Patents

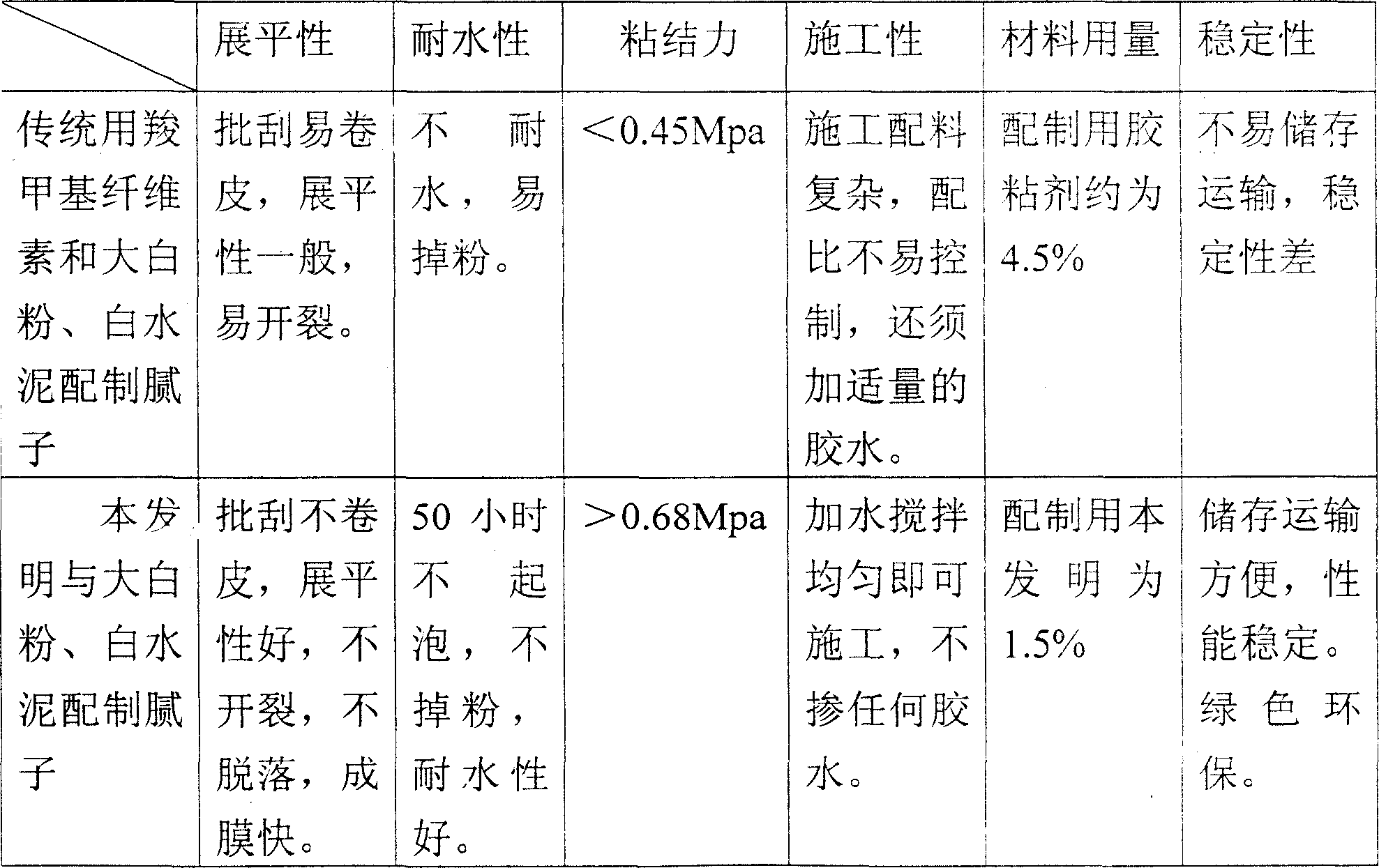

Literature

368 results about "Benzenesulfonates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic salts and esters of benzenesulfonic acid.

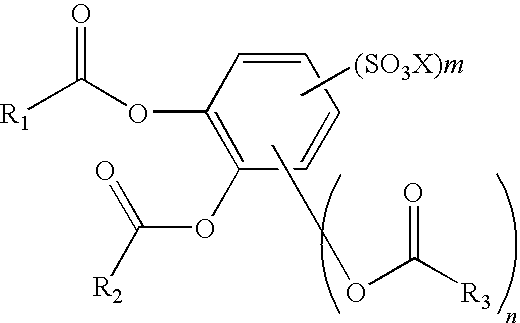

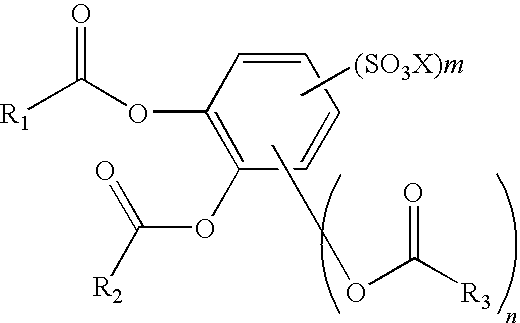

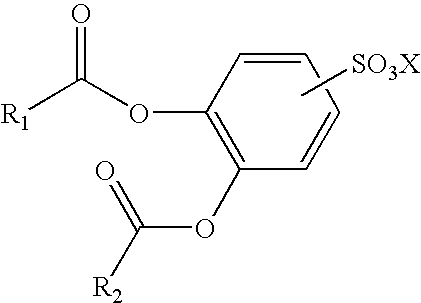

Composition containing an esterified substituted benzene sulfonate

InactiveUS7585376B2Non-ionic surface-active compoundsOrganic detergent compounding agentsBenzenesulfonatesChemistry

Owner:PROCTER & GAMBLE CO

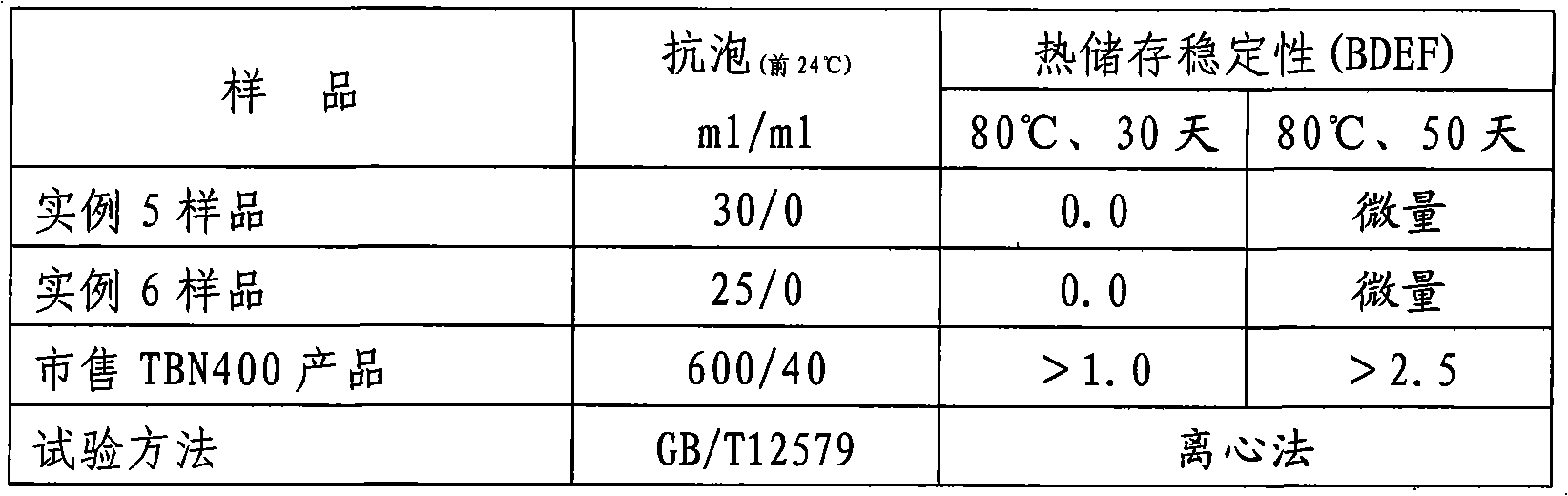

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

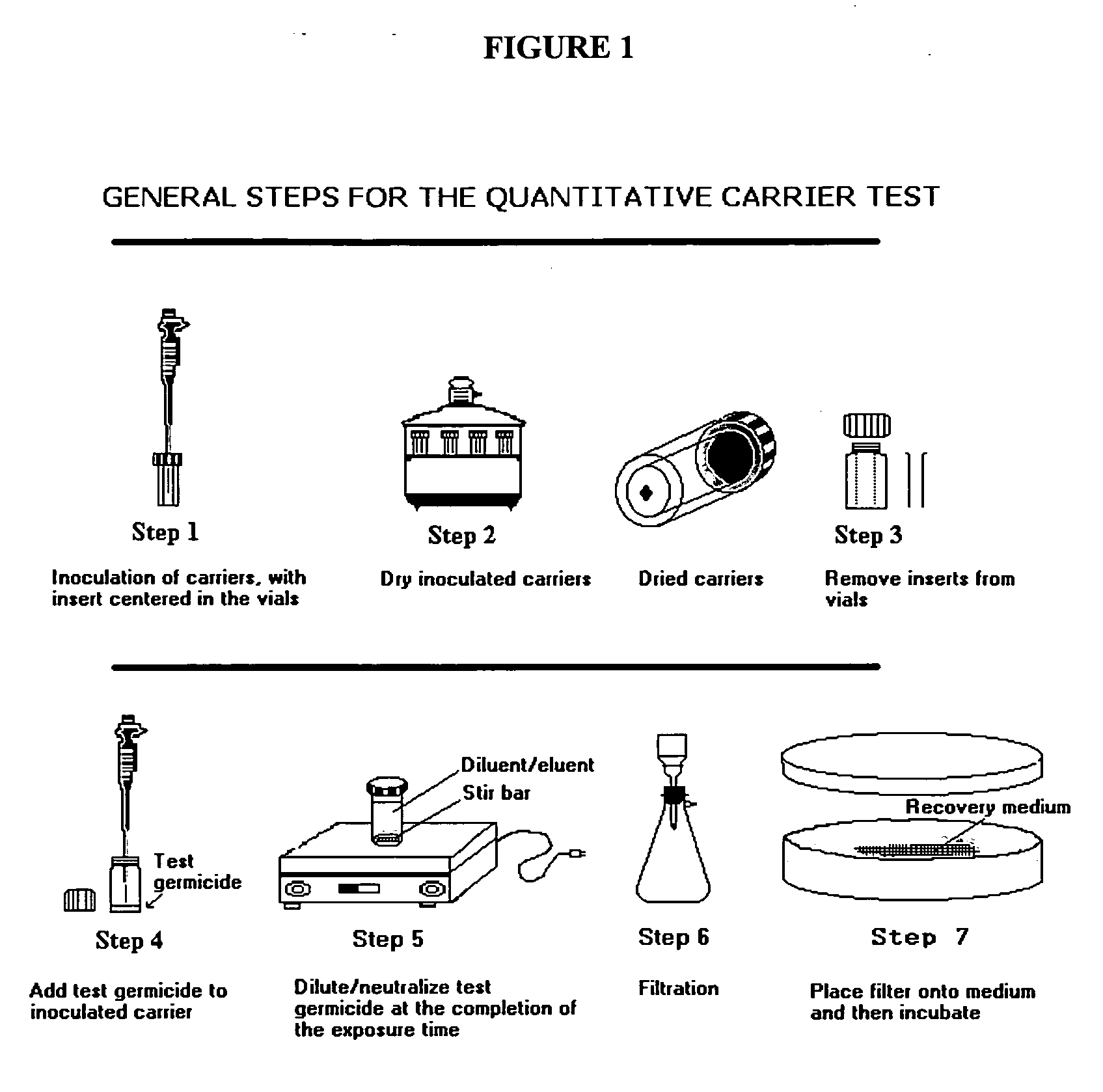

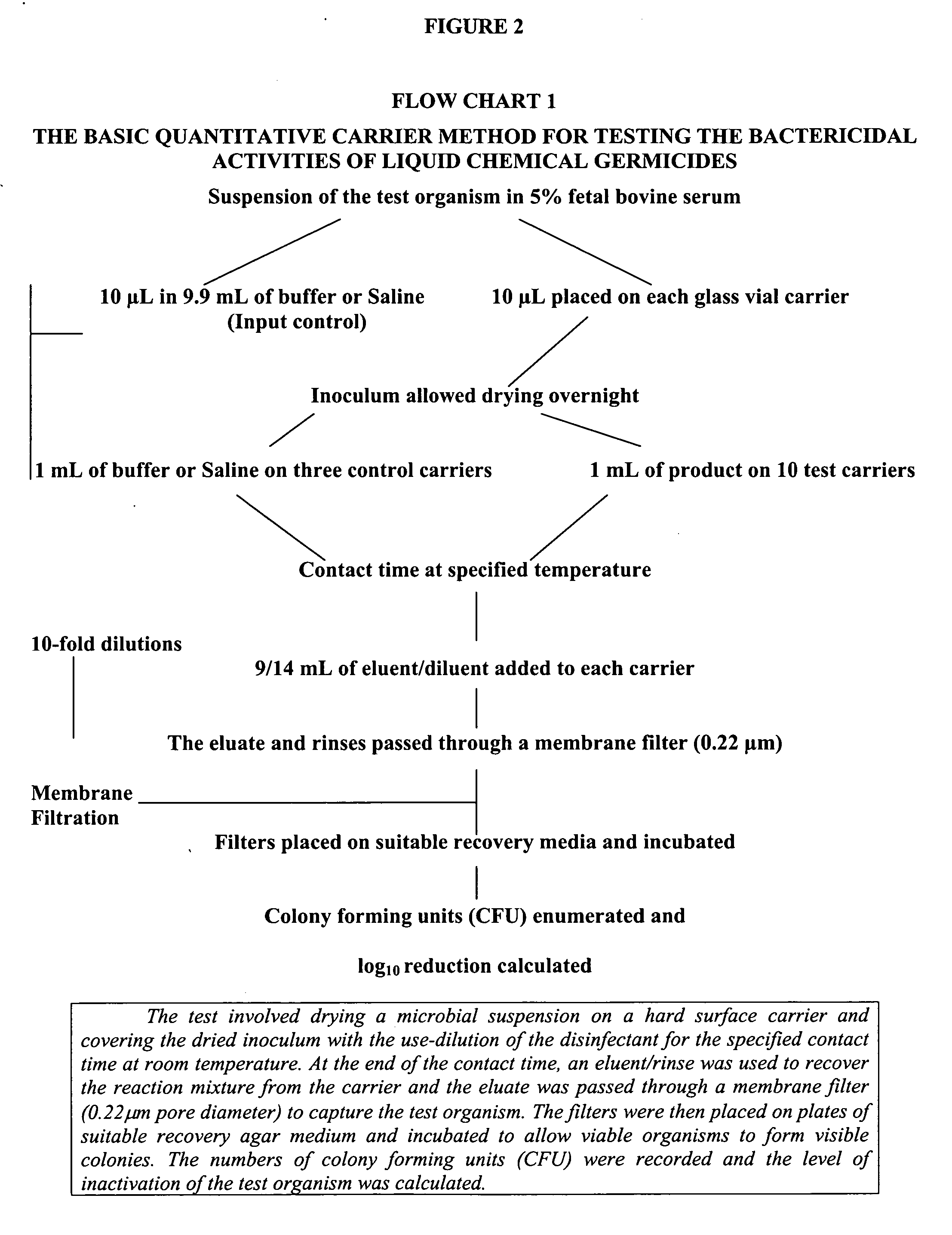

Hydrogen peroxide disinfectant containing a cyclic carboxylic acid and/or aromatic alcohol

