Patents

Literature

157 results about "Stroke frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

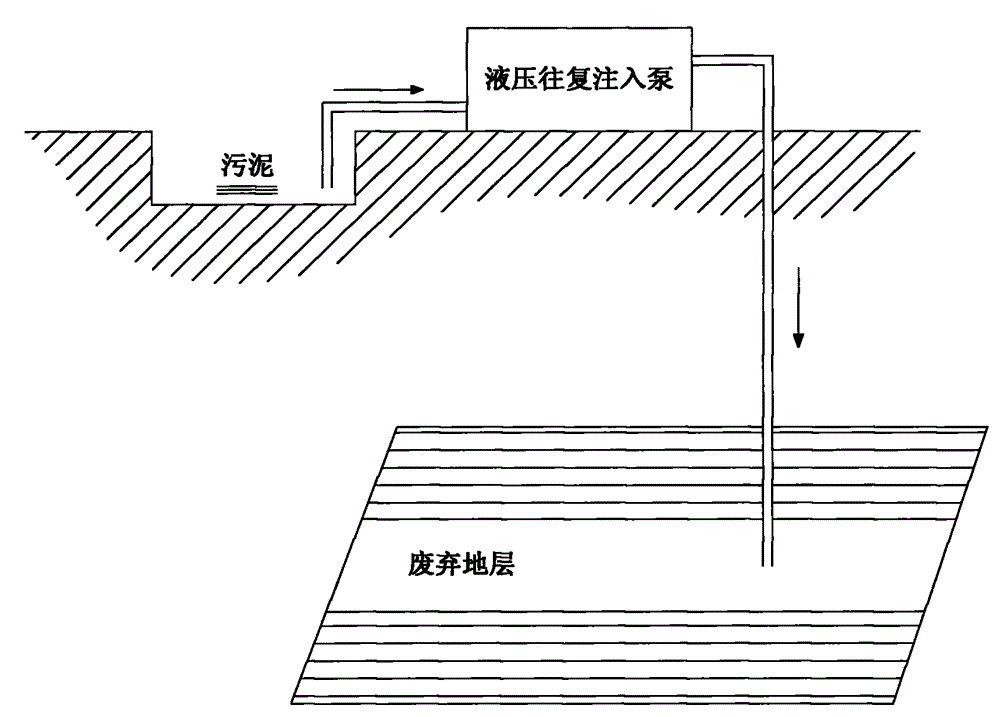

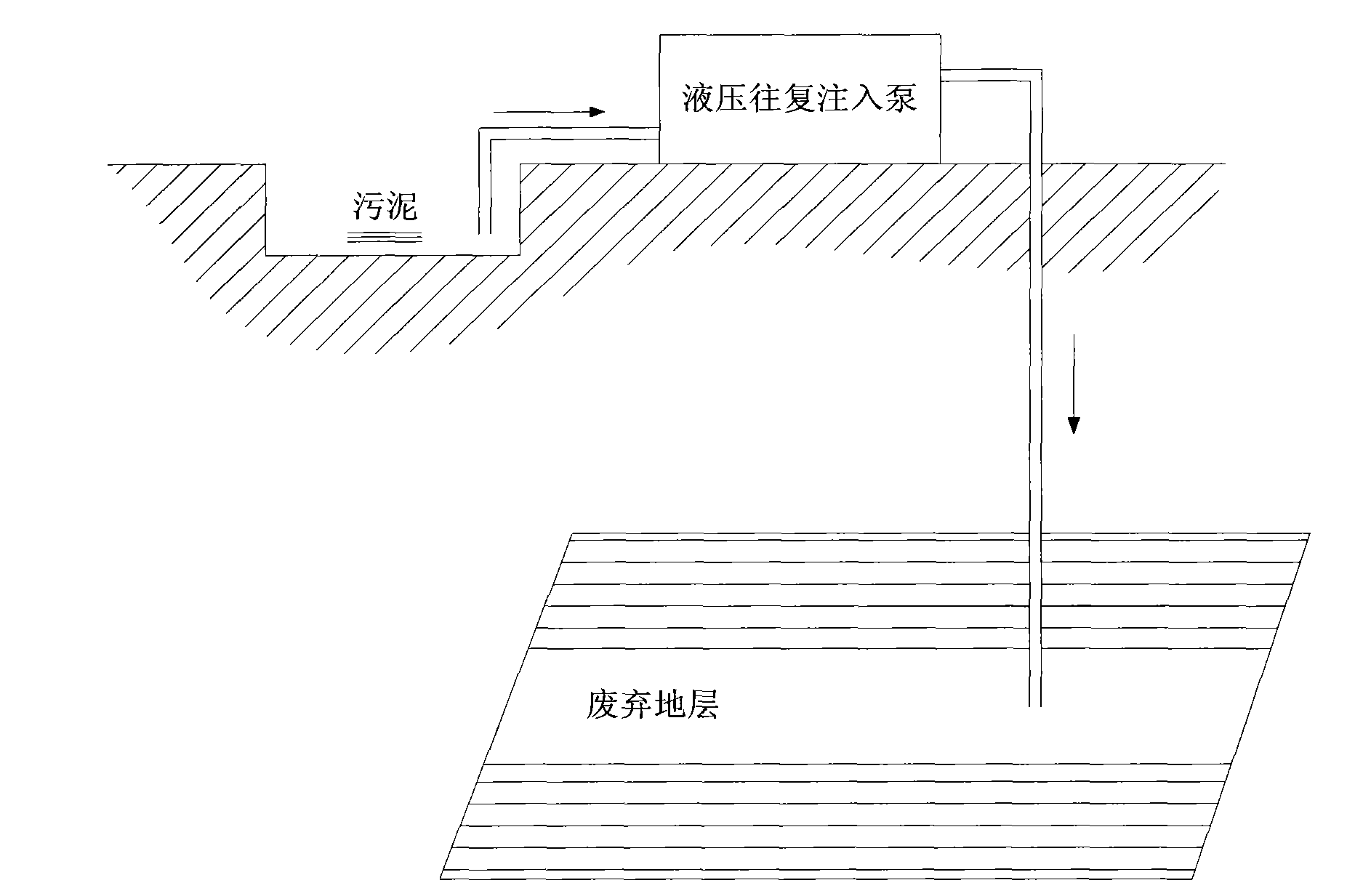

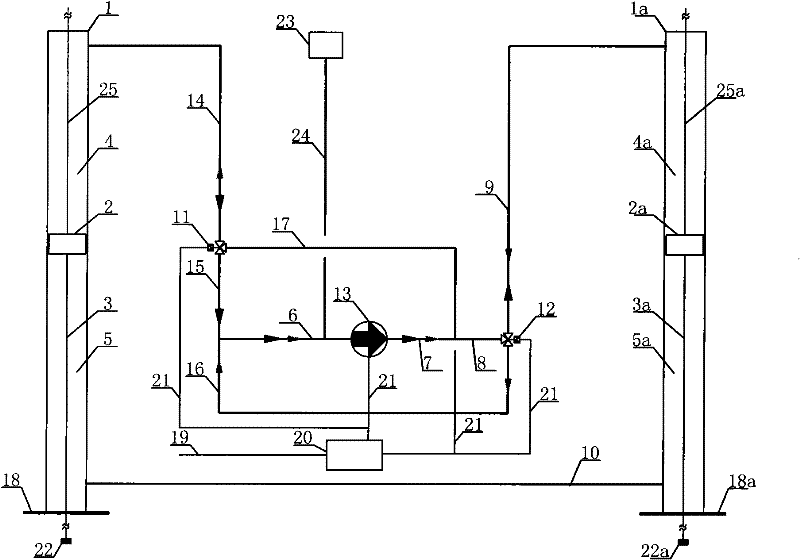

Harmless treatment method for reinjection of oil mining sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Harmless reinjection treatment method for petroleum exploitation sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

