Patents

Literature

438results about How to "Avoid oil spills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

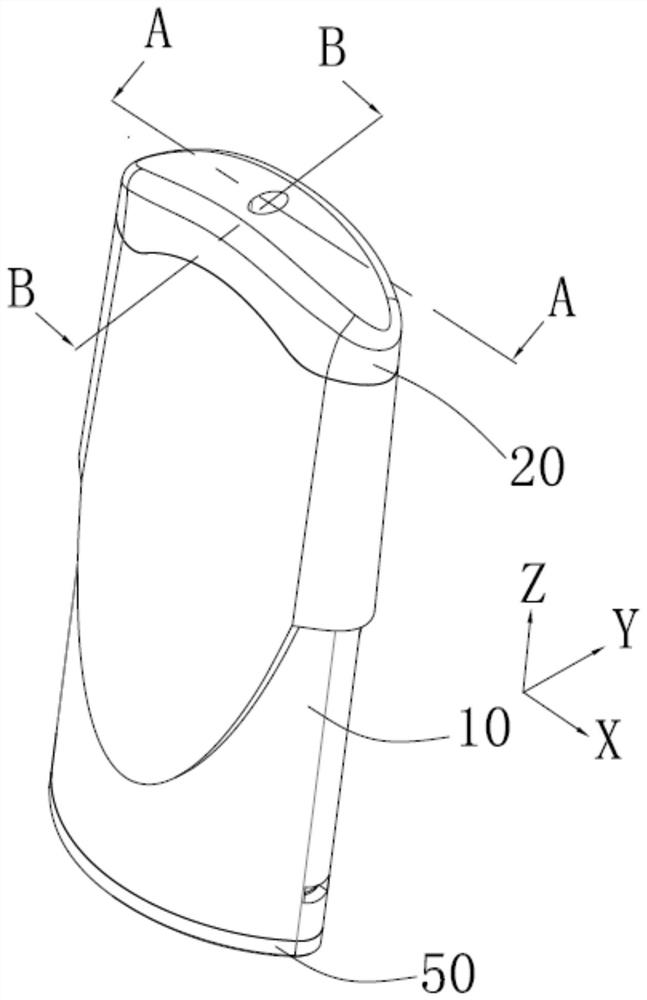

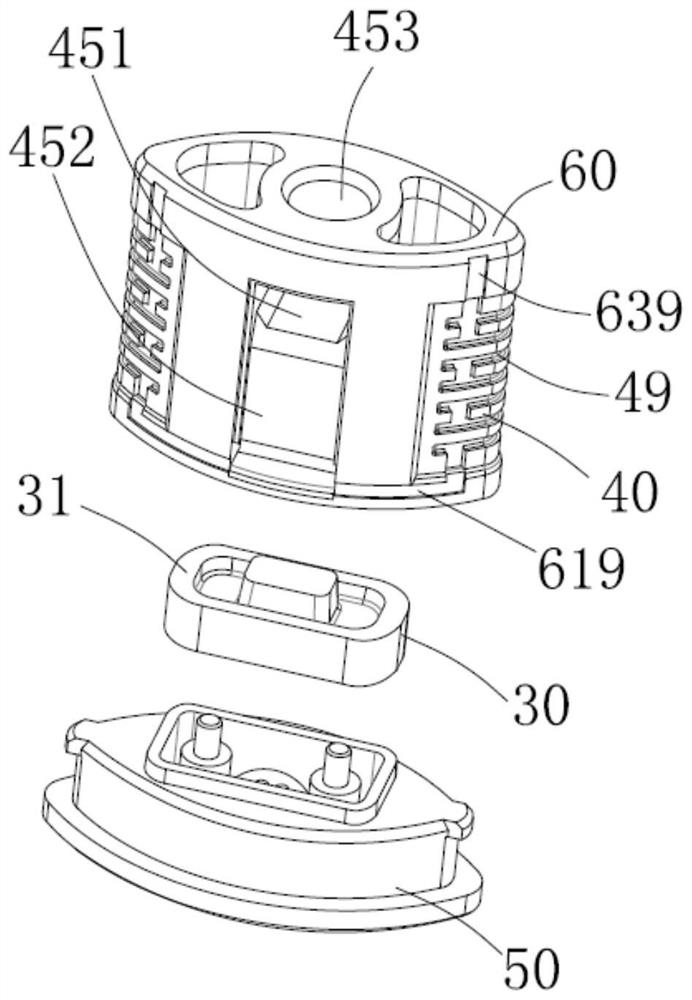

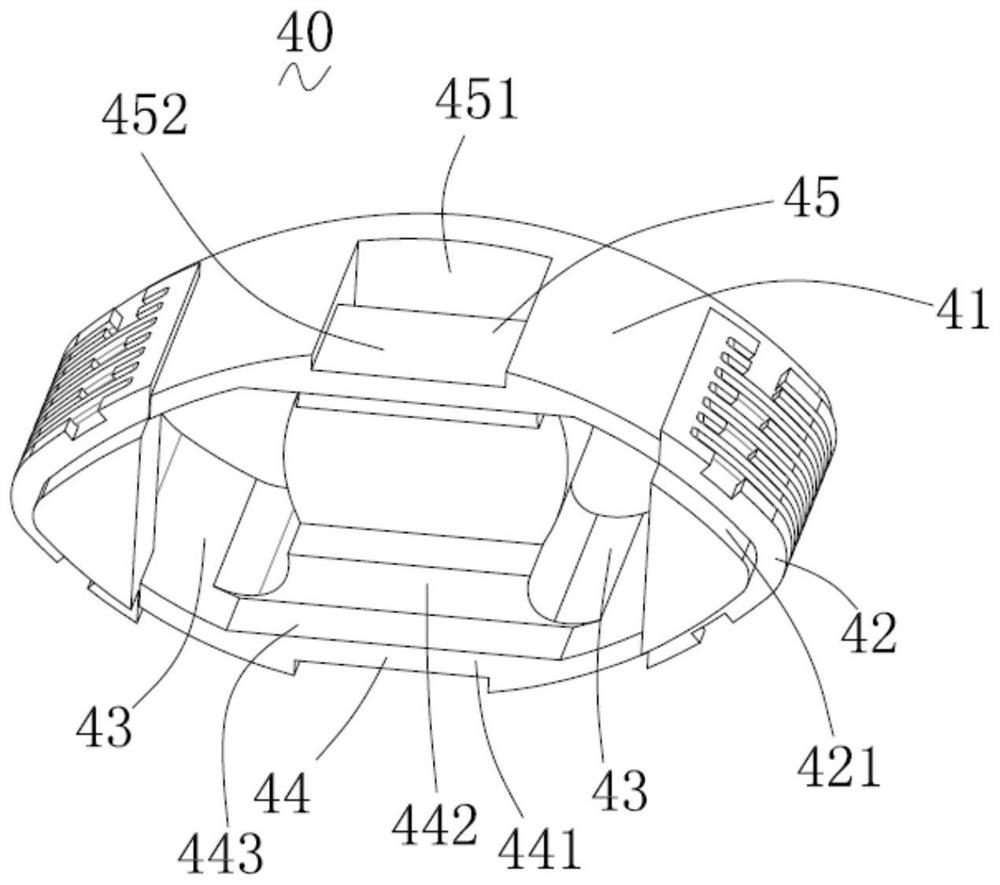

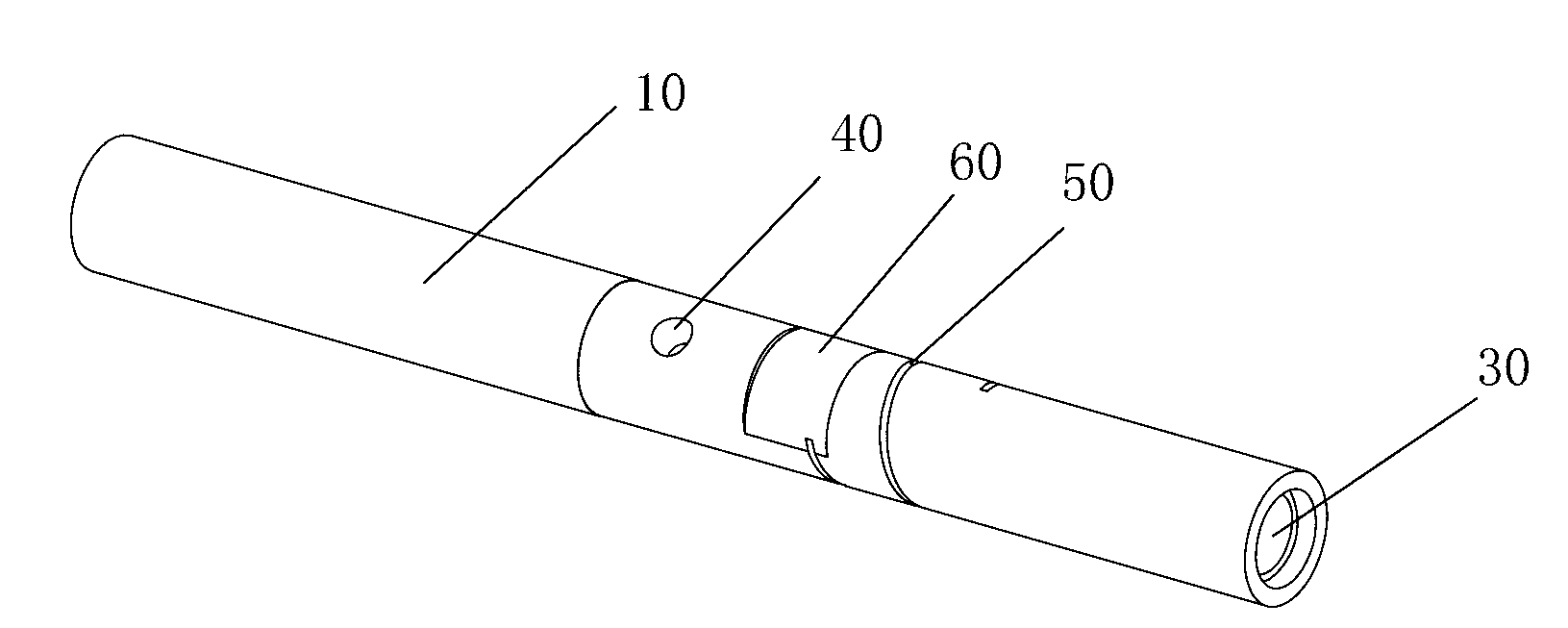

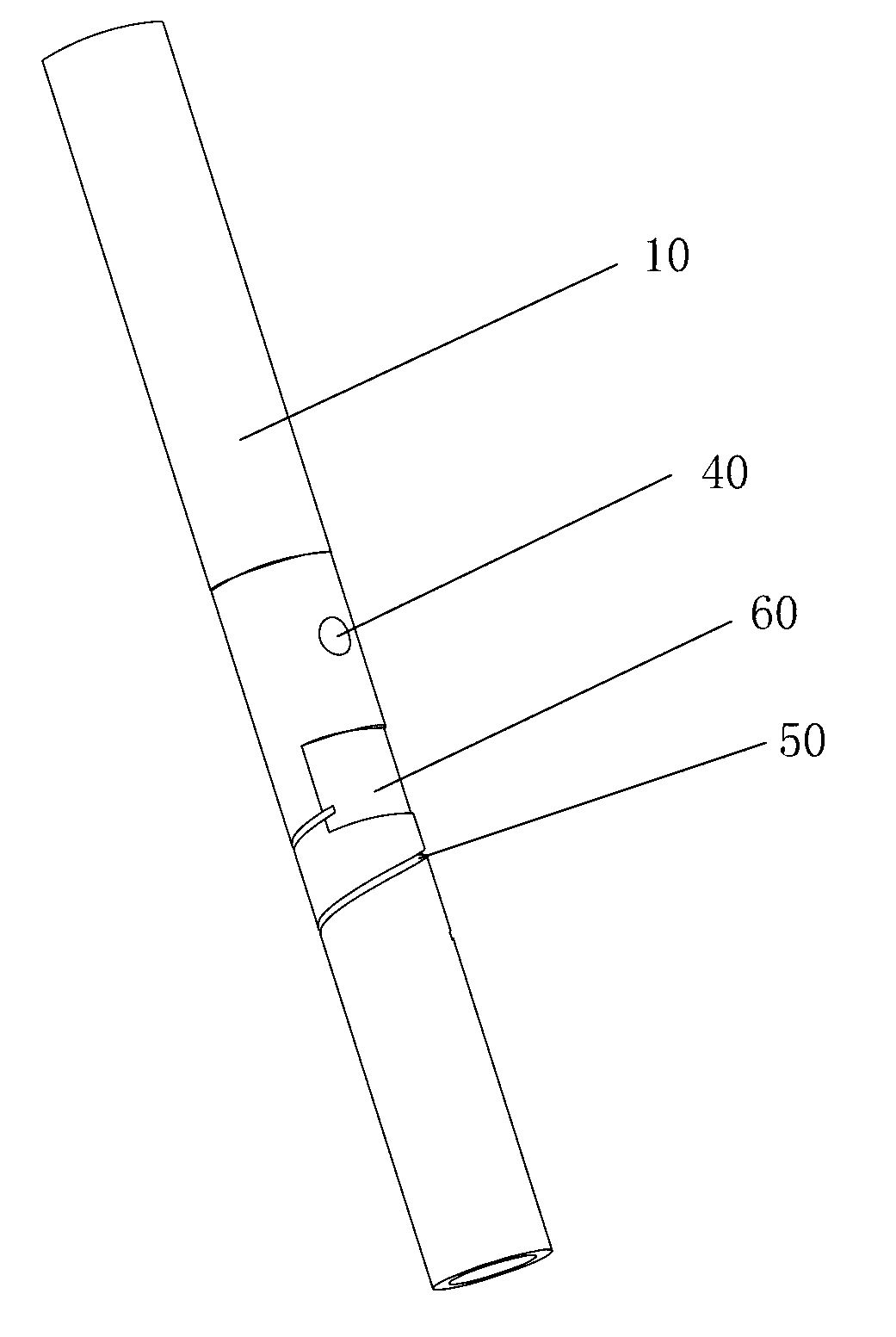

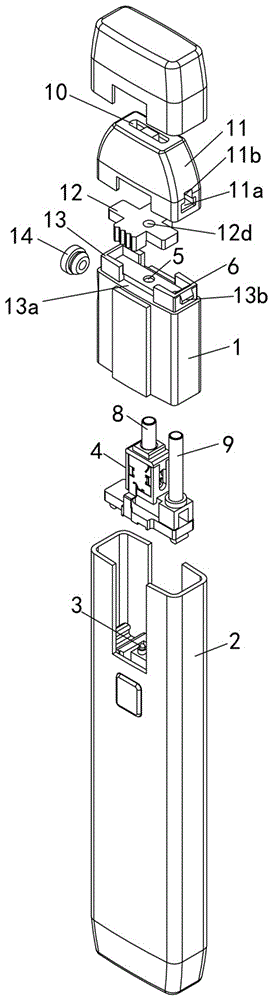

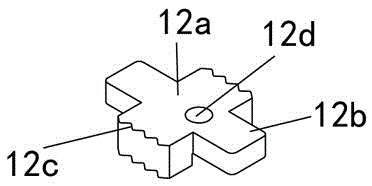

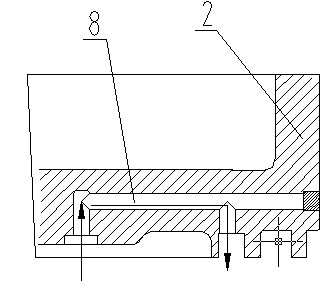

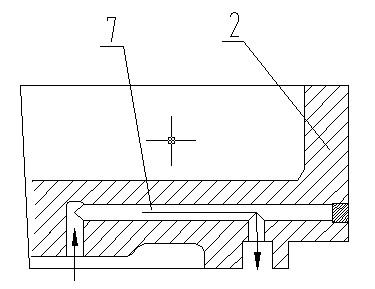

Oil storage device, electronic cigarette atomizer and electronic cigarette

ActiveCN105876870BSolve the problem of bad taste of smokingAvoid oil spillsTobacco devicesEngineeringElectronic cigarette

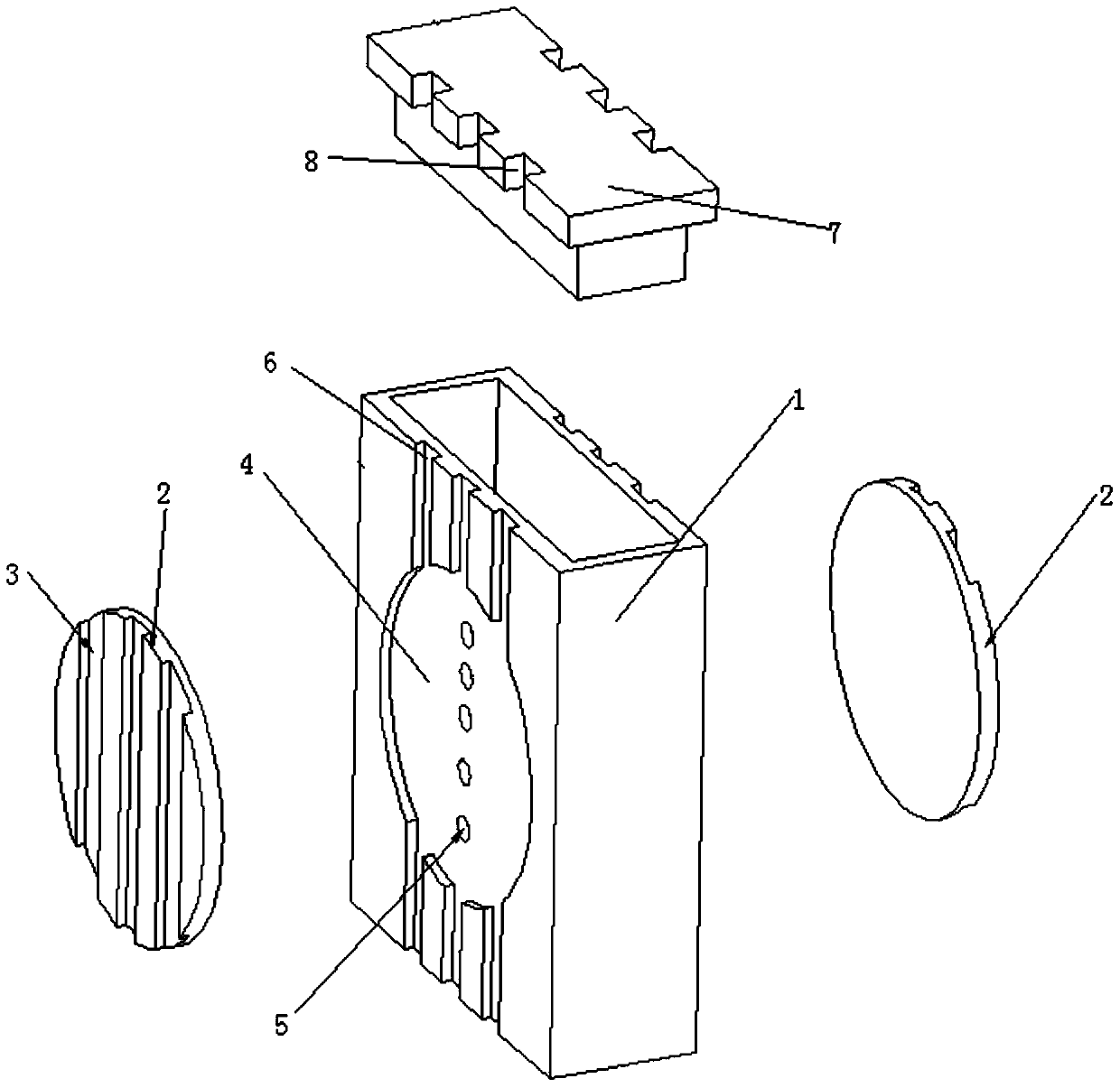

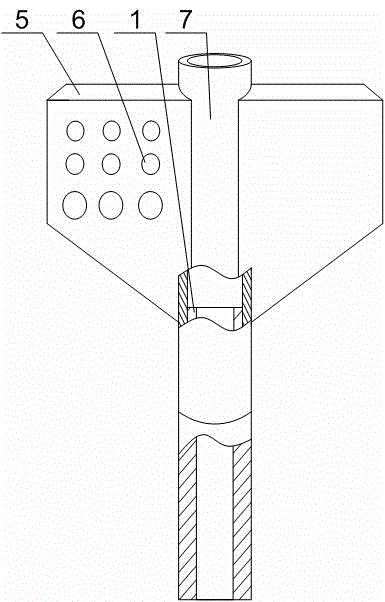

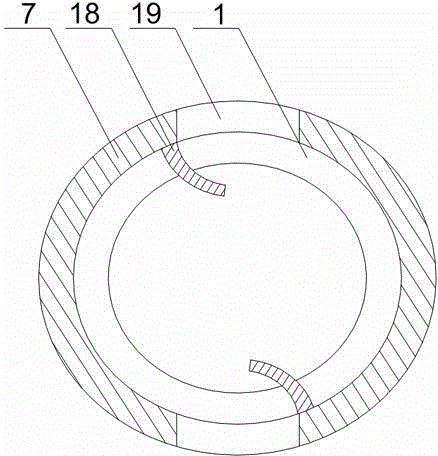

The invention discloses a cigarette liquid storage device, an electronic cigarette atomizer and an electronic cigarette. The cigarette liquid storage device comprises a body, wherein a cigarette liquid guider is fixedly arranged on an outer wall on at least one side of the body; the cigarette liquid guider is communicated with an inner cavity of the body; a vent groove is formed in a surface, far away from the body, of the oil guider. The cigarette liquid storage device provided by the invention is provided with the oil guider; cigarette liquid can be directly conducted to an atomization component through the oil guider; the oil guider can be integrally molded with the body, and can be also fixed in ways of inlaying and the like; the cigarette liquid storage device is simple in structure and is convenient to use; the electronic cigarette atomizer which is provided by the invention adopts an ultrasonic atomization component, is high in capacity usage ratio, and solves a problem that the cigarette liquid heated by an existing heating wire easily generates a burnt smell and causes that a smoking taste becomes poor; meanwhile, the surface of the oil guider is provided with the vent groove which can not only allow a gas to pass through, but also can avoid a phenomenon of liquid leakage caused by too large contact area between a fluid guider and the ultrasonic atomization component; the cigarette liquid storage device, the electronic cigarette atomizer and the electronic cigarette are simple and exquisite in structure, and are convenient to mount and dismount.

