Harmless reinjection treatment method for petroleum exploitation sludge

A technology of harmless treatment and oil extraction, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of waste of oil resources, unfavorable environment, high treatment cost, etc. The effect of mining rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

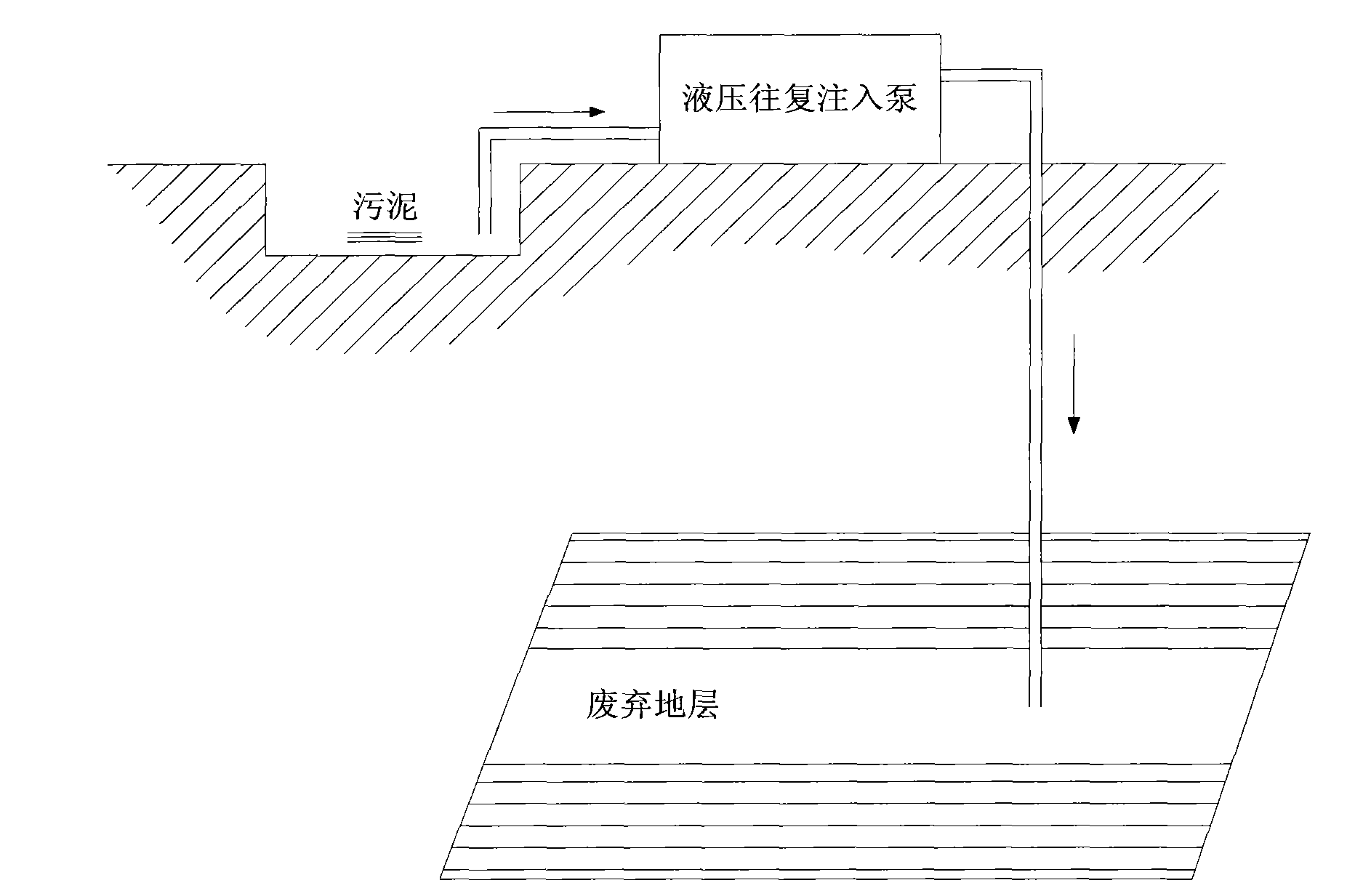

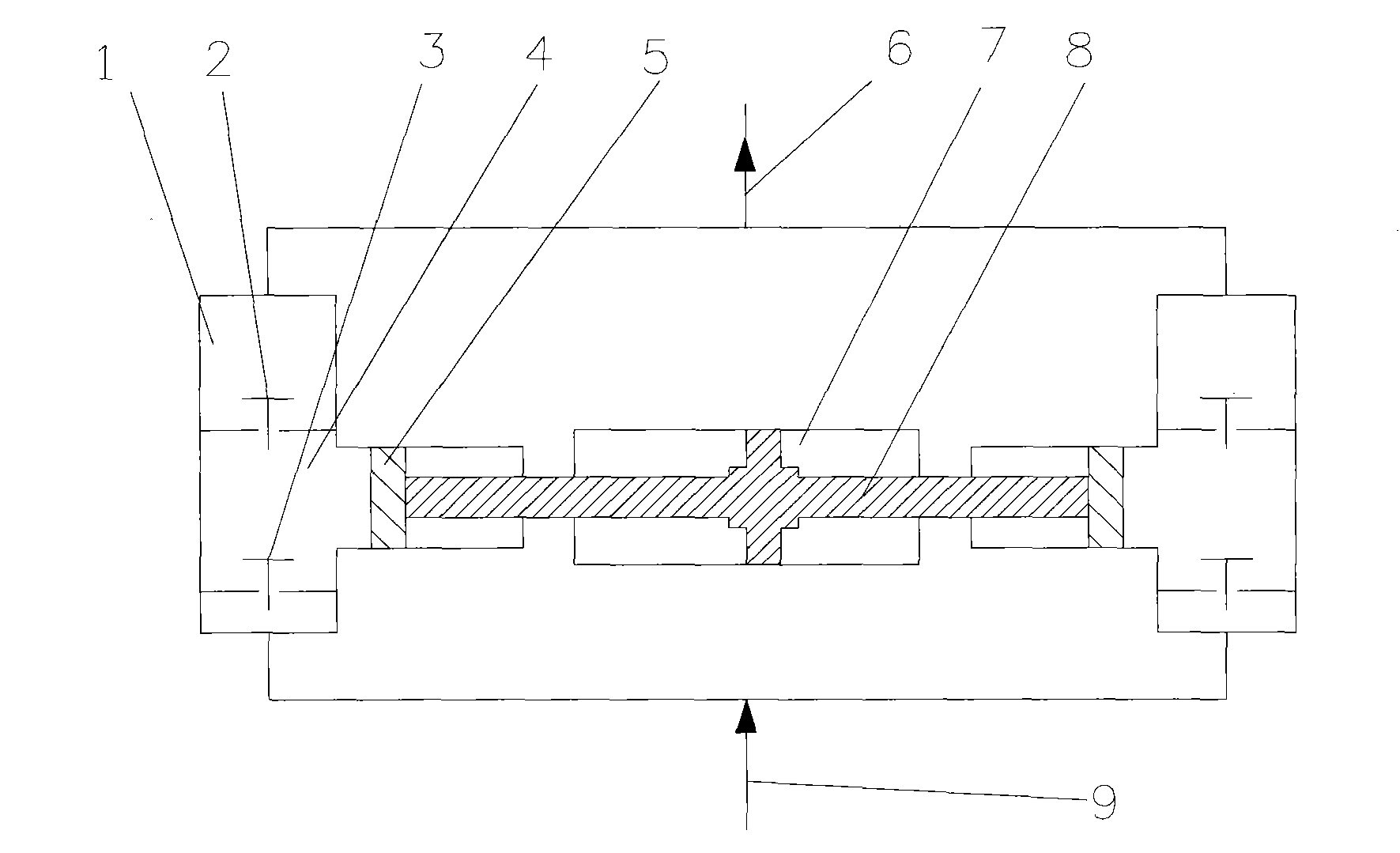

[0019] Such as figure 1 and figure 2 As shown, a harmless treatment method for reinjection of oil mining sludge. The mining sludge is crude oil extracted from Shengli Oilfield. After oil-water separation, the resulting oilfield mining sludge is sampled and analyzed. 35%, crude oil is about 29%, water is about 35%, the muddy composition is mainly coarse-fine siltstone, of which the particle size is less than 30 microns, accounting for 83%, after deoiling and dehydrating, passing through a standard sieve, 75% The above can pass through the 200 mesh sieve, and 100% can pass through the 100 mesh sieve; add a suspending agent of 0.1% of the quality of the oil mining sludge to the mining sludge, and add a solidifying agent of 0.14% of the quality of the oil mining sludge in the mining sludge; The pumping station composed of parallel hydraulic injection pumps sends the oil mining sludge to the waste layer of the oil field. The hydraulic injection pump adopts a 35KW electric motor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com