An aqueous disinfecting solution and dry powdered composition which may be dissolved in water to provide the solution. The solution has a pH of from 0.6 to 7 and comprises (a) hydrogen peroxide in a concentration of from 0.01 to 6% w / w; and (b) at least one component chosen from cyclic carboxylic acids and aromatic alcohols, in a concentration of from 0.01 to 4 w / w %, all based on the total weight of the solution. The cyclic carboxylic acids are preferably 2-furan carboxylic acid, benzoic acid and salicylic acid. Furthermore, the solution preferably contains at least one C6-C12 alkyl diphenyl sulfonate surfactant and a nonionic surfactant. Additional optional ingredients include anionic surfactants, corrosion inhibitors, cation sequestering agents, and buffers.

Owner:JOHNSONDIVERSEY INC

Safe and environment-friendly concentrated special cleaning agent for vegetables and fruits

ActiveCN102250696AImprove efficiencyGood value for moneySurface-active detergent compositionsDetergent compounding agentsSucrosePesticide residue

The invention relates to a safe and environment-friendly cleaning agent for vegetables and fruits, which can effectively remove pesticide residue on the surface of the vegetables and fruits without causing secondary pollution to the surfaces of the vegetables and fruits, and is safe, environment-friendly, free from phosphorus, alkali, sodium alkyl benzenesulfonate and capable of protecting the environment and health of people. The formula of the safe and environment-friendly cleaning agent is neutral and particularly contains natural aloes and protects skin from being hurt. The safe and environment-friendly cleaning agent for vegetables and fruits comprises the following raw materials in part by weight: 1.0 to 8.0 parts of chelating agent, 8 to 20 parts of sucrose ester, 3 to 12 parts of alkyl glucoside, 1.5 to 15 parts of Tween, 3 to 15 parts of solubilizer, 0.3 to 5.0 parts of thickener, 0.2 to 1.5 parts of hand-care component, 0.03 to 0.08 part of preservative, citric acid (in an amount capable of regulating the pH value to 6.5 to 8.5), 50 to 70 percent of water and 0.02 to 0.08 percent of food-grade essence (which is added according to actual needs).

Owner:于文 +1

Alkyl toluene sulfonate detergent

InactiveUS6995127B1High selectivityLong life-timeSurface-active detergent compositionsDetergent compounding agentsSulfonateBenzenesulfonates

This invention is directed to detergent compositions which employ sulfonated alkyltoluenes as surfactants, wherein the sulfonated alkyltoluenes have a higher content of the sulfonated 2-phenyl alkyltoluenes isomers than was previously available in sulfonated alkyltoluene surfactants of the prior art. Cleaning compositions according to the invention are more effective as cleaning agents over their counterparts of prior art which contain sulfonated alkyltoluenes having lower contents of the 2-phenyl alkyltoluene isomers, owing to an unexpected increase in tolerance of water hardness minerals normally associated with precipitation of the active detergent agent. Solid sulfonate salts of alkyltoluenes are also provided, including dry cleaning formulations containing same. The alkyltoluenes of this invention may be combined with alkylbenzene surfactants in order to provide detergent blends having increased water hardness tolerance, lower Krafft temperature, and increased cleaning performance over what was previously afforded by the prior art.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

Composition containing an esterified substituted benzene sulfonate

InactiveUS20070105742A1Organic detergent compounding agentsNon-ionic surface-active compoundsBenzenesulfonatesBenzene sulfonate

Owner:THE PROCTER & GAMBLE COMPANY

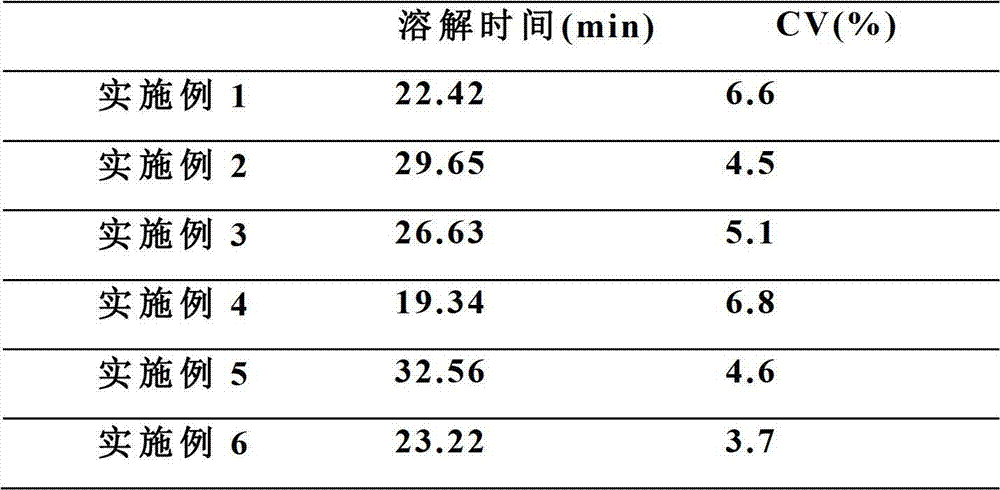

Water-soluble copolyester and preparation method thereof

The invention discloses a water-soluble copolyester and a preparation method thereof. The invention is characterized in that the water-soluble copolyester is obtained by sequentially carrying out esterification or ester exchange reaction and polycondensation reaction on dicarboxylic acid or esters thereof, m-benzenesulfonate, 2,5-furyl-diformic acid and dibasic alcohol as raw materials; the glass transition temperature of the water-soluble copolyester is 30-60 DEG C; and under the condition of 35 DEG C and orthochlorophenol as a solvent, the intrinsic viscosity of the water-soluble copolyester is at least 0.25 dL / g. By partially or totally substituting terephthalic acid with biomass-base 2,5-furyl-diformic acid, the technique reduces the consumption of the fossil raw material, and the water-soluble polyester has better environment-friendly characteristic and sustainable development performance, and has higher water solubility.

Owner:苏州瀚海化学有限公司

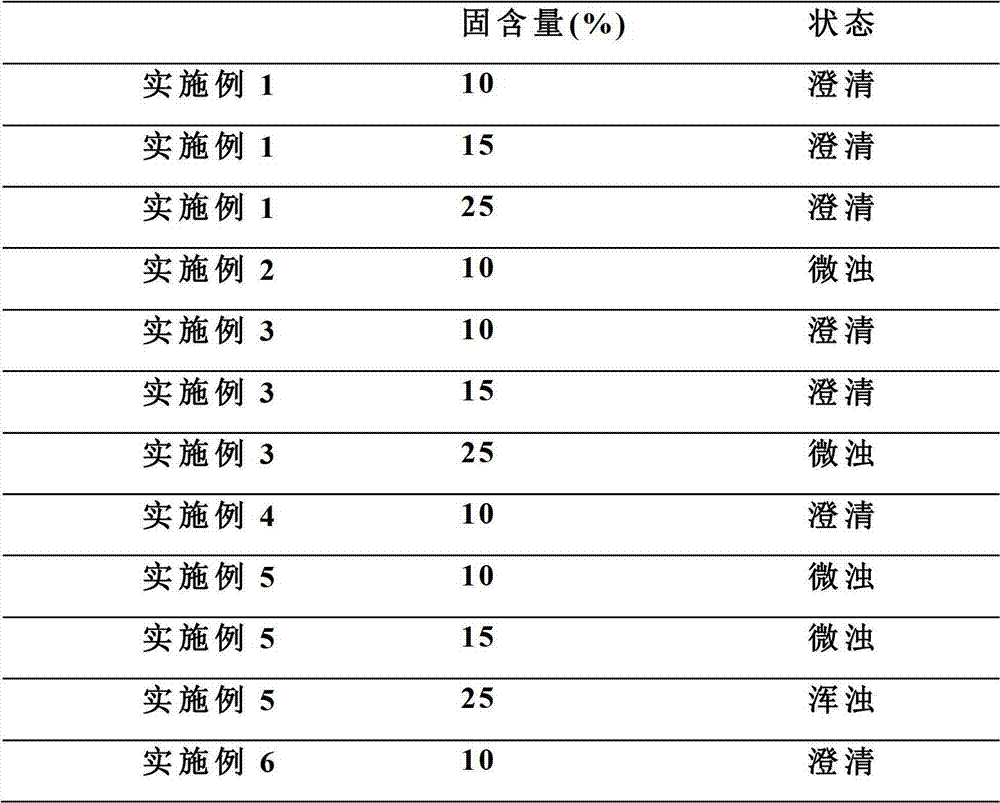

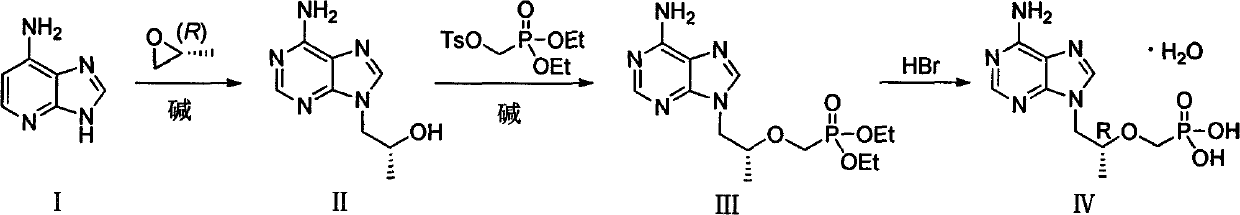

Preparation method of antiviral medicine

ActiveCN103374038ARaw materials are easy to getSimple process routeGroup 5/15 element organic compoundsCarboxylic acid salt preparationAntiviral drugBenzenesulfonates

The invention discloses a preparation method of anantiviral medicine tenofovirdisoproxil fumarate. The preparation method disclosed by the invention comprises the following steps of: performing addition reaction on adenine serving as raw material and (R)-epoxypropane in the presence of alkali; then, performing substitution reaction with (diethyoxyl phosphoracyl) methyl-4-methyl benzenesulfonate; then, hydrolyzing by using a hydrobromic acid solution; crystallizing to obtain tenofovir monohydrate; and reacting the product tenofovir monohydrate with chloromethyl isopropyl carbonate and fumaric acid to obtain tenofovirdisoproxil fumarate. The selected initial raw material is low in cost and easily available, and the synthetic line is simplified and the utilization ratio of the raw material and the total yield are improved. The intermediate obtained in the reaction is purified by the recrystallization method, so that the yield is high, less three-wastes are generated in the reaction process, and the cost is low; therefore, the preparation method is favorable for industrial production.