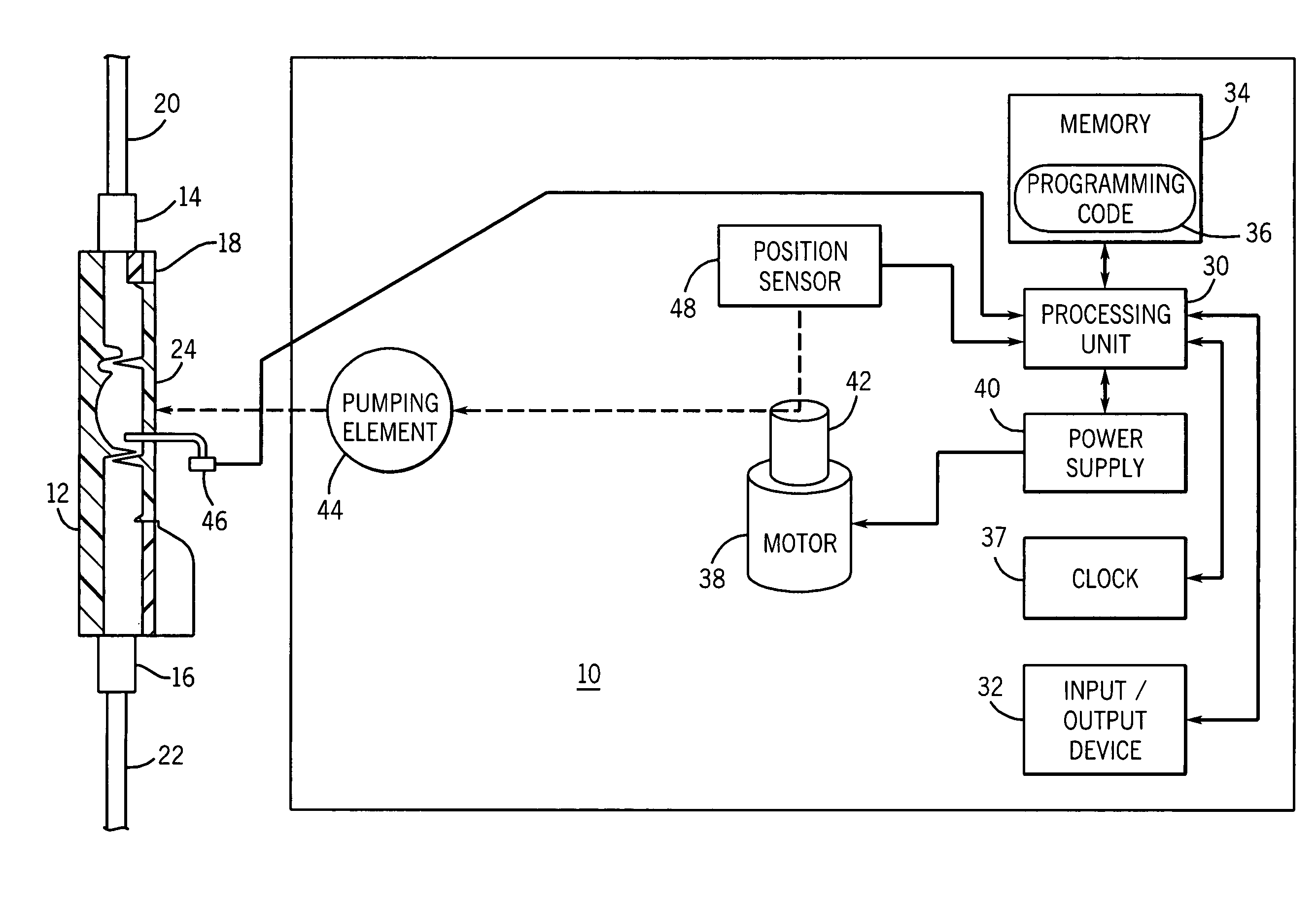

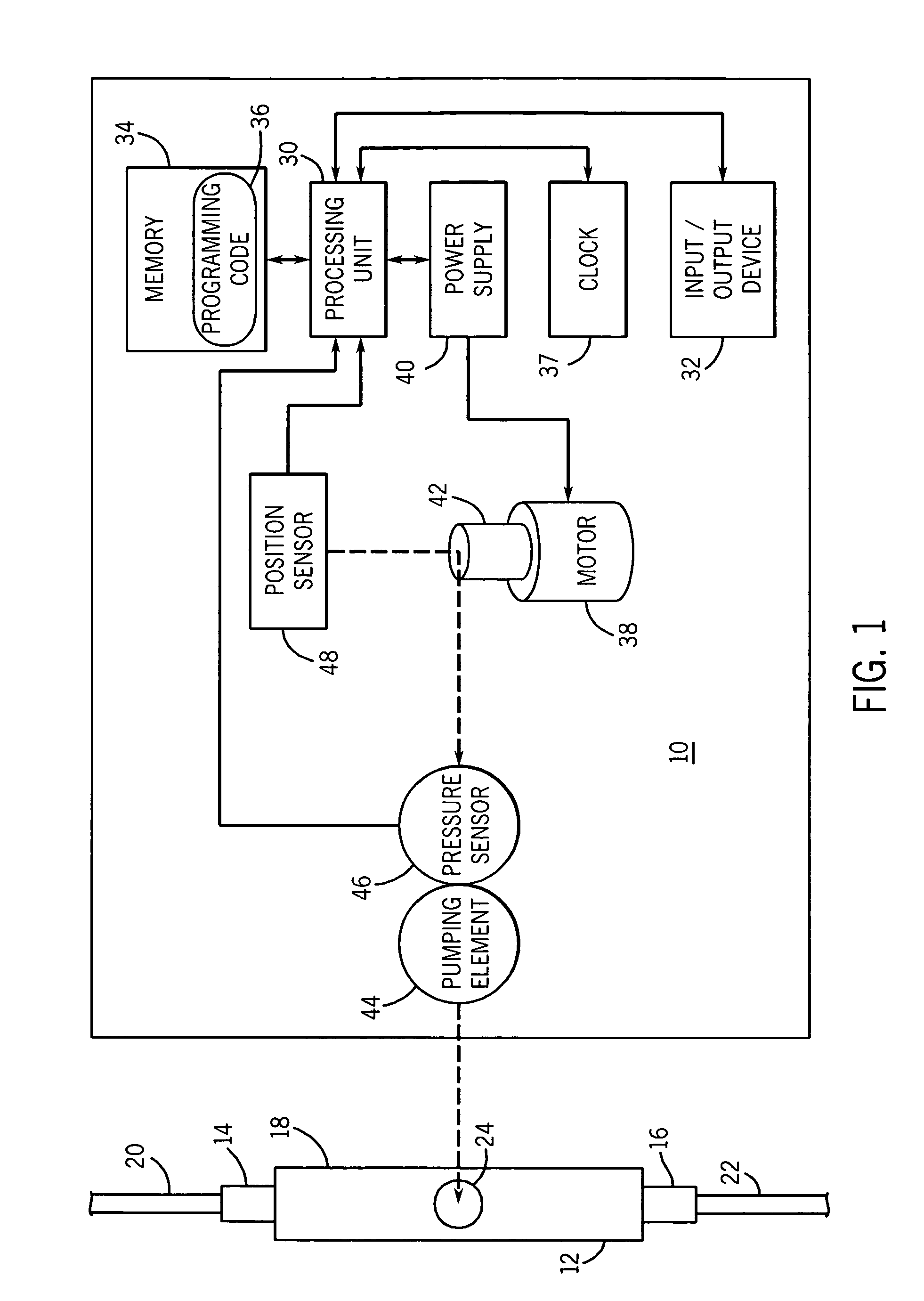

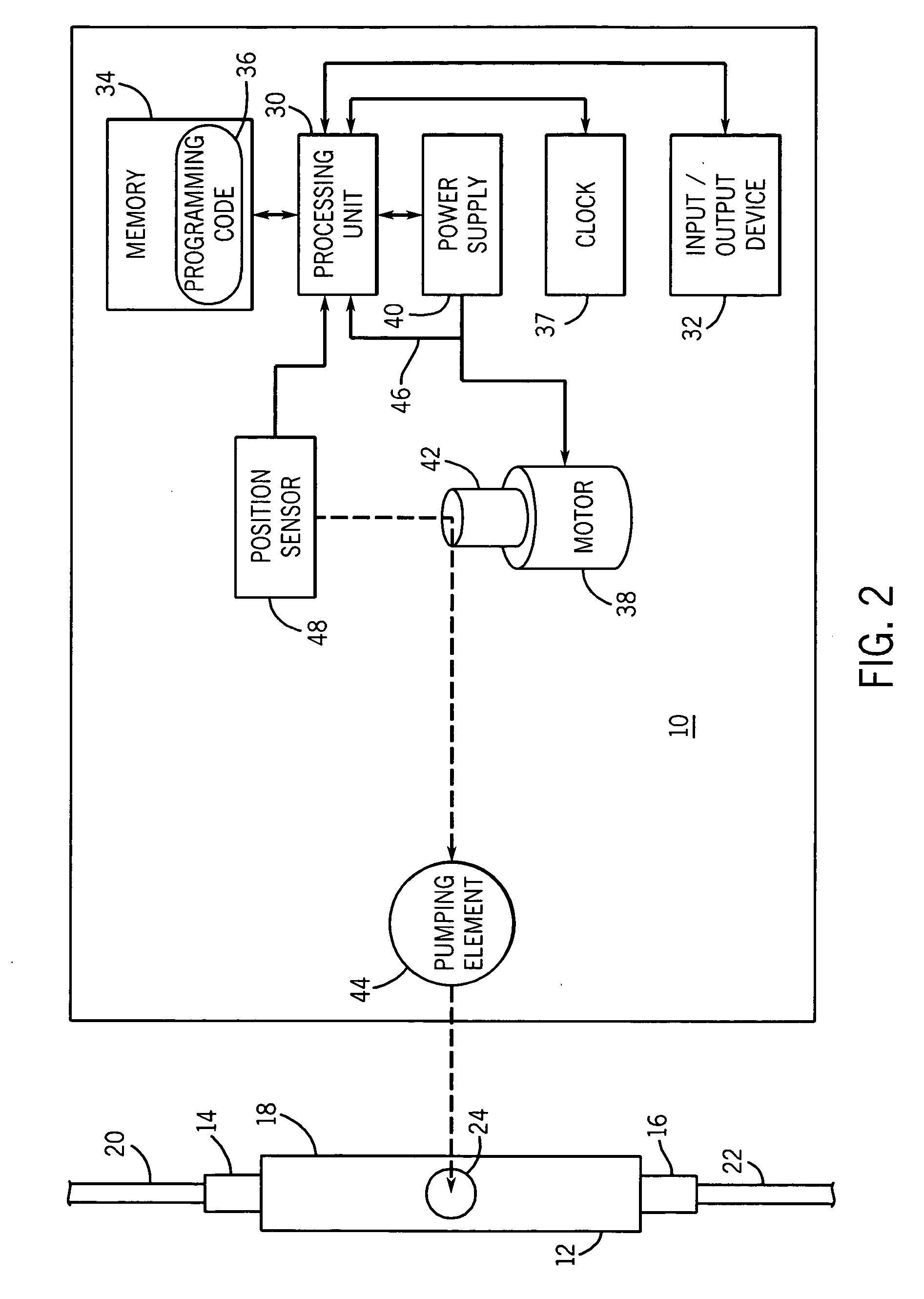

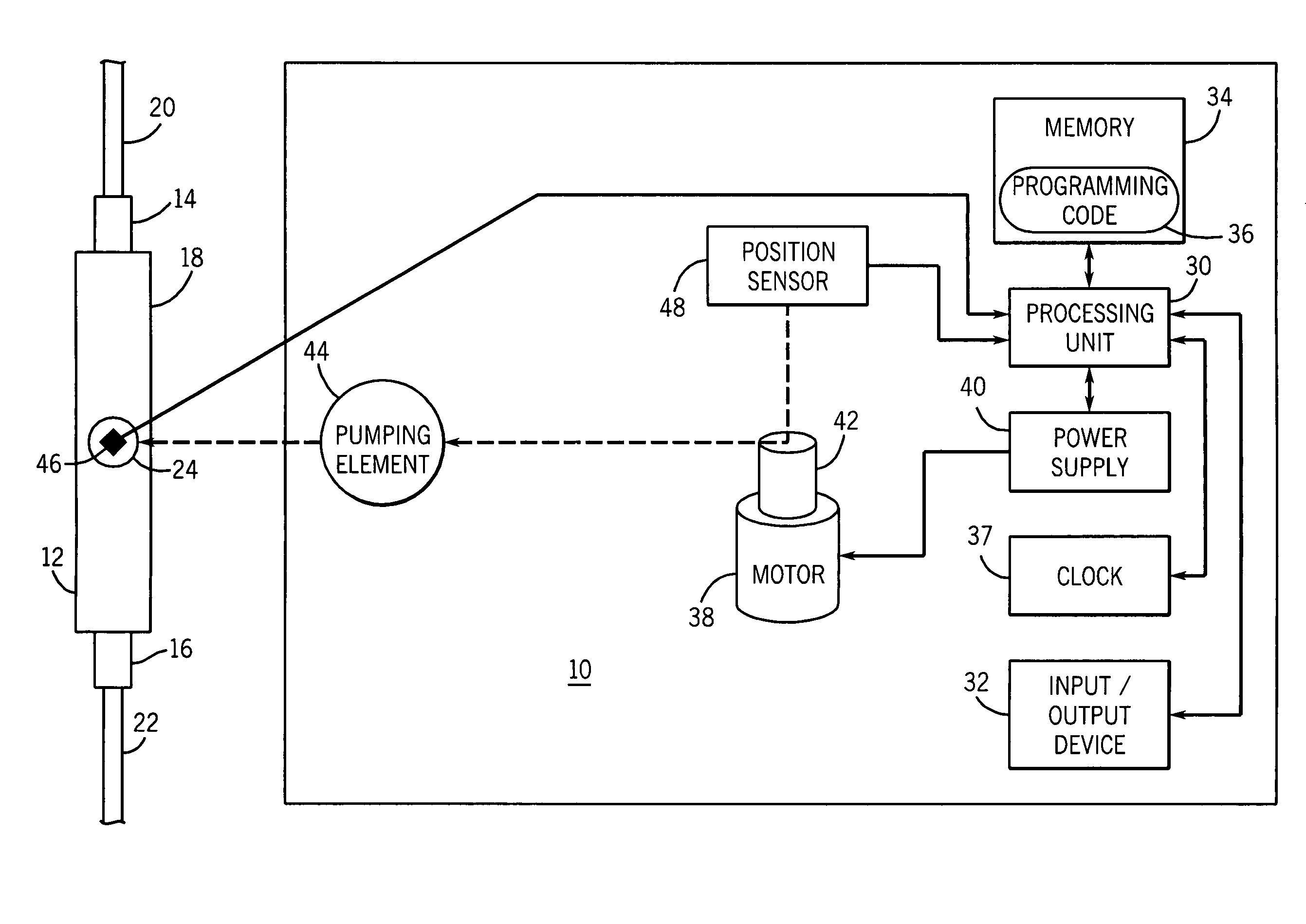

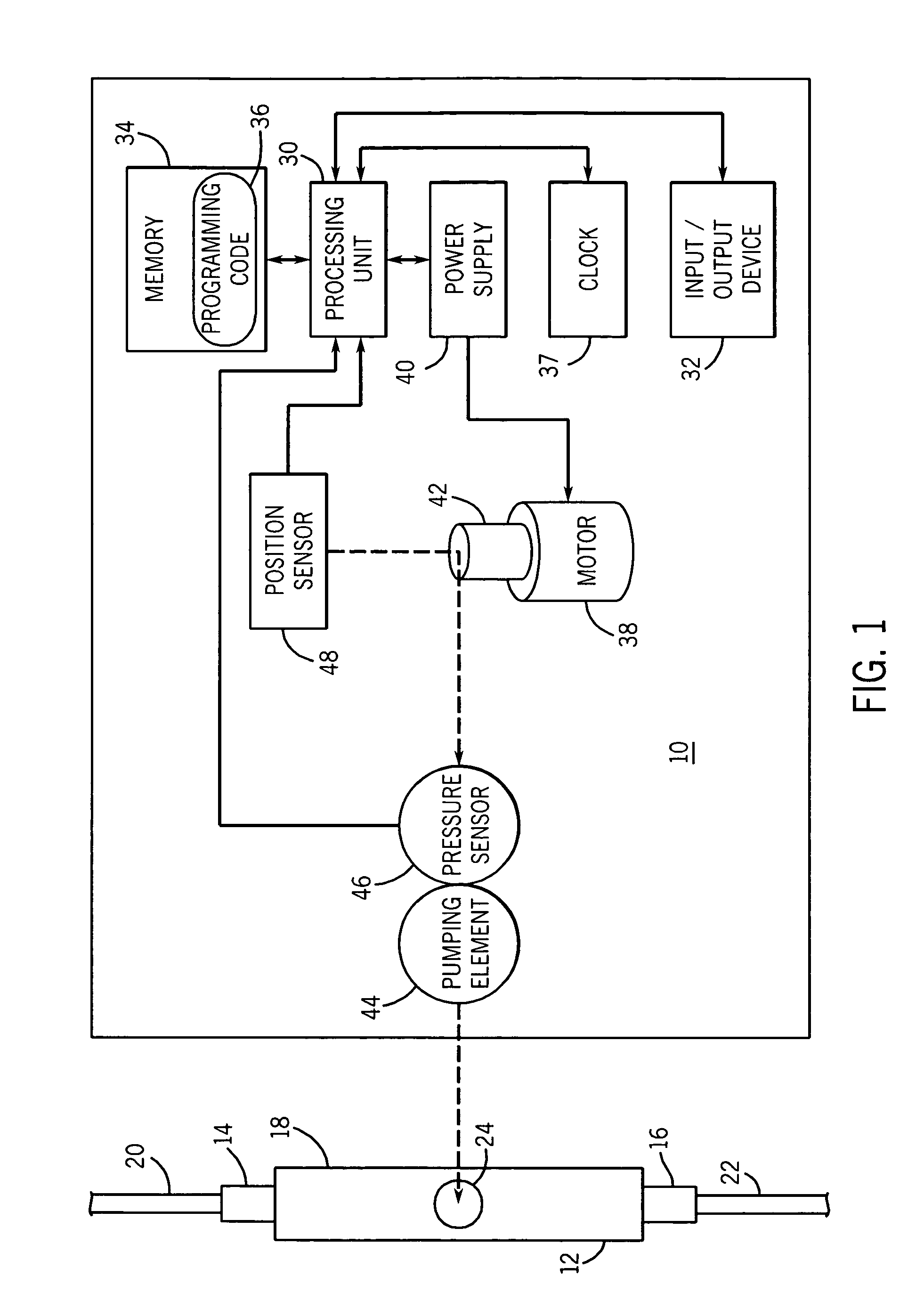

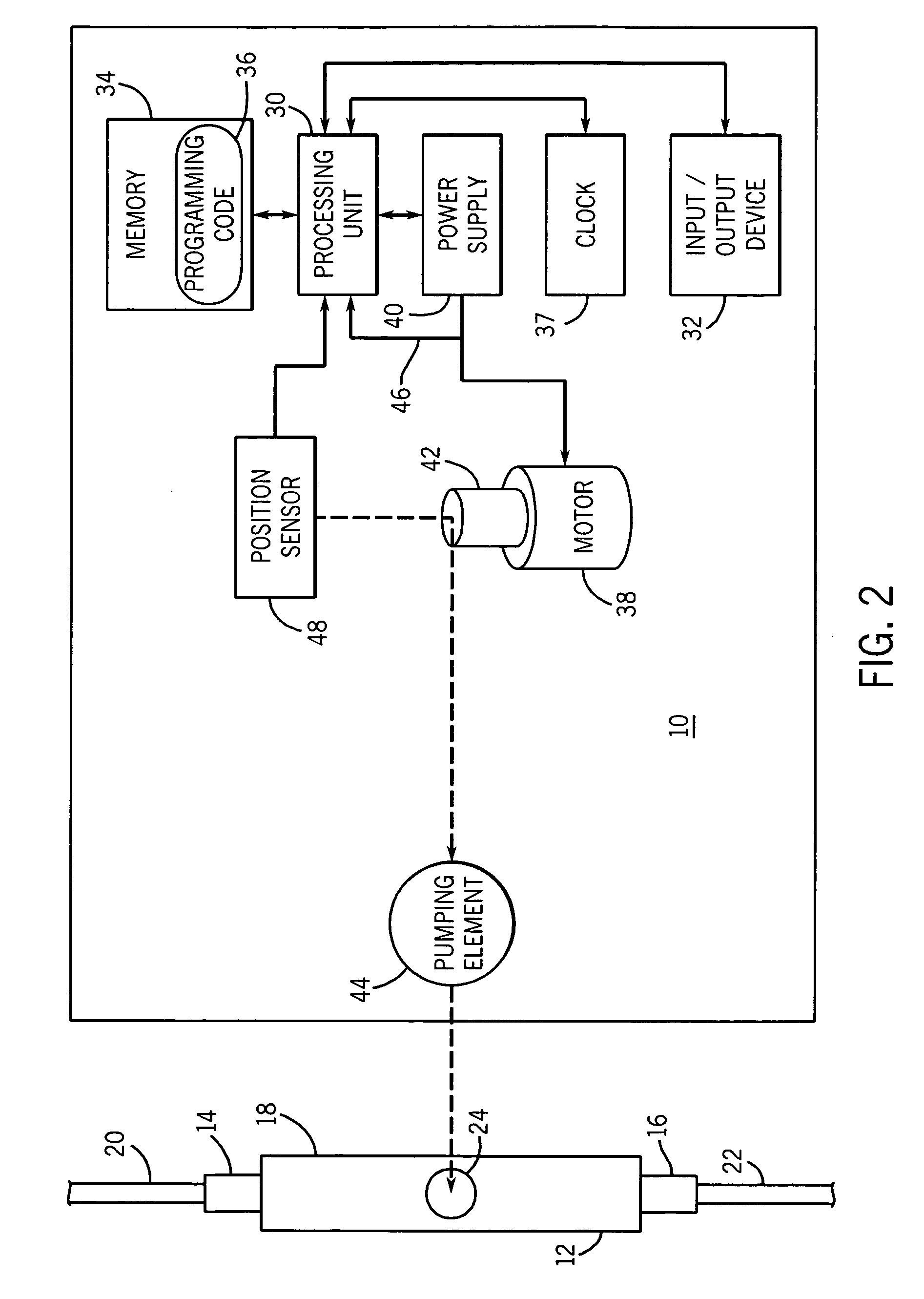

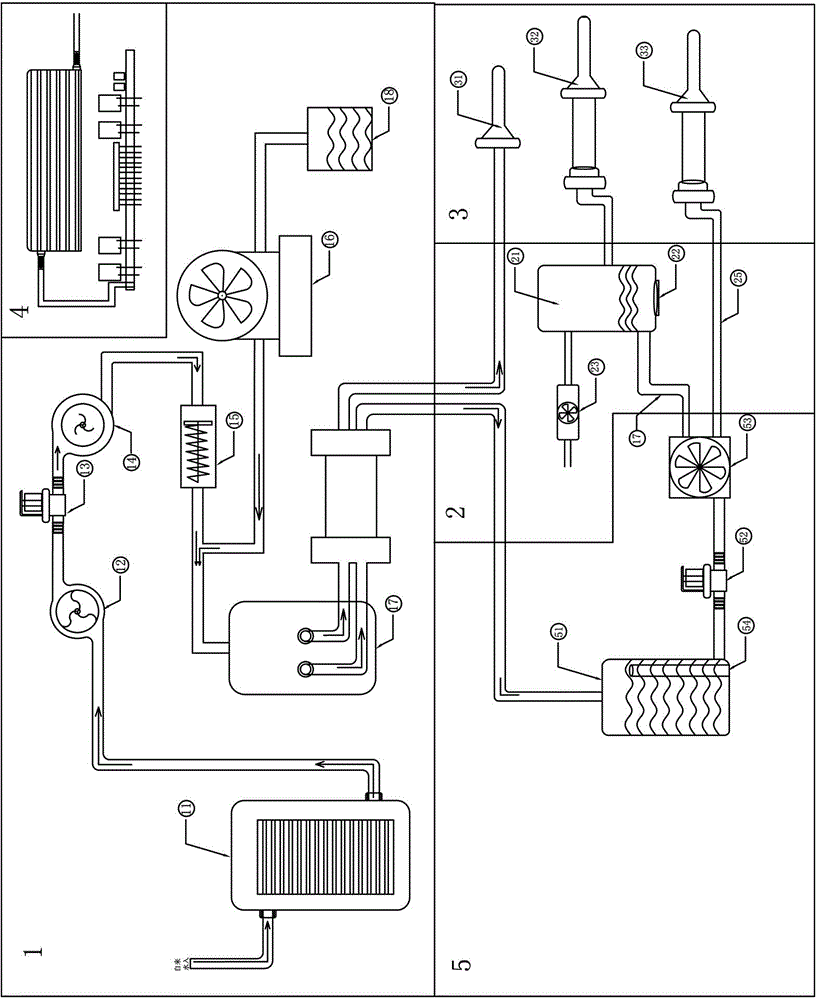

Medical infusion pump with closed loop stroke feedback system and method

ActiveUS20050214129A1Flexible member pumpsMedical devicesLeft ventricular Stroke volumeStroke frequency

A medical pump with a closed loop stroke feedback system and method, for use with a pumping chamber, for example in a cassette, is disclosed. The pump includes a pumping element that intermittently pressurizes a pumping chamber during a pumping cycle. A pressure sensor detects the pressure exerted by the pumping element on the pumping chamber. A position sensor detects the position of the pumping element. A processing unit processes pressure data from the pressure sensor and position data from the position sensor to determine a calculated stroke volume of the pump for a pump cycle, and to adjust a stroke frequency of the pump to compensate for variation in the stroke volume.

Owner:ICU MEDICAL INC +1

Medical infusion pump with closed loop stroke feedback system and method

A medical pump with a closed loop stroke feedback system and method, for use with a pumping chamber, for example in a cassette, is disclosed. The pump includes a pumping element that intermittently pressurizes a pumping chamber during a pumping cycle. A pressure sensor detects the pressure exerted by the pumping element on the pumping chamber. A position sensor detects the position of the pumping element. A processing unit processes pressure data from the pressure sensor and position data from the position sensor to determine a calculated stroke volume of the pump for a pump cycle, and to adjust a stroke frequency of the pump to compensate for variation in the stroke volume.

Owner:ICU MEDICAL INC +1

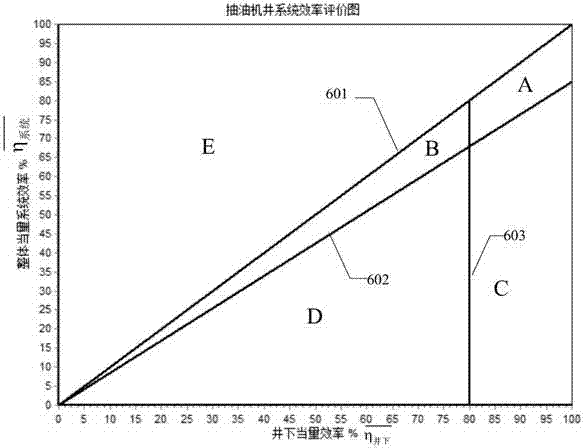

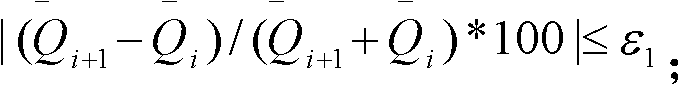

Parameter adjusting method and system for improving system efficiency of rod-pumped well

ActiveCN103498647AImprove system efficiencyImprove efficiencyFluid removalPressure dataStroke frequency

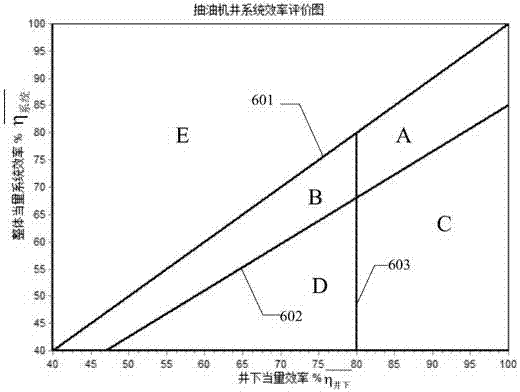

The invention discloses a parameter adjusting method and system for improving the system efficiency of a rod-pumped well. The method comprises the steps that the downhole equivalent efficiency and the equivalent system efficiency are determined according to the ground efficiency of a pumping well system, the ground efficiency ideal value, the downhole efficiency of the pumping well system and the downhole efficiency ideal value, and an efficiency evaluation map of the pumping well system is established; the area is divided when the equivalent efficiency in the efficiency evaluation map of the pumping well system is smaller than the downhole equivalent efficiency according to the preset ground equivalent efficiency and the preset downhole equivalent efficiency; the active power, the polished rod loads, the stroke, the stroke frequency, the liquid production capacity of a single well pumping well, the dynamic liquid depth of the single well pumping well, wellhead oil pressure data and wellhead casting pressure data are collected to determine the downhole equivalent efficiency of a single well and the equivalent system efficiency of the single well, determine the area dividing positions of the single well in the evaluation map, and adjust the parameters of the pumping well system. The system efficiency level of different type pumping wells is evaluated fairly, and the method for improving the system efficiency of the pumping well is provided.

Owner:PETROCHINA CO LTD

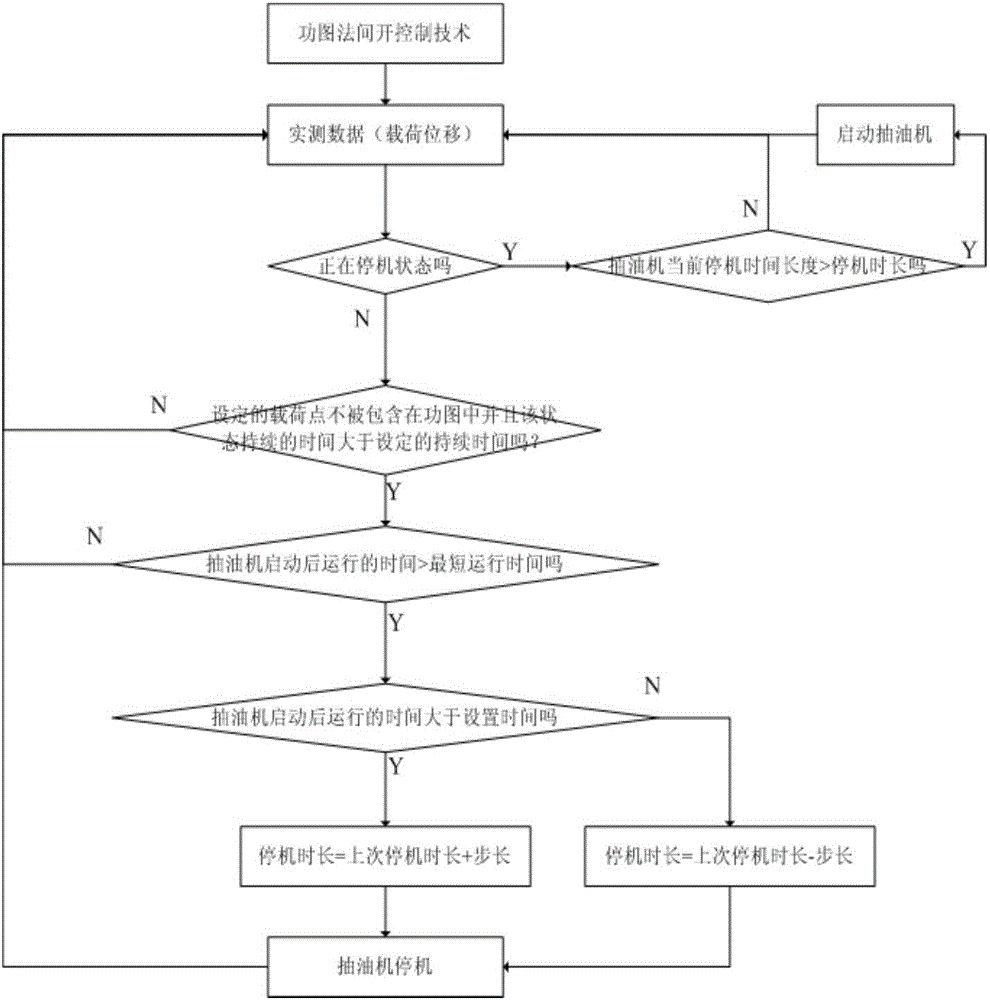

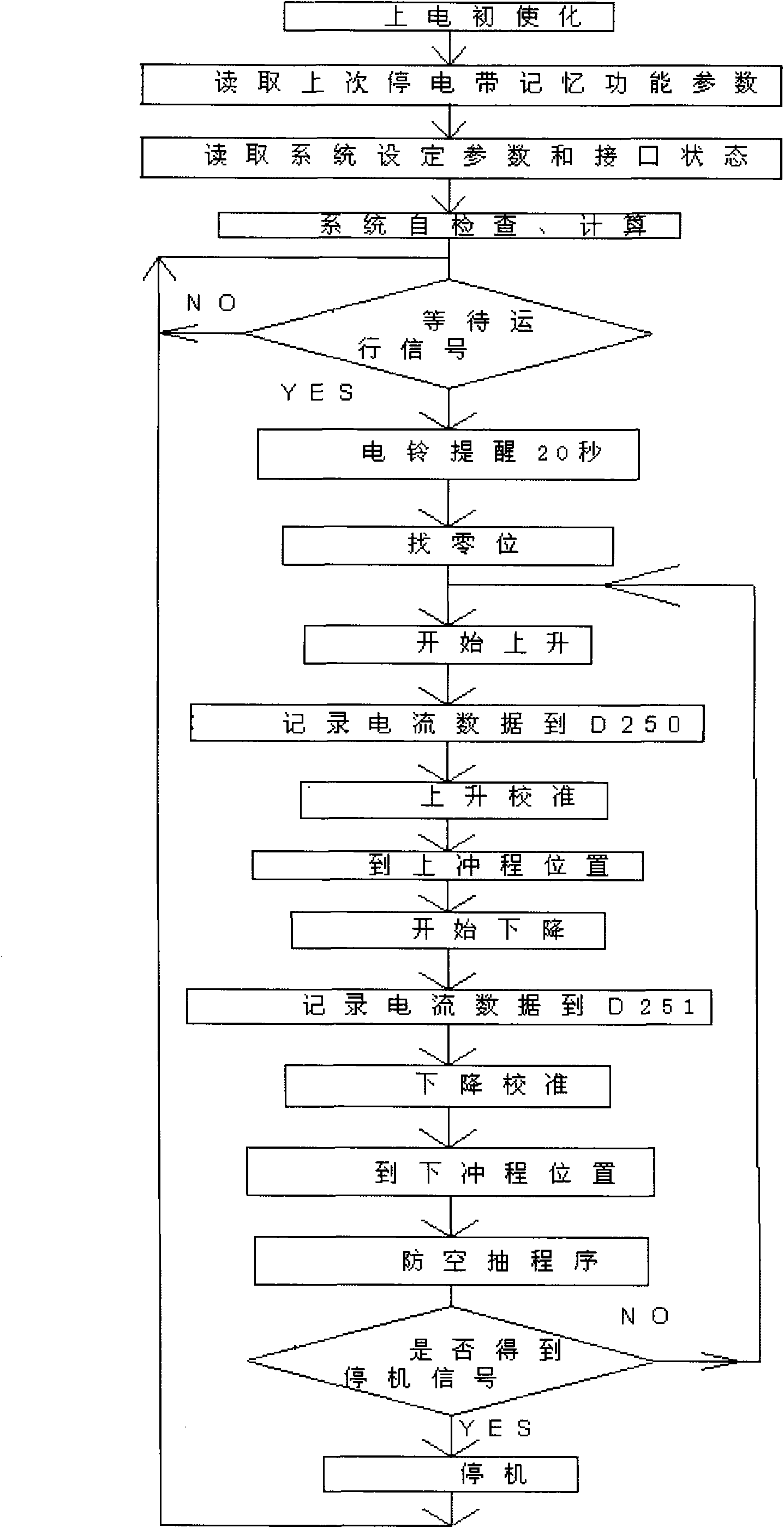

Oil well intermittent pumping control system and method

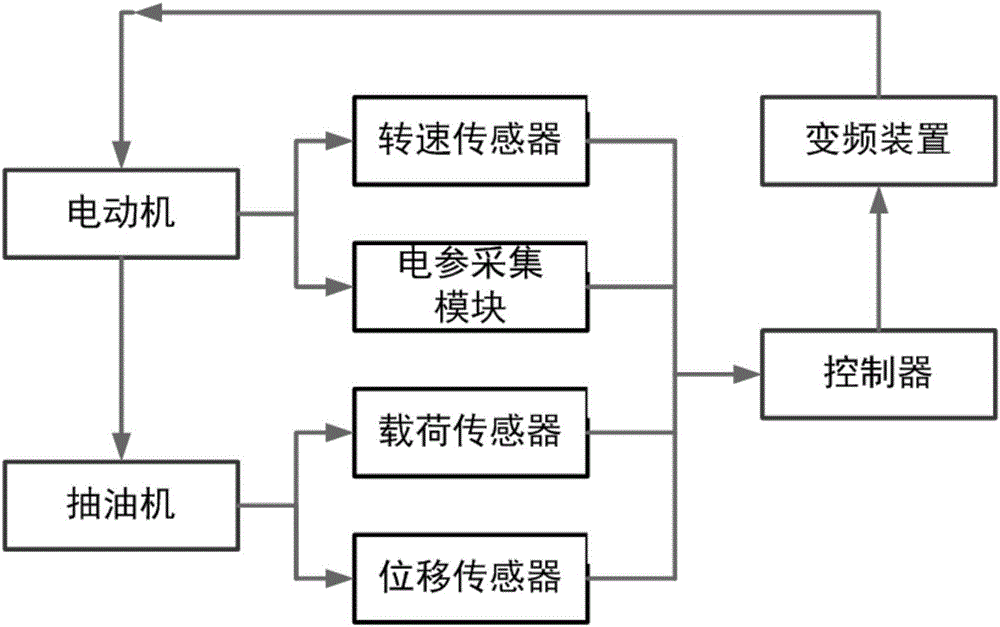

ActiveCN106762584ARealize energy saving and consumption reductionReduce lossConstructionsFluid removalPower flowControl system

The invention discloses an oil well intermittent pumping control system and method. The oil well intermittent pumping control system comprises an oil pumping unit, a controller and a motor, wherein the motor is connected with the oil pumping unit and used for driving the oil pumping unit; a rotational speed sensor and an electric parameter acquisition module are arranged on the motor and used for acquiring the output shaft rotational speed and the current and voltage value of the motor and sending to the controller; a load sensor and a displacement sensor are arranged on the oil pumping unit, connected with the controller and used for sending measured values of the load and the displacement of a well sucker rod of the oil pumping unit to the controller; and the controller is connected with the motor through a frequency converter and used for controlling start and stop of the motor. According to the oil well intermittent pumping control system, reasonable control is performed according to actual liquid outlet conditions, the requirement for supply and production coordination of an oil well is satisfied, intelligent stroke frequency adjustment and intelligent dynamic interval pumping control are utilized to realize energy saving and consumption reduction of the oil well and to reduce the loss of running equipment, follow-up control meets the demand for precise control of the oil well within a stroke cycle, the running efficiency of an oil well system is further improved, and the energy consumption is reduced.

Owner:PETROCHINA CO LTD

Automatic trimming and reshaping integrated automobile stamping die and stamping process thereof

The invention relates to an automatic trimming and reshaping integrated automobile stamping die and a stamping process thereof. The die comprises a lower die seat and an upper die seat, wherein a trimming male die is fixed on the lower die seat; a trimming work module consists of a second trimming male die, a trimming discharging plate, a trimming female die, a trimming pressing plate, a lower spring, an upper spring, a lower fixing plate and an upper fixing plate; a reshaping work module consists of a second reshaping male die and a reshaping female die; the first trimming male die is also used as a first reshaping male die; and left, right, front and rear driving devices are arranged at the front, rear, left and right positions of the lower die seat. A trimming die and a reshaping die are integrated, the functions of two sets of dies are realized on one set of die, the stroke frequency of a machine tool is reduced, time for assembling and replacing the die is shortened, and stampingcost is reduced.

Owner:FUZHEN TECH RES ANHUI

Reciprocating rack linear driving oil pumping unit

InactiveCN102182428ASmooth runningSmall current fluctuationFluid removalMechanical energy handlingEnergy conservationGear transmission

The invention discloses a reciprocating rack linear driving oil pumping unit, which comprises a rack, a walking beam, driving and transmission parts, a unit body part, an air balanced part, an energy storage part and a control part, wherein the rotation of a motor controlled by a controller around a vertical shaft is changed into the rotation of gears around a horizontal shaft by direction changing of a gear transmission box; the gears drive racks in the unit body of the oil pumping unit to perform up-and-down reciprocating linear motion so as to drive a polish rod for oil pumping; and the controller analyzes the operating situation of the oil pumping unit according to a data signal which is measured by a sensor, automatically optimizes and adjusts the stroke and stroke frequency of the oil pumping unit, and can transmit the signal to a production management department for manual remote monitoring control. By adoption of technologies of reciprocating induction motor driving, rack linear driving, real-time monitoring and adjustment, air balance and capacitor energy storage, the reciprocating rack linear driving oil pumping unit is smooth in operation, low in current fluctuation and low in reactive electric quantity loss of the motor, has the advantages of simple mechanism, compact structure, simple and convenient installation, high control, low occupation, light weight, low cost, energy conservation, environmental friendliness and the like, and can be widely applied to low-yield and low-efficiency wells, thickened oil wells and production wells in edge areas.

