Patents

Literature

2454 results about "Sucker rod" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

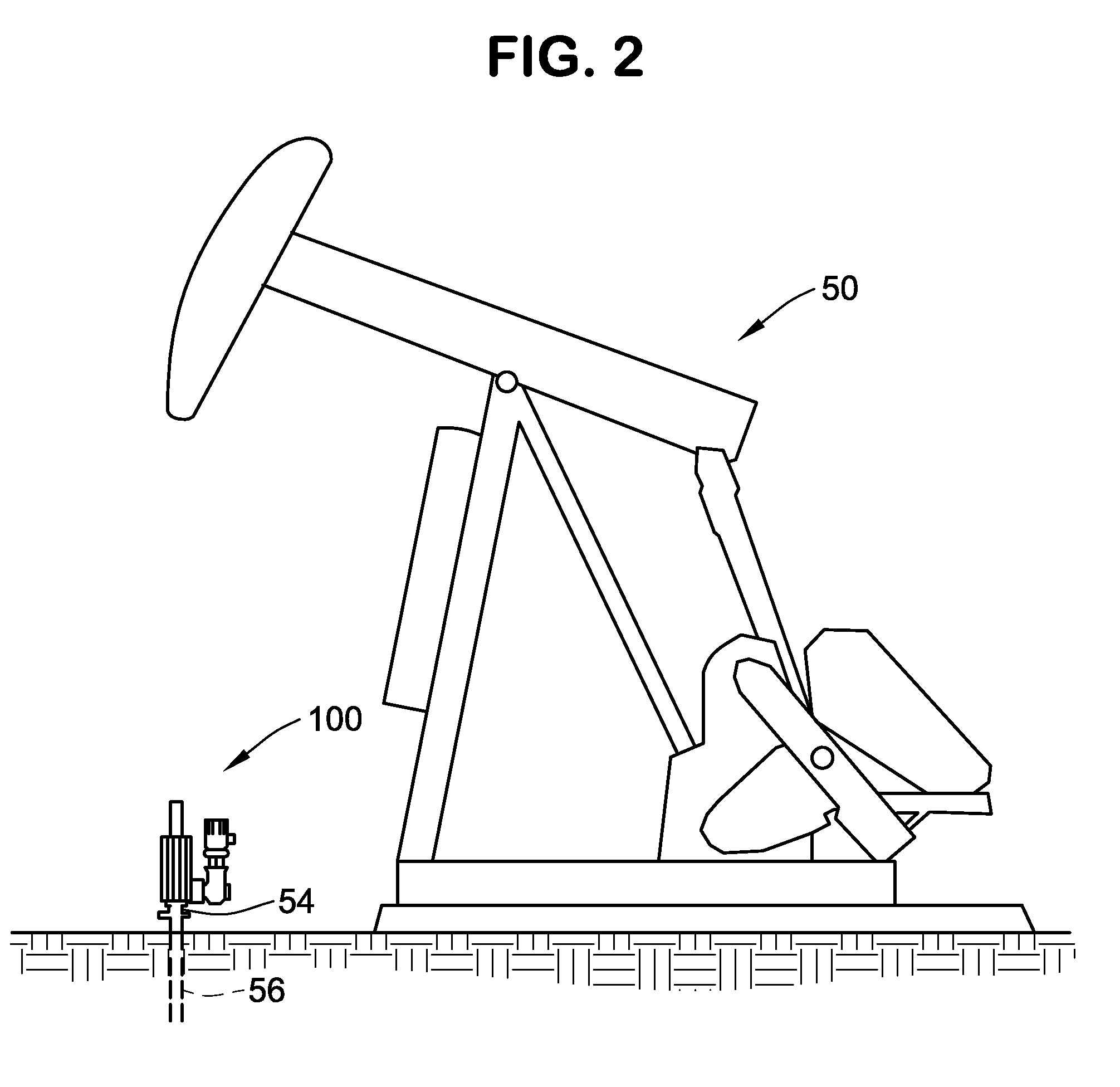

A sucker rod is a steel rod, typically between 25 and 30 feet (7 to 9 meters) in length, and threaded at both ends, used in the oil industry to join together the surface and downhole components of a reciprocating piston pump installed in an oil well. The pumpjack is the visible above-ground drive for the well pump, and is connected to the downhole pump at the bottom of the well by a series of interconnected sucker rods. Sucker rods are also commonly available made of fiberglass in 37 1/2 foot lengths and diameters of 3/4, 7/8, 1, and 1 1/4 inch. These are terminated in metallic threaded ends, female at one end and male at the other.

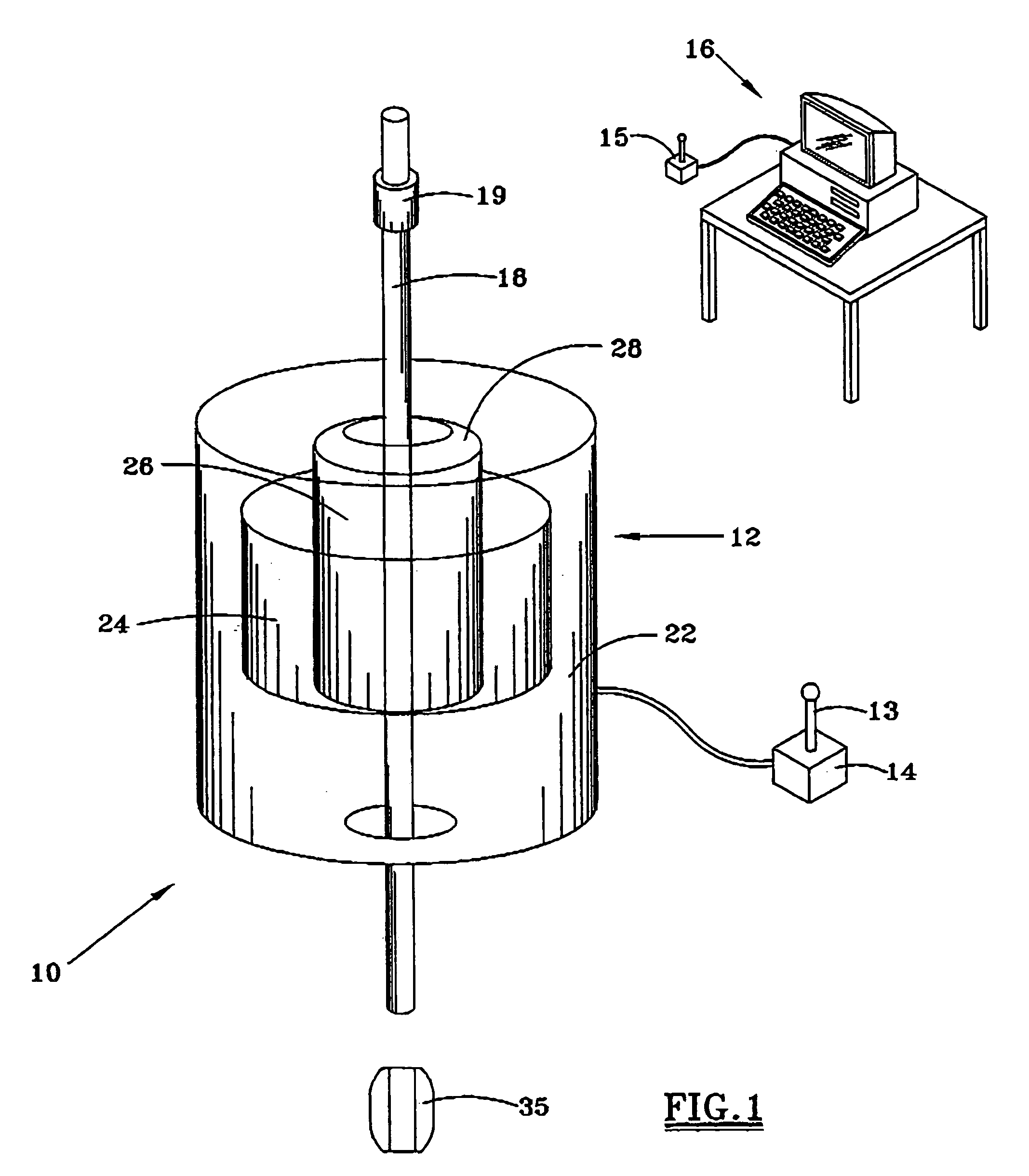

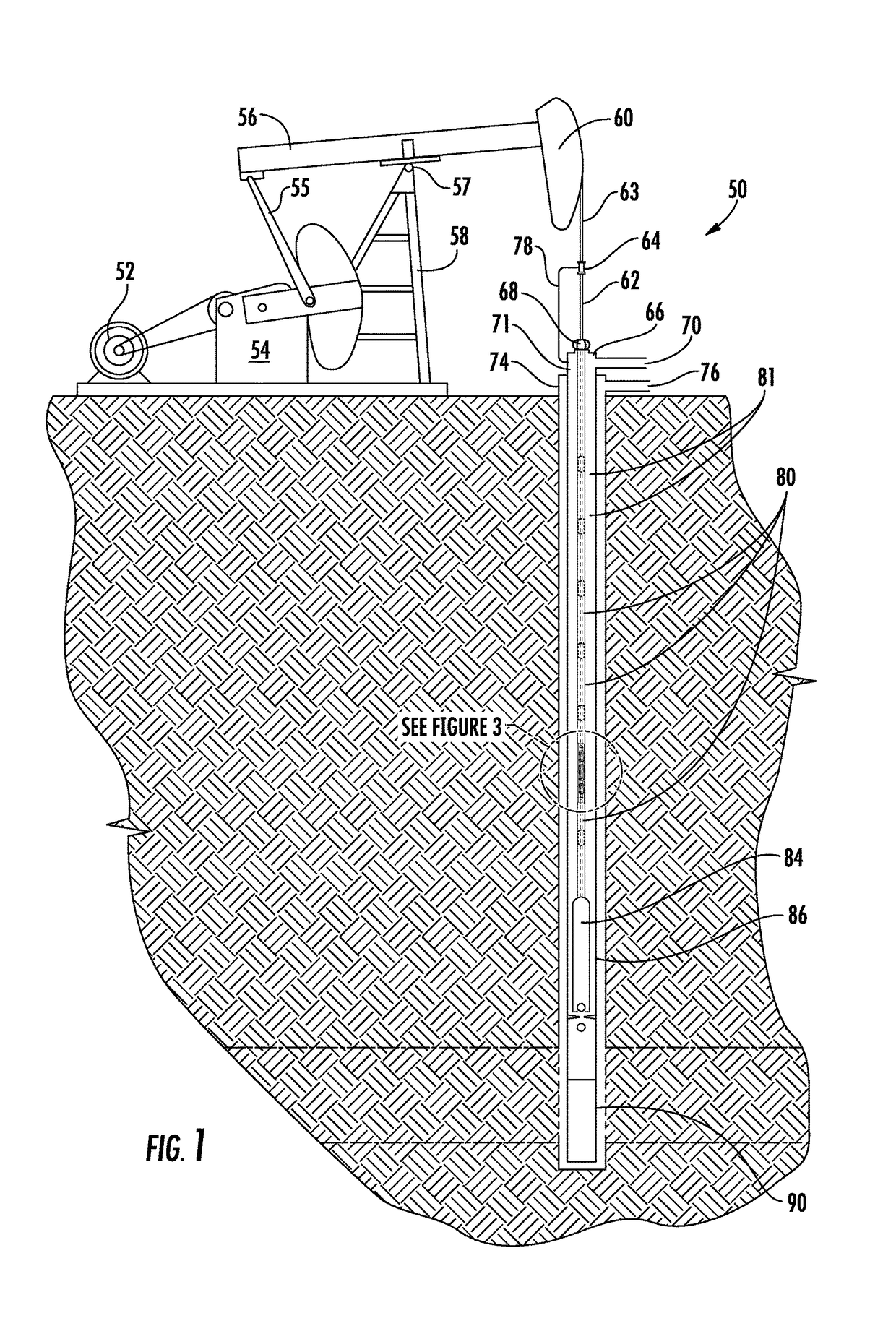

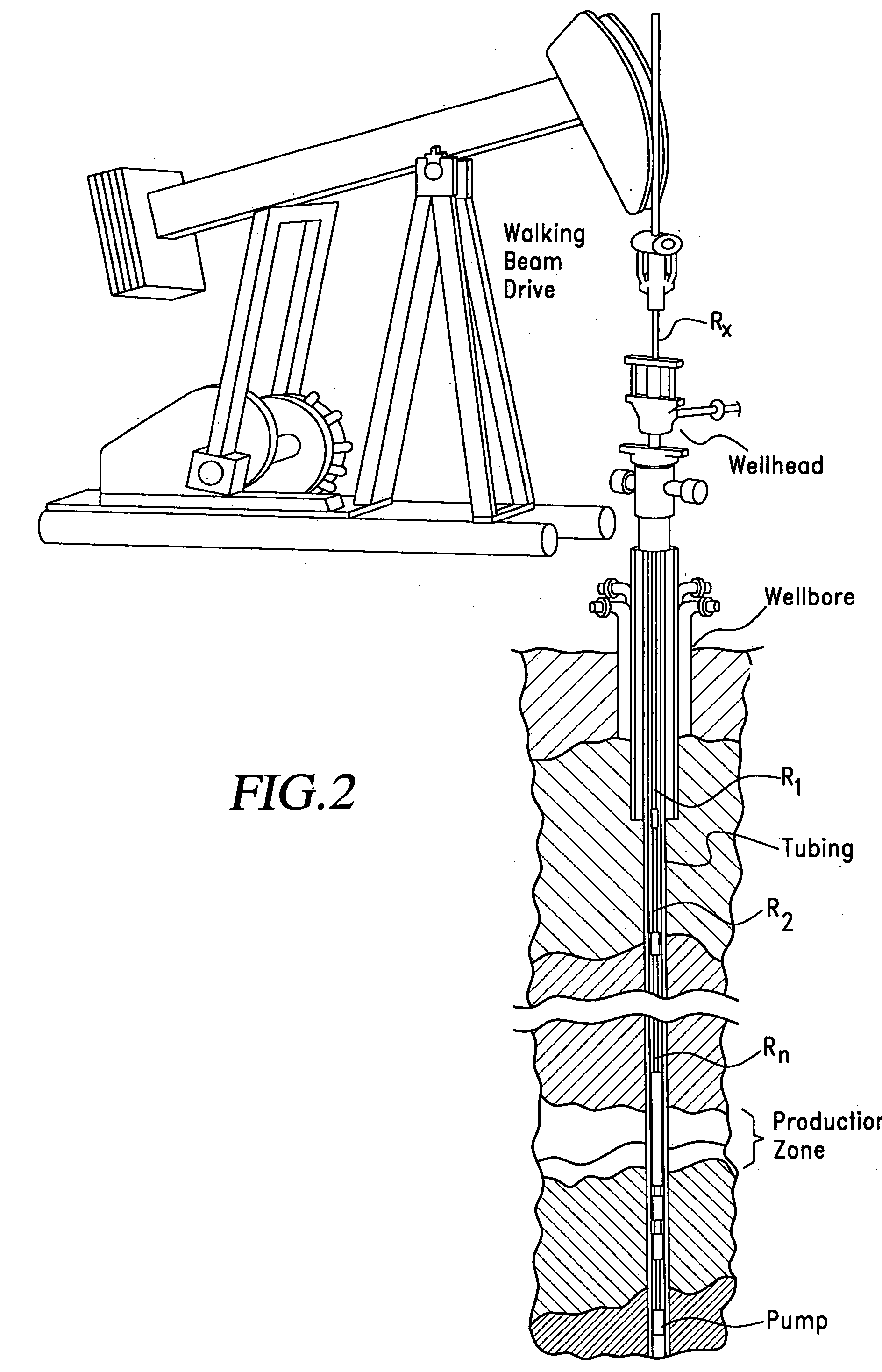

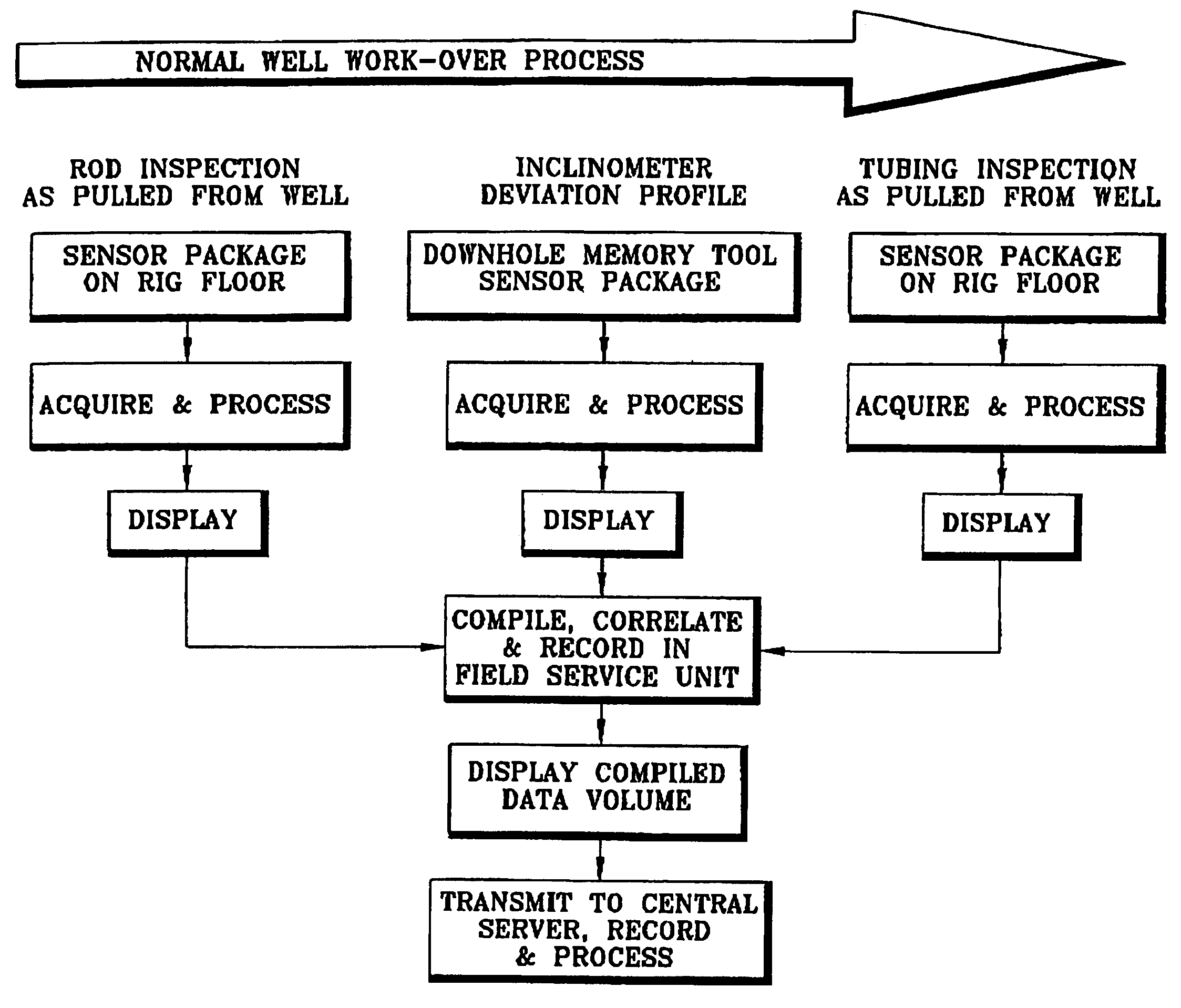

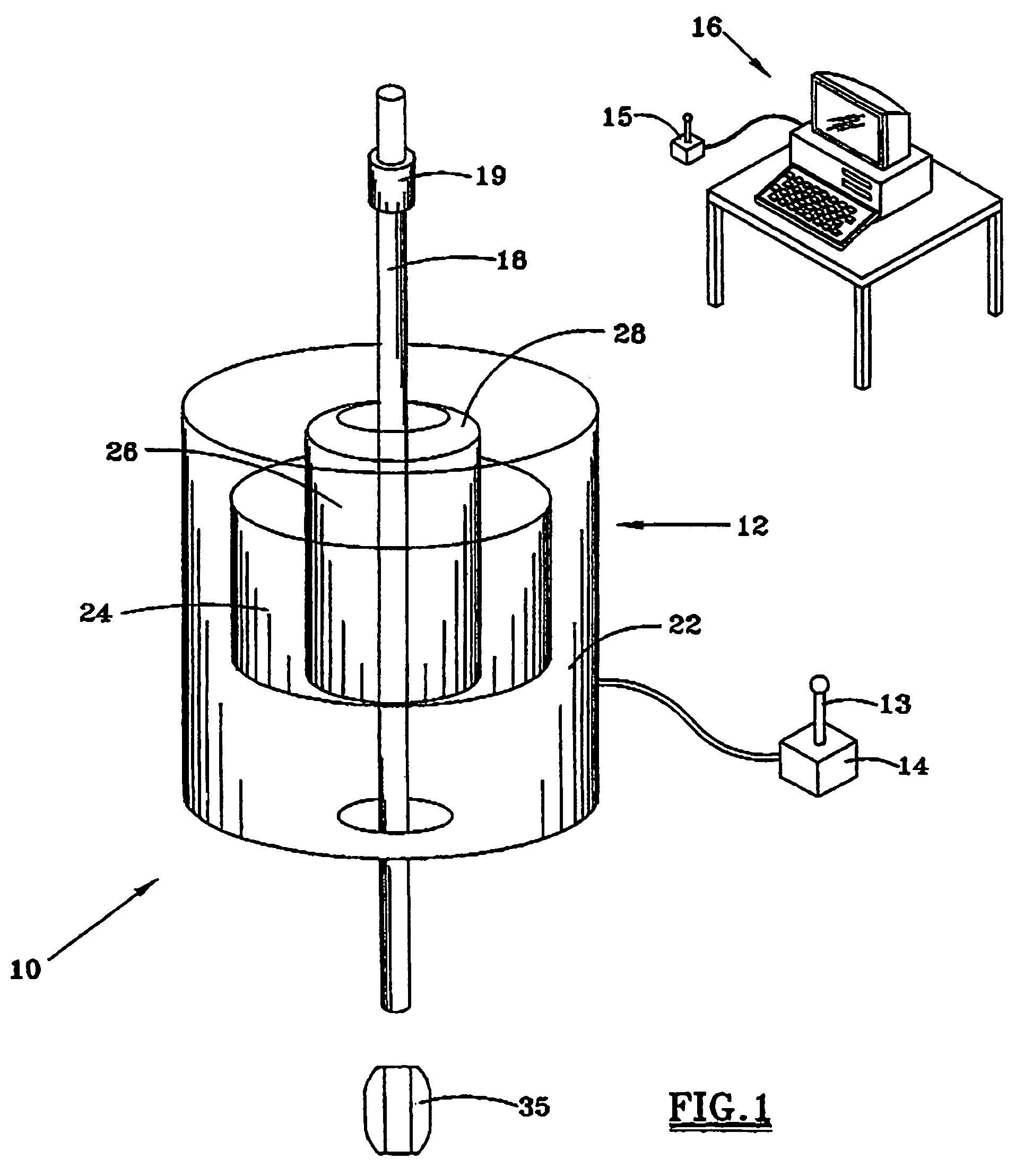

Wellbore evaluation system and method

ActiveUS20060271299A1Electric/magnetic detection for well-loggingSurveySection planeData acquisition