Owner:GUANGZHOU BAIYUNSHAN PHARMA HLDG CO LTD BAIYUNSHAN PHARMA GENERAL FACTORY

Prepn process of RE nano oxide

Nano RE oxide is prepared through the process of: selecting single RE oxide R2O3, where R is La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y and Sc, or their mixture as raw material; dissolving in water solution of nitric acid or hydrochloric acid to reach a RE ion density of 0.1-0.4 mol / L; heating to 30-80 deg.c; adding dispersant sodium dodecyl benzenesulfonate, polyoxyethylenated alcohol, SPAN-80 or Tween-80 and precipitant to form RE carbonate precipitate; filtering, drying, and heating to 700-900 deg.c to obtain single or mixed nano RE oxide. The nano RE oxide has grain size smaller than 40 nm and specific surface area of 20-40 sq m / g.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

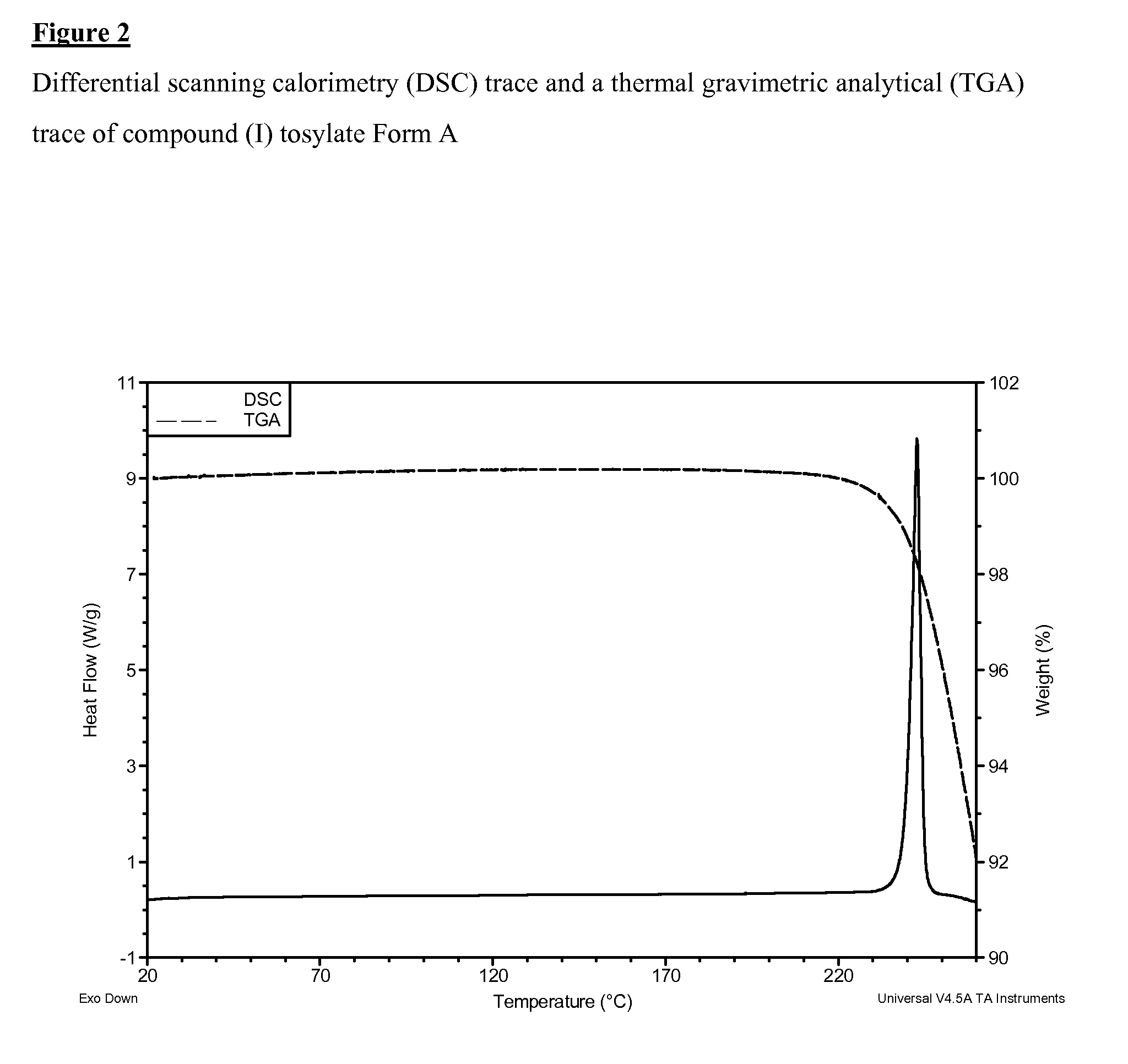

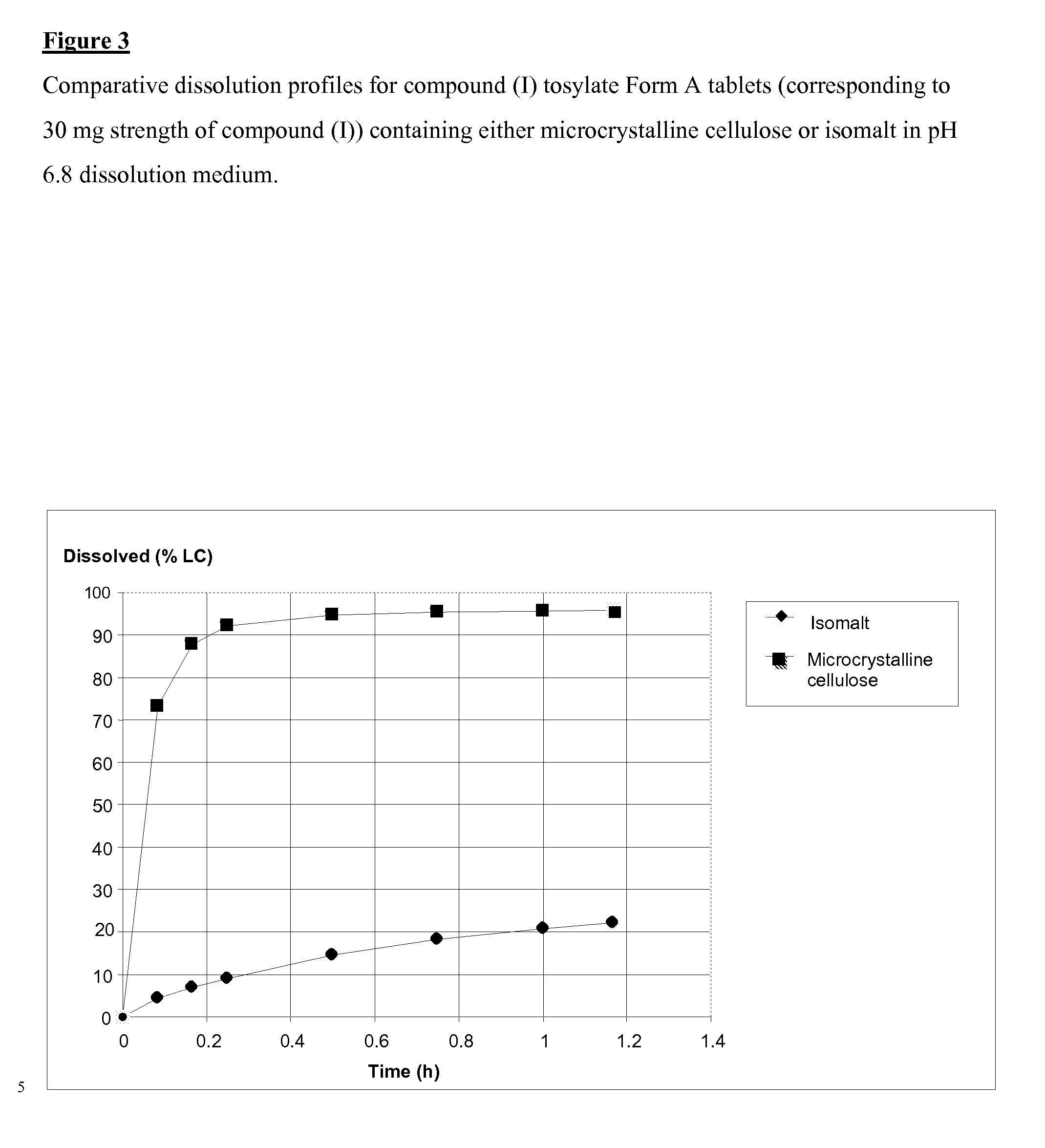

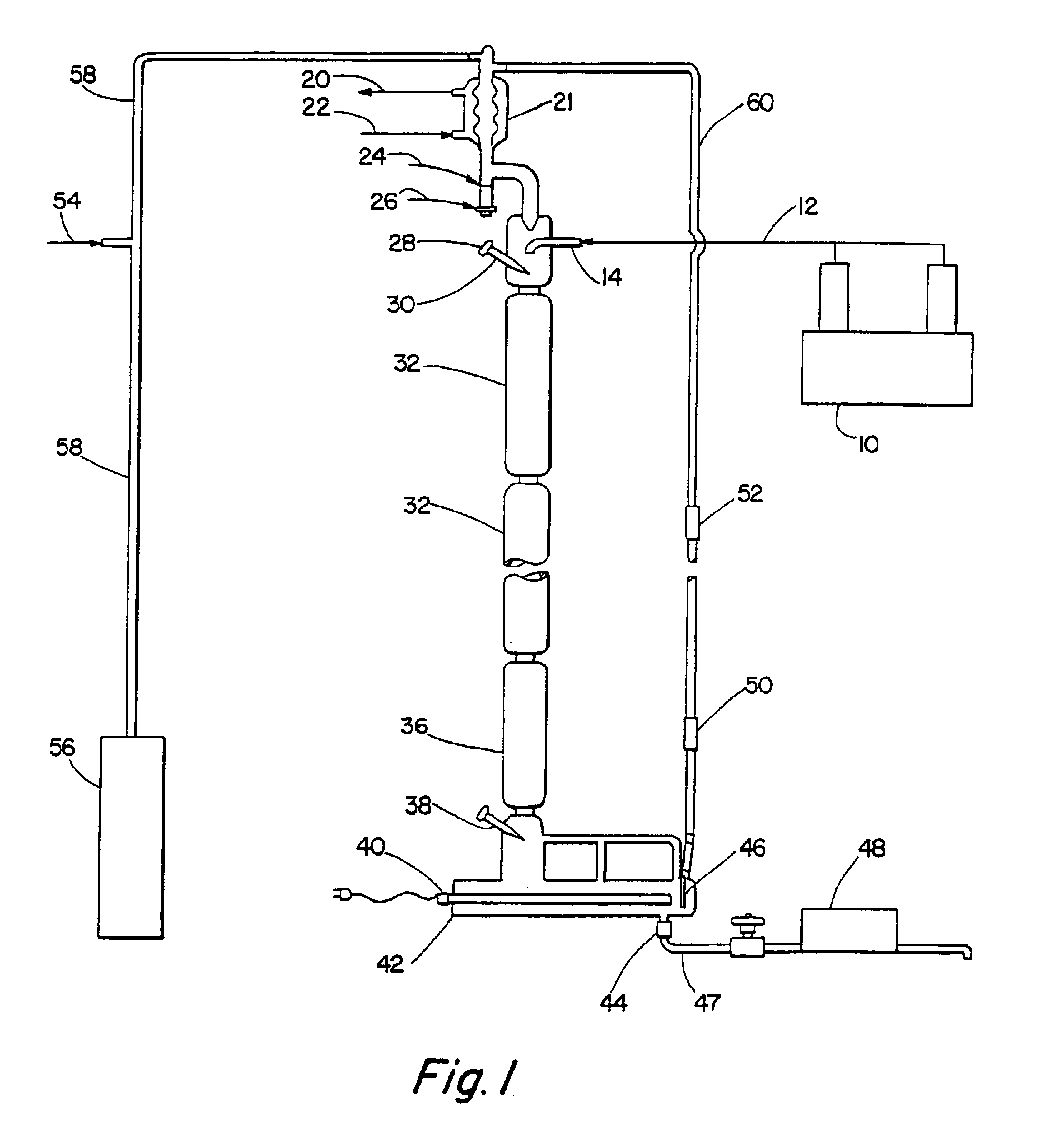

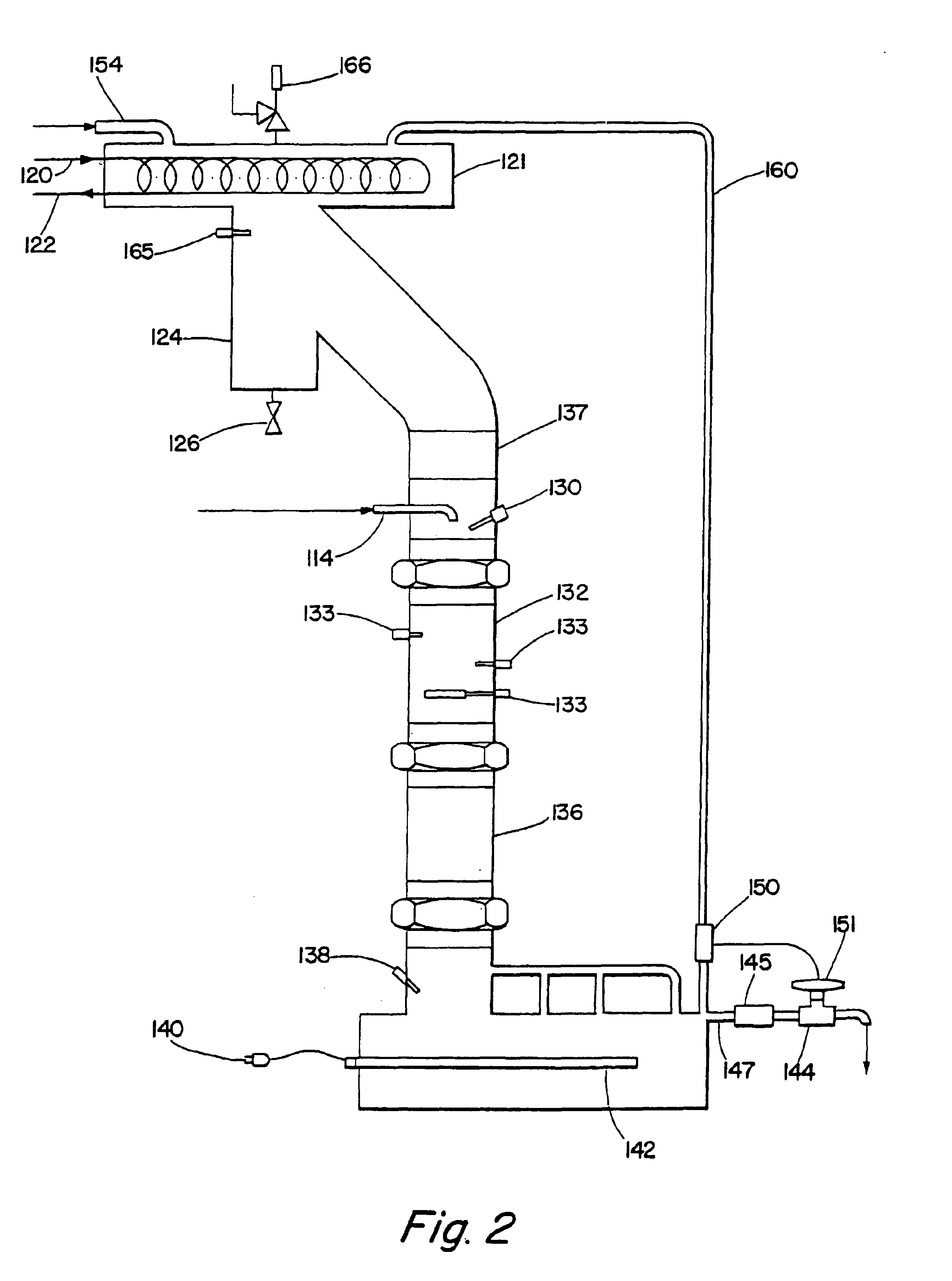

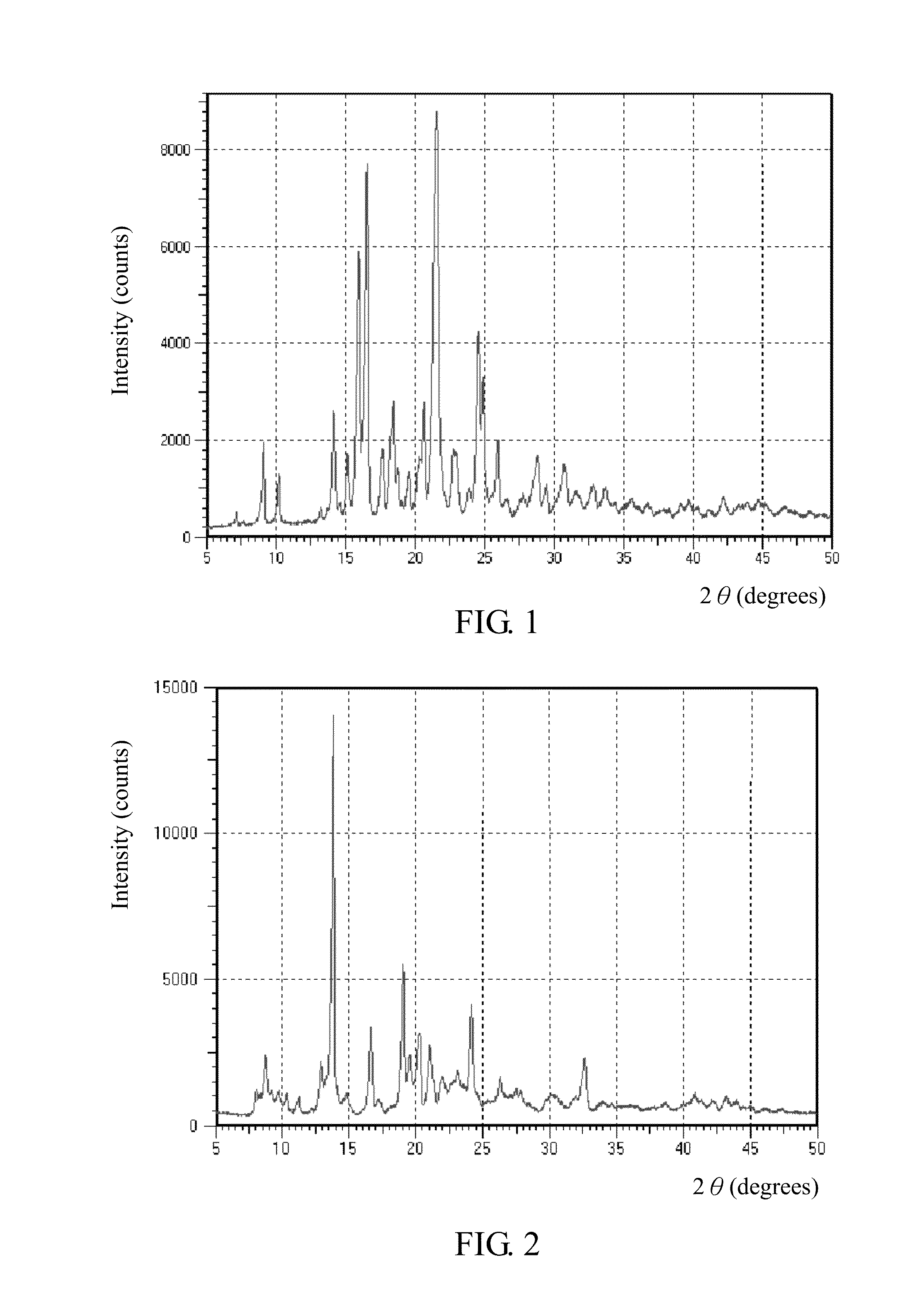

SALTS OF 2-FLUORO-N-METHYL-4-[7-(QUINOLIN-6-YL-METHYL)-IMIDAZO[1,2-b][1,2,4]TRIAZIN-2-YL]BENZAMIDE AND PROCESSES RELATED TO PREPARING THE SAME

ActiveUS20090291956A1Inhibit proliferative activityInhibit growthBiocideOrganic chemistryKetoneC-Met

The present invention is directed to dihydrochloric acid and dibenzenesulfonic acid salts of the c-Met kinase inhibitor 2-fluoro-N-methyl-4-[7-(quinolin-6-ylmethyl)-imidazo[1,2-b][1,2,4]triazin-2-yl]benzamide, and pharmaceutical compositions thereof, useful in the treatment of cancer and other diseases related to the dysregulation of kinase pathways. The present invention further relates to processes and intermediates for preparing 2-fluoro-N-methyl-4-[7-(quinolin-6-ylmethyl)imidazo[1,2-b][1,2,4]triazin-2-yl]benzamide, and salts thereof.

Owner:INCYTE

Soil modifier for earth pressure balance shield

InactiveCN105295933AImprove stabilitySimple preparation processBuilding constructionsOrganic fertilisersSulfonateSoil science

The invention relates to a soil modifier for earth pressure balance shield. The soil modifier is a foaming agent mixed from a foaming agent, a foam stabilizing agent and water. The foaming agent comprises of sodium alkyl sulfate, alkylbenzene sulfonate, alpha-alkenyl sodium sulfonate and fatty alcohol-polyoxyethylene ether. Each group is in the following weight percentage: 1-13% of sodium alkyl sulfate, 0.3-18% of alkylbenzene sulfonate, 0.5-15% of alpha-alkenyl sodium