Owner:钟立国 +6

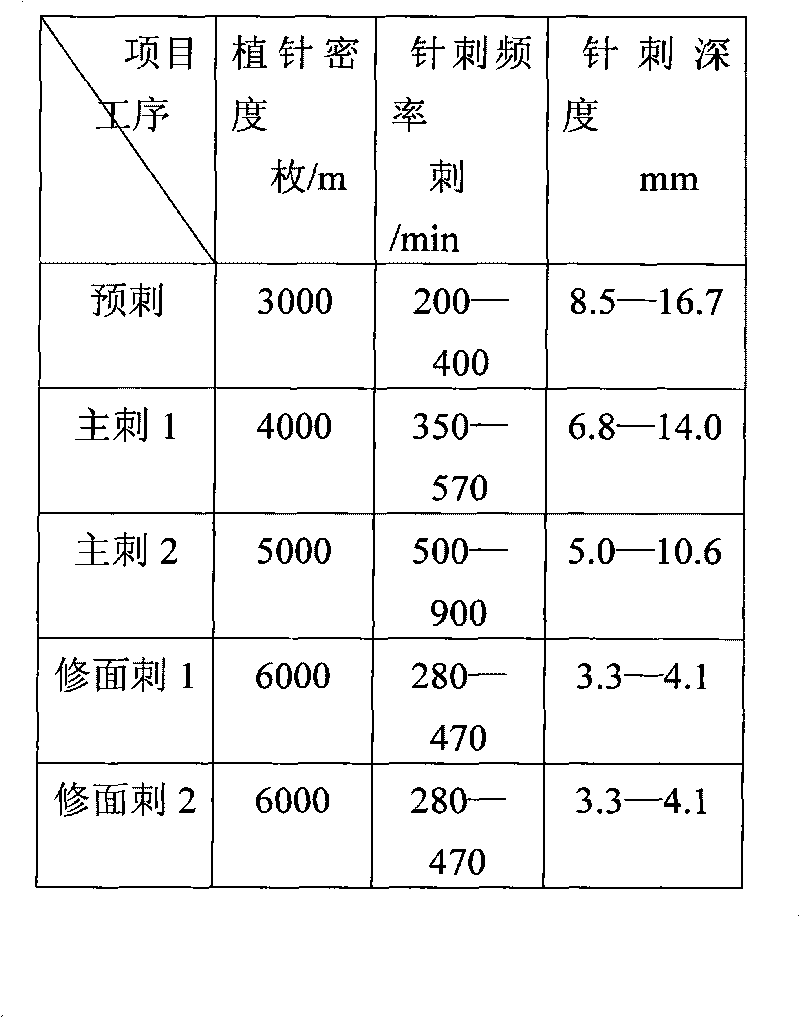

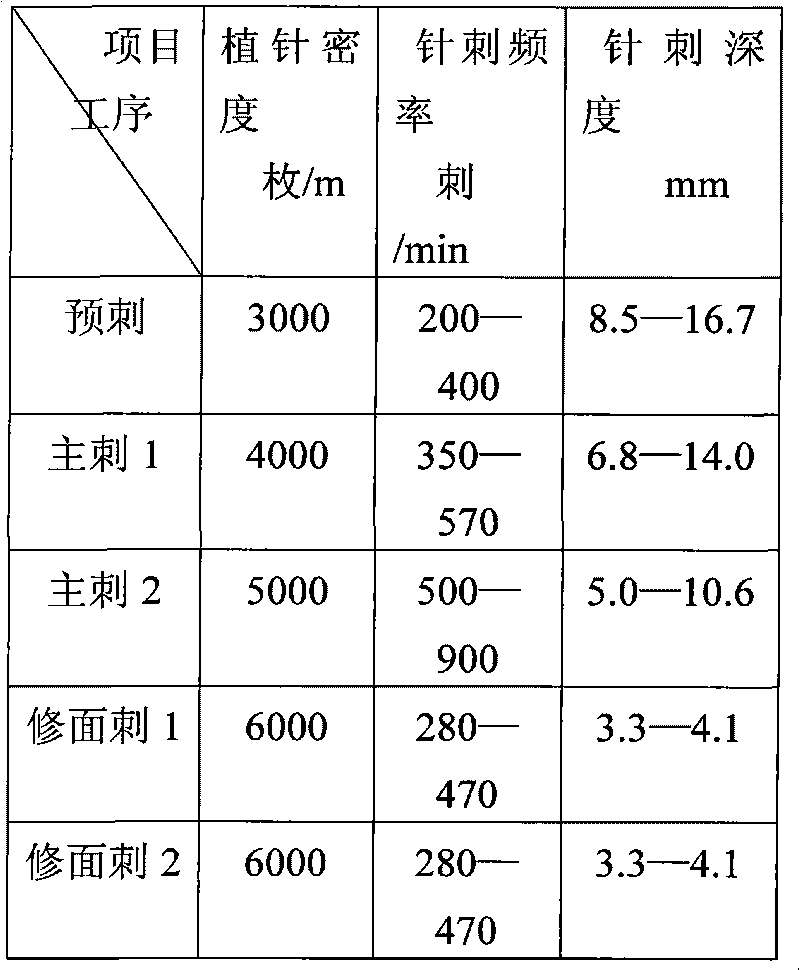

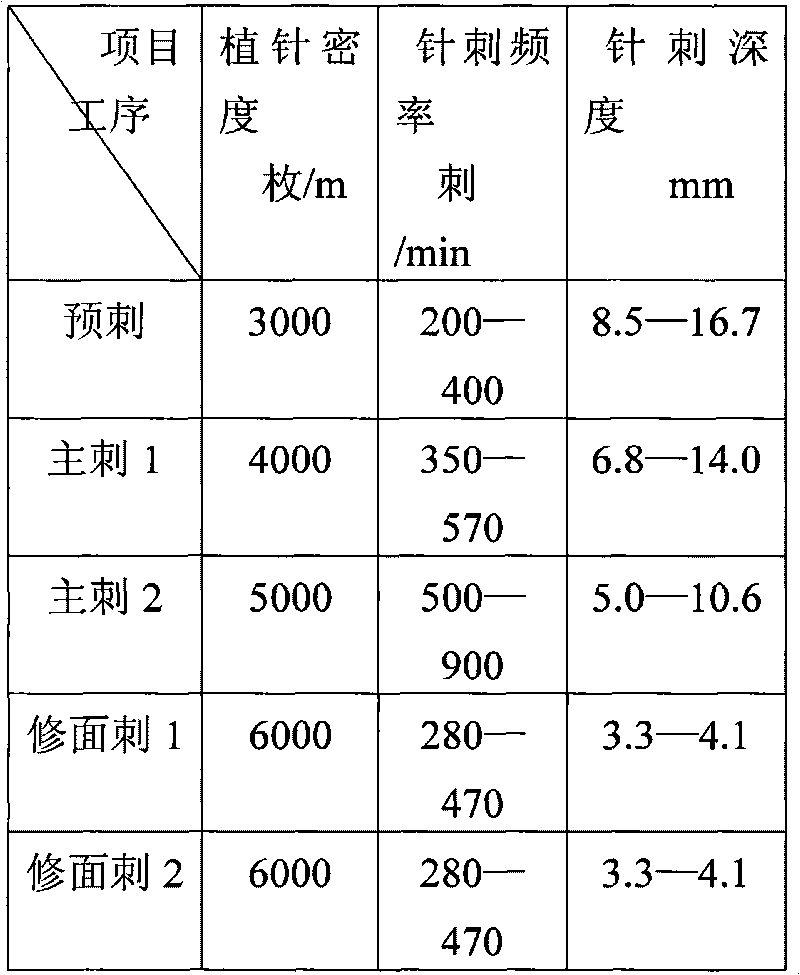

Manufacturing method of base fabric of non-woven cleaning fabric

InactiveCN101705576AGood flexibilityImprove wear resistanceNon-woven fabricsViscoseVolumetric Mass Density

The invention belongs to daily necessities, and particularly relates to a manufacturing method of base fabric of non-woven cleaning fabric. The manufacturing method is characterized in that viscose fibre and terylene fibre or viscose fibre and polypropylene fibre are mixed, the proportion of the viscose fibre is 30 to 90 percent and the proportion of the terylene fibre or the polypropylene fibre is 10 to 70 percent; the fibre raw materials are opened and mixed, and form a single-layer fibre mesh after carding procedure; a lapping machine adopts a cross lapping manner and reasonably selects the moving direction and speed of the fibre mesh to manufacture even multilayer fibre meshes; and the fibre mesh after being lapped are finished through multiple needling by adjusting reasonable needle density and stroke frequency. The automobile cleaning base fabric manufactured by using the manufacturing method and optimized by the technique has higher strength, good softness, no drop of chips, better wearing resistance and size stability, easy operation and control of manufacturing technique, stable product quality and lower cost.

Owner:张金六

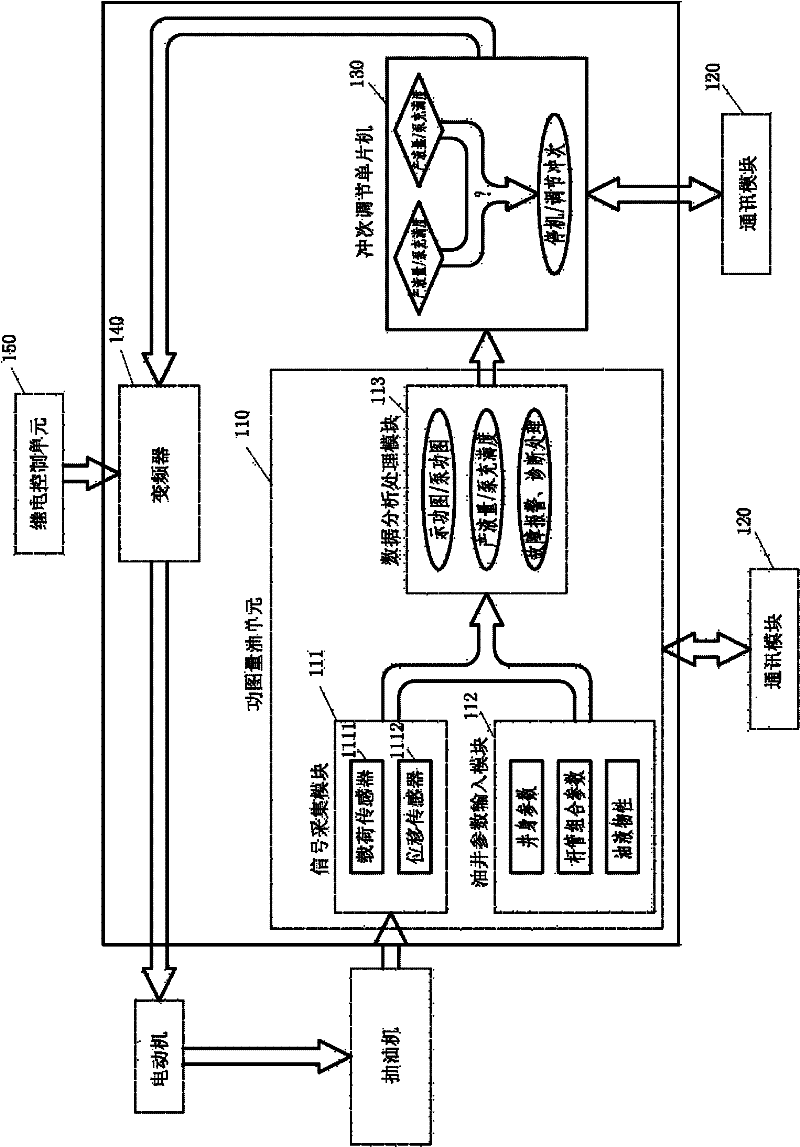

Stroke frequency regulating device of oil pumping machine

ActiveCN102213084AReal-time monitoring of working conditionsLow failure rateAC motor controlFluid removalMicrocontrollerMicrocomputer

The invention provides a stroke frequency regulating device of an oil pumping machine. The stroke frequency regulating device comprises an indicator diagram oil gauging unit, a stroke frequency regulating single-chip microcomputer and a frequency converter, wherein the indicator diagram oil gauging unit is used for acquiring oil well data and processing the oil well data according to oil well parameters to obtain the pump efficiency and the liquid yield of an oil well; the stroke frequency regulating single-chip microcomputer is connected with the indicator diagram oil gauging unit and is used for judging to obtain the minimal working stroke frequency data of the oil pumping machine according to the pump efficiency and the liquid yield of the oil well; and the frequency converter is connected with the stroke frequency regulating single-chip microcomputer and is used for regulating the working frequency of an electric motor of the oil pumping machine according to the minimal working stroke frequency data. According to the invention, the working stroke frequency can be precisely regulated according to the liquid yield per day of a specific oil well; in addition, the stroke frequency regulation of the oil pumping machine is completely digitalized, and can be controlled remotely without manual operation on site; the stroke frequency regulating device provided by the invention has the features of response instantaneity and high stroke frequency regulating precision and can monitor the working condition of the oil pumping machine in real time, so that the fault rate of a mechanical mining system is reduced.

Owner:PETROCHINA CO LTD

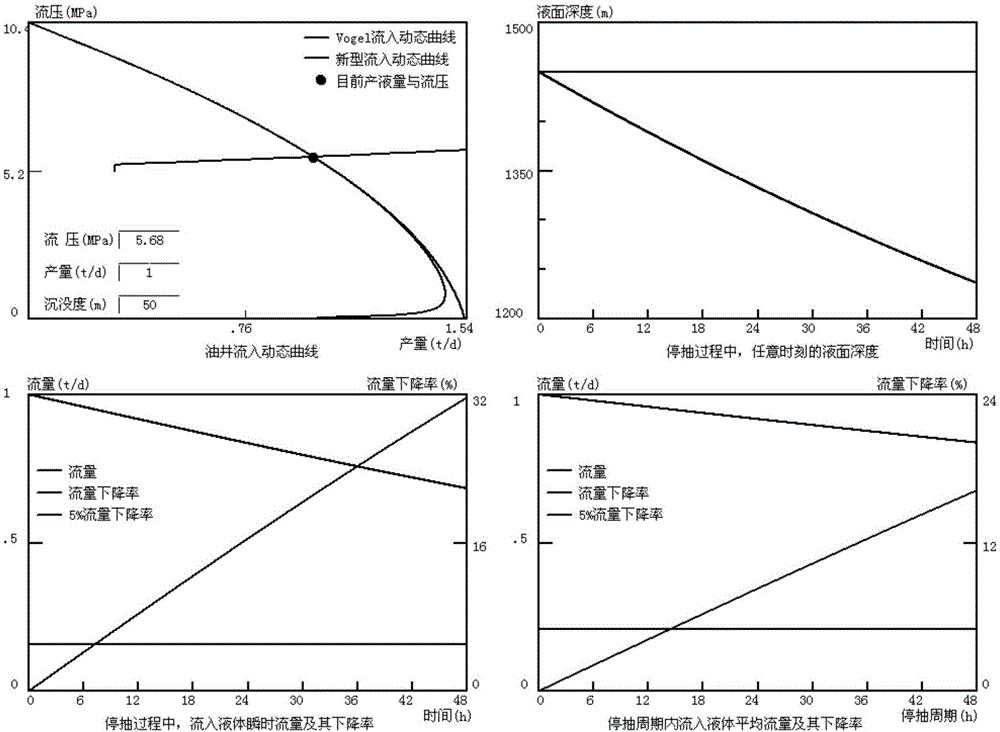

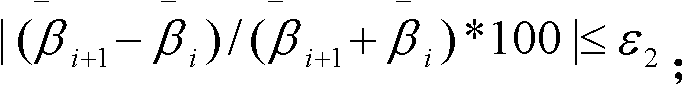

Indicator diagram-based oil pumping machine regulating and controlling method

InactiveCN104570991AAdvantages of regulation methodOptimize operating parametersEnergy industryFluid removalFrequency conversionClosed loop

The invention relates to an indicator diagram-based oil pumping machine regulating and controlling method. The method comprises the following steps: acquiring production parameters of an oil pumping machine well in real time; drawing an indicator diagram of an oil producing well by combining the parameters of the pump hanging, the pump diameter, the stroke, the stroke frequency and the liquid production capacity of an oil well, and calculating the saturation degree of the indicator diagram; performing analysis processing on the data of the indicator diagram and drawing a static load line; solving dynamic fluid level data of the oil well by utilizing dynamic fluid level calculating software; determining the reasonable submergence depth of the oil well according to the dynamic fluid level data of the oil well; performing analysis and calculation on the real-time production parameters of the oil well through a computer to obtain reasonable operating parameters of an oil pumping machine; remotely and intelligently regulating output frequency by utilizing a frequency conversion technology; changing the operating rotating speed of a motor of the oil pumping machine, so that the real-time closed-loop regulation of the working conditions of the oil well is realized. The regulating and controlling method disclosed by the invention is mainly used for optimizing the operating parameters of the oil pumping machine; the operating parameters of the oil pumping machine are regulated in real time; the automatic closed-loop control is realized.

Owner:PETROCHINA CO LTD

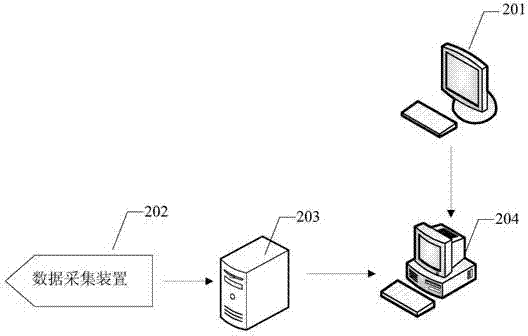

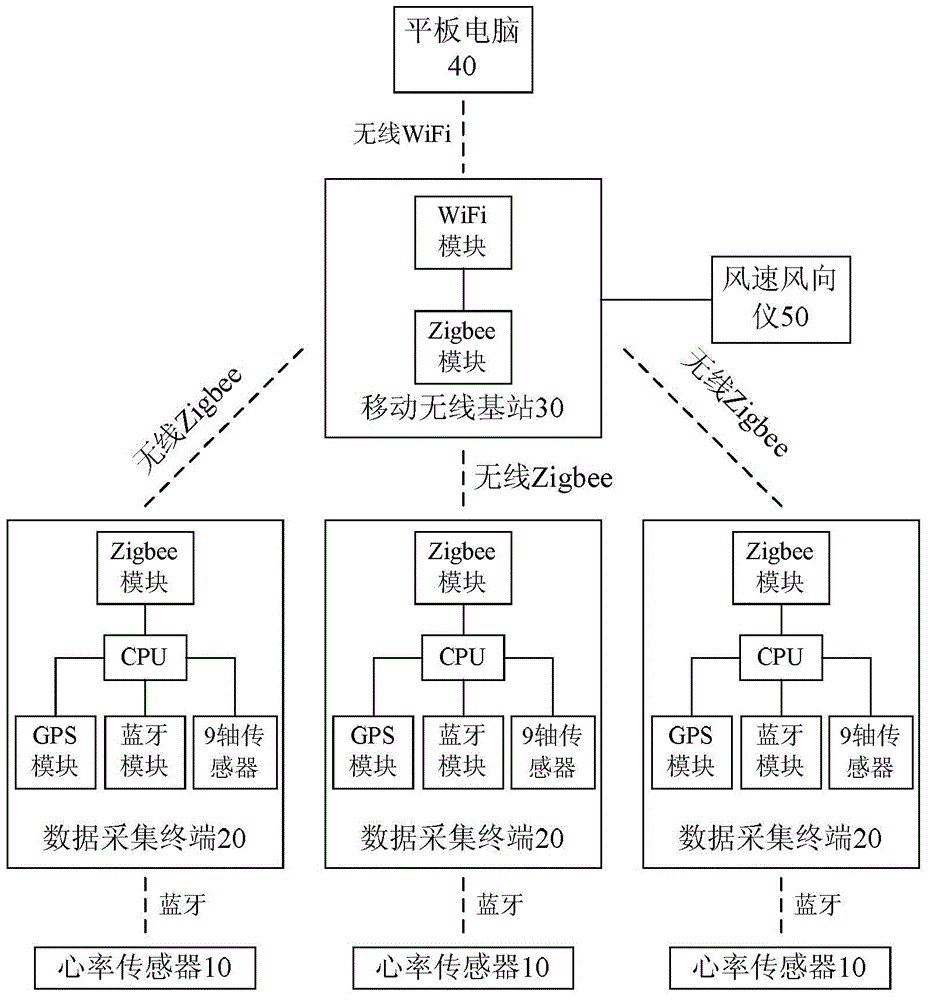

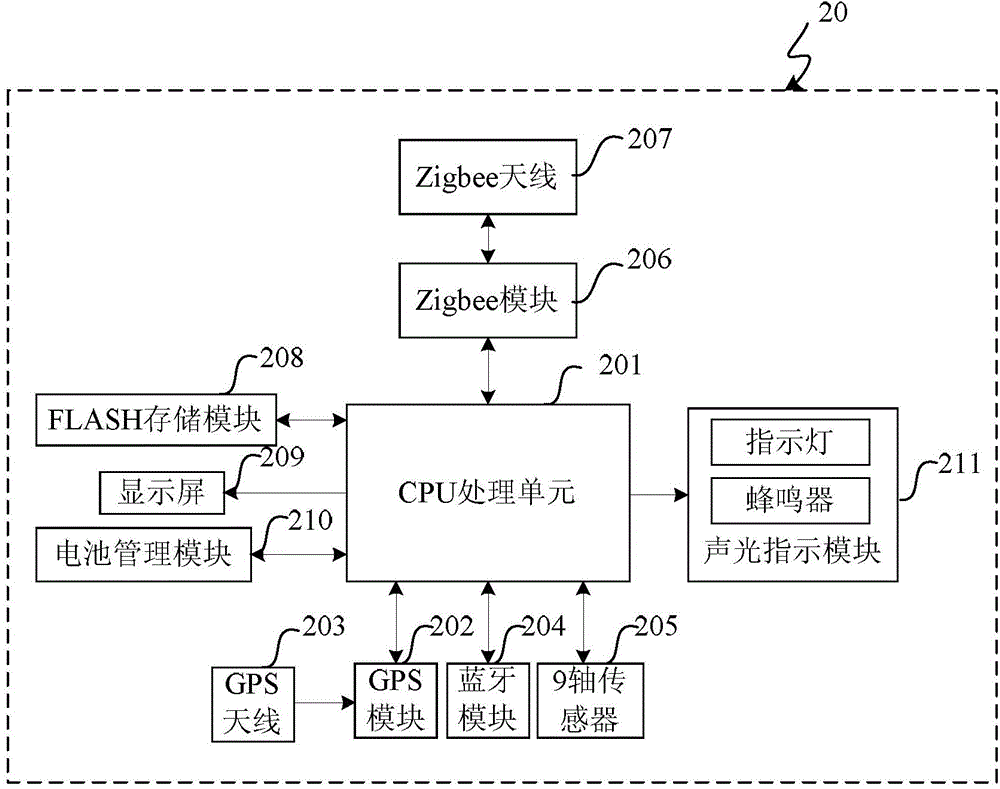

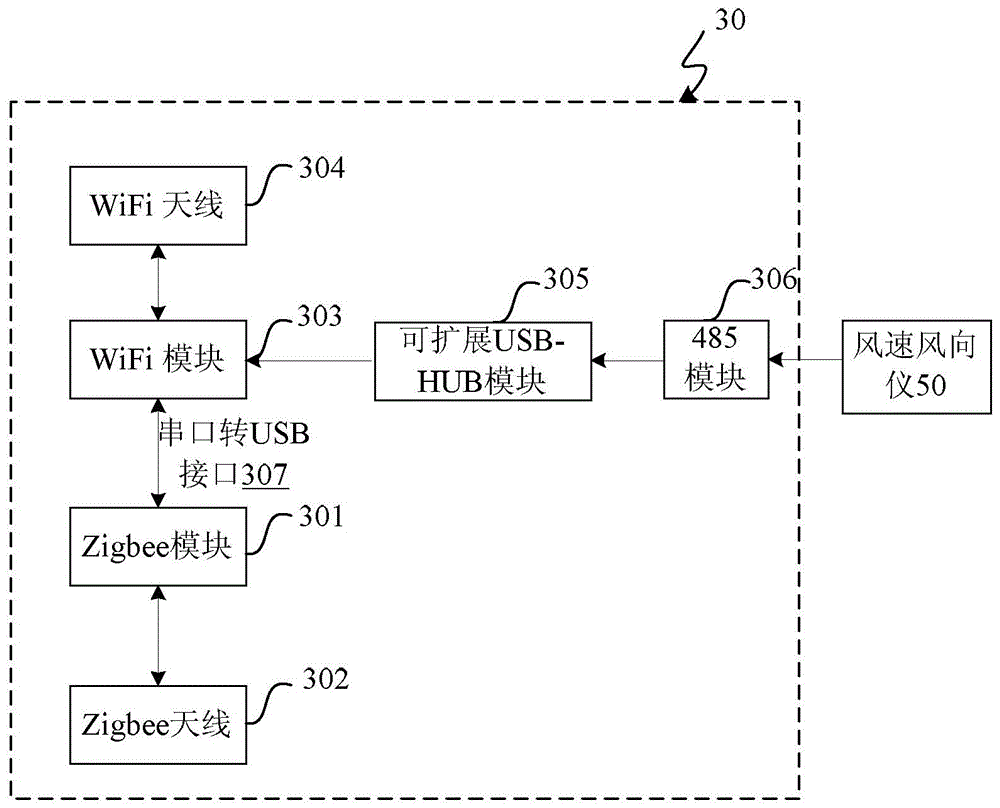

Rowing specialized training real-time monitoring system

InactiveCN104548563AEasy to analyze different training sessionsFacilitate the analysis of differences between different athletes in the same training sessionSport apparatusData acquisitionBluetooth

The invention discloses a rowing specialized training real-time monitoring system. The rowing specialized training real-time monitoring system comprises a heart rate sensor, a data acquiring terminal, a mobile wireless base station and a tablet person computer, wherein an athlete wears the heart rate sensor; the heart rate sensor is connected with a data acquiring terminal in a Bluetooth mode; the data acquiring terminal is connected with the mobile wireless base station in a Zigbee mode so that data can be transmitted; and the mobile wireless base station is connected with the tablet person computer in a WiFi (wireless fidelity) mode. By the rowing specialized training real-time monitoring system, data such as the heart rate, the speed, the acceleration, the rowing angle, the stroke frequency, the displacement and the result forecast of the athlete in a rowing process can be monitored in real time, a report, a curve graph and a bar graph of various indexes of the athlete can be checked and guided out, the training intensity load of the athlete is quantified, specialized training load indexes of the athlete are monitored in real time, so that a coach can objectively evaluate a training effect and make a training plane in a targeted manner, and the training effect is improved.