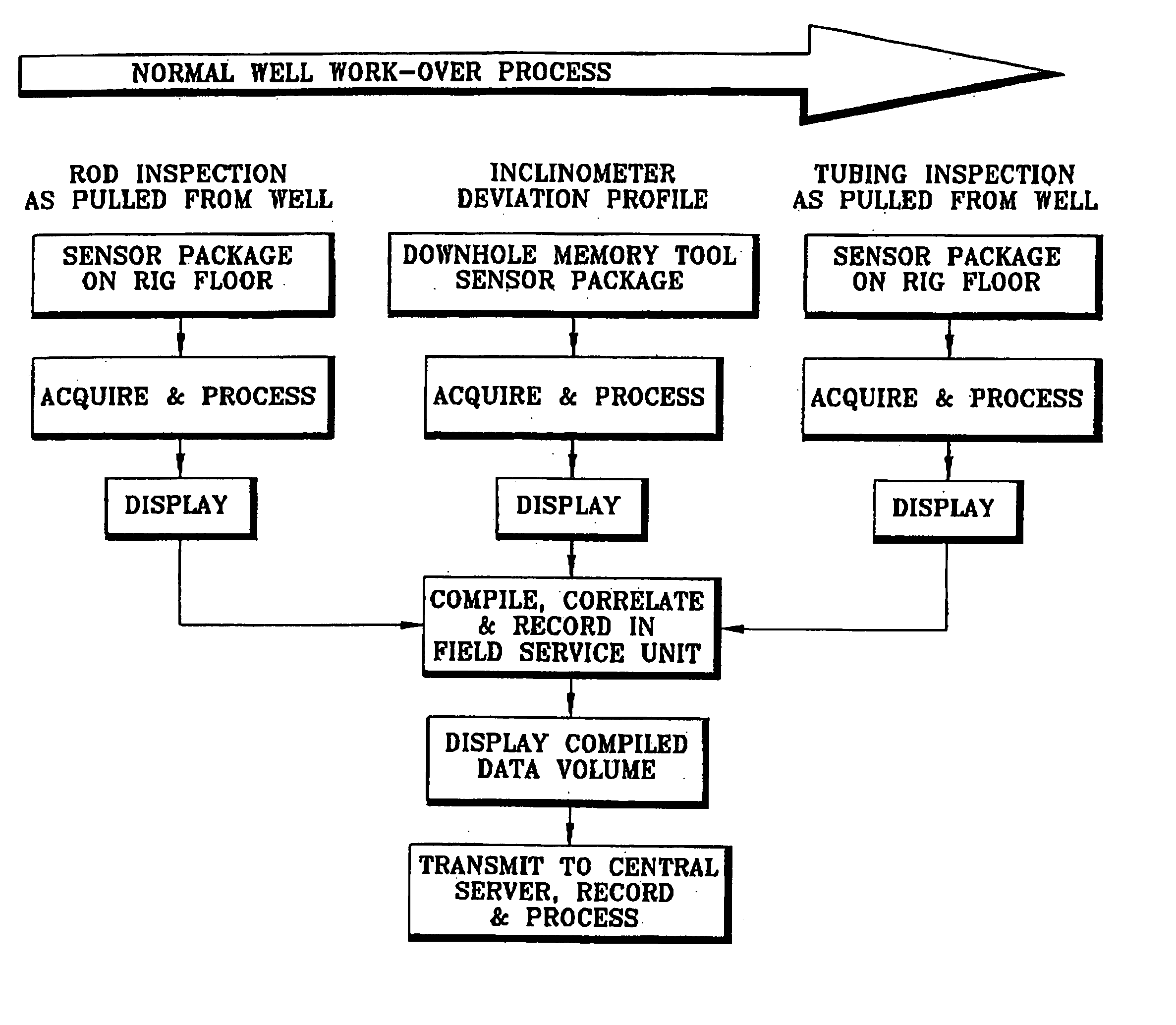

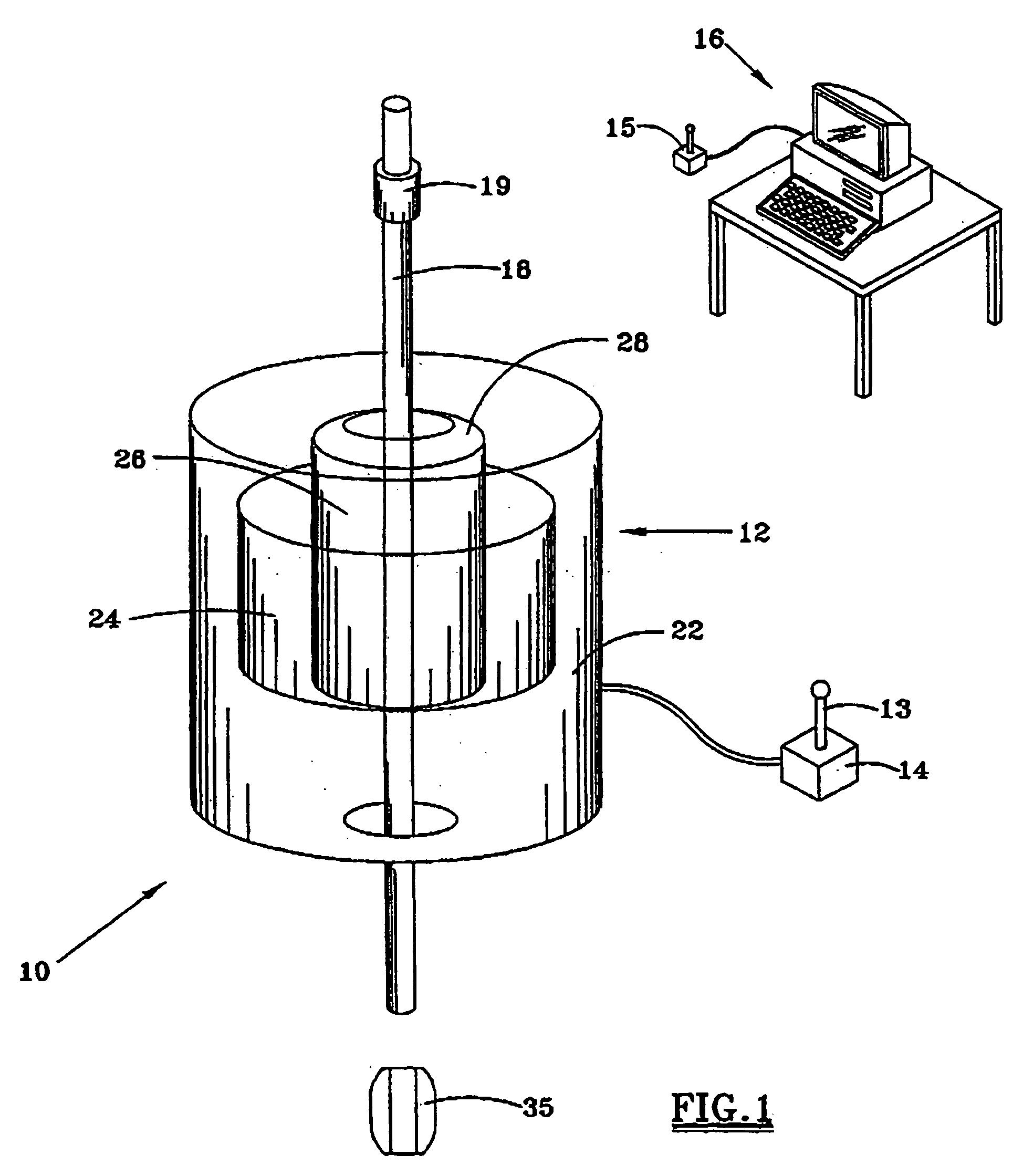

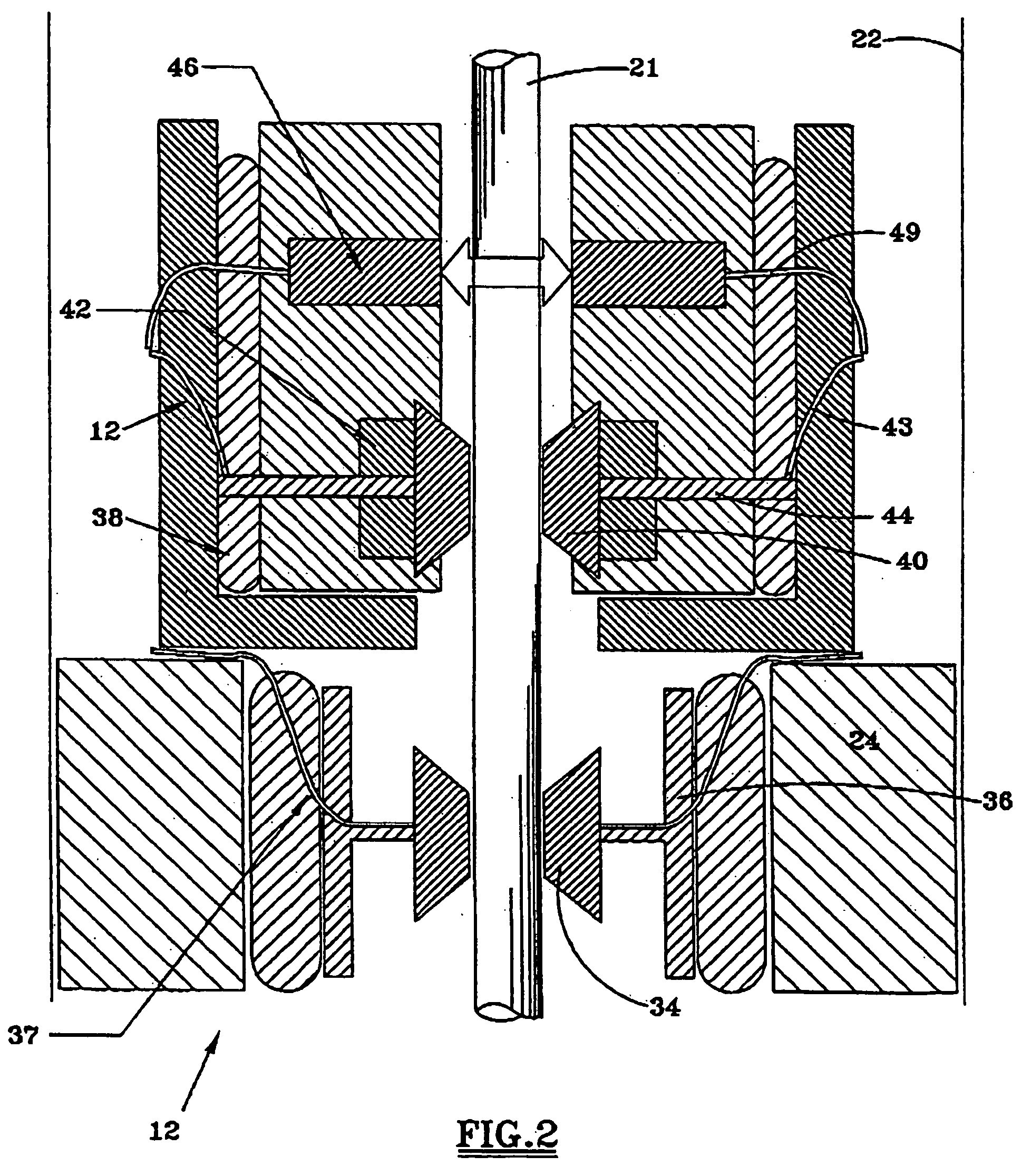

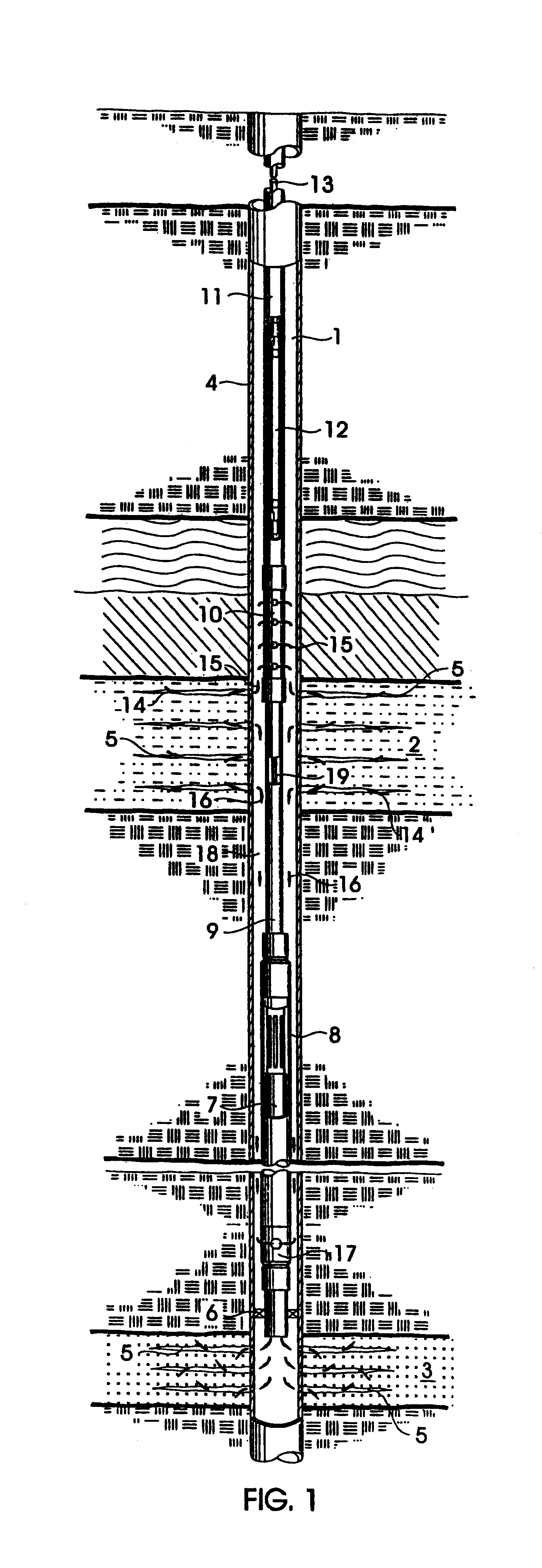

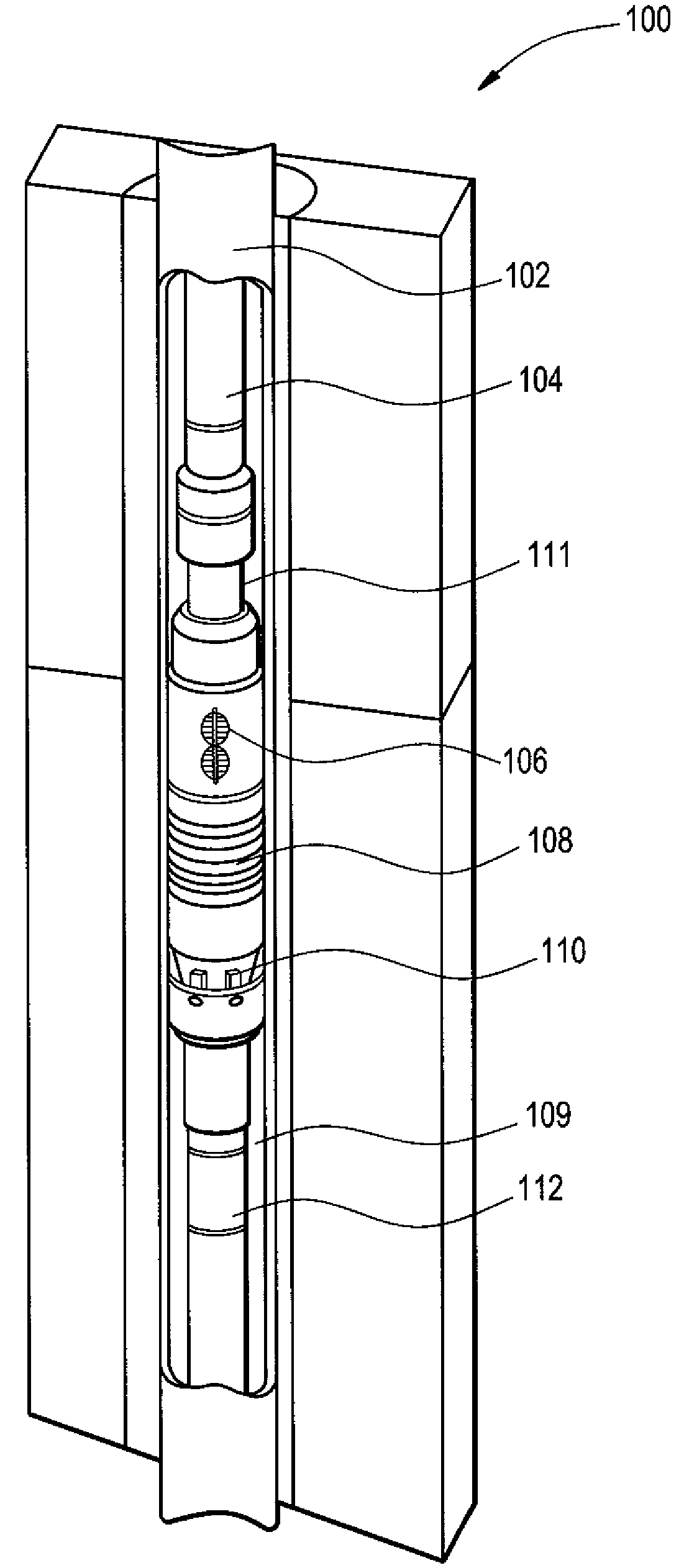

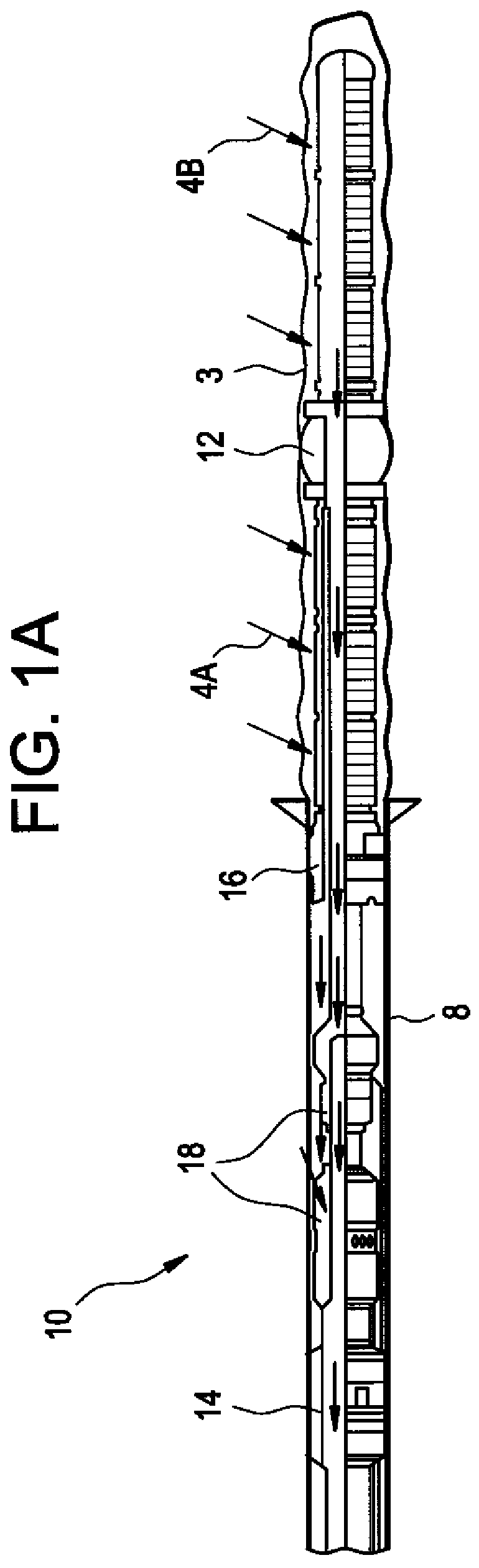

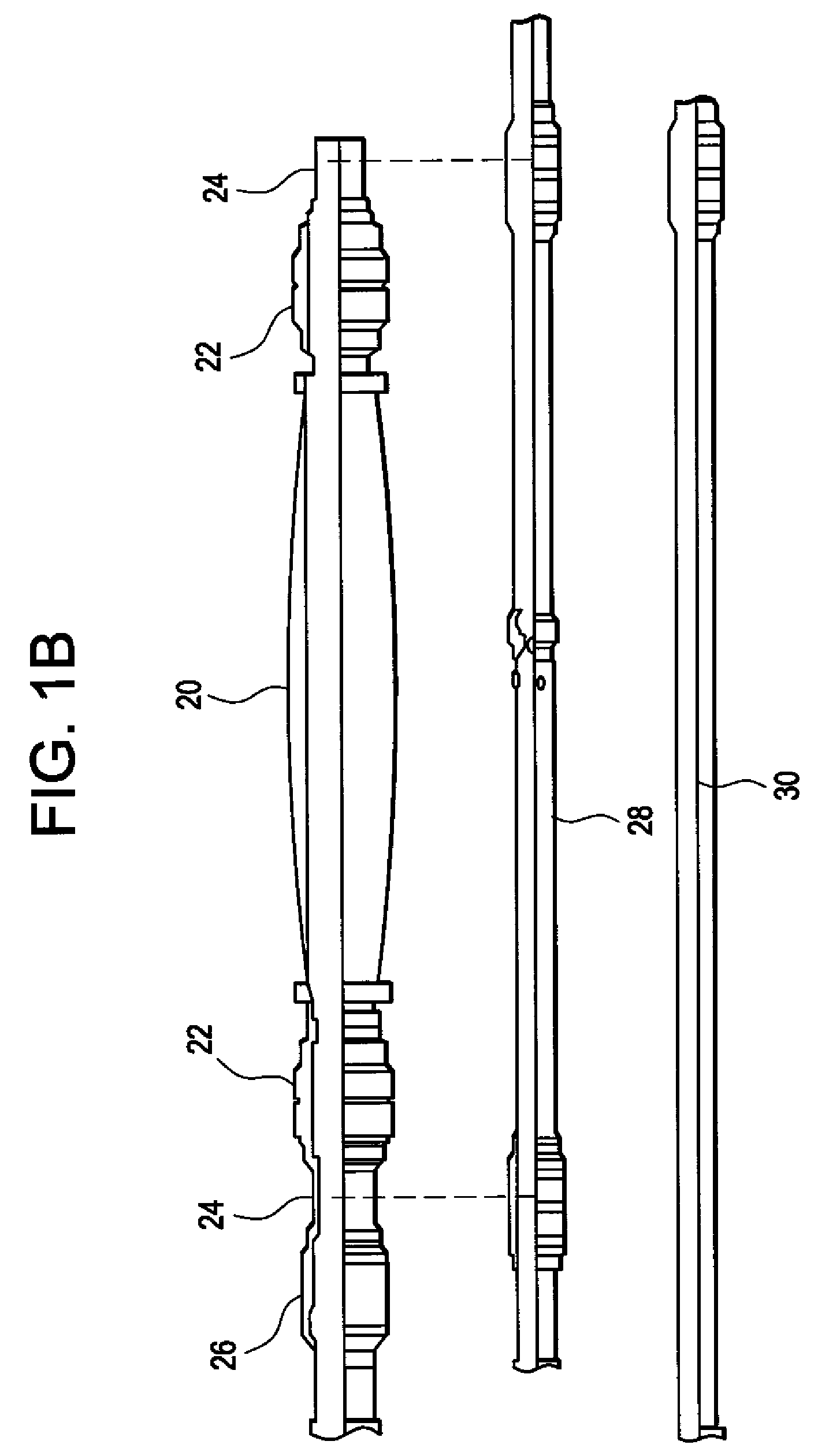

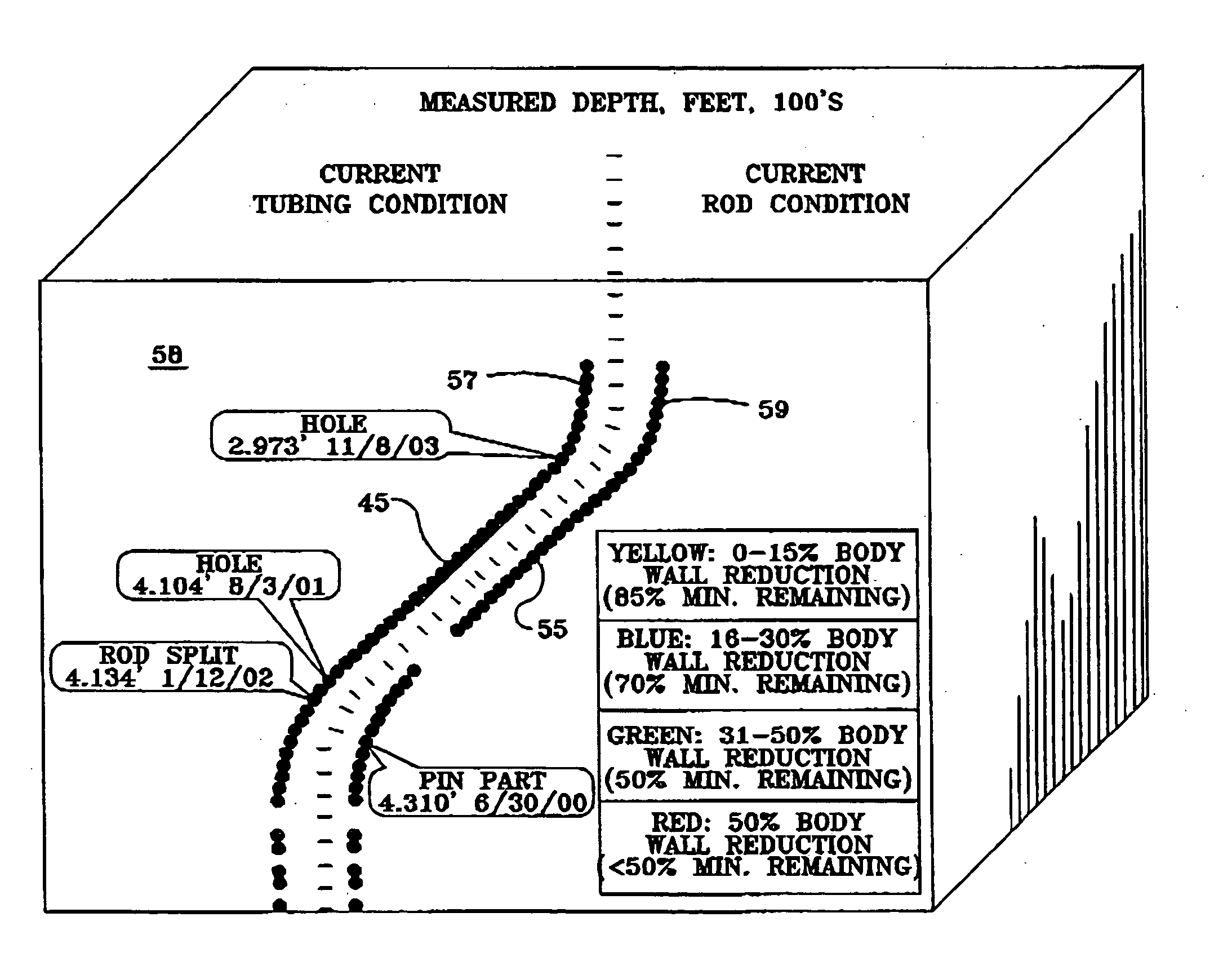

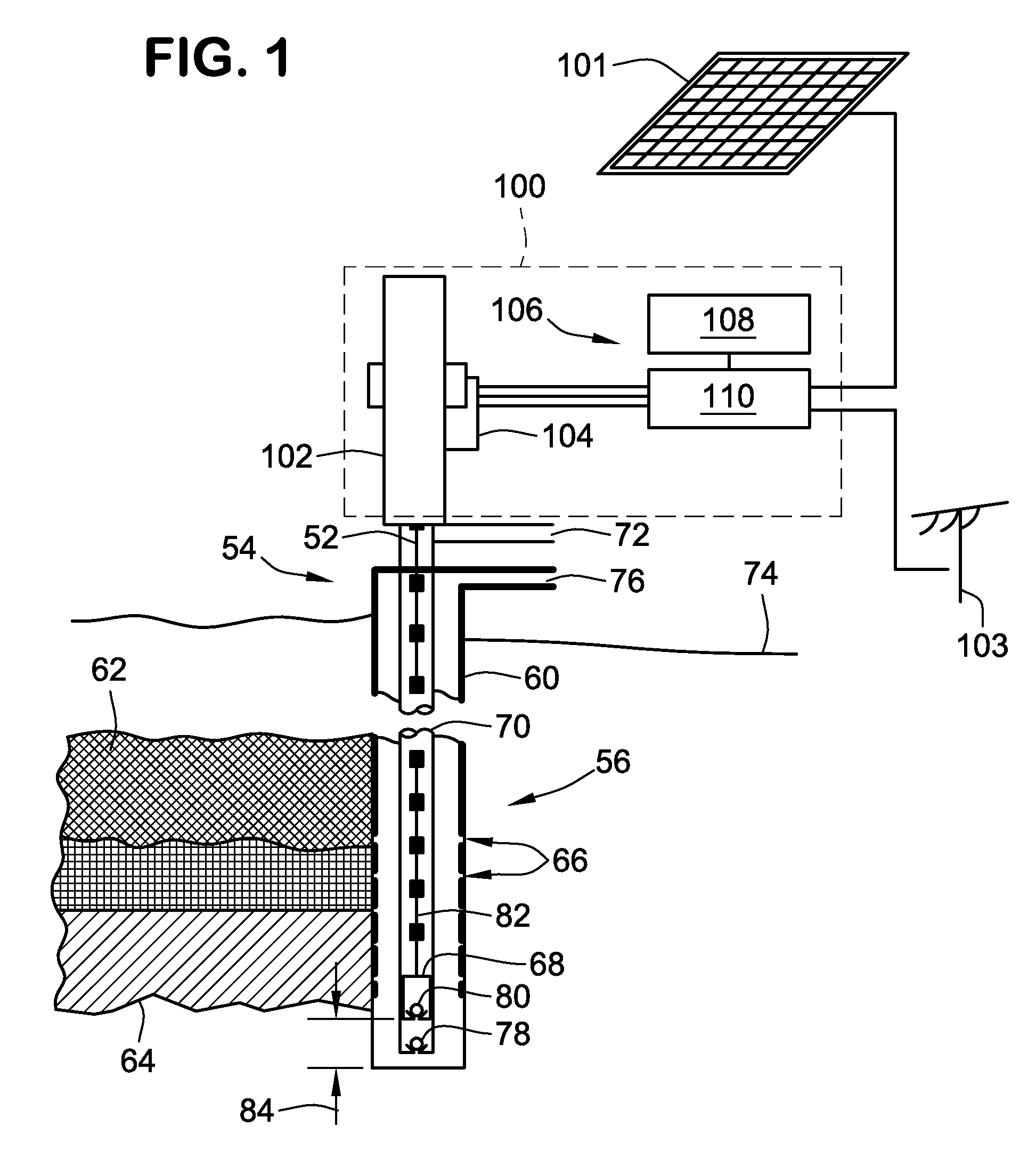

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the production tubing string in the well, and a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile. A data acquisition computer is in communication with the sensors for computing and comparing the deviation profile and the rod profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

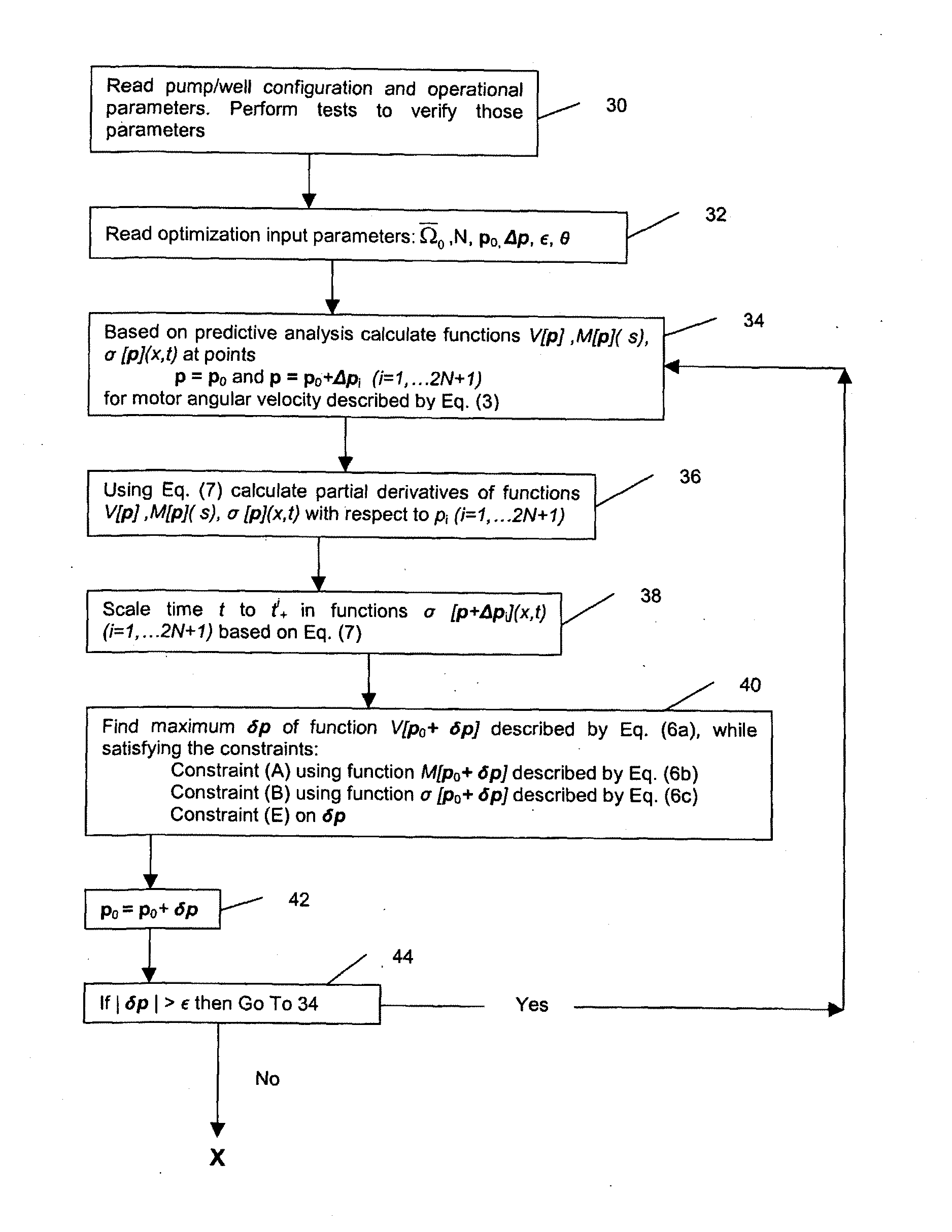

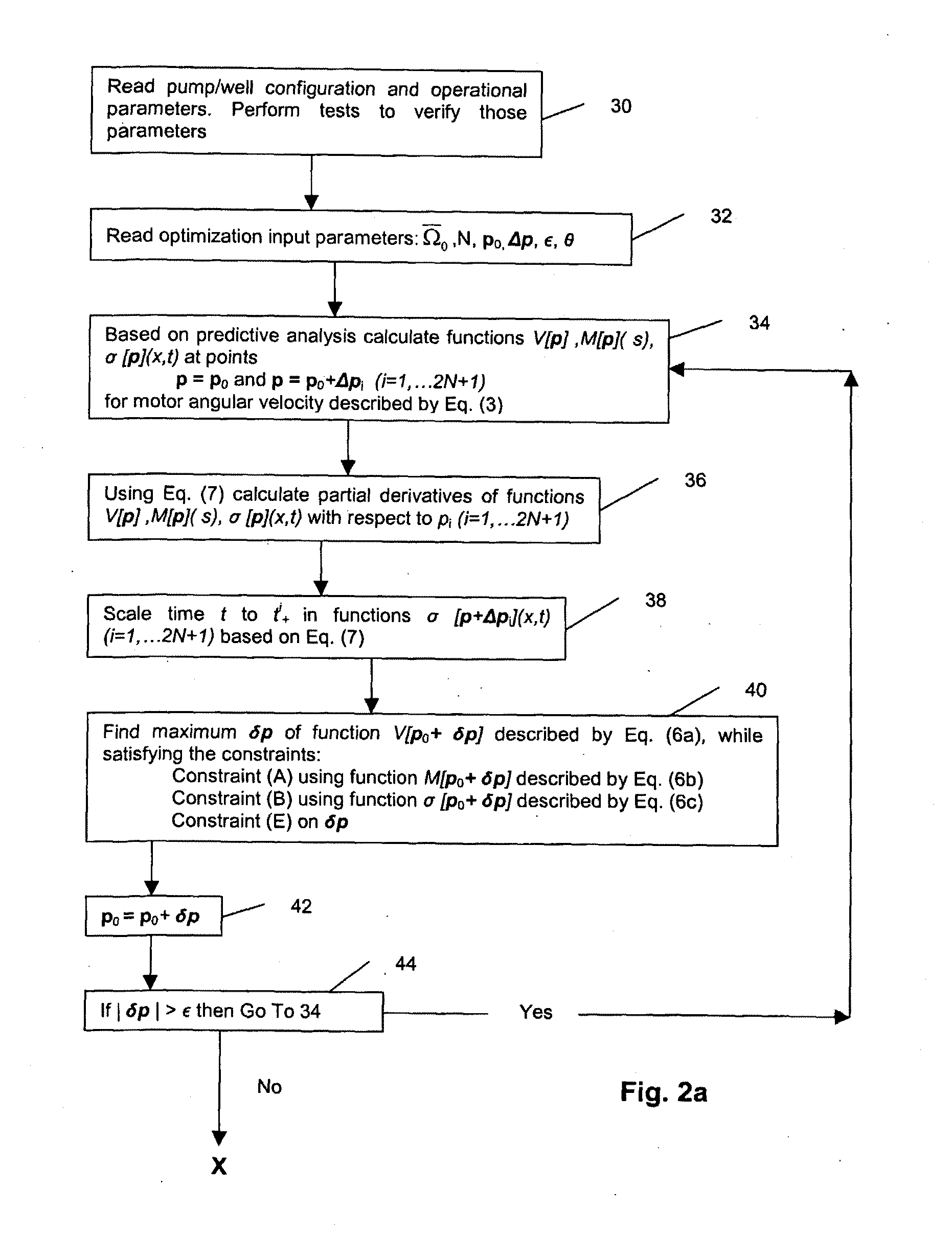

Method and System for Optimizing Downhole Fluid Production

InactiveUS20080240930A1Maximize oil productionReduce operating costsFluid parameterSurveyEngineeringUltimate tensile strength

