Patents

Literature

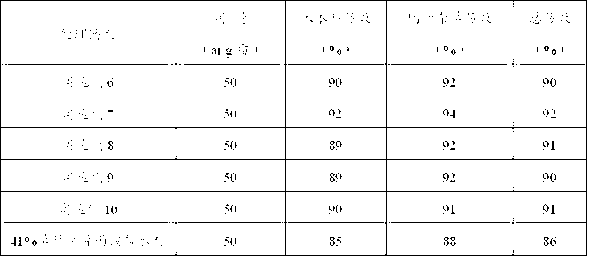

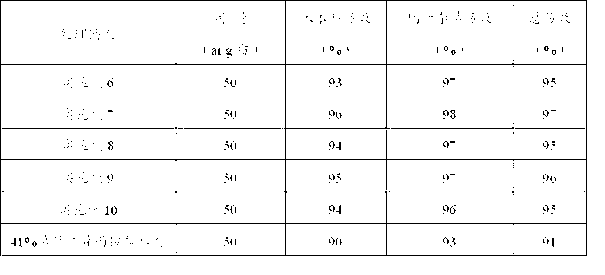

2019 results about "Benzene sulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkyl benzene sulfonate (ABS) is an organic chemical compound primarily used as a surfactant. Its chemical formula is C 6H 5CnH 2n+1, where n lies between 10 and 16. ABS is a major component of anionic detergents. Alkyl benzene sulfonates have two types depending on their chain structures: branched and linear chain.

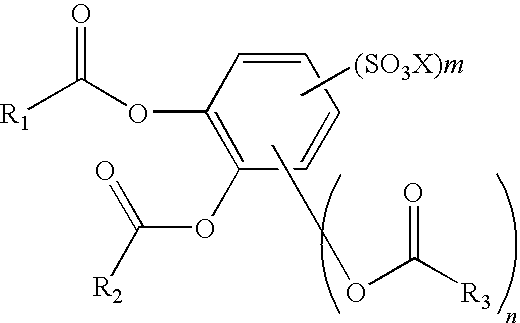

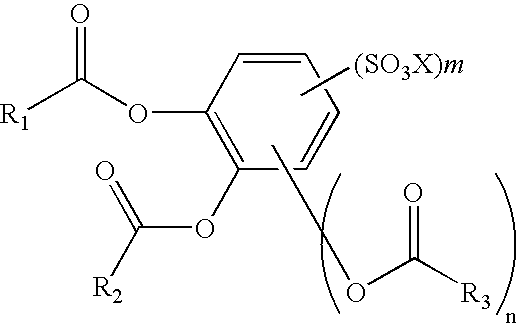

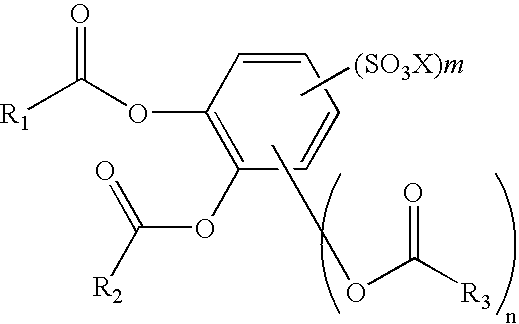

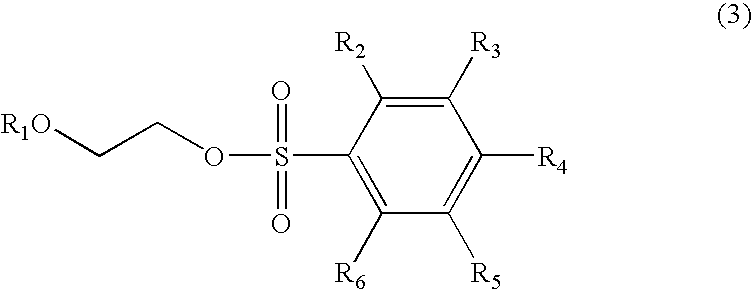

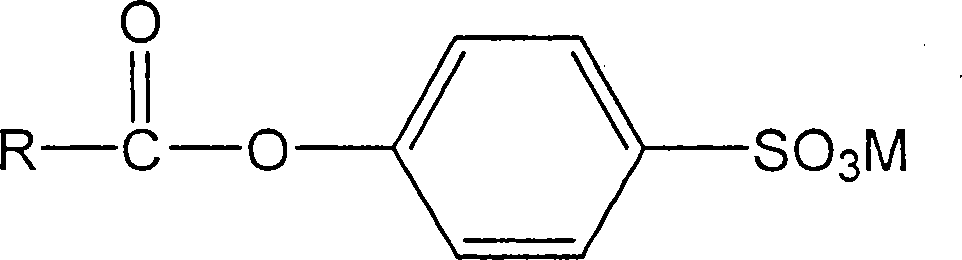

Composition containing an esterified substituted benzene sulfonate

InactiveUS7585376B2Non-ionic surface-active compoundsOrganic detergent compounding agentsBenzenesulfonatesChemistry

Owner:PROCTER & GAMBLE CO

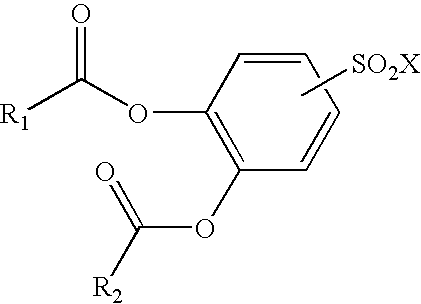

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

Foaming agent composition and purpose thereof

The invention relates to a foaming agent composition and purpose thereof and mainly solves problems of a foaming agent in a prior foam flooding reinforcement oil extraction technology, such as weak stability, deposition with divalent ion and incapability of satisfying demands of foam flooding on stratum with high temperature and high mineralization. According to the invention, a technical scheme well solves the problems by employing a foaming agent composition containing fatty alcohol polyoxyethylene ether benzene sulfonate, alpha-alkene sulfonate and water and can be used in tertiary oil recovery foam flooding.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition capable of greatly improving crude oil recovery efficiency and preparation method thereof

ActiveCN102464974AStrong interfacial tension abilityImprove performanceTransportation and packagingSulfonic acids salts preparationSurface-active agentsFatty alcohol

The invention relates to a composition capable of greatly improving crude oil recovery efficiency and a preparation method thereof, which mainly solve the problems in the prior art that the oil-displacing agent containing a surface active agent has poor oil displacement efficiency and high application concentration and alkali in alkaline-surfactant-polymer flooding brings corrosion and dirt harm on stratum and oil wells. By adopting the technical scheme of the surface active agent composition comprising fatty alcohol polyoxyethylene ether benzene sulfonate, polymer and water, the problems canbe well solved, and the composition can be used in tertiary recovery of an oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Foaming agent composition used for high temperature and high salt oil reservoir

Owner:CHINA PETROLEUM & CHEM CORP +1

Detergent compositions with unique builder system for enhanced stain removal

ActiveUS20080064619A1Good decontamination effectImproves stain removalInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholBleach

A unique liquid laundry detergent with enhanced stain removal capacity on bleachable stains is described that comprises linear alkyl benzene sulfonate, alkyl ether sulfate, alcohol ethoxylate, alkali metal silicate, polyacrylate, and optionally carbonate. The composition is remarkably effective at stain removal although the composition is entirely devoid of enzymes and the wash conditions devoid of any bleach additives.

Owner:HENKEL KGAA

Highly effective ferrous sulfide deactivation cleaning agent

ActiveCN101255383AWash thoroughlyAvoid spontaneous combustion accidentsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChlorine dioxideThiourea

A highly efficient inactivating detergent for ferrous sulfide is disclosed, which is characterized by that it comprises 0.1-10% of chlorine dioxide, 0.1-10% of surfactant, 0.1-5% of citric acid, 0.1-5% of EDTA, 0.1-5% of corrosion inhibitor and water. The surfactant is one or more from dodecyl sulphonate, dodecyl benzene sulfonate, condensate of alkyl phenol and epoxyethane and condensate of aliphatic alcohol and epoxyethane. The corrosion inhibitor is urotropine, dibutyl thiourea or alkyl pyridine. Using the inventive inactivating detergent in cleaning petroleum refining apparatus, ferrous can be thoroughly oxygenized, inactivated and sulfated on one aspect, to prevent occurrence of self-ignition accident, oil crust can be totally washed from the apparatus on the other aspect, which makes the invention has characteristics of high efficiency, secure and environmental protective.

Owner:CHINA PETROLEUM & CHEM CORP

Pesticide and fertilizer mixing particle agent for controlling soil insects and production method thereof

InactiveCN101717316AReduce dosageReduce pollutionFertiliser formsFertilizer mixturesChlorpyrifosVegetable oil

The invention relates to a pesticide and fertilizer mixing particle agent for controlling soil insects, which has the advantages of low cost, no pollution, no peculiar smell, strong absorption capability, good release effect, prevention of water and soil loss, control of underground insects, and enhancement of utilization rate of fertilizer efficiency, and is suitable for leek, corn, peanut and soybean. The mixing particle agent contains the following raw materials based on the total weight: 0.1%-10% of chlorpyrifos, 5%-20% of coating agent, 6%-15% of adhesive, 6%-10% of dispersant, and 45%-80% of NPK compound fertilizer, wherein the NPK compound fertilizer accounts for 25%-60% of the total weight of the medicine and fertilizer mixing particle agent; the coating agent is light-weight clay or low-grade diatomite; the dispersant is calcium dodecyl benzene sulfonate; and the adhesive is clay, dextrin or the mixture of the clay and the dextrin. The production method is characterized in that the adhesive, the dispersant and the NPK compound fertilizer are mixed and granulated by a granulator; the chlorpyrifos is dissolved in vegetable oil or organic solvent, diluted, uniformly sprayed to the surface of the prepared particle, coated by the coating agent, and sieved, and then the particle agent with the diameter of 1.0-4.75mm is prepared.

Owner:锦州硕丰农药集团有限公司

Preparation method and application of selenium-enriched cadmium-resistant foliar fertilizer special for rice

InactiveCN105819986AReduce usageEliminate the risk of poisoningFertilising methodsNitrogenous fertilisersSucroseSilicic acid

The invention provides a preparation method and application of a selenium-enriched cadmium-resistant foliar fertilizer special for rice .The preparation method of the selenium-enriched cadmium-resistant foliar fertilizer special for the rice comprises the following steps that sodium selenite, zinc sulfate, manganese sulfate and ferrous sulfate are dissolved in water and prepared into an original mother liquid, wherein the concentration of sodium selenite ranges from 30 g / l to 60 g / l; the original mother liquid is mixed with an amino acid solution of which the mass concentration ranges from 15% to 20%, shaking chelating is conducted, and a chelating liquid is obtained; the chelating liquid and a single silicic acid aqueous solution are mixed to be uniform to be prepared into a mixed liquid; sodium alkyl benzene sulfonate is added, the mixture and filtrate obtained through saccharose alcohol fermentation are stirred at 25 DEG C to 35 DEG C for secondary chelating, and the selenium-enriched cadmium-resistant foliar fertilizer special for the rice is obtained .By means of the preparation method and application of the selenium-enriched cadmium-resistant foliar fertilizer special for the rice, 90% or above of inorganic selenium is converted into organic selenium such as selenomethionine and selenocystine, the poisoning risk is eliminated, the absorption conversion rate of selenium is increased, the raw material amount is reduced, the cost is reduced, and the rice has a good cadmium-resistant property.

