Front anti-collision beam of small car

A technology for front anti-collision beams and small cars, applied in bumpers and other directions, can solve the problems of many sheet metal parts, increase the weight of the vehicle, and affect the appearance, and achieve the effect of simplifying the process, reducing the weight of the car body, and saving the cost of consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

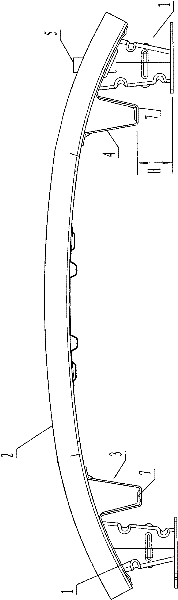

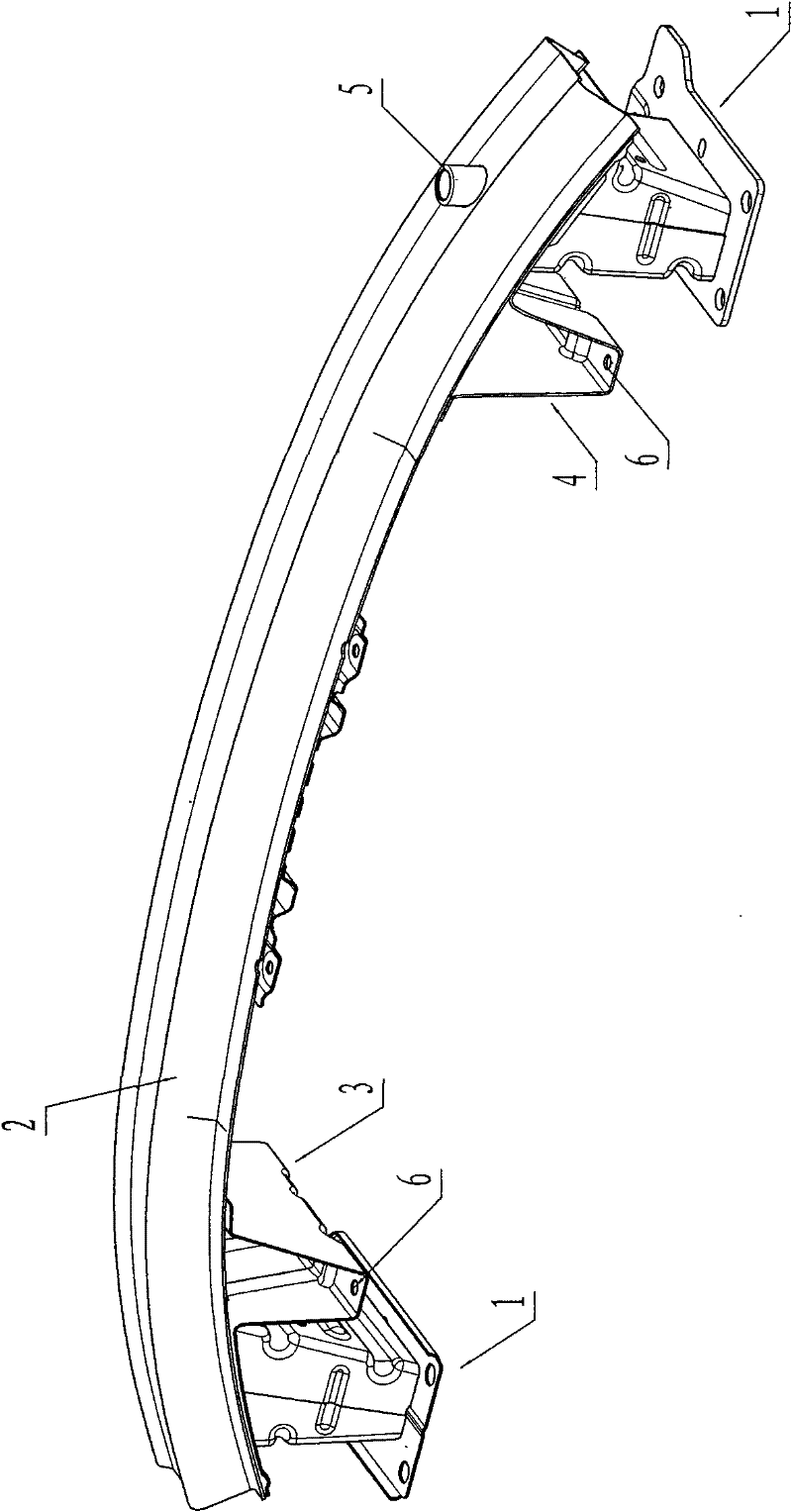

[0021] see figure 1 , Figure 4 , The composition of the present invention includes a beam 2 and energy-absorbing boxes 1 arranged symmetrically on both sides of the beam.

