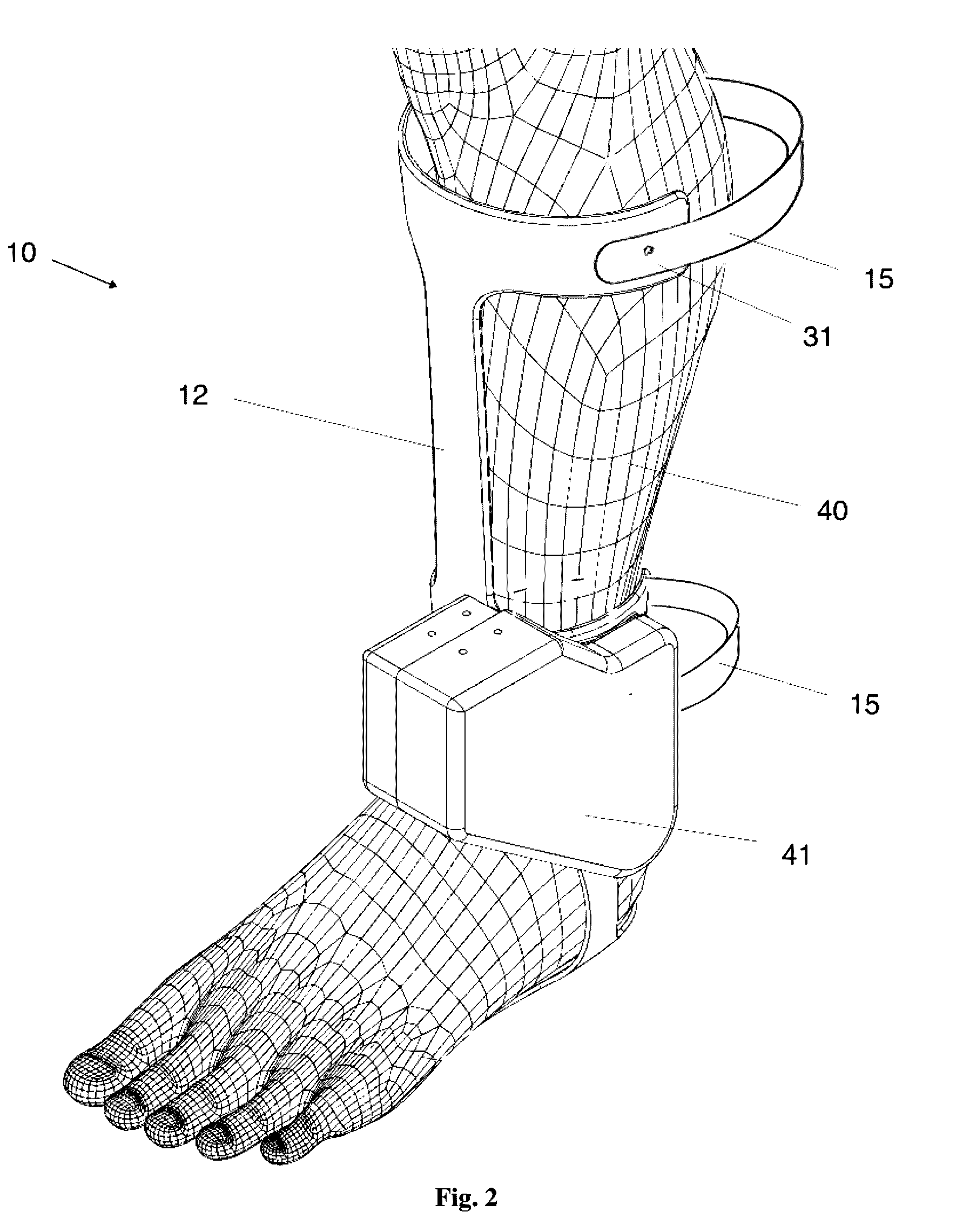

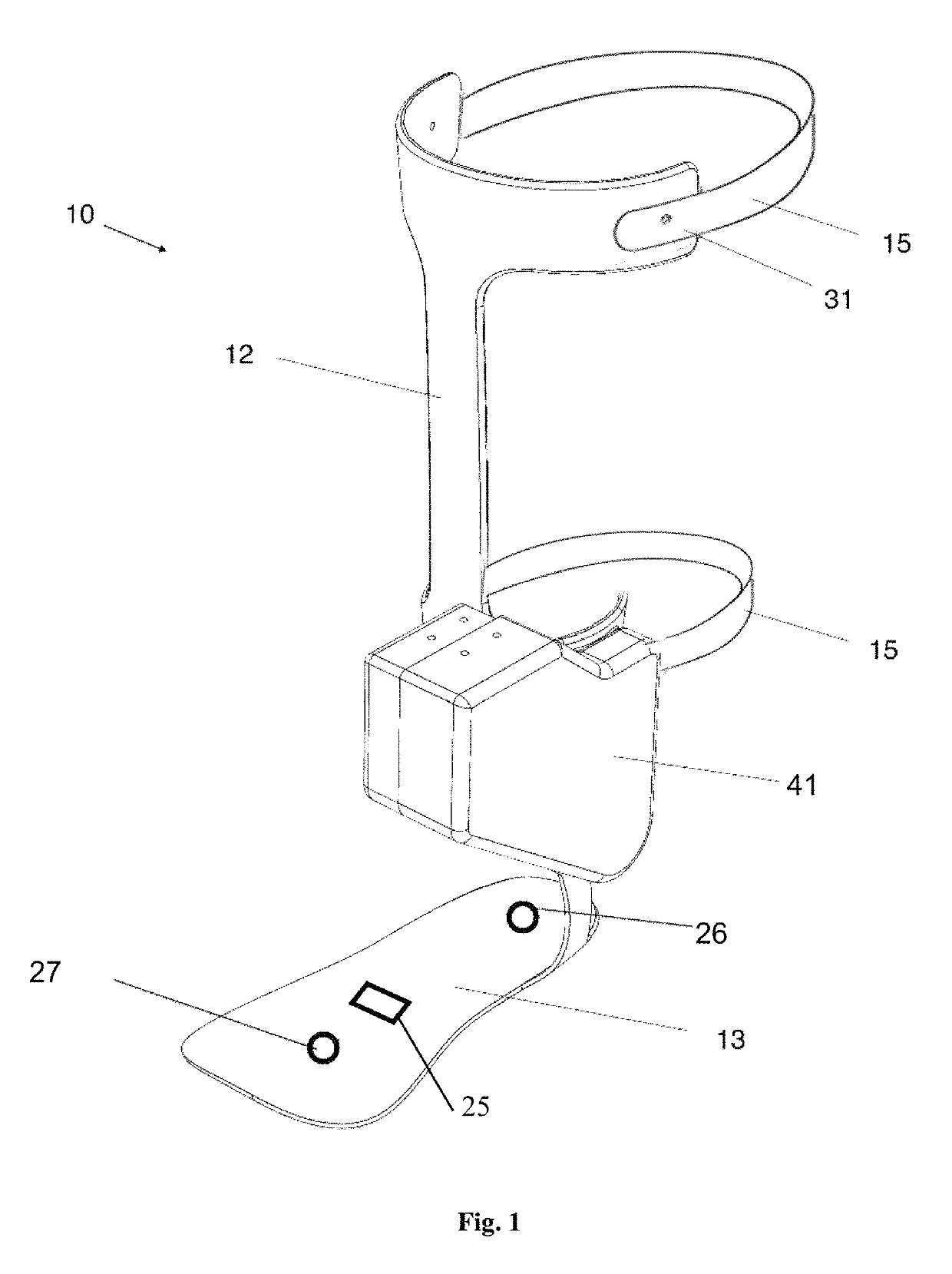

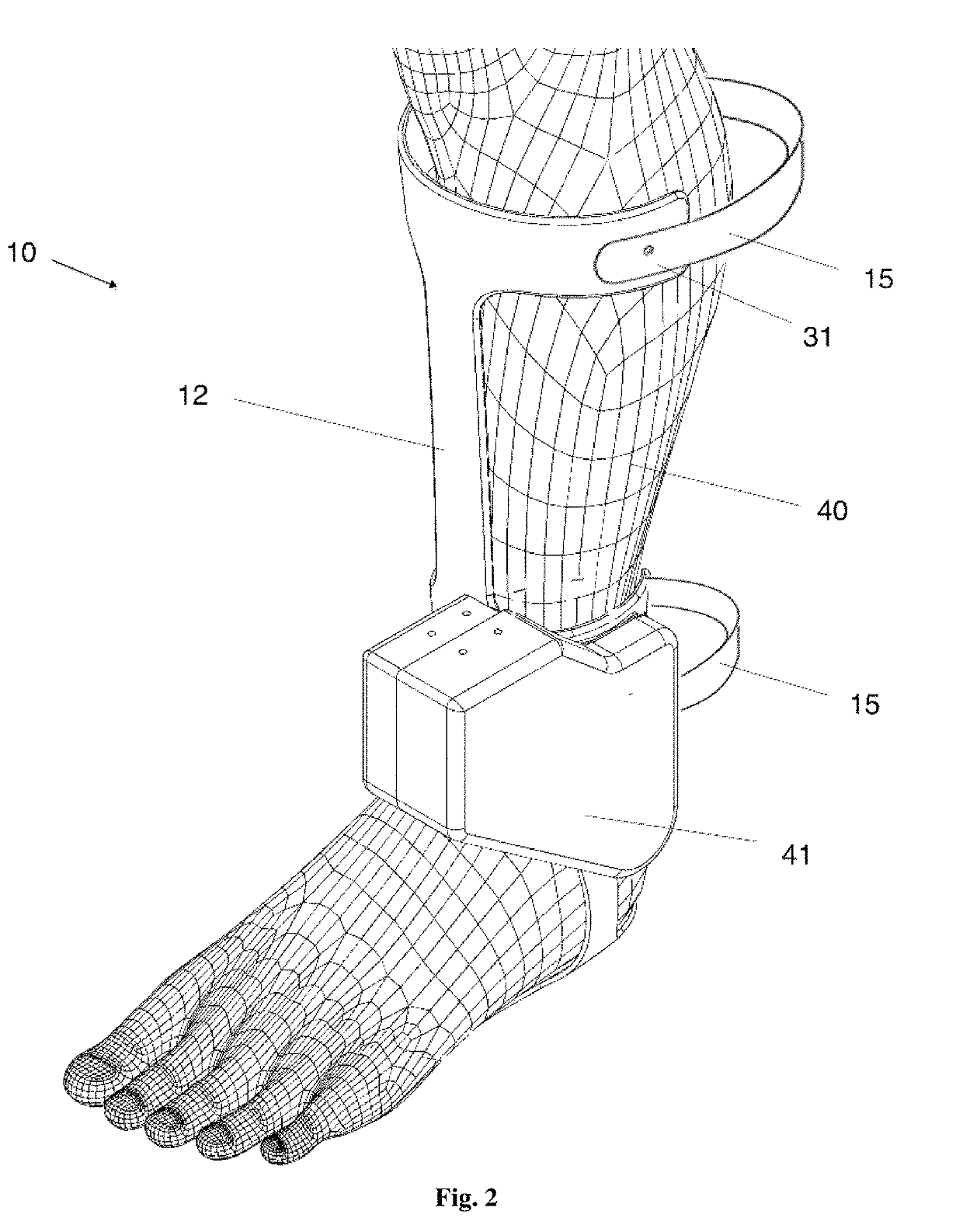

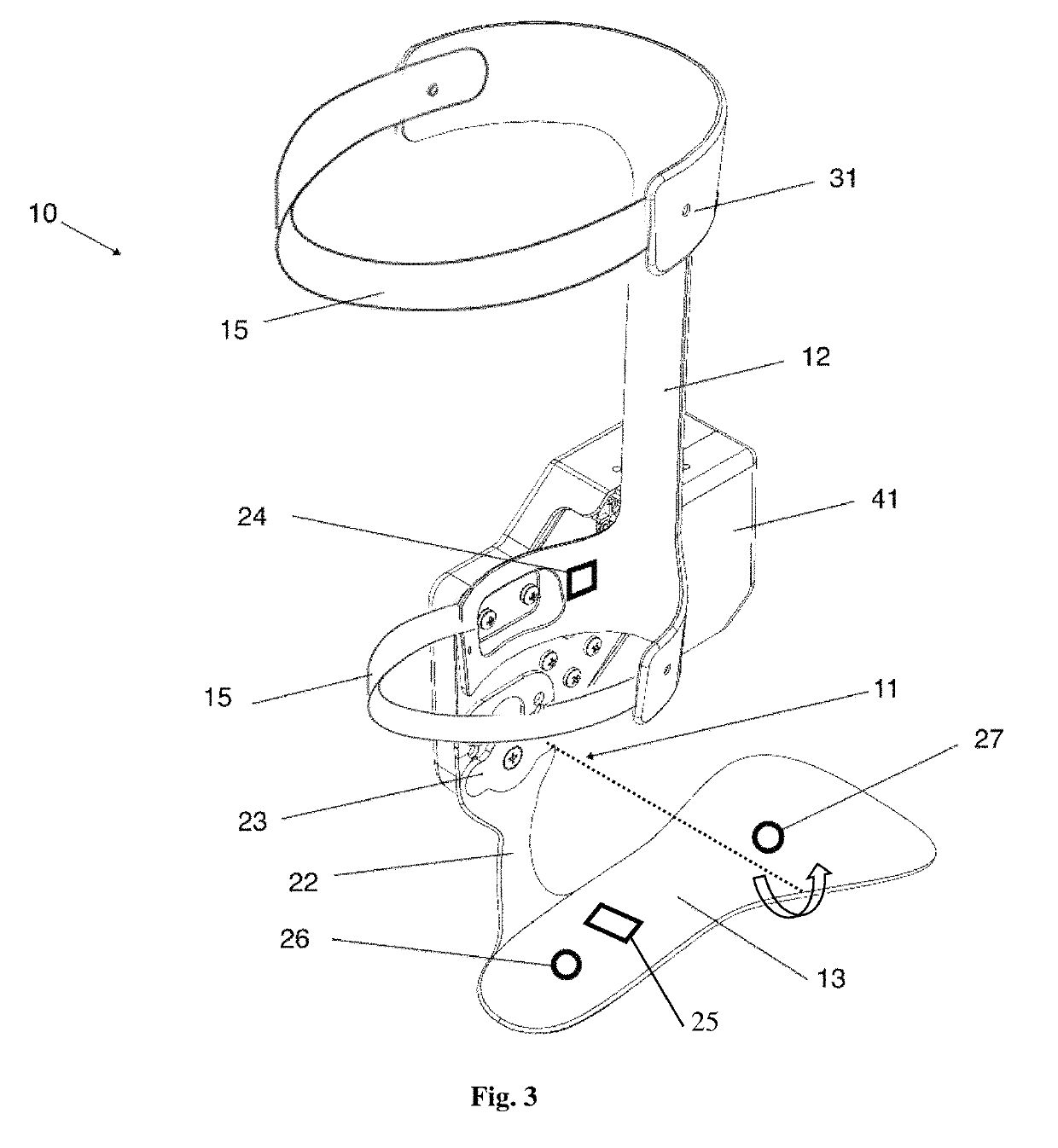

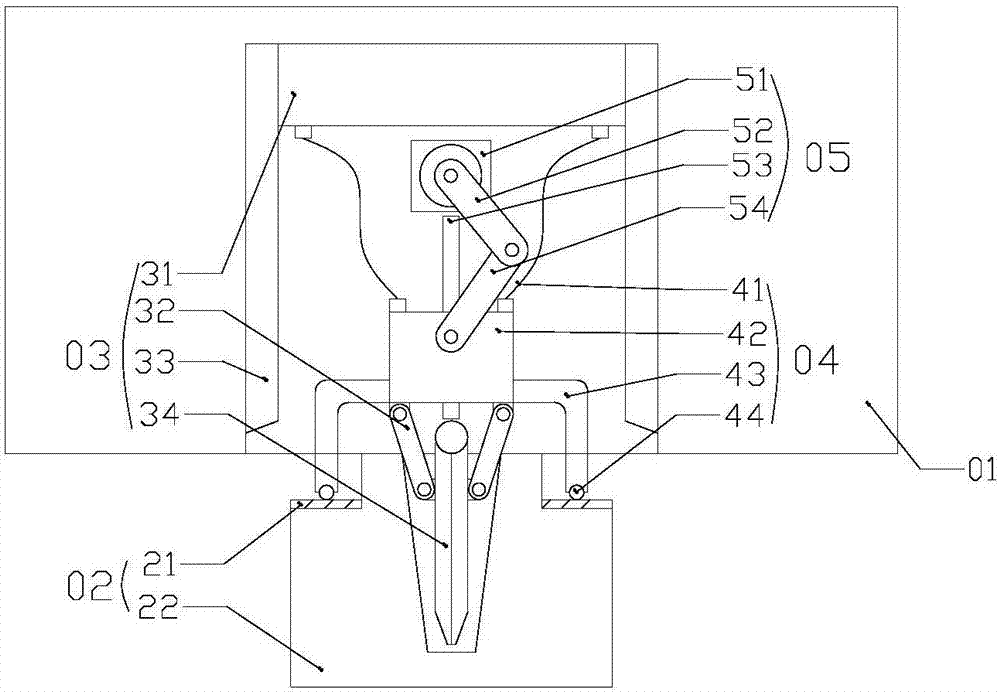

Exoskeleton Ankle Robot

ActiveUS20160331557A1Less cumbersomeDiagnosticsChiropractic devicesTruncal muscle weaknessJoint problem

A portable electrical motor-driven exoskeleton ankle joint robot with gear transmission and control system which is intended to provide walking assistance in different speed and walking conditions to persons with disability in walking or muscle weakness or joint problem.