Owner:CHINA TOBACCO HUNAN INDAL CORP

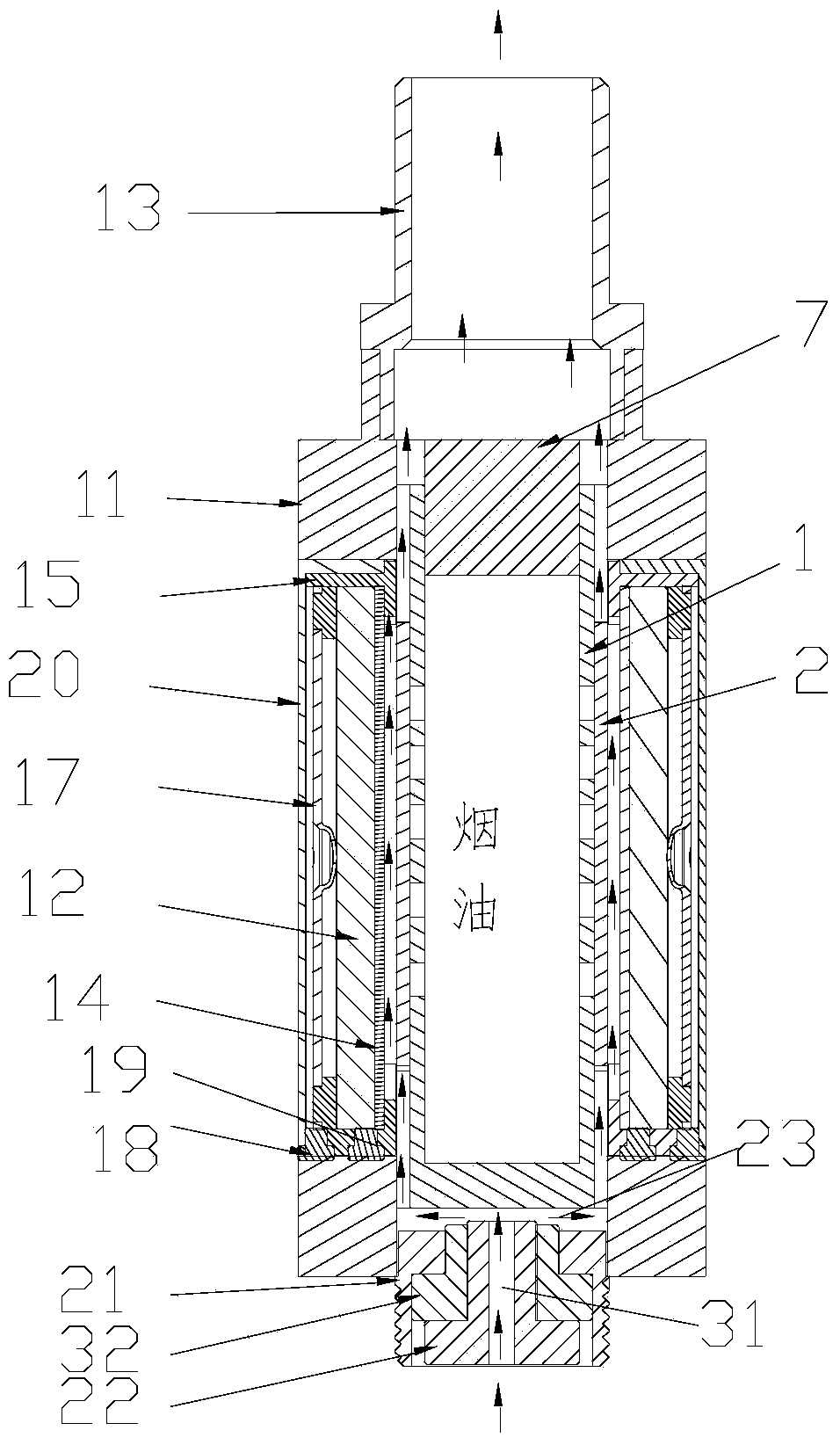

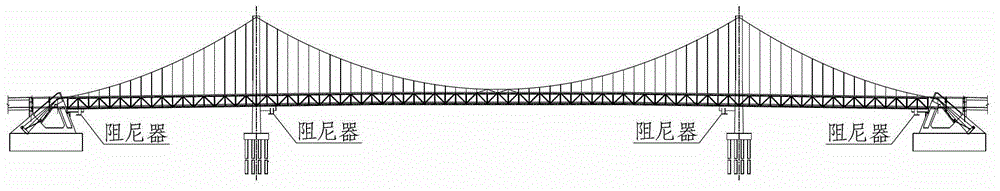

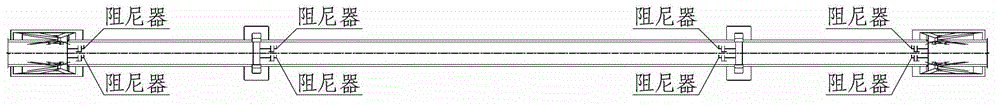

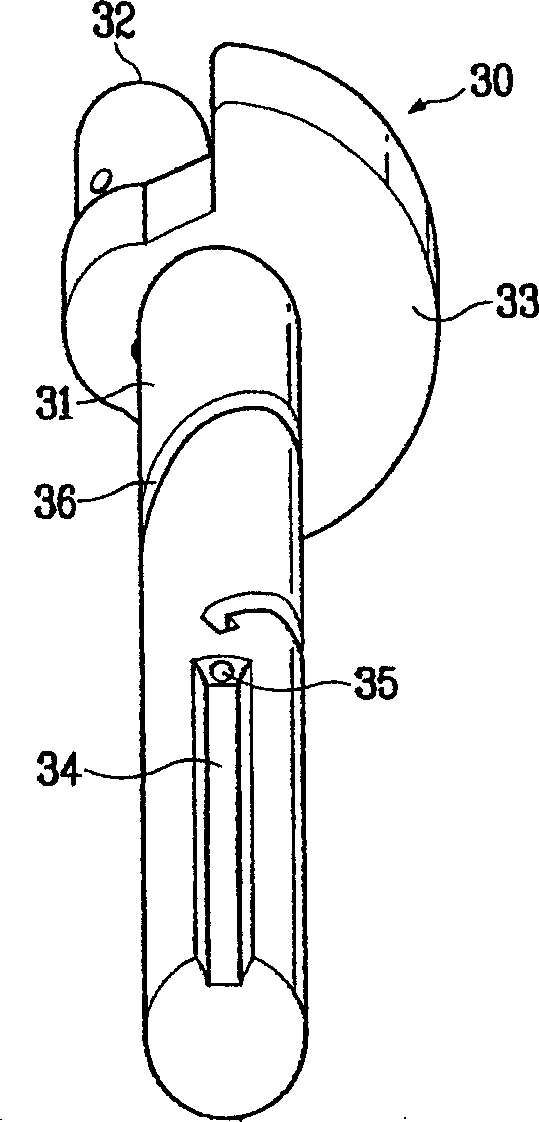

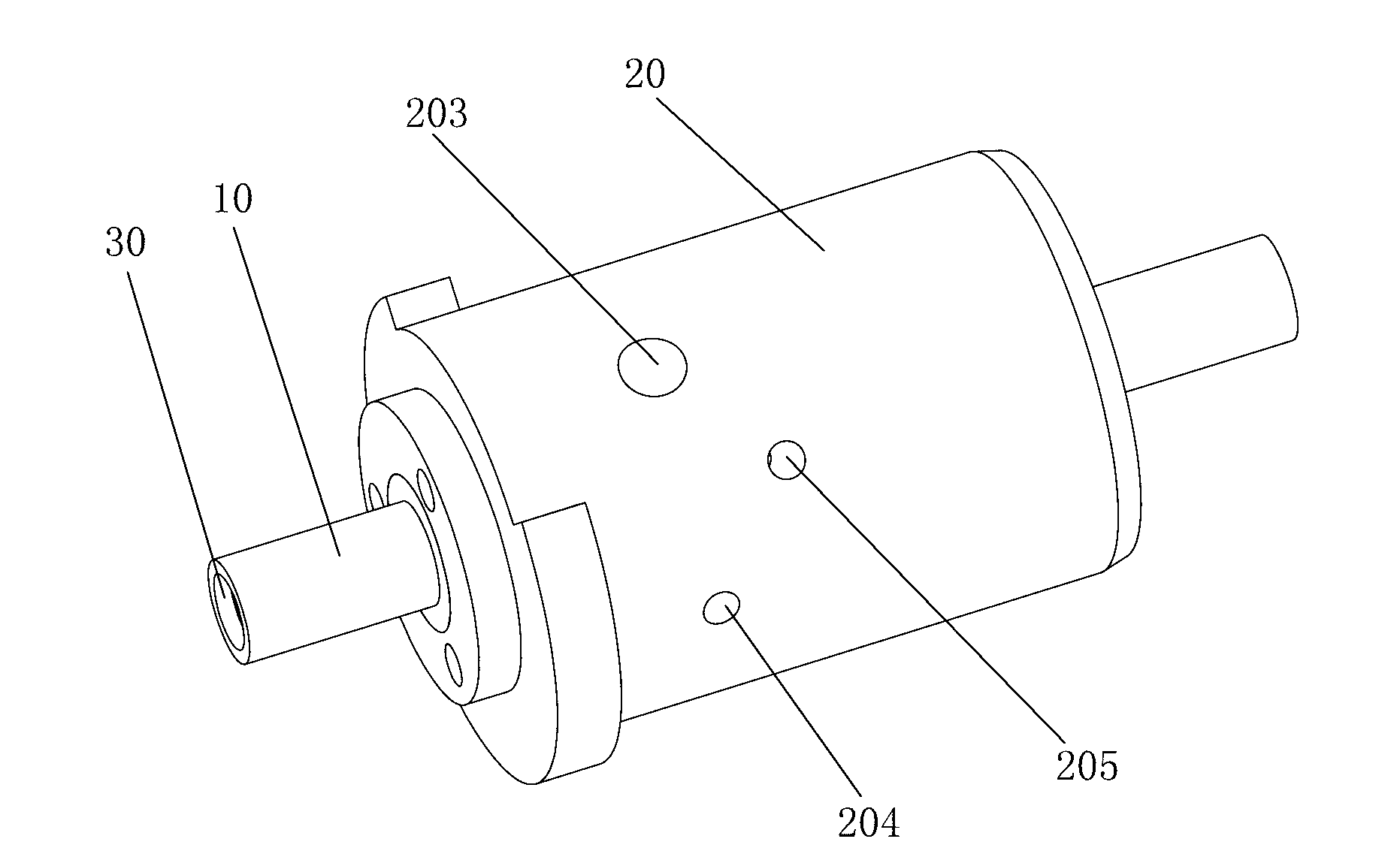

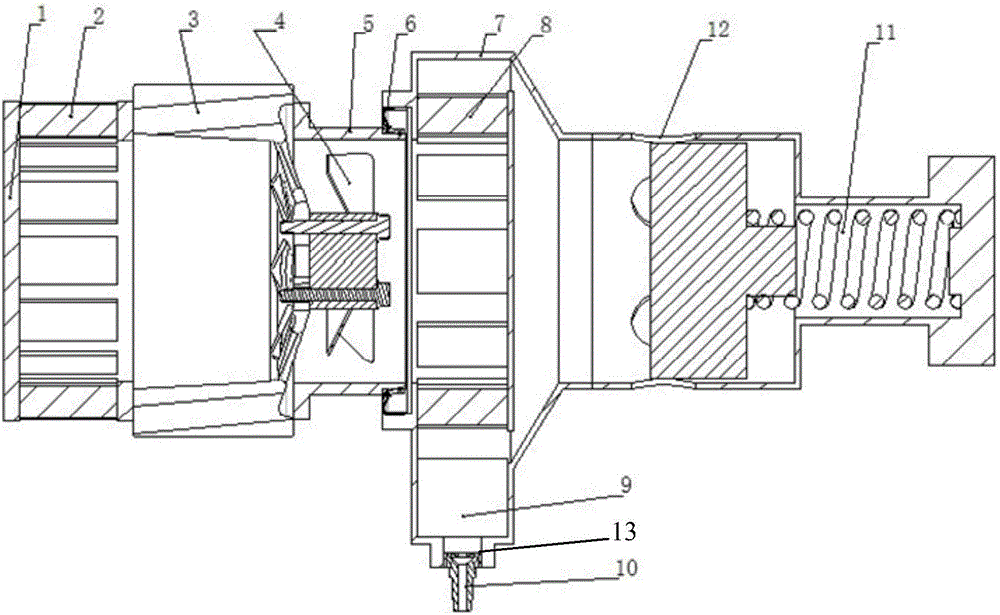

Fluid viscous damper with working switch

InactiveCN102720124AExtended service lifeAvoid oil spillsBridge structural detailsShock proofingHydraulic cylinderCable stayed

The invention provides a fluid viscous damper with a working switch, and belongs to the technical field of structural energy consumption to absorb shock (vibration). The fluid viscous damper of the working switch is characterized in that a fixed connecting rod is arranged between a piston rod end connecting rod and a fixed end on one side of the typical fluid viscous damper, an inner sleeve rod and a cylindrical outer sleeve are relatively sliding, and the fixed connecting rod prevents a damper piston and an outer wall of a hydraulic cylinder from relatively moving; when the displacement of the inner sleeve rod reaches a stated maximum displacement value, a brake switch on a pop-up stopper in the outer sleeve is contacted, and the pop-up stopper pops up and clamps a brake head of an inner sleeve rod end together with a fixed stopper, so that the inner sleeve rod is locked and does not slide relative to the outer sleeve, the fixed connecting rod is stressed and destroyed by an impact force, and the damper begins to consume energy for shock absorption. The fluid viscous damper with the working switch has the effects and advantages that the fluid viscous damper is expected to be applied to structures such as a suspension bridge provided with a central buckle or a cable-stayed bridge provided with a floating system, the service life of the damper can be prolonged, and the damper is enabled to play a role of correspondingly consuming energy for shock absorption when a large shock occurs.

Owner:DALIAN UNIV OF TECH

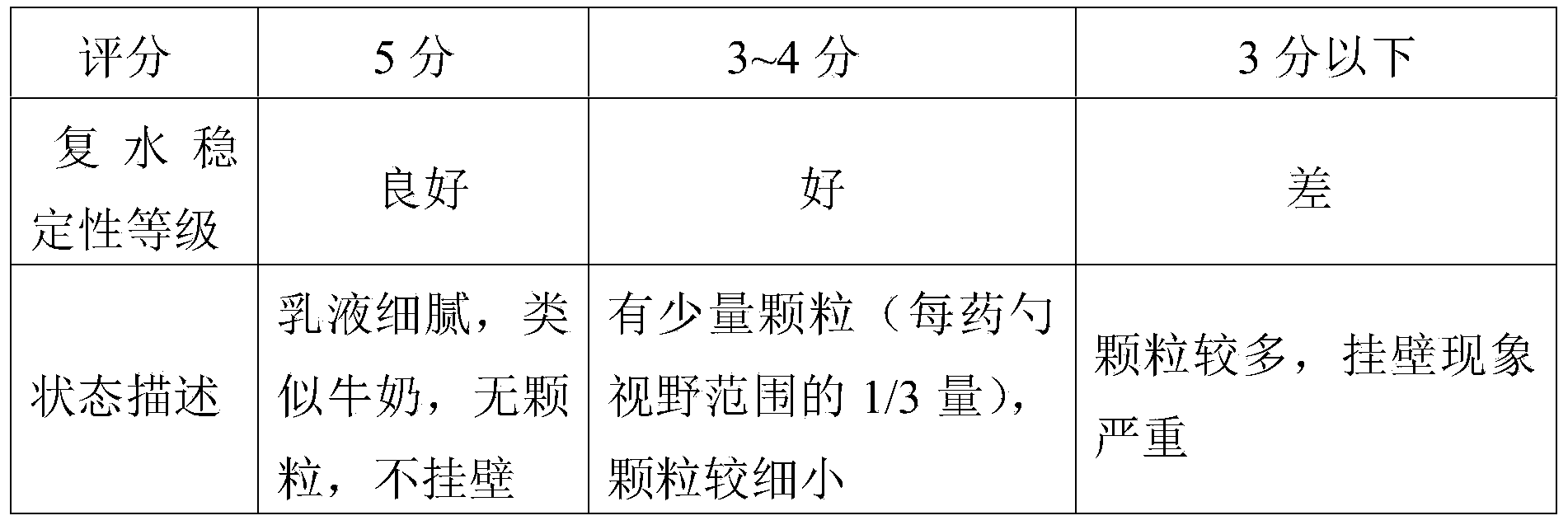

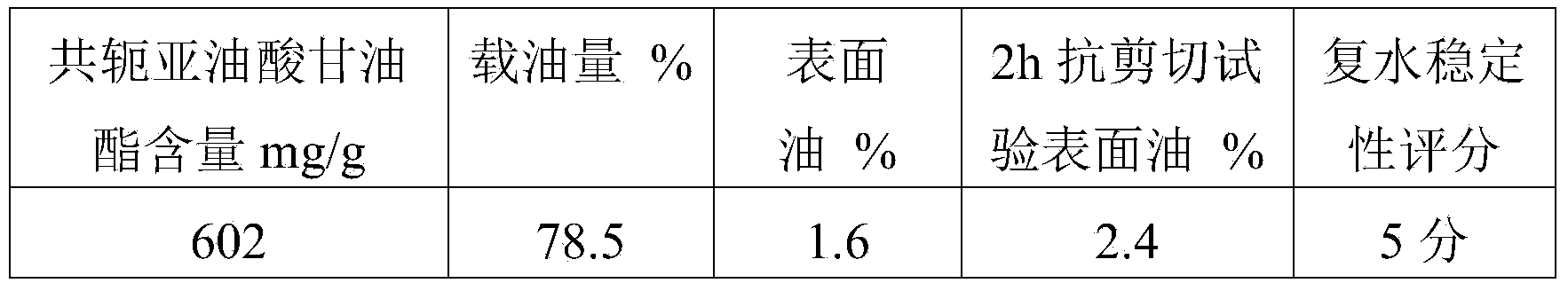

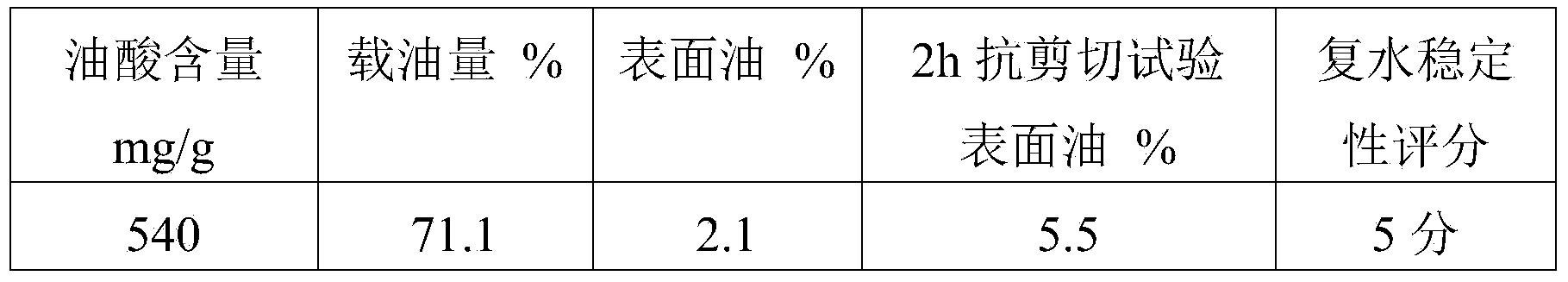

Preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring

InactiveCN104304838ASolve the fragile problemReduce dosageSugar food ingredientsVitamin food ingredientsBiotechnologyDairy foods

The invention provides a preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring. The preparation method comprises the following steps: adding protein type wall materials into water, stirring for dissolving the materials at 40-70 DEG C, adjusting the pH of an obtained solution to 7.0-12.0, reacting under the condition of 40-70 DEG C for 0.5-4 hours, adding sugar type wall materials and a stabilizing agent into an obtained reaction solution, and stirring for dissolving, thereby obtaining a water phase solution; adding an antioxidant and an emulsifier into nutrition lipid type core materials, and stirring for dissolving at 40-70 DEG C, thereby obtaining an oil phase solution; and mixing the water phase solution with the oil phase solution, emulsifying and homogenizing, and spray-drying, thereby obtaining the micro-capsule powder. The content of total fat in the micro-capsule powder reaches up to 60%-85%, and the content of surface oil in the micro-capsule powder is lower than 5%. The micro-capsule powder has tolerance to mechanical force, is good in self-emulsifying capability, can be dissolved to form uniform and stable fine emulsion without floating particles and sediments, can be applied to the field of food, and can be added to food such as bread, cookies, nutrition bars and milk products and also be taken as solid granules.

