Method for determining oil pumping machine well system parameter

A technology for pumping wells and system parameters, which is applied to earthwork drilling, mechanical equipment, wellbore/well components, etc., can solve the problem of not fully considering the influence of the instantaneous transmission efficiency of the pumping well system, not fully considering the influence of the gas phase, and not Fully consider load characteristics and other issues to achieve the effect of improving production management level, wide application and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

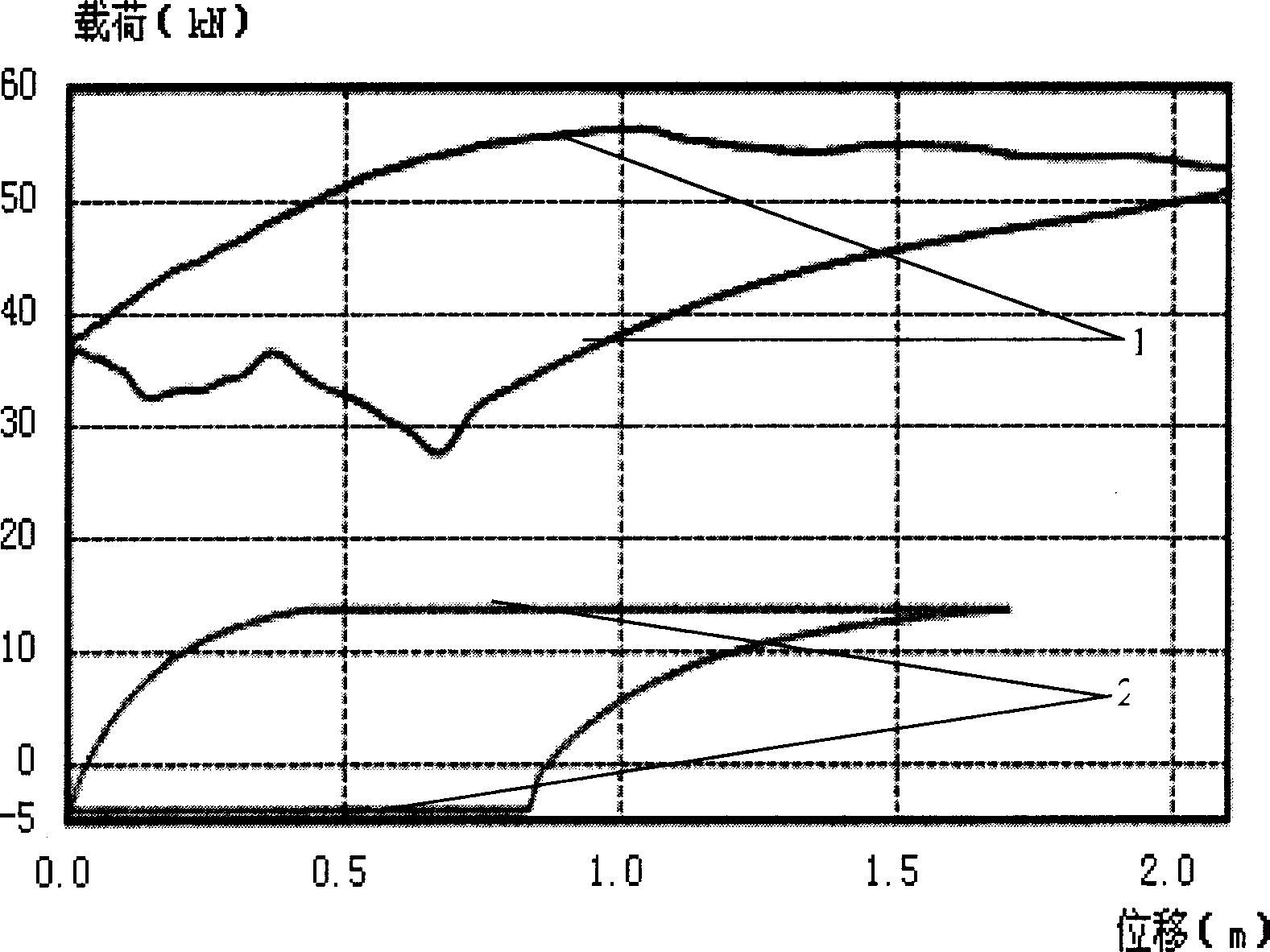

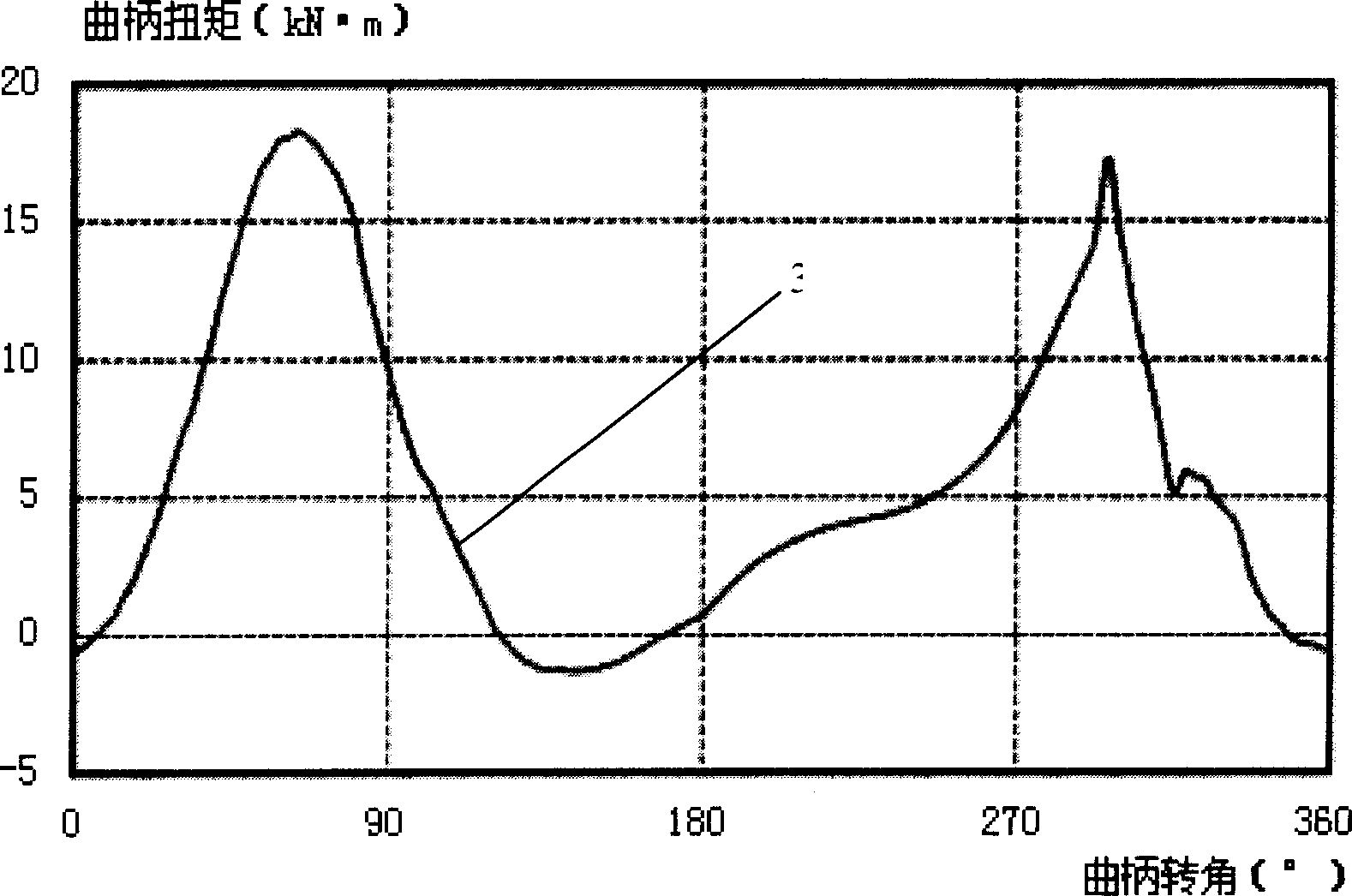

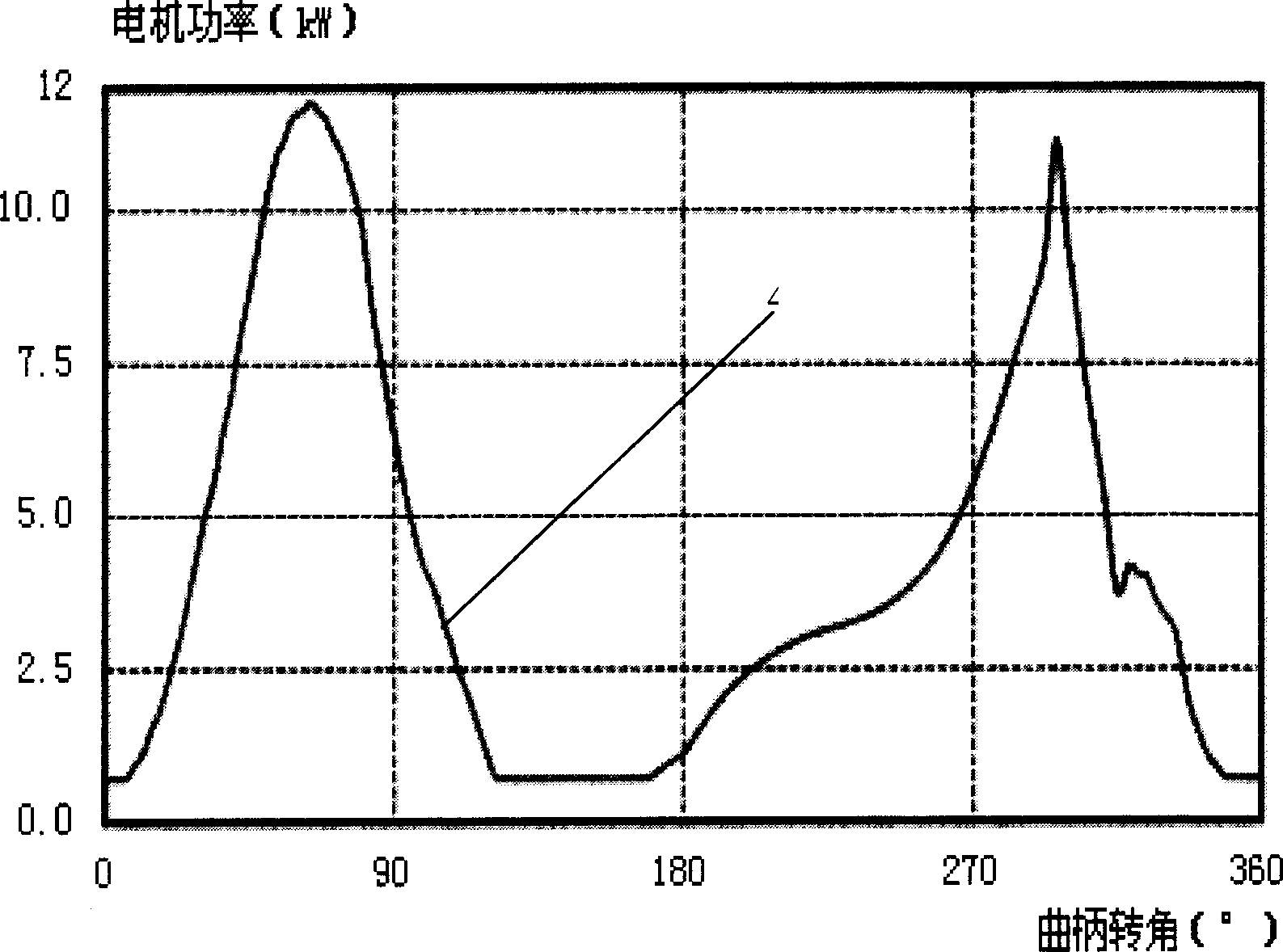

[0093] Well No. 1: The basic data of the oil well are: the depth of the middle part of the oil layer is 1865m, the density of crude oil is 0.88, the viscosity of crude oil is 26.76mPa·s, the stroke