Owner:AGRI RESOURCE & ENVIRONMENT RES INST GUANGXI ACADEMY OF AGRI SCI

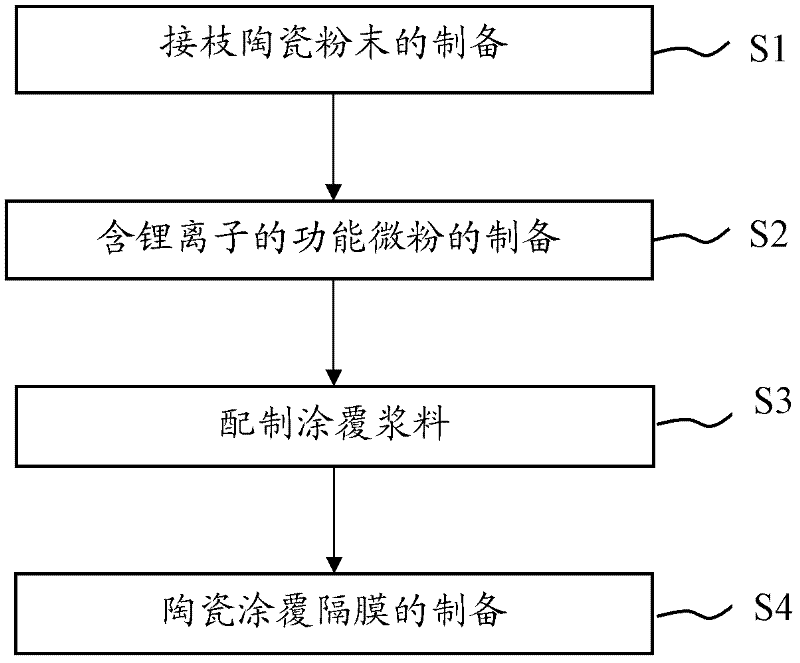

Ceramic coating membrane and preparation method thereof

ActiveCN102569700AImprove hydrophilicityHigh ion exchange capacityCell component detailsLithiumPolyolefin

The invention discloses a ceramic coating membrane and a preparation method thereof. The steps are as follows: the preparation of stem grafting ceramic powder, the preparation of functional power containing lithium-ion, the preparation of coating slurry and the preparation of ceramic coating membrane. The preparation method of ceramic coating membrane, provided by the invention is that: benzene sulfonate containing lithium is grafted on the surface of the ceramic powder, and then the ceramic powder grafted is coated on a polyolefin microporous membrane, thereby obtaining the ceramic coating membrane is obtained. The preparation method has the advantages of simple process, low requirements to equipment, easiness in condition control and low cost, and is suitable for industrial production. Due to the ion exchange capacity and hydrophily of the ceramic coating membrane prepared by the method, the ceramic coating membrane has a strong electrolyte infiltrating capability, is high in membrane breaking temperature, and has improved safety.

Owner:SHENZHEN SENIOR TECH MATERIAL

Formulation of surfactant oil displacement system for anionic and nonionic oil displacement

ActiveCN101705083ASignificant precipitation and oil increase effectImprove oil displacement efficiencyDrilling compositionAlkanePhosphate

The invention provides a composition of a surfactant oil displacement system for anionic and nonionic oil displacement. The composition consists of 18% C18 sodium alkyl benzene sulfonate, C16 fatty acid, 25% C2 alkanolamide, 7% C8 alkylphenol polyoxyethylene ether phosphate, 17% ethanol, 3% octanol, 30% water; the alkyl is a hydrocarbyl group with linear chain, branched chain and ring structures in a calibrated carbon atom range, and also can be substituted by one or more halogens, alkyls or alkoxys; the sodium sulfonates are formed by sulfonating different alkanes or arenes by SO3 or chlorosulfonic acid in chloroalkane environment and then neutralizing the sulfonate and sodium hydroxide; and the esterification derivatives are sulfates or phosphates. The formulation has highoil displacement efficiency, strong oil deposit adaptability and good popularization prospect.

