Temperature-resistant high-efficiency tight gas reservoir fracturing waterproof locking agent and application thereof

A technology of waterproof locking agent and dense gas, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problem of not being able to eliminate the damage of water locking, and achieve lower capillary resistance, convenient use and good wetting performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

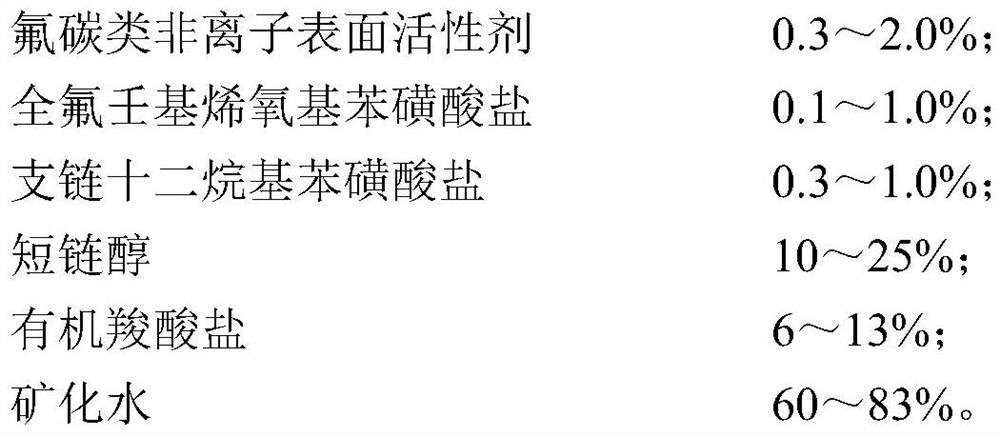

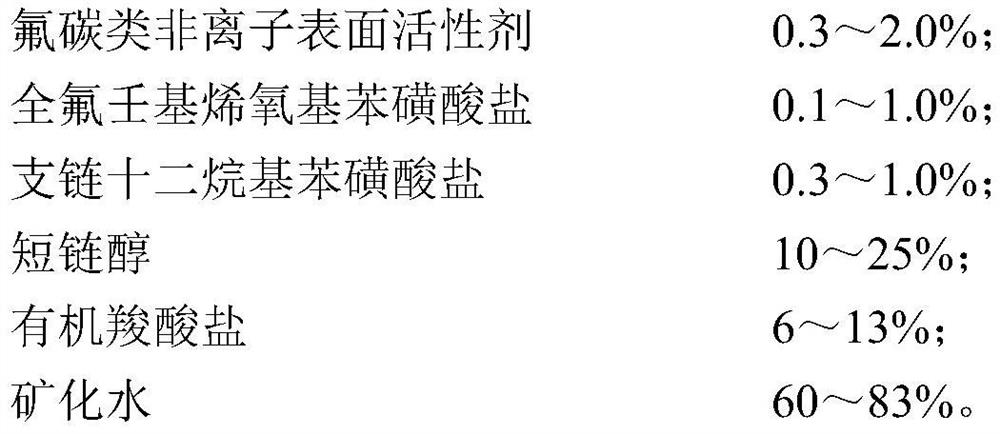

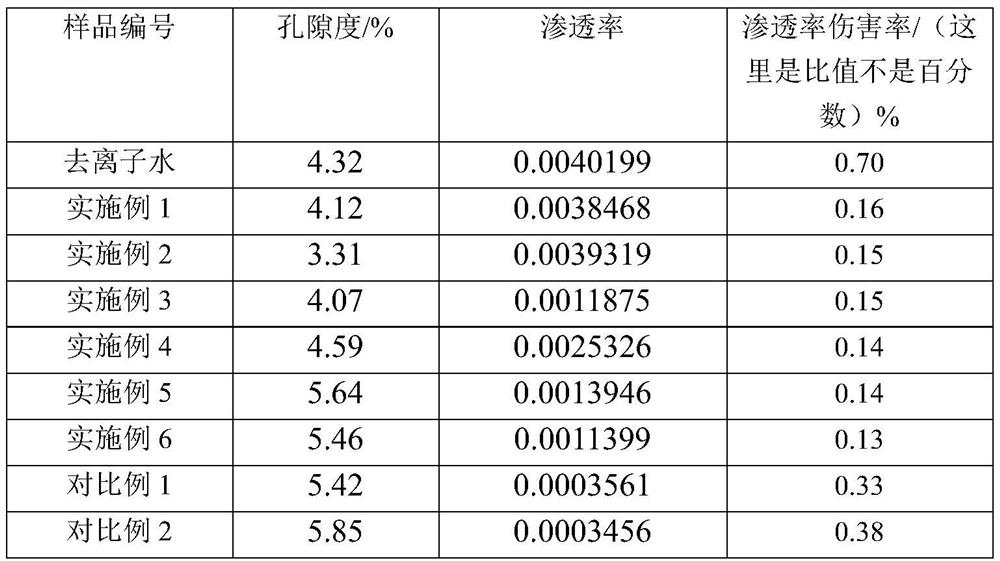

[0043] A waterproof locking agent for tight gas reservoir fracturing, comprising the following components by mass percentage: 0.3% perfluorooctylsulfonamide polyoxyethylene ether nonionic surfactant, perfluorononylenoxybenzenesulfonic acid Salt 0.4%, branched chain dodecylbenzene sulfonate surfactant 0.3%, potassium formate 13.0%, isopropanol 15%, mineralized water 71.0%.

Embodiment 2

[0045] A waterproof locking agent for tight gas reservoir fracturing, comprising the following components by mass percentage: 0.6% perfluorooctylsulfonamide polyoxyethylene ether nonionic surfactant, perfluorononylenyloxybenzenesulfonic acid Salt 0.1%, branched chain dodecylbenzene sulfonate surfactant 0.3%, potassium formate 13.0%, isopropanol 15%, mineralized water 71.0%.

Embodiment 3

[0047] A waterproof locking agent for tight gas reservoir fracturing, comprising the following components by mass percentage: 0.6% perfluorooctylsulfonamide polyoxyethylene ether nonionic surfactant, perfluorononylenyloxybenzenesulfonic acid Salt 0.8%, branched chain dodecylbenzene sulfonate surfactant 0.6%, potassium formate 13.0%, isopropanol 15%, mineralized water 70.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com