sulfonate, 0.5-3% of fatty alcohol-polyoxyethylene ether, 0.1-2% of foam stabilizing agent and the balance of water. The soil modifier can be used for earth pressure balance shield construction, has good stabilizing effect on excavation faces of different geological structures. Compared with other foaming agents, the soil modifier has higher foaming expansion rate and better stability, and can better improve the plastic flow property and permeability of soil body.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Stabilized decoating liquid

A stable deplating liquid that contains sulfuric acid and hydrogen peroxide, and a stabilizer blocking the degration of hydrogen peroxide and increasing the deplating rate containing either one or the composite of n-C4H9NH2 and n-C8H17NH2, The mentioned stabilizer may also contains the reserve salt containing sodium m-nitro-benzenesulfonate(O2N-C6H4-SO3Na) that can strip copper or nickel layer without eroding plastic surface. In this stable deplating liquid, presence of the stabilizer can inhibit the rapid degration of hydrogen peroxide catalyzed by copper ion, increase the service time of the liquid, decrease the cost and increase the deplating rate of nickel and copper. Furthermore, the contained sodium m-nitro-benzenesulfonate will remove copper layer and nickel and protect the plastic surface from corrosion in combination with other components.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

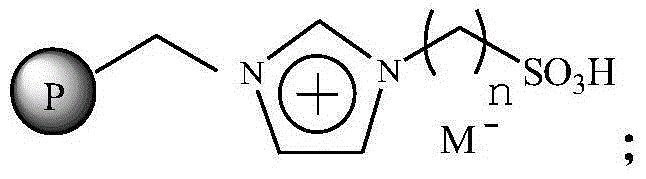

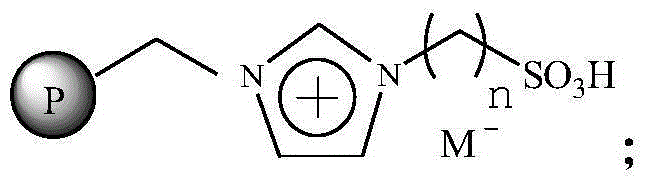

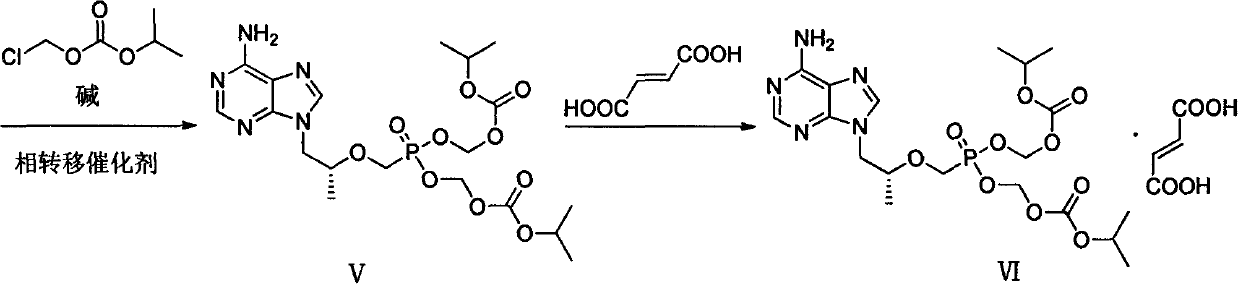

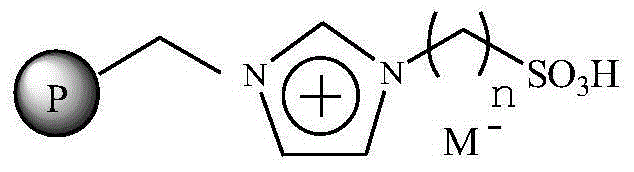

Immobilized ionic liquid catalyst and application thereof

InactiveCN106391112AHigh catalytic activityNot easy to inactivateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTetrafluoroborateTriflic acid

The invention relates to an immobilized ionic liquid catalyst and application thereof. The immobilized ionic liquid catalyst has a general structural formula as defined in the specification. In the general structural formula, P is a nanogel resin matrix; n is an integer in a range of 2 to 12; and M<-> is a negative ion selected from a group consisting of a trifluoromethanesulfonate group, a p-toluenesulfonate group, a benzenesulfonate group, a methanesulfonate group, a tetrafluoroborate group and a hexafluorophosphate group. The immobilized ionic liquid catalyst can be applied to industrial olefine acid addition for preparation of corresponding esters.