Owner:DESHI ENERGY TECH GRP CO LTD

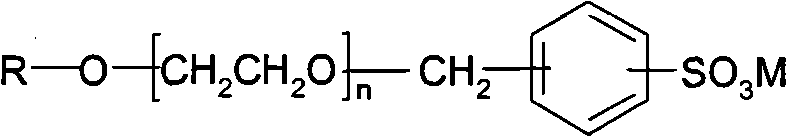

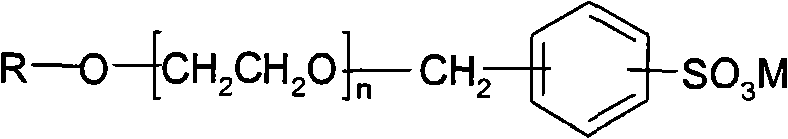

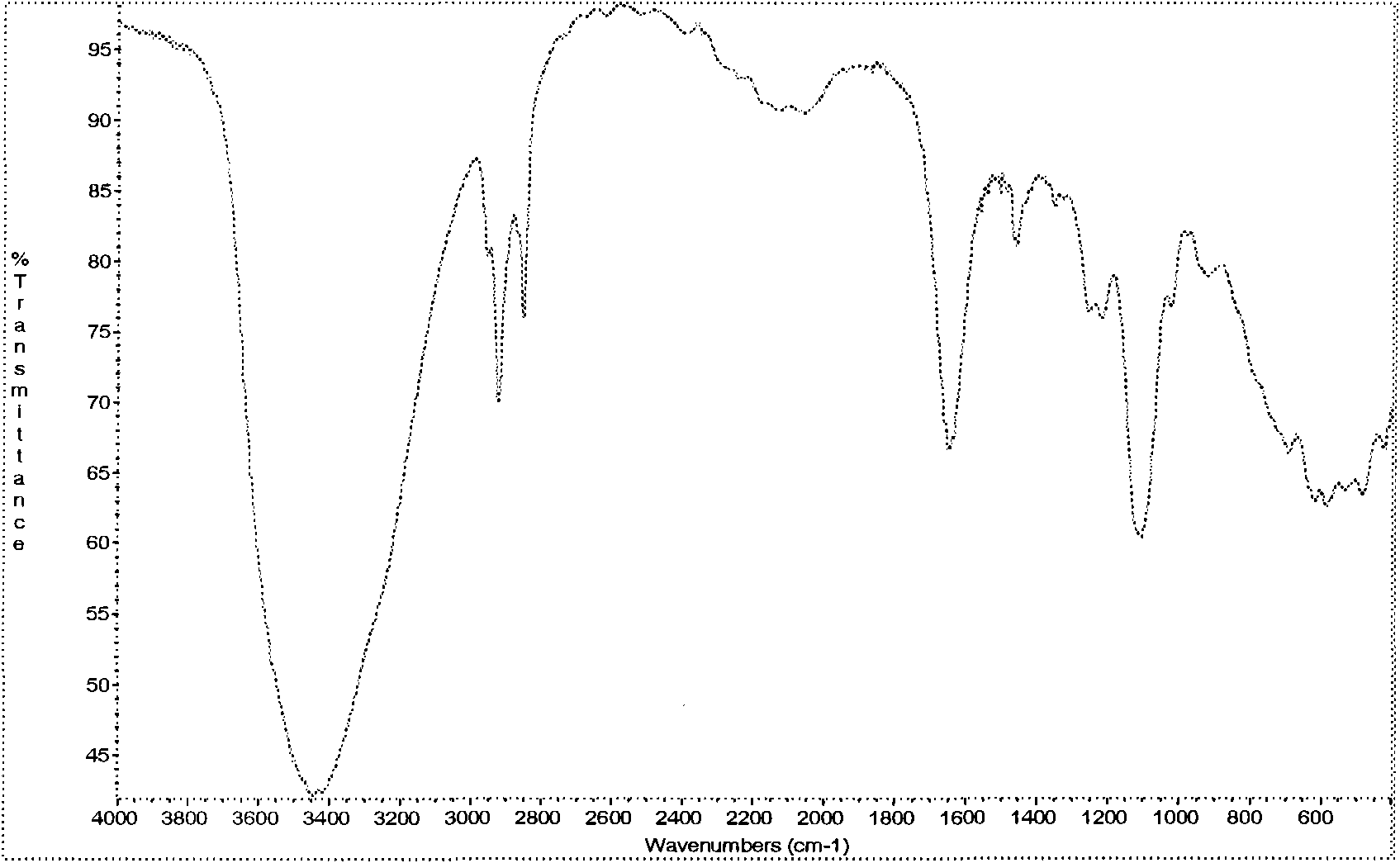

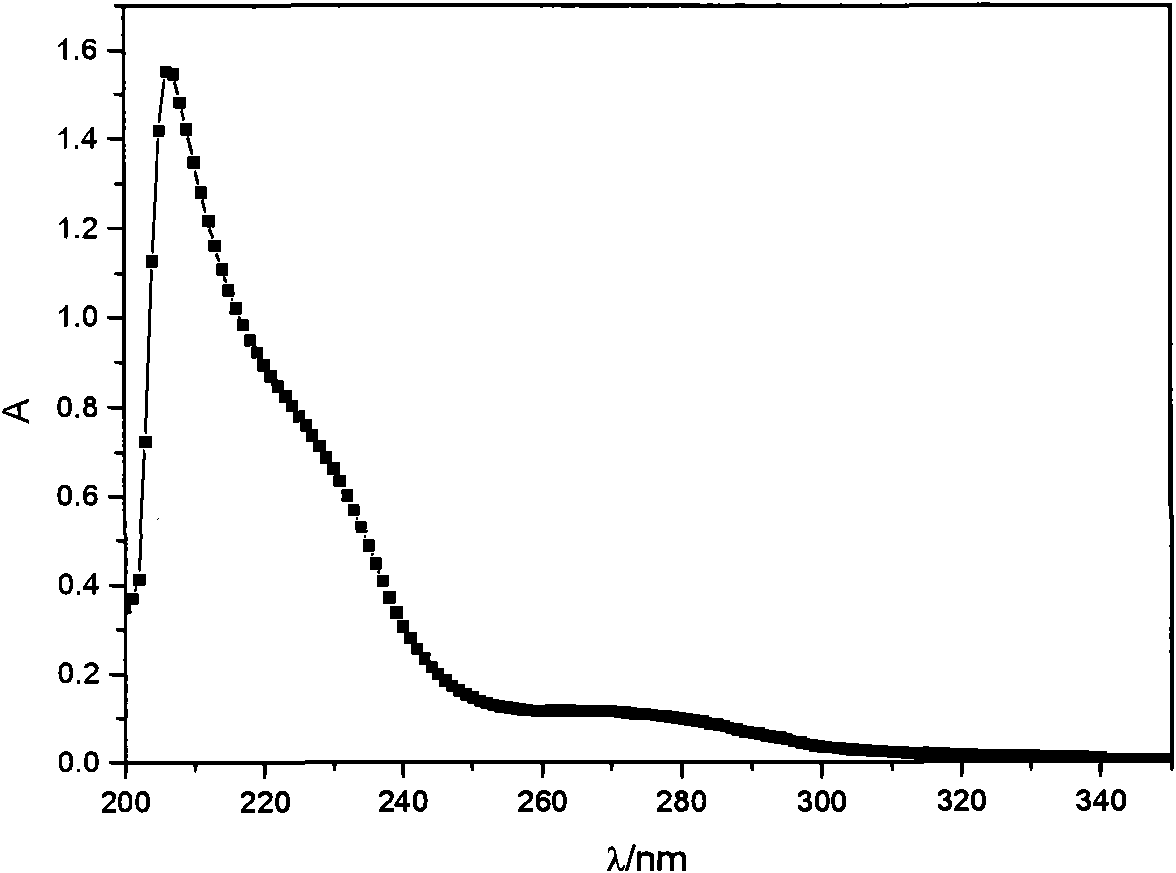

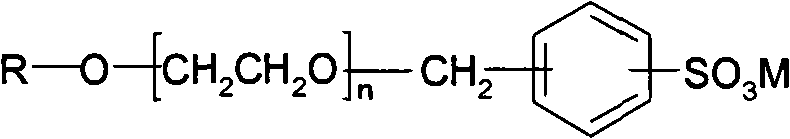

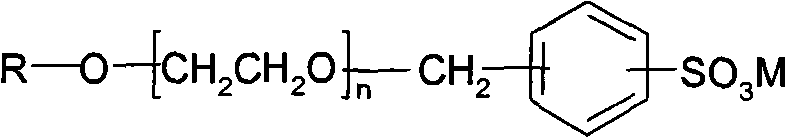

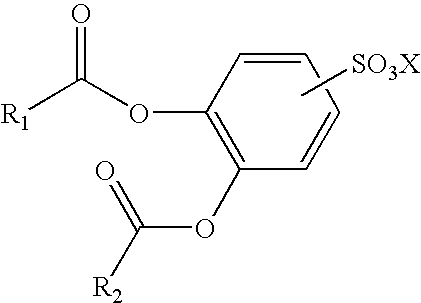

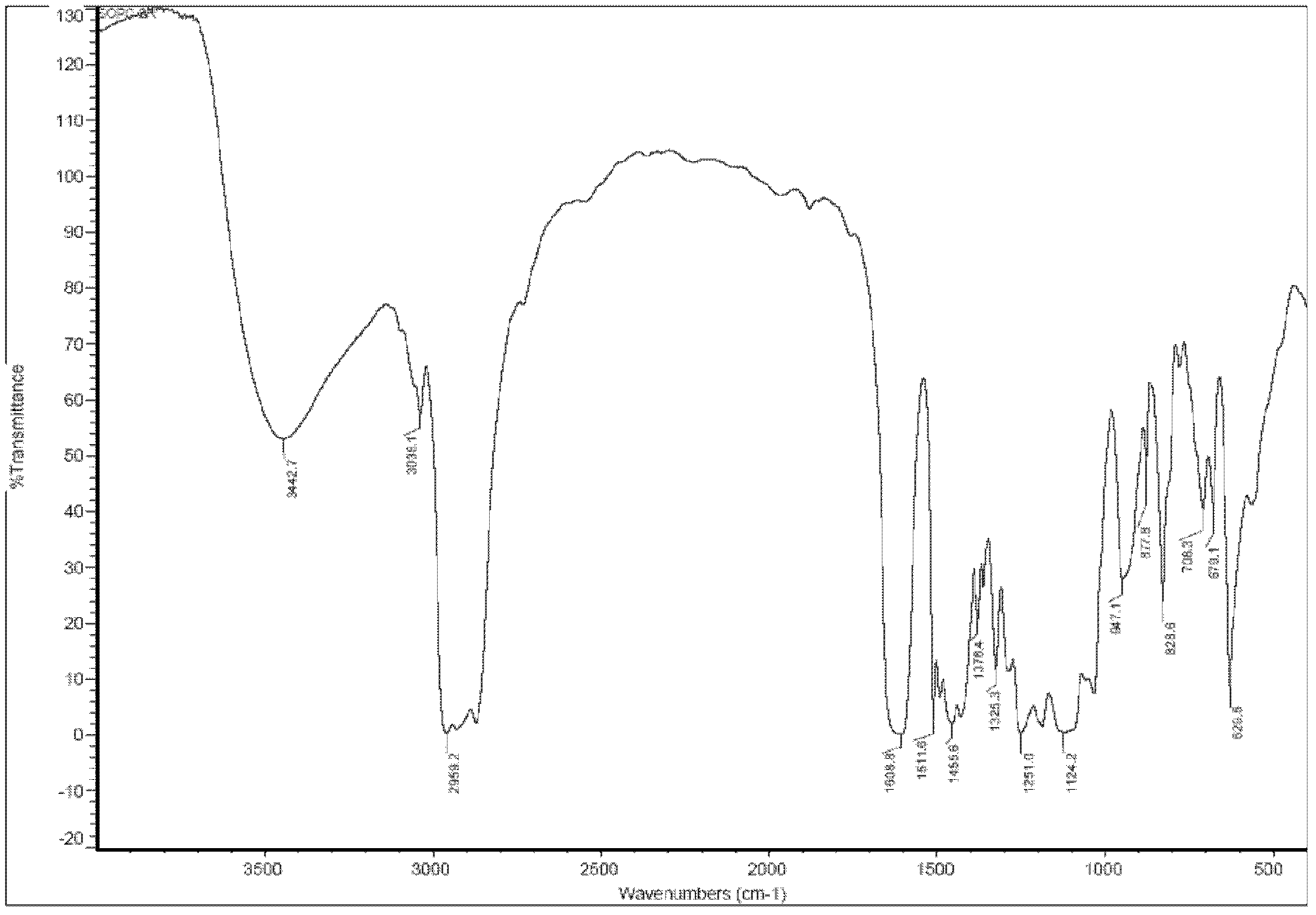

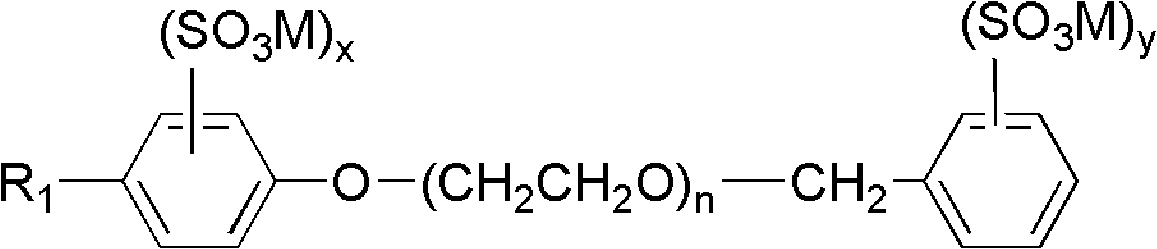

Fatty alcohol-polyoxyethylene ether benzene sulfonate and preparation method thereof

InactiveCN102372658AImprove technical effectSulfonic acids salts preparationDrilling compositionAlkaline earth metalFoaming agent

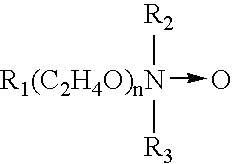

The invention relates to fatty alcohol-polyoxyethylene ether benzene sulfonate and a preparation method thereof. The problems that a foam agent is poor in heat stability, is precipitated when meeting divalent ions and cannot meet the requirement of high-temperature and high-salinity stratum foam flooding in the conventional foam flooding enhanced oil extraction technology are mainly solved. The alcohol-polyoxyethylene ether benzene sulfonate with a molecular general formula (I) is adopted, wherein M is alkali metals, alkaline-earth metals or ammonium groups, R is alkyl groups having 8 to 24 carbon atoms, and n is an integral number from 3 to 20. Through the technical scheme, the problems are better solved. The method can be used for foam flooding enhanced oil extraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Impermeable anti-cracking concrete

The invention discloses an impermeable anti-cracking concrete which comprises the following components in parts by weight: 180-280 parts of cement, 50-70 parts of ore powder, 50-80 parts of fly ash, 920-980 parts of gravel, 700-750 parts of scrap, 100-200 parts of sand, 170-200 parts of water, 0.5-0.9 part of water reducing agent, 0.3-0.7 part of air entraining agent, 1-2 parts of polyacrylamide, 0.05-0.1 part of sodium alkyl benzene sulfonate, 0.2-0.4 part of ethylene glycol, 0.05-0.1 part of sodium carboxymethyl cellulose, 1.3-1.7 parts of commercial aluminum sulfate, 0.2-0.5 part of high-strength steel-wire-like fiber, 0.01-0.04 part of lauryl sodium sulfate, 0.7-1.3 parts of silica fume, 3.45-4.5 parts of anhydrite, 2.3-3 parts of sulfoaluminate clinker, 0.3-0.7 part of activator, 10-35 parts of hydrogen polypropylene fiber, 18-42 parts of graphite particle and 4.5-7 parts of foaming agent. The impermeable anti-cracking concrete has the advantages of high earthquake resistance, high shock resistance, high cracking resistance, high impermeability and high durability, and has the functions of fire resistance, sound insulation and thermal insulation.

Owner:CHANGAN UNIV

Lubricating and cutting fluid

InactiveCN101768502AImprove the lubrication effectImprove rust resistanceAdditivesWater basedPhosphoric acid

The invention relates to a lubricating and cutting fluid, which contains 12-20% of naphthene base crude oil, 15-25% of castor grease, 20-30% of poly-ester of polybasic acid and polyalcohol, 12-18% of sodium alkyl benzene sulfonate, 5-10% of refined tall oil, 1-3% of alkyl phosphoric acid and 1-4% of tricarboxylic acid salt. A surfactant used in the lubricating and cutting fluid has excellent properties of lubricating, washing and rust protection; an extreme-pressure lubricant and a rust preventer are added into water-based cutting fluid, so as to further improve the properties of lubricating and rust protection of the water-based cutting fluid, so that the water-based cutting fluid has good lubricity, rust protection, cooling property and washing property and can obviously improve the surface finishment of a workpiece and reduce the wear effect of a cutter.