Owner:INNOBIO CORP LTD

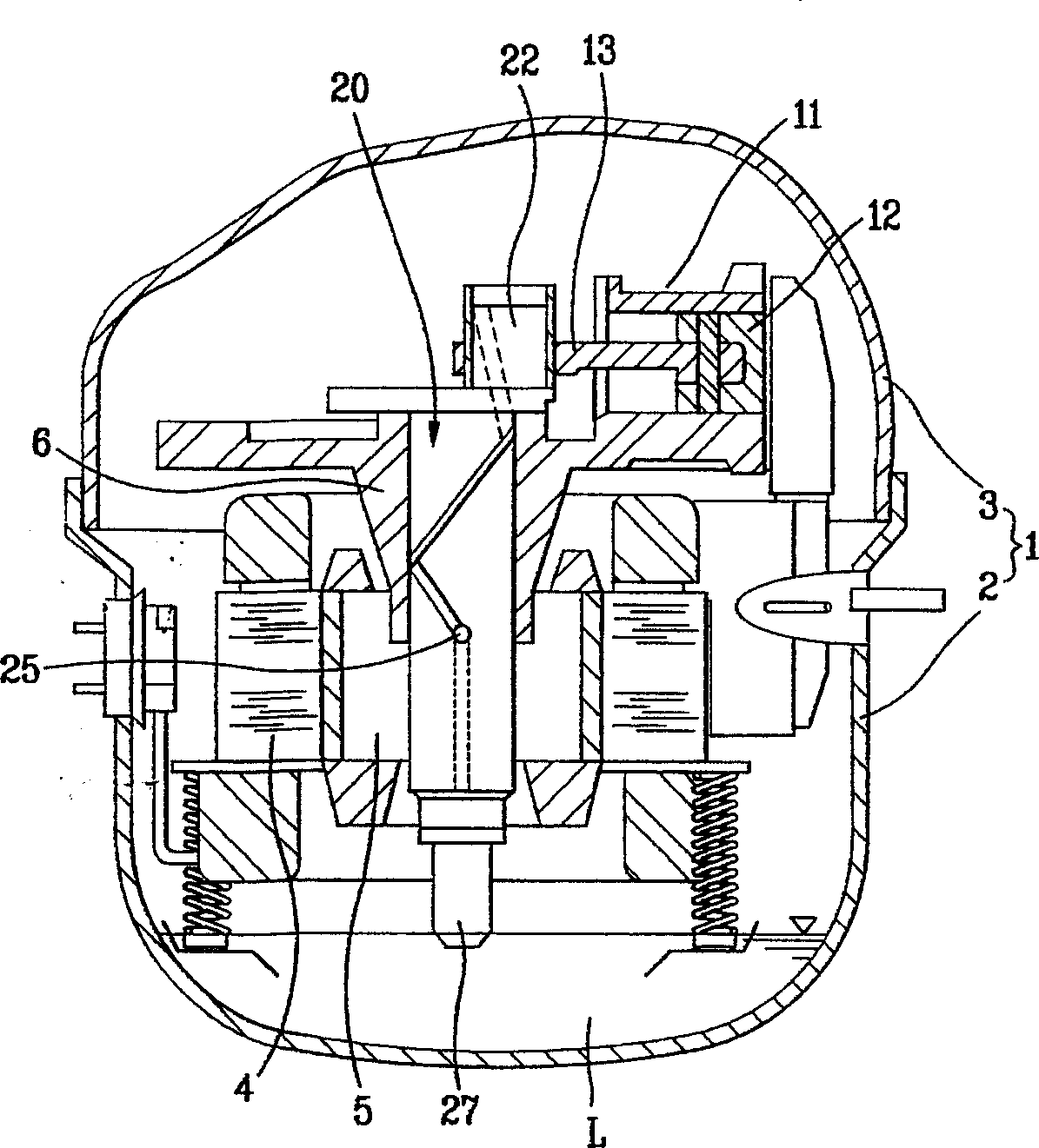

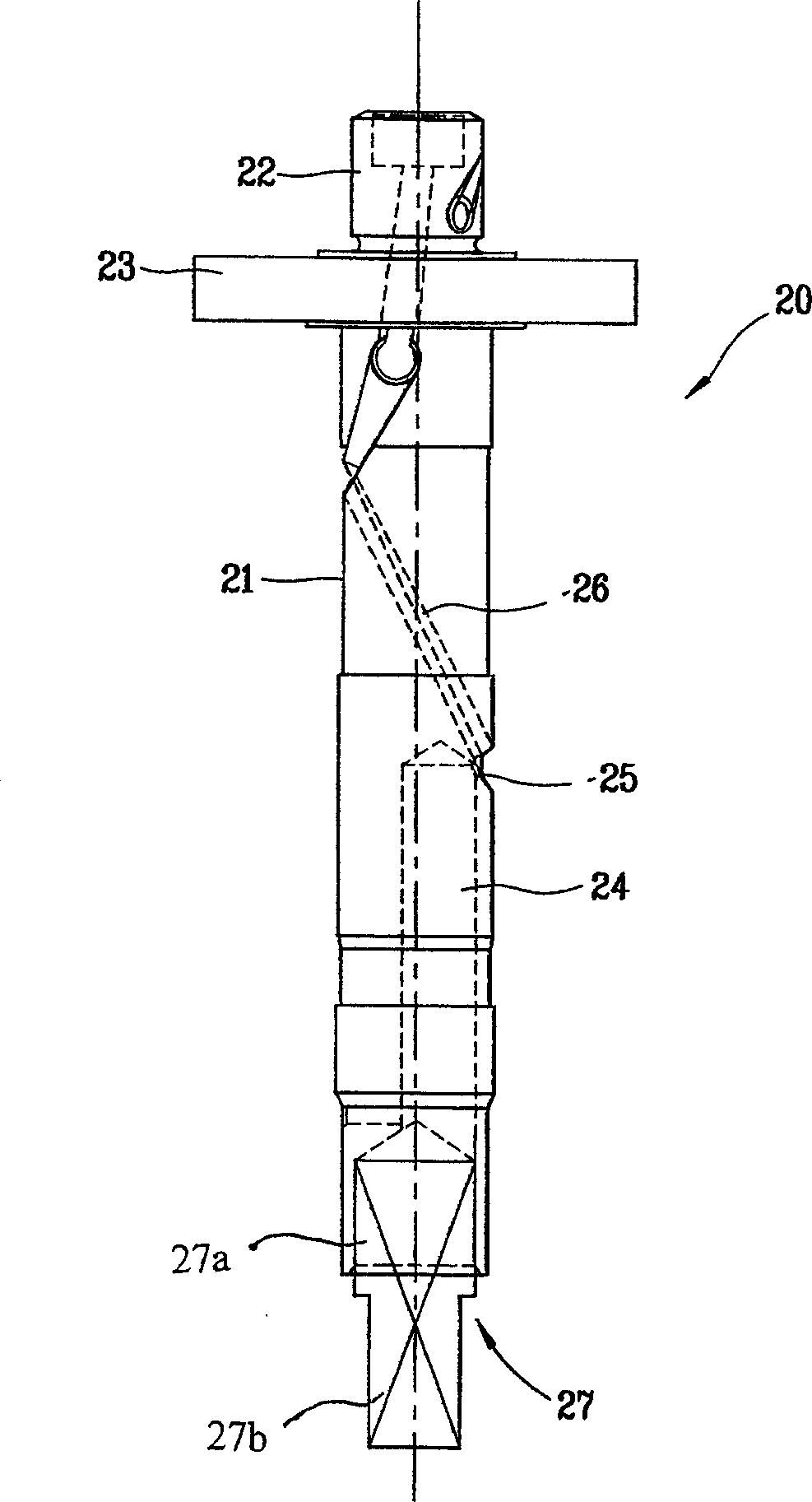

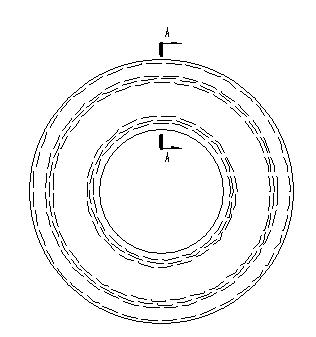

Crank shaft of refrigeration compressor

InactiveCN1427154AIncrease centrifugal forceAvoid oil spillsPositive displacement pump componentsPositive-displacement liquid enginesRefrigeration compressorLow speed

A crankshaft of refrigerating compressor features that a channel of cooling machine oil is formed along the circumference in order to raise the cooling machine oil up by a centrifugal force. It is composed of a solid cylindrical shaft inserted in rotor and bearing, an eccentrical part communicated with the said channel of cooling oil, and an oil pump for pumping oil to the said channel. Its advantages are supplying cooling oil even at low speed and no leakage of cooling oil.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

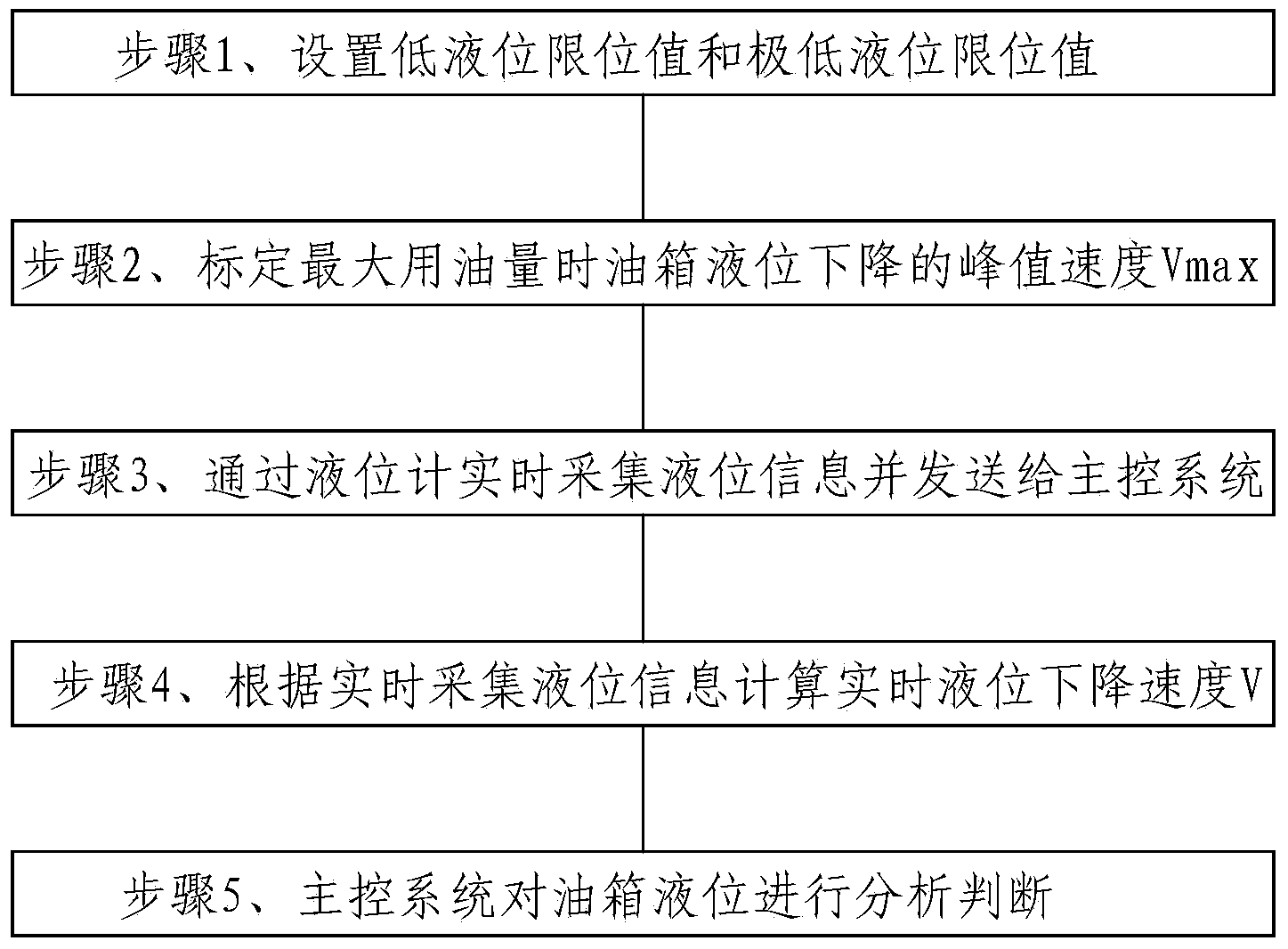

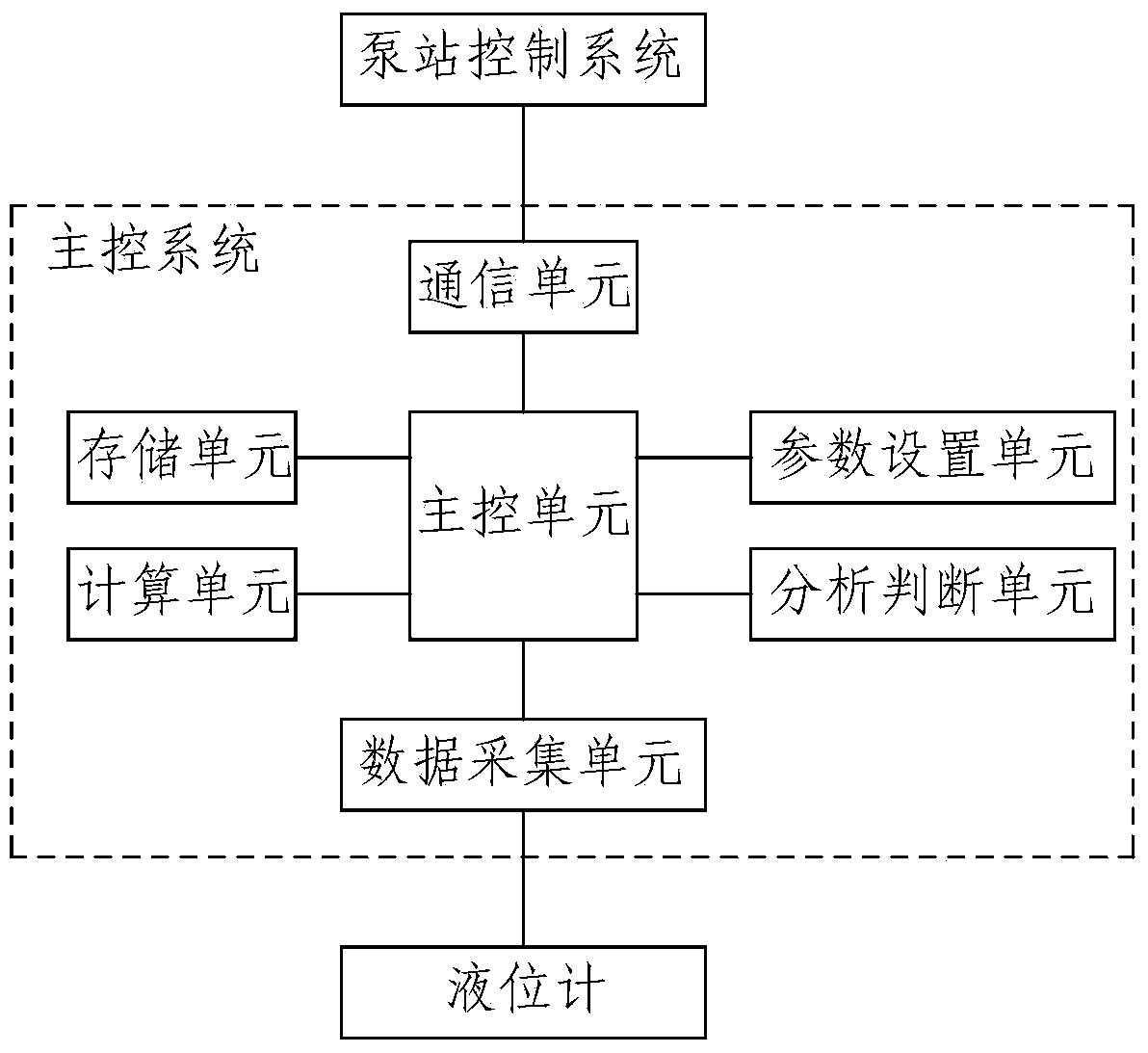

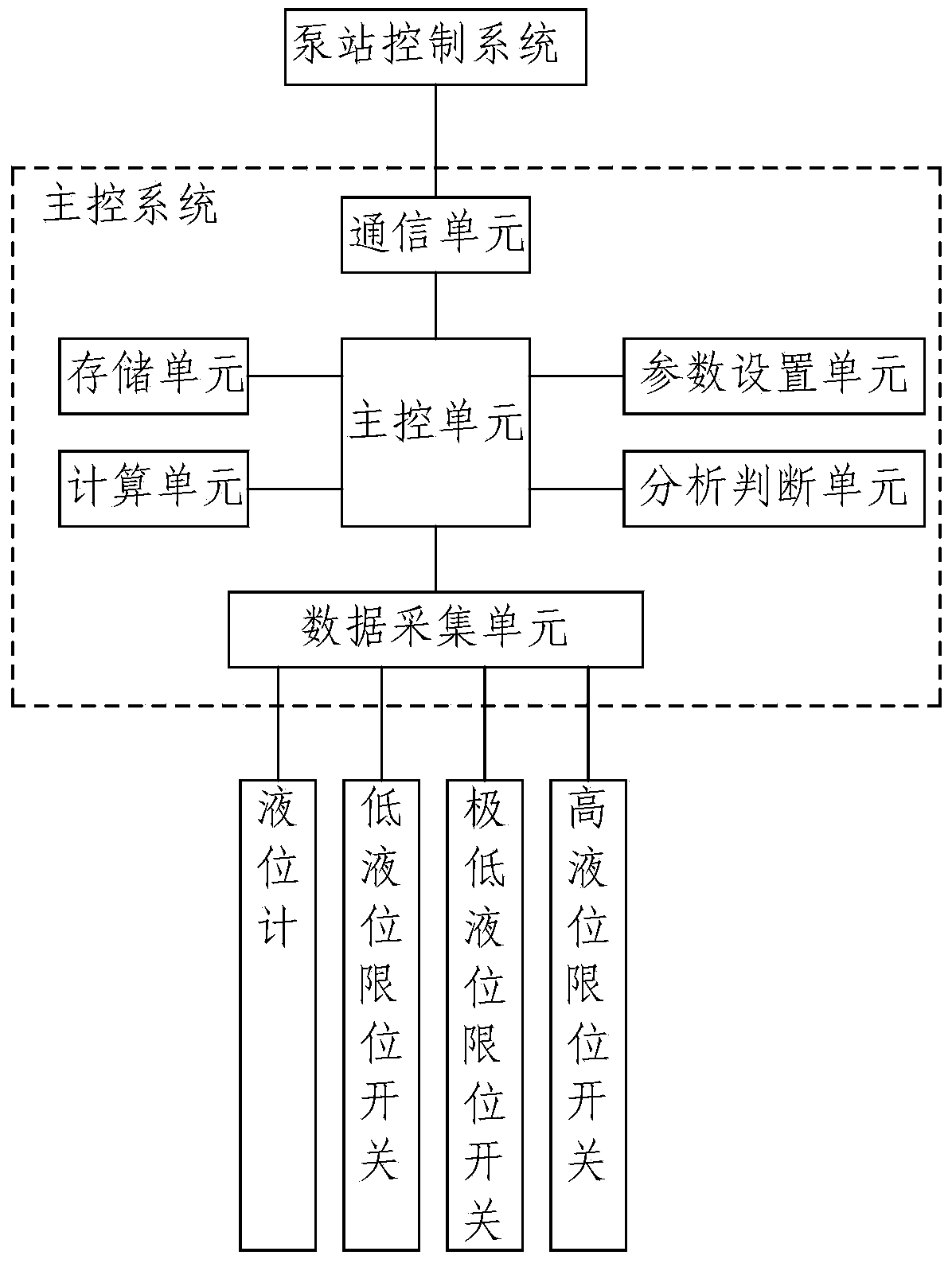

Pump station oil leakage prevention and control method and system of hydraulic system and lubrication system

InactiveCN104047926AReduce pollutionProtection securityFluid-pressure actuator testingLubrication elementsControl systemFuel tank

The invention discloses a pump station oil leakage prevention and control method and system of a hydraulic system and a lubrication system. The method comprises the following steps that firstly, a low liquid level limiting value and an ultralow liquid level limiting value of an oil tank of a pump station are set; secondly, the peak value speed Vmax of decrease of the liquid level of the oil tank when the pump station operates normally and needs the maximum oil use amount is calibrated; thirdly, liquid level information is collected in real time through a liquidometer and sent to a master control system; fourthly, the master control system calculates the real-time decrease speed V of the liquid level of the oil tank according to the liquid level information collected in real time; fifthly, the master control system analyzes and judges the liquid level of the oil tank and sends an alarm warning and a pump stop control instruction. The pump station oil leakage prevention and control method and system of the hydraulic system and the lubrication system prevent the phenomenon of mass oil leakage, implement necessary pump stop control when the oil liquid level continuously descends, lower economic loss and environment pollution caused by oil leakage to the maximum extent, protect safety of a mainframe and prevent damage caused by sudden machine stop in the operating process.

Owner:JIGANG GRP

Composite material for bearings as well as preparation method and application of composite material

The invention discloses a composite material for manufacturing high-speed light-load oil-free lubrication bearings. The composite material is prepared by taking polytetrafluoroethylene as a base material, filling proper antifriction toughening materials such as glass fiber, copper powder, graphite, molybdenum disulfide and carbon fiber and carrying out synthesis and sintering. The composite material has the advantages of being small in frictional coefficient and low in frictional abrasion when in friction with high-speed moving parts such as carbon steel and the like under the condition of micro-oil or oil-free lubrication, can be widely used for manufacturing the water-based liquid lubricated sliding bearings, also can be used for manufacturing the high-speed light-load oil-free or micro-oil sliding bearings, is particularly suitable for the industries of ocean operation tools, textile machinery and food machinery, and has the characteristics of low cost and simple manufacturing process.

Owner:DONGGUAN UNIV OF TECH

Machine oil pump of I.C. engine

ActiveCN1563780AAvoid oil spillsRotary piston pumpsLubricating pumpsGear pumpInternal combustion engine

The present invention relates to one kind of engine oil pump for internal combustion engine and is the improvement of inner meshed cycoidal gear pump of the present inventor for further eliminating oil leakage problem. The present invention consists of pump casing, inner rotor, outer rotor, shaft and flow distributing plate. The inner rotor is located inside the outer toro, fixed on the shaft and installed inside the casing; the inwards concave disc pump casing has one position boss in the opening for the flow distributing plate to be embedded; and the shaft has noe end set inside the central hole in the flow distributing plate. The present invention has positioning boss for installing the engine oil pump and diesel engine in the pump casing, rather than the flow distributing plate, and this makes it possible for oil leaking from the fitting seam between the flow distributing plate and the pump casing to flow fluently into the diesel engine to avoid oil leakage.