Owner:CHINA PETROLEUM & CHEM CORP +1

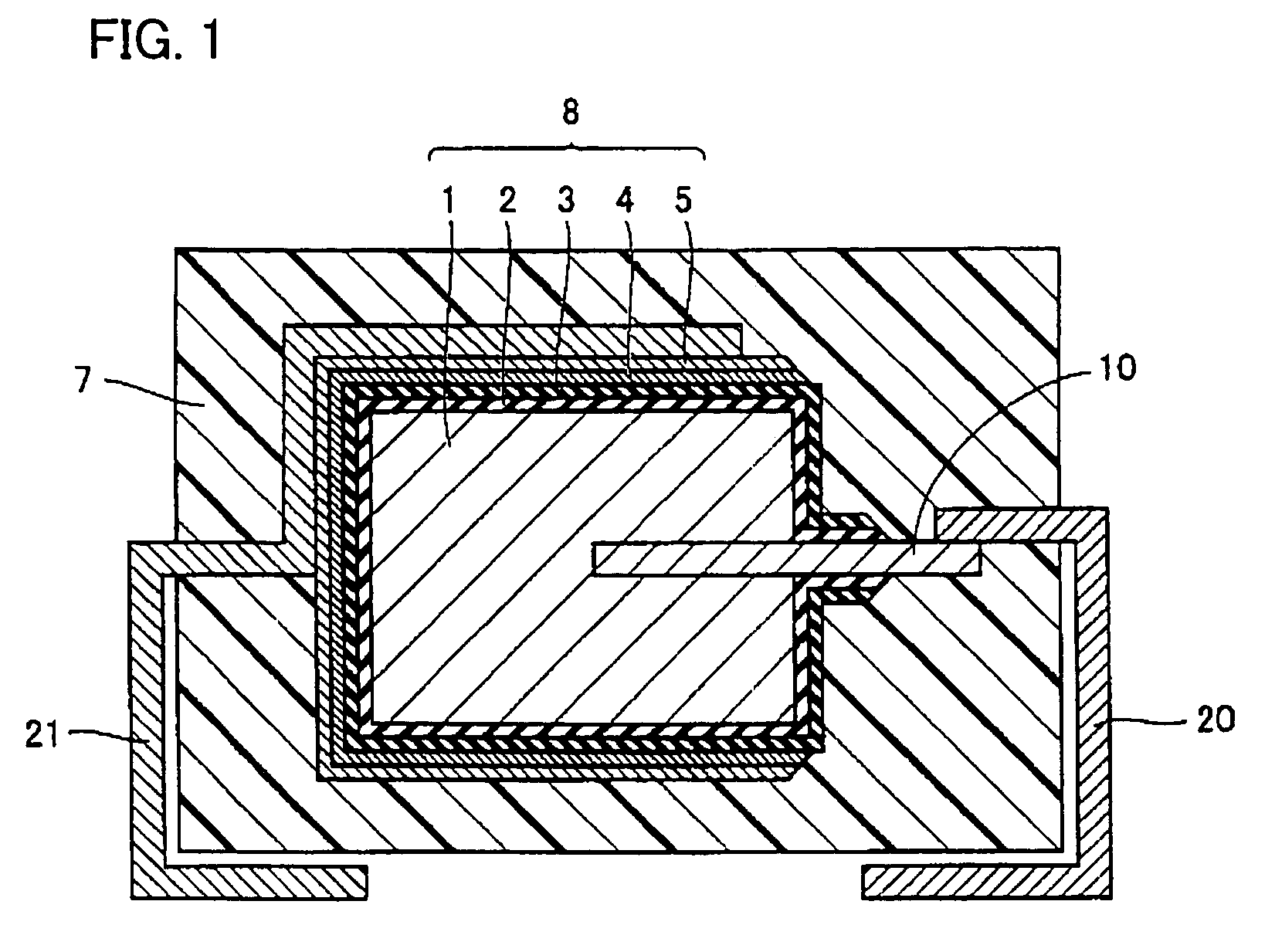

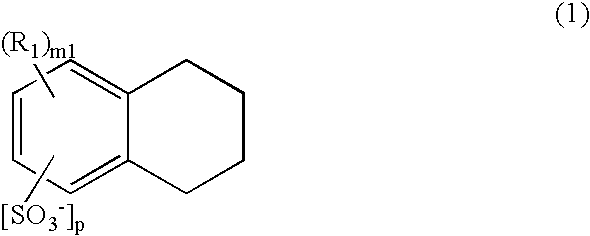

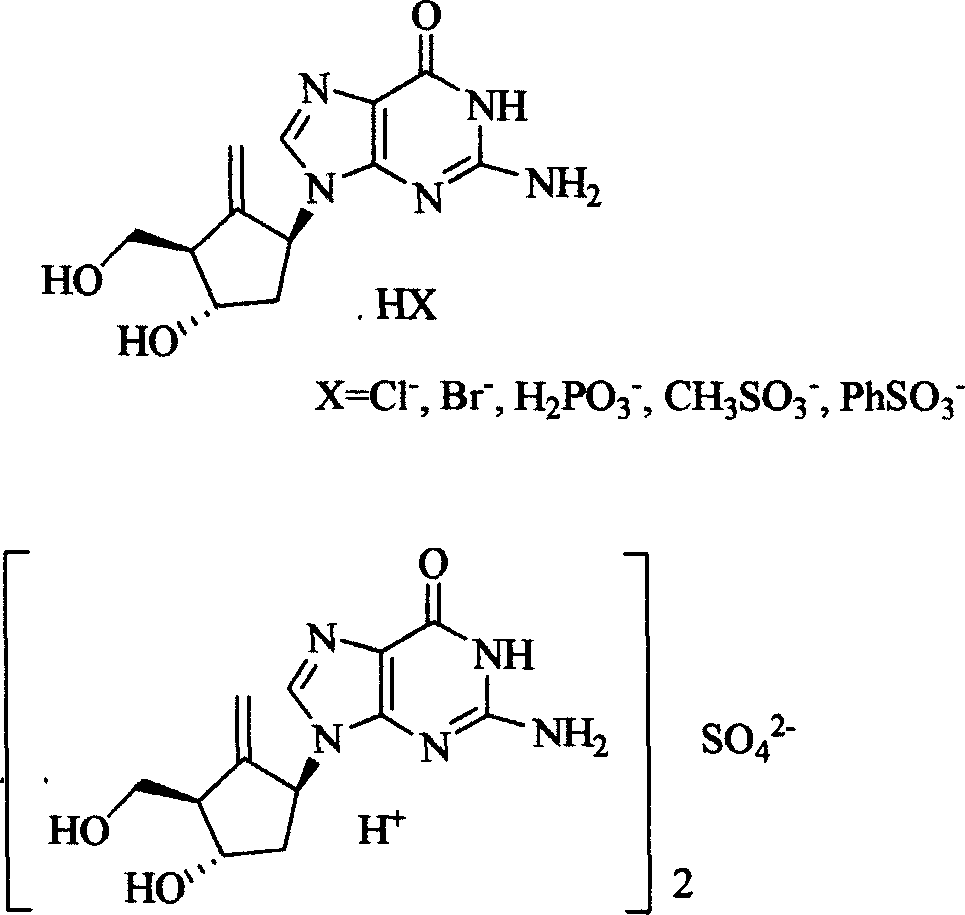

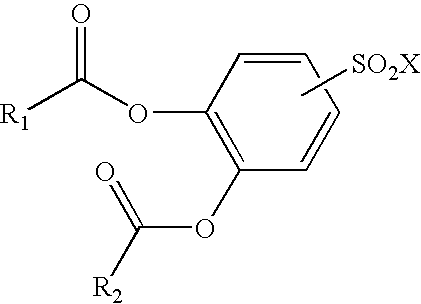

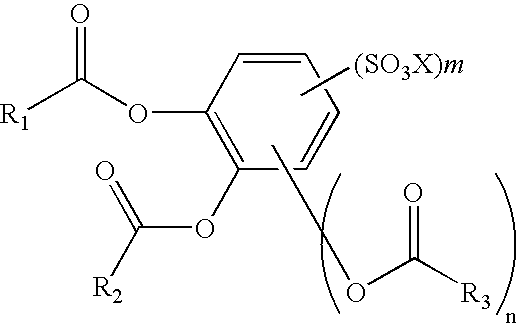

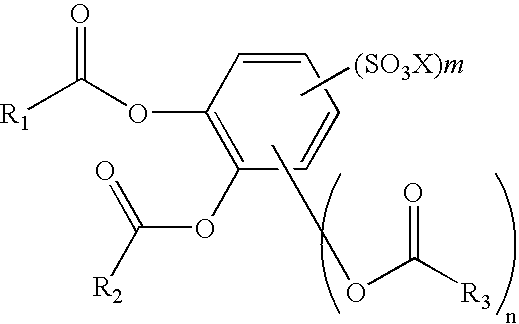

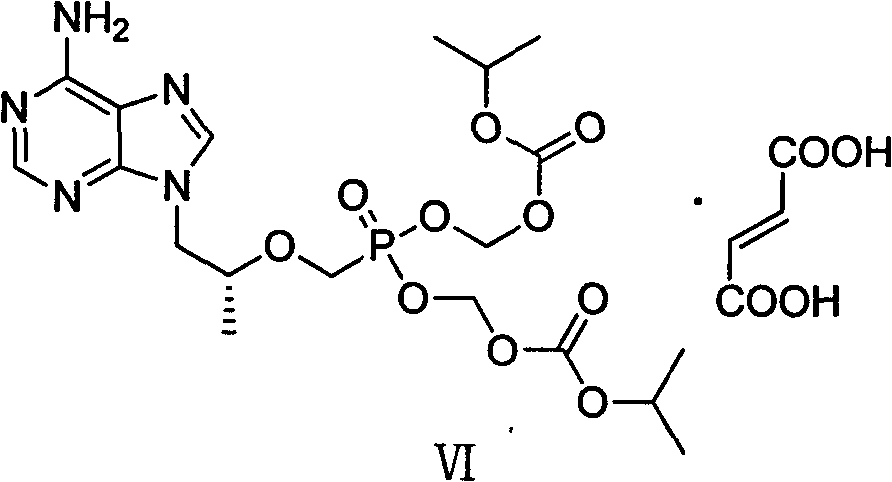

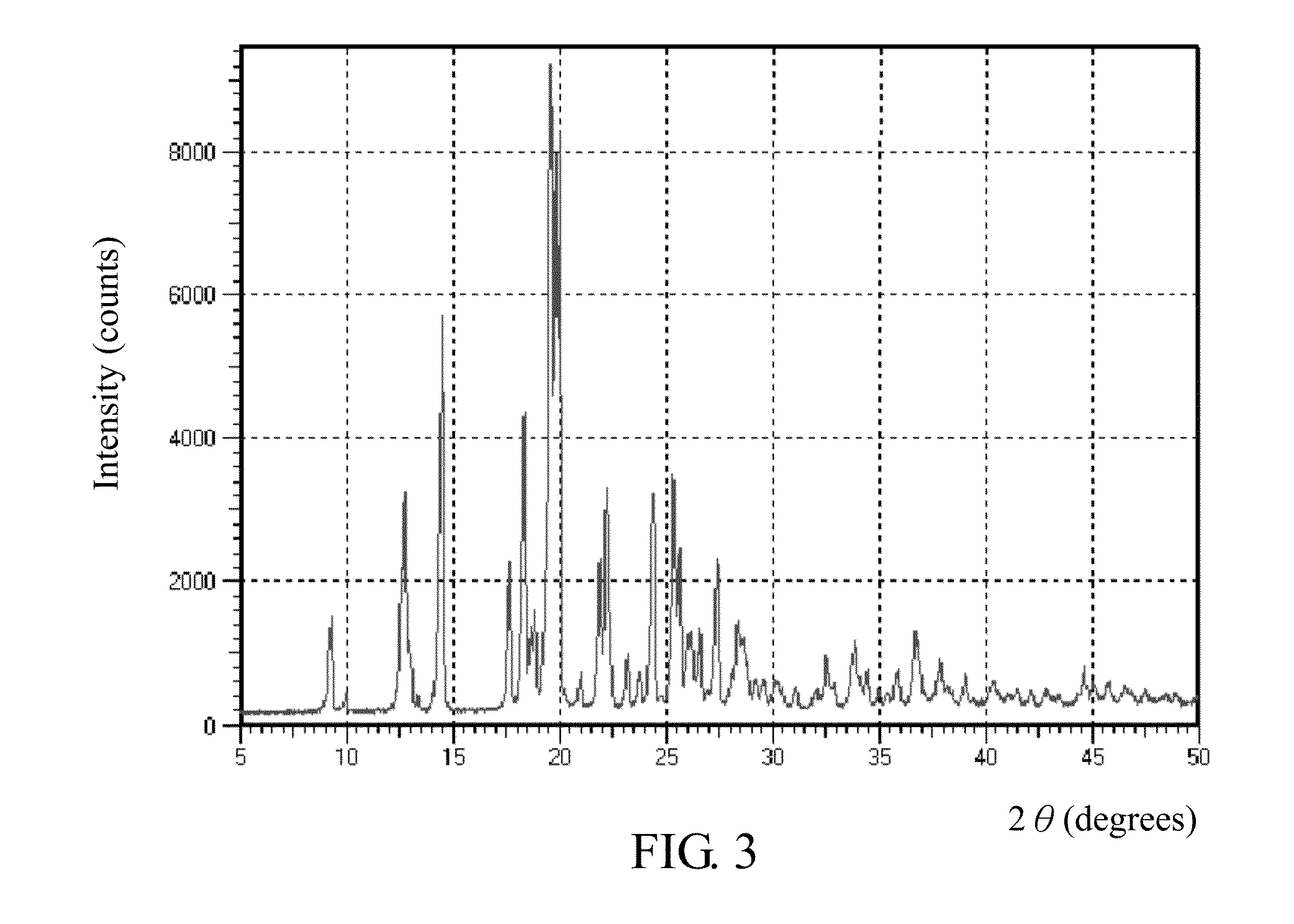

2-[[[2-[(hydroxyacetyl)amino]-4-pyridinyl]methyl]thio]-n-[4-(trifluoromethoxy)phenyl]-3-pyridinecarboxamide benzenesulfonate, crystal of same, crystal polymorph thereof, and methods for production thereof

InactiveUS20120116088A1Good storage stabilityImprove securityOrganic active ingredientsSenses disorderThio-Phenyl group

In the course of developing 2-[[[2-[(hydroxyacetyl)amino]-4-pyridinyl]methyl]thio]-N-[4-(trifluoromethoxy)phenyl]-3-pyridinecarboxamide (compound A), there are the multiple problems: 1) compound A or its salt is difficult to be recrystallized, the storage stability largely differs depending on the kind of the salt, and it is very difficult to obtain a salt of compound A having excellent storage stability; 2) in a crystallization process of compound A, it is very difficult to control a crystal polymorph, and 3) compound A (free body) causes mineral deposition in the stomach when it is orally administered repeatedly. For solving these problems, we made examination focusing on the kind of the salt and, as a result, found that 1) benzenesulfonate of compound A does not decompose by light, humidity and other factors in a 1-week preliminary stability test (severe test), and has no problem in its storage stability, 2) a method of selectively producing two kinds of crystal forms of benzenesulfonate of compound A, and that 3) no mineral deposition in the stomach is observed even after a 4-week repeated oral administration.

Owner:SANTEN PHARMA CO LTD

Method of synthesizing bepotastine or benzenesulfonic acid salt thereof and intermediates used therein

InactiveUS20140046068A1High optical puritySafe and effective and low-costOrganic chemistryAlpha hydroxy acidBenzenesulfonic acid

The present invention relates to a novel method of synthesizing bepotastine or its benzenesulfonic acid salt and novel intermediates used therein. The present invention uses L-α-hydroxy acid for chiral resolution to form an L-α-hydroxy acid salt of a compound represented by the following formula (VII-1), so as to synthesize bepotastine or its benzenesulfonic acid salt in high optical purity.