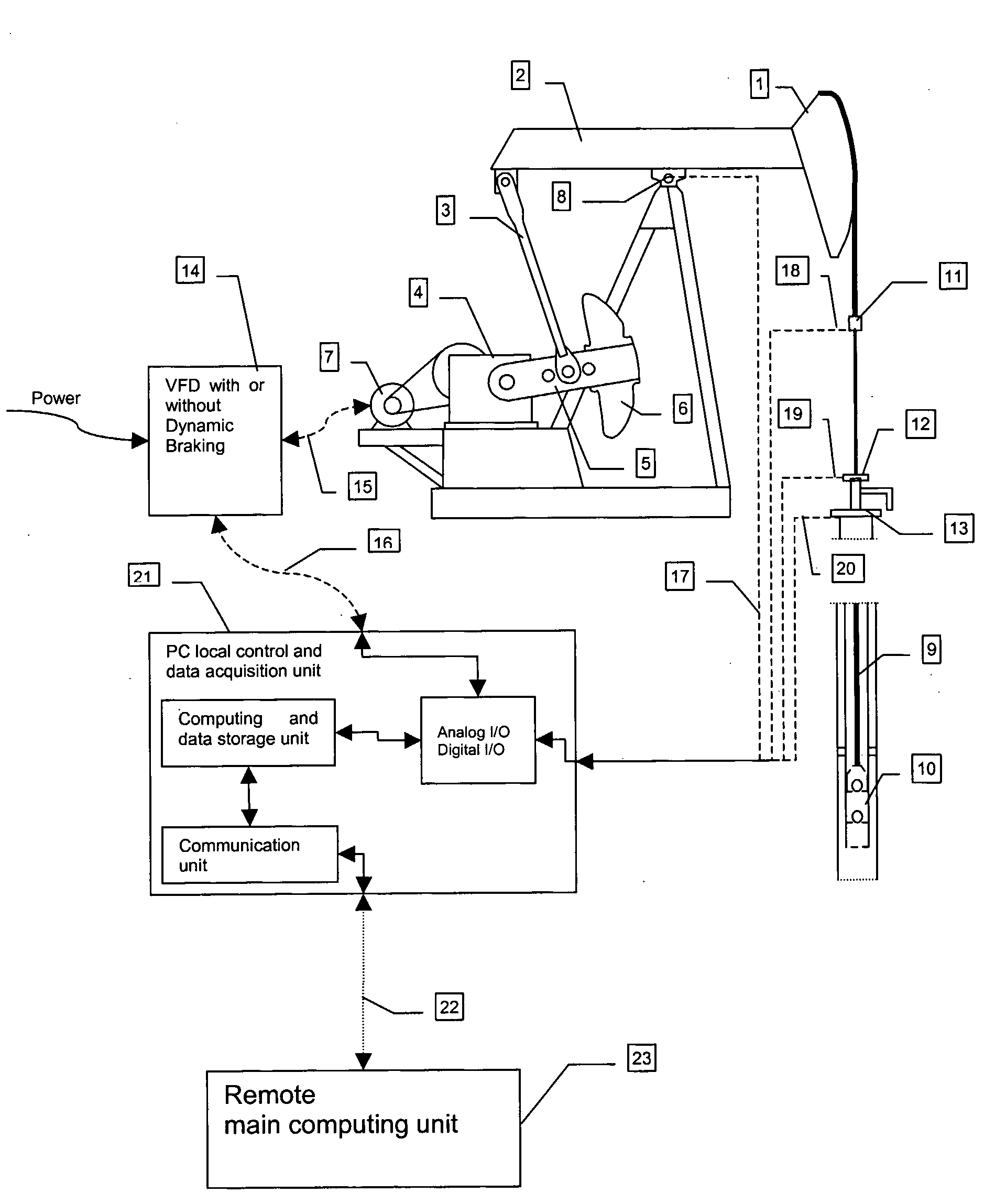

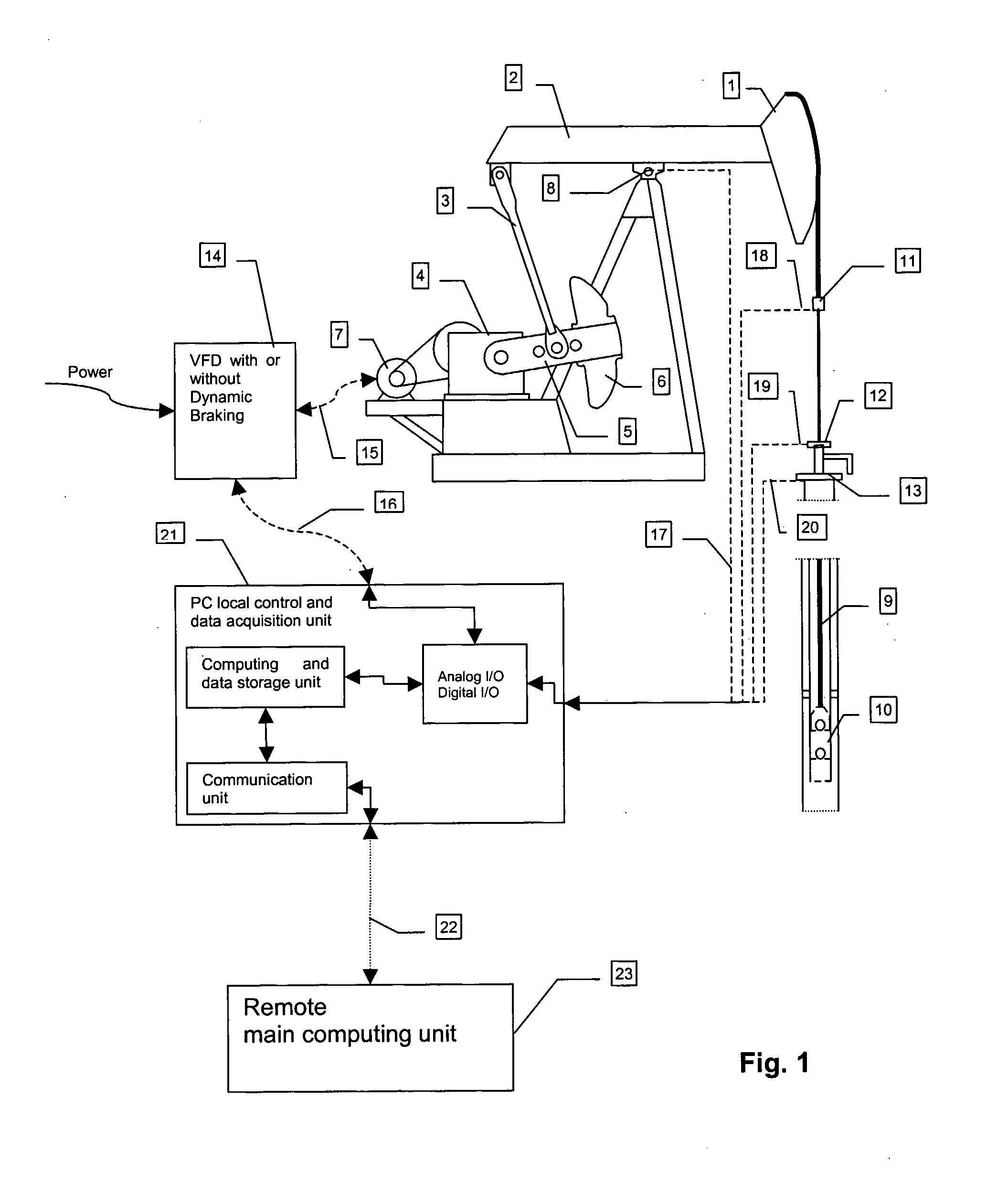

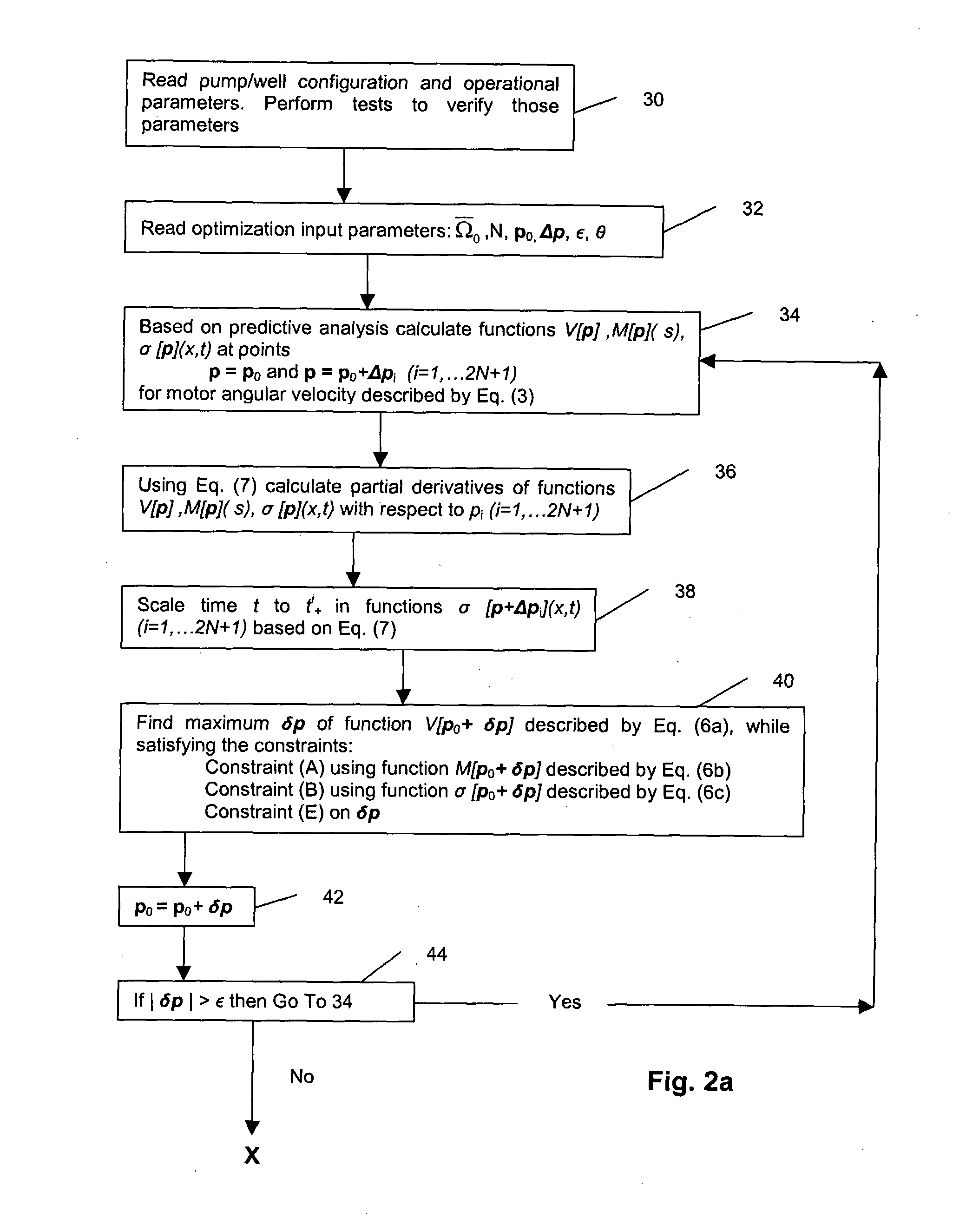

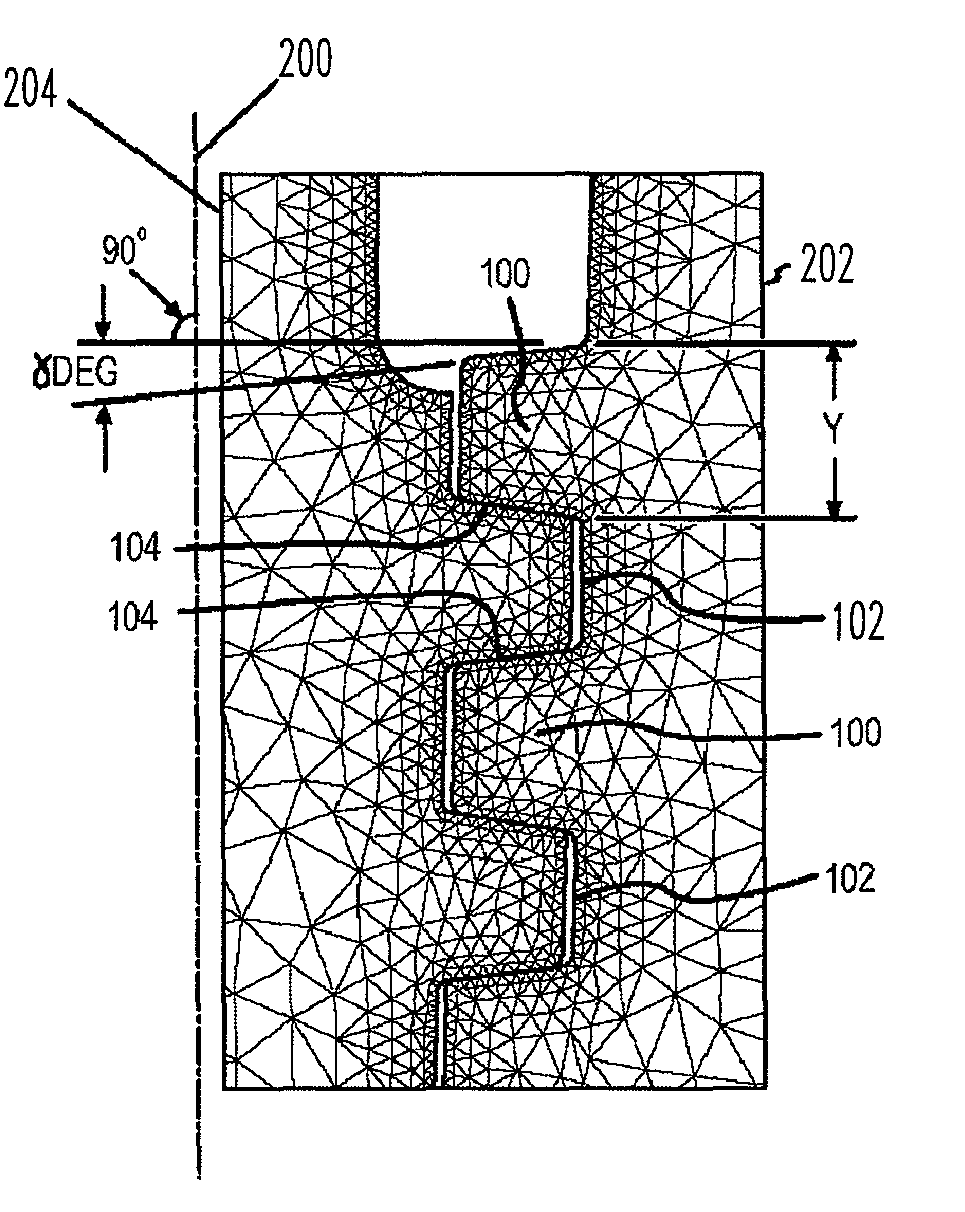

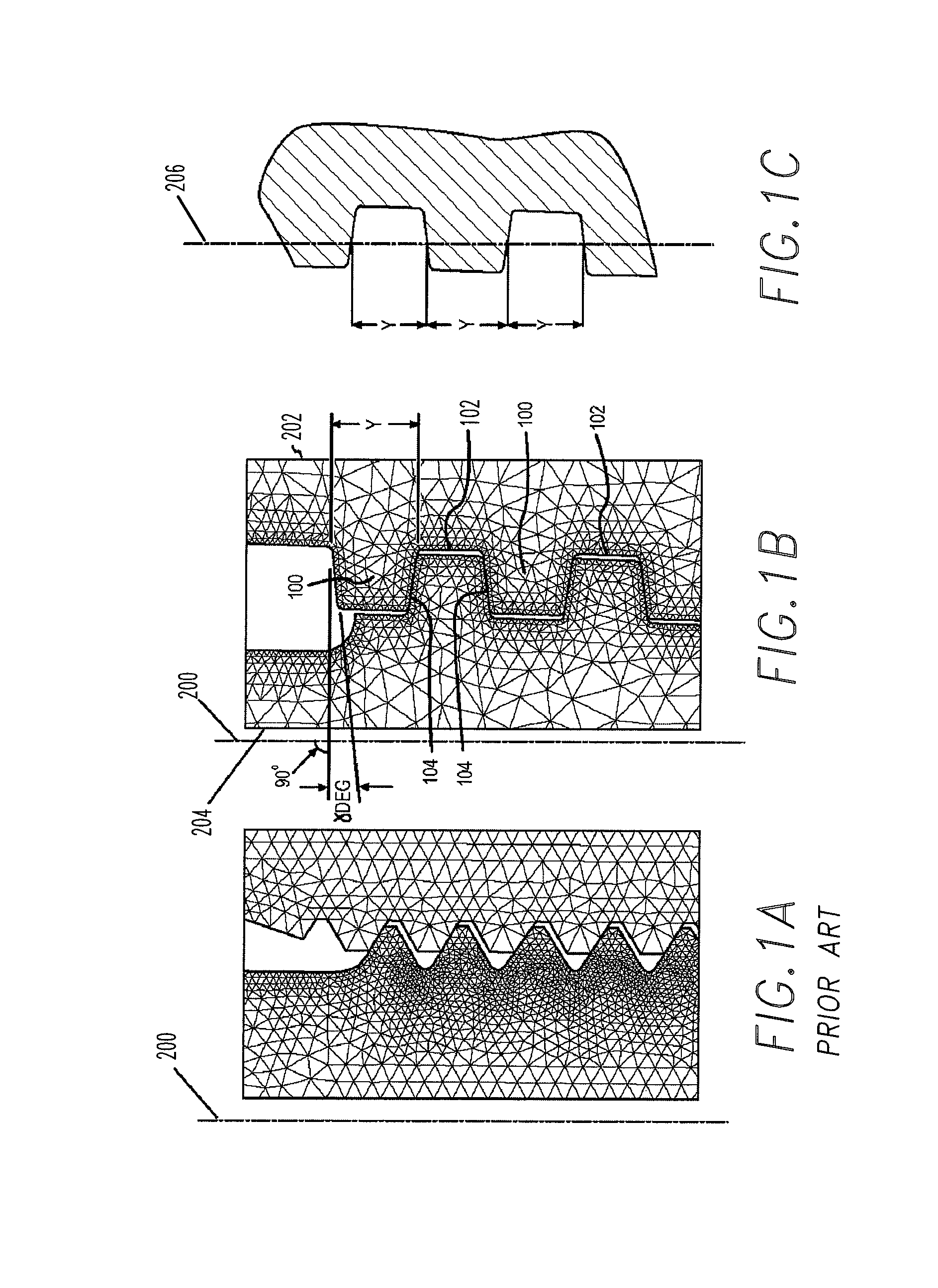

A method and system for pumping unit with an elastic rod system is applied to maximize fluid production. The maximum stroke of the pump and the shortest cycle time are calculated based on all static and dynamic properties of downhole and surface components without a limitation to angular speed of the prime mover. Limitations of structural and fatigue strength are incorporated into the optimization calculation to ensure safe operation while maximizing pumped volume and minimizing energy consumption. Calculated optimal prime mover speed is applied to the sucker rod pump by means of beam pumping, long stroke or hydraulic pumping unit by controlling velocity, acceleration and torque of the electric prime mover or by controlling pressure and flow rate in hydraulically actuated sucker rod pumping system.

Owner:PUMPWELL SOLUTIONS

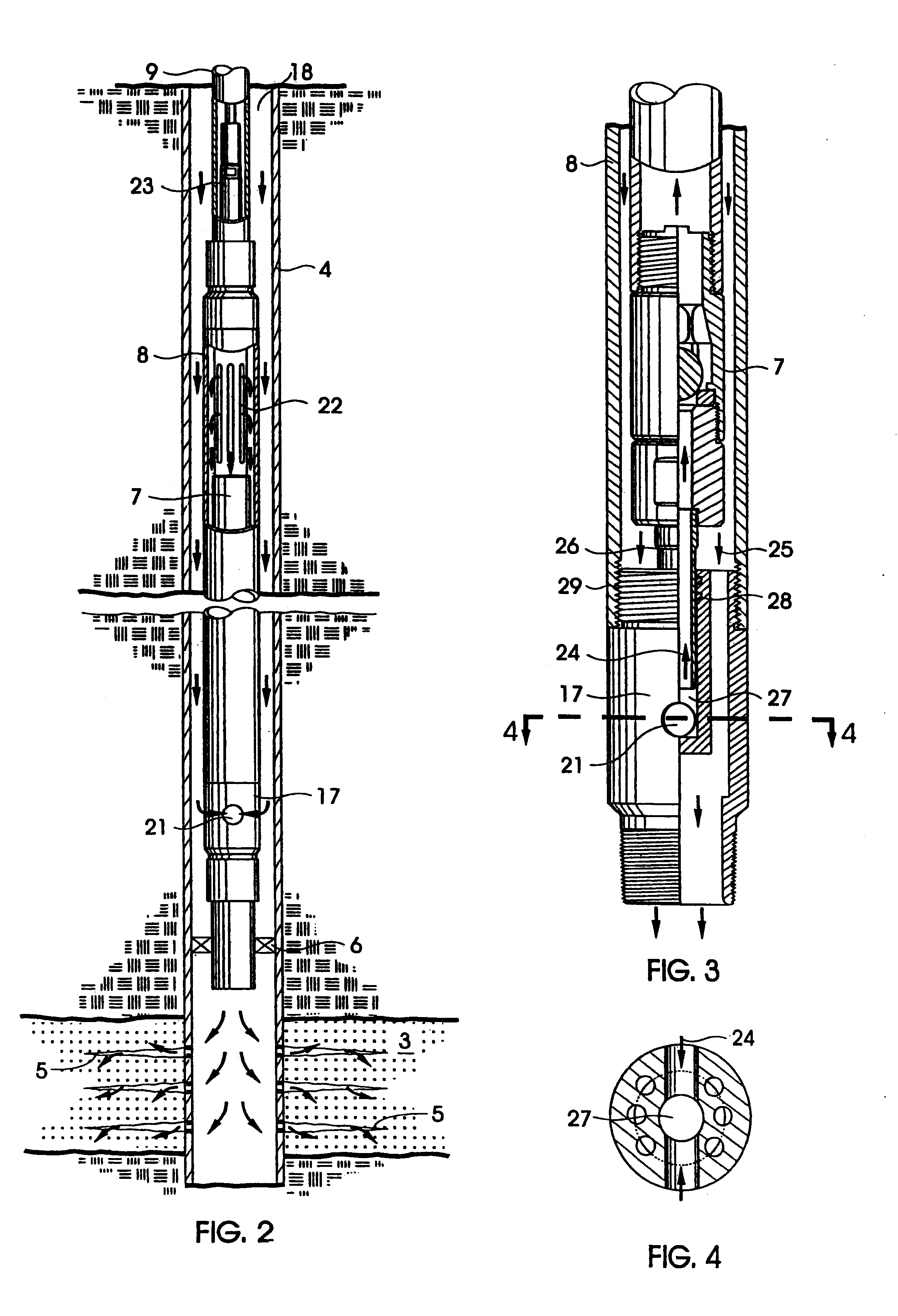

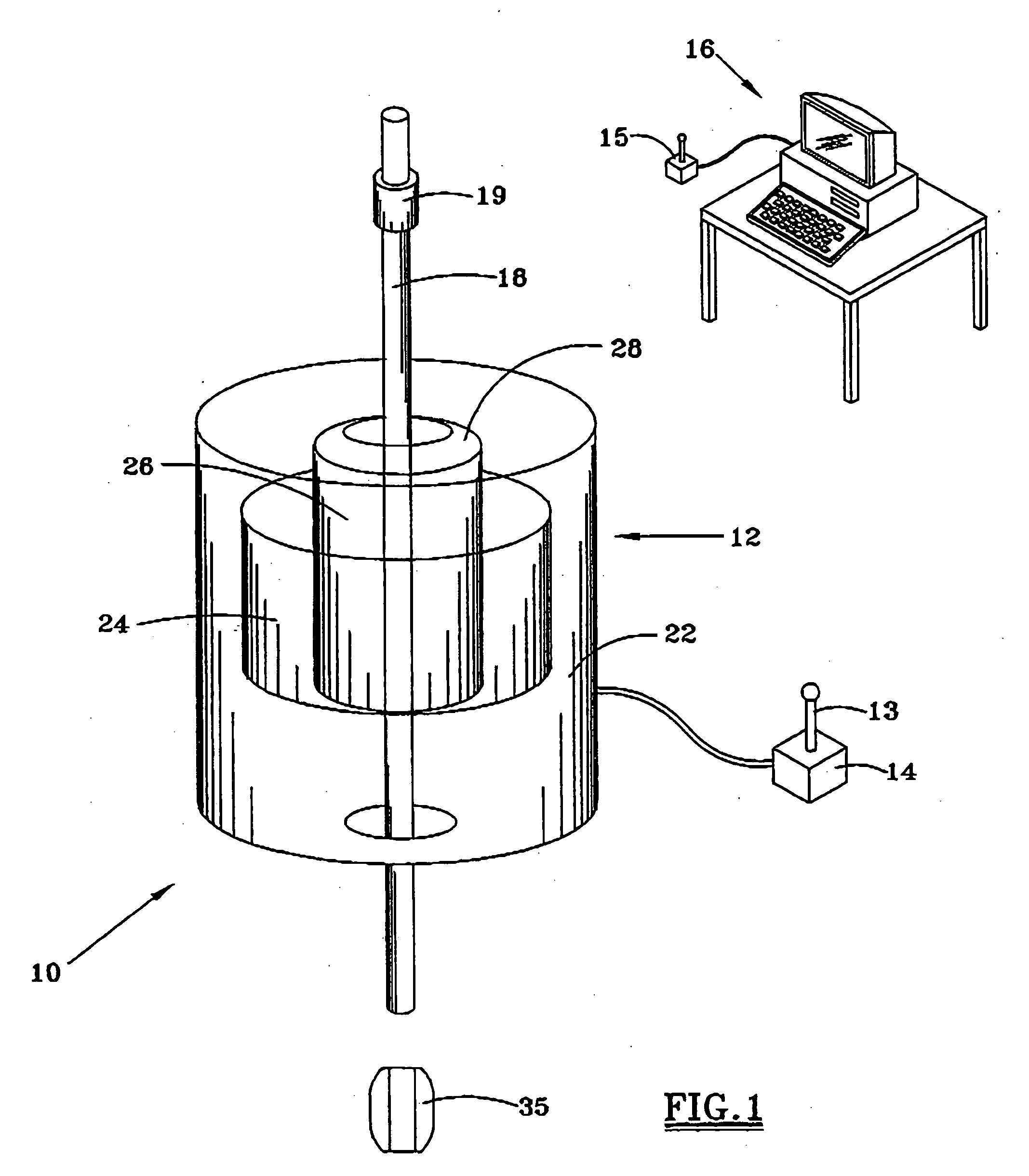

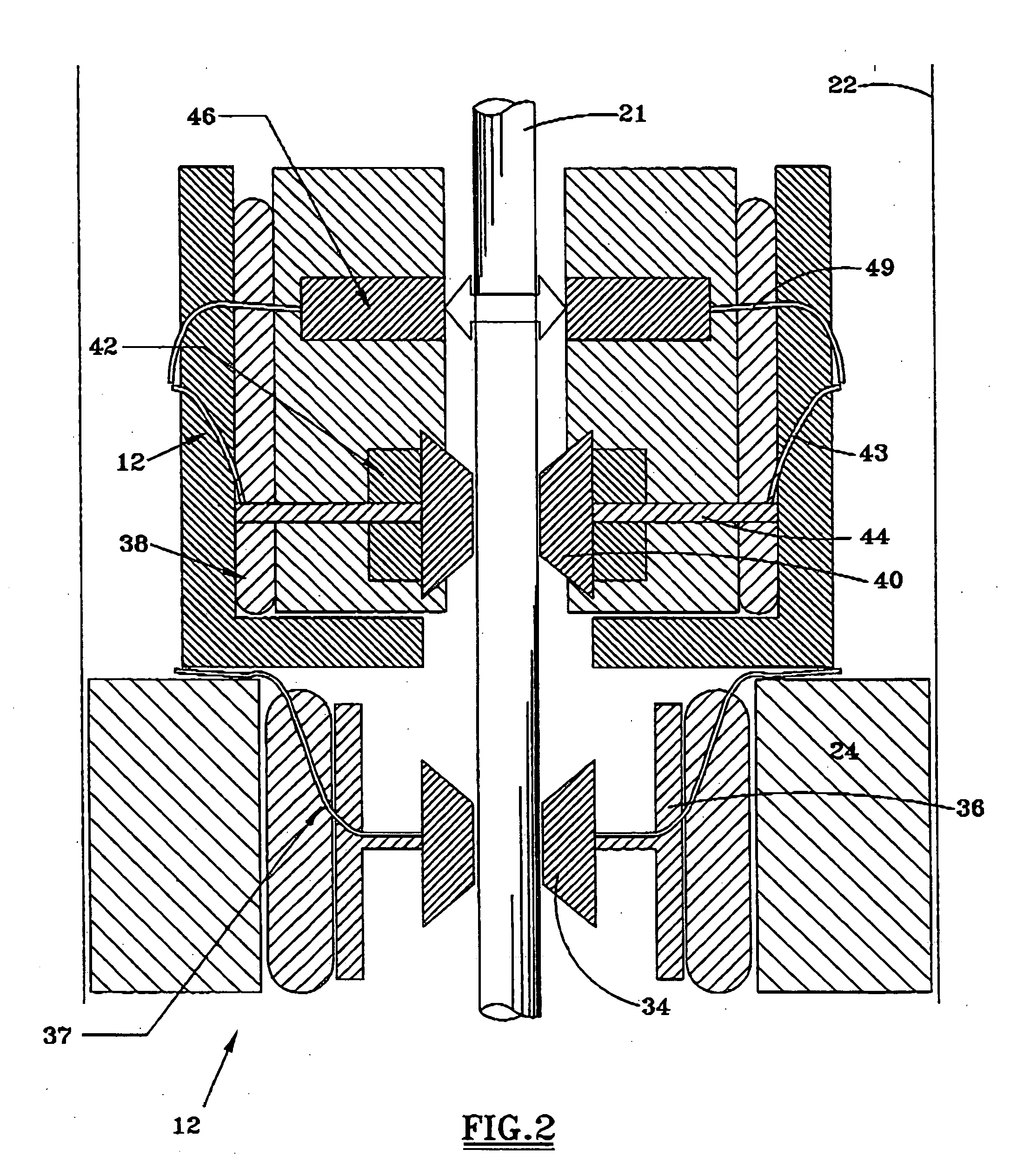

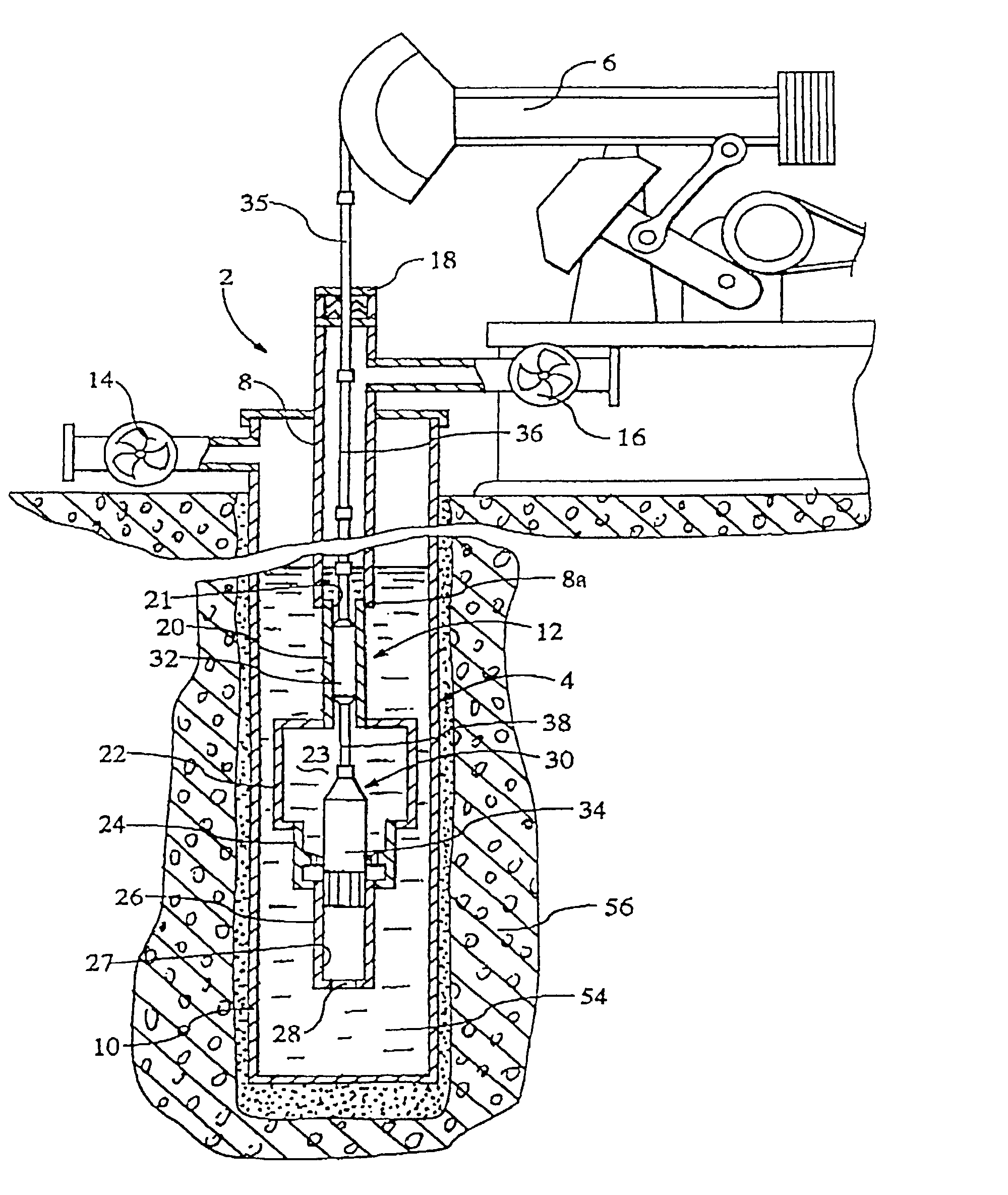

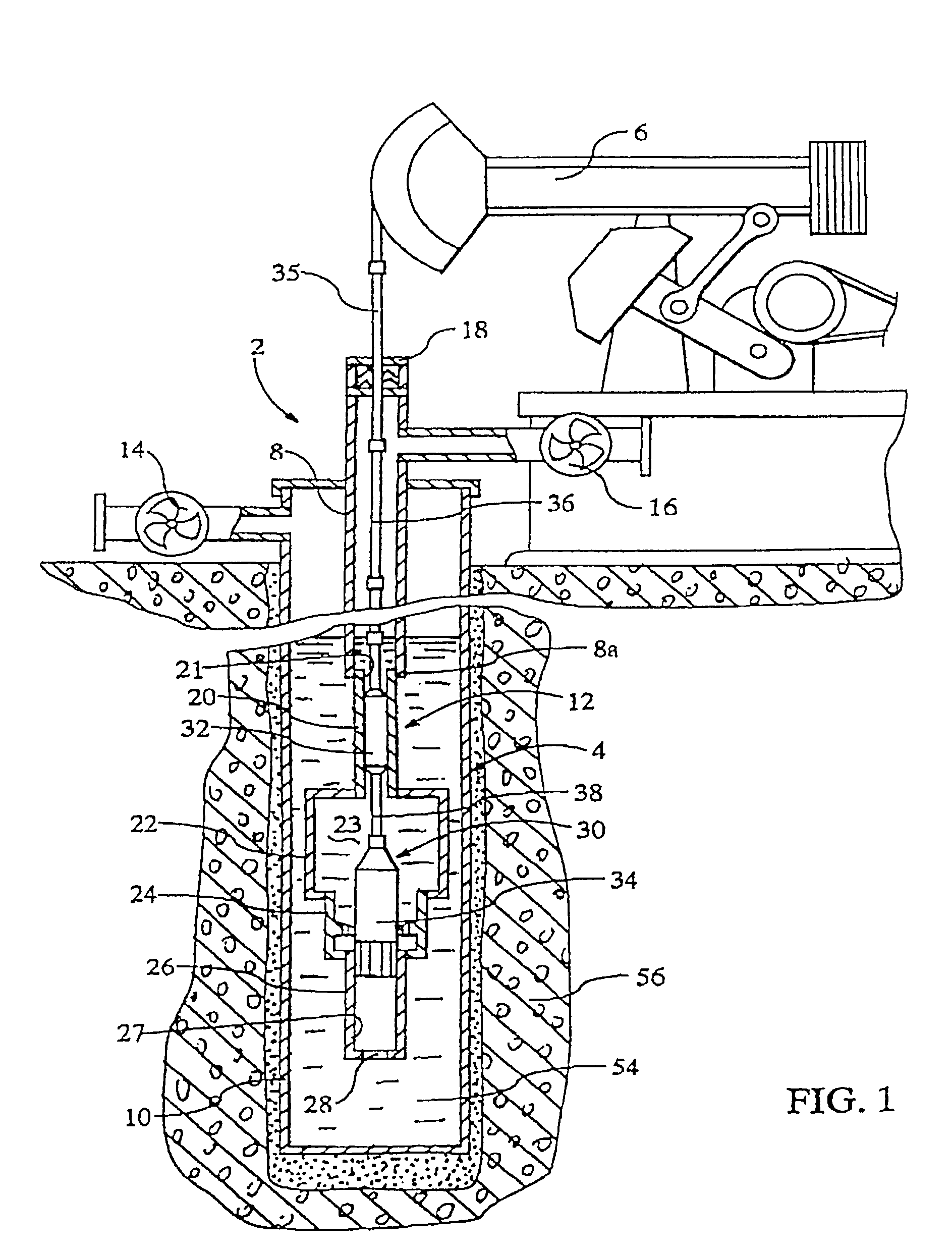

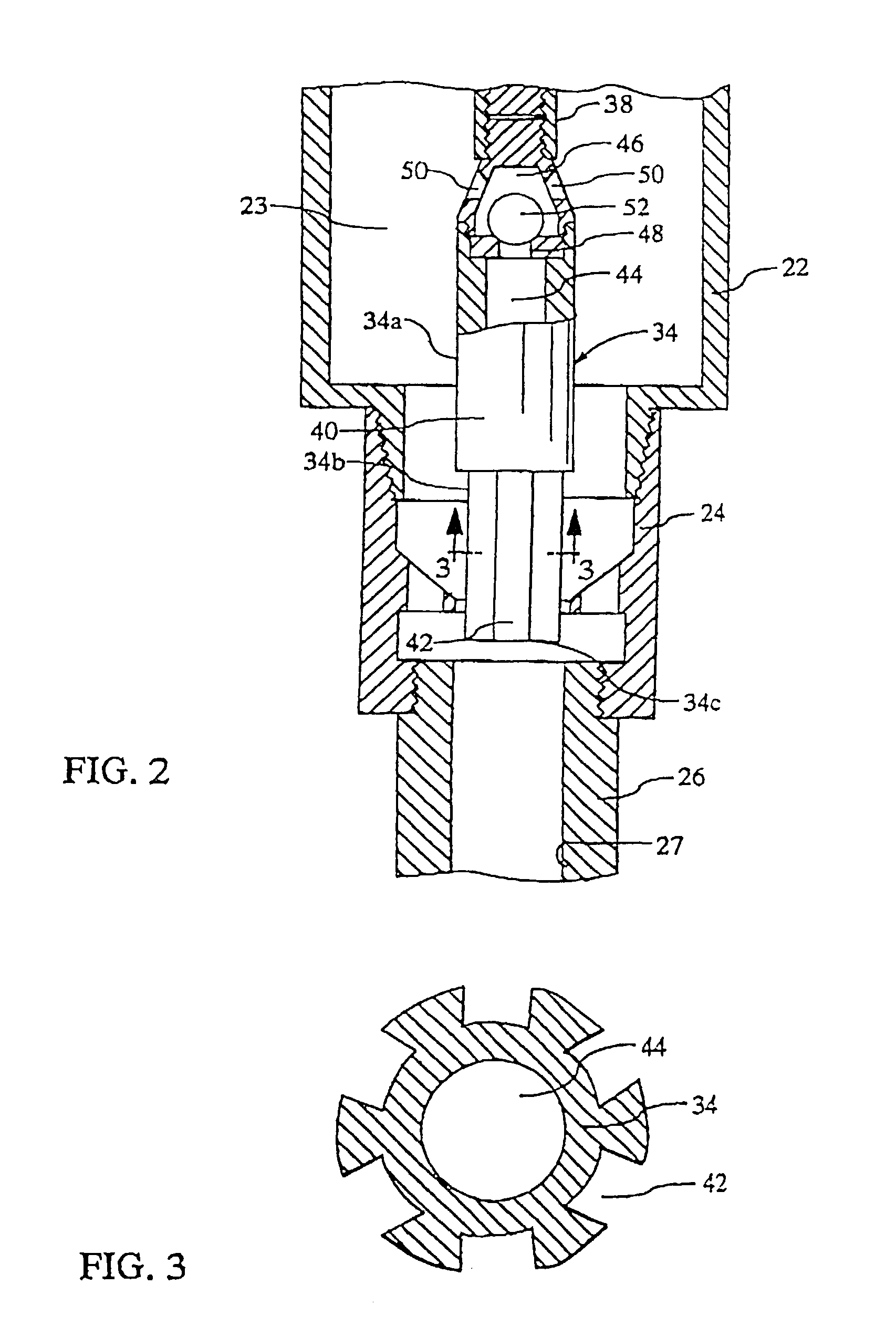

Dual pump gravity separation system

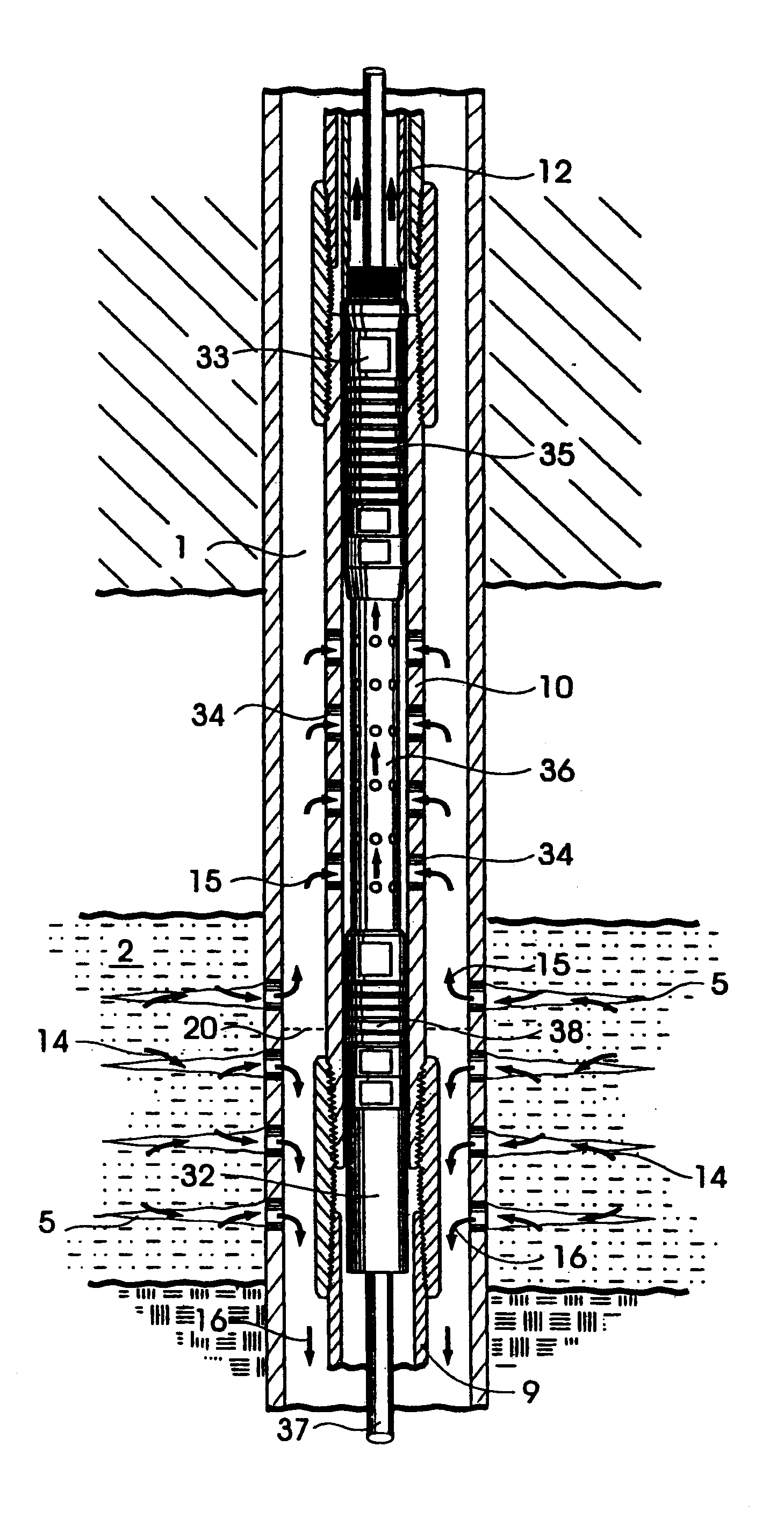

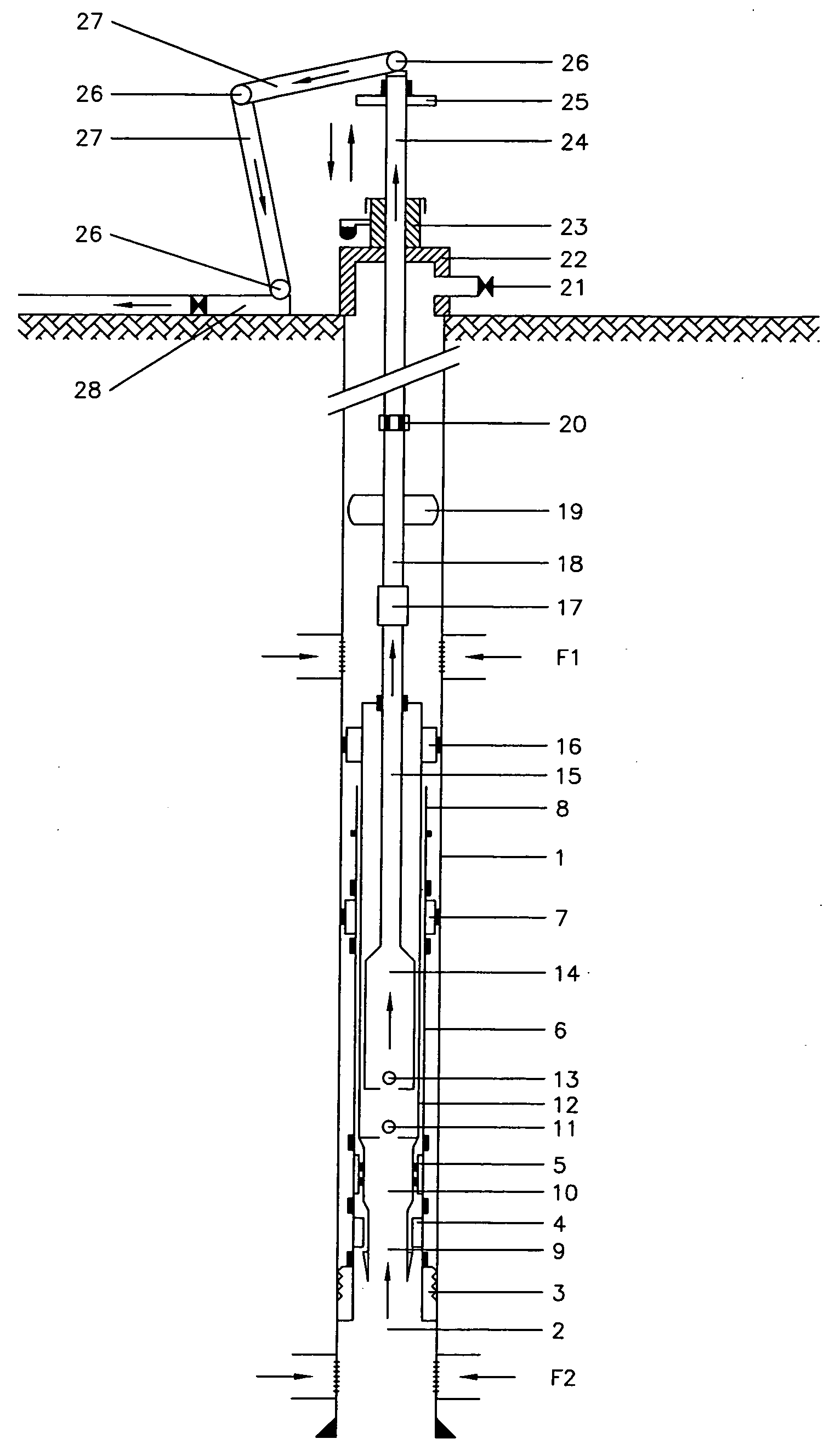

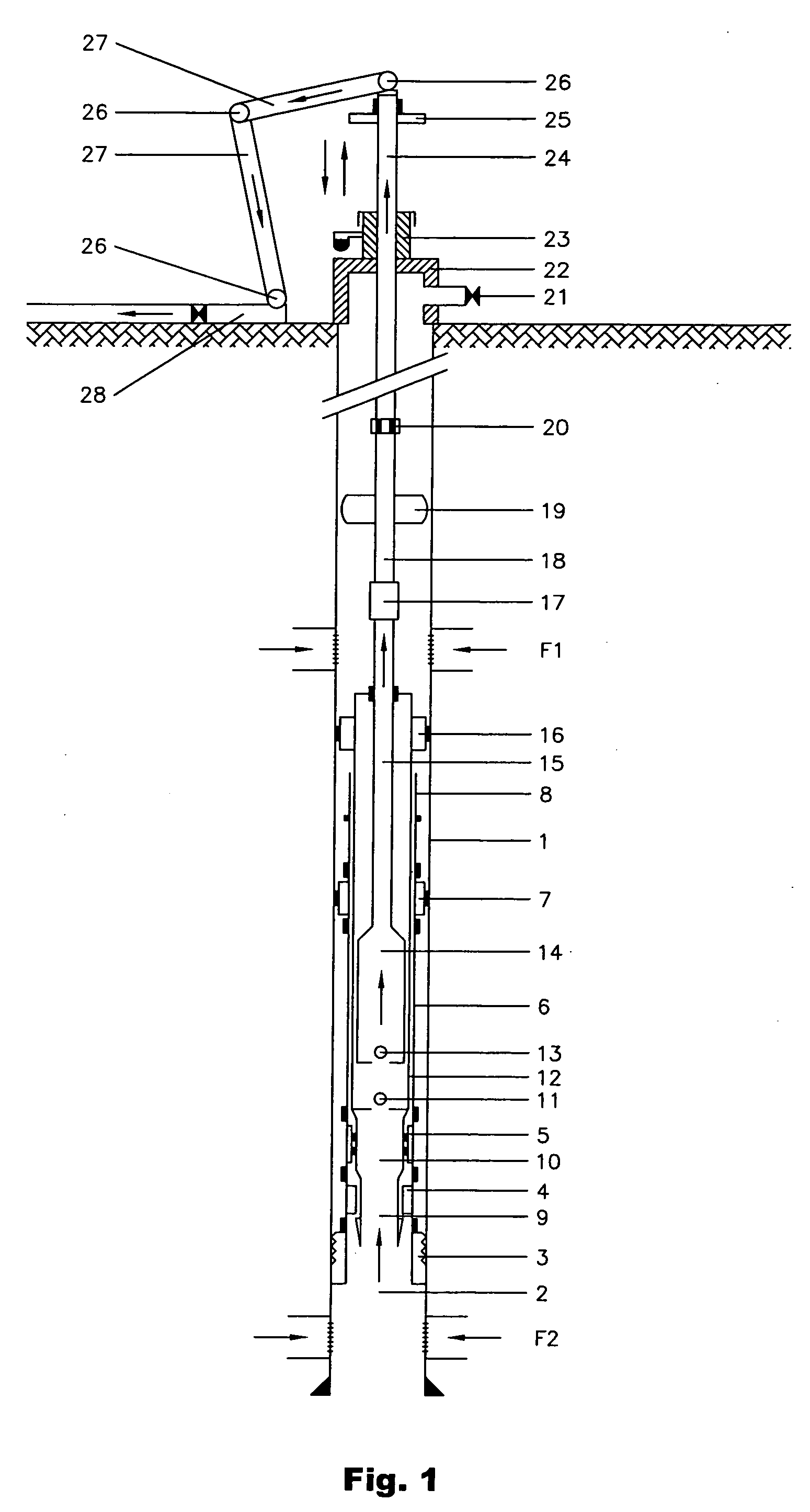

A system of reciprocating bottom hole sucker rod pumps, situated in an oil well, to produce an oil rich stream to surface and inject a water stream to a same wellbore disposal zone. Two pumps vertically in tandem are actuated by a single sucker rod string. Separate intakes for each pump are situated so as to allow for gravity to segregate oil and water in the wellbore before reaching the intakes. Both streams are produced out of the pumps on the upstroke. Injection of the water stream is facilitated by an outer housing around the bottom pump to redirect flow to a disposal zone.

