Automatic screwing device of oil pumping machine packing and with remote monitoring function

A remote monitoring and pumping unit technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problem of increased labor intensity of well patrolling, threats to the lives of well patrolling personnel, and increased cost of well patrolling, etc. problems, to achieve the effect of saving manpower, saving manpower patrol expenses, improving work efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

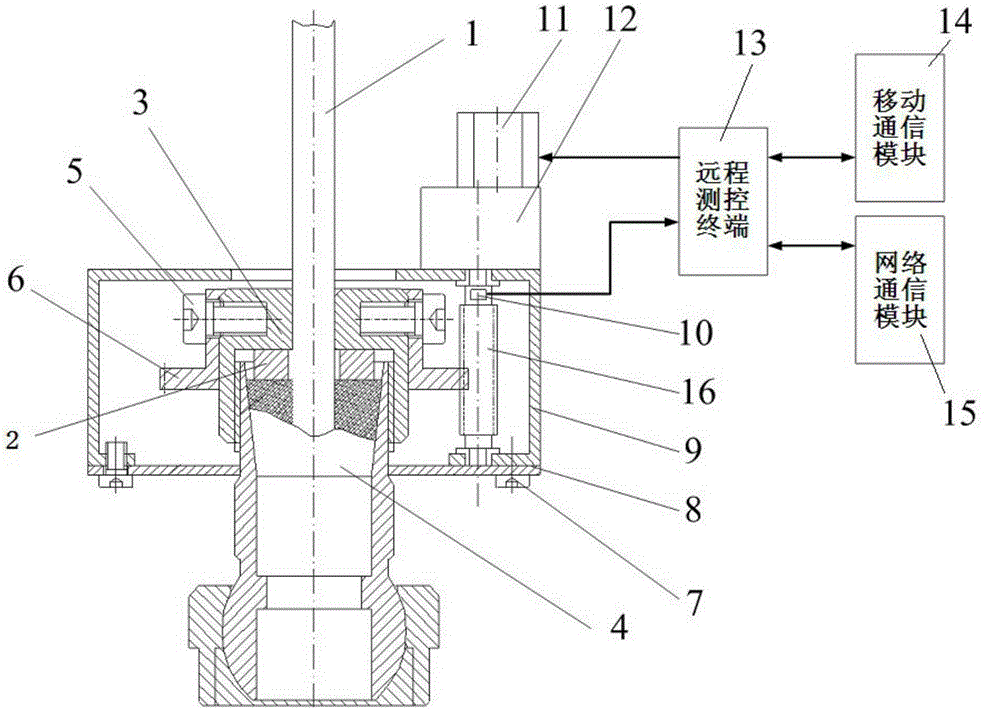

[0013] An automatic tightening device for pumping unit packing with remote monitoring function, such as figure 1 As shown, it includes polished rod 1, upper gland 2, screw-in nut 3, packing 4, driven gear 6, bottom plate 8, housing 9, force sensor 10, motor 11, torque machine 12, remote measurement and control terminal 13, mobile Communication module 14, network communication module 15 and driving gear 16, described screw-in nut 3 is set to two, is arranged on both sides of polished rod 1 respectively; Described upper gland 2 and packing 4 are all set on screw-in nut 3, installed in the packing box; the driven gear 6 is set on the screw nut 3 through the screw I5; the motor 11 is connected with the torque machine 12; the bottom plate 8 and the housing 9 are fixedly connected through the screw II7 The force sensor 10 is arranged at the journal position of the driving gear 16, and the output end of the force sensor 10 is connected with the remote measurement and control terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com