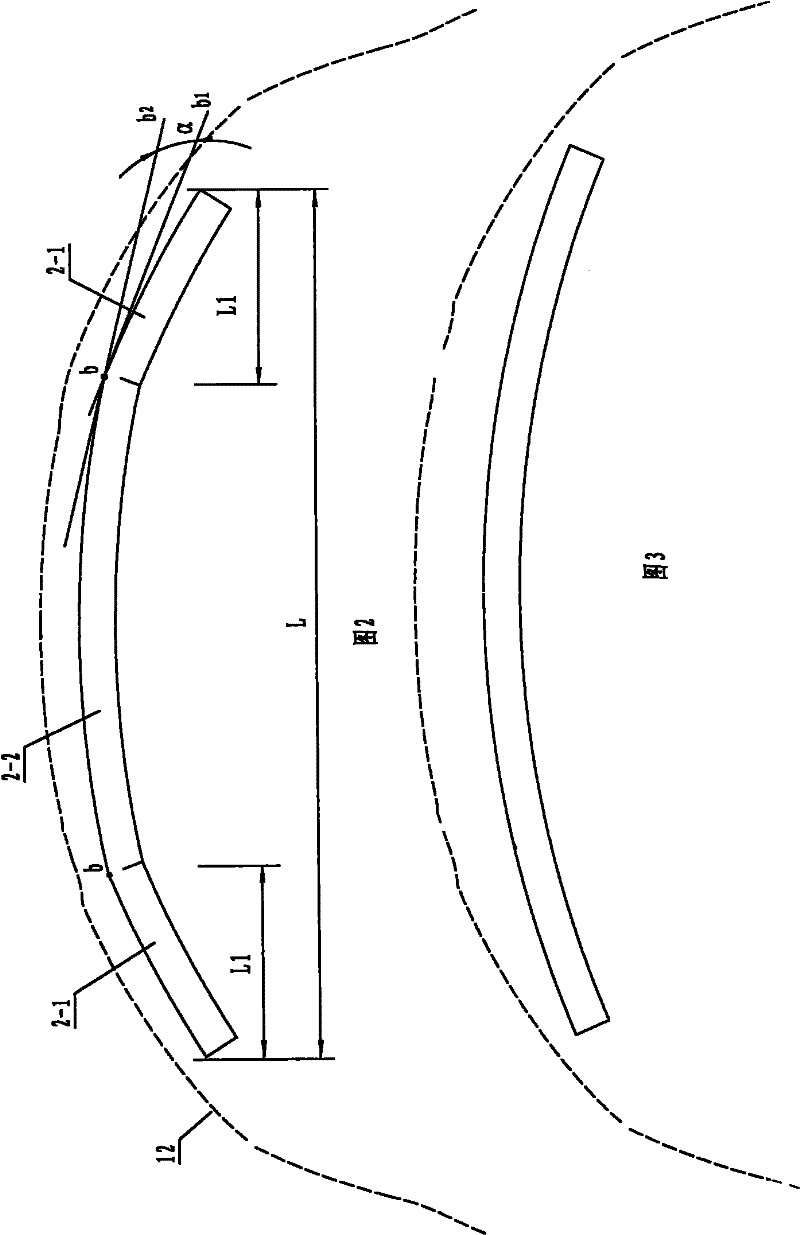

[0022] see figure 2 , in order to adapt to changes in the design of the outer profile of the automobile skin 12, the bumper beam 2 basically meets the requirements of the skin-fitting design, the beam 2 of the present invention is a three-section structure, and the arc radii of each section of the beam are equal, wherein, The two beam side sections 2-1 are bent inwardly with respect to the beam middle section 2-2 by a kink angle α. In other words, point b on the beam is the bending point, and the left and right points adjacent to the bending point fall on the side section of the beam and the middle section of the beam respectively, and the angle between the tangent lines b1 and b2 of the above two points is α. When the above-mentioned structure is used to make the crossbeam, it is sufficient to bend t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com