Owner:北京中体动力数字技术有限公司

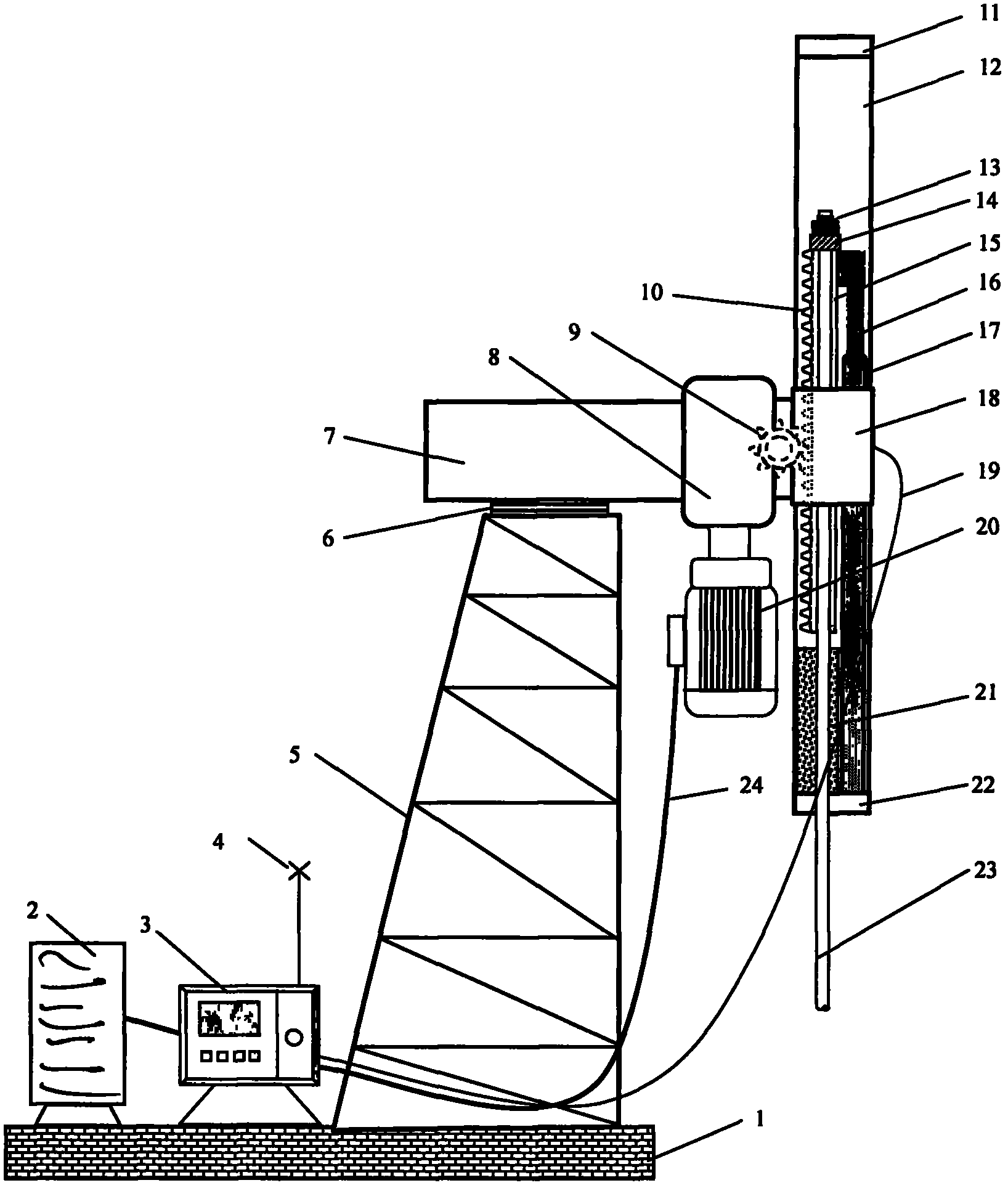

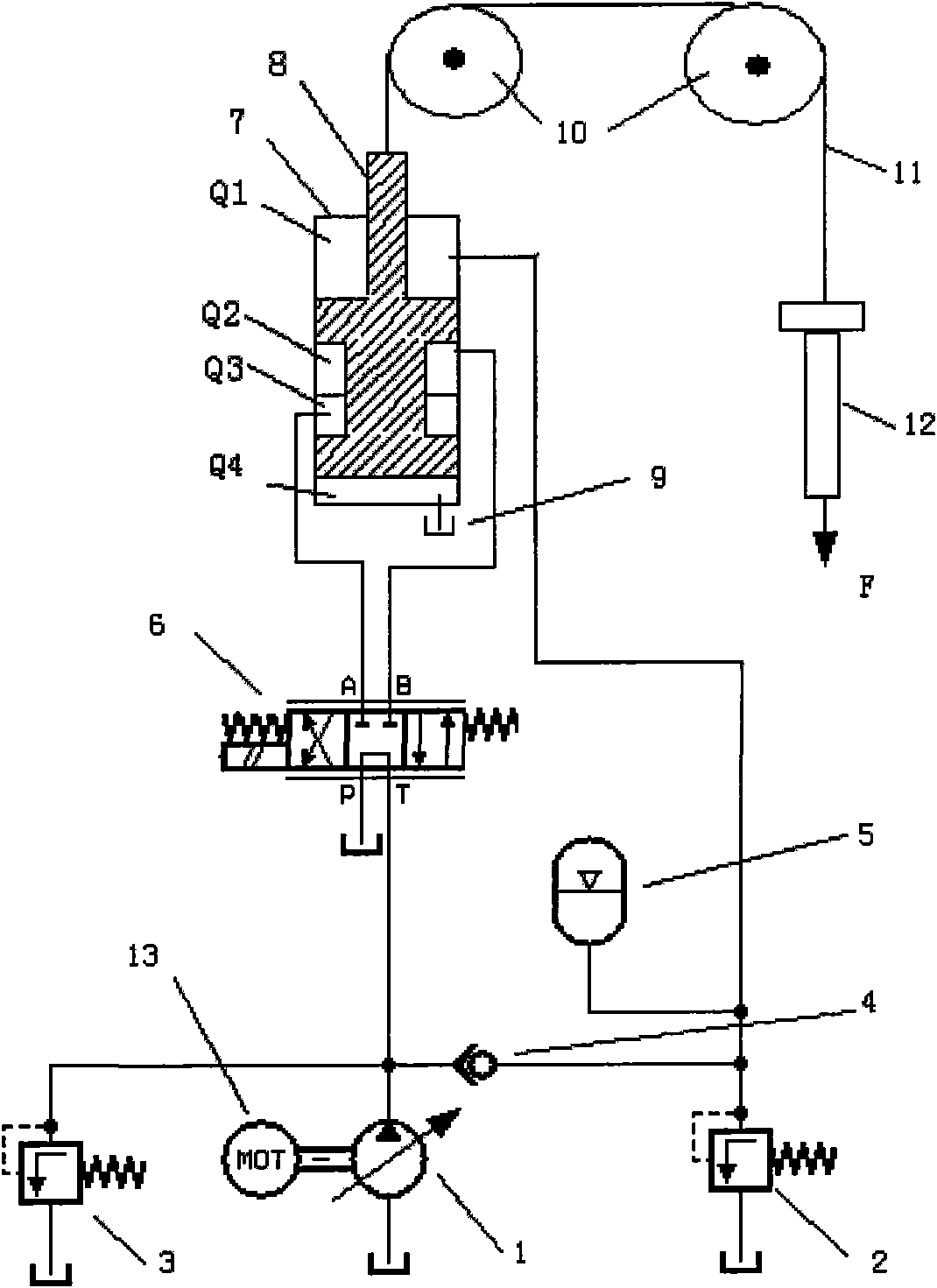

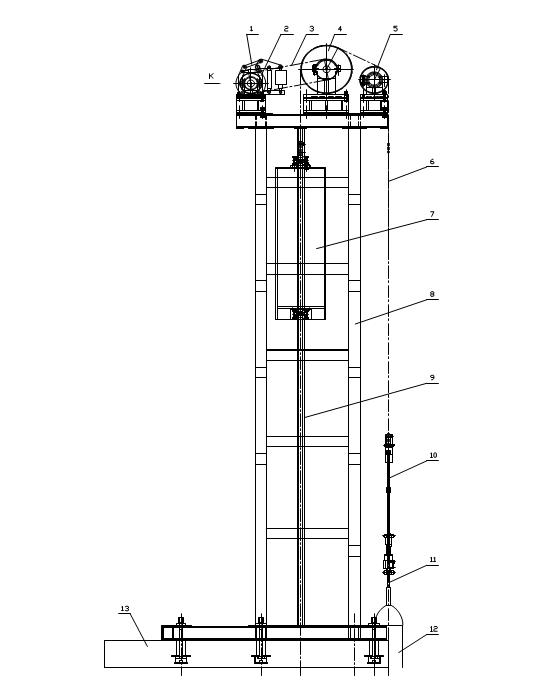

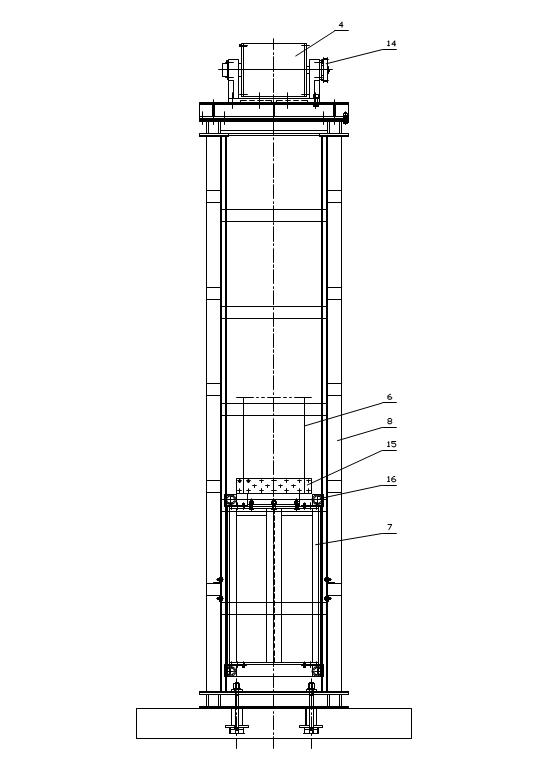

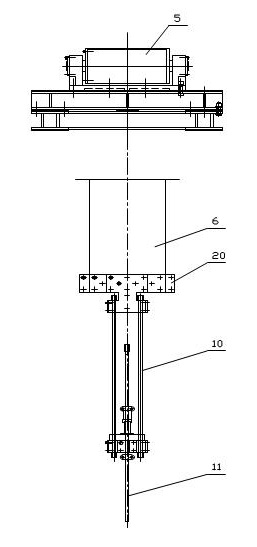

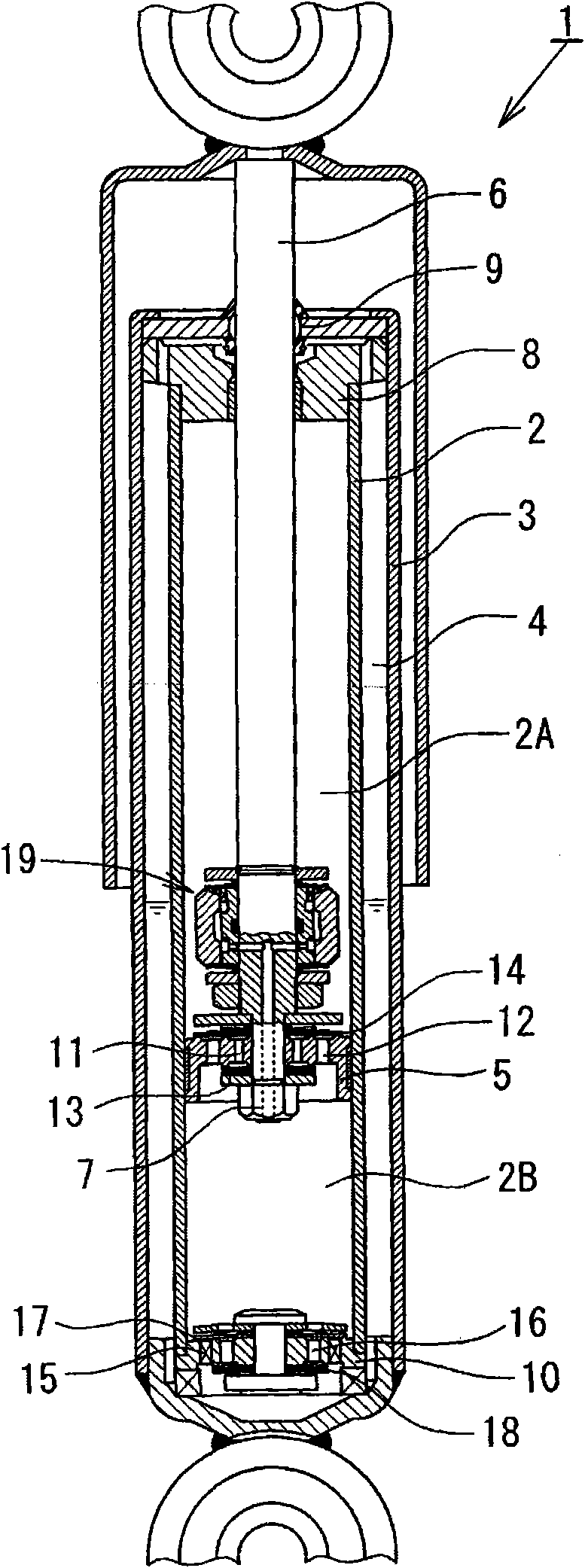

Novel energy-saving hydraulic pumping unit

The invention relates to a novel energy-saving hydraulic pumping unit, which comprises a hydraulic pump 1, an overflow valve 2, an overflow valve 3, a one way valve 4, an energy accumulator 5, an electro-hydraulic direction-changeover valve 6, a compound cylinder 7, a piston rod 8, an oil tank 9, a pulley 10, a rope 11, a pumping rod 12, a motor 13 and the like. The novel energy-saving hydraulic pumping unit adopts a hydraulic driving system and an energy accumulator balanced system, utilizes the energy accumulator 5 to collect gravitational potential energy released by the pumping rod 12 system and store the energy of the motor 13 in the down stroke, releases the energy in the up stroke, and can effectively reduce the installed power and the speed fluctuation of the motor to achieve the energy-saving effect. The novel energy-saving hydraulic pumping unit also has the advantages of large lifting force, light weight, convenient adjustment of stroke length and stroke frequency and the like of the conventional hydraulic pumping unit.

