Method for controlling tower-type pumping unit

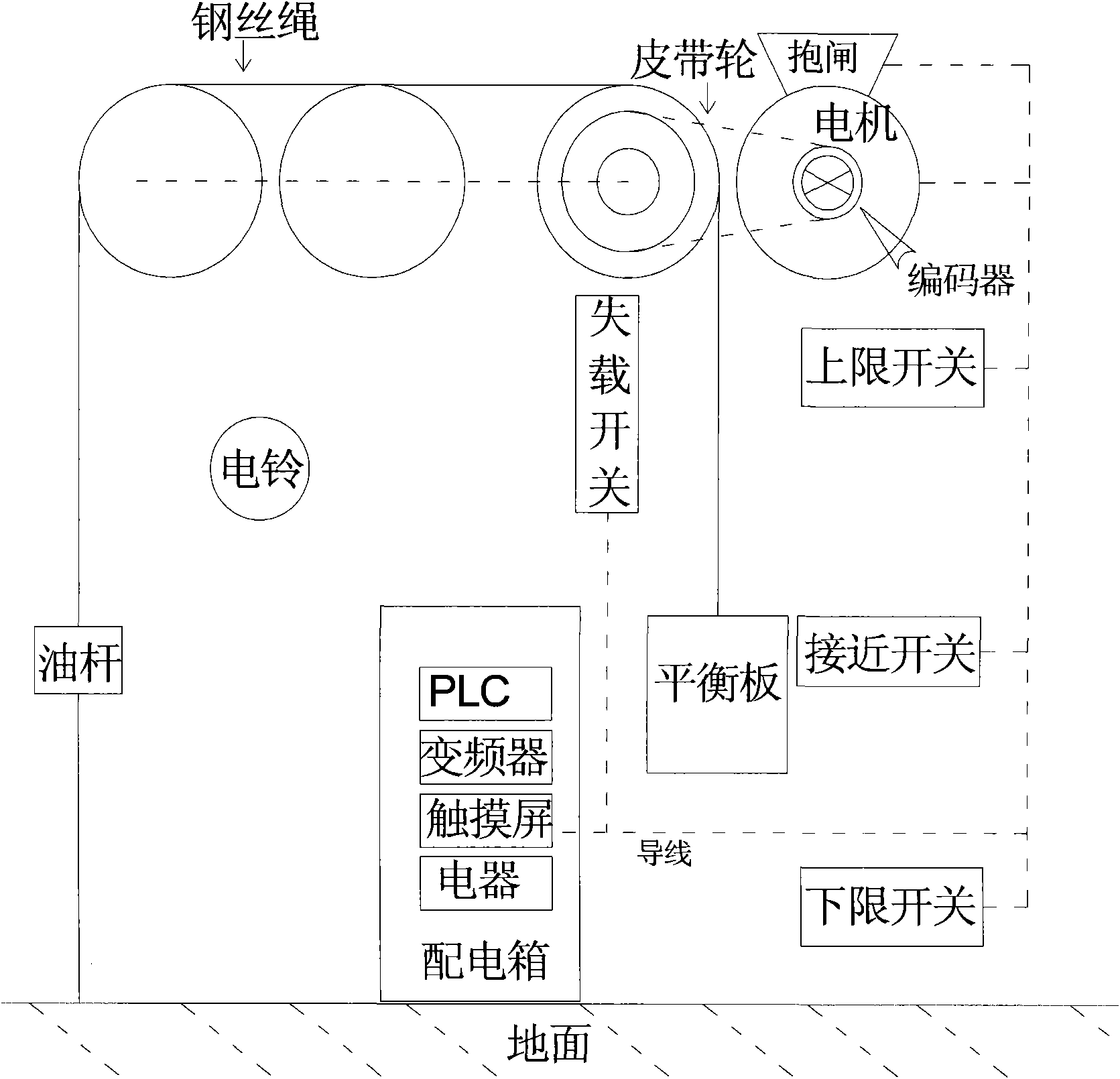

A technology for a tower pumping unit and a control method, which is applied in the directions of earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of stroke error, frequent wire rope damage, large error, etc., and achieve the effect of reducing belt slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