Owner:QUINNS OILFIELD SUPPLY +1

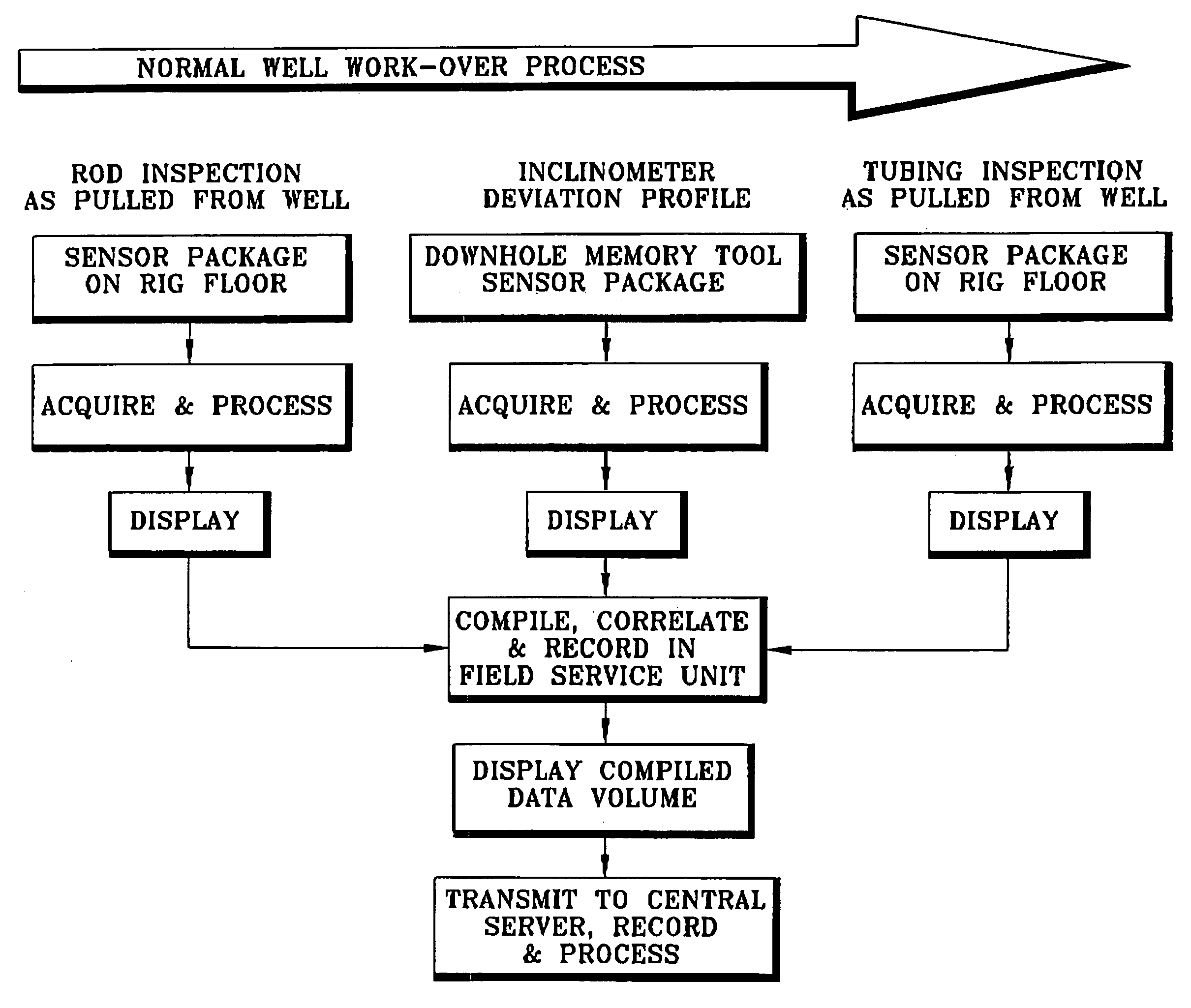

Wellbore evaluation system and method

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the well, a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile, and a tubing sensor senses and measures wear and corrosion to the production tubing string as it is removed from the well to determine a tubing profile. A data acquisition computer is in communication with the sensors for computing and comparing two or more of the respective deviation profile, rod profile, and tubing profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

Oilfield apparatus comprising swellable elastomers having nanosensors therein and methods of using same in oilfield application

An oilfield apparatus has a swellable elastomeric composition that includes a swellable elastomer and one or more nanosensors dispersed therein. An oilfield assembly for exploring for, drilling for, testing for, or producing hydrocarbons includes various oilfield elements such as tubing, jointed pipe, sucker rods, submersible pump motor protector bags, packer elements, blow out preventer elements, zonal isolation tool elements, etc; and one or more of the oilfield elements has a swellable elastomeric composition that includes a swellable elastomer and one or more nanosensors dispersed therein. A method of selecting one or more oilfield elements has a component of an elastomeric composition that includes a swellable elastomer and one or more nanosensors dispersed therein; and a method of using the one or more oilfield elements in an oilfield operation, thus exposing the oilfield element to an oilfield environment.

Owner:SCHLUMBERGER TECH CORP

Wellbore evaluation system and method

ActiveUS20050267686A1Electric/magnetic detection for well-loggingSurveySection planeData acquisition

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the well, a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile, and a tubing sensor senses and measures wear and corrosion to the production tubing string as it is removed from the well to determine a tubing profile. A data acquisition computer is in communication with the sensors for computing and comparing two or more of the respective deviation profile, rod profile, and tubing profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

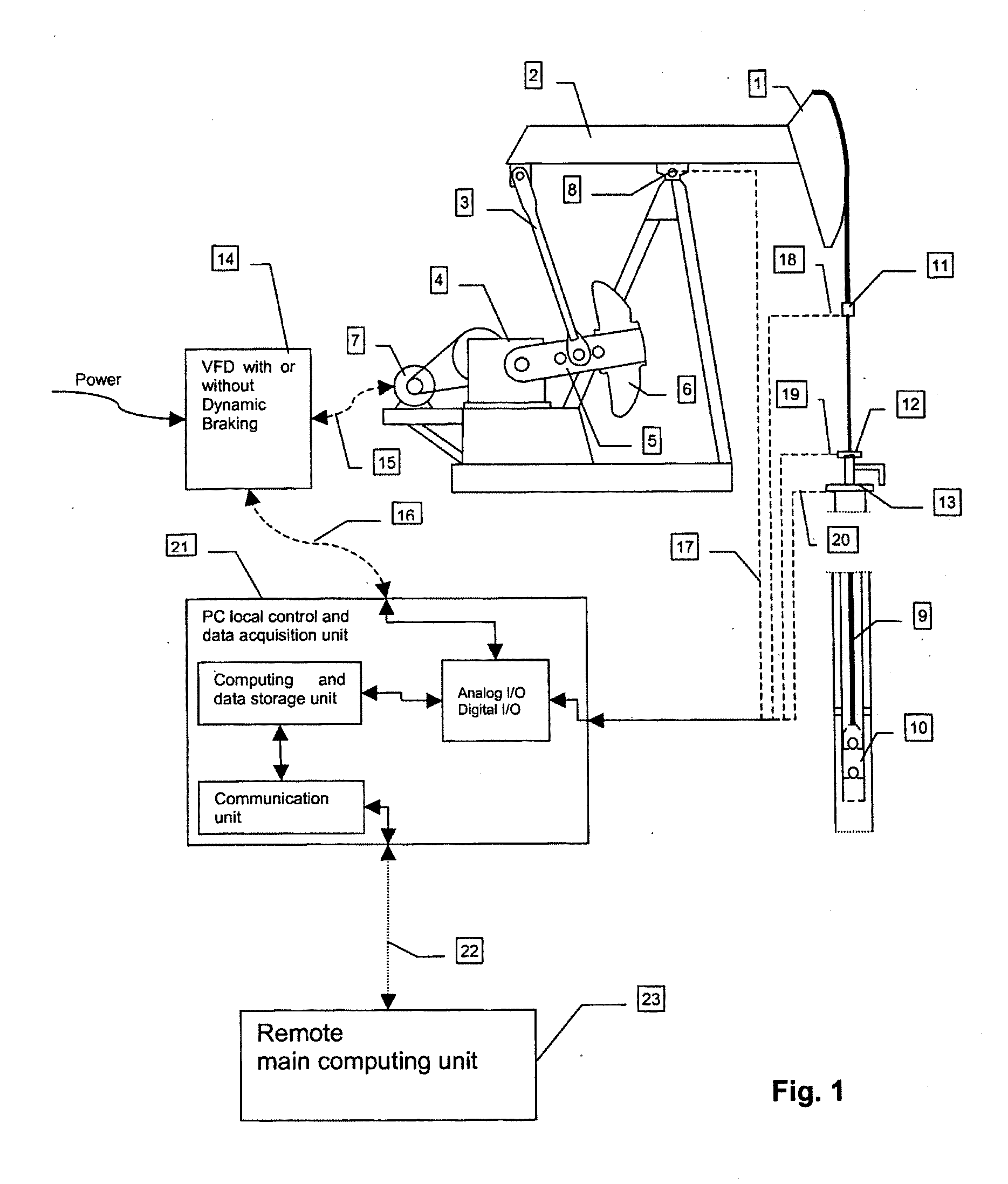

Method and system for optimizing downhole fluid production

ActiveUS20130151216A1Maximize productionReduce operating costsFluid parameterConstructionsEngineeringCycle time

A method and system for pumping unit with an elastic rod system is applied to maximize fluid production. The maximum stroke of the pump and the shortest cycle time are calculated based on all static and dynamic properties of downhole and surface components without a limitation to angular speed of the prime mover. Limitations of structural and fatigue strength are incorporated into the optimization calculation to ensure safe operation while maximizing pumped volume and minimizing energy consumption. Calculated optimal prime mover speed is applied to the sucker rod pump by means of beam pumping, long stroke or hydraulic pumping unit by controlling velocity, acceleration and torque of the electric prime mover or by controlling pressure and flow rate in hydraulically actuated sucker rod pumping system.

Owner:AMBYINT INC

Continous sucker rod made of fiber reinforced composition and its making method

InactiveCN1461870AImprove the bonding force between layersImprove wear resistanceDrilling rodsLayered productsGlass fiberPolymer science

A continuous sucker rod made of fibre reinforced composition has a covered complex structure. Its covering layer uses the transversely arranged aramid fibres or ultrahigh-molecular polyethene fibres as weft and the glass fibres-aramid fibre or ultrahigh-molecular polyethene fibres band structure in longitudinal direction. Its preparing process includes such steps as dewinding fibres, surface treating, immersing in resin, covering solidifying, post-solidifying and twining. Its advantages are high strength and adhesion, and good antiwear nature.

Owner:胜利油田孚瑞特石油装备有限责任公司 +1

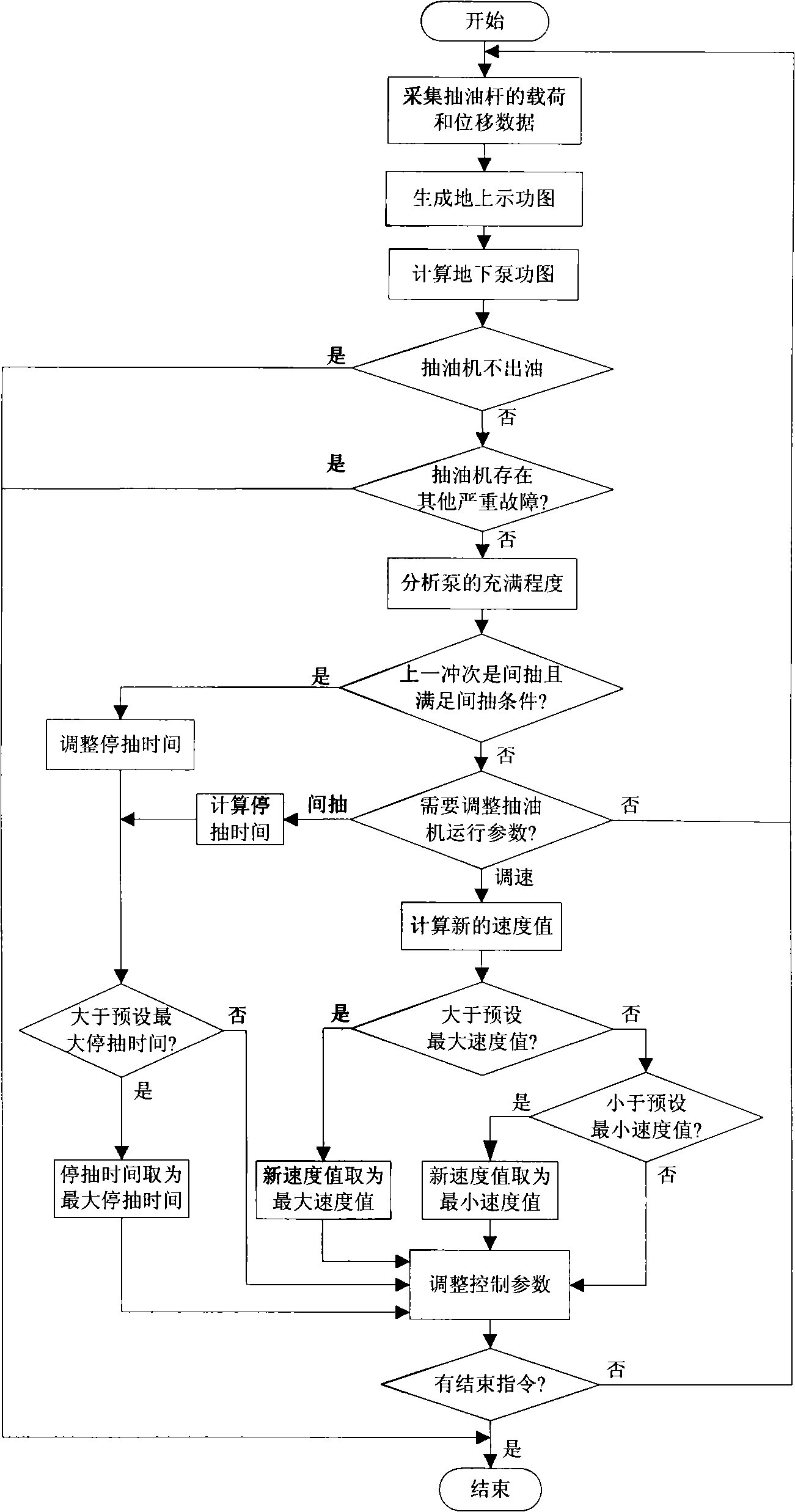

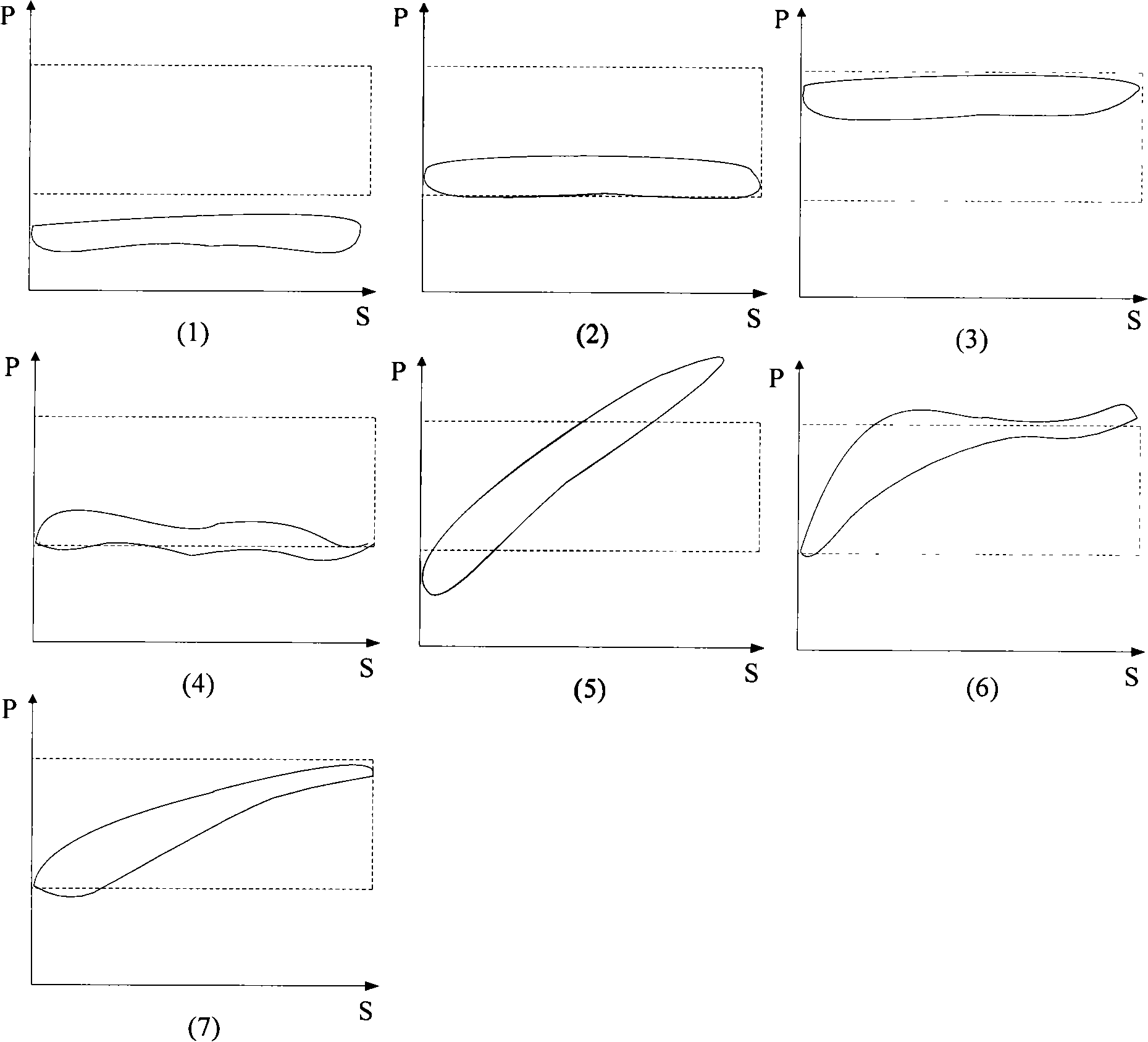

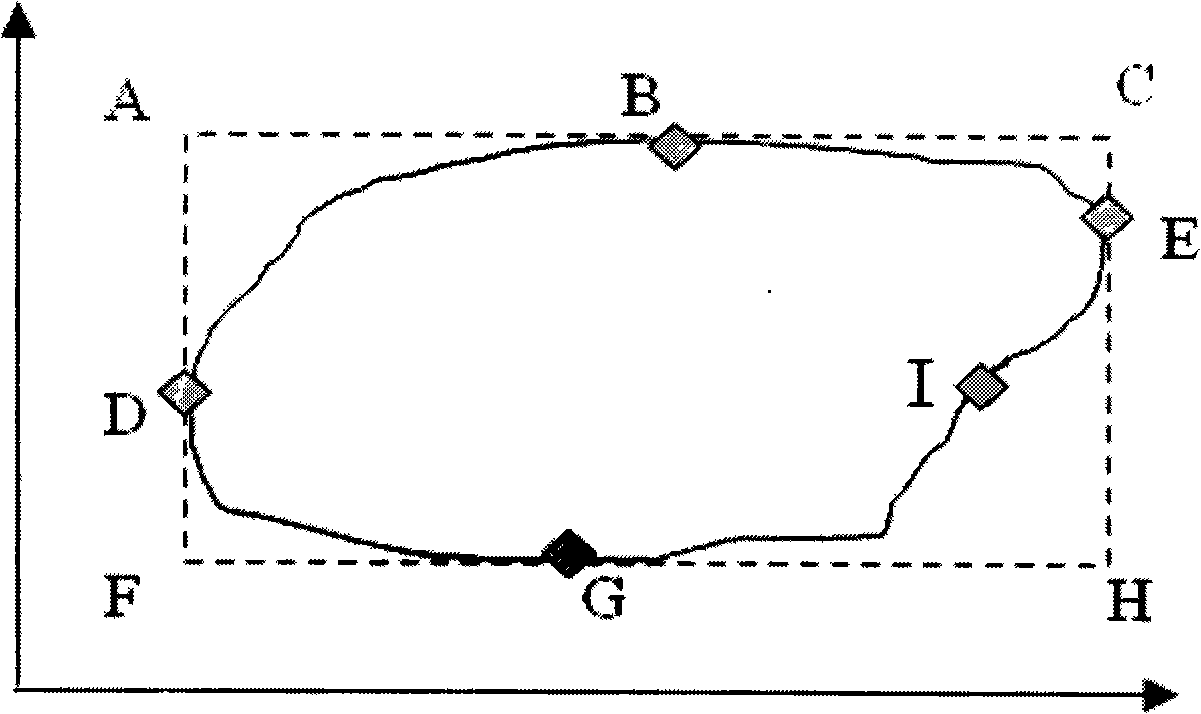

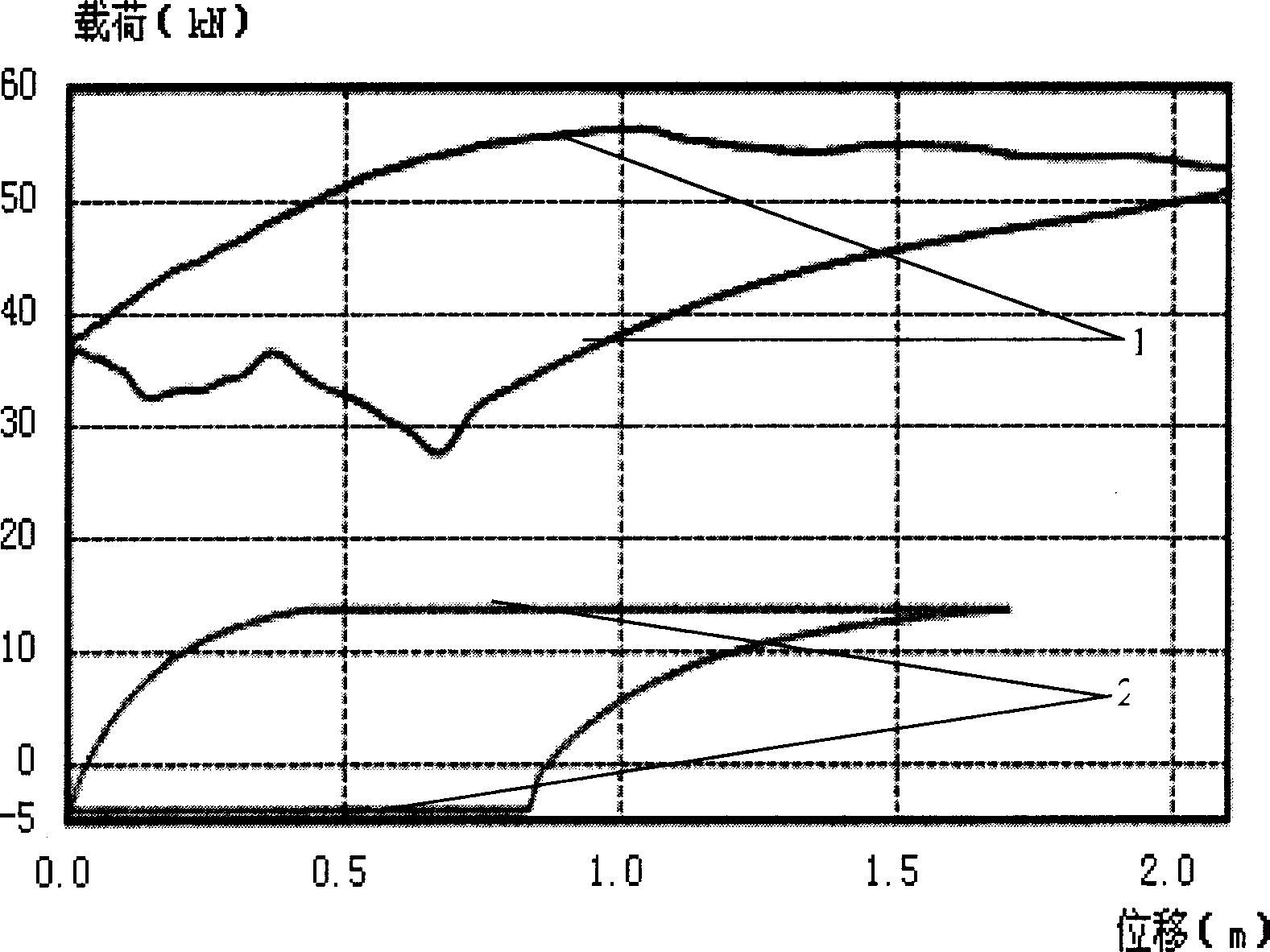

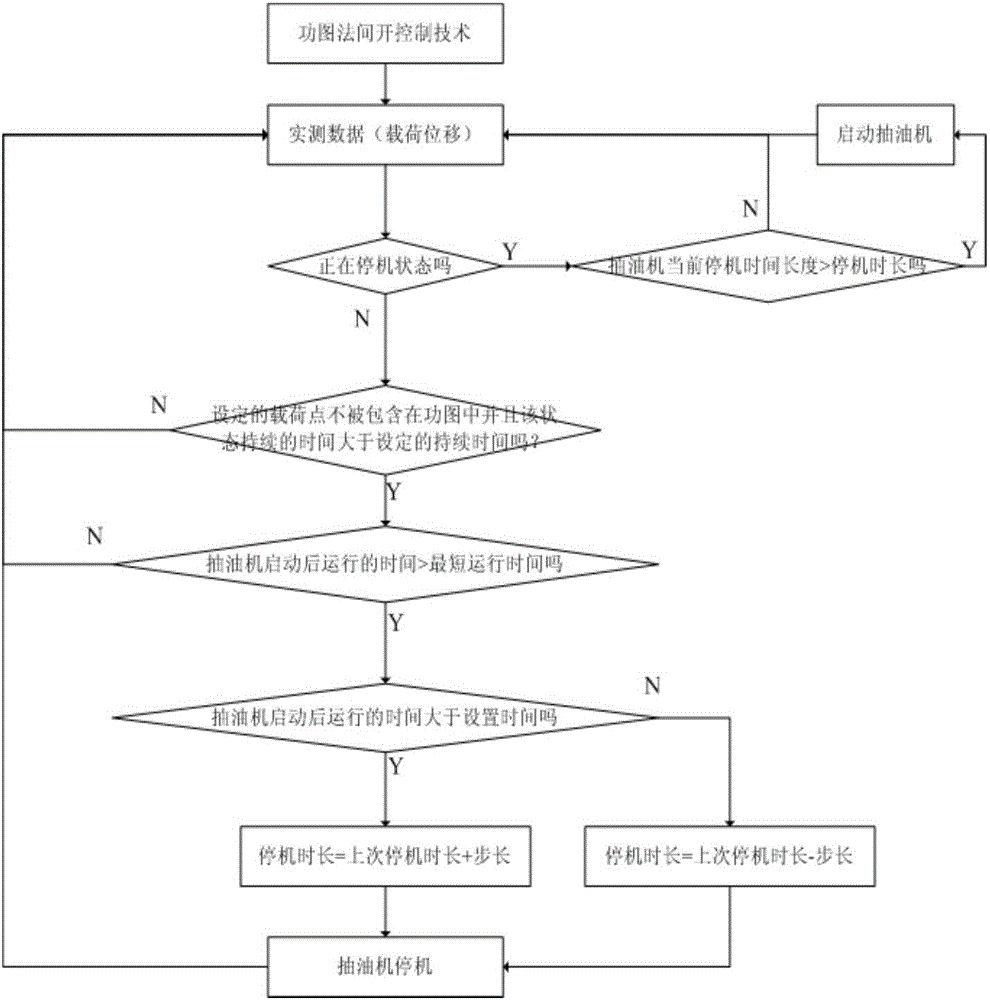

Sucker-rod pump oil pumping machine oil pumping control method and its system

InactiveCN101285463ASave electricityImprove pumping productivityElectric testing/monitoringPump controlPower diagramWave equation

The invention relates to a method and a system for oil pumping control of an oil pumping unit with a sucker rod pump. In the method, a ground indicating diagram is generated by collecting suspension center load and displacement data of the oil pumping unit; an underground pump power diagram is obtained by calculation according to a wave equation; according to the graphic characteristic of the pump power diagram, fuzzy logic is applied to carry out analysis and control to a traveling valve leakage loss and other pump working conditions; if serious fault occurs, the machine is stopped for detection; otherwise, operating parameters are adjusted according to the full degree of the pump obtained by analysis; if an indirect pumping condition is satisfied, the pumping stop time is calculated or adjusted for carrying out indirect pumping control; otherwise, a new stroke parameter is calculated according to the full degree of the pump. An ARM embedded type oil pumping controller adopting the method can combine the pump power diagram diagnosis with the real-time oil pumping control, realize fault protection, pumping stop, indirect pumping or stroke parameter adjustment and remarkably improve working efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH +1

