Shoe sole pressing machine

A technology of a pressing machine and a pressing mechanism, which is applied to shoe soles, footwear, applications, etc., can solve the problems of oil leakage of rotary joints, winding of oil pipes, low cost, etc., so as to avoid oil leakage, improve work efficiency and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments.

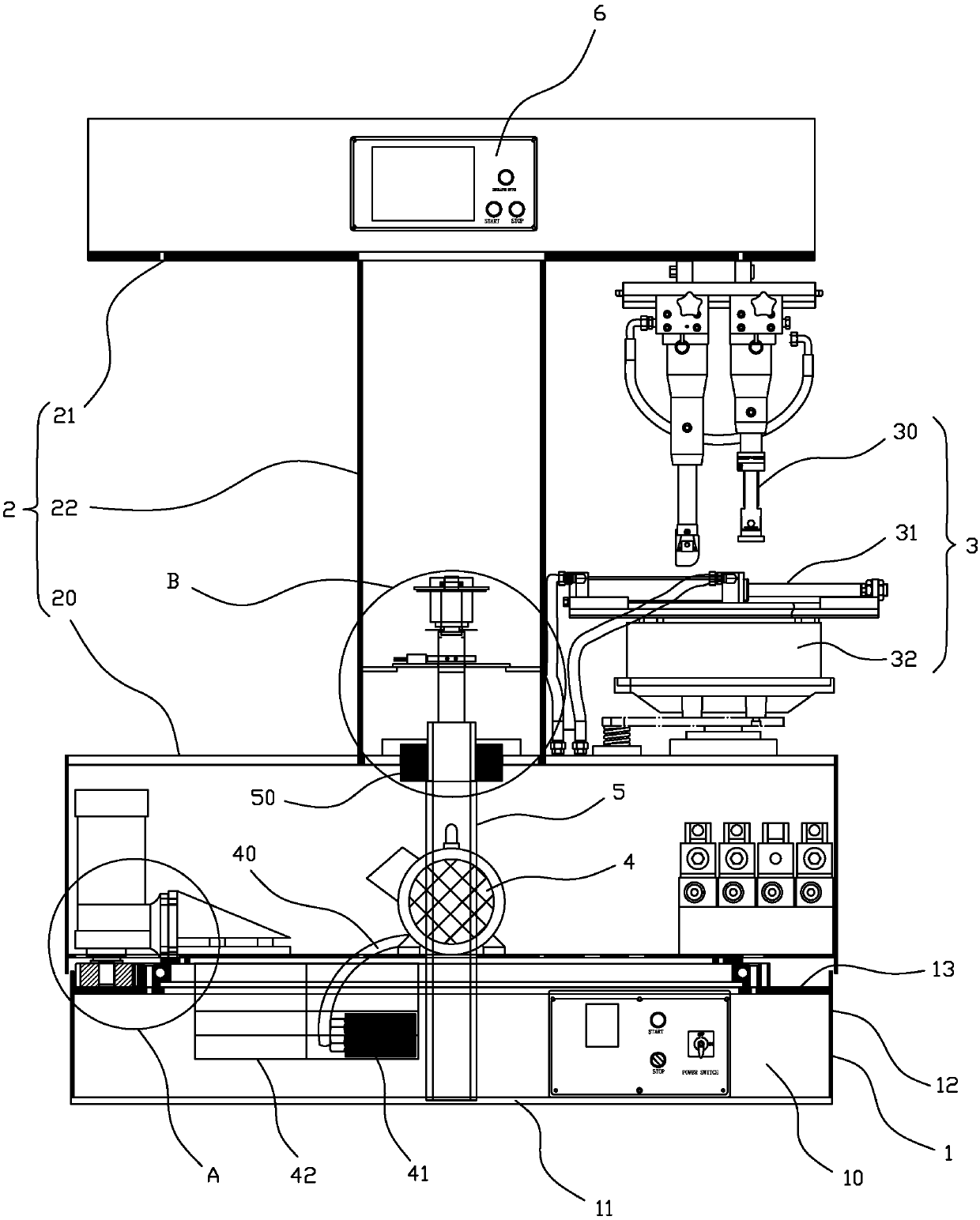

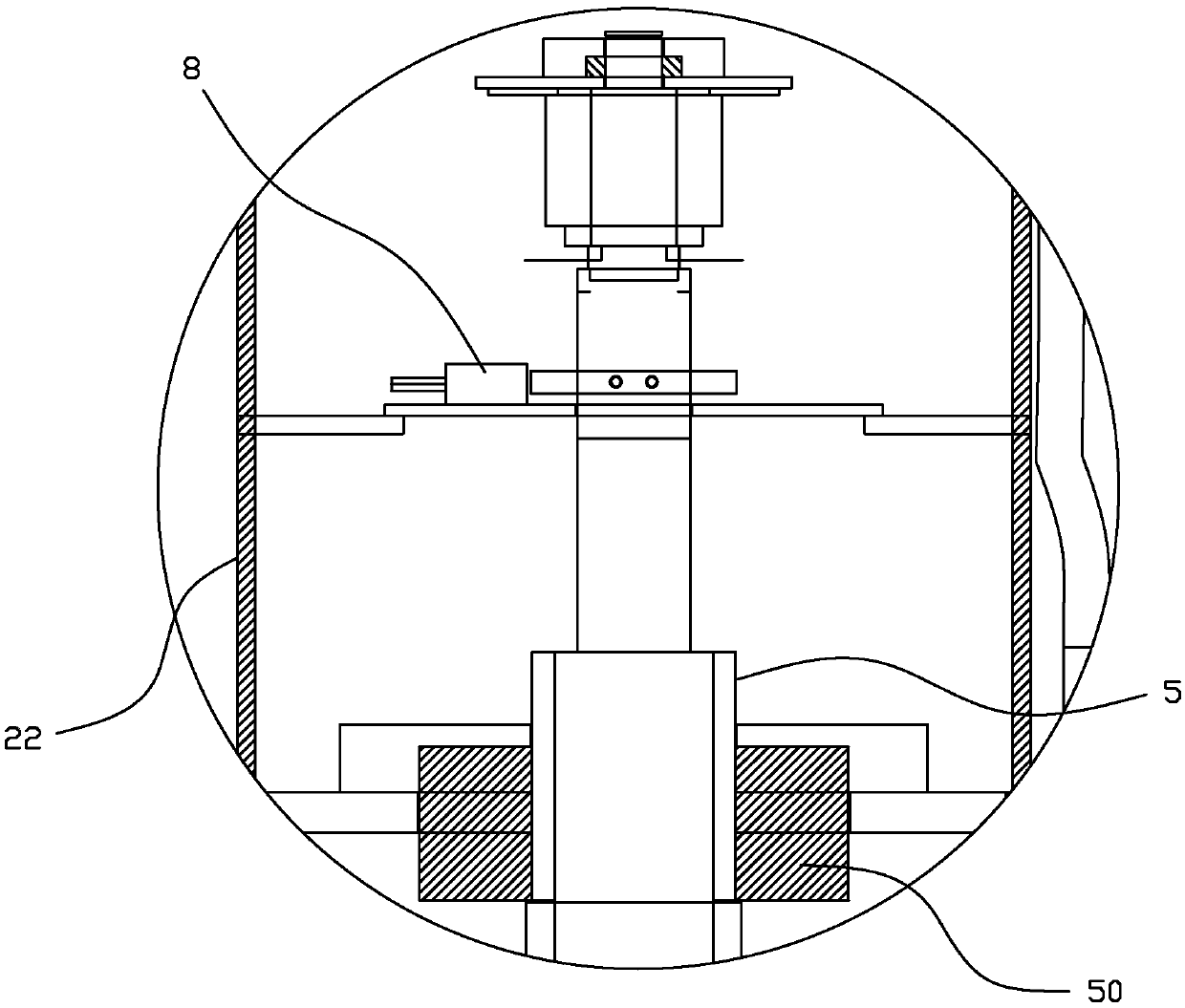

[0023] refer to Figure 1 to Figure 3 , a shoe sole pressing machine of the present invention, comprising a base 1, a rotary frame 2 rotatably arranged on the base 1, four pressing mechanisms 3 whose circumference is distributed on the rotary frame 2, arranged on the rotary frame 2 for An oil pump 4 for supplying hydraulic oil to the pressing mechanism 3 , a driving mechanism for driving the slewing frame 2 to rotate, a center shaft 5 and a controller 6 arranged on the base 1 and extending along the rotation axis of the slewing frame 2 .

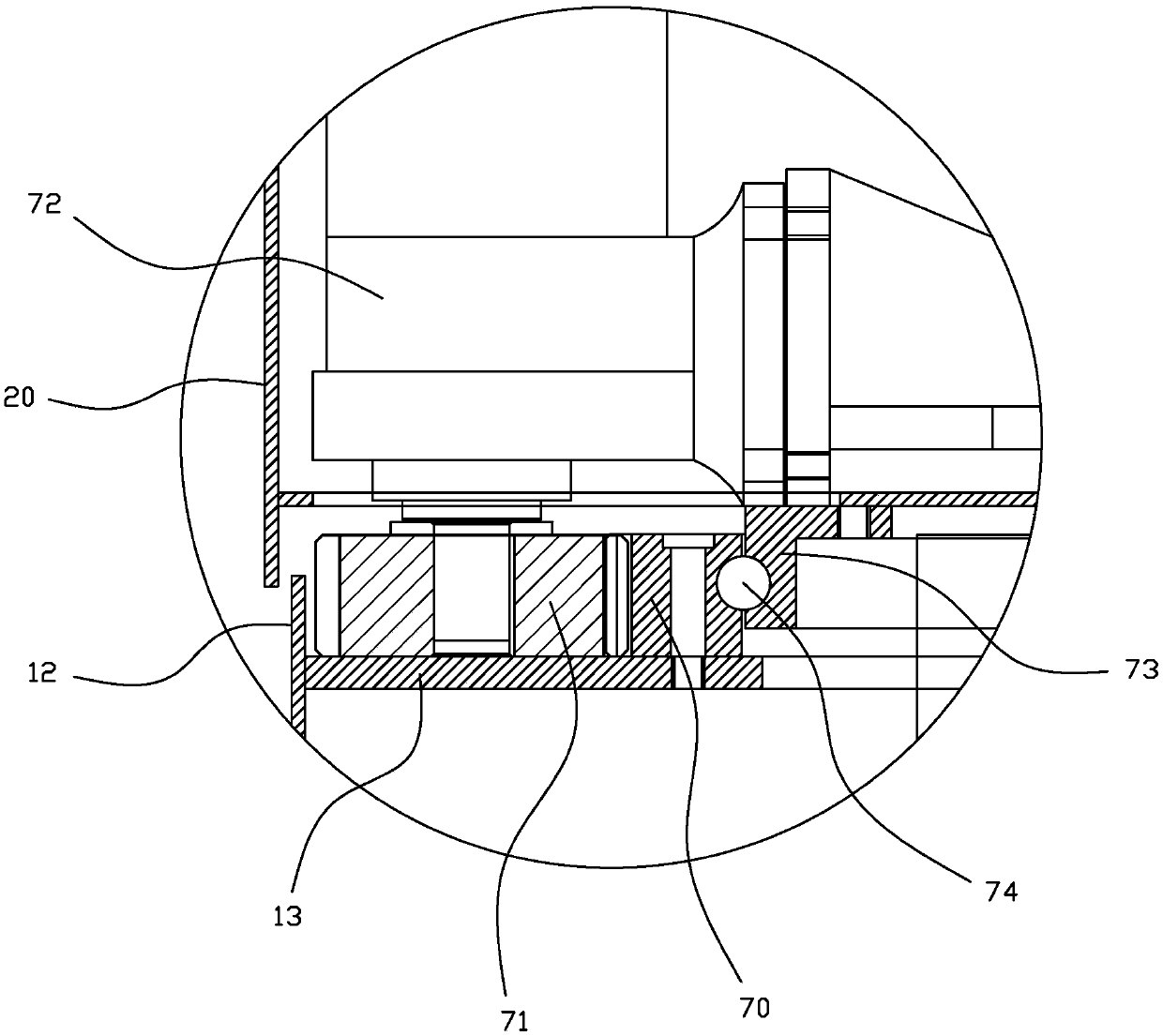

[0024] The slewing frame 2 includes a bottom 20 , a top 21 and a column 22 supported between the bottom 20 and the top 21 , and the four pressing mechanisms 3 are uniformly distributed around the bottom 20 and the top 21 . The pressing mechanism 3 includes a pressing rod assembly 30 arranged on the top 21, a workbench 31 which can be lifted and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com