Owner:盐城市大丰区生产力促进中心

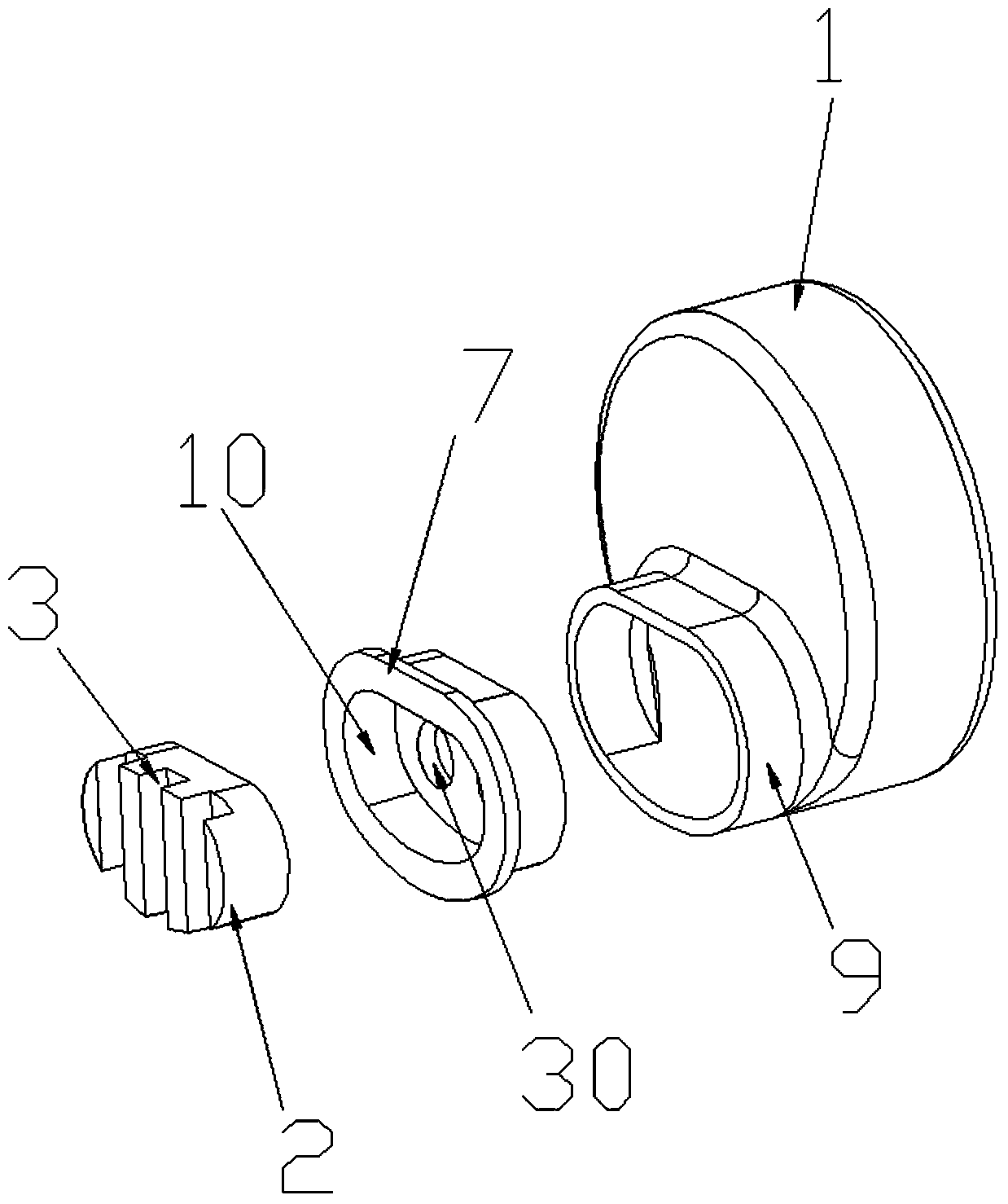

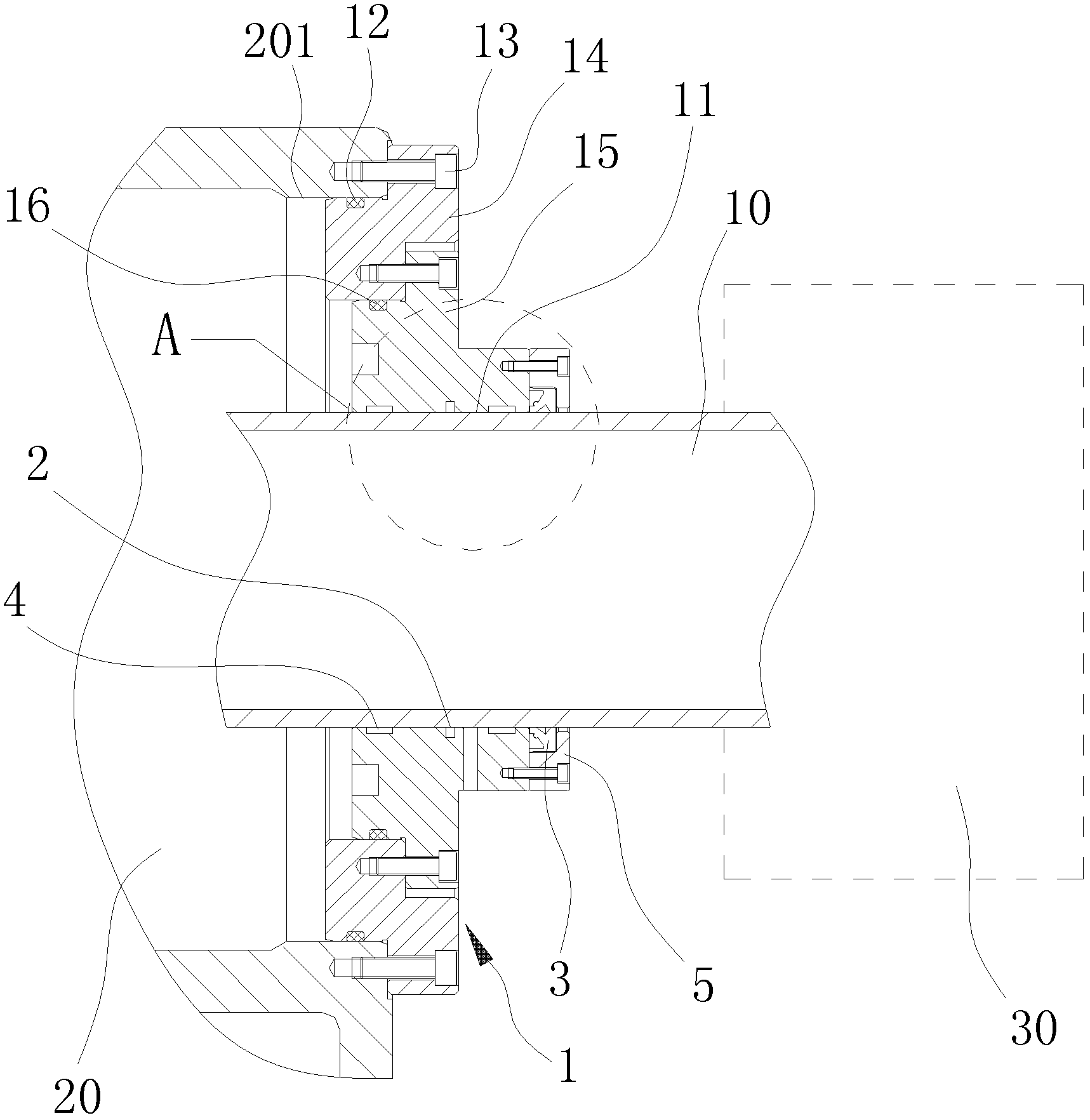

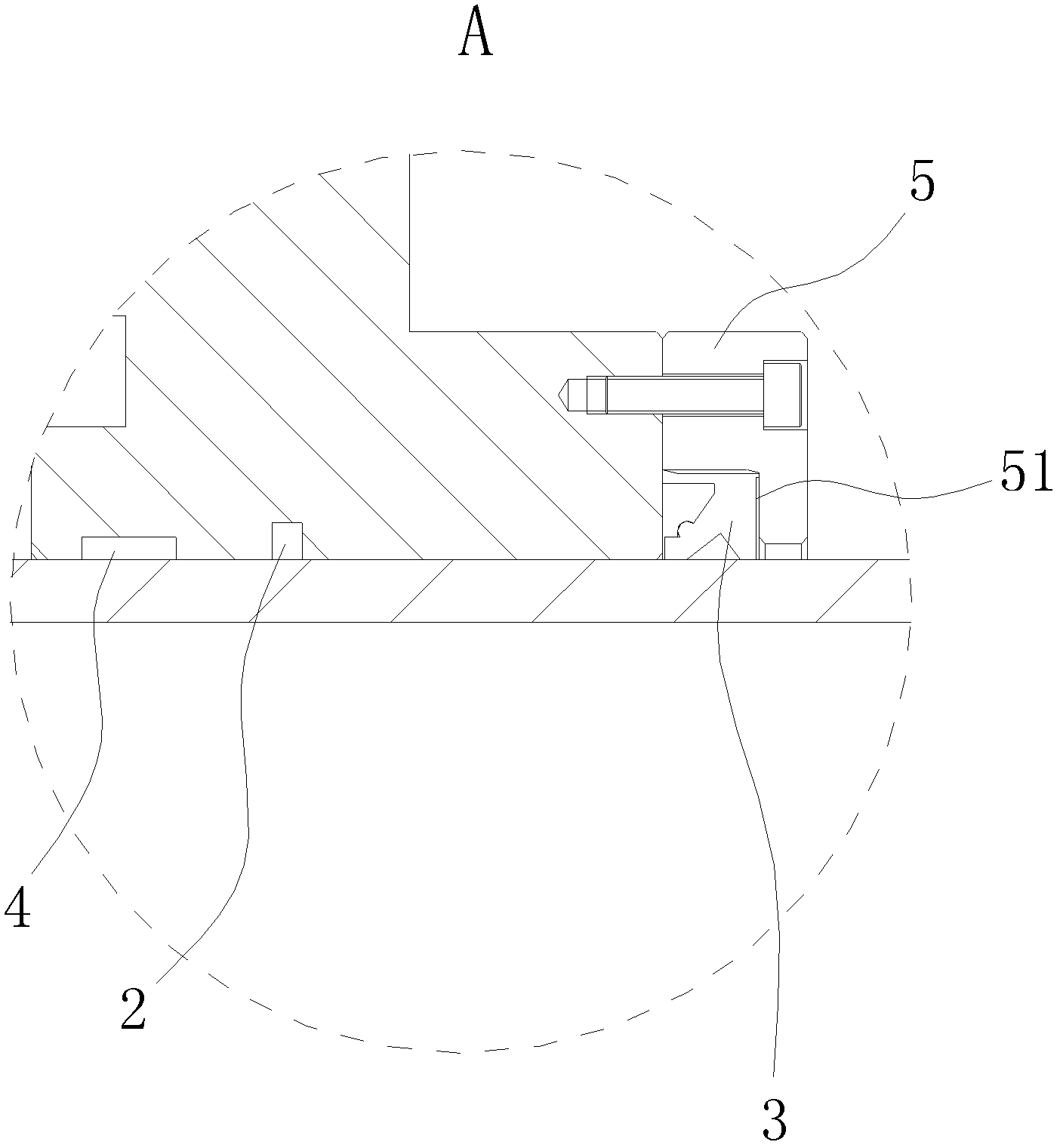

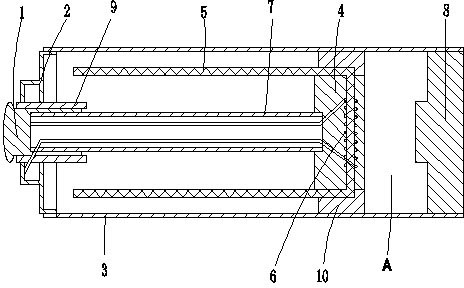

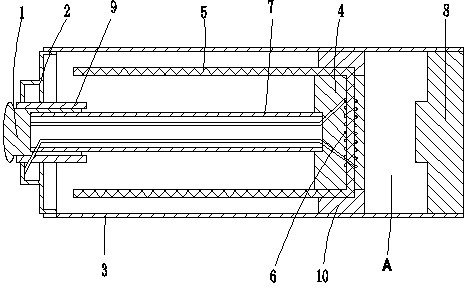

Smoke cartridge and electronic cigarette

The invention relates to a smoke cartridge. The smoke cartridge comprises a smoke cartridge tube provided with a flue and a liquid storage cavity, a sealing body arranged in the smoke cartridge tube and used for sealing the liquid storage cavity, an atomization core arranged in the sealing body and a base fixedly held with the smoke cartridge tube, wherein the sealing body comprises a sealing piece and a sealing piece formed on the sealing piece or arranged on the sealing piece in a sleeving manner; the sealing piece comprises a closed end, an accommodating end formed by extending downwards from the closed end, an oil duct penetrating through the closed end and extending to the accommodating end and an air duct separated from a flow channel; a balance air groove is formed in the transverseouter side of the sealing piece; air gaps communicating with the balance air groove in the vertical direction are formed in the transverse outer side of the sealing piece; and the liquid storage cavity communicates to an atomization cavity or the air duct through the air gaps and the balance air groove. The smoke cartridge can effectively keep air pressure balance in the liquid storage cavity.

Owner:DONGGUAN ALPHA ELECTRONICS TECH CO LED +1

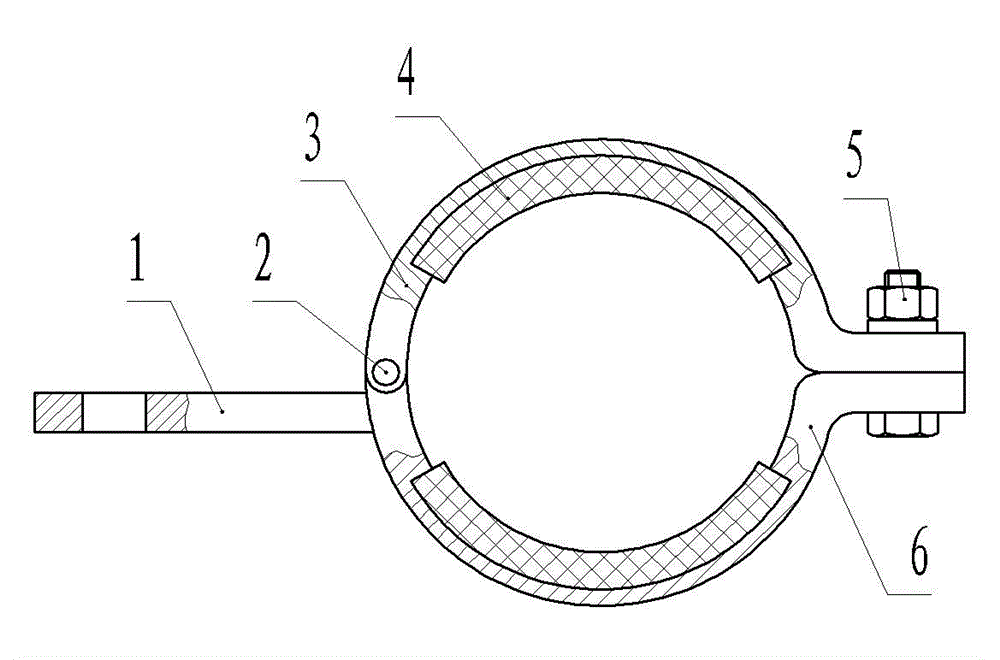

Automobile oil pipe fixing support

InactiveCN104455743AReduce vibrationAvoid oil spillsPipe supportsPipe elementsCushionPetroleum engineering

The invention discloses an automobile oil pipe fixing support, and relates to the technical field of automobile part manufacturing. The automobile oil pipe fixing support comprises a mounting plate with a mounting hole, one end of the mounting plate is fixedly connected with a supporting plate, a pressing plate is hinged to the end, close to the mounting plate, of the supporting plate, the free end of the pressing plate and the free end of the supporting plate are connected with two opposite lug plates respectively, and the two lug plates are connected through a bolt. Opposite grooves are formed in the inner side of the pressing plate and the inner side of the supporting plate respectively, elastic cushion blocks with concave arc faces are embedded in the grooves, and the concave arc faces of the elastic cushion blocks stretch out of the grooves. Compared with the prior art, an oil pipe is arranged between the two elastic cushion blocks, the vibration of the oil pipe is reduced through the buffer function of the elastic cushion blocks, the situation that due to the fact that the connecting position of the oil pipe is loosened, oil leakage and noise are generated is avoided, and normal use is guaranteed.

Owner:LIUZHOU CITY TONGJIN AUTOMOBILE PARTS MFG CO LTD

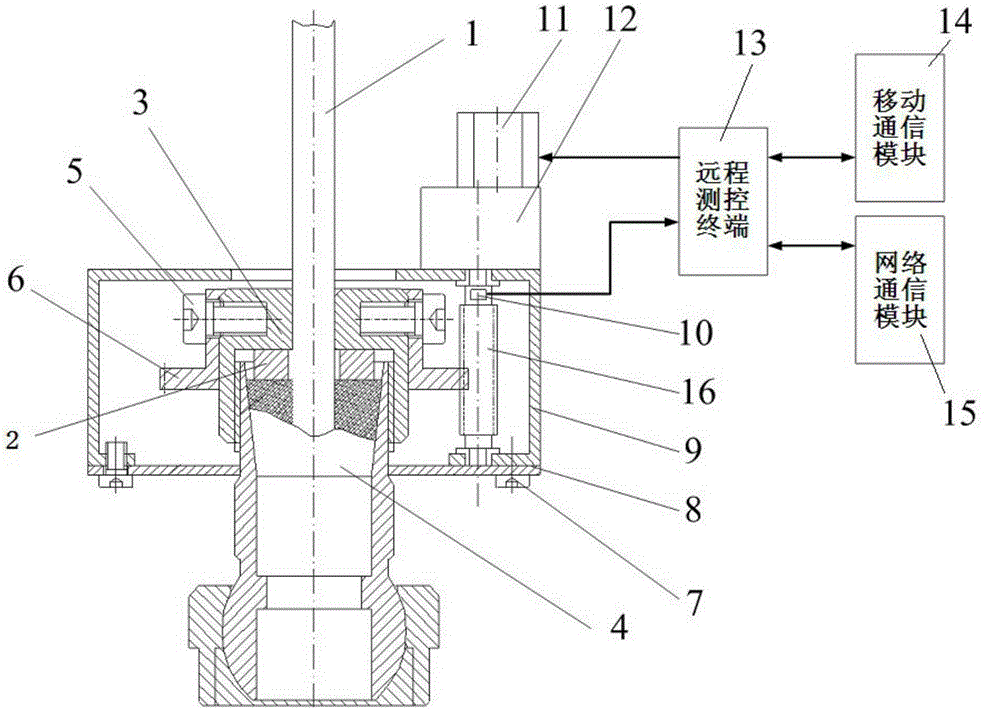

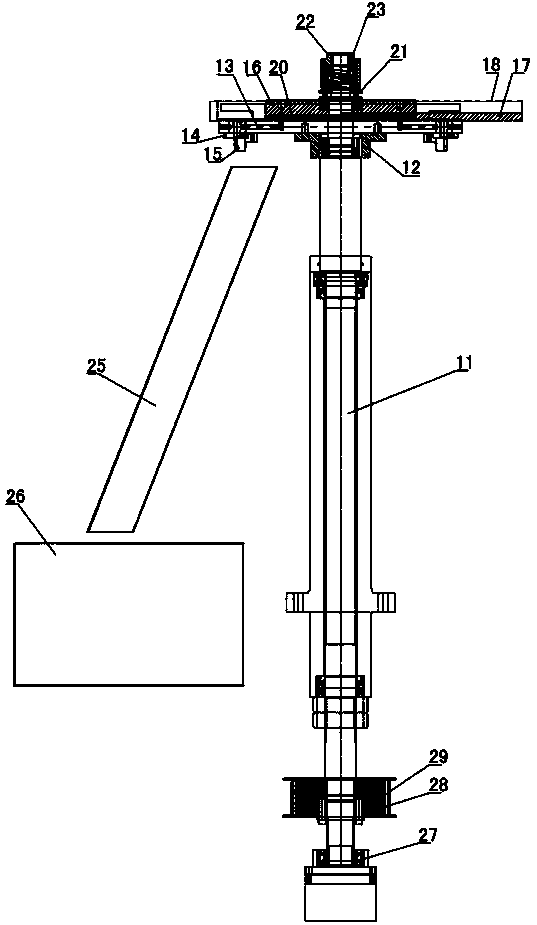

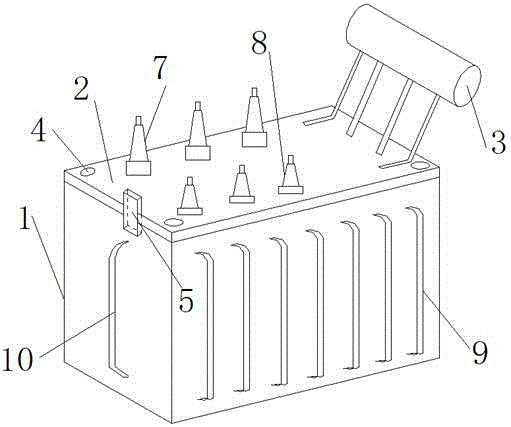

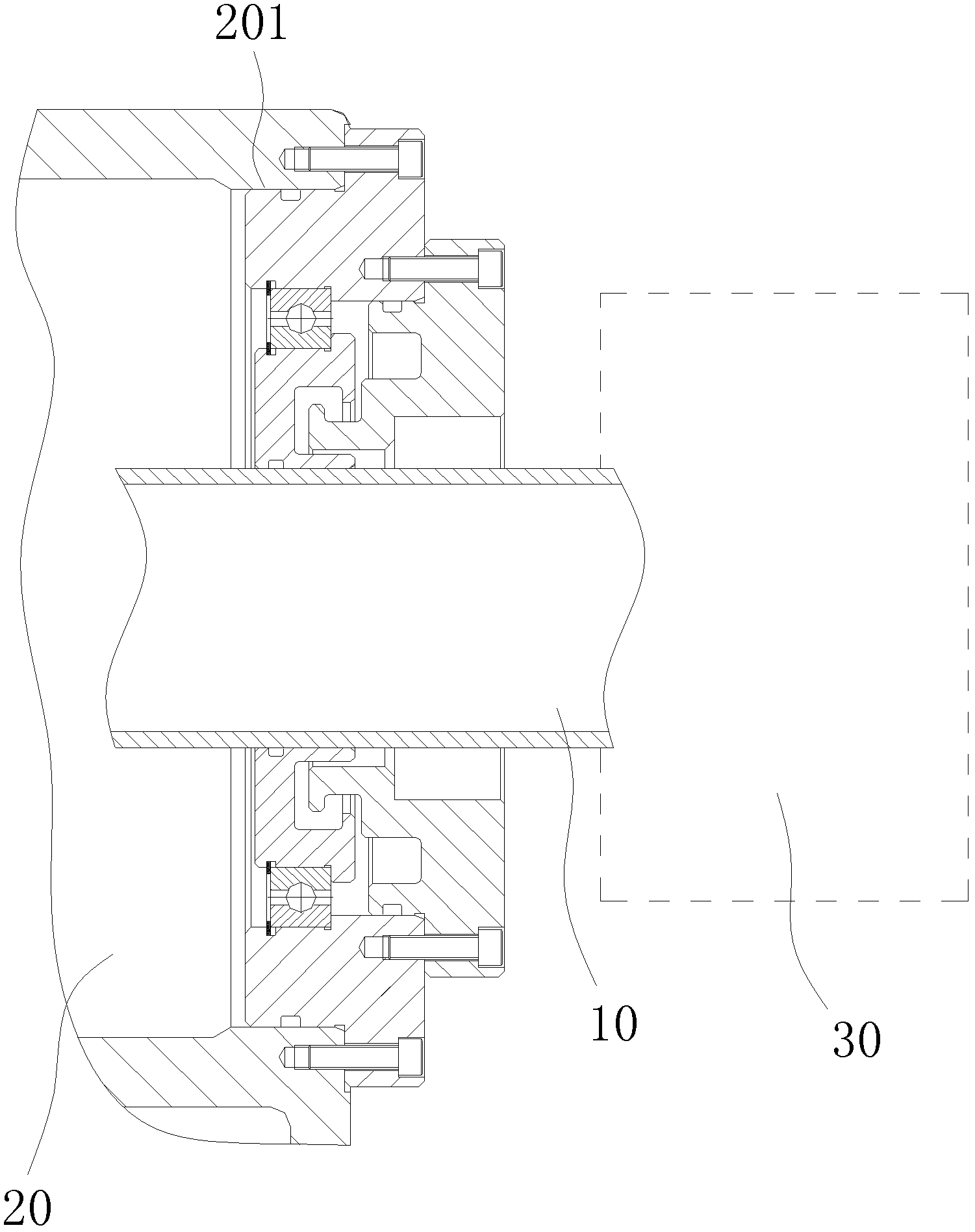

Automatic screwing device of oil pumping machine packing and with remote monitoring function

ActiveCN105156059ASave human effortSave manpower patrol well expensesSealing/packingRemote controlElectric machine

The invention discloses an automatic screwing device of an oil pumping machine packing and with a remote monitoring function and belongs to the technical field of mechanical equipment. The automatic screwing device comprises a polished rod, an upper gland, two screwing nuts, the packing, a driven gear, a baseplate, a shell, a force sensor, a motor, a torquer, a remote measuring and controlling terminal, a mobile communication module, a network communication module and a driving gear, the screwing nuts are arranged on two sides of the polished rod respectively, both the upper gland and the packing are arranged below the screwing nuts, the motor is connected with the torquer, the force sensor is arranged at a shaft neck of the driving gear, the output end of the force sensor is connected with the remote measuring and controlling terminal, the output end of the remote measuring and controlling terminal is connected with the motor, and the mobile communication module and the network communication module are connected with the remote measuring and controlling terminal. The automatic screwing device can realize automatic detection and on-site or remote control and can screw the packing, so that manpower well inspection expenditure is saved, working efficiency and safety are improved, oil leakage is avoided, and energy resources are saved.