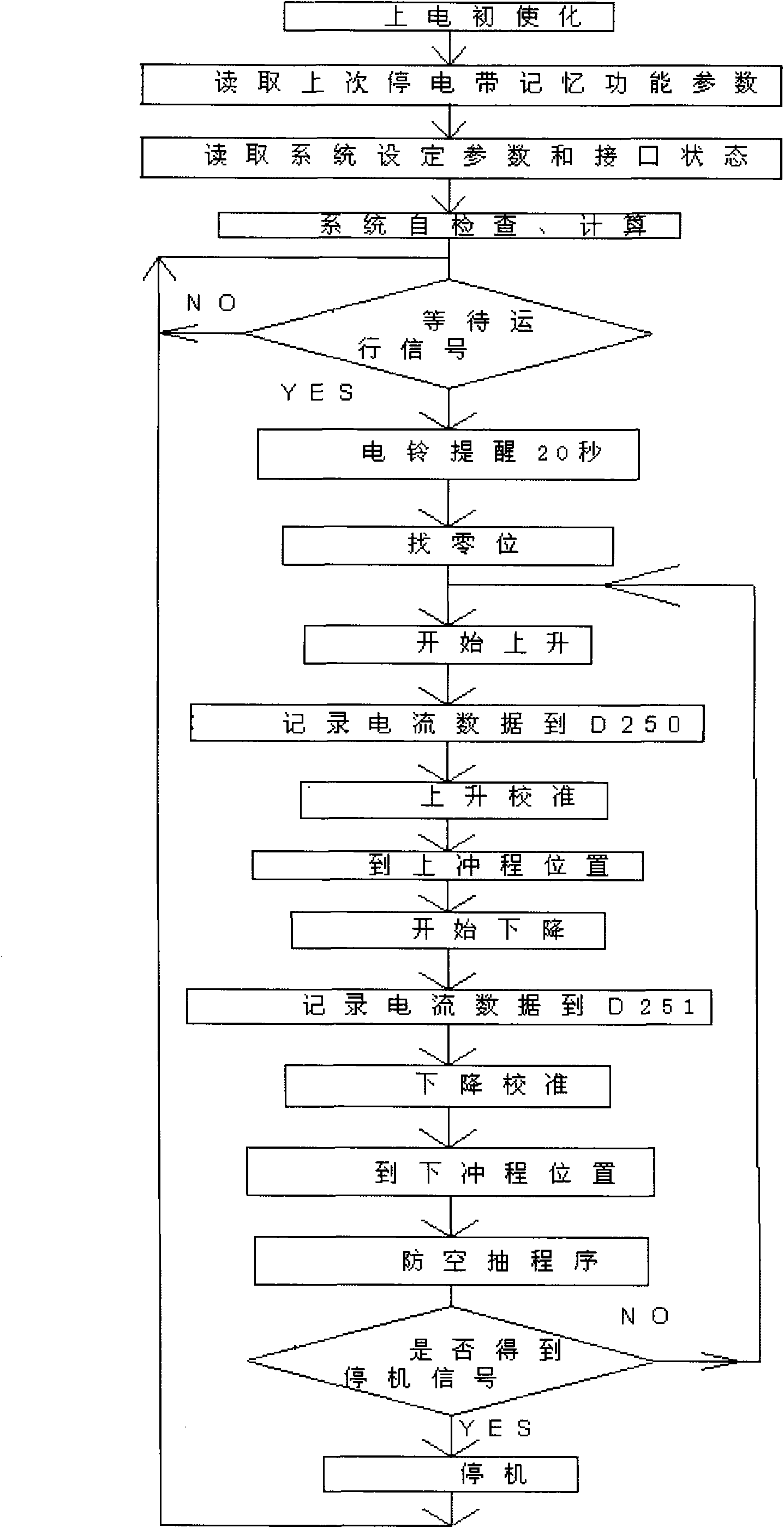

[0032] like figure 2 As shown, it is an overall flowchart of a control method for a tower pumping unit provided by the present invention, and its steps are:

[0033] Step 1. The tower pumping unit is initialized after power-on. After power-on, set the parameters that need to be initialized to the initial value, such as clearing the counter D300 to be used in step 12, etc.; after power-on and initialization, read the last power failure With memory parameters, read the state of the EEPROM parameters saved in the last power failure, so that the system control mode is consistent with the last time.