Owner:SICHUAN UNIV

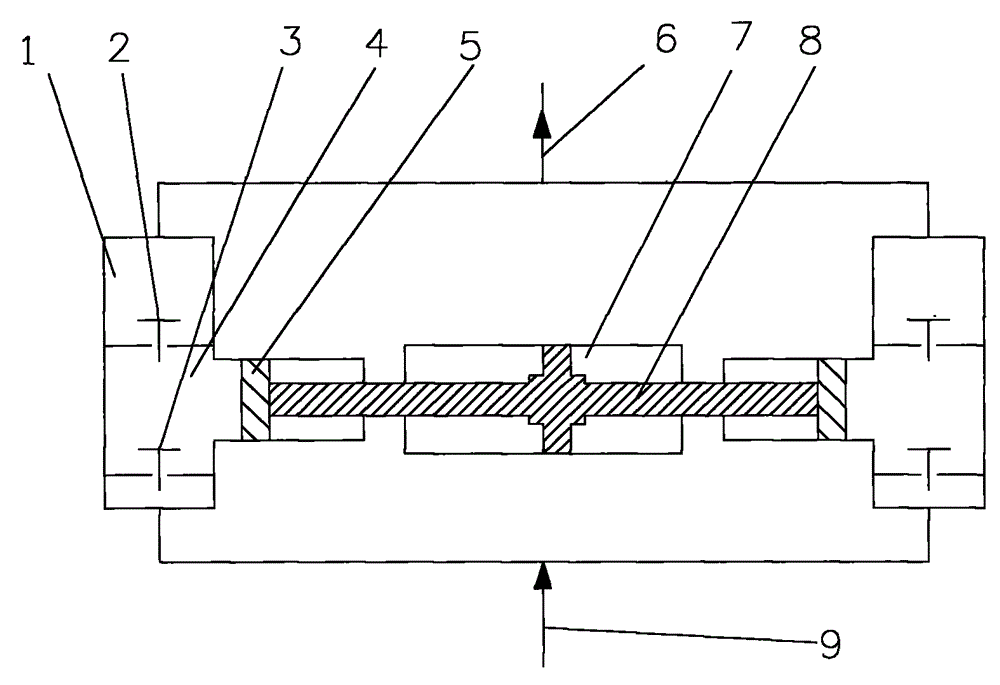

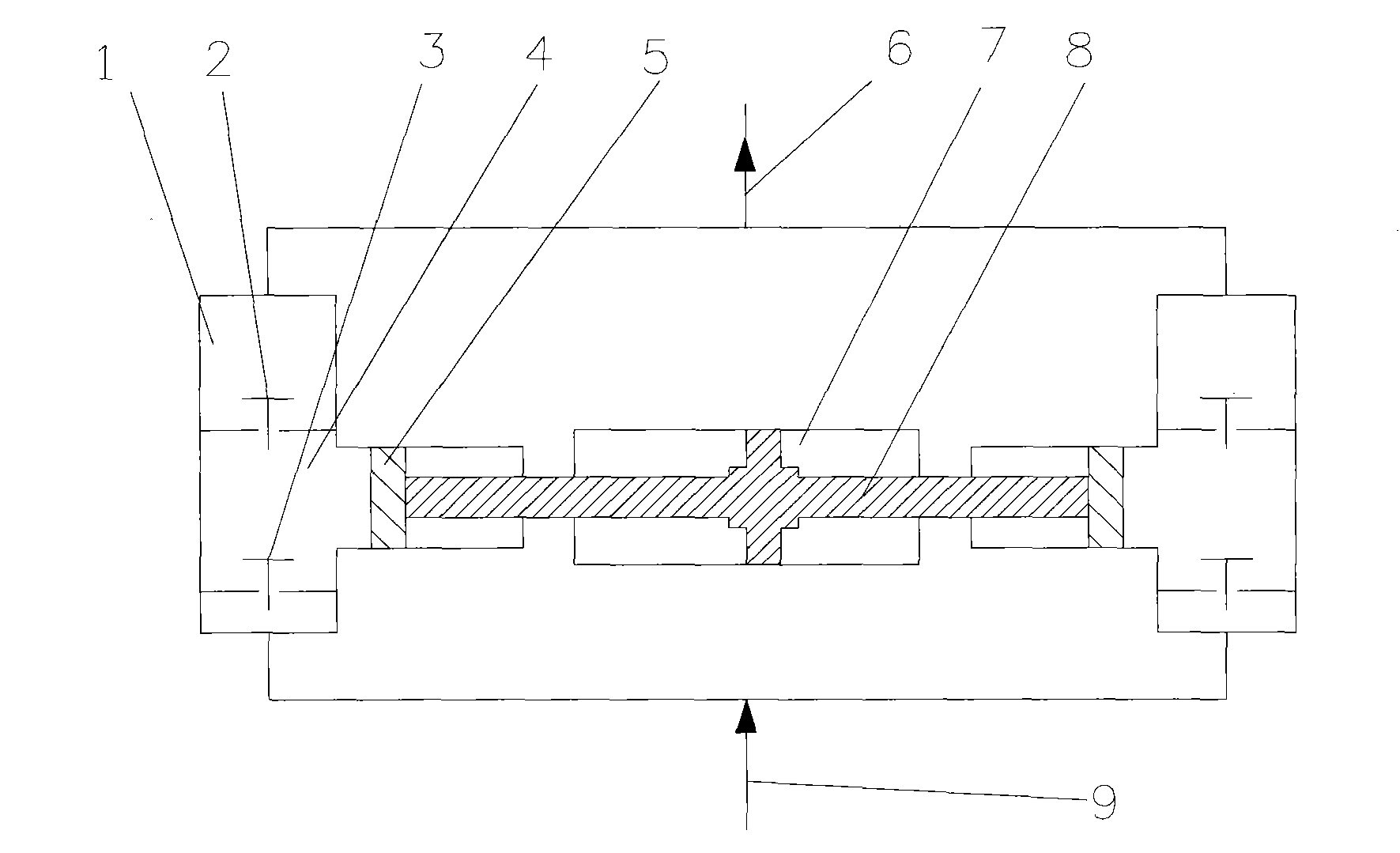

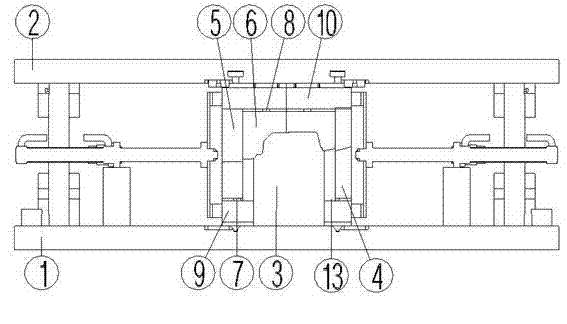

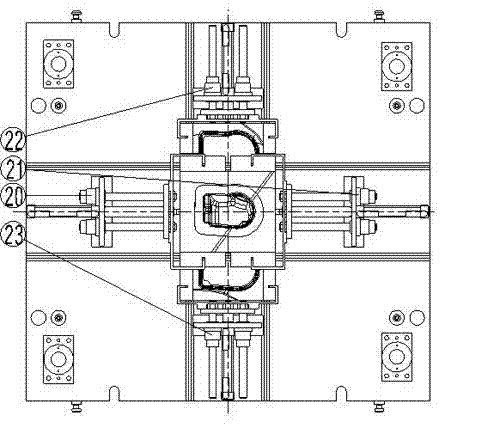

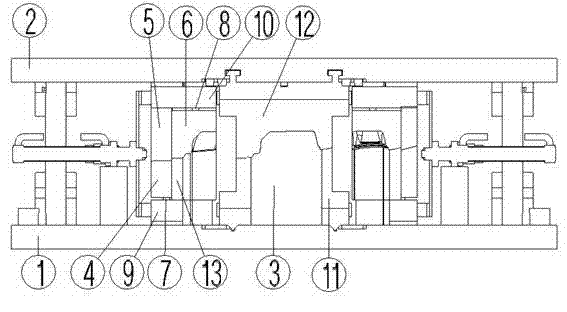

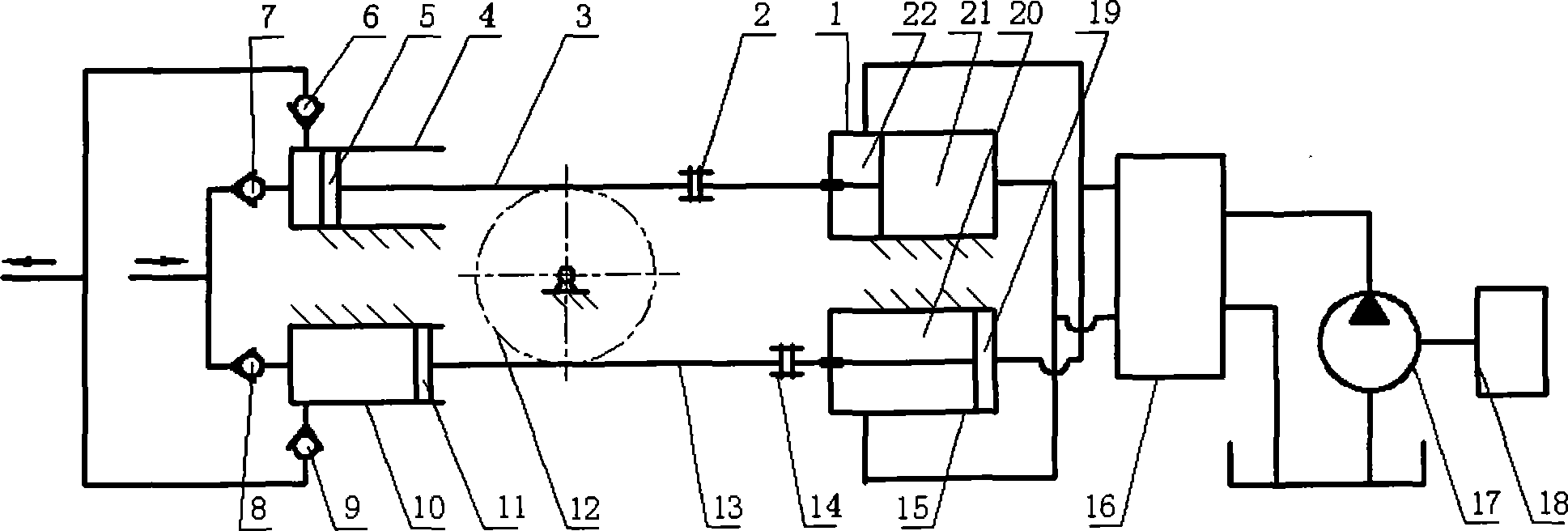

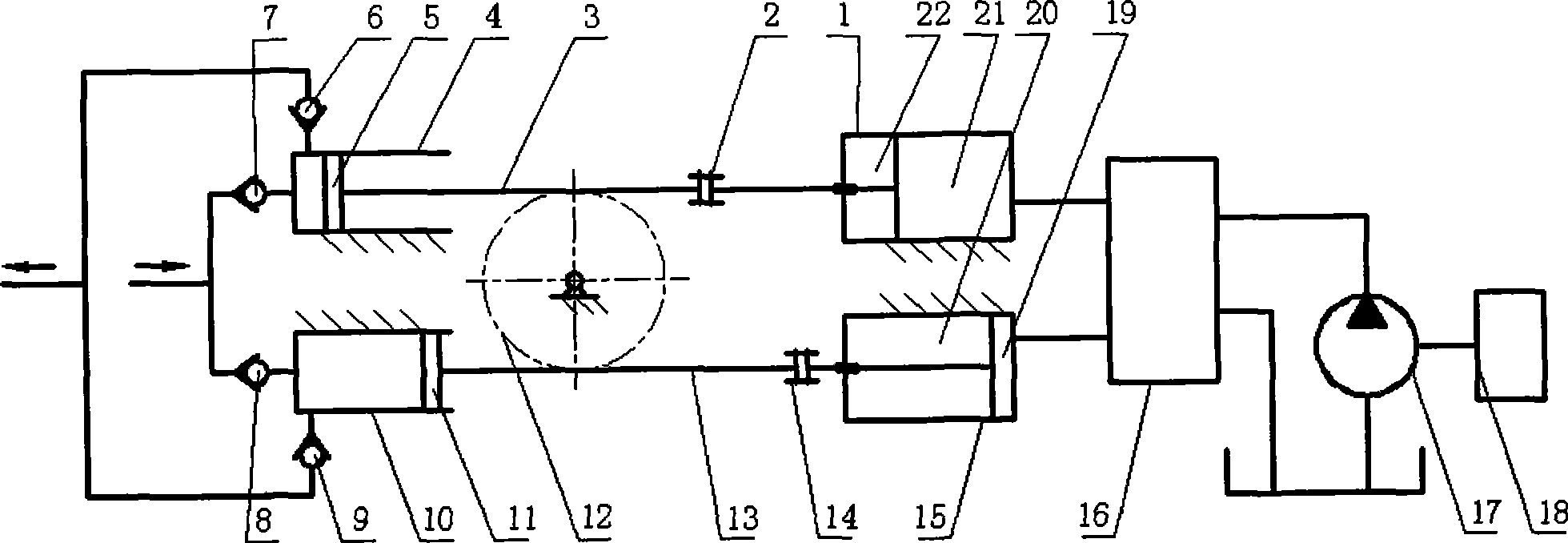

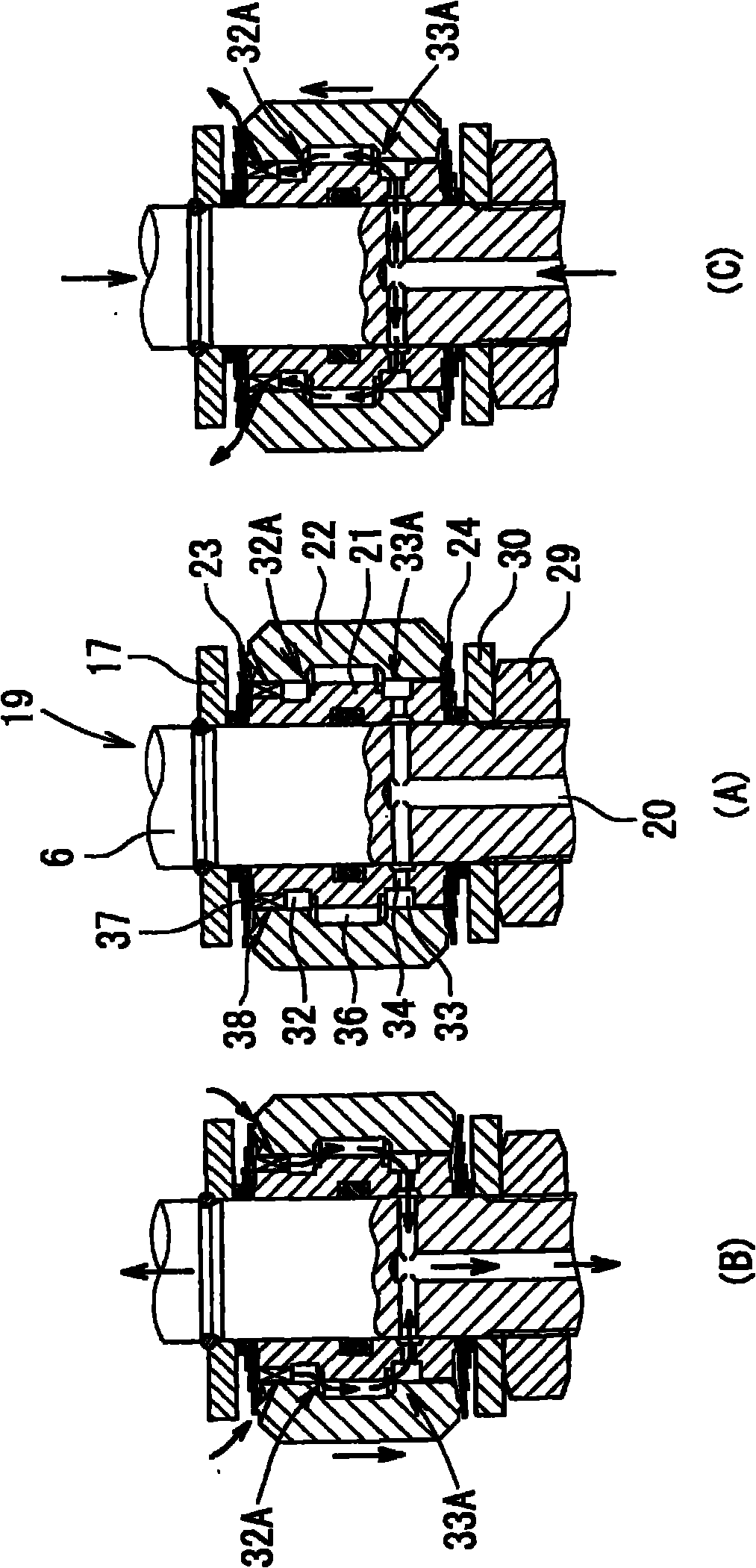

Rack-and-pinion coupled hydraulic multi-cylinder reciprocating pump

InactiveCN101476553AReduce degradationReduce shearPiston pumpsPositive-displacement liquid enginesPhase differenceGear wheel

The invention relates to a gear wheel and rack coupled hydraulic multi-cylinder reciprocating pump, which consists of a hydraulic oil cylinder, a coupling, a cylinder sleeve of a working hydraulic cylinder, a piston, a piston rod, a gear wheel, a suction valve, a discharge valve, a hydraulic directional control valve, a hydraulic oil pump, an electric motor, and the like which are assembled and connected. The piston rod is provided with a rack; the hydraulic oil cylinder and the piston rod are arranged parallelly; the gear wheel is engaged with racks on the two piston rods simultaneously; and the two piston rods are arranged according to the movement phase difference of 180 degrees. Two hydraulic oil cylinders and two working hydraulic cylinders form a basic unit, and for the two hydraulic oil cylinders in the basic unit, oil can be provided to both non-rod chambers and rod chambers, and can be only provided to the non-rod chambers of the oil cylinders. The invention can be combined into a multi-cylinder reciprocating pump with two cylinders, four cylinders, six cylinders, and more even cylinders. The hydraulic multi-cylinder reciprocating pump has the advantages of high systematic efficiency, long stroke, low stroke frequency, large displacement, high pump pressure, long service life of wearing parts, small fluctuation of the displacement and the pump pressure, good suction performance, and simple and convenient maintenance.

Owner:SOUTHWEST PETROLEUM UNIV

Method for controlling tower-type pumping unit

Owner:上海神源电气有限公司

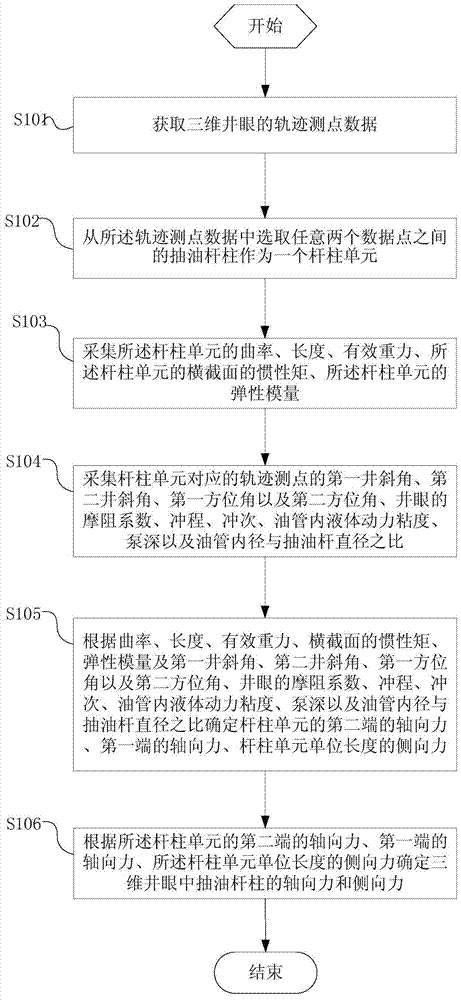

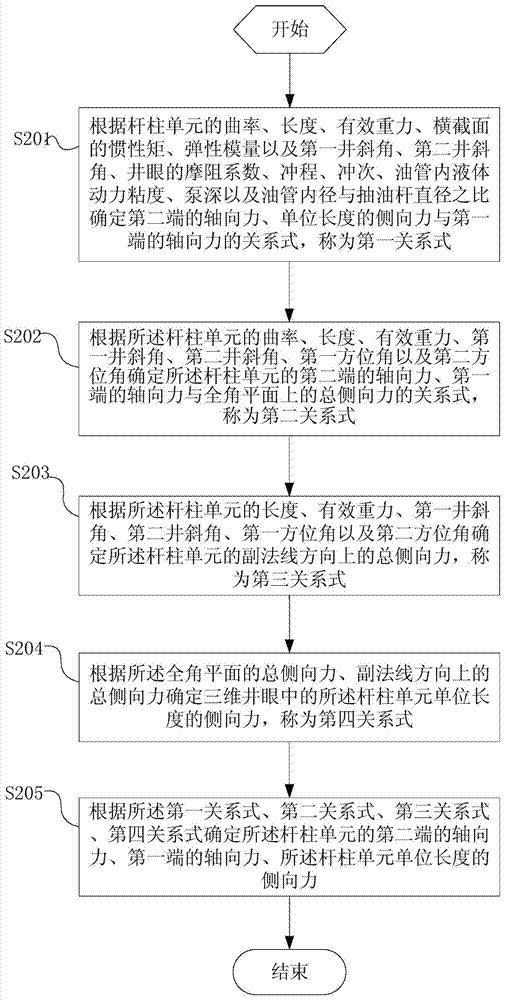

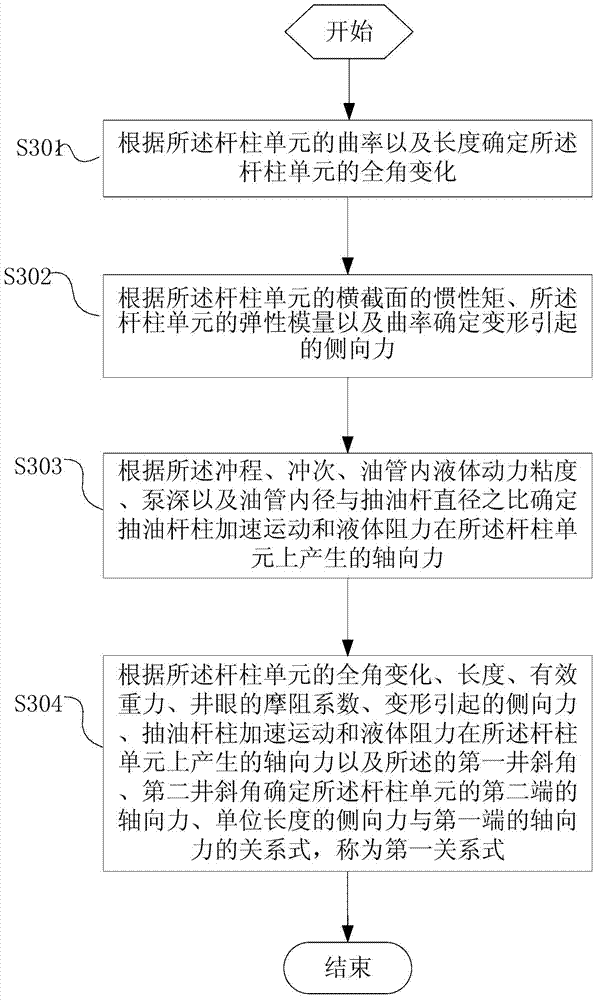

Method and device for measuring axial force and lateral force of rod strings in three-dimensional well

ActiveCN103616117AMeet oil production engineering requirementsMeasurement of force componentsLiquid dynamicsEngineering

The invention provides a method and device for measuring axial force and lateral force of rod strings in a three-dimensional well. The method comprises the steps of obtaining track measure point data of the three-dimensional well, selecting one rod string between any two data points from the track measure point data to be used as a rod string unit, collecting the curvature, the length, the effective gravity, the inertia moment and the elasticity modulus of the rod string unit, collecting the first hole drift angle, the second hole drift angle, the first azimuth angle, the second azimuth angle, the well friction resistance coefficient, the stroke, the stroke frequency, the liquid dynamic viscosity in an oil pipe, the pump depth and the ratio between the inner diameter of the oil pipe and the diameter of the rod string of the track measure point corresponding to the rod string unit, determining the axial force of the second end, the axial force of the first end, and the lateral force of the unit length of the rod string unit, and determining the axial force and the lateral force of the rod strings in the three-dimensional well. The method can be used for designing and calculating the control measures of oil extraction eccentricity preventing of a sucker-rod pump, and also can be used for force analysis of the rod strings in the three-dimensional well.

Owner:PETROCHINA CO LTD

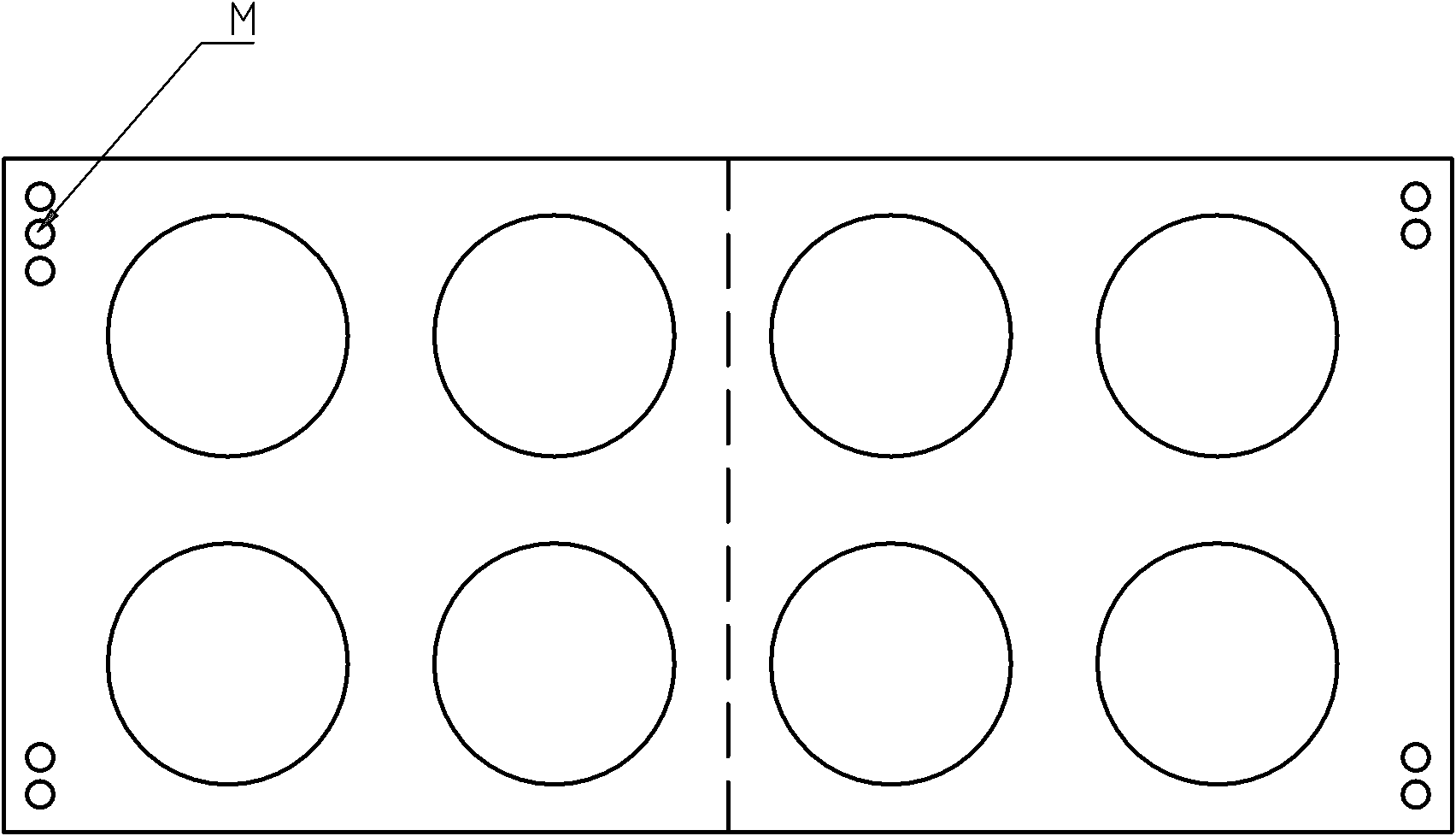

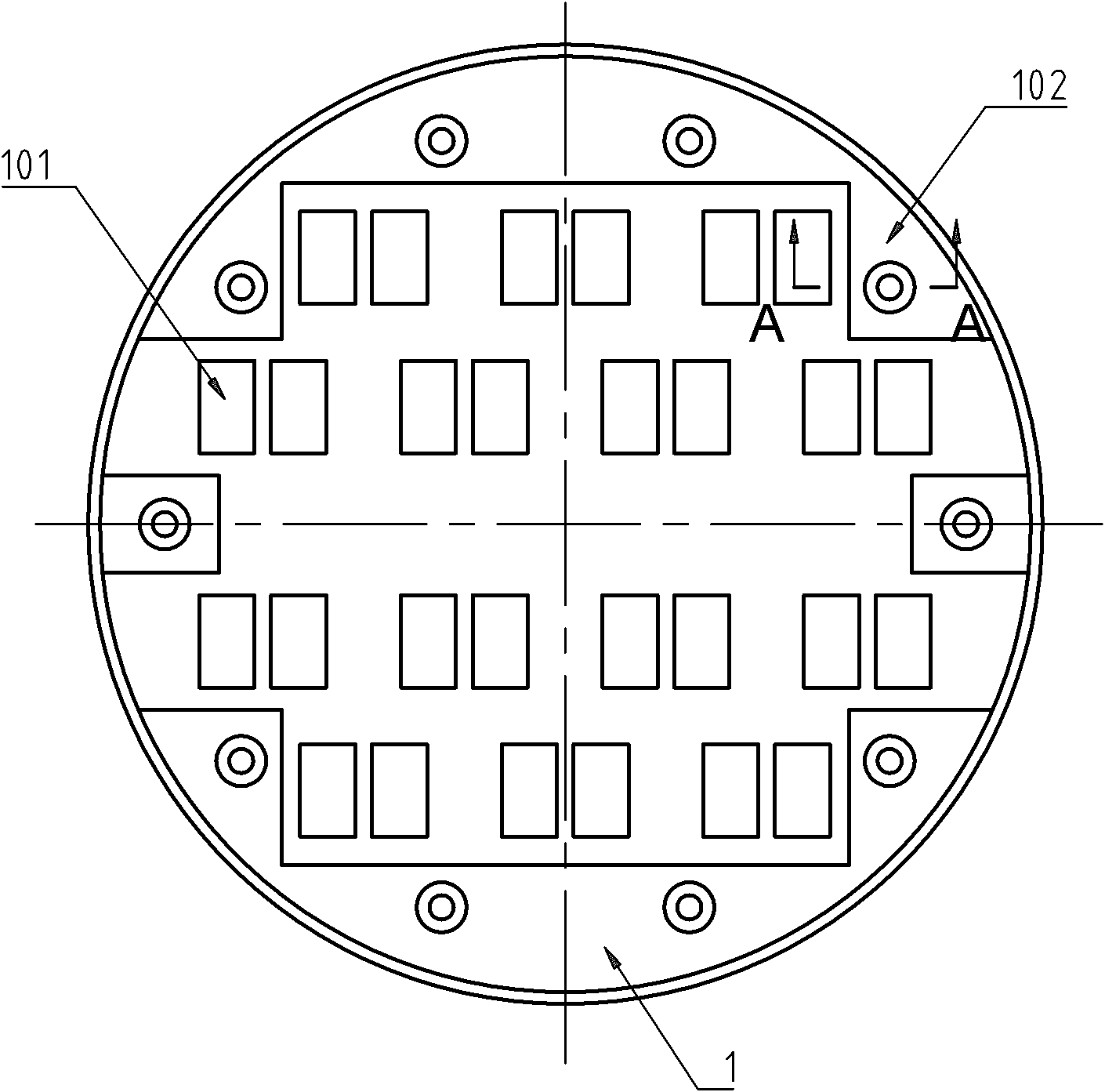

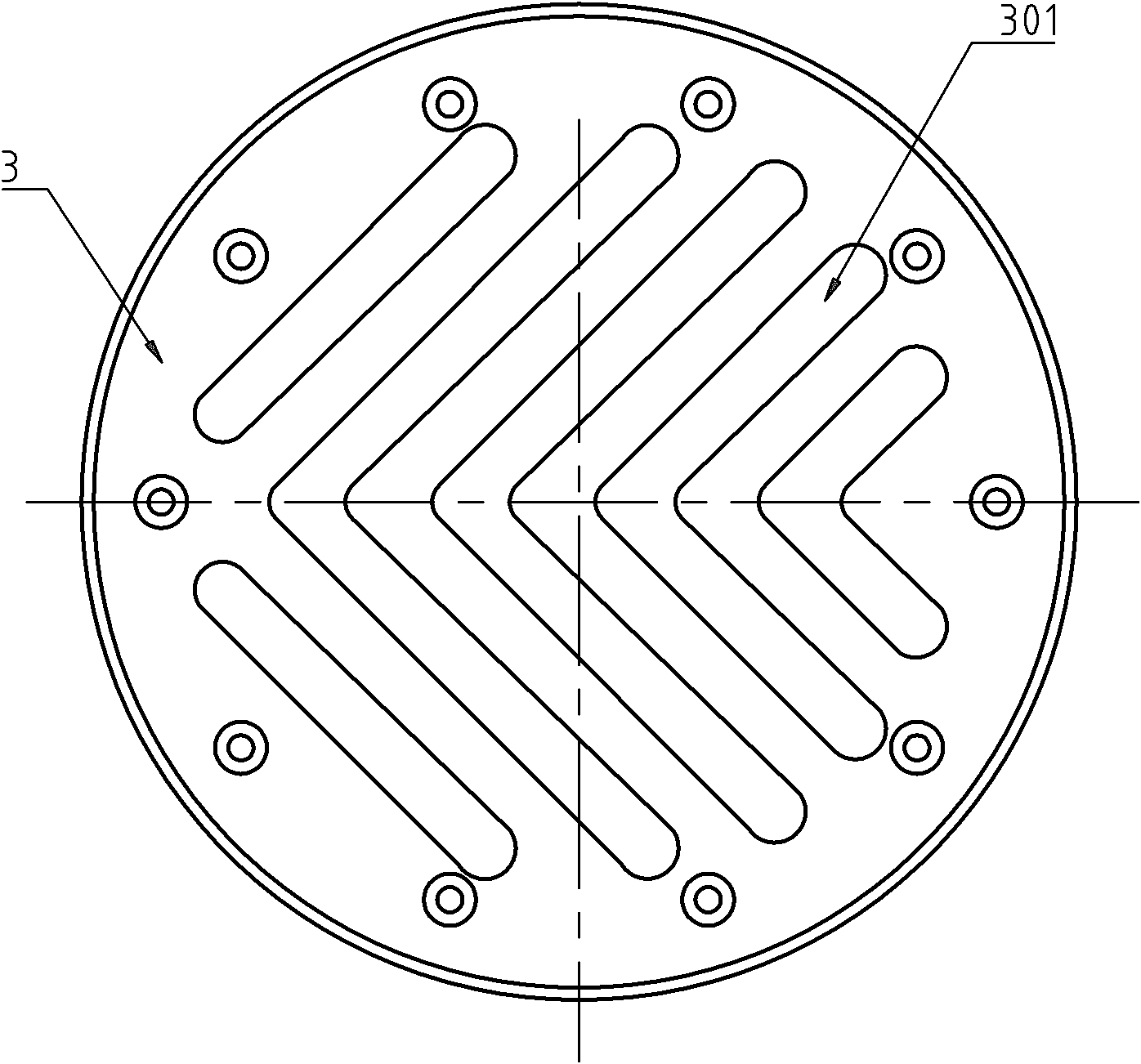

LED (light emitting diode) printed circuit board and production method thereof

InactiveCN102316667AImprove cooling effectReduce molding processing costsPrinted circuit detailsPrinted circuit manufactureHeat conductingEngineering

The invention discloses an LED (light emitting diode) printed circuit board and a production method thereof. The LED printed circuit board comprises a front copper foil, a back copper foil and a plurality through holes, wherein the front copper foil comprises a bonding pad, a wire and a heat-radiating copper foil which is insulated from the bonding pad and the wire; the through holes pass through a board body, and are communicated with the heat-radiating copper foil and the back copper foil; and the insides of the through holes are filled with rivet-shaped heat-conducting copper colloids, and the rivet-shaped heat-conducting copper colloids are connected with the heat-radiating copper foil and the back copper foil. According to the invention, the heat generated by an LED is conducted into the back heat-radiating copper foil by utilizing the outstanding heat-conducting performance of the copper colloid, thereby improving the heat-conducting efficacy of the LED printed circuit board, overcoming the defects that an aluminum-based material in the prior art only can achieve an effect of heat radiation but not heat conduction, and improving the heat radiation effect of the LED printed circuit board. The LED printed circuit board and production method thereof provided by the invention are suitable for the continuous production of molds, the stroke-frequency service life of a produced mold can be prolonged, the production efficiency is improved, and the formation machining cost of the LED printed circuit board is lowered.

Owner:深圳松维电子股份有限公司

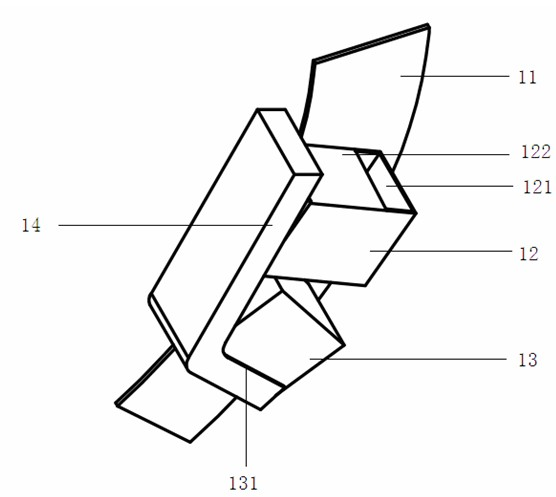

Double-roller tower type oil-pumping unit device

The invention discloses a double-roller tower type oil-pumping unit device. A roller type speed reducer drives a driven roller to rotate through an opening belt, one end of the opening belt is connected with a weight box, the other end of the opening belt is connected with a suspension assembly, the other end of the suspension assembly is connected with one end of a belt clip, the other end of the belt clip is connected with one end of an oil pumping rod, the other end of the oil pumping rod is movably connected with an oil pumping unit, and a brake is connected with a coupler assembly; an output shaft of an electric motor is connected with a belt wheel shaft through the coupler assembly, a driving synchronous belt wheel is installed on the belt wheel shaft, a driven synchronous belt wheel is installed on an input shaft of the roller type speed reducer, and synchronous belts sequentially are wounded the driving synchronous belt wheel and the driven synchronous belt wheel and then are rotationally driven to connect; and guide wheels are installed on both sides of the weight box, a guide rail is fixed on a rack, and the rack is fixed on a concrete foundation by bolts. The double-roller tower type oil-pumping unit device has the characteristics of simple structure, good stability, non-skid performance of the belts, long stroke, low stroke frequency and long fatigue service life, is convenient to use, is easy to regulate strokes and stroke frequencies and is widely used for the oil extraction industry.