Owner:长春市艾必利务科技有限公司 +1

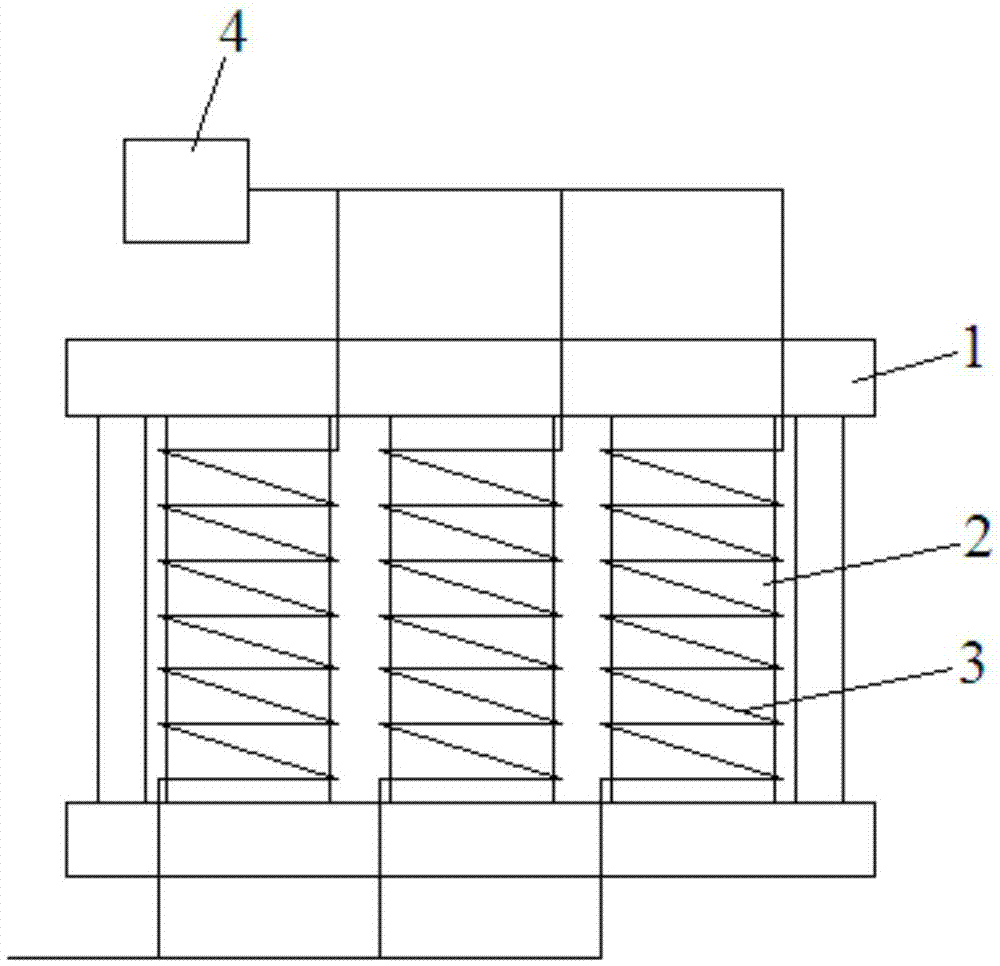

Cooling mechanism of energy-saving type power transformer

InactiveCN105448479ALight weightSimple structureTransformers/inductances coolingTransformerConductor Coil

The invention discloses a cooling mechanism of an energy-saving type power transformer. The cooling mechanism comprises three-phase windings installed inside a transformer box body, wherein a cooling pipe is twined outside each of the three-phase windings, one end of the cooling pipe is connected to an air pump, and the other end of the cooling pipe stretches out of the transformer box body. The cooling mechanism of the energy-saving type power transformer provided by the invention is simple in structure, and air is introduced into the cooling pipe through the air pump, so that the purpose of cooling windings inside the power transformer can be realized, thus the power transformer can be quickly cooled in a safe and reliable way, the dead weight of the power transformer can be reduced, and the material and cost can be saved; and meanwhile, the situation of oil leakage caused by the cooling of insulating oil can be avoided.

Owner:PEOPLE ELE APPLIANCE GRP JIANGSU SINUO COMPLETE EQUIP & ENG CO LTD

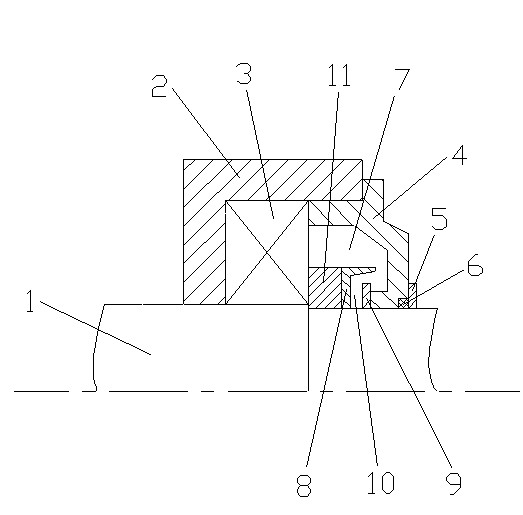

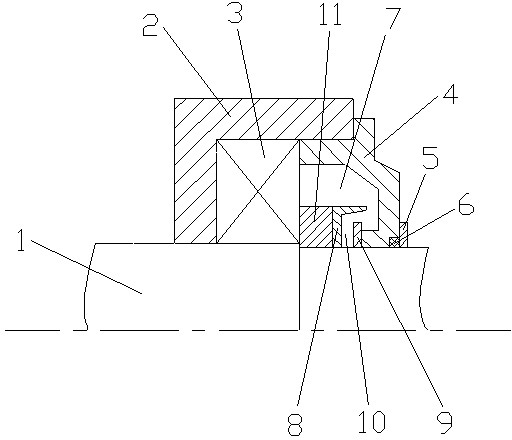

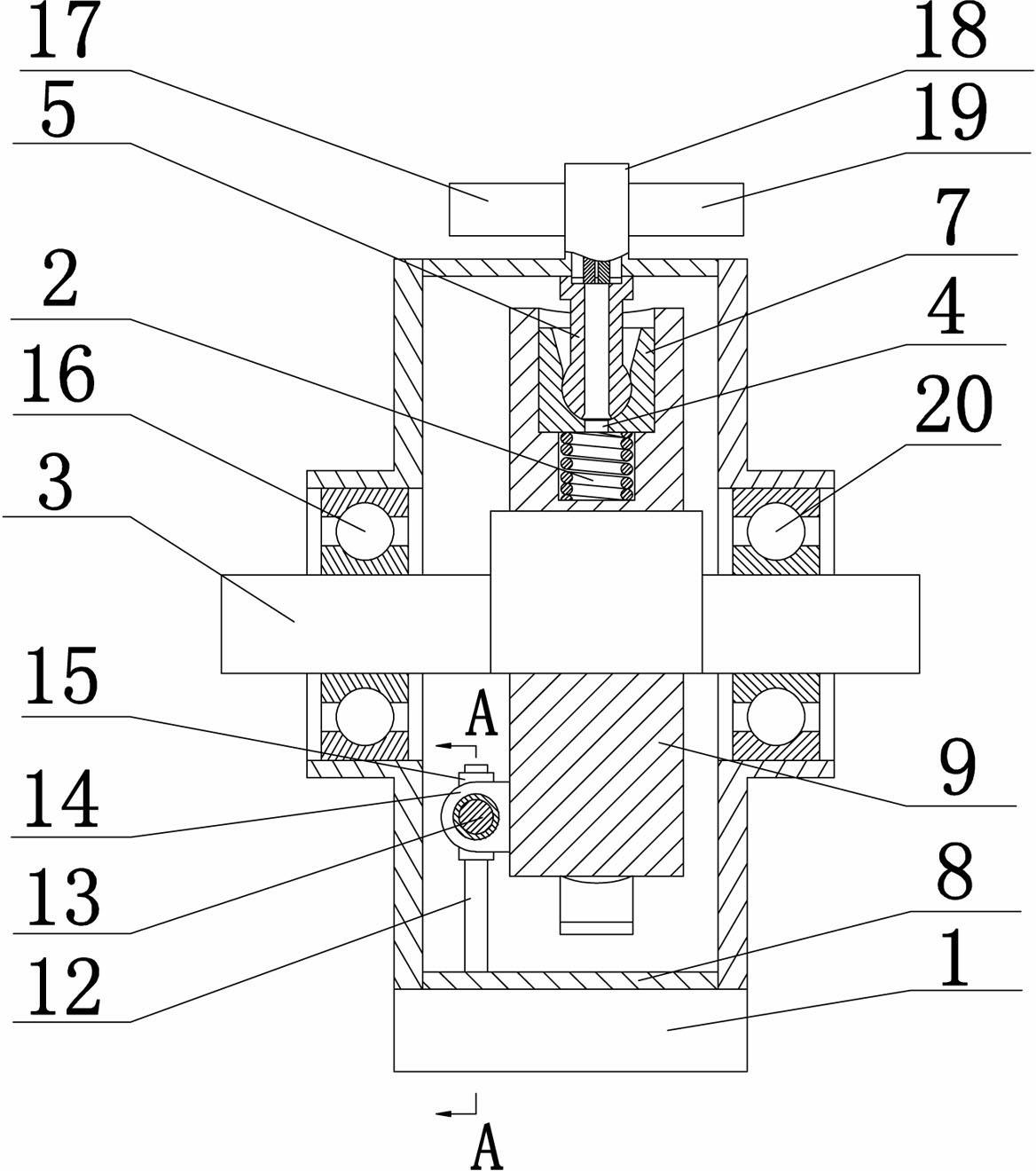

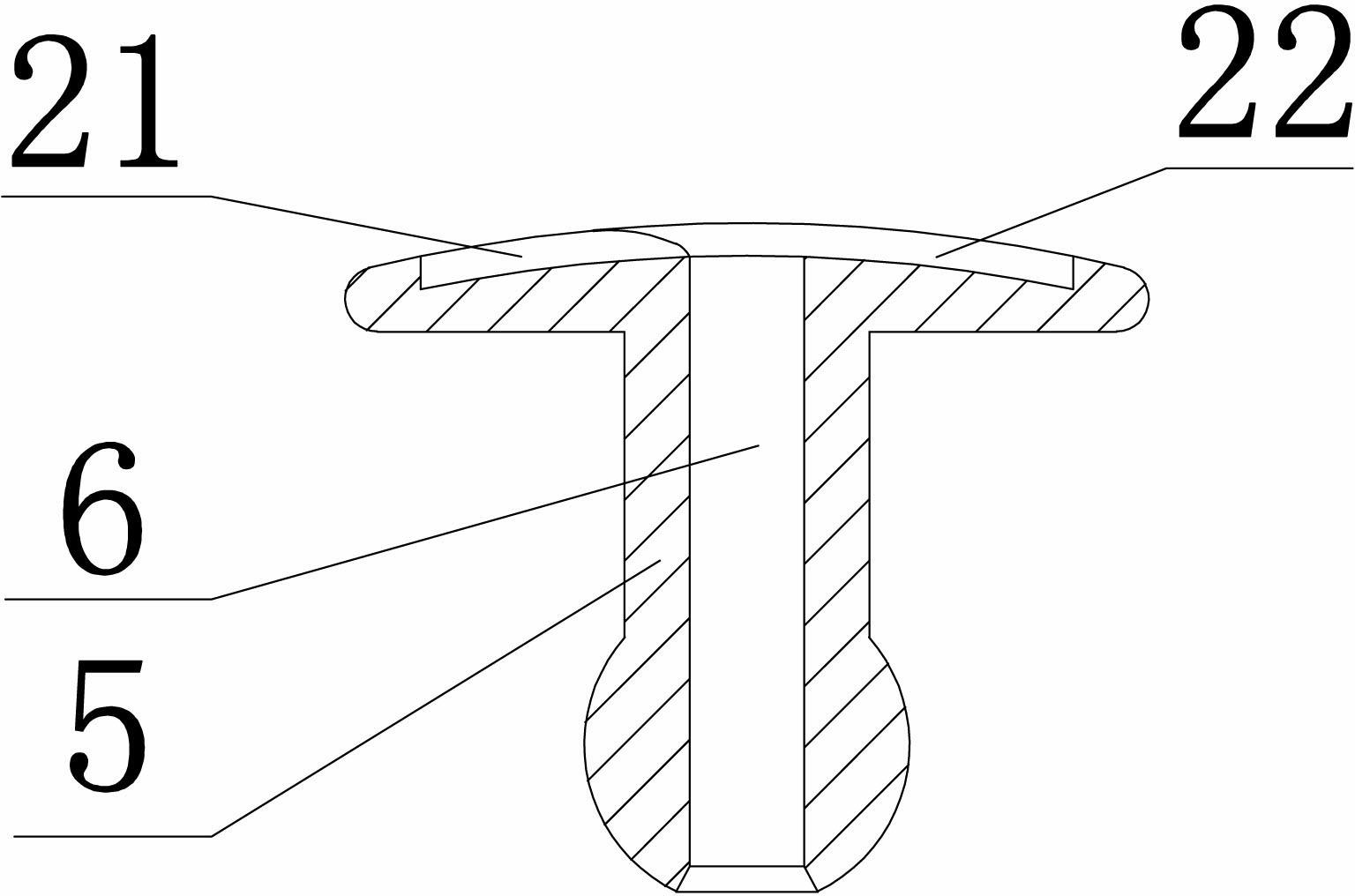

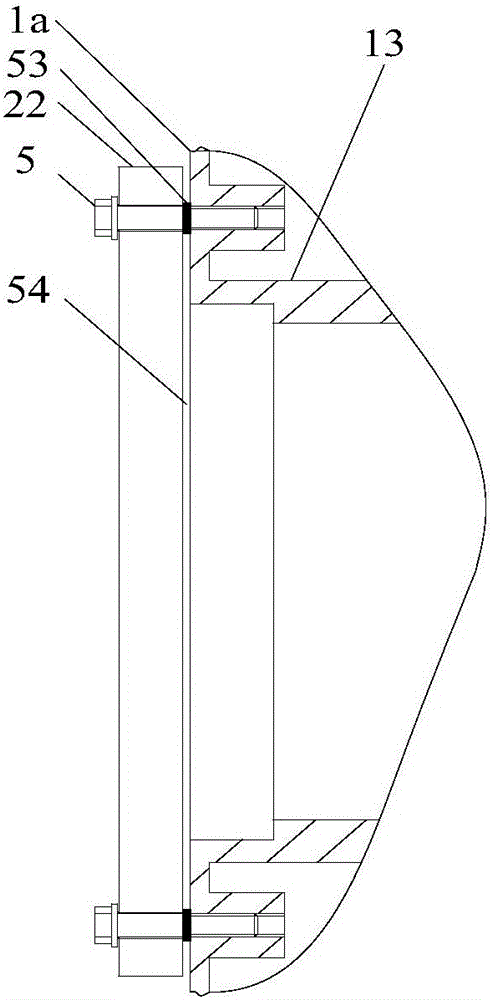

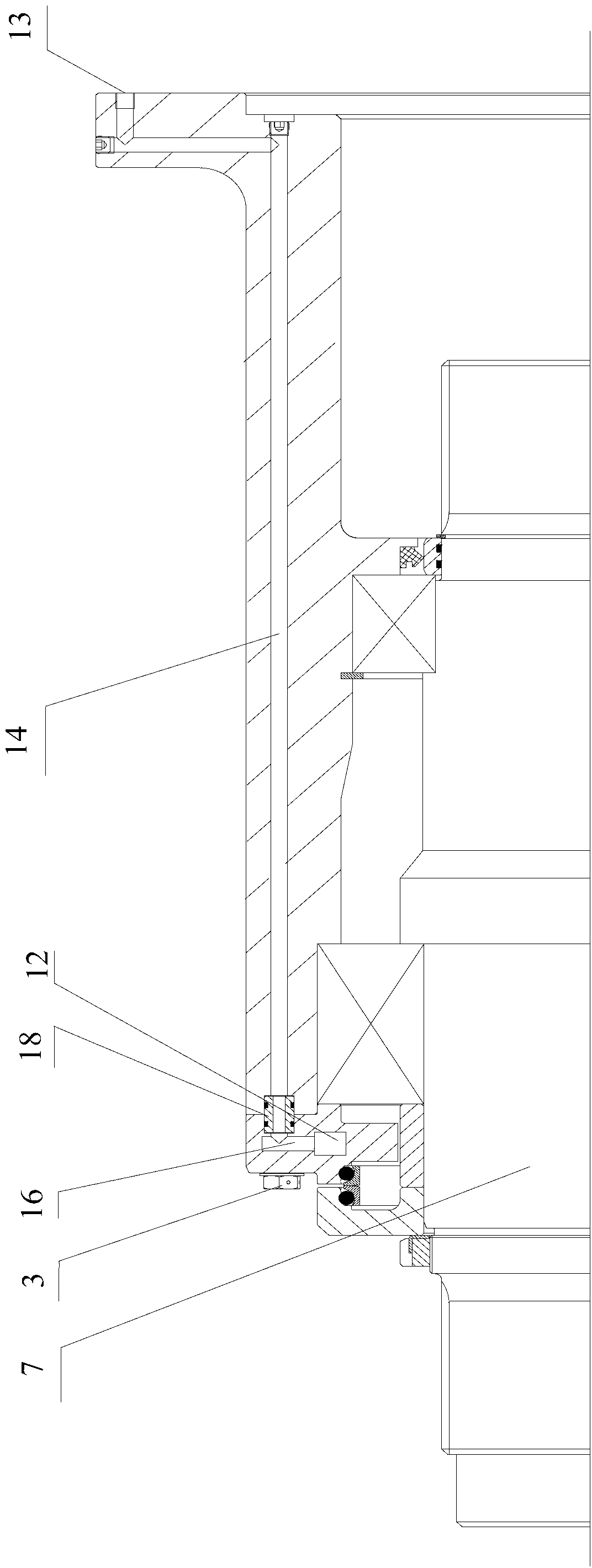

Sealing device of fan bearing seat

InactiveCN102588326AAvoid oil spillsPlay a damping rolePump componentsPumpsEngineeringMechanical engineering

The invention discloses a sealing device of a fan bearing seat. The sealing device comprises a main shaft, wherein the main shaft is equipped with a bearing seat, a bearing, a bearing seat end cover and a gland in sequence; a felt is arranged on the bearing seat end cover; a first space is reversed between the bearing and the bearing seat end cover; an oil retainer and an oil catcher are arranged in the first space; the inner hole of the oil retainer is provided with a conical degree; a second space is reversed between the oil retainer and the oil catcher; and the first space is communicated with the second space. According to the invention, the whole space of the sealing device of the fan bearing seat is of a labyrinth shape; a great quantity of liquid oil threw out by the bearing can firstly be caught by the oil catcher, a small quantity of liquid oil flows past from the second space, however, the oil retainer can play the damping effect on the liquid oil and the felt can play the third sealing effect, so the sealing effect is greatly improved, the phenomenon of oil leakage of the fan bearing seat is avoided, the production cost is saved and the production efficiency is improved.