[0034] Step 2. Read the pre-set parameters and check the status of each input and output interface, and then the system performs self-test;

[0035] Step 3. Calculate and set up and down stroke frequency and inverter acceleration and deceleration time;

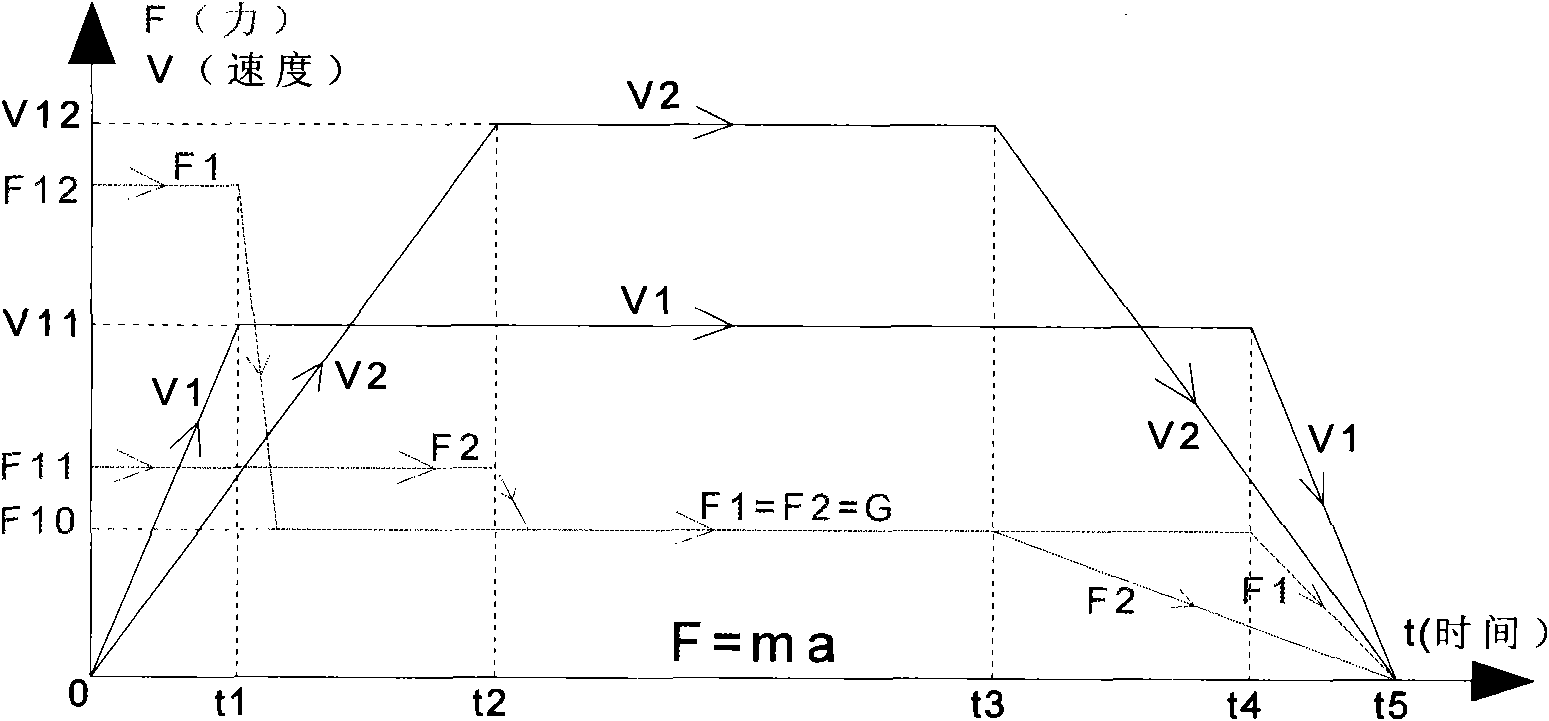

[0036] like image 3 Shown is the principle explanatory diagram of the above steps, in this drawing, F=ma is Newton's second law...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com