Anti-collapse structure beside roadway based on breaking roof 110 construction method

A technology for crushing roofs and roadways, which is applied in ground mining, shaft lining, tunnel lining, etc., can solve problems such as mine disasters and high pressure, and achieve the effects of ensuring safety, reducing impacts, and increasing mining rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

[0019] Longwall mining 110 method is a new type of coal mining method, which is characterized in that one working face only corresponds to one roadway, and no coal pillars are required.

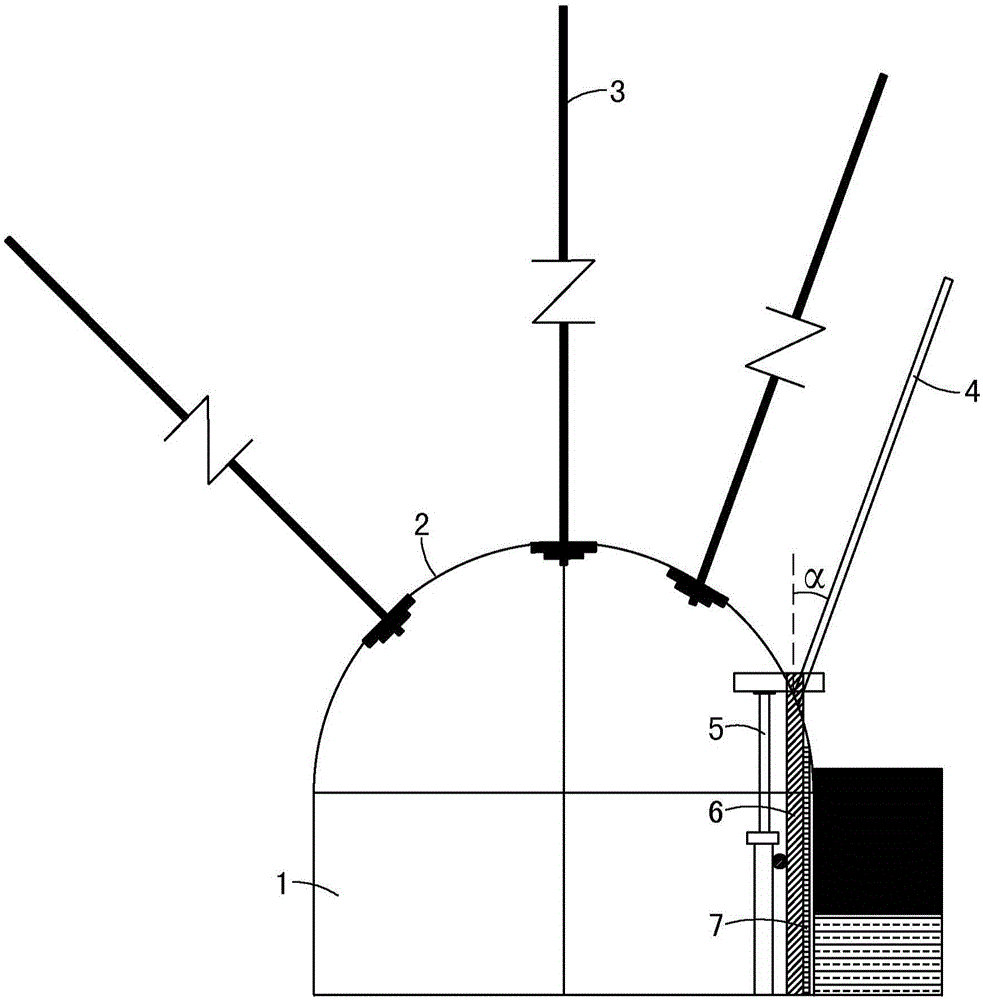

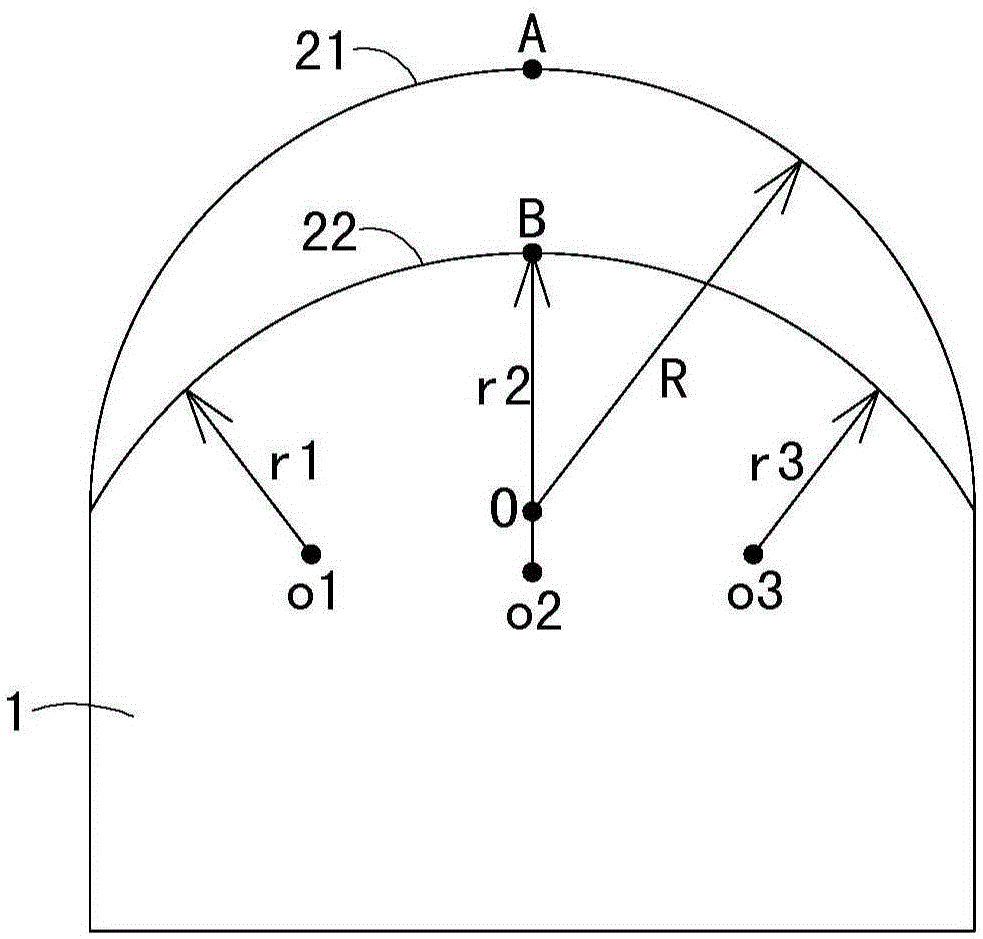

[0020] The roadside collapse prevention structure of the broken roof 110 construction method of the present invention is applied to the 110 construction method. Such as figure 1 As shown, in this exemplary embodiment, the roadway 1 is retained after mining, roof cutting and pressure relief at the previous working face, and the roof 2 of the roadway 1 is arched.

[0021] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com