Owner:周生祥

Speed reducer lubricating device for oilfield pumping unit

The invention discloses a speed reducer lubricating device for an oilfield pumping unit, and belongs to the field of speed reducer lubrication. The speed reducer lubricating device comprises an oil lifter and an oil storage tray; the oil lifter is arranged on a driven gear; and the oil storage tray is fixed on a box seat and positioned beside an oil wiper in the cavity of a box body. The speed reducer lubricating device has the advantages that lubrication of bearings of a driven shaft and an intermediate shaft is ensured under the condition of meeting low stroke frequency of a speed reducer for the oilfield pumping unit; and the oil lifter is provided with two oil boxes which are opened in two directions respectively, so that the oil lifter can lift the lubricating oil no matter the rotating direction of the speed reducer is clockwise or anticlockwise.

Owner:XUZHOU DONGFANG TRANSMISSION MACHINERY

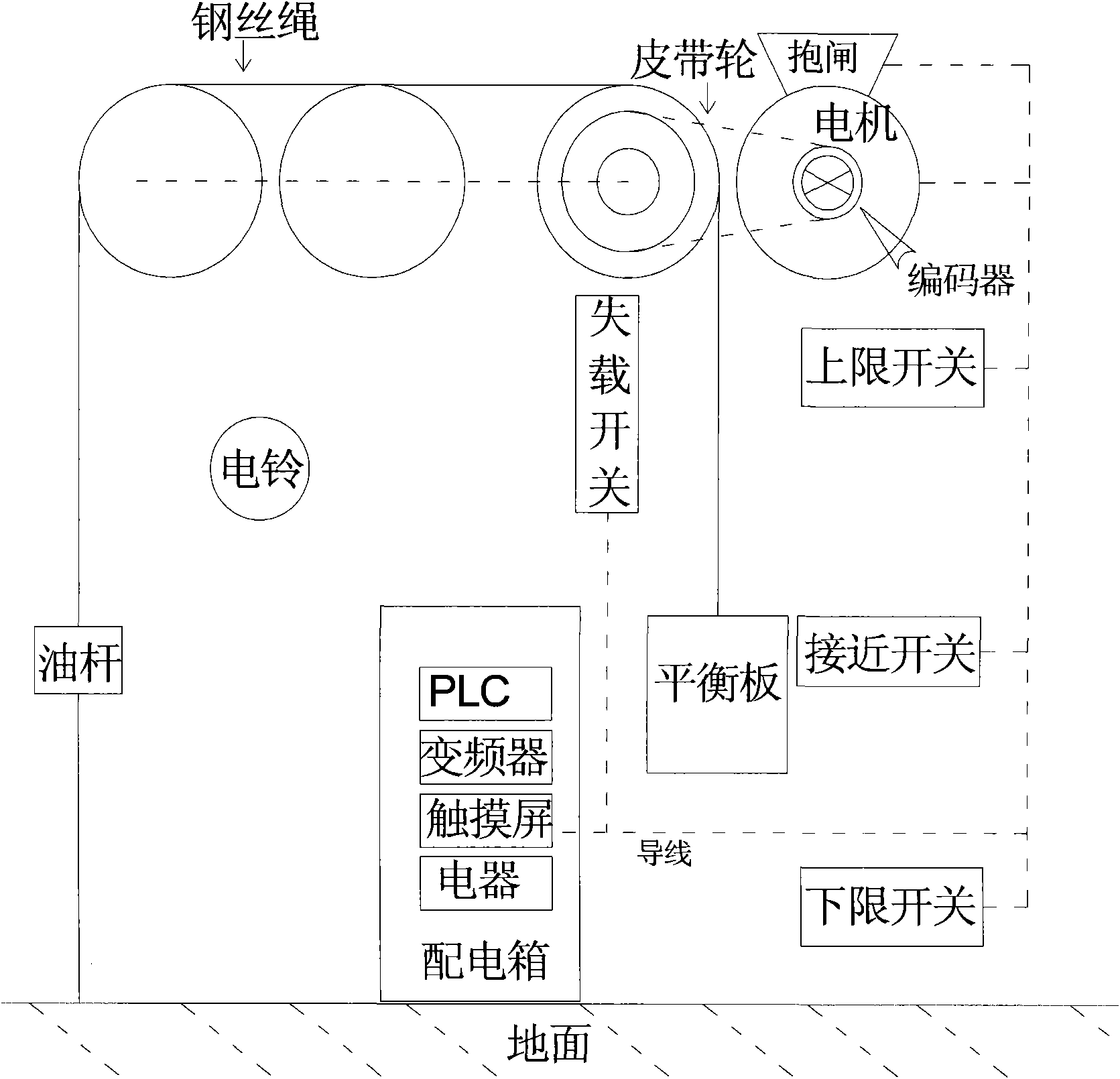

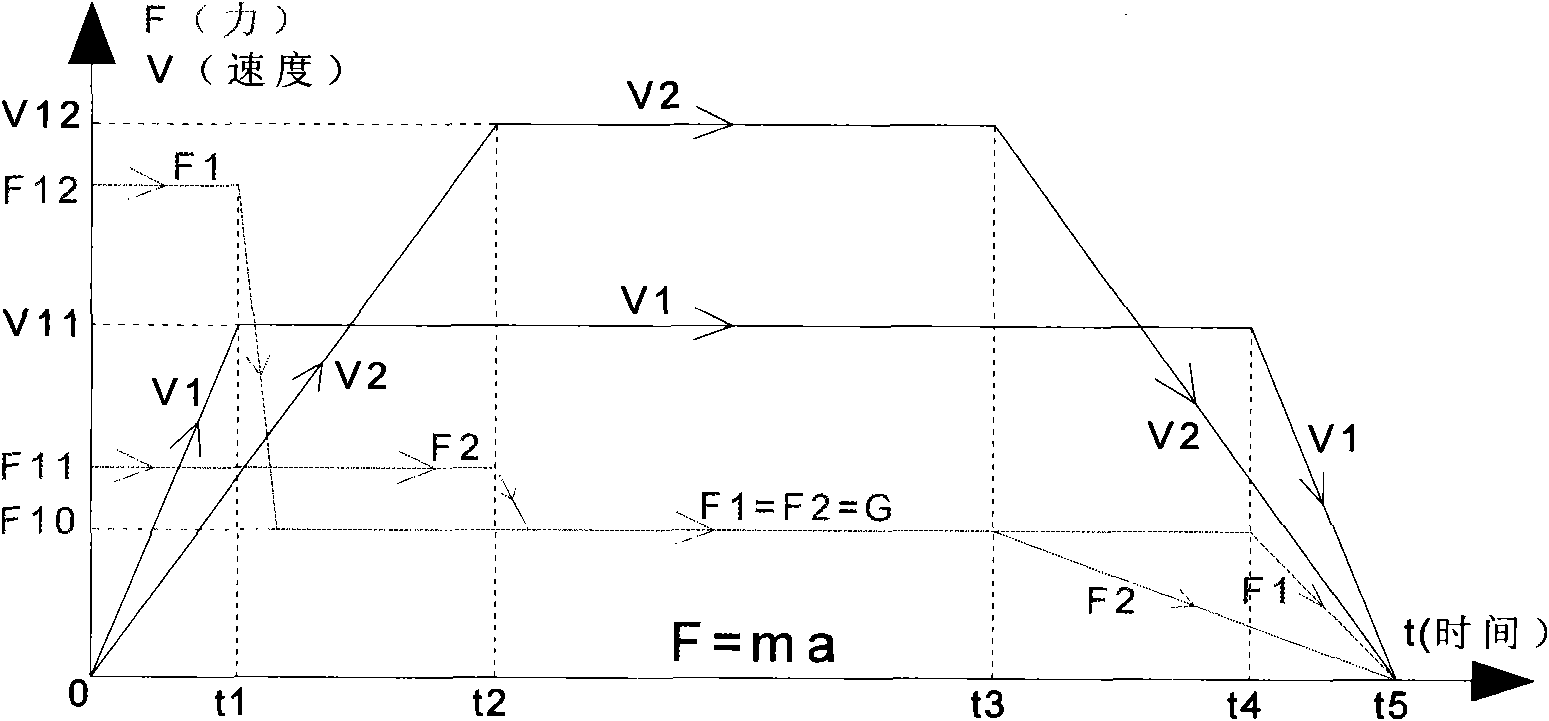

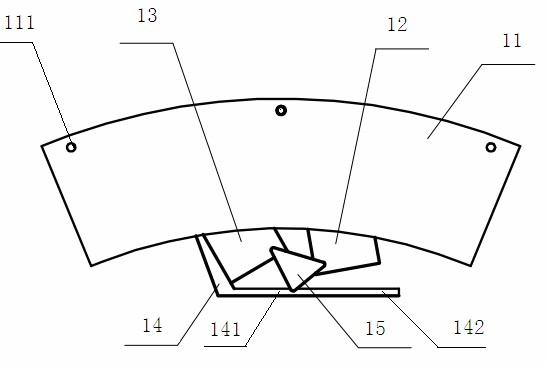

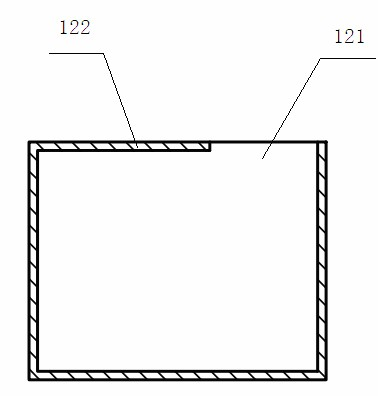

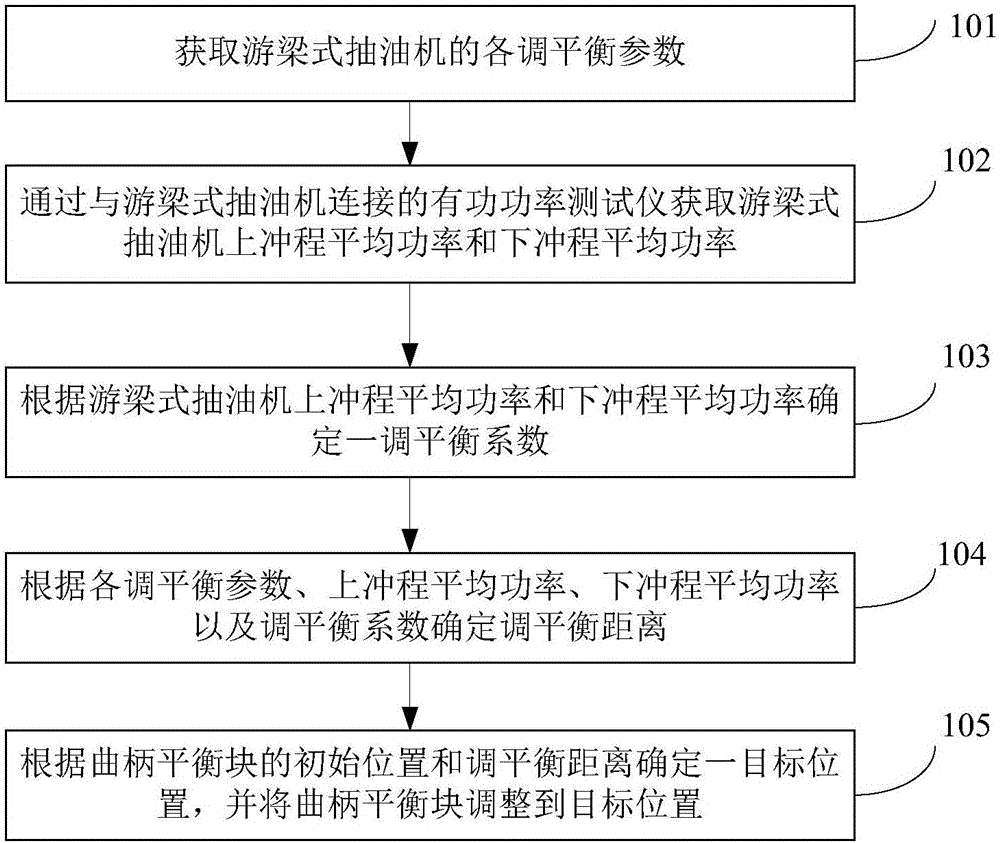

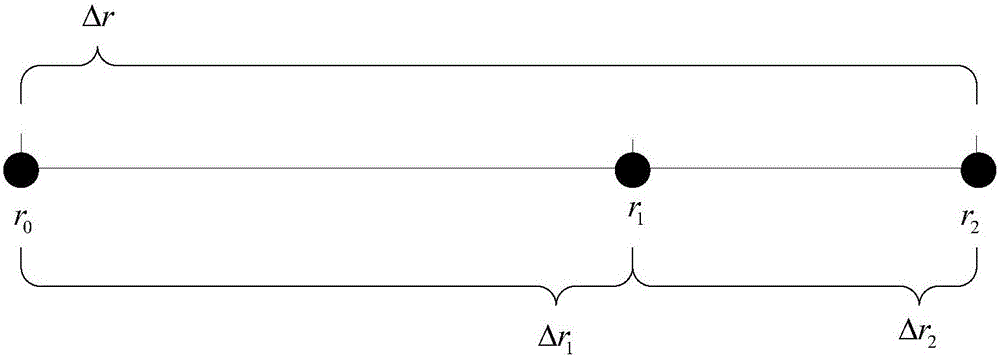

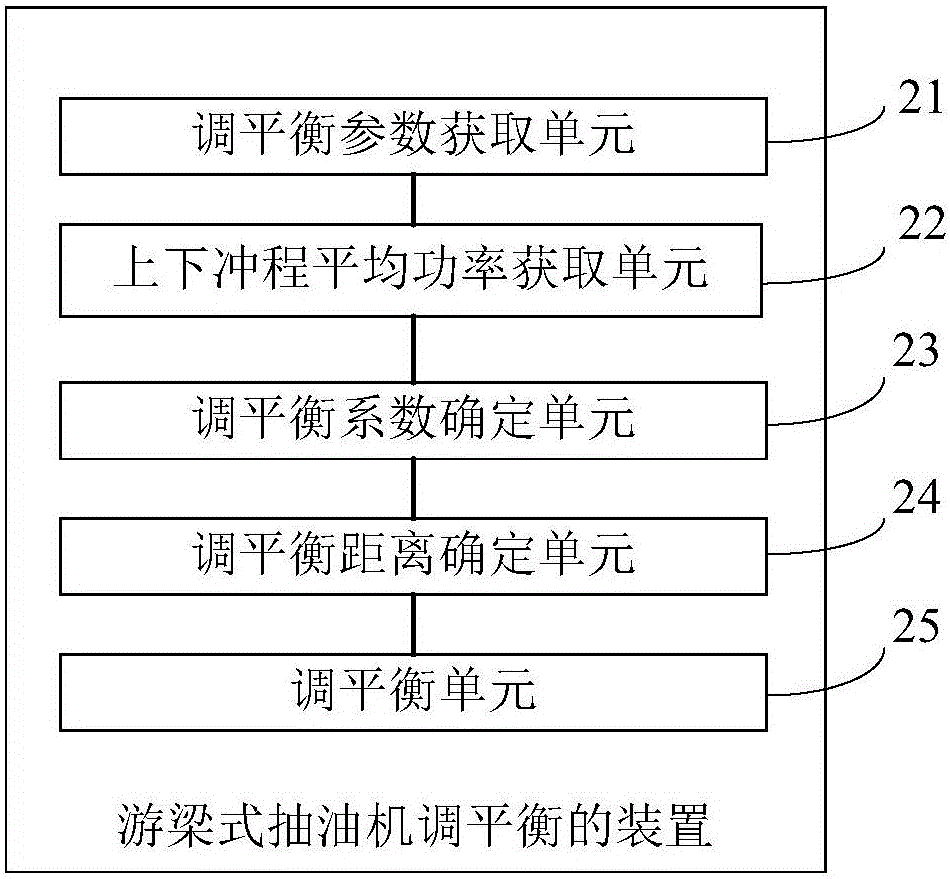

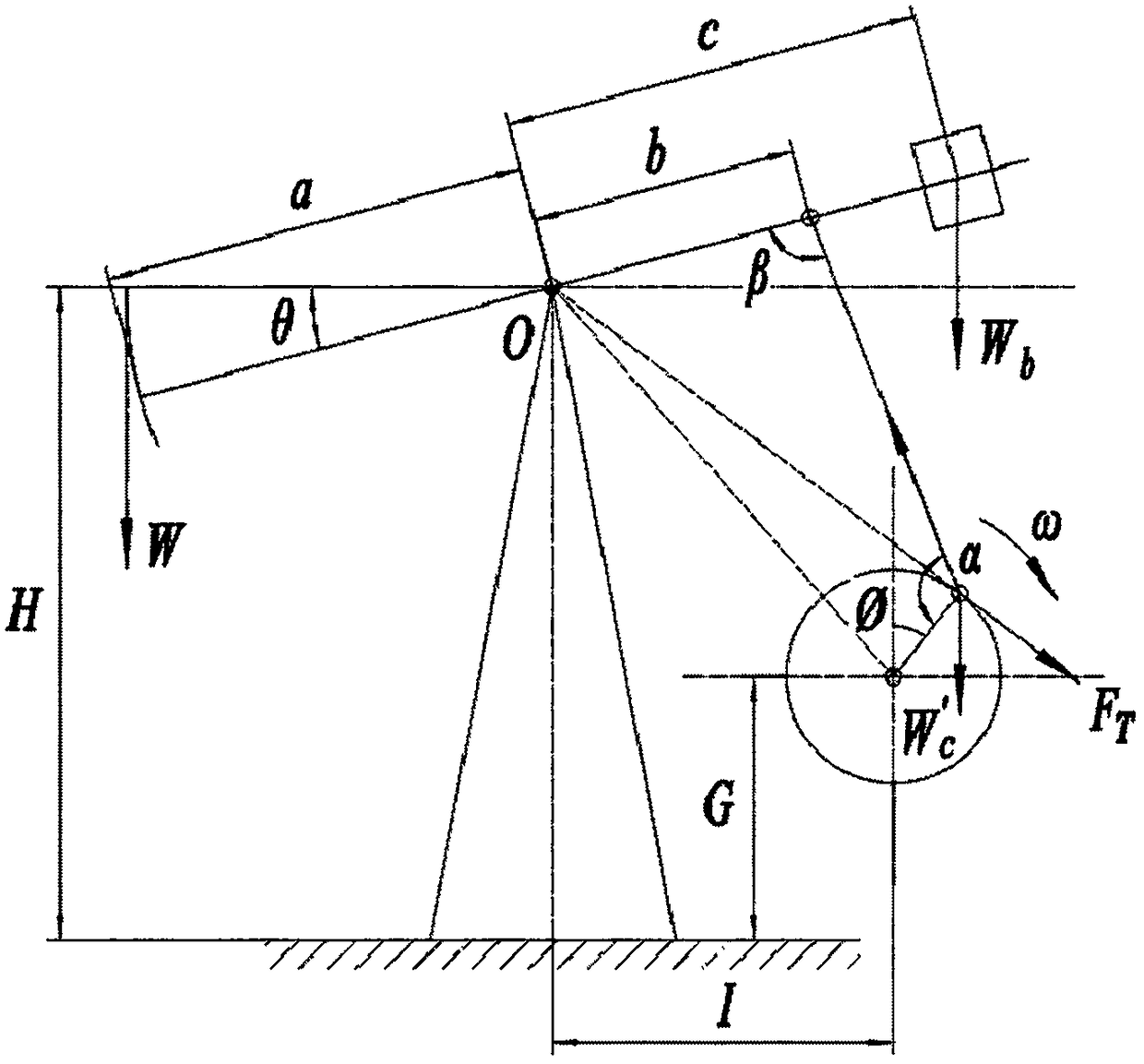

Walking-beam pumping unit balance adjusting method and device

ActiveCN105909215AImprove balanceGood balance effectConstructionsFlexible member pumpsStroke frequencyEngineering

The invention provides a walking-beam pumping unit balance adjusting method and device and relates to the technical field of walking-beam pumping units. The method includes the steps that all balance adjusting parameters of a walking-beam pumping unit are obtained and include the weight of each crank balance block, the number of the crank balance blocks, the initial positions of the crank balance blocks, the ground efficiency of the walking-beam pumping unit and polish rod stroke frequency of the walking-beam pumping unit; upstroke average power and downstroke average power of the walking-beam pumping unit are obtained through an active power tester connected with the walking-beam pumping unit; accordingly, a balance adjusting coefficient is determined; then the balance adjusting distance is determined; and a target position is determined according to the initial positions of the crank balance blocks and the balance adjusting distance, and the crank balance blocks are adjusted to the target position. By means of the walking-beam pumping unit balance adjusting method and device, walking-beam pumping unit balance adjusting can be performed through active power, and the balance adjusting effect of the walking-beam pumping unit is better.

Owner:PETROCHINA CO LTD

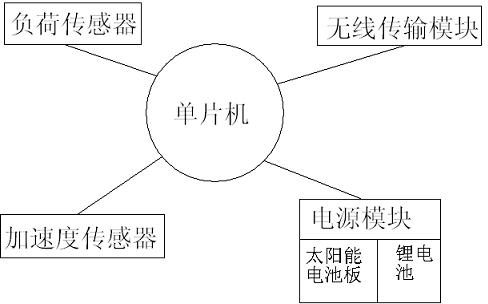

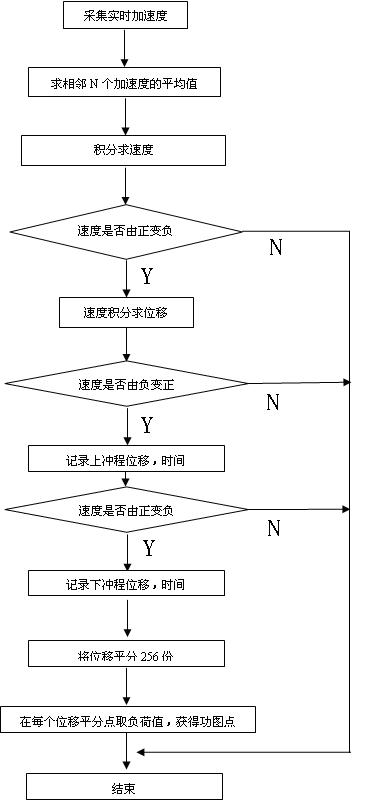

Acceleration-based indicator diagram data acquisition device of oil pumping unit

ActiveCN102435366AHigh precisionEasy to operateWork measurementTorque measurementMicrocontrollerWireless transmission

The invention discloses an acceleration-based indicator diagram data acquisition device of an oil pumping unit. The device comprises a singlechip, an acceleration sensor arranged on a polish rod of the oil pumping unit, a load sensor and a power module for supplying power, wherein the singlechip comprises a timer; the device is characterized in that: the indicator diagram data of the oil pumping unit is calculated by the following steps of: acquiring the acceleration and real-time load; calculating the average of multiple adjacent accelerations; calculating the zero value of the acceleration; integrating to obtain the speed; integrating to obtain an upper stroke and a lower stroke; equally dividing into multiple points according to distance; and adding the load corresponding to the point to obtain the indicator diagram data of the oil pumping unit. In the acceleration-based indicator diagram data acquisition device of the oil pumping unit disclosed by the invention, by improving the algorithm, the stroke and stroke frequency of the oil pumping unit are calculated simply by adopting the acceleration sensor to acquire the acceleration, and the accuracy and operability are greatly improved. Moreover, the device is convenient to install and use through a wireless transmission mode and a solar cell power supply mode.