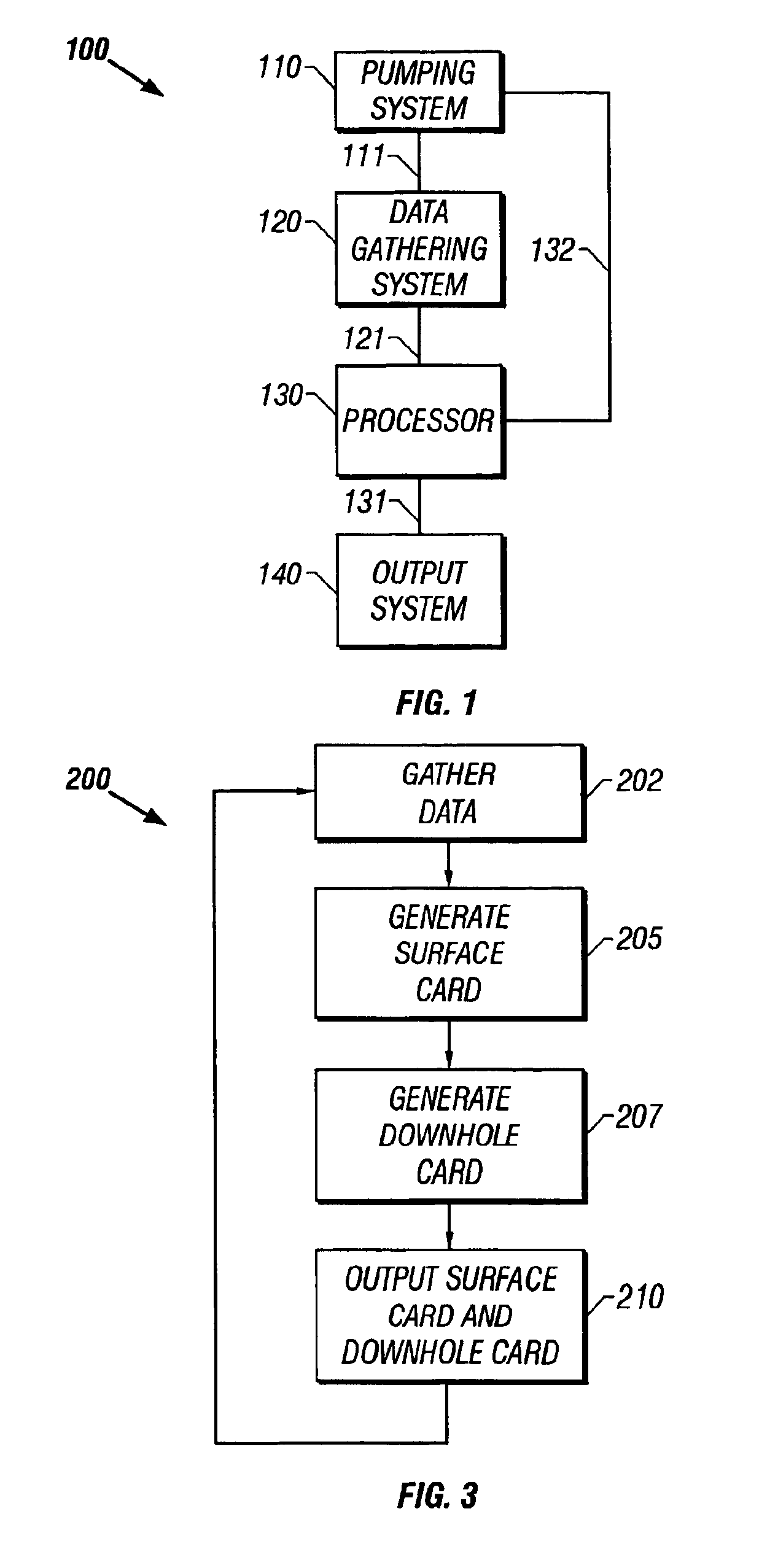

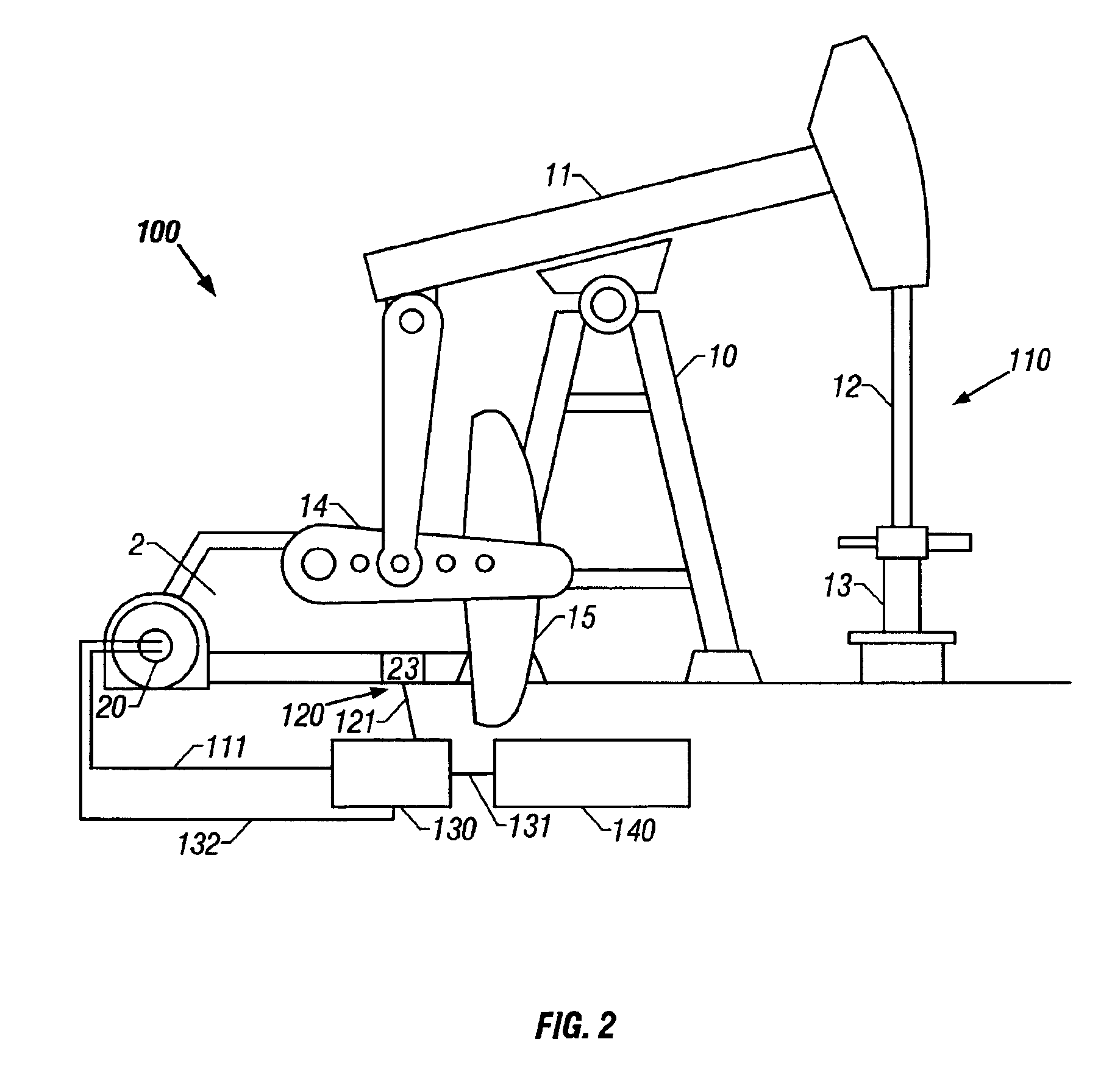

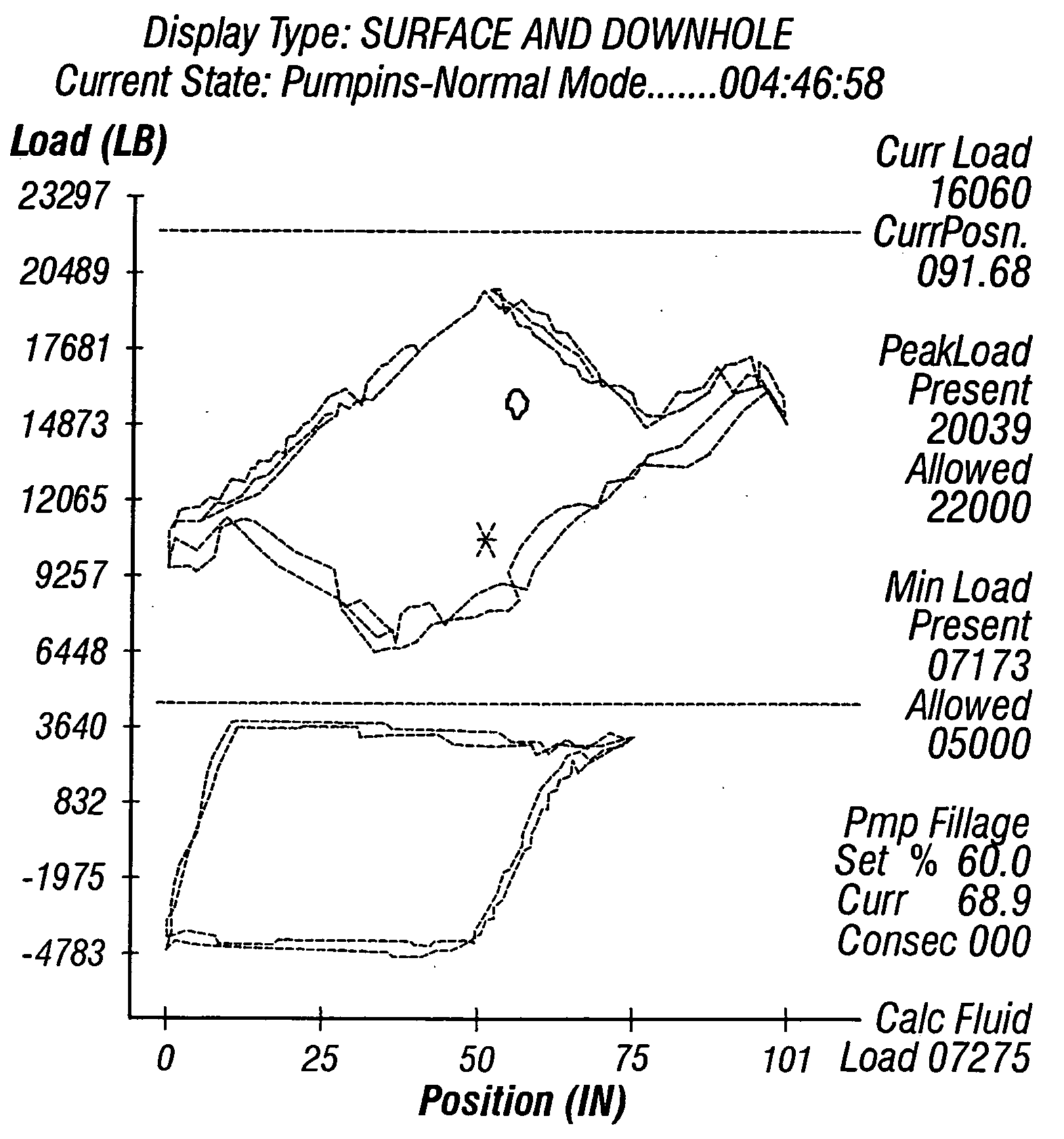

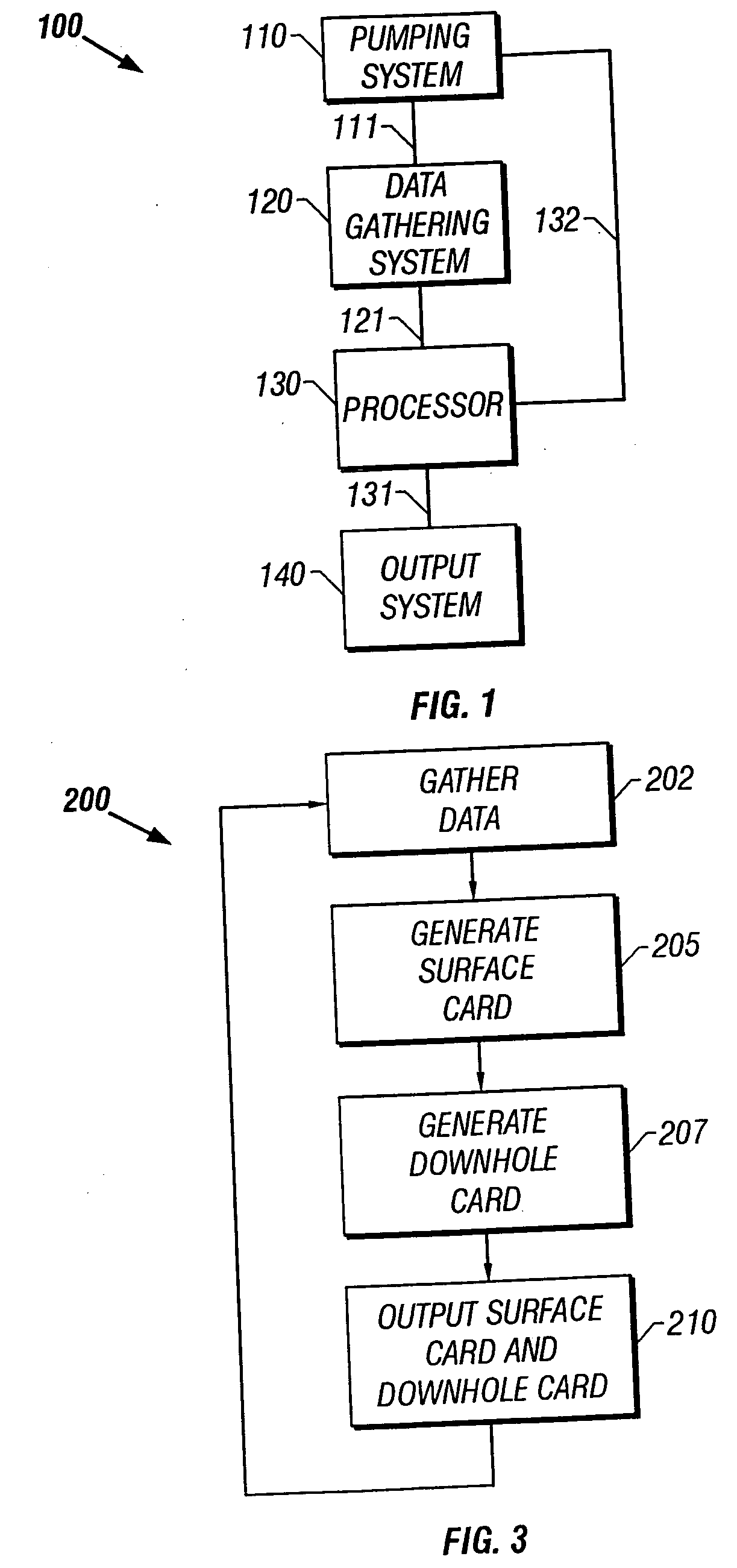

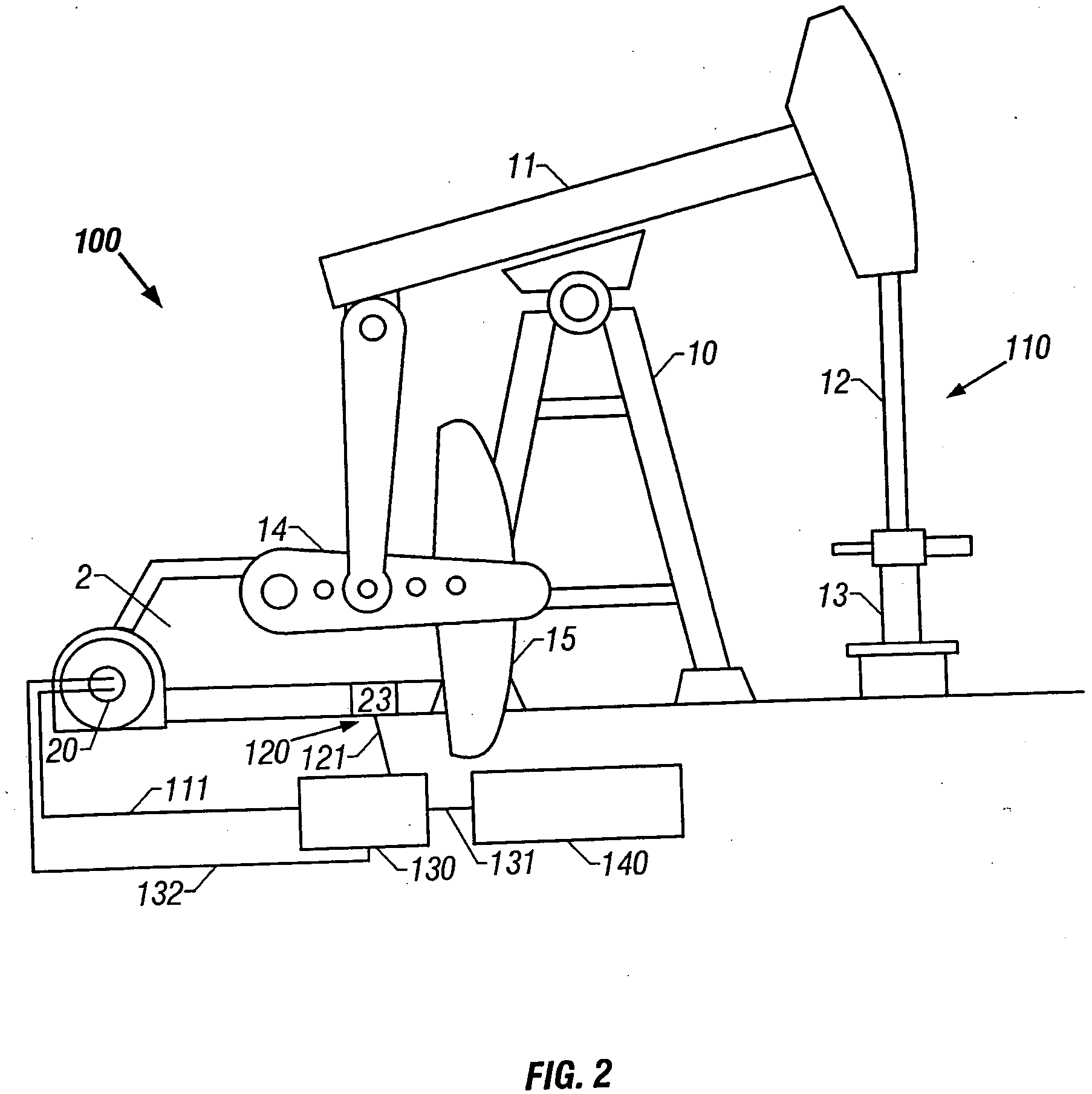

Methods, apparatus and products useful in the operation of a sucker rod pump during the production of hydrocarbons

InactiveUS6857474B2Electric/magnetic detection for well-loggingConstructionsProcess engineeringWellbore

Apparatus, methods and products for monitoring / controlling a reciprocating well producing hydrocarbons from a wellbore, which determine the surface card from a well operating characteristics, determine the downhole card, and display both at the same scale for position.

Owner:RAVDOS HLDG INC

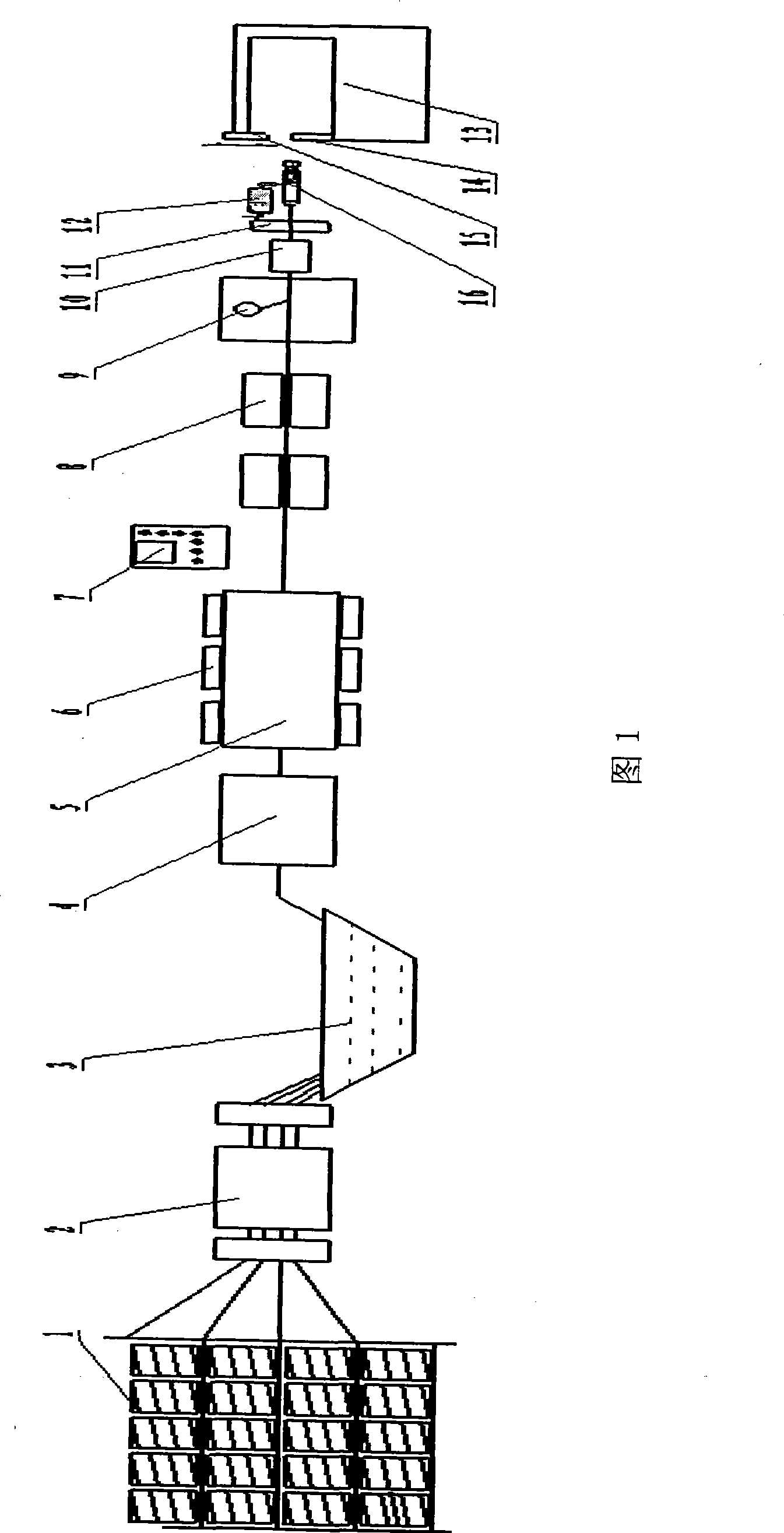

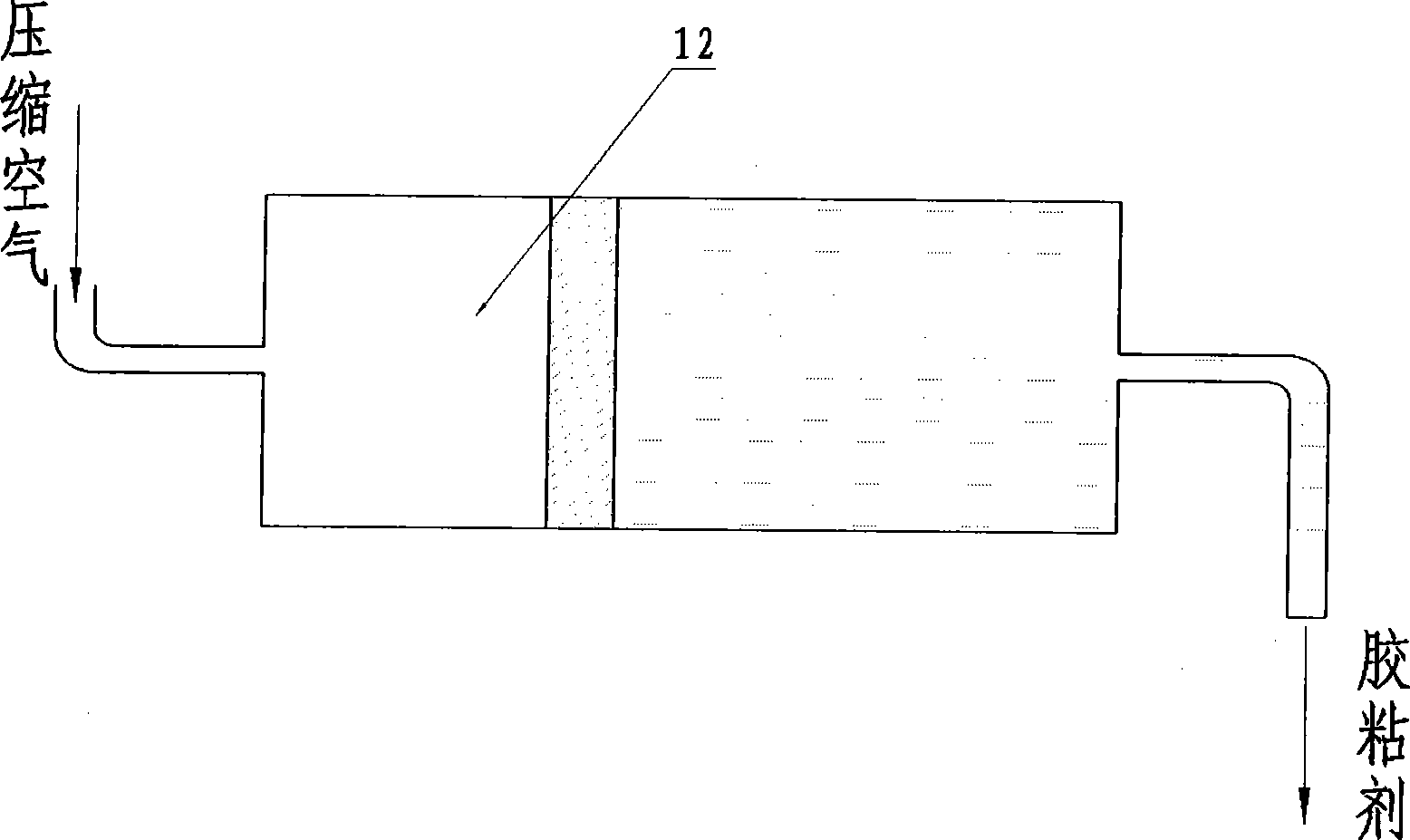

Preparation method and device of eccentric wear prevention pumping rod

InactiveCN101396874AExcellent performance of anti-eccentric wearPrevent slippageDrilling rodsDomestic articlesPre stressResin matrix

The invention relates to a method for preparing a composite material sucker rod which can prevent camber wear and a device thereof. Combining pultrusion and winding, fibre is immersed by resin matrix, and the composite material sucker rod is prepared by pultrusion, curing and shaping; the surface of the rod body is continuously wound with wearing fibre immersed by resin matrix glue after shaping; the rod body of the sucker rod, the surface of which is provided with a camber wear preventing layer of a spiral bar shape is obtained by curing; the rod body of the sucker rod is cut to be in fixed length, is connected with a metal joint by glue, and is treated in a joint curing furnace; the whole sucker rod is stretched by inherent stress. The surface of the rod body of the sucker rod is provided with the camber wear preventing layer of a spiral bar shape, thus having excellent camber wear preventing performance while ensuring a high intensity of the sucker body; the inverse cone structure of the metal joint and the pressure injection glue connection process ensure the joint part has the properties of high intensity and fatigue proof, the service life of which is consistent with the composite material rod body, and the reliability of the products is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

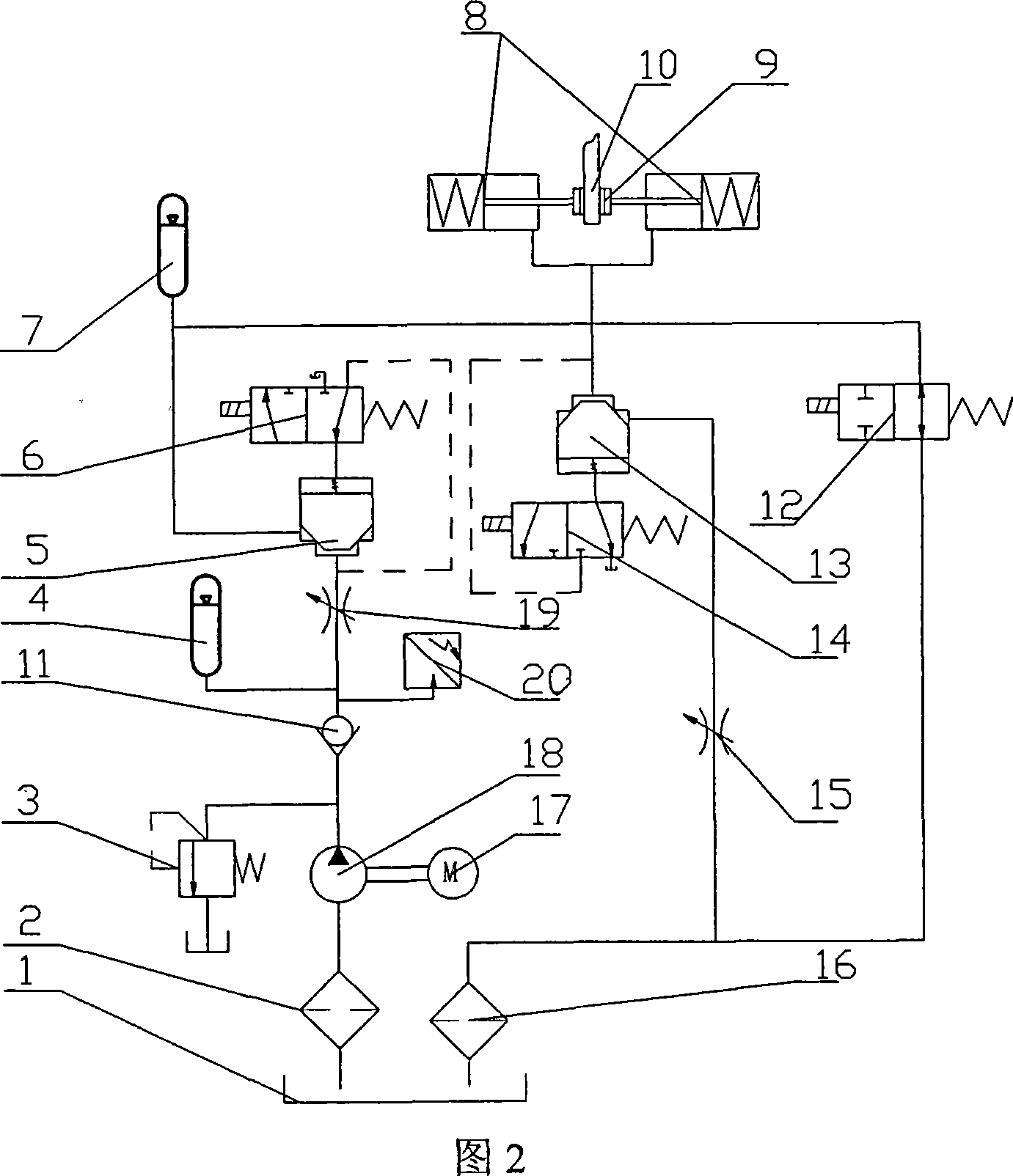

Large and middle wind turbine digital intelligent hydraulic brake system

InactiveCN101033733AWork reliablySimple structureWind motor controlAxially engaging brakesTime ratioFuel tank

The invention discloses a digital, intelligent and hydraulic brake system of large and medium wind machine. The output end of the oil supply system links uniflow valve. Its output end joints to the first accumulator, pressure relay and input end of first plug-in valve through the first throttle valve. The output end of first plug-in valve links the second accumulator. Equip hydraulic cylinders with brake blocks on sucker-rod cavity end, two of which are taken as one group and are located relatively. The sucker-rod cavities of the hydraulic cylinders connect with the output ends of the first and second plug-in valve and the third linking switch valve through the bus. The output end of the second plug-in valve meets oil tank through second throttle valve. Two high-speed switch valves are taken as pilot stage together with two plug-in valves to form digital electro-hydraulic proportional valve. Brake blocks are equipped on both sides of brake chuck of the wind machine to change the open-close time ratio of high-speed switch valves and adjusts hydraulic braking force of the brake chuck. When meeting the working condition of unit braking, adjust the duty ratio of high-speed switch valves in unit time depending on wind speed and main shaft speed to realize intelligent control on braking force.