Owner:SUZHOU MAIDER MACHINERY

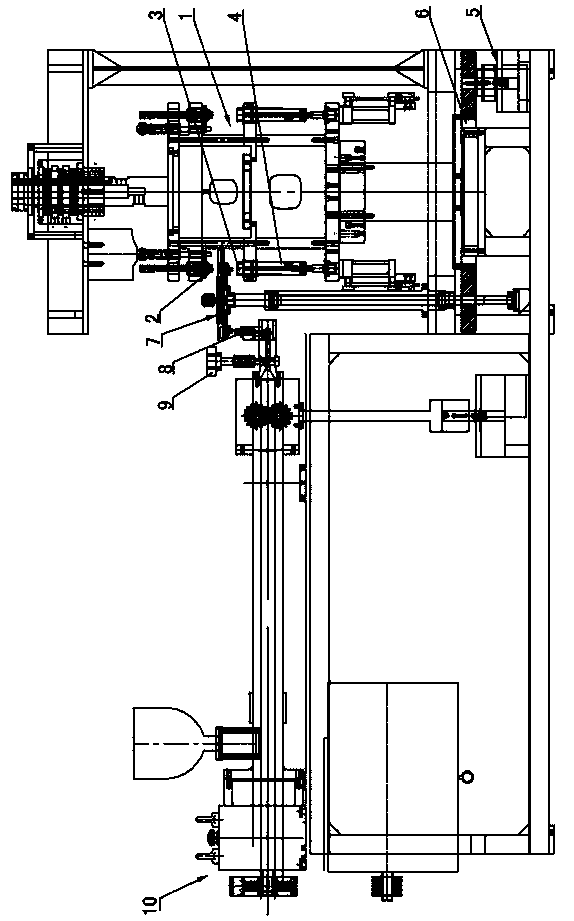

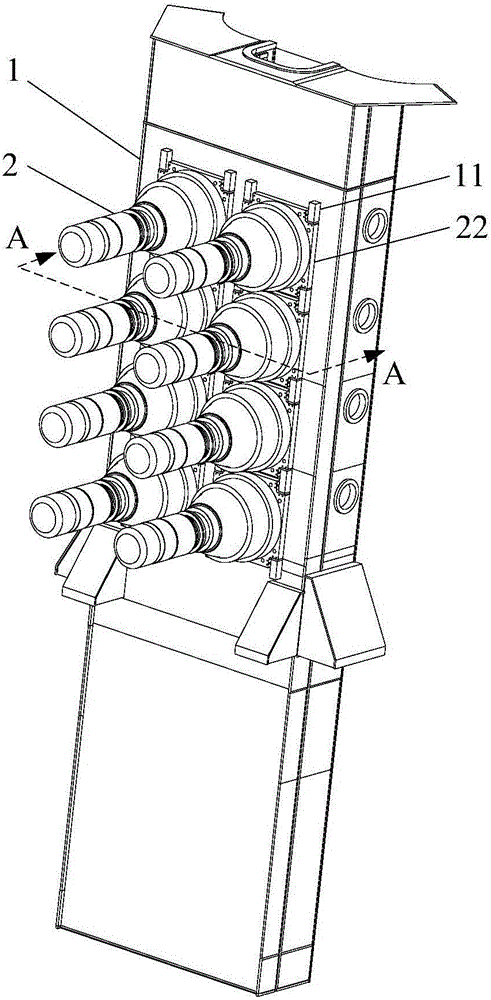

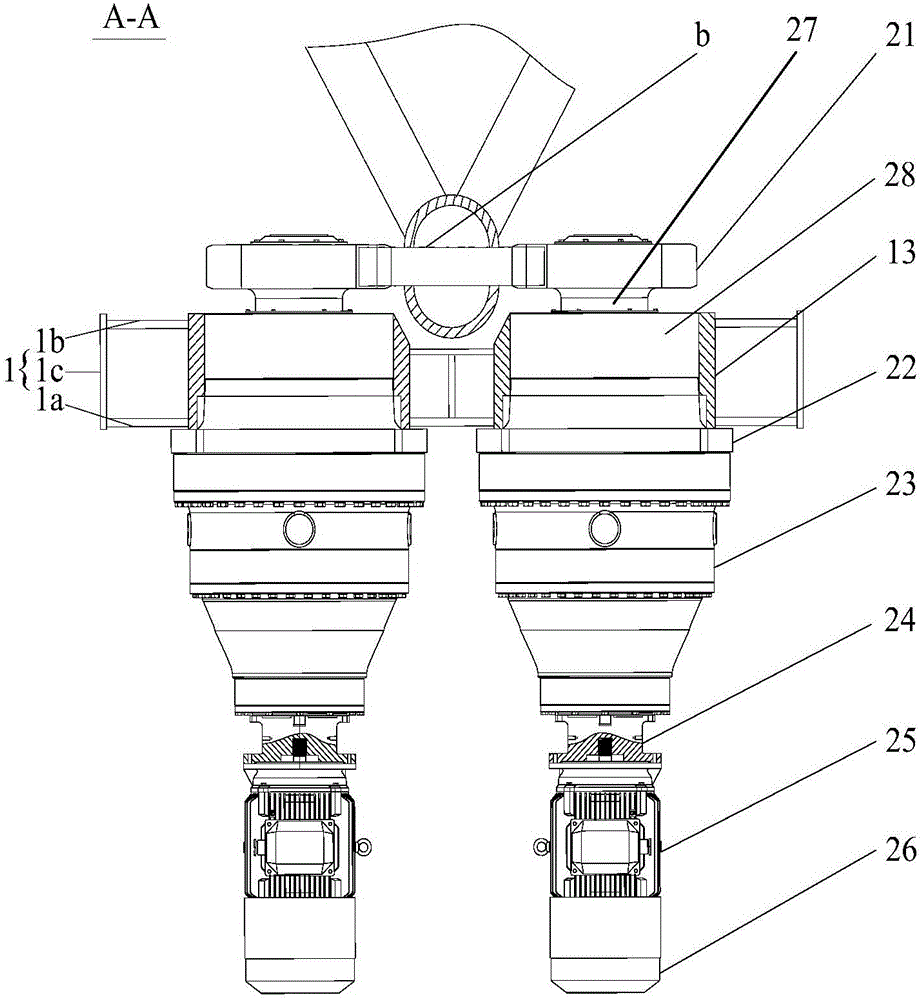

Integral loading cap discharge type bottle cap mould pressing forming machine

The invention relates to an integral loading cap discharge type bottle cap mould pressing forming machine. The integral loading cap discharge type bottle cap mould pressing forming machine comprises a main machine assembly, an upper mold, a lower mold, an oil cylinder assembly, a transmission mechanism, a rotary support, a loading cap discharge assembly, a discharge hole head, a discharge hole reversing mechanism and an extruding mechanism, wherein the oil cylinder assembly is driven by a hydraulic system, the loading cap discharge assembly comprises a material separating main shaft, the material separating main shaft is provided with a material separating plate, a scraper is mounted under the material separating plate, and is matched with the discharge hole reversing mechanism, a water separating and material blowing plate is mounted on the material separating plate, a cap separating impeller and a cap discharge baffle ring are mounted outside the water separating and material blowing plate, a material separating and air blowing hole A, a binder blowing hole B and a material return air blowing hole C are formed in the water separating and material blowing plate, a plurality of material falling holes are formed in the material separating plate, and drive the material separating plate to correspond to the material separating and air blowing hole A, the binder blowing hole B and the material return air blowing hole C through the material separating main shaft by virtue of the transmission mechanism, and a material return pipe and a material return box are arranged below a material scraping knife rest.

Owner:TAIZHOU HUANGYAN YIJING PLASTIC & MOLD

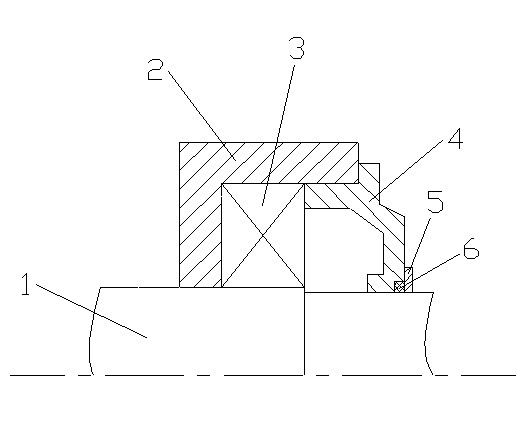

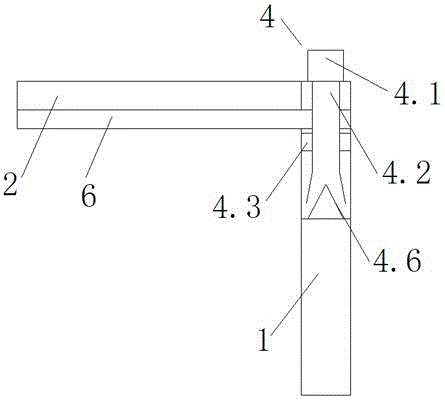

Front shaft sleeve assembly of lower shaft

ActiveCN103184662AImprove qualityAvoid oil spillsLubrication/cooling devicesEngineeringSewing machine

The invention relates to the technical field of accessories of sewing machines, in particular to a front shaft sleeve assembly of a lower shaft. The front shaft sleeve assembly of the lower shaft comprises a lower shaft and a shaft sleeve sleeved outside the lower shaft, wherein the lower shaft rotates inside the shaft sleeve; a blind hole is axially formed in the lower shaft body; the blind hole is a rotating shuttle oil supply pipeline; a through hole communicated with the rotating shuttle oil supply pipeline is radially formed on the outer surface of the lower shaft body inside the shaft sleeve; a groove and a reflowing slot are sequentially formed on the outer surface of the lower shaft body on the end where the rotating shuttle oil supply pipeline is arranged and one side of the through hole; and the reflowing slot can guide oil to the groove when the lower shaft rotates. Through the reflowing slot with the screwing direction opposite to the rotating direction of the lower shaft, in the case of rotation of the lower shaft, oil adhered to the lower shaft can reflow into the groove to form circulation, so that a phenomenon of oil leakage from a clearance between the lower shaft and the shaft sleeve is avoided and the quality of a product is improved; therefore, the front shaft sleeve assembly of the lower shaft is applicable to a sewing machine.

Owner:JACK SEWING MASCH CO LTD

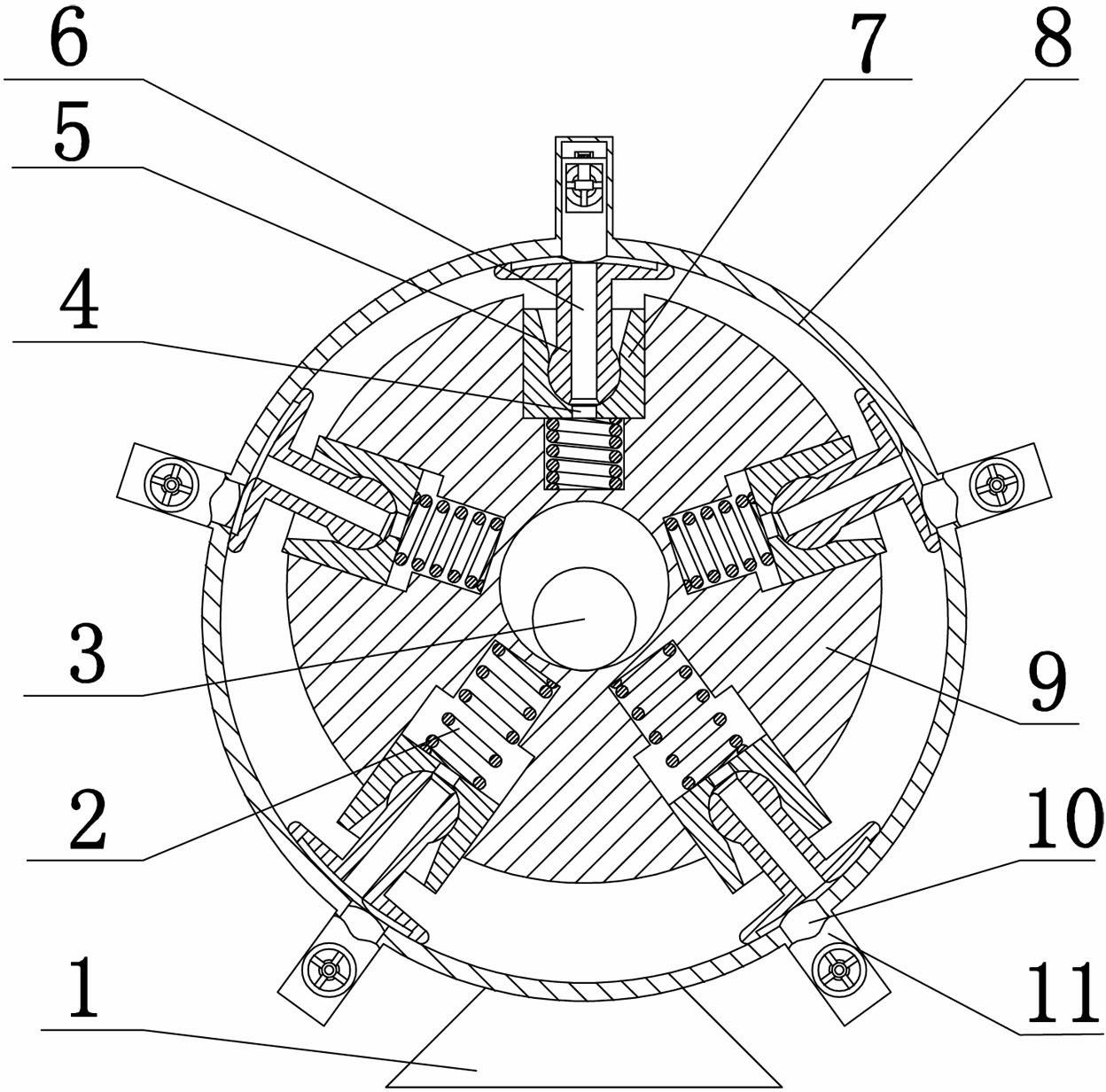

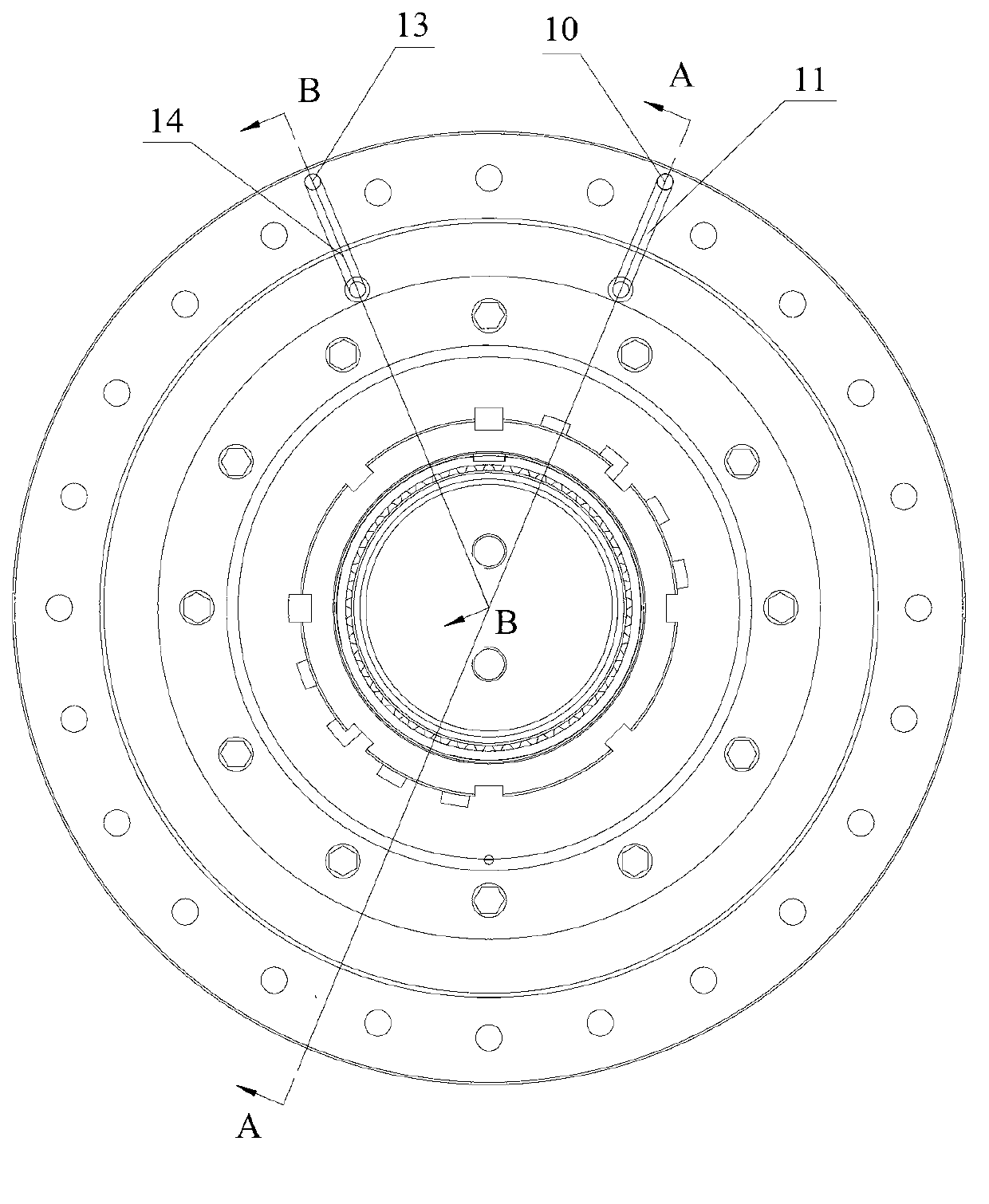

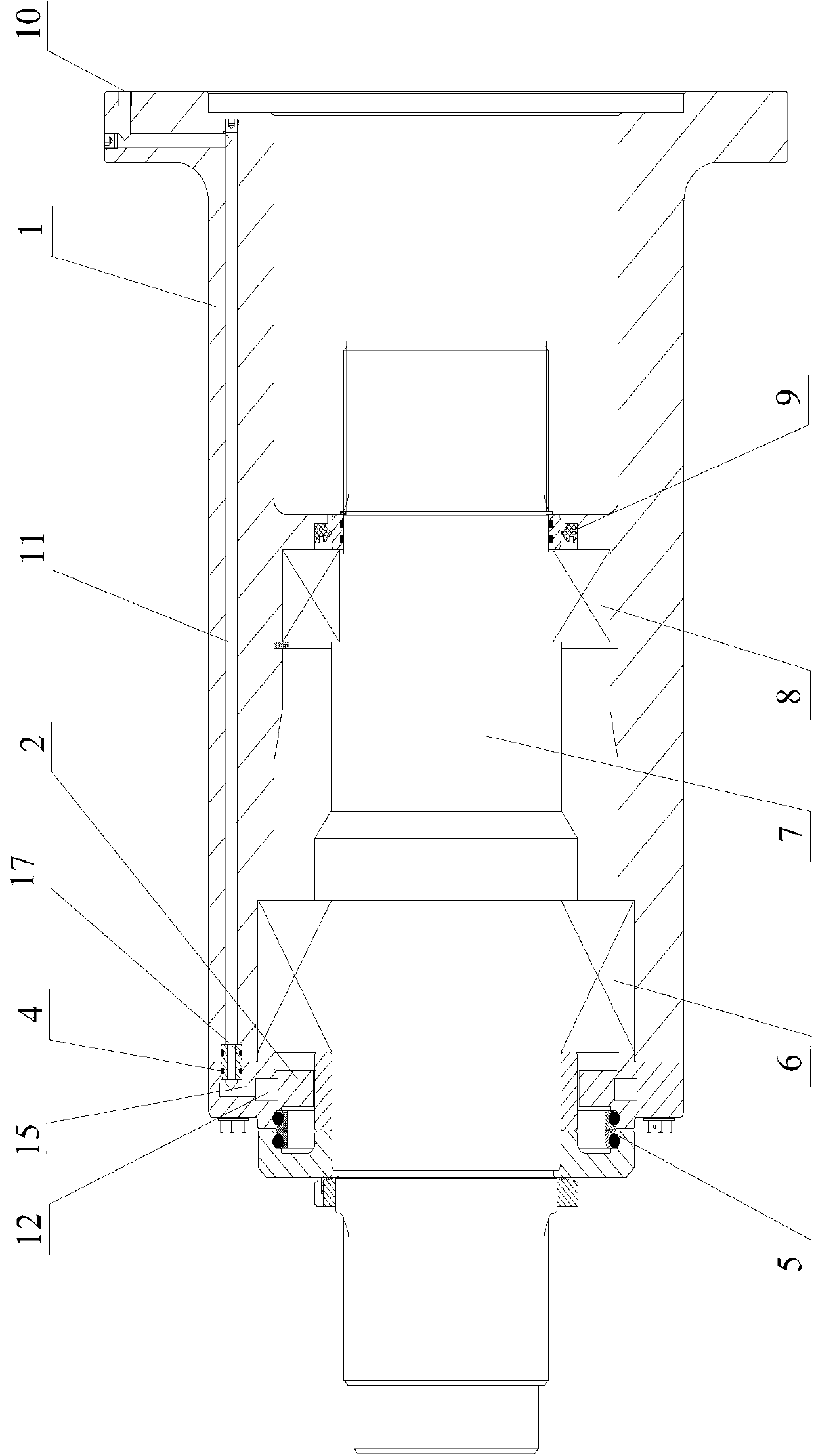

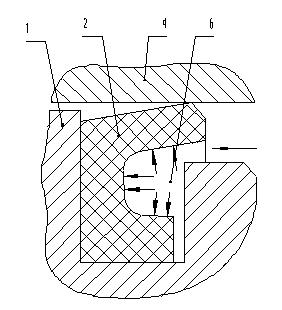

Connecting rod sliding shoe type flow distribution radial plunger pump

InactiveCN102644575ASensitive and reliable oil controlAvoid oil spillsPositive displacement pump componentsPositive-displacement liquid enginesRadial piston pumpEngineering

The invention discloses a connecting rod sliding shoe type flow distribution radial plunger pump, which comprises an eccentric shaft, a stator, a rotor, plungers, connecting rod sliding shoes and oil control valves and is characterized in that the bottom of the stator is fixedly connected with a base. A group of stator oil holes are evenly distributed on the inner wall of the stator along the radial direction, the group of stator oil holes are correspondingly connected with a group of oil control valves, the eccentric shaft is arranged in the stator, the rotor is arranged in the stator and connected to the outer side of the eccentric shaft in sleeved mode, a rotor anti-rotation mechanism is arranged at the bottom of the rotor, a group of plunger holes are evenly distributed on the rotor along the radial direction, a group of plungers are respectively arranged in the group of plunger holes, plunger return springs are arranged between the bottoms of the plunger holes and the plungers, the tops of a group of connecting rod sliding shoes are respectively arranged in the group of plungers and hinged to a group of plunger balls, and the bottoms of the group of connecting rod sliding shoes are slidingly connected with the inner wall of the stator and corresponds to the group of stator oil holes. The connecting rod sliding shoe type flow distribution radial plunger pump is sensitive and reliable in oil distribution, small in hydraulic oil leakage, low in fault rate and capable of effectively overcoming defects of a flow distribution mode of an existing radial plunger pump.

Owner:吕慧彬

Electric gear and rack lifting mechanism of ocean platform

ActiveCN105970896AAvoid destructionEasy to measureArtificial islandsUnderwater structuresHydraulic brakeRack and pinion

The invention discloses an electric gear and rack lifting mechanism of an ocean platform, and belongs to the field of ocean platforms. The lifting mechanism comprises a mounting frame and a lifting unit, wherein the lifting unit comprises a lifting gear shaft, a lifting gearbox, a motor and a first electromagnetic brake; a second electromagnetic brake is arranged between an input shaft of the lifting gearbox and an output shaft of the motor, so that the problem that brake time is too long due to adoption of a hydraulic brake is avoided; a mounting flange is fixed to the mounting frame by adopting a catch bolt, and a gasket is arranged on a shaft shoulder of the catch bolt, so that the mounting flange can shift on the catch bolt; the mounting flange is positioned by a torsion baffle block, so that torque is transmitted onto the mounting frame through the torsion baffle block, and therefore, the problem that the catch bolt is possibly damaged due to deformation of the mounting frame is avoided; and only one end of the lifting gear shaft is arranged in a bearing base, and therefore, the electric gear and rack lifting mechanism is simple to mount, and is convenient for measuring mounting and engaging occasions of gears and racks.