Owner:NANJING RECON TECH

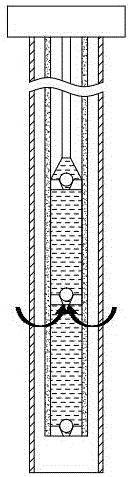

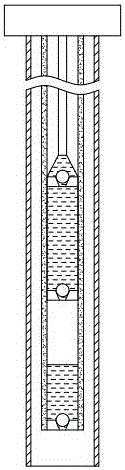

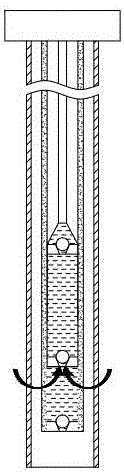

Reciprocating saw comprising a program-controlled feed conveyor for advancing the item to be cut

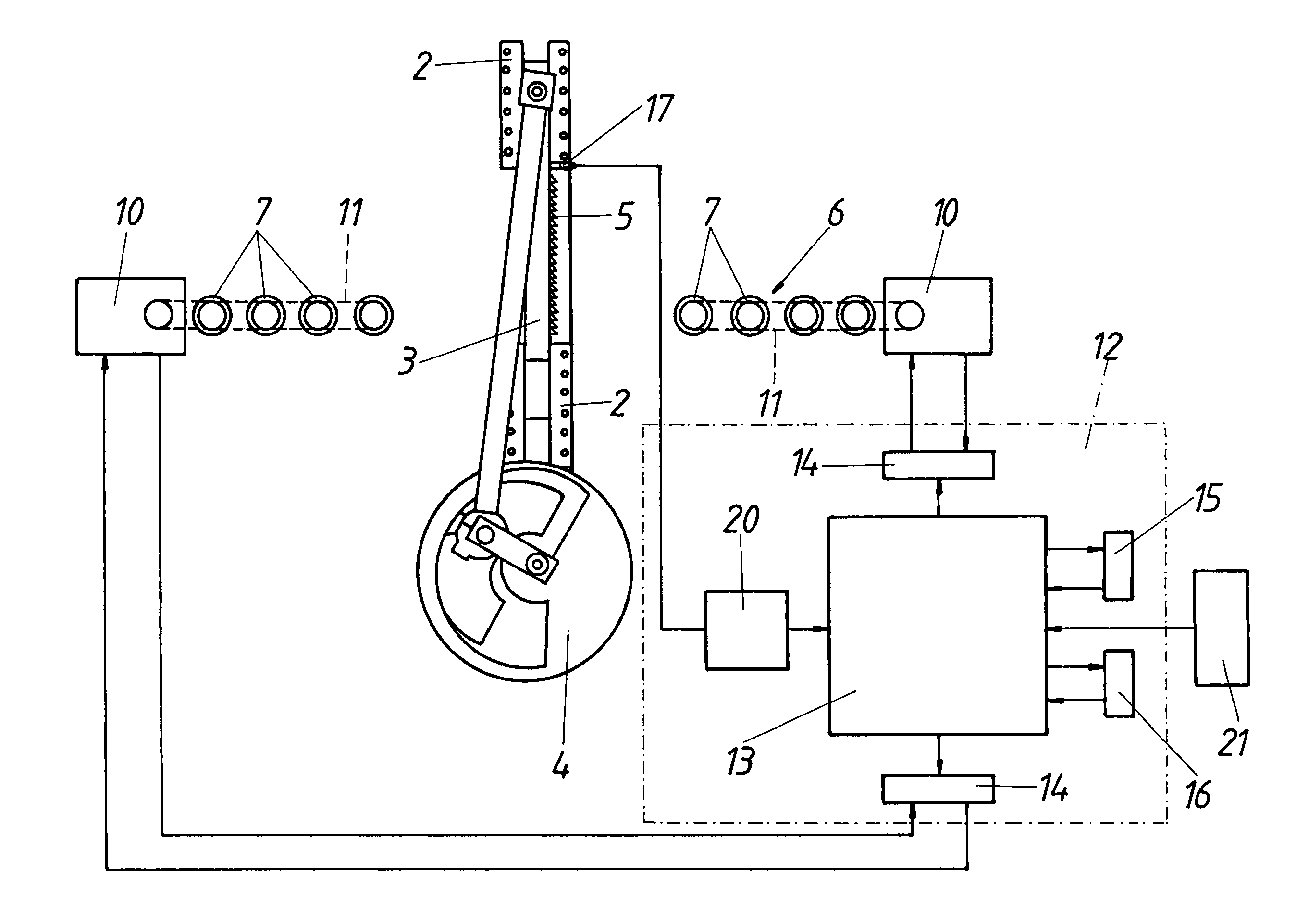

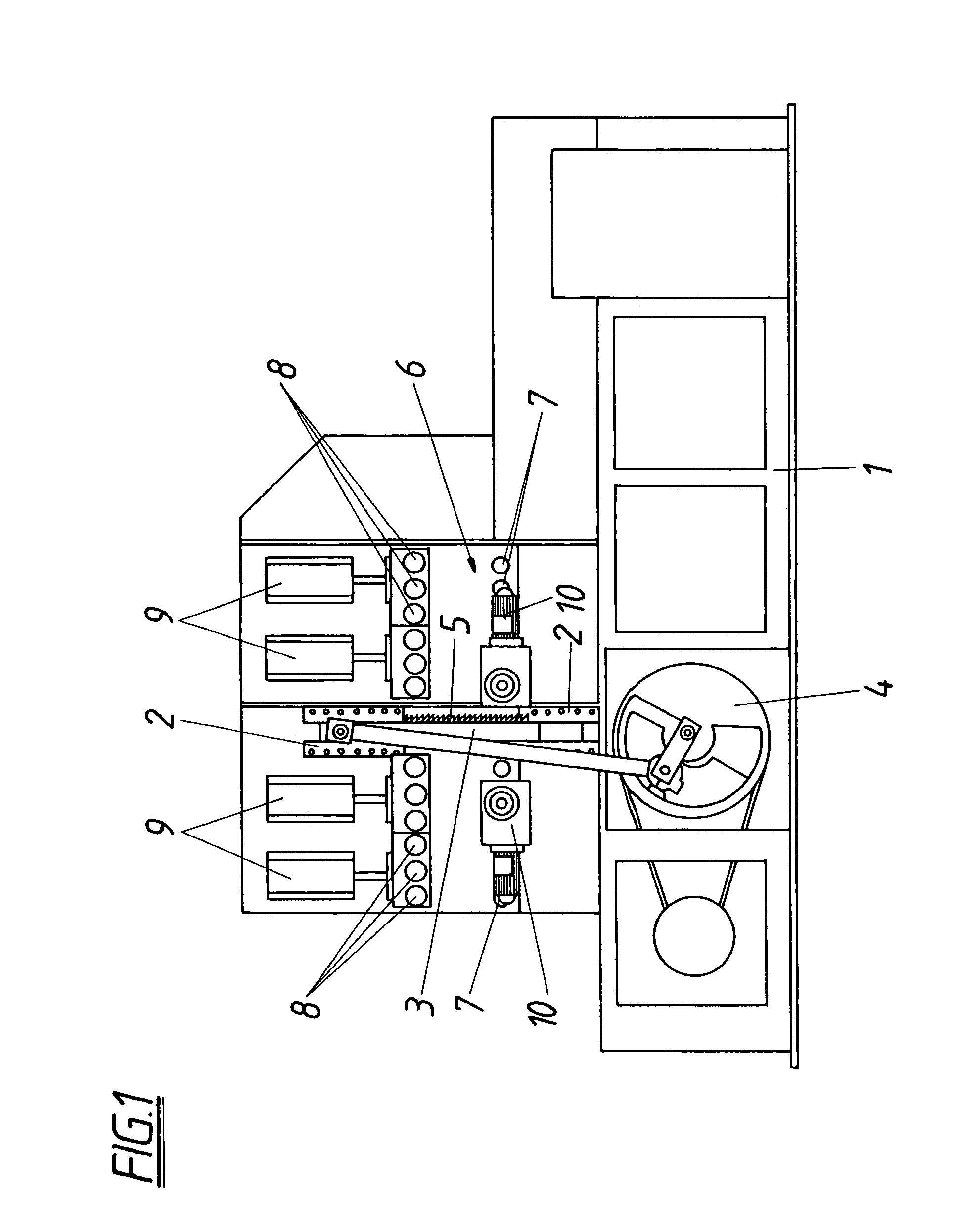

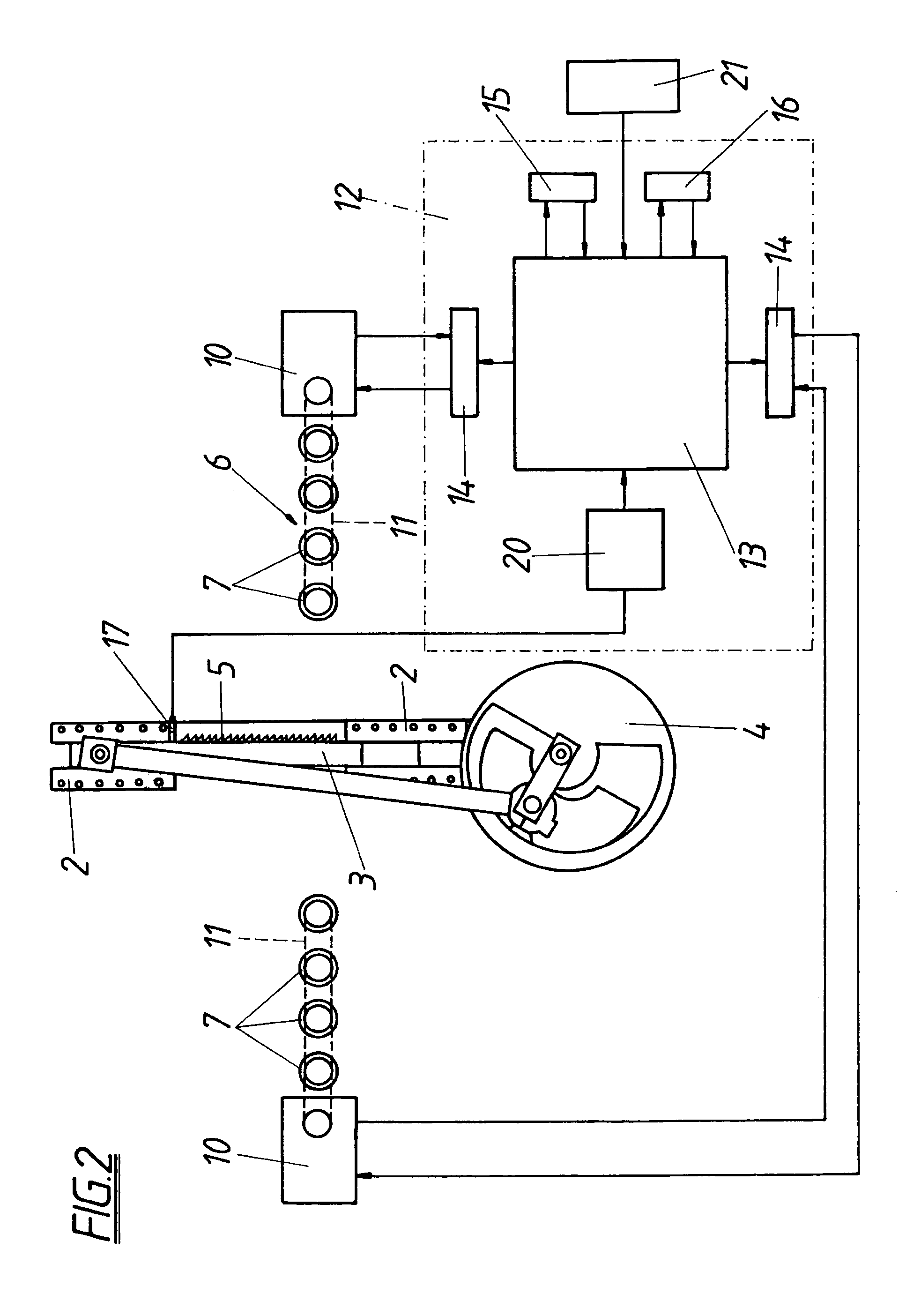

InactiveUS7032486B1Improve coordinationEasy constructionMetal sawing devicesFeeding devicesControl systemStroke frequency

The description refers to a mill saw with a saw gate (3) driven via a slider-crank drive (4), whose parallel saw blades (5), which cut in only one stroke direction, are provided with a bias, and with a feed conveyor (6) for the stock to be cut, which is driven intermittently during the cutting stroke of the saw gate (3) as a function of the cutting speed by means of at least one motor (10) separated from the slider-crank drive (4) and connected to a controlling system (12). To achieve favorable construction features, it is suggested that the controlling system (12) connected to a signal transmitter (17) for a preset position of rotation of the slider-crank drive (4) controls the motor (10) in dependence on the response of the signal transmitter (17) according to a stored control program for one conveying step adaptable to the respective stroke frequency of the slider-crank drive (4).

Owner:WINTERSTEIGER

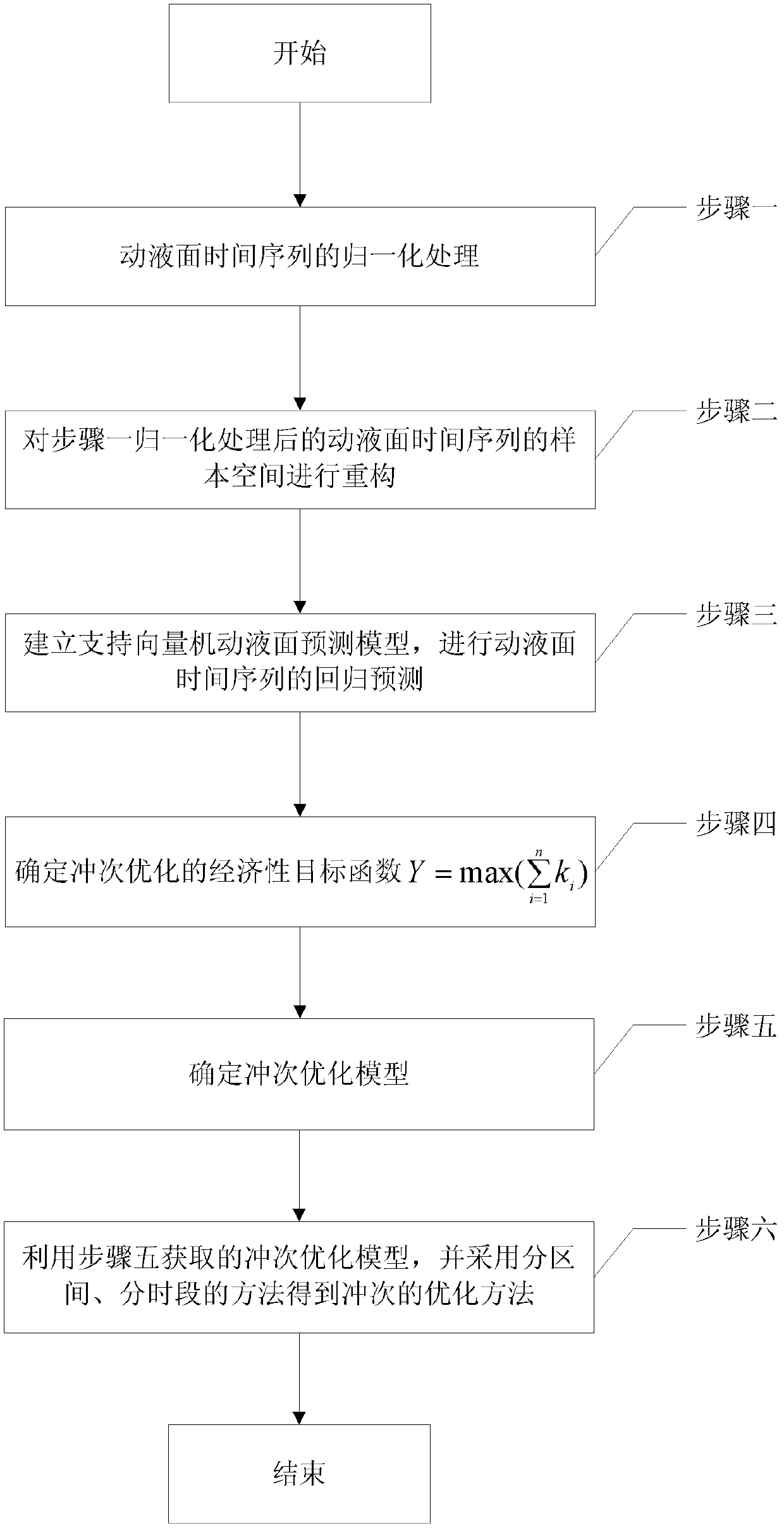

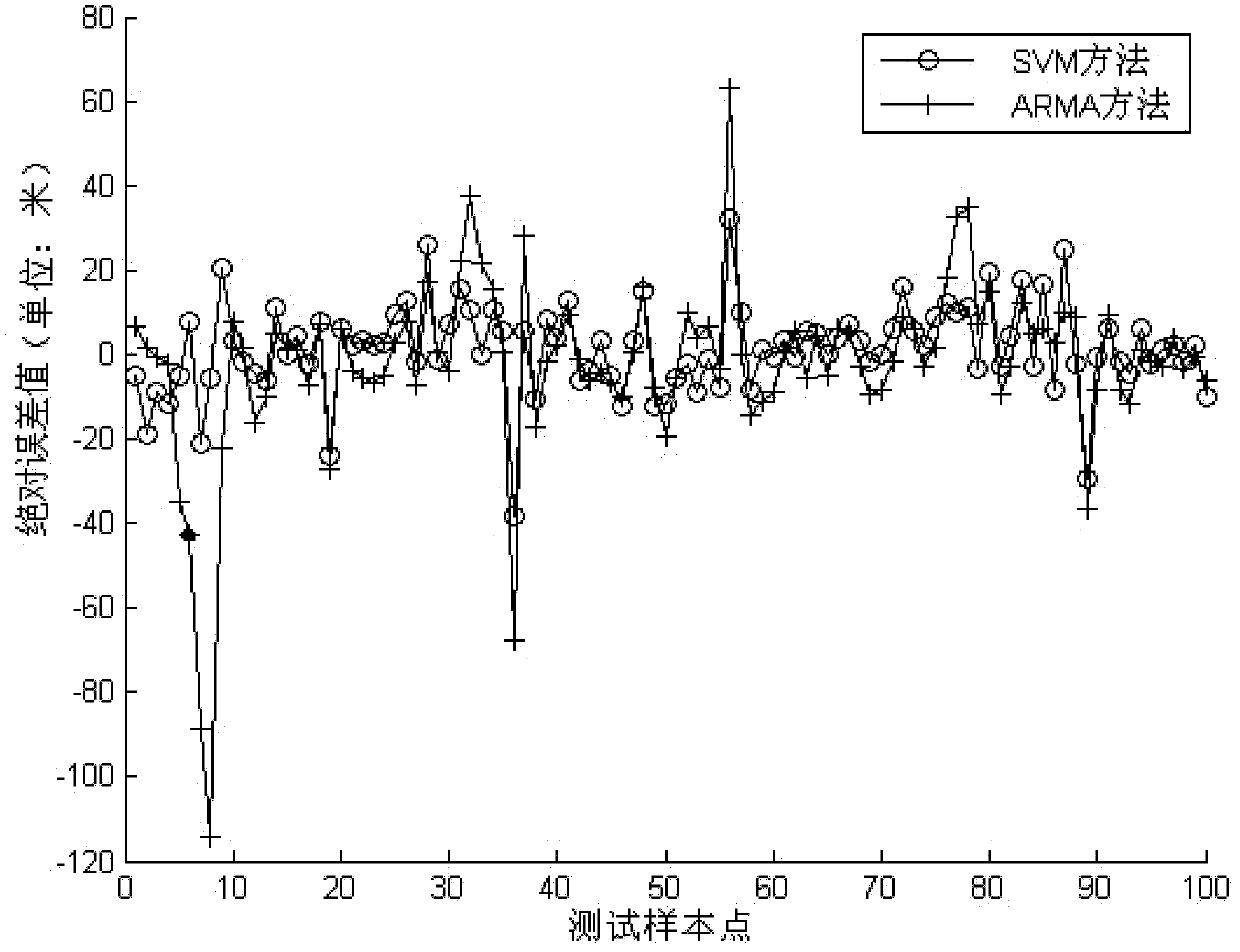

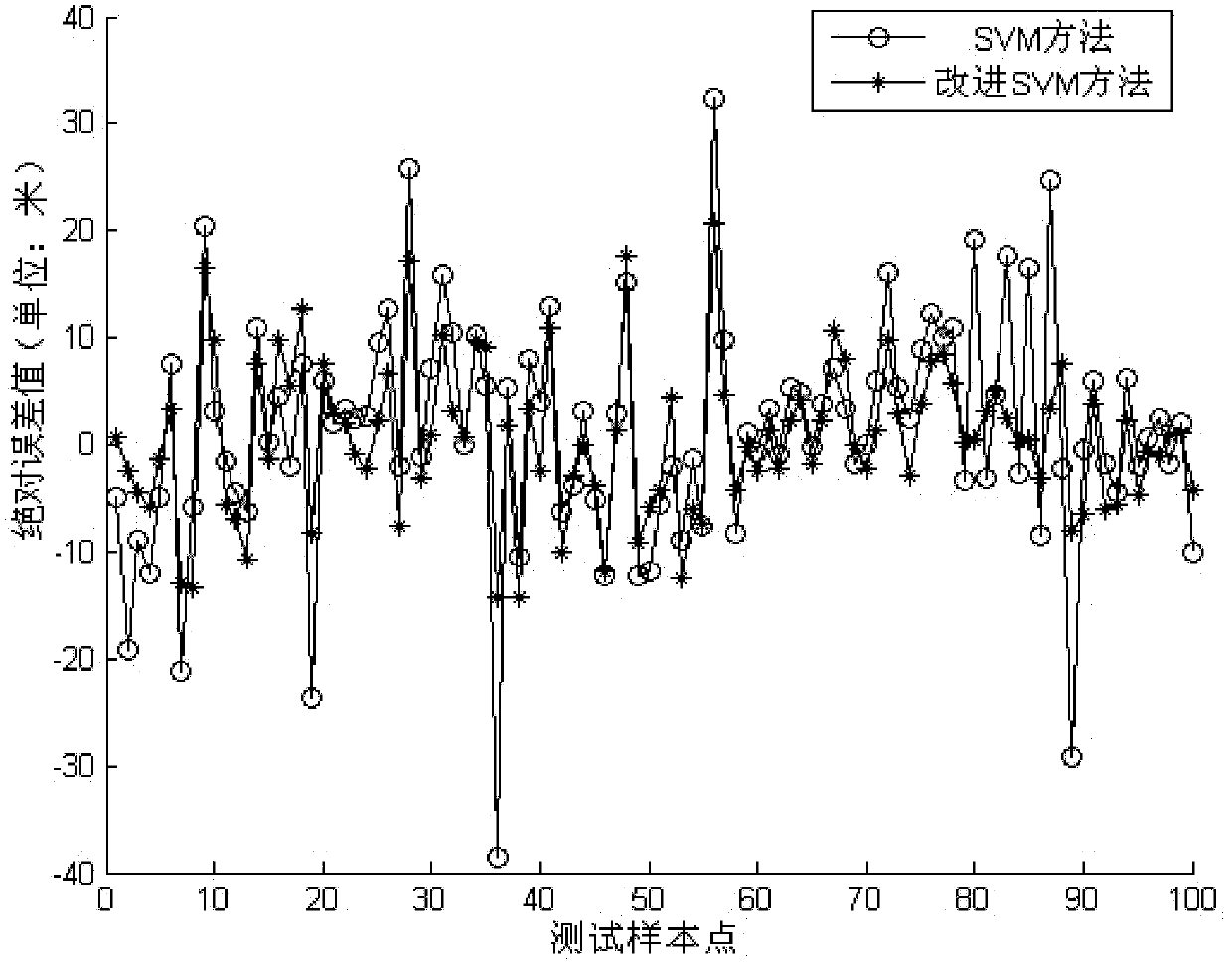

Working fluid level prediction-based optimization method for stroke frequency of submersible reciprocating oil pumping unit

InactiveCN102354111AHigh degree of control automationImprove energy savingAdaptive controlWorking fluidEngineering

The invention relates to a stroke frequency method of a submersible reciprocating oil pumping unit, more particularly to a working fluid level prediction-based optimization method for a stroke frequency of a submersible reciprocating oil pumping unit. Therefore, problems that there is no reasonable stroke frequency optimization control method for a submersible reciprocating oil pumping unit and alinear motor can not be adjusted according to an oil well state can be solved. The method comprises the following steps that: step one, normalization processing is carried out on a working fluid level time sequence; step two, a sample space of the working fluid level time sequence that has been processed by the normalization processing is reconstructed; step three, working fluid level prediction model supporting a vector machine is established and regression prediction on the working fluid level time sequence is carried out; step four, an economic target function of stroke frequency optimization is determined; step five, a stroke frequency optimization model is determined; step six, with utilization of the stroke frequency optimization model obtained in the step five, an optimization method for the stroke frequency is obtained by employing section division and time interval division methods. According to the invention, the method is applied to an oil well of a submersible reciprocating oil pumping unit.