Owner:SHANGHAI AORUNKE LUBRICANT

Water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and preparation method of matt-leather-membrane aqueous coating adhesive

ActiveCN104831540AAssociative functionCombined with styleFibre treatmentIsooctyl acrylatePolymer science

The invention relates to a water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and a preparation method of the matt-leather-membrane aqueous coating adhesive. The preparation method comprises the steps of emulsifying isooctyl acrylate, isobornyl methacrylate, glycidyl methacrylate, trifluoroethyl methacrylate, vinyl trimethoxysilane, hydroxypropyl acrylate, fatty alcohol ethoxylate XL90 and dodecyl benzene sulfonate to trigger polymerization, and compounding a thickening agent, namely an associated polyurethane flatting rheological agent, a cross-linking agent, namely terminated isocyanate, a flatting agent, namely polymethyl urea resin and silicon dioxide with the particle size of 2-7 microns, so as to obtain the matt-leather-membrane aqueous coating adhesive.

Owner:DANDONG UNIK TEXTILE

Gelled light duty liquid cleaning composition

InactiveUS20050020467A1Good suspensionFine foamNon-ionic surface-active compoundsAqueous liquid non-soap compositionsMagnesium saltLinear alkylbenzene sulfonate

A gelled light duty cleaning composition comprising: a C8-C18 ethoxylated alkyl ether sulfate surfactant, a magnesium salt of a C8-C18 linear alkyl benzene sulfonate, a sodium salt of a C8-C18 linear alkyl benzene sulfonate, an amine oxide surfactant, a polyalkylglucoside, a hydrophobic ethoxylated nonionic surfactant and water.

Owner:COLGATE PALMOLIVE CO

Agricultural thickening synergist and application thereof

ActiveCN103210915AGood wetting and synergistic effectImprove performanceBiocideAnimal repellantsAgricultural scienceActive agent

The invention discloses an agricultural thickening synergist. The agricultural thickening synergist comprises the following components by mass percent: 1-40% of fatty alcohol polyoxyethylene ether sulfate, 0-30% of alkyl glycoside, 5-15% of sodium lauroyl sarcosinate, 5-10% of sodium alkyl benzene sulfonate, 5-15% of ammonium sulfate and the balance of water. The invention also discloses an application of the agricultural thickening synergist in a glyphosate isopropamide salt water agent and a glyphosate salt water agent. The agricultural thickening synergist has the characteristics of better wetting synergy effect, more stable performance and better thickening synergy effect; by using the glyphosate salt water agent, the agricultural thickening synergist has high viscosity, the adhesive force and moisture property of the liquid medicine are improved, the internal absorption and conductivity of the glyphosate are realized, and the pharmacological function can be fully realized. Besides, the agricultural thickening synergist has excellent biological degradability, has high safety to the environment and organisms, and meets the development requirement of the agricultural surface active agent in the future.

Owner:范强

Smokeless polishing treatment solution for high-gloss aluminum profile and method of use

The invention provides a smoke-free polishing treatment solution for a high-gloss aluminum sectional material and a use method thereof. The smoke-free polishing treatment solution is characterized by comprising 85% H3PO4, 98% H2SO4, 30% hydrogen peroxide or potassium permanganate or perchloric acid or sodium molybdate or ammonium persulfate or sodium vanadate, cerium nitrate or sodium silicate, imidazoline or benzotriazole or phytic acid or thiourea, sodium dodecyl benzene sulfonate or sodium benzene sulfonate or sodium toluene sulfonate or sodium xylene sulfonate, and nickel chloride or nickel sulfate or lead acetate. Compared with the prior art, the smoke-free polishing treatment solution provided by the invention has advantage of no generation of high-pollution NOx yellow smoke, and enables the surface of the aluminum sectional material to have excellent gloss and no pitting microscopic defects.

Owner:GUANGDONG XINGFA ALUMINUM

Composition containing an esterified substituted benzene sulfonate

InactiveUS20070105742A1Organic detergent compounding agentsNon-ionic surface-active compoundsBenzenesulfonatesBenzene sulfonate

