Hydraulic energy-saving multi-well pumping unit

A pumping unit and hydraulic technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of huge equipment, increased cost, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

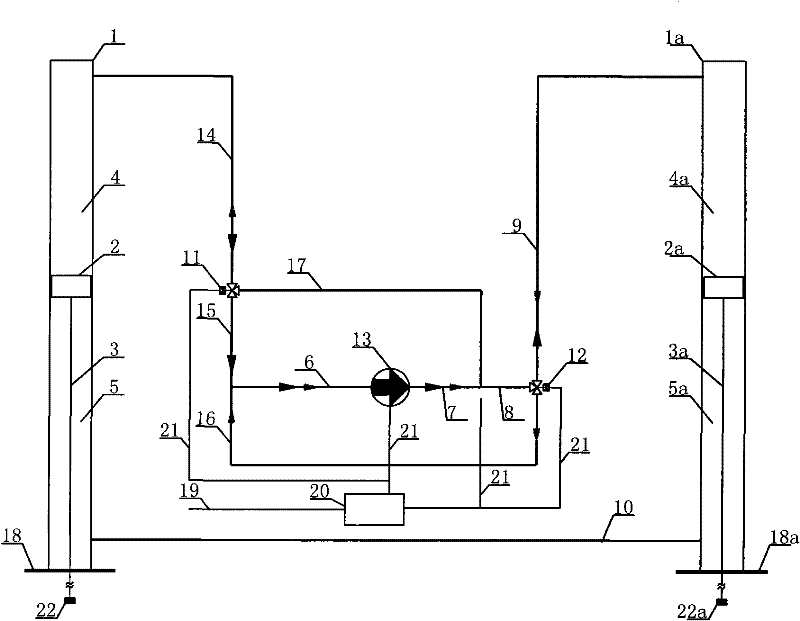

Embodiment 1

[0017] Embodiment 1: The hydraulic energy-saving multi-well pumping unit in this embodiment includes a hydraulic system, an automatic reversing valve, an oil well sucker rod connector, a control cabinet, and connecting pipelines. There are two corresponding single pumping units in the hydraulic system. Piston rod double-acting hydraulic cylinders 1 and 1a are equipped with piston 2 and piston 2a respectively in hydraulic cylinders 1 and 1a, and the lower parts of piston 2 and piston 2a are respectively fixed with lower piston rod 3 and lower piston rod 3a; In cylinder 1, the part of the hydraulic cylinder above the piston 2 is called the upper push cylinder 4, and the part of the hydraulic cylinder below the piston 2 is called the lower push cylinder 5; in the other hydraulic cylinder 1a, the part of the hydraulic cylinder above the piston 2a is called the upper push cylinder. The hydraulic cylinder 4a below the piston 2a is called the lower hydraulic cylinder 5a; the base 18 i...

Embodiment 2

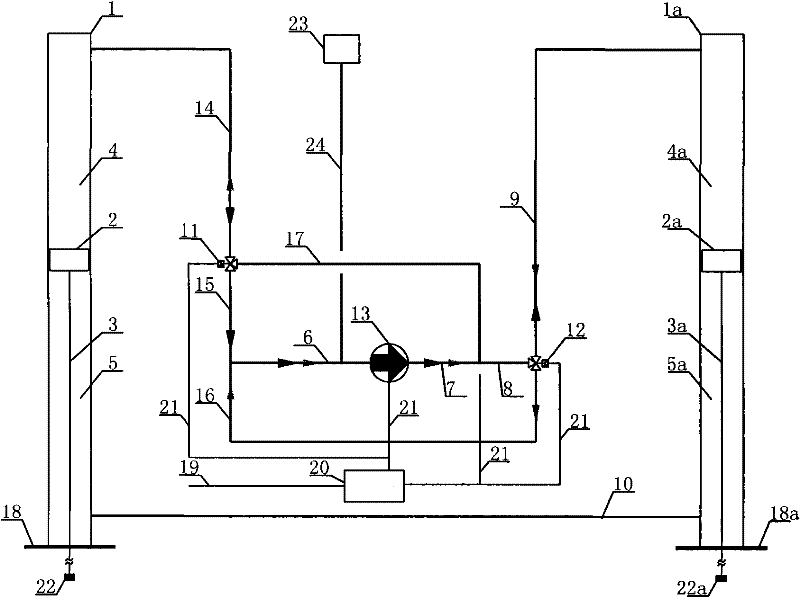

[0019] Embodiment 2: The structure of this embodiment is that a liquid replenishment pipe 24 and a liquid replenishment tank 23 are installed on the pipeline 6 connected to the inlet end of the hydraulic pump 13 . Other structures are the same as in Embodiment 1.

Embodiment 3

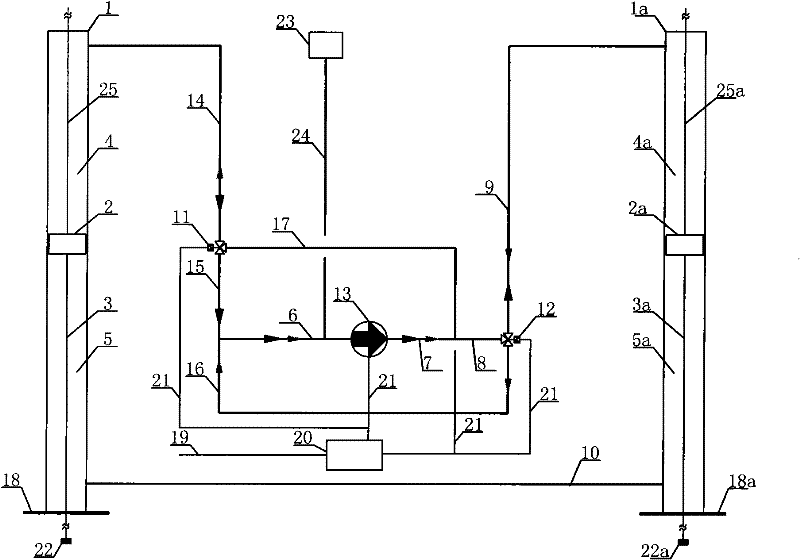

[0020] Embodiment 3: The hydraulic cylinder in this embodiment is a double-piston-rod double-acting hydraulic cylinder. The upper part of the piston 2 in the hydraulic cylinder 1 in this embodiment is fixed with a piston rod 25; the piston 2a in the hydraulic cylinder 1a The top is fixed with a piston rod 25a. Other structures are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com