Owner:HARBIN INST OF TECH

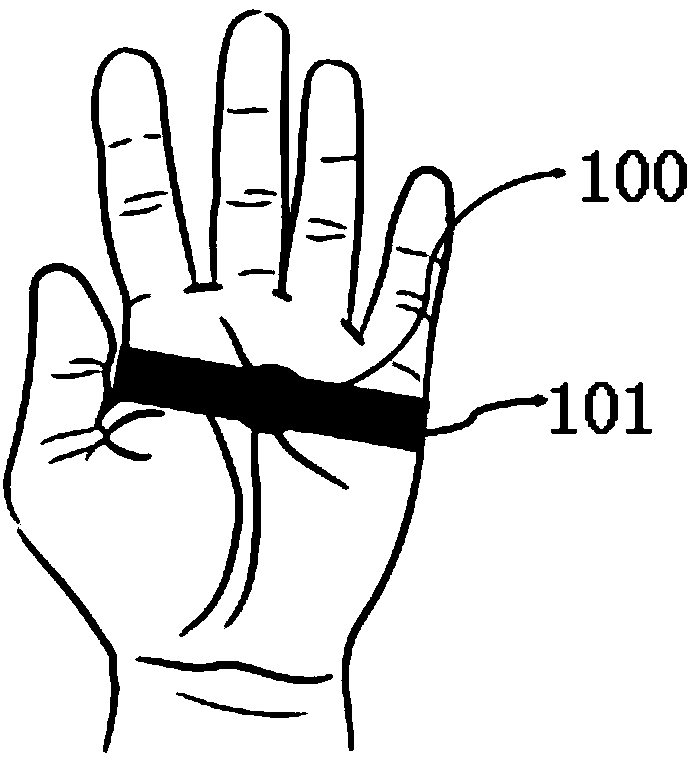

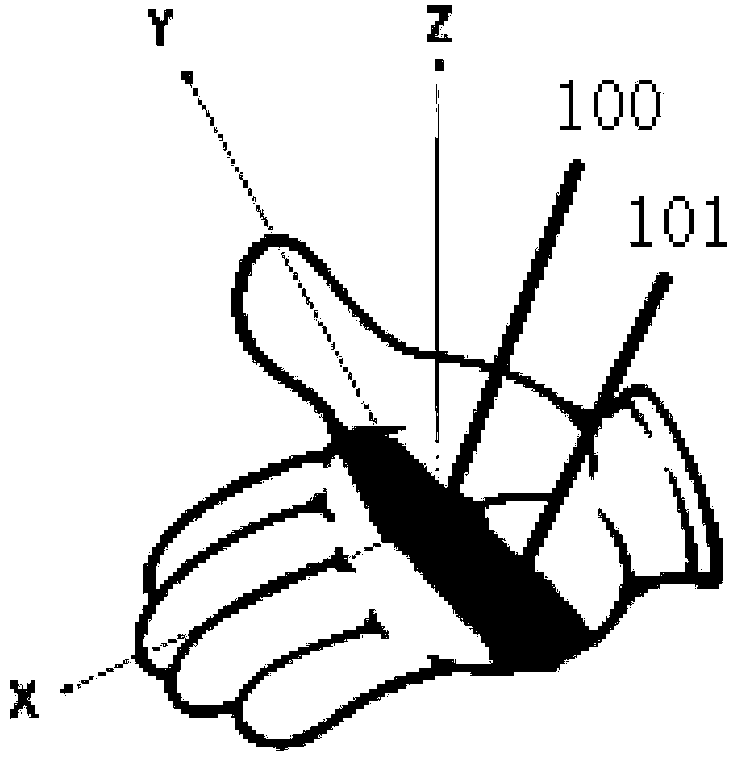

Sensor-based swimming stroke analyzer and sensor-based swimming stroke analysis method

ActiveCN108452504ATimely Voice FeedbackCorrect swimming actionGymnastic exercisingGyroscopeTriaxial accelerometer

The invention relates to a sensor-based swimming stroke analyzer and a sensor-based swimming stroke analysis method. The sensor-based swimming stroke analysis method comprises the following steps: (1)a palm data acquisition device which comprises a sensor module is worn on the palm of a trainer, and the sensor module comprises a triaxial accelerometer, a gyroscope sensor, and a wireless communication module; (2) a bone conduction sensor device is worn on the head of the trainer; (3) analysis is carried out; (4) the bone conduction sensor device is utilized for feedback of analytical data by voice in time. The invention uses the triaxial accelerometer and the gyroscope sensor to obtain swimming stroke characteristic data, and analyzes basic parameters (such as stroke frequency, stroke length, stroke speed and efficiency) of swimming training by processing and converting acquired data sensed by the triaxial accelerometer and the gyroscope sensor into graphical data, and the gyroscope sensor is used for measuring the inclination angle and rotational angle of the bottom of a swimmer.

Owner:昆山快乐岛运动电子科技有限公司

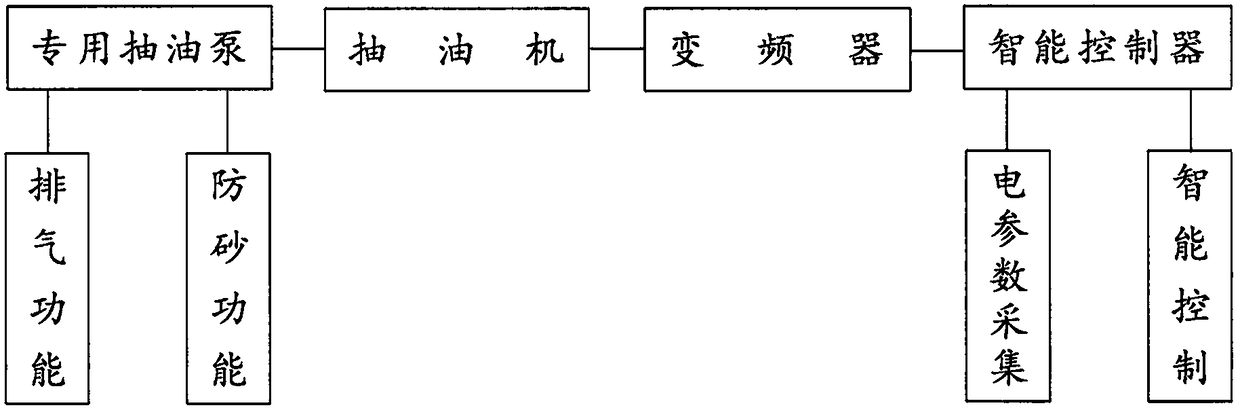

Swabbing parameter matching non-stop intermittent oil pumping and production system

InactiveCN109424337AGuaranteed reliabilityFit clearance is smallConstructionsFluid removalElectricityWorking fluid

The invention relates to a swabbing parameter matching non-stop intermittent oil pumping and production system. The system is characterized by being composed of an intelligent controller, a frequencyconverter and a special oil pump. An electric parameter test acquisition device is installed in the intelligent controller, embedded software is written in the intelligent controller, the active powerof a pumping unit is tested in real time, the working fluid level depth of an oil well is calculated according to the active power and structural parameters of the pumping unit, on this basis, when the working fluid level reaches a certain range, an intelligent program is started automatically, every time after the pumping unit reaches a top dead center, a crank is controlled to swing within a small angle range instead of immediate starting of a lower stroke, the time is provided for filling of the special oil pump, after the crank swings for a set time, an oil production program is started,and the operations are repeated; the oil pump is kept to always work under the optimal submergence condition while the high pumping efficiency is ensured; meanwhile, the pumping diameter of the oil pump is increased, the oil production stroke frequency of the pumping unit is greatly reduced under the condition of the same liquid yield, and the energy consumption of the system is reduced.

Owner:DAQING SENENPU MACHINERY MFG

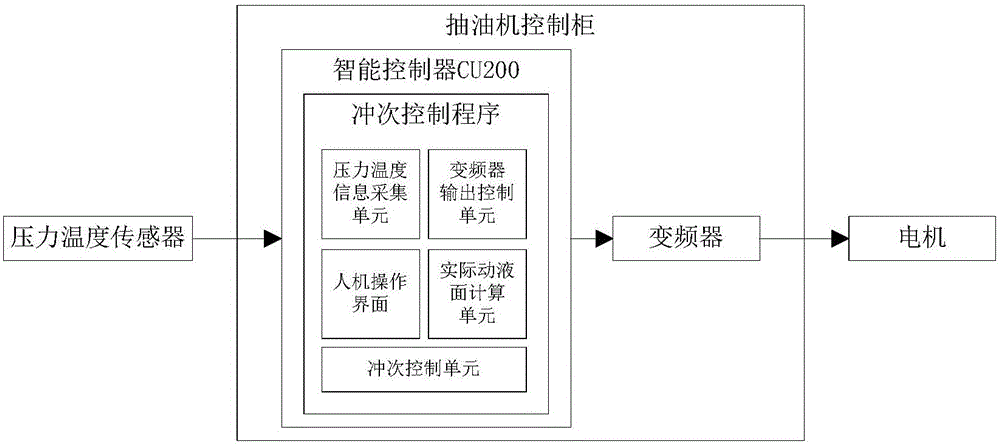

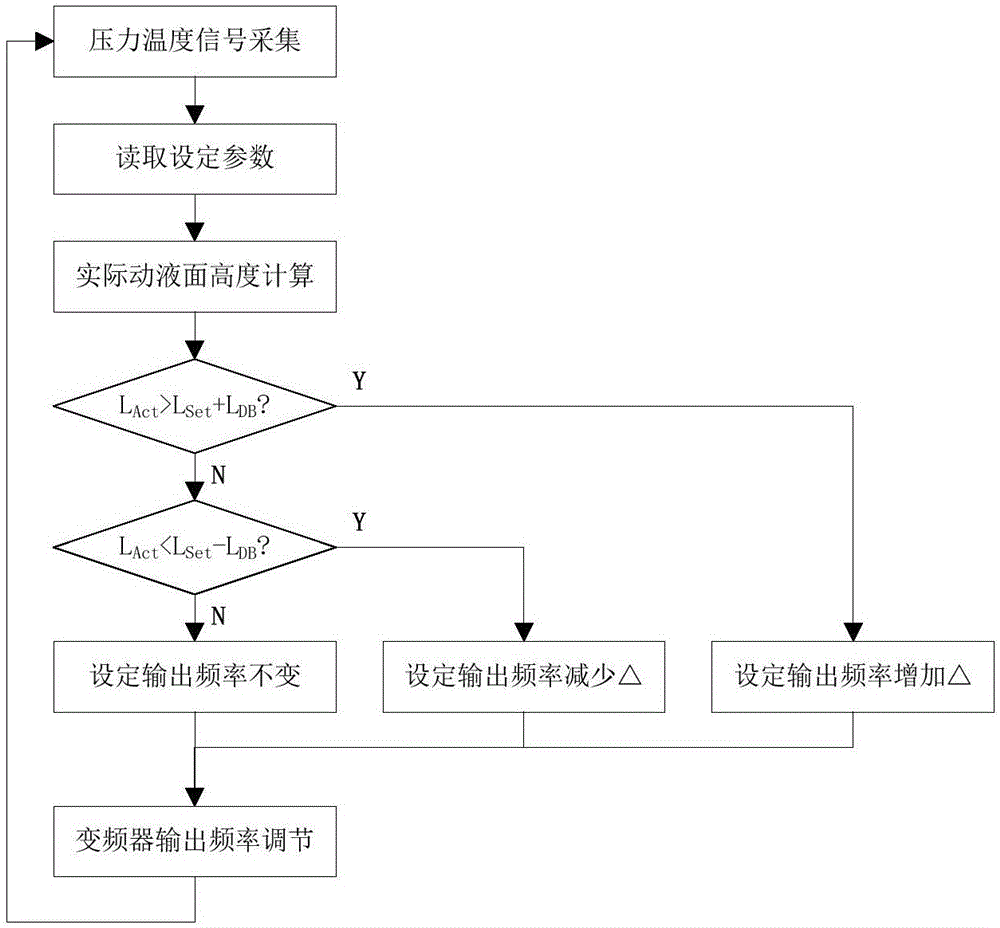

Intelligent stroke frequency control device and method of electric submersible pump oil pumping system

InactiveCN106121987ASimplify workloadAvoid empty pumpingFluid removalPump controlFrequency changerWorking fluid

The invention belongs to the field of oil drilling and production, and relates to an intelligent stroke frequency control device and method of an electric submersible pump oil pumping system. The device comprises a pressure and temperature sensor, an intelligent stroke frequency controller and a frequency converter which are sequentially connected, wherein the pressure and temperature sensor is located at a suction inlet of an electric submersible pump and used for collecting downhole pressure and temperature information; the frequency converter is connected with a pumping unit and used for adjusting the frequency of a motor of the pumping unit; and the intelligent stroke frequency controller comprises a pressure and temperature information collection unit, a man-machine operating interface, an actual working fluid level calculating unit, a stroke frequency adjusting unit and a frequency converter output control unit. The overall local control scheme of data collection, processing and control is provided, pumping unit control assistance by a remote computer is not needed, empty pumping of the pumping unit is effectively avoided, and the oil recovery efficiency of an oil field is improved.

Owner:XIAN BODE ENERGY EQUIP

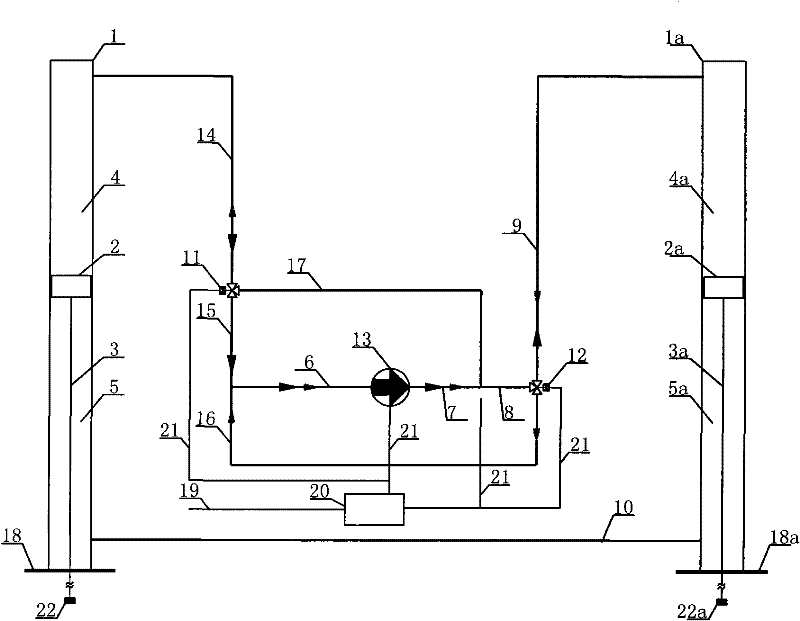

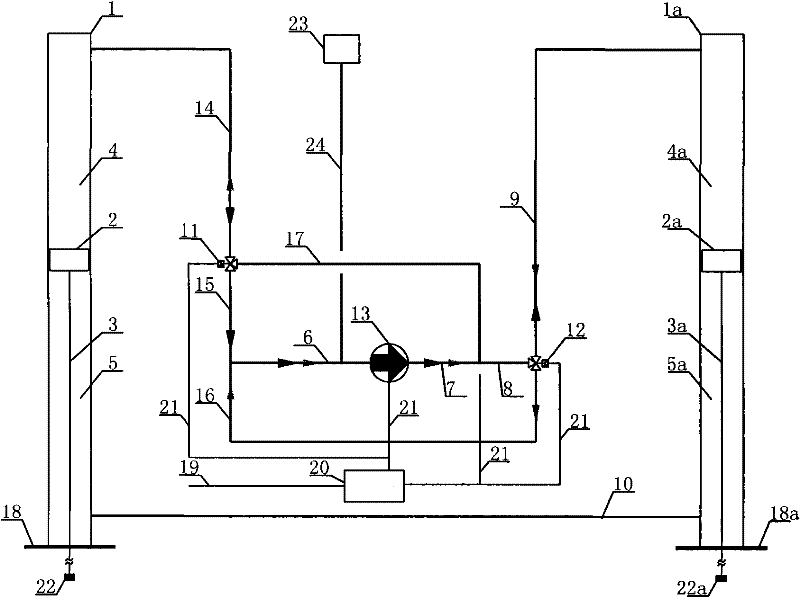

Hydraulic energy-saving multi-well pumping unit

InactiveCN102235159AHigh energyReduce energy consumptionFluid removalHydraulic cylinderControl engineering

The invention discloses a hydraulic energy-saving multi-well pumping unit which comprises a hydraulic system, automatic reversing valves, an oil well sucker rod connector, a control cabinet and connecting pipelines, wherein at least two hydraulic cylinders are connected with a hydraulic pump through the connecting pipeline; each hydraulic cylinder is a double-acting hydraulic cylinder; the automatic reversing valves are respectively arranged on an inlet pipeline and an outlet pipeline of the hydraulic pump; lower push-in cylinders of all the double-acting hydraulic cylinders are communicated with one another; upper push-in cylinders of the hydraulic cylinders are divided into two relatively-balanced parts; each part is connected with the automatic reversing valve through the pipeline and is communicated with the inlet pipeline and the outlet pipeline at two ends of the hydraulic pump through the pipelines; and a connector connected with an oil well sucker rod is arranged at the lower end of a lower piston rod at the lower part of a hydraulic cylinder piston. The hydraulic energy-saving multi-well pumping unit has the advantage of low manufacturing cost and provides a powerful support for the popularization of an exploiting and energy-saving technology of an oil field; and compared with the traditional beam-pumping unit, the hydraulic energy-saving multi-well pumping unit is adopted to save steel by 40-90 percent, save energy by 30-70 percent and ensure that the stroke is 0-8 meters and the stroke frequency is 1-20 times.

Owner:陈万仁

Subacid electrolyzed oxidizing water gynecological anti-infection treatment facility

ActiveCN104958830AHelps maintain an acidic environmentOvercome the application limitations of being only used in the field of disinfectionEnemata/irrigatorsMedical devicesEcological environmentAnti-infective therapy

The invention discloses a subacid electrolyzed oxidizing water gynecological anti-infection treatment facility. The subacid electrolyzed oxidizing water gynecological anti-infection treatment facility comprises a controller, a treatment contact component, a subacid electrolyzed oxidizing water generation device and an atomization assembly; a water pressure reducing valve is additionally arranged on the subacid electrolyzed oxidizing water generation device on the basis of original oxidation reduction potential water so as to control the water inlet flow, a brine pump is additionally arranged so as to adjust the circulation stroke frequency, and therefore subacid water with the PH value ranging from 3.5 to 5.5, the oxidation reduction potential (ORP) ranging from +800 mV to +1000 mV and the available chlorine content ranging from 80 mg / L to 150 mg / L is generated; and then the atomization assembly and the treatment contact component are additionally arranged so as to meet the requirements of female genital tract anti-infection treatment. The application limit that a traditional subacid electrolyzed oxidizing water generation device is only used in the disinfection field is overcome, and a new gynecological anti-infection physical treatment scheme which is wide in antibacterial spectrum, rapid in sterilization, non-toxic and free of stimulation, is favorable for maintaining a genital tract acid environment, and is favorable for genital tract micro-ecological environment reconstruction is provided for clinic.

Owner:珠海市索利达医疗器械有限公司

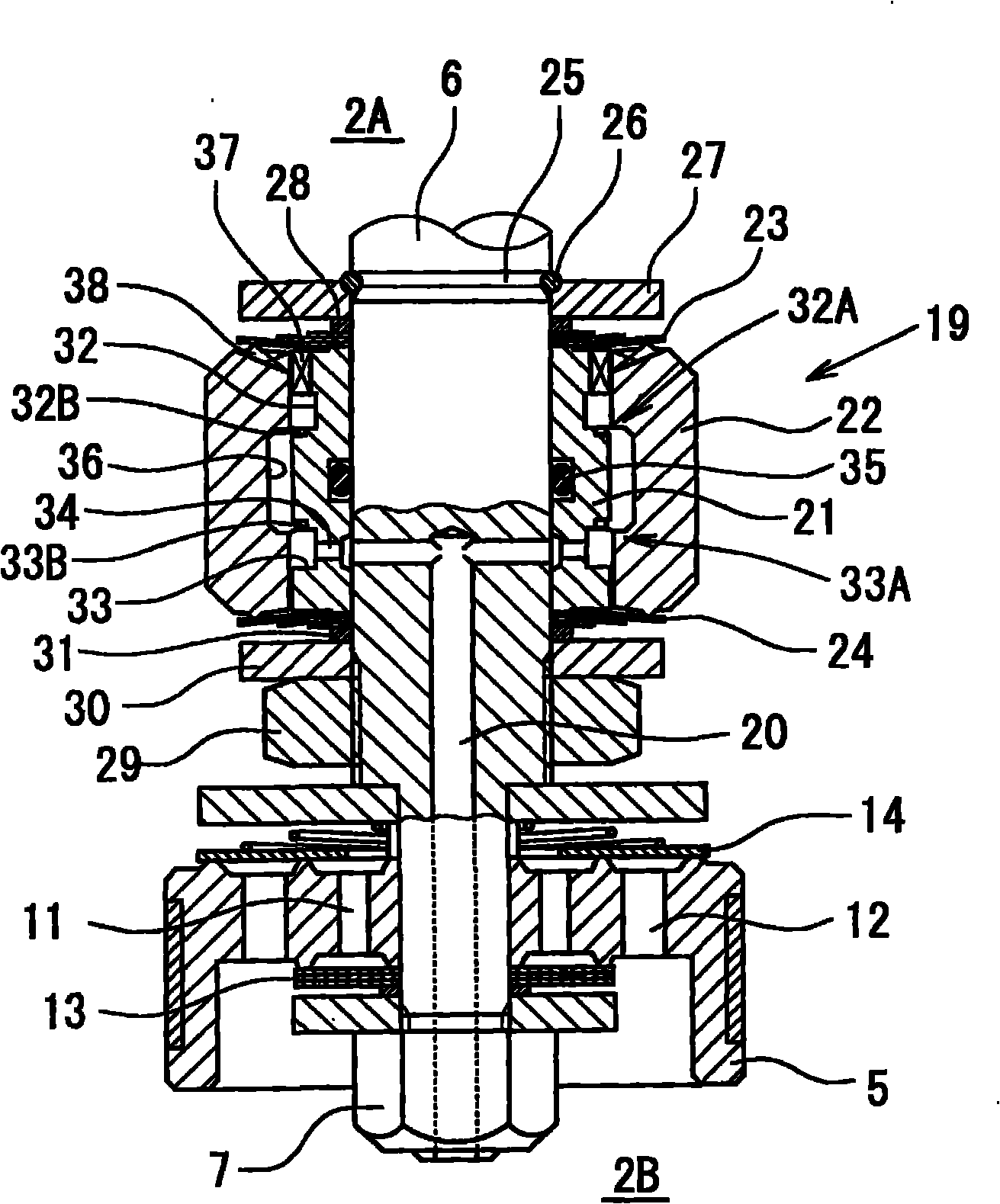

Shock absorber

InactiveCN101988553AImprove responsivenessStable damping force characteristicsSpringsShock absorbersEngineeringStroke frequency

The present invention provides a shock absorber that is adjustable in damping force according to the stroke frequencies of a piston rod so as to improve responsibility of the damping force and obtain stable damping force properties. A piston (5) connected with a piston rod (6) is inserted into a cylinder (2). A damping-force adjusting mechanism (19) adjusts a passage area of a by-pass passage (20) communicated between upper, lower chambers (2A,2B) of the cylinder. A plate spring elastically retains a shutter and the opening of the variable pass at the extending and shrinking sides is adjusted by shift of the shutter and the shutter moves using the fluid force generated by shrinking. According to the characteristic of the vibration system composed of the shutter and the plate spring, the resistance is applied on the shift of the shutter and the damping force is adjusted according to the stroke frequency of the piston rod. Because the difference pressure between the upper, lower chambers of the cylinder is used as the push force of the shutter, the inefficacy stroke is suppressed to the minimum limit and the desired damping force is quickly raised.

Owner:HITACHI AUTOMOTIVE SYST LTD

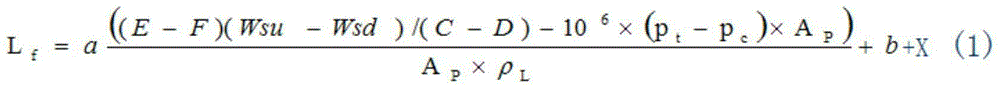

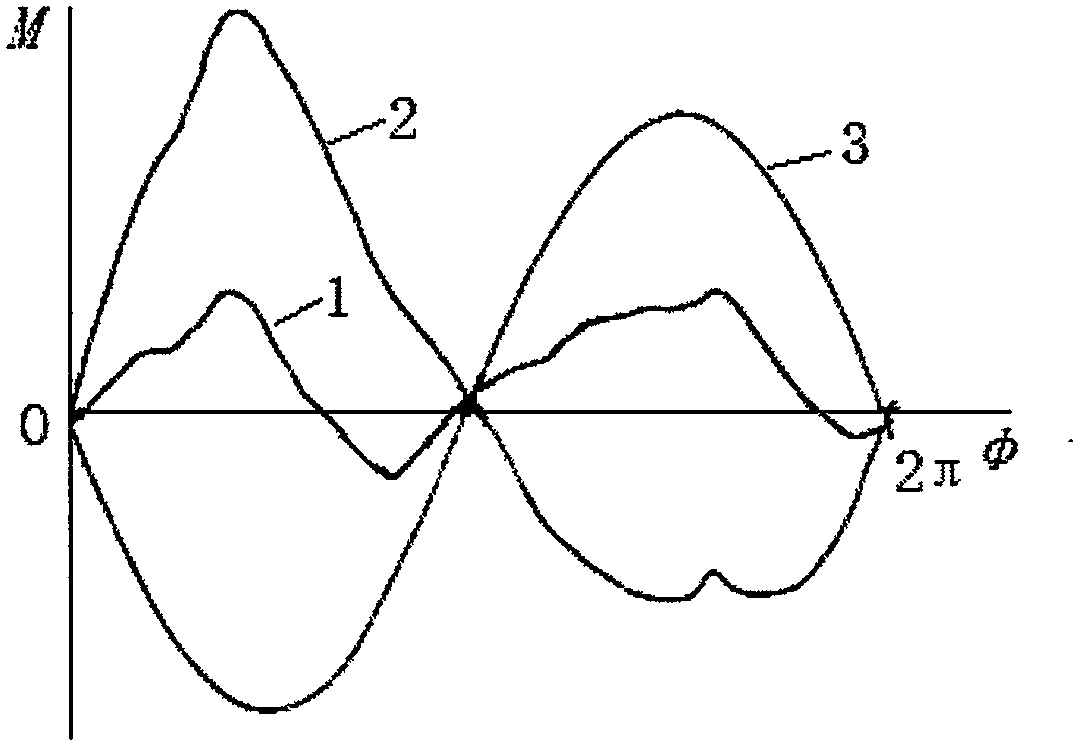

Method for calculating liquid output of oil pumping unit through active power difference

The invention provides a method for calculating the liquid output of an oil pumping unit through the active power difference and relates to a flow measurement method. The area integral of the down stroke active power in an active power curve I to time is subtracted from the area integral of the down stroke active power in an active power curve II to time, and the area integral difference is obtained. The area integral difference corresponds to an actual filling degree difference of the oil pumping unit, and then the stroke frequency liquid output II corresponding to the active power curve II can be worked out according to the stroke frequency liquid output I, measured actually, of the active power curve I. Then the stroke frequency liquid outputs II corresponding to all the active power curves II are accumulated according to time, and the total daily liquid output, the total monthly liquid output and the total yearly liquid output can be worked out. According to the method, the difference method is adopted for calculation, frequent correction is not needed, and an operator just need to conduct correction after large change of the well condition happens. A correction method is simple, and the accuracy rate is high.

Owner:大庆恒通电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com