Owner:THE PROCTER & GAMBLE COMPANY

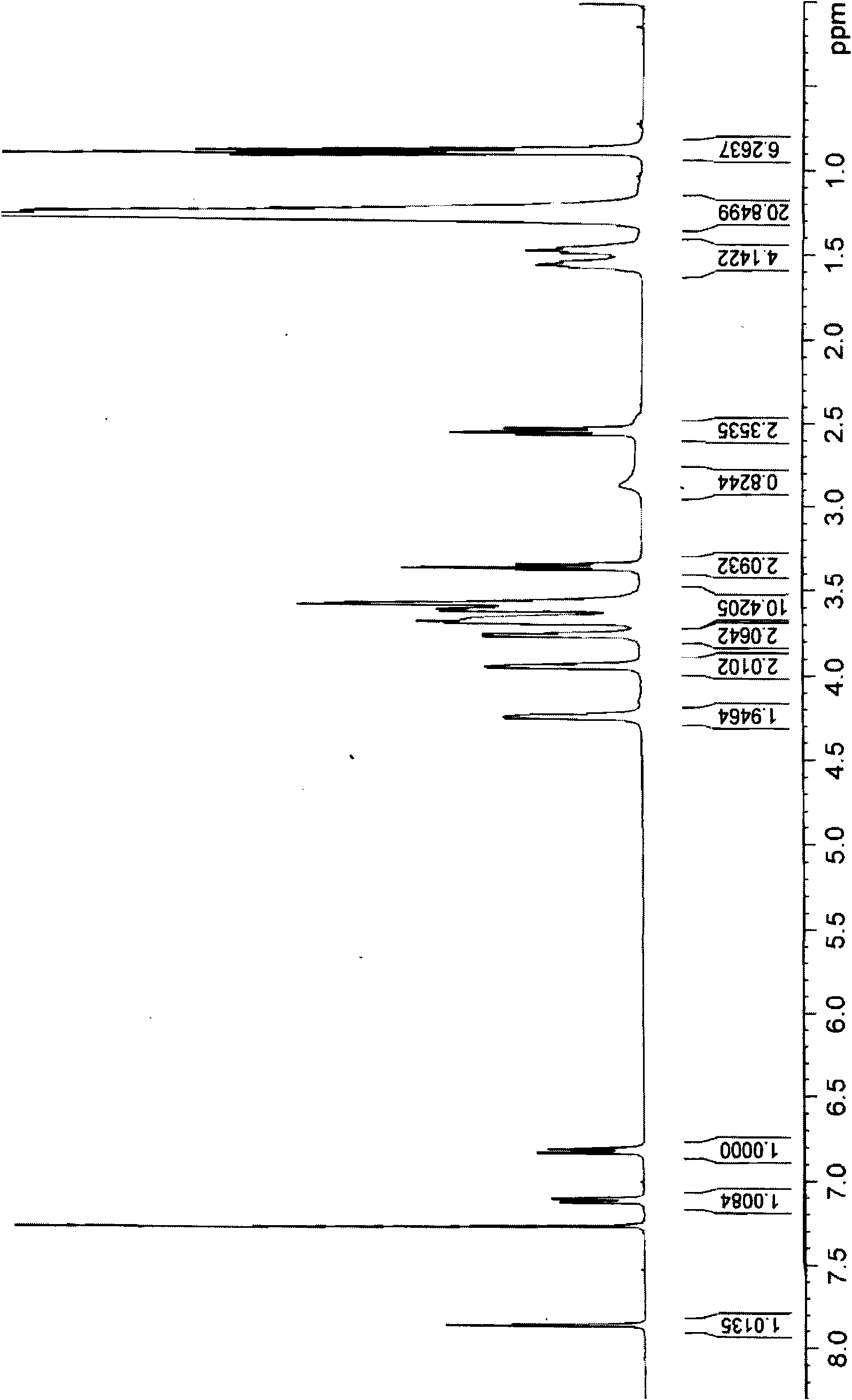

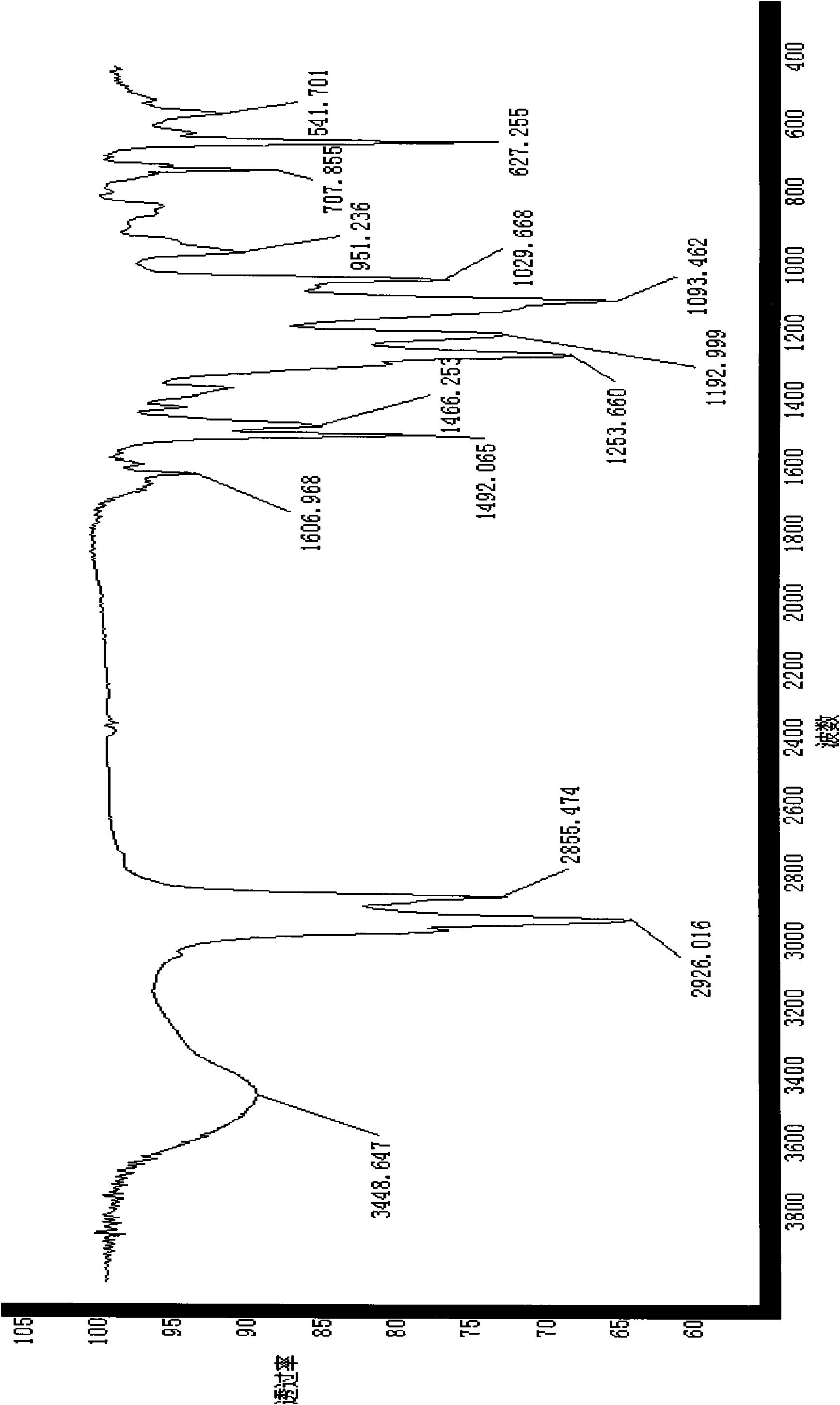

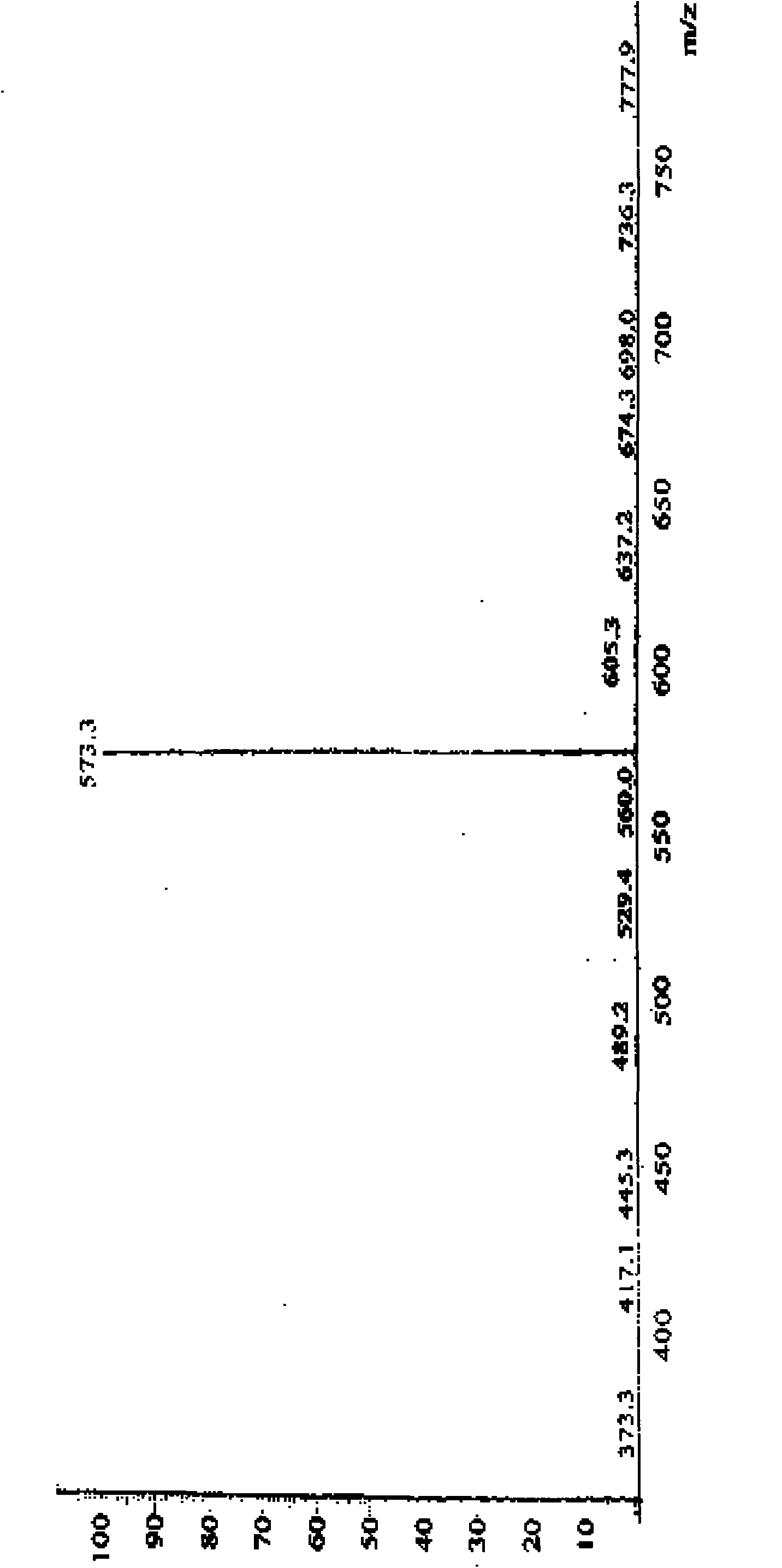

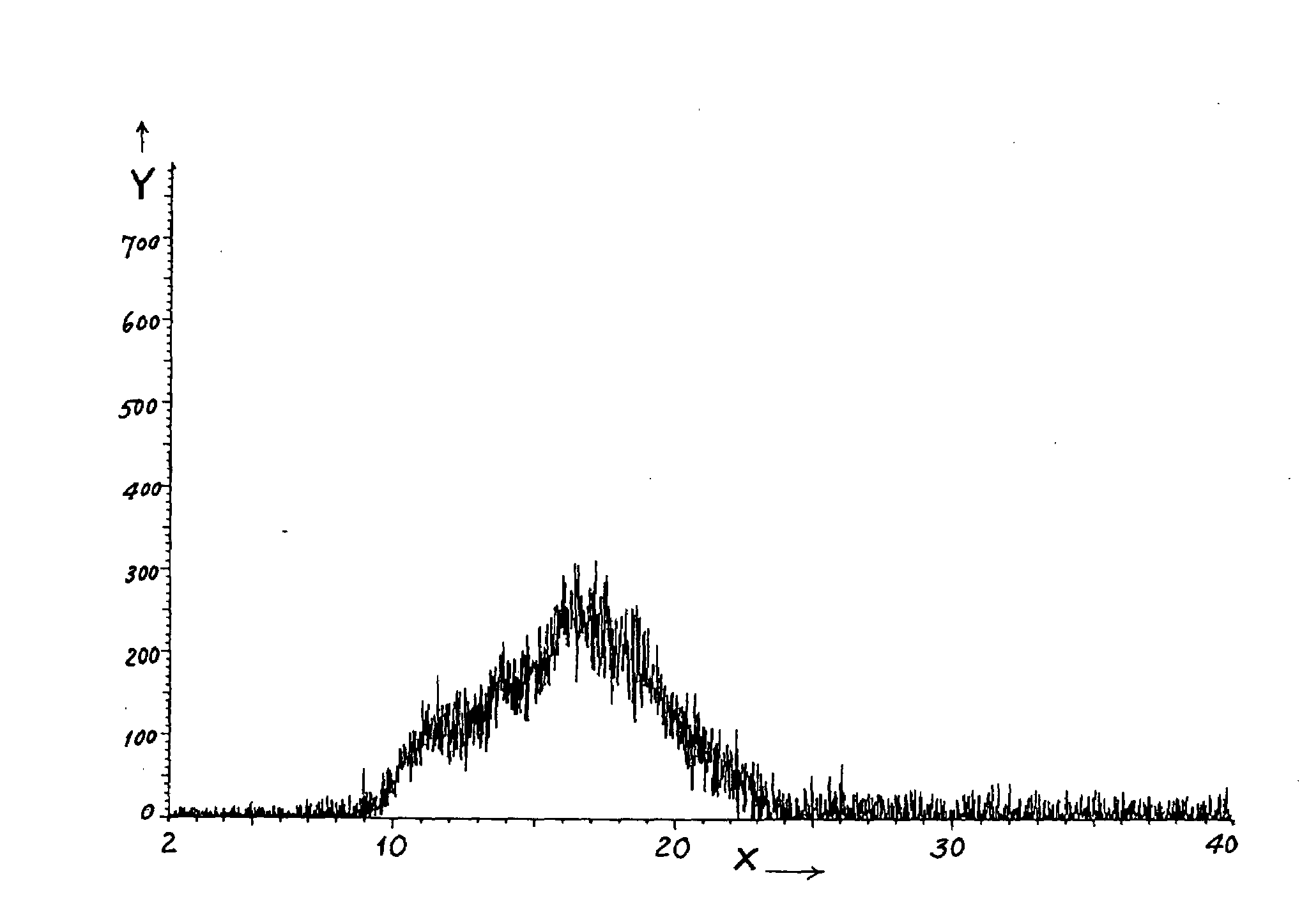

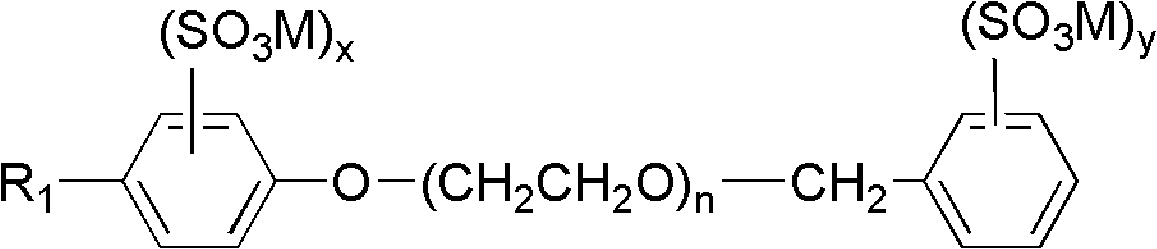

Alkyl-blocked alkylphenol polyoxyethylene ether benzene sulfonate surfactant and preparation method and application thereof

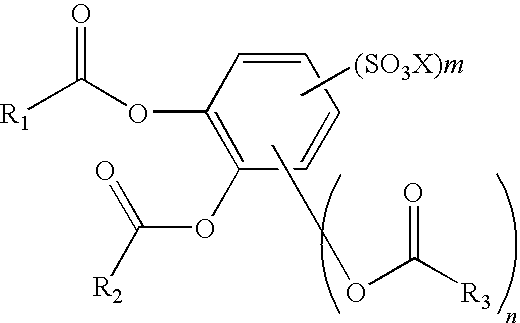

The invention belongs to the field of efficient surfactant, in particular relates to an alkyl-blocked alkylphenol polyoxyethylene ether benzene sulfonate surfactant and preparation method and application thereof. The surfactant contains nonionic hydrophilic group polyoxyethylene and negative ion hydrophilic group sulfonate, the special molecular structure determines that the surfactant has good water-solubility, lower critical micelle concentration, excellent capability of reducing surface tension / interfacial tension, efficient foaming and foam stabilizing capability and outstanding temperature endurance and salt endurance, has good application prospect in a plurality of fields of pesticides, mineral flotation, tertiary oil recovery, and the like, and can be used as an effective oil displacement agent in tertiary oil recovery. The surfactant has the structure.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Heavy grease stain environment-friendly type water base cleaning compound

InactiveCN103834487AGood decontamination effectGood compatibilityOrganic detergent compounding agentsSurface-active detergent compositionsWater basedTriclosan

The invention discloses a heavy grease stain environment-friendly type water base cleaning compound comprising 10-15% of surfactant, 1-3% of additive, 1-5% of antiseptic, 3-5% of organic amine and remaining tap water; the ingredient of the surfactant comprises 4-5% of aliphatic acid methyl esters ethoxylate, 2-3.5% of APG, 1-3% of fatty alcohol polyoxyethylene ether sodium sulfate (AES), 0.5-1% of straight chain sodium alkyl benzene sulfonate (LAS) and 0.5-2% of aliphatic acid methyl esters ethoxylate; the additive is one or more from a group formed by sodium citrate, citric acid, lactic acid and DL-malic acid; the organic amine is one or more from a group formed by triethanolamine, n-butylamine, diethanolamine and N-methyl diethanolamine; the antiseptic at least is triclosan or tetrachloro isophthalonitrile; through the said method, the heavy grease stain environment-friendly type water base cleaning compound has anti bacterium, heavy grease stain cleaning and environmental protection performances.