Owner:THE HONG KONG POLYTECHNIC UNIV

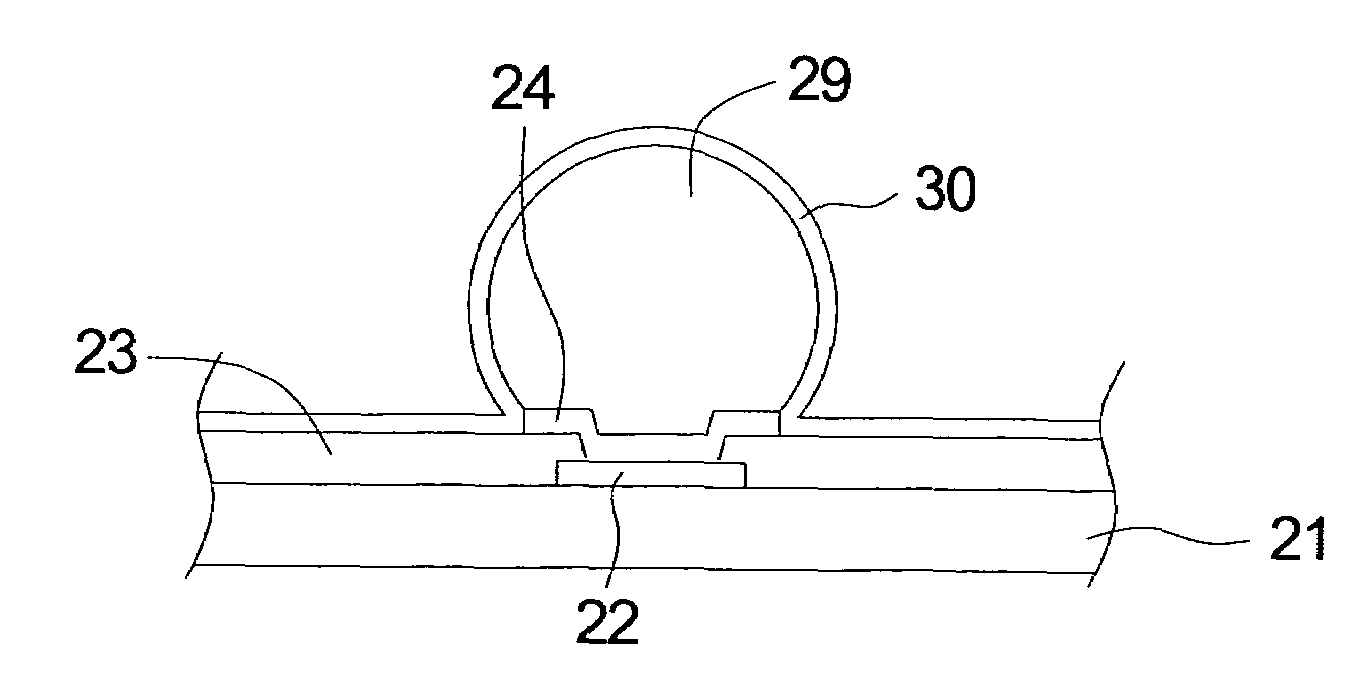

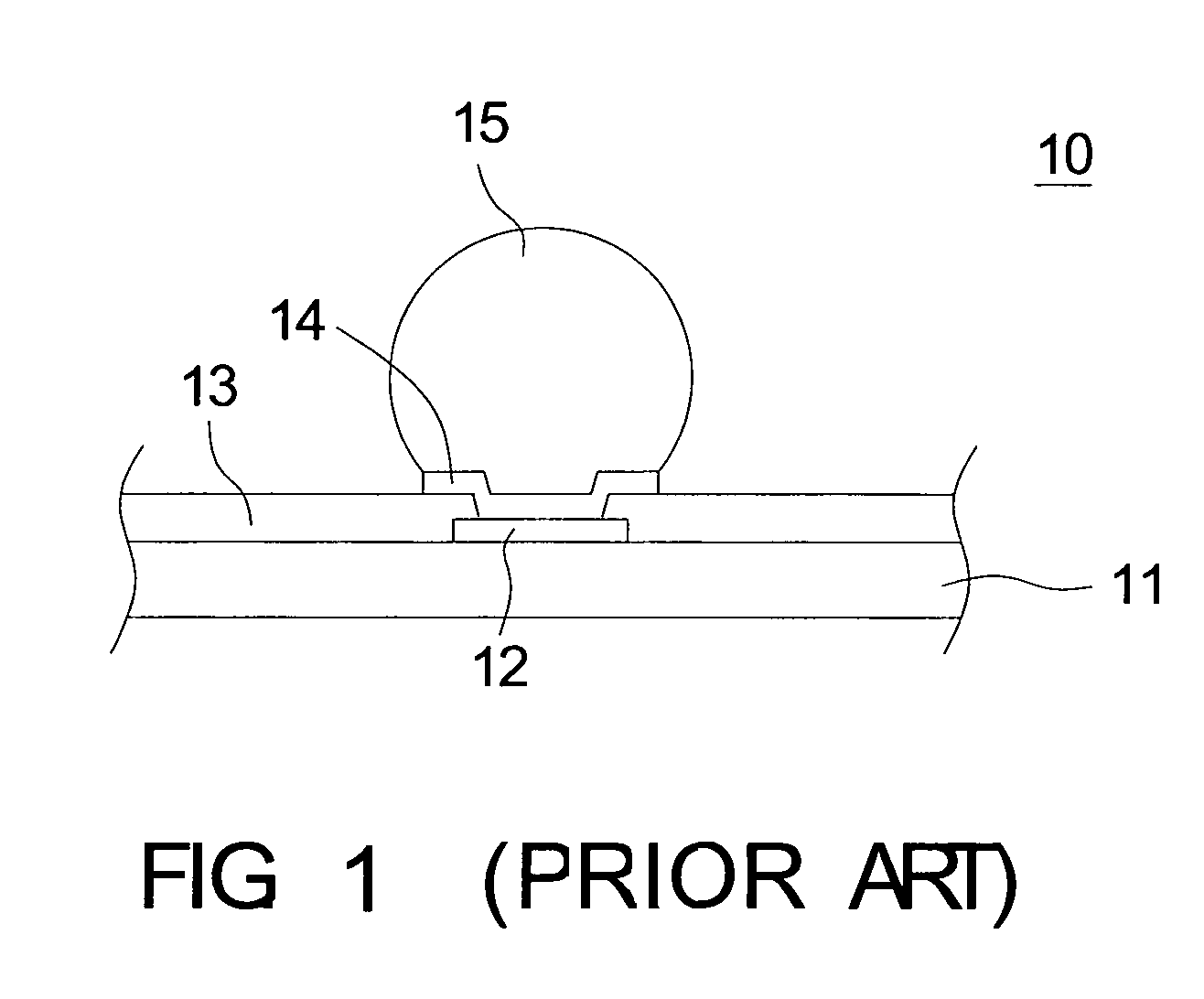

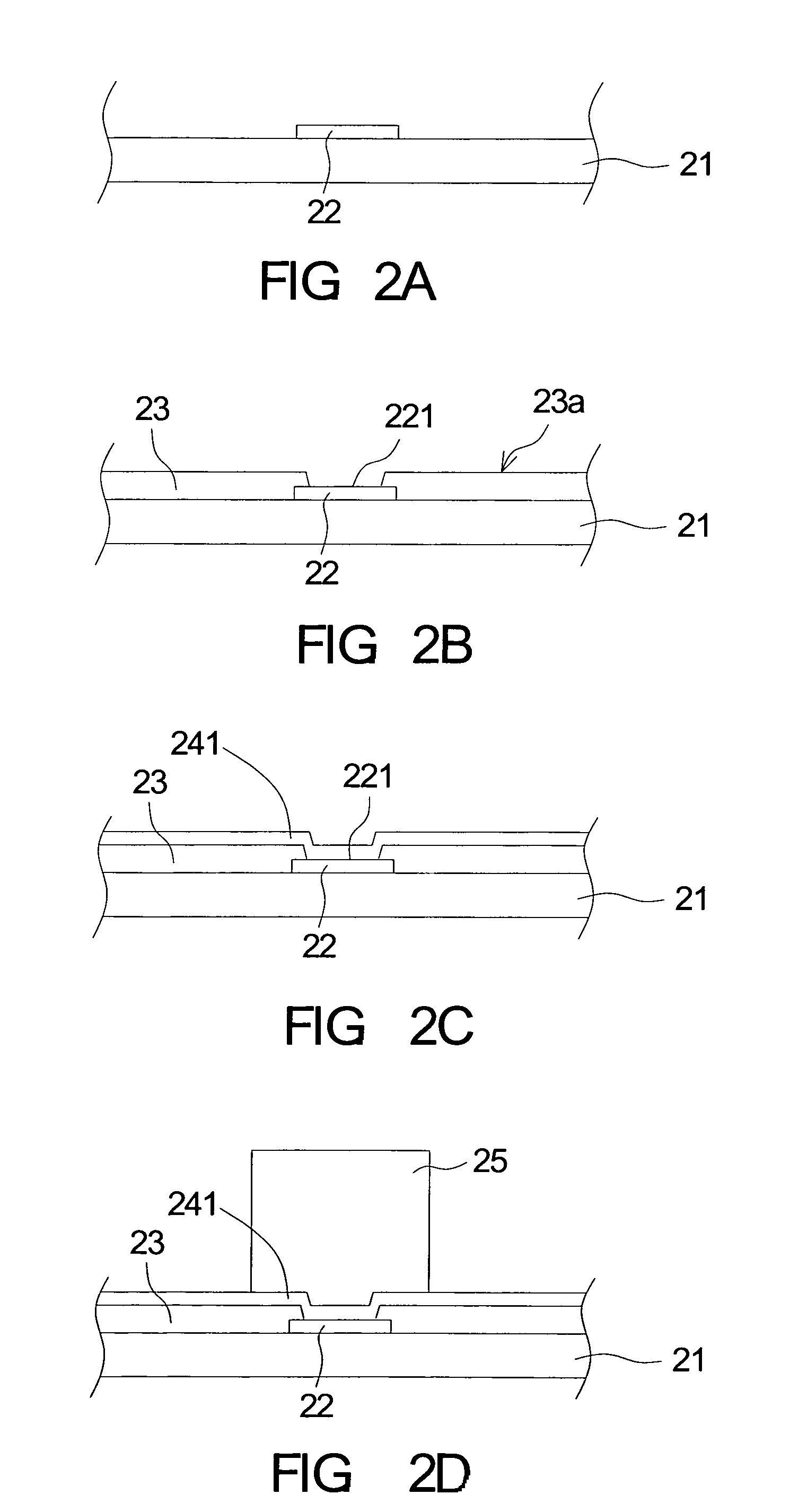

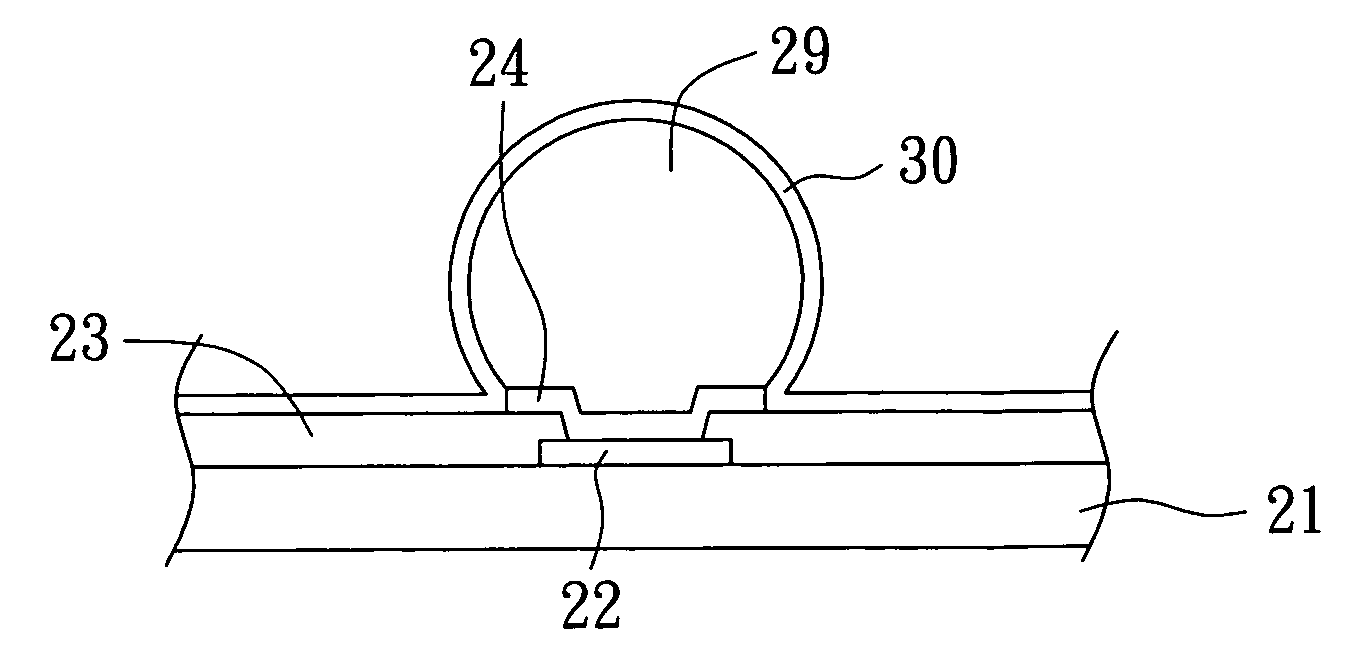

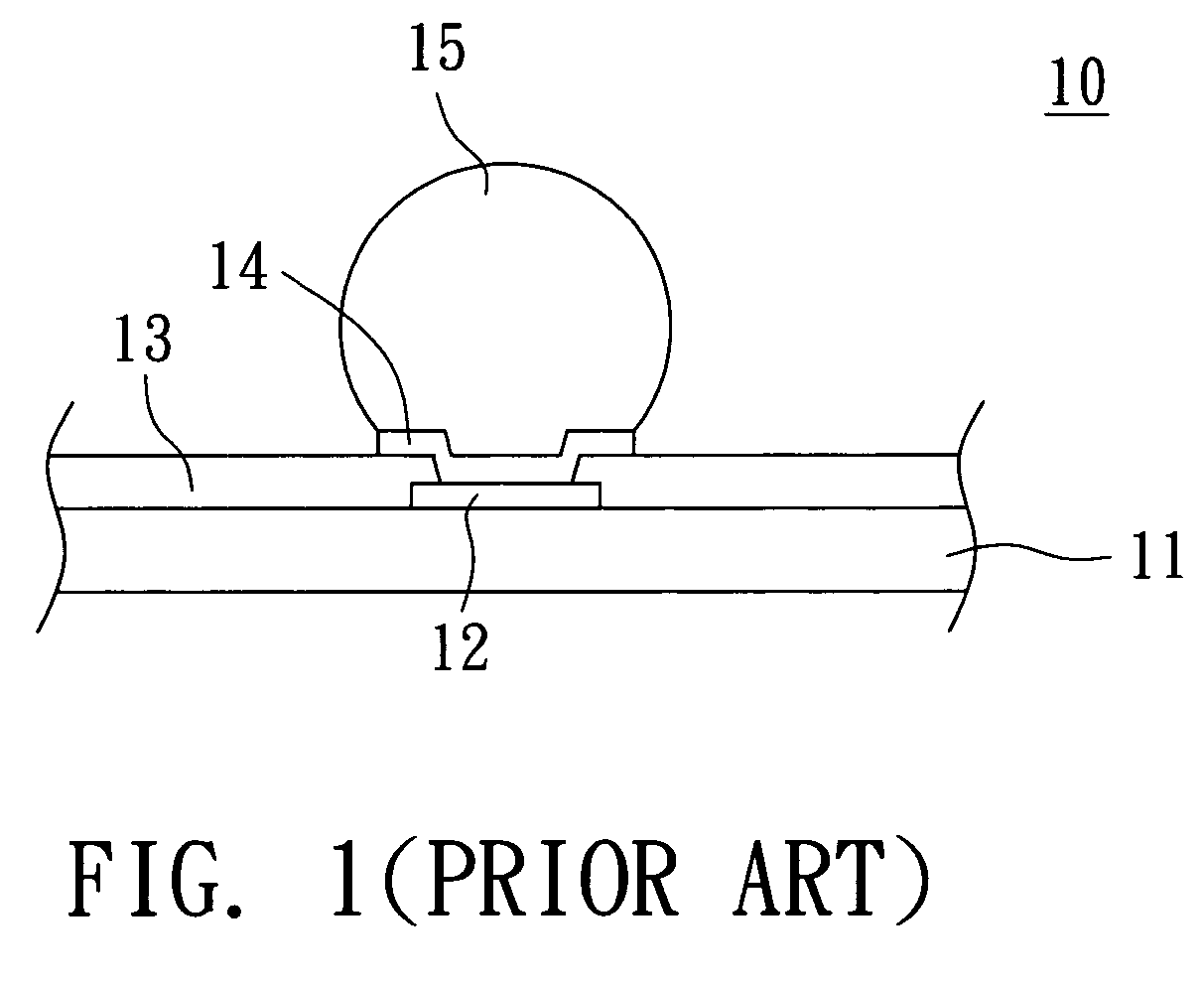

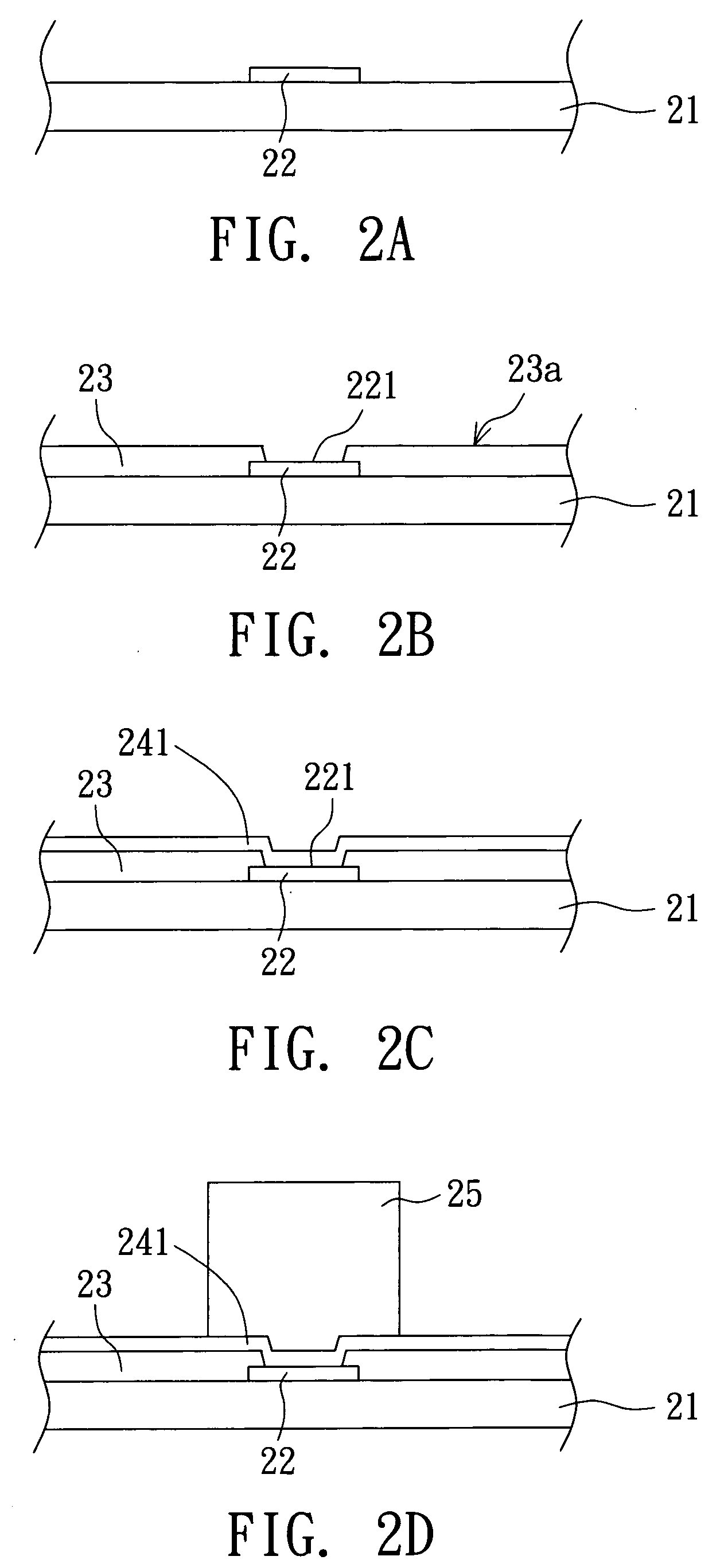

Fabrication method of a wafer structure

ActiveUS7501311B2Improve Wafer QualitySemiconductor/solid-state device detailsSolid-state devicesJoint problemOxidation resistant

A wafer fabricating method at least includes the steps of providing a wafer having an active surface with a plurality of pads, forming a plurality of bumps on the pad, and forming an organic protective layer on the bump and the active surface. Besides improving the quality of the wafer, the wafer structure according to the invention is oxidation-resistant, thus avoiding the cold-joint problem when soldered to the substrate.

Owner:ADVANCED SEMICON ENG INC

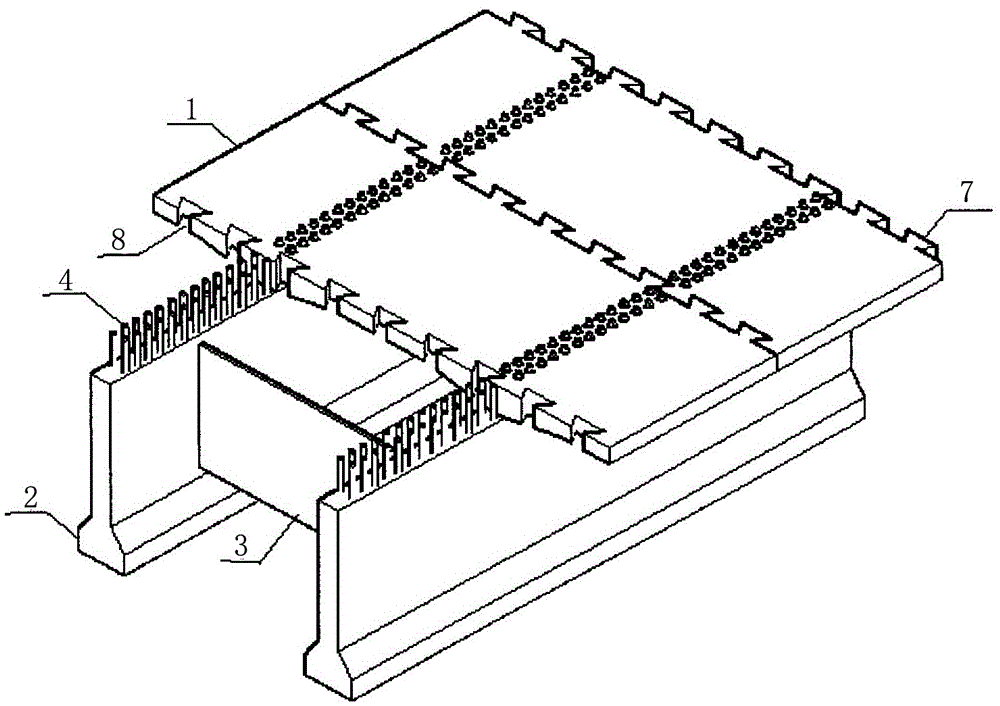

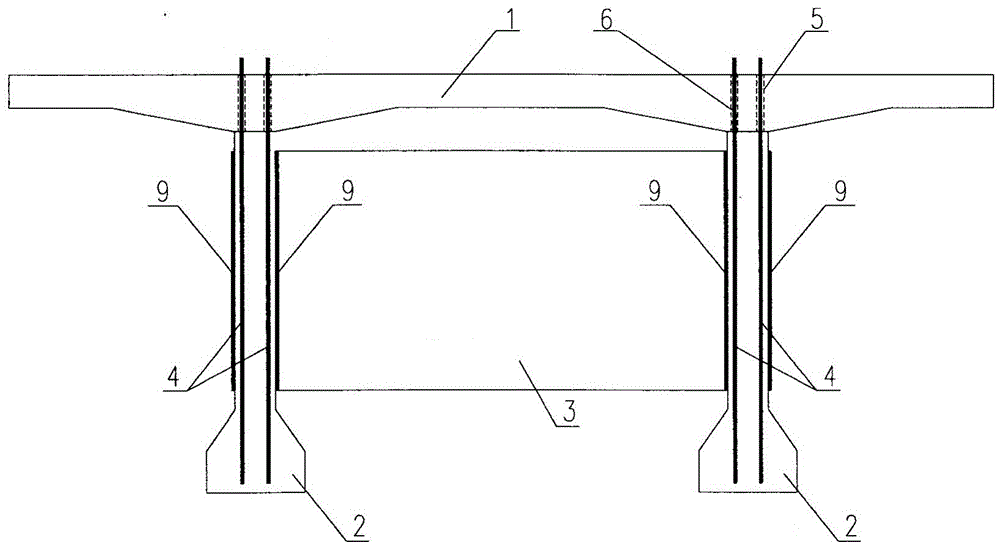

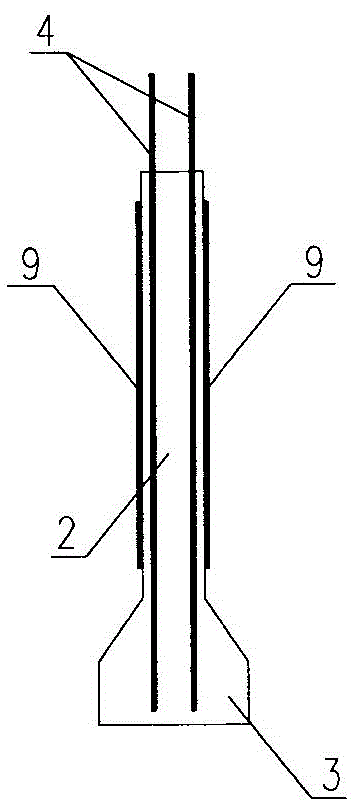

Prefabricated T beam and construction method

The invention discloses a prefabricated T beam and a construction method. The prefabricated T beam comprises bridge panels, a longitudinal beam and a steel transverse partition plate. The bridge panels and the longitudinal beam are prefabricated parts. The adjacent bridge panels are connected in an embedded mode. The portions, at the upper end of the longitudinal beam, of the bridge panels are evenly provided with preformed holes. Pre-buried deformed steel bars are arranged inside a bridge beam of the longitudinal beam. A pre-buried steel plate is arranged on the side face of the longitudinal beam. The pre-buried deformed steel bars need to stretch out of the upper edges of the spliced bridge panels on the basis of the length. The steel transverse partition plate is fixedly connected with the pre-buried steel plate on the longitudinal beam. The construction method comprises the steps of prefabricating the bridge panels and the longitudinal beam; connecting the steel transverse partition plate with the longitudinal beam after the longitudinal beam is suspended to a bridge pier and abutment; placing the bridge panels on the longitudinal beam, and connecting the adjacent bridge panels in the embedded mode; pouring epoxy mortar concrete into the preformed holes. The bridge panels and the longitudinal beam of the T beam are partially prefabricated separately, and therefore the wet joint problem existing in concrete T beam splicing is effectively solved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Fabrication method of a wafer structure

ActiveUS20060094223A1Improve Wafer QualityAvoid problemsSemiconductor/solid-state device detailsSolid-state devicesJoint problemOxidation resistant

A wafer fabricating method at least includes the steps of providing a wafer having an active surface with a plurality of pads, forming a plurality of bumps on the pad, and forming an organic protective layer on the bump and the active surface. Besides improving the quality of the wafer, the wafer structure according to the invention is oxidation-resistant, thus avoiding the cold-joint problem when soldered to the substrate.