Owner:ZHEJIANG UNIV

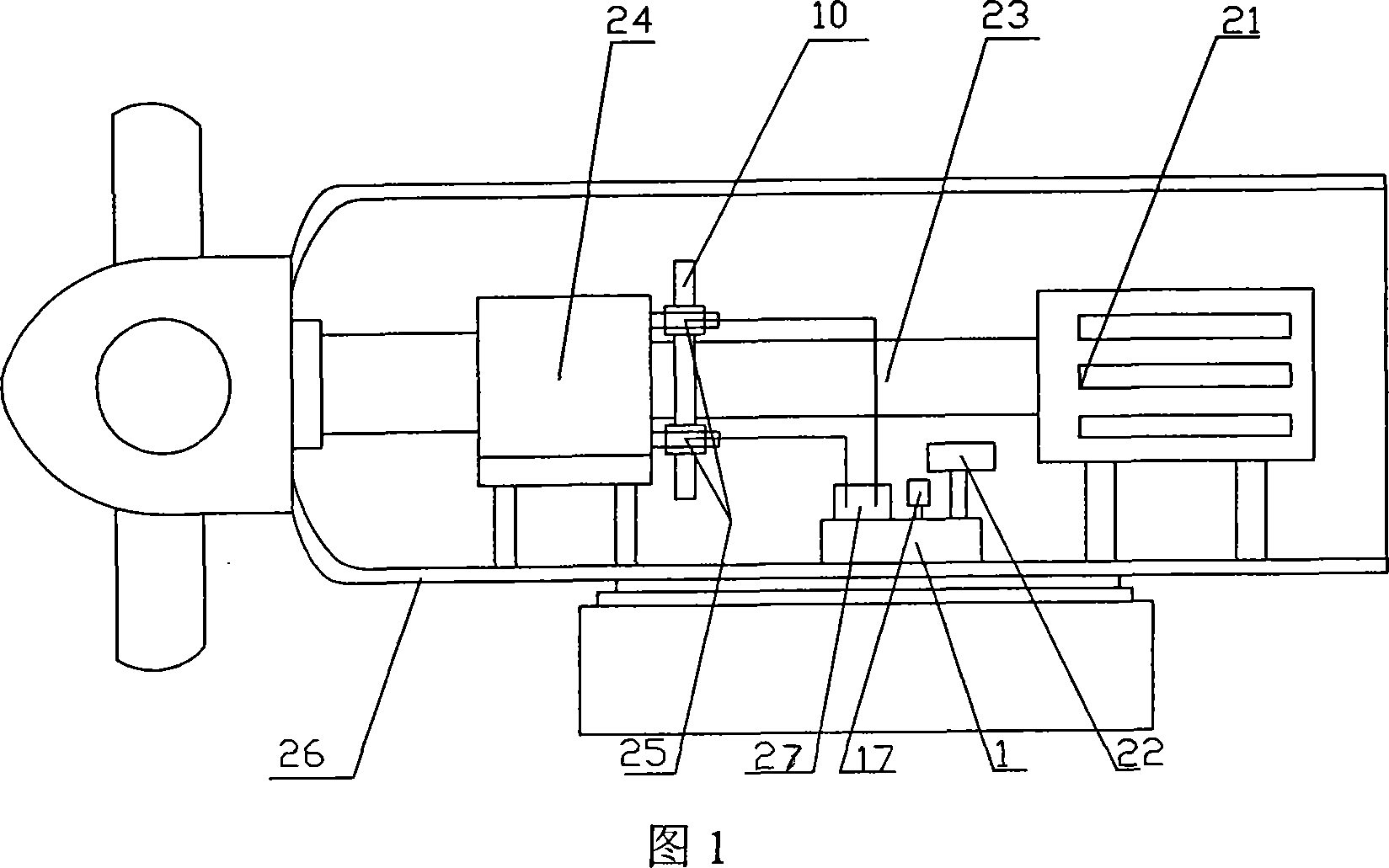

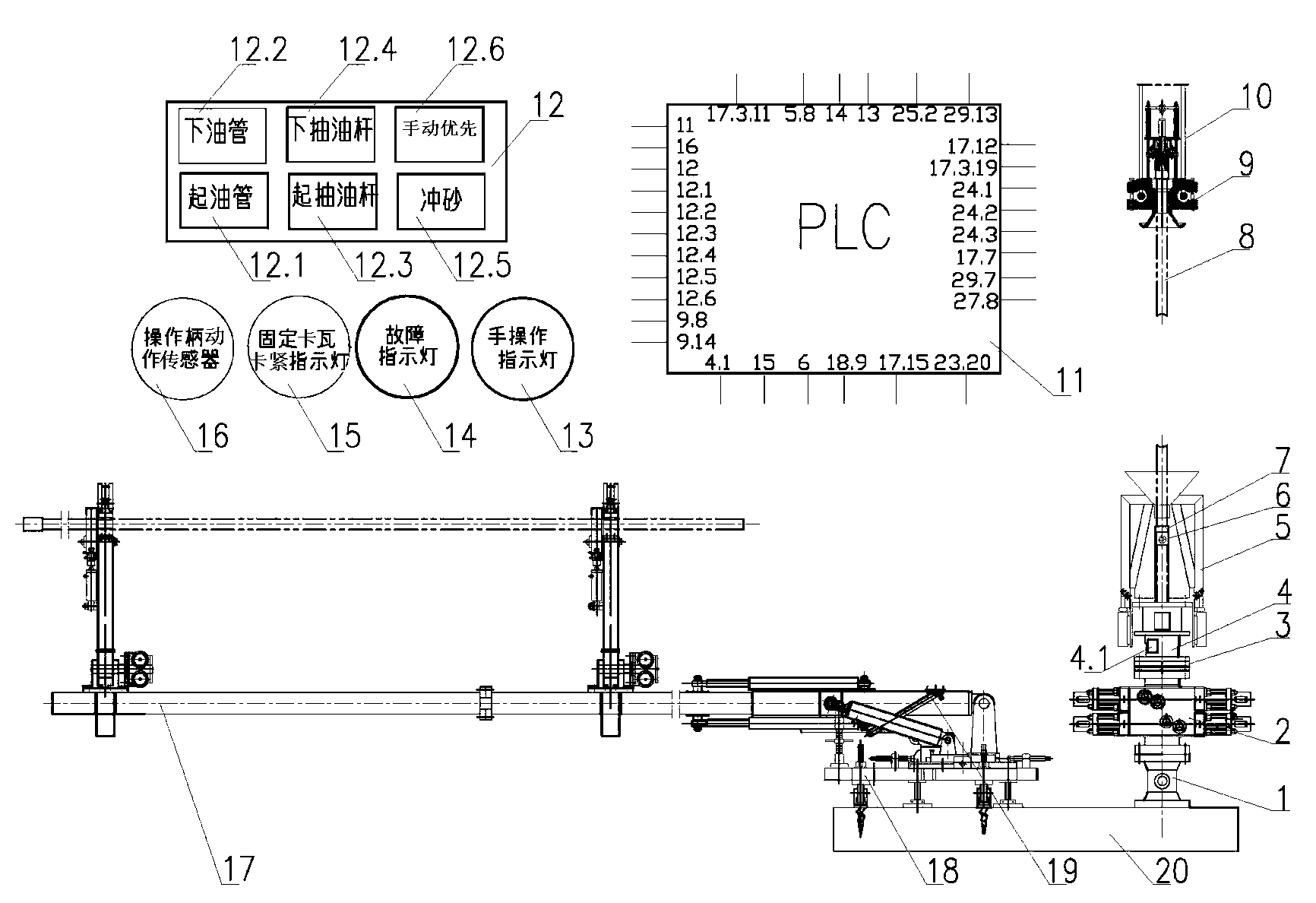

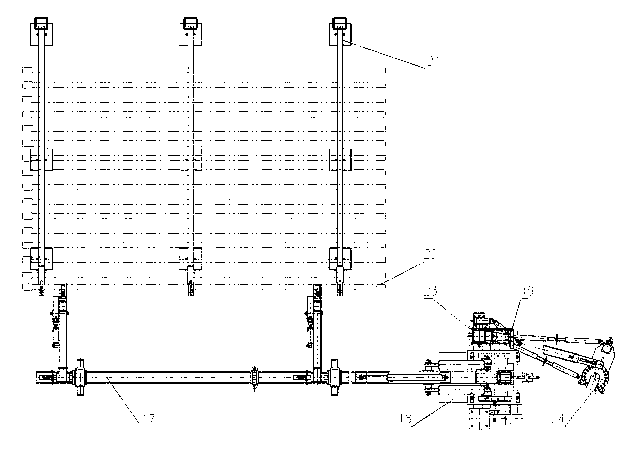

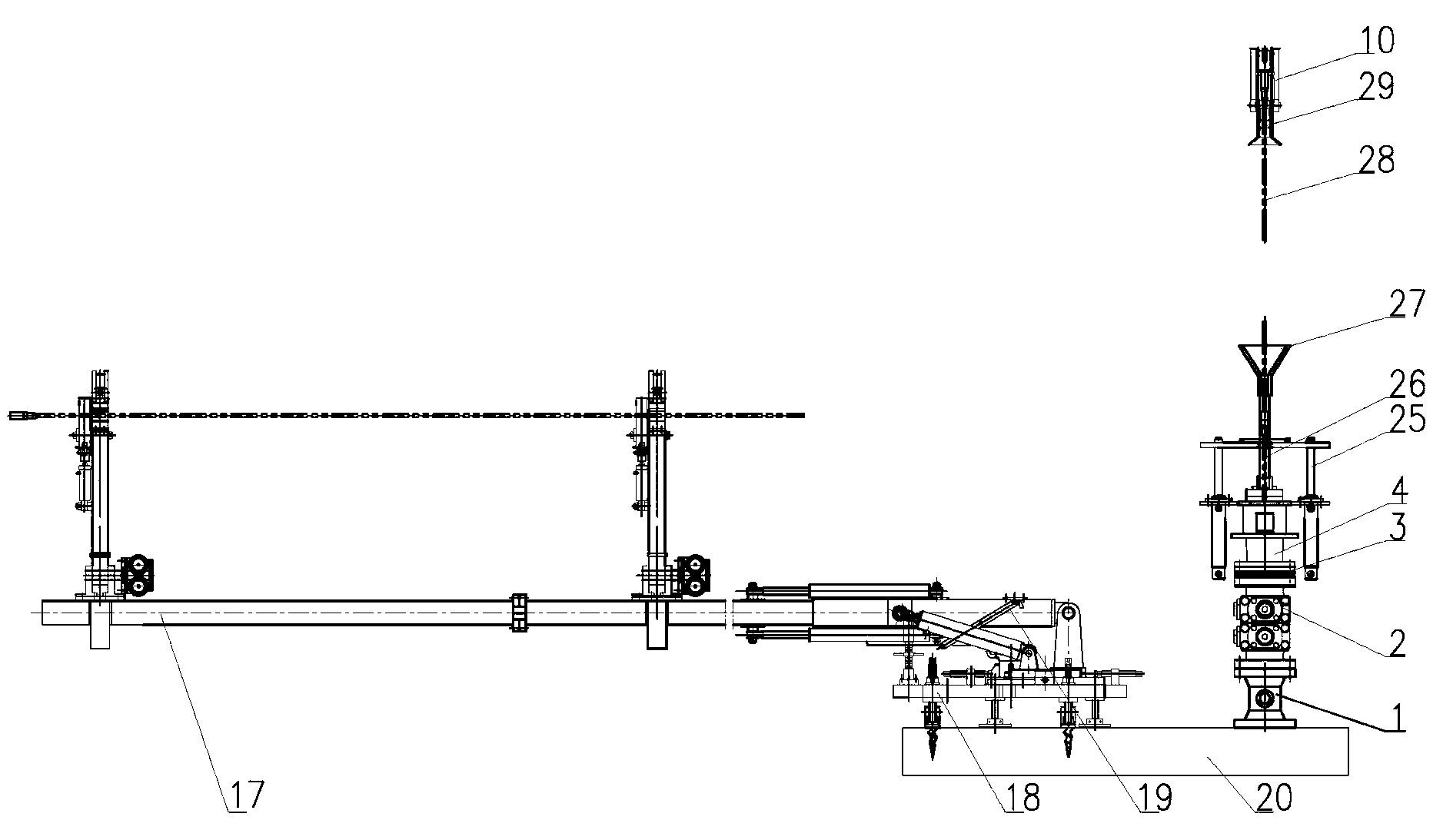

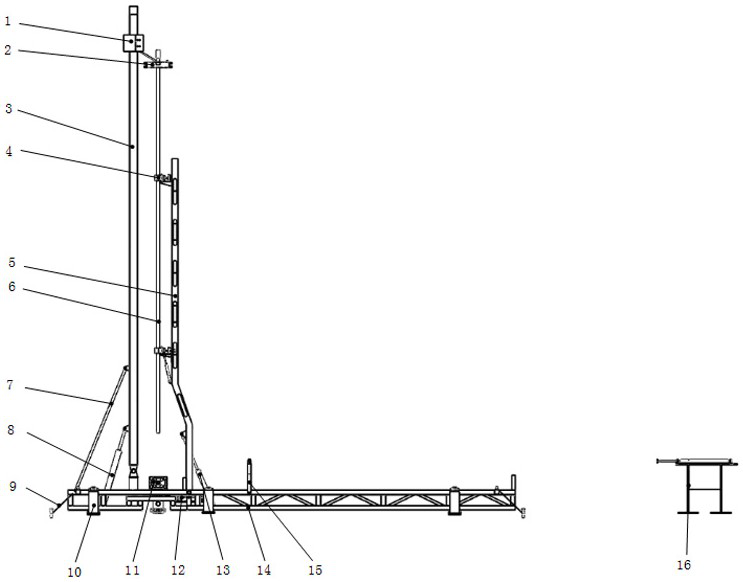

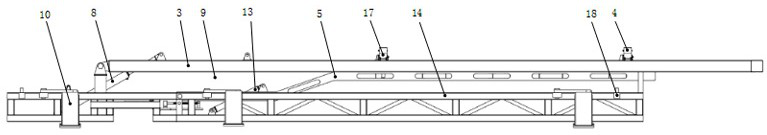

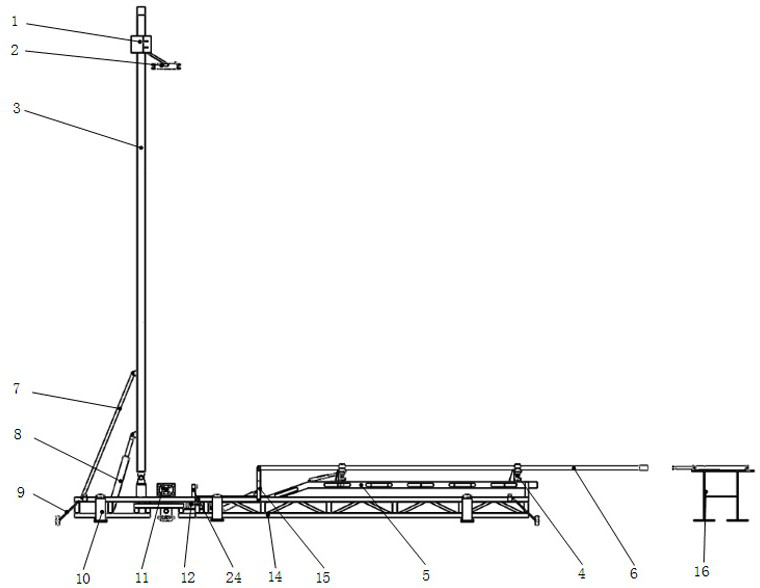

Automatic running and pulling system of oilfield workover string

InactiveCN103061692APrevent airborne sprayReduce pollutionDrilling rodsDrilling casingsButt jointControl system

The invention relates to an automatic running and pulling system of an oilfield workover string, which comprises a blowout preventer, fixing slips, an oil pipe / sucker rod guide mechanism, an oil pipe / sucker rod locating mechanism, an oil pipe / sucker rod elevator component, a mechanical arm component, hydraulic clamps, a hydraulic clamps bracket, a control system, a base component and a string bent, wherein the mechanical arm component and the hydraulic clamps bracket are installed on the base component and are connected through a linkage component to carry out linkage movement, and the string bent is arranged on the side surface of the mechanical arm component and moves in match with the mechanical arm component. With the adoption of the automatic running and pulling system of the oilfield workover string, the automation of movements of snatching up, butt joint, clamping, upper unloading, elevating, lowering, arrangement and the like can be realized, manual string running and pulling operation at a wellhead is replaced, an equipment mechanism is simplified as much as possible, and an operation program is optimized.

Owner:崔诗光

Sucker rod apparatus and methods for manufacture and use

ActiveUS9869135B1Improve wear resistanceReduce capital investmentDrilling rodsMetal-working apparatusFiberCoupling

A sucker rod string improved by the use of wear resistant, high temperature resistant, fiber-reinforced phenolic composite materials as centralizing guides on sucker rods and couplings, both molded on the rod and prepared as snap-on couplings for in-the-field use, and on magnet rod inserts, both rod box and pin magnet rod inserts, in which the thermosetting composites are used as sleeves, encapsulating housings, and centralizing guides. The magnet rod inserts and couplings are designed to be machined so that worn phenolic composite can be removed and replaced with fresh composite without removing or damaging the magnet. Processes are disclosed for integrating composite thermoset molding into sucker rod, coupling, and magnet rod insert manufacture and for refurbishing used components of a sucker rod string.

Owner:RFG TECH PARTNERS LLC

Method for determining oil pumping machine well system parameter

ActiveCN1900478AHigh precisionImprove system efficiencyFlexible member pumpsFluid removalWave equationPetroleum

Solving wave equation with damp calculates rate of change from swabbing parameters including stroke, number of strokes, diameter of pump, depth of pump, diameter and length of sucker rod etc. to system effectiveness. Sorting rate of change is carried out according to magnitude of absolute value. Under limiting conditions of well yield, load, torque moment etc, analyzing degree of sensitivity of swabbing parameters, the invention optimizes a group of optimal swabbing parameters for oil pumping well system. The method can calculate out polished rod horsepower, efficiencies of sucker rod, and oil pipe difficult to calculate out before. Carrying out quantitative analysis for each factor affecting system effectiveness, the invention solves issue of designing complex parameters so as to raise system effectiveness. The invention is applicable to oil pumping well system composed of inclined well or straight well, different typed pumping units and electric motor.

Owner:PETROCHINA CO LTD

Casinghead gas corrosion resistant pumping rod steel and manufacturing method thereof

InactiveCN101440461AImproved corrosion cracking performanceGood plasticityTemperature control deviceFurnace typesNiobiumManganese

The invention provides steel for a pumping rod resisting casinghead gas corrosion and a manufacture method thereof. The steel comprises the following chemical compositions by mass percentage: 0.05 to 0.25 percent of carbon, 0.50 to 2.00 percent of silicon, 1.10 to 2.50 percent of manganese, 0.02 to 0.50 percent of molybdenum, 0.02 to 0.50 percent of nickel, 0.50 to 1.50 percent of chromium, 0.01 to 0.10 percent of vanadium, 0.005 to 0.050 percent of aluminum, 0.02 to 0.10 percent of niobium, 0.05 to 0.50 percent of copper, 0.01 to 0.10 percent of titanium, less than or equal to 0.015 percent of sulphur, less than or equal to 0.020 percent of phosphorus, and the balance being ferrum. The method is to manufacture a pumping rod wire through a design of adding the niobium and other trace alloy elements and corresponding compositions into steel, and controlled rolling and controlled cooling organization control technology. The pumping rod manufactured by the wire has excellent oilwell medium corrosion resistance, proper strength, excellent plastic tenacity and excellent welding performance, thereby improving the service life and reliability of the pumping rod, and improving the whole stability of pumping equipment, and further solving the problem that the prior pumping rod has repeated stress failure caused by endurance of complex casinghead gas corrosion.

Owner:BAOSHAN IRON & STEEL CO LTD +1

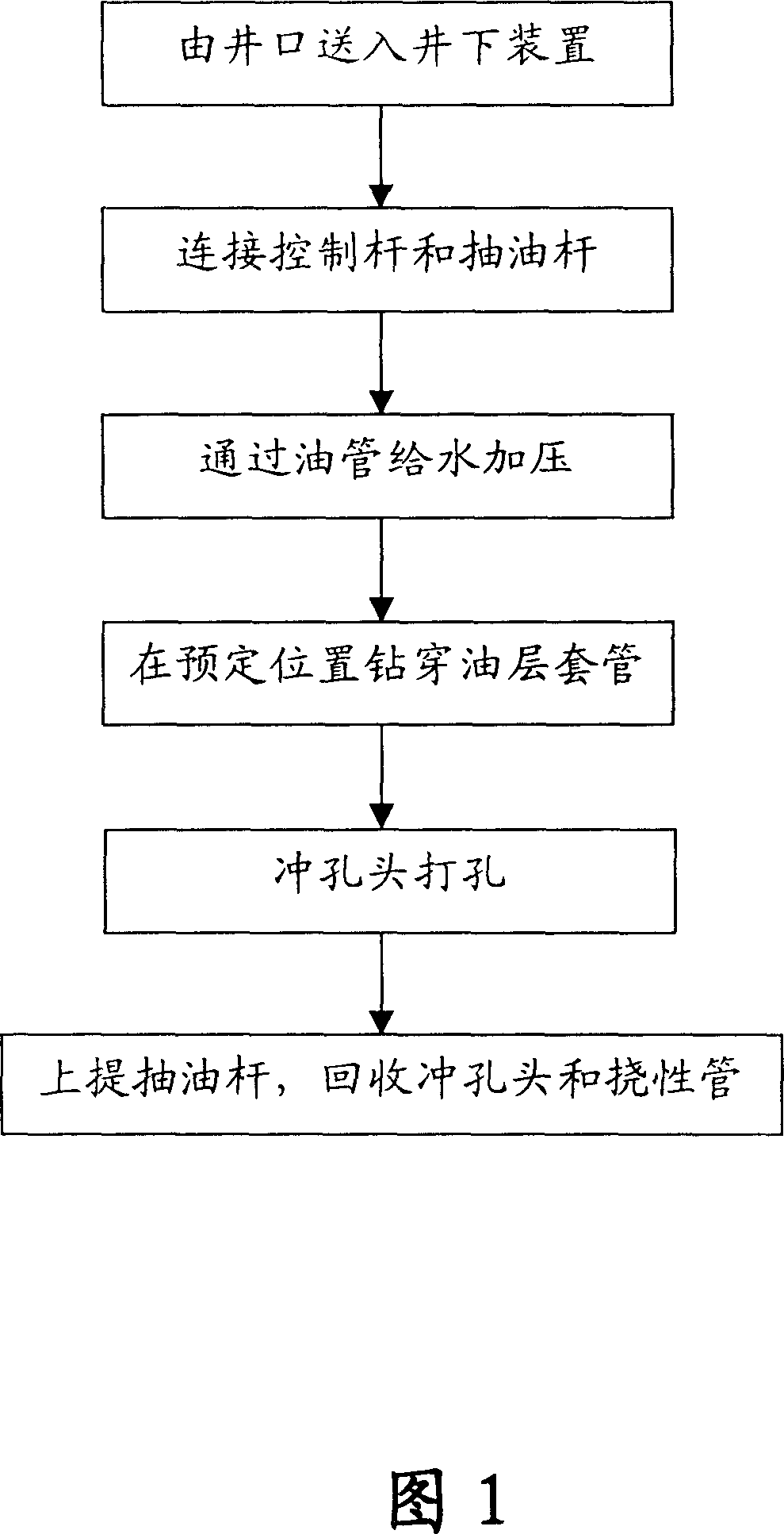

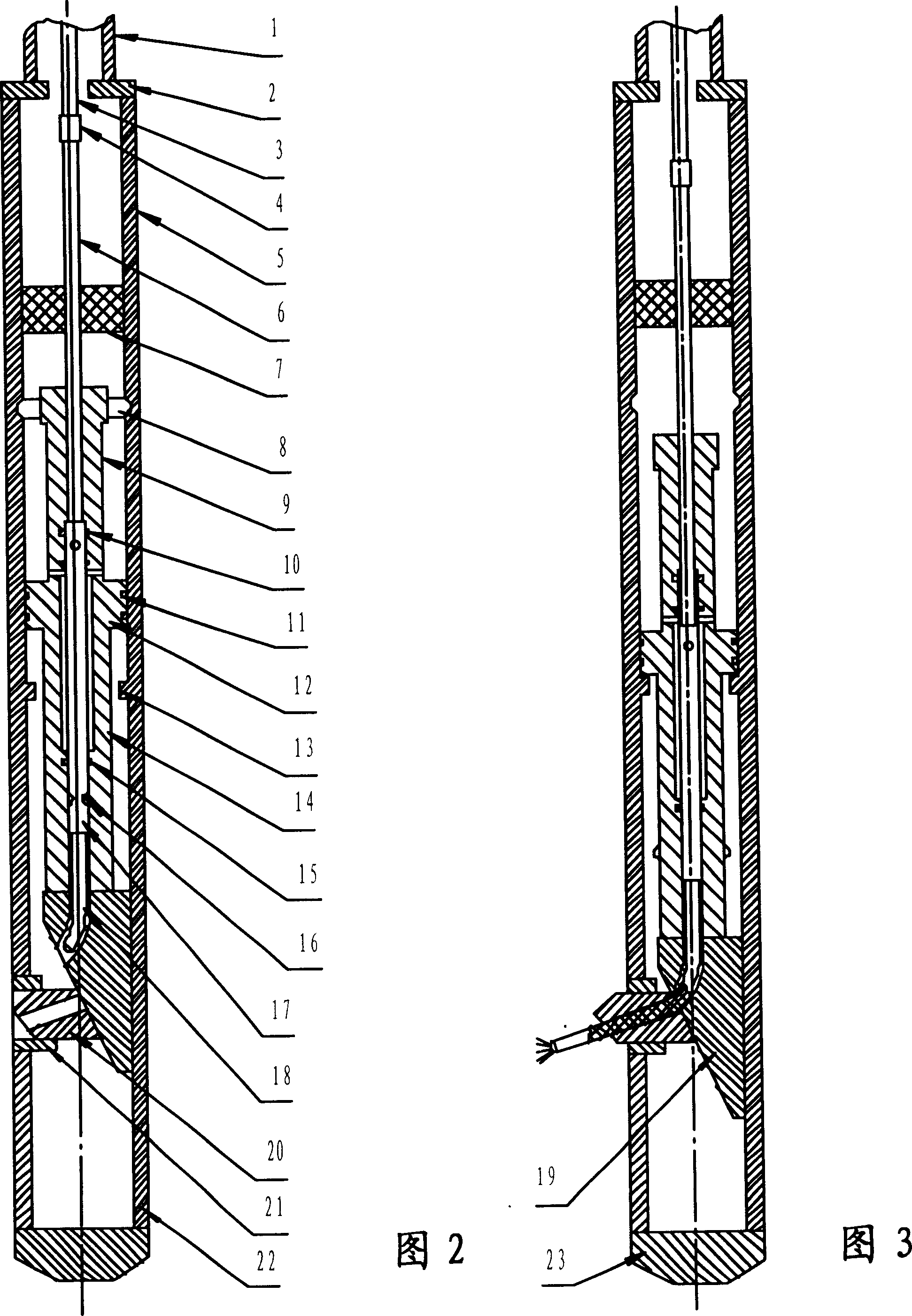

High pressure water jet-flow deep penetrating perforating and its auxiliary crushing method and apparatus

The present invention is high pressure water jet perforating and auxiliary pressure fracturing method and apparatus. The apparatus includes a sheath, a releasing adaptor in the upper end of the sheath, a guiding pipe plug in the lower end, a piston inside the sheath, a wedge connected to the lower end of the piston, a ram head connected to the wedge, a jetting hose with nozzle in the top and connected to a core tube, a control rod connected to the hose and the sucker rod, an upper lock to limit the piston and a lower lock to limit the core tube. Compared with available technology, the present invention has the advantages of further greater treating depth, long and large perforation, increased drainage area and capacity, no contamination to perforation, simplified perforating and pressure fracturing process and saving in oil producing cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

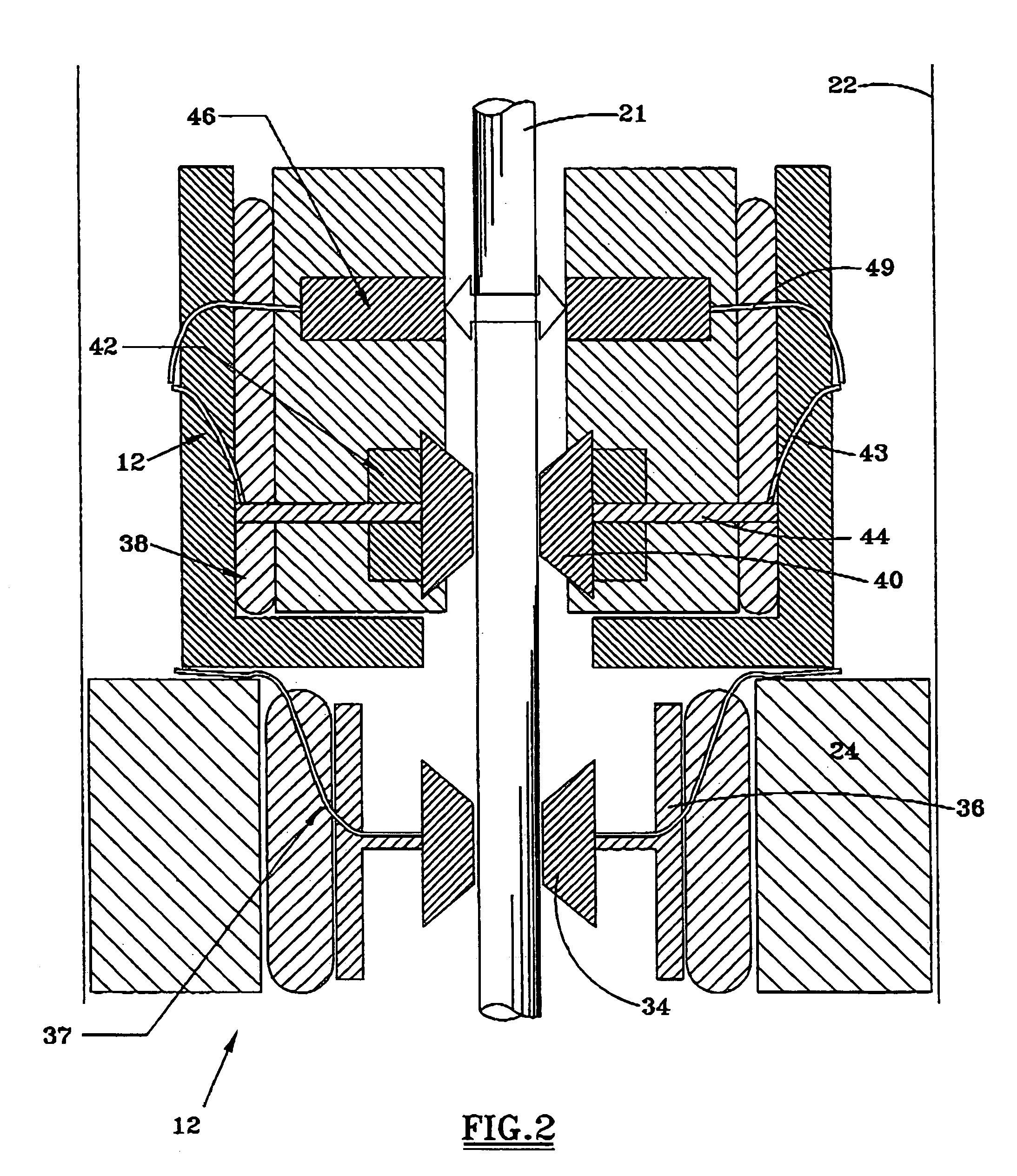

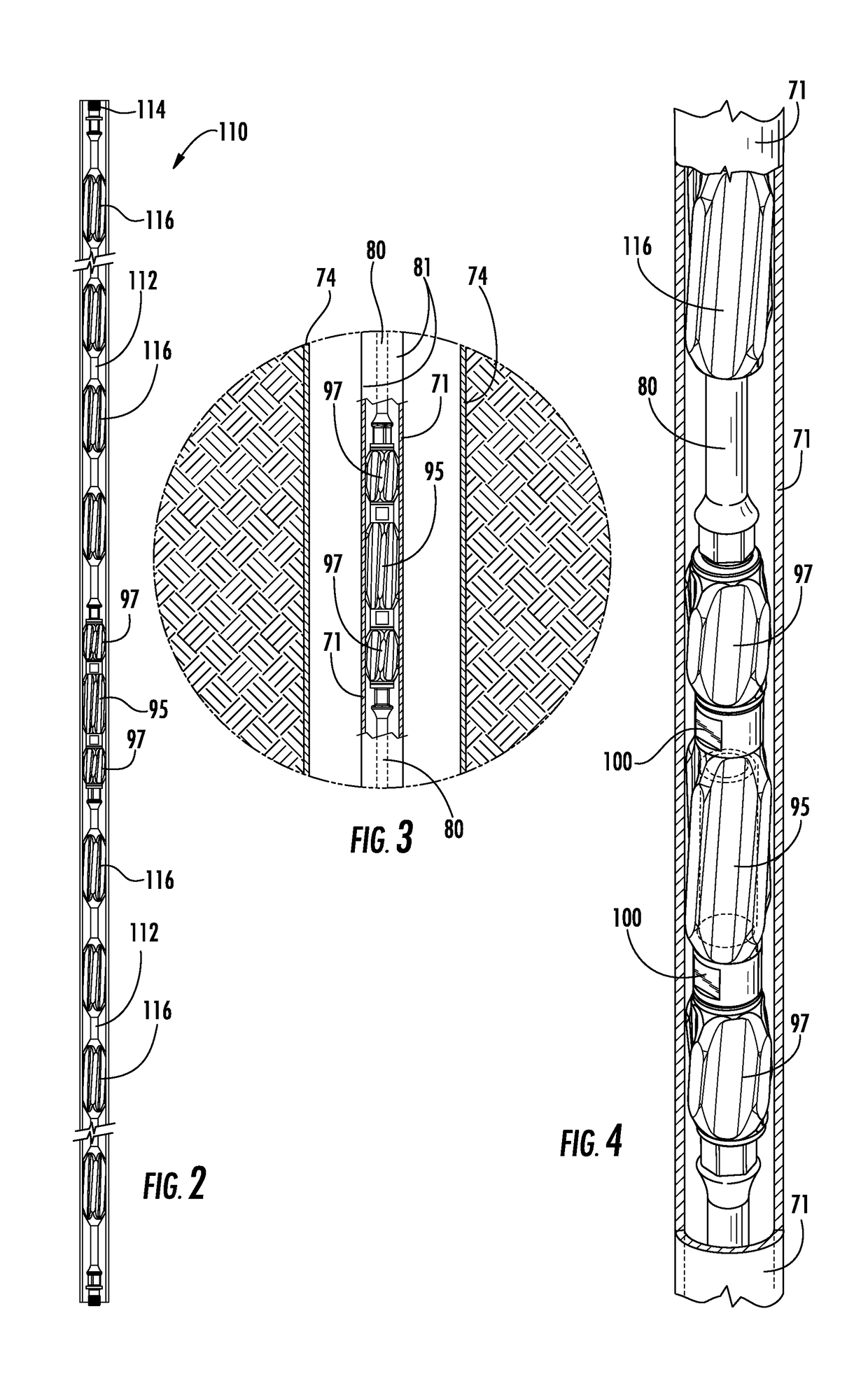

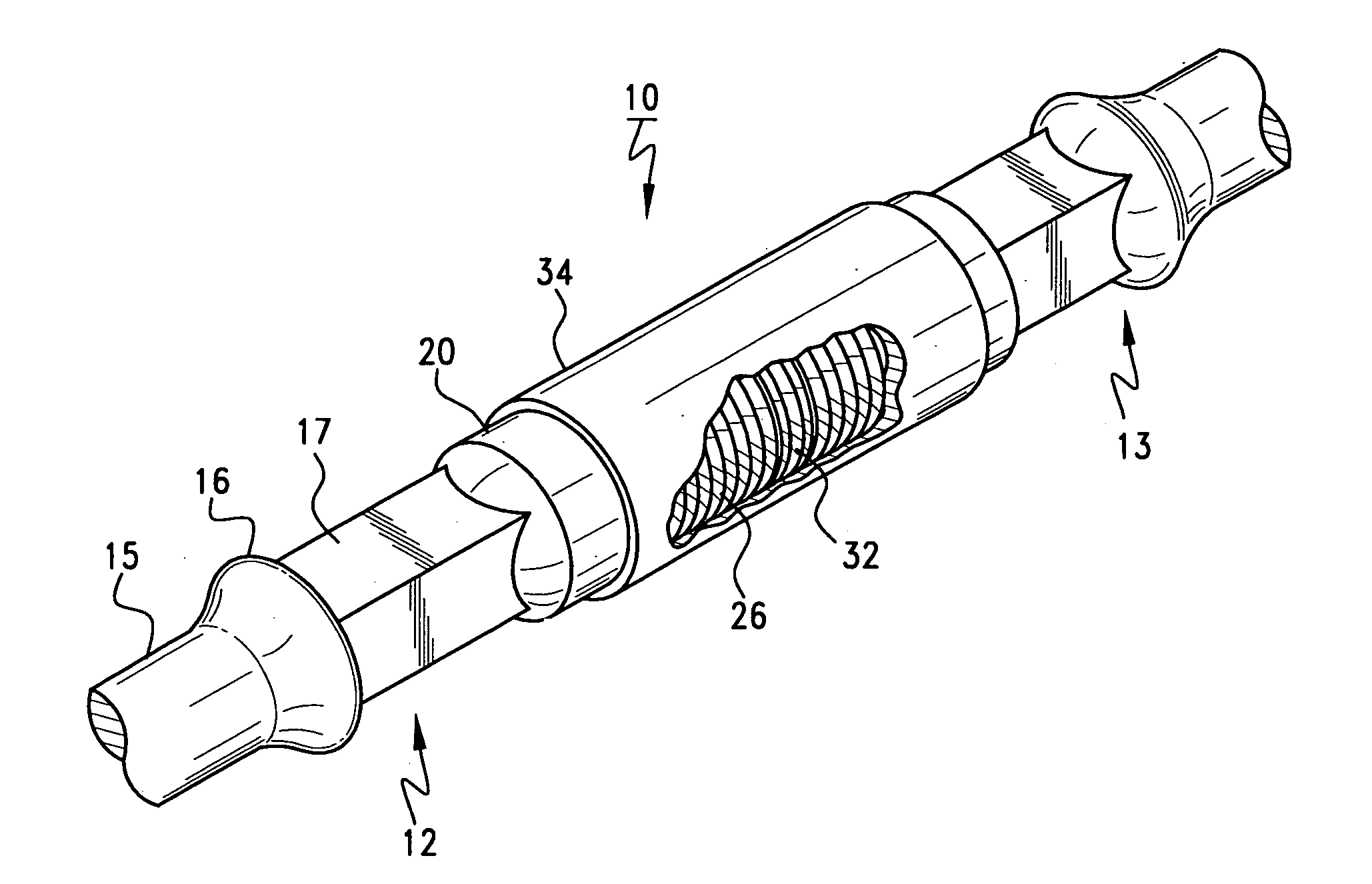

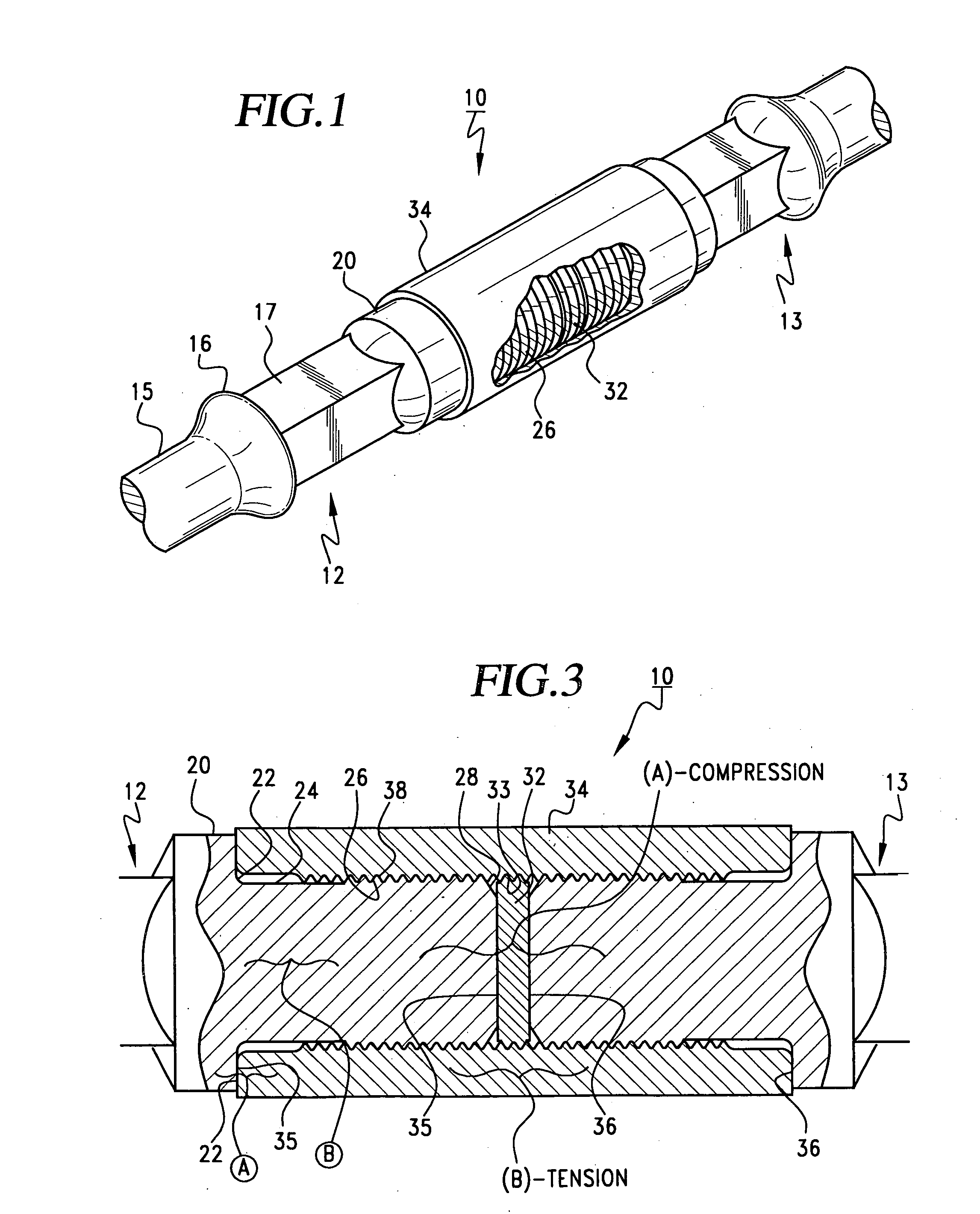

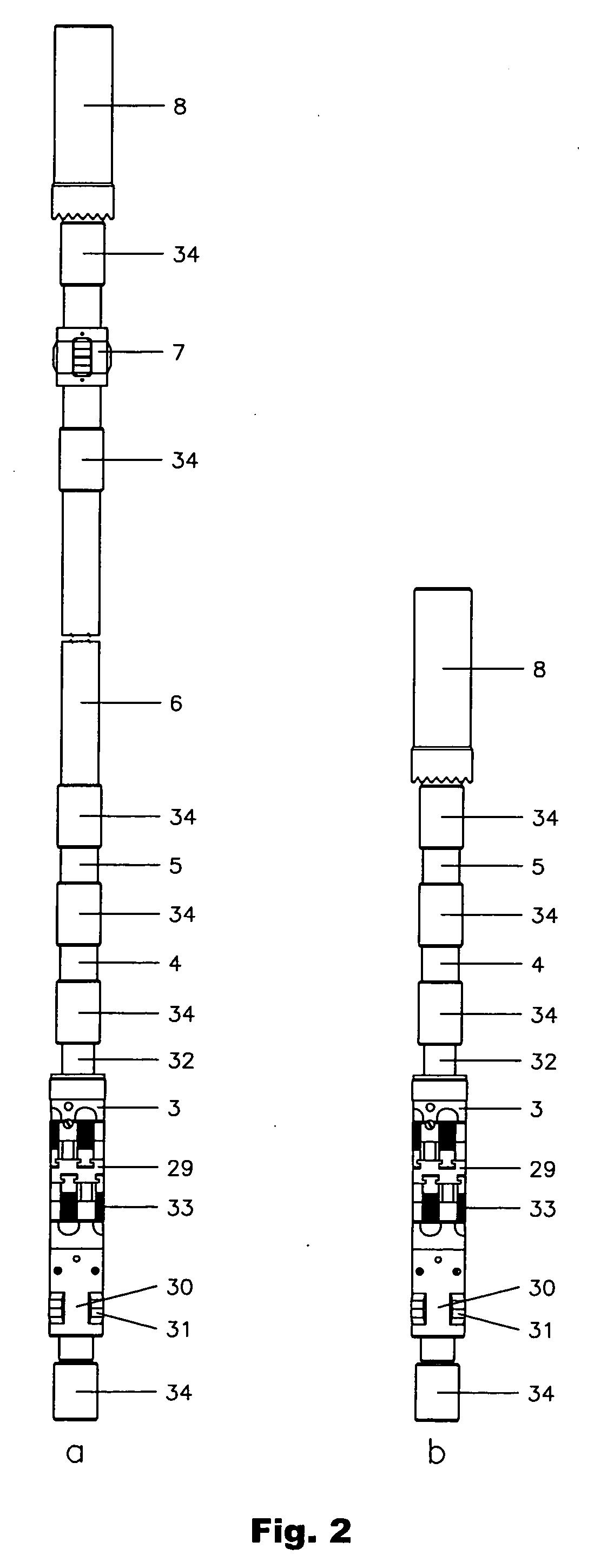

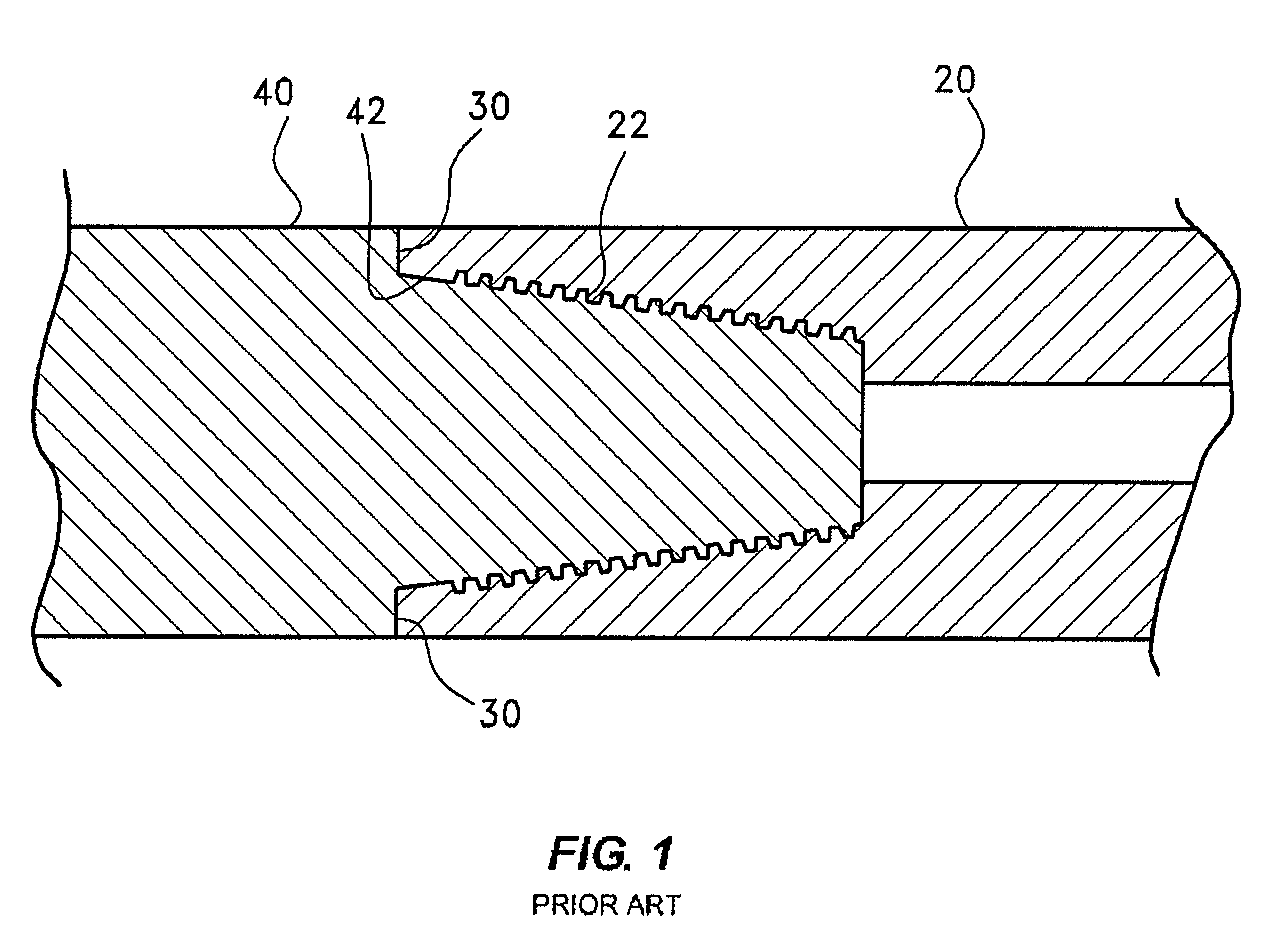

Connectable rod system for driving downhole pumps for oil field installations

InactiveUS20060273601A1Improve torque performanceUnique and useful tensionDrilling rodsDrilling casingsEngineeringAxial distance

Improved sucker rod joints for down hole petroleum pumping applications are provided within the form factor of standard API sucker rods, such that existing inventory in suitable condition is fully usable in more demanding applications. The pin ends are selected or processed such as to provide preselected axial distance between a flat pin end and at least one reference surface, such as a threaded region or reference shoulder or both. The coupler is dimensioned such that the pin ends are in abutment either with each other or with opposite sides of an intervening torque washer in the central region, when the connection is made to a selected level of thread engagement. Furthermore, the engagement is such as to put the pin ends in compression and the coextensive length of coupler in tension. This increases frictional restraints and locks the elements together to resist fatigue failure upon cycling and to insure together with an anaerobic adhesive sealant, against back threading. This arrangement enables standard quality sucker rods to be employed in a configuration which is mechanically secure and highly resistant to tensile, bending and torsional forces, thus assuring a greater strength at the joint than in the rod itself, and resisting the effects of material fatigue arising from long term and stressful cycling operations.