Owner:SUZHOU LOTTE CHEM TECH

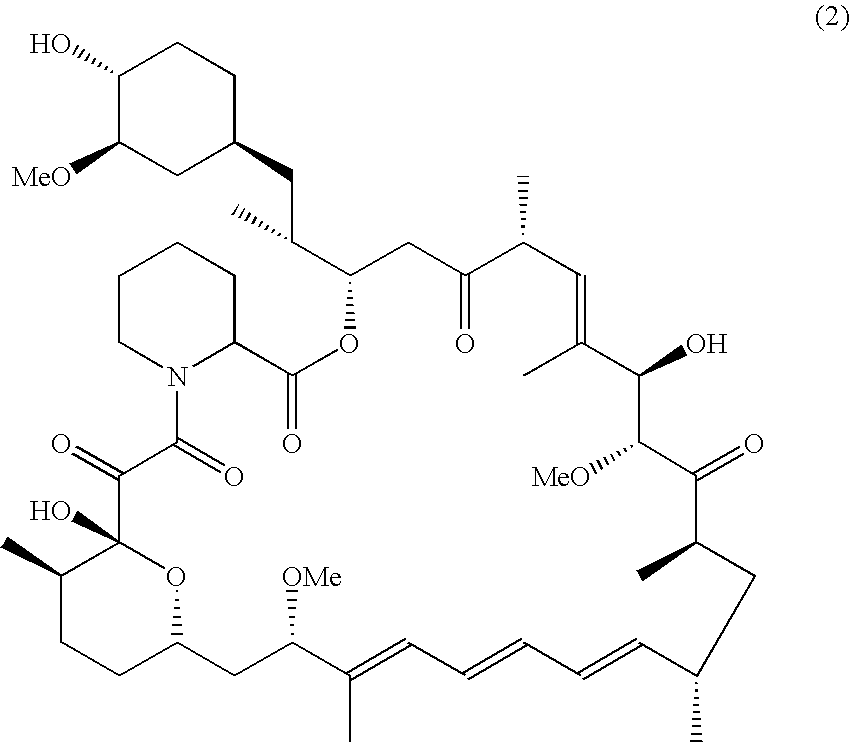

Process for making Biolimus A9

A process for making Biolimus A9 comprises reacting sirolimus (or rapamycin) with alkyl benzene sulfonate under the catalyzing of organic base and in the presence of organic solvent to undergo a nucleophilic substitution reaction to obtain the Biolimus A9 with high yield, not only for small-scale laboratory experiment, but also for rendering reproducibility of high yield even after process amplification.

Owner:CHUNGHWA CHEM SYNTHESIS & BIOTECH

Displacement method utilizing compound containing sulfonate negative non-surface active agent

The invention relates to a displacement method utilizing a compound containing sulfonate negative non-surface active agent, which mainly solves the problems in the prior art that the displacement efficiency of the displacement agent containing the surface active agent is poor under the high-temperature high-salt condition, the application concentration is high and alkali in a tertiary composite displacement causes the corrosion and scale accumulation harm on the stratum and an oil well. The displacement method adopts alkylphenol polyoxyethylene ether benzene sulfonate, polymer and water to be mixed into displacement agent compound, under the magnesium chloride injection water condition that the displacement temperature is 30 to 83DEG C, the total mineralization degree is more than 8000mg / L, magnesium ion is more than 200mg / L and calcium ion is more than 30mg / L, dehydrated crude oil is contacted with the compound, so that the crude oil in a core can be adequately displaced, and the compound comprises the following components in parts by weight: (1) 0.01 to 5 parts of alkylphenol polyoxyethylene ether benzene sulfonate; (2) 0.01 to 3 parts of polymer; and (3) 90 to 99.9 parts of injection water. Due to the adoption of the technical scheme, the problems can be well solved, and the displacement method can be used in the tertiary oil recovery of an oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

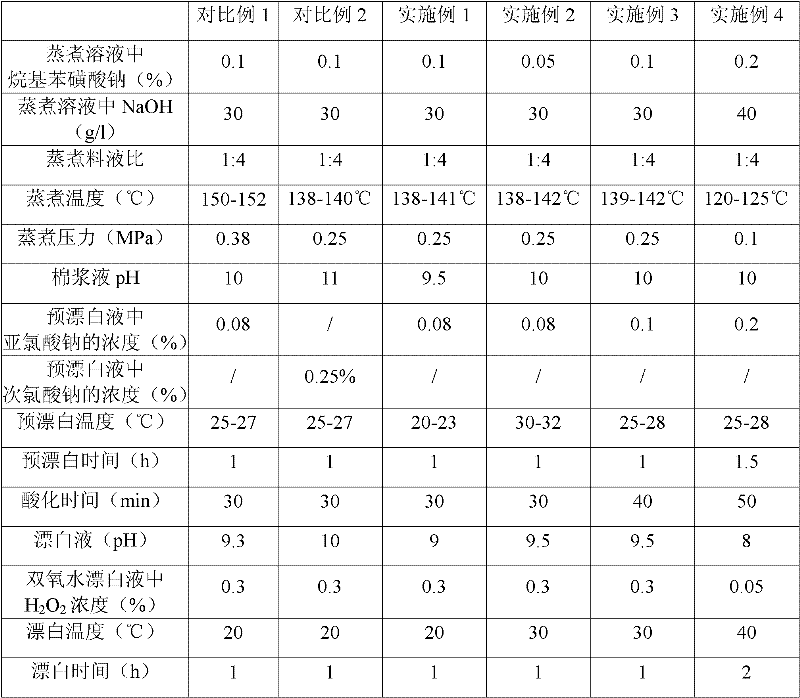

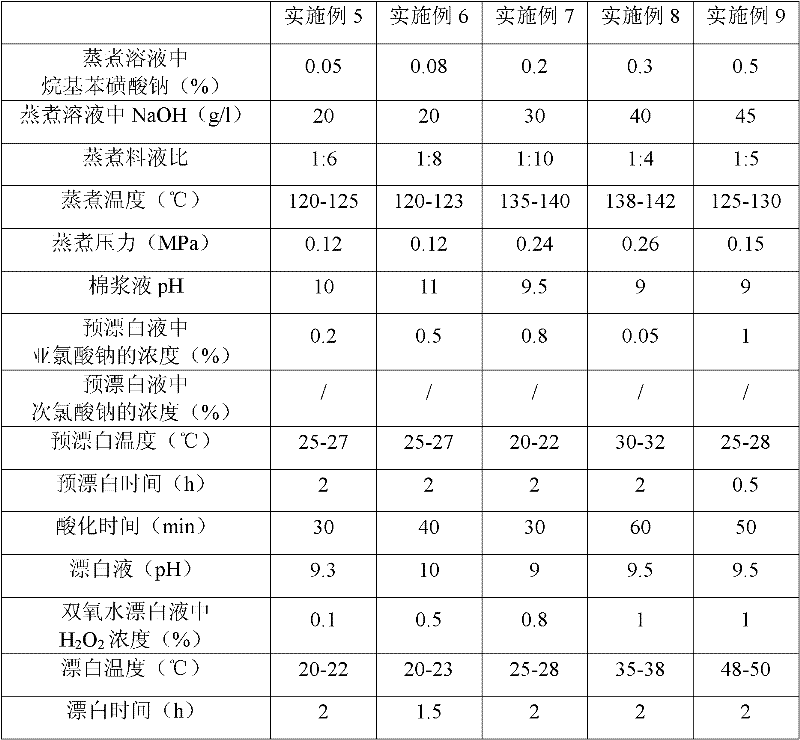

Method for producing ultrahigh-viscosity refined cotton

InactiveCN102251422AMeet the requirements for the production of ultra-high viscosity productsReduce water consumptionPulp bleachingPulping with inorganic basesCelluloseManufacturing technology

The invention relates to a method for producing ultrahigh-viscosity refined cotton, and belongs to the technical field of refined cotton manufacture. The invention aims to provide the ultrahigh-viscosity refined cotton, the finished whiteness of which is more than 75 percent, the viscosity of which is more than 1,500mPa.s and the impurity content of which is low. The method comprises the following processes of: (1) selecting materials, opening cotton and digesting, wherein the NaOH content of the digesting solution is 20 to 45g / l, and sodium alkyl benzene sulfonate serving as an emulsifying agent is 0.05 to 0.5 weight percent; (2) pre-bleaching, wherein the concentration of sodium chlorite is 0.05 to 1 weight percent; (3) acidifying for 30 to 60 minutes when the pH is 2 to 4; (4) bleaching with hydrogen peroxide, namely washing the acidified cotton pulp, regulating the pH to be between 8 and 11, adding H2O2, and bleaching for 1 to 2 hours; and (5) drying to obtain a finished product. The ultrahigh-viscosity refined cotton product with viscosity of more than 1,500mPa.s and whiteness of more than 75 percent is produced by the method; and the method can meet the requirements of cellulose ether and cellulose ester manufacturers for producing ultrahigh-viscosity products.

Owner:SICHUAN NITROCELLULOSE CORP

Water-based metal-degreasing cleaning agent

The invention discloses a water-based metal-degreasing cleaning agent. The water-based metal-degreasing cleaning agent comprises the components in percent by weight: 10-30% of composite surface active agent, 5-10% of cleaning additive, 2-5% of corrosion inhibiting agent, 0.4-0.8% of hard-water resistant agent, 0.05-0.2% of defoaming agent and the balance of deionized water. By mass, the composite surface active agent is a mixture compounded by LAS (sodium alkyl benzene sulfonate), AEO-9 (Fatty alcohol polyoxyethylene ether) and TX-10 (alkylphenol ethoxylates) according to the mass ratio of 1:2:1; the corrosion inhibiting agent is a mixture compounded by benzotriazole (BTA) and benzimidazole (BIA) according to the mass ratio of 1:1; the cleaning additive is a mixture compounded by 4A zeolite, sodium metasilicate and sodium carbonate according to the mass ratio of 1:1:1; the defoaming agent is a polyether-modified organic silicon defoaming agent. The water-based metal-degreasing cleaning agent disclosed by the invention has the characteristics of low surface tension, fast defoaming, long foam-inhibiting time, low cost and less use amount and the like.