Owner:EVERLIGHT USA INC

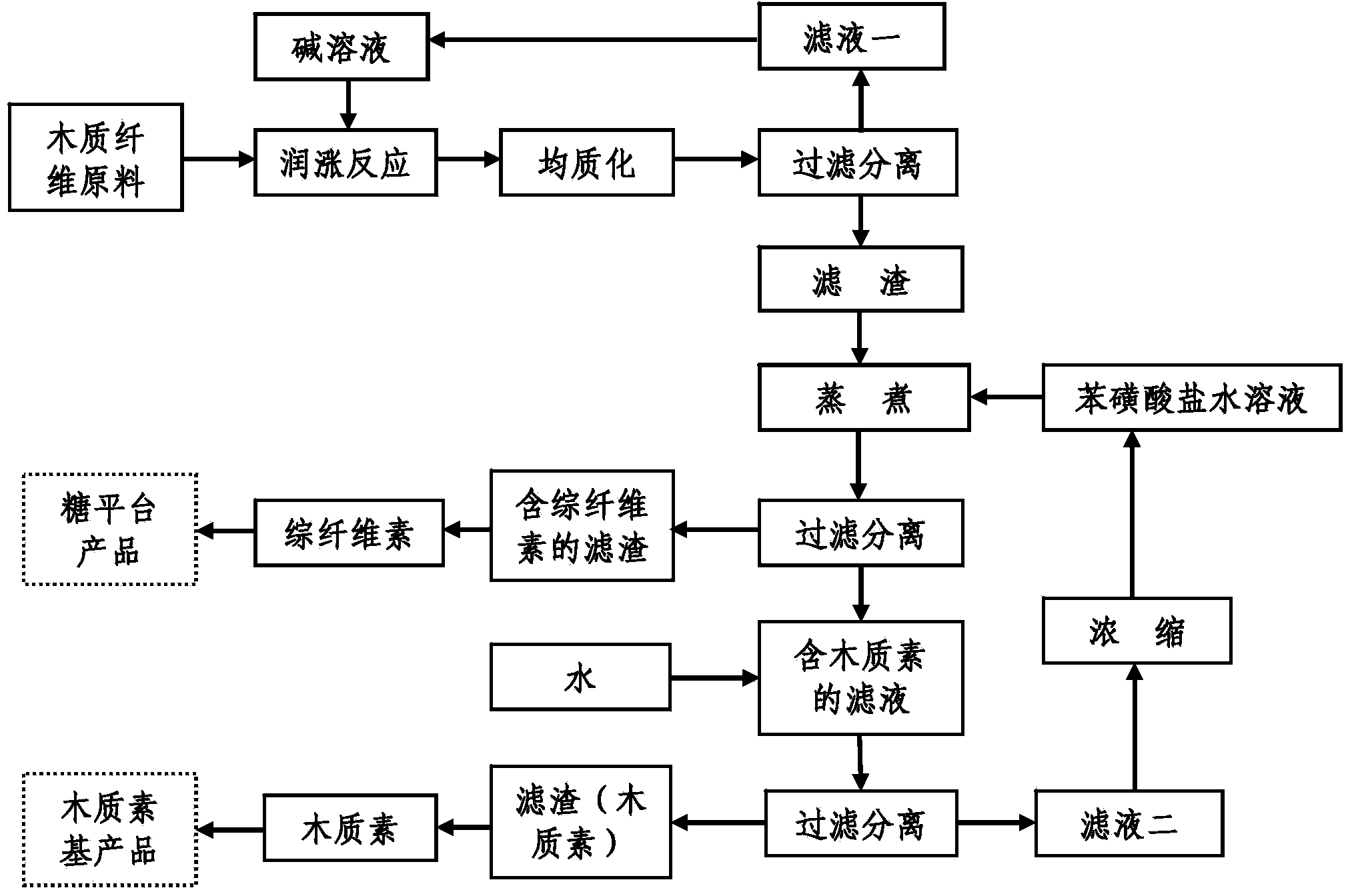

Method for separating lignin and holocellulose from wood fiber raw materials and application thereof

InactiveCN104389216AHigh extraction yieldImprove saccharification efficiencyPaper material treatmentCelluloseFiber

The invention relates to utilization and technology of agriculture and forestry biological data, in particular to a method for separating lignin and holocellulose from wood fiber raw materials. The method comprises the following steps: a, wood fiber raw materials are mixed with an alkali liquor and then soaked and moistened; b, the soaked and moistened wood fiber raw materials are homogenized and then filtered and separated to obtain solid residues and a filtrate I; c, the solid residues which are washed with water are added into a benzene sulfonate water solution for digestion, and the digested solid residues are filtered and separated to obtain residues containing holocellulose and a filtrate containing lignin; d, the residues containing holocellulose are washed to obtain holocellulose; e, water is added into the filtrate containing lignin to separate lignin, filtering is performed to obtain lignin residues and a filtrate II, and the lignin residues are washed and dried to obtain lignin. The method provided by the invention is simple and feasible in process, environment-friendly, and low in toxicity, the lignin extraction yield is high, and the saccharification efficiency of holocellulose obtained through separation is also high.

Owner:INT CENT FOR BAMBOO & RATTAN

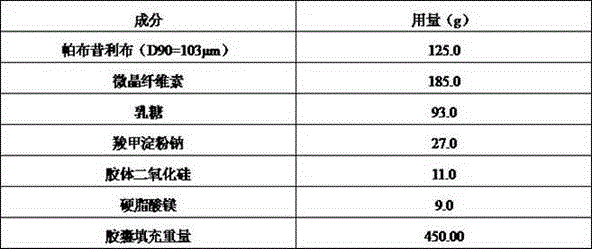

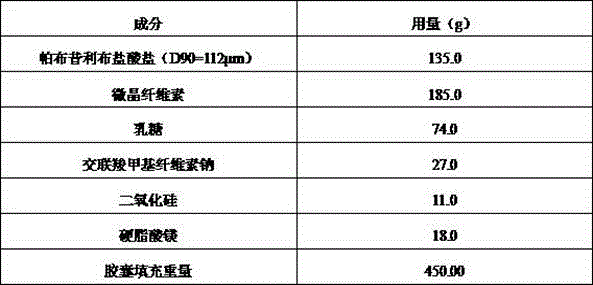

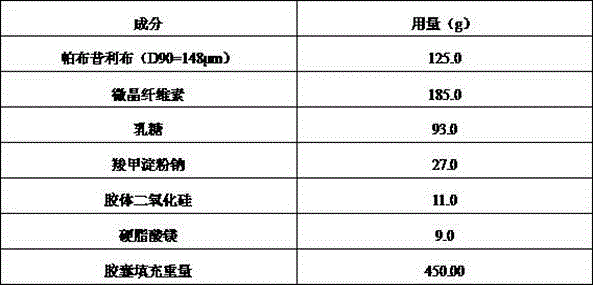

Palbociclib pharmaceutical composition and preparation method thereof

ActiveCN105748435AShorten absorption timeGuaranteed validityOrganic active ingredientsCapsule deliveryMedicineBiological availability

The invention discloses a palbociclib pharmaceutical composition, comprising palbociclib or its medicinal salt and a pharmaceutically acceptable auxiliary material, wherein the palbociclib or its medicinal salt is 50-150 Mum, and the medicinal salt includes isethionates, hydrochlorides, sulfates or benzene sulfonates.Direct mixing and capsuling process of raw and auxiliary materials is used for the pharmaceutical composition provided herein, the biological availability is high, product quality stability is good, the technical process is easy to control, inter-batch reproducibility is good, and the composition is easy to industrialize.

Owner:河北泽运生物医药科技有限公司

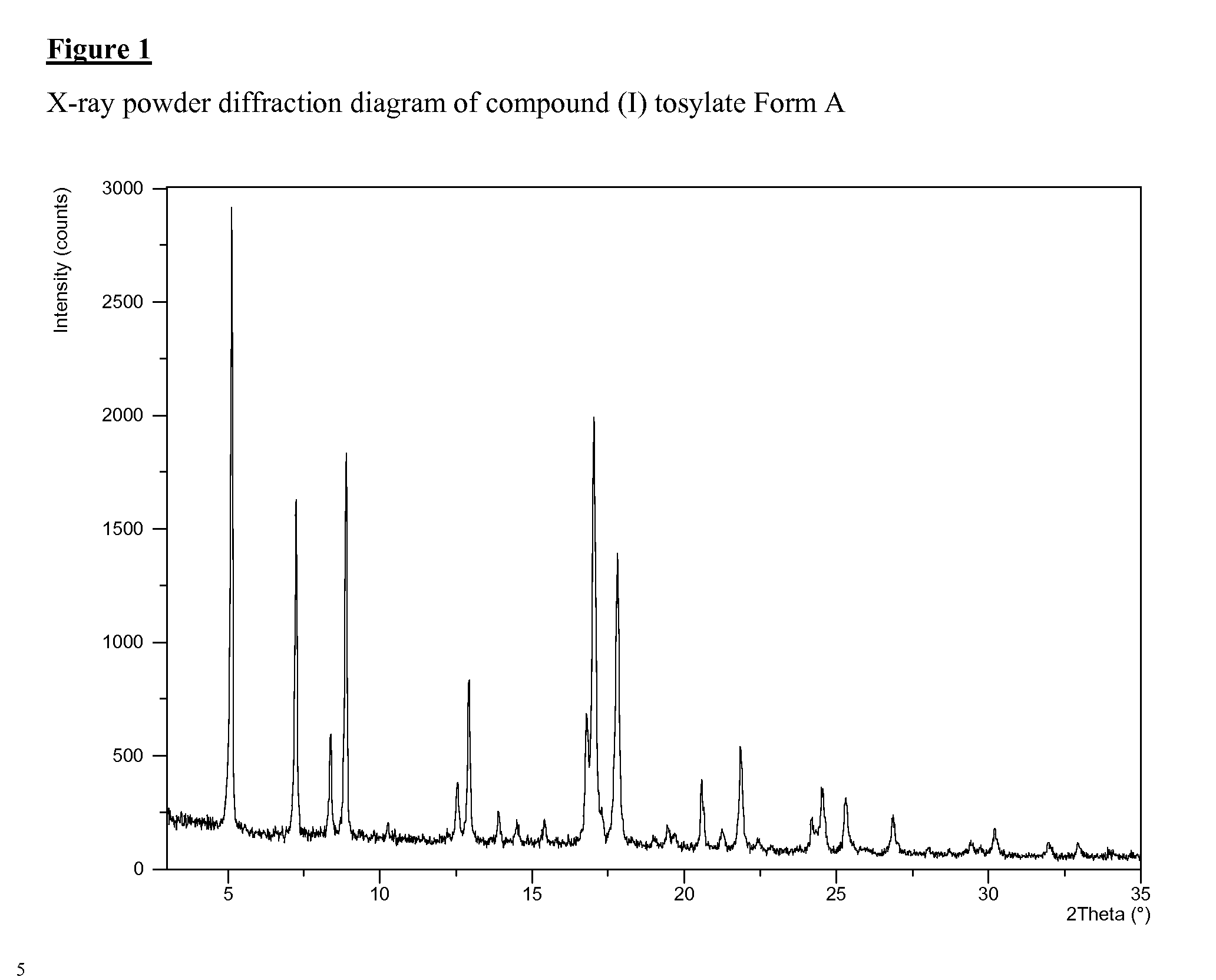

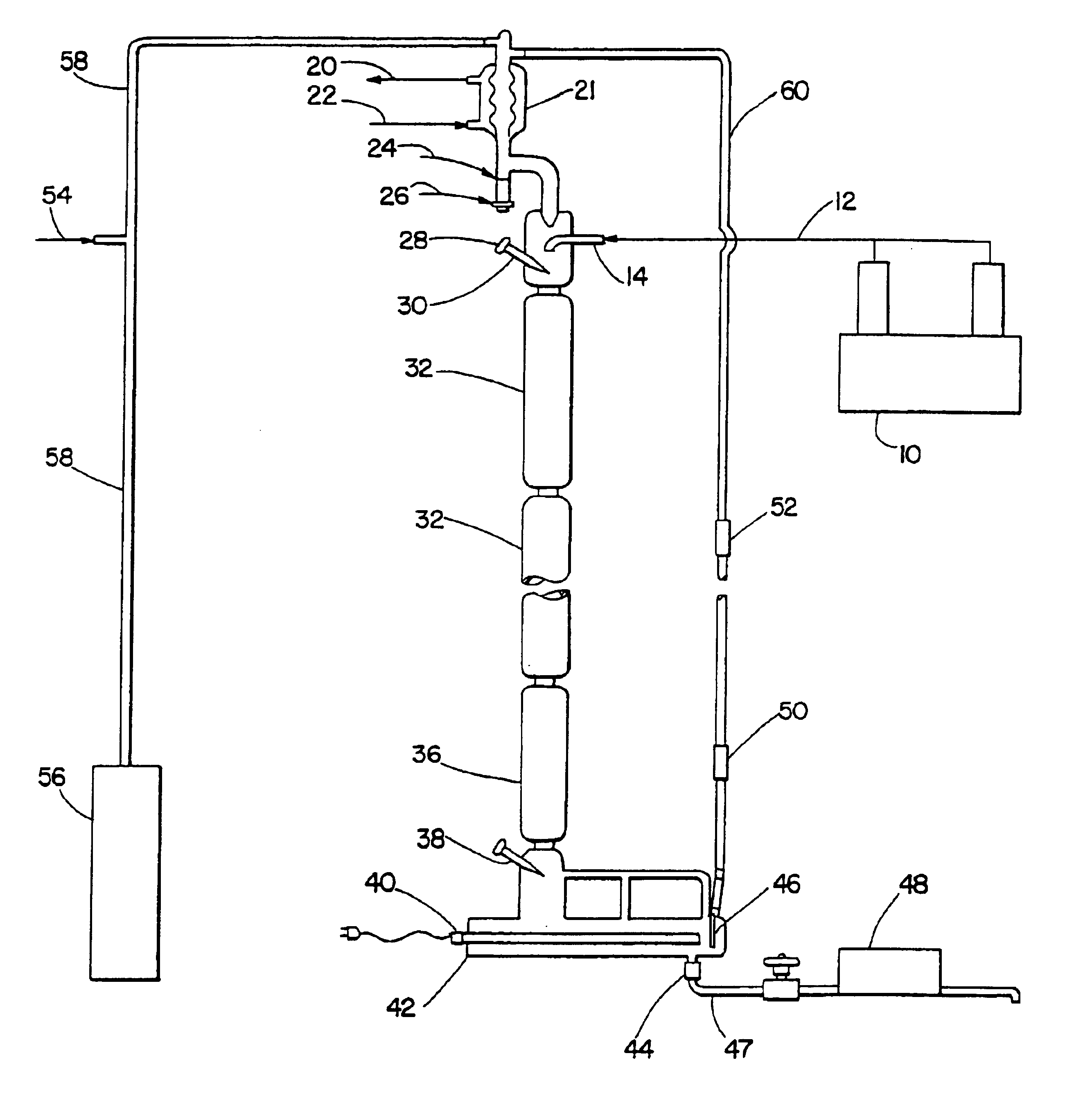

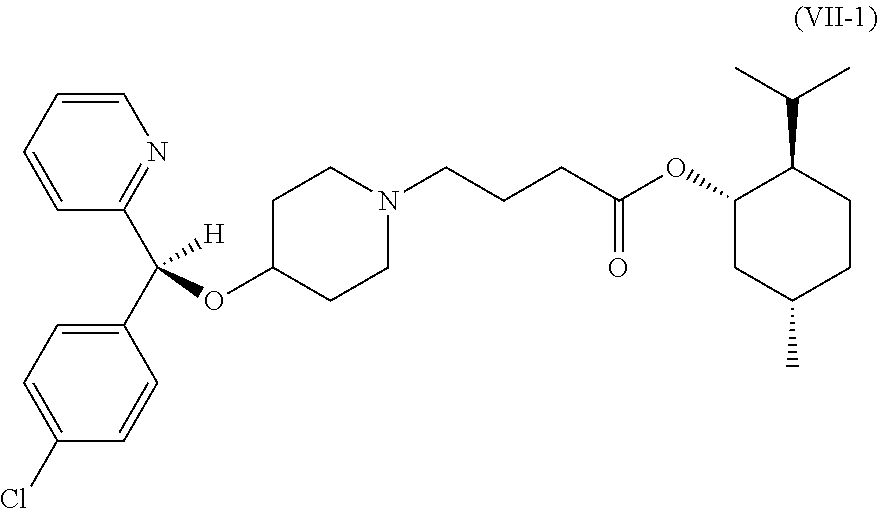

Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione

The present invention relates to crystalline forms of (3R,6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione benzenesulfonate salt and pharmaceutical compositions thereof. Also disclosed are processes for the preparation the above compounds and methods for use thereof.