Owner:ADVANCED SEMICON ENG INC

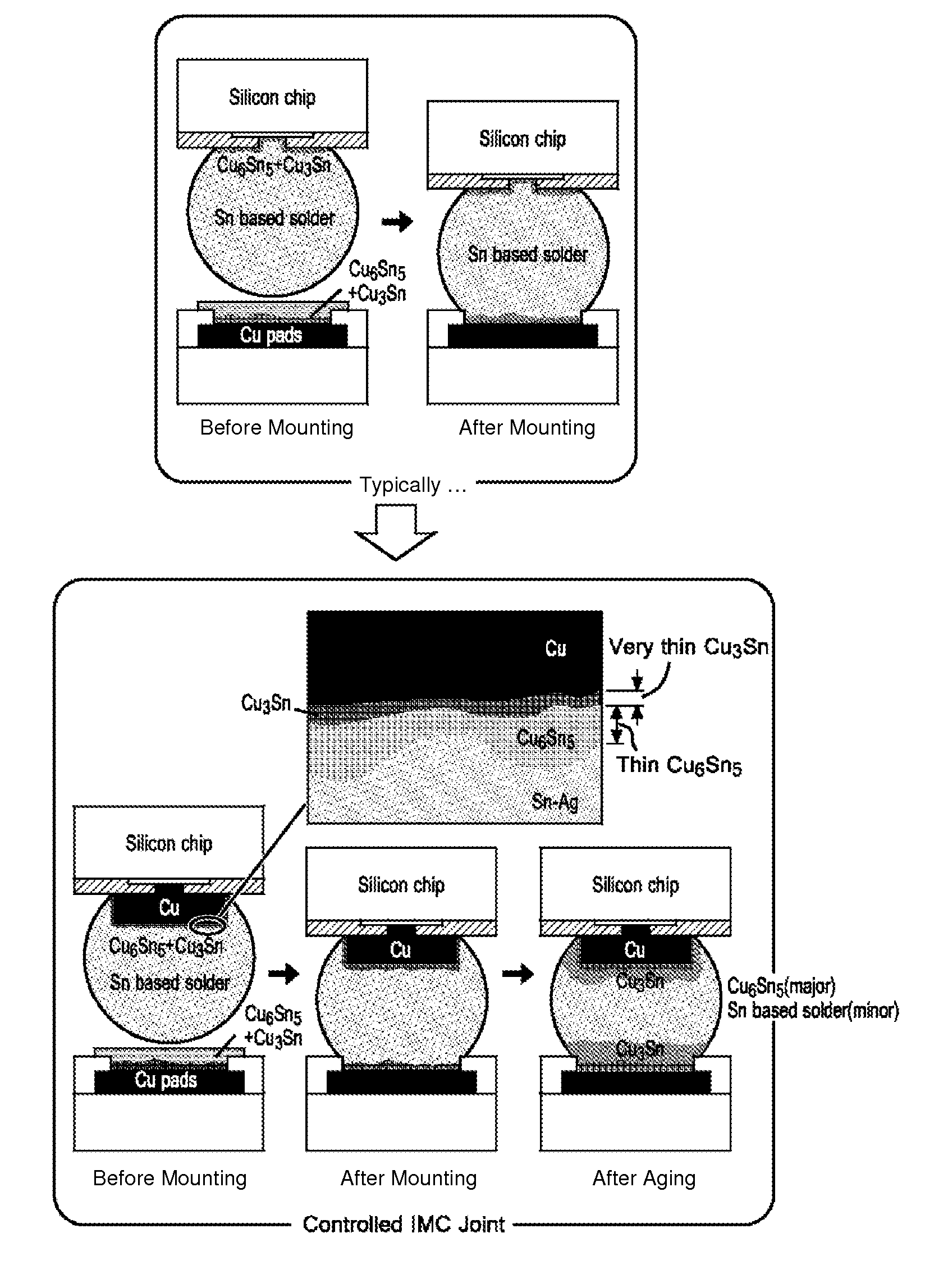

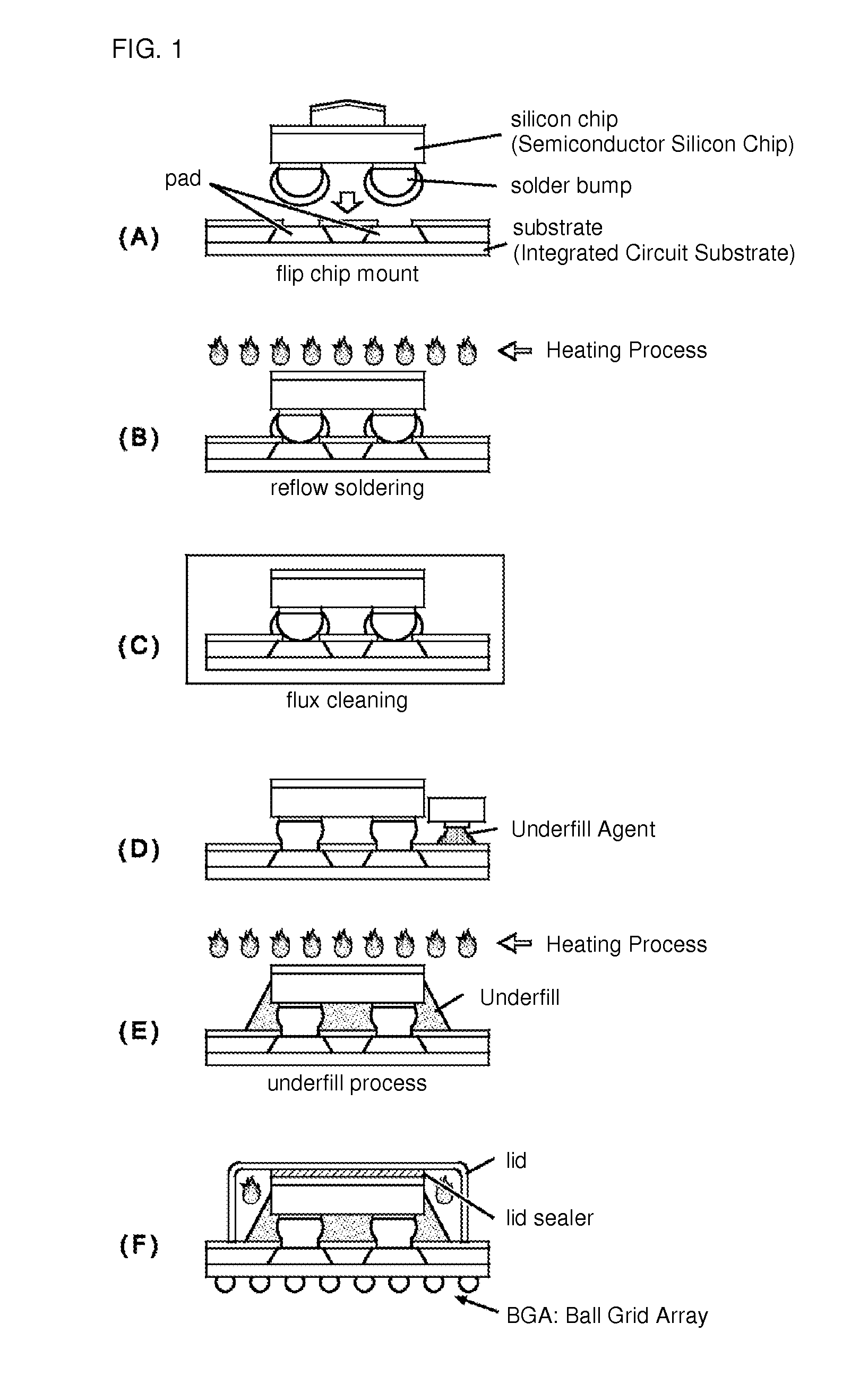

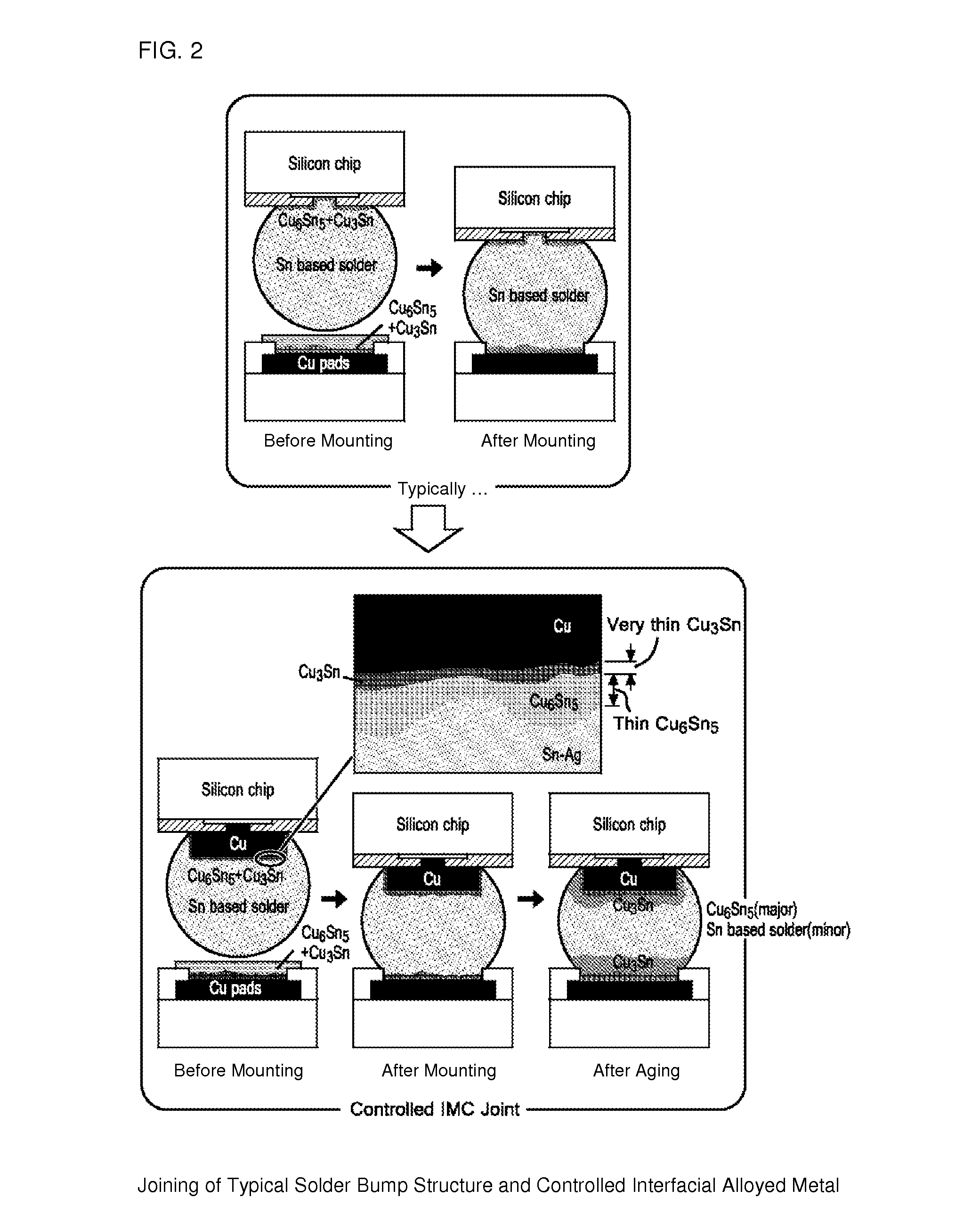

Interfacial alloy layer for improving electromigration (EM) resistance in solder joints

ActiveUS20140061889A1Improve electromigration (EM) resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceJoint problem

ProblemTo improve the electromigration (EM) resistance of a solder joint.SolutionThe present invention provides a unique structure for an interfacial alloy layer which is able to improve the electromigration (EM) resistance of a solder joint, and a unique method of forming this structure. More specifically, in this unique structure, a controlled interfacial alloy layer is provided on both sides of a solder joint. In order to form this structure, aging (maintenance of high-temperature conditions) is performed until an interfacial alloy layer of Cu3Sn has a thickness of at least 1.5 μm.

Owner:IBM CORP

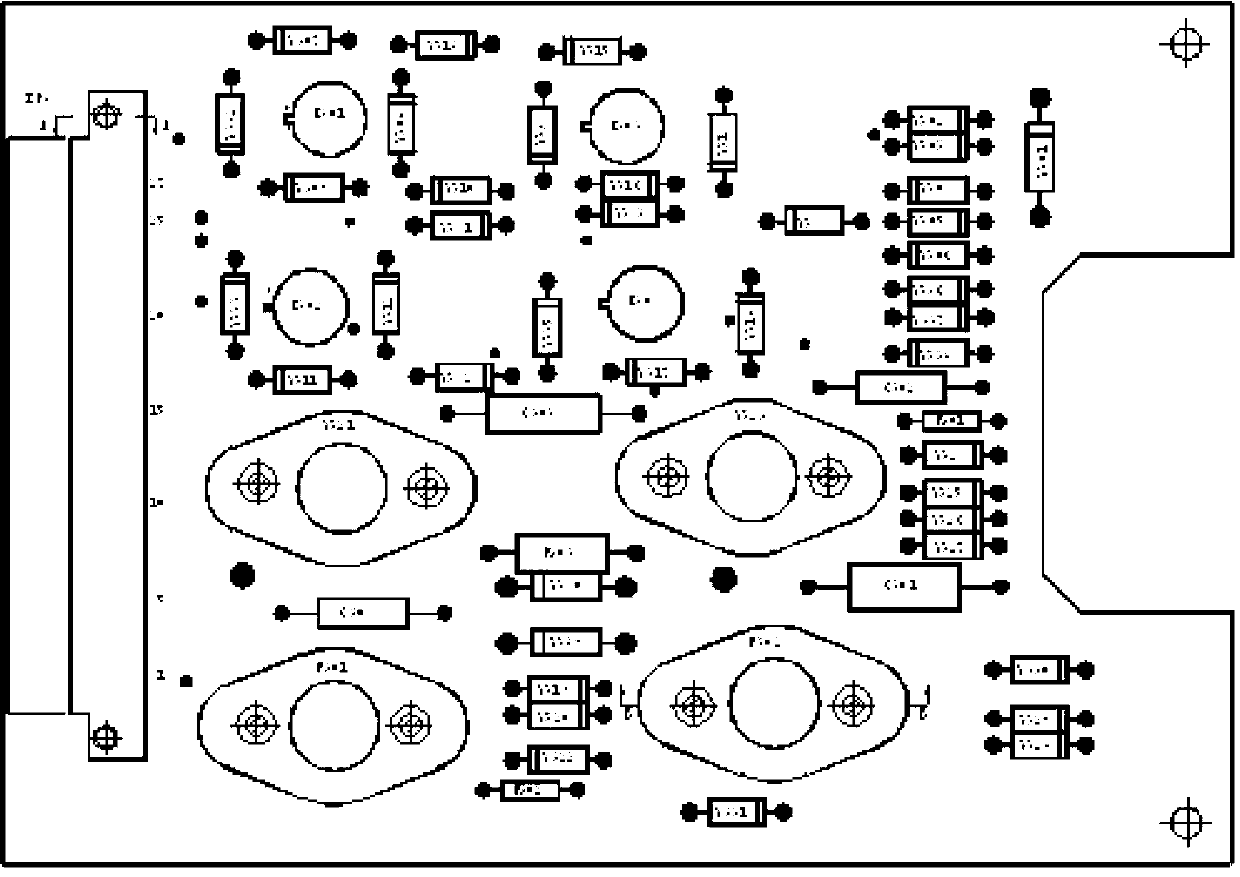

Wave crest soldering technique of printed circuit board

InactiveCN103002670AShorten the timeSolve secondary manual weldingPrinted circuit assemblingJoint problemEngineering

The invention relates to a wave crest soldering technique of a printed circuit board, comprising the following steps: sticking a paster device on a soldering surface to the soldering surface by using red gum; then roasting a printed board for curing; then performing tin coating of a through hole device, bending plug-in mounting, point fixing, shear pin and the like; and then enabling the printed board to pass through a crest soldering machine once so that the paster device and the through hole device are soldered together through soldering tin wave crest; and therefore, the time is saved, and the problems of secondary manual soldering and solder-reflow can be solved. The wave crest soldering technique of the printed circuit board disclosed by the invention has the beneficial effects that the wave crest soldering technique is simple in operation and easy to realize; the cold solder joint problem of manual soldering can be prevented; the problem that components and parts are heated in second time when solder-reflow is used also can be prevented; moreover, the efficiency is improved, and the cost is reduced. Therefore, the practicability is better. The technique is easy to popularize and relatively high in use value.

Owner:SHAANXI AVIATION ELECTRICAL

Nutritional preparation comprising ribose and folic acid and medical use thereof

Trauma, surgery, inflammation, subfertility, lactation problems, gut disorders, infant nutrition, cancer, arthritis and other joint problems, vascular problems and cardio-or cerebro vascular problems, ischaemia, aging, impaired immune function, burns, sepsis, malnutrition, problems with liver or kidneys, malaria, cystic fibrosis, migraine, neurological problems, respiratory infections, improvement of sports results, muscle soreness, drug intoxication and pain can be treated with a nutritional composition containing effective amounts of ribose and folic acid, optionally combined with other components such as niacin, histidine, glutamine, orotate, vitamin B6 and other components.