Owner:SUZHOU LOTTE CHEM TECH

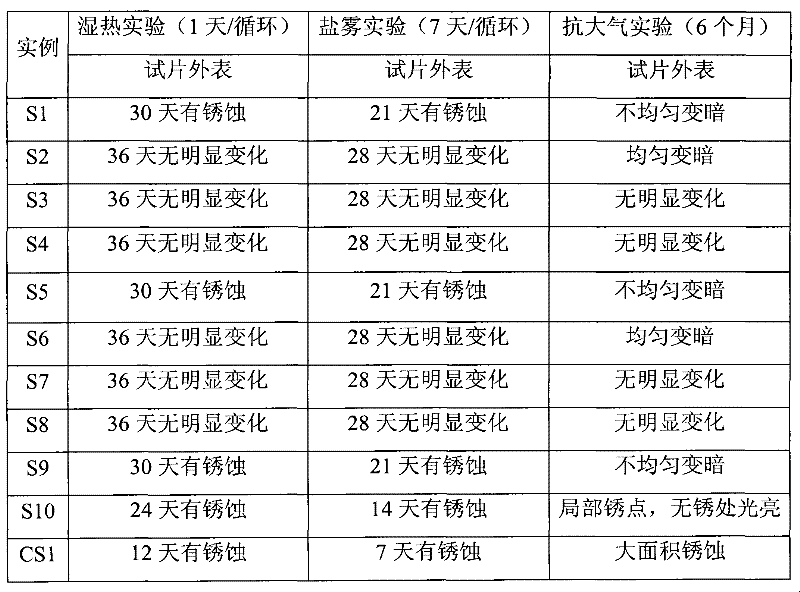

Rust preventive oil and preparation method thereof

The invention provides a rust preventive oil. The rust preventive oil comprises a composite antirust agent and base oil. The composite antirust agent is a mixture of a rare earth-beta-dione complex and at least one of barium petroleum sulfonate, sodium petroleum sulfonate, calcium petroleum sulfonate, barium dinonylnaphthalene sulfonate, barium heavy alkyl benzene sulfonate, non-barium heavy alkyl benzene sulfonates, a lanolin magnesium soap, a lanolin aluminum soap, aluminium stearate, a oxidized petroleum ester barium soap and zinc naphthenate. The invention also provides a preparation method of the rust preventive oil. The preparation method comprises putting the base oil into a reaction vessel, adding the composite antirust agent into the base oil, stirring the mixture with heating to dehydrating the mixture, and then filtering to obtain the rust preventive oil. The rust preventive oil prepared by the invention can keep a rust-preventing effect for a long time in three environments of a temperature and humidity experiment, a salt spray experiment and an atmospheric corrosion resistance experiment, and thus can satisfy needs.

Owner:BYD CO LTD

Mite-removing laundry liquid

ActiveCN102051279AImprove securityPrevent mildewOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsAlcoholActive component

The invention relates to a mite-removing laundry liquid which comprises the following main active components in parts by mass: 5-10 parts of dodecyl dimethyl lycine, 7-12 parts of sodium alcohol ether sulfate, 6-10 parts of fatty alcohol polyoxyethylene ether, 4-8 parts of sodium linear alkyl benzene sulfonate, 0.5-1 part of antibiotic mildewproof miticide (MGU-350), 0.2-0.5 part of chelator and 1-5 parts of thickening agent. The mite-removing laundry liquid has the advantage of strong detergency, does not damage the surface and has the effect of removing mites.

Owner:BEIJING REWARD HOME CARE CHEM

Preparation method for polymer-containing crude oil demulsifier

ActiveCN102329635AImprove surface activityGood hydrophilic and lipophilicDewatering/demulsification with chemical meansDemulsifierWater quality

The invention relates to a preparation method for a polymer-containing crude oil demulsifier. At present, the demulsifier has a poor demulsification effect on the polymer-containing crude oil demulsifier and poor water quality of removed sewage during crude oil gathering and delivery in an oil field. The method comprises the following steps of: preparing an intermediate; preparing ethylene oxide or propylene oxide block copolyether; preparing alkyl benzene sulfonate; and preparing the polymer-containing crude oil demulsifier. The polymer-containing crude oil demulsifier prepared by the invention has high surface activity, superior hydrophilic and lipophilic performances and performance of processing polymer-containing emulsified crude oil, and can be used for processing the polymer-containing emulsified crude oil in a crude oil overflow and sedimentation system.

Owner:西安长庆化工集团有限公司

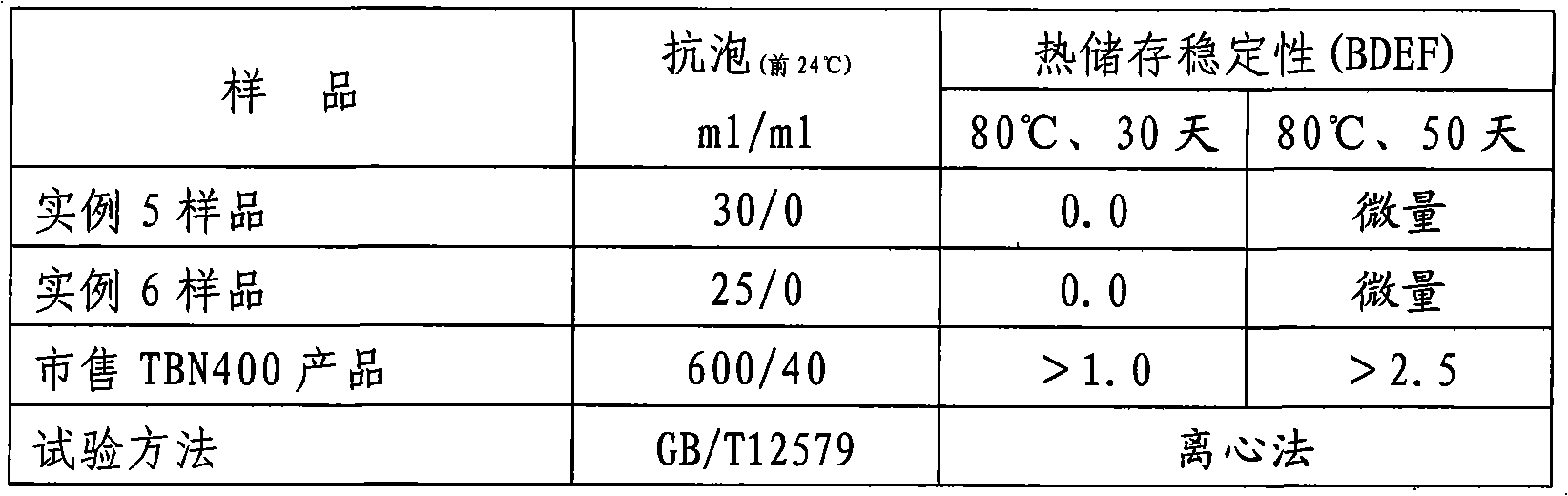

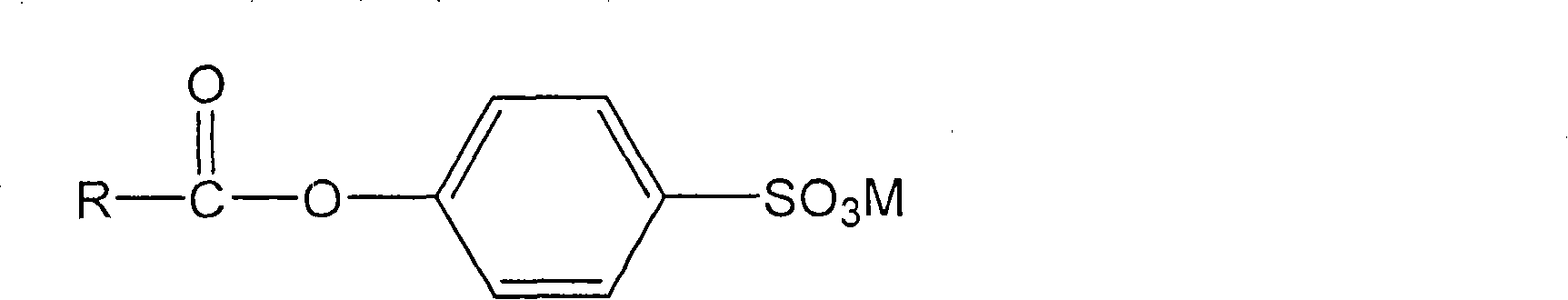

Cold-pad-batch method for textile materials

InactiveCN101135113AAchieve the bleaching effectAvoid damageTextile storage in wounded formFibre treatmentEngineeringBatch method

The present invention discloses process of cold padding, stacking and actively bleaching fabric. The process includes through steps, including one step of compounding bleaching solution and padding, one step of winding and stacking, and one step of hot water washing and cold water washing. The present invention adopts alkanoylxy benzene sulfonate bleaching activator, hydrogen peroxide / activator bleaching system, and cold padding and stacking treatment to reach excellent fabric bleaching effect. Compared with traditional bleaching technology, the present invention has the advantages of excellent fabric bleaching effect, lowered alkali consumption, reduced stacking time, less fabric damage, raised production efficiency and environment friendship.