Owner:CARSTENSEN KENNETH J

Wellbore evaluation system and method

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the production tubing string in the well, and a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile. A data acquisition computer is in communication with the sensors for computing and comparing the deviation profile and the rod profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

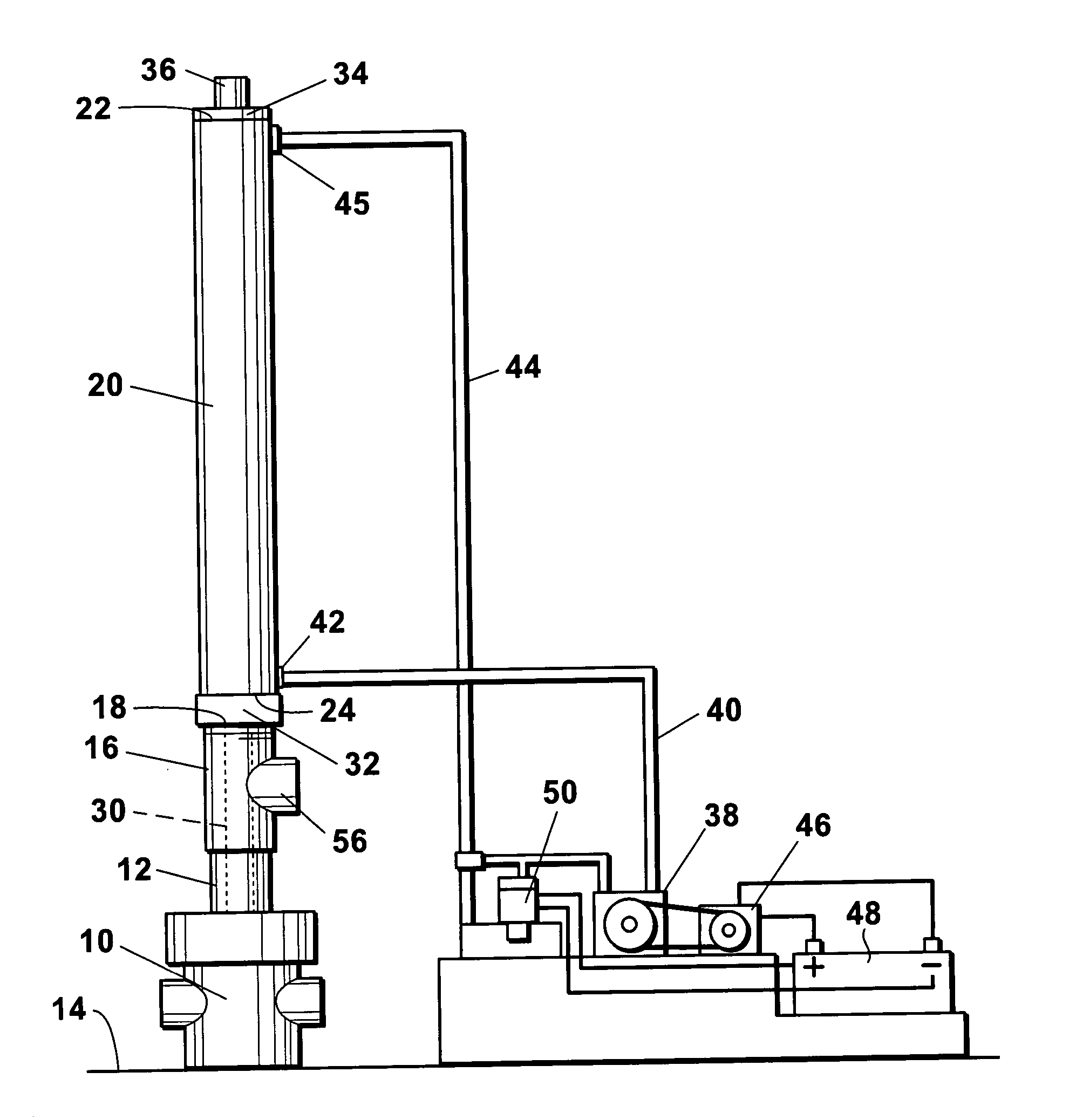

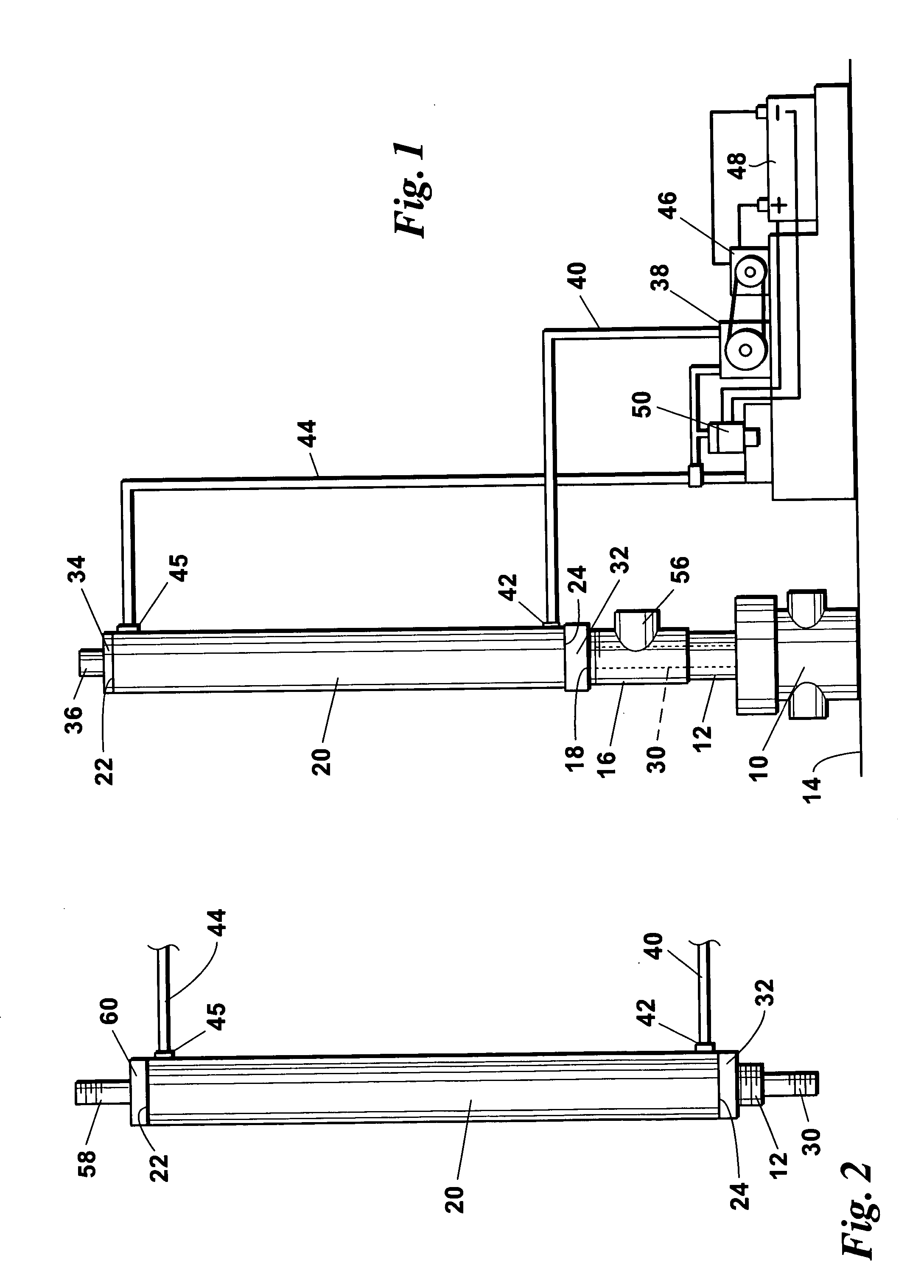

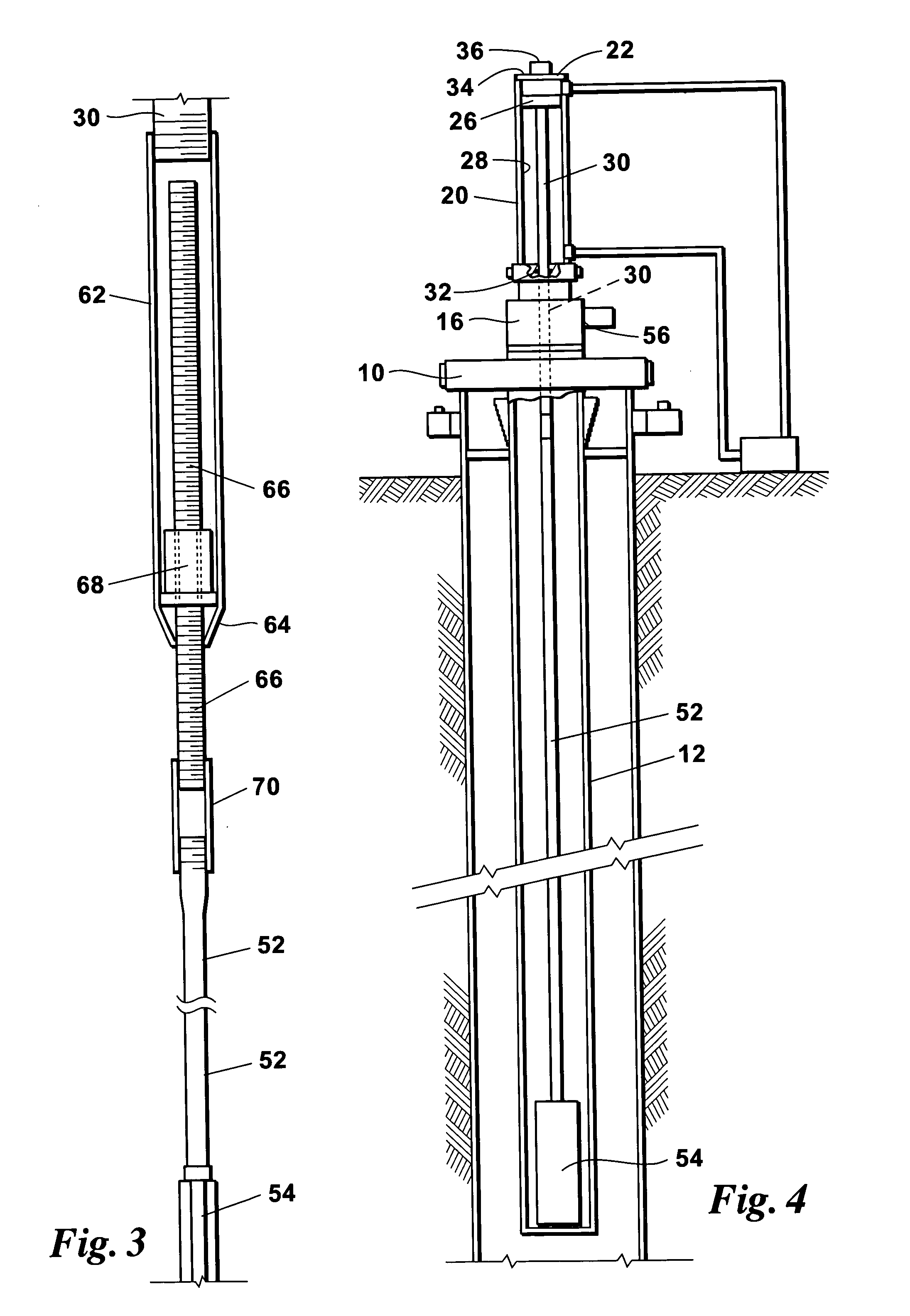

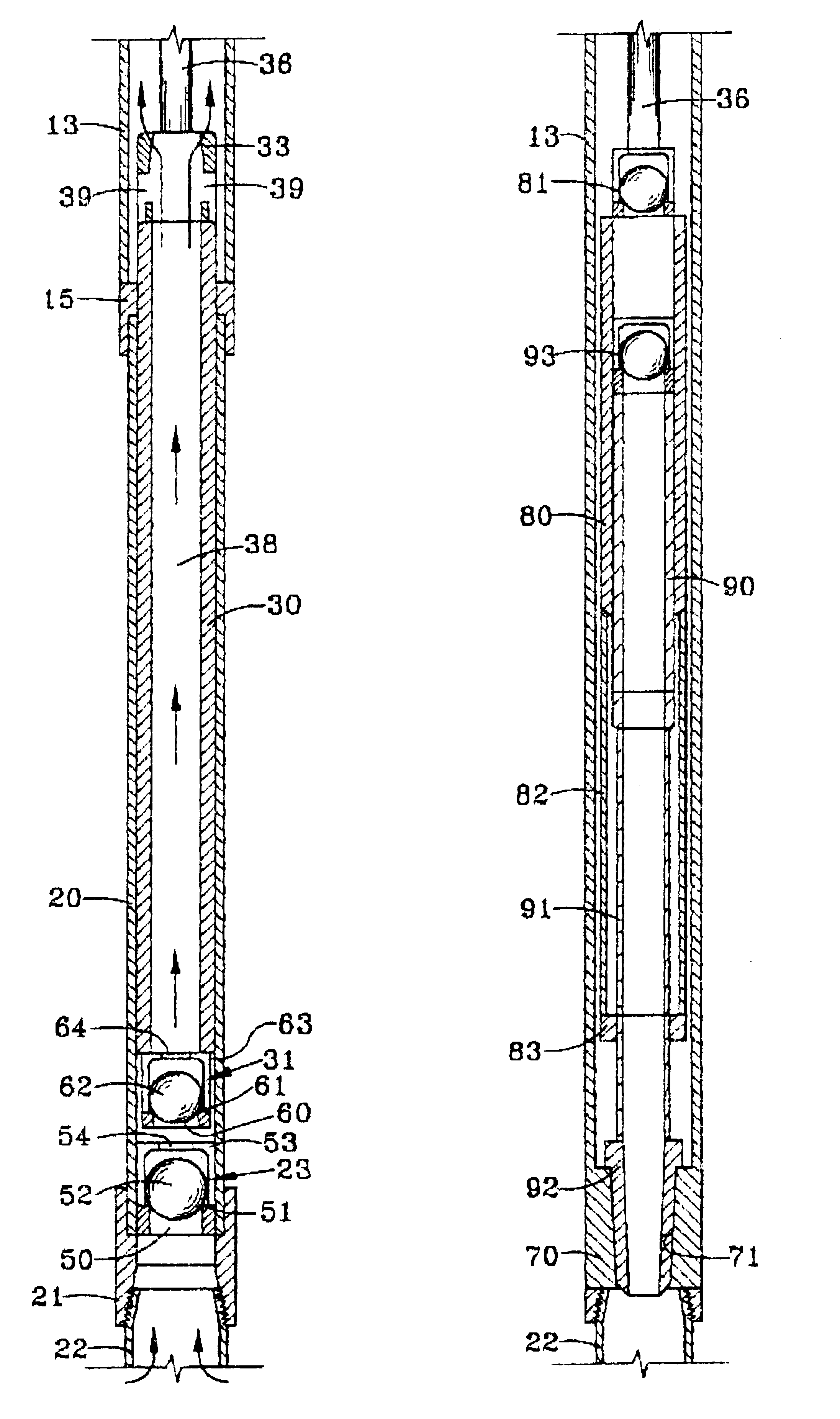

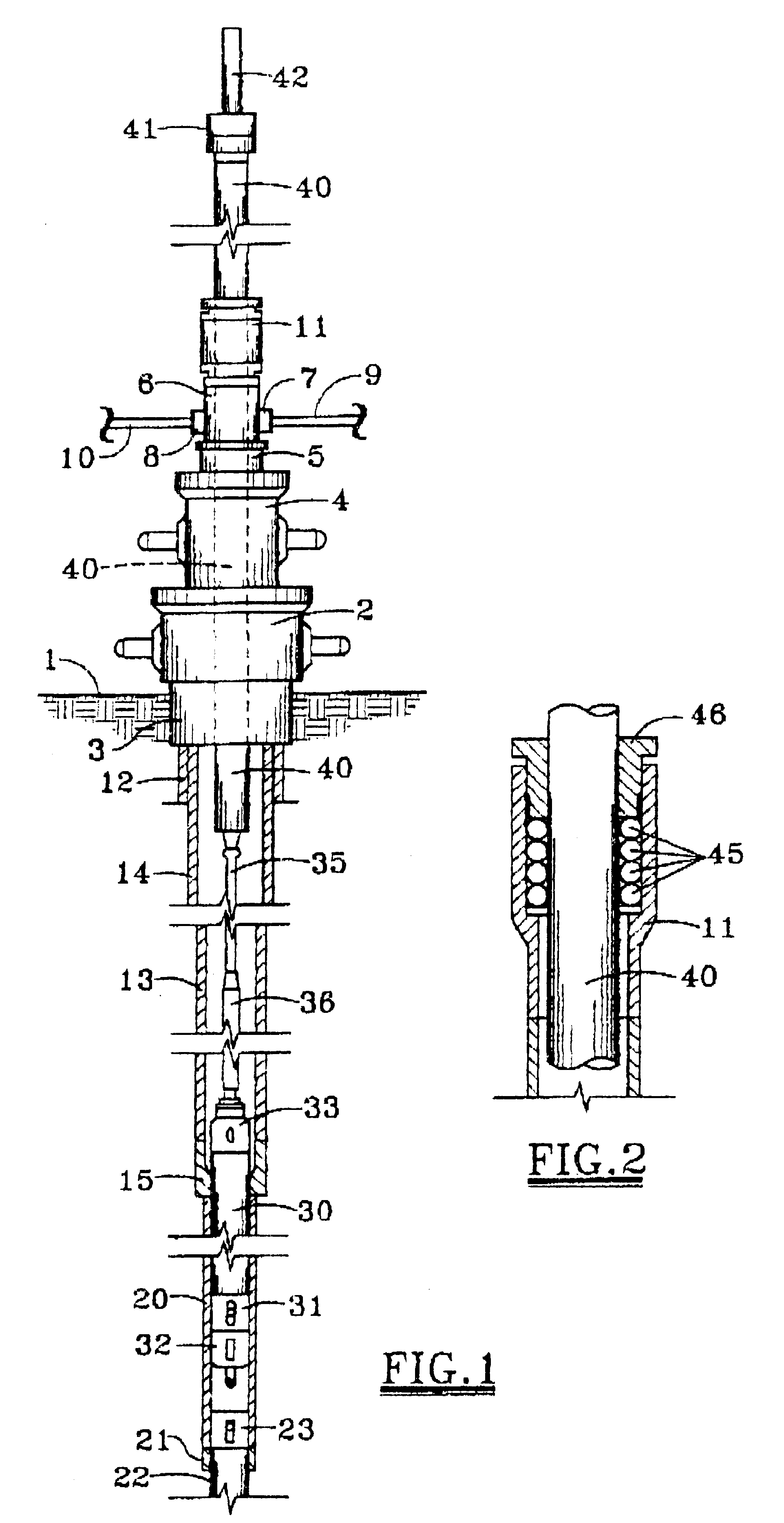

Hydraulic pump jack sytem for reciprocating oil well sucker rods

InactiveUS20060171821A1Efficiently actuatedConstructionsPositive displacement pump componentsHydraulic cylinderReciprocating motion

A pumping system for vertical reciprocation of a string of sucker rods within oil well tubing having a positive displacement pump at the bottom thereof, includes a vertically positioned elongated hydraulic cylinder supported above the tubing and in alignment therewith, the cylinder having a vertically displaceable piston therein. A pump rod is affixed to the piston and extends beyond the bottom end of the cylinder. A seal member affixed to the lower end of the cylinder sealably and reciprocally receives the piston rod. A Tee fitting is secured between the tubing and the cylinder bottom end and reciprocally receives the piston rod. A controlled hydraulic power system provides fluid pressure to the cylinder to vertically reciprocate the piston and thereby the piston rod and tubing string to pump crude oil upwardly in the tubing, the crude oil flowing under pressure into the Tee fitting and out through a side opening.