Owner:NV NUTRICIA

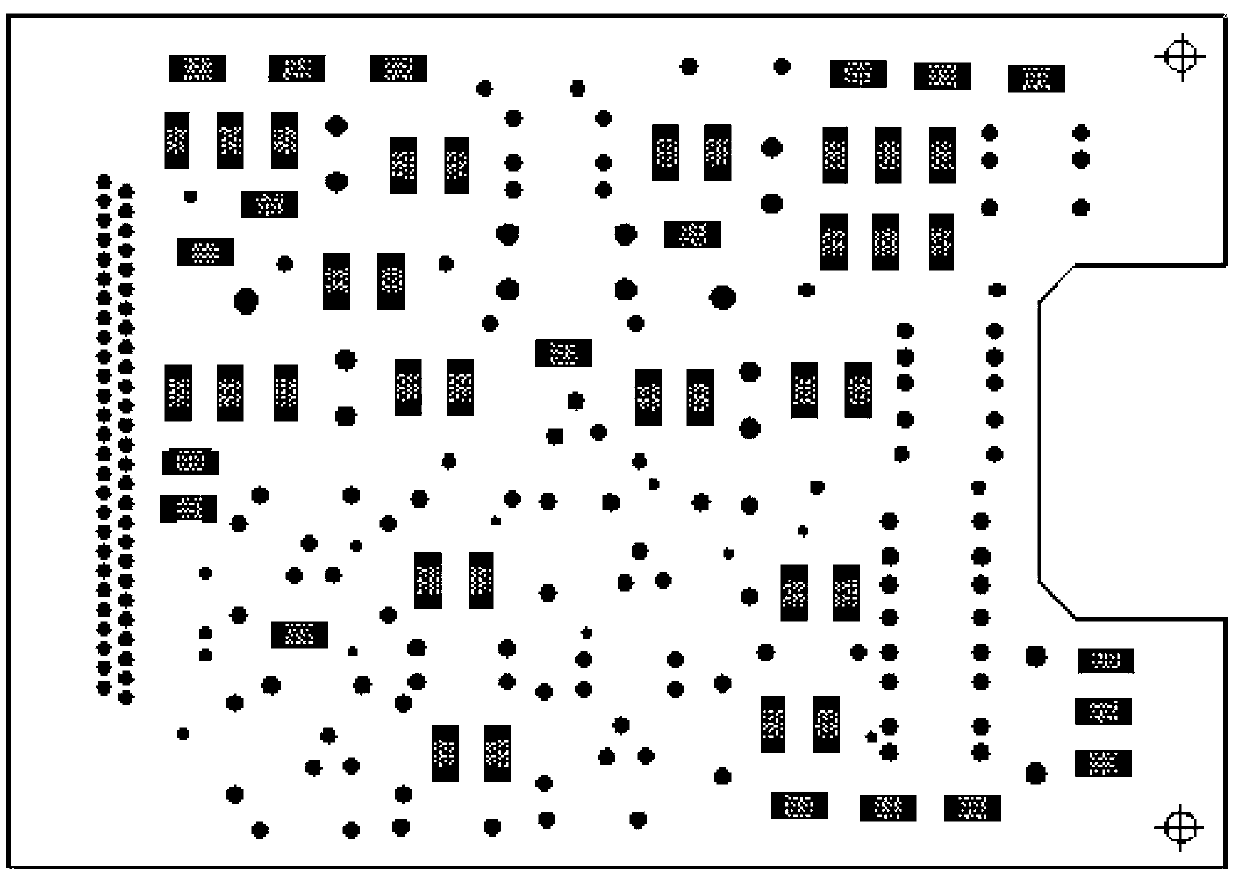

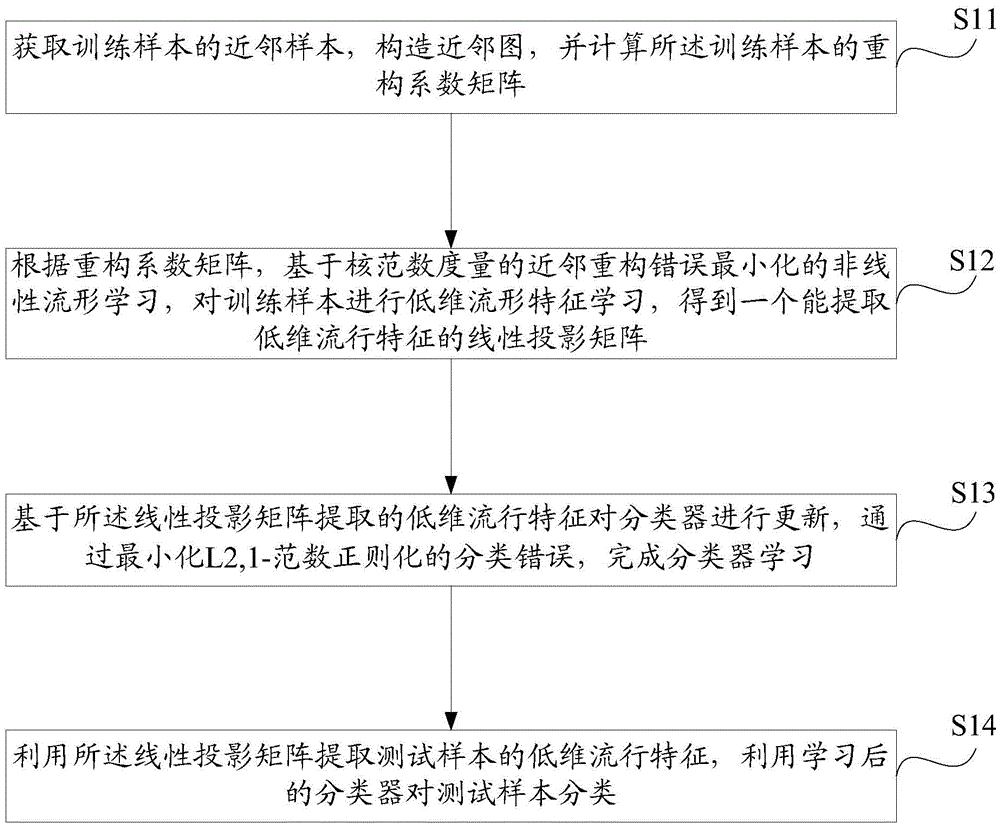

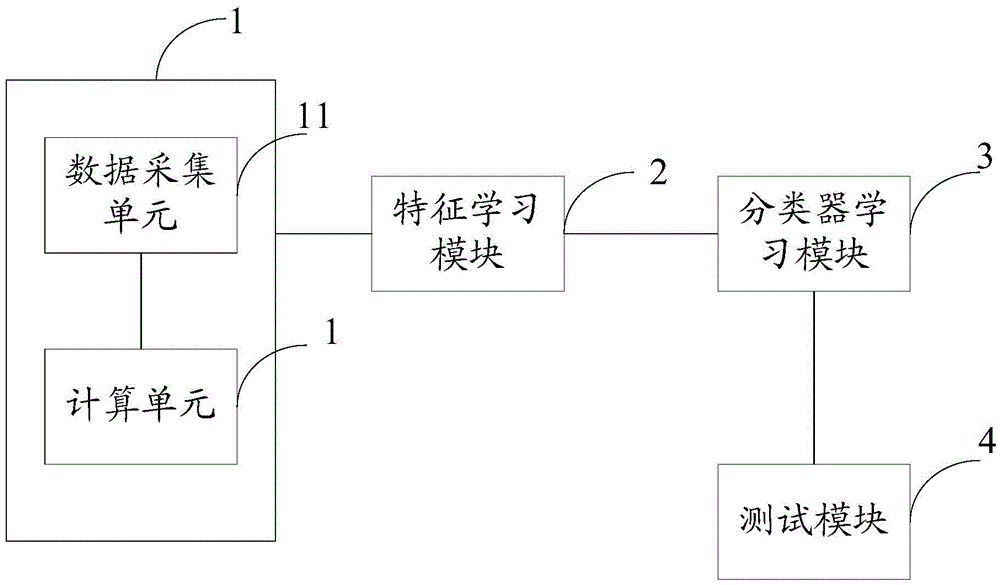

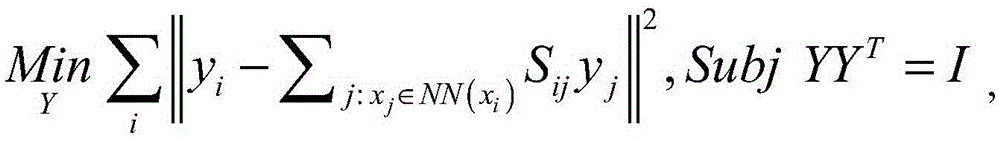

Combined method and system for extracting and classifying features of images

ActiveCN105608478AEnhanced description abilityImprove classification accuracyCharacter and pattern recognitionHat matrixJoint problem

The invention discloses a combined method and system for extracting and classifying features of images. The combined method comprises the following steps: firstly, constructing a neighbor graph according to the similarity of training samples and calculating and reconstructing a coefficient matrix; introducing nonlinear manifold learning with minimum neighbor reconstructing error measured on the basis of nuclear norm measurement, performing low-dimension manifold feature learning on a training image sample, thereby acquiring a linear projection matrix capable of extracting the low-dimension manifold feature of the sample; utilizing the low-dimension manifold feature of the training sample to minimize L2,1-norm regularization classifying error, completing robust sparse classifier learning and outputting the optimal classifier, thereby extracting and classifying the features of the tested sample. Compared with the prior art, the method has the advantage that the combination of nuclear norm measurement and L2,1-norm regularization is adopted for effectively increasing the descriptiveness of feature extraction and classification accuracy.

Owner:苏州恒志汇智能科技有限公司

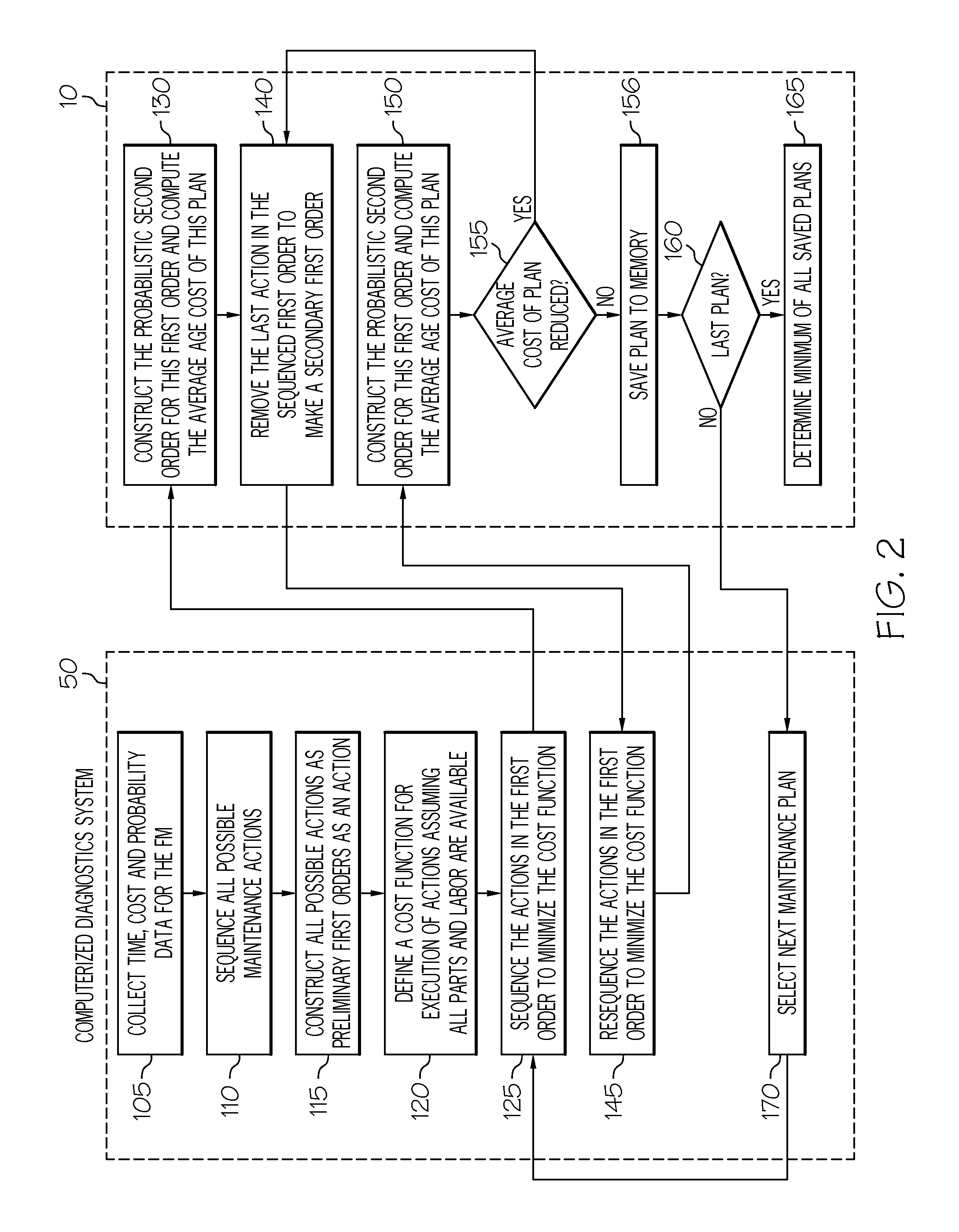

Systems and methods for the solution to the joint problem of parts order scheduling and maintenance plan generation for field maintenance

Methods and apparatus are provided for selecting a maintenance plan such that the cost of the maintenance plan is the lowest or near the lowest. The method comprises receiving a set of maintenance actions, wherein one of the repair actions is likely to repair the failure mode. The set of maintenance actions is sequenced in the increasing order of their waiting times. Each maintenance action has an associated cost equal to a waiting time cost, an execution time cost and a material cost, wherein the waiting time of each maintenance action is the time required to requisition and receive material required to perform the maintenance action. The method also constructs a maintenance plan comprising a first requisition and a second requisition by assigning each of the sequence of maintenance actions to one of the first or the second requisition.

Owner:HONEYWELL INT INC

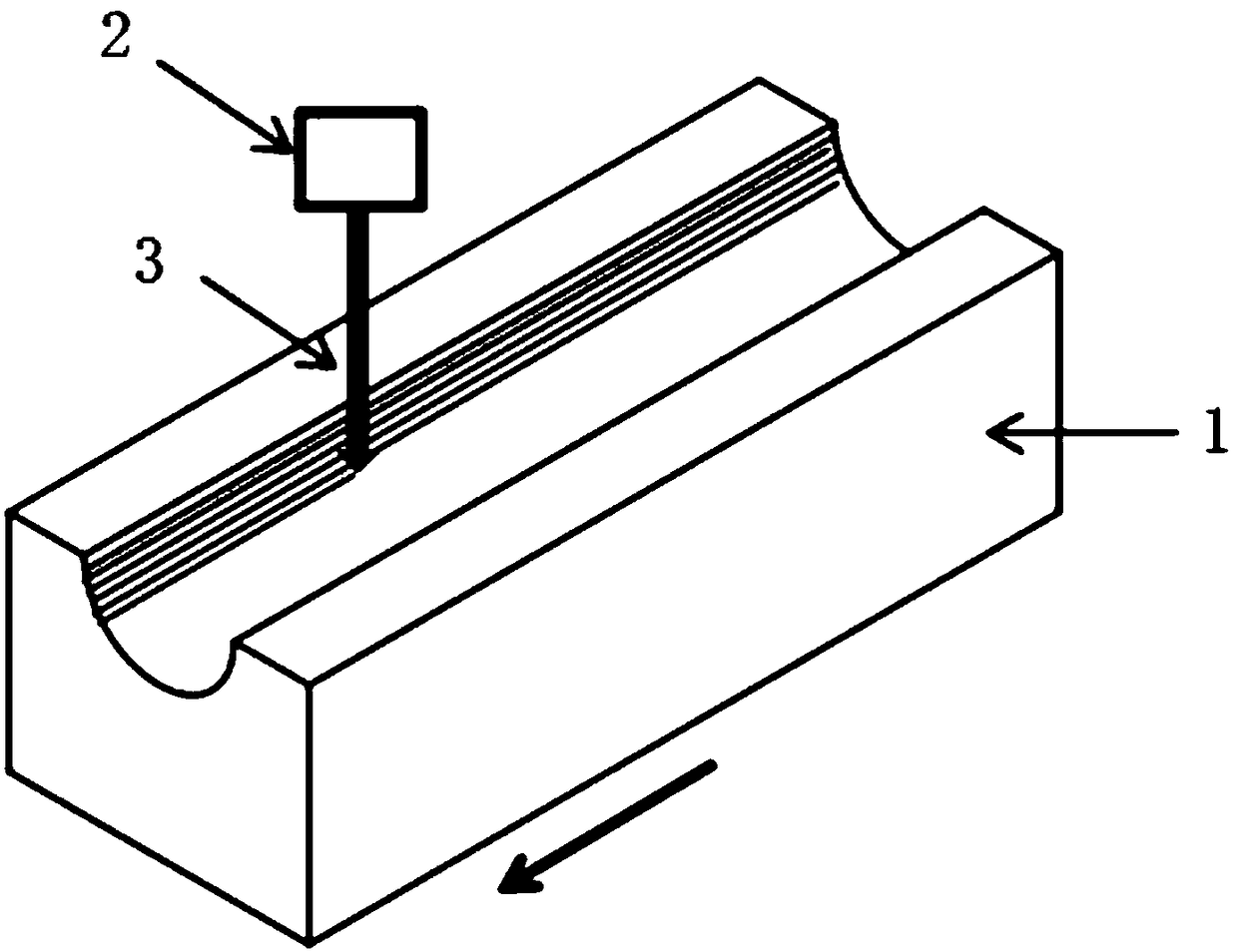

Seamless flexible plate making technology

InactiveCN105799306ASolve the seam problemGood printing adaptabilityForme preparationJoint problemLaser engraving

The invention discloses a seamless flexible plate making technology. The seamless flexible plate making technology comprises 1, coating a flitch plate sleeve roller as a base roller with black rubber and carrying out processing through a grinding machine to obtain a rubber layer with thickness of 7-10mm, 2, preparing a carving file according to requirements and inputting the carving file into carving software of a carving machine, 3, inputting actual sizes of the rubber roller into the carving machine, introducing the carving file and carrying out pattern graving on the rubber roller, and 4, preparing a seamless flexible printing plate according to characteristics of diameter error automatic scaling and automatic circumferential joint through the laser carving machine. The seamless flexible plate making technology solves flexible plate joint problems and improves printing adaptability.

Owner:SHANGHAI YUNCHENG PLATE MAKING

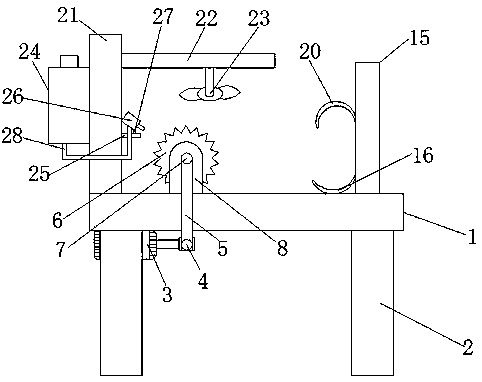

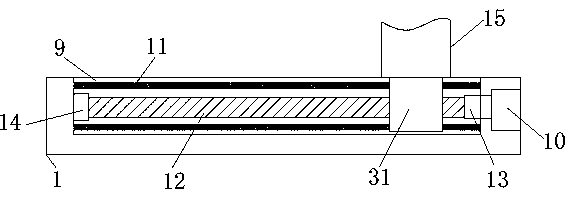

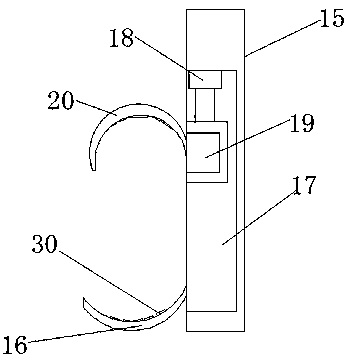

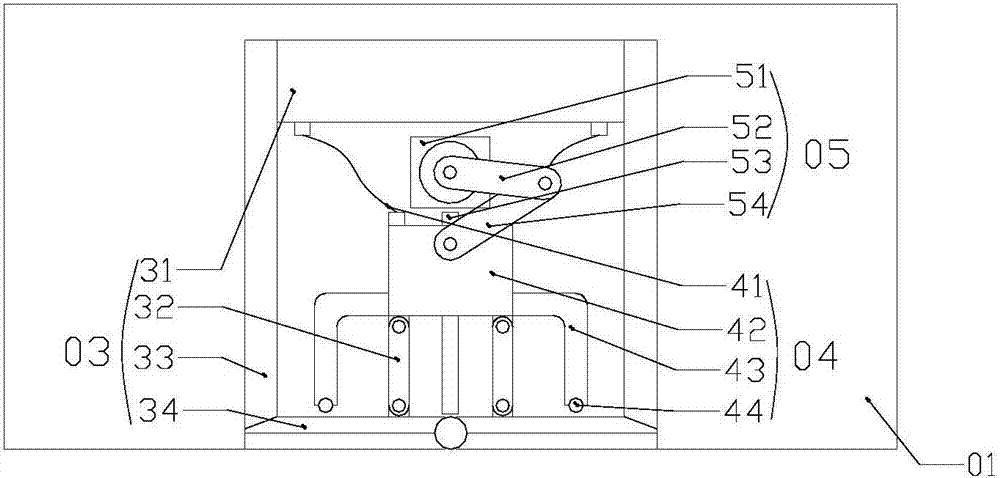

Metal hose cutting device convenient to adjust

InactiveCN107855829AEasy to adjustSolve the problem of uniform lengthMetal sawing devicesMetal sawing accessoriesMachine partsJoint problem

The invention discloses an easy-to-adjust metal hose cutting device, which relates to the technical field of parts processing. The easy-to-adjust metal hose cutting device includes a support plate, a support leg is fixedly installed on the bottom end of the support plate, a motor is fixedly installed on the upper part of one side of the support leg, and the output end of the motor is fixedly connected with a moving wheel. This easy-to-adjust metal hose cutting device solves the problem that the existing devices are generally fixed and cannot be adjusted when cutting pipes of different sizes, so that the length of the reserved joint cannot be guaranteed to be uniform. Rails, motors, guide rails, threaded rods, couplings, bearings, support frames, U-shaped grooves, chutes, electric push rods, clamping blocks, cover plates and fixed blocks, and the role of motors and electric push rods It can be adjusted according to the size of the pipe, and the cutting depth can be adjusted according to the operation of the motor, which is convenient for use.

Owner:无锡华利达金属制品有限公司

Exoskeleton ankle robot

A portable electrical motor-driven exoskeleton ankle joint robot with gear transmission and control system which is intended to provide walking assistance in different speed and walking conditions to persons with disability in walking or muscle weakness or joint problem.