Owner:ZHEJIANG SCI-TECH UNIV

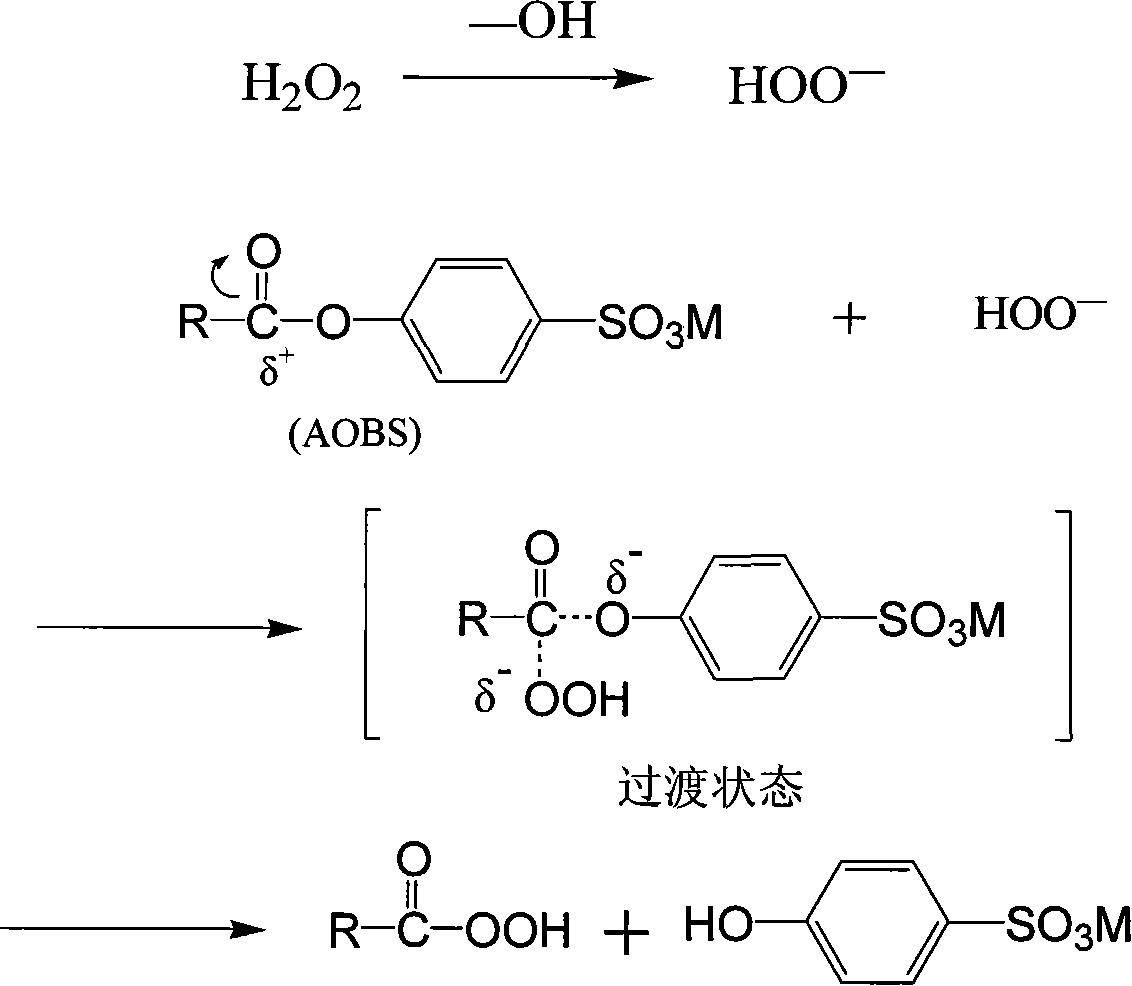

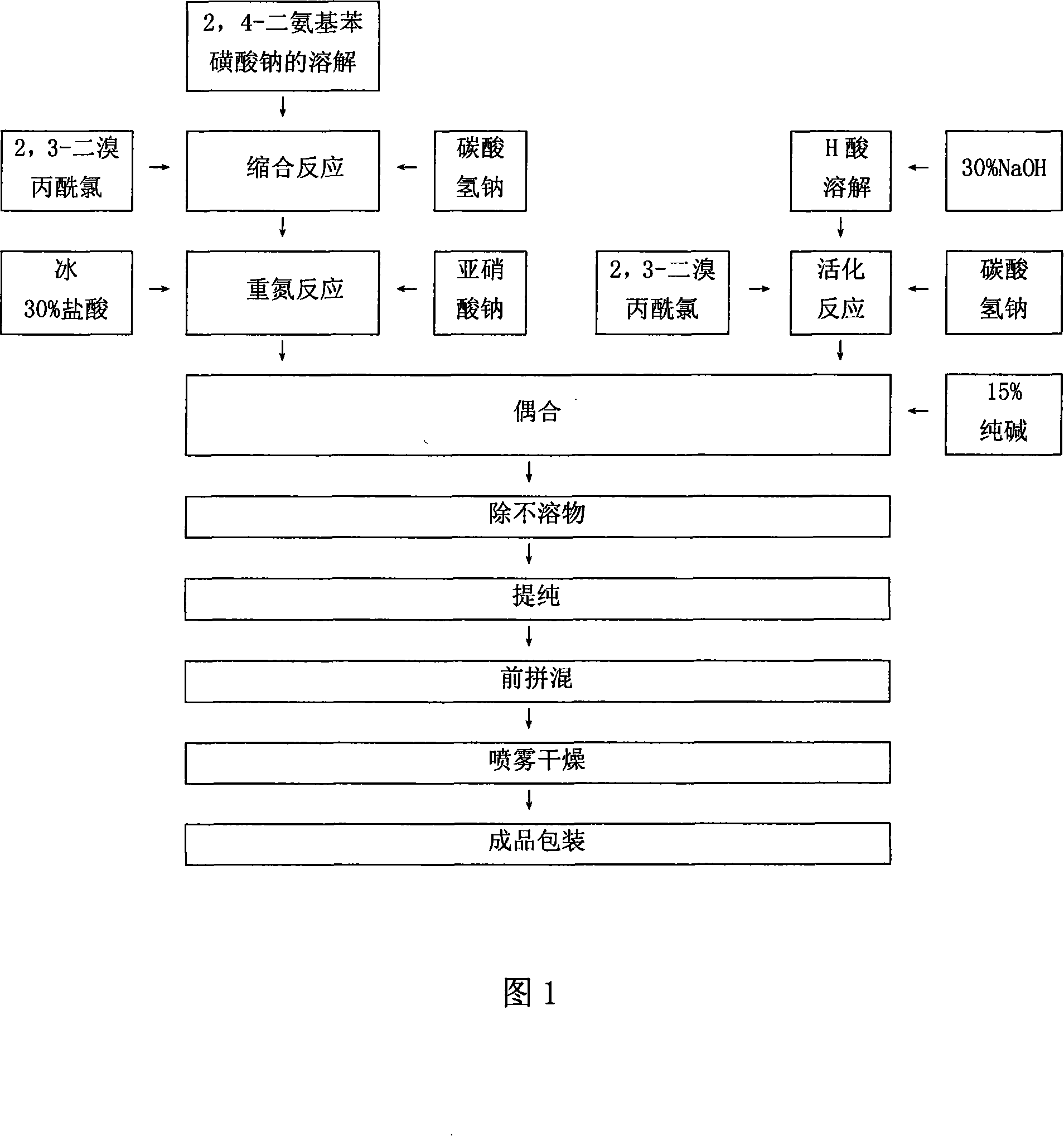

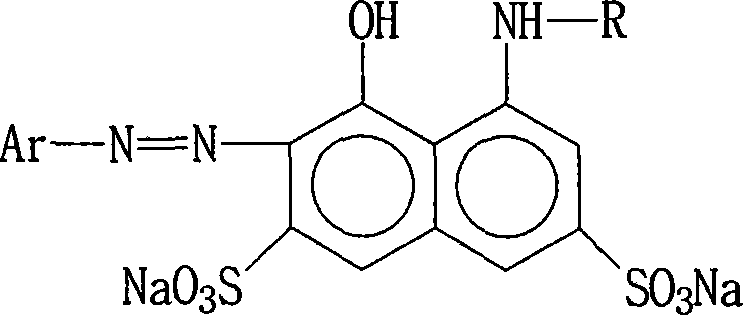

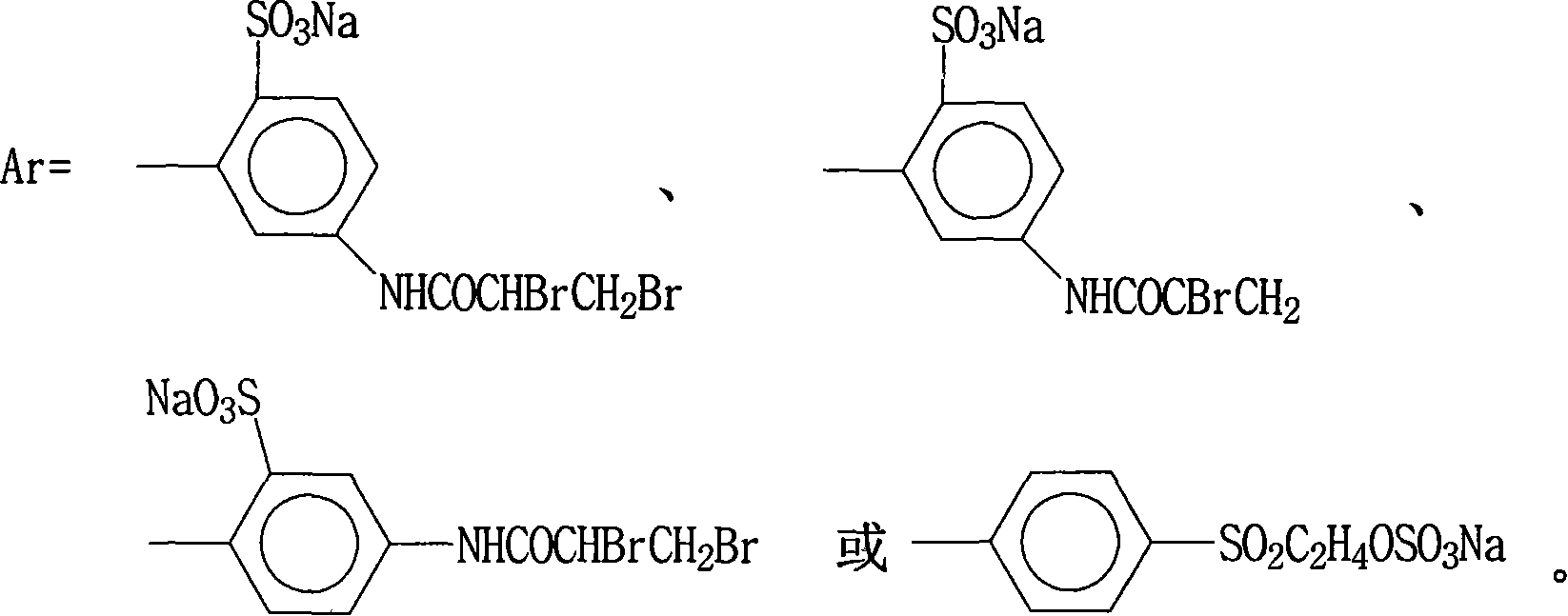

Red reactive dyestuffs and preparation method thereof

The invention discloses a red reactive dye and a process for preparation, which utilizes 2, 4-diamino benzene sulfonate, H-acid and 2, 3-dibromo propionyl chlorine to be main raw material. The process for preparation comprises condensing, diazotizing, activating, coupling, adding auxiliary agent, improving dye strength, adjusting color cast, adjusting intensity, drying and packing. The red reactive dyes which is got by the invention has higher reactivity, excellent dissolvability brilliant and attractive color cast, great light fastness properties and high adsorbability and fixation yield. The front blending and mixing technique after adding auxiliary agent and handling film can avoid producing water and waste slag, which plays a great promoting effect to environment.

Owner:TIANJIN DEK CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com