Multi component sealant for prefabricated concrete building joints and preparation method thereof

A concrete building and prefabricated technology, applied in the field of sealants, can solve the problems of long construction period, large energy consumption, etc., achieve good waterproof and sealing effects, solve joint problems, and avoid rainwater penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a multi-component sealant for any of the above prefabricated concrete building joints, comprising the following steps:

[0036] Prepare component A, component B and component C, and the sequence of preparing component A, component B and component C is not limited;

[0037] The preparation method of component A is: add silane-modified polyether polymer I, silane-modified polyether polymer II, plasticizer, nano-calcium carbonate, ground calcium carbonate, thixotropic agent and functional auxiliary to the reactor. agent, blended under vacuum for 1 to 2 hours to obtain component A;

[0038] The preparation method of component B is as follows: add plasticizer, heavy calcium carbonate, kaolin, and catalyst to the reaction kettle, and blend under vacuum conditions for 1 to 2 hours to obtain component B of weather-resistant sealant for prefabricated concrete joints ;

[0039] C component is color paste;

[0040] Pack...

Embodiment 1

[0044] With 20 parts of silane modified polyether polymer I, 10 parts of silane modified polyether polymer II, 25 parts of plasticizer, 30 parts of nanometer calcium carbonate, 10 parts of heavy calcium carbonate, 2 parts of thixotropic agent, 3 parts Functional additives, blended for 1 to 2 hours under vacuum protection, to obtain component A of weather-resistant sealant for prefabricated concrete joints; 25 parts of plasticizer, 60 parts of heavy calcium carbonate, 5 parts of kaolin, 10 parts of catalyst Blending for 1 to 2 hours under vacuum protection to obtain component B of weather-resistant sealant for prefabricated concrete joints. Mix components A and B according to the mass ratio of 10:1, add an appropriate amount of component C, mix and stir for 15 minutes and then start construction.

Embodiment 2

[0046] With 25 parts of silane modified polyether polymer I, 5 parts of silane modified polyether polymer II, 20 parts of plasticizer, 30 parts of nanometer calcium carbonate, 15 parts of heavy calcium carbonate, 2.5 parts of thixotropic agent, 2.5 parts Functional additives, blended for 1 to 2 hours under vacuum protection, to obtain component A of weather-resistant sealant for prefabricated concrete joints; 30 parts of plasticizer, 50 parts of heavy calcium carbonate, 8 parts of kaolin, 12 parts of catalyst Blending for 1 to 2 hours under vacuum protection to obtain component B of weather-resistant sealant for prefabricated concrete joints. Mix components A and B according to the mass ratio of 10:1, add an appropriate amount of component C, mix and stir for 15 minutes and then start construction.

PUM

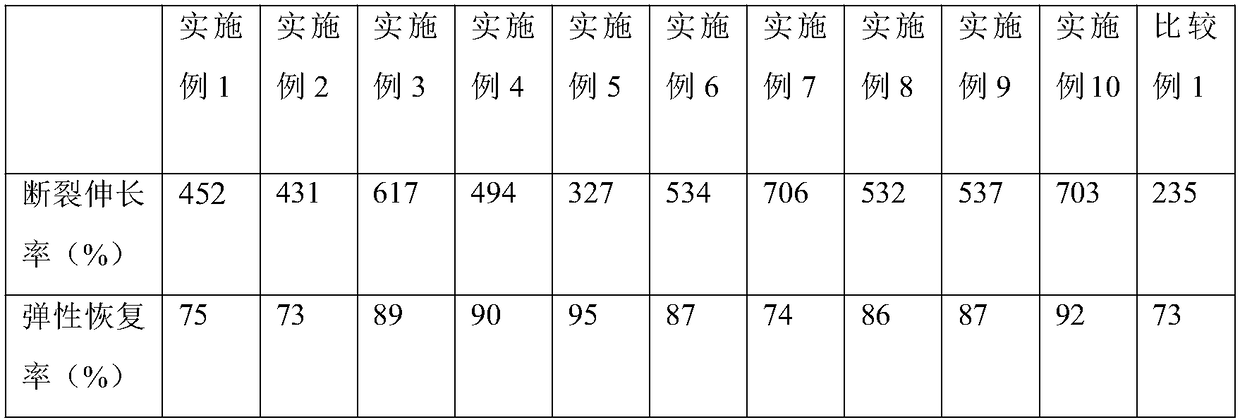

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com