Owner:THE HONG KONG POLYTECHNIC UNIV

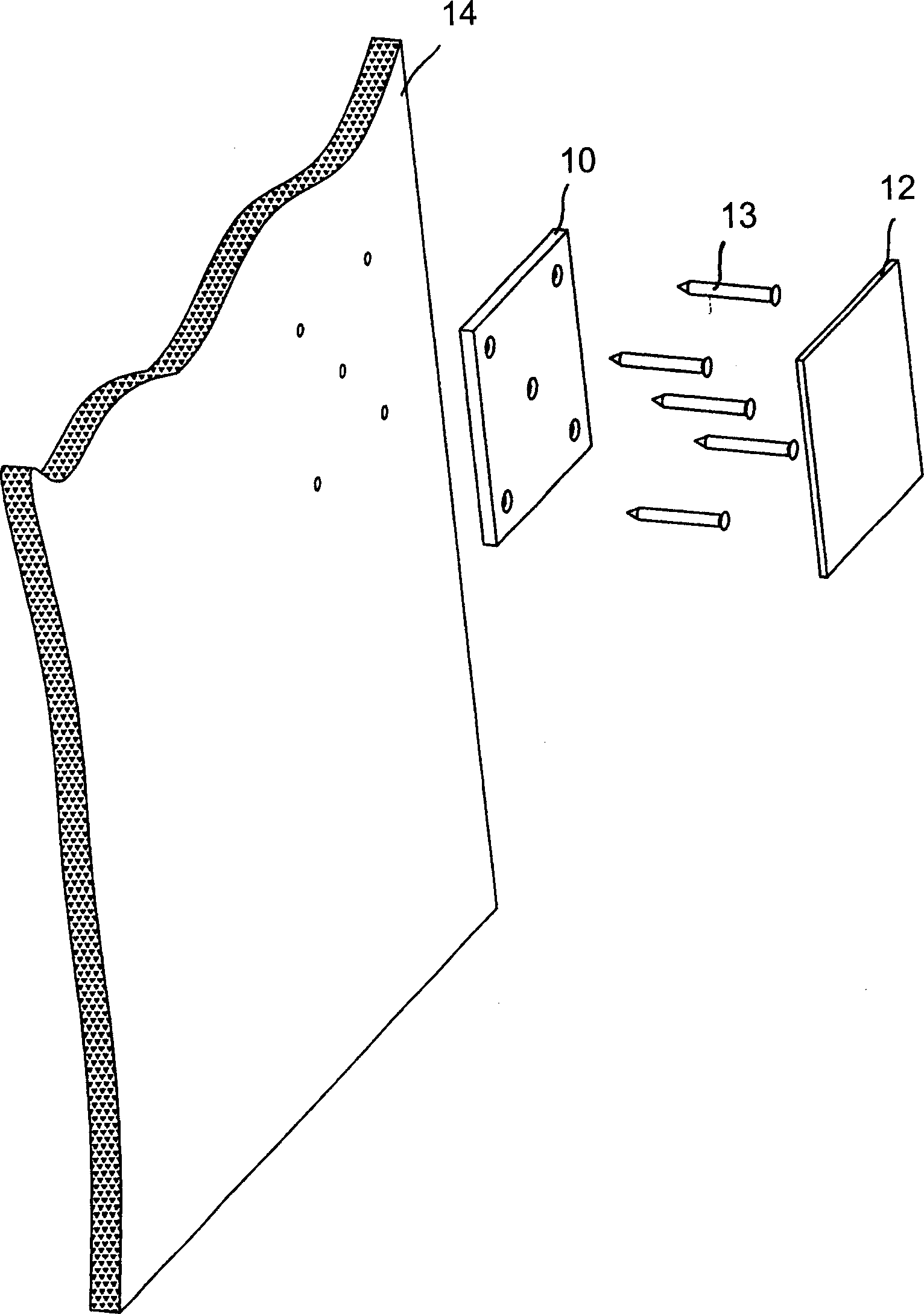

Automatic charging unmanned aerial vehicle for power line inspection

PendingCN107128490ASolve the problem of not being able to connectSimple structureBatteries circuit arrangementsEfficient propulsion technologiesJoint problemUncrewed vehicle

The invention provides an automatic charging unmanned aerial vehicle for power line inspection. The automatic charging unmanned aerial vehicle is characterized by comprising a battery compartment, a driving mechanism and a special plug, wherein the battery compartment is positioned at the bottom of the unmanned aerial vehicle; the driving mechanism is positioned inside the battery compartment; the battery compartment comprises a compartment body, a storage battery, a hinged compartment door and compartment door connecting rod; the compartment body comprises a downward opening; the storage battery is positioned above the interior of the compartment body; the hinged compartment door is opened from two sides to the middle; one end of the compartment door connecting rod is hinged with the inner walls of the compartment door; the driving mechanism is positioned below the storage battery inside the battery compartment; the lower side of the driving mechanism is connected with the special plug; the special plug comprises a plug body, a wire, a landing bracket and a conductive bar; the plug body is connected with the wire; the other end of the wire is connected with the storage battery; the lower side of the plug body is hinged with the other end of the compartment door connecting rod; two sides of the plug body are connected with the landing bracket; and the bottom of the landing bracket is connected with the conductive bar. According to the automatic charging unmanned aerial vehicle for power line inspection disclosed by the invention, the charging part of the unmanned aerial vehicle can be prevented from being influenced by outside weather, and the joint problem of the connector and the interface in the process of charging the unmanned aerial vehicle can be well solved.

Owner:STATE GRID QINGHAI ELECTRIC POWER CO HAINAN POWER SUPPLY CO +2

Heat preservation board of wall

InactiveCN1734028AReasonable structureSolve fit problemsConstruction materialHeat proofingBrickJoint problem

This invention discloses a wall heat preservation felt, which arranges a groove on the bubble felt which has a certain thickness, and it is close to the one side of the wall, wherein the groove is the dovetail groove or the conical hole. When the felt applies to the wall, the slurry which is applies on the wall is put into the dovetail groove or the conical hole of the felt, and the slurry can support the felt firmly after hydrating, which likes the 'expansion bar' or the 'expansion annul' which is embedded in the felt. The conventional felt face is smooth, which applies to the wall depends on the slurry and uses the expansion snail fixation technology The structure of the felt in this invention is logical, the joint with the wall still uses the conventional join wall brick technology, the construction process is simple, the manual work cost and material cost all decrease, which is convenient for extending and using and solves the joint problem between the bubble felt and the wall.

Owner:SHANGHAI KELI MACROMOLECULE MATERIAL

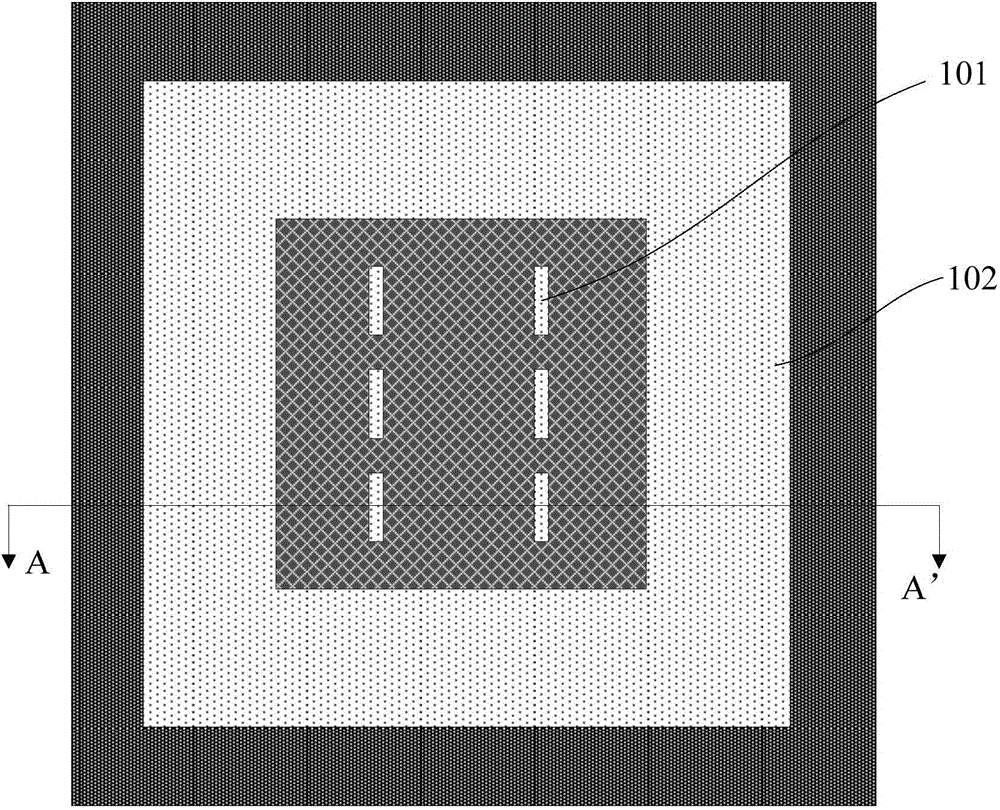

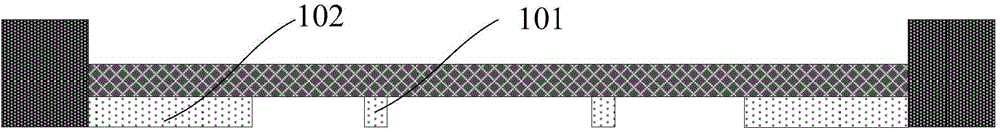

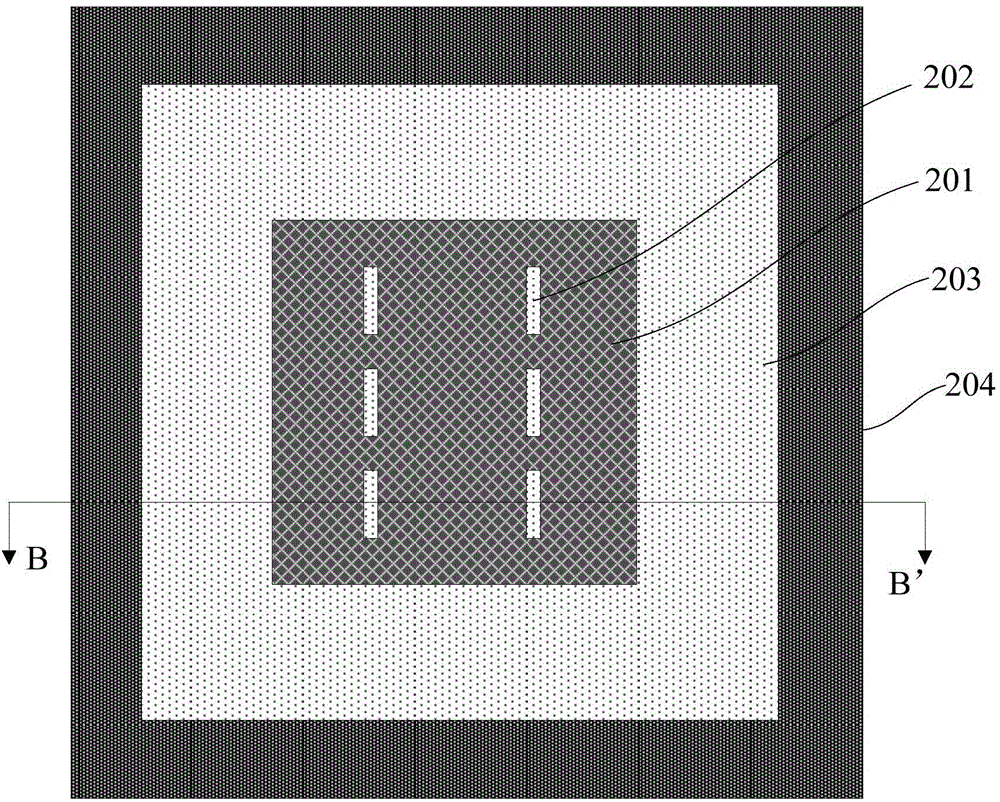

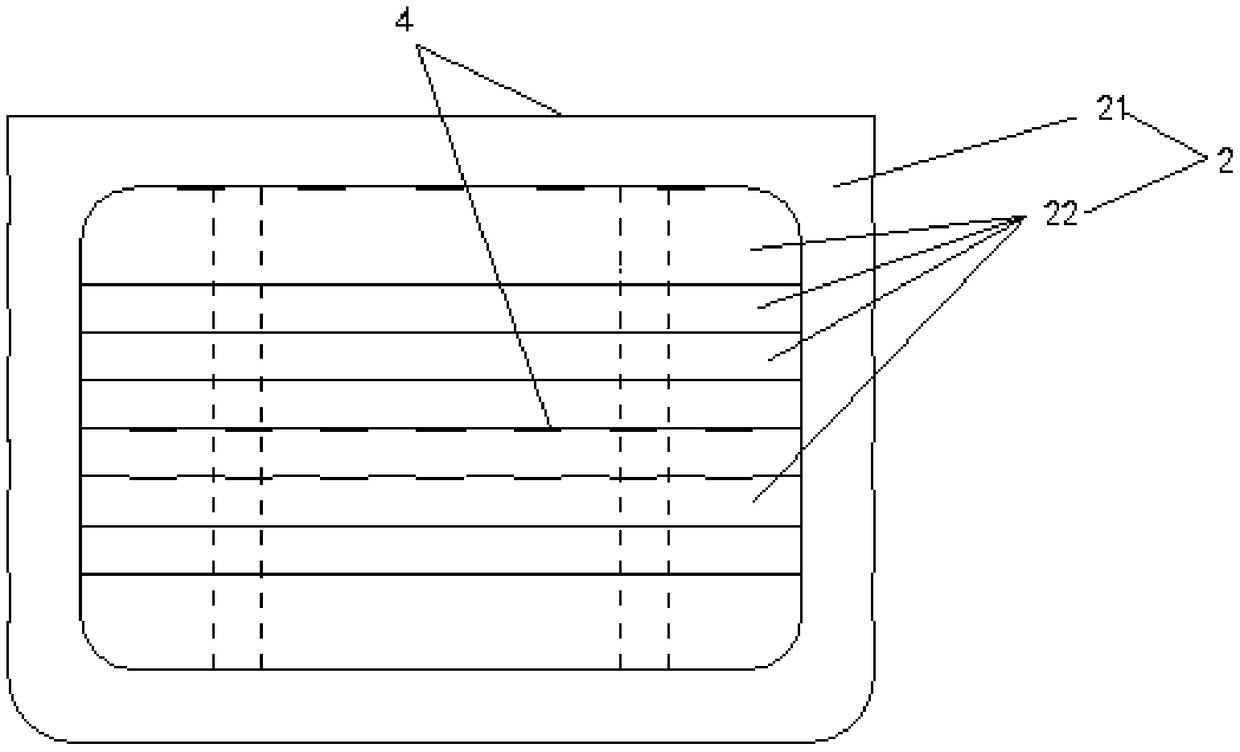

Screen printing plate and solar battery manufacturing method

InactiveCN104417025AEasy to manufactureSimple structureFinal product manufactureScreen printersJoint problemElectrical battery

The invention discloses a screen printing plate and a solar battery manufacturing method. The screen printing plate comprises a piece of screen cloth and a block layer fixed at the screen cloth, wherein the block layer comprises a pattern part and a non-pattern part which surrounds the pattern part, and the thickness of the pattern part is smaller than that of the non-pattern part. Through designing the block layer of which the pattern part thickness is smaller than the non-pattern part thickness, the screen printing plate is capable of lowering the height difference at the joint between back silver and back aluminum of a solar battery manufactured through the screen printing plate and improving the bridging effect of the back aluminum, and accordingly the cold solder joint problem of the back silver of the component end due to the bridging effect can be improved. By means of the screen printing plate, the quality of the solar battery can be improved. The screen printing plate is simple in structure, easy to manufacture and suitable for industrial production. The screen printing plate and the solar battery manufacturing method effectively overcome the disadvantages of the prior art and have high industrial utilization value.

Owner:MOTECH SUZHOU NEW ENERGY

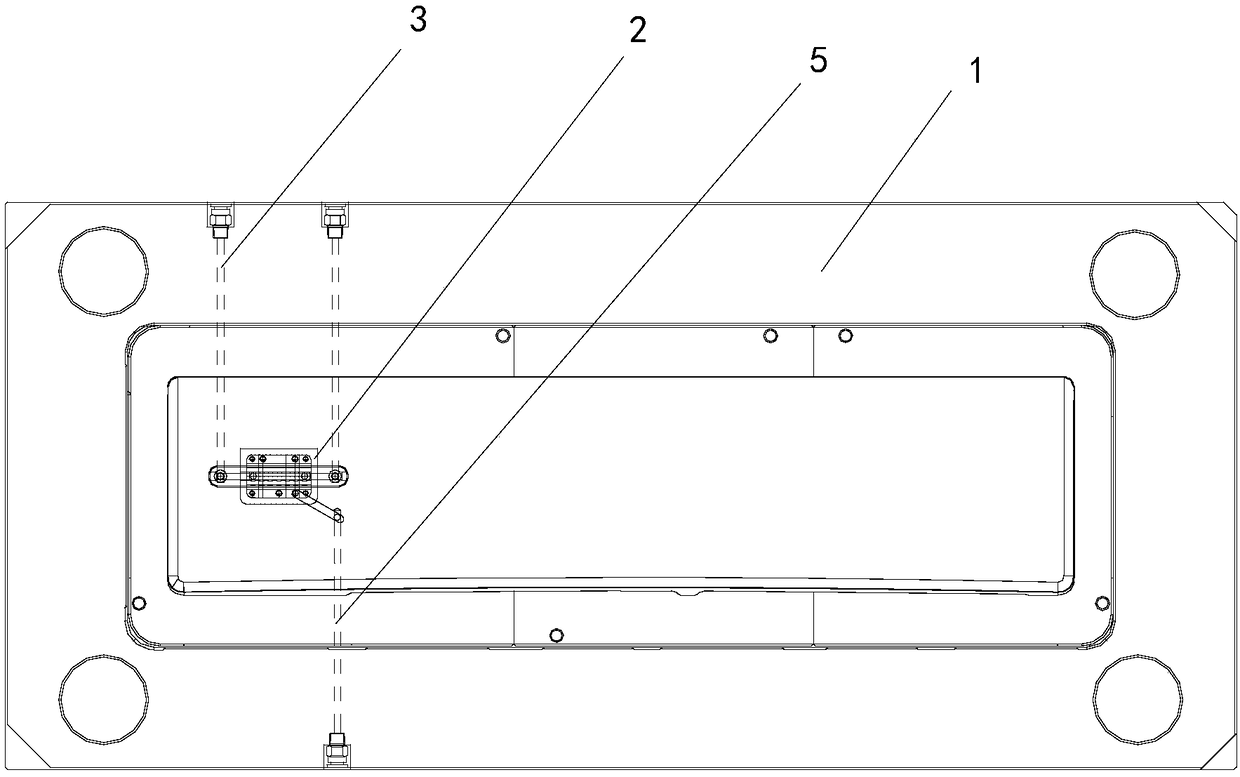

Injection mould and Injection molding method

The invention provides an injection mould and an injection molding method. The injection mould comprises a moving template and at least moving mould insert arranged on the moving template according toa predetermined position. According to the invention, on the basis of cooperation of the moving mould insert, a waterway, and a gas circuit, air in a mould cavity can flow out, so that mould exhausting is enhanced; the temperature of the moving mould insert during the injection molding process is ensured; because the mould is heated before injection and pressure maintaining, a phenomenon that mobility of the material flow is affected because of too low material flow temperature caused by heat losses of the material flow due to heat transferring and thus a hungry joint problem of an injectionmolding part is avoided. Besides, after injection and pressure maintaining, the mould is cooled by the heat exchange with the waterway, so that the cooling speed and the thermal insulation effect of the mould are controlled; and the material flow temperature is controlled and the material flow flowing efficiency is increased, so that the moulding quality of the thin wall region of a to-be-mouldedelement and the yield of the to-be-moulded element are improved effectively.