Owner:WUHAN MARINE MACHINERY PLANT

Special outdoor thermal insulation electrical equipment

InactiveCN106128710AAnti-theftImprove the fixing strengthTransformers/inductances coolingPinsLow voltageThermal insulation

The invention relates to special outdoor thermal insulation electrical equipment. The special outdoor thermal insulation electrical equipment comprises a transformer and a power distribution cabinet, wherein the transformer comprises a transformer box body, a transformer box cover, an iron core and a coil winding; the coil winding is wound around the iron core in a wrapping manner; the iron core and the coil winding are both arranged in the transformer box body; the transformer box body is filled with transformer oil; a conservator is arranged on the transformer box cover; a thermal insulation plate is arranged on the inner surface of the cabinet body of the power distribution cabinet; the transformer box cover is fastened on the transformer box body through fastening bolts; an alarm protection structure is arranged between the transformer box cover and the transformer box body; a sealing rubber mat is also arranged between the transformer box cover and the transformer box body; high-voltage wire-outlet sleeve pipes and low-voltage wire-outlet sleeve pipes are also arranged on the transformer box cover; main radiating pipes are arranged on the front and back sides of the transformer box body; auxiliary radiating structures are arranged on the left and right sides of the transformer box body; an anti-theft oil drain valve is arranged at the bottom of the transformer box body; and the transformer also comprises a high-voltage wiring structure, a low-voltage wiring structure and a wire-breaking detection apparatus.

Owner:国网山东省电力公司鱼台县供电公司 +1

Electronic cigarette

The invention provides an electronic cigarette. The electronic cigarette comprises an outer tube, a battery assembly, an atomization assembly and an upper cover, wherein the outer tube sleeves the battery assembly; the atomization assembly detachably sleeves the outer tube and is in electric connection and matching with the battery assembly; the upper cover is arranged on the atomization assembly, and a suction nozzle hole is formed in the top of the upper cover; the atomization assembly comprises an oil storage shell and an atomizer, wherein an air inlet hole and a smoke outlet are formed in the top surface of the oil storage shell, and the atomizer is fixedly arranged in the oil storage shell; the bottom of the oil storage shell is sealed through the atomizer; an air locking device is further arranged above the top surface of the oil storage shell; and the air locking device is used for opening and closing the air inlet hole and the smoke outlet. The air inlet hole and the smoke outlet which are used as two ends of an air channel are formed in the top surface of the oil storage shell at a high place, and the air locking device is used for opening and closing the air inlet hole and the smoke outlet, so that the air channel can be sealed; and the bottom of the oil storage shell is sealed through the atomizer, so that the problem that tobacco tar leaks through the air channel is effectively avoided and the bottom of the atomization assembly is clean and has no leakage.

Owner:周成龙

Oil-gas separator assembly and internal combustion engine

ActiveCN106224056AEasy to separateAvoid resistanceCombination devicesDispersed particle filtrationImpellerExternal combustion engine

The invention relates to an oil-gas separator assembly which comprises a rotary separation segment and a static filter segment. The rotary separation segment comprises a rotating piece, a rotary framework fixedly arranged on the outer side of the rotating piece, a connecting pipe fixedly connected to the inner side of the rotating piece and a rotary impeller fixedly connected to the rotating piece and located in the connecting pipe. A through hole allowing an oil-gas mixture to pass is formed in the rotating piece. A rotary filter element rotating along with the rotary framework is arranged in the rotary framework. The rotary impeller is used for sucking the oil-gas mixture into the oil-gas separator assembly. The static filter segment comprises a shell in sealing fit with the connecting pipe, static frameworks arranged in the shell, exhaust holes formed in the shell and an oil drainage hole formed in the bottom of the shell. A static filter element is arranged in each static framework. According to the oil-gas separator assembly, the pressure of a crankcase cannot be raised while oil-gas separation is effectively carried out, and meanwhile the service life of the filter elements is effectively prolonged. The invention further discloses an internal combustion engine provided with the oil-gas separator assembly.

Owner:WEICHAI POWER CO LTD

Scraping-rolling machine boring rod spiral sealing mechanism and scraping-rolling machine

InactiveCN102588596AGuaranteed uptimeImprove sealingEngine sealsBoring barsReciprocating motionEngineering

The invention discloses a scraping-rolling machine boring rod spiral sealing mechanism and a scraping-rolling machine, wherein the scraping-rolling machine boring rod spiral sealing mechanism comprises a flange plate, a reciprocating sealing piece and a rotary sealing piece; the outer edge of the flange plate is fixedly connected with a wall plate at an opening part of an oil receiver, so that the flange plate covers the opening part; an installation hole is arranged in the middle of the flange plate, and a boring rod is arranged in the installation hole in a penetrating way; the reciprocating sealing piece is arranged between the inner wall of the installation hole and the boring rod; and the rotary sealing piece is sheathed on the boring rod and is clung to the end surface of the flange plate, close to a boring rod box. The scraping-rolling machine boring rod spiral sealing mechanism and the scraping-rolling machine can realize the rotary sealing and the reciprocating sealing of the boring rod simultaneously, and are simple in structure and stable in performance.

Owner:SANY GRP

Process for processing space ring of double-section drive axle for automobile

InactiveCN101700613AImprove machining accuracyExtended service lifeSolid state diffusion coatingFurnace typesEngineeringCorrosion resistant

The invention relates to a process for processing a space ring of a double-section drive axle for an automobile, comprising the following steps: the end surface and the excircle of a blank are roughly lathed with a lathe, and the end surface, the inner hole and the excircle of the blank are finely lathed; the processed work piece is quenched under high frequency, and the quenched work piece is loaded in a furnace so that the quenched work piece is glowed and compact and uniform corrosion-resistant white bright layer is formed on the surface of the glowed work piece; the excircle of the glowed work piece is firstly roughly ground and then finely ground with a grinder with the roughness of the work piece being controlled between Ra 0.3 and Ra 0.5 until the space ring is produced. The process can improve the processing precision of the space ring and the assembling precision of the space ring and an oil seal, further save the energy, enhance the work efficiency and facilitate the operation and is particularly suitable for deep hole and slit nitridation.

Owner:青岛元通汽车法兰有限公司

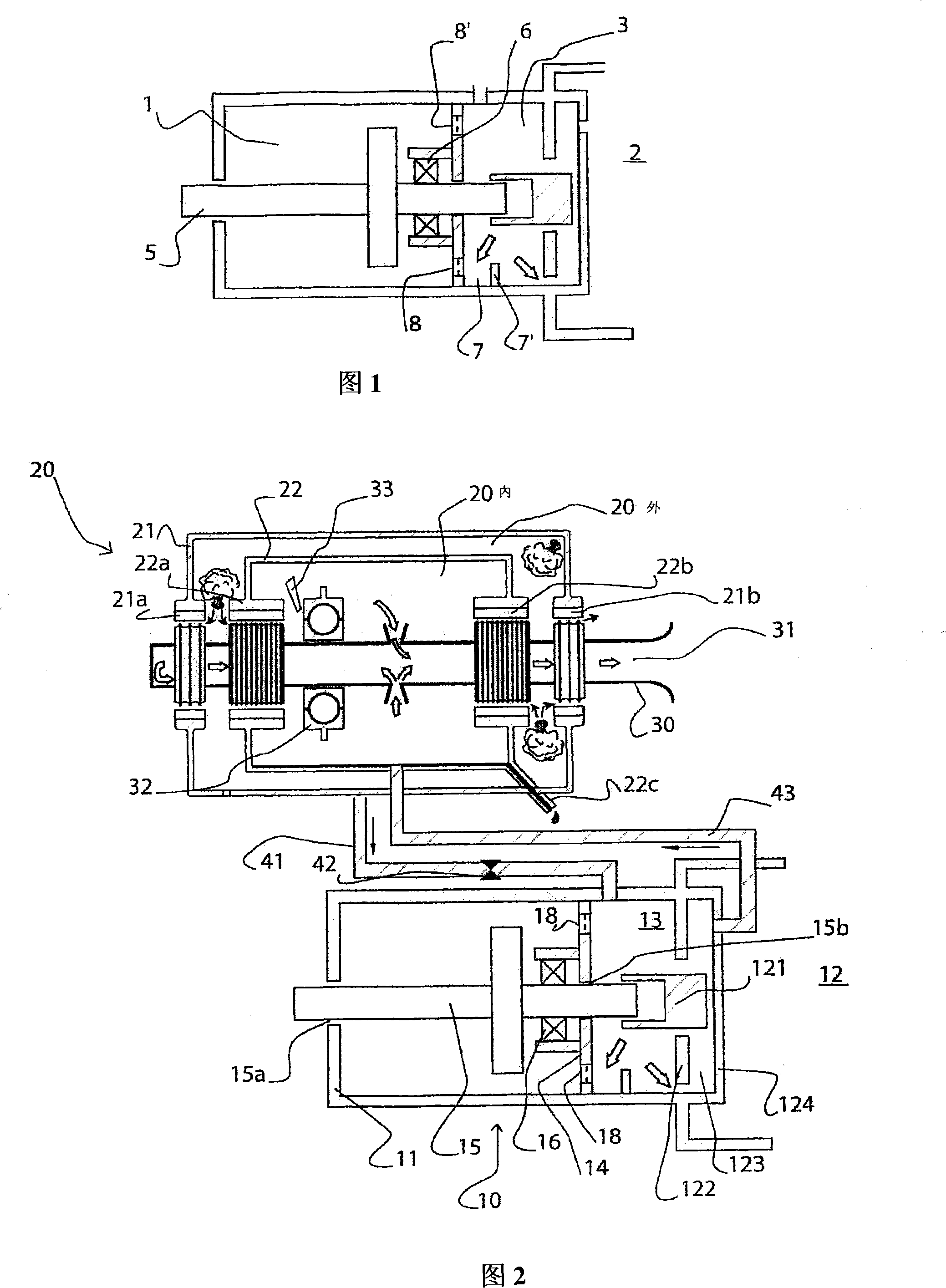

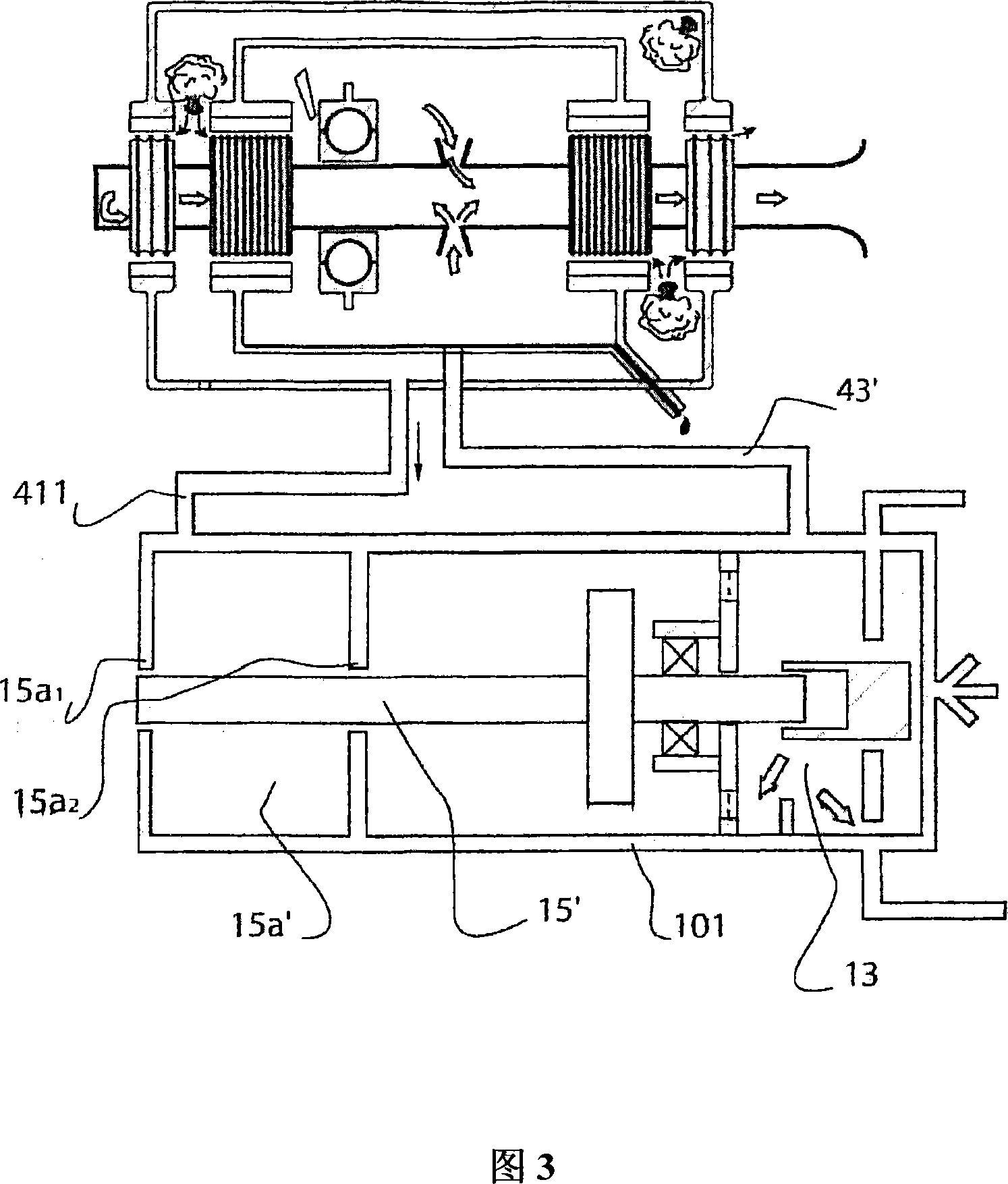

Gas turbine engine with a gearbox-mounted starter

ActiveCN101235730AReduced risk of emptyingAvoid oil spillsGas turbine plantsEngine componentsTurbineGas turbines

The engine has an auxiliary gearbox (12) connected mechanically to a shaft (30) of the engine for driving auxiliary machines. An air starter (10) having an oil enclosure is mounted on the gearbox, where the oil enclosure and the gearbox are communicated with each other such that lubricating oil in the starter is distributed from the gearbox. The oil enclosure is pressurized by an air source e.g. bearing's pressurization enclosure, that is independent from the gearbox. An air return conduit (43) is connected on a wall (124) of the gearbox.

Owner:HISPANO SUIZA SA

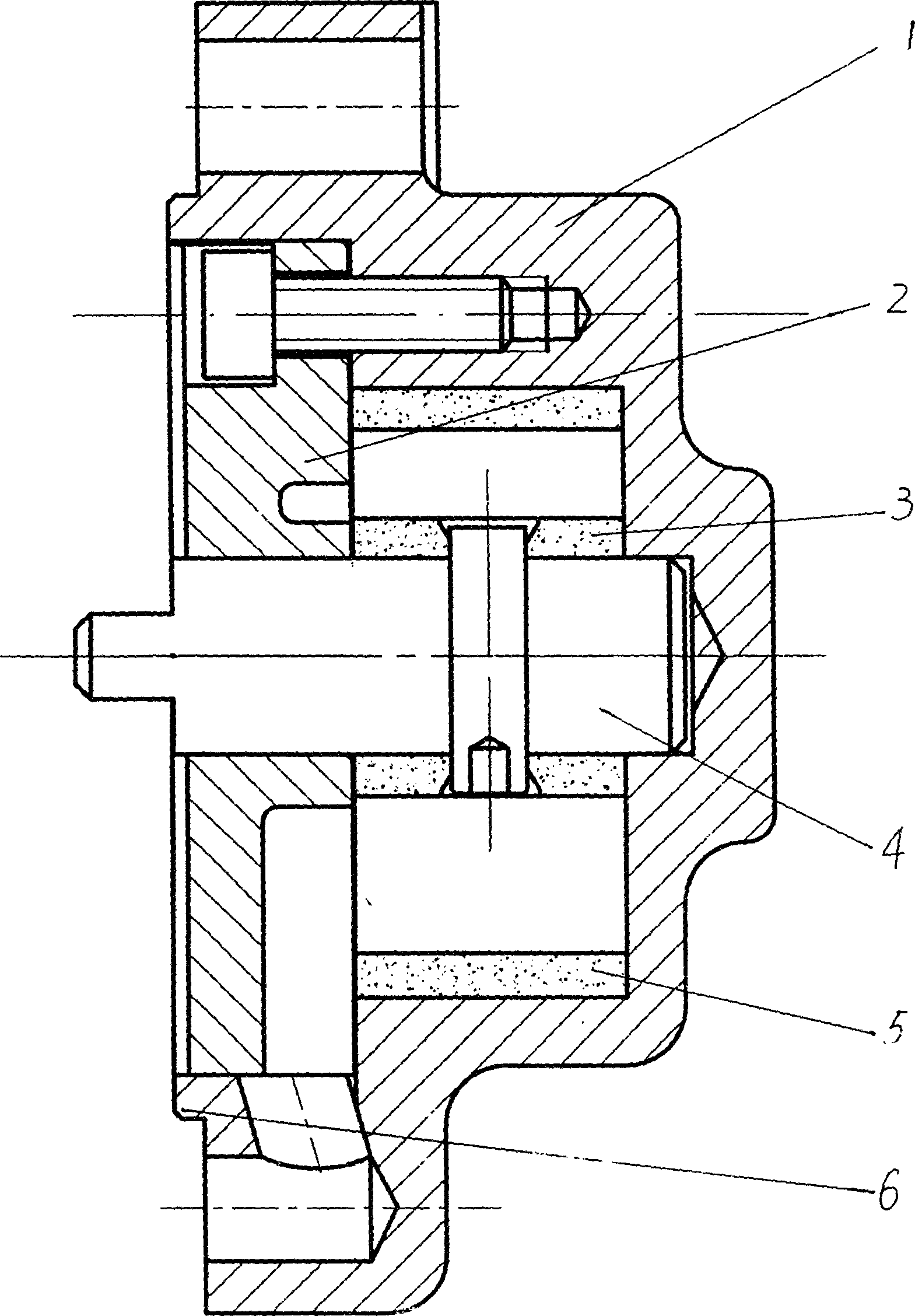

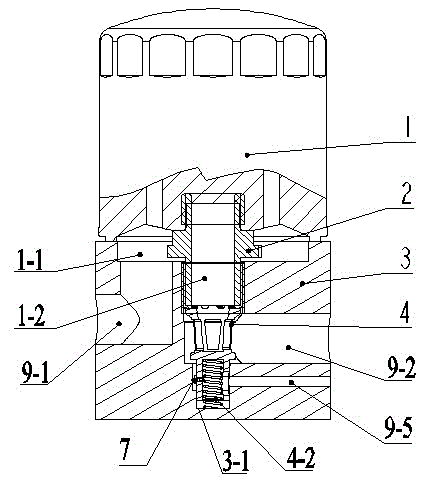

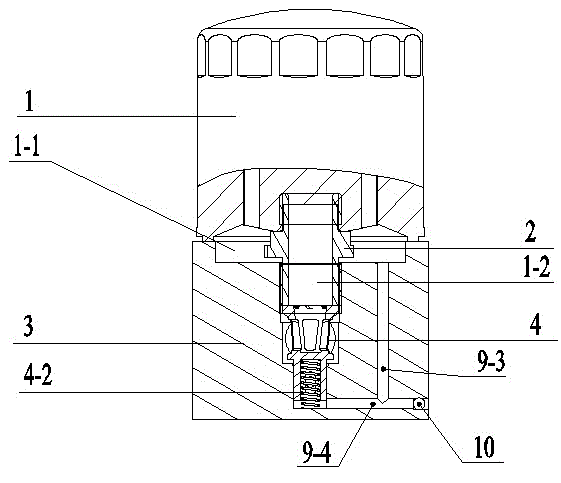

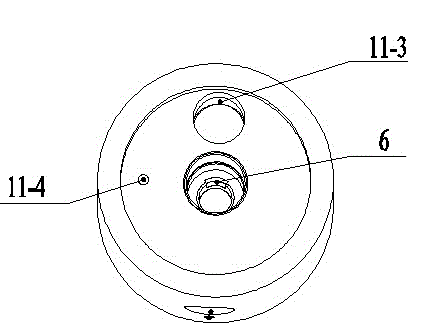

Engine oil filter assembly and assemble method and disassembly method thereof

ActiveCN102720560AHigh strengthWell toleratedLubricant mounting/connectionLubrication pressure controlOil filterWaste management

The invention discloses an engine oil filter assembly. The engine oil filter assembly comprises an engine oil filter and an installation base, wherein the engine oil filter is used for filtering engine oil, the installation base is used for supporting the engine oil filter, an oil return control mechanism is arranged inside a cavity of the installation base, the engine oil filter is installed on the oil return control mechanism through a connecting pipe, the oil return control mechanism comprises an oil return device body and a sealing face cavity, an oil outlet which is connected with a filtered engine oil outlet pipeline during installation of the engine oil filter is arranged on the oil return device body, an oil return opening which is connected with an oil return pipe during disassembly of the engine oil filter is arranged on the sealing face cavity, an oil return spring which is fixedly connected with the oil return device body is arranged inside the sealing face cavity, the top end of the oil return spring is connected with the oil return device body, and the bottom end of the oil return spring extends out of the sealing face cavity and presses against the bottom face of the cavity of the installation base. The invention also provides an assemble method and a disassembly method of the engine oil filter assembly. The engine oil filter assembly has the advantages of being simple in structure, reliable to operate and high in strength and is applicable to engine oil filtering and oil returning of the engine oil of various engine oil engines.