Owner:BROWN T LEON

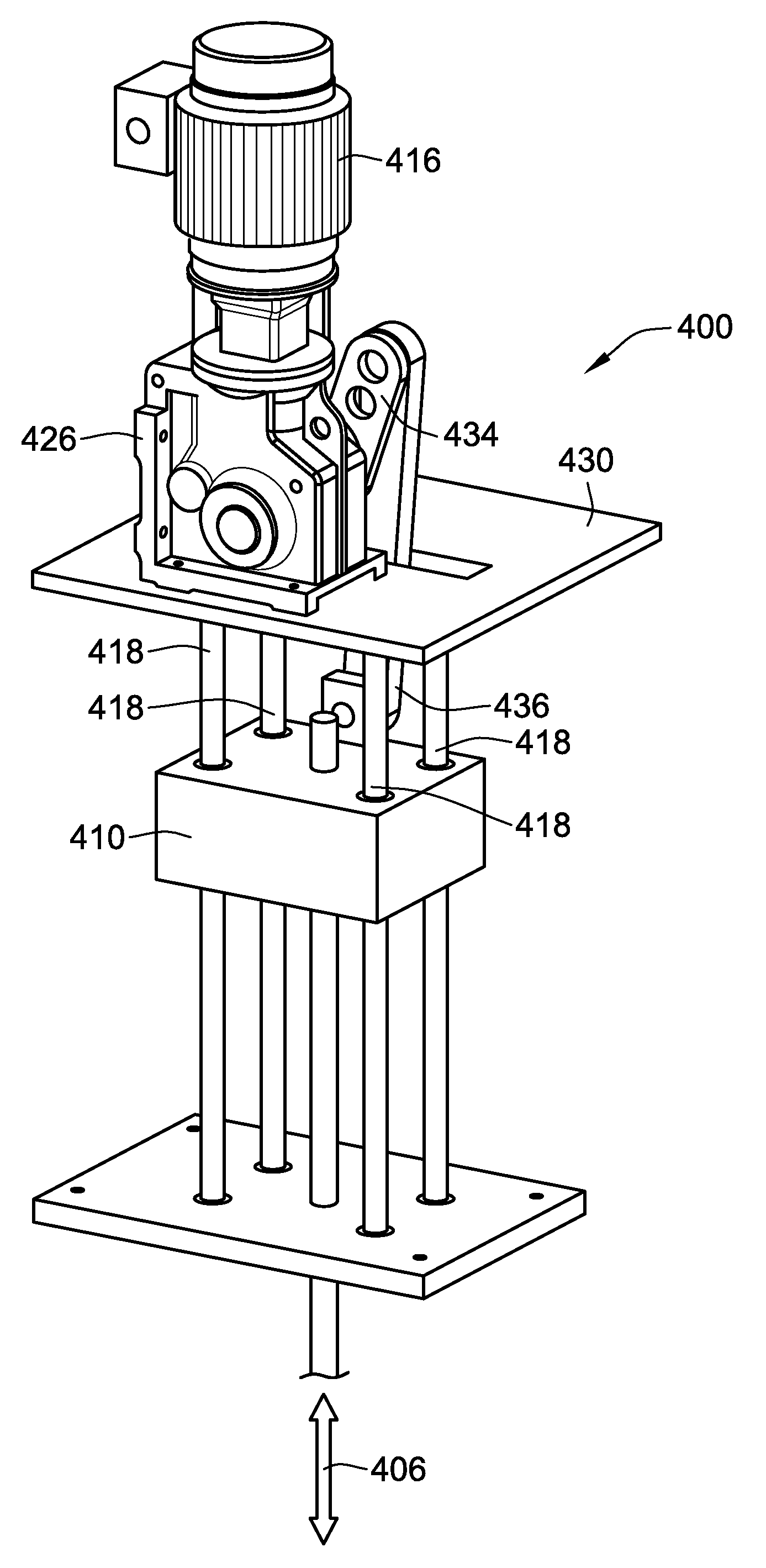

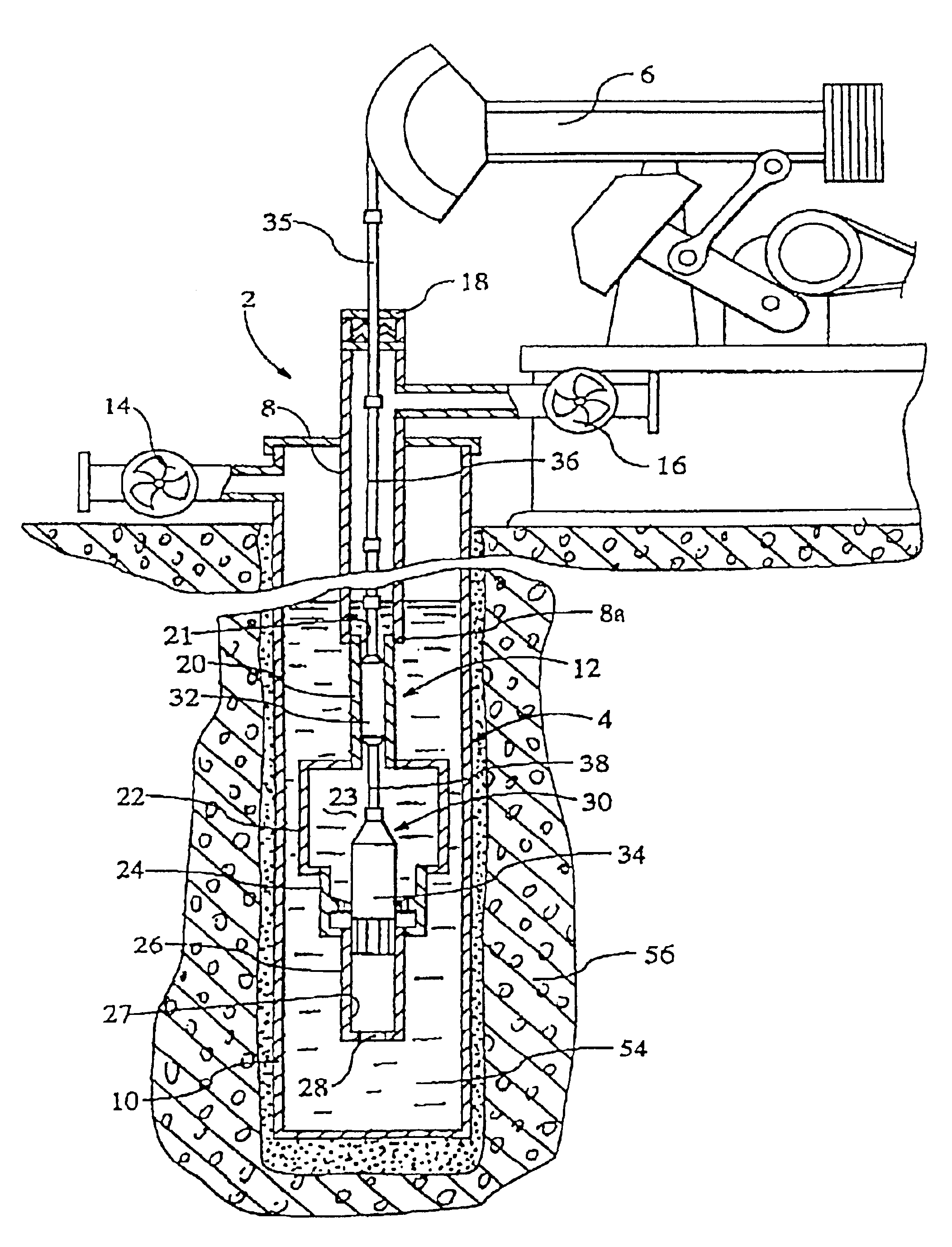

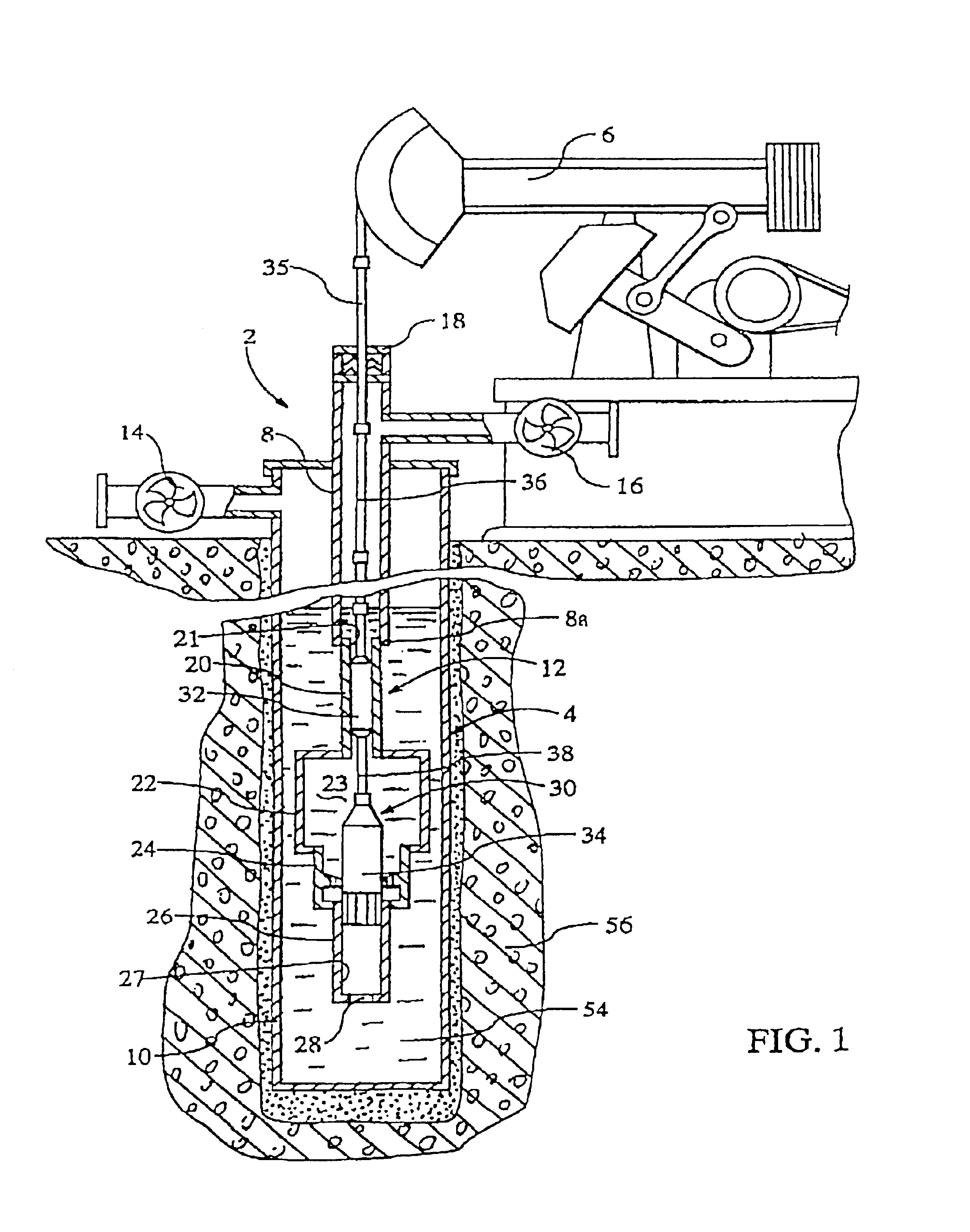

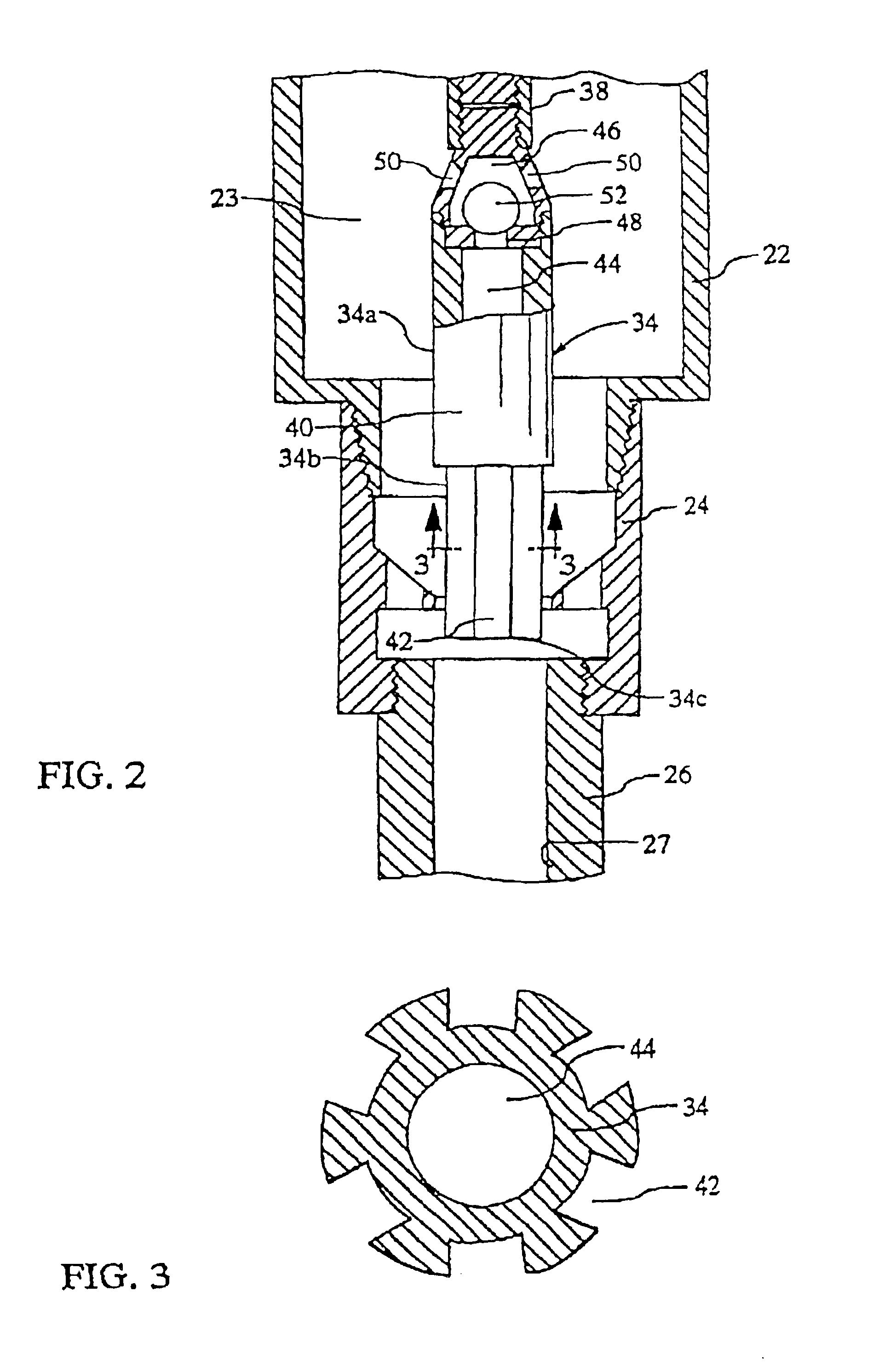

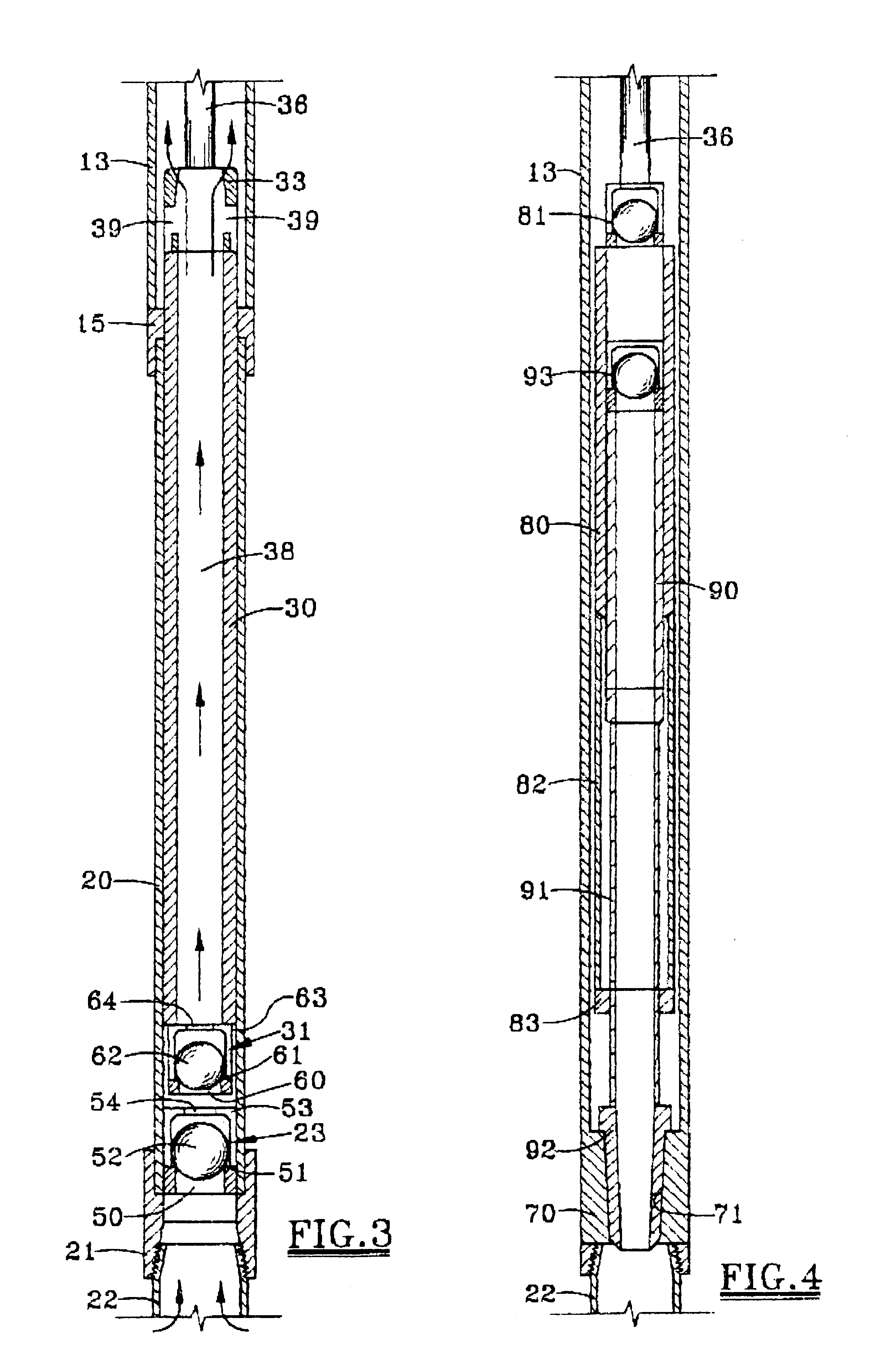

Method and apparatus for seismic stimulation of fluid-bearing formations

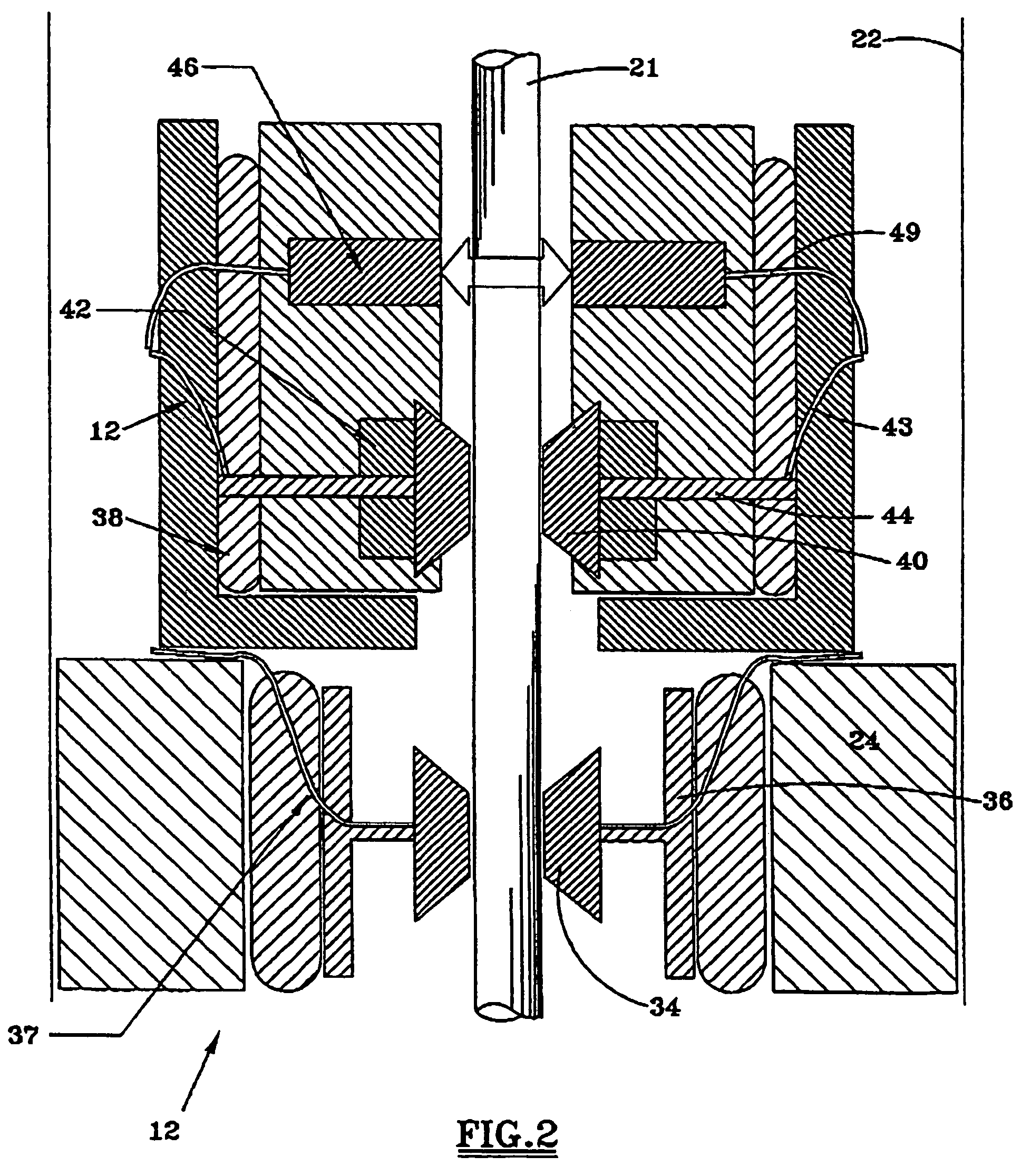

InactiveUS20030201101A1Volume of compression is reducedLarge caliberConstructionsFluid removalShock waveEngineering

An apparatus and seismic method for producing an shock wave in an oil well borehole, with a pumping unit arranged at the wellhead, a tubing string extending downward into the production casing of the well, a hollow cylinder assembly connected with the bottom of the tube string, and pair of plungers arranged within the cylinder assembly and connected with the pumping unit with sucker rods and a polish rod for compressing liquid contained within the cylinder assembly and discharging the compressed liquid into the production casing, thereby generating a shock wave. The cylinder assembly includes an upper cylinder, a lower cylinder below the upper cylinder, a crossover cylinder below the upper and lower cylinders, and a compression chamber cylinder containing a compression chamber arranged between the crossover cylinder and the upper cylinder. The lower cylinder is adapted to receive the lower plunger, and the upper cylinder is adapted to receive the upper plunger. The lower plunger has a larger diameter than the upper plunger, and the plunger movement effects the volume of the compression chamber by reduction, the liquid contained therein becomes compressed and is discharged on the down stroke into the well. In addition, remote seismic data is collected and processed from remote well locations.

Owner:APPLIED SEISMIC RES CORP

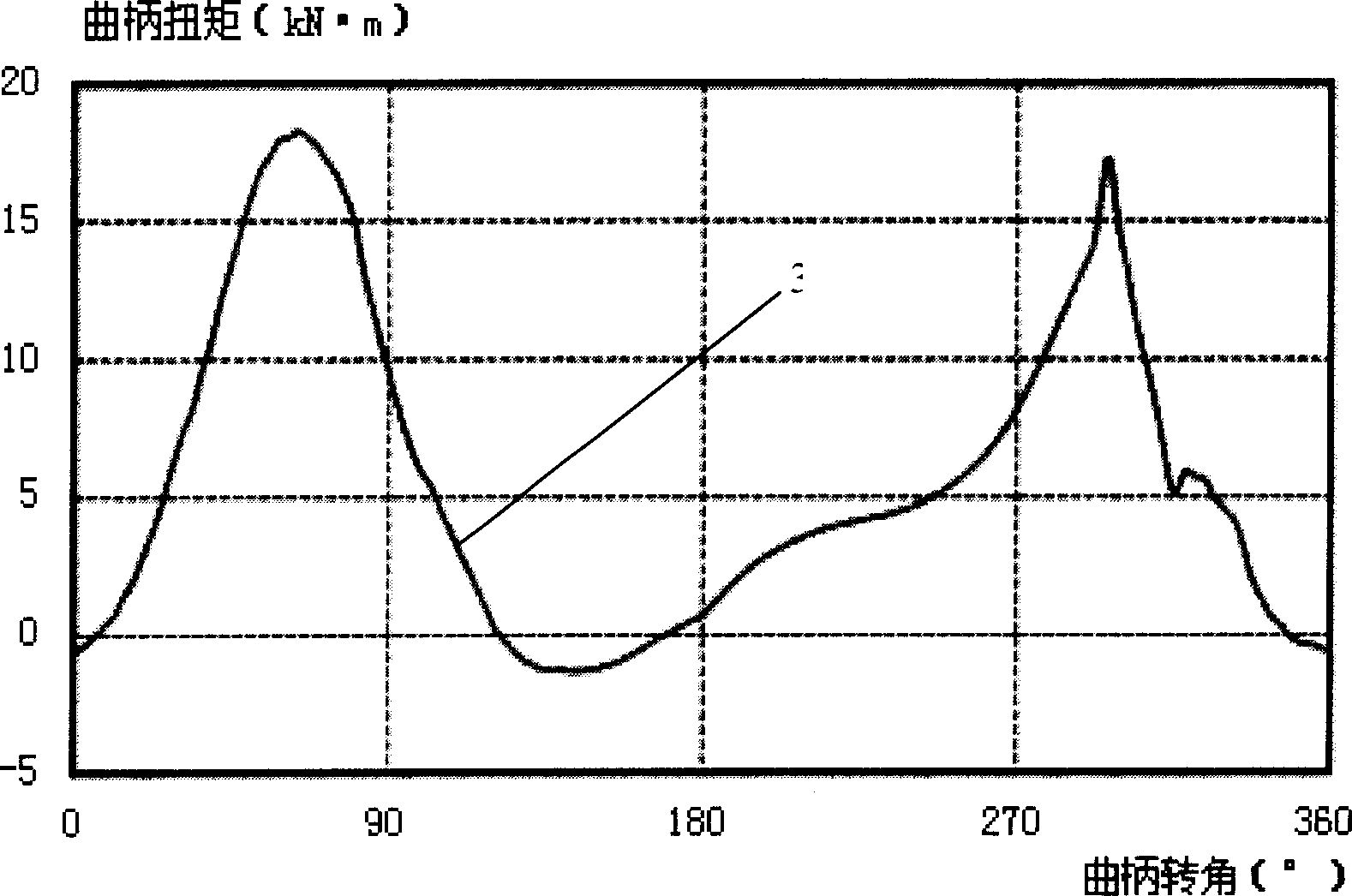

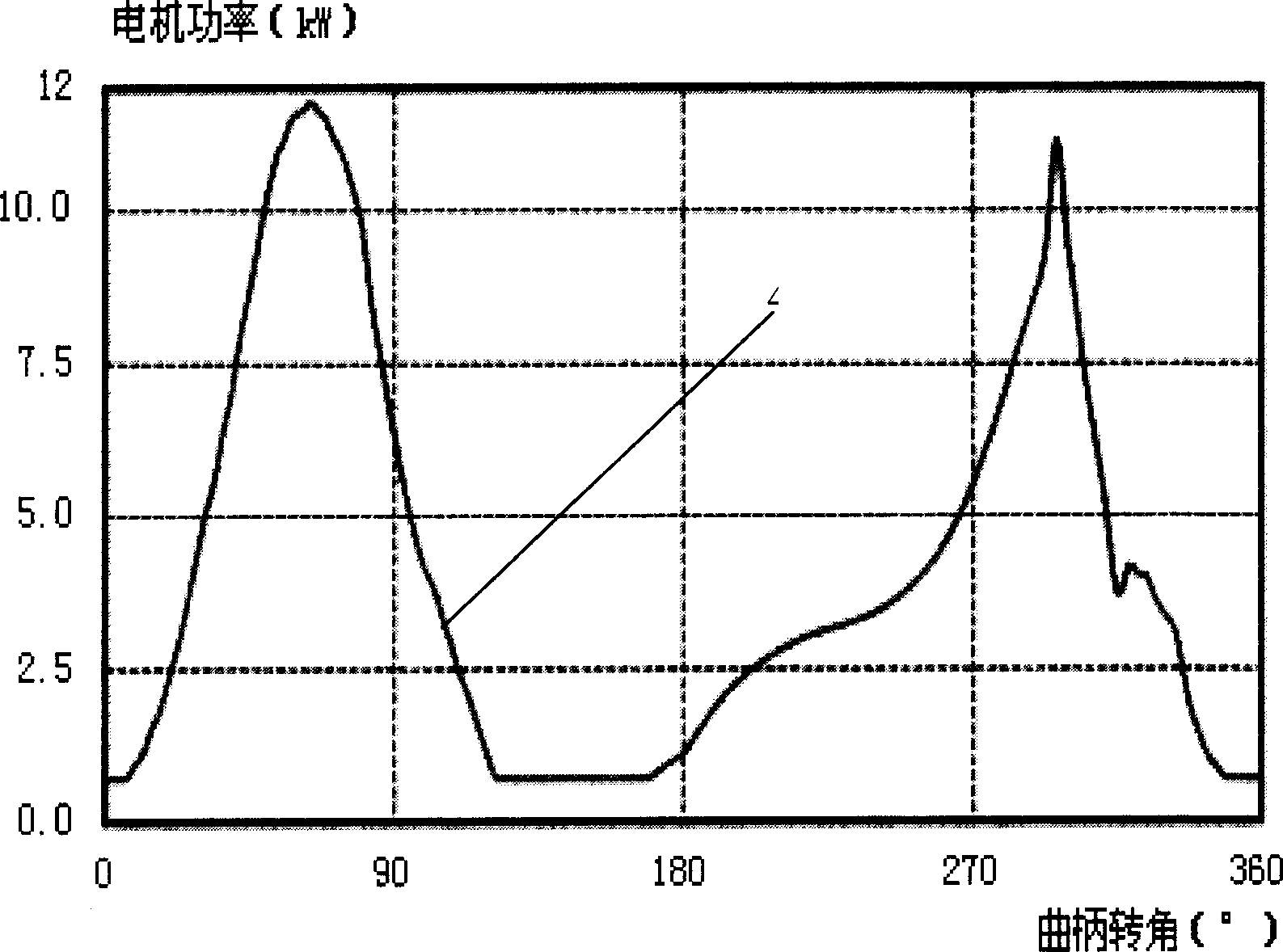

Cranked Rod Pump Apparatus And Method

ActiveUS20090097994A1Easy alignmentDrilling rodsPositive displacement pump componentsMotor driveActuator

An improved apparatus and method are provided, for pumping fluids, such as water and / or hydrocarbons, from a subterranean formation or reservoir, through use of a cranked rod pumping (CRP) apparatus for imparting reciprocating substantially vertical motion to a rod of a sucker-rod pump having a pump stroke. The CRP apparatus includes a motor driven cranked mechanical actuator arrangement. The cranked mechanical actuator arrangement includes a substantially vertically moveable member attached to the rod of the sucker-rod pump for imparting and controlling vertical motion of the rod of the sucker-rod pump. The actuator arrangement may include pneumatic counterbalancing.

Owner:UNICO LLC

Assembly and method of alternative pumping using hollow rods without tubing

InactiveUS20060278398A1Simple and robustReduce riskDrilling rodsConstructionsMotion transferSucker rod

Assembly and method for extracting fluids, preferably crude oil, from a drilled well within a geological formation by means of reciprocating pumping with hollow sucker rods. The assembly includes: a) a stationary bottom set attached to the casing at the desired depth and providing the rod pump anchoring system; b) a reciprocating axial movement rod pump having an anchoring system and a centralizer; c) a centralized hollow rod string extending within the well, which is connected to the mobile member of the pump; d) a hollow polished rod connected to the hollow rod string and linked to a system that imparts the reciprocating axial movement to the pump; e) a production bridge connecting the polished rod to the driving tubing through rotating joints, and f) a rigid head that provides a venting exit of the annular space formed between the string and the casing.

Owner:YPF SA

Method and apparatus for seismic stimulation of fluid-bearing formations

InactiveUS6899175B2Reduce volumeLarge caliberConstructionsFluid removalEngineeringMechanical engineering

An apparatus and seismic method for producing an shock wave in an oil well borehole, with a pumping unit arranged at the wellhead, a tubing string extending downward into the production casing of the well, a hollow cylinder assembly connected with the bottom of the tube string, and pair of plungers arranged within the cylinder assembly and connected with the pumping unit with sucker rods and a polish rod for compressing liquid contained within the cylinder assembly and discharging the compressed liquid into the production casing, thereby generating a shock wave. The cylinder assembly includes an upper cylinder, a lower cylinder below the upper cylinder, a crossover cylinder below the upper and lower cylinders, and a compression chamber cylinder containing a compression chamber arranged between the crossover cylinder and the upper cylinder. The lower cylinder is adapted to receive the lower plunger, and the upper cylinder is adapted to receive the upper plunger. The lower plunger has a larger diameter than the upper plunger, and the plunger movement effects the volume of the compression chamber by reduction, the liquid contained therein becomes compressed and is discharged on the down stroke into the well. In addition, remote seismic data is collected and processed from remote well locations.

Owner:APPLIED SEISMIC RES CORP

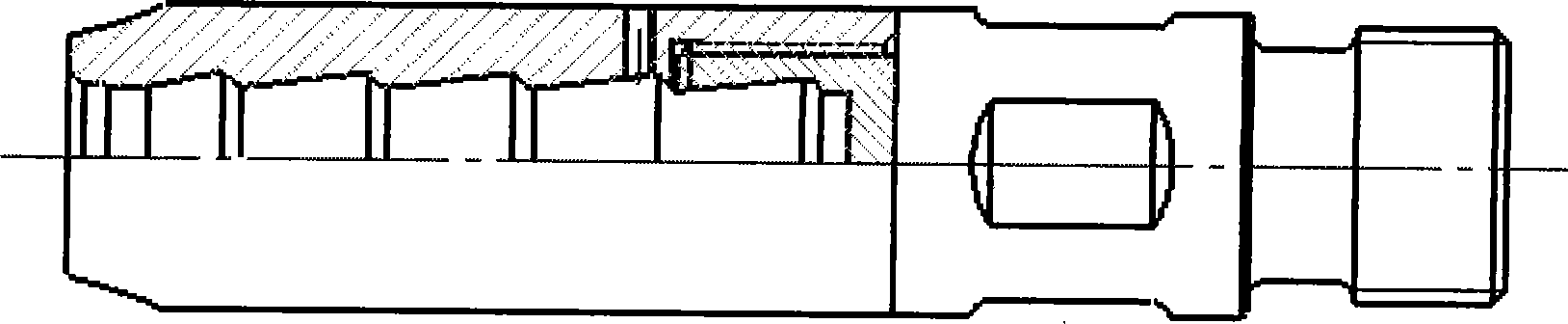

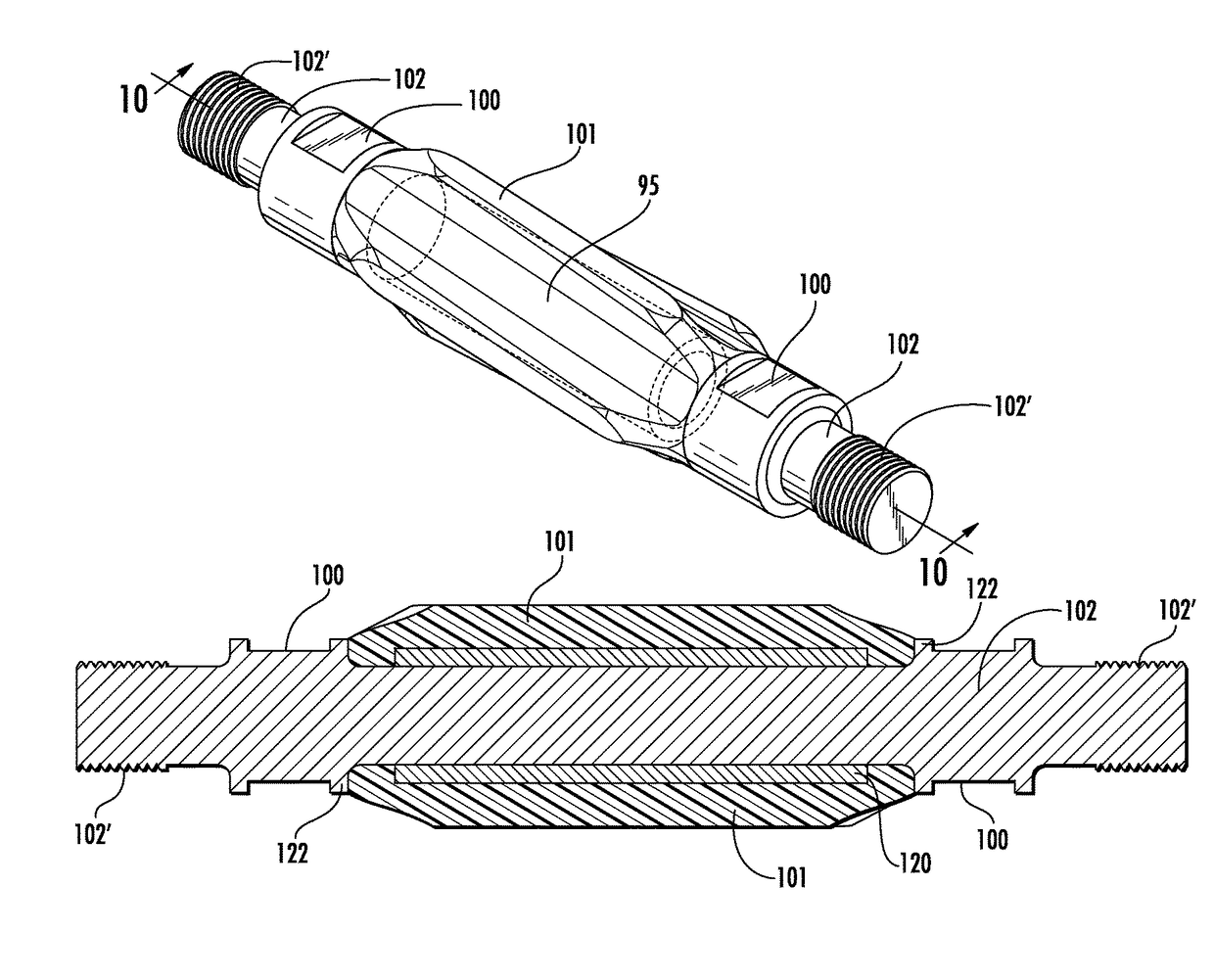

Sucker rod connection with improved fatigue resistance, formed by applying diametrical interference to reduce axial interference

ActiveUS7735879B2Improve the immunityEasy to controlHose connectionsScrew threaded jointsEngineeringScrew thread

A sucker rod connection is disclosed. The sucker rod connection comprises a tapered male member including a plurality of trapezoidal threads, and, a tapered female member also including a plurality of trapezoidal threads, in which the male member is capable of being received in threaded engagement with the female member, wherein the threads of the male member are in flank-to-flank contact, both flanks on each thread, with the threads of the female member, thereby creating diametrical interference between the male and female members preventing disengagement and substantially reducing axial interference between the male and female members.

Owner:SIDERCA I C

Methods, apparatus and products useful in the operation of a sucker rod pump during the production of hydrocarbons

InactiveUS20050155759A1Generated in real timeSurveyConstructionsHydrocotyle bowlesioidesProcess engineering

Apparatus, methods and products for monitoring / controlling a reciprocating well producing hydrocarbons from a wellbore, which determine the surface card from a well operating characteristics, determine the downhole card, and display both at the same scale for position.

Owner:LUFKIN INDUSTRIES

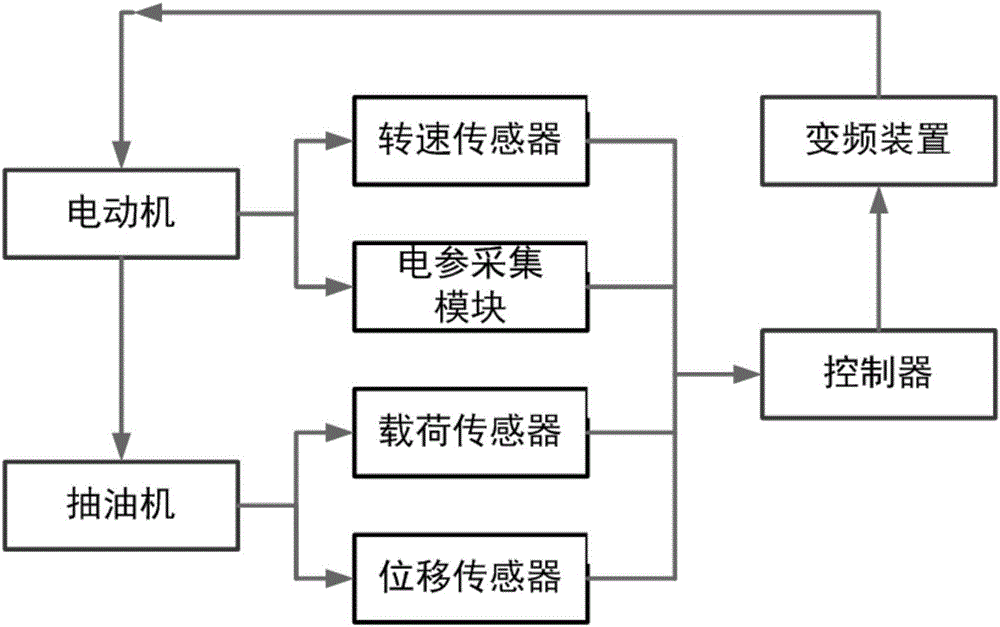

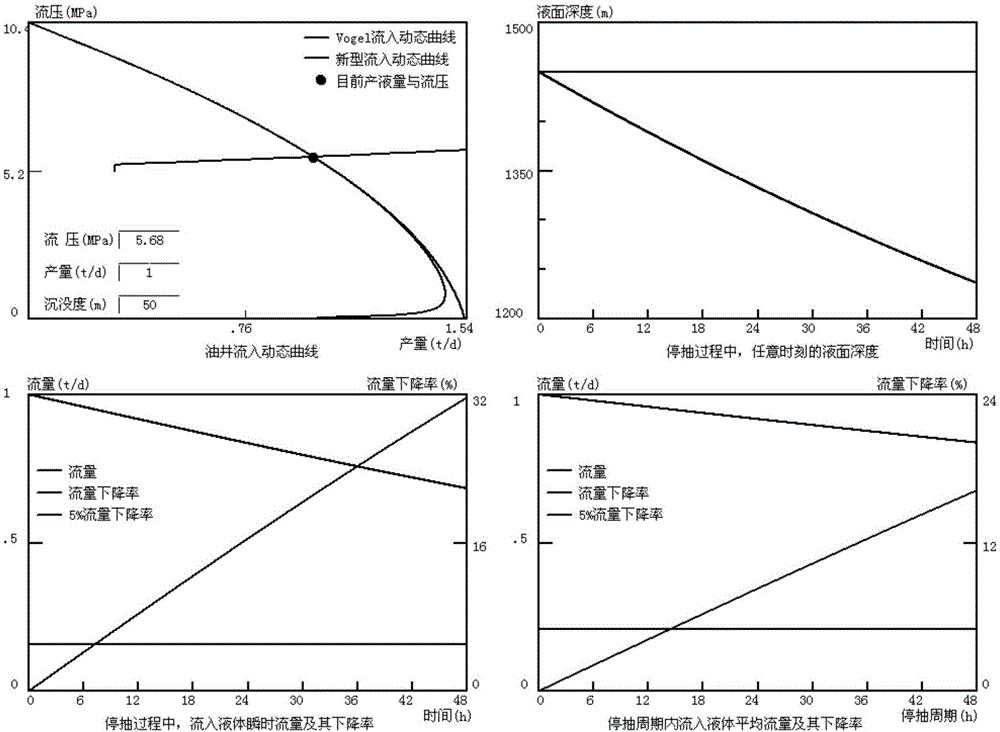

Oil well intermittent pumping control system and method

ActiveCN106762584ARealize energy saving and consumption reductionReduce lossConstructionsFluid removalPower flowControl system

The invention discloses an oil well intermittent pumping control system and method. The oil well intermittent pumping control system comprises an oil pumping unit, a controller and a motor, wherein the motor is connected with the oil pumping unit and used for driving the oil pumping unit; a rotational speed sensor and an electric parameter acquisition module are arranged on the motor and used for acquiring the output shaft rotational speed and the current and voltage value of the motor and sending to the controller; a load sensor and a displacement sensor are arranged on the oil pumping unit, connected with the controller and used for sending measured values of the load and the displacement of a well sucker rod of the oil pumping unit to the controller; and the controller is connected with the motor through a frequency converter and used for controlling start and stop of the motor. According to the oil well intermittent pumping control system, reasonable control is performed according to actual liquid outlet conditions, the requirement for supply and production coordination of an oil well is satisfied, intelligent stroke frequency adjustment and intelligent dynamic interval pumping control are utilized to realize energy saving and consumption reduction of the oil well and to reduce the loss of running equipment, follow-up control meets the demand for precise control of the oil well within a stroke cycle, the running efficiency of an oil well system is further improved, and the energy consumption is reduced.

Owner:PETROCHINA CO LTD

Organosilicone-nano compound modified polyurea corrosion-resisting coating for mechanical recovery well environment and preparation method for organosilicone-nano compound modified polyurea corrosion-resisting coating

InactiveCN102702947AEasy to processEasy toughnessAnti-corrosive paintsPolyurea/polyurethane coatingsTO-18Polyol

The invention discloses an organosilicone-nano compound modified polyurea corrosion-resisting coating for a mechanical recovery well environment. The coating comprises the following components in percentage by volume: 50 percent of component A and 50 percent of component R, wherein the component A is semi-prepolymer which is synthesized by using 30 to 50 parts of polyisocyanates of which functionality degree is 2 to 2.7, 20 to 40 parts of polyol and 10 to 30 parts of organosilane; free isocyanate accounts for 13 to 18 percent of the semi-prepolymer; and the component R comprises the following components in part by weight: 10 to 30 parts of nano powder, 40 to 60 parts of amino-terminated polyether, and 5 to 30 parts of amine chain extender. The invention also discloses a preparation method for the organosilicone-nano compound modified polyurea corrosion-resisting coating for the mechanical recovery well environment. The coating has the advantages that when sprayed on a pretreated sucker rod by the method, the component A and the component R are cured quickly, and are wear-resistant and high temperature-resistant; and by matching of primer, the coating is strong in adhesion and is suitable for the mechanical recovery well environment of which the well depth is less than 2,500m.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Wellhead positioned integrated guide vertical well repair catwalk and application method

ActiveCN111927347ARealize direct deliveryImprove work efficiencyDrilling rodsDrilling casingsMechanical engineeringSucker rod

The invention relates to a wellhead positioned integrated guide vertical well repair catwalk and an application method. According to the technical scheme of the wellhead positioned integrated guide vertical well repair catwalk, the two sides of a base are connected with a plurality of hydraulic supporting legs and a plurality of ground anchors and used for supporting the vertical catwalk; a lifting arm cylinder is hinged to a lifting arm; a guide rod is hinged to a guide rod cylinder; a guide rod diagonal brace is hinged to the guide rod; the lifting arm cylinder can drive the lifting arm to be turned over from the horizontal state to the vertical state; the guide rod cylinder can drive the guide rod to be turned over from the horizontal state to the vertical state; the guide rod diagonalbrace can make the guide rod maintain the vertical state; and the guide rod diagonal brace can be taken down in a transportation state for independent storage. The wellhead positioned integrated guidevertical well repair catwalk has the beneficial effects that an oil pipe or a sucker rod is turned over by 90 degrees and conveyed to above a wellhead instead of an original lifting mode; the intermediate link that the oil pipe or the sucker rod in an original lifting catwalk is conveyed to the wellhead and is in an inclined state is omitted; and the oil pipe or the sucker rod is directly conveyed from the horizontal state to the vertical state, and the working efficiency in the catwalk is improved.

Owner:SLOF KANGBEI IND & TRADING

Downstroke sucker rod pump and method of use

InactiveUS6497561B2Reduce electricity costsPositive displacement pump componentsFlexible member pumpsReciprocating motionEngineering

Owner:SKILLMAN MILTON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com