Owner:ZHUHAI GREE PRECISION MOLD CO LTD

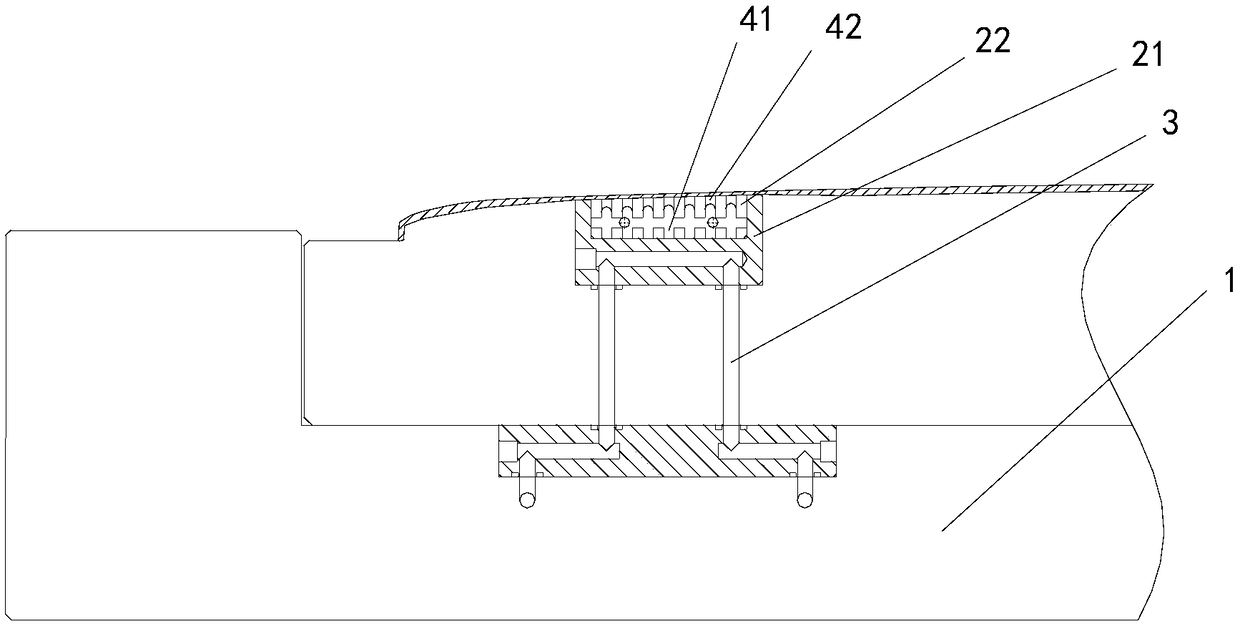

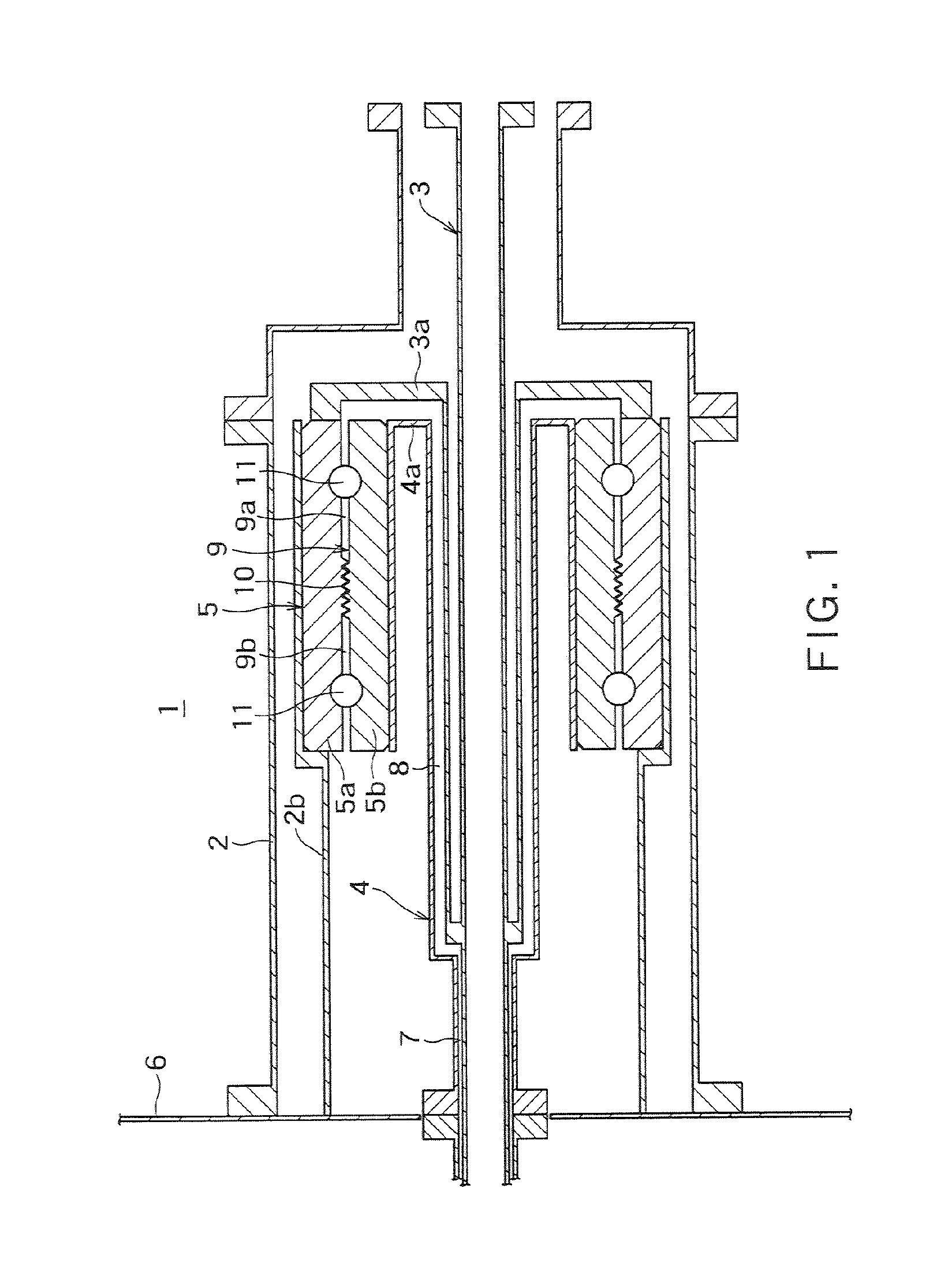

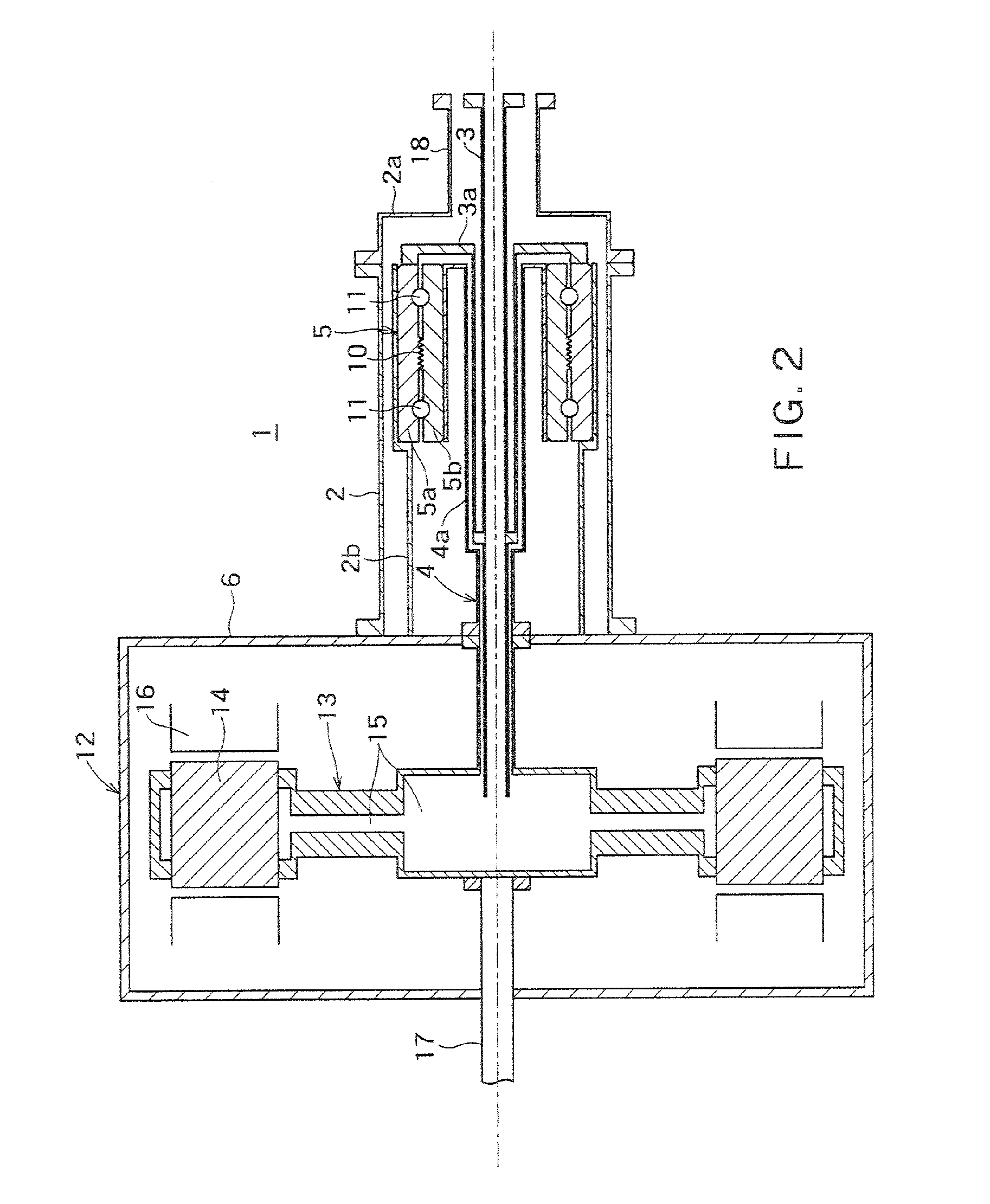

Cryo-rotary joint

ActiveUS20120133126A1Small outer diameterLength in directionEngine sealsThermal insulationJoint problemVacuum chamber

Problem to be SolvedTo provide a small, lightweight, cryo-rotary joint.SolutionA joint includes a housing 2, a refrigerant tube 3 connected to a refrigerant source and communicated with a target part in a rotating machine, a rotating member 4 loosely fitted inside with the refrigerant tube and fixed to a rotary part of the rotating machine, and a relatively rotating member 5 having a fixed-side member 5a and rotating-side member 5b, wherein the fixed-side member is connected to the refrigerant tube via a refrigerant tube extension section 3a, the rotating-side member is connected to the rotating member via a rotating member extension section 4a, a refrigerant zone is formed by spaces 7 and 8 defined by the refrigerant tube, rotating member, and refrigerant tube and rotating member extension sections, a sealing member 10 is installed between the fixed-side and rotating-side members, and a vacuum chamber and pressure chamber are defined within the housing.

Owner:TOKYO UNIV OF MANNE SCI & TECH

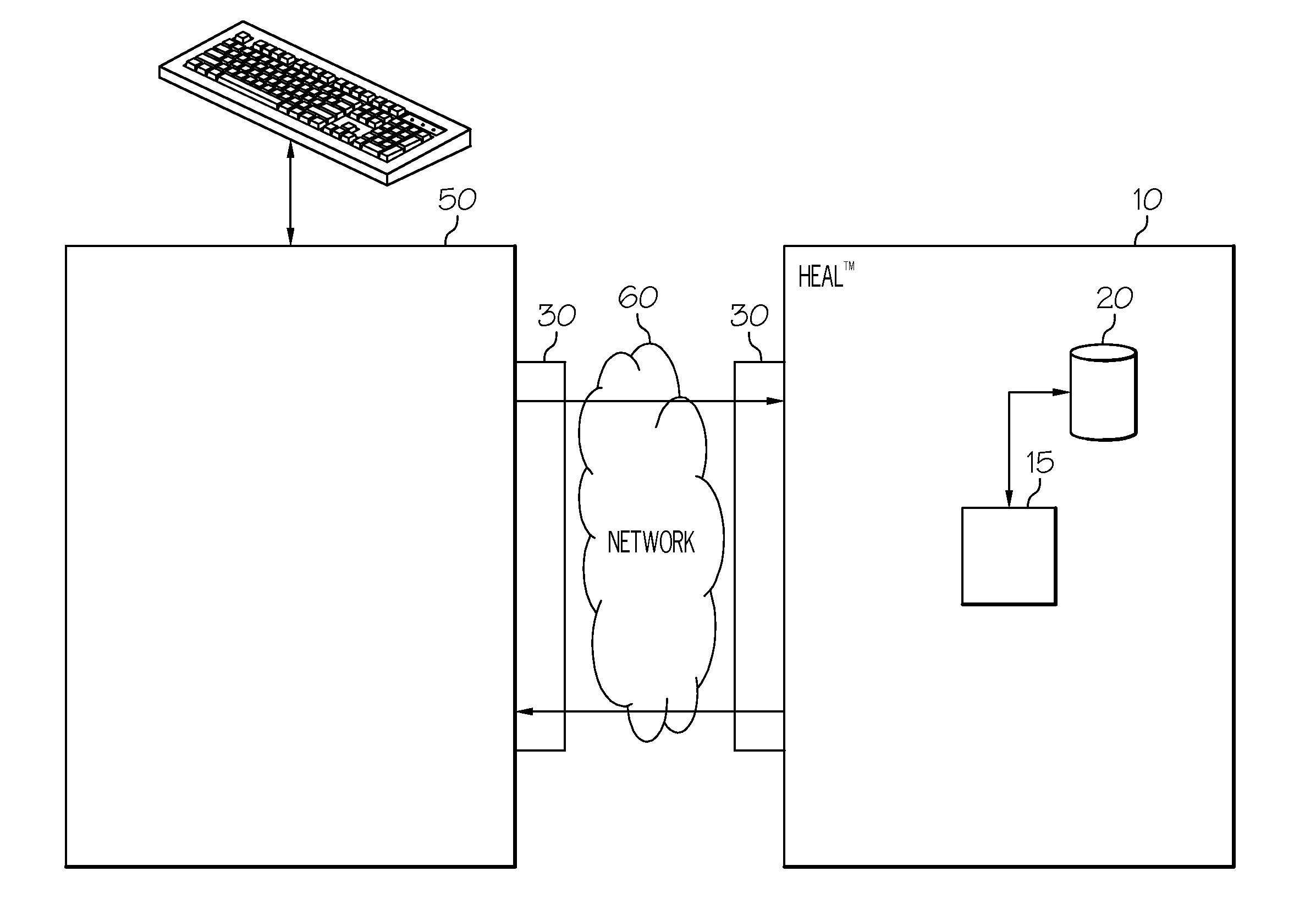

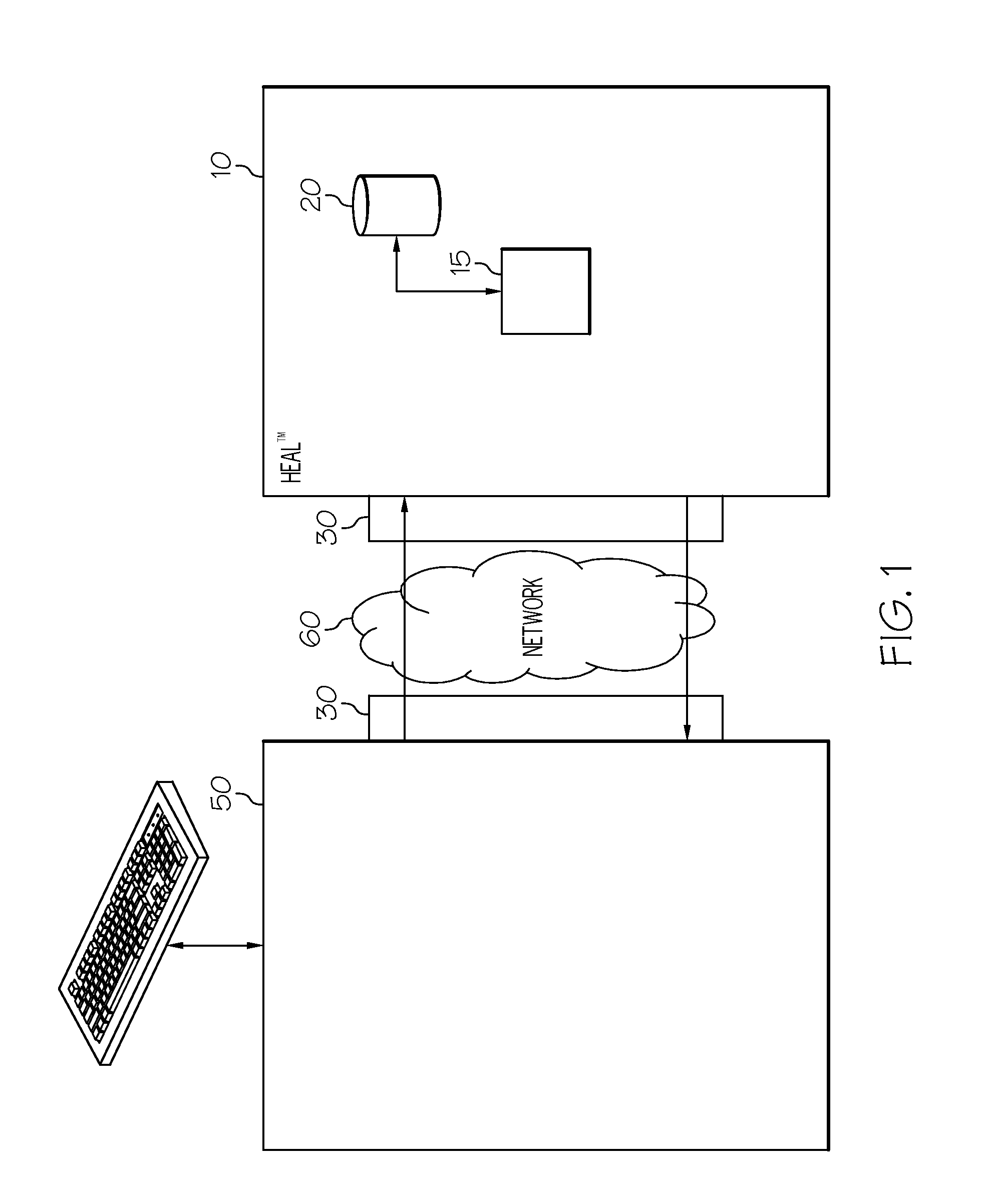

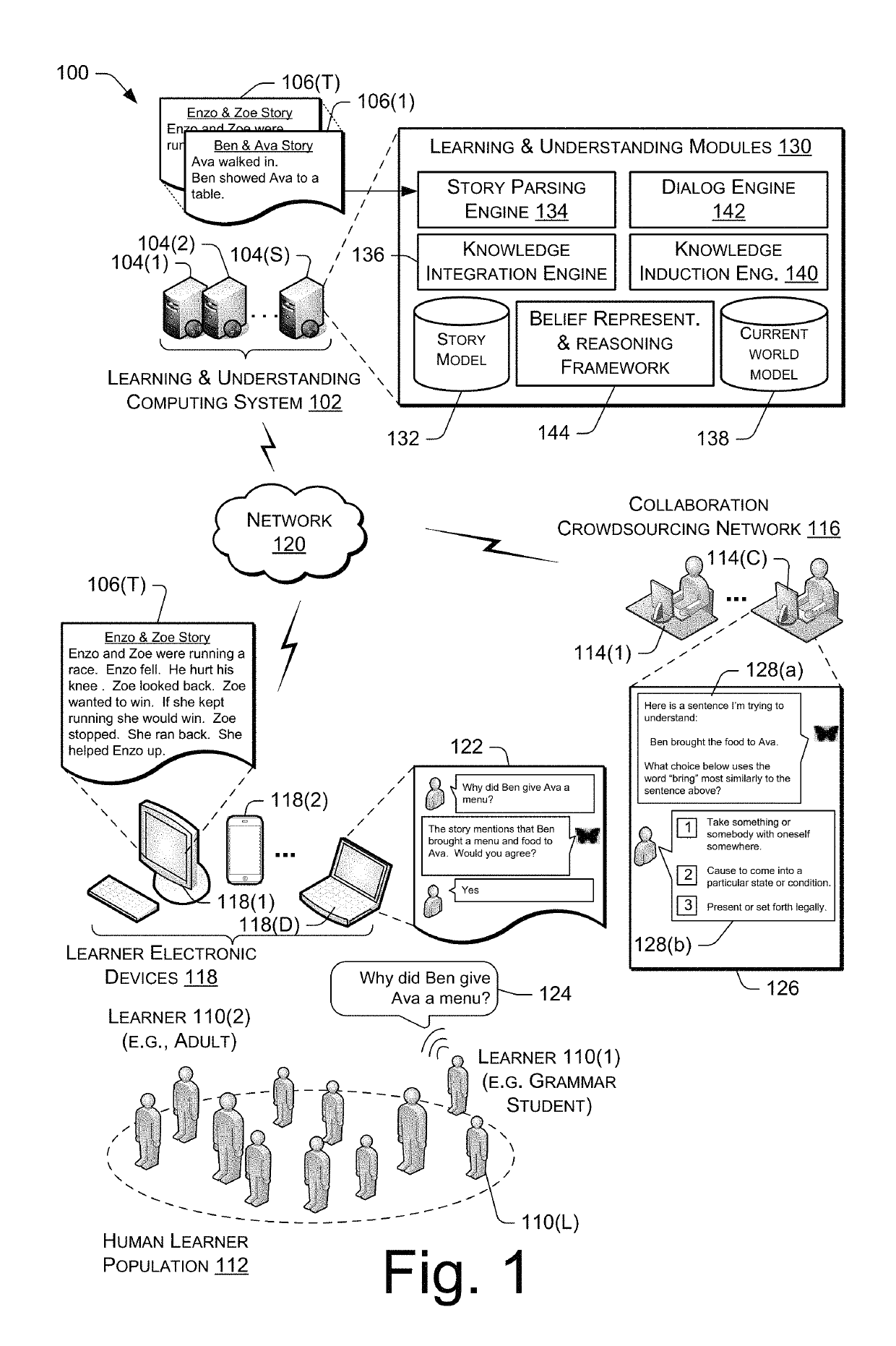

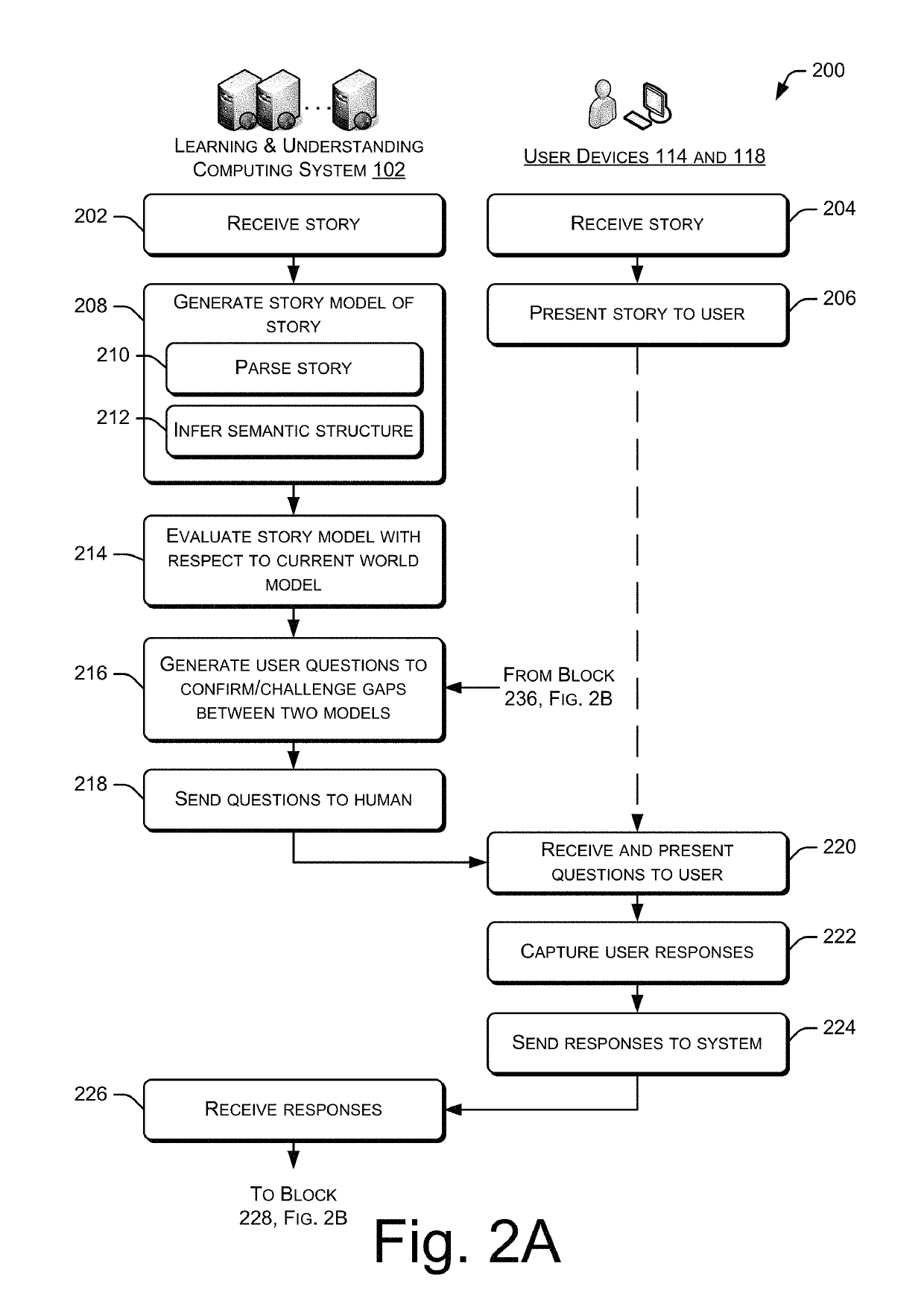

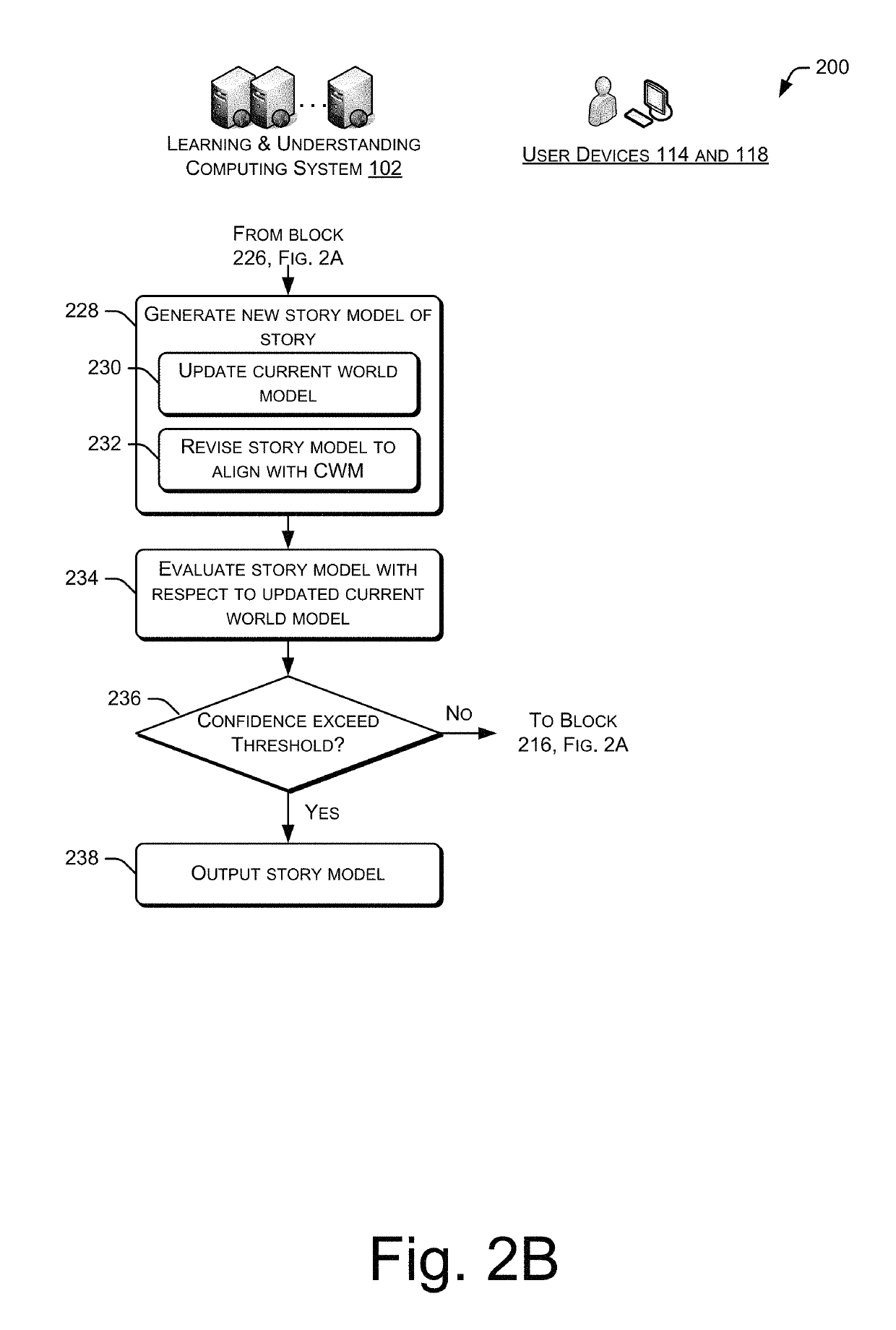

Architecture and processes for computer learning and understanding

An architecture and processes enable computer learning and developing an understanding of arbitrary natural language text through collaboration with humans in the context of joint problem solving. The architecture ingests the text and then syntactically and semantically processes the text to infer an initial understanding of the text. The initial understanding is captured in a story model of semantic and frame structures. The story model is then tested through computer generated questions that are posed to humans through interactive dialog sessions. The knowledge gleaned from the humans is used to update the story model as well as the computing system's current world model of understanding. The process is repeated for multiple stories over time, enabling the computing system to grow in knowledge and thereby understand stories of increasingly higher reading comprehension levels.

Owner:ELEMENTAL COGNITION LLC

Ultra-large width three-dimensional laser engraving method and system

InactiveCN108436278AHigh precisionAvoid seamsLaser beam welding apparatusLaser processingJoint problem

The invention relates to an ultra-large width three-dimensional laser engraving method and system. The ultra-large width three-dimensional laser engraving method comprises the steps that a laser control system acquires three-dimensional data of an object to be engraved or a target model and laser engraving parameters, wherein the laser engraving parameters include the speed parameter; bearing platform movement parameters are calculated according to the laser engraving parameters, wherein the bearing platform movement parameters include the bearing platform moving speed and the step pitch; andthe laser control system is started to carry out laser engraving, and based on the bearing platform movement parameters, the bearing platform is controlled to move so that the scanning head width of the laser control system covers laser processing lines or a processing face of the object to be engraved or the target model all the time. According to the ultra-large width three-dimensional laser engraving method and system, due to the fact that the object to be engraved and a laser running track are linked, continuous laser outlet processing of laser is kept all the time, all the processing lines are not disconnected, the joint problem caused by splicing is avoided, finally a smooth and complete processing surface is obtained, and higher-precision ultra-large width three-dimensional laser engraving is achieved.

Owner:BEIJING JCZ TECH

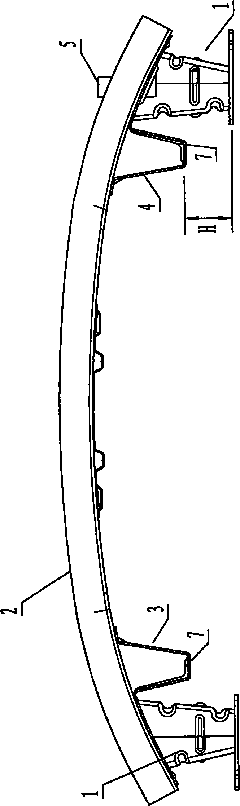

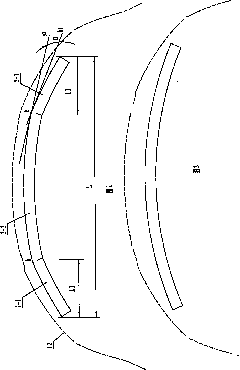

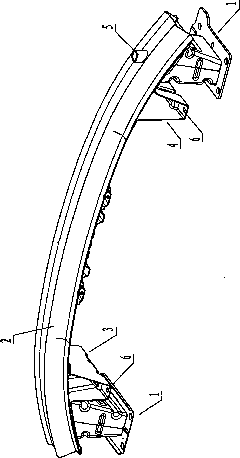

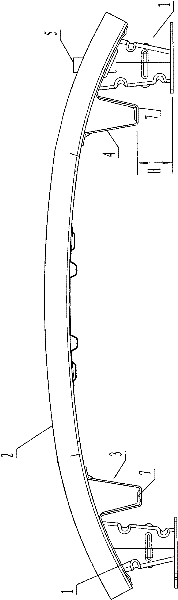

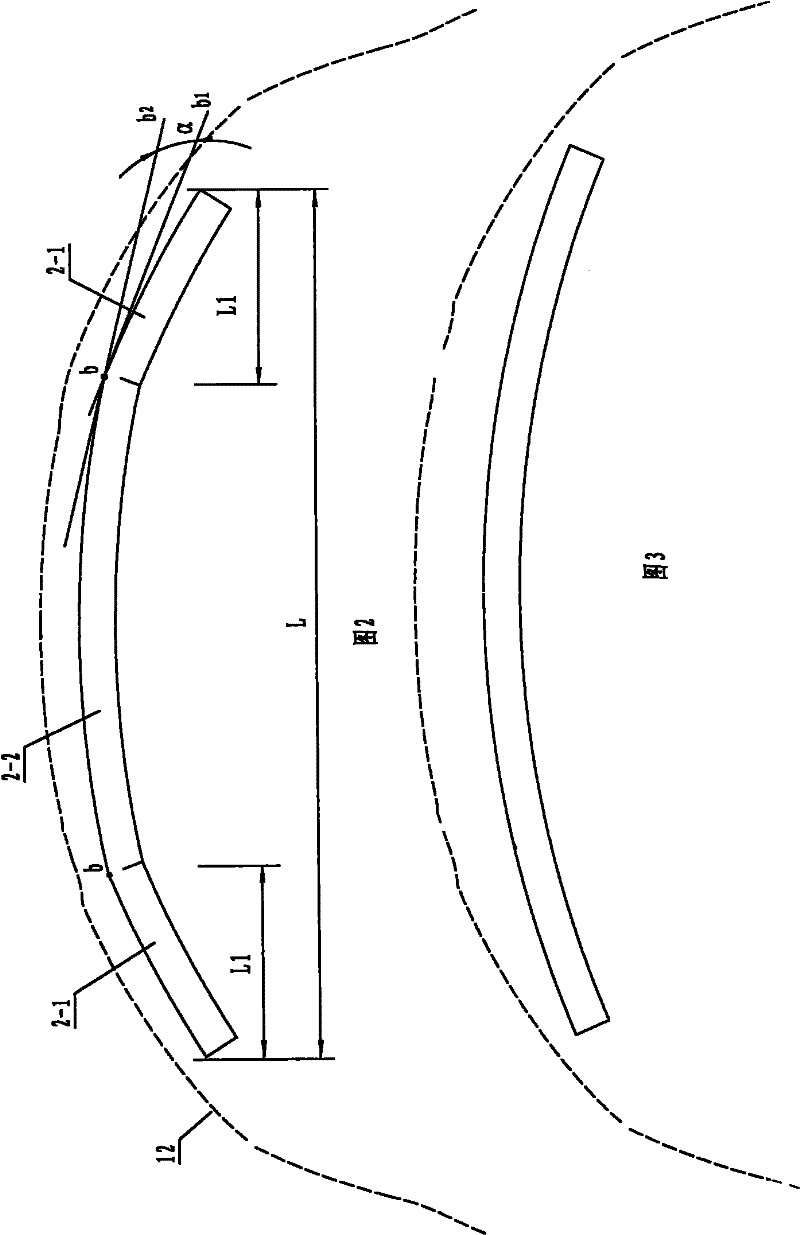

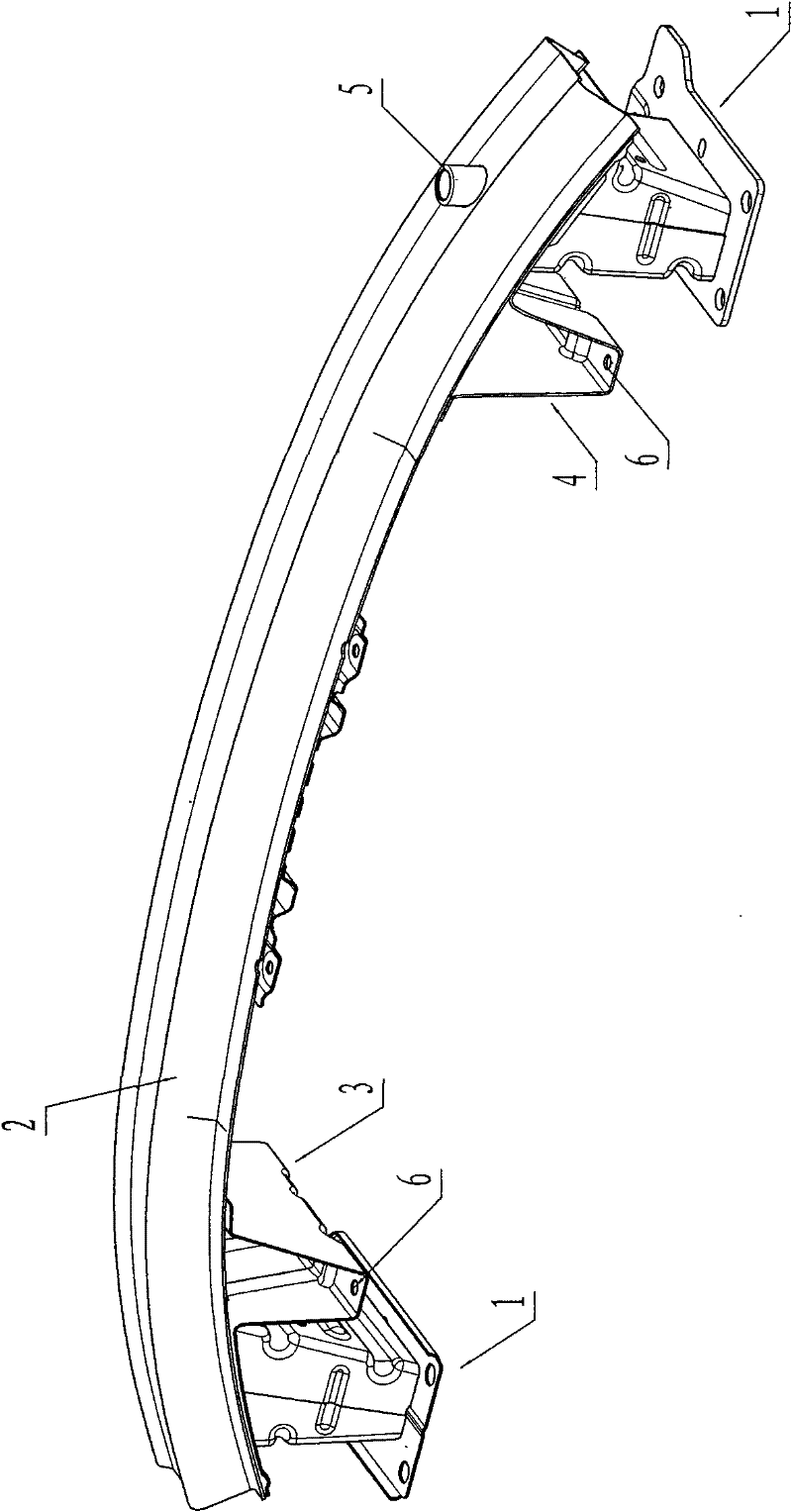

Front anti-collision beam of small car

The invention relates to a front anti-collision beam of a small car, which is used for solving the joint problem of a cross beam and skin, and comprises the cross beam and energy absorbing boxes symmetrically arranged at the two sides of the cross beam, wherein the cross beam is in a three-section structure, and each section of the cross beam is of an equivalent radius arc; and the two side sections of the cross beam bend inwards at a bending angle of alpha relative to the middle section of the cross beam, and alpha ranges from 3 degrees to 15 degrees. The invention has the following characteristics that: 1. the cross beam adopts the equivalent radius three-section arc structure, and when the radian of the outer surface of the cross beam is inconsistent with the radian of the outer surface of the skin, the angle of the bending angle between arcs can be changed to meet the requirements of the joint design of the outer arc surface of the cross beam and the outer surface of the skin; 2. a water tank support is arranged on the cross beam so as to replace a plurality of stamping parts for installing a water tank, thereby reducing the weight of a car body, saving material cost and simplifying process; 3. a release assembly is installed on a mounting plate at one side of the water tank support, so that the weight of the car body is further reduced, and the shape of the anti-corrosion beam is attractive.

Owner:LINGYUN INDAL CORP

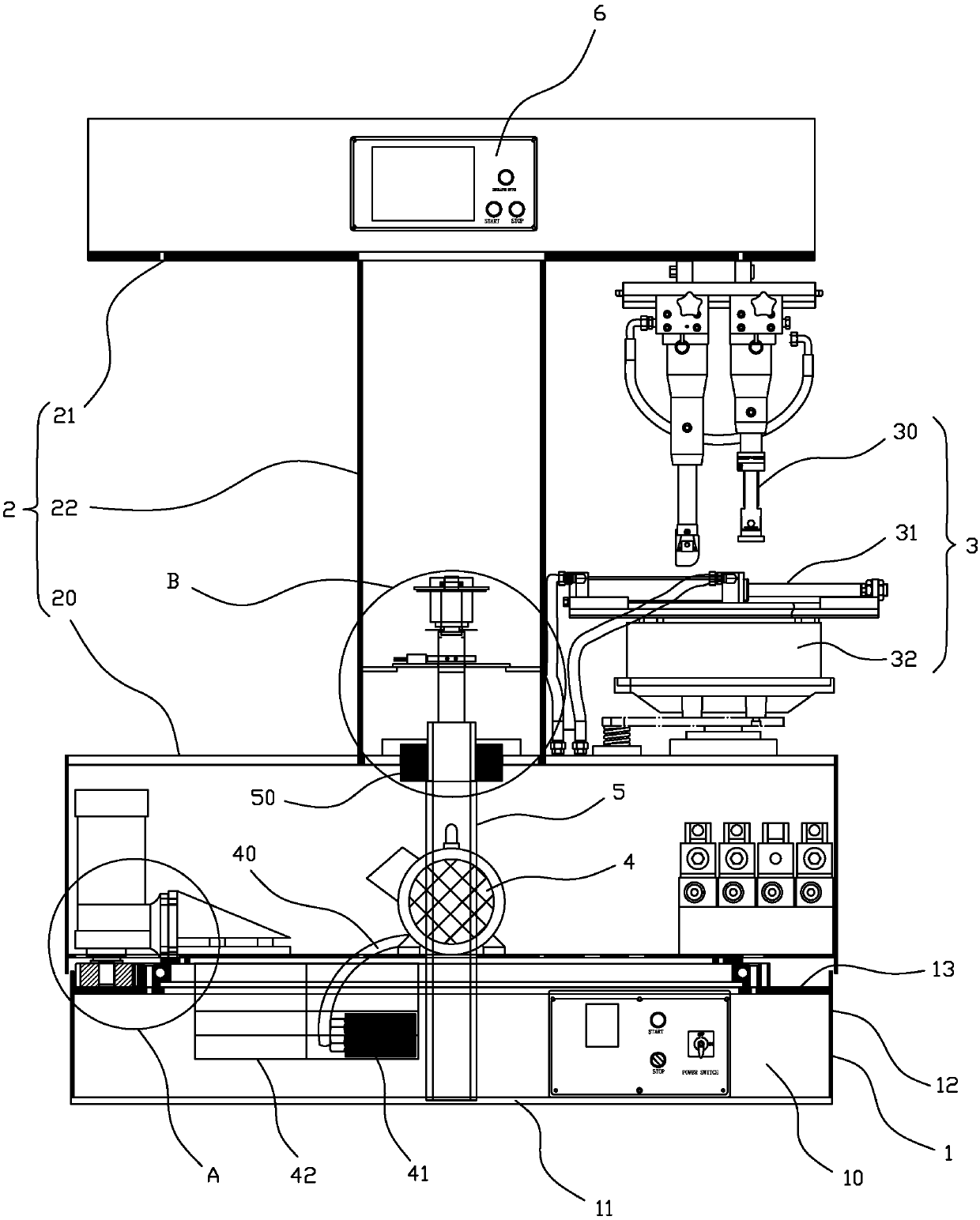

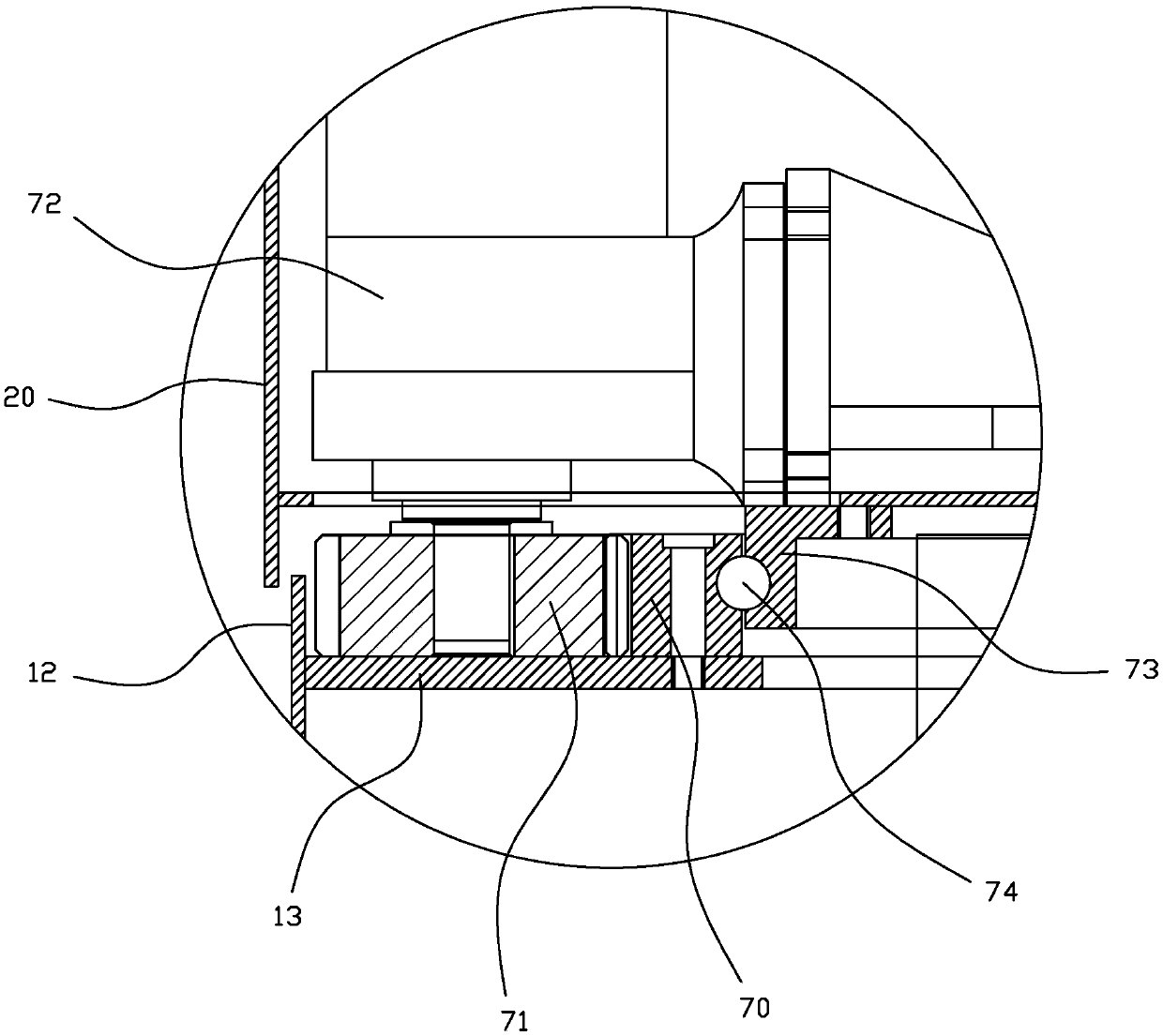

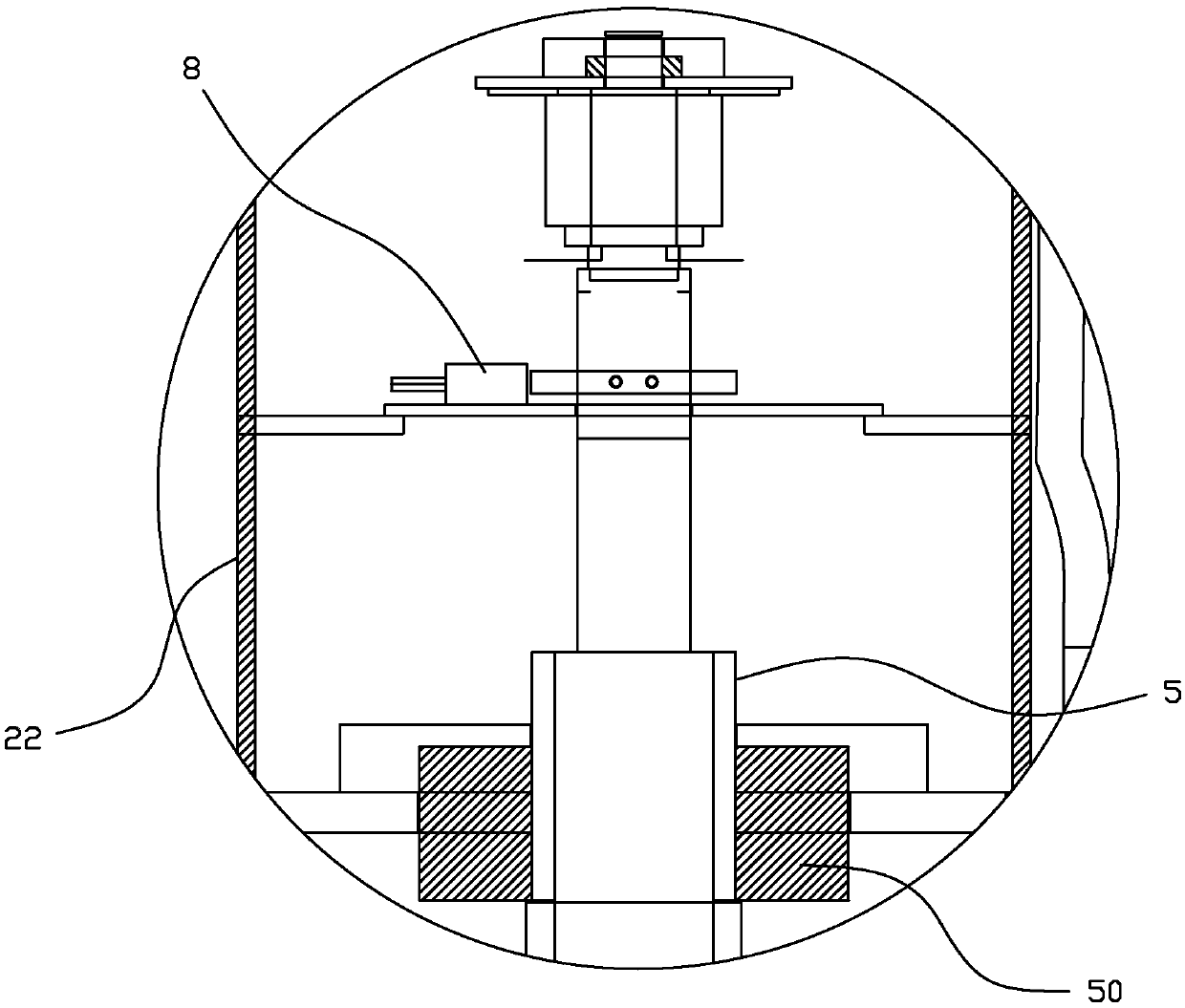

Shoe sole pressing machine

A shoe sole pressing machine, comprising a base, a rotary frame rotatably arranged on the base, a plurality of pressing mechanisms distributed on the rotary frame, and an oil pump arranged on the rotary frame for supplying hydraulic oil to the pressing mechanism And the driving mechanism for driving the slewing frame to rotate. An oil tank is arranged in the base, and the input pipe of the oil pump extends into the oil tank. The invention distributes a plurality of lamination mechanisms on the slewing frame and realizes automatic positioning through the detection mechanism. After the worker completes the lamination work of one station, he can rotate to the next station for operation without waiting. Realize continuous operation, can effectively improve the working efficiency of pressing, and are easy to operate; at the same time, the oil tank is set to a structure that does not interfere with the oil pump input pipe rotating with the slewing frame, which solves the problem of oil pipe winding during slewing in the prior art, and also avoids slewing The problem of joint oil leakage is solved, and the structure is simple, the mechanical strength is high, and the cost is low.

Owner:庄国伟

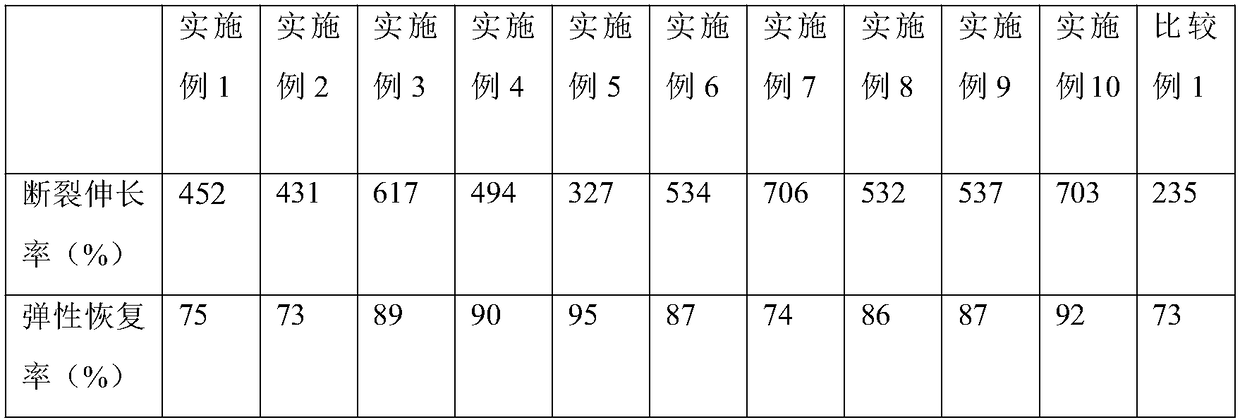

Multi component sealant for prefabricated concrete building joints and preparation method thereof

InactiveCN108165223AGood adhesionGood waterproof and sealing performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesJoint problemEnd-group

The invention discloses a multi component sealant for prefabricated concrete building joints and a preparation method thereof. The multi component sealant includes an A component, a B component and anappropriate amount of a C component; the mass ratio of A component to B component is 10:1, every 100 parts of the A component include 20-50 parts of a silane-modified polyether polymer I, 5-50 partsof a silane-modified polyether polymer II, 5-35 parts of a plasticizer, 10-30 parts of nano calcium carbonate, 5-20 parts of heavy calcium carbonate, 0.1 to 3 parts of a thixotropic agent and 0.1 to 5parts of a functional auxiliary; the silane-modified polyether polymer I and the silane-modified polyether polymer II are polyoxypropylene ethers with hydrolysable silicon alkyl groups as end groups,every 100 parts of the B component include 15-35 parts of the plasticizer, 40-60 parts of the heavy calcium carbonate, 1-10 parts of kaolin and 1-20 parts of a catalysts, and the C component is colorpaste. The multi component sealant has good adhesion, excellent waterproof and sealing effect and elastic recovery rate reaching 90%, effectively resists the displacement of a prefabricated concretebuilding, has elongation at break reaching 700%, and effectively solves the joint problem caused by the displacement.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

Aluminum-based carbon fiber composite core wire

InactiveCN104517674ANo "bamboo" phenomenon"Bamboo" phenomenon will not appearNon-insulated conductorsPower cablesFiberJoint problem

The invention discloses an aluminum-based carbon fiber composite core wire comprising a core and an aluminum alloy conductor sleeving the core. The aluminum alloy conductor is stranded around the core which is made of aluminum-based carbon fiber composite. Copper layer is arranged on the outer surface of the core and covered with a pyrolytic carbon layer. The aluminum alloy conductor covers the pyrolytic carbon layer. The aluminum-based carbon fiber composite core wire comprises, by volume percent, 2-5% of the carbon fiber, 1.2-1.5% of the copper layer, 1-10% of the pyrolytic carbon layer and the rest of industrial virgin aluminum. The aluminum-based carbon fiber composite core wire has the advantages that the bamboo joint problem is avoided, conductivity is high, bending strength and extension strength are strong, and better high-temperature and heat resistance is achieved.

Owner:STATE GRID CORP OF CHINA +2

Food replenisher beneficial for joints and preparation method thereof

The invention discloses a food replenisher beneficial for joints and a preparation method thereof. The food replenisher comprises a dahurian rose fruit extract, dahurian rose fruit collagen and calcium lactate. By utilizing the food replenisher, the bone mineral density is effectively improved, and the joint problems are prevented and treated. Compared with the prior art, the food replenisher is simple in formula, convenient to use and good in curative effect. The invention further provides a reasonable and accessible preparation method.

Owner:张金荣

Delustering polypropylene filling material

The invention discloses a delustering polypropylene filling material. The delustering polypropylene filling material is prepared from, by mass, 30 to 35 parts of polypropylene, 10 to 15 parts of quartz sand, 18 to 22 parts of plaster stone powder, 1 to 4 parts of an organic delustering agent, 1 to 3 parts of a foaming agent, 5 to 8 parts of natural fiber, and 0.5 to 1.5 parts of a processing auxiliary agent. The beneficial effects are that: combination of polypropylene with the organic delustering agent is adopted, the other raw materials are added, the obtained delustering polypropylene filling material is high in performance stability, is capable of solving joint problems, is excellent in compatibility, cohesive properties, is firm, is long in service life, and is capable of satisfying requirements of the building industry.

Owner:太仓佩利斯高分子材料有限公司

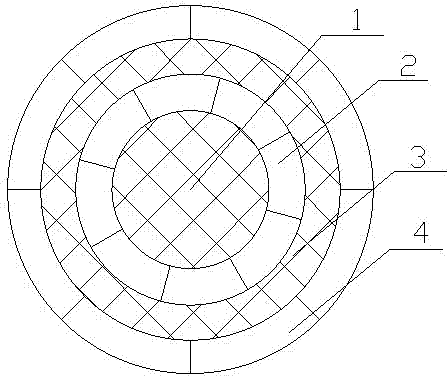

Front anti-collision beam of small car

The invention relates to a front anti-collision beam of a small car, which is used for solving the joint problem of a cross beam and skin, and comprises the cross beam and energy absorbing boxes symmetrically arranged at the two sides of the cross beam, wherein the cross beam is in a three-section structure, and each section of the cross beam is of an equivalent radius arc; and the two side sections of the cross beam bend inwards at a bending angle of alpha relative to the middle section of the cross beam, and alpha ranges from 3 degrees to 15 degrees. The invention has the following characteristics that: 1. the cross beam adopts the equivalent radius three-section arc structure, and when the radian of the outer surface of the cross beam is inconsistent with the radian of the outer surface of the skin, the angle of the bending angle between arcs can be changed to meet the requirements of the joint design of the outer arc surface of the cross beam and the outer surface of the skin; 2. a water tank support is arranged on the cross beam so as to replace a plurality of stamping parts for installing a water tank, thereby reducing the weight of a car body, saving material cost and simplifying process; 3. a release assembly is installed on a mounting plate at one side of the water tank support, so that the weight of the car body is further reduced, and the shape of the anti-corrosionbeam is attractive.

Owner:LINGYUN INDAL CORP

A Realization Method of Skeleton Skinning Animation

The invention discloses an implementation method of skinned skeletal animation. The implementation method comprises the following steps: A, constructing a skeleton model and a skinned mesh model which constitute a role model; B, determining a skeleton which influences the mesh vertexes on the skinned mesh model, and determining the influence weight according to a geometrical relationship and a physical relationship between the skeleton and the vertexes; C, carrying out calculus of interpolation between each two adjacent key frames according to a key frame sequence of skeleton movement, which is stored in a role model file, and determining new position and new orientation of each skeleton at certain moment; and D, calculating new position and new orientation of each vertex under a world coordinate system according to skeleton index and corresponding influence weight which influence each vertex and are stored in each vertex on the skinned mesh model, and thus achieving skinned skeleton animation. According to the implementation method disclosed by the invention, the joint problem in skeletal animation is solved, the effect is real and vivid, and is more flexible compared with that of vertex animation, and little memory space is occupied while a favorable animation effect is finished; the skinned skeletal animation can be constructed more easily and rapidly.

Owner:WUXI FANTIAN INFORMATION TECH

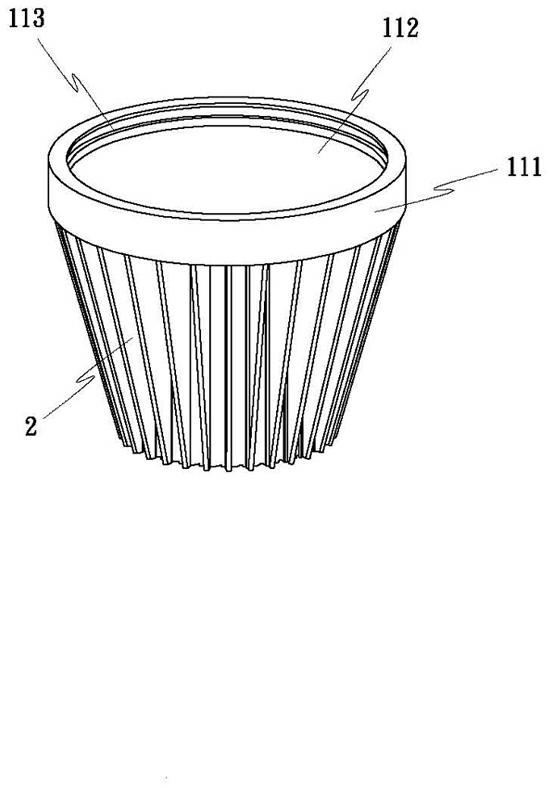

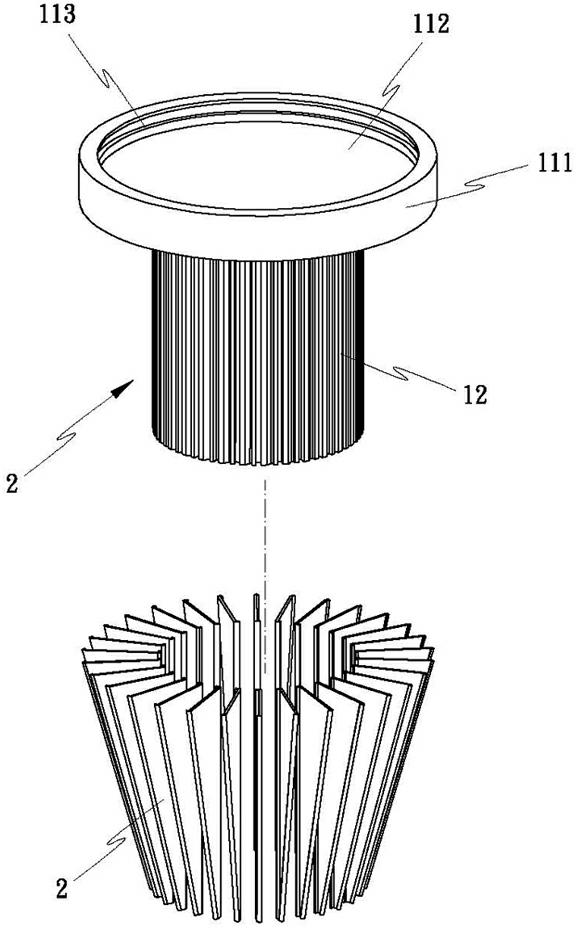

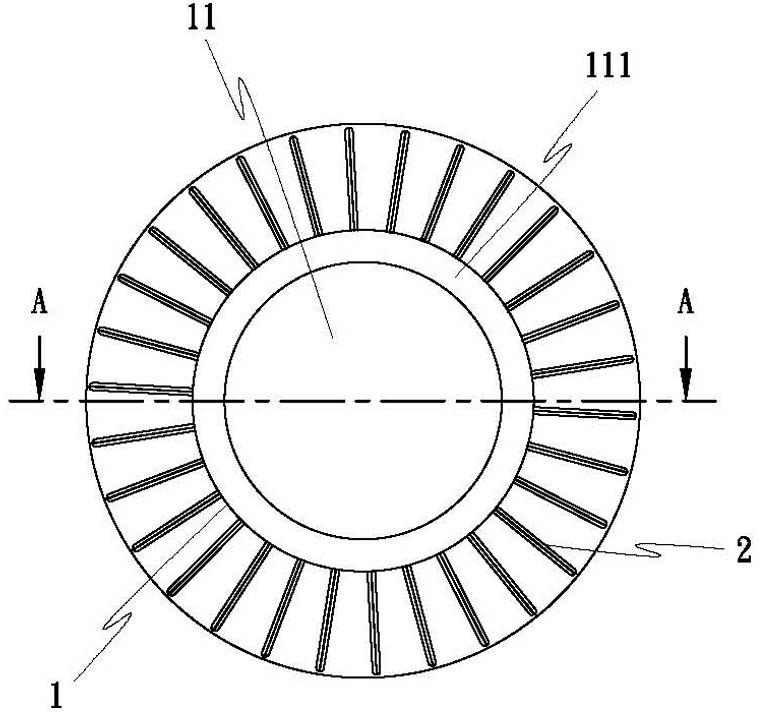

Radiating pipe base and machining method thereof

ActiveCN102564191ASimple processNo capillarityGlobesSemiconductor devices for light sourcesJoint problemIngot

The invention relates to a radiating pipe base and a machining method of the radiating pipe base. The radiating pipe base is provided with a hollow pipe body, a closed surface which is molded with the hollow pipe body by one time and connected with the hollow pipe body integrally is arranged at the front end or the middle section of the hollow pipe body, a plurality of clamp grooves which are molded with the hollow pipe body and the closed surface by one time are arranged on the outer pipe wall of the hollow pipe body and are used for surrounding and combining by a plurality of radiating fins relatively; and the hollow pipe body, the closed surface and the clamp grooves are used for the one-time molding of quantitative aluminum ingot blanks by stamping or extruding (oil pressure). The radiating pipe base is an integral molding assembly, and is formed by one-time processing according to the manufacturing process, the process is simple and convenient, the joint problem and capillary phenomenon can be avoided, and the thermal resistance can not be caused, so that the heat energy can be completely absorbed and transferred, and the radiating effect can be improved.

Owner:DONG GUAN HAN XU HARDWARE & PLASTIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com