Owner:GLAXO GRP LTD

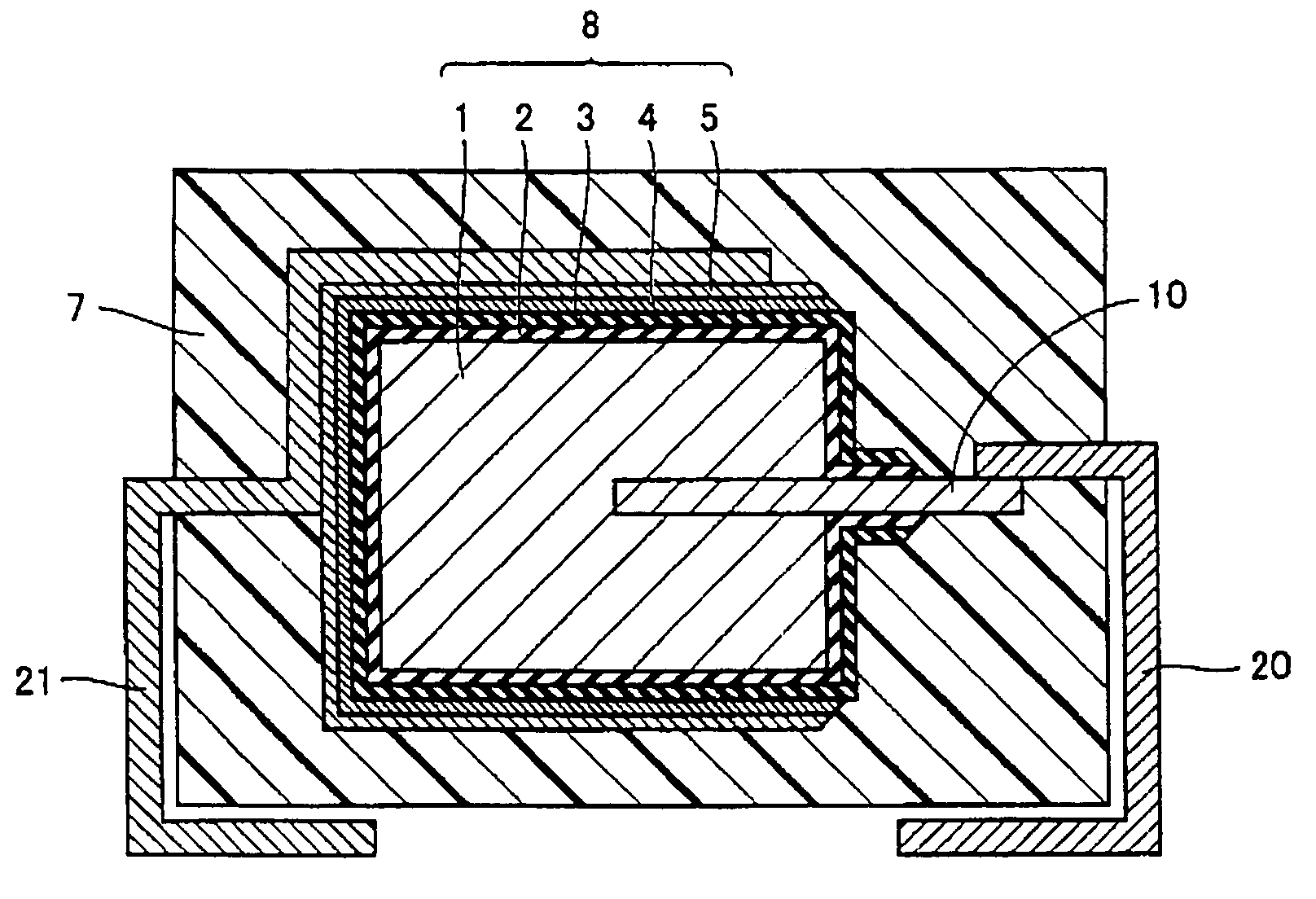

Solid electrolytic capacitor

ActiveUS6982865B2Low ESRImprove heat resistanceHybrid capacitor electrolytesSolid electrolytic capacitorsDopantElectrolysis

Owner:SANYO ELECTRIC CO LTD

Method for preparing peroxidating urea

InactiveCN1915972ASimple production processAdapt to large-scale industrial productionOrganic chemistryCarbamide peroxideBenzenesulfonates

This invention relates to a method for preparing high-stability carbamide peroxide. The method comprises: (1) adding urea and stabilizer into 25-40 wt. % H2O2; (2) stirring so that urea is completely dissolved, and drying to obtain carbamide peroxide crystals. The stabilizer is a mixture of zinc tartrate, tartaric acid and dodecyl benzenesulfonate at a weight ratio of (1-2) : (45-49): (45-50). The mol ratio of urea to H2O2 is 1: (1.0-1.2). The method has such advantages as high yield, simple process, no wastes and high product stability, and is suitable for mass production.

Owner:ZHEJIANG UNIV OF TECH

Novel salt 628

ActiveUS20100216843A1Improved physical propertyHigh solubilityBiocideOrganic chemistryPhenyl groupTrifluoromethyl

6-Methyl-5-(1-methyl-1H-pyrazol-5-yl)-N-{[5-(methylsulfonyl)pyridin-2-yl]methyl}-2-oxo-1-[3-(trifluoromethyl)phenyl]-1,2-dihydropyridine-3-carboxamide 4-methylbenzenesulfonate and a novel crystalline form thereof are disclosed together with processes for preparing such salt and form, pharmaceutical compositions comprising such a salt and form, and the methods of treatment using such a salt and form.

Owner:ASTRAZENECA AB

Immobilized ionic liquid catalyst and application thereof

InactiveCN106391115AHigh catalytic activityNot easy to inactivateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTetrafluoroborateTriflic acid

The invention relates to an immobilized ionic liquid catalyst and application thereof. The immobilized ionic liquid catalyst has a general structural formula as defined in the specification. In the general structural formula, P is a nanometer macroporous resin matrix; n is an integer in a range of 2 to 12; M<-> is a negative ion selected from a group consisting of a trifluoromethanesulfonate group, a p-toluenesulfonate group, a benzenesulfonate group, a methanesulfonate group, a tetrafluoroborate group and a hexafluorophosphate group; and the nanometer macroporous resin matrix is a nanometer macroporous copolymer prepared from styrene monomer, copolymerization monomer, a graphene material and a pore-forming agent through in-situ copolymerization. The immobilized ionic liquid catalyst can be applied to industrial olefine acid addition for preparation of corresponding esters.

Owner:CHINA PETROLEUM & CHEM CORP +1

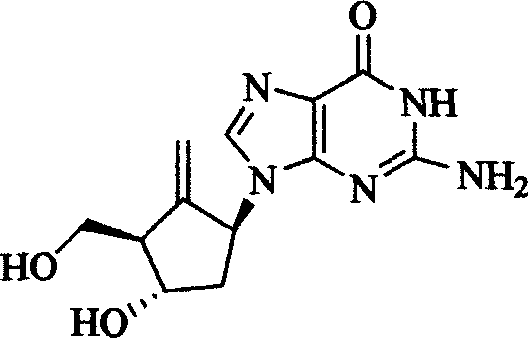

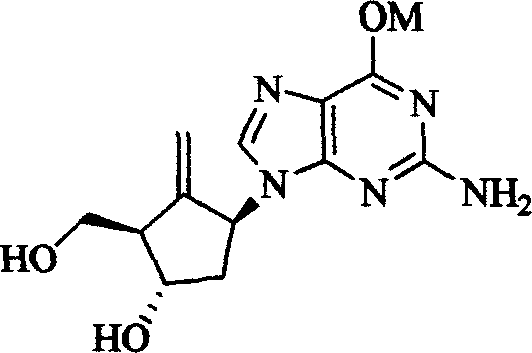

Entecavir salt, and preparation

This invention discloses a method for preparing entecavir acid-addition salts, entecavir magnesium salt and entecavir barium salt. The entecavir acid-addition salts are prepared from entecavir and inorganic or organic acids, and are preferential entecavir hydrochloride, entecavir bromate, entecavir sulfate, entecavir phosphate, entecavir sulfonate, and entecavir benzenesulfonate. The entecavir slats are stable, and have higher water solubility than entecavir itself, thus are more suitable to manufacture anti-HBV drugs.

Owner:MAI DE

Anionic emulsifier, and preparation method and application thereof

The invention discloses an anionic emulsifier, and a preparation method and application thereof. The anionic emulsifier is prepared from sulfanilic acid, epoxy active diluent and epoxy resin according to a mol ratio of 1: 1: 1.05-1.15. Specifically, the preparation method comprises a step of preparing the anionic emulsifier with a solid content of 50 to 55% from epoxy resin, epoxy active diluent and sulfanilic acid under the catalysis of triphenyl phosphine. The structure of the anionic emulsifier provided by the invention is unique and innovative; and a benzenesulfonate group, an epoxy group (provided by the epoxy resin) and a lipophilic chain segment are introduced into a same molecule, so excellent emulsification performance of the anionic emulsifier is guaranteed, and the anionic emulsifier can be ideally applied to epoxy emulsion. The anionic emulsifier is a reactive anionic emulsifier and has strong emulsification and epoxidation capacity; and the anionic emulsifier can crosslink with an epoxy hardener so as to reduce the mobility of the anionic emulsifier in a paint film, so influence on water resistance is reduced.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Foaming agent composition used for high temperature and high salt oil reservoir

The invention relates to a foaming agent composition used for a high temperature and high salt oil reservoir, which mainly solves the problems existed in a foam flooding reinforcement oil extraction technology that the foaming agent has poor thermal stability, deposition is generated when meeting with divalent ion, the requirements of the foam flooding in a high temperature and high salinity stratum are not satisfied. According to the invention, the technical scheme of the foaming agent composition which is composed of polyoxyethylene alkyl ether benzene sulfonate, alkybenzene sulfonate and water is used for better solving the problems, and can be used for oil extraction by reinforcing the foam flooding.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of cellulose based conductive hydrogel

InactiveCN106519287AUniform network structureStable network structureBenzoyl peroxideDibenzoyl Peroxide

The invention discloses a preparation method of a cellulose based conductive hydrogel. The preparation method comprises the following steps: (1) dissolving microcrystalline cellulose (MCC) with 1-Butyl-3-methylimidazolium chloride, reacting in a N2 protective atmosphere, and adding N,N-methylenebisacrylamide and benzoyl peroxide to prepare a pure microcrystalline cellulose hydrogel; and (2) soaking the pure microcrystalline cellulose hydrogel obtained in the step (1) in a mixed solution of FeCl3 and sodium p-benzenesulfonate, and immersing in a pyrrole water solution to prepare the cellulose based conductive hydrogel. The cellulose based conductive hydrogel prepared by the method has the advantages of uniform stable network structure, excellent conductivity, swelling property and heat stability, favorable electric conductivity and favorable swelling property; and the equilibrium swelling rate can be up to about 500%.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