is 2.6m, and the stroke frequency is 5.12min -1 , pump depth 1200.58m, pump diameter 38mm, liquid production rate 17t / d, dynamic liquid surface 1048m, water content 91.2%, oil pressure 0.96MPa, casing pressure 0.2MPa, pumping unit model CYJ10-5-53HB (according to pumping Pumping unit geometric dimensions can be obtained from the pumping unit model), the rated power of the motor is 18.5kW; the D-class sucker rod combination is Φ25mm×252.94m+Φ22mm×337.36m+Φ19mm×593.8m, and the inner diameter of the tubing is Φ62mm.

[0094] ①The parameter values currently used by the well: stroke 2.6m, stroke frequency 5.12min -1 , pump diameter 38mm, pump depth 1200m, sucker rod diameter and length combination Φ25mm×252.94m+Φ22mm×337.36m+Φ19mm×593.8m, motor installed power 18.5kW and other variable...

example 2

[0122] Well No. 2: The basic data of the oil well are: the depth of the middle part of the oil layer is 2000m, the density of crude oil is 0.86, the viscosity of crude oil is 4mPa·s, the stroke is 2m, and the stroke frequency is 9.11min -1 , pump depth 1512m, pump diameter 38mm, liquid production rate 22.11t / d, dynamic liquid surface 1018m, water content 64.5%, oil pressure 0.3MPa, casing pressure 0.4MPa, pumping unit model CYJ10-3-53HB (according to pumping Pumping unit geometric dimensions can be obtained from the pumping unit model), the rated power of the motor is 18.5kW; the D-class sucker rod combination Ф22mm×400m+Φ19mm×500m+Φ22mm×612m, the inner diameter of the oil pipe is Φ62mm.

[0123] ① The parameter values currently used by the well: stroke 2m, stroke times 9.11min -1 , pump diameter 38mm, pump depth 1512m, sucker rod diameter and length combination Φ22mm×400m+Φ19mm×500m+Φ22mm×612m, motor installed power 18.5kW and other variable parameters, calculate the change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com