Owner:GREAT WALL MOTOR CO LTD

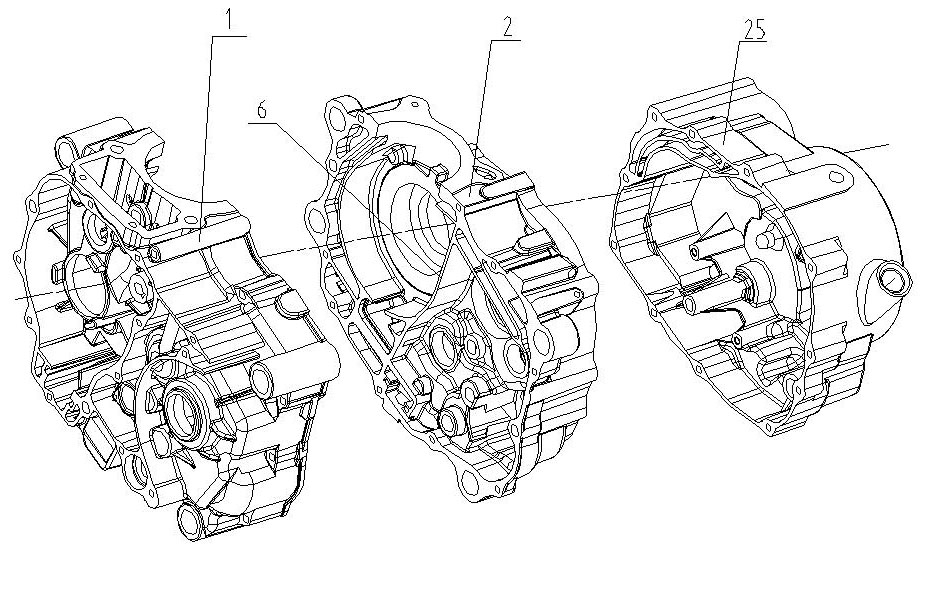

Motorcycle engine

InactiveCN101943080AReduce the temperatureReduce or even eliminate the phenomenon of excessive consumptionCasingsMachines/enginesOil separationFour-stroke engine

The invention provides a motorcycle engine. A sealing tendon is arranged between a power cavity and a transmission cavity of a left case and a right case, the sealing tendon is used as an oil separation belt to completely separate the power cavity and the transmission cavity of the engine after the assembly of the left case and the right case, the left case and the right case respectively form a power cavity lubrication oil way and a transmission cavity lubrication oil way which are mutually independent, the power cavity lubrication oil way is communicated with an oil sump at the bottom of the power cavity, and the transmission cavity lubrication oil way is communicated with an oil sump at the bottom of the transmission cavity; and two oil pumps are installed on the right case and are respectively communicated with the power cavity lubrication oil way and the transmission cavity lubrication oil way. By using the technical scheme, the invention realizes the separation of thermal engine lubrication oil and cold engine lubrication oil without changing the shape of the four-stroke engine and the position of the suspension interface of the traditional motorcycle, thereby being beneficial to improving the performance of the engine and prolonging the service life of the engine. The respective oil pump of the two independent lubrication systems can work reliably.

Owner:CHONGQING LONCIN MOTOR

Unit atomizing cartridge

The invention discloses a unit atomizing cartridge, which comprises a shell, leakproof silica gel is tightly mounted on the top end of the shell, and a cathodal part is mounted on the bottom end of the shell; a ceramic holder is mounted in the middle upper part of the head of the cavity of the shell, and an atomization chamber is formed between the ceramic holder and the leakproof silica gel; a silica gel plug made of an insulator is mounted in the middle of the cathodal part, and an anodal part is inserted in the silica gel plug; oil-guiding cotton is clamped on the ceramic holder, a heatingwire is wound on the oil-guiding cotton, two leads are led out from both ends of the heating wire, one lead is connected with the anodal part, and the other lead is connected with the cathodal part. The whole unit atomizing cartridge is integrated, the structure is compact, the size is small, and thereby the unit atomizing cartridge is convenient to carry daily; the area under the ceramic holder and upon the cathodal part is a tobacco oil storage bin, the whole cubage is large, and thereby the atomization time is prolonged; the smoke outlet and the shell share the same cavity, the mist outletis big, and thereby the mist discharge is high; because the oil supply system is moved under the heating wire, the storage of tobacco oil is greatly increased, the phenomenon of oil leakage is thoroughly prevented as well, and the stability and continuity of oil supply are enhanced.

Owner:张哲滔

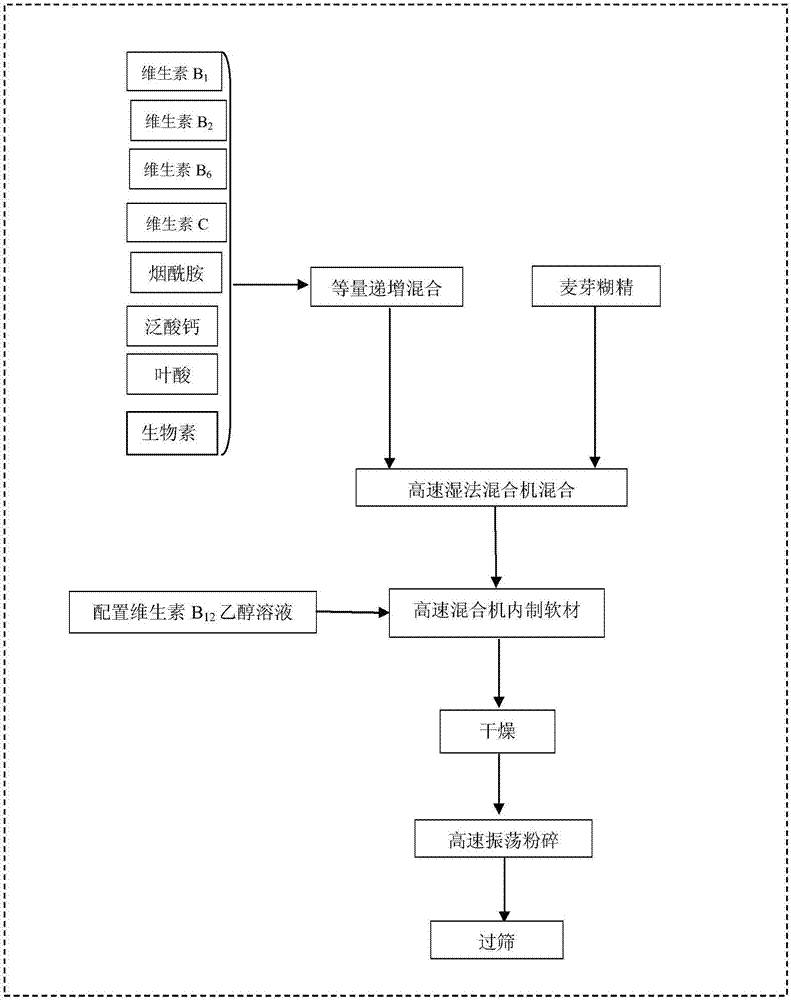

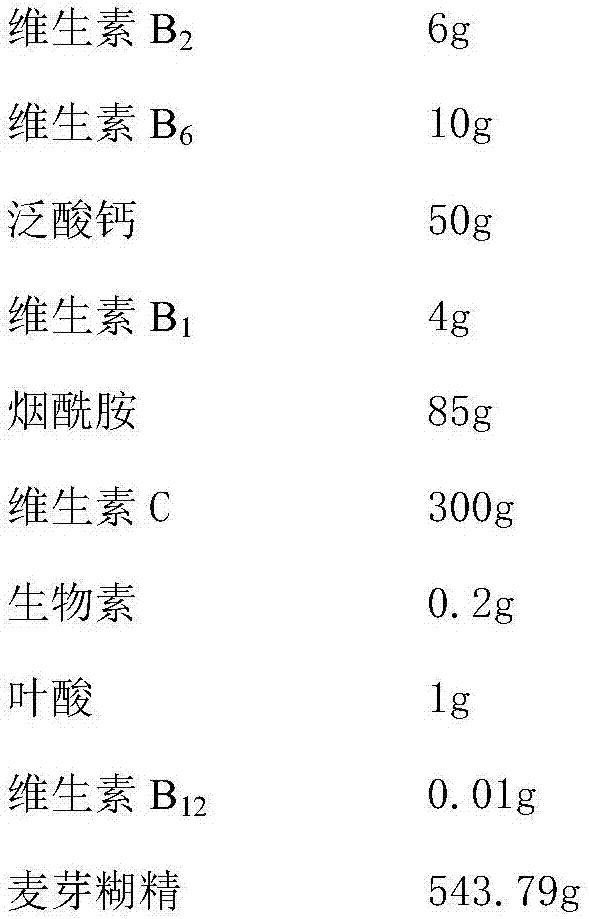

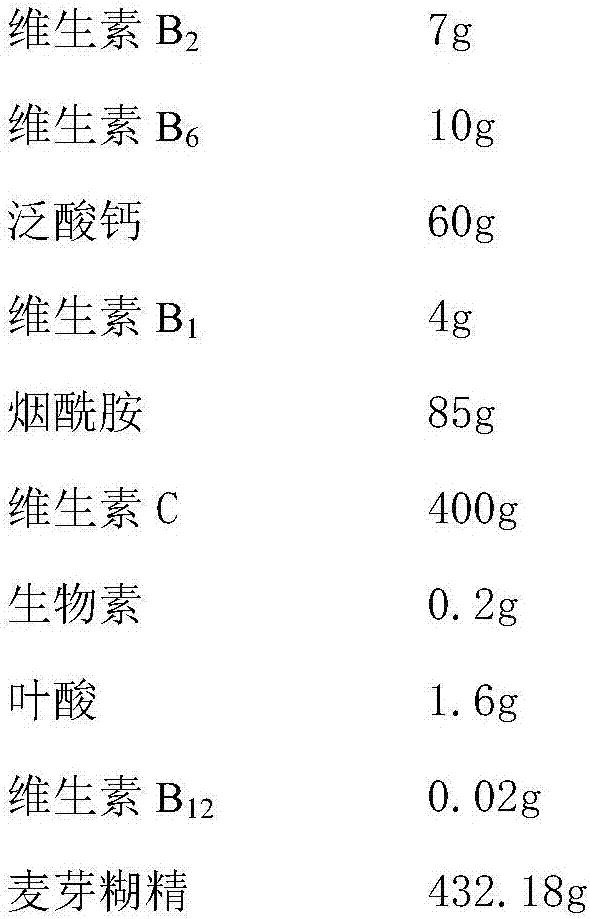

Vitamin premix suitable for soft capsule preparation and preparation method of vitamin premix

InactiveCN107969704AGuarantee the quality of productionEnhance physical fitnessMetabolism disorderCapsule deliveryChemistryFolic acid

The invention relates to a vitamin premix suitable for soft capsules and a preparation method of the vitamin premix. The vitamin premix comprises the following raw materials of vitamin B1, vitamin B2,vitamin C, nicotinamide, vitamin B6, calcium pantothenate, vitamin B12, biotin, folic acid and maltodextrin. The preparation method comprises the following steps of making the raw materials into softmaterials, performing drying, performing crushing, and performing screening so as to make uniform fine powder of which the fineness is greater than or equal to 100 meshes. According to the vitamin premix and the preparation method thereof, a technology for making the soft materials by a wet method material mixing manner is firstly used, so that the condition of component changes caused by spray drying and high temperature generally used in the preparation of the premix is avoided. The fineness of granules of the prepared vitamin premix can achieve 200 meshes, the materials are uniformly distributed, the classifying phenomenon in the production and transportation process cannot occur, and the stability is good.

Owner:山东禹王制药有限公司

Oil filter for treating dirty oil in electrical cabinet profile bending machine

ActiveCN104587738AEasy to separateImprove adsorption capacityLiquid degasificationFiltration circuitsMagnetic filterOil filter

The invention discloses an oil filter for treating dirty oil in an electrical cabinet profile bending machine. The oil filter comprises a filter tank and an oil guide pipe, wherein the oil guide pipe penetrates through the outer wall of the filter tank and is placed at the upper end inside the filter tank; the top end of the filter tank is communicated with a condensation tank; a heating chamber is fixedly formed in the side wall of the filter tank, the oil guide pipe penetrates through the heating chamber, and a heater is mounted in the heating chamber; an oil injection column communicated with the oil guide pipe is rotationally arranged at the end part of the oil guide pipe, hollow wing plates are fixed on the two sides of the oil injection column, and a plurality of oil injection holes are formed in the opposite sides of the two wing plates; through holes communicated with the oil injection holes are formed in the oil injection column; an oil pump is fixed at the bottom of the filter tank, and the oil outlet end of the oil pump penetrates through the filter tank and is connected with a magnetic filter. Gas enters the condensation tank from the top of the filter tank and is newly fluidized under the condensation effect of the condensation tank to be convenient for centralized collection and treatment, and the purposes of improving the absorption of impurities in liquid when oil for bending is filtered and further improving the filtering efficiency of the oil for bending are further achieved.

Owner:SICHUAN XINGZHI ZHIHUI INTPROP OPERATION CO LTD

Heading machine and water-cooled cutting arm thereof

ActiveCN102996125AAchieve the purpose of coolingAvoid oil spillsSlitting machinesWater channelEngineering

The invention discloses a heading machine and a water-cooled cutting arm of the heading machine. The water-cooled cutting arm comprises a coupling barrel, a front bearing used for supporting a spindle in the coupling barrel, and a bearing gland which is connected to the end of the coupling barrel and is used for axially positioning the front bearing, wherein a side wall of the coupling barrel and a side wall of the bearing gland are provided with cooling water channels which are communicated with each other; and a water inlet and a water outlet are formed on the cooling water channel. The cooling water channel is formed in the coupling barrel, and a cooling temperature control member is not required to be arranged on the outer side of the coupling barrel, so that the structure of the cutting arm is simplified, and the problem that the cooling water easily leaks because the water jacket is required to be welded or mounted with the coupling barrel is solved.

Owner:SANY HEAVY EQUIP

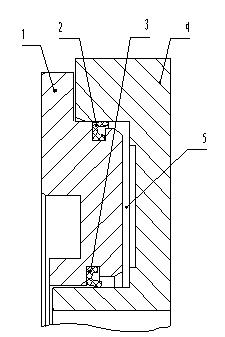

Low-pressure reciprocating mechanism of engineering machinery chassis

InactiveCN101915311AGuaranteed tightnessAvoid oil spillsEngine sealsFluid-pressure actuatorsReciprocating motionEngineering

The invention discloses a low-pressure reciprocating mechanism of an engineering machinery chassis, which belongs to the technical field of engineering machinery and is used for improving the sealing effect of the reciprocating mechanism. The technical scheme of the reciprocating mechanism is that: the reciprocating mechanism comprises an annular piston and a piston seat, wherein the inner surface of the annular piston is provided with an inner sealing circular groove which is coaxial with the piston; an inner lip-shaped sealing ring is arranged in the inner sealing circular groove; the outer surface of the annular piston is provided with an outer sealing circular groove which is coaxial with the piston; an outer lip-shaped sealing ring is arranged in the outer sealing circular groove; after improvement, the inner surface of the piston is provided with an inner oil guide groove which is communicated with the inner sealing circular groove; the outer surface of the piston is provided with an outer oil guide groove which is communicated with the outer sealing circular groove; and both the inner oil guide groove and the outer oil guide groove are positioned in an annular hydraulic oil cavity which is formed by enclosing the piston, the piston seat, the inner lip-shaped sealing ring and the outer lip-shaped sealing ring. The low-pressure reciprocating mechanism of the engineering machinery chassis can ensure the sealing effect thereof under the high temperature working condition and the low temperature working condition and completely prevent the occurrence of oil leakage phenomenon.

Owner:XUANHUA CONSTR MACHINERY +1

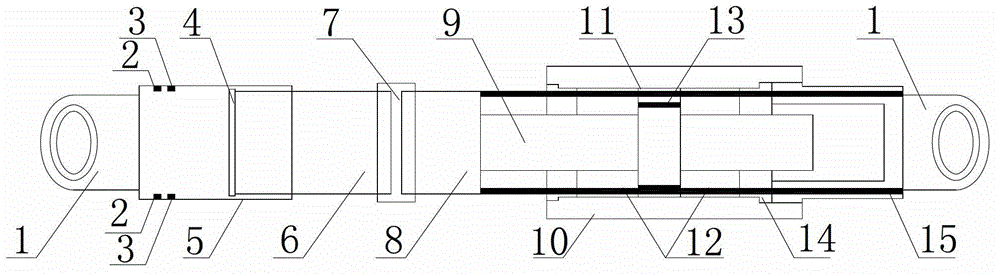

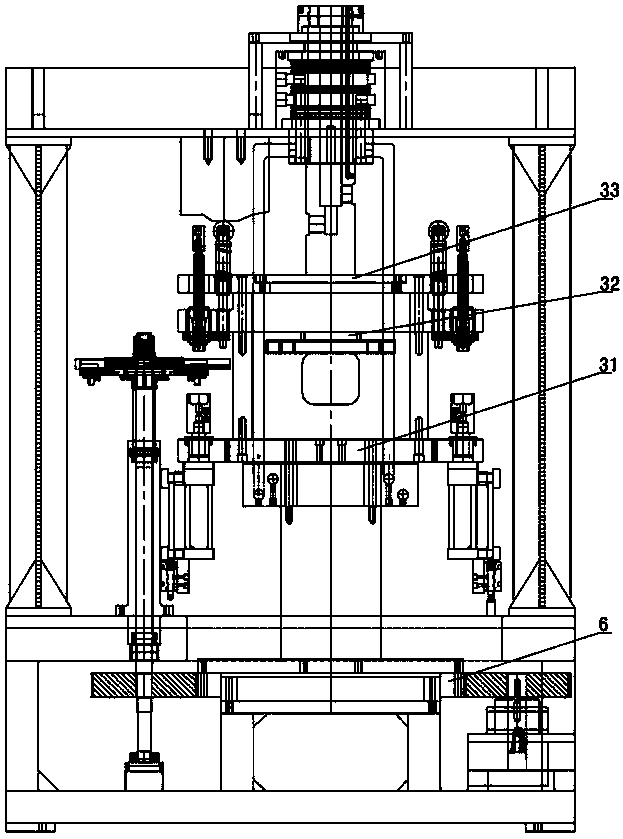

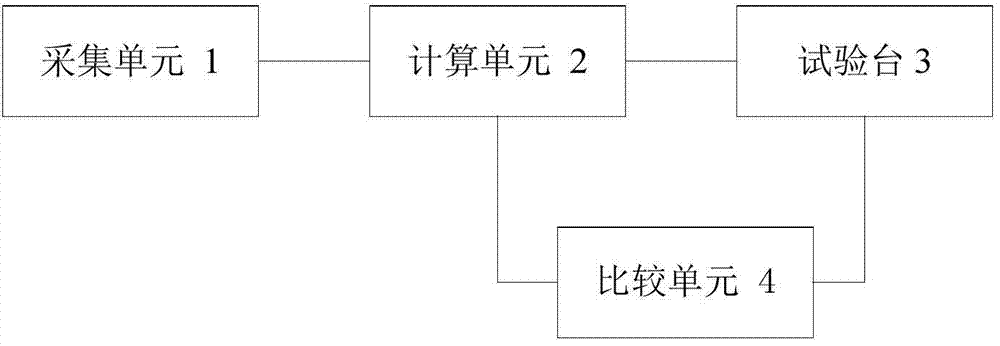

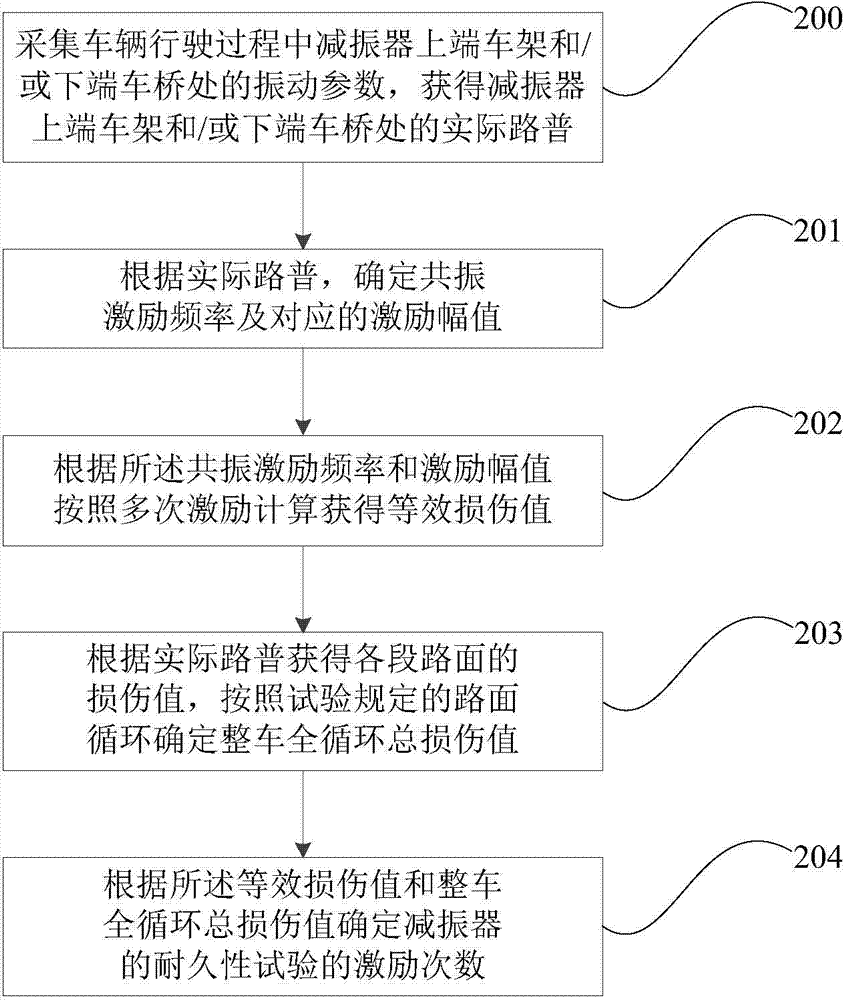

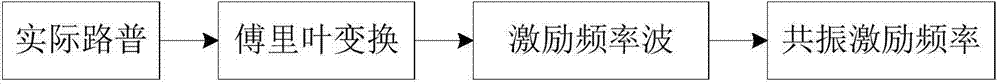

Test apparatus and test method for durability of vehicle vibration damper

ActiveCN104849073AAvoid oil spillsAvoid failureVehicle suspension/damping testingVehicle frameRoad surface

The invention relates to the technical field of vehicle tests, and discloses a test apparatus and a test method for the durability of a vehicle vibration damper. The test apparatus comprises an acquisition unit (1) respectively arranged on an upper vehicle frame and / or a lower axle of the damper and used for acquiring vibration parameters of the upper vehicle frame and / or the lower axle of the damper in a driving process of a vehicle and obtaining the actual road investigation; and a calculation unit used for determining the resonance excitation frequency and the corresponding excitation amplitude according to the actual road investigation, obtaining the equivalent damage value according to the resonance excitation frequency, the excitation amplitude, and multiple excitation calculations, obtaining the damage values of various pavements according to the actual road investigation, determining the general damage value of full cycle of the whole vehicle according to the pavement cycle prescribed by a test, and determining the excitation frequency of the durability tests for the vibration damper according to the equivalent damage value and the general damage value of the full cycle of the whole vehicle. According to the test apparatus for the durability of the vehicle vibration damper, the excitation frequency of the durability tests of the vibration damper can be obtained, and a reasonable service lifetime can be accurately determined.

Owner:BEIQI FOTON MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com