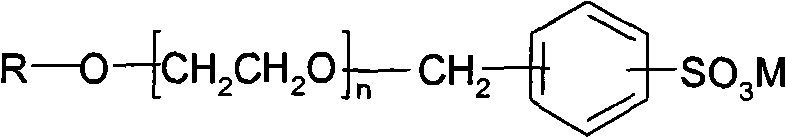

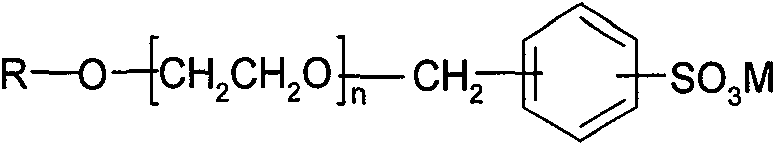

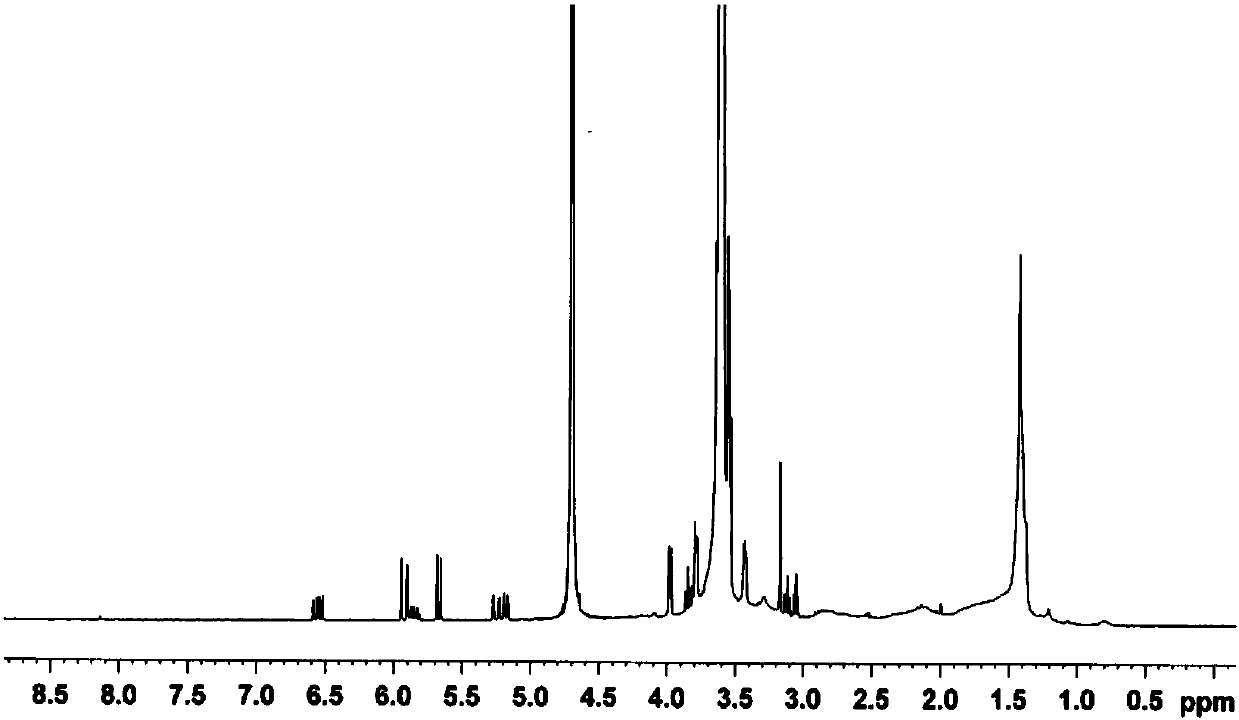

Polycarboxylic dispersant for oil-well cement and preparation method of polycarboxylic dispersant

ActiveCN107602773AImprove salt toleranceImprove temperature resistanceDrilling compositionSulfonatePolymer science

The invention discloses a polycarboxylic dispersant for oil-well cement and a preparation method of the polycarboxylic dispersant, and belongs to the technical field of oil-well cement additives. Thepolycarboxylic dispersant is a copolymer which is prepared from monomers composed of acrylic acid, N-vinyl pyrrolidone, itaconic acid, 2-acrylamido-2-methylpropanesulfonic acid, sodium vinyl sulfonate, sodium vinyl benzenesulfonate and allyl polyethylene glycol, wherein the weight-average molecular weight of allyl polyethylene glycol is 300-2400, and when the total mass of the monomers is 100%, the monomers comprises 0.5-20% of acrylic acid, 0.5-15% of N-vinyl pyrrolidone, 0.5-10% of itaconic acid, 5-60% of 2-acrylamido-2-methylpropanesulfonic acid, 0.5-30% of sodium vinyl sulfonate, 0.5-30% of sodium vinyl benzenesulfonate and 20-70% of allyl polyethylene glycol; the weight-average molecular weight of the polycarboxylic dispersant is 5000-250,000. The polycarboxylic dispersant has the advantages of good salt tolerance, high temperature resistance and rheological properties.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

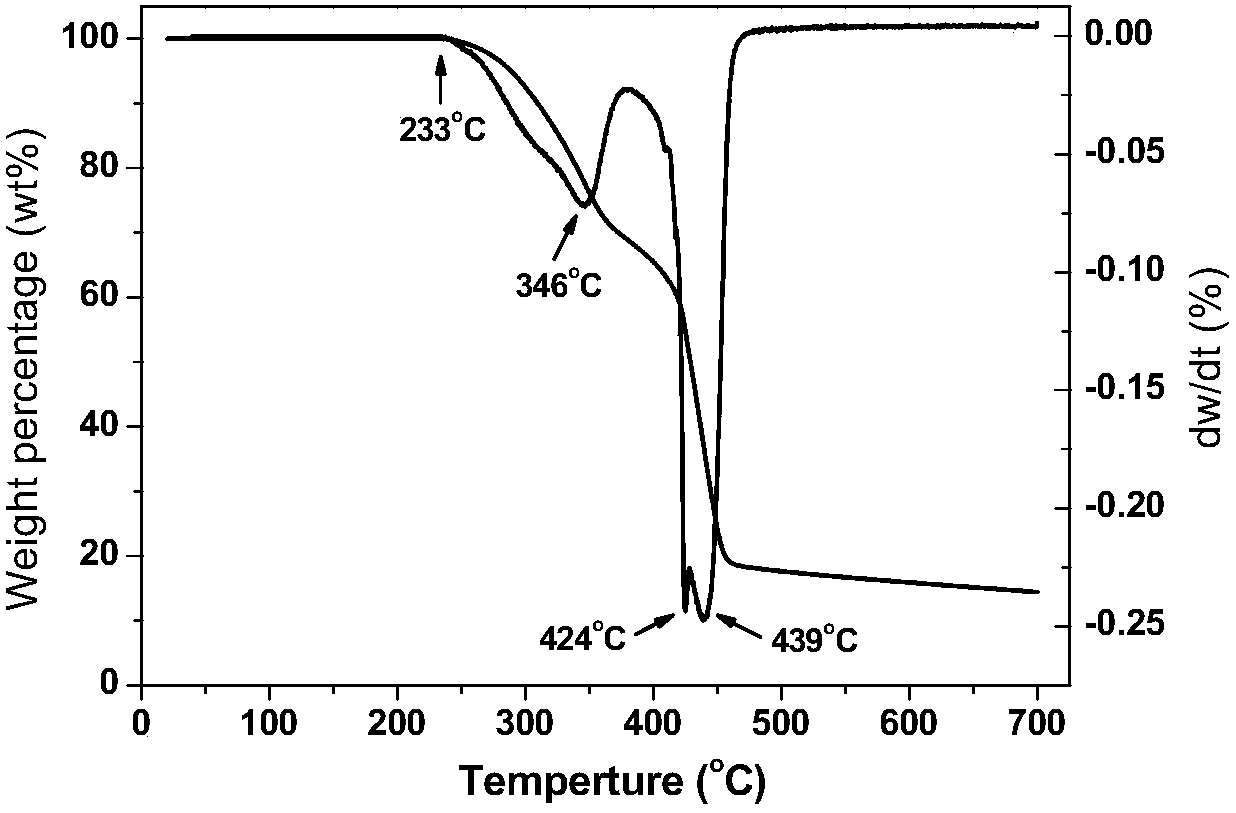

Foam flooding agent

ActiveCN102766448AReduce interfacial tensionImprove surface activityDrilling compositionPhosphoniumSulfate

The invention provides a foam flooding agent which comprises the following components in parts by weight: 30-60 parts of A polyalkylsodium benzenesulfonate, 5-15 parts of B surfactant, 0-15 parts of C tetrakis(hydroxymethyl)phosphonium sulfate, 5-10 parts of D tween-20 and 25-55 parts of E water. The invention has the following advantages: 1. the activity is high, so the oil-water interface surface tension can be lowered without adding alkali; 2. the foam flooding agent can resist high temperature and high salt, can not be decomposed at 220 DEG C, and can resist total ion concentration; and 3. compared with other existing foam flooding agents, the 50 DEG C half life period of foam is up to 400 minutes, the foam volume is 330mL, and the foam flooding agent has favorable compatibility with other surfactants and enhances the oil recovery rate by 15% in laboratory simulation.

Owner:天津市瑞德赛恩新材料开发有限公司

Active carbon and preparation method thereof

The invention discloses a preparation method of active carbon. The preparation method comprises the following steps: (1) performing drip washing on residues obtained in the process of producing ethanol through cellulose fermentation so as to wash off organic acids and inorganic salts in the residues; (2) soaking the washed residues in the step (1) by using a mixed solution of chitosan, glutaraldehyde and sodium dodecyl benzenesulfonate; (3) putting the soaked residues in the step (2) into a carbonizing furnace, heating to 150-200 DEG C in an air atmosphere, treating for 20-60min, then raising the temperature to 600-800 DEG C in an inert atmosphere, and carbonizing for 60-240min (4) after carbonizing, inflating water vapor or CO2 for treating for 10-30 min, and cooling to prepare the active carbon. By the preparation method, with biomass-fermented residues obtained during production of the cellulosic ethanol as raw materials, the active carbon with a high adsorptive property is prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-soluble anticarack gelatine powder, and application in building materials of powder

This invention relates to a construction binder, which is prepared by: adding carboxymethyl amylocellulose ether, hydroxypropyl methylcellulose, lignin fibers, sodium dodecyl benzenesulfonate, bentonite and polyacrylamide into a mixer, and dry-stirring for a certain time until complete mixing. This invention fully exploits the advantages of organic and inorganic materials. The obtained construction binder has such advantages as high binding strength, high water-retaining rate, good anti-crack performance, good waterproof performance, no odor and no toxicity, and is environmentally friendly. The construction binder can be used as an additive for powdery building materials such as dry-mixed heat-insulation mortar, anti-crack mortar, brushing gypsum, putty powder, construction binder and polymeric mortar.

Owner:兰州海锋建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![SALTS OF 2-FLUORO-N-METHYL-4-[7-(QUINOLIN-6-YL-METHYL)-IMIDAZO[1,2-b][1,2,4]TRIAZIN-2-YL]BENZAMIDE AND PROCESSES RELATED TO PREPARING THE SAME SALTS OF 2-FLUORO-N-METHYL-4-[7-(QUINOLIN-6-YL-METHYL)-IMIDAZO[1,2-b][1,2,4]TRIAZIN-2-YL]BENZAMIDE AND PROCESSES RELATED TO PREPARING THE SAME](https://images-eureka.patsnap.com/patent_img/f86edc4f-d7a1-4901-998d-640bf82cd6b1/US20090291956A1-20091126-D00000.png)

![SALTS OF 2-FLUORO-N-METHYL-4-[7-(QUINOLIN-6-YL-METHYL)-IMIDAZO[1,2-b][1,2,4]TRIAZIN-2-YL]BENZAMIDE AND PROCESSES RELATED TO PREPARING THE SAME SALTS OF 2-FLUORO-N-METHYL-4-[7-(QUINOLIN-6-YL-METHYL)-IMIDAZO[1,2-b][1,2,4]TRIAZIN-2-YL]BENZAMIDE AND PROCESSES RELATED TO PREPARING THE SAME](https://images-eureka.patsnap.com/patent_img/f86edc4f-d7a1-4901-998d-640bf82cd6b1/US20090291956A1-20091126-D00001.png)

![SALTS OF 2-FLUORO-N-METHYL-4-[7-(QUINOLIN-6-YL-METHYL)-IMIDAZO[1,2-b][1,2,4]TRIAZIN-2-YL]BENZAMIDE AND PROCESSES RELATED TO PREPARING THE SAME SALTS OF 2-FLUORO-N-METHYL-4-[7-(QUINOLIN-6-YL-METHYL)-IMIDAZO[1,2-b][1,2,4]TRIAZIN-2-YL]BENZAMIDE AND PROCESSES RELATED TO PREPARING THE SAME](https://images-eureka.patsnap.com/patent_img/f86edc4f-d7a1-4901-998d-640bf82cd6b1/US20090291956A1-20091126-D00002.png)

![2-[[[2-[(hydroxyacetyl)amino]-4-pyridinyl]methyl]thio]-n-[4-(trifluoromethoxy)phenyl]-3-pyridinecarboxamide benzenesulfonate, crystal of same, crystal polymorph thereof, and methods for production thereof 2-[[[2-[(hydroxyacetyl)amino]-4-pyridinyl]methyl]thio]-n-[4-(trifluoromethoxy)phenyl]-3-pyridinecarboxamide benzenesulfonate, crystal of same, crystal polymorph thereof, and methods for production thereof](https://images-eureka.patsnap.com/patent_img/90279850-ad65-4a0d-aa43-43eaa0e681f2/US20120116088A1-20120510-C00001.png)

![2-[[[2-[(hydroxyacetyl)amino]-4-pyridinyl]methyl]thio]-n-[4-(trifluoromethoxy)phenyl]-3-pyridinecarboxamide benzenesulfonate, crystal of same, crystal polymorph thereof, and methods for production thereof 2-[[[2-[(hydroxyacetyl)amino]-4-pyridinyl]methyl]thio]-n-[4-(trifluoromethoxy)phenyl]-3-pyridinecarboxamide benzenesulfonate, crystal of same, crystal polymorph thereof, and methods for production thereof](https://images-eureka.patsnap.com/patent_img/90279850-ad65-4a0d-aa43-43eaa0e681f2/US20120116088A1-20120510-C00002.png)

![Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione](https://images-eureka.patsnap.com/patent_img/e2a917ec-9ec7-48de-ba08-cc4b3458c342/US08716286-20140506-D00001.png)

![Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione](https://images-eureka.patsnap.com/patent_img/e2a917ec-9ec7-48de-ba08-cc4b3458c342/US08716286-20140506-D00002.png)

![Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione](https://images-eureka.patsnap.com/patent_img/e2a917ec-9ec7-48de-ba08-cc4b3458c342/